Page 1

CENTRIFUGAL PUMP

2" Honda AC-CP2GH

Subaru AC-CP2GS

3" Honda AC-CP3GH

Subaru AC-CP3GS

NOTE: ENGINE IS SHIPPED WITHOUT OIL. REFER TO ENGINE

Centrifugal Pump Operator's Manual 1

MANUAL.

Page 2

Introduction

CONFORME À LA NORME NMB-002 DU CANADA.

Congratulations on the purchase of your new Centrifugal Pump! You can be assured

your product was constructed and designed with quality and performance in mind. Each

component has been rigorously tested to ensure the highest level of acceptance.

This operator's manual was compiled for your benet. By reading and following the

simple safety, installation, operation, maintenance and troubleshooting steps described

in this manual, you will receive years of trouble-free operation from your new unit. The

contents of this manual are based on the latest product information available at the time

of publication. The manufacturer reserves the right to make changes in price, color, materials, equipment, specications or models at any time without notice.

Once the unit has been removed from the box, immediately write in the serial number of

your unit in the space provided below.

Inspect for signs of obvious or concealed freight damage. If damage does exist, le a claim

with the transportation company immediately. Be sure that all damaged parts are replaced

and that the mechanical problems are corrected prior to operation of the unit. If you require

service, contact your Customer Service.

SERIAL NUMBER_________________________________

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

1. Model Number

Please have the following information available for all service calls:

2. Serial Number

3. Date and Place of Purchase

WARNING/AVERTISSEMENT

RISK OF BURNS:

HOT SURFACES.

MUFFLER AND

ADJACENT AREAS

MAY EXCEED 150°F.

THIS SPARK IGNITION SYSTEM COMPLIES WITH

CANADIAN ICES-002.

CE SYSTÈME D’ALLUMAGE PAR ÈTINCELLE EST

2 Centrifugal Pump Operator's Manual

RISQUE DE BRULURES:

SURFACES CHAUDES LE

TUYAU D'ÉCHAPPEMENT ET

LES RÉGIONS ADJACENTES

PEUVENT DÉPASSER LES 65°C.

34-0767-E/F-052901-ENG.

Warning: This product contains lead, a

chemical known to the State of California

to cause birth defects or other reproductive

harm.

Wash your hands after handling this product.

PROTECT YOUR INVESTMENT......

Use only John Deere Fuel Protect

Fuel Stabilizer with Ethanol Protection

TY27534 or TY27535. Developed to

ensure Optimum Performance and

Protection.

IMPORTANT...Use Year Round!

34-1904 012011

Page 3

Table of Contents

CONTENTS

INTRODUCTION ............................................................................ 2

SAFETY .......................................................................................... 4

FIRE AND VENTILATION PRECAUTIONS ............................ 5

IMPORTANT SAFETY INSTRUCTIONS ................................ 5

PRE-OPERATION. .......................................................................... 7

OPERATION ................................................................................... 9

HOW TO USE ....................................................................... 8

STARTING AND OPERATING THE ENGINE ......................... 9

STOPPING THE ENGINE ................................................... 10

SHUTDOWN ....................................................................... 10

WATER HAMMERING......................................................... 10

STORAGE ........................................................................... 10

TROUBLE SHOOTING ................................................................. 11

SERVICE ....................................................................................... 12

CHECK ENGINE OIL .......................................................... 12

CHANGE ENGINE OIL ........................................................ 13

GASOLINE ENGINE OIL ..................................................... 13

CLEAN AIR FILTER ELEMENT ........................................... 13

CLEANING AND GAPPING SPARK PLUGS ....................... 14

ADJUSTING RPD ............................................................... 15

CLEANING SEDIMENT CUP .............................................. 15

SOLUTIONS ................................................................................. 16

ACCESSORIES ............................................................................. 17

Centrifugal Pump Operator's Manual 3

Page 4

Safety

RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. When you see this symbol

on your new unit or in this manual, be alert to the potential

for personal injury.

Follow recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS

A "DANGER, WARNING or CAUTION" safety warning will be

surrounded by a "SAFETY ALERT BOX." This box is used to

designate and emphasize Safety Warnings that must be followed when operating the Semi-Trash Pump.

Accompanying the Safety Warnings are "signal words" which

designate the degree or level of hazard seriousness. The

"signal words" used in this manual are as follows:

DANGER: Indicates an imminently hazardous situation

which, if not avoided, WILL result in death or

serious injury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, COULD result in death or

serious injury.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided MAY result in minor or

moderate injury.

READ OPERATING INSTRUCTIONS

Always become familiar with all the instructions and

warnings before operating any unit.

IMPROPER OR UNSAFE USE OF THIS PUMP CAN

RESULT IN DEATH OR SERIOUS BODILY INJURY!

THIS MANUAL CONTAINS IMPORTANT INFORMATION ABOUT PRODUCT SAFETY. PLEASE READ

AND UNDERSTAND THIS MANUAL BEFORE OPERATING THE SEMI-TRASH PUMP. Keep this manual

available for other users and owners before they use the

pump. This manual should be stored in a safe place.

4 Centrifugal Pump Operator's Manual

Page 5

Safety

IMPORTANT

FIRE & VENTILATION PRECAUTIONS:

1. This unit was designed for outdoor use only. NEVER operate this unit in an enclosed

area. ALWAYS make certain there is adequate air (oxygen) for combustion as well as

ventilation to prevent the presence of poisonous carbon monoxide gases. Beware

of poorly ventilated areas or exhaust fans which can cause inadequate combustion

or engine overheating.

2. NEVER operate this unit in the presence of ammable vapors or combustible dust,

gases or other combustible materials. (A spark may cause an explosion or re.)

When servicing this machine, be especially careful to properly dispose of any

ammable materials. DO NOT spray ammable liquids.

3. ENGINE FUEL TANK:

a. DO NOT SMOKE WHILE FILLING ENGINE FUEL TANK

b. NEVER ll the engine fuel tank while the unit is running or hot. Allow the engine to

cool two minutes before refueling.

c. DO NOT refuel indoors or in a poorly ventilated area.

d. ALWAYS refuel slowly to avoid the possibility of spilled fuel which may cause a risk

of re.

4. DO NOT operate the unit if gasoline is spilled. Wipe unit clean and move the unit

away from the spill. Avoid creating any ignition until the gasoline has evaporated.

5. DO NOT store the unit near an open ame or any equipment such as a stove, furnace,

water heater, etc., which utilizes a pilot light or devices which can create a spark.

IMPORTANT

WARNING: TO REDUCE THE RISK OF INJURY, READ THIS OPERATOR’S

MANUAL COMPLETELY BEFORE USING. WHEN USING THIS

PRODUCT, THE FOLLOWING BASIC PRECAUTIONS SHOULD ALWAYS

BE FOLLOWED:

The following is required by California State law, Section 4442 of the California Public

Resources Code. Other states may have similar laws. Federal laws apply on federal

lands.

See your engine or equipment dealer for spark arrester mufer options.

IMPORTANT SAFETY INSTRUCTIONS

1. Do not touch mufer or any part of the engine.

2. Use this pump for clean or cloudy water.

3. Use correct type of suction hose.

4. Do not run pump without water inside the pump. This will result in pump damage.

5. Use reinforced suction hose for suction side of the proper size. Please purchase

suitable hose to t to connection diameter and suitable length.

6. Ensure that the suction is securely tightened onto the suction side of the pump.

Centrifugal Pump Operator's Manual 5

Page 6

Safety

7. Replace name plate if damaged/peeled, please

order from dealer.

8. This pump was designed to pump clear water.

Pumping muddy or high contaminants could result

in mechanical seal failure.

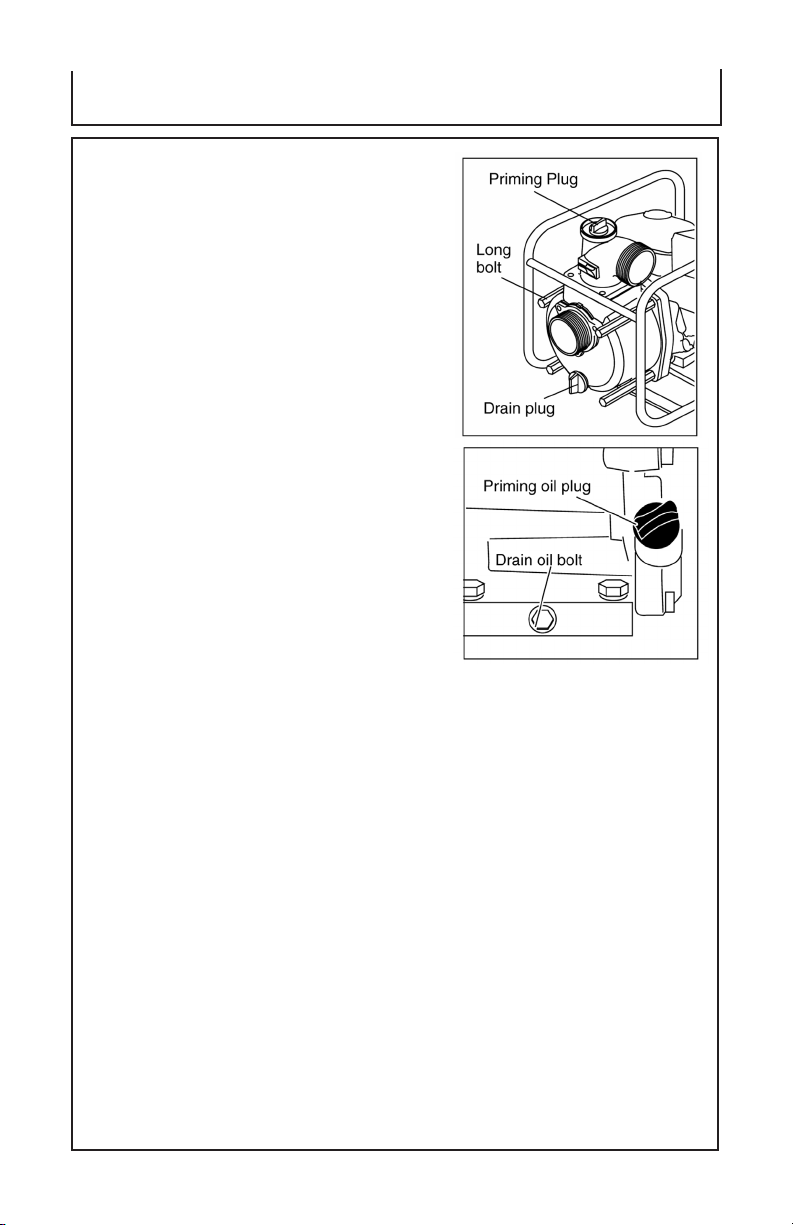

9. Priming: this pump is self-priming, however it still

requires the pump body to be lled with water.

