Page 1

JOHN DEERE

WORLDWIDE COMMERCIAL & CONSUMER

EQUIPMENT DIVISION

Powerhead - PA01186

CS71 20” - UT10919

CS71 24” - UT10920

CS71 28” - UT10921

Powerhead - PA01187

CS81 20” - UT10923

CS81 24” - UT10924

CS81 28” - UT10925

Chain Saws

OPERATOR’S MANUAL

OM PS04120

Revision C

Page 2

INTRODUCTION

Thank You for Purchasing a John

Deere Product

We appreciate having you as a customer and wish you

many years of safe and satisfied use of your machine.

The Operator's Manual

Your operator's manual is for your protection. READ IT.

Keep it handy for reference. Know what you are doing

before you begin assembly of the unit. Proper preparation and upkeep go hand-in-hand with satisfactory performance of the saw and safety.

This manual should be considered a permanent part of

your machine and should remain with the machine if you

sell it.

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to

cause cancer, birth defects or other reproductive harm.

CALIFORNIA PROPOSITION 65

Record your Identification numbers below.

Be sure you have Serial Number and Unit (UT) Number,

your dealer will need these when you order parts.

UT Number _________________________________

Model _____________________________________

Serial Number_______________________________

All information, illustrations and specifications in this manual may vary according to Country requirements and are subject to

change without notice by the manufacturer.

All information, illustrations and specifications in this manual are based on the latest information at the time of publication.

2

The right is reserved to make changes at any time without notice.

©2000 Deere & Co.

English

Page 3

TABLE OF CONTENTS

Product Identification

Chain Saw Components ............................................................................................................................... 4

Safety

Understanding Safety Labels ........................................................................................................................ 5

State and Local Requirements ...................................................................................................................... 5

Precautions Against Kickback ....................................................................................................................... 6

Basic Safety Precautions .............................................................................................................................. 6

Understanding Your Chain Saw Safety Devices ............................................................................................ 8

Assembly

Assembling the Bar and Chain ...................................................................................................................... 9

Operation

Chain Tension ............................................................................................................................................ 11

Breaking-in the Chain ................................................................................................................................. 11

Bucking Spike............................................................................................................................................. 11

Fueling ....................................................................................................................................................... 12

Chain Oil System ........................................................................................................................................ 12

Starting the Engine ..................................................................................................................................... 13

Breaking-in the Engine................................................................................................................................ 13

Stopping the Engine.................................................................................................................................... 13

Carburetor Adjustment................................................................................................................................ 13

Chain Brake Operation ............................................................................................................................... 14

Preparation for Cutting................................................................................................................................ 15

Tree Felling ................................................................................................................................................ 16

Bucking ...................................................................................................................................................... 17

Limbing and Pruning ................................................................................................................................... 18

Maintenance

Maintenance Chart ..................................................................................................................................... 19

Chain Maintenance ..................................................................................................................................... 20

Guide Bar Maintenance .............................................................................................................................. 21

Installing the Safe-T-Tip® Nose Guard........................................................................................................ 22

Fuel Filter ................................................................................................................................................... 22

Air Filter ...................................................................................................................................................... 22

Starter Unit ................................................................................................................................................. 22

Engine ........................................................................................................................................................ 23

Spark Plug.................................................................................................................................................. 23

Spark Arresting Muffler ............................................................................................................................... 23

Chain Brake................................................................................................................................................ 24

Oil Pump (Automatic/Adjustable)................................................................................................................. 24

Bar and Chain Combinations

Recommended Bar and Chain Combinations.............................................................................................. 25

Troubleshooting

Using Troubleshooting Chart ...................................................................................................................... 26

Storage

Storing Chain Saw (1 month or longer) ....................................................................................................... 27

Technical Data

CS71 .......................................................................................................................................................... 27

CS81 .......................................................................................................................................................... 27

Warranty

Limited Warranty ........................................................................................................................................ 28

Federal Emissions Warranty ....................................................................................................................... 29

3English

Page 4

PRODUCT IDENTIFICATION

Chain Saw Components

1

1 - Throttle Trigger Lockout

2 - Half Throttle Lock

3 - Carburetor Adjustment Screws

4 - Front Handle

5 - Chain Brake Lever / Hand Guard

6 - Muffler

7 - Safe-T-Tip®

8 - Compression Relief Valve

9 - Clutch Cover

10 - Choke Lever

11 - Throttle Trigger

4

3

2

12 - Rear Handle

13 - Chain

14 - Guide Bar

15 - Air Filter Cover

16 - Ignition Switch

17 - Fuel Tank Cap

18 - Starter Handle

19 - Oil Tank Cap

20 - Combination Wrench

5

6

12

13

20

11

7

8

10

9

15

14

16

19

4 English

18

17

Page 5

Understanding Safety Labels

SAFETY

This symbol indicates Warning, Danger, and

Caution.

The SAFE-T-TIP® Nose Guard on your bar

nose prevents kickback.

DANGER! Beware of Kickback.

Avoid bar nose contact.

Hold saw properly with both hands.

Wear eye, hearing and head protection when

operating this equipment.

Your manual contains special messages to

bring attention to potential safety concerns,

machine damage as well as helpful operating and servicing information. Please read

all the information carefully to avoid injury

and machine damage.

Wear non-slip, heavy-duty protective gloves

when handling the chain saw and saw chain.

State and Local Requirements

Your saw is equipped with a temperature limiting muffler, a spark

arresting screen and dual bucking spikes in order to comply with

the requirements of SAE Recommended Practice J335 and

California Codes 4442 and 4443. All national forest land and

land managed by the states of California, Maine, Washington, and Oregon require internal combustion engines to be

equipped with a spark arrester screen by law. Other states

and federal agencies are enacting similar regulations.

If you operate a chain saw in a state or locale where such

regulations exist, you are legally responsible for maintaining the

operating condition of these parts. Failure to do so is a violation

of a law. Spark arrester maintenance is described in the

Maintenance-Spark Arresting Muffler Section of the manual.

WARNING

Muffler surfaces are very hot during and after operation

of the chain saw, keep all body parts away from the

muffler. Serious burns may occur if contact is made

with the muffler.

WARNING

Exposure to vibrations through prolonged use of gasoline powered hand tools could cause blood vessel or

nerve damage in the fingers, hands, and wrists of

people prone to circulation disorders or abnormal swellings. Prolonged use in cold weather has been linked to

blood vessel damage in otherwise healthy people. If

symptoms occur such as numbness, pain, loss of

strength, change in skin color or texture, or loss of

feeling in the fingers, hands, or wrists, discontinue the

use of this tool and seek medical attention.

5English

Page 6

SAFETY

Precautions Against Kickback

Kickback is a dangerous reaction that can lead to serious

injury. Do not rely only on the safety devices provided with

your saw. As a chain saw user, you must take special safety

precautions to help keep your cutting jobs free from accident or injury.

WARNING

KICKBACK WARNING

KICKBACK occurs when the moving chain contacts an

object at the upper portion of the tip of the guide bar or

when the wood closes in and pinches the saw chain in

the cut. Contact at the upper portion of the tip of the

guide bar can cause the chain to dig into the object and

stop the chain for an instant. The result is a lightning

fast, reverse reaction which kicks the guide bar up and

back toward the operator. If the saw chain is pinched

along the top of the guide bar, the guide bar can be

driven rapidly back toward the operator. Either of these

reactions can cause loss of saw control which can result

in serious injury.

Do not rely exclusively upon the safety devices built into

your saw. As a chain saw user, you should take several

steps to keep your cutting jobs free from accident or

injury.

Basic Safety Precautions

Push and Pull

The reaction force is always opposite to the direction the chain

is moving when wood contact is made. Thus, the operator must

be ready to control the PULL (A) when cutting on the bottom

edge of the bar, and PUSH (B) when cutting along the top edge.

A

B

• With a basic understanding of kickback, you can reduce or

eliminate the element of surprise. Sudden surprise contributes to accidents.

• Keep a good firm grip on the saw with both hands when the

engine is running. Place your right hand on the rear handle

and the left hand on the front handle with your thumbs and

fingers encircling the chain saw handles. A firm grip together

with a stiff left arm will help you reduce kickback and maintain

control of the saw.

• Make sure that the area in which you are cutting is free from

obstructions. Do not let the nose of the guide bar contact a log,

branch, fence, or any other obstruction that could be hit while

you are operating the saw.

• Keep SAFE-T-TIP® Anti-Kickback Nose Guard properly

mounted on the guide bar to prevent kickback.

• Always cut with the engine running at full speed. Fully

squeeze the throttle trigger and maintain a steady cutting

speed.

• Do not overreach or cut above chest height.

• Follow the sharpening and maintenance instructions for the

saw chain.

• Use only the replacement guide bars and low kickback chains

specified for your saw.

• Do not adapt your powerhead to a bow guide or use it to power

any attachments or devices not listed for your saw.

ATTENTION

Your Chain Saw has been fully factory tested. It is normal

to find some slight oil residue on the saw.

• Always hold the chain saw with both hands when the engine

is running. Use a firm grip with thumbs and fingers encircling

the chain saw handles.

• Never operate a chain saw when you are fatigued.

• Keep all parts of your body away from the saw chain when the

engine is running.

