Page 1

AC-2500E

High Pressure Washer

Operator’s Manual 1

Page 2

Introduction

THANK YOU for purchasing a John Deere product.

READ THIS MANUAL carefully to learn how to operate

and service your machine correctly. Failure to do so could

result in personal injury or equipment damage. This manual

and safety signs on your machine may also be available in

other languages. (See your John Deere dealer to order.)

THIS MANUAL SHOULD BE CONSIDERED a permanent

part of your machine and should remain with the machine

when you sell it.

MEASUREMENTS in this manual are given in both

metric and customary U.S. unit equivalents. Use only

correct replacement parts and fasteners. Metric and inch

fasteners may require a specific metric or inch wrench.

RIGHT HAND AND LEFT HAND sides are determined by

facing the motor end of the machine.

The SERIAL NUMBER is located in the Specification or

Identification Numbers section. Accurately record all the

numbers to help in tracing the machine should it be stolen.

Your dealer also needs these numbers when you order

parts. File the identification numbers in a secure place

off the machine.

WARRANTY is provided from your John Deere dealer for

customers who operate and maintain their equipment as

described in this manual. The warranty is explained on

the warranty certificate shown in this manual.

This warranty provides you the assurance that your

dealer will back products where defects appear within

the warranty period. Should the equipment be abused,

or modified to change its performance beyond the original

factory specifications, the warranty will become void.

2 Operator’s Manual

Page 3

Contents

Page

Safety ........................................................................ 5

Controls ................................................................. 13

Preparing the Washer ............................................ 14

Operating the Washer ............................................18

Troubleshooting .....................................................24

Storage ....................................................................26

Specifications .........................................................29

Warranty ..................................................................30

Notes ........................................................................ 31

All information, illustrations and specifications in this manual are based

on the latest information available at the time of publication. The right is

reserved to make changes at any time without notice.

Operator’s Manual 3

Page 4

Contents

4 Operator’s Manual

Page 5

W

A

R

N

I

N

G

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

C

A

U

T

I

O

N

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

Safety

RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. When you see this symbol

on your machine or in this manual, be alert to the potential

for personal injury.

Follow recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS

A signal word--DANGER, WARNING or CAUTION--is used

with the safety-alert symbol. DANGER identifies the most

serious hazards.

DANGER or WARNING safety signs are located near

specific hazards. General precautions are listed on

CAUTION safety signs. CAUTION also calls attention to

safety messages in this manual.

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual and on

your machine safety signs. Keep safety signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from your John Deere dealer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machine in proper working condition.

Unauthorized modifications to the machine may impair the

function and/or safety and affect machine life.

If you do no understand any part of this manual and need

assistance, contact your John Deere dealer.

Operator’s Manual 5

Page 6

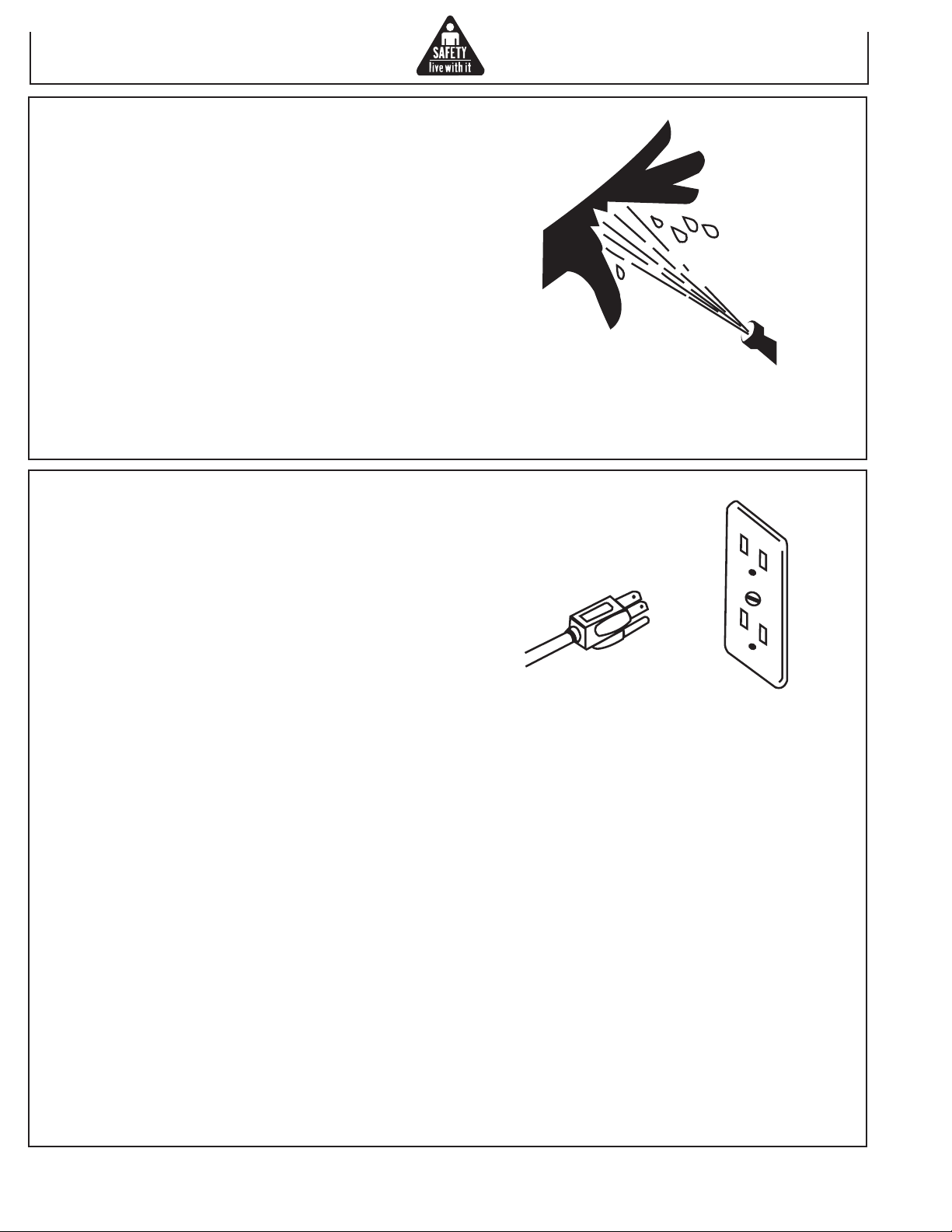

PROTECT AGAINST HIGH PRESSURE

SPRAY

Spray from high pressure nozzles can penetrate the skin

and cause serious injury. Keep spray from contacting

hands or body.

Never point the gun at yourself or anyone else. Never

put your hand, fingers or body directly over the spray

nozzle. Always keep operating area clear of all persons.

Use extreme caution when operating near children.

If an accident does occur and the spray appears

to have penetrated the skin, SEEK EMERGENCY

ME D I C A L CA R E . DO NO T TR E AT AS A

SIMPLE CUT. If you are using cleaning agents,

be prepared to tell a physician exactly what kind.

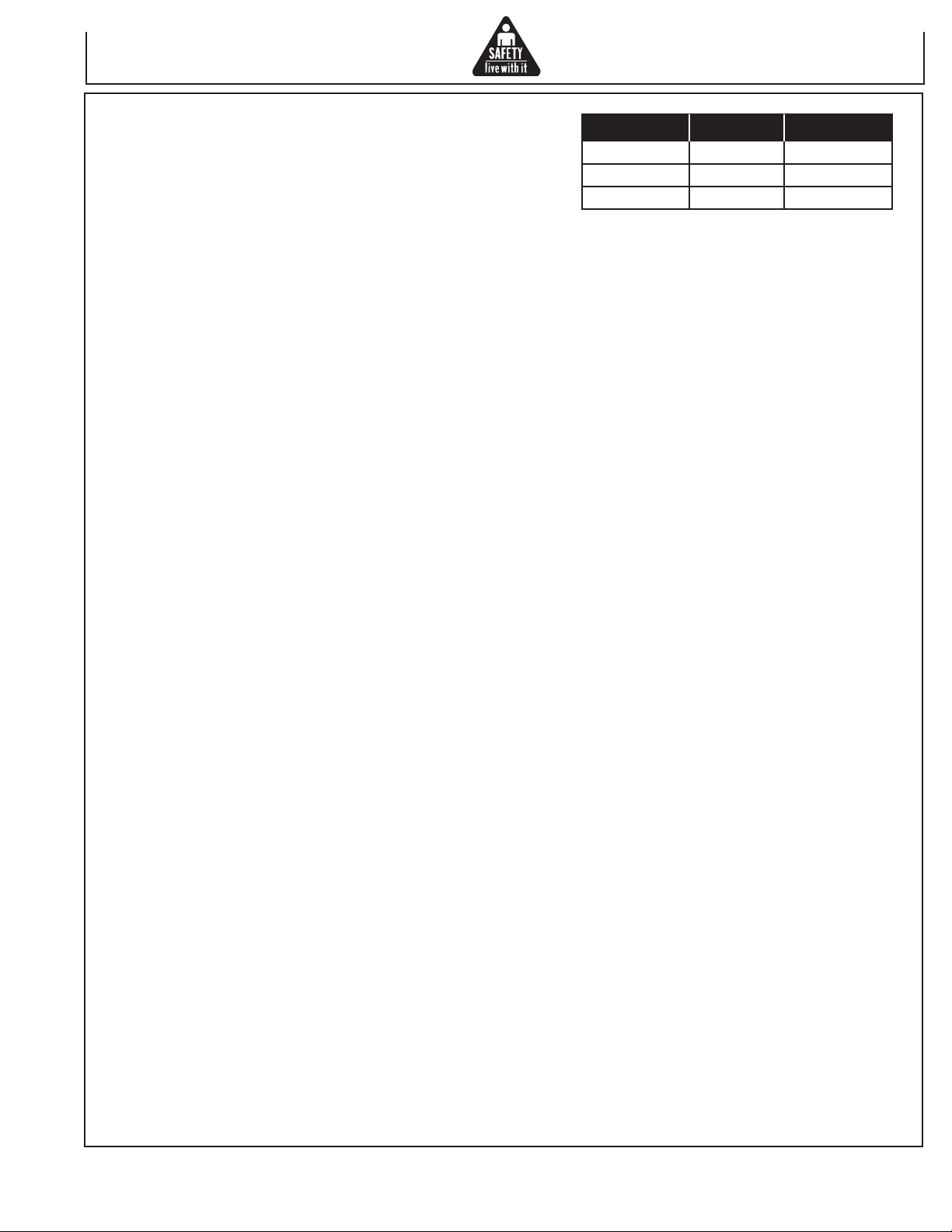

GROUNDING INSTRUCTIONS

This product must be grounded. If it should malfunction

or breakdown, grounding provides a path of least

resistance for electric current to reduce the risk of electric

shock. This product is equipped with a cord having an

equipment-grounding conductor and a grounding plug.

The plug must be plugged into an appropriate outlet that

is properly installed and grounded in accordance with

local codes and ordinances.

DANGER - Improper connection of the equipmentgrounding conductor can result in a risk of electrocution.

Check with a qualified electrician or service person if

you are in doubt as to whether the outlet is properly

grounded. Do not modify the plug provided with the

product--if it will not fit, have a proper outlet installed by

a qualified electrician.

GR O UN D FAU LT CI RC U IT I NT E R RU P TE R

PROTECTION

This pressure washer is provided with a Ground Fault

Circuit Interrupter (GFCI) built into the power cord. This

device provides additional protection from the risk of

electric shock. Should replacement of the plug or power

cord become necessary, use only identical replacement

parts that include GFCI protection.

DO NOT drop the GFCI as damage could result. If the

GFCI is accidentally dropped, be certain to test the GFCI

before using to ensure it is working properly. (Follow

instructions on GFCI for test procedures.)

DO NOT pull on the electrical cord to disconnect from

the outlet, OR carry the unit by the cord.

