Page 1

R

HIGH-SPEED 1-NEEDLE LOCKSTITCH MACHINE WITH

AUTOMATIC THREAD TRIMMER

DDL-9000

ENGINEER’S MANUAL

29338001

No.00

Page 2

PREFACE

This Engineer’s Manual is written for the technical personnel who are responsible for the service and maintenance of

the machine.

The Instruction Manual for this machine intended for the maintenance personnel and operators at an apparel factory

contains operating instructions in detail. And this manual describes “Standard Adjustment, “Adjustment Procedures”,

“Results of Improper Adjustment”, and other important information which are not covered in the Instruction Manual.

It is advisable to use the relevant Instruction Manual and Parts List together with this Engineer’s Manual when carrying

out the maintenance of this machine.

Page 3

CONTENTS

1. OUTLINE .................................................................................................................................1

1-1 Features.........................................................................................................................................................1

1-2 Specifications (Table of DDL-9000 series specifications) ........................................................................2

1-3 Application ....................................................................................................................................................4

1-4 Cautions when operating.............................................................................................................................4

2. OPERATION............................................................................................................................5

2-1 Configuration ................................................................................................................................................5

2-2 Check points before trial operation and operation ................................................................................... 5

3. CONFIGURATION...................................................................................................................9

3-1 Adjusting the needle stop position.............................................................................................................9

3-2 Adjusting the wiper (WB type).....................................................................................................................9

3-3 Principle of thread trimming......................................................................................................................10

3-4 Sequence of thread trimming ....................................................................................................................10

3-5 Observing and adjusting the thread trimmer cam timing.......................................................................12

3-6 Adjusting the position of moving knife movement .................................................................................13

3-7 Properly installing the counter knife ........................................................................................................ 15

3-8 Rising amount of the thread tension disk No. 2 ......................................................................................16

3-9 Sharpening the knife blade........................................................................................................................16

3-10 Replacing the moving knife ..................................................................................................................... 17

3-11 Replacing the thread guide for knife ......................................................................................................18

3-12 Adjusting the thread take-up picker .......................................................................................................18

3-13 Adjusting the clutch plate and the thread trimmer solenoid................................................................19

3-14 Driving arm stopper..................................................................................................................................19

3-15 Installing/removing the knife installing base .........................................................................................20

3-16 Adjusting the position of the touch-back switch...................................................................................21

3-17 Adjusting the position of the handwheel ............................................................................................... 21

3-18 Adjusting the automatic presser lifter (AK118) .....................................................................................21

3-19 Optionals (Presser foot micro-lifter) ....................................................................................................... 25

3-20 AE-8 (Bobbin thread remaining amount detector) ................................................................................25

3-21 ED-4 (Compact material end sensor)......................................................................................................25

3-22 PK-70 and -71 (3-step pedal)....................................................................................................................25

3-23 Adjusting the tension release change-over ...........................................................................................26

3-24 Adjusting the presser foot micro-lifter ...................................................................................................26

3-25 Installing the operation panel..................................................................................................................26

3-26 Dimensions of table..................................................................................................................................27

3-27 Points of adjustment and assembly of the feed mechanism ............................................................... 28

3-29 Points of adjusting and assembling the thread take-up and the needle bar mechanism .................34

3-29 Replacing the motor ................................................................................................................................. 35

3-30 Replacing the timing belt ......................................................................................................................... 35

3-31 Points of adjusting and assembling of the bobbin winder...................................................................36

3-32 Points of adjusting and assembling of the lubrication mechanism (SS, SH) .....................................37

3-33 Applying the exclusive grease ................................................................................................................38

3-34 Removing/attaching the gear box cover ................................................................................................39

3-35 Points of adjuting the sewing..................................................................................................................40

3-36 Adjusting the amount of oil in the hook ................................................................................................. 42

4. TROUBLES AND CORRECTIVE MEASURES (MECHANICAL PARTS)............................ 44

5. TROUBLES IN SEWING AND CORRECTIVE MEASURES ................................................50

6. BOBBIN CASE WITH IDLE-PREVENTION SPRING ........................................................... 60

* For the control box and the operation panel, read the Instruction Manual for the SC-900.

Page 4

1. OUTLINE

1-1 Features

1) Different from the conventional sewing machines with oil pan type, this machine has no oil reservoir and stain

of the materials and oil stain when performing maintenance or moving the machine do not occur.

2) For DS type, an exclusive complete dry hook is employed and there is no oil tank. It is possible to completely

protect the sewing materials from oil stain.

3) A compact AC servomotor is built in the machine head. It is not necessary to fix the belt on the machine head

when setting up the machine, and to perform adjustment as before. In addition, there is no stain from the worn

powder of V-belt.

4) Workability such as handling of materials, easy-to observe needle entry area, etc. is taken seriously. Sewing

space is enough expanded.

5) Noise and vibration when sewing are decreased to improve the sewing environment and to decrease the

operator’s burden.

6) Smooth feeding of materials has been obtained by the improvement of feed dog and thread take-up lever. As

a result, low-tension sewing has been realized.

7) Calibration markings have been added to the respective adjusting sections such as presser spring regulator

and so on considering adjusting operations.

8) The superior portions of JUKI existing lockstitch machines with automatic thread trimmer have been succeeded

to the operation panel and the control box of these machines, and reliability and easy operability have been

improved.

−1 −

Page 5

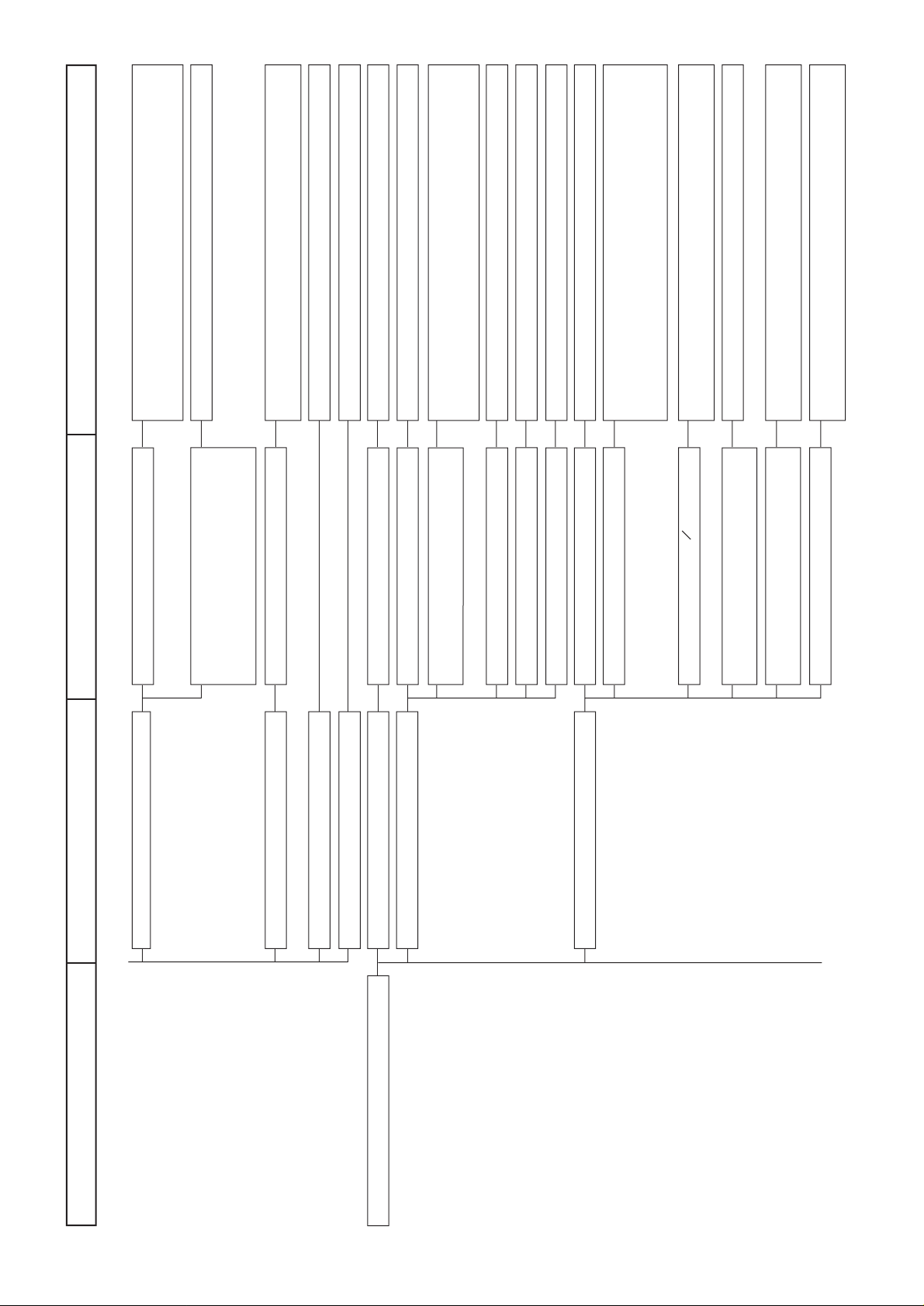

1-2 Specifications (Table of DDL-9000 series specifications)

SS (Minute-quantity lubrication type)

1

Max. sewing speed

2

Bed size

3

Number of revolution of resistor pack

4

Max. stitch length (normal/reverse

feed)

5

Needle bar stroke

6

Thread trimming system

7

Bobbin winder

8

Wiper (WB only)

9

Automatic reverse feed

10

Lubrication system

11

No. of needle used

12

Lift of presser foot (knee lifter)

13

Throat plate

14

Feed dog (Part No.)

15

Presser foot (standard)

16

Kind of hook (Part No.)

