Page 1

J9

Snowblower for Lawn Tractors

42-Inch

OPERATOR’S MANUAL

OMGX10742 J9

North American Version

Litho in U.S.A.

Page 2

INTRODUCTION

Introduction

Thank You for Purchasing a John Deere Product

We appreciate your business and wish you many years of

safe and satisfied use of your machine.

Using Your Operator’s Manual

This manual is an important part of your machine and

should remain with the machine when you sell it.

Reading your operator’s manual will help you and others

avoid personal injury or damage to the machine.

Information given in this manual will provide the operator

with the safest and most effective use of the machine.

Knowing how to operate this machine safely and correctly

will allow you to train others who may operate t his machine.

Sections in your operator’s manual are placed in a specific

order to help you understand all the safety messages and

learn the controls so you can operate this machine safely.

You can also use this manual to answer any specific

operating or servicing questions. A convenient index

located at the end of this book will help you to find needed

information quickly.

The machine shown in this manual may differ slightly from

your machine, but will be similar enough to help you

understand our instructions.

cCAUTION: Avoid injury!

This symbol and text highlight potential

hazards or death to the operator or bystanders

that may occur if the hazards or procedures are

ignored.

IMPORTANT: Avoiddamage!Thistextisusedtotell

the operator of actions or conditions that might

result in damage to the machine.

NOTE: General information is given throughout the

manual that may help the operator in the operation or

serviceofthemachine.

RIGHT-HAND and LEFT-HAND sides are determined by

facing in the direction the machine will travel when going

forward. When you see a broken line arrow (------>), the

item referred to is hidden from view.

Special Messages

Your manual contains special messages to bring attention

to potential safety concer ns, machine damage as well as

helpful operating and servicing information. Please read all

the information carefully to avoid injury and machine

damage.

Introduction

Page 3

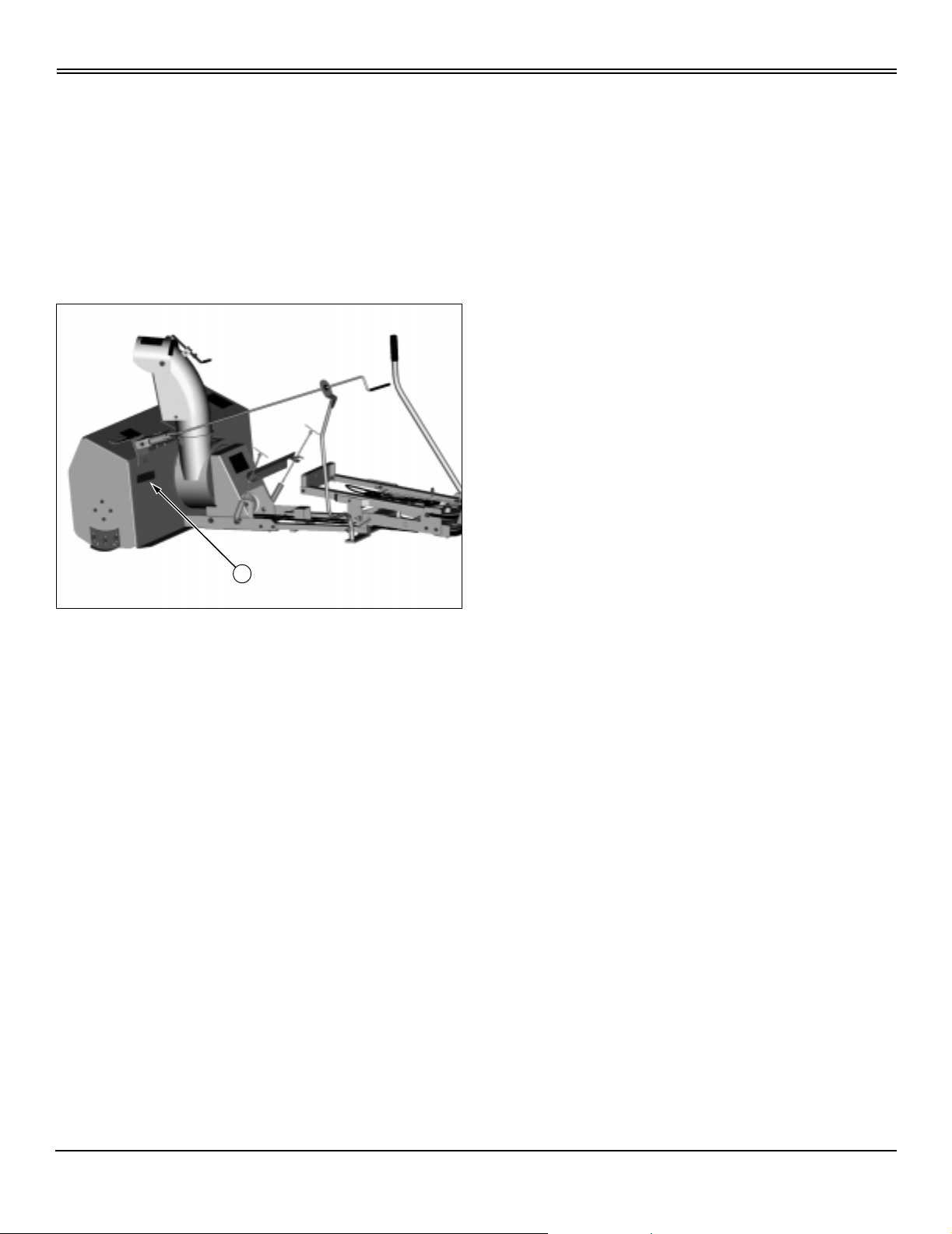

PRODUCT IDENTIFICATION

Product Identification

Record Identification Numbers

42-Inch Snowblower

Serial No. (010001-)

If you need to contact an Authorized Service Center for

information on servicing, always provide the product model

and serial number.

You will need to locate the model and serial number for the

machine and fortheengineofyour machine and record the

information in the spaces provided below.

A

DATE OF PURCHASE:

_________________________________________

DEALER NAME:

_________________________________________

DEALER PHONE:

_________________________________________

PRODUCT IDENTIFICATION NUMBER (A):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

Product Identification

Page 4

TABLEOFCONTENTS

Tableof Contents

Contents

Safety...........................................................................................1

Assembly........................................................................................4

PreparingVehicle..................................................................................8

Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Removing.......................................................................................14

Operating.......................................................................................16

ReplacementParts................................................................................22

Service ........................................................................................23

Troubleshooting ..................................................................................27

Storage.........................................................................................28

Index...........................................................................................29

All information, illustrations and

specifications in this manualare based

on the latest information at the time of

publication. The right is reserved to

make changes at any time without

notice.

COPYRIGHT© 1999

Deere & Co.

