Page 1

AC-1500EH, AC-2000EH,

®

C US

201473

AC-3000EH, AC-3000EH-3

High Pressure Washers

John Deere Operator's Manual 1

CAUTION

RISK OF INJURY!

READ MANUAL BEFORE OPERATING!

This manual is an important part of the pressure washer and must

remain with the unit when you sell or rent it!

Page 2

TABLE OF CONTENTS

INTRODUCTION ...................................................................................................................... 3

IMPORTANT SAFETY INSTRUCTIONS .............................................................................. 4-7

RISK OF ELECTRIC SHOCK OR ELECTROCUTION ................................................ 4

RISK OF EXPLOSION OR FIRE ................................................................................. 5

RISK OF ASPHYXIAITON .......................................................................................... 5

RISK OF INJECTION OR SEVERE CUTTING INJURY .............................................. 6

RISK OF BURNS ......................................................................................................... 6

RISK OF BURSTING ................................................................................................... 6

RISK FROM MOVING PARTS ..................................................................................... 6

RISK OF BODILY INJURY ........................................................................................... 7

FEATURES ......................................................................................................................... 8-11

AC-1500EH & AC-2000EH FEATURES ................................................................... 8-9

AC-3000EH & AC-3000EH-3 FEATURES .............................................................10-11

INSTALLATION & PREPARATION INSTRUCTIONS ...................................................... 12-15

ATTIRE ...................................................................................................................... 12

SET-UP ...................................................................................................................... 12

POWER CORD CONNECTION ............................................................................ 12-13

BURNER FUEL TANK ...............................................................................................

ADJUSTABLE PRESSURE DUAL LANCE ................................................................

DUAL LANCE CONNECTION ................................................................................... 14

WATER SUPPLY ........................................................................................................ 14

UNLOADER ............................................................................................................... 15

HEAT DUMP VALVE ..................................................................................................

PRE-START INSPECTION PROCEDURES ..............................................................

13

14

15

15

OPERATING INSTRUCTIONS ......................................................................................... 16-19

FLUSHING THE SYSTEM ......................................................................................... 16

START-UP/COLD WATER OPERATION ................................................................... 16

HOT WATER OPERATION ........................................................................................

STEAM OPERATION .................................................................................................

CLEANING WITH DETERGENTS ............................................................................. 18

SHUTDOWN .............................................................................................................. 19

STORAGE & MAINTENANCE INSTRUCTIONS ..............................................................

SPECIFIC MAINTENANCE ...................................................................................... 19

WINTERIZING ...........................................................................................................

TROUBLESHOOTING ...................................................................................................... 21-23

MAINTENANCE CHART ....................................................................................................... 24

STATEMENT OF WARRANTY .... ......................................................................................... 25

17

18

19-20

20

2 John Deere Operator's Manual

Page 3

INTRODUCTION

Congratulations on the purchase of your new hot water pressure washer! You can be assured your hot water pressure

washer was constructed and designed with quality and performance in mind. Each component has been rigorously

tested to ensure the highest level of acceptance.

This operator's manual was compiled for your benefit. By reading and following the simple safety, installation, operation,

maintenance and troubleshooting steps described in this manual, you will receive years of trouble free operation from your

new hot water pressure washer. The contents of this manual are based on the latest product information available at the

time of publication. Manufacturer reserves the right to make changes in price, color, materials, equipment, specifications

or models at any time without notice.

! IMPORTANT !

These paragraphs are surrounded by a "SAFETY ALERT BOX". This box is used to designate and

emphasize Safety Warnings that must be followed when operating this pressure washer.

Accompanying the Safety Warnings are "signal words" which designate the degree or level

of hazard seriousness. The "signal words" used in this manual are as follows:

DANGER: Indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, COULD

result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided MAY

result in minor or moderate injury.

The symbols set to the left of this paragraph are "Safety Alert Symbols". These symbols

are used to call attention to items or procedures that could be dangerous to you or other

persons using this equipment.

ALWAYS PROVIDE A COPY OF THIS MANUAL TO ANYONE USING THIS EQUIPMENT. READ

ALL INSTRUCTIONS BEFORE OPERATING THIS PRESSURE WASHER AND ESPECIALLY

POINT OUT THE "SAFETY WARNINGS" TO PREVENT THE POSSIBILITY OF PERSONAL

INJURY TO THE OPERATOR.

Once the unit has been uncrated, immediately write in the serial number of your unit in the space provided below.

SERIAL NUMBER_________________________________

Inspect for signs of obvious or concealed freight damage. If damage does exist, file a claim with the transportation

company immediately. Be sure that all damaged parts are replaced an that the mechanical and electrical problems are

corrected prior to operation of the unit. If you require service, contact your Customer Service.

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 319-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

1. Model Number

2. Serial Number

3. Date and Place of Purchase

Please have the following information available for all service calls:

John Deere Operator's Manual 3

Page 4

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using this product, basic precautions should always be observed, including the following:

READ ALL SAFETY INSTRUCTIONS BEFORE USING PRESSURE WASHER

HAZARD

RISK OF

ELECTRIC SHOCK

OR ELECTROCUTION

POTENTIAL CONSEQUENCE

Serious injury or death could occur if

the pressure washer is not properly

grounded. Your pressure washer

is powered by electricity and may

cause electric shock or electrocution

if not used properly.

Electrical shock may occur from

electrical cord.

Electrical shock may occur if

pressure washer is not operated

properly.

Serious injury or death may occur if

electrical repairs are attempted by

unqualified persons.

PREVENTION

This product must be grounded. Make sure

the pressure washer is equipped with a

GFCI built into the power supply cord. If this

is not available, the pressure washer must

be plugged into a receptacle that is protected

by a GFCI. Disconnect when not in use.

If your unit is equipped with a GFCI, DO

NOT drop the GFCI as damage could

result. If the GFCI is accidentally dropped,

be certain to test the GFCI before using

to ensure it is working properly. (Follow

instructions on GFCI for test procedures.)

Always be certain the unit is receiving proper

voltage. Before plugging the unit into a

compatible power source, be certain the

switch is in the "OFF" position. Disconnect

when not in use.

Do not modify plug provided with the

product. If it will not fit the outlet, have

a proper outlet installed by a qualified

electrician. Do not use any type of adapter.

Check power cord for signs of crushing,

cutting or heat damage. If replacement of

plug or cord is needed, use only identical

replacement parts.

Do not use extension cords with this

pressure washer.

Keep all connections dry and off the ground.

Do not allow electrical cords to lay in water

or in such a position where water could

come in contact with them. Do not touch

plug with wet hands.

Do not pull on the electrical cord to

disconnect from the outlet.

Do not direct spray on or into electrical

installations of any kind! This includes

electrical outlets, light bulbs, fuse boxes,

transformers, the unit itself, etc.

Do not allow metal components of the

pressure washer to come in contact with live

electrical components.

Never operate the pressure washer with

safety guards/covers removed or damaged.

Any electrical wiring or repairs performed

on this pressure washer should be done by

Authorized Service Personnel in accordance

with National and Local electrical codes.

Before opening any electrical enclosure,

always shut off the pressure washer, relieve

pressure and unplug the pressure washer

from the power source. Allow the pressure

washer to cool down. Never assume the

pressure washer is safe to work on just

because it is not operating. It could restart at

any time! Service in a clean, dry, flat area.

4 John Deere Operator's Manual

Page 5

IMPORTANT SAFETY INSTRUCTIONS

READ ALL SAFETY INSTRUCTIONS BEFORE USING PRESSURE WASHER

HAZARD

RISK OF

EXPLOSION OR FIRE

POTENTIAL CONSEQUENCE PREVENTION

Serious injury or death may occur

from normal sparks in the multiple

ignition sources or burner exhaust.

Serious injury or death may occur

as a result of improper fueling.

Serious injury or death may occur

if system safety's are not properly

maintained.

Always operate pressure washer in a well

ventilated area free of flammable vapors,

combustible dust, gases or other combustible

materials.

Do not store the pressure washer near an

open flame or any equipment such as a stove,

furnace, water heater, etc., which utilizes a pilot

light or sparking device.

Do not use this pressure washer to spray

flammable material!

Do not smoke while filling burner fuel tank.

Never fill the burner fuel tank while the pressure

washer is running or hot. Allow to cool two

minutes before refueling.

Do not refuel indoors or in a poorly ventilated

area.

Always refuel slowly to avoid the possibility of

spilled fuel which may cause a risk of fire.

Burner Fuel Tank:

Use No. 1 or No. 2 fuel oil/diesel or

kerosene.Do not use gasoline, crankcase

drainings or oil containing gasoline or

solvents.

Do not operate the unit if diesel fuel is spilled.

Wipe the pressure washer clean and move it

away from the spill. Avoid creating any ignition

until the diesel fuel has evaporated.

This pressure washer has a Safety Relief

device which should never be altered,

modified, removed or made inoperative. If

the device fails, replace immediately with

only genuine manufacturer replacement

part.

RISK OF

ASPHYXIATION

John Deere Operator's Manual 5

Serious injury or death may occur

from inhaling burner exhaust or

dangerous vapors.

Never operate this pressure washer in an

enclosed area. Always make certain there

is adequate ventilation (fresh outside air) for

breathing and combustion. This will prevent

the buildup of dangerous carbon monoxide

gases. Beware of poorly ventilated areas, or

areas with exhaust fans which can cause poor

air exchange.

Follow all safety instructions provided with the

materials you are spraying. Use of a respirator

may be required when working with some

materials. Do not use this pressure washer

to dispense hazardous detergents.

Page 6

IMPORTANT SAFETY INSTRUCTIONS

READ ALL SAFETY INSTRUCTIONS BEFORE USING PRESSURE WASHER

POTENTIAL CONSEQUENCE PREVENTIONHAZARD

RISK OF INJECTION

OR

SEVERE CUTTING INJURY

RISK OF BURNS

Serious injury or death could

occur from high pressure spray

penetrating the skin.

Serious injury may occur from

touching the heat exchanger. This

area can remain hot for some

time after the pressure washer is

shutdown.

Keep clear of nozzle and spray! Never put

your hand, fingers or body directly over the

spray nozzle.

Do not direct discharge stream at persons or

self.

This product is to be used only by trained

operators.

Always keep operating area clear of all

persons.

Close supervision is necessary when used near

children. DO NOT allow children to operate

this unit!

SEEK EMERGENCY MEDICAL CARE if the

spray appears to have penetrated the skin!

DO NOT TREAT AS A SIMPLE CUT!!

High pressure hoses and fuel lines should be

inspected daily for signs of wear. If evidence

of failure exists, promptly replace all suspect

hoses and fuel lines to prevent curely locked

when not in use.

Before removing the spray nozzle or servicing

the unit, ALWAYS shut off the unit and trigger

the gun to release trapped pressure. (Even

after you shut off the unit, there is high pressure

water left in the pump, hose and gun until you

release it by triggering the gun.)

