Page 1

Power Flow™ High Performance for 48-

Inch, 54-Inch, and 60-Inch High Capacity

PRO Mower Decks

(Serial No. 010001 -XXXXXX)

OPERATOR'S MANUAL

*DCY**omuc19492*

Power Flow™

OMUC19492 ISSUE G8 (MULTI-LINGUAL)

*OMUC19492*

Proposition 65 Warning

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer,

birth defects, and other reproductive harm.

If this product contains a gasoline engine:

High Performance

CALIFORNIA

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

The State of California requires the above two warnings.

Additional Proposition 65 Warnings can be found in this manual.

John Deere Turf Care

North American Edition

PRINTED IN U.S.A.

Page 2

Page 3

Power Flow™ High Performance for 48-

Inch, 54-Inch, and 60-Inch High Capacity

PRO Mower Decks

(Serial No. 010001 -XXXXXX)

OPERATOR'S MANUAL

Power Flow™ High Performance

*OMUC19492*

If this product contains a gasoline engine:

OMUC19492 ISSUE G8 (ENGLISH)

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer,

birth defects, and other reproductive harm.

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

The State of California requires the above two warnings.

Additional Proposition 65 Warnings can be found in this manual.

John Deere Turf Care

North American Edition

PRINTED IN U.S.A.

Page 4

Introduction

Thank You for Purchasing a John Deere Product

We appreciate having you as a customer and wish you many years of

safe and satised use of your machine.

MX00654,000020B-19-10MAY17

Using Your Operator’s Manual

Read this entire operator’s manual, especially the safety information,

before operating.

This manual is an important part of your machine. Keep all manuals in

a convenient location so they can be accessed easily.

Use the safety and operating information in the attachment operator’s

manual, along with the machine operator’s manual, to operate and

service the attachment safely and correctly.

If your attachment manual has a section called Preparing the Machine,

it means that you will have to do something to your tractor or vehicle

before you can install the attachment. The Assembly and Installation

sections of this manual provide information to assemble and install the

attachment to your tractor or vehicle. Use the Service section to make

any needed adjustments and routine service to your attachment.

If you have any questions or concerns with the assembly, installation,

or operation of this attachment, see your local John Deere dealer or

call the John Deere Customer Contact Center at 1-800-537-8233 for

assistance.

Warranty information on this John Deere attachment can be found in

the warranty that came with your John Deere tractor or vehicle.

TH84124,00000D9-19-23MAY13

Order Service Parts Online

Visit http://JDParts.deere.com for your Internet connection to parts

ordering and information.

TC00531,00000E9-19-06MAR15

Special Messages

Your manual contains special messages to bring attention to potential

safety concerns and machine damage, as well as helpful operating and

servicing information. Please read all the information carefully to avoid

injury and machine damage.

CAUTION: Avoid injury! This symbol and text highlight

potential hazards or death to the operator or bystanders that

may occur if the hazards or procedures are ignored.

IMPORTANT: Avoid damage! This text is used to tell the operator

of actions or conditions that might result in damage to the

machine.

NOTE: General information is given throughout the manual that may

help the operator in the operation or service of the machine.

MX00654,000020D-19-05JUN17

Service Literature

If you would like to purchase a copy of the Parts Catalog or Technical

Manual for this machine, visit The John Deere Technical Information

Store at:

https://techpubs.deere.com/?cid=VURL_TechInfoStore

or call:

● U.S. & Canada: 1-800-522-7448.

● All Other Regions: Your John Deere dealer.

TH84124,0000199-19-15AUG17

Parts

We recommend John Deere quality parts and lubricants, available at

your John Deere dealer.

When you order parts, your John Deere dealer needs the serial

number or product identication number (PIN) for your machine or

attachment. These are the numbers that you recorded in the Product

Identication section of this manual.

2

Page 5

Contents

CCoonntteennttss

Introduction.... .. . .. .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. .. .. . .. .. .. 2

Product Identication.... .. . .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. 3

Safety Labels with Text. . .. .. . .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. . 4

Safety Labels without Text... . .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. . 4

Safety... . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. .. . .. .. .. 5

Assembly.. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. . .. .. . 6

Preparing Vehicle. . .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. 9

Installing.. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. . .10

Removing and Storing.. .. . .. .. .. .. .. .. . .. .. .. .. .. .. .. . .. .. .12

Operating..... . .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .14

Service.... .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. . .14

Troubleshooting. .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. . .. .16

John Deere Quality Statement.... .. . .. .. .. .. .. .. . .. .. .. .. .17

Index.. . .. .. .. . .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . 18

Product Identication

Mower Deck Identication

Mower decks in the following instructions are identied by a code

designation. The codes are as follows:

Code Description

48HC 48 inch High Capacity PRO Deck

54HC 54 inch High Capacity PRO Deck

60HC 60 inch High Capacity PRO Deck

OUO2005,0000620-19-02APR18

Product Compatibility

This Power Flow™ is compatible with the 48", 54", and 60" High

Capacity PRO mower decks for ZTrak Z700 series mowers.

OUO2005,0000621-19-27MAR18

Record Identication Numbers

Power Flow™

HC Series High Performance Serial No. (010001 - )

If you need to contact an Authorized Service Center for information on

servicing, always provide the product model and serial number.

You will need to locate the model and serial number for the Power

Flow™ and record the information in the spaces provided below.

Original Instructions. All information, illustrations and specications in this

manual are based on the latest information available at the time of

publication. The right is reserved to make changes at any time without

notice.

COPYRIGHT © 2018

DEERE & COMPANY

Moline, Illinois

All rights reserved.

DATE OF PURCHASE:

GXT002367—UN—01JUL15

_________________________________________

DEALER NAME:

_________________________________________

DEALER PHONE:

_________________________________________

PRODUCT SERIAL NUMBER (A):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

OUO2005,0000622-19-27MAR18

Power Flow is a trademark of Deere & Company

3

Page 6

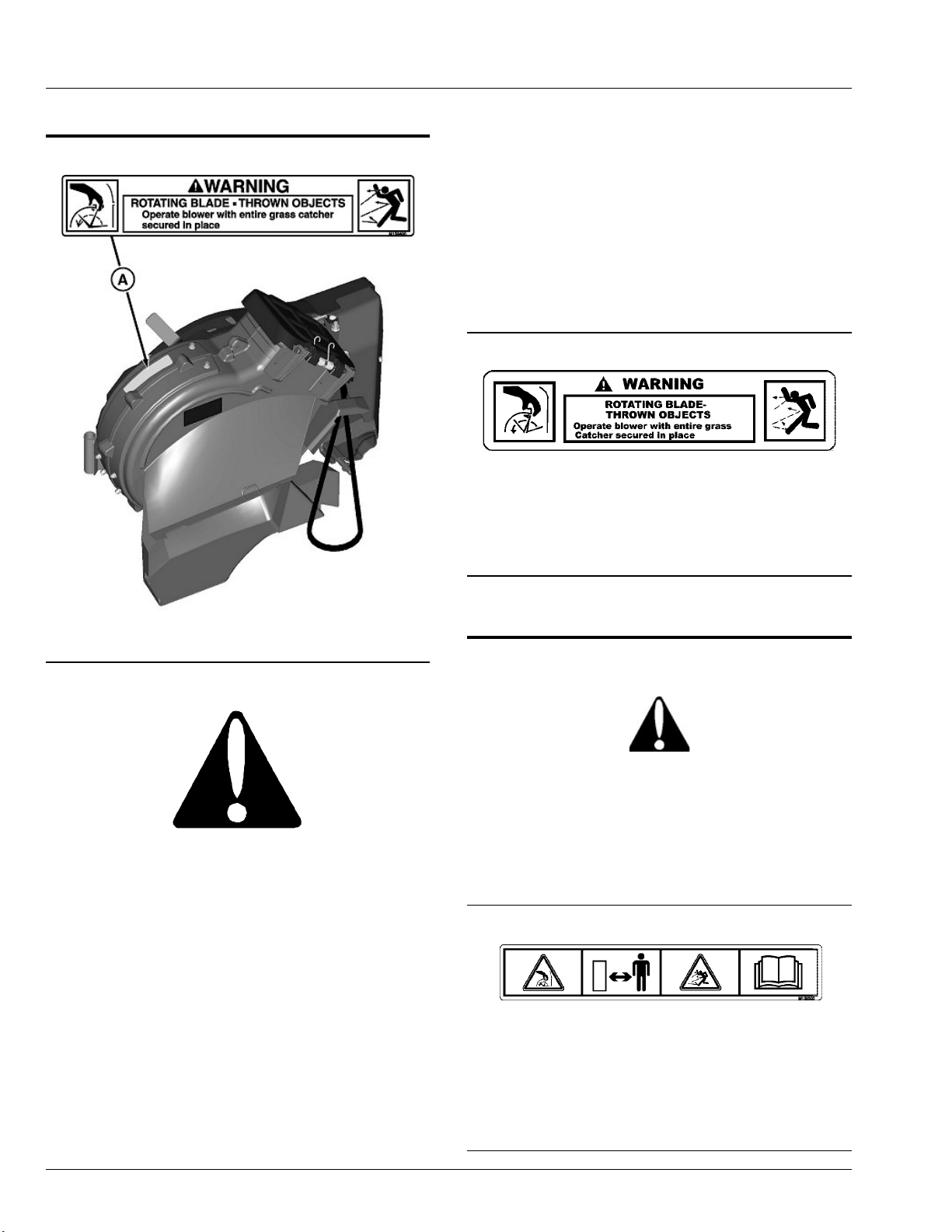

Safety Labels with Text

Safety Labels with Text

Safety Label Location

Replace missing or damaged safety labels. Use this operator’s manual

for correct safety label placement.

There can be more safety information contained on parts and

components sourced from suppliers that is not reproduced in this

operator’s manual.

French or Spanish Safety Labels and Operator’s Manual

Operator’s manuals and safety labels with content in French or

Spanish are available for this machine through authorized John Deere

dealers. See your John Deere dealer.

NOTE: Both text and no-text labels are shown. Your machine is only

equipped with one of these types of labels.

MP47322,00F4601-19-21JUN18

WARNING

If French labeling is required, place M133741 label over existing label. If Spanish

labeling is required, place M158499 label over existing label. Place M158500

label over existing label if the PowerFlow kit is "global" and includes the text-free

safety signs in base equipment.

ROTATING BLADES - THROWN OBJECTS

Operate Blower with entire grass catcher secured in place

OUMX068,0000CB7-19-27AUG15

GXT001246—UN—28OCT13

A—WARNING - M158480

OUMX068,0000CB4-19-27AUG15

GXT002440—UN—12JUL15

Understanding the Machine Safety Labels

The machine safety labels shown in this section are placed in

important areas on your machine to draw attention to potential safety

hazards. DANGER or WARNING safety labels are located near

specic hazards.

The operator’s manual also explains any potential safety hazards

whenever necessary in special safety messages that are identied with

the word, CAUTION, and the safety-alert symbol.

On your machine safety labels, the words DANGER, WARNING, and

CAUTION are used with this safety-alert symbol. DANGER identies

the most serious hazards:

● DANGER; The signal word DANGER indicates a hazardous

situation which, if not avoided, will result in death or serious injury.

● WARNING; The signal word WARNING indicates a hazardous

situation which, if not avoided, could result in death or serious injury.

● CAUTION; The signal word CAUTION indicates a hazardous

situation which, if not avoided, could result in minor or moderate

injury. CAUTION may also be used to alert against unsafe practices

associated with events which could lead to personal injury.

MXAL42363—UN—22MAY13

Safety Labels without Text

Understanding the Machine Safety Labels without Text

TCT005498—UN—11SEP12

At several important places on this machine, safety signs are afxed

which signify potential danger. The hazard is identied by a pictorial in

a warning triangle. An adjacent pictorial provides information on how to

avoid personal injury. These safety signs, their placement on the

machine, and a brief explanatory text are shown in this Safety section.

There can be additional safety information contained on parts and

components sourced from suppliers that is not reproduced in this

operator’s manual.

MX00654,0000389-19-21JUN18

Avoid Injury From Thrown Objects

MXT009202—UN—19SEP13

● Do not put hands or feet under or into mower when engine is

running.

● Thrown Objects - Before mowing, clear area of objects that may be

thrown by blade. Do not operate mower without discharge chute or

entire grass catcher in place.

● Stay a safe distance from machine.

● Read operator’s manual.

OUMX068,0000238-19-19SEP13

4

Page 7

Safety

Safety

Read Safety in Machine Operator’s Manual

Read the general safety operating precautions in your machine

operator’s manual for additional safety information.

OUMX068,0000230-19-18SEP13

Operating Safely

Read, understand and follow all instructions in this attachment manual,

the machine operator’s manual and safety signs on equipment before

starting.

Use proper front ballast. Remove ballast when the material collection

system is removed.

Hopper extends beyond machine. Be aware of surrounding objects

when making short turns.

Do not operate material collection system unless entire grass catcher

is fastened in place with hopper cover securely latched.

Do not let anyone ride on the mower or material collection system.

Riders are subject to injury such as being struck by foreign objects or

being thrown off. Riders may obstruct the operator’s view and cause a

collision.

Before hopper removal or installation:

● Stop mower.

● Disengage mower or PTO.

● Stop engine and remove key.

● Wait for engine and all moving parts to stop before leaving the

operator seat.

presence of children. Keep children indoors when the machine and

attachment are operated and under the watchful care of another

responsible adult.

● Never assume that children will remain where you last saw them.

Stay alert to the presence of children. Turn the machine off if a child

enters the work area.

● Do not let children or an untrained person operate the machine.

● Do not carry or let children ride on any attachment or machine even

with the attachment off. Do not tow children in a cart or trailer.

OUMX068,0000233-19-18SEP13

Avoid Injury From Thrown Objects

TCAL41689—UN—08APR13

● When operating the vehicle with the MCS attachment installed

make sure all chutes and hoses are securely in place. Keep hopper

closed or MCS in operating position.

● Stop the engine and wait for all moving parts to stop before

removing or lifting any attachment components.

● Avoid injury from impeller blades and thrown objects. Remove

attachment when operating vehicle in side discharge mode. Make

sure deector shield is in place on mower deck if attachment is

removed.

Before backing up machine:

● Stop machine.

● Look behind hopper for children.

