Page 1

ST0521M

ST0521E

Snow Thrower

OPERATOR’S

MANUAL

MTF-031039C

Page 2

INTRODUCTION

Congratulations on your purchase of a Frontier Snowthrower. It has been designed, engineered and manufactured to give you

the best possible dependability and performance. However, like all mechanical products, your machine will occasionally require adjustment and maintenance. This handbook should be read before operating or performing and adjustments on your

machine.

The instructions in this Owner’s Manual are written for a person with some mechanical ability. Like most service books, not

all the steps are described. Steps on how to loosen or tighten fasteners are steps anyone can follow with some mechanical

ability. Read and follow these instructions before you use the unit.

Know your product:: If you understand the unit and how the unit operates, you will get the best performance. As you read

this manual, compare the illustrations to the unit. Learn the location and the function of the controls. To help prevent an accident, follow the operating instructions and the safety rules. Keep this manual for future reference.

IMPORTANT: Many units are not assembled and are sold in cartons. It is the responsibility of the owner to make sure the as-

sembly instructions in this manual are exactly followed. Other units are purchased in an assembled condition. On assembled

units, it is the responsibility of the owner to make sure the unit is correctly assembled. The owner must carefully check the unit

according to the instructions in this manual before it is first used.

The warranty, found in this manual, details the coverage and limitations of this product. Registration of the warranty is

necessary and must be preformed by the dealer within sixty (60) days from the date of retail sale or delivery. The

Warranty Registration Form is located on the Frontier website.

RESPONSIBILITY OF THE OWNER

The responsibility of the owners to follow the instructions below.

1. Carefully read and follow the rules for safe operation.

2. Follow all the assembly instructions.

3. Inspect the unit.

4. Make sure that the operator of the unit knows how to correctly use all standard and accessory equipment.

5. Operate the unit only with guards, shields, and other safety items in place and working correctly.

6. Correctly adjust the unit.

7. Service the unit only with authorized or approved replacement parts.

8. Complete all maintenance on the unit.

PRODUCT INFORMATION

The owner must be certain that all the product information is included with this unit.

This information includes the INSTRUCTION BOOKS, the REPLACEMENT PARTS

and the WARRANTIES. This information must be included to make

sure state laws and other laws are followed.

Read And Keep This Book For

Future Reference. This Book Contains Important Information On:

SAFETY, ASSEMBLY, OPERATION AND MAINTENANCE.

MTF-031039C

2

Page 3

RULES FOR SAFE OPERATION

IMPORTANT

WARNING: Always disconnect the spark plug wire and place it where it cannot make contact with

spark plug to prevent accidental starting during: Preparation, Maintenance, or Storage of your

snowthrower.

Safe Operation Practices for Snowthrowers

As Recommended By: American National Standards Institute.

Engine Exhaust, some of its constituents, and

certain vehicle components contain or emit

chemicals known to the State of California to

cause cancer and birth defects or other reproductive harm.

Battery posts, terminals and related accessories contain lead and lead compounds, chemicals known to the State of California to cause

cancer and birth defects or other reproductive

harm. WASH HANDS AFTER HANDLING.

IMPORTANT: Safety standards require operator presence

controls to minimize the risk of injury. Your snowthrower is

equipped with such controls. Do not attempt to defeat the

function of the operator presence control under any circumstances.

Training

1. Read the operating and service instruction manual carefully. Be thoroughly familiar with the controls and the

proper use of the equipment. Know how to stop the unit

and disengage the controls quickly.

2. Never allow children to operate the equipment. Never

allow adults to operate the equipment without proper

instruction.

3. Keep the area of operation clear of all persons, particularly small children and pets.

4. Exercise caution to avoid slipping or falling especially

when operating in reverse.

Preparation

1. Thoroughly inspect the area where the equipment is to

be used and remove all doormats, sleds, boards, wires,

and other foreign objects.

2. Disengage all clutches before starting the engine

(motor).

3. Do not operate the equipment without wearing adequate

winter outer garments. Wear footwear that will improve

footing on slippery surfaces.

4. Handle fuel with care; it is highly flammable.

MTF-031039C

a. Use an approved fuel container.

b. Never remove fuel tank cap or add fuel to a running en-

gine (motor) or hot engine (motor).

c. Fill fuel tank outdoors with extreme care. Never fill fuel

tank indoors.

d. Replace fuel cap securely and wipe up spilled fuel.

e. Never store fuel or snowthrower with fuel in the tank

inside of a building where fumes may reach an open

flame or spark.

f. Check fuel supply before each use, allowing space for

expansion as the heat of the engine (motor) and/or sun

can cause fuel to expand.

5. For all units with electric starting motors use electric

starting extension cords certified CSA/UL. Use only with

a receptacle that has been installed in accordance with

local inspection authorities.

6. Adjust the snowthrower height to clear gravel or crushed

rock surface.

7. Never attempt to make any adjustments while the engine (motor) is running (except when specifically recommended by manufacturer).

8. Let engine (motor) and snowthrower adjust to outdoor

temperatures before starting to clear snow.

9. Always wear safety glasses or eye shields during operation or while performing an adjustment or repair to protect eyes from foreign objects that may be thrown from

the snowthrower.

Operation

1. Do not operate this machine if you are taking drugs or

other medication which can cause drowsiness or affect

your ability to operate this machine.

2. Do not use this machine if you are mentally or physically

unable to operate this machine safely.

3. Do not put hands or feet near or under rotating parts.

Keep clear of the discharge opening at all times.

4. Exercise extreme caution when operating on or crossing

gravel drives, walks or roads. Stay alert for hidden hazards or traffic.

5. After striking a foreign object, stop the engine (motor),

remove the wire from the spark plug, thoroughly inspect

snowthrower for any damage, and repair the damage

before restarting and operating the snowthrower.

6. If the unit should start to vibrate abnormally, stop the

engine (motor) and check immediately for the cause.

Vibration is generally a warning of trouble.

3

Page 4

RULES FOR SAFE OPERATION

7. Stop the engine (motor) whenever you leave the operating position, before unclogging the auger/impeller housing or discharge chute and when making any repairs,

adjustments, or inspections.

8. When cleaning, repairing, or inspecting, make certain

the auger/impeller and all moving parts have stopped

and all controls are disengaged. Disconnect the spark

plug wire and keep the wire away from the spark plug to

prevent accidental starting.

9. Take all possible precautions when leaving the snowthrower unattended. Disengage the auger/ impeller, stop

engine (motor), and remove key.

10.Do not run the engine (motor) indoors, except when

starting the engine (motor) and for transporting the

snowthrower in or out of the building. Open the outside

doors; exhaust fumes are dangerous (containing CARBON MONOXIDE, an ODORLESS and DEADLY GAS).

11.Do not clear snow across the face of slopes. Exercise

extreme caution when changing direction on slopes. Do

not attempt to clear steep slopes.

12.Never operate the snowthrower without proper guards,

plates or other safety protective devices in place.

13.Never operate the snowthrower near enclosures, automobiles, window wells, drop- offs, and the like without

proper adjustment of the snow discharge angle. Keep

children and pets away.

14.Do not overload the machine capacity by attempting to

clear snow at too fast a rate.

15.Never operate the machine at high transport speeds on

slippery surfaces. Look behind and use care when backing up.

16.Never direct discharge at bystanders or allow anyone in

front of the unit.

17.Disengage power to the collector/impeller when snowthrower is transported or not in use.

18.Use only attachments and accessories approved by the

manufacturer of the snowthrower (such as tire chains,

electric start kits, ect.).

19.Never operate the snowthrower without good visibility or

light. Always be sure of your footing and keep a firm

hold on the handles. Walk;never run.

20.Do not over- reach. Keep proper footing and balance at

all times.

21.Exercise caution if operating on steep sloping surfaces.

22.This snowthrower is for use on sidewalks, driveways

and other ground level surfaces.

23.Do not use the snowthrower on surfaces above ground

level such as roofs of residences, garages, porches or

other such structures or buildings.

MTF-031039C

Maintenance And Storage

1. Check shear bolts and other bolts at frequent intervals

for proper tightness to be sure the equipment is in safe

working condition.

2. Never store the snowthrower with fuel in the tank inside

a building where ignition sources are present such as

hot water and space heaters, clothes dryers, and the

like. Allow the engine (motor) to cool before storing in

any enclosure.

3. Always refer to operator’s guide instructions for important details if the snowthrower is to be stored for an extended period.

4. Maintain or replace safety and instruction labels, as

necessary .

5. Run the snowthrower a few minutes after throwing

snow to prevent freeze- up of the auger/impeller.

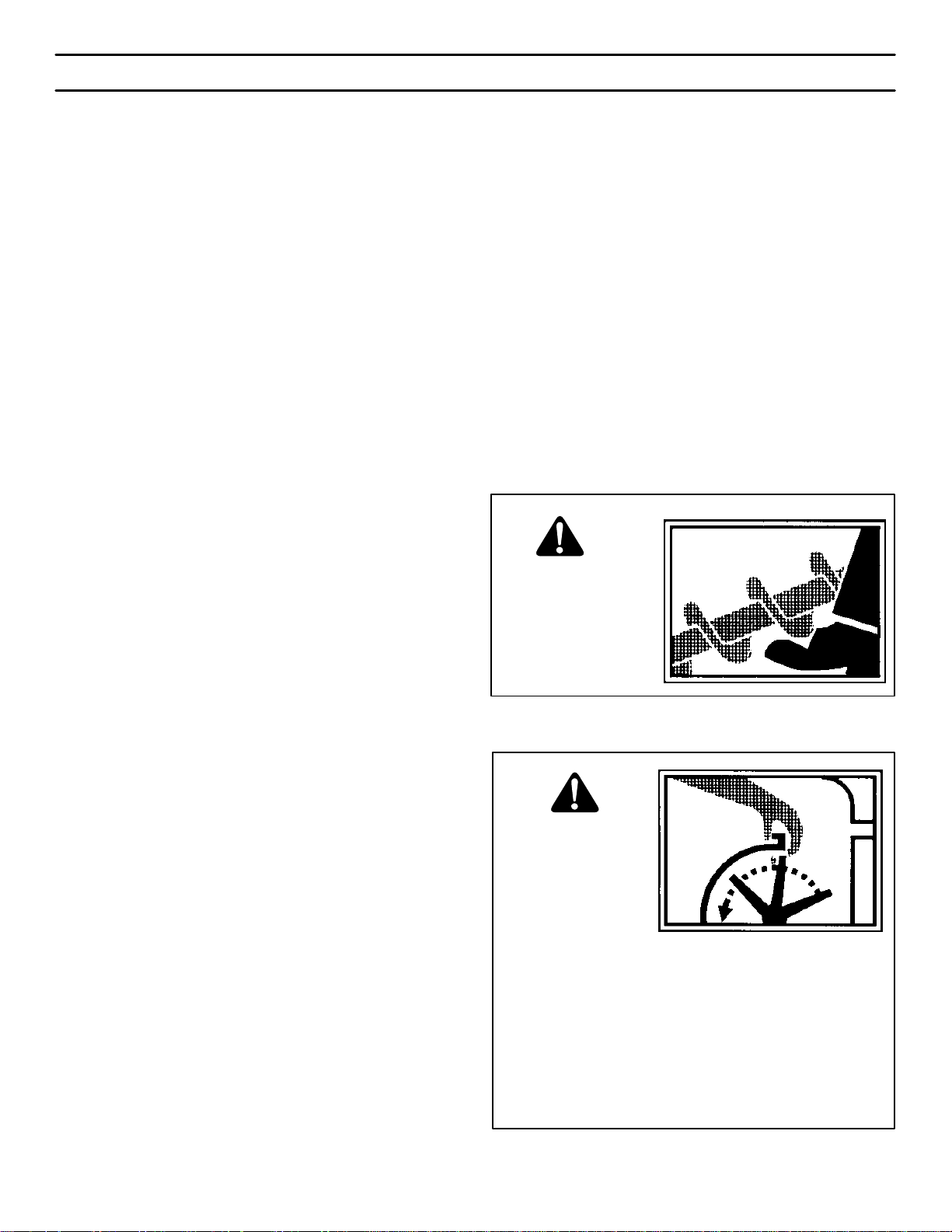

WARNING: Avoid

injury from rotating

auger- keep hands,

feet, and clothing

away.

WARNING: Do not

use hands to unclog discharge

chute.

• Stop engine/motor before removing debris.

• Do not walk in front of running machine.

• Do not discharge at bystanders.

• Keep people and pets a safe distance from the

machine.

• Before leaving machine, shut off engine/ motor

and remove key.

4

Page 5

TABLE OF CONTENTS

SAFETY DECALS 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OWNER’S INFORMATION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ASSEMBLY 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PARTS BAGS CONTENTS: 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TOOLS REQUIRED FOR ASSEMBLY 8. . . . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO REMOVE THE SNOW THROWER FROM THE CARTON 8.

HOW TO INSTALL THE CHUTE CRANK 8. . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO ASSEMBLE THE HANDLE 9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO INSTALL THE CHUTE 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE AND SNOW THROWER OPERATING CONTROLS 11. . . . . . .

SNOWTHROWER OPERATION 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO STOP THE SNOWTHROWER 12. . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO CONTROL SNOW DISCHARGE 12. . . . . . . . . . . . . . . . . . . . . . .

HOW TO THROW SNOW 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO MOVE FORWARD 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO MIX THE FUEL MIXTURE 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEFORE STARTING THE ENGINE 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO STOP THE ENGINE 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO START THE ENGINE 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO REMOVE SNOW FROM THE AUGER HOUSING 15. . . . . . . .

SNOW THROWING TIPS 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE RECOMMENDATIONS 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MTF-031039C

LUBRICATION 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO LUBRICATE THE IDLER ARM 17. . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO ADJUST THE BELT TENSION 18. . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO REPLACE THE AUGER BELT 18. . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO FREE THE AUGER CABLE 19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO ADJUST THE CHUTE CRANK 20. . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO ADJUST THE AUGER CONTROL CABLE 20. . . . . . . . . . . . . . .

HOW TO REPLACE THE DRIVE BELT 21. . . . . . . . . . . . . . . . . . . . . . . . . .

HOW TO REPLACE THE AUGER 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TO ADJUST THE CARBURETOR 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TO ADJUST OR REPLACE THE SPARK PLUG 23. . . . . . . . . . . . . . . . . . .

