Page 1

Cultivator attachment

Accessoire de cultivateur

Accesorio de cultivador

Operator’s manual

Manuel d’utilisation

Manual de instrucciones

GB

FR

ES

Page 2

2 –

English

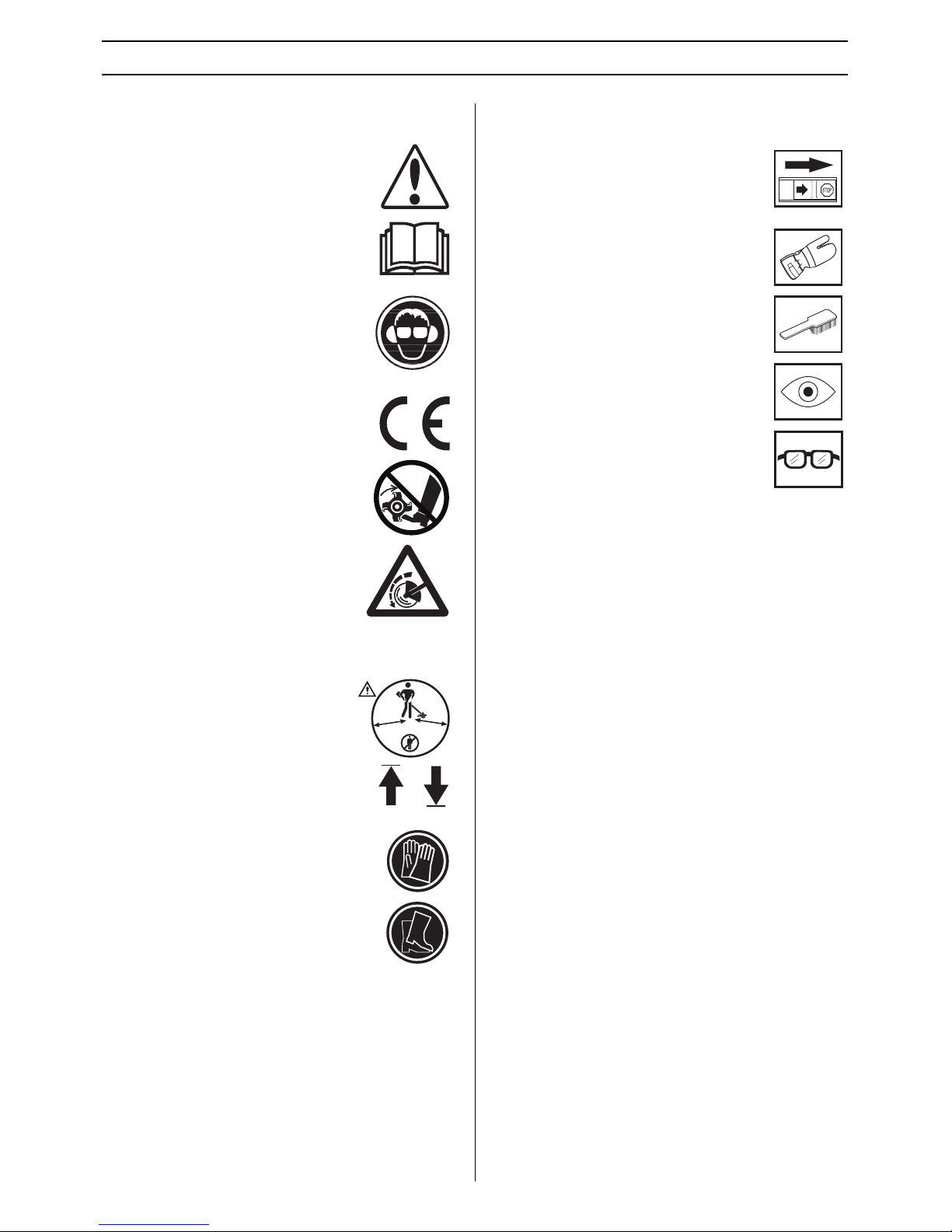

KEY TO SYMBOLS

Symbols

WARNING! The machine can be a dangerous

tool if used incorrectly or carelessly, which can

cause serious or fatal injury to the operator or

others.

Please read the operator’s manual carefully

and make sure you understand the

instructions before using the machine.

