JUKI IP-200/LK-1900A Instruction Manual

ENGLISH

IP-200 / LK-1900A

CONTENTS

1. NAME OF EACH SECTION OF THE OPERATION PANEL ...............................................................4

1-1 Body.........................................................................................................................................................4

1-2 Buttons to be used in common.............................................................................................................6

2. BASIC OPERATION OF THE SEWING MACHINE.............................................................................7

3. LCD DISPLAY SECTION AT THE TIME OF SEWING SHAPE SELECTION.....................................8

3-1 Sewing shape data input screen...........................................................................................................8

3-2 Sewing screen.......................................................................................................................................11

4. PERFORMING SEWING SHAPE SELECTION.................................................................................14

5. SEWING SHAPE LIST.......................................................................................................................17

6. PERFORMING ITEM DATA CHANGE..............................................................................................19

7. CHECKING PATTERN SHAPE.........................................................................................................21

8. USING TEMPORARY STOP .............................................................................................................23

8-1 To continue performing sewing from some point in sewing...........................................................24

8-2 To perform re-sewing from the start...................................................................................................25

9. WINDING BOBBIN THREAD ............................................................................................................26

9-1 When performing winding bobbin thread while performing sewing...............................................26

9-2 When performing winding bobbin thread only..................................................................................26

10. USING COUNTER ...........................................................................................................................27

10-1 Setting procedure of the counter......................................................................................................27

10-2 Count-up releasing procedure..........................................................................................................30

10-3 How to change the counter value during sewing............................................................................31

11. PERFORMING NEW REGISTER OF USERS' PATTERN...............................................................32

12. PERFORMING NEW REGISTER OF PATTERN BUTTON.............................................................33

13. LCD DISPLAY SECTION AT THE TIME OF PATTERN BUTTON SELECTION............................35

13-1 Pattern button data input screen......................................................................................................35

13-2 Sewing screen.....................................................................................................................................38

14. PERFORMING PATTERN BUTTON NO. SELECTION...................................................................41

14-1 Selection from the data input screen ...............................................................................................41

14-2 Selection by means of the shortcut button .....................................................................................42

15. CHANGING CONTENTS OF PATTERN BUTTON..........................................................................43

16. NAMING PATTERN BUTTON.........................................................................................................45

17. COPYING PATTERN BUTTON.......................................................................................................46

18. CHANGING SEWING MODE...........................................................................................................48

19. LCD DISPLAY SECTION AT THE TIME OF COMBINATION SEWING.........................................49

1

19-1 Pattern input screen...........................................................................................................................49

19-2 Sewing screen.....................................................................................................................................51

20. PERFORMING COMBINATION SEWING.......................................................................................54

20-1 Selection of combination data ..........................................................................................................54

20-2 How to edit combination data ...........................................................................................................55

21. CHANGING MEMORY SWITCH DATA...........................................................................................57

21-1 How to change memory switch data ................................................................................................57

21-2 Memory switch data list.....................................................................................................................59

22. ERROR CODE LIST ........................................................................................................................66

23. USING COMMUNICATION FUNCTION ..........................................................................................73

23-1 Handling possible data ......................................................................................................................73

23-2 Performing communication by using the smart media..................................................................75

23-3 Performing communication by using RS-232C...............................................................................78

23-4 Take-in of the data..............................................................................................................................79

24. INFORMATION FUNCTION.............................................................................................................81

24-1 Observing the maintenance inspection information ......................................................................82

24-2 Inputting the inspection time ............................................................................................................85

24-3 Releasing procedure of the warning ................................................................................................87

24-4 Observing the production control information ...............................................................................88

24-4-1 When displaying from the information screen..........................................................................................88

24-4-2 When displaying from the sewing screen................................................................................................. 90

24-5 Performing setting of the production control information.............................................................91

24-6 Observing the working measurement information.........................................................................95

25. TRIAL SEWING FUNCTION............................................................................................................99

25-1 Performing trial sewing......................................................................................................................99

25-2 Thread tension value display color list..........................................................................................102

26. PERFORMING ADJUSTMENT OF ORIGIN OF PRESSER..........................................................103

27. PERFORMING KEY LOCK............................................................................................................104

28. DISPLAYING VERSION INFORMATION......................................................................................106

29. USING CHECK PROGRAM...........................................................................................................107

29-1 To display the check program screen............................................................................................107

29-2 Performing compensation of touch panel.....................................................................................109

29-3 Performing LCD check.....................................................................................................................112

29-4 Performing sensor check ................................................................................................................113

29-5 Number of rotations of main motor check.....................................................................................115

29-6 Performing output check.................................................................................................................116

29-7 Performing X/Y motors/origin sensors check...............................................................................117

29-8 Performing presser/thread trimmer motor/origin sensor check .................................................118

2

29-9 Performing thread clamp motor/origin sensor check...................................................................119

30. CHANGING THREAD TENSION COMMAND AT EVERY NEEDLE ENTRY POINT....................120

30-1 Adding or changing thread tension command at every needle entry point...............................120

30-2 Deleting thread tension command at every needle entry point...................................................122

31. PERFORMING RELEASE OF GREASE-UP ERROR...................................................................124

32. COMMUNICATION SCREEN OF MAINTENANCE PERSONNEL LEVEL...................................125

32-1 Data which are possible to be handled..........................................................................................125

32-2 Displaying maintenance personnel level.......................................................................................126

33. INFORMATION SCREEN OF THE MAINTENANCE PERSONNEL LEVEL.................................127

33-1 Display of error record.....................................................................................................................127

33-2 Display of the cumulative working information ............................................................................129

3

② ③ ④ ⑤

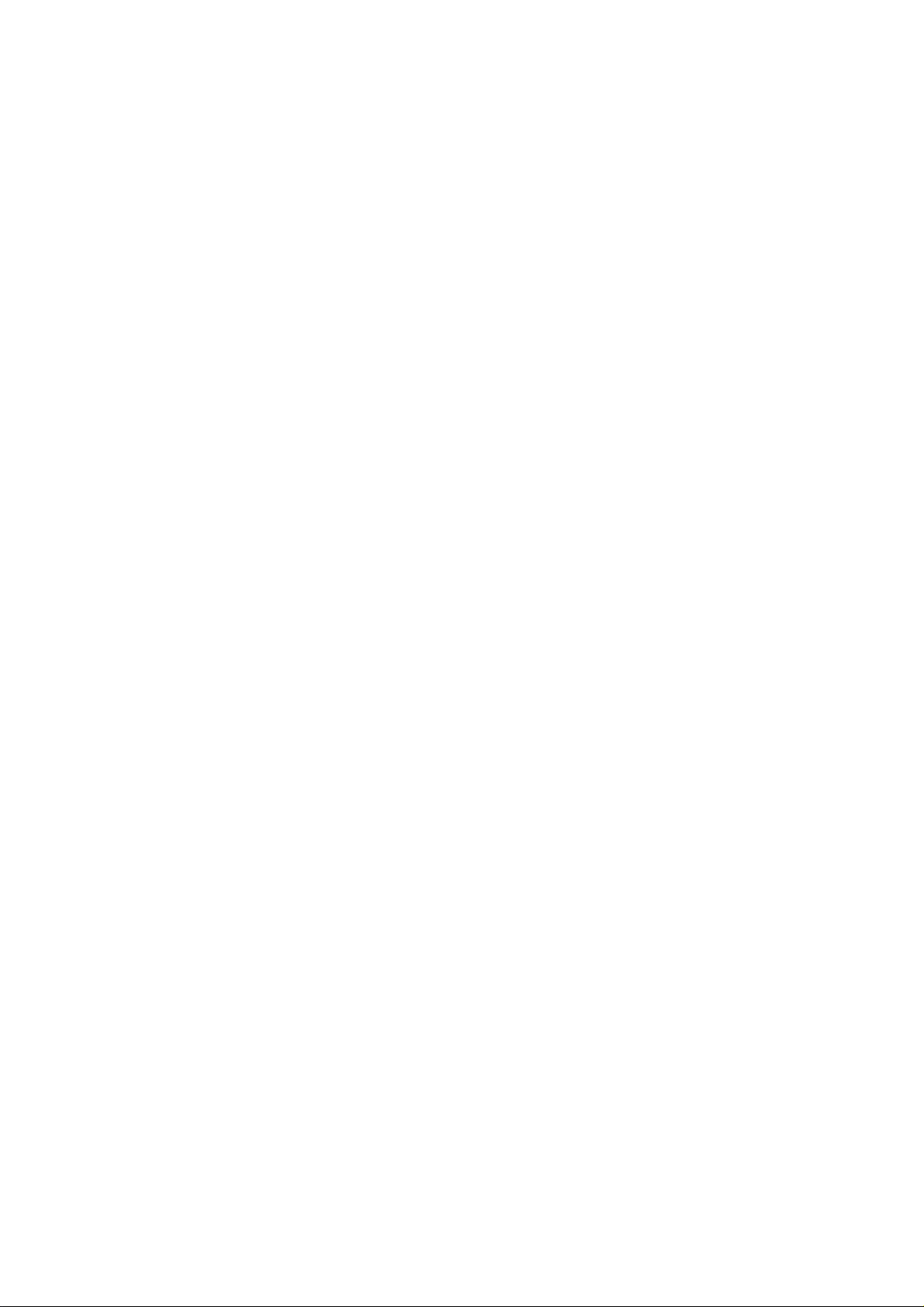

1. NAME OF EACH SECTION OF THE OPERATION PANEL

1-1 Body

(Front) (Right side)

①

⑥

⑦

⑧

⑨

⑩

⑪

4

① Touch panel・LCD display section

②

③

④

⑤

READY key →

INFORMATION key →

COMMUNICATION key →

MODE →

Changeover of the data input screen and the sewing

screen can be performed

Changeover of the data input screen and the

information screen can be performed

Changeover of the data input screen and the

communication screen can be performed.

Changeover of the data input screen and the mode

changeover screen which performs various detail

settings can be performed.

.

⑥ Smart media card slot (Close the cover for use. )

⑦ Slide switch (Not used. OFF)