• Always carry the chain saw with the engine stopped and chain

brake engaged, the guide bar and saw chain to the rear, and

the muffler away from your body. When transporting your

chain saw, use the appropriate guide bar scabbard.

• Apply chain brake prior to any repositioning of the operator in

the cutting area.

• Always use caution when handling fuel. Move the chain saw

at least 10 feet (3m) from the fueling point before starting the

engine.

• Do not operate a chain saw with one hand! Serious injury to

the operator, helpers, bystanders, or any combination of these

persons may result from one-handed operation. A chain saw

is intended for two-handed use.

• Never let anyone use your chain saw who has not received

adequate instructions in its proper use. This applies to rentals

as well as privately owned saws. Keep the handles dry, clean,

and free of oil or fuel mixture.

• Before you start the engine, make sure the saw chain is not

contacting any object.

• Shut off the engine before setting down the saw. Do not leave

the engine running unattended.

• As an additional safety precaution, apply the chain brake prior

to setting down the saw.

• Operate the chain saw only in well ventilated areas.

6 English

Page 7

SAFETY

Safety Apparel

• Wear snug fitting clothing. Do not wear scarves, jewelry,

neckties, or other loose fitting clothing, which could be drawn

into the engine or catch the chain or underbrush. Wear

overalls, jeans or chaps made of cut resistant material or ones

that contain cut resistant inserts.

• Wear non-slip safety footwear.

• Wear non-slip, heavy duty gloves to improve your grip and to

protect your hands.

• Wear eye, hearing, and head protection when operating this

equipment.

Kickback

KICKBACK (A) occurs when the moving chain contacts an

object at the Kickback Danger Zone (B) of the guide bar zone.

The result is a lightning fast, reverse reaction which kicks the

guide bar up and back towards the operator. This reaction can

cause loss of control which can result in serious injury.

A

Refueling (DO NOT SMOKE!)

• To reduce the risk of fire and burn injury, handle fuel with

care. It is highly flammable.

• Mix and store fuel in a container approved for gasoline.

• Mix fuel outdoors where there are no sparks or flames.

• Select bare ground, stop engine, and allow to cool before

refueling.

• Loosen fuel cap slowly to release pressure and to keep fuel

from escaping around the cap.

• Tighten fuel cap securely after refueling.

• Wipe spilled fuel from the unit. Move 10 feet (3m) away from

refueling site before starting engine.

• Never attempt to burn off spilled fuel under any circumstances.

Maintenance

• Never operate a chain saw that is damaged, improperly

adjusted, or is not completely and securely assembled. Be

sure that the saw chain stops moving when the throttle control

trigger is released. If the saw chain moves at idle speed, the

carburetor may need adjusting, see Operation-Carburetor

Adjusting Section. If the saw chain still moves at idle speed

after adjustment has been made, contact a John Deere

Servicing Dealer for adjustment and discontinue use until the

repair is made.

A

A

B

WARNING

All chain saw service, other than items in the Operator's

Manual maintenance instructions, should be performed

by competent chain saw service personnel. (If improper

tools are used to remove the flywheel or clutch, or if an

improper tool is used to hold the flywheel in order to

remove the clutch, structural damage to the flywheel

could occur which could subsequently cause the flywheel to burst and serious injury could result).

In The Cutting/Work Area

• Do not operate a chain saw in a tree.

• Keep bystanders and animals out of the work area. Do not

allow other persons to be nearby during starting or cutting

with the chain saw.

• Never start cutting until you have a clear work area, secure

footing, and a planned retreat path from the falling tree.

• Use extreme caution when cutting small size brush and

saplings, because slender material may catch the saw chain

and be whipped toward you or pull you off balance.

• When cutting a limb that is under tension, be alert for springback

so that you will not be struck when the tension in the wood

fibers is released.

• Do not cut from a ladder, this is extremely dangerous. Leave

this operation for professionals.

7English

Page 8

SAFETY

Understanding Your Chain Saw Safety

Devices

Safe-T-Tip® Anti-Kickback Nose Guard

The SAFE-T-TIP® (A) prevents kickback from happening, because it covers the tip of the bar where kickback is generated.

Inexperienced persons should never attempt any kind of cutting

where the SAFE-T-TIP® would have to be removed from the bar

tip.

Those users, such as professional loggers, who may need to

draw the tip through the cut, make boring cuts, or cut logs bigger

than the bar length should replace the SAFE-T-TIP® as soon as

those cuts are complete. When cutting with it removed, the user

must rely on careful use of the proper techniques as shown in the

manual to avoid kickback.

NOTE: See Maintenance-Bar and Chain Section, for installing the Safe-T-Tip® nose guard.

A

Low Kickback Saw Chain

The rakers (depth gauges) ahead of each cutter can minimize

the force of a kickback reaction by preventing the cutters from

digging in too deeply at the kickback zone. Only use replacement chain that is equivalent to original chain or has been

certified as low kickback chain per ANSI B175.1.

Low kickback saw chain is chain that has met the kickback

performance requirements of ANSI B175.1 - 1991 (American

National Standard for Power Tools - Gasoline-Powered Chain

Saws-Safety Requirements) when tested on the representative

sample of chain saws below 3.8 c.i.d. specified in ANSI B175.1

- 1991.

Chain Brake

Chain brakes are designed to rapidly stop the chain from

rotating. When the chain brake lever / hand guard is pushed

toward the bar, the chain should stop immediately . A chain

brake does not prevent kickback.

B) RUN POSITION

C) BRAKE POSITION

Chain brake should be cleaned and tested daily. Clean the

chain brake per the Maintenance-Chain Brake Section and

test per the Operation-Chain Brake Operation Section.

WARNING

Even with daily cleaning of the mechanism, the dependability of a chain brake to perform under field conditions

cannot be certified. Keep the Safe-T-Tip® nose guard on

your saw's guide bar, and use proper cutting techniques.

Run Position

(B)

Brake

Position

(C)

Guide Bars

Generally, guide bars with small radius tips have somewhat

lower kickback potentials.

John Deere gasoline saws meet the kickback-reduction requirements of ANSI B175.1 without requiring small radius tip bars.

When making a replacement be sure to order one of the JOHN

DEERE bars listed for your saw in this operator's manual. The

proper size SAFE-T-TIP® nose guard comes installed on the

bar. Use only guide bars that have a provision for mounting the

SAFE-T-TIP®.

8 English

Page 9

ASSEMBLY

Assembling the Bar and Chain

1. Ensure that the chain brake is not set by pulling the chain

brake lever / hand guard towards the front handle as shown

in Illustration (A). Refer to Safety-Chain Brake and Operation-Chain Brake Sections for additional information.

2. Remove the two (2) bar nuts (B) and the clutch cover (C).

3. Remove and discard the plastic shipping spacer (D) that

has been installed on the bar studs in place of the bar for

shipping purposes.

4. Adjust the chain tensioning pin (E) fully towards the rim

sprocket (F) using the chain tensioning screw (G).

WARNING

Check the chain tension frequently when operating the

chain saw. Never touch or adjust the chain while the

motor is running. The saw chain is very sharp, always

wear protective gloves when performing maintenance to

the chain.

A

5. The guide bar contains a bar stud slot (H) that fits over the

bar studs. The guide bar also contains two chain tensioning

pin holes (J) which fit over the chain tensioning pin and

two lubrication holes (K). The bar is reversible and either

tensioning pin hole may be utilized with the chain

tensioning pin.

6. Place the guide bar (L) onto the bar studs (M) so that the

chain tensioning pin (E) fits into the chain tensioning pin hole.

CAUTION

Failure to assure that the chain tensioning pin is in the

chain tensioning pin hole will result in severe damage to

the chain saw during reassembly of the clutch cover.

7. Position the bar tip through the chain loop as shown in

Illustration (

8. Fit the chain (P) over the rim sprocket (F) and into bar groove.

The cutters on the top of the guide bar should face toward the

bar tip, in the direction of the chain rotation. See insert (Q) in

Illustration below.

Severe damage can occur to the rim sprocket, clutch drum,

guide bar and chain, if the chain is not correctly seated into

the rim sprocket.

N).

CAUTION

J

D

C

B

H

Q

E

K

M

L

N

F

F

P

E

G

9English

Page 10

ASSEMBLY

9. Replace the clutch cover (C) and install the two (2) bar nuts

(B). Tighten the bar nuts finger tight only, see Illustration (R).

The bar must be free to move for tension adjustment.

NOTE: If the clutch cover does not slide on freely, check

that the chain brake is not engaged. To disengage chain

brake with clutch cover removed, grasp clutch cover as

shown in Illustration (S) and pull back on chain brake

lever / hand guard.

10. Remove all slack from chain by turning the chain tensioning

screw (G) clockwise, assuring that the chain seats into the bar

groove during tensioning.

11.Lift the tip of the guide bar up to check for sag, see

illustration (T). Release the tip of the guide bar, and turn

the chain tensioning screw (G) 1/2 turn clockwise. Repeat

this process until sag (U) does not exist.

12. Hold the tip of the guide bar up and tighten the bar nuts

securely as shown in Illustration (V).

