ENGLISH

INSTRUCTION MANUAL

* "CompactFlash(TM)" is the registered trademark of SanDisk Corporation, U.S.A.

– i –

CONTENTS

1. SETUP OF HARDWARE .................................................................................................1

1-1. Installing IPOP circuit board .........................................................................................................1

1-2. Installing the panel.........................................................................................................................1

2. HOW TO USE THE OPERATION PANEL .......................................................................2

2-1. Names and functions of each components .................................................................................2

2-2. Adjusting the contrast of the operation panel display ...............................................................4

2-3. Production control switch connecting connector ......................................................................4

2-4. Screen list .......................................................................................................................................5

2-5. How to operate the operation panel for sewing stitching patterns ...........................................7

(1) Free stitching pattern .........................................................................................................................7

(2) Constant dimension stitching pattern ..............................................................................................8

(3) Overlapped stitching pattern .............................................................................................................9

(4) Square stitching pattern ...................................................................................................................10

2-6. How to use the bobbin thread counter ......................................................................................12

2-7. Sewing counter ............................................................................................................................13

2-8. Needle up/down compensation switch ......................................................................................13

2-9. ON/OFF switch of the material edge sensor .......................................................................13

2-10. Automatic thread trimming switch .....................................................................................13

2-11. One-shot automatic stitching switch .................................................................................13

2-12. Thread trimming prohibition switch ...................................................................................14

3. INFORMATION ..............................................................................................................14

3-1. Operator level ...............................................................................................................................14

(1) Sewing management information ...................................................................................................14

(2) Production control function .............................................................................................................17

(3) Working measurement function ......................................................................................................19

3-2. Maintenance personnel level ......................................................................................................20

(1) Sewing common data function ........................................................................................................20

3-3. Setting for functions ....................................................................................................................41

(1) How to change over to the function setting mode ........................................................................41

(2) Function setting list ..........................................................................................................................43

4. EXTERNAL INTERFACE ...............................................................................................46

5. ERROR DISPLAY ..........................................................................................................46

– ii –

1. SETUP OF HARDWARE

Refer to Instruction Manual for SC-510 together with this Instruction Manual.

WARNING :

• To prevent personal injury caused by abrupt start of the sewing machine, carry out the work after turning OFF

the power switch and a lapse of 5 minutes or more.

• To prevent damage of device caused by maloperation and wrong specifications, be sure to connect all the

corresponding connectors to the specied places.

• To prevent personal injury caused by maloperation, be sure to lock the connector with lock.

• As for the details of handling respective devices, read carefully the Instruction Manuals supplied with the

devices before handling the devices.

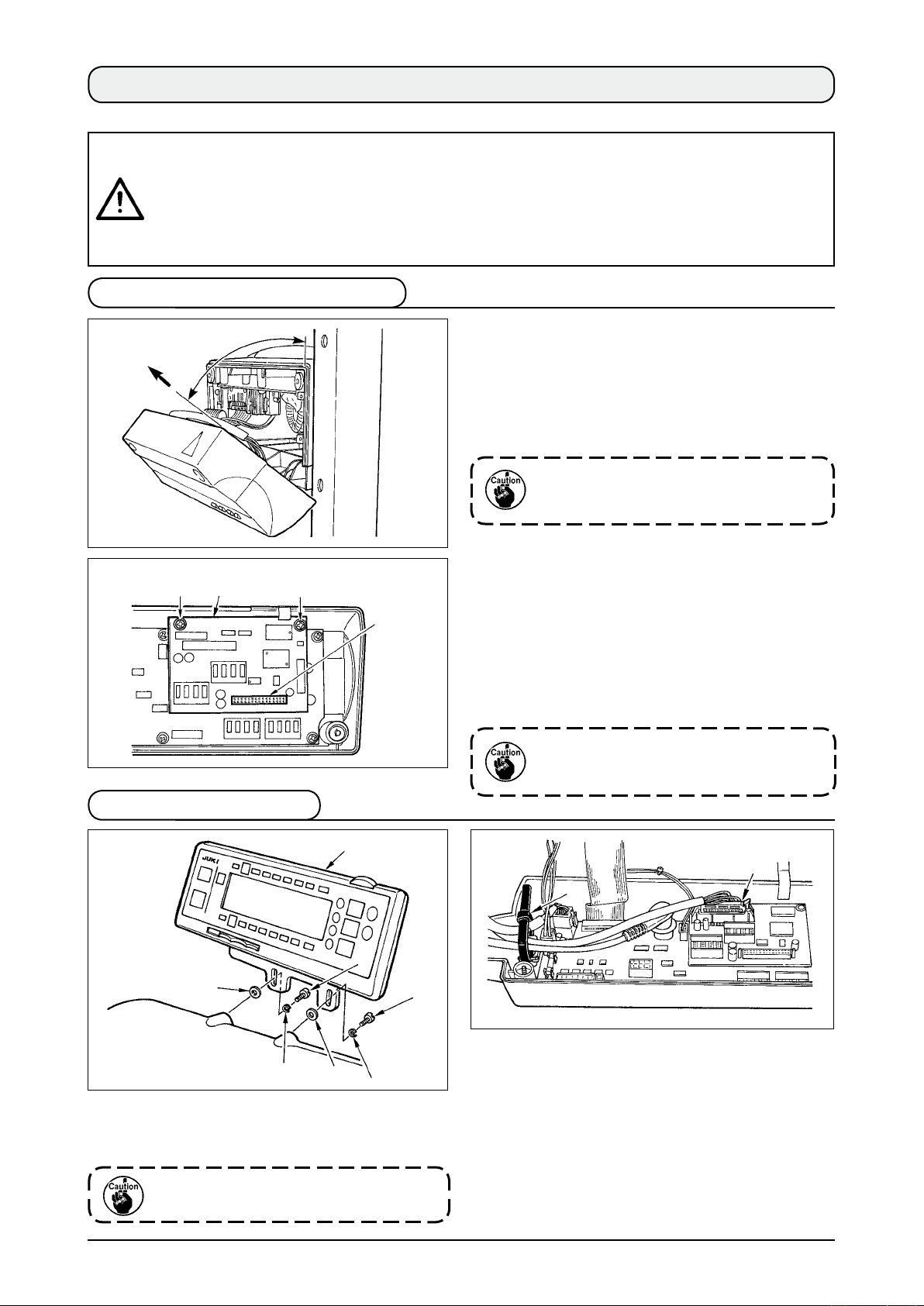

1-1. Installing IPOP circuit board

IPOP circuit

board

1

45˚

1

CN41

1) Loosen two screws in the front cover of control

box and open the front cover.

2) Remove connectors and ground wire of the circuit

board attached to the front cover.

3) Place the front cover at an angle of approximate

45°, draw it in the direction of arrow, and remove

it from the box main unit.

Do not draw the front cover forcibly since

there is the possibility that the click of front

cover is broken.

4)

Securely insert CN41 of IPOP circuit board supplied

as accessories to white connector CN41 on the

front cover circuit board from the upper side.

5) Fix IPOP circuit board with two screws 1 supplied

as accessories.

6) Place the front cover at an angle of approximate

45°, attach it to the box main unit, and attach

connectors and ground wire which have been

removed in step 2).

When removing IPOP c ircuit board, turn

OFF the power and remove it after 5 minutes

or more have passed.

1-2. Installing the panel

1

2

3

4

1) Install operation panel

using screws

supplied as accessories.

4

Do not disassemble the operation panel to

prevent it from breakage.

, washers

2

1

3

on the machine head

and spring washers

3

2

4

CN121

5

2) Set the panel cord same as the other machine

head cords, insert it to CN121 of the control box,

and lock it.

3) Put it together with other machine head cords and

bundle them with clip band 5.

4) Close the front cover and tighten two screws,

while taking care not to put the cords in the front

cover.

