Page 1

John Deere SprayMaster

TM

Power W asher

Series PM182401, for Specific Installations on

John Deere Model 4700 Field Sprayer with optional Rinse Tank

Operation, Repair, and Parts Manual

Description

Driving a dirty sprayer on public roads and highways may violate

state and county health codes in some states. A clean sprayer

drops nothing on the roads and highways. Field cleaning of the

sprayer from one job to the next is a good business practice and

insures happy customers. Cleaning a sprayer in town requires

containment of the spray materials to prevent contamination of local

water supplies.

General Safety Information

The following special attention notices are used to notify and advise

the user of this product of procedures that may be dangerous to the

user or result in damage to the product.

NOTE: Notes are used to notify of installation, operation, or

maintenance information that is important but not safety related.

Form

1469-JD

01-00

The John Deere SprayMaster Power Washer, complete On-Board

Hydraulic Powered High Pressure Wash System is designed to

make short work of the cleaning process. With 4 gpm @ 1500 psi,

50 feet of high pressure hose, and a trigger gun with a 36'' lance, you

can quickly clean the sprayer before it leaves the field. The

generous 120 gallon on board water supply ensures uninterrupted

cleaning.

• Do not pump at pressures higher than the maximum recommended

pressure.

o

• Maximum liquid temperature is 140

valve life when the water temperatures are above 110

pressure feed system of 40 to 60 psi should be incorporated.

F. for better packing and

o

F, a

CAUTION: Caution is used to indicate the presence of a

hazard, which will or can cause minor injury or property

damage if the notice is ignored.

WARNING: Warning denotes that a potential hazard exists and

indicates procedures that must be followed exactly to either

eliminate or reduce the hazard, and to avoid serious personal

injury, or prevent future safety problems with the product.

DANGER: Danger is used to indicate the presence of a hazard

that will result in severe personal injury, death, or property

damage if the notice is ignored.

Start-up and Maintenance

Before Starting Up

• Check that the oil is at the correct level using the Dipstick,

topping off if necessary (See Figure 1). Use a nondetergent,

SAE 30 weight oil.

Dipstick

FIGURE 1

Dipstick Location

• Change oil after 40 hours of break-in operation. Thereafter,

change the oil every year or 500 hours, whichever comes first.

NOTE: During warm months keep the power Washer Pump

filled with water and the Outlet Pressure Hose and Gun

Assembly attached. For storage during freezing conditions,

flush the Pump with the specified John Deere Winterizing

Fluid, N209391-CA (Canada) or N209318-US (U.S.). Leave this

fluid in the Pump with the Outlet pressure hose and Gun

attached.

• Release all pressure within the system before servicing any

component.

• The high-pressure gun and lance should be securely held by

hand or in a holding device before the unit is started. Make sure

the lance is not pointed toward any person or animal. Failure to

do so could result in serious injury.

• Periodically inspect the pump and the system components.

Perform routine maintenance as required (see Repair Section).

• Do not use these pumps for pumping water or other liquids for

human or animal consumption.

During Bypass Operation

• When the water is diverted back to the pump inlet side, a

temperature rise occurs. A thermal relief is included to keep the

water temperature at a maximum of 145

o

F.

Unloader Valve Safety Information

• Maximum pressure is set at the factory and cannot be adjusted to

a higher pressure.

• Do not tamper with the unloader valve settings or with the locking

ring; doing so will void the warranty. Damage to the pressure

washer may result.

WARNING: Water discharged from the thermal relief valve is

hot (145

o

F).

Page 2

Operation

1. Check the water level in the rinse tank. Never operate the

Pressure Wash Pump without a water supply.

NOTE: Periodically check the Line Strainer and clean the Line

Strainer if it is necessary (See Figure 2).

2. Open the water supply valve.

CAUTION: Do not operate any other hydraulic functions on the

4700 while the Power Washer is in use.

3. Set the engine speed to 1,500 RPM.

4. Activate the Hydraulic Motor by placing the Lever on the

Hydraulic Control Valve in the DOWN position (See Figure 3).

5. Point the Spray Gun at the target area and squeeze the Spray

Gun Trigger (See Figure 4).