13.Chain is correctly tensioned when there is no slack on the

underside of the guide bar, the chain is snug, but it can be

turned by hand without binding, see Illustration (W). Ensure that the chain brake is not set.

NOTE: If chain is too tight, it will not rotate. Loosen bar

nuts slightly and turn adjusting screw 1/4 turn counterclockwise. Lift the tip of the guide bar up and

retighten bar nuts.

-

G

+

T

WARNING

Check the chain tension frequently when operating the

chain saw. Never touch or adjust the chain while the

motor is running. The saw chain is very sharp, always

wear protective gloves when performing maintenance to

the chain.

R

C

B

S

U

V

W

10 English

Page 11

OPERATION

Chain Tension

WARNING

Never touch or adjust the chain while the motor is running.

The saw chain is very sharp, always wear protective

gloves when performing maintenance to the chain.

1. Stop the engine before setting the chain tension. Make sure

the guide bar nuts are loose, turn the chain tensioning screw

clockwise to tension the chain. Refer to Assembly-Assembling the Bar and Chain Section.

A cold chain is correctly tensioned when there is no slack

on the underside of the guide bar, the chain is snug, but it

can be turned by hand without binding.

2. Chain must be re-tensioned whenever the flats (A) on the drive

link tangs hang out of the bar groove. See Illustration (B).

3. During normal saw operation, the temperature of the chain will

increase. The drive link tangs of a correctly tensioned warm

chain will hang approximately .050 (1.25 mm) out of the bar

groove. See Illustration (C). To help determine the correct

warm chain tension, the tip of the combination wrench (D) can

be used as a guide.

CAUTION

Chain tensioned while warm, may be too tight upon

cooling. Check the "cold tension" before next use.

Breaking-in the Chain

New chains will stretch and must be tightened frequently. Lift the

chain out of the bar groove and lubricate the bar groove with

additional oil, see Illustration (E). Place the chain saw on a piece

of cardboard or scrap plywood. Start the chain saw (refer to the

Operation-Starting Engine Section) and allow it to run at moderate speed for approximately one (1) minute. Stop the engine.

Check that the oil pump is working properly. Safe-T-Tip® antikickback device and the cardboard should have excess oil from

the chain rotation if the oil pump is working properly, see

Illustration (F). Adjust the chain tension (refer to OperationChain Tension Section). Start the saw again and make a few cuts

in a log to heat up the chain. Stop the engine and re-adjust chain

again. Repeat this process until the chain retains proper warm

tension adjustment as shown in Illustration (C) in OperationChain Tensioning Section. Do not touch the ground with the

chain.

E

B

C

A

.050 (1.25 mm)

.050 (1.25 mm)

Bucking Spike

Your chain saw is fitted with dual bucking spikes (G).

The bucking spikes are very sharp and can cause injury.

Be extremely careful when working near the bucking

spike. Removal of one of both bucking spikes will

D

violate the saws compliance of SAE J335 and other

standards. See Safety-State and Local Requirements.

F

WARNING

G

11English

Page 12

OPERATION

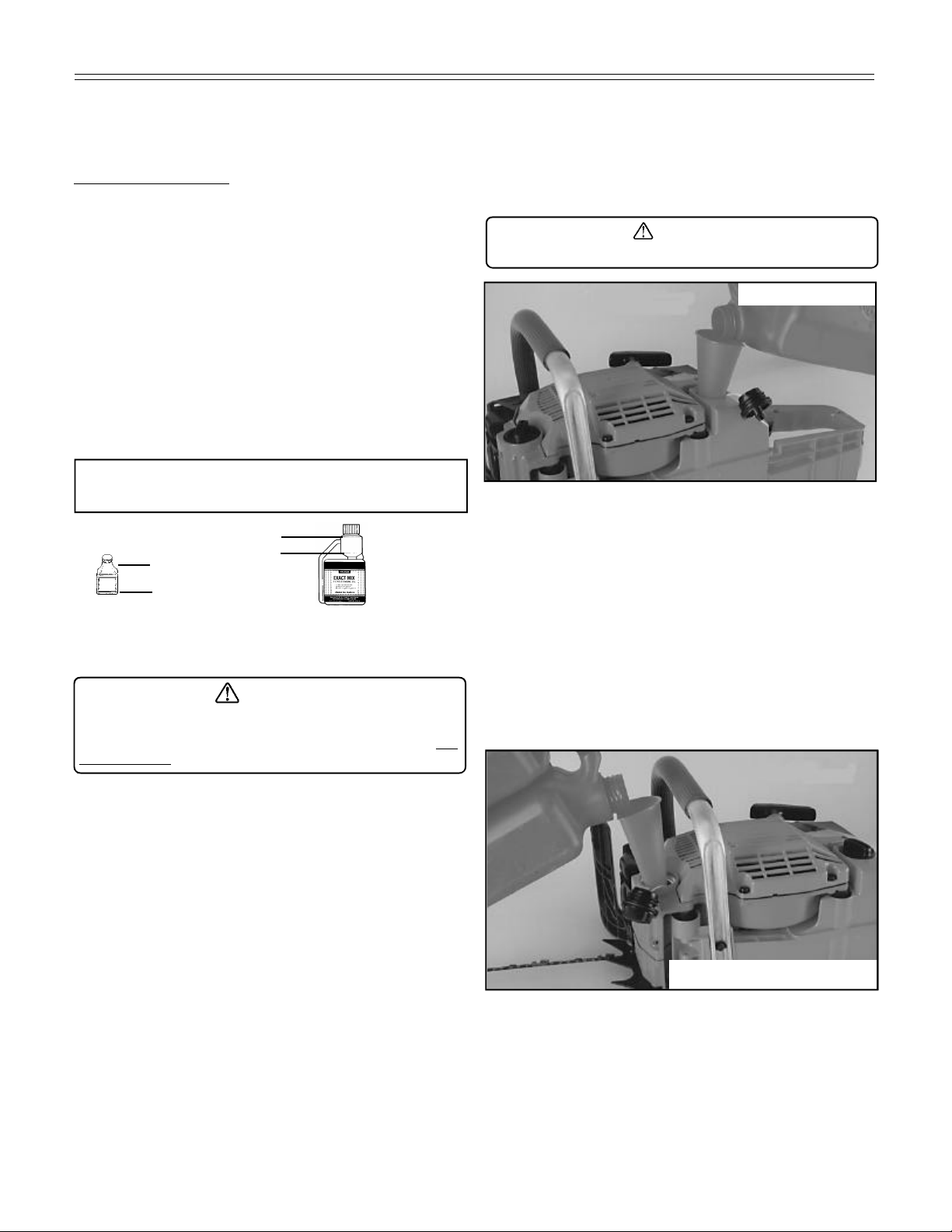

Fueling

This product is powered by a 2-cycle engine and requires premixing gasoline and 2-cycle oil. Pre-mix unleaded gasoline and

2-cycle engine oil in a clean container approved for gasoline.

RECOMMENDED FUEL: THIS ENGINE IS CERTIFIED TO OPERATE ON UNLEADED GASOLINE INTENDED FOR AUTOMOTIVE USE WITH AN OCTANE RATING OF 87 ([R + M] / 2) OR

HIGHER.

Mix JOHN DEERE Premium Exact Mix™ Oil with gasoline

according to the instructions on the package. If Premium Exact

Mix™ oil is not available, use a high quality 2-cycle engine oil,

mixed at 2.6 oz. per gallon (US).

DO NOT USE AUTOMOTIVE OIL OR 2-CYCLE OUTBOARD

OIL.

NOTE: Premium Exact Mix™ fuel mix contains a fuel

stabilizer and will stay fresh up to 30 days. DO NOT mix

quantities larger than usable in a 30 day period. A 2-cycle oil

containing a fuel stabilizer is recommended.

Fuel Mixture

Premium Exact Mix ™ (50:1)

Gasoline Oil

1 gallon (US).............................................. 2.6 oz.

1 Liter ........................................................ 20cc (20 ml)

2.6 oz.

2.6 oz.

OR

Filling the Tank

WARNING

Always shut off engine before fueling. Never add fuel to

a machine with a running or hot engine. Move at least 10

feet (3m) from refueling site before starting engine. DO

NOT SMOKE!

1 pt.

}

3. Carefully pour fuel mixture into the tank. Avoid spillage.

4. Prior to replacing the fuel cap, clean and inspect the gasket.

5. Immediately replace fuel cap and hand tighten. Wipe up any

fuel spillage.

6. It is normal for smoke to be emitted from a new engine during

and after first use.

WARNING

Check for fuel leaks, if any are found, correct before use.

Fuel Mixture

Chain Oil System

1. Use JOHN DEERE Bar and Chain Oil. It is designed for

chains and chain oilers and is formulated to perform over a

wide temperature range with no dilution required. If not

available, use any new SAE-30 weight engine oil.

NOTE: Do not use dirty, used or otherwise contaminated

oils. Damage may occur to the oil pump, bar, or chain.

2. Fill the oil tank every time engine is fueled.

3. The automatic oil pump is a positive displacement pump

operated through gears driven off the clutch drum assembly.

The pump will not oil at idle speeds.

4. Chain saw should use approximately one tank of oil per tank

of fuel.

Refer to the Safety-Refueling Section for additional Safety

Precautions.

