Page 1

POWERTECH E 4.5 &

Doosan purchased Bobcat Company from Ingersoll-Rand Company in

2007. Any reference to Ingersoll-Rand Company or use of trademarks,

service marks, logos, or other proprietary identifying marks belonging

to Ingersoll-Rand Company in this manual is his torical or nominative

in nature, and is not meant to suggest a current affiliation between

Ingersoll-Rand C

ompany and Doosan

Company or the products of

e

ith

er.

6.8L Diesel Engines

Level 16 Electronic

Fuel System With

Denso HPCR

TECHNICAL MANUAL

POWERTECH E 4.5 & 6.8 L Diesel

Engines—Level 16 Electronic Fuel

System with Denso HPCR

CTM502 31MAY07 (ENGLISH)

For complete service information also see:

POWERTECH 4.5 L and 6.8 L Diesel

Engines—Base Engine ................. CTM104

Alternators and Starter Motors ........... CTM77

OEM Engine Accessories ...... CTM67 (English Only)

John Deere Power Systems

LITHO IN U.S.A.

Page 2

Foreword

Introduction

This manual is written for an experienced technician.

Essential tools required in performing certain service

work are identified in this manual and are

recommended for use.

This manual (CTM502) covers only Level 16 Electronic

Fuel System with the Denso High Pressure Common

Rail (HPCR) and 2-valves per cylinder for PowerTech

“E” engines. It is one of seven volumes on 4.5 L and

6.8 L engines. The following companion manual covers

the base engine.

• CTM104—Base Engine

Live with safety: Read the safety messages in the

introduction of this manual and the cautions presented

throughout the text of the manual.

This is the safety-alert symbol. When you see this

symbol on the machine or in this manual, be alert to

the potential for personal injury.

Use this component technical manual in conjunction

with the machine technical manual. An application

listing in Section 01, Group 001 identifies

product-model/component type-model relationship. See

the machine technical manual for information on

component removal and installation, and gaining

access to the components.

Information is organized in sections and groups for the

various components requiring service instruction. At

the beginning of each group are summaries of the up

coming group.

Before beginning repair on an engine, clean the

engine.

This manual contains SI Metric units of measure

followed immediately by the U.S. customary units of

measure. Most hardware on these engines are metric

sized.

Some components of this engine may be serviced

without removing the engine from the machine. Refer

to the specific machine technical manual for

information on components that can be serviced

without removing the engine from the machine and for

engine removal and installation procedures.

Read each block of material completely before

performing service to check for differences in

procedures or specifications.

CALIFORNIA PROPOSITION 65 WARNING: Diesel

engine exhaust and some of its constituents are

known to the State of California to cause cancer,

birth defects, and other reproductive harm.

CD03523,000016D –19–30MAY07–1/1

CTM502 (31MAY07) 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=2

Page 3

SECTION 01—General

Group 000—Safety

Group 001—Engine Identification

Group 002—Fuels, Lubricants, and Coolant

Contents

01

SECTION 02—Repair and Adjustments

Group 090—Electronic Fuel System Repair and

Adjustments

Group 110—Electronic Engine Control Repair and

Adjustment

SECTION 03—Theory Of Operation

Group 130—Electronic Fuel System Operation

Group 135—Air and Exhaust Operation

Group 140—Electronic Control System Operation

SECTION 04—Diagnostics

Group 150—Observable Diagnostics and Tests

Group 160—Trouble Code Diagnostics and Tests

SECTION 05—Tools

Group 170—Electronic Fuel/Control System Repair

Tools and Other Material

Group 180—Diagnostic Service Tools

SECTION 06—Specifications

Group 200—Repair Specifications

Group 210—Diagnostic Specifications

02

03

04

05

06

All information, illustrations and specifications in this manual are based on

the latest information available at the time of publication. The right is

reserved to make changes at any time without notice.

COPYRIGHT2006

DEERE & COMPANY

Moline, Illinois

A John Deere ILLUSTRUCTIONManual

CTM502 (31MAY07) i 4.5 & 6.8 L Level 16 Electronic Fuel System

All rights reserved

060407

PN=1

INDX

Page 4

01

02

03

04

05

Contents

06

INDX

CTM502 (31MAY07) ii 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=2

Page 5

Page

Group 000—Safety ....................01-000-1

Group 001—Engine Identification

Engine Serial Number Plate Information .....01-001-1

OEM Engine Option Code Label ...........01-001-3

Information Relative to Emissions

Regulations .........................01-001-3

Emissions Control System Certification

Label ..............................01-001-4

Engine Application Charts ................01-001-5

Group 002—Fuels, Lubricants, and Coolant

Diesel Fuel ...........................01-002-1

Bio-Diesel Fuel ........................01-002-2

Minimizing the Effect of Cold Weather on

Diesel Engines.......................01-002-3

Handling and Storing Diesel Fuel ..........01-002-4

Lubricity of Diesel Fuel ..................01-002-5

Testing Diesel Fuel .....................01-002-5

Engine Oil and Filter Service Intervals.......01-002-5

Diesel Engine Oil ......................01-002-6

Diesel Engine Break-In Oil ...............01-002-7

Oil Filters.............................01-002-7

Alternative and Synthetic Lubricants ........01-002-8

Lubricant Storage ......................01-002-8

Mixing of Lubricants ....................01-002-8

Grease ..............................01-002-9

Diesel Engine Coolant..................01-002-10

Supplemental Coolant Additives ..........01-002-11

Operating in Warm Temperature Climates . .01-002-12

Additional Information About Diesel

Engine Coolants and Supplemental Coolant

Additives ..........................01-002-13

Testing Diesel Engine Coolant ...........01-002-14

Drain Intervals for Diesel Engine Coolant . . .01-002-15

01

Section 01

General

Contents

CTM502 (31MAY07) 01-1 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=1

Page 6

01

Contents

CTM502 (31MAY07) 01-2 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=2

Page 7

Work In Ventilated Area

Engine exhaust fumes can cause sickness or death. If it is

necessary to run an engine in an enclosed area, remove

the exhaust fumes from the area with an exhaust pipe

extension.

If you do not have an exhaust pipe extension, open the

doors and get outside air into the area

Group 000

Safety

01

000

1

Recognize Safety Information

This is a safety-alert symbol. When you see this symbol

on your machine or in this manual, be alert to the

potential for personal injury.

Follow recommended precautions and safe operating

practices.

Work in Clean Area

Before starting a job:

• Clean work area and machine.

• Make sure you have all necessary tools to do your job.

• Have the right parts on hand.

• Read all instructions thoroughly; do not attempt

shortcuts.

DX,AIR –19–17FEB99–1/1

TS220 –UN–23AUG88

T81389 –UN–07DEC88

DX,ALERT –19–29SEP98–1/1

CTM502 (31MAY07) 01-000-1 4.5 & 6.8 L Level 16 Electronic Fuel System

DX,CLEAN –19–04JUN90–1/1

T6642EJ –UN–18OCT88

060407

PN=7

Page 8

01

000

Dispose of Waste Properly

2

Improperly disposing of waste can threaten the

environment and ecology. Potentially harmful waste used

with John Deere equipment include such items as oil, fuel,

coolant, brake fluid, filters, and batteries.

Use leakproof containers when draining fluids. Do not use

food or beverage containers that may mislead someone

into drinking from them.

Safety

Do not pour waste onto the ground, down a drain, or into

any water source.

Air conditioning refrigerants escaping into the air can

damage the Earth’s atmosphere. Government regulations

may require a certified air conditioning service center to

recover and recycle used air conditioning refrigerants.

Inquire on the proper way to recycle or dispose of waste

from your local environmental or recycling center, or from

your John Deere dealer.

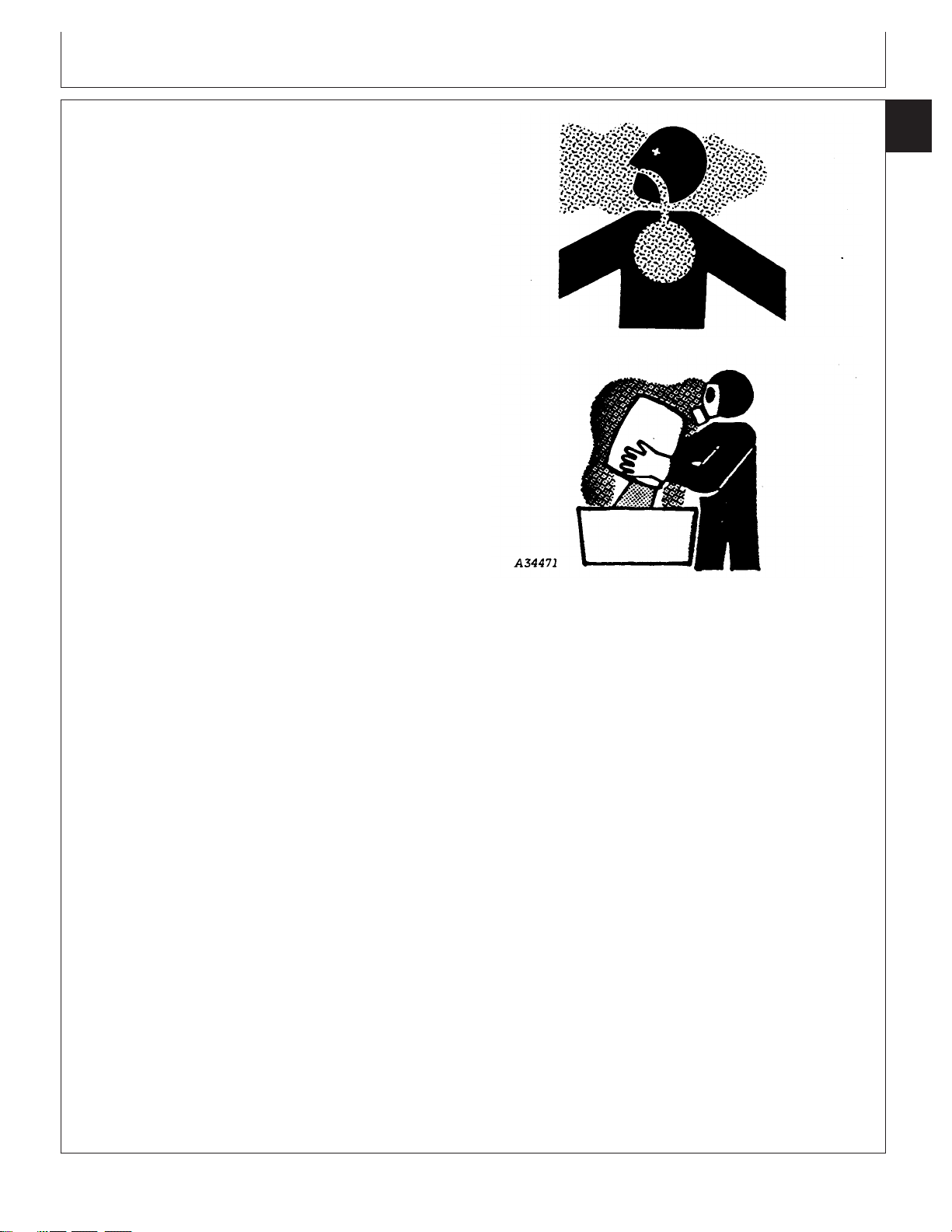

Avoid Harmful Asbestos Dust

Avoid breathing dust that may be generated when

handling components containing asbestos fibers. Inhaled

asbestos fibers may cause lung cancer.

Components in products that may contain asbestos fibers

are brake pads, brake band and lining assemblies, clutch

plates, and some gaskets. The asbestos used in these

components is usually found in a resin or sealed in some

way. Normal handling is not hazardous as long as

airborne dust containing asbestos is not generated.

TS1133 –UN–26NOV90

DX,DRAIN –19–03MAR93–1/1

TS220 –UN–23AUG88

Avoid creating dust. Never use compressed air for

cleaning. Avoid brushing or grinding material containing

asbestos. When servicing, wear an approved respirator. A

special vacuum cleaner is recommended to clean

asbestos. If not available, apply a mist of oil or water on

the material containing asbestos.

Keep bystanders away from the area.

