Page 1

ENGLISH

DDL-8700A-7

INSTRUCTION MANUAL

i

Page 2

CONTENTS

!

. SPECIFICATIONS ..................................................................................... 1

@

. SET-UP ...................................................................................................... 3

1. Installation .................................................................................................................. 3

2. Installing the pedal sensor ....................................................................................... 4

3. Installing the power switch ....................................................................................... 4

4. Attaching the connecting rod ................................................................................... 6

5. Winding the bobbin thread ....................................................................................... 7

6. Adjusting the height of the knee lifter ..................................................................... 8

7. Installing the thread stand ........................................................................................ 8

8. Lubrication ................................................................................................................. 9

9. Adjusting the amount of oil (oil splashes) .............................................................. 9

10. Attaching the needle ...............................................................................................11

11. Setting the bobbin into the bobbin case ............................................................. 12

12. Adjusting the stitch length .................................................................................... 12

13. Presser foot pressure ............................................................................................ 12

14. Hand lifter ............................................................................................................... 12

15. Adjusting the height of the presser bar ............................................................... 13

16. Threading the machine head ................................................................................ 13

17. Thread tension ....................................................................................................... 14

18. Thread take-up spring ........................................................................................... 14

19. Adjusting the thread take-up stroke .................................................................... 14

20. Needle-to-hook relationship ................................................................................. 15

21. Height of the feed dog ........................................................................................... 15

22. Tilt of the feed dog ................................................................................................. 16

23. Adjusting the feed timing ...................................................................................... 16

24. Cunter knife ............................................................................................................ 17

25. Pedal pressure and pedal stroke ......................................................................... 17

26. Adjustment of the pedal ........................................................................................ 18

#

. FOR THE OPERATOR ............................................................................ 19

1. Operating procedure of the sewing machine ........................................................ 19

2. Built-in panel of the machine head ........................................................................ 21

3. Operating procedure of the sewing pattern .......................................................... 22

4. One-touch setting .................................................................................................... 24

5. Production support function .................................................................................. 25

6. Setting of functions ................................................................................................. 28

7. Function setting list ................................................................................................. 29

8. Detailed explanation of selection of functions ..................................................... 33

9. Automatic compensation of neutral point of the pedal sensor ........................... 43

10. Selection of the pedal specications ................................................................... 43

i

Page 3

11. Setting of the auto lifter function ......................................................................... 44

12. Selecting procedure of the key-lock function ..................................................... 45

13. Removing the rear cover ....................................................................................... 46

14. Connection of the pedal of standing-work machine .......................................... 48

15. External input / output connector ........................................................................ 48

16. Connection of the material end sensor ............................................................... 49

17. Initialization of the setting data ............................................................................ 50

$

. MAINTENANCE ...................................................................................... 51

1. Replacing the fuse ................................................................................................... 51

2. Adjusting the machine head ................................................................................... 52

3. Connector layout drawing ...................................................................................... 53

4. Error codes ............................................................................................................... 54

ii

Page 4

!

. SPECIFICATIONS

Supply voltage Single phase 100 to 120V 3-phase 200 to 240V Single phase 220 to 240V

Frequency 50Hz/60Hz 50Hz/60Hz 50Hz/60Hz

ing environ-

Operat

ment

Input 2

Temperature : 5 to 35˚C

Hum

idity 35 - 85 % or less

10VA 210VA 210VA

Temperature : 5 to 35˚C

Humidity 35 - 85 % or less

Temperature : 5 to 35˚C

Humidity 35 - 85 % or less

DDL-8700A - 7

S :

Medium-weight materials

H : Heavy-weight materials

DDL-8700AS-7 DDL-8700AH-7

Max. sewing speed 5,000 sti/min 4,000 sti/min

Thread trimming speed 300 sti/min 300 sti/min

Stitch length

Presser foot l

(by knee l

Needle

Lubricating oil JUKI MACHINE OIL #7 JUKI MACHINE OIL #7

• The sewing speed will vary depending on the sewing conditions.

• The sewing speed preset at the time of shipping ......AS-7 : 4,000sti/min.

...... AH-7 : 3,500sti/min.

1

: Needle used depends on the destination.

*

*1

ift

ifter)

DB x 1 (#14) #9 to 18 DB x 1 (#21) #20 to 23

4mm 5mm

13 mm 13 mm

Noise

- Equivalent continuous emission sound pressure level (LpA) at the workstation :

A-weighted value of 79.5 dB; (Includes KpA = 2.5 dB); according to ISO 10821- C.6.2 -ISO

11204 GR2 at 4,000 sti/min.

– 1 –

Page 5

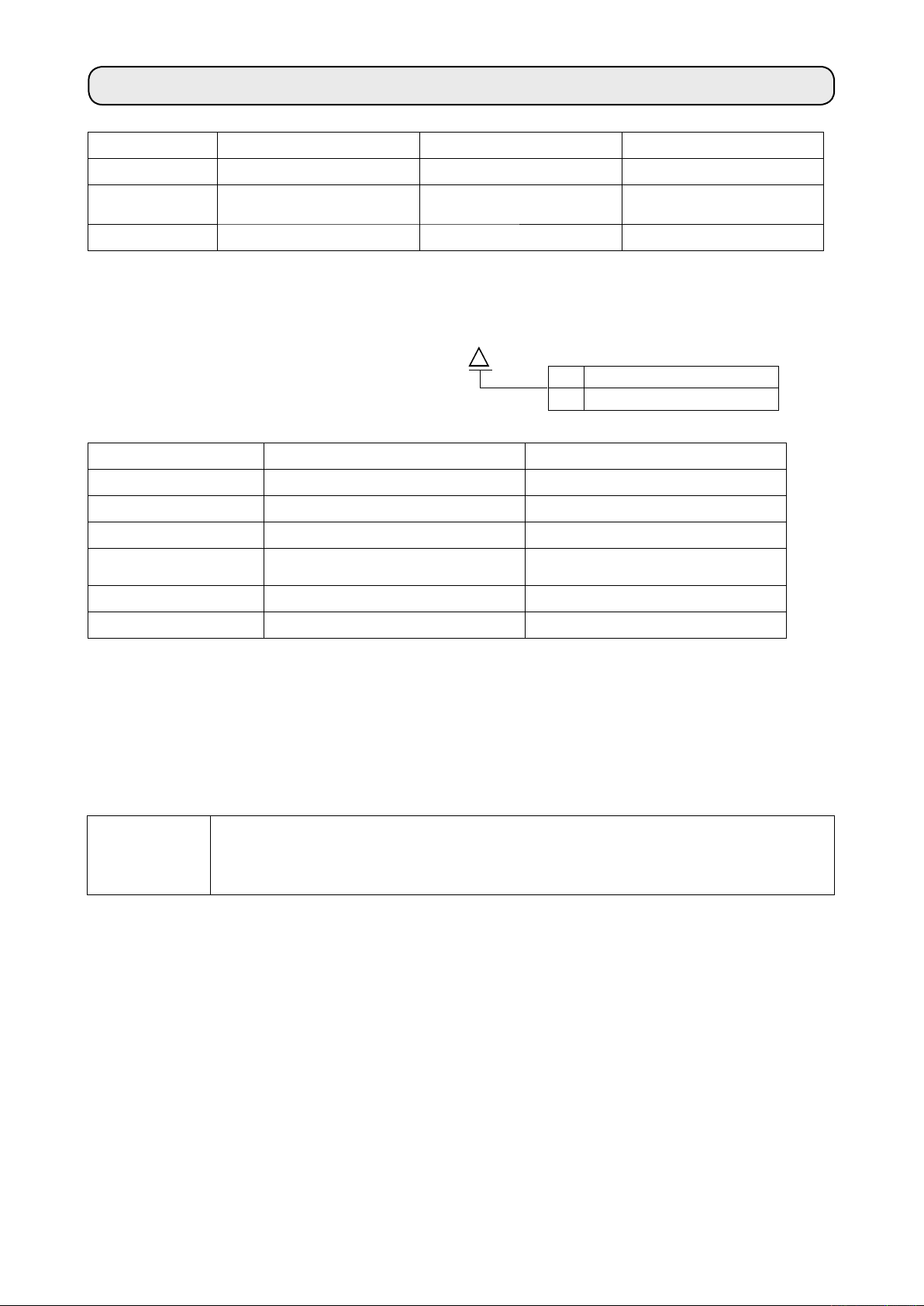

depth 10

DRAWING OF TABLE

(Hinge side only)

2-ø3.4 bottom surface, depth 10

bottom surface, depth 20

– 2 –

Page 6

@

. SET-UP

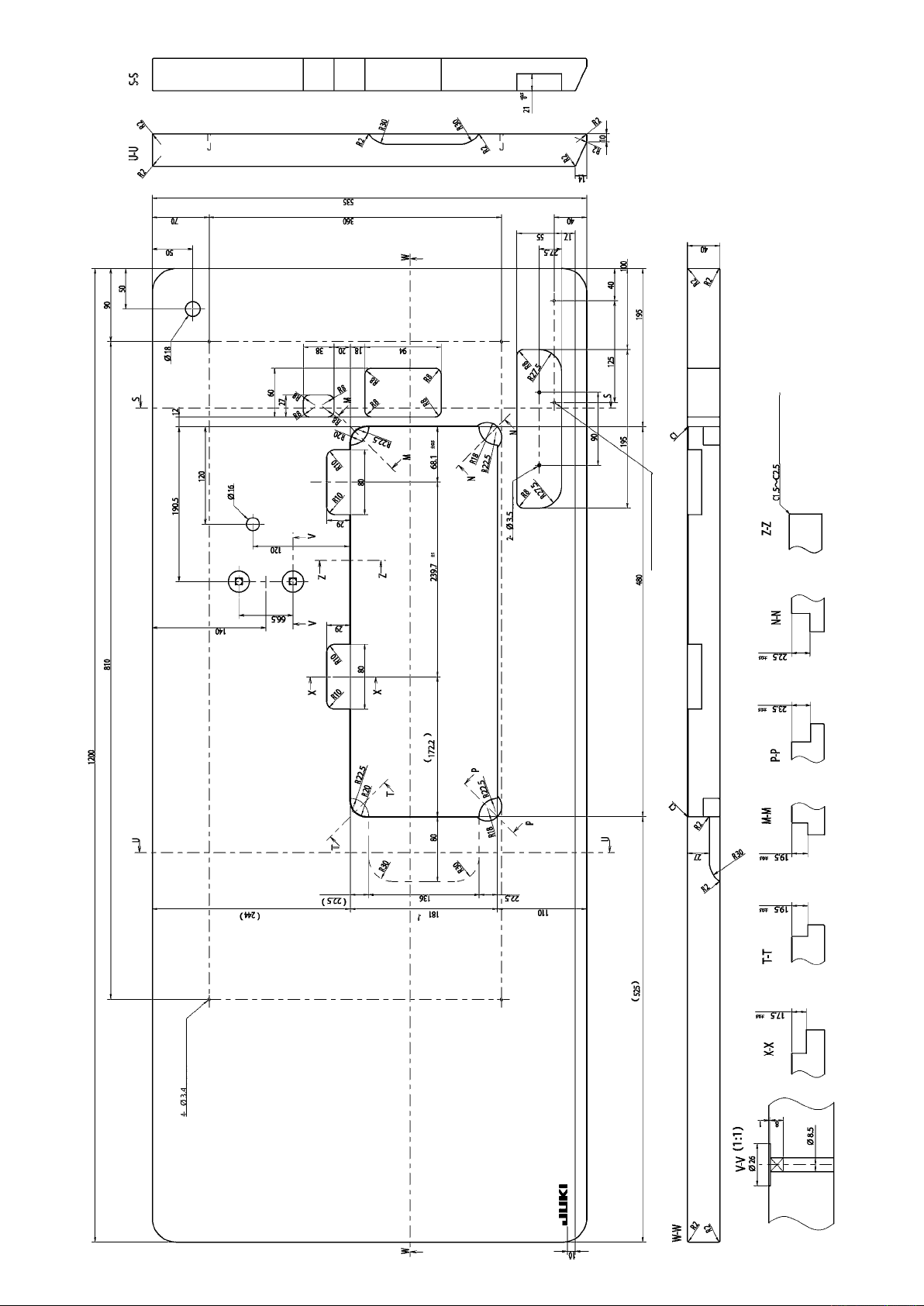

1. Installation

1) Carry the sewing machine with two persons as

shown in the gure above.

(Caution) Do not hold the handwheel.

8

3

1

Needle bar side

1

23.5mm

2

4

A

B

3

1

19.5mm

3

2) Do not put protruding articles such as the screw-

driver and the like at the location where the sew-

ing machine is placed.

3) The under cover should rest on the four cor-

ners of the mach

ine table groove. Mount rubber

hinge seat 8 on the table and x it on the table

ith a nail.

w

ontrol box side

C

1

23mm

2

4

19.5mm

3

A

B

4) Fix two rubber seats 1 on side A (operator’s s

on side B (h

3

9

5) Fit knee lifter pressing rod 6. F

to table rubber h

6)

Securely attach head support rod !0 to the table unt

(Caution) Be sure to install the machine head support bar supplied with the unit.

inged side) using a rubber-based adhesive. Then place under cover 4 on the xed seats.

6

7

it hinge 7 into the opening in the machine bed, and t the machine head

inge 8 before plac

ing the machine head on cushions 9 on the four corners.

ide) using nails 2 as

!1

!2

!0

il it goes no further.

illustrated above. Fix two cushion seats

8

7) Draw out cable !1 of the control box through cable draw-out hole !2 to route

sewing machine table.