6 Operator’s Manual

Page 7

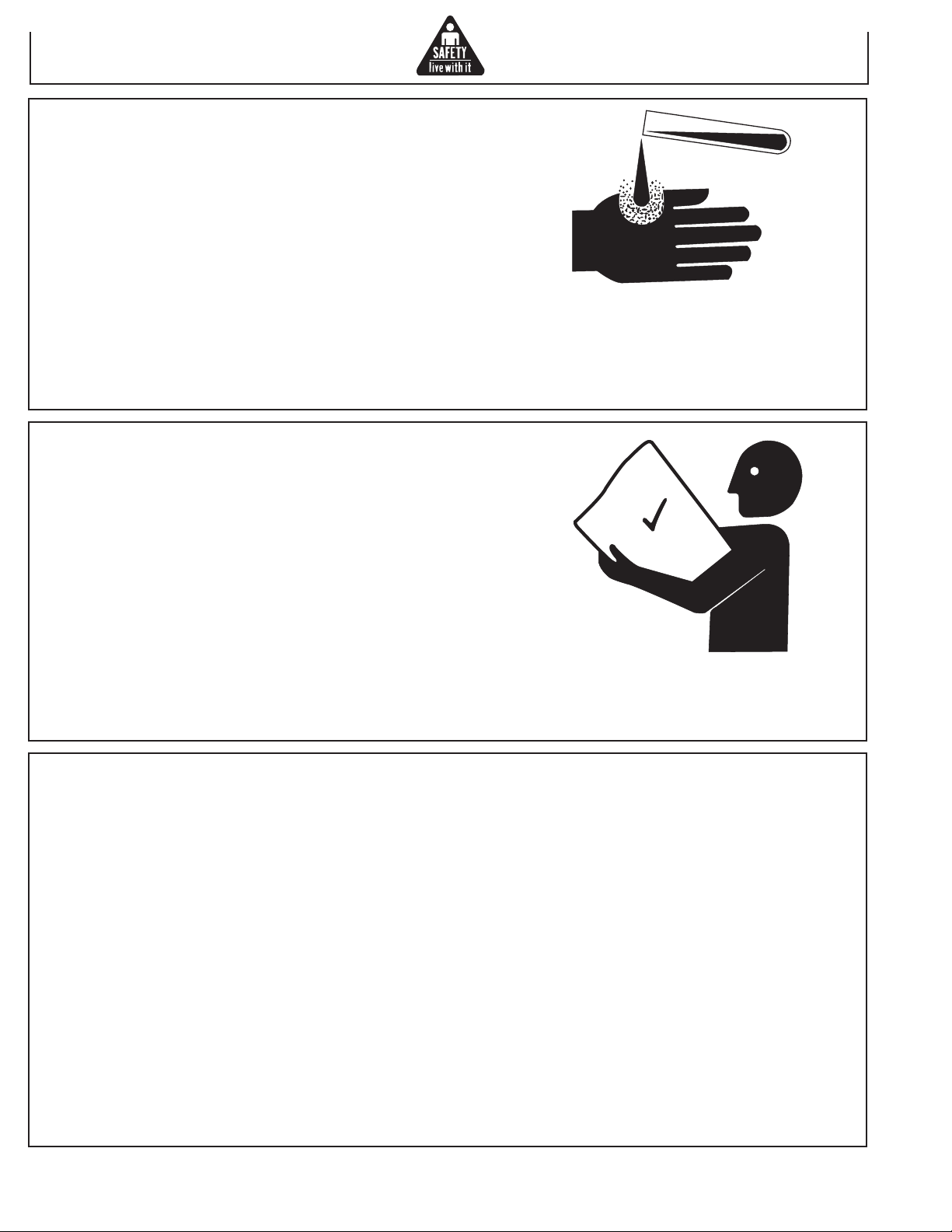

EXTENSION CORDS

Extension cords are not recommended for use on this pressure

washer. If the use of an extension cord is unavoidable, it must

be plugged into a GFCI found in circuit boxes or protected

receptacles.

Use only 3-wire extension cords that have 3-prong grounding type

plugs and 3-pole cord connectors that accept the plug from the

washer. Use only extension cords that are intended for outdoor

use. These extension cords are identified by a marking “Acceptable

for use with outdoor appliances; store indoors while not in use”.

Use only extension cords having an electrical rating not less than

the rating of the product. Do not use damaged extension cords.

Examine extension cord before using and replace if damaged. Do

not abuse extension cord and do not yank any cord to disconnect.

Keep cord away from heat and sharp edges. Always disconnect

the extension cord from the receptacle before disconnecting the

product from the extension cord.

WARNING: To reduce the risk of electrocution, keep all

connections dry and off the ground. Do not touch plug with

wet hands.

Use of smaller cords will cause electric motor stalling or circuit

breaker stoppage.

AC1000E-C AC1500E-C

Cable Length Wire Gauge Wire Gauge

Up to 50 Feet 14 AWG 12 AWG

50 to 100 Feet 12 AWG 10 AWG

Check power cord for damage before using. There is a hazard of

electrical shock from crushing, cutting or heat damage.

Always be certain the unit is receiving proper voltage. Before

plugging the unit into a compatible power source, be certain the

switch is in the "OFF" position. Disconnect when not in use.

DO NOT use the unit in an area where flammable gas vapors may

be present. An electric spark could cause an explosion or fire.

DO NOT direct water spray on or into electrical installations of

any kind. This includes electrical outlets, light bulbs, fuse boxes,

transformers, the unit itself, etc. Severe electrical shock may

occur.

John Deere does not recommend the owner attempt any electrical

repairs to this unit.

Operator’s Manual 7

Page 8

CLEANING DETERGENT PRECAUTIONS

MSDS

DO NOT use solvents or highly corrosive detergents or acid type cleaners

with this pressure washer. Use only mild detergents.

KNOW YOUR DETERGENTS! Be prepared to tell a physician exactly

what you are using in the event of an emergency. Read the Material

Safety Data Sheet (MSDS) provided with your detergent and all detergent

labels. Follow all appropriate instructions regarding preparation use,

safety and transportation. Keep ALL detergents out of the reach of

children.

DO NOT use this pressure washer to dispense hazardous detergents.

DO NOT alter the detergent injection feature in any manner not prescribed

in this manual. Use only genuine John Deere replacement parts for

necessary repairs.

HANDLE CHEMICAL PRODUCTS SAFELY

Direct exposure to hazardous chemicals can cause injury. Potentially

hazardous chemicals used with the pressure washer includes such items

as detergents.

A Material Safety Data Sheet (MSDS) provides specific details on detergents;

physical and health hazards, safety procedures and emergency response

techniques.

Check the MSDS before you start any job using a detergent. That way

you will know exactly what the risks are and how to do the job safely. Then

follow procedures and recommended equipment. (See your John Deere

dealer for MSDS Sheets on products used with this equipment.)

ADJUSTMENT PRECAUTIONS

NEVER alter or modify the equipment, be sure any accessory items and

system components being used will withstand the pressure developed.

Use ONLY genuine Mi-T-M parts for repair of your pressure washer.

Failure to do so can cause hazardous operating conditions and will void

warranty.

NEVER make adjustments to the machinery while it is connected to the

power source.

Know how to stop the pressure washer and bleed pressures quickly. Be

thoroughly familiar with controls.

Before servicing the unit; turn the unit off, disconnect from the power

source, relieve the water pressure, and allow the unit to cool down.

Service in a clean, dry, flat area.

Follow the maintenance instructions specified in this manual.

8 Operator’s Manual

Page 9

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of injury, read this operator’s

manual completely. When using this product, the following

basic precautions should always be followed:

1. Read all the instructions before using the product.

2. This product is equipped with a Ground Fault Circuit Interrupter

(GFCI) in the power cord to reduce the risk of electrical shock.

If replacement of the plug or cord is needed, use only identical

replacement parts.

3. Follow the grounding instructions included in this manual.

4. High pressure water spray can cut skin. Do not direct spray

at persons. Keep operating area clear of all persons or pets.

Warn children that the water spray can cut. Supervise children

closely.

5. Do not allow children or untrained person to operate the

washer.

6. Do not spray electrical switches, receptacles or light bulbs, or

glass or fragile objects that may shatter.

7. Dirt and debris removed by spray can cause eye injury. Wear

eye protection.

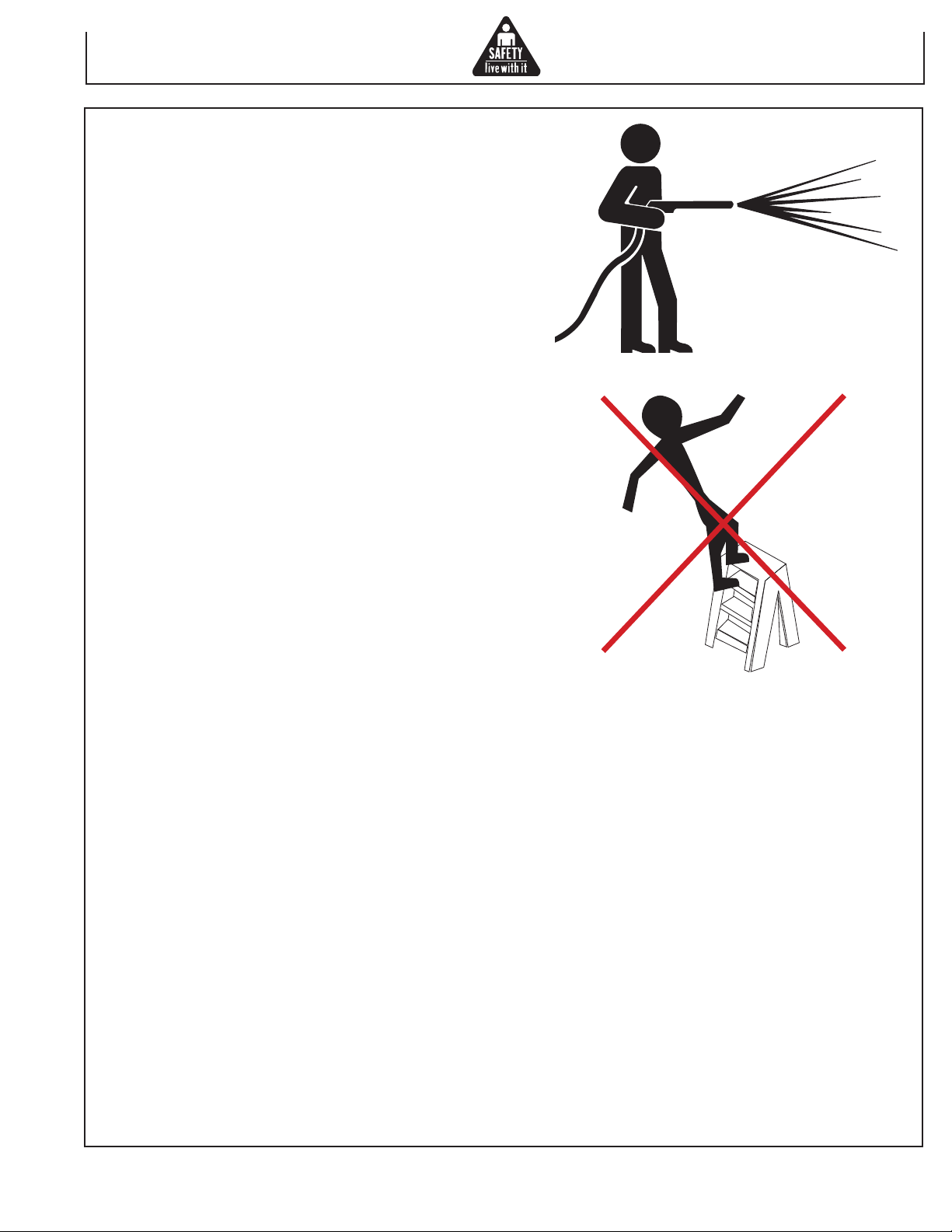

8. NEVER squeeze the trigger unless securely braced. The thrust

from the water traveling through the nozzle may be powerful

enough to cause the operator to lose balance if unprepared.

Wet surfaces can be slippery. Wear shoes and keep both feet

on the ground. Do not climb on items being cleaned. Do not

overreach or stand on unstable support. Keep good footing

and balance at all times. NEVER trigger the gun while on a

ladder or roof.

9. When the spray trigger is released, water pressure is trapped

in the discharge hose. Release trapped pressure by triggering

the spray gun after the washer is turned off.

10. Do not operate the washer when fatigued or under the

influence of drugs or chemicals. Stay alert. Watch what you

are doing.

11. Follow the maintenance instruction specified in this manual.

12. ALWAYS hold on firmly to the gun/wand assembly when

starting and operating the unit. Failure to do so can cause

the wand to fall and whip dangerously. NEVER operate the

gun with the trigger wired in the open position. To prevent

accidental discharge, the trigger gun should be securely locked

when not in use.

Operator’s Manual 9

Page 10

IMPORTANT SAFETY INSTRUCTIONS

13. NEVER ALLOW CHILDREN OR ADOLESCENTS TO

OPERATE THIS UNIT!

14. Read and follow all handling, operations, maintenance and

safety instructions listed in this manual and provide such

information to ANYONE who will be operating this unit.

15. This pressure washer is provided with a Ground Fault Circuit

Interrupter (GFCI) built into the plug or the power supply cord,

Should replacement of the cord or plug become necessary,

use only identical replacement parts that include GFCI

protection.

16. In freezing temperatures, the unit must always be warm

enough to ensure there is no ice formation in the pump. DO

NOT start this unit if it has been transported in an open or

underheated vehicle without first allowing the pump to thaw.

17. When connecting the water inlet to the water supply mains,

local regulations of your water company must be observed.