Always wear:

• Approved hearing protection

• Protective goggles or a visor

This product is in accordance with applicable

EC directives.

Warning: rotating cutter. Keep hands and feet

clear.

Warning: the cutter continues to rotate even

after the engine has stopped.

When the engine has stopped, stop the

cutter from rotating by lowering the cutter

onto the ground. The arrow indicates the

direction of rotation.

The operator of the machine must ensure,

while working, that no persons or animals

come closer than 15 metres.

Arrows which show limits for the position of

the guard.

Always wear approved protective gloves.

Wear sturdy, non-slip boots.

Other symbols/decals on the machine refer to special

certification requirements for certain markets.

Switch off the engine by moving the stop

switch to the STOP position before carrying

out any checks or maintenance.

Always wear approved protective gloves.

Regular cleaning is required.

Visual check.

Protective goggles or a visor must be worn.

50FT

15 m

50FT

15 m

Page 3

English

– 3

CONTENTS

Contents Note the following before starting:

Jonsered has a policy of continuous product development

and therefore reserves the right to modify the design and

appearance of products without prior notice.

Long-term exposure to noise can result in permanent hearing

impairment. So always use approved hearing protection.

Please read the operator’s manual carefully and make sure

you understand the instructions before using the machine.

These instructions supplement the instructions that were

included with the machine. For other procedures, please refer

to the operating instructions for the machine.

The machine is only designed for cultivating.

KEY TO SYMBOLS

Symbols ....................................................................... 2

CONTENTS

Contents ...................................................................... 3

Note the following before starting: ................................ 3

SAFETY INSTRUCTIONS

Personal protective equipment ..................................... 4

Machine ′ s safety equipment ........................................ 4

General safety precautions .......................................... 5

General working instructions ....................................... 6

WHAT IS WHAT?

What is what on the cultivator attachment? ................. 7

ASSEMBLY

Fitting the bevel gear ................................................... 8

Assembling the guard. ................................................. 8

STARTING AND STOPPING

Check before starting ................................................... 9

MAINTENANCE

Bevel gear .................................................................... 10

Replacing the tine ........................................................ 10

Maintenance schedule ................................................. 10

TECHNICAL DATA

Technical data .............................................................. 11

!

WARNING! Under no circumstances may the

design of the machine be modified without

the permission of the manufacturer. Always

use genuine accessories. Non-authorized

modifications and/or accessories can result

in serious personal injury or the death of the

operator or others.

!

WARNING! This accessory may only be used

together with the intended clearing saw/

trimmer, see under heading ”Approved

accessories” in chapter Technical data in the

machine’s Operator’s Manual.