● Keep bystanders away when unloading material collection system.

Operate safely on slopes:

● Empty hopper when half full.

● Do not operate on steep slopes.

● Before turning, slow down.

● Avoid sudden starts and stops.

● Do not park machine with material collection system on slopes.

OUMX068,0000231-19-27MAR14

Parking Safely

1. Stop machine on a level surface, not on a slope.

2. Disengage mower blades or any other attachments.

3. Lower attachments to the ground.

4. Lock the park brake.

5. Stop the engine.

6. Remove the key.

7. Wait for engine and all moving parts to stop before you leave the

operator’s seat.

8. Close fuel shut-off valve, if your machine is equipped.

9. Disconnect the negative battery cable or remove the spark plug wire

(s) (for gasoline engines) before servicing the machine.

OUO1023,0000035-19-21FEB13

Protect Children

● Tragic accidents can occur if the operator is not alert to the

OUMX068,0000234-19-18SEP13

Avoid Injury From Rotating Blades

MXT008720—UN—19SEP13

● Keep hands and feet away from rotating blades and blower

assembly when engine is running.

● Stop engine and wait for moving parts to stop before servicing

components.

● Do not operate MCS or blower unless all attachment components

are in place and latched.

OUMX068,0000235-19-18SEP13

Practice Safe Maintenance

● Only qualied, trained adults should service this machine.

● Understand service procedure before doing work. Keep area clean

and dry.

● Do not operate the engine in a conned space where dangerous

carbon monoxide fumes can collect.

● Never lubricate, service or adjust the machine or attachment while it

is moving. Keep safety devices in place and in working condition.

Keep hardware tight.

● Keep hands, feet, clothing, jewelry, and long hair away from any

moving parts, to prevent them from getting caught.

● Lower any attachment completely to the ground or to an existing

attachment mechanical stop before servicing the attachment.

Disengage all power and stop the engine. Lock park brake and

remove the key. Let machine cool.

5

Page 8

Assembly

● Disconnect battery or remove spark plug wire (for gasoline engines)

before making any repairs.

● Before servicing machine or attachment, carefully release pressure

from any components with stored energy, such as hydraulic

components and springs.

● Release hydraulic pressure by lowering attachment or cutting units

to the ground or to a mechanical stop and move hydraulic control

levers.

● Securely support any machine or attachment elements that must be

raised for service work. Use jack stands or lock service latches to

support components when needed.

● Never run engine unless park brake is locked.

● Keep all parts in good condition and properly installed. Fix damage

immediately. Replace worn or broken parts. Replace all worn or

damaged safety and instruction decals.

● Check all hardware at frequent intervals to be sure the equipment is

in safe working condition.

● Do not modify machine or safety devices. Unauthorized

modications to the machine or attachment may impair its function

and safety.

OUMX068,0000236-19-04AUG17

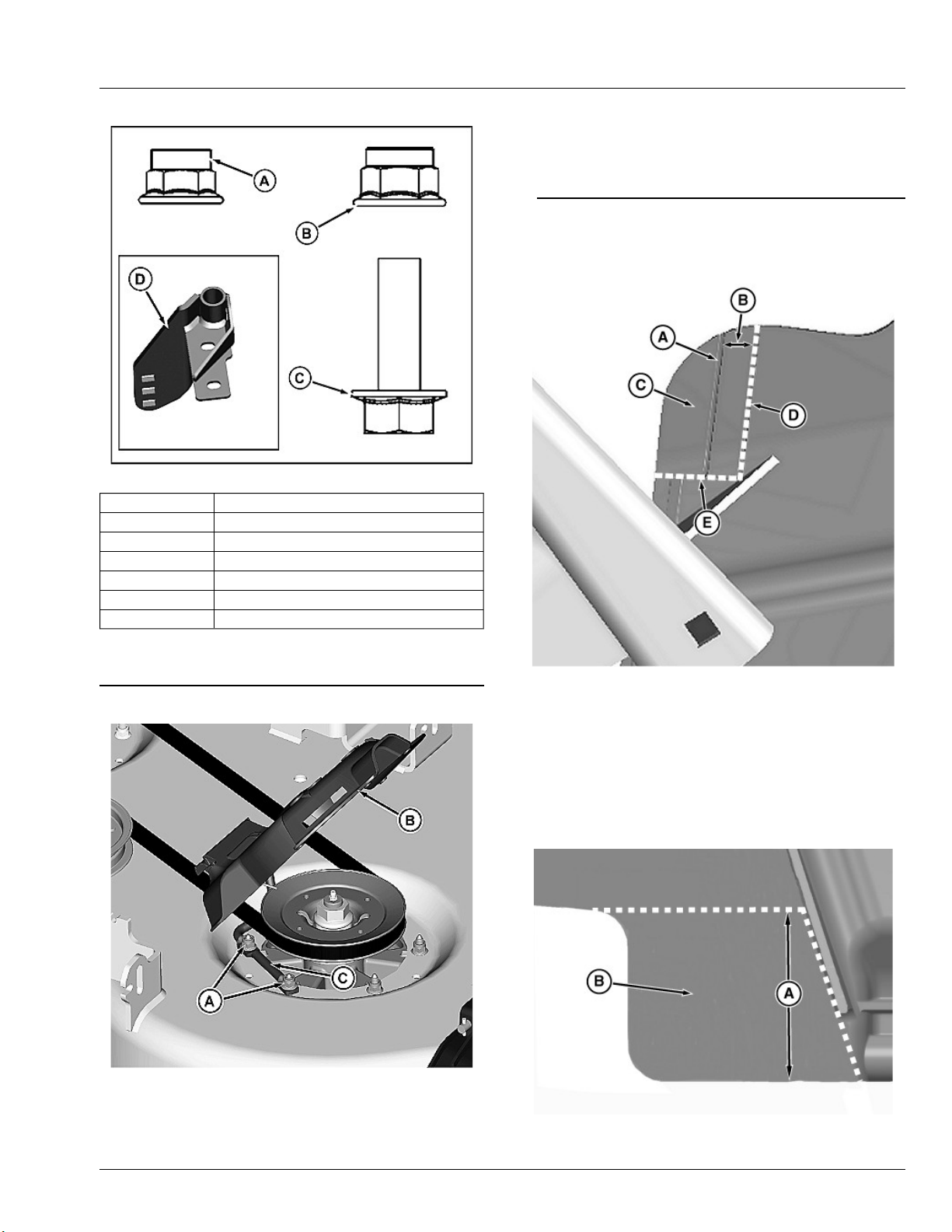

Assembly

Identify Parts

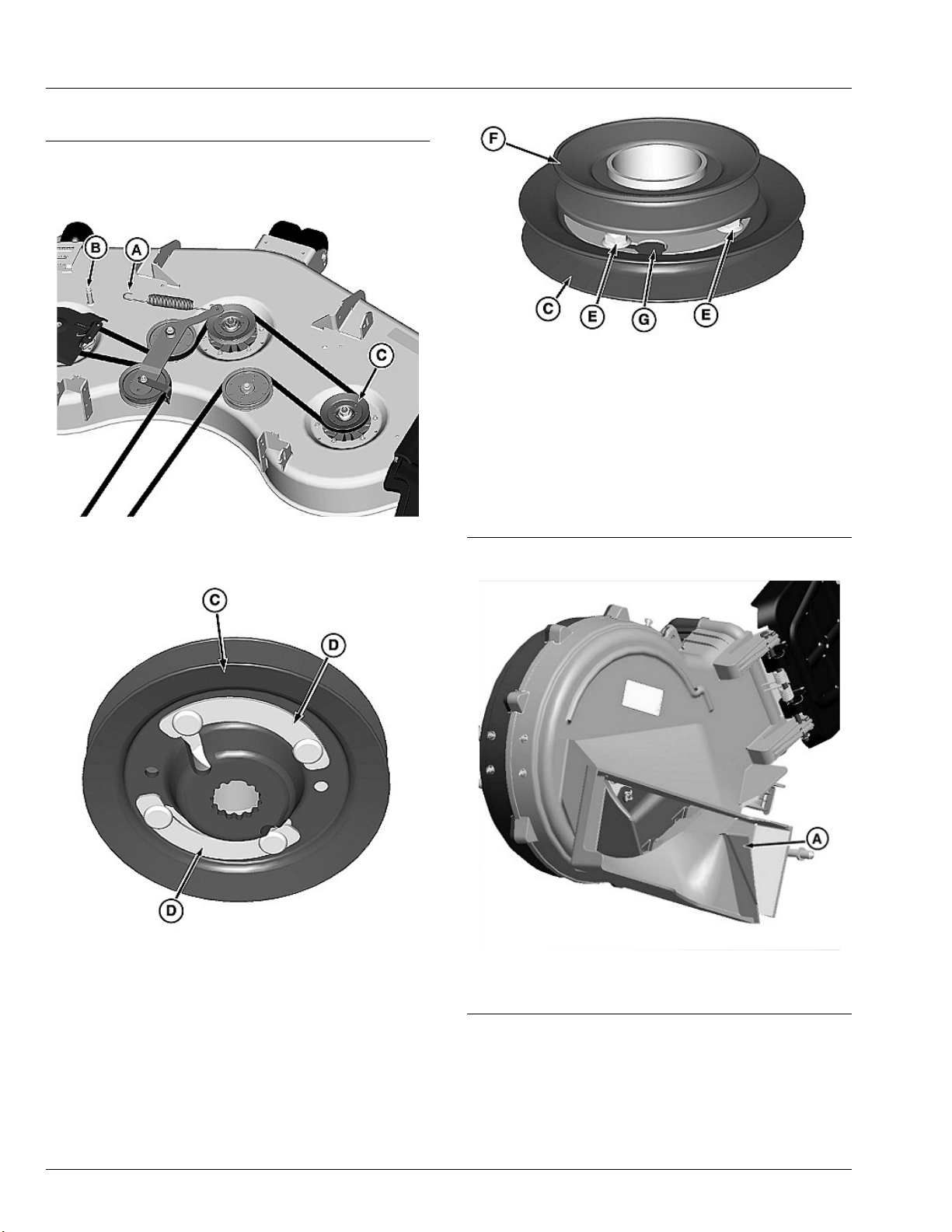

Parts in Kit (48HC and 54HC)

Quantity Description

1 Power Flow™ (A)

1 Support Bracket, Belt Shield (B)

1 Deck Belt Shield (C)

1 Bent Pin (D)

1 Double Sheave (E)

2 Sheave Retaining Plates (F)

Parts in Kit (60HC)

TCT015744—UN—14MAY18

TCT015745—UN—14MAY18

Quantity Description

1 Power Flow™ (A)

1 Support Bracket, Belt Shield (B)

1 Deck Belt Shield (C)

1 Bent Pin (D)

1 Double Sheave (E)

2 Sheave Retaining Plates (F)

6

Page 9

Assembly

Parts in Bag

Quantity Description

4 Locknut, Flange, M6 (A)

4 Locknut, Flange, M8 (B)

2 Bolt, M8x25 (C)

1 Front Mounting Bracket (D)

1 Warning Label, French

1 Warning Label, Spanish

Picture Note: Actual size shown, except for part D shown in box.

TCT015746—UN—14MAY18

2. Install two lock nuts back onto spindle and tighten to specication.

Specication

Spindle Mounting Lock Nut—Torque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 N·m

OUMX068,00014DC-19-29JUN18

(18 lb·ft)

Modify Discharge Chute

48HC and 54HC

OUO2005,0000623-19-28JUN18

Remove Right-Hand Belt Shield

Picture Note: 60 in deck is shown.

1. Remove two lock nuts (A) and belt shield (B) with wireform (C).

(Retain belt shield and wireform for future use.)

TCT015747—UN—14MAY18

View from under 54 in deck shown.

TCT014335—UN—29JUN18

1. Locate embossed line (A) on the deck discharge chute.

2. Measure 25 mm (1 in) (B) above line and mark section (C).

● To verify measurements, be certain that length is approximately

68.0 mm (2-11/16 in) (D) and inward dimension is approximately

46.0 mm (1-13/16 in) (E).

● Cut out along the dashed line and remove section (C).

60HC

1. Measure up 70 mm (2.76 in) (A) from the outside edge.

TCT014336—UN—29JUN18

7

Page 10

2. Cut out along the dashed line and remove section (B).

OUO2005,0000624-19-29JUN18

Install Double Sheave (48HC, 54HC, and 60HC Decks)

1. Disengage PTO.

Assembly

2. Remove end of the tension spring (A) from bracket (B) on deck.

TCT015748—UN—14MAY18

3. Remove mower deck belt from right spindle sheave (C). Inspect and

replace belt if needed.

Picture Note: Sheaves removed from spindle for clarity.

TCT015750—UN—14MAY18

4. Install upper sheave retaining plates (D) onto right spindle sheave

(C) loosely by inserting them up through holes in right spindle

sheave (C) . Start four locknuts (E) onto the threads.

5. Install upper sheave (F) onto the right spindle sheave (C), lining up

large end of key slots (G) in upper sheave with nuts on sheave

retaining plates.

6. Rotate the upper sheave (F) counterclockwise to position the nuts

over the small end of the key slots. Tighten hardware to 13 N·m (10

lb·ft).

