Page 1

AC-6000SB

TOOLBOX

Toolbox Installation Instructions 1

Page 2

Introduction

Congratulations on the purchase of your new toolbox! You can be assured your toolbox

was constructed and designed with quality and performance in mind. Each component has

been rigorously tested to ensure the highest level of acceptance.

This installation manual was compiled for your benefit. Please read and follow the simple

installation instructions described in this manual. The contents of this manual are based

on the latest product information available at the time of publication. The manufacturer

reserves the right to make changes in price, color, materials, equipment, specifications or

models at any time without notice.

Inspect for signs of obvious or concealed freight damage. If damage does exist, file a claim

with the transportation company immediately. Be sure that all damaged parts are replaced

and that the mechanical problems are corrected prior to installation. If you require service,

contact your Customer Service.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

1. Model Number

2. Date and Place of Purchase

Please have the following information available for all service calls:

2 Toolbox Installation Instructions

Page 3

Table of Content

SAFETY .................................................................................................................4-5

GENERAL SAFETY RULES....................................................................4-5

FUNCTIONAL DESCRIPTION ...............................................................................

MODEL ....................................................................................................6

NAME OF PARTS ..................................................................................6

INSTALLATION .......................................................................................................7-11

MAINTENANCE......................................................................................................12-13

CLEANING INSTRUCTIONS..................................................................12

LUBRICATION INSTRUCTIONS ............................................................12-13

NOTES ....................................................................................................................14-15

6

Toolbox Installation Instructions 3

Page 4

Safety

RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. When you see this symbol in

this manual, be alert to the potential for personal injury.

Follow recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS

A "DANGER, WARNING or CAUTION" safety warning will be

surrounded by a "SAFETY ALERT BOX." This box is used to

designate and emphasize Safety Warnings that must be fol

lowed when installing this toolbox.

Accompanying the Safety Warnings are "signal words" which

designate the degree or level of hazard seriousness. The

"signal words" used in this manual are as follows:

-

DANGER

which, if not avoided, WILL result in

WARNING

which, if not avoided, COULD result in

CAUTION: Indicates a potentially hazardous situation

which, if not avoided MAY result in

: Indicates an imminently hazardous situation

death or

serious injury.

: Indicates a potentially hazardous situation

death or

serious injury.

minor or

moderate injury.

GENERAL SAFETY RULES

WARNING: Read and understand all

instructions.

Failure to follow all

instructions listed below, may

result in serious personal injury.

