Page 1

ENGLISH

IP-110 TYPE F

INSTRUCTION MANUAL

* "CompactFlash(TM)" is the registered trademark of SanDisk Corporation, U.S.A.

i

No.00

40

Page 2

CONTENTS

1. INSTALLING THE OPERATION PANEL .......................................................................1

2. CONNECTING THE CORD ...........................................................................................1

3. MACHINE HEAD SETTINGS ........................................................................................2

4. ADJUSTING THE MACHINE HEAD ANGLE

(DIRECT-DRIVE MOTOR TYPE SEWING MACHINE ONLY) .......................................3

5. EXPLANATION OF THE OPERATION PANEL.............................................................4

5-1. Names and functions of each components .................................................................................4

5-2. Adjusting the contrast of the operation panel screen ................................................................6

5-3. Connection of the production support switch ............................................................................6

5-4. Basic screen ...................................................................................................................................7

5-5. How to operate the operation panel for sewing stitching patterns ...........................................9

(1) Reverse stitching pattern ...................................................................................................................9

(2) Overlapped stitching pattern ...........................................................................................................11

(3) Programmed stitching pattern

(4) Cycle sewing pattern ........................................................................................................................16

.........................................................................................................12

6. BOBBIN COUNTER ....................................................................................................18

7. NO. OF PCS. COUNTER .............................................................................................19

8. RE-SEWING SWITCH .................................................................................................19

9. NEEDLE UP/DOWN COMPENSATION SWITCH .......................................................20

10. ON/OFF SWITCH OF THE MATERIAL EDGE SENSOR ......................................20

11. AUTOMATIC THREAD TRIMMING SWITCH ........................................................20

12. ONE-SHOT AUTOMATIC STITCHING SWITCH ...................................................20

13. THREAD TRIMMING PROHIBITION SWITCH ......................................................21

14. SIMPLIFIED FUNCTION SETTING .............................................................................22

15. KEY-LOCK FUNCTION SETTING ..............................................................................23

16. FUNCTION SETTING ..................................................................................................24

17. OPTIONAL INPUT/OUTPUT SETTINGS ....................................................................29

18. AUTOMATIC COMPENSATION OF NEUTRAL POINT OF THE PEDAL SENSOR ....30

19. INITIALIZATION OF THE SETTING DATA .................................................................31

20. INFORMATION ............................................................................................................32

(1) Maintenance management function ................................................................................................32

(2) Working measurement function ......................................................................................................36

21. EXTERNAL INTERFACE ............................................................................................38

22. ERROR DISPLAY ........................................................................................................38

22-1. Error code list (Error display in panel).....................................................................................39

i

Page 3

WARNING :

This Instruction Manual describes the operation panel IP-110F.

Be sure to use this operation panel after having read to fully understand the "Safety precautions" in

the Instruction Manual for the SC-920 (control box).

In addition, be careful not to splash water or oil on it, or shock such as dropping and the like since

this product is a precision instrument.

1. INSTALLING THE OPERATION PANEL

WARNING :

To prevent personal injury caused by abrupt start of the sewing machine, carry out the work after

turning OFF the power switch and ascertaining that the motor has completely stopped.

2

4

1

6

3

5

1) Remove side plate setscrews 1 from the side plate.

2) Install operation panelInstall operation panel 2 on the machine head using screws 5, plain washer 3, toothed washer 6 and

rubber seat 4 supplied with the panel.

1. DDL-9000B (Not provided with AK) is given as an example of installing procedure.

2. Screw to install the panel changes according to the machine head used. Refer to Table 1 and con-

rm the kind of screw.

< The relation between the respective machine heads and the positions of installing hole of the bracket are as described in the table. >

Table 1

1

2 3

4

5 6

DDL-9000A

DDL-9000B

DLN-9010

LH-3500A

Installing hole

-

1

5

-

1

5

-

2

5

-

2

5

M5 X 12

M5 X 16

3/16-28 L=14

M5 X 14 Side plate setscrew

Screw

Screw supplied with panel

as accessories

Screw supplied with panel

as accessories

Screw supplied with panel

as accessories

2. CONNECTING THE CORD

1

A

1) Route cord 1 of the operation panel through

hole A in the table toward the underside of the

table.

2) Refer to the Instruction Manual for the SC-920

for how to connect the connector.

- 1 -

Page 4

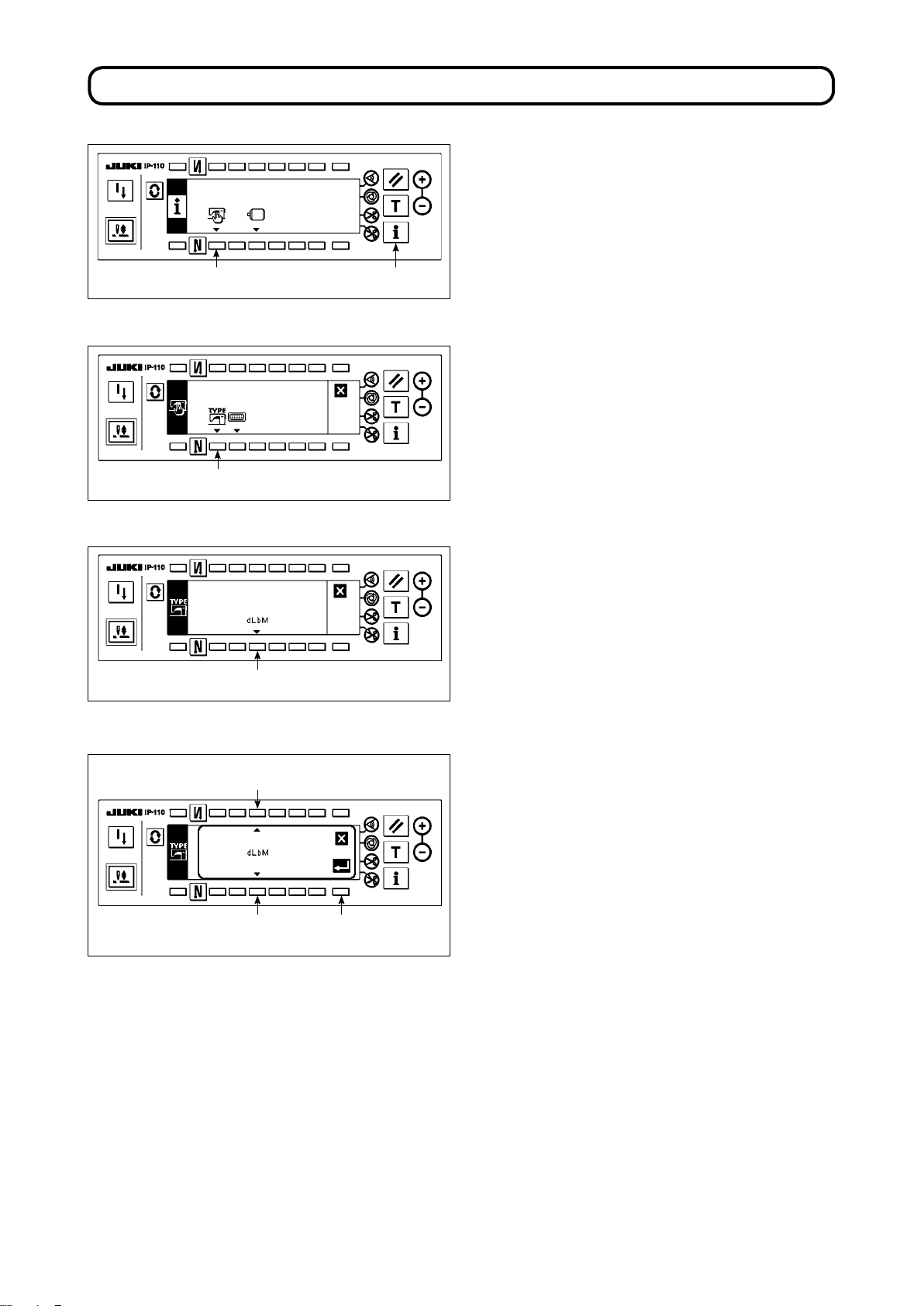

3. MACHINE HEAD SETTINGS

[Function settings list screen]

2 1

[Sewing common data screen]

3

[Machine head type display screen]

1) Keeping switch 1 held pressed, turn the power

ON. Then the screen is changed over to the

function settings list screen.

When you press switch 2, the screen is

changed over to the sewing common data

screen.

2) When you press switch 3, the screen is

changed over to the machine head type display

screen.

3) The displayed machine head type is the machine

head you have selected. When you press switch

, the screen is changed over to the machine

4

head type setting popup screen.

4

[Machine head type setting popup screen]

5

6 7

4) You may selected the machine head as desired

by pressing switches 5 and

* Refer to the separate sheet of "Sewing machine

setup precaution" or the "Machine head list"

given on the separate sheet for the machine

head types.

5) Once you have determined the machine head

type, press switch 7. The screen is changed

over to the “machine head type display screen"

to display the machine head type you have

selected. Turn the power switch OFF to exit from

the machine head setting.

6

.

- 2 -

Page 5

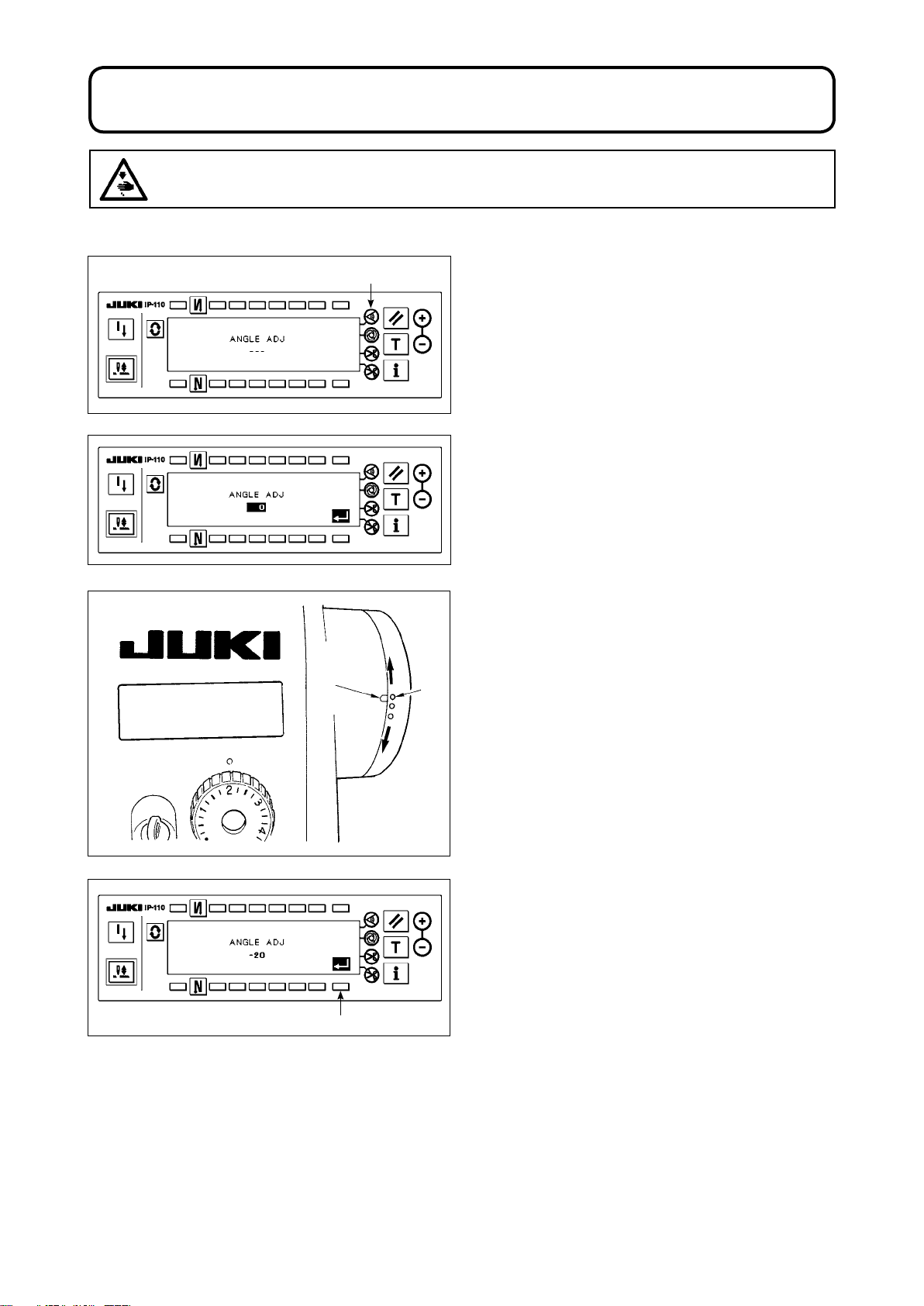

4. ADJUSTING THE MACHINE HEAD ANGLEADJUSTING THE MACHINE HEAD ANGLE (DIRECT-DRIVE MOTOR TYPE SEWING MACHINE ONLY)

WARNING :

Be sure to perform the angle adjustment of the machine head by the operation below before using

the machine head.