17

Part No. of needle bar

18

Thread tension (asm.) (Part No.)

19

Thread take-up spring

20

Thread tension spring

21

Presser spring

22

Bobbin case asm.

23

Bobbin

24

Feed dog height (reference)

25

Lubrication of needle bar

26

Drive system

27

Transmission mechanism

28

Motor output

29

Power supply

30

Solenoid drive power source

31

Additional function

32

Device/optional

* 4,000 rpm or less when stitch length is 4 mm

or more and RP hook is used.

4,000 rpm (excluding a part of export territory)

Built-in at top surface of machine head type

(with bobbin thread retainer)

Side sweeping type driven by solenoid

Lubricating to oil tank for hook lubrication

Use New Defrix Oil No. 1.

By plunger pump

Equivalent to DB X 1 #9 to 18 (Equivalent to

SCHMETZ Nm65 to 110)

10 mm (max. 15 mm, AK : max. 10 mm)

Standard : 3-row 11028008

Export standard : 4-row B1109012i0B

B1613012A00 (3-row feed dog),

B1613012i00 (4-row feed dog)

B15240120BA (excluding a part of export

territory)

Lubrication hook (11038650)

Lubrication hook with needle guard

(11141355)

For DB X 1 (11035003)

FOR SCHMETZ (11141207)

Standard with calibration markings (23626054)

11038759 (standard with spring)

B9117552A00 (aluminum)

For export B911701200 (iron)

0.75 to 0.85 mm (standard)

Minute-quantity lubrication by oil wick

Built-in compact AC servomotor

3-phase 200V, single phase 100V

Micro-lifter screw is provided as standard.

Tension release reset function when sewing

thick overlapped section

AK-118 (window plate type auto-lifter)

AE-8 (bobbin thread remaining amount

detector)

ED-4 (compact material end detector)

Dial micro-lifter

Turret presser (existing one can be used.)

Optional switch (23632656)

Exclusive grease for maintenance

500g tin (Part No. 23640204)

5,000 rpm

178 mm X 517 mm

5 mm

30.7 mm

Horizontal type

Built-in solenoid type

(with engraved marker line)

Standard (22921605)

Standard (22921704)

Standard (B1505227000A)

Timing belt system

Rated output 450W

DC 34V

DS (dry-head type)

4,000 rpm

←

←

←

←

←

←

←

←

Oil tank is not provided (complete

nonlubrication).

←

←

←

←

←

RP hook (22890206)

RP hook with needle guard (22890404)

For DB X 1 (22886907)

For SCHMETZ (22887004)

←

←

←

←

22896252 (with spring for dry-head)

←

←

Nonlubrication

←

←

←

←

←

←

←

←

AE-8 (bobbin thread remaining amount

detector)

* Replace with existing RP hook (11079456).

This device can be used only when sewing

speed is 3,000 rpm or less.

←

←

←

←

←

−2 −

Page 6

(Table of DDL-9000 series specifications)

DF

(for extra-light-weight materials, foundation)

1

Max. sewing speed

2

Bed size

3

Number of revolution of resistor pack

4

Max. stitch length (normal/reverse

feed)

5

Needle bar stroke

6

Thread trimming system

7

Bobbin winder

8

Wiper (WB only)

9

Automatic reverse feed

10

Lubrication system

11

No. of needle used

12

Lift of presser foot (knee lifter)

13

Throat plate

14

Feed dog (Part No.)

15

Presser foot (standard)

16

Kind of hook (Part No.)

17

Part No. of needle bar

18

Thread tension (asm.) (Part No.)

19

Thread take-up spring

20

Thread tension spring

21

Presser spring

22

Bobbin case asm.

23

Bobbin

24

Feed dog height (reference)

25

Lubrication of needle bar

26

Drive system

27

Transmission mechanism

28

Motor output

29

Power supply

30

Solenoid drive power source

31

Additional function

32

Device/optional

3,500 rpm (excluding a part of export territory)

Built-in at top surface of machine head type

(with bobbin thread retainer)

Side sweeping type driven by solenoid

Oil tank is not provided (complete

nonlubrication).

Equivalent to DB X 1 #8 to 11 (Equivalent to

SCHMETZ Nm65 to 75)

Equivalent to DB X 1SF #9 to 11

10 mm (max. 15 mm), AK : max. 10 mm

Standard : 4-row 11001906 (with engraved

marker line)

Export standard : 4-row B1109012i0B

B1613155W00 (4-row feed dog),

B1613012i00 (4-row feed dog)

B1524555DBB (excluding a part of export

territory)

RP hook (22890206)

Hook with needle guard (22890404)

For DB X 1 (22886907)

For SCHMETZ (22887004)

For light-weight materials with calibration

markings (23627250)

Micro-lifter screw is provided as standard.

Tension release reset function when sewing

thick overlapped section

AK-118 (window plate type auto-lifter)

AE-8 (bobbin thread remaining amount

detector)

* Replace with existing RP hook (11079456).

This device can be used only when sewing

speed is 3,000 rpm or less.

ED-4 (compact material end detector)

Turret presser (existing one can be used.)

Exclusive grease for maintenance

500g tin (Part No. 23640204)

178 mm X 517 mm

Built-in solenoid type

Low tension (D3128555D00)

Low tension (D3129555D00)

Extra low tension (11162104)

22896252 (with spring for dry-head)

B9117552A00 (aluminum)

0.75 to 0.85 mm (standard)

Built-in compact AC servomotor

Timing belt system

Rated output 450W

3-phase 200V, single phase 100V

Optional switch (23632656)

3,500 rpm

4 mm

30.7 mm

Horizontal type

Nonlubrication

DC 34V

Dial micro-lifter

SH for heavy-weight material)

4,500 rpm

(4,000 rpm or less when stitch length is 4 mm

or more.)

←

4,000 rpm

5 mm

35 mm

Moving knife for thick thread with bobbin thread

clamp

←

←

←

Lubricating to oil tank for hook lubrication. Use

New Defrix Oil No. 1. Plunger pump is used.

Equivalent to DB X 1 #19 to 23

(Equivalent to SCHMETZ Nm120 to 160)

←

Standard : 4-row 11400801

11403003 (4-row feed dog)

D1524555EBL

Lubrication hook (11092251)

H type (11091303)

For heavy-weight materials with calibration

markings (23626062)

Standard (22921605)

High tension (22962005)

High tension (B1505552000A)

11038759 (standard with spring)

B9117012000 (iron)

1 to 1.2 mm (standard)

Minute-quantity lubrication by oil wick

←

←

←

←

←

←

←

←

AE-8 (bobbin thread remaining amount

detector)

←

←

←

←

←

−3 −

Page 7

1-3 Application

1) Standard type (SS)

It is suited for the wide using range from light-weight general fabrics to medium- and heavy-weight fabrics.

(It is especially suited for the process for which a high speed revolution of the sewing machine is required or

the process for which hook lubrication is required in accordance with the nature of thread used.)

2) Dry type (DS)

It is suited for the wide using range from light-weight general fabrics to medium- and heavy-weight fabrics.

(It is most suited for the process of sewing newly developed materials in the market of ladies’ wear, shirts, silk,

coat, etc., or the complete dry process of light-weight fabric, etc. to which the oil stain is particularly disliked.

3) For hard-to-sew materials and foundation garment (DF)

It is suited for the process for which handling performance under low speed and low pressure of presser foot

is particularly required when sewing foundation garment or the like.

(Particularly, this type is effective for the assembly process of brassieres or the like, or sewing hard-to-sew

materials. It is suited for the process for which handling at low speed is required.)

4) For heavy-weight materials (SH)

It is suited for sewing heavy-weight materials such as denim, vinyl leather, etc.

1-4 Cautions when operating

1) Be sure to drain oil from oil tank and attach the air vent cap (red rubber cap) attached to the air vent (gold

bushing) located on the side of machine bed when transporting the sewing machine.

2) When placing the SS or SH type sewing machine head on a stand or the like before setting up the sewing

machine head on the table, take care whether there is a protrusion under the machine head to protect the oil

tank from damage.

3) Even when using RP hook with the SS type machine, do not drain oil from oil tank. (Seizure of hook shaft

metal will result.)

In addition, when using the RP hook, loosen the oil amount adjusting screw until it will go no further and adjust

so that oil does not come out from the front of hook shaft.

4) To protect accident when performing maintenance, be sure to securely set the safety switch connector to the

control box.

5) Oil is kept in the gear box for lubrication. Replacement of oil is not necessary. Do not remove the lid of gear

box unless it is necessary.

* When the lid of the box has been removed, it is necessary to replace the packing with a new one.

6) When making the sewing machine run idle, be sure to operate the sewing machine after removing the bobbin

case.

When the bobbin thread is in the bobbin case, the thread is protruded from the bobbin case by running idle of

the machine and the thread is entangled in hook race or hook shaft. As a result, the machine will be out of

order.

−4 −

Page 8

2. OPERATION

2-1 Configuration

(9)

(12)

(8)

(13)

(16)

(2)

(6)

(4)

(19)

(3)

(10)

(11)

(14)

(1)

(17)

(18)

(15)

(7)

Fig. 1

(5)

(1) Power switch (8) Touch-back switch (14) Tension release change-over screw

(2) Operation panel (9) Wiper device (15) Micro-lifter screw

(3) Pulley cover (10) Screw for level adjustment (16) Under cover

(4) Thread stand of table/stand (Caster) (17) Oil hole

(5) PSC box (11) Resistor pack (18) Air vent

(6) Max. speed control knob (12) Bobbin winder

(19) Oil amount indication window (SS, SH)

(7) Operation pedal (13) Thread trimmer retainer

2-2 Check points before trial operation and operation

1) Make sure that the wiring to the control box is securely performed.