6. The standard Power Washer is equipped with an adjustable

cleaning angle nozzle. The cleaning angle may be varied

throughout its range by rotating the black outer body clockwise

(CW) or counterclockwise (CCW).

7. If your Power Washer is equipped with the optional Detergent

Injection System. The nozzle must be set in Low Pressure

Mode to activate the injector and draw soap. For rinsing, the

nozzle should be set in High pressure Mode. Pushing the black

nozzle body forward places the nozzle in the Low Pressure

Mode. Pulling the black nozzle body back places the nozzle in

the High Pressure Mode.

NOTE: When finished using the Power Washer, make sure the

Power Washer is shut off (Hydraulic Control Valve lever in the

UP position) before operating other hydraulic functions on the

4700 (See Figure 5).

8. Store all the Power Washer components in brackets provided

for their storage.

Pump Strainer

FIGURE 2

Hydraulic

Control

Valve

Lever

FIGURE 3

FIGURE 4

Hydraulic

Control

Valve

Lever

FIGURE 5

Troubleshooting

SYMPTOM PROBABLE CAUSE(S) CORRECTIVE ACTION

The pump runs but Pump is not primed. Open water supply valve and fill rinse tank.

produces no flow.

Pump fails to prime. Air is trapped in pump. Squeeze and release trigger several times. If pump still does

Low pressure at nozzle. Pump is partially primed. Repeat steps from above .

Air leak in suction hose or pump Make sure all the inlet fittings are tight and not leaking.

inlet fittings.

Partially clogged strainer. Unscrew strainer bowl and clean screen.

Pump loses prime, Air leak in suction hose or pump Make sure all the inlet fittings are tight and not leaking.

pressure fluctuates, and/ inlet fittings.

or pump makes Partially clogged strainer. Unscrew strainer bowl and clean screen.

chattering noise.

Rapid cycling of pressure Water leakage down stream from Check for leaks in discharge pressure hose, pipe fittings,

when gun trigger is unloader valve. gun wand, and nozzle assembly.

closed.

4700 Sprayer operation Lever on Hydraulic Control Valve Shut Power Washer OFF by returning Control Lever up to the

is unusually slow. is in the DOWN position and OFF position

the Power Washer is running.

Hydraulic Motor Oil Backward plumbing of hydraulics. Verify proper plumbing of hydraulics to Motor; Motor Supply Hose to

Seal leaks. "PRESS" port and Return Hose to "TANK" port.

If the Power Washer is used and/or not maintained properly, it may be necessary to service the pump and/or

Unloader Valve. Refer to the proper Sections in this manual for servicing instructions.

not prime, disconnect the discharge hose and run until air is

evacuated, then reattach the discharge hose.

- 2 -

Page 3

Pump Repair Instructions

PACKING REPLACEMENT

PMKIT2747 and PMKIT2745

1. Water leakage between the Head and the Crankcase indicates

the Plunger Packings require replacement.

