Page 1

OPERATOR/SERVICE MANUAL

MODELS: SD-43, SD-54, PD-43

PD-54, PDB-43, PDB-54

RHINO MODEL SHOWN: PD54

JOHN DEERE DIESEL

A 100% employee-owned American manufacturer

REVISION: B 6/01 P/N 56322

Page 2

Page 3

TABLE OF CONTENTS

OPERATOR/SERVICE MANUAL

RHINO 43/54

FOREWORD ................................................................................................... 6

LIMITED WARRANTY ....................................................................................... 7

SECTION 1 - TECHNICAL DATA ...................................................................... 9 - 11

1.1 Specifications .......................................................................................... 10

1.2 Engine RPM ............................................................................................ 10

1.3 Machine Data .......................................................................................... 11

1.4 Machine Sound Level Test ...................................................................... 11

SECTION 2 - HEALTH & SAFETY ................................................................... 13 - 19

SECTION 3 - OPERATION ................................................................................. 21 - 29

3.1 Introduction and Operating Principle ...................................................... 22

3.2 Diesel Fuel .............................................................................................. 23

3.3 Engine Break-in ...................................................................................... 23

3.4 Engine Oil and Filter ............................................................................... 23

3.5 Warning Light ......................................................................................... 23

3.6 Hydraulic Oil, Filter, and Breather ......................................................... 23 - 24

3.7 Engine Coolant........................................................................................ 24

3.8 Visual Inspection ..................................................................................... 24

3.9 Air Cleaner .............................................................................................. 24 - 25

3.10 Before Starting ........................................................................................ 25

3.11 To Start ................................................................................................... 25

3.12 To Stop ................................................................................................... 25

3.13 Idling Engine ........................................................................................... 25

3.14 Warming Engine...................................................................................... 25 - 26

3.15 Parking Brake .......................................................................................... 26

3.16 Brake Light ............................................................................................. 26

3.17 To Operate ............................................................................................... 26

3.18 Forward/Reverse/Neutral ........................................................................ 26

3.19 Throttle ................................................................................................... 26

3.20 Gauges ................................................................................................... 26

3.21 Panel Fuse ............................................................................................... 27

3.22 Cold Weather Starting / Intake Heater Button ........................................ 27

3.23 Blade Lever ............................................................................................. 27

3.24 Horn/Back-up Alarm ............................................................................... 27

3.25 ROPS/FOPS/Seat Belt ............................................................................ 27

3.26 Tires/Lugnuts .......................................................................................... 27

3.27 Drum/Scrapers ........................................................................................ 28

3.28 Cleaning .................................................................................................. 28

3.29 Eccentrics ................................................................................................ 28

3.30 Compaction Tips ..................................................................................... 28

3.31 Tie Downs ............................................................................................... 28

3.32 Towing (Bypass) ..................................................................................... 28 - 29

3.33 Storage ................................................................................................... 29

Page 4

SECTION 4 - MAINTENANCE........................................................................... 31 - 55

4.1 Important ................................................................................................. 32

4.2 Maintenance Schedule ............................................................................ 32

4.3 Important Maintenance Information ....................................................... 34

4.4 Engine Oil and Filter ............................................................................... 34

4.5 Additional Service Information .............................................................. 34

4.6 Hydraulic Oil and Filter .......................................................................... 34 - 35

4.7 Hydraulic Breather .................................................................................. 35

4.8 Engine Cooling System........................................................................... 35 - 36

4.8.1 Replacing Engine Coolant......................................................... 36

4.8.2 Adding Engine Coolant ............................................................. 36 - 37

4.8.3 Disposing of Coolant................................................................. 37

4.9 Air Cleaner .............................................................................................. 37

4.9.1 Air Cleaner Service ................................................................... 37

4.9.2 Air Cleaner Replacement .......................................................... 37 - 38

4.9.3 Element Storage ........................................................................ 38

4.10 Fuel Filter ................................................................................................ 38

4.10.1 Water Separator ......................................................................... 38

4.10.2 Fuel Filter Replacement ............................................................ 38 - 39

4.10.3 Bleeding Fuel System ............................................................... 39

4.10.4 Bleeding at Fuel Injection Pump ............................................... 39

4.10.5 Bleeding at Fuel Injection Nozzles ........................................... 39 - 40

4.11 Fan/Alternator Belt ................................................................................. 40

4.12 Grease Fittings ........................................................................................ 40

4.13 Frame Hinge............................................................................................ 40

4.14 Blade Pins ............................................................................................... 40

4.15 Battery ................................................................................................... 40

4.15.1 Servicing Battery....................................................................... 40 - 41

4.15.2 Battery Installation .................................................................... 41

4.15.3 Charging/Jumping Battery ........................................................ 41 - 42

4.16 Engine Crankcase Vent Tube .................................................................. 42

4.17 Engine Valve Clearance .......................................................................... 42

4.18 Emission Regulation/Engine RPM ......................................................... 42

4.19 Fuel Injectors .......................................................................................... 42 - 43

4.19.1 Test Fuel Injection Nozzles ....................................................... 43

4.20 Fuel Tank................................................................................................. 43

4.21 Fuel Lines................................................................................................ 43

4.22 Hydraulic Hoses/Connections ................................................................. 43 - 44

4.23 Forward/Reverse/Neutral Adjustment .................................................... 44

4.24 Neutral Interlock ..................................................................................... 44

4.25 Control Cables: Forward/Reverse, Throttle, Blade................................. 44

4.26 Eccentrics ................................................................................................ 45