DX,DUST –19–15MAR91–1/1

CTM502 (31MAY07) 01-000-2 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=8

Page 9

Safety

Handle Fuel Safely—Avoid Fires

Handle fuel with care: it is highly flammable. Do not refuel

the machine while smoking or when near open flame or

sparks.

Always stop engine before refueling machine. Fill fuel tank

outdoors.

Prevent fires by keeping machine clean of accumulated

trash, grease, and debris. Always clean up spilled fuel.

Prepare for Emergencies

01

000

3

TS202 –UN–23AUG88

DX,FIRE1 –19–03MAR93–1/1

Be prepared if a fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital, and fire department near your telephone.

Handle Starting Fluid Safely

Starting fluid is highly flammable.

Keep all sparks and flame away when using it. Keep

starting fluid away from batteries and cables.

To prevent accidental discharge when storing the

pressurized can, keep the cap on the container, and store

in a cool, protected location.

Do not incinerate or puncture a starting fluid container.

DX,FIRE2 –19–03MAR93–1/1

TS291 –UN–23AUG88

TS1356 –UN–18MAR92

CTM502 (31MAY07) 01-000-3 4.5 & 6.8 L Level 16 Electronic Fuel System

DX,FIRE3 –19–16APR92–1/1

060407

PN=9

Page 10

01

000

Handle Fluids Safely—Avoid Fires

4

When you work around fuel, do not smoke or work near

heaters or other fire hazards.

Store flammable fluids away from fire hazards. Do not

incinerate or puncture pressurized containers.

Make sure machine is clean of trash, grease, and debris.

Do not store oily rags; they can ignite and burn

spontaneously.

Avoid High-Pressure Fluids

Safety

TS227 –UN–23AUG88

DX,FLAME –19–29SEP98–1/1

Escaping fluid under pressure can penetrate the skin

causing serious injury.

Avoid the hazard by relieving pressure before

disconnecting hydraulic or other lines. Tighten all

connections before applying pressure.

Search for leaks with a piece of cardboard. Protect hands

and body from high pressure fluids.

If an accident occurs, see a doctor immediately. Any fluid

injected into the skin must be surgically removed within a

few hours or gangrene may result. Doctors unfamiliar with

this type of injury should reference a knowledgeable

medical source. Such information is available from Deere

& Company Medical Department in Moline, Illinois, U.S.A.

X9811 –UN–23AUG88

DX,FLUID –19–03MAR93–1/1

CTM502 (31MAY07) 01-000-4 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=10

Page 11

Use Proper Lifting Equipment

Lifting heavy components incorrectly can cause severe

injury or machine damage.

Follow recommended procedure for removal and

installation of components in the manual.

Safety

01

000

5

Illuminate Work Area Safely

Illuminate your work area adequately but safely. Use a

portable safety light for working inside or under the

machine. Make sure the bulb is enclosed by a wire cage.

The hot filament of an accidentally broken bulb can ignite

spilled fuel or oil.

Live With Safety

Before returning machine to customer, make sure

machine is functioning properly, especially the safety

systems. Install all guards and shields.

DX,LIFT –19–04JUN90–1/1

TS226 –UN–23AUG88

TS223 –UN–23AUG88

DX,LIGHT –19–04JUN90–1/1

Service Machines Safely

Tie long hair behind your head. Do not wear a necktie,

scarf, loose clothing, or necklace when you work near

machine tools or moving parts. If these items were to get

caught, severe injury could result.

Remove rings and other jewelry to prevent electrical

shorts and entanglement in moving parts.

CTM502 (31MAY07) 01-000-5 4.5 & 6.8 L Level 16 Electronic Fuel System

DX,LIVE –19–25SEP92–1/1

TS231 –19–07OCT88

TS228 –UN–23AUG88

DX,LOOSE –19–04JUN90–1/1

060407

PN=11

Page 12

01

000

Handle Chemical Products Safely

6

Direct exposure to hazardous chemicals can cause

serious injury. Potentially hazardous chemicals used with

John Deere equipment include such items as lubricants,

coolants, paints, and adhesives.

A Material Safety Data Sheet (MSDS) provides specific

details on chemical products: physical and health hazards,

safety procedures, and emergency response techniques.

Safety

Check the MSDS before you start any job using a

hazardous chemical. That way you will know exactly what

the risks are and how to do the job safely. Then follow

procedures and recommended equipment.

(See your John Deere dealer for MSDS’s on chemical

products used with John Deere equipment.)

Protect Against Noise

Prolonged exposure to loud noise can cause impairment

or loss of hearing.

Wear a suitable hearing protective device such as

earmuffs or earplugs to protect against objectionable or

uncomfortable loud noises.

TS1132 –UN–26NOV90

DX,MSDS,NA –19–03MAR93–1/1

DX,NOISE –19–03MAR93–1/1

CTM502 (31MAY07) 01-000-6 4.5 & 6.8 L Level 16 Electronic Fuel System

TS207 –UN–23AUG88

060407

PN=12

Page 13

Safety

Remove Paint Before Welding or Heating

Avoid potentially toxic fumes and dust.

Hazardous fumes can be generated when paint is heated

by welding, soldering, or using a torch.

Remove paint before heating:

• Remove paint a minimum of 100 mm (4 in.) from area

to be affected by heating. If paint cannot be removed,

wear an approved respirator before heating or welding.

• If you sand or grind paint, avoid breathing the dust.

Wear an approved respirator.

• If you use solvent or paint stripper, remove stripper with

soap and water before welding. Remove solvent or

paint stripper containers and other flammable material

from area. Allow fumes to disperse at least 15 minutes

before welding or heating.

Do not use a chlorinated solvent in areas where welding

will take place.

01

000

7

TS220 –UN–23AUG88

Do all work in an area that is well ventilated to carry toxic

fumes and dust away.

Dispose of paint and solvent properly.

Stay Clear of Rotating Drivelines

Entanglement in rotating driveline can cause serious injury

or death.

Keep tractor master shield and driveline shields in place

at all times. Make sure rotating shields turn freely.

Wear close fitting clothing. Stop the engine and be sure

PTO driveline is stopped before making adjustments,

connections, or cleaning out PTO driven equipment.

DX,PAINT –19–24JUL02–1/1

TS1644 –UN–22AUG95

CTM502 (31MAY07) 01-000-7 4.5 & 6.8 L Level 16 Electronic Fuel System

DX,PTO –19–12SEP95–1/1

060407

PN=13

Page 14

01

000

Service Cooling System Safely

8

Explosive release of fluids from pressurized cooling

system can cause serious burns.

Shut off engine. Only remove filler cap when cool enough

to touch with bare hands. Slowly loosen cap to first stop

to relieve pressure before removing completely.

Safety

Follow Safety Instructions

Carefully read all safety messages in this manual and on

your machine safety signs. Keep safety signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from your John Deere dealer.

Learn how to operate the machine and how to use

controls properly. Do not let anyone operate without

instruction.

Keep your machine in proper working condition.

Unauthorized modifications to the machine may impair the

function and/or safety and affect machine life.

If you do not understand any part of this manual and need

assistance, contact your John Deere dealer.

DX,RCAP –19–04JUN90–1/1

TS281 –UN–23AUG88

TS201 –UN–23AUG88

DX,READ –19–03MAR93–1/1

CTM502 (31MAY07) 01-000-8 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=14

Page 15

Safety

Use Proper Tools

Use tools appropriate to the work. Makeshift tools and

procedures can create safety hazards.

Use power tools only to loosen threaded parts and

fasteners.

For loosening and tightening hardware, use the correct

size tools. DO NOT use U.S. measurement tools on

metric fasteners. Avoid bodily injury caused by slipping

wrenches.

Use only service parts meeting John Deere specifications.

Construct Dealer-Made Tools Safely

01

000

9

TS779 –UN–08NOV89

DX,REPAIR –19–17FEB99–1/1

Faulty or broken tools can result in serious injury. When

constructing tools, use proper, quality materials, and good

workmanship.

Do not weld tools unless you have the proper equipment

and experience to perform the job.

LX1016749 –UN–01JUL97

DX,SAFE,TOOLS –19–10OCT97–1/1

CTM502 (31MAY07) 01-000-9 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=15

Page 16

01

000

Practice Safe Maintenance

10

Understand service procedure before doing work. Keep

area clean and dry.

Never lubricate, service, or adjust machine while it is

moving. Keep hands, feet , and clothing from

power-driven parts. Disengage all power and operate

controls to relieve pressure. Lower equipment to the

ground. Stop the engine. Remove the key. Allow machine

to cool.

Securely support any machine elements that must be

raised for service work.

Keep all parts in good condition and properly installed. Fix

damage immediately. Replace worn or broken parts.

Remove any buildup of grease, oil, or debris.

On self-propelled equipment, disconnect battery ground

cable (-) before making adjustments on electrical systems

or welding on machine.

Safety

On towed implements, disconnect wiring harnesses from

tractor before servicing electrical system components or

welding on machine.

Understand Signal Words

A signal word—DANGER, WARNING, or CAUTION—is

used with the safety-alert symbol. DANGER identifies the

most serious hazards.

DANGER or WARNING safety signs are located near

specific hazards. General precautions are listed on

CAUTION safety signs. CAUTION also calls attention to

safety messages in this manual.

TS218 –UN–23AUG88

DX,SERV –19–17FEB99–1/1

TS187 –19–30SEP88

DX,SIGNAL –19–03MAR93–1/1

CTM502 (31MAY07) 01-000-10 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=16

Page 17

Replace Safety Signs

Replace missing or damaged safety signs. See the

machine operator’s manual for correct safety sign

placement.

Safety

01

000

11

Protect Against High Pressure Spray

Spray from high pressure nozzles can penetrate the skin

and cause serious injury. Keep spray from contacting

hands or body.

If an accident occurs, see a doctor immediately. Any high

pressure spray injected into the skin must be surgically

removed within a few hours or gangrene may result.

Doctors unfamiliar with this type of injury should reference

a knowledgeable medical source. Such information is

available from Deere & Company Medical Department in

Moline, Illinois, U.S.A.

DX,SIGNS1 –19–04JUN90–1/1

TS201 –UN–23AUG88

TS1343 –UN–18MAR92

DX,SPRAY –19–16APR92–1/1

Avoid Heating Near Pressurized Fluid Lines

Flammable spray can be generated by heating near

pressurized fluid lines, resulting in severe burns to

yourself and bystanders. Do not heat by welding,

soldering, or using a torch near pressurized fluid lines or

other flammable materials. Pressurized lines can

accidentally burst when heat goes beyond the immediate

flame area.