Never allow any part of your body to contact

the heat exchanger.

Do not leave unit unattended after shutdown

until it is completely cooled down as described

in the "SHUTDOWN" procedures listed on page

20 of this manual.

RISK OF BURSTING

RISK FROM MOVING PARTS

6 John Deere Operator's Manual

Serious injury may occur from a

pressure washer malfunction or

exploding accessories if incorrect

system components, attachments

or accessories are used.

Serious injury or death may occur

if attempting to start the pressure

washer when the pumping system

is frozen.

Serious injury may occur to the

operator from moving parts on

the pressure washer.

Never make adjustments to the factory set

pressures.

Never exceed manufacturers maximum

allowable pressure rating of attachments.

Do not allow any hoses to make contact with heat

exchanger to prevent the possibility of bursting.

Avoid dragging the hoses over abrasive surfaces

such as cement.

Use only manufacturer recommended repair

parts for your pressure washer.

In freezing temperatures, the unit must always

be warm enough to ensure there is no ice

formation in the pump. Do not start the pressure

washer if it has been transported in an open or

underheated vehicle without first allowing the

pump to thaw.

Never make adjustments to the unit while it

is connected to the power source.

Do not operate the unit without all protective

covers in place.

Follow the maintenance instructions specified

in the manual.

Page 7

IMPORTANT SAFETY INSTRUCTIONS

READ ALL SAFETY INSTRUCTIONS BEFORE USING PRESSURE WASHER

HAZARD

RISK OF BODILY INJURY Serious injury or death may occur

POTENTIAL CONSEQUENCE

from detergents contacting the

skin.

Serious injury can occur from

loose debris being propelled at a

high speed from the spray gun.

Injury may occur if the operator

loses his balance caused by the

thrust of water traveling through

the spray nozzle.

Injury may occur from the

pressure washer.

PREVENTION

SEEK EMERGENCY MEDICAL CARE if you are

using cleaning agents and the spray appears to

have penetrated the skin! DO NOT TREAT AS

A SIMPLE CUT! Be prepared to tell a physician

exactly what kind of detergents you were using by

reading the Material Safety Data Sheet (MSDS)

provided with your detergent.

Never use any solvents or highly corrosive

detergents or acid type cleaners with this pressure

washer.

Protective equipment such as rubber suits, gloves

and respirators are advisable, especially when

using cleaning detergents.

Keep all detergents out of the reach of children!

ALWAYS wear protective goggles when operating

the unit to shield the eyes from flying debris and

detergents.

DO NOT direct spray toward fragile materials such

as glass for shattering could occur.

If the pressure washer is equipped with an Auto

start/stop feature, the unit will shutdown until

the gun is triggered. To prevent accidental high

pressure discharge, do not leave unit unattended

while in this mode.

Stay alert-watch what you are doing. Do not

operate the unit when fatigued or under the

influence of alcohol or drugs.

NEVER squeeze the trigger unless securely

braced.

DO NOT overreach or stand on unstable support.

Keep good footing and balance at all times.

Wet surfaces can be slippery, wear protective

foot gear and keep good footing and balance at

all times.

NEVER trigger the gun while on a ladder or

roof.

ALWAYS hold on firmly to the gun/lance assembly

when starting and operating the unit. Failure

to do so can cause the lance to fall and whip

dangerously.

Know how to stop the pressure washer and bleed

pressures quickly. Be thoroughly familiar with

controls.

DO NOT leave pressurized unit unattended. Shut

off the pressure washer and release trapped

pressure before leaving.

DO NOT operate the unit if you see any fuel, oil or

water leaks from the machine. DO NOT resume

operation until the unit has been inspected and

repaired by a qualified service person.

Place unit in a clean, dry, flat area for servicing.

Before servicing the unit: turn the unit off, relieve

the water pressure from the trigger gun, and allow

the unit to cool down. Service in clean, dry, flat

area. If applicable, block wheels to prevent unit

from moving.

Do not move the unit by pulling on the hose.

!SAVE THESE INSTRUCTIONS!

John Deere Operator's Manual 7

Page 8

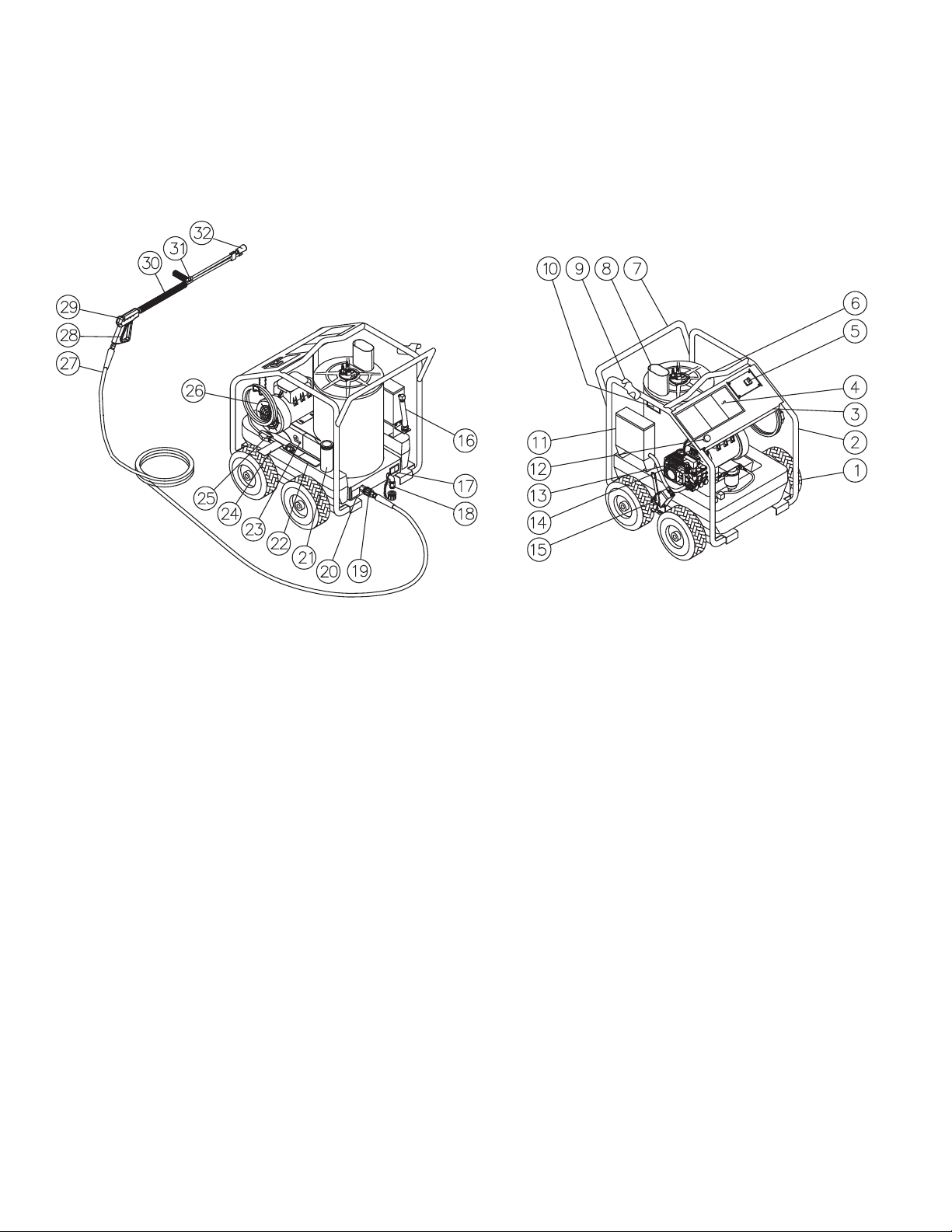

AC-1500EH & AC-2000EH FEATURES

OMHSE105-040705-RZ

8 John Deere Operator's Manual

Page 9

FEATURES LISTING

1. Pneumatic Wheels

2. Protective Rollcage

3. Control Panel

4. Decal- Warning/Caution/Operation

5. Switch-Off/Pump/Burner

6. Center Balanced Lifting Eye

7. Convenient Push/Pull Handle

8. Heat Exchanger Exhaust

9. Wand Holder

10. Decal- Warning: Hot

11. Water Float Tank

12. Detergent Metering Valve

13. High Pressure Pump w/Unloader

14. Pressure Switch

15. Brake

16. Water Inlet

17. Decal- Warning: Risk of Explosion

18. Coil Drain

19. High Pressure Outlet

20. Decal- Data Plate

21. Burner Fuel Tank

22. Decal- Caution: Risk of Fire

23. Burner Air Regulation

24. Decal- Hang Tag

25. 35FT Electrical Cord

26. TEFC Pump Motor

27. High Pressure Hose

28 Trigger Safety Lock

29. Trigger Gun

30. Insulated Lance

31. Adjustable Pressure Dual Lance

32. Nozzle

SPECIFIC UNIT INFORMATION

BODY/FRAME: One piece, welded construction, full roll cage

with solid steel axles, lifting hook and convenient push/pull

handle.

PORTABILITY: Four pneumatic tires for easy mobility.

FINISH: Powder coated

HIGH PRESSURE HOSE: 3/8" x 50'

TRIGGER GUN ASSEMBLY: Trigger controlled, safety lock

off, insulated lance.

DUAL LANCE:

John Deere Operator's Manual 9

Insulated, with adjustable pressure.