Page 4

4 –

English

SAFETY INSTRUCTIONS

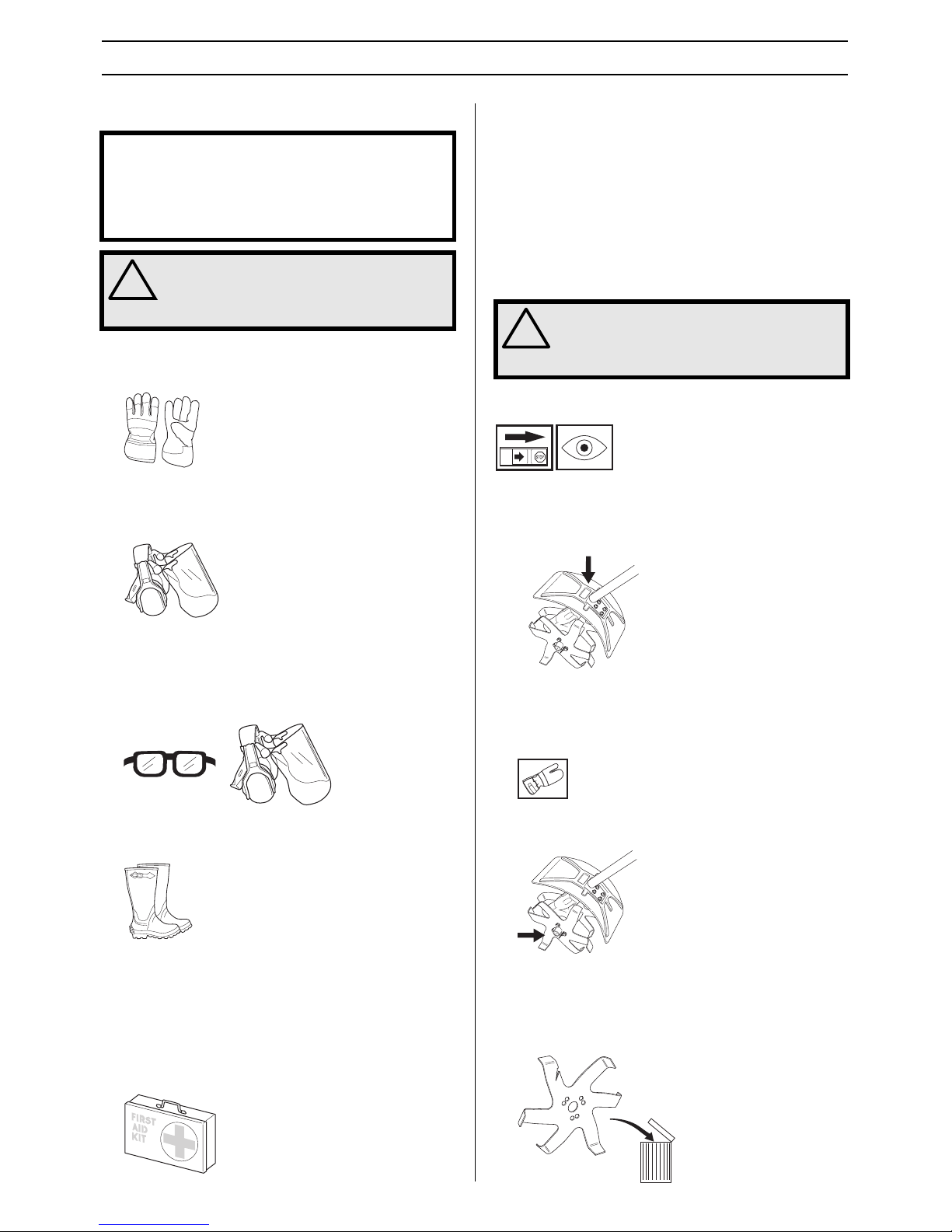

Personal protective equipment

GLOVES

Gloves should be worn when necessary, e.g., when fitting

cutting attachments.

HEARING PROTECTION

Wear hearing protection that provides adequate noise

reduction.

EYE PROTECTION

Always wear approved eye protection. If you use a visor then

you must also wear approved protective goggles. Approved

protective goggles must comply with standard ANSI Z87.1 in

the USA or EN 166 in EU countries.

BOOTS

Wear sturdy, non-slip boots.

CLOTHING

Wear clothes made of a strong fabric and avoid loose clothing

that can catch on twigs and branches. Always wear heavy,

long pants. Do not wear jewellery, shorts sandals or go

barefoot. Secure hair so it is above shoulder level.

FIRST AID KIT

Always have a first aid kit nearby.

Machine

′′

′′

s safety equipment

This section describes the machine ′ s safety equipment, its

purpose, and how checks and maintenance should be carried

out to ensure that it operates correctly. See the ”What is

what?” section to locate where this equipment is positioned

on your machine.

The life span of the machine can be reduced and the risk of

accidents can increase if machine maintenance is not carried

out correctly and if service and/or repairs are not carried out

professionally. If you need further information please contact

your nearest service workshop.

Cutting attachment guard

This guard is intended to prevent loose objects from being

thrown towards the operator. The guard also protects the

operator from accidental contact with the cutting attachment.

• Ensure that the guard is undamaged and is not cracked.

• Replace the guard if it has been exposed to impact or is

cracked.

Cutting equipment

The tines are designed and machined to withstand the loads

resulting from cultivating.

The two basic rules:

1 Only use cutting attachments with the guards we

recommend! See the chapter on Technical data.

2 Check the cutting attachment for damage or cracks. A

damaged cutting attachment should always be replaced.

IMPORTANT! You must use approved personal protective

equipment whenever you use the machine. Personal

protective equipment cannot eliminate the risk of injury but

it will reduce the degree of injury if an accident does

happen. Ask your dealer for help in choosing the right

equipment.