CTM502 (31MAY07) 01-000-11 4.5 & 6.8 L Level 16 Electronic Fuel System

DX,TORCH –19–10DEC04–1/1

TS953 –UN–15MAY90

060407

PN=17

Page 18

01

000

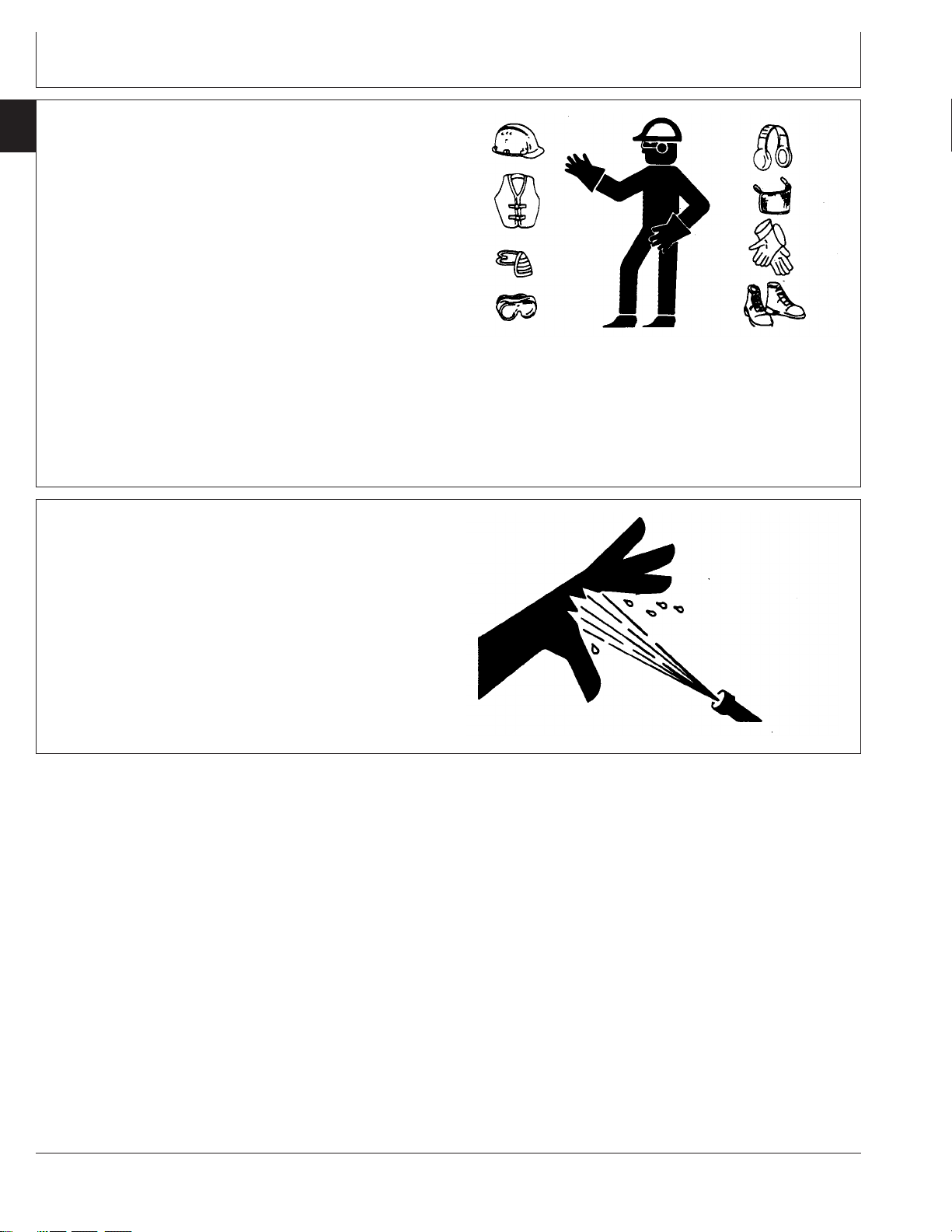

Wear Protective Clothing

12

Wear close fitting clothing and safety equipment

appropriate to the job.

Prolonged exposure to loud noise can cause impairment

or loss of hearing.

Wear a suitable hearing protective device such as

earmuffs or earplugs to protect against objectionable or

uncomfortable loud noises.

Operating equipment safely requires the full attention of

the operator. Do not wear radio or music headphones

while operating machine.

Wait Before Opening High-Pressure Fuel System

Safety

TS206 –UN–23AUG88

DX,WEAR –19–10SEP90–1/1

High-pressure fluid remaining in fuel lines can cause

serious injury. Only technicians familiar with this type of

system should perform repairs. Before disconnecting fuel

lines, sensors, or any other components between the

high-pressure fuel pump and nozzles on engines with

High Pressure Common Rail (HPCR) fuel system, wait a

minimum of 15 minutes after engine is stopped.

DX,WW,HPCR2 –19–07JAN03–1/1

TS1343 –UN–18MAR92

CTM502 (31MAY07) 01-000-12 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=18

Page 19

Safety

Handle Agricultural Chemicals Safely

Chemicals used in agricultural applications such as

fungicides, herbicides, insecticides, pesticides,

rodenticides, and fertilizers can be harmful to your health

or the environment if not used carefully.

Always follow all label directions for effective, safe, and

legal use of agricultural chemicals.

Reduce risk of exposure and injury:

• Wear appropriate personal protective equipment as

recommended by the manufacturer. In the absence of

manufacturer’s instructions, follow these general

guidelines:

– Chemicals labeled ’Danger’: Most toxic. Generally

require use of goggles, respirator, gloves, and skin

protection.

– Chemicals labeled ’Warning’: Less toxic. Generally

require use of goggles, gloves, and skin protections.

– Chemicals labeled ’Caution’: Least toxic. Generally

require use of gloves and skin protection.

• Avoid inhaling spray or dusts.

• Always have soap, water, and towel available when

working with chemicals. If chemical contacts skin,

hands, or face, wash immediately with soap and water.

If chemical gets into eyes, flush immediately with water.

• Wash hands and face after using chemicals and before

eating, drinking, smoking, or urination.

• Do not smoke or eat while applying chemicals.

• After handling chemicals, always bathe or shower and

change clothes. Wash clothing before wearing again.

• Seek medical attention immediately if illness occurs

during or shortly after use of chemicals.

• Keep chemicals in original containers. Do not transfer

chemicals to unmarked containers or to containers used

for food or drink.

• Store chemicals in a secure, locked area way from

human or livestock food. Keep children away.

• Always dispose of containers properly. Triple rinse

empty containers and puncture or crush containers and

dispose of properly.

01

000

13

TS220 –UN–23AUG88A34471 –UN–11OCT88

CTM502 (31MAY07) 01-000-13 4.5 & 6.8 L Level 16 Electronic Fuel System

DX,WW,CHEM01 –19–05APR04–1/1

060407

PN=19

Page 20

01

000

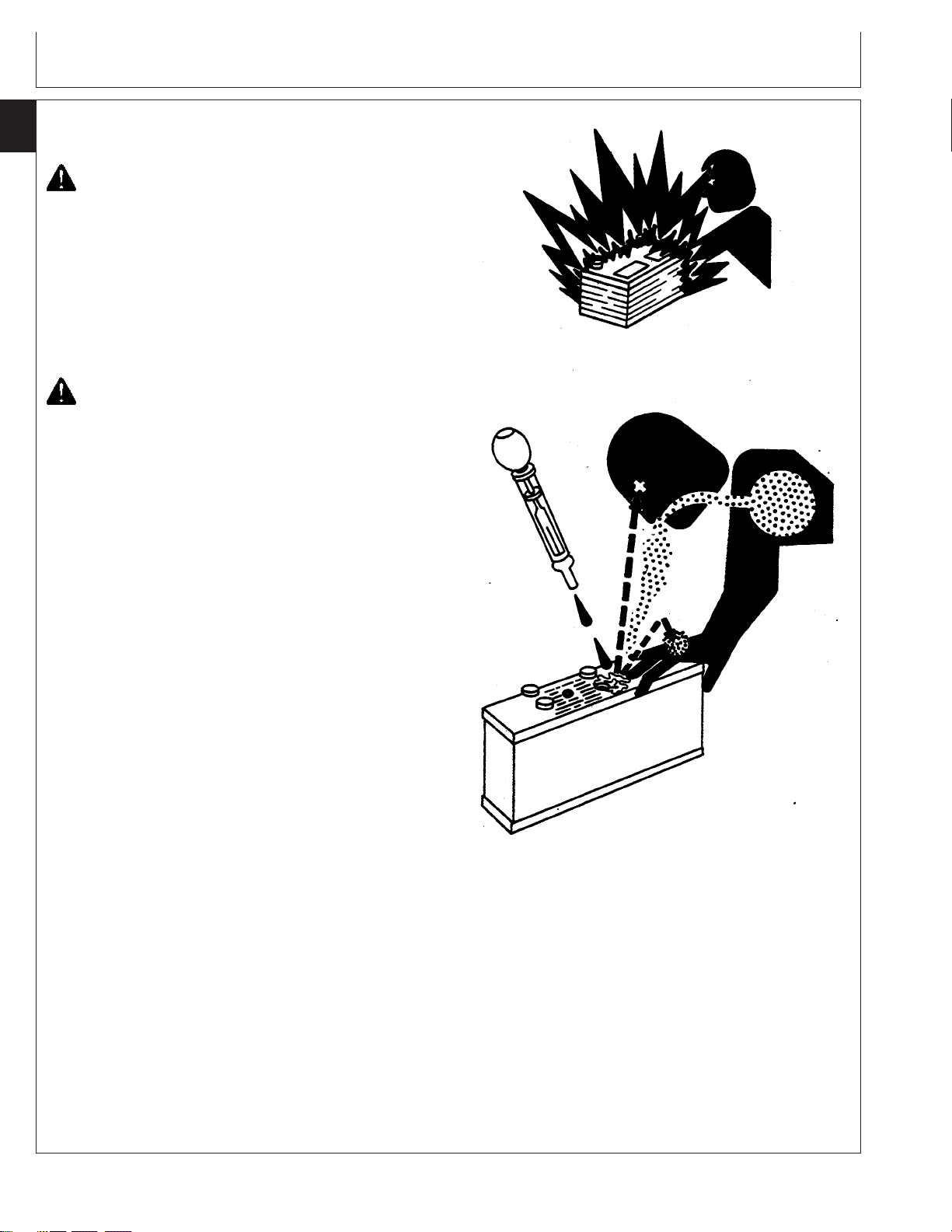

Handling Batteries Safely

14

CAUTION: Battery gas can explode. Keep

sparks and flames away from batteries. Use a

flashlight to check battery electrolyte level.

Never check battery charge by placing a metal

object across the posts. Use a voltmeter or

hydrometer.

Safety

Always remove grounded (—) battery clamp

first and replace it last.

CAUTION: Sulfuric acid in battery electrolyte is

poisonous. It is strong enough to burn skin, eat

holes in clothing, and cause blindness if

splashed into eyes.

Avoid the hazard by:

1. Filling batteries in a well-ventilated area.

2. Wearing eye protection and rubber gloves.

3. Avoiding breathing fumes when electrolyte is

added.

4. Avoiding spilling or dripping electrolyte.

5. Using proper jump start procedure.

If you spill acid on yourself:

1. Flush your skin with water.

2. Apply baking soda or lime to help neutralize

the acid.

3. Flush your eyes with water for 15—30

minutes. Get medical attention immediately.

Explosion

TS204 –UN–23AUG88

If acid is swallowed:

1. Do not induce vomiting.

2. Drink large amounts of water or milk, but do

not exceed2L(2qt.).

Acid

3. Get medical attention immediately.

WARNING: Battery posts, terminals, and related

accessories contain lead and lead compounds, chemicals

known to the State of California to cause cancer and

reproductive harm. Wash hands after handling.

DPSG,OUO1004,2758 –19–23JAN07–1/1

CTM502 (31MAY07) 01-000-14 4.5 & 6.8 L Level 16 Electronic Fuel System

TS203 –UN–23AUG88

060407

PN=20

Page 21

Safety

Install Fan Guards

Rotating cooling system fans can cause serious injury.

Keep fan guards in place at all times during engine

operation. Wear close fitting clothes. Stop engine and be

sure fan is stopped before making adjustments or

connections, or cleaning near the front of the engine.

01

000

15

Avoid Hot Parts

Avoid skin contact with exhaust manifolds, turbochargers

and mufflers. Keep flammable materials clear of the

turbocharger.

External dry exhaust parts become very hot during

operation. Turbochargers may reach temperatures as high

as 500°C (932°F) under full load, and naturally aspired

exhaust manifolds may reach 600°C (1112°F) under full

load. This may ignite paper, cloth or wooden materials.

Parts on engines that have been at full load and reduced

to no load idle will maintain approximately 150°C (302°F).