John Deere Worldwide Commercial and

Consumer Equipment Division

Horicon, WI

All rights reserved

Table of Contents

OMGX10742 J9 - English

Page 5

SAFETY

Safety

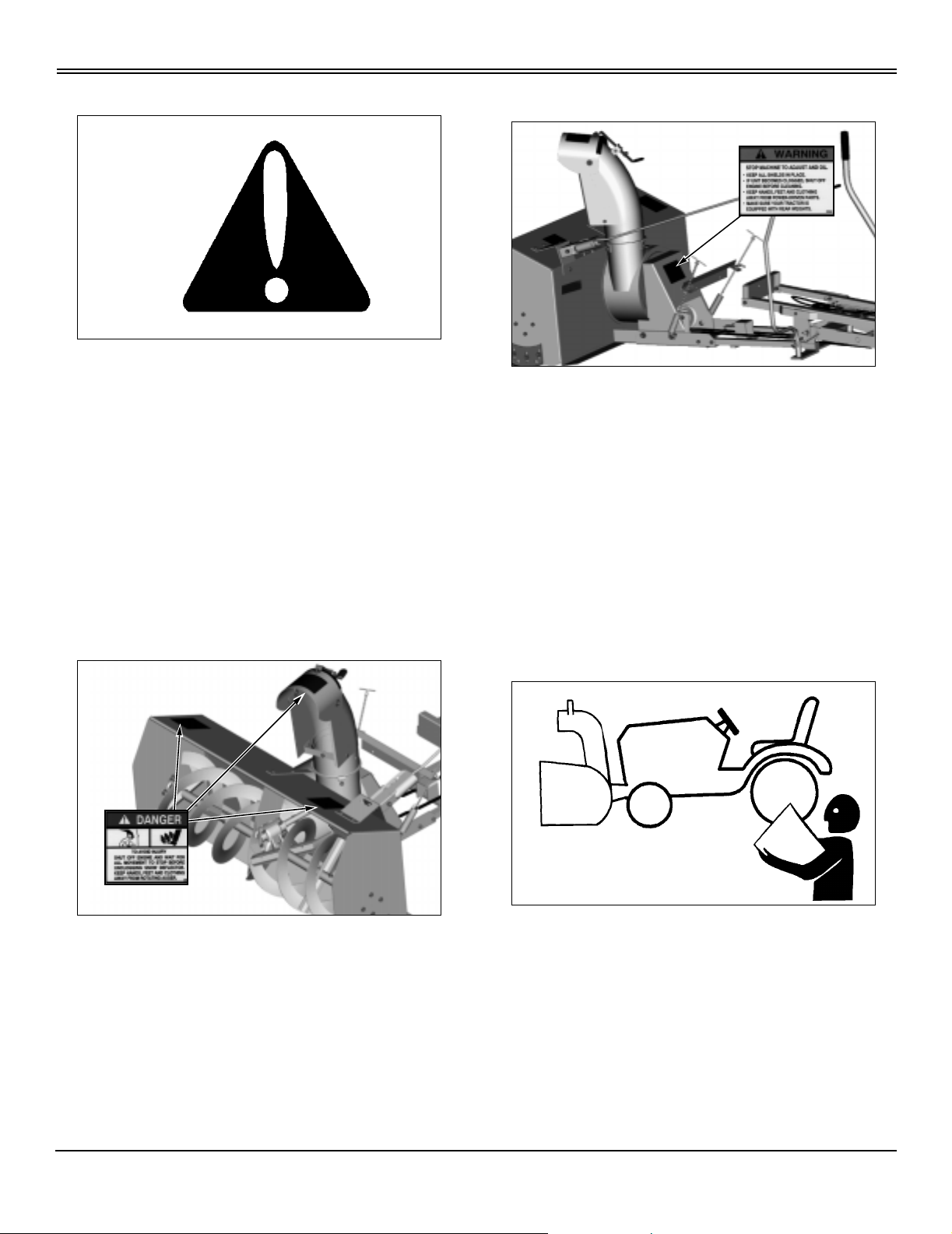

Understanding The Machine Safety Labels

The machine safety labels shown in this section are placed

in impor tant areas on your machine to draw attention to

potential safety hazards.

On your machine safety labels, the words DANGER,

WARNING, and CAUTION are used with this safety-alert

symbol, (

hazards.

The operator’s manual also explains any potential safety

hazards whenever necessary in special safety messages

that are identified with the word, CAUTION, and the safetyalert symbol, (

c). DANGER identifies the most serious

c).

WARNING

Picture Note: Decal located on pulley cover of

snowblower housing.

• Stop machine to adjust and oil.

• Keep all shields in place.

• If unit becomes clogged, shut off engine before

cleaning.

• Keep hands, feet and clothing away from power-driven

parts.

• Make sure your tractor is equipped with rear weights.

DANGER

Picture Note: One decal located on chute spout

and two on top surface of snowblower housing.

To avoid injury

• Shut off engine and wait for all movement to stop before

unclogging snow deflector.

• Keep hands, feet and clothing away from rotating auger.

Operate Safely

• Read the Tractor and Snowblower Operator’s Manual

carefully. Be thoroughly familiar with the controls and the

proper use of the equipment. Know how to stop the tractor

and disengage the controls quickly.

• Check vehiclebrake action beforeyou operate. Adjust or

service brakes as necessary.

• Inspect machine before you operate. Be sure hardware

is tight. Repair or replace damaged badly worn, or missing

parts. Be sure guards and shields are in good condition

and fastened in place. Make any necessary adjustments

Safety - 1

Page 6

SAFETY

before you operate.

• Clear work area of objects that might be thrown. Keep

people and pets out of the work area. Keep children

indoors when blowing s now. Turn the machine off if anyone

enters the area.

• If you hit an object, stop the machine and inspect it.

Make repairs before you operate. Keep machine properly

maintained and in good working order.

• DO NOT leave machine unattended when it is running.

• Only operate during daylight or with good artificial light.

• Drive up and down-not across slopes.

• DO NOT operate near edge of ditch or bank. Avoid

holes, rocks, and roots. Be alert for hidden hazards.

• Older adults are involved in a large percentage of riding

mower accidents involving injury. These operators should

evaluate their ability to operate a mower and a snowblower

safely enough to protect the operator and others from

serious injury.

Parking Safely

1. Stop machine on a level surface, not on a slope.

2. Disengage mower blades.

3. Lower attachments to the ground.

4. Lock the park brake.

5. Stop the engine.

6. Remove the key.

7. Wait for engine and all moving parts to stop before you

leave the operator’s seat.

• Look carefully behind tractor before you back up.

• DO NOT let anyone, especially children, ride on

machine or attachment. Riders are subjectto injury such as

being struck by foreign objects and being thrown off. Riders

may also obstruct the operator’s view, resulting in the

machine being operated in an u nsafe manner.

• Do not wear radio or music headphones while operating

the machine. Safe operation requires your full attention.

• DO NOT let children or an untrained person operate

machine.

• Be alert for traffic when crossing or wor king near

roadways.

• Be alert. DO NOT operate snowblower when you are

tired or ill or under the influence of drugs or alcohol.

• Keep clear of the discharge opening at all times.

• DO NOT operate tractor at high speeds. Operate

snowblowerat full throttle and a safe, slow travel speed.

• Do not throw snow toward bystanders, buildings, or

automobiles.

• Throw snow downwind, if possible.

• Clean snowblower after you use it.

• Be extremely careful if you must clear snow from a

gravel surface.

Wear Appropriate Clothing

• Always wear safety glasses or eye shields during

operation to protect eyes from foreign objects that may be

thrown from the machine.

• Wear adequate winter outer garments and footwear that

will improve footing on slippery surfaces.

• Wear close fitting clothing and safety equipment

appropriate for the job.

• Loud noise can cause impairment or loss of hearing,

wearasuitableprotectivedevicesuchasearplugs.

• Operate slowly and carefully on slopes and in sharp

turns.

Safety - 2

Page 7

SAFETY

Avoid Injury from Moving Parts

• Keep hands, feet and clothing away from snowblower

and discharge chute when auger is turning.

• Stop auger when you are not throwing snow.

