Page 1

Operator’s manual

Manual d’utilisation

Manual de instrucciones

EN (2-30)

FR (31-60)

ES (61-90)

Please read these instructions and make sure you understand them before using the machine.

Lire attentivement et bien assimiler le manuel d’utilisation avant d’utiliser la machine.

Lea detenidamente el manual de instrucciones y asegúrese de entender su contenido antes de utilizar la máquina.

Page 2

E n g l i s h --- 2

115305026 Rev. 3 7/15/10

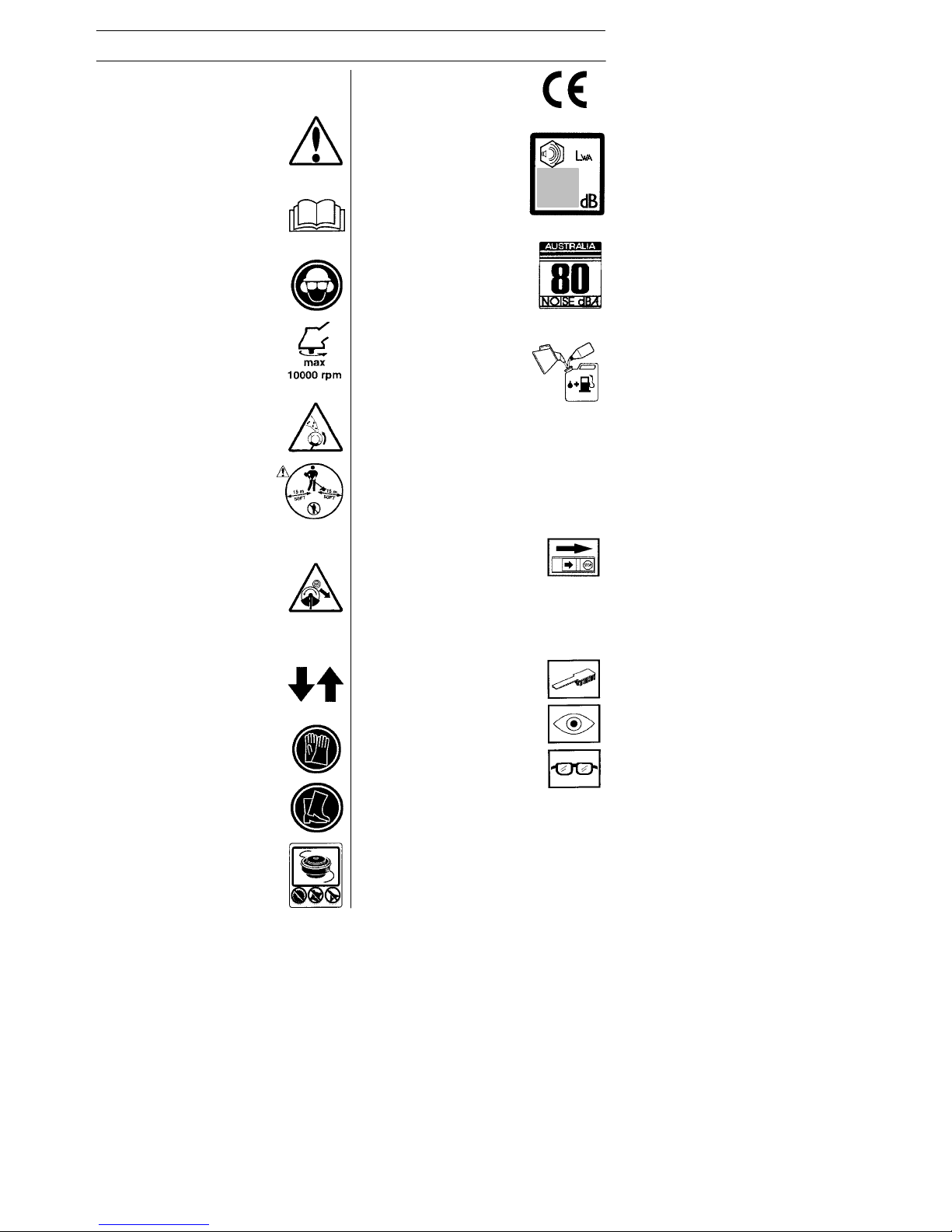

SYMBOL EXPLANATION

This product is in accordance

with applicable EC directives.

Noise emission to the

environment according to the

European Community’s

Directive. The machine’s

emission is specified in the

T echnical data section and

on label.

Sound pressure level at

7,5 metres.

Use unleaded or quality leaded

petrol and two--stroke oil

mixed at a ratio of 2% (1:50).

Other symbols/decals on the machine

refer to special certification requirements

for certain markets.

Stop the engine by pushing

and holding the stop switch

in the STOP position. CAUTION!

The stop switch automatically

returns to the start position.

In order to prevent unintentional

starting, the spark plug cap must be

removed from the spark plug when

assembling, checking and/or

performing maintenance.

Regular cleaning is required.

Visual check.

Approved eyeprotection must

always be used.

Symbols

WARNING: Clearingsaws, brush-

cutters an dtrimmers can be dangerous! Careless or incorrect use

can result inserious or fatal

injury to the operator or others.

Please read the operator’s manual

care fully andmake sure you

understand the instructions

before using the machine.

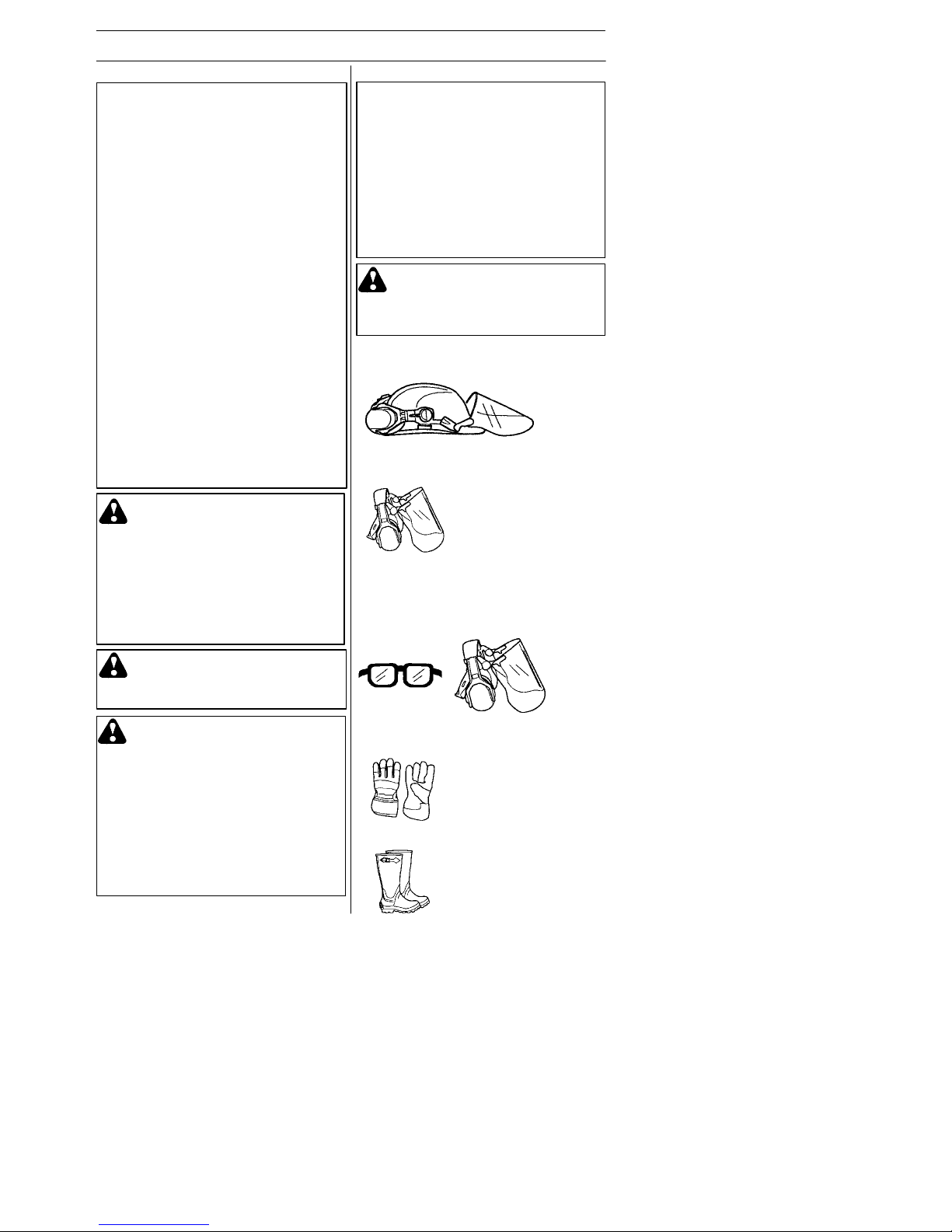

Always wear:

S A protective helmet where there

is a risk of falling objects

S Hearing protection

S Approved eye protection

Max. speed ofoutput shaft, rpm

Beware of thrown objects and

ricochets.

The operator of themachine

shall ensure, while working,

that no persons or animals

come closer than 15 metres.

Machines fitted with grass blades

can be thrownviolently tothe side

when the blade comes into contact

with a fixed object. The blade is

capable of amputating an arm or

leg. Always keep people and

animals at least 15 metres from

the machine.

Arrows which show limits for

handle mounting.

Always wear approved protective

gloves.

Use anti--slip andstableboots.

Only usenon--metallic, flexible

cutting attachments, i.e. trimmer

heads with trimmerline.