1. Clean surface around fuel cap to prevent contamination.

2. Loosen fuel cap slowly.

12 English

Bar and Chain Oil

Page 13

OPERATION

Starting the Engine

WARNING

Keep body to the left of the chain line. Never straddle the

saw or chain, or lean over past the chain line.

• Place the chain saw on level ground and ensure that no objects

or obstructions are in immediate vicinity which could come in

contact with the bar and chain. Hold the front handle firmly with

the left hand and put your right foot onto the base of the rear

handle, see illustration (A).

• Set the chain brake by pushing the chain brake lever / hand

guard forward (towards the bar), to the Brake Position as

shown in Illustration (B). Refer to Safety-Chain Brake and

Operation-Chain Brake Sections for additional information.

• Move the ignition switch (C) to the start position “I”.

• Pull the choke lever (D) to the fully extended position ( / Full

Choke), as shown in Illustration (E). Depress the throttle

trigger lockout (F) and squeeze the throttle trigger (G), depress

the half-throttle lock button (H) with your thumb and release the

throttle trigger (G). This sets the throttle trigger to the halfthrottle position.

• Depress the compression relief valve (J). Pull the starter rope

until the first firing of the engine is heard (no more than five (5)

pulls), a new unit may require additional pulls.

NOTE: Compression relief valve automatically resets

after the first firing.

• Push the choke lever (D) completely in to the engine run

position, as shown in Illustration (E).

• Depress the compression relief valve (J) and pull the starter

rope until the engine starts.

• Immediately after the engine has started, depress the throttle

trigger lockout (F), quickly squeeze and release the throttle

trigger (H). This releases the throttle trigger from the halfthrottle position and lets the engine idle. Place chain brake

lever / hand guard into the run position as shown in Illustration

(B). Refer to Safety-Chain Brake and Operation-Chain Brake

Sections for additional information.

NOTE - STARTING WARM ENGINE:

Follow above starting instructions, but do not use the full

choke position for start up.

A

E

C

D

H

Run

F

G

Full

Choke

J

Breaking-in the Engine

Engine break-in period is approximately 20 hours or 30 tanks of

fuel.

During this period avoid using the chain saw at prolonged highspeed operation.

Stopping the Engine

Release the throttle trigger (G) and let the engine return to idle. To

stop the engine, move the ignition switch (C) to the “ ” stop

position. Do not put the chain saw on the ground when the chain

is still moving. For additional safety, set the chain brake when the

saw is not in use.

In the event that the “ ” stop switch will not function, pull the

choke lever out to the fully extended position ( / Full Choke )

to stop the engine.

Run

Position

B

Brake

Position

Carburetor Adjustment

Before adjusting the carburetor, clean the starter cover vents as

shown in Illustration (K), and air filter as shown in Illustration (L),

refer to Operation-Starting Unit and Maintenance-Air Filter Sections for details. Allow the engine to warm up prior to carburetor

adjustment.

LK

13English

Page 14

OPERATION

Carburetor Adjustment - Cont'd

This engine is designed and manufactured in order to comply

with EPA (Environmental Protection Agency) Phase 1 regulations. The carburetor is factory set and should not require

adjusting. The carburetor will permit only limited adjustment of

the “L” (Low Jet) and “H” (High Jet) needles. Any adjustment

should be done by a John Deere Servicing Dealer.

Under no circumstances should the “L” (Low Jet) and “H” (High

Jet) needles be forced outside the range of adjustment.

WARNING

Serious damage can occur to the engine if improper

adjustments are made to the “L” and “H” needles.

Do not force the “L” and “H” needles outside the adjustment range!

Idle Speed Adjustment

• If the engine starts, runs, and accelerates but will not idle; turn

the idle speed screw “T” clockwise to increase idle speed.

• If the chain turns at idle, turn the idle speed screw “T”

counterclockwise to reduce the idle RPM and stop the chain

movement. If the saw chain still moves at idle speed, contact

a John Deere Servicing Dealer for adjustment and discontinue

use until the repair is made.

WARNING

THE SAW CHAIN SHOULD NEVER TURN AT IDLE. Turn

the idle speed screw “T” counterclockwise to reduce

the idle RPM and stop the chain, or contact a John Deere

Servicing Dealer for adjustment and discontinue use

until the repair is made.

Serious personal injury may result from the saw chain

turning at idle.

Chain Brake Operation

Refer to Safety-Chain Brake Section before use.

The chain brake Run Position (A) and Brake Position (B) are

illustrated below.

The chain brake operating condition should be checked prior to

each use as follows:

1. Start the engine and grasp front and rear handles securely

with both hands.

2. Pull the throttle trigger to bring the chain saw up to full speed.

Using the back of your left hand, engage the chain brake by

pushing the chain brake lever / hand guard toward the bar

while the chain is rotating rapidly, see illustration (C).

3. The chain brake should engage and stop the chain immediately, if not, take the saw to a John Deere Servicing Dealer for

repair and discontinue use until the repair is made.

4. Reset the chain brake back into the run position by grasping

the guide bar side (right side from operator's position) of the

chain brake lever / hand guard and pull toward the front handle

until an audible click is heard. See Illustration (D).

WARNING

If chain brake does not stop the chain immediately, take

the saw to a John Deere Servicing Dealer for repair prior

to use.

Run Position

(A)

Brake

Position

(B)

H

L

T

WARNING

Weather conditions and altitude may affect carburetion.

Do not allow bystanders close to the chain saw while

adjusting the carburetor.

14 English

C

D

Page 15

OPERATION

Preparation for Cutting

Proper Grip on Handles

Refer to Safety Section for appropriate Safety Equipment.

1. Wear non-slip gloves for maximum grip and protection.

2. Maintain a proper grip (A) on the saw whenever the engine is

running. The fingers should encircle the handlebar and the

thumb is wrapped under the handlebar. This grip is least likely

to be broken (by a kickback or other sudden reaction of the

saw). Any grip in which the thumb and fingers are on the same

side of the handle (B), is dangerous because a slight kick of the

saw can cause loss of control.

A

3. Hold the saw firmly with both hands. Always keep your LEFT

HAND on the front handlebar and your RIGHT HAND on the

rear (throttle) handle as shown in Illustration (C), so that your

body is to the left of the chain line. Never use a cross-handed

grip, or any stance which would place your body or arm across

the chain line.

B

C

Basic Cutting Procedure

Practice cutting a few small logs using the following technique

to get the "feel" of using your saw before you begin a major

sawing operation.

1. Take the proper stance in front of the wood with the saw idling.

2. Accelerate the engine to full throttle just before entering the cut

by squeezing the throttle trigger.

3. Begin cutting with the saw against the log.

4. Keep the engine at full throttle the entire time you are cutting.

5. Allow the chain to cut for you; exert only light downward

pressure. If you force the cut, damage to the bar, chain, or

engine can result.

6. Release the throttle trigger as soon as the cut is completed,

allowing the engine to idle. If you run the saw at full throttle

without a cutting load, unnecessary wear or damage can

occur to the chain, bar, and engine.

7. Do not put pressure on the saw at the end of the cut.

Work Area Precautions

• Cut only wood or materials made from wood; no sheet metal,

no plastics, no masonry, no non-wood building materials.

• Never allow children to operate your saw. Allow no person to

use this chain saw who has not read this Operator's Manual or

received adequate instructions for the safe and proper use of

this chain saw.

• Keep everyone - helpers, bystanders, children, and animals a

safe distance from the cutting area. During felling operations,

the safe distance should be a least twice the height of the

largest trees in the felling area. During bucking operations,

keep a minimum distance of 15 feet (4.5m) between workers.

Proper Cutting Stance

• Weight should be balanced on both feet - feet on solid ground.

• Keep arm with elbow locked in a "straight arm" position (D) to

withstand any kickback force.

• Your body should always be to the left of the chain line (E).

• Thumb on underside of handlebar (F).

E

D

F

• Always cut with both feet on solid ground to prevent being

pulled off balance.

• Do not cut above chest height, as a saw held higher is difficult

to control against kickback forces.

• Do not fell trees near electrical wires or buildings. Leave this

operation for professionals.

• Cut only when visibility and light are adequate for you to see

clearly.

15English

Page 16

OPERATION

Tree Felling

Unusual Hazardous Tree Felling Conditions

• Do not fell trees during periods of high wind or heavy precipi-

tation. Wait to do your cutting until the hazard has ended.

• Do not cut down trees having an extreme lean or large trees

that have rotten limbs, loose bark, or hollow trunks. Have

these trees pushed or dragged down with heavy equipment,

then cut them up.

WARNING

Do not cut trees that have an extreme lean or hollow trunks.

Proper notching and back cutting cannot be performed on

trees with extreme lean or hollow trunks. Have these trees

dragged down with heavy equipment prior to cutting.

WARNING

Do not cut trees near electrical wires or buildings.

WARNING

Check the tree for damaged or dead branches that could

fall and hit you during felling.

WARNING

Periodically glance at the top of the tree during the backcut

to assure the tree is going to fall in the desired direction.

WARNING

If the tree starts to fall in the wrong direction, or if the saw

gets caught or hung up during the fall, leave the saw and

save yourself!