• Stop vehicle engine before you unplug, repair, or adjust

snowblower.

Avoid Injury from Hitting Obstructions

Practice Safe Maintenance

• Understand service procedure before doing work. Keep

area clean and dry.

• Never lubricate, service, or adjust machine while it is

moving. Keep safety devices in place and in working

condition. Keep hardware tight.

• Keep hands, feet, clothing, jewelry, and long hair away

from any moving parts, to prevent them from getting

caught.

• Lower attachments to the ground before servicing

machine. Disengage all power and stop the engine. Lock

park brake and remove the key. Let machine cool.

• Securely support any machine elements that must be

raised for serv ice work.

• Raise snowblower when you drive between jobs.

• Slow down when you remove snow. Be cautious on

slopes, when you make turns or when close to buildings or

trees.

• Never run engine unless park brake is locked.

• Keep all parts in good condition and properly installed.

Fix damage immediately. Replace worn or broken parts.

Remove any buildup of grease, oil, or debris.

• Disconnect battery negative (-) cable before making

adjustments on electrical systems or welding on machine.

• Do not modify machine. Unauthorized modifications

may impair its function and safety.

• Do not wear radio or music headphones while servicing

the machine. Safe ser vice requires your full attention.

Safety - 3

Page 8

ASSEMBLY

Assembly

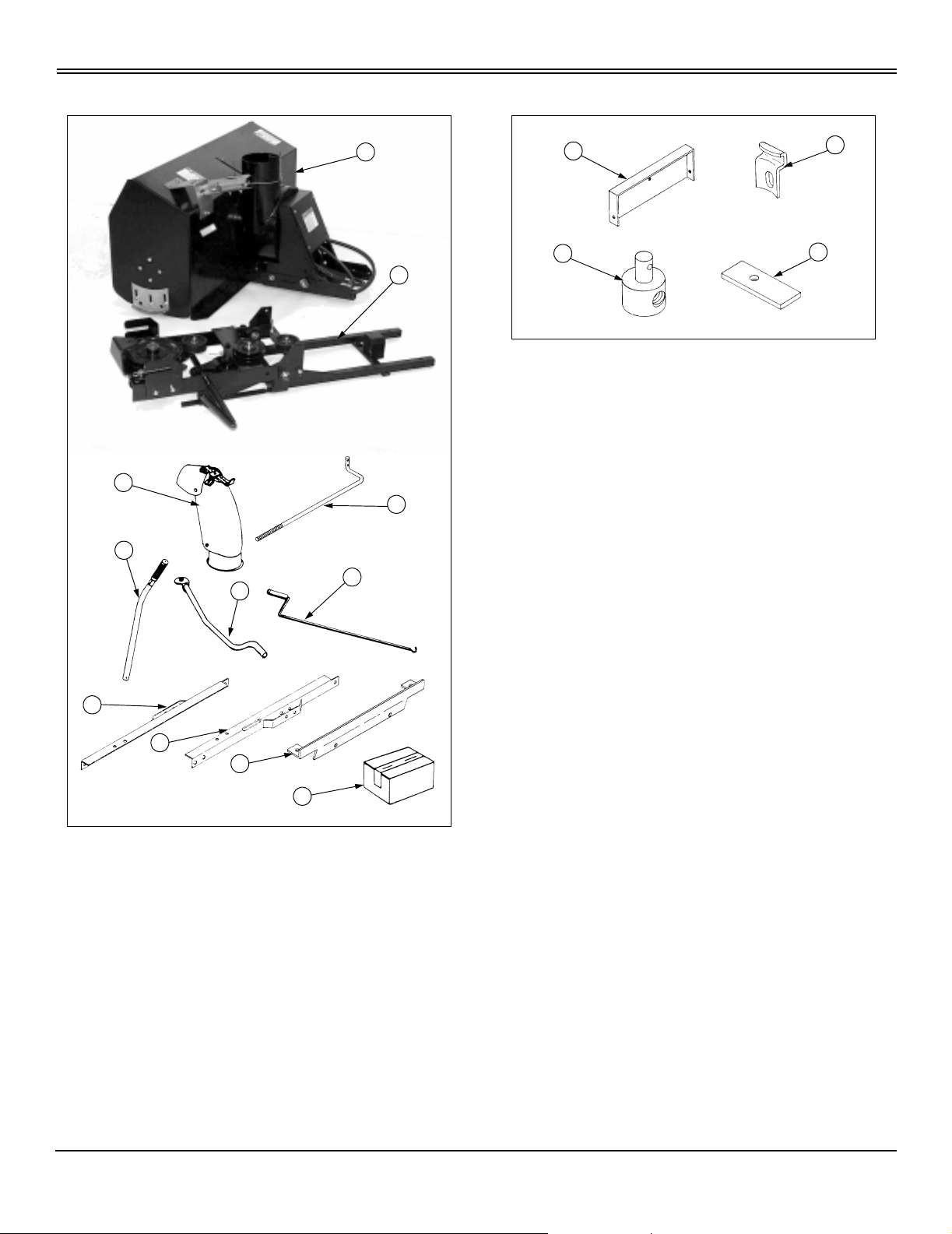

Identify Parts

C

E

BoxofParts

A

B

A

C

B

D

M95927

Qty Description Size

1 (A) Front Axle Bracket

3 (B) Anchor Stacks

1 (C) Adjustable Control Rod

Anchor

D

2 (D) Spacer Shims

1 V-Belt, Upper

F

G

2 Lift Assist Springs

2 Chain and Toggle Assembly

H

I

J

K

A - Snowblower Assembly

B - Mounting Frame Assembly

C - Discharge Chute Assembly

D - Clutch Link Rod

E - Lift Handle

F - Chute Control Support Rod

G - Chute Control Rod

H - Left-Hand Mounting Angle

I - Right-Hand Mounting Angle

J - Lift Spring Anchor Bracket

K-BoxofParts

M95926

2 Tail Reflectors

2 Clevis Pins

1 Handle Grip

2 Hair Cotter Pins 2-7/8 Lg

4 Hair Cotter Pins 1-5/8 Lg

1 CotterPin 1/8x11/4

2 Hex Nuts 1/2-13

6 Hex Head Bolts 5/16-18 x 1 3/4

2 Hex Head Bolts 3/8-16 x 1

2 Hex Head Bolts 1/2-13 x 2

9 Hex Nylock Nuts 5/16-18

4 Hex Nylock Nuts 3/18-16

2 Hex Lock N uts 1/2-13

2 Hex Head Bolts 3/8-16 x 1 1/4

2 Hex Jam Nuts 7/16-14

3 Carriage Bolts 5/16-18 x 3/4

Assembly - 4

Page 9

Assembling Snowblower

ASSEMBLY

I

E

F

E

B

F

A

C

D

C

C

1. Raise the rear of the snowblower and slide the lift

handle (A) under the channel bracket (B).

2. Place spacer shims (C) inside the rear of the mounting

channel with the short end toward the front of the

snowblower and align holes.

3. Slide mounting frame (D) inside channel bracket.

4. Check that holes in spacer shims are aligned with holes

in lower frame bar.

5. Insert 5/16 x 1 3/4-Inch bolts (E), one on each side,

through vertical hole of the lower mounting frame bar,

spacer shim, and channel bracket and secure with 5/16Inch Nylock nuts. Do not tighten at this time.

