J.P. Instruments EDM 900 User Manual

Pilot’s Guide

Engine Data Management

EDM-900

Primary

TSO/STC

Copyright 2011 J.P. Instruments, Inc.

All Rights Reserved

J.P. INSTRUMENTS INC.

Information: P. O. Box 7033

Huntington Beach, CA 92646

Factory: 3185 B Airway

Costa Mesa, CA 92626

(714) 557-5434 Fax (714) 557-9840

www.jpinstruments.com

www.JPITech.com

www.buyJPI.com

Printed in the United States of America |

Rev A |

Last printed

For Your Safe Flight |

Page 1 |

Table of Contents

Section-1 |

Getting Started |

4 |

View Angle |

4 |

|

Rotation |

|

6 |

Fuel Flow Computer Basics (independent of fuel quantity) |

6 |

|

Display Screen Basics |

7 |

|

Horizontal Display Mode |

7 |

|

Vertical Display Mode |

8 |

|

Remote Annunciate Light Basics |

8 |

|

RPM and MAP Display Basics |

9 |

|

Linear Bar Graph Display Basics |

9 |

|

Scanner® Information Area |

10 |

|

LeanFind Basics |

11 |

|

Section 2 - |

Interpreting Data |

12 |

Operation for each Phase of Flight |

12 |

|

Typical Normal Measurements |

14 |

|

Section 3 - Displays and Controls |

17 |

|

Control Buttons |

17 |

|

Scanner Displays |

19 |

|

Additional Displays Hobbs, Revisions, and Alarm Limits |

21 |

|

Dimming the Display |

22 |

|

Section 4 - |

Operating Modes |

22 |

Automatic Mode |

22 |

|

Manual Mode |

23 |

|

Section 5 - |

LeanFind |

24 |

LeanFind Procedure—General Explanation |

28 |

|

Expanded Leaning Procedures |

31 |

|

Common Misapplications |

32 |

|

Section 6 - Fuel Flow Operation |

33 |

|

Fuel Management |

33 |

|

Start Up Fuel |

34 |

|

Resetting ‘USD’ |

35 |

|

Trip Mode (Accumulate Trip Totalizer) |

35 |

|

Scanner Fuel Flow Display Select |

35 |

|

Section 7 - |

Alarms |

36 |

Section 8 - Memory and Data Download |

37 |

|

Downloading Data from the EDM |

37 |

|

Transferring data from the USB Flash Drive to a PC |

38 |

|

Section 9 - First Time Setup and Customization |

38 |

|

Section 10 - |

Adjusting Manifold Pressure & %HP |

41 |

Adjusting the HP Constant for Rich of Peak Operation |

41 |

|

Adjusting the MAP |

41 |

|

Adjusting the HP Value |

42 |

|

Section 11 - |

Programming the Fuel Flow |

42 |

Page 2 |

Engine Data Management |

|

Fuel Flow K factor |

43 |

|

Programming Trip Mode |

45 |

|

Setting the GPS Com Format |

45 |

|

Troubleshooting the EDM |

47 |

|

Diagnostic Testing on Startup and During Flight |

47 |

|

Diagnostic Messages |

47 |

|

Section 12 - |

Appendices |

48 |

Shock Cooling (CLD) |

48 |

|

List of ALL messages in EDM-900 |

49 |

|

Navigation Data Formats |

50 |

|

Navigation Data Ports for GPS Comm |

50 |

|

Interface connections to selected GPS models |

50 |

|

Section 13 - |

Technical Support |

51 |

For Your Safe Flight |

Page 3 |

Section-1 |

Getting Started |

This is a summary of basic operation. Detailed descriptions of all operations appear later in this Pilot’s Guide.

EDM-900 primary instrument has preset alarm limits and cautionary ranges per the POH (user cannot change them) typically for the following measurements of: oil temperature, oil pressure, fuel pressure, fuel quantity, cylinder head temperature, turbine inlet temperature, manifold pressure, and RPM.

