ENGLISH

CONTENTS

1. INSTALLING THE OPERATION PANEL ................................................................... 1

2. CONNECTING THE CORD........................................................................................2

3. HOW TO USE THE OPERATION PANEL .................................................................. 3

3-1. Names and functions of each components........................................................................ 3

3-2. Adjusting the contrast of the operation panel display ...................................................... 5

3-3. Production control switch connecting connector.............................................................. 5

4. STANDARD PANEL................................................................................................... 6

4-1. Screen list .............................................................................................................................. 6

4-2. How to operate the operation panel for sewing stitching patterns .................................. 8

(1) Reverse stitching pattern...................................................................................................................8

(2) Overlapped stitching pattern........................................................................................................... 10

(3) Programmed stitching pattern ........................................................................................................11

(4) Cycle sewing pattern........................................................................................................................ 15

4-3. How to use the bobbin thread counter.............................................................................. 17

4-4. No. of pcs. counter .............................................................................................................. 18

ENGLISH

4-5. Re-sewing switch ................................................................................................................ 18

4-6. Needle up/down compensation switch ............................................................................. 19

4-7. ON/OFF switch

4-8. Automatic thread trimming switch

4-9. One-shot automatic stitching switch

4-10. Thread trimming prohibition switch

4-11. Key lock.............................................................................................................................. 19

4-12. Information......................................................................................................................... 20

(1) Sewing management information ...................................................................................................20

(2) Production control function ............................................................................................................24

(3) Working measurement function ...................................................................................................... 26

4-13. Setting for functions ......................................................................................................... 28

(1) How to change over to the function setting mode ........................................................................28

(2) Function setting list .........................................................................................................................31

of the material edge sensor ............................................................... 19

.............................................................................. 19

........................................................................... 19

........................................................................... 19

5. PANEL FOR LH-4168/4188.....................................................................................34

5-1. Screen list ............................................................................................................................ 34

5-2. How to operate the operation panel for sewing stitching patterns ................................ 38

(1) Reverse stitching pattern.................................................................................................................38

(2) Overlapped stitching pattern........................................................................................................... 40

(3) Corner pattern................................................................................................................................... 41

(4) Step pattern.......................................................................................................................................47

(5) Cycle sewing pattern........................................................................................................................ 50

5-3. How to use the bobbin thread counter.............................................................................. 51

5-4. No. of pcs. counter .............................................................................................................. 52

5-5. Re-sewing switch ................................................................................................................ 53

5-6. Needle up/down compensation switch ............................................................................. 54

5-7. ON/OFF switch

of the material edge sensor ............................................................... 54

5-8. Automatic thread trimming switch .............................................................................. 54

5-9. One-shot automatic stitching switch

5-10. Thread trimming prohibition switch

........................................................................... 54

........................................................................... 54

5-11. Key lock .............................................................................................................................. 54

5-12. Information......................................................................................................................... 55

(1) Sewing management information ................................................................................................... 55

(2) Production control function ............................................................................................................ 59

(3) Working measurement function ......................................................................................................61

5-13. Setting for functions ......................................................................................................... 63

(1) How to change over to the function setting mode ........................................................................ 63

(2) Function setting list ......................................................................................................................... 66

(3) Communication mode ...................................................................................................................... 70

6. EXTERNAL INTERFACE ......................................................................................... 74

7. ERROR DISPLAY .................................................................................................... 74

7-1. Error code list (Error display in panel) ............................................................................... 75

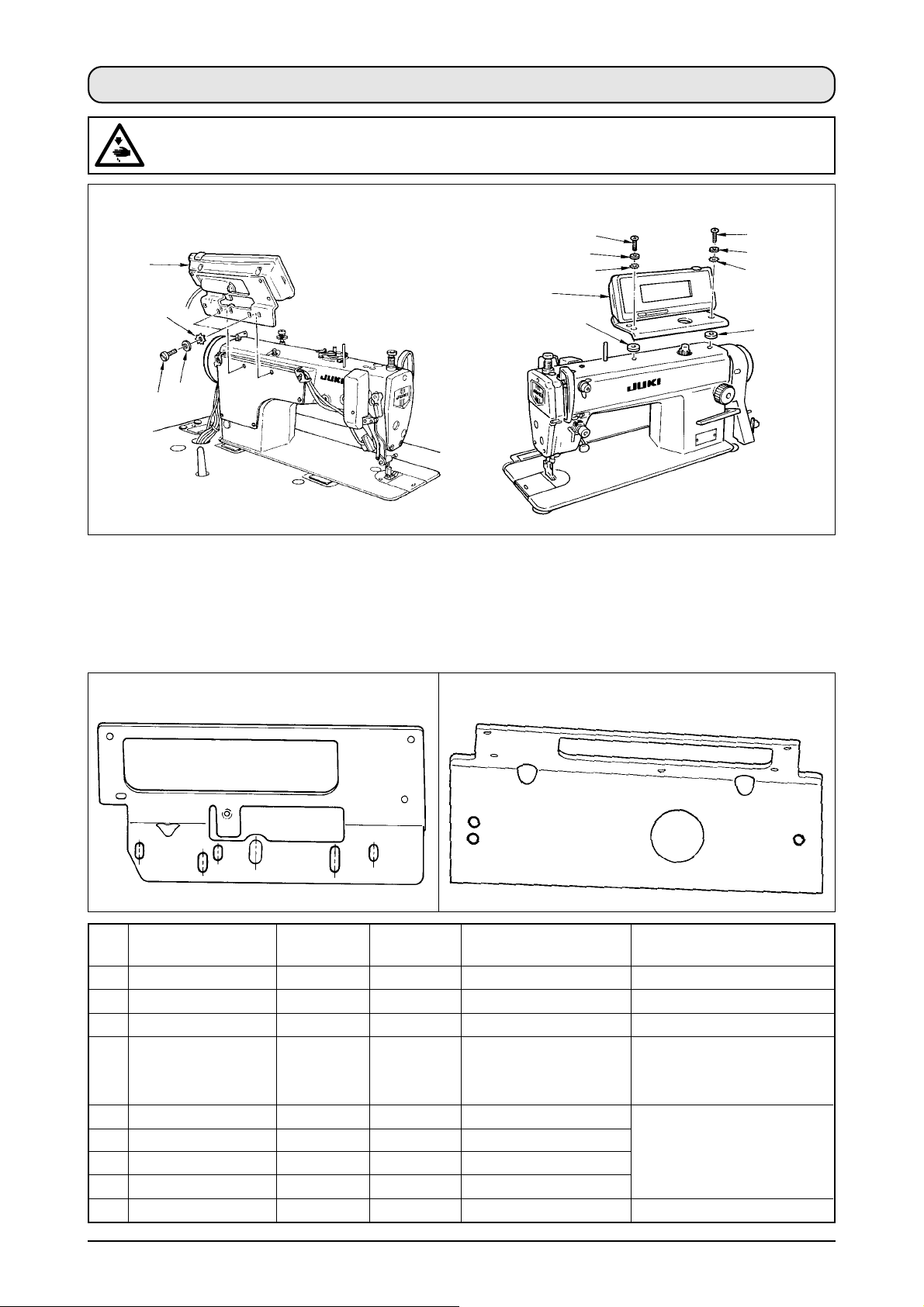

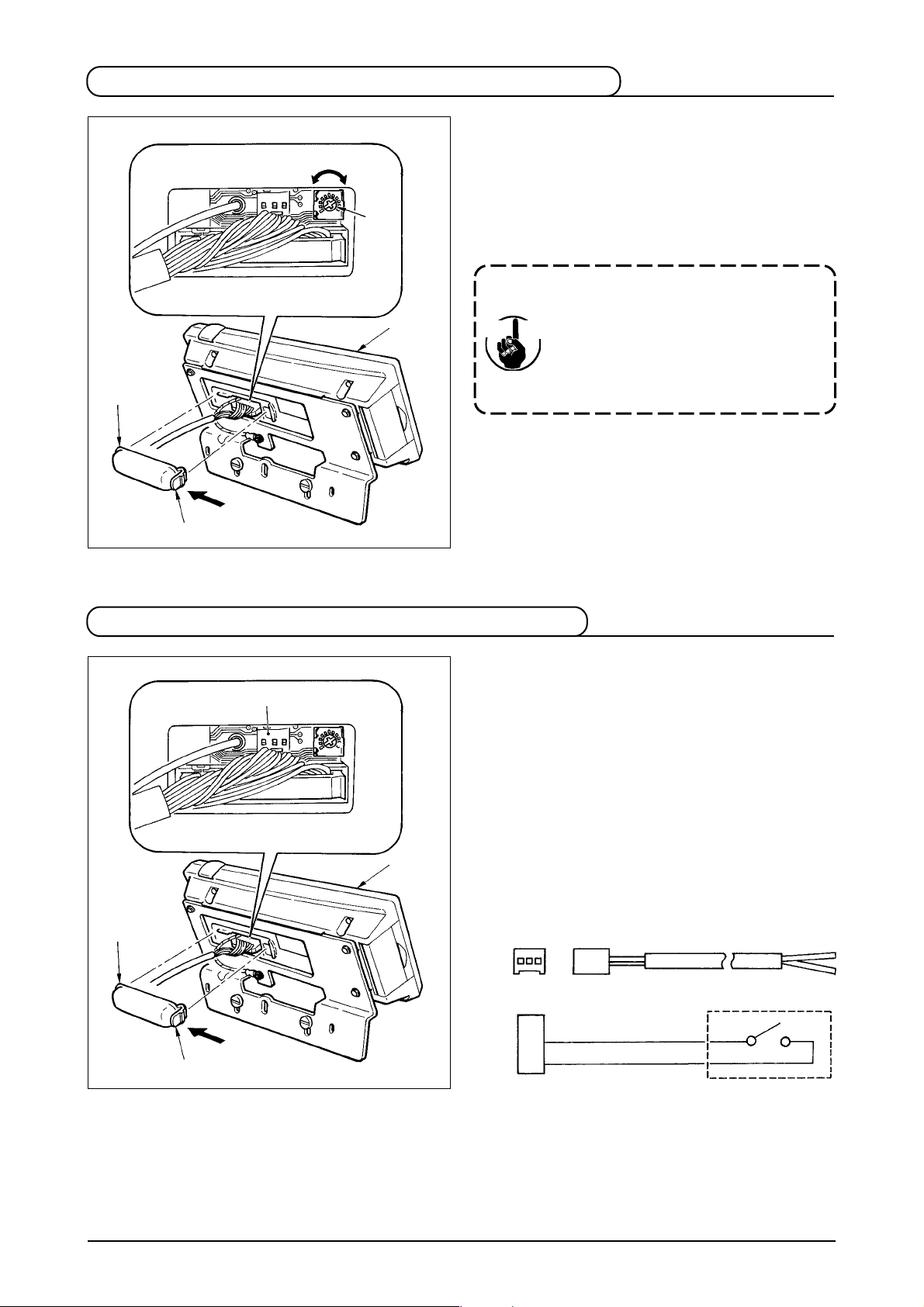

1. INSTALLING THE OPERATION PANEL

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

Type B (Type name plate TYPE B0*)

笊

Type C (Type name plate TYPE C0*)

笆

笳

笘

笆

笳

笘

笊

笆

笘

笳

笙

笙

1) Attach operation panel 笊 to the machine head using screw 笆, plain washer 笳, toothed lock washer 笘 and

spacer 笙 (for type C) supplied with the operation panel. Select and use screw 笆referring to the table.

2) The positions of the holes in the bracket for installing the operation panel are different from each other

according to the respective models. Refer to the table below.

IP-100 / bracket type classified by model correspondence table

Type B

笊

笆

Mounted machine

No.

head

DDL-9000

1

DLN-9010

2

LH-31** , LH-35**

3

LZ-228* N

4

笳

笘

Bracket type

Type B

Type B

Type B

Type B

笙

Installing

hole used

2 − 4

2 − 4

1 − 5

3 − 4

Type C

笆

笊

Part No. of screw

SS4121415SP(3/16-28)

SS4121415SP(3/16-28)

SS6111210SP(11/64-40)

SS4121415SP(3/16-28)

笳

Remarks

To be fixed on the exclusive

bracket for installing standard

panel

DDL-5550N

5

DDL-8700

6

DLN-5410N

7

DLU-5494N

8

LH-41**

9

Type C

Type C

Type C

Type C

Type B

1 − 3

1 − 3

1 − 3

1 − 3

2 − 4

SS7121410SN(3/16-24)

SS7121410SN(3/16-24)

SS7121410SN(3/16-24)

SS7121410SN(3/16-24)

SS4121415SP(3/16-28)

– 1 –

Use 2 – 3 in case of optional

unit (V0 and the like).

2. CONNECTING THE CORD

WARNING :

Turn OFF the power and start the work after 5 minutes or more have passed so as to prevent accidents

caused by abrupt start of the sewing machine.

笆

綏

笊

1) Pass cord 笊 and FG cord 笳 (for type C) of the

operation panel through hole 綏 in the machine table

to route it to the underside of the table.

笳

笘

笳

笊

2) Connect the connector of cord 笊 to connector

CN34 笆 in the control box.

Bottom surface of table

笙

3) For type C, fix FG cord 笳 to the power switch with wood screw 笘 supplied with the panel as accessories.

Wire FG cord 笳 after bundling it with the power cable and the like with cable clip band 笙 supplied with the

panel as accessories.