6. Insert 5/16 x 1 3/4-Inch bolts (F), two on each side,

through horizontal holes of channel bracket and lower

frame bar and secure with 5/16-Inch Nylock nuts. Tighten

nuts.

7. Tighten nuts on vertical bolts.

8. Raise the rear of the snowblower and remove the lift

handle from under it.

Picture Note: Underside of mounting frame shown

to illustrate correct routing of lower V-belt.

9. Install lower V-beltaround mounting bracket idlers and

pulley (I) as shown.

IMPORTANT: Avoid damage! Route upper V-belt

INSIDEthreebeltguides.Routingbeltincorrectly

can cause belt damage.

J

M

K

L

K

K

10.Install upper V-belt (J) to idlers as shown.

11.Check belt routing. Make sure upper V-belt is routed

INSIDE two belt guides (K) and belt guide (L).

12.Check position of belt guide (L).

• Tractors with V-Twin engines and 46-Inch mower

deck: Belt guide (L) should remain in outer hole as

shown.

• All other tractors: Move belt guide (L) to inner hole

(M).

Assembly - 5

Page 10

ASSEMBLY

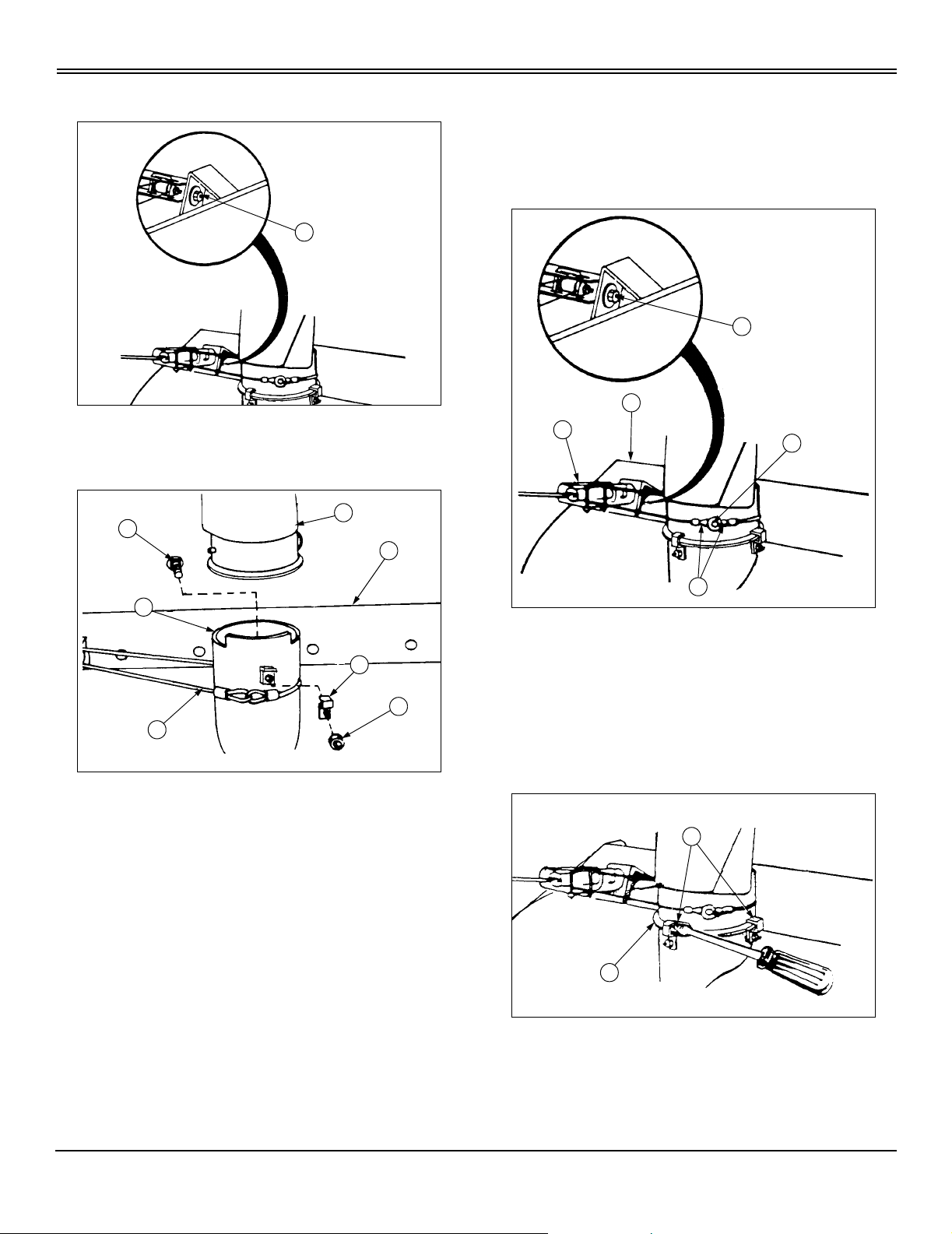

Assemble Discharge Chute to Auger Housing

A

M95940

1. Loosen 3/8-Inch nut and lock washer (A) that holds

chute control cable assembly to the auger housing and

move cable down away from anchor mounts.

G

B

D

stack anchors.

NOTE: Make sure top strand coming off chute control

cable assembly goes around front of discharge chute.

9. Move the chute control cable (H) u p from the stack of

the auger housing onto the bottom of the discharge chute.

A

D

K

J

C

E

F

H

M95939

2. Insert 5/16 x 3/4-Inch carriage bolt (B) through one of

the holes in the stack (C) of the auger housing (D) with the

head of the bolt to the inside of the stack.

3. Place one stack anchor (E) onto the bolt.

4. Install 5/16-18 Nylock hex nut (F) finger tight onto bolt.

5. Install, finger tight, two other carriage bolts, stack

anchors, and Nylock nuts to the remaining two holes of the

stack.

6. Lubricate the outside of the auger housing stack (C) and

the inside of the discharge chute (G) with WD-40 or an

equivalent.

I

M95940

10.Place both loops (I) of the chute control cable over the 1/

4-Inch hex bolt and flat washer (J) on the right hand side of

the discharge chute.

11.While keeping tight pressure to the left on the chute

control cable assembly (K), remove cable tie from the

cable,slide the chute control cable assembly to the left until

cable is taut and retighten 3/8-Inch nut and lock washer (A)

assembly to secure chute control cable assembly.

M

L

M95941

7. Install discharge chute onto the stack of the auger

housing with the discharge opening facing forward.

8. Place hook of stackanchors overthe lip of the discharge

chute, push stack anchors up, pull out to seat square of

carriage bolt in hole and tighten Nylock nut at all three

Assembly - 6

12.To obtain optimum clearance and chute rotation

proceed as follows:

• Make sure discharge chute is lubricated. (See

Lubricating Discharge Chute in Service section.)

Page 11

ASSEMBLY

• If rotation difficulty continues use a screwdriver to pry

out carefully on all three of the chute clips to obtain a 1/

16 to 1/8-Inch gap between base (L) and chute clips (M)

or until chute rotates freely.

Assembly - 7

Page 12

PREPARING VEHICLE

PreparingVehicle

Install Tractor Weights and Chains

cCAUTION: Avoid injury!

The machine may become unstable when

operating with snowblower.

Use wheel weights to improve stability when

operating with snowblower.

Remove weights from tractor after snowblower

is removed.

NOTE: Before you attach snowblower, REMOVE

MOWER DECK from tractor. (See Removing and

Storing Mower section in your Tractor O perator’s

Manual.)