In some areas the unit must not be connected directly to the

public drinking water supply. This is to ensure that there is

no feedback of the detergents into the water supply. (Direct

connection is permitted if a back flow preventer is installed.)

18. High pressure hoses should be inspected daily for signs of

wear. If evidence of failure exists, promptly replace all suspect

hoses to prevent the possibility of injury from the high pressure

spray. If a hose or fitting is leaking , NEVER place your hand

directly on the leak.

19. DO NOT operate the unit if you see any pump oil or water

leaks from the machine. DO NOT resume operation until the

unit has been inspected and repaired by a qualified service

person.

20. DO NOT operate the unit without all protective covers in

place.

21. To reduce the risk of injury, maintain a safe distance from

persons while operating this unit. Close supervision is

necessary when operating the unit near children.

22. DO NOT leave pressurized unit unattended. Shut off the unit

and release trapped pressure before leaving.

23. DO NOT move the unit by pulling on the hose.

SAVE THESE INSTRUCTIONS

10 Operator’s Manual

Page 11

WEAR PROTECTIVE CLOTHING

Wear close fitting clothing and safety equipment

appropriate to the job.

Wear a suitable hearing protective device such as

earmuffs or earplugs to protect against objectionable or

uncomfortable loud noises.

Operating equipment safely requires the full attention of

the operator. Do not wear radio or music headphones while

operating machine.

PREPARE FOR EMERGENCIES

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital and fire department near your telephone.

Be prepared if a fire starts.

INSPECT HIGH PRESSURE WASHER

Be sure all covers, guards and shields are in place.

Locate all operating controls and safety labels.

Keep all hardware and plumbing fittings tight.

Inspect power cord for damage before using. There is a hazard

of electrical shock from crushing, cutting or heat damage.

Inspect high pressure hose for kinking, cuts or abrasive

wear.

SERVICE HIGH PRESSURE WASHER SAFELY

Before servicing washer, disconnect unit from power source,

relieve water pressure and allow unit to cool down.

Service washer in a clean dry flat area.

Operator’s Manual 11

Page 12

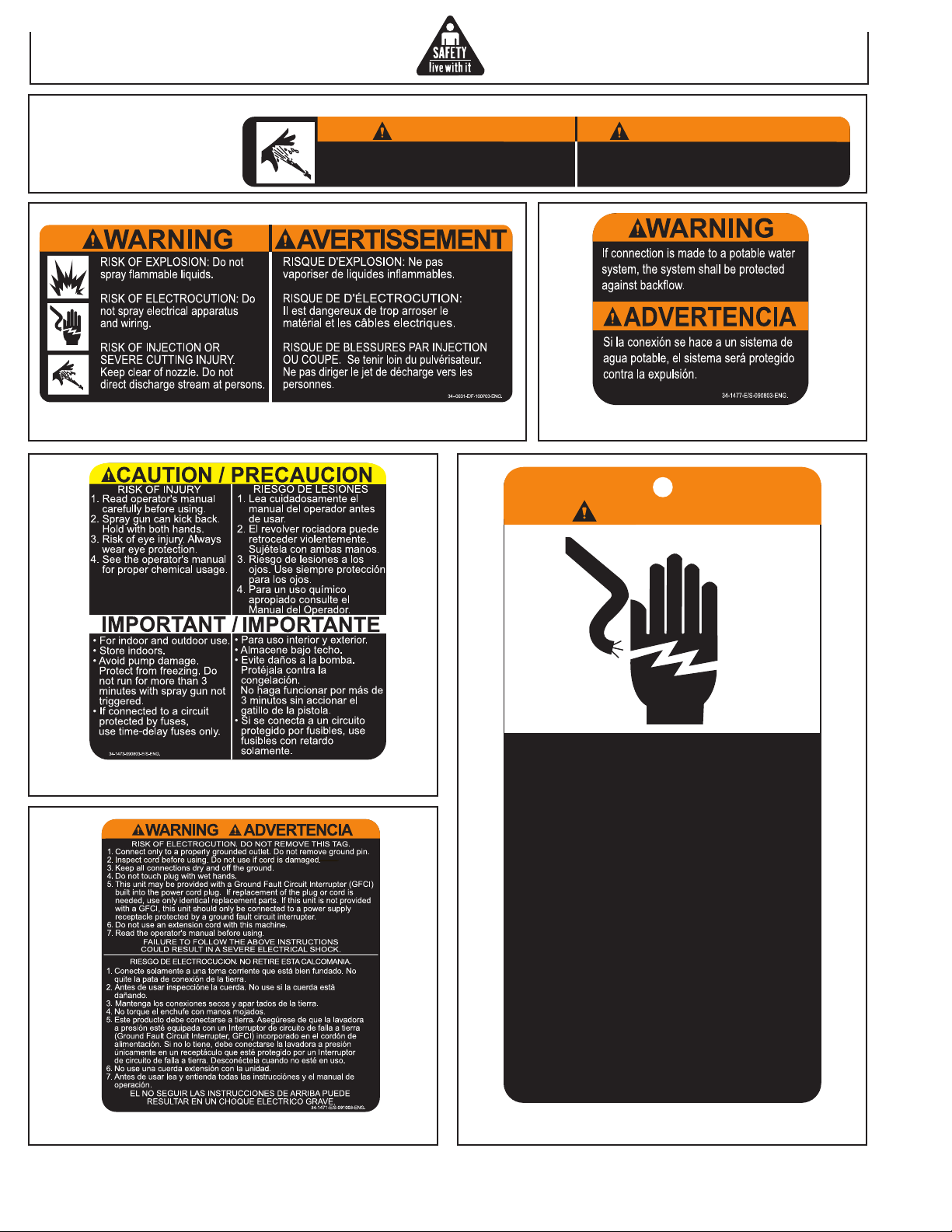

SAFETY SIGNS

RISK OF ELECTROCUTION.

DO NOT REMOVE THIS TAG.

FAILURE TO FOLLOW THE ABOVE

INSTRUCTIONS COULD RESULT

IN A SEVERE ELECTRICAL SHOCK.

34-1035-E/F/S-111899-ENG

1. Connect only to a properly grounded outlet. Do not

remove ground pin.

2. Inspect cord before using. Do not use if cord is

damaged.

3. Keep all connections dry and off the ground.

4. Do not touch plug with wet hands.

5. This unit may be provided with a Ground Fault Circuit

Interrupter (GFCI) built into the power cord plug. If

replacement of the plug or cord is needed, use only

identical replacement parts. If this unit is not provided

with a GFCI, this unit should only be connected to a

power supply receptacle protected by a ground fault

circuit interrupter.

6. Do not use an extension cord with this machine.

7. Read the operator's manual before using.

WARNING

RISK OF INJECTION OR SEVERE INJURY.

Never put your hand, fingers or body directly

ov

er the spray nozzle.

34-1253-030801-ENG.

WARNING

ADVERTENCIA

RIESGO DE INYECCION O LISION SEVERA

Nunca coloque la mano, los dedos o el cuerpo

directamente sobre la boquilla de rocío.