⑧ Connector for RS-232C communication

⑨ Variable resistor for color LCD screen contrast adjustment

⑩ Connector for external input

⑪ Cable

5

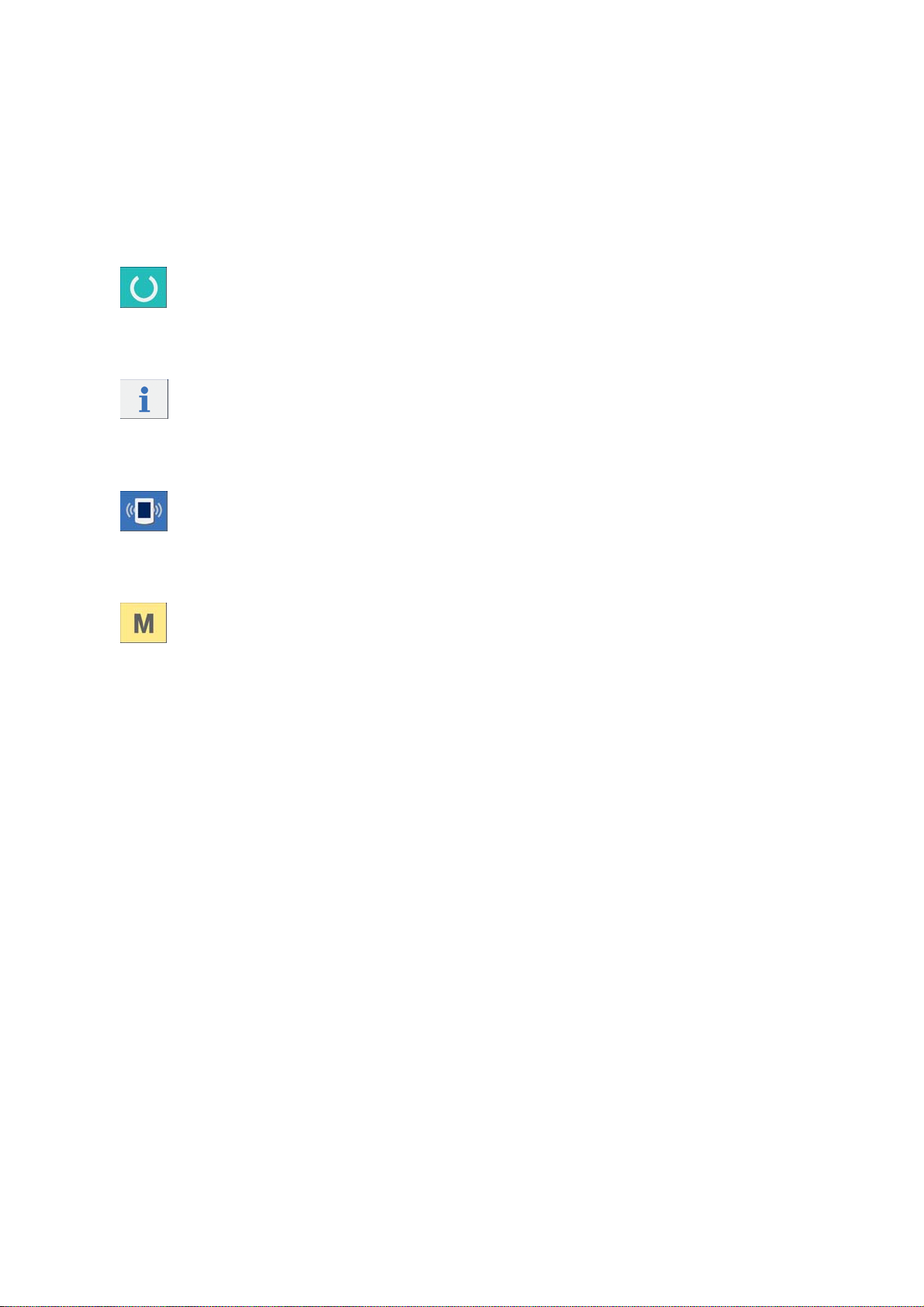

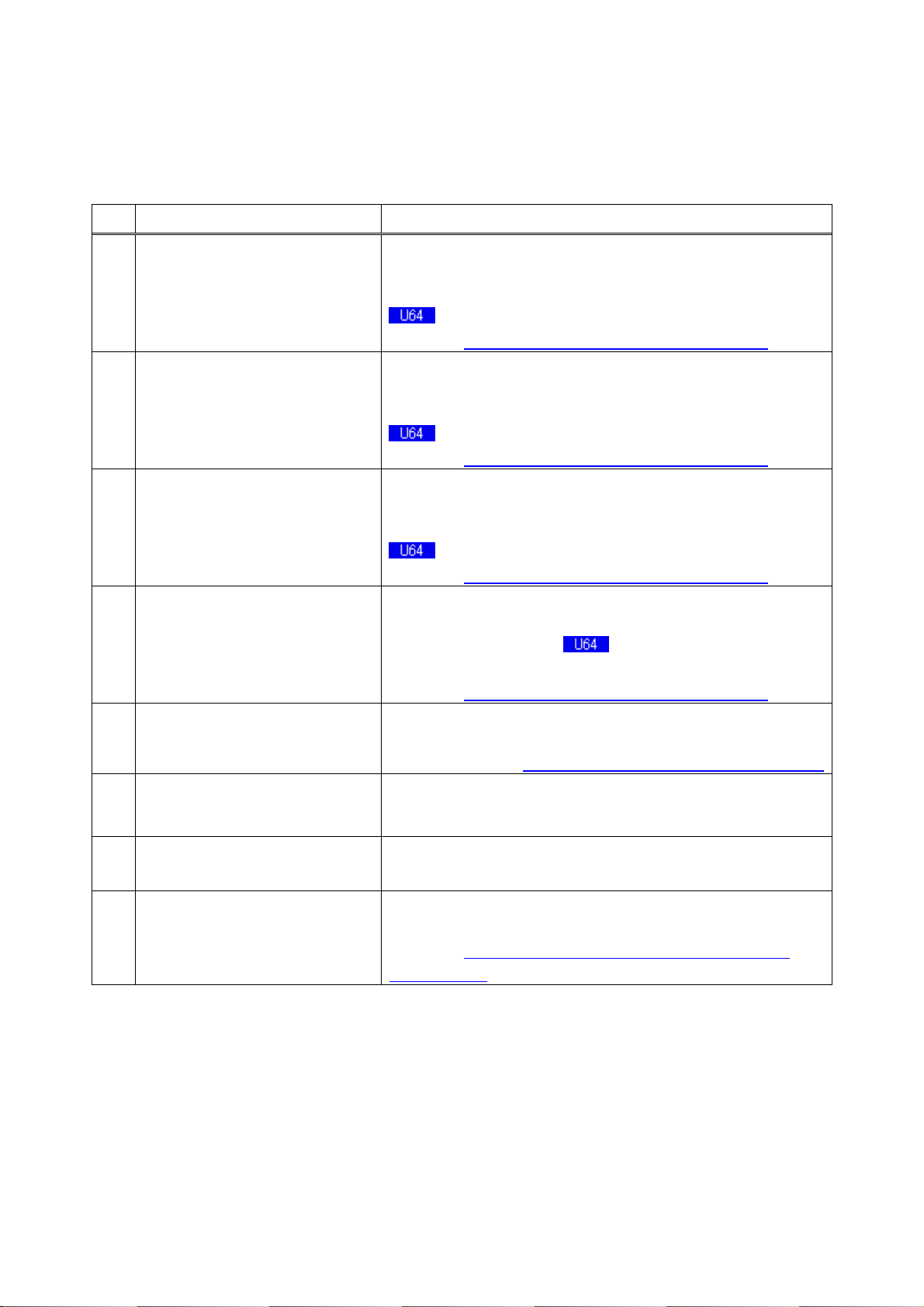

1-2 Buttons to be used in common

The buttons which perform common operations in each screen of IP200 are as follows :

CANCEL button →

In case of the data change screen, the data being

ENTER button →

UP SCROLL button →

DOWN SCROLL button →

RESET button →

NUMERAL INPUT button →

This button closes the pop-up screen.

changed can be cancelled.

This button determines the changed data.

This button scrolls the button or the display in the upward

direction.

This button scrolls the button or the display in the

downward direction

This button performs the release of error.

This button displays ten keys and input of numerals can

be performed.

.

CHARACTER INPUT button →

→ Refer to

PRESSER DOWN button →

To raise the presser, press PRESSER UP button

BOBBIN WINDER button →

6

This button displays the character input screen.

16. NAMING PATTERN BUTTON. p.45.

This button lowers the presser and displays the presse

down screen.

displayed in the presser down screen.

This button performs bobbin thread winding.

Refer to

→

thread while performing sewing , p26.

9-1 When performing winding bobbin

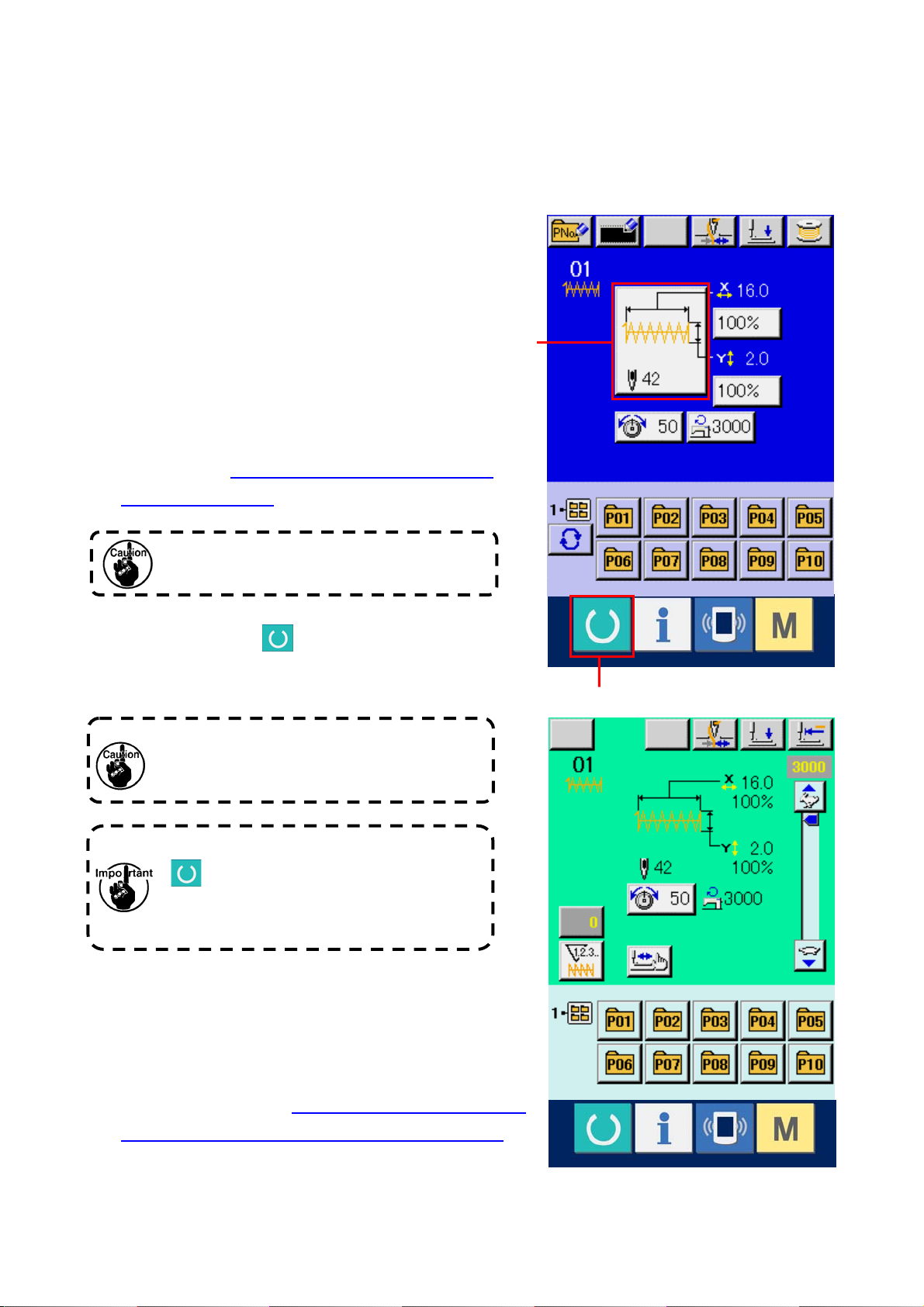

2. BASIC OPERATION OF THE SEWING MACHINE

① Turn ON the power switch

② Select the pattern No. you desire to sew.

When the power is turned ON, the data input

screen is displayed. Pattern No. button (B) which is

selected at present is displayed in the center of the

screen. Press the button to select the sewing

shape. For selecting procedure of the sewing

shape, refer to

4. PERFORMING SEWING SHAPE

SELECTION, p. 214.

Refer the pattern No. to the separate table.

When READY key

(C) is pressed, the back

color of LCD display is changed to green, and the

sewing machine is set to the sewing possible state.

When the presser is raised, be careful that

fingers are not caught in the presser since the

presser moves after having lowered.

B

C

When turning OFF the power without pressing

key, the set values of pattern No. , X/Y

scale, number of max. ro tatio n, and thread

tension are not memorized.

③ Start sewing.

Set the sewing product to the presser portion, and

operate the pedal to start the sewing machine, and

sewing starts.

* For the screen, refer to

3. LCD DISPLAY SECTION AT

THE TIME OF SEWING SHAPE SELECTION, p. 28.