-

Page 10

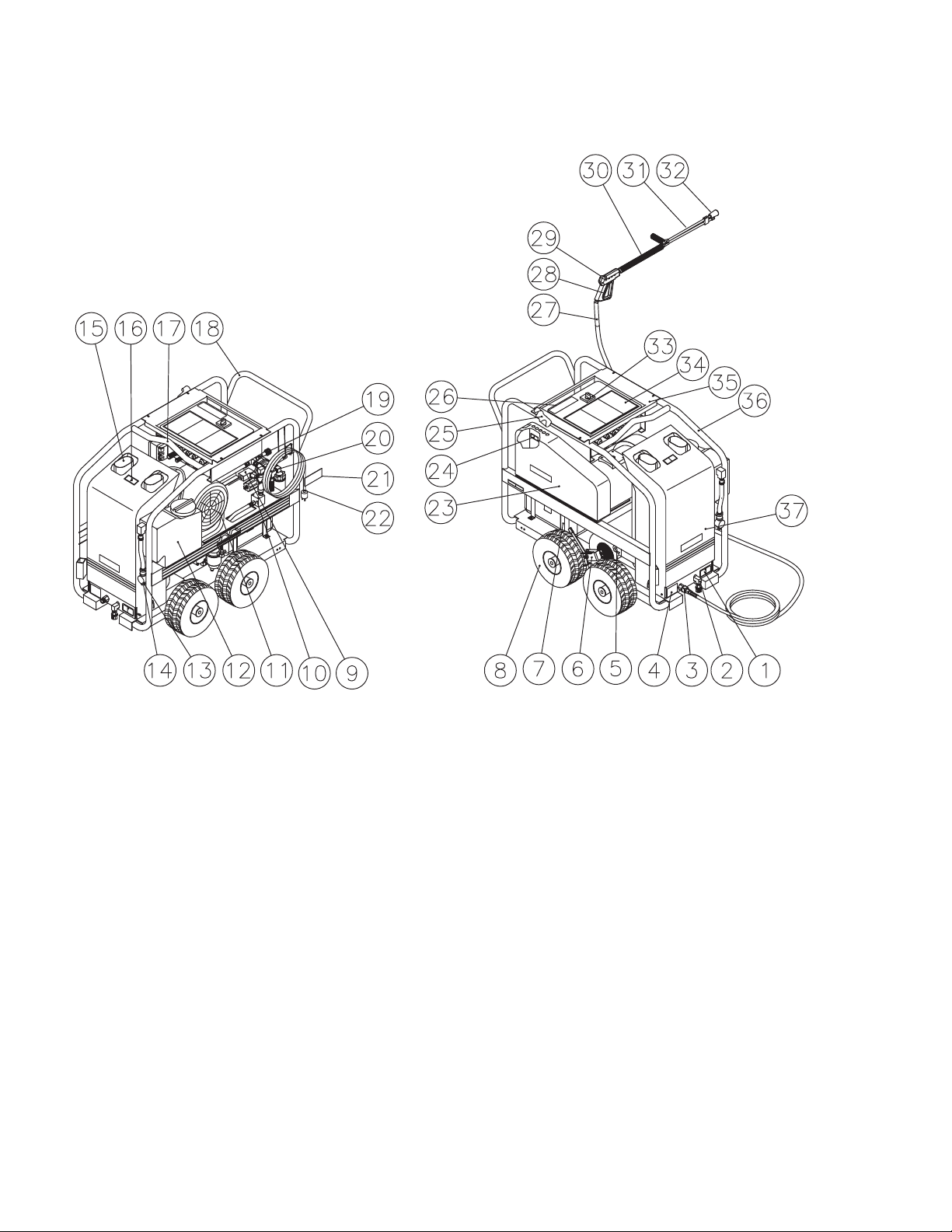

AC-3000EH & AC-3000EH-3 FEATURES

0MHSE015 GENERIC-032905-RZ

10 John Deere Operator's Manual

Page 11

FEATURES LISTING

1. Decal- Warning: Risk of Explosion

2. Coil Drain

3. High Pressure Outlet

4. Data Plate

5. Burner Air Regulation

6. Brake

7. Burner Fuel Tank

8. Pnuematic Wheels

9. Pressure Switch

10. High Pressure Hose w/Unloader

11. TEFC Pump Motor

12. Water Float Tank

13. Water Strainer w/Bowl

14. Water Inlet

15. Heat Exchanger Exhaust

16. Decal- Warning: Hot

17. Center Balance Lift Eye

18. Convient Push/Pull Handle

19. Detergent Metering Valve

20. Decal- Caution: Risk of Fire

21. Decal- Hang Tag

22. Electric Cord

23. Beltguard

24. Decal- Warning: Beltguard in Place

25. Wand Holder

26. Decal- Warning: Electric

27. High Pressure Hose

28. Trigger Safety Lock

29. Trigger Gun

30. Insulated Lance

31. Adjustable Pressure Dual Lance

32. Nozzle

33. Switch (On/Off/Burner)

34. Decal- Warning/Caution/Operation

35. Control Panel

36. Protective Roll Cage

37. Protective Cover Assembly

SPECIFIC UNIT INFORMATION

BODY/FRAME: One piece, welded construction, full roll cage with solid steel

axles, lifting hook and convenient push/pull handle.

PORTABILITY: Four pneumatic four-ply tires for easy mobility.

FINISH: Powder coated

HIGH PRESSURE HOSE: 3/8" x 50'

TRIGGER GUN ASSEMBLY: Trigger controlled, safety lockoff, insulated lance.

DUAL LANCE: Insulated, with adjustable pressure.

John Deere Operator's Manual 11

Page 12

INSTALLATION & PREPARATION INSTRUCTIONS

ATTIRE:

Proper attire is essential to your safety. It is advised to utilize whatever means

necessary to protect eyes, ears, and skin. Additional safety attire (such as

respiratory mask) may be required when using detergent cleaning agents with

this washer.

DANGER

RISK OF EXPLOSION OR FIRE!

DO NOT PLACE UNIT IN AN

AREA WHERE FLAMMABLE

GAS VAPORS MAY BE PRESENT.

A SPARK COULD CAUSE AN

EXPLOSION OR FIRE!

RISK OF UNIT BURSTING!

DO NOT STORE/OPERATE UNIT

IN FREEZING ENVIRONMENTS!

WARNING

RISK OF ASPHYXIATION!

USE THIS PRODUCT ONLY IN

WELL VENTILATED AREAS!

DO NOT OPE R ATE IN AN

ENCLOS E D AREA. THE

EXHAUST CONTAINS CARBON

MONOXIDE, A POISONOUS,

ODORLESS AND INVISIBLE

GAS. BREATHING THIS GAS

CAN CAUSE SERIOUS INJURY,

ILLNESS & POSSIBLE DEATH.

DANGER

RISK OF ELECTROCUTION!

THIS UNIT MUST BE CONNECTED

TO A PROPERLY GROUNDED

OUTLET. DO NOT USE AN

ADAPTER OR REMOVE THE

THIRD GROUNDING PRONG.

SET-UP:

1. This unit should only be placed on a level surface to ensure proper lubrication

for the water pump while operating. NEVER spray water directly on the

unit.

2. Do not use unit in an area:

a. with insufficient ventilation.

b. where there is evidence of oil or fuel leaks.

c. where flammable gas vapors may be present.

3. Engage brake to prevent the unit from moving while operating.

4. Do not allow the unit to be exposed to rain, snow or freezing temperatures.

If any part of the unit becomes frozen, excessive pressure may build up in

the unit which could cause it to burst resulting in possible serious injury to

the operator or bystanders.

5. Pump oil level should be checked before each use. Make certain the oil is

on the "Full" mark on the dipstick or in the center of the oil sight glass. If

the level appears to be low, fill with pump oil SAE20 or 30.

POWER CORD CONNECTION:

1. Make certain the motor switch is in the "OFF" position.

2. Ensure electrical supply is identical to the specifications listed on the pressure

washer data plate.

3. GROUNDING INSTRUCTIONS: This product must be grounded. If it should

malfunction or breakdown, grounding provides a path of least resistance for

electric current to reduce the risk of electric shock. This product is equipped

with a cord having an equipment-grounding conductor and a grounding

plug. The plug must be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes and ordinances.

4. DANGER: Improper connection of the equipment-grounding conductor can

result in a risk of electrocution. Check with a qualified electrician or service

personnel if you are in doubt as to whether the outlet is properly grounded.

Do not modify the plug provided with the product - if it will not fit the outlet,

have a proper outlet installed by a qualified electrician. Do not use any type

of adaptor with this product.

5. GROUND FAULT CIRCUIT INTERRUPTER PROTECTION:

a. SINGLE PHASE: If this pressure washer is provided with a Ground

Fault Circuit Interrupter (GFCI) built into the plug or the power supply

cord, test the GFCI each time it is plugged into an outlet according to

instructions on the GFCI. DO NOT use the pressure washer if the test

fails! The GFCI provides additional protection from the risk of electric

shock. Should replacement of the plug or cord become necessary, use

only identical replacement parts that include GFCI protection.

CONTINUED

12 John Deere Operator's Manual

Page 13

INSTALLATION & PREPARATION INSTRUCTIONS

POWER CORD CONNECTION CONT'D.:

5. b. SINGLE PHASE: If this pressure washer is not provided

with a GFCI, this pressure washer should only be connected

to a receptacle that is protected by a Ground Fault Circuit

Interrupter (GFCI) to comply with the National Electric Code

(NFPA 70) and to provide additional protection from the risk of

electric shock.

c. THREE PHASE: These pressure washers are not provided with

GFCI protection.

6. EXTENSION CORDS: Manufacturer DOES NOT RECOMMEND

THE USE OF EXTENSION CORDS! If use of an extension cord is

unavoidable, it must be plugged into a GFCI found in circuit boxes or

protected receptacles. When using an extension cord, consult a qualified

electrician to determine the proper wire gauge needed for the length of

the extension cord.

SINGLE PHASE: Use only 3-wire extension cords that have 3-prong

grounding-type plugs and 3-pole cord connectors that accept the

plug from the product.

THREE PHASE: Use only 4 wire extension cords that have 4-prong

grounding type plugs and 4-pole cord connectors that accept the

plug from the product.

Use only extension cords that are intended for outdoor use. These

extension cords are identified by a marking "Acceptable for use with

outdoor appliances; store indoors while not in use." Use only extension

cords having an electrical rating not less than the rating of the product.

Do not use damaged extension cords. Examine extension cord before

using and replace if damaged. Do not abuse extension cord and do not

yank on any cord to disconnect. Keep cord away from heat and sharp

edges. Always connect and disconnect the extension cord from the

receptacle before connecting and disconnecting the product from the

extension cord.

7. Ensure the area between the pressure washer cord and outlet is kept

dry.

8. Insert the male plug into a grounded AC outlet. DO NOT use an adapter

OR remove the grounding plug!!

BURNER FUEL TANK:

1. Review "Risk of Explosion or Fire" pg. 5, before fueling.

2. Locate the Safety Decals on your unit and heed their warnings.

3. Fill the burner fuel tank with good quality, clean No. 1 or No. 2 fuel oil/

diesel or kerosene. Do not use gasoline!

WARNING

RISK OF ELECTROCUTION!

TO REDUCE THE RISK OF

ELECTROCUTION, KEEP ALL

CONNECTIONS DRY AND OFF

THE GROUND. DO NOT TOUCH

PLUG WITH WET HANDS.

DANGER

RISK OF FIRE!

-D O NOT SM OKE W HIL E

FUELING!

-DO NOT FILL THE FUEL TANK

WHILE UNIT IS RUNNING OR

HOT. ALLOW UNIT TO COOL

FOR TWO MINUTES BEFORE

RE-FUELING.

-DO NOT FILL FUEL TANK TO

POINT OF OV E R F L O W ING.

ALLOW APPROXIMATELY 1/4"

OF TANK SPACE FOR FUEL

EXPANSION.

WARNING

RISK OF EXPLOSION OR FIRE!

ALWAYS STORE FUEL AWAY

FROM THE WASHER WHILE THE

UNIT IS RUNNING OR HOT.

John Deere Operator's Manual 13

Page 14

WARNING

RISK OF INJECTION CAUSING

SEVERE INJURY!