[Machine head angle adjusting screen]

3

1

1) Keeping switch 1 held pressed, turn the power

ON. Then the screen is changed over to the

machine head angle adjusting screen.

2) Turn the machine head pulley by hand until the

main shaft reference signal is detected. Then,

the angle transmitted by the main shaft reference

signal is displayed in reverse video. (The value

shown in the gure is a value for reference.)

3) In this state, align the white dot 2 of the hand-

wheel with the concave 3 of the handwheel

cover as shown in the gure.

2

4

4) Once the angle is determined, press switch 4.

The angle displayed in reverse video is now dis-

played in normal video and the angle is replaced

by the adjusted one. Turn the power switch OFF

to exit from the angle adjustment.

- 3 -

Page 6

5. EXPLANATION OF THE OPERATION PANEL

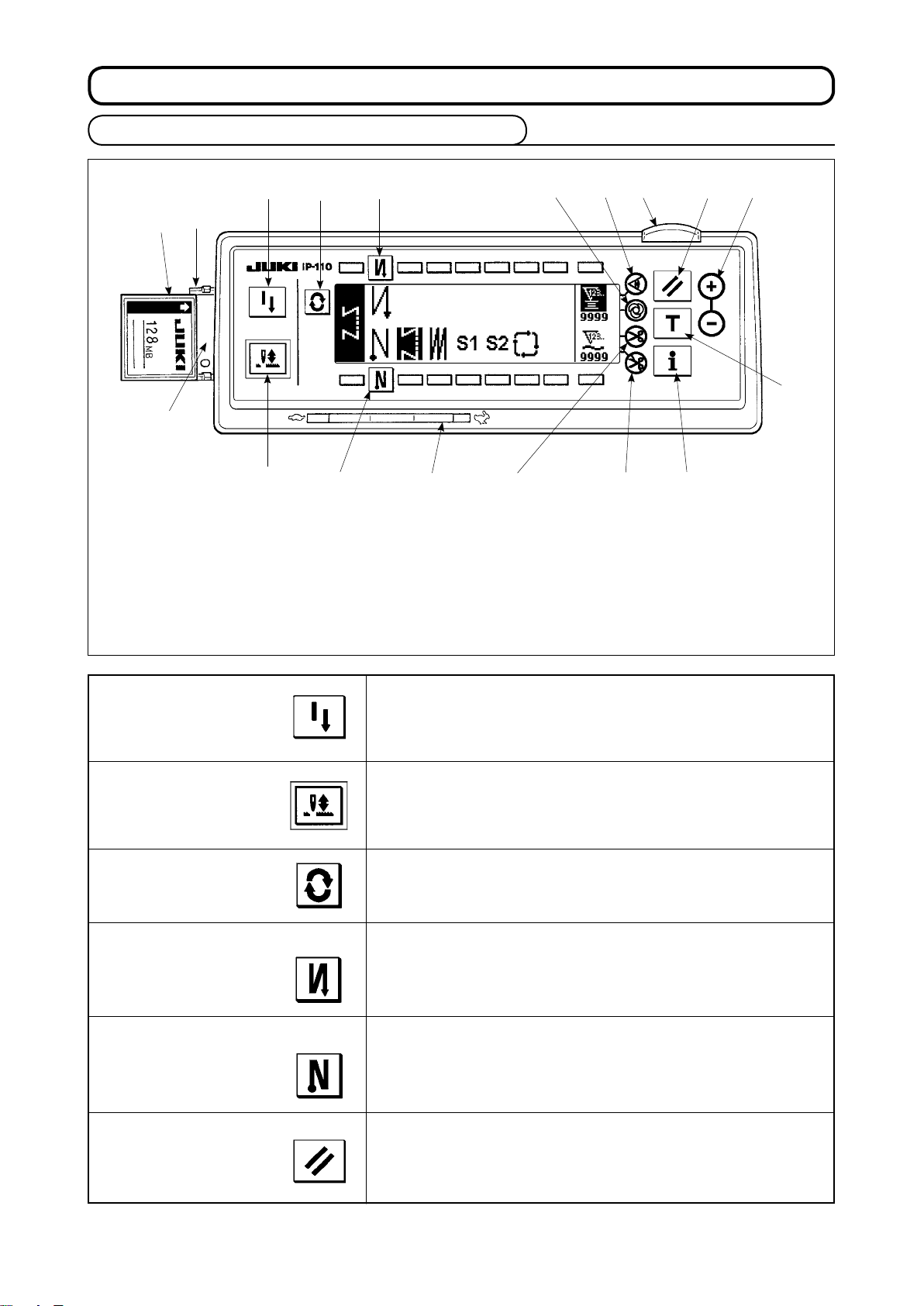

5-1. Names and functions of each components

9

!8

!7

!6

1

3 4

!0

!5

6

!3

7

2

Re-sewing switch

1

Needle up/down compensating switch

2

Screen changeover switch

3

With/without reverse feed stitch at sewing start switch

4

With/without reverse feed stitch at sewing end switch

5

Reset switch

6

Teaching switch

7

Re-sewing switch

1

Needle up/down

2

5

compensating switch

Screen changeover

3

switch

!4

Information switch

8

Material edge sensor switch

9

One-shot automatic sewing switch

!0

With/without automatic thread trimmer switch

!1

Thread trimming prohibiting switch

!2

Counter value setting switch

!3

Max.speed limitation variable resistor

!4

!1

!2

8

Power display lamp

!5

Media cover

!6

Media slot

!7

(Media inserting opening)

CompactFlash(TM)

!8

(Optional : Part No.40091100)

This switch is used to continue sewing from the step on the way

after replacing bobbin thread when bobbin thread has run out

during program stitching step.

This is the switch to perform needle up/down compensating stitching.

(Needle up/down compensating stitching and one stitch compensating

stitching can be changed over with function setting No. 22.)

This is the switch to change over the screen.

With/without reverse feed stitch

4

at sewing start switch

With/without reverse feed stitch

5

at sewing end switch

Reset switch

6

This is the switch to turn ON/OFF automatic reverse feed stitch

at sewing start.

* This switch cannot be used with the sewing machine which is

not provided with automatic reverse feed stitching device.

This is the switch to turn ON/OFF automatic reverse feed stitch

at sewing end.

* This switch cannot be used with the sewing machine which is

not provided with automatic reverse feed stitching device.

This is the switch to make the value of bobbin thread counter or

sewing counter the set value.

- 4 -

Page 7

Teaching switch

7

This is the switch to set the setting of the number of stitches with

the value of number of stitches which has been actually sewn.

Information switch

8

Material edge sensor switch

9

One-shot automatic

!0

sewing switch

With/without automatic

!1

thread trimmer switch

Thread trimming

!2

prohibiting switch

This is the switch to perform various function settings.

Rendered effective when the material edge sensor is installed on

the machine.

Used for selecting whether or not the material edge sensor is

used during sewing.

When this switch is set to effective at the time of program

stitching, the sewing machine automatically operates up to the

specied number of stitches.

When this switch is set to effective at the time of using the

material end sensor for the reverse feed stitching pattern, the

thread trimmer automatically trims the thread upon completion of

sewing the specied number of stitches.

This switch prohibits all thread trimmings.

* This switch cannot be used with the sewing machine which is

not provided with the automatic thread trimming device.

Counter value setting

!3

switch

Max. speed limitation variable

!4

resistor

Power display lamp

!5

Media slot cover

!6

Media slot

!7

(Media inserting opening)

This is the switch to set the value of bobbin thread counter or No.

of pcs. counter.

When moving the resistor in the left direction, max. speed is limited.

This lamp lights up when the power switch is turned ON.

This is the cover for media inserting opening.

To open the cover, place your nger on the notch located on the

side of the cover as shown in the gure and push the cover in the

direction of left slanting rear.

* There are some functions that are not able to be operated

with the cover opened. Do not close the cover unless the

CompactFlash(TM) is completely inserted.

To set CompactFlash(TM), place the label face of the

CompactFlash(TM) to the front and insert the part that has a

small hole (place the notch of the edge to the rear) to the panel.

To remove the CompactFlash(TM), hold it between your ngers

and draw it out.

* When the inserting direction of the CompactFlash(TM) is wrong,

the panel and the CompactFlash(TM) may be damaged. Do not

insert anything other than the CompactFlash(TM).