– 3 –

7

it to the underside of the

Page 7

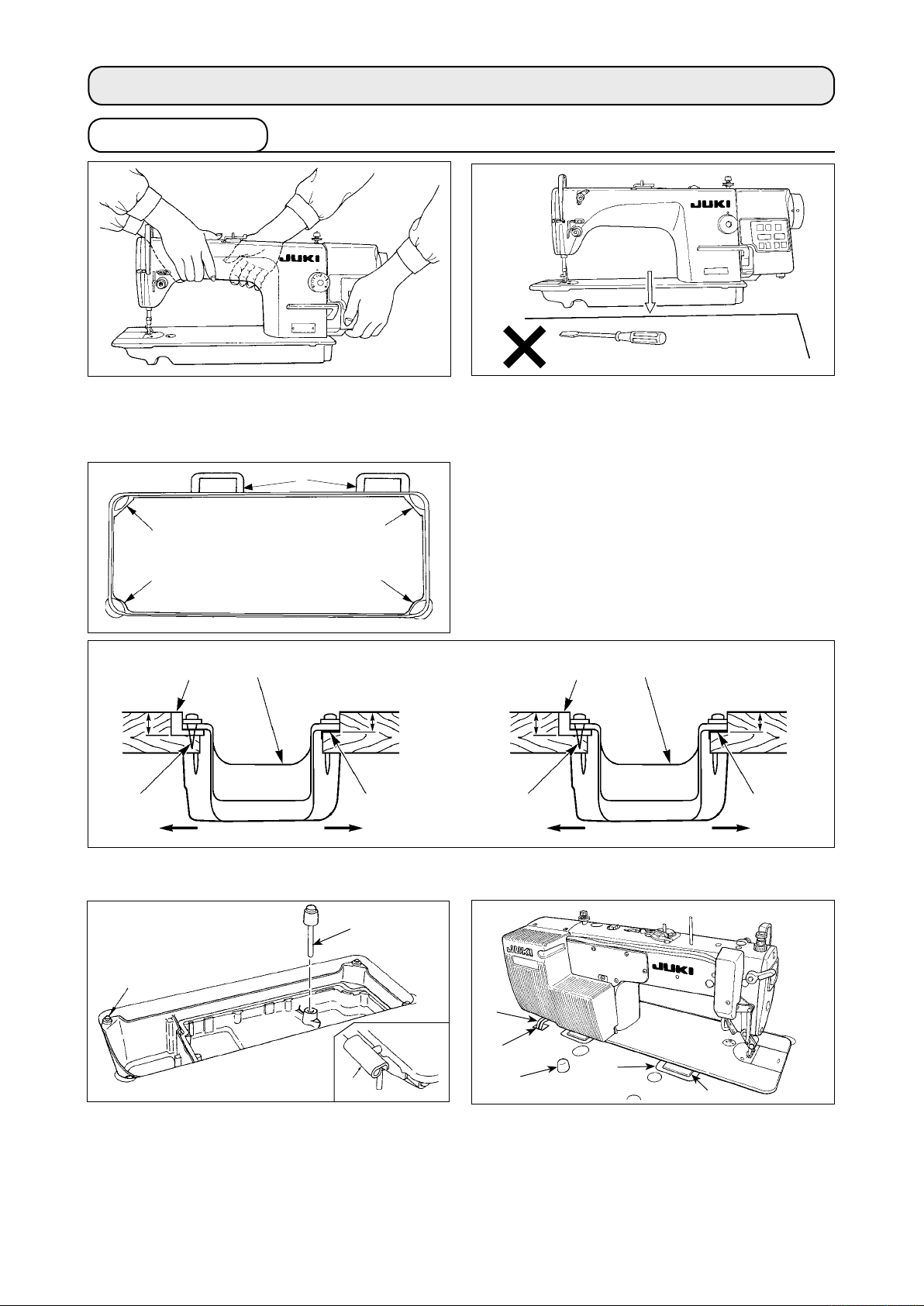

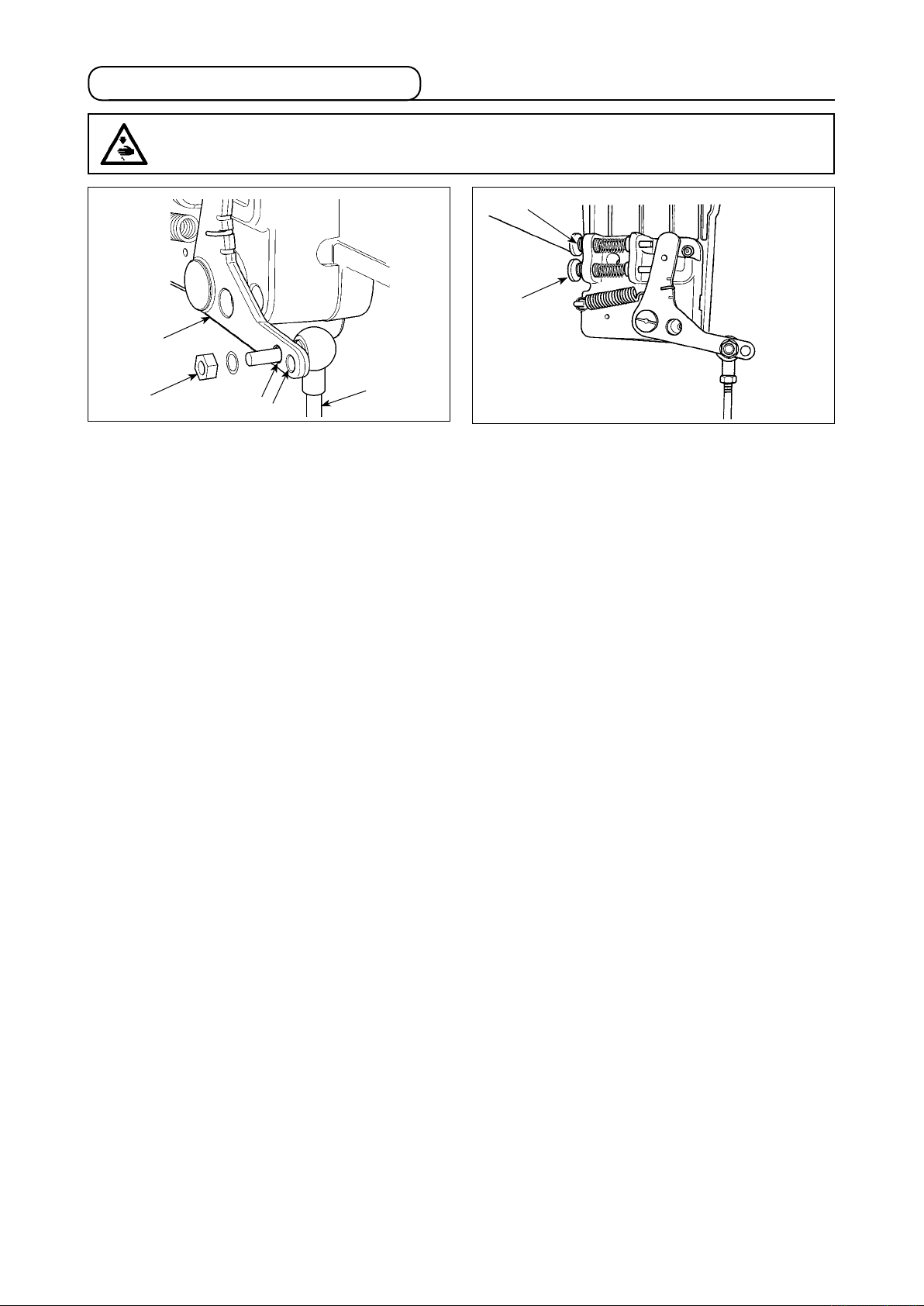

2. Installing the pedal sensor

1

1

The explanation applies to the case the

pedal sensor is installed on the table for

the DDL-8700A-7.

1) Install the pedal sensor on the table

by means of mounting bolt asm. 1

supplied with the unit. At this time,

insert the nut and washer supplied

with the unit as accessories as shown

in the gure so that the control box is

securely xed.

2) After the completion of installation of

the pedal sensor on the table, place

the sewing machine head on the

table.

washer

WARNING :

• To protect against personal injury resulting from abrupt start of the sewing machine, be sure to

turn the power OFF, unplug the machine and wait for ve minutes or more before installing the

pedal sensor.

•

To prevent damage of device caused by maloperation and wrong specifications, be sure to

connect all the corresponding connectors to the specied places. (If any of the connectors is

inserted into a wrong connector, not only the device corresponding to the connector can break

but also it can start abruptly, inviting the risk of personal injury.)

•

To prevent personal injury caused by maloperation, be sure to lock the connector with lock.

• As for the details of handling respective devices, read carefully the Instruction Manuals supplied

with the devices before handling the devices.

3. Installing the power switch

Plain

Spring

washer

Hexagonal

nat

(Caution) Do not insert the power plug into the plug receptacle.

1

1) Remove screw 1 on the side face of the power

switch cover to open the power switch cover.

– 4 –

2

2)

Pass AC input cord 2 coming from the control box

3

through the rear face of the power switch. Bundle

the cord with cable clip band 3 to secure it.

Page 8

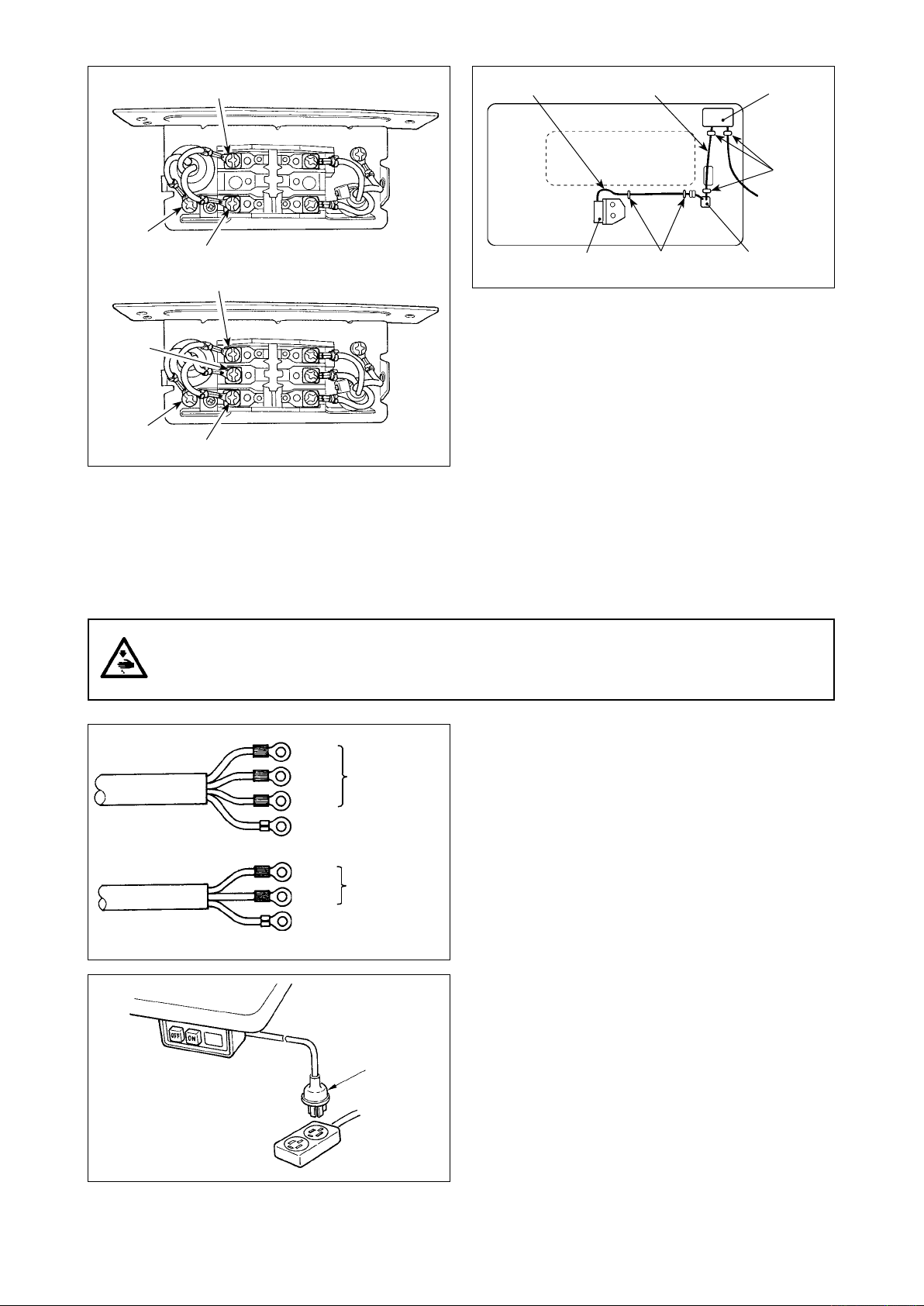

1ø 100V-120V

220V-240V

White

Pedal sensor cable

AC cable

Power switch

Staples

(large)

Green/

Yellow

3ø 200V-240V

Black

Green/

Yellow

Black

White

R

ed

3) Securely x the terminals of the AC input cord

by tightening the screws at the specied loca-

tions.

4) Close the power switch cover. Tighten screw 1

on the side face of the power switch cover.

WARNING :

1. Be sure to attach the ground wire (green/yellow) to the specied location (on the ground side).

2. Take care not to allow terminals to come in contact with each other.

3. When closing the power switch cover, take care not to allow the cord to be caught under it.

C

Pedal sensor

Staples (small)

able draw-out

hole

5) Firstly attach the staple supplied with the unit as

accessories to the cable. Then, hammer them

into the sewing machine table.

At this time, attach the staples at the locations

shown in the gure.

3ø 200V-240V

1ø 100V-120V

220V-240V

Black

C 200V-240V

ed

A

AC 100V-120V

AC 220V-240V

3

R

White

Green / Yellow

(ground wire)

Black

White

Green / Yellow

(ground wire)

6) Connect the power cord to the power plug.

As shown in the gure, connect the white and black

(and red) wires to the power supply side and the

green/yellow one to the grounding side.