-THE TRIGGER GUN SHOULD

ALWAYS BE LOCKED IN THE OFF

POSITION WHEN NOT IN USE!

-NEVER LOOK DIRECTLY AT

THE NOZZLE UNLESS IT IS

DISCONNECT E D FROM THE

TRIGGER GUN/DUAL LANCE

ASSEMBLY!

INSTALLATION & PREPARATION

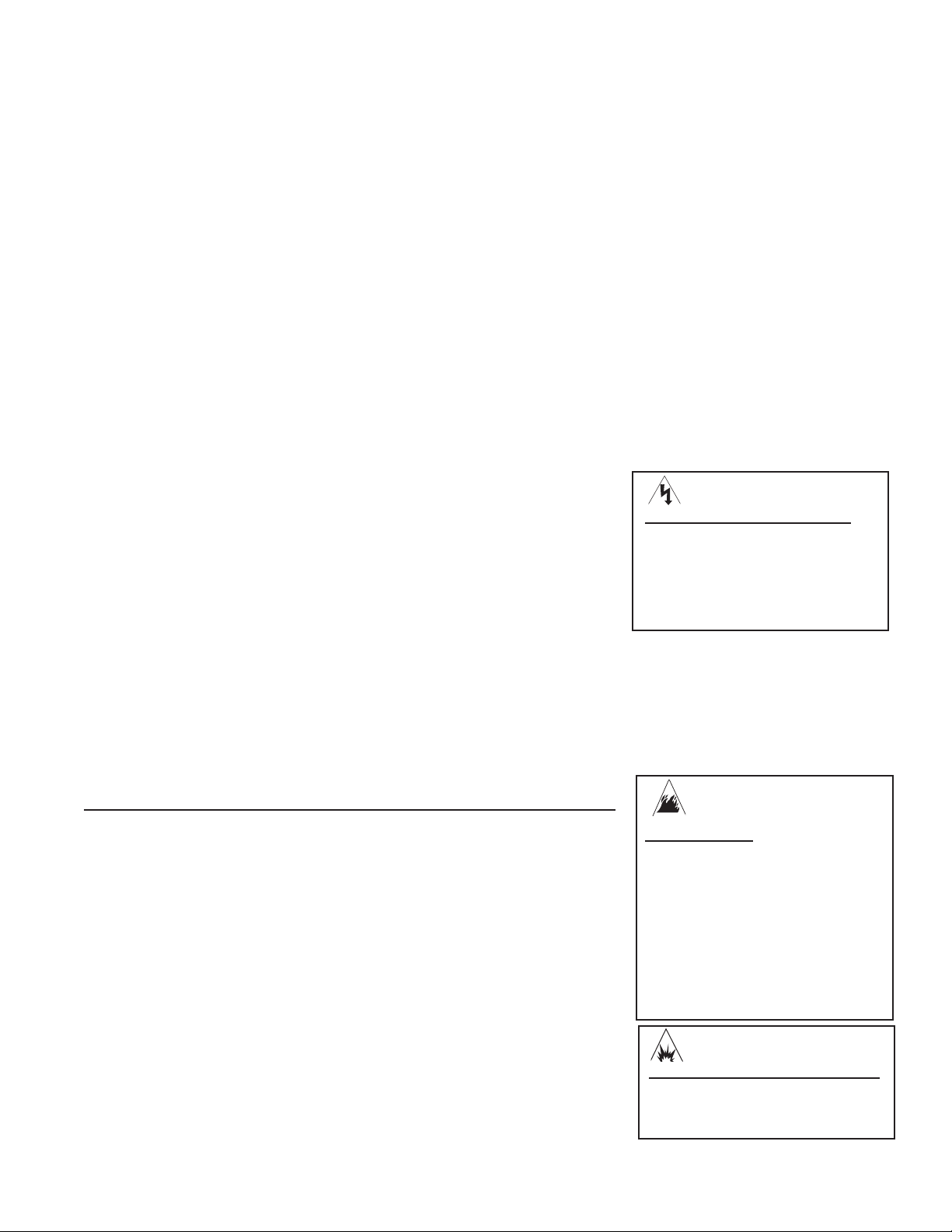

ADJUSTABLE PRESSURE DUAL LANCE:

This unit features an Adjustable Pressure Dual Lance which allows the user

to select a high or low pressure "fan" spray. Simply rotate the adjustable grip

on the dual lance to achieve the desired pressure selection.

1. Selection of high pressure can be achieved by turning the adjustable grip

on the Dual Lance assembly counterclockwise as shown in the figure

below.

2. Selection of low pressure can be achieved by turning the adjustable grip

on the Dual Lance clockwise as shown in the figure below.

DUAL LANCE CONNECTION:

1. Be certain the trigger gun is locked in the "OFF" position.

2. Connect the dual lance assembly to the trigger gun assembly at this time

(if applicable). Be certain the connection is securely tightened.

WATER SUPPLY:

1. Select a water supply hose which is a quality grade of garden hose measuring

at least 3/4" ID and no longer than 50 feet.

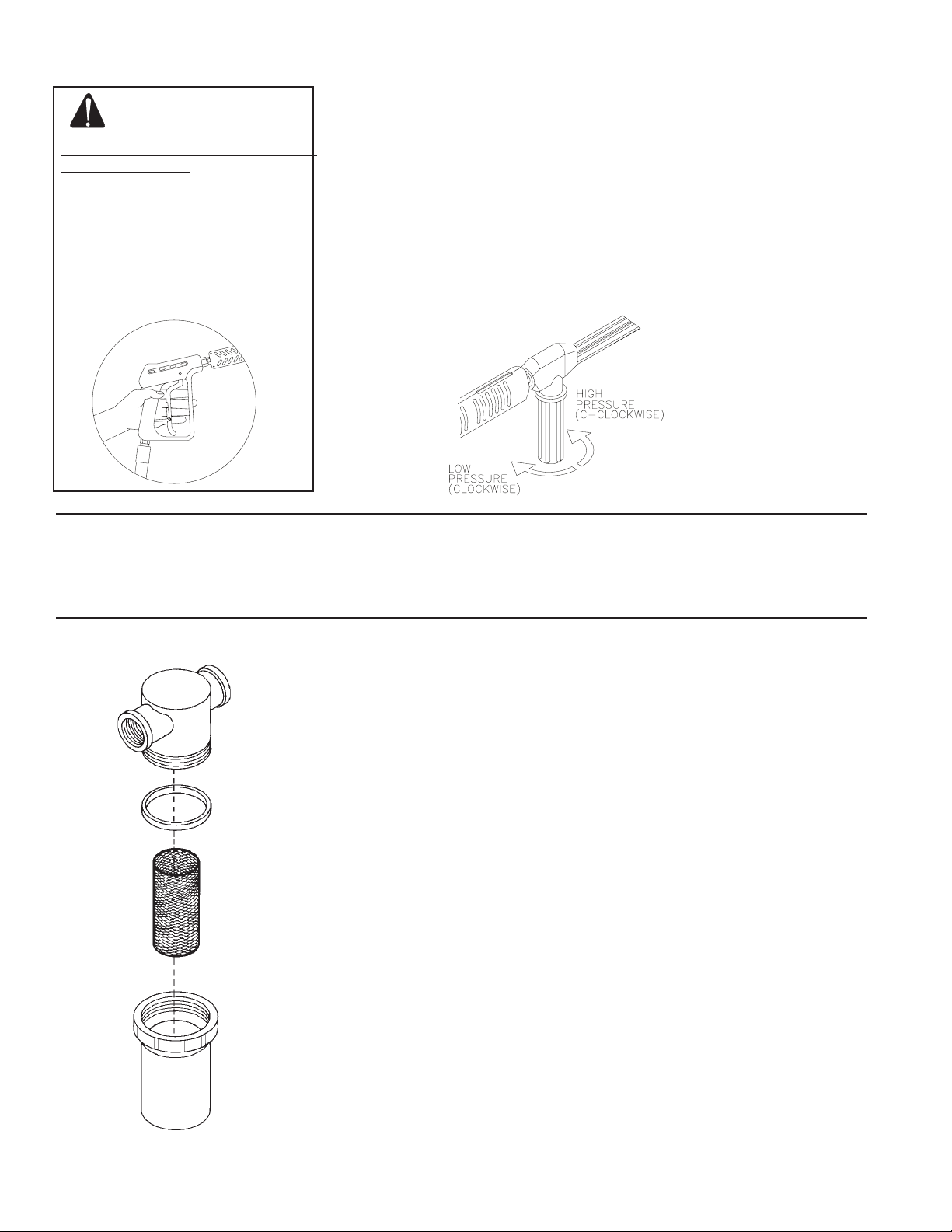

2. If your unit is equipped with a water strainer, ensure it is clean and free of

any obstructions. Periodic cleaning of the water strainer will help prevent

pump problems. As a strainer becomes obstructed, it restricts proper flow of

water to the pump. This can result in cavitation which will cause premature

failure of pump packings.

a. Unscrew the strainer bowl from the unit.

b. Remove strainer screen and clean or replace.

3. Connect one end of the water supply hose to the water inlet of the unit.

Connect the other end of the hose to your pressurized water supply.

NOTE: If there is a high mineral content in your water, it is recommended that

a water softener be used to prevent the possibility of excessive scale

buildup inside the heat exchanger coil.

4. Follow the incoming water requirements listed below:

a. Water pressure must be between a minimum of 20 pounds per square

inch (PSI) and a maximum of 125 PSI.

b. Incoming GPM must be approximately one gallon more than the outgoing

GPM stated on the pressure washer nameplate. (You can check GPM

by timing how long it takes to fill a 5 gallon container.)

c. Incoming water temperature must not exceed 125°F. Excessive pump

damage may result if the water temperature exceeds this acceptable

level.

5. Never allow the unit to operate without the incoming water line attached and

the water supply completely turned on.