- 5 -

Page 8

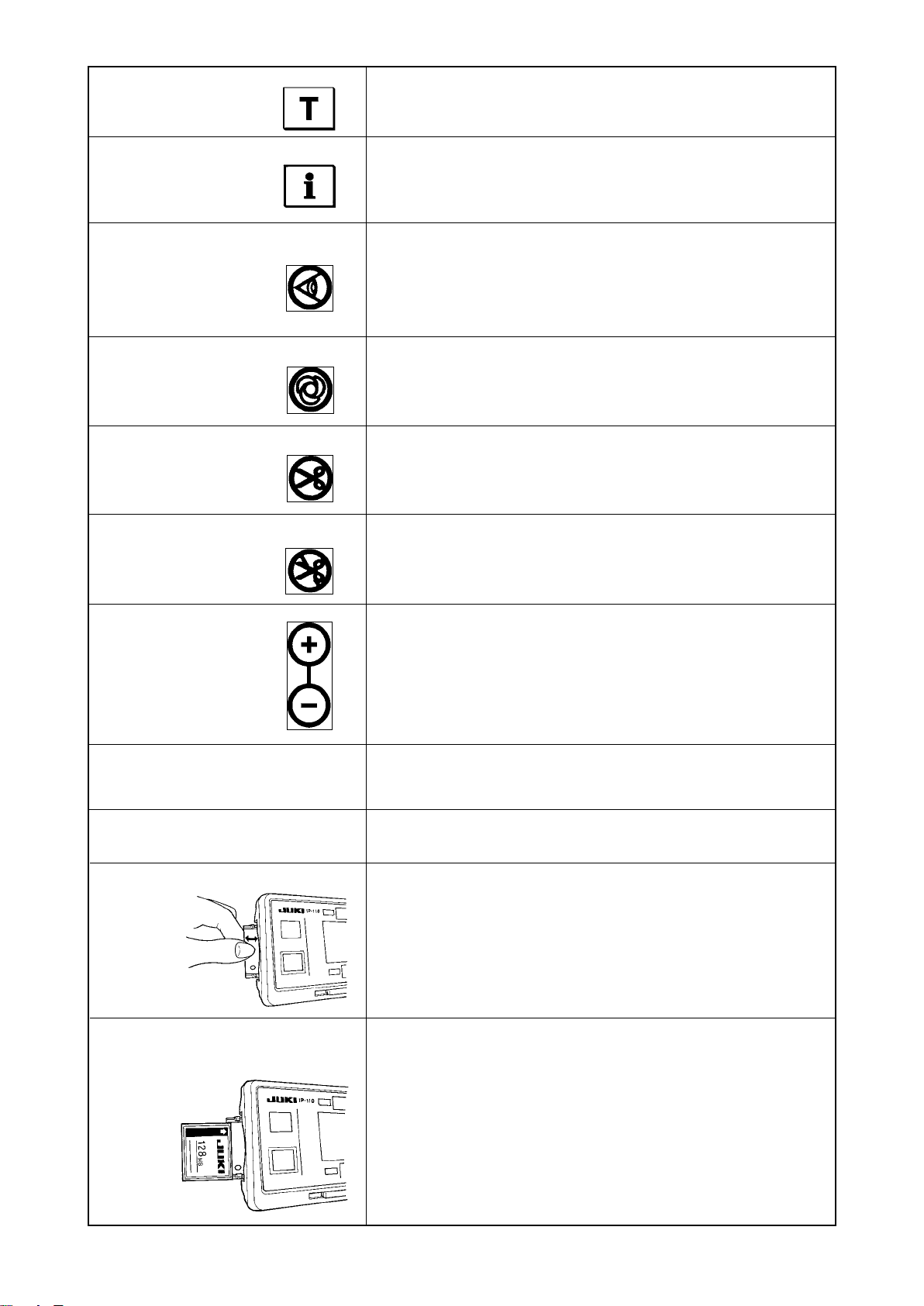

5-2. Adjusting the contrast of the operation panel screen

1) Press in the direction of arrow mark the click of

of cord outlet cover

A

breakage, do not touch the circuit board

pattern and the connector terminal.

el to prevent it from breakage.

2

A

Light

Shade

3

section

the rear of operation panel 1 and remove the

cover.

2) Turn LCD screen display brightness adjustment

variable resistor 3 to adjust the brightness (con-

trast) of LCD screen.

1. To prevent the operation panel from

1

2. Do not disassemble the operation pan-

assembled in

2

5-3. Connection of the production support switch

1) Press in the direction of arrow mark the click of

3

1

2

A

section

the rear of operation panel 1 and remove the

cover.

2) Connect the optional junction cable connector to

connector CN105 3 of the production support

switch.

Note) Pr e pare the switch ma i n u n i t by t h e

Optional relay cable A (asm.)

JUKI Part No. 40008168

3 2 1

CN105

+ 5V

SW

GND

of cord outlet cover

A

assembled in

2

customers or ask JUKI business office

about it.

1

2

3

- 6 -

Page 9

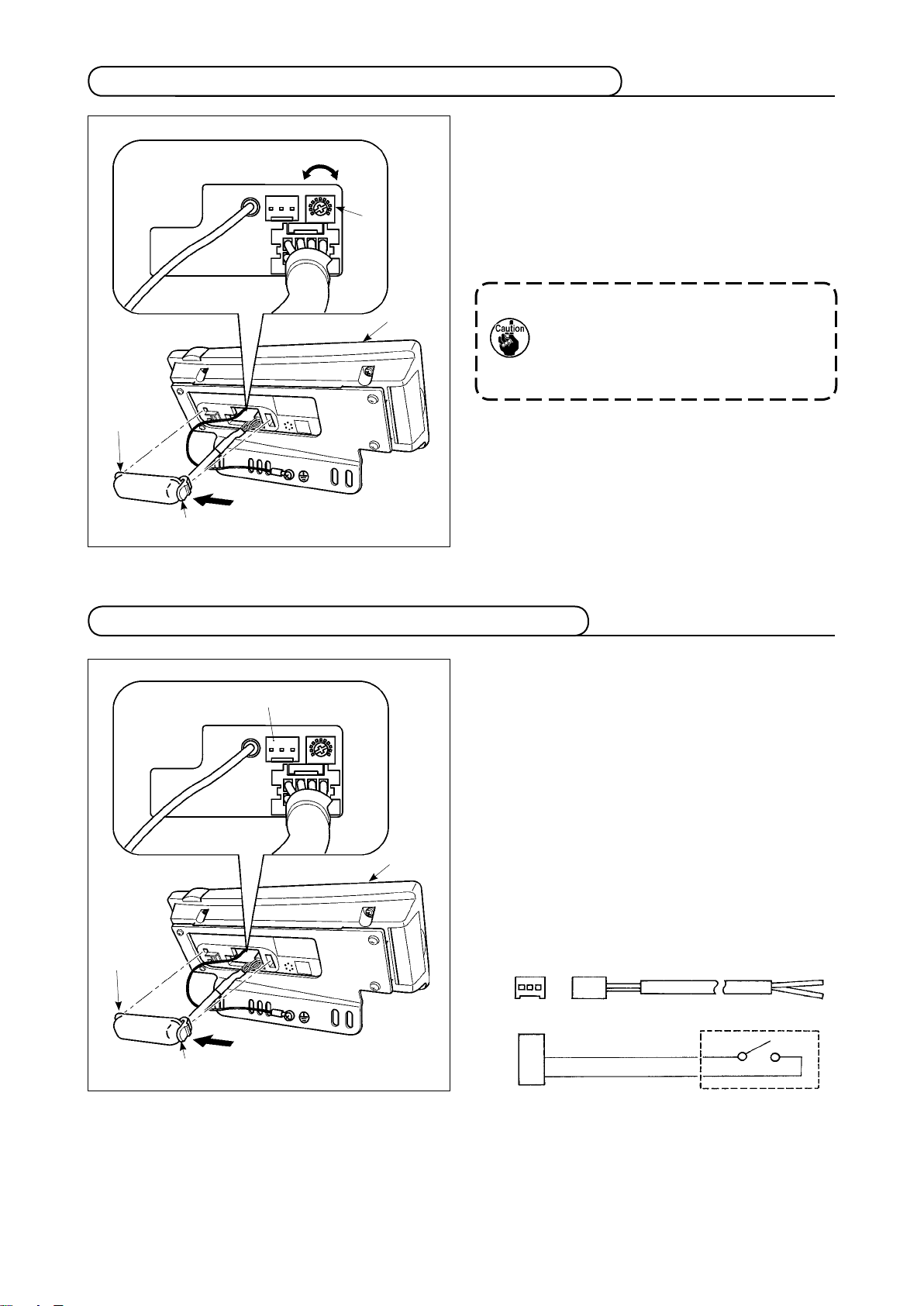

5-4. Basic screen

WELCOME screen is displayed immediately after turning ON the power.

The screen immediately after WELCOME screen becomes the screen that performs the sewing pattern

setting that was selected when turning OFF the power previously.

Every time switch is pressed, the screen changes.

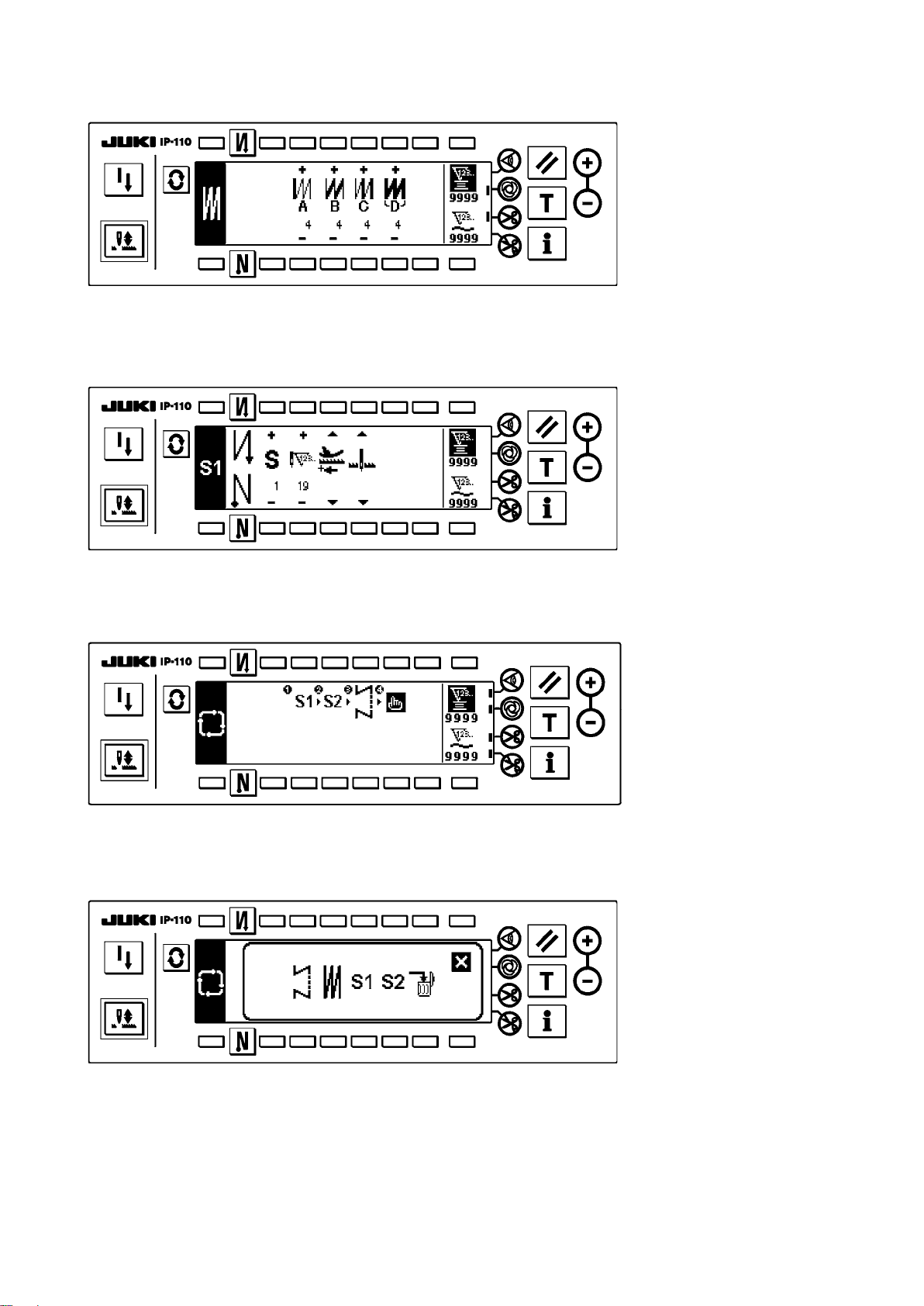

Pattern list screen

■

Selection of the respective shapes is performed.

Number of stitches of back tuck stitching setting screen

■

Setting of number of stitches of reverse stitching is performed.