34-1253

Location: Wand

Location: Motor Housing

34-1473

Location: Electrical Box

34-0631

Location: Frame Assembly

34-1477

12 Operator’s Manual

Location: Frame Assembly

34-1471

34-1035

Location: Electrical Cord

Page 13

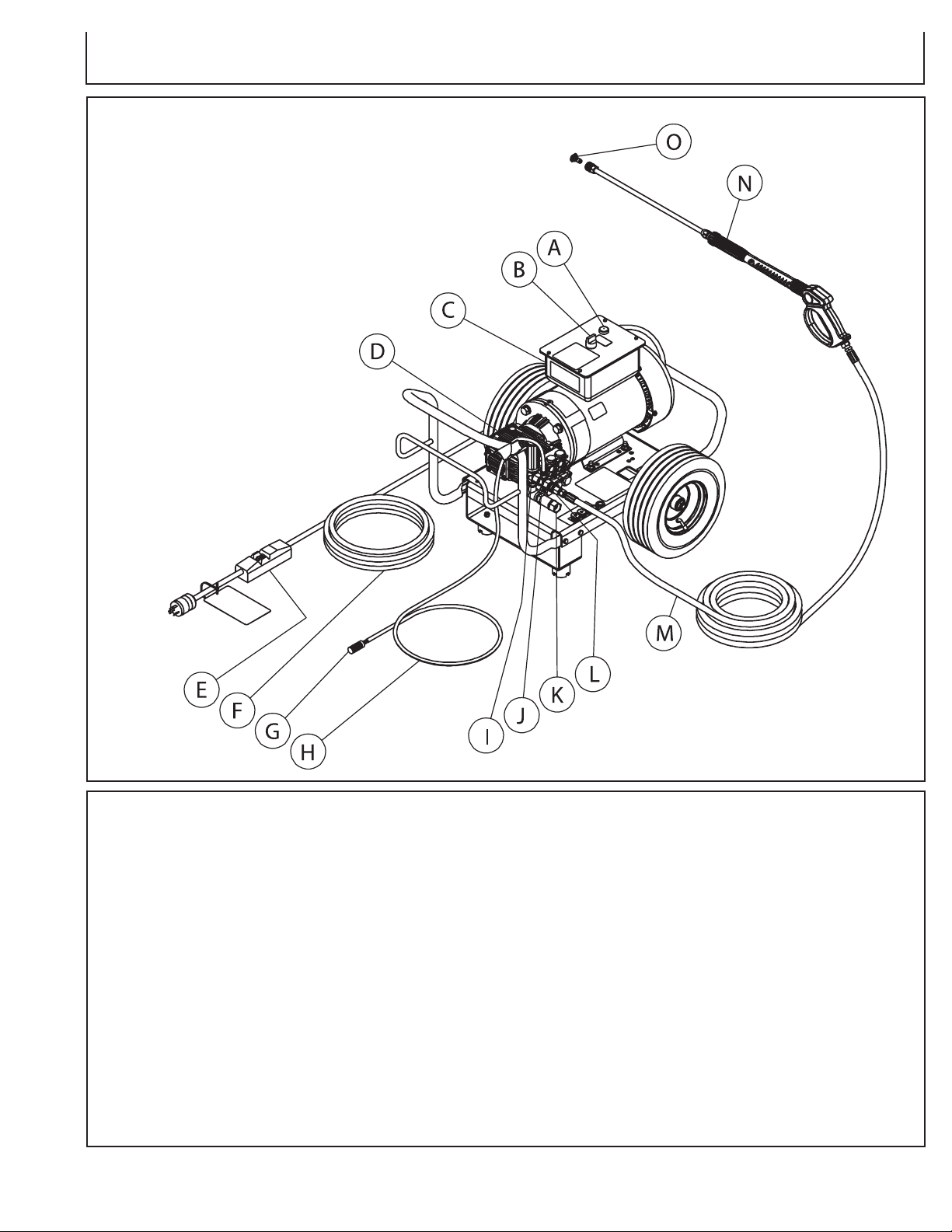

CONTROLS

Controls

A -- Motor Overload

B -- On/Off Switch

C -- Motor

Operator’s Manual 13

D -- Pump

E -- GFCI

F -- Power Cord

G -- Detergent Strainer

H -- Detergent Hose

I -- Adjustable Unloader

Knob

J -- Adjustable Injector

K -- Water Inlet

L -- Water Outlet

M -- High Pressure

Discharge Hose

N -- Gun Assembly

O -- Quick Connect Nozzle

Page 14

Preparing the Washer

SET-UP

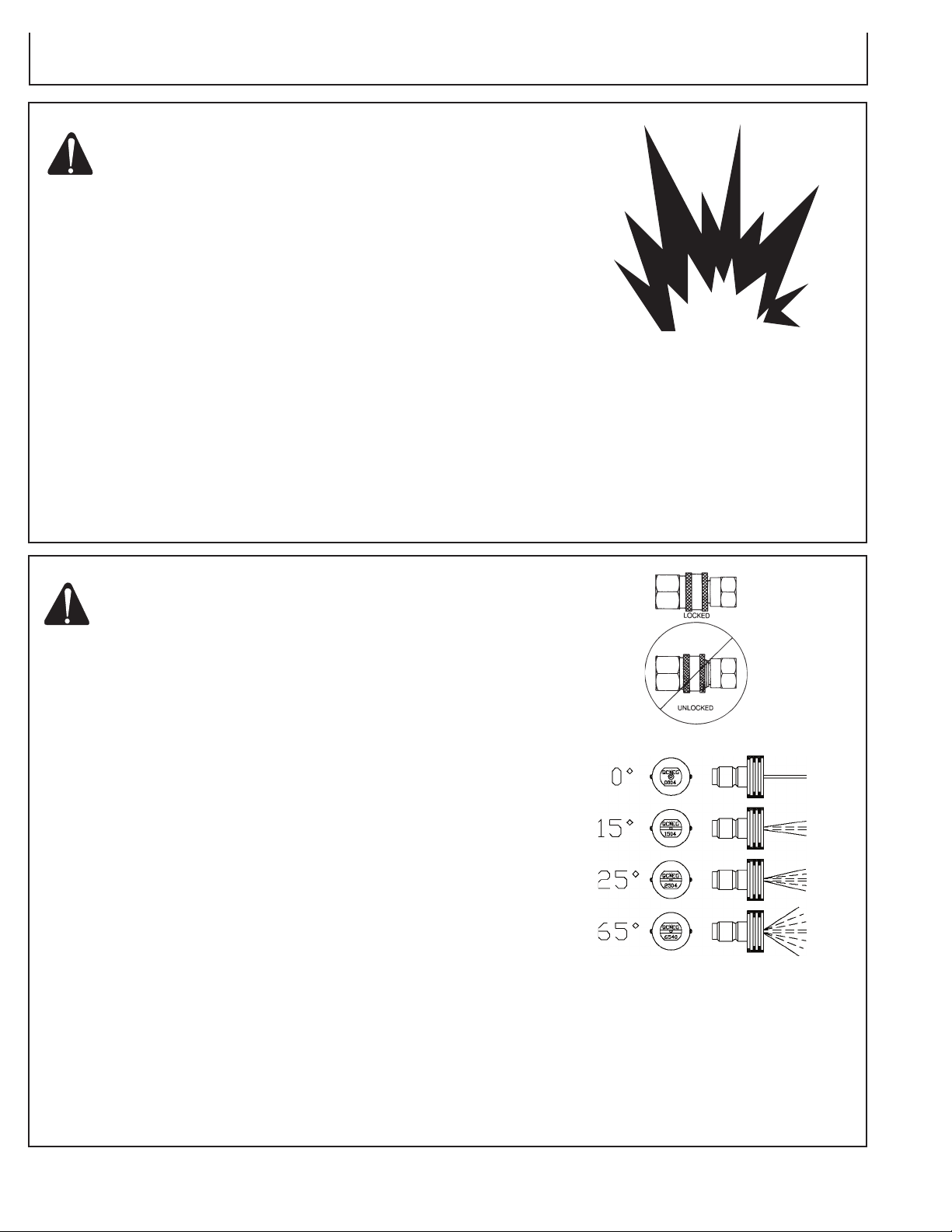

WARNING: RISK OF EXPLOSION! DO NOT OPERATE

UNIT IN AN AREA WHERE FLAMMABLE GAS

VAPORS MAY BE PRESENT. AN ELECTRIC

SPARK MAY CAUSE AN EXPLOSION.

RISK OF BURSTING! DO NOT STORE / OPERATE

UNIT IN A FREEZING ENVIRONMENT

1. This unit should only be placed on a level surface to ensure proper

lubrication for the water pump while operating. NEVER spray

water directly on the unit!

2. Do not place unit in an area:

a. where there is evidence of oil or gas leaks.

b. where flammable gas vapors may be present.

3. Do not allow the unit to be exposed to rain, snow or freezing

temperatures. If any part of the unit becomes frozen; excessive

pressure may build up in the unit which could cause it to

burst, resulting in possible serious injury to the operator or

bystanders.

4. Before initial use, replace the oil travel plug with the dipstick

provided with the unit. Be certain the oil level is in the center of

the sight glass before each use. If low, fill with John Deere HyGuard pump oil. DO NOT OVERFILL!

NOZZLE REVIEW

WARNING: RISK OF INJECTION CAUSING SEVERE

INJURY!

NEVER LOOK DIRECTLY AT THE NOZZLE

ORIFICE UNLESS IT IS DISCONNECTED FROM THE

GUN/WAND ASSEMBLY!

Various nozzles may be quick-connected into the end of the wand

to change the spray pattern or use the detergent feature. When

using Quick Connects (Q.C.), be certain the connection is securely

locked. If not, the high pressure water may shoot the nozzle from

the wand, causing severe injury or serious damage. To determine

spray fan, refer to the actual number stamped on the nozzle. The

first two digits indicate the spray fan in degrees, i.e.; 00=0”, 15=15°,

25=25°, 65=detergent/low pressure.

1. The 0” nozzle (RED): This is a blasting nozzle. It delivers a

very concentrated stream of water. Be cautious when using the

straight narrow stream. It is not recommended for use on painted

or wood surfaces, or items attached with adhesive backings.

Uses: Removing weeds from sidewalk cracks, stubborn stains

from concrete, masonry, aluminum and steel, caked mud from

equipment, and cleaning lawn mower undersides.

2. The 15° nozzle (YELLOW): This is a chiseling nozzle. The

spray should be directed at a 45° angle to the surface and used

like a scraper to remove paint, grease and dirt. Uses: Surface

preparation (removing mildew stains and paint chips).

3. The 25° nozzle (GREEN): This is a flushing nozzle. This pattern is

best suited for flushing dirt, mud, and grime. Uses: Wet sweeping

leaves from walks, curbs and driveways, cleaning stable floors,

washing swimming pool bottoms, degreasing engines.

4. The 65° nozzle (BLACK): This is a low pressure detergent

application nozzle. This broad spray pattern distributes solution

over vast areas under low pressure. Uses: Detergent application,

misting or rinsing.

14 Operator’s Manual

Page 15

Preparing the Washer

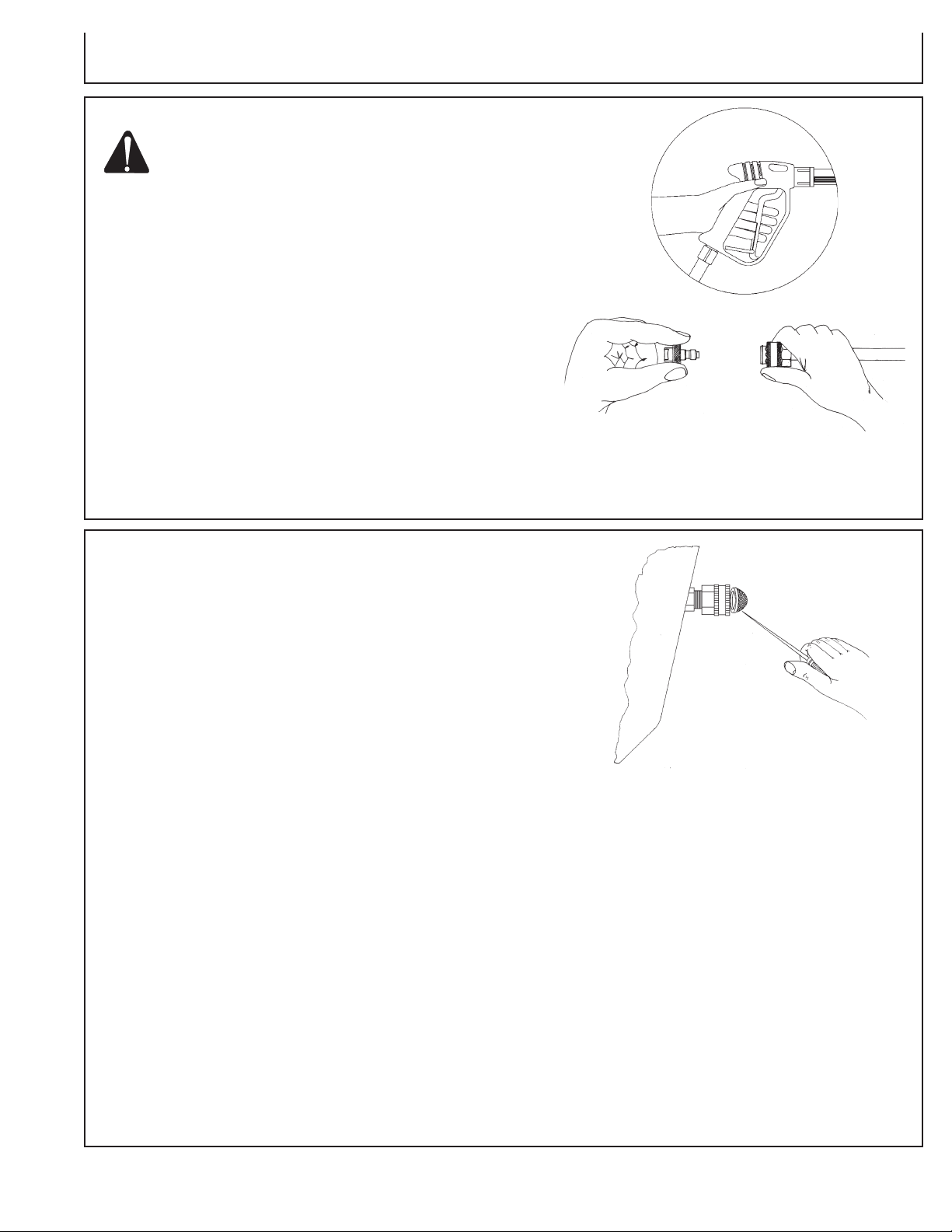

NOZZLE CONNECTION

WARNING: RISK OF SEVERE INJURY! THE

TRIGGER GUN SHOULD ALWAYS BE

LOCKED IN THE OFF POSITION WHEN NOT

IN USE!

1. Be certain the trigger gun is locked in the "OFF"

position.

2. The nozzle assembly should be disconnected from the

gun/wand assembly at this by retracting the locking ring

on the quick-connect fitting to remove the nozzle.

WATER SUPPLY

1. Select a water supply hose which is a quality grade of garden

hose measuring at least 3/4" ID and no longer than 50 feet.

2 Check the water inlet strainer to ensure it is clean and free of

any obstructions. Periodic cleaning of the water strainer will help

prevent pump problems. As a strainer becomes obstructed, it

restricts proper flow of water to the pump. This can result in

cavitations which will cause premature failure of pump packings

and valves. Using a screw driver, remove the screen; clean or

replace if necessary.

3. Connect the hoses.

a. Connect one end of the water supply hose to the water inlet

of the unit.

b. Connect the other end of the hose to your pressurized water

supply.

NOTE: Do not use a non-pressurized water supply (i.e. from a

well or pond) with this unit.

c. Connect the high pressure discharge hose to the water outlet

of the unit.

4. Follow the incoming water requirements listed below:

a. Water pressure must be a minimum of 25 pounds per square

inch (PSI) and a maximum of 125 PSI. (A typical outdoor

faucet will generally supply this PSI if turned completely

"ON".)

b. Incoming GPM must be approximately one gallon more than

the outgoing GPM stated on the pressure washer nameplate.

(You can check GPM by timing how long it takes to fill a 5

gallon container.

c. Incoming water temperature must not exceed 125°F (52°C).

Excessive pump damage may result if the water temperature

exceeds this acceptable level.

5. Never allow the unit to operate without the incoming water line

attached and the water supply turned all the way on.

Operator’s Manual 15

Page 16

Preparing the Washer

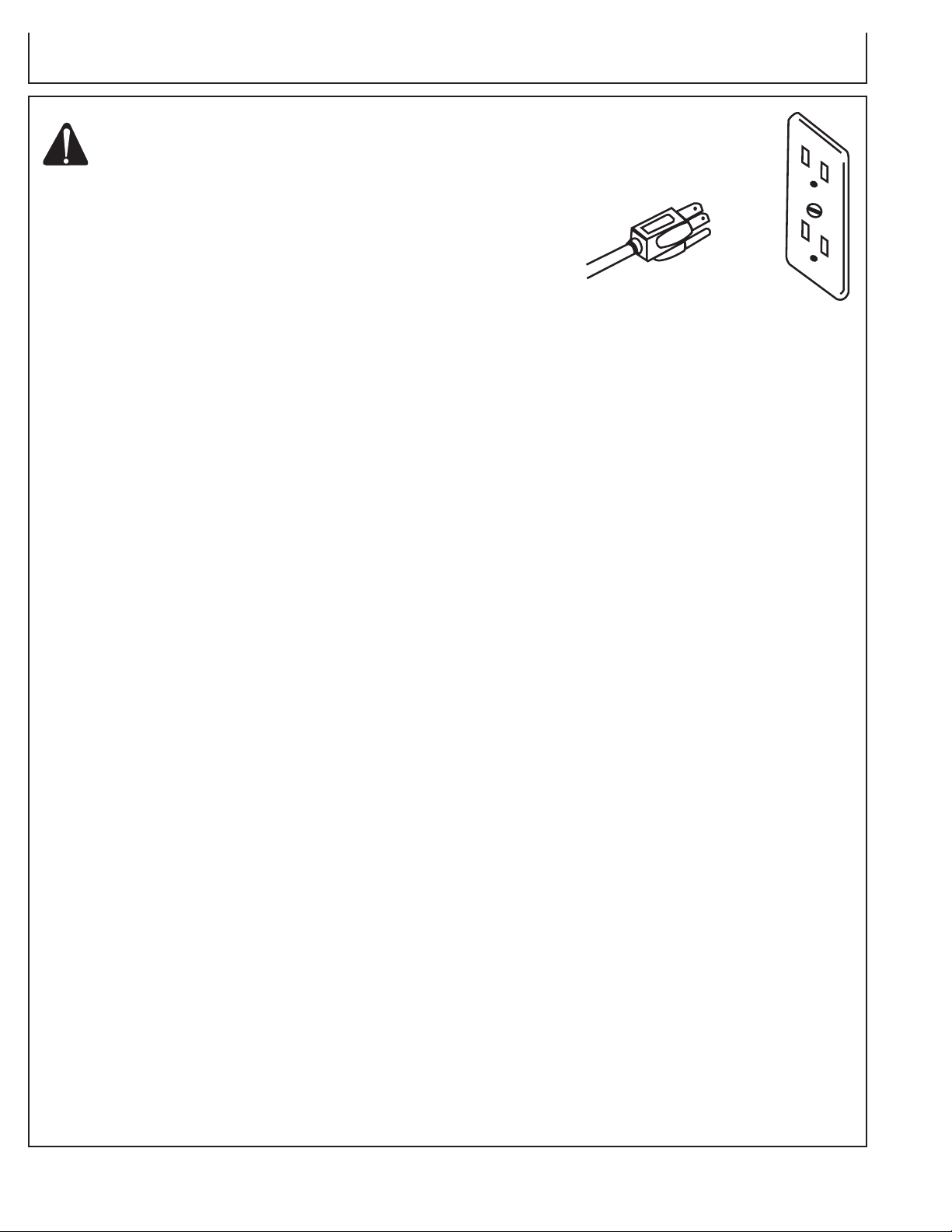

POWER CORD CONNECTION

WARNING: RISK OF ELECTROCUTION! THIS UNIT MUST BE

CONNECTED TO A PROPERLY GROUNDED OUTLET.

