Page 1

I0

Snow Blade

46 Inch

OMGX10902 I0

OPERATOR’S MANUAL

North American Version

Litho in U.S.A.

Page 2

INTRODUCTION

Introduction

Thank You for Purchasing This Product

We appreciate having you as a customer and wish you

many years of safe and satisfied use of your machine.

Using Your Operator’s Manual

This manual is an important part of your machine and

should remain with the machine when you sell it.

Reading your operator’s manual will help you and others

avoid personal injury or damage to the machine.

Information given in this manual will provide the operator

with the safest and most effective use of the machine.

Knowing how to operate this machine safely and correctly

will allow you to train others who may operate this machine.

This manual and safety signs on your machine may also be

available in other languages (see your John Deere dealer

to order).

Sections in your operator’s manual are placed in a specific

order to help you understand all the safety messages and

learn the controls so you can operate this machine safely.

You can also use this manual to answer any specific

operating or servicing questions. A convenient index

located at the end of this book will help you to find needed

information quickly.

IMPORTANT: Avoid damage! This text is used to tell

the operator of actions or conditions that might

result in damage to the machine.

NOTE: General information is given throughout the

manual that may help the operator in the operation or

service of the machine.

The machine shown in this manual may differ slightly from

your machine, but will be similar enough to help you

understand our instructions.

RIGHT-HAND and LEFT-HAND sides are determined by

facing in the direction the machine will travel when going

forward. When you see a broken line arrow (------>), the

item referred to is hidden from view.

Before delivering this machine, your dealer performed a

predelivery inspection to ensure best performance.

Special Messages

Your manual contains special messages to bring attention

to potential safety concerns, machine damage as well as

helpful operating and servicing information. Please read all

the information carefully to avoid injury and machine

damage.

c

CAUTION: Avoid injury! This symbol and text

highlight potential hazards or death to the

operator or bystanders that may occur if the

hazards or procedures are ignored.

Introduction

Page 3

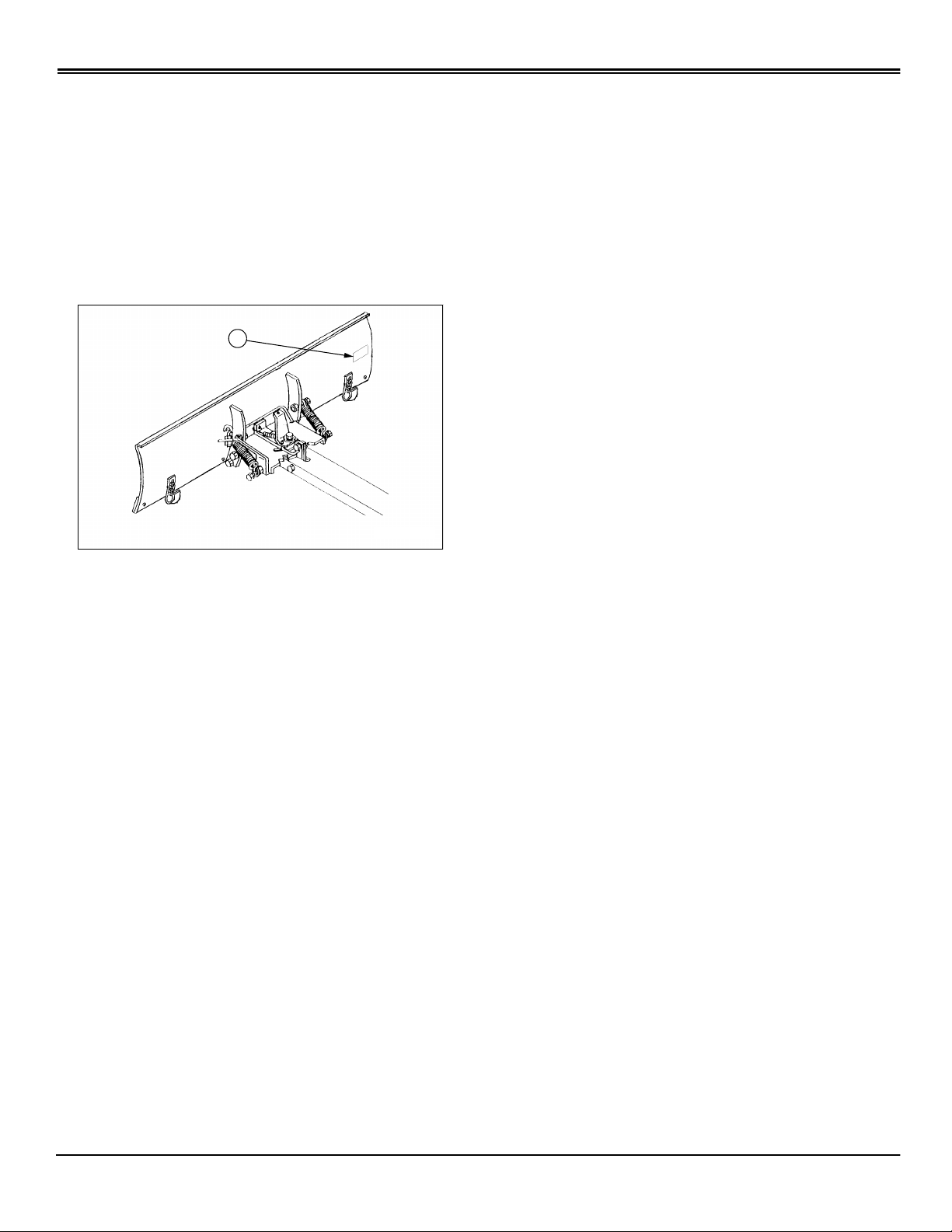

PRODUCT IDENTIFICATION

Product Identification

Record Identification Numbers

Snow Blade for Lawn Tractors

46 Inch

Serial No. (010001 - )

If you need to contact an Authorized Service Center for

information on servicing, always provide the product model

and serial number.