When reverse stitching pattern is selected

<

When programmed stitching pattern 1 is selected

<

>

>

- 7 -

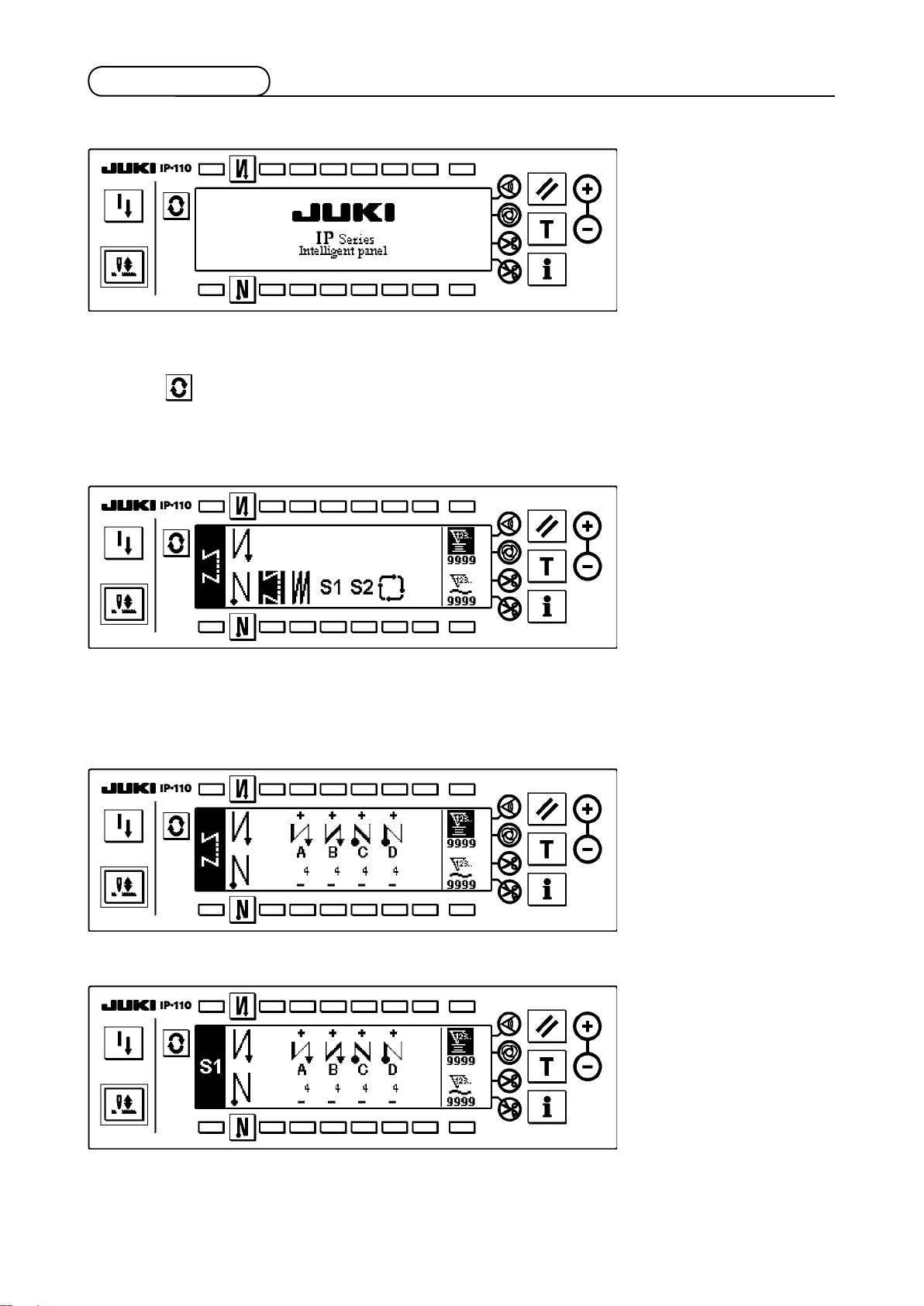

Page 10

Number of stitches of overlapped stitching setting screen

■

Setting of number of stitches of overlapped stitching is performed.

Programmed stitching setting screen

■

Setting of the respective conditions of programmed stitching is performed.

When programmed stitching pattern 1 is selected

<

>

Cycle sewing setting screen

■

Setting of the step of cycle sewing is performed.

Cycle sewing pattern setting pop-up

■

Setting of the pattern of cycle sewing is performed.

- 8 -

Page 11

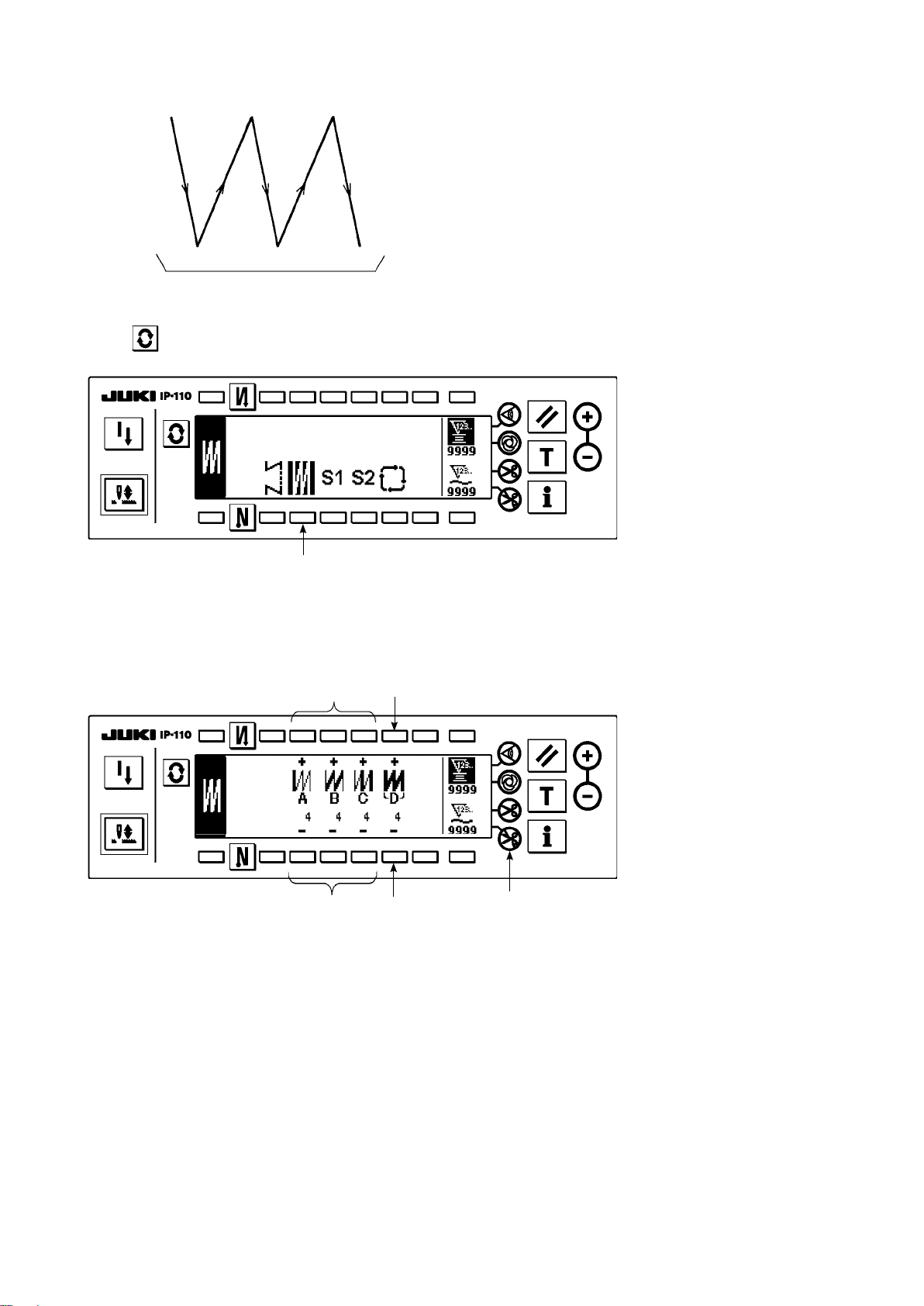

5-5. How to operate the operation panel for sewing stitching patterns

(1) Reverse stitching pattern

2

OFF ON ON

OFF

A

B

Sewing

pattern

C

D

OFF OFF

3

ON ON

Press to display the pattern list screen.

A

B

C

D

1

1) Press switch 1 to select the reverse stitching pattern, and the screen is automatically changed over to

the number of stitches of reverse stitching setting screen to display the number of stitches which has

already been set.

- 9 -

Page 12

2

4

3

5

2) When changing the number of stitches, change it with switches 4 and 5 for setting the number of stitch-

es A through D.

(The range of the number of stitches that can be changed : 0 to 99 stitches)

3) Press switch 2 to set the reverse stitching at the start of sewing.

No setting Reverse stitching

at the start of sewing

Double reverse stitching

at the start of sewing

4) Press switch 3 to set the reverse stitching at the end of sewing.

No setting Reverse stitching

at the end of sewing

Double reverse stitching

at the end of sewing

- 10 -

Page 13

(2) Overlapped stitching pattern

A C C

B B

D

Press to display the pattern list screen.

1

1) Press switch 1 to select the overlapped stitching pattern, and the screen is automatically changed over

to the number of stitches of overlapped stitching setting screen to display the number of stitches which

has already been set.

2

3

2) When changing the number of stitches, change it with switches 2 and 3 for setting the number of stitch-

es for processes A through C. To change the number of times of the whole processes, change it with

switches 4 and 5 for setting the number of processes D.

(The range of the number of stitches A, B and C that can be changed : 0 to 19 stitches. The range of the

number of processes D that can be changed : 0 to 9 times)

3) Depress the front part of the pedal once, and the sewing machine will repeat the normal stitching and

reverse stitching as many as the number of specied times. Then the sewing machine will automatically

make the thread trimmer actuate and will stop to complete the overlapped stitching procedure. (The one-

shot automatic stitching cannot be turned OFF.)

4) When thread trimming prohibiting function 6 is selected, the machine will stop with the needle up upon

completion of the overlapped stitching procedure without performing thread trimming.

4

5

6

- 11 -

Page 14

(3) Programmed stitching pattern

The constant-dimension stitching process can be programmed as many as 20 operation steps. The sewing

conditions including the number of stitches, needle up/down stop mode, automatic thread trimming,

continuous operation steps, lifting/lowering of presser foot and normal/reverse feed stitching can be

separately specified for the respective operation steps. If the lifting of presser foot is specified, the time

during which the presser foot is raised can be also specied.

Example of programmed stitching pattern

4

Step 4

4

4

4

20 20

10

Step 3Step 1

10

Step 2

Press to display the pattern list screen.

Programming procedure is des cribed below

taking the pattern on the left side as an example.

1

1) Press switch 1 to select the programmed stitching pattern, and the screen is automatically changed over

to the programmed stitching setting screen to display the number of stitches and data on the operation

step 1 which have already been specied.

[Step 1]

2 4 6

3 5 7 9

8

!0

!1

- 12 -

Page 15

1) Conrm that step 1 is displayed on the panel. Now, set the number of stitches to 20 using switches 2 and 3.

2) Set the feeding direction to the normal direction using switches 4 and 5.

3) Set the stop state of the sewing machine to the needle-down stop mode using switches 8 and 9.

If the number of stitches is set to 0 stitch or the stop-state of the sewing machine is set to the auto-

matic thread trimming mode , the machine will not proceed to the subsequent operation step.

4) Set the position of the presser foot, when the sewing machine stops, to the upper stop position using

switches 8 and 9.

(If you want to specify, In particular, the length of time during which the presser foot Is raised, set It as

desired using switches !0 and !1. In the Initial state, the length of time Is 60 seconds. Possible setting

range of the time during which the presser foot Is raised : 0.1 sec. to 99.9 sec.)

Settings done by switches 8, 9, !0 and !1 are only available under the setting where the auto-lifter

can be used (i.e., FL ON).

[Step 2]

!2

2

3

5) Press switch !2 once to display step 2.

6) Set the number of stitches to 10 using switches 2 and 3.

[Step 3]

!2

2

3

7) Set the feeding direction to the normal direction, the stop-state of the sewing machine to the needle-

down stop mode and the position of the presser foot to the upper stop position as in the case of step 1.

8) Press switch !2 once to display step 3.