– 2 –

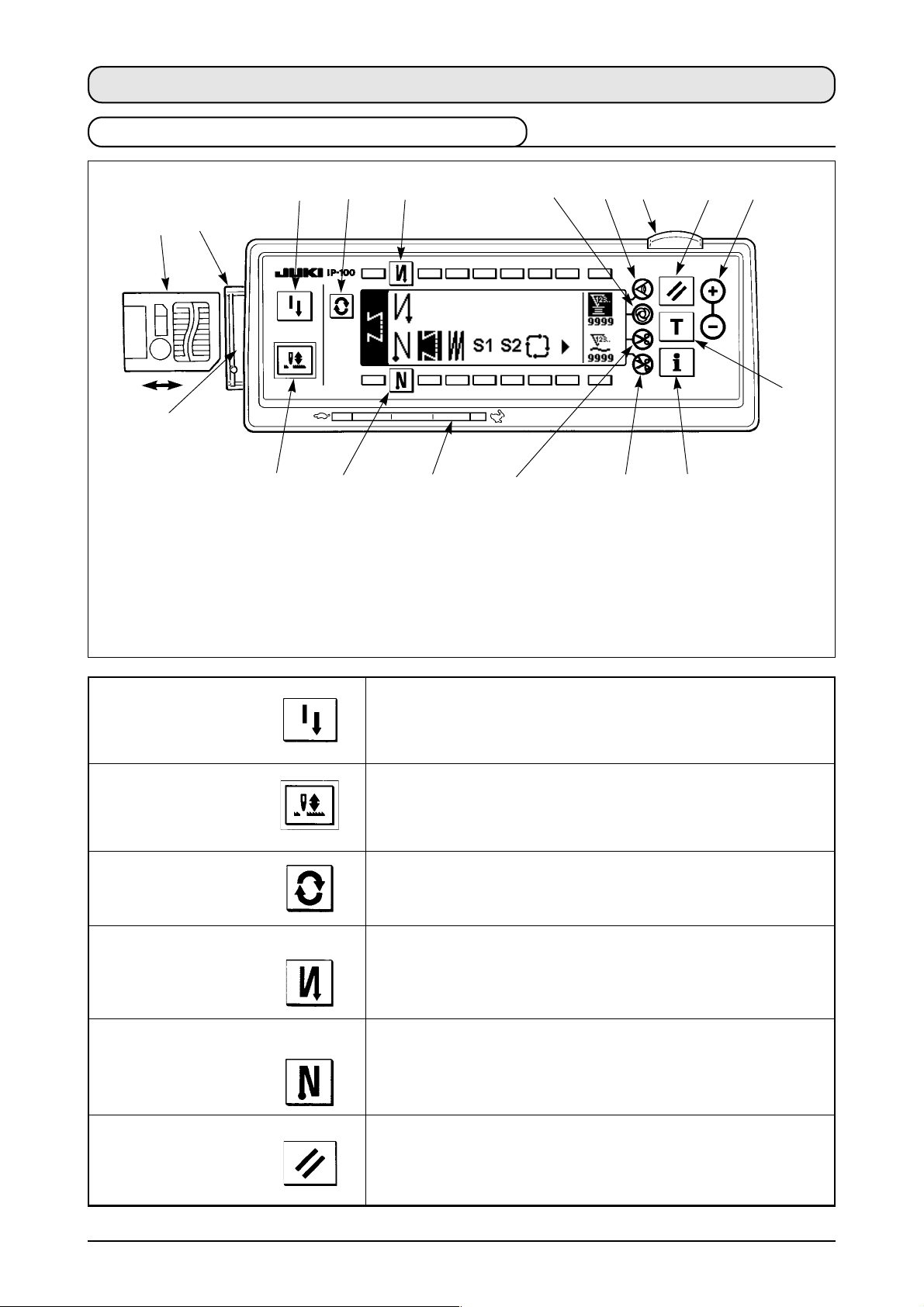

3. HOW TO USE THE OPERATION PANEL

3-1. Names and functions of each components

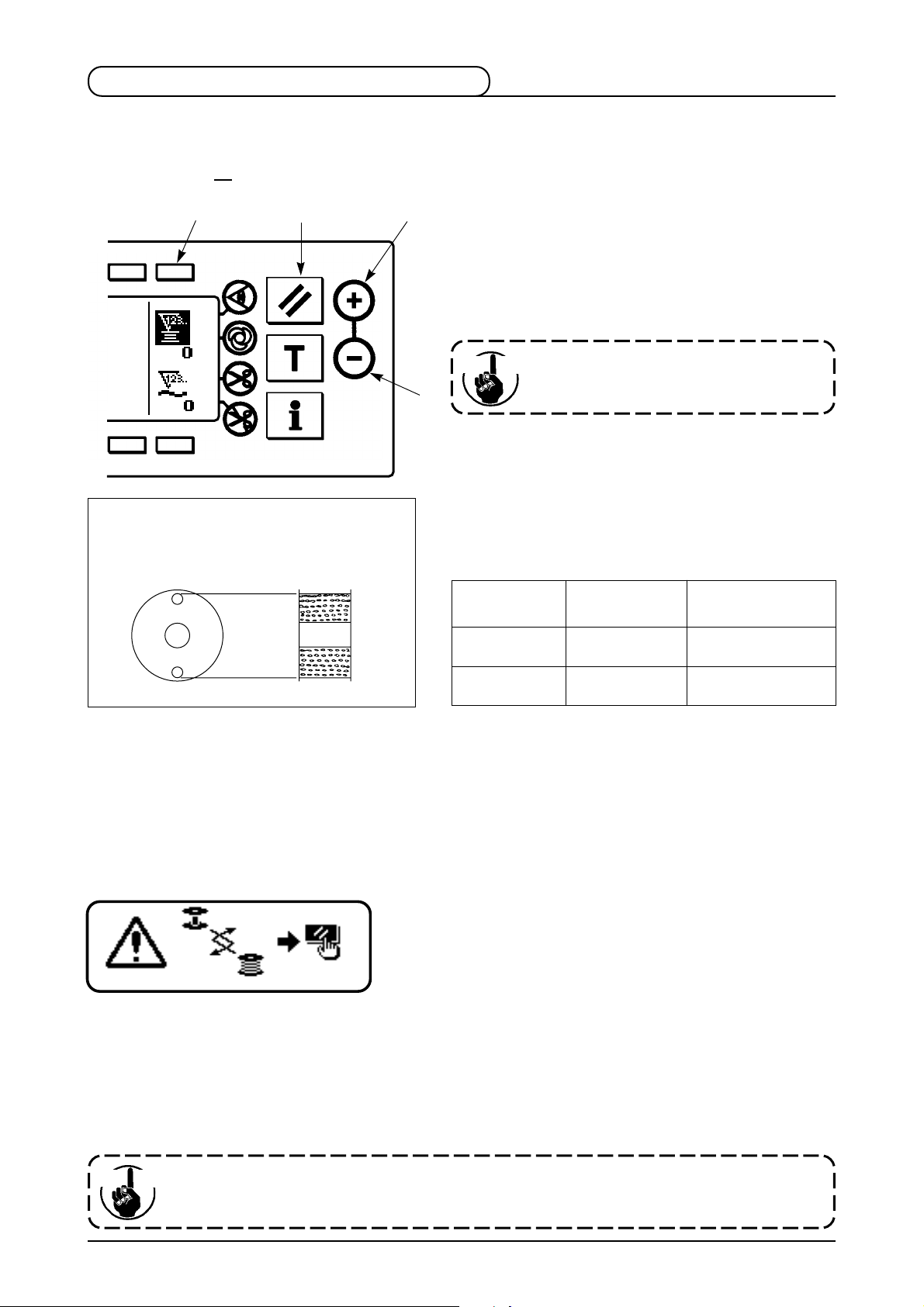

笳

筥

笊

筅

筵

笆

笊 Re-sewing switch

笆 Needle up/down compensating switch

笳 Screen changeover switch

笘

With/without reverse feed stitch at sewing start switch

笙

With/without reverse feed stitch at sewing end switch

笞 Reset switch

笵 Teaching switch

笙

笘

筐

笶

笋

笨 Information switch

笶 Material edge sensor switch

筐 One-shot stitching switch

筺

With/without automatic thread trimmer switch

笄Thread trimming prohibiting switch

筍Counter value setting switch

笋

Max.speed limitation variable resistor

筍

筌

笞

笵

笄

筌Power display lamp

筅 Smart media cover

筵 Smart media slot

(Smart media inserting opening)

筥 Smart media

Optional :

( )

Part No.HX005750000

笨筺

笊 Re-sewing switch

笆 Needle up/down

compensating switch

笳 Screen changeover

switch

笘 With/without reverse feed stitch

at sewing start switch

笙 With/without reverse feed stitch

at sewing end switch

笞 Reset switch

This switch is used to continue sewing from the step on the way

after replacing bobbin thread when bobbin thread has run out during

program stitching step.

This is the switch to perform needle up/down compensating stitching.

(Needle up/down compensating stitching and one stitch compensating

stitching can be changed over with function setting No. 22.)

This is the switch to change over the screen.

This is the switch to turn ON/OFF automatic reverse feed stitch at

sewing start.

* This switch cannot be used with the sewing machine which is not

provided with automatic reverse feed stitching device.

This is the switch to turn ON/OFF automatic reverse feed stitch at

sewing end.

* This switch cannot be used with the sewing machine which is not

provided with automatic reverse feed stitching device.

This is the switch to make the value of bobbin thread counter or

sewing counter the set value.

– 3 –

笵 Teaching switch

This is the switch to set the setting of the number of stitches with

the value of number of stitches which has been actually sewn.

笨 Information switch

笶 Material edge sensor switch

筐

One-shot stitching switch

筺 With/without automatic

thread trimmer switch

笄 Thread trimming

prohibiting switch

This is the switch to perform various function settings.

Rendered effective when the material edge sensor is installed on

the machine.

Used for selecting whether or not the material edge sensor is used

during sewing.

When this switch is set to effective at the time of program stitching,

the sewing machine automatically operates up to the specified

number of stitches.

When this switch is set to effective at the time of program stitching,

the sewing machine automatically performs thread trimming when

the specified number of stitches has been completed.

This switch prohibits all thread trimmings.

* This switch cannot be used with the sewing machine which is not

provided with the automatic thread trimming device.

筍 Counter value setting

switch

笋 Max. speed limitation variable

resistor

筌 Power display lamp

筅Smart media cover

筵 Smart media slot

(Smart media inserting opening)

This is the switch to set the value of bobbin thread counter or No. of

pcs. counter.

When moving the resistor in the left direction, max. speed is limited.

This lamp lights up when the power switch is turned ON.

This is the cover for smart media inserting opening.

To open the cover, place your finger on the notch located on the

side of the cover as shown in the figure and push the cover in the

direction of left slanting rear.

* There are some functions that are not able to be operated with

the cover opened.

Do not close the cover unless smart media is completely inserted.

To set smart media, insert smart media into smart media slot and

push it until it is almost hidden.

To remove smart media, push it further again and it protrudes to

the position where it can be held between your fingers. Now, draw

it out.

* Be very careful of the inserting direction of smart media.

– 4 –

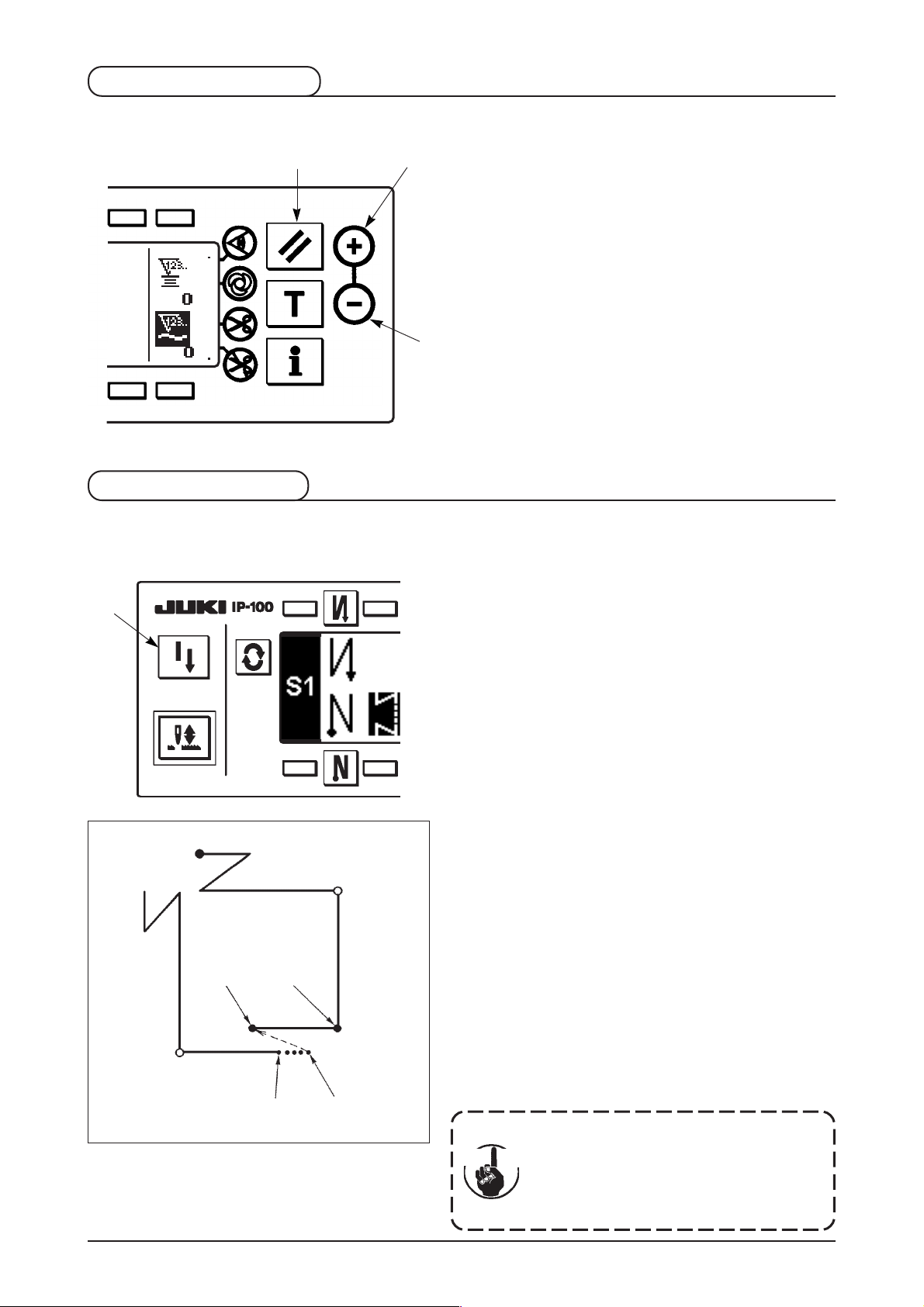

3-2. Adjusting the contrast of the operation panel display

1) Press in the direction of arrow mark the click of

section 綏 of cord outlet cover 笆 assembled in the

rear of operation panel 笊 and remove the cover.

2) Turn LCD screen display brightness adjustment

variable resistor 笳 to adjust the brightness

(contrast) of LCD screen.

1. To prevent the operation panel from

breakage, do not touch the circuit

Cau tion

board pattern and the connector

terminal.

2. Do not disassemble the operation

panel to prevent it from breakage.

笆

綏

Light

Shade

笳

笊

3-3. Production control switch connecting connector

1) Press in the direction of arrow mark the click of

笳

笊

笆

綏

section 綏 of cord outlet cover 笆 assembled in the

rear of operation panel 笊 and remove the cover.

2) Connect the optional relay cable connector to

CN105 笳 of the production control switch

connecting connector.

Note) Prepare the switch main unit by the

customers or ask JUKI business office

about it.

Optional relay cable A (asm.)

