Page 1

AC-2000GH, AC-2400GH,

AC-2400GS, AC-2500GH,

AC-2600GH, AC-2700GH,

AC-2700GS, AC-3000GS,

AC-3300GH AND AC-3500GH

HIGH PRESSURE WASHERS

AC-Series Operator’s Manual-E/F 1

Page 2

Introduction

THANK YOU for purchasing a John Deere product.

READ THIS MANUAL carefully to learn how to operate

and service your machine correctly. Failure to do so

could result in personal injury or equipment damage.

This manual and safety signs on your machine may also

be available in other languages. (See your John Deere

dealer to order.)

THIS MANUAL SHOULD BE CONSIDERED a permanent

part of your machine and should remain with the machine

when you sell it.

MEASUREMENTS in this manual are given in both

metric and customary U.S. unit equivalents. Use only

correct replacement parts and fasteners. Metric and inch

fasteners may require a specic metric or inch wrench.

RIGHT HAND AND LEFT HAND sides are determined by

the direction the machine will travel when going forward.

WRITE SERIAL NUMBER in the Specification or

Identication Numbers section. Accurately record all the

numbers to help in tracing the machine should it be stolen.

Your dealer also needs these numbers when you order

parts. File the identication numbers in a secure place

off the machine.

WARRANTY is provided from your John Deere dealer for

customers who operate and maintain their equipment as

described in this manual. The warranty is explained on

the warranty certicate shown in this manual.

This warranty provides you the assurance that your John

Deere dealer will back products where defects appear

within the warranty period. Should the equipment be

abused, or modied to change its performance beyond

the original factory specifications, the warranty will

become void. Setting fuel delivery above specications

or otherwise overpowering the machine will result in such

action.

Warranty and product support for the engines is provided

by Honda®. The Honda engine warranty is explained in

the Honda Warranty Certicate that accompanies this

pressure washer. Additional copies of the Engine Warranty

Certicate are available from your John Deere dealer.

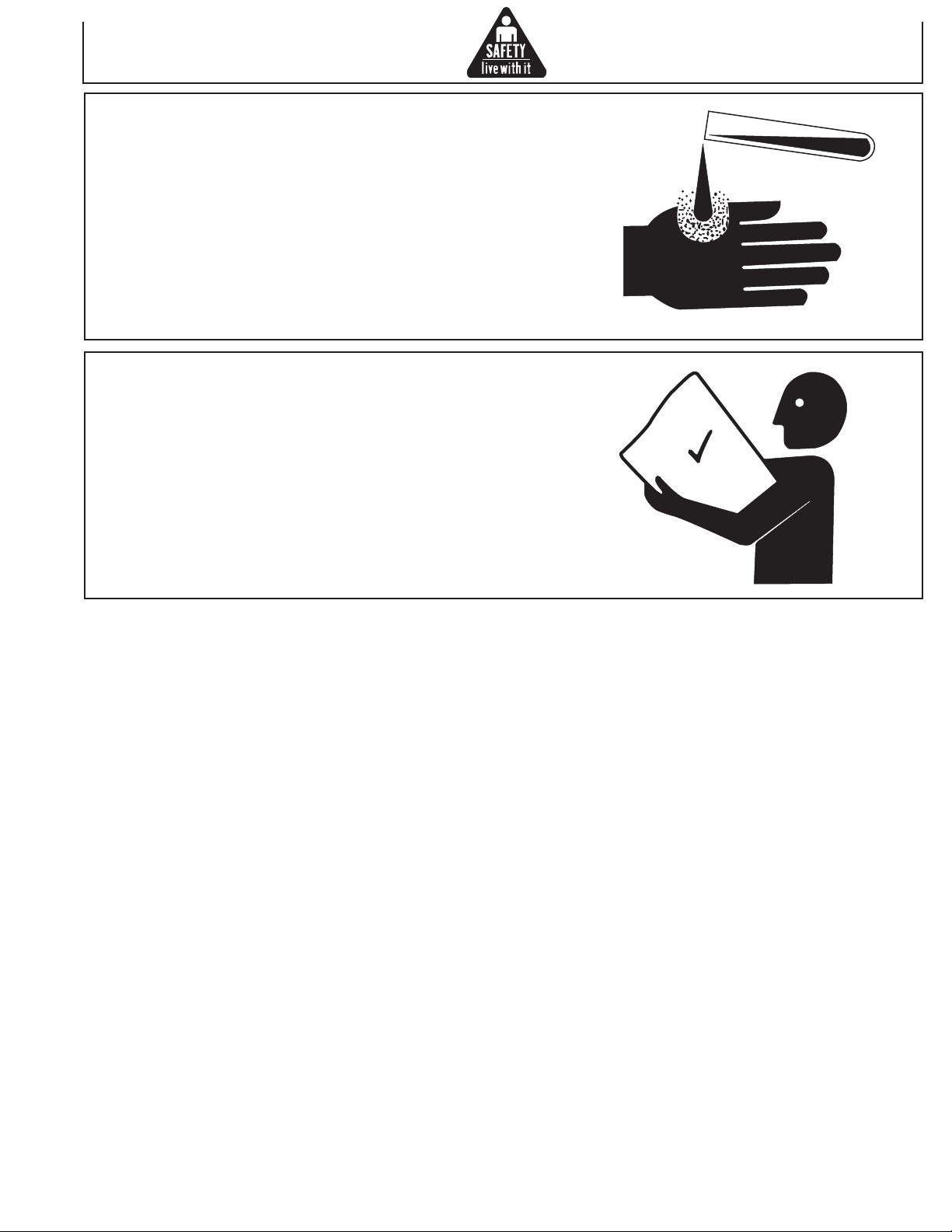

Warning: This product contains lead, a

chemical known to the State of California

to cause birth defects or other reproductive

harm.

Wash your hands after handling this product.

2 AC-Series Operator’s Manual-E/F

Page 3

Contents

Page

Safety .................................................................................. 5

Safety Signs ..................................................................... 10

Controls ........................................................................... 12

Preparing the Washer

Check Engine Oil ................................................................. 14

Gasoline Engine Oil ............................................................. 14

Filling Fuel Tank ................................................................... 15

Inlet Water Supply Requirements ....................................... 16

Check Pump Oil ...................................................................17

Connect Discharge Hose to Gun ......................................... 18

Connect Hoses and Prime Pump ........................................ 19

Installing Nozzle .................................................................. 20

Final Checklist ..................................................................... 20

Operating the Washer

Starting and Operating Engine ........................................... 21

Stopping the Engine ............................................................ 21

Adjusting Water Pressure .................................................... 22

Locking Trigger Gun ............................................................ 23

Changing Nozzle ................................................................. 23

Selecting the Proper Nozzle ................................................ 23

0° Nozzle-Red ..................................................................... 23

15° Nozzle-Yellow ................................................................ 24

25°Nozzle-Green ................................................................. 24

40° Nozzle-White ................................................................. 24

Detergent Injector Nozzle-Black (Brass) ............................. 24

Cleaning Horizontal Surfaces .............................................. 25

Cleaning Vertical Surfaces .................................................. 25

Removing Paint ................................................................... 26

Cleaning Radiator Fins ........................................................ 26

Detergent Usage Guide ....................................................... 27

Cleaning with Detergents .................................................... 28

Shut-down ........................................................................... 30

Troubleshooting .............................................................. 31

Maintenance Chart ........................................................... 33

Service

Cleaning Water Inlet Screen ................................................ 34

Cleaning Detergent Hose Strainer ....................................... 34

Checking Water Pump Oil ................................................... 35

Changing Water Pump Oil ................................................... 36

Check Engine Oil ................................................................. 37

Gasoline Engine Oil ............................................................. 37

Changing Engine Oil ............................................................ 37

Servicing Air Cleaner .......................................................... 38

Cleaning and Gapping Spark Plug ...................................... 39

Adjusting Idle Speed ............................................................ 39

Cleaning Sediment Cup ....................................................... 39

Adjust Belt Tension (AC-2500GH only)............................... 40

Storage

Storing Washer .................................................................... 41

Removing Washer from Extended Storage ......................... 41

Specications

Specications ................................................................42-43

Record Serial Number ......................................................... 43

Page

Accessories

High Pressure Hose ........................................................... 44

Water Filter .......................................................................... 44

Pressure Gauge .................................................................. 44

Pressure Gauge .................................................................. 44

Detergent Injector ................................................................ 45

All-Purpose Cleaning ........................................................... 45

Surface Preparation ............................................................. 45

Degreasing .......................................................................... 45

HY-GARD® ........................................................................... 46

Spray Wax ........................................................................... 46

Rust Inhibiting Antifreeze ..................................................... 46

Detergent Booster ............................................................... 46

Plus-4 Motor Oil ................................................................... 47

Gasoline Conditioner & Stabalizer ....................................... 47

Warranty ............................................................................ 48

All information, illustrations and specications in this manual are based

on the latest information available at the time of publication. The right is

reserved to make changes at any time without notice.

AC-Series Operator’s Manual-E/F 3

Page 4

Contents

4 AC-Series Operator’s Manual-E/F

Page 5

Safety

RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. When you see this symbol

on your machine or in this manual, be alert to the potential

for personal injury.

Follow recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS

A signal word--DANGER, WARNING or CAUTION--is used

with the safety-alert symbol. DANGER identies the most

serious hazards.

DANGER or WARNING safety signs are located near specic hazards. General precautions are listed on

CAUTION safety signs. CAUTION also calls attention to

safety messages in this manual.

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual and on

your machine safety signs. Keep safety signs in good condition. Replace missing or damaged safety signs. Be sure

new equipment components and repair parts include the

current safety signs. Replacement safety signs are available from your John Deere dealer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machine in proper working condition. Unauthorized modications to the machine may impair the function

and/or safety and affect machine life.

If you do no understand any part of this manual and need

assistance, contact your John Deere dealer.

AC-Series Operator’s Manual-E/F 5

Page 6

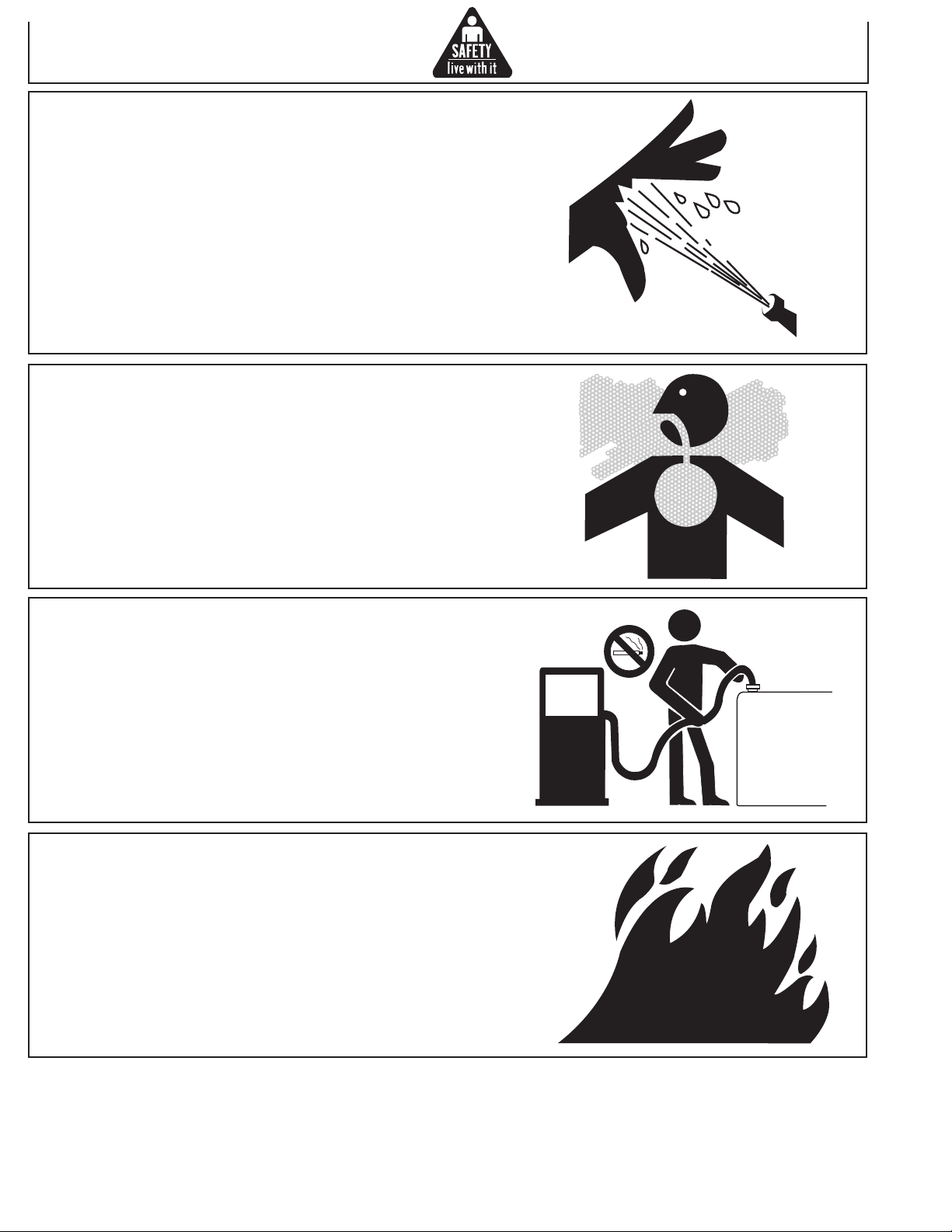

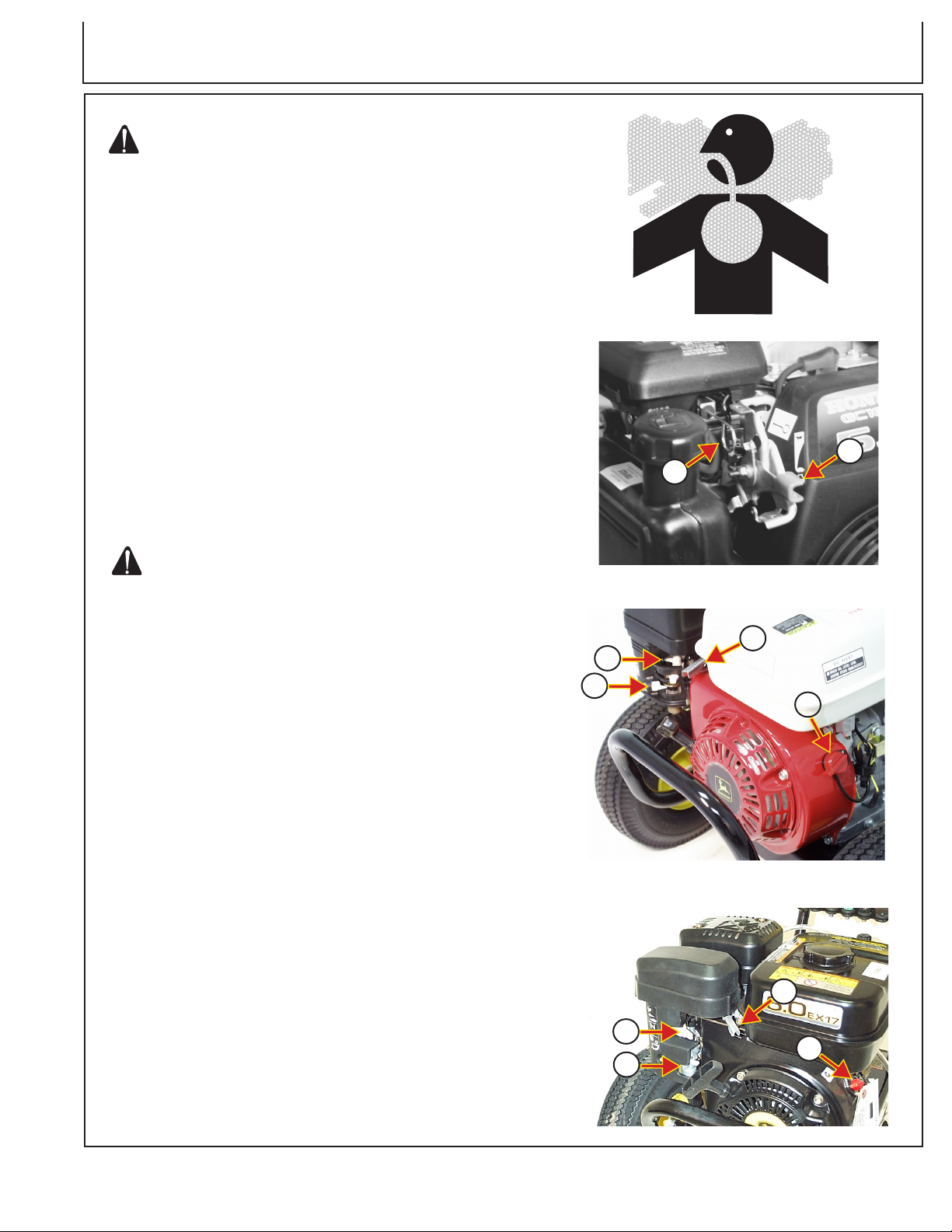

PROTECT AGAINST HIGH PRESSURE

SPRAY

Spray from high pressure nozzles can penetrate the skin

and cause serious injury. Keep spray from contacting

hands or body.

If an accident occurs, see a doctor immediately. Any high

pressure spray injected into the skin must be surgically

removed within a few hours or gangrene may result.

Doctors unfamiliar with this type of injury should reference a knowledgeable medical source. Such information

is available from Deere & Company Medical Department

in Moline, Illinois, U.S.A.

WORK IN A VENTILATED AREA

Engine exhaust fumes can cause sickness or death. If

it is necessary to run an engine in an enclosed area,

remove the exhaust fumes from the area with an exhaust

pipe extension.

If you do not have an exhaust pipe extension, open the

doors and get outside air into the area.