7

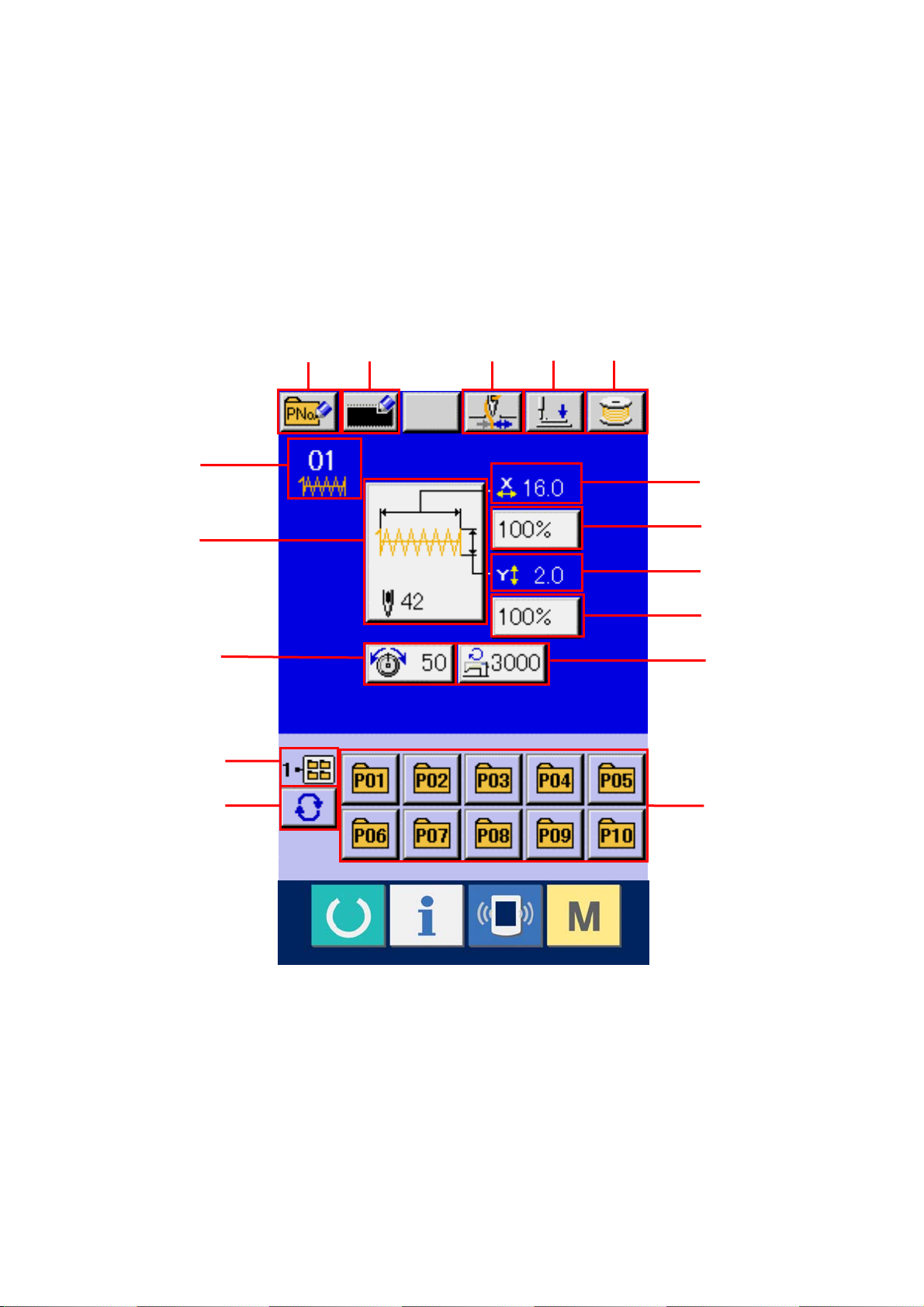

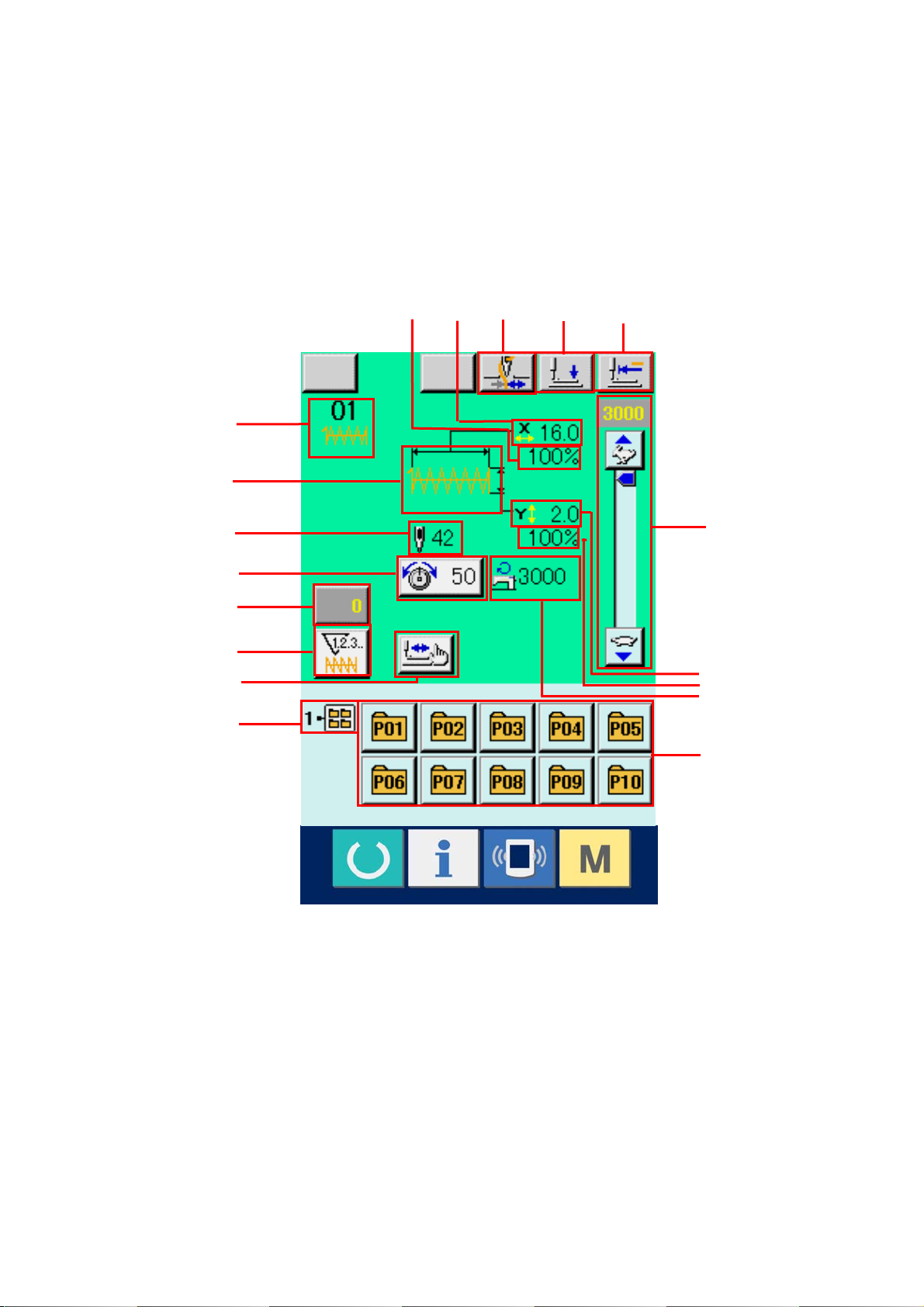

3. LCD DISPLAY SECTION AT THE TIME OF SEWING SHAPE SELECTION

3-1 Sewing shape data input screen

F

A

B

C E

D

I

J

G

K

L

H

M

N

O

P

8

Button and display Description

PATTERN BUTTON NEW

A

REGISTER button

USERS' PATTERN NEW REGISTER

B

button

THREAD CLAMP button Effective/ineffective of thread clamp is selected.

C

PRESSER DOWN button Presser can be lowered and the presser down screen is displayed.

D

BOBBIN WINDER button Bobbin thread can be wound.

E

SEWING SHAPE NO. display

F

Pattern button new register screen is displayed.

→ Refer to 12. PERFORMING NEW REGISTER OF PATTERN

BUTTON. p. 33.

Users' pattern new register screen is displayed.

→ Refer to

PATTERN. p. 32.

To raise the presser, press the presser up button which is displayed in

the presser down screen.

→ Refer to 9. WINDING BOBBIN THREAD. p. 26.

Kind and No. of the sewing shape being selected at present are

displayed.

There are three kinds of sewing shapes below.

11. PERFORMING NEW REGISTER OF USERS'

: Thread clamp ineffective

: Thread clamp effective

: Standard pattern

: LK-1900 pattern

SEWING SHAPE SELECTION

G

button

H NEEDLE THREAD TENSION

SETTING button

: Users' pattern

Sewing shape being selected at present is displayed on this button

and when the button is pressed, the sewing shape selection screen is

displayed.

→ Refer to

Needle thread tension value which is set to the pattern data being

selected at present is displayed on this button and when the button is

pressed, the item data change screen is displayed.

→ Refer to.

4. PERFORMING SEWING SHAPE SELECTION, p. 214.

6. PERFORMING ITEM DATA CHANGE, p. 219.

9

Button and display Description

I X ACTUAL SIZE VALUE display Actual size value in X direction of sewing shape being selected at

present is displayed.

When the actual size value input is selected by setting memory switch

, X actual size value setting button is displayed.

→ Refer to

J X SCALE RATE SETTING button Scale rate in X direction of sewing shape being selected at present is

displayed on this button.

When the scale input is set to non-selection by setting memory switch

→ Refer to

K Y ACTUAL SIZE VALUE display Actual size value in Y direction of sewing shape being selected at

present is displayed.

When the actual size value input is selected by setting memory switch

→ Refer to

L Y SCALE RATE SETTING button

M MAX. SPEED LIMITATION Maximum speed limitation which is set at present is displayed on this

N FOLDER NO. display Pattern register button which is displayed indicates the folder No.

Scale rate in Y direction of sewing shape being selected at present is

displayed on this button. When the scale input is set to non-selection

by setting memory switch

scale is displayed.

→ Refer to

button and when the button is pressed, the item data change screen is

displayed.→ Refer to

which has been stored

6. PERFORMING ITEM DATA CHANGE, p. 219.

, the button goes out and the X scale is displayed.

6. PERFORMING ITEM DATA CHANGE, p. 219.

, Y actual size value setting button is displayed.

6. PERFORMING ITEM DATA CHANGE, p. 219.

, the button goes out and the Y

6. PERFORMING ITEM DATA CHANGE, p. 219.

6. PERFORMING ITEM DATA CHANGE, p. 219.

O FOLDER SELECTION button Folders to display the patterns are displayed in order.

P PATTERN REGISTER button PATTERN REGISTER buttons stored in N FOLDER NO. display are

displayed.

→ Refer to

BUTTON. p. 33

12. PERFORMING NEW REGISTER OF PATTERN

10

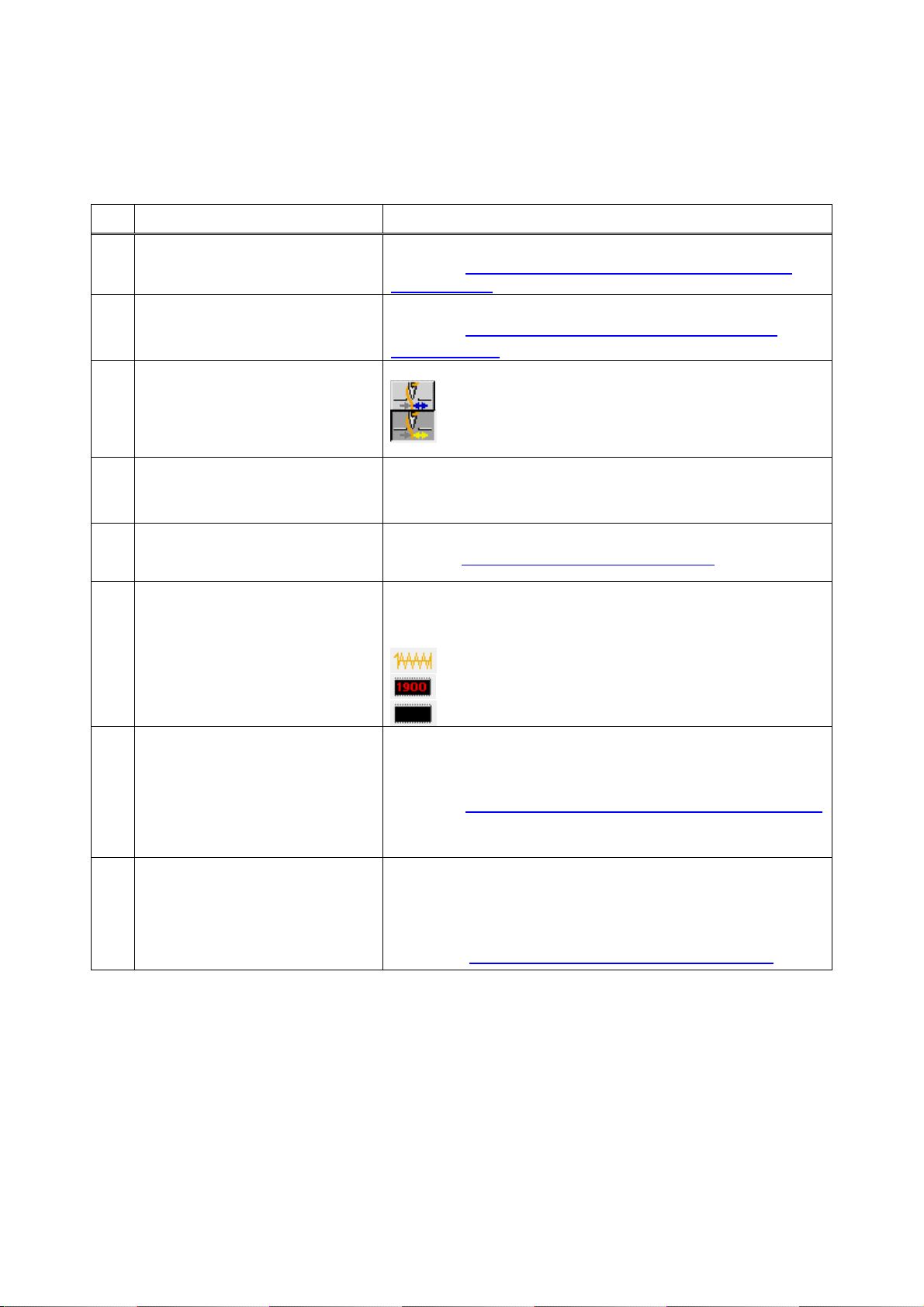

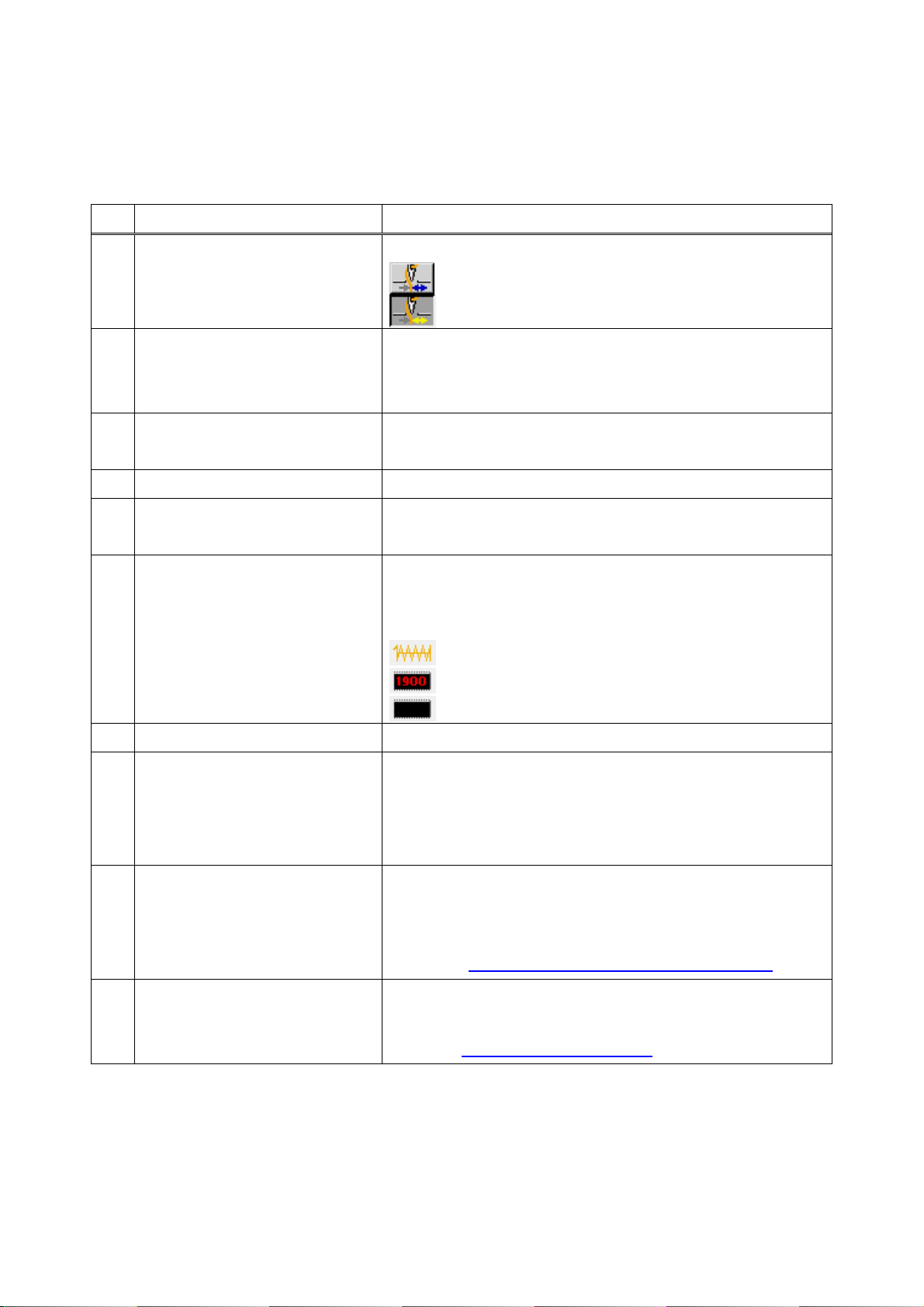

3-2 Sewing screen

E

D

A

B C

F

G

H

N

I

J

K

L

M

O

P

Q

R

11

Button and display Description

A THREAD CLAMP button Effective/ineffective of the thread clamp is selected.

: Thread clamp ineffective

: Thread clamp effective

B PRESSER DOWN button Presser can be lowered and the presser down screen is displayed.

To raise the presser, press the presser up button which is displayed in

the presser down screen.

C RETURN TO ORIGIN button This button returns the presser to the start of sewing and raises the

presser at the time of temporary stop.

D X SCALE RATE display Scale rate in X direction of sewing shape being selected is displayed.

E X ACTUAL SIZE VALUE display Actual size value in X direction of sewing shape being selected is

displayed.

F SEWING SHAPE NO. display Kind and No. of sewing shape being selected at present are

displayed.

There are three kinds of sewing shapes below.

: Standard pattern

: LK-1900 pattern

: Users' pattern

G SEWING SHAPE display Sewing shape being selected at present is displayed.

H SEWING SHAPE Total number of

stitches display

I NEEDLE THREAD TENSION

SETTING button

J COUNTER VALUE CHANGE button Existing counter value is displayed on this button. When the button is

Total number of stitches of the sewing shape being selected at

present is displayed.

* It is displayed only when the sewing shape being selected is the

standard pattern.

Needle thread tension value which is set to the pattern data being

selected at present is displayed on this button and when the button is

pressed, the item data change screen is displayed.

→ Refer to.

pressed, the counter value change screen is displayed.

→ Refer to

6. PERFORMING ITEM DATA CHANGE, p. 219.

10. USING COUNTER, p. 27.

12

Button and display Description

K COUNTER

CHANGE OVER button

L STEP SEWING botton

M FOLDER NO. display Pattern register button which is displayed indicates the folder No.