SAVE THESE INSTRUCTIONS

4 Toolbox Installation Instructions

Page 5

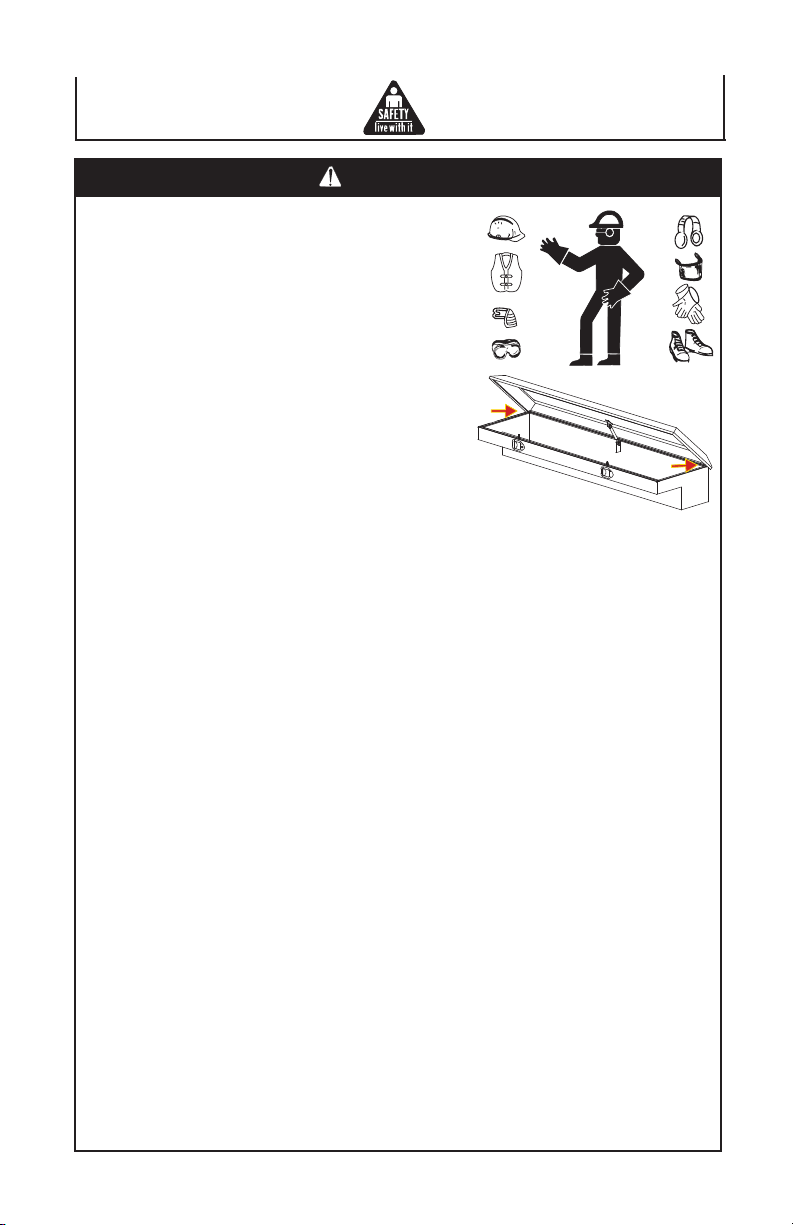

CAUTION

THIS INSTALLATION REQUIRES THE USE OF

POWER TOOLS. SAFETY GLASSES SHOULD BE

WORN AT ALL TIMES DURING THE USE OF THE

POWER TOOLS.

IF YOU ARE UNABLE TO LIFT A MINIMUM OF

75 LBS., THEN THIS INSTALLATION WILL RE

QUIRE THE USE OF TWO PEOPLE.

PINCH AREA BETWEEN BODY AND LID OF

TOOLBOX.

-

Toolbox Installation Instructions 5

Page 6

Functional Description

Black

MODEL:

AC-6000SB

NOTE: Some illustrations in this installation manual may show details that differ

from those on your own toolbox.

NAME OF PARTS:

Side Mount Toolbox:

Mounting Bracket (2) Mounting Bracket (2) Foam Tape (2)

1/4" Flat Washer (4) 3/8" Flat Washer (6) 1/4" x 1" Sheet Metal

Screw (Black) (2)

1/4" x 1" Sheet 3/8" x 1" Button 3/8" Locknut (6)

Metal Screw (4) Head Screw (8)

Plastic Plug (2) TB-Channel (6) TB-Divider (3)

CO-Tape (18)

TOOLS REQUIRED:

7/16" Wrench / Socket Drill with a 1/4" Drill bit Scissors Safety Glasses

6 Toolbox Installation Instructions

Page 7

Installation

A

B

C

A

A

A

INSTALLATION INSTRUCTIONS:

CAUTION: IF YOU ARE UNABLE TO LIFT A

MINIMUM OF 75 LBS., THEN THIS

INSTALLATION WILL REQUIRE THE

USE OF TWO PEOPLE.

Use the pictures below as a guide in locating the side

mount toolbox (A).

Note: If the side mount toolbox (A) is to be installed

with a front mount toolbox (As shown in Drawings

B and C), be sure to leave enough space

between the toolboxes to allow clearance to open

both toolbox lids.

Toolbox Installation Instructions 7

Page 8

Installation

A

B

B

INSTALLATION INSTRUCTIONS:

CAUTION: THIS INSTALLATION REQUIRES

THE USE OF POWER TOOLS. SAFETY

GLASSES SHOULD BE WORN AT ALL

TIMES DURING THE USE OF THE POWER

TOOLS.

CAUTION: PINCH AREA BETWEEN BODY AND

LID OF TOOLBOX. (FIG. 1)

1. Peel backing off the foam tape. (Fig. 2)

2. Place foam tape (B) onto the bottom of the

side mount toolbox (A) to protect the bed rail of

the vehicle. (Fig. 3)

(Fig.1)

(Fig. 2)

(Fig. 3)

8 Toolbox Installation Instructions

Page 9

Installation

A

INSTALLATION INSTRUCTIONS (CONTINUED):

CAUTION: SAFETY GLASSES SHOULD BE WORN

DURING THIS STEP OF THE INSTALLATION.

4. Drill 3/16“ holes through the inside of the side mount

toolbox (A) (Fig. 4) and the pickup truck bed rail according

to the part number listed below:

• 91 - Drill four holes through the bed rail.