2) Make sure that the safety switch securely works. (Check whether the warning buzzer beeps when the sewing

machine head is tilted.)

3) Check that the red rubber cap of air vent (17) located on the front side of machine bed has been removed.

4) First, make the sewing machine run at low speed and check that there is no abnormal noise.

5) Depress the back part of the pedal and check that the thread trimmer securely functions.

6) For the SS type, check that oil is kept in oil tank.

7) For the SS type, check that the amount of oil in the hook is appropriate.

−5 −

Page 9

(1) Power switch

Power switch for motor, PSC, operation panel, etc.

(2) Operation panel

This panel can set automatic reverse feed stitching, pattern sewing, etc.

(3) Pulley cover

This is a cover for safety and prevents dust which enters inside motor.

(4) Thread stand

(5) PSC box

Circuits to control the sewing machine and motor, output circuits to function the respective outputs (thread

trimmer solenoid, back solenoid, etc.), pedal sensor to detect the pedal operation, and power circuits to function

the respective functions are stored in this box.

(6) Max. speed control knob (Max. speed limitation variable resistor)

This is a variable resistor to limit the maximum speed by analog.

(7) Operation pedal

Speed control of sewing machine, thread trimming operation or presser lifting operation (for AK-118 type only)

can be performed through the operation of depressing the front part or back part of the pedal.

(8) Touch-back switch

This is a hand operated switch to perform reverse feed stitching.

(9) Wiper device

Needle thread after thread trimming is wiped out by wiper signal output from the PSC box.

(10) Screw for level adjustment of table/stand (Caster)

Adjust the screw in accordance with the floor on which the operator works so that there is no play and less

vibration.

(11) Resistor pack

This is used to automatically identify the model of sewing machine used.

(12) Bobbin winder

This is a bobbin winder built in the machine hed.

(13) Thread trimmer retainer

This works to cut and retain bobbin thread wound with the bobbin winder.

(14) Tension release change-over screw

When handling the materials at the corner of thick overlapped section or the like by using the knee lifter, this

screw makes thread release work and prevents thread from partial defective thread tightness.

(15) Micro-lifter screw

When sewing hard-to-sew materials such as velvet or the like, sewing can be performed in a condition that

the presser foot is slightly lifted.

(16) Under cover

This cover prevents lint or dust which occurs at the time of sewing from falling on the floor.

(17) Oil hole

For the SS and SH types, when oiling into oil tank, use this hole after removing the cap.

(18) Air vent

This is used to prevent the inside pressure from being increased due to rise of tempearture in the gear box

when the sewing machine is operated.

(19) Oil amount indication window (SS, SH)

This indicates the oil amount in oil tank. Fill oil when the top end of indication rod comes to the lower engraved

marker line.

−6 −

Page 10

(Trial operation)

1) Operation when the power is turned ON

When turning ON the power switch, the sewing machine rotates up to the needle-up position excluding the

case where the needle position at that time is the position other than the up-stop position and stops at needleup position.

2) Pedal operation

Pedal can be operated in four steps.

High speed

Low speed

Stop

Thread

trimming

High speed

Low speed

Stop (neutral)

Thread trimming

Fig. 2

① The machine runs at low sewing speed when you lightly depress the front part of the pedal.

② The machine runs at high sewing speed when you further depress the front part of the pedal. (However, when

the automatic reverse feed stitching switch is preset, the machine runs at high speed after it completes reverse

feed stitching.)

③ The machine stops (with its needle up or down according to the set of stop position) when you reset the pedal

to stop (neutral).

④ The machine trims threads and stops with its needle up when you fully depress the back part of the pedal.

○ The machine will completely perform thread trimming even if you reset the pedal to its neutral position

immediately after the machine started thread trimming action.

At this time, if you depress the front part of the pedal instead of neutral, thread trimming is performed

normally. However, safety circuit works and the machine continues to stop after completing thread trimming.

At this time, return the pedal to the neutral position once.

○ Wiper works when the wiper is provided (WB type).

−7 −

Page 11

3) Pedal operation with the pedal type auto-lifter (AK118)

Pedal can be operated in five steps.

High speed

Low speed

Stop

Presser foot lifting

Thread trimming

High speed

Low speed

Stop (neutral)

Presser foot lifting

Thread trimming

Fig. 3

① The machine runs at low speed when you lightly depress the front part of the pedal.

② The machine runs at high speed when you further depress the front part of the pedal. (However, when the

automatic reverse feed stitching switch is preset, the machine runs at high speed after it completes reverse

feed stitching.)

③ The machine stops (with its needle down) when you reset the pedal to stop (neutral).

④ The presser foot goes up when you lightly depress the back part of the pedal.

⑤ If you furthrer depress the back part, the presser foot comes down and the thread trimmer is actuated. After

the machine has stopped with its needle up, the presser foot goes up.

○ Wiper works when the wiper is provided (WB type).

−8 −

Page 12

3. CONFIGURATION

3-1 Adjusting the needle stop position

1) Adjusting the upper stop position (Upper stop position

after thread trimming)

The standrad needle stop position is obtained, when

needle stops after thread trimming, by aligning the red

marker dot on the machine arm with the white marker

dot on the handwheel.

Stop the needle in its highest position, and loosen screw

(A) in the figure on the right to perform adjustment within

the slot of the screw.

○ To advance needle stop position → Direction (1)

○ To delay needle stop position → Direction (2)

2) Adjusting the lower stop position

The lower needle stop position when the pedal is

returned to the neutral position after the front part of

the pedal is depressed can be adjusted by loosening

screw (B) in the figure on the right and adjusting within

the slot of the screw.

○ To advance needle stop position → Direction (1)

○ To delay needle stop position → Direction (2)

[Caution] Do not rotate the machine with screws (A)

and (B) loosened.Just loosen the screws,

and do not remove them.

(2)

Fig. 4

(2)

Fig. 5

(1)

(A)

Handwheel

(1)

(B)

3-2 Adjusting the wiper (WB type)

1. Adjusting the wiper position

Adjust the wiper position in accordance with the thickness

of fabric to be sewn.

Normally, adjust it as follows :

1) Turn the handwheel in the normal direction to align white

marker dot (1) with marker dot (2) on the machine arm.

2) Insert wiper (3) into wiper shaft (4) so that a clearance

of 2 mm is provided between the top end of the wiper

and the top end of the needle. At this time, adjust so

that the distance from the flat section of the wiper to

the center of the needle is 1 mm. Securely fix the wiper

with wiper adjusting screw (5) as if pressing wiper (3)

with wiper collar (6) .

[Caution] Do not loosen the wiper solenoid setscrew.

When the wiper is not used, turn OFF the

wiper seesaw switch.

Wiper seesaw

switch

(4)

(3)

Fig. 6

1 mm

Fig. 7

2 mm

(2)

(1)

(6)

(5)

−9 −

Fig. 8

Page 13

3-3 Principle of thread trimming

1. Blade point of hook scoops needle thread.

Fig. 9

3. Moving knife catches needle and bobbin threads (advances).

Fig. 10

3-4 Sequence of thread trimming

Knife catches

Low speed to

high speed

Depress front part

of pedal

Depress back

part of pedal

Detection

Thread handling

Thread trimmer

solenoid is actuated.

2. Moving knife handles threads (recedes).

4. Thread trimming

thread.

End of tension release

Cam and roller are

disengaged.

Power

switch ON

Thread

trimming

Up-stop

signal

Thread trimmer solenoid OFF

Sewing machine stops

with needle up.

Needle goes up.

Reverse feed stitching at

sewing start

Pedal neutral

position

Needle down

stop

Sewing machine rotates from

needle down to needle up.

Cam engagement

Tension release

Reverse feed stitching

at sewing end

[Caution] This sequence shows the state that the automatic reverse feed stitching switch is turned ON at

the start of sewing and at the end of sewing.

−10 −

Page 14

(Reference) 1. M arke r dot on th e handwheel shows the standard value of cam timing. The timing can be more advanced

by 2˚ or more delayed by 5˚ than that in case of cotton thread or synthetic thread. At this time, however,

confirm that moving knife securely separates two pieces of needle thread at the bottom face of throat

plate. If the cam timing is excessively advanced or delayed, the needle thread remaining at the top of

needle will be shorter and may slip from the needle immediately after thread trimming. In addition,

roller may not enter the groove of thread trimmer cam. So, be careful.

2. Basically, the thread trimmer cam timing is common to cotton thread and synthetic thread. For the thin

synthetic thread, however, if the following troubles occur :

① One or several stitches skip at the start of sewing.

② Thread slips from needle at the start of sewing.

Perform the following adjustments for synthetic thread (special) (In case of thin threads)

③ Align marker dot on the machine arm (Fig 13 (3)) with green marker dot on the handwheel (Fig.

13 (1)) and adjust thread tension No. 1 to lengthen the thread remaining on the needle after

thread trimming within the range that nothing interferes with the finish of sewing.

④ Make one stitch of soft start at the start of sewing.

[Caution] Adjustment ① is not applied to thick threads.

When thread trimmer cam timing is delayed (in the direction of green), phenomena such as

dispersion of adjustment, non-trimming of thread without completing thread trimming depending

on the kinds of threads may occur.

In this case, slightly delay the needle upper stop position.