Rotating Fan

TS677 –UN–21SEP89

OUO1083,00005FE –19–17DEC03–1/1

TS271 –UN–23AUG88

Hot Surface

CTM502 (31MAY07) 01-000-15 4.5 & 6.8 L Level 16 Electronic Fuel System

OUO1083,00005FF –19–22DEC05–1/1

060407

PN=21

Page 22

01

000

16

Safety

CTM502 (31MAY07) 01-000-16 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=22

Page 23

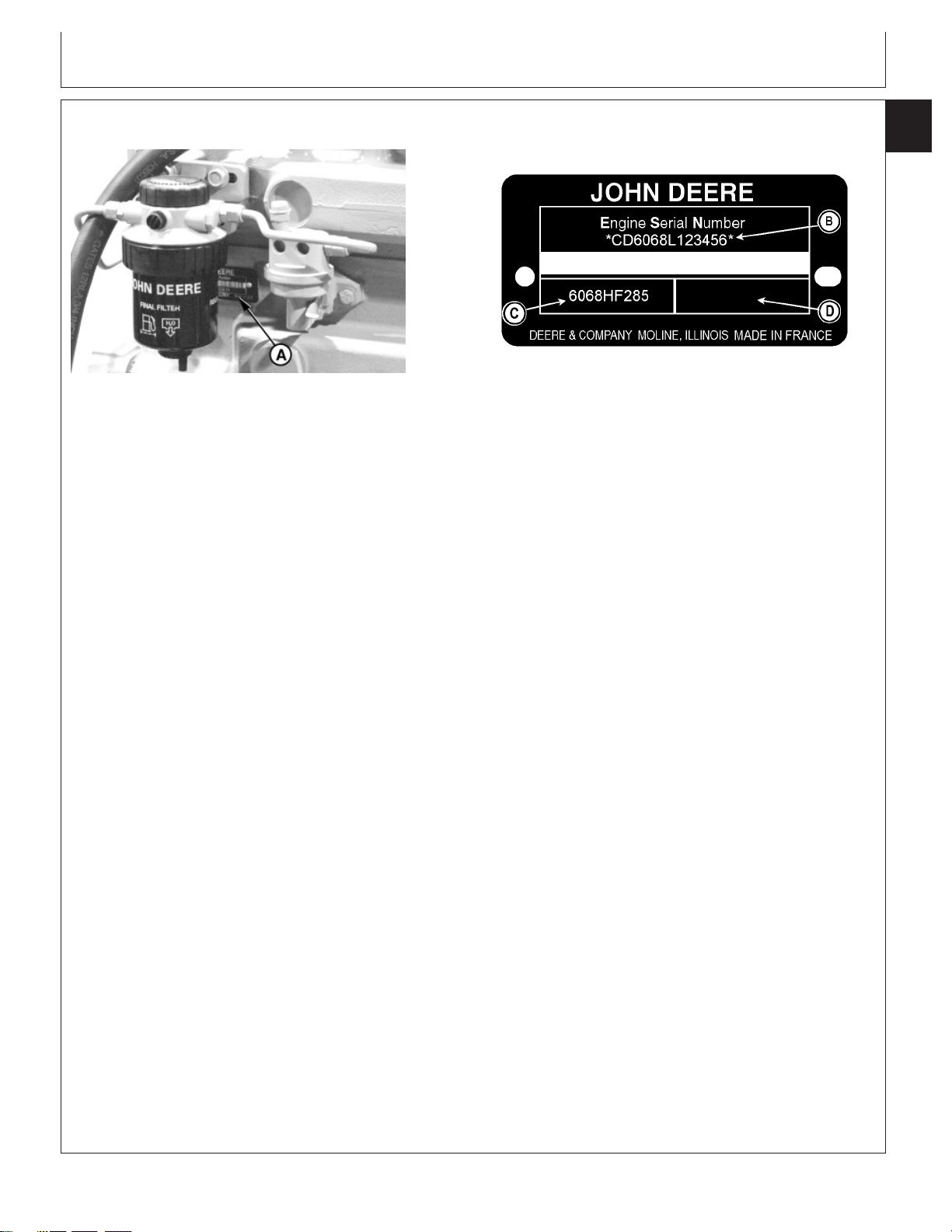

Engine Serial Number Plate Information

Group 001

Engine Identification

01

001

1

RG7778 –UN–11NOV97

A—Engine Serial Number Plate B—Engine Serial Number (13 C—Application Data or Type D—Internal Factory

IMPORTANT: The engine serial number plate can

be easily destroyed. Remove the

plate or record the information

elsewhere, before “hot tank”

digits) Identification (Saran

Each engine has a 13-digit John Deere engine serial

number identifying the producing factory, engine

displacement, emission “Tier” level and sequential

engine number. The following is an example:

Engine Serial Number/Application Data Plate

engines only)

cleaning the block.

Engine Serial Number (B)

CD6068L123456

CD ............................................................ Factory producing engine

6 ................................................................ Number of Cylinders

068 ............................................................ Liter displacement (6.8 liters)

L ................................................................ Emission Tier Level

123456 ...................................................... 6-digit sequential engine number

Factory Producing Engine

CD ............................................................ Saran, France

JO ............................................................. Rosario, Argentina

PE ............................................................. Torreon, Mexico

Emission Tier Level

L, M or N .................................................. Tier 3/Stage IIIA emission certified engine

CD30857 –UN–21AUG06

Engine Application Data (C)

The second line of information on the serial number

plate identifies the engine/machine or OEM

relationship. See ENGINE APPLICATION CHARTS

later in this group. The following is an example:

CTM502 (31MAY07) 01-001-1 4.5 & 6.8 L Level 16 Electronic Fuel System

Continued on next page

CD03523,000016E –19–04MAY07–1/2

060407

PN=23

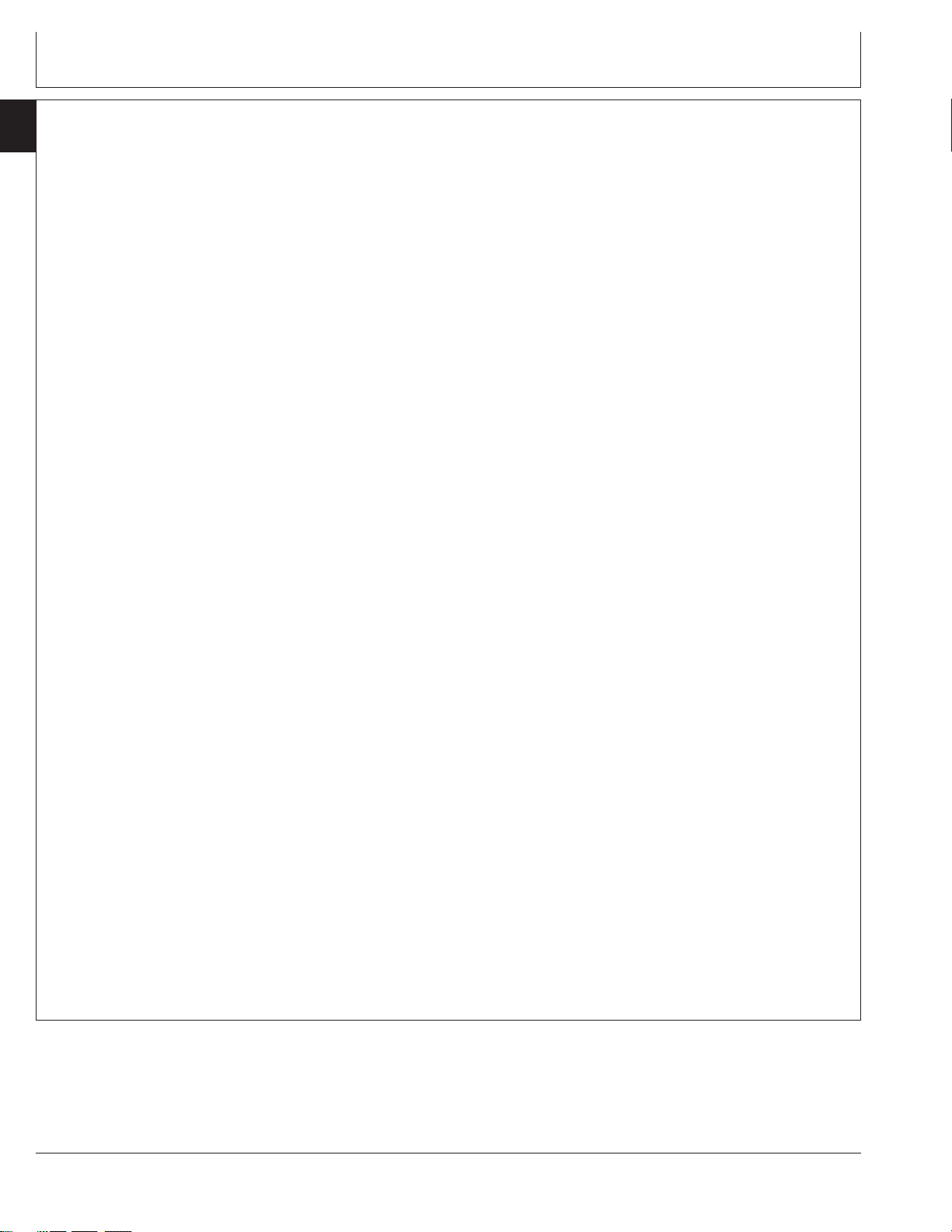

Page 24

Engine Identification

01

001

6068HF285

2

6 ................................................................ Number of Cylinders

068 ............................................................ Liter displacement (6.8 liters)

H ............................................................... Aspiration code

F ............................................................... User factory code

285 ............................................................ Application code

Aspiration code

A ............................................................... Turbocharged and Air-to-Coolant Aftercooled

D ............................................................... Naturally aspirated

H ............................................................... Turbocharged and Air-to-Air Aftercooled

T ............................................................... Turbocharged, no aftercooling

User Factory Code

AP ............................................................. Industries JohnDeere Mexico S.A. de C.V. (Saltillo/Monterrey, Mexico)

AT ............................................................. Agritalia srl (Vittoria, Sicily, Italy)

BE ............................................................. Bell EquipmnetCo. (Richards Bay, South Africa)

CQ ............................................................ John Deere Brazil (Horizontina, Brazil)

DW ............................................................ John Deere Davenport Works (Davenport, Iowa)

E ............................................................... John Deere Ottumwa Works (Ottumwa, Iowa)

F ............................................................... OEM (Outside Equipment Manufacturers)

FF ............................................................. Deere-Hitachi (Kernersville, North Carolina)

FG ............................................................. Goldoni S.P.A. (Modena, Italy)

FM ............................................................ Marine Engines

FS ............................................................. SDMO Applications

FU ............................................................. Power Unit for Generator Set

H ............................................................... John Deere Harvester Works (East Moline, Illinois)

KV ............................................................. John Deere Commercial Worksite Products (Knoxville, Tennessee/ Dubuque, Iowa)

L ................................................................ John Deere Werke Mannheim (Germany)

LV ............................................................. John Deere Commercial Products (Augusta, Georgia)

N ............................................................... John Deere Des Moines Works (Des Moines, Iowa)

P ............................................................... Industrias John Deere Mexico S.A. de C.V. (Saltillo/Monterrey, Mexico)

PY ............................................................. Larson & Toubro Ltd. (Pune, India)

RW ............................................................ John Deere Waterloo Tractor Works (Waterloo, Iowa)

T ............................................................... John Deere Dubuque Works (Dubuque, Iowa)

T8 ............................................................. Cameco Industries (Thibodaux, Louisiana)

TJ .............................................................. John Deere Forestry (Timberjack, Sweden/Finland/Canada)

YC ............................................................. John Deere Jialian Harvester Co. Limited (China)

Z ............................................................... John Deere WERKE Zweibrucken (Germany)

Application Code

285 etc. ................................................... This is the specific engine model for a given application. In this example (285), “2” denotes

CTM502 (31MAY07) 01-001-2 4.5 & 6.8 L Level 16 Electronic Fuel System

2-valves per cylinder and “85” denotes Tier 3 engines.

CD03523,000016E –19–04MAY07–2/2

060407

PN=24

Page 25

OEM Engine Option Code Label

Engine Identification

01

001

3

OEM Engine Option Code Label

A—Engine Base Code

An option code label is secured to the top of the valve

cover and identifies the factory installed options on

each OEM engine to ensure correct parts acquisition.