Rear Wheel Weights and Rear Tire Chains are

recommended for stability and traction.

• Rear Wheel Weights - Kit Part N umber BG10189

• Rear Tire Chains - Kit Part Number BG10188

Check Tire Pressure

Install Spring Anchor Bracket to Front of Tractor

A

1. Remove two s crews (A) from the front of the tractor.

2. Align holes of the spring anchor bracket (B) with the

holes of the tractor and reinstall two metric screws to

secure the spring anchor bracket.

B

M95928

Install Front Axle Bracket to Rear Side of Front Axle

IMPORTANT: Avoid damage! To prevent tire

damage, DO NOT use more than maximum tire

pressureshownonsidewalloftire.

Check tire pressure with an accurate gauge.

Add or remove air, if necessary.

Front Tire Rear Tire

100kPa(14psi) 70kPa(10psi)

Check Tractor Engine Oil and Battery

Refer to your Tractor Operator’s Manual for Cold Weather

Starting procedures.

C

B

A

M95929

1. Remove 10mm nut and washer (A) from the rear of the

tractor front axle.

2. Position the front axle bracket (B) over the exposed bolt

with the flanged edges toward the rear of the tractor.

3. Secure the front axle bracket to the front axle (C) with

the 10mm nut and washer.

Preparing Vehicle - 8

Page 13

Install Mounting Angles

2

PREPARING VEHICLE

B

A

C

D

M9593

1. Assemble 1/2-Inch standard nut (A) onto 1/2 x 2-Inch

hex bolt (B) and run it down to the end of the treads.

2. Lock the nut in place with two wrenches.

F

E

H

J

G

I

M95930

8. Insert 3/8 x 1 1/4-Inch bolt (G) down through mower

mounting bracket of tractor (H), through 7/16-Inch jam nut

(I) used as spacer, through mounting angle, then secure

with 3/8-Inch Nylock nut (J).

9. Install a mounting angle to the other side of the tractor

using the same procedure as first mounting angle.

10.Tighten securely the finger tight bolt and nut at each

side of the front axle bracket.

Install Clutch Link Rod to Tractor

C

B

M95931

3. At the rear end of one mounting angle (C) insert 1/2 x 2Inch bolt into hole.

4. Secure with 1/2-Inch lock nut (D).

5. Install 1/2 x 2-Inch bolt with 1/2-Inch standard nut and

1/2-Inch lock nut into same hole of other mounting angle

using same procedure as above.

6. Insert 3/8 x 1-Inch bolt (E) through from the inside of the

frontaxlebracket(F).

7. Place mounting angle over end of 3/8 x 1-Inch bolt and

secure finger tight with 3/8-Inch Nylock nut.

C

E

A1

A

B

1. Pre-adjust clutch link rod (A) to approximately 384 mm

(15 In.) (A1) from the center of the bent end of the clutch

rod to t he center of the adjustable anchor (B).

2. Insert 1/8 x 1 1/4-Inch cotter pin (C) into hole nearest

thebendoftheclutchrodandspreadendstosecure.

D

E

A

Preparing Vehicle - 9

3. Insert bent end of clutch link rod up into the hole in the

tractor attachment engagement lever (D). S ecure with hair

Page 14

PREPARING VEHICLE

cotter pin (E).

4. Temporarily lay adjustable end of clutch link rod on top

of the left side mounting angles until you are ready to

attach to the snowblower.

Install Reflective Tape

A

Apply two reflectors (A), one on each side of rear hitch

plateandaminimumof305mm(12in.)fromtheground.

M95935

Preparing Vehicle - 10

Page 15

INSTALLING

Installing

Place Tractor Over Snowblower Frame

cCAUTION: Avoid injury! Attachment is heavy.

Keep hands and feet out from under attachment

when removing or installing.

1. Park machine safely. (See Parking Safely in the Safety

Section).

2. Move the tractor mower lift handle to the raised position.

3. Position snowblower directly in front of t he tractor.

A

sliding rear slots of upper mounting frame onto 1/2 x 2-Inch

bolts (B) protr uding from mounting angles of tractor.

Install Upper V-Belt

cCAUTION: Avoid injury! The engine may

accidently start while servicing the machine.

Remove the key and disconnect any spark plug

wires before servicing.

IMPORTANT: Avoid damage! Route upper V-belt

INSIDEthreebeltguides.Routingbeltincorrectly

can cause belt damage.

1. Move tractor attachment lever into disengaged (OFF)

position.

A

B

M95942

4. Roll tractor forward until right front tire makes contact

with the lift bar (A).

5. Roll right front tire by hand forward over lift bar.

Attach Upper Mounting Frame

B

A

M95943

D

C

B

2. Check belt routing. Make sure that upper V-beltis routed

INSIDE the clutch idler pulley (A), two belt guides (B) and

belt guide (C).

3. Check position of belt guide (C).

• Tractors with V-Twin engines and 46-Inch mower

deck: Belt guide (C) should remain in outer hole as

shown.

• All other tractors: Move belt guide (D) to inner hole

(M).

1. Position upper mounting frame (A) in line with tractor

frame.

2. Move snowblower lift bar rearward to the raised position.

3. Lift rear of upper mounting frame and roll tractor forward

Installing - 11

Page 16

INSTALLING

Set Lower V-Belt Tension

F

E

4. Move belt guide (E) and roll upper V-belt around tractor

engine drive pulley (F).

Attach Lower Mounting Frame to Tractor

1. Move snowblower lift bar forward to the lowered

position.

2. Slide snowblower lift handle under rear of lower

mounting frame and lift up to raise front mounting brackets

into clevises of mounting angles.

C

A

B

B

A

Pull tensioning chain (A) to tighten lower V-belt and secure

with hair cotter pin (B).

Install Clutch Link Rod

1. Place the tractor attachment lever in the disengaged

(OFF) position.

D

A

3. Align the hole in the front mounting brackets (A) with

hole in mounting angle clevis (B) and secure with clevis pin

andhaircotterpins(C).

4. Remove the lift handle from under the snowblower.

C

B

2. Move idler arm (A) to the left side of the snowblower

frame and hold against the stop.

3. Adjust the length of the clutch link rod (B) until the

mounting anchor (C) can be assembled into the clutch bell

crank.

4. Attach clutch rod link with hair cotter pin (D).

Installing - 12

Page 17

INSTALLING

Install Lift Handle

A

B

1. Slide the lift handle (A) over the end of the lift bar (B)

with the grip offset toward the operator’s position of the

tractor.

2. Adjust lift height.

Install Lift Assist Springs

6. If chain and spring are not taunt, remove the hair cotter

pin, apply a little more pressure and reinstall the hair cotter

pin.

7. Assemble lift assist spring on other side of tractor using

the same procedure.

Install Chute Control Support

C

F

B

A

E

D

1. Pull lift handle back to place snowblower in the raised

position.

B

A

C

D

E

2. Thread the chain and toggle assembly (A) through the

spring anchor bracket (B) mounted on the front of the

tractor.

3. Hook one end of the lift assist spring (C) into the hole of

the channel box bracket (D) and the other end into the last

link of t he chain and toggle.

4. Pull the toggle end of the chain and toggle, exerting

slight pressure on lift assist spring.

1. Assemble chute control rod (A) crank handle through

hole in chute control support (B) from the back side of the

decal plate.

2. Hook the loop of the chute control rod into the eyebolt of

the chute level wind assembly (C).