STORAGE 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLE SHOOTING CHART 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REPLACEMENT PARTS 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PARTS SCHEMATICS 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

Page 6

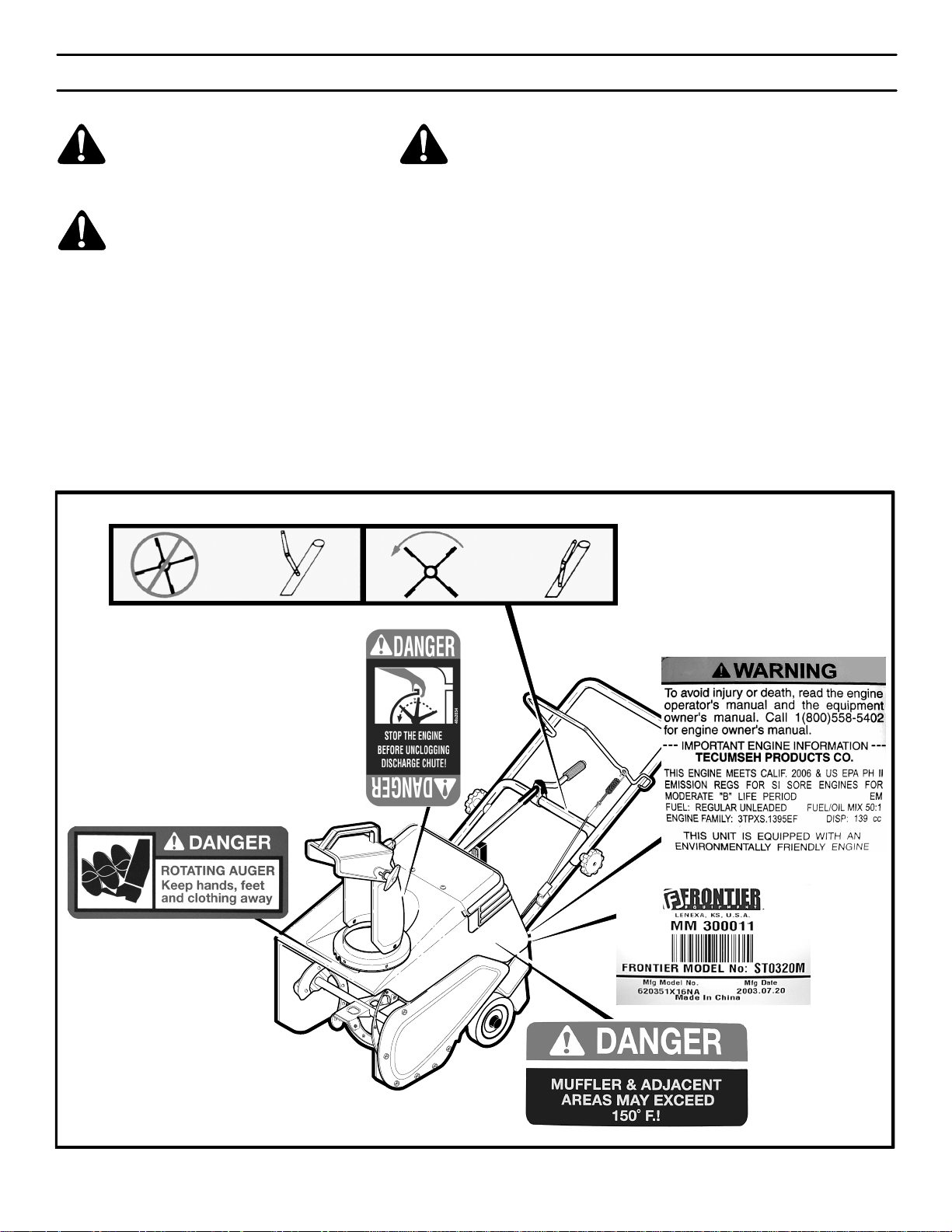

SAFETY DECALS

WARNING: If safety decals are damaged or missing, replace immediately.

Look for this symbol to indicate important safety precautions. This symbol indicates: “Attention! Become Alert! Your Safety Is At Risk.”

Before operation of your snowthrower, read the safety decals as shown on your snowthrower. The cautions and

warnings are for your safety. To avoid a personal injury or

damage to your snowthrower, understand and follow all

safety decals. If you have any questions regarding the

meaning or how to comply with the instructions, do not operate until you understand the purpose for the warning or

danger given in the safety decal. If you do not understand

the meaning, then thoroughly read all safety and operation

instructions in this Owner’s Manual or contact your local

dealer.

If any safety decals become worn or damaged and cannot

be read, order replacement decals from your local dealer.

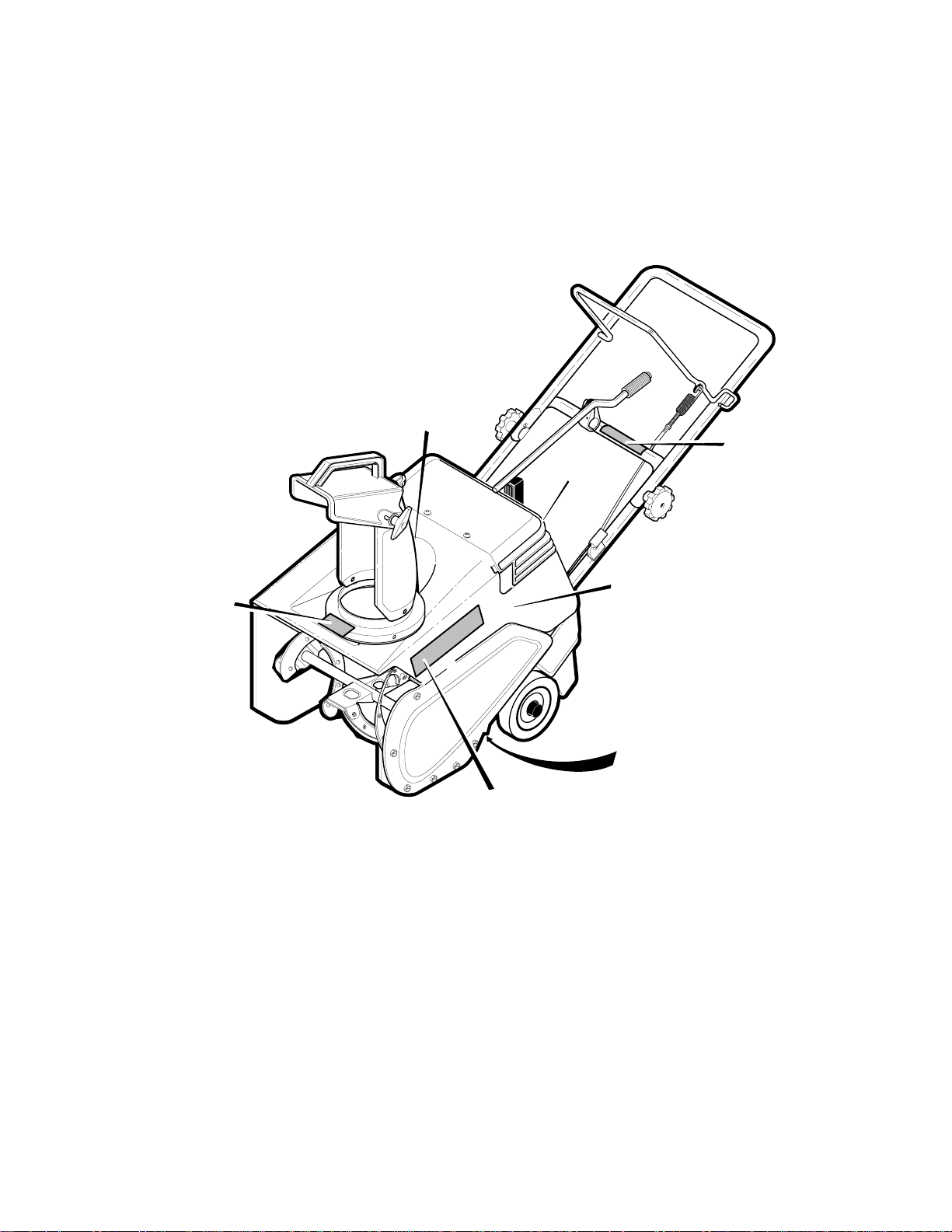

Identifying Your Snowthrower

The snowthrower has two (2) identifying numbers: (1) unit

model number: (2) unit serial number. The two preceding

numbers are required to insure that the proper replacement parts are obtained when required. If you have any

questions concerning parts, service, or technical data, contact the dealer where the unit was purchased.

For complete warranty information refer to the warranty in

the Owner’s Information section of this manual.

MTF-031039C

Figure 1

6

Page 7

OWNER’S INFORMATION

THREE YEAR LIMITED WARRANTY

Murray warrants to the original purchaser of this Frontier Branded Snowthrower that this unit shall be free from defects in

material and workmanship under normal use and service for a period of Three (3) Year from the date of purchase; however,

this warranty does not cover accessories (such as electric starters) and Normal Wear Parts (except as noted below) as the

companies that manufacture these items furnish their own warranties and provide service through their authorized field

service facilities. For additional information, see the warranties covering these particular parts. If you are uncertain whether

your unit contains or is equipped with one or more of these parts, consult your dealer prior to purchase. Subject to the terms

and conditions noted in this Limited Warranty, we shall, at our option, repair or replace at no cost to the original purchaser

any part covered by this Limited Warranty during the applicable warranty period.

Normal Wear Parts are defined as drive belts, augers, shear pins, tires and headlights. These parts are warranted to be free

from defects in material and workmanship as delivered with the product. Any claim for repair or replacement of Normal Wear

Parts must be made within thirty (30) days of the date of purchase. No claims involving damage caused from material use,

abuse or misuse will be honored.

This Murray Three (3) Year Limited Warranty for your Frontier Branded Snowthrower is your exclusive remedy; however,

this warranty is void or does not apply to any unit that has been tampered with, altered, misused, abused. If used for

commercial and/or professional (non-homeowner) uses, the duration of this warranty is ninety (90) days after the date of

purchase. Your warranty does not cover minor mechanical adjustments which are not due to any defect in material or

workmanship. For assistance in making such adjustments, consult your Operator’s Manual.

The engine on this Frontier Branded Snowthrower is warranted to the original purchaser for only a Two (2) Year Limited

Warranty. See your engine manual for information regarding the warranty policy and items covered under warranty. See

your authorized John Deere/Frontier Dealer for service or replacement parts.

To make a claim under this Murray Three (3) Year Limited Warranty for your Frontier Branded Snowthrower, return the unit

(or if authorized in advance, the defective part) along with your proof of purchase to an Authorized John Deere/Frontier Dealer

near you. To locate the nearest Authorized John Deere/Frontier Dealer, check the Yellow Page listings in your local telephone

directory. If you return the entire unit, John Deere/Frontier will repair all warranty items. If authorize to return the defective

part only, John Deere/Frontier will either replace or repair the part. This Murray Three (3) Year Limited Warranty for your

Frontier Branded Snowthrower gives you specific legal rights, and you may also have other rights which vary from state to

state.

This Limited Warranty is given in lieu of all other expressed and implied warranties including the implied

warranty of merchantability and warranty of fitness for a particular purpose. If you need additional information on this

written warranty or assistance in obtaining service, contact you local John Deere/Frontier Dealer.

MT

FOR YOUR RECORDS

DATE PURCHASED:

MODEL NO:

SERIAL NO:

MTF-031039C

STORE WHERE PURCHASED:

ADDRESS:

CITY: STATE:

TELEPHONE :

Record this information about your unit so that you will

be able to provide it in case of loss or theft.

7

Page 8

ASSEMBLY

PARTS BAGS CONTENTS:

1 - 2.6 ounces 2-cycle oil

1 - Owner’s Manual

TOOLS REQUIRED FOR ASSEMBLY

1-Knife

1-Pliers

2-Adjustable Wrenches

HOW TO REMOVE THE SNOW THROWER

FROM THE CARTON

1. Locate all parts that are packed separately and remove

from the carton.

2. Remove and discard the packing material from around

the snow thrower.

WARNING: Always wear safety glasses or eye

shields while assembling the snowthrower.

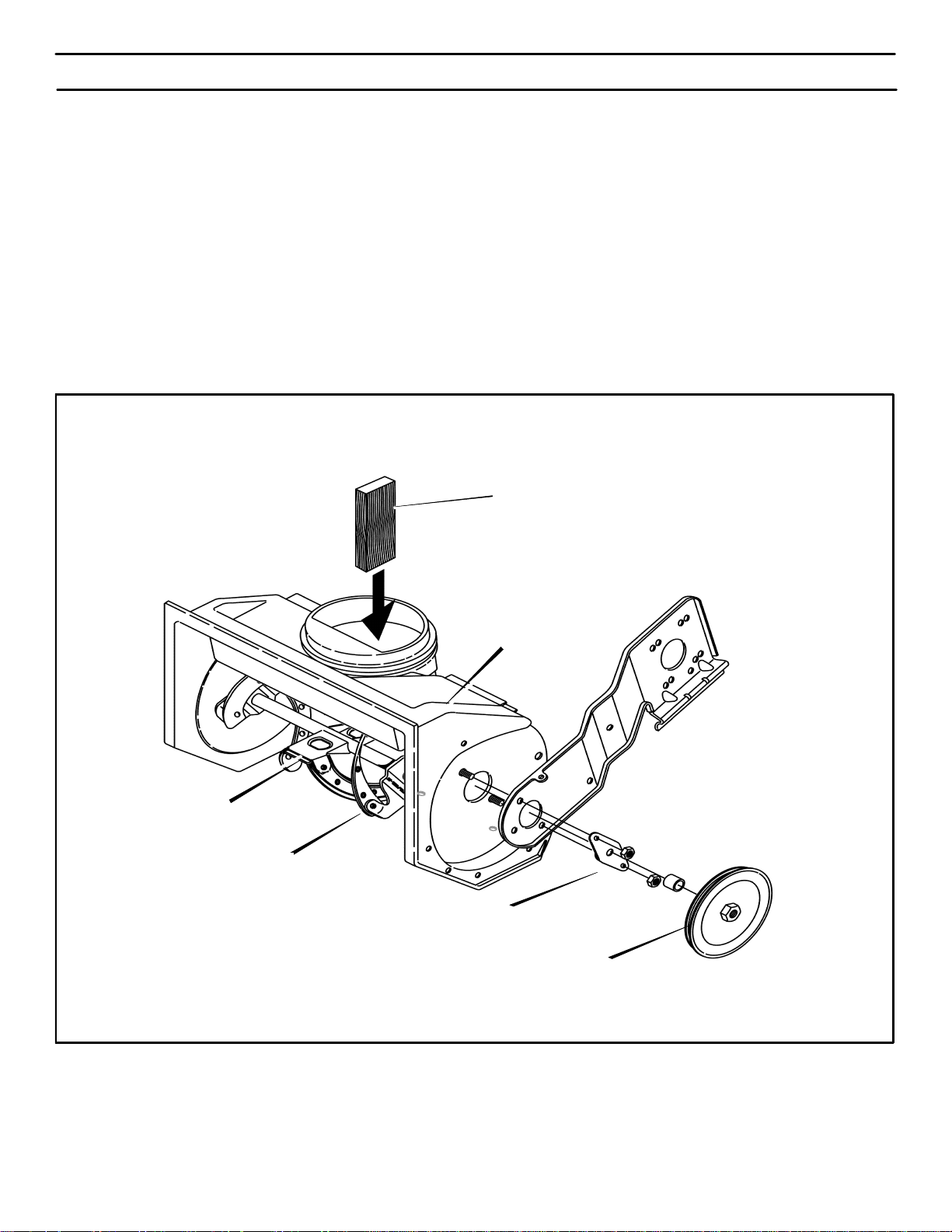

Figure 6 shows the snow thrower in the operating position.