You will need to locate the identification number for the

machine and for the engine. Record the information in the

spaces provided below.

A

M92898C

DATE OF PURCHASE:

_________________________________________

DEALER NAME:

_________________________________________

DEALER PHONE:

_________________________________________

SERIAL NUMBER (A):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

Product Identification

Page 4

TABLE OF CONTENTS

Table of Contents

Safety .....................................................................................................................................................................................1

Preparing Vehicle ...................................................................................................................................................................3

Installing .................................................................................................................................................................................4

Removing ...............................................................................................................................................................................6

Operating................................................................................................................................................................................7

Troubleshooting ....................................................................................................................................................................10

Storage .................................................................................................................................................................................11

Assembly ..............................................................................................................................................................................12

Specifications .......................................................................................................................................................................18

Index.....................................................................................................................................................................................19

All information, illustrations and

specifications in this manual are based

on the latest information at the time of

publication. The right is reserved to

make changes at any time without

notice.

COPYRIGHT© 2000

Deere & Co.

John Deere Worldwide Commercial and

Consumer Equipment Division

Horicon, WI

All rights reserved

Previous Editions

COPYRIGHT© 1999

Table of Contents

OMGX10902 I0 - English

Page 5

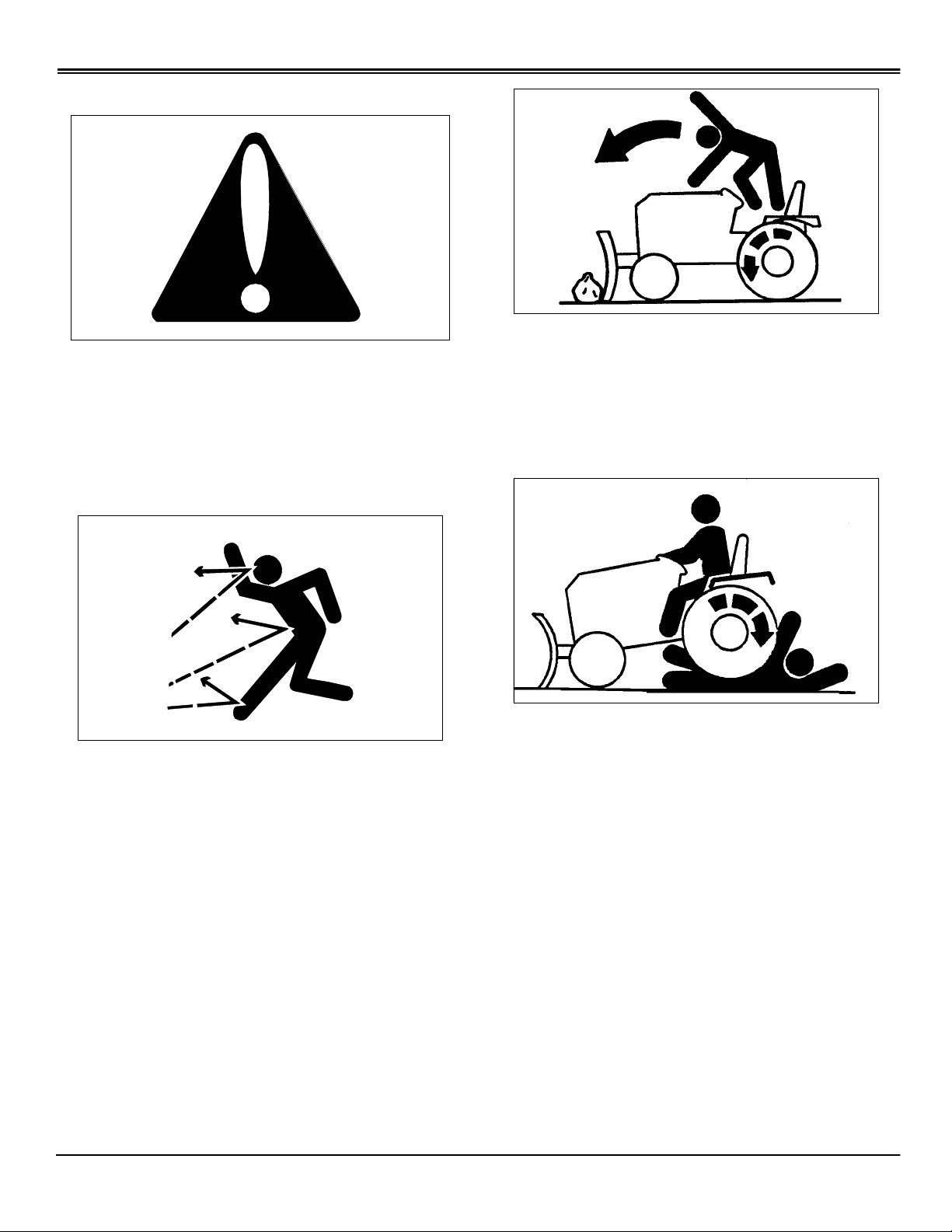

Safety

Understanding The Safety-Alert Symbol

SAFETY

• DO NOT leave machine unattended when it is running.