N SPEED variable resistor Number of rotations of the sewing machine can be changed.

O Y ACTUAL SIZE VALUE display Actual size value in Y direction of sewing shape being selected is

P Y SCALE RATE display Scale rate in Y direction of sewing shape being selected is displayed.

Q MAX. SPEED LIMITATION display Maximum speed limitation which is set at present is displayed.

R PATTERN REGISTER button Pattern register buttons stored in M FOLDER NO. display are

Display of sewing counter/No. of pcs. counter can be changed over.

→ Refer to 10. USING COUNTER, p. 27.

Step sewing screen is displayed. Checking of the pattern shape can

be performed.

→ Refer

which has been stored.

displayed.

displayed.

→ Refer to

BUTTON. p.33.

7. CHECKING PATTERN SHAPE, p.21.

12. PERFORMING NEW REGISTER OF PATTERN

13

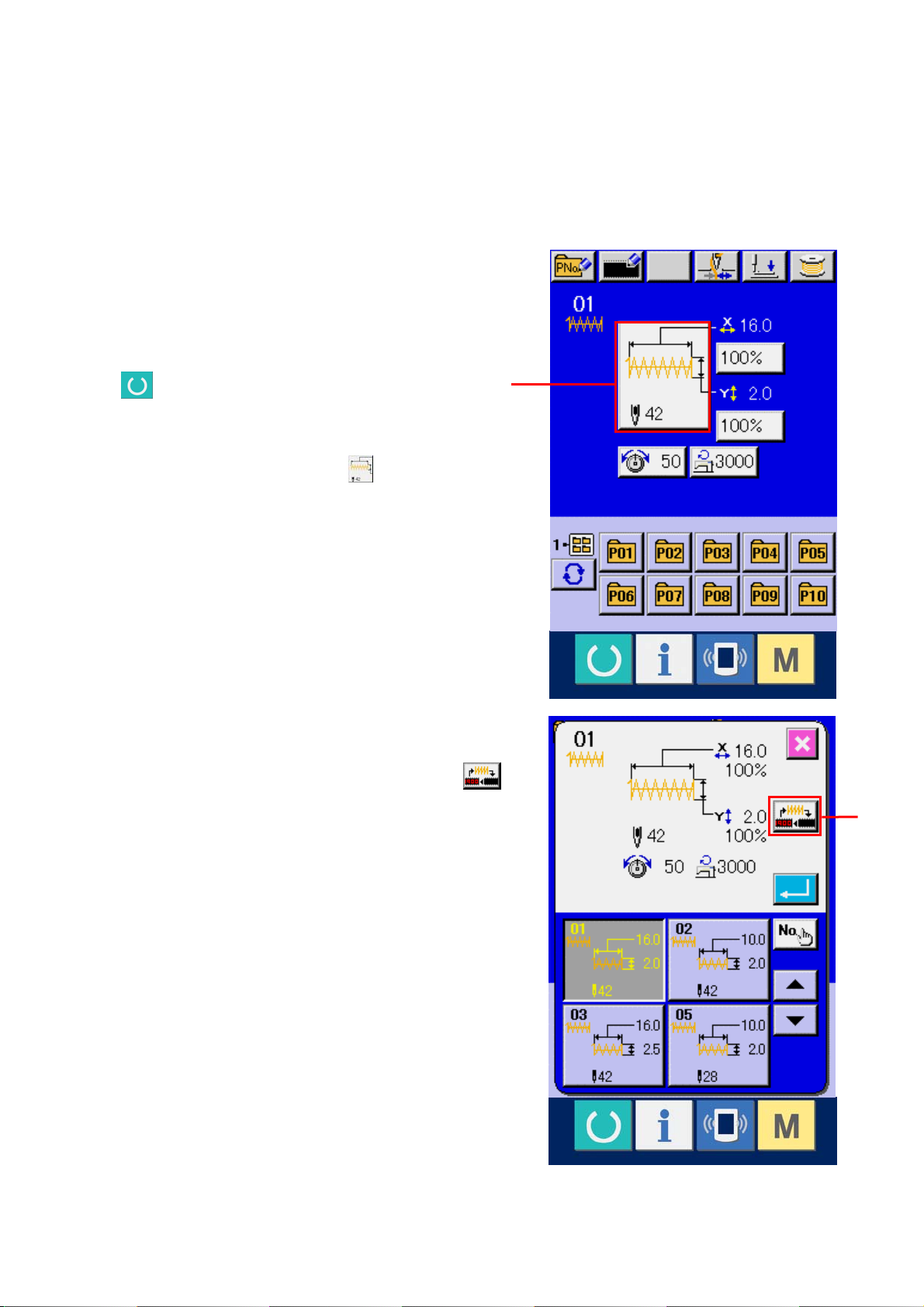

4. PERFORMING SEWING SHAPE SELECTION

① Display the data input screen.

Only in case of the data input screen (blue), the

selection of sewing shape is possible. In case of

the sewing screen (green), press READY switch

and display the data input screen (blue).

② Call the sewing shape selection screen.

Press SEWING SHAPE button

sewing shape selection screen is displayed.

③ Select the kind of sewing shape.

There are three kinds of sewing shapes in large.

Press SEWING SHAPE SELECTION button

(B).

(A) and the

A

B

14

E

④ Determine the kind of sewing shape.

There are three kinds of sewing shapes below.

Select the kind you desire from among them.

Pictograph Name

Standard pattern 64

LK-1900 pattern 99

Users' pattern 200

Maximum number

of patterns

Select the sewing shape you desire from

SEWING SHAPE SELECTION buttons (C)

and press ENTER

(D) button.

The sewing shape list screen corresponding

to the kind of sewing shape you selected is

displayed.

* For LK-1900 pattern, the SELECT button

is not displayed when ROM is not set to

C

D

MAIN p. c. b.

⑤ Select the sewing shape.

When UP or DOWN SCROLL button (E) is

pressed, the SEWING SHAPE buttons (F) are

changed over in order. Here, press the

SEWING SHAPE button you desire to select.

The details of the selected shape is displayed

at the upper part of the screen.

⑥ Determine the sewing shape.

When ENTER button

(G) is pressed,

the sewing shape is determined and the data

input screen is displayed.

G

F

15

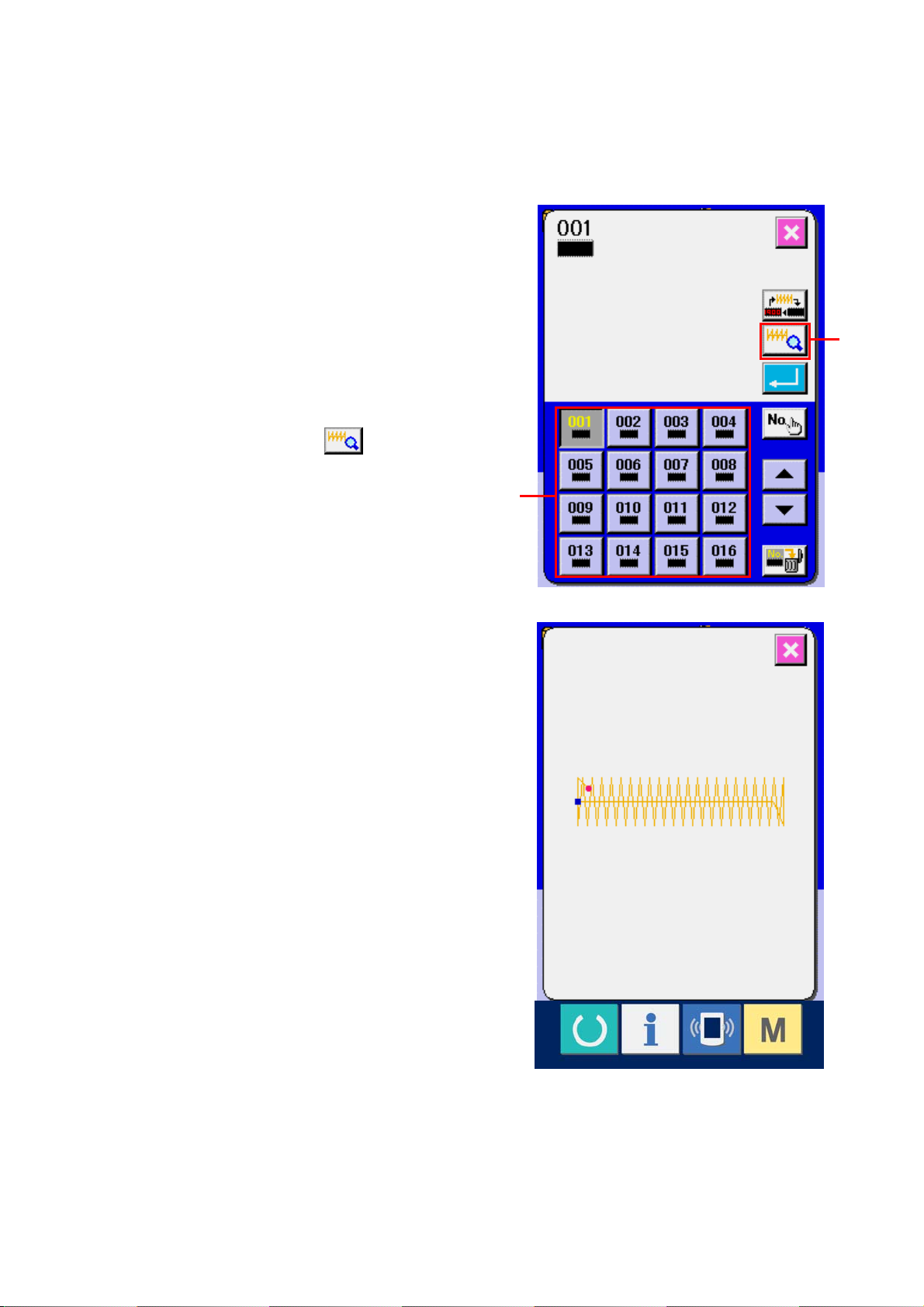

When the sewing shape is LK-1900 pattern or users'

pattern, the screen as shown on the right side is

displayed.

PATTERN NO. SELECTION buttons (H) which have

been registered to LK-1900 pattern or users' pattern

are displayed. Press the button of the pattern No. you

desire to select.

In addition, when you desire to confirm the shape you

selected, press VIEWER button

viewer screen is displayed and the selected shape is

displayed.