References to the right or left hand side of the snow thrower are from the viewpoint of the operator’s position behind

the unit.

3. Cut down all four corners of the carton and lay the side

panels flat.

4. Cut off the plastic bag that covers the snowthrower.

5. Hold onto the lower handle and pull the snow thrower off

the carton.

CAUTION: DO NOT back over cables.

6. Remove the packing material from the handle assembly.

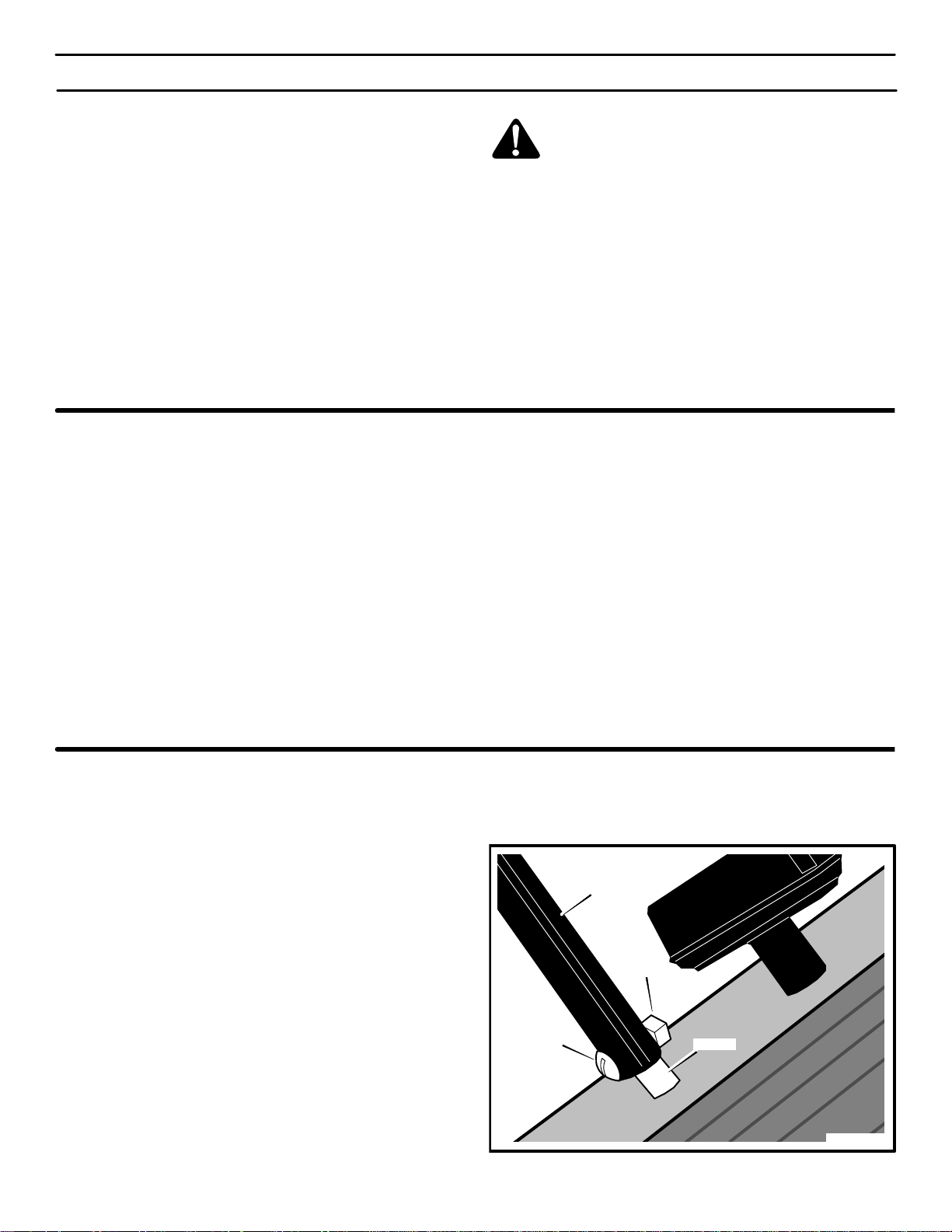

HOW TO INSTALL THE CHUTE CRANK

1. Remove the screw and nut from the shaft (see

Figure 2).

2. Put the chute crank rod through the bracket on the lower handlebar.

3. Install the chute crank rod onto the shaft.

4. Fasten the chute crank rod with the screw and nut that

were removed in step 1.

5. Raise the upper handle to the operating position. Hold

the upper handle apart to prevent scratching the lower

handle.

6. Line up the holes.Tighten the knobs.

MTF-031039C

Chute Crank

Rod

Nut

Screw

8

Shaft

Figure 2

Page 9

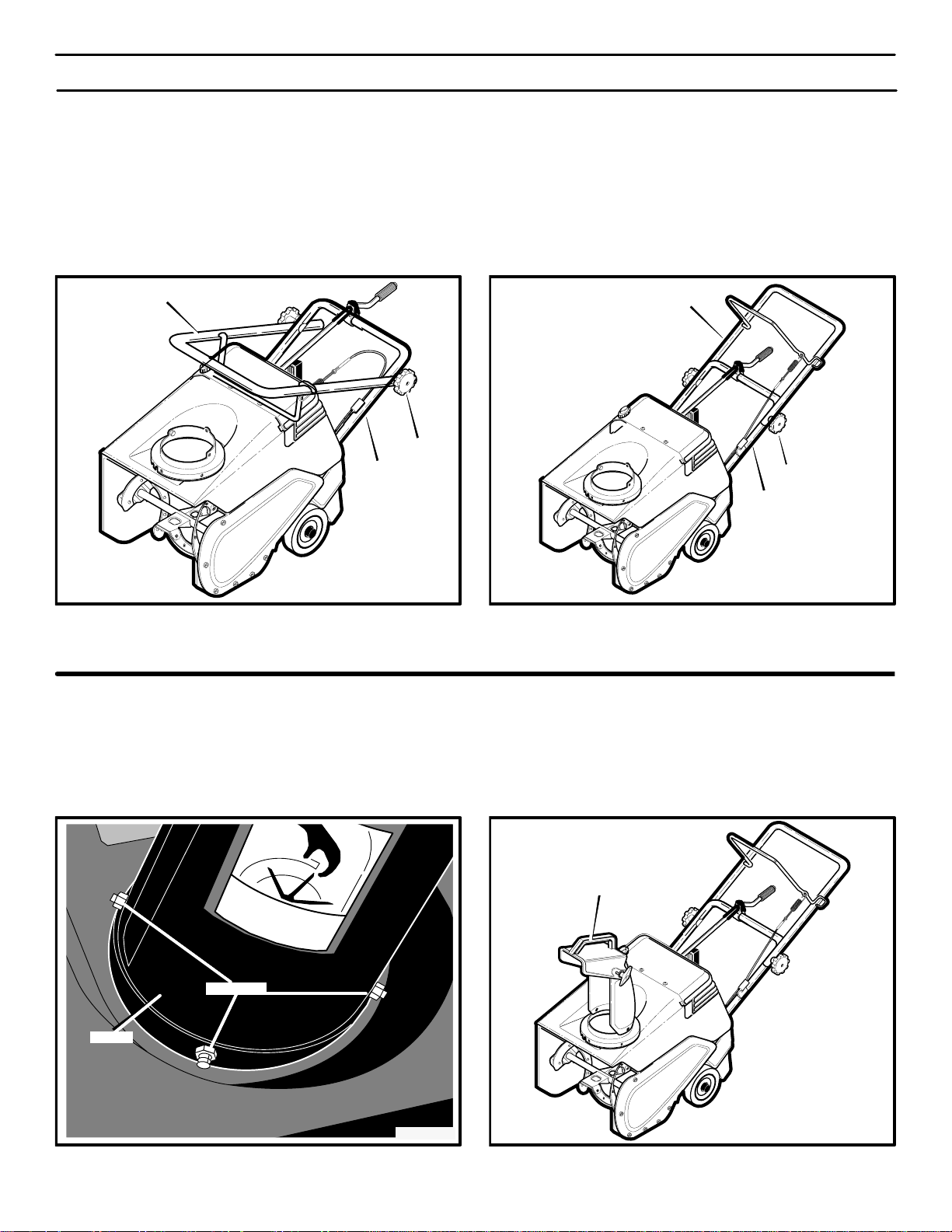

HOW TO ASSEMBLE THE HANDLE

ASSEMBLY

1. Remove the packing material from the upper and

lower handles.

2. Loosen the knobs on each side of the handle. (See

Figure 3)

3. Raise the upper handle to the operating position (see

Figure 4). Hold the upper handle apart to prevent

scratching the lower handle.

Upper Handle

Knob

Lower Handle

Figure 3

NOTE: Make sure the cables are not caught between

the upper and lower handle.

4. Tighten the knobs.

Upper Handle

Knob

Lower Handle

Figure 4

HOW TO INSTALL THE CHUTE

1. Remove the three bolts and lock nuts from the chute

base (see Figure 5).

Locknuts

Chute

Figure 5

MTF-031039C

2. Install the chute with the bolts and locknuts. Make

sure the locknuts are to the outside as shown.

Chute

Figure 6

9

Page 10

ASSEMBLY

n

CHECKLIST

Before you operate your new snowthrower, to ensure that

you receive the best performance and satisfaction from

this quality product, please review the following checklist:

n All assembly instructions have been completed.

n The discharge chute rotates freely.

n No remaining loose parts in carton.

While learning how to use your snow thrower, pay extra

attention to the following important items:

n Make sure the fuel tank is filled with the correct mixture

(50:1 ratio) of gasoline and oil.

n Become familiar with the location of all controls and un-

derstand their function.

n Before starting the engine, make sure all controls oper-

ate correctly.

MTF-031039C

10

Page 11

OPERATION

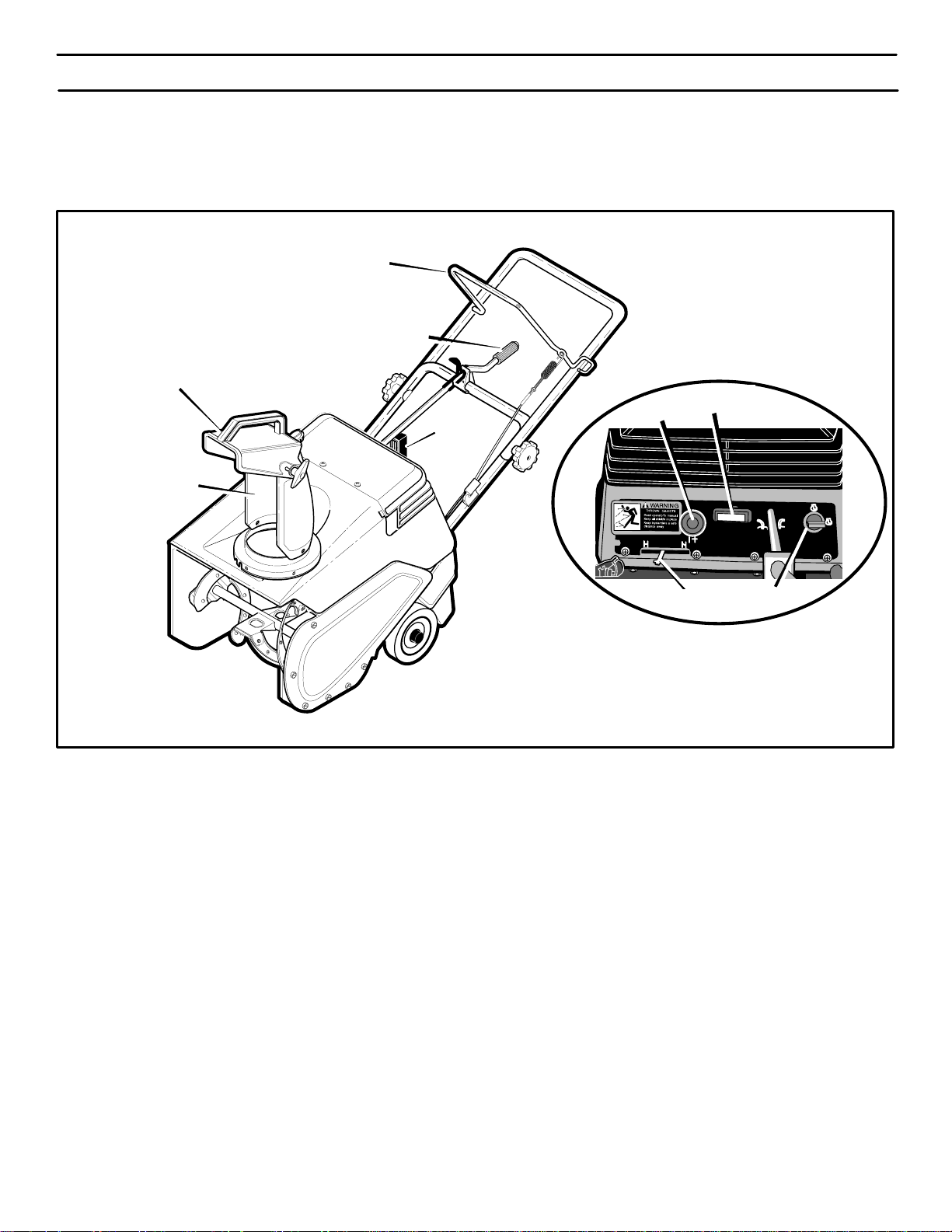

KNOW YOUR SNOWTHROWER

READ THIS OWNER’S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR SNOWTHROWER. Compare the

illustrations with your SNOWTHROWER to familiarize yourself with the location of various controls and adjustments. Save

this manual for future reference.