JUKI Part No. 40008168

3 2 1

CN105

1

+ 5V

2

SW

3

GND

– 5 –

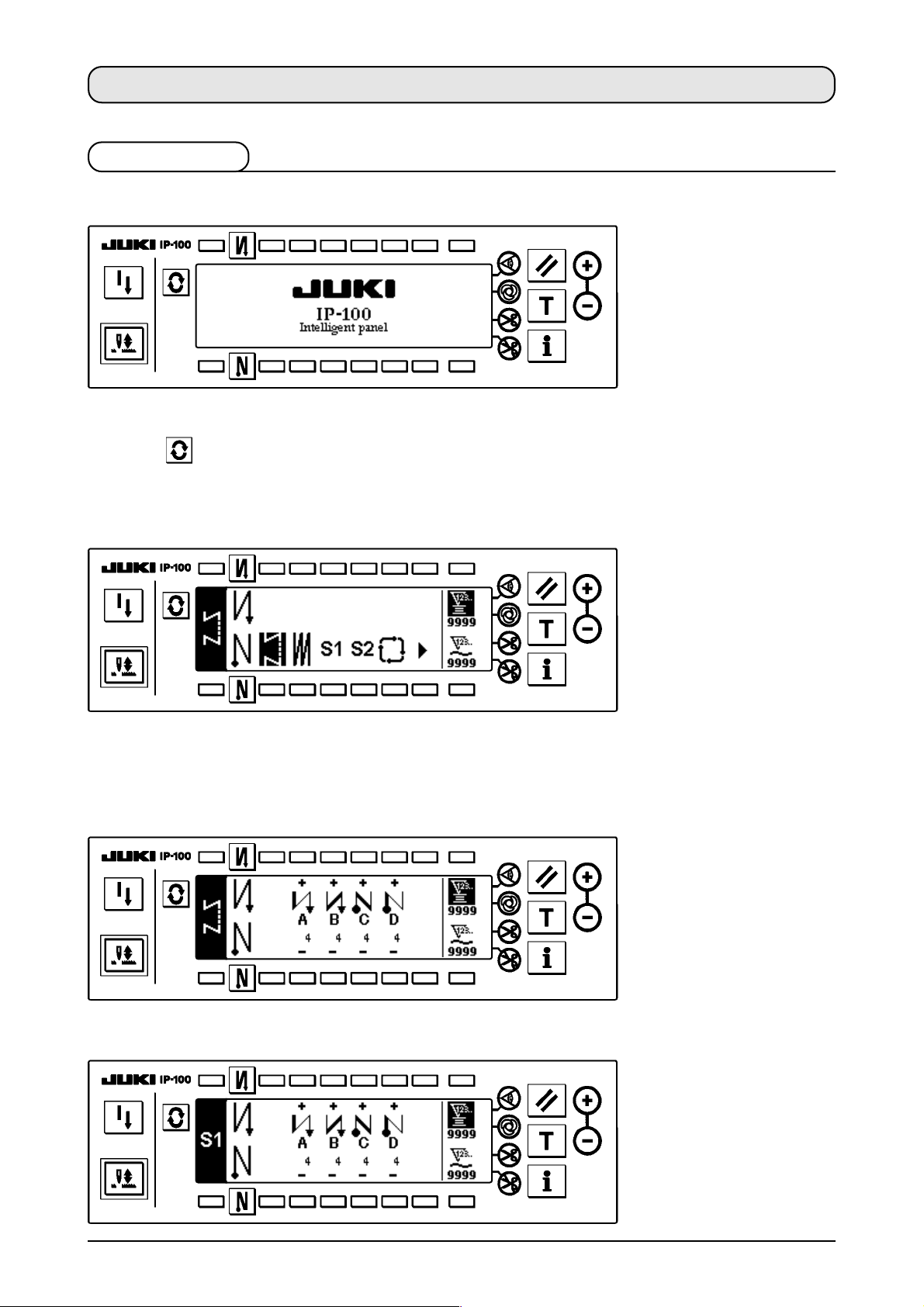

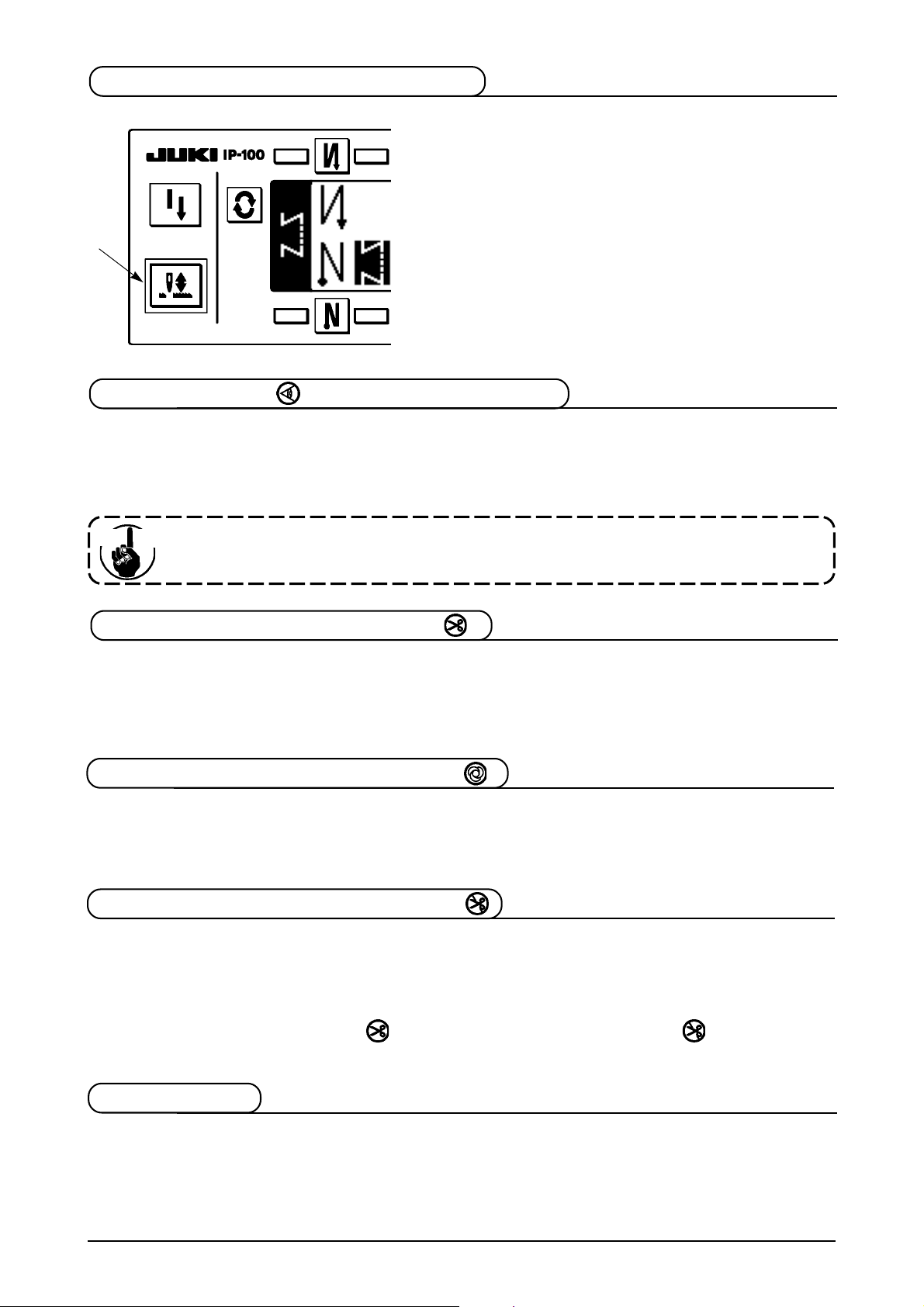

4. STANDARD PANEL

4-1. Screen list

WELCOME screen is displayed immediately after turning ON the power.

The screen immediately after WELCOME screen becomes the setting screen of pattern selection.

Every time

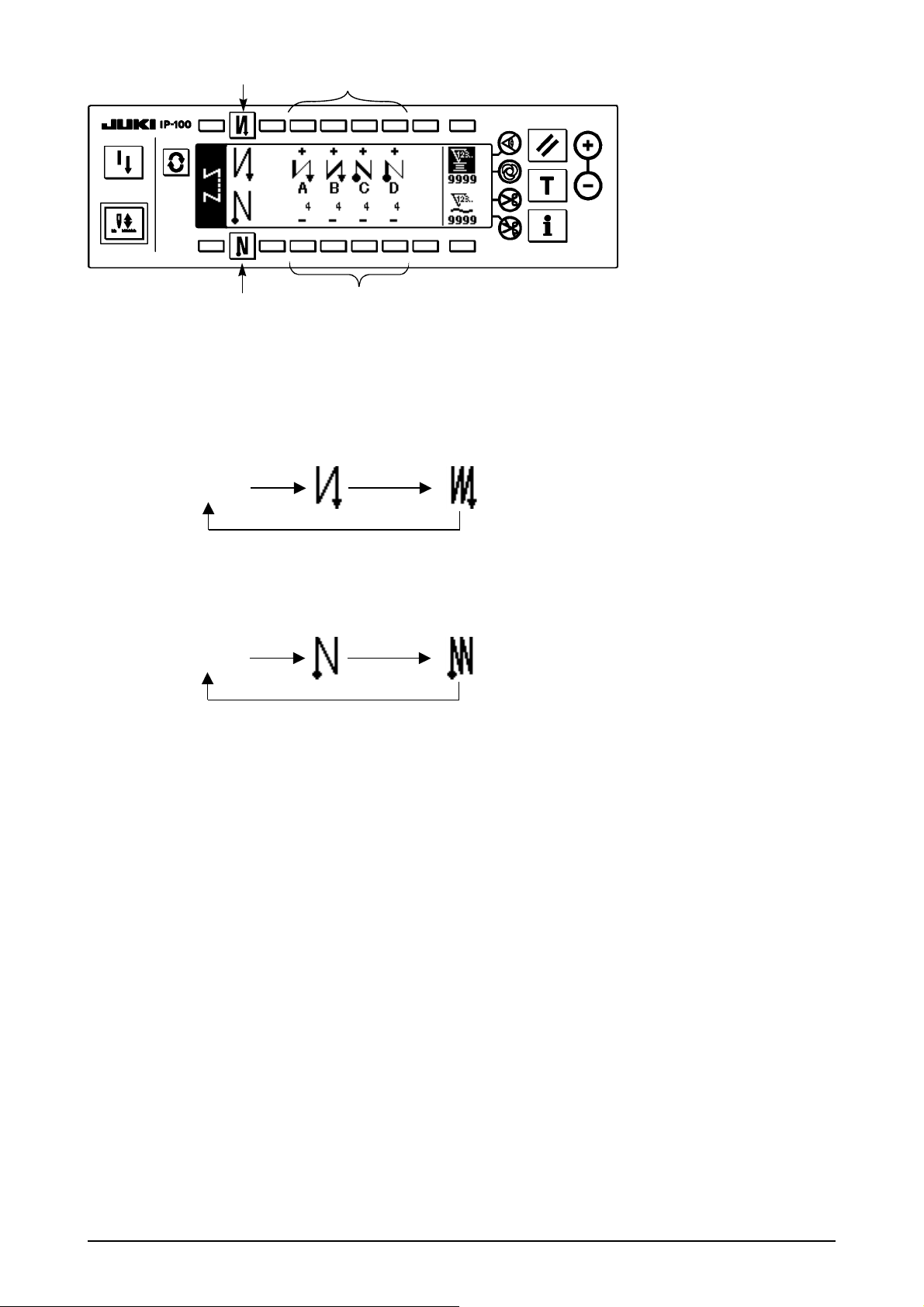

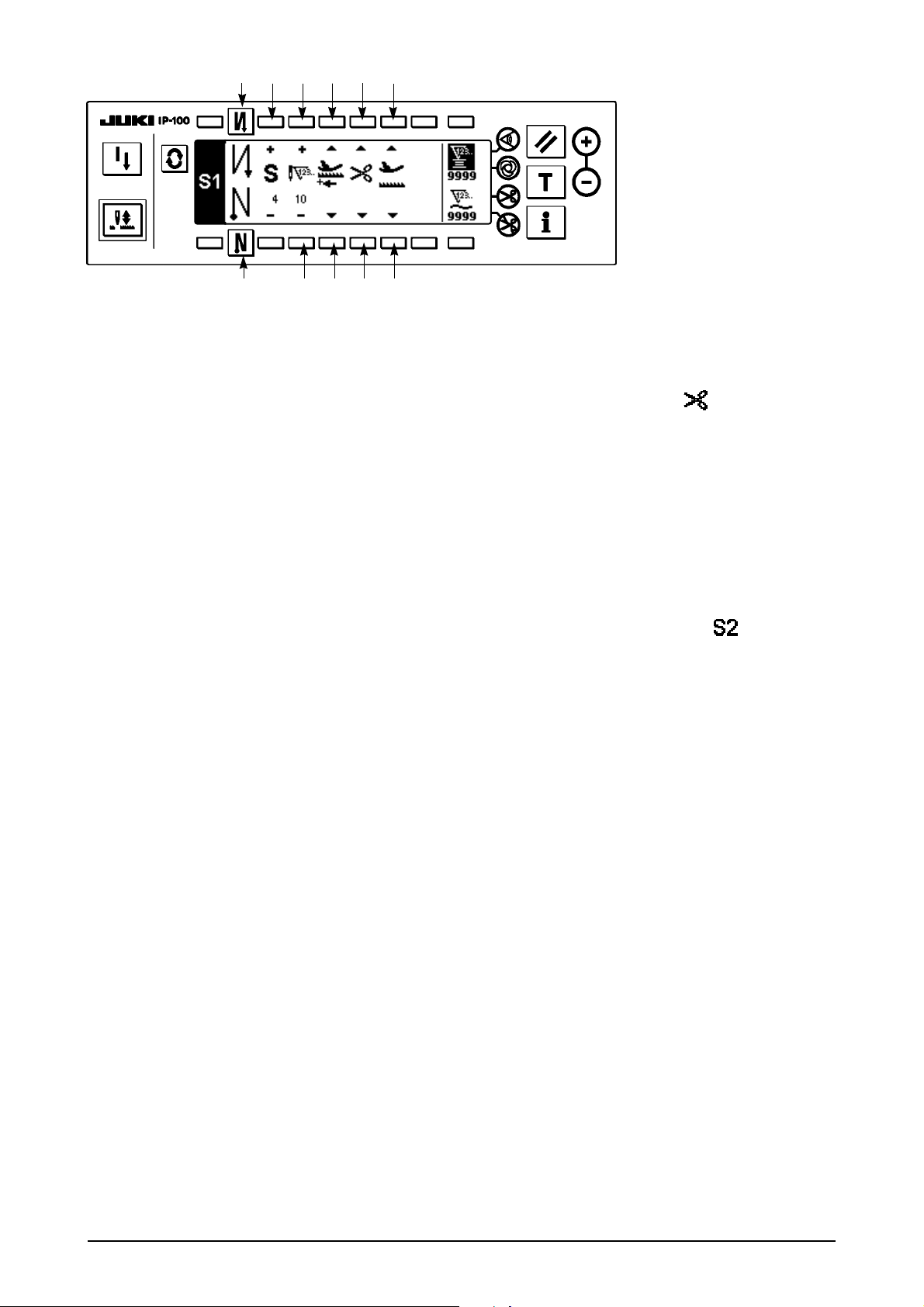

■ Pattern list screen

Selection of the respective shapes is performed.

■ Number of stitches of back tuck stitching setting screen

Setting of number of stitches of reverse stitching is performed.

<When reverse stitching pattern is selected>

switch is pressed, the screen changes.

<When programmed stitching pattern 1 is selected>

– 6 –

■ Number of stitches of overlapped stitching setting screen

Setting of number of stitches of overlapped stitching is performed.

■ Programmed stitching setting screen

Setting of the respective conditions of programmed stitching is performed.

<When programmed stitching pattern 1 or 2 is selected>

ENGLISH

■ Cycle sewing setting screen

Setting of the step of cycle sewing is performed.

■ Cycle sewing pattern setting pop-up

Setting of the pattern of cycle sewing is performed.

– 7 –

■ Output display screen

Final target set value, current target value and actual results up to now are displayed.

4-2. How to operate the operation panel for sewing stitching patterns

(1) Reverse stitching pattern

笆

OFF ON ON

OFF

A

B

Sewing

pattern

C

D

OFF OFF

笳

ON ON

Press to display the pattern list screen.

A

B

C

D

笊

1) Press switch 笊 to select the reverse stitching pattern, and the screen is automatically changed over to the

number of stitches of reverse stitching setting screen to display the number of stitches which has already

been set.

– 8 –

笆

笘

笳

2) When changing the number of stitches, change it with switches 笘 and 笙 for setting the number of stitches

A through D.

(The range of the number of stitches that can be changed : 0 to 99 stitches)

3) Press switch 笆 to set the reverse stitching at the start of sewing.