Running the pump without lling with water can

result in mechanical seal failure.

10. Hose connections: If the pump fails to pump

water in a short time, the suction hose connection

could be leaking air. Stop the engine and check

the suction hose connection and re-start the

engine.

11. Drain water from pump after each use, especially if

the temperature will be at or below freezing. Failure

to do so can result in damage to the pump.

12. Suddenly stopping the discharge of water can

result in Water Hammer, which can break the

pump housing.

6 Centrifugal Pump Operator's Manual

Page 7

Pre-Operation

-40°F

-22°F

-4°F

14°F

32°F

50°F

68°F

86°F

104°F

122°F

50°C

40°C

30°C

20°C

10°C

0°C

-10°C

-20°C

-30°C

-40°C

SAE 10W-40

SAE 10W-30

SAE 5W-30

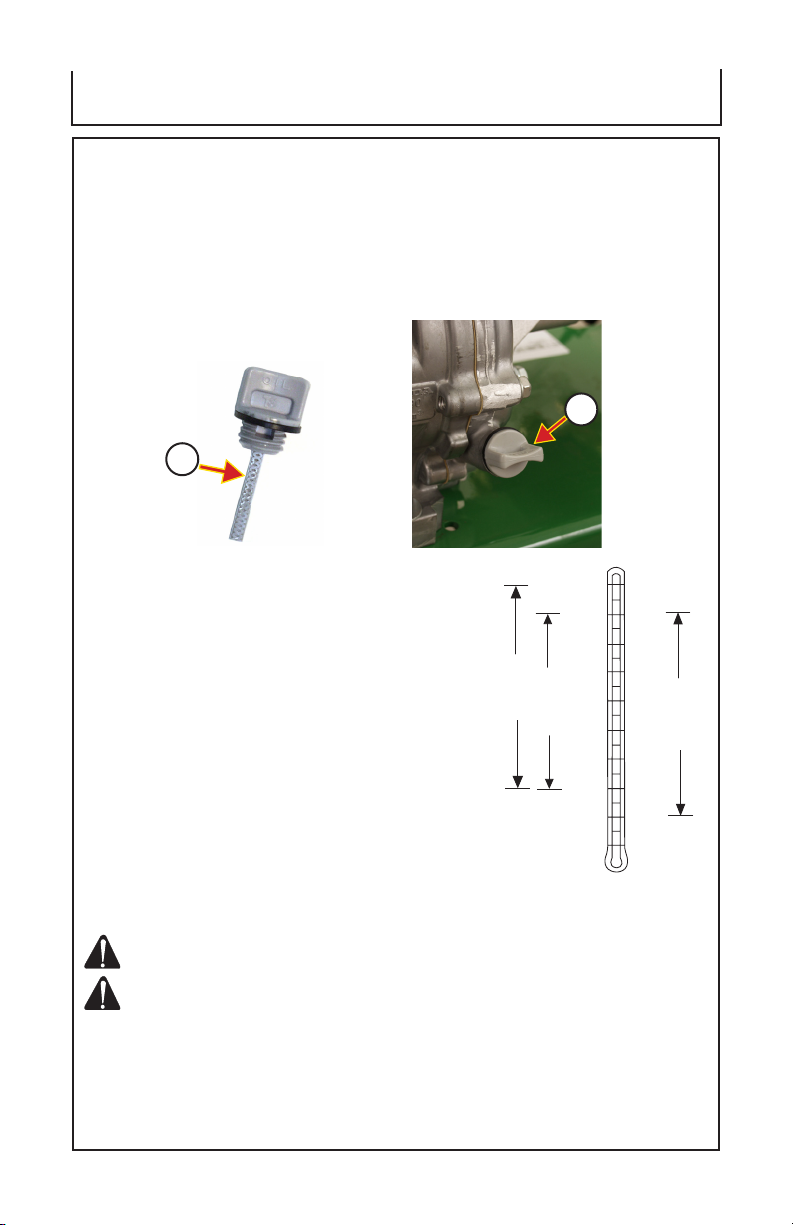

CHECK ENGINE OIL

NOTE: All units are shipped without engine oil. Refer to engine manual to ll.

1. Place unit on level surface.

2. Remove oil ller cap/dipstick (A) and wipe it clean.

3. Insert ller cap/dipstick into oil ller neck, but DO NOT screw it in.

4. Remove dipstick. Proper oil level is at midpoint of dipstick (A). Add oil if necessary

to bring oil level to top of threads (B).

5. Install and tighten cap.

B

A

GASOLINE ENGINE OIL

Use oil viscosity based on the expected air temperature

range during the period between oil changes.

John Deere TURF-GARDTM is preferred. Also recommended is John Deere PLUS-4®.

Other oils may be used if they meet one or more of the

following:

• API Service Classication SH

• API Service Classication SG

• CCMC Specication G4

• CCMC Specication G5

BEFORE USE

1. Engine is shipped without oil. Refer to engine manual for proper oil

specications.

WARNING FLAMMABLE! AVOID FIRE WHEN REFUEL OR MAINTENANCE.

CAUTION FLAMMABLE! DO NOT SMOKE WHEN MIXING FUEL AND REFUEL

Centrifugal Pump Operator's Manual 7

NEAR OPEN FIRE.

ANY FUEL SPILLAGE MUST BE CLEANED COMPLETELY BEFORE

STARTING THE ENGINE.

STOP ENGINE AND WAIT UNTIL THE ENGINE HAS COOLED DOWN

BEFORE REFUELING.

Page 8

Pre-Operation

DO NOT USE OLD FUEL OVER 30 DAYS. FUEL SHOULD BE CLEAN

AND FRESH. FUEL AROUND THE BOTTOM OF DRUM CONTAINS DIRT,

IMPURITIES AND WATER. UNUSED FUEL IN TANK (IF KEPT MORE

THAN 30 DAYS) MAY CAUSE ENGINE FAILURE.

BEFORE STARTING ENGINE, PLEASE CHECK IF ENGINE OIL IS FILLED

TO REQUIRED LEVEL.

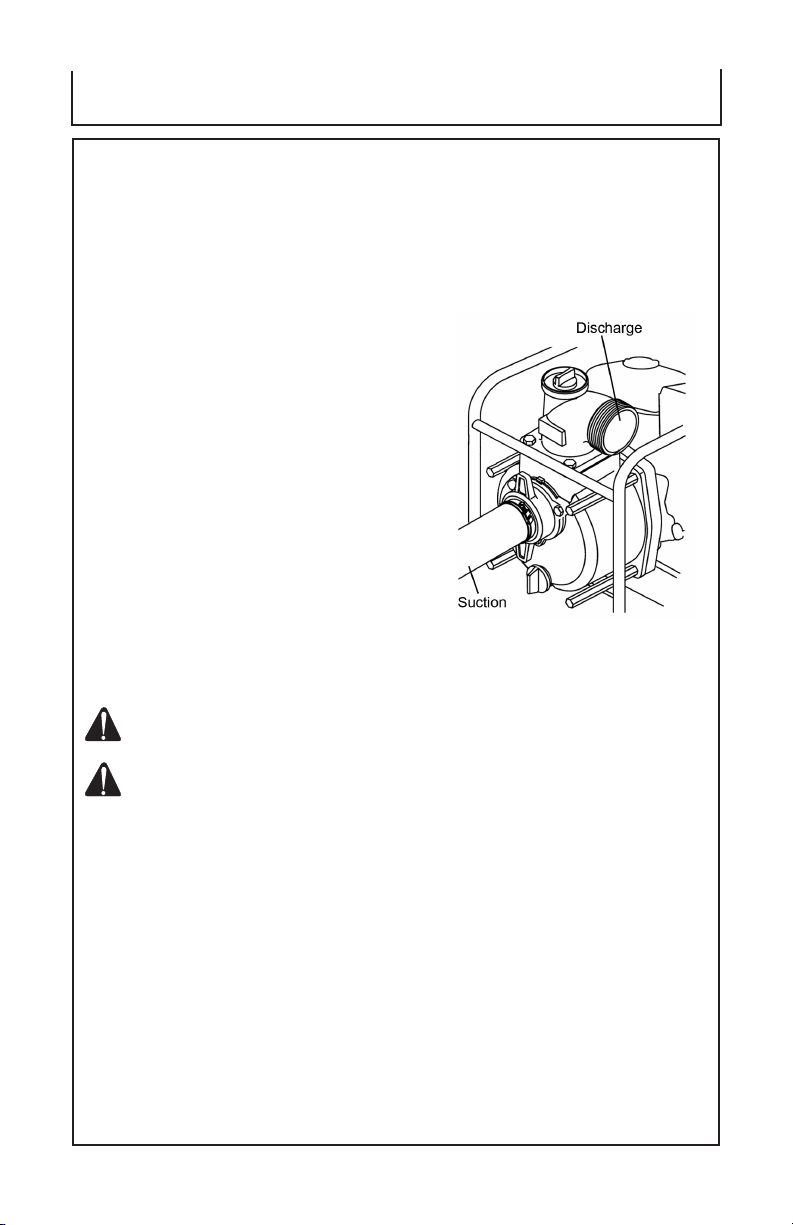

2. Make sure suction hose is connected properly.

Note: Failure to use approved non-collaps-

ible suction hose and recommended

hose strainer at all times during operation of pump will void the warranty

of the pump and engine.