(Caution) 1. Be sure to prepare the power plug

3

which conforms to the safety stan-

dard.

2.

Be sure to connect the ground lead

(green/yellow) to the grounding side.

7) Check that the power switch is in the OFF state.

Then, insert the power plug coming from the power

switch into the plug receptacle.

(Caution) In prior to the connection of the power

plug, re-check the supply voltage speci-

cation indicated on the power box.

– 5 –

Page 9

4. Attaching the connecting rod

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and a lapse of 5 minutes or more.

2

5

4

3

B

A

1) Fix connecting rod 1 to

installing hole B of

1

pedal lever 2 with nut 3.

2)

Installing connecting rod 1 to

w

ill lengthen the pedal depressing stroke, and

installing hole A

the pedal operation at a medium speed will be

easier.

3) The pressure increases as you turn reverse de-

pressing regulator screw 4

in, and decreases as

you turn the screw out.

(Caution) 1. If the screw is excessively loosened,

the spring will come off.

Loosen the screw to such an extent

that the top of the screw can be observed from the case.

2.

W hen eve r y ou have adjusted the

screw, be sure to secure the screw by

tightening metal nut 5 to prevent the

screw from loosening.

– 6 –

Page 10

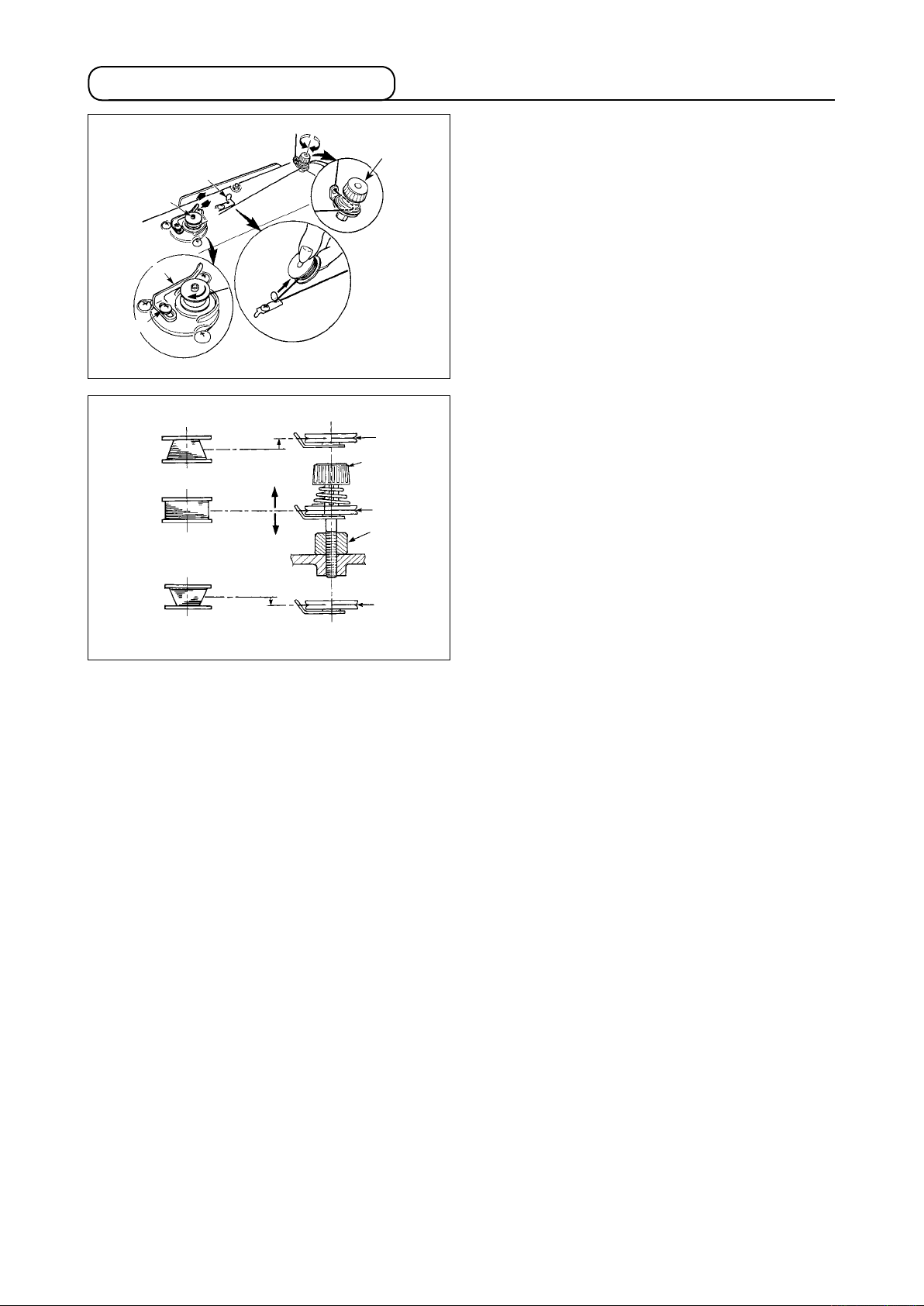

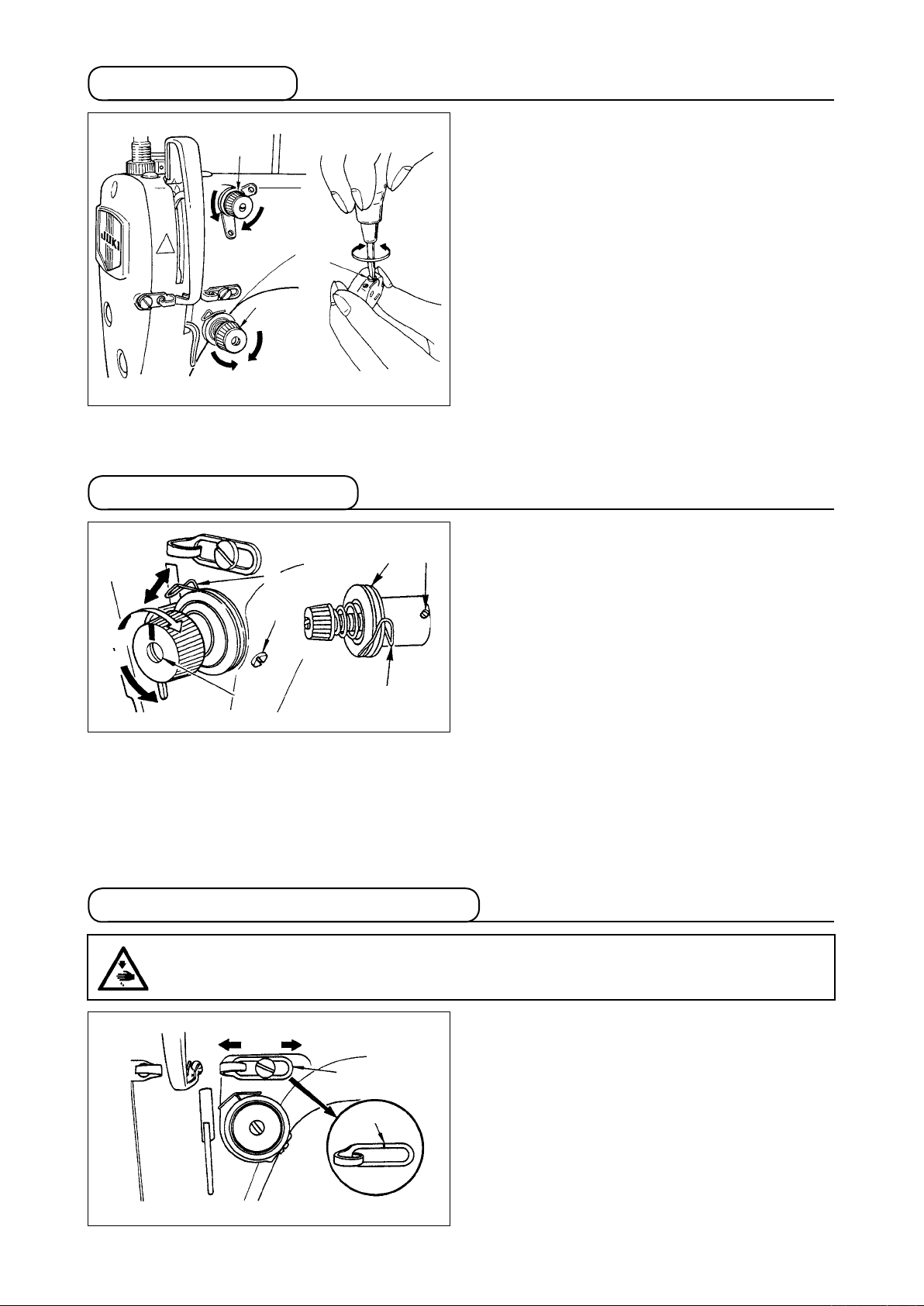

5. Winding the bobbin thread

3

B

1

2

4

A

C

D

E

7

5

6

6

6

8

1) Insert the bobbin deep into the bobbin winder

spindle 1 unt

il it will go no further.

2) Pass the bobbin thread pulled out from the

spool rested on the right side of the thread stand

following the order as shown in the gure on the

left.

Then, wind clockwise the end of the bobbin

thread on the bobbin several times.

(In case of the aluminum bobbin, after winding

clockwise the end of the bobbin thread, wind

counterclockwise the thread coming from the

bobbin thread tension several times to wind the

bobbin thread with ease.)

3) Press the bobbin winder trip latch 2

direction of A and start the sew

in the

ing machine.

The bobbin rotates in the direction of C and the

bobb

in thread is wound up. The bobbin winder

spindle 1 automat

ically as soon as the winding

is nished.

4) Remove the bobbin and cut the bobbin thread

with the thread cut retainer 3.

5) When adjusting the winding amount of the bob-

bin thread, loosen setscrew 4 and move bobbin

winding lever 2 to the direction of A or B. Then

tighten setscrew 4.

To the direction of A : Decrease

To the direction of B : Increase

6) In case that the bobbin thread is not wound evenly on the bobbin, remove the handwheel, loosen screw

and adjust the he

5

•

It is the standard that the center of the bobbin is as high as the center of thread tension disk 6.

• Adjust the position of thread tension disk 6 to the d

ight of bobbin thread tension 8.

irection of D when the winding amount of the bobbin

thread on the lower part of the bobbin is excessive and to the direction E when the winding amount of

the bobbin thread on the upper part of the bobbin is excessive.

After the adjustment, tighten screw 5.

7) To adjust the tension of the bobbin winder, turn the thread tension nut 7.

(Caution)

1. When winding the bobbin thread, start the winding in the state that the thread between the bobbin

and thread tension disk 6 is tense.

2. When winding the bobbin thread in the state that sewing is not performed, remove the needle thread

from the thread path of thread take-up and remove the bobbin from the hook.

3. There is the possibility that the thread pulled out from the thread stand is loosened due to the inu-

ence (direction) of the wind and may be entangled in the handwheel. Be careful of the direction of

the wind.