4.26.1 Eccentric Housing Oil ............................................................... 45

4.27 Charge System......................................................................................... 45

4.28 Panel Fuse: 20 AMP................................................................................ 45

4.29 Engine Installation Guidelines ................................................................ 45 - 46

4.30 Engine Mounting..................................................................................... 46

4.31 Hardware ................................................................................................. 46

4.31.1 Loctite ....................................................................................... 46

4.32 Roll Over Protective Structures (ROPS)................................................. 46

4.32.1 Maintenance of ROPS/Seat Belts (Inspection & Repair) ......... 46

Page 5

4.33 Horn/Back-up Alarm ............................................................................... 47

4.33.1 Back-up Alarm Switch .............................................................. 47

4.34 Scrapers ................................................................................................... 47

4.35 Troubleshooting ...................................................................................... 48 - 53

4.36 Electrical Troubleshooting ...................................................................... 54

4.37 Service Record ........................................................................................ 55

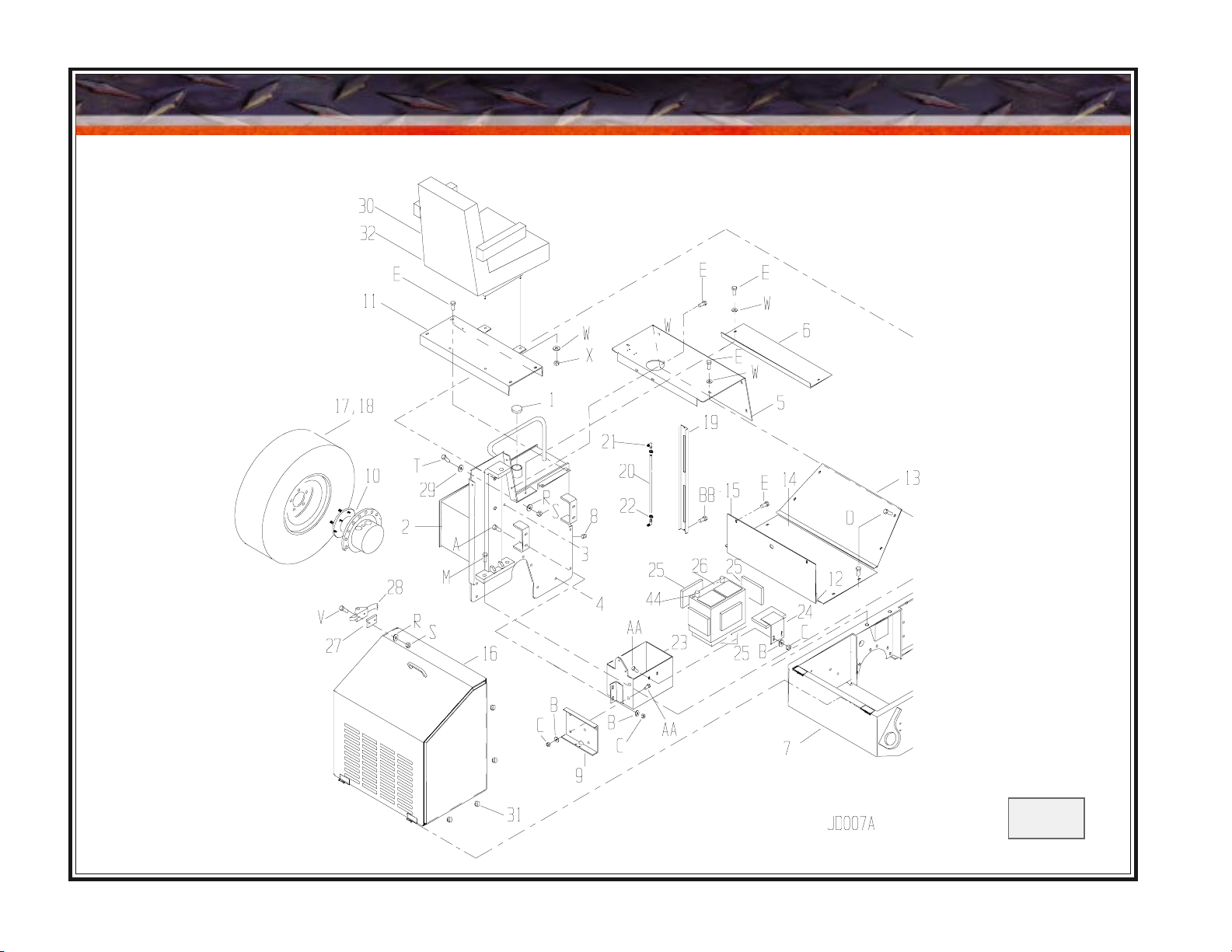

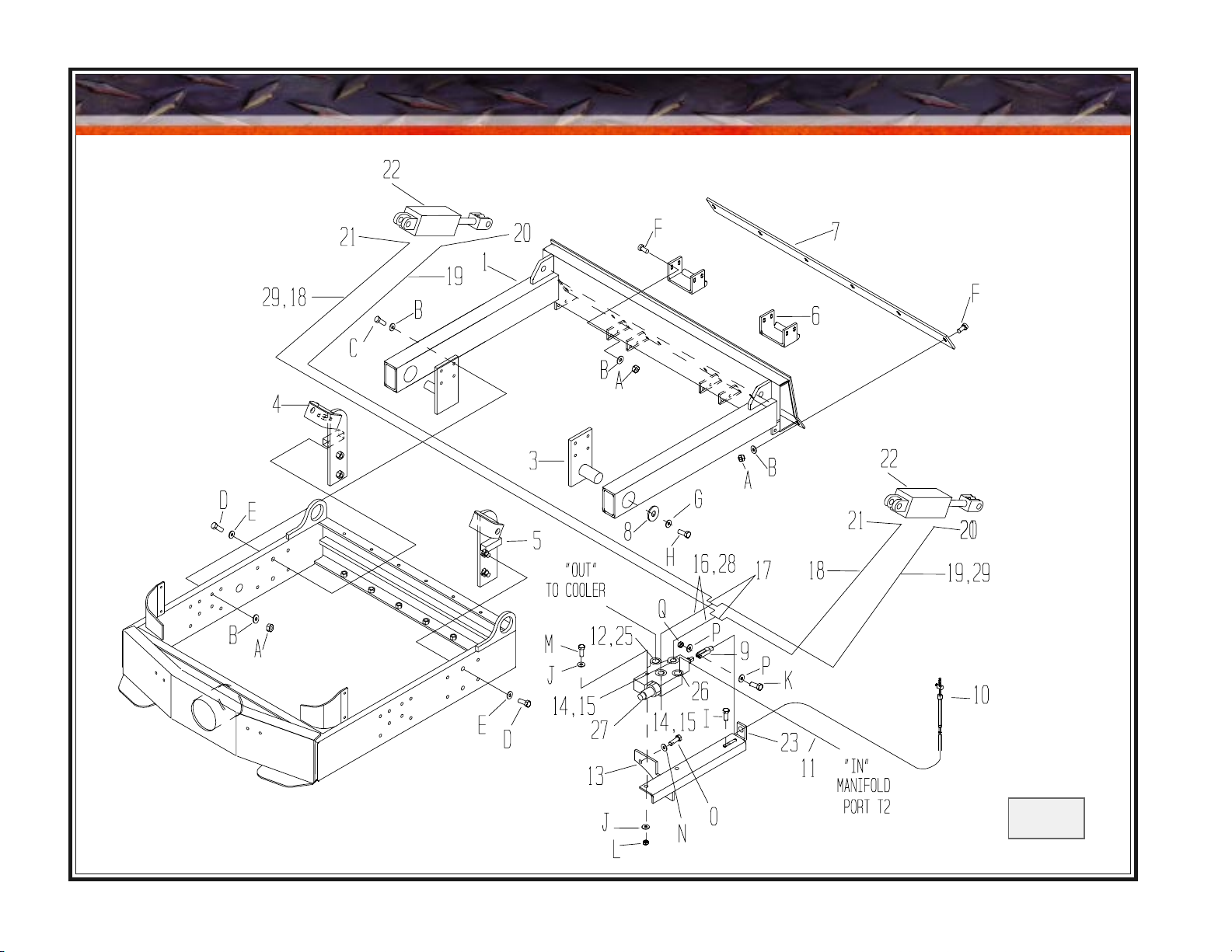

SECTION 5 - EXPLODED DIAGRAMS & PARTS LIST................................ 57 - 97

5.1 Hardware Key ......................................................................................... 59

5.2 Torque Charts and Guidelines ................................................................. 60 - 61

5.3 Drum Assembly ....................................................................................... 62 - 65

5.4 Main Frame ............................................................................................. 66 - 69

5.5 Radiator/Engine Mount ........................................................................... 70 - 71

5.6 Engine ................................................................................................... 72 - 75

5.7 Air Cleaner .............................................................................................. 76 - 77

5.8 Controls ................................................................................................... 78 - 81

5.9 Drive System Hydraulics ........................................................................ 82 - 85

5.10 Steering/Eccentric System Hydraulics .................................................... 86 - 87

5.11 Blade ................................................................................................... 88 - 89

5.12 Hydraulic Schematic ............................................................................... 90 - 91

5.13 Wiring ................................................................................................... 92 - 93

5.14 Decal Identification ................................................................................. 94 - 97

CALIFORNIA PROPOSITION 65 WARNING .............................................................. 99

Page 6

FOREWORD

These instructions include:

Safety regulations

Operating instructions

Maintenance instructions

These instructions have been prepared for

operation on the construction site and for the

maintenance engineer.

These instructions are intended to simplify

operation of the machine and to avoid

malfunctions through improper operation.

Observing the maintenance instructions will

increase the reliability and service life of the

machine when used on the construction site and

reduce repair costs and downtimes.

Always keep these instructions at the place of

use of the machine.

Only operate the machine as instructed and

follow these instructions.

Warranty Information

Please enter the following data. This will help expedite

any service or warranty work.

1. Machine Type: _______________________

Machine S/N: ________________________

2. Engine Type: _________________________

Engine S/N: __________________________

3. VIN: _______________________________

4. Purchase Date: _______________________

5. Dealer/Distributor Information:

Name: ______________________________

Address: ____________________________

____________________________________

Observe the safety regulations as well as the

guidelines of the civil engineering trade

association. Observe safety rules for the

operation of equipment and the pertinent

regulations for the prevention of accidents.

Stone Construction Equipment, Inc. is not liable

for the function of the machine when used in an

improper manner and for other than the intended

purpose.

Operating errors, improper maintenance and the

use of incorrect operating materials are not

covered by the warranty.

The above information does not extend the

warranty and liability conditions of business of

Stone Construction Equipment, Inc.

Stone Construction Equipment, Inc.

P.O. Box 150, Honeoye, New York 14471

Phone: (800) 888-9926

Fax: (716) 229-2363

Phone #: ____________________________

Fax #: ______________________________

Location of above information:

1. Information on S/N tag.

2. Information on engine tag.

3. Information on S/N tag - if applicable.

4. Date you purchased machine.

5. Dealer machine was purchased from.

- 6 -

Page 7

L i m i t e d W a r r a n t y

The Manufacturer warrants that products manufactured shall be free from defects in material and

workmanship that develop under normal use for a period of 90 days for concrete vibrators and electric

pumps, one year for Rhino®, Bulldog®, Wolfpac Rollers, trowels, Stompers®, saws, forward plates,

engine powered pumps, and 6 months for all other products from the date of shipment. The foregoing

shall be the exclusive remedy of the buyer and the exclusive liability of the Manufacturer. Our warranty

excludes normal replaceable wear items, i.e. gaskets, wear plates, seals, O-rings, V-belts, drive chains,

clutches, etc. Any equipment, part or product which is furnished by the Manufacturer but manufactured by

another, bears only the warranty given by such other manufacturer . (The Manufacturer extends the warranty

period to “Lifetime” for the drum bearings and seals for the mortar mixers, and agrees to furnish, free of

charge, the bearings and seals only upon receipt of the defective parts. The warranty is two years for

eccentric bearings on the forward plate compactors, mortar and plaster mixer drums, trowel gearboxes

and five years on the Bulldog trench roller eccentric bearings.) A Warranty Evaluation Form must accompany

all defective parts. Warranty is voided by product abuse, alterations, and use of equipment in applications

for which it was not intended, use of non-manufacturer parts, or failure to follow documented service

instructions. The foregoing warranty is exclusive of all other warranties whether written or oral, expressed

or implied. No warranty of merchantability or fitness for a particular purpose shall apply. The agents,

dealer and employees of Manufacturer are not authorized to make modification to this warranty , or additional

warranties binding on Manufacturer. Therefore, additional statements, whether oral or written, do not

constitute warranty and should not be relied upon.

The Manufacturer’s sole responsibility for any breach of the foregoing provision of this contract, with respect

to any product or part not conforming to the Warranty or the description herein contained, is at its option (a)

to repair, replace or refund such product or parts upon the prepaid return thereof to location designated

specifically by the Manufacturer. Product returns not shipped prepaid or on an economical transportation

basis will be refused (b) as an alternative to the foregoing modes of settlement - the Manufacturer’s dealer

to repair defective units with reimbursement for expenses, except labor, and be reviewed with the

Manufacturer prior to repair. A Warranty Evaluation Form must accompany all warranty claims.

Except as set forth hereinabove and without limitation of the above, there are no warranties or other

affirmations which extends beyond the description of the products and the fact hereof, or as to operational

efficiency, product reliability or maintainability or compatibility with products furnished by others. In no

event whether as a result of breach of contract or warranty or alleged negligence, shall the Manufacturer

be liable for special or consequential damages including but not limited to: Loss of profits or revenues, loss

of use of the product or any associated product, cost of capital, cost of substitute products, facilities or

services or claims of customers.

No claim will be allowed for products lost or damaged in transit. Such claims should be filed with the carrier

within fifteen days.

Effective April 1, 1998.

Bred Tough, Technology Born T o Work.

The Way It Ought T o Be.

Stone Construction Equipment, Inc.