Always provide option code information and engine

base code when ordering repair parts. A listing of

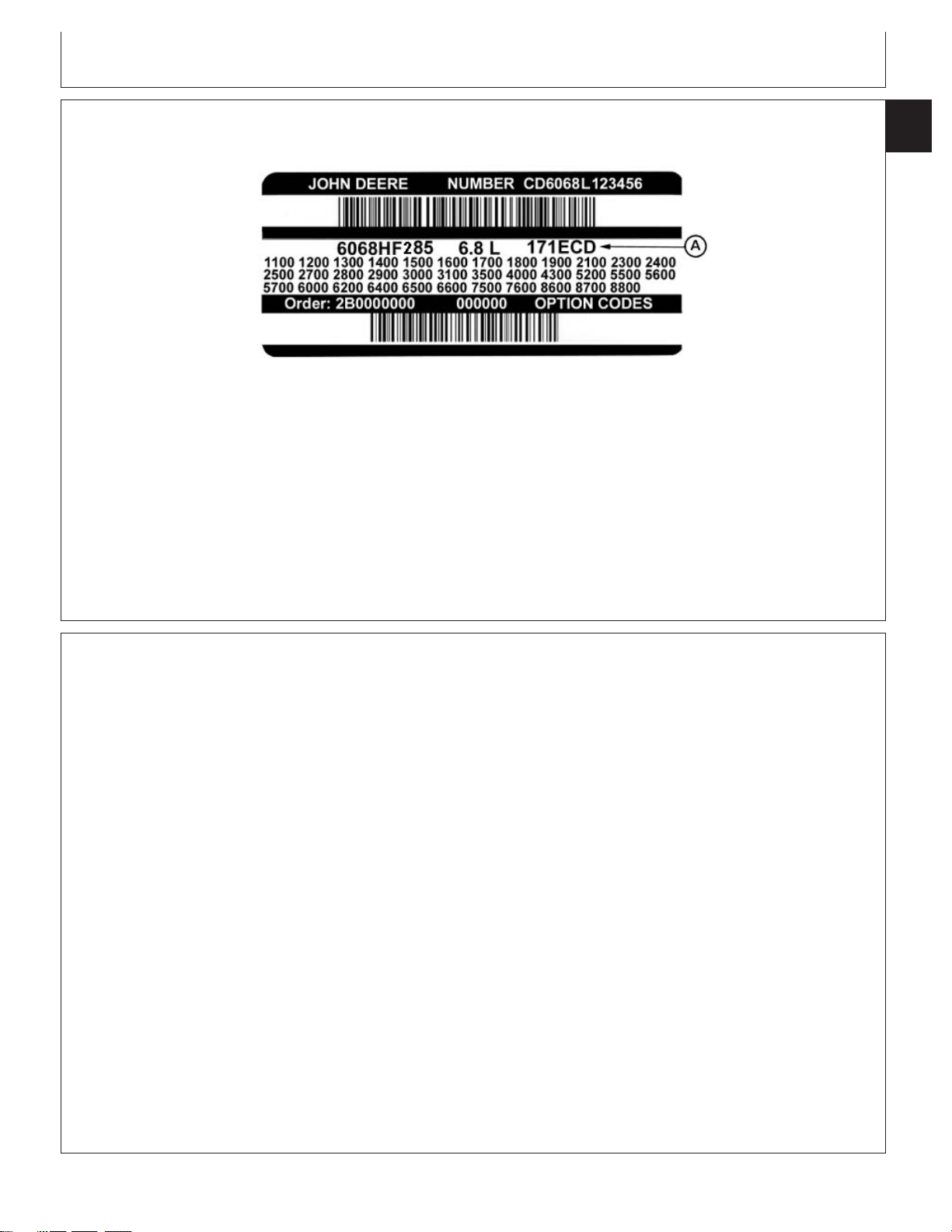

Information Relative to Emissions Regulations

Depending on the final destination, engines can meet

the emissions regulations according to the US

Environmental Protection Agency (EPA), California Air

Resources Board (CARB) and for Europe, the

Directive 97/68/EC relating the measures against the

emissions of particles and gaseous pollutant from

internal combustion engines. Such engines are called

“CERTIFIED” and receive an emission label stuck on

the engine.

CD30858 –UN–21AUG06

option codes is given in parts catalogs and operator’s

manuals.

NOTE: Before “hot tank” cleaning, ensure that option

codes are recorded elsewhere.

CD03523,000016F –19–21AUG06–1/1

component where the principle effect of that

component is to bypass, defeat, or render inoperative

any engine component or device which would affect

the engine’s conformance to the emission regulations.

To summarize, it is illegal to do anything except

return the engine to its original published

specifications.

List of emission-related components:

The regulations prohibit tampering with the

emission-related components listed below which would

render that component inoperative or to make any

adjustment on the engine beyond published

specifications. It is also illegal to install a part or

CTM502 (31MAY07) 01-001-3 4.5 & 6.8 L Level 16 Electronic Fuel System

• Fuel injection system

• Intake manifold

• Turbocharger

• Charge air cooling system

• Piston

RG40854,0000007 –19–10APR02–1/1

060407

PN=25

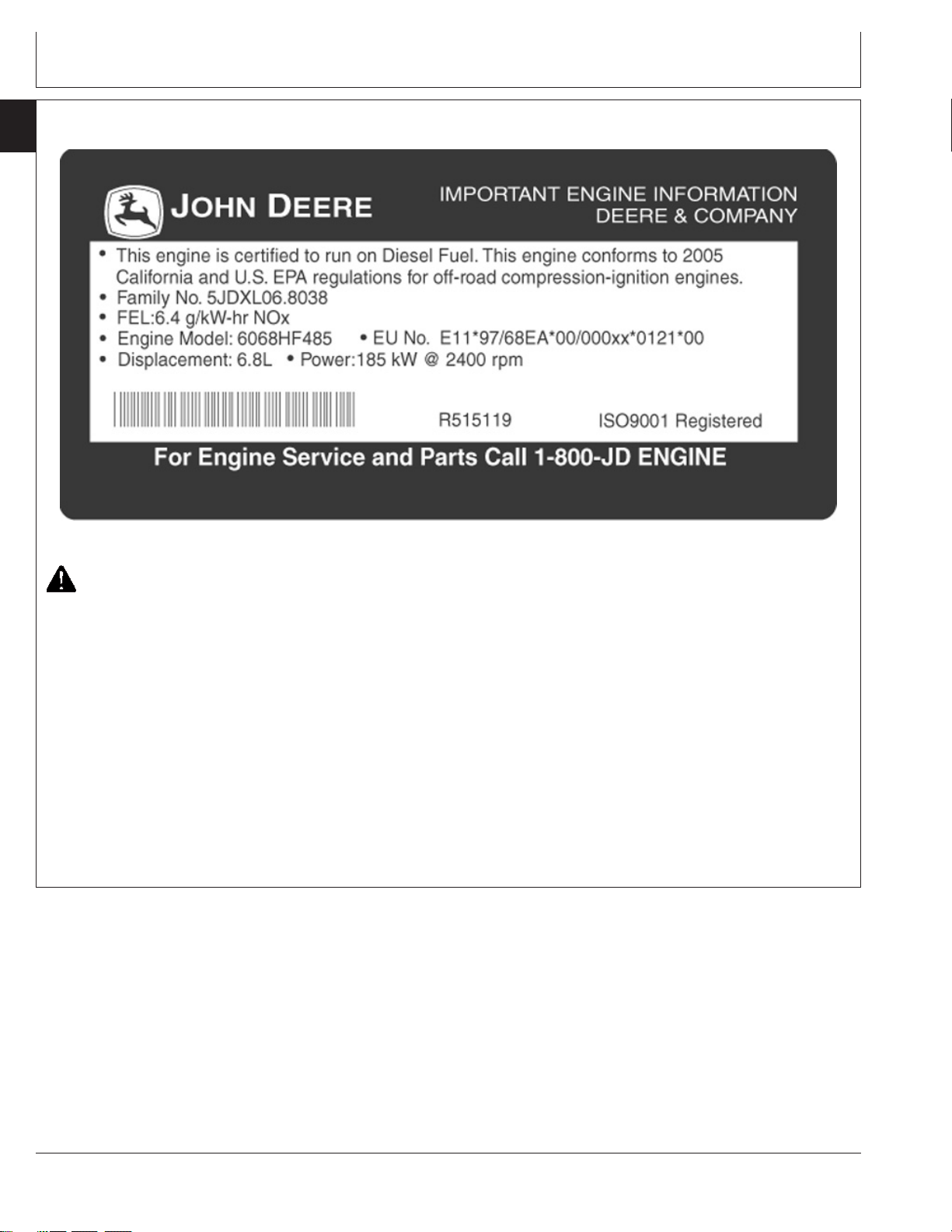

Page 26

01

001

Emissions Control System Certification Label

4

Engine Identification

6.8L Engine Emissions Label

CAUTION: Statutes providing severe

penalties for tampering with emissions

controls may apply at the user’s location.

The emissions warranty described below applies only

to those engines marketed by John Deere that have

been certified by the United States Environmental

Protection Agency (EPA) and/or California Air

Resources Board (CARB); and used in the United

States and Canada. The presence of an emissions

label like the one shown signifies that the engine has

been certified with the EPA and/or CARB. The EPA

and CARB warranties only apply to new engines

RG14852 –UN–26APR06

having the certification label affixed to the engine and

sold as stated above in the geographic areas. The

presence of an EU number in the third line of the label

signifies that the engine has been certified with the

European Union countries per Directive 97/68/EC. The

emissions warranty does not apply to the EU

countries.

NOTE: The hp/kW rating on the engine emissions

certification label specifies the gross engine

hp/kW, which is flywheel power without fan. In

most applications this will not be the same

rating as the advertised vehicle hp/kW rating.

RG19661,000022E –19–17APR07–1/1

CTM502 (31MAY07) 01-001-4 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=26

Page 27

Engine Identification

Engine Application Charts

This component technical manual (CTM502) covers

repair and diagnosis of Level 16 Electronic Fuel

System on PowerTech “E” 4.5 & 6.8 L engines

produced by John Deere SARAN “CD” (France) and

John Deere TORREON “PE” (Mexico). Refer to the

chart below to know which applications are covered by

this manual.

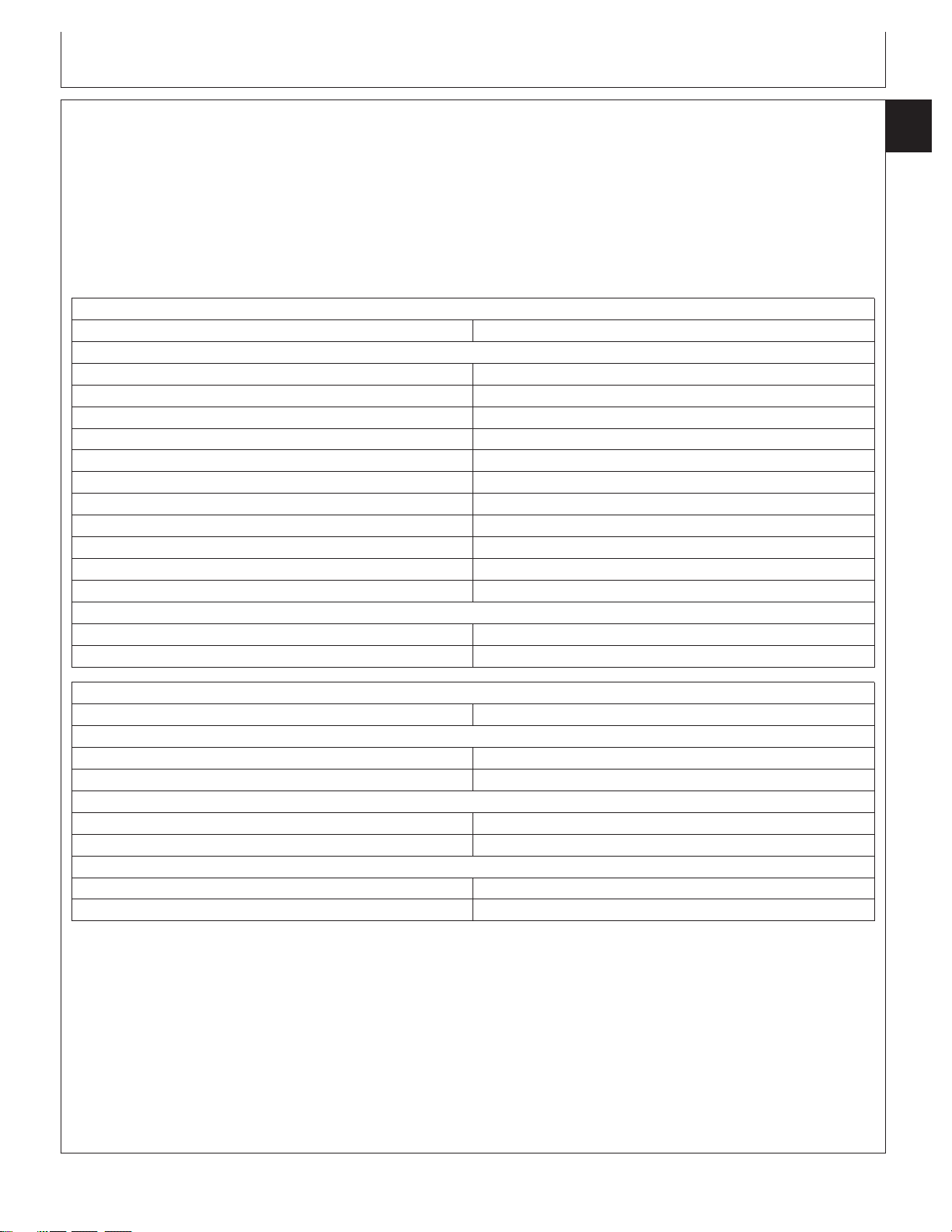

JOHN DEERE AGRICULTURAL EQUIPMENT

Machine Model Engine Model

6230 Advantage Tractor CD4045HL282

6230 Premium Tractor (North America) CD4045HL280

6330 Advantage Tractor CD4045HL283

6330 Premium Tractor (North America) CD4045HL281

6430 Advantage Tractor CD4045HL283

6430 Premium Tractor (North America) CD4045HL281

7130 Advantage Tractor CD6068HL280

7130 Premium Tractor (North America) PE6068HRW72

7230 Advantage Tractor CD6068HL280

7230 Premium Tractor (North America) PE6068HRW72

7330 Premium Tractor (North America) PE6068HRW74

1450 CWS Combine CD6068HCQ82

W330 Combine CD6068HCQ82

NOTE: Information on how to remove and reinstall the

Tractor

Combine

01

001

5

engine in the vehicle is contained in the

relevant machine Technical Manual.