!

WARNING! Listen out for warning signals or

shouts when you are wearing hearing

protection. Always remove your hearing

protection as soon as the engine stops.

!

WARNING! Never use a machine that has

faulty safety equipment! Carry out the

inspection, maintenance and service

routines listed in this section.

Page 5

English

– 5

SAFETY INSTRUCTIONS

General safety precautions

• Never allow children to use the machine.

• Ensure that no-one comes closer than 15 m while you are

working.

• Never allow anyone else to use the machine without first

ensuring that they have understood the contents of the

operator’s manual.

Safety instructions before starting work

• Inspect the working area. Remove all loose objects, such

as stones, broken glass, nails, steel wire, string, etc. that

could be thrown out or become wrapped around the cutter

or cutter guard.

• Keep unauthorised persons at a distance. Children,

animals, onlookers and helpers should be kept outside the

safety zone of 15 m. Stop the machine immediately if

anyone approaches.

• Check the entire machine before starting. Replace

damaged parts. Check that there are no fuel leaks and

that all guards and covers are complete and fastened

securely. Check all nuts and screws.

• Check that the tines are undamaged and show no signs of

cracking or other damage. Replace the tines if necessary.

• Make sure the cutter guard is fitted and not damaged.

• Check that the tines and tine guard are secured correctly.

• When adjusting the carburettor, make sure that the tines

are held against the ground and that no one else is in the

vicinity.

• Check that the blades do not move when the engine is

idling.

• Make sure the handle and safety features are in order.

Never use a machine that has any parts missing or has

been modified in relation to the specification.

• Only use the machine for the purpose it was intended for.

!

WARNING! Always stop the engine before

doing any work on the cutting attachment.

This continues to rotate even after the

throttle has been released. Ensure that the

cutting attachment has stopped completely

and disconnect the HT lead from the spark

plug before you start to work on it.

!

WARNING! Never use a machine with faulty

safety equipment. The machine’s safety

equipment must be checked and maintained

as described in this section. If your machine

fails any of these checks contact your

service agent to get it repaired.

IMPORTANT!

Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could affect your

vision, your judgement or your co-ordination.

Wear personal protective equipment. See instructions

under the heading Personal protective equipment.

Never use a machine that has been modified in any way

from its original specification.

Never use the machine in extreme weather conditions such

as severe cold, very hot and/or humid climates.

Never use a machine that is faulty. Carry out the checks,

maintenance and service instructions described in this

manual. Some maintenance and service measures must be

carried out by trained and qualified specialists. See

instructions under the heading Maintenance.

All covers and guards must be fitted before starting. Ensure

that the spark plug cap and ignition lead are undamaged to

avoid the risk of electric shock.

!

WARNING! Faulty blades can increase the

risk of accidents.

Page 6

6 –

English

SAFETY INSTRUCTIONS

General working instructions

Basic safety rules

1 Look around you:

- To ensure that people, animals or other things cannot

affect your control of the machine.

- To ensure that people, animals, etc., do not come into

contact with the cutting attachment or loose objects

that are thrown out by the cutting attachment.

2 Do not use the machine in bad weather, such as dense

fog, heavy rain, strong wind, intense cold, etc. Working in

bad weather is tiring and can lead to dangerous

conditions, e.g. slippery surfaces.

3 Make sure you can move and stand safely. Check the area

around you for possible obstacles (roots, rocks, branches,

ditches, etc.) in case you have to move suddenly. Take

great care when working on sloping ground.

4 The engine must be switched off before moving.

5 Never put the machine down with the engine running

unless you have it in clear sight.

CAUTION! Do not use the machine unless you are able to call

for help in the event of an accident.

Basic working techniques

• Always ensure you have a safe and stable working

position.

• Always hold the machine with both hands. Hold the

machine on the right of your body.

• When the engine is switched off, keep your hands and feet

away from the blades until they have stopped.

• Make sure your hands and feet do not come near the

cutter when the engine is running.

• Always keep the tines close to the ground.

• Always slow the engine to idle speed after each working

operation. Long periods at full throttle without any load on

the engine (i.e. without the resistance that the cutting

attachment exerts on the engine when you are using the

machine) can lead to serious engine damage.