32 East Main Street, P . O. Box 150

Honeoye, NY 14471-0150

- 7 -

Phone: 1-800-888-9926 • 1-716-229-5141

Fax: 1-716-229-2363

www.stone-equip.com • e-mail: sceny@mcimail.com

4/98 P/N 51018

Page 8

Page 9

1. TECHNICAL DATA

- 9 -

Page 10

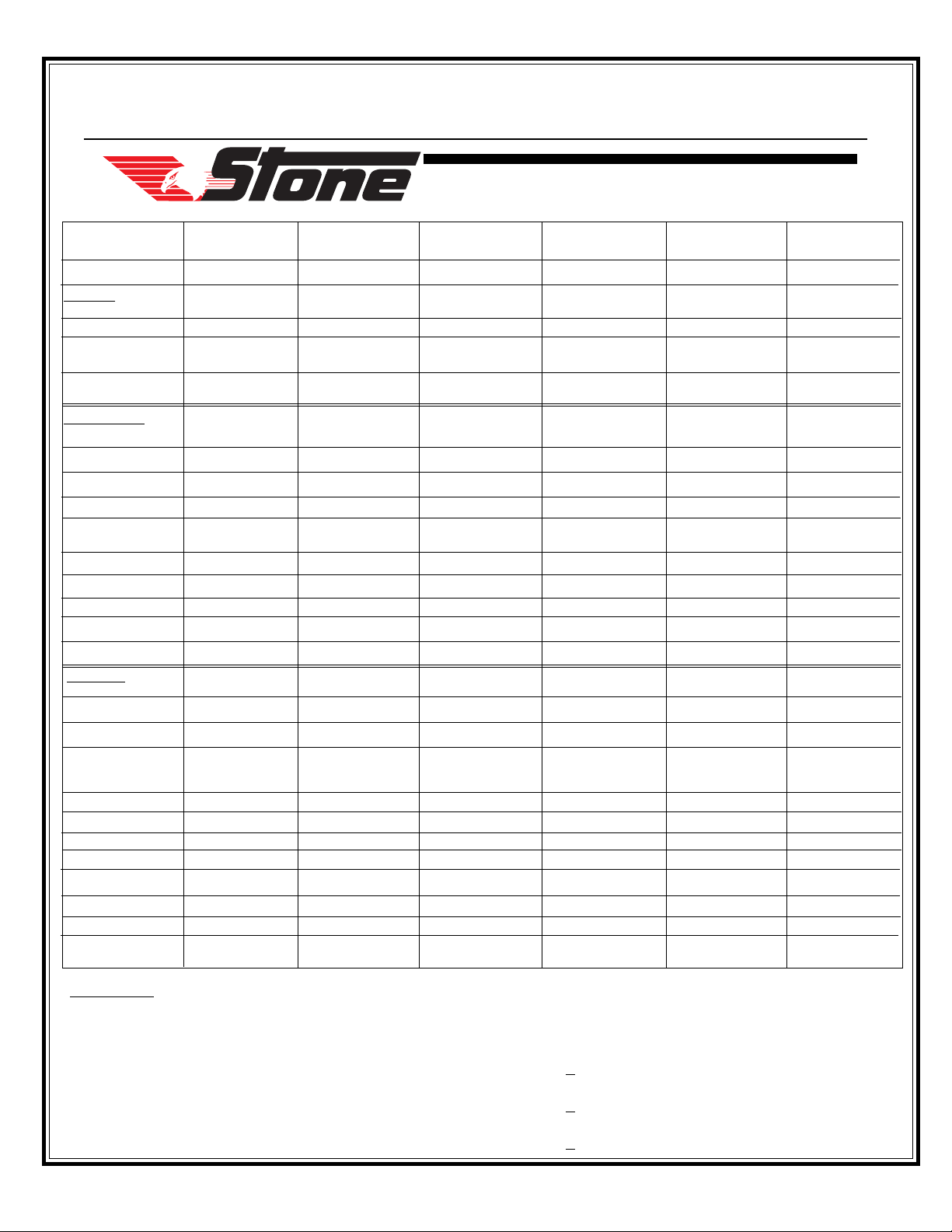

1. TECHNICAL DATA

MODEL

Drum Type

Dimensions

Operating Wt. (Kg)

Drum Width (cm)

H x L x W (cm)

Tires (cm)

Operating System

Engine (kW)

RPM (Hertz)

Fuel Capacity (liters)

Steering

Frame

Drive System

Eccentric Drive

Cooling

Parking Brake

Security Braking Sys.

Performance

Centrifugal Force (Kn)

Frequency (Hertz)

Total Applied Force

(Kn)

Speed

Low Gear

High Gear

(kilometers/hour)

Amplitude (mm)

Articulating Angle

Oscillating Angle

Gradeability

Inside Turning Radius

(meter)

Wall Clearance (cm)

Curb Clearance (cm)

Area Cap.

(Sq.Ft./Hr.) (M2)

STONE

SD 43

Smooth

6100# (2767)

43" (109,2)

97" x 124" x 51"

(246,4 x 315 x 124,5)

9.5 x 16 (24,1 x 40,6)

Diamond Tread

58 hp John Deere

(43.25)

2500 (41,7)

20 gal. (757)

Power

Articulating,

Oscillating

Positraction

Hydrostatic

Water

Mechanical

Hydrostatic

12,000# (53,38)

2100 (35)

14,900# (66,28)

0-2 mph (0-3,22)

0-4 mph (0-6,44)

.071" (1,80)

o

35

o

9

90%

94.25" (2,39)

2 1/2" (6,35)

14" (35,56)

37,840 sq.ft/hr.

(3515,5)

STONE

SD 54

Smooth

6540# (2966,5)

54" (137,2)

97" x 124" x 59"

(246,4 x 315 x 149,9)

9.5 x 16 (24,1 x 40,6)

Diamond Tread

58 hp John Deere

(43.25)

2500 (41,7)

20 gal. (757)

Power

Articulating,

Oscillating

Positraction

Hydrostatic

Water

Mechanical

Hydrostatic

12,000# (53,38)

2100 (35)

15,100# (67,17)

0-2 mph (0-3,22)

0-4 mph (0-6,44)

.062" (1,57)

o

35

o

9

90%

88.75" (2,25)

2 1/2" (6,35)

14" (35,56)

47,520 sq.ft/hr.

(4414,8)

1.1 Specifications Stone Rhino

STONE

PD 43

Padfoot

6409# (2907,1)

43" (109,2)

97" x 124" x 51"

(246,4 x 315 x 124,5)

9.5 x 16 (24,1 x 40,6)

Cleated Tractor

58 hp John Deere

(43.25)

2500 (41,7)

20 gal. (757)

Power

Articulating,

Oscillating

Positraction

Hydrostatic

Water

Mechanical

Hydrostatic

12,000# (53,38)

2100 (35)

15,209# (67,65)

0-2 mph (0-3,22)

0-4 mph (0-6,44)

.059" (1,50)

o

35

o

9

70%

94.25" (2,39)

2 1/2" (6,35)

14" (35,56)

37,840 sq.ft/hr.

(3515,5)

STONE

PD 54

Padfoot

6880# (3120,7)

54" (137,2)

97" x 124" x 59"

(246,4 x 315 x 149,9)

9.5 x 16 (24,1 x 40,6)

Cleated Tractor

58 hp John Deere

(43.25)

2500 (41,7)

20 gal. (757)

Power

Articulating,

Oscillating

Positraction

Hydrostatic

Water

Mechanical

Hydrostatic

12,000# (53,38)

2100 (35)

15,419# (68,59)

0-2 mph (0-3,22)

0-4 mph (0-6,44)

.053" (1,35)

o

35

o

9

70%

88.75" (2,25)

2 1/2" (6,35)

14" (35,56)

47,520 sq.ft/hr.

(4414,8)

STONE

PD 54

Padfoot

6880# (3120.7)

54" (137.2)

97' x 124' x 59'

(246.4 x 315 x 149.9)

9.5 x 16 (24.1 x 40.6)

Cleated Tractor

58 hp John Deere

(43.25)

2500 (41.7)

20 gal (757)

Power

Articulating

Oscillating

Positraction

Hydrostatic

Water

Mechanical

Hydrostatic

12,000# (53,38)

2100 (35)

15,808# (70,32)

0-2 mph (0-3,22)

0-4 mph (0-6,44)

.059" (1,50)

o

35

o

9

70%

94.25" (2,39)

7" (17,78)

14" (35,56)

37,840 sq.ft/hr.

(3515,5)

®

STONE

PDB 54

Padfoot w/blade

7275# (3300)

54" (137,2)

97" x 136" x 68"

(246,4 x 315 x 172,7)

9.5 x 16 (24,1 x 40,6)

Cleated Tractor

58 hp John Deere

(43.25)

2500 (41,7)

20 gal. (757)

Power

Articulating,

Oscillating

Positraction

Hydrostatic

Water

Mechanical

Hydrostatic

12,000# (53,38)

2100 (35)

16,075# (71,51)

0-2 mph (0-3,22)

0-4 mph (0-6,44)

.053" (1,35)

o

35

o

9

70%

88.75" (2,25)

7" (17,78)

14" (35,56)

47,520 sq.ft/hr.

(4414,8)

Standard Features: 2 drum scrappers; ROPS/FOPS; gauges – oil pressure, volt meter, coolant temp, hour meter, fuel sight, hydraulic oil sight; warning lights - oil pressure and

temperature; horn; back-up alarm; neutral safety start; padded seat w/flip-up arm rests; seat belt; secondary parking brake

1.2 ENGINE RPM

IDLE RPM 1,200 + 100 18Hz

FULL RPM 2,500 + 100 41Hz

ECCENTRIC FULL SPEED RPM 2,100 + 100 34Hz

- 10 -

Page 11

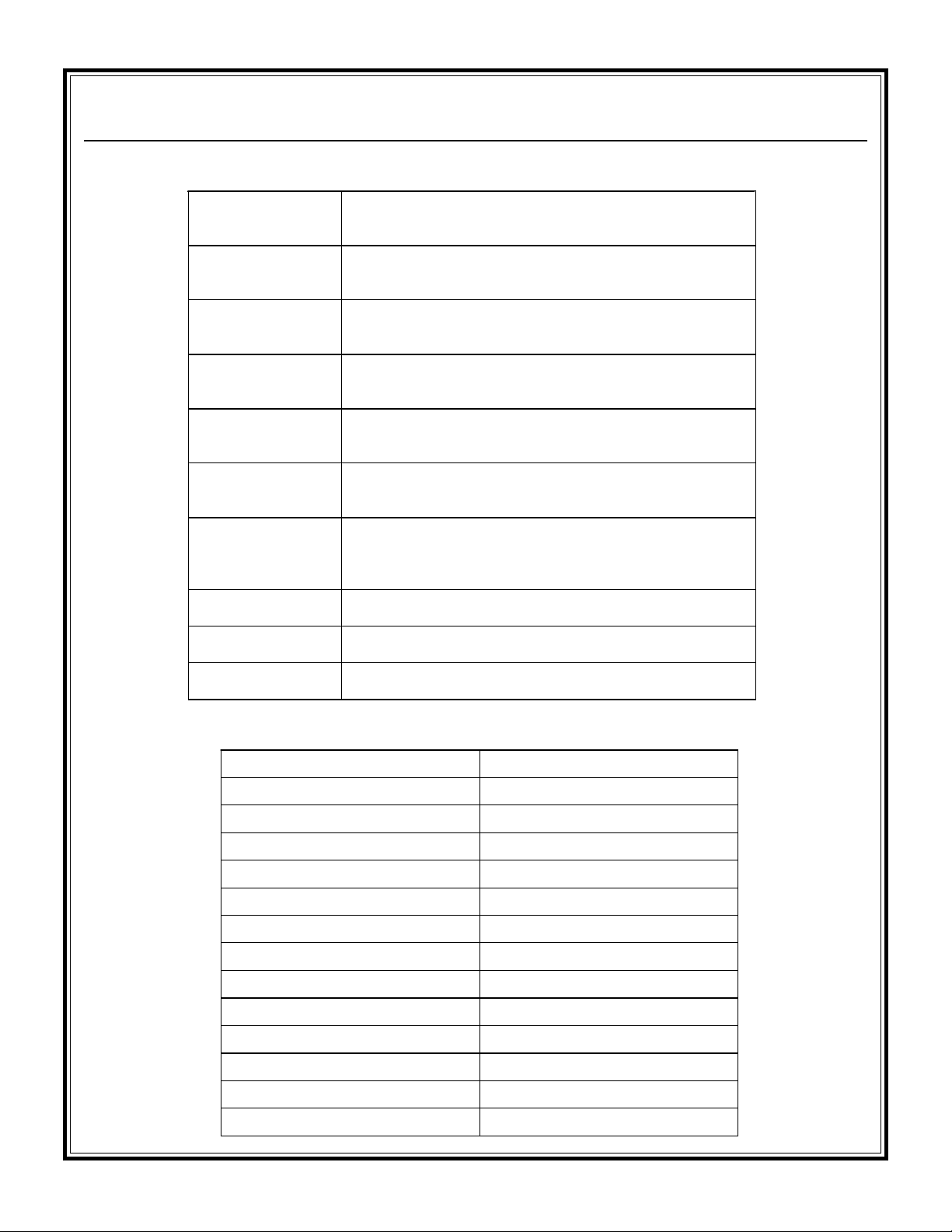

1. TECHNICAL DATA

1.3 MACHINE DATA

Brakes

Service

Parking

Recommended Fuel Diesel fuel blend meeting ASTM D975 or EN 590

Premium diesel fuel conditioner is also recommended

Electric 12 Volt system battery BCI group 24

Hydraulic Oil Mobilfluid 424

Engine Oil 1st 100 hours John Deere br eak-in oil (T Y22041) then

SAE 15W/40 API CG-4 or API CF-4 6.5 quarts (6.0 liters)