No setting Reverse stitching

at the start of sewing

4) Press switch 笳 to set the reverse stitching at the end of sewing.

No setting Reverse stitching

at the end of sewing

笙

Double reverse stitching

at the start of sewing

Double reverse stitching

at the end of sewing

– 9 –

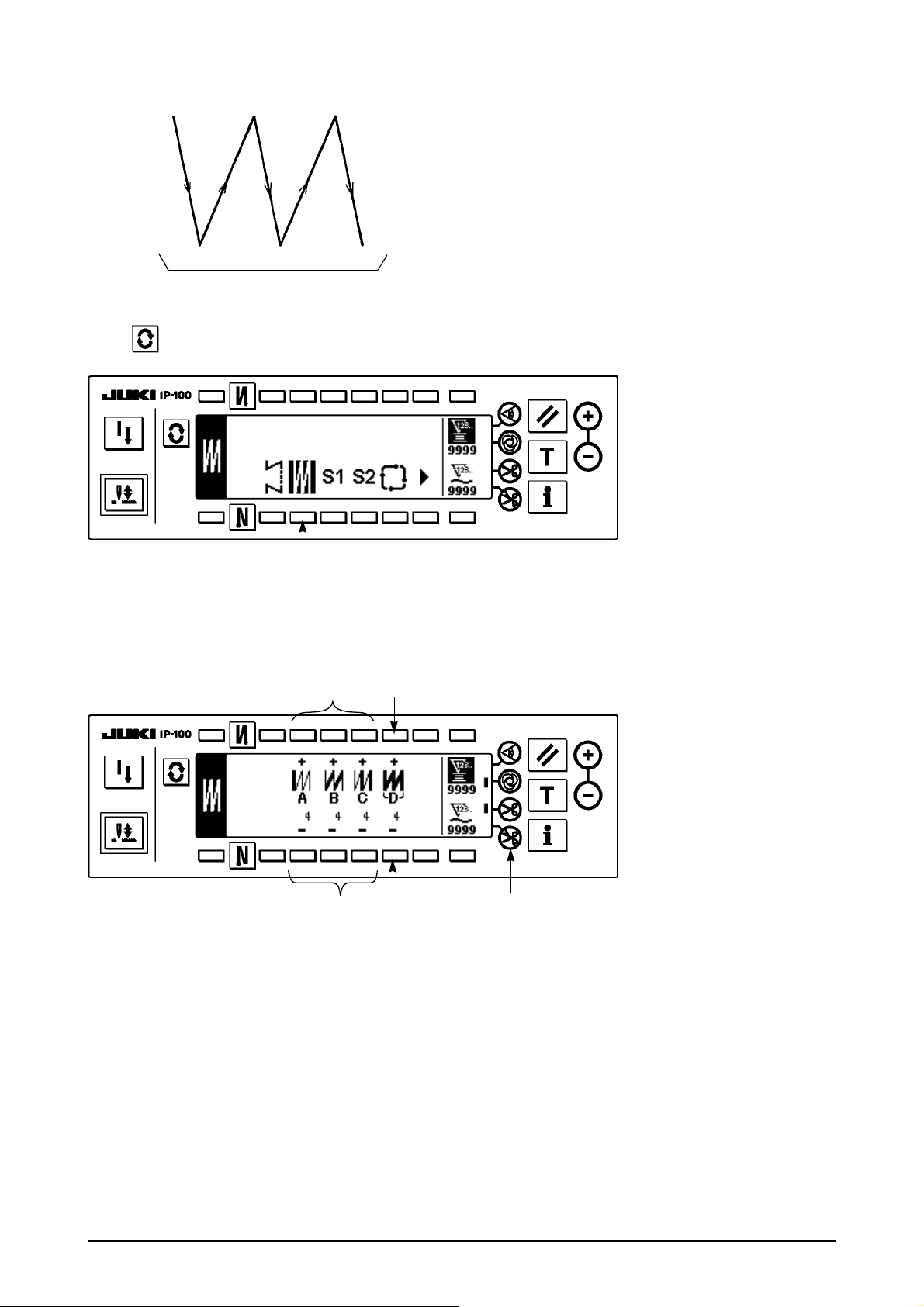

(2) Overlapped stitching pattern

A C C

B B

D

Press to display the pattern list screen.

笊

1) Press switch 笊 to select the overlapped stitching pattern, and the screen is automatically changed over to

the number of stitches of overlapped stitching setting screen to display the number of stitches which has

already been set.

笆

笳

2) When changing the number of stitches, change it with switches 笆 and 笳for setting the number of stitches

for processes A through C. To change the number of times of the whole processes, change it with switches

笘 and 笙 for setting the number of processes D.

(The range of the number of stitches A, B and C that can be changed : 0 to 19 stitches. The range of the

number of processes D that can be changed : 0 to 9 times)

3) Depress the front part of the pedal once, and the sewing machine will repeat the normal stitching and

reverse stitching as many as the number of specified times. Then the sewing machine will automatically

make the thread trimmer actuate and will stop to complete the overlapped stitching procedure. (The oneshot automatic stitching cannot be turned OFF.)

4) When thread trimming prohibiting function 笞 is selected, the machine will stop with the needle up upon

completion of the overlapped stitching procedure without performing thread trimming.

笘

笙

笞

– 10 –

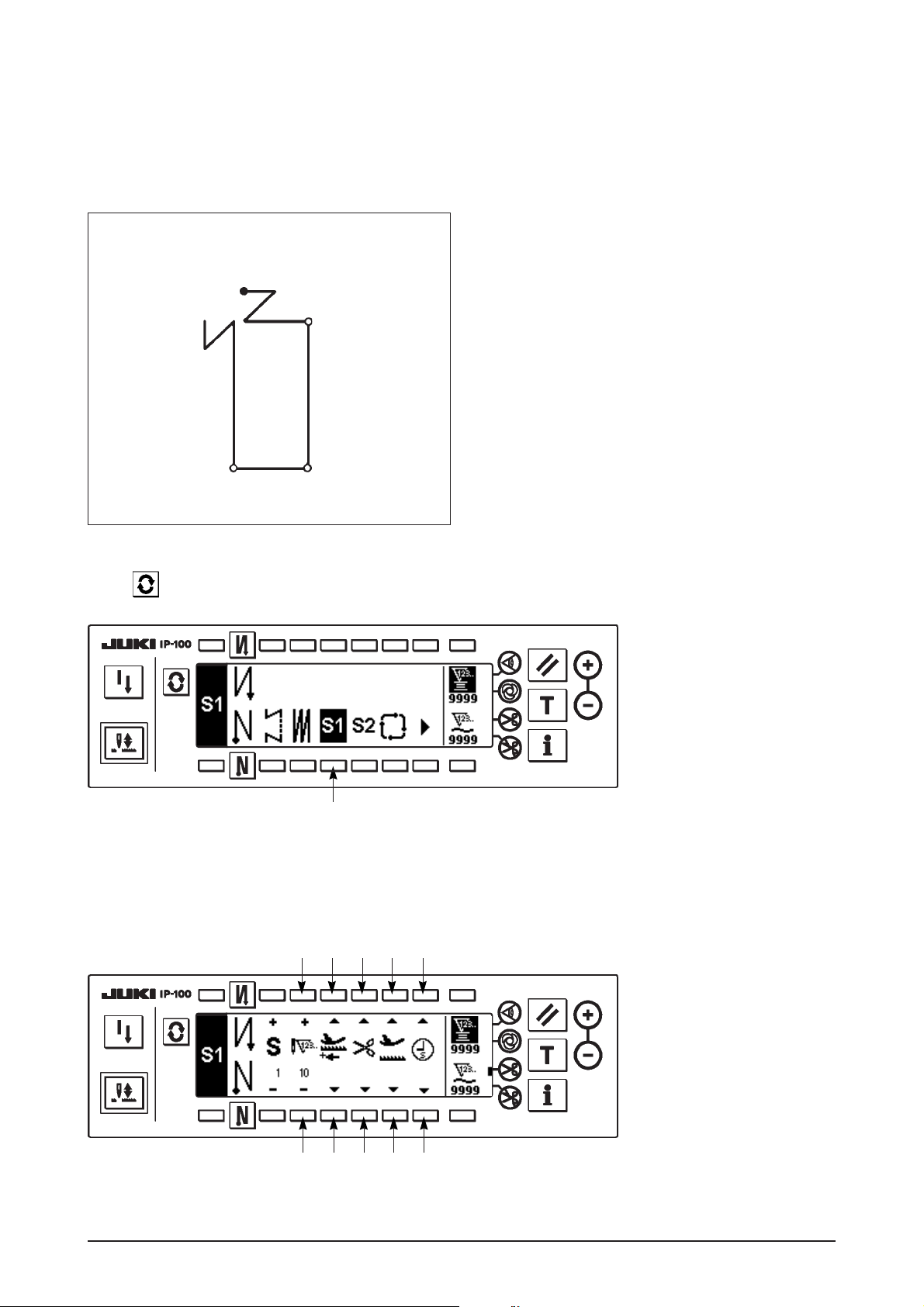

(3) Programmed stitching pattern

The constant-dimension stitching process can be programmed as many as 20 operation steps. The sewing

conditions including the number of stitches, needle up/down stop mode, automatic thread trimming, continuous

operation steps, lifting/lowering of presser foot and normal/reverse feed stitching can be separately specified

for the respective operation steps. If the lifting of presser foot is specified, the time during which the presser foot

is raised can be also specified.

Example of programmed stitching pattern

4

Step 4

4

4

4

20 20

10

Step 3Step 1

10

Step 2

Programming procedure is described below taking

the pattern on the left side as an example.

ENGLISH

Press to display the pattern list screen.

笊

1) Press switch 笊 to select the programmed stitching pattern, and the screen is automatically changed over to

the programmed stitching setting screen to display the number of stitches and data on the operation step 1

which have already been specified.

[Step 1]

2 4 笞 笨 筐

3 5 笵 笶 筺

– 11 –

1) Confirm that step 1 is displayed on the panel. Now, set the number of stitches to 20 using switches 笆

and 笳.

2) Set the feeding direction to the normal direction using switches 笘 and 笙.

3) Set the stop state of the sewing machine to the needle-down stop mode using switches 笞 and 笵.

Cau tion

4) Set the position of the presser foot, when the sewing machine stops, to the upper stop position using switches

笨 and 笶.

(If you want to specify, in particular, the length of time during which the presser foot is raised, set it as desired

using switches 筐 and 筺. If you do not specify the length of time during which the presser foot is raised, it will

be automatically set to 60 seconds.

Possible setting range of the time during which the presser foot is raised : 0.1 sec. to 99.9 sec.)

Cau tion

[Step 2]

If the number of stitches is set to 0 stitch or the stop-state of the sewing machine is set to

the automatic thread trimming mode , the machine will not proceed to the subsequent

operation step.

Setting with switches 8 and 9, or !0 and !1 is possible only in the state that the use of

auto lifter can be performed (FL ON). It is possible to change over FL ON / OFF by turning

ON the power while pressing UP switch of the control box.

笄 2

3

5) Press switch 笄 once to display step 2.

6) Set the number of stitches to 10 using switches 笆 and 笳.

[Step 3]

7) Set the feeding direction to the normal direction, the stop-state of the sewing machine to the needle-down

stop mode and the position of the presser foot to the upper stop position as in the case of step 1.

8) Press switch 笄 once to display step 3.

9) Set the number of stitches to 20 using switches 笆 and 笳.

10) Set the feeding direction to the normal direction, the stop state of the sewing machine to the needle-down

stop mode and the position of the presser foot to the upper stop position as in the case of steps 1 and 2.

笄 2

3

– 12 –

[Step 4]

笄 笆 笘 笞 笨

筍

笋

11) Press switch 笄 once to display step 4.

12) Set the number of stitches to 10 using switches 笆 and 笳.

13) Set the feeding direction to the normal direction using switches 笘 and 笙.

14) Set the stop state of the sewing machine to the automatic thread trimming mode using switches 笞

and 笵.

15) Set the position of the presser foot, when the sewing machine stops, to the upper stop position using

switches 笨 and 笶.

16) Select the reverse stitching using switches 筍 and 笋. This completes the data setting procedure.

17) It is also possible to specify the double reverse stitching using switches 筍 and 笋.

Every time each step is finished, operate the touch-back switch, and the sewing machine runs at a low speed

(stitch compensation operation).

You can program another sewing processes in the programmed stitching pattern 2 following the

aforementioned procedure.