DO NOT USE AN ADAPTER OR REMOVE THE THIRD

GROUNDING PRONG.

TO REDUCE THE RISK OF ELECTROCUTION, KEEP ALL

CONNECTIONS DRY AND OFF THE GROUND. DO NOT

TOUCH PLUG WITH WET HANDS.

1. Make certain the motor switch is in the "OFF" position.

2. Ensure electrical supply is identical to the specifications listed on the pressure

washer data plate.

3. GROUNDING INSTRUCTIONS: This product must be grounded. If it should

malfunction or breakdown, grounding provides a path of least resistance for

electric current to reduce the risk of electric shock. This product is equipped

with a cord having an equipment-grounding conductor. The plug must be

plugged into an appropriate outlet that is properly installed and grounded

in accordance with all local codes and ordinances.

4. DANGER: Improper connection of the equipment-grounding conductor

can result in a risk of electrocution. Check with a qualified electrician or

service personnel if you are in doubt as to whether the outlet is properly

grounded. Do not modify the plug - if it will not fit the outlet, have a proper

outlet installed by a qualified electrician. Do not use any type of adaptor

with this product.

5. GROUND FAULT CIRCUIT INTERRUPTER PROTECTION: This pressure

washer is provided with a Ground Fault Circuit Interrupter (GFCI) built into

the plug or the power supply cord, test the GFCI each time it is plugged into

an outlet according to instructions on the GFCI. DO NOT use the pressure

washer if the test fails! The GFCI provides additional protection from the risk

of electric shock. Should replacement of the plug or cord become necessary,

use only identical replacement parts that include GFCI protection.

6. EXTENSION CORDS: Mi-T-M DOES NOT RECOMMEND THE USE OF

EXTENSION CORDS! If use of an extension cord is unavoidable, it must

be plugged into a GFCI found in circuit boxes or protected receptacles.

Use only 3-wire extension cords that have 3-prong grounding-type plugs

and 3-pole cord connectors that accept the plug from the product.

Use only extension cords that are intended for outdoor use. These extension

cords are identified by a marking "Acceptable for use with outdoor appliances;

store indoors while not in use." Use only extension cords having an electrical

rating not less than the rating of the product. Do not use damaged extension

cords. Examine extension cord before using and replace if damaged. Do

not abuse extension cord and do not pull on any cord to disconnect. Keep

cord away from heat and sharp edges. Always connect or disconnect the

extension cord from the receptacle before connecting or disconnecting the

product from the extension cord.

7. Ensure the area between the pressure washer cord and outlet is kept dry.

8. Insert the male plug into a grounded AC outlet. DO NOT use an adapter

OR remove the grounding plug!!

16 Operator’s Manual

Page 17

Preparing the Washer

UNLOADER

The unloader valve on your machine is equipped with an adjustment

knob to adjust the pressure. Should less pressure be required, simply

turn the adjustment knob counterclockwise. To set back to maximum, turn

adjustment knob completely clockwise. DO NOT OVERTIGHTEN!

CAUTION

THE UNLOADER. BREAKAGE WILL RESULT IN

IMMEDIATE LOSS OF WATER PRESSURE AND COSTLY

REPAIRS.

: RISK OF UNIT DAMAGE! DO NOT OVERTIGHTEN

THERMAL RELIEF VALVE

To ensure the bypass water temperature does not exceed acceptable levels,

never allow the pressure washer to operate in the bypass mode (with the unit

running and the trigger closed) for more than three minutes.

A thermal relief valve has been added to this unit to protect the pump. It may begin

to open and release water if the water temperature in the pump has exceeded

140° F. This will allow fresh, cool water to enter the system, therefore preventing

premature failure of pump packings.

PRE-START INSPECTION PROCEDURES

Before starting the unit, perform the following procedures:

1. Check the oil level in the pump.

2. Inspect the inlet water strainer. Clean or replace if necessary. See

"Water Supply".

3. Check all hose connections to ensure they are securely tightened. See

"Water Supply".

4. Inspect for system water leaks and oil leaks. Be sure that all damaged

parts are replaced and that the mechanical problems are corrected prior to

operation of the unit. If service is needed, contact Customer Service.

5. Inspect high pressure hose for kinking, cuts or leaks. If a cut or leak is

found, DO NOT USE HOSE! Replace hose before starting unit. See

"Miscellaneous Safety Precautions". Be sure that all damaged parts

are replaced and that the mechanical problems are corrected prior to

operation of the unit. If you need service, contact Customer Service.

6. Inspect electrical cord for cuts. If a cut is found, DO NOT TOUCH OR

USE ELECTRICAL CORD! Replace cord before starting the unit.

Operator’s Manual 17

Page 18

Operating the Washer

PRIMING THE PUMP

1. It is essential to prime the pump on initial start-up and each time

the water supply is disconnected from the unit after initial use.

2. Lay the high pressure hose out to remove any loops. Water flow will

constrict the hose, creating tight loops if the hose is not straight.

3. Securely connect the gun assembly to the high pressure hose.

NOTE: The nozzle assembly should NOT be connected to the gun

assembly at this time. See "Nozzle Connection" .

4. With the trigger gun locked in the "OFF" position, turn the water

supply completely on. Pointing the gun in a safe direction, unlock

the trigger gun and squeeze the trigger.

5. Low pressure water will begin flowing from the hose/gun assembly.

This allows the unit to prime and purge any air from the system.

The unit is primed when water flow is uninterrupted by air.

6. Once the unit is primed, release the trigger and lock the gun in the

"OFF" position. Securely connect the nozzle assy. (See "Nozzle

Connection")

18 Operator’s Manual

Page 19

Operating the Washer

START-UP

WARNING: RISK OF INJECTION CAUSING SEVERE INJURY! KEEP

CLEAR OF NOZZLE! NEVER PLACE HAND OR FINGERS

IN FRONT OF NOZZLE!

DO NOT DIRECT DISCHARGE STREAM AT PEOPLE OR

PETS!

BE CERTAIN THE ADJUSTABLE NOZZLE ASSY. IS

SECURELY CONNECTED TO THE WAND TO PREVENT

AN ACCIDENTAL DISCHARGE!

CAUTION: RISK OF DAMAGE. DO NOT ALLOW SPRAY PATTERN

TO REMAIN ON A FIXED AREA FOR AN EXTENDED

PERIOD OF TIME. POSSIBLE DAMAGE MAY OCCUR TO

THE AREA.

1. Refer to the "Safety Precautions" before starting the unit.

2. Locate the Safety Decals on your unit and heed their warnings.

3. With the gun locked in the "OFF" position, point the trigger gun away from

yourself or anyone else. Ensure water supply is turned completely on.

4. Disengage the safety lock-off on the gun and squeeze the trigger. Low

pressure water will begin flowing from the nozzle.

5. Before starting the unit, brace yourself as the gun will kick-back from the high

pressure created by the pump once the unit has started.

6. Move the On/Off Switch to the "ON" position. This switch includes a circuit

breaker for protection of the motor. In case of excess load, the circuit breaker

will automatically move the switch to the "OFF" position. To restart, move the

On/Off Switch to the "ON" position again.

7. Once the unit is turned on, perform the following procedures with the gun

open:

a. Inspect for system water leaks and oil leaks. If an oil leak is found, TURN

UNIT OFF IMMEDIATELY! Be sure that all damaged parts are replaced

and that the mechanical problems are corrected prior to operation of the

unit. If you require service, contact your John Deere dealer.

b. Inspect high pressure hose for kinking cuts and leaks. If a cut or leak

is found, DO NOT TOUCH HOSE AT CUT OR LEAK!!! TURN UNIT

OFF IMMEDIATELY! Replace hose before re-starting the unit. See

"Miscellaneous Safety Precautions”. Be sure that all damaged parts are

replaced and that the mechanical problems are corrected prior to operation

of the unit. If you require service, contact your John Deere dealer.

c. Inspect electrical cord for cuts. If a cut is found, DO NOT TOUCH OR

USE ELECTRICAL CORD! Replace cord before starting the unit.

8. Trigger the gun several times and try adjusting the spray pattern. Be certain

to LOCK the trigger gun in the "OFF" position whenever moving the adjustable

nozzle. NEVER look directly into the nozzle! High pressure water creates a

risk of severe injury!

9. Do not allow unit to operate in bypass mode (with trigger closed) for more

than three minutes without triggering the gun. Failure to follow this simple

rule can cause premature failure of pump packing seals, resulting in costly

pump repair.

10. Because your pressure washer delivers a high pressure spray and a variety

of spray patterns, there are many cleaning jobs that can be done without

the use of detergents. If a cleaning agent is required, see "Cleaning With

Detergents" for the correct procedures.

Operator’s Manual 19

Page 20

Operating the Washer

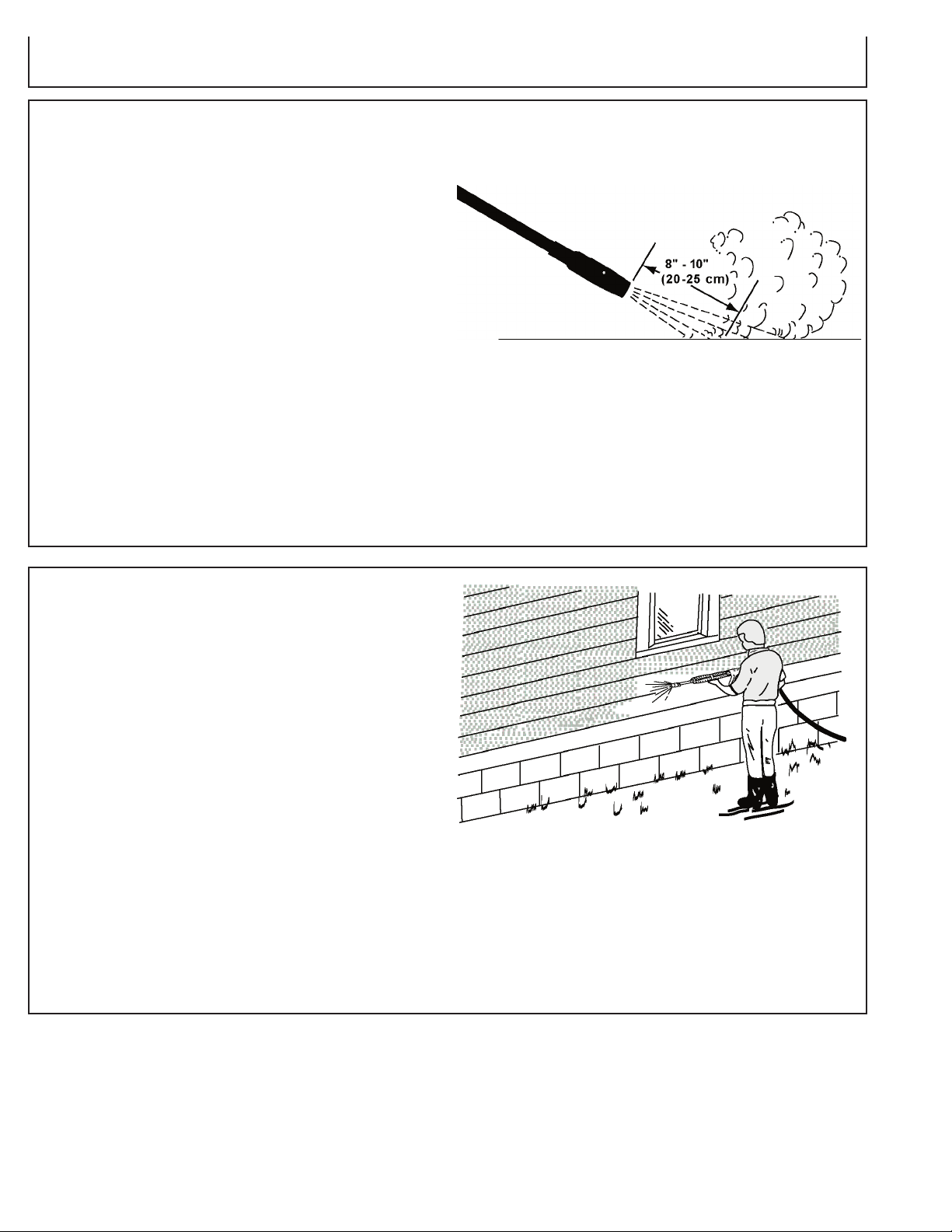

CLEANING HORIZONTAL SURFACES

Move nozzle wand from side to side. Direct spray at an

angle to force debris ahead and away from the cleared

area.