Page 3

E n g l i s h --- 3

115305026 Rev. 3 7/15/10

CONTENTS

Contents

KEY TO SYMBOLS

Symbols 2.........................

CONTENTS

Contents 3........................

Note the following before starting 3....

WHAT IS WHAT?

What is what? 4...................

GENERAL SAFETY PRECAUTIONS

Important 5........................

Personal protective equipment 5......

Machine’s safety equipment 6........

Cutting equipment 8.................

ASSEMBLY

Fitting the handlebar 11...............

Fitting the harness 11................

Fitting blades and trimmer heads 12....

Fitting a blade guard, grass blade and

grass cutter 12......................

Fitting the blade guard andsaw blade 13

Fitting the trimmer guardand

trimmer head 13.....................

FUEL HANDLING

Fuel safety 14.......................

Fuel 14............................

Fueling 15..........................

STARTING AND STOPPING

Check before starting 16..............

Starting and stopping 16..............

WORKING TECHNIQUES

General working instructions 18........

MAINTENANCE

Carburetor 23.......................

Muffler 24..........................

Spark plug 24.......................

Air filter 25..........................

Bevel gear 25.......................

Maintenance schedule 26.............

TECHNICAL DATA

Technical data 27....................

EC--declaration of conformity

(Applies to Europe only) 28............

Note the following before

starting:

Please read the operator’s manual carefully.

Jonsered has a policy of continuous product

development and therefore reserves the right

to modify the design and appearance of

products without prior notice.

WARNING: A clearing saw,

brushcutter or trimmer can be

dangerous if used incorrectly or

carelessly, and can cause serious

or fatal injury to the operator or

others. It isextremely important

that you read and understand the

contents of this operator’s manual.

WARNING: Under no circum-

stances may the design of the

machine be modified without the

permissionof the manufacturer.

Always use genuine accessories.

Non--authorized modifications

and/or accessories can result

in serious personal injury or the

death of the operator or others.

WARNING: Long--term exposure

to noise can result in permanent

hearing impairment. So always use

approved hearing protection.

Page 4

E n g l i s h --- 4

115305026 Rev. 3 7/15/10

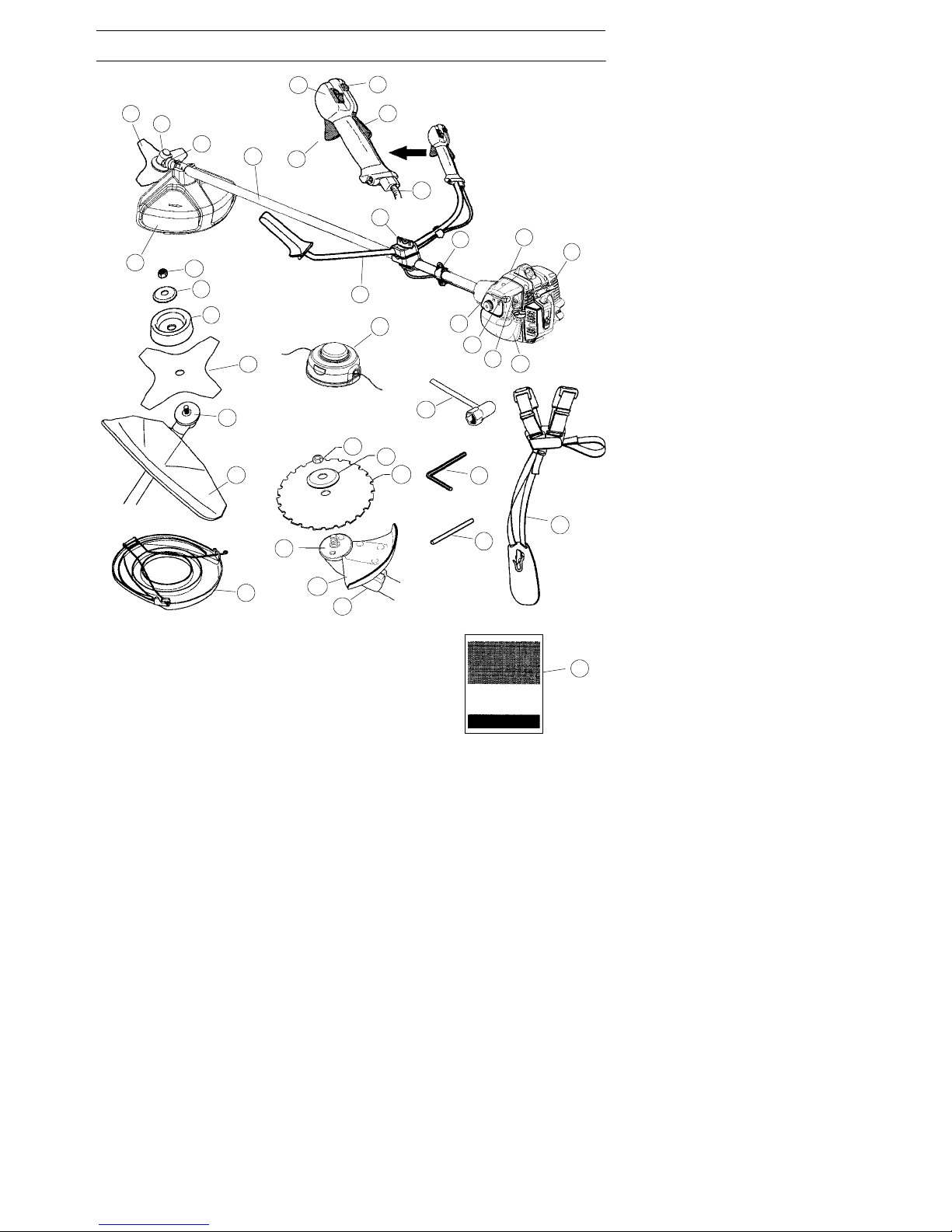

WHAT IS WHAT?

5

2

9

10

6

16

21

23

25

1

3

8

11

15

13

14

7

12

30

17

4

4

4

27

22

18

19

20

1

21

24

29

28

26

31

18

32

33

1. Grass blade 18. Locking nut

2. Grease filler cap 19. Support flange

3. Bevel gear 20. Support cup

4. Cutting attachmentguard 21. Drive disc

5. Shaft 22. Trimmer head

6. Handlebar 23. Socket spanner

7. Throttle control 24. Transport guard

8. Stop switch 25. Hex wrench

9. Throttle lock--out 26. Locking pin

10. Harness clamp 27. Harness

11. Cylinder cover 28. Start throttlebutton

12. Starter handle 29. Adjusting the throttle wire

13. Fueltank 30. Saw blade

14. Choke control 31. Mounting plate/adapter

15. Primer bulb 32. Support flange

16. Air filter cover 33. Operator’s manual

17. Handle adjustment

What is what?

Page 5

E n g l i s h --- 5

115305026 Rev. 3 7/15/10

GENERAL SAFETY PRECAUTIONS

IMPORTANT!A clearing saw, brushcutter

or trimmer can be dangerous if used incorrectly or carelessly, and can cause serious

or fatal injury to the operator or others. It is

extremely important that you read and understand the contents of this operator’s

manual. You must use approved personal

protective equipment whenever you use the

machine. Personal protective equipment

cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident

does happen. Ask your dealer for help in

choosing the right equipment.

HELMET

A helmet should beworn ifthe brush being

cleared is taller than 2metres.

HEARING PROTECTION

Wear hearing protection that provides

adequate noise reduction.

EYE PROTECTION

Always wear approved eye protection. If

you use avisor then you must also wear

approved protective goggles. Approved

protective goggles must comply with EN

166 in EU countries.

GLOVES

Gloves should be worn whennecessary,

e.g., when fitting cutting attachments.

BOOTS

Wear sturdy, non--slipboots.

Personal protective equipment

WARNING: Listen out for warn-

ing signals or shouts when you are

wearing hearing protection. Always

remove your hearing protection as

soon as the engine stops.

Important

IMPORTANT! The machine is only designed

for trimming grass, grass clearing and/or

forestry clearing. The only accessories you

can operate with this engine unit are the cutting attachments we recommend in the section

on Technical data. Never use the machine if

you are tired, if you have drunk alcohol, or if

you are taking medication that could affect

your vision, your judgement or your co--ordination. Never use the machine in extreme weather conditions such as severe cold, very hot

and/or humid climates. W ear personal protective equipment. See instructions under the

heading Personal protective equipment.

Never use a machine that has been modified

in any way from its original specification.

Never use a machine that is faulty. Carry out

the checks, maintenance and service instructions described in this manual. Some maintenance and service measures must be carried

out by trained and qualified specialists. See

instructions under the heading Maintenance.

All covers and guards must be fitted before

starting. Make sure the spark plug cap and

lead are not damaged. Otherwise you could

get an electric shock. The machine operator

must ensure that no people or animals come

closer than 15 metres while working. When

several operators a re working in the same

area, the safety distance should be at least

15 metres.

WARNING: Never allow children

to use or be in the vicinity of the

machine. As the machine is equipped

withaspring--loadedstopswitchand

can be started by low speed and

force on the starter handle, even

small children under some circumstances can produce the force necessary to start the machine. This can

mean a risk of serious personal injury . Therefore remove the s pa rk plug

cap when the machine is not under

close supervision.

WARNING: Using an incorrect

cutting attachment or an incorrectly

filed blade can increase the risk of

accidents.

WARNING: This machine pro-

duces an electromagnetic field

during operation. Under some circumstances, this field may interfere

with active or passive medical

implants. To reduce the risk of

serious or fatal injury, we recommend persons with medical

implants to consult their physician

and the medical implant manufacturer before operating this machine.