– 1 –

– 2 –

2. HOW TO USE THE OPERATION PANEL

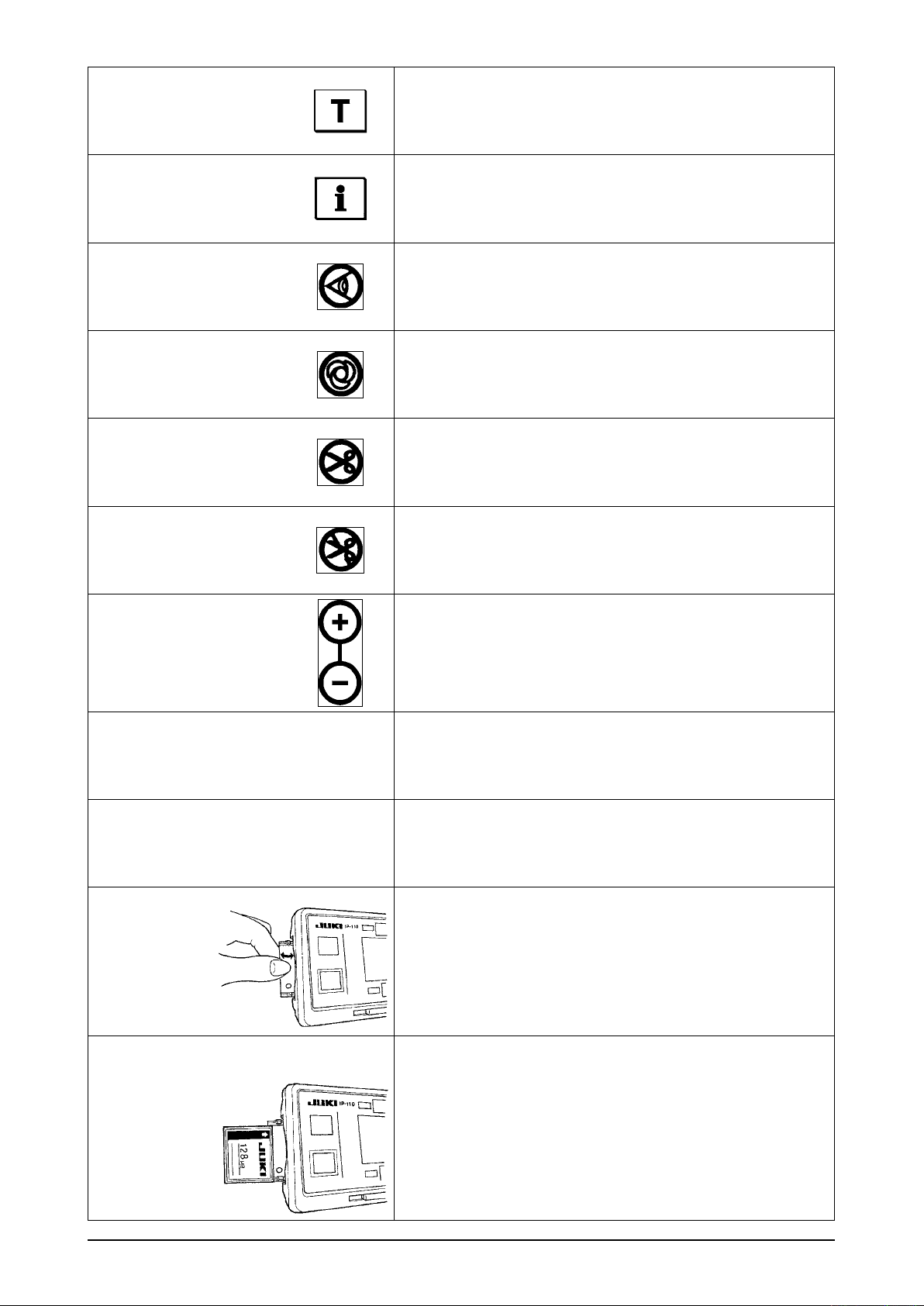

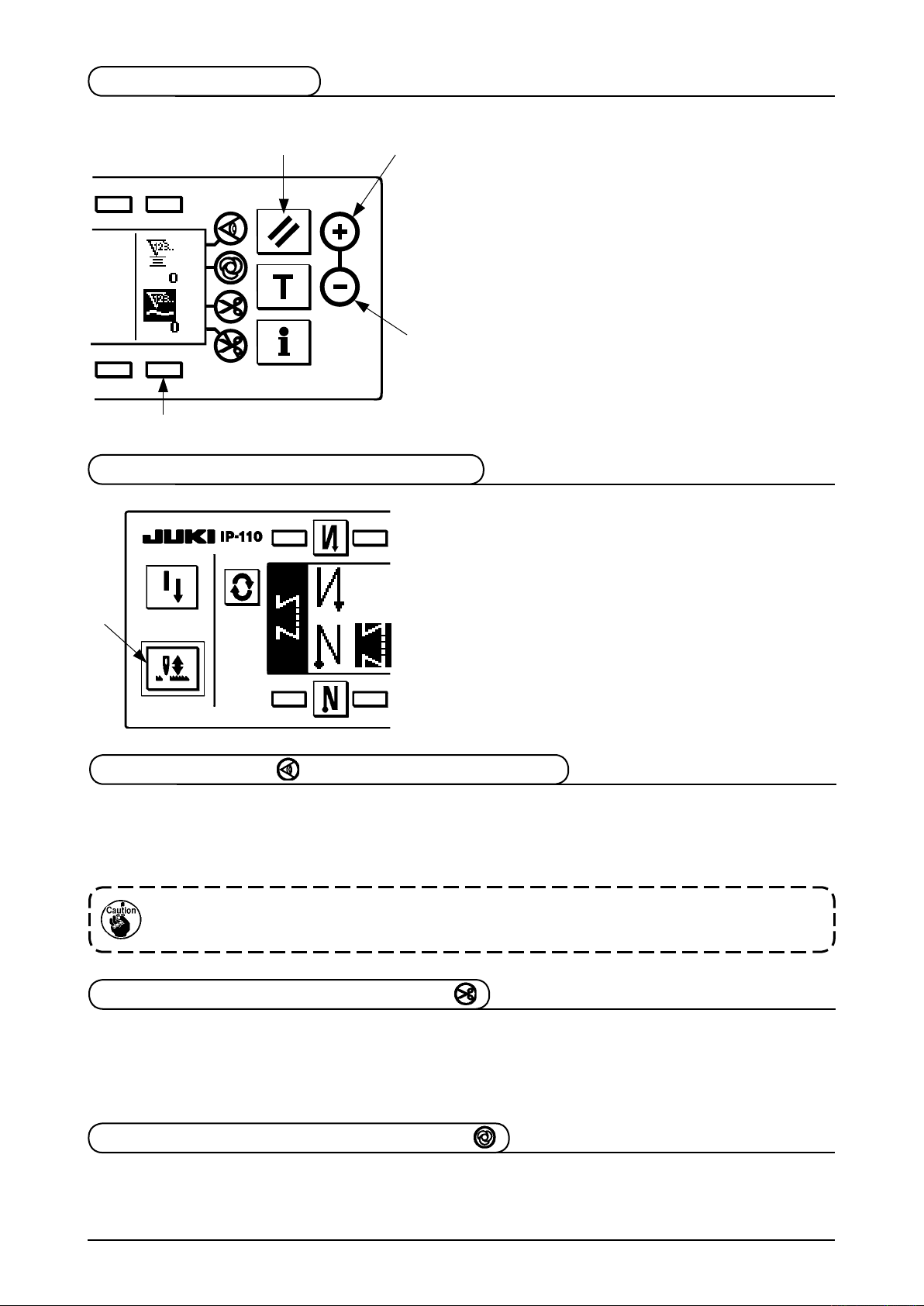

2-1. Names and functions of each components

!6

!8

!7

2

Re-sewing switch

1

Needle up/down compensating switch

2

Screen changeover switch

3

With/without reverse feed stitch at

4

sewing start switch

With/without reverse feed stitch at

5

sewing end switch

Reset switch

6

Teaching switch

7

1

3

5

8

9

!0

!1

!2

!3

!4

4

!4

Information switch

Material edge sensor switch

One-shot stitching switch

With/without automatic thread trimmer

switch

Thread trimming prohibiting switch

Counter value setting switch

Max.speed limitation variable resistor

!1

!0

9

!5

!2

Power display lamp

!5

Media cover

!6

Media slot (Media inserting opening)

!7

CompactFlash(TM)

!8

(Optional: Part No. 40000100)

8

6

!3

7

Re-sewing switch

1

Needle up/down

2

compensating switch

Unused

This is the switch to perform needle up/down compensating stitching.

(Needle up/down compensating stitching and one stitch compensating

stitching can be changed over with function setting No. 22.)