OUO2005,0000625-19-14MAY18

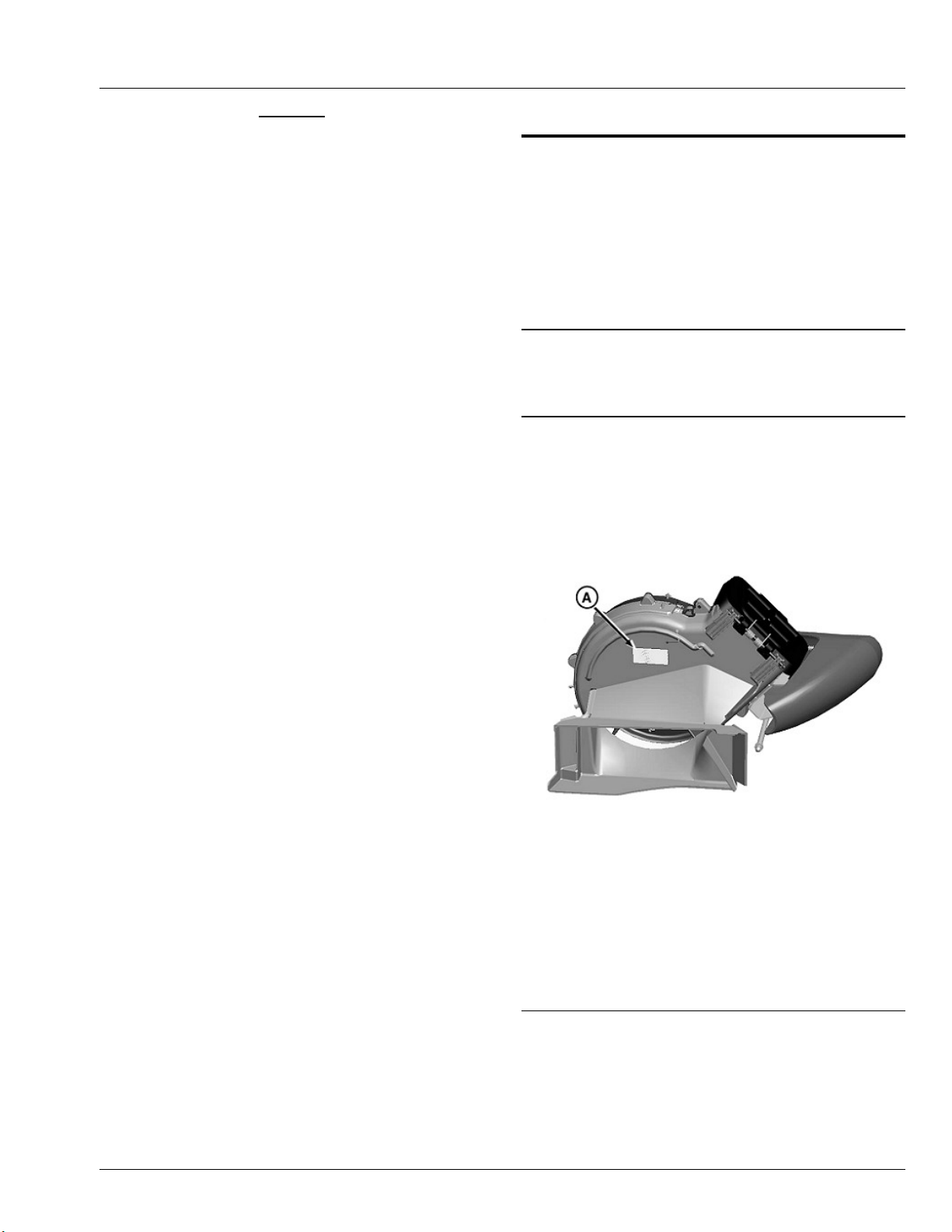

48HC Power Flow Preparation

Picture Note: Sheave removed from spindle for clarity.

TCT015749—UN—14MAY18

1. Trim along ridge on inlet to remove small triangular section (A) as

GXT002371—UN—01JUL15

shown.

OUMX068,0000CA3-19-12JUL15

8

Page 11

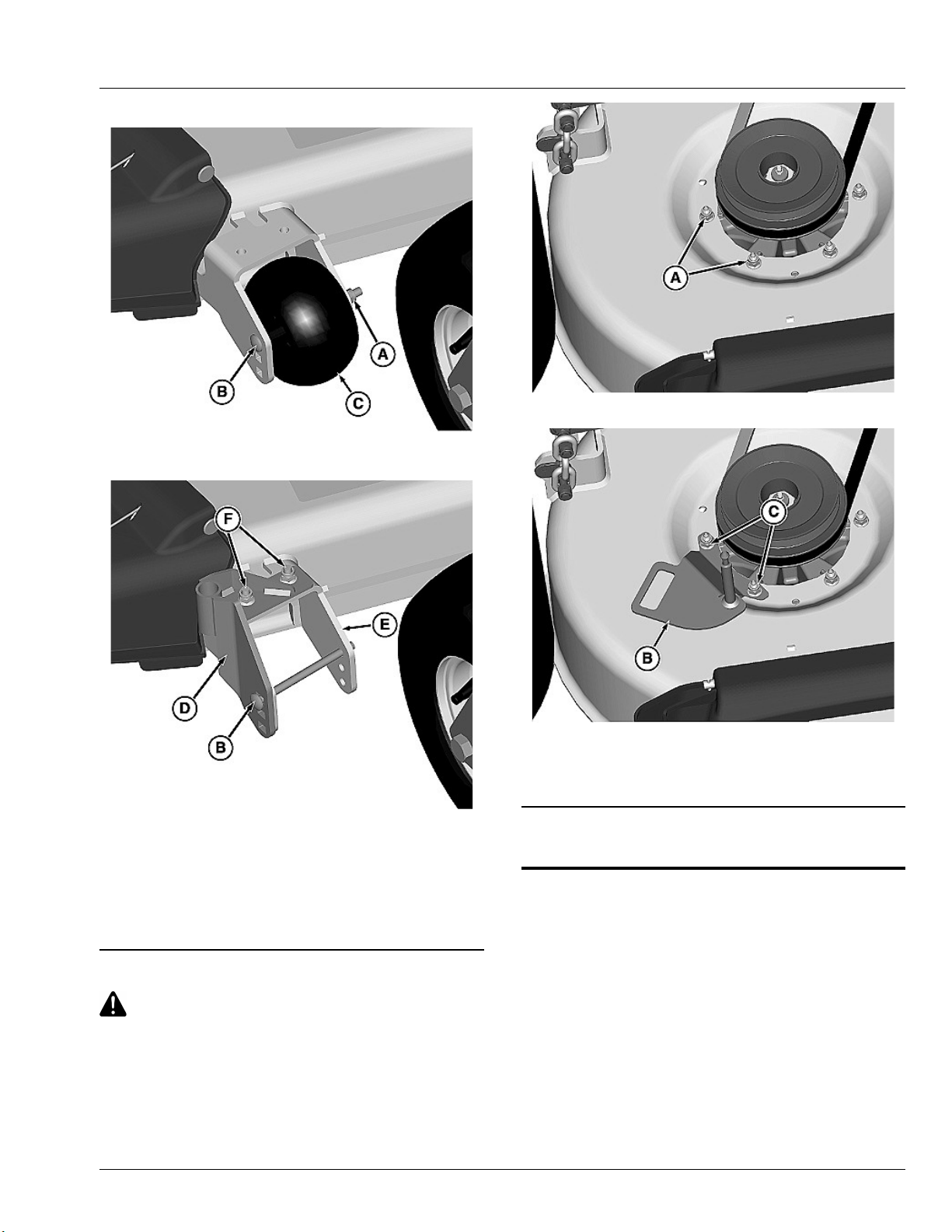

Install Front Mounting Bracket

Preparing Vehicle

1. Remove nut (A), bolt (B), and anti-scalp wheel (C) and spacer from

TCT015751—UN—14MAY18

right front location. Keep parts so they can be reinstalled later.

TCT015752—UN—14MAY18

2. Install front blower support bracket (D) on the right front gauge

wheel bracket (E) with two M8x25 bolts (F) and M8 locknuts.

Tighten to 34 N·m (25 lb·ft). Ensure anti-scalp wheel bolt (B) can t

through before tightening.

3. Reinstall anti-scalp wheel, spacer, and hardware after the blower

bracket is installed. Tighten the anti-scalp wheel hardware to 34

N·m (25 lb·ft).

OUO2005,0000626-19-14MAY18

Install Belt Shield Support Bracket

CAUTION: Avoid injury! Mower blades are sharp. Always

wear gloves when handling mower blades or working near

blades.

1. Remove two M8 locknuts (A) from the right spindle.

TCT015753—UN—14MAY18

TCT015754—UN—14MAY18

2. Assemble the belt shield support bracket (B) to the deck using new

set of M8 locknuts (C).

3. Tighten the hardware to 37 N·m (27 lb·ft).

OUO2005,0000627-19-14MAY18

Preparing Vehicle

Install Proper Mower Blades

IMPORTANT: Avoid damage! When replacing mower blades,

always use genuine John Deere Service Parts.

● For best performance, always use correct mower blade

for the job being performed.

● Always follow safety and service instructions in the

machine operator’s manual when changing mower

blades.

For maximum performance from blower assembly, install correct

mower blades for application:

● Mulching Blades — Not for use with blower assembly, except

when operated in conjunction with MulchControl™ kit.

MulchControl is a trademark of Deere & Company

9

Page 12

Installing

● Standard Blades — Standard blades are designed for bagging,

side discharging, and all mowing conditions.

OUO2005,000039A-19-03NOV16

Installing

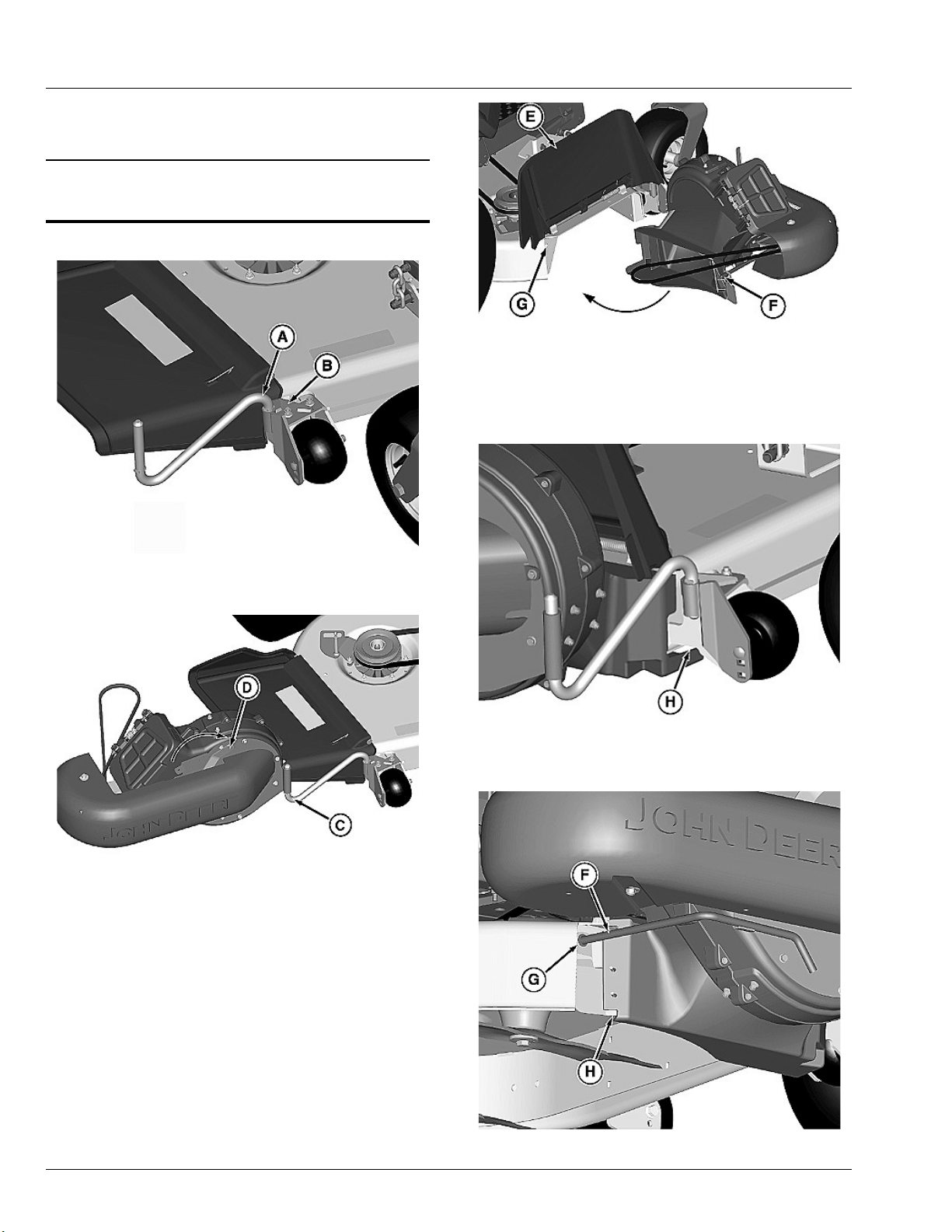

Installing Blower Assembly

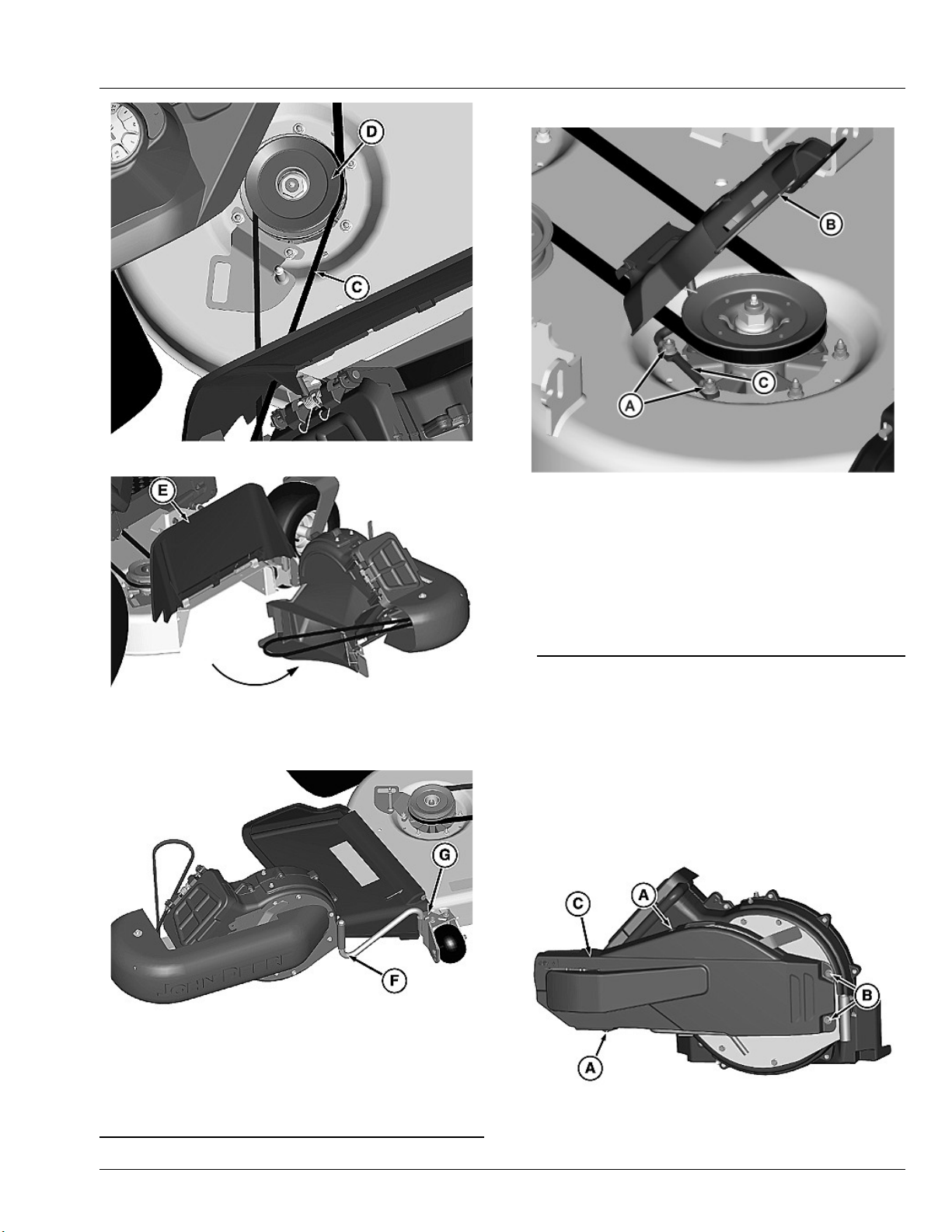

1. Install short end (A) of the large bent rod in the front mounting

TCT015755—UN—14MAY18

bracket (B).