3. Fill pump with water before use.

4. Priming: this pump is self-priming, however it

still requires the pump body to be lled with

water. Running the pump without lling with

water can result in mechanical seal failure.

5. Hose connections: If the pump fails to pump

water in a short time, the suction hose

connection could be leaking air. Stop the engine

and check the suction hose connection and

re-start the engine.

As pump is self-priming type, ll water fully from priming port into pump before running. Insufcient water can cause damage to pump.

CAUTION RUNNING WITHOUT FILLING WITH WATER CAN DAMAGE

MECHANICAL SEAL.

WARNING THIS PUMP IS NOT INTENDED FOR USE WITH CHEMICALS OR

FERTILIZERS. IF USED FOR APPLICATIONS PUMPING CHEMICALS

OR FERTILIZERS, THE 2-YR LIMITED WARRANTY WILL NOT BE

HONORED AS MOST CHEMICALS AND FERTILIZERS WILL CAUSE

PREMATURE CORROSION AND SHORTEN THE LIFE OF THE PUMP.

THE PUMP SHOULD BE FLUSHED WITH CLEAN WATER AFTER

PUMPING ANY LIQUIDS WHICH MAY BE CONSIDERED CAUSTIC OR

CORROSIVE.

8 Centrifugal Pump Operator's Manual

Page 9

Operation

HOW TO USE

1. Ensure pump is fully lled up with water.

2. Ensure strainer at the end of suction hose is in water. (if any mud or sand is at the

3. Ensure no one or anything that can be damaged by water, is not in front of the

bottom of water, suspend hose above the bottom.)

discharge hose end.

STARTING AND OPERATING ENGINE

CAUTION: DO NOT RUN ENGINE IN AN ENCLOSED AREA.

EXHAUST GAS CONTAINS CARBON MONOXIDE, AN

ODORLESS AND POISONOUS GAS THAT CAN CAUSE

SICKNESS OR DEATH.

IMPORTANT: DURING FIRST TWO HOURS OF ENGINE OPERATION,

ENGINE MAY OPERATE AT LOW OR ERRATIC RPM AS THE ENGINE

MOVING PARTS BREAK IN.

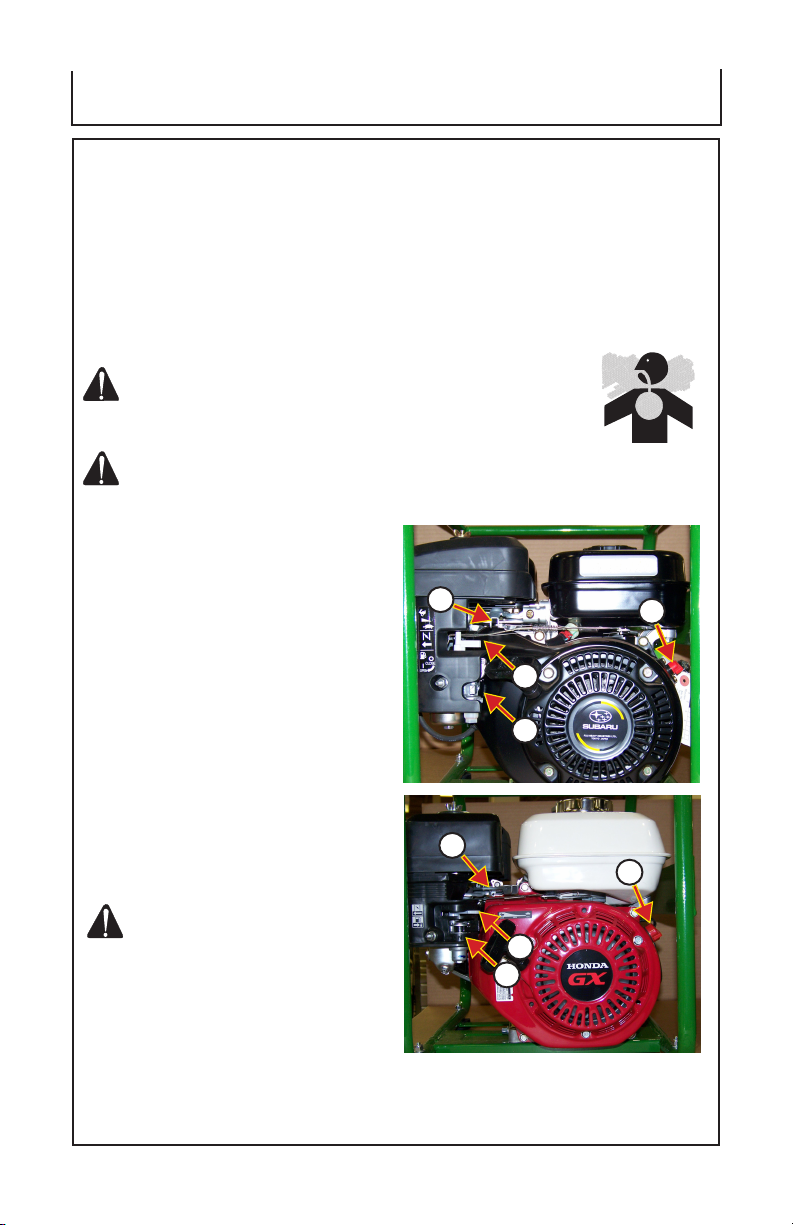

1. Set fuel valve lever (A) right to ON

position.

2. Move choke control lever (B) left to

“CHOKE” position.

NOTE: A warm engine requires less

choking than a cold engine.

3. Move throttle lever (C) left to the fast

position.

NOTE: For best engine performance

it is recommended the engine be

operated with the throttle in the

FAST position.

4. Turn the engine switch (D) to “ON” to

position.

5. Pull recoil starter grip lightly until

resistance is felt, then pull briskly until

engine starts.

C

B

A

C

D

D

IMPORTANT: DO NOT ALLOW

STARTER GRIP TO SNAP BACK

AGAINST ENGINE. RETURN

IT GENTLY TO PREVENT

DAMAGE TO STARTER.

6. Move “CHOKE” control lever (B) right to

open position as soon as engine warms

up enough to run smoothly. If engine is

warm, move choke lever right as soon

as engine starts.

B

A

Centrifugal Pump Operator's Manual 9

Page 10

Operation

STOPPING THE ENGINE

IMPORTANT: TO STOP ENGINE IN EMERGENCY, TURN ENGINE SWITCH (D)

DOWN TO “OFF” POSITION.

1. Move throttle lever (C) fully to the right.

2. Turn engine switch (D) to “OFF” position.

3. Move fuel valve (A) left to “OFF” position.

SHUTDOWN

IMPORTANT: SHUTDOWN PROCEDURES SHOULD BE FOLLOWED AT THE

END OF EACH CLEANING OPERATION.

1. Run engine at idle for 2-3 minutes. (Refer to pictures on previous page)

2. Turn engine off by:

a. Moving throttle lever (A) fully to the right.

b. Turn engine switch (B) to “OFF” position.

c. Move fuel valve (C) left to “OFF” position.