Note: Fuel quantity gauges must be calibrated to the aircraft and will not be functional until the fuel calibration process has been performed.

View Angle

The best view angle for the pilot is in the horizontal mode with the buttons on the bottom. The best Portrait mode is with the buttons on the right.

View angles are per the table below:

|

Horizontal |

Left |

65 Degrees |

Viewing |

|

|

|

|

Right |

65 Degrees |

|

angle |

|

|

|

Vertical |

Left |

60 Degrees |

|

|

|

|

|

|

|

Right |

50 Degrees |

|

|

|

|

Page 4 |

Engine Data Management |

List of abbreviations and acronyms

|

Gauge Function |

|

|

Message Area |

|

|

|

|

Alarm Abbreviation |

|

|

|

|

|

|

|

|

|

Primary |

|

Primary |

||

|

Engine rotational speed |

RPM xxxx |

|||

|

|

|

|||

|

Engine Manifold Pressure |

MAP xx.x in hg |

|||

|

|

|

|||

|

Engine Cylinder Head Temp |

CHT2 xxx oF |

|||

|

Engine Oil Temperature |

|

O-T xxx oF |

||

|

Engine Oil Pressure |

O-P xxx oF |

|||

|

Fuel Pressure |

F-P xx PSI |

|||

|

|

|

|

||

|

Fuel Flow to engine |

|

F-F xx.x GPH |

||

|

|

|

|||

|

Comp. Discharge Temp. |

CDT xxx oF |

|||

|

Turbine inlet Temp. Left side |

TIT-L xxxx oF |

|||

|

Turbine Inlet Temp. Right side |

TIT-R xxxx oF |

|||

|

Single Turbine Inlet Temp. |

TIT xxxx oF |

|||

|

Non-Primary |

Non-Primary |

|||

|

|

|

|||

|

Exhaust Gas Temp. |

EGT2 xxxx oF |

|||

|

Shock Cooling of CHT |

CLD xx o/MIN |

|||

|

Differential Temp. of EGT |

DIF xx oF |

|||

|

Bus Voltage |

Volts xx.x |

|||

|

|

|

|||

|

Amperage Load |

AMPS xx |

|||

|

|

|

|||

|

Outside Air Temp. |

OAT xx oF |

|||

|

Estimated Time to Empty |

Est. T to E xx:xx H:M |

|||

|

|

|

|||

|

Fuel used to date |

USED xx.x GAL |

|||

|

|

|

|||

|

Estimated Remaining fuel |

Est. REM xx GAL |

|||

|

|

|

|||

|

Estimated Fuel required to Waypoint |

Est. WP REQ xx GAL |

|||

|

|

|

|

|

|

|

Estimated Fuel Remaining at |

|

Est. WP RES xx GAL |

||

|

Waypoint |

|

|||

|

|

|

|

||

|

Nautical Miles per Gallon |

ECON xx.x MPG |

|||

|

|

|

|||

|

Brightness, Dim control |

DIM/BRT |

|||

|

|

|

|

|

|

For Your Safe Flight |

Page 5 |

Rotation

Holding the step button in for 5 seconds, with the engine OFF, will produce the gray arrow. This arrow can be rotated to a new up position by tapping the LF button and then the STEP button. If for some reason you chose the one bad angle (Landscape looking up from the buttons), return the instrument to JPI and JPI will rotate the screen.

Fuel Flow Computer Basics (independent of fuel quantity)

The fuel flow computer tracks the fuel flowing to the engine and computes various values based on this. At installation, then each time you refuel the aircraft, you must inform the EDM about how much useable fuel is onboard. This is done via the REFUEL function.