Auger Drive Lever

Chute Control Rod

Chute Deflector

Recoil

Starter

Handle

Discharge Chute

ENGINE AND SNOW THROWER OPERATING CONTROLS

The engine operating controls and their functions are as

follows:

Auger Drive Lever - Starts and stops the auger.

Chute Control Rod - Changes the direction of snow throw-

ing through the discharge chute.

Chute Deflector - Changes the distance the snow is

thrown.

Primer

Button

Choke Control

Recoil

Starter

Ignition Switch

Key

Figure 7

Ignition Switch Key - Must be inserted and turned to the

ON position to start the engine.

Recoil Starter Handle - Starts the engine manually.

Electric Starter Button - (Not shown) On electric start mod-

els, use to start the engine when using the 120V electric

starter.

Choke Control - Used to start a cold engine.

Discharge Chute - Changes the direction the snow is

thrown.

MTF-031039C

Primer Button - Injects fuel directly into the carburetor

manifold for fast starts in cold weather.

11

Page 12

OPERATION

SNOWTHROWER OPERATION

The most effective use of the snowthrower will be established

by experience, taking into consideration the terrain, wind

conditions and building location which will determine the

direction of the discharge chute.

NOTE: Do not discharge snow toward a building as

hidden objects could be thrown with sufficient force to

cause damage.

WARNING: Read Owner’s Manual before operating machine. This machine can be dangerous

if used carelessly.

Never operate the snowthrower without all guards,

covers, and shields in place.

Never direct discharge toward windows or allow bystanders near machine while engine is running.

Stop the engine whenever leaving the operating position.

Disconnect spark plug before unclogging the impeller

housing or the discharge chute and before making repairs or adjustments.

When leaving the machine, remove the ignition key.

To reduce the risk of fire, keep the machine clean and

free from spilled gas, oil and debris.

NOTE: If the snowthrower continues to slowly move

forward, see “How To Adjust The Auger Control

Cable” in the Maintenance Section.

8. To stop the engine, move the ignition key to the OFF

position.

HOW TO CONTROL SNOW DISCHARGE

1. Turn the chute control rod to set the direction of the

snow throwing. (See Figure 7)

2. Loosen the wing knob on the chute deflector and move

the deflector to set the distance. Move the deflector (Up)

for more distance, (Down) for less distance. Then tighten

the wing knob (See Figure 8).

Deflector Down

Deflector Up

HOW TO STOP THE SNOWTHROWER

7. To stop throwing snow, release the auger drive lever.

(See Figure 9).

HOW TO THROW SNOW

1. Engage the auger drive lever. (See Figure 9).

2. To stop throwing snow, release the auger drive lever.

HOW TO MOVE FORWARD

1. Hold the auger drive lever against the handle (See

Figure 9). The auger will begin rotating.

2. To go forward, raise the handle to allow the rubber au-

ger blades to contact the ground. Maintain a firm hold on

the handle as the snowthrower starts to move forward.

Guide the snowthrower by moving the handle either left

or right. Do not attempt to push the snowthrower.

3. To stop, release the auger drive lever.

Wing Knob

Figure 8

NOTE: If the auger continues to rotate, see “How To

Adjust The Auger Control Cable” in the Maintenance

section.

Auger

Drive Lever

“Z” Hook

Figure 9

MTF-031039C

12

Page 13

OPERATION

BEFORE STARTING THE ENGINE

WARNING: Experiences indicates that alcohol

blended fuels (called gasohol or those using

ethanol or methanol) can attract moisture

which leads to separation and formation of acids during storage. Acidic gas can damage the fuel system

of an engine while in storage.

NOTE: To avoid engine problems, the fuel system

must be emptied before storage for 30 days or longer.

Start the engine and let it run until the fuel lines and

carburetor are empty. Use the carburetor bowl drain

to empty residual gasoline from the float chamber.

Use fresh fuel next season. See the Storage section in

this manual for additional information.

Never use engine or carburetor cleaner products in the

fuel tank or permanent damage can occur.

HOW TO MIX THE FUEL MIXTURE

The two cycle engine, used on this snow thrower, requires

a mixture of gasoline and oil for lubrication of the bearings

and other moving parts. The correct fuel mixture ratio is

50:1 (2.6 oz. oil per one gallon of gas - see the Fuel Mixture Chart). Gasoline and oil must be pre-mixed in a clean

gasoline container. Always use fresh, clean, unleaded gasoline.

FUEL MIXTURE CHART (mixture 50:1)

U.S. IMPERIAL SI. (Metric)

GAS OIL GAS OIL GAS OIL

1 Gal. 2.6

oz.

1 Gal. 3.1 oz. 4

liter

80

ML

Mix gasoline and oil as follows:

1. Pour one (1) U.S. quart of fresh, clean, unleaded automotive gasoline into a one gallon size gasoline container.

2. Add 2.6 ounces of clean, high quality, two-cycle oil to

the gasoline container.

IMPORTANT: Do not use outboard motor oil or

multi-viscosity oils,such as 10W-30 or 10W-40.

3. Install the fuel cap onto the gasoline container. Vigorously shake the gasoline container to mix the oil with

the gasoline.

4. Add an additional three (3) U.S. quarts of gasoline to

the gallon container. Again shake the gasoline container.

WARNING: Gasoline is flammable. Always use

caution when handling or storing gasoline.

Do not fill fuel tank while snow thrower is running, when it is hot, or when snow thrower is in an

enclosed area.

Keep away from open flame or an electrical spark and

do not smoke while filling the fuel tank.

Never fill the tank completely. Fill the tank to within

1/4”-1/2” from the top to provide space for expansion

of fuel.

Always fill fuel tank outdoors and use a funnel or

spout to prevent spilling.

Make sure to wipe up any spilled fuel before stating

the engine.

Store gasoline in a clean, approved container and

keep the cap in place on the container.

MTF-031039C

Do not fill the fuel tank with gasoline that does not have oil mixed in it. Shake the gasoline container before

each filling of the fuel tank.

OIl

(2.6 oz.)

Gasoline

1U.S.

Quart

1 U.S. Gallon container

Shake Can

Add more gas

(3 U. S. Quarts)

13

1 U.S.

Gallon

Special

Gasoline

Figure 10

Page 14

OPERATION

BEFORE STARTING THE ENGINE

1. Before you service or start the engine, familiarize yourself with the snow thrower. Be sure you understand the

function and location of all controls.

2. Be sure that all fasteners are tight.

HOW TO START THE ENGINE

The following starting instructions include directions for both

Recoil Start and Electric Start engines. For models that are

Recoil Start only, disregard the Electric Start information.

Electric Start models are equipped with a 120 volt AC electric starter and also a recoil starter. Before starting the engine, make certain that you have read the following

information.

The starter i s d esigned t o o perate o n 120 volt A .C.

household current. Carefully follow all instruc-

tions in the “How To Start The Engine” section.

To connect a 120 volt A.C. power c ord, always c onnect

the power cord to the switch box on the engine first.

Then, plug t he o ther e nd into the r eceptacle. When disconnecting the p ower c ord, a lways u nplug t he e nd f rom

the receptacle first.

3. Before starting the engine, make sure all controls operate correctly.

HOW TO STOP THE ENGINE

To stop the engine, move the ignition key to the stop position.

S Push four times if temperature is below 15° F (-10° C).

S Push five time if temperature is below 0° F (-18° C).

9. (Electric Start) Push on the electric start button until

the engine starts. Do not crank for more than 10 seconds

at a time. The electric starter is thermally protected. If the

electric starter overheates, it will automatically stop and

can only be restarted when it has cooled to a safe temperature. A wait of about 5 to 10 minutes is required to

allow the electric starter to cool.

10. (Recoil Start) Rapidly pull the recoil starter handle. Do

not allow the recoil starter handle to snap back. Slowly

return the recoil starter handle.

11. If the engine does not start in 5 or 6 tries, See the “Trouble

Shooting Chart” Instructions.

12. (Electric Start) When the engine starts, release the

electric start button.

HOW TO START A COLD ENGINE

1. Fill the fuel tank with a fresh, clean fuel mixture. See

“How To Mix The Fuel Mixture”.

2. Move the choke control to FULL position.

3. Make sure the auger drive lever is in the disengaged

(released) position.

4. Insert the ignition key and turn to the ON position.

5. Move the choke control to the full choke position.

6. (Electric Start) Connect the power cord to the switch

box located on the engine.

7. (Electric Start) Plug the other end of the power cord into

a 120 VOL T, A.C. receptacle. (See the WARNING in this

section).

8. Push the primer button while covering the vent hole as

follows: Remove finger from primer button between

primes.

S Do not prime if temperature above 50° F (10° C).

S Push twice if temperature is 50° F (10° C) to

15°F (-10° C).

MTF-031039C

13. (Electric Start) First disconnect the power cord from the

receptacle. Then, disconnect the power cord from the

switch box.

14. As the engine warms up, move the choke control to 1/2

choke position. When the engine runs smoothly, move

the choke control to the off position.

NOTE: Allow t h e e ngine to warm up for several minutes

before blowing snow in temperatures below 05F.

WARM START

If restarting a warm engine after a short shutdown, leave

choke at “OFF” and do not push the primer button. If the en-

gine fails to start, follow the Cold Start instructions.

WARNING: Never run engine indoors or in enclosed, poorly ventilated areas. Engine exhaust

contains CARBON MONOXIDE, AN ODORLESS

AND DEADLY GAS. Keep hands, feet, hair and loose

clothing away from any moving parts on engine and

snow thrower.

The temperature of muffler and nearby areas may exceed 1505F. Avoid these areas.

DO NOT allow children or young teenagers to operate

or be near snow thrower while it is operating.

14

Page 15

OPERATION

HOW TO REMOVE SNOW FROM THE AUGER

HOUSING

WARNING: Do not attempt to remove snow or

debris that may become lodged in auger

housing without taking the following precau-

tions.

SNOW THROWING TIPS

1. When the handle is raised, the auger blades will engage

the ground and the snow thrower will move forward.

When the auger drive lever is released, the auger blades

will stop. If the blades do not stop, see “How To Adjust

The Auger Control Cable” in the Service And Adjustment

section.

2. Most efficient snow throwing is accomplished when the

snow is removed immediately after if falls.

3. For complete snow removal, slightly overlap each previous path.

4. Whenever possible, discharge the snow down wind.

5. The distance the snow will be discharged can be adjusted by moving the discharge chute deflector. Raise

the deflector for more distance or lower the deflector for

less distance.

6. In windy conditions, lower the chute deflector to direct the

discharged snow close to the ground where it is less likely to blow into unwanted areas.

7. For safety and to prevent damage to the snow thrower,

keep the area to be cleared free of stones, toys and other

foreign objects.

8. Do not use the auger propelling feature when clearing

gravel or crushed rock driveways. Move the handle down

to slightly raise the auger.

9. The forward speed of the snow thrower is dependent on

the depth and weight of the snow. Experience will establish the most effective method of using the snow thrower

under different conditions.

1. Release the auger drive lever.

2. Remove the ignition key.

3. Disconnect the spark plug wire.

4. Do not place your hands in the auger housing or the dis-

charge chute. Use a pry bar to remove any snow or debris.

10. After each snow throwing job, allow the engine to run for

a few minutes. The snow and accumulated ice will melt

off the engine.

11. Clean the snow thrower after each use.

12. Remove ice, snow and debris from the entire snow

thrower. Flush with water to remove all salt or other

chemicals. Wipe snow thrower dry.

DRY AND AVERAGE SNOW

1. Snow up to eight inches deep can be removed rapidly

and easily by walking at a moderate rate. For snow or

drifts of a greater depth,slow your pace to allow the discharge chute to dispose of the snow as rapidly as the auger receives the snow.

2. Plan to have the snow discharged in the direction the

wind is blowing.

WET PACKED SNOW

Move slowly into wet, packed snow. If the wet, packed snow

causes the auger to slow down or the discharge chute begins

to clog, back off and begin a series of short back and forth

jabs into the snow . These short back and forth jabs, four to six

inches, will “belch” the snow from the chute.

SNOW BANKS AND DRIFTS

In snow of greater depth than the unit, use the same “jabbing”

technique described above. Turn the discharge chute away

from the snow bank. More time will be required to remove

snow of this type than level snow.

MTF-031039C

15

Page 16

SERVICE RECOMMENDATIONS

N

H

SERVICE RECOMMENDATIONS

PROCEDURE

S

Tighten all screws and nuts

O

Lubricate Chute Control

Flange

W

FIRST

2

HOUR

√ √

√ √

BEFORE

EACH

USE

OFTEN

EVERY

5

HOURS

EVERY

10

HOURS

EVERY

25

HOURS

BEGINNING

EACH

SEASON

√

BEFORE

STORAGE

T

Lubricate Auger Bail

H

R

Check Auger Drive Cable

O

Adjustment

(See Cable Adjustment)

W-

√ √

√

E

Check Drive Belt

R

The warranty on this snowthrower does not cover items that have been subjected to operator abuse or negligence. To receive

full value from the warranty , operator must maintain snowthrower as instructed in this manual. The following Service Recom-

mendations are supplied to assist operator to properly maintain snow thrower. This is a check list only. Adjustment referred

to will be found in Adjustments/Repairs section of this manual.

√

AFTER EACH USE

1. Check for any loose or damaged parts.

2. Tighten any loose fasteners.

3. Check and maintain the auger.

4. After each use, remove all snow and slush off of the

snowthrower to prevent freezing of auger or controls.

5. Check controls to make sure they are functioning

properly.