JOHN DEERE CONSTRUCTION and FORESTRY EQUIPMENT

Machine Model Engine Model

Backhoe, Loader

444J Loader PE4045HDW53

544J Loader PE4045HDW70

Crawler Dozer, Crawler Loader

700J Crawler Dozer PE6068HT066

750J Crawler Dozer PE6068HT063

Excavator

160DLC Excavator PE4045HT056

200DLC Excavator PE6068HT069

CTM502 (31MAY07) 01-001-5 4.5 & 6.8 L Level 16 Electronic Fuel System

Continued on next page

CD03523,0000170 –19–23MAY07–1/2

060407

PN=27

Page 28

Engine Identification

01

001

6

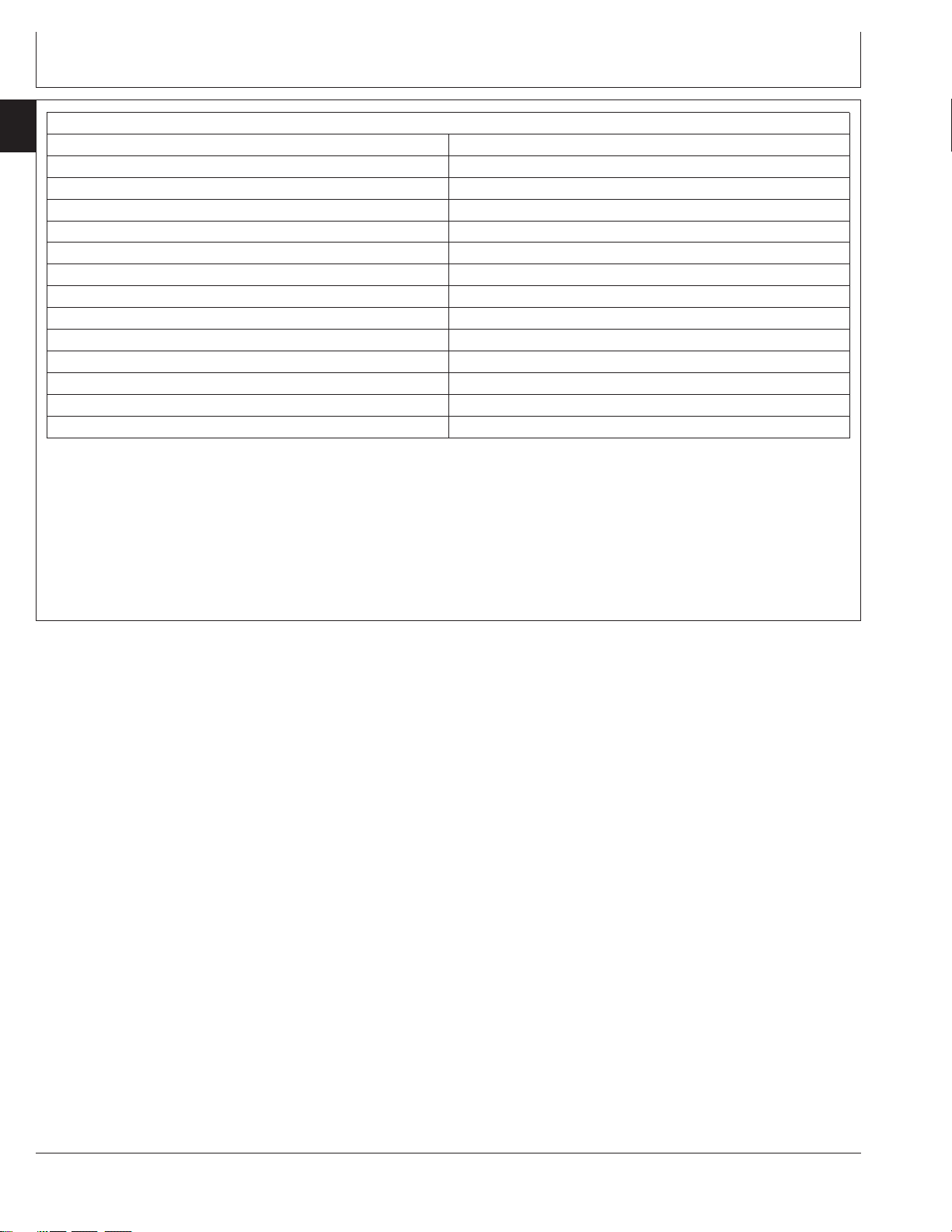

Engine Model Application

4045TF285

4045HF285

4045HF279 Generator set

4045HFS73 Generator set

4045HFS82 Generator set

4045HFS83 Generator set

4045HFU79 Generator set

6086HF285

6068HF279 Generator set

6068HFS73 Generator set

6068HFS82 Generator set

6068HFS83 Generator set

6068HFU79 Generator set

JOHN DEERE OEM (OUTSIDE EQUIPMENT MANUFACTURERS)

CD03523,0000170 –19–23MAY07–2/2

CTM502 (31MAY07) 01-001-6 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=28

Page 29

Diesel Fuel

Consult your local fuel distributor for properties of the

diesel fuel available in your area.

Group 002

Fuels, Lubricants, and Coolant

01

002

1

scar diameter of 0.45 mm as measured by ASTM

D6079 or ISO 12156-1.

In general, diesel fuels are blended to satisfy the low

temperature requirements of the geographical area in

which they are marketed.

Diesel fuels specified to EN 590 or ASTM D975 are

recommended.

Required fuel properties

In all cases, the fuel shall meet the following

properties:

Cetane number of 45 minimum. Cetane number

greater than 50 is preferred, especially for

temperatures below -20°C (-4°F) or elevations above

1500 m (5000 ft).

Cold Filter Plugging Point (CFPP) below the

expected low temperature OR Cloud Point at least

5°C(9°F) below the expected low temperature.

Fuel lubricity should pass a minimum level of 3100

grams as measured by ASTM D6078 or maximum

Sulfur content:

• Diesel fuel quality and fuel sulfur content must

comply with all existing emissions regulations for the

area in which the engine operates.

• Use of diesel fuel with sulfur content less than

0.10% (1000 ppm) is STRONGLY recommended.

• Use of diesel fuel with sulfur content 0.10% (1000

ppm to 0.50% (5000 ppm) may result in REDUCED

oil and filter change intervals.

• BEFORE using diesel fuel with sulfur content greater

than 0.50% (5000 ppm), contact your John Deere

dealer.

• DO NOT use diesel fuel with sulfur content greater

than 1.0%.

IMPORTANT: Do not mix used diesel engine oil or

any other type of lubricating oil with

diesel fuel.

IMPORTANT: Improper fuel additive usage may

cause damage on fuel injection

equipment of diesel engines.

DX,FUEL1 –19–17NOV05–1/1

CTM502 (31MAY07) 01-002-1 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=29

Page 30

01

002

Bio-Diesel Fuel

2

Consult your local fuel distributor for properties of the

bio-diesel fuel available in your area.

Fuels, Lubricants, and Coolant

leaving deposits on injectors and in

the combustion chamber.

Bio-diesel fuels may be used ONLY if the bio-diesel

fuel properties meet the latest edition of ASTM D6751,

EN 14214, or equivalent specification.

It is recommended to purchase bio-diesel fuel blended

with B100 from a BQ-9000 Accredited Producer or a

BQ-9000 Certified Marketer as recommended by the

National Bio-diesel Board.

The maximum allowable bio-diesel concentration is a

5% blend (also known as B5) in petroleum diesel fuel.

It has been found that bio-diesel fuels may improve

lubricity in concentrations up to this 5% blend.

When using a blend of bio-diesel fuel, the engine oil

level must be checked daily when the air temperature

is –10°C (14°F) or lower. If oil becomes diluted with

fuel, shorten oil change intervals accordingly.

IMPORTANT: Raw pressed vegetable oils are NOT

acceptable for use as fuel in any

concentration in John Deere

engines.

These oils do not burn completely,

and will cause engine failure by

A major environmental benefit of bio-diesel fuel is its

ability to biodegrade. This makes proper storage and

handling of bio-diesel fuel especially important. Areas

of concern include:

• Quality of new fuel

• Water content of the fuel

• Problems due to aging of the fuel

Potential problems resulting from deficiencies in the

above areas when using bio-diesel fuel in

concentrations above 5% may lead to the following

symptoms:

• Power loss and deterioration of performance

• Fuel leakage

• Corrosion of fuel injection equipment

• Coked and/or blocked injector nozzles, resulting in

engine misfire

• Filter plugging

• Lacquering and/or seizure of internal components

• Sludge and sediments

• Reduced service life of engine components

Consult your fuel supplier for additives to improve

storage and performance of bio-diesel fuels.

DX,FUEL7 –19–14NOV05–1/1

CTM502 (31MAY07) 01-002-2 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=30

Page 31

Fuels, Lubricants, and Coolant

Minimizing the Effect of Cold Weather on Diesel Engines

John Deere diesel engines are designed to operate

effectively in cold weather.

CAUTION: Do not use any starting fluid with

an engine equipped with glow plugs

01

002

3

However, for effective starting and cold weather

operation, a little extra care is necessary. The

information below outlines steps that can minimize the

effect that cold weather may have on starting and

operation of your engine. See your John Deere dealer

for additional information and local availability of cold

weather aids

Use Winter Grade Fuel

When temperatures fall below 5°C (40°F), winter grade

fuel (Grade No. 1-D fuel in North America) is best

suited for cold weather operation. Winter grade fuel

has a lower cloud point and a lower pour point.

Cloud point is the temperature at which wax will begin

to form in the fuel and this wax causes fuel filters to

plug. Pour point is the temperature at which fuel

begins to thicken and becomes more resistant to flow

through fuel pumps and lines.

NOTE: On an average, winter grade fuel has a lower

BTU (heat content) rating. Using winter grade

fuel may reduce power and fuel efficiency, but

should not cause any other engine

performance effects. Check the grade of fuel

being used before troubleshooting for low

power complaints in cold weather operation.

Coolant Heater

An engine block heater (coolant heater) is an available

option to aid cold weather starting.

Seasonal Viscosity Oil and Proper Coolant

Concentration

Use seasonal grade viscosity engine oil based ion the

expected air temperature range between oil changes

and proper concentration of low silicate antifreeze as

recommended. (See DIESEL ENGINE OIL and

ENGINE COOLANT requirements this section.)

Diesel Fuel Flow Additive

Use John Deere Premium Diesel Fuel Conditioner

(Winter) or equivalent to treat fuel during the cold

weather season. This winter formulation is a

combination diesel fuel conditioner and anti-gel

additive.