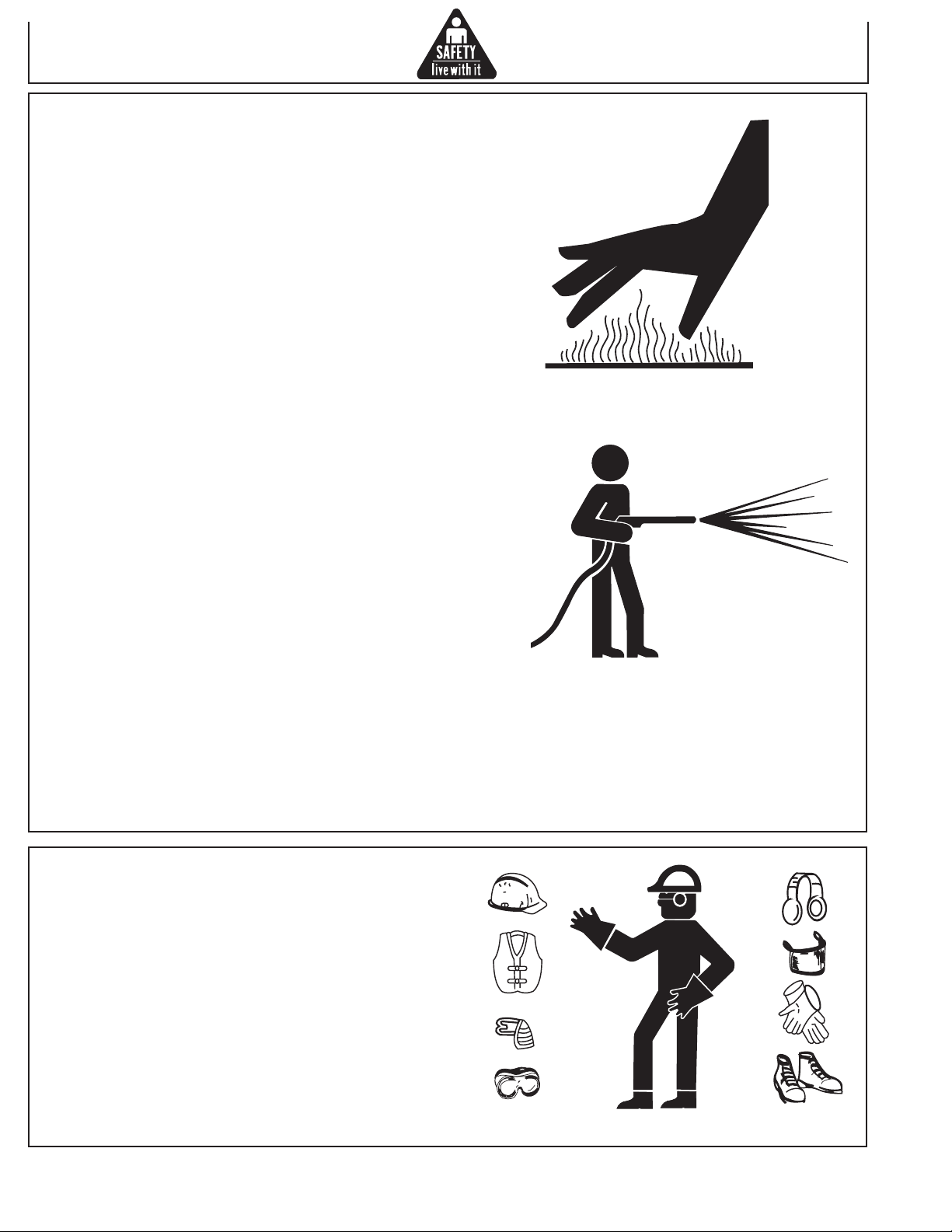

HANDLE FUEL SAFELY-AVOID FIRES

Handle fuel with care: it is highly ammable. Do not refuel the machine while smoking or when near open ame

or sparks.

Always stop engine before refueling machine. Fill fuel

tank outdoors.

Prevent res by keeping machine clean of accumulated

trash, grease and debris. Always clean up spilled fuel.

DRAIN GASOLINE WHEN STORING

MACHINE

Gasoline stored in fuel tank can explode.

Never store equipment with gasoline in the tank inside a

building where fumes may reach an open ame or spark.

Always drain gasoline from fuel tank and carburetor bowl

when storing machine. Allow engine to cool before storing.

6 AC-Series Operator’s Manual-E/F

Page 7

CLEANING DETERGENT PRECAUTIONS

MSDS

Know the detergent being used. Be prepared to tell a

physician exactly what you are using in the event of an

emergency. Read all detergent labels and follow all

instructions exactly regarding preparation, use, safety,

transportation, and disposal. Keep all detergents out of

the reach of children, pets and livestock.

NEVER spray combustible liquids of any kind.

Do not use highly corrosive detergents or acid-type

cleaners with this washer.

HANDLE CHEMICAL PRODUCTS SAFELY

Direct exposure to hazardous chemicals can cause injury.

Potentially hazardous chemicals used with the pressure

washer includes such items as detergents.

A Material Safety Data Sheet (MSDS) provides specic

details on detergents; physical and health hazards,

safety procedures and emergency response techniques.

Check the MSDS before you start any job using a detergent. That way you will know exactly what the risks are

and how to do the job safely. Then follow procedures and

recommended equipment. (See your John Deere dealer

for MSDS Sheets on products used with this equipment.)

AC-Series Operator’s Manual-E/F 7

Page 8

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of injury, read this operator’s

manual completely. When using this product, the following

basic precautions should always be followed:

1. Read all the instructions before using the product.

2. High pressure water spray can cut skin. Do not “lock”

trigger in the open position. Do not direct spray at

persons. Keep operating area clear of all persons

and pets. Warn children that the water spray can

cut. Supervise children closely.

3. Do not allow children or untrained persons to operate

the washer.

4. Do not spray electrical switches, receptacles or light

bulbs, or glass or fragile objects that may shatter

5. Dirt and debris removed by spray can cause eye

injury. Wear eye protection.

6. Do not move washer with engine running. Always stop

engine and allow washer to cool before handling.

7. Wet surfaces can be slippery. Wear shoes and keep

both feet on the ground. Do not climb on items being

cleaned. Do not overreach or stand on unstable

support. Keep good footing and balance at all times.

8. When the spray trigger is released, water pressure

is trapped in the discharge hose. Release trapped

pressure by triggering the spray gun after the washer

is turned off.

9. Do not operate the washer when fatigued or under

the inuence of drugs or chemicals. Stay alert.

Watch what you are doing.

10. Do not operate the washer if fuel, pump oil or water

leaks are visible. Resume operation ONLY after

washer has been inspected and repaired.

11. Follow the maintenance instruction specied in this

manual.

WEAR PROTECTIVE CLOTHING

Wear close tting clothing and safety equipment appropriate to the job.

Prolonged exposure to loud noise can cause impairment or

loss of hearing.

Wear a suitable hearing protective device such as earmuffs

or earplugs to protect against objectionable or uncomfortable loud noises.

Operating equipment safely requires the full attention of

the operator. Do not wear radio or music headphones while

operating machine.

8 AC-Series Operator’s Manual-E/F

Page 9

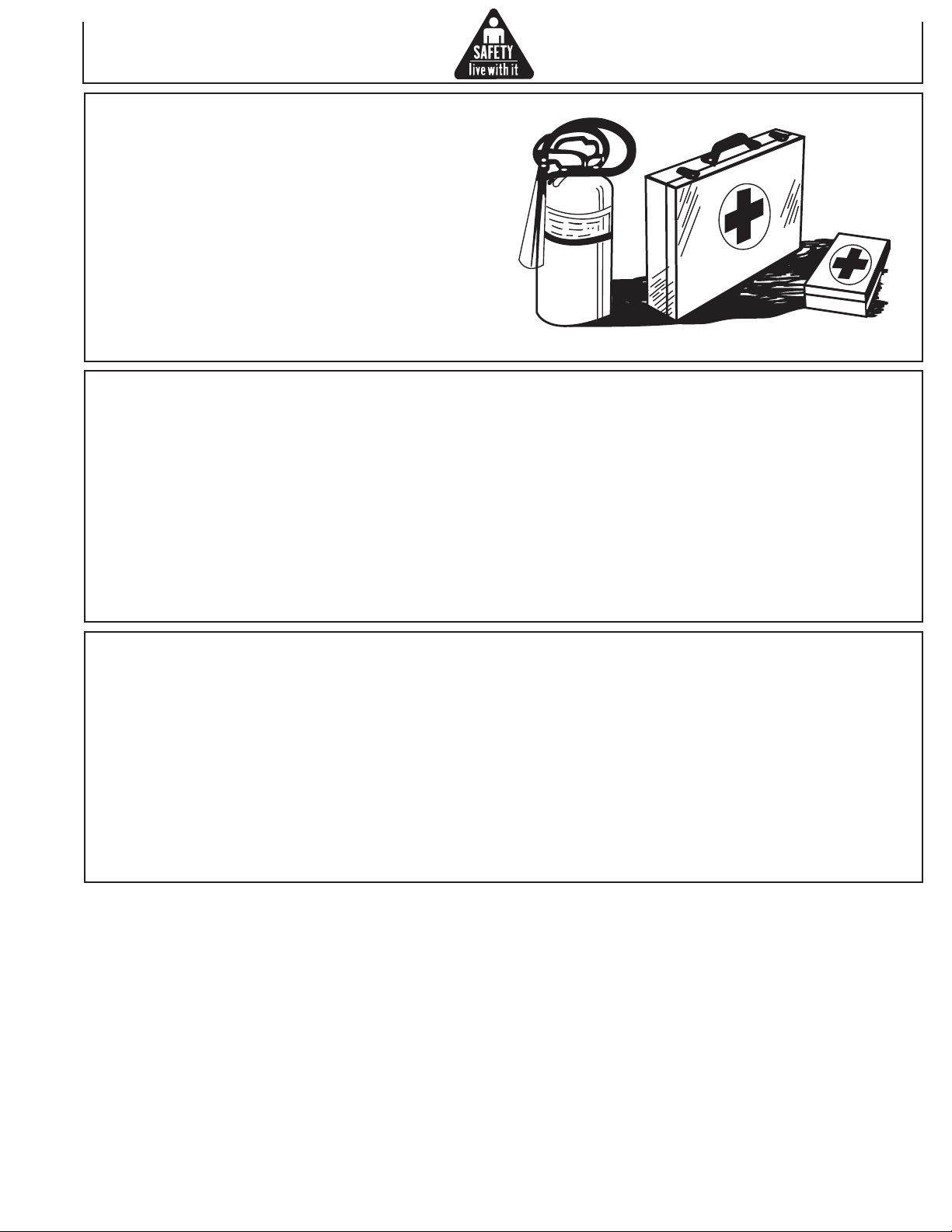

PREPARE FOR EMERGENCIES

Be prepared if a re starts.

Keep a rst aid kit and re extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital and re department near your telephone.

INSPECT HIGH PRESSURE WASHER

Be sure all covers, guards and shields are in place.

Locate all operating controls and safety labels.

Keep all hardware and plumbing ttings tight.

SERVICE HIGH PRESSURE WASHER SAFELY

Before servicing washer, disconnect spark plug wire, relieve

water pressure and allow unit to cool down.

Service washer in a clean dry at area. If applicable, block

wheels to prevent unit from rolling.

AC-Series Operator’s Manual-E/F 9

Page 10

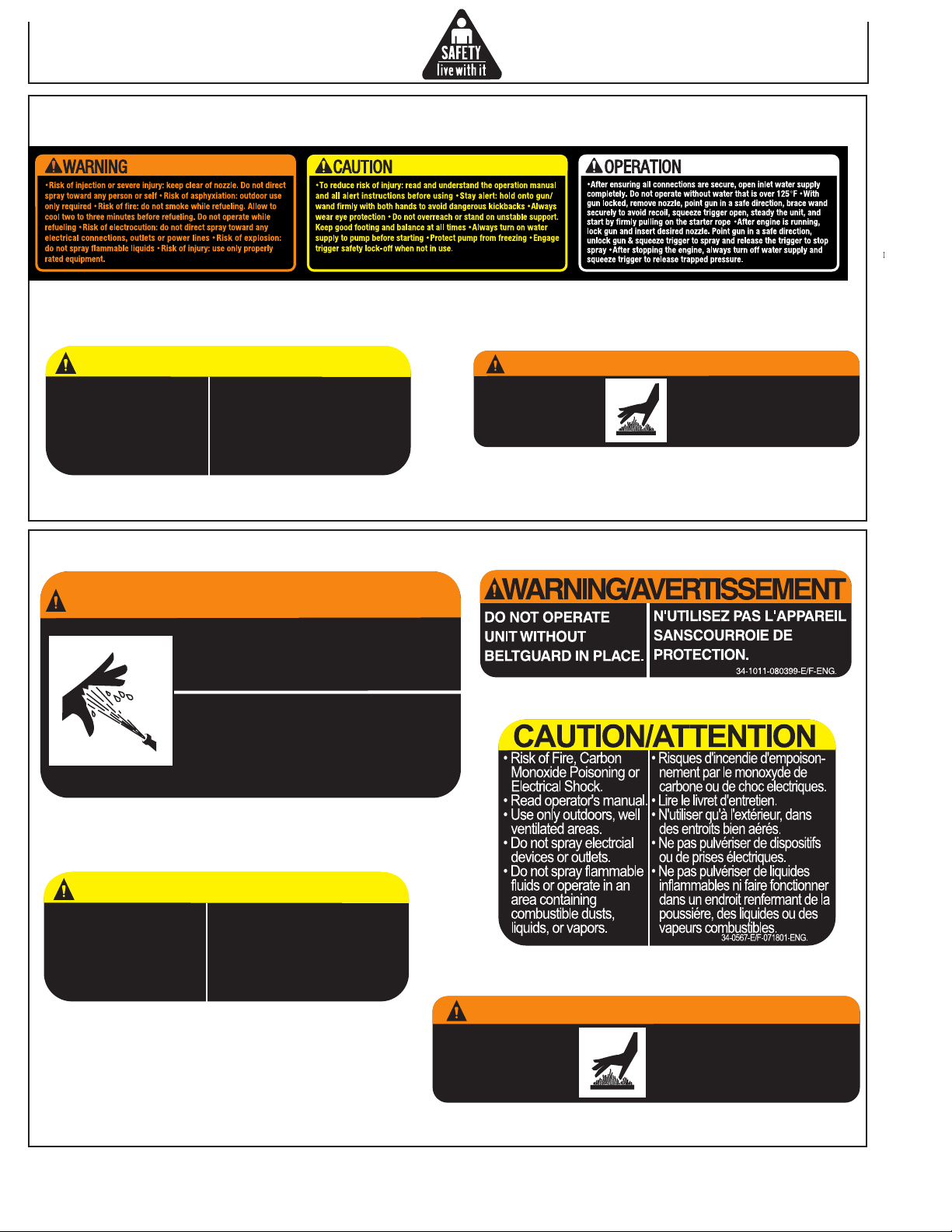

SAFETY SIGNS FOR AC-2000GH, AC-2400GH, AC-2600GH, AC-2700GH, AC-3300GH,

CAUTION/ATTENTION

RISQUE DE FEU: Ne pas

ajouter de combustible lorsque

le produit est en marche ou

encore chaud. Laisser le

moteur refroidir pendant 2

minutes avant de faire le plein.

34-0768-E/F-122199-ENG.

RISK OF FIRE: Do not

add fuel when the

product is operating or

hot. Allow engine to cool

for 2 minutes before

refueling.

WARNING/AVERTISSEMENT

RISQUE DE BRULURES:

SURFACES CHAUDES LE

TUYAU D'ÉCHAPPEMENT ET

LES RÉGIONS ADJACENTES

PEUVENT DÉPASSER LES 65°C.

34-0767-E/F-052901-ENG.

RISK OF BURNS:

HOT SURFACES.

MUFFLER AND

ADJACENT AREAS

MAY EXCEED 150°F.

WARNING/AVERTISSEMENT

Water under pressure may cause serious

injury. Do not point spray nozzle at any

part of the body or place in mouth. Do not

point spray nozzle at any persons.

L'eau sous pression peut provoquer des

blessures. Ne pas diriger la buse de

pulverisatior vers toute partie du corps et

ne pas la placer dans la bouche. Ne pas

diriger la buse de pulverisatior vers toute

personnes.

34-0568-E/F-071801-ENG.

CAUTION/ATTENTION

RISQUE DE FEU: Ne pas

ajouter de combustible lorsque

le produit est en marche ou

encore chaud. Laisser le

moteur refroidir pendant 2

minutes avant de faire le plein.

34-0768-E/F-122199-ENG.

RISK OF FIRE: Do not

add fuel when the

product is operating or

hot. Allow engine to cool

for 2 minutes before

refueling.

WARNING/AVERTISSEMENT

RISQUE DE BRULURES:

SURFACES CHAUDES LE

TUYAU D'ÉCHAPPEMENT ET

LES RÉGIONS ADJACENTES

PEUVENT DÉPASSER LES 65°C.

34-0767-E/F-052901-ENG.

RISK OF BURNS:

HOT SURFACES.

MUFFLER AND

ADJACENT AREAS

MAY EXCEED 150°F.

AC-2400GS, AC-2700GS AND AC-3000GS

AC-2000GH & AC-2600GH= 34-1023 / AC-2400GH=34-0760 / AC-2700GH=34-0759 / AC-3300GH=34-0761

AC-2400GS=34-1379 / AC-2700GS=34-1380 / AC-3000GS=34-1381

34-0768

Location: Fuel Tank-Top

SAFETY SIGNS FOR AC-2500GH

Location: Handle Placard

34-0767

Location: Fuel Tank-Top

Location: Beltguard-Inside

34-1011

Location: Beltguard-Left Side

34-0568

34-0768

Location: Fuel Tank-Top

Location: Beltguard-Backside

34-0567

10 AC-Series Operator’s Manual-E/F

Location: Beltguard-Top

34-0767

Page 11

SAFETY SIGNS FOR AC-3500GH

PEUVENT DÉPASSER LES 65°C.

Location: Beltguard-Inside

34-1011

WARNING/AVERTISSEMENT

RISK OF BURNS:

HOT SURFACES.

MUFFLER AND

ADJACENT AREAS

MAY EXCEED 150°F.

Location: Fuel Tank-Top

RISQUE DE BRULURES:

SURFACES CHAUDES LE

TUYAU D'ÉCHAPPEMENT ET

LES RÉGIONS ADJACENTES

34-0767

34-0767-E/F-052901-ENG.

CAUTION/ATTENTION

RISK OF FIRE: Do not

add fuel when the

product is operating or

hot. Allow engine to cool

for 2 minutes before

refueling.

34-0768-E/F-122199-ENG.

Location: Fuel Tank-Top

RISQUE DE FEU: Ne pas

ajouter de combustible lorsque

le produit est en marche ou

encore chaud. Laisser le

moteur refroidir pendant 2

minutes avant de faire le plein.

34-0768

WARNING

RISK OF INJECTION OR SEVERE INJURY.

Never put your hand, fingers or body directly

over the spray nozzle.

34-1269-E/F-031501-ENG.

34-01269

Location: Lance

AVERTISSEMENT

D'INCEDIE OU INJECTION OU BLESSURES

À LA SÉVÈRE. Ne jamais mettre la main, les

doigts ou une partie du corps directement sur

la buse de pulvérisation.