14 John Deere Operator's Manual

Page 15

INSTALLATION & PREPARATION

UNLOADER:

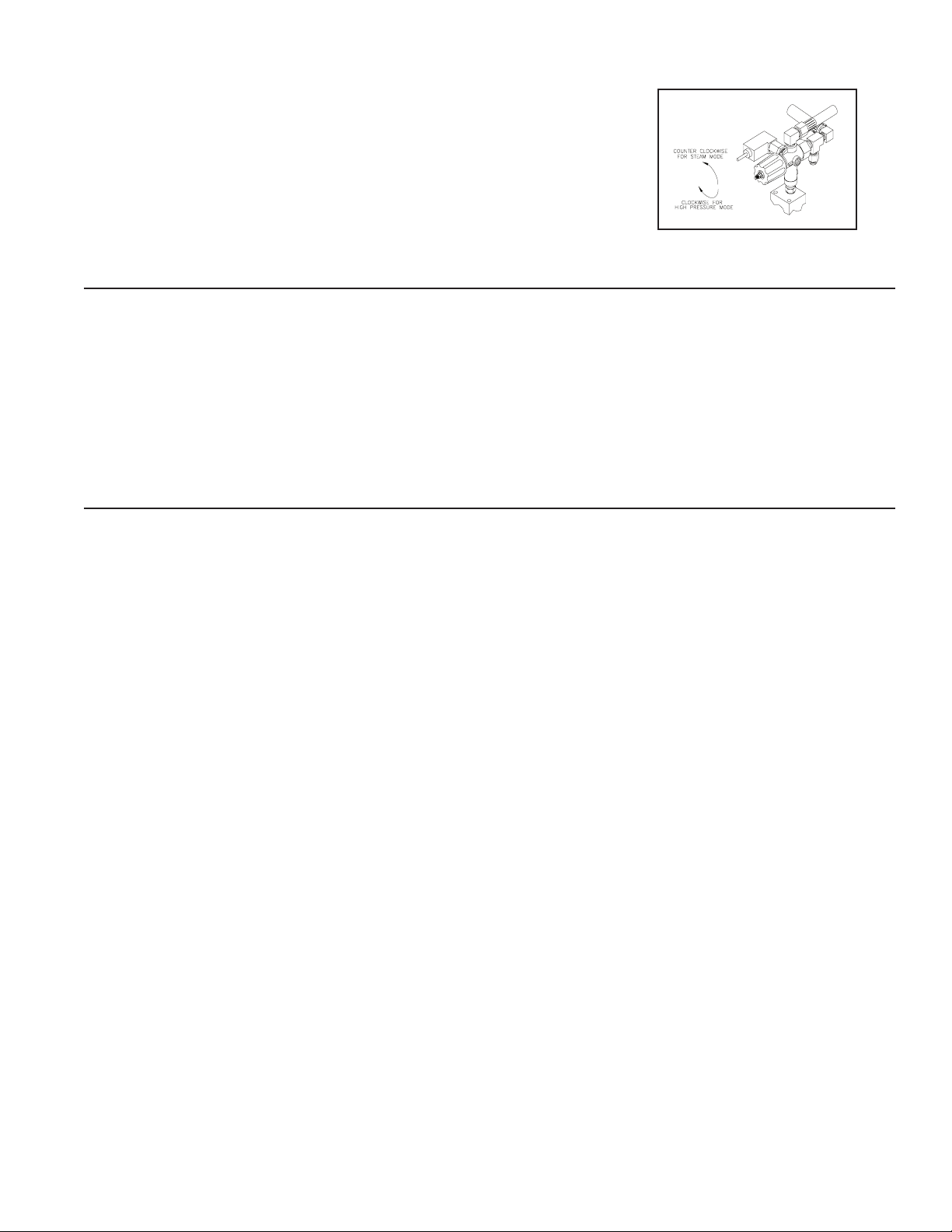

Standard Models:

The unloader has been preset at the factory.

Steam Option Models:

The unloader has an adjustment knob which has a minimum/maximum

setting. Move the unloader clockwise to the maximum setting for Cold/Hot

water operation. Move counterclockwise to minimum setting for Steam

operation.

HEAT DUMP VALVE:

To ensure the water temperature does not exceed acceptable levels, never allow

the pressure washer to operate in the bypass mode (with the unit running and

the trigger closed) for more than three minutes.

A heat dump valve has been added to this unit to protect the pump. This valve

will open and release water if the water temperature in the pump has exceeded

140° F. This will allow fresh, cool water to enter the system, therefore preventing

premature failure of pump packings.

UNLOADER VALVE

PRE-START INSPECTION PROCEDURES:

Before starting the unit, perform the following procedures:

1. Inspect the electrical cords for cuts. If a cut is found, DO NOT TOUCH OR

USE CORD! Replace cord before starting unit.

2. Check the oil level in the pump.

3. Inspect the water inlet strainer. Clean or replace if necessary. See "Water

Supply", #2, pg 14.

4. Check all hose connections to ensure they are securely tightened.

5. Inspect for system water leaks, oil leaks and fuel leaks. If a fuel leak is

found, DO NOT START UNIT! See "Risk of Explosion or Fire", pg. 5. Be

sure that all damaged parts are replaced and that the mechanical problems

are corrected prior to operation of the unit. If you require service, contact

Customer Service.

6. Inspect high pressure hoses for kinking, cuts and leaks. If a cut or leak

is found, DO NOT USE HOSE! Replace hose before starting unit. See

"Risk of Injection or Severe Cutting Injury", pg. 7. Be sure that all damaged

parts are replaced and that the mechanical problems are corrected prior to

operation of the unit. If you require service, contact Customer Service.

John Deere Operator's Manual 15

Page 16

WARNING

THE FOLLOWING PAGES CONTAIN OPERATING AND

MAINTENANCE INSTRUCTIONS

DO NOT ATTEMPT TO OPERATE THIS PRESSURE

WASHER UNTIL YOU HAVE READ AND UNDERSTOOD

ALL SAFETY PRECAUTIONS AND INSTRUCTIONS

LISTED IN THIS MANUAL.

INCORRECT OPERATION OF THIS UNIT CAN CAUSE

SERIOUS INJURY!!

DO NOT ALTER OR MODIFY THIS EQUIPMENT

IN ANY MANNER!

16 John Deere Operator's Manual

Page 17

OPERATING INSTRUCTIONS

FLUSHING THE SYSTEM:

This unit has a steel coil which, after setting, will cause the water remaining in

the coil from the previous usage to turn brown or black. This water must be

flushed from the system before start-up. This procedure should be performed

without the high pressure hose, gun and dual lance assembly installed.

1. Turn on the water supply.

2. Move the switch to the "Pump" position. Low pressure water will begin

flowing from the water outlet. This allows the unit to flush any particles from

the system. The unit is flushed when the water is clear.

3. Once the system is flushed, move the switch to the "OFF" position and

connect the high pressure hose to the water outlet of the unit.

4. Connect the trigger gun and dual lance assembly to the high

pressure hose.

START-UP/COLD WATER OPERATION:

CAUTION

RISK OF UNIT DAMAGE.

BE CERTAIN THE HOSE, GUN

& DUAL LANCE ASSY. ARE

NOT CONNECTED TO T H E

UNIT WHILE FLUSHING THE

SYSTEM. FLUSHING ALLOWS

MINERAL DEPOSITS TO BE

RELEASED FROM THE SYSTEM

WHICH WOULD OBSTRUCT

OR DAMAGE THE GUN AND

NOZZLE ASSEMBLY RESULTING

IN COSTLY REPAIRS.

1. Refer to the "Safety Precautions" pgs. 4-7 before starting the unit.

2. Locate the Safety Decals on your unit and heed their warnings.

3. Ensure that the switch is in the "OFF" position.

4. Pointing the trigger gun in a safe direction, unlock the trigger gun and

squeeze the trigger. Brace yourself for possible gun kickback when the

pump starts.

5. Move the switch to the "Pump" position.

6. Once the unit has started, perform the following procedures with the gun

open:

a. Inspect for system water leaks, oil leaks and fuel leaks.

If a fuel leak is found, TURN UNIT OFF IMMEDIATELY! See "Risk of

Explosion or Fire", pg. 5. Be sure that all damaged parts are replaced

and that the mechanical problems are corrected prior to operation of

the unit. If you require service, contact Customer Service.

b. Inspect high pressure hoses for kinking, cu ts and leaks.

If a cut or leak is found, DO NOT TOUCH HOSE AT LEAK!!! TURN UNIT

OFF IMMEDIATELY! Replace hose before starting the unit. See "Risk

of Injection or Severe Cutting Injury" pg. 6. Be sure that all damaged

parts are replaced and that the mechanical problems are corrected

prior to operation of the unit. If you require service, contact Customer

Service.

7. At this point, the unit is operating as a cold water pressure washer. Trigger

the gun several times and try adjusting the water pressure by rotating the

grip on the dual lance. NEVER place hand or fingers in front of the nozzle

or look directly into the nozzle! High pressure water creates a risk of severe

injury!

8. Do not allow unit to operate in bypass mode (with trigger closed) for more

than three minutes without triggering the gun. Failure to follow this simple

rule can cause premature failure of pump packings, resulting in costly pump

repair.

NOTE: If this unit is equipped with an Auto Start/Stop feature, the pressure

washer will shutdown if the gun is not triggered after a designated

amount of time. The pressure washer will start again once the gun

is triggered. The Auto Start/Stop feature is preset at the factory for

shutdown at 90 seconds. It can be adjusted by an Authorized Service

Technician to shutdown from no usage after a minimum of 3 seconds

to a maximum of 5 minutes.

9. Your pressure washer can deliver high pressure spray and a variety of spray

patterns using cold water. If you wish to use the Hot Water, Steam application

or Cleaning with Detergents, see page 18 for the correct procedures.

WARNING

RISK OF INJECTION CAUSING

SEVERE INJURY!

-KEEP CLEAR OF NOZZLE! NEVER

PLACE HAND OR FINGERS IN

FRONT OF NOZZLE!

-DO NOT DIRECT DISCHARGE

STREAM AT PEOPLE OR PETS!

-AUTO START/STOP FEATURE

WILL SHUTDOWN THE PRESSURE WASHER UNTIL GUN IS

TRIGGE R ED. TO PREVENT

ACCIDENTAL HIGH PRESSURE

DISCHARGE, DO NOT LEAVE

UNIT UNATTENDED WHILE IN

THIS MODE.

CAUTION

RISK OF DAMAGE.

DO NOT ALLOW SPRAY PATTERN

TO REMAIN ON A FIXED AREA

FOR AN EXTENDED PERIOD OF

TIME. POSSIBLE DAMAGE MAY

OCCUR TO THE AREA.

John Deere Operator's Manual 17

Page 18

WARNING

RISK OF BURN!

THE WATER TEMPERATURE

COULD BECOME VERY HOT

DURING HOT WATER/STEAM

OPERATION. BE CAUTIOUS

WHEN ADJUSTING PRESSURE

OR CONTROLLING THE TRIGGER

GUN/DUAL LANCE ASSEMBLY.

OPERATING INSTRUCTIONS

HOT WATER OPERATION:

1. Follow the steps 1-8 outlined for "START-UP/COLD WATER

OPERATION".

2. Move the switch to the "Burner" position. On initial start-up, water will

begin turning hot in approximately 20 seconds and will reach maximum

temperature in approximately 2-1/2 minutes, provided the trigger remains

squeezed. The burner will stop firing when the trigger is released.

NOTE: While spraying, it is normal for the burner to fire intermittently. The

high limit switch will cause combustion to cease when the temperature

of the discharged water exceeds the temperature setting of the switch.

Combustion will begin again when the water temperature drops below

the minimum setting .