6. If any parts are worn or damaged, replace immediately.

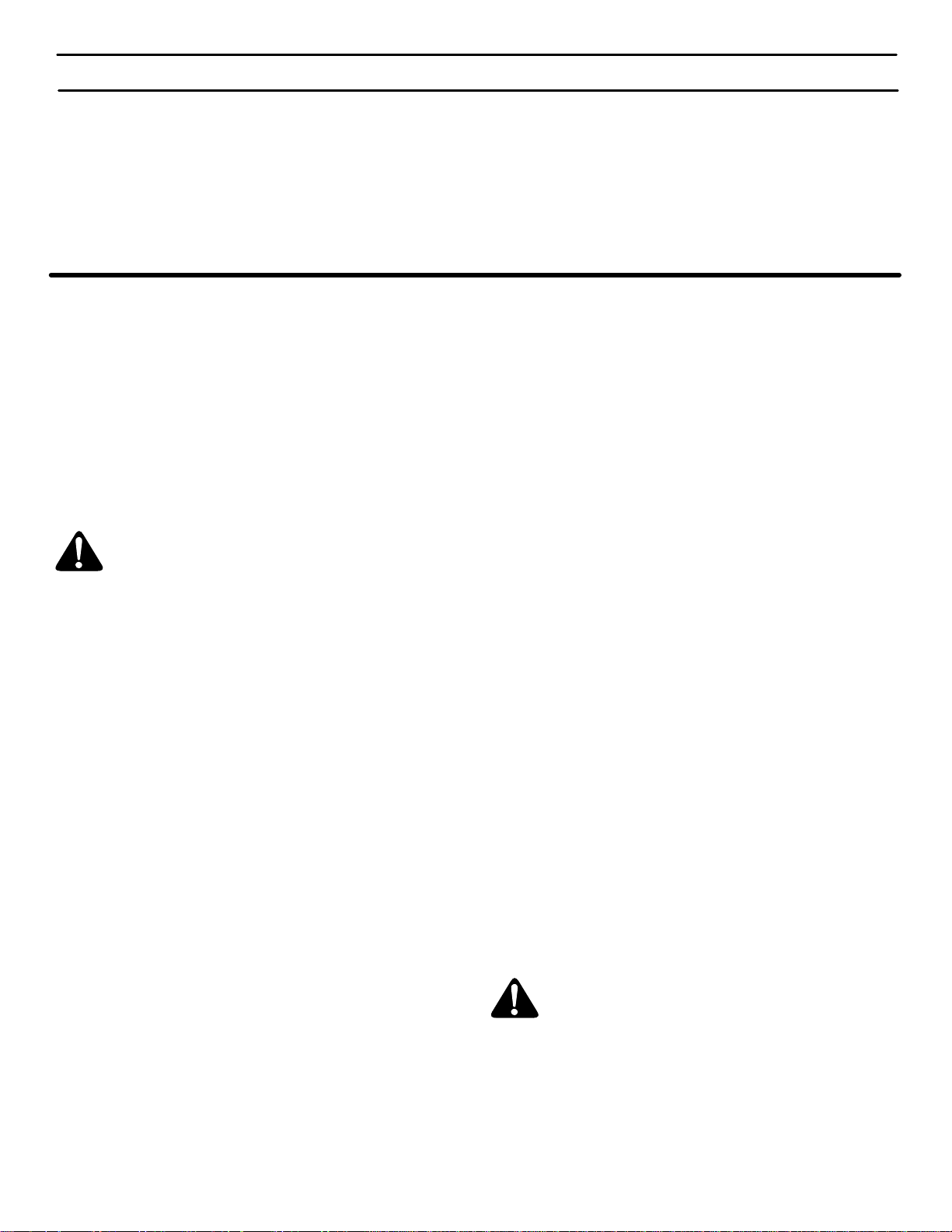

LUBRICATION

Before Storage

1. Lubricate the chute control flange. Apply a clinging

type of grease such as Lubriplate (see Figure 11).

2. Apply oil to the pivot point on each side of the auger

bail (see Figure 11).

3. Wipe off the excess oil.

Chute Control

Flange

Auger Bail

Pivot

Point

Figure 11

MTF-031039C

16

Page 17

SERVICE RECOMMENDATIONS

HOW TO LUBRICATE THE IDLER ARM

CAUTION: DO NOT get oil on the belt or pulleys.

1. Remove the screws from the belt cover . Remove the belt

cover.

2. Apply a drop of oil to the idler arm at point B (see

Figure 12).

3. Pivot the auger bail up and down several times.

4. Wipe off the excess oil.

5. Install the cover.

Idler Arm

B

Figure 12

MTF-031039C

17

Page 18

MAINTENANCE

HOW TO ADJUST THE BELT TENSION

IMPORTANT: When you release the auger bail, the auger must stop rotating. If the auger does not stop, adjust the belt tension as follows:

1. Disconnect the spark plug wire from the spark plug.

2. Remove the belt cover.

3. Loosen the idler pulley nut (see Figure 14).

4. Move the idler pulley to the bottom of the idler arm

slot. If the idler pulley is already in the bottom position, replace the auger belt. See How To Replace The

Auger Belt in the Maintenance section.

5. Tighten the idler pulley nut.

6. Install the belt cover.

HOW TO REPLACE THE AUGER BELT

1. Disconnect the spark plug wire from the spark plug.

2. Remove the belt cover.

3. Remove the belt guide (see Figure 14).

4. Remove the auger belt from the engine drive pulley.

5. Push down the idler arm to move the brake away the

auger drive pulley. Remove the auger belt from the

auger drive pulley.

6. Loosen the idler pulley nut. Move the idler pulley to the

top of the idler arm slot. Tighten the idler pulley nut.

7. Install a new auger belt.

8. Install the belt guide. Make sure the fasteners that

secure the belt guide are tight.

9. Check the operation. When you release the auger

bail, the auger must stop turning. When you engage

the auger bail, there MUST be clearance between the

brake arm and the auger drive pulley.

10. When you release the auger bail, the auger must stop

rotating. Make sure the brake contacts the auger

drive pulley (Figure 14) and that the auger cable

spring (Figure 13) has slack (no tension). If not, check

the cable spring adjustment as follows:

11. Remove the boot from the auger cable spring as follows:

S Disconnect the end of the idler spring from the

idler arm (see Figure 14).

S Remove the auger belt from the idler pulley.

S Remove the end of the auger cable spring from

the auger bail (see Figure 13).

S Remove the boot from the auger cable spring.

S Attach the end of the auger cable spring to the

auger bail.

12. To adjust the auger cable spring:

S Install the auger belt to the idler pulley (see

Figure 14).

S Attach the idler spring to the idler arm.

S Loosen the jam nut (see Figure 13).

S Turn the adjuster until the auger cable is slightly

slack.

S Tighten the jam nut.

13. Remove the idler spring from the idler arm (see

Figure 14). Remove the auger belt from the idler

pulley. Install the boot to the auger cable spring.

14. Install the auger belt, idler spring, and belt cover.

Auger Cable Spring

Jam Nut

Adjuster

Auger Cable

Auger

Bail

Figure 13

MTF-031039C

Auger

Drive

Pulley

Brake

Idler Arm

Auger

Belt

Idler

Spring

18

Idler Pulley

Belt Guide

Idler Pulley

Nut

Engine Drive

Pulley

Figure 14

Page 19

MAINTENANCE

HOW TO REPLACE THE SCRAPER BLADE

1. Remove the fasteners that secure the scraper blade

(Figure 15).

2. Install a new scraper blade and secure with the

fasteners removed in step 1.

HOW TO FREE THE AUGER CABLE

IMPORTANT: If the auger cable will not move when you

ENGAGE the bail, the auger cable could be frozen inside the conduit. DO NOT pull on the auger cable.

Instead, thaw the conduit and lubricate the auger

cable.

1. Thaw the conduit so the auger cable moves freely.

2. Work grease into the opening on the top of the conduit

where the auger cable enters.

Scraper Blade

Figure 15

MTF-031039C

Conduit

Figure 16

19

Page 20

WARNING: To prevent accidental starting when

making any adjustments or repairs, always disconnect the spark plug wire and place it where

it cannot make contact with the spark plug .

MAINTENANCE

HOW TO ADJUST THE CHUTE CRANK

If the chute crank will not rotate fully to the left or right, adjust

as follows.

1. Remove the top cover. See “How To Remove The Top

Cover”.

2. Loosen the nuts.

3. Move the crank adjusting bracket to allow 1/8 inch

(3mm) clearance between the notch in the flange and

the outer diameter of the worm gear.

4. Tighten the nuts.

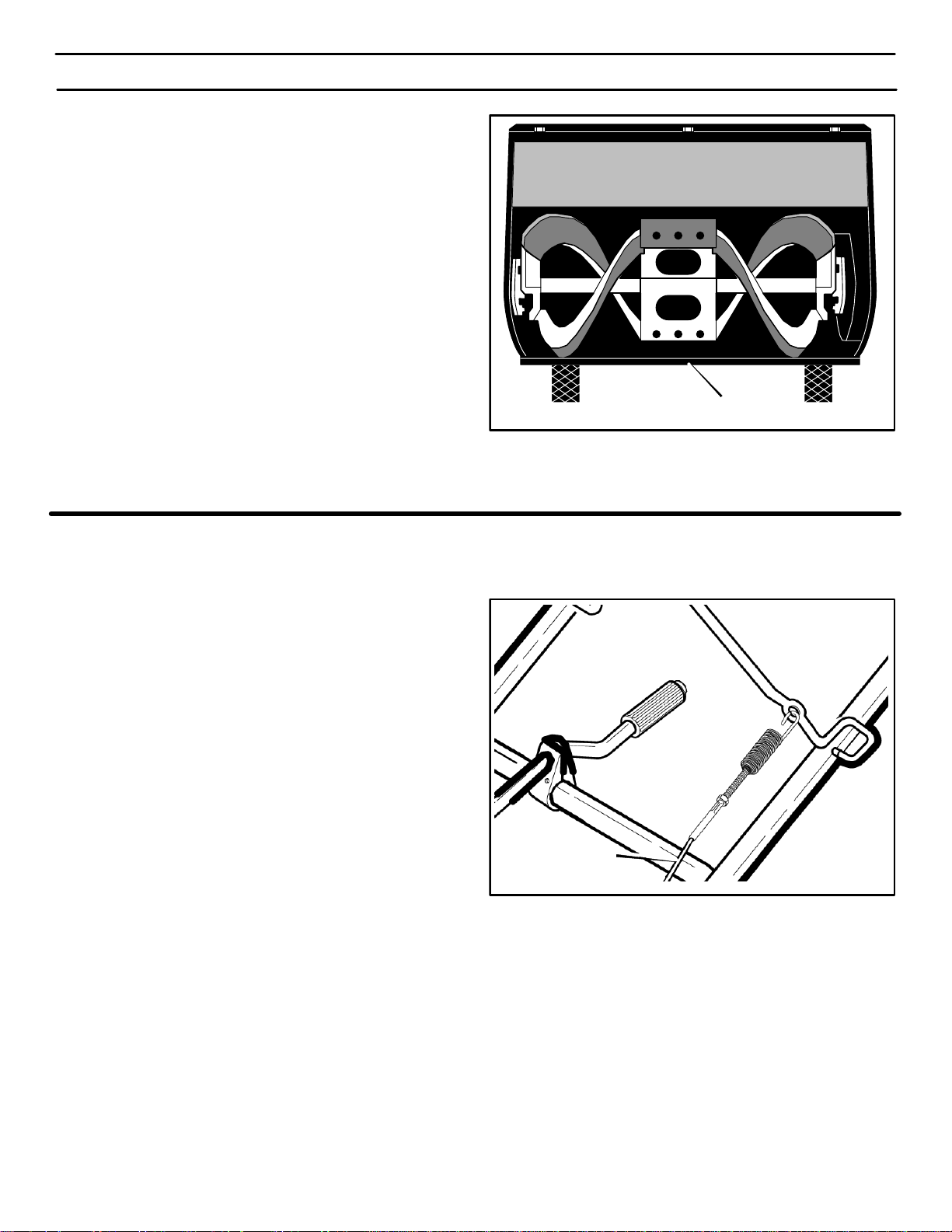

HOW TO ADJUST THE AUGER CONTROL CABLE

The auger control cable is adjusted at the factory. During normal use, the auger control cable can become stretched and

the auger drive lever will not properly engage or disengage

the auger.

1. Remove the “Z” hook from the auger drive lever

(Figure 18).

Nut

Flange

1/8” (3mm)

Crank Adjusting

Bracket

Worm Gear

Figure 17

2. Slide the cable boot off the cable adjustment bracket

(Figure 19).

3. Push the bottom of the auger control cable through the

cable adjustment bracket until the “Z” hook can be removed.

4. Remove the “Z” hook from the cable adjustment brack-

et. Move the “Z” hook down to the next adjustment hole.

5. Pull the auger control cable up through the cable ad-

justment bracket.

6. Put the cable boot over the cable adjustment bracket.

7. Install the “Z” hook to the auger drive lever.

8. To check the adjustment, start the snow thrower. Make

sure the auger does not rotate when the auger drive lever

is released.

Auger Drive

Lever

Z-Hook

Cable Boot

Cable Adjustment

Bracket

Figure 18

Auger Control Cable

Z-Hook

Figure 19

MTF-031039C

20

Page 21

MAINTENANCE

HOW TO REPLACE THE DRIVE BELT

The drive belt is of special construction and must be replaced with original factory replacement belt available from

your nearest authorized service center.

1. Remove the belt cover. See “How To Remove The Belt

Cover”.

2. Remove the drive belt from the idler pulley. (See

Figure 20 and Figure 21)

3. Remove the drive belt from the engine pulley. Be

careful, not to bend the belt guides.

4. Remove the drive belt from the auger pulley. (See

Figure 21)

5. Remove the old drive belt.

Idler Pulley

Drive Belt

Idler Pulley

Belt Guide

Engine PUlley

Belt Guide

Figure 20

Engine

Pulley

6. To install the new drive belt, reverse the above steps.

7. Make sure the drive belt is seated properly on the pul-

leys.

NOTE: When the auger control lever is engaged, the

belt guides must be 1/16” from the drive belt . (See

Figure 22)

8. Install belt cover. See “How To Remove The Belt Cov-

er”.

Idler Pulley

Drive Belt

Drive Belt

Auger Pulley

Engine Pulley

Figure 21

MTF-031039C

21

1/16 inch

Belt Guide

Figure 22

Page 22

HOW TO REPLACE THE AUGER

MAINTENANCE

1. Remove the belt cover. See “How To Remove The Belt

Cover”.

2. Remove the drive belt. See “How To Replace The Drive

Belt”.

3. Remove the auger pulley from the auger shaft

(threads are left hand; turn clockwise to remove). (See

Figure 23).

4. To keep the auger from rotating, set a 2”x4” piece of

wood on the center paddle to secure auger.

5. Remove the fasteners from the bearing assembly. Re-

move the bearing assembly from the auger housing.

6. Slide the auger out of the bearing assembly on the

right side of the snow thrower.

7. Tip the auger enough to allow the auger to slide out of

the auger housing.

8. To install auger, reverse the above steps.

Wood

Center Paddle

Auger Housing

Auger

Bearing Assemlby

Auger Pulley

Figure 23

MTF-031039C

22

Page 23

MAINTENANCE

TO ADJUST THE CARBURETOR

The carburetor is not adjustable. Engine performance

should not be affected at altitudes up to 7,000 feet. For

operation at higher elevations, contact your nearest authorized service center.