IMPORTANT: Treat fuel when outside temperature

drops below 0°C (32°F). For best

results, use with untreated fuel.

Follow all recommended instructions

on label.

Air Intake Heater

An air intake heater is an available option to aid cold

weather starting.

Winterfronts

Use of fabric, cardboard , or solid winterfronts is not

recommended with any John Deere engine. Their use

can result in excessive engine coolant, oil, and charge

air temperatures. This can lead to reduced engine life,

CAUTION: Do not use any starting fluid with

an air intake heater.

loss of power and poor fuel economy. Winterfronts

may also put abnormal stress on fan and fan drive

components potentially causing premature failures.

Starting Fluid

A starting fluid port on the intake is available to aid

cold weather starting.

Continued on next page

CTM502 (31MAY07) 01-002-3 4.5 & 6.8 L Level 16 Electronic Fuel System

DX,FUEL10 –19–16DEC05–1/2

060407

PN=31

Page 32

Fuels, Lubricants, and Coolant

01

002

If winterfronts are used, they should never totally close

4

off the grill frontal area. Approximately 25% area in the

center of the grill should remain open at all times. At

no time should the air blockage device be applied

directly to the radiator core.

Radiator Shutters

If equipped with a thermostatically controlled radiator

shutter system, this system should be regulated in

such a way that the shutters are completely open by

Handling and Storing Diesel Fuel

the time the coolant reaches 93°C (200°F) to prevent

excessive intake manifold temperatures. Manually

controlled systems are not recommended.

If air-to-air aftercooling is used, the shutters must be

completely open by the time the intake manifold air

temperature reaches the maximum allowable

temperature out of the charge air cooler.

For more information, see your John Deere dealer.

DX,FUEL10 –19–16DEC05–2/2

CAUTION: Handle fuel carefully. Do not fill

the fuel tank when engine is running.

DO NOT smoke while you fill the fuel tank or

service the fuel system.

Fill the fuel tank at the end of each day’s operation to

prevent water condensation and freezing during cold

weather.

Keep all storage tanks as full as practicable to

minimize condensation.

Ensure that all fuel tank caps and covers are installed

properly to prevent moisture from entering.

Monitor water content of the fuel regularly.

When using bio-diesel fuel, the fuel filter may require

more frequent replacement due to premature plugging.

Check engine oil level daily prior to starting engine. A

rising oil level may indicate fuel dilution of the engine

oil.

IMPORTANT: The fuel tank is vented through the

filler cap. If a new filler cap is

required, always replace it with an

original vented cap.

When fuel is stored for an extended period or if there

is a slow turnover of fuel, add a fuel conditioner to

stabilize the fuel and prevent water condensation.

Contact your fuel supplier for recommendations.

DX,FUEL4 –19–19DEC03–1/1

CTM502 (31MAY07) 01-002-4 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=32

Page 33

Fuels, Lubricants, and Coolant

Lubricity of Diesel Fuel

Most diesel fuels manufactured in the United States,

Canada, and the European Union have adequate

lubricity to ensure proper operation and durability of

fuel injection system components. However, diesel

fuels manufactured in some areas of the world may

lack the necessary lubricity.

IMPORTANT: Make sure the diesel fuel used in

your machine demonstrates good

lubricity characteristics.

Testing Diesel Fuel

01

002

5

Fuel lubricity should pass a minimum load level of

3100 grams as measured by ASTM D6078 or a

maximum scar diameter of 0.45 mm as measured by

ASTM D6079 or ISO 12156-1.

If fuel of low or unknown lubricity is used, add John

Deere PREMIUM DIESEL FUEL CONDITIONER (or

equivalent) at the specified concentration.

DX,FUEL5 –19–27OCT05–1/1

DIESELSCAN is a John Deere fuel analysis program

that can be used to monitor the quality of your fuel. The

DIESELSCAN analysis verifies fuel type, cleanliness,

water content, suitability for cold weather operation, and

whether the fuel meets specifications.

Check with your John Deere dealer for availability of

DIESELSCAN kits.

DIESELSCAN is a trademark of Deere & Company

Engine Oil and Filter Service Intervals

See applicable operator’s manual for service intervals.

DX,FUEL6 –19–14NOV05–1/1

DM80898,000025E –19–27NOV06–1/1

CTM502 (31MAY07) 01-002-5 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=33

Page 34

Fuels, Lubricants, and Coolant

01

002

Diesel Engine Oil

6

Use oil viscosity based on the expected air temperature

range during the period between oil changes.

o

50 C

o

40 C

o

122 F

o

104 F

John Deere PLUS-50 oil is preferred.

Oils meeting one of the following specifications are also

recommended:

• ACEA Oil Sequence E7

• ACEA Oil Sequence E6

Extended service intervals may apply when John Deere

PLUS-50, ACEA E7, or ACEA E6 engine oils are used.

Consult your John Deere dealer for more information.

Other oils may be used if they meet one or more of the

following:

• John Deere TORQ-GARD SUPREME

• API Service Category CJ-4

• API Service Category CI-4 PLUS

• API Service Category CI-4

• ACEA Oil Sequence E5

• ACEA Oil Sequence E4

Multi-viscosity diesel engine oils are preferred.

SAE 15W-40

SAE 10W-40

SAE 10W-30

o

30 C

o

20 C

o

10 C

o

0 C

o

-10 C

o

-20 C

o

-30 C

o

-40 C

o

86 F

o

68 F

o

50 F

o

32 F

o

14 F

o

-4 F

o

-22 F

o

-40 F

SAE 0W-40

SAE 5W-30

Oil Viscosities for Air Temperature Ranges

TS1684 –UN–09OCT06

Diesel fuel quality and fuel sulfur content must comply

with all existing emissions regulations for the area in

which the engine operates.

DO NOT use diesel fuel with sulfur content greater than

1.0% (10 000 ppm).

PLUS-50 is a trademark of Deere & Company

TORQ-GARD SUPREME is a trademark of Deere & Company

DX,ENOIL11 –19–13SEP06–1/1

CTM502 (31MAY07) 01-002-6 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=34

Page 35

Fuels, Lubricants, and Coolant

Diesel Engine Break-In Oil

New engines are filled at the factory with John Deere

ENGINE BREAK-IN OIL. During the break-in period,

add John Deere ENGINE BREAK-IN OIL as needed to

maintain the specified oil level.

Change the oil and filter after the first 100 hours of

operation of a new or rebuilt engine.

After engine overhaul, fill the engine with John Deere

ENGINE BREAK-IN OIL.

If John Deere ENGINE BREAK-IN OIL is not available,

use a diesel engine oil meeting one of the following

during the first 100 hours of operation:

• API Service Classification CE

• API Service Classification CD

• API Service Classification CC

• ACEA Oil Sequence E2

• ACEA Oil Sequence E1

01

002

7

After the break-in period, use John Deere PLUS-50

or other diesel engine oil as recommended in this

manual.

IMPORTANT: Do not use PLUS-50 oil or engine

oils meeting any of the following

during the first 100 hours of

operation of a new or rebuilt engine:

API CJ-4 ACEA E7

API CI-4 PLUS ACEA E6

API CI-4 ACEA E5

API CH-4 ACEA E4

API CG-4 ACEA E3

API CF-4

API CF-2

API CF

These oils will not allow the engine

to break-in properly.

PLUS-50 is a trademark of Deere & Company.

DX,ENOIL4 –19–13SEP06–1/1

Oil Filters

Filtration of oils is critical to proper operation and

lubrication.

Always change filters regularly as specified in this manual.

Use filters meeting John Deere performance

specifications.

DX,FILT –19–18MAR96–1/1

CTM502 (31MAY07) 01-002-7 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=35

Page 36

Fuels, Lubricants, and Coolant

01

002

Alternative and Synthetic Lubricants

8

Conditions in certain geographical areas may require

lubricant recommendations different from those printed

in this manual.

Some John Deere brand coolants and lubricants may

not be available in your location.

Synthetic lubricants may be used if they meet the

performance requirements as shown in this manual.

The temperature limits and service intervals shown in

this manual apply to both conventional and synthetic

oils.

Consult your John Deere dealer to obtain information

and recommendations.

Lubricant Storage

Your equipment can operate at top efficiency only

when clean lubricants are used.

Use clean containers to handle all lubricants.

Whenever possible, store lubricants and containers in

an area protected from dust, moisture, and other

contamination. Store containers on their side to avoid

water and dirt accumulation.

Re-refined base stock products may be used if the

finished lubricant meets the performance requirements.

DX,ALTER –19–15JUN00–1/1

Make certain that all containers are properly marked to

identify their contents.

Properly dispose of all old containers and any residual

lubricant they may contain.

DX,LUBST –19–18MAR96–1/1

Mixing of Lubricants

In general, avoid mixing different brands or types of oil.

Oil manufacturers blend additives in their oils to meet

certain specifications and performance requirements.

Mixing different oils can interfere with the proper

functioning of these additives and degrade lubricant

performance.

CTM502 (31MAY07) 01-002-8 4.5 & 6.8 L Level 16 Electronic Fuel System

Consult your John Deere dealer to obtain specific

information and recommendations.

DX,LUBMIX –19–18MAR96–1/1

060407

PN=36

Page 37

Fuels, Lubricants, and Coolant

Grease

Use grease based on NLGI consistency numbers and the

expected air temperature range during the service interval.

John Deere SD POLYUREA GREASE is preferred.

The following greases are also recommended

• John Deere HD LITHIUM COMPLEX GREASE

• John Deere HD WATER RESISTANT GREASE

• John Deere GREASE-GARD

Other greases may be used if they meet the following:

NLGI Performance Classification GC-LB

IMPORTANT: Some types of grease thickeners are

not compatible with others. Consult

your grease supplier before mixing

different types of grease

01

002

9

TS1673 –UN–31OCT03

GREASE-GARD is a trademark of Deere & Company

DX,GREA1 –19–07NOV03–1/1

CTM502 (31MAY07) 01-002-9 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=37

Page 38

Fuels, Lubricants, and Coolant

01

002

Diesel Engine Coolant

10

The engine cooling system is filled to provide

year-round protection against corrosion and cylinder

liner pitting, and winter freeze protection to -37°C

(-34°F). If protection at lower temperatures is required,

consult your John Deere dealer for recommendations.

John Deere COOL-GARD Prediluted Coolant is

preferred for service.

John Deere COOL-GARD Prediluted Coolant is

available in a concentration of either 50% ethylene

glycol or 55% propylene glycol.

Additional recommended coolants

The following engine coolant is also recommended:

Other low silicate ethylene glycol base coolants for

heavy-duty engines may also be used if they meet one

of the following specifications:

• ASTM D4985 ethylene glycol base prediluted (50%)

coolant

• ASTM D4985 ethylene glycol base coolant

concentrate in a 40% to 60% mixture of concentrate

with quality water

Coolants meeting ASTM D4985 require an initial

charge of supplemental coolant additives, formulated

for protection of heavy duty diesel engines against

corrosion and cylinder liner erosion and pitting. They

also require periodic replenishment of additives during

the drain interval.

• John Deere COOL-GARD Coolant Concentrate in a

40% to 60% mixture of concentrate with quality

water.

John Deere COOL-GARD coolants do not require use

of supplemental coolant additives, except for periodic

replenishment of additives during the drain interval.

Other fully formulated coolants

Other fully formulated low silicate ethylene or

propylene glycol base coolants for heavy-duty engines

may be used if they meet one of the following

specifications:

• ASTM D6210 prediluted (50%) coolant

• ASTM D6210 coolant concentrate in a 40% to 60%

mixture of concentrate with quality water

Coolants meeting ASTM D6210 do not require use of

supplemental coolant additives, except for periodic

replenishment of additives during the drain interval.

Coolants requiring supplemental coolant additives

Other coolants

It is possible that neither John Deere COOL-GARD nor

coolants meeting one of the coolant standards listed

above is available in the geographical area where

service is performed. If these coolants are unavailable,

use a coolant concentrate or prediluted coolant with a

quality additive package that provides cylinder liner

cavitation protection and protects the cooling system

metals (cast iron, aluminum alloys, and copper alloys

such as brass) from corrosion.