Engine Coolant 50/50 Mixture antifreeze / distilled water meeting ASTM 4985,

coolant additive is also recommended

Eccentric Oil SAE 20W/50 API SJ or API SH

Hydrostatic

Automatic spring applied

800 CCA 78 amp charge system

Capacity 20 gallons (76 liters)

SD / PD 43: 1 quart (.95 liter)

SD / PD 54: 15 quarts (1.4 liters)

Engine / HP John Deere 3029DF 58 HP (43 kW) int. @ 2,500 RPM

Torque 153 ft. lbs. (208 Nm) int. @ 1,200 RPM

Fuel Economy .377 lb./hp - hr. (230 g/kWh) @ 1,600 RPM

1.4 MACHINE SOUND LEVEL TEST

Machine Type: PDB54 Rhino

Sound Level Meter Calibration Date: August 6, 1997

Meter Type: Simpson Model 886-2 Type 2

Test Date: August 6, 1997

Test Conditions:

Temperature 70° Fahrenheit / 20° Celsius

Ambient Sound 60 dba Slow Mode

Soil Condition Silts and Clays

Moisture Limit N/A

Engine Speed: 2,500 RPM / 41 Hz

Frequency: 2,100 VPM / 34 Hz

Test Site: Honeoye, New York, USA

Sound Level at Operator Position: 93 dba Without Vibe

93 dba With Vibe

- 11 -

Page 12

Page 13

2. HEALTH & SAFETY

- 13 -

Page 14

2. HEALTH & SAFETY

SAFETY USE

These machines are designed to carry out the function

of compacting material of the non-cohesive, bituminous

and granular varieties.

Safety Precautions

If used correctly they will provide an effective and safe

means of compaction and meet the appropriate

performance standards.

It is essential that the operator of the machine is

adequately trained in its safe operation, be authorized

to operate it, and have sufficient knowledge of the

machine to ensure that it is in full working order before

being put to use.

- 14 -

Page 15

2. HEALTH & SAFETY

Safety Precautions

Before using this equipment, study this entire manual

to become familiar with its operation. Do not allow

untrained or unauthorized personnel, especially

children, to operate this equipment. Use only factory

authorized parts for service.

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages and decals in this manual

and on your machine safety signs. Keep decals in good

condition. Replace missing or damaged decals. Be sure

new equipment components and repair parts include the

current safety signs. Replacement safety signs and decals

are available through your dealer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machine in proper working condition.

Unauthorized modifications to the machine may impair the

function and/or safety and affect machine life.

When warning decals are destroyed or missing, contact

the Manufacturer immediately at 1-800-888-9926 for

replacement. For the safety of yourself and others, it is

imperative that the following rules are observed.

Failure to do so may result in serious injury or death.

If you do not understand any part of this manual and need

assistance, contact your dealer.

UNDERSTAND SIGNAL WORDS

A signal word DANGER, WARNING, or CAUTION is

used with the safety-alert symbol. DANGER identifies the

most serious hazards.

DANGER or WARNING safety signs are located near

specific hazards. General precautions are listed on

CAUTION safety signs. CAUTION also calls attention to

safety messages in this manual.

This notation appears before warnings in the text. It means that

the step which follows must be carried out to avoid the possibility

of personal injury or death. These warnings are intended to help

the technician avoid any potential hazards encountered in the

normal service procedures. We strongly recommend that the

reader takes advantage of the information provided to prevent

personal injury or injury to others.

- 15 -

Page 16

2. HEALTH & SAFETY

USE COMMON SENSE WHEN HANDLING FUELS

Transport and handle fuel only when contained in approved safety

container.

Do not smoke when refueling or during any other fuel handling

operation.

Do not refuel while the engine is running or while it is still hot.

If fuel is spilled during refueling, wipe it off from the engine

immediately and discard the rag in a safe place.

Do not operate the equipment if fuel or oil leaks exist - repair

immediately.

Never operate this equipment in an explosive atmosphere.

Operator must always be seated with seat belt on when

roller is running.

Never allow more than one person on roller.

Always turn engine off before dismounting from roller.

Always apply parking brake when not in use.

Never park roller on a hill.

Never operate roller on slope greater than 15 degrees.

Do not operate the roller in standing water.

Safety Precautions

Ear protection required when operating this equipment.

Exposure to loud noise can cause impairment or loss of

hearing.

HOT SURFACES

Muffler, engine, and engine shroud may be hot.

Allow all components in the engine compartment to cool before

performing any service work.

Never operate unit in a poorly ventilated or enclosed area.

Avoid prolonged breathing of exhaust gases.

Engine exhaust fumes can cause sickness or death.

- 16 -

Page 17

2. HEALTH & SAFETY

Qualified personnel only. No untrained operators. Serious injury may

occur.

Users must be trained to operate this roller. Read the Operator's

Manual and Engine Owner's Manual. Learn to operate this roller

safely.

Do not articulate on grades larger than 15o, roller may tip over.

Do not operate across the sides of hills, roller may tip over.

Do not operate at the edge of mats or roads, roller may tip over.

Do not stand. Be seated, with seat belt on, when roller is running.

Do not park the roller on hills.

Always turn off engine and apply brake before dismounting.

Caution: Escaping hydraulic fluid under pressure can have sufficient

force to penetrate the skin, causing serious personal injury.

Hydraulic system produces high pressures--incorrect hose replacement

can cause serious personal injury. When performing service, refer to

Operator's Manual for hose identification and connections.

Hydraulic fluid escaping under pressure from a very small hole can be

almost invisible. Use a piece of cardboard or wood to search for

possible leaks.

Never use your hands to detect pressure leaks.

Hydraulic tank temperature can reach 180

Safety Precautions

o

F maximum.

SERVICE COOLING AND HYDRAULIC SYSTEMS SAFELY

Pressurized release of fluids from hydraulic or coolant systems can

cause serious burns.

Shut off engine. Only remove filler cap when cool enough to touch

with bare hands. Slowly loosen cap to first stop to relieve pressure

before removing completely.

Never perform any work on the roller while it is running. Before

working on the roller, stop the engine and disconnect the spark plug

wire(s) to prevent accidental starting, block drums to prevent rolling.

Keep engine cover closed during the operation.

Keep hands, clothing and jewelry away from all moving parts.

Keep all guards in place.

- 17 -

Page 18

2. HEALTH & SAFETY

Keep feet clear of all drums.

Keep work area free of bystanders.

For foot protection wear steel toe shoes or toe pads.

Caution: Keep away from the machines articulation area

when the engine is running.

Only start engine from operators seat.

Before starting machine, make sure that there are no persons

or obstacles near or under machine.

PRACTICE SAFE MAINTENANCE

Understand service procedure before doing work. Keep area clean

and dry.

Safety Precautions

Never lubricate, service, or adjust machine while it is moving. Keep

hands, feet, and clothing from power-driven parts. Disengage all

power and operate controls to relieve pressure. Lower equipment

to the ground. Stop the engine. Remove the key. Allow machine

to cool.

Securely support any machine elements that must be raised for

service work.

Keep all parts in good condition and properly installed. Fix damage

immediately. Replace worn or broken parts. Remove any buildup

of grease, oil, or debris.

Disconnect battery ground cable (-) before making adjustments on

electrical systems or welding on machine.

PREPARE FOR EMERGENCIES

Be prepared if a fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service, hospital,

and fire department near your telephone.

- 18 -

Page 19

2. HEALTH & SAFETY

Starting fluid (ether) is highly flammable. Do not use or an explosion

or fire may result.

WEAR PROTECTIVE CLOTHING

Wear close fitting clothing and safety equipment appropriate to

the job.

Prolonged exposure to loud noise can cause impairment or loss of

hearing.

Wear a suitable hearing protective device such as earmuffs or

earplugs to protect against objectionable or uncomfortable loud

noises.

Operating equipment safely requires the full attention of the

operator. Do not wear radio or music headphones while

operating machine.

Safety Precautions

PREVENT BYPASS STARTING

Avoid possible injury or death from engine runaway.

Do not start engine by shorting across starter terminal. Engine will

start with drive system engaged if normal circuitry is bypassed.

Start engine only from operators seat with seat belt on and

forward/reverse in neutral.

DISPOSE OF WASTE PROPERLY

Improperly disposing of waste can threaten the environment and

ecology. Potentially harmful waste used with John Deere equipment

includes such items as oil, fuel, coolant, brake fluid, filters, and

batteries.

Use leakproof containers when draining fluids. Do not use food or

beverage containers that may mislead someone into drinking from

them.

Do not pour waste onto the ground, down a drain, or into any water

source.

Air conditioning refrigerants escaping into the air can damage the

Earths atmosphere. Government regulations may require a certified

air conditioning service center to recover and recycle used air

conditioning refrigerants.

Inquire on the proper way to recycle or dispose of waste from your

local environmental or recycling center.

- 19 -

Page 20

Page 21

3. OP ERATION

- 21 -

Page 22

3. OPERATION

3.1 INTRODUCTION AND OPERATING PRINCIPLE

This roller is ergonomically engineered to optimize operator interface with the total machine its really user

friendly. Besides good visibility to the roll-edge, as well as the work surface, youll find that the controls are

exactly in the right places for maximum comfort. And it is very convenient to monitor all the consumables fuel,

hydraulic oil, etc.

Our common sense approach to servicing is a valuable benefit. Thanks to our modular design, everything that

needs servicing is located behind one of the easy-access service panels or is under the rear cowl.

For maneuverability and productivity, nothing beats the proven performance of center-point articulation. Because

the drum and tires track each other exactly, tight turns are achieved smoothly. The roller is equipped with full

positive traction, front to rear and side to side, which keeps the roller moving through various conditions.

Theres power steering a feature no operator wants to be without. A variable hydrostatic drive system provides

infinitely variable speed control from 0 to 4 mph. The eccentric delivers a centrifugal force sufficient to

compact all types of soil. Superior vibration isolation to the operator is achieved by mounting heavy-duty shock

mounts between the eccentric and support frames.