Location: Beltguard-Backside

AC-Series Operator’s Manual-E/F 11

34-1010

Page 12

Controls

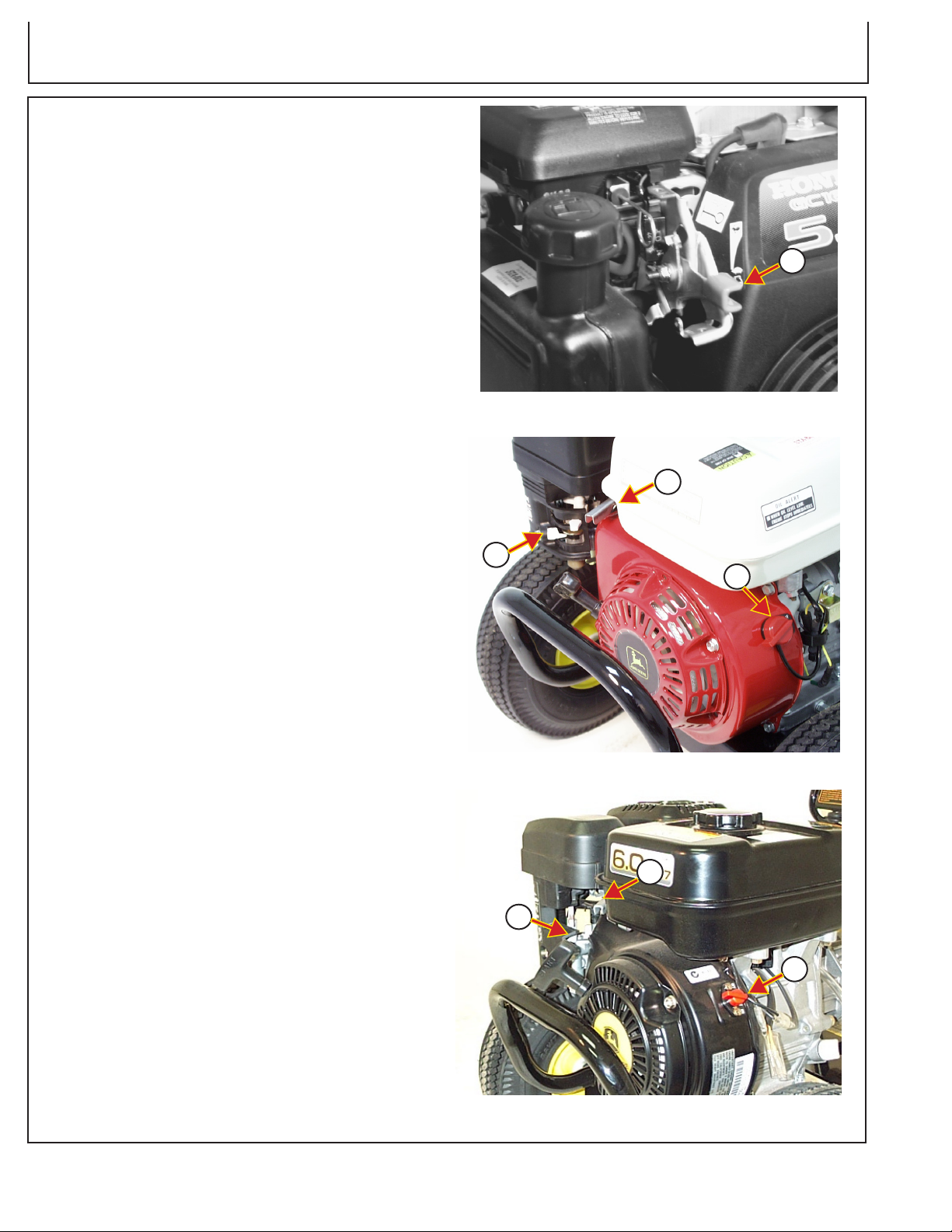

AC-2000GH

B

A

C

AC-2500GH

AC-2400GH

D

B

A

PIC60-101599R0

D

C

AC-2400GS

B

PIC161-101599R1

D

A

C

PIC161R-121902R0

AC-2600GH

D

AC-2700GH

B

A

D

B

A

PIC164-101599R1

AC-2700GS

B

A

C

PIC60-101599R0

D

B

A

C

PIC62-101599R1

12 AC-Series Operator’s Manual-E/F

C

PIC62R-121902R0

Page 13

Controls

AC-3000GS

D

B

A

C

HONDA ENGINE

I

J

K

AC-3300GH

B

A

C

PIC63R-121902R0

D

SUBARU ENGINE

AC-3500GH

PIC63-101599R0

D

A

B

JCW-3504-0JHB

GUN, WAND, HOSE

G

H

E

I

J

K

H

PIC66-101599R0

F

A-- Water Supply Inlet

B-- High Pressure Outlet

C-- Detergent Hose

D-- Pressure Adjusting Knob

E-- High Pressure Hose

F-- Gun

G-- Nozzle

H-- Engine On/Off Switch

I -- Throttle

J-- Choke

K-- Fuel Shut-off Valve

PIC65-101599R1

PIC66R-121902R0

AC-Series Operator’s Manual-E/F 13

Page 14

Preparing the Washer

-40°F

-22°F

-4°F

14°F

32°F

50°F

68°F

86°F

104°F

122°F

50°C

40°C

30°C

20°C

10°C

0°C

-10°C

-20°C

-30°C

-40°C

SAE 10W-40

SAE 10W-30

SAE 5W-30

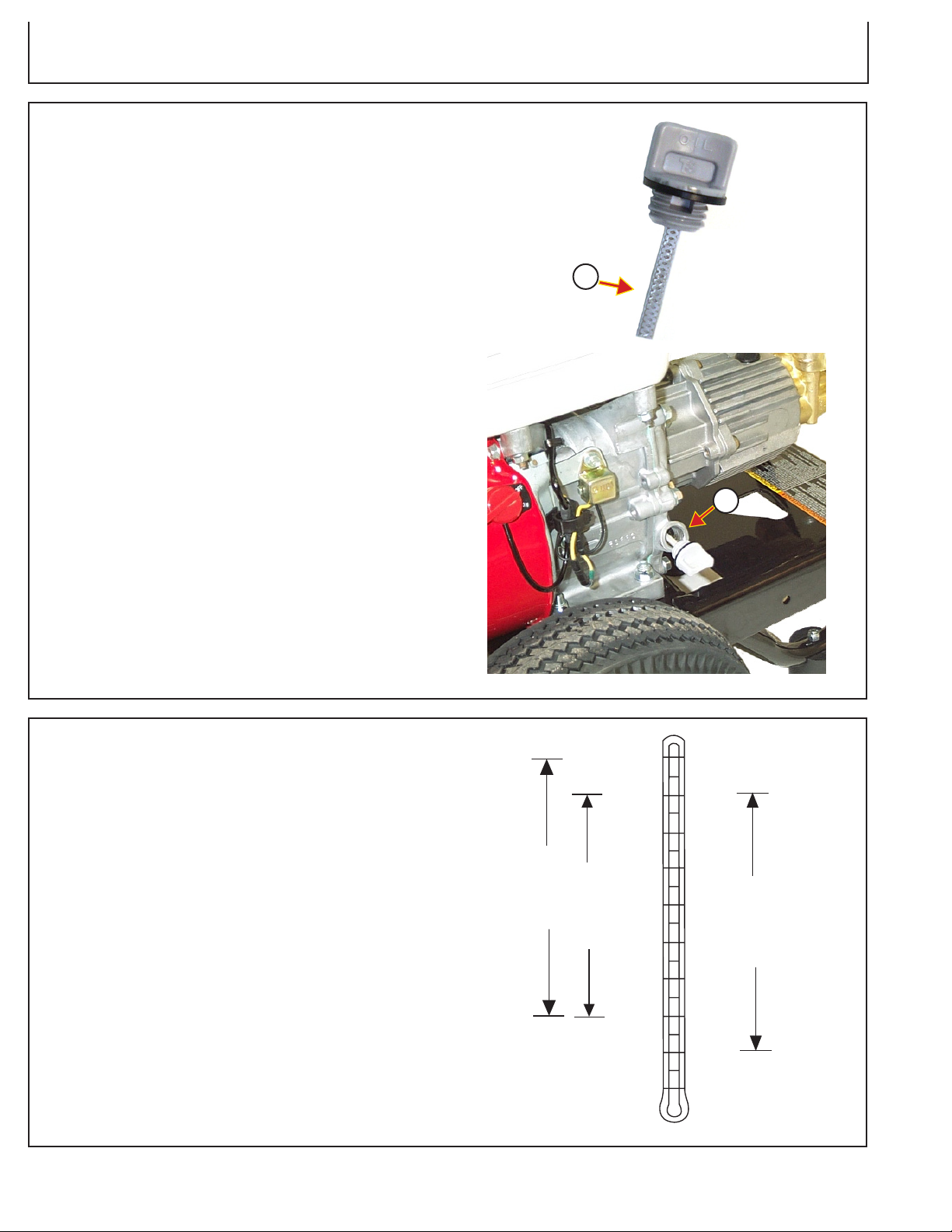

CHECK ENGINE OIL

NOTE: All washers are shipped with engine oil. Check

proper level. (AC-2400GH illustrated.)

1. Place unit on level surface.

2. Remove oil ller cap/dipstick (A) and wipe it clean.

3. Insert ller cap/dipstick into oil ller neck, but DO NOT

screw it in.

4. Remove dipstick. Proper oil level is at midpoint of

dipstick (A). Add oil if necessary to bring oil level to

top of threads (B).

5. Install and tighten cap.

NOTE: Oil can be checked using ller cap on either side

of engine.

A

PIC110-102899R0

B

GASOLINE ENGINE OIL

Use oil viscosity based on the expected air temperature

range during the period between oil changes.

John Deere TURF-GARDTM is preferred. Also

recommended is John Deere PLUS-4®.

Other oils may be used if they meet one or more of the

following:

•API Service Classication SH

•API Service Classication SG

•CCMC Specication G4

•CCMC Specication G5

PIC67-102899R1

DWG13-102299R0

14 AC-Series Operator’s Manual-E/F

Page 15

Preparing the Washer

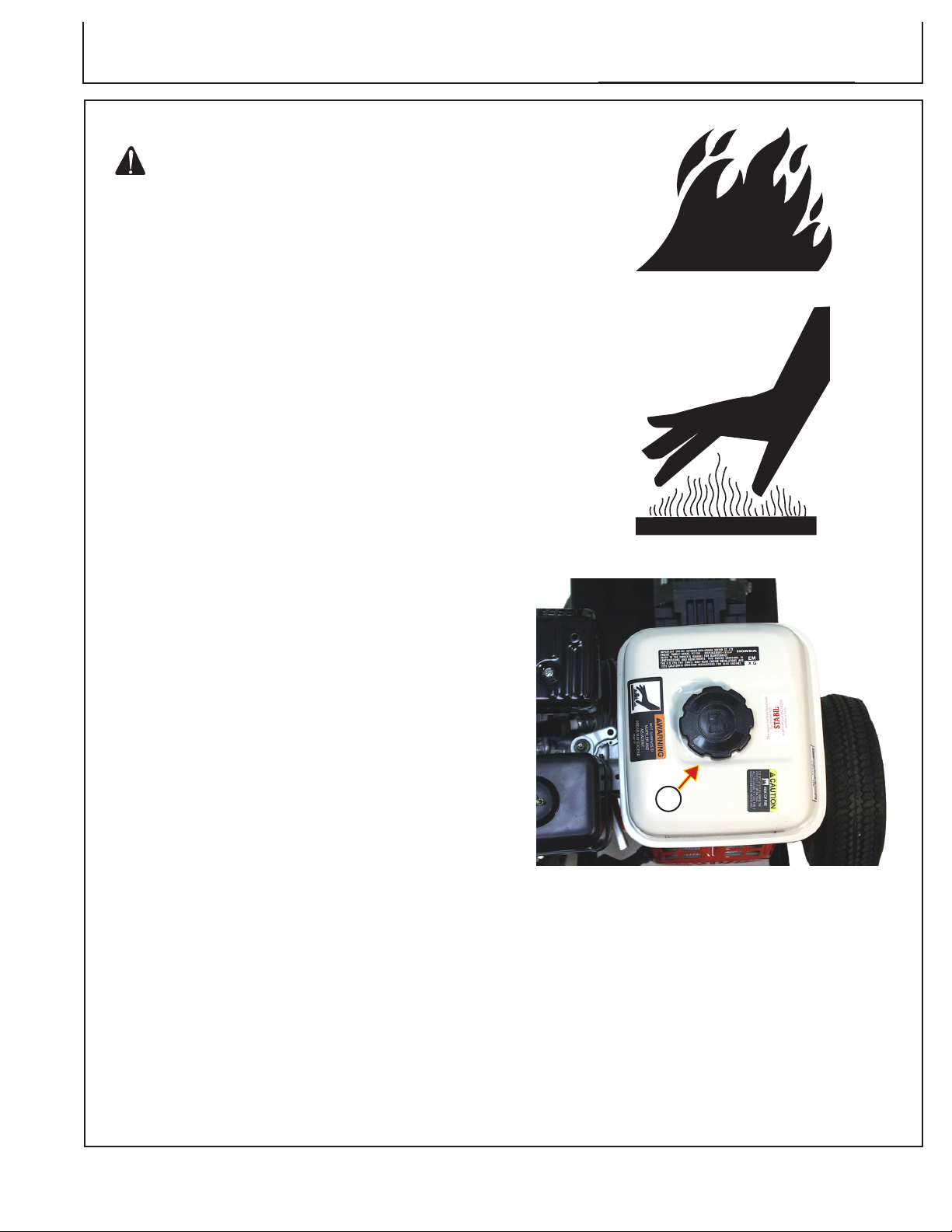

FILLING FUEL TANK

CAUTION: Risk of re. Handle fuel carefully.

-Do not add fuel when product is operating. Stop

engine and allow engine to cool for two minutes

before refueling. Hot surfaces can cause burns

and ignite spilled fuel. Do not touch mufer.

-Fill fuel tank outdoors away from ames and

open sparks.

-Do not smoke when lling fuel tank.

-Do not overll fuel tank. (There should be no

fuel in ller neck.)

-Avoid spilling fuel. Wipe clean after refueling.

-Move from refueling area before starting.

-Prevent fires by keeping engine clean of

accumulation, grease, trash and debris.

IMPORTANT: Do not permit dirt or other foreign matter

to enter the fuel system. This will cause

hard starting, poor performance and

engine damage. Always use clean fuel

storage containers and funnels.

Use clean, fresh, lead-free gasoline. Do not use stale

gasoline or gasoline that has been stored for a long

time. Stale gasoline does not vaporize properly, causing

hard starts. Use of TY15977 gasoline stabilizer is highly

recommended . Use of leaded gasoline or gasohol is NOT

recommended.

IMPORTANT: Do not mix oil with gasoline.

1. Wipe dust and dirt from around fuel tank. Remove

ller cap (A) and place cap in a clean area away from

mufer.

2. Slowly ll the fuel tank to bottom of ller neck with lead

free gasoline. Do not overll, leave approximately 5mm

(0.19 in.) of open space at the top of the tank for fuel

expansion.

3. Replace and tighten ller cap.

Fuel Tank Capacity

AC-2000GH .................................. 1.72L (0.46 gal)

AC-2400GH .................................. 3.60L (0.95 gal)

AC-2400GS .................................. 3.60L (0.95 gal)

AC-2500GH .................................. 6.51L (1.72 gal)

AC-2600GH .................................. 1.72L (0.46 gal)

AC-2700GH .................................. 3.60L (0.95 gal)

AC-2700GS .................................. 3.60L (0.95 gal)

AC-3000GS .................................. 6.00L (1.58 gal)

AC-3300GH .................................. 6.51L (1.72 gal)

AC-3500GH .................................. 6.51L (1.72 gal)

A

AC-Series Operator’s Manual-E/F 15

Page 16

Preparing the Washer

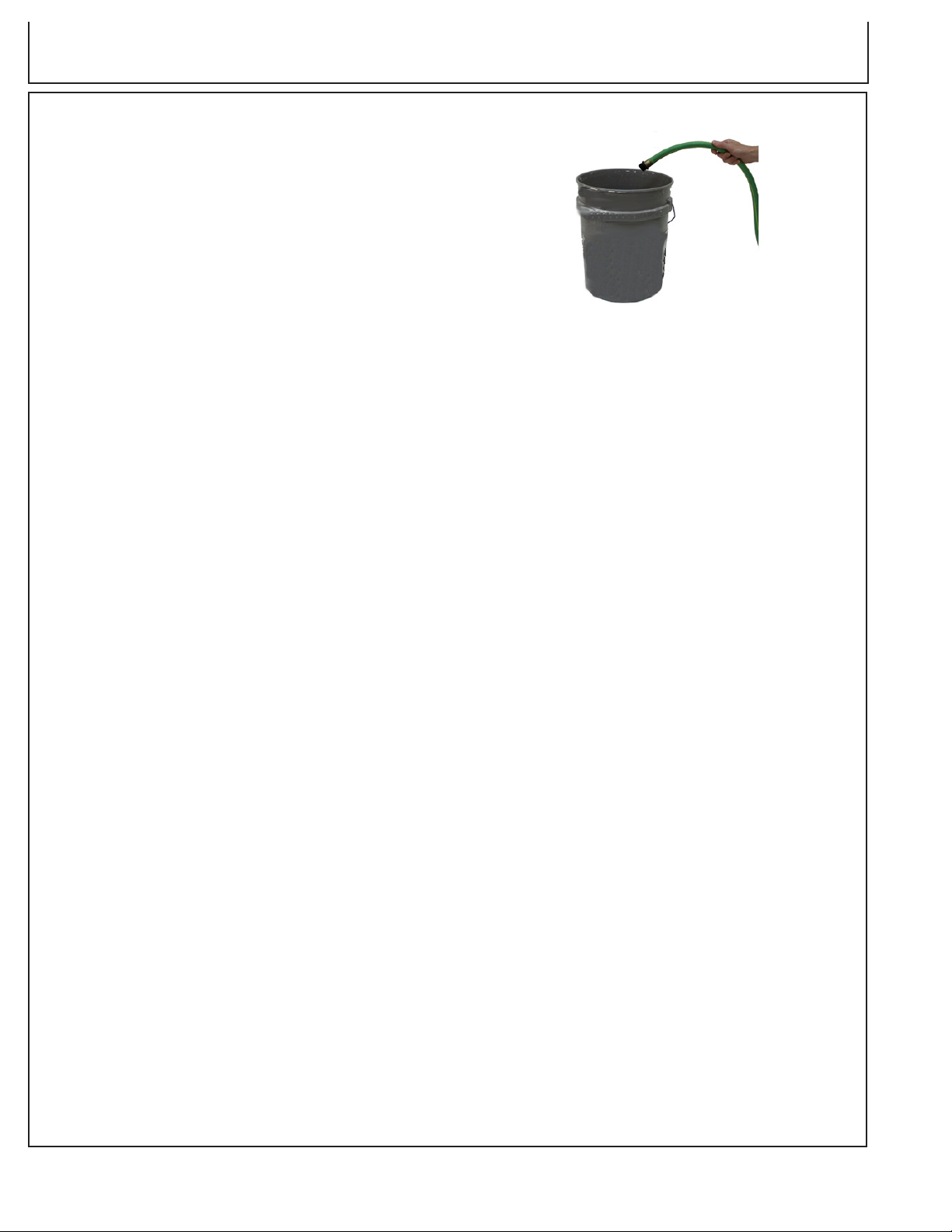

INLET WATER SUPPLY REQUIREMENTS

1. Inlet water supply must be a minimum of 20 PSI (1.4

bar).