9) Set the number of stitches to 20 using switches 2 and 3.

10) Set the feeding direction to the normal direction, the stop state of the sewing machine to the needle-

down stop mode and the position of the presser foot to the upper stop position as in the case of steps 1

and 2.

- 13 -

Page 16

[Step 4]

!3

!2

2 4 6 8

!4

3 5 7 9

11) Press switch !2 once to display step 4.

12) Set the number of stitches to 10 using switches 2 and

13) Set the feeding direction to the normal direction using switches 4 and

3

.

.

5

14) Set the stop state of the sewing machine to the automatic thread trimming mode using switches 6

.

and

7

15) Set the position of the presser foot, when the sewing machine stops, to the upper stop position using

switches 8 and 9.

16) Select the reverse stitching using switches !3 and !4. This completes the data setting procedure.

17) It is also possible to specify the double reverse stitching using switches !3 and

!4

.

Every time each step is nished, operate the touch-back switch, and the sewing machine runs at a low speed

(stitch compensation operation).

You can p rog ram an oth er sewing processes in th e programmed stitching pattern 2 following the

aforementioned procedure.

In case of pattern 2, the display on the left end of the screen becomes .

When switch is pressed in the programmed stitching setting screen, the screen is changed over to the

number of stitches of reverse stitching screen and the number of stitches of reverse stitching at the time

of programmed stitching can be set. The number of stitches of reverse stitching can be separately set for

patterns 1 and 2.

- 14 -

Page 17

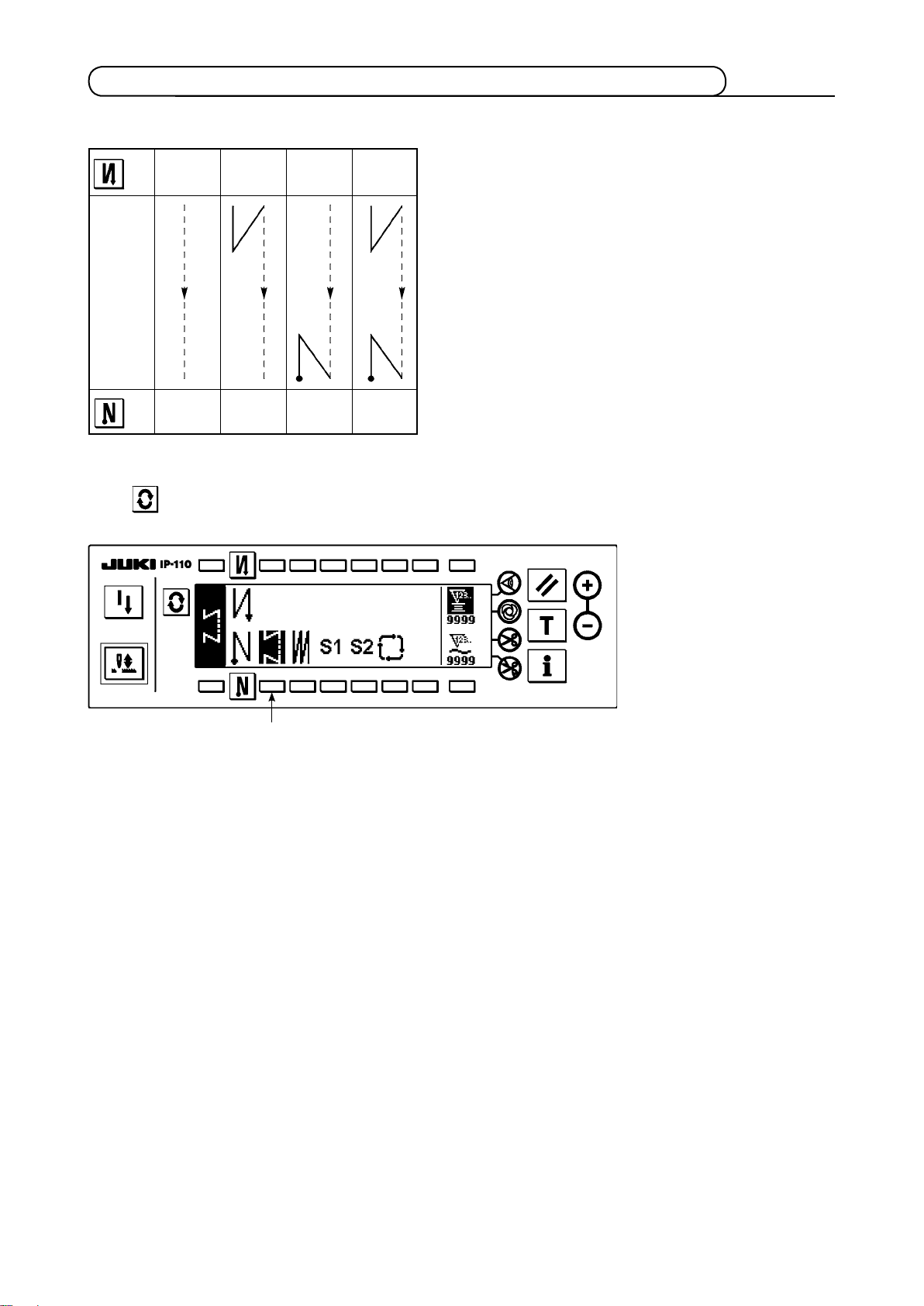

Teaching mode

<

>

In the teaching mode, it is possible to set the number of stitches of the step in a programmed stitching pattern

to the number of stitches that has been actually sewn.

2

1

1) In the programmed stitching setting screen, press teaching switch 1 to select the teaching mode.

2) The indication shown on the number of stitches input section changes to . This shows that the sewing

machine has entered the teaching mode.

3) Depress the front part of the pedal to make the sewing machine perform sewing until the last stitch of the

current operation step is reached.

The number of stitches cannot be inputted by turning the hand wheel by hand or operating the nee-

dle up/down switch.

4) Return the pedal to its neutral position to make the sewing machine stop running. Now, the number of

stitches which has been sewn is displayed.

5) Proceed to the subsequent step using switch 2 or make the sewing machine perform thread trimming.

This completes the input of the number of stitches for operation step 1.

One-shot automatic stitching

<

>

The one-shot automatic stitching function can be separately set by steps.

1

1) In the programmed stitching pattern setting screen, press one-shot automatic stitching switch 1 to select

the one-shot automatic stitching function.

2) A mark is displayed on LCD section of the switch, which shows the one-shot automatic stitching function

has been selected.

3) In the step where the one-shot automatic stitching function has been selected, the sewing machine

will automatically continue sewing, once the sewing machine starts running, until the end of the step is

reached.

- 15 -

Page 18

Continuous stitching mode

<

In this mode, it is possible to make the sewing machine execute the subsequent step after the completion of

the current step.

1) In the programmed stitching pattern setting screen, select the continuous stitching mode using switches

2

.

and

1

2) As long as the continuous stitching mode is selected, you can make the sewing machine execute the

subsequent step set in the program after the completion of the current step by depressing the front part

of the pedal.

>

1

2

To operate the operation panel in combination with the material edge sensor

<

• When the operation panel is used in combination with the material edge sensor, the sewing process can

be completed not by the predetermined number of stitches but by the input signal of the material edge

sensor.

• Carefully read the Instruction Manual for the material edge sensor before using the sensor with the

operation panel.

>

(4) Cycle sewing pattern

Reverse stitching pattern, overlapped stitching pattern, programmed stitching pattern 1 and programmed

stitching pattern 2 can be set and sewn as desired. (As many as eight different patterns can be set.)

1

1) Press switch 1 to display the cycle sewing edit pattern setting pop-up.

- 16 -

Page 19

4 6 8

2

!0 !2

5 7 9

3

!1

Switches 2 and 3 : These switches set the reverse stitching pattern.

Switches 4 and 5 : These switches set the overlapped stitching pattern.

Switches 6 and 7 : These switches set the programmed stitching pattern 1.

Switches 8 and 9 : These switches set the programmed stitching pattern 2.

Switches !0 and !1 : These switches delete the editing step.

Switch !2 : The screen returns to the cycle sewing setting screen.

[Example of setting]

2) Every time the thread trimmer actuates, the machine proceeds to the subsequent pattern which has been

selected. (The step which is being executed is shown in reverse video during execution.)

If the thread trimmer actuates before completion of a pattern, the machine will proceed to the subse-

quent program.

- 17 -

Page 20

6. BOBBIN COUNTER

The number of stitches sewn by the sewing machine is detected. The detected number of stitches is decremented from the

preset counter value (in units of the number of stitches preset using function setting No. 7 "Unit of bobbin thread counting

down." When the counter value changes from the positive value to the negative value (...→ 1

sets of two consecutive blips) and the notication is shown on the popup window to alert the operator to change the bobbin.

-1), the buzzer sounds (3

0

→

→

1

2

Initial value on the bobbin thread counter

for reference

3

1) Press switch 1 to select the bobbin thread counter.

Then press counter reset switch 2 to return the

value indicated on the bobbin thread counter to the

initial value (it has been factory-set to “0” at the time

of delivery).

The bobbin thread counter cannot be reset

during sewing. In this case, make the thread

4

trimmer actuate once.

2) Set an initial value using counter value setting

switches 3 and

4

.

The table below gives the initial se tting valu es for

reference when the bobbin is wound with thread to the

extent that the pinhole in the outside of the bobbin case

is reached as shown in the gure on the left side.

Thread

used

Polyester spun

thread #50

Cotton thread #50

Length of thread

wound round the

bobbin

36 m 1200

31 m 1000

Value on bobbin

thread counter

(stitch length : 3 mm)

(stitch length : 3 mm)

Thread tension rate 100 %

* Actually, the bobbin thread counter is affected by the material thickness and the sewing speed. So, adjust

the initial value of the bobbin thread counter in accordance with the operating conditions.

3) Once the initial value is specied, start the sewing machine.

4) When a minus value is shown on the counter, the buzzer peeps three times and the pop-up display appears, replace the bobbin thread.

Bobbin thread replacement warning pop-up

5) After the bobbin thread has been properly replaced, press counter reset switch 2 to return the value on

the bobbin thread counter to the initial value. Now, re-start the sewing machine.

6) If the remaining amount of bobbin thread is excessive or the bobbin thread runs out before the bobbin

thread counter indicates a minus value, adjust the initial value appropriately using counter value setting

switches 3 and

4

.

If the remaining amount of bobbin thread is excessive ..... Increase the initial value using the “+” switch.

If the remaining amount of bobbin thread is insufcient .... Decrease the initial value using “–” switch.

1. Uneven performance may occur in accordance with the winding way of thread or the thickness of

materials and it is necessary to set the thread trimming amount with some surplus.

2. If the bobbin thread counter is used in combination with the bobbin thread remaining amount de-

tecting device, the bobbin thread counter indicates the number of detections of the bobbin thread

remaining amount detecting device. So, be sure to use the device after carefully reading the Instruction Manual for the bobbin thread remaining amount detecting device.

- 18 -

Page 21

7. NO. OF PCS. COUNTERNO. OF PCS. COUNTER

The No. of pcs. counter counts up the number of nished products every time the machine performs thread

2

...........

→ 9999)

3

The value on the No. of pcs. counter can be modied

using counter value setting switches 3 and 4. The

value on the No. of pcs. cou nter is reset to "0" by

pressing counter reset switch 2.

4

trimming. (0 → 1 → 2

8. RE-SEWING SWITCHRE-SEWING SWITCH

The re-sewing switch is used when the bobbin thread runs out during the programmed stitching pattern

sewing steps or the like.

1) The bobbin thread runs out during the operations

steps for sewing.

1

D

C

Step 4

B

A

Step 3Step 1

d

Step 2

a

e

b c

2) Bring the pedal to its neutral position to make the

sewing machine stop. Now, depress the back part

of the pedal to make the thread trimmer actuate.

