Page 1

AC-70, AC-115

AND AC-165

SPACE HEATERS

Page 2

Introduction

THANK YOU for purchasing a John Deere product.

READ THIS MANUAL carefully to learn how to operate

and service your machine correctly. Failure to do so

could result in personal injury or equipment damage.

This manual and safety signs on your machine may

also be available in other languages. (See your John

Deere dealer to order.)

THIS MANUAL SHOULD BE CONSIDERED a

permanent part of your machine and should remain

with the machine when you sell it.

MEASUREMENTS in this manual are given in both

metric and customary U.S. unit equivalents. Use only

correct replacement parts and fasteners. Metric and

inch fasteners may require a specific metric or inch

wrench.

RIGHT HAND AND LEFT HAND sides are determined

by facing the motor end of the machine.

The SERIAL NUMBER is located in the Specification

or Identification Numbers section. Accurately record

all the numbers to help in tracing the machine should

it be stolen. Your dealer also needs these numbers

when you order parts. File the identification numbers

in a secure place off the machine.

WARRANTY is provided from your John Deere

dealer for customers who operate and maintain their

equipment as described in this manual. The warranty

is explained on the warranty certificate shown in this

manual.

This warranty provides you the assurance that your

dealer will back products where defects appear

within the warranty period. Should the equipment

be abused, or modified to change its performance

beyond the original factory specifications, the warranty

will become void.

2 Operator’s Manual

Page 3

Contents

Page

Safety ........................................................................ 4

Controls ................................................................. 10

Assembly .................................................................. 11

Preparation ............................................................... 12

Operation ................................................................ 14

Troubleshooting .....................................................

Service .................................................................... 18

Storage .................................................................... 25

Specifications ......................................................... 26

Warranty ..................................................................27

Notes ........................................................................ 28

16

All information, illustrations and specifications in this manual are based on the latest

information available at the time of publication. The right is reserved to make changes at any

time without notice.

Operator’s Manual 3

Page 4

W

A

R

N

I

N

G

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

C

A

U

T

I

O

N

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

Safety

RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. When you see this

symbol on your machine or in this manual, be alert to

the potential for personal injury.

Follow recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS

A signal word--DANGER, WARNING or CAUTION--is

used with the safety-alert symbol. DANGER identifies

the most serious hazards.

DANGER or WARNING safety signs are located near

specific hazards. General precautions are listed on

CAUTION safety signs. CAUTION also calls attention

to safety messages in this manual.

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual and on

your machine safety signs. Keep safety signs in good

condition. Replace missing or damaged safety signs.

Be sure new equipment components and repair parts

include the current safety signs. Replacement safety

signs are available from your John Deere dealer.

Read this owner’s manual carefully and completely before

trying to assemble, operate, or service this space heater.

Improper use of this space heater can cause serious injury

or death from burns, fire, explosion, electrical shock, and

carbon monoxide poisoning.

Make certain you read and understand all warnings.

Keep this manual for reference. It is your guide to safe

and proper operation of this space heater.

If you do no understand any part of this manual and need

assistance, contact your John Deere dealer.

4 Operator’s Manual

Page 5

CARBON MONOXIDE - POISONOUS GAS

DANGER: CARBON MONOXIDE POISONING MAY LEAD TO

DEATH!

Space heaters exhaust contains carbon monoxide - a poisonous gas

that can kill you. You CAN NOT smell or see this gas.

Carbon Monoxide Poisoning: Early signs of carbon monoxide poisoning

resemble the flu, with headaches, dizziness, and/or nausea. If you have

these signs, the space heater may not be working properly. Get fresh air at

once! Have space heater serviced. Some people are more affected by carbon

monoxide than others. These include pregnant women, persons with heart

or lung disease or anemia, those under the influence of alcohol, and those

at high altitudes.

Never use a space heater in enclosed or partially-enclosed spaces without

proper ventilation. Use only in well-vented areas. Before using space heater,

provide at least a three-square-foot (2800 square cm) opening of fresh,

outside air for each 100,000 Btu / Hr (30 kw) of rating. Space heaters can

produce high levels of carbon monoxide very quickly. When you use a space

heater, remember that you cannot smell or see carbon monoxide. Even if you

can’t smell exhaust fumes, you may still be exposed to carbon monoxide.