(I). Then the

I

H

16

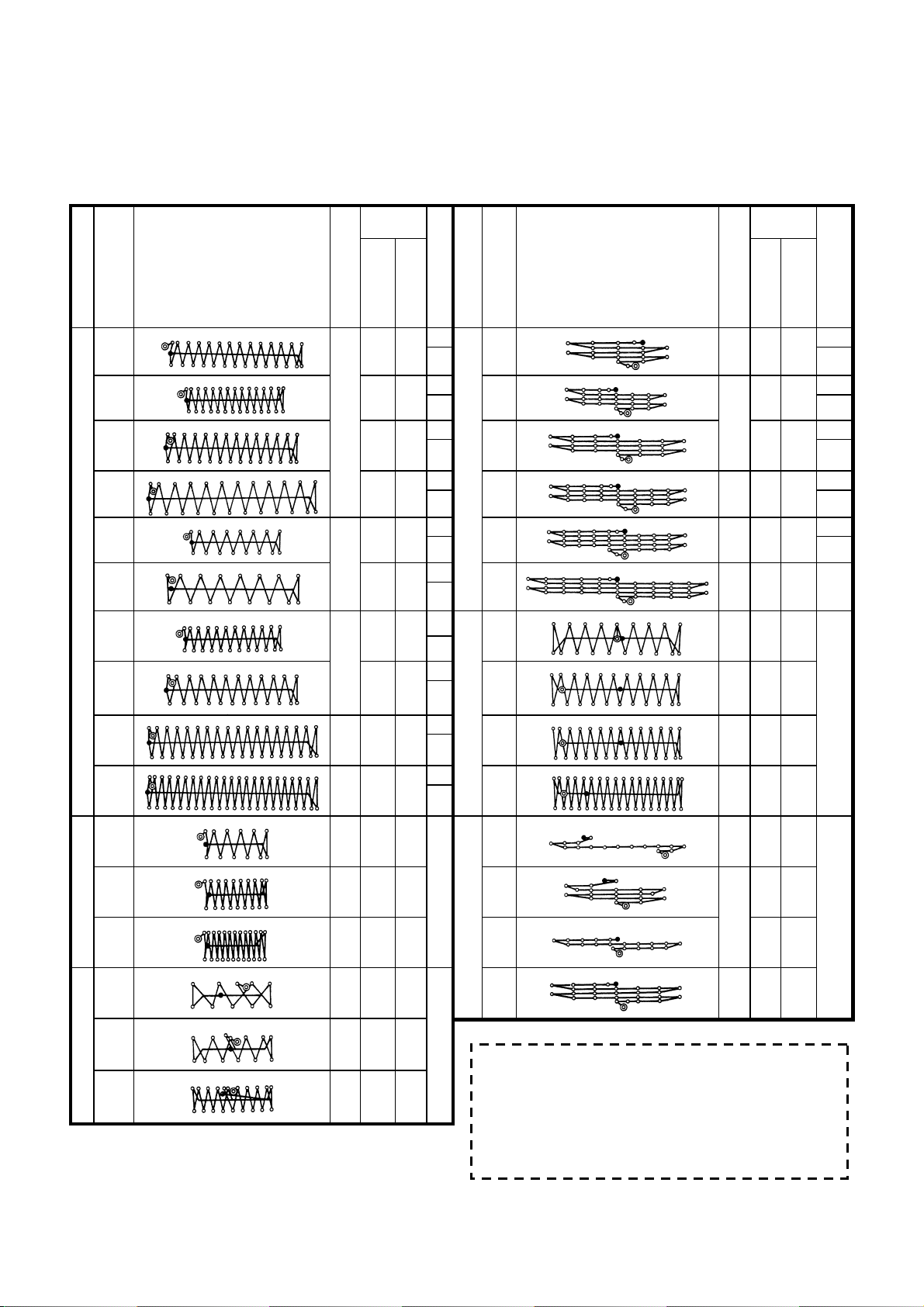

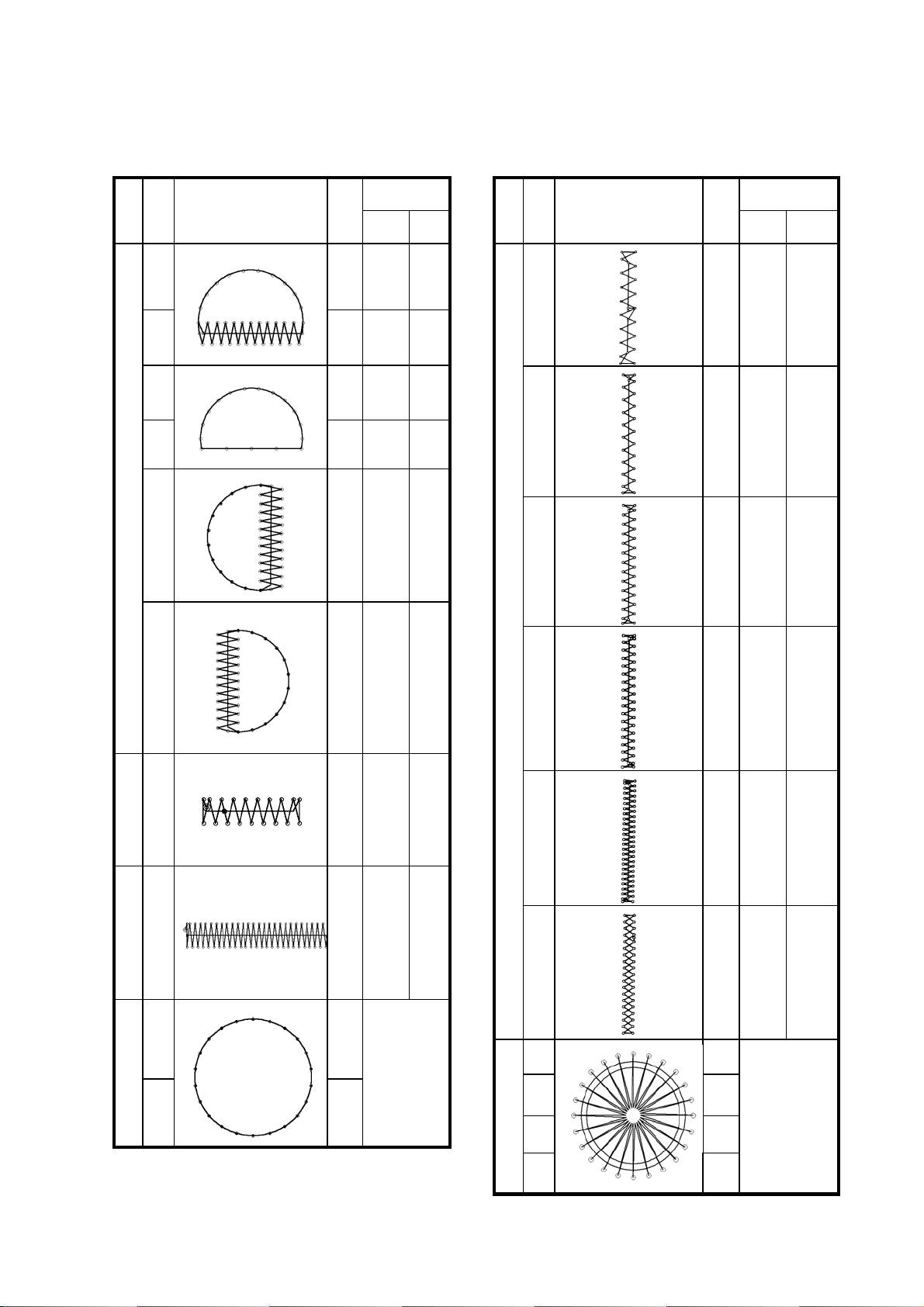

5. SEWING SHAPE LIST

Sewing

size (mm)

Sewing

size (mm)

No Stitch diagram

(51)

3

4

6

Large bar-tacking

8

9

*

10

11

12

13

Small bar-tacking

14

15

Lengthwise

Number of stitches

2.0 16

42

2.0 10

2.5 16

3.0 24

28

2.0 10

2.5 16

2.0 10

36

2.5 16

56 3.0 24

64 3.0 24

21 2.5 6 27

28 2.5 6 28

36 2.5 6

14 2.0 8

21 2.0 8

Crosswise

(Note 2) No. of presser

1 1 1

2

1 1 2

2

1 6 *

4

6 6 *

7

Linear bar-tacking

1 6 5

2

1*

4

17

2

1*

4

6*

7

Lengthwise bar-tacking

6

7

8

5

Lengthwise linear bar-tacking

No Stitch diagram

17

18

19

20

21

22

23

(Other side)

24

(Other side)

25

(Other side)

26

(Other side)

(Other side)

(Other side)

29

(Other side)

30

(Other side)

Number of stitches

(Note 2) No. of presser

Crosswise

Lengthwise

21 0 10

0 10

28

2

2

0 25

7

36 0 25

7

41 0 25

44 0 35

7

(Not

e 3)

28 20 4.0

9

(This side)

36 20 4.0

(This side)

42 20 4.0

(This side)

56 20 4.0

(This side)

18 20 0

11

(This side)

21

10 0

(This side)

20 0

(This side)

28 20 0

(This side)

(Note)

1. Sewing size shows the dimensions when the scale rate is 100%.

2. Refer the No. of presser to the separate table of presser.

3. For No. 22, process the presser blank for use.

4. Use the patterns with * marks for sewing denim.

16

Knit goods bar-tacking

28 2 0 8

5. No51 is for the machine whthout tread clamp.

17

Sewing size

stitches

Lengt

(mm)

hwise

wise

Cross

No

41

No

31 52 7 10

Stitch diagram

Number of

Stitch diagram

Sewing size

(mm)

stitches

Number of

Lengt

hwise

29 20 2. 5

wise

Cross

32

33 24 6 10

34

35

Semilunar bar-tacking

36

37

63 7 12

42

31 6 12

48 10 7

43

48 10 7

44

Lengthwise bar-tacking

90 3 24

45

39 25 2. 5

45 25 2. 5

58 30 2. 5

75 30 2. 5

Large bar-tacking

38 28 2 8

Knit goods bar-tacking

39 28

40

Round bar-tacking

48

18

Φ12

46

47 91

48 99

49 148

Radial tacking

50 164

42 30 2. 5

Φ8

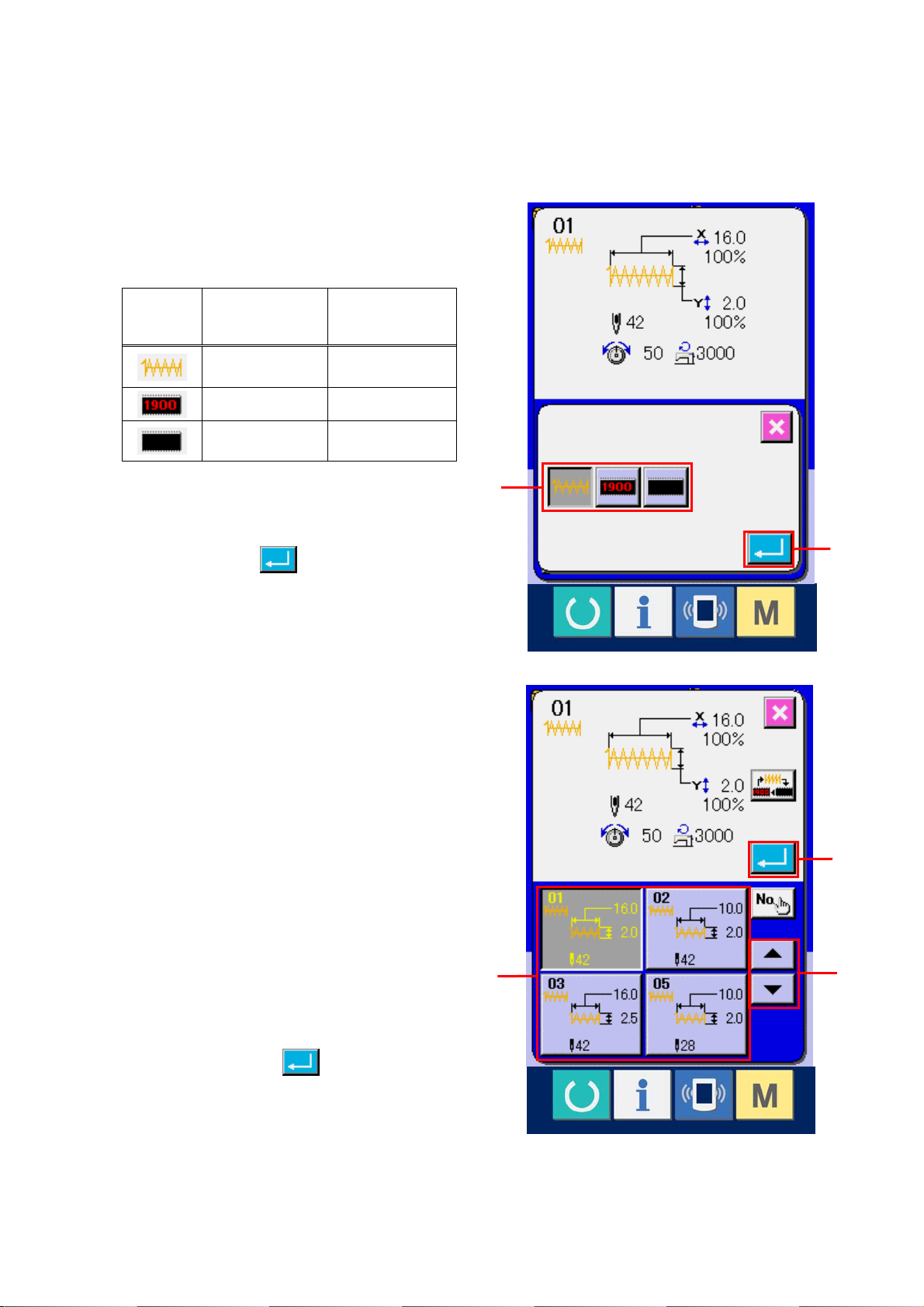

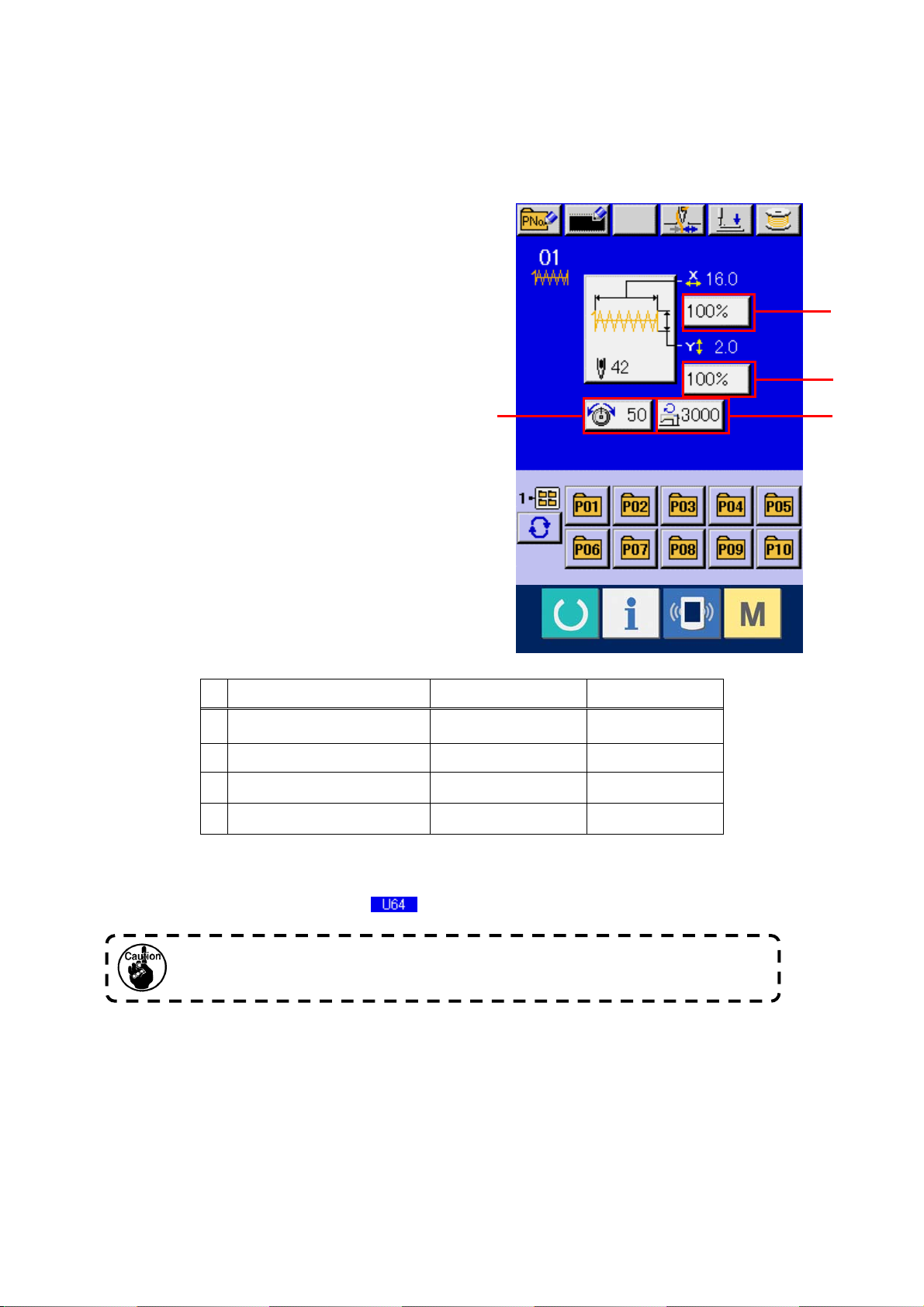

6. PERFORMING ITEM DATA CHANGE

① Display the data input screen.

In case of the data input screen, the change

of item data can be changed. In case of the

sewing screen (green), press READY switch

to display the data input screen (blue).

* Thread tension value can be changed even in

the sewing screen.

② Display the item data input screen.

When the button of the item data you desire to

change is pressed, the item data input screen

is displayed.

There are four items of the item data below.

Item Input range Initial value

A Scale rate in X direction 20 to 200 (%) 100(%)

A

B

C D

B Scale rate in Y direction 20 to 200 (%) 100(%)

C Thread tension 0 to 200 50

D Max. speed limitation 400 to 3,000 (rpm) 3,000 (rpm)

* A Scale rate in X direction and B Scale rate in Y direction can be changed to actual size value input

by selection of the memory switch

.

The setting exceeding 100% is dangerous since needle and the cloth presser interferes

with each other and needle breakage or the like will occur.