1. Pick your escape route (or routes in case the intended route

is blocked). Clear the immediate area around the tree, and

make sure there are no obstructions in your planned path of

retreat. Clear path of safe retreat (A) 45° from planned line of

fall (B).

2. Consider the force and direction of the wind, the lean and

balance of the tree, and the location of large limbs. These

things influence the direction in which the tree will fall. Do not

try to fell a tree along a line different from its natural line of fall.

3. Cut a notch (C) about 1/3 the diameter of the trunk in the side

of the tree. Make the cuts of the notch so they intersect at a

right angle to the line of fall. This notch should be cleaned out

to leave a straight line. To keep the weight of the wood off the

saw, always make the lower cut of the notch before the upper

cut.

4. The backcut is always made level and horizontal, and at a

minimum of 2 inches (5 cm) above the horizontal cut of the

notch (D).

5. Never cut through to the notch. Always leave a band of wood

between the notch and back cut (approximately 2 inches (5

cm) or 1/10 the diameter of the tree). This is called "hinge" (E)

or “hingewood.” It controls the fall of the tree and prevents

slipping or twisting or shoot-back of the tree off the stump.

6. On large diameter trees, stop the back cut (F) before it is deep

enough for the tree to either fall or settle back on the stump.

Then insert soft wooden or plastic wedges (G) into the cut so

they do not touch the chain. The wedges can be driven in, little

by little, to help jack the tree over.

NOTE:

When bucking or felling with a wedge, it may be necessary

to remove the Safe-T-Tip® anti-kickback device to allow

the bar to be drawn through the cut. After the cut is

complete, the tip should be replaced immediately.

7. As tree starts to fall, stop the engine and put saw down

immediately. Retreat along cleared path, but watch the action

in case something falls your way.

WARNING

Never cut through to the notch when making a backcut.

The hinge controls the fall of the tree, this is the section of

wood between the notch and backcut.

E

2" (5 cm) or

D

2" (5 cm)

1/10 DIA

E

F

C

B

B

A

16 English

G

Page 17

OPERATION

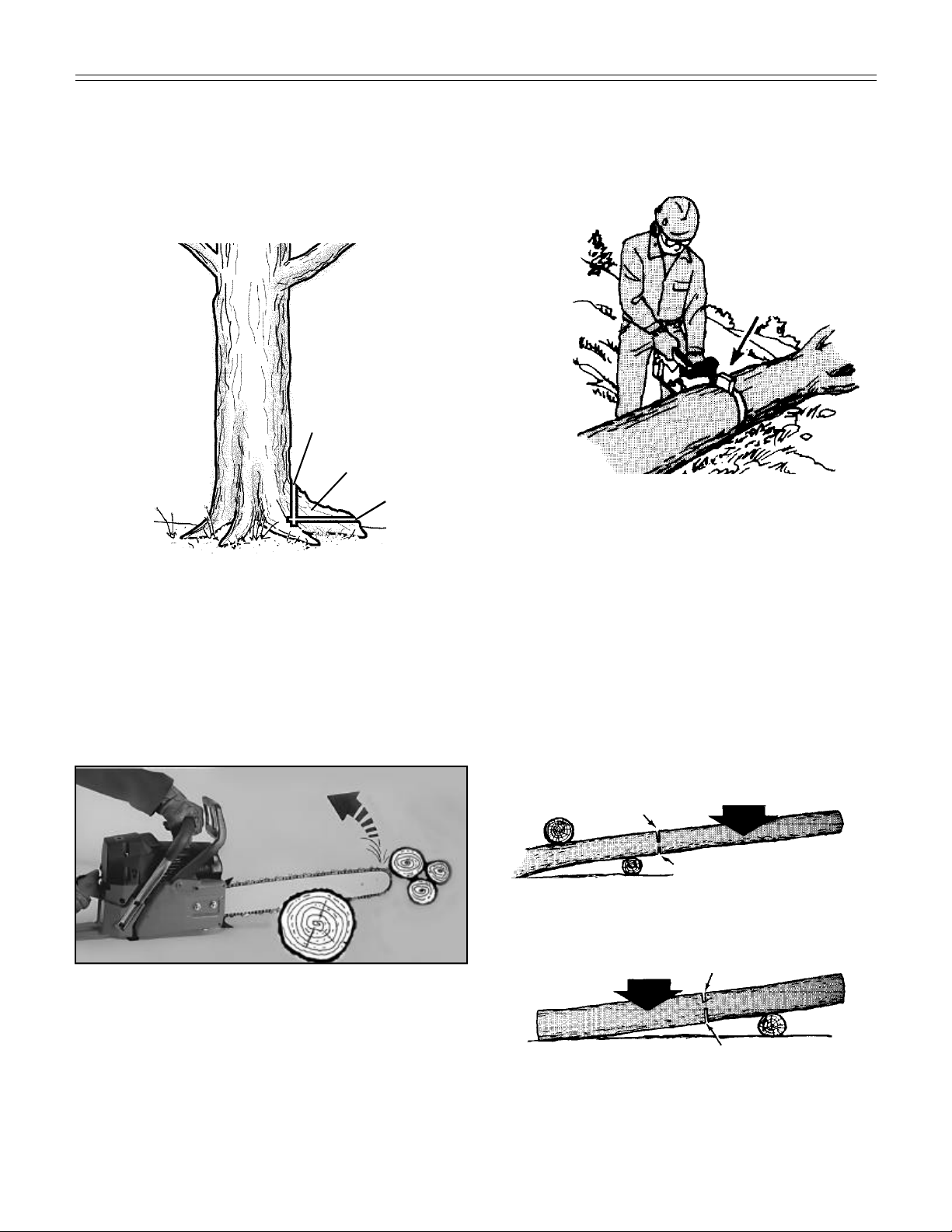

Buttress Roots

A buttress root is a large root extending from the trunk of the tree

above ground. Large buttress roots should be removed prior to

felling. Make the vertical cut (A) into the buttress first, followed

by the horizontal cut (B). Remove the resulting loose section (C)

from the work area. Utilize the proper instructions from the

Operation-Tree Felling section of the manual after the large

buttress roots have been removed.

A

C

B

Bucking

Bucking is the term used for cutting a fallen tree to the desired

log length.

• Cut only one log at a time.

• Support small logs on a saw horse or another log while

bucking.

• Keep a clear cutting area. Make sure that no objects can

contact the guide bar nose and chain during cutting, this can

cause kickback (D). To avoid the danger, keep the Safe-TTip® anti-kickback device attached while cutting.

Bucking with a Wedge

If the wood diameter is large enough for you to insert a soft

bucking wedge (E) without touching the chain, you should use the

wedge to hold the cut open to prevent pinching.

E

NOTE:

When bucking or felling with a wedge, it may be necessary to

remove the Safe-T-Tip® anti-kickback device to allow the bar

to be drawn through the cut. After the cut is complete, the tip

should be replaced immediately.

Logs Under Stress

• Make the first bucking cut (F) 1/3 of the way through the log and

finish with a 2/3 cut (G) on the opposite side. As the log is being

cut, it will tend to bend. The saw can become pinched or hung

in the log if you make the first cut deeper than 1/3 of the

diameter of the log.

Log Supported at One End:

D

• During bucking operations always stand on the uphill side so

that the cut-off section of the log can not roll over you.

• Sometimes it is impossible to avoid pinching (with just standard cutting techniques) or difficult to predict which way a log

will settle when cut. To avoid pinching while cutting, review the

following sections, Bucking with a Wedge and Logs Under

Stress.

(G) FINISHING CUT

LOAD

(F) 1st CUT 1/3 Dia

Log Supported at Both Ends:

LOAD

(F) 1st CUT 1/3 Dia

(G) FINISHING CUT

Give special attention to logs under stress to prevent the bar and

chain from pinching.

17English

Page 18

OPERATION

Types of Cutting Used

Overbucking

Begin on the top side of the log with the bottom of the saw against

the log; exert light pressure downward.

Underbucking

Begin on the under side of the log with the top of the saw against

the log; exert light pressure upward. During underbucking, the

saw will tend to push back at you. Be prepared for this reaction

and hold the saw firmly to maintain control.

• When pruning trees it is important not to make the flush cut

next to the main limb or trunk until you have cut off the limb

further out to reduce the weight. This prevents stripping the

bark from the main member. Underbuck the branch 1/3

through for your first cut, your second cut should overbuck to

drop the branch off. Now make your finishing cut smoothly and

neatly against the main member so the bark will grow back to

seal the wound.

Second cut

LOAD

First cut

1/3 diameter

Finishing cut

Limbing and Pruning

• Work slowly, keeping both hands on the saw with a firm grip.

Maintain secure footing and balance.

• Keep the tree between you and the chain while limbing (A).

Cut from the side of the tree opposite the branch you are

cutting.

• Do not cut from a ladder, this is extremely dangerous. Leave

this operation for professionals.

• Do not cut above chest height as a saw held higher is difficult

to control against kickback.

WARNING

Never climb into a tree to limb or prune. Do not stand

on ladders, platforms, a log or in any position which can

cause you to lose your balance or control of the saw.

A

WARNING

If the limbs to be pruned are above chest height, hire a

professional to perform the pruning.

