Page 1

DDL-900BB

INSTRUCTION MANUAL

Page 2

CONTENTS

I. SPECIFICATIONS ........................................................................................ 1

II. SET-UP ........................................................................................................ 3

1. Installation ......................................................................................................................................... 3

2. Installing the pedal sensor ...............................................................................................................4

3. Installing the power switch (for CE) ................................................................................................ 5

4. Connecting the connector ...............................................................................................................6

5. How to install the power plug .......................................................................................................... 7

6. Attaching the connecting rod ..........................................................................................................7

7. Winding the bobbin thread ..............................................................................................................8

8. Adjusting the height of the knee lifter ............................................................................................. 9

9. Installing the thread stand ...............................................................................................................9

10. Lubrication ......................................................................................................................................10

11. Adjusting the amount of oil (oil splashes) .................................................................................... 11

12. Attaching the needle .......................................................................................................................13

13. Setting the bobbin into the bobbin case ......................................................................................14

14. Adjusting the stitch length .............................................................................................................14

15. Presser foot pressure ..................................................................................................................... 14

16. Hand lifter ........................................................................................................................................14

17. Adjusting the height of the presser bar ........................................................................................ 15

18. Threading the machine head .........................................................................................................15

19. Thread tension ................................................................................................................................16

20. Thread take-up spring ....................................................................................................................16

21. Adjusting the thread take-up stroke .............................................................................................16

22. Needle-to-hook relationship ..........................................................................................................17

23. Height of the feed dog .................................................................................................................... 17

24. Tilt of the feed dog .......................................................................................................................... 18

25. Adjusting the feed timing ...............................................................................................................18

26. Checking the knife unit ..................................................................................................................19

27. Adjusting the condensation stitching ........................................................................................... 20

28. Pedal pressure and pedal stroke ...................................................................................................22

29. Adjustment of the pedal .................................................................................................................23

30. Marker dots on the handwheel ......................................................................................................23

III. FOR THE OPERATOR ............................................................................. 24

1. Operating procedure of the sewing machine ............................................................................... 24

2. Setting procedure of the machine head .......................................................................................25

3. Operation panel built in the machine head ..................................................................................26

4. Operating procedure of the sewing pattern .................................................................................27

5. One-touch setting ...........................................................................................................................29

6. Setting of functions ........................................................................................................................30

7. Production support function .........................................................................................................31

8. Function setting list ........................................................................................................................ 33

9. Detailed explanation of selection of functions ............................................................................37

10. Automatic compensation of neutral point of the pedal sensor .................................................. 47

11. Selection of the pedal specications ............................................................................................48

12. Setting of the auto lifter function ..................................................................................................48

13. Selecting procedure of the key-lock function .............................................................................. 49

14. Initialization of the setting data .....................................................................................................49

15. LED hand light .................................................................................................................................50

16. Height adjustable one-touch type reverse stitching switch ....................................................... 50

IV. MAINTENANCE ....................................................................................... 51

1. Adjusting the machine head ..........................................................................................................51

2. Error codes ...................................................................................................................................... 52

i

Page 3

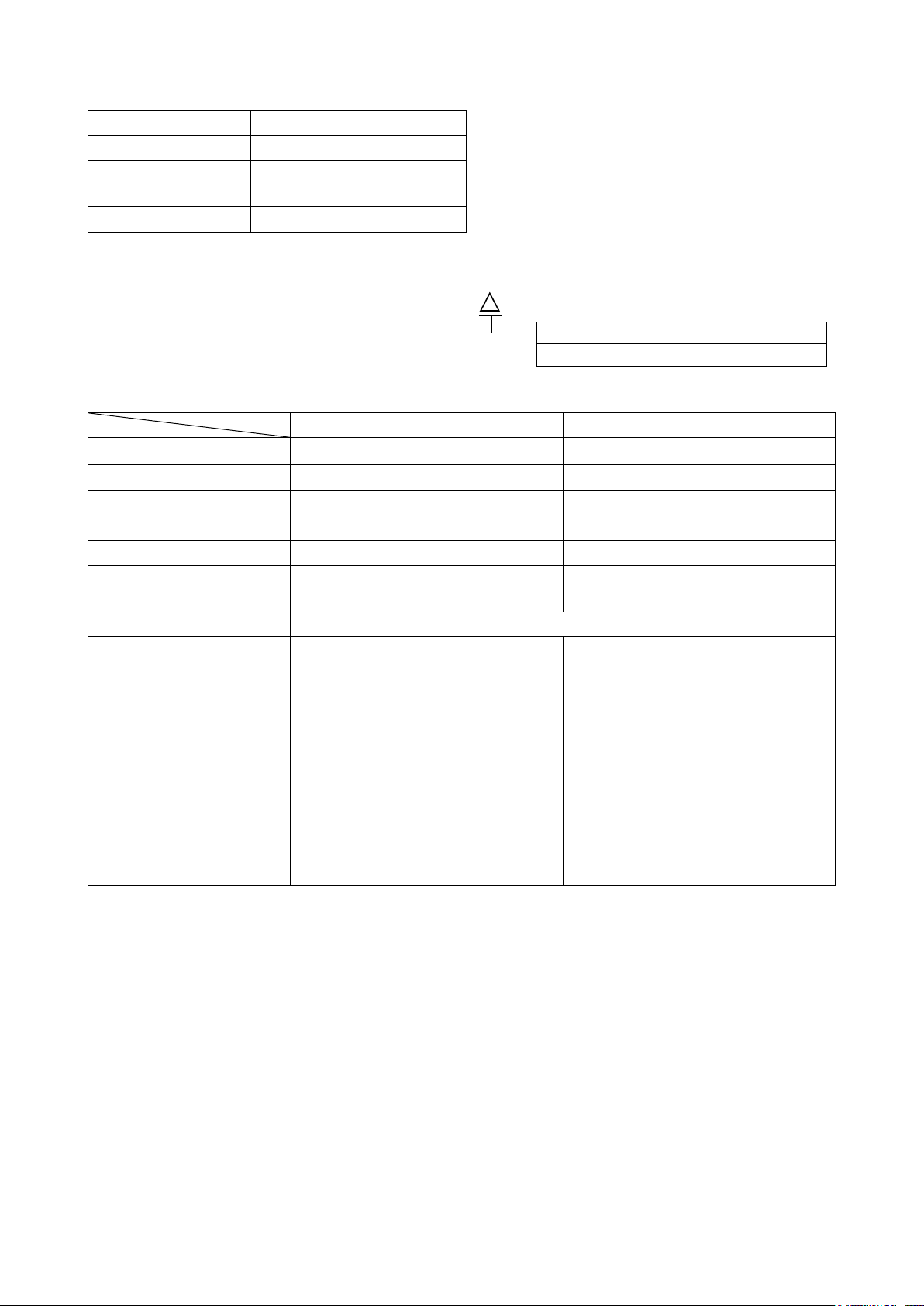

I. SPECIFICATIONS

Supply voltage Single phase 220V/230V/240V

Frequency 50Hz/60Hz

Operating environment

Input 210VA

Temperature : 5 to 35˚C

Humidity 35 - 85 %

DDL-900BB-

S : Light- to Medium-weight materials

H : Heavy-weight materials

DDL-900BB-S DDL-900BB-H

Application

Max. sewing speed 5,000 sti/min 4,000 sti/min

Thread trimming speed 210 sti/min 210 sti/min

Stitch length 4 mm 5 mm

Presser foot lift (by knee lifter) 13 mm 13 mm

Needle

Lubricating oil JUKI CORPORATION GENUINE OIL 7

Noise

*1

Light- to Medium-weight materials Heavy-weight materials

DB × 1 (#14) #9 to 18, 134 (Nm 90) Nm

65 to 110 (for CE)

- Equivalent continuous emission

sound pressure level (LpA) at the

workstation :

A-weighted value of 81.0 dB; (Includes

KpA = 2.5 dB); according to ISO

10821- C.6.2 -ISO 11204 GR2 at

4,000 sti/min.

A-weighted value of 80.0 dB; (Includes

KpA = 2.5 dB); according to ISO

10821- C.6.2 -ISO 11204 GR2 at

3,500 sti/min.

- Equivalent continuous emission

sound pressure level (LpA) at the

workstation :

A-weighted value of 83.0 dB; (Includes

KpA = 2.5 dB); according to ISO

10821- C.6.2 -ISO 11204 GR2 at

4,000 sti/min.

A-weighted value of 80.0 dB; (Includes

KpA = 2.5 dB); according to ISO

10821- C.6.2 -ISO 11204 GR2 at

3,500 sti/min.

DB x 1 (#21) #20 to 23

• The sewing speed preset at the time of shipping : 4,000 sti/min

*1 : Needle used depends on the destination.

– 1 –

Page 4

DRAWING OF TABLE

S-S

0

+0.5

2R

U-U

2R

70

190

40

18

30R

40

90

75

300※

130

C

60

H

I

20

E

D

8R

R30

2R

535

360

±1

141

43

S

R242.5

8R

10※ R

30.5※

6.5※

6※

M

105※

20R

22.5R

G

±1

±1

10R

10R

29

±0.5

141

171

M

±0.5

80

21.5

W

9

14

86.5

75※

±0.5

68.1

±1

239.7

R30

8R

98.2※

10※ R

N

0

+0.5

21

2R

153

55

±0.5

21.5 84

8R

52

6※

45.2※

±0.5

R242.5

8R

N

18R

8R

22.5R

F

27.5R

2R

2R

2R

14

15

27.5

30R

100

27.5R

215※

40

2R

2R

S

±0.5

±0.5

90

195

1

±1

480

±0.5

±0.5

Z-Z

M-M

±0.5

±0.5

N-N

23.5

23.5

P-P

J

19.5

19.5

1200

Z

10R

±1

810

X

10R

U

244( )

A

Z

T-T

±0.5

80

X

29

±0.5

22.5R

20R

T

22.5( )

)(

172.2

T

30R

136

-1

181

0

22.5R

P

1

P

80

18R

30R

22.5

110

U

27

505※( )

17.5

±0.5

X-X

R30

B

30R

100

W

390

30R

W-W

2R

2R

4xø3.4 on the bottom surface, depth 20 (Drill a hole at the time of set-up.)

Installing position of drawer stopper (on the reverse side)

ø18 drilled hole

A

B

C

drilled hole

3xø13 drilled hole

2xø3.5 ± 0.3, depth 10

2xø3.5 ± 0.3, depth 10

ø40±0.5

ø16 depth 30

ø16 depth 30

D

E

F

C1.5 to C2.5 (hinge side only)