– 7 –

Page 11

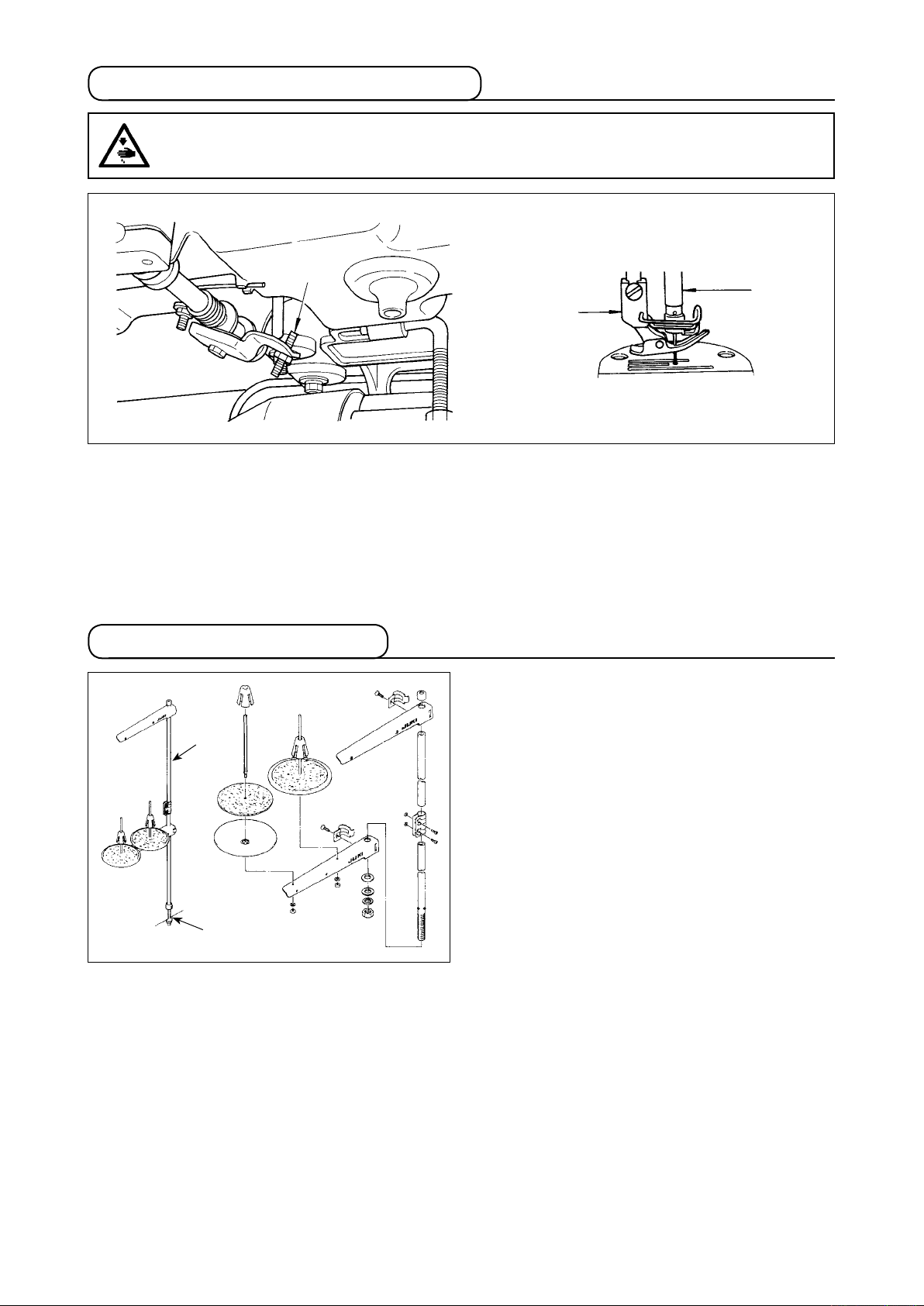

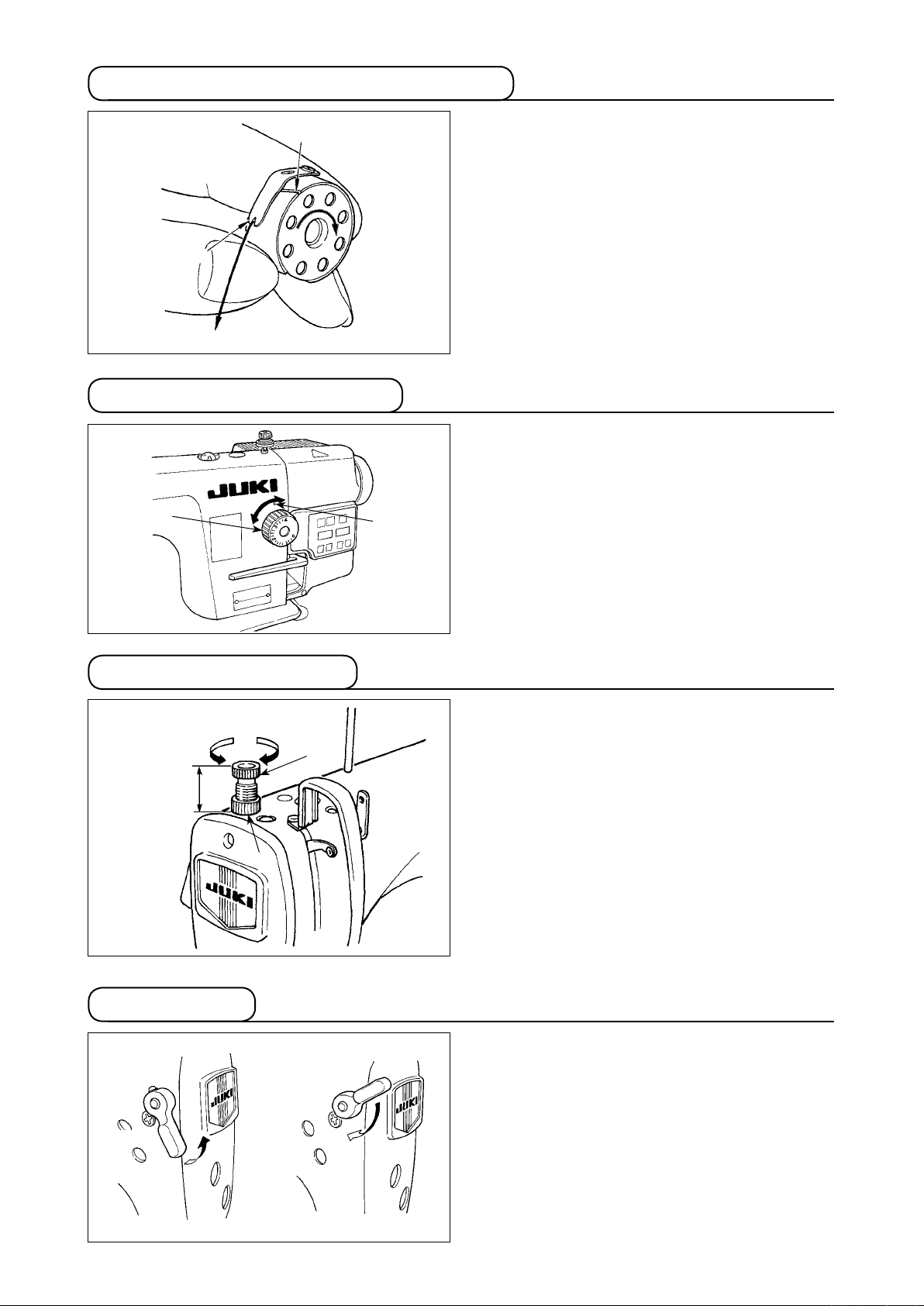

6. Adjusting the height of the knee lifter

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

1

2

3

1) The standard height of the presser foot lifted using the knee lifter is 10 mm.

2) You can adjust the presser foot lift up to 13 mm using knee lifter adjust screw 1.

3) When you have adjusted the presser foot lift to over 10 mm, be sure that the bottom end of needle bar

in its lowest position does not hit presser foot 3.

2

7. Installing the thread stand

2

1

1) Assemble the thread stand unit, and insert it in

the hole in the machine table.

2) Tighten nut 1.

3) For ceiling wiring, pass the power cord through

spool rest rod 2.

– 8 –

Page 12

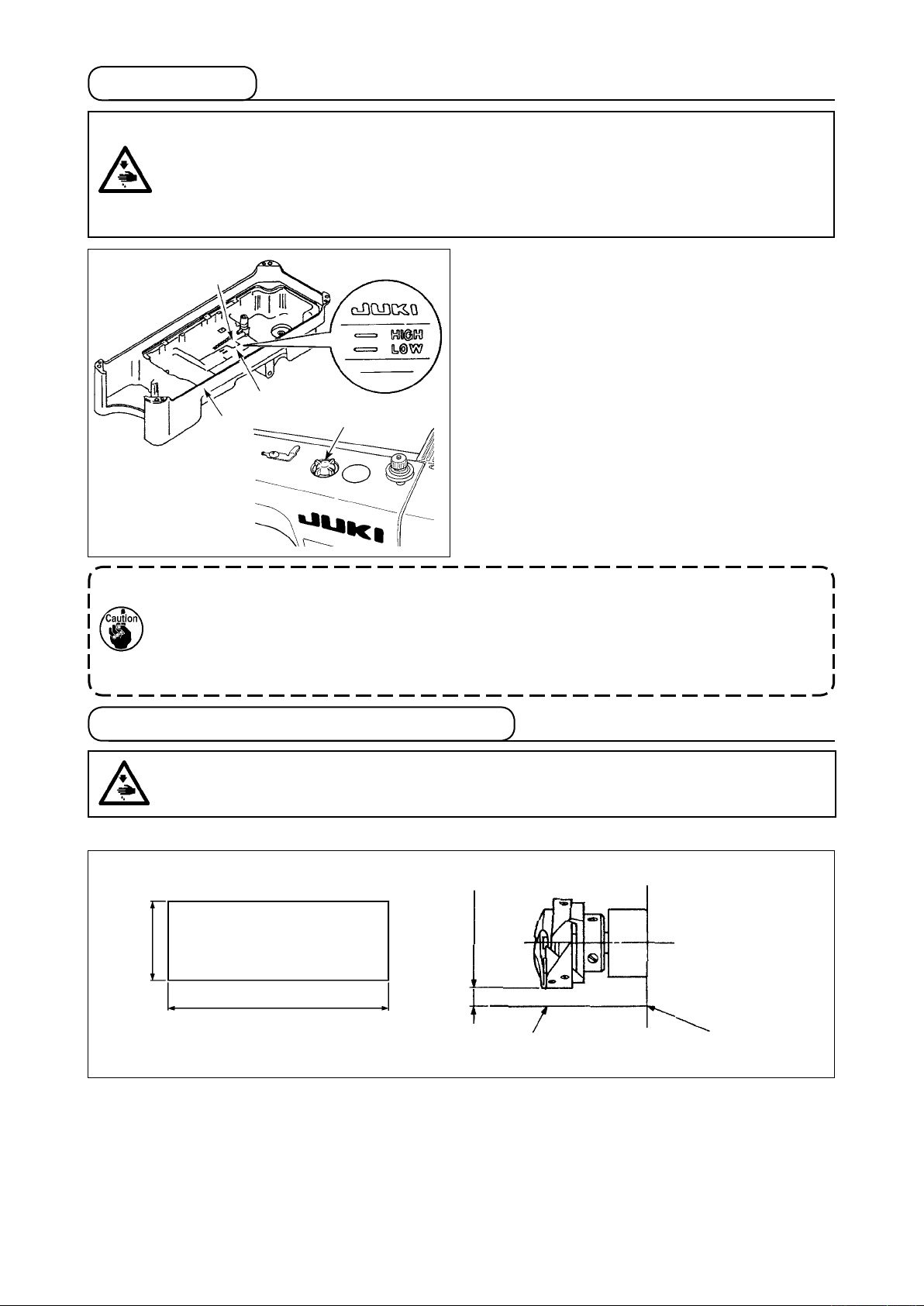

8. Lubrication

WARNING :

1. Do not connect the power plug until the lubrication has been completed so as to prevent

accidents due to abrupt start of the sewing machine,

2.

To prevent the occurrence of an inammation or rash, immediately wash the related portions if

oil adheres to your eyes or other parts of your body.

3.

If oil is mistakenly swallowed, diarrhea or vomitting may occur. Put oil in a place where children

cannot reach.

A

1

B

2

1) Before starting the sewing machine, ll oil pan

with JUKI MACHINE OIL #7 up to HIGH mark

1

.

A

2)

When the oil level lowers below LOW mark B,

rell the oil pan with the specied oil.

3) When you operate the machine after lubrica-

tion, you will see splashing oil through oil sight

window 2

if the lubrication is adequate.

4) Note that the amount of the splashing oil is un-

related to the amount of the lubr

icating oil.

1. When you use a new sewing machine or a sewing machine after an extended period of dis-

use, use the sewing machine after performing break-in at 2,000 sti/min or less.

2. For the oil for hook lubrication, purchase JUKI NEW DEFRIX OIL No. 1 (Part No. : MD-

FRX1600C0) or JUKI MACHINE OIL #7 (Part No. : MML007600CA).

3. Be sure to lubricate clean oil.

9. Adjusting the amount of oil (oil splashes)

WARNING :

Be extremely careful about the operation of the machine since the amount of oil has to be checked

by turning the hook at a high speed.

(1) Conrmation of the amount of oil in the hook

Amount of oil (oil splashes) conrmation paper

1

25 mm

70 mm

Position to conrm the amount of oil (oil splashes)

2

3 - 10 mm

Oil splashes conrmation paper

Closely t the paper against the wall

surface of the bed.

* When carrying out the procedure described below in 2, remove the slide plate and take extreme caution

not to allow your ngers to come in contact with the hook.

1) If the machine has not been sufciently warmed up for operation, make the machine run idle for approxi-

mately three minutes. (Moderate intermittent operation)

2) Place the amount of oil (oil spots) conrmation paper under the hook immediately after the machine

stops running.

3) Conrm the height of the oil surface in the oil reservoir is within the range between “HIGH” and “LOW”.

4) Conrmation of the amount of oil should be completed in ve seconds. (Check the period of time with a

watch.)

– 9 –

Page 13

(2) Adjusting the amount of oil (oil spots) in the hook

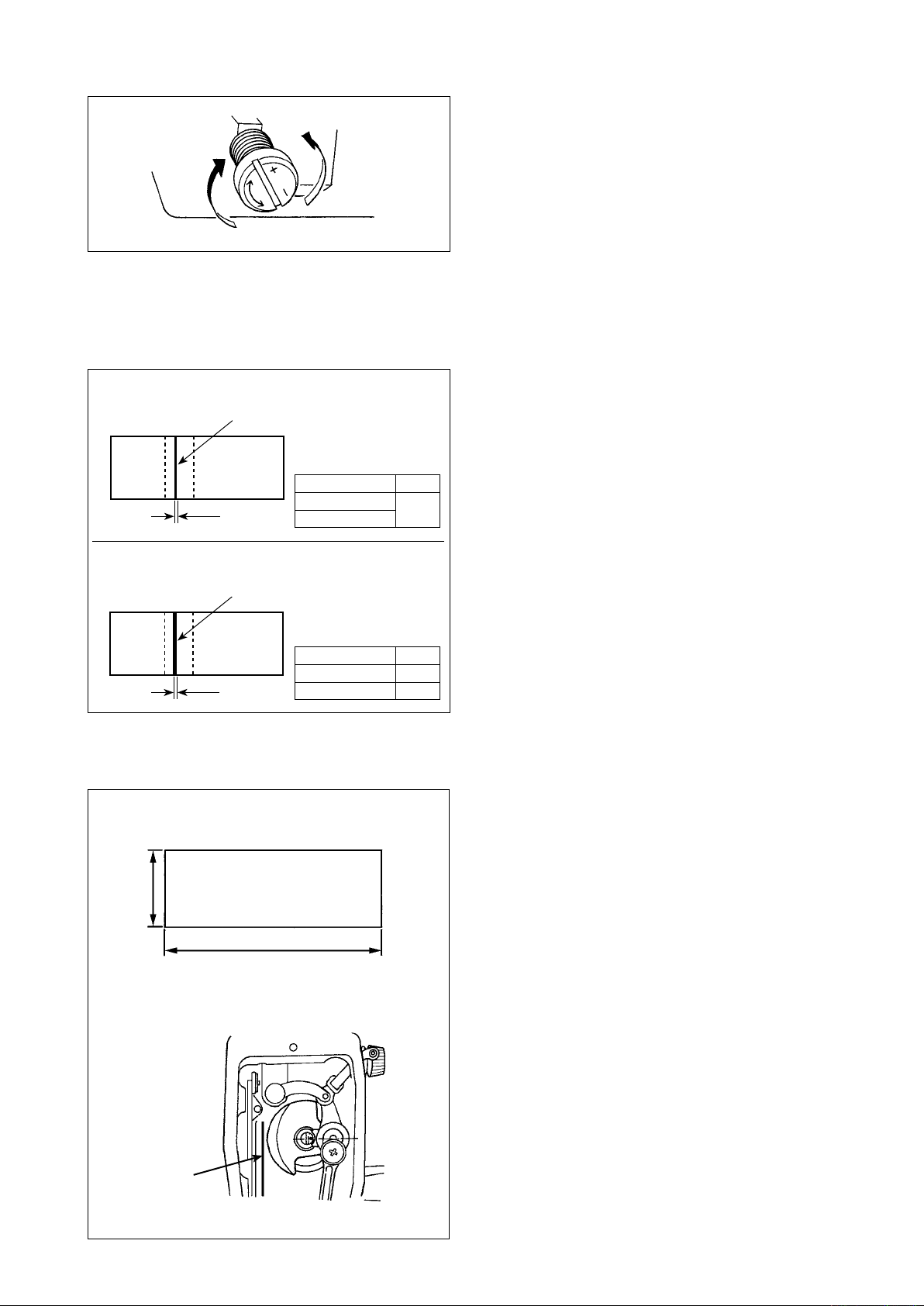

1) Turning the oil amount adjustment screw attached

on the hook driving shaft front bushing in the “+”

direction (in direction A) w

oil (oil spots) in the hook, or in the “–” direction (in

d

B

A

irection B) w

2) After the amount of oil in the hook has been prop-

erly adjusted w

make the sewing machine run idle for approximately

30 seconds to check the amount of oil in the hook.