• Pay extra attention when pulling the cultivator towards you

while working.

• If heavy vibration occurs, stop the machine. Disconnect

the HT lead from the spark plug. Check that the machine

is not damaged. Repair any damage.

Safety instructions after completing work

• Make sure the cutting attachment has stopped before

cleaning, carrying out repairs or an inspection.

Disconnect the HT lead from the spark plug.

• Wear heavy-duty gloves when repairing the cultivator.

• Store the machine out of reach of children.

• Use only original spare parts for repairs.

IMPORTANT!

This section takes up the basic safety precautions for

working with a cultivator.

If you encounter a situation where you are uncertain how to

proceed you should ask an expert. Contact your dealer or

your service workshop.

Avoid all usage which you consider to be beyond your

capability.

!

WARNING! At times grass and stones can

become caught in the tines. Always stop the

engine when cleaning.

!

WARNING! Watch out for thrown objects.

Always wear eye protection. Never lean over

the cutting attachment guard. Stones,

rubbish, etc. can be thrown up into the eyes

causing blindness or serious injury.

Keep unauthorised persons at a distance.

Children, animals, onlookers and helpers

should be kept outside the safety zone of 15

m. Stop the machine immediately if anyone

approaches.

The bevel gear can get hot during use and

may remain so for a while afterwards. You

could get burnt if you touch it.

Page 7

English

– 7

WHAT IS WHAT?

What is what on the cultivator attachment?

1

2

3

4

5

6

7

8

1 Blade guard

2 Shaft

3 Blades

4 Split pin

5 Cotter pin

6 Grease filler cap, bevel gear

7 Bevel gear

8 Operator ′ s manual

Page 8

8 –

English

ASSEMBLY

Fitting the bevel gear

• Assembling the angle gear on the shaft. Turn the shaft so

that the splines on the drive axle mate in the angle gear.

• First tighten the screw H and then the screw M.

Assembling the guard.

• Remove the four screws C and the two screws F from the

bracket A.

• Place the rubber sleeve D on the shaft E. The rubber

sleeve should sit between the arrow markings on the

shaft.

• Place the bracket A around the rubber sleeve and fit the

screws F loosely.

• Guide the guard B onto the shaft so that the hole in the

guard aligns with the hole in the bracket. Tighten the

screws C.

• Align the bracket with guard so that it sits straight in

relation to the tines.

• Tighten the screws F.

M

H

F

A

C

D

E

F

A

A

4 x C

B

Page 9

English

– 9

STARTING AND STOPPING

Check before starting

For safety reasons follow these recommendations!

• Inspect the working area. Remove any objects that could

be thrown out.

• Check that the machine is in perfect working order. Check

that all nuts and screws are tight.

• Check the tines and tine guard to ensure they are

undamaged and show no signs of cracking. Replace the

tine and tine guard if they have been exposed to impact or

are cracked.

Page 10

10 –

English

MAINTENANCE

Bevel gear

The bevel gear is filled with the right quantity of grease at the

factory. However, before using the machine you should check

that the bevel gear is filled three-quarters (40g) full with

grease. Use JONSERED special grease.

CAUTION! The gear housing must not be filled completely

with grease. The grease expands as the machine heats up

during operation. If the gear housing was completely filled

with grease it could damage the seals and lead to leakage of

grease.

The grease in the bevel gear does not normally need to be

changed except if repairs are carried out.