Page 6

E n g l i s h --- 6

115305026 Rev. 3 7/15/10

GENERAL SAFETY PRECAUTIONS

CLOTHING

Wear clothes made ofa strong fabric and

avoid loose clothing that can catch on

shrubs and branches. Always wear heavy,

long pants. Do not wear jewelry, shorts

sandals or gobarefoot. Secure hair so it is

above shoulder level.

FIRST AID KIT

A first aidkit should be carried by operators of clearing saws, brushcutters or trimmers.

Machine’s safety equipment

This section describes the machine’s safety equipment, its purpose, and how checks

and maintenance shouldbe carried out to

ensure that it operates correctly. See the

“What is what” section to locate wherethis

equipment is positionedon your machine.

The life span ofthe machine canbe reduced and the risk of accidents can increase if machine maintenance is not carried out correctly and if service and/or repairs are not carried out professionally. If

you need further information please contact

your nearest service workshop.

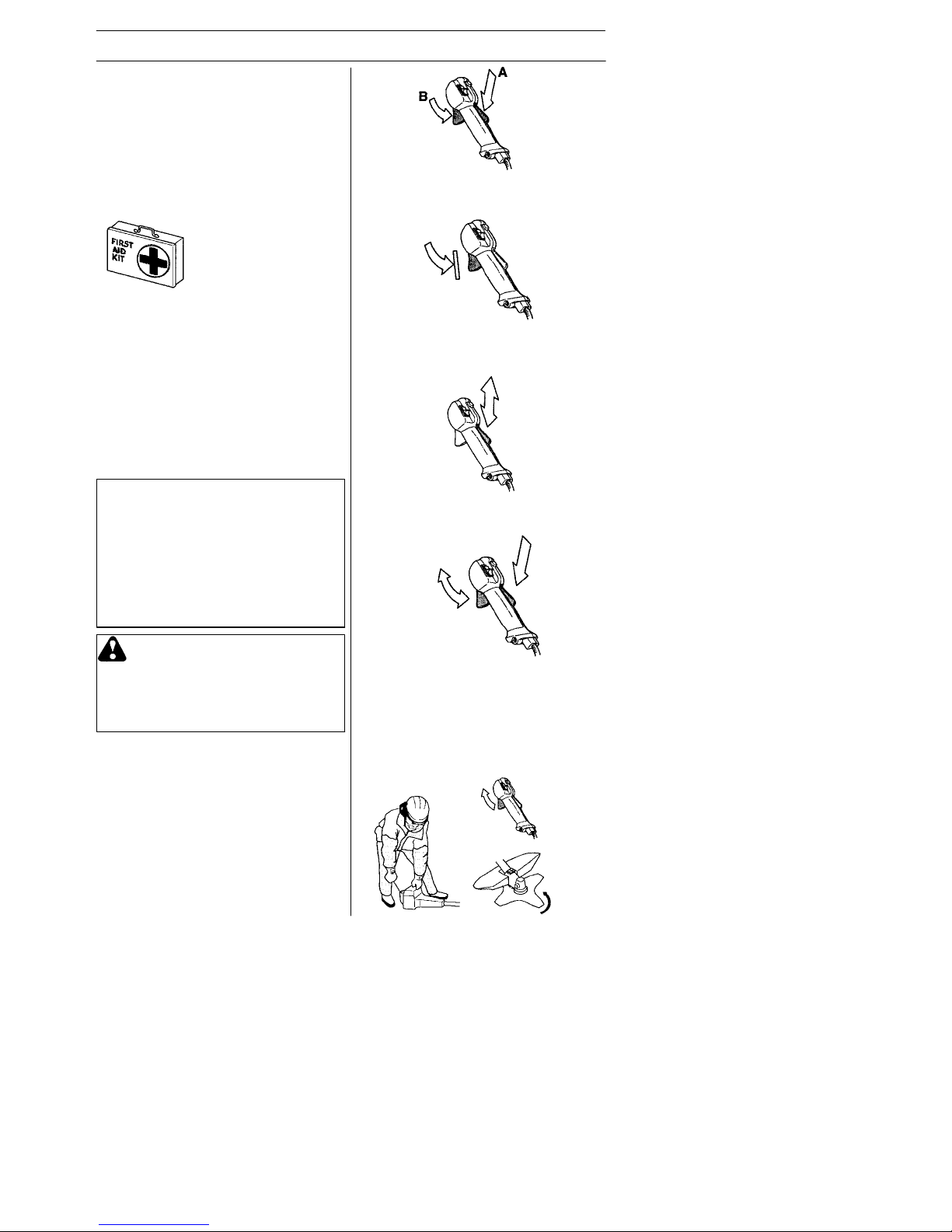

Throttle lock--out

The throttle lock--out is designed to prevent

accidental operationof thethrottle control.

When you press the lock--out (A) (i.e.when

you grasp thehandle) itreleases the

throttle control (B). When you release the

handle, the throttle control and the throttle

lock--out both move back to their original

positions. This movement is controlled by

two independent return springs. This arrangement means that thethrottle control is

automatically locked at the idle setting.

IMPORTANT! All servicing and repair work

on the machine requires special training. This

is especially true of the machine’s safety

equipment. If your machine fails any of the

checks described below you must contact

your service agent. When you buy any of our

products we guarantee the availability of professional repairs and service. If the retailer

who sells your machine is not a servicing

dealer, ask him for the address of your nearest service agent.

WARNING: Never use a machine

that has faulty safety equipment!

Follow the c ontrol, maintenance

and service instructions described

in this section. If your machine fails

any of these checks contact your

service agent to get it repaired.

Make sure thethrottle control is locked at

the idle setting when the throttle lock--out is

released.

Press thethrottle lock--out and make sure it

returns to its original position when you release it.

Check that the throttle control and throttle

lock--out move freely and that thereturn

springs work properly.

See instructions under the heading Start.

Start the machine andapply full throttle.

Release the throttle and check that the

cutting attachment stops and remains at a

standstill. Ifthe cutting attachment rotates

with the throttle inthe idle position thenthe

carburettor idle setting must be checked.

See instructions under the heading

Maintenance.

Page 7

E n g l i s h --- 7

115305026 Rev. 3 7/15/10

GENERAL SAFETY PRECAUTIONS

In countries that have a warm and dry

climate there is a significant risk offire.

We therefore fit certain mufflers with a spark

arrestor mesh. Check whether the muffler

on your machineis fitted with this kind of

mesh.

For mufflers, it is very important that you

follow the instructions on checking, maintaining, and servicing your machine.

Never use a machine that has a faulty

muffler.

Stop switch

Make sure theengine stops when you push

and hold the stop switch.

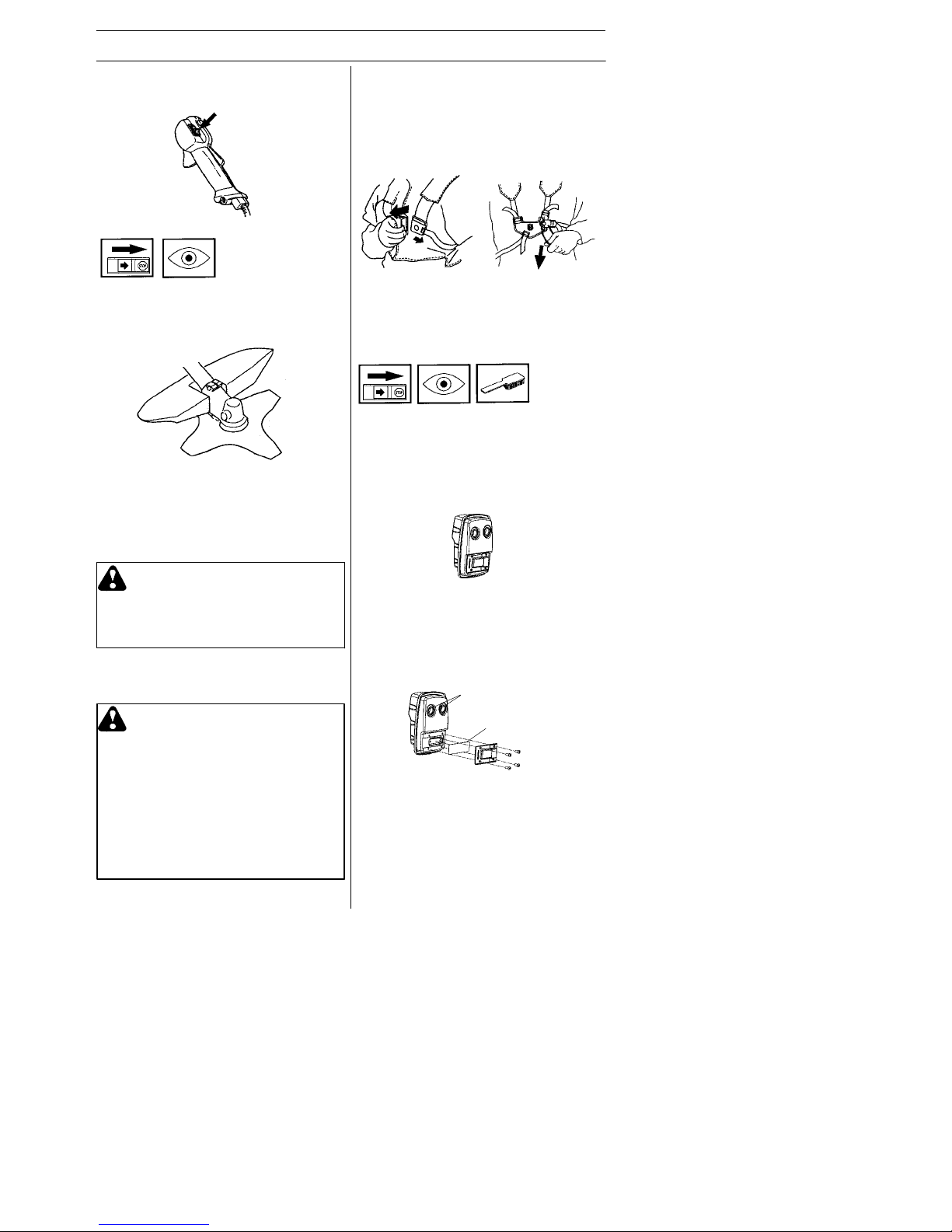

Cutting a ttachment guard

This guard is intended to prevent loose

objects from beingthrown towards the

operator. Theguard also protects the

operator from accidental contact with the

cutting attachment.