If you start to feel sick, dizzy, or weak while using a space heater, get to fresh

air RIGHT AWAY. DO NOT DELAY. The carbon monoxide from space heaters

can rapidly lead to full incapacitation and death.

If you experience serious symptoms, get medical attention immediately.

Inform medical staff that carbon monoxide poisoning is suspected. If you

experienced symptoms while indoors, have someone call the fire department

to determine when it is safe to re-enter the building.

NEVER operate the space heater in an explosive atmosphere, near

combustible materials or where ventilation is not sufficient to carry away

exhaust fumes. Exhaust fumes can cause serious injury or death.

Follow the instructions that come with your space heater. Locate the unit

outdoors and away from doors, windows, and vents that could allow the

carbon monoxide gas to come indoors.

NEVER run space heaters inside homes, garages, sheds, or other semienclosed spaces without proper ventilation. These spaces can trap poisonous

gases EVEN IF you run a fan or open doors and windows. Use only in wellvented areas. Before using space heater, provide at least a three-square-foot

(2800 square cm) opening of fresh, outside air for each 100,000 Btu / Hr (30

kw) of rating.

If you start to feel sick, dizzy, or weak while using the space heater, shut

if off and get fresh air RIGHT AWAY. See a doctor. You may have carbon

monoxide poisoning.

Install battery-operated carbon monoxide alarms or plug-in carbon monoxide

alarms with battery back-up in your home, according to the manufacturer’s

installation instructions. The carbon monoxide alarms should be certified to

the requirements of the latest safety standards for carbon monoxide alarms.

(UL 2034, IAS 6-96, or CSA 6.19.01).

Test your carbon monoxide alarm frequently and replace dead batteries.

Operator’s Manual 5

Page 6

SAFETY WARNING WHEN REFUELING

Use only kerosene, #1#2 diesel / fuel oil, JET A or JP-8 fuels to

avoid risk of fire or explosion. Never use gasoline, naphtha, paint

thinners, alcohol, or other highly flammable fuels.

Personnel involved with fueling shall be qualified and thoroughly

familiar with the manufacturer’s instructions and applicable

regulations regarding the safe fueling of heating units.

Only the type of fuel specified on the space heater’s data plate

shall be used.

All flame, including the pilot light, if any, shall be extinguished and

the space heater allowed to cool, prior to fueling.

During fueling, all fuel lines and fuel-line connections shall be

inspected for leaks. Any leaks shall be repaired prior to returning

the space heater to service.

At no time shall more than one day’s supply of space heater fuel

be stored inside a building in the vicinity of the space heater. Bulk

fuel storage shall be outside the structure.

All fuel storage shall be located a minimum of 25 feet (762cm) from

space heaters, torches, welding equipment, and similar sources

of ignition (exception: the fuel reservoir integral with the space

heater unit).

Whenever possible, fuel storage shall be confined to areas where

floor penetrations do not permit fuel to drip onto or be ignited by

a fire at lower elevation.

Fuel storage shall be in accordance with the authority having

jurisdiction.

Observe all safety regulations for the safe handling of fuel.

Handle fuel in safety containers. If the container does not have a

spout, use a funnel.

Do not overfill the fuel tank, leave room for the fuel to expand.

Do not refill fuel tank while the engine is running. Before

refueling the space heater, turn it off and let it cool down.

Fill the tank only on an area of bare ground. While fueling the

tank, keep heat, sparks and open flame away. Carefully clean

up any spilled fuel before starting engine.

Always fill fuel tank in an area with plenty of ventilation to avoid

inhaling dangerous fumes.

NEVER store fuel for your space heater in the home. Gasoline,

propane, kerosene, and other flammable liquids should be stored

outside of living areas in properly-labeled, non-glass safety

containers. Do not store them near a fuel-burning appliance, such

as a natural gas water heater in a garage. If the fuel is spilled or

the container is not sealed properly, invisible vapors from the fuel

can travel along the ground and can be ignited by the appliance’s

pilot light or by arcs from electric switches in the appliance.