Attempting to operate the washer with less than

adequate water supply will cause rapid wear of

packings, valves and bearings that will dramatically

shorten pump life. Symptoms of inadequate water

supply are pump shuddering and attening of the

supply hose.

2. Inlet water ow must be at least 125% of pump rated

ow (see table below). Check volume by timing how

long it takes to ll a 5 gallon (19 L) container. For

example, a ow rate of 3.0 GPM would ll a 5 gallon

container in 5/3 minute (100 seconds).

3. Water supply hose should be a good grade of garden

hose with a minimum I.D. 5/8 in. (16mm) and no longer

than 50 ft. (15.24 m). If longer supply hose must be

used, check to be certain ow is at least equal to the

“GPM Supply Required” value listed at the bottom of

this page for your washer.

4. If non-pressurized (static draw) water supply is used,

check to be certain ow is at least 125% of pump

rated ow (see table below). In static draw situations,

water ow rate (GPM) can be increased by elevating

the water supply tank or changing to a larger inside

diameter water supply hose.

5. Adding on extension to the supply hose will reduce

water ow rates. Check for adequate water ow rate

each time an extension is added. Water ow rates

can be increased by using the largest possible internal

diameter supply hose.

PIC4-092299R0

IMPORTANT: Inlet water temperature must not be more

than 125° F (60° C). Damage to the pump

may result.

Washer Rated Flow GPM Supply

(GPM) Required

AC-2000GH ............... 2.5 ............................3.1

AC-2400GH ............... 2.4 ............................3.0

AC-2400GS ............... 2.4 ............................3.0

AC-2500GH ............... 4.4 ............................5.5

AC-2600GH ............... 2.4 ............................3.0

AC-2700GH ............... 2.4 ............................3.0

AC-2700GS ............... 2.4 ............................3.0

AC-3000GS ............... 3.0 ............................3.8

AC-3300GH ............... 3.3 ............................4.1

AC-3500GH ............... 3.7 ............................4.6

16 AC-Series Operator’s Manual-E/F

Page 17

Preparing the Washer

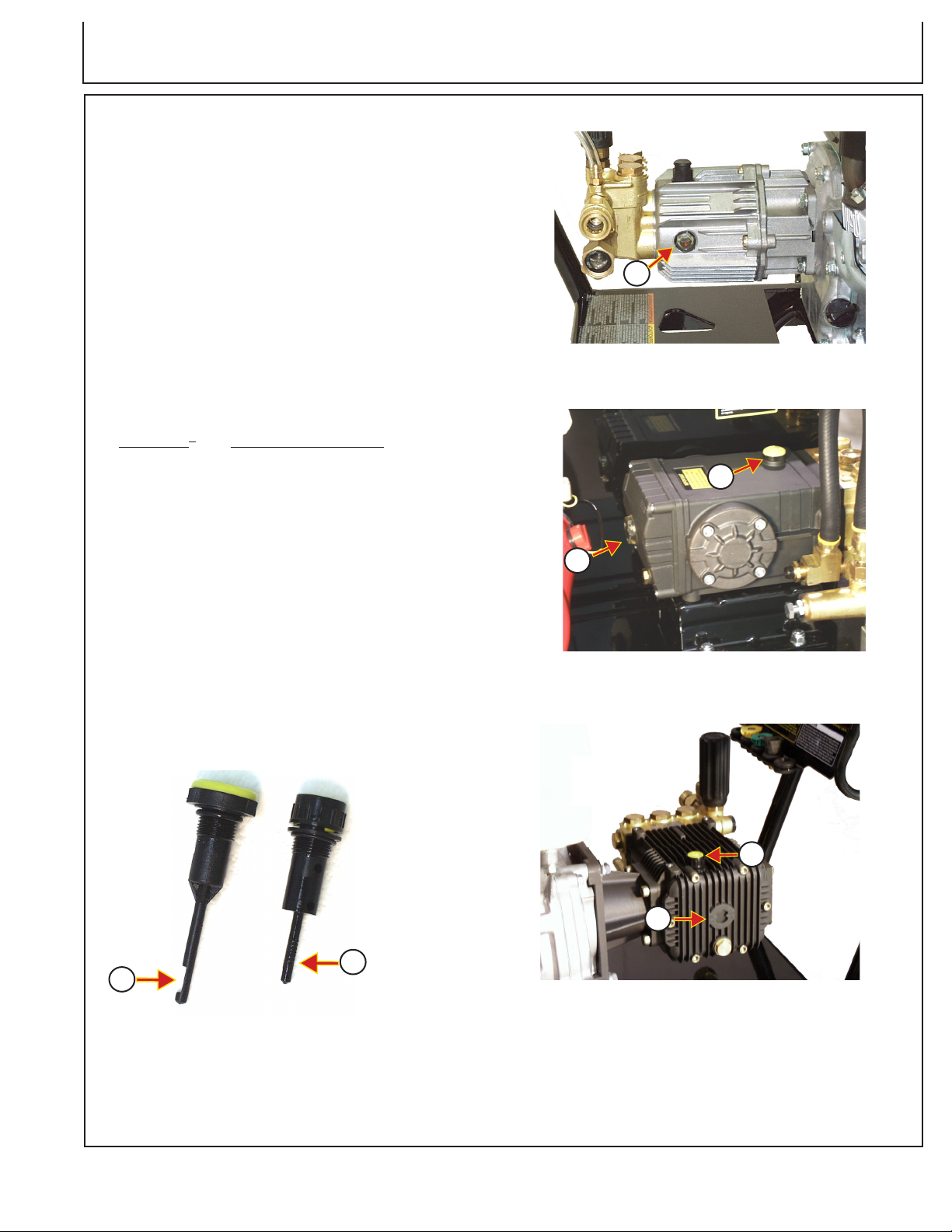

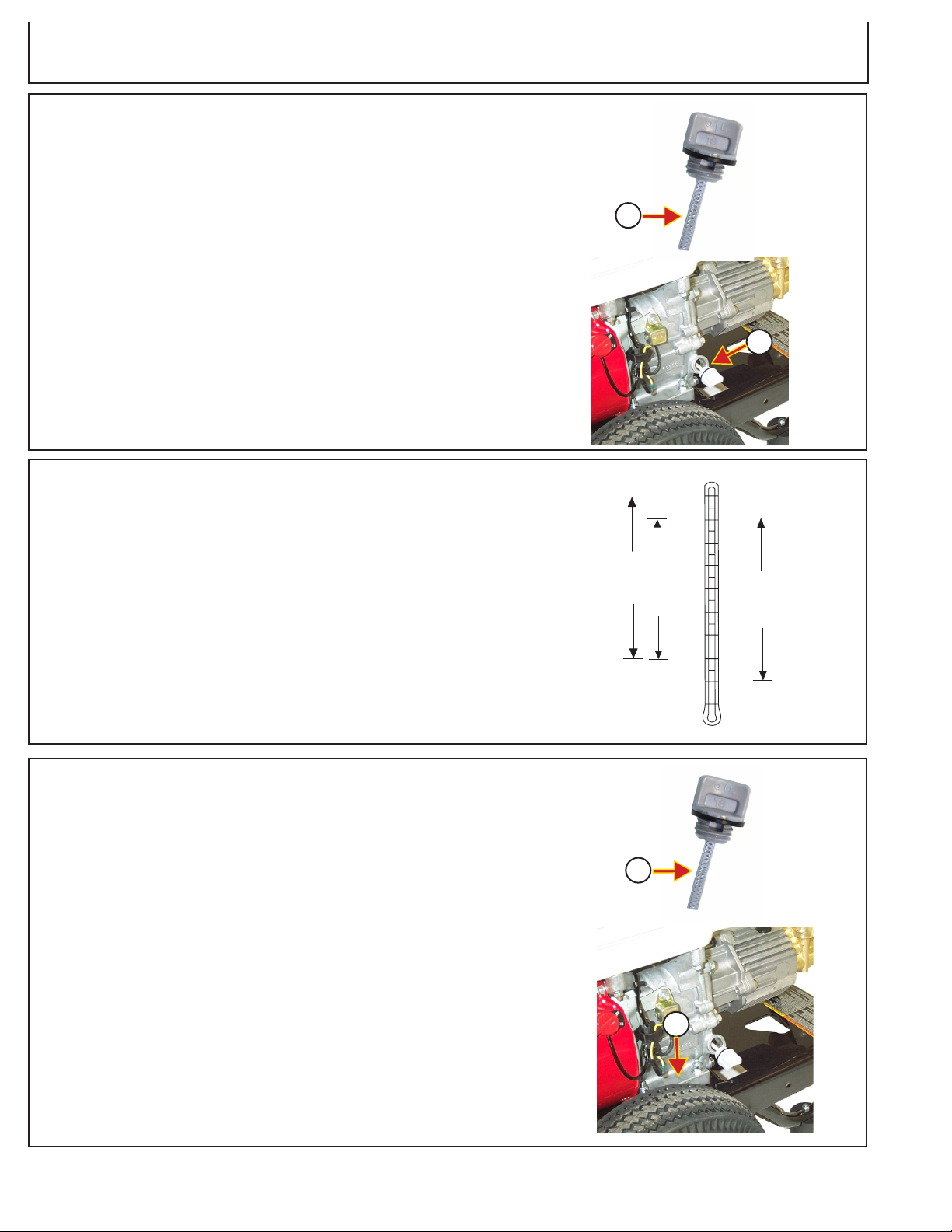

CHECK PUMP OIL

1. Put unit on level surface.

2. Check oil as follows:

•ALL MODELS: View level through clear window (A). Oil

should ll sight glass.

•Additional method for AC-2500GH, AC-2700GH,

AC-3300GH, AC-2700GS, AC-3000GS and AC-3500GH

only:

- Remove dipstick (B) and wipe clean. Put dipstick

in hole. Remove dipstick and check level. Oil level

should be located at notch (C) on AC-2500GH and

at dipstick ring (D) on AC-2700GH, AC-3300GH,

AC-2700GS, AC-3000GS and AC-3500GH.

3. Add HY-GARD® or SAE75W-90 Synthetic oil if

necessary. Do not overll.

HY-GARD® SAE75W-90 Synthetic

AC-2500GH AC-2000GH

AC-2700GH AC-2400GH

AC-2700GS AC-2400GS

AC-3000GS AC-2600GH

AC-3300GH

AC-3500GH

A

PIC69•101199R1

AC-2000GH / AC-2400GH

AC-2600GH / AC-2400GS

B

A

PIC72-101199R0

PIC70-101199R0

AC-2500GH

B

PIC71•102299R0

A

D

C

AC-2700GH / AC-3300GH

AC-2700GS / AC-3000GS / AC-3500GH

AC-Series Operator’s Manual-E/F 17

Page 18

Preparing the Washer

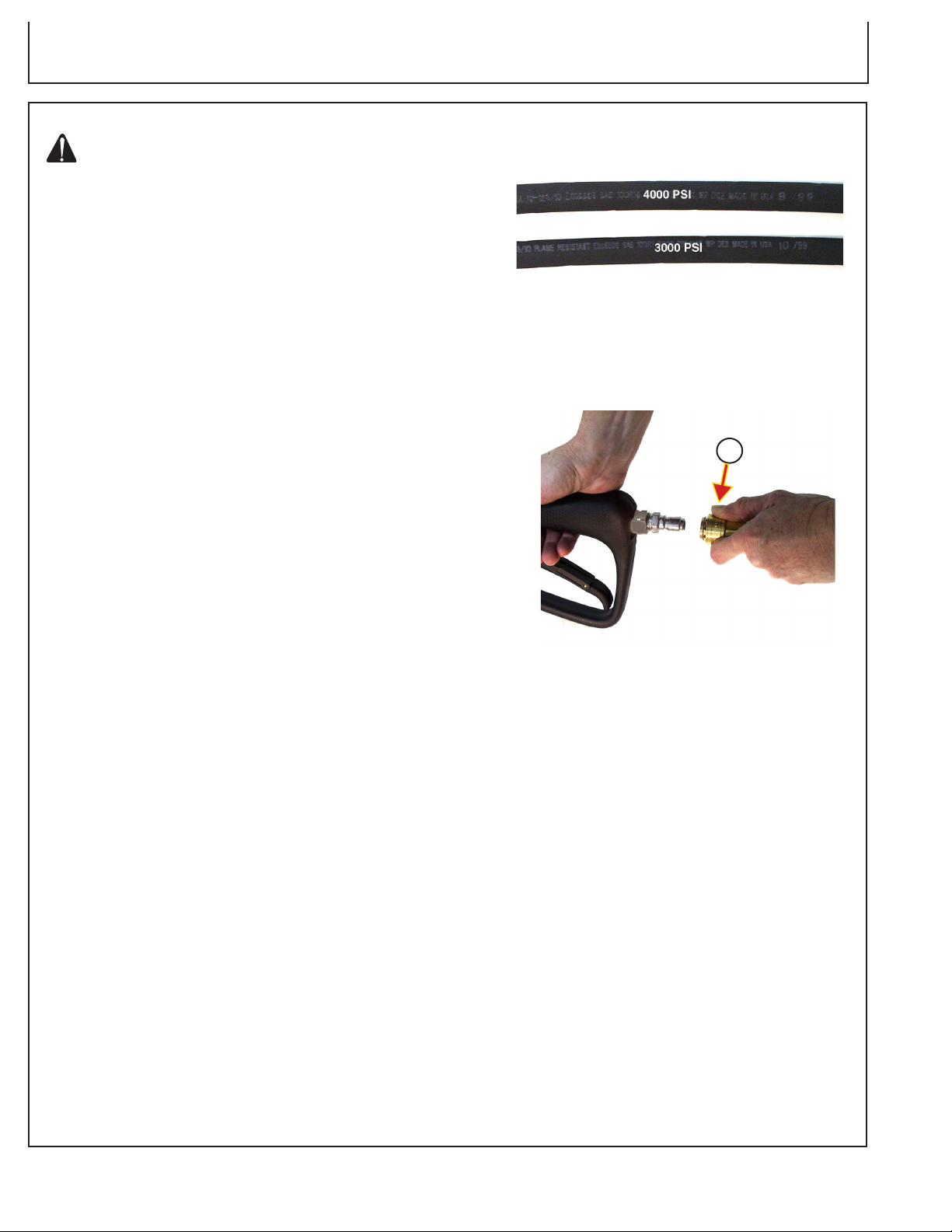

CONNECT DISCHARGE HOSE TO GUN

CAUTION: Check pressure rating printed on the

hose. Use proper hoses.

Use ONLY hose #851-0338, working pressure of

4000 PSI with the AC-3300GH and AC-3500GH

pressure washer.

Hose #851-0007, with working pressure of

3000 PSI can safely be used on AC-2000GH,

AC-2400GH, AC-2400GS, AC-2500GH, AC-2600GH,

AC-2700GH, AC-2700GS and AC-3000GS.

1. Retract locking ring (A) of hose quick-connect tting

and insert gun quick-connect male tting.

2. Slide locking ring forward. Tug hose gently to ensure

solid connection.

PIC74•102299R0

NOTE: Some hoses are pre-assembled to the gun and can

not be detached.

IMPORTANT: DO NOT attach nozzle wand to gun handle

until water system is primed.

A

PIC75•102299R0

18 AC-Series Operator’s Manual-E/F

Page 19

Preparing the Washer

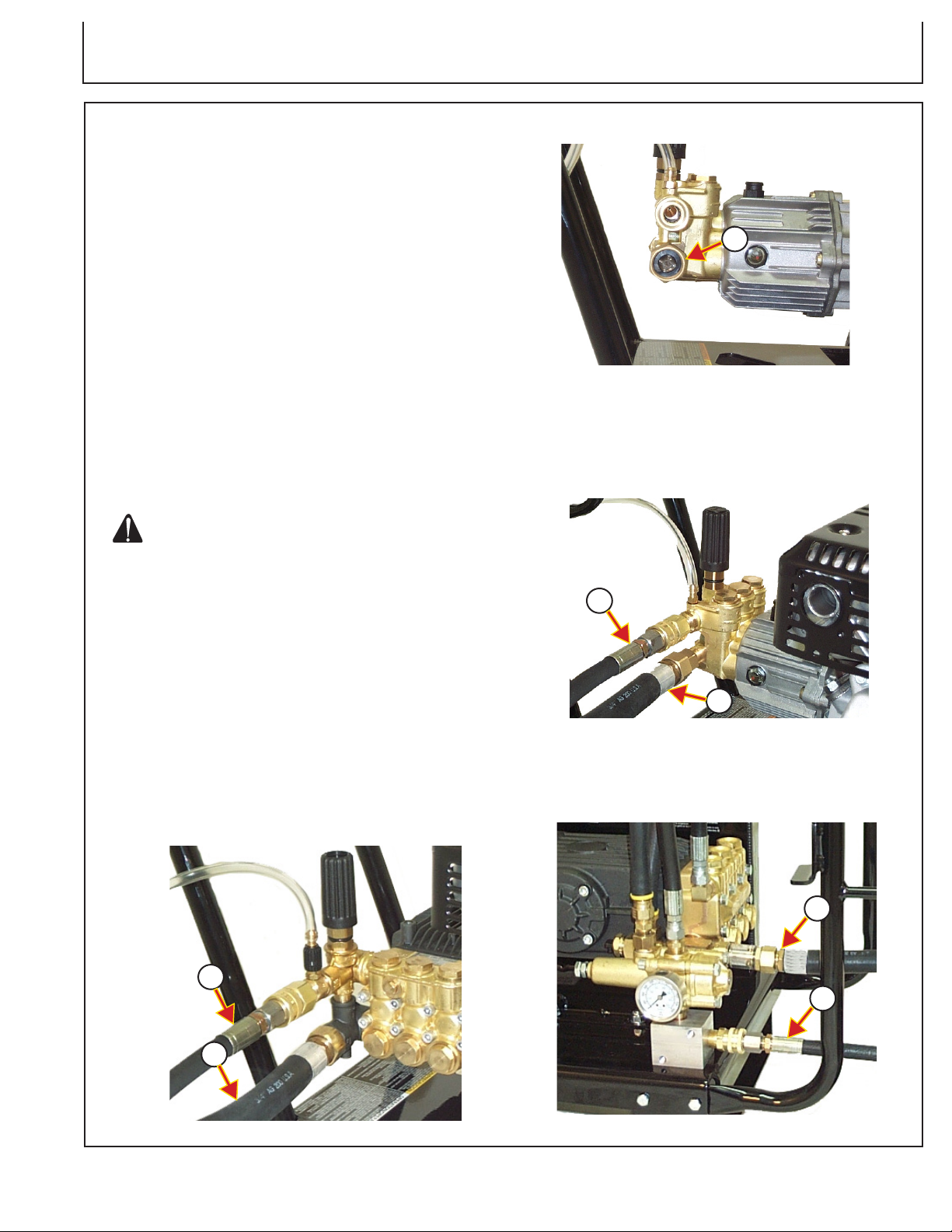

CONNECT HOSES AND PRIME PUMP

IMPORTANT: Be sure that inlet water screen (A) is clean and in

place before connecting water supply hose to

AC-200 0GH, AC-24 00GH, AC-26 00GH,

AC-27 00GH, AC- 3300G H, AC-240 0GS,

AC-2700GS and AC-3000GS washers. The

water pump and valves could be damaged

from contaminants.