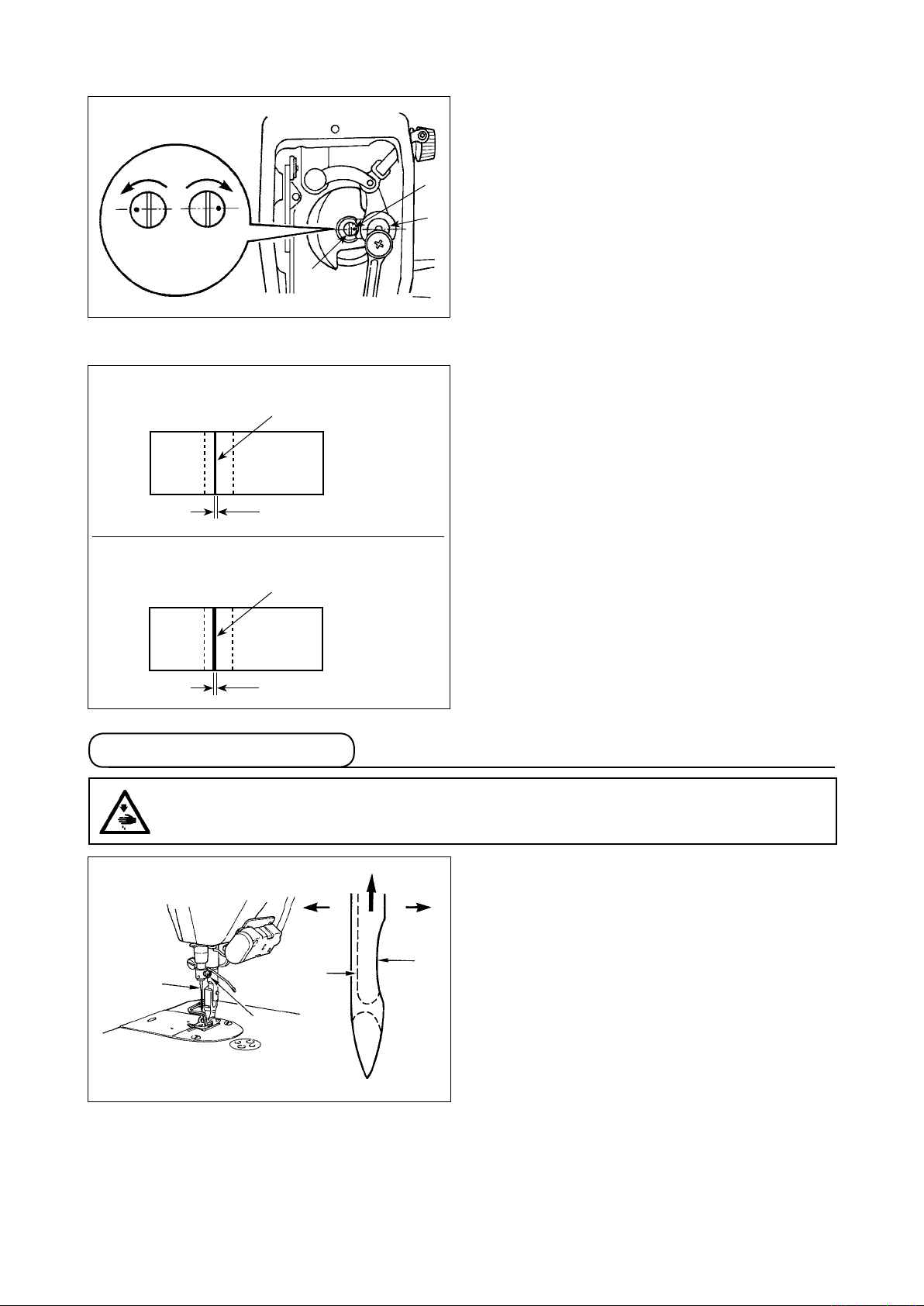

(3) Sample showing the appropriate amount of oil in the hook

ill increase the amount of

ill decrease it.

ith the oil amount adjustment screw,

Appropriate amount of oil (small)

Splashes of oil from the hook

should be nely adjusted in accordance with sewing

processes.

Be careful not to excessively increase/decrease the

amount of oil in the hook. (If the amount of oil is too

1) The amount of oil shown in the samples on the left

* mm

DDL-8700AS-7

DDL-8700AH-7

* mm

1mm

small, the hook will be seized (the hook will be hot).

If the amount of oil is too much, the sewing product

may be stained with oil.)

Appropriate amount of oil (large)

Splashes of oil from the hook

2) Adjust the amount of oil in the hook so that the

oil amount (oil splashes) should not change while

checking the oil amount three times (on the three

sheets of paper).

* mm

* mm

DDL-8700AS-7

DDL-8700

AH-7

2mm

3mm

(4) Conrmation of the amount of oil supplied to the face plate parts

Amount of oil (oil splashes) conrmation paper

1

25 mm

70 mm

Position to conrm the amount of oil

2

(oil splashes)

Oil splashes

conrmation paper

* When carrying out the work described below in

2), remove the face plate and take extreme cau-

tion not to allow your ngers to come in contact

with the thread take-up lever.

1) If the machine has not been sufciently warmed

up for operation, make the machine run idle for

approximately three minutes. (Moderate inter-

mittent operation)

2) Place the amount of oil (oil spots) conrmation

paper under the hook immediately after the ma-

chine stops running.

3) Conrm the height of the oil surface in the oil

reservoir is within the range between “HIGH”

and “LOW”.

4) The time required for the conrmation of the

amount of oil (oil splashes) should be completed

in ten seconds. (Measure the period of time with

a watch.)

– 10 –

Page 14

(5) Adjusting the amount of oil supplied to the face plate parts

1) Adjust the amount of oil supplied to the thread

take-up and needle bar crank 2 by turn

just p

in 1.

C

maximum

1

minimum

B

1

A

2) The minimum amount of oil is reached when

is brought close to needle bar

is brought to the position just op-

2

marker dot A

crank 2 by turning the adjust pin in direction B.

3)

The maximum amount of oil is reached when

marker dot A

pos

ite from the needle bar crank by turning the

adjust pin in direction C.

(6) Sample showing the appropriate amount of oil supplied to the face plate parts

ing ad-

Appropriate amount of oil (small)

S

plashes of oil from the thread take-up lever

1 mm

Appropriate amount of oil (large)

S

plashes of oil from the thread take-up lever

2 mm

10. Attaching the needle

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

1) The state given in the gure shows the appropr

ate amount of o

il (oil splashes). It is necessary

to nely adjust the amount of oil in accordance

with the sewing processes. However, do not

excessively increase/decrease the amount of oil

in the hook. (If the amount of oil is too small, the

hook will be seized (the hook will be hot). If the

amount of oil is too much, the sewing product

may be stained with oil.)

2) Adjust the amount of oil in the hook so that the

oil amount (oil splashes) should not change

while checking the oil amount three times (on

the three sheets of paper).

i-

Use the specied needle for the machine. Use the

p

roper needle in accordance with the thickness of

D

B

thread used and the kinds of the materials.

1) Turn the handwheel until the needle bar reaches

the highest point of its stroke.

2) Loosen screw 2, and hold needle 1 w

ith its

indented part A facing exactly to the right in

direction B.

3)

Insert the needle fully into the hole in the needle

1

C

A

2

bar in the direction of the arrow until the end of

hole is reached.

4) Securely tighten screw 2.

5) Check that long groove C of the needle

(Caution) When polyester lament thread is used, if the indented part of the needle is tilted toward opera-

tor's side, the loop of thread becomes unstable. As a result, hangnail of thread or thread breakage may

occur. For the thread that such phenomenon is likely to occur, it is effective to attach the needle with its

indented part slightly slanting on the rear side.

is facing exactly to the left in direction D.

– 11 –

Page 15

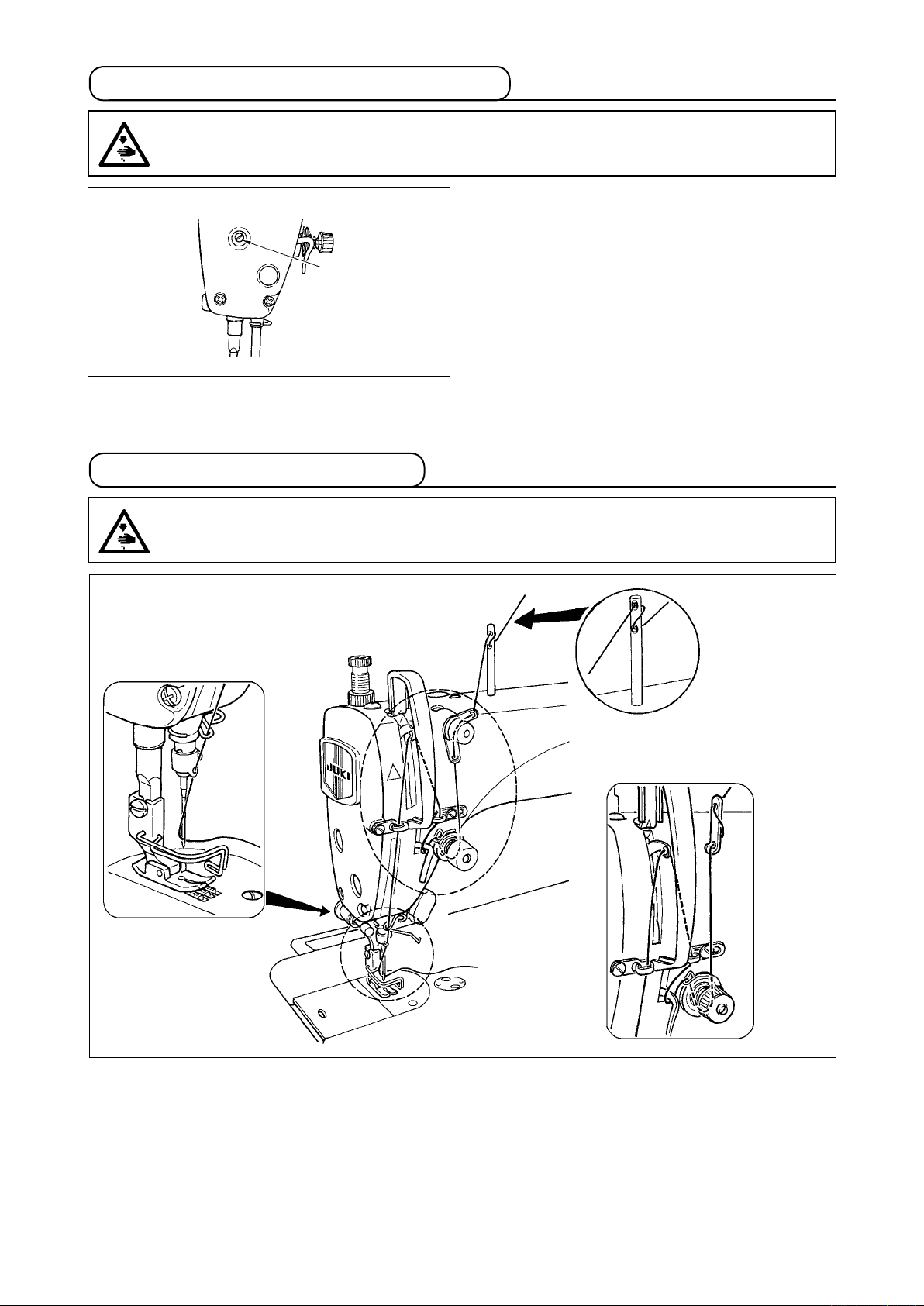

11. Setting the bobbin into the bobbin case

A

B

C

12. Adjusting the stitch length

1

A

1) Pass the thread through thread slit A, and

pull the thread in direction C. By so do

ing, the

thread will pass under the tension spring and

come out from notch B.

2)

Check that the bobbin rotates in the direction of

the arrow when thread is pulled.

* The dial calibration is in millimeters.

1) Turn stitch length dial 1

in the direction of the

arrow, and align the desired number to marker

dot A on the machine arm.