3. Allow engine to cool, then wipe pump down with a damp cloth.

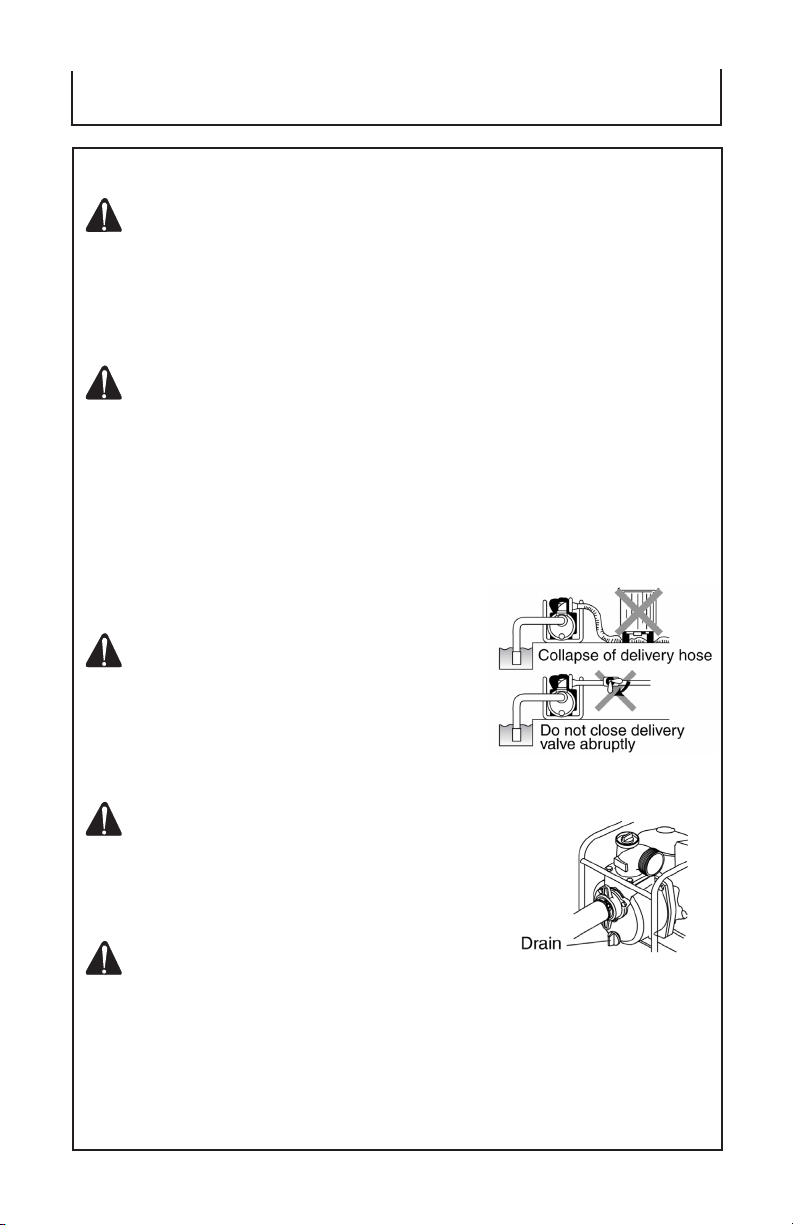

WATER HAMMERING

CAUTION: DO NOT ALLOW ANY VEHICLE TO

RUN OVER THE DELIVERY HOSE. DO NOT

CLOSE THE DELIVERY VALVE ABRUPTLY

BECAUSE WATER-HAMMER MAY OCCUR.

THIS MAY RESULT IN HEAVY DAMAGE TO

THE PUMP.

STORAGE

1. Drain water after use.

CAUTION: WATER TRAPPED INSIDE PUMP WILL

FREEZE AND MAY DAMAGE THE PUMP.

AFTER USE, DRAIN WATER FROM PUMP BY

REMOVING THE DRAIN PLUG AFTER EACH

USE, AND BEFORE STORAGE.

2. Long storage. Refer to engine manual for long term

storage.

CAUTION: DO NOT SMOKE AS FUEL IS HIGHLY

FLAMMABLE.

10 Centrifugal Pump Operator's Manual

Page 11

Trouble Shooting

SYMPTOM PROBLEM SOLUTION

Cannot pull or hard

to pull recoil starter Debris caught in impeller Dismantle & clean impeller

Not enough delivery

volume Air leakage on suction Check suction hose and

side suction connections

Engine not performing Check & repair engine

see John Deere dealer

Damage to mechanical Replace mechanical seal

seal see John Deere dealer

Suction lift is too high Make suction lift lower

Suction hose is too long Shorten suction hose or

or smaller in diameter enlarge diameter

Leakage of water from Stop leakage of water

discharge hose

Worn out impeller Replace the impeller

see John Deere dealer

Pump does not Air goes in from suction Check hose and suction

prime side connections (See Solution 2)

Insufcient priming water Pour more water into

inside pump pump casing for priming

Drain plug is loose Tighten drain plug rmly.

Damage of mechanical seal Replace mechanical seal

see John Deere dealer

Wrong suction hose used Use correct suction hose

Water leakage between engine Damaged mechanical

and pump seal. Replace see John

Deere dealer.

Engine does not Refer to engine manual

start see John Deere dealer

Centrifugal Pump Operator's Manual 11

Page 12

Service

First

Month

or 20

hours

Clean Air Filter X (1)

Change Air Filter X

Change Engine Oil X X

Clean and Gap Spark Plug X

Change Spark Plug X

Clean Sediment Cup X

Adjust Valve Clearance X (2)

Clean Fuel tank and lter X (2)

Check Fuel Tube X (2)

Clean Detergent Strainer X

Clean Inlet Water Screen X

Note: Perform oil change after rst 20 hours of use and then at recommended

intervals. Change engine oil every 25 hours when used under heavy load or

in a high ambient temperatures.

(1) Service more frequently when used in dusty areas.

(2) Should be serviced by authorized dealer unless owner has proper tools and

is mechanically procient.

Every 3

Months

or 50

hours

Every 6

Months

or 100

hours

Every

Year

or 300

hours

CHECK ENGINE OIL

NOTE: All pumps are shipped without engine oil.

1. Stop engine.

2. Place unit on level surface.

3. Remove oil ller cap/dipstick and wipe it clean (B).

4. Insert ller cap/dipstick into oil ller neck, but DO NOT screw it in.

5. Remove dipstick. Proper oil level is at midpoint of dipstick (A). Add oil if necessary

to bring oil level to top of threads.

6. Install and tighten cap.

B

A

12 Centrifugal Pump Operator's Manual

Page 13

Service

-40°F

-22°F

-4°F

14°F

32°F

50°F

68°F

86°F

104°F

122°F

50°C

40°C

30°C

20°C

10°C

0°C

-10°C

-20°C

-30°C

-40°C

SAE 10W-40

SAE 10W-30

SAE 5W-30

CHANGING ENGINE OIL

IMPORTANT: Change oil after rst 20 hours of operation and every 100 hours

thereafter.

1. Put unit on level surface.

2. Run engine a few minutes to warm oil.

3. Stop engine.

4. Remove oil ller cap and drain plug and drain oil into container. Do not pollute,

dispose of waste oil properly.

5. Install drain plug. Fill with oil to top of threads. Install cap.

GASOLINE ENGINE OIL

Use oil viscosity based on the expected air temperature

range during the period between oil changes.

John Deere TURF-GARDTM is preferred. Also recommended is John Deere PLUS-4®.

Other oils may be used if they meet one or more of the

following:

• API Service Classication SH

• API Service Classication SG

• CCMC Specication G4

• CCMC Specication G5

CLEAN AIR FILTER ELEMENT

1. Remove wing nut (A) and remove air cleaner cover. Push lower part of tabs (A) inward

and through tab holders to remove cleaner cover .

2. Remove second wing nut (B) to remove air cleaner assembly.

3. Separate air cleaner elements. Check both elements for holes or tears. Replace if

damaged.

4. Wash foam element (C) in solution of household detergent and warm water. Rinse

thoroughly and allow to dry thoroughly. Soak element in clean engine oil. Squeeze

out excess oil.

NOTE: Engine will smoke during initial start-up if too much oil is left on foam.

5. Remove excess dirt from paper element (D) by tapping lightly on hard surface, or

by blowing compressed air from inside the element. Do NOT brush dirt. Brushing

will force dirt into element bers. Replace paper element after 300 hours, or if

excessively dirty.

6. Install air cleaner in reverse order as removed.

Centrifugal Pump Operator's Manual 13

NOTE: SEE PICTURES ON NEXT PAGE

Page 14

Service

HONDA

A

B

SUBARU

PIC93•102299R0

PIC94-102299R0

C

A

PIC156R•121902R0

B

PIC94R-121902R0

C

D

PIC95-102299R0

PIC95R-121902R0

CLEANING AND GAPPING SPARK PLUG

1. Remove and inspect spark plug. If porcelain is

cracked or electrodes are pitted, install a new

spark plug.

IMPORTANT: DO NOT CLEAN SPARK

PLUG IN A MACHINE USING ABRASIVES.

2. If spark plug is in good condition, clean plug by scraping or using a wire brush.

Wash with a commercial solvent.

3. Use a round wire-type feeler gauge to check for a gap of 0.70 to 0.80 mm (0.028 to

0.031 inches.)

4. Carefully bend outer electrode to adjust gap.

14 Centrifugal Pump Operator's Manual

PIC99-102299R0

Page 15

Service

5. Install spark plug.

Reinstalling used plug: Tighten 1/8 - 1/4 turn after spark plug seats to compress

washer.

Installing new plug: Use NGK BPR6ES

ADJUSTING RPM

1. Start engine. Allow it to warm to normal

operating temperature.

2. Move throttle lever to its minimum position.

3. With engine idling, turn throttle stop screw (A)

to obtain standard idle speed.

NOTE: Standard idle speed is 1250 - 1550

RPM.

NOTE: Idle should be serviced every 300

hours by an authorized dealer. Operator

should adjust only if mechanically procient and using proper tools.

CLEANING SEDIMENT CUP

CAUTION: CLEAN SEDIMENT CUP IN A

WELL VENTILATED AREA, AWAY FROM

SPARKS OR FLAME, INCLUDING ANY

APPLIANCE WITH A PILOT LIGHT. DO NOT

USE GASOLINE OR A LOW FLASH-POINT

SOLVENT TO CLEAN THE FUEL VALVE. A FIRE

OR EXPLOSION COULD RESULT.

NOTE:Clean sediment cup after every 100 hours of use.

1. Turn fuel valve (A) to left as illustrated to shut

off the fuel ow.

2. Remove cap screw (B) with a 10mm wrench.

Remove sediment cup (C) and o-ring.

3. Remove any sediment or other foreign matter

and wash in nonammable or high ash point

solvent. Dry thoroughly.

4. Install o-ring and sediment cup with cap

screw.

5. Turn fuel valve right to “ON” position and check

for fuel leaks.

A

B

A

C

Centrifugal Pump Operator's Manual 15

Page 16

Solutions

Solution 1: Remove debris in impeller. (Do not remove impeller)

Solution 2: Check suction hose. Most cases of lack of priming

or low water ow are caused by air leakage on the suction

side of the pump.

Suction test:

a. Remove suction hose

b. Start engine with water inside the pump.

c. Press the palm of your hand to cover the suction inlet,

hold and wait 30 seconds. If you feel suction on your

palm, the pump is working ne. Check suction hose

and connections.

d. Check if rubber seal is installed.