See page 33 for detailed information

Control Button Basics

Four operating buttons control all functions of the EDM. These buttons change labels depending on the current state of the EDM.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Page 6 |

Engine Data Management |

|||

Display Screen Basics

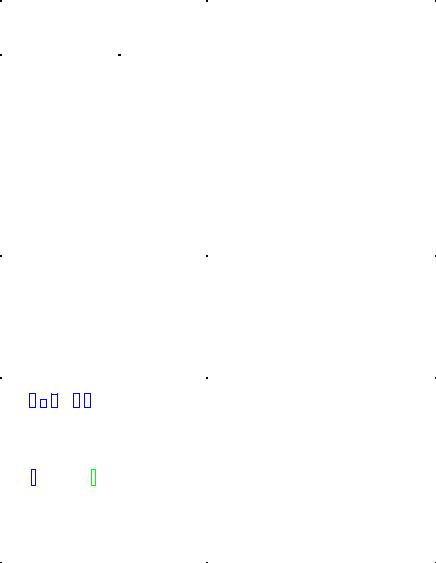

The display screen is arranged into three sections. The top left is the MAP and RPM section. The bottom left is the Scanner® section or message area. On the right side are the horizontal primary strip gauges. Non-Primary gauges have a digital read out only. The instrument ranges and alarm limits are configured to match those of your aircraft POH when the EDM is set up as a Primary instrument. TIT column is to the right of the last EGT/CHT when applicable.

Horizontal Display Mode

For Your Safe Flight |

Page 7 |

Vertical Display Mode

Remote Annunciate Light Basics

The Remote Annunciator Light ‘RAL’ provides notification that an alarm is present in the display, for all Primary gauges. Upon power up, the RAL shows Red and yellow indicating it is functional. Before each flight, confirm that it is functional. Non-functioning RAL must be repaired before flight.

Remote Annunciator Light (RAL)

Page 8 |

Engine Data Management |

Horizontal mode |

Vertical mode |

RPM and MAP Display Basics

In the vertical mode to the right and the Horizontal mode above MAP (Manifold Pressure) and RPM (Revolutions per Minute) are shown. Operations exceeding red line cause the digital value to turn red or yellow with the RAL coming on and a digital value in the Scanner message area.

Linear Bar Graph Display Basics

The Bar Graphs section contains dedicated bar graphs with digital display. An example is shown here. Pointers move horizontal left to right showing value changes and digital readouts turn red

when primary exceedances occur. Non primary functions flash white.

Horizontal mode |

Vertical mode |

For Your Safe Flight |

Page 9 |

Scanner® Information Area

The Scanner® Information Area provides expanded information in the form of alpha-numeric messages, parameters and calculations. In Auto-Scan, parameters will ‘scan by’ once every 4 seconds (default). This rate can be changed in Pilot Programming Mode. Tap the STEP button for ‘Manual’ selection of any parameter. Parameters for the installed options will be displayed. To start the automatic scan tap LF and then STEP.