The operator’s manual explains any potential safety

hazards whenever necessary in special safety messages

that are identified with the word, CAUTION, and the safetyalert symbol, (

c

).

Operate Safely

• Check vehicle brake action before you operate. Adjust

or service brakes as necessary.

• Inspect machine before you operate. Be sure hardware

is tight. Repair or replace damaged, badly worn, or missing

parts. Be sure guards and shields are in good condition

and fastened in place. Make any necessary adjustments

before you operate.

• Clear work area of objects that might be thrown. Keep

people and pets out of the work area. Stop machine if

anyone enters the area.

• DO NOT operate machine at high speeds.

• DO NOT use blade as a battering ram.

• Look carefully behind machine before you back up.

• DO NOT let anyone, ESPECIALLY CHILDREN, ride on

machine or vehicle.

• DO NOT let children or untrained person operate

machine.

• Only operate during daylight or with good artificial light.

• Be careful of traffic when operating near or crossing

roadways.

• Do not wear radio or music headphones while operating

the machine. Safe operation requires your full attention.

• DO NOT operate equipment when you are tired, ill, or

under the influence of drugs or alcohol.

• If you hit an object, stop the machine and inspect it.

Make repairs before you continue to operate. Keep

machine and attachments properly maintained and in good

working order.

• Raise blade when you are driving between jobs or when

you are not moving snow.

Safety - 1

Page 6

SAFETY

Wear Appropriate Clothing

• Wear close fitting clothing and safety equipment

appropriate for the job.

• Loud noise can cause impairment or loss of hearing,

wear a suitable protective device such as earplugs.

Park Safely

• Stop machine on a level surface, not on a slope.

• Disengage Power Take-Off (PTO).

• Lower attachments to the ground.

• Lock the park brake.

• Stop the engine.

• Remove the key.

• Wait for engine and all moving parts to stop before you

leave the operator’s seat.

• Close fuel shut-off valve, if your machine is equipped.

Safety - 2

Page 7

PREPARING VEHICLE

Preparing Vehicle

Remove Mower Deck

The mower deck must be removed from before installing

the snow blade. See your machine operator’s manual or

mower deck manual for removal instructions.

Ballasting Requirements

Follow these recommendations to help improve traction:

• Install tire chains on turf tires or install bar tires on the

machine.

• Install rear wheel weights.

Ballast weights can be purchased from your Authorized

Service Center. See your machine operator’s manual for

further information.

Check Tire Pressure

See your machine’s operator’s manual for proper tire

pressures.