Screen changeover

3

This is the switch to change over the screen.

switch

With/without reverse feed

4

stitch at sewing start

switch

This is the switch to turn ON/OFF automatic reverse feed stitch at

sewing start.

* This switch cannot be used with the sewing machine which is not

provided with automatic reverse feed stitching device.

With/without reverse

5

feed stitch at sewing end

switch

This is the switch to turn ON/OFF automatic reverse feed stitch at

sewing end.

* This switch cannot be used with the sewing machine which is not

provided with automatic reverse feed stitching device.

Reset switch This is the switch to make the value of bobbin thread counter or

6

sewing counter the set value.

Teaching switch

7

Information switch This is the switch to perform various function settings.

8

Unused

Material edge sensor

9

switch

One-shot stitching switch

!0

With/without automatic

!1

thread trimmer switch

Thread trimming

!2

prohibiting switch

Counter value setting

!3

switch

Rendered effective when the material edge sensor is installed on

the machine.

Used for selecting whether or not the material edge sensor is used

during sewing.

When this switch is set to effective, the sewing machine

automatically operates up to the specied number of stitches.

When this switch is set to effective, the sewing machine

automatically performs thread trimming when the specied number

of stitches has been completed.

This switch prohibits all thread trimmings.

* This switch cannot be used with the sewing machine which is not

provided with the automatic thread trimming device.

This is the switch to set the value of bobbin thread counter or No. of

pcs. counter.

Max. speed limitation

!4

variable resistor

Power display lamp This lamp lights up when the power switch is turned ON.

!5

Media slot cover This is the cover for media inserting opening.

!6

Media slot (Media inserting opening)

!7

When moving the resistor in the left direction, max. speed is limited.

To open the cover, place your ngers on the notch located on the

side of the cover as shown in the gure and push the cover in the

direction of left slanting rear.

* There are some functions that are not able to be operated

with the cover opened. Do not close the cover unless the

CompactFlash(TM) is completely inserted.

To set the CompactFlash(TM), place the label face of the

CompactFlash(TM) to the front and insert the part that has a small

hole (place the notch of the edge to the rear) to the panel.

To remove the CompactFlash(TM), hold it between your ngers and

draw it out.

* When the inserting direction of the CompactFlash(TM) is wrong,

the panel and the CompactFlash(TM) may be damaged. Do not

insert anything other than the CompactFlash(TM).

– 3 –

– 4 –

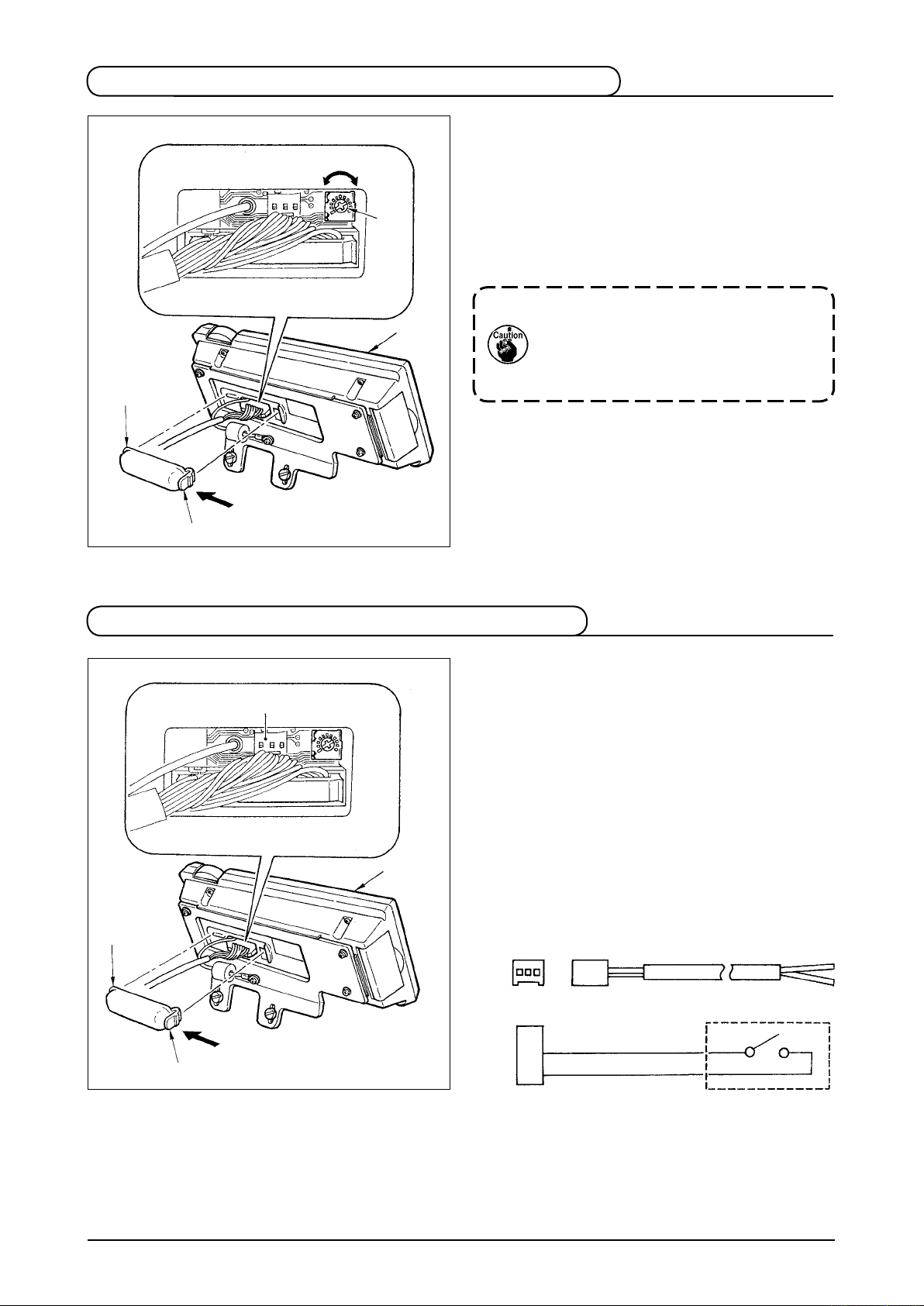

2-2. Adjusting the contrast of the operation panel display

1) Press in the direction of arrow mark the click of

section A of cord outlet cover

Light

2

A

Shade

3

1

the rear of operation panel

cover.

2) Turn LCD screen display brightness adjustment

var i able res i stor

(contrast) of LCD screen.

1. To prevent the operation panel from

breakage, do not touch the circuit board

pattern and the connector terminal.

2. Do not disassemble the operation panel

to prevent it from breakage.

assembled in

2

and remove the

1

t o adjust the brig h tness

3

2-3. Production control switch connecting connector

1) Press in the direction of arrow mark the click of

section A of cord outlet cover

3

1

2

A

the rear of operation panel

cover.

2) Connect t h e optional r e l ay cable con n e ctor

to CN105

connecting connector.

Note) Prepare the switch main unit by the

customers or ask JUKI business ofce

about it.

Optional relay cable A (asm.)