Check thatthe guardis undamagedand not

cracked. Replace the guard if it has been

exposed to impact or is cracked.

Always use the recommended guard for the

cutting attachment you are using. See the

“Technical data” section.

Use of incorrectly wound trimmerline or an

incorrect cutting attachment increases the

level of vibration.

WARNING: Never use a cutting

attachment without an approv ed

guard. See the section on “T echni cal

data”. If an incorrect or faulty guard

is fitted this can cause serious

personal injury.

WARNING: Overexposure to

vibration can lead to circulatory

damage or nerve dam age in people

whohaveimpairedcirculation.

Contact your doctor if you experience symptoms of overexposure to

vibration. Such symptoms include

numbness, loss of feeling, tingling,

pricking, pain, loss of strength,

changes in skin color or condition.

These symptoms normally appear

in the fingers, hands or wrists. The

risk increases at low temperatures.

Muffler

The muffler is designedto reduce thenoise

level and to direct the exhaust gases away

from the operator.

CAUTION! Muffleris fitted witha catalytic

convertic designed to reduce harmful exhaust gases.

Muffler bolts

Spark arrestor mesh

Harness quick release

There is an easily accessible, harness

quick release fitted at the front in case of an

emergency that requires you to freeyourself from the machine and harness.

See instructions under the heading Adjusting the harness.

Check thatthe harness straps are correctly

positioned. Once the harness and machine

have been adjusted, check that the harness

quick release works correctly.

Page 8

E n g l i s h --- 8

115305026 Rev. 3 7/15/10

GENERAL SAFETY PRECAUTIONS

WARNING: Bear in mind that:

Engine exhaust fumes contain carbon monoxide, which can cause

carbon monoxide poisoning. For

this reason you shoul d not start or

run the m achine indoors, or anywhere that is poorly ventilated .

The exhaust fumes from the engine

are hot and may contain sparks

which can start a fire. Never start

the machine indoors or near combustible material!

When

f

itting, tighten the nut in the opposite

direction to the direction of rotation of the

cutting attachment. Toremoveit, undothe

nut in the samedirectionas the cutting attachment rotates. (CAUTION! The nuthas

a left--hand thread.) Tighten the nutusing

the socket spanner.

IMPORTANT!

Only use cutting attachments with the guards

we recommend! See the section on

“T echnical data”.

Refer to the instructions for the cutting attachment to check the correct way to load the

trimmer line and the correct line diameter .

Keep the teeth of the blade correctly sharpened! Follow our recommendations. Also refer to the instructions on the blade packaging.

Maintain the correct blade setting! Follow our

instructions and use the recommended file

gauge.

WARNING: Theinsideofthe

muffler contain chemicals that may

be carcinogenic. Avoid contact with

these elements in the event of a

damaged muffler .

The nylon lining inside the locking nut must

not be so worn that you can turn it by

hand. The lining should of fer a resistance

of at least 1.5Nm. Thenut should be replaced after it has been put on approx. 10

times.

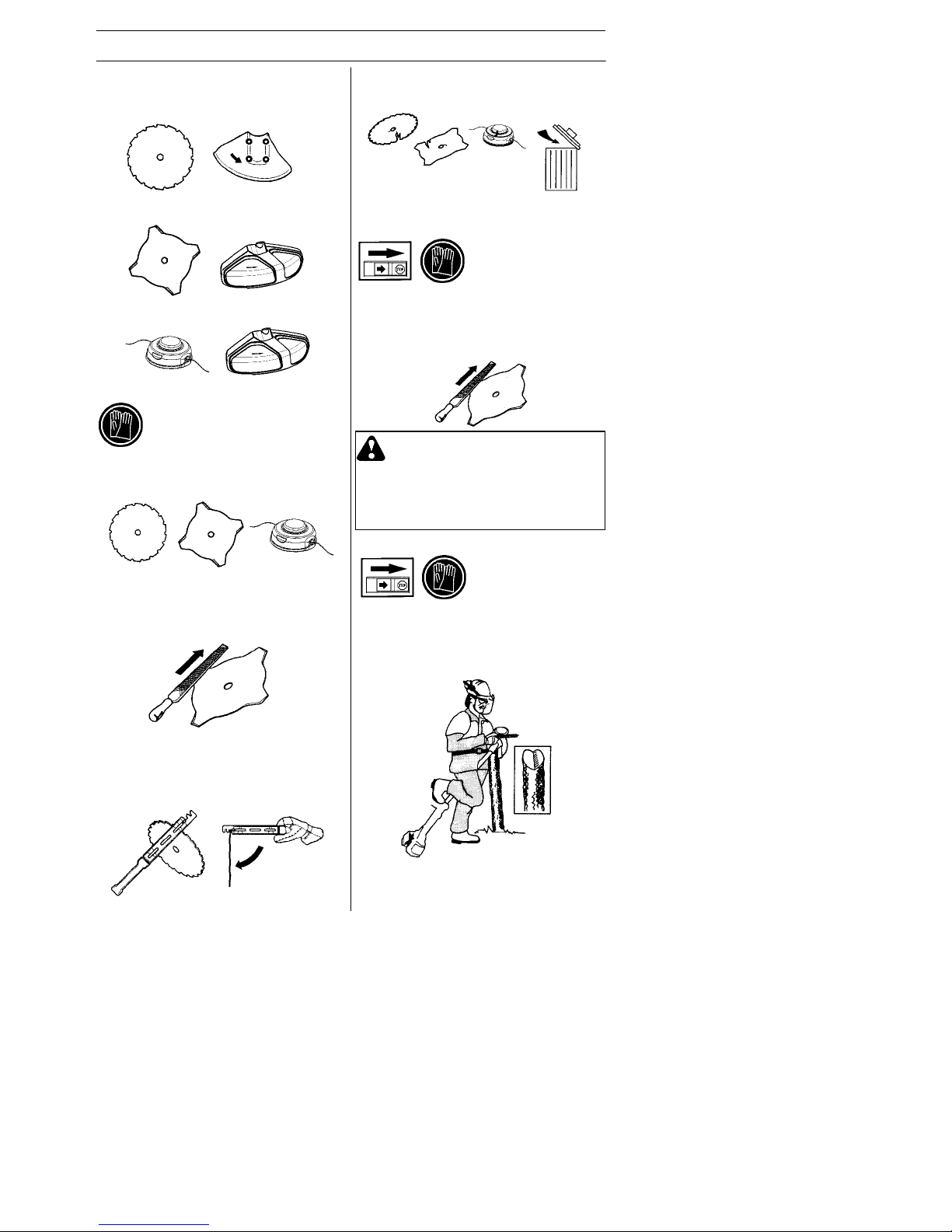

Cutting equipment

This section describes how to choose and

maintain your cutting equipment in order to:

S Redu ce the risk of blade thrust.

S Obtain maximum cutting performance.

S Extend the life of cutting equipment.

Regularly check that the muffler is securely

attached to the machine.

Locking nut

A locking nutis used tosecure some types

of cutting attachment.

WARNING: Always stop the en-

gine before doing any work on the

cutting attachment. This continues

to rotate even after the throttle has

been released. Ensure that the

cutting attachment has stopped

completely and disconnect the

lead from the spark plug before

you start to work on it.

WARNING: Using an incorrect

cutting attachment or an incorrectly sharpened blade increases the

risk of kickback.

WARNING: Mufflers fitted with

catalytic converters get very hot

during use and remain so for some

time after stopping. This also appl ies

at idle speed. Contact can result in

burns to the skin. Remem ber the risk

of fire!

Page 9

E n g l i s h --- 9

115305026 Rev. 3 7/15/10

GENERAL SAFETY PRECAUTIONS

General rules

Only use cutting attachments withthe

guards we recommend! Seethe section on

Technical data.

Keep the teeth of theblade correctly sharpened! Follow our instructions and usethe

recommended file gauge. Anincorrectly

sharpened or damaged bladeincreases the

risk of accidents.

Keep the correct setting on the saw blade!

Follow our instructions and use therecommended setting tool. An incorrectly set saw

blade increases the risk of jammingand

blade thrust, and damageto thesaw blade.

Cutting equipment

Saw blades areintended for cutting fibrous

types of wood.

Grass blades and grass cutters are

intended for cutting coarse grass.

A trimmer head is intended for trimming

grass.

Sharpening grass cutters and

grass blades

S See the cutting attachment packaging for

correct sharpening instructions. Sharpen

blades and cutters using a single--cut flat file.

S Sharpen all edges equally to maintain the

balance of the blade.

Check the cutting attachment

f

or damage

or cracks. A damaged cutting attachment

should always be replaced.

WARNING: Always discard a

blade that is bent, twisted, cracked,

broken or damaged in any other

way. Never attempt to straighten

a twisted blade so that it can be reused. Only use original blades of

the specified type.