19

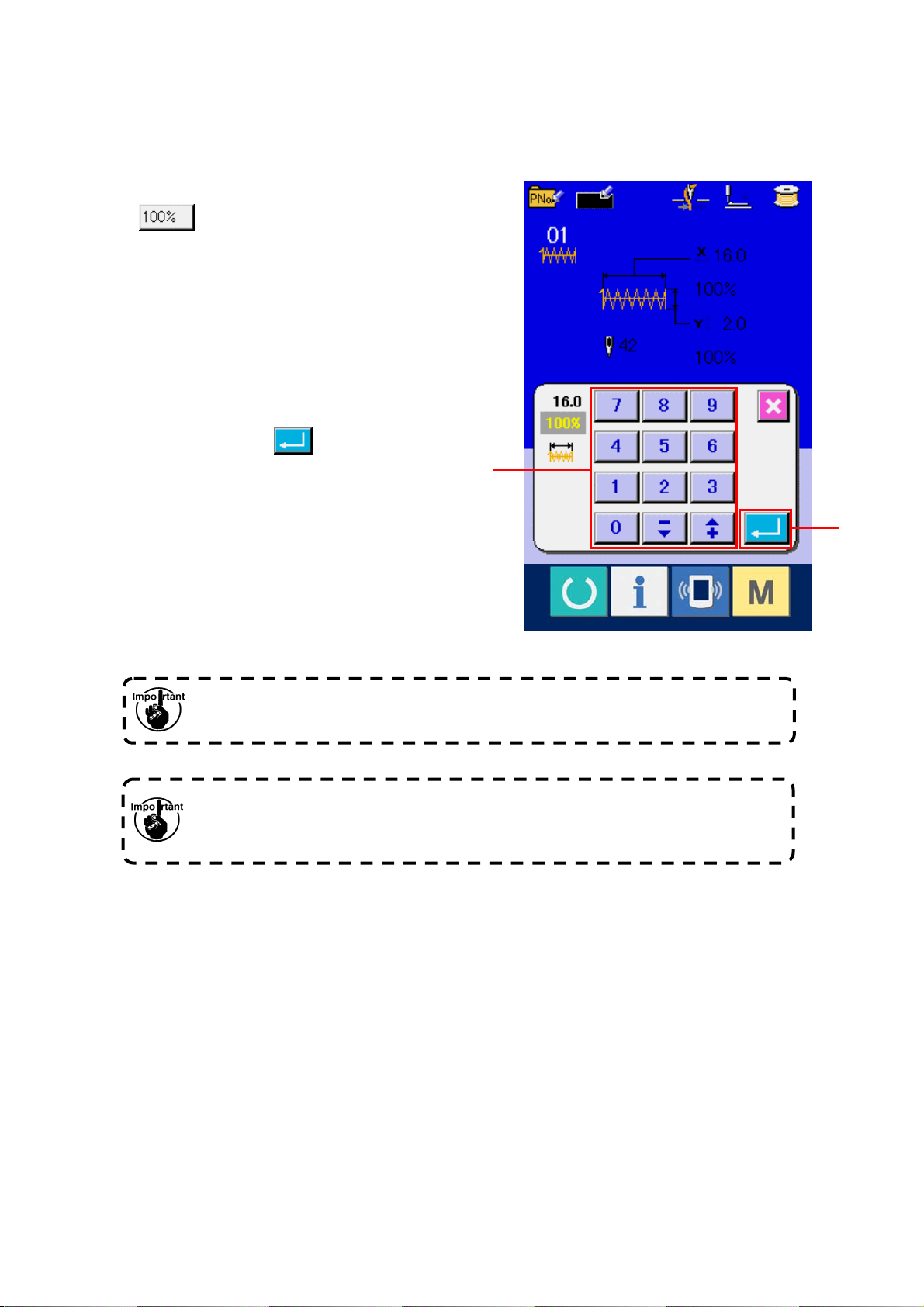

For example, input X scale rate.

Press

(A) to display the item data input

screen.

③ Input the data.

Input the value you desire with ten keys and

+/- keys (E).

④ Determine the data.

When ENTER button

the data is determined.

(F) is pressed,

E

* For the other item data, the data can be

changed by the same operation.

F

When turning OFF the power without pressing RE ADY key, the set values of pattern

No. , X/Y scale, number of max. rotation, and thread tension are not memorized.

In case thread tension is changed in the read state, the set value w hen the power is

turned OFF without pressing READY key or without performing sewing is not stored in

memory.

20

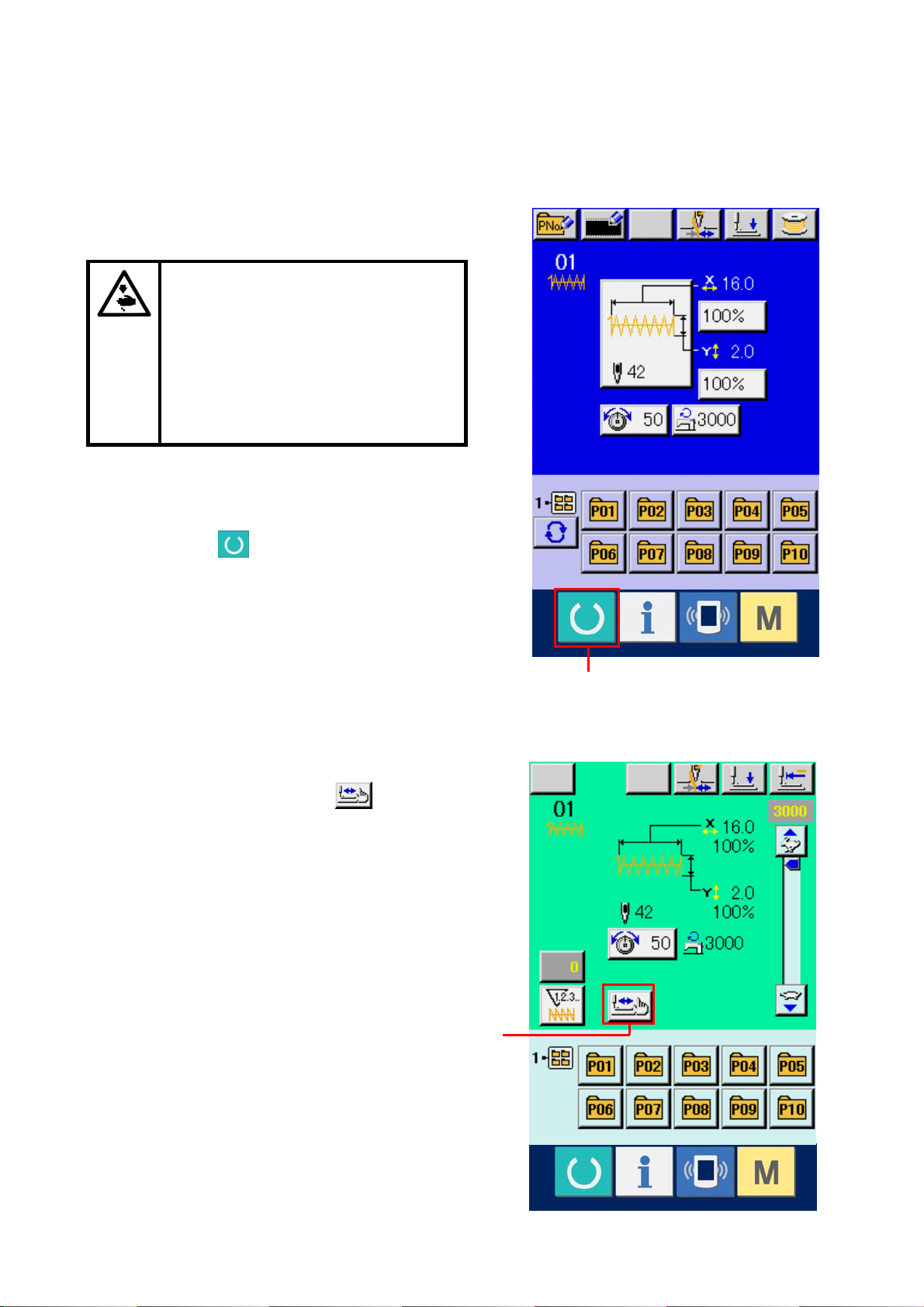

7. CHECKING PATTERN SHAPE

Make sure without fail of the contour

of the sewing pattern after selection

of the sewing pattern. If the sewing

pattern extends outside the work

clamp feet, the needle will interfere

with the work clamp feet during

sewing, causing dangerous troubles

including needle breakage.

① Display the sewing screen.

Display the data input screen (blue) and press

READY key

LCD changes to green and sewing is possible.

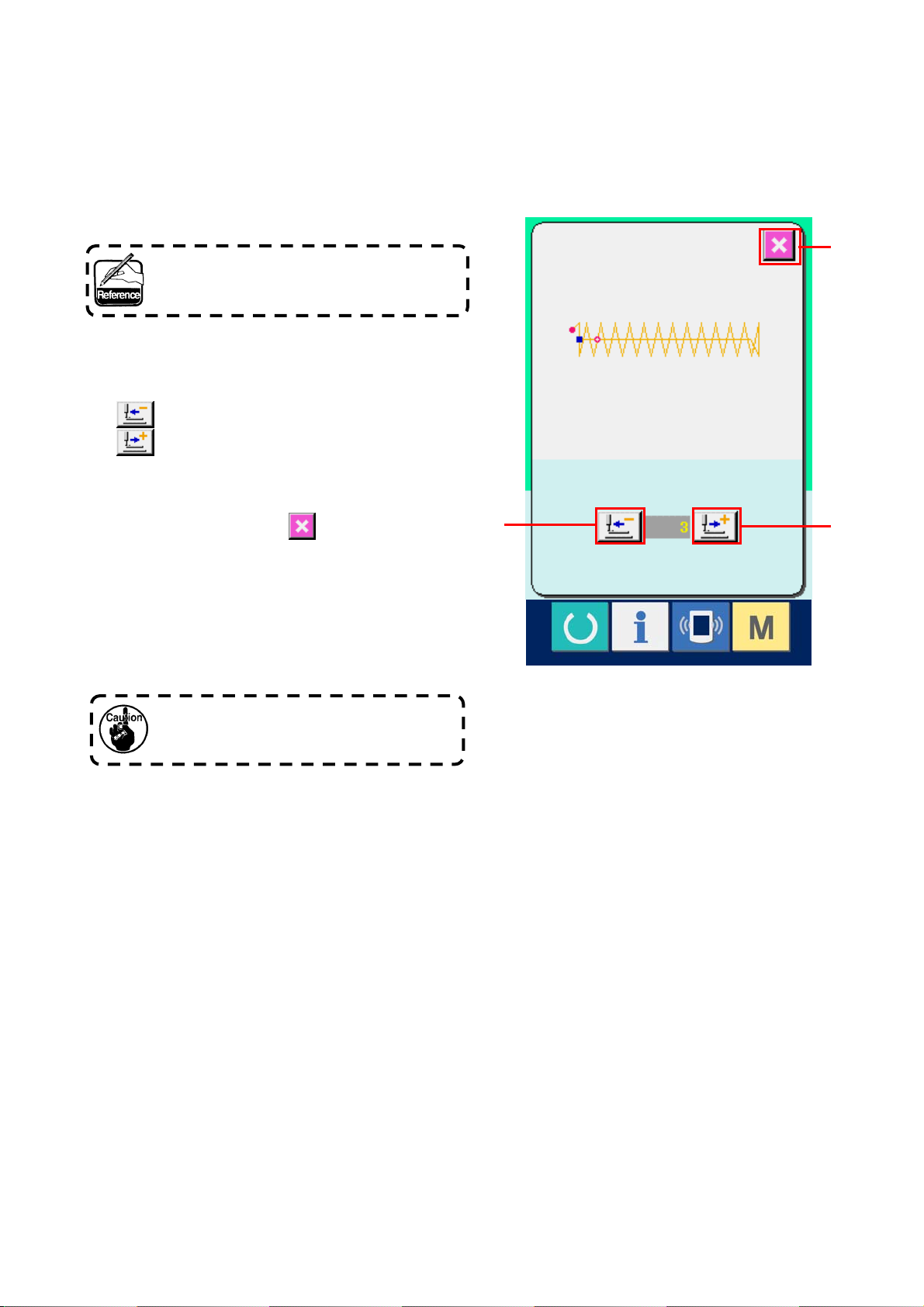

② Display the step sewing screen.

When STEP SEWING button

pressed, the step sewing screen is displayed.

(C). Then the back-light of

(B) is

A

21

B

③ Lower the presser with the foot switch.

The work clamp feet do not go up even

when the foot sw itch is detached.

④ Proceed stitching wi th the presser lowered.

Check the shape with PRESSER BACK button

(C) and PRESSER FORWARD button

(D).

⑤ Finish checking the shape.

When CANCEL button

(E) is pressed, the

screen returns to the sewing screen. When the

checking of the shape is not in the position of

the start of sewing or that of the end of sewing,

press the foot switch. Then it is possible to

C

E

D

sew from the midway of checking.

The presser does not come down

immediately after turning ON the power.