4. Fully raise mower deck discharge chute (E), and pivot Power

TCT015757—UN—14MAY18

Flow™ toward deck. Insert bent pin (F) into hole (G) in the right

rear deck bracket.

TCT015758—UN—14MAY18

2. Install Power Flow™ on the long end (C) of bent pin.

TCT015756—UN—14MAY18

3. Move tension lever (D) to release position.

TCT015759—UN—14MAY18

10

Page 13

Installing

5. Power Flow™ must install on mower deck discharge areas (H) as

shown, as you insert pin (F) into hole (G).

6. Hold Power Flow™ securely against mower deck discharge area.

7. Install blower belt (I) onto the top sheave (J).

TCT015760—UN—14MAY18

9. Move tension lever (D) to lock position.

TCT015762—UN—14MAY18

NOTE: Be sure to put the blower tensioner in engaged position so the

belt is under tension when checking the clearances.

TCT015763—UN—14MAY18

10. There are slots on the MCS blower belt shield bracket (N) that

allow for some adjustment. Check the position of the MCS blower

belt shield support bracket and adjust as needed. The belt shield

post (O) should have adequate clearance with both blower belt

strands (P).

Assembly may vary slightly from image shown. Belt routing is identical.

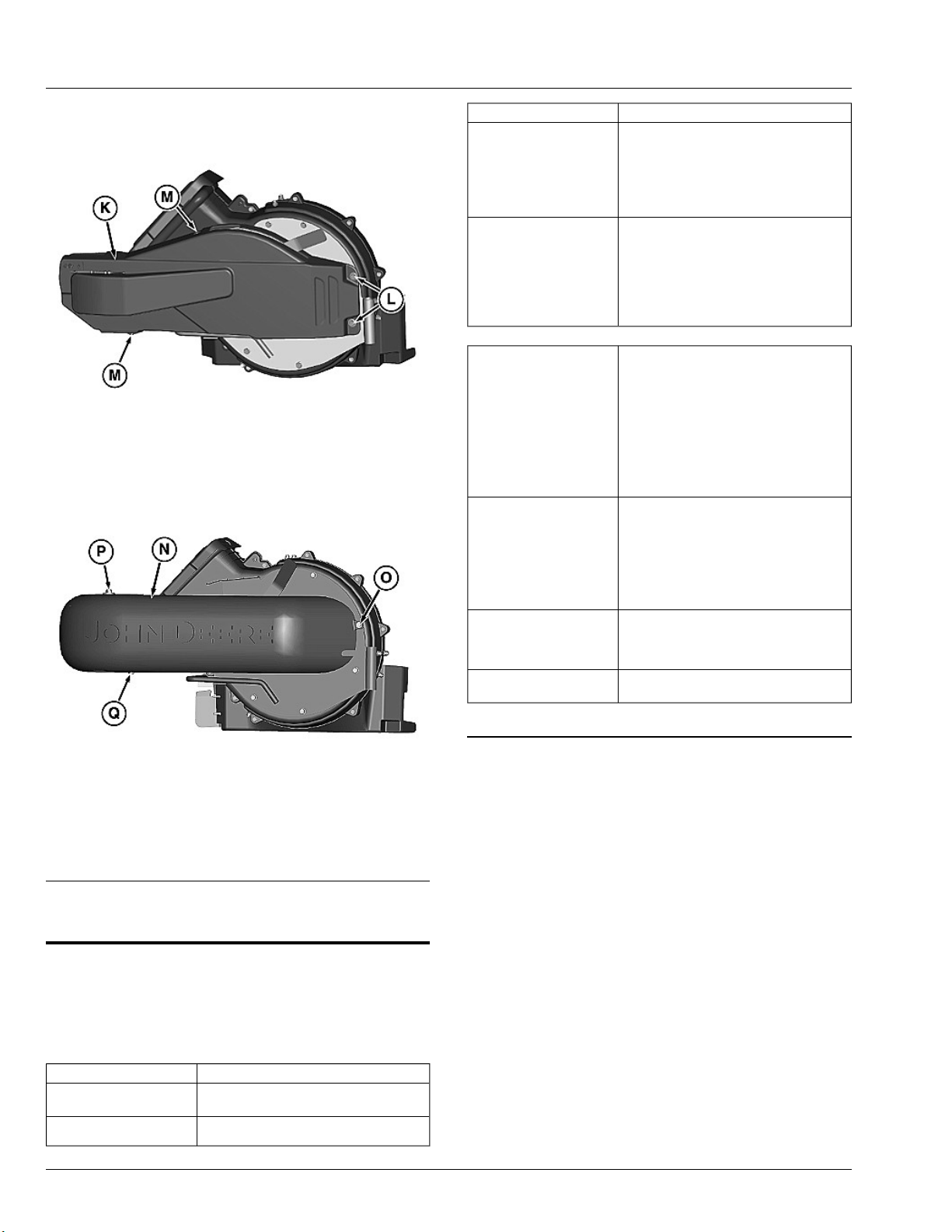

8. The drive belt must run:

a. From the mower deck top sheave (J),

b. To idler (K),

c. To top of sheave (L),

d. To V-idler sheave (M),

e. Back to the mower deck top sheave (J).

TCT015761—UN—14MAY18

11

Page 14

Removing and Storing

Removing and Storing

Removing Power Flow™

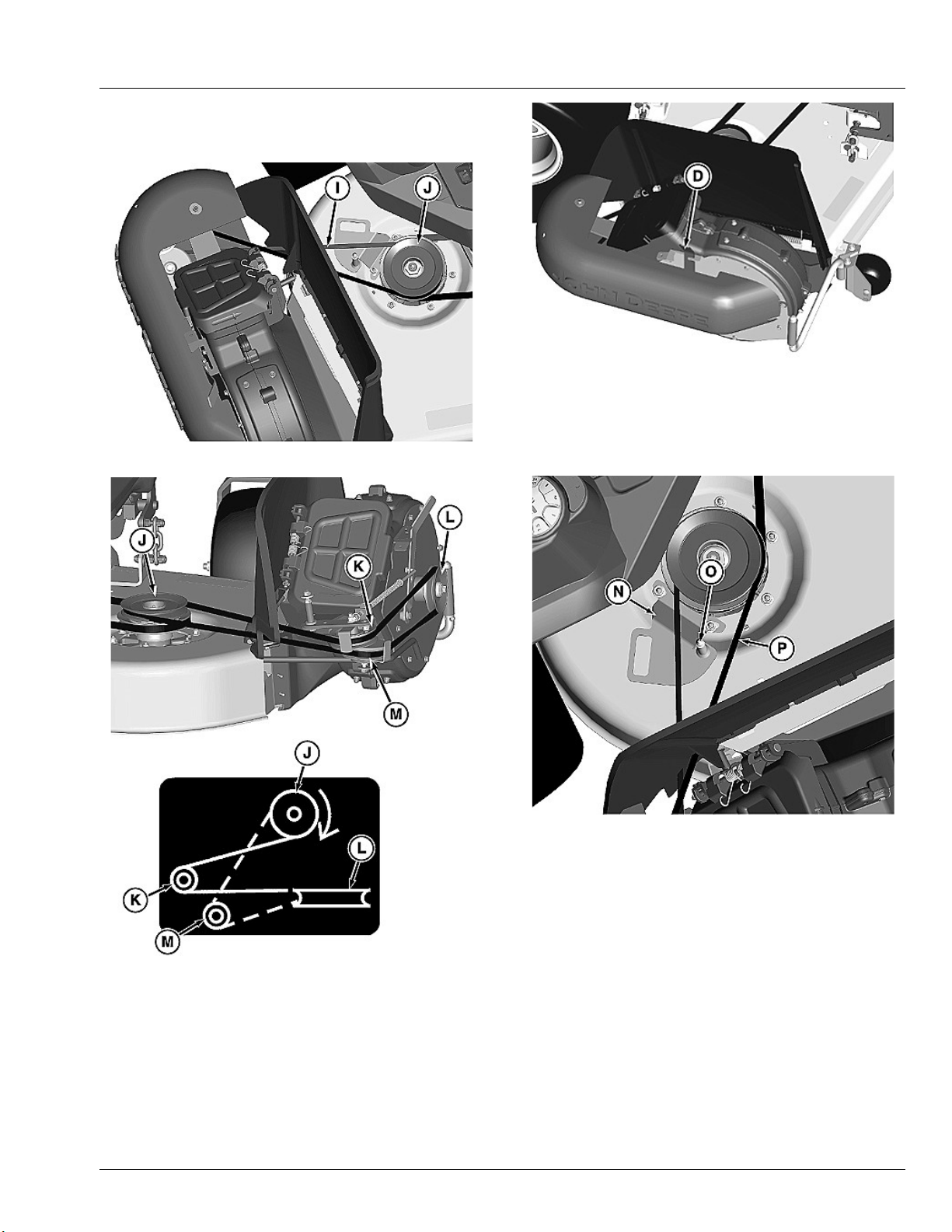

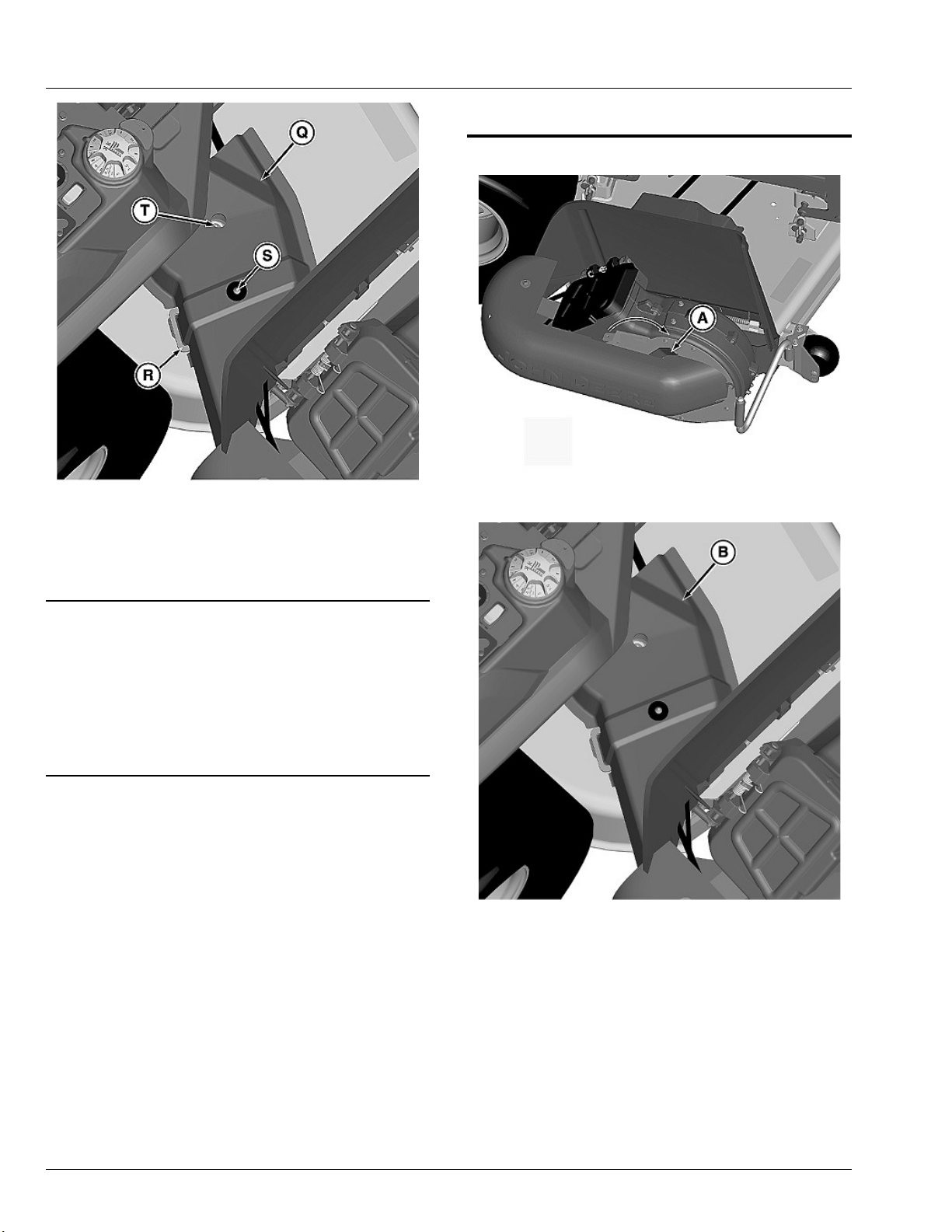

11. Install the MCS blower belt shield (Q) onto the support bracket:

TCT015764—UN—14MAY18

● Insert tab into opening (R) on support bracket and lower belt

shield grommet over post (S).