笳 笙 笵 笶

– 13 –

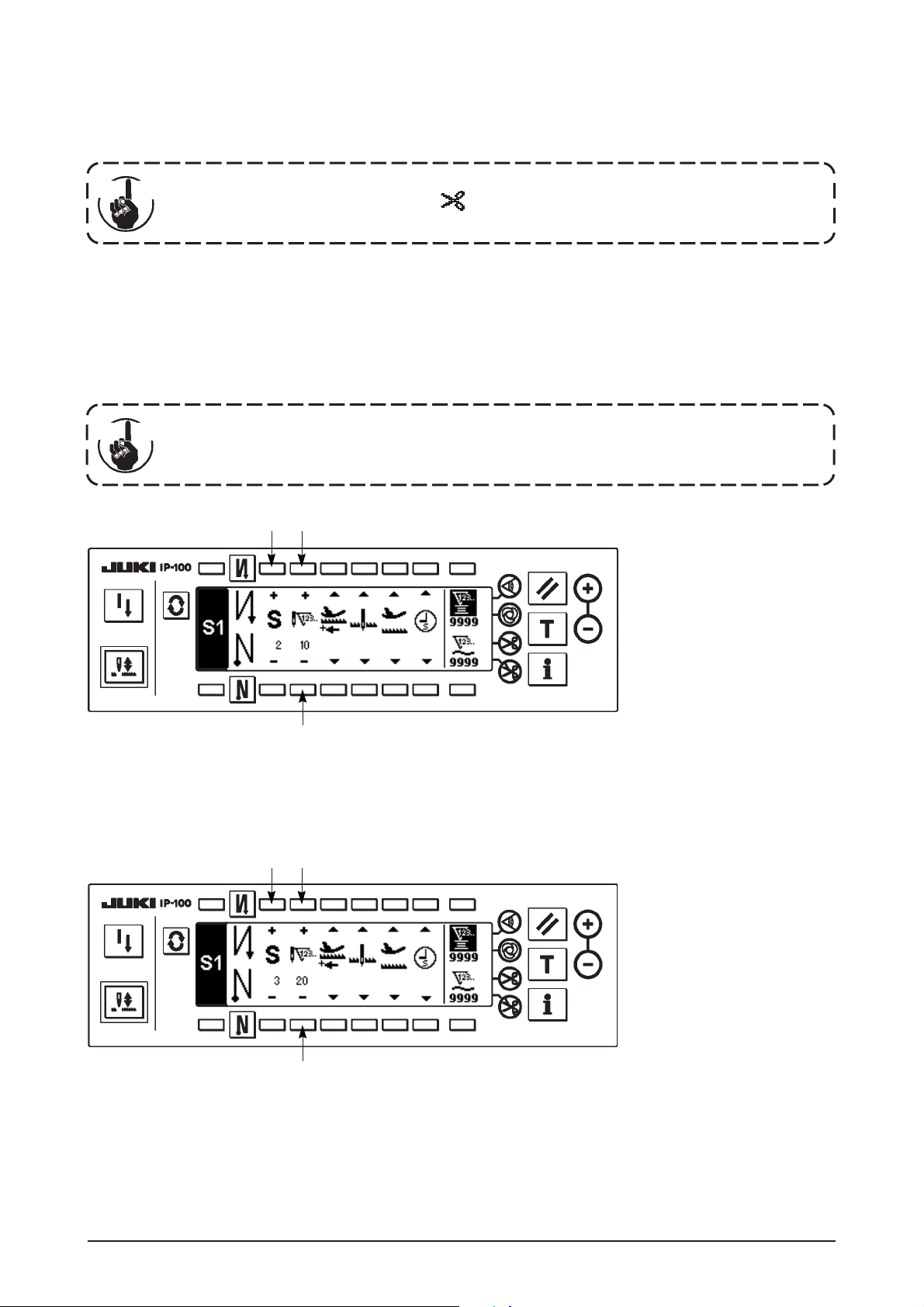

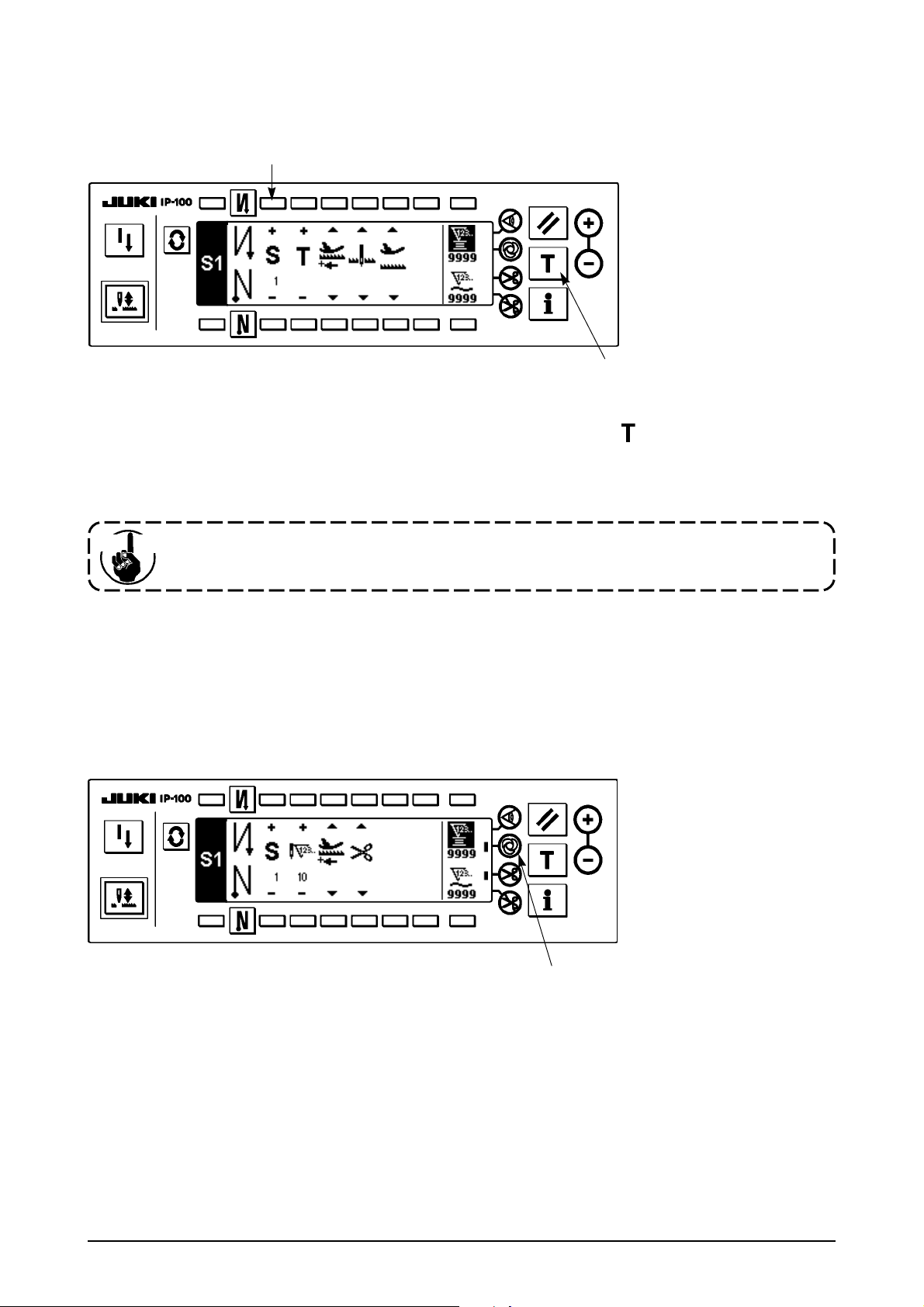

< Teaching mode >

In the teaching mode, it is possible to set the number of stitches of the step in a programmed stitching pattern

to the number of stitches that has been actually sewn.

笆

笊

1) In the programmed stitching setting screen, press teaching switch 笊 to select the teaching mode.

2) The indication shown on the number of stitches input section changes to . This shows that the sewing

machine has entered the teaching mode.

3) Depress the front part of the pedal to make the sewing machine perform sewing until the last stitch of the

current operation step is reached.

Cau tion

4) Return the pedal to its neutral position to make the sewing machine stop running. Now, the number of

stitches which has been sewn is displayed.

5) Proceed to the subsequent step using switch 笆 or make the sewing machine perform thread trimming. This

completes the input of the number of stitches for operation step 1.

< One-shot automatic stitching >

The one-shot automatic stitching function can be separately set by steps.

The number of stitches cannot be inputted by turning the hand wheel by hand or operating

the needle up/down switch.

笊

1) In the programmed stitching pattern setting screen, press one-shot automatic stitching switch 笊 to select

the one-shot automatic stitching function.

2) A mark is displayed on LCD section of the switch, which shows the one-shot automatic stitching function has

been selected.

3) In the step where the one-shot automatic stitching function has been selected, the sewing machine will

automatically continue sewing, once the sewing machine starts running, until the end of the step is reached.

– 14 –

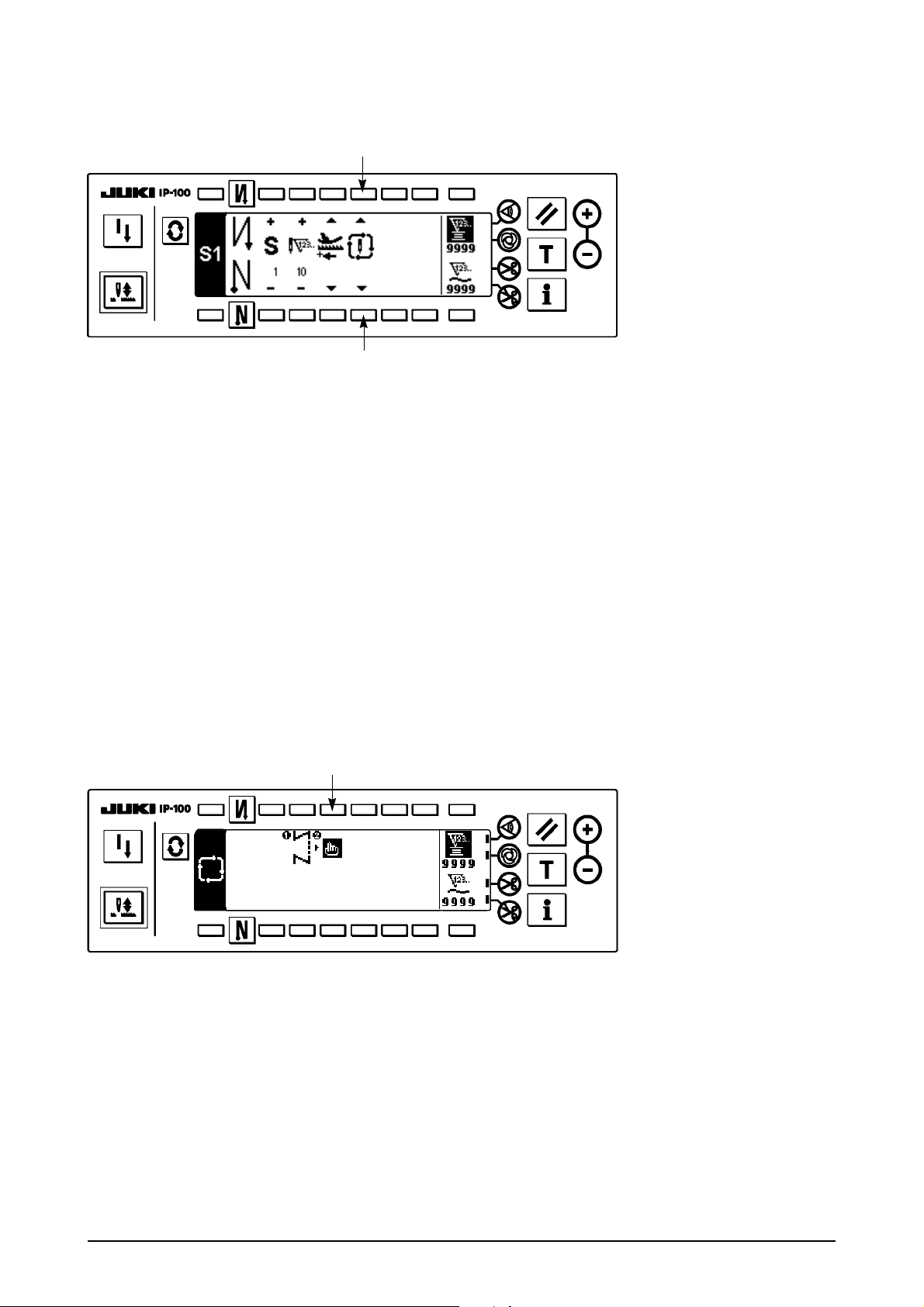

< Continuous stitching mode >

In this mode, it is possible to make the sewing machine execute the subsequent step after the completion of the

current step.

笊

笆

1) In the programmed stitching pattern setting screen, select the continuous stitching mode using switches 笊

and 笆.

2) As long as the continuous stitching mode is selected, you can make the sewing machine execute the

subsequent step set in the program after the completion of the current step by depressing the front part of

the pedal.

< To operate the operation panel in combination with the material edge sensor >

蘆 When the operation panel is used in combination with the material edge sensor, the sewing process can be

completed not by the predetermined number of stitches but by the input signal of the material edge sensor.

蘆 Carefully read the Instruction Manual for the material edge sensor before using the sensor with the operation

panel.

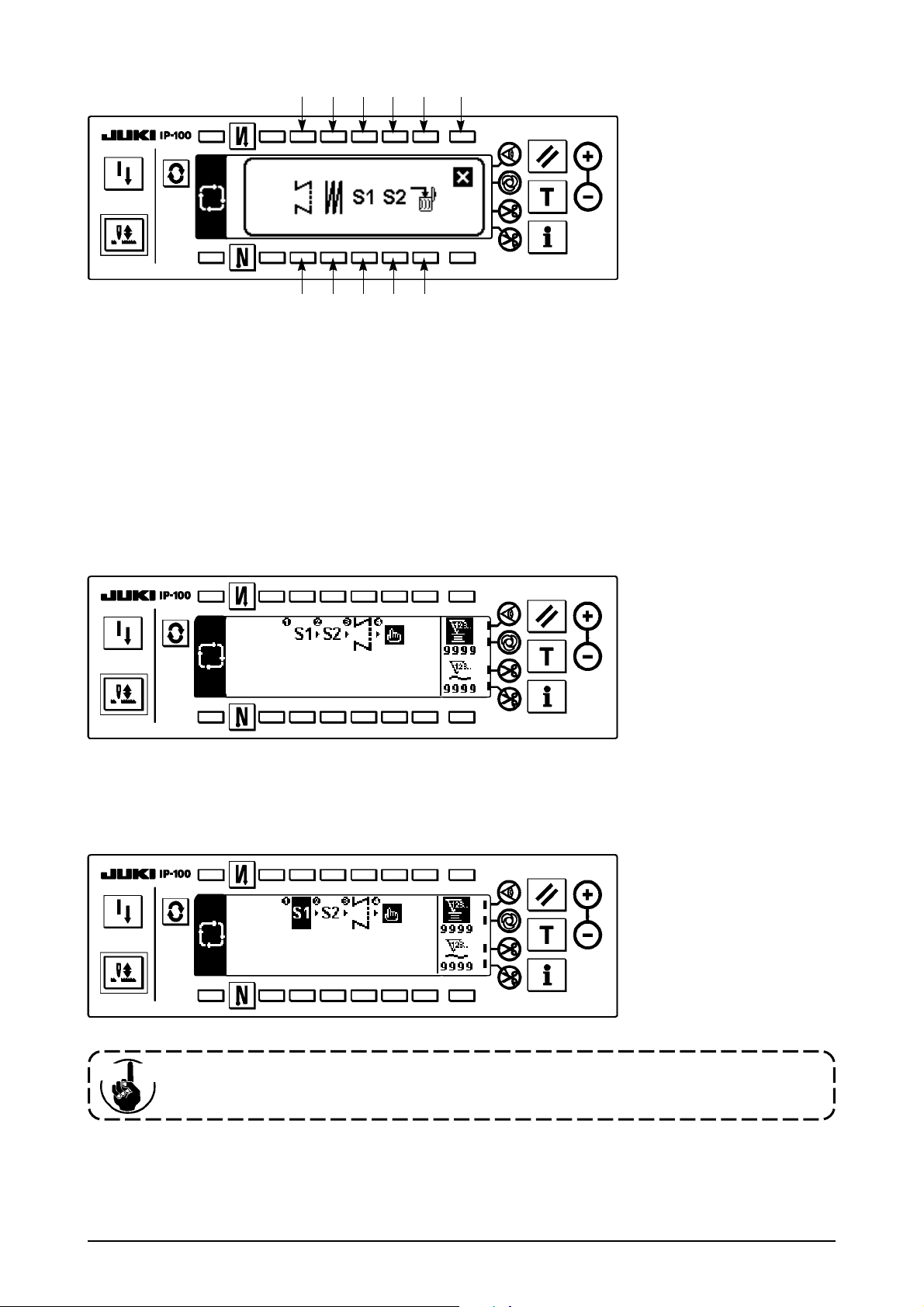

(4) Cycle sewing pattern

Reverse stitching pattern, overlapped stitching pattern, programmed stitching pattern 1 and programmed stitching

pattern 2 can be set and sewn as desired. (As many as eight different patterns can be set.)

笊

1) Press switch 笊 to display the cycle sewing edit pattern setting pop-up.

– 15 –

笆

笘 笞 笨 筐 笄

笙 笵 笶 筺

笳

Switches 笆 and 笳 : These switches set the reverse stitching pattern.

Switches 笘 and 笙 : These switches set the overlapped stitching pattern.

Switches 笞 and 笵 : These switches set the programmed stitching pattern 1.

Switches 笨 and 笶 : These switches set the programmed stitching pattern 2.

Switches 筐 and 筺 : These switches delete the editing step.

Switch 笄 : The screen returns to the cycle sewing setting screen.

[Example of setting]

2) Every time the thread trimmer actuates, the machine proceeds to the subsequent pattern which has been

selected. (The step which is being executed is shown in reverse video during execution.)

Cau tion

If the thread trimmer actuates before completion of a pattern, the machine will proceed to

the subsequent program.