3. Loosen chute control support bolt (D).

4. Place chute control support over post on chute control

support bracket (E).

5. Tighten chute control support bolt into hole in post.

6. Slide plastic handle grip (F) onto handle of chute control

rod.

5. Insert large hair cotter pin (E) through chain just above

thespringanchorbracket.

Installing - 13

Page 18

REMOVING

Removing

Removing Snowblower

cCAUTION: Avoid injury! Attachment is heavy.

Keep hands and feet out from under attachment

when removing or installing.

NOTE: Store all hair cotter pins and clevis pins in

snowblower assembly for storage.

1. Park machine safely. (See Parking Safely in the Safety

Section).

B

E

4. Lower snowblower and remove lift handle (E).

A

2. Loosen chute control support bolt(A) then removechute

control support and chute control rod (B) as one assembly.

D

C

3. R aise snowblower and remove lift assist spring (C)

along with chain and toggle (D) from each side of unit.

F

5. Disconnect clutch link rod (F) from tractor attachment

engagement lever.

H

G

6. Remove upper V-belt from engine drive pulley (G).

7. Use lift handle to relieve weight from clevis pins (H) and

remove hair cotter pins and clevis pins from front mounting

brackets. Lower upper mounting frame to ground.

Removing - 14

Page 19

REMOVING

J

I

8. Roll tractor forwardcarefully until rear of upper mounting

frame (I) can be lowered from 1/2 x 2-Inch bolts (J) in

mounting angles.

cCAUTION: Avoid injury! When the snowblower

is removed, remove any weights that were

added to the tractor.

12.Removeany weights that were installed when preparing

the tractor.

M95942

9. Roll tractor backward off of the snowblower .

M

K

L

10.Remove both left hand and right hand mounting angles

(K) from tractor. Replace hardware (L) into holes of

mounting angles for storage.

11.Front axle bracket (M) and spring anchor bracket may

be left mounted to tractor is desired.

M95931

Removing - 15

Page 20

OPERATING

Operating

Before Operating Snowblower

• Learn all controls and how they work. Read your

Tractor's O perator Manual, if necessary.

•STOPengine.

• LOCK park brake.

•Removekey.

• Make operating adjustments as necessary.

• Tighten loose hardware.

Daily Operating Checklist

Check snowblower for loose fasteners.

Lubricate discharge chute.

Controls and Adjustment Levers

B

A

C

D

Snowblowing Tips

Install tire chains and rear weights on tractor.

Adjust runners before you clear snow.

Operate snowblower at full throttle.

Operate snowblower at safe, SLOW travel speed.

Slow down:

• On slopes.

• When you make turns.

• When you throw snow close to buildings or trees.

Always transport with the snowblower in the RAISED

position and the attachment clutch lever DISENGAGED.

Throw snow downwind, if possible.

If you hit an object:

• STOP snowblower immediately.

• Fix damage before you use snowblower again.

Before you clean or unplug snowblower:

E

• Move attachment clutch lever to the DISENGAGED

position.

• STOP engine.

J

K

F

I

H

A - Snow Deflector

B - Snow Deflector Control Handle

C - Snowblower Lift Handle

D - Attachment Clutch Lever

E - Chute Control Rod

F - Lift Assist Springs

G - Skid Shoes

H - Scraper

I - Snow Augers

J - Auger Housing

K - Discharge Chute

• Remove key.

• LOCK park brake.

• Wait for ALL moving parts to STOP.

• Lower snowblower to the ground.

• Remove spark plug wires.

• Clean snowblower after you use it.

G

Stopping Tractor and Snowblower

When stopping tractor, do the following:

1. Depress clutch/brake pedal fully.

2. Put transmission in NEUTRAL position.

Operating - 16

Page 21

OPERATING

Adjusting Chute

A

B

C

M95964

3. Pull back on attachment clutch lever(A) to DISENGAGE

auger.

4. Lower snowblower to ground.

5. STOP engine.

6. LOCK park brake (B).

7. Remove key (C).

Raising and Lowering Snowblower

A

M95958

The snowblower has a discharge radius of 240 degrees

and is controlled by the chute control rod. The discharge

chute stop bolt will prohibit rotation beyond this point.

A

Turn chute control rod (A) to the right to direct snow to the

right side of the tractor and to the left for the opposite effect.

To adjust chute rotation see Adjusting Discharge Chute

Drive Tube in Service section.

To RAISE snowblower: Pull lift handle (A) all the way back.

To LOWER snowblower: Push lift handle (A) all the way

forwardandlowersnowblowertogroundlevel.

Operating - 17

Adjusting Distance of Snow Discharge

A

The distance snow will be discharged can be adjusted by

B

Page 22

OPERATING

moving the snow deflector (A).

To increase distance snow is discharged, pull down on

snow deflector control handle (B) and lock in position.

Adjusting Lift Height

cCAUTION: Avoid injury! Rotating auger is

dangerous.

Before making adjustment:

• Park the machine safely and lock the park

brake before getting off the seat.

• Turn the snowblower off.

• Stop the engine.

• Wait for all moving parts to stop.

B

not, repeat process.

Adjusting Lift Assist Springs

cCAUTION: Avoid injury! Rotating auger is

dangerous.

Before making adjustment:

• Parkthemachinesafelyandlockthepark

brake before getting off the seat.

• Turn the snowblower off.

• Stop the engine.

• Wait for all moving parts to stop.

The lift assist springs (A) help in carrying the weight of the

snowblower.

For extra scraping ability in packed or hardened snow,

reduce tension of lift assist springs.

C

A

M95955

1. Place snowblower on ground level.

2. Loosen jam nut (A) and turn lift height adjustment bolt

(B):

• RIGHT to INCREASE lift height

• LEFT to DECREASE lift height

3. Raise snowblower and recheck lift height.

C

A

1. Put snowblower in the raised position and pull up on

chain and toggle (B) and remove hair cotter pin (C).

D

B

4. If up stop (C) hits front tractor axle retighten jam nut. If

Operating - 18

2. Allow severallinks of chain to pass down through hole in

thespringanchorbracket(D)andreplacehaircotterpin

justabovethespringanchorbracket.

• To decrease scraping action when snowblower is

Page 23

used on rough surfaces, increase tension o n lift assist

spring by removing hair cotter pin and pulling several

links up through hole in spring anchor bracket and

replacing hair cotter pin.

3. Adjust chain and toggles evenly.

Adjusting Skid Shoes

OPERATING

A

cCAUTION: Avoid injury! Rotating auger is

dangerous.

Before making adjustment:

• Park the machine safely and lock the park

brake before getting off the seat.

• Turn the snowblower off.

• Stop the engine.

• Wait for all moving parts to stop.

IMPORTANT: Avoid damage! Both the scraper and

skid shoes are subject to wear and are designed for

easy replacement. Replace before wear is excessive

to prevent damage to the auger housing or snow

auger.

The skid shoe mounted on each side of the header housing

adjusts the distance the scraper blade is raised above the

surface.

• When removing snow from an uneven surface or a

gravel driveway, it is advisable raising scraper as high

above the surface as possible to prevent possible damage

to the snow auger and to help prevent stones from being

thrown with snow.

• On blacktop or concrete, keep the scraper as close to

the scraping surface as possible.

AdjustingSkidShoesforUseonGravelDrivewaysor Uneven Surfaces

NOTE: Make sure both skid shoes are adjusted to keep

scraper level even with scraping surface.