At this point, the unit is operating as a hot water pressure washer. Be

extremely cautious when adjusting the pressure and controlling the

trigger gun/dual lance assembly to avoid the possibility of burns.

STEAM OPERATION:

1. Follow steps 1-8 outlined for "STARTUP/COLD WATER OPERATION".

2. Ensure the quick-connect at the end of the dual lance is cool enough to

touch, then remove the high pressure nozzle and replace it with the steam

nozzle. Remove the high pressure hose and replace it with the steam

hose.

3. Turn unloader knob completely counterclockwise to the minimum setting.

4. Turn the switch to "Steam".

NOTE: The burner will shut down if the switch is moved to "Steam" without

first setting the unloader to minimum or operating in the high pressure

mode.)

At this point, the unit will operate as a steam pressure washer. Be

extremely cautious when adjusting the pressure and controlling the

trigger gun/dual lance assembly to avoid the possibility of burns.

CLEANING WITH DETERGENTS:

NOTE: This feature is designed for use with mild detergents only. Since the

cleaning solution travels through various parts of the pressure washer,

do not use corrosives as they will cause extensive damage as well as

pose a considerable safety hazard.

1. Refer to "Risk of Bodily Injury / Detergents" pg. 7. Be certain to wear

protective safety attire as stated on pg. 12.

2. Prepare detergent solution according to label directions. (Never pump acids,

alkalines, abrasive fluids or solvents through the unit. Due to the unknown

DETERGENT METERING VALVE

18 John Deere Operator's Manual

and often corrosive characteristics of many detergents commonly used in

the pressure washer cleaning industry, it is recommended to use only mild

detergents with this unit.)

3. Fully immerse the strainer end of the clear vinyl detergent hose into the

detergent solution.

4. Adjust the amount of detergent desired. Turn the metering valve completely

counterclockwise to set at maximum siphon rate.

5. To apply solution; unlock the trigger gun and squeeze the trigger. In a few

moments a detergent/water mixture will exit the nozzle. Start spraying

the lower portion of the surface being cleaned and move up, using long

overlapping strokes. Applying from the bottom up helps avoid streaking.

Allow to soak briefly. Avoid working on hot surfaces or in direct sunlight to

minimize the chances of the detergent drying, which may result in damaging

surfaces. Be certain to apply cleaning solution to a small section at a

time.

6. To rinse; lock the trigger gun in the "OFF" position, turn the detergent

metering valve to the "OFF" position. Unlock the trigger gun and spray. It

will take about 30 seconds to purge all detergent from the line. For best

rinsing results, start at the top and work down.

7. Siphon a gallon of water through the detergent injection system after each

use. This prevents the possibility of corrosion or detergent residue causing

mechanical problems during the next use.

Page 19

SHUTDOWN:

OPERATING INSTRUCTIONS

1. Move the switch to the "Pump" position.

2. Squeeze the trigger and discharge the water for a period of three minutes

to cool the heat exchanger and high pressure hose. (Insufficient cool down

period of the high pressure hose will cause excessive wear and eventual

rupturing of the hose.)

3. Move the switch to the "OFF" position. (Auto Start/Stop Option will shut

the unit down, but total shutdown requires switch to be moved to the

"OFF" position.)

4. Turn off the water supply and trigger the gun momentarily to relieve trapped

pressure.

5. Disconnect and drain the high pressure hose, gun, and dual lance. Wipe the

unit clean and store in a non-freezing environment.

DANGER

RIS K OF INJEC T ION CAUSI N G

SEVERE INJURY!

-AUTO START/STOP FEATURE WILL

SHUTDOWN THE PRESSURE WASHER

UNTIL THE GUN IS TRIGGERED.

TOTAL SHUTDOWN REQUIRES "OFF/

PUMP/BURNER/STEAM" SWITCH TO

BE MOVED TO THE OFF POSITION.

-TO PREVENT ACCIDENTAL HIGH

PRESSURE DISCHARGE, DO NOT

LEAVE UNIT UNATTENDED UNTIL

"O FF / PU M P/ B UR N ER / ST E AM "

SWITCH IS IN THE OFF POSITION.

SPECIFIC MAINTENANCE:

STORAGE & MAINTENANCE INSTRUCTIONS

PUMP: Change the pump oil after the first 50 hours of operation. After initial change,

every 3 months or 250 hour intervals are recommended. If oil appears dirty or

milky, changes may be required in greater frequency. Use pump oil SAE20 or

30 and fill only to the center of the oil sight glass. DO NOT overfill.

QUICK COUPLERS: There are o-ring seals inside the couplers which will deteriorate.

To replace, simply install a replacement o-ring to correct the leak. (Additional

o-rings can be purchased from your dealer.)

NOZZLE: Water flow through the spray nozzle will erode the orifice, making it

larger, resulting in a pressure loss. Nozzles should be replaced whenever

pressure is less than 85% of the maximum. The frequency of replacement will

depend upon such variables as mineral content in the water and number of

hours the nozzle is used.

FUEL WATER SEPARATOR: The fuel filter has a built in water separator.

Occasionally the water has to be drained from the separator. Follow the

procedures listed below:

1. Check the collection bowl daily.

2. Ensure the unit is off and place an oil catch basin under the

fuel cartridge.

3. Loosen the drain plug to allow the fuel/water contaminents to

flow into the catch basin.

4. Retighten the drain plug when completed.

5. Dispose of drainage according to environmental regulations in

your area.

BURNER AIR ADJUSTMENT: The air shutter has been factory preset for proper

operation between sea level and 2000 feet elevation at standard conditions

(60°F ambient water and air temperatures). To assure maximum combustion

efficiency at colder temperatures and higher altitudes, it will be necessary

to adjust the air supply to the combustion chamber. A smoke spot test is

recommended during any air shutter adjustment. This will aid in maximizing

the burner efficiency and avoid the inefficient operation and excessive

sooting of the combustion chamber.

1. The machine must be running and the burner on.

2. Take a smoke spot test to determine if more or less air is

required for proper combustion.

a. If the test is greater than a #3 smoke, turn the shutter

arm counterclockwise to increase the air flow into the

combustion chamber.

b. If the test is yellowish in color, turn the shutter arm

clockwise to decrease the air flow into the combustion

chamber.

3. Hold onto the air shutter adjusting arm and loosen the locking nut.

Move the shutter in 1/8" increments and retighten the locking nut

after each 1/8" movement.

4. Trigger the gun on and off slowly to make sure there is proper

ignition. Slight or no puffing on the ignition, and a smoke spot test

of 0-3 is good.

5. Repeat steps 2 and 3 until step 4 is attained.

LEAKS: Promptly eliminate any leaks found in the pumping system by removing

suspect parts, applying thread sealant to the threads and reinstalling.

NOTE: If using teflon tape, be certain no tape gets inside any plumbing to prevent

the possibility of a plugged spray nozzle.

John Deere Operator's Manual 19

Page 20

WARNING

32˚F 0˚C

RISK OF UNIT BURSTING.

DO NOT STORE / OPERATE

UNI T IN A FRE EZ ING

ENVIRONMENT!

COIL DRAIN PLUG

STORAGE & MAINTENANCE INSTRUCTIONS

WINTERIZING:

1. For storage and transportation purposes in subfreezing ambient temperatures, it

will be necessary to winterize this unit. This unit must be protected to the lowest

incurred temperature for the following reasons:

a. If any part of the pumping system becomes frozen; excessive pressure may

build up in the unit which could cause the unit to burst resulting in possible

serious injury to the operator or bystanders.

b. The pumping system in this unit may be permanently damaged if frozen.

FREEZE DAMAGE IS NOT COVERED BY WARRANTY.

If you must store your unit in an area where the temperature may fall below

32°F,

you can protect your unit by following the procedure outlined below.

1. Gather the following items:

a. Two 5 gallon containers.

b. One gallon of antifreeze. (Use an environmentally safe antifreeze.)

c. Water supply.

d. Three foot hose, 1/2-3/4 I.D. with a 3/4 inch male garden hose fitting.

2. Procedure:

a. To start winterizing, unit must be run according to the "Start-up Cold Water

Operation" listed on page 18.

b. After running, shut off the unit and water supply.

c. Relieve system pressure by pointing the trigger gun in a safe direction and

squeezing the trigger until water flow ceases to exit the Dual Lance Assy.

d. Lock the trigger gun in the OFF position and adjust the Dual Lance to the low

pressure mode.

NOTE: Proper winterizing is based on the recommended manufacturer's instructions

listed on the "Protection Chart" shown on the back label of most antifreeze

containers.

e. Remove lid from float tank.

f Start the unit and squeeze the trigger gun until the float tank is almost

empty.

g. Stop the unit.

h. Mix antifreeze and water in a container that can be used for pouring the solution

into the float tank.

i. Start the unit. Point the trigger gun into the empty container. Trigger the

gun until the antifreeze begins to exit the trigger gun. Continue cycling the

trigger gun several times until all the antifreeze mixture is siphoned from the

container.

j. Stop the unit.

k. Disconnect the hose and trigger gun from the unit and drain any excess

antifreeze back into the 5 gallon container.

l. Drain hose, trigger gun and dual lance assembly and store with the unit in a

safe non-freezing area.

m. Store antifreeze solution for next use or dispose of according to state EPA

laws.

3. OPTIONAL PROCEDURE:

a. Shut the unit and water supply off.

b. Relieve system pressure by pointing the trigger gun in a safe direction and

squeezing the trigger until water flow ceases to exit the nozzle.

c. Disconnect and drain the hose, trigger gun and dual lance assembly.

d. Remove the coil drain plug from the heat exchanger inlet.

e. Start the unit and allow it to run until all the water exits the unit. Once the water

has stopped flowing from the unit, turn off.

NOTE: When using this procedure, use caution as ice chips can form from drops of water

20 John Deere Operator's Manual

which could cause the unit to burst if starting before completely thawed.

Page 21

TROUBLESHOOTING

SYMPTOM PROBABLE CAUSE REMEDY

Pump motor will not run. Circuit overload. Check wall breaker or fuse.

GFCI tripped. Reset.

Motor overload. Reset thermal overload button on

pump motor or inside electrical

control panel.

Auto Start/Stop Option in use. Point gun in a safe direction an

squeeze trigger.

No discharge at nozzle when Inadequate water supply. Ensure hose is 3/4" diameter and

trigger mechanism is squeezed. incoming water supply is turned on.

Low or fluctuating pressure. Kink in water inlet hose. Remove kink.

Kink in high pressure discharge hose. Replace kinked high pressure hose.

Water inlet screen obstructed. Remove screen, clean or replace.

Pump sucking air. (Prime eliminated) Tighten all water intake connections

Eliminate leaks in intake line.

Adjustable Grip on Dual Lance Turn grip counterclockwise to move

is not in high pressure mode. to high pressure.

Obstructed or worn spray nozzle. Remove, clean or replace.