13. Presser foot pressure

B

29 to 32 mm

A

1

2

14. Hand lifter

1) Loosen nut 2.

As you turn presser spring regu-

lator 1 clockwise (in direction A), the presser

foot pressure will be increased.

2) As you turn the presser spring regulator counter-

clockwise (in direction B), the pressure will be

decreased.

3) After adjustment, tighten nut 2.

The standard value of the pressure regulating thumb

screw is 29 to 32 mm.

1) The presser foot is lifted by moving the lever

upward.

2)

The presser foot is lowered by moving the lever

downward.

– 12 –

Page 16

15. Adjusting the height of the presser bar

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

1

16. Threading the machine head

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

1) Loosen setscrew 1, and adjust the presser bar

height or the angle of the presser foot.

2) After adjustment, securely tighten the setscrew

.

1

– 13 –

Page 17

17. Thread tension

1

B

A

2

3

E

F

(1) Adjusting the needle thread tension

1) The length of thread remaining at the needle

tip after thread trimming is shortened by turning tension regulating nut No. 1 1 clockw

direction A.

2)

It is lengthened by turning the nut counterclock-

wise in direction B.

3) The needle thread tension is increased by turning tension regulating nut No. 2 2 clockw

direction C.

4)

It is decreased by turning the nut counterclock-

wise in direction D.

ise in

ise in

C

D

18. Thread take-up spring

1

2

A

B

3

1

5

4

(2) Adjusting the bobbin thread tension

1) The bobbin thread tension is increased by turning tension regulating screw 3 clockw

ise in

direction E.

2)

It is decreased by turning the screw counter-

clockwise in direction F.

(1) Changing the stroke of thread take-up

spring

1) Loosen setscrew 2.

2) As you turn tension post 3 clockw

t

will be increased.

3) As you turn the knob counterclockwise (in direct

1

ise (in direc-

ion A), the stroke of the thread take-up spr

ion B), the stroke w

ill be decreased.

ing

(2) Changing the pressure of thread take-up

spring

1) Loosen setscrew 2,

2)

Loosen setscrew 4.

3) As you turn tension post 3 clockw

t

4) As you turn the tension post counterclockwise (in

direction B), the pressure will be decreased.

1

and remove tension post 3.

ion A), the pressure w

ise (in direc-

ill be increased.

19. Adjusting the thread take-up stroke

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

BA

1

C

1) When sewing heavy-weight materials, move

thread guide 1 to the left (in direction A) to

increase the length of thread pulled out by the

thread take-up.

2) When sewing light-weight materials, move

thread guide 1 to the right (in direction B) to

decrease the length of thread pulled out by the

thread take-up.

3) Normally, thread guide 1 is positioned in a way

that marker line C is aligned with the center of

the screw.

– 14 –

Page 18

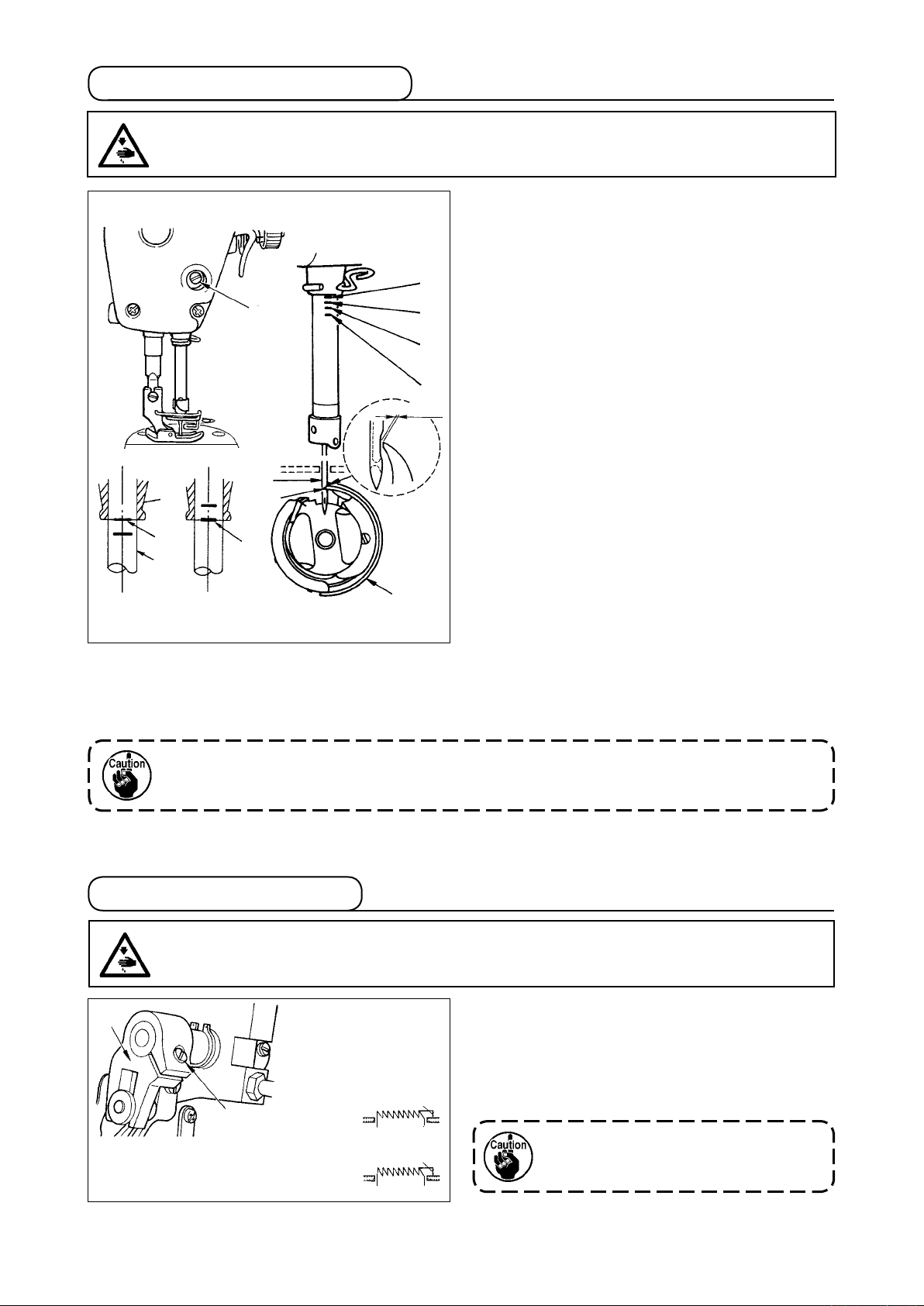

20. Needle-to-hook relationship

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

1

4

3

A

2

5

B

C

D

A

B

0.04 to 0.1 mm

a

(1) Adjust the timing between the needle and

the hook as follows :

1) Turn the handwheel to bright the needle bar

down to the lowest point of its stroke, and

loosen setscrew 1.

(Adjusting the needle bar height)

2)

(For a DB needle)

needle bar 2 with the bottom end of needle bar

lower bushing 3, then tighten setscrew 1.

(For a D

A needle)

needle bar 2 w

lower bushing 3, then tighten setscrew 1.

Align marker line A on

Align marker line C on

ith the bottom end of needle bar

(Adjusting position of the hook a)

3)

(For a DB needle)

setscrews, turn the handwheel and align marker

line B on ascend

tom end of needle bar lower bush

(For a DA needle)

setscrews, turn the handwheel and align marker

line D on ascend

tom end of needle bar lower bush

Loosen the three hook

ing needle bar 2 with the bot-

ing 3.

Loosen the three hook

ing needle bar 2 with the bot-

ing 3.

4) After making the adjustments mentioned in the above steps, align hook blade point 5 with the center

of needle 4. Provide a clearance of 0.04 mm to 0.1 mm (DDL-8700AH-7 : 0.06 to 0.17mm) (reference

value) between the needle and the hook, then securely tighten setscrews in the hook.

If the clearance between the blade point of hook and the needle is smaller than the specied

value, the blade point of hook will be damaged. If the clearance is larger, stitch skipping will

result.

21. Height of the feed dog

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

1

2

0.75 to 0.85 mm

DDL-8700AS-7

1.15 to 1.25 mm

DDL-8700

AH-7

To adjust the height of the feed dog :

Loosen screw 2 of crank 1.

1

Move the feed bar up or down to make adjust-

2

ment.

Securely t

3

If the clamping pressure is insufcient,

ighten screw 2.

th e motion of the forked po rtion becomes heavy.

– 15 –

Page 19

22. Tilt of the feed dog

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

B

A

Front up

a

Front down

c

1

b

d

Standard

T

hroat plate

1) The standard tilt (horizontal) of the feed dog

a

is obtained when marker dot A on the feed

bar shaft is aligned with marker dot B on feed

b

d

rocker 1.

2) To tilt the feed dog with its front up in order to

c

prevent puckering, loosen the setscrew, and

turn the feed bar shaft 90˚ in the direction of the

arrow, using a screwdriver.

3) To tilt the feed dog with its front down in order

to prevent uneven material feed, turn the feed

bar shaft 90˚ in the opposite direction from the

arrow.

Whenever the feed dog tilt is adjusted,

the feed dog height will be changed. So,

it is necessary to check the height after

tilt adjustment.

23. Adjusting the feed timing

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

Standard feed timing

1

2

Advanced feed timing

3

Delayed feed timing

1) Loosen screws 2 and 3 in feed eccentric cam

, move the feed eccentric cam in the direction

1

of the arrow or opposite direction of the arrow,

and rmly tighten the screws.

2)

For the standard adjustment, adjust so that the

top surface of feed dog and the top end of needle

eyelet are ush with the top surface of throat plate

when the feed dog descends below the throat

plate.

3) To advance the feed timing in order to prevent

uneven material feed, move the feed eccentric

cam in the direction of the arrow.

4) To delay the feed timing in order to increase

stitch tightness, move the feed eccentric cam in

the opposite direction from the arrow.

Be careful not to move the feed eccen-

tric cam too far, or else needle breakage

may result.

– 16 –

Page 20

24. Cunter knife

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

a

C

Moving knife

a

Standard : 4.0mm (DDL-8700AH-7: 4.5mm)

c

1

b

c

B

Center of needle

b

A

1

If the knife does not cut thread sharply, immediately

re-sharpen counter knife 1

and re-

install it properly.

as illustrated in Fig. C

1) If the mounting position of the counter knife is

moved in direction A from the standard mount-

ing position, the thread length after thread trim-

ming will be increased accordingly.

2) If the mounting position is moved in direction B,

the thread length will be decreased accordingly.

When sharpening again the knife blade,

extra special care must be taken on the

handling of the knife.

25. Pedal pressure and pedal stroke

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

2

1

3

(1) Adjusting the pressure required to de-

press the front part of the pedal

When the pedal pressure spring 1

the lower side, the pedal pressure will decrease,

and when hooked to the upper side, the pedal

pressure will increase.

is hooked to

(2) Adjusting the pressure required to de-

press the back part of the pedal

The pressure increases as you turn reverse de-

pressing regulator screw 2

in, and decreases as

you turn the screw out.

(3) Adjusting the pedal stroke

The pedal stroke decreases when you insert con-

necting rod 3

into the left hole.

– 17 –

Page 21

26. Adjustment of the pedal

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

1

2

5

4

(1) Installing the connecting rod

1) Move pedal 3 to the r

by the arrows so that motor control lever 1 and

connect

(2) Adjusting the pedal angle

ing rod 2 are stra

1) The pedal tilt can be freely adjusted by changing

the length of the connecting rod.

2) Loosen adjust screw 4, and adjust the length of

connecting rod 2.

ight or left as illustrated

ightened.

3

– 18 –

Page 22

#

. FOR THE OPERATOR

1. Operating procedure of the sewing machine

itch to turn ON

3

3

4

5

1

1) Press ON button 1 of the power sw

the power.

(

Caution) If the backlight of the operation panel

does not light up after the power switch

turned ON, immediately turn the power

is

OFF and check the voltage. In addition,

in such a case as this, re-turn ON the

power swit ch when 2 to 3 minutes or

have passed after turning OFF the

more

power switch.

When the needle bar is not in UP position, it auto-

2)

mat

ically turns to the UP position.

(Caution) When turning ON the power for the rst

time, there is the case where the timing is slightly retarded to perform the

initialization

power, the needle bar moves. Do not put

your hands or things under the needle.

3)

The pedal is operated in the following four steps:

a. The machine runs at low sewing speed when you

lightly depress the front part of the pedal.

b. The machine runs at high sewing speed when you

further depress the front part of the pedal. 3

(If the automat

preset, the machine runs at high speed after it com-

pletes reverse feed stitching.)

c. The machine stops (with its needle up or down)

when you reset the pedal to its original position.

d. The machine trims threads when you fully depress

the back part of the pedal.

work. When turning ON the

ic reverse feed stitching has been

5

* When the auto-lifer (AK device) is used, one more operating switch is provided between the sewing

machine stop switch and thread trimming switch. The presser foot goes up when you lightly depress the

back part of the pedal 4, and

When start

ing sewing from the state that the presser foot has been lifted with the Auto-lifter and you

if you further depress the back part 5, the thread trimmer is actuated.

depress the back part of the pedal, the presser foot only comes down.

• If you reset the pedal to its neutral position during the automatic reverse feed stitching at seam start, the

machine stops after it completes the reverse feed stitching.

• The machine will perform normal thread trimming even if you depress the back part of the pedal immedi-

ately following high or low speed sewing.

• The machine will completely perform thread trimming even if you reset the pedal to its neutral position

immediately after the machine started thread trimming action.

Presser foot operation by

pedal

Pedal depressing depth for

thread trimming

PFL KFL

Enabled D

Deep Shallow

isabled

– 19 –

Page 23

– 20 –

7

4) Reverse feed stitching at the beginning of sewing, reverse feed stitching at the end of sewing

and various sewing patterns can be set on builtin panel 6 of the machine head.