Preparing Vehicle - 3

Page 8

Installing

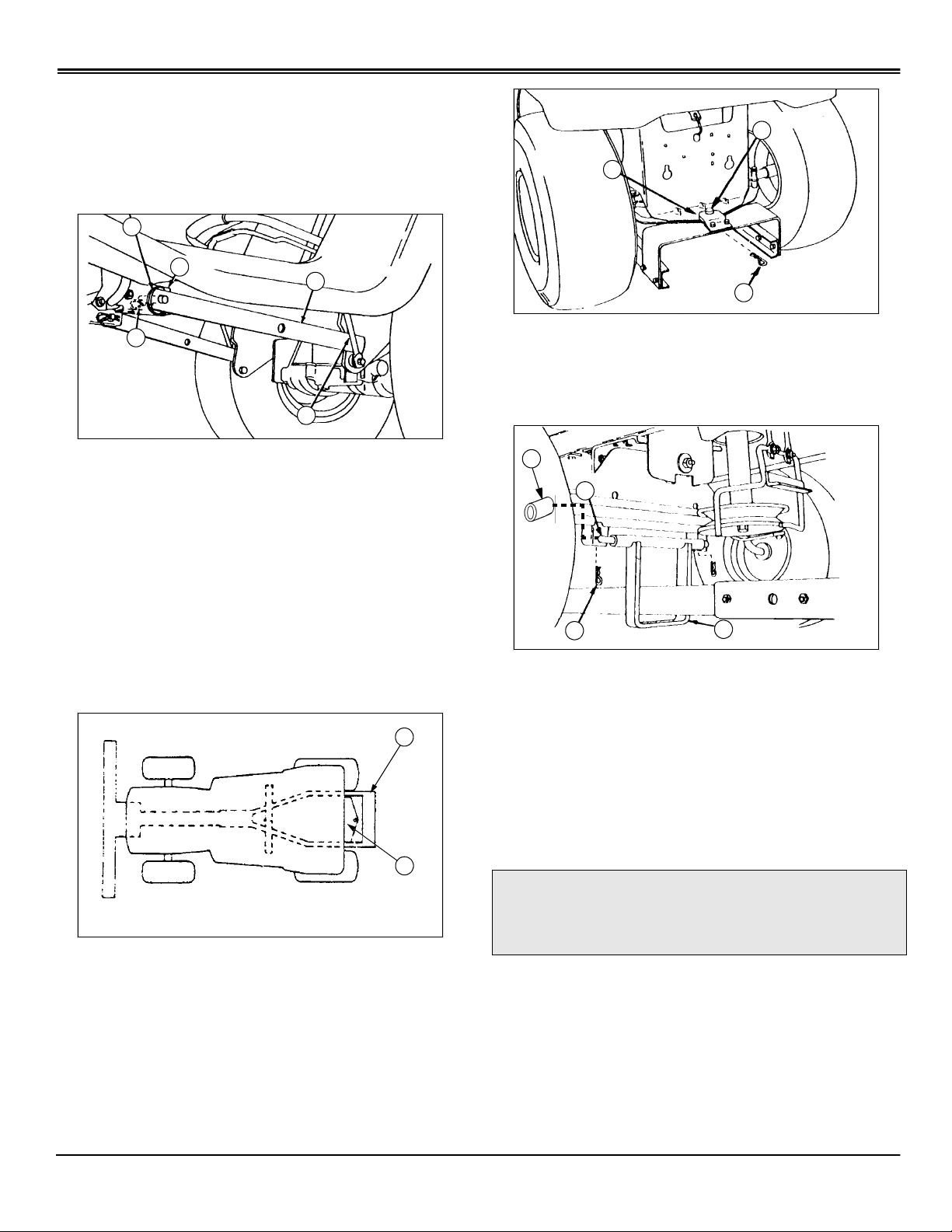

Install Lift Arms

INSTALLING

NOTE: Align the machine directly behind the blade

assembly before parking the machine.

1. Park the machine safely. (See Parking Safely in the

Safety section.)

A

D

B

E

C

2. Install one 1/2 x 1-1/2 x 3/16 in. flat washer (A) onto the

pin of each lift arm (B).

3. Insert the blank end of the lift arms behind the guide

rods (C) of the machine lift at each side of machine.

NOTE: The lift handle must be in its lowest position.

D

C

E

3. Raise rear of blade frame and slide onto drawbar (C) of

machine.

4. Fasten with hitch pin (D) and large spring locking pin

(E).

I

F

4. Insert the pins of the lift arms into the holes in the frame

rail (D) of the machine and secure with spring locking pins

(E).

Install Blade

A

B

M92905

1. Unlock park brake, put gear transmission in neutral or

pull out free-wheeling lever and push machine forward until

rear mounting bracket (A) of blade assembly is behind

drawbar (B) of machine.

H

G

5. Insert long end of each front stabilizer pin (F) into tube

of front stabilizer bracket (G).

6. Insert short end of each front stabilizer pin into front

mower mounting holes located on underside of front axle,

place spacer (I) over end of pin and secure with spring

locking pins (H).

Install Lift Links to Blade Frame and Lift Arms

c

CAUTION: Avoid injury! Lift lever is under

tension. Grasp lift lever securely and release

lock mechanism slowly.

1. Put lift lever one notch up from its lowest position.

2. Lock park brake.

Installing - 4

Page 9

INSTALLING

Install Pivot Handle Support

B

C

A

D

2. Insert threaded end of lift links down through holes in lift

channel (A) and bent end of lift links through holes in lift

arms (B).

3. Fasten bent ends of lift links (C) to lift arms with spring

locking pin.

4. Thread 3/8 in. nylock nut and 5/16 in. flat washer (D),

one on each side until they seat against lift channel (C).

Install Pivot Control Handle

F

A

B

A

E

C

M92907

1. Slide eye of pivot handle support (A) onto pivot control

handle (B).

E

C

D

A

M85797

C

D

B

E

M92906

1. Insert handle end of pivot control handle (A) through eye

bolt (B) and slide it all the way to bracket end of pivot

control handle.

2. Hook pivot release rod (C) into hole of bracket at end of

pivot control handle and fasten with spring clip (D).

3. Lay pivot control handle along side of machine onto

wheel and footrest of machine. Make sure hook of bracket

on end of pivot control handle is to the right of the eye bolt.

4. Slide 3/8 x 1 in. flat washer onto handle end of pivot

control handle and slide all the way to eye bolt.

5. Install spring locking pin (E) through pivot control handle

to hold washer against eye bolt.

6. Install rubber handle grip (F) to handle of pivot control

handle.

2. Insert pivot handle support through 1/2 in. hole in thrust

channel (C) and place strap over nut (D) of thrust channel.

Secure with spring locking pin (E) on opposite side of thrust

channel.

Installing - 5

Page 10

Removing

Remove Blade

REMOVING

c

CAUTION: Avoid injury! Before removing frame

assembly: Make sure hands and arms are not

under frame assembly.

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Put blocks of wood or a board under blade.

3. Push machine lift lever down lowering blade onto blocks

or board and lock lever in lowest position.

E

G

D

A

B

C

F

4. Remove spring locking pins (A) and remove lift links (B)

from lift straps (C). Install locking pins back to lift links.