Note: In case of water

leakage between

engine and pump,

usually the cause is

damaged mechanical seal. Please ask

shop for assistance

and replace mechanical seal.

16 Centrifugal Pump Operator's Manual

Page 17

Accessories

2" DISCHARGE SUCTION KIT: 70-0524

Includes:

• 20' 2" Suction hose (15-0293)

• 50' 2" Discharge hose (15-0295)

• 2" Suction strainer (19-0628)

3" DISCHARGE SUCTION KIT: 70-0525

Includes:

• 20' 3" Suction hose (15-0294)

• 50' 3" Discharge hose (15-0296)

• 3" Suction strainer (19-0629)

Centrifugal Pump Operator's Manual 17

Page 18

Warranty

John Deere warrants all parts, (except those referred to below), of

your new pump to be free from defects in materials and workmanship during the following periods:

For Two (2) Years from the date of original purchase.

Defective parts not subject to normal wear and tear will be repaired

or replaced at our option during the warranty period. In any event,

reimbursement is limited to the purchase price paid.

Exclusions

1. Engine/Motor are covered under separate warranty by its respective manufacturer and is subject to the terms set forth therein.

2. Normal wear parts: Mechanical Seal

3. This warranty does not cover parts damaged due to normal

wear, misapplication, misuse, operation at other than recommended . Failure to follow recommended operating and maintenance

procedures also voids warranty.

4. The use of other than genuine manufacturer repair parts will

void warranty.

5. Parts returned, prepaid to our factory or to an Authorized

John Deere Service Center will be inspected and replaced free

of charge if found to be defective and subject to warranty. There

are no warranties which extend beyond the description of the

face hereof. Under no circumstances shall the manufacturer bear

any responsibility for loss of use of the unit, loss of time or rental,

inconvenience, commercial loss or consequential damages.

For Service or Warranty Consideration, contact

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

563-556-7484 / 800-553-9053 / Fax 563-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

18 Centrifugal Pump Operator's Manual

Page 19

Introduction

CONFORME À LA NORME NMB-002 DU CANADA.

Félicitations de l'achat de votre nouveau la clé à outil! Vous pouvez être assuré que votre

nouveau la outil a été construit avec le plus haut niveau de précision et de abilité. Chaque

composant a été rigoureusement testé par des techniciens pour assurer la qualité, la durabilité

et la performance de ce outil.

Ce manuel opérateur a été dressé pour que vous en retiriez le meilleur parti. Par la

lecture et l'application des mesures simples de sécurité, d'installation et d'opération,

d'entretien et de dépannage décrites dans ce manuel, votre nouveau outil. Fonctionnera

sans faille pendant de nombreuses années. Le contenu de ce manuel est basé sur la

dernière information disponible du produit au moment de la publication. Félicitations

se réserve le droit d'effectuer des changements de prix, de couleur, de matériaux,

d'équipement, de caractéristiques ou de modèles à tout moment sans communication

préalable.

Une fois l'appareil déballé, écrivez immédiatement le numéro de série de votre appareil

dans l'espace çidessous.

NUMÉRO DE SÉRIE_________________________________

Assurez vous qu'il n'y a pas de signes de dommages évidents ou cachés suite au transport.

En cas de dommage, remplissez immédiatement une réclamation avec la compagnie de

transport. Assurez vous que toutes les pièces endommagées sont remplacees et les

problémes mécaniques et électriques corrigés avant l'utilisation de l'appareil. Si vous avez

besoin d'assistance, entrez en contact avec votre service clientèle.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068-0050

Tél.: JD-KLEEN (1-877-535-5336) Fax 563-556-1235

du lundi au vendredi de 8h00 à 17h, CST (heure centrale)

Veuillez avoir les informations suivantes disponibles pour toute intervention:

1. Numéro de modèle

2. Numéro de série

3. Date et lieu d'achat

WARNING/AVERTISSEMENT

RISK OF BURNS:

HOT SURFACES.

MUFFLER AND

ADJACENT AREAS

MAY EXCEED 150°F.

RISQUE DE BRULURES:

SURFACES CHAUDES LE

TUYAU D'ÉCHAPPEMENT ET

LES RÉGIONS ADJACENTES

PEUVENT DÉPASSER LES 65°C.

34-0767-E/F-052901-ENG.

AVERTISSEMENT: Ce produit contient

du plomb, un produit chimique qui est

connu par l'état de Californie comme

étant la cause de cancer et de

malformations congénitales ou autres

effets nocifs de reproduction.

Laver vos mains après avoir manipulé ce produit.

THIS SPARK IGNITION SYSTEM COMPLIES WITH

CANADIAN ICES-002.

CE SYSTÈME D’ALLUMAGE PAR ÈTINCELLE EST

Centrifugal Pump Operator's Manual 19

Page 20

Table des matières

INTRODUCTION .......................................................................... 19

SÉCURITÉ .................................................................................... 21

AVERTISSEMENT DE SÉCURITÉ LORS

DU RAVITAILLEMENT EN CARBURANT ............................ 22

INSTRUCTIONS IMPORTANTES DE SÉCURITÉ ............... 23

PRE-FONCTIONNEMENT. ........................................................... 24

VÉRIFICATION DE L’HUILE À MOTEUR ............................. 24

HUILE À MOTEUR À ESSENCE ......................................... 24

AVANT L’UTILISATION .................................................................. 24

FONCTIONNEMENT .................................................................... 26

COMMENT UTILISER ......................................................... 26

COUP DE BÉLIER .............................................................. 26

ENTREPOSAGE ................................................................. 26

DÉMARRAGE DU MOTEUR ............................................... 26

ARRÊT DU MOTEUR .......................................................... 27

ARRÊT DE L’APPAREIL DE LAVAGE ET DU MOTEUR ...... 28

DÉPANNAGE ............................................................................... 29

SERVICE ....................................................................................... 30

SOLUTIONS ................................................................................. 34

ACCESSORIES ............................................................................. 35

GARANTIE ....................................................................................36

20 Centrifugal Pump Operator's Manual

Page 21

SÉCURITÉ

RECONNAÎTRE LES SYMBOLES DE MISE

EN GARDE

Voici le symbole de mise en garde. Lorsqu'il apparaît sur

la outil ou dans la présente publication, c'est pour prévenir

d'un risque potentiel de blessure.

Respecter tous les conseil de sécurité ainsi que les consignes générales de prévention des accidents.

COMPRENDRE LES TERMES DE MISE EN

GARDE

Les avertissements de sécurité "DANGER, AVERTISSEMENT

ou ATTENTION" seront entourés par un "ENCADRE ALERTE

SECURITE".Cet encadré est utilisé pour indiquer et souligner

les avertissements de sécurité qui doivent être suivis en

actionnant d'outils. En plus des avertissements de sécurité,

des "mots d'alerte" sont utilisés pour indiquer le degré ou

niveau de risque. Les "mots d'alerte" utilisés dans ce manuel

sont comme suit:

DANGER: INDIQUE UNE SITUATION AU DANGER

IMMINENT QUI, SI ELLE N'EST PAS ÉVITÉE,

ENTRAINERA LA MORT OU DES BLESSURES

GRAVES

.AVERTISSEMENT: INDIQUE UNE SITUATION

POTENTIELLEMENT DANGEREUSE QUI, SI ELLE

N'EST PAS ÉVITÉE, POURRAIT ENTRAÎNER LA

MORT OU DES BLESSURES GRAVES.

ATTENTION: INDIQUE UNE SITUATION

POTENTIELLEMENT DANGEREUSE,QUI, SI

ELLE N'EST PAS ÉVITÉE, PEUT ENTRAÎNER

DES BLESSURES MINEURES OU PEU GRAVES

ET DES DÉGATS AU COMPRESSEUR.

LISEZ LES INSTRUCTIONS D’UTILISATION

Familiarisez vous toujours avec l’ensemble des instructions

et avertissements avant de faire fonctionner tout outil.

UNE UTILISATION INCORRECTE OU DANGEREUSE DE

CET OUTIL MOTORISÉ PEUT ENTRAÎNER LA MORT OU

DE SÉRIEUSES BLESSURES COPORELLES! CE MODE

D'EMPLOI CONTIENT D'IMPORTANTES INFORMATIONS

À PROPOS DE LA SÉCURITÉ DE CE PRODUIT. PRIÈRE

DE LIRE ET DE COMPRENDRE CE MODE D'EMPLOI

AVANT D'UTILISER L'OUTIL MOTORISÉ.

Garder ce mode d'emploi à la disponibilité des autres

utilisateurs et propriétaires avant qu'ils utilisent l'outil

motorisé. Ce mode d'emploi doit être conservé dans un

endroit sûr.

Centrifugal Pump Operator's Manual 21

Page 22

SÉCURITÉ

IMPORTANT

MESURES DE PRÉCAUTIONS-INCENDIE & VENTILATION

1. Cet appareil n'a été conçu que pour utilisation à l'extérieur. N'utilisez JAMAIS cet

appareil dans un lieu clos. Assurez-vous toujours qu'il y a assez d'air (oxygène)

pour la combustion ainsi que pour la ventilation an d'éviter la présence de gaz

dangereux d'oxyde de carbone. Méez-vous des secteurs mal aérés ou des

ventilateurs qui peuvent causer une combustion insufsante ou un surchauffement

du moteur.

2. N'utilisez JAMAIS l'appareil en présence de vapeurs inammables ou de poussières

combustibles, de gaz ou d'autres matériaux combustibles (Une étincelle pourrait

causer une explosion ou un incendie.) Pendant l'entretien de l'appareil, faites

particulièrement attention à vous débarrasser correctement de tous matériaux

inammables. NE JAMAIS pulvériser de liquides inammables.