Depending on the material to be removed and nozzle

pressure, hold nozzle end 8 to 10 inches (20 to 25 cm) from

the surface and use slow, overlapping strokes. If debris

is easy to remove, move nozzle back to cover more area

for faster cleaning.

CLEANING VERTICAL SURFACES

IMPORTANT: Remember that the washer can deliver

a high pressure spray that can break

glass and gouge soft wood and other

materials.

When cleaning building interiors or exteriors without

detergents, work from top to bottom. This will help

eliminate streaks. In interiors, start with the ceiling first,

then the walls and the floor last.

Clean around windows carefully. If glass panes are not

well-caulked and puttied, the high pressure spray could

break the glass.

Never spray directly overhead. Always spray ahead to

avoid dripping or falling debris.

20 Operator’s Manual

Page 21

Operating the Washer

REMOVING PAINT

IMPORTANT: Remember that high pressure spray can

gouge soft woods and other materials, as

well as loosen grout.

1. Place nozzle end in high pressure position and very

narrow spray pattern.

2. Direct spray at a 45° angle about 4 to 12 inches (10 to

30 cm) from surface.

3. Spray in a back and forth motion, try to get beneath the

loose and bubbled paint.

4. Do not be concerned with the paint that remains. It

should be sufficiently bonded so as not to cause

repainting problems.

5. Some remaining paint may curl up at the edges. These

edges should be scraped with a steel brush or scraper

just before painting.

CLEANING RADIATOR FINS

IMPORTANT: Some engine and radiator manufacturers

may not permit cleaning radiators with a

high pressure washer. See equipment

Operator’s Manual.

1. Use clean water without detergent.

IMPORTANT: Spray straight into the radiator to prevent

bending fins.

2. If possible, direct spray in the direction opposite to

normal air flow through the radiator.

Operator’s Manual 21

Page 22

Operating the Washer

DETERGENT USAGE GUIDE

CAUTION: Use detergents carefully. Read

labels thoroughly and follow all instructions

for preparation, use, safety, transportation and

disposal. Be prepared to tell a physician exactly

what detergents you are using in the event of an

emergency. Keep all detergents out of reach of

children.

Be aware that two detergents can be mixed

on the sprayed surface. In this regard, some

detergents may give off harmful fumes or start

an unpredictable chemical reaction when mixed

with another detergent.

NEVER SPRAY FLAMMABLE LIQUIDS such as

gasoline, fuel oil, alcohol, naptha, etc.

Be sure to read and follow all detergent labels exactly

regarding preparation, use, safety, transportation, and

disposal. Keep in mind that the washer’s detergent

system further dilutes the detergent with water, and that

some detergents may not be concentrated enough to

properly work with the system.

Some detergents may not give premix instructions and

may require experimenting to determine proper dilution

for your application.

If you are not familiar with the detergent, always test

a small area of the surface to be cleaned for adverse

reaction. Do this a day in advance. Thoroughly rinse

area with water.

22 Operator’s Manual

Page 23

Operating the Washer

CLEANING WITH DETERGENTS

1. Refer to "Detergent Cleaning Precautions"before working with detergents.

Be certain to wear protective safety attire.

2. Prepare detergent solution according to label directions. Never pump

acids, alkaline, abrasive fluids or solvents through the unit.

3. Your injector is equipped with an adjustment knob on the pump head,

you may adjust the amount of detergent desired by turning the knob

completely counterclockwise to set at the maximum siphon rate.

4. Immerse the detergent strainer into the detergent solution to allow

detergent to siphon.

5. With the trigger gun locked in the "OFF" position, securely quick-connect

the detergent spray nozzle (#6540° BLACK) into the end of the wand.

NOTE: This injection system is designed to apply detergents under low

pressure only. It will not allow detergent solutions to be introduced

into the system unless the detergent nozzle (6540 Black) is

installed.

6. To apply solution; unlock the trigger gun and squeeze the trigger. In a

few moments a detergent/water mixture will exit the low pressure nozzle.

Start spraying the lower portion of the surface being cleaned and move

up, using long overlapping strokes. Applying from the bottom up helps

avoid streaking. Allow to soak briefly. DO NOT allow detergent solution

to dry on the surface. (Avoid working on hot surfaces or in direct sunlight

to minimize the chances of the detergent drying, which may result in

damaging painted surfaces.) Be certain to rinse a small section at a

time.

7. To rinse; lock the trigger gun in the "OFF" position, securely quick-connect

the desired high pressure nozzle into the end of the wand. Unlock the

trigger gun and spray. It will take about 30 seconds to purge all detergent

from the line. For best rinsing results, start at the top and work down.

8. Siphon a gallon of water through the low pressure detergent injection

system after each use. This prevents the possibility of corrosion or

detergent residue causing mechanical problems during the next use.

QUICK CONNECT DETERGENT

SHUT-DOWN

1. Move the On/Off switch to the "OFF" position to turn unit off.

2. Turn the water supply "OFF".

3. Pointing the gun in a safe direction, trigger gun momentarily to relieve

any trapped pressure.

4. Once pressure is relieved, disconnect the nozzle assembly.

5. Disconnect the unit from the power source.

6. Disconnect and drain gun, wand and hoses.

7. Wipe unit clean and store with gun, wand and hoses in a safe area.

Operator’s Manual 23

Page 24

Troubleshooting

Symptom Problem Solution

Pump motor will not start, or stops GFCI tripped. Turn unit "OFF". Test GFCI by

while operating. pressing reset button.

Tripped circuit breaker or fuse Disconnect all other plugs on the

blown in circuit fuse box. circuit being used and reset circuit

breaker OR check and replace fuse.

Loose or disconnected plug. Reconnect plug.

Tripped circuit breaker in unit. Allow to cool and restart unit.

Unit is frozen. Allow to thaw. If any part of the unit

becomes frozen; excessive pressure

may build up in the unit which could

possible serious injury to the

operator or bystanders.

Circuit breaker trips or fuse Circuit overload. Check that the circuit is rated

blows in the fuse box. correctly.

120 V/15 A/60 Hz for 1000 PSI

120 V/20 A/60 Hz for 1500 PSI

Disconnect all plugs on the circuit.

When connecting to a circuit

protected by fuses, use time delay

fuses only.

Extension cord is too long or wire Use correct electrical requirements.

is too small.

Too much pressure. Use Adjusting Knob on Unloader to

reduce pressure.

cause the unit to burst resulting in

GFCI trips. Incorrect voltage. Ensure electrical supply is

120 V/15 A/60 Hz for 1000 PSI

120 V/20 A/60 Hz for 1500 PSI

Electrical short to ground. Contact your John Deere dealer.

Motor runs but there is no Inadequate water supply. Ensure hose is 3/4" diameter and

discharge at nozzle when trigger incoming water supply is turned on.

mechanism is squeezed.

Kink in water inlet hose. Remove kink.

Kink in high pressure discharge hose. Replace hose.

Water is leaking from

Relief Valve. less than 140°F.

Water temperature in unit is too high. Do not allow unit to operate in

bypass mode (with the trigger gun

closed) for more than three minutes.

Defective valve. Replace.

24 Operator’s Manual

Thermal Water inlet temperature is too high. Incoming water temperature must be

Page 25

Troubleshooting

Symptom Problem Solution

Low or fluctuating pressure. Water inlet screen obstructed. Remove screen, clean or replace.

Pump sucking air. (Prime lost) Tighten all water intake connections.

Eliminate leaks in intake line.

Not in high pressure mode. Pull the nozzle cover toward the gun

to engage in high pressure mode.

Obstructed or worn orifice. Remove and clean, or replace.

Bypass valve not operating correctly. Repair or replace.

Oil appears milky or foamy. Water in oil. Change pump oil. Fill to proper level.

Oil leaking from unit. DO NOT USE!!!!! Contact Customer Service.

Detergent will not siphon into Low Detergent strainer is not completely Check; submerge if necessary.

Pressure Detergent mode. submerged in detergent solution

Detergent strainer is obstructed. Inspect, clean or replace.

Detergent hose is obstructed, cut Inspect, clean or replace.

or kinked.

Not in Low Pressure mode. Push nozzle cover away from the gun.

Nozzle assembly is plugged. Clean or replace.

Too many high pressure hose Use one extension maximum.

extensions attached to the water outlet.

Ball & Spring in Venturi stuck. Remove, clean or replace.

Water flows back into detergent Ball & Spring in Venturi reversed, Remove, clean or replace.

container. missing or corroded.

Water flows from the nozzle when Gun is malfunctioning. Repair or replace.

the trigger gun is in the "OFF"

position.

Operator’s Manual 25

Page 26

Storage

Storage

SPECIFIC MAINTENANCE

PUMP:

The pump oil must be changed after the first 25 hours of operation.

Once the initial oil change has been completed, it is recommended the

oil be changed every 3 months or 250 hour intervals. If oil appears

dirty or milky, changes may be required at a greater frequency. Use

John Deere Hy-Guard and fill only to the center of the oil sight glass. DO NOT

OVERFILL!

NOZZLES:

Water flow through the spray nozzle will erode the orifice, making it larger,

resulting in a pressure loss. Nozzles should be replaced whenever pressure

is less than 85% of the maximum. The frequency of replacement will depend

upon such variables as mineral content in the water and number of hours the

nozzle is used.

QUICK COUPLERS:

There is an o-ring seal inside the female quick coupler. This o-ring will deteriorate

or, if the unit is allowed to pump without the high pressure hose or nozzle

attached, the o-ring may be blown out occasionally. Simply insert a replacement

o-ring to correct the leak. (Additional o-rings can be purchased from your John

Deere dealer.)

26 Operator’s Manual

Page 27

Storage

32˚F 0˚C

WINTERIZING

WARNING: RISK OF UNIT BURSTING! DO NOT STORE OR OPERATE

UNIT IN A FREEZING ENVIRONMENT!

For storage and transportation purposes in subfreezing ambient temperatures, it

will be necessary to winterize this unit. This unit must be protected to the lowest

incurred temperature for the following reasons:

1. If any part of the pumping system becomes frozen; excessive pressure may

build up in the unit which could cause the unit to burst resulting in possible

serious injury to the operator or bystanders.

2. The pumping system in this unit may be permanently damaged if frozen.

FREEZE DAMAGE IS NOT COVERED BY WARRANTY.

If you must store your unit in an area where the temperature may fall below 32°F,

you can protect your unit by following the procedure outlined below.

1. Gather the following items:

a. Two 5 gallon containers.

b. One gallon of antifreeze. (John Deere recommends an environmentally

safe antifreeze.)

c. Water supply.

d. Three foot hose, 1/2-3/4 I.D. with a 3/4 inch male garden hose fitting.

2. Procedure:

a. To start winterizing, unit must be run and primed according to the "Start-

b. After running and priming, shut off the unit and water supply.

c. Relieve system pressure by pointing the trigger gun in a safe direction

d. Lock the trigger gun in an OFF position and remove the nozzle.

e. Remove the water supply hose from the unit and attach the 3 foot hose

f. Shut off the detergent injector if applicable.

g. Fill one 5 gallon bucket with water.

h. Holding the 3 foot hose in an upright position, completely fill the hose

i. Turn the unit on. Trigger the gun several times until all the air is worked

NOTE: Proper winterizing is based on the recommended manufacturer's

j. With the trigger gun held open, siphon enough water out of the 5 gallon

k. Point the wand into the empty container and start the unit.

l. Trigger the gun until the antifreeze begins to exit the wand. Release

m. Detach the 3 foot hose from the unit and drain any excess antifreeze

n. Disconnect the hose/gun/wand assembly from the unit and drain any

o. Store the hose, gun and wand with the unit in a safe area.

p. Store antifreeze solution for next use or dispose of according to state

Operator’s Manual 27

up Procedures" listed on page 14.

and squeezing the trigger until water flow ceases to exit the nozzle.

securely to the inlet connection.

with water. Then plug the hose outlet with your thumb or finger. Place

the plugged end into the 5 gallon bucket of water.

out of the system (unit is primed).

instructions listed on the "Protection Chart" shown on the back label of

most antifreeze containers.

bucket until there is just enough water left to mix with the antifreeze.

the trigger for 3 seconds, then trigger the gun for 3 seconds. Continue

cycling the gun several times until all the antifreeze mixture is siphoned

from the container.

back into the 5 gallon container.

excess antifreeze back into the 5 gallon container.