G

H

I

J

– 2 –

Page 5

II. SET-UP

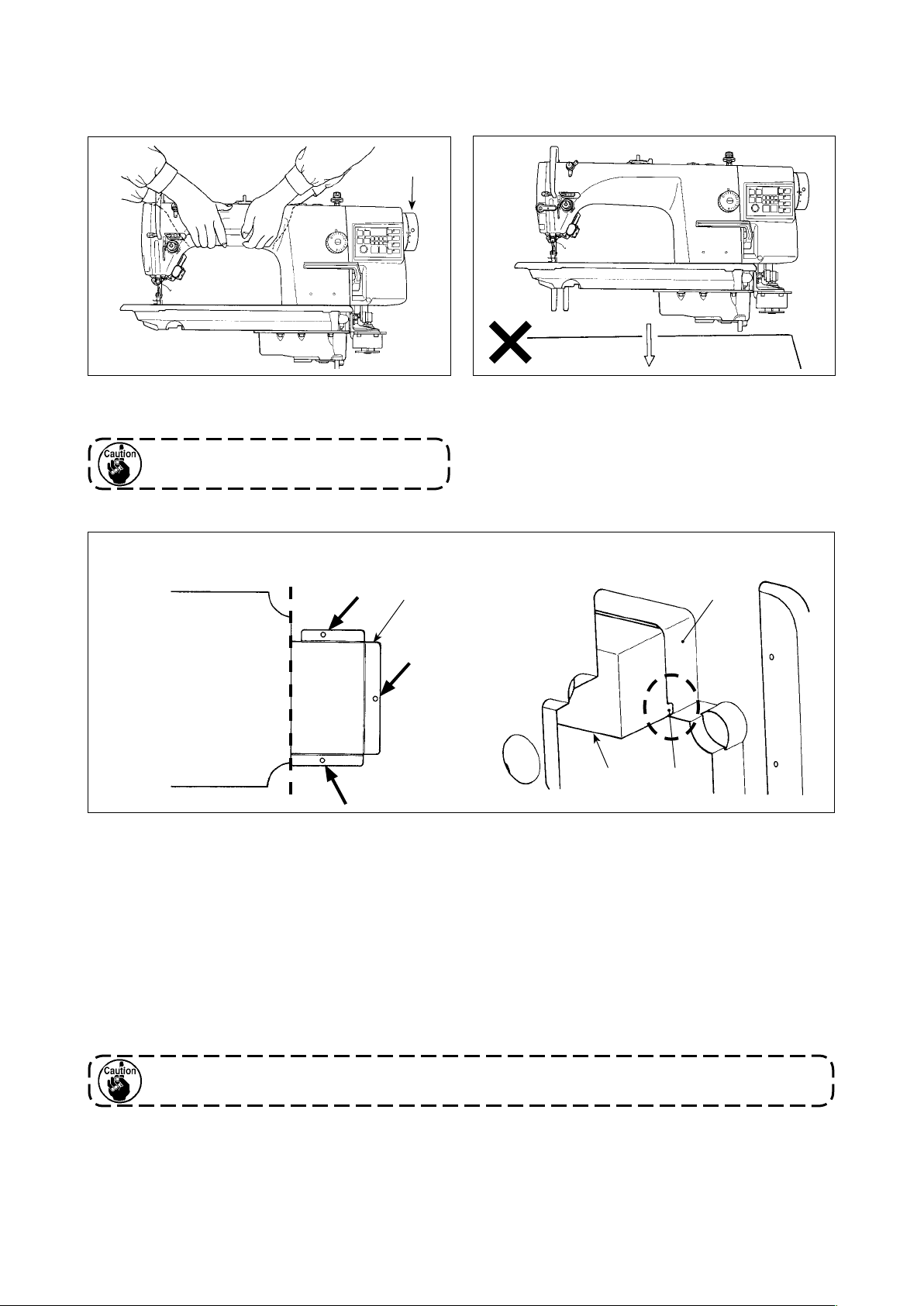

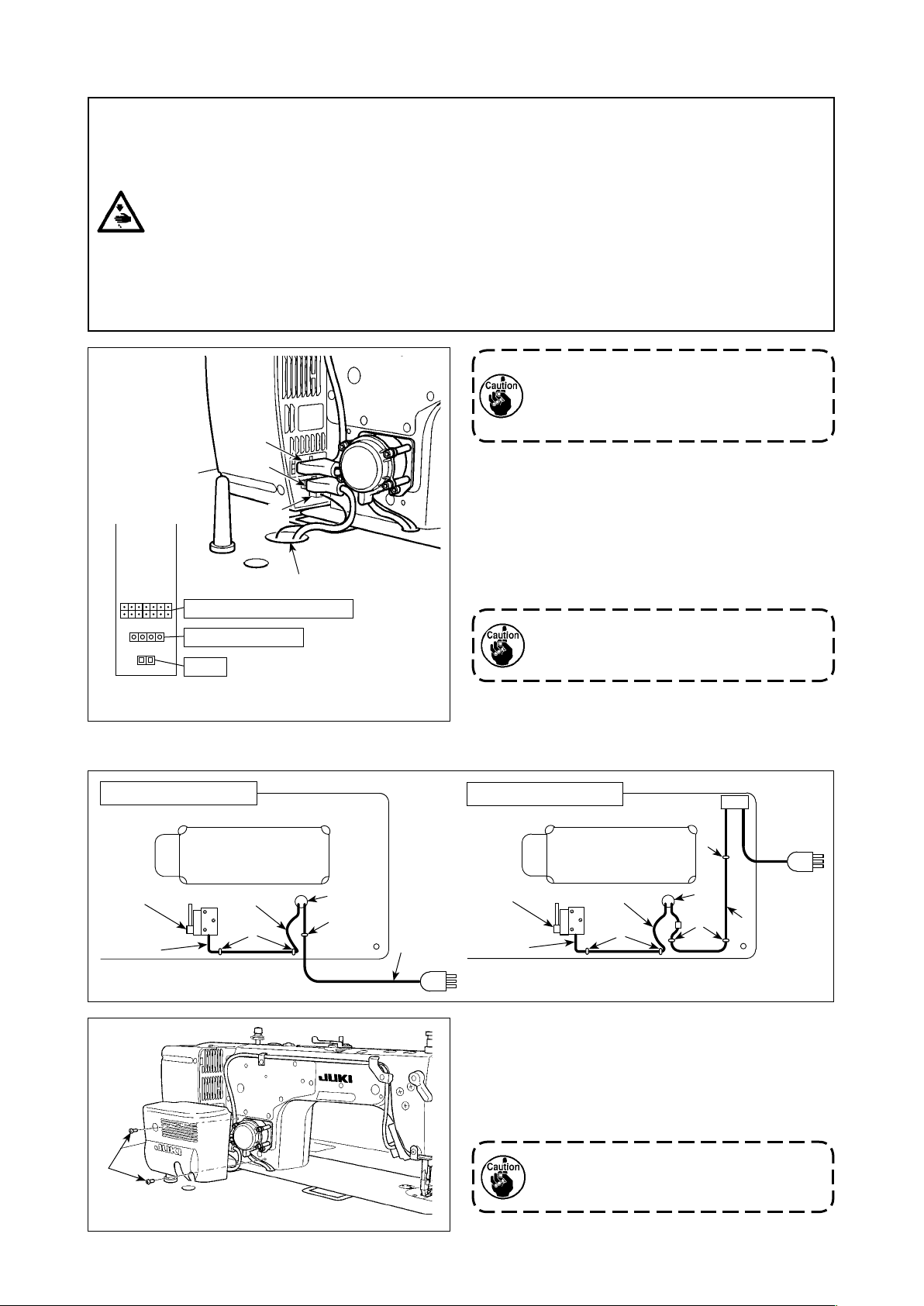

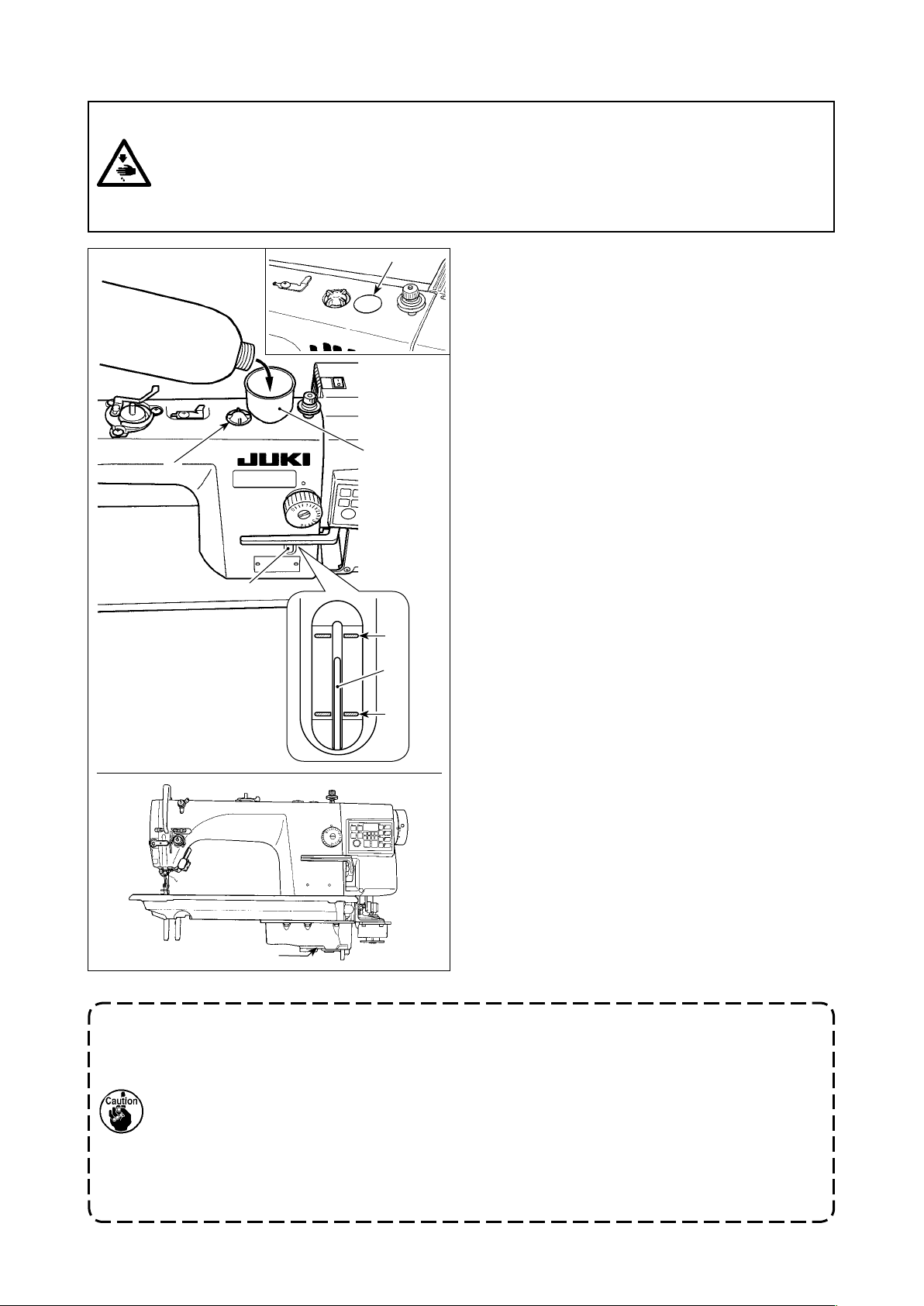

1. Installation

❶

1) Carry the sewing machine with two persons as

shown in the gure above.

Do not hold the handwheel ❶.

Undersurface of table Top surface of table

A

❷

3) Fix condensation stitching cover ❷ on the undersurface of table.

1. The condensation stitching cover is contained in the accessory bag. Fix it with three screws (at the

three locations respectively indicated with an arrow).

2. Be sure to x condensation stitching cover ❷ so that there is no clearance between the cover and the

undersurface of table. If there is a clearance between them, the reverberating sound may be produced

when the sewing machine is running.

3. With respect to the lateral position of condensation stitching cover ❷, the cover should be aligned

with line A at the opening section in the table. With respect to the longitudinal position of condensation

stitching cover ❷, press projecting section ❸ of the cover against side B of table.

2) Do not put protruding articles such as the screw-

driver and the like at the location where the

sewing machine is placed.

B

❷ ❸

Be sure to install condensation stitching cover ❷ without exceptions.

– 3 –

Page 6

❼

❺

❹

❺

❼

C

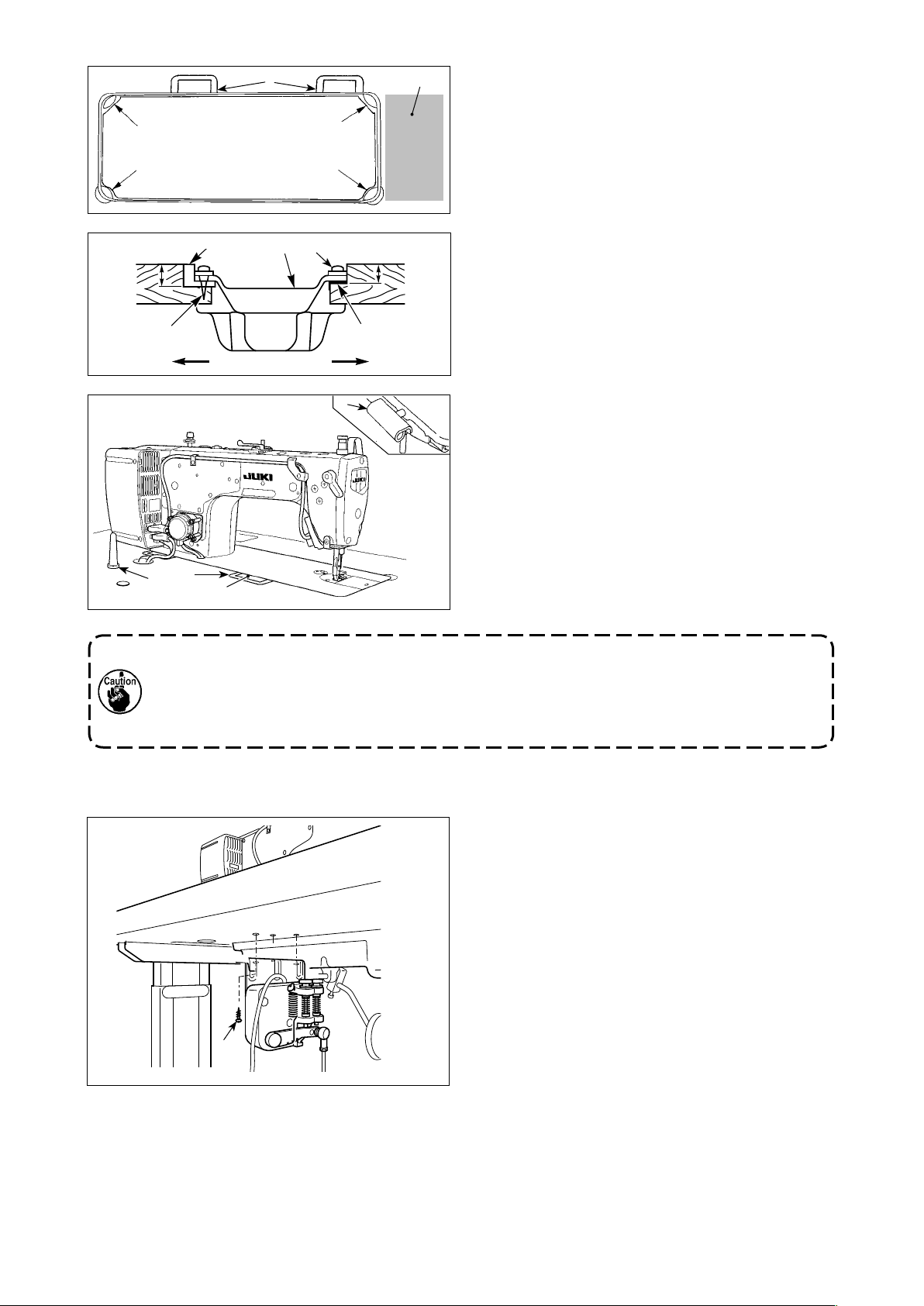

4) Adjust so that the underside cover is supported at

the four corners of the table. Mount rubber hinge

seat ❹ on the table and x it on the table with a

nail.

❺

❽

19.5mm23.5mm

5) Two rubber seats ❺ for supporting the head por-

tion on the operator side A are xed on the extended portion of the table by hitting the nail ❻ ,

and the other two rubber cushion seats ❼ on the

❾

❼

hinge side B are xed by using a rubber-based

adhesive. Then, underside cover ❽ is placed.

6) Fit hinge ❾ into the opening in the machine bed,

❻

A B

and t the machine head to table rubber hinge

before placing the machine head on cushions

on the four corners.

7) Securely t machine head support stand in

the hole (60 x 141 x ø16, depth 30) (refer to H in

DRAWING OF TABLE p. 2) in the table.

1. Be sure to install the machine head support rod supplied with the unit.

2. If a pair of scissors or the like is caught between the control box and the table, the control box

cover can break. To prevent such an accident, do not place anything on C section.

3. Be aware that the control box breakage and/or oil leakage can occur if operating the sewing

machine with the machine head support rod removed.

❾

2. Installing the pedal sensor

❶

1) Install the pedal sensor to the table with mounting

screws ❶ supplied with the unit.

It is necessary to install the pedal sensor at such

a position that the connecting rod is perpendicu-

lar to the table.