1. Place snowblower in raised position.

2. Place 2 x 4 blocks under both ends of the scraper.

3. Lower snowblower scraper onto blocks.

M95957

4. Loosen six nuts (A) on the inside of the auger housing

which secure the skid shoes.

5. Allow skid shoes to drop to the ground.

6. Retighten six nuts securing skid shoes.

7. Lower snowblower to the ground.

Adjusting Skid Shoes for Use on Concrete or Even Surfaces

1. Place snowblower in raised position.

2. Loosen six nuts (A) on the inside of auger housing

which secure the skid shoes.

3. Lower snowblower to ground level.

4. Retighten six nuts to secure skid shoes.

Unplugging Discharge Chute

cCAUTION: Avoid injury! Rotating auger is

dangerous.

• Parkthemachinesafelyandlockthepark

brake before getting off the seat.

• Turn the snowblower off.

• Stop the engine.

• Wait for all moving parts to stop.

• Disconnect spark plug wire(s) to prevent

engine from starting accidently.

If snowblower becomes plugged with snow or jammed due

to hitting an obstruction, proceed as follows:

Operating - 19

Page 24

OPERATING

Operating Snowblower

cCAUTION: Avoid injury! Thrown objects can be

dangerous. Before you operate snowblower:

Clear area of bystanders and pick up objects

A

B

1. Turn discharge chute control rod to desired direction of

discharge.

2. Move snow deflector to desired discharge distance.

which may be thrown by snowblower.

1. STOP tractor.

2. Pull back on attachment clutch lever (A) to

DISENGAGE.

3. STOP the engine.

4. LOCK the park brake (B).

5. Remove the key (C).

6. Wait for auger to STOP.

7. Lower snowblower to the ground.

8. Remove spark plug wires.

C

M95964

D

3. Start engine.

A

M95964

4. Put throttle lever (A) to FAST (r) position.

5. Move attachment clutch lever forward to ENGAGED

position.

6. Push forwardon lift handle and lower snowblowerto the

ground.

9. Remove lift handle (D) and use it to push snow back

down into auger housing.

10.Reassemble lift handle.

11.Replace spark plug wires.

12.Resume snow removal.

IMPORTANT: Avoid damage! For best snowblower

and engine performance, operate engine at FULL

THROTTLE when blowing snow.

7. Select lowest tractor ground speed at tractor full throttle

and engage tractor ground drive.

Transporting

IMPORTANT: Avoid damage! Always lower

snowblower to trailer deck when transporting.

1. Drive tractor and snowblower onto heavy-duty trailer.

Operating - 20

Page 25

OPERATING

2. LOWER snowblower to trailer deck.

3. STOP engine.

4. LOCK park brake.

5. Fasten tractor and snowblower to deck with straps,

chains, or cables.

6. Trailer must have lights and signs required by law.

Operating - 21

Page 26

REPLACEMENT PARTS

ReplacementParts

Service Literature

If you would like a copy of the Parts Catalog or Technical

Manual for this machine call:

• U.S. & Canada: 1-800-522-7448.

• All Other Regions:YourJohnDeeredealer.

Parts

WE RECOMMEND quality parts and lubricants, available

at your Authorized Service Center.

PART NUMBERS MAY CHANGE, use part numbers listed

below when you order. If a number changes, your service

center will have the latest number.

WHEN YOU ORDER PARTS, your service center needs

your machine serial number and engine serial number.

Thesearethenumbersthatyouhaverecordedonthe

inside front cover of this manual.

ITEM PART NUMBER

Upper V-Belt GXH24570

Lower V-Belt GXH24522

Skid Shoes GXH3045

Scraper Blade GXH24499

(Part numbers are subject to change without notice. Part

Numbers may be different outside the U.S.A.)

Replacement Parts - 22

Page 27

SERVICE

Service

Service Intervals

Before Each Use Check unit for loose fasteners.

Lubricate discharge chute.

Every10HoursorEachYear Lubricate all zerks.

Lubricate auger bearings.

Lubricate discharge chute.

Lubricate lift bar.

Check and adjust lift height.

Check skid shoes and scraper blade and replace if necessary.

Check V-belts and replace if worn.

Check snow auger and straighten if necessary.

As Required Check discharge chute drive tube.

Check lift assist springs.

Lubricants

The following lubricants are preferred:

• Light Machine Oil (SAE30 API-S6)

• General Purpose Grease

• WD-40 or equal

Lubricate Lift Bars

Check skid shoes.

Lubricate Vertical Jack Shaft

A

Lubricate vertical jack shaft zerk (A) with General Purpose

A

Grease.

Lubricate lift bars (A) with Light Machine Oil (SAE30

APIS6).

Service-23

Page 28

SERVICE

Lubricate Auger

B

C

A

Lubricate auger bearings (A), auger tubes (B), and

discharge fan (C) with General Purpose Grease.

B

Lubricate Discharge Chute

A

bolt (A).

B

A

M95959

• Tighten lock nut (B) 1/8 turn and check rotation of

discharge chute dr ive tube by turning chute control rod.

• A small amount of resistance should be encountered.

DO NOT overtighten. Tighten until discharge chute holds

its position.

Chute Control Cable Hook-Up

Chute control cable is wound around discharge chute drive

tube 2 1/2 turns each way; both ends of equal length. This

will allow equal angle of discharge chute in both directions.

Lubricate discharge chute (A) with WD-40 or equivalent.

Adjusting Discharge Chute Drive Tube

cCAUTION: Avoid injury! Rotating auger is

dangerous.

• Park the machine safely and lock the park

brake before getting off the seat.

• Turn the snowblower off.

• Stop the engine.

• Wait for all moving parts to stop.

• Disconnect spark plug wire(s) to prevent

engine from starting accidently.

If discharge chute will not hold its position and tends to

rotate, adjust lock nut on end of discharge chute tube eye

Replacing Upper V-Belt

1. Remove the snowblower from the tractor, if necessary.

2. Remove damaged V-belt.

3. Install new V-belt on upper idlers as shown.

Service-24

Page 29

SERVICE

IMPORTANT: Avoid damage! Route upper V-belt

INSIDE three belt guides. Routing belt incorrectly

can cause belt damage.

A

B

K

B

B

4. Check belt routing. Make sure that upper V-beltis routed

INSIDE the clutch idler pulley (A) and three belt guides (B).

5. Reassemble snowblower to the tractor.

B

2. Remove the drive pulley guard (B) from the auger

housing.

3. Roll lower V-belt off of jack shaft pulley, idlers and

mounting bracket pulley and remove it from the

snowblower.

Replacing Lower V-Belt

NOTE: It is not necessary to remove the snowblower

for this procedure. The snowblower was removed for

illustration only.

A

1. Remove hair cotter pin from belt tensioner (A) and

loosen lower V-belt tension.

D

C

4. Install new V-belt under two idler pulleys (C) and roll it

around the jack shaft pulley (D) inside the auger housing.

Service-25

Page 30

SERVICE

E

Picture Note: Underside of mounting frame shown

to illustrate correct routing of lower V-belt.

5. Assemble new lower V-belt around mounting bracket

pulley and idlers (E) as shown.

6. Install the drive pulley guard to the rear of the auger

housing.

7. Set lower V-belt tension.

Service-26

Page 31

TROUBLESHOOTING

Troubleshooting

Using Troubleshooting Chart

If you are experiencing a problem that is not listed in this

chart, see your authorized service center dealer for service.