● Check to make sure spindle grease tting (T) is accessible and

belts clear shield.

OUO2005,0000628-19-14MAY18

Adjusting Mower Deck

IMPORTANT: Avoid damage! Adjust mower deck right-hand

wheels after each installation to provide adequate support

for the Power Flow™ while traveling over the mowing area.

1. Adjust cutting height and level mower deck side-to-side and frontto-rear as described in the tractor operator’s manual.

2. Lower mower deck to preset cutting height.

OUMX068,00014DD-19-28JUN18

1. Move tension lever (A) to release position.

TCT015765—UN—14MAY18

TCT015766—UN—14MAY18

2. Remove deck belt shield (B).

12

Page 15

Removing and Storing

Installing Right-Hand Belt Shield

3. Remove drive belt (C) from top sheave (D)

TCT015767—UN—14MAY18

TCT015768—UN—14MAY18

4. Raise mower deck discharge chute (E) and pivot Power Flow™

away from deck.

1. Remove two lock nuts (A).

TCT014334—UN—29JUN18

2. Install belt shield (B) with wireform (C) onto spindle studs.

3. Install two lock nuts (A) back onto spindle studs securing wireform

to the mower deck.

4. Tighten lock nuts to specication.

Specication

Spindle Mounting Lock Nut—Torque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 N·m

OUMX068,00014DF-19-29JUN18

(18 lb·ft)

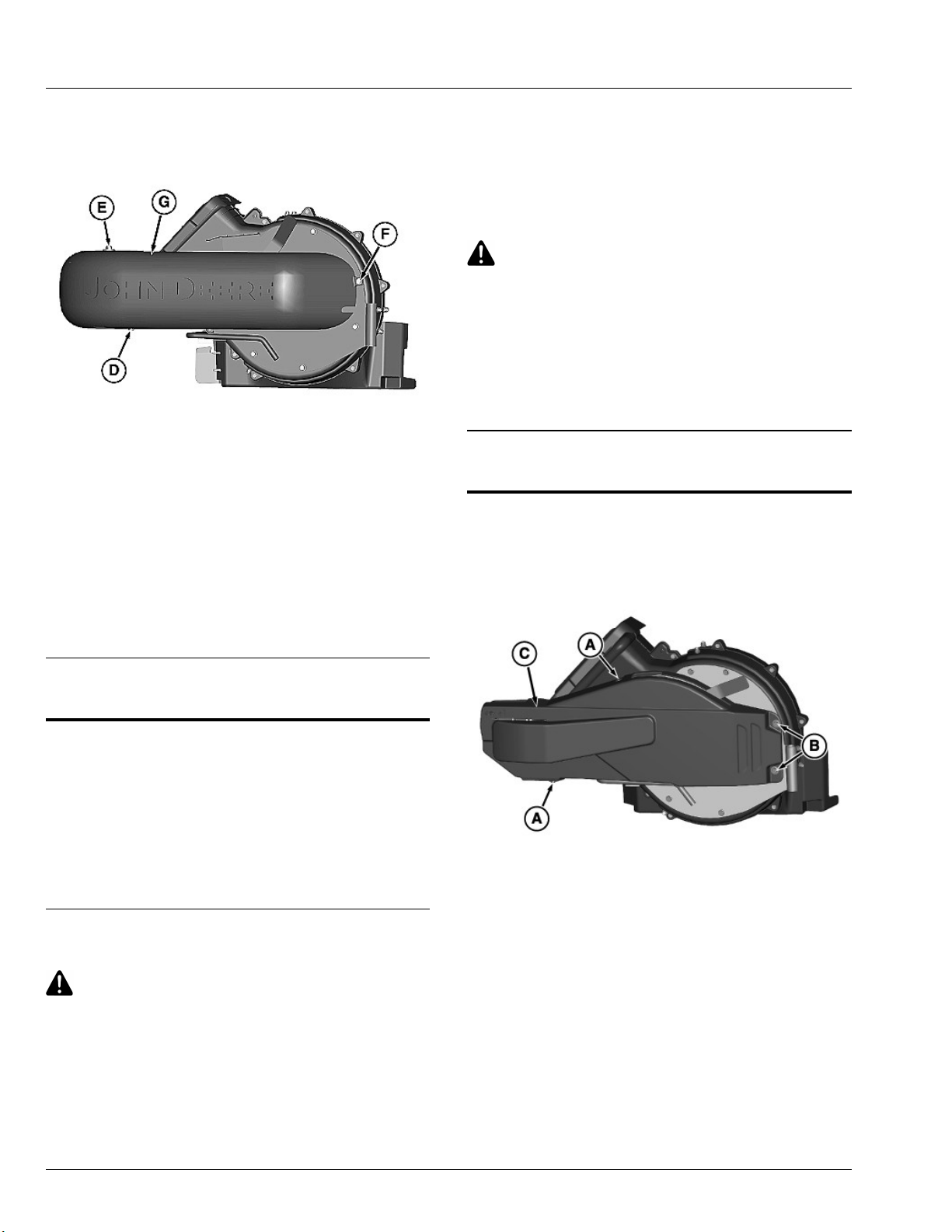

Storing Power Flow™

1. Remove Power Flow™ from the mower deck.

IMPORTANT: Avoid damage! Grass build up, if allowed to dry out,

can break off into small, hard pieces and be propelled inside

blower assembly. Premature failure can result.

2. Clean exterior and interior of Power Flow™.

3. Remove belt shield:

48HC and 54HC

5. Remove Power Flow™ from the long end of the bent pin (F).

TCT015769—UN—14MAY18

6. Remove short end of the bent pin from the front mounting bracket

(G).

OUO2005,0000629-19-29JUN18

a. Remove two retainers (A) on the top and bottom of the belt

TCT015770—UN—14MAY18

shield.

13

Page 16

Operating

b. Remove two bolts (B) attaching belt shield to Power Flow™.

c. Remove belt shield (C).

60HC

TCT015771—UN—14MAY18

a. Remove nut and washer (D) on the bottom of the belt shield.

b. Remove nut and washer (E) on the top of the belt shield.

c. Remove bolt (F) attaching belt shield to Power Flow™.

d. Remove belt shield (G).

4. Remove all grass accumulation around belt, idler, and sheaves.

5. Remove and inspect drive belt. Replace belt if needed.

6. Install belt shield.

7. Store Power Flow™ in a clean, dry area. It is best to enclose it in its

original shipping carton.

OUO2005,000062A-19-29JUN18

Checking For Plugging While Driving

If grass builds up in front of mower discharge chute, check for plugged

chute or problems with blower assembly (if equipped).

If there is a trail of clippings behind mower or clippings blow to the side,

check for plugged chute, full collector bags, or problems with blower

assembly.

Removing Debris From Inspection Points:

CAUTION: Avoid injury! Do not use hands or feet to clear

plugged mower deck or blower assembly. Stored energy can

cause blades to rotate.

1. Park machine safely. Wait for all moving parts to stop before getting

off to inspect machine.

2. Open hopper cover. Check chute outlet.

3. Remove chute from mower deck or blower assembly. Check chute

inlet.

4. Check under mower deck for debris.

BS62576,00014C5-19-09DEC15

Service

Removing Drive Belt

1. Remove Power Flow™ from the mower deck.

2. Remove belt shield from Power Flow™:

48HC and 54HC

Operating

Using the Blower Assembly

Starting Blower Assembly

Whenever tractor PTO is engaged to start mower deck, blower

assembly will automatically start. (See tractor operator’s manual for

PTO operating instructions.)

Stopping Blower Assembly

Whenever tractor PTO is disengaged to stop mower deck, blower

assembly will automatically stop.

BS62576,00014C4-19-09DEC15

Unplugging Mower, Bagger, or Material Collection System

CAUTION: Avoid injury! Do not attempt to unplug

attachment with machine running.

• Rotating blades are dangerous. Shut off the engine and

remove the key before getting off the seat to inspect the

machine and attachment.

• Thrown objects can cause serious injury. Make sure all

machine parts are stopped before raising hopper top or

removing chutes.

a. Remove two retainers (A) on the top and bottom of the belt

TCT014330—UN—29JUN18

shield.

b. Remove two bolts (B) attaching belt shield to Power Flow™.

c. Remove belt shield (C).

60HC

14

Page 17

Service

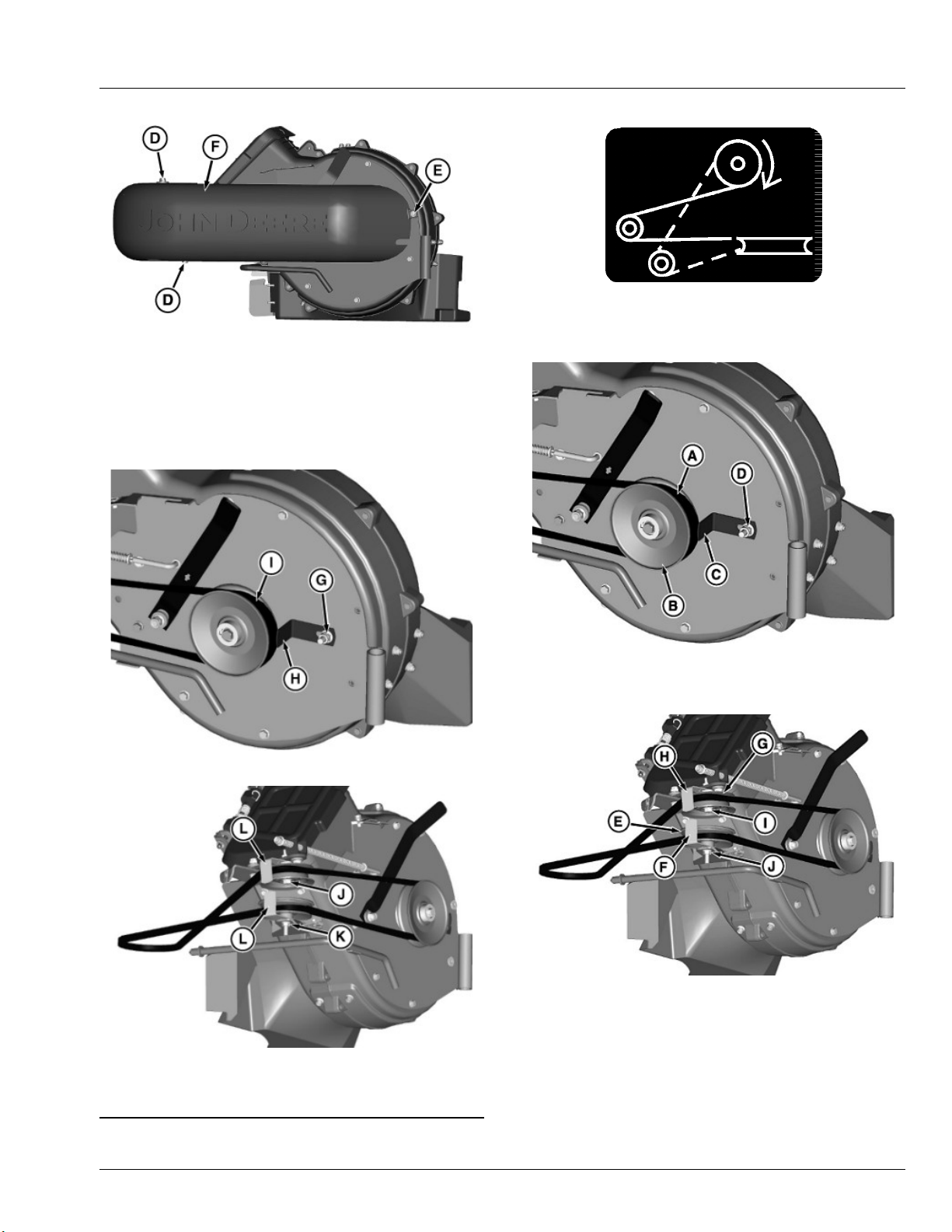

Installing Drive Belt

NOTE: This image illustrates correct belt installation. If belt is not

MXT009092—UN—16SEP13

installed correctly, it is possible that the Power Flow™ fan rotates

backwards.

a. Remove nut and washer (D) on the top and bottom of the belt

TCT014331—UN—29JUN18

shield.

b. Remove bolt (E) attaching belt shield to Power Flow™.

c. Remove belt shield (F).

3. Remove all grass accumulation around belt, idler, and sheaves.

TCT014332—UN—29JUN18

4. Loosen nut (G) and slide belt guide (H) over to remove belt (I).

1. Place belt (A) over driven sheave (B).

GXT002395—UN—08JUL15

2. Adjust belt guide (C) to belt and tighten nut (D) while holding guide

in place.

5. Loosen nut on bolt (J) on idler and nut (K) on sheave.

TCT014333—UN—29JUN18

6. Move belt guides (L) away from idler and sheave, and remove belt.

OUMX068,00014DE-19-29JUN18

3. Route belt:

GXT002396—UN—08JUL15

a. Between the v-idler sheave (E) and belt bracket (F) with belt

“V” in groove,

b. Between the idler (G) and belt bracket (H) with belt “face” in

groove.

4. Move belt brackets (F) and (H) perpendicular to outer edges of

sheave and idler. Leave 3 mm (1/8 in) clearance between brackets

and outer edges.

5. Tighten nut on bolt (I) and nut (J) to 20—40 N·m (15—29 lb·ft).

15

Page 18

Troubleshooting

6. Install belt shield to Power Flow™:

48HC and 54 HC

a. Install belt shield (K) onto Power Flow™.

b. Secure front of belt shield with two bolts (L).

c. Secure rear of belt shield with two retainers (M).

60HC

TCT015774—UN—14MAY18

IF CHECK

Blower Assembly

Performance is Poor.

Grass not being picked

up completely.

Collection chute plugged.

● Locking handle not fully engaged.

● Belt worn.

● Belt installed incorrectly.

● Mower blades not correct type for

application.

● Ground speed too fast for grass

conditions.

● Locking handle not fully engaged.

● Belt worn.

● Mower blades not correct type for

application.