3. RÉSERVOIR DE CARBURANT DU MOTEUR:

a. NE JAMAIS FUMER EN REMPLISSANT LE RÉSERVOIR DE CARBURANT DU

MOTEUR.

b. NE JAMAIS remplir le réservoir de carburant du moteur pendant que l'appareil

marche ou est chaud. Permettre au moteur de refroidir pendant deux minutes

avant le réapprovisionnement en carburant.

c. NE PAS réapprovisionner en carburant à l'intérieur ou dans un secteur mal

aéré.

d. Remplisser TOUJOURS le réservoir de carburant lentement pour éviter que

du carburant ne soit renversé, ce qui pourrait causer un risque d'incendie.

4. NE PAS se servir de l'appareil si de l'essence est renversée. Essuyez l'appareil

et éloignez-le de la aque. Evitez de créer toute sorte d'ignition jusqu'à ce que

l'essence se soit evaporée.

5. NE rangez PAS l'appareil près d'une amme ou d'un équipement tel qu'un four, un

fourneau, un chauffe-eau, etc., équipé d'une lampe témoin ou de dispositifs qui

peuvent créer une étincelle.

IMPORTANT

Ce qui suit est requis par la Loi d'Etat de Californie, Section 4442 du Code de Resources Publiques de Californie. D'autres états ont peut être des lois semblables..

Les Lois Fédérales s'appliquent sur les terres fédérales.

UN ÉCLATEUR DOIT ÊTRE AJOUTÉ AU SILENCIEUX DE CET APPAREIL SI IL

VA SERVIR SUR TOUTE TERRE NON AMENDÉ COUVERTE DE FORÊT,

DE BROUSSAILLE OU D'HERBE. L'ÉCLATEUR DOIT ÊTRE MAINTENU

EN BONNE CONDITION DE MARCHE PAR L'UTILISATEUR.

Voir votre concessionnaire de moteur ou d'équipement pour vos options d'éclateur

pour silencieux.

22 Centrifugal Pump Operator's Manual

Page 23

SÉCURITÉ

INSTRUCTIONS IMPORTANTES DE MISE EN GARDE

1. Ne pas toucher le pot d’échappement ou toute partie du moteur.

2. Se servir de cette pompe pour de l’eau propre

ou de l’eau d’nuageux.

3. Se servir du bon type de tuyau aspirateur.

4. Ne pas faire fonctionner la pompe sans eau à

l’intérieur de la pompe. Ceci endommagera la

pompe.

5. Utiliser le tuyau aspirateur du coté aspiration.

Acheter un tuyau approprié pour le diamètre de

raccord et de la bonne longueur.

6. Raccorder fermement le tuyau avec le raccord

et le collier de serrage lors du raccord du tuyau

d’aspiration ou de refoulement à la pompe.

7. Remplacer la plaque de fabrication si elle est

endommagée/détachée. Ordre de revendeur.

8. Cette pompe a été conçue pour pomper l'eau

propre ou nuageuse. Le pompage de l'eau

boueuse ou haute de retenue a pu avoir comme

conséquence l'échec de joint mécanique.

9. Amoricage : cette pompe est auto-amorçante,

toutefois elle exige toujours du corps de la pompe

d'être rempli avec de l'eau. Le fonctionnement

de la pompe sans remplir avec de l'eau peut

avoir comme conséquence l'échec de joint

mécanique.

10. Raccordements de tuyau : Si la pompe ne pompe pas l'eau en peu de temps, le

raccordement de tuyau d'aspiration pourrait couler l'air. Arrêtez le moteur et vériez

le raccordement de tuyau d'aspiration et remettez en marche le moteur.

11. Évacuez l'eau la pompe après chaque utilisation, particulièrement si la température sera

à ou au-dessous de zéro. Le manque de faire ainsi peut avoir comme conséquence les

dommages à la pompe.

12. Soudainement l'arrêt de la décharge de l'eau peut avoir comme conséquence le coup

de bélier, qui peut casser le logement de pompe.

Centrifugal Pump Operator's Manual 23

Page 24

PRE-FONCTIONNEMENT

-40°F

-22°F

-4°F

14°F

32°F

50°F

68°F

86°F

104°F

122°F

50°C

40°C

30°C

20°C

10°C

0°C

-10°C

-20°C

-30°C

-40°C

SAE 10W-40

SAE 10W-30

SAE 5W-30

VÉRIFICATION DE L’HUILE À MOTEUR

REMARQUE: Tous les appareils de lavages sont expédiés avec l’huile à moteur.

Vérier le niveau d’huile.

1. Placer l’appareil de lavage sur une surface plane.

2. Retirer le bouchon de remplissage d’huile/jauge (A) et l’essuyer.

3. Remettre la jauge d’huile dans le moteur mais NE PAS resserrer.

4. Retirer la jauge. Le niveau d’huile devrait être au repère au milieu de la jauge (A).

Ajouter de l’huile au besoin pour que le niveau d’huile arrive à la partie supérieure

du letage (B).

5. Installer et resserrer le bouchon de remplissage.

B

A

HUILE À MOTEUR À ESSENCE

Déterminer la viscosité de l’huile d’aprés la gamme de

température prévue durant la période entre les vidanges

d’huile.

L’huile suivante est recommandée.

• TURF-GARD

est également recommandée:

• PLUS-4® de John Deere D’autres huiles

peuvent être utilisées si elles répondent à

une ou plusieurs des normes suivantes:

• Classication de service API-SH

• Classication de service API-SG

• CCMC - Spécication G4

• CCMC - Spécication G5

MD

de John Deere L’huile suivante

AVANT L’UTILISATION

1. Engine is shipped without oil. Refer to engine manual for proper oil

specications.

AVERTISSEMENT: FLAMMABLE! EVITER TOUT FEU OU FLAMME LORS DU

RAVITAILLEMENT EN CARBURANT OU DE L’ENTRETIEN.

ATTENTION: FLAMMABLE! NE PAS FUMER LORS DU MÉLANGE DE

24 Centrifugal Pump Operator's Manual

CARBURANT ET NE PAS RAVITAILLER EN CARBURANT PRÈS D’UN

FEU DIRECT.

Page 25

PRE-FONCTIONNEMENT

TOUT DÉVERSEMENT DE CARBURANT

DOIT ÊTRE COMPLÈTEMENT

NETTOYÉ AVANT DE DÉMARRER LE

MOTEUR.

METTRE LE MOTEUR À L’ARRÊT ET

ATTENDRE QU’IL REFROIDISSE AVANT

LE RAVITAILLEMENT EN CARBURANT.

NE PAS UTILISER DE CARBURANT

ÂGÉ DE PLUS DE 30 JOURS. LE

CARBURANT DOIT ÊTRE PROPRE ET

FRAIS.

AVANT DE DÉMARRER LE MOTEUR,

VÉRIFIER QUE L’HUILE DU MOTEUR

EST BIEN REMPLIE JUSQU’AU BON

NIVEAU.

2. S’assurer que le tuyau aspirateur est raccordé correctement.

Note : Le manque d'utiliser le tuyau non-collapsible approuvé d'aspiration et le

tamis recommandé de tuyau à tout moment lors du fonctionnement de la

pompe videra la garantie de la pompe et du moteur.

3. Remplir la pompe avec de l’eau avant son utilisation.

4. Amoricage : cette pompe est auto-amorçante, toutefois elle exige toujours du corps

de la pompe d'être rempli avec de l'eau. Le fonctionnement de la pompe sans remplir

avec de l'eau peut avoir comme conséquence l'échec de joint mécanique.

5. Raccordements de tuyau : Si la pompe ne pompe pas l'eau en peu de temps, le

raccordement de tuyau d'aspiration pourrait couler l'air. Arrêtez le moteur et vériez

le raccordement de tuyau d'aspiration et remettez en marche le moteur.

Comme cette pompe est à amorçage automatique, il est nécessaire de complètement remplir d’eau l’orice d’amorçage avant le fonctionnement. Une quantité d’eau

insufsante peut endommager la pompe.

ATTENTION: LE FAIT D’UTILISER LA POMPE SANS LA REMPLIR D’EAU

PEUT ENDOMMAGER LA GARNITURE MECANIQUE.

CETTE POMPE N'EST PAS PRÉVUE POUR L'USAGE AVEC DES PRODUITS

CHIMIQUES OU DES ENGRAIS. SI UTILISÉ POUR DES APPLICATIONS

POMPANT DES PRODUITS CHIMIQUES OU DES ENGRAIS, LA

GARANTIE LIMITÉE DE 2 ANNÉES NE SERA PAS HONORÉE CAR LA

PLUPART DES PRODUITS CHIMIQUES ET ENGRAIS CAUSERONT

LA CORROSION PRÉMATURÉE ET RACCOURCIRONT LA VIE DE LA

POMPE. LA POMPE DEVRAIT ÊTRE RINCÉE AVEC DE L'EAU PROPRE

APRÈS POMPAGE DE TOUS LES LIQUIDES QUI PEUVENT ÊTRE

CONSIDÉRÉS CAUSTIQUE OU CORROSIVE."

Centrifugal Pump Operator's Manual 25

Page 26

FONCTIONNEMENT

COMMENT UTILISER

1. S’assurer que la pompe est complètement remplie d’eau.

2. S’assurer que le tamis au bout du tuyau aspirateur est dans l’eau.

3. S’assurer qu’il n’y a aucun obstacle du coté du tuyau de

COUP DE BELIER

ENTREPOSAGE

1. Vider l’eau après l’utilisation.

2. Entreposage de longue durée. Tout carburant dans le réservoir

(S’il y a de la boue ou du sable au fond de l’eau, suspendre le

tuyau pour éviter le fond).

refoulement.