2) After the completion of installation of the pedal

sensor on the table, place the sewing machine

head on the table.

– 4 –

Page 7

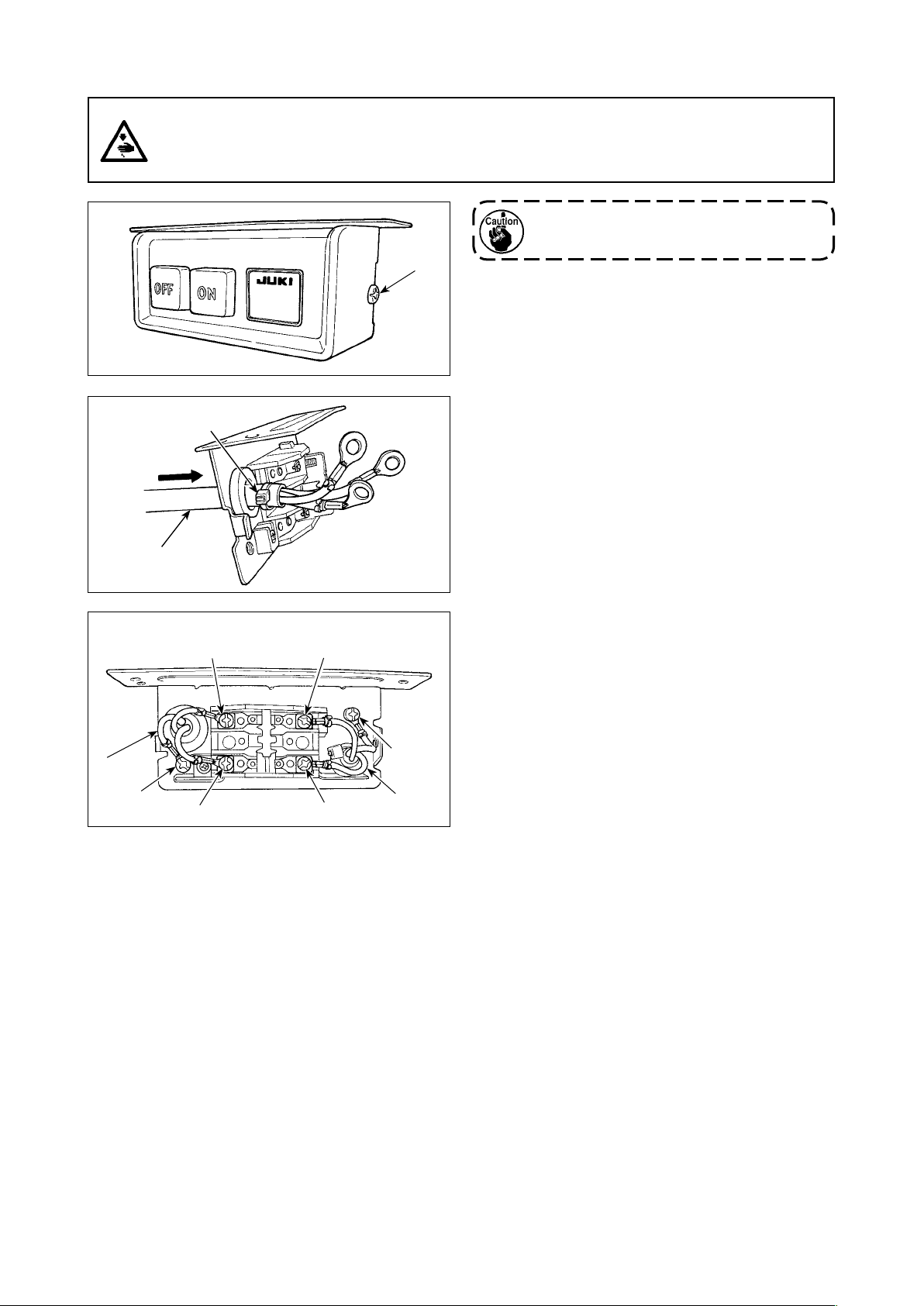

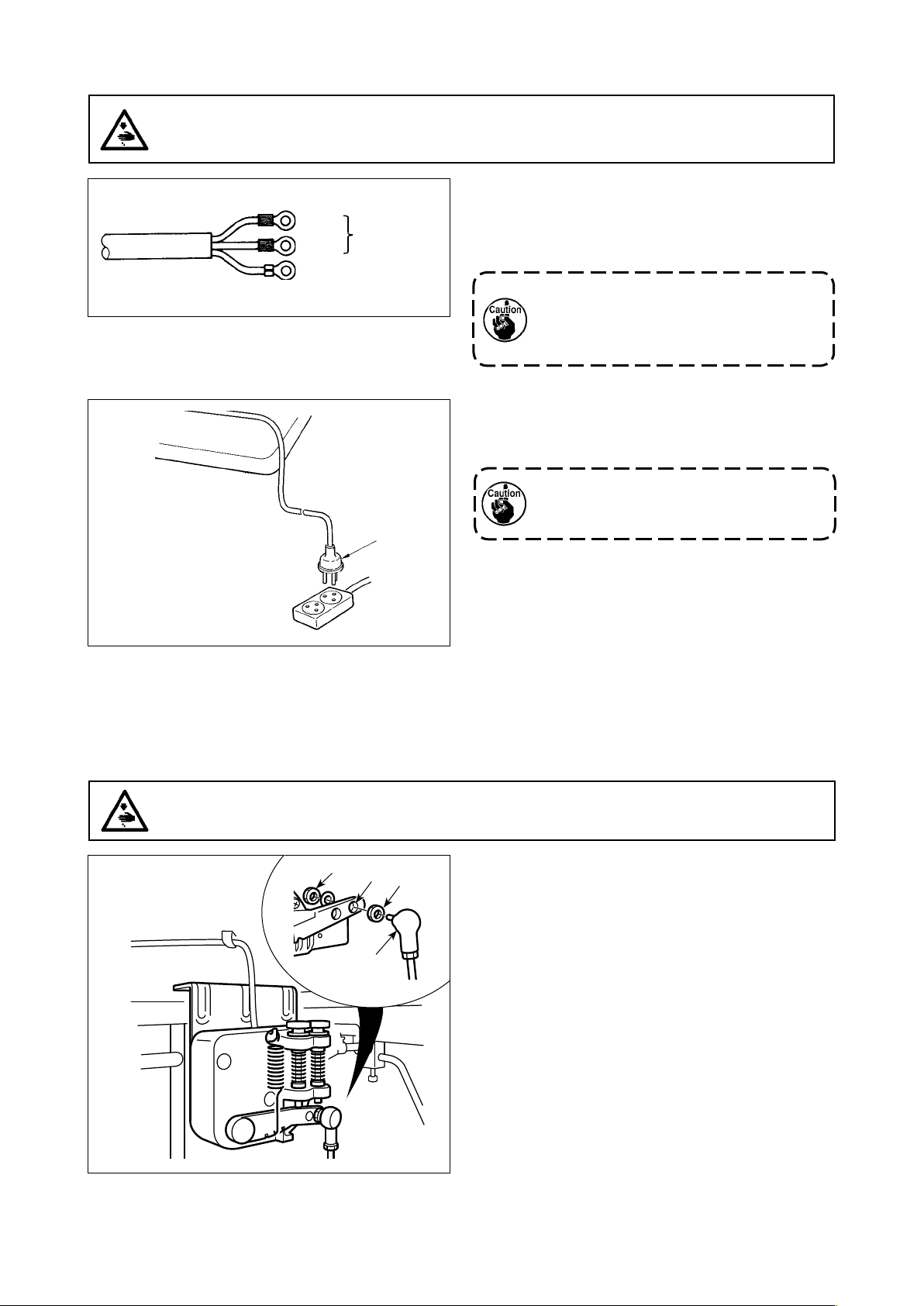

3. Installing the power switch (for CE)

WARNING :

1. Be sure to attach the ground wire (green/yellow) to the specied location (on the ground side).

2. Take care not to allow terminals to come in contact with each other.

3. When closing the power switch cover, take care not to allow the cord to be caught under it.

❹

❶

Do not insert the power plug into the plug

receptacle.

1

) Remove screw ❶ on the side face of the power

switch cover to open the power switch cover.

2) Pass AC input cord ❷(40145128),

❸(M6102461DAA) through the rear face of the

power switch. Bundle the cord with cable clip

band ❹ to secure it.

❷

1ø 220V-240V

❷

Green/

Yellow

Blue Blue

Brown Brown

Green/

Yellow

❸

3) Securely x the terminals of the AC input cord

❷(40145128), ❸(M6102461DAA) by tightening

the screws at the specied locations.

4) Close the power switch cover. Tighten screw ❶

on the side face of the power switch cover.

– 5 –

Page 8

4. Connecting the connector

WARNING :

• To protect against personal injury resulting from abrupt start of the sewing machine, be sure to

turn the power OFF, unplug the machine and wait for ve minutes or more before installing the

pedal sensor.

• To prevent damage of device caused by maloperation and wrong specications, be sure to connect

all the corresponding connectors to the specied places. (If any of the connectors is inserted into

a wrong connector, not only the device corresponding to the connector can break but also it can

start abruptly, inviting the risk of personal injury.)

• To prevent personal injury caused by maloperation, be sure to lock the connector with lock.

• Do not connect the power plug until the connection of cords is completed.

• Fix the cords while taking care not to forcibly bend them or excessively clamp them with staples.

• As for the details of handling respective devices, read carefully the Instruction Manuals supplied

with the devices before handling the devices.

❸

❷

❶

❹

Machine head connector

AC power supply

Pedal

Connector connection diagram

Do not insert the power plug into the wall

outlet.

Check to be sure that the power switch is

turned OFF.

1) Connect the connectors listed below to the con-

trol box in the order of ❶ to ❸.

❶ Pedal sensor cable

❷ AC input cable

❸ Machine head connector

For the connection ports of the cables, refer to

the connector layout drawing.

Be sure to fully insert the connectors into

the corresponding ports until they are

locked.

2) Draw out cable of the control box through cable

draw-out hole ❹ to route it to the underside of

the sewing machine table.

Underside of the table

Pedal sensor

❶

❻

Slack

❺

❹

❺

❷

Underside of the table

❺

Pedal sensor

❶

Slack

❺

(For CE)

❹

❺

❷

3) Fix pedal sensor cable ❶ and AC input cable ❷

with a staple ❺.

4) Attach the solenoid cover with two solenoid cover

setscrews ❻ which are supplied with the unit as

accessories.

Take care not to allow the cords to be

caught under the cover when attaching

the cover.

– 6 –

Page 9

5. How to install the power plug

WARNING :

1. Be sure to attach the ground wire (green/yellow) to the specied location (on the ground side).

2. Take care not to allow terminals to come in contact with each other.

1ø 220-240V

Blue

Brown

Green / Yellow

(ground wire)

AC 220-240V

❶

1) Connect the power cord to power plug ❶. Con-

nect the blue and brown wires (1ø) to the power

supply side and the green/yellow wire to the earth

side as illustrated in the gure.

1. Be sure to prepare the power plug ❶

which conforms to the safety standard.

2. Be sure to connect the ground lead

(green/yellow) to the grounding side.

2) Check that the power switch is in the OFF state.

Then, insert the power plug ❶ coming from the

power switch into the plug receptacle.

In prior to the connection of the power

plug ❶, re-check the supply voltage spec-

ication indicated on the control box.

* The power plug ❶ is different in shape ac-

cording to the destination of the sewing

machine.

6. Attaching the connecting rod

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and a lapse of 5 minutes or more.

❸

❶

❷

❸

Fix connecting rod ❶ to installing hole of pedal lever

❷ with nut ❸.