Damaged or obstructed valve assy. Remove, clean or replace.

on pump.

Pump packings worn. Replace packings.

Unloader/Bypass valve not operating Repair or replace.

correctly.

Scale build-up in heat exchanger coil. Descale coil.

Water is leaking from Heat DumpValve. Water inlet temperature is too high. Incoming water temperature must be

less than 125°.

Water temperature is too high. Do not allow unit to operate in

bypass mode (with the trigger gun

closed) for more than three minutes.

Defective valve. Replace.

Oil appears milky or foamy. Water in oil. Change pump oil. Fill to proper

level.

Oil leaking from unit. Worn seals or o-rings. Contact Customer Service.

Detergent will not siphon . Detergent strainer is not completely Check, submerge if necessary.

submerged in detergent solution.

Detergent strainer obstructed. Inspect, clean or replace.

Detergent hose cut, obstructed or Inspect, clean or replace.

kinked.

Detergent adjusting knob turned to Open adjusting knob. Refer to

closed position. "Cleaning with Detergents" pg. 18.

John Deere Operator's Manual 21

Page 22

TROUBLESHOOTING

SYMPTOM PROBABLE CAUSE REMEDY

Water flows back into detergent Check valve missing or corroded. Remove, clean or replace.

container.

Water flows from the nozzle when the Trigger gun is malfunctioning. Repair or replace.

trigger gun is locked in the "OFF"

position.

Water is leaking under heat exchanger Coil drain plug is not installed. Install.

coil.

Safety Relief device is relieving 1. Detect and correct unloader or

caused by an unloader or pressure pressure switch problem.

switch malfunction. 2. Replace safety relief device.

NEVER run unit without safety

relief device. Doing so can

cause an explosion!

Burner will not ignite Switch is not in "Burner" Check switch position.

position.

No voltage. Contact Customer Service.

Out of fuel. Refuel. (Reset burner primary

control on cad cell options.)

Fuel pickup screen obstructed. Consult Service.

Trigger gun is closed. Open trigger gun for pressure.

Pressure switch override. Pressure should be over 250 PSI

to allow burner to come on.

High limit switch override. Unit will automatically reignite when

cool.

Flexible coupler broken. Replace.

Dirty or clogged fuel filter/water sep. Drain or replace as necessary.

Fuel pump sucking air. Tighten all fuel intake connections.

Eliminate leaks in intake line.

Fuel pump inoperative. Check pressure, replace if needed.

Dirty or clogged fuel nozzle. Replace.

Improper burner air adjustment. Adjust as explained on page 19.

Ignition transformer failure. Replace.

Ignition electrodes damaged or worn. With unit running and trigger gun

closed, look through burner sight

glass to ensure there is sparking

across electrodes.

Fuel solenoid valve failure. Replace.

High PSI mode. Verify Burner/Steam switch is in

"Burner" mode.

Steam Option: Steam Mode. Verify Burner/Steam switch is in

"Steam" mode.

Steam mode: Pump Head PSI too Reduce pressure to 350PSI.

high.

Cad Cell Option: Primary control lock-out. Reset.

22 John Deere Operator's Manual

Page 23

TROUBLESHOOTING

SYMPTOM PROBABLE CAUSE REMEDY

Burner motor will not run. Switch is not in "Burner" position. Check switch position.

No voltage. Contact Customer Service.

Motor overload. Motor automatically resets when

cool.

Fuel pump siezed. Allow motor to cool. Repair or

replace.

Blower Fan seized. Allow motor to cool. Repair or

replace.

Burner runs erratically. Water in the fuel oil. Drain fuel filter/water separator.

Drain fuel tank, and replace with

clean fuel.

Dirty fuel filter/water separator. Replace element.

Dirty fuel nozzle. Replace.

Fuel pickup screen obstructed. Consult Service.

Improper air adjustment setting. Adjust as explained on page 19.

Fuel pump malfunctioning. Replace.

Burner runs, but will not heat. Poor or improper fuel supply. Check fuel to ensure it is correct.

Drain tank and replace filter if

necessary and refill with proper fuel.

Low fuel pump pressure. Check fuel pump pressure, adjust or

replace if needed.

Dirty fuel nozzle. Replace.

Fuel pickup screen obstructed. Consult Service.

Improper air adjustment setting. Adjust as explained on page 19.

Scale build up in heat exchanger coil. Consult your Customer Service.

Burner discharges white smoke. Low on fuel. Refuel. If white smoke persists,

consult Customer Service.

Poor or improper fuel supply. Check fuel pump pressure, adjust or

replace if needed.

Dirty fuel nozzle. Replace.

Fuel pickup screen obstructed. Consult Service.

Improper air adjustment setting. Adjust as explained on page 19.

Cold combustion chamber start-up. Run burner for several minutes.

Excessive air supply. Adjust as explained on page 19.

Burner discharges black smoke. Insufficient air supply. Adjust as explained on page 19.

Combustion chamber loaded with Consult your Customer Service.

unburned fuel.

John Deere Operator's Manual 23

Page 24

MAINTENANCE CHART

PROCEDURE DAILY 3 MONTHS 6 MONTHS 9 MONTHS 12 MONTHS

Inspect electrical cord X

Test GFCI X

Test voltage and amp draw X

Check water pump oil level X

Change water pump oil ** X X X X

Oil leak inspection X

Fuel leak inspection X

Water leak inspection X

Hose inspection X

Water inlet filter inspection X

Check fuel filter/water separator X

Inspect belt X X X X

Replace high pressure nozzle*** X X X X

Replace fuel filter/water separator X

Inspect fuel pump filter* X

Replace fuel nozzle* X

Check burner air adjustment X X X X

Check burner electrodes* X

Test water pressure* X X X X

Test fuel pressure* X X X X

Test water temperature* X X X X

Descale coil**** X

* Must be performed by an authorized service technician.

** The pump oil must be changed after the first 50 hours of operation and every 250 hours or 3 months, whichever

comes first.

*** High pressure nozzle should be replaced whenever pressure is less than 85%.

**** Scale build-up will vary with mineral content in the water and amount of usage. Descaling can range from weekly

to yearly maintenance.

24 John Deere Operator's Manual

Page 25

STATEMENT OF WARRANTY

The manufacturer warrants all parts, (except those referred to below), of your new hot

water pressure washer to be free from defects in materials and workmanship during the

following periods:

For Five (5) Years from the date of original purchase:

High Pressure Pump

For Three (3) Years from the date of original purchase:

Heat Exchanger Coil

For Two (2) Years from the date of original purchase:

Frame Plumbing

Guard or Shields Pulleys

For One (1) Year from the date of original purchase:

Selector Switches GFCI Cord

Starter Contactor Overload

Adjustable Thermostat

For Six (6) months from the date of original purchase:

Ignition Transformer Burner Motor

For Ninety (90) days from the date of original purchase:

Regulating Valve Electrodes

Safety Switches Fuel solenoid

Fuel Pump

For Thirty (30) days from the date of original purchase:

High Pressure Hose Trigger Gun

Strainers / Filters Dual Lance

Defective parts not subject to normal wear and tear will be repaired or replaced at our

option during the warranty period. In any event, reimbursement is limited to the purchase

price paid.

EXCLUSIONS

1. The motor is covered under separate warranty by its respective manufacturer and is

subject to the terms set forth therein.

2. Normal wear parts:

Pump Packings Spray Nozzles

Pump Valves Detergent Valves

Fuel Filters Quick Couplers

3. This warranty does not cover parts damaged due to normal wear, misapplication,

misuse, operation at other than recommended speeds, pressures or temperature. Parts

damaged or worn because of the use of caustic liquids or by operation in abrasive or

corrosive environments or under conditions causing pump cavitation are not warranted.

Failure to follow recommended operating and maintenance procedures also voids

warranty.

4. The use of other than genuine repair parts will void warranty. Parts returned, prepaid to

our factory or to an Authorized Service Center will be inspected and replaced free of

charge if found to be defective and subject to warranty. There are no warranties

which extend beyond the description of the face hereof. Under no circumstances shall

the manufacturer bear any responsibility for loss of use of the unit, loss of time or

rental, inconvenience, commercial loss or consequential damages.

For Service or Warrnay Consideration, contact

Mi-T-M® Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

John Deere Operator's Manual 25

Page 26

TABLE DES MATIÈRES

INTRODUCTION .................................................................................................................... 27

INSTRUCTIONS IMPORTANTES DE SÉCURITÉ ........................................................... 28-34

RISQUE DE DÉCHARGE ÉLECTRIQUE OU D'ÉLECTROCUTION ................... 28-29

RISQUE D'EXPLOSION OU D'INCENDIE ................................................................

RISQUE D'ASPHYXIE .............................................................................................. 31

RISQUE DE PIQÛRE OU DU COUPURE GRAVE ................................................... 31

RISQUE DE BRÛLURES ...........................................................................................

RISQUE D'

RISQUE PROVENANT DES PIÈCES MOBILES ...................................................... 32

RISQUE DE BLESSURES CORPORELLES ........................................................ 33-34

CARACTERISTIQUES ...................................................................................................... 36-39

CARACTÉRISTIQUES DU AC-1500EH & AC-2000EH ....................................... 36-37

CARACT

ÉCLATEMENT ......................................................................................... 32

ÉRISTIQUES DU AC-3000EH & AC-3000EH-3 .................................... 38-39

30

32

TENUE ....................................................................................................................... 40

INSTALLATION .......................................................................................................... 40

RACCORDEMENT DU CORDON DE SECTEUR ................................................ 40-41

RÉSERVOIR DE CARBURANT ................................................................................. 41

DOUBLE LANCE A PRESSION REGLABLE ............................................................. 42

RACCORDEMENT DE LA DOUBLE LANCE ............................................................ 42

APPROVISIONNEMENT EN EAU ............................................................................. 42

DÉCHARGEUR ......................................................................................................... 43

SOUPAPE DE DÉCHARGE DE LA CHALEUR ......................................................... 43

PROCÉDURES d'INSPECTION ET DE PRÉ DÉMARRAGE .................................... 43

VIDANGE DU SYSTÈME .......................................................................................... 45

MISE EN ROUTE/ FONCTIONNEMENT A L'EAU FROIDE ................................. 45-46

FONCTIONNEMENT A L'EAU CHAUDE ................................................................... 46

FONCTIONNEMENT A LA VAPEUR ......................................................................... 47

NETTOYAGE AVEC DES DÉTERGENTS ................................................................. 47

ARRÊT .......................................................................................................................

ENTRETIEN PARTICULIER ................................................................................ 48-49

PR

INSTRUCTIONS D'INSTALLATION ET DE PRÉPARATION ........................................... 40-43

CONSIGNES D'UTILISATION ..........................................................................................