The additive package must be part of one of the

following coolant mixtures:

• ethylene glycol or propylene glycol base prediluted

(40% to 60%) coolant

• ethylene glycol or propylene glycol base coolant

concentrate in a 40% to 60% mixture of concentrate

with quality water

Water quality

COOL-GARD is a trademark of Deere & Company

Continued on next page

DX,COOL3 –19–27OCT05–1/2

CTM502 (31MAY07) 01-002-10 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=38

Page 39

Fuels, Lubricants, and Coolant

Water quality is important to the performance of the

cooling system. Distilled, deionized, or demineralized

water is recommended for mixing with ethylene glycol

and propylene glycol base engine coolant concentrate.

IMPORTANT: Do not use cooling system sealing

additives or antifreeze that contains

sealing additives.

Supplemental Coolant Additives

IMPORTANT: Do not mix ethylene glycol and

propylene glycol base coolants.

DX,COOL3 –19–27OCT05–2/2

01

002

11

The concentration of coolant additives is gradually

depleted during engine operation. For all

recommended coolants, replenish additives between

drain intervals by adding a supplemental coolant

additive every 12 months or as determined necessary

by coolant testing.

John Deere COOLANT CONDITIONER is

recommended as a supplemental coolant additive in

John Deere engines.

IMPORTANT: Do not add a supplemental coolant

additive when the cooling system is

drained and refilled with John

DeereCOOL-GARD.

COOL-GARD is a trademark of Deere & Company

If other coolants are used, consult the coolant supplier

and follow the manufacturer’s recommendation for use

of supplemental coolant additives.

The use of non-recommended supplemental coolant

additives may result in additive drop-out and gelation

of the coolant.

Add the manufacturer’s recommended concentration of

supplemental coolant additive. DO NOT add more than

the recommended amount.

DX,COOL4 –19–07NOV03–1/1

CTM502 (31MAY07) 01-002-11 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=39

Page 40

01

002

Operating in Warm Temperature Climates

12

John Deere engines are designed to operate using

glycol base engine coolants.

Always use a recommended glycol base engine

coolant, even when operating in geographical areas

where freeze protection is not required.

IMPORTANT: Water may be used as coolant in

emergency situations only.

Fuels, Lubricants, and Coolant

Foaming, hot surface aluminum and

iron corrosion, scaling, and

cavitation will occur when water is

used as the coolant, even when

coolant conditioners are added.

Drain cooling system and refill with

recommended glycol base engine

coolant as soon as possible.

DX,COOL6 –19–18MAR96–1/1

CTM502 (31MAY07) 01-002-12 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=40

Page 41

Fuels, Lubricants, and Coolant

Additional Information About Diesel Engine Coolants and Supplemental Coolant Additives

01

002

13

Engine coolants are a combination of three chemical

components: ethylene glycol or propylene glycol

antifreeze, inhibiting coolant additives, and quality

water.

Coolant specifications

Some products, including John Deere COOL-GARD

Prediluted Coolant, are fully formulated coolants that

contain all three components in their correct

concentrations. Do not add an initial charge of

supplemental coolant additives to these fully

formulated products.

Coolants meeting ASTM D6210 do not require an

initial charge of supplemental coolant additives.

Some coolant concentrates, including John Deere

COOL-GARD Coolant Concentrate, contain both glycol

antifreeze and inhibiting coolant additives. Mix these

products with quality water, but do not add an initial

charge of supplemental coolant additives.

Coolants meeting ASTM D4985 require an initial

charge of supplemental coolant additives.

Replenish coolant additives

simple mixture of ethylene glycol or propylene glycol

and water will not give adequate protection.

Use of supplemental coolant additives reduces

corrosion, erosion, and pitting. These chemicals

reduce the number of vapor bubbles in the coolant and

help form a protective film on cylinder liner surfaces.

This film acts as a barrier against the harmful effects

of collapsing vapor bubbles.

Avoid automotive-type coolants

Never use automotive-type coolants (such as those

meeting ASTM D3306). These coolants do not contain

the correct additives to protect heavy-duty diesel

engines. They often contain a high concentration of

silicates and may damage the engine or cooling

system.

Water quality

Water quality is important to the performance of the

cooling system. Distilled, deionized, or demineralized

water is recommended for mixing with ethylene glycol

and propylene glycol base engine coolant concentrate.

All water used in the cooling system should meet the

following minimum specifications for quality:

The concentration of coolant additives is gradually

depleted during engine operation. Periodic

replenishment of inhibitors is required, even when

John Deere COOL-GARD or another fully formulated

coolant is used. Follow the recommendations in this

manual for the use of supplemental coolant additives.

Why use supplemental coolant additives?

Operating without proper coolant additives will result in

increased corrosion, cylinder liner erosion and pitting,

Chlorides <40 mg/L

Sulfates <100 mg/L

Total dissolved solids <340 mg/L

Total hardness <170 mg/L

pH 5.5 to 9.0

Freeze protection

The relative concentrations of glycol and water in the

engine coolant determine its freeze protection limit.

and other damage to the engine and cooling system. A

COOL-GARD is a trademark of Deere & Company

Continued on next page

CTM502 (31MAY07) 01-002-13 4.5 & 6.8 L Level 16 Electronic Fuel System

DX,COOL7 –19–19DEC03–1/2

060407

PN=41

Page 42

01

002

14

Ethylene Glycol Freeze Protection Limit

40% -24°C (-12°F)

50% -37°C (-34°F)

60% -52°C (-62°F)

Propylene Glycol Freeze Protection Limit

40% -21°C (-6°F)

50% -33°C (-27°F)

60% -49°C (-56°F)

Testing Diesel Engine Coolant

Fuels, Lubricants, and Coolant

DO NOT use a coolant-water mixture greater than

60% ethylene glycol or 60% propylene glycol.

DX,COOL7 –19–19DEC03–2/2

Testing Diesel Engine Coolant

Maintaining adequate concentrations of glycol and

inhibiting additives in the coolant is critical to protect

the engine and cooling system against freezing,

corrosion, and cylinder liner erosion and pitting.

Test the coolant solution at intervals of 12 months or

less and whenever excessive coolant is lost through

leaks or overheating.

Coolant test strips

Coolant test strips are available from your John Deere

dealer. These test strips provide a simple, effective

COOLSCAN is a trademark of Deere & Company

COOLSCAN PLUS is a trademark of Deere & Company

method to check the freeze point and additive levels of

your engine coolant.

Compare the results to the supplemental coolant

additive (SCA) chart to determine the amount of

inhibiting additives in your coolant and whether more

John Deere COOLANT CONDITIONER should be

added.

COOLSCAN and COOLSCAN PLUS

For a more thorough evaluation of your coolant,

perform a COOLSCAN or COOLSCAN PLUS analysis,

where available. See your John Deere dealer for

information.

DX,COOL9 –19–19DEC03–1/1

CTM502 (31MAY07) 01-002-14 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=42

Page 43

Fuels, Lubricants, and Coolant

Drain Intervals for Diesel Engine Coolant

Drain the factory fill engine coolant, flush the cooling

system, and refill with new coolant after the first 3

years or 3000 hours of operation.

01

002

15

operation, provided that the coolant is tested annually

AND additives are replenished, as needed, by adding

a supplemental coolant additive.

Subsequent drain intervals are determined by the

coolant used for service. At each interval, drain the

coolant, flush the cooling system, and refill with new

coolant.

When John Deere COOL-GARD is used, the drain

interval may be extended to 5 years or 5000 hours of

COOL-GARD is a trademark of Deere & Company

If John Deere COOL-GARD is used but the coolant is

not tested OR additives are not replenished by adding

a supplemental coolant additive, the drain interval is 3

years or 3000 hours of operation

If COOL-GARD is not used, the drain interval is

reduced to 2 years or 2000 hours of operation.

DX,COOL11 –19–19DEC03–1/1

CTM502 (31MAY07) 01-002-15 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=43

Page 44

01

002

16

Fuels, Lubricants, and Coolant

CTM502 (31MAY07) 01-002-16 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=44

Page 45

Section 02

Repair and Adjustments

Page Page

Group 090—Electronic Fuel System Repair and

Adjustments

Fuel System - General Information .........02-090-1

Relieve Fuel System Pressure ............02-090-1

Fuel System Components ................02-090-2

Replace Fuel Filter Element (Primary or

Final) ..............................02-090-3

Remove and Install Fuel Filter Base (Primary

and Final) ..........................02-090-5

Remove Fuel Transfer Pump .............02-090-6

Install Fuel Transfer Pump ...............02-090-7

Remove and Install High Pressure Fuel

Pump..............................02-090-8

Remove and Install Suction Control Valve. . . 02-090-12

Remove and Install High Pressure

Common Rail .......................02-090-16

Remove and Install Flow Dampers ........02-090-17

Remove and Install Pressure Limiter.......02-090-19

Remove and Install Fuel Injection Wire

Harness Assembly ...................02-090-21

Injector Identification Tag Information ......02-090-25

Remove Electronic Injector (EI) ...........02-090-26

Clean Electronic Injector (EI) Bore ........02-090-29

Clean Electronic Injector (EI) Orifice .......02-090-29

Clean Electronic Injector (EI) Body ........02-090-29

Inspect Electronic Injector (EI) Body .......02-090-29

Install Electronic Injector (EI) .............02-090-30

Remove and Install Fuel Leak-Off Line .....02-090-34

Contents

Remove and Install Fuel Transfer Pump

Pressure Sensor .....................02-110-7

Remove and Install Crankshaft Position

Sensor .............................02-110-8

Remove and Install Pump Position Sensor . . .02-110-8

Remove and Install Water-In-Fuel (WIF)

Sensor .............................02-110-9

Install Wiring Harness for Engine Mount

ECU..............................02-110-10

Install Wiring Harness for Remote ECU ....02-110-18

Connectors ..........................02-110-29

Connector Repair .....................02-110-30

Repair WEATHERPACK Connector ......02-110-31

Repair Cinch Flex Box Connector .........02-110-34

METRI-PACK(Push Type) .............02-110-42

Repair HD Series DEUTSCH Connectors . . .02-110-44

Repair SUMITOMO Connectors .........02-110-47

02

Group 110—Electronic Engine Control Repair and

Engine Control Unit (ECU) Maintenance .....02-110-1

Remove and Install Engine Control Unit

(ECU) on Engine (Optional Equipment) ....02-110-2

Remove and Install Adaptation Parts for

Engine Control Unit (ECU) Mounted on

Engine (Optional Equipment) ............02-110-3

Remove and Install Engine Coolant

Temperature (ECT) Sensor .............02-110-4

Remove and Install Fuel Temperature

Sensor .............................02-110-4

Remove and Install Manifold Air Temperature

(MAT) Sensor .......................02-110-5

Remove and Install Oil Pressure Sensor .....02-110-5

Remove and Install Fuel Rail Pressure

Sensor .............................02-110-6

CTM502 (31MAY07) 02-1 4.5 & 6.8 L Level 16 Electronic Fuel System

Adjustment

060407

PN=1

Page 46

02

Contents

CTM502 (31MAY07) 02-2 4.5 & 6.8 L Level 16 Electronic Fuel System

060407

PN=2

Page 47

Electronic Fuel System Repair and Adjustments

Fuel System - General Information

Group 090

The Level 16 Engine Control Unit (ECU) is used to

control the High Pressure Common Rail (HPCR) fuel

system. The HPCR fuel system includes the high

pressure fuel pump, high pressure common rail, and

electronic injectors.

The electronic injectors can not be serviced. If any part

of the component fails, the entire injector must be

replaced.

Electronic injectors cannot be tested for opening

pressure, as they are controlled electronically.

Relieve Fuel System Pressure

CAUTION: High-pressure fluid remaining in fuel

lines can cause serious injury. Before

disconnecting fuel lines, sensors, or any other

components between the high-pressure fuel

pump and nozzles on engines with High

Pressure Common Rail (HPCR) fuel system,

wait a minimum of 15 minutes after engine is

stopped.

When servicing injectors it is important to complete the

injector calibration procedure. Each injector has a

specific calibration and this information can be

obtained by scanning the bar code on the service

injector box and downloading the injector information

from the John Deere Custom Performance web site.

An alternative is to enter the injector serial number and

part number stamped on the injector. If the ECU is not

programmed with the correct information for each

injector and the correct cylinder that it is in then engine