DISPLAY |

PARAMETER |

DESCRIPTION |

|

EGT 1436 CHT 382 |

EGT/CHT |

Shows successive pairs of EGT & |

|

CHT per STEP tap. |

|||

|

|

||

TIT 1580 oF |

TIT |

Single Turbine Inlet Temp. |

|

TIT-L and -R 1490 |

TIT-L, TIT -R |

Two Turbine Inlet Temp. Left and |

|

oF |

Right engine side |

||

Oil-T 204 oF |

OIL TEMP |

Oil temperature in degrees F |

|

Oil-P 64 PSI |

OIL PRES |

Oil pressure in psi |

|

F-P16 PSI |

FUEL PRES. |

Fuel pressure in psi |

|

F-F 2.7GPH |

FUEL FLOW |

Fuel flow in GPH |

|

CLD 75 oF |

SHOCK |

CHT cooling rate (deg/min) |

|

|

COOL |

|

|

VOLTS 13.9 |

BATTERY |

Battery/Bus voltage |

|

AMPS -6 |

Amperage |

Set up per the specific aircaraft |

|

OAT 23 oF |

OAT |

Outside air temperature F or C |

|

DIF 40 oF |

DIF |

Hottest minus coldest EGT |

|

CRB 56 oF |

CRB |

Carburetor Air Temp (only allowed if |

|

|

|

IAT not present) |

|

CDT 145 oF |

CDT |

Compressor Discharge Temp (only |

|

|

|

allowed if CRB not present) |

|

IAT 105 oF |

IAT |

Induction Air Temp |

|

|

FUEL |

Calculated fuel remaining on board |

|

Est. REM 68.0 GAL |

based on what the pilot put in as |

||

REMAINING |

|||

|

maximum. |

||

|

|

||

|

FUEL |

Calculated fuel required to reach |

|

WP REQ 12.7 GAL |

waypoint or destination (GPS |

||

REQUIRED |

|||

|

interface must be corrected) |

||

|

|

||

Est. WP REM 63 GAL |

FUEL |

Calculated fuel reserve at waypoint |

|

RESERVE |

(GPS interface must be correct) |

||

|

|||

|

Nautical |

Calculated fuel miles per units |

|

ECON 9.8 MPG |

MILES PER |

||

(GPS interface required) |

|||

|

GALLON |

||

|

|

||

|

Estimated |

Calculated time remaining to fuel |

|

EST. T to E 04:32 |

Time to |

exhaustion in Hours and Minutes at |

|

H:M |

Empty |

present power. |

|

GPH 15.0 GPH |

FUEL FLOW |

Actual fuel flow rate in Gallons per |

|

RATE |

hour |

||

|

|||

USD 7.2 GAL |

FUEL USED |

Actual fuel used by the engine |

|

|

|

|

|

FUEL-P 64 PSI |

FUEL PRES |

Fuel pressure in PSI |

|

|

|

|

Page 10 Engine Data Management

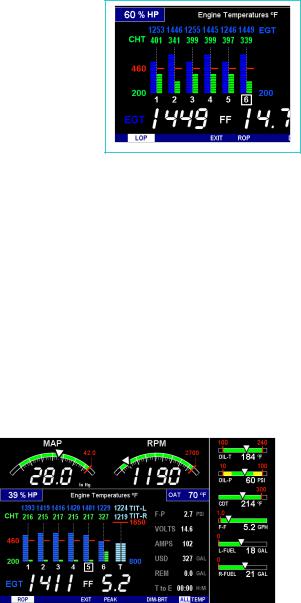

LeanFind Basics

Simply pre-lean, tap the LF button (Lean Find) and begin leaning. The EDM will assist you in finding the first cylinder to peak. This example is for Rich of Peak, ROP. See page 24 for a more detailed description of leaning. Press LOP to exit the ROP mode and enter the LOP mode.

1.Establish cruise at approximately 65 to 75% power and pre-lean the mixture to 50°F estimated rich of peak EGT on any cylinder.

2.Wait about 30 seconds, then tap the LF button.

3.Begin leaning the mixture smoothly without stopping. Turn a vernier about ¼ turn per second; retract a non-vernier or quadrant lever so that EGT rises about 10°F per second.

4.Stop leaning when you see LEANEST for two seconds, followed by— for example— EGT1449 FF14.7 The left number is the current temperature of the first EGT to peak and the right number is the current fuel flow.

5.Now tap the PEAK button to display the EGT difference from peak which is very useful for setting desired degrees below peak.

6.Slowly enrich the mixture noting that the EGT difference diminishes as EGT climbs back to peak, followed by it going minus again. Stop enriching at the desired EGT difference (such as ‘EGT -75’).

7.You can also see what the peak EGT was by holding the PEAK button.

8.Tap STEP to exit the Lean Find Mode.

For Your Safe Flight |

Page 11 |

Section 2 - Interpreting Data

Operation for each Phase of Flight

(Worth adding to your run-up checklist)

Engine

Run-Up

Take-Off,

Climb, and

Full

Throttle

Operations

Suggested setup:

Set engine to run-up RPM

Normalize view:

Manual mode

Verify:

Uniform rise of about 50°F in all EGTs in single magneto operation.

Uniform rise of EGTs with application of the mixture control.

Be alert for:

unusually low voltage (less than nominal battery voltage)

cold OIL and normal oil pressure

abnormally high CHT

Large drop in EGT on one cylinder in single magneto operation—may be fouled spark plug.