EPA laws.

Page 28

Storage

WINTERIZING

3. Optional Procedure:

a. Shut the unit off.

b. Relieve system pressure by pointing the trigger gun in a safe direction and

squeezing the trigger until water flow ceases to exit the nozzle.

c. Disconnect and drain the hose, gun and wand.

d. Start the unit and allow it to run until all the water exits the unit. Once the

water has stopped flowing from the unit, turn off.

NOTE: When using this procedure, caution should be used as ice chips can form

from drops of water which could cause the unit to burst if starting before

completely thawed.

STARTING UNIT AFTER EXTENDED STORAGE

1. BE CERTAIN the unit is NOT plugged into the power source.

2. Prior to restarting the unit, thaw out any possible ice from the wand, gun, hose

and unit.

3. After following all "PREPARATION" instructions, start the unit momentarily and

immediately turn "OFF" to ensure all parts are lubricated before operation.

28 Operator’s Manual

Page 29

Specifications

POWER WASHER

MODEL NO.

SERIAL NO.

DATE CODE

Made in U.S.A.

34-0075

MAX. GPM

MAX. PSI

NOZZLE SIZE

HP / PHASE

AMPS

VOLTS / HZ

MAX.INLET WATER

TEMPERATURE,°F

Conforms to UL Std. 1776

SPECIFICATIONS

ITEM SPECIFICATION

AC-2500E

Water Pump ......................................... 3.2 GPM (12.1 L/min)

Pressure at Pump Manifold ................. 2500 PSI (172.3 Bar)

Electric Motor ...................................... 230 volts, 24.1 amps, single phase, 60 Hertz, 6.0 HP

Electric Cord ........................................ 40 ft. power supply cord with GFCI.

Discharge Hose ................................... 25 ft. x 3/8 in. (7 m x 6.4 mm)

Nozzle Size .......................................... 4.0

RECORD SERIAL NUMBER

Write you model number, machine serial number (see

serial number tag (A) in illustration) and date of purchase

in the spaces provided below. Your dealer needs this

information when ordering parts.

Model No. ______________________________________________

Machine Serial No. _______________________________________

Date of Purchase ________________________________________

(To be filled in by purchaser)

Operator’s Manual 29

Page 30

STATEMENT OF WARRANTY

The John Deere warrants all parts, (except those referred to below), of your new pressure

washer to be free from defects in materials and workmanship during the following

periods:

For Five (5) Years from the date of original purchase:

High Pressure Pump

For Two (2) Years from the date of original purchase:

Cart Assembly Plumbing

For One (1) Year from the date of original purchase:

GFCI Selector Switch

For Ninety (90) days from the date of original purchase:

Trigger Gun/Wand High Pressure Hose

Unloader Valve Strainer/Filter

Defective parts not subject to normal wear and tear will be repaired or replaced at our

option during the warranty period. In any event, reimbursement is limited to the purchase

price paid.

EXCLUSIONS

1. Normal wear parts:

Pump Packings Spray Nozzles

Pump Valves Detergent Valves

Quick Couplings/Screw Connect O-rings

2. This warranty does not cover parts damaged due to normal wear, misapplication,

misuse, operation at other than recommended speeds, pressures or temperature. Parts

damaged or worn because of the use of caustic liquids or by operation in abrasive or

corrosive environments or under conditions causing pump cavitation are not warranted.

Failure to follow recommended operating and maintenance procedures also voids

warranty.

3. The use of other than genuine manufacturer repair parts will void warranty.

4. Warranty will be void if used in any application other than consumer/homeowner.

Parts

returned, prepaid to our factory or to an Authorized John Deere Service Center will be

inspected and replaced free of charge if found to be defective and subject to warranty.

There are no warranties which extend beyond the description of the face hereof.

Under no circumstances shall the manufacturer bear any responsibility for loss of use

of the unit, loss of time or rental, inconvenience, commercial loss or consequential

damages.

For Service or Warranty Consideration, contact

®

Mi-T-M

Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

30 Operator’s Manual

Page 31

Note

Manual del Operado 31

Page 32

Introducción

Gracias para comprando este John Deere producto.

Lea este manual con cuidado para aprender como operar

y heacerie servicao su máquina correcto. Falla resultaría

en lesiones personales o daño a equipo. Este el manual

y muestras de seguridad en su máquina pueden también

estar disponibles en otras idiomas. (véase a su distribuidor

de John Deere para ordenar)

Este manual debe considerar una parte permanente de su

máquina y debe quedar con máquina cuando venderla.

Medidas en este manual se dan en sistema métrico y en

equivalentes de unidades de Estado Unidos. Use sólo

partes y cierres de reemplazar correctos. Cierres métricos

y pulgadas necesitarian un tirón especial de métrico o

pulgada.

Lados de mano derecha y mano izquierda se determinan

de que da al fin de máquina.

El número de serie está situada en sección de

especificaciones o números de identificación. Escriba

correcta todos números para ayndaría en encontrar la

máquina si sea robado. Su concesionario también necesite

estos números cuando ordenaría partes. Ponga números

de identificación en lugar seguro atuera de máquina.

Garantía provece de concesionario John Deere para

quien opere y mantenga su equipo como describido en

este manual. Este manual está explicado en certificado

de garantía que se vea en este manual.

Esta garantía provece la seguridad que su concesionario

John Deere daría garantia de productos donde defectos

aparecen durante tiempo de garantia. Debe abusar al

equipo o cambios para modificar la función atrás de

especificaciones de fabrica la garantia será vació.

32 Manual del Operador

Page 33

Materias

Pagiña

Seguridad ...............................................................34

Mandos ..................................................................43

Preparación de lavadora ........................................ 44

Operación de lavadora .......................................... 48

Localización de fallas ............................................ 54

Almacenamiento ..................................................... 56

Especificaciónes .................................................... 59

Nota .......................................................................... 60

Garantia ...................................................................63

Toda información, ilustraciónes, y especificaciones en este manual se

basa en información lo último que disponible al tiempo de publicación. Se

reserva el dercho de efectuar combios sin previo aviso.

Manual del Operado 33

Page 34

Materias

34 Manual del Operador

Page 35

W

A

R

N

I

N

G

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

C

A

U

T

I

O

N

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

Seguridad

PELIGRO

ADVERTENCIA

PRECAUCION

R E C O N O Z C A I N F O R M A C I Ó N D E

SEGURIDAD

Este es el símbolo de alerta de seguridad. Cuando mire

este símbolo en la máquina o manual, sea alerta de

posbildad o potencia de graves personales.

Siga precauciones recomendables y practicas de

operación.

COMPRENDA PALABRAS DE ALERTAS

Una palabra de alerta -- PELIGRO, ADVERTENCIA,

PRECAUCIÓN -- se usa con el símbolo de alerta de

seguridad. Peligro indica la situación más seria.

Señales de seguridad como PELIGRO y ADVERTENCIA

está situada cerca de riesgos específicos. Precauciones

generales están en una lista en las señales de seguridad

precaución a mensajes de seguridad en este manual.

SIGA LAS INSTRUCCIÓNES DE SEGURIDAD

Lea con ciudado todos mensajes de seguridad en este

manual y en las señales de seguridad en máquina.

Mantengase señales de seguridad en condición bueno.

Reemplace desaparecidos o señales de seguridad con

daño. Asegurese que componentes nueros de equipo

y partes de reparación incluir las señales de seguridad

último. Señales de seguridad para reemplace son

disponible de su concesario.

Aprenda como operar la máquina y como usar los mandos

corecta. No permita nadie para operar sin instrucciones.

Mantengase la máquina en condición corecta para

trabajar. Modificaciónes con no autorizado a la máquina

pueden afectar la función y/o seguridad y afecta la vida

de máquina.

Si usted no entiende cualquier parte de este manual y no

necesita ayuda, entre en contacto con a su distribuidor.

Manual del Operado 35

Page 36

PROTEJA EN CONTRA DE ROCÍO DE PRESIÓN

ALTA

Rocío de boquillas de presión altas se puede penetrar el

piel y causando lesiones graves. Mantengase rocio de

contactando con manos o cuerpo.

Nunca apunte la pistola hacia usted ni hacia otra persona.

Nunca coloque su mano, dedos o cuerpo directamente

sobre la boquilla de rociado. Mantenga siempre el área

de operación despejada de todas las personas. Ejerza una

precaución extrema al operar cerca de niños.

Requiera cuidado medico de emergencia si ocurriera

un accidente y el rocío parece haber penetrado

el piel. No lo trate como un corte simple. Si usted

está usando agentes limpiadores, esté preparado

a informar a su médico exactamente de que clase.

INSTRUCCIONES DE CONEXION A TIERRA

Este equipo debe conectarse a tierra. La conexión a tierra

provee un camino de resistencia reducida a la corriente

elétrica para reducir el riesgo de choque, en caso de

malfuncionamiento o falla. Este producto está equipado

con un cordón que tiene un conductor de conexión a tierra

del equipo y un enchufe de conexión a tierra. El enchufe

debe enfucharse o un tomacorriente apropriado que esté

correctamente instalado y conectado a tierra de acuerdo

con todos los códigos y ordenanzas locales.

PELIGRO - La conexión incorrecta del conductor de

conexión a tierra del equipo puede resultar en un riesgo

de electrocución. Si usted tiene dudas acerca de si el

tomacorriente está correctamente conectado a tierra,

consulte con un electricista calificado o personal de servicio.

No modifique el enchufe provisto con el produeto. Haga

instalar un tomacorriente a propiado por un electricista

calificado, si el enchufe no entra. No use ningún tipo de

adaptador con este equipo.

PROTECCIÓN DEL INTERRUPTOR DE FALLA DE LA

CONEXIÓN A TIERRA INCORPORADA EN CORDÓN

ELÉCTRICO.

Este mecanismo provee una protección adicional contra el

riesgo de choque eléctrico. Use sólo piezas de repuesto

idénticas que incluyan protección GFCI, Si fuera necesario

reemplazar el cordón elétrico o tapon.

No deje caer el GFCI ya que podriá resultar en daños. Si

el GFCI cae accidentamente asegurese examinar el GFCI

antes de usando para asegurese trabajando correctamente.

(Vea instrucciones en GFCI para procedimientos de

examinar.)

Para desconectar del tomacorriente, NO tire del cordón

eléctrico, NI transporte la unidad por el cordón.

36 Manual del Operador

Page 37

CORDONES DE EXTENSION

El uso de cordones de extension no es recomienda con lavador

de presión alta. Si no puede evitarse el uso de un cordón de

extensión, el mismo debe enchufarse a un GFCI ubicado en las

cajas de circuitos o receptáculos rotegidos.

Use sólo cordones de extensión de 3 conductores que tengan

enchufes de tipo de conexión a tierra de tres hojas conectores

de cordón de 3 polos que aceptan el enchufe del producto. Use

sólo cordones de extensión que estén diseñados para uso al

aire libre. Esos cordones de extensión están identificados por

una marca que dice, “Aceptable para usar con artefactos al aire

libre, almacene bajo techo mientras no se usa.” Use cordones

de extensión que tengan una clasificación nominal que no sea

menor que la clasificación nominal del producto. No use cordones

de extensión dañados. Antes de usar examine el cordón de

extensión y reemplácelo si está dañado. NO maltrate el cordón

de extensión y no tire del mismo para desconectarlo. Mantenga el

cordón de textensión alejado del calor y de bordes aguzados. Antes

de desconectar el equipo del cordón de extensión, desconecte

siempre el cordón de extensión del receptáculo.

ADVERTENCIA: Mantenga todas las conexiones secas y

alejadas de tierra para reducir el riesgo de electrocución. No

toque el enchufe con las manos mojadas.

Usar de cordones más pequoños causará ahogarse de motores

eléctricos o parando de ruptura de circuito.

AC1000E-C AC1500E-C

Longitud del cable Calibre del

conductor

Hasta 50 pies 14 AWG 12 AWG

Entre 50 y 100 pies 12 AWG 10 AWG

Calibre del

conductor

Antes de usar inspeccione por daños al cordón eléctrico. Existe un

riesgo de choque eléctrico resultante de daño por aplastamiento,

corte o calor.