J

I

M92907

7. Remove spring locking pin (I) from pivot control handle

support (J) and install spring locking pin back to handle

support.

8. Remove rubber handle grip and slide pivot control

handle support off of pivot control handle.

L

M

K

5. Remove spring locking pins (D) and washers (E).

Remove lift straps (C) from behind guide rods (F) and

frame rails (G). Install spring locking pins and washers

back to lift links.

F

H

G

6. Remove spring locking pins (H), spacers, and front

stabilizer pins (F) from tube of front stabilizer bracket (G).

Install spring locking pins back into stabilizer pins.

M92906

9. Remove spring locking pin (K) and spring clip (L) and

unhook pivot release rod (M) from pivot control handle.

Install spring clip and spring locking pin.

10.Remove pivot control handle and install rubber handle

grip to handle.

O

P

N

11.Remove spring locking pin (N) and clevis pin (O) from

drawbar (P). Lower frame assembly to the ground.

12.Remove blade assembly from under machine.

Removing - 6

Page 11

Operating

Before Operating Blade

1. Learn all controls and how they work. Read your

machine's operator manual, if necessary.

2. Lock park brake.

3. Stop engine.

4. Remove key.

OPERATING

B

5. Make operating adjustments as necessary.

6. Tighten loose hardware.

Rotating Scraper Blade

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Raise blade and place wood block under frame channel.

B

A

M92908

A

3. Tighten both 3/8 nylock nuts (A) up to the bottom of the

lift channel (B).

Leveling Blade from Side to Side

1. Park machine on a level surface.

2. Place mower lift handle in the TRANSPORT (upper)

position.

A

3. Remove six 5/16 carriage bolts and six 5/16 nylock nuts

(A) to remove scraper blade (B).

4. Turn scraper blade over and install scraper blade.

5. Adjust skid shoes.

Adjusting Lift Height

1. Park machine safely. (See Parking Safely in the Safety

section.)

2. Place the mower lift lever one notch up from its lowest

position.

Operating - 7

Picture Note: Level side to side (A).

3. Measure at each end of blade.

NOTE: Do not adjust nut of lift link up more than two

turns without lowering opposite side lift link.

B

4. If one side of blade is low, adjust nut (B) on lift link UP

on that side to level blade.

Page 12

OPERATING

Adjusting Skid Shoes

When clearing snow on smooth surfaces, skid shoes

should be approximately 1/4 inch above ground level.

When clearing snow on uneven surfaces, skid shoes

should keep blade above ground level. Height above

ground level should be based on the unevenness of your

surface.

1. Park machine on a level surface.

2. Raise lift lever to the TRANSPORT (upper) position.

3. Place a block of wood beneath each end of the blade.

4. Lower blade onto blocks of wood.

A

For transport, pull lift lever back to the highest position.

Adjusting Blade Angle

A

MX6533A

Picture Note: Reference Blade Angling Label (A)

located on the back side of the blade in the upper

left corner.

MX6534

5. Loosen nuts (A) and adjust skid shoes as necessary.

Tighten nuts.

Using Lift Lever to Raise and Lower Blade

A

B

1. Push down on lift lever (A) slightly and hold locking lever

(B) down with thumb.

2. Move lift lever (A) DOWN to LOWER blade or UP to

RAISE blade.

3. Release locking lever lock (B) to keep lift lever (A) in

position.

For scraping/snow removal, push lift lever down to the

lowest position.

B

M92909

1. Place blade in the raised position.

2. Turn release latch (B) counterclockwise and hold.

3. Push forward on pivot control handle to angle blade to

the right, or pull back on pivot control handle to angle blade

to the left.

4. Release pivot control handle to lock in position.

5. Lower blade to the operating position.

Operating Tips

c

CAUTION: Avoid injury! DO NOT use blade as a

battering ram. Do Not operate at a high speed.

Hitting a solid object at high speeds can injure

the operator and damage the blade.

Operate blade at slow travel speed.

This blade is designed to move new loose snow in depths

Operating - 8

Page 13

OPERATING

up to 6 inches. Blade is not intended to move gravel or dirt.

Operate engine at full throttle for best performance, control

ground speed using lower gears or foot controls.

Put Blade On An Angle:

• When clearing material to the side.

• To decrease amount of power required to move

material.

• To decrease rear wheel slippage.

Use Blade In Straight-across Position:

• To move material straight ahead.

After You Are Finished Using Blade:

• Park machine on hard, level surface.

• Stop engine.

• Lock park brake.

• Remove key.

• Put blocks of wood or a board under blade.

• Lower blade onto blocks of wood by pushing lift lever

forward until it locks down in lowest position.

Operating - 9

Page 14

TROUBLESHOOTING

Troubleshooting

Using Troubleshooting Chart

If you are experiencing a problem that is not listed in this

chart, see your Authorized Service Center for service.

When you have checked all the possible causes listed and

you are still experiencing the problem, see your Authorized

Service Center.

IF CHECK

Engine Lugs Down Run engine at full throttle.

Blade angle.

Raise blade to float position.

Adjust skid shoes.

Blade Digs In Too Deep Raise blade to float position.

Adjust skid shoes.

Rear Wheels Slip Add rear weights and chains.