−11 −

Page 15

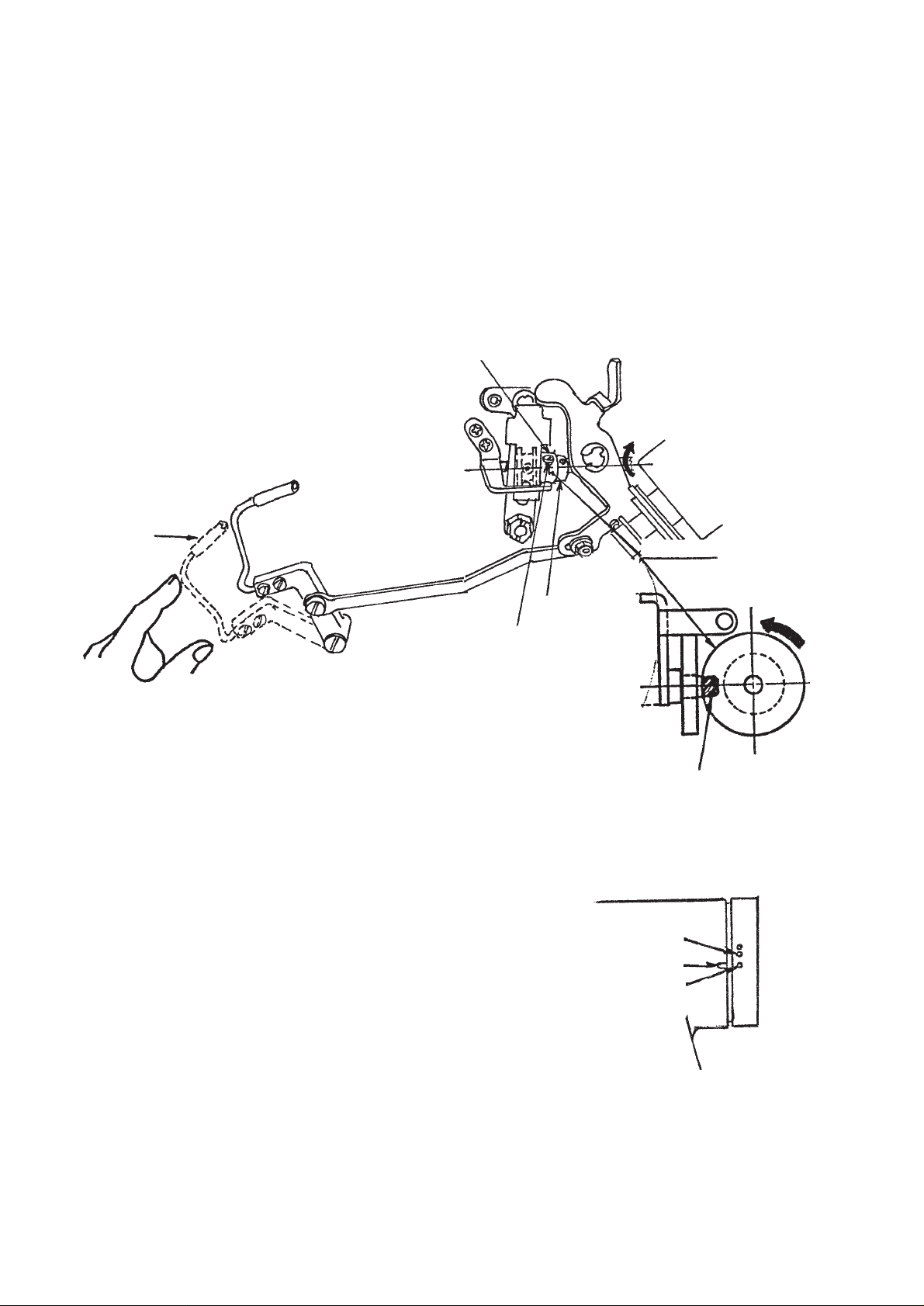

3-5 Observing and adjusting the thread trimmer cam timing

1) Proper observing of the thread trimmer cam timing

Thread trimmer cam timing for both cotton and synthetic threads can be easily adjusted by aligning marker dot

on the machine arm with that on the handwheel.

Tilt the machine head, turn the handwheel by hand until the thread take-up lever goes up slightly near the

upper dead point, press thread take-up picker (Fig. 12 (1)) to the right with fingers, and roller enters the cam

groove of thread trimmer cam to engage with each other. At the same state, turn the handwheel in the reverse

direction as against the normal operation of the sewing machine, and there is a position where the sewing

machine does not rotate. At this time, adjust the cam timing so that marker dot (Fig. 13 (1)) of the machine arm

shown in Fig. 13 is aligned with marker dot (Fig. 13 (1)) on the handwheel. This is the cam timing for cotton

thread and synthetic thread.

Thread trimmer cam

(1)

2) Adjusting the thread trimmer cam timing

First, loosen two setscrews (Fig. 12) in the thread

trimmer cam in the order of No. 1 and No. 2, and align

marker dot on the hand wheel with marker dot on the

machine arm. (Fig. 13 (1) and red (2) or green (3) )

Next, pressing thread take-up picker (Fig. 12 (1) ) to

the right, engsage cam and roller, turn cam only with

finger top in the reverse direction as against the rotating

direction of hook driving shaft without turning the hook

driving shaft (arrow mark in Fig. 12). Press the cam to

roller (Fig. 12) at the position where the cam does not

rotate, and tighten setscrews in the cam in the order of

No. 2 and No. 1.

When the cam collar has not been moved, press the

thread trimmer cam to the cam collar and tighten the

setscrews in the order of No. 2 and No. 1.

Setscrew No. 2

Fig. 12

Cam collar

Thread trimmer cam

Turn cam by hand in

this direction.

Roller

(3)

Green

(1)

(2)

Red

Fig. 13

−12 −

Page 16

3-6 Adjusting the position of moving knife movement

1) Proper movement of the moving knife

The position of moving knife when it moves until it will go no further is the position where the front top end of

moving knife is receded 2.5 to 3 mm from the center of the needle. When the amount of recession is excessively

small, the moving knife cannot scoop needle thread or bobbin thread when trimming thread, and if the amount

is excessively large, feed dog may come in contact with moving knife. Therefore, properly adjust the moving

knife position.

Reference for positioning the moving knife at the predetermined position is the position where the V groove

indicated on the knife installing base is aligned with the periphery of moving knife.

Moving knife

V groove for positioning

moving knife

2.5 to 3 mm

0.5 mm

(0.2 to 0.7)

Center of needle

When moving knife recedes most.

Fig. 14

Predetermined position

2) Adjusting the moving knife position

Adjustment is performed by changing the right and left positions of moving knife link pin (Fig. 15 (1)) when the

sewing machine stops.

① Loosen the lock nut of moving knife link pin (Fig. 15 (1)).

② Following the predetermined position in Fig. 14, move the moving knife link pin to the left and right so that

V groove (Fig. 14) for positioning moving knife on the knife installing base is aligned with the periphery of

moving knife.

③ Tighten the lock nut of moving knife link pin at the proper position.

Set the position of moving knife pin to the right to increase the amount of recession, and to the left to

decrease the amount.

3) When adjustment cannot be performed by moving knife link pin only

① Loosen the lock nut of moving knife link pin (Fig. 15 (1)).

−13 −

Page 17

② Adjust so that the center of moving knife link pin

is aligned with V groove (Fig. 15 (2)) of the center

of slot in knife driving arm (Fig. 15 (3)), and tighten

the lock nut to fix the pin.

③ Loosen two setscrews (Fig. 15 (4)) in driving arm

stopper (Fig. 15 (5)).

④ Move knife driving arm (Fig. 15 (2)) so that V

groove (Fig. 14) on the knife installing base is

aligned with the periphery of moving knife, press

it to driving arm stopper (Fig. 15 (4)) at that

position, and tighten setscrews (Fig. 15 (5)).

(4)

(5)

(2)

(7)

(6)

(3)

(1)

Fig. 15

⑤ Loosen the respective two setscrews in thread trimmer cam (Fig. 15 (7)) and cam collar (Fig. 15 (6)).

⑥ Align marker dot (red : Fig. 13 (2) or green (3)) on the handwheel with marker dot (Fig. 13 (1)) on the

machine arm.

⑦ Turn with finger top setscrew No. 2 (Fig. 15 (7)) in the thread trimmer cam so that it comes to this side, and

press the thread take-up picker to the right when the setscrew comes to this side.

⑧ Move the cam to the right and left to engage the cam with the roller.

⑨ In this state, lightly pulling the cam to the right, move it in the direction of arrow (this side) until it will rotate

no further.

⑩ Temporarily tighten setscrew No. 2 (Fig. 15 (7))

in the cam.

⑪At this time, check the following matters :

a) Marker dot on the handwheel is aligned with

that on the machine arm.

b) Roller smoothly enters the groove in the cam.

c) Amount of recession of knife is 2.5 to 3 mm

(SH : 3 to 3.5 mm).

⑫ Securely tighten two setscrews in the cam.

⑬ Press cam collar to the cam, and tighten one

setscrew.

Fig. 16

[Caution] ○ Amount of recession of knife is largely affected even when adjustment of left and right

positions of moving knife link pin is finely performed.

○ Check whether moving knife handles thread as shown in Fig. 16.

−14 −

Page 18

3-7 Properly installing the counter knife

The dimension of proper installation of the counter knife is as shown in Fig. 17. The standard distance from thread

guide for knife attached so that needle enters the center of window to the top end of counter knife blade is 0.5

mm.

At this time, a clearance of approximate

4 mm is provided between the center of

needle and the top end of counter knife

blade.

The top end of counter knife blade is 0.6

mm above the installing face. (Fig. 18)

Sharpness will change when installing

angle of the top end of counter knife blade

Moving knife

Thread guide

for knife

Center of needle

Approx.

4 mm

is changed. Sharpness is shown only

when cutting blade sections of counter

0.5 mm

knife and moving knife are closely

engaged with each other.

When adjusting or replacing the counter

knife, be sure to check the sharpness and

(3)

(2)

Shorter Longer

Length of thread after trimming

adjust the installing angle of counter knife.

Counter knife can be installed by moving

Fig. 17

to the right from the standard installing

position.