6

5) For some types of the sewing machine heads,

reverse feed is performed by pressing touch-back

switch 7.

2

6) When sewing is completed, press OFF button 2 of

the power switch to turn OFF the power switch after

conrming that the sewing machine has stopped.

Caution) In the case the machine is not used for

(

a long time, remove the power plug from

the plug receptacle.

Page 24

2. Built-in panel of the machine head

1

E

7

B

A

3

1

DC

2

4 5 6

switch : Used for changing over effective/ineffective of the reverse feed stitching pattern.

2

3

switch : Used for changing over effective/ineffective of the overlapped stitching pattern.

switch : Used for conrming the contents of setting and for changing over effective/ineffective of

the reverse feed stitching at sewing start.

4

switch : Used for selecting the process (A, B, C, D) the number of stitches for which is to be

changed.

* The selected process ashes on and off.

switch : Used for changing the content of the selected display (ashing section) and for changing

5

over effective/ineffective of the reverse stitch at sewing end.

switch : Used for changing the content of the selected display (ashing section).

6

7

switch : It is used to call the production support function and to call the one-touch setting (it

should be held pressed for one second).

icators A and B : Various pieces of information are displayed.

Ind

LED C : Lights up when the reverse feed stitching pattern is effective.

LED D : Lights up when the overlapped stitching pattern is effective.

LED E : Lights up when the production support function is displayed.

– 21 –

Page 25

– 22 –

3. Operating procedure of the sewing pattern

(Caution) Refer to the Instruction Manual for each operation panel for how to operate sewing patterns us-

ing other operation panel than the built-in panel of the machine head.

(1) Reverse feed stitching pattern

Reverse feed stitching at sewing start and reverse feed stitching at sewing end can be separately pro-

grammed.

C

1 2

[Setting procedure of the reverse feed stitching]

) Effective/ineffective of the reverse feed stitching

1

A

B

pattern can be changed over by pressing

switch 1.

When the reverse feed st

dered effective, LED C l

itching pattern is ren-

ights up, the number of

stitches of the reverse feed stitching at sew-

i

ng start is displayed on A, and the number of

stitches of the reverse feed stitching at sewing

end is displayed on indicator B.

Select a process (A, B, C or D) the number of

stitches for which is to be changed by using

543

6

switch 4.

The number which is ashing on and of

f repre-

sents the process which is being set.

Change the number of stitches for the selected

process by using

.

6

Press

switch 3 to conrm the

switch 5 and switch

change you

have made. (The number of stitches that can be

set is 0 to 15.)

(Caution) The sewing machine cannot perform sew-

ing when the display of the number of stitches

for a process is ashing on and off.

Without reverse

stitching

everse

R

stitching

Double reverse

stitching

53

play is not ashing on and off, every press on

switch 3 changes over the reverse feed

stitching mode from the "reverse feed stitching

at sewing start," "double reverse feed stitching

at sewing start" and "no reverse feed stitching at

sewing start."

2) When the number of reverse feed stitches dis-

In addition, every time

switch 5

is pressed,

the reverse feed stitching feature changes over

from the reverse feed stitching at sewing end to

the double reverse stitch at sewing end, then to

no reverse feed stitching at sewing end, in turn.

Page 26

(2) Overlapped stitching pattern

Overlapped stitching pattern can be programmed.

A

C

D

C

B

D

2

A

B

A : Number of stitches of normal stitching setting

0 to 15 stitches

B : Number of stitches of reverse stitching setting

0 to 15 stitches

C : Number of stitches of normal stitching setting

0 to 15 stitches

D : Number of times of repetition

0 to 9 times

(Caution) When process D is set to 5 times, the sewing is repeat

ed as A / B /

C / B / C.

[Setting procedure of the overlapped stitching]

1

) Effective/ineffective of the overlapped stitching

pattern can be changed over by pressing

B

switch 2.

When the overlapped st

dered effective, LED D l

itching pattern is ren-

ights up.

-

2) Select a process (A, B, C or D) the number of

stitches for which is to be changed by using

switch 4.

The number which is ashing on and of

f repre-

sents the process which is being set.

543

3) Change the number of stitches for the selected process by using

4) Press

switch 3 to conrm the change you have made.

(The sewing machine does not run unless the setting has been conrmed by pressing

(Caution) The overlapped stitching pattern is carried out under automatic operation mode. Once the pedal

is depressed, the sewing machine will automatically perform sewing of the number of overlapped

stitches.

6

switch 5 and switch 6.

switch 3.)

– 23 –

Page 27

– 24 –

4. One-touch setting

A part of function setting items can be easily changed in the normal sewing state.

(Caution) For the setting of functions other than those covered in this part, refer to "#-6. Setting of func-

tions" p. 28.

Thread trimming function (

1

: Thread trimming operation is not performed (solenoid output prohibition: Thread trimmer, wiper)

: Thread trimming operation is effective.

7

543

6

)

[One-touch setting procedure]

1) Keep

switch 7 held pressed for one second

to place the panel in the function setting mode.

2) Change over the item to be set by using

switch 3 or switch 4. Then, the set value

can be changed by using switch 5 and

switch 6.

3) To return to the normal sewing state, press

switch 7.

(Caution) The setting is conrmed by pressing

switch 7. On

edge sensor, thread trimming by the material

edge sensor and the number of stitches of the

material edge sensor are not displayed in the

default setting at the time of delivery.

e-shot automatic sewing, material

Wiper function (

2

One-shot automatic stitching function (

3

(Caution) This function is rendered effective when the material end sensor function is set. It is not pos-

sible to prohibit the one-shot operation during overlapped sewing operation. The number of revolution

is the value which is set for setting No. 38.

Setting of the max. speed of stitch (

4

: Wiper does not operate after thread trimming.

:

One-shot automatic stitching function is ineffective.

)

: Wiper operates after thread trimming

)

:

One-shot automatic stitching is effective.

)

The highest speed of stitch of the machine head is set. The upper limit of the set value differs with the

type of machine head to which the SC is connected.

Setting range : 150 - Max. value [sti/min]

Material end sensor function (

5

: Material end sensor function is ineffective.

: Once the material end is detected, the sewing machine stops running after having sewn the

number of stitches set with

* This function is rendered effective when the material edge sensor is set with function setting No. 12.

Thread trimming function by material end sensor (

6

: Automatic thread trimming function after the detection of material end is ineffective.

: Once the material end is detected, the sewing machine performs thread trimming after having

sewn the number of stitches set with

* This function is rendered effective when the material edge sensor is set with function setting No. 12.

)

7

(

7

).

(

)

).

Number of stitches for material end sensor (

7

The number of stitches to be sewn from the detection of material end to the stop of the sewing machine

)

Number of stitches that can be set: 0 to 19 (stitches)

(Caution) This function is rendered effective when the material end sensor function is set.

stitches specied is inadequate, the sewing machine can fail to stop within the preset number of stitches

depending on the number of revolutions of the sewing machine.

Adjustment of quantity of light of LED light (

8

The quant

ity of light of the LED light is adjusted

)

If the number of

Setting range : 0 to 100

Page 28

5. Production support function

The production support function consists of three different functions (six different modes) such as the produc-

tion volume management function, operation measuring function and bobbin counter function. Each of them

has its own production support effect. Select the appropriate function (mode) as required.

Production volume management function

■

arget No. of pcs. display mode [F100]

T

Target/actual No. of pcs difference display mode [F200]

The target number of pieces, actual number of pieces and the difference between the target and actual

number of pieces along with the operation time are displayed to notify the operators of a delay and ad-

vance

in real time. Sewing machine operators are allowed to engage sewing while constantly checking

his/her work pace. This helps raise target awareness, thereby increasing productivity. In addition, a delay

in work can be found at an early stage to enable early detection of problems and early implementation of

corrective measures.

Operation measuring function

■

Sewing machine availability rate display mode [F300]

Pitch time display mode [F400]

Average number of revolutions display mode [F500]

Sewing machine availability status is automatically measured and displayed on the control panel. The

data obtained can be used as basic data to perform process analyses, line arrangement and equipment

efciency checkup.

Bobbin counter function

■

Bobb

In order to change bobbins before the current bobbin runs out of thread, the time for replacing the bob-

in counter display mode

bin is notied.

[

To use the production support mode]

721

543

(Caution) Modes F100 to F500 have been factory-

set in the OFF state at the time of delivery.

The mode state is changed over to ON/OFF ac-

cording to the setting of the bobbin thread coun-

ter function (function setting No. 6).

6

Keep

switch 7 held pressed (one second) in

the normal sewing state to call the one-touch setting

screen.

Then, press

switch 1 or switch 2 to set

each production support mode in ON/OFF state to

call the one-touch setting screen.

Press

switch 3 or switch 4 to select the

mode to be set in the ON/OFF state.

ON/OFF of the display can be changed over by

press

ing

switch 5 or switch 6.

To return to the normal sewing state, press

switch 7.

– 25 –

Page 29

– 26 –

Sewing can be performed with the production support data displayed on the control panel.

[Basic operation of the production support modes]

E

7

When

1)

switch 7 is pressed in the normal

sewing state, LED E lights up to enter the pro-

duction support mode.

2)

Production support function can be changed

over by pressing

switch 3 or switch 4.

A

B

3) Data attached marked with (*1) in Table 1 "In-

" can be changed by means of

A

switch 6.

4) When you keep

dicator

switch 5 and

543

6

switch 6 held pressed for two seconds, indicator B and LED E ash on and

off. While they are ashing on and off, data marked with (*2) in Table 1 "Display under modes" can be

changed by pressing

When you press

switch 5 and switch 6.

switch 7, the value marked with (*2) is conrmed and indicator B and LED E stop

ashing on and off.

5)

The value with a sharp mark (*3) in Table 1 "Display of modes" can be changed only immediately after

resetting by using

switch 5 and switch 6.

6) Refer to the table "Mode resetting operation," for the resetting procedure of data.

7) To return to the normal sewing state, press

switch 7.

Data to be displayed under the respective modes are as described in the table below.

Table 1: Display of modes

Mode name Indicator

Target No . of pcs. display

mode (F100)

Target/actual No. of pcs. difference display mode [F200]

Sewing machine availability

rate display mode (F300)

Pit c h t i me d isp l ay m ode

(F400)

Average number of revolutions display mode (F500)

Bobbin co u n t e r display

mode

A

Actual number of pieces

: piece)

Difference between target

number of pieces and actual

number of pieces (d : piece)

(*1)

oP-r Sewing machine availability

Pi-T Pitch time in the previous

ASPd Average number of revolu-

bbn Bobbin counter value (*3) -

(*1)

(Unit

Target number of pieces

: piece)

Target pitch time

(Unit : 100 msec) (*2)

rate in the previous sewing

(Unit : %)

sewing (Unit : 1sec)

tions in the previous sewing

(Unit : sti/min)

Indicator

(*2)

B

Ind ica tor B (when

switch 5 is pressed)

(Unit

-

-

Display of average availability rate of sewing

machine (Unit : %)

Display of average pitch

time (Unit : 100 msec)

Display of average number

of revolutions

(Unit : sti/min)

Page 30

Table 2: Mode resetting operation

Mode name

arget No. of pcs. display mode

T

(F100)

arget/actual No. of pcs. difference

T

display mode (F200)

ewing machine availability rate

S

display mode (F300)

Pitch time display mode (F400) Resets average pitch time Resets average availability rate of sewing

Average number o f revolutions

display mode (F500)

Bobbin counter display mode Resets the bobbin counter value

Switch 5 (held pressed for 2

seconds)

Resets the actual number of pieces

Resets the difference between target

number of pieces and actual number

of pieces

Resets the actual number of pieces

Resets the difference between target

number of pieces and actual number

of pieces

Resets average availability rate of

sewing machine

Resets average number of revolu-

t

ions of sewing machine.

(Note that only the bobbin counter is

Switch 5 (held pressed for 4 sec-

onds)

-

-

Resets average availability rate of sewing

machine.

Resets average pitch time.

Resets average number of revolutions of

sewing machine.

machine.

Resets average pitch time.

Resets average number of revolutions of

sewing machine.

Resets average availability rate of sewing

machine.

Resets average pitch time.

Resets average number of revolutions of

sewing machine.

-

immediately reset by pressing

switch 5.)

[Detailed setting of production volume management function (F101, F102)]

721

When

switch 7 is held pressed (for three sec-

onds) under the target No. of pcs. display mode

(F100) or the target/actual No. of pcs. difference

display mode (F200), the detailed setting of the pro-

duct

ion volume management function can be carried

out.

The setting state of the number of times of thread

trimming (F101) and that of the target achievement

buzzer (F102) can be changed over by pressing

switch 3 or

switch 4.

The number of times of thread trimming for sewing

543

6

one piece of garment can be set by pressing

switch 5 or

switch 6

in the setting state of the number of times of thread trimming (F101).

It is possible to set whether the buzzer sounds or not when the actual number of pieces has reached the tar-

get

volume by pressing

switch 5 or switch 6 i

n the setting state of the target achievement buzzer

(F102).

– 27 –

Page 31

– 28 –

6. Setting of functions

Functions can be selected and specied.

(Caution) Refer to the Instruction Manual for each operation panel for how to operate sewing patterns us-

ing other operation panel than the built-in panel of the machine head.

1) Turn ON the power with switch 7 held

7

pressed.

(The

item which has been changed during the

previous work is displayed.)

* If the screen display does not change, re-carry

out operation described in step 1).

(Caution)

Be sure to re-turn ON the power switch

when one or more seconds have passed after

t

urning it OFF. If the power switch is re-turned

ON immediately after turning it OFF, the sewing

machine may fail to operate normally. In such a

case,

be sure to turn ON the power switch again

properly.

2) To move the setting No. forward, press

switch 4.

press

(Caution) If the setting No. is moved forward (or

backward), the previous (or subsequent) content

of the setting is conrmed. Be careful when the

content of a setting is changed (when the

switch is touched).