Troubleshooting - 10

Page 15

STORAGE

Storage

Storing Blade

Clean the blade with water under pressure.

If possible, store blade indoors on hard, level surface.

If you store blade outside:

• Put blocks of wood or a board under blade.

• Cover blade with a waterproof cover.

Inspect blade. Repair or replace badly worn or damaged

parts. Check all bolts, nuts, and pins to make sure they are

secure.

Apply touch-up paint where needed to prevent rust.

Oil all pivot points so that they will work freely.

Grease blade pivot plate, thrust channel, pivot plate

reinforcement and pivot release bracket.

Storage - 11

Page 16

Assembly

Box of Parts

ASSEMBLY

Key Description

C

A

D

A Blade Assembly

B Pivot Plate

C Rear Mounting Bracket

D Lift Channel

E Pivot Control Handle

E

F Pivot Handle Support

G

F

G (2) Rear Support Channel

H Thrust Channel

B

I Blade Pivot Bracket

J Front Stabilizer Bracket

K Pivot Release Rod

H

L(2) Strap

J

I

M

M (2) Front Stabilizer Pin

N (2) Spacer

O (2) Lift Link

P Pivot Plate Reinforcement

N

K

L

P

O

Q Pivot Control Rod

R Pivot Release Bracket

S Rear Locating Bracket

T (2) Lift Arm

Q

U Drawbar Support Plate

Operator’s Manual

S

Bag of Parts

R

Bag of Parts

T

M92899

Qty Description Size

2 Return Spring

U

1 Full Thread Bolt 3/8 x 4-1/2 in.

1 Rubber Handle Grip

1 Idler Spring

1 Spacer 3/8 x 1/2 x 1/4 in.

Assembly - 12

Page 17

ASSEMBLY

Qty Description Size

2 Flat Washer 5/16 Flat

3 Cotter Pin .094 x.75

1 Flat Washer 1/2 x 2 in.

2 Flat Washer 3/8 x 1-1/2 in.

4 Hex Head Bolt 5/16 x 1-1/4 in.

2 Hex Head Bolt 5/16 x 5/8 in.

4 Hex Head Bolt 5/16 x 2-1/2 in.

3 Flat Washer 3/8 x 1 in.

3 Lock Washer 3/8 in.

1 Nylock Nut 5/8 in.

1 Eye Bolt 3/8 x 2 in.

6 Hex Lock Nut 5/16 in.

1 Hex Head Bolt 5/8 x 1-3/4 in.

2 Hex Head Bolt 1/2 x 1in.

Install Drawbar Support Plate

B

A

1. Place drawbar support plate (A) under rear axle and

under drawbar (B).

2. Align drawbar holes with axle holes.

3. Install four 5/16 x 2-1/2 in. hex head bolts (C) and four 5/

16 in. lock nuts (D).

C

D

Install Parts to Blade Assembly

8 Spring Locking Pin .095 DIA x 1-5/8 in.

1 Spring Locking Pin 0.148 DIA x 2-7/8 in.

1 Flat Washer 21/32 x 1-5/16 in.

1 Hitch Pin 5/8 x 1-7/8 in.

2 Spring Clip .065 DIA x.72 in. OD

1 Full Thread Bolt 3/8 x 2-1/2 in.

2 Hex Lock Nut 1/2 in.

2 Flat Washer 1/2 x 1-1/2 x 3/16 in.

8 Nut/Lock Washer Assembly 5/16 in.

13 Hex Head Bolt 3/8 x 1 in.

18 Nylock Nut 3/8 in.

3 Hex Nut 3/8 in.

Grease

Use a SAE Multi-purpose grease based on the expected air

temperature range during the service interval.

C

B

A

E

D

M93033B

1. Assemble spring anchor bolts:

a. Turn one 5/16 in. nut and lock washer assembly (B)

onto the 5/16 x 1-1/4 in. hex head bolt (A) with lock

washer away from the head of the bolt.

b. Insert the bolt and nut assembly (A & B) through hole

in rib of blade assembly then assemble with a second 5/

16 in. nut and lock washer assembly (C) onto bolt (A).

c. Adjust inside nut and lock washer (B) flush with end

of thread on bolt then tighten nut and lock washer (C)

against blade rib.

d. Assemble second 5/16 x 1-1/4 in. bolt to opposite

side of blade assembly using the same procedure.

Assembly - 13

Page 18

ASSEMBLY

2. Assemble breakover stop bolt:

• Install one 5/16 x 5/8 in. hex bolt (D) into bottom hole

of each rib on blade assembly and fasten with 5/16 in.

lock nut (E).

Assemble Pivot Plate to Thrust Channel

D

B

A

C

E

F

M93035

1. Assemble the pivot plate (A) and the pivot plate

reinforcement (B) on top of the thrust channel (C).

2. Lubricate thrust channel, pivot plate, and pivot plate

reinforcement in areas of contact with light multi-purpose

grease.

3. Insert 5/8 x 1-3/4 in. hex head bolt (D) through the pivot

plate reinforcement, pivot plate, and the thrust channel and

fasten with 21/32 x 1-5/16 in. flat washer (E) and 5/8 in.

nylock nut (F).

4. Loosen 5/8 in. nylock nut approximately 1/4 turn to allow

the assembly to pivot freely.