At this time, the feeding length of needle

thread and bobbin thread is lengthened

more not only as much as the moving

Counter knife

distance of knife than the standard time,

but also thread trimming timing is delayed.

As a result, the length of needle thread

0.6 mm

Fig. 18

remaining at the top end of needle is extra

lengthened. (Fig. 20)

For the synthetic thread, move counter knife to the right to delay thread trimming timing.

To completely adjust, however, it is also necessary to adjust thread trimmer cam timing.

Bottom section of throat

plate (Machine bed)

Counter knife

(1)

Moving knife

To be center

Counter knife

Fig. 19

−15 −

Hook

When counter knife is

moved to the right

Standard

Moving knife

Thread take-up picker

Fig. 20

Page 19

Properly installing the thread guide for knife

Install the thread guide for knife so that the needle enters just in the center of the window (hole).

3-8 Rising amount of the thread tension disk No. 2

1) Observing the rising amount of the thread tension disk No. 2

Lift the presser foot at the position where the thread take-up lever comes slightly to this side of its upper dead

point. Then, check that the rising amount of the thread tension disk No. 2 is 0.5 to 1mm when thread take-up

picker (Fig. 12 (1)) is pressed to the right.

2) Adjusting the rising amount of the thread tension

disk No. 2

① To increase the rising amount, loosen screw

(Fig. 21 (1)) and move thread release wire (2)

to the right.

② To decrease the rising amount, loosen screw

(1) and move thread release wire (2) to the

left. After performing adjustment, securely

tighten screw (1).

Fig. 21

(2)

(1)

3-9 Sharpening the knife blade

The shape of blade top of the counter knife affects most the sharpness of the knife.

In many cases, the sharpness is improved by sharpening the blade of the counter knife only.

It is important that the blade face of the counter knife comes in contact with the blade section of the moving knife.

○ The sharpness is improved by sharpening face A in Fig. 22 only. (Pay attention to the angle shown in Fig. 22.)

Moving knife

Take corner and polish well.

Sharpen this face. (Face A)

Blade top (Face B)

X

Fig. 22

Counter knife

C and D sections of moving knife should

simultaneously come in contact with counter knife.

D

Fig. 23

○ The sharpness is deteriorated when the top end of face B has been worn out and got round. Carefully sharpen

the blade without changing the angle.

Counter knife

C

−16 −

Page 20

○ When the sharpness is insufficient although the blade

face is enough sharpened, it is because the left and

right blade faces of moving knife and counter knife

do not simulataneously come in contact with each

other. At this time, adjust the inclination of the counter

knife.

(Reference) To improve the contact of the blades

of moving knife and counter knife, it is

effective to change the angle of the

arrow mark shown in Fig. 24.

When the side of D in Fig. 23 is hard to

cut, decrease this angle, and when the

side of C is hard to cut, increase the

angle.

3-10 Replacing the moving knife

When replacing the moving knife, replace it in the

following procedure.

1) Remove moving knife hinge screw (Fig. 26 (1)).

2) Slide moving knife link (Fig. 26 (2)) to this side, and

draw moving knife link (2) from knife forked pin (Fig.

26 (3)).

3) Loosen and take out moving knife hinge screw (Fig.

25 (3)) using 3 mm hexagonal wrenck key (Fig. 25

(4)).

4) Loosen and remove knife forked base hinge screw

(Fig. 25 (1)). Lift up knife forked base (Fig. 25 (2))

and remove the pin of moving knife from the forked

groove in the knife forked base.

5) Remover the pin of moving knife, slide the moving

knife to the left and take it out from the bottom face

of knife forked base.

Counter knife

Fig. 24

(1)

(2)

(3)

(4)

Fig. 25

Perform installation in the reverse order of the

aforementioned procedure.

When tightening the moving knife hinge screw, move

the moving knife by hand and check that it smoothly

moves without play.

Next, securely insert the forked groove in the knife forked

base into the moving knife pin, and tighten the knife

forked base hinge screw.

Insert the moving knife link into knife forked pin (Fig. 26

(3)), and attch moving knife link hinge screw

(Fig. 26

(1)

Finally, move the moving knife link to the left and right,

and check that the moving knife moves.

−17 −

(1)

).

(2)

(3)

Fig. 26

Page 21

3-11 Replacing the thread guide for knife

When replacing the thread guide for knife, loosen screws (2) and (3) shown in Fig. 17, and replace it with screw

(1) tightened.

If the installing angle of counter knife is moved, perform re-adjustment referring to the item of 3-7 “Properly

installing the counter knife”.

3-12 Adjusting the thread take-up picker

If thread take-up picker (Fig. 27 (3)) excessively enters in the direction of bobbin case when trimming thread,

bobbin does not rotate and bobbin thread is trimmed shorter than the standard. As a result, slip-off of thread

occurs at the start of sewing.

On the contrary, if it insufficiently enters, needle thread slips from the top end of thread take-up picker when

trimming thread. As a result, needle thread remaining at the needle top after thread trimming is shorter resulting

in slip-off of thread.

Marker line

(3)

(4)

Fig. 27

1) Proper position of the thread take-up picker

Adjust the thread take-up picker so that bobbin thread is

lightly pulled out in the state that clutch plate (Fig. 27 (1))

is pressed in the direction of the arrow mark (right side).

At this time, as shown in Fig. 28, adjust so that a clearance

of 1.0 to 1.5 mm is provided between the top end of thread

take-up picker (bobbin presser) and the notch in the upper

section of bobbin. In addtion, after the clutch plate has

been pressed to the right, lightly press thread take-up

picker (3) and adjust so that the rear end of bobbin presser

is aligned with the marker line on the thread take-up picker

in the state that the play is removed.

(2)

(1)

1.0 to 1.5 mm

Fig. 28

2) Adjusting the thread take-up picker

Loosen screws (Fig. 27 (4)) and adjust so that the top end (bobbin presser) of thread take-up picker is located

as shown in Fig. 28.

To adjust the depth of thread take-up picker, move the position of picker link pin (Fig. 27 (2)).

After performing adjustment, tighten the lock nut of picker lik pin.

−18 −

Page 22

3-13 Adjusting the clutch plate and the thread trimmer solenoid

The stroke of thread trimmer solenoid is 6 mm.

Installing positions of the clutch plate and the solenoid are the positions where the clearance of section A is 0.1 to

0.5 mm when the thread trimmer solenoid is drawn (Fig. 30).

In this state, tighten solenoid setscrew (Fig. 30 (10)).

(3)

Solenoid stroke 6 mm

(4)

3-14 Driving arm stopper

Driving arm

stopper

Section A

Fig. 30

Driving arm

(10)

(1)

(2)

Stopper section

stopper

A

Roller arm

Fig. 31

−19 −

Page 23

Needle

Moving knife

Needle entry position

Fig. 32

1) Press the roller arm in the direction of the arrow mark to press it to the stopper section of the thread trimmer

control plate.

2) At this time, adjust with screws (1) and (2) so that the stopper section works at the position where the moving

knife does not reach the needle entry position.

3-15 Installing/removing the knife installing base

1) Remove the hook and the bobbin case holder.

2) Lift up moving knife link (Fig. 33 (1)) to this side and remove it from knife forkd pin (Fig. 33 (2)) after removing

moving knife link hinge screw (Fig. 33 (3)).

3) Remove knife installing base setscrew (Fig. 33 (5)), and remove knife installing base (Fig. 25 (4)).

Perform the installation in the reverse order of the aforementioned procedure.

(5)

(2)

(3)

(4)

(5)

Fig. 33

(1)

−20 −

Page 24

3-16 Adjusting the position of the touch-back switch

The height of the touch-back switch can be changed by turning push button (1). When you desire to further

change the position, loosen setscrew (2) to slide it up or down, or loosen setscrew (3) to move it up or down

together with switch base (4).

In addition, tightening torque of setscrew (2) should be moderate since the screw is tightened in the plastic base.

And, securely and strongly tighten setscrew (3).

(3)

(2)

(4)

(1)

3-17 Adjusting the position of the handwheel

When removing the handwheel, be sure to check the following matters for adjustment.

1) Provide a clearance of 1 mm between handwheel

(1) and the pulley cover. If the clearance is too narrow,

the position detector solenoid comes in contact with

the synchronizer. If it is too wide, defective detection

may occur.

2) Be sure to adjust screw No. 1 in the handwheel to

the flat section of the motor shaft, and tighten the

screws in the order of No. 1 and No. 2.

1 mm

3-18 Adjusting the automatic presser lifter (AK118)

1) Remove the side plate of the sewing machine head

and remove hinge screw (2) of knee lifter side rod (1).

(2)

(1)

−21 −

Page 25

2) Remove hinge screw (4) in knee lifter link (3),

replace the link with knee lifter link (5) to which

spring (6) supplied with the machine is set, and

install it with hinge screw (7).

At this time, tilt the machine head and check that

knee lifter connecting rod (8) enters in the hole of

connecting rod guide (9).

3) Tighten knee lifter side rod pin (10) with knee lifter

link (5) which has been replaced using screw.

Then, install knee lifter side rod with pin (1).

(3)

(4)

(Caution) 1. Knee lifter side rod is easily

loosened. Securely tighten it.

2. Apply grease to the respective

hinge screw sections.

4) Install knee lifter link spring retainer (14) on wire

presser base (15) so that tension release wire (12)

and oil pipe (13) are pressed with the hook. At

this time, pay attention to the routing of oil pipe

(13) and wire (12).

5) Hook knee lifter link spring (6) to the notch of knee

lifter link spring retainer (14).

6) Install the AK device (asm.) (16) on the machine

arm.

At this time, install it so that the slot of solenoid

link (17) is set to knee lifter side rod pin (10).

(Caution) Apply grease to the slot of solenoid link

(17).