IMPORTANT: Never tamper with the engine governor,

which is factory set for proper engine speed. Over-speeding the engine above the factory high speed setting can be

dangerous. If the engine-governed high speed needs an

adjustment, contact an authorized service center. They

have the proper equipment and experience to make any

necessary adjustments.

TO ADJUST OR REPLACE THE SPARK PLUG

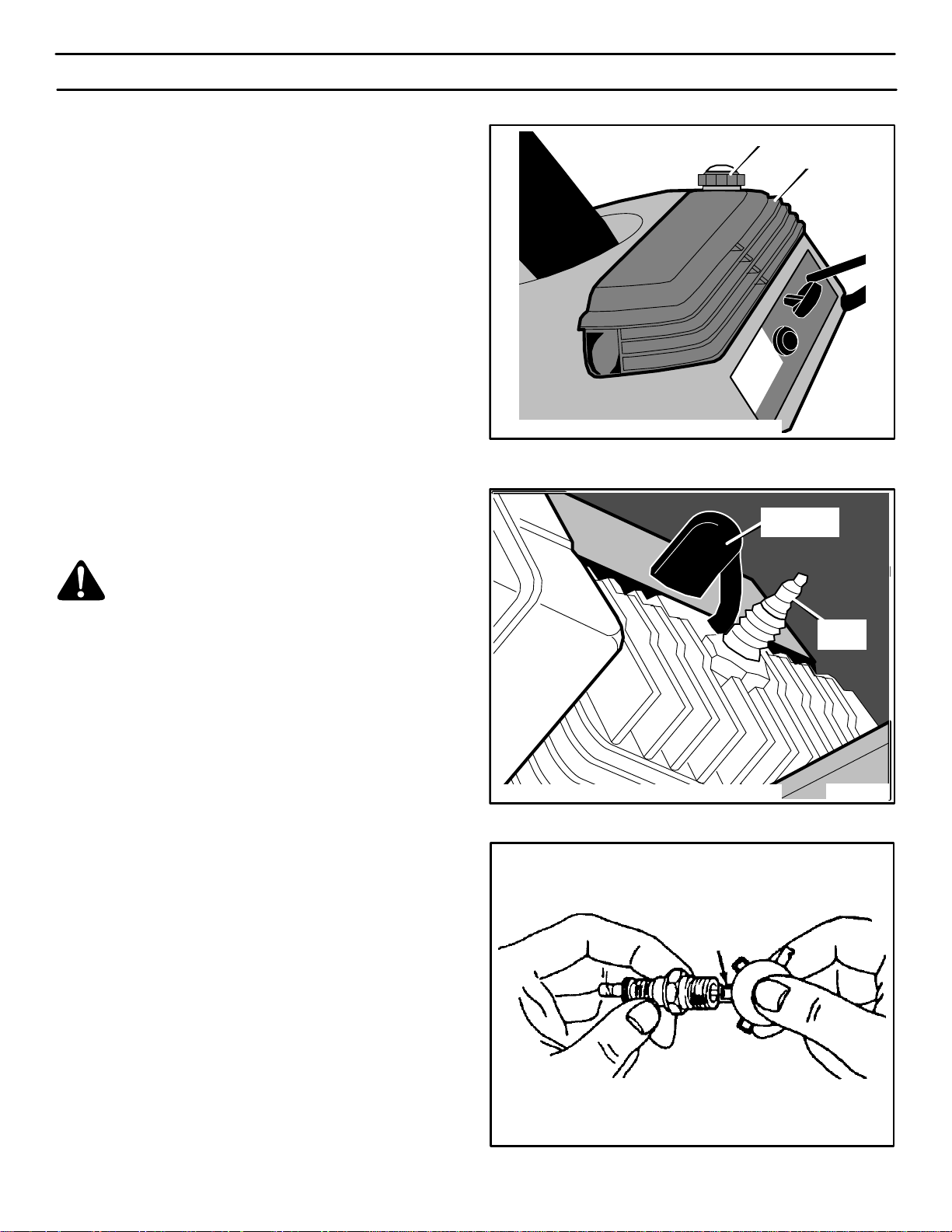

Fuel Cap

Shroud

Check the spark plug every twenty-five (25) hours. Re-

place the spark plug if the electrodes are pitted or burned

or if the porcelain is cracked.

The spark plug is housed in the engine compartment under

the top cover and cannot be seen under normal conditions.

WARNING: STOP the engine. Wait for it to cool

before removal of spark plug.

CAUTION: DO NOT clean the plug with abrasives.

1. Remove the fuel cap (see Figure 24).

2. Remove the screws from the shroud. Remove the

shroud. Install the fuel cap.

3. Disconnect the spark plug wire (see Figure 25).

4. Clean the area around the spark plug base to prevent dirt

from entering the engine when the spark plug is removed.

5. Remove the spark plug.

Spark Plug

Wire

Figure 24

Spark

Plug

Figure 25

6. Check the spark plug. If the spark plug is cracked,

fouled or dirty, it must be replaced .

7. Set the gap between the electrodes of the new spark

plug at 0.030 inch (Figure 26).

8. Install the spark plug in the cylinder head and firmly tight-

en. Recommended torque is 18 to 20 foot pounds. Attach

the spark plug wire.

9. Remove the fuel cap and install the shroud (see

Figure 24).

10. Install the fuel cap.

MTF-031039C

.030” (0.76 mm) Gap

Figure 26

23

Page 24

STORAGE

OFF SEASON STORAGE

WARNING: Never store the engine, with fuel i n

the tank, indoors or in a poor ventilated enclo-

sure where fuel fumes could reach an open

flame, spark or pilot light as on a furnace, water heater ,

clothes dryer, etc.

Handle gasoline carefully. It is highly flammable and

careless use could result In serious fire damage to your

person and /or property.

Drain fuel into approved containers outdoors, away

from open flame.

If the snowthrower is to be stored for thirty (30) days or more

at the end of the snow season, the following steps are

recommended to prepare your snowthrower for storage.

NOTE: Gasoline must be removed or treated to prevent

gum deposits from forming in the tank, filter, hose, and

carburetor during storage.

1. To remove gasoline, run engine until tank is empty and

engine stops.

If you do not want to remove the gasoline, add fuel stabilizer

to any gasoline left in the tank to minimize gum deposits and

acids. If the tank is almost empty, mix stabilizer with fresh

gasoline in a separate container and add some to the tank.

ALWAYS FOLLOW INSTRUCTIONS ON STABILIZER

CONTAINER. THEN RUN ENGINE AT LEAST 10 MINUTES

AFTER STABILIZER IS ADDED TO ALLOW MIXTURE TO

REACH CARBURETOR. STORE SNOWTHROWER IN

SAFE PLACE.

2. Lubricating the piston/cylinder area. This can be done by

first removing the spark plug and squirting clean engine

oil into the spark plug hole. Then cover the spark plug

hole with a rag to absorb oil spray. Next, rotate the engine

by pulling the starter two or three times. Finally, reinstall

spark plug and attach spark plug wire.

3. Thoroughly clean the snowthrower.

4. Lubricate all lubrication points (see “Lubrication“ in the

Service Recommendations section).

5. Insure that all nuts, bolts, and screws are securely fastened. Inspect all visible moving parts for damage,

breakage, and wear. Replace if necessary.

6. Touch up all rusted or chipped paint surfaces; sand lightly

before painting.

7. Cover the bare metal parts of the blower housing and auger with rust preventative.

8. If possible, store your snowthrower indoors and cover it

to give protection from dust and dirt.

9. On models with folding handles, loosen the knobs that

secure the upper handle. Rotate the upper handle back.

10. If the machine must be stored outdoors, block up the snowthrower and insure the entire machine is off the

ground. Cover the snowthrower with a heavy tarpaulin.

REMOVING THE SNOWTHROWER FROM

STORAGE

When removing the snowthrower from storage, follow the

steps below.

1. Put the upper handle in the operating position, tighten the

knobs that secure the upper handle.

2. Fill the fuel tank with a fresh fuel-oil mixture. See “How

to Mix The Fuel Mixture” in the Operation section.

3. Lubricate the auger bail and idler arm.

4. Check the spark plug. Make sure the gap is correct. If the

spark plug is worn or damaged, replace before using.

5. Make sure all fasteners are tight.

6. Make sure all guards, shields, and covers are in place.

7. Make sure all adjustments are correct.

MTF-031039C

24

Page 25

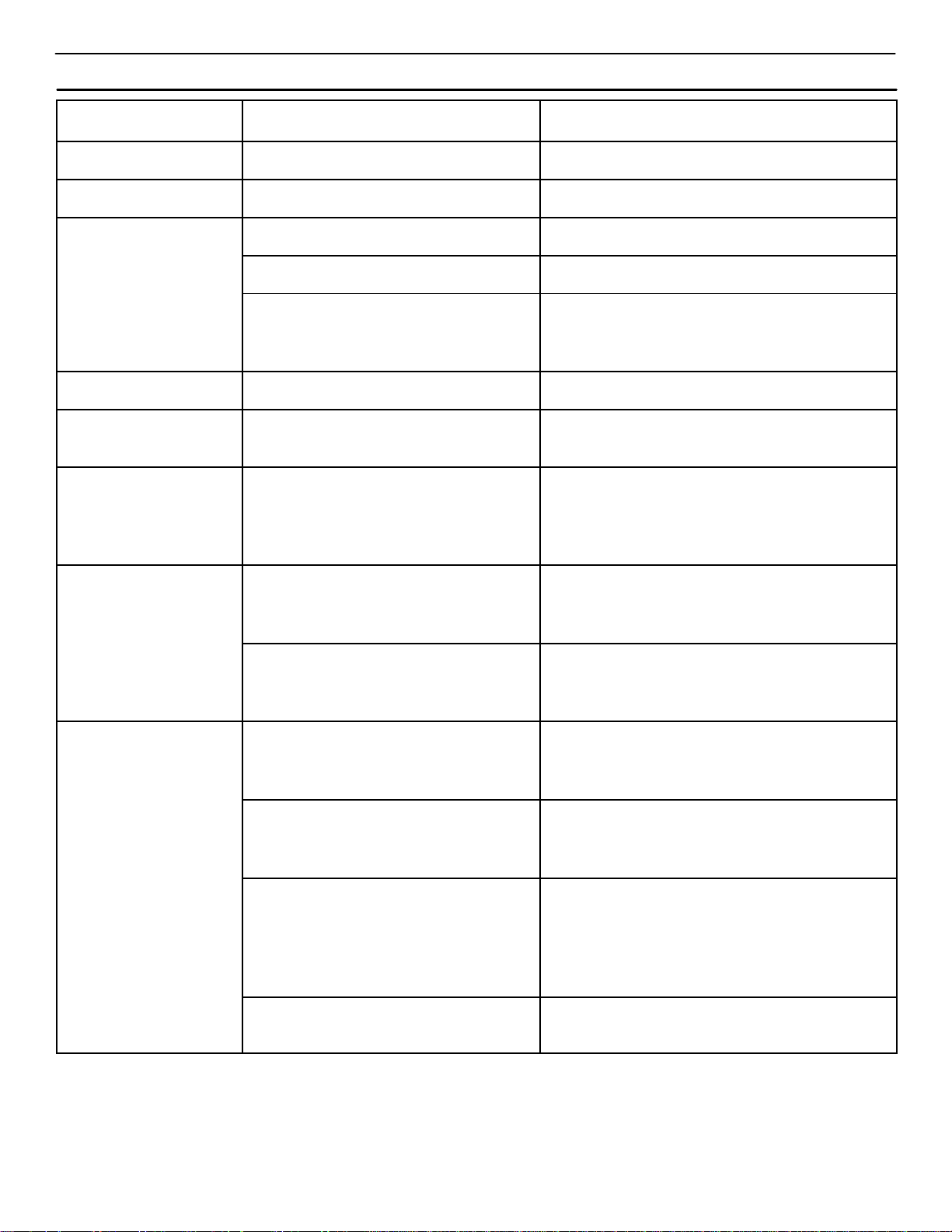

TROUBLE SHOOTING CHART

PROBLEM LOOK FOR REMEDY

Difficult starting Defective spark plug. Replace defective spark plug.

Engine runs erratically Blocked fuel line. Clean fuel line.

Empty gas tank. Check fuel supply,

Stale gasoline. Add fresh gasoline.

Water or dirt in fuel system. Remove carburetor bowl to drain fuel tank. Refill

with fresh fuel. CAUTION: Do not remove

carburetor bowl when the engine is hot.

Engine stalls Unit running on CHOKE. Set choke lever to RUN position.

Loss of power Gas cap vent hole is plugged. Remove ice and snow from cap. Be sure vent

hole is clear.

Excessive vibration Loose parts. Stop engine immediately and remove spark plug

wire. Tighten all bolts and make all necessary

repairs. If vibration continues, have the unit

serviced by a competent repairman.

Unit fails to propel

itself

Unit fails to discharge

snow

Drive belt loose or damaged. Replace drive belt. Refer to Drive Belt

Replacement in the Maintenance section of this

manual.

Incorrect adjustment of traction drive

cable.

Auger drive belt loose or damaged. Replace or adjust auger drive belt. Refer to Drive

Auger control cable not adjusted

correctly.

Discharge chute clogged. Stop engine immediately and disconnect spark

Foreign object lodged in auger. Stop engine immediately and disconnect spark

Adjust traction drive cable. Refer to Cable

Adjustment in the Maintenance section of this

manual.

Belt Replacement and Drive Belt Adjustment in

the Maintenance section of this manual.

Adjust auger control cable. Refer to Cable

Adjustment in the Maintenance section of this

manual.

plug wire. Refer to the first Warning in

Snowthrower Operation in the Operation

section of this manual. Clean discharge chute

and inside of auger housing.

plug wire. Remove object from auger housing.

Identifying Your Snowthrower

Your new snowthrower has two (2) identifying numbers: (1) unit model number: (2) unit serial number. The two preceding

numbers are required to insure that the proper replacement parts are obtained when required. If you have any questions

concerning parts, service, or technical data, contact your nearest John Deere/Frontier dealer.

For complete warranty information refer to the warranty in the Owner’s Information section of this manual.

MTF-031039C

25

Page 26

NOTES

MTF-031039C

26

Page 27

REPLACEMENT PARTS

WE RECOMMEND JOHN DEERE/FRONTIER quality parts and lubricants available at your John Deere/Frontier dealer.

PART NUMBERS MAY CHANGE. When you order replacement parts, use the part numbers listed below and on the fol-

lowing pages. If a part number changes, your John Deere/Frontier dealer will have the latest part number.

WHEN YOU ORDER PARTS, your John Deere/Frontier dealer must have your snowthrower model and serial number and

your engine model number. This is the model and serial number that you recorded in the “Owner’s Information” section of

this Owner’s Manual.