– 16 –

4-3. How to use the bobbin thread counter

The machine detects the number of stitches. The preset value on the bobbin thread counter is subtracted in

accordance with the number of stitches detected. (Every time the detector detects 10 stitches, 1 is subtracted

from the preset value on the bobbin thread counter.) When the value on the counter becomes a minus value as

........

(

→ 1 → 0 → –1), the buzzer (peeps three times) and the pop-up display inform that the time to change the

bobbin thread has come.

笊

笆

笳

1) Press switch 笊 to select the bobbin thread counter. Then

press counter reset switch 笆 to return the value indicated

on the bobbin thread counter to the initial value (it has

been factory-set to “0” at the time of delivery).

Cau tion

The bobbin thread counter cannot be

reset during sewing. In this case, make

笘

the thread trimmer actuate once.

2) Set an initial value using counter value setting switches

笳 and 笘.

The table below gives the initial setting values for reference

Initial value on the bobbin thread counter

for reference

when the bobbin is wound with thread to the extent that

the pinhole in the outside of the bobbin case is reached

as shown in the figure on the left side.

Thread

used

Polyester spun

thread #50

Cotton thread #50

Length of thread

wound round the

bobbin

36 m

31 m

Value on bobbin

thread counter

1200

(stitch length : 3 mm)

1000

(stitch length : 3 mm)

Thread tension rate 100 %

*Actually, the bobbin thread counter is affected by the material thickness and the sewing speed. So, adjust the

initial value of the bobbin thread counter in accordance with the operating conditions.

3) Once the initial value is specified, start the sewing machine.

4) When a minus value is shown on the counter, the buzzer peeps three times and the pop-up display appears,

replace the bobbin thread.

Bobbin thread replacement warning pop-up

5) After the bobbin thread has been properly replaced, press counter reset switch 笆 to return the value on the

bobbin thread counter to the initial value. Now, re-start the sewing machine.

6) If the remaining amount of bobbin thread is excessive or the bobbin thread runs out before the bobbin thread

counter indicates a minus value, adjust the initial value appropriately using counter value setting switches 笳

and 笘.

If the remaining amount of bobbin thread is excessive ..... Increase the initial value using the “+” switch.

If the remaining amount of bobbin thread is insufficient .... Decrease the initial value using “–” switch.

Cau tion

If the bobbin thread counter is used in combination with the bobbin thread remaining amount detecting

device, the bobbin thread counter indicates the number of times of detection of the bobbin thread

remaining amount detecting device. So, be sure to use the device after carefully reading the Instruction

Manual for the bobbin thread remaining amount detecting device.

– 17 –

4-4. No. of pcs. counter

The No. of pcs. counter counts up the number of finished products every time the machine performs thread

trimming. (0 → 1 → 2

...........

→ 9999)

笆

笳

The value on the No. of pcs. counter can be modified

using counter value setting switches 笳 and 笘. The value

on the No. of pcs. counter is reset to "0" by pressing

counter reset switch 笆.

笘

4-5. Re-sewing switch

The re-sewing switch is used when the bobbin thread runs out during the programmed stitching pattern sewing

steps or the like.

1) The bobbin thread runs out during the operations steps

for sewing. 糴

笊

D

C

Step 4

B

A

Step 3Step 1

紆

紂

Step 2

糴糶

糺

2) Bring the pedal to its neutral position to make the

sewing machine stop. Now, depress the back part of

the pedal to make the thread trimmer actuate. 糶

3) Turn ON re-sewing switch 笊. 糺

4) Replace the bobbin. Slightly feed the material on the

machine in the reverse direction to return the material

to the position where the sewing was interrupted to

allow the sewing machine to sew over the finished seam

in step 2. 紆

5) Depress the front part of the pedal until stop position

紂 of step 2 is reached.

6) Turn ON re-sewing switch 笊 again at position 紂 where

the sewing has been interrupted, and the next step will

be indicated on the operation panel. Now, you can restart sewing of the programmed stitching pattern.

* If the needle thread breaks or any other trouble occurs,

which is caused by re-sewing switch 笊 during the

operation steps (紆 → 紂) in the free sewing mode, bring

the pedal to its neutral position, Then depress the back

part of the pedal to actuate the thread trimmer. Thread

the machine head and slightly feed the material in the

reverse direction, and press re-sewing switch 笊. This

enables the sewing machine to continue the sewing under

the free sewing mode. Then operate the operation panel

as described in the aforementioned steps 5) and 6).

To return to the first step of the programmed

stitching pattern without using re-sewing

Cau tion

switch 笊, depress the back part of the pedal

to actuate the thread trimmer. This makes the

operation panel give the step indication 1.

Now, you can start sewing from the first step

of the programmed stitching pattern.

– 18 –

4-6. Needle up/down compensation switch

Every time needle up/down compensation switch 笊 is

pressed, the needle goes up when it is in its lowest position

or comes down when it is in its highest position. This

compensates the stitch by a half of the predetermined stitch

length.

笊

Note, however, that the machine does not run continuously

at a low speed even if you keep the switch held pressed.

Also, note that the needle up/down compensation switch is

inoperative after turning the handwheel by hand.

Thread trimming is operative only at the time of stitch

compensation after depressing the front part of the pedal once.

4-7. ON/OFF switch of the material edge sensor

• When the material edge sensor, which is optionally available, is connected to the operation panel, the ON/

OFF switch of the material edge sensor becomes effective.

• If the material edge sensor is specified, the sewing machine will automatically stop running or perform thread

trimming when the sensor detects the material edge.

Cau tion

If the material edge sensor is used in combination with the operation panel, carefully read

the Instruction Manual for the material edge sensor beforehand.

4-8. Automatic thread trimming switch

• This switch is used to automatically actuate the thread trimmer in a process where the sewing machine

automatically stops or when the material edge sensor is used.

(if the automatic reverse stitching (for end) is specified, the thread trimmer will actuate after the sewing machine

completes the automatic reverse stitching (for end).)

4-9. One-shot automatic stitching switch

• This switch is used, in the constant-dimension stitching mode, rectangular stitching mode, or in the process

where the material edge sensor is specified, to make the sewing machine automatically perform sewing at the

specified speed until the end of the process is reached only by driving the sewing machine once.

4-10. Thread trimming prohibition switch

• This switch is used to temporarily make the thread trimming function inoperative.

The other performance of sewing machine is not affected by this switch.

(If the automatic reverse stitching (for end) is specified, the sewing machine will perform the automatic reverse

stitching at the end of sewing.)

• If the automatic thread trimming switch and the thread trimming prohibition switch are both specified,

the machine will not perform thread trimming but stop with its needle up.

4-11. Key lock

• In order to prevent the specified data on the number of stitches or the processes (A, B, C and D, or step

information) from changing by mistake, the setting switch can be locked. (Even with the setting key locked,

the pattern to be sewn and the value on the bobbin thread counter can be changed.)

• For the setting procedure, refer to 4-13 Setting for functions and set function No. 17, Key lock function (key

lock is effective with setting of “1”).

– 19 –

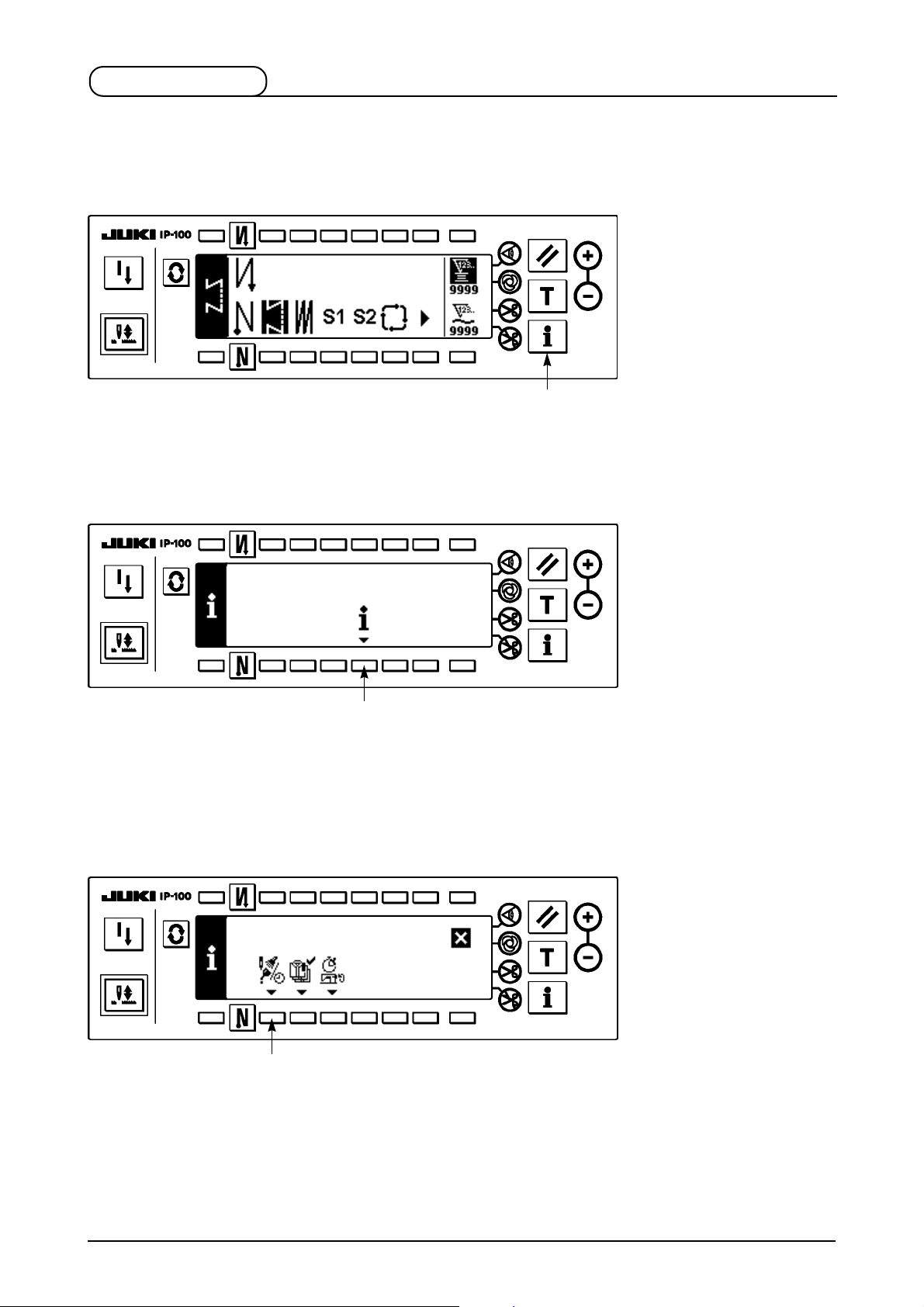

4-12. Information

Setting and checking of various data can be performed with the information.

For the information, there are the operator level and the maintenance personnel level.

[Operator level]

笊

1) Turn ON the power.

2) Press switch 笊 to display the information screen.

■ Information screen (operator level)

笊 : Sewing management

information

笊

(1) Sewing management information

For the sewing management information, there are the maintenance management function, production control

function and working measurement function.

[Maintenance management function]

笊

1) Press 笊 to display the maintenance function screen.

– 20 –

■ Maintenance function screen

2

4

[Explanation of the respective items]

笆 Time of replacement of needle ..... Unit : X 1,000 stitches

笳 Time of cleaning ............................ Unit : Hour

笘 Time of replacement of oil ............. Unit : Hour

[Explanation of the contents of display]

(Numerator / denominator)

* Number of remaining stitches up to *thousand stitches / **thousand stitches

3

Example) Replacement of needle

100 / 1600

kn

ENGLISH

Time of replacement of needle is informed every 1,600 thousand stitches.

Time of replacement of needle is informed after 100 thousand stitches.

When 笆, 笳 and 笘 switches are pressed, the clear checking screen is displayed.

■ Clear screen

笊 : The screen returns to the maintenance function screen without performing clearing.

笆 : The screen returns to the maintenance function screen after executing clearing.

笊

笆

– 21 –

■ Warning screen

Warning screen is displayed when the warning time is reached.

笊

笆

笊 : When 笊 is pressed, the screen can be cleared. However, the counter itself cannot be cleared. In case of

the replacement of needle, the warning screen is displayed at intervals of 10 minutes until clearing is

performed. In case of other warnings, the warning screen is displayed at the time of turning ON the power

until the counter is cleared.

笆 : When 笆 is pressed, the screen is cleared and the counter value is cleared as well. From this time, counting

starts newly.

[Setting of the warning setting time]

■ Infomation screen

笊

1) Press switch 笊 for approximately three seconds in the information screen.

– 22 –

■ Sewing management information selection screen

2

2) Press 2 to display the maintenance function screen.

(For other functions, refer to the Engineer’s Manual.)

■ Maintenance function screen

ENGLISH

3

笙

3, 4, 5 : Inspection time (number of times of thread trimming) input screen is displayed.

6 : Number of times of thread trimming per sewing ... Unit : Number of times

■ Inspection time (number of times of thread trimming) input screen

4

笞

7 8

Clear checking screen is displayed in 7. (It is not displayed when the number of times of thread trimming is

specified.)

After inputting the setting time, determine the time with 8.

In case of stopping the warning function, set the set value to “0”.

Impor tant

It is possible to individually set replacement of needle, cleaning, and replacement of oil

respectively.

In case of stopping all, set “0” to each.

– 23 –

(2) Production control function

笊

1) Press 笊 to display the production control screen.

■ Production control screen

2

4

[Explanation of the respective items]

Number of pcs. of current target ........... Unit : Piece

Number of pcs. of final target ................ Unit : Piece

Current output ....................................... Unit : Piece

Time required to sew one piece (pitch time) ............ Unit : Second

3

5

This item displays that the measurement is stopped.

2) Press 笆, 笳, 笘 and 笙 to display the production control input screen.

This item displays that the measurement is

being performed.

– 24 –

■ Production control input screen

6

7

笵

3) Set the respective setting items with 笵. Setting time inputted in 笞 is shown in reverse video.

ENGLISH

Cau tion

Minimum setting possible value of pitch time is 0.50 seconds.

When 0.00 second is set, make the current target non-display.

Reference

4) Press 笨 in the shape list screen.

■ Output display screen

笶

笨

!1

筐

!2

5) The output display screen is displayed. Sewing is possible with this screen.

Set value can be changed with switches 9 and !0 (Editing of the final target value and pitch time cannot be

performed in this screen.)

The current target value and the current output can be cleared (make them “0”) with switch !1.

Setting of start/stop of the output display function can be performed with switch !2.

– 25 –

(3) Working measurement function

笊

1) Press 笊 to display the working measurement function screen.

■ Working measurement function screen

[Explanation of the respective items]

Working factor .....................Unit : %

Working mean speed .......... Unit : rpm

Pitch time ............................ Unit : Second

Machine time .......................Unit : Second

笆

笳

2) Press 笳 to start the working measurement.

3) To stop the measurement, press 笳 again.

4) The result of measurement can be cleared with 笆.

Cau tion

When “Clear” is not executed, the measurement from the last time can be continued.

– 26 –

[Maintenance personnel level]

笊

1) Turn ON the power.

2) Press switch 笊 for approximately three seconds to display the information screen.

■ Information screen (Maintenance personnel level)

笆 笳 笘 笙 笞

笆 Ver display ..... For the details, refer to the Engineer’s Manual.

笳 Function setting ..... Refer to the item “Function setting procedure”.

笘 Sewing management information

笙 Communication mode ..... For the details, refer to the Engineer’s Manual.