Assemble Pivot Release Bracket, Pivot Plate, and Thrust Channel

G

C

B

D

J

1. Lubricate large hole and two faces of pivot release

bracket (A) with light multi-purpose grease.

2. Assemble idler spring (B) into smallest hole of pivot

release bracket (A).

3. Place 3/8 in. lock washer (C), 3/8 x 1-1/2 in. flat washer

(D), pivot release bracket (A), large 1/2 x 2 in. flat washer

(F), and spacer (E) onto 3/8 x 2-1/2 in. full thread bolt (G).

NOTE: Make sure pivot release bracket and large

1/2 x 2 in. flat washer (F) pivot freely after bolt is tight.

4. Align holes in thrust channel (H) with pivot plate

reinforcement (I) and thread 3/8 x 2-1/2 in. full thread bolt

(G) with parts assembled into hole and tighten securely.

D

A

F

E

I

H

M93036

NOTE: Tightening of nut (J) will cause loosening of 3/8

x 2-1/2 bolt (G) unless bolt is held with a back-up

wrench.

5. Place 3/8 x 1-1/2 in. flat washer (D) onto bottom of

3/8 x 2-1/2 in. full thread bolt and fasten with 3/8 in. nylock

nut (J). Loosen nut approximately 1/4 turn until pivot plate

pivots freely.

6. Hook other end of idler spring (B) to pivot plate

reinforcement.

Assembly - 14

Page 19

ASSEMBLY

Assemble Pivot Latch Strap

G

F

E

G

B

C

A

1. Insert 3/8 x 4-1/2 in. full thread bolt (A) through one side

of thrust channel (B), approximately half way.

C

D

M93038

Install Pivot Control Rod

NOTE: Pivot control rod (A) must be rotated from

pictured orientation in order to access grooved side of

spring locking pin hole.

D

C

A

C

1. Assemble pivot control rod (A) into pivot latch straps (B)

and fasten with two cotter pins (C) by inserting each

through the grooved side of the pivot control rod on each

side of pivot latch straps.

2. Assemble other end of pivot control rod (A) into hole of

pivot release bracket (D) and fasten with cotter pin (C).

B

M93037

2. Assemble one 3/8 in. hex nut (D) (non-locking) and 3/8

in. lock washer (C) onto hex bolt (A) approximately 1 inch

from head of bolt.

3. Place two pivot latch straps (E) together and fasten with

3/8 x 1 in. hex bolt (F) and 3/8 in. nylock nut (G). Insert

pivot latch straps through slot of the thrust channel and

onto the hex bolt (A).

NOTE: Bolt (A) must pivot freely after 3/8 in. nylock nut

(G) is assembled.

4. Assemble second 3/8 in. hex nut (D) and 3/8 in. lock

washer (C) onto 3/8 x 4-1/2 in. full thread bolt and hand

tighten against pivot latch straps. Adjust two 3/8 in. hex

nuts to allow hex bolt (A) to pass through other side of

thrust channel and fasten bolt with 3/8 in. nylock nut (G).

5. Fasten pivot latch straps (E) in the center of slot of the

thrust channel with 3/8 in. hex nuts (D).

Assemble Blade Pivot Bracket and Eye Bolt

B

D

G

F

H

A

B

E

C

A

E

1. Turn one 5/16 in. nut and lock washer assembly (A)

onto one 5/16 x 1-1/4 in. hex bolt (B) with lock washers

Assembly - 15

M93039

Page 20

ASSEMBLY

away from the head of the bolt. Assemble two nuts and

bolts in this manner.

2. Place blade pivot bracket (C) on the left side of the pivot

plate (D). Insert bolt and nut assembly (A and B) and fasten

with another nut and lock washer assembly (E).

3. Install nut flush with end of bolt (B) and fasten to plate

with outside nut.

4. Install second bolt and nut assembly (A and B) into right

side of pivot plate and fasten with another nut and lock

washer assembly (E).

5. Assemble 3/8 in. hex nut (F) onto 2 in. eye bolt (G) and

turn it onto the eye end of the threads. Place wrench

through eyebolt to hold while tightening.

6. Assemble eyebolt to the blade pivot bracket (C) and

fasten with a 3/8 in. nylock nut (H). Loosen 3/8 in. lock nut

approximately 1/4 turn to allow eyebolt to pivot freely.

Assemble Pivot Plate to Blade Assembly

1. Lay blade assembly flat on the ground.

Assemble Breakover Return Springs

c

CAUTION: Avoid injury! Springs under

tension. Use caution when attaching springs.

B

A

D

C

1. Hook one end of the return spring (A) onto the anchor

bolt (B) of the blade assembly.

M92901B

B

C

A

2. Install pivot plate (A) between the ribs (B) of the blade

assembly and fasten with two 1/2 x 1 in. hex

bolts (C) and two 1/2 in. lock nuts (D).

3. Loosen lock nuts (D) approximately 1/4 turn to allow

pivot plate to pivot freely.

D

M92900B

2. Using a box-end wrench (C) or spring puller hook it onto

the lower end of the return spring, press or pull down and

hook return spring over the spring anchor bolt (D) of the

pivot plate.