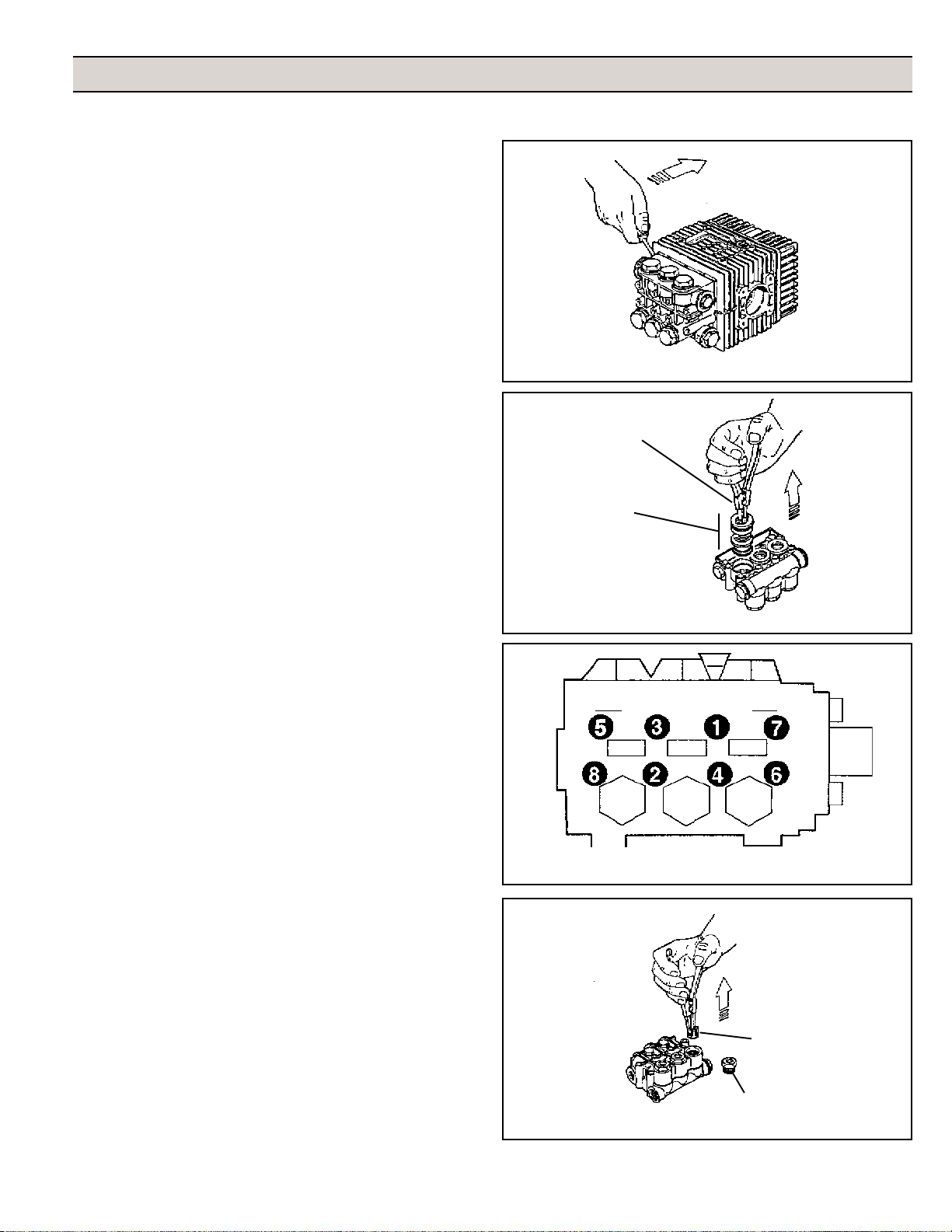

2. Use a Hex wrench to remove the Head Bolts; then, remove the

Head from the Crankcase by rotating the Crankshaft while using

a screwdriver to carefully pry between the Head and the

Crankcase (See Figure 6).

3. After the Head has been removed, use an Extractor Pliers

to remove the Plunger Seal Retainers, and Packings (See

Figure 7).

4. Using a small bladed screwdriver, remove the Low Pressure

Packing from the Retainer.

5. Insert a Low Pressure Packing into the Retainer by forming the

Seal into a kidney or oval shape; then, work the Seal into place

in the Retainer.

6. Apply a thin film of oil the Retainer O-ring; then, replace the

Retainer O-ring.

7. Apply a thin film of oil to all Seals; then, place the High Pressure

Packing and Cup Spreader into the head bore.

8. Place the Brass Packing Retainer into the Head and push the

Retainer in until the Retainer O-ring is sealed in the Head.

9. Check the Plungers for damage or cracking (refer to Plunger

Replacement section).

10. Repeat Steps 5 through 8 for the rest of the Cylinders.

11. Lightly oil the Plungers and install the Head onto the Plungers.

12. Push the head against the Crankcase; then, secure the Head to

the Crankcase with the Head Bolts.

13. Tighten the Head Bolts to 88 in lbs. torque, in the sequence

shown (See Figure 8).

FIGURE 6

Extractor Pliers

Plunger Seal

Retainers, and

Packing

FIGURE 7

VALVE REPLACEMENT

PM34300424

1. Erratic or low pressure operation may be caused by debris or

foreign material in the Valves or worn Poppets or a combination

of worn Poppets and/or Seats.