JUKI Part No. 40008168

3 2 1

CN105

1

+ 5V

2

SW

GND

3

assembled in

2

and remove the

1

of the production control switch

3

2-4. Screen list

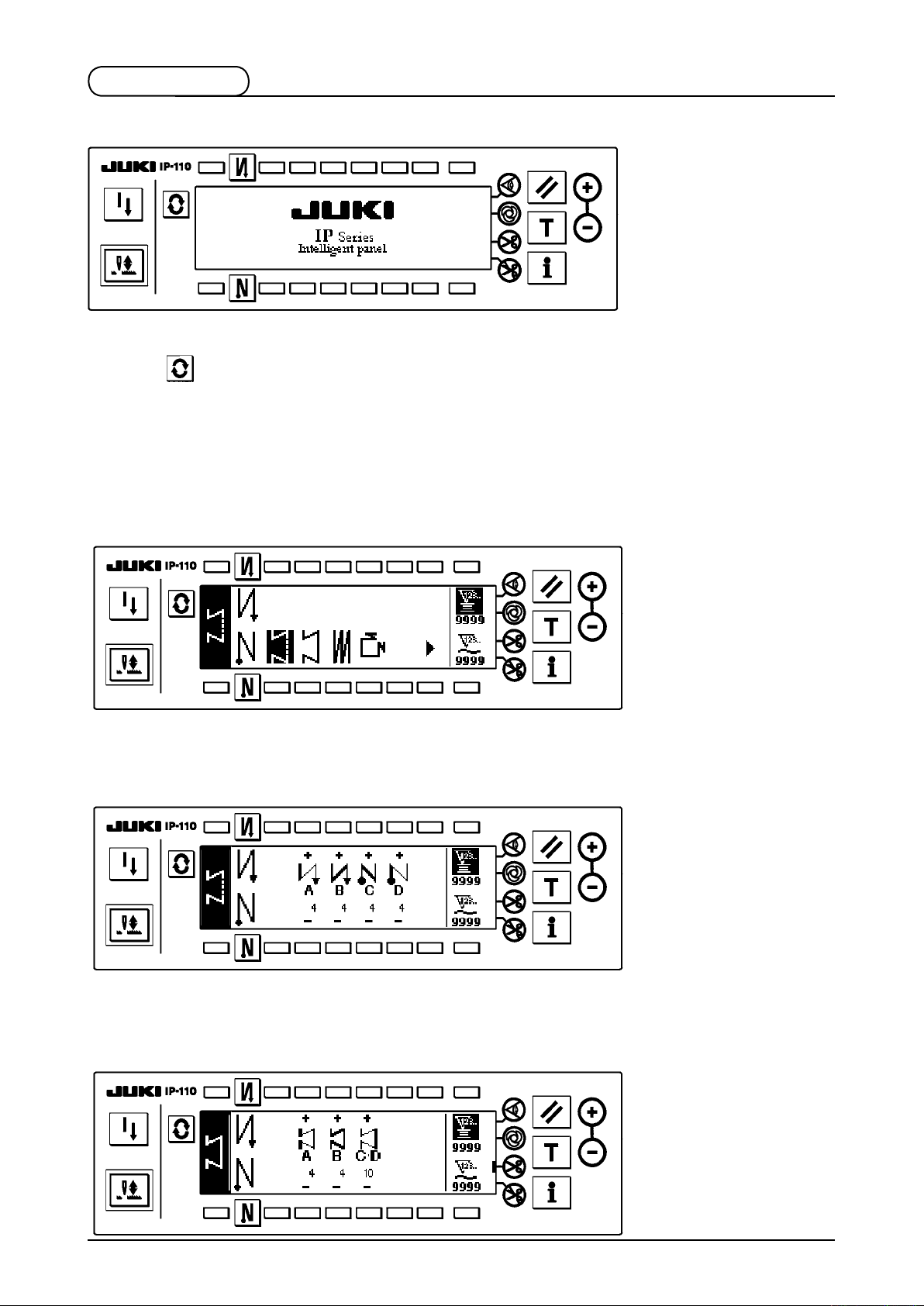

WELCOME screen is displayed immediately after turning ON the power.

The screen immediately after WELCOME screen becomes the setting screen of pattern selection.

Every time

When connecting with the sewing machine of MO system, MF system, MH system and DLN system, or setting

1 of Function setting No. 6 Clutch motor function or 1 of the setting No. 106 Pattern control function, the output

display screen is displayed.

Pattern list screen

■

Selection of the respective shapes is performed.

Number of stitches of free stitching setting screen

■

Setting of number of stitches of free stitching is performed.

switch is pressed, the screen changes.

Number of stitches of constant dimension stitching setting screen

■

Setting of number of stitches of constant dimension stitching is performed.

– 5 –

– 6 –

Number of stitches of overlapped stitching setting screen

■

Setting of number of stitches of overlapped stitching is performed.

Number of stitches of square stitching setting screen

■

Setting of number of stitches of square stitching is performed.

Output display screen

■

Final target set value, current target value and actual results up to now are displayed.

Output display screen (for sewing machines of MO system, MF system, MH system and DLN system)

■

Final target set value, current target value and actual results up to now are displayed.

In case of the sewing machines of MO system, MF system, MH system and DLN system, only this screen

is displayed.

When Function setting No. 76 Clutch motor function is set to 1 or the setting No. 106 Pattern control

function is set to 1, also only this screen is displayed.

2-5. How to operate the operation panel for sewing stitching patterns

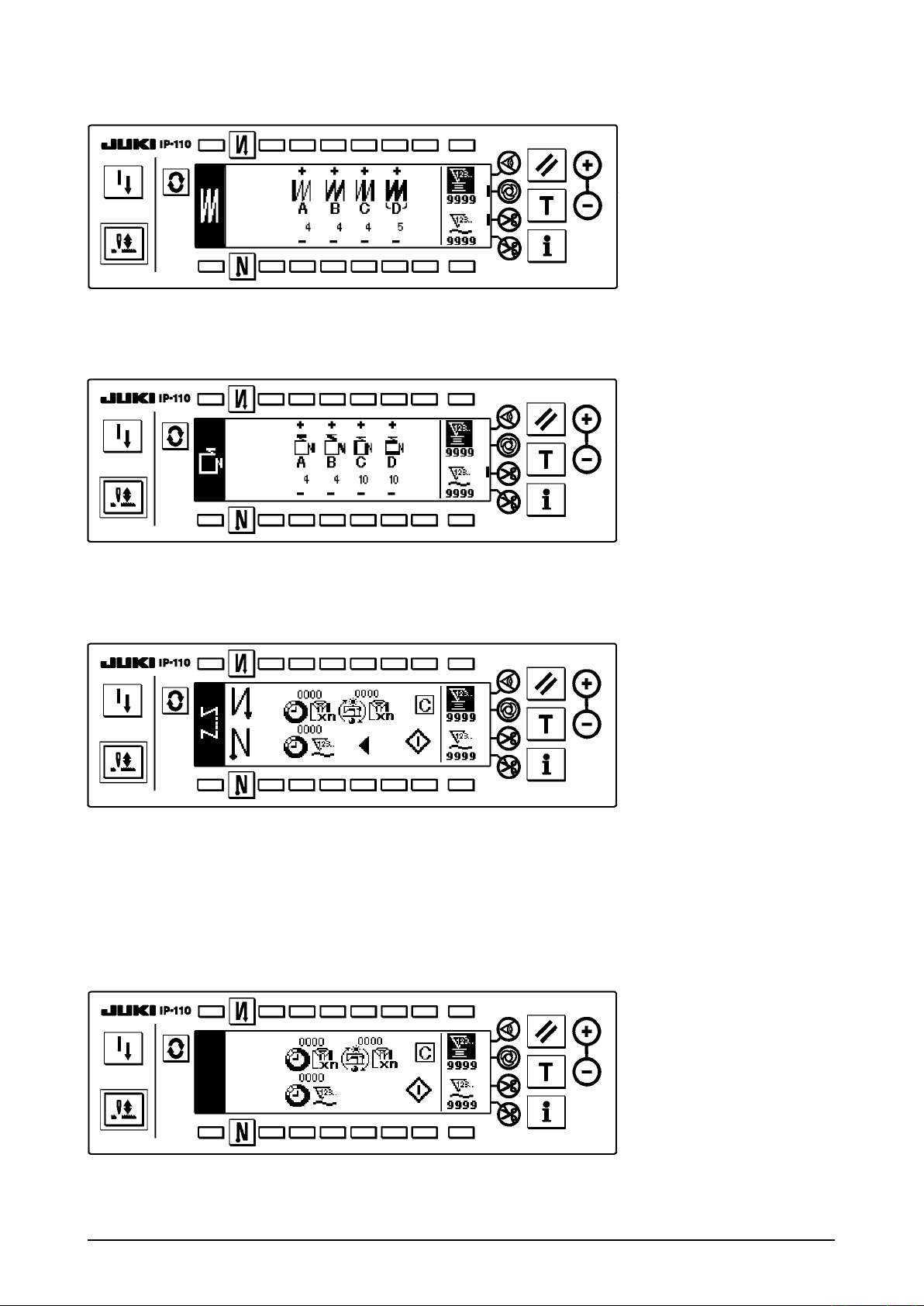

(1) Free stitching pattern

2

OFF ON ON

OFF

A

B

Sewing

pattern

C

D

OFF OFF

3

ON ON

Press to display the pattern list screen.

A

B

C

D

1

1) Press switch

to select the free stitching pattern, and the screen is automatically changed over to

1

the number of stitches of free stitching setting screen to display the number of stitches which has been

already set.