3) Turn ON re-sewing switch 1.

4) Replace the bobbin. Slightly feed the material on

the machine in the reverse direction to return the

material to the position where the sewing was interrupted to allow the sewing machine to sew over the

nished seam in step 2. d

5) Depress the front part of the pedal until stop position e of step 2 is reached.

6)

Turn ON re-sewing switch e again at position 1

where the sewing has been interrupted, and the next

step will be indicated on the operation panel. Now,

you can re-start sewing of the programmed stitching

pattern.

*

If the needle thread breaks or any other trouble occurs, which is caused by re-sewing switch 1 during the operation steps (d → e) in the free sewing

mode, bring the pedal to its neutral position, Then

depress the back part of the pedal to actuate the

thread trimmer. Thread the machine head and slightly

feed the material in the reverse direction, and press

re-sewing switch 1. This enables the sewing machine

to continue the sewing under the free sewing mode.

Then operate the operation panel as described in the

aforementioned steps 5) and 6).

a

b

c

To return to the rst step of the programmed

st it ching p attern without using re-sewi ng

switch 1, depress the back part of the pedal

to actuate the thread trimmer. This makes the

operation panel give the step indication 1.

Now, you can start sewing from the rst step

of the programmed stitching pattern.

- 19 -

Page 22

9. NEEDLE UP/DOWN COMPENSATION SWITCHNEEDLE UP/DOWN COMPENSATION SWITCH

Every time needle up/ down co mpen sation swit ch

is pressed, the needle goes up when it is in its lowest

position or comes down when it is in its highest position.

This compensates the stitch by a half of the predetermined

stitch length.

1

Note, however, that the machine does not run continuously

at a low speed even if you keep the switch held pressed.

Also, note that the needle up/down compensation switch is

inoperative after turning the handwheel by hand.

Thread trimmi ng i s opera tive on ly a t the t ime of stitch

compensation after depressing the front part of the pedal once.

10. ON/OFF SWITCHON/OFF SWITCH OF THE MATERIAL EDGE SENSOR

1

• When material edge sensor 1 is pressed, ON/OFF of the material edge

sensor is changed over.

• Wh en the mate rial ed ge s ensor, wh ich is opti onally avai lable, is

connected to the operation panel, the ON/OFF switch of the material

edge sensor becomes effective.

• If th e material ed ge sensor is specified, th e s ewing machine will

automatically stop running or perform thread trimming when the sensor

detects the material edge.

If the material edge sensor is used in combination with the opera-

tion panel, carefully read the Instruction Manual for the material

edge sensor beforehand.

1

11. AUTOMATIC THREAD TRIMMING SWITCHAUTOMATIC THREAD TRIMMING SWITCH

• When automatic thread trimming switch 1 is pressed, ON/OFF of the

automatic thread trimming is changed over.

• This switch is rendered effective, when the material end sensor is turned

ON for the reverse feed stitching pattern, to automatically activate the

thread trimmer upon detection of the material end.

(if the automatic reverse stitching (for end) is specified, the thread

trimmer will actuate after the sewing machine completes the automatic

reverse stitching (for end).)

1

12. ONE-SHOT AUTOMATIC STITCHING SWITCHONE-SHOT AUTOMATIC STITCHING SWITCH

1

• When one-shot automatic stitching switch 1 is pressed, ON/OFF of the

one-shot automatic stitching is changed over.

• This switch is used, in the constant-dimension stitching mode, rectangular

stitching mode, or in the process where the material edge sensor is

specied, to make the sewing machine automatically perform sewing at

the specied speed until the end of the process is reached only by driving

the sewing machine once.

- 20 -

Page 23

13. THREAD TRIMMING PROHIBITION SWITCH

• When thread trimming prohibition switch 1 is pressed, ON/OFF of the

thread trimming prohibition is changed over.

• This switch is used to temporarily make the thread trimming function

inoperative.

The other performance of sewing machine is not affected by this switch.

(If the automatic reverse stitching (for end) is specified, the sewing

machine will perform the automatic reverse stitching at the end of sewing.)

• If the automatic thread trimming switch and the thread trimming

prohibition switch are both specied, the machine will not perform

thread trimming but stop with its needle up.

1

- 21 -

Page 24

14. SIMPLIFIED FUNCTION SETTING

WARNING :

If the solenoid is used under the air drive mode, the solenoid can burn out. Be sure to carefully avoid

the wrong setting of the presser foot lifting device specication.

Function setting items can be simplied in part.

[Simplied function setting screen]

642

3 1

5 7 8

1) Keeping thread trimming prohibiting switch

2) Function items can be changed by pressing

1

held pressed, turn the power ON. Then, the

screen is changed over to the simplied function setting screen. The details displayed on the

screen represent the current settings.

switches 2 and

3, 4

and

5

or

6

and

7

.

* Wiper function (WiP): Switches 2 and

3

This function activates the wiper.

oFF : The wiper does not operate after thread trimming.: The wiper does not operate after thread trimming. The wiper does not operate after thread trimming.

on : The wiper operates after thread trimming (standard setting at the time of delivery): The wiper operates after thread trimming (standard setting at the time of delivery) The wiper operates after thread trimming (standard setting at the time of delivery)

* Auto-lifter (FL): Switches 4 and

5

This function activates the auto-lifter function when the presser foot lifting device (AK) is installed on the

sewing machine.

For the presser foot lifting device specications, solenoid drive mode (+33 V) or air drive mode (+24 V)

can be selected.

The drive source voltage (CN37) is changed over between +33 V and + 24 V according to the drive

mode specication selection.

oFF :: Auto-lifter does not operate. (standard setting at the time of delivery)

(The presser foot does not automatically go up when the program sewing is completed.)

on S :: Auto-lifter operates. (Solenoid drive mode [+33 V])

on A :: Auto-lifter operates. (Air drive mode [+24 V])

* Needle position changeover function for the time when the sewing machine stops (nP): Switches 6 and

7

The needle position at the time when the sewing machine stops can be changed over.

Lo : Lower stop position (standard setting at the time of delivery): Lower stop position (standard setting at the time of delivery) Lower stop position (standard setting at the time of delivery)

UP : Upper stop position: Upper stop position Upper stop position

3) Once you have completed the setting, press switch 8. The screen is changed over to the power switch

OFF notication screen.

[Power switch OFF notication screen]

4) Turn OFF the power switch to exit from the sim-

plied function setting.

If "on" (auto-lifter operates) is selected without the auto-lifter installed, the machine startup is mo-

mentarily delayed at the beginning of sewing. In addition, the one-touch type reverse feed (touch-back)

switch may be disabled. To avoid these troubles, be sure to select "oFF" (auto-lifter does not oper-

ate) when the auto-lifter device is not installed.

- 22 -

Page 25

15. KEY-LOCK FUNCTION SETTING

In order to prevent settings of the number of stitches or detailed settings for processes (A, B, C and D), it

is possible to lock the function setting switches in the current state. (Even under the key-lock mode, the

patterns or bobbin counter can be changed.)

[Key-lock function setting screen]

3

4 5

2

1

1) Keeping thread trimming prohibiting switch 1

and counter value setting switch (+) 2 held

simultaneously, turn the power ON. Then, the

screen is changed over to the key-lock function

setting screen. Setting displayed on the screen

represents the current setting of the key-lock

function.

2) The key-lock function can be changed over

between "on" (key-lock function is effective) and

"oFF" (key-lock function is ineffective [standard

setting at the time of delivery]) by pressing

switches 3 and 4.

3) Once you have completed the setting, press

switch 8. The screen is changed over to the

power switch OFF notication screen.

[Power switch OFF notication screen]

4) Turn OFF the power switch to exit from the sim-

plied function setting.

[Number of reverse feed stitches setting screen] (Example of display)

6

5) When the key-lock function is "on" (key-lock

function is effective), key icon 6 is displayed on

the screen.

- 23 -

Page 26

16. FUNCTION SETTING

Functions of the sewing machine can be programmed and the number of stitches and the number of

revolutions can be changed.

Refer to the Instruction Manual for the SC-920 for how to change the function setting items and for the details

of the functions.

[Function settings list screen]

1) Keeping switch 1 held pressed, turn the power

ON. Then the screen is changed over to the

function settings list screen.

When you press switch 2, the screen is

changed over to the function setting display

screen.

12

[Function setting display screen]

3

Function

setting No.

Set value

2) Function setting item number can be incremented

or decremented by pressing switches 3 and

4

.

3) Once you have determined the target function

setting number, press switch 5. The screen

is changed over to the function setting popup

screen.

4 5

[Function setting popup screen]

6

4) Function setting item number can be incremented

or decremented by pressing switches 6 and 7.

5) Once you have completed set value changing,

press switch 8. The screen is changed over

to the function setting display screen and the

changed set value is displayed on the screen.

6) Turn OFF the power switch to exit from the func-

7 8

tion setting.

* To change two or more different function setting

numbers, repeat the aforementioned steps of

procedure 2) through 5) as required.

Example) [To change the number of stitches 0 to 3 using the soft-start function (function setting No. 1)]

[Function setting display screen]

3

1) Press switches 3 and 4 to select function setting No. 1.

4 5

2) Press switch 5. The screen is changed over to

the function setting popup screen.

- 24 -

Page 27

[Function setting popup screen]

6

7

[Function setting display screen]

3) Press switches 6 and 7 to change the set

value to 3.

4) Press switch 8. The screen is changed over to

the function setting display screen.

8

5) The changed set value is displayed on the func-

tion setting display screen.

6) Turn OFF the power switch to exit from the func-

tion setting.

Refer to the Instruction Manual for the function setting list and the details of the function setting

items.

Function setting list

No

1 Soft start

2 Material end

3

4 Number of

5

6 Bobbin thread

7 Unit of bobbin

*

Item Description

function

sensor function

Thread trimming

function by

material end

sensor

stitches for

material end

sensor

Flicker reducing

function

counting

function

thread counting

down

The number of stitches to be sewn at a low speed when the softstart function is used at the start of sewing.

0 : The function is not selected.

1 to 9 : The number of stitches to be sewn under the soft-

start mode.

This item is not used on the IP-110F.

This item is not used on the IP-110F.

This item is not used on the IP-110F.

Flicker reducing function

0 : Flicker reducing function is not operative.

1 : Flicker reducing function is effective

Bobbin thread counting function

0 : Bobbin thread counting function is not operative.

1 : Bobbin thread counting function is operative.

Unit of bobbin thread counting down

0 : 1 Count/10 stitches

1 : 1 Count/15 stitches

2 : 1 Count/20 stitches

3 : 1 Count/thread trimming

Setting range

0 to 9

(Stitches)

0/1

0/1

0 to 19

(Stitches)

0/1

0/1

0 to 3

Indication of function setting

1 0

2 0

3 0

4 5

5 0

6 1

7 0

Do not change the set values with asterisk (*) mark as they are functions for maintenance. If the standard set value set at the

*

time of delivery is changed, it is in danger of causing the machine to be broken or the performance to be deteriorated.

If it is necessary to change the set value, please purchase the Engineer’s Manual and follow the instructions.

- 25 -

Page 28

No

8 Number of

*

9 Thread

10 Setting of

11 Operation

13 Function of

*

14 Sewing counter Counting function of sewing (number of completion of process)

15 Thread wiping

21 Function of

22 Needle up/down

25 Thread trimming

29 Initial motion

30 Function of

31

32 Effective

33 Thread trimming

35 Number of

*

36 Number of

*

37 Number of

Item Description

rotation of

reverse feed

stitching

trimming

prohibiting

function

needle bar stop

position when

the sewing

machine stops.

conrmation

sound for

operation panel

prohibiting start

of the sewing

machine by

bobbin thread

counter

function after

thread trimming

neutral presser

lifting

correction

switch

changeover

function

operation after

turning the

handwheel by

han

time of backtack

reverse feed

stitching on the

way

Number of

stitches of reverse

feed stitching on

the way

condition of

reverse feed

stitching on the

way when the

sewing machine

is stopping.

function by

reverse feed

stitching on the

way

rotation at a low

speed

rotation of

thread trimming

rotation of softstart

Sewing speed of reverse feed stitching

This item is not used on the IP-110F.