(8)

(5)

(7)

(6)

(10)

(1)

(11)

(9)

(8)

(16)

Slot

Apply grease.

(10)

−22 −

(6)

(10)

(14)

(12)

(13)

(15)

Notch

(14)

Page 26

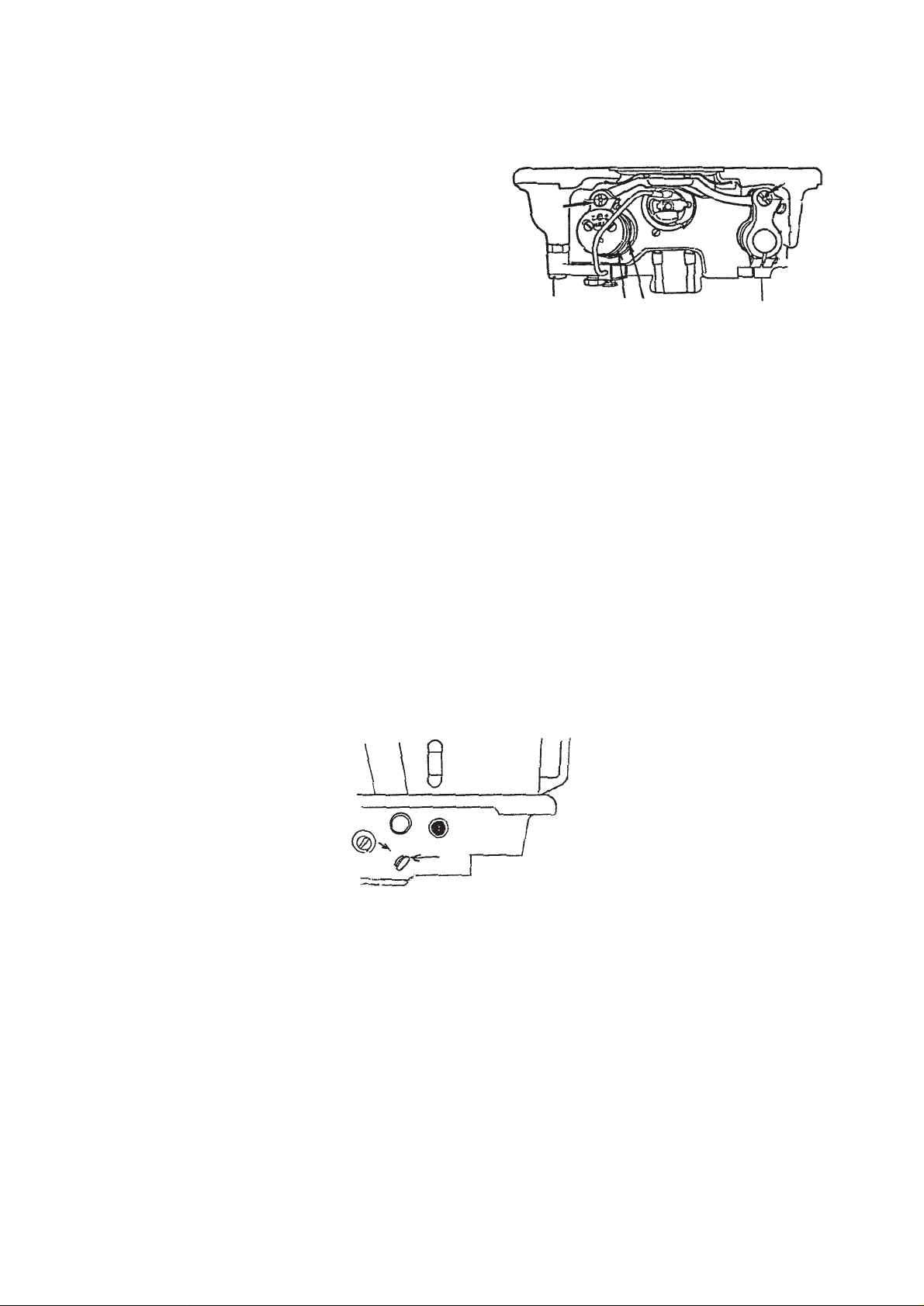

7) Pass cord (16) of AK device (asm.) through the

hole of the table and insert 2P connector (18) into

2P connector (19) (2P white CN9) located on the

control circuit board.

Arrange the cord with other cords using cord

clamp (20) and cable band (21) so that they do

not hang loose.

8) Bundle the cord with other cords using the cord

band supplied with the machine.

(18)

(20)

(21)

9) Remove the face plate of the machine head, and

lower the presser foot to make a state that lifting

plate (22)is pressed down. Turn solenoid shaft

(23) to the left with screwdriver (A) and tighten

screw (24) using hexagonal wrench key (B). At

this time, set the solenoid in the state that it is

pressed in the direction of the arrow mark.

(Caution) Check that there is a clearance

between the bottom face of presser bar

guide bracket (25) and the top end of

lifting plate (22) in the state that the

presser foot comes in close contact

with the throat plate.

10) When using the AK device, use it after removing

the head support rod on the table.

(22)

(A)

(24)

(B)

(23)

Clearance

−23 −

(25)

Page 27

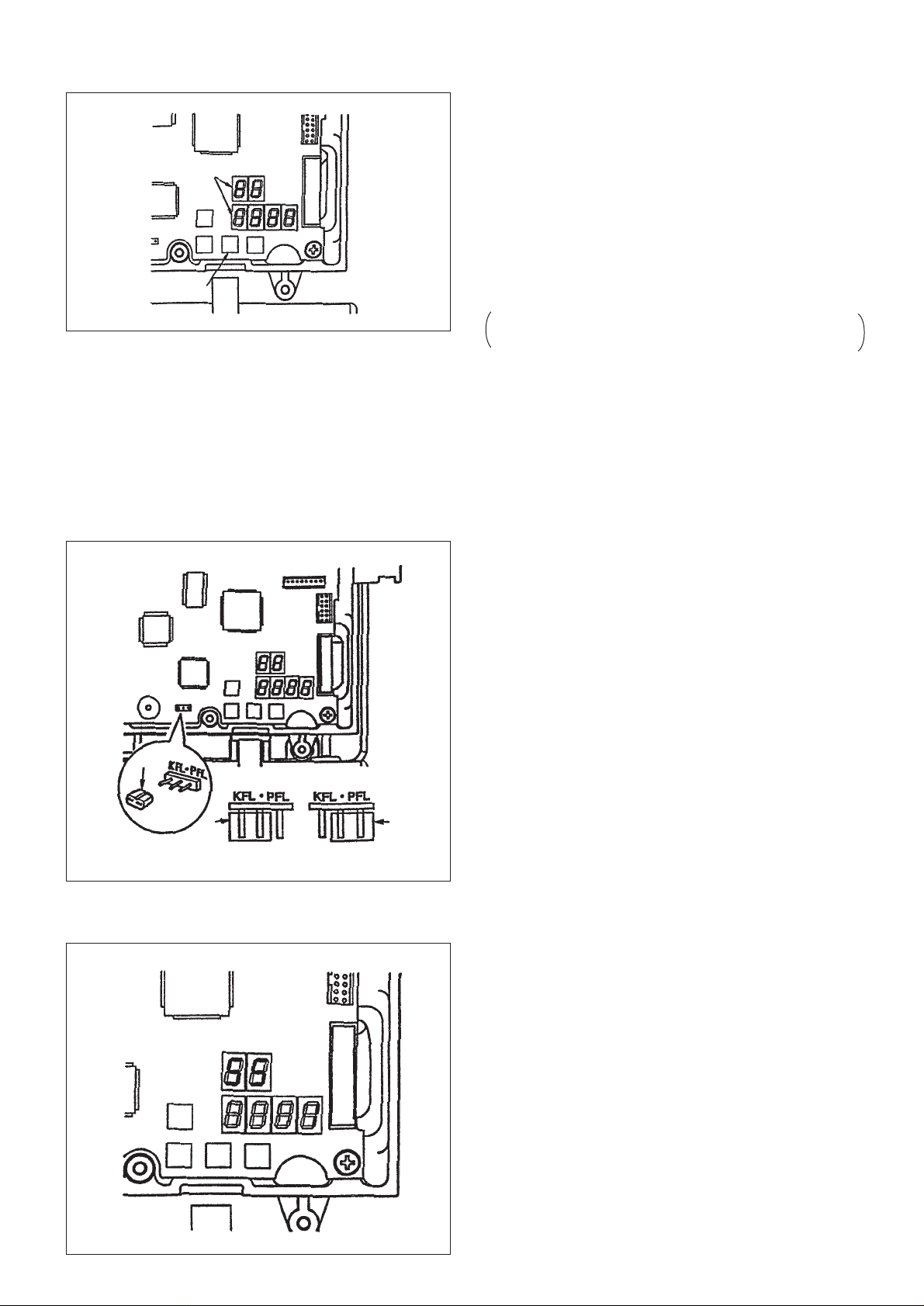

Selecting the automatic presser lifting function

1) Pressing switch (1) in the control box, turn ON the

power switch.

2) LED will be displayed (2) (FL ON) with “beep”, and

the automatic presser lifting function becomes

(2)

effective.

3) Turn OFF the switch once and again turn it ON.

4) Repeat operations 1) through 3), and LED display will

be “FL ON. The automatic presser lifting function does

not work.

FL ON : Automatic presser lifting function is effective.

(1)

FL OFF : Automatic presser lifting function does not work.

Similarly, the presser foot does not automatically go

up when programmed stitching is completed.

(Caution) 1. Turn ON the power again after one second or more has passed without fail.

(If the action of ON/OFF of the power is quick, setting may not be well changed over.)