22

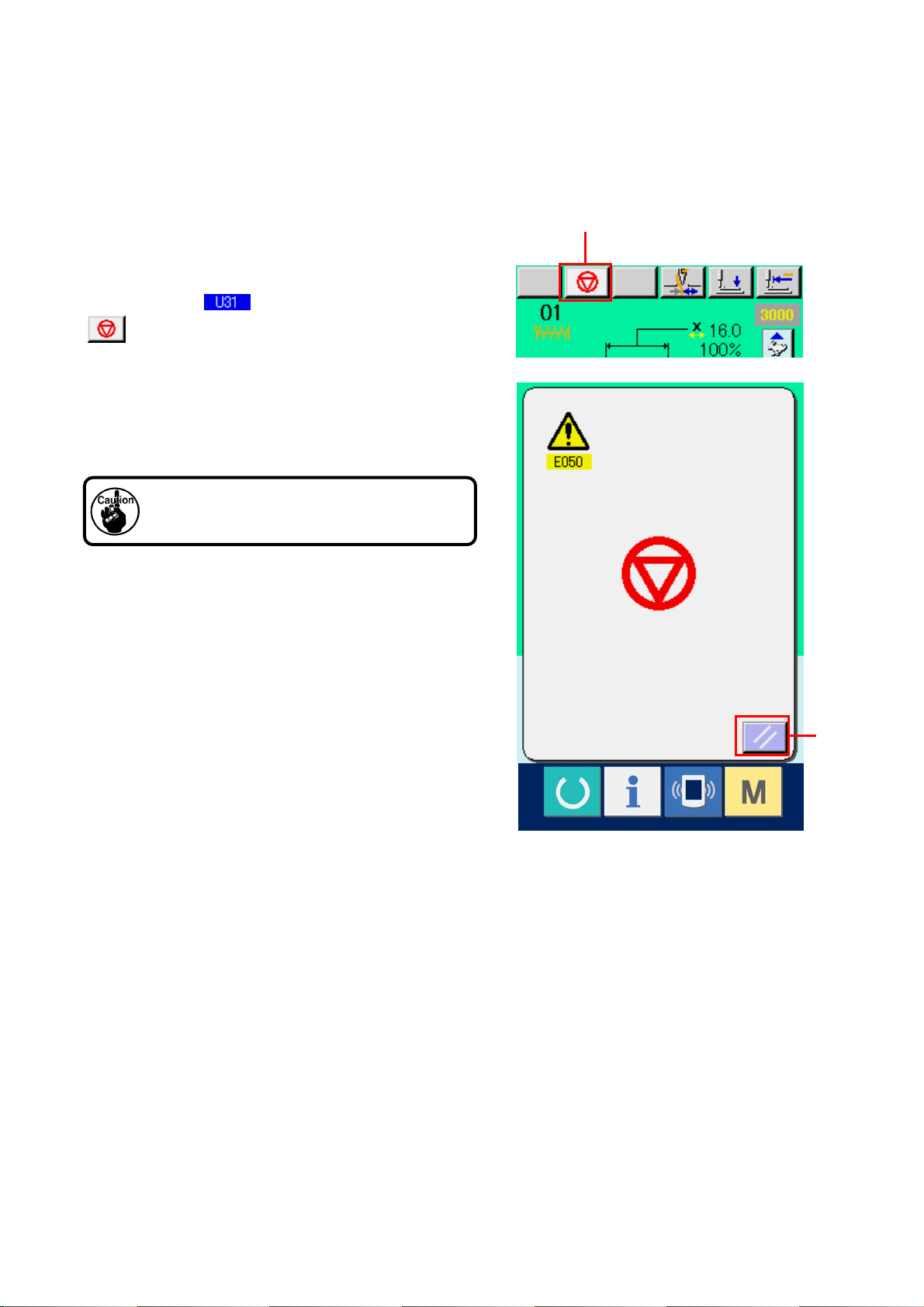

8. USING TEMPORARY STOP

When the panel temporary stop button is selected with

memory switch

(A) is displayed on the sewing screen. When the

temporary stop switch is pressed during sewing, the

sewing machine can be stopped. At this time, the error

screen is displayed to inform that the stop switch is

pressed.

Perform the same operation when the external

switch is used for the temporary stop.

, TEMPORARY STOP button

A

B

23

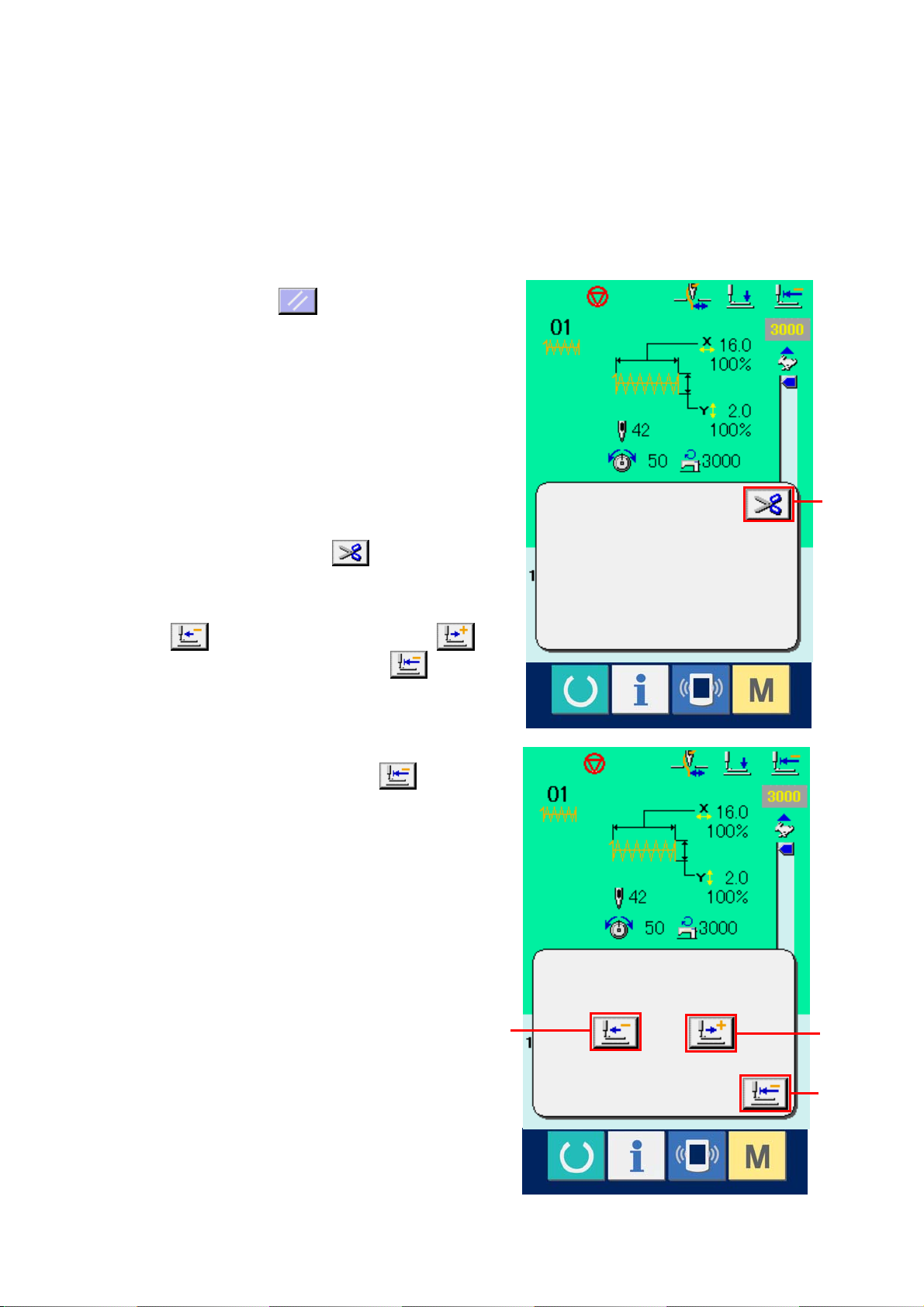

8-1 To continue performing sewing from some point in sewing

① Release the error.

Press RESET button

(B) to release the

error and the sewing screen is displayed.

② Perform thread trimming.

Press THREAD TRIM button

perform When thread trimming has been

performed, FEED BACK button

(D) ,FEED FORWARD button

RETERN TO ORIGIN button

displayed on the screen.

(C) to

C

(E) and

(F) are

③ Adjust the presser to the re-sewing pssition.

When FEED BACK button

(D) is pressed,

the peresser returnds stich and by stitch and

when FEED FORWARD button

(E) is

pressed, it advances stich by sitich. Move the

presser to the re-sewing position.

④ Re-start the sewing

When the pedal is depressed, sewing starts

again.

D

E

F

24

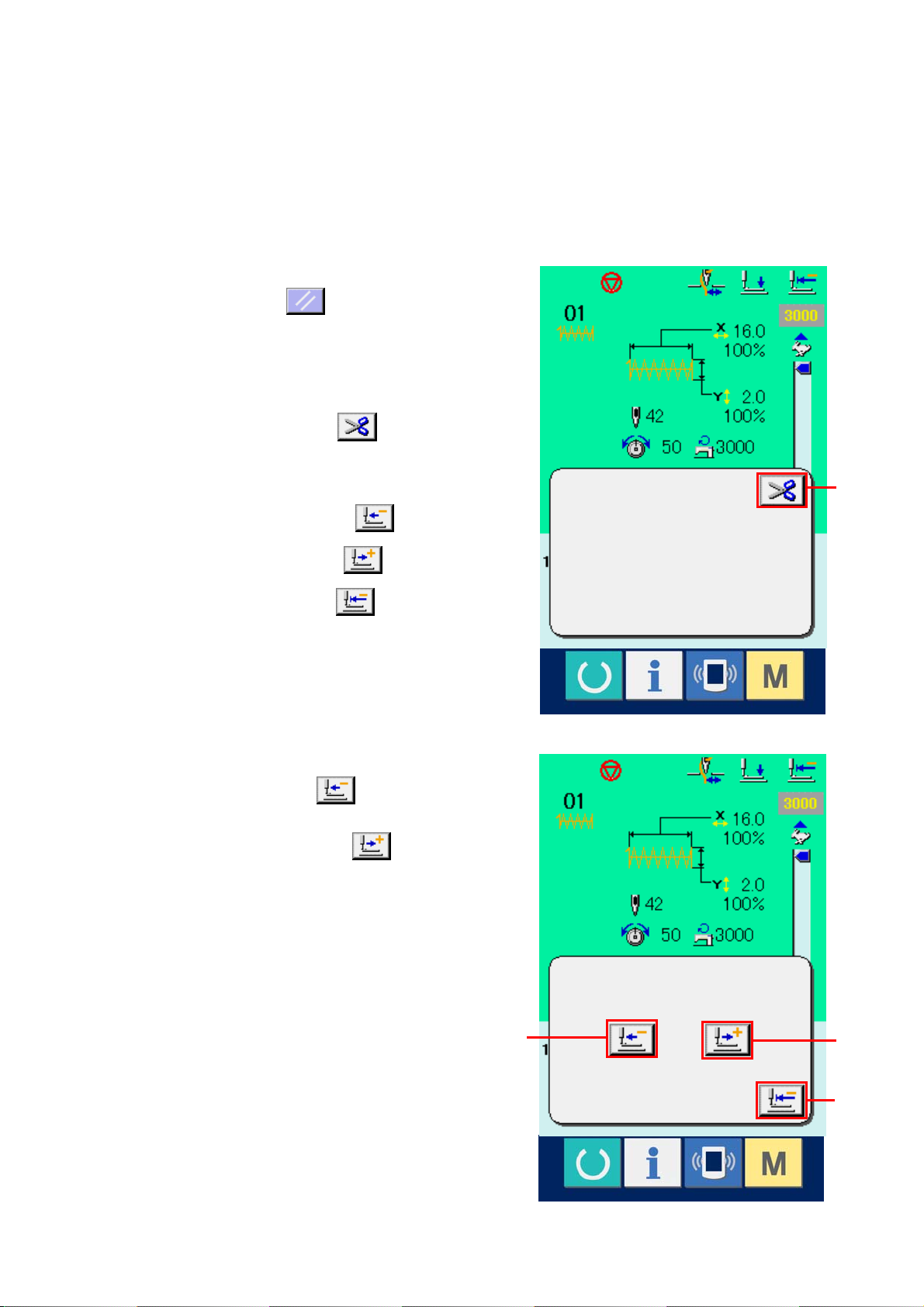

8-2 To perform re-sewing from the start

① Release the error.

Press RESET button

error and the sewing screen is displayed.

② Perform thread trimming.

Press THREAD TRIM button

thread trimming.

When thread trimming is performed, FEED BACK

button

(E) and RETURN TO ORIGIN button

are displayed on the screen.

③ Return to the origin.

(D), FEED FORWARD button

(B) to release the

(C) to perform

C

(F)

When RETURN TO ORIGIN button

pressed, the pop-up is closed, the sewing

screen is displayed and the machine returns to

the position of the start of sewing.

④ Perform again the sewing work from the

start

When the pedal is depressed, sewing starts

again.

25

(F) is

D

E

F

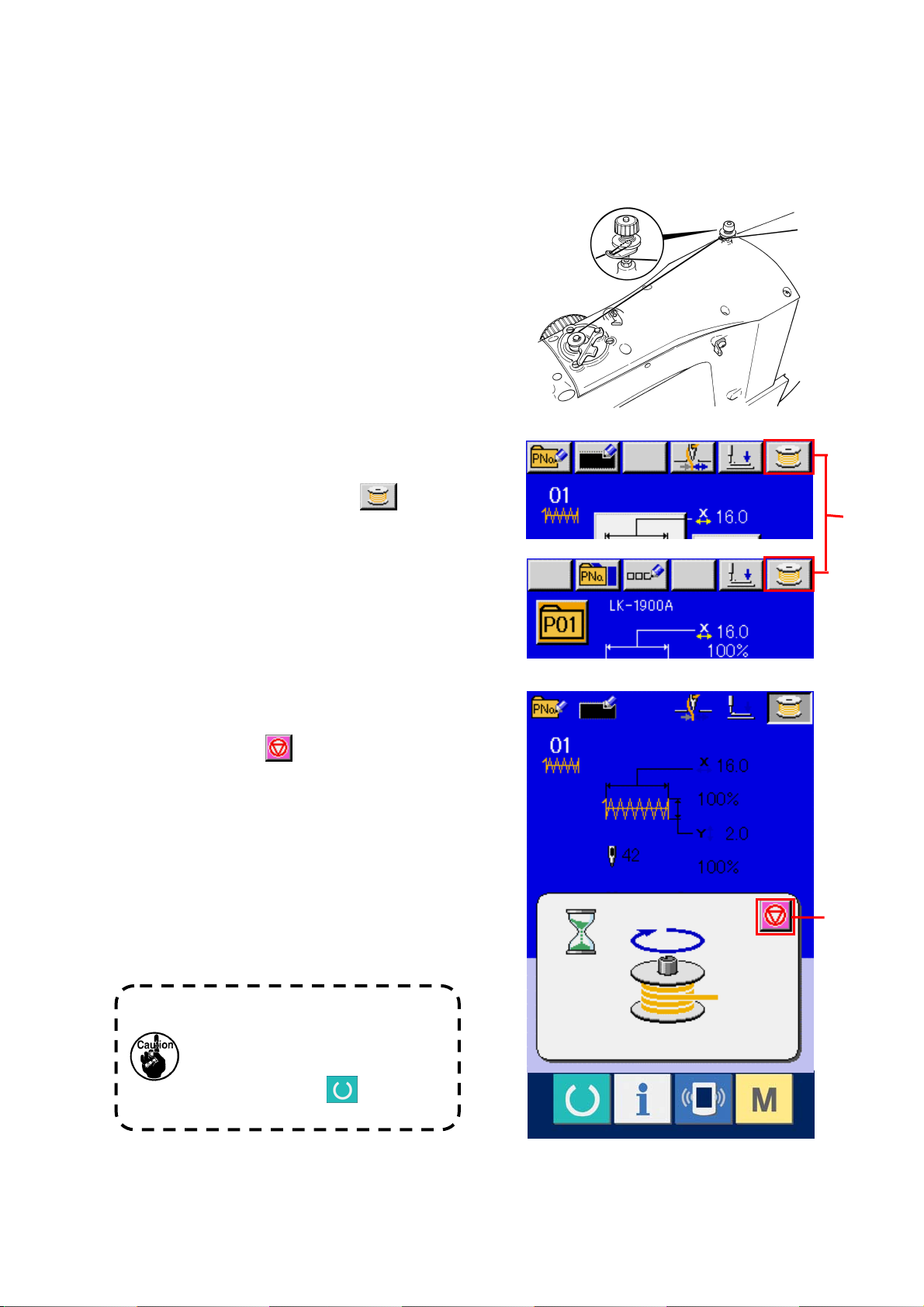

9. WINDING BOBBIN THREAD

9-1 When performing winding bobbin thread

while performing sewing

Pass the thread to wind bobbin thread as shown in

the figure on the right side.