• 92 - Drill six holes through the bed rail.

• 93 - Drill eight holes through the bed rail.

Secure into position using 1/4 x 1“ sheet metal screws.

Tighten into place using a 3/8“ wrench / or socket.

NOTE: Do not overtighten the sheet metal screws. Make sure

that if your vehicle already has a crossover toolbox

installed, that you position your side mount toolbox so that

it is aligned with the crossover toolbox.

(Fig.4)

Toolbox Installation Instructions 9

Page 10

Installation

Vehicle Floor

G

E

J

F

I

I

I

J

F

F

A

C

B

INSTALLATION INSTRUCTIONS (CONTINUED):

5. Hold the side mount toolbox (A) level while positioning

mounting brackets (B / C) as shown below. Once the side

mount toolbox (A) is level and the mounting brackets (B /C)

are in the desired position, use a pair of vise-grips to hold them

together. Now use the existing holes in mounting bracket (B)

as a guide to drill two 3/8“ holes through mounting bracket (C).

Secure both mounting brackets (B / C) together using a 3/8 x

1“ button head bolt (I), 3/8” flat washer (F), and 3/8” hex nut (J)

at each location. Tighten the 3/8“ hex nut (J) until snug using a

9/16” wrench / or socket.

Reposition mounting brackets (B / C) and then re-check the

side mount toolbox (A) to make sure that it is level. Use the

existing holes in the bottom of mounting bracket (C) and

mark the vehicle floor. Drill two 3/16“ holes in the vehicle

floor at the marked locations. Secure mounting brackets (C)

to the vehicle floor using 1/4 x 1“ black sheet metal screws

(G) and 1/4“ black flat washers (E). Tighten into place using a

3/8“ wrench / or socket.

Now use the existing hole in the top of mounting bracket (B) as

a guide to drill a 3/8“ hole through the bottom of side mount

toolbox (A). Secure the top of mounting bracket (B) to the side

mount toolbox using a 3/8 x 1“ button head bolt (I), 3/8“ flat

washer (F), and 3/8” hex nut (J). Tighten into place using a 3/8”

wrench / or socket.

6. Place plastic plugs into the holes in the bottom of the toolbox.

10 Toolbox Installation Instructions

(Fig. 5)

Page 11

Installation

B

Front

Rear

C

A

C

A

D

INSTALLATION INSTRUCTIONS (CONTINUED):

Optional Side Mount Toolbox - Divider installation instructions:

1. Peel the backing off of each piece of CO-Tape (B) and then place the CO-Tape

pieces (B) onto the back of each TB-Channel (C) as shown below.

Note: There are only three TB-Dividers (D) supplied with the side mount toolbox (A).

2. Now determine exactly where you would like to place the toolbox dividers. Mark out

the locations for each TB-Channel (C) in the side mount toolbox (A) and then stick

the TB-Channels (C) onto these locations.

Note: You should place a TB-Channel (C) at each marked location at both the front and

back of the side mount toolbox (A) to allow the TB-Divider (D) to slide into place.

3. Now slide a TB-Divider (D) into the TB-Channel (C) at each location.

Toolbox Installation Instructions 11

Page 12

Maintenance

MAINTENANCE INSTRUCTIONS:

CLEANING INSTRUCTIONS:

To maintain the luster of your toolbox, use a mild detergent.

NOTE: Locks are provided as a deterrent to inadvertent opening or easy access to

the contents of your toolbox. Contents stored in the toolbox are the

responsibility of the user.

LUBRICATION INSTRUCTIONS:

All locks, latches, latching rods, and hinges should be lubricated regularly to assure

smooth and proper operation for the life of the toolbox. Lubricate the following locations.

TOOLBOX LATCH ASSEMBLY:

12 Toolbox Installation Instructions

Page 13

Lever Assembly

Push-Button Latch Assembly

Lubricate

Maintenance

MAINTENANCE INSTRUCTIONS (CONTINUED):

TOOLBOX PUSH-BUTTON LATCH ASSEMBLY:

TOOLBOX CATCH ASSEMBLY:

Toolbox Installation Instructions 13

Page 14

Notes

14 Toolbox Installation Instructions

Page 15

Notes

Toolbox Installation Instructions 15

Page 16

Form #37-0826-071904

16 Toolbox Installation Instructions

©Copyright 2004, John Deere

Manufactured for Deere & Company

Moline, Illinois 61265

John Deere Toolbox

Loading...

Loading...