IMPORTANT: If washer is to be connected to a well water

system, use 19-0206 water inlet lter (A). This

will increase sand ltering capability and

avoid damage to the pump.

A

PIC77•102299R1

NOTE: Filling supply hose with water before attaching to pump

will greatly reduce priming time.

1. Prime water supply hose. Shut off water.

2. Connect water supply hose (B) to washer inlet. Be sure

water supply and hose meet specications. Do not turn

water on at this time.

CAUTION: Check pressure rating printed on

the hose. Use proper hoses. Use ONLY hose

#851-0338, working pressure of 4000 PSI with the

AC-3300GH and AC-3500GH pressure washers.

Hose #85 1-00 07, w ith work ing pres sure of

3000 PSI can safely be used on AC-2000GH,

AC-2400GH, AC-2400GS, AC-2500GH, AC-2600GH,

AC-2700GH, AC-2700GS and AC-3000GS.

3. Connect high pressure hose (C) to washer outlet. Give

hose a slight tug to be sure hose is connected.

4. Open water supply. Squeeze trigger on gun. Allow water to

run (without engine running) until water runs out of pressure

hose. Start engine and cycle trigger on gun until “crackling”

sound (air in lines) stops. Turn off water supply.

AC-2000GH / AC-2400GH

AC-2600GH / AC-2400GS

C

PIC78•102299R1

B

AC-2000GH / AC-2400GH

AC-2600GH / AC-2400GS

B

C

C

PIC80-A•102299R1

AC-2700GH / AC-2700GS / AC-3000GS / AC-3500GH AC-2500GH

AC-Series Operator’s Manual-E/F 19

B

PIC79•102299R1

Page 20

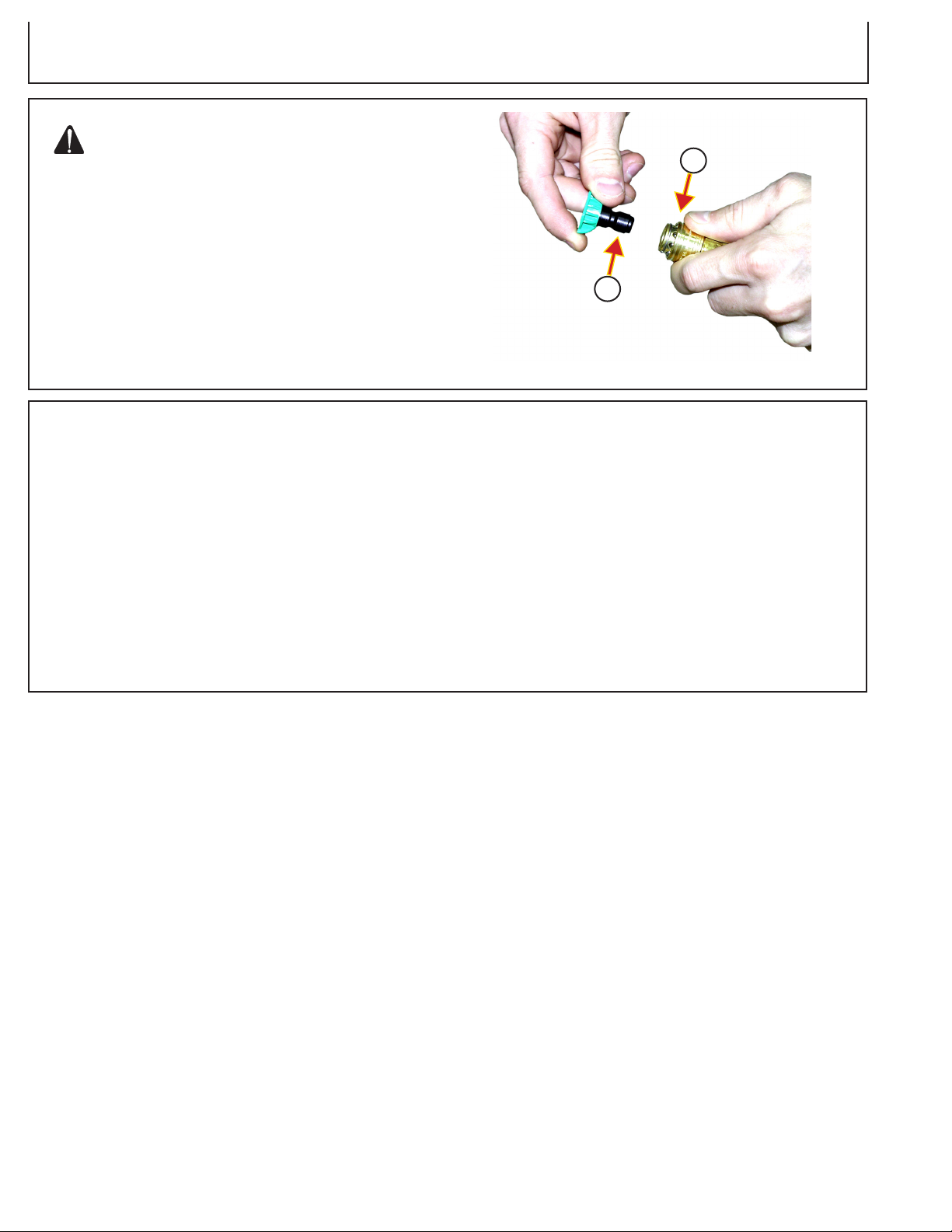

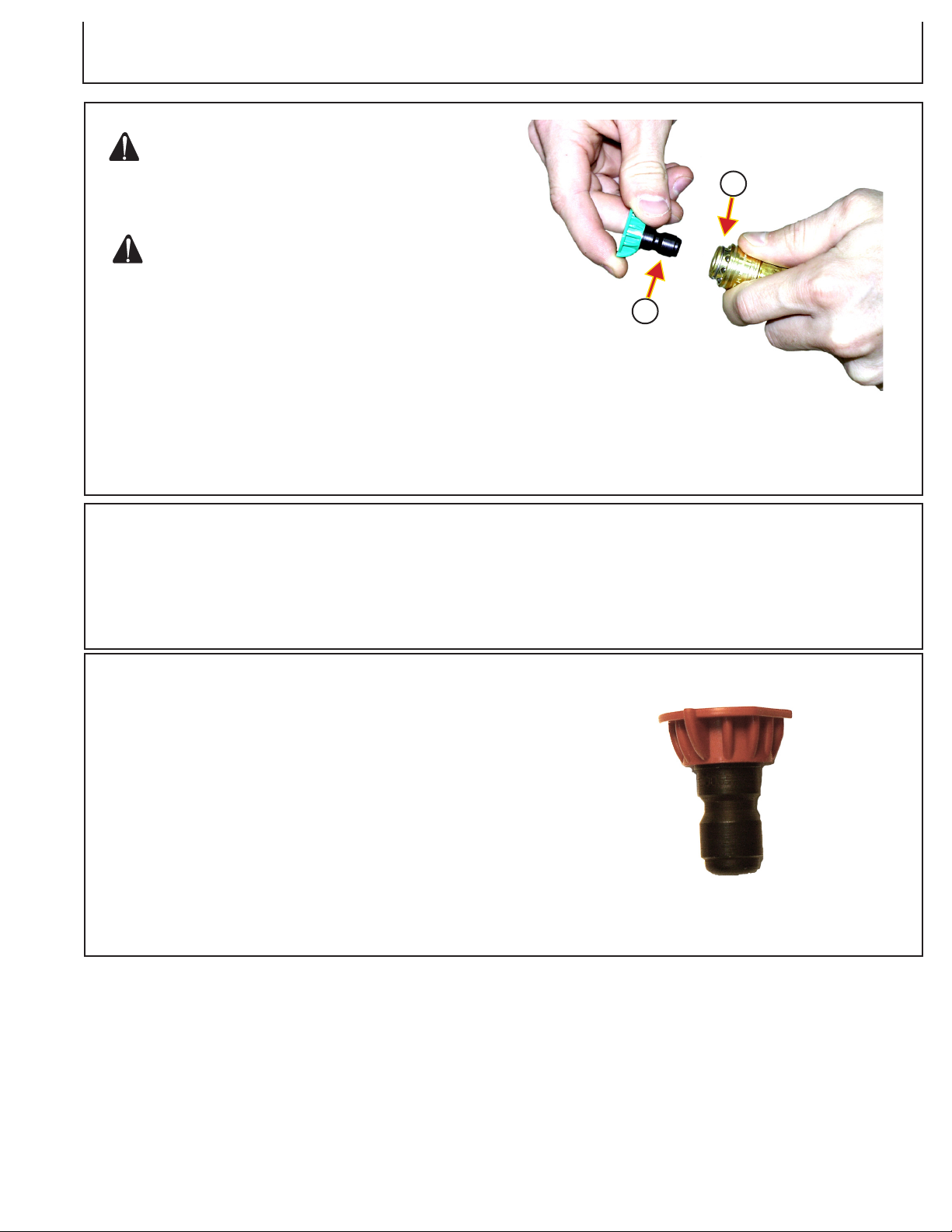

INSTALLING NOZZLE

CAUTION: To avoid injury from escaping uids

under pressure, relieve the pressure in the

system by stopping the washer and depressing

gun trigger. Lock trigger before changing or

adjusting nozzle.

Be sure nozzle is tightly attached before operating

to help prevent nozzle release.

Preparing the Washer

A

1. Retract locking ring (A) of quick-connect tting and

insert male quick-connect tting of nozzle (B).

2. Push ring forward and lock nozzle in place. Be sure

nozzle is fastened to wand.

FINAL CHECKLIST

1. Check engine oil and fuel.

2. Check water pump oil level.

3. Open water supply completely.

4. Check all hose connections.

5. Check hoses for kinks.

B

PIC81•102299R0

20 AC-Series Operator’s Manual-E/F

Page 21

Operating the Washer

STARTING AND OPERATING ENGINE

CAUTION: Do not run engine in an enclosed area.

Exhaust gas contains carbon monoxide, an odorless

and poisonous gas that can cause sickness or

death.

IMPORTANT: To prevent possible pump damage, do not

IMPORTANT: During rst two hours of engine operation,

NOTE: AC-2000GH, AC-2400GH & AC-2400GS illustrated.

1. Set fuel valve lever (A) right to ON position. (Not applicable

on AC-2000GH / AC-2600GH.)

2. Move choke control lever (B) left to “CHOKE” position.

(AC-2000GH / AC-2600GH: Pull choke control lever (B)

out.)

NOTE: A warm engine requires less choking than a cold

engine.

3. Move throttle lever (C) to the left. (AC-2000GH / AC2600GH: Move throttle lever (C) upward.)

4. Turn engine switch (D) to “ON” position. (Not applicable

on AC-2000GH / AC-2600GH)

5. Place foot on washer frame.

6. Point nozzle away from people, animals or fragile materials

and squeeze gun trigger.

CAUTION: Be sure nozzle output end is not directed

at bystander or objects. Pressurized output spray

will start almost instantaneously at engine start-up

and can cause serious personal injury or property

damage. Release trigger immediately upon engine

start.

7. Pull recoil starter grip lightly until resistance is felt, then pull

briskly until engine starts.

IMPORTANT: Do not allow starter grip to snap back against

IMPORTANT: To avoid loss of lubrication to the engine,

8. As engine starts to falter, move choke control lever (B) right

to OPEN position.

9. Position throttle lever (C) to desired speed.

STOPPING THE ENGINE

AC-2000GH / AC-2600GH ONLY:

IMPORTANT: To stop engine in emergency, turn throttle (C)

1. Move throttle lever (C) to “OFF”.

2. Trigger gun to relieve spray.

ALL OTHER MODELS:

IMPORTANT: To stop engine in emergency, turn engine

NOTE: AC-2400GH and AC-2400GS illustrated.

1. Move throttle lever (C) fully to the right.

2. Turn engine switch (D) to “OFF” position.

3. Move fuel valve (A) left to “OFF” position.

4. Trigger gun to relieve spray.

AC-Series Operator’s Manual-E/F 21

allow washer pump to run in bypass (with gun

trigger released) for longer than 3 minutes.

engine may operate at low or erratic RPM as

the engine moving parts break in.

engine. Return it gently to prevent damage

to starter.

operate engine on a level surface. Do not

exceed a 15° slope or automatic low oil

switch will stop engine. (Not applicable on

AC-2000GH / AC-2600GH)

down to ‘OFF” position.

switch (D) to ‘OFF” position.

C

B

AC-2000GH

C

B

A

D

AC-2400GH

C

B

D

A

AC-2400GS

DWG14-102299R0

PIC158•113099R0

PIC66•102299R0

PIC66R•121902R0

Page 22

Operating the Washer

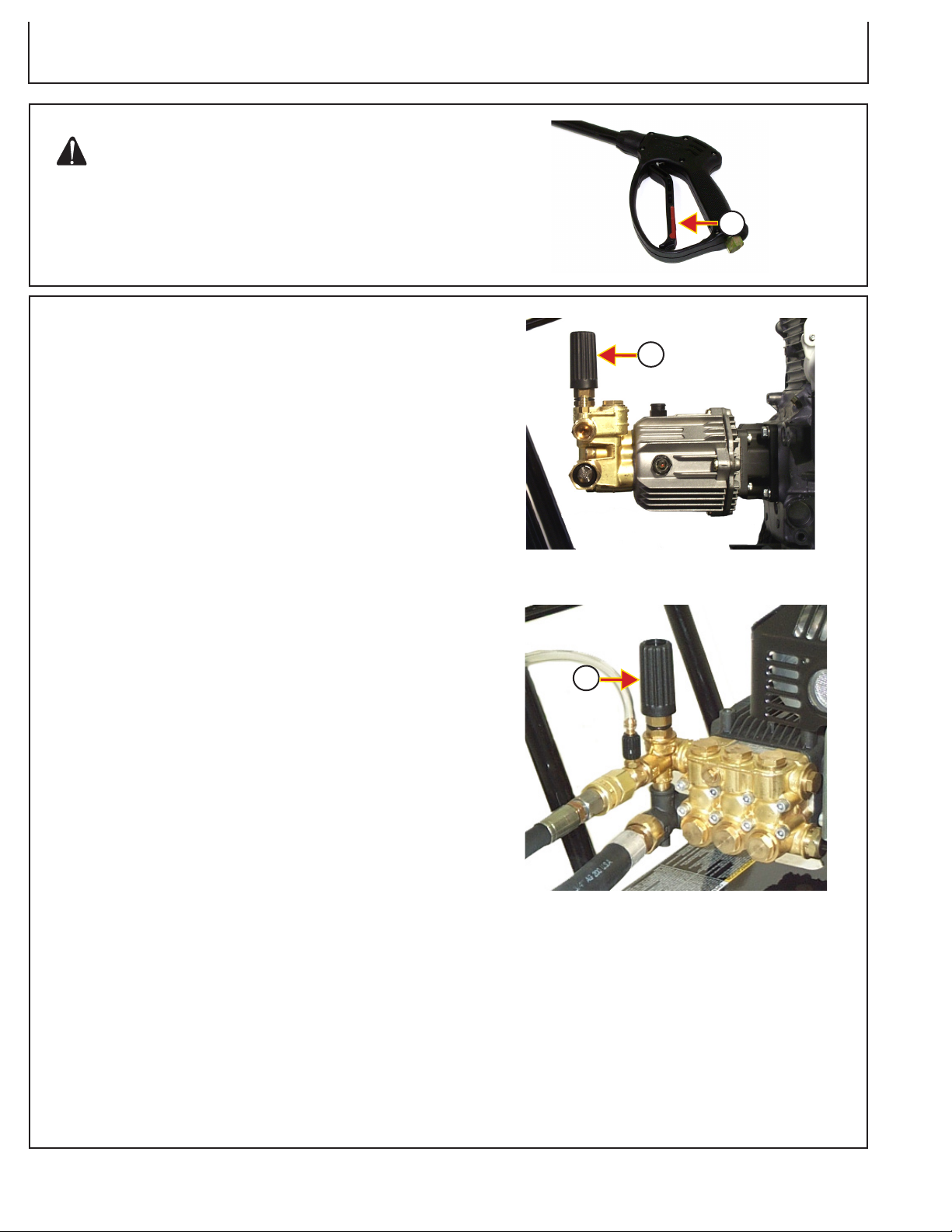

LOCKING GUN TRIGGER

CAUTION: Gun trigger should be locked when not

in use or whenever adjustments are being made

to gun or nozzle. This will help prevent accidental

discharge of high pressure uid.

1. Pivot lock (A) down to prevent trigger engagement.

2. Pivot lock up to release trigger.

ADJUSTING WATER PRESSURE

Turn pressure adjusting knob (A) clockwise to increase

pressure and counterclockwise to decrease pressure.

NOTE: Water pressure is preset on AC-2500GH washers

and should only be serviced by an authorized

dealer.

PIC73-102299R1

A

A

PIC155-113099R0

AC-2000GH / AC-2400GH

AC-2600GH / AC-2400GS

A

AC-2700GH / AC-3300GH

AC-2700GS / AC-3000GS / AC-3500GH

PIC83-090199R1

22 AC-Series Operator’s Manual-E/F

Page 23

CHANGING NOZZLE

CAUTION: High pressure spray can cause serious

injury. Keep away from spray. Never point the gun

at yourself or anyone else. Never put your hand,

ngers, eyes or body directly over spray. Do not

point spray toward fragile materials.

Operating the Washer

A

CAUTION: To avoid injury from escaping uids

under pressure, relieve the pressure in the system

by stopping the washer and depressing gun

trigger. Lock trigger before changing or adjusting

nozzle.

Be sure nozzle is tightly attached before operating

to help prevent nozzle release.

1. Retract locking ring (A) of quick-connect tting and

remove nozzle (B).

2. Insert nozzle and push ring forward and lock nozzle in

place. Be sure nozzle is fastened to wand.

SELECTING THE PROPER NOZZLE

Pressure and volume are partially determined by the size

of the orice in the nozzle. Standard numbers are on the

nozzles to indicate spray pattern and orice size. For

example, a nozzle stamped 25055 has a 25° spray pattern

and a 5.5 orice.

0° NOZZLE-RED

This nozzle is a blasting nozzle, delivering a concentrated

stream of water.

IMPORTANT: Care must be used to avoid gouging wood

or damaging fragile surfaces.

PIC81-102299R0

B

Recommended uses are as follows:

-Removing stains from concrete, masonry, aluminum

and steel.

-Remove weeds from sidewalk cracks.

-Remove caked-on mud from equipment.

-Clean lawn mower underdeck.

AC-Series Operator’s Manual-E/F 23

PIC85-102299R0

Page 24

Operating the Washer

15° NOZZLE-YELLOW

This nozzle provides a chiseling effect suitable for surface

preparation. The spray should be directed at a 45° angle to

the surface. Recommended uses are:

-Removing peeling paint.