– 7 –

Page 10

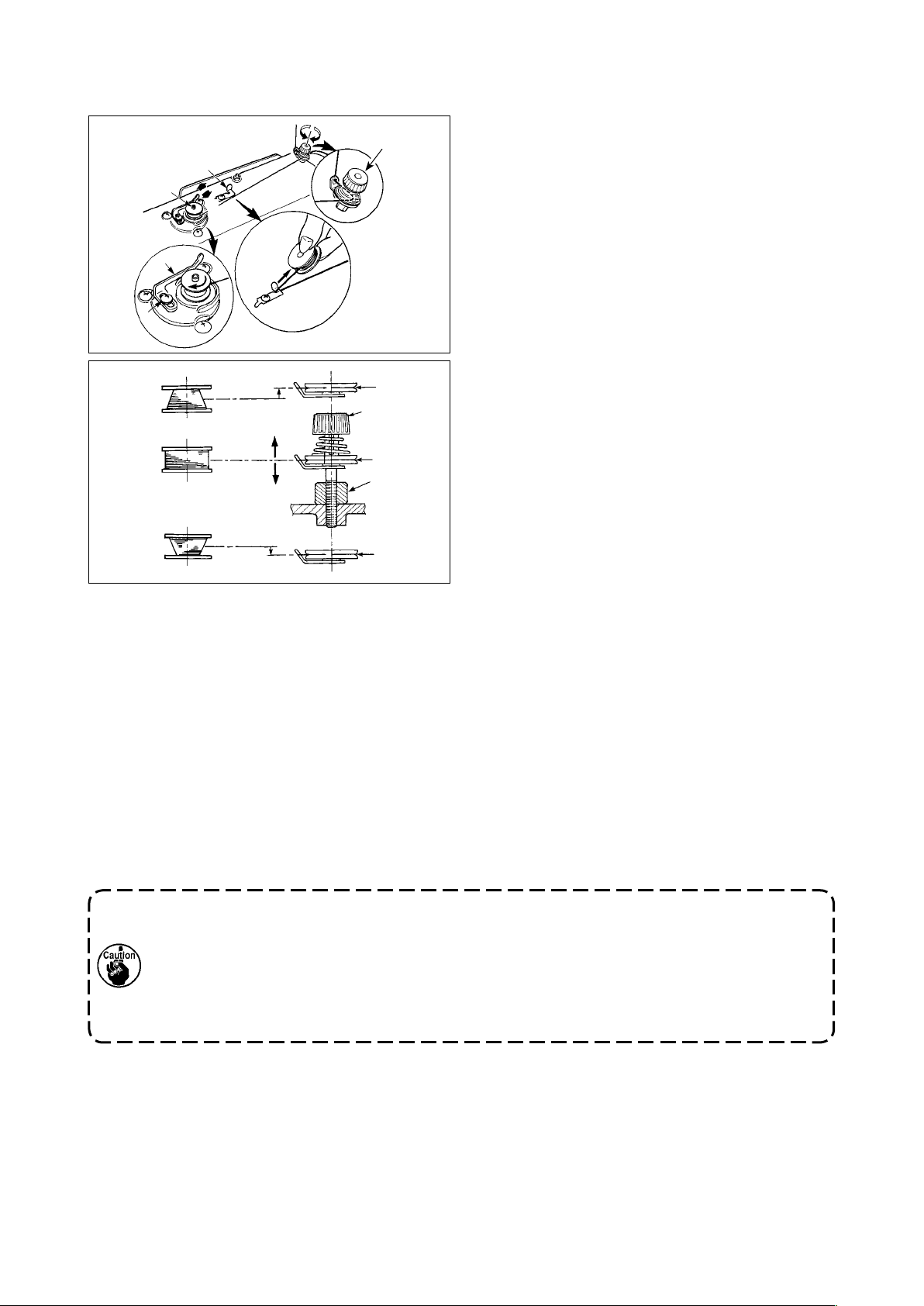

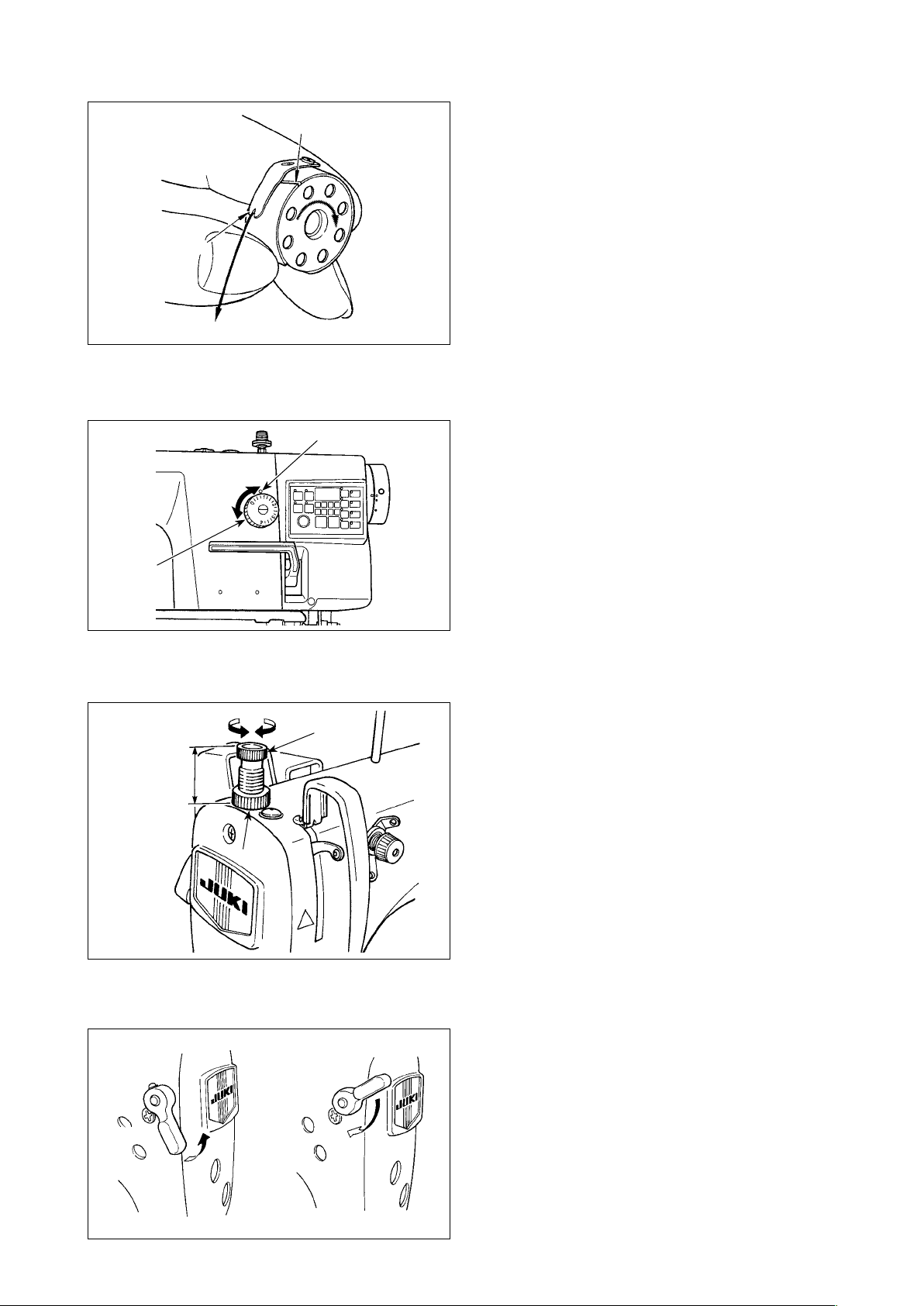

7. Winding the bobbin thread

1) Insert the bobbin deep into the bobbin winder

❽

❸

B

❶

A

❷

❹

C

❻

❼

D

❻

❺

E

❻

6) In case that the bobbin thread is not wound evenly on the bobbin, loosen screw ❺ and adjust the height

of bobbin thread tension ❽.

• It is the standard that the center of the bobbin is as high as the center of thread tension disk ❻.

• Adjust the position of thread tension disk ❻ to the direction of D when the winding amount of the bobbin

thread on the lower part of the bobbin is excessive and to the direction E when the winding amount of

the bobbin thread on the upper part of the bobbin is excessive.

After the adjustment, tighten screw ❺.

7) To adjust the tension of the bobbin winder, turn the thread tension nut ❼.

spindle ❶ until it will go no further.

2) Pass the bobbin thread pulled out from the

spool rested on the right side of the thread stand

following the order as shown in the gure on the

left. Then, wind clockwise the end of the bobbin

thread on the bobbin several times.

(In case of the aluminum bobbin, after winding

clockwise the end of the bobbin thread, wind

counterclockwise the thread coming from the

bobbin thread tension several times to wind the

bobbin thread with ease.)

3) Press the bobbin winder trip latch ❷ in the direc-

tion of A and start the sewing machine. The bob-

bin rotates in the direction of C and the bobbin

thread is wound up. The bobbin winder spindle ❶

automatically as soon as the winding is nished.

4) Remove the bobbin and cut the bobbin thread

with the thread cut retainer ❸.

5) When adjusting the winding amount of the bobbin

thread, loosen setscrew ❹ and move bobbin

winding lever ❷ to the direction of A or B. Then

tighten setscrew ❹.

To the direction of A : Decrease

To the direction of B : Increase

1. When winding the bobbin thread, start the winding in the state that the thread between the

bobbin and thread tension disk ❻ is tense.

2. When winding the bobbin thread in the state that sewing is not performed, remove the needle

thread from the thread path of thread take-up and remove the bobbin from the hook.

3. There is the possibility that the thread pulled out from the thread stand is loosened due to

the inuence (direction) of the wind and may be entangled in the handwheel. Be careful of the

direction of the wind.

– 8 –

Page 11

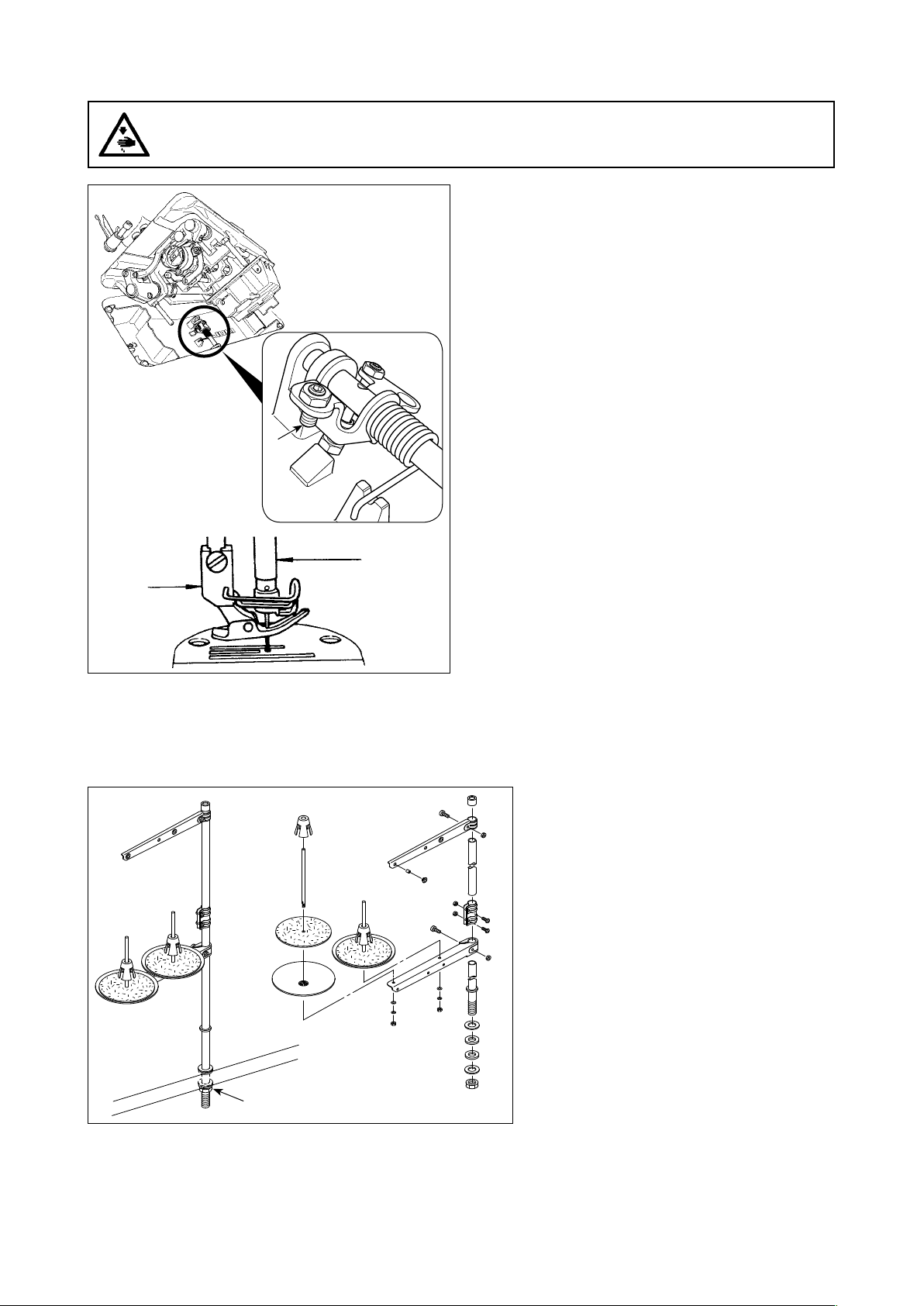

8. Adjusting the height of the knee lifter

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

❶

1) The standard height of the presser foot lifted

using the knee lifter is 10 mm.

2) You can adjust the presser foot lift up to 13 mm

using knee lifter adjust screw ❶.

3) When you have adjusted the presser foot lift

to over 10 mm, be sure that the bottom end of

needle bar ❷ in its lowest position does not hit

presser foot ❸.

❸

9. Installing the thread stand

❷

1) Assemble the thread stand unit, and

insert it in the hole in the machine table.

2) Tighten nut ❶.

❶

– 9 –

Page 12

10. Lubrication

WARNING :

1. Do not connect the power plug until the lubrication has been completed so as to prevent accidents due to abrupt start of the sewing machine,

2. To prevent the occurrence of an inammation or rash, immediately wash the related portions if oil

adheres to your eyes or other parts of your body.

3. If oil is mistakenly swallowed, diarrhea or vomitting may occur. Put oil in a place where children

cannot reach.

❻

❷

❺

❹

A

❸

B

❶

1) Before running the sewing machine, remove

rubber plug ❶ from the top of the machine arm,

and add oil through the oil inlet using accessory

funnel ❹ supplied with the sewing machine.

2) Fill the oil tank with the oil until the top end of

oil amount indicating rod ❸ comes between the

upper engraved marker line A and the lower

engraved marker line B of oil amount indicating

window ❷.

If the oil is lled excessively, it will lead from the

junction between the oil shield and bed, or from

the junction between the rubber plug and bed,

or proper lubrication will not be performed. So,

be careful. In addition, when the oil is vigorously

lled, it may overow from the oil hole. So, be

careful.

* When oil is added until MAX. line A is reached,

the oil quantity becomes 600 cc.

* Check the oil quantity while the sewing ma-

chine is at rest.

* Check the quantity of oil in the oil tank by view-

ing the oil surface from the side of oil amount

indicating window ❷.

3) When you operate the sewing machine, rell oil if

the top end of oil amount indicating rod ❸ comes

down to the lower engraved marker line B of oil

amount indicating window ❷.

4) When you operate the machine after lubrication,

you will see splashing oil through oil sight window

❻ if the lubrication is adequate.

* Note that the amount of the splashing oil is

unrelated to the amount of the lubricating oil.

1. When you use a new sewing machine or a sewing machine after an extended period of disuse, use the sewing machine after performing break-in at 2,000 sti/min or less.

2. For the oil lubrication, purchase JUKI CORPORATION GENUINE OIL 7 (Part No. :

MML007600CA). In the case any oil other than JUKI CORPORATION GENUINE OIL 7 is used,

check the quantity of oil in the hook and in the frame before using the sewing machine. (Refer

to "11. Adjusting the amount of oil (oil splashes)" p. 11.)