● Mow grass only when dry.

● Reduce mower ground speed.

● Empty hopper.

● Clean screen in hopper top.

● Unplug chute.

● Check cutting edge of mower blades.

● Increase engine speed to full throttle.

● Check for worn or slipping belt.

● Mow grass only when dry.

● Empty hopper.

● Clean screen in hopper top.

● Reduce mower ground speed.

● Stop mower when hopper is full;

monitor hopper more frequently.

a. Install belt shield (N) onto Power Flow™

TCT015855—UN—14MAY18

b. Install bolt (O) attaching front of belt shield to Power Flow™.

c. Install nut (P) on the top of belt shield.

d. Install retainer (Q) on the bottom of belt shield.

OUO2005,000062C-19-14MAY18

Troubleshooting

Using Troubleshooting Chart

If you are experiencing a problem that is not listed in this chart, see

your authorized dealer for service.

When you have checked all the possible causes listed and you are still

experiencing the problem, see your authorized dealer.

Grass blows out between

hopper tops and chute.

Hopper top is too tight or

too loose.

● Adjust chute level for better sealing.

● Adjust hood hold-down for better

sealing.

● Adjust hopper top hinge.

OUO2004,0000862-19-14MAR14

IF CHECK

Blower Assembly Will Not

Turn On

Blower Assembly Plugs.

● Belt worn or broken.

● Ground speed too fast for grass

conditions.

16

Page 19

John Deere Quality Statement

John Deere Quality Statement

John Deere Quality

John Deere equipment is more than just a purchase, it’s an investment

in quality. That quality goes beyond our equipment to your John Deere

dealer’s parts and service support. This support is needed to keep you

a satised customer.

That’s why John Deere has initiated a process to handle your

questions or problems, should they arise. The following three steps will

help guide you through the process.

Step 1

Refer to your operator’s manual

A. It has many illustrations and detailed information on the safe and

proper operation of your equipment.

B. It gives troubleshooting procedures, and specication information.

C. It gives ordering information for parts catalogs, service and technical

manuals.

D. If your questions are not answered in the operator’s manual, then go

to Step 2.

Step 2

Contact your dealer

A. Your John Deere dealer has the responsibility, authority, and ability

to answer questions, resolve problems, and fulll your parts and

service needs.

B. First, discuss your questions or problems with your dealer’s trained

parts and service staff.

C. If the parts and service people are unable to resolve your problem,

see the dealership manager or owner.

D. If your questions or problems are not resolved by the dealer, then go

to Step 3.

Step 3

Contact John Deere

A. Your John Deere dealer is the most efcient source in addressing

any concern, but if you are not able to resolve your problem after

checking your operator’s manual and contacting your dealer, contact

John Deere for assistance.

B. For prompt, effective service, please have the following ready

before you call:

● The name of the dealer with whom you’ve been working.

● Your equipment model number.

● Number of hours on machine (if applicable).

● Your serial number which you recorded on the inside front cover of

this manual.

● If the problem is with an attachment, your attachment identication

number.

C. Then call 1-800-537-8233 (United States and Canada) and our

advisor will work with your dealer to investigate your concern. If you

are outside the United States and Canada, visit the following website:

http://www.deere.com/globalhome/ deerecom/global_home.

page?CC=true

Select your country and then click on the Contact Us link.

SP66632,00043A7-19-10MAY17

17

Page 20

Index

Assembly

Belt shield support bracket, install . . . .. .. . .. .. .. .. .. .. .. . .. .. .. .. .. 9

Discharge Chute, Modify . . .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. 7

Double sheave, install (48HC, 54HC, and 60HC

Decks) . . .. .. .. . .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. . .. .. 8

Front mounting bracket, install .... . . .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. 9

Modify shields

48C Mower deck. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. .. . . 8

B

A

Belt shield, right-hand

Install . . . .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. . .. . 13

Remove ... . . . .. .. .. .. .. .. .. . .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. .. . .. .. . 7

Blower assembly, install .. . . .. .. . .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. . 10

D

Drive Belt

Installing ... . . .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. . .. .. .. .. .. .. .. 15

Removing .. . . .. .. . .. .. .. .. .. .. . .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. .. .. 14

I

Identify parts

Parts in Kit

Parts in Bag.... . . .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. . .. .. 6

L

Labels, safety with text .. . . .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. 4

Labels, safety without text ... . .. . .. .. .. .. . .. .. .. .. .. .. .. . .. .. .. .. . . 4

Mower Deck Identication . . . .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. . 3

Mower deck, adjust . . . .. .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. .. . .. .. .. . 12

O

M

Operating

Blower assembly . . . .. . .. .. .. .. .. .. .. . .. .. .. .. . .. .. .. .. .. .. . .. .. .. . 14

Unplugging mower, bagger, or MCS .. . . .. .. . .. .. .. .. .. .. . .. .. .. . 14

P

Preparing vehicle

Mower blades, install . . .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. . . 9

Product Compatibility ... . . .. .. .. .. .. . .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. 3

R

Removing and storing

Removing Power Flow™ . .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. . 12

Storing Power Flow™ .... . . .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. 13

Replacement parts ... . . .. .. .. .. . .... . . .. .. .. .. . .. .. .. .. .. .. . .. .. .. . 2

S

Safety labels, with text .. .. . .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. . 4

Safety labels, without text .. . . . .. .. .. .. .. .. . .. .. .. .. . .. .. .. .. .. .. .. . 4

Safety, Operating . . . .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. . .. .. 5

T

Troubleshooting Chart .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. .. . 16

18

Page 21

Power Flow™ hautes performances pour

unités de coupe PRO haute capacité 48,

54 et 60 pouces

(Nº de série 010001 -XXXXXX)

LIVRET D'ENTRETIEN

Power Flow™ à hautes performances

OMUC19492F ÉDITION G8 (FRENCH)

*OMUC19492f*

John Deere Turf Care

Édition nord-américaine

PRINTED IN U.S.A.

Page 22

Introduction

Merci d'avoir acheté un produit John Deere

Nous sommes heureux de vous compter parmi nos clients et

souhaitons que votre machine vous apporte satisfaction et sécurité

pendant de nombreuses années.

MX00654,000020B-28-10MAY17

Utilisation du livret d'entretien

Lire l'intégralité de ce livret d'entretien, et les consignes de sécurité en

particulier, avant toute utilisation.

Ce livret est très important quant à l'utilisation de la machine.

Conserver tous les livrets dans un endroit facile d'accès.

Si un équipement est utilisé, suivre les recommandations d'utilisation

et de sécurité dans le livret d'entretien de l'équipement et dans celui de

la machine pour une utilisation correcte et sûre de l'équipement.

Si le livret de cet équipement contient une section Préparation de la

machine, cela signie qu'une intervention sur le tracteur ou le véhicule

est requise pour pouvoir installer l'équipement. Les sections Montage

et Pose de ce livret proposent des informations pour le montage et la

pose de l'équipement sur le tracteur ou véhicule. Suivre les indications

de la section Entretien pour effectuer tous les réglages nécessaires et

l'entretien régulier de l'équipement.

En cas de questions ou de problèmes lors du montage, de la pose ou

de l'utilisation de cet équipement, contacter le concessionnaire John

Deere local ou appeler le Centre de contact clientèle de John Deere au

1-800-537-8233 pour obtenir de l'assistance.

Les informations relatives à la garantie de cet outil John Deere gurent

dans la garantie qui accompagne le tracteur ou véhicule John Deere.

TH84124,00000D9-28-23MAY13

Lors de la commande de pièces, le concessionnaire John Deere a

besoin du numéro de série ou du numéro d'identication du produit

(NIP) de la machine ou de l'équipement. Ils s'agit des numéros

reportés dans la section Identication du produit de ce livret.

Commande de pièces de rechange en ligne

Consulter le site http://JDParts.deere.com pour des informations et

pour la commande de pièces en ligne.

TC00531,00000E9-28-06MAR15

Remarques

Ce manuel contient des remarques pour attirer votre attention sur

d'éventuels problèmes de sécurité, des dommages possibles sur la

machine et des informations sur le fonctionnement et l'entretien. Lire

attentivement toutes ces informations pour éviter les blessures et les

dommages sur la machine.

ATTENTION: Éviter les blessures! Ce symbole et ce texte

attirent l'attention sur les risques de blessures sérieuses

voire mortelles pour le conducteur ou les passagers en cas

de non-respect des recommandations.

IMPORTANT: Éviter toute détérioration! Ce texte permet de

prévenir le conducteur des actions ou conditions pouvant

provoquer un dommage sur la machine.

NOTE: Des informations d'ordre général sont fournies tout au long du

manuel pour aider le conducteur à utiliser et entretenir la

machine.

MX00654,000020D-28-05JUN17

Publications d'entretien

Pour obtenir un exemplaire du Catalogue de pièces ou du Manuel

technique de cette machine, consulter la boutique d'informations

techniques de John Deere à l'adresse :

https://techpubs.deere.com/?cid=VURL_TechInfoStore

ou appelez au :

● États-Unis & Canada : 1-800-522-7448.

● Toutes autres régions : Le concessionnaire John Deere.

TH84124,0000199-28-15AUG17

Pièces

L'utilisation des pièces de rechange et des lubriants de haute qualité

John Deere, disponibles auprès du concessionnaire, est

recommandée.

2

Page 23

Table des matières

TTaabbllee ddeess mmaattiièèrreess

Introduction.... .. . .. .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. .. .. . .. .. .. 2

Identication du produit..... . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. 3

Autocollants de sécurité avec texte. . .. .. .. .. .. . .. .. .. .. .. . 4

Autocollants de sécurité sans texte. . .. .. .. .. .. . .. .. .. .. .. . 4

Sécurité. . .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. 5

Ensemble.. . .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. . 6

Préparation du véhicule.. . .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .10

Montage...... .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. 11

Dépose et remisage.. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. 13

Fonctionnement. .. .. .. . .. .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. . .. .15

Entretien..... .. . .. .. .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .15

Pannes et remèdes.. .. .. .. .. .. . .. .. .. .. .. .. . .. .. .. .. .. . .. .. .17

Garantie de qualité John Deere... . .. .. .. . .. .. .. .. .. . .. .. .. 19

Index.. . .. .. .. . .. .. .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . .. .. .. .. .. . 20

Identication du produit

Identication de l'unité de coupe

Les unités de coupe gurant dans les instructions suivantes sont

identiés par des codes. Les codes sont les suivants:

Code Description

48HC Unité de coupe PRO haute capacité de

48 pouces

54HC Unité de coupe PRO haute capacité de

54 pouces

60HC Unité de coupe PRO haute capacité de

60 pouces

OUO2005,0000620-28-02APR18

Compatibilité du produit

Ce Power Flow™ est compatible avec les unités de coupe PRO haute

capacité de 48, 54 et 60 pouces pour les tondeuses de la série ZTrak

Z700.

OUO2005,0000621-28-27MAR18

Enregistrement des numéros d'identication

Power Flow™

Série HC haute performance, n° de série (010001 - )

Pour toute demande d'informations relatives à l'entretien auprès d'un

centre de réparation agréé, toujours fournir le numéro de modèle et le

numéro de série du produit.

Repérer les numéros de modèle et de série du Power Flow™ et les

inscrire dans les espaces prévus à cet effet ci-dessous.

Livret original. Toutes les informations, illustrations et caractéristiques

contenues dans la présente publication sont à jour au moment de la

publication, le constructeur se réservant le droit d'apporter sans

notication toute modication jugée appropriée.

COPYRIGHT © 2018

DEERE & COMPANY

Moline, Illinois

All rights reserved.

DATE D'ACHAT:

GXT002367—UN—01JUL15

_________________________________________

NOM DU CONCESSIONNAIRE:

_________________________________________

Nº DE TÉLÉPHONE DU CONCESSIONNAIRE:

_________________________________________

NUMÉRO DE SÉRIE DU PRODUIT (A):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

OUO2005,0000622-28-27MAR18

Power Flow est une marque commerciale de Deere & Company

3

Page 24

Autocollants de sécurité avec texte

Autocollants de sécurité avec texte

Emplacement des autocollants de sécurité

A—AVERTISSEMENT - M158480

OUMX068,0000CB4-28-27AUG15

Comprendre les autocollants de sécurité de la machine

GXT002440—UN—12JUL15

blessures légères ou modérées. ATTENTION peut aussi avertir

contre un mauvais comportement dans des situations pouvant

mener à des blessures.

Remplacer les autocollants de sécurité manquants ou endommagés.

Utiliser ce livret d'entretien pour connaître le placement correct des

autocollants de sécurité.

Des pièces et composants provenant de fournisseurs peuvent être

porteurs d'informations supplémentaires relatives à la sécurité non

reproduites dans ce livret d'entretien.

Autocollants de sécurité et livret d'entretien en français ou en espagnol

Des livrets d'entretien et des autocollants de sécurité en français et en

espagnol sont disponibles pour cette machine auprès des

concessionnaires John Deere agréés. Voir le concessionnaire John

Deere.

NOTE: Les autocollants avec et sans texte sont illustrés. Cette

machine n'est équipée que d'un de ces types d'autocollants.

MP47322,00F4601-28-21JUN18

AVERTISSEMENT

Si un autocollant en français est nécessaire, placer l'autocollant M133741 sur

l'autocollant existant. Si un autocollant en espagnol est nécessaire, placer

l'autocollant M158499 sur l'autocollant existant. Placer l'autocollant M158500 sur

l'autocollant existant si le kit Power Flow est "global" et comprend les indications

LAMES ROTATIVES – OBJETS PROJETÉS

Ne pas faire fonctionner la soufante tant que le bac de ramassage

d'herbe tout entier n'est pas solidement xé en place

de sécurité sans texte dans l'équipement de base.

OUMX068,0000CB7-28-27AUG15

GXT001246—UN—28OCT13

Les autocollants de sécurité représentés dans cette section sont

MXAL42363—UN—22MAY13

placés à des endroits importants de la machine pour attirer l'attention

sur certains dangers éventuels. Les autocollants DANGER ou

AVERTISSEMENTsont situés près des zones de dangers spéciques.

Le cas échéant, le livret d'entretien explique également les dangers

éventuels dans des messages de sécurité spéciaux précédés du

terme ATTENTION et du symbole de mise en garde.