Sharpeningthe sawblade

S See the cutting attachment packaging for

correct sharpening instructions.

S A correctly sharpened blade is essential for

working ef ficiently and to avoid unnecessary

wear to the blade and clearing saw .

S Makesure that the blade is wellsupported

when you file it. Use a 5.5 mm round file

with a file holder.

Page 10

E n g l i s h --- 1 0

115305026 Rev. 3 7/15/10

GENERAL SAFETY PRECAUTIONS

S Thefiling angle is 15 degrees. File alter-

nate teeth to the right and those in between to the left. If theblade has been

heavily pitted by stones it may be necessary todress the top edges of the teeth

with a flat file, in exceptional cases. If so,

this should bedone before filing with a

round file. The top edges must be filed

down by the same amount for all the

teeth.

S Adjust theblade setting. This should be

1mm.

Trimmer head

S Only use the recommendedcutting at-

tachments. Seethe section on “T echnical

data”.

IMPORTANT!

Always ensure the trimmer line is wound

tightly and evenly around the drum, otherwise the machine will generate harmful

vibration.

S Smaller machines generally require small

trimmer heads and vice versa. This is because when clearing using trimmer line

the engine must throw out the trimmer

line radially fromthe trimmerhead and

overcome the resistance of the grass

being cleared.

S The length of thetrimmer lineis also im-

portant. A longer trimmer line requires

greater engine power than a shorter

trimmer line of the same diameter.

S Make sure that thecutter on thetrimmer

guard is intact. This is used to cut the

trimmer line to the correct length.

S To increase the lifeof the trimmer line it

can be soaked in water for a couple of

days. This will make the line tougher so

that it lasts longer .

Page 11

E n g l i s h --- 1 1

115305026 Rev. 3 7/15/10

ASSEMBLY

NOTE: Make sureunit is assembled cor-

rectly as shown in this manual.

Fitting the handlebar

S Remove the screw at the rear of the

throttle handle.

S Slidethe throttle handle on tothe right

side of the handlebar(seeillustration).

S Alignthe screw hole in the throttle han-

dle with the hole inthe handlebar.

S Refit the screw in the hole in the rear of

the throttle handle.

S Threadthe screw through the handle

and handlebar. Tighten the screw.

S Position thehandle bar as shown. Fit the

mounting components as shown.

S Put on the harness and hang the machine

from the harness clamp. Now make a final

adjustment so that the machine is in a

comfortable working position when it hangs

from the harness. T ighten the knob.

Adjusting the harness

S At the front of the harness is an easily

accessible quick release. Use the quick

release in any emergency situation that

requires you to free yourself from the

machine and harness.

Spreading the load on your

shoulders

S A well--adjusted harness andmachine

makes work much easier.

S Put on the harness. Adjust the harness

for the best working position. Tension the

side straps so that the weight is evenly

distributed across both shoulders.

Fitting the harness

Proper harness and handlebar adjustments must bemade with theengine completely stopped before usingunit.

WARNING: When using a

brushcutter, it must always be

hooked securely to the harness.

Otherwise, you will be unable to

control the brushcutter safely.

This can result in injury to yourself

or others. Never use a harness with

a defective quick release.

Page 12

E n g l i s h --- 1 2

115305026 Rev. 3 7/15/10

ASSEMBLY

Fitting a blade guard, grass

blade and grass cutter

S Hook the blade guard/combination guard

(A) onto the fitting on the shaft and secure

with the bolt.

CAUTION! Use therecommendedblade

guard. See the Technical data section.

S Fitthe drive disc (B) on the output shaft.

S Turn theblade shaft until oneof the

holes in the drive disc aligns with the

corresponding holein the gearhousing.

S Insert the locking pin (C) in the hole to

lock the shaft.

S Place the blade (D), support cup (E) and

support flange (F) on theoutput shaft.

S Fitthe nut (G). The nut must be tight-

ened to a torque of35--50Nm (3.5--5

kpm). Use the socket spanner in thetool

kit. Hold theshaft of the spanner as

close to theblade guard as possible. To

tighten the nut, turn the spanner in the

opposite directionto thedirectionof rotation (CAUTION! left--hand thread).

Fitting blades and trimmer

heads

WARNING: Never use a cutting

attachment without an approved

guard. See the section on Technical data. If an incorrect or faulty

guard is fitted this can cause serious personal injury.

IMPORTANT!

Ifasawbladeorgrassbladeistobeused,

the machine must be equipped with the correct handlebar , blade guard and harness.

Correct balance

Let the cutting attachment rest lightly on the

ground. If you use a saw blade, it should balance about 4 inches (10 cm) above the

ground to prevent contact with stones and

the like. Adj ust the position of the harness

clamp to balance the unit correctly.

Correct height

Adjust the harness so that thecutting attachment is parallel to theground.

WARNING: When fitting the

cutting attachment it is extremely

important that the raised section

on the drive disc/support flang e

engages correctly in the centre hole

of the cutting attachment. If the

cutting attachment is fitted incorrectly it can result in serious and/or fatal

personal injury.

Page 13

E n g l i s h --- 1 3

115305026 Rev. 3 7/15/10

ASSEMBLY

Fitting the blade guard and

saw blade

S Remove the mounting plate (H). Fit the

adapter (I) and bracket (J) with the two

screws (K) as shown. Fit theblade

guard (A) to theadapter using the 4

screws (L) as shown.

CAUTION! Use therecommendedblade

guard. See the Technical data section.

S Fitthe drive disc (B) on the output shaft.

S Turn theblade shaft until oneof the

holes in the drive disc aligns with the

corresponding holein the gearhousing.

S Insert the locking pin (C) in the hole to

lock the shaft.

S Place the blade (D) and support flange

(F) on the output shaft.

S Fitthe nut (G). The nut must betight-

ened to a torque of35--50 Nm (3.5--5

kpm). Use the socket spanner in thetool

kit. Hold theshaft of the spanner as

close to theblade guard as possible. To

tighten the nut, turn the spanner in

the opposite direction tothe direction of

rotation (CAUTION! left--hand thread).

S Whenloosening andtightening the saw

blade nut, there is a risk of injury from the

teeth of the saw blade. You should therefore always ensure that your handis

shielded by theblade guardwhen doing

this. Always use a socket spanner with a

shaft that is long enough toallow this.

The arrow in the diagram shows the area

where you should operate the socket

spanner when loosening or tightening

the nut.

Fitting the trimmer guard and

trimmer head

S Fitthe correct trimmer guard (A) for use

with the trimmer head. Hook the trimmer

guard/combination guard ontothe fitting

on the shaft andsecure withthe bolt (D).

S Fitthe drive disc (B) on the outputshaft.

S Turn theshaft until one of the holes in the

drive disc aligns with the corresponding

hole in the gear housing.

S Insert the locking pin (C) in the hole to

lock the shaft.

S Screw on the trimmer head (H) in the op-

posite directionto thedirectionof rotation.

S To dismantle, follow the instructions in

the reverse order.

A

A

DB

C

H

Page 14

E n g l i s h --- 1 4

115305026 Rev. 3 7/15/10

FUEL HANDLING

Fuel safety

Never start themachine:

1. If you have spilled fuel on it. Wipe off the

spillage and allow remaining fuel to evaporate.

2. If you have spilled fuel on yourself or your

clothes, change your clothes. Wash any

part of your body that has come in contact

with fuel. Use soap and water .

3. If the machine is leaking fuel. Check regularly for leaks from the fuel cap and fuel

lines.

Tr ansport and storage

S Store and transport the machine and fuel

so that thereis norisk of any leakage or

fumes coming into contact with sparks or

naked flames, for example,from electrical machinery, electric motors, electrical

relays/switches or boilers.

S Whenstoringand transporting fuel al-

ways use approved containers intended

for this purpose.

S Whenstoringthe machine for longperi-

ods the fuel tank must be emptied.Contact your local petrol station to findout

where to dispose of excess fuel.

S Ensure the machine is cleaned and that

a complete service is carried out before

long--term storage.

S Thetransportguard must always be

fitted to the cutting attachment whenthe

machine is being transported or in storage.

S Inorder toprevent unintentional starting

of the engine, the spark plug cap must

always be removed during long--term

storage, if themachine is not under

close supervision and when performing

all service measures.

S Secure the machine during transport.

Fuel

CAUTION! The machine is equipped with a

two- -stroke engine and must always be run

using a mixture of petrol and two-stroke

engine oil. It is important to accurately measure the amount of oil to be mixed to ensure

that the correct mixture is obtained. When

mixing small amounts of fuel, even small

inaccuracies can drastically affect the ratio

of the mixture.

Petrol

CAUTION! Always use a good quality pet-

rol/oil mixture (at least 90 octane).

Use low--emission petrol, also known as

alkylate petrol, if itis available.

S The lowest octane recommended is 90.

If you run the engine on a lower octane

than 90, it can result in knocking. This

gives rise to a high engine temperature,

which can result in serious engine damage.

S When working at continuous highrevs, a

higher octane rating is recommended.

Two--stroke oil

S For best results and performance, use

JONSERED two--stroke oil, which is

specially formulatedfor our two--stroke

engines. Mixture 1:50 (2%).

S If JONSERED two- -stroke oil is not avail-

able, you may use another two-stroke oil of

good quality that is intended for air cooled

engines. Contact your dealer when selecting an oil. Mixing ratio 1:33 (3%).

S Never use two--stroke oil intended for

water--cooled outboard engines,

sometimes referredto as outboard oil.

S Never use oil intended for four--stroke

engines.

WARNING: Take care when han-

dling fuel. Bear in mind the risk of

fire, explosion and inhaling fumes.