The following instructions were compiled to provide you information on how to obtain long and trouble-free use

of the roller. Periodic maintenance of the roller is essential. Read this manual in its entirety and follow the

instructions carefully. Failure to do so may cause injury to you or a bystander.

- 22 -

Page 23

3. OPERATION

3.2 DIESEL FUEL

Do not mix oil with fuel. The engine has a separate oil

reservoir in the crankcase. Diesel fuel blend meeting

ASTM D915 or EN590 and a premium diesel fuel

conditioner is recommended.

WARNING

FUEL IS BOTH TOXIC AND FLAMMABLE. DO

NOT SMOKE WHILE WORKING WITH FUEL.

DO NOT USE NEAR OPEN FLAME. ALWAYS

STOP ENGINE BEFORE REFUELING. CLEAN UP

SPILLED FUEL BEFORE STARTING. AVOID

FIRES BY KEEPING ENGINE CLEAN OF

ACCUMULATED GREASE AND DEBRIS.

START, STORE, AND REFUEL ON LEVEL

GROUND TO PREVENT PERSONAL INJURY. DO

NOT RUN UNIT IN AN ENCLOSED, NONVENTILATED AREA. AVOID PROLONGED

BREATHING OF VAPORS AND SKIN CONTACT.

SERIOUS ILLNESS OR LOSS OF LIFE COULD

RESULT.

KEEP THE VENT HOLE IN FUEL TANK CAP

OPEN. IF VENT HOLE IS PLUGGED, PRESSURE

MAY BUILD UP IN TANK, CAUSING

DANGEROUS SPRAYING OF FUEL WHEN TANK

CAP IS REMOVED. A VACUUM MAY ALSO BE

CREATED DURING OPERATION, WHICH

COULD STOP FUEL FLOW. DIESEL FUEL IS

MANDATORY FOR USE IN THIS ENGINE.

ALWAYS USE CLEAN FUEL. LOW QUALITY OR

CONTAMINATED FUEL WILL DAMAGE FUEL

INJECTION COMPONENTS.

DIESEL FUEL STORED IN GALVANIZED

CONTAINERS REACTS CHEMICALLY WITH

THE ZINC COATING ON THE CONTAINER. THE

CHEMICAL REACTION CREATES POWDERY

FLAKES OF ZINC SULFIDE. IF WATER IS

PRESENT IN THE FUEL, A ZINC HYDROXIDE

GEL WILL FORM.

3.3 ENGINE BREAK-IN

IMPORTANT Read Engine Manual for break-in

requirements. 1st 100 hours John Deere break-in oil

only (TY 22041). Do not add oil until level is in the

add area on the dipstick. Do not fill above the

crosshatched area on the dipstick. 1st 100 hours run

engine at full throttle. Operate engine at heavy

loads, do not idle longer than 5 minutes. Check oil

frequently, do not exceed 100 hours with break-in

oil.

3.4 ENGINE OIL AND FILTER

Change oil and filter at 100 hours, then every 250

hours. Use SAE 15W-40 API CG-4 or API CF-4. Refer

to Engine Manual for additional oil types and

recommendations. Do not mix different brands or

types of oil. Mixing oils can degrade lubrication

performance.

3.5 WARNING LIGHT

Unit is equipped with a warning light for low pressure

and/or hot engine temperature.

Specifications:

Oil pressure at full speed: 40 50 psi

(2.75 3.45 bar)

Coolant temperature range: 180° - 202°F

(82° - 94°C)

3.6 HYDRAULIC OIL, FILTER, BREATHER

WARNING

PRESSURIZED RELEASE OF FLUIDS FROM

HYDRAULIC SYSTEM CAN CAUSE SERIOUS

BURNS. SHUT OFF ENGINE. ONLY REMOVE

BREATHER CAP WHEN COOL ENOUGH TO

TOUCH WITH BARE HANDS. SLOWLY LOOSEN

CAP TO FIRST STOP TO RELIEVE PRESSURE

BEFORE REMOVING COMPLETELY.

Check the hydraulic oil level. Use the sight gauge

located on the hydraulic tank. A 1/4 1/2 air bubble

will be seen at the top of the gauge showing the fluid

level.

- 23 -

Page 24

3. OPERATION

For satisfactory operation, the following oil

conditions apply:

1. Accurate level readings can be checked

only when the fluid is cold.

2. If the natural color of the fluid has become black

or milky, it is possible that an overheating or

water contaminant problem exists.

3. Do not mix hydraulic fluids. Mobil 424 is

recommended for the hydraulic system.

CAUTION: After a new unit has run 5 hours, the

oil filter should be changed. This is to rid the

system of any trapped contamination from the wearin of the parts. Refer to Maintenance for hydraulic

filter change.

3.7 ENGINE COOLANT

WARNING

CHECK COOLING SYSTEM CAREFULLY.

EXPLOSIVE RELEASE OF FLUIDS FROM

PRESSURIZED COOLING SYSTEM CAN

CAUSE SERIOUS BURNS.

To check coolant level:

1. Shut off engine, allow to cool.

2. Only remove filler cap when cool enough to

touch with bare hands. Slowly loosen cap to

first stop to relieve pressure before removing

completely.

3. Remove cap, coolant level should just touch the

bottom of radiator filler neck. If coolant is

required, see Adding Coolant in the

Maintenance section of this manual.

IMPORTANT: Do not overfill radiator. Refer to

Coolant Maintenance if additional coolant is

required. Never pour cold liquid into a hot

engine, as it may crack cylinder head or block.

DO NOT operate engine without coolant for even

a few minutes. If coolant leaks or abnormal

temperature is detected, contact a service

technician immediately.

replace the water pump seal. Contact your engine

distributor or servicing dealer for repairs.

3.8 VISUAL INSPECTION

Make a thorough inspection of the engine compartment

daily. Look for oil or coolant leaks, worn fan belt,

loose connections and trash build-up. Remove trash

build-up and have repairs made as needed if leaks are

found.

NOTE:Wipe all fittings, caps, and plugs before

performing any maintenance to reduce the chance of

system contamination.

Air intake system hoses and connections for

cracks and loose clamps.

Fan belt for cracks, breaks, or other damage.

Water pump for coolant leaks.

3.9 AIR CLEANER

IMPORTANT: The air intake system must not leak.

Any leak, no matter how small, may result in engine

failure due to abrasive dirt and dust entering the

intake system.

1. Inspect all intake hoses (piping) for cracks.

2. Check clamps on piping which connect the air

cleaner and engine.

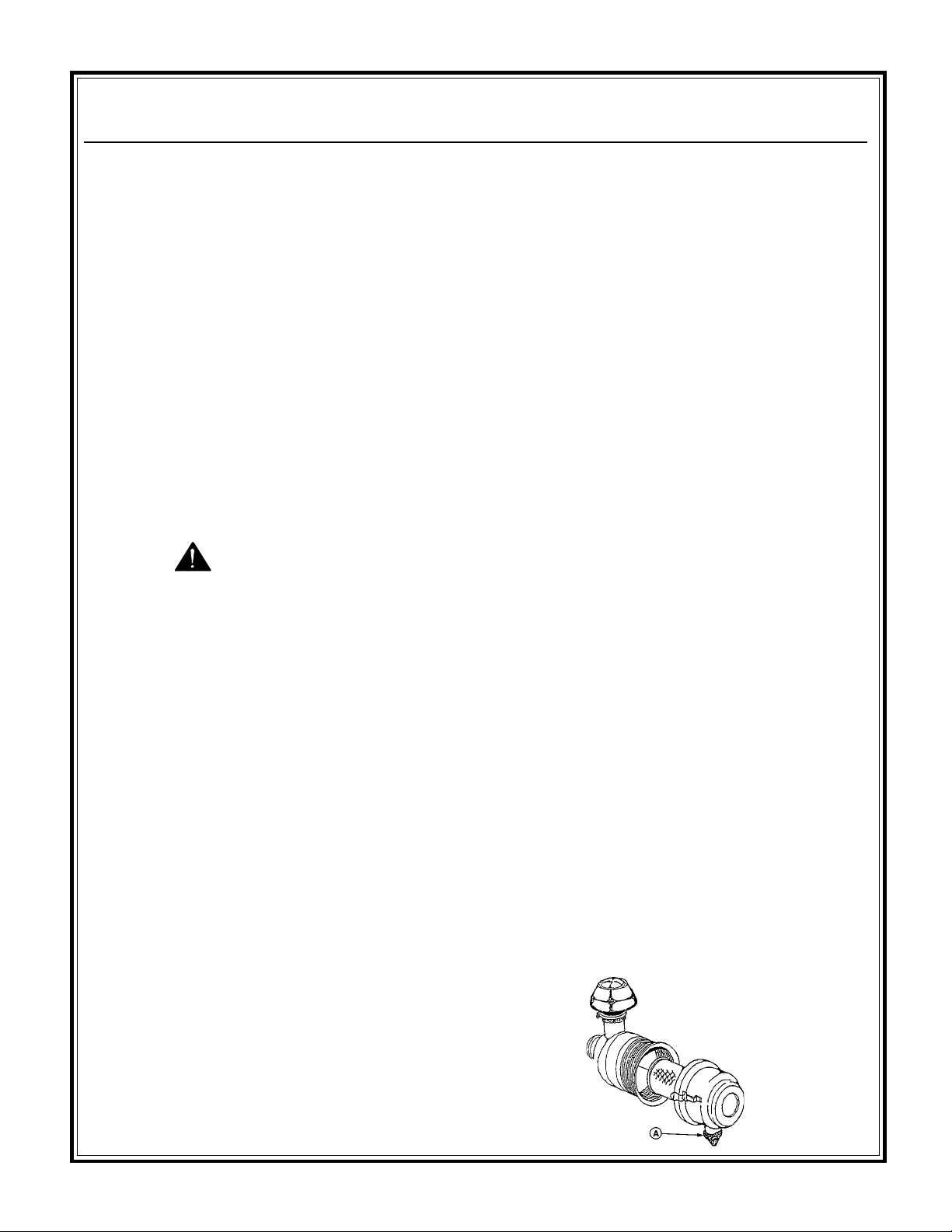

3. Squeeze dust unloader valve (A) on air cleaner

assembly to remove dust deposits. If clogged,

remove and clean the dust unloader valve. Replace

if damaged.

IMPORTANT: Do not operate engine without the

dust unloader valve.

NOTE:It is normal for a small amount of leakage to

occur as the engine cools down and parts contract.

Excessive coolant leakage may indicate the need to

- 24 -

Page 25

3. OPERATION

WARNING

BEFORE STARTING ENGINE IN A CONFINED

BUILDING, INSTALL PROPER OUTLET

EXHAUST VENTILATION EQUIPMENT.