Sur les autocollants de sécurité de la machine, ce symbole de mise en

garde est accompagné du terme DANGER, AVERTISSEMENT ou

ATTENTION. Le terme DANGER signale les dangers les plus graves :

● DANGER: le terme DANGER identie une situation dangereuse

qui, si elle n'est pas évitée, entraînera des blessures graves, voire

mortelles.

● AVERTISSEMENT: le terme AVERTISSEMENT identie une

situation dangereuse qui, si elle n'est pas évitée, peut entraîner des

blessures graves, voire mortelles.

● ATTENTION: le terme ATTENTION identie une situation

dangereuse qui, si elle n'est pas évitée, peut entraîner des

Autocollants de sécurité sans texte

Comprendre les autocollants de sécurité sans texte de la machine

TCT005498—UN—11SEP12

Des autocollants de sécurité sont apposés à différents endroits

importants sur cette machine pour signaler les dangers potentiels.

Chaque danger est identié par un pictogramme dans un triangle

d'avertissement. Un deuxième pictogramme illustre le comportement à

adopter pour éviter tout risque d'accident. Un récapitulatif de ces

autocollants de sécurité, de leur emplacement, ainsi qu'une courte

explication de leur signication se trouvent ci-après dans la section

Sécurité.

Il peut exister des informations supplémentaires relatives à la sécurité

sur des pièces et des composants provenant de fournisseurs qui ne

sont pas reproduites dans ce livret d'entretien.

MX00654,0000389-28-21JUN18

4

Page 25

Sécurité

Projection de corps étrangers

MXT009202—UN—19SEP13

● Ne pas engager les pieds, ni les mains dans la tondeuse, avec le

moteur en marche.

● Objets projetés - Avant de commencer à tondre, retirer de l'aire de

travail tous les objets susceptibles d'être projetés par la lame. Ne

pas utiliser la tondeuse sans la goulotte d'évacuation ou le

ramasseur d'herbe complet en place.

● Rester à distance de sécurité de la machine.

● Lire le livret d'entretien.

OUMX068,0000238-28-19SEP13

Sécurité

Lire la section Sécurité du livret d’entretien

Lire les consignes générales de sécurité pour l'utilisation, contenues

dans le livret d'entretien pour toute information supplémentaire relative

à la sécurité.

OUMX068,0000230-28-18SEP13

Utilisation en toute sécurité

Avant toute utilisation, lire, comprendre et suivre toutes les instructions

gurant dans le livret de cet équipement et dans le livret d’entretien de

la machine, ainsi que les autocollants de sécurité gurant sur

l'équipement.

Lester correctement la machine Déposer le lest une fois le bac de

ramassage déposé.

La trémie dépasse de la machine. Faire attention aux objets

environnants en prenant des virages serrés.

Ne pas faire fonctionner le système de ramassage de matériau si le

récupérateur d'herbe intégral n'est pas xé en place et si le couvercle

de la trémie n'est pas verrouillé.

Ne transporter personne sur la tondeuse ou sur le bac de ramassage.

Les passagers risquent d'être blessés, heurtés par des objets ou

projetés hors de la machine. Ils risquent également de gêner la

visibilité du conducteur et d'entraîner une collision.

Avant la pose ou la dépose de la trémie :

● Arrêter l’unité de coupe.

● Désenclencher l’unité de coupe ou la PdF.

● Arrêter le moteur et retirer la clé de contact.

● Attendre l'arrêt du moteur et de toutes les pièces en mouvement

avant de quitter le siège du conducteur.

Avant de faire reculer la machine:

● Arrêter la machine.

● S’assurer qu’il n’y a pas d’enfants derrière la trémie.

● Ne laisser personne se tenir à proximité lors du déchargement du

bac de ramassage.

Fonctionnement en toute sécurité sur les pentes:

● Vider la trémie lorsqu'elle est à demi pleine.

● Ne pas utiliser sur les pentes raides.

● Ralentir avant les virages.

● Éviter les démarrages et arrêts brusques.

● Ne pas garer une machine munie d'un bac de ramassage sur une

pente.

OUMX068,0000231-28-27MAR14

Stationnement en toute sécurité

1. Arrêter la machine sur une surface plane et non sur un terrain en

pente.

2. Désengager les lames de la tondeuse et tous les autres

équipemens.

3. Abaisser les équipements au sol.

4. Serrer le frein de stationnement.

5. Arrêter le moteur.

6. Retirer la clé de contact.

7. Avant de quitter le fauteuil du conducteur, attendre l'arrêt du moteur

et de toutes pièces en mouvement.

8. Fermer le robinet d'arrêt de carburant, si la machine en est équipée.

9. Déconnecter le câble négatif de la batterie ou retirer le(s) câble(s)

de(s) bougie(s) d'allumage (pour les moteurs à essence) avant

d’effectuer l’entretien de la machine.

OUO1023,0000035-28-21FEB13

Protection des enfants

● Des accidents tragiques ont lieu avec des enfants si l’opérateur

n’est pas au courant de leur présence. Éloigner les enfants lors de

l’utilisation de la machine et de l’équipement et les coner à la garde

d’un adulte responsable.

● Ne jamais supposer que les enfants vont rester à l'endroit où ils ont

été vus pour la dernière fois. Toujours se tenir sur ses gardes en

présence d'enfants. Arrêter la machine si un enfant pénètre dans

l'aire de travail.

● Ne pas permettre aux enfants ni aux adultes non formés d'utiliser la

machine.

● Ne pas transporter d’enfants ou les laisser monter sur un

quelconque équipement ou sur la machine, même lorsque

l’équipement est arrêté. Ne pas transporter d'enfants dans une

petite voiture ou dans une remorque.

OUMX068,0000233-28-18SEP13

Risque de blessure par projection d'objets

TCAL41689—UN—08APR13

● Lors de l’utilisation du véhicule avec un bac de ramassage, veiller à

ce que tous les canaux et exibles soient fermement xés en place.

Garder la trémie fermée ou le système de ramassage de matériau

en position de fonctionnement.

● Arrêter le moteur et attendre l’arrêt de toutes les pièces en

mouvement avant de déposer ou de relever tout organe d'un

équipement.

● Risque de blessures par pales de la turbine et projections d’objets.

Déposer l’outil lorsque la machine est utilisée en mode d’évacuation

latérale. Veiller à ce que la tôle déectrice soit en place sur l'unité de

coupe si l’équipement est déposé.

OUMX068,0000234-28-18SEP13

5

Page 26

Ensemble

Risque de blessures par lames rotatives

MXT008720—UN—19SEP13

● Garder les pieds et les mains à l'écart des lames en rotation et de la

soufante lorsque le moteur tourne.

● Avant d’effectuer l’entretien, arrêter le moteur et attendre que toutes

les pièces en mouvement soient arrêtées.

● Ne pas utiliser le système de ramassage de matériau ou

l'ensacheuse tant que tous les éléments ne sont pas bien installés

et verrouillés.

OUMX068,0000235-28-18SEP13

Sécurité de l'entretien

● Seuls des adultes formés et qualiés peuvent effectuer l’entretien

de la machine.

● Bien comprendre la procédure d'entretien avant de commencer.

Travailler dans un lieu propre et sec.

● Ne pas faire tourner le moteur dans un espace conné où des

émanations de monoxyde de carbone peuvent s'accumuler.

● Ne jamais lubrier, entretenir ni régler la machine ou un équipement

en mouvement. Maintenir les dispositifs de sécurité en place et en

bon état de fonctionnement. Maintenir la boulonnerie serrée.

● Éloigner les mains, pieds, vêtements, bijoux et longs cheveux des

pièces en mouvement pour les empêcher de se faire happer.

● Abaisser tout équipement au sol ou jusqu'à une butée mécanique

présente sur l'équipement avant d'effectuer l'entretien de

l'équipement. Désengager toute source d'alimentation et arrêter le

moteur. Serrer le frein de stationnement et retirer la clé de contact.

Laisser la machine refroidir.

● Débrancher la batterie ou retirer le l de la bougie d'allumage (pour

les moteurs à essence) avant d'effectuer une quelconque remise en

état.

● Avant tout entretien de la machine ou de l'équipement, dissiper

soigneusement la pression de tout composant accumulant de

l'énergie, les composants hydrauliques et les ressorts par exemple.

● Relâcher la pression hydraulique en abaissant l'équipement ou les

unités de coupe au sol ou jusqu'à une butée mécanique et déplacer

les leviers de commande hydraulique.

● Soutenir solidement tous les éléments de la machine ou de

l'équipement qui doivent être relevés pour l'entretien. Utiliser des

chandelles ou verrouiller des loquets d'entretien pour soutenir les

composants lorsque nécessaire.

● Ne jamais faire tourner le moteur si le frein de stationnement n'est

pas serré.

● Garder toutes les pièces en bon état et bien montées. Réparer les

dégâts immédiatement. Remplacer les pièces usées ou cassées.

Remplacer tout autocollant de sécurité ou d'instruction usé ou

endommagé.

● Vérier toute la boulonnerie à intervalles rapprochés pour s'assurer

que l'équipement peut fonctionner en toute sécurité.

● Ne pas modier la machine ou les dispositifs de sécurité. Toute

modication non autorisée apportée à la machine ou à l’équipement

risque d'affecter son fonctionnement et d'en compromettre la

sécurité.

OUMX068,0000236-28-04AUG17

Ensemble

Identication des pièces

Pièces du kit (48HC et 54HC)

TCT015744—UN—14MAY18

Quantité Description

1 Power Flow™ (A)

1 Support de xation, garant de courroie (B)

1 Garant de courroie d'unité de coupe (C)

1 Goupille pliée (D)

1 Poulie double (E)

2 Plaques de maintien de poulie (F)

6

Page 27

Ensemble

Pièces du kit (60HC)

Quantité Description

1 Power Flow™ (A)

1 Support de xation, garant de courroie (B)

1 Garant de courroie d'unité de coupe (C)

1 Goupille pliée (D)

1 Poulie double (E)

2 Plaques de maintien de poulie (F)

TCT015745—UN—14MAY18

Sachet de pièces

TCT015746—UN—14MAY18

Quantité Description

4 Écrou de blocage à embase M6 (A)

4 Contre-écrou à embase M8 (B)

2 Vis, M8 x 25 (C)

1 Support de montage avant (D)

1 Autocollant d'avertissement, français

1 Autocollant d'avertissement, espagnol

Note de l'illustration: Taille réelle illustrée, hormis la partie D illustrée dans la boîte.

OUO2005,0000623-28-28JUN18

Dépose du garant de courroie droit

Note de l'illustration: Unité de coupe de 60 pouces illustrée.

TCT015747—UN—14MAY18

1. Déposer les deux écrous de blocage (A) et le garant de courroie (B)

avec le support métallique (C). (Conserver le garant de courroie et

le support métallique à des ns d'utilisation ultérieure.)

7

Page 28

Ensemble

2. Reposer les deux écrous de blocage sur la fusée et serrer au

couple prescrit.

Valeur prescrite

Écrou de blocage de montage de la

fusée—Couple de serrage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 N m

OUMX068,00014DC-28-29JUN18

(18 lb ft)

Modication du canal d'éjection

48HC et 54HC

60HC

TCT014336—UN—29JUN18

1. Mesurer 70 mm (2.76 in) vers le haut depuis le bord extérieur.

2. Couper le long de la ligne pointillée et retirer la section (B).

OUO2005,0000624-28-29JUN18

Poser la poulie double (unités de coupe 48HC, 54HC et 60HC)

1. Désenclencher la prise de force.

Unité de coupe de 54 pouces vue du dessous.

TCT014335—UN—29JUN18

1. Repérer la ligne estampée (D) sur le canal d'éjection de l'unité de

coupe.

2. Mesurer une longueur de 25 mm (1 in) (B) au-dessus de la ligne et

marquer cette partie (C).

● Pour vérier les mesures, s'assurer que la longueur est d'environ

68,0 mm (2-11/16 in) (D) et la dimension vers l'intérieur d'environ

46,0 mm (1-13/16 in) (E).

● Couper le long de la ligne pointillée et retirer la section (C).

2. Retirer l'extrémité du ressort (A) du support (B) sur l'unité de coupe.

TCT015748—UN—14MAY18

3. Retirer la courroie de l'unité de coupe de la poulie (C) de l'axe droit.

Inspecter la courroie et la remplacer si nécessaire.

8

Page 29

Ensemble

Préparation du Power Flow 48HC

Note de l'illustration: La poulie a été déposée de l'axe pour la clarté de

Note de l'illustration: Les poulies ont été déposées de l'axe pour la clarté de

l'illustration.

l'illustration.

TCT015749—UN—14MAY18

TCT015750—UN—14MAY18

4. Poser les plaques de maintien (D) de la poulie supérieure sur la

poulie de fusée droite (C) sans les serrer en les insérant dans les

trous de cette dernière (C). Amorcer les quatre écrous de blocage

(E) sur les letages.

5. Poser la poulie supérieure (F) sur la poulie de l'axe droit (C), en

alignant les grandes extrémités des fentes (G) de la poulie

supérieure sur les écrous sur les plaques de maintien de la poulie.

6. Faire pivoter la poulie supérieure (F) dans le sens antihoraire pour

placer les écrous au-dessus des petites extrémités des fentes.

Serrer la boulonnerie à 13 Nm (10 lb-ft).

OUO2005,0000625-28-14MAY18

1. Découper le long de l’arête de l’orice d’entrée une petite section

GXT002371—UN—01JUL15

triangulaire (H) comme illustré.

OUMX068,0000CA3-28-12JUL15

Pose du support de montage avant

TCT015751—UN—14MAY18

1. Déposer l'écrou (A), le boulon (B), la roue anti-scalp (C) et

l'entretoise de l'emplacement avant droit. Garder les pièces an de

pouvoir les remonter plus tard.

9

Page 30

Préparation du véhicule

2. Poser le support de montage de soufante avant (D) sur le support

TCT015752—UN—14MAY18

de roue de jauge avant droit (E) avec les deux vis M8x25 (F) et les

écrous de blocage M8. Serrer à 34 Nm (25 lb-ft). S'assurer que le

boulon de roue anti-scalp (B) s'insère avant de le serrer.