Suggested setup:

Standard view

Automatic mode

Verify:

EGTs and CHTs consistent with past climbs. EGTs should be in the 1100 to 1300°F range (100° to 300°F cooler than cruise) due to fuel cooling.

Be alert for:

High EGT in one cylinder, 300°F above the others may indicate plugged injector or leaking manifold gasket on a carbureted engine. At high density altitude an overly rich mixture can significantly reduce engine power.

If all EGT columns go off scale to the top of the column, be sure you are not in Normalize view, as indicated by the symbol NRM above the Scanner® section.

Page 12 |

Engine Data Management |

After the engine is warmed up, use LeanFind to lean the mixture.

Cruise

Suggested setup:

Normalize view

Automatic mode

Be alert for:

Uneven EGTs (injected engines). Make fine adjustments to throttle, then RPM, then mixture to level the display columns.

Abnormal patterns of EGTs and CHT. (see Engine Diagnosis Chart on page 15).

Suggested setup:

Standard view

Manual mode

Descent |

Be alert for: |

|

CLD: shock cooling alarm is set to -60°F. Average |

|

cool rates of -40°F/minute to -50°F/minute are normal, |

|

depending on the engine size. |

For Your Safe Flight |

Page 13 |

Typical Normal Measurements

The following chart lists typical normal measurement values that you will observe for most general aircraft engines. Your particular engine’s ranges may not fall within these values.

Measurement |

Normal range |

Comments |

EGTs in Cruise

EGT span (DIF)

TIT

CHTs

CHT span

OIL T

1350°F |

|

under 200 HP engines |

|

1550°F |

|

high performance engines |

|

|

(EGT should drop 200°F when |

||

|

|||

|

|

full throttle is applied) |

|

|

|

|

|

70 to 90°F |

|

fuel injected engines |

|

120 to 150°F |

|

carbureted engines |

|

|

|||

|

|

|

|

1600°F average |

|

100° higher than EGT |

|

|

|

|

|

350°F (OAT 60°F) |

|

normally aspirated engines |

|

410°F |

|

Turbocharged engines |

|

|

|

|

|

50 to 70°F |

|

100° with gasket probes |

|

|

|

|

|

200°F |

|

oil cooler thermostat typically |

|

|

|

opens at 180°F |

OIL P

FUEL P (injected)

FUEL P (carbureted)

Shock cooling*

30 to 60 psi |

|

varies with aircraft type |

14 to 18 psi |

|

varies with aircraft type |

0.5 to 8 psi |

|

|

|

|

|

-40°/minute |

|

tightly cowled engines |

-55°/minute |

|

Bonanza |

-200°/minute |

|

helicopter |

*Maintain a cooling rate magnitude of less than -50°/minute. You will find that the cylinder with the greatest shock cooling may shift from front cylinders (during climb out) to the rear cylinders (during descent ).

Page 14 |

Engine Data Management |

Engine Diagnosis Chart

The following chart will help you diagnose engine problems in your aircraft.

|

|

|

|

|

|

|

|

Display |

|

|

|

|

|

|

|

Symptom |

Probable |

Recommende |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cause |

d Action |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TIT ~100° |

This is normal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

higher than |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EGTs |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

75° to 100° |

Spark plug not |

Enrich mixture to |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EGT rise for |

firing due to fouling, |

return EGT to |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

one cylinder |

faulty plug, wire or |

normal. Have |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

during flight |

distributor. |

plugs checked. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EGT Increase |

Improper timing: |

Check EGT for |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

or decrease |

high EGT |

each magneto to |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

after ignition |

retarded ignition; |

determine any |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

maintenance |

low EGT |

uneven timing. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

advanced ignition. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Loss of EGT |

Stuck valve. Other |

Have valve train |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

for one |

cylinders are okay. |

checked. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

cylinder. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine rough |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Loss of EGT |