3. Be sure to lubricate clean oil.

4. Be aware oil leakage can occur if the surface of added oil quantity exceeds MAX. line A.

5. Transporting the sewing machine with the sewing machine lled with oil can give rise to the

risk of oil leakage. Be sure to discharge oil from the sewing machine through drain cock ❺.

– 10 –

Page 13

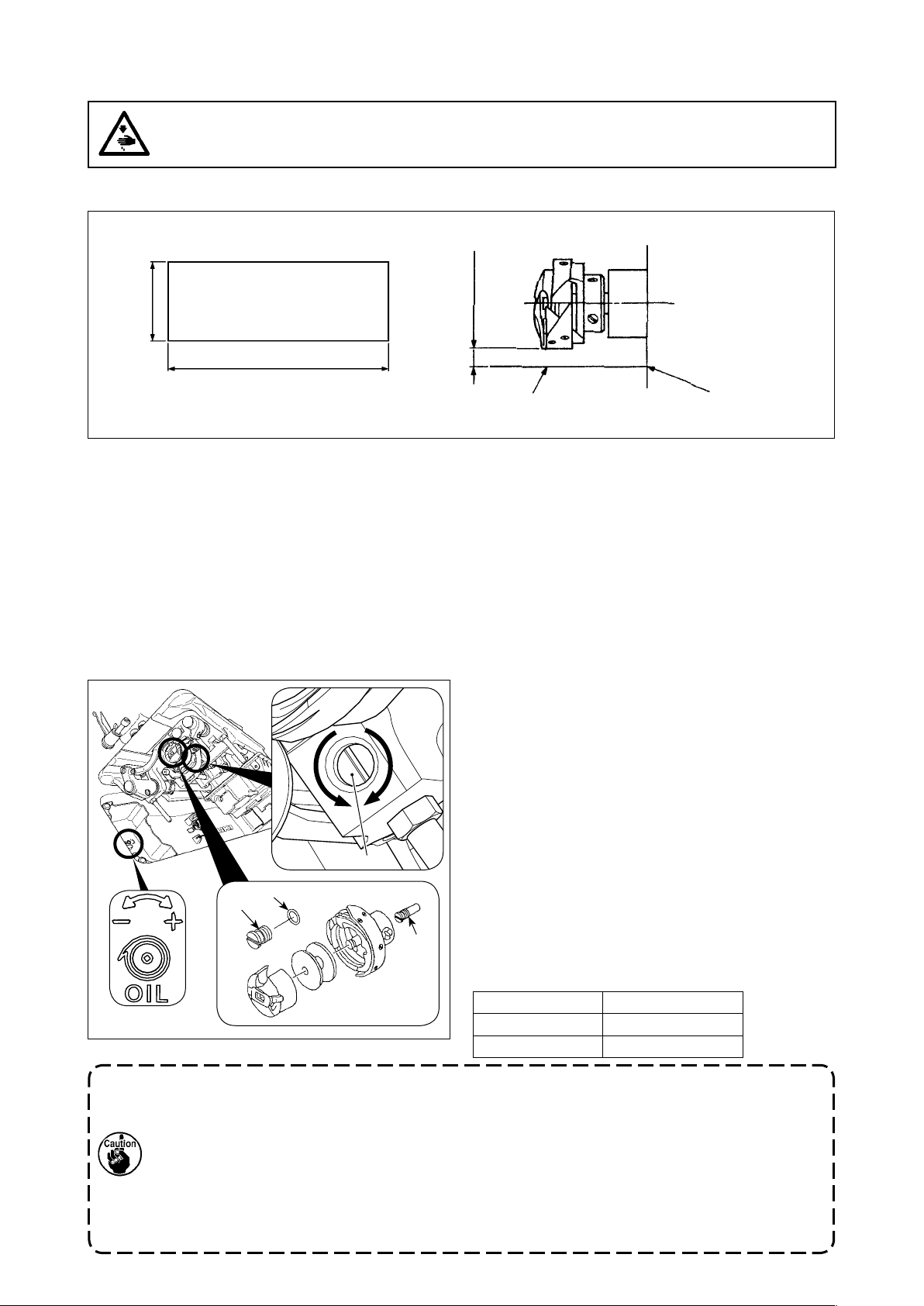

11. Adjusting the amount of oil (oil splashes)

WARNING :

Be extremely careful about the operation of the machine since the amount of oil has to be checked

by turning the hook at a high speed.

(1) Conrmation of the amount of oil in the hook

Amount of oil (oil splashes) conrmation paper

①

25 mm

70 mm

Oil splashes conrmation paper

Position to conrm the amount of oil (oil splashes)

②

3 - 10 mm

Closely t the paper against the wall

surface of the bed.

* When carrying out the procedure described below in 2), remove the slide plate and take extreme caution

not to allow your ngers to come in contact with the hook.

1) If the machine has not been sufciently warmed up for operation, make the machine run idle for approxi-

mately three minutes. (Moderate intermittent operation)

2) Place the amount of oil (oil spots) conrmation paper under the hook immediately after the machine stops running.

3) Check to be sure that the oil surface in the oil shield rests in the range between the "MAX. line" and the

"MIN. line".

4) Conrmation of the amount of oil should be completed in ve seconds. (Check the period of time with a watch.)

(2) Adjusting the amount of oil (oil spots) in the hook

1) Tilt the sewing machine. Turn oil amount adjust-

ment screw ❶, which is mounted on the front

bushing of lower shaft, in the "+" direction (direc-

B

A

tion A) to increase the oil amount (oil spots), or

in the "-" direction (direction B) to decrease it.

* The oil-amount +/- indication mark is shown on

the underside cover.

❶

2) After the amount of oil in the hook has been

properly adjusted with the oil amount adjustment

❸

❹

screw ❶, make the sewing machine run idle for

approximately 30 seconds to check the amount

❷

of oil in the hook.

< RP hook (dry hook) part number >

228-90404 RP HOOK C

228-90206 RP HOOK

228-90305 RP HOOK S

[In case of using the RP hook (dry hook) with the DDL-900BB]

1. Remove hook driving shaft oil wick setscrew ❷ and attach hook driving shaft stopper screw

❸ (part number : 11079506) and rubber ring ❹ (part number : RO036080200).

2. Loosen oil amount adjustment screw ❶ up to the minimum so as to reduce the oil amount in

the hook. However, do not completely stop the oil and be careful not to allow oil adjustment

screw ❶ to come off.

3. In the case the RP hook (dry hook) is used, never discharge oil. Though it is possible to stop

oil supplied to the parts other than the hook, however, the other mechanical sections need

lubrication.

– 11 –

Page 14

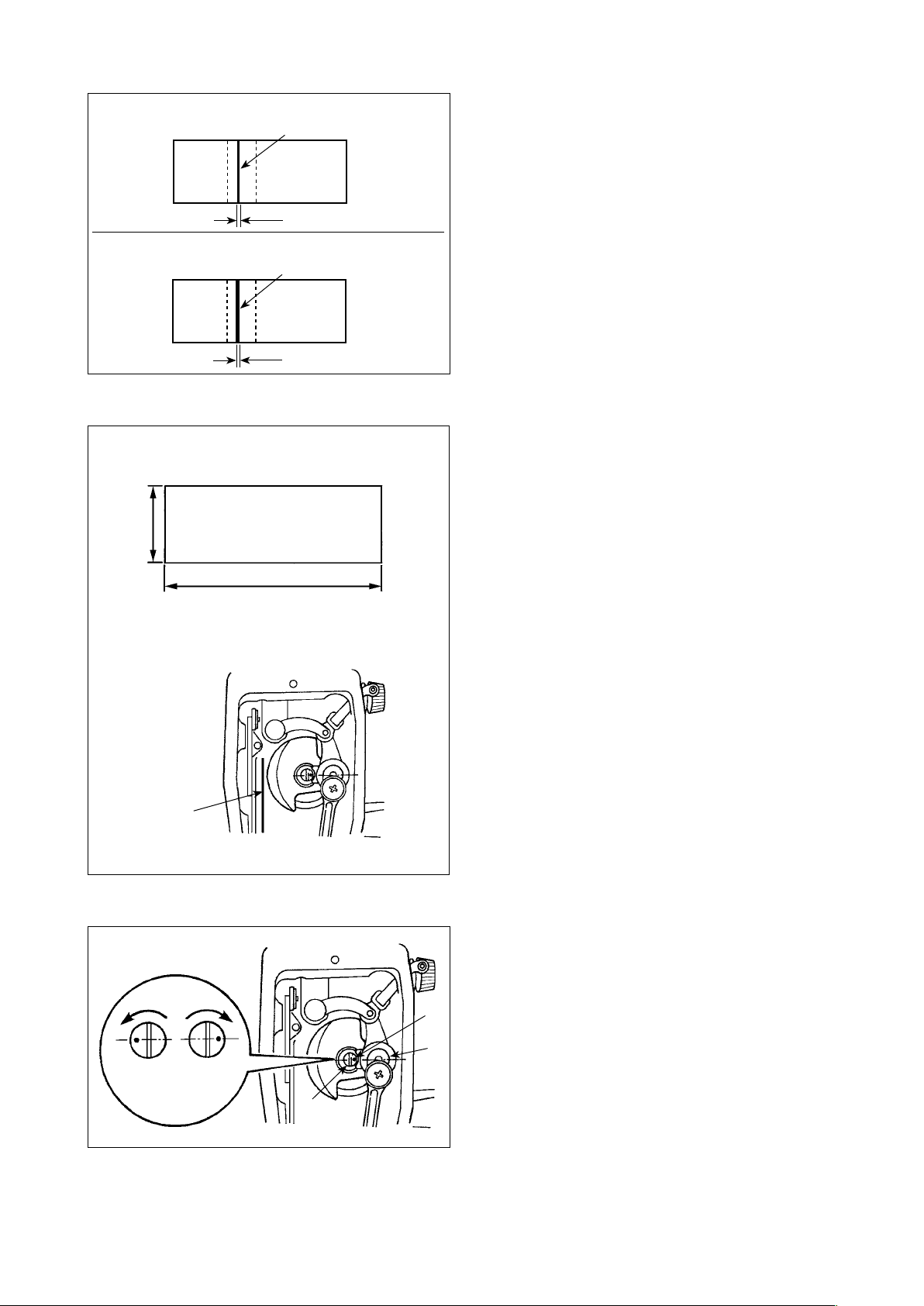

(3) Sample showing the appropriate amount of oil in the hook

Appropriate amount of oil (small)

Splashes of oil from the hook

1 mm

Appropriate amount of oil (large)

Splashes of oil from the hook

2 mm

1) The amount of oil shown in the samples on the

left should be nely adjusted in accordance with

sewing processes. Be careful not to excessively

increase/decrease the amount of oil in the hook.

(If the amount of oil is too small, the hook will be

seized (the hook will be hot). If the amount of oil

is too much, the sewing product may be stained

with oil.)

2) Check the oil amount (oil splashes) three times

(with three sheets of paper).

(4) Conrmation of the amount of oil supplied to the face plate parts

Amount of oil (oil splashes) conrmation paper

①

25 mm

70 mm

Position to conrm the amount of oil

②

(oil splashes)

Oil splashes

conrmation paper

* When carrying out the work described below in

2), remove the face plate and take extreme cau-

tion not to allow your ngers to come in contact

with the thread take-up lever.

1) If the machine has not been sufciently warmed

up for operation, make the machine run idle for

approximately three minutes. (Moderate intermit-

tent operation)

2) Place the amount of oil (oil spots) conrmation

paper under the hook immediately after the ma-

chine stops running.

3) Check to be sure that the oil surface in the oil

shield rests in the range between the "MAX. line"

and the "MIN. line".

4) The time required for the conrmation of the

amount of oil (oil splashes) should be completed

in ten seconds. (Measure the period of time with

a watch.)

(5) Adjusting the amount of oil supplied to the face plate parts

1) Adjust the amount of oil supplied to the thread

take-up and needle bar crank ❷ by turning adjust

C

Maximum

❶

Minimum

B

A

❷

❶

– 12 –

pin ❶.

2) The minimum amount of oil is reached when

marker dot A is brought close to needle bar

crank ❷ by turning the adjust pin in direction B.

3) The maximum amount of oil is reached when

marker dot A is brought to the position just

opposite from the needle bar crank by turning the

adjust pin in direction C.

Page 15

(6) Sample showing the appropriate amount of oil supplied to the face plate parts

Appropriate amount of oil (small)

S

plashes of oil from the thread take-up lever

1 mm

Appropriate amount of oil (large)

S

plashes of oil from the thread take-up lever

2 mm

1) The state given in the gure shows the appropri-

ate amount of oil (oil splashes). It is necessary to

nely adjust the amount of oil in accordance with

the sewing processes. However, do not exces-

sively increase/decrease the amount of oil in the

hook. (If the amount of oil is too small, the face

plate parts will be hot or seize. If the amount of oil

is too much, the sewing product may be stained

with oil.)

2) Check the oil amount (oil splashes) three times

(with three sheets of paper).

12. Attaching the needle

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

Use the specied needle for the machine. Use the

proper needle in accordance with the thickness of

❶

D B

A

C

❷

thread used and the kinds of the materials.

1) Turn the handwheel until the needle bar reaches

the highest point of its stroke.

2) Loosen screw ❷, and hold needle ❶ with its

indented part A facing exactly to the right in

direction B.

3) Insert the needle fully into the hole in the needle

bar in the direction of the arrow until the end of

hole is reached.

4) Securely tighten screw ❷.

5) Check that long groove C of the needle is facing

exactly to the left in direction D.

When polyester lament thread is used,

if the indented part of the needle is tilted

toward operator's side, the loop of thread

becomes unstable. As a result, hangnail

of thread or thread breakage may occur.

For the thread that such phenomenon

is likely to occur, it is effective to attach

the needle with its indented part slightly

slanting on the rear side.

– 13 –

Page 16

13. Setting the bobbin into the bobbin case

A

B

C

14. Adjusting the stitch length

A

1) Pass the thread through thread slit A, and pull

the thread in direction C. By so doing, the thread

will pass under the tension spring and come out

from notch B.