3. Remettre en place la roue anti-scalp, l'entretoise et la boulonnerie

une fois le support de soufante installé. Serrer la boulonnerie de la

roue anti-scalp à 34 N·m (25 lb.-ft.).

OUO2005,0000626-28-14MAY18

Pose du support de xation de garant de courroie

ATTENTION: Risque de blessures! Les lames de la tondeuse

sont coupantes. Toujours porter des gants pour manipuler

les lames de tondeuse ou travailler à proximité.

2. Monter le support de xation de garant de courroie (B) sur l'unité de

TCT015754—UN—14MAY18

coupe à l'aide de l'ensemble d'écrous de blocage M8 (C) neuf.

3. Serrer la boulonnerie à 37 N·m (27 lb·ft).

OUO2005,0000627-28-14MAY18

Préparation du véhicule

Montage des lames correctes de tondeuse

IMPORTANT: Éviter toute détérioration! N'utiliser que des pièces

d'origine John Deere pour le remplacement des lames de

tondeuse.

● Pour de meilleures performances, toujours utiliser une

lame adaptée au travail à effectuer.

● Toujours respecter les consignes de sécurité et

d’entretien gurant dans le livret d’entretien de la

machine lors du remplacement des lames de tondeuse.

Pour obtenir le meilleur rendement possible avec la soufante, poser

les lames appropriées pour chaque travail :

● • Lames à paillis – Ne pas utiliser avec la soufante, sauf si

utilisées avec le kitMulchControl™.

● Lames standard – Les lames standard sont conçues pour

l'ensachage, l'éjection latérale et toutes les conditions de tonte.

OUO2005,000039A-28-03NOV16

1. Retirer les deux écrous de blocage M8 (A) de la fusée droite.

TCT015753—UN—14MAY18

MulchControl est une marque commerciale de Deere & Company

10

Page 31

Montage

Installation de la soufante

Montage

1. Introduire l'extrémité courte (A) de la grande tige courbée dans le

TCT015755—UN—14MAY18

support de montage avant (B).

TCT015756—UN—14MAY18

2. Installer le Power Flow™ sur la partie longue (C) de la goupille

pliée.

3. Déplacer le levier de tension (D) pour relâcher la position.

4. Relever à fond le canal d'éjection (E) de l'unité de coupe et pivoter

TCT015757—UN—14MAY18

le Power Flow™ vers l'unité de coupe. Introduire la goupille pliée

(F) dans le trou (G) du support arrière droit de l'unité de coupe.

TCT015758—UN—14MAY18

11

TCT015759—UN—14MAY18

Page 32

Montage

5. Installer le Power Flow™ sur les zones d'éjection (H) de l'unité de

coupe tel qu'illustré, tout en introduisant la goupille (F) dans le trou

(G).

6. Maintenir fermement le Power Flow™ contre la zone d'éjection de

l'unité de coupe.

7. Poser la courroie de soufante (I) sur la poulie supérieure (J).

TCT015760—UN—14MAY18

9. Déplacer le levier de tension (D) pour le verrouiller en position.

TCT015762—UN—14MAY18

NOTE: Veiller à placer le tendeur de la soufante en position engagée

pour que la courroie soit sous tension avant de vérier les

écartements.

TCT015763—UN—14MAY18

10. Les fentes du support de xation de garant de courroie de

soufante du bac de ramassage (N) permettent d'effectuer des

réglages. Vérier la position du support de xation du garant de

courroie de soufante du bac de ramassage et régler selon le

besoin. Le montant de garant de courroie (O) doit être

sufsamment écarté des deux brins de la courroie de la soufante

(P).

Un ensemble monté peut varier de l’illustration dans le présent document. Le

cheminement de la courroie sera identique.

TCT015761—UN—14MAY18

8. Le cheminement de la courroie d'entraînement doit être le suivant :

a. De la poulie (J) supérieure de l'unité de coupe,

b. Au tendeur (K),

c. À la partie supérieure de la poulie (L),

d. À la poulie du tendeur en V (M),

e. Retour à la poulie supérieure (J) de l'unité de coupe.

12

Page 33

Dépose et remisage

Dépose et remisage

Dépose du Power Flow™

11. Poser le garant de courroie de soufante du bac de ramassage (Q)

TCT015764—UN—14MAY18

sur le support de xation:

● Insérer la languette dans l'ouverture (R) du support de xation

et abaisser le passe-câble du garant de courroie sur le montant

(S).

● S'assurer que le graisseur de fusée (T) est accessible et que

les courroies ne touchent pas le garant.

OUO2005,0000628-28-14MAY18

Réglage de l'unité de coupe

IMPORTANT: Éviter toute détérioration! Régler les roulettes

droites de l'unité de coupe après chaque installation an

d'assurer un soutien adéquat à la turbine Power Flow™ lors

du déplacement sur les zones de tonte.

1. Régler la hauteur de coupe et l'assiette transversale et longitudinale

de l'unité de coupe selon les instructions du livret d'entretien du

tracteur.

2. Abaisser l'unité de coupe à la hauteur de coupe prédénie.

OUMX068,00014DD-28-28JUN18

1. Déplacer le levier de tension (A) pour déverrouiller la position.

TCT015765—UN—14MAY18

TCT015766—UN—14MAY18

2. Déposer le garant de courroie (B) de l'unité de coupe.

13

Page 34

Dépose et remisage

6. Retirer la partie courte de la goupille pliée du support de montage

avant (G).

Pose du garant de courroie droit

OUO2005,0000629-28-29JUN18

3. Dépose de la courroie d'entraînement (C) de la poulie supérieure

TCT015767—UN—14MAY18

(D)

TCT015768—UN—14MAY18

4. Soulever le vireur de balles (E) de l'unité de coupe et faire pivoter le

Power Flow™ à l'écart de l'unité de coupe.

1. Retirer les deux écrous de blocage (A).

TCT014334—UN—29JUN18

2. Poser le garant de courroie (B) avec le support métallique (C) sur

les goujons de fusée.

3. Reposer les deux écrous de blocage (A) sur les goujons de fusée

xant le support métallique sur l'unité de coupe.

4. Serrer les écrous de blocage à la valeur prescrite.

Valeur prescrite

Écrou de blocage de montage de la

fusée—Couple de serrage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 N m

OUMX068,00014DF-28-29JUN18

(18 lb ft)

Remisage du Power Flow™

1. Déposer le composant Power Flow™ de l'unité de coupe.

IMPORTANT: Éviter toute détérioration! Les résidus d'herbe, en

séchant, risquent de former des boulettes dures qui

pourraient pénétrer en force dans la soufante. Cela peut

provoquer une défaillance prématurée.

2. Nettoyer l'intérieur et l'extérieur du Power Flow™.

3. Déposer le garant de courroie:

48HC et 54HC

5. Détacher le Power Flow™ de la partie longue de la goupille pliée

TCT015769—UN—14MAY18

(F).

14

Page 35

Fonctionnement

TCT015770—UN—14MAY18

a. Déposer les deux dispositifs de retenue (A) de la partie

supérieure et de la partie inférieure du garant de courroie.

b. Déposer les deux boulons (B) xant le garant de courroie au

Power Flow™.

c. Déposer le garant de courroie (C).

60HC

Fonctionnement

Fonctionnement de la soufante

Mise en marche de la soufante

La soufante se met en marche automatiquement dès que la PdF du

tracteur est enclenchée pour le démarrage de l'unité de coupe (Voir le

livret d’entretien du tracteur pour l'utilisation de la prise de force.)

Arrêt de la soufante

La soufante s'arrête automatiquement dès que la PdF du tracteur est

désenclenchée pour mettre l'unité de coupe à l’arrêt.

BS62576,00014C4-28-09DEC15

Débourrage de la tondeuse, de l'ensacheuse ou du bac de ramassage

ATTENTION: Éviter les blessures! Ne pas essayer de

débourrer l'équipement lorsque la machine fonctionne.

• Les lames rotatives sont dangereuses. Arrêter le moteur et

retirer la clé de contact avant de quitter le fauteuil pour

examiner la machine et l'accessoire.

• Les objets projetés peuvent causer des blessures graves.

S'assurer que toutes les pièces de la machine sont arrêtées

avant de relever le haut de la trémie ou de déposer les

canaux.

a. Déposer l'écrou et la rondelle (D) de la partie inférieure du

TCT015771—UN—14MAY18

garant de courroie.

b. Déposer l'écrou et la rondelle (E) de la partie supérieure du

garant de courroie.

c. Déposer le boulon (F) xant le garant de courroie (B) au Power

Flow™.

d. Déposer le garant de courroie (G).

4. Éliminer toute accumulation d'herbe autour de la courroie, du

tendeur et des poulies.

5. Déposer et inspecter l'arbre d'entraînement. Remplacer la courroie

si nécessaire.

6. Poser le garant de courroie.

7. Remiser le Power Flow™ dans un endroit sec et propre. Il est

recommandé de l'entreposer dans son carton d'expédition.

OUO2005,000062A-28-29JUN18

Vérication du bourrage lors de la conduite

Si de l'herbe s'accumule devant la goulotte d'évacuation de la

tondeuse, vérier la goulotte bouchée ou la soufante (suivant

équipement).

S'il y a une traînée d'herbe coupée derrière la tondeuse ou des herbes

coupées projetées sur le côté, vérier que le canal n'est pas obstrué,

que les bacs de ramassage ne sont pas pleins ou que la soufeuse ne

présente aucun problème.

Retrait des débris des points d'inspection:

ATTENTION: Éviter les blessures! Ne pas utiliser les mains

ou les pieds pour déblayer le carter de tonte ou la soufeuse

bouchée. L'énergie emmagasinée peut faire tourner les

lames.

1. Garer la machine en toute sécurité. Attendre que toutes les pièces

en mouvement se soient arrêtées avant de quitter le fauteuil pour

inspecter la machine.

2. Ouvrir le couvercle du bac incorporateur. Contrôler la sortie du

canal.

3. Retirer le canal du carter de tonte ou de la soufeuse. Contrôler

l'entrée du canal.

4. Vérier l'absence de débris sous l'unité de coupe.

BS62576,00014C5-28-09DEC15

Entretien

Dépose de la courroie d'entraînement

1. Déposer le composant Power Flow™ de l'unité de coupe.

2. Déposer le garant de courroie du Power Flow™:

48HC et 54HC

15

Page 36

Entretien

a. Déposer les deux dispositifs de retenue (A) de la partie

TCT014330—UN—29JUN18

supérieure et de la partie inférieure du garant de courroie.

b. Déposer les deux boulons (B) xant le garant de courroie au

Power Flow™.

c. Déposer le garant de courroie (C).

60HC

TCT014331—UN—29JUN18

a. Déposer l'écrou et la rondelle (D) de la partie supérieure et de

la partie inférieure du garant de courroie.

b. Déposer le boulon (E) xant le garant de courroie (B) au Power

Flow™.

c. Déposer le garant de courroie (F).

3. Éliminer toute accumulation d'herbe autour de la courroie, du

tendeur et des poulies.

4. Desserrer l'écrou (G) et glisser le guide de courroie (H) au-dessus

TCT014332—UN—29JUN18

pour retirer la courroie (I).

TCT014333—UN—29JUN18

5. Desserrer l'écrou du boulon (J) du tendeur et l'écrou (K) de la

poulie.

6. Écarter les guides de courroie (L) du tendeur et de la poulie et

déposer la courroie.

OUMX068,00014DE-28-29JUN18

Pose de la courroie d'entraînement

MXT009092—UN—16SEP13

NOTE: Cette image indique comment monter la courroie correctement.

Si la courroie n'est pas correctement posée, le ventilateur du

Power Flow™ risque de tourner dans le sens inverse.

16

Page 37

Pannes et remèdes

1. Poser la courroie (A) au-dessus de la poulie menée (B).

GXT002395—UN—08JUL15

2. Ajuster le guide de courroie (C) à la courroie et serrer l'écrou (D)

tout en maintenant le guide de courroie en place.

GXT002396—UN—08JUL15

3. Acheminer la courroie :

a. Entre la poulie du tendeur à gorge en "V" (E) et le support de

courroie (F) avec le côté en "V" de la courroie tourné vers la

gorge,

b. Entre le tendeur (G) et le support de courroie (H) avec le côté

"face" de la courroie tourné vers la gorge.

4. Déplacer les supports de courroie (F) et (H) perpendiculairement

aux bords extérieurs de la poulie et du tendeur. Maintenir un jeu de

3 mm (1/8 in) entre les supports et les bords extérieurs.

5. Serrer l'écrou sur le boulon (I) et l'écrou (J) à 20—40 N.m (15—29 lb

ft).

6. Poser le garant de courroie sur le Power Flow™:

48HC et 54 HC

a. Poser le garant de courroie (K) sur le Power Flow™.

TCT015774—UN—14MAY18

b. Fixer l'avant du garant de courroie avec les deux boulons (L).

c. Fixer l'arrière du garant de courroie avec les deux dispositifs de

retenue (M).

60HC

TCT015855—UN—14MAY18

a. Pose du garant de courroie (N) sur le Power Flow™

b. Poser le boulon (O) xant l'avant du garant de courroie au

Power Flow™.

c. Poser l'écrou (P) sur la partie supérieure du garant de courroie.

d. Poser le dispositif de retenue (Q) sur la partie inférieure du

garant de courroie.

OUO2005,000062C-28-14MAY18

Pannes et remèdes

Utilisation du tableau de dépannage

En cas de problème ne gurant pas dans ce tableau, consulter le

concessionnaire John Deere pour assistance.

Lorsque toutes les causes possibles listées ci-dessous ont été

contrôlées et que le problème persiste, consulter le concessionnaire

agréé.

17

Page 38

Pannes et remèdes

SYMPTÔME CONTRÔLER

La souferie ne tourne

pas.

La soufante se bouche.

Les performances de la

soufante sont

médiocres.

L’herbe n’est pas

complètement ramassée.

● Courroie trapézoïdale usagée ou

rompue.

● Vitesse de déplacement trop élevée

pour les conditions de récolte.

● Poignée de verrouillage partiellement

désengagée.

● La courroie est usée.

● Courroie mal installée.

● Les lames de l’unité de coupe ne sont

pas adaptées à l’application.

● Vitesse de déplacement trop élevée

pour les conditions de récolte.

● Poignée de verrouillage partiellement

désengagée.

● La courroie est usée.