Failed probe |

Swap probes to |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

for one |

or |

determine if probe |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

cylinder; no |

failed wire harness. |

or wire harness is |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

digital EGT |

|

bad. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Decrease in |

Intake valve not |

Have valve lifter or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EGT for one |

opening fully; faulty |

rocker arm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

cylinder |

valve lifter. |

checked. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Increase in |

Low compression |

Check |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DIF at low |

(blow by) in |

compression. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RPM |

cylinder |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EGT and |

Normal for |

Check injectors |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CHT not |

carbureted |

and plugs. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

uniform |

engines. Dirty fuel |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

injectors or fouled |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

plugs. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Decrease in |

Decrease in airflow |

Check for change |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EGT for all |

into the induction |

in manifold |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

cylinders |

system. Carb or |

pressure. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

induction ice. |

|

For Your Safe Flight |

|

Page 15 |

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

Display |

|

|

|

|

Symptom |

Probable |

Recommended |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Cause |

Action |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Slow rise in |

Burned exhaust |

Have compression |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EGT. Low |

valve. CHT is low |

checked. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CHT |

due to low power |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

output. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

High CHT on |

Obstruction under |

Check for improper |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

cylinders on |

cowling. |

installed baffling, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

one side of |

|

cowl flap |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

engine |

|

misalignment or bird |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

nests. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rapid rise in |

Detonation. |

Reduce power. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CHT of one |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

cylinder |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sudden off |

Pre-ignition |

Full rich and reduce |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

scale rise for |

|

power. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

any or all |

Normalize view |

Change to Standard |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

cylinders |

|

view |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

or failed probe |

Check probe |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

(no picture) |

|

|

|

|

Loss of peak |

Poor ignition or |

Have magneto |

||||||||||||||

|

|

|

|

|

|

|

|

|

EGT |

vapor in fuel |

tested. |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

injection system. |

|

|

|

|

|

|

(no picture) |

|

|

|

|

Decrease in |

Detonation. |

Enrich mixture, |

||||||||||||||

|

|

|

|

|

|

|

|

|

peak or flat |

Usually the result |

reduce power and |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EGT |

of 80 Octane fuel |

relean mixture. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

response to |

in 100 Octane |

Repeat to find power |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

leaning |

engine. |

setting where normal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

process |

|

peak is obtained or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

run rich. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Below 10,000 |

Weak or defective |

Apply booster pump. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ft. full throttle |

mechanical fuel |

If EGTs drop, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

causes EGTs |

pump. |

replace fuel pump. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

to rise |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CHT more |

Leaking exhaust |

Look for white |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

than 500°, |

gasket blowing on |

powder around |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EGT normal. |

CHT probe. |

cylinder to determine |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Adjacent EGT |

|

leak area. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

may be low |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Page 16 |

|

|

|

|

Engine Data Management |

|||||||||||||||||||||

Section 3 - Displays and Controls

The EDM monitors engine temperatures, pressures and voltages, assists in adjusting the fuel/air mixture, and helps diagnose engine malfunctions. There are multiple components of the user interface:

Four front panel operating buttons below the bottom of the display.

RPM and MAP display in the upper left corner of the display

Scanner analog display including cylinder number and index square in the lower left corner of the display

Scanner digital display for numeric readouts and messages at the bottom left

Bar graph displays on the right half of the display

Control Buttons

Four operating buttons control all functions of the EDM. These buttons may change labels depending on the current operating mode of the EDM. The term tap is used to denote pressing a button momentarily. The term hold is used to denote pressing and holding a button for five seconds or longer. Button layout is shown below:

1st Button

In the Automatic mode, tapping the STEP button stops Scanner autosequencing and changes to Manual mode. Each tap of the STEP button then displays the next measurement in the sequence. Holding the STEP button sequences in reverse order.

In the LeanFind mode tapping the EXIT button will terminate the LeanFind mode and change to the Automatic mode.

In the Program mode tapping the NEXT button will advance to the next item.

2nd Button

In Automatic or Manual modes, tapping the LF button will activate the LeanFind mode.

For Your Safe Flight |

Page 17 |

Loading...

Loading...