笞 Smart media format ..... For the details, refer to the Engineer’s Manual.

Cau tion

When the smart media format is executed, all data which have been currently recorded

will disappear. Be careful not to use the format for any other than the initialization of the

smart media.

– 27 –

4-13. Setting for functions

(1) How to change over to the function setting mode

Cau tion

Do not perform switch operations other than those described in the following explanations.

Be sure to re-turn the power switch ON after one second or more has passed. If the power is turned

ON immediately after turning it OFF, the sewing machine may not work normally. In this case, turn

ON the power again.

WARNING :

To avoid possible personal injuries caused by movement other than that you desired, do not operate

the switches in the procedure other than those required, as described below, to specify the functions.

There are two kinds of function settings, Level 1 and Level 2.

Level 1 : Change of setting can be performed without turning OFF the power switch.

Level 2 : It is necessary to turn OFF the power switch after change of setting.

For the details of setting No., see P.31.

[Setting procedure of Level 2]

1) Turn ON the power. When the needle bar is not in its UP position, turn the handwheel to bring the needle bar

to its UP position.

2) Press switch 笊 for

approximately three

seconds.

笊

笳

笳

笆

Setting No.

Set value

3) Press switch 笆 for

approximately three

seconds.

4) This screen is the function

setting screen.

Change the setting No. with

“+/–” Key of switch 笳 .

For the details of setting

No., see P. 31.

Example) Changing the

flicker reducing

function (Setting

No. 5)

笘

Change the setting No. to “5”

with “+” Key of switch 笳 in the

figure above.

・Press switch 笘 .

– 28 –

笙

笙

・ Change set value with “+/–”

Key of switch 笙.

笞

The set value has been

changed from “0” to “3”.

・ When this changed value is

acceptable, press switch 笵.

When you desire to return

the value to the previous

one, press switch 笞.

笵

[Setting procedure of Level 1]

・ Turn OFF the power switch

and turn ON the power

switch after approximately

one second.

・ Change of the set value is

determined by turning OFF

the power switch.

1) Press switch 笊 for

approximately three

seconds.

笊

笆

2) Press switch 笆 .

– 29 –

笳

3) This screen is the function

setting screen.

Change the setting No.

with “+/–” Key of switch 笳.

For the details of setting

No., see P. 31.

笳

Setting No.

笘

笙

Set value

Example) Changing the

number of

rotation of

reverse feed

stitching

(Setting No. 8)

Change the setting No. to “8”

with “+” Key of switch 笳 in the

figure above.

・ Press switch 笘.

・ Change the set value with

“+/–” Key of switch 笙.

笙

笞

・ Set value has been changed

from 1350 to 1250.

・ When this changed value is

acceptable, press switch 笵.

Press switch 笞 when you

desire to return the value to

the former one.

笵

・ Press switch 笨 in case of

sewing.

– 30 –

笨

(2) Function setting list

For the details of the items, refer to the Instruction Manual for SC-910.

* DDL-8700 is given as an example here. However, initial value changes according to the machine head

to be connected.

Function No.

1

5

6

7

8

10

11

12

Function name

Number of stitches of soft-start

Flicker prevention

Bobbin thread counting function

Counting down unit

Number of rotation of reverse feed stitching

Specifying position of needle bar when the sewing

machine stops

Click sound of key switch

* This fanction makes ineffective the key click

sound of panel.

Compact panel SW2 function

Setting level

1

2

1

1

1

2

2

2

Panel display

Standard set value

N-SOFT

T-ACC

SCBOB

RATIO

S-BT

1900

NPS

SOUND

SW2

0

0

1

0

0

1

0

Setting range

0 to 9

0 to 8

0 to 1

0 to 2

150 to 3000

0 to 1

0 to 1

0 to 8

13

14

15

17

18

19

20

21

22

24

25

26

27

28

29

30

31

Bobbin thread counter stop function

No. of pcs. counting function

Number of times of detection of run-out of bobbin

thread remaining amount

Key lock function

Bird’s nest prevention function

Bird's nest needle thread release function

Number of condensation stitches

Lifting presser foot when pedal is in neutral position

Operation panel SW function

Fine adjustment rate of number of rotation

Motion after turning handwheel by hand

(Thread trimming)

Motor brake locking force

Motor lock retry returning force

Number of stitches of bird’s nest needle thread

release

BT initial start time

Reverse feed stitching on the way function

Number of stitches of reverse feed stitching on

the way

2

2

2

2

2

2

1

1

2

2

2

2

2

1

2

2

2

ASCNT

0

NTO

1

BTDS

1

KEYLOCK

0

BNC

0

THOLD

0

N-CS

0

N-NPL

0

F-CMSP

0

F-FAS

0

F-TRMC

1

F-RTPC

0

F-RTRC

50

F-UTHR

1

T-RSS

250

OBT

0

N-OBT

4

0 to 2

0 to 1

0 to 19

0 to 1

0 to 2

0 to 1

0 to 9

0 to 1

0 to 1

–15 to 15

0 to 1

0 to 9

1 to 100

0 to 30

50 to 300

0 to 1

0 to 19

– 31 –

Function No.

32

33

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

51

52

53

55

56

57

58

59

60

61

Effective condition of reverse feed stitching on

the way

Thread trimming function by reverse feed stitching

on the way

Number of minimum rotation by pedal

Number of rotation of thread trimming

Number of rotation of soft-start

Number of rotation of soft-start

Position at the start of rotation

Position at the start of acceleration

Position where cloth presser starts lifting

Position where cloth presser starts lowering

Position 2 where thread trimming starts

Position where sewing machine reaches its

highest sewing speed

Compensation value of neutral point of pedal

Cloth presser lifting function

Holding time of lifting cloth presser

Position 1 where thread trimming starts

Lowering time of cloth presser

Compensation of ON timing of reverse feed

stitching at the start of sewing

Compensation of OFF timing of reverse feed

stitching at the start of sewing

Compensation of OFF timing of reverse feed

stitching at the end of sewing

Lifting cloth presser after thread trimming

Reverse revolution to lift needle after thread trimming

Bobbin thread remaining amount after thread

trimming

Holding predetermined position of needle bar

Selection of motion of reverse feed stitching at the

start of sewing

Stop after reverse feed stitching at the start of sewing

Stop of the sewing machine by detection of bobbin

thread remaining amount

Setting level

2

2

1

2

1

1

2

2

2

2

2

2

2

2

2

2

2

1

1

1

2

2

2

2

2

2

2

Panel display

Standard set value

OBTS

0

OBTT

0

S-POS

200

S-TRM

210

S-SOFT

800

S-ASS

2000

P-SSP

30

P-LSA

60

P-FLW

– 21

P-FLD

10

P-TRM2

– 51

P-MAX

150

P-ANP

0

FLSEL

0

T-FL

60

P-TRM1

– 35

T-FLWT

140

T-SON

10

T-SOFF

16

T-EOFF

18

FLAT

1

RATRM

0

BTDF

0

HPOS

0

SBTO

1

SBTQ

0

ASBOB

1

Setting rangeFunction name

0 to 1

0 to 1

20 to 400

20 to 250

150 to 5500

200 to Max

10 to 50

10 to 100

– 60 to – 10

8 to 50

– 60 to – 10

10 to 150

– 15 to 15

0 to 1

10 to 600

– 60 to – 10

0 to 250

– 36 to 36

– 36 to 36

– 36 to 36

0 to 1

0 to 1

0 to 1

0 to 1

0 to 1

0 to 1

0 to 1

– 32 –

Function No.

64

65

66

67

68

69

70

71

72

73

75

76

87

89

91

Number of rotation of start of reverse feed stitching

at the end of sewing

Condensation compensation 1

Condensation compensation 2

Number of times of air purge drive

Air purge starting position

Air purge pause position

Function of soft-down of cloth presser

Limitation of re-acceleration from reduction of

speed

Limitation of acceleration at the start of rotation

Motor lock retry function

Normal rotating direction of motor

Hard mode

Pedal acceleration characteristics

Tension release after thread trimming

Motion after turning handwheel by hand (needle

up/down, compensation, reverse feed stitching on

the way)

Setting level

2

2

2

2

2

2

2

2

1

1

2

2

2

2

2

Panel display

Standard set value

S-WAIT

180

T-CS1

– 15

T-CS2

– 15

N-ABSS

2

A-ABS

27

A-ABE

12

F-SDFL

0

F-ACRA

0

F-ACR

0

F-RET

1

DM

1

F-SCS

0

F-PCS

0

TRS

0

F-PMAT

1

Setting rangeFunction name

0 to 250

– 36 to 0

– 36 to 0

0 to 9

0 to 35

0 to 35

0 to 1

0 to 5

0 to 5

0 to 1

0 to 1

0 to 1

0 to 2

0 to 1

0 to 1

92

93

94

96

101

Function of reducing speed of reverse feed

stitching at the start of sewing

Function of one stitch compensation SW added

to needle up/down compensation SW

Continuous stitching + one-shot stitching non-stop

function

Max. number of rotation

Selection of No. of pcs. counter

* This fanction changes over the No. of pcs.

counter to whether measuring by thread

trimming or measuring by the production control

switch.

2

2

2

2

2

F-DSBT

0

F-MADF

0

F-SBTC

0

S-MAX

4000

F-MAC

0

0 to 1

0 to 1

0 to 1

50 to Max

0 to 1

– 33 –

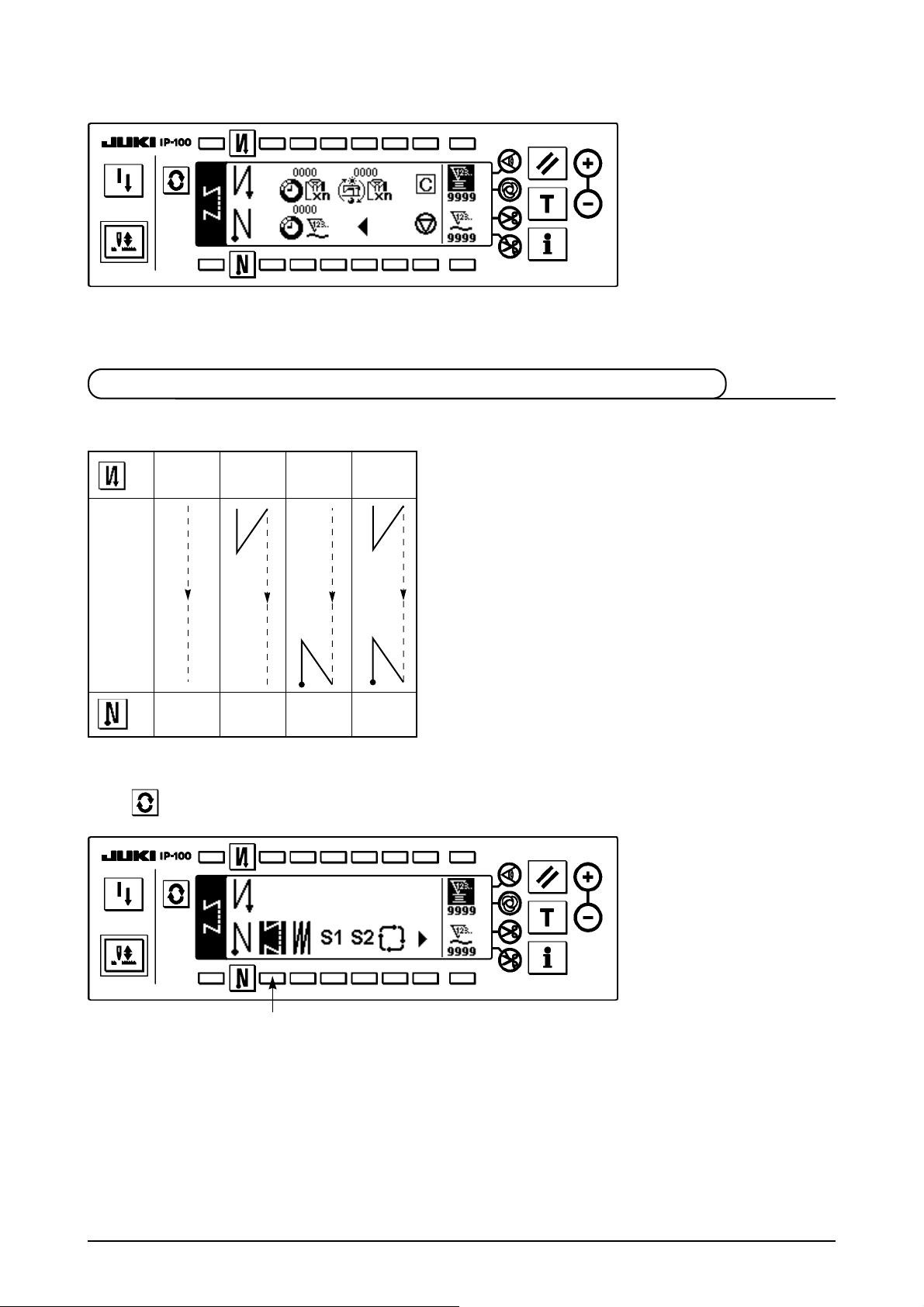

5. PANEL FOR LH-4168/4188

5-1. Screen list

WELCOME screen is displayed immediately after turning ON the power.

The screen immediately after WELCOME screen becomes the setting screen of pattern selection.

Every time

■ Pattern list screen

Selection of the respective shapes is performed.

■Corner pattern selection pop-up

Corner pattern No. is selected.

switch is pressed, the screen changes.

■Step pattern selection pop-up

Step pattern No. is selected.

– 34 –

■ Number of stitches of back tuck stitching setting screen

Setting of number of stitches of reverse stitching is performed.

<When reverse stitching pattern is selected>

<When corner pattern is selected>

<When step pattern is selected>

■ Number of stitches of overlapped stitching setting screen

Setting of number of stitches of overlapped stitching is performed.

– 35 –

■ Corner pattern setting screen

Setting of the corner pattern is displayed.

■ Step edit screen

Contents of the step are set.

■ Corner edit screen

Contents of the corner are set.

■Step pattern setting screen

Setting of the respective conditions of the step pattern is performed.

– 36 –

■ Cycle sewing setting screen

Setting of the step of cycle sewing is performed.

■ Cycle sewing step setting pop-up

Setting of the step of cycle sewing is performed.

■ Cycle sewing step No. selection pop-up

Setting of the corner pattern and the step cycle sewing is performed.

■ Output display screen

Final target set value, current target value and actual results up to now are displayed.

– 37 –

5-2. How to operate the operation panel for sewing stitching patterns

(1) Reverse stitching pattern

笆

OFF ON ON

OFF

A

B

Sewing

pattern

C

D

OFF OFF

笳

ON ON

Press to display the pattern list screen.

A

B

C

D

1

1) Press switch 笊 to select the reverse stitching pattern, and the screen is automatically changed over to the

number of stitches of reverse stitching setting screen to display the number of stitches which has already

been set.

– 38 –

2

4

3

2) When changing the number of stitches, change it with switches 笘 and 笙 for setting the number of stitches

A through D.

(The range of the number of stitches that can be changed : 0 to 99 stitches)

3) Press switch 笆 to set the reverse stitching at the start of sewing.

No setting Reverse stitching

at the start of sewing

4) Press switch 笳 to set the reverse stitching at the end of sewing.

No setting Reverse stitching

at the end of sewing

5

Double reverse stitching

at the start of sewing

Double reverse stitching

at the end of sewing

– 39 –

(2) Overlapped stitching pattern

A

B B

Press to display the pattern list screen.