2. Remove the Valve Caps; then, using a needle-nosed plier, pull

out the Valve Assembly (See Figure 9).

3. Inspect the Valve for debris or foreign material and signs of wear.

If the Valve is worn or damaged, replace the Valves and the

valve O-rings.

4. Install the new Valve Assemblies; then, install the Valve Caps

and tighten them to 25 ft lbs. torque.

FIGURE 8

Valve

Assembly

Valve Cap

FIGURE 9

- 3 -

Page 4

PLUNGER REPLACEMENT

PMKIT2746

1. If damage to the Plungers is noted during Packing Replacement,

continue with Plunger Replacement.

2. Remove the Pump Head from the Crankcase as described in

PACKING REPLACEMENT.

3. Remove the Plunger Retaining Nut and the Plunger Retaining

Nut Washer; then, carefully slide the Plunger off the Lower

Plunger (See Figure 10).

4. Remove and discard the old O-ring and Slinger Ring from the

Lower Plunger (See Figure 10).

5. Install the new Slinger onto the loser Plunger.

6. Apply a thin film of oil to the Lower Plunger; then, install the new

O-ring.

7. Slide the Plunger onto the Lower Plunger.

8. Apply a drop of blue anaerobic thread locking compound to the

Plunger Retaining Nut; then, install the Plunger Retaining Nut

and Washer onto the Lower Plunger.

O-ring

&

Slinger Ring

FIGURE 10

Plunger

Lock

Washer

Plunger

Retaining Nut

9. Tighten the Plunger Nut to 88 in lbs.

10. Install the new Plunger Packings as described in PACKING

REPLACEMENT.

Hydraulic Motor Repair Instructions

HYDRAULIC MOTOR DISASSEMBLY

CAUTION: Dirt and other contaminants can damage hydraulic

motor components. Always maintain a clean work area when

working with hydraulic motors or components.