2

3

2) When changing the number of stitches, change it with switches

4

5

and 5 for setting the number of

4

stitches A through D.

(The range of the number of stitches that can be changed : 0 to 99 stitches)

– 7 –

– 8 –

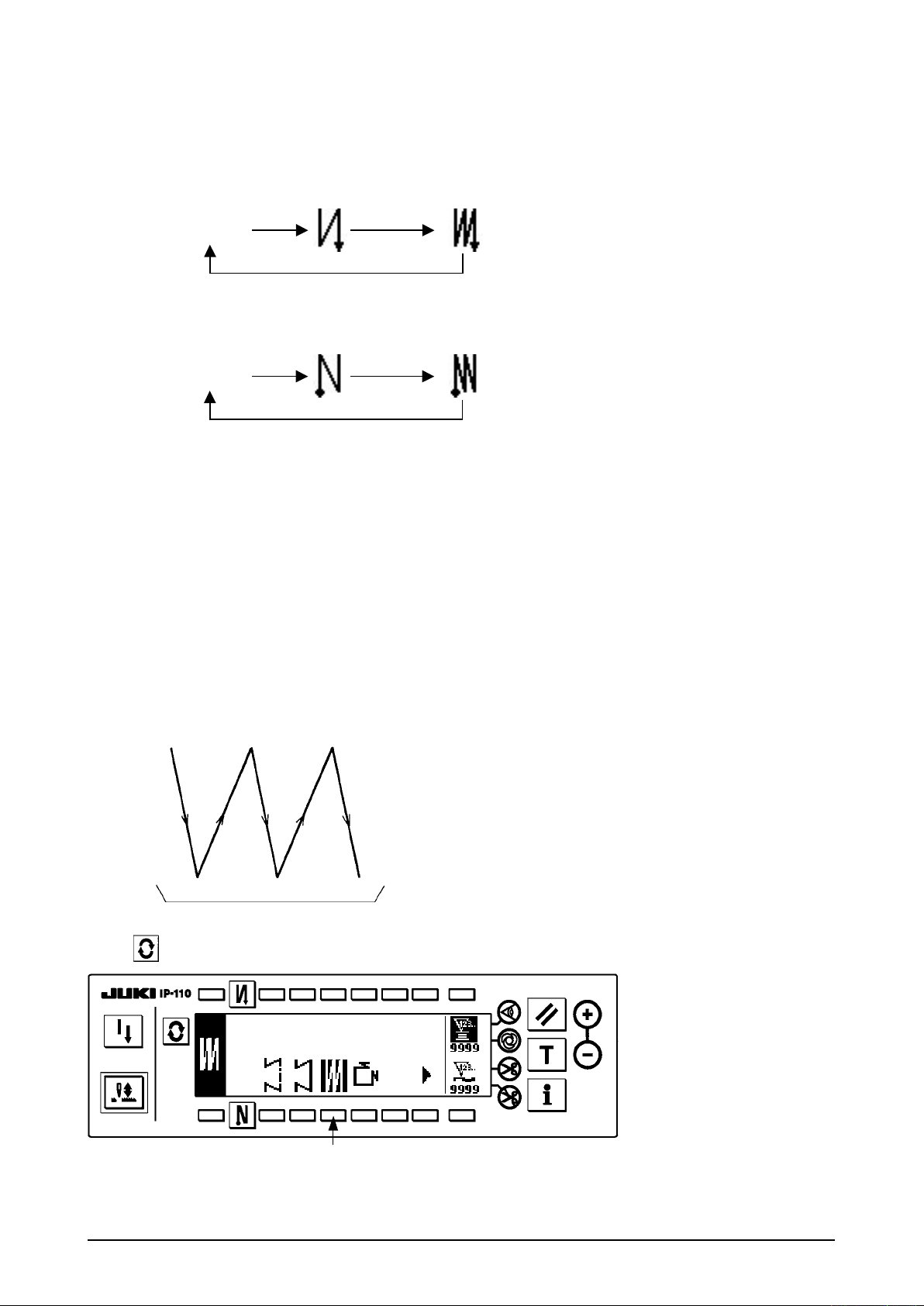

3) Press switch

to set the reverse stitching at the start of sewing.

2

No setting Reverse stitching

at the start of sewing

4) Press switch

to set the reverse stitching at the end of sewing.

3

No setting Reverse stitching

at the end of sewing

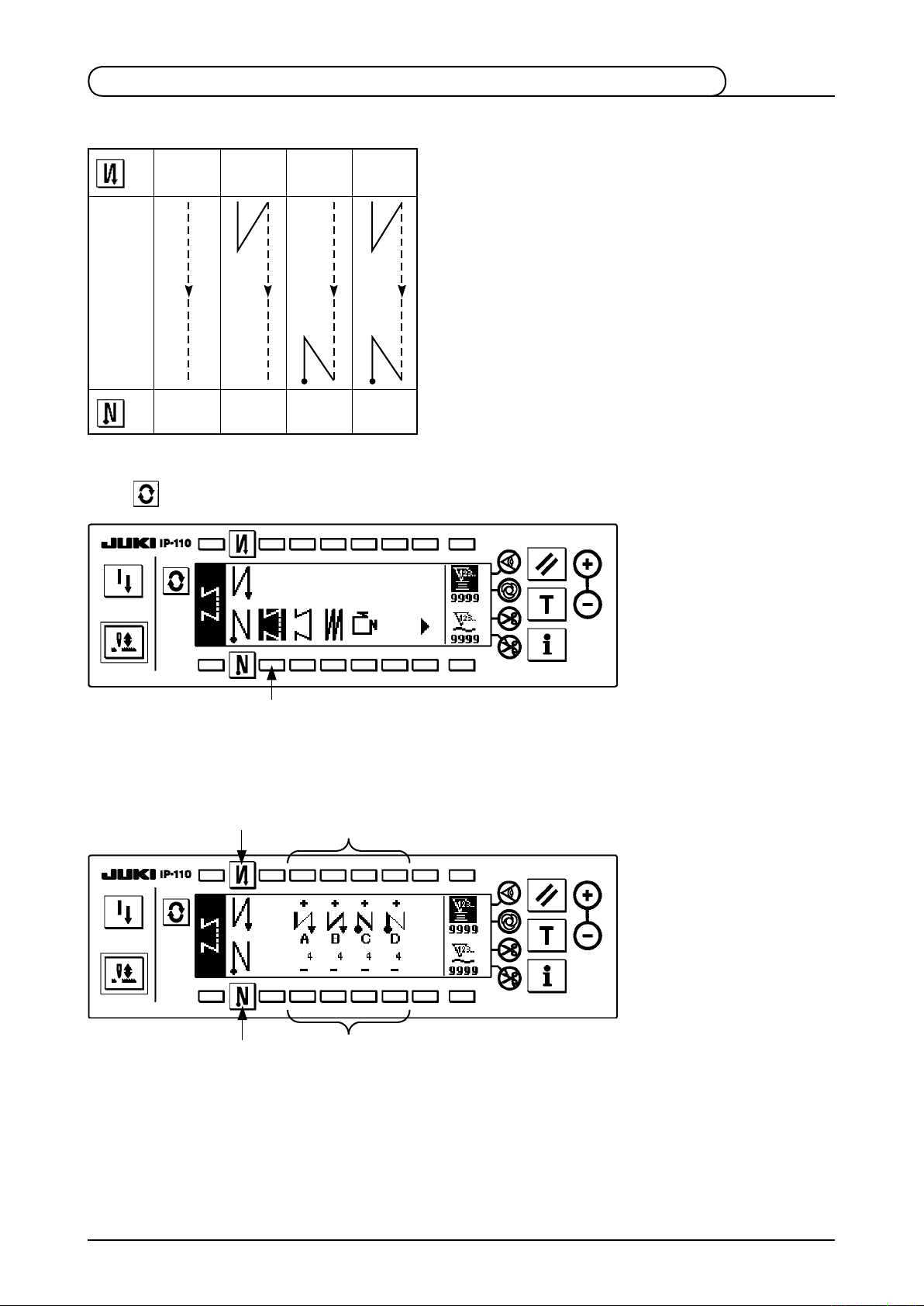

(2) Constant dimension stitching pattern

2

Sewing

pattern

OFF ON ON

A

B

C D

C D C D

OFF

B

A

A

B

C D

B

A

Double reverse stitching

at the start of sewing

Double reverse stitching

at the end of sewing

3

OFF OFF

1) Press switch

ON ON

1

to select the constant dimension stitching pattern, and the screen is automatically

1

Press to display the pattern list screen.

changed over to the number of stitches of constant dimension stitching setting screen to display the

number of stitches which has been already set.