To move the setting No. backward,

switch 3.

/

Example) Changing the maximum number of revolu-

tions (setting No. 96)

Press

543

6

ting No. "96."

switch 3 or switch 4 to call set-

The current set value is displayed on indicator B.

Press

switch 5 to change the sett

ing to

"2500."

The content of setting of the setting No. returns

*

to the initial value by pressing

switch 5 and

switch 6 s

3)

After completion of the changing procedure, press

imultaneously.

switch 3 or switch 4 to conrm the updat-

ed value.

(Caution) If the power is turned OFF before carry-

ing out this procedure, the changed content is

543

setting No. When

No. After completion of the operation, the machine is returned to the normal sewing state by turning

OFF the power and re-turning it ON.

switch 4 is pressed, the display on the panel changes to the subsequent setting

6

not updated. When

display on the panel changes to the previous

switch 3 is pressed, the

Page 32

7. Function setting list

No.

1 Soft start

2 Mater

3

4 Number of

5 F

6 Bobb

7 Unit of bobbin

*

8 Number of

*

9 Thread

10 Setting of

11 Operat

12 Optinal switch

13 Function of

*

14 Sewing counter Counting function of sewing (number of completion of process)

15 Thread wiping

Item Description

function

ial end

sensor function

Thread trimming

function by

material end

sensor

itches for

st

material end

sensor

licker reducing

function

in thread

counting

function

thread counting

down

rotation of

reverse feed

stitching

trimming

prohibiting

function

needle bar stop

pos

ition when

the sewing

machine stops.

ion

conrmation

sound for

operation panel

function

selection

prohibiting start

of the sewing

machine by

bobbin thread

counter

function after

thread trimming

The number of stitches to be sewn at a low speed when the softstart function is used at the start of sewing.

0 : The function is not selected.

1 to 9 : The number of stitches to be sewn under the soft-

start mode.

Material end sensor function.

0 : Material end detection function is not operative.

1 : After detecting material end, the specified number of

stitches (No. 4) will be sewn, and the sewing machine will

stop.

Thread trimming function by material end sensor.

0 : Automatic thread trimming function after detection of ma-

terial end is not operative.

1 : After detecting material end, the specified number of

stitches (No. 4) will be sewn, and the sewing machine will

stop and perform automatic thread trimming.

Number of stitches for material end sensor.

Number of stitches from detection of material end to stop of the

sewing machine.

Flicker reducing function

0 : Flicker reducing function is not operative.

1 : Flicker reducing function is effective

Bobbin thread counting function

0 : Bobbin thread counting function is not operative.

1 : Bobbin thread counting function is operative.

Unit of bobbin thread counting down

0 : 1 Count/10 stitches

1 : 1 Count/15 stitches

2 : 1 Count/20 stitches

3 : 1 Count/thread trimming

Sewing speed of reverse feed stitching

Thread trimming prohibiting function.

0 : Thread trimming is effective.

1 : Thread trimming is prohibited.

(Output of solenoid is prohibited. : Thread trimmer and wiper)

Position of needle bar is specified when the sewing machine

stops.

0: The needle bar stops at its lower position.

1: The needle bar stops at its upper position.

Operation conrmation sound for operation panel

0 : Operation conrmation sound is not generated

1 : Operation conrmation sound is generated.

Switching of function of optional switch.

Function of prohibiting start of the sewing machine by bobbin thread counting

0 : When counting is out (-1 or less) Function of prohibiting

start of the sewing machine is not operative.

1 : When counting is out (-1 or less) Function of prohibiting

start of the sewing machine after thread trimming is operative.

2 : When counting is out (-1 or less), the sewing machine

stops once. Function of prohibiting start of the sewing

machine after thread trimming is operative.

0 : Sewing counter function is not operative.

1 : Sewing counter function is operative. (Every time thread

trimming is performed)

2 : With the sewing counting switch input function

Thread wiping operation after thread trimming is specied.

Thread wiping is not carried out after thread trimming

0 :

1 : Thread wiping is carried out after thread trimming

Setting range

0 to 9

(Stitches)

0/1

0/1

0 to 19

(Stitches)

0/1

0/1

0 to 3

150 to 3,000

(sti/min)

0/1

0/1

1

0/

0 to 2

0 to 2

0/1

Indication of function setting

1

2

3

4

5

6

7

8 1 9 0 0

9

1 0

1 1

1 2 o P T _

1 3

1 4

1 5

0

0

0

5

0

1

0

0

0

1

0

1

1

Ref. page

33

33

33

33

33

33

33

33

33

34

37

21 Function of

automatic

presser foot

lifting at pedal's

neutral position

Function of lifting presser foot when the pedal is in neutral position.

0 : Function of neutral automatic presser lifting is not opera-

tive.

1 : Selection of function of neutral presser lifting.

0/1

2 1

0

37

* Do not change the set values with asterisk (*) mark as they are functions for maintenance. If the standard set value set at the

time of delivery is changed, it is in danger of causing the machine to be broken or the performance to be deteriorated.

If it is necessary to change the set value, please purchase the Engineer’s Manual and follow the instructions.

– 29 –

Page 33

– 30 –

No.

22 Needle up/down

25 T

29 Setting of one-

30 Funct

31

32 Ef

33 T

35 Number of

*

36 Number of

*

37 Number of

38 One-shot speed One-shot speed (The max. value depends on the number of ro-

39 Pedal stroke

*

40 Low speed

*

41 Starting position

*

42 Starting position

*

43

*

44

*

45

*

47

48

*

49

Item Description

correction

switch

changeover

function

hread trimming

operation after

turning the

handwheel by

han

touch type

reverse feed

solenoid pull-in

time

ion of

reverse feed

stitching on the

way

Number of

stitches of reverse

feed stitching on

the way

fective

condition of

reverse feed

stitching on the

way when the

sewing machine

is stopping.

hread trimming

function by

reverse feed

stitching on the

way

rotation at a low

speed

rotation of

thread trimming

rotation of softstart

at the start of

rotation

section of pedal

of lifting presser

foot by pedal

of lowering

presser foot

Pedal stroke 2 for

starting thread

trimming

Pedal stroke

for reaching the

maximum number

of rotation

Compensation of

neutral point of

the pedal

Auto-lifter

selecting function

Pedal stroke 1 for

starting thread

trimming

Lowering time of

presser foot

Function of the needle up/down correction switch is changed

over.

0 : Needle up/down compensation

1 : One stitch compensation

Thread trimming operation after moving the needle away from

its upper or lower position by turning the handwheel by hand is

specied.

0 : Thread trimming operation is carried out after turning the

handwheel by hand

1 : Thread trimming operation is not carried out after turning

the handwheel by hand

This function sets the suction time of initial motion of back-tack

solenoid.

50 ms to 500 ms

Function of reverse feed stitching on the way

0 : Normal one-touch type reverse feed stitching function

1 : Function of reverse feed stitching on the way is operative.

Number of stitches of reverse feed stitching on the way.

Effective condition of reverse feed stitching on the way

0 : Function is not operative when the sewing machine stops.

1 : Function is operative when the sewing machine stops.

Thread trimming function by reverse feed stitching on the way

0 : Automatic thread trimming function after completion of

reverse feed stitching on the way is not operative.

1 : Automatic thread trimming after completion of reverse

feed stitching on the way is performed.

Lowest speed by pedal

(The MAX value differs by machine head.)

Thread trimming speed

(The MAX value differs by machine head.)

Sewing speed at the start of sewing (soft-start)

(The MAX value differs by machine head.)

ion of the sewing machine head.)

tat

Position where the sewing machine starts rotating from pedal

neutral position (Pedal stroke)

Position where the sewing machine starts accelerating from

pedal neutral position (Pedal stroke)

Position where the cloth presser starts lifting from pedal neutral

position (Pedal stroke)

Starting position of lowering presser foot

Stroke from the neutral position

Position 2 where the thread trimming starts from pedal neutral

position (When the function of lifting presser foot by pedal is provided.) (Pedal stroke)

(Effective only when Item No. 50 is set at 1.)

Position where the sewing machine reaches its highest sewing

speed from pedal neutral position (Pedal stroke) 10 to 150

Compensation value of the pedal sensor

Limitation time of waiting for lifting solenoid type auto-lifter device

Position where thread trimming starts from pedal neutral position

(Standard pedal) (Pedal stroke)

(Effective only when Item No. 50 is set at 0.)

Sets the time required until the lowering of the presser foot is

completed after a depress on the pedal

Setting range

0/1

0/1

50 to 500

(ms)

0/1

0 to 19

(Stitches)

0/1

0/1

150 to MAX

(sti/min)

100 to MAX

(sti/min)

100 to MAX

(sti/min)

150 to MAX

(sti/min)

10 to 50

(0.1 mm)

10 to 100

(0.1 mm)

– 60 to –10

(0.1mm)

8 to 50

(0.

1 mm)

– 60 to –10

(0.1 mm)

(0.1 mm)

–15 to 15

10 to 600

(second)

– 60

10

to –

(0.1 mm)

0

to 500

10 ms)

(

Indication of function setting

2 2

2 5

2 9

3 0

3 1

3 2

3 3

3 5

3 6

3 7

2 5 0

2 0 0

3 0 0

8 0 0

3 8 2 5 0 0

3 9

4 0

4 1

4 2

4 3

4 4

4 5

4 7

4 8

4 9

3 0

6 0

– 2 1

1 0

– 5 1

1 5 0

6 0

– 3 5

1 4 0

0

1

0

4

0

0

0

Ref. page

37

37

38

38

38

38

33

38

39

41

* Do not change the set values with asterisk (*) mark as they are functions for maintenance. If the standard set value set at the

time of delivery is changed, it is in danger of causing the machine to be broken or the performance to be deteriorated.

If it is necessary to change the set value, please purchase the Engineer’s Manual and follow the instructions.

Page 34

No.

50

Pedal

specication

51 Compensation of

solenoid-on timing

of reverse feed

stitching at the

start of sewing

52 Compensation of

solenoid-off timing

of reverse feed

stitching at the

start of sewing

53 Compensation

of solenoid-off

timing of reverse

feed stitching at

the end of sewing

Foot lift after

55

thread trimming

Reverse

56

revolut

the needle after

thread trimming

Function

58

of holding

predetermined

upper/lower

pos

ition of the

needle bar

Function of Auto/

59

Manual changeover of reverse

feed st

the start of sewing

Function of stop

60

immediately after

reverse feed

st

itching at the

start of sewing

Change-

64

over speed of

condensat

stitch or EBT (end

back tack)

Function of soft-

70

down of presser

foot

Double reverse

71

feed stitching

function

Sewing

72

machine startup

selecting

function

Retry function

73

One-shot function

76

84

Initial motion

suction time of

*

presser foot lifting

solenoid

Item Description

Type of pedal sensor is selected.

0 : KFL

1 : PFL

Refer to

“#-10. Selection of the pedal specications” p.43.

Compensation of starting the solenoid for reverse feed stitching

when reverse feed stitching at the start of sewing is performed.

Compensation of releasing the solenoid for reverse feed stitching when reverse feed stitching at the start of sewing is performed.

Compensation of releasing the solenoid for reverse feed stitching when reverse feed stitching at the end of sewing is performed.

Function of lifting presser foot at the time of (after) thread trimming

0 : Not provided with the function of automatic lifting of work-

clamp after thread trimming

1 : Provided with the function of lifting presser foot

after thread trimming

ion to lift

itching at

ion

Function of reverse revolution to lift the needle at the time of (after) thread trimming

0 : Not provided with the function of reverse revolution to lift

the needle after thread trimming

1 : Provided with the function of reverse revolution to lift the

needle after thread trimming

Function of holding predetermined upper/lower position of the needle bar

0 : Not provided with the function of holding predetermined

upper/lower position of the needle bar

1 : Provided with the function of holding predetermined upper/

lower position of the needle bar (holding force is weak.)

2 : Provided with the function of holding predetermined upper/

lower position of the needle bar (holding force is medium.)

3 : Provided with the function of holding predetermined upper/

lower position of the needle bar (holding force is strong.)

This function can specify the sewing speed of reverse feed

stitching at the start of sewing.

0 : The speed will depend on the manual operation by pedal, etc.

1 :

The speed will depend on the specied reverse feed stitching speed (No. 8).

Function at the time of completion of reverse feed stitching at

the start of sewing

0 : Not provided with the function of temporary stop of the

sewing machine at the time of completion of reverse feed

stitching at the start of sewing

1 : Provided with the function of temporary stop of the sew

ing machine at the time of completion of reverse feed

stitching at the start of sewing.

Initial speed when starting condensation stitch or EBT

Presser foot is slowly lowered.

0 : Presser foot is rapidly lowered.

1 : Presser foot is slowly lowered.

Effective/ineffective of double reverse feed stitching is changed

over.

Current limit at the startup of sewing machine is specied.

This function is used when needle cannot pierce materials .

(Needle-bar returning force before re-trying: 1 (small) - 10 (large))

One-shot operation up to the material end is specied.

Suction motion time of presser foot lifting solenoid

fective

0 : Inef

1 : Effective

0 : Normal (Current limit is applied during startup)

1 : Rapid (Current limit is not applied during startup)

0 : Re-try function is not provided

1 - 10: Re-try function is provided

0 : One-shot operation is not performed.

1 : One-shot operation is performed.

automatically

Setting range

– 36 to 36

– 36 to 36

– 36 to 36

0 to 3

-

0 to 250

(sti/min)

50 to 500

0/1

(10°)

(10°)

(10°)

0/1

0/1

0/1

0/1

0/1

0/1

0/1

0/1

0/1

(ms)

Indication of function setting

5 0

5 1

5 2

5 3

5 5

5 6

5 8

5 9

6 0

6 4

7 0

7 1

7 2

7 3

7 6

8 4

1 2

1 8

1 6

1 8 0

2 5 0

1

1

0

0