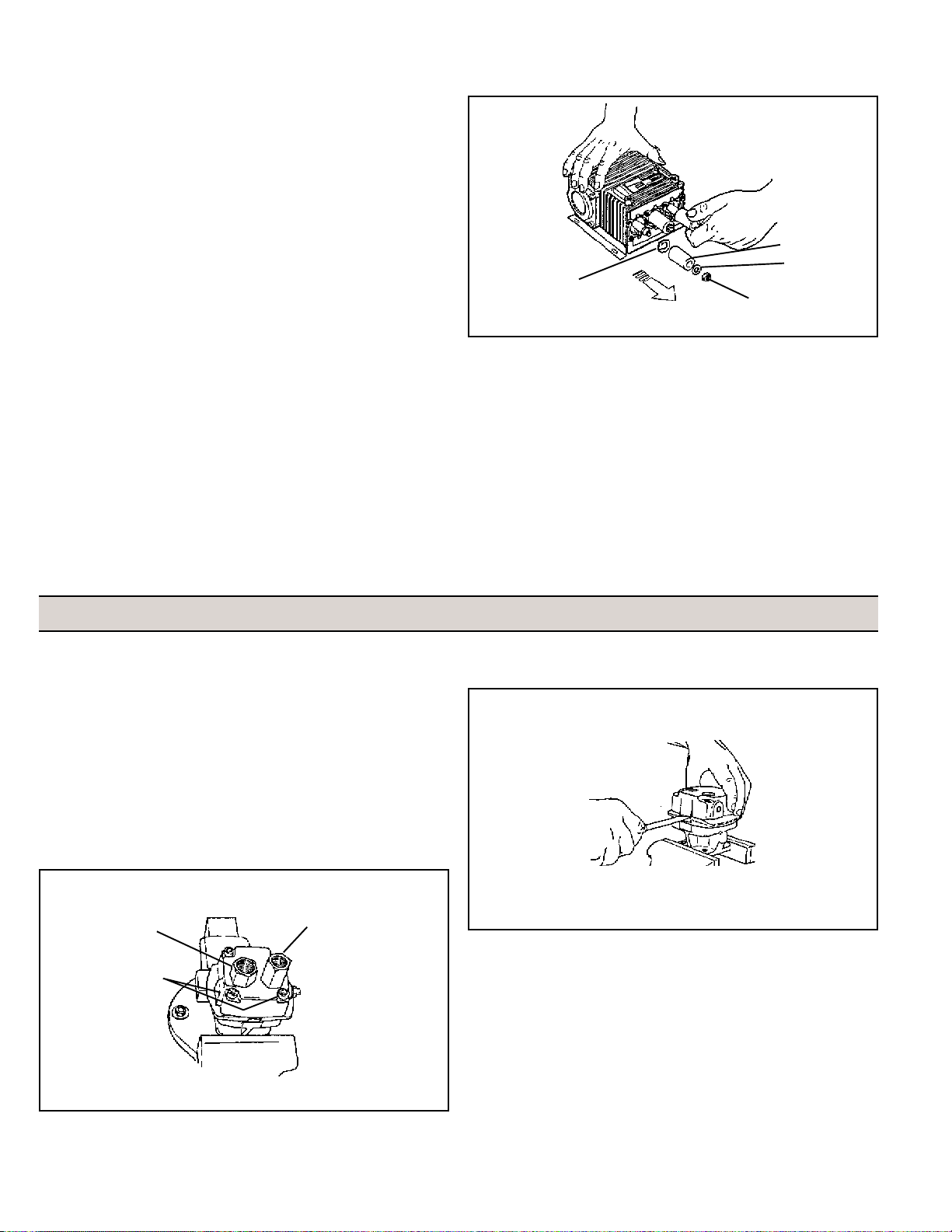

1. Place the Hydraulic Motor in a vise (See Figure 11).

2. Using a 1-1/16’’ Box wrench, remove the Tank Port Adapter and

Pressure Port Adapter (See Figure 11).

3. Using a 1/4’’ Hex wrench, remove the Socket Head Cap Screws

from the Motor End Plate (See Figure 11).

Pressure Port

Adapter

Socket Head

Cap Screws

Tank Port

Adapter

FIGURE 12

4. Remove bottom parts of the Gerotor.

5. Remove and save the Shaft Key.

6. Remove and discard the old O-ring from the Motor End Plate and

Body.

FIGURE 11

NOTE: If the Motor End Plate will not lift off easily, use a small

screwdriver to carefully pry apart the boss portion of the End

Plate and Gerotor Housing (See Figure 12). If the Gerotor

Housing will not easily lift off, carefully pry apart the boss area

between the Gerotor Housing and the Motor Body.

7. Inspect the Motor End Plate, Body, and Gerotor Housing for

signs of wear or gouging. If wear or gouging has occurred in both

the Motor End Plate, and Body, these components must be

replaced. If the Gerotor Housing is damaged, the Gerotor parts

must also be replaced.

8. While the Motor is disassembled, clean all components in an

approved part cleaning solvent.

- 4 -

Page 5

REMOVING THE SHAFT ASSEMBLY FROM THE

MOTOR BODY

1. Remove the Slinger Ring from the Motor Shaft.

WARNING: Always wear safety goggles when working with

spring or tension loaded fasteners or devices.

2. Remove the Retaining Ring next to the Ball Bearing in the Front

Motor Body.

NOTE: If the Bearing is binding against the Retaining Ring

preventing easy removal of the Retaining Ring, slide a 1''

diameter section of pipe over the Shaft; then, gently press

down with an Arbor Press to relieve the pressure on the

Retaining Ring.

3. Place the Motor Body in a Support Fixture with the threaded

portion of the Shaft inside the Support Fixture; then, using an

Arbor Press, press the Shaft Assembly out of the Motor Body

(See Figure 13).

Motor Body

Shaft

Assembly

Support

Fixture

5. Thread the Impeller Nut on the end of the Shaft; then, using an

Arbor Press; press the Shaft through the Bearing, Seal Spacer,

and Seal (See Figure 14).

6. Inspect the sealing area of the Shaft and other components for

wear and replace then if necessary.