2

4

6

!0

3

5

7

8

9

2) When changing the number of stitches of the reverse stitching, change it with switches

setting the number of stitches of A and B.

In addition, when changing the number of stitches of the constant dimension stitching, change it with

switches 6 and

(The range of the number of stitches that can be changed : A and B = 0 to 19 stitches, C D = 0 to 500 stitches)

for setting the number of stitches of C D.

7

and 5 for

4

3) Press switch

4) Press switch 3 to set the reverse stitching at the end of sewing.

5)

When automatic thread trimming switch

processes C D have been completed. (When setting the reverse stitching at the end of sewing, thread

trimming is automatically performed after the reverse stitching at the end of sewing has been completed.

When automatic thread trimming switch 8 is not selected, press the touch-back switch after processes C

D have been completed, and the sewing machine rotates at low speed. (Compensation stitching operation)

In addition, when the pedal is returned to the neutral position and the front part of it is depressed again,

the sewing can be continued regardless of the setting of the number of stitches.

6) When thread trimming prohibiting switch 9 is selected, the sewing machine will stop with the needle up

without performing thread trimming.

7) When one-shot automatic stitching switch

without a break by depressing the front part of the pedal.

to set the reverse stitching at the start of sewing.

2

No setting

No setting Reverse stitching

Reverse stitching

at the start of sewing

at the end of sewing

8

!0

Double reverse stitching

at the start of sewing

Double reverse stitching

at the end of sewing

is selected, thread trimming is automatically performed after

is selected, automatic sewing is performed at the set speed

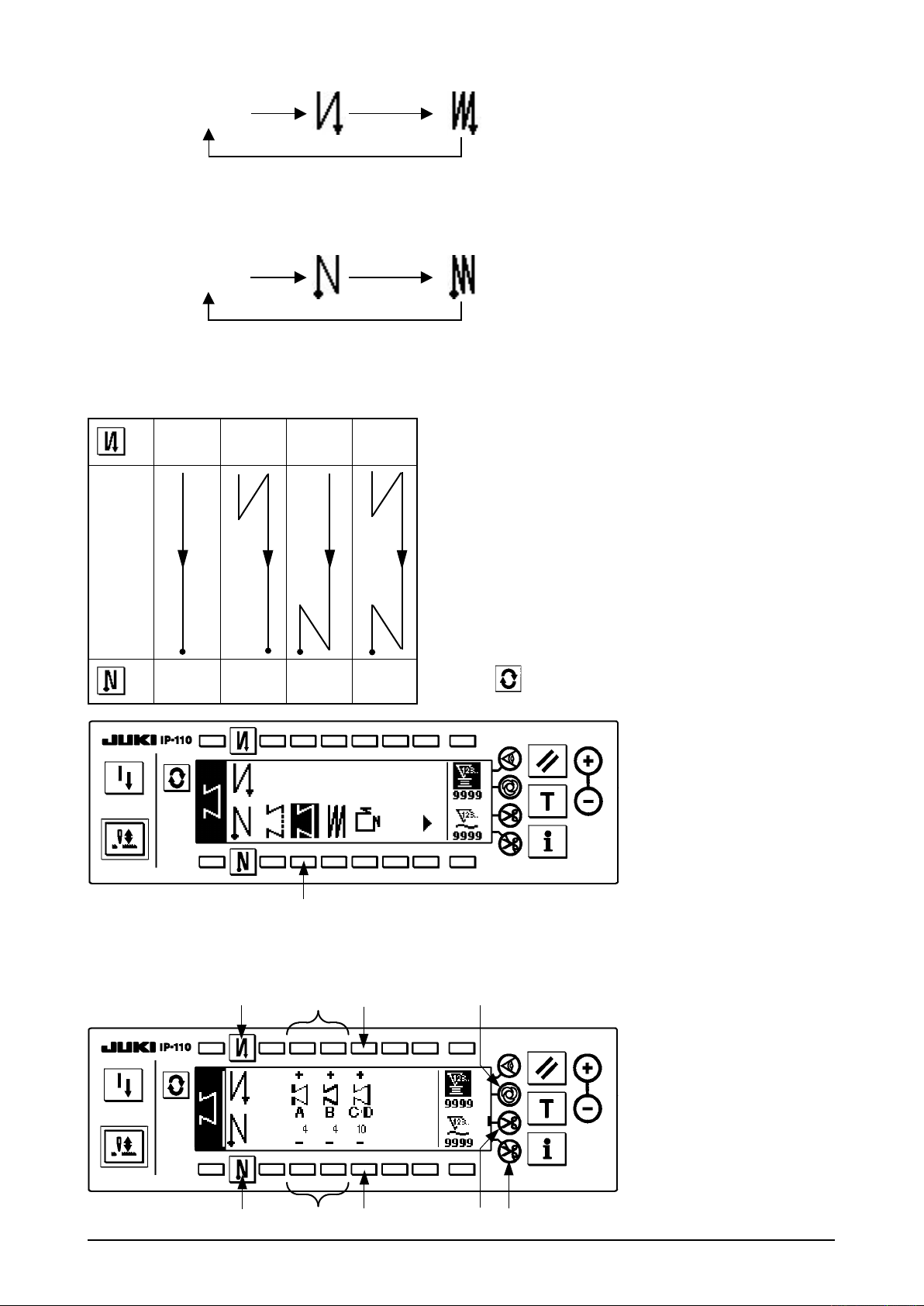

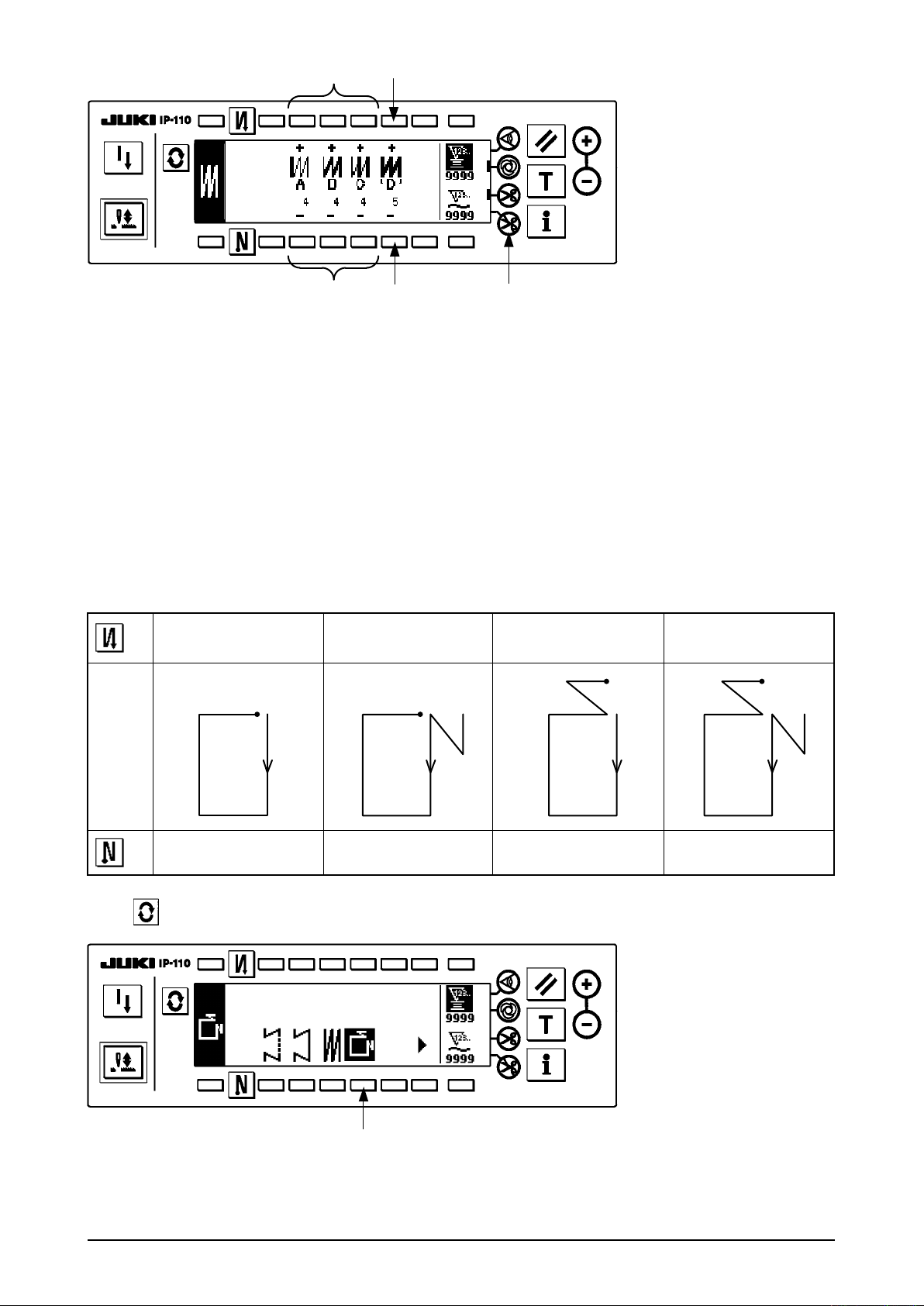

(3) Overlapped stitching pattern

A C C

B B

D

Press to display the pattern list screen.

1

1) Press switch 1 to select the overlapped stitching pattern, and the screen is automatically changed over to

the number of stitches of overlapped stitching setting screen to display the number of stitches which has

already been set.

– 9 –

– 10 –

2

4

3 5 6

2) When changing the number of stitches, change it with switches

2

and

for setting the number of

3

stitches for processes A through C. To change the number of times of the whole processes, change it with

switches

4

and

for setting the number of processes D.

5

(The range of the number of stitches A, B and C that can be changed : 0 to 19 stitches. The range of the

number of processes D that can be changed : 0 to 9 times)

3) Depress the front part of the pedal once, and the sewing machine will repeat the normal stitching and