Springpoles

A springpole (B) is any log, branch, rooted stump, or sapling

which is bent under tension by other wood so that it springs back

if the wood holding it is cut or removed. On a fallen tree, a rooted

stump has a high potential of springing back to the upright

position during the bucking cut to separate the log from the

stump. Watch out for springpoles. They are potentially dangerous.

B

WARNING

Springpoles are dangerous and could strike the operator, causing the operator to lose control of the chain

saw. This could result in severe or fatal injury to the

operator.

18 English

Page 19

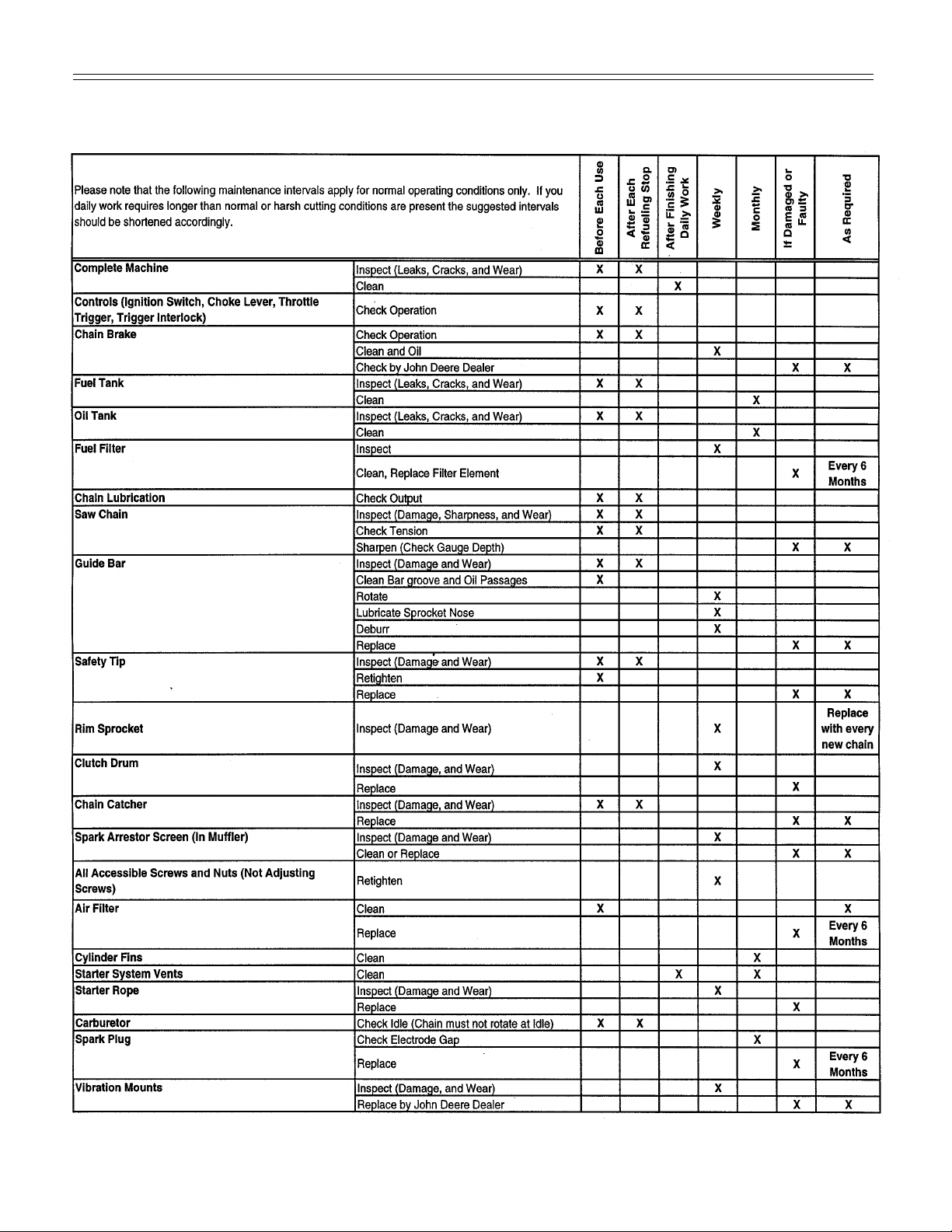

Maintenance Chart

MAINTENANCE

19English

Page 20

MAINTENANCE

Chain Maintenance

Use only Dual Raker low-kickback chain on this saw. This fastcutting chain will provide kickback reduction when properly

maintained.

For smooth and fast cutting, Raker chain needs to be maintained properly. The chain requires sharpening when the wood

chips are small and powdery, the chain must be forced through

the wood during cutting, or the chain cuts to one side. During

maintenance of your chain, consider the following:

1. Improper filing angle of the side plate can increase the risk of

a severe kickback.

2. Raker (depth gauge) clearance (A): Too low increases the

potential for kickback; not low enough decreases cutting

ability.

3. If cutter teeth have hit hard objects such as nails and stones,

or have been abraded by mud or sand on the wood, have

servicing dealer sharpen chain.

NOTE: Inspect the rim sprocket for wear or damage when

replacing the chain. If signs of wear or damage are present in the

areas indicated in illustration (B), have the rim sprocket replaced by a John Deere Servicing Dealer.

A

1. Tighten the chain tension enough that the chain does not

wobble. Do all of your filing at the mid-point of the bar. Wear

gloves for protection.

2. Use a 7/32" diameter round file and holder.

3. Keep the file level with the top plate of the tooth as shown in

Illustration (C). Do not let the file dip or rock.

4. Using light but firm pressure, stroke towards the front corner of

the tooth as shown in Illustration (D). Lift file away from the

steel on each return stroke.

5 Put a few firm strokes on every tooth. File all left hand cutters

(E) in one direction. Then move to the other side and file the

right hand cutters (F) in the opposite direction. Occasionally

remove filings from the file with a wire brush.

C

D

B

How to Sharpen the Cutters

Be careful to file all cutters to the specified angles and to the

same length, as fast cutting can be obtained only when all

cutters are uniform.

Cutting Corner

Top Plate

Rivet Hole

Heel

Gullet

Parts of a Cutter

Side Plate

Depth Gauge

Toe

F

WARNING

Dull or improperly sharpened chain can cause excessive engine speed during cutting which may result in

severe engine damage.

WARNING

Improper chain sharpening increases the potential of

kickback.

Failure to replace or repair damaged chain can cause

serious injury.

The saw chain is very sharp, always wear protective

gloves when performing maintenance to the chain.

F

E

E

20 English

Page 21

MAINTENANCE

Top Plate Angle

File holders are marked with guide marks to align file properly to

produce correct TOP PLATE ANGLE.

G)CORRECT- 30

H) LESS THAN 30° - For Cross Cutting.

I) MORE THAN 30°- Feathered Edge Dulls Quickly.

o

G

H

Side Plate Angle

J) CORRECT- 85

Produced automatically if correct diameter file is used in file

holder.

K) “HOOK”- “Grabs” and dulls quickly. Increases potential of

KICKBACK.

Results from using a file with diameter too small, or file held

too low.

L) BACKWARD SLOPE- Needs too much feed pressure, causes

excessive wear to bar and chain.

Results from using a file with diameter too large, or file held

too high.

o -

o

90

I

J

L

K

Use a Flat File and a Depth Gauge Jointer to lower

all gauges uniformly.

P) FLAT FILE

Q)DEPTH GAUGE JOINTER

Depth gauge jointers available in .020" to .035" (0.5mm to

0.9mm). After lowering each depth gauge, restore original

shape by rounding the front (R). Be careful not to damage

adjoining drive links with the edge of the file.

P

Q

R

Guide Bar Maintenance

Every day of use, reverse the guide bar on the saw to distribute

the wear for maximum bar life. The bar should be cleaned every

day of use and checked for wear and damage.

Feathering or burring of the bar rails is a normal process of bar

wear. Such faults should be smoothed with a file or stone as

soon as they occur.

A bar with any of the following faults should be replaced.

• Wear inside the bar rails which permits the chain to lay over

sideways.

• Bent guide bar.

• Cracked or broken rails.

• Spread rails.

In addition, guide bars with a sprocket at their tip must be

lubricated periodically with a grease syringe to extend the guide

bar life.

Turn the guide bar and check that the lubrication holes and chain

groove are free from impurities.

Depth Gauge Clearance

1. The depth gauge (M) should be maintained at a clearance (N)

between .025 (0.6 mm) and .030" (0.75 mm). Use a depth

gauge tool for checking the depth gauge clearances.

2. Every time the chain is filed, check the depth gauge clearance.

M

N

21English

Page 22

MAINTENANCE

Installing the Safe-T-Tip® Nose Guard

CAUTION: Check that the switch is in the “ ” stop position

before you do any work on the saw.

WARNING

Although the guide bar comes with a SAFE-T-TIP® antikickback device already installed, you need to check the

tightness of the mounting screw (A) before each use.

Tighten the mounting screw (A) of the nose guard as instructed

below. These are specially hardened screws. If the screw

cannot be installed tightly, replace both the screw and the SAFET-TIP® before further operation. Do not replace with an ordinary

screw.