ALWAYS USE SAFETY APPROVED FUEL

STORAGE AND PIPING. NEVER RUN THE

ROLLER WITHOUT THE PANELS IN PLACE OR

SEVERE PERSONAL INJURY MAY OCCUR.

3.10 BEFORE STARTING

1. Check for proper fluid levels, engine oil,

coolant, fuel, and hydraulic oil.

2. Check the air cleaner.

3. Check throttle, levers, and controls for smooth

operation.

4. Check seat belt, horn, and back-up alarm

operation.

3.12 TO STOP

WARNING

ALWAYS OBEY THE FOLLOWING

PROCEDURES BEFORE DISMOUNTING FROM

THE ROLLER.

1. Place the forward/reverse lever in the NEUTRAL

position.

2. Throttle engine down to its slowest speed.

3. Turn key switch to OFF position to stop the

engine. Remove ignition key.

NOTE:Before stopping an engine that has been

operating at working load, idle engine at

least 2 minutes.

3.13 IDLING ENGINE

3.11 TO START

1. Operator must always be seated and seat belt

must be worn.

2. Forward/reverse must be in NEUTRAL position

and eccentric switch should be in OFF position.

3. Throttle should be set at idle.

4. Turn key clockwise until the engine cranks over.

Release the key when the engine starts.

DO NOT crank engine for more than 20

seconds at a time.

5. Check all gauges for normal engine operation.

If operation is not normal, stop the engine and

determine the cause.

NOTE:If temperature is below 0° C (32° F), it may be

necessary to use cold weather starting aid. See Cold

Weather Starting later in this section.

WARNING

DO NOT USE STARTING FLUID (ETHER).

ENGINE IS EQUIPPED WITH INTAKE HEATER.

AN EXPLOSION OR FIRE MAY RESULT. REFER

TO COLD WEATHER STARTING

INSTRUCTIONS.

IMPORTANT: Avoid excessive engine idling.

Prolonged idling may cause the engine coolant

temperature to fall below its normal range. This, in

turn, causes crankcase oil dilution, due to

incomplete fuel combustion, and permits formation

of gummy deposits on valve, pistons, and piston

rings. It also promotes rapid accumulation of

engine sludge and unburned fuel in the exhaust

system.

3.14 WARMING ENGINE

IMPORTANT: To assure proper lubrication,

operate engine at idle with no load for 5 minutes.

Extend this period when operating at temperatures

below freezing.

1. Check oil pressure gauge as soon as engine

starts. If gauge needle does not rise above

minimum oil pressure specification of

(1.05 bar) (15.0 psi) within 5 seconds, stop the

engine and determine the cause. Normal

engine oil pressure is (3.45 bar + 1.03 bar)

(50 + 15 psi) at rated full load speed

(1800 2500 rpm) with oil at normal operating

temperature of 105° C (221° F).

2. Watch coolant temperature gauge. Do not

place engine under full load until it is properly

- 25 -

Page 26

3. OPERATION

warmed up. The normal engine coolant

temperature range is 82° - 94° C (180° - 202° F).

NOTE:It is good practice to operate the engine under

a lighter load and at lower speeds than normal for the

first few minutes after start-up.

WARNING

NEVER OPERATE ON SLOPES GREATER THAN

15 DEGREES OR TIPPING MAY OCCUR.

3.18 FORWARD/REVERSE/NEUTRAL

3.15 PARKING BRAKE

WARNING

BLOCK THE DRUMS TO PREVENT ROLLING

OF THE MACHINE OR SEVERE PERSONAL

INJURY MAY OCCUR. NEVER PARK ROLLER

ON A HILL.

When engine is not running, the brake is applied.

When the engine is running and the forward/reverse

lever is in NEUTRAL, the brake will apply within 2

seconds.

3.16 BRAKE LIGHT

When the key is turned to ON, the brake light should

come on within 2 seconds. Shifting into forward or

reverse, the light should go out.

3.17 TO OPERATE

The forward/reverse lever should be aligned with

NEUTRAL on the console when the roller is moving

neither forward nor backward with the engine running.

The neutral interlock switch should not allow the

engine to start unless the forward reverse lever is in

neutral.

3.19 THROTTLE

Pull throttle out to increase engine speed. Push throttle

to reduce engine speed. For best performance, run

engine at full throttle.

3.20 GAUGES

IMPORTANT: Any time an electric gauge or meter

does not register correctly, replace it with a new

one. Do not attempt to repair it.

Oil Pressure Gauge Indicates engine oil pressure.

IMPORTANT: Follow Manufacturers "Before

Starting" and "Break-in" procedures on engine.

Always allow engine to warm up five minutes

before applying load.

Start and apply full throttle. Move forward/reverse

lever slowly forward to gain speed desired. The same

procedure is for reverse. To slow down, move

forward/reverse lever toward NEUTRAL.

To gain power or speed by moving forward/reverse

lever slightly off of NEUTRAL will produce the

greatest amount of torque. Moving the lever all the

way forward or reverse will give the greatest amount

of speed.

Coolant Temperature Gauge Indicates the

engine coolant temperature.

Volt Meter Indicates charging current within

electrical system.

Hour Meter Indicates the operating hours of the

engine while key switch is in the ON position. The

hour meter should be used as a guide for scheduling

maintenance.

WARNING

AVOID LEAVING THE KEY ON WHEN

MACHINE IS NOT RUNNING. THIS WILL

HAVE AN EFFECT ON THE HOUR METER

READINGS.

- 26 -

Page 27

3. OPERATION

3.21 PANEL FUSE 20 AMP

Protects electrical system.

WARNING

NEVER USE FUSE WITH A DIFFERENT RATING

FROM THAT SPECIFIED. SERIOUS DAMAGE

TO THE ELECTRICAL SYSTEM OR A FIRE MAY

RESULT.

3.22 COLD WEATHER STARTING / INTAKE

HEATER BUTTON

WARNING

DO NOT USE STARTING FLUID (ETHER).

ENGINE IS EQUIPPED WITH AIR INTAKE

HEATER. AN EXPLOSION OF FIRE MAY

RESULT. FOR COLD WEATHER STARTING, SEE

INSTRUCTIONS BELOW.

1. Turn the key to the ON position (do not crank

engine).

2. Press INTAKE HEATER BUTTON for

approximately 30 seconds. Start engine using

starter switch. As soon as the engine starts, release

button.

3. Never operate the starter for more than 20

seconds at a time. If engine does not start,

release the starter switch and wait at least one

minute before trying again.

4. Do not adjust the throttle setting. Allow the

engine to idle for 5 minutes to warm up. At

temperatures below freezing, extend warm up

time.

3.23 BLADE LEVER (OPTIONAL)

3.24 HORN AND BACK-UP ALARM

Check operation daily. It is the drivers responsibility

to operate equipment safely.

3.25 ROPS / FOPS / SEAT BELT

Inspect daily. Certified factory installed for operator

protection. Do not remove or modify.

WARNING

DANGER: AVOID CRUSHING. DO NOT JUMP

IF MACHINE TIPS. ALWAYS WEAR SEAT

BELT.

DO NOT OPERATE THIS MACHINE IF THE

ROLLOVER PROTECTIVE STRUCTURE

(ROPS) IS STRUCTURALLY DAMAGED,

SHOWS CRACKS, IS NOT PROPERLY

SECURED AS ORIGINALLY INSTALLED, OR

HAS BEEN ROLLED. DO NOT REPAIR,

MODIFY, OR ADD ATTACHMENTS TO ROPS

UNLESS AUTHORIZED IN WRITING BY THE

MANUFACTURER.

DO NOT ADD ATTACHMENTS TO THE

MACHINE THAT INTRUDE INTO OPERATORS

PROTECTIVE AREA, REDUCE VISIBILITY,

RESTRICT EMERGENCY EXITS, OR ADD

WEIGHT EXCEEDING CERTIFICATION

WEIGHT OF ROPS. DO NOT OPERATE

MACHINE UNLESS SEAT BELT CONFORMING

TO SAE AND/OR ASAE STANDARDS IS

FASTENED. SEE OPERATORS MANUAL OR

CONTACT YOUR DEALER FOR COMPLETE

INSPECTION REQUIREMENTS AND

MAINTENANCE INSTRUCTIONS.

Controls the leveling blade height for pre-leveling

loose soil.

IMPORTANT: Do not use the blade to dig or

bulldoze or machine damage may occur.

3.26 TIRES/LUG NUTS

WARNING

DO NOT EXCEED RATED PRESSURE 35 PSI.

Clean and check daily:

1. Tires are properly inflated.

2. Lug nuts are in place and tight

190 ft. lbs. (140 Nm).

- 27 -

Page 28

3. OPERATION

3.27 DRUM/SCRAPPERS

Clean and inspect daily to prevent excess mud and

debris from building up. Replace if missing or worn.

Pad drum scrappers are adjustable, see Maintenance

section.

3.28 CLEANING

WARNING

DIRT AND MUD BUILT UP WILL REDUCE

MACHINE PERFORMANCE AND/OR CAUSE

FAILURES.

Use pressurized water to remove dirt and mud. Clean

and inspect entire machine daily. Use extra care when

cleaning radiator and oil cooler.

When cleaning machine, caution should be used

around regulator area. Direct spraying of the

regulator is not good. (Regulator should be covered

or protected if direct spraying will happen).

Excessive water pressure may also loosen wire

connections or start terminals corroding. After

cleaning, all terminals should be dried if wet and

connections checked for proper seating.

3.29 ECCENTRICS

When vibratory compaction is necessary, engage

eccentrics by pushing the vibration switch to the ON

position. For best performance run engine at full

rpm. The eccentrics should be turned off whenever

the roller is stopped or stopped to change direction.

Do not run the eccentric on any non-yielding surface

such as concrete or aged asphalt.

3.30 COMPACTION TIPS

Avoid sharp turns, steer gradually. If articulation is a

new concept, we suggest the operator take 20 minutes

or so to get used to the feel of the unit.

Recommended compaction speed should be at

3 m.p.h. or less to achieve a uniform compaction.

WARNING

DO NOT ARTICULATE ON GRADES LARGER

THAN 15, ROLLER MAY TIP OVER.

DO NOT OPERATE ACROSS THE SIDES OF

HILLS, ROLLER MAY TIP OVER.

DO NOT OPERATE AT THE EDGE OF MATS OR

ROADS, ROLLER MAY TIP OVER.

DO NOT STAND, ALWAYS WEAR SEAT BELT.

3.31 TIE DOWNS

WARNING

TIE DOWNS ARE NOT INTENDED FOR LIFTING

PURPOSES.

Equipment is equipped with front and rear tie down

rings for shipping purposes. Use only these tie downs

to secure unit.

3.32 TOWING (BYPASS)

WARNING

NEVER PUSH OR PULL THE ROLLER WITH THE

ENGINE OFF. WHEN ENGINE IS NOT RUNNING,

THE BRAKE IS APPLIED. WHEN THE ENGINE

IS RUNNING AND THE FORWARD/REVERSE

LEVER IS IN NEUTRAL, THE BRAKE WILL

APPLY WITHIN 2 SECONDS.