reverse stitching as many as the number of specied times. Then the sewing machine will automatically

make the thread trimmer actuate and will stop to complete the overlapped stitching procedure. (The oneshot automatic stitching cannot be turned OFF.)

4) When thread trimming prohibiting function

is selected, the machine will stop with the needle up upon

6

completion of the overlapped stitching procedure without performing thread trimming.

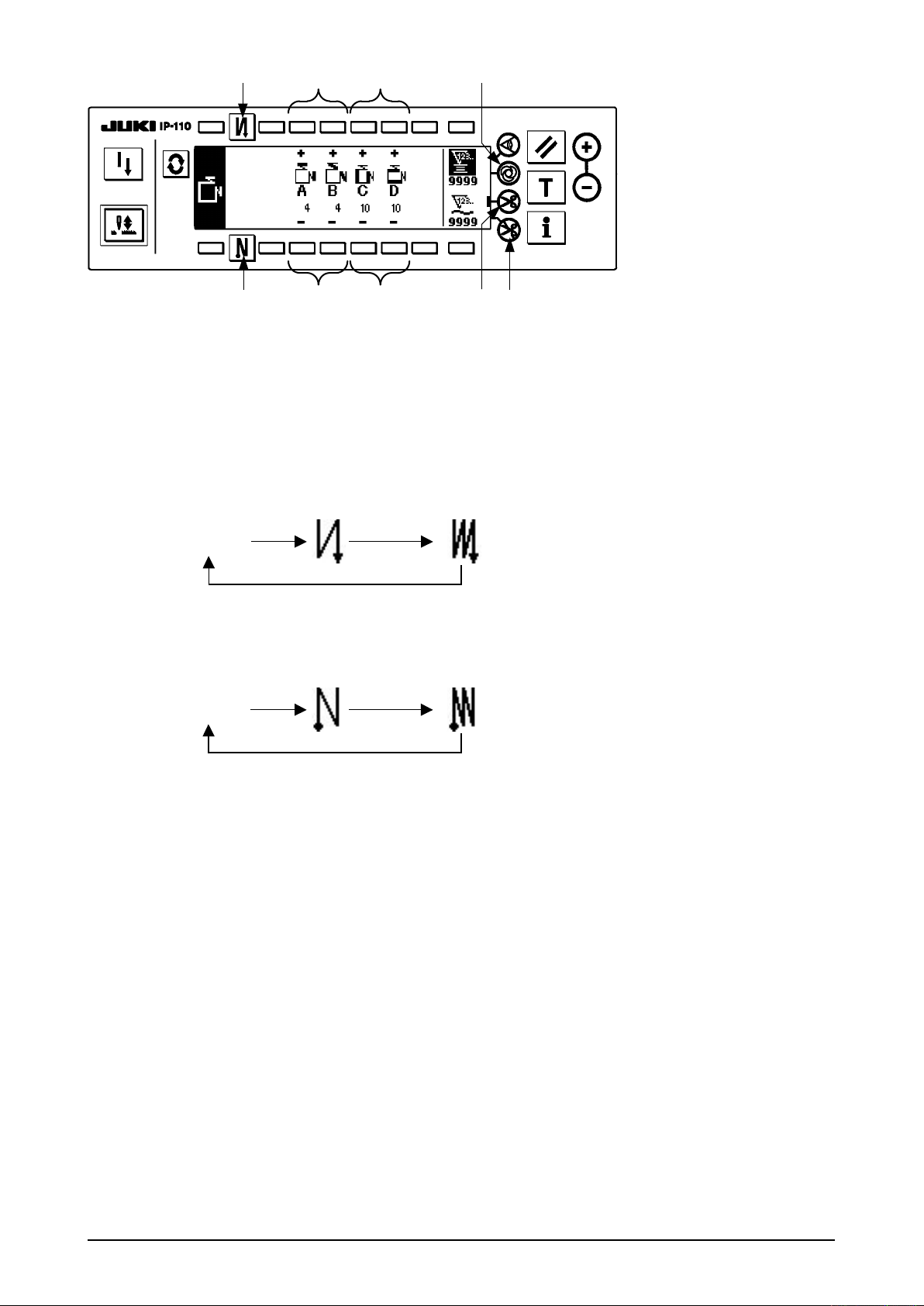

(4) Square stitching pattern

2

Sewing

pattern

OFF

D

C

C

D

C

A

B

C

OFFON ON

A

B

D

C

C

C

A

B

D

A

B

C

3

D

OFF

D

D

ONOFF

D

ON

Press to display the pattern list screen.

1

1) Press switch 1 to select the square stitching pattern, and the screen is automatically changed over to

the number of stitches of square stitching setting screen to display the number of stitches which has been

already set.

2

4

6

!0

53 9

2) When changing the number of stitches of reverse stitching, change it with switches

the number of stitches of A and B.

In addition, when changing the number of stitches of square stitching, change it with switches 6 and 7

for setting the number of stitches of C and D.

(The range of the number of stitches that can be changed : A and B = 0 to 19 stitches, C and D = 0 to 99

stitches)

3) Press switch

No setting Reverse stitching

4) Press switch

to set the reverse stitching at the start of sewing.

2

at the start of sewing

to set the reverse stitching at the end of sewing.

3

7 8

Double reverse stitching

at the start of sewing

and 5 for setting

4

No setting Reverse stitching

at the end of sewing

5) The sewing machine automatically stops after completion of the process at processes C and D. At this

time, the sewing machine rotates at low speed when the touch-back switch is pressed (compensation

stitching operation). In addition, when the pedal is returned to the neutral position and the front part of it is

depressed again, the sewing can be continued regardless of the setting of the number of stitches.

6) When automatic thread trimming switch 8 is selected, thread trimming is automatically performed after

completion of the last process. (When the reverse feed stitching at the end of sewing is set, the reverse

feed stitching at the end of sewing becomes the last process, and automatic thread trimming is performed

after completion of the process.)

7) When thread trimming prohibiting switch 9 is selected, the sewing machine will stop with the needle up

without performing thread trimming.

8) When one-shot automatic stitching switch

without a break by depressing the front part of pedal at processes C and D.

9) When the sewing machine is provided with auto-lifter, the presser foot automatically goes up after

completion of the process at processes C and D.