Whenyouhavecheckedallthepossiblecauseslistedand

you are still experiencing the problem, see your authorized

service center.

IF CHECK

Auger Housing Vibration Failed bearing. (See your Authorized Service Center.)

Lower V-Belt Fluttering Lower V-belt too loose.

No grease on J-shaft housing zerk.

Clogged Discharge Chute Tractor ground speed too fast.

Not operating with tractor at FULL throttle.

Snow too deep.

Discharge Chute is Difficult to Rotate or Will Not Hold

Position

Snowblower Does Not Operate Upper or lower V-belt not in pulley grooves.

Burned Rubber Smell Worn or broken V-belt.

Snowblower Will Not Lift Adjusting bolt in too far.

SnowblowerKills Tractor Engine Object jammed in snow auger or discharge fan.

Discharge chute drive tube nut too loose.

Chute control cable too loose.

Discharge chute and stack ring are dry.

Worn or broken V-belt.

Broken shear bolt.

Upper V-belt outside of belt retainers.

V-belts not in pulley grooves.

Object jammed in snow auger or discharge fan.

Object jammed between upper and lower mounting frame.

Very hard or heavy snow.

Very wet snow.

Troubleshooting - 27

Page 32

STORAGE

Storage

Storing Snowblower

Remove snowblower from tractor.

Clean the snowblower with standard garden hose.

Check V-belts, snow auger chain, scraper blade, and skid

shoes and replace if worn. Do not install new belts until you

take snowblower out of storage.

If possible, store snowblower indoors on hard, level surface.

If you store snowblower outside:

• Put blocks or a board under snowblower.

• Cover snowblower with a waterproof cover.

Inspect snowblower. Repair or replace badly worn or

damaged parts.

Apply touch-up paint where needed to prevent rust.

Lubricate snowblower.

Storage - 28

Page 33

INDEX

Index

A

Angles, Install Mounting ........................................9

Auger, Lubricate ...................................................24

B

Battery, Check Tractor Engine Oil and ...................8

Bell Crank, Install Clutch Link Rod to Clutch .....12

Belt, Install Upper .................................................11

Belt, Replacing Lower ..........................................25

Belt, Replacing Upper ...........................................24

Belt, Set Lower V-belt Tension ............................12

Bracket to Front of Tractor, Install Spring Anchor .8

Bracket to Rear Side of Front Axle, Install Front Axle

8

C

Chains, Install Tractor Weights ..............................8

Chains, Install Tractor Weights and ........................8

Chute Control Support to Frame, Install ...............13

Chute Drive Tube, Adjusting Discharge ...............24

Chute to Auger Housing, Assemble Discharge ......6

Chute, Adjusting ...................................................17

Chute, Lubricating Discharge ...............................24

Chute, Unplugging Discharge ...............................19

Clutch Link Rod to Clutch Bell Crank, Install .....12

Clutch Link Rod to Tractor, Install .........................9

Controls and Adjustment Levers ..........................16

D

Discharge Chute, Unplugging ...............................19

Discharge, Adjusting Distance of Snow ...............17

F

Frame to Tractor, Attach Lower Mounting ...........12

Frame to Tractor, Attach Upper Mounting ...........11

H

Handle, Install Lift ................................................13

Height, Adjusting Lift ...........................................18

L

Labels, Safety ..........................................................1

Levers at Operator Station ....................................16

Lift Assist Springs, Adjusting ...............................18

Lift Bars, Lubricate ...............................................23

Lift Handle, Install ................................................13

Lift Height, Adjusting ...........................................18

Lubricants .............................................................23

Lubricate Auger ....................................................24

Lubricate Lift Bars ................................................23

Lubricate Vertical Jack Shaft Zerk .......................23

Lubricating Discharge Chute ................................24

M

Mounting Angles, Install ........................................9

O

Oil and Battery, Check Tractor Engine ..................8

Operating Checklist, Daily ...................................16

Operating Safety .....................................................1

Operating Snowblower ...................................16, 20

P

Parts for Assembly ..................................................4

Parts, Replacement ................................................22

R

Raising and Lowering Snowblower ......................17

Reflective Tape, Install .........................................10

Rod to Clutch Bell Crank, Install Clutch Link .....12

Rod to Tractor, Install Clutch Link .........................9

S

Safety Decals ..........................................................1

Safety, Operating ....................................................1

Safety, Service Machine .........................................3

Safety-Alert Symbol; Labels, Safety ......................1

Service Intervals ...................................................23

Service Literature; Literature, Service; Parts Catalog;

Technical Manual .................................................22

Service Parts .........................................................22

Shaft Zerk, Lubricate ............................................23

Shoes, Adjusting Skid ...........................................19

Skid Shoes, Adjusting ...........................................19

Snowblower Assembly ...........................................5

Snowblower Frame, Installing ..............................11

Snowblower, Before Operating ............................16

Snowblower, Operating ........................................20

Snowblower, Raising and Lowering .....................17

Snowblower, Removing ........................................14

Snowblower, Stopping Tractor and ......................16

Snowblower, Storing ............................................28

Snowblowing Tips ................................................16

Spring Anchor Bracket to Front of Tractor, Install 8

Springs, Adjusting Lift Assist ...............................18

Springs, Install Lift Assist ....................................13

Stopping Tractor and Snowblower .......................16

Storing Snowblower .............................................28

Index - 29

Page 34

T

Tape, Install Reflective .........................................10

Tire Pressure, Check ...............................................8

Transporting ..........................................................20

Troubleshooting Chart ..........................................27

W

Weights and Chains, Install Tractor ........................8

INDEX

Index - 30

Page 35

QUALITY STATEMENT

QualityStatement

Your product, designed and built by John Deere, is more

than just a purchase, it’s an investment in quality. That

quality goes beyond our equipment to your dealer’s parts

and service support.

That’s why John Deere has initiated a process to handle

your questions or problems, should they arise. If you have

questions or problems w ith your new product, please follow

the steps below.

To locate your nearest authorized servicing dealer, please

call the toll free number listed in your Tractor Operator’s

Manual.

Step 1

Refer to your operator’s manual

A. It has many illustrations and detailed information on the

safe and proper operation of your equipment.

B. It gives troubleshooting procedures, and specification

information.

C. It gives ordering information for parts catalogs, service

and technical manuals.

D. If your questions are not answered in the operator’s

manual,thengotoStep2.

Step 2

Contact your dealer

A. Your authorized servicing dealer has the responsibility,

authority, and ability to answerquestions, resolveproblems,

and fulfill your parts and service needs.

B. First, discuss your questions or problems with your

dealer’s trained parts and service staff.

C.If the parts and service people are unable to resolve your

problem, see the dealership manager or owner.

D. If your questions or problems are not resolved by the

dealer,thengotoStep3.

Step 3

Call the Customer Communications Center

A. Your authorized servicing dealer is the most efficient source in addressing any concern, but if you are not able to

resolve your problem after checking your operator’s manual and contacting your dealer, call the Customer

Communications Center.

B. For prompt, effective service, please have the following ready before you call:

• The name of the dealer with whom you’ve been working.

• Your equipment model number.

• Number of hours on machine (if applicable).

C. Then refer to your Tractor Operator’s Manual to locate the Customer Communications Center toll free number and call

our advisor who will work with your dealer to investigate your concern.

• Your 13-digit serial number which you recorded on the

inside front cover of this manual.

• If the problem is with an attachment, your attachment

identification number.

Quality Statement - 31

Loading...

Loading...