1. In addition to preventing chain contact with solid objects at the

nose of the bar, the SAFE-T-TIP® also helps keep the chain

away from abrasive surfaces such as the ground. Keep it on

the right hand side of the bar (B), where it will be between the

chain and the ground during flush-with-ground cutting.

2. The mounting screw requires a 3/8" wrench (or adjustable

wrench) to achieve the recommended tightness of 70-100

inch-pounds (8-11 Nm). A tightness within this range can be

achieved by the following method.

a) Mount the SAFE-T-TIP® on the bar nose. (See illustration

for details.) Locking rivet or tab fits in square hole in guide

bar (C). Tighten the screw with your finger.

b) From the finger-tight position (D), tighten the screw an

additional 1/2 - 3/4 of a turn using a wrench (E).

Air Filter

Loosen the two air filter screws (G) by turning counterclockwise,

remove air filter cover (H) and check the air filter (I) each day;

shake the filter and clean with a soft brush. If heavily contaminated, clean with soapy water, rinse, and dry thoroughly prior to

installing. Reinstall the air filter. Place the air filter cover onto the

chain saw. Tighten the two air filter cover screws securely.

WARNING

Never run the engine without the air filter, serious

damage could result.

H

G

I

Starter Unit

Use a brush or compressed air to keep the cooling vents of the

starter assembly free and clean of debris.

A

B

D

E

C

Fuel Filter

Check the fuel filter (F) periodically. Replace it if contaminated

or damaged.

F

22 English

Page 23

MAINTENANCE

Engine

Clean the cylinder & flywheel fins with compressed air or a brush

periodically. Dangerous overheating of engine may occur due to

impurities on the cylinder.

WARNING

Never run the saw without all the parts, including the

drivecase cover and starting housing, securely in place.

Because parts can fracture and pose a danger of thrown

objects, leave repairs to the flywheel and clutch to

trained John Deere Servicing Dealers.

Spark Arresting Muffler

The muffler is equipped with a spark arrester screen. A faulty

spark arrester screen can create a fire hazard. Through normal

use the screen can become dirty and should be inspected

weekly and cleaned as required.

To clean:

• Allow the muffler to cool.

• Remove the two (2) deflector screws (A).

• Remove the deflector (B) and spark arrester (C).

• Clean and inspect the spark arrester screen. If the spark

arrester screen is damaged, faulty or deteriorated, replace the

screen.

• Reassemble components in reversed order of removal and

torque deflector screws to 43 in/lbs (4.9 Nm).

A

Spark Plug

This engine uses a Champion RCJ-7Y with .02 (0.5 mm) electrode gap. Use an exact replacement and replace every six

months or more frequently, if necessary.

0.02" (0.5mm)

RCJ-7Y

B

C

A

23English

Page 24

MAINTENANCE

Chain Brake

If the chain brake does not work properly, remove the clutch

cover and clean the chain brake components. Check wear on

the brake band (A) and replace if worn or deformed. The band

thickness should not be less than 0.024" (.60mm), or worn

halfway through.

Always keep the chain brake mechanism clean and lightly

lubricate the linkage (B).

Always test the chain brake performance after servicing or cleaning per the Operation - Chain Brake Section.

Check and, if damaged, replace the chain catcher / safety

stop (C).

C

A

Oil Pump (automatic/adjustable)

Flow adjustment is pre-set by the manufacturer. Oil flow can be adjusted

by the operator according to specific requirements by means of the special

adjusting screw (D). Oil flow occurs only when the chain is moving.

D

B

B

24 English

Page 25

BAR AND CHAIN COMBINATIONS

Recommended Bar and Chain Combinations

For 3/8 Pitch Chain (.050 gauge)

Length Replaceable Chain Chain

of Bar Sprocket Nose Part Number Description

Guide Bar

Part Number

20" ............... UPR20J1LJ.............................. UPJ1L272D .......................38LD50-72

24" ............... UPR24J1LJ.............................. UPJ1L283D .......................38LD50-83

28" ............... UPR28J1LJ.............................. UPJ1L294D .......................38LD50-94

Optional Bar and Chain Combinations

For 3/8 Pitch Chain (.050 gauge)

Length Replaceable Chain Chain

of Bar Sprocket Nose Part Number Description

Guide Bar

Part Number

16"................ UPR16J1LJ.............................. UPJ1L262D .......................38LD50-62

18"................ UPR18J1LJ.............................. UPJ1L267D .......................38LD50-67

For 3/8 Pitch Chain (.063 gauge)

Length Replaceable Chain Chain

of Bar Sprocket Nose Part Number Description

Guide Bar

Part Number

20" ............... UPR20J3LJ.............................. UPJ3L272D .......................38LD63-72

24" ............... UPR24J3LJ.............................. UPJ3L283D .......................38LD63-83

28" ............... UPR28J3LJ.............................. UPJ3L294D .......................38LD63-94

32" ............... UPR32J3LD............................. UPJ3L2A4D .......................38LD63-104

25English

Page 26

TROUBLESHOOTING

Using Troubleshooting Chart

If you are experiencing a problem that is not listed in this chart, see your John Deere Servicing Dealer for service.

When you have checked all the possible causes listed and you are still experiencing the problem, see your John Deere Servicing

Dealer.

PROBLEM POSSIBLE CAUSE SOLUTION

Engine will not start:

(Make sure Ignition switch

is in start position “I”.)

Engine starts but will not accelerate properly:

Engine starts but will not run

properly at high speed .

Engine does not reach full

speed and / or emits excessive smoke:

Engine starts, runs, and accelerates but will not idle.

1. No spark

2. Flooded engine.

Carburetor requires “L” (Low jet) adjustment.

Carburetor requires “H” (High jet) adjustment.

1. Check oil fuel mixture.

2. Air filter dirty.

3. Spark arrester screen dirty.

4. Carburetor requires “H” (High jet) adjustment.

Carburetor requires adjustment.

1. Check Spark. Remove air filter cover. Remove spark

plug from cylinder. Reattach the spark plug wire and

lay spark plug on top of cylinder. Pull the starter rope

and watch for spark at spark plug tip. If there is no

spark, repeat test with a new spark plug.

2. With the ignition switch off, remove spark plug. Move

choke lever to run position (pushed in completely) and

pull starter cord 5 to 20 times. This will clear excess

fuel from engine. Clean and reinstall spark plug. Pull

starter three times with choke lever at run. If engine

does not start, move choke lever to choke and repeat

normal starting procedure. If engine still fails to start,

repeat procedure with a new spark plug.

Contact a John Deere Servicing Dealer for carburetor

*

adjustment.

Contact a John Deere Servicing Dealer for carburetor

*

adjustment.

1. Use fresh fuel and the correct 2-cycle oil mix.

2. Clean per instruction in Maintenance-Air Filter Section.

3. Clean per instructions in Maintenance-Spark Arresting Muffler Section.

4. * Contact a John Deere Servicing Dealer for carburetor

adjustment.

Turn idle speed screw “T” clockwise to increase idle

speed. (If chain turns at idle, turn idle speed screw “T”

counterclockwise to decrease speed). Wear protective

equipment and observe all safety instructions.

Bar and Chain Running Hot

and Smoking:

Engine starts and runs, but

chain is not rotating:

1. Chain oil tank empty.

2. Check chain tension.

3. Check for oiler function.

1. Chain brake engaged.

2. Check guide bar and chain assembly.

3. Check guide bar and chain for damage.

1. Oil tank should be filled every time that fuel tank is

filled.

2. Tension chain per instructions in Operation-Chain

Tension section.

3. Run at full throttle 15 to 30 seconds. Stop saw and

check for oil dripping from Safe-T-Tip and guide bar.

If oil is present the chain may be dull or bar may be

damaged. If no oil contact a John Deere Servicing

Dealer.

1. Release chain brake, see Operation-Chain Brake

Section.

2. Refer to Assembly-Assembling the Bar and Chain

Section.

3. Inspect guide bar and chain for damage.

H

L

T

Note: This engine complies with EPA (Environmental Protection Agency) and CARB (California Air Resource Board) regulations which

*

require exhaust emission control. As a result, the carburetor adjustment needles are equipped with plastic caps that limit the rotation from

the original factory adjustment. If your unit exhibits specific performance problems that can not be corrected by the Trouble Shooting

Section, the unit should be taken to a John Deere Servicing Dealer for repair.

26 English

Page 27

STORAGE (1 month or longer)

Storing Chain Saw (1 month or longer)

1. Drain all fuel from tank into a container approved for gasoline.

Run engine until it stops. This will remove all fuel-oil mix which

could become stale and leave varnish and gum in the fuel

system.

2. Clean all foreign material from the saw. Store it in a wellventilated place that is inaccessible to children. Keep away

from corrosive agents such as garden chemicals and de-icing

salts.

3. Abide by all Federal and local regulations for the safe storage

and handling of gasoline. Excess fuel should be used in other

2-cycle engine powered equipment.