Double reverse stitching

at the end of sewing

is selected, automatic sewing is performed at the set speed

!0

– 11 –

– 12 –

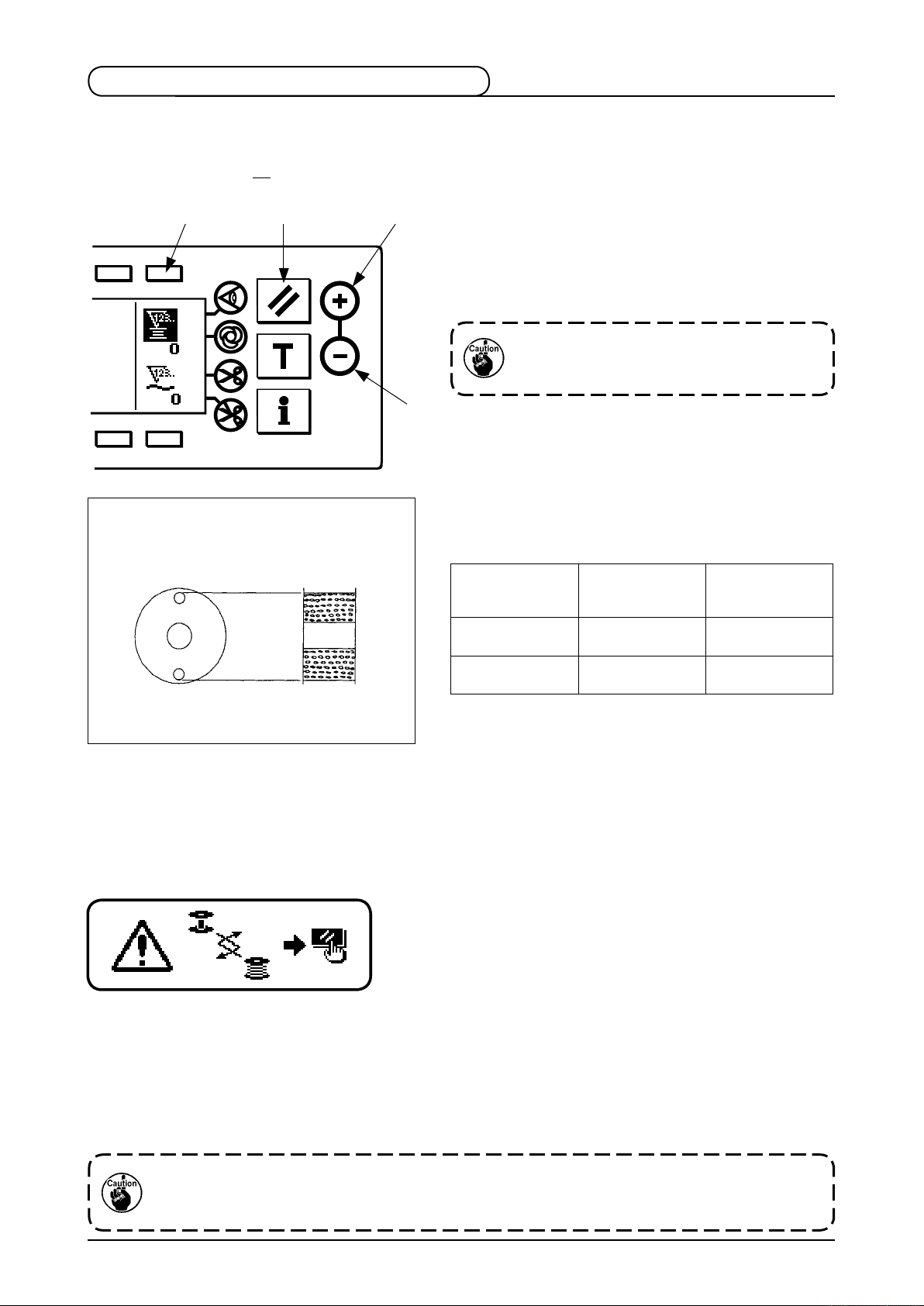

2-6. How to use the bobbin thread counter

The machine detects the number of stitches. The preset value on the bobbin thread counter is subtracted in

accordance with the number of stitches detected. (Every time the detector detects 10 stitches, 1 is subtracted

from the preset value on the bobbin thread counter.) When the value on the counter becomes a minus value

........

as (

→

change the bobbin thread has come.

Initial value on the bobbin thread counter

for reference

0 → –1), the buzzer (peeps three times) and the pop-up display inform that the time to

1

→

1 2

3

1) Press switch

to select the bobbin thread counter.

1

Then press counter reset switch

to return the

2

value indicated on the bobbin thread counter to the

initial value (it has been factory-set to “0” at the time

of delivery).

The bobbin thread counter cannot be reset

during sewing. In this case, make the thread

trimmer actuate once.

4

2) Set an init ial v alue u sing c ounter value setti ng

switches 3 and 4.

The table below gives the initial setting values for

reference when the bobbin is wound with thread to the

extent that the pinhole in the outside of the bobbin case

is reached as shown in the gure on the left side.

Length of thread

Thread used

Polyester spun

thread #50

Cotton thread #50 31 m

wound round the

bobbin

36 m

Thread tension rate 100 %

Value on bobbin

thread counter

1200

(stitch length : 3 mm)

1000

(stitch length : 3 mm)

* Actually, the bobbin thread counter is affected by

the material thickness and the sewing speed. So,

adjust the initial value of the bobbin thread counter in

accordance with the operating conditions.

3) Once the initial value is specied, start the sewing machine.

4) When a minus value is shown on the counter, the buzzer peeps three times and the pop-up display

appears, replace the bobbin thread.

Bobbin thread replacement warning pop-up

5) After the bobbin thread has been properly replaced, press counter reset switch 2 to return the value on

the bobbin thread counter to the initial value. Now, re-start the sewing machine.

6) If the remaining amount of bobbin thread is excessive or the bobbin thread runs out before the bobbin

thread counter indicates a minus value, adjust the initial value appropriately using counter value setting

switches 3 and 4.

If the remaining amount of bobbin thread is excessive ..... Increase the initial value using the “+” switch.

If the remaining amount of bobbin thread is insufcient .... Decrease the initial value using “–” switch.

If the bobbin thread counter is used in combination with the bobbin thread remaining amount

detecting device, the bobbin thread counter indicates the number of times of detection of the bobbin

thread remaining amount detecting device. So, be sure to use the device after carefully reading the

Instruction Manual for the bobbin thread remaining amount detecting device.

2-7. Sewing counter

Count-up is performed every time thread trimming is performed. (0

4

1

2

After selecting the sewing counter by pressing switch 1,

the counter value can be modified using counter value

setting switches 2 and

value returns to "0" by pressing counter reset switch

3

2-8. Needle up/down compensation switch

Every time needle up/down compensation switch 1

is pressed, the needle goes up when it is in its lowest

position or comes down when it is in its highest position.

This compensates the stitch by a half of the predetermined

stitch length.

Note, however, that the machine does not run

1

continuously at a low speed even if you keep the switch

held pressed.

Also, note that the needle up/down compensation switch

is inoperative after turning the handwheel by hand.

Thread trimming is operative only at the time of stitch

compensation after depressing the front part of the pedal

once.

→

1

...........

→

2

3

→ 9999)

. In addition, the sewing counter

4

.

2-9. ON/OFF switch of the material edge sensor

• When the material edge sensor, which is optionally available, is connected to the operation panel, the ON/

OFF switch of the material edge sensor becomes effective.

• If the material edge sensor is specied, the sewing machine will automatically stop running or perform

thread trimming when the sensor detects the material edge.

If the material edge sensor is used in combination with the operation panel, carefully read the

Instruction Manual for the material edge sensor beforehand.

2-10. Automatic thread trimming switch

• This switch is used to automatically actuate the thread trimmer in a process where the sewing machine

automatically stops or when the material edge sensor is used.

(if the automatic reverse stitching (for end) is specied, the thread trimmer will actuate after the sewing

machine completes the automatic reverse stitching (for end).)

2-11. One-shot automatic stitching switch

• This switch is used, in the constant-dimension stitching mode, rectangular stitching mode, or in the process

where the material edge sensor is specied, to make the sewing machine automatically perform sewing at

the specied speed until the end of the process is reached only by driving the sewing machine once.

– 13 –

Loading...

Loading...