QUICK REFERENCE PART NUMBERS

The following is a list of replacement parts that you may need for routine service and maintenance. If you do not see the

replacement part you need in the following chart, then check the full list of replacement part illustrations following this

page.

ITEM

Belt MT37x130

Scraper Blade MT302418

Spark Plug Champion RCJ8Y

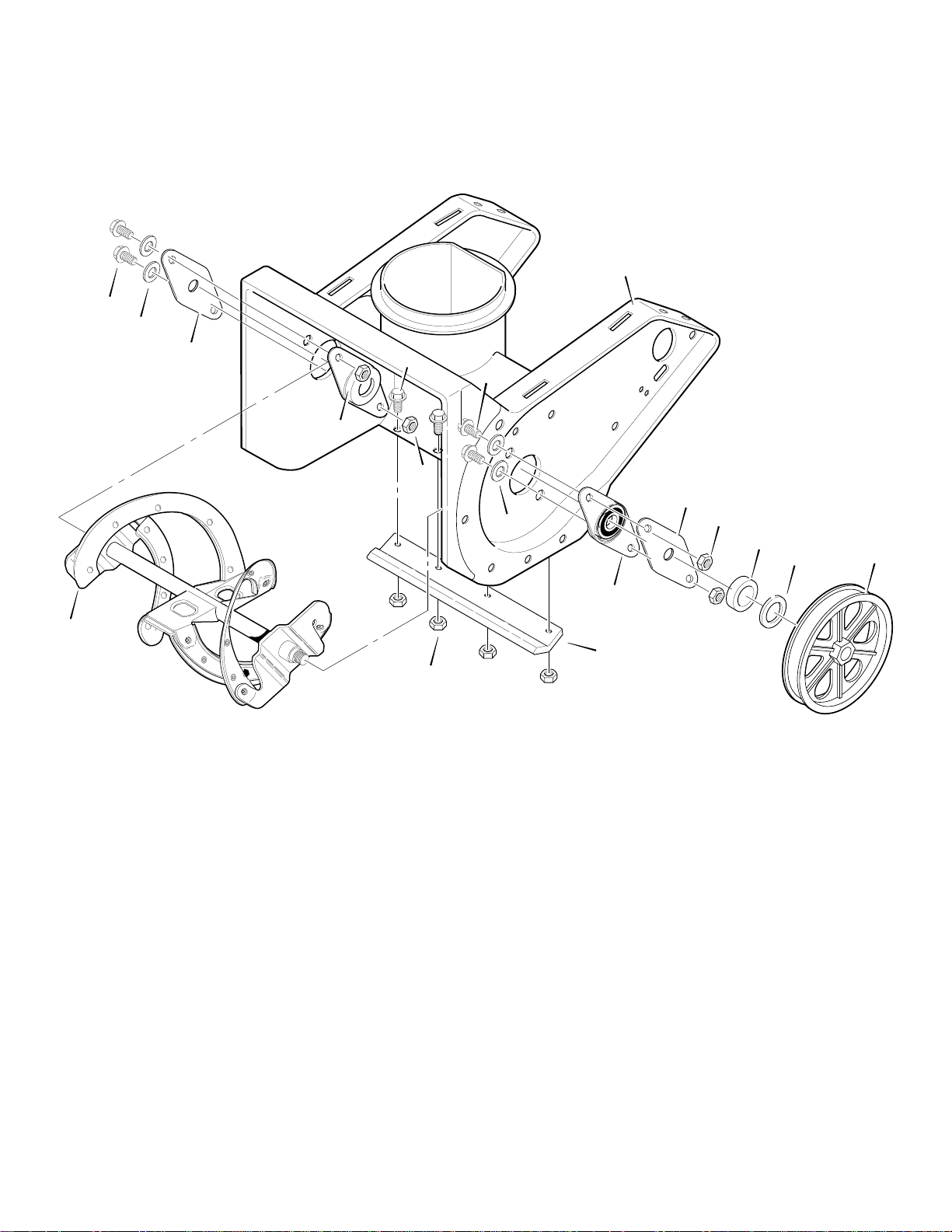

* Part Numbers are subject to change without notice.