TECHNICAL DATA

CS71

ENGINE:

Displacement: 4.3 cu. in (70.8 cc)

Bore: 1.97 in (50 mm)

Stroke: 1.42 in (36 mm)

PERFORMANCE:

Idle Speed: 2,800 RPM

WOT (With Bar and Chain): 13,200-13,700 RPM

Power: 5.1 hp/3.8kW (9,300 RPM)

CS71 and CS81

FUEL AND OIL SYSTEMS:

Carburetor: Multi Position Diaphragm Carburetor

Air Filter: 60 Micron Nylon Media

Fuel Tank Capacity: 29.76 oz. (880 ml)

Fuel Mix: See Operation-Fueling Section

Oil Tank Capacity: 14.88 oz. (440 ml)

Chain Lubrication: Automatic Speed Controlled Positive

CS81

ENGINE:

Displacement: 4.9 cu. in (80.7 cc)

Bore: 2.0 in (52 mm)

Stroke: 1.5 in (38 mm)

PERFORMANCE:

Idle Speed: 2,800 RPM

WOT (With Bar and Chain): 12,800

(Electronically Limited to

13,000 +/- 200)

Power: 5.7 hp/4.2kW (9,000 RPM)

Displacement Pump

IGNITION SYSTEM:

Spark Plug: Champion RCJ-7Y

Spark Plug Gap: 0.02 in. (0.5 mm)

27English

Page 28

WARRANTY

John Deere - Limited Warranty

The manufacturer warrants to the original retail purchaser that this product is free from defects in material and workmanship and

agrees to repair or replace, at manufacturer's discretion, any defective product free of charge within these time periods from the date

of purchase:

• Two years, if the product is used for personal, family, or household use;

• 120 days, if the product is used for professional, commercial, or income producing purposes.

• 90 days, if the product is used for rental purposes.

This warranty is not transferable and does not cover damage resulting from defects other than in material or workmanship.

Warranty Exclusions and Limitations

The following items are not covered by this warranty:

• Non-defective parts that are normal wear items or service required when performing regular maintenance of the product, i.e.,

spark plugs, air filters, fuel filters, starter ropes, guide bar, saw chain, sprockets, clutch drums, etc.

• Engine failure or engine problems due to inadequate lubrication concerning the use of two-cycle engine oil.

• Damage caused by unreasonable use, including the failure to provide reasonable and necessary maintenance.

• Conditions resulting from misuse, alteration or accident.

• Natural discoloration of plastic material due to ultraviolet light.

• Tune-ups on gasoline engines.

This warranty applies only to products sold within the United States of America, the District of Columbia, Canada, Mexico, the

Commonwealth of Puerto Rico, the Virgin Islands, Guam, the Canal Zone, or American Samoa.

SAVE YOUR SALES SLIP

Proof of purchase in the form of your dated sales receipt, cash register slip, etc. showing the serial number and the model of your

product will be required before our dealers can perform warranty service on the product. You must at your own expense, arrange

to deliver or ship the product for warranty repairs and arrange for pickup or return of the product after repairs have been made.

This warranty does not apply to any trade accessory, engine, or electric motor which is separately warranted by another manufacturer

and not manufactured by the manufacturer.

THIS LIMITED WARRANTY IS IN LIEU OF ALL OTHER EXPRESS WARRANTIES. ANY IMPLIED WARRANTY OF

FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY OR OTHERWISE, APPLICABLE TO THIS PRODUCT,

SHALL BE LIMITED IN DURATION TO THE DURATION OF THIS LIMITED WARRANTY. THE MANUFACTURER SHALL

NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE

LIMITATION MAY NOT APPLY TO YOU. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF

INCIDENTAL, OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

HOW TO OBTAIN WARRANTY SERVICE

Warranty service can be obtained from a John Deere Servicing Dealer authorized to make warranty repairs. If you need warranty

service, check first with the dealer from whom you purchased the product. FOR WARRANTY SERVICE INFORMATION OUTSIDE

THE USA AND CANADA, PLEASE CONTACT YOUR LOCAL JOHN DEERE SERVICING DEALER.

The manufacturer will not make any reimbursements for warranty service, except to JOHN DEERE Servicing Dealers authorized

to make warranty repairs. You must present your sales receipt when making any claim for warranty service.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

If you have any questions regarding your warranty rights and responsibilities, you should contact your John Deere

Servicing Dealer, or the John Deere Customer Communications Center, 1-800-537-8233 (USA/Canada).

28 English

Page 29

WARRANTY

John Deere

Federal Emission Design and Defect Limited Warranty

Utility and Lawn and Garden Engines

John Deere warrants to the initial purchaser and each subsequent owner, that this utility equipment engine (herein engine) is designed, built, and

equipped to conform at the time of initial sale to all applicable regulations of the U.S. Environmental Protection Agency (EPA), and that the engine

is free of defects in, materials and workmanship that would cause this engine to fail to conform with EPA regulations during its warranty period. This

emission warranty is applicable in all States, except the State of California.

For the parts listed under PARTS COVERED, the dealer or service center authorized by John Deere will, at no cost to you, make the necessary

diagnosis, repair, or replacement necessary to ensure that the engine complies with applicable U.S. EPA regulations.

MANUFACTURERS WARRANTY COVERAGE

The warranty period for this engine begins on the date of sale to the ultimate purchaser and continues for a period of two years.

OWNER’S WARRANTY RESPONSIBILITIES:

As the engine owner, you are responsible for the performance of the required maintenance listed in you owner’s manual. John Deere recommends

that you retain all receipts covering maintenance on your engine, but John Deere cannot deny a warranty claim solely for the lack of receipts or for

your failure to ensure the performance of all scheduled maintenance.

As the engine owner, you should however be aware that John Deere may deny your warranty coverage if your engine or a part has failed due to

abuse, neglect, improper maintenance or unapproved modifications.

You are responsible for presenting your engine to the nearest dealer or service center authorized by John Deere when a problem exists. If

you have any questions regarding your warranty rights and responsibilities, you should contact the John Deere Customer Communications

Center at 1-800-537-8233 (USA/Canada) for the information.

PARTS COVERED

Listed below are the parts covered by the Federal Emission Design and Defect Warranty. Some parts listed below may require scheduled maintenance and are warranted up to the first scheduled replacement point for that part. The warranted parts include:

Carburetor, Spark Plug, Ignition, Air Filter & Fuel Filter.

LIMITATIONS

The Federal Emission Design and Defect Warranty shall not cover any of the following:

(a) conditions resulting from tampering, misuse, improper adjustment (unless they were made by the dealer or service center authorized by

John Deere during a warranty repair), alteration, accident, failure to use the recommended fuel and oil, or not performing required mainte-

nance services,

(b) the replacement parts used for required maintenance services,

(c) consequential damages such as loss of time, inconvenience, loss of use of the utility engine of equipment, etc.,

(d) diagnosis and inspection fees that do not result in eligible warranty service being performed, and

(e) any non authorized replacement part, or malfunction of authorized parts due to use of non authorized parts.

MAINTENANCE AND REPAIR REQUIREMENTS

You are responsible for the proper use and maintenance of the engine. You should keep all receipts and maintenance records covering the

performance of regular maintenance in the event questions arise. These receipts and maintenance records should be transferred to each subsequent owner of the engine. John Deere reserves the right to deny warranty coverage if the owner has not properly maintained the engine. John

Deere will not deny warranty repairs, however, solely because of the lack of repair maintenance or failure to keep maintenance records.

MAINTENANCE, REPLACEMENT OR REPAIR OF EMISSION CONTROL DEVICES AND SYSTEMS MAY BE PERFORMED BY ANY REPAIR

ESTABLISHMENT OR INDIVIDUAL; HOWEVER, WARRANTY REPAIRS MUST BE PERFORMED BY A DEALER OR SERVICE CENTER AUTHORIZED BY JOHN DEERE. THE USE OF PARTS THAT ARE NOT EQUIVALENT IN PERFORMANCE AND DURABILITY TO AUTHORIZED

PARTS MAY IMPAIR THE EFFECTIVENESS OF THE EMISSION CONTROL SYSTEM AND MAY HAVE A BEARING ON THE OUTCOME OF A

WARRANTY CLAIM.

If other than the parts authorized by John Deere are used for maintenance replacements or for the repair of components affecting emission control,

you should assure yourself that such parts are warranted by their manufacturer to be equivalent to the parts authorized by John Deere in their

performance and durability.

OBTAINING WARRANTY SERVICE

To obtain Warranty service, take your engine to the nearest Authorized John Deere Dealer. Bring your sales receipts showing the date of purchases

for this engine. The dealer or service center authorized by John Deere, will perform the necessary repairs or adjustments within a reasonable

amount of time and will furnish you with a copy of the repair order. All parts and accessories replaced under this warranty become the property of

John Deere.

HOW TO MAKE A CLAIM

All repairs qualifying under this limited warranty must be performed by a dealer or service center authorized by John Deere. If any

emission-related part is found defective during the warranty period, you shall notify the John Deere Customer Communications

Center at 1-800-537-8233 (USA/Canada) and you will be directed to the appropriate warranty service facilities where the warranty

repair can be performed.

29English

Page 30

NOTES

30 English

Page 31

JOHN DEERE

WORLDWIDE COMMERCIAL & CONSUMER

EQUIPMENT DIVISION

Powerhead - PA01186

CS71 20” - UT10919

CS71 24” - UT10920

CS71 28” - UT10921

Tronçonneuse

MANUEL DE L’UTILISATEUR

Merci d’avoir acheté un produit John

Deere