In an emergency or during a breakdown, it may be

necessary or desirable to tow the roller. This may be

accomplished by mechanically releasing the brake and

bypassing the transmission pump. If these procedures

are followed carefully, the roller may be moved short

distances at LOW speed without running the engine.

The brake is located in the front wheel motor, which

drives the drum of the roller. There is an access hole in

the front frame to assist in releasing the brake. Refer to

the Drum Assembly #39 22770 Kit Bypass to identify

these parts. The threaded hole in the center of the

wheel motor requires a M12 bolt long enough to extend

beyond the frame when fully engaged. A bolt, washer,

and nut is included in a separate package for this

- 28 -

Page 29

3. OPERATION

purpose. Fully install the nut and washer on the bolt.

Insert this assembly through the hole in the frame such

that the washer is over the hole with the nut against the

outside of this washer. Thread the bolt, finger tight

into the wheel motor to the bottom of the hole. Now

tighten the nut against the washer until the brake is

compressed and released. This should require about 44

ft. lbs. torque. Do not torque the bolt. Be careful not

to over-torque beyond releasing the brake.

The bypass valve is located on the transmission pump.

The seat and battery plate should be removed for

access to the transmission pump. The bypass valve is

controlled by a shaft with cross-drilled holes and

maybe a slot in the end. This shaft may be turned

manually to open the valve and allow the motor to turn.

The valve is fully open with two revolutions of the

shaft. DO NOT OPEN VALVE PAST TWO TURNS.

The valve must be fully closed for normal operation.

The torque required to close the valve is only 7 to 10 ft.

lbs.

DAMAGE MAY RESULT FROM OVERTORQUING.

3.33 STORAGE

IMPORTANT: The front wheel motor has a rubber

plug in the M12 hole to prevent contamination.

Reinstall the rubber plug after towing

1. Store the roller on level ground with drums

blocked and parking brake on.

2. Remove the key. Operations of roller by

untrained persons could result in personal injury.

3. During extended storage, drums can be coated with

any type of oil or grease to prevent rusting.

4. Storage instructions for the engine are stated in the

Engine Manual and should be carried out.

- 29 -

Page 30

Page 31

4. MAINTENANCE

- 31 -

Page 32

4.1 IMPORTANT

F

The person attempting any of the

following maintenance tasks must be

authorized to do so and have read

and understood all sections within

this manual.

- 32 -

Page 33

4. MAINTENANCE

4.2 MAINTENANCE SCHEDULE CHART

- 33 -

Page 34

4. MAINTENANCE

4.3 IMPORTANT MAINTENANCE

INFORMATION

WARNING

REMOVE THE KEY AND / OR DISCONNECT

BATTERY TO AVOID ACCIDENTAL

IGNITION OF ENGINE. SEVERE PERSONAL

INJURY MAY OCCUR. ROLLER MUST BE

PARKED ON LEVEL GROUND WITH

PARKING BRAKE APPLIED, ENGINE OFF,

AND DRUM BLOCKED. NEVER WORK ON

THE ROLLER WITH ENGINE RUNNING.

SEVERE PERSONAL INJURY MAY OCCUR.

ALLOW ALL COMPONENTS IN THE

ENGINE COMPARTMENT TO COOL

BEFORE PERFORMING ANY SERVICE

WORK.

IMPORTANT: Read John Deere Emission

Warranty Statement and Engine Manual before

service or maintenance.

4.4 ENGINE OIL AND FILTER

IMPORTANT: Read Engine Manual and Engine

Break-in covered in Operating section of this

manual.

packing contacts filter housing. DO NOT

overtighten filter element.

7. Install oil pan drain plug.

8. Fill engine crankcase with correct engine oil

through timing gear cover opening of rocker arm

cover opening.

IMPORTANT: Immediately after completing any

oil change, crank engine for 30 seconds without

permitting engine to start. This will help insure

adequate lubrication to engine components

before engine starts.

9. Start engine and run to check for possible leaks.

10. Stop engine and check oil level after 10

minutes. Oil level reading should be between

arrows or within crosshatch of dipstick.

4.5 ADDITIONAL SERVICE INFORMATION

This is not a detailed service manual. If you want more

detailed service information see John Deere Manuals:

55319 Manual Engine

55320 Manual Parts

55321 Manual Technical

4.6 HYDRAULIC OIL/FILTER

Change oil and filter at 100 hours, then every 250

hours. Use SAE 15W-40 API CG-4 or API CF-4.

1. Run engine approximately 5 minutes to warm up

oil. Shut engine off.

2. Remove oil pan drain plug, drain into suitable

container.

3. Drain crankcase oil from engine while warm.

4. Remove and discard oil filter using a filter

wrench.

5. Clean filter mounting pad.

IMPORTANT: Filtration of oils is critical to

proper lubrication. Always change filter

regularly. Use filter meeting John Deere

performance specifications.

6. Oil new filter seal and install new filter element,

tighten approximately 3/4 1 - 1/4 turn after

WARNING

PRESSURIZED RELEASE OF FLUIDS FROM

HYDRAULIC SYSTEM CAN CAUSE SERIOUS

BURNS.

SHUT OFF ENGINE. ONLY REMOVE BREATHER

CAP WHEN COOL ENOUGH TO TOUCH WITH

BARE HANDS. SLOWLY LOOSEN CAP TO FIRST

STOP TO RELIEVE PRESSURE BEFORE

REMOVING COMPLETELY.

ESCAPING HYDRAULIC FLUID UNDER

PRESSURE CAN HAVE SUFFICIENT FORCE TO

PENETRATE THE SKIN, CAUSING SERIOUS

PERSONAL INJURY. HYDRAULIC FLUID

ESCAPING UNDER PRESSURE FROM A VERY

SMALL HOLE CAN BE ALMOST INVISIBLE. USE

A PIECE OF CARDBOARD OR WOOD TO

SEARCH FOR POSSIBLE LEAKS. NEVER USE

YOUR HANDS TO DETECT PRESSURE LEAKS.

- 34 -

Page 35

4. MAINTENANCE

HYDRAULIC TANK TEMPERATURE CAN

REACH 180 DEGREES F MAXIMUM.

Refer to Operating section of this manual for hydraulic

oil conditions and recommendations.

Before disconnecting any hydraulic components, be

sure engine is shut off and relieve all pressure. Before

applying pressure to system, be sure all connections are

tight and lines, fittings, and hoses are not damaged.

IMPORTANT: When hoses, oil filter, and/or

hydraulic components are changed, start the engine

and purge the air from the system prior to checking

the oil level. To do this, idle the engine for three

minutes with control lever in NEUTRAL position.

Slowly engage forward to reverse. This allows fluid

to replace air introduced with filter change. If this

procedure is not followed, partial or complete

failure of the pump may result.

Change hydraulic oil filter at 5 hours then every 100

hours.

1. Remove and discard hydraulic oil filter using a

filter wrench.

2. Oil new filter seal and install new filter element,

tighten approximately 3/4 1 - 1/4 turn after

packing contacts filter housing. DO NOT

overtighten filter element.

IMPORTANT: Immediately after completing filter

change, crank engine for 30 seconds without

permitting engine to start. This will help insure

adequate lubrication to components before engine

starts.

3. Start engine and run to check for possible leaks.

4. Stop engine and replenish hydraulic oil.

WARNING

NEVER OVERFILL THE HYDRAULIC TANK.

USE THE SIGHT GAUGE LOCATED ON THE

HYDRAULIC TANK. A 1/4 1/2 AIR BUBBLE

WILL BE SEEN AT THE TOP OF THE GAUGE

SHOWING THE FLUID LEVEL.

Change hydraulic oil every 800 hours. Use Mobil 424.

1. Run engine approximately 5 minutes to warm up

oil. Shut engine off.

2. Remove breather cap and oil drain plug, drain

into suitable container.

3. Apply thread sealant to breather cap and drain

plug, install drain plug.

4. Fill hydraulic tank with correct hydraulic oil

(approximately 20 gallons). Use the sight gauge to

watch for proper oil level, install breather cap.

IMPORTANT: Immediately after completing oil

change, crank engine for 30 seconds without

permitting engine to start. This will help insure

adequate lubrication to components before engine

starts.

5. Start engine and run to check for possible leaks.

6. Stop engine and replenish hydraulic oil.

4.7 HYDRAULIC BREATHER

Replace every 800 hours or yearly. P/N 35483.

WARNING

PRESSURIZED RELEASE OF FLUIDS FROM

HYDRAULIC SYSTEM CAN CAUSE SERIOUS

BURNS. SHUT OFF ENGINE. ONLY REMOVE

BREATHER CAP WHEN COOL ENOUGH TO

TOUCH WITH BARE HANDS. SLOWLY LOOSEN

CAP TO FIRST STOP TO RELIEVE PRESSURE

BEFORE REMOVING COMPLETELY.

4.8 ENGINE COOLING SYSTEM

WARNING

EXPLOSIVE RELEASE OF FLUIDS FROM

PRESSURIZED COOLING SYSTEM CAN

CAUSE SERIOUS BURNS. SHUT OFF ENGINE.

ONLY REMOVE FILLER CAP WHEN COOL

ENOUGH TO TOUCH WITH BARE HANDS.

SLOWLY LOOSEN CAP TO FIRST STOP TO

RELIEVE PRESSURE BEFORE REMOVING

COMPLETELY.

- 35 -

Page 36

4. MAINTENANCE

WARNING

To check coolant level, refer to Operating section of

this manual and Engine Manual.

Inspect cooling system every 600 hours or 12 months.

1. Check entire cooling system hoses. Replace

hoses when hard, flimsy, or cracked.

2. Thoroughly inspect all cooling system hoses.

Replace hoses when hard, flimsy, or cracked.

IMPORTANT: Air must be expelled from cooling

system when system is refilled. Loosen

temperature-sending unit fitting at rear of cylinder

head to allow air to escape when filling system.

Retighten fitting when all the air has been expelled.

3. Test the coolant solution at 600 hours or 12 month

intervals and whenever excessive coolant is lost

through leaks or overheating to ensure the

necessary protection. Coolant test strips are

available from your John Deere dealer. These test

strips provide a simple, effective method to check

the freeze point and additive levels of your engine

coolant.

4. After 600 hours or 12 months of engine operating

time, recharge your engine coolant with the

recommended amount (see label on container) of

TY16004 or TY16005 Liquid Coolant Conditioner.

ALWAYS maintain coolant at correct level and

concentration. DO NOT operate engine without

coolant for even a few minutes.

If frequent coolant makeup is required, the glycol

concentration should be checked with JT05460

Refractometer to assure that the desired freeze point is

maintained. Follow manufacturers instructions

provided with Refractometer.