-Removing mildew stains.

25° NOZZLE-GREEN

This is a ushing nozzle. It produces a brush effect with

a narrower spray pattern and more concentrated spray

pressure. Recommended uses are:

-Wet sweeping leaves from walks and drives.

-Cleaning stable oors.

-Cleaning swimming pool bottoms.

-Cleaning barbecue grill.

PIC86-102299R0

PIC87-092299R0

40° NOZZLE-WHITE

This nozzle is a general purpose nozzle with a wide angle

spray pattern. It is recommended for rinsing and light

cleaning. Uses are as follows:

-Cleaning windows and aluminum siding.

-Vehicles (normal road dirt).

-Cleaning sidewalks, drives and patios.

DETERGENT INJECTOR NOZZLE-BLACK

(BRASS)

This nozzle must be used with and is included in the

detergent injector kit. This nozzle will allow a soft

spray to soak on a surface with a liquid detergent. It is

recommended for applying cleaning solution for removing

mildew and oxidation stain from houses; or cleaning

effervescent brick.

PIC88-102299R0

PIC89-102299R0

24 AC-Series Operator’s Manual-E/F

Page 25

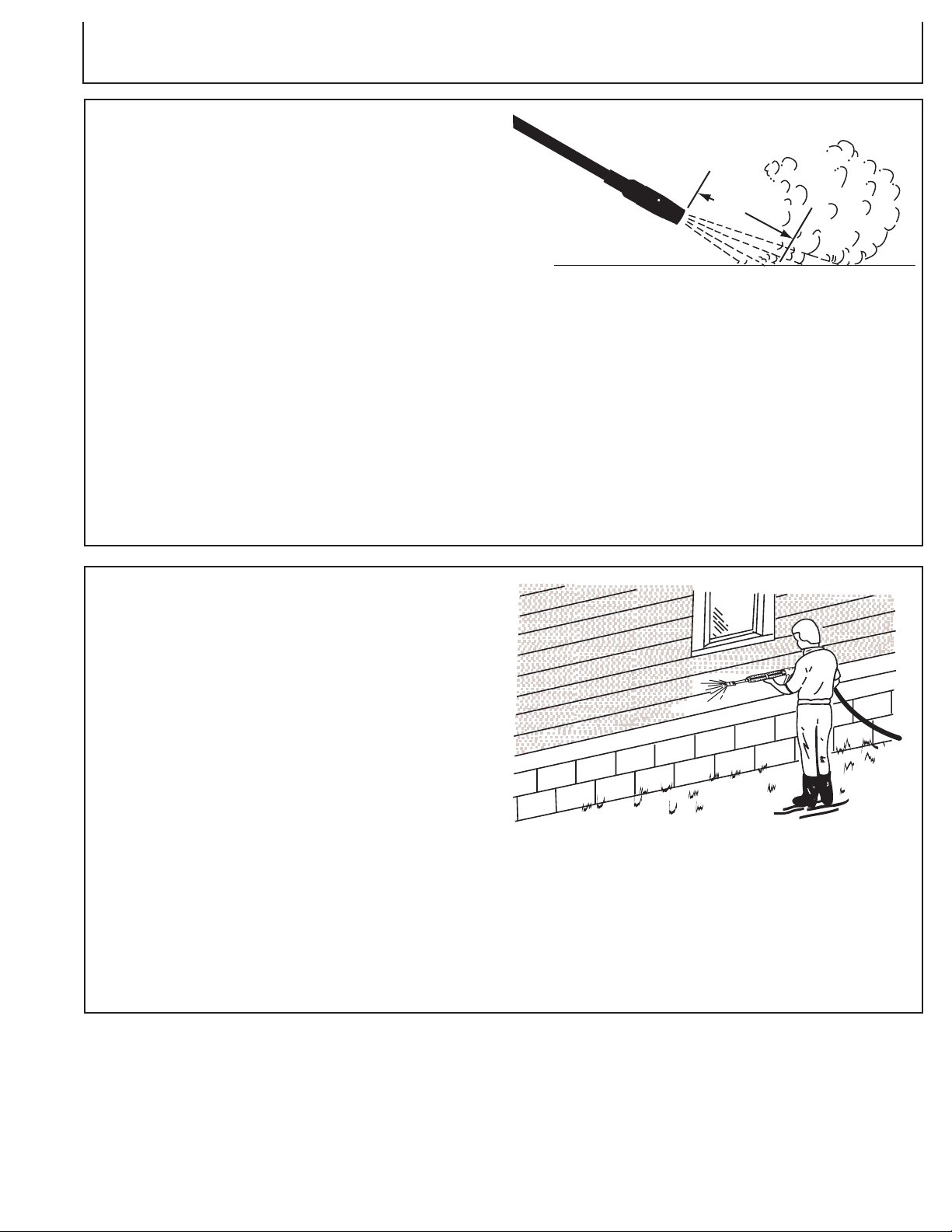

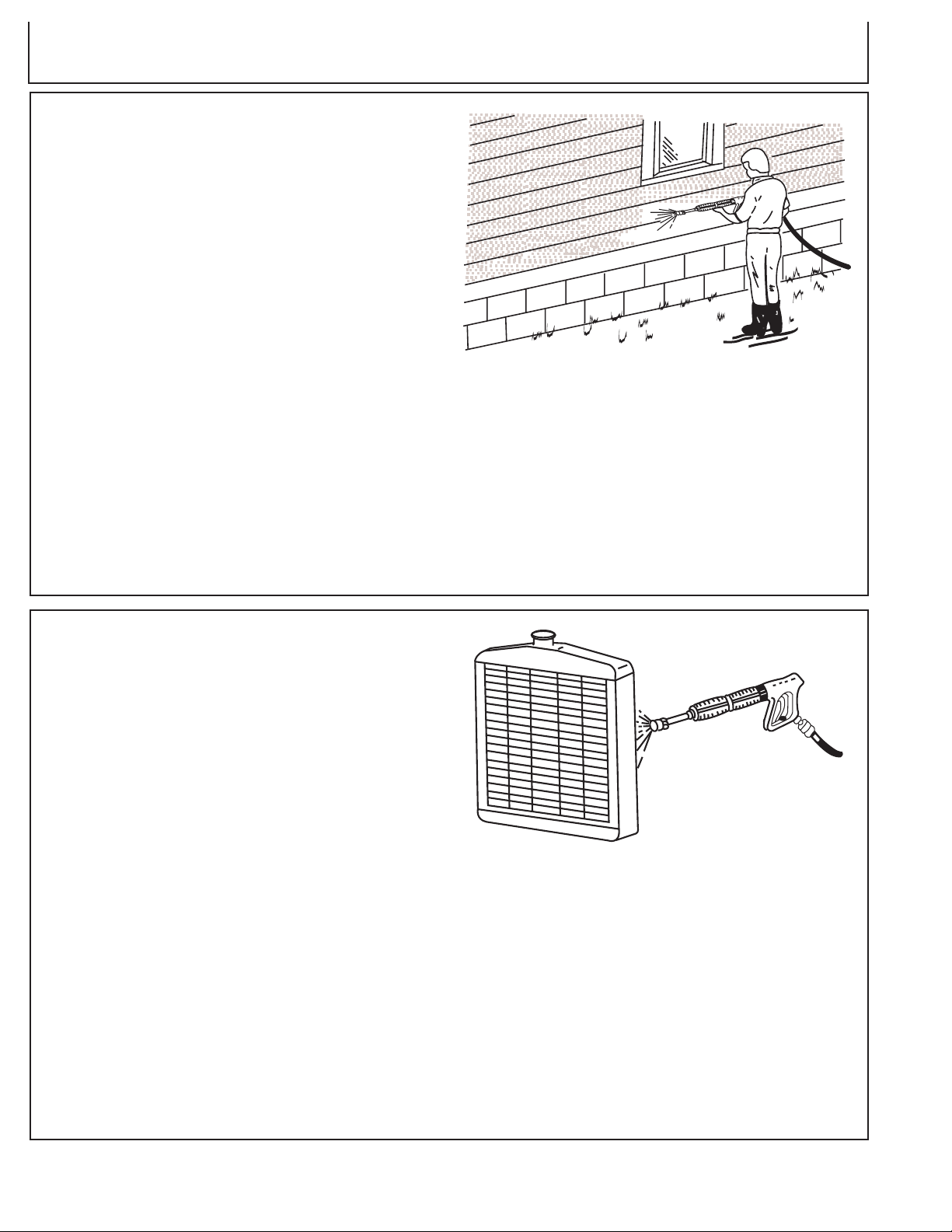

Operating the Washer

8" - 10"

(2 0-25 cm)

CLEANING HORIZONTAL SURFACES

Move nozzle wand from side to side. Direct spray at an

angle to force debris ahead and away from the cleared

area.

Depending on the material to be removed and nozzle

pressure, hold nozzle end 8 to 10 inches (20 to 25 cm) from

the surface and use slow, overlapping strokes. If debris

is easy to remove, move nozzle back to cover more area

for faster cleaning.

CLEANING VERTICAL SURFACES

IMPORTANT: Remember that the washer can deliver

a high pressure spray that can break

glass and gouge soft wood and other

materials.

When cleaning building interiors or exteriors without

detergents, work from top to bottom. This will help

eliminate streaks. In interiors, start with the ceiling rst,

then the walls and the oor last.

Clean around windows carefully. If glass panes are not

well-caulked and puttied, the high pressure spray could

break the glass.

Never spray directly overhead. Always spray ahead to

avoid dripping or falling debris.

AC-Series Operator’s Manual-E/F 25

Page 26

Operating the Washer

REMOVING PAINT

IMPORTANT: Remember that high pressure spray can

gouge soft woods and other materials, as

well as loosen grout.

1. Direct spray at a 45° angle about 4 to 12 inches (10 to

30 cm) from surface.

2. Spray in a back and forth motion, try to get beneath

the loose and bubbled paint.

3. Do not be concerned with the paint that remains. It

should be sufficiently bonded so as not to cause

repainting problems.

4. Some remaining paint may curl up at the edges. These

edges should be scraped with a steel brush or scraper

just before painting.

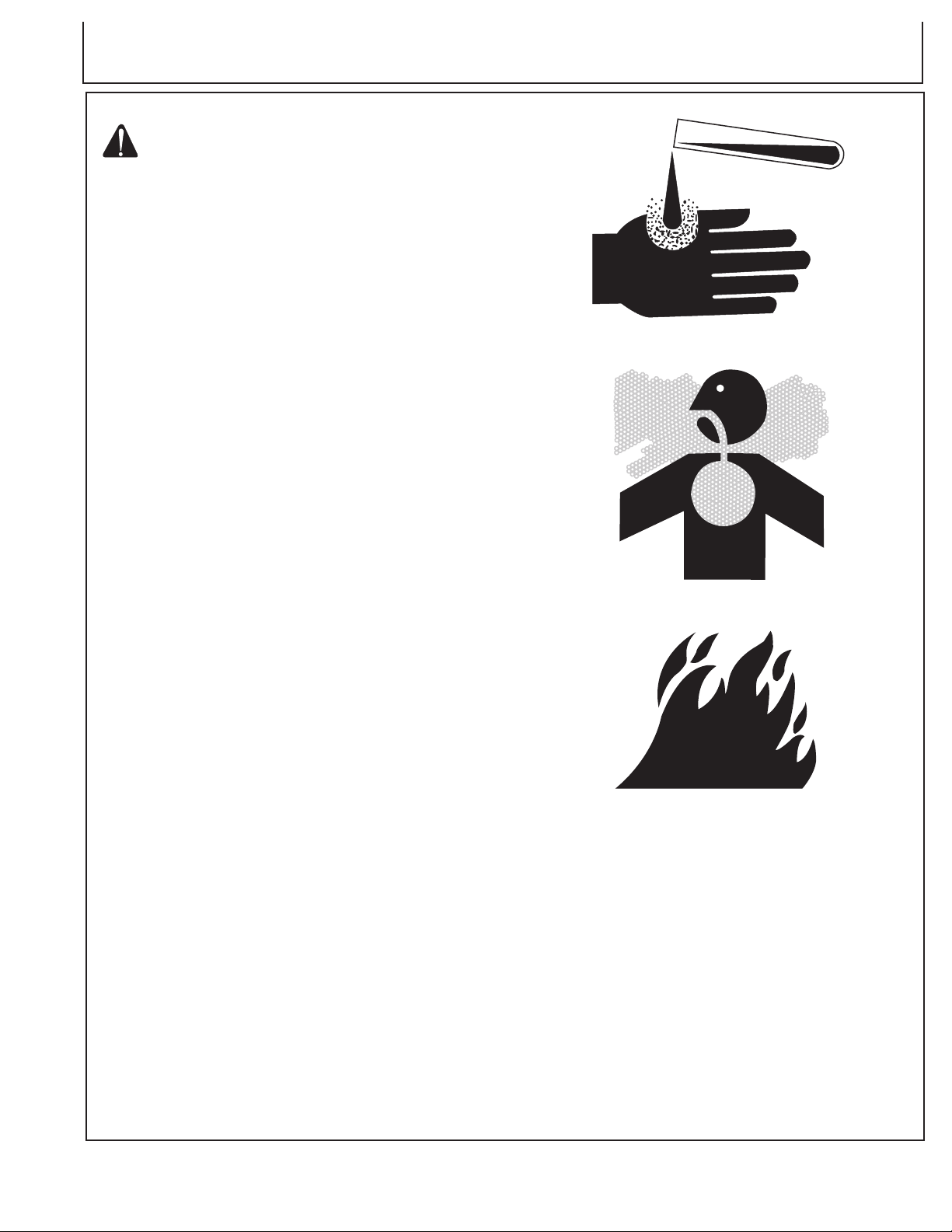

CLEANING RADIATOR FINS

IMPORTANT: Some engine and radiator manufacturers

may not permit cleaning radiators with a

high pressure washer. See equipment

Operator’s Manual.

1. Use clean water without detergent.

IMPORTANT: Spray straight into the radiator to prevent

bending ns.

2. If possible, direct spray in the direction opposite to

normal air ow through the radiator.

26 AC-Series Operator’s Manual-E/F

Page 27

Operating the Washer

DETERGENT USAGE GUIDE

CAUTION: Use detergents carefully. Read

labels thoroughly and follow all instructions

for preparation, use, safety, transportation and

disposal. Be prepared to tell a physician exactly

what detergents you are using in the event of an

emergency. Keep all detergents out of reach of

children.

Be aware that two detergents can be mixed

on the sprayed surface. In this regard, some

detergents may give off harmful fumes or start

an unpredictable chemical reaction when mixed

with another detergent.

NEVER SPRAY FLAMMABLE LIQUIDS such as

gasoline, fuel oil, alcohol, naptha, etc.

The washers are designed to dispense John Deere

approved cleaners and degreasers.

IMPORTANT: Using detergents other than John Deere

approved cleaners and degreasers is

NOT recommended.

If the use of detergents other than those approved by

John Deere is desired, be sure to read and follow all

detergent labels exactly regarding preparation, use,

safety, transportation, and disposal. Keep in mind that the

washer’s detergent system further dilutes the detergent

with water, and that some detergents may not be

concentrated enough to properly work with the system.

Some detergents may not give premix instructions and

may require experimenting to determine proper dilution

for your application.

If you are not familiar with the detergent, always test

a small area of the surface to be cleaned for adverse

reaction. Do this a day in advance. Thoroughly rinse

area with water.

AC-Series Operator’s Manual-E/F 27

Page 28

Operating the Washer

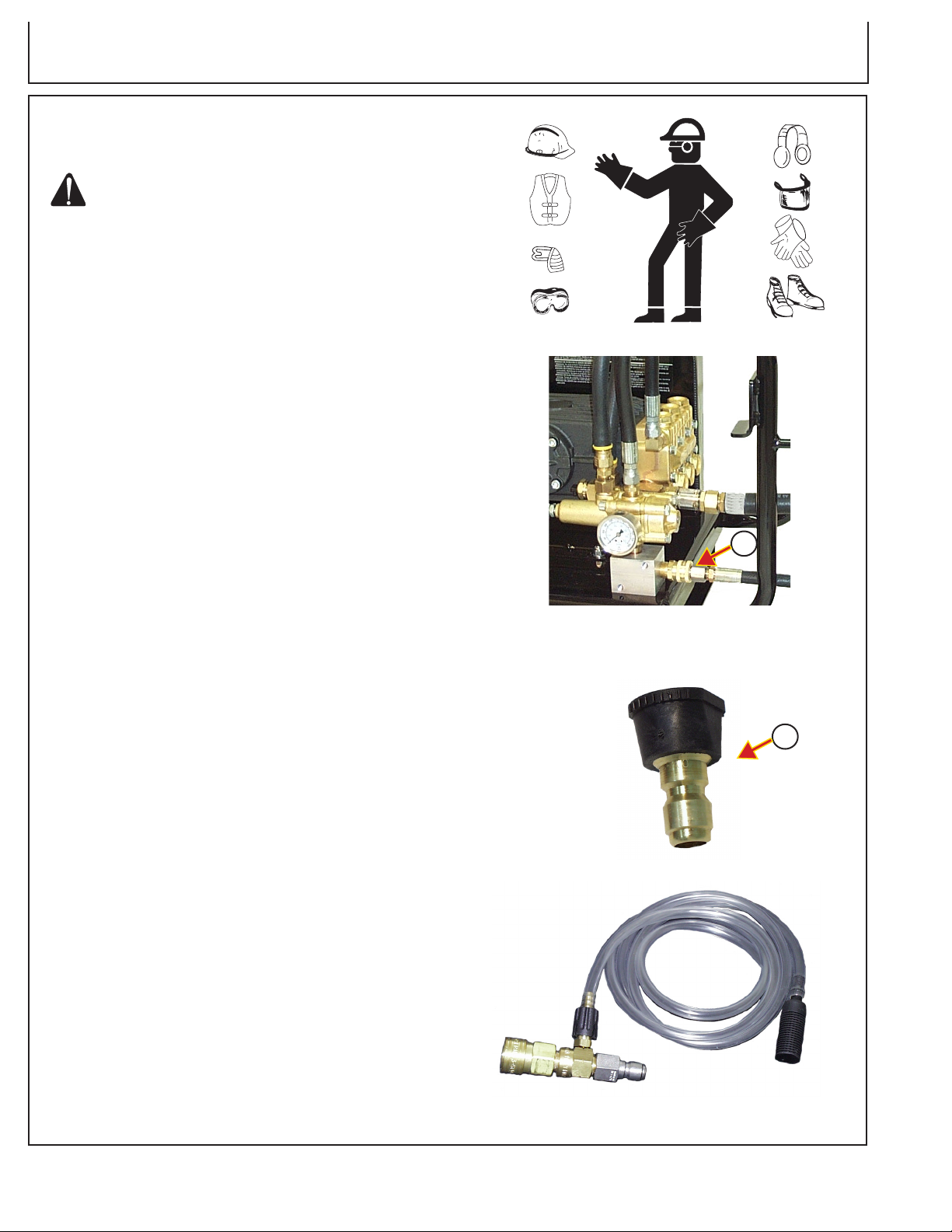

CLEANING WITH DETERGENTS

(ACCESSORY ON AC-2500GH & AC-3500GH

ONLY)

CAUTION: Wear goggles, respirator, and

protective clothing to help prevent injury from

detergents and spray.