2. If this function is not properly selected, the automatic presser lifter does not work.

3. If “FL ON” is selected without installing the automatic presser lifter, the starting at the start

of sewing is momentarily delayed. In addition, the touch-back switch may not work. Be sure

to select “FL OFF” when the automatic presser lifter is not installed.

Selecting the presser foot lifting by pedal

The presser foot can be lifted with the operation of

depressing the back part of the pedal by changing jumper

(1) located on the control circuit board.

Follow the silk screen indication located on the upper side

of the jumper to change.

PFL : Presser foot can be lifted by depressing the back

part of the pedal.

KFL : Presser lifting operation by pedal is not performed.

(Caution) 1. When changing the jumper, be sure to

do the work after turning OFF the power.

(1)

If the jumper is changed while the power

is ON, the setting does not change. The

main unit may be broken.

2. When PFL is selected, the thread

(1)

KFL setting PFL setting

(1)

trimming point will automatically

descends.

Selecting the automatic presser foot lifting after thread trimming

1) This function can be selected by function setting No.

55 of the SC-900.

1 : Presser foot automatically goes up after thread

trimming.

(Standard setting at the time of delivery)

(When the programmed stitcing is selected with CP-

360 panel, it works according to the setting of the

operation panel.)

0 : Automatic presser foot lifting after thread trimming

is not performed.

(Similarly, the presser foot does not automatically

go up when the programmed stitching is

completed.)

(Caution) For the details of the function setting, refer

−24 −

to the Instruction Manual for the SC-900.

Page 28

3-19 Optionals (Presser foot micro-lifter)

When straight stitching is not performed since slip-off of fabrics occurs dut to the pressure of presser foot in case

of fluffy masterials such as velevet or the like, or hard-to-sew materials, if presser foot micro-lifter (2311056) is

used, the presser foot can be minutely lifted at the face plate section with ease, and sewing can be performed. As

a result, handling and finish of fabrics are improved.

(Assembling the presser foot micro-lifter)

1) Remove the setscrew in the hand lifter, and remove the plastic

hand lifter.

2) Remove the face plate, insert micro-lifter hand lifter (1) into hand

lifter cam shaft (2) while pressing hand lifter cam shaft (2) with

fingers so that it does not move in the direction of inside of the

machine arm, and securely tighten it with setscrew (3).

3) Temporarily tighten two setscrews under the face plate, insert

collar (4) supplied with the machine into the upper setscrew

section, insert guide hole A of installing base (5) into the top

end of hand lifter cam shaft, and securely tighten the micro-lifter

with setscrew (6) through washer (7) while checking that microlifter hand lifter (1) lightly moves.

(Adjustment)

1) Loosen micro-lifter nut (8), turn micro-lifter hand lifter knob (9) to

this side, and the presser foot gradually goes up.

2) Tighten nut (8) to fix the micro-lifter at the position where the

optimum condition of the sewing materials is obtained after trial

sewing.

A

(A)

(3)

(1)

(7)

(6)

(8)

(5)

(9)

(2)

3-20 AE-8 (Bobbin thread remaining amount detector)

When the amount of remaining bobbin thread reaches the set value, buzzer will sound to warn the operator not to

perform the next operation of depressing the front part of the pedal.

It is especially effective for the splicing and the process where resewing is not possible.

For installation, optional printed circuit board A (M97014610A0) which is separately available is required.

For the details, refer to the Instruction Manual attached at the time of purcahse of the device.

(Caution) This device cannot be used with DS and DF types. When it is compelled, use this device with

existing RP hook 11079456 and at sewing speed of 3,000 rpm or less.

3-21 ED-4 (Compact material end sensor)

When the sensor detects a material end, the sewing machine automatically stops and thread trimming is

performed.This enhances productivity by allowing the operator to conduct sewing work without running to look

out for missing stitches.

For installation, optional printed circuit board A (M9701460A0) which is separately available is required.

Refer to the Instruction Manual attached at the time of purchase of the device.

3-22 PK-70 and -71 (3-step pedal)

Refer to the Instruction Manual attached at the time of purchase of the device.

−25 −

Page 29

3-23 Adjusting the tension release change-over

When the sole of the presser foot is lifted 3.5 mm or more with the knee pad or AK device, the tension release

works and the thread tension disk rises. As a result, tension is not applied to the needle thread.

When the presser foot is lifted by the thickness of the overlapped section of the fabric instead of the knee lifter, the

tension release does not work.

Especially when the knee lifter is used at the thick section to handle the material during sewing, thread tension

may become deffective.

In this case, the tension release can be released by performing the following adjustments.

(Thread trimming function is not affected since the tension release works when thread trimming.)

1) Remove rubber cap (1) located on the rear face of face plate of

the machine head.

When the machine is provided with the wiper, perform the work

after removing the wiper base.

2) Loosen change-over screw (2) with 3 mm hexagonal wrenck

key. Turn it downward until it will go no further, and tighten it

again. Tension release is possible with the knee lifter. Turn it

upward until it will go no further, and tighten it again. Tension

release is not possible with the knee lifter.

(1)

(2)

3-24 Adjusting the presser foot micro-lifter

The presser foot can be minutely lifted with ease using the microlifter screw installed on the machine head to perform the sewing.

1) Loosen micro-lifter nut (1), and turn micro-lifter screw (2) to the

right to gradually lift the presser foot.

2) Tightn and fix nut (1) at the position where the optimum condition

of the sewing material is obtained through trial sewing.

(Caution) When the micro-lifter is not used, make the height of

micro-lifter screw (2) from its installing face on the

machine arm 11 mm or more.

when the micro-lifter is working, the presser foot is

in the state that it is rising under the standard sewing

condition. As a result, feed force is excessively

deteriorated.

3-25 Installing the operation panel

If the installation of the operation panel is improper, noise of snarl

may occur when the machine runs at high speed.

When installing the panel, remove two setscrews (2) in the side

plate and install it with the screws supplied with the panel in the

state that rubber (1) of the panel installing plate is securely pressed

to the upper face of the machine arm.

(1)

(2)

(1)

11mm or more

(1)

−26 −

(2)

Page 30

3-26 Dimensions of table

The bed size of this machine is the same as that of JUKI LH model. This machine cannot be set to the table for the

exising lockstitch sewing machines.

Refer to the following dimensions only when JUKI exclusive table is not used since the main dimensions of the

table are described below.

[Reference dimensions of table]

C

Section C

Rubber cushion installing

drawing for reference

C1 chamfer

E

Section E

1

ø26

± 0.5

8

19.5

Section A (3 places)

Section D (2 places)

23.5 ± 0.5

Section E (2 places)

ø8.5

B

A

C

C1 chamfer

JUKI stand installing position

D

F (reverse side)

17.5 ±0.5

Section C (2 places)

E

ø16

ø26

9.5 ± 1

Section B (1 place)

32 ± 1

R2

25

R30

Section F

R2

C1.5 to 2.5 chamfer

(To prevent machine from

being caught when tilting

it)

(40)

−27 −

Page 31

3-27 Points of adjustment and assembly of the feed mechanism

(Adjusting the feed driving components)

* To obtain the movement in the direction of the horizontal feed, feed rocker shaft (1) is rocked by means of feed

rocker cam attached to feed driving shaft (2), connecting links A (4) and B (3) of feed rocker rod (19), feed

adjusting link (5), and feed rocker arm (6).

* Seizure, abnormal exothermic, pitch error, lever snarl, or defective return of lever will result due to the torque

of the sewing machine unless centering and play adjustment of the aforementiond parts are securly performed.

Perform readjustment in the following procedure when these phenomena are likely to occur.

1) Remove the lid of the gear box.

Refer to the item 3-34 for removing and attaching it.

2) Remove rubber cap (7) located on the side face of

the machine bed and loosen setscrew (8) in the feed

rocker arm.

* Apply sealant to the rubber cap to prevent it from oil

blurredness when attaching it again.

3) Loosen two setscrews (13) in the feed rocker cam.

When attaching the setscrew No. 1 again, check that

it is set on the flat section.

When loosening amount of the setscrew No. 1 is

small, it can be saved for the setscrew to be slipped

from the flat section.

4) When there is no trouble with feed adjusting link (5),

the strain can be removed by adjusting the lateral

position of the feed rocker cam or the feed rocker

arm. Turn the handwheel several times and the feed

rocker cam moves to the position where there is no

strain. In this state, quietly tighten setscrew No. 1.

Further, tighten setscrew No. 2.

5) Then, similarly, turning the handwheel by hand, adjust

feed rocker arm (6) to the position where there is no

strain, and tighten the setscrew.

6) If there is a play when pressing feed adjusting link

(5) to the right and left, perform the following

adjustments before adjustments 4) and 5).

7) Remove rubber cap (9) in the adjusting link fulcrum

shaft and loosen setscrew (10) in the fulcrum shaft,

insert a screwdriver from the hole from which the

rubber cap is removed to lightly press the fulcrum

shaft, then securely tighten setscrew (10) in the

fulcrum shaft.

The play in this section will affect largely the lever

snarl. It is the point to assemble it while lightly pressing

the fulcrum shaft.

* When the adjusting link does not smoothly move

although there is no lateral play in adjusting link

connecting link (14), remove rubber cap (11) in the

adjusting link fulcrum shaft, loosen setscrew (12) in

the fulcrum shaft on this side, move the feed lever up

and down to fit adjusting link (5), and adjust fulcrum

shaft (15) to the position where the strain does not

occur.

(1)

(11)

(19)

(15)

(12)

(8)

(4)

(3)

(7)

(6)

(5)

(14)

(13)

(10)

(9)

(16)

(2)

(17)

(18)

−28 −

Page 32

(Adjusting the feed adjustment components)

* When there is a lateral play in feed changing shaft (16),

lever snarl, or longitudinal play of the feed dog will be

large. Securely tighten setscrew (17) in the feed changing

shaft arm A with a rather large-sized screwdriver, and

assemble the shaft with thrust collar (18) so that it smoothly

turns without play. (Refer to the illustraion on the previous

page.)