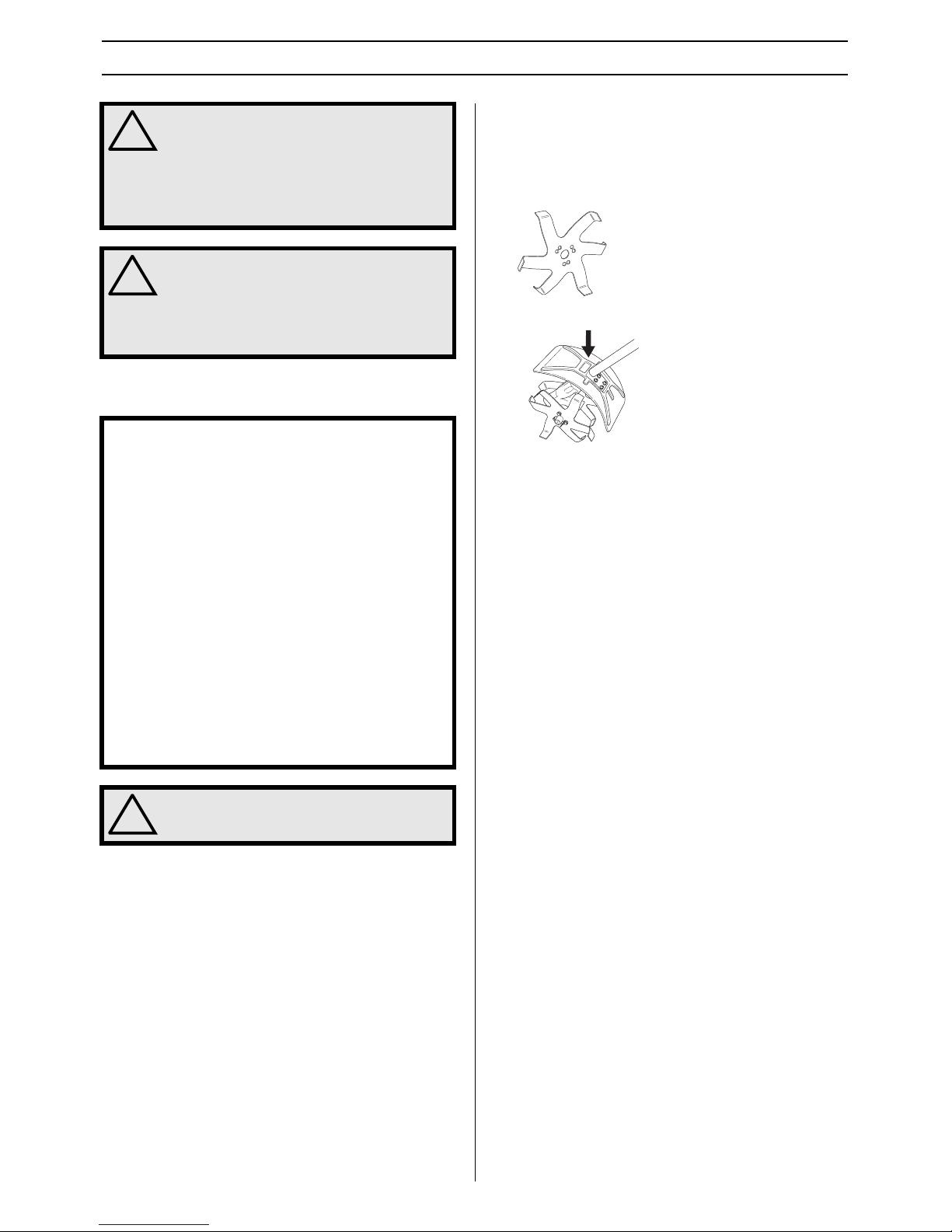

Replacing the tine

Loosen the split pin and cotter pin.

Remove the tine unit from the angle gear’s output axle.

Loosen the 3 screws holding the tine.

Replace the tine with a new and assemble in the reverse

order.

Maintenance schedule

Below you will find some general maintenance instructions. If

you need further information please contact your service

workshop.

Daily maintenance

1 Check that the guard is undamaged and not cracked.

Replace the guard if it has been exposed to impact or is

cracked.

2 Check that the blades do not move when the engine is

idling or when the choke is in the start throttle position.

3 Check that the tines are undamaged and show no signs of

cracking or other damage. Replace the tines if necessary.

Weekly maintenance

1 Check that the bevel gear is filled three-quarters (40g) full

with lubricant. Fill if necessary using special grease.

1

Page 11

English

– 11

TECHNICAL DATA

Technical data

Technical data CA 150

Weight

Weight, kg 2,9

Blades

Diameter tines, mm 220

Working width, mm 150

Tine speed at engine speed 10,500 r/min 215

Page 12

´®z+R'r¶02¨

´®z+R'r¶02¨

Page 13

Page 14

2005-03-31

1150078-20

´®z+R'r¶02¨

´®z+R'r¶02¨

Loading...

Loading...