ASEGURESE siempre que la unidad está recibiendo el voltaje

apropiado. Asegúrese que el interruptor está en la posición “OFF”,

antes de enchufar la unidad a una fuente de potencia compatible.

Desconecte cuando no se usa.

NO use la unidad en un lugar donde puedan estar presentes

vapores inflamables de gas. Una chispa eléctrica puede causar

una explosión o incendio.

NO dirija el rociado de agua a o dentro de instalaciones eléctricas

de ningún tipo. Esto incluye tomacorrientes eléctricos, lámparas

eléctricas, cajas de fusibles, transformadores, la unidad misma,

etc. Puede ocurrir un choque eléctrico grave.

John Deere no recomienda que el usuario intente ninguna

reparación eléctrica a esta unidad.

Manual del Operador 37

Page 38

PRECAUCIONES PARA LIMPIEZA CON DETERGENTES

MSDS

NO use solventes ni detergentes altamente corrosivos, ni limpiadores

de tipo ácido con esta lavadora a presión. Use detergentes John Deere

solamente.

¡CONOZCA SUS DETERGENTES! En el caso de una emergencia, esté

preparado a informar al médico exactamente lo que usted está usando.

Lea La Hoja de Datos de Seguridad del Material (MSDS) provista con

su detergente John Deere y todas las etiquetas de los detergentes.

Observe todas las instrucciones apropiadas acerca de la preparación,

uso, seguridad y transporte. Mantenga TODOS los detergentes fuera

del alcance de los niños.

NO use esta lavadora a presión para dispensar detergentes

riesgosos.

NO altere de ninguna manera no recomendada en este manual la

característica de inyección de detergente. Para las reparaciones

necesarias use piezas genuinas de repuesto John Deere solamente.

MANEJE CON CIUDADO PRODUCTOS QUIMICAS

Exposición directo a quimicas de daño puede causar lesiones. Quimicas

potenciament de daño se usen con lavador de presión incluyen articúlos

como detergentes.

Una pagiña de material seguridad información (MSDS) provee detalles

especificos en detergentes, daños de fisicos y salud, procedimientos de

seguridad y technicos de repuesta emergencia.

Revise MSDS antes de empezar algo trabajo usando un detergente. Para

que ud sabe todos reisgos y como hacer trabajo con cuidado. Observe

las instrucciones y equipo recomiendo.

PRECAUCIONES DE AJUSTE

NUNCA altere ni modifique el equipo, asegúrese que todos los artículos

accesorios y los componentes del sistema que se usan resistirán la

presión desarrollada. Use SOLO piezas genuinas John Deere para

reparar su lavadora a presión. El no hacerlo puede causar condiciones

operativas riesgosas y cancelará la garantía.

NUNCA efectúe ajustes a la máquina mientras esté conectada al motor,

sin sacar primero el cable de encendido de la bujía. El girar la máquina a

mano durante el ajuste o la limpieza podría arrancar el motor y la máquina,

lo que causará lesiones graves al operador.

Sepa cómo detener la lavadora a presión y purgar las presiones

rápidamente. Esté completamente familiarizado con los controles.

Apague la unidad, desconéctela de la red eléctrica, elimine la presión

de agua, y permita que la unidad se enfríe, antes de repararla. Preste

servicio en un área limpia, seca y plana. Para evitar que la unidad se

mueva, bloquee las ruedas.

Observe las instrucciones de mantenimiento especificadas en este

manual.

38 Manual del Operador

Page 39

ADVERTENCIAS IMPORTANTES DE SEGURIDAD

ADVERTENCIA: Para reducir el riesgo de lesiones, lea

este manual de operador completamente. Cuando usando

este producto, seguir siempre las precauciones basicas

consiguentes:

1. Lea todas instrucciones antes de usando el producto.

2. Esta lavadora a presión está provista de un Interruptor de

circuito de Falla a tierra (GFCI) integrado en el enchufe del

cordón de suministro eléctrico. Use sólo piezas idénticas de

repuesto que incluyan protección de GFCI, sí fuera necesario

reemplazar el cordón.

3. Observe las instrucciones de tierra incluyen en este manual.

4. Rocío de presión alta puede cortar el piel. No atomizar directo

a personas. Mantengase area de operación sin personas o

animales. Dé advertencia a niños que el rocío de agua puede

cortar. Mire los niños con cuidado.

5. ¡NUNCA permita que los niños o adolescentes operen esta

unidad!

6. No dirija el rociado en interruptores eléctricos, recepáculos,

lamparas eléctricas, vidrio, o objectos frágiles que puede

romper.

7. Suciedad y escombro que fue quitado de rocío puede causar

lesiones de ojos. Use antiparras protectoras.

8. NO SE INCLINE ni se pare sobre un apoyo inestable. Las

superficies húmedas pueden ser resbalosas, use equipo

protector de calzado y manténgase bien parado y en equilibrio

en todo momento. Las superficies húmedas pueden ser

resbalosas. Lleve zapatos y mantenga dos pies en la tierra.

No escale en artículos que están limpiando. No se incline ni

se pare sobre un apoyo inestable. Manténgase bien parado y

en equilibrio en todo momento. NUNCA accione el gatillo de

la pistola mientras esté en una escalera o en el techo.

9. Cuando el gatillo de rocío sea liberado, presión de agua sea

atrapado en la manguera de descarga. Libere presión atrapado

como gatillando la pistola de rocío después de apagado de

lavador.

10. No opere la unidad cuanto esté fatigado o bajo la influencia

de alcohol o drogas. Esté alerta. Observe lo que hace.

11. Observe las instrccuiones de mantenimento especificados

en este manual.

12. SIEMPRE sujete firmemente el conjunto de pistola/vara al

arrancar y operar la unidad. El no hacerlo puede causar que

la vara caiga y azote peligrosamente. NUNCA opere la pistola

con el gatillo conectado en la posición abierta. La pistola a

gatillo debería estar bien asegurado cuando no se usa, para

evitar una descarga accidental.

Manual del Operador 39

Page 40

ADVERTENCIAS IMPORTANTES DE SEGURIDAD

13. ¡NUNCA PERMITA QUE LOS NIÑOS O ADOLESCENTES

OPEREN ESTA UNIDAD!

14. Lea y observe todas las instrucciones de manejo,

funcionamiento, mantenimiento y seguridad incluidas en este

manual y facilite esta información a TODAS LAS PERSONAS

que operarán esta unidad.

15. Esta lavadora a presión está provista de un Interruptor de

Circuito de Falla a Tierra (GFCI) integrado en el enchufe del

cordón de suministro eléctrico. Use sólo piezas idénticas de

repuesto que incluyan protección de GFCI, si fuera necesario

reemplazar el cordón.

16. La unidad debe estar suficientemente caliente como para

asegurar que no haya formación de hielo en la bomba, a

temperaturas de congelación. NO arranque esta unidad

si ha sido transportada en un vehículo abierto o sin

suficiente calefacción, sin permitir primero que la bomba se

descongele.

17. Deben observarse los reglamentos locales de su compañía de

agua, al conectar la entrada de agua a las cañerías maestras

de agua. En algunas áreas la unidad no debe conectarse

directamente al suministro público de agua potable. Esto es

para asegurar que no haya realimentación de los detergentes

al suministro de agua. (Se permite la conexión directa si se

instala un supresor del flujo de retroceso.)

18. Las mangueras de alta presión deberían inspeccionarse

diariamente por señas de desgaste. Si existe evidencia de falla,

reemplace rápidamente todas las mangueras sospechosas

para evitar la posibilidad de lesiones ocasionadas por rociado

a alta presión. Si una manguera o adaptador está perdiendo,

NUNCA coloque su mano directamente sobre la pérdida.

19. NO opere la unidad si ve pérdidas de aceite de la bombao

agua de la máquina. NO reanude la operación hasta que la

unidad haya sido inspeccionada y reparada por una persona

calificada de servicio.

20. No opere la unidad sin todas las cubiertas protectoras en

su sitio.

21. NO deje desatendida la unidad presurizada. Apague la unidad

y descargue la presión interna antes de alejarse.

22. NO deje sin atención la unidad presurizada. Apague la unidad

y descargue la presión atrapada antes de alejarse.

23. NO mueva la unidad tirando de la manguera.

¡GUARDE ESTAS INSTRUCCIONES!

40 Manual del Operador

Page 41

USE ROPA PROTECTORA

Use ropa medida cerca y equipo de seguridad apropiado

al trabajo.

Use devise protector de oído como orejeras o tapón para

el oído para protectar en contra de ruidos inaceptables y

altos.

Operando equipo de seguridad necesita todo atencion de

operador. No use auriculares de radio o música mientras

operando máquina.

PREPARE PARA EMERGENCIAS

Mantenga primeros auxilios y extinguidor cerca.

Mantenga números de emergencia para doctores, servicio

de ambulancia, hospital, y departamento de fuego cerca de

telefono.

Sea preparado si un fuego empiece.

INSPECCIONES LAVADORA DE PRESIÓN

ALTA

Asegúrese todas tapas, guardias, y escudos están en

lugar.

Encontre todos controles operando y etiguetas de

seguridad.

Mantenga todas instalaciones eléctricas de ferretería y

conerías apretados.

Inspeccione cordón eléctrico para daño antes de usando.

Hay un riesgo de electrocución de aplastante, cortando, o

daño de calor.

Inspeccione manguera de presión alta para vueltas, cortos,

o agotado abrasivo.

SERVICIO CON CIUDADO LAVADOVA DE

PRESIÓN ALTA

Apague la unidad, desconéctela de la red eléctrica, elimine

la presion de agua y permita que la unidad se enfrié antes

de repararla.

Preste servicio en un área limpie, seca y planca.

Manual del Operador 41

Page 42

ADVERTISSEMENT

•Brancher seulement á une prise correctement mise á la

terre. Ne pas enlever la broche de mise á la terre.

•Vérifier le cordon avant l'utilisation. Ne pas utiliser le cordon

s' il est endommage.

•Conserver toutes les connexions au sec et au-dessus du sol.

•Ne pas toucher la prise avec des mains humides.

•Cet appareil peut être équipé d'un disjoncteur de fuite à la

terre incorporé dans la fiche du cordon électrique. S'il s'avère

nécessaire de remplaçer la fiche ou le cordon, n'utiliser que

des pièces de rechange identiques. Si cet appareil ne

comporte pas un disjoncteur de fuite à la terre, ne le relier

qu'à une prise de courant protégée par un disjoncteur de

fuite à la terre.

•L' utilisation d' une rallonge n' est pas recommandée

.

•Lire le manuel de l' opérateur av

ant d' utiliser l' appareil.

RISQUE D' ÉLECTROCUTION NE

PAS ENLEVER CETTE ÉTIQUETTE

DES CHOCS ÉLECTRIQUES SÉVÉRES

SERONT POSSIBLES SI LES DIRECTIVES

CI-DESSUS NE SONT PAS SUIVIES.

•Conecte solamente a una toma corr

iente que está bien

fundado. No quite la pata de conexión de la tierra.

•Antes de usar inspeccióne la cuerda.

No use si la cuerda està

dañando.

•Mantenga los conexiones secos y apar tados de la tierra.

•No torque el enchufe con manos mojados.

•Este producto debe conectarse a tierra.

Asegúrese de que la

lavadora a presión esté equipada con un Interruptor de

circuito de falla a tierra (Ground Fault Circuit Interrupter,

GFCI) incorporado en el cordón de alimentación. Si no lo

tiene, debe conectarse la lavadora a presión únicamente en

un receptáculo que esté protegido por un Interruptor de

circuito de falla a tierra. Desconéctela cuando no esté en uso.

•No use una cuerda extensión con la unidad.

•Antes de usar lea y entienda todas las instr

ucciónes y el

manual de operación.

ADVERTENCIA

SI NO SIGA LAS INSTRUCCIÓNES HAY EL

RIESGO DE ELECTR

OCUCIÓN SEVERA.

RIESGO DE ELECTROCUCION.

NO QUITE ESTA ETIQUETA.

WARNING

RISK OF ELECTROCUTION. DO NOT REMOVE THIS TAG.

FAILURE TO FOLLOW THE ABOVE INSTRUCTIONS

COULD RESULT IN A SEVERE ELECTRICAL SHOCK.

1. CONNECT ONLY TO A PROPERLY GROUNDED OUTLET. DO NOT

REMOVE GROUND PIN.

2. INSPECT CORD BEFORE USING. DO NOT USE IF CORD IS DAMAGED.

3. KEEP ALL CONNECTIONS DRY AND OFF THE GROUND.

4. DO NOT TOUCH PLUG WITH WET HANDS.

5. THIS PRODUCT IS PROVIDED WITH A GROUND FAULT CIRCUIT

INTERRUPTER (GFCI) BUILT INOT THE POWER CORD PLUG. IF