50,100,15

10 0,20 0,30

15 0,30 0,45

20 0,40 0,60

Petrol,

litre

Two- -stroke oil, litre

2% (1:50) 3% (1:33)

WARNING: Fuel and fuel fumes

are highly inflammable and can

cause serious injury when inhaled

or allowed to come in contact with

the skin. For this reason observe

caution when handling fuel and

make sure there is adequate ventilation.

Page 15

E n g l i s h --- 1 5

115305026 Rev. 3 7/15/10

FUEL HANDLING

S Always start by filling half the amount of

the petrol to be used. Then add the entire

amount of oil. Mix (shake) the fuel mixture.

Add the remaining amount of petrol.

S Mix (shake) the fuel mixture thoroughly

before filling the machine’s fuel tank.

S Donot mix more than one month’s sup-

ply of fuel ata time.

S If the machine is not used for some time,

the fuel tank should be emptied and

cleaned.

WARNING: The catalytic con-

verter muffler gets very hot during

and after use. This also applies

during idling. Be aware of thefire

hazard, especially when working

near flammable substances and/or

vapors.

Fueling

WARNING: Taking the following

precautions, will lessen the risk of

fire:

Do not smoke or place hot objects

near fuel.

Always shut off the engine before

refueling.

Always stop the engine and let it

cool for a few minutes before refuelling.

When refueling, open the fuel cap

slowly so that any excesspressure

is released gently.

Tighten the fuel cap carefully after

refueling.

Always move the machine away

from the refueling area before

starting.

Min. 3 metres

Mix

i

ng

S Always mix the petroland oil ina clean

container intended for fuel.

S Cleanthe areaaround thefuel cap.

Contamination in the tank can cause

operating problems.

S Ensure that the fuel is well mixed by shak-

ing the container before filling the tank.

Page 16

E n g l i s h --- 1 6

115305026 Rev. 3 7/15/10

STARTING AND STOPPING

Check before starting

S Check the blade to ensure that no cracks

have formed at the bottom of the teeth or

by the centre hole. The most common reason why cracks are formed is that sharp

corners have been formed at the bottom of

the teeth while sharpening or that the blade

has been used with dull teeth. Discard a

blade if cracks are found.

S Check that the support flange is not

cracked due to fatigue or due to being

tightened too much. Discard the support

flange if it is cracked.

S Ensure the locking nut has not lost its cap-

tive force. The nut lock should have a

locking force of at least 1.5 Nm. The tightening torque of the locking nut should be

35--50 Nm.

S Check that the trimmer headand trimm er

guard are not damaged or cracked.

Replace the trimmer head or trimmer

guard if they have been exposed to

impact or are cracked.

S Never use the machine without a guard

nor with a defective guard.

S All covers must be correctly fitted and un-

damaged before you start the machine.

Cold engine

Primer bulb: Press the primer bulb 10

times until fuel begins to fillthe bulb. The

primer bulb need not becompletely filled.

Choke: Move theblue engine choke lever

over to the closed position.

Starting

Hold the body of the machine on the

ground using your left hand (CAUTION!

Not with your foot!).

Firmly grip thestarter ropehandle with

your right hand.DO NOT squeeze

throttle trigger.Slowly pull out thecord

until you feel some resistance (the starter

pawls grip); then quickly and powerfully

pull the cord.

Never wrap the starter cord around

your hand.

Repeat pulling the cord untilthe engine

attempts to start. Move the blue engine

choke lever to the½ position. Pull starter

rope until engine runs. Move the blue

engine choke lever tothe opened position.

WARNING: The complete clutch,

clutch cover , and shaft must be

fitted before the machine is started,

otherwise parts could com e loose

and cause personal injury .

Always move the machine away

from the refueling area before

starting. Place the machine on a

flat surface. Ensure the cutting attachment cannot come into contact

with any object.

Make sure no unauthorized

persons are in the working area,

otherwise there is a risk of serious

personal injury. The safety

distance is 15 metres.

Starting and stopping

Page 17

E n g l i s h --- 1 7

115305026 Rev. 3 7/15/10

STARTING AND STOPPING

Warmengine

With a warm engine, move theblue engine

choke lever to the½ position. Pull starter

rope until engine runs. Movethe blue

engine choke lever tothe opened position.

CAUTION!

Do not put any part of your body in marked

area. Contact can result in burns to the

skin, or electrical shock if the spark plug

cap has beendamaged. Always use

gloves. Donot use a machine withdamaged spark plugcap.

CAUTION! Do not pull the starter cord all

the way out and do not let go ofthe starter

handle when the cord is fully extended.

This can damagethe machine.

NOTE: If engine dies, return blue engine

choke lever to theclosed position and

repeat starting steps.

For throttle handles with a start

throttle lock--out:

Set the throttle tothe start position by first

pressing the throttle lock--out and the

throttle trigger, then pressing thestart

throttle button (A). Then release the throttle

lock--out and the throttle trigger, followed

by the start throttle button. Thethrottle

function is now activated. To return the engine to idle, press the throttle lock--out and

throttle trigger again.

Stopping

Stop the engine by pushing and holding

the stop switch in the STOP position until

the engine stops.

CAUTION! The stop switch automatically

returns to thestart position. In order to prevent unintentional starting, the spark plug

cap must be removed from the spark plug

when assembling, checking and/or performing maintenance.

WARNING: When the engine is

started with the choke in the closed

position the cutting attachment will

start to rotate immediately.

Page 18

E n g l i s h --- 1 8

115305026 Rev. 3 7/15/10

WORKING TECHNIQUES

General working instructions

IMPORTANT!

This section describes the basic safety precautions for working with trimmers. If you

encounter a situation where you are uncertain how to proceed you should ask an expert. Contact your servicing dealer.

Avoid all usage which you consider to be

beyond your capability.

You must understand the difference between

forestry clearing, grass clearing and grass

trimming before use.

Basic safety rules

1. Look around you:

S To ensure that people, animals or other

things cannot affect your control of the

machine.

S To ensure that people, animals, etc.,

do not come into contact with the cutting attachment or loose objects that

are thrown out by the cutting attachment.

S CAUTION!Do not use themachine

unless youare ableto call for helpin

the event of anaccident.

2. Inspect the working area. Remove all

loose objects, such as stones, broken

glass, nails, steel wire, string, etc. that

could be thrown out or become wrapped

around the cutting attachment.

3. Do not use the machine in bad weather ,

such as dense fog, heavy rain, strong

wind, intense cold, etc. Working in bad

weather is tiring and often brings added

risks, such as icy ground, unpredictable

felling direction, etc.

4. Make sure you can move and stand safely. Check the area around you for possible

obstacles (roots, rocks, branches, ditches,

etc.) in case you have to move suddenly.

T ake great care when working on sloping

ground.

5. T ake great care when cutting a tree that is

in tension. A tree that is in tension may

spring back to its normal position before or

after being cut. If you position yourself

incorrectly or m ake the cut in the wrong

place the tree may hit you or the machine

and cause you to lose control. Both

situations can cause serious personal injury .

6. Keep a good balance and a firm foothold.

7. Always hold the machine with both hands.

Hold the machine on the right side of your

body.

8. Keep the cutting attachment below waist

level.

9. Switch off the engine before moving to

another area. Fit the transport guard before

carrying or transporting the equipment any

distance.

10.Never put the machine down with the engine running or while the cutting attachment

is rotating.

WARNING: Neither the operator

of the machine nor anyone else

may attempt to remove the cut material while the engine is running or

the cutting equipment is rotating,

as this can result in serious injury.

Stop the engine and cutting equipment before you remove material

that has wound around the blade

shaft as otherwise there is a risk of

injury. The bevel gear can get hot

during use and may remain so for a

while afterwards. You could get

burned if you touch it.

The ABC of clearing

S Always use the correct equipment.

S Make sure the equipment is well adju sted.

S Follow the safety precautions.

S Organize your work carefully.

S Always use full throttle when starting to cut

with the blade.

S Always use sharp blades.

S Avoid stones.

S Control the fellingdirection (take advan-

tage of the wind).

Page 19

E n g l i s h --- 1 9

115305026 Rev. 3 7/15/10

WORKING TECHNIQUES

WARNING: Sometimes branches

or grass get caught between the

guard and cutting attachment.

Always stop the engine before

cleaning.

WARNING: Watch out for

thrown objects. Always wear approved eye protection. Never lean

over the cutting attachment guard.

Stones, rubbish, etc. can be thrown

up into the eyes causing blindness

or serious injury. Keep unauthorised persons at a distance. Children, animals, onlookers and helpers should be kept outside the

safety zone of 50 feet (15 meters).

Stop the machine immediately if

anyone approaches. Never swing

the machine around without first

checking behind you to make sure

noone is within the safety zone.

Working methods

WARNING: Machines fitted with

saw blades or grass blades can be

thrown violently to the side when

the blade comes into contact with a

fixed object. This is called blade

thrust. A blade thrust can be violent

enough to cause the machine and/

or operator to be propelled in any

direction, and possibly lose control

of the machine. Blade thrust can

occur without warning if the machine snags, stalls or binds. Blade

thrust is more likely to occur in

areas where it is difficult to see the

material being cut.

Avoid cutting with the area of the

blade between the 12 o’clock and 3

o’clock positions. Because of the

speed of rotation of the blade kickback can occur if you attempt to

cut thick stems with this area of the

blade.

Basic working techniques

S Always slow the engineto idle speed after

each working operation. Longperiods at

full throttle without any load on theengine

can lead to serious engine damage.

S Work systematically to and fro across the

area, clearing a width of around 12--15 feet

(4- -5 meters) on each pass. This exploits

the full reach of the machine in both directions and gives the operator a convenient

and varied working area to work in.