IMPORTANT: DO NOT direct pressure washer spray at

the washer.

1. Mix detergent as instructed by the manufacturer.

2. Be sure that water supply is adequate and turned on

fully.

3. Install detergent valve at location (A).

4. Insert detergent hose into solution. Be sure that hose

is clear and fully submerged in solution.

IMPORTANT: The detergent system will work only if the

detergent nozzle is installed.

5. Install detergent nozzle (B). (Black nozzle with brass

body.)

6. Start washer and squeeze gun trigger. If detergent

does not spray within one minute, check to make

sure the detergent hose is in the solution and is not

plugged.

A

PIC90-101599R1

AC-2500GH Illustrated

B

Detergent Injector

28 AC-Series Operator’s Manual-E/F

PIC89-102299R0

PIC55-101599R0

Page 29

Operating the Washer

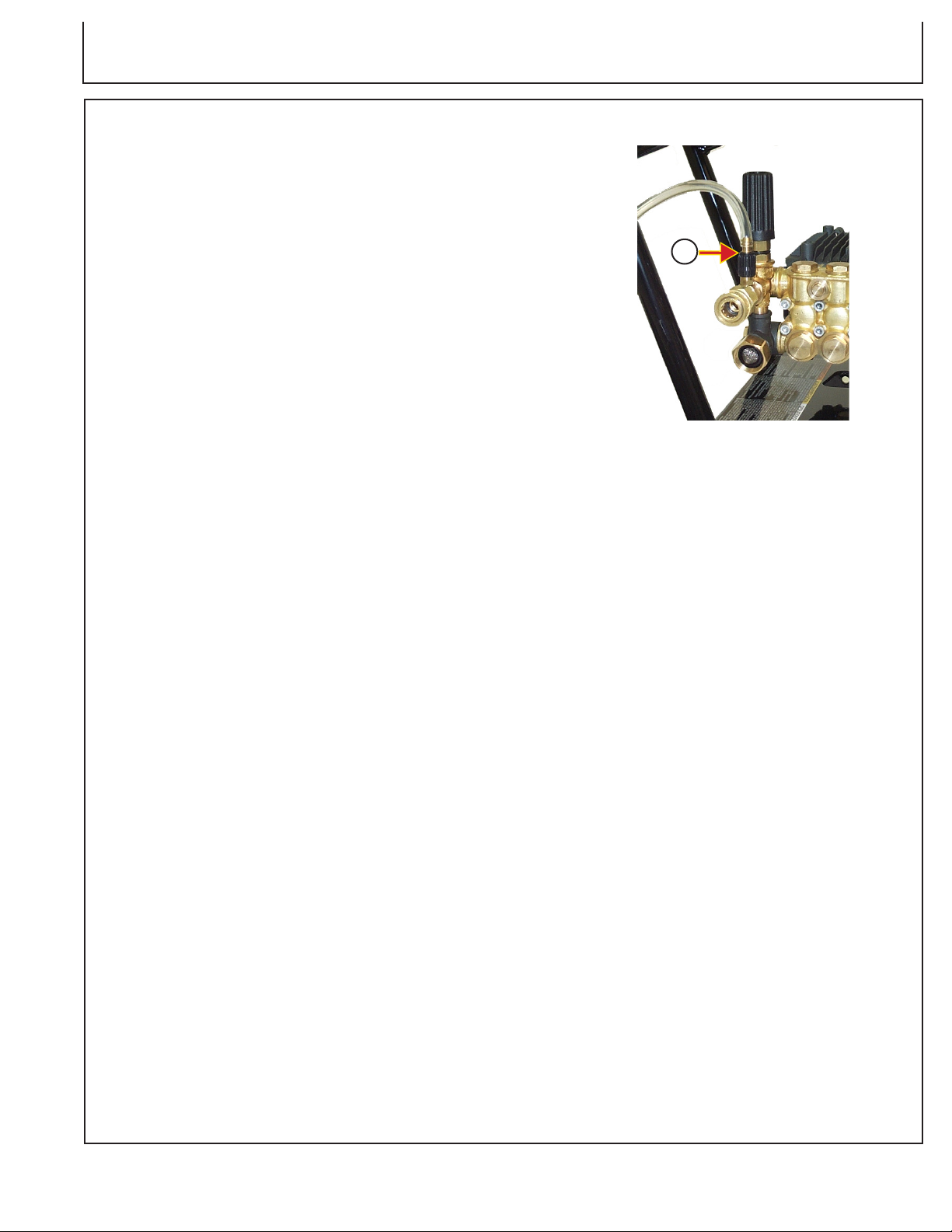

NOTE: Detergent ow rate (concentration) can be adjusted

using plastic knob for AC-2700GH / AC-2700GS and

AC-3300GH / AC-3000GS / AC-3500GH washers.

Turn knob counterclockwise for increased detergent

ow (higher concentration). Siphon ratios will vary

due to temperature and viscosity of detergent.

7. To help avoid streaking, apply detergent to the lowest

surface rst, and move up, using long overlapping

strokes. Allow solution to soak for several minutes.

IMPORTANT: Remember that high pressure spray can

gouge soft woods, damage other materials

and loosen grout.

8. Install a pressure nozzle. With the nozzle approximately

6 to 10 inches (15 to 25 cm) and at an angle to the

surface, power rinse the area from the top down.

9. If surface is not clean, repeat the above procedures.

IMPORTANT: To avoid damage and contamination with

other detergents, siphon a gallon (3.78 L) of

clear water through the system after each

use.

A

PIC92-102299R1

AC-2700GH / AC-3300GH

AC-2700GS / AC-3000GS / AC-3500GH

AC-Series Operator’s Manual-E/F 29

Page 30

Operating the Washer

SHUTDOWN

IMPORTANT: Shutdown procedures should be followed

at the end of each cleaning operation.

1. If a detergent was used, place detergent inlet strainer

in CLEAN water and operate trigger to spray water for

a period of three minutes. This will ush the system of

detergents and help prevent the detergent valve from

sticking or corrosion.

2. Run engine at idle for 2-3 minutes.

3. Turn engine off:

A

AC-2000GH / AC-2600GH:

a. Move throttle lever (A) to “OFF”.

ALL OTHER MODELS: (AC-2400GH / AC-2400GS

illustrated.)

a. Move throttle lever (A) fully to the right.

b. Turn engine switch (B) to “OFF” position.

c. Move fuel valve (C) left to “OFF” position.

4. Turn inlet water supply off. Squeeze trigger momentarily

to relieve pressure. Disconnect hoses.

5. Allow engine to cool, then wipe washer down with a

damp cloth.

PIC158•113099R0

AC-2000GH / AC-2600GH

A

C

B

PIC93-102299R0

AC-2400GH

A

C

B

AC-2400GS

30 AC-Series Operator’s Manual-E/F

PIC93R-121902R0

Page 31

Troubleshooting

Symptom Problem Solution

No discharge at nozzle when Low pressure or no water supply. Ensure hose is 5/8 in. inside diameter

trigger mechanism is squeezed. and incoming water supply is turned

on.

Obstruction in nozzle. Clean or replace nozzle.

Low or uctuating discharge Inadequate water supply. Use larger I.D. size of hose and

pressure. provide specied inlet water pressure

and volume.

Kink in water inlet hose or in high Remove kink.

pressure discharge hose.

Water inlet screen obstructed. Remove screen, clean or replace.

Pump sucking air. (Pump prime lost.) Tighten all water intake connections.

Eliminate leaks in intake line.

Not in high pressure mode. Install high pressure nozzle.

Obstructed or worn spray nozzle. Remove and clean or replace.

Bypass valve not operating correctly. See your John Deere dealer.

Belt slipping.

(AC-2500GH & AC-3500GH only.) Tighten belt.

Water ows from nozzle when Gun malfunction. DO NOT USE!! See your John Deere

trigger is released. dealer.

Pump oil is white or milky color. Water in oil. Change oil. Avoid directing water

spray at pump.

Detergent will not siphon into Strainer not completely submerged Check, submerge if necessary.

Low Pressure Detergent mode. in solution.

(Accessory on AC-2500GH

& AC-3500GH) Strainer obstructed. Inspect, clean or replace.

Siphon hose cut, obstructed or Inspect, clean or replace.

kinked.

Not in Low Pressure mode. Install detergent nozzle.

Nozzle assembly plugged. Clean or replace.

Too many high pressure hose Use only one extension hose

extensions attached to outlet. maximum.

Detergent valve stuck closed. See your John Deere dealer.

Water ows back into detergent Detergent valve jammed, missing See your John Deere dealer.

container. or corroded.

Oil leaking from pump. Pump failed. DO NOT USE!! See your John Deere

dealer.

Water leaks from brass valve Thermal Relief Valve opening to Do not run washer with gun trigger

on pump. protect pump. closed for more than 3 minutes.

Trigger gun to close valve.

AC-Series Operator’s Manual-E/F 31

Page 32

Troubleshooting

Symptom Problem Solution

Engine does not start. Fuel tank empty. Fill fuel tank.

Washer on too steep of slope Level washer.

causing low oil switch to engage.

Low oil level causing low oil switch Add oil.

to engage. (Excluding AC-2000GH

& AC-2600GH)

Improper fuel. Drain and Replace. Use correct fuel.

Old fuel. Drain and Replace. Use fresh fuel.

Spark plug wire loose or Connect spark plug.

disconnected.

Spark plug not gapped correctly. Check and set spark plug gap.

Spark plug failed. Install new spark plug.

Ignition parts failed. See your John Deere dealer.

Engine starts hard or loses Dirt or water in fuel tank. Drain and clean fuel tank.

power.

Vent in gas cap plugged. Clean vent or install new gas cap.

Air cleaner element dirty. Clean or replace air cleaner element.

Spark plug not gapped correctly. Check and set spark plug gap.

Spark plug failed. Clean, regap and tighten spark plug or

install new spark plug.

Ignition parts failed. See your John Deere dealer.

Cylinder exhaust ports plugged. See your John Deere dealer.

Engine runs erratically. Carburetor out of adjustment. See your John Deere dealer.

Spark plug failed. Install new spark plug.

Spark plug not gapped correctly. Check and set spark plug gap.

Cooling ns are plugged. Clean cooling ns.

Engine idles poorly. Air lter element dirty. Clean or replace element.

Carburetor out of adjustment. See your John Deere dealer.

Cooling ns plugged. Clean cooling ns.

Engine overheats. Blower housing or cooling ns Clean blower housing and cooling

plugged. ns.

32 AC-Series Operator’s Manual-E/F

Page 33

Service Chart

First 20 hours Every 25 hours Every 100 hours Every 250 hours Every 300 hours

Clean Air Filter ......................................................................................... X (2)

Change Air Filter .......................................................................................................................................................X (3)

Change Engine Oil .........................X (1) ................................................. X

Clean and Gap Spark Plug ...................................................................... X

Change Spark Plug ...................................................................................................................................................X

Clean Sediment Cup ................................................................................ X

Adjust Idle Speed ......................................................................................................................X (4)

Adjust Valve Clearance .............................................................................................................X (4)

Change Pump Oil...........................X (1) ..................................................................................X

Clean Inlet Water Screen ............................................ X

Clean Siphon Hose Strainer .......................................X

Check/Adjust Belt Tension

(AC-2500GH & AC-3500GH

only) ............................................... ............................X

(1) Perform oil change after rst 20 hours of use and

then at recommended intervals.

(2) Service more frequently when used in dusty

areas.

(3) Replace paper element only.

(4) Should be serviced by authorized dealer unless

owner has proper tools and is mechanically

procient.

AC-Series Operator’s Manual-E/F 33

Page 34

Service

CLEAN INLET WATER SCREEN-ALL MODELS

EXCLUDING AC-2500GH & AC-3500GH

IMPORTANT: Do not operate washer with inlet water

screen removed. Without screen, foreign

matter can enter and damage pump or

valves.

1. Inspect inlet water screen for dirt buildup.

2. To clean screen, remove and back-ush with clean

water or compressed air.

A

3. Replace corroded or damaged screen with cone shape

pointing out.

NOTE: If screens plug frequently, installation of additional

Water Filter 851-0207 is recommended.

CLEAN INLET WATER SCREEN-AC-2500GH

AND AC-3500GH

IMPORTANT: Do not operate washer with inlet water

screen removed. Foreign material may

enter and damage pump or valves.

Inspect the inlet screen (A) periodically for build-up of

scale, dirt and grit. Clean if necessary. Replace screen if

corroded of broken.

PIC77-102299R1

A

PIC79-102299R1

CLEAN DETERGENT HOSE STRAINER

Check detergent hose strainer for detergent or contaminant

buildup.

Remove strainer from hose and back ush with clean water

and a stiff brush.

NOTE: If strainer frequently becomes plugged, check

detergent to be sure it is thoroughly mixed.

34 AC-Series Operator’s Manual-E/F

PIC21-101599R0

Page 35

CHECKING WATER PUMP OIL

IMPORTANT: If oil is white or foaming, water is in the

oil reservoir. Change oil.

NOTE: Wa t e r in oil occurs as a result of sp r a y or

condensation. Milky oil is not indicative of a pump

malfunction.

Service

1. Stop engine.

2. Put unit on level surface.

3. Oil level can be checked as follows:

•ALL MODELS: View level through clear window (A). Oil

should ll sight glass.

•Additional method for AC-2500GH, AC-2700GH,

AC-3300GH, AC-2700GS, AC-3000GS and AC-3500GH

only:

- Remove dipstick (B) and wipe clean. Put dipstick

in hole. Remove dipstick and check level. Oil level

should be located at notch (C) on AC-2500GH and

at dipstick ring (D) on AC-2700GH, AC-3300GH,

AC-2700GS, AC-3000GS and AC-3500GH.

4. Add HY-GARD® or SAE75W-90 Synthetic oil if

necessary. Do not overll.

HY-GARD® SAE75W-90 Synthetic

AC-2500GH AC-2000GH

AC-2700GH AC-2400GH

AC-2700GS AC-2400GS

AC-3000GS AC-2600GH

AC-3300GH

AC-3500GH

A

A

AC-2000GH / AC-2400GH

AC-2600GH / AC-2400GS

B

AC-2500GH

PIC155•113099R0

PIC70-101199R0

B

PIC72-101199R0

A

D

C

AC-2700GH / AC-3300GH

AC-2700GS / AC-3000GS / AC-3500GH

AC-Series Operator’s Manual-E/F 35

PIC71•102299R0

Page 36

Service

CHANGING WATER PUMP OIL

IMPORTANT: Change pump break-in oil after first 20

hours of operation and at 250 hour intervals

thereafter.

1. Put unit on level surface.

2. With water owing through pump, run unit for a few

minutes to warm oil.

A

3. Stop engine and close water supply.

4. Remove drain plug (A) to drain oil into container. Do not

pollute; dispose of waste oil properly.

NOTE: Drain plug (A) is located on bottom of pump on

AC-2000GH, AC-2400GH, AC-2400GS and

AC-2600GH washers. It is located at front end of

pump on AC-2500GH, AC-2700GH, AC-2700GS,

AC-3000GS, AC-3300GH and AC-3500GH.

5. Add SAE75W-90 Synthetic oil through fill tube

on A C-2000GH , AC -2400GH, AC- 2 600GH and

AC-2400GS or HY-GARD® through dipstick holes in

other models (B). Fill to sight glass or to notch/ring in

dipstick. Oil capacity is:

AC-2000GH .......................... 4.5 oz. (0.14 qt., 0.13L)

AC-2400GH .......................... 4.5 oz. (0.14 qt., 0.13L)

AC-2400GS .......................... 4.5 oz. (0.14 qt., 0.13L)

AC-2500GH .......................... 40.6 oz. (1.27 qt., 1.20L)

AC-2600GH .......................... 4.5 oz. (0.14 qt., 0.13L)

AC-2700GH .......................... 14 oz. (0.42 qt., 0.40L)

AC-2700GS .......................... 14 oz. (0.42 qt., 0.40L)

AC-3000GS .......................... 14 oz. (0.42 qt., 0.40L)

AC-3300GH .......................... 15 oz. (0.47 qt., 0.44L)

AC-3500GH .......................... 15 oz. (0.47 qt., 0.44L)

PIC101-101599R1

AC-2000GH / AC-2400GH

AC-2400GS / AC-2600GH

B

A

PIC102-101599R0

AC-2500GH

B

PIC71•102299R0

A

AC-2700GH / AC-3300GH

AC-2700GS / AC-3000GS / AC-3500GH

36 AC-Series Operator’s Manual-E/F

Page 37

-40°F

-22°F

-4°F

14°F

32°F

50°F

68°F

86°F

104°F

122°F

50°C

40°C

30°C

20°C

10°C

0°C

-10°C

-20°C

-30°C

-40°C

SAE 10W-40

SAE 10W-30

SAE 5W-30

CHECK ENGINE OIL

NOTE: All washer are shipped with engine oil. Check proper

level. (AC-2400GH illustrated.)

1. Stop engine.

2. Place unit on level surface.

3. Remove oil ller cap/dipstick and wipe it clean.

4. Insert ller cap/dipstick into oil ller neck, but DO NOT

screw it in.

5. Remove dipstick. Proper oil level is at midpoint of

dipstick (A). Add oil if necessary to bring oil level to

top of threads (B).

6. Install and tighten cap.

Service

A

PIC110-102299R0

B

NOTE: Oil can be checked using ller cap on either side

of engine.

GASOLINE ENGINE OIL

Use oil viscosity based on the expected air temperature

range during the period between oil changes.

John Deere TURF-GARDTM is preferred. Also

recommended is John Deere PLUS-4®.

Other oils may be used if they meet one or more of the

following:

•API Service Classication SH

•API Service Classication SG

•CCMC Specication G4

•CCMC Specication G5

CHANGING ENGINE OIL

IMPORTANT: Change oil after rst 20 hours of operation

and every 100 hours thereafter.

NOTE: AC-2400GH illustrated.

1. Put unit on level surface.

2. Run engine a few minutes to warm oil.

PIC67-102299R1

DWG13-102299R0

PIC96-102299R0

A

3. Stop engine.

4. Remove oil ller cap (A) and drain plug (B) from either

side of engine to drain oil into container. Do not pollute,

dispose of waste oil properly.

5. Install drain plug (B). Fill with oil to top of threads. Install

cap. Oil capacity is :

-AC-2000GH & AC-2400GH: 0.6L (0.63 qts.)

-AC-2400GS & AC-2600GH: 0.6L (0.63 qts.)

-AC-2700GH & AC-2700GS: 0.6L (0.63 qts.)

-AC-2500GH & AC-3000GS: 1.1L (1.16 qts.)