3. Repeat procedure for spring on other side of blade.

Assemble Pivot Release Rod

C

A

B

Assemble pivot release rod (A) down into pivot release

bracket (B) and fasten with spring clip (C).

Assembly - 16

Page 21

ASSEMBLY

Assemble Rear Support Channels to Thrust Channel

B

A

C

D

M92903a

1. Install front stabilizer bracket (A) over thrust

channel (B).

2. Assemble one rear support channel to each side of the

thrust channel and fasten with four 3/8 x 1 in. hex

bolts (C) and four 3/8 in. nylock nuts (D) with the head of

the bolt to the inside. Hand tighten nuts only.

Assemble Lift Channel and Rear Mounting Bracket to Rear Support Channels

C

C

A

D

G

F

E

C

E

E

B

M92904a

1. Assemble the lift channel (A) to rear support

channels (B) with the open side of the lift channel upward.

2. Fasten lift channel with two 3/8 x 1 in. hex bolts (C), two

3/8 x 1 in. flat washers (D), and two 3/8 in. nylock nuts (E).

Hand tighten nuts only.

3. Slide rear mounting bracket (F) over rear support

channels (B) with the double holes to the rear and fasten

with four 3/8 x 1 in. hex bolts (C) and four 3/8 in. nylock

nuts (E). Hand tighten nuts only.

4. Place rear locating bracket (G) on top of rear mounting

bracket (F) and fasten with two 3/8 x 1 in. hex bolts (C) and

two 3/8 in. nylock nuts (E).

5. Tighten all hardware on rear support channels.

Assembly - 17

Page 22

SPECIFICATIONS

Specifications

Blade Specifications

Blade Width

Straight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1168 mm (46 in.)

Angled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1041 mm (41 in.)

Range of Lift (Blade positioned straight forward)

Above Ground Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152 mm (6 in.)

Below Ground Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 mm (2 in.)

Blade Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356 mm (14 in.)

Angling Positions

Number of Positions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Right and Left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25°

Weight (Approximate) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30.8 kg (68 lb)

(Specifications and design subject to change without notice.)

Specifications - 18

Page 23

INDEX

Index

A

Assembly ........................................................................ 12

B

Ballasting Requirements .................................................. 3

Blade Angle, Adjusting

Blade Storage

Blade from Side to Side, Leveling

Blade, Before Operating

Blade, Install

Blade, Rotating Scraper

................................................................. 11

..................................................................... 4

D

Dealer Set-up ................................................................. 12

H

Handle Support, Install Pivot ............................................ 5

Handle, Install Pivot Control

Height, Adjusting Lift

L

Leveling Blade from Side to Side ..................................... 7

Lift Lever to Raise and Lower Mower, Using

Lift Links to Blade Frame and Lift Arms, Install

..................................................... 8

.................................... 7

................................................... 7

................................................... 7

............................................. 5

........................................................ 7

.................... 8

................ 4

M

Mower Deck, Remove ...................................................... 3

O

Operating Safely ............................................................... 1

Operating Tips

.................................................................. 8

S

Safety, Operating ............................................................. 1

Scraper Blade, Rotating

Skid Shoes, Adjusting

Specifications

................................................................. 18

................................................... 7

...................................................... 8

T

Tire Pressure .................................................................... 3

Troubleshooting Chart, Using

......................................... 10

Index - 19

Page 24

QUALITY STATEMENT

Quality Statement

Your product, designed and built by John Deere, is more

than just a purchase, it’s an investment in quality. That

quality goes beyond our equipment to your dealer’s parts

and service support.

That’s why John Deere has initiated a process to handle

your questions or problems, should they arise. If you have

questions or problems with your new product, please follow

the steps below.

To locate your nearest authorized servicing dealer, please

call the toll free number listed in your machine Operator’s

Manual.

Step 1

Refer to your operator’s manual

A. It has many illustrations and detailed information on the

safe and proper operation of your equipment.

B. It gives troubleshooting procedures, and specification

information.

C. It gives ordering information for parts catalogs, service

and technical manuals.

D. If your questions are not answered in the operator’s

manual, then go to Step 2.

Step 2

Contact your dealer

A. Your authorized servicing dealer has the responsibility,

authority, and ability to answer questions, resolve problems,

and fulfill your parts and service needs.

B. First, discuss your questions or problems with your

dealer’s trained parts and service staff.

C. If the parts and service people are unable to resolve your

problem, see the dealership manager or owner.

D. If your questions or problems are not resolved by the

dealer, then go to Step 3.

Step 3

Call the Customer Communications Center

A. Your authorized servicing dealer is the most efficient source in addressing any concern, but if you are not able to

resolve your problem after checking your operator’s manual and contacting your dealer, call the Customer

Communications Center.

B. For prompt, effective service, please have the following ready before you call:

• The name of the dealer with whom you’ve been working.

• Your equipment model number.

• Number of hours on machine (if applicable).

C. Then refer to your Tractor Operator’s Manual to locate the Customer Communications Center toll free number and call

our advisor who will work with your dealer to investigate your concern.

• Your 13-digit serial number which you recorded on the

inside front cover of this manual.

• If the problem is with an attachment, your attachment

identification number.

Quality Statement - 20

Loading...

Loading...