PART NUMBER *

MTF-031039C

27

Page 28

FRONTIER MODEL ST0521M

FACTORY MODEL 621501x16NA

FRONTIER MODEL ST0521E

9

1

FACTORY MODEL 621500x16NA

ENGINE ASSEMBLY

10

11

12

13

14

7

6

5

4

3

17

18

2

7

28

29

19

15

26

16

20

25

24

21

23

22

MTF-031039C

27

28

Page 29

FRONTIER MODEL ST0521M

FACTORY MODEL 621501x16NA

FRONTIER MODEL ST0521E

Key No. Part No. Description

1 MT760632

MT760631

2 MT340381E701 AUGER HOUSING, 21”

3 MT313780 SCREW, .31-18x .5

4 MT301419E701 SUPPORT, FRAME

5 MT301415E701 SUPPORT, ENGINE

6 MT71391 NUT.31-18 HEX

7 MT71391 NUT .31-18 HEX

9 MT314135 HANDLE, UPPER

10 MT314142 COVER, CABLE SPRING

11 MT316001 CABLE, DRIVE

12 MT73826 LOCKNUT .25-20 HEX

13 MT71067 WASHER .286-0.62-.07

14 MT70971 SCREW .25-20x1.50

15 MT71060 WASHER .318-0.56-.05

16 MT313676 SCREW, .31-18x .63

17 MT301421 PLATE, REAR

18 MT45892 BOLT, CARRIAGE .38-16x1.50

19 MT339017 SPRING, IDLER BRAKE

20 MT333784 PULLEY, 4.5 HP

21 MT333805 BOLT, SHOULDER .625x.280

22 MT71391 NUT.31-18 HEX

23 MT120386 WASHER, FLAT .312X .73X.065

24 MT340428 GUIDE, BELT

25 MT590 JAM NUT.38-16 HEX

26 MT48924 PULLEY, IDLER

27 MT37x130 BELT, POLY-V 10 RIB 35.14

28 MT333594 BOLT, SHOULDER

29 MT339415 BRACKET, IDLER ARM

-- MTF-031039C OWNER’S MANUAL

FACTORY MODEL 621500x16NA

ENGINE ASSEMBLY

ENGINE, RECOIL START

ENGINE, ELECTRIC START

MTF-031039C

29

Page 30

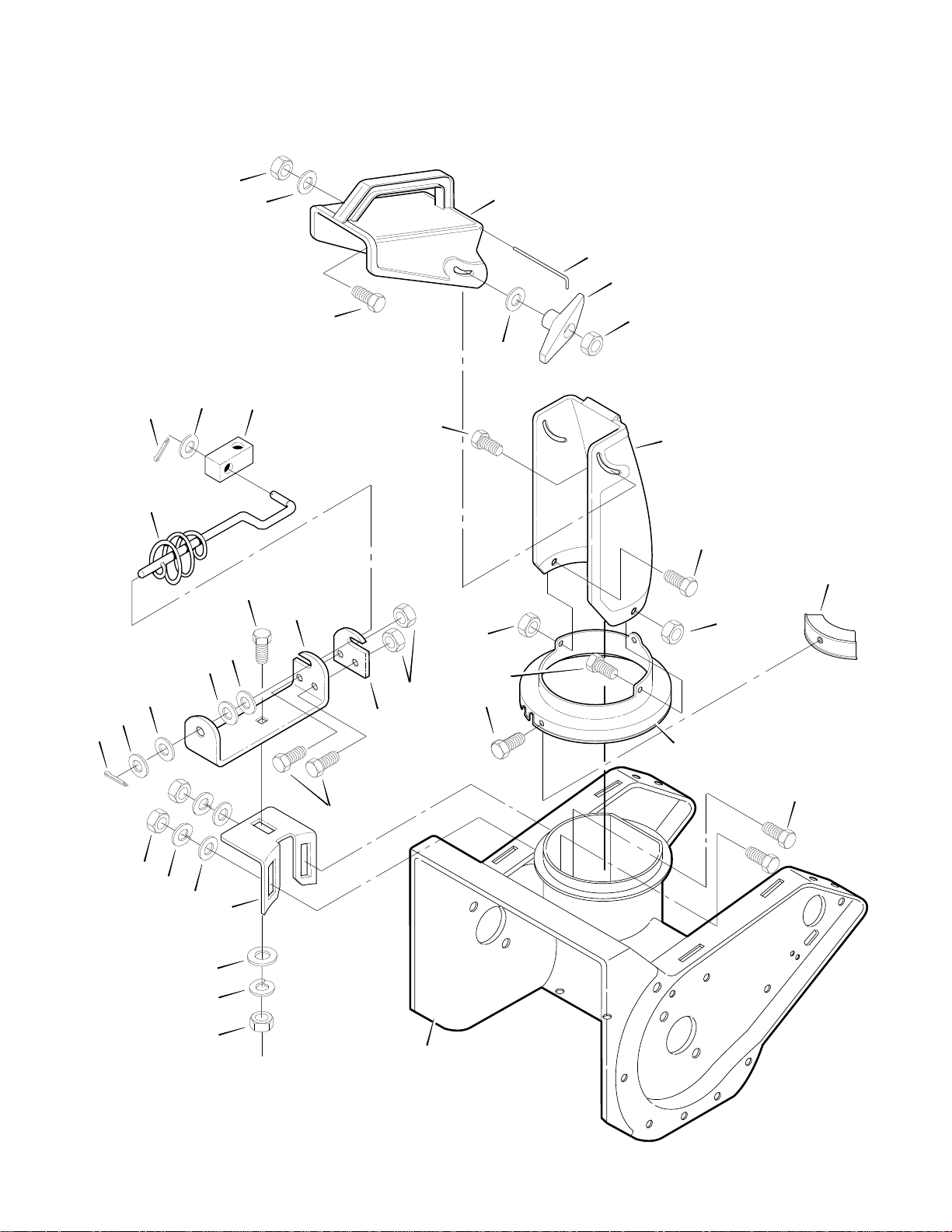

FRONTIER MODEL ST0521M

FACTORY MODEL 621501x16NA

FRONTIER MODEL ST0521E

9

8

2

10

11

15

16 14

7

18

17

6

FACTORY MODEL 621500x16NA

FRAME ASSEMBLY

12

13

19

20

15

11

21

5

4

3

2

1

25

22

17

18

23

24

5

11

25

MTF-031039C

11

25

11

26

25

11

30

Page 31

FRONTIER MODEL ST0521M

FACTORY MODEL 621501x16NA

FRONTIER MODEL ST0521E

Key No. Part No. Description

1 MT340381E701 AUGER HOUSING 21”

2 MT323387 CLAMP, TUBING

3 MT323395 TUBING, FUEL

4 MT56679 FILTER, FUEL

5 MT313780 SCREW .31-18x.50

6 MT323363 TUBING, FUEL

7 MT47345 CLAMP, TUBING

8 MT326142 FUEL TANK

9 MT327018 CAP, FUEL

10 MT311671 CLAMP, WORM DR

11 MT309814 SCREW 10-24x.62

12 MT308677 BRACKET, FUEL TANK

13 MT997316 NUT, LOCK 10-24

14 MT274707 SCREW 10-24x.50

15 MT318139 SCREW .25-20x.62

16 MT301420E701 PLATE, REAR MT RH

17 MT71391 NUT, LOCK .31-18

18 MT313676 SCREW .31-18x.75

19 MT301419E701 FRAME SUPPORT

20 MT311738E701 HEAT SHIELD

21 MT760631 ENGINE w/ELECTRIC START

22 MT301421E701 PLATE, REAR MT LH

23 MT302635 NUT, LOCK .25-20

24 MT303041 WASHER, FLAT

25 MT590 NUT.38-16 HEX JAM CTRLK

26 MT305869 BOTTOM SHROUD

FACTORY MODEL 621500x16NA

FRAME ASSEMBLY

MTF-031039C

31

Page 32

FRONTIER MODEL ST0521M

FACTORY MODEL 621501x16NA

FRONTIER MODEL ST0521E

1

18

16

17

FACTORY MODEL 621500x16NA

HANDLE ASSEMBLY

3

4

6

9

5

8

6

7

10

15

14

15

15

14

15

12

13

11

9

17

Key No. Part No. Description Key No. Part No. Description

1 MT307747 DRIVEBAR

3 MT309815 SCREW 10-24x1.00

4 MT329935 KNOB

5 MT308716 BRACKET, UPPER CRANK

6 MT311936 WASHER, FORMED

7 MT314135 HANDLE, UPPER w/FOAM

8 MT308715 BRACKET, LOWER CRANK

9 MT337584 BOLT, FORMED HEAD

10 MT310169 SCREW .25-20x.62

MTF-031039C

11 MT71055 NUT, LOCK 10-24

12 MT301421E701 PLATE, REAR MT LH

13 MT301419E701 FRAME SUPPORT

14 MT71391 NUT, LOCK .31-18

15 MT71060 WASHER, LOCK

16 MT301420E701 PLATE, REAR MT RH

17 MT313676 SCREW .31-18x.75

18 MT309964E701 LOWER HANDLE

32

4

Page 33

FRONTIER MODEL ST0521M

FACTORY MODEL 621501x16NA

FRONTIER MODEL ST0521E

1

2

3

4

1

5

FACTORY MODEL 621500x16NA

AUGER HOUSING

6

1

3

5

2

7

8

9

12

MTF-031039C

4

10

11

Key No. Part No. Description

1 MT579052 SCREW .25-20X.63

2 MT71067 WASHER, FLAT .281x.63x.065

3 MT54836 PLATE, BEARING RETAINER

4 MT583459 PLATE & BEARING ASSY

5 MT73826 NUT, LOCK .25-20

6 MT340381E701 AUGER HOUSING 21”

7 MT578101 SPACER, SLEEVE

8 MT40677 WASHER, FLAT .640x1.25x.06

9 MT333446 PULLEY, POLY V

10 MT302418 SCRAPER BLADE

11 MT302635 NUT, LOCK .25-20

12 MT321961E701 AUGER ASSY

33

Page 34

FRONTIER MODEL ST0521M

FACTORY MODEL 621501x16NA

FRONTIER MODEL ST0521E

15

16

17

6

5

14

13

22

FACTORY MODEL 621500x16NA

DISCHARGE CHUTE

18

19

20

21

16

23

24

28

8

9

6

7

7

6

5

10

1

2

3

4

3

2

12

11

25

24

26

25

27

29

MTF-031039C

1

30

34

Page 35

FRONTIER MODEL ST0521M

FACTORY MODEL 621501x16NA

FRONTIER MODEL ST0521E

Key No. Part No. Description

1 MT15X144 NUT.31-18 HEX

2 MT71060 WASHER, LOCK

3 MT71071 WASHER, FLAT .349-0.69-.07

4 MT302505E701 BRKT, WORM ADJUST

5 MT71081 PIN, COTTER.094x0.75L

6 MT12452 WASHER, FLAT .400-0.75-.02

7 MT313431 WASHER, SPRING .395-0.73-.01

8 MT340720 BOLT-CARRIAGE .31-18x0.75

9 MT300728E701 BRKT, CHUTE ROD HOLE

10 MT313686 SCREW.25-20x0.50 HHC

11 MT307741 PLATE, CHUTE ROD

12 MT73826 NUT, LOCK.25-20 HEX

13 MT51564 BLOCK, PIVOT CHUTE

14 MT307742 ROD ASSEMBLY, LOWER CHUTE

15 MT71391 NUT, LOCK .31-18 HEX

16 MT71071 WASHER, FLAT .349-0.69-.07

17 MT578088 SCREW.31-18x0.75

18 MT305861 CHUTE, UPPER

19 MT310562 WIRE FORM, HINGE

20 MT57171 WINGKNOB

21 MT15X144 NUT.31-18 HEX

22 MT302843 BOLT-CARRIAGE .31-18x1.50

23 MT305862 CHUTE, LOWER

24 MT313686 SCREW.25-20x0.50

25 MT15X143 NUT, FLANGED LOCK .25-20

26 MT56962 SCREW.25-14x0.62

27 MT307842 CHUTE RING

28 MT300790 CLIP, CHUTE RING

29 MT340720 BOLT-CARRIAGE .31-18x0.75

30 MT340381E701 AUGER HSG, 21”

FACTORY MODEL 621500x16NA

DISCHARGE CHUTE

MTF-031039C

35

Page 36

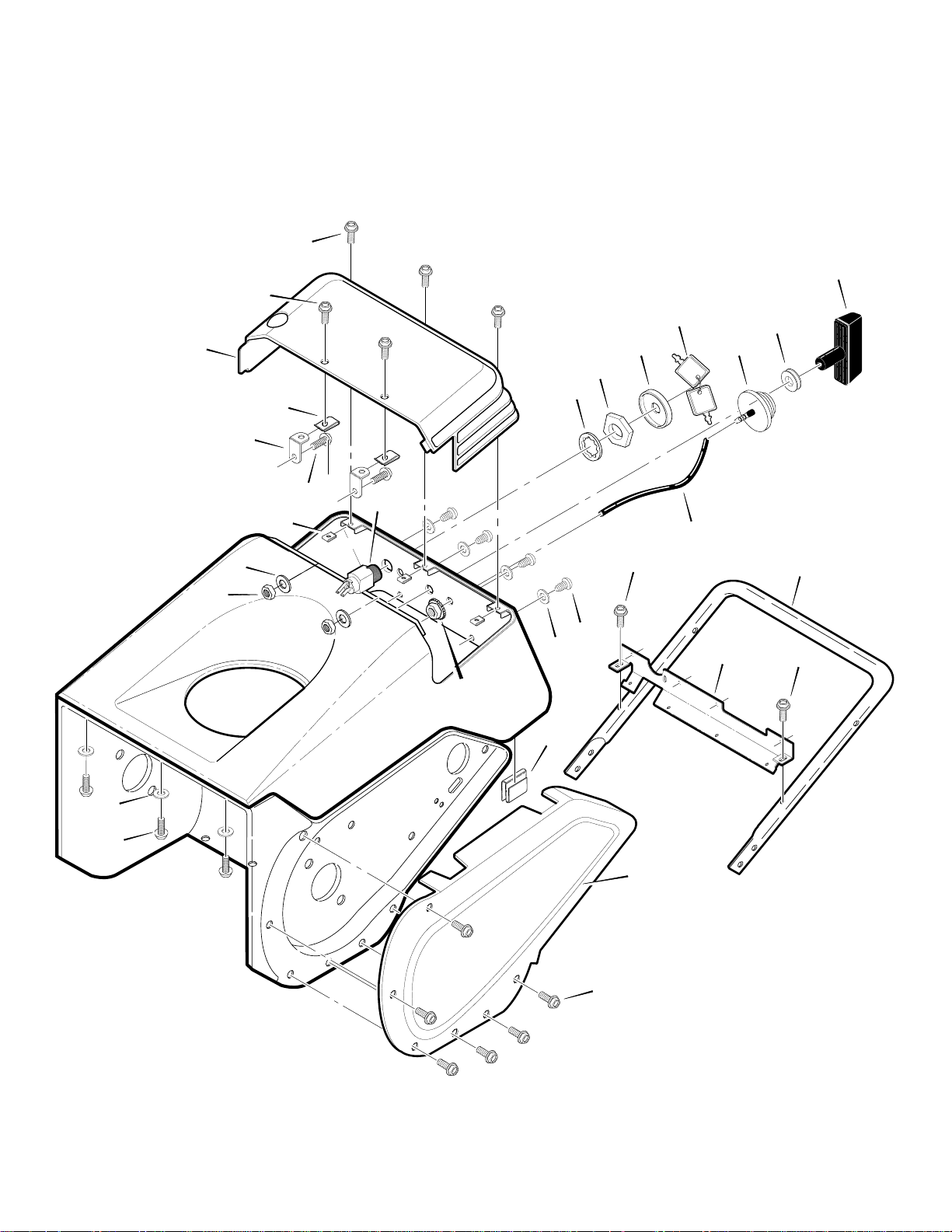

FRONTIER MODEL ST0521M

FACTORY MODEL 621501x16NA

FRONTIER MODEL ST0521E

10

9

8

5

7

6

5

11

FACTORY MODEL 621500x16NA

TOP COVER ASSEMBLY

18

15

14

13

12

19

17

16

4

3

19

22

2

1

20

20

23

26

25

24

20

MTF-031039C

36

Page 37

FRONTIER MODEL ST0521M

FACTORY MODEL 621501x16NA

FRONTIER MODEL ST0521E

Key No. Part No. Description

1 MT309813 SCREW 10-14x.63

2 MT711666 WASHER, FLAT

3 MT71055 NUT, LOCK 10-24

4 MT303041 WASHER, FLAT

5 MT309811 NUT, U TYPE

6 MT12342 SCREW 10-24x.50

7 MT312102 BRACKET, ACCESS COVER

8 MT305871 COVER, ENGINE ACCESS

9 MT312094 SCREW 10-16x.62

10 MT312362 SCREW 10-16x.75

11 MT56992 INGNITION SWITCH

12 MT313683 WASHER, INTERNAL LOCK

13 MT300193 NUT, .62-32 PLASTIC

14 MT300194 BOOT, SWITCH

15 MT49643 KEYS & RING

16 MT54601 PRIMER BULB

17 MT57587 GROMMET & WASHER

18 MT333643 KNOB, STANDARD T

19 MT1259 HOSE, PRIMER

20 MT309814 SCREW 10-24x.63

21 MT303008 NUT .25-20 KEPS

22 MT313057 S CLIP

23 MT397761 BRACKET, SHROUD MTG

24 MT309964E701 LOWER HANDLE

25 MT310798 SCREW 10-24x.38

26 MT302416 COVER, BELT

FACTORY MODEL 621500x16NA

TOP COVER ASSEMBLY

MTF-031039C

37

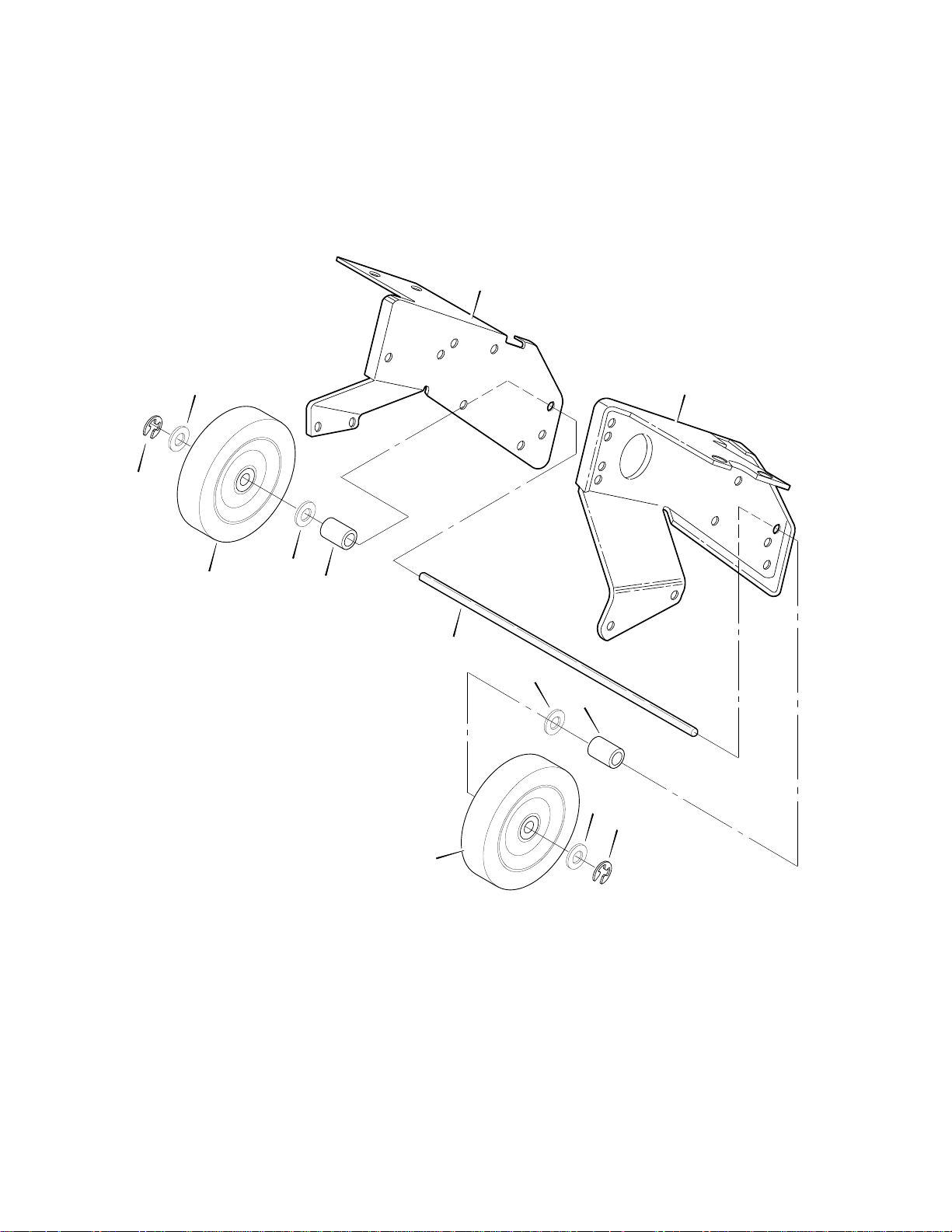

Page 38

FRONTIER MODEL ST0521M

FACTORY MODEL 621501x16NA

FRONTIER MODEL ST0521E

2

1

FACTORY MODEL 621500x16NA

WHEEL ASSEMBLY

7

6

3

2

4

5

2

4

2

1

3

Key No. Part No. Description

1 MT577598 RING, RET. E

2 MT71072 WASHER, FLAT .406x.81x.07

3 MT1501741 7.75”X1.75” WHEEL

4 MT309656 SPACER, SLEEVE

5 MT307719 AXLE SHAFT

6 MT301421E701 PLATE, REAR MT LH

7 MT301420E701 PLATE, REAR MT RH

MTF-031039C

38

Page 39

FRONTIER MODEL ST0521M

FACTORY MODEL 621501x16NA

FRONTIER MODEL ST0521E

8

7

6

FACTORY MODEL 621500x16NA

CHUTE ROD ASSEMBLY

9

10

1

5

2

3

4

Key No. Part No. Description

1 MT331532 PUSH NUT

2 MT307755 KNOB, GRIP

3 MT12452 WASHER, FLAT .400x.75x.02

4 MT71081 PIN, COTTER

5 MT307742 ROD, CHUTE CNTRL LWR

6 MT51564 BLOCK, PIVOT

7 MT307756 ROD, CHUTE CNTRL MID

8 MT314159 NUT, LOCK 10-32

9 MT314158 SCREW, 10-32X.88

10 MT309449 ROD, CHUTE UPPER

MTF-031039C

39

Page 40

FRONTIER MODEL ST0521M

FACTORY MODEL 621501x16NA

FRONTIER MODEL ST0521E

2

FACTORY MODEL 621500x16NA

DECALS

3

4

5

1

7

6

Key No. Part No. Description

1 MT48x5262 DECAL, DANGER AUGER

2 MT48x2034 DECAL, DANGER CHUTE

3 MT337524 DECAL, AUGER CONTROL

4 MT340709

MT340708

5 MT69880 DECAL, HOT MUFFLER

6 MT48x5260 DECAL, FRONTIER ST0521

7 MT48x5202 DECAL, EPA

* MTF-031039C OPERATOR’S MANUAL

DECAL, CONTROL PANEL ST0521E (621500x16NA)

DECAL, CONTROL PANEL ST0521M (621501x16NA)

MTF-031039C

* Not Illustrated

40

Page 41

FRONTIER MODEL ST0521E FACTORY MODEL 621500x16NA

ELECTRIC STARTER

Ref. Hardware

(Bolts)

1

Ref. Electric

Starter

6

Ref. Engine

Ref. Top Cover

5

2

4

3

MTF-031039C

Key No. Part No. Description

1 NA INCLUDED WITH ENGINE

2 MT271163 NUT, KEPS 8-32

3 MT414106 WASHER, FLAT

4 MT311633 SCREW 8-32x3.00

5 MT56023 CORD, EXTENSION

6 MT57569 RETAINER

41

Page 42

NOTES

MTF-031039C

42

Page 43

NOTES

MTF-031039C

43

Page 44

SPECIFICATIONS ST0521M, ST0521E

Engine Tecumseh Snow King 2-Cycle

Horsepower 5 hp

Starter ST0521M Recoil

ST0521E Electric

Fuel Capacity 1.5 quart

Drive System Auger

Tire Diameter 7”

Clearing Width 21”

Housing Height 12”

Auger Diameter 9”

Auger Type Rubber-edged

Chute Rotation Remote

Chute Turning Radius

Deflector Control Manual

Weight ST0521M 89 lbs

ST0521E 93 lbs

Warranty - Engine 2 years

Warranty - Machine 3 years

190_

MTF-031039C

44

Loading...

Loading...