S Clear a strip around 250 feet (75 meters)

long. Move your fuel can as work progresses.

S On sloping ground you should work along

the slope. It is much easier to work along a

slope than it is to work up and down it.

S You should plan the strip so that you avoid

going over ditches or other obstacles on

the ground. Y ou should also orient the strip

to take advantage of wind conditions, so

that cleared stems fall in the cleared area

of the stand.

S Before you start clearing, check the clear-

ing area, the type of terrain, the slope of

the ground, whether there are stones, hollows etc.

S Start at whichever end of the area is easi-

est, and clear an open space from which

to work.

Forestry clearing using a saw blade

S Therisk of blade thrust increases with in-

creasing stem size. Y oushould therefore

avoid cutting with the area of theblade between 12 o’clock and 3 o’clock.

Page 20

E n g l i s h --- 2 0

115305026 Rev. 3 7/15/10

WORKING TECHNIQUES

S Tofell to the left, the bottom ofthe tree

should be pushed to the right. Tilt the

blade and bring it diagonally downto

the right, exerting firmpressure. At the

same time pushthe stem usingthe blade

guard. Cut withthe area of the blade between 3 o’clock and 5 o’clock. Apply full

throttle before advancing the blade.

S To fellto the right, the bottom of thetree

should be pushed to the left. Tilt the blade

and bring it diagonally up to theright. Cut

with the area ofthe blade between 3

o’clock and5 o’clock so that thedirection

of rotation of theblade pushes thebottom

of the tree to the left.

S To fella treeforwards, the bottom of the

tree should be pulledbackwards. Pull the

blade backwards with a quick, firm movement.

S Largestems must be cut from two sides.

First determine which direction the stem

will fall. Make the first cut on thefelling

side. Then finish cutting the stem fromthe

other side. Adjust the cutting pressure to

match the size of the stem and thehardness of thewood. Smallstems require

more pressure, while large stems require

less pressure.

S Ifthe stems are tightly packed, adapt your

walking pace to suit.

S Ifthe blade jams in astem, never jerk the

machine free. If you do this the blade,

bevel gear, shaft or handlebar may be

damaged. Release the handles, grip the

shaft with bothhands andgently pull the

machine free.

Brush cutting with a saw blade

S Thinstems and brush aremown down.

Work with a sawing movement, swinging

sideways.

S Try to cut several stems in a single sawing

movement.

S Withgroups of hardwoodstems, first clear

around the group. Start by cutting the

stems high uparound the outside of the

group to avoid jamming.Then cut the

stems to therequired height. Now try to

reach in with the blade andcut from the

center of thegroup. Ifit is still difficult to

gain access, cut the stems high upand let

them fall. This will reduce the risk of jamming.

Page 21

E n g l i s h --- 2 1

115305026 Rev. 3 7/15/10

WORKING TECHNIQUES

Grass trimming wit h a tr i mmer head

Trimming

S Hold the trimmer head just above the ground

at an angle. It is the end of the trimmer line

that does the work. Let the trimmer line work

at its own pace. Never press the trimmer

lineintotheareatobecut.

S The trimmer line can easily remove grass

and weeds up against walls, fences, trees

and borders, however it can alsodamage

sensitive bark on trees and bushes, and

damage fence posts.

S Reduce the risk of damaging plants by

shortening the trimmer line to 10--12 cm

and reducing the engine speed.

S When trimming you should use less than

full throttle sothat the trimmer line lasts

longer and to reduce the wear on the

trimmer head.

Grass clearing usi ng a gr ass blade

S Grass blades and grass cutters must not be

used on woody stems.

S A grass blade is used for all types of tall or

coarse grass.

S Thegrassiscutdownwithasideways,

swinging movement, where the movement

from right--to--left is the clearing stroke and

the movement from left--to--right is the return

stroke. Let the left--hand side of the blade

(between 8 and 12 o’clock) do the cutting.

S If the blade is angled to the left when clear-

ing grass, the grass will collect in a line,

which makes it easier to collect, e.g. by

raking.

S Trytoworkrhythmically.Standfirmlywith

your feet apart. M ove forward after the return stroke and stand firmly again.

S Let the support cup rest lightly against the

ground. It is used to protect the blade from

hitting the ground.

S Reduce the risk of material wrapping

around the blade by following these instructions:

S Always work at full throttle.

S Avoid the previously cut material during

the return stroke.

S Stop the engine, unclip the harness and

place the machine on the ground before

you star tto collectthe cut

material.

Clearing

S Theclearing technique removes all un-

wanted vegetation. Keep the trimmer

head just abovethe ground and tilt it. Let

the end of the trimmer line strike the

ground around trees, posts, statues and

the like. CAUTION! This technique

increases the wear on thetrimmer line.

S Thetrimmer linewears quicker and must

be fed forward moreoften whenworking

against stones, brick, concrete, metal

fences, etc., thanwhen coming into contact with trees and wooden fences.

Cutting

S Thetrimmer is ideal for cuttinggrass that

is difficult to reach using a normal lawn

mower. Keep the trimmer line parallelto

the ground when cutting. Avoid pressing

the trimmer head against the ground as

this can ruin the lawn and damagethe

tool.

Page 22

E n g l i s h --- 2 2

115305026 Rev. 3 7/15/10

WORKING TECHNIQUES

S Donot allow the trimmerhead to con--

stantly come into contact with the ground

during normal cutting.Constant contact

of this type can cause damage andwear

to the trimmer head.

Sweeping

S Thefan effect ofthe rotating line can be

used for quick and easy clearing up.

Hold the trimmer lineparallel toand

above the area tobe swept and move

the tool to and fro.

S Whencutting and sweeping youshould

use full throttle to obtain the bestresults.

WARNING: Neither the operator

of the machine nor anyone else may

attempt to remove the cut material

while the en gine is running or the

trimmer line is rotating, as this can

result in serious injury. Stop the

engine and trimmer head before you

remove material that has wound

around the drive shaft as otherwise

there is a risk of injury. The bevel

gear can get hot during use and may

remain so for a while afterwards. You

could get burned if you touch it.

WARNING: Watch out for thrown

objects. Always wear eye protection.

Never lean over the cutting attachment guard. Stones, rubbish, etc.

canbethrownupintotheeyes

causing blindness or serious injury.

Keep unauthorized persons at a distance. Children, animals, onlookers

and helpers should be kept outside

thesafetyzoneof 15metres. Stop

the machine immediately if anyone

approaches.

Page 23

E n g l i s h --- 2 3

115305026 Rev. 3 7/15/10

MAINTENANCE

Idle Speed

Screw--T

Adjusting the st ar t throttle speed

The correct start throttle speedis set by

means of an adjuster on the rear of the

handle next to thecable. Use this screw (4

mm Allen screw) to increase ordecrease

the start throttle speed.

Proceed as follows:

1. Run the machine at idle.

2. Press the start throttle lock as described

under the heading Starting and stopping.

3. If the start throttle speed is too low (below

4000 rpm), turn adjuster screw (A) clockwise until the cutting attachment starts to

rotate. Then turn adjuster screw (A)

clockwise an additional 1/2 turn.

4. If the start throttle speed is too high, turn

adjuster screw (A) counterclockwise

until the cutting attachment stops. Then

turn adjuster screw (A) clockwise an

additional 1/2 turn.

Carburetor

Y our Jonsered product has been designed

and manufactured to specifications that reduce harmful emissions. After the engine

has used 8--10 tanks of fuel, the engine will

be run--in. To ensure that it continues to run

at peak performance and tominimize harmful exhaust emissions after the run--inperiod, ask your servicing dealer to adjust your

carburetor.

The li

f

e span ofthe machine can be reduced

and the risk of accidents can increase if

machine maintenance is not carried out

correctly and if service and/or repairs are not

carried out professionally . If you need further

information, please contact your nearest

authorised service dealer .

WARNING: The complete clutch,

clutch cover, and shaft mu st be

fitted before the machine is started,

otherwise parts could come loose

and cause personal injury.

Function

S Thecarburetor governs the engine’s

speed via thethrottle control. Air and fuel

are mixed in thecarburetor.

S TheT--screw regulates thethrottle setting

at idle speed. Ifthe T--screw is turned

clockwise this gives a higher idlespeed;

turning it counterclockwise gives a lower

idle speed.

Basic setting

S Thebasic carburetor settings are ad-

justed during testing at the factory.Fine

adjustment should becarried out by a

skilled technician.

Rec. idle speed:

See “T echnical data” section.

Recommended max. speed:

See “T echnical data” section.

CAUTION! If the cutting attachmentrotates

when the engine is idling the idleadjustment

screw Tshould beturned counterclockwise

until the cutting attachment stops.

WARNING: If the idle speed can-

not be adjusted so that the cutting

attachment stops, contact your

servicing dealer . Do not use the

machine until it has been correctly

adjusted or repaired.

Fine adjustment of the idle speed--T

Adjust the idle speed using the idleadjustment screw--T if itis necessary to readjust.

First, turn theidle adjustment screw--T

clockwise untilthe cutting attachment starts

to rotate. Then, turnthe screw counterclockwise untilthe cutting attachment stops.

The idle speed is correctly adjusted when

the engine will run smoothly in every position. The idle speedshould also be well

below the speed at which the cutting attachment starts to rotate.

4mm

Page 24

E n g l i s h --- 2 4

115305026 Rev. 3 7/15/10

MAINTENANCE

If the mesh is frequently blocked, this can

be a sign that the performance of thecatalytic converter is impaired. Contact your

servicing dealer to inspect the muffler. A

blocked meshwill cause the machine to

overheat and result in damageto the cylinder and piston.