INSTALLING THE NEW SHAFT SEAL

1. The sealing lips on a new Seal must be expanded to fit on the

Shaft. Press the Seal onto the large end of the Shaft with the

Seal Lip facing out. Do not push the Seal past the Shaft keyway.

2. Remove the Seal from the Shaft after the seal lip has been

expanded.

3. With the seal lip facing the large end of the Shaft, slide the Seal

over the threaded end of the Shaft; then, gently push it onto the

raised area of the Shaft, stopping approximately 1/4'' from the

large retaining ring groove.

WARNING: Always wear safety goggles when working with

spring or tension loaded fasteners or devices.

4. Install the Seal Spacer, Thrust Bearing Race, Thrust Bearing,

second Thrust Bearing Race, and the large Retaining Ring over

the threaded end of the Shaft.

INSTALLING THE SHAFT BEARING

FIGURE 13

HYDRAULIC MOTOR SHAFT DISASSEMBLY

WARNING: Always wear safety goggles when working with

spring or tension loaded fasteners or devices.

1. Remove the Large Retaining Ring from the Shaft.

2. Remove the Thrust Bearing Assembly (includes the Thrust

Bearing and two Thrust Bearing Races) from the Shaft and the

Seal Spacer.

3. Remove the Small Retaining Ring next to the Shaft Ball Bearing.

4. Place the Shaft (threaded end up) in a pipe support fixture; then,

place the two Support Bars included in the repair kit opposite

each other and between the Seal on the Shaft and the support

fixture (See Figure 14).

1. Install the Spacer Ring, and Ball Bearing over the threaded

end of the Shaft.

2. Insert the Shaft (threaded end down) into the Support Fixture.

3. Place the two support bars opposite each other and between

the Bearing and the Fixture; then, using an Arbor Press,

carefully press the Shaft down, but allowing enough room for

the Retaining Ring next to the Bearing to be installed.

CAUTION: The Spacer Ring between the Seal and Bearing must

be free floating, not binding.

4. Place the Shaft Assembly into the Motor Body Bearing Bore with

the threaded end facing up (See Figure 15).

FIGURE 14

FIGURE 15

- 5 -

Page 6

NOTE: A fixture is required for the next Step; fabricate this

fixture from a 1'' diameter by 4'' long section of PVC pipe. When

using this fixture make sure all surfaces are clean and the

support edges are smooth.

5. Place the fixture over the Shaft and using an Arbor Press, press

the Shaft Assembly down until the Retaining Rings can be

installed in its groove in the bearing bore of the Motor Body.

WARNING: Always wear safety goggles when working with

spring or tension loaded fasteners or devices.

7. Apply a thin film of oil to the O-ring and install it on the Motor End

Plate.

8. Place the End Plate on the Gerotor Housing, making sure the

holes in the End Plate line up with the Pins in the Gerotor

Housing.

10. Apply a drop of blue anaerobic thread locking compound to the

threads of the four Socket Head Cap Screws; then, using the

four Socket Head Cap Screws, secure the Motor End Plate to the

Gerotor Housing.

6. Install the Retaining Ring into the groove of the Bearing Bore.

HYDRAULIC MOTOR FINAL ASSEMBLY

1. Place the Motor Body in a vise with the large end of the Shaft

facing up.

2. Apply a thin film of oil to the O-ring; then, install the O-ring in the

Motor Body.

3. Install the Woodruff key or Roll Pin on the Shaft; then, place the

Inner Gear onto the Shaft, making sure the Gerotor slot lines up

with the Key in the Shaft.

4. Install the outer portion of the Gerotor, making sure the Gerotor

is centered within the o-ring groove on the Body.

5. Install the Gerotor housing, making sure the pins in the Gerotor

Housing line up with their respective holes in the Body.

6. Apply a thin coating of hydraulic or mineral oil to the area

between the Inner and outer Gerotor, the Outer Gerotor, and the

Gerotor Housing.

Replacement Parts

11. Alternately and evenly, tighten the four Socket Head Cap

Screws to 15 ft lbs. torque.

12. Install a new O-ring in both Port Adapters.

13. Install the Pressure Port Adapter onto the Motor; then, install the

Tank Port Adapter onto the Motor.