CC

D

1

1) Press switch 笊 to select the overlapped stitching pattern, and the screen is automatically changed over to

the number of stitches of overlapped stitching setting screen to display the number of stitches which has

already been set.

2

3

2) When changing the number of stitches, change it with switches 笆 and 笳for setting the number of stitches

for processes A through C. To change the number of times of the whole processes, change it with switches

笘 and 笙 for setting the number of processes D.

(The range of the number of stitches A, B and C that can be changed : 0 to 19 stitches. The range of the

number of processes D that can be changed : 0 to 9 times)

3) Depress the front part of the pedal once, and the sewing machine will repeat the normal stitching and

reverse stitching as many as the number of specified times. Then the sewing machine will automatically

make the thread trimmer actuate and will stop to complete the overlapped stitching procedure. (The oneshot automatic stitching cannot be turned OFF.)

4) When thread trimming prohibiting function 笞 is selected, the machine will stop with the needle up upon

completion of the overlapped stitching procedure without performing thread trimming.

4

5

6

– 40 –

(3) Corner pattern

The corner stitching process can be programmed as many as 8 processes (as many as 16 processes when

repeating is effective) in advance. The needle bar to be stopped and the number of stitches of sewing with

single needle can be specified in advance for the respective processes.

Press switch to display the pattern list screen.

1

1) Press switch 1 to display the corner pattern No. selection pop-up.

2

2) When switches 2 are pressed and the corner pattern No. is selected, the screen is automatically changed

over to the corner pattern setting screen to display the state of the pattern which has been already specified.

– 41 –

3) The table below shows the initial setting of each pattern.

Pattern

No.

1

2

3 to 8

Indication

Corner type of the

corner stitching

processes

/ A/G / A/

/C/F/C/C/

F/C/

/A/

Example of sewing

Attaching pocket

on jeans or the

like

Sewing collars

of jackets or the

like

– 42 –

4) The table below shows the initial setting of each corner type.

Corner

type

A

B

C

Indicating

section

Needle bar to be

stopped and the

number of stitches

Left-hand

needle bar

Inside corner

1 stitch

Outside corner

1 stitch

Right-hand

needle bar

Inside corner

1 stitch

Outside corner

1 stitch

Left-hand

needle bar

Inside corner

2 stitch

Outside corner

2 stitch

Example of sewing

Corner

type

F

G

H

Indicating

section

Needle bar to be

stopped and the

number of stitches

Right-hand

needle bar

Inside corner

3 stitch

Outside corner

3 stitch

Left-hand

needle bar

Inside corner

1 stitch

Outside corner

0 stitch

Right-hand

needle bar

Inside corner

1 stitch

Outside corner

0 stitch

Example of sewing

Left-hand

D

E

Right-hand

needle bar

Inside corner

2 stitch

Outside corner

2 stitch

Left-hand

needle bar

Inside corner

3 stitch

Outside corner

3 stitch

L

R

needle bar

Inside

corner

Outside

corner

Number of stitches

is determined by

operating the pedal.

Right-hand

needle bar

Inside

corner

Outside

corner

Number of stitches

is determined by

operating the pedal.

/

/

– 43 –

5) Modification of the pattern

[To add the step]

1. When adding the step, press the switch to which nothing is registered (example in the illustration is SW 1).

1

2. Corner type which is used in the step and the kind of return are selected in the step edit pop-up.

1

2

1 and 2 : These switches select the corner type.

3 and 4 : These switches select the kind of return.

5 : Change is determined and the screen returns to the step setting screen.

There are 4 kinds of returns in total.

: Return is performed after executing the selected corner step.

: Return is not performed.

: It is the step on the way of return. It cannot be selected in the last step.

3

54

: 2-needle sewing is performed after executing the selected corner, and return is performed.

Cau tion

When or is selected in the kinds of returns, the step after it is deleted.

– 44 –

[To change the step]

1. In order to edit the step which has been already registered, press the switch of the step you desire to edit.

(Example in the illustration is switch of 1)

1

Setting procedure is the same as that of adding the step.

ENGLISH

[To delete the step]

1. When deleting the step, press the switch 1 of step which is one before the process you desire to delete.

As an example, select the step in which "B" exists to delete after "C".

1

– 45 –

2. Set the kind of return to or with switch 2 in the step pop-up screen.

Cau tion

Even when or is selected on the way of return, it is not reflected.

3. Step after the set step is deleted. (Screen is the case where is set in the kinds of returns.)

6) Edit of the corner

Contents of the corners A to H are edited.

Press switch 1 to display the corner edit pop-up.

1

135

2

4 6 8

1 and 2 : These switches change the corner type of the object to be edited.

3 and 4 : These switches select the needle bar to be stopped for inside corner.

5 and 6 : These switches set the number of stitches for inside corner.

7 and 8 : These switches select the needle bar to be stopped for outside corner.

9 and !0 : These switches set the number of stitches for outside corner.

!1 : This switch stores the data of all corners which have been edited, and the screen returns to the

step setting screen.

Cau tion

Edit of corner L and corner R cannot be performed.

79

!0

!1

– 46 –

(4) Step pattern

The constant-dimension stitching process can be programmed as many as 20 operation steps. The sewing

conditions including the number of stitches, needle bar to be stopped, up/down stop mode, automatic thread

trimming, continuous steps, lifting/lowering of presser foot and normal/reverse feed stitching can be separately

specified for the respective operation steps.

Programming procedure is described below taking the

pattern on the left side as an example.

Step 10

Step 9

Step 8

Step 7

Step 6

Step 5

Step 4

Press to display the pattern list screen.

Step 1

Step 2

Step 3

1

1) Press switch 1 to display the step pattern No. selection pop-up.

2

2) When switches 2 are pressed and step pattern No. is selected, the screen is automatically changed over

to the step pattern setting screen to display the state of the pattern which has been already specified.

– 47 –

[Step 1]

135

2 4 6

3) Confirm that step 1 is displayed on the panel. Now, set the number of stitches to 39 using switches 1 and 2.

4) Change the needle bar to be stopped to the needle bar not to be stopped using switches 3 and 4.

5) Set the stop state of the sewing machine to the needle-down stop mode using switches 5 and 6.

6) Set the feeding direction to the normal direction using switches 7 and 8.

Cau tion

When the number of stitches is “0” or the stop state selects automatic thread trimming ,

it is not possible to go to the next step.

79

8

!0

7) Set the state of the presser foot at the time of stop to the down stop using switches 9 and !0.

8) Input the steps after the operations above as shown in the table below.

Number

of stitches

Step 2 2 Left Normal direction Needle-down stop Up stop

Step 3 2 Left Normal direction Needle-down stop Down stop

Step 4 20 Without stop Normal direction Needle-down stop Down stop

Step 5 2 Left Normal direction Needle-down stop Up stop

Step 6 2 Left Normal direction Needle-down stop Down stop

Step 7 20 Without stop Normal direction Needle-down stop Down stop

Step 8 2 Left Normal direction Needle-down stop Up stop

Step 9 2 Left Normal direction Needle-down stop Down stop

Step 10 39 Without stop Normal direction Up stop

Needle bar to

be stopped

Feeding

direction

Stop state

Automatic thread

trimming

State of presser foot

at the time of stop

– 48 –

(Reference) In case of sewing of lapels of jacket or the like, refer to the table below.

Step 11

Step 12

Step 17

Step 18

Step 13

Step 16

Step 15

State of presser foot

at the time of stop

Step 1

Number

of stitches

Step 2

Step 9

Step 8

Step 3

Step 7

Step 4

Needle bar to

be stopped

Step 5

Step 6

Feeding

direction

Step 10

Step 14

Stop state

Step 1 35 Without stop Normal direction Needle-down stop Down stop

Step 2 2 Left Normal direction Needle-down stop Up stop

Step 3 2 Left Normal direction Needle-down stop Down stop

Step 4 15 Without stop Normal direction Needle-down stop Down stop

Step 5 5 Right Normal direction Needle-down stop Up stop

Step 6 5 Right Normal direction Needle-down stop Down stop

Step 7 20 Without stop Normal direction Needle-down stop Down stop

Step 8 2 Left Normal direction Needle-down stop Up stop

Step 9 2 Left Normal direction Needle-down stop Down stop

Step 10 126 Without stop Normal direction Needle-down stop Down stop

Step 11 2 Left Normal direction Needle-down stop Up stop

Step 12 2 Left Normal direction Needle-down stop Down stop

Step 13 20 Without stop Normal direction Needle-down stop Down stop

Step 14 5 Right Normal direction Needle-down stop Up stop

Step 15 5 Right Normal direction Needle-down stop Down stop

Step 16 15 Without stop Normal direction Needle-down stop Down stop

Step 17 2 Left Normal direction Needle-down stop Up stop

Step 18 2 Left Normal direction Needle-down stop Down stop

Step 19 35 Without stop Normal direction Up stop

Automatic thread

trimming

ENGLISH

Step 19

– 49 –

(5) Cycle sewing pattern

Reverse stitching pattern, overlapped stitching pattern, corner pattern and step pattern can be set and sewn

as desired. (As many as eight patterns can be set.)

1

1) Press switch 1 to the cycle sewing edit pattern setting pop-up.

1 3

2 4 6

Switches 1 and 2 : These switches set the reverse stitching pattern.

Switches 3 and 4 : These switches set the overlapped stitching pattern.

Switches 5 and 6 : These switches display the corner pattern No. setting pop-up.

Switches 7 and 8 : These switches display the step pattern No. setting pop-up.

Switches 9 and !0: These switches delete the editing step.

Switch !1 : The screen returns to the cycle sewing setting screen.

2

5

7

8

9

筐

筺

When registering the corner pattern or the step pattern to the cycle sewing step, select pattern No. using

switches of 2 in the pattern No. setting screen.

– 50 –

[Example of setting]

2) Every tine the thread trimmer actuates, the machine proceeds to the subsequent pattern which has been

selected. (The step which is being executed is shown in reverse video during execution.)

ENGLISH

Cau tion

If the thread trimmer actuates before completion of a pattern, the machine will proceed to

the subsequent program.

5-3. How to use the bobbin thread counter

The machine detects the number of stitches. The preset value on the bobbin thread counter is subtracted in

accordance with the number of stitches detected. (Every time the detector detects 10 stitches, 1 is subtracted

from the preset value on the bobbin thread counter.) When the value on the counter becomes a minus value as

........

(

→ 1 → 0 → –1), the buzzer (peeps three times) and the pop-up display inform that the time to change the

bobbin thread has come.

When IP-100 is mounted on LH-4168 and LH-4188, the bobbin thread counters are separately installed for lefthand bobbin and right-hand bobbin . However, the display on the panel is either one of them, and the

display can be changed with switch 1.

1

2

3

1) Press switch 笊 to select the bobbin thread counter. Then

press counter reset switch 笆 to return the value indicated

on the bobbin thread counter to the initial value (it has

been factory-set to “0” at the time of delivery).

4

Cau tion

2) Set an initial value using counter value setting switches

笳 and 笘.

The bobbin thread counter cannot be

reset during sewing. In this case, make

the thread trimmer actuate once.

– 51 –

Initial value on the bobbin thread counter

for reference

The table below gives the initial setting values for reference

when the bobbin is wound with thread to the extent that

the pinhole in the outside of the bobbin case is reached

as shown in the figure on the left side.

Thread tension rate 100 %

Sewing machine

LH-4168

LH-4188

Thread

used

Polyester spun thread #60

Polyester filament #80

Core spun thread #20

Core spun thread #20

Length of thread wound

round the bobbin

Approx. 51 m

Approx. 130 m

Approx. 14 m

Approx. 27 m

Value on bobbin

thread counter

2000 (stitch length : 2.5 mm)

6500 (stitch length : 2 mm)

400 (stitch length : 3.5 mm)

770 (stitch length : 3.5 mm)

*Actually, the bobbin thread counter is affected by the material thickness and the sewing speed. So, adjust the

initial value of the bobbin thread counter in accordance with the operating conditions.

3) Once the initial value is specified, start the sewing machine.

4) When a minus value is shown on the counter, the buzzer peeps three times and the pop-up display appears,

replace the bobbin thread.

Bobbin thread replacement warning pop-up

5) After the bobbin thread has been properly replaced, press counter reset switch 笆 to return the value on the

bobbin thread counter to the initial value. Now, re-start the sewing machine.

6) If the remaining amount of bobbin thread is excessive or the bobbin thread runs out before the bobbin thread

counter indicates a minus value, adjust the initial value appropriately using counter value setting switches 笳

and 笘.

If the remaining amount of bobbin thread is excessive ..... Increase the initial value using the “+” switch.

If the remaining amount of bobbin thread is insufficient .... Decrease the initial value using “–” switch.

5-4. No. of pcs. counter

The No. of pcs. counter counts up the number of finished products every time the machine performs thread

trimming. (0 → 1 → 2

...........

→ 9999)

2

3

The value on the No. of pcs. counter can be modified

using counter value setting switches 笳 and 笘. The value

on the No. of pcs. counter is reset to "0" by pressing

counter reset switch 笆.

4

– 52 –

5-5. Re-sewing switch

The re-sewing switch is used when the bobbin thread runs out during the corner pattern sewing step or the step

pattern sewing step. Explanation of the re-sewing switch is given using the corner pattern as an example.

d

1

a

C

b

1) When the bobbin thread has run out during the sewing

of a corner a, take the position at which you have

noticed run out of the bobbin thread as b. Bring the

pedal to its neutral position to allow the sewing

machine to stop.

2) Depress the back part of the pedal to perform thread

trimming.

3) Press re-sewing switch 1. c

4) Replace the bobbin with a new bobbin and sew over the

finished seam. d

5) Depress the front part of the pedal and continue to depress

the pedal until the stop position of the current step.

6) When re-sewing switch 1 is turned ON again at the stop

position, the step is changed over to the subsequent step,

and the corner pattern can be continued.

* When thread breakage or the like occurs during the free

stitching operation d using re-sewing switch 1, set the

pedal to neutral and perform thread trimming operation by

depressing the back part of the pedal. Perform threading and

slightly return the material edge. Then press re-sewing

switch 1 and the free stitching can be continued. After this,

the operation is the same as steps 5) and 6).

ENGLISH

Cau tion

When returning to the first step without

using re-sewing switch 1, the step

display returns to “1” and the sewing can

be performed from the first by

depressing the back part of the pedal to

perform thread trimming.

– 53 –

5-6. Needle up/down compensation switch

Every time needle up/down compensation switch 笊 is

pressed, the needle goes up when it is in its lowest position

or comes down when it is in its highest position. This

compensates the stitch by a half of the predetermined stitch

length.

1

Note, however, that the machine does not run continuously

at a low speed even if you keep the switch held pressed.

Also, note that the needle up/down compensation switch is

inoperative after turning the handwheel by hand.

Thread trimming is operative only at the time of stitch

compensation after depressing the front part of the pedal once.

5-7. ON/OFF switch of the material edge sensor

• When the material edge sensor, which is optionally available, is connected to the operation panel, the ON/

OFF switch of the material edge sensor becomes effective.

• If the material edge sensor is specified, the sewing machine will automatically stop running or perform thread

trimming when the sensor detects the material edge.

Cau tion

If the material edge sensor is used in combination with the operation panel, carefully read

the Instruction Manual for the material edge sensor beforehand.

5-8. Automatic thread trimming switch

• This switch is used to automatically actuate the thread trimmer in a process where the sewing machine