[Adjusting the feed “0” point]

Adjust the initial position from the adjusting link to the feed

adjusting base in the following procedure.

1) Remove the side plate, loosen two setscrews (4) in the

feed adjusting base, turn feed adjusting pin (5) with

wrench, and temporarily tighten two setscrews (4) of the

feed adjusting pin in the state that notch A of the pin comes

to the side plate side.

2) Remove the reverse feed solenoid, and set the feed dial

to “0”.

3) Loosen setscrew (7) in feed changing shaft arm B (6),

move adjusting link (5) (illustration on the previous page)

with fingers, and securely tighten setscrew (7) in feed

changing shaft arm B (6) at the position where connecting

link A (8) is aligned with connecting link B (9).

* Set the lateral position of feed changing shaft arm B to

the position where a clearance of 1 mm is provided

between the arm and the metal, and check that strain does

not occur in adjusting rod (11).

(5)

A

(4)

(11)

(10)

(18)

Clearance

[Adjusting the ratio of normal to reverse feed]

1) After adjusting feed “0” point, and actually place a piece

of paper under the presser foot. Then, make normal feed

of 10 stitches and reverse feed of 10 stitches by operation

of the feed lever to check that proper ratio of normal to

reverse feed is obtained. Adjust the feed dial with three

graduations. If the ratio of normal to reverse feed is not

proper, gradually turn the feed adjusting base pin with

wrench and securely tighten two setscrews (4) of the pin

at the position where the ratio of normal to reverse feed is

proper since feed adjusting base pin (5) is eccentric.

* Turning clockwise feed adjusting base pin (5) increases

normal feed, and counterclockwise increases reverse feed.

[Adjusting the position of the feed lever]

1) Adjust the tightening position of feed lever arm (10), when

the feed dial is set to graduation “5”, so that a clearance is

provided between the arm and the claw section of feed

adjusting rod (11).

After the adjustment, make a slight play when the

graduation of the feed dial is “5” and the feed lever is lightly

pressed. If the play is excessive, operability is deteriorated,

and if it is excessively small, the feed lever may move by

the shock at the time of automatic reverse feed.

[Automatic back solenoid]

1) Loosen setscrew (1) and move the solenoid up or down

to adjust the position of the automatic back solenoid.

Setting the graduation of the feed dial at “5”, press the

feed lever until it will go no further. At this time, make a

state that plunger rubber (2) in the solenoid exactly moves,

and securely tighten setscrew (1) in the solenoid installing

base with a rather large-sized screwdriver.

(6)

(7)

(8)

(8)

To be aligned.

(9)

(9)

(1)

(1)

(2)

−29 −

Page 33

(Adjusting the feed mechanism of feed base components)

[Adjusting the longitudinal position of the feed dog]

1) Adjust the marker dot of feed driving base pin (1) to

the right and feed rocker base pin (2) to the upper

right at approximately 45˚.

(Adjust in the state when adjustment of the feed base

pin has been completed.)

2) Set the feed dial at “5”.

3) Temporarily tighten the setscrew in feed rocker base

arm (3), turn the handwheel to observe the symmetry

of the feed dog in terms of the groove of the throat

plate. Tighten the setscrew in feed rocker base arm

(3) at the position where the central symmetry is

obtained.

[Adjusting the lateral position of the feed dog]

1) After adjusting the longitudinal position of the feed

dog, in the state that the feed dog is fixed in the almost

center of the setscrew in the feed base, check the

clearance in the lateral direction of the throat plate.

If the slippage is small, it can be adjusted with the

play in the installing hole of the feed dog. If it is large,

however, readjust the lateral position of feed driving

base arm (4) and feed rocker base arm (3).

* Loosen setscrew (4) in the feed driving cam, loosen

the swetscrew in the feed rocker base arm (3), and

adjust the lateral position of the feed dog.

Determine the longitudinal position of feed rocker arm

(3) referring to the points of adjusting the longitudinal

position of the feed dog.

* Tighten setscrew (4) in the feed driving cam in the

state that the central marker line on feed driving cam

plate (5) is aligned with marker line (6) in the feed

driving shaft.

Turn the handwheel several times to and fro by hand

before tightening to prevent the adjustment from the

state that the feed driving base arm in terms of the

feed rocker base arm is improperly positioned.

When the feed driving cam does not lightly turn before

tightening the setscrew in the feed driving cam, there

is a defective part. So, be careful.

(1)

(5)

(6)

(4)

(2)

45˚

(3)

−30 −

Page 34

(Adjusting the feed timing and dimensions of the feed base components

[Inclination and height of the feed dog]

* Standard adjustment value of the inclination of the

feed dog : Marker dot (6) in feed rocker base pin

(3) is positioned to the upper right 45˚ and marker

(1)

(5)

(3)

(6)

dot (5) in feed driving base pin (1) is positioned to

the right for reference. At this time,the inclination

(2)

of the feed dog is slightly raised to this side when

it starts going up from the top surface of the throat

plate and coming down from it.

* Making this side of the feed dog raised, bite of the fabric is improved and material slippage is decreased.

When improving puller effect with this side of the feed dog raised or changing the inclination in accordance

with the sewing conditions, loosen screws (2) and (4), and turn feed rocker base shaft (3) and feed driving

base shaft (1) with screwdriver to adjust it.

After the adjustment, fix the feed dog with screws (5) and (6) while lightly pressing with fingers feed driving and

feed rocker base shafts (1) and (3) to the rear side.

(Caution) If there is a play in the feed base, noise or defective straight stitching will result.

Max. front up

Marker dot

45˚

(4)

Marker dot

Max. this side up

Marker dot

Marker dot

Fig. 1

Fig. 2

Turn the marker dot in feed driving shaft base (1) in the upper direction to tilt the feed dog with its front up. (Fig. 1)

Turn the marker dot in feed driving shaft base (1) in the lower direction to tilt the feed dog with this side up. (Fig. 2)

However, if adjusting it with feed driving shaft base (1) only, the maximum height of the feed dog is changed.

Simultaneously perform the adjustment of raising and lowering the marker dot in feed rocker base shaft (3) when

you do not desire to change the height.

* The standard height of the feed dog is 0.8 to 0.85

mm. If the height of the feed dog is raised, feed

force is improved.However, jumping of the presser

foot at high speed or defects of light-weight

0.8 to 0.85

A

materials is likely to occur.

* If the height of the feed dog is excessively raised,

return on this side (section A side) of the feed

dog occurs and feed of materials may be affected.

If it is compelled to raise the height, adjust the

inclination of the feed dog with its front up to

decrease the return.

−31 −

Page 35

[Locus and timing of the feed dog]

☆ Locus of feed and feed driving timing in terms of the

needle can be changed by loosening setscrew (10)

in feed driving cam (9).

* Standard adjustment value is the state that marker

dot (7) is aligned with marker dot (8) in the center.

(9)

(10)

★ Loosen setscrew (9) in feed driving cam (10) and turn

it to this side (direction C), and adjust the marker line

to “-” side (Fig. A). Then, feed driving timing in terms

of feed rocker is advanced. Change in the horizontal

direction at the start of feed is decreased and the

fabric is securely fed resulting in decrease of irregular

stitches.

• Feed force is slightly decreased since the feed

dog near the end of feed lowers faster.

★ Loosen setscrew (9) in feed driving cam (10) and turn

it to the front side (direction D) , and adjust the marker

line to “+” side (Fig. B). Then, feed driving timing in

terms of feed rocker is delayed. Start of feed is smooth

and light-weight materials become hard to be

damaged although bite to the fabric is slightly

deteriorated. In addition, the feed dog securely feeds

fabric at the end of feed and puckering is reduced

due to puller effect.

Standard adjustment

(7)

(8)

(7)

Fig. A

(8)

(7)

(8)

Fig. B

(Caution) Whenever the timing of feed driving cam (9) is changed, the feed timing in terms of the needle

will be changed.

When the timing of feed driving cam is excessively changed, readjust it referring to [Adjusting

the needle and feed timing].

(Reference for the position of the feed driving shaft in terms of the needle bar)

Whether the timing of the needle and the assembling position of the feed driving shaft are in the normal position

can be checked by the following manner.

◎ When “+1” to “+3” of the marker line are positioned right above in the state that the marker line at the top end of

feed driving shaft is adjusted to the “0” position of the feed driving cam plate when the needle bar is brought to

its upper dead point, the position is normal although it is slighly different by the adjustment of timing.

Right above around here

* Reference for the position of the

feed driving cam at the needle

bar upper dead point

−32 −

Page 36

[Adjusting the needle and feed timing]

When performing adjustment of feed driving cam timing, or inclination and height of the feed dog, the needle and

feed timing will change. As a result, defective sewing or needle breakage may result.

In this case, adjust the timing in the following procedure.

1) Checking the timing of lowering of the feed dog

Turn the handwheel by hand and check the top end of needle eyelet in the state that the top end of the feed

dog is aligned with the top surface of the throat plate at the end of feed.

In this state, when the top end of the needle eyelet has been already lowered from the top surface of the throat

plate, the needle pierces the material in the state that the material is being fed when sewing the thick section,

and needle breakage due to needle bend may result.

On the contrary, when the top end of the needle eyelet is excessively positioned above the top surface of the

throat plate, stitch tightness is deteriorated.

↓

Perform adjustment in the following procedure so that the feed dog is lowered at the top end of the needle

eyelet except when intentionally changing the adjustment.

2) Adjusting the timing

☆Adjusting places are three, lower sprocket, thread trimmer cam and hook.