2) Check that the bobbin rotates in the direction of

the arrow when thread is pulled.

* The dial calibration is in millimeters (reference

value).

1) Turn stitch length dial ❶ in the direction of the

arrow, and align the desired number to marker

dot A on the machine arm.

❶

15. Presser foot pressure

AB

29 to 32 mm

❷

16. Hand lifter

❶

1) Loosen nut ❷. As you turn presser spring regulator ❶ clockwise (in direction A), the presser foot

pressure will be increased.

2) As you turn the presser spring regulator ❶ counter-clockwise (in direction B), the pressure will be

decreased.

3) After adjustment, tighten nut ❷.

The standard value of the pressure regulating thumb

screw is 29 to 32 mm.

1) The presser foot is lifted by moving the lever

upward.

2) The presser foot is lowered by moving the lever

downward.

– 14 –

Page 17

17. Adjusting the height of the presser bar

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

❶

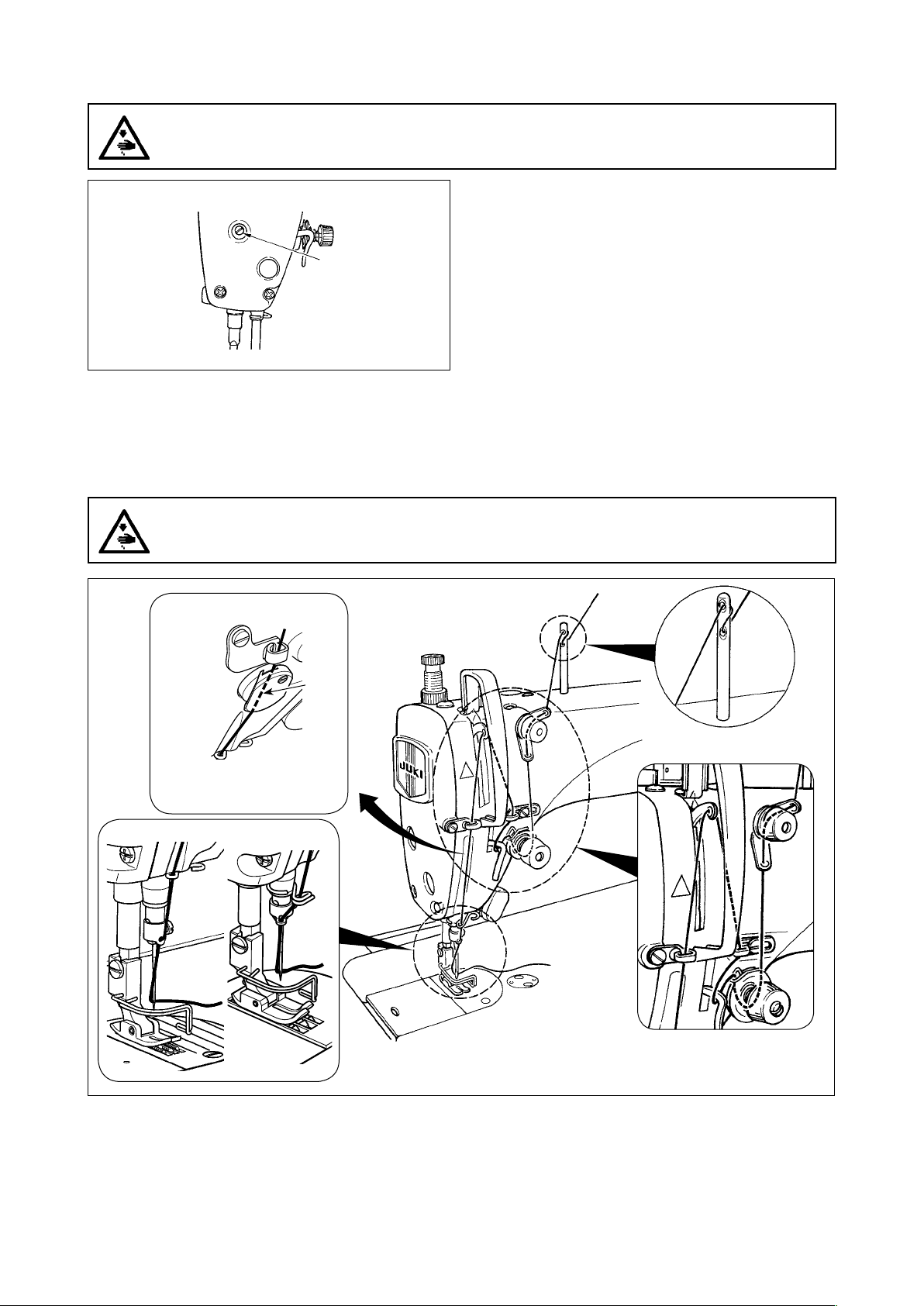

18. Threading the machine head

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

1) Loosen setscrew ❶, and adjust the presser bar

height or the angle of the presser foot.

2) After adjustment, securely tighten the setscrew

❶.

[NB type]

(Note)

Be sure to pass the thread

through the section A.

[S type] [H type]

A

– 15 –

Page 18

19. Thread tension

❶

B

❷

A

❸

E

F

(1) Adjusting the needle thread tension

1) The length of thread remaining at the needle tip

after thread trimming is shortened by turning tension regulating nut No. 1 ❶ clockwise in direction

A.

2) It is lengthened by turning the nut counterclockwise in direction B.

3) The needle thread tension is increased by turning

tension regulating nut No. 2 ❷ clockwise in direction C.

4) It is decreased by turning the nut counterclockwise in direction D.

C

D

20. Thread take-up spring

❶

❷

A

B

❸

❶

❺

❹

(2) Adjusting the bobbin thread tension

1) The bobbin thread tension is increased by turning

tension regulating screw ❸ clockwise in direction

E.

2) It is decreased by turning the screw counterclockwise in direction F.

(1) Changing the stroke of thread take-up

spring ❶

1) Loosen setscrew ❷.

2) As you turn tension post ❸ clockwise (in direction A), the stroke of the thread take-up spring

will be increased.

3) As you turn tension post ❸ counterclockwise (in

direction B), the stroke will be decreased.

(2) Changing the pressure of thread take-up

spring ❶

1) Loosen setscrew ❷, and remove thread tension

asm. ❺.

2) Loosen setscrew ❹.

3) As you turn tension post ❸ clockwise (in direction A), the pressure will be increased.

4) As you turn the tension post ❸ counterclockwise

(in direction B), the pressure will be decreased.

21. Adjusting the thread take-up stroke

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

A

B

❶

C

1) When sewing heavy-weight materials, move

thread guide ❶ to the left (in direction A) to

increase the length of thread pulled out by the

thread take-up.

2) When sewing light-weight materials, move thread

guide ❶ to the right (in direction B) to decrease

the length of thread pulled out by the thread takeup.

3) Normally, thread guide ❶ is positioned in a way

that marker line C is aligned with the center of

the screw.

– 16 –

Page 19

22. Needle-to-hook relationship

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

❶

C

D

❸

A

❷

DDL-900BB 0.04 to 0.10

If the clearance between the blade point

of hook and the needle is smaller than the

specied value, the blade point of hook

will be damaged. If the clearance is larger,

stitch skipping will result.

❹

E

B

Dimension F (mm)

A

B

❺

Adjust the timing between the needle and

the hook as follows :

1) Turn the handwheel to bright the needle bar

down to the lowest point of its stroke, and loosen

setscrew ❶.

Adjusting the needle bar height.

2) [For a DB/DP needles]

Align marker line A on the needle bar ❷ with the

bottom end of the needle bar lower bushing ❸,

then tighten clamping screw ❶ of the needle bar

F

connection.

[For a DA needle]

Align marker line C on the needle bar ❷ with the

bottom end of the needle bar lower bushing ❸,

then tighten clamping screw ❶ of the needle bar

connection.

Adjusting position of the hook ❺.

3) [For a DB/DP needles]

Loosen three setscrews of the hook, turn the

handwheel and align marker line B on ascending

the needle bar ❷ with bottom end of the needle

bar lower bushing ❸.

[For a DA needle]

Loosen three setscrews of the hook, turn the

handwheel and align marker line D on ascending

the needle bar ❷ with bottom end of the needle

bar lower bushing ❸.

4) After making the adjustments mentioned in the

above steps, align the blade point E of hook ❺

with the center of needle ❹. Provide a clearance

of dimension F (reference value) between the

needle ❹ and the hook ❺, then securely tighten

three setscrews of the hook.

23. Height of the feed dog

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

❶

❷

0.75 to 0.85 mm (S type)

1.15 to 1.25 mm (H type)

To adjust the height of the feed dog :

1) Loosen screw ❷ of crank ❶.

2) Move the feed bar up or down to make adjust-

ment.

3) Securely tighten screw ❷.

If the clamping pressure is insufcient,

the motion of the forked portion becomes

heavy.

– 17 –

Page 20

24. Tilt of the feed dog

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

B

A

❶

Front up b Standard

a

Front down d Throat plate

c

a

b

c

25. Adjusting the feed timing

d

1) The standard tilt (horizontal) of the feed dog is

obtained when marker dot A on the feed bar

shaft is aligned with marker dot B on feed rocker

❶.

2) To tilt the feed dog with its front up in order to

prevent puckering, loosen the setscrew, and

turn the feed bar shaft 90˚ in the direction of the

arrow, using a screwdriver.

3) To tilt the feed dog with its front down in order to

prevent uneven material feed, turn the feed bar

shaft 90˚ in the opposite direction from the arrow.

Whenever the feed dog tilt is adjusted,

the feed dog height will be changed. So, it

is necessary to check the height after tilt

adjustment.

❷

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

1) Remove rubber plug ❹ from the top surface of

the machine arm.

2) Loosen setscrews ❷ and ❸ of feed eccentric

cam ❶ through adjustment hole A. Adjust the

feed timing by moving the feed eccentric cam

in the direction of the arrow or in the opposite

direction of the arrow. Then, rmly tighten the

setscrews.

3) For the standard adjustment, adjust so that the

top surface of feed dog and the top end of needle

eyelet are ush with the top surface of throat

plate when the feed dog descends below the

throat plate.

4) To advance the feed timing in order to prevent

uneven material feed, move the feed eccentric

cam in the direction of the arrow.

5) To delay the feed timing in order to increase

stitch tightness, move the feed eccentric cam in

the opposite direction from the arrow.

❶

❸

❹

A

Standard feed timing

Advanced feed timing

Delayed feed timing

– 18 –

Be careful not to move the feed eccentric

cam too far, or else needle breakage may

result.

Page 21

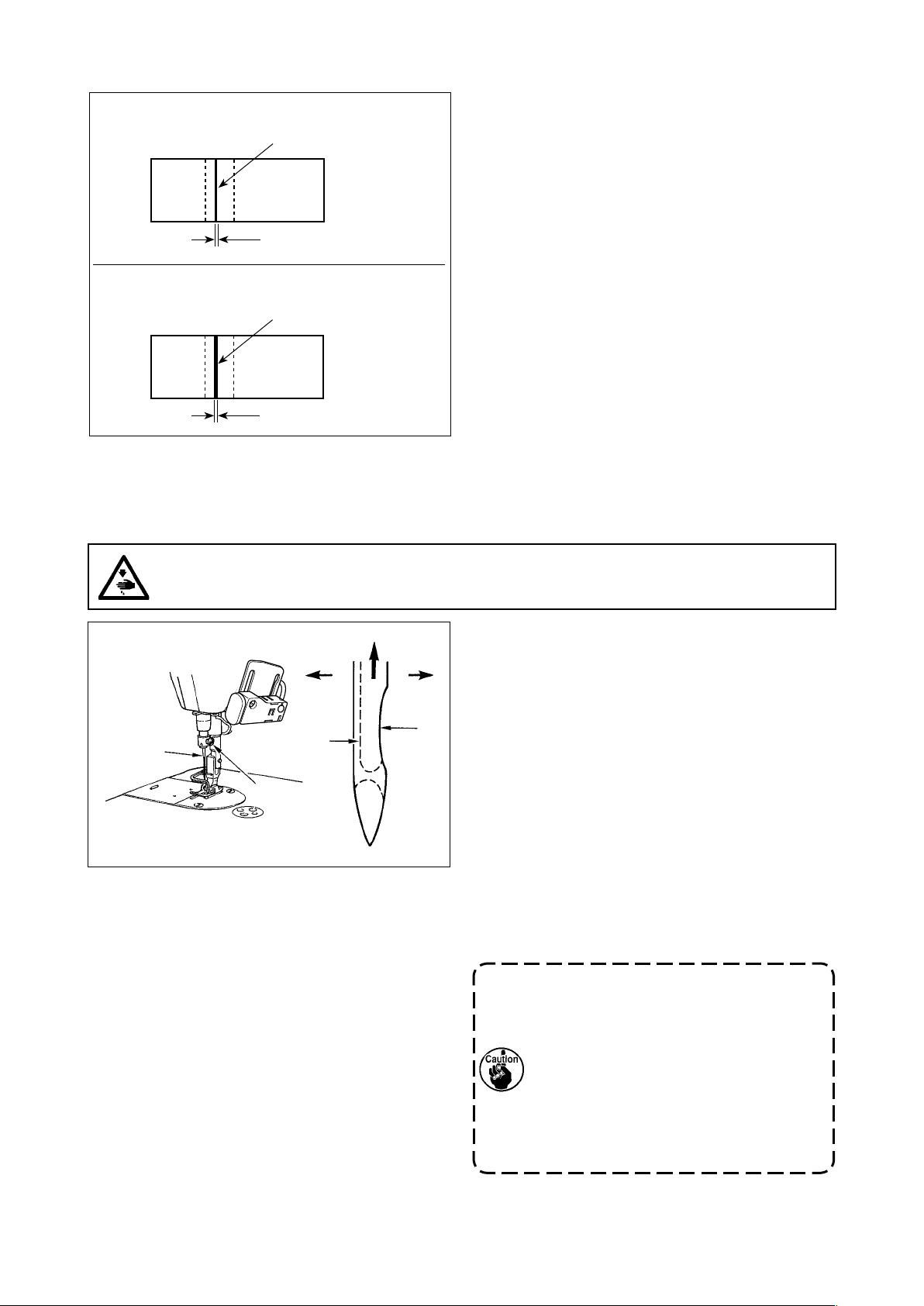

26. Checking the knife unit

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

❶

Standby state of the knife

A

7.5mm(7mm to 8mm

❶

❷

❷

)

1)

Check to make sure that the power switch is in the

OFF state. Remove the gauge (presser foot, throat

plate and feed dog) from around the needle.