14. Remove the Hydraulic Motor from the vise and rotate the Shaft

by hand to check for binding of the Shaft.

15. Install a Slinger ring over the Motor shaft.

16. Apply a drop of blue anaerobic thread locking compound to the

threads of the four Hex Head Bolts; then, using the four Hex

Head Bolts, secure the Motor into the pump Mounting Flange.

17. Alternately and evenly, tighten the four Hex Head Bolts.

To 4700 Hydraulic load

Sensor

PM34300553

To 4700 Hydraulic

Supply

PM34300565

TO 4700 Hydraulic

Return

PM34300555

FIGURE 16

Replacement Components

Control Valve

PM34300552

Complete Motor

PM25000020C1

Motor Supply

PM34300554

Complete Pump

PMXMA4G20ESX

-6-

Bracket & Hardware Kits:

Gun & lance Bracket hardware PM34300561

Pump Mounting Bracket PM34300556

Detergent Injection

See Options (Page 10)

High Pressure Hose

See Options (Page 10)

Unloader

PM339001042B

PM34300557

To Rinse Tank

Page 7

Complete Pump

Part No. PMXMA4G20ESX

1

FIGURE 17

Service Parts for Pressure Pump

10

11

7

6

4

8

5

3

2

9

Piston Kit PMKIT2746

Ref. Description Qty.

8 Piston 3

Valve Kit PM34300424

Ref. Description Qty.

1 Complete Valve 6

2 O-ring 6

Water Seal Kit PMKIT2747

Ref. Description Qty.

4 Gasket 3

6 O-ring 3

5 Gasket 3

Lance

PM3365000436

Oil Seal Kit PMKIT2787

Ref. Description Qty.

10 Cap 1

11 O-ring 1

9 Seal 1

7 Seal 3

Cup Spreader Kit PMKIT2745

Ref. Description Qty.

3 Support Ring 3

Nozzle

PM332420015

Gun

PM33810032

FIGURE 18

Gun, Lance, and Nozzle, Replacement Components

Replacement Hose

Order direct by calling:

1-877-535-5336

Part No. 851-0007

- 7 -

Page 8

Complete Motor

PM25000020C1

6

4

7

8

7

5

1

3

2

FIGURE 19

Service Parts for Hydraulic Motor

Motor Kit PM

Ref. Description Part No. Qty.

1 Retaining Ring PM18100014 1

2 Ball Bearing PM20000010 1

3 Shaft Seal PM21040005 1

4 Thrust Bearing Assembly PM20290014 1

5 Shaft PM05132500 1

6 Key PM16100012 1

7 O-ring PM17200110 2

8 Gerotor PM39000024 1

Unloader Kit PM34300484

Ref. Description Qty.

1 Washer 1

2 O-ring 1

3 O-ring 1

4 O-ring 1

5 Washer 1

6 O-ring 1

7 O-ring 1

8 Valve Seat 1

9 O-ring 1

10 Piston 1

11 Spring 1

12 O-ring 1

13 O-ring 1

1

2

3

4

5

6

Complete Unloader Valve

PM339001042B

7

8

FIGURE 20

Service Parts for Unloader

- 8 -

9

10

11

12

13

Page 9

Hose Reel (PM34300560)

Optional Equipment

Includes:

Reel

Hardware

Jumper Hose

Hose Wrap (PM34300563)

Includes:

Wrap Bracket

Hardware

FIGURE 21

Hose Reel (PM34300560)

FIGURE 22

Hose Wrap (PM34300563)

Detergent Injection Kit (PM34300562)

Includes: Detergent

Attachment Bracket

Hardware

Tube

Strainer

Detergent

One Gallon: U.S. - N209615

Canada - N209616

FIGURE 23

Detergent Injection Kit (PM34300562)

FIGURE 24

Detergent

- 9 -

Page 10

NOTES

- 10 -

Page 11

NOTES

- 11 -

Page 12

Printed in U.S.A.

01/2000

Deere & Company

One John Deere Place

Moline, Illinois 61265

- 12 -

Loading...

Loading...