ATTENTION: NE LAISSER AUCUN

VEHICULE ROULER SUR LE TUYAU DE

REFOULEMENT. NE PAS BRUSQUEMENT

FERMER LE CLAPET DE REFOULEMENT

CE QUI POURRAIT OCCASIONNER

UN COUP DE BELIER ET GRAVEMENT

ENDOMMAGER LA POMPE.

ATTENTION: L’EAU À L’INTÉRIEUR DE

LA POMPE PEUT GELER À DES

TEMPÉRATURES INFÉRIEURES À 0°C

EN HIVER ET PEUT ENDOMMAGER LA

POMPE. APRÈS L’UTILISATION, VIDER

L’EAU DU BOUCHON DE VIDANGE AVANT

L’ENTREPOSAGE.

ou dans le carburateur doit être complètement vidé. Le carburant

inutilisé dans le réservoir (s’il est conservé pendant plus de 30

jours) peut être la cause d’une défaillance du moteur.

ATTENTION: NE PAS FUMER CAR LE CARBURANT EST

HAUTEMENT INFLAMMABLE.

DÉMARRAGE DU MOTEUR

ATTENTION: NE PAS FAIRE FONCTIONNER LE MOTEUR

À L’INTÉRIEUR. LES FUMÉES D’ÉCHAPPEMENT

CONTIENNENT DE L’OXYDE DE CARBONE, UN GAZ

TOXIQUE ET SANS ODEUR.

IMPORTANT: DURANT LE DEUX PREMIÈRES HEURES

D’OPÉRATION DU MOTEUR, LE MOTEUR PEUT

FONCTIONNER À UN RÉGIME FAIBLE OU ERRATIQUE

PENDANT LA PÉRIODE DE RODAGE DES PIÈCES

MOBILES.

26 Centrifugal Pump Operator's Manual

Page 27

FONCTIONNEMENT

1. Placer le levier d’alimentation en

2. Déplacer le levier du volet de départ

3. Déplacer la manette d’accélération (C)

4. Déplacer le contacteur de moteur (D)

5. Tirer doucement sur la corde de

carburant (A) à la position «ON»

(départ).

(B) à la position «CHOKE» (volet de

départ).

REMARQUE: Habituellement, il n’est

pas nécessaire d’ouvrir le volet

d’air autant pour un moteur

chaud que pour un moteur froid.

légèrement vers la gauche.

à la position «ON» (départ).

lancement jusqu’à ce qu’une résistance

se fasse sentir et tirer ensuite rapidement

jusqu’à ce que le moteur démarre.

C

B

A

C

D

D

IMPORTANT: NE PAS LAISSER LA

POIGNÉE DU DÉMARREUR

RETOURNER BRUSQUEMENT

AU MOTEUR. LA REMETTRE

EN PLACE DOUCEMENT

POUR NE PAS ENDOMMAGER

LE DÉMARREUR.

6. Déplacer la manette de contrôle du

starter (B) vers la droite en position ouverte dès que le moteur est assez réchauffé

pour bien tourner. Si le moteur est chaud, déplacer la manette du starter vers la

droite dès que le moteur démarre.

B

A

ARRÊT DU MOTEUR

IMPORTANT: POUR ARRÊTER LE MOTEUR EN CAS D’URGENCE, TOURNER

LA MANETTE D’ACCÉLÉRATION VERS LE BAS (D) À LA POSITION

«STOP» (ARRÊT).

1. Déplacer la manette d’accélération (C) complètement vers la droite.

2. Tourner le contacteur du moteur (D) à la position «OFF» (arrêt).

3. Déplacer le levier d’alimentation en carburant (A) vers la gauche à la position «OFF»

(arrêt).

4. Appuyer sur la gâchette pour éliminer la pression.

ARRÊT DE L’APPAREIL DE LAVAGE ET DU MOTEUR

IMPORTANT: LES PROCÉDURES D’ARRÊT DEVRAIENT ÊTRE SUIVIES À LA

FIN DE CHAQUE OPÉRATION DE NETTOYAGE.

Centrifugal Pump Operator's Manual 27

Page 28

FONCTIONNEMENT

1. Faire tourner le moteur au ralenti pendant 2-3 minutes.

2. Arrêter le moteur

a. Déplacant la manette d’accélération (A) complètement vers la droite.

b. Tourner le contacteur de moteur (B) à la position «OFF» (arrêt)

c. Déplacer la soupape de carburant (C) vers la gauche à la position «STOP»

(ARRÊT).

3. Laisser le moteur refroidir et ensuite essuyer avec un chiffon humide.

28 Centrifugal Pump Operator's Manual

Page 29

Dépannage

SYMPTÔME

Le lanceur à rappel est

difcile ou impossible à

tirer.

Pas assez de volume de

refoulement

La pompe n’amorce pas

l’eau

PROBLÈME

Obstacles dans la roue à

aubes

Fuite d’air du coté aspiration

Puissance fournie du moteur

faible

Garniture mécanique endommagée

Hauteur d’aspiration est

élevée

Le tuyau d’aspiration est

trop long ou trop petit de

diamètre

Fuite d’eau du tuyau ou conduit de refoulement

Obstacles dans la roue à

aubes

Usure de la roue à aubes

De l’air rentre par le coté

aspiration

Quantité d’eau d’amorçage

dans le corps de la pompe

insufsante

Le bouchon de vidange

n’est pas serré

Garniture mécanique endommagée

SOLUTION

Démonter et nettoyer la roue

à aubes

Vérier la tuyauterie du coté

aspiration (voir solution 2)

Vérier réparer le moteu

Remplacer mécanique endommagée

Hauteur d’aspiration est

élevée

Le tuyau d’aspiration est

trop long ou trop petit de

diamètre

Vérier et arrêt Fuite d’eau

Démonter et nettoyer la roue

à aubes (voir solution 1

Remplacer de roue à aubes)

Vérier la tuyauterie du coté

aspiration (voir solution 2)

Verser plus d’eau dans le

corps de la pompe pour

l’amorcer. (Consulter la partie Avant le Fonctionnement

5)

Serrer le bouchon de vidange fermement.

.

Remplacer mécanique endommagée

Mauvais tuyau aspirateur est

utilisé

Utiliser correctement le

tuyau aspirateur.

Centrifugal Pump Operator's Manual 29

Page 30

SERVICE

CALENDRIER premier

mois

ou 20

heures

Nettoyer le ltre à air X (1)

Changer le ltre à air X

Vidanger l’huile à moteur X X

Nettoyer et régler l’écartement

des bougie

Changer la bougie d’allumgae X

Régler le jeu des soupapes X

Régler le jeu de soupape X (2)

Nettoyer le réservoir de carbu-

rant.

Inspecter le conduit de carburant X (2)

Nettoyer la crépine du tuyau-

siphon

Nettoyer la crépine

d’alimentation

Note: Faire la vidange d’huile après 20 heures d’utilisation et par la suite aux

intervalles recommandés. Changer l’huile toutes les 25 heures lors d’une

utilisation sous de fortes charges ou sous des températures ambiantes

élevées.

(1) Faire l’entretien plus fréquemment lorsque la machine est utilisée dans des

endroits poussiéreux.

(2) L’entretien devrait être effectué par un concessionnaire agréé à moins que le

propriétaire posséde les outils appropriés et soit un mécanicien compétent.

tous les

3 mois

ou 50

heures

tous les

6 mois

ou 100

heures

X

X (2)

X

X

haque

année

ou 300

heures

VÉRIFICATION DE L’HUILE Á MOTEUR

1. Arrêter le moteur.

2. Placer l’appareil de lavage sur

une surface plane.

3. R e t i rer l e bouchon d e

remplissage d’huile/jauge et

l’essuyer.

4. Remettre la jauge d’huile dans

le col de remplissage mais NE

PAS resserrer.

5. Retirer la jauge. Le niveau d’huile devrait être au repére

au milieu de la jauge (A). Ajouter de l’huile au besoin

pour que le niveau d’huile arrive à la partie supérieure du letage (B).

6. Installer et resserrer le bouchon de remplissage.

30 Centrifugal Pump Operator's Manual

A

B

Page 31

SERVICE

-40°F

-22°F

-4°F

14°F

32°F

50°F

68°F

86°F

104°F

122°F

50°C

40°C

30°C

20°C

10°C

0°C

-10°C

-20°C

-30°C

-40°C

SAE 10W-40

SAE 10W-30

SAE 5W-30

VIDANGE DE L’HUILE À MOTEUR

IMPORTANT: Vidanger l’huile à moteur après les 20 premières heures

d’utilisation et par la suite prolonger l’intervalle entre les vidanges à 100

heures.

1. Placer l’appareil sur une surface plane.

2. Faire fonctionner le moteur pendant quelques minutes pour réchauffer l’huile.

3. Arrêter le moteur.

4. Déposer le bouchone de remplissage (C) et le bouchon de vidange (B) d’un côté du

moteur et vidanger l’huile dans un récipient. Ne pas polluer, éliminer l’huile usagée

correctement.

5. Installer le bouchon de vidange (C). Remplir d’hile jusqu’à la partie supérieure du

letage. Installer le bouchon de remplissage.

HUILE À MOTEUR À ESSENCE

Déterminer la viscosité de l’huile d’après la gamme de

température prévue durant la période entre les vidanges

d’huile.