2) In the standby state of loop spreading knife ❶, the

distance from the center of needle A to the tip of

loop spreading knife ❶ is 7.5 mm (7 mm to 8 mm).

Be aware that, if the distance between

loop spreading knife ❶ and center of needle A is reduced, thread loop is likely to

interfere with loop spreading knife ❶.

3) With respect to the alignment position of loop

spreading knife ❶ and thread trimming knife ❷,

the distance from the needle and the tip of thread

trimming knife ❷ is 0.6 to 0.7 mm when the

marker dot on loop spreading knife is aligned with

the tip of thread trimming knife ❷.

Be aware that, if the aligning position of the

loop spreading knife and the thread trim-

ming knife does not align with center of needle A, the length of thread remaining on the

material after thread trimming will be longer.

❶

Enlarged

detailed view

Marker

dot

❶

0.6 to 0.7mm

❶

2 to 2.5mm

❷

❷

❷

4) The amount of engagement between loop spreading knife ❶ and thread trimming knife ❷ is 2 to

2.5 mm as measured from center of needle A.

Be aware that, if the amount of engage-

ment between them is insufcient, faulty

thread trimming can occur.

The needle thread may be trimmed excessively short in the case thread such as lament thread which is likely to cause unstable thread loop formation is used or thread

trimming is carried out at a position where

there is no material. If the aforementioned

phenomenon occurs, it should be corrected

by carrying out the below-stated procedure.

• Make the thread take-up spring stroke

larger than the standard value.

• Make the pitch for thread trimming during

condensation stitch larger than the standard pitch.

• Turn OFF the condensation stitch opera-

tion when carrying out thread trimming at

a position where there is no material.

– 19 –

Page 22

27. Adjusting the condensation stitching

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

27-1. Condensation stitching pitch

Stitch pitch

Condensation pitch

27-2. How to adjust the condensation amount

Condensation stitching is sewn with pitch which is

smaller than the normal stitching pitch. With this

function, thread raveling can be prevented and the

length of thread remaining on the material after

thread trimming can be shortened. The DDL-900BB

is provided with the condensation stitching function

(at the beginning and end of sewing).

* The condensation stitching function at the

end of sewing has been factory-enabled at the

time of shipment.

1) Tilt the machine head.

2) Set stitch dial ❶ at a scale mark so as to adjust

the condensation stitching pitch to a smaller val-

ue.

S type: Approx. 0.5mm. (0.3 to 0.5mm)

H type: Approx. 0.8mm. (0.8 to 1.0mm)

❶

1. In the case of performing the condensation stitching at the beginning of sewing, the AK (assistance function) and the NB cannot be used together simultaneously. As a substitute for the

AK (assistance function), decrease the pressure foot pressure or carry out any other appropriate operation.

2. The condensation stitching pitch at the beginning of sewing and that at the end of sewing can

only be set to a same value.

– 20 –

Page 23

❷

3) Loosen condensation stitching fulcrum screw ❷

(hexagon head screw).

4) Lower feed lever ❸. Push up condensation

❸

stitching solenoid ❹ to its stroke end by hand as

illustrated.

Turn condensation stitching fulcrum eccentric

shaft ❺ with a screwdriver until the screwdriver

stops rotating. At that position, x condensation

stitching fulcrum screw ❷ (hexagon head screw).

* After the adjustment, put a sheet of paper under

the presser foot, lower feed lever ❸ and press

❺

❹

condensation stitching solenoid ❹ until it is

brought to its stroke end by hand. In this state,

check the condensation stitching pitch amount by

turning the pulley (as a reference, sew about 10

stitches).

1. If the condensation pitch is decreased, the phenomenon where the needle enters the same

needle entry point will likely to occur, resulting in unstable formation of thread loop at the time

of thread trimming. As a result, thread trimming fault is likely to occur. It is therefore necessary to adjust the condensation pitch carefully. (The needle entry phenomenon differs according to the material to be sewn and the needle count, the pitch should be increased if thread

trimming failure occurs.)

2. The condensation operation should be turned OFF before thread trimming is performed at a

position where there is no material since thread loop formation at the time of thread trimming

becomes unstable.

In addition, the thread take-up spring stroke should be adjusted to be slightly larger.

3. In the case of using condensation stitching at the beginning of sewing, the condensation

stitch pitch and the normal stitch pitch cannot be changed over with accuracy, resulting in the

employment of the medium stitch pitch between them, if the sewing machine starts sewing at

a high speed.

To carry out sewing with the correct stitch pitches, increase the number of condensation

stitches at the beginning of sewing by two stitches and set the soft-start sewing speed to 400

sti/min or less.

– 21 –

Page 24

27-3. How to adjust the number of condensation stitches

* The number of condensation stitches can be

set to 0 to ve.

1. Turn the power ON while keeping switch

held pressed.

The indication on the display section is changed

to "n. ".

The numeric character displayed on the right side

of "n. " represents the function setting number.

2. Press and switches ❾ to change the num-

❾

❾'

⇩

⇩

4. Press and switches ❾ and change the set value (the number of stitches).

Example: "0" (the condensation stitching function is placed in OFF)

ber of function setting.

(No. 18 for setting the number of condensation

stitches at the end of sewing, or No. 16 for setting

the number of condensation stitches at the begin-

ning of sewing)

* and switches ❾' (two switches on the

left) are used for changing the number in the

"fast-feed" mode.

3. Press switch to change the setting.

The indication is changed to the set value. (The

default value has been set to "2" (two stitches).

5. Press switch to conrm the set value.

6. The display returns to the state described in 1.

To additionally change the set value for other function setting numbers, repeat the steps of procedure from 2.

7. When you have completed the set value changing, press switch . The sewing machine is restored

to its normal sewing state.

28. Pedal pressure and pedal stroke

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

(1) Adjusting the pressure required to

depress the front part of the pedal

1) This pressure can be changed by changing the

❷

❶

❸

(3) Adjusting the pedal stroke

1) The pedal stroke increases when you insert

connecting rod ❸ into the right hole.

– 22 –

mounting position of pedaling pressure adjust

spring ❶.

2) The pressure decreases when you hook the

spring on the left side.

3) The pressure increases when you hook the

spring on the right side.

(2) Adjusting the pressure required to

depress the back part of the pedal

1) This pressure can be adjusted using regulator

screw ❷.

2) The pressure increases as you turn the regulator

screw in.

3) The pressure decreases as you turn the screw

out.

Page 25

29. Adjustment of the pedal

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

❶

❷

❺

(1) Installing the connecting rod

1) Move pedal ❸ to the right or left as illustrated

by the arrows so that motor control lever ❶ and

connecting rod ❷ are straightened.

(2) Adjusting the pedal angle

1) The pedal tilt can be freely adjusted by changing

the length of the connecting rod ❷.

2) Loosen adjust screw ❹, and adjust the length of

connecting rod ❺.

❹

30. Marker dots on the handwheel

❶

(Blue)

❷

(Green)

❸

❸

Check the marker dots on the handwheel with the

presser foot lifted after thread trimming.

・ The upper stop position of the needle bar is

reached when marker dot ❶ on the cover is

aligned with blue marker dot ❷ on the handwheel.

・ The operating timing of the thread trimming cam

is when marker dot ❶ on the cover is aligned with

green marker dot ❸ on the handwheel.

– 23 –

Page 26

III. FOR THE OPERATOR

1. Operating procedure of the sewing machine

❶

❸

1) Lightly press the power switch ❶ by hand to turn

the power ON. Power switch ❶ is in the ON state

when the "I" mark side is pressed. It is in the OFF

state when the "○" side is pressed.

1. Do not strongly tap the power switch

by hand.

1

2

0

3

4

* The mounting location

and shape of the power

switch ❶ differs with the

place of destination.

2. If the power indicator LED on the

panel does not light up after having

turned ON the power switch ❶, im-

mediately turn OFF the power switch

❶ and check the supply voltage. In

addition, in such a case as this, re-

turn ON the power switch when 2 to

3 minutes or more have passed after

turning OFF the power switch ❶.

2) When the power switch ❶ is turned ON, the

❶

(For CE)

sewing machine automatically turns to bring the

needle bar to its UP position in the case the needle bar is not in that position.

❹

When turning ON the power, the needle

bar moves. Do not put your hands or

things under the needle.

❷

3) The pedal is operated in the following four steps:

a. The machine runs at low sewing speed when you lightly depress the front part of the pedal. ❷

b. The machine runs at high sewing speed when you further depress the front part of the pedal. ❷

(If the automatic reverse feed stitching has been preset, the machine runs at high speed after it completes reverse feed stitching.)

c. The machine stops (with its needle up or down) when you reset the pedal to its original position.

d. The machine trims threads when you fully depress the back part of the pedal. ❹

* When the auto-lifer (AK device) is used, one more operating switch is provided between the sewing ma-

chine stop switch and thread trimming switch. The presser foot goes up when you lightly depress the back

part of the pedal ❸, and if you further depress the back part ❹, the thread trimmer is actuated.

❺

❻

A

4) Reverse feed stitching at the beginning of sewing,

reverse feed stitching at the end of sewing and

various sewing patterns can be set on built-in panel

❺ of the machine head.

– 24 –

5) When one-touch type reverse feed switch ❻ is

pressed, the sewing machine performs reverse

feed stitching.

Page 27

6) When you have nished sewing, conrm rst that the sewing machine has stopped. Then, press power

switch ❶ to turn the power OFF.

1. Do not place your hands under the lever (section A in the gure) in the case of operating the

one-touch type reverse feed switch or of automatic reverse feed.

2. In the case the machine is not used for a long time, remove the power plug from the plug

receptacle.

2. Setting procedure of the machine head

* This item has been factory-adjusted at the time of shipment. Carry out the machine head setting procedure

in the case the control box is replaced, or in any case where it is necessary.

1) Refer to "III-6. Setting of functions" p.30 and

call the function setting No. 95.

❾

2) Press switch .

3) Select the machine head type by pressing

and switches ❾

Display

9bbS DDL-900BB S

9bbH DDL-900BB H

.

Machine head type

4) After the selection of the type of the machine

head, press switch to conrm the se-

lection. The settings are automatically initialized

according to the type of the machine head.

– 25 –

Page 28

3. Operation panel built in the machine head

Ⓒ Ⓔ❸ ❺

Ⓐ

❶

Ⓓ

Ⓑ

❷

❹

❾

Used to change over the automatic reverse

❶

❷

❸

❹

❺

❻

❼

❽

feed stitching at the beginning of sewing

between enable and disable.

Used to change over the automatic reverse

feed stitching at the end of sewing between

enable and disable.

Used to change over the automatic double

reverse feed stitching at the beginning of

sewing between enable and disable.

Used to change over the automatic double

reverse feed stitching at the end of sewing

between enable and disable.

Used to change over the reverse feed

stitching pattern between enable and

disable.

Used to change over the overlapped stitch-

ing pattern between enable and disable.

Used to change over the constant-dimen-

sion stitching pattern between enable and

disable.

Display section A

❾

Ⓖ

❼

Ⓕ

❻

Ⓗ

❽

Used to change the contents displayed

on the display section.

Used to carry out compensating stitch-

ing in half-stitch steps.

Used to change over the one-shot

automatic stitching between enable and

disable.

Used to change over the soft-start func-

tion between enable and disable.

Used to change over the needle bar

stop position at the time of stopping

sewing between up and down.

Used to change over the thread trim-

ming operation between enable and

disable.

Used to change over the operation

mode to the function setting mode.

Used to conrm the settings changed

under the function setting mode.

– 26 –

Page 29

4. Operating procedure of the sewing pattern

Refer to the Instruction Manual for each operation panel for how to operate sewing patterns us-

ing other operation panel than the built-in panel of the machine head.

(1) Reverse feed stitching pattern

Reverse feed stitching at sewing start and reverse feed stitching at sewing end can be separately pro-

grammed.

[Setting procedure of the reverse feed stitching]

1) Effective/ineffective of the reverse feed stitching

pattern can be changed over by pressing

switch ❺.

When the reverse feed stitching pattern is en-

Ⓖ

❼

Ⓕ

❻

Ⓗ

❽

abled, LED Ⓔ lights up and the display section

A shows the number of reverse feed stitches at

the beginning of sewing and that at the end of

sewing.

Use and switches ❾ to change the num-

ber of stitches for the target process (A, B, C or

D). (The number of stitches that can be set is 0 to

15.)

The numbers of stitches for processes A, B, C

and D are displayed on display section A from

left to right in the order from A to D.

❶

❷

❹

Display section A

❸

❾

❺Ⓔ

2) Enable/disable of the reverse feed stitching at the beginning of sewing is set by pressing switch ❶.

Enable/disable of the reverse feed stitching at the end of sewing is set by pressing switch ❷.

Enable/disable of the double reverse feed stitching at the beginning of sewing is set by pressing

switch ❸.

Enable/disable of the double reverse feed stitching at the end of sewing is set by pressing switch ❹.

The number which exceeds 9 is indicated as follows:

A = 10, b = 11, c = 12, d = 13, E = 14, and F = 15.

(2) Overlapped stitching pattern

Overlapped stitching pattern can be programmed.

A

B

C

B

D

C

A : Number of stitches of normal stitching setting : 0 to 15 stitches

B : Number of stitches of reverse stitching setting : 0 to 15 stitches

C : Number of stitches of normal stitching setting : 0 to 15 stitches

D : Number of times of repetition : 0 to 15 times

1. When process D is set to 5 times, the sewing is repeated as

A → B → C → B → C.