Muffler bolts

CAUTION! Never use a machine that has

a faulty or loose muffler. Ensure themuffler

bolts are tight.

Spark arrestor mesh

WARNING: Mufflers fitted with

catalytic converters get very hot

during use and remain so for some

time after stopping. This also applies at idle speed . Contact can result in burns to the skin. Remember

theriskoffire!

WARNING: Theinsideofthe

muffler contain chemicals that may

be carcinogenic. Avoid contact with

these elements in the event of a

damaged muffler .

WARNING: Bear in mind that:

Engine exhaust fumes contain carbon monoxide, which can cause

carbon monoxide poisoning. For

this reason you should not start or

run the ma chine indoors, or anywhere that is poorly ventilated.

The exhaust fumes from the engine

are hot and may conta in sparks

which can start a fire. Never start

the machine indoors or near combustible material!

Spark plug

The spark plug condition is influenced by:

S Incorrect carburetor adjustment.

S Anincorrect fuel mixture (too much or in-

correct type of oil).

S A dirty air filter.

These factors cause deposits on the spark

plug electrodes, which may result in operating problems and starting difficulties.

If the machine is low on power, difficult to

start or runs poorly at idle speed: always

check thespark plug first before taking

any further action.

If the spark plug is dirty, clean it andcheck

that the electrodegap is 0.024 inch (0.6

mm). The spark plug should be replaced

after about a month inoperation or earlier if

necessary.

0.024 inch (0.6 mm)

CAUTION! Always use the recommended

spark plug type! Use of the wrong spark

plug can damage the piston/cylinder.

Muffler

CAUTION! Muffler is fitted with a catalytic

converter designed to reduce harmful exhaust gases.

The muffler is designedto reduce the noise

level and to direct the exhaust gases away

from the operator. The exhaust gases are

hot and can contain sparks, which may

cause fire ifdirected against dry and combustible material.

Mufflers are equipped witha special spark

arrestor mesh. The mesh should be

checked and,if necessary. cleaned by a

servicing dealer. If the mesh is damaged,

it should be replaced.

Unit/Maintenance Safety

Disconnect the spark plug before performing maintenance, except carburetor adjustments.

Page 25

E n g l i s h --- 2 5

115305026 Rev. 3 7/15/10

MAINTENANCE

Bevel gear

The bevel gear is filled with the right quantity of grease at the factory.However, before using the machine you shouldcheck

that the bevel gearis filled three--quarters

full with grease. Use JONSRED special

grease.

The grease in the bevelgear does not normally need to be changed except if repairs

are carried out.

Air filter

The air filter must be regularly cleaned to

remove dust and dirt inorder toavoid:

S Carburetor malfunctions

S Starting problems

S Loss of engine power

S Unnecessary wear to engineparts

S Excessive fuelconsumption

Clean the filter every 25 hours, or more

regularly if conditions are exceptionally

dusty.

Cleaning the air filter

Remove the air filter cover and takeout the

filter. Wash it clean in warm, soapy water.

Rinse thoroughly. Ensure that the filter is dry

before refitting it.

An air filter that has been in use for a long

time cannot be cleaned completely .The

filter must therefore be replaced with a new

one at regular intervals. A damaged air

filter must always be replaced.

Page 26

E n g l i s h --- 2 6

115305026 Rev. 3 7/15/10

MAINTENANCE

Maintenance

Daily

Maintenance

Weekly

Maintenance

Monthly

Maintenance

Maintenance schedule

The following is a list of themaintenance thatmust beperformed onthe machine. Most of

the items are described in the Maintenance section. The user must only carry out the maintenance and service work described in this Operator’s Manual. More extensive work must

be carried out by an authorised service workshop.

Clean the outside of the machine.

Make sure thethrottle trigger lock and the

throttle function correctly from a safety point

of view.

Check that the stop switch works correctly.

Check that the cutting attachment does not

rotate at idle.

Clean the air filter. Replaceif necessary.

Check that the cutting attachment guard is

undamaged and not cracked. Replace the

cutting attachment guard if ithas been

exposed to impact or is cracked.

Check that the trimmerhead is undamaged

and not cracked. Replace the trimmerhead

if necessary.

Check that the locking nut of the cutting

equipment is tightened correctly.

Check that nuts and screws are tight.

Check that there areno fuel leaks from the

engine, tank or fuellines.

Check thestarter and starter cord.

Clean the outside of the spark plug. Re-

move it and check the electrode gap. Adjust

the gap to 0,6 mm orreplacethe spark plug.

Check that the spark plug is fitted with a

suppressor.

Clean the outside of the carburetor and the

space around it.

Check that the bevel gear is filled three-quarters full with lubricant. Fill ifnecessary

using specialgrease.

Check the fuel filter from contamination and

the fuel hose fromcracks or other defects.

Replace if necessary.

Check all cables and connections.

Check the clutch, clutch springs and the

clutch drum for wear. Replaceif necessary

by an autorized service workshop.

Replace the spark plug. Check that the

spark plug is fitted with asuppressor.

Clean or replacethe spark arrestor mesh

on the muffler.

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Page 27

E n g l i s h --- 2 7

115305026 Rev. 3 7/15/10

TECHNICAL DATA

Model CC 2128 (M10LH arbor shaft thread) -- Centre hole in blades/cutters, ∅ 25,4 mm

Approved accessories Type Cutt ing attachment / guard, part. no.

Grass blade/grass cutter Grass 255--4 1 inch 504 00 13--03 /545 08 18--79

(∅ 250 4--teeth)

Saw blade Scarlet 200--22 1 inch 537 27 75--04 / 537 21 71--01

(∅ 200 22--teeth)

Trimmer head T25(∅ 2,4 -- 2,7 mm lin e) 537 33 83--06/ 545 0818--79

Plastic blades Tricut 300 mm (separate 531 00 38--11 / 545 08 18--79

blades have part number

531 00 77--15)

Support cup Fixed --

Technical data

CC 2128

Engine

Cylinder displacement, cm

3

28

Cylinder bore, mm 35

Stroke, mm 28,7

Idle speed, rpm 2800--3200

Recommended max. fast idle speed, rpm 11000

Speed of output shaft, rpm 8000

Max. engine output, according to ISO 8893,kW 0,8

Catalytic converter muffler Y es

Speed--regulated ignition system Yes

Ignition system

Spark plug Champion RCJ--8Y

Electrode gap, mm 0,6

Fuel and lubrication system

Fuel tank capacity,liter 0,4

Weight

Weight without fuel, cutting attachment and guard, kg 4,8

Noise emissions

(see note 1)

Sound power level, measured dB(A) 109

Sound power level, guaranteed L

WA

dB(A) 114

Noise levels

(see note 2)

Equivalent sound pressure level at theoperators’ ear,

measured according to EN/ISO 11806 and ISO 22868, dB(A)

Equipped with saw blade (original) 100

Equipped with grass blade (original) 100

Equipped with trimmer head(original) 100

Vibration levels

(see Note 3)

Equivalent vibration levels (a

hv,eq

) at handles, measured

according to EN ISO 11806 and ISO 22867, m/s

2

Equipped with saw blade (original), left/right 3,2/4,4

Equipped with grass blade (original), left/right 3,8/3,8

Equipped with trimmer head(original),left/right 3,7/4,4

Note 1: Noise emissions in the environmentmeasuredas sound power (L

WA

) in conformity with EC directive 2000/14/EC. Reported sound power level for the machinehas been

measured with the original cutting attachment that gives the highest level. The dif ference

between guaranteed and measured sound power is that the guaranteed sound power also

includes dispersion in the measurement result and the variations between different machines of thesamemodel according to Directive2000/14/EC.

Note 2: Reported data for equivalent sound pressure level for the machine has a typical

statisticaldispersion (standard deviation) of 1 dB(A).

Note 3: Reported data for equivalent vibration level has a typical statistical dispersion

(standard deviation) of 1m/s

2

.

Page 28

E n g l i s h --- 2 8

115305026 Rev. 3 7/15/10

DECLARATION OF CONFORMITY

EC Declaration of Conformity (Only applies to Europe)

We, Husqvarna AB, SE-561 82 Huskvarna, Sweden, tel: +46--36--146500, as authorised

representative inthe Community,declare thatthe brushcutter modelJonsered CC 2128with

serial numbers dating from 2009and onwards(the yearis clearly stated on the rating plate,

followed by the serial number), comply with the requirements of the COUNCIL’S

DIRECTIVES:

of 17 May 2006 “relating tomachinery” 2006/42/EC;

of15 December2004“relatingto electromagnetic compatibility”2004/108/EC, and applicable

supplements; and

of 8 May 2000“relating to the noise emissionsin the environment” in accordance with Annex

Vof2000/14/EC. For information relatingto noise emissions, see Technical data section.

The following standards have been applied: EN ISO 12100--1/A1:2009, EN ISO

12100--2/A1:2009, CISPR 12:2007, EN 11806:2008.

SMP, The Swedish Machinery Testing Institute, Fyrisborgsgatan 3 S--754 50 Uppsala,

Sweden, has performed voluntary type examination on behalf of Husqvarna AB. The

certificate(s) are numbered: SEC/09/2046.

09 -- 11 -- 0 1

Ronnie E. Goldman,Director of Engineering

Authorized representative for Husqvarna AB and

responsible for technical documentation

Page 29

E n g l i s h --- 2 9

115305026 Rev. 3 7/15/10

Trimmer Head Line Loading Instructions

20i

10i

3m

6m

1

23

45

6

78

9

Page 30

E n g l i s h --- 3 0

115305026 Rev. 3 7/15/10

Plastic Blades (Tri Cut)

12

3

4

5

6

7

8

Loading...

Loading...