L’huile suivante est recommandée:

• TURF-GARDMD de John Deere L’huile suivante

est également recommandée:

• PLUS-4® de John Deere D’autres huiles

peuvent être utilisées si elles répondent à

une ou plusieurs de normes suivantes:

• Classication de service API-SH

• Calssication de service API-SG

• CCMC Spécication G4

• CCMC Spécication G5

ENTRETIEN DU FILTRE À AIR

1. Retirer l’écrou papillon (A) et déposer le couvercle.

2. Retirer le deuxième écrou papillon (B) pour déposer l’ensemble de ltre à air.

3. Séparer les éléments du ltre à air. Véer les deux éléments pour s’assurer qu’ils

ne comportent aucun trou ou déchirure. Les remplacer s’ils sont endommagés.

4. Laver l’éléments en mousse (C) dans un détergent liquide et de l’eau. Rincer à fond

avec de l’eau courante et laisser sécher complètement à l’air avant de réinstaller.

Faire tremper l’élément dans de l’huile à moteur nouvelle et exprimer l’excédent.

REMARQUE: Le moteur produira de la fumée la première fois que l’appareil sera

5. Enlever l’excès de poussière sur l’élément en papier (D) en donnant de petits coups

6. Installer le ltre à air en suivant les étapes de dépose dans l’order inverse.

Centrifugal Pump Operator's Manual 31

utilisé si vous laissez trop d’huile sur l’élément en mousse.

sur une surface dure ou en envoyant de l’air comprimé à l’intérieeur de l’élément.

NE PAS brosser l’élément. Le brossage forcera la saleté dans les bres de l’élément.

Remplacer l’élément en papier après 300 heures ou s’il est très sale.

Page 32

SERVICE

HONDA

A

B

SUBARU

PIC93•102299R0

PIC94-102299R0

C

A

PIC156R•121902R0

B

PIC94R-121902R0

C

D

PIC95-102299R0

PIC95R-121902R0

NETTOYAGE ET ÉCARTEMENT DE LA BOUGIE D’ALLUMAGE

1. Déposer et inspecter la bougie d’allumage.

Si la porcelaine est fendillé ou les électrodes

sont corrodés, installer une nouvelle bougie

d’allumage..

IMPORTANT: Ne pas nettoyer la bougie dans une machine utilisant un nettoyeur

abrasif.

2. Si la bougie est en bonne condition, la nettoyer en grattant ou en utilisant une brosse

métallique. Laver avec un solvant commercial.

3. Utiliser une jauge d’épaisseur de type à l rond pour obtenir un écartement de 0,

70-0, 80 mm (0.028-0.031 po).

32 Centrifugal Pump Operator's Manual

PIC99-102299R0

Page 33

SERVICE

4. Plier seulement l’électrode extérieur lorsque vous réglez l’écartement.

5. Installer la bougie d’allumage.

Installation de la bougie usagée: Tourner 1/8-1/4 de tour après avoir placé la bougie

pour comprimer l’appareil de lavage.

Installation d’une nouvelle bougie: Utiliser une bougie NGK BPR6ES

RÉGLAGE DU RÉGIME MOTEUR

1. Faire démarrer le moteur. Le laiser réchauffer à

une température normale d’opéracion.

2. Placer le levier d’accélérateur en position

minimum.

3. Avec le moteur tournant au ralenti, tourner la vis

de butée (A) de la manette d’accélération pour

obtenir une marche au ralenti standard.

REMARQUE: La marche au ralenti standard est de 1250-1550 tr/min.

REMARQUE: L’entretien de la marche au ralenti devrait être exécuté à toutes les

300 heures par un concessionnaire agréé. L’utilisateur devrait effectuer un

réglage seulement s’il possède les outils appropriés et qu’il est un mécanicien

compétent.

NETTOYAGE DU BOL DE SÉDIMENTATION

ATTENTION: NETTOYER LE BOL DE

SÉDIMENTATION DANS UN ENDROIT BIEN

AÉRÉ, LOIN DES ÉTINCELLES OU DES

FLAMMES INCLUANT TOUT APPAREIL

COMPORTANT UNE VEILLEUSE. NE PAS

UTILISER D’ESSENCE OU UN SOLVANT À

POINT D’ÉCLAIR FAIBLE POUR NETTOYER LA

SOUPAPE DE CARBURANT. UN INCENDIE OU

UNE EXPLOSION POURRAIT EN RÉSUTLER.

REMARQUE: Nettoyer le bol de sédimentation

après chaque 100 heures d’utilisation.

1. Tourner la soupape de carburant (A) vers la gauche,

tel qu’illustré pour arrêter le débit de carburant.

2. Enlever la vis à tête hexagonale (B) avec une clé

de 10 mm et déposer le bol de sédimentation (C)

et le joint torique.

3. Enlever tout sédiment ou autres corps étrangers

et laver dans un solvant à point d’éclair élevé ou

ininammable. Bien sécher.

4. Installer le joint torique et le bol de sédimentation

avec la vis à tête hexagonale.

5. Tourner la soupape de carburant vers la droite à

la position «ON» (marche) et vérier pour des fuites de carburant.

A

A

C

B

Centrifugal Pump Operator's Manual 33

Page 34

Solutions

Solution 1: Retirer tout obstacle de la roue à aubes. (Ne retirer pas la roue)

Solution 2: Vérifier le

tuyau d’aspiration.

Une fuite d’air du

coté aspiration est en

général la cause d’un

manque d’aspiration

ou d’un refoulement

faible.

Dans tel cas:

a. Retirer le tuyau aspirateur

b. Démarrer le moteur avec de l’eau à l’intérieur de la pompe.

c. Couvrir le trou d’aspiration, dont le tuyau a été détaché, sur le coté de la

pompe en appuyant avec la paume de votre main et attendre 30 secondes.

S’il y a effet de succion sur votre paume, la pompe marche correctement

mais le tuyau n’a pas été raccordé correctement. Le rattacher correctement.

d. Vérier que le joint de caoutchouc est en place et qu’il n’y a pas de trou sur

le tuyau aspirateur.

S’assurer que la bougie n’est pas mouillée ou tachée. Nettoyer la bougie avec un

chiffon si elle s’avère mouillée ou tachée. Vérier l’écartement des bougies.

L’écartement doit être de 0.6 à 0.7mm. Régler l’écartement pour qu’il soit dans

ces dimensions.

Note: Si le moteur ne démarre toujours pas après le nettoyage de la bougie

ou le réglage de l’écartement, il sera peut être nécessaire de remplacer la

bougie.start even after you clean plug or adjust gap of plug.

ATTENTION : IL Y A

PLUSIEURS GENRES

DE BOUGIES. VÉRIFIER

ET CHOISIR LES

BOUGIES CORRECTES

SELON LE MANUEL

DE L’OPÉRATEUR DU

MOTEUR.

Note: En général, une garniture

mécanique endommagée est

la cause d’une fuite d’eau

entre le moteur et la pompe.

Contacter votre service

après vente pour de l’aide

et remplacer la garniture

mécanique.

ATTENTION:

CONTACTER VOTRE

CONCESSIONNAIRE LE

PLUS PROCHE POUR LE

SERVICE APRÈS VENTE.

34 Centrifugal Pump Operator's Manual

Page 35

Accessoires

3" ; KIT D'ASPIRATION DE DÉCHARGE : 70-0525

Inclut :

• 20' ; 3" ; Tuyau d'aspiration (15-0294)

• 50' ; 3" ; Tuyau de décharge (15-0296)

• 3" ; Tamis d'aspiration (19-0629

3" ; KIT D'ASPIRATION DE DÉCHARGE : 70-0525

Inclut :

• 20' ; 3" ; Tuyau d'aspiration (15-0294)

• 50' ; 3" ; Tuyau de décharge (15-0296)

• 3" ; Tamis d'aspiration (19-0629)

Centrifugal Pump Operator's Manual 35

Page 36

GARANTIE

John Deere garantit toutes les pièces (à l’exception de celles

stipulées ci-dessous), de votre nouveau groupe électrogène en

cas de défauts de matériaux et de fabrication pendant les périodes

suivantes:

Pendant deux (2) années à partir de la date d’achat initiale.

Les pièces défectueuses ne résultant pas d’une usure normale

seront réparées ou remplacées à notre choix pendant la période

de garantie. Quoi qu’il arrive, le remboursement est limité au prix

d’achat.

Pieces exclues de la garantie

1. Le moteur et le générateur sont garanti séparément par son

fabricant et est sujet aux limites ci-inclus.

2. Cette garantie ne couvre pas les pièces endommagées par l’usure

normale, une mauvaise utilisation, une utilisation abusive ou un

fonctionnement autre que recommandé. La garantie ne couvre

pas les dégâts provoqués par un mauvais suivi des procédures

de fonctionnement et d’entretien .

3. L’utilisation de pièces de réparation autres que celles d’origine

annule la garantie.

4. Les pièces renvoyées en port payé, à notre usine ou à un centre

de réparation John Deere agréé seront inspectées et remplacées

gratuitement si elles s’avérent être défectueuses et couvertes

par la garantie. Il n’existe aucune garantie prolongeant les dates

d’expiration stipulées ci-dessus. Le fabricant n’est en aucun

cas responsable des pertes d’usage, de temps ou de location,

des dérangements causés, des pertes commerciales ou des

dommages qui en résultent.

Pour toute question de service ou de garantie, s’adresser à

Mi-T-M Corporation, 8650 Enterprise Drive, Peosta, IA 52068-0050

Tél.: 563-556-7484 / 800-553-9053 / Fax 563-556-1235

Du lundi au vendredi de 8h00 à 17h00, heure centrale

36 Centrifugal Pump Operator's Manual

Page 37

Centrifugal Pump Operator's Manual 37

Page 38

#37-1048-022309

©

Copyright 2009. John Deere

Manufactured for Deere & Company,

Moline, Illinois 61265

Centrifugal Pump

110 Code No. C99110961 N

Loading...

Loading...