2. The number which exceeds 9 is indicated as follows:

A = 10, b = 11, c = 12, d = 13, E = 14, and F = 15.

[Setting procedure of the overlapped stitching]

1) Effective/ineffective of the overlapped stitching pattern can be changed over by pressing switch ❻.

When the overlapped stitching pattern is rendered effective, LED Ⓕ lights up.

2) Press and switches ❾ to change the number of stitches for target process (A, B, C or D).

– 27 –

Page 30

(3) Constant-dimension stitching pattern

The constant-dimension stitching pattern can be set.

[How to set the constant-dimension stitching]

• Straight stitching

1) Press switch ❼ to select the constant-dimension sewing pattern.

When the constant-dimension stitching pattern is enabled, LED Ⓖ lights up.

2) When the constant-dimension sewing pattern is selected, the number of stitches of process E can be set

by pressing switch ❼ again.

3) The number of stitches (0 to 999) for the constant-dimension stitching can be selected by pressing

and switches ❾.

• Label sewing

1) Press switch ❽ to select the label sewing.

When the selection is effective, LED Ⓗ lights up.

Every time switch ❽ is pressed, the indication of processes E to H will be changed over.

2) Display the target process the number of stitches of which is to be changed. In this state, the number of

stitches of the processes (E, F, G or H) can be changed by pressing and switches ❾.

– 28 –

Page 31

5. One-touch setting

A part of function setting items can be easily changed in the normal sewing state.

Keep switch held pressed (for two seconds

or more) to carry out setting.

* If the indication shown on the screen does not

change, keep the switch held pressed again.

❾

[Setting items]

SPd ( )

When function setting No. 20 is set at "0": nip ( )

When function setting No. 20 is set at "1" : Wip ( )

TrM ( )

n. ( )

[Setting procedure (example: WiP)]

1) Press and switches ❾ to select the setting item. (Example: WiP)

2) Press switch . The current set value is displayed. (Example: on)

Sewing speed

Thread clamp (wiper) operation : ON/OFF

Thread trimming operation after one-shot automatic stitch-

ing: ON/OFF

Function setting

3) Press and switches ❾ to change the set value. (Example: oFF)

4) Press switch to conrm the set value.

5) Press

1. In the case the function setting (n.) is selected, operation using switch cannot be

carried out. Once the setting of the function setting is nished, press switch to

nish setting. (Refer to "III-6. Setting of functions" p.30 for further details about setting of

functions.)

2. Once the power switch is turned off, be sure to wait for ten seconds or more before turning

it on again. If the power is re-turned on immediately after it has been turned off, the sewing

machine may not operate normally. In such a case, turn the power on again correctly.

switch to nish the one-touch setting.

– 29 –

Page 32

6. Setting of functions

Set value for the function setting can be changed.

'

❾

❾

1) Turn the power ON while keeping switch

held pressed.

The indication on the display section is changed

to "n. ".

The numeric character displayed on the right side

of "n." represents the function setting number.

(The gure shows the case of "No. 96 Maximum

sewing speed".)

2) Press and switches ❾ to change the

number of function setting.

and switches ❾' (two switches on

the left) are used for changing the number

in the "fast-feed" mode.

3) Press switch to change the setting.

The indication is changed to the set value.

(The gure shows the case where the set value is

changed from the indication "n.96" to "4000" (set

⇩

❾

value) by pressing switch .)

4) Press and switches ❾ to change the set

value.

5) Press switch to conrm the set value.

6) The display returns to the state described in 1).

To additionally change the set value for other

function setting numbers, repeat the steps of

procedure from 2).

When you have completed the set value

changing, press switch . The sewing

machine is restored to its normal sewing state.

– 30 –

Page 33

7. Production support function

The production support function enables "sewing counting", "bobbin-thread counting" and "number of

stitches counting".

Ⓒ

Ⓐ

Ⓓ

Ⓑ

Ⓔ

Ⓕ

Ⓖ

1) When switch is pressed while the sew-

ing machine is in the sewing state, the product

support function is invoked.

At this time, LEDs Ⓐ, Ⓑ, Ⓒ and Ⓓ light up.

2) Every time switch is pressed, the

function display will be changed over in the

order of the "sewing counting function", the

"bobbin-thread counting function", the "number

of stitches counting function" and the "sewing

state".

* Sewing counting function (LED Ⓔ lights up)

The value indicated on the counter is increased every time the preset number of times of thread trimming

is reached.

It is possible to prohibit the sewing machine from starting when the value indicated on the counter reach-

es the preset one, if desired.

* Bobbin thread counting function (LED Ⓕ lights up)

The number of stitches sewn is detected. The preset value indicated on the counter is subtracted accord-

ing to the detected number of stitches.

Once the value indicated on the counter becomes a negative value, the bobbin thread has to be replaced.

* Number of stitches counting function (LED Ⓖ lights up)

The number of stitches is counted from the start of sewing until thread trimming is carried out.

[Sewing counting function]

Display section A

Ⓒ

Ⓔ

1) Counted value is indicated on display section A.

2) The value on the counter can be changed by

Ⓐ

pressing and switches ❾.

3) The value on the counter is reset to 0 (zero) by

Ⓓ

Ⓑ

pressing switch .

4) The sewing counting function setting can be

changed by keeping switch held

pressed (for two seconds).

5) The function setting changing operation is n-

ished by pressing switch .

❾

The setting items which can be changed are as follows:

* No. 181 ..... Target number of products

* No. 182 ..... Operation to be carried out when the target number of products is reached

0 : No operation

1 : Sewing machine operation is disabled

When the value on the counter equals to the target number of products, the sewing ma-

chine will not run even if the pedal is depressed. At this time, the display automatically

changed to “sewing counter function”. To release the sewing machine from the disabled

state, the value on the counter is reset to 0 (zero) by pressing switch .

* No. 183 ..... The number of times of thread trimming to be carried out during one sewing sequence

The number of times of thread trimming for stopping the sewing counter is set.

– 31 –

Page 34

[Bobbin thread counting function]

Ⓒ

Ⓐ

Ⓓ

Ⓑ

❾

[Number of stitches counting function]

Ⓒ

Ⓐ

Ⓓ

Ⓑ

Ⓕ

Ⓖ

1) Operate this function in the state where sewing is

nished.

The value on the counter cannot be changed if

thread trimming has not been carried out.

2) The value on the counter is reset to the initial

value by pressing switch .

3) In this state, the initial value can be changed by

pressing and switches ❾.

1) The number of stitches is automatically counted

from the start of sewing until thread trimming is

carried out.

2) Once thread trimming is carried out, the value on

the counter is reset to 0 (zero).

– 32 –

Page 35

8. Function setting list

No. Item Description Setting range Default

1 Soft start function The number of stitches to be sewn at a low speed when the soft-start

2 Material end sensor

function

3 Thread trimming

function by material end

sensor

4 Number of stitches for

material end sensor

5 Flicker reducing function Flicker reducing function

* 7 Unit of bobbin thread

counting down

* 8 Sewing speed of re-

verse feed stitching

12 Optional switch function

selection

function is used at the start of sewing.

(* This setting is enabled when the thread clamp function is in the OFF

state.)

0 : The function is not selected.

1 to 9 : The number of stitches to be sewn under the soft-start mode.

Material end sensor function.

0 : Material end detection function is not operative.

1 : After detecting material end, the specied number of stitches (No. 4)

will be sewn, and the sewing machine will stop.

Thread trimming function by material end sensor.

0 : Automatic thread trimming function after detection of material end is

not operative.

1 : After detecting material end, the specied number of stitches (No.

4) will be sewn, and the sewing machine will stop and perform automatic thread trimming.

Number of stitches for material end sensor.

Number of stitches from detection of material end to stop of the sewing

machine.

0 : Flicker reducing function is not operative.

1 : Flicker reducing function is effective.

Unit of bobbin thread counting down

0 : 1 Count/10 stitches

1 : 1 Count/15 stitches

2 : 1 Count/20 stitches

Sewing speed of reverse feed stitching is set.

Switching of function of optional switch.

0 to 9

(Stitches)

0/1

0/1

0 to 19

(Stitches)

0/1

0 to 2

150 to 3,000

(sti/min)

1 9 0 0

o P T _

Ref.

page

37

1

0

0

5

37

0

0

37

* 13 Function of prohibiting

start of the sewing machine by bobbin thread

counter

15 Thread clamp function

at the start of sewing

20 Changeover between

thread clamp and thread

wiper

21 Function of automatic

presser foot lifting at

pedal's neutral position

22 Needle up/down correc-

tion switch changeover

function

25 Thread trimming oper-

ation after turning the

handwheel by hand

* 27 Thread clamp sewing

speed

29 Back-tack initial opera-

tion time

30 Function of reverse feed

stitching on the way

31 Number of stitches of

reverse feed stitching on

the way

32 Effective condition of

reverse feed stitching on

the way when the sewing machine is stopping.

* Do not change the set values with asterisk (*) mark as they are functions for maintenance. If the standard set value set at the time of

delivery is changed, it is in danger of causing the machine to be broken or the performance to be deteriorated. If it is necessary to

change the set value, please purchase the Engineer’s Manual and follow the instructions.

Function of prohibiting start of the sewing machine by bobbin thread

counting

0 : When counting is out (-1 or less) Function of prohibiting start of the

sewing machine is not operative.

1 : When counting is out (-1 or less) Function of prohibiting start of the

sewing machine after thread trimming is operative.

2 : When counting is out (-1 or less), the sewing machine stops once.

Function of prohibiting start of the sewing machine after thread

trimming is operative.

Operation of the thread clamp or of the wiper at the start of sewing is set.

0 : Thread clamp does not operate

1 : Thread clamp operates

This function item is used for changing over the operation of the thread

clamp and the thread wiper.

0 : Thread clamp operates

1 : Thread wiper operates

Function of lifting presser foot when the pedal is in neutral position.

0 : Function of neutral automatic presser lifting is not operative.

1 : Selection of function of neutral presser lifting.

Function of the needle up/down correction switch is changed over.

0 : Needle up/down compensation

1 : One stitch compensation

Thread trimming operation after moving the needle away from its upper

or lower position by turning the handwheel by hand is specied.

0 : Thread trimming operation is carried out after turning the handwheel

by hand.

1 : Thread trimming operation is not carried out after turning the hand-

wheel by hand.

The sewing speed when the thread clamp operates is set.

This function sets the suction time of initial motion of back-tack solenoid.

Function of reverse feed stitching on the way

0 : Normal one-touch type reverse feed stitching function

1 : Function of reverse feed stitching on the way is operative.

(In the case the function of reverse feed stitching on the way is enabled,

function No. 26 cannot be used.)

Number of stitches of reverse feed stitching on the way

Effective condition of reverse feed stitching on the way

0 : Function is not operative when the sewing machine stops.

1 : Function is operative when the sewing machine stops.

0 to 2

0/1

0/1

0/1

0/1

0/1

100 to MAX

(sti/min)

50 to 500

(ms)

0/1

0 to 19

(Stitches)

0/1

0

1

1

0

0

1

3 0 0

2 5 0

0

4

0

41

41

41

41

41

– 33 –

Page 36

No. Item Description Setting range Default

33 Thread trimming

function by reverse feed

stitching on the way

* 35 Sewing speed at a low

speed

* 36 Sewing speed of thread

trimming

37 Sewing speed of soft-

start

38 Sewing speed of one-

shot stitching

* 39 Operation-start pedal

stroke

* 40 Low speed section of

pedal

* 41 Starting position of lifting

presser foot by pedal

* 42 Starting position of

lowering presser foot

* 43 Pedal stroke 2 for start-

ing thread trimming

* 44 Pedal stroke for

reaching the maximum

sewing speed

* 45 Corrected neutral posi-

tion of the pedal

47 Auto-lifter selecting

function

* 48 Pedal stroke 1 for start-

ing thread trimming

49 Lowering time of presser

foot

* 50 Pedal specication Type of pedal is selected.

51 Compensation of

solenoid-on timing of

reverse feed stitching at

the start of sewing

52 Compensation of

solenoid-off timing of

reverse feed stitching at

the start of sewing

53 Compensation of

solenoid-off timing of

reverse feed stitching at

the end of sewing

55 Foot lift after thread

trimming

56 Reverse revolution to lift

the needle after thread

trimming

58 Function of holding

predetermined upper/

lower position of the

needle bar

59 Function of Auto/Manual

change-over of reverse

feed stitching at the start

of sewing

* Do not change the set values with asterisk (*) mark as they are functions for maintenance. If the standard set value set at the time of

delivery is changed, it is in danger of causing the machine to be broken or the performance to be deteriorated. If it is necessary to

change the set value, please purchase the Engineer’s Manual and follow the instructions.

Thread trimming function by reverse feed stitching on the way

0 : Automatic thread trimming function after completion of reverse feed

stitching on the way is not operative.

1 : Automatic thread trimming after completion of reverse feed stitching

on the way is performed.

Lowest speed by pedal (The MAX value differs by machine head.)

Thread trimming speed (The MAX value differs by machine head.)

Sewing speed at the start of sewing (soft-start) (The MAX value differs by

machine head.)

Sewing speed of one-shot stitching (The MAX value differs by machine

head.)

The pedal position at which the sewing machine starts operation from the

neutral position of the pedal (Pedal stroke)

Position where the sewing machine starts accelerating from pedal neutral

position (Pedal stroke)

Position where the cloth presser starts lifting from pedal neutral position

(Pedal stroke)

Starting position of lowering presser foot

Stroke from the neutral position

Position 2 where the thread trimming starts from pedal neutral position

(When the function of lifting presser foot by pedal is provided.) (Pedal

stroke)

Position where the sewing machine reaches its highest sewing speed

from pedal neutral position (Pedal stroke)

The neutral position of the pedal sensor is set.

Limitation time of waiting for lifting solenoid type auto-lifter device

Position where thread trimming starts from pedal neutral position (Standard pedal) (Pedal stroke)

Sets the time required until the lowering of the presser foot is completed

after a depress on the pedal.

0 : Presser foot is not operated by the pedal (KFL)

1 : Presser foot is operated by the pedal (PFL)