Position of needle bar is specified when the sewing machine

stops.

0 : Predetermined lowest position

1 : Predetermined highest position

Operation conrmation sound for operation panel

0 : Operation conrmation sound is not generated

1 : Operation conrmation sound is generated.

Function of prohibiting start of the sewing machine by bobbin thread counting

0 : When counting is out (-1 or less) Function of prohibiting

start of the sewing machine is not operative.

1 : When counting is out (-1 or less) Function of prohibiting

start of the sewing machine after thread trimming is operative.

2 : When counting is out (-1 or less), the sewing machine

stops once. Function of prohibiting start of the sewing

machine after thread trimming is operative.

0 : Sewing counter function is not operative.

1 : Sewing counter function is operative. (Every time thread

trimming is performed)

2 : With the sewing counting switch input function

Thread wiping operation after thread trimming is specied.

0 : Thread wiping is not carried out after thread trimming

1 : Thread wiping is carried out after thread trimming

Function of lifting presser foot whe n the pedal is in neutr al

position.

0 : Function of neutral automatic presser lifting is not opera-

tive.

1 : Selection of function of neutral presser lifting.

Function of the needle up/down correction switch is changed

over.

0 : Needle up/down compensation

1 : One stitch compensation

Thread trimming operation after moving the needle away from

its upper or lower position by turning the handwheel by hand is

specied.

0 : Thread trimming operation is carried out after turning the

handwheel by hand

1 : Thread trimming operation is not carried out after turning

the handwheel by hand

This function sets the suction time of initial motion of back-tack

solenoid.

50 ms to 500 ms

Function of reverse feed stitching on the way

0 : Function of reverse stitching on the way is not operative.

1 : Function of reverse feed stitching on the way is operative.

Number of stitches of reverse feed stitching on the way.

Effective condition of reverse feed stitching on the way

0 : Function is not operative when the sewing machine stops.

1 : Function is operative when the sewing machine stops.

Thread trimming function by reverse feed stitching on the way

0 : Automatic thread trimming function after completion of

reverse feed stitching on the way is not operative.

1 : Automatic thread trimming after completion of reverse

feed stitching on the way is performed.

Lowest speed by pedal

(The MAX value differs by machine head.)

Thread trimming speed

(The MAX value differs by machine head.)

Sewing speed at the start of sewing (soft-start)

(The MAX value differs by machine head.)

Setting range

150 to 3,000

(sti/min)

0/1

0/1

0/1

0 to 2

0 to 2

0/1

0/1

0/1

0/1

50 to 500

(ms)

0/1

0 to 19

(Stitches)

0/1

0/1

150 to MAX

(sti/min)

100 to MAX

(sti/min)

100 to MAX

(sti/min)

Indication of function setting

8 1900

9 0

10 0

11 1

13 0

14 1

15 1

21 0

22 0

25 1

29 70

30 0

31 4

32 0

33 0

35 200

36 420

37 800

Do not change the set values with asterisk (*) mark as they are functions for maintenance. If the standard set value set at the

*

time of delivery is changed, it is in danger of causing the machine to be broken or the performance to be deteriorated.

If it is necessary to change the set value, please purchase the Engineer’s Manual and follow the instructions.

- 26 -

Page 29

No

38 One-shot speed One-shot speed (The max. value depends on the number of

39 Pedal stroke

*

40 Low speed

*

41 Starting position

*

42 Starting position

*

43

*

44

*

45

*

47

48

*

49

50

Item Description

rotation of the sewing machine head.)

at the start of

rotation

section of pedal

of lifting presser

foot by pedal

of lowering

presser foot

Pedal stroke 2 for

starting thread

trimming

Pedal stroke

for reaching the

maximum number

of rotation

Compensation of

neutral point of

the pedal

Auto-lifter

selecting function

Pedal stroke 1 for

starting thread

trimming

Lowering time of

presser foot

Selection of

the pedal

specication

Position where the sewing machine starts rotating from pedal

neutral position (Pedal stroke)

Position where the sewing machine starts accelerating from

pedal neutral position (Pedal stroke)

Position where the cloth presser starts lifting from pedal neutral

position (Pedal stroke)

Starting position of lowering presser foot

Stroke from the neutral position

Position 2 where the thread trimming starts from pedal neutral

position (When the function of lifting presser foot by pedal is

provided.) (Pedal stroke)

Position where the sewing machine reaches its highest sewing

speed from pedal neutral position (Pedal stroke) 10 to 150

Compensation value of the pedal sensor

Limitation time of waiting for lifting solenoid type auto-li fter

device

Position where thread trimming starts from pedal neutral position

(Standard pedal) (Pedal stroke)

Lo w er i ng ti me of pre sse r foo t afte r t he ped al has been

depressed.

(Start of rotation of the sewing machine is delayed during this

time.)

Change the setting according to the pedal specication.

0 : KFL

1 : PFL

Setting range

150 to MAX

(sti/min)

10 to 50

(0.1 mm)

10 to 100

(0.1 mm)

– 60 to –10

(0.1mm)

8 to 50

(0.1 mm)

– 60 to –10

(0.1 mm)

(0.1 mm)

–15 to 15

10 to 600

(second)

– 60

to – 10

(0.1 mm)

0

to 250

(10 ms)

0/1

Indication of function setting

38 2500

39 30

40 60

41 -21

42 10

43 -51

44 150

45 0

47 60

48 -35

49 140

50 1

51 Compensation of

solenoid-on timing

of reverse feed

stitching at the

start of sewing

52 Compensation of

solenoid-off timing

of reverse feed

stitching at the

start of sewing

53 Compensation

of solenoid-off

timing of reverse

feed stitching at

the end of sewing

Foot lift after

55

thread trimming

Reverse

56

revolution to lift

the needle after

thread trimming

Function

58

of holding

predetermined

upper/lower

position of the

needle bar

Function of Auto/

59

Manual changeover of reverse

feed stitching at

the start of sewing

Function of stop

60

immediately after

reverse feed

stitching at the

start of sewing

Compensation of starting the solenoid for reverse feed stitching

when reverse feed stitching at the start of sewing is performed.

Co mp en sa ti on of relea si ng the sol en oi d fo r reverse fee d

stitching when reverse feed stitching at the start of sewing is

performed.

Co mp en sa ti on of relea si ng the sol en oi d fo r reverse fee d

stitching when reverse feed stitching at the end of sewing is

performed.

Function of lifting presser foot at the time of (after) thread trimming

0 : Not provided with the function of lifting presser foot after

thread trimming

1 :

Provided with the function of lifting presser foot

after thread trimming

Function of reverse revolution to lift the needle at the time of

(after) thread trimming

0 : Not provided with the function of reverse revolution to lift

the needle after thread trimming

1 : Provided with the function of reverse revolution to lift the

needle after thread trimming

Function of holding predetermined upper/lower position of the needle bar

0 : Not provided with the function of holding predetermined

upper/lower position of the needle bar

1 : Provided with the function of holding predetermined upper/

lower position of the needle bar (holding force is weak.)

2 : Provided with the function of holding predetermined upper/

lower position of the needle bar (holding force is medium.)

3 : Provided with the function of holding predetermined upper/

lower position of the needle bar (holding force is strong.)

This function can specify the sewing speed of reve rse feed

stitching at the start of sewing.

0 : The speed will depend on the manual operation by pedal, etc.

1 :

The speed will depend on the specied reverse feed stitching speed (No. 8).

Function at the time of completion of reverse feed stitching at

the start of sewing

0 : Not provided with the function of temporary stop of the

sewing machine at the time of completion of reverse feed

stitching at the start of sewing

1 : Provided with the function of temporary stop of the sew-

ing machine at the time of completion of reverse feed

stitching at the start of sewing.

automatically

– 36 to 36

(10°)

– 36 to 36

(10°)

– 36 to 36

(10°)

0/1

0/1

0 to 3

0/1

0/1

51 -8

52 10

53 15

55 1

56 0

58 0

59 1

60 0

Do not change the set values with asterisk (*) mark as they are functions for maintenance. If the standard set value set at the

*

time of delivery is changed, it is in danger of causing the machine to be broken or the performance to be deteriorated.

If it is necessary to change the set value, please purchase the Engineer’s Manual and follow the instructions.

- 27 -

Page 30

No

Change-

64

over speed of

condensation

stitch or EBT (end

back tack)

Function of soft-

70

down of presser

foot

Double reverse

71

feed stitching

function

Item Description

Initial speed when starting condensation stitch or EBT

Presser foot is slowly lowered.

0 : Presser foot is rapidly lowered.

1 : Presser foot is slowly lowered.

This item is not used on the IP-110F.

Setting range

0 to 250

(sti/min)

0/1

0/1

Indication of function setting

64 180

70 0

71 1

Sewing

72

machine startup

selecting

function

Retry function

73

One-shot function

76

84

Initial motion

*

Do not change the set values with asterisk (*) mark as they are functions for maintenance. If the standard set value set at the

*

suction time of

presser foot lifting

solenoid

87

Function of pedal

curve selection

90

Initial motion up

stop function

Function of prohibiting

91

compensation

operation after turning

handwheel by hand

Function of

92

reducing speed

of reverse feed

stitching at the

start of sewing

Function added to

93

needle up/down

compensating

switch

Continuous +

94

One-shot nonstop

function

Max. number of

96

rotation setting

Needle cooler

103

output OFF

delay time

Main shaft

120

reference angle

compensation

Up position

121

starting angle

compensation

DOWN position

122

starting angle

compensation

Setting of

124

energy-saving

function during

standby

Current limit at the startup of sewing machine is specied.

0 : Normal (Current limit is applied during startup)

1 : Rapid (Current limit is not applied during startup)

This function is used when needle cannot pierce materials .

0 : Normal

1 : Retry function is provided.

This item is not used on the IP-110F.

Suction motion time of presser foot lifting solenoid

Pedal curve is selected. (Improving pedal inching operation)

Number of rotations

Automatic UP stop function is set immediately after turning ON the

power.

0 : off

1 : on

It is effective in combination with the machine head provided

with tension release function.

0 : Tension release function is ineffective.

1 : Tension release function is effective.

Function to reduce speed at the time of completion of reverse

feed stitching at the start of sewing.

0 : Speed is not reduced.

1 : Speed is reduced.

Operation of needle up/down compensating switch is changed

after turning ON the power or thread trimming.

0 : Normal (needle up/down compensating stitching only)

1 : One stitch compensating stitching is performed only when

aforementioned changeover is made. (Upper stop / upper

stop)

Th e func ti on tha t d oe s not st o p the se wi ng mac hi n e by

combining continuous stitching with one-shot stitching using the

program sewing function which is available in the IP operation

panel.

0 : Normal (The sewing machine stops when a step is com-

pleted.)

1 : The sewing machine does not stop when a step is com-

pleted and proceeds to next step.

Max. number of rotation of the sewing machine head can be set.

(The MAX value differs by machine head.)

Delay time from the stop of sewing machine to the output OFF is

specied using the needle cooler output function.

Main shaft reference angle is compensated.

Angle to detect UP position starting is compensated.

Angle to detect DOWN position starting is compensated.