Water may be used as coolant in emergency situations

only.

Foaming, hot surface aluminum and iron corrosion,

scaling, and cavitation will occur when water is used as

the coolant, even when coolant conditioners are added.

Drain cooling system and refill with recommended

glycol base engine coolant as soon as possible.

4.8.1 Replacing Engine Coolant

Every 1200 hours or 24 months, the coolant should be

replaced. The coolant system should also be flushed

and pressure tested. Refer to Engine Manual.

4.8.2 Adding Coolant

NOTE: TY16004 or TY16005 Liquid Coolant

Conditioner is a non-chromate inhibitor and should be

used only with low silicate, ethylene-glycol base

antifreeze. It does not protect the cooling system from

freezing. See "Adding Coolant."

Usually recharging your engine coolant with the

recommended amount of TY16004 or TY16005 Liquid

Coolant Conditioner at 600 hours or 12 months of

operation is adequate. However, with a CoolScan

analysis report you will be given a more thorough

evaluation of your engine coolant condition along with

detailed service recommendations. Refer to Engine

Manual.

IMPORTANT: Do not add supplemental coolant

additives when the cooling system is drained and

refilled with John Deere ANTIFREEZE/SUMMER

COOLANT or John Deere COOL GARD.

CAUTION: Explosive release of fluids from

pressurized cooling system can cause serious burns.

Shut off engine. Only remove filler cap when cool

enough to touch with bare hands. Slowly loosen cap to

first stop to relieve pressure before removing

completely.

IMPORTANT: Never pour cold liquid into a hot

engine, as it may crack cylinder head or block. DO

NOT operate engine without coolant for even a few

minutes.

Air must be expelled from cooling system when

coolant is added.

1. Loosen temperature sending unit fitting at rear

of cylinder head to allow air to escape when

filling system.

- 36 -

Page 37

4. MAINTENANCE

IMPORTANT: When adding coolant to the system,

use the appropriate coolant solution. Coolant 50/50

mixture of antifreeze/distilled water meeting ASTM

4985, ASTM D5345 (pre-diluted coolant) or John

Deere COOL-GARD. 50/50 mixture provides

protection to -34° F (-37° C). Do not overfill cooling

system. A pressurized system needs space for heat

expansion without overflowing at top of radiator.

2. Fill until coolant level touches bottom of

radiator filler neck.

3. Tighten fitting when air has been expelled from

system.

4.8.3 Disposing of Coolant

Improperly disposing of engine coolant can threaten

the environment and ecology.

Use leakproof containers when draining fluids. Do not

use food or beverage containers that may mislead

someone into drinking from them.

1. Remove air cleaner cover.

2. Remove primary (outer) element only.

3. Thoroughly clean all dirt from inside filter housing.

4. Air cleaner has rubber dust unloader valve on the

air cleaner. Squeeze valve tip to release any

trapped dirt particles.

5. Inspect filter to determine if it is practical to clean

or for damage after cleaning filter.

a. Hold a bright light inside element and

check carefully for holes. Discard

any element that shows the smallest hole

or rupture.

b. Be sure outer screen is not dented.

Vibration would quickly wear a hole in

filter.

c. Be sure filter gasket is in good condition.

If gasket is damaged or missing, replace

element.

6. Gently pat sides of element with palm of hand to

loosen dirt. DO NOT tap element against a

hard surface.

Do not pour waste onto the ground, down a drain, or

into any water source.

Inquire on the proper way to recycle or dispose of

waste from your local environmental or recycling

center or from your dealer.

4.9 AIR CLEANER

4.9.1 Air Cleaner Service

IMPORTANT: Do not operate engine without the

dust unloader valve.

For daily inspection refer to the Operating section of

this manual.

Clean the primary (outer) filter element every 100

hours.

IMPORTANT: Always replace secondary safety

(inner) filter elements. DO NOT attempt to clean

them. Do not blow air from outside portion of filter

with air nozzle. Wear safety glasses and remove

bystanders.

WARNING

ONLY A SPECIAL AIR CLEANING GUN SHOULD

BE USED. CONCENTRATED AIR PRESSURE

FROM AN ORDINARY AIR NOZZLE MAY

SEVERELY DAMAGE FILTER ELEMENT. DO

NOT EXCEED 30 psi (2.1 bar) WHEN CLEANING

FILTER ELEMENT.

7. Insert the cleaning gun into element, hold air

nozzle about 1" (25.4) mm from perforated metal

retainer. Force air through filter from inside to

outside and move air gun up and down pleats to

remove as much dirt as possible.

8. Repeat steps 6 and 7 to remove additional dirt.

9. Inspect element for damage after cleaning.

Replace element if any damage is found.

Service air cleaner more frequently in dusty conditions.

4.9.2 Air Cleaner Replacement

Replace primary (outer) element every 600 hours.

1. Remove air cleaner cover.

- 37 -

Page 38

4. MAINTENANCE

2. Remove primary (outer) element only.

3. Thoroughly clean all dirt from inside filter housing.

4. Air cleaner has a rubber dust unloader valve on the

air cleaner. Squeeze valve tip to release any

trapped dirt particle.

IMPORTANT: Remove secondary safety (inner)

element ONLY for replacement. DO NOT attempt

to clean, wash, or reuse secondary element.

Replacement of secondary element is usually

necessary ONLY when primary element has a hole

in it.

5. To replace secondary element, remove retaining

nut and secondary element. Immediately replace

secondary element with new element to prevent

dust from entering air intake system.

6. Install new primary element and tighten wing nut

securely. Install cover assembly and tighten

retaining wing nut securely.

4.9.3 Element Storage

Seal element in a plastic bag and store in shipping

container to protect against dust and damage.

NOTE: Air cleaner element MUST BE DRY before

storing in plastic bag.

4.10 FUEL FILTER

4.10.1 Water Separator

Fuel filter is equipped with a water drain plug, check/

drain every 50 hours or 2 weeks.

NOTE: Drain water into a suitable container and

dispose of properly.

1. Loosen drain plug at bottom of fuel filter two or

three turns.

2. Loosen air bleed plug two full turns on fuel filter

base and drain water from bottom until fuel starts

to drain out.

3. When fuel starts to drain out, tighten drain plug

securely by hand or using a coin.

After draining water from the fuel filter, the filter must

be primed by bleeding all air from the fuel system.

4. Operate primer lever of the fuel supply pump until

fuel flow is free from air bubbles.

5. Tighten bleed plug securely by hand or using a

coin, continue operating hand primer until pumping

action is not felt. Push hand primer inward (toward

engine) as far as it will go.

If the fuel system needs further bleeding of air, see

Bleeding Fuel System in Maintenance section of this

manual.

4.10.2 Fuel Filter Replacement

WARNING

ESCAPING FLUID UNDER PRESSURE CAN

PENETRATE THE SKIN CAUSING SERIOUS

INJURY. RELIEVE PRESSURE BEFORE

DISCONNECTING FUEL OR OTHER LINES.

TIGHTEN ALL CONNECTIONS BEFORE

APPLYING PRESSURE. KEEP HANDS AND BODY

AWAY FROM PINHOLES AND NOZZLES THAT

EJECT FLUIDS UNDER HIGH PRESSURE. USE

A PIECE OF CARDBOARD OR PAPER TO

SEARCH FOR LEAKS. DO NOT USE YOUR

HAND.

IF ANY FLUID IS INJECTED INTO THE SKIN, A

DOCTOR FAMILIAR WITH THIS TYPE INJURY

MUST SURGICALLY REMOVE IT WITHIN A

FEW HOURS OR GANGRENE MAY RESULT.

DOCTORS UNFAMILIAR WITH THIS TYPE OF

INJURY MAY CALL THE DEERE & COMPANY

MEDICAL DEPARTMENT IN MOLINE, ILLINOIS,

OR OTHER KNOWLEDGEABLE MEDICAL

SOURCE.

Replace fuel filter every 600 hours or 12 months.

1. Thoroughly clean fuel filter assembly and

surrounding area.

2. Loosen drain plug and drain fuel into a suitable

container.

- 38 -

Page 39

4. MAINTENANCE

NOTE: Lifting up on retaining ring as it is rotated

helps to get it past raised locators.

3. Firmly grasp the retaining ring and rotate it

counterclockwise 1/4 turn. Remove ring with

filter element.

4. Inspect filter mounting base for cleanliness. Clean

as required.

NOTE: Raised locators on fuel filter canister must be

indexed properly with slots in mounting base for

correct installation.

5. Install new filter element onto mounting. Be sure

element is properly indexed and firmly seated on

base. It may be necessary to rotate filter for correct

alignment.

6. Remove filter element from water separator bowl.

Drain and clean separator bowl. Dry with

compressed air. Install water separator bowl onto

new element. Tighten securely.

7. Align keys on filter element with slots in filter

base.

8. Install retaining ring onto mounting base making

certain dust seal is in place on filter base. Hand

tighten ring (about 1/3 turn) until it snaps into

the detent. DO NOT overtighten retaining ring.

A PIECE OF CARDBOARD OR PAPER TO

SEARCH FOR LEAKS. DO NOT USE YOUR

HAND.

IF ANY FLUID IS INJECTED INTO THE SKIN, A

DOCTOR FAMILIAR WITH THIS TYPE INJURY

MUST SURGICALLY REMOVE IT WITHIN A

FEW HOURS OR GANGRENE MAY RESULT.

DOCTORS UNFAMILIAR WITH THIS TYPE OF

INJURY MAY CALL THE DEERE & COMPANY

MEDICAL DEPARTMENT IN MOLINE, ILLINOIS,

OR OTHER KNOWLEDGEABLE MEDICAL

SOURCE.

Whenever the fuel system has been opened up for

service (lines disconnected or filters removed), it will

be necessary to bleed air from the system.

1. Loosen the air bleed vent screw on fuel filter head

two full turns by hand on fuel filter base.

2. Operate supply pump primer lever until fuel flow

is free from air bubbles.

3. Tighten bleed plug securely by hand or using a

coin, continue operating hand primer until pumping

action is not felt. Push hand primer inward (toward

engine) as far as it will go.

4. Start engine and check for leaks.

NOTE: The proper installation is indicated when a

click is heard and a release of the retaining ring is

felt. A plug is provided with the new element for

plugging the used element.

9. Bleed the fuel system. See Bleeding Fuel System

in Maintenance section of this manual.

4.10.3 Bleeding Fuel System

WARNING

ESCAPING FLUID UNDER PRESSURE CAN

PENETRATE THE SKIN CAUSING SERIOUS

INJURY. RELIEVE PRESSURE BEFORE

DISCONNECTING FUEL OR OTHER LINES.

TIGHTEN ALL CONNECTIONS BEFORE

APPLYING PRESSURE. KEEP HANDS AND BODY

AWAY FROM PINHOLES AND NOZZLES THAT

EJECT FLUIDS UNDER HIGH PRESSURE. USE