-AC-3300GH & AC-3500GH: 1.1L (1.16 qts.)

AC-Series Operator’s Manual-E/F 37

B

PIC67-102299R1

Page 38

CLEAN AIR FILTER ELEMENT

AC-2000GH ONLY:

1. Push lower part of tabs (A) inward and through tab

holders to remove cleaner cover.

2. Remove paper element (D).

3. Remove excess dirt from paper element (D) by

tapping lightly on hard surface, or by blowing

compressed air from inside the element. Do NOT

brush dirt. Brushing will force dirt into element

bers. Replace paper element after 300 hours,

or if excessively dirty.

ALL OTHER WASHERS: (AC- 2400GH AN D

AC-2400GS illustrated.)

1. Remove wing nut (A) and remove air cleaner

cover (AC-2400GH / AC-2500GH / AC-2700GH /

AC-3300GH / AC-3500GH). Push lower part

of tabs (A) inward and through tab holders to

remove cleaner cover (AC-2400GS / AC-2700GS /

AC-3000GS).

Service

A

PIC156-102299R0

D

PIC157-102299R0

2. Remove second wing nut (B) to remove air cleaner

assembly.

3. Separate air cleaner elements. Check both

elements for holes or tears. Replace if damaged.

4. Wash foam element (C) in solution of household

detergent and warm water. Rinse thoroughly and

allow to dry thoroughly. Soak element in clean

engine oil. Squeeze out excess oil.

NOTE: Engine will smoke during initial start-up if too

much oil is left on foam.

5. Remove excess dirt from paper element (D) by

tapping lightly on hard surface, or by blowing

compressed air from inside the element. Do NOT

brush dirt. Brushing will force dirt into element

bers. Replace paper element after 300 hours,

or if excessively dirty.

6. Install air cleaner in reverse order as removed.

A

B

PIC93•102299R0

B

PIC94-102299R0

A

PIC156R•121902R0

PIC94R-121902R0

C

C

D

PIC95-102299R0

D

AC-2400GH

38 AC-Series Operator’s Manual-E/F

AC-2400GS

PIC95R-121902R0

Page 39

Service

CLEANING AND GAPPING SPARK PLUG

1. Remove and inspect spark plug. If porcelain is cracked

or electrodes are pitted, install a new spark plug. (See

step 5.)

IMPORTANT: Do not clean spark plug in a machine

using abrasives.

2. If spark plug is in good condition, clean plug by scraping

or using a wire brush. Wash with a commercial

solvent.

3. Use a round wire-type feeler gauge to check for a gap

of 0.70 to 0.80 mm (0.028 to 0.031 inches.)

4. Carefully bend outer electrode to adjust gap.

5. Install spark plug.

Reinstalling used plug: Tighten 1/8 - 1/4 turn after spark

plug seats to compress washer.

Installing new plug: Use the following;

NGK BPR6ES (AC-2000GH, AC-2400GH, AC-2500GH,

AC-2600GH, AC-2700GH, AC-3300GH and AC-3500GH)

NGK BR6HS (AC-2400GS, AC-2700GS and AC-3000GS)

or W20EPR-U (Nippondenso) plug. Tighten 1/2 turn after

spark plug seats to compress washer.

PIC99-102299R0

ADJUSTING IDLE SPEED

1. Start engine. Allow it to warm to normal operating

temperature.

2. With engine idling, turn throttle stop screw (A) to obtain

standard idle speed.

NOTE: Standard idle speed is 1250 - 1550 RPM.

NOTE: Idle should be serviced every 300 hours by an

authorized dealer. Operator should adjust only if

mechanically procient and using proper tools.

CLEANING SEDIMENT CUP

CAUTION: Clean sediment cup in a well ventilated

area, away from sparks or ame, including any

appliance with a pilot light. Do not use gasoline

or a low ash-point solvent to clean the fuel valve.

A re or explosion could result.

NOTE: AC-2400G illustrated, but procedure is the same for

other washers.

NOTE: Clean sediment cup after every 100 hours of use.

1. Turn fuel valve (A) to left as illustrated to shut off the

fuel ow.

2. Remove cap screw (B) with a 10mm wrench. Remove

sediment cup (C) and o-ring.

3. Remove any sediment or other foreign matter and

wash in nonammable or high ash point solvent. Dry

thoroughly.

A

PIC98-102299R0

DWG15-102299R0

A

C

PIC100-102299R0

4. Install o-ring and sediment cup with cap screw.

B

5. Turn fuel valve right to “ON” position and check for fuel

leaks.

AC-Series Operator’s Manual-E/F 39

Page 40

ADJUST BELT TENSION AC-2500GH & AC-3500GH ONLY

NOTE: Check/adjust belt tension after every 25 hours of

use.

1. Twist locking screw (A) 1/4 turn and lift off belt guard.

Service

A

2. Inspect belts for wear, cracks or fraying. Replace belts

if damaged.

3. Loosen the four bolts (A) holding pump mounting

bracket to chassis.

4. Tighten adjusting cap screw (B) to take slack out of

belt.

5. In the four-bolt pattern that holds the pump mounting

bracket to chassis, rst tighten mounting bracket corner

bolt which is closest to both the motor and the belts.

(Right rear bolt in illustration.)

6. Continue tightening adjusting cap screw (B) until

pulleys are aligned parallel to straightedge (C), and

13mm (1/2 inch) deection occurs at belt midpoint (D)

when belt is depressed with nger.

NOTE: Process may have to be repeated several times to

maintain pulley alignment while producing 13mm

(1/2 inch) belt deection.

7. Tighten all four pump mounting bracket bolts (A).

8. Install guard.

A

B

C

D

PIC104-101599R0

PIC105-102299R0

A

PIC106-102299R0

40 AC-Series Operator’s Manual-E/F

Page 41

Storage

STORING THE WASHER

IMPORTANT: Protect washer from freezing temperatures.

CAUTION: If the washer will be used where food is

prepared, stored or consumed, or where sanitation

is required, use a nontoxic antifreeze.

1. Stop engine.

2. Change engine oil. (See Engine Service section.)

3. Add TY15977 Gasoline Stabalizer as directed on label.

4. With water owing through gun, run engine ve minutes

to draw stabilized gasoline into carburetor. Stop engine.

5. Close water supply and remove inlet supply hose. Install

short piece of hose on water inlet. Fill short hose with

water, cap open end with nger and place in a container

of TY8261 John Deere Rust Inhibiting Antifreeze.

6. Start engine. Place nozzle into container and trigger gun

for 30 seconds.

If unit will experience freezing conditions,

pump must be filled with antifreeze to

prevent cracking of pump manifold and

relief valve due to water expansion. Draining

alone will not remove all the water.

NOTE: Trigger must be released to pull antifreeze into relief

7. Release trigger for 30 seconds to direct antifreeze into

IMPORTANT: Dispose of the sprayed solution according

8. Disconnect supply line.

9. Turn fuel valve to “OFF” position.

10. Remove spark plug and squirt 10 cc of 2 cycle oil into

11. Install spark plug and pull starter handle slowly until

12. Store washer in a clean, dry area AWAY FROM any device

valve.

relief valve

to instructions on the antifreeze container.

cylinder. Turn crankshaft over 5 times to distribute the oil

throughout cylinder.

compression is felt and stop there.

CAUTION: Gasoline fumes can accumulate and

explode if exposed to an open ame or spark. If

storing washer with fuel in tank, be certain there

are no open ame, pilot lights or spark activated

devices (i.e. stoves, furnaces, water heaters) in the

storage area.

that has a pilot light or is spark activated (stove, furnace,

water heater).

REMOVING WASHER FROM EXTENDED

STORAGE

Prepare washer as previously directed. Connect and open water

supply. Squeeze trigger on gun. Allow water to run (without

engine running) until water runs out of the pressure hose.

Dispose of antifreeze solution according to the instructions on the

antifreeze container.

AC-Series Operator’s Manual-E/F 41

Page 42

Specications

SPECIFICATIONS

ITEM Model AC-2000GH Model AC-2400GH Model AC-2500GH Model AC-2600GH Model AC-2700GH

Operating Pressure 1900-2050 2300-2400 PSI 2375-2500 PSI 2450-2575 PSI 2580-2720 PSI

Measured at Pump Manifold ......... (131-141 Bar) (159-165 Bar) (164-172 Bar) (169-176 Bar) (178-188 Bar)

Measured at discharge 1750-1900 PSI 2000-2250 PSI 2375-2500 PSI 2300-2425 PSI 2430-2570 PSI

Hose Outlet ................................... (121-131 Bar) (152-155 Bar) (164-172 Bar) (159-167 Bar) (168-177 Bar)

Relief Pressure (Measured at 2200-2600 PSI 2400-2800 PSI Not Measurable 2600-3000 PSI 2700-3100 PSI

Discharge Hose Outlet) ................ (152-179 Bar) (165-193 Bar) At Outlet (179-207 Bar) (186-214 Bar)

Inlet Water Supply (Minimum) ...... 3.0 GPM 3.0 GPM 5.5 GPM 3.0 GPM 3.0 GPM

(11.4 L/min) (11.4 L/min) 20.8 L/min) (11.4 L/min) (11.4 L/min)

Pump Flow .................................... 2.4-2.5 GPM 2.2-2.4 GPM 4.2-4.6 GPM 2.2-2.4 GPM 2.2-2.4 GPM

(9.1-9.5 L/min) (8.3-9.1 L/min) (15.9-17.4 L/min) (8.3-9.1 L/min) (8.3-9.1 L/min)

Pump Oil Capacity ........................ 4.5 oz. 4.5 oz. 40.6 oz. 4.5 oz. 14 oz.

(0.14 qt., 0.13 L) (0.14 qt., 0.13L) (1.27 qt., 1.20L) (0.14 qt., 0.13 L) (0.44 qt., 0.41L)

Nozzle Size Code ......................... 3.5 3.0 5.5 3.0 3.0

Engine ..........................................Honda Honda Honda Honda Honda

Model .................................... GC160 GX160 GX340 GC190 GX200

Spark Plug ............................BPR6ES (NGK) BPR6ES (NGK) BPR6ES (NGK) BPR6ES (NGK) BPR6ES (NGK)

Plug Gap ............................... 0.028-0.031 in. 0.028-0.031 in. 0.028-0.031 in. 0.028-0.031 in. 0.028-0.031 in.

(0.70-0.80 mm) (0.70-0.80 mm) (0.70-0.80 mm) (0.70-0.80 mm) (0.70-0.80 mm)

Engine Oil Capacity ...................... 0.6 qt. (0.63L) 0.6 qt. (0.63L) 1.1 qt. (1.16L) 0.6 qt. (0.63L) 0.6 qt. (0.63L)

Fuel Tank Capacity .......................0.46 gal. (1.72L) 0.95 gal. (3.60L) 1.72 gal. (6.51L) 0.46 gal. (1.72L) 0.95 gal. (3.60L)

42 AC-Series Operator’s Manual-E/F

Page 43

PRESSURE WASHER

Made in U.S.A.

34-0075

MAX. GPM

MAX. PSI

NOZZLE SIZE

H.P.

CODE

MODEL NO.

Specications

SPECIFICATIONS

ITEM Model AC-3300GH Model AC-2400GS Model AC-2700GS Model AC-3000GS Model AC-3500GH

Operating Pressure 3250-3350 PSI 2300-2400 PSI 2580-2720 PSI 3250-3350 PSI 3400-3500 PSI

Measured at Pump Manifold ......... (224-231 Bar) (159-165 Bar) (178-188 Bar) (224-231 Bar) (234- 241 Bar)

Measured at discharge 3100-3200 PSI 2000-2250 PSI 2430-2570 PSI 3100-3200 PSI 3350-3450 PSI

Hose Outlet ................................... (214-221 Bar) (152-155 Bar) (168-177 Bar) (214-221 Bar) (231-238 Bar)

Relief Pressure (Measured at 3300-3800 PSI 2400-2800 PSI 2700-3100 PSI 3300-3800 PSI 3600-4000 PSI

Discharge Hose Outlet) ................ (228-262 Bar) (165-193 Bar) (186-214 Bar) (228-262 Bar) (248-276 Bar)

Inlet Water Supply (Minimum) ...... 4.2 GPM 3.0 GPM 3.0 GPM 4.2 GPM 4.6 GPM

(15.9 L/min) (11.4 L/min) (11.4 L/min) (15.9 L/min) (17.4 L/min)

Pump Flow .................................... 3.2-3.4 GPM 2.2-2.4 GPM 2.2-2.4 GPM 2.8-3.1 GPM 3.6-3.7 GPM

(12.1-12.9 L/min) (8.3-9.1 L/min) (8.3-9.1 L/min) (10.6-11.7 L/min) (13.6-14.0 L/min)

Pump Oil Capacity ........................ 15 oz. 4.5 oz. 4.5 oz. 14 oz. 15 oz.

(0.47qt., 0.44L) (0.14 qt., 0.13L) (0.14 qt., 0.13L) (0.42 qt., 0.40L) (0.47qt., 0.44L)

Nozzle Size Code ......................... 3.5 3.0 3.0 3.5 4.0

Engine ..........................................Honda Subaru Subaru Subaru Honda

Model .................................... GX340 EX17 EX21 EX27 GX390

Spark Plug ............................BPR6ES (NGK) BR6HS (NGK) BR6HS (NGK) BR6HS (NGK) BPR6ES (NGK)

Plug Gap ............................... 0.028-0.031 in. 0.028-0.031 in. 0.028-0.031 in. 0.028-0.031 in. 0.028-0.031 in.

(0.70-0.80 mm) (0.70-0.80 mm) (0.70-0.80 mm) (0.70-0.80 mm) (0.70-0.80 mm)

Engine Oil Capacity ...................... 1.1 qt. (1.16L) 0.6 qt. (0.63L) 0.6 qt. (0.63L) 1.1 qt. (1.16L) 1.1 qt. (1.16L)

Fuel Tank Capacity .......................1.72 gal. (6.51L) 0.95 gal. (3.60L) 0.95 gal. (3.60L) 1.58 gal. (6.00L) 1.72 gal. (6.50L)

RECORD SERIAL NUMBER

Write you model number, machine serial number and date

of purchase in the spaces provided below. Your dealer

needs this information when ordering parts.

NOTE: Serial number is located on the right side of vertical

face of base plate at front of pump. (Near base of

handle.)

Model No. ______________________________________________

Machine Serial No. _______________________________________

Date of Purchase ________________________________________

(To be lled in by purchaser)

AC-Series Operator’s Manual-E/F 43

Page 44

Accessories

HIGH PRESSURE HOSE EXTENSION:

FOR AC-2000GH, AC-2400GH, AC-2400GS, AC-2500GH,

AC-2600GH, AC-2700GH, AC-2700GS & AC-3000GS:

851-0007

FOR AC-3300GH & AC-3500GH: 851-0338

IMPORTANT: DO NOT use more than 1 extension hose. The higher

restriction will cause unloader valve to function all the

time.

One additional pressure hose may be connected to the existing hose. This

allows the operator to move around a greater distance without moving

unit.

WATER FILTER: 19-0206

STANDARD ON AC-2500GH & AC-3500GH

Use when water supply is a rural well or a static draw to

help lter incoming water.

PIC165-012800R0

851-0007 & 851-0338

PIC34-090199R1

WATER FILTER: 851-0207

FOR AC-2000GH, AC-2400GH, AC-2600GH &

AC-2400GS

Use when water supply is a rural well or a static draw to

help lter incoming water.

PRESSURE TEST GAUGE: 852-0044

FOR AC-2700GH, AC-3300GH, AC-2700GS,

AC-3000GS & AC-3500GH

This glyerine lled gauge indicates working and relief

pressures.

PIC34-090199R0

PIC109-102299R0

44 AC-Series Operator’s Manual-E/F

Page 45

Accessories

DETERGENT INJECTOR: AW-8000-J000

FOR AC-2500GH & AC-3500GH

The detergent injector supplies low pressure soap or

cleaning solution at a rate of approximately one part

detergent to 17 parts water.

The detergent injector is installed between the pump and

high pressure hose and is adjustable to provide detergent

proportionately at 100 PSI.

ALL-PURPOSE CLEANER: AW-4018-JD01

Use John Deere All Purpose Cleaner concentrate for

most cleaning jobs. Contains water-soluble solvents for

soil penetration on vehicles and is safe to use on rubber

and wax nishes.

PIC55-101599R0

PIC35-090199R0

SURFACE PREPARATION: AW-4034-JD01

Use John Deere Surface Preparation to clean, remove

mildew, and condition surfaces of all types of siding, farm

buildings and mobile homes. It is safe to use on ferrous

and nonferrous metal surfaces and removes mildew stains

and chalk buildup.

DEGREASING: AW-4059-JD01

Apply John Deere Degreaser as directed by container

label, allow to soak for a few minutes, then wash with all

purpose cleaner. Rinse with clear water.

Cover sensitive parts such as air cleaner, electrical

components, etc. when cleaning engines.

PIC36-090199R0

PIC37-090199R0

AC-Series Operator’s Manual-E/F 45

Page 46

Accessories

HY-GARD®-TY6354

Use John Deere HY-GARD® when adding or changing oil

in pressure washer pump.

SPRAY WAX-TY8277

Mix John Deere Spray Wax at a ratio of ONE ounce of

wax to 1-1/2 gallon of water to give a long lasting nish to

painted metal surfaces.

PIC38-092499R0

PIC39-092499R0

RUST-INHIBITING ANTIFREEZE-TY8261

Use John Deere Rust Inhibiting Antifreeze to help prevent

rust and corrosion from occurring on carbon steel and cast

iron, while protecting from damage due to freezing.

DETERGENT BOOSTER-TY8276

Use John Deere Detergent Booster at a ratio of ONE

part detergent booster to THREE parts AW-4018-JD01

cleaner.

PIC40-090199R0

PIC43-090199R0

46 AC-Series Operator’s Manual-E/F

Page 47

Accessories

PLUS-4 MOTOR OIL: AR63231

John Deere Plus-4 Motor Oil is a superior, fuel efcient

all-season engine oil.

GASOLINE CONDITIONER & STABALIZER:

TY15977

Use John Deere Gasoline Conditioner and Stabilizer to

help prevent formation of gum or varnish in fuel system.

PIC150-113099R0

PIC151-113099R0

AC-Series Operator’s Manual-E/F 47

Page 48

STATEMENT OF WARRANTY

AC-SERIES

The manufacturer warrants all parts, (except those referred to below), of your new

pressure washer to be free from defects in materials and workmanship during the

following periods:

For Five (5) Year from the date of original purchase:

High Pressure Pump

For Two (2) Years from the date of original purchase:

Cart Assembly Plumbing

Pulleys/Drive System

For Ninety (90) days from the date of original purchase:

Trigger Gun High Pressure Hose

Pressure Gauge Unloader

Defective parts not subject to normal wear and tear will be repaired or replaced at our

option during the warranty period. In any event, reimbursement is limited to the purchase

price paid.

EXCLUSIONS

1. Normal wear parts:

Pump Packings Spray Nozzles

Pump Valves Quick Connects