9-2 When performing winding bobbin thread only

① Display the bobbin winding screen.

Press BOBBIN WINDER button

(A) in the

data input screen (blue) and the bobbin winding

screen is displayed.

② Start bobbin wi nding.

Depress the start pedal, and the sewing machine

rotates and starts winding bobbin thread.

③ Stop the sewing machine.

Press STOP button

(B) and the sewing

machine stops and returns to the normal mode.

Or, depress the start pedal again during winding

bobbin and the sewing machine stops while the

bobbin thread winding mode stays as it is.

Depress the start pedal again and the bobbin

winding starts again. Use this way when winding

bobbin thread around plural bobbins.

A

B

Bobbin winder does not work

immediately after turning ON the

power. Perform the bobbin winding

after setting pattern No. or the like

once, pressing the

making the sewing LED light up.

key, and

26

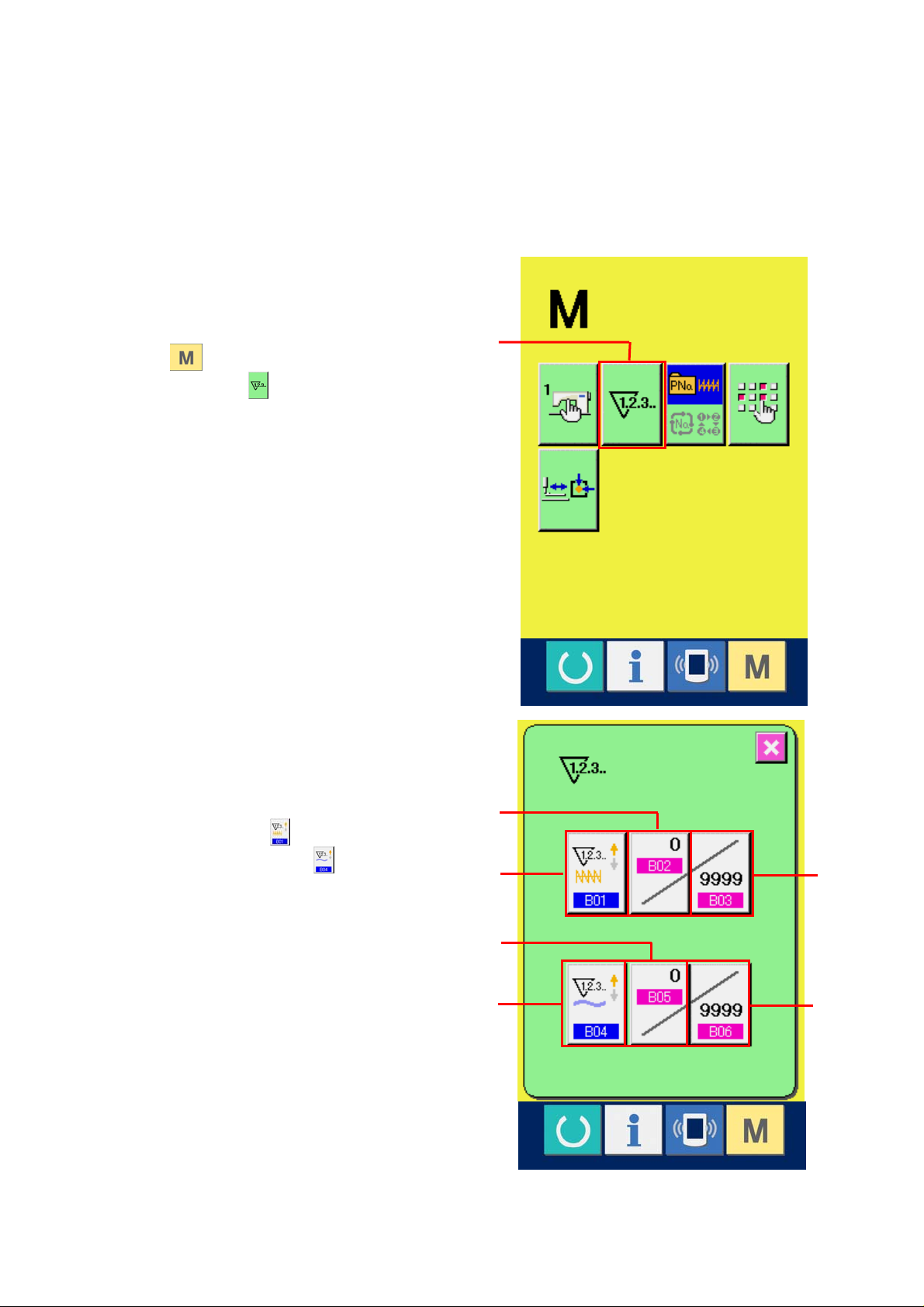

10. USING COUNTER

10-1 Setting procedure of the counter

① Display the counter setting screen.

Press

SETTING button

screen. When this button is pressed, the

counter setting screen is displayed.

② Selection of kinds of counters

This sewing machine has two kinds of

counters, i. e. , sewing counter and No. of pcs.

switch and the COUNTER

(A) is displayed on the

A

counter. Press SEWING COUNTER KIND

SELECTION button

KIND SELECTION button

the counter kind selection screen. The kinds

of the respective counters can be set

separately.

27

(B) or NO. OF PCS.

(C) to display

E

C

D

B

F

G

[ Sewing counter ]

UP counter

:

Every time the sewing of one shape is performed,

the existing value is counted up. When the existing

value is equal to the set value, the count-up screen

is displayed.

DOWN counter

:

Every time the sewing of one shape is performed,

the existing value is counted down.

When the existing value is reached to "0", the

count-up screen is displayed.

Counter not used

[ No. of pcs. Counter ]

UP counter

:

Every time one combination sewing is performed,

the existing value is counted up. When the existing

value is equal to the set value, the count-up screen

is displayed.

DOWN counter

:

Every time one combination sewing is performed,

the existing value is counted down. When the

existing value is reached to "0", the count-up

screen is displayed.

Counter not used

28

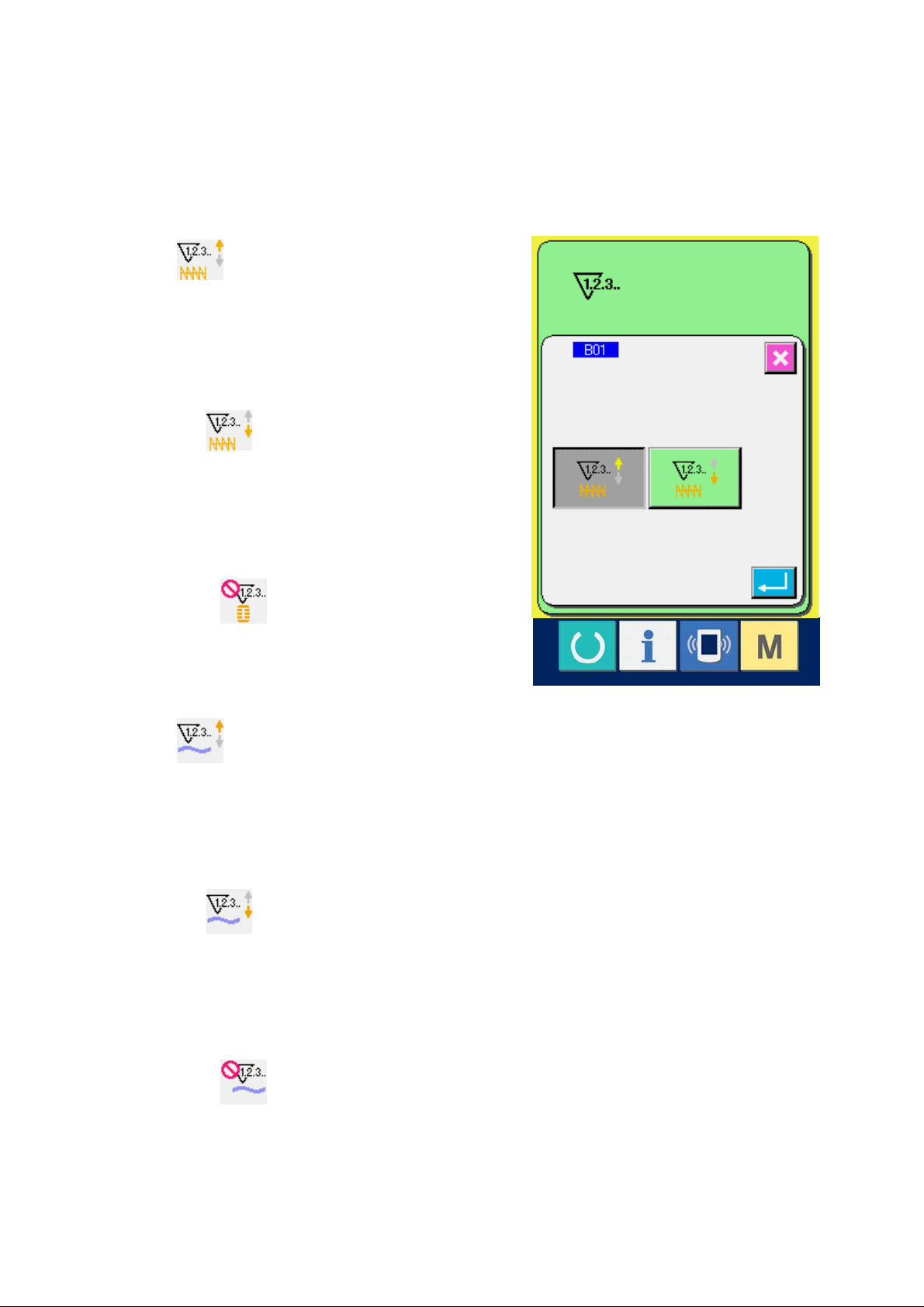

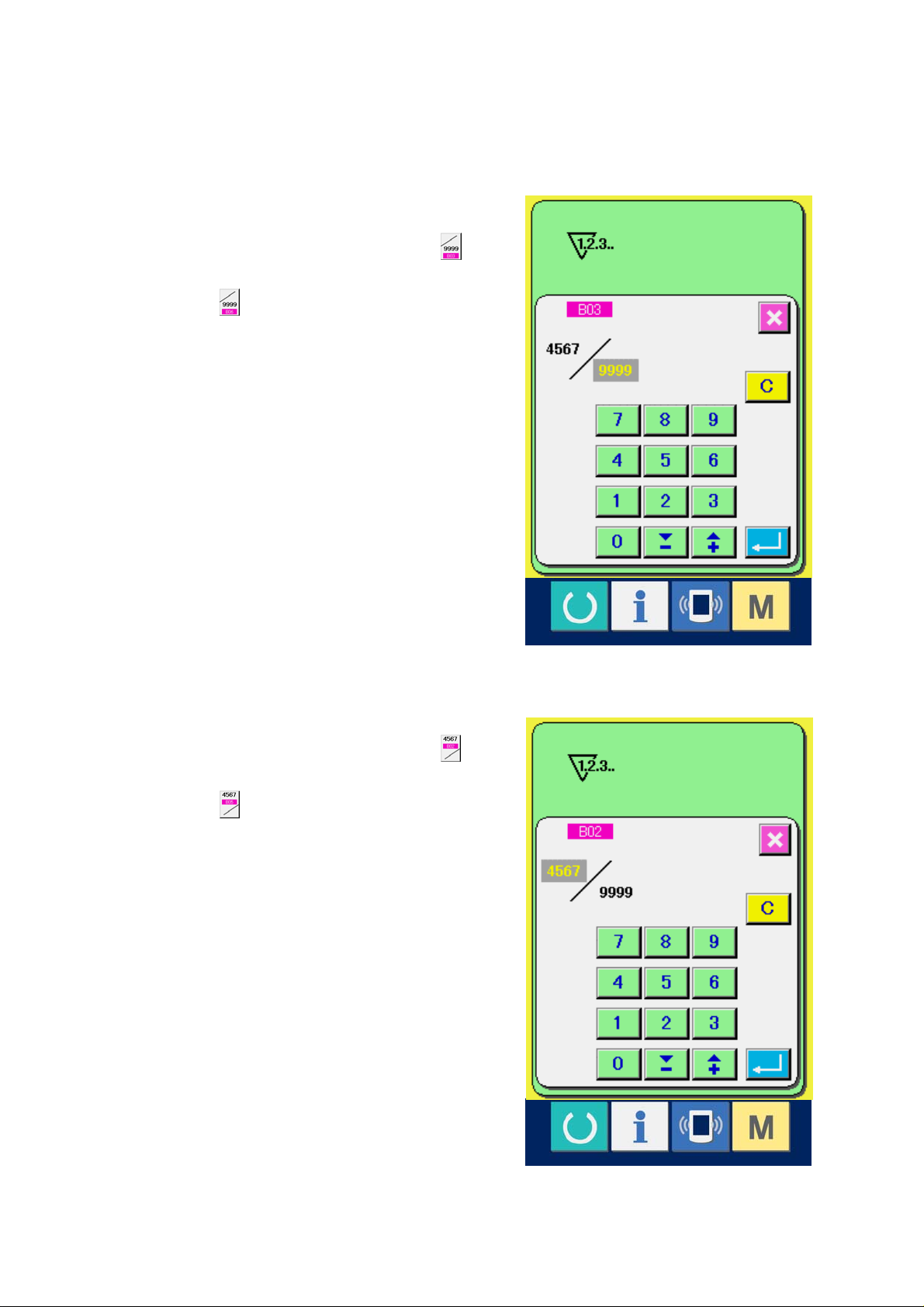

③ Change of counter set value

In case of the sewing counter, press button

(F) and in case of the No. of pcs. counter,

press button

screen is displayed.

Here, input the set value.

When "0" is inputted in the set value, the

display of count-up screen is not performed.

(G) and the set value input

④ Change of counter existing value

In case of the sewing counter, press button

(D) and in case of the No. of pcs. counter,

press button

input screen is displayed.

Here, input the existing value.

(E) and the existing value

29

Loading...

Loading...