INSTUCTIONS DE STOCKAGE ET D'ENTRETIEN ........................................................ 48-51

ÉPARATION DE L'APPAREIL POUR L'HIVER ................................................ 50-51

DÉPANNAGE .................................................................................................................... 52-56

45-48

48

TABLEAU D'ENTRETIEN ...................................................................................................... 57

NOTE...... ................................................................................................................................ 58

BON DE DE GARANTIE. .............. ........................................................................................ 59

26 John Deere le manuel de l'utilisateur

Page 27

INTRODUCTION

Félicitations de l’achat de votre nouveau nettoyeur haute pression! Vous pouvez être assuré que votre nouveau

nettoyeur haute pression a été construit et conçu avec qualité et performance à l’esprit. Chaque composant a été

rigoureusement testé afin d’atteindre le plus haut niveau de fiabilité.

Le manuel de l’utilisateur a été dressé pour que vous en retiriez le meilleur parti. Par la lecture et l'application des

mesures simples de sécurité, d’installation, d'opération, d’entretien et de dépannage décrites dans ce manuel, votre

nouveau nettoyeur haute pression fonctionnera sans faille pendant de nombreuses années. Le contenu de ce manuel

est basé sur la dernière information disponible du produit au moment de la publication. Le fabricant se réserve le droit

d’effectuer des changements de prix, de couleur, de matériaux, d’équipement, de caractéristiques ou de modèles à

tout moment sans préavis.

! IMPORTANT !

Ces paragraphes sont entourés par un “ ENCADRÉ ALERTE SÉCURITÉ “. Cet encadré est utilisé pour indiquer et

souligner les avertissements de sécurité qui doivent être suivis en utilisant ce nettoyeur haute pression.

En plus des avertissements de sécurité, des "mots d'alerte" sont utilisés pour indiquer le degré ou niveau de risque.

Les "mots d'alerte" utilisés dans ce manuel sont les suivants:

DANGER: Indique une situation au danger imminent qui, si elle n’est pas évitée,

ENTRAINERA la mort ou des blessures graves.

AVERTISSEMENT: Indique une situation potentiellement dangereuse qui, si elle n’est pas

évitée, POURRAIT entraîner la mort ou des blessure graves.

ATTENTION: Indique une situation potentiellement dangereuse, qui, si elle n'est pas évitée,

PEUT entraîner des dommages corporels mineurs ou modérés.

Les symboles plaçés à gauche de ce paragraphe sont des "symboles d'alerte de sécurité".

Ces symboles sont utilisés pour souligner les objets ou les procédures qui pourraient être

dangereux pour vous ou tout autre personne utilisant cet équipement.

FOURNISSEZ TOUJOURS UNE COPIE DE CE MANUEL A TOUTE PERSONNE UTILISANT

CET EQUIPEMENT. LISEZ TOUTES LES INSTRUCTIONS AVANT D'UTILISER CE NETTOYEUR

ET SOYEZ PARTICULIEREMENT ATTENTIF AUX "AVERTISSEMENT DE S

ÉCURITÉ" POUR

EMPECHER LA POSSIBILITÉ DE BLESSURES POUR L'UTILISATEUR

Une fois l'appareil déballé, écrivez immédiatement le numéro de série de votre appareil dans l'espace ci-dessous

NUMERO DE SÉRIE_________________________________

Assurez-vous qu’il n’y a pas de signes de dommages évidents ou cachés suite au transport. En cas de dommage,

remplissez immédiatement une réclamation avec la compagnie de transport. Assurez-vous que toutes les pièces

endommagées sont remplacées et les problèmes mécaniques et électriques corrigés avant l’utilisation de l’appareil.

Si vous avez besoin d'assistance, entrez en contact avec votre service clientèle.

Mi-T-M

®

Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 319-556-1235

Lundi- Vendredi 8:00- 17:00 CST (Heure Centrale)

Veuillez avoir les informations suivantes disponibles pour toute intervention:

1. Numéro de modèle

2. Numéro de série

3. Date et lieu d'achat

John Deere le manuel de l'utilisateur 27

Page 28

AVERTISSEMENT: Lors de l'utilisation de ce produit, des précautions de base doivent toujours être observées, incluant les

INSTRUCTIONS IMPORTANTES DE SÉCURITÉ

suivantes:

LIRE TOUTES LES INSTRUCTIONS AVANT UTILISATION DU NETTOYEUR A PRESSION

RISQUE

RISQUE DE DÉCHARGE

ÉLECTRIQUE OU

D'ÉLECTROCUTION

CONSÉQUENCE POTENTIELLE

Des risques de mort ou de

blessures graves peuvent

survenir si la machine n’est pas

reliée à la terre correctement.

Votre nettoyeur haute pression

est alimenté par électricité et

pourrait provoquer une décharge

électrique ou une électrocution si il

n’est pas utilisé correctement.

Cet appareil doit être relié à la terre.

Assurez-vous que le nettoyeur haute

pression est équipé d’un GFCI (Disjoncteur

Différentiel à fuite de terre) dans le cordon

d’alimentation d’énergie. Si ce n’est pas le

cas, le nettoyeur haute pression doit être

branché à un réceptacle qui est protégé par

un GFCI. Débranchez entre les utilisations.

Si votre appareil est équipé d’un GFCI,

ne laissez pas tomber le GFCI car des

dommages pourraient en résulter. Si vous

laissez tomber accidentellement le GFCI,

testez le avant l’utilisation suivante pour

vous assurer qu’il est en état de marche.

(suivez les instructions du GFCI pour les

procédures de test)

Assurez-vous que l’appareil reçoit toujours

le voltage approprié. Avant de brancher

l’appareil à une source d’énergie compatible,

assurez-vous que le commutateur est en

position “off ”. Débranchez entre chaque

utilisation.

PRÉVENTION

Un choc électrique peut se produire

par le fil électrique

Ne modifiez en aucun cas la prise fournie

avec le produit. Si celle ci n’entre pas dans

la prise femelle, faites en installer une

par un électricien qualifié. Ne pas utiliser

d’adaptateur.

Vérifiez que le cordon d’alimentation n’a

pas d’écrasement, de coupures ou de

dommages résultant de la chaleur. Si une

prise ou un cordon d’alimentation a besoin

d’être changé, remplacez le avec un produit

identique.

N’utilisez pas de rallonge électrique avec ce

produit.

Maintenez toutes les connections au sec et

pas sur le sol. Ne pas laisser de fil électrique

tremper dans l’eau ou dans une position telle

que le contact avec l’eau serait possible.

Ne pas toucher la prise avec les mains

mouillées

Ne pas tirer sur le fil électrique pour le

débrancher de la prise.

28 John Deere le manuel de l'utilisateur

Page 29

AVERTISSEMENT: Lors de l'utilisation de ce produit, des précautions de base doivent toujours être observées, incluant

INSTRUCTIONS IMPORTANTES DE SÉCURITÉ

les suivantes:

LIRE TOUTES LES INSTRUCTIONS AVANT UTILISATION DU NETTOYEUR A PRESSION

RISQUE

RISQUE DE DÉCHARGE

ÉLECTRIQUE OU

D'ÉLECTROCUTION

CONSÉQUENCE POTENTIELLE

Un choc électrique peut se

produire si le nettoyeur haute

pression n’est pas utilisé

correctement.

Ne dirigez pas le jet sur ou dans des

installations électriques d’aucune sorte !

Ceci inclut les prises électriques, les

ampoules, les boites à fusibles, les

transformateurs électriques, l’appareil luimême.

Ne pas laisser de composant métallique

de la machine entrer en contact avec des

composants électriques sous tension.

Ne jamais mettre en marche le nettoyeur

haute pression avec les protections/carters

démontés ou endommagés.

PRÉVENTION

Des risques de mort ou de

blessures graves peuvent

survenir si des réparations

électriques sont effectuées par

des personnes incompétentes.

Toute réparation ou câblage électrique

effectué sur le nettoyeur doit être réalisé

par le Personnel de Service Autorisé

et selon les dispositions électriques en

vigueur.

Avant d’ouvrir n’importe quel boîtier

électrique, coupez toujours le nettoyeur

haute pression, relâcher la pression et

débranchez la machine de la source

d’énergie. Laisser le nettoyeur haute

pression refroidir. Ne partez pas du

principe qu’il est sans risque d’effectuer un

travail sur le nettoyeur haute pression juste

parce qu’il n’est pas en route. Il pourrait

se remettre en marche à tout moment!

Tout travail doit s’effectuer dans un endroit

propre, sec, et plat.

John Deere le manuel de l'utilisateur 29

Page 30

INSTRUCTIONS IMPORTANTES DE SÉCURITÉ

LIRE TOUTES LES INSTRUCTIONS DE SÉCURITÉ AVANT UTILISATION

RISQUE

RISQUE D'EXPLOSION OU

D'INCENDIE

CONSÉQUENCE POTENTIELLE

Il y a un risque de mort ou de

blessures graves dues à des

étincelles normales dans les

multiples sources d’allumage ou

dans l’échappement du brûleur.

Il y a un risque de mort

ou de blessures graves si

l’approvisionnement en carburant

n’est pas correctement effectué.

PRÉVENTION

Utilisez toujours le nettoyeur dans un

endroit bien aéré où il n’y a pas de

vapeurs inflammables , de la poussière de

combustible, des gaz ou d’autres matériaux

combustibles.

Ne rangez pas le nettoyeur haute pression

près d’une flamme ou d’un équipement tel

qu’un fourneau, d’un four, d’un chauffe-eau,

etc., équipé d’une lampe témoin ou d’un

dispositif d’ étincellement.

N’employez pas ce nettoyeur haute pression

pour pulvériser un matériau inflammable!

Ne fumez pendant le remplissage du

réservoir de carburant.

Ne jamais remplir le réservoir de carburant

alors que la machine est chaude ou en

marche. Laissez refroidir deux minutes avant

le réapprovisionnement en combustible.

Ne réapprovisionnez pas en combustible en

intérieur ou dans un secteur mal aéré.

Remplissez toujours le réservoir de

carburant lentement pour éviter que du

carburant ne soit renversé, ce qui pourrait

causer un risque d’incendie.

Réservoir de carburant:

Utiliser du fuel oil n° 1 ou n° 2 / diesel

ou kérosène. Ne pas utiliser d’essence,

d’écoulements de carter ou d’huile

contenant de l’essence, de l’huile/diesel ou

des dissolvants.

Il y a un risque de mort ou

de blessures graves si les

sécurités du système ne sont pas

correctement entretenues.

30 John Deere le manuel de l'utilisateur

N’utilisez pas l’appareil si du carburant

diesel est renversé. Essuyez le nettoyeur

haute pression et éloignez-le de la flaque.

Évitez d’allumer quoi que ce soit jusqu’à

l’évaporation totale du diesel.

Ce nettoyeur haute pression est muni

d'un dispositif de sécurité qui ne doit en

aucun cas être changé, modifié, retiré

ou être rendu inopérant. Si ce dispositif