Set ting to re duc e the power consumption while the sewing

machine is in standby state

0 : Energy-saving mode is ineffective

1 : Energy-saving mode is effective

2

0

1

Pedal stroke

0/1

0/1

0/1

50 to 500

(ms)

0/1/2

0/1

0/1

0/1

0/1

0/1

150 to MAX

(sti/min)

100 to

2000 ms

–50 to 50

–15 to 15

–15 to 15

0/1

72 0

73 1

76 0

84 140

87 0

90 1

91 1

92 0

93 0

94 0

96 4000

103 500

120 -23

121 5

122 0

124 0

time of delivery is changed, it is in danger of causing the machine to be broken or the performance to be deteriorated.

If it is necessary to change the set value, please purchase the Engineer’s Manual and follow the instructions.

- 28 -

Page 31

17. OPTIONAL INPUT/OUTPUT SETTINGS

The optional input/output function is used for outputting signals which are allocated to the connectors and

for controlling a certain simple operation of the sewing machine by allocating various functions to the input/

output connectors of the SC-920 (control box).

Refer to the Instruction Manual for the SC-920 for details.

[Function settings list screen]

1) Keeping switch 1 held pressed, turn the power

ON. Then the screen is changed over to the

function settings list screen.

When you press switch 2, the screen is

changed over to the sewing common data

12

[Sewing common data screen]

screen.

2) When you press switch 3, the screen is

changed over to the option input/output setting

screen.

3

[Option input/output setting screen]

• To allocate a function to the input connectorTo allocate a function to the input connector

4 6 8

!0 !2 !4

3) Press switches 4 and 5 to select the optional

input number corresponding to the input connector pin number.

noP noP

901 0 951 0

4)

Press switches 6 and 7 to select the function

code number and abbreviation of the input function.

5) Press switches 8 and 9 to select the input

status (L: Active when Low is input, or H: Active

5 7 9

!1 !3 !5 !6

when High is input) of the selected input function. If function code No. 0 is selected, the input

status selection is not required.

• To allocate a function to the output connector

6) Press switches !0 and !1 to select the optional output number corresponding to the output connector pin

number.

7) Press switches !2 and !3 to select the function code number and abbreviation of the output function.

8) Press switches !4 and !5 to select the output status (L: Low is output when Low is active, or H: High is

output when High is active) of the selected input function. If function code No. 0 is selected, the output

status selection is not required.

9) Once you have completed the setting, press switch !6. The screen is changed over to the sewing com-

mon data screen.

10) Turn OFF the power switch to exit from the function setting.

Refer to the Instruction Manual for the SC-920 for the input/output connector numbers and pin num-

bers and the relation between these numbers and the displayed number.

- 29 -

Page 32

(Example) [To allocate the thread trimming function to the input connector (CN48,1)

[Option input/output setting screen]

4 6

noP noP

901 0 951 0

5 7

8

TSW noP

L

901 4 951 0

9

[Sewing common data screen]

!6

1) Press switches 4 and 5 to select input display

No. 901 which represents the input connector

(CN48, 1.)

2) Press switches 6 and 7 to select the function

code No. 4 and abbreviation "TSW" of the input

function.

3) Press switches 8 and 9 to select the input

status of the input function. Set the input status

code "L" if the thread trimmer activates when the

input signal is Low, or "H" if the thread trimmer

activates when the signal is High.

4) Press switch !6. The screen is changed over to

the sewing common data screen.

5) Turn OFF the power switch to exit from the function setting.

Refer to the Instruction Manual for the SC-920 for the input/output connector numbers and pin num-

bers and the relation between these numbers and the displayed number.

18. AUTOMATIC COMPENSATION OF NEUTRAL POINT OF THE PEDAL SENSOR

Whenever you have replaced the parts such as the pedal sensor and spring, be sure to carry out the

following procedure.

[Pedal-sensor neutral-point automatic compensation screen]

1

1) Keep one-shot automatic sewing switch

pressed, turn the power ON. Then, the screen is

changed over to the pedal-sensor neutral-point

automatic compensation screen.

2) When the neutral point of the pedal sensor is

properly corrected, the message "OK" and the

compensation value (the compensation value

"0" shown in the gure on the left is a value for

reference) are displayed and the buzzer sounds

(one short blip).

3) Turn OFF the power switch to exit from the func-

tion setting.

1

held

1. The pedal is depressed when the power is turned ON, the correct compensating operation cannot

be carried out. Never place your foot or anything on the pedal. The audible warning sounds (two sin-

gle tones, i.e., two blips) and neither the message "OK" nor the compensation value are displayed.

2. If any message or value other than "OK" or the compensation value, refer to the Engineer's Manual.

- 30 -

Page 33

19. INITIALIZATION OF THE SETTING DATA

Data on the function setting items can be returned to the standard set values.

[Function setting data initialization screen]

1) Keeping reset switch 1 and counter value

1 2

3

switch (+) 2 held simultaneously pressed, turn

the power ON. Then the screen is changed over

to the function setting data initialization screen.

2) When you press switch 3, the process for

totally returning the function setting data to the

standard set values (initialization operation) is

executed.

3) Once the process is completed (approximately

one second later), the buzzer sounds (three

single tones, i.e., blip, blip, blip) and screen is

changed over to the power switch OFF notication screen.

Do not run the power OFF during the ini-

tialization operation. It can damage the

program of the main body.)

[Power switch OFF notication screen]

4) Turn OFF the power switch to exit from the ini-

tialization.

1. The neutral point compensation value of the pedal sensor is also initialized by carrying out the

initialization operation. It is therefore necessary to carry out the automatic compensation of the

neutral point of the pedal sensor without exceptions before using the sewing machine.

(Refer to "18. Automatic compensation of neutral point of the pedal sensor" p. 30.)

2. The machine head angle adjustment value is also initialized by carrying out the initialization oper-

ation It is therefore necessary to carry out the machine head angle adjustment without exceptions

before using the sewing machine.

(Refer to "4. Sewing machine angle adjustment" p.3.)

3. Sewing data programmed on the operation panel are not initialized by carrying out the initializa-

tion operation.

- 31 -

Page 34

20. INFORMATION

Various data can be set or checked on the information screen.

Operator level

1) Turn ON the power.

2) Press switch 1 to display the information screen.

Information screen

■

1

: Sewing management

1

information

: Date and time setting

2

1

Sewing management information

●

The sewing management information consists of the maintenance management function and working

measurement function.

2

(1) Maintenance management function

Sewing management function screen

■

1

1) Press switch 1 to change over the screen to the maintenance management function screen.

- 32 -

Page 35

Maintenance function screen

■

The time for needle changing, the time for cleaning and the time for oil changing can be set to continuously

display numeric values or display the notication after the lapse of preset time.

Refer to the Engineer's Manual for details.

2

3

4

[Explanation of the respective items]

Time of replacement of needle ..... Unit : X 1,000 stitches

2

Time of cleaning ............................ Unit : Hour

3

Time of replacement of oil ............. Unit : Hour

4

[Explanation of the contents of display]

(Numerator / denominator)

* Number of remaining stitches up to *thousand stitches /

**

Example) Replacement of needle

100 / 1600 k

thousand stitches

Time of replacement of needle is informed every 1,600 thousand stitches.

Time of replacement of needle is informed after 100 thousand stitches.

When 2, 3 and 4 switches are pressed, the clear checking screen is displayed.

Clear screen

■

1

2

: The screen returns to the maintenance function screen without performing clearing.

1

: The screen returns to the maintenance function screen after executing clearing.

2

- 33 -

Page 36

Warning screen

■

Warning screen is displayed when the warning time is reached.

1

2

: When 1 is pressed, the screen can be cleared. However, the counter itself cannot be cleared. In case

1

of the replacement of needle, the warning screen is displayed at intervals of 10 minutes until clearing

is performed. In case of other warnings, the warning screen is displayed at the time of turning ON the

power until the counter is cleared.

: When 2 is pressed, the screen is cleared and the counter value is cleared as well. From this time,

2

counting starts newly.

[Setting of the warning setting time]

Infomation screen

■

1

1) Press switch 1 for approximately three seconds in the information screen.

Sewing management function screen

■

2

2) Press 2 to display the maintenance function screen.

(For other functions, refer to the Engineer’s Manual.)

- 34 -

Page 37

Maintenance function screen

■

3

5

: Input screen of time of replacement of needle (number of stitches : unit : X 1,000 stitches) is displayed.

3

: Input screen of time of cleaning (time : unit : h) is displayed.

4

: Input screen of time of replacement of oil (time : unit : h) is displayed.

5

Various input screen (Time for needle changing, time for cleaning and the time for oil changing)

■

4

7 8

Press 7 to display the clear checking screen. After inputting the set value, press 8 to determine.

In case of stopping the warning function, set the set value to “0”.

It is possible to individually set replacement of needle, cleaning, and replacement of oil respectively.

In case of stopping all, set “0” to each.

- 35 -

Page 38

(2) Working measurement function

Sewing management function screen

■

1

1) Press switch 1 to change over the screen to the working measurement function screen.

Working measurement function screen

■

Working factor, working mean speed, pitch time and machine time can be measured on this screen.

2

3

[Explanation of the respective items]

Working factor .................................. Unit : %

Working mean speed .......................Unit : sti/min

Pitch time .........................................Unit : Second

Machine time ...................................Unit : Second

2) Press 3 to start the working measurement.

3) To stop the measurement, press 3 again.

4) The result of measurement can be cleared with 2.

When “Clear” is not executed, the measurement from the last time can be continued.

- 36 -

Page 39

Date and time setting

●

The current date and time can be set to display on the screen.

Information screen

■

1

1) Press switch 1 to change over the screen to the date and time setting screen.

Date and time setting screen

■

2345678

!0!1!2

9

2) Press switches 2 and 3, 4 and 5, and 6 and 7 to increment/decrement the date.

3) Press switches 8 and 9, !0 and !1, and !2 and !3 to increment/decrement the time.

4) Once you have set the date and time, press switch !4. The screen is changed over to the information

screen.

Information screen

■

5) The set date and time are displayed on the information screen and the clock starts to operate. (When

you have set the date and time to "2009-10-01 10:00:00" and press switch !4, the screen display will be

as shown in the above gure.)

!3 !4

- 37 -

Page 40

21. EXTERNAL INTERFACE

External interface means the section to connect the operation panel and the system which is different from

the operation panel.

For the use and details, refer to the Engineer's Manual.

1) Media slot

Media slot is installed in the face cover located on the left side of operation panel.

2) RS-232C port

RS-232C connector is installed in the rubber cap located on the back side of operation panel.

3) General input port (Production support switch connecting connector)

General input connector, CN105 is installed in the cord outlet cover located on the back side of operation

panel.

22. ERROR DISPLAY

There are two different kinds of errors, those output from the operation panel and those from the

SC-920 (control box). Both kinds of errors are notied by the error screen and the buzzer.

Three different kinds of screens of the panel display screen appear due to the difference of the procedures.

1) Error screen disappears when the operator removes the cause.

Example) Cover of the slot of media is open. Close the cover.

2) Press the reset switch, and remove the cause of error after erasing the error screen.

3) Remove the cause of error after turning OFF the power.

- 38 -

Page 41

22-1. Error code list (Error display in panel)

There are the following error codes in this device. These error codes interlock (or limit function) and inform

the problem so that the problem is not enlarged when any problem is discovered. When you request our

service, please conrm the error codes.

No. Description of error detected Cause of occurrence expected Items to be checked

− Media cover open • Cover of the slot of media is open. • Close the cover.

E000 Execution of data initialization

(This is not the error.)

E003 Disconnection of

synchronizer connector

E004 Synchronizer lower position

sensor failure

E005 Synchronizer upper position

sensor failure

E007 Overload of motor • When the machine head is locked.

E011 Media is not inserted. • Media is not inserted. • Turn the power OFF and check the media.