6 Operator’s Manual

Page 7

ELECTRICAL HAZARDS

DANGER- IMPROPER CONNECTION OF THE

EQUIPMENT-GROUNDING CONDUCTOR CAN

RESULT IN A RISK OF ELECTROCUTION. CHECK

WITH A QUALIFIED ELECTRICIAN OR SERVICE

PERSON IF YOU ARE IN DOUBT AS TO WHETHER

THE UNIT IS PROPERLY GROUNDED.

Use only the electrical voltage and frequency specified on

model plate.

Space heater must be grounded. Use only a properly

grounded three-wire extension cord. Plug into grounded

outlet only. If it should malfunction or breakdown, grounding

provides a path of least resistance for electric current to

reduce the risk of electric shock.

The space heater is a potential source of electrical shock if

not kept dry. Keep the space heater dry and do not use in

rain or wet conditions. To protect from moisture, operate it

on a dry surface under an open, canopy-like structure. Dry

your hands if wet before touching the space heater.

Check that the entire cord is free of cuts or tears and that

the plug has all three prongs, especially a grounding pin.

Operator’s Manual 7

Page 8

IMPORTANT SAFETY INSTRUCTIONS

W

A

R

N

I

N

G

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

C

A

U

T

I

O

N

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

1. Use only in areas free of flammable vapors or high dust

content.

2. Minimum clearance from any combustible materials: 8

feet (244 cm) from hot air outlet; 4 feet (122 cm) from

top; and 4 feet (122 cm) from sides and inlet.

3. Locate space heater on a stable and level surface while

hot or operating or a fire may occur.

4. Use only in well-vented areas. Before using space

heater, provide at least a three-square-foot (2800 square

cm) opening of fresh, outside air for each 100,000 Btu

/ Hr (30 kw) of rating.

5. Keep children and animals away from space heater at

all times.

6. Never start space heater when combustion chamber is

hot or if fuel has accumulated in combustion chamber.

7. When used with thermostat, space heater may start at

anytime.

8. When space heater is moved or stored, it must be in a

level position or fuel spillage may occur.

9. Use space heater only in accordance with local

ordinances and codes.

10. Never use gasoline, crankcase drainings, naphtha,

paint thinners, alcohol, or other highly flammable

fuels.

11. Never use space heater where gasoline, paint thinner, or

other highly flammable vapors are present.

12. Never use space heater in living or sleeping areas.

13. Never leave a space heater plugged in without adult

supervision if children or animals are likely to be

present.

14. Never move, handle, refuel, or service a hot,

operating, or plugged-in space heater.

15. Never attach duct work to front or rear of space

heater.

16. Never attach space heater to external fuel tank.

17. Space heaters used in the vicinity of tarpaulins, canvas,

or similar enclosure materials shall be located a

safe distance from such materials. The recommended

minimum safe distance is 10 feet (304.8cm). It is

further recommended that these enclosure materials

be of a fire retardant nature. These enclosure

materials shall be securely fastened to prevent them

from igniting or from upsetting the space heater due to

wind action.

18. Unplug space heater when not in use.

19. Never block air inlet (rear) or air outlet (front) of

space heater.

SAVE THESE INSTRUCTIONS

8 Operator’s Manual

Page 9

WEAR PROTECTIVE CLOTHING

Wear close fitting clothing and safety equipment appropriate

to the job.

Wear a suitable hearing protective device such as

earmuffs or earplugs to protect against objectionable or

uncomfortable loud noises.

Operating equipment safely requires the full attention of

the operator. Do not wear radio or music headphones while

operating machine.

PREPARE FOR EMERGENCIES

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital and fire department near your telephone.

Be prepared if a fire starts.

INSPECT SPACE HEATER

Be sure all covers, guards and shields are tight and in

place.

Locate all operating controls and safety labels.

Inspect power cord for damage before using. There is a

hazard of electrical shock from crushing, cutting or heat

damage.

Remove all packing items applied to space heater for

shipment. Remove all items from carton. Check items for

any shipping damage. If space heater is damaged, promptly

inform dealer where you bought space heater.

SERVICE SPACE HEATER SAFELY

Before servicing the space heater, disconnect all equipment

and battery (if equipped) and allow unit to cool down.

Service space heater in a clean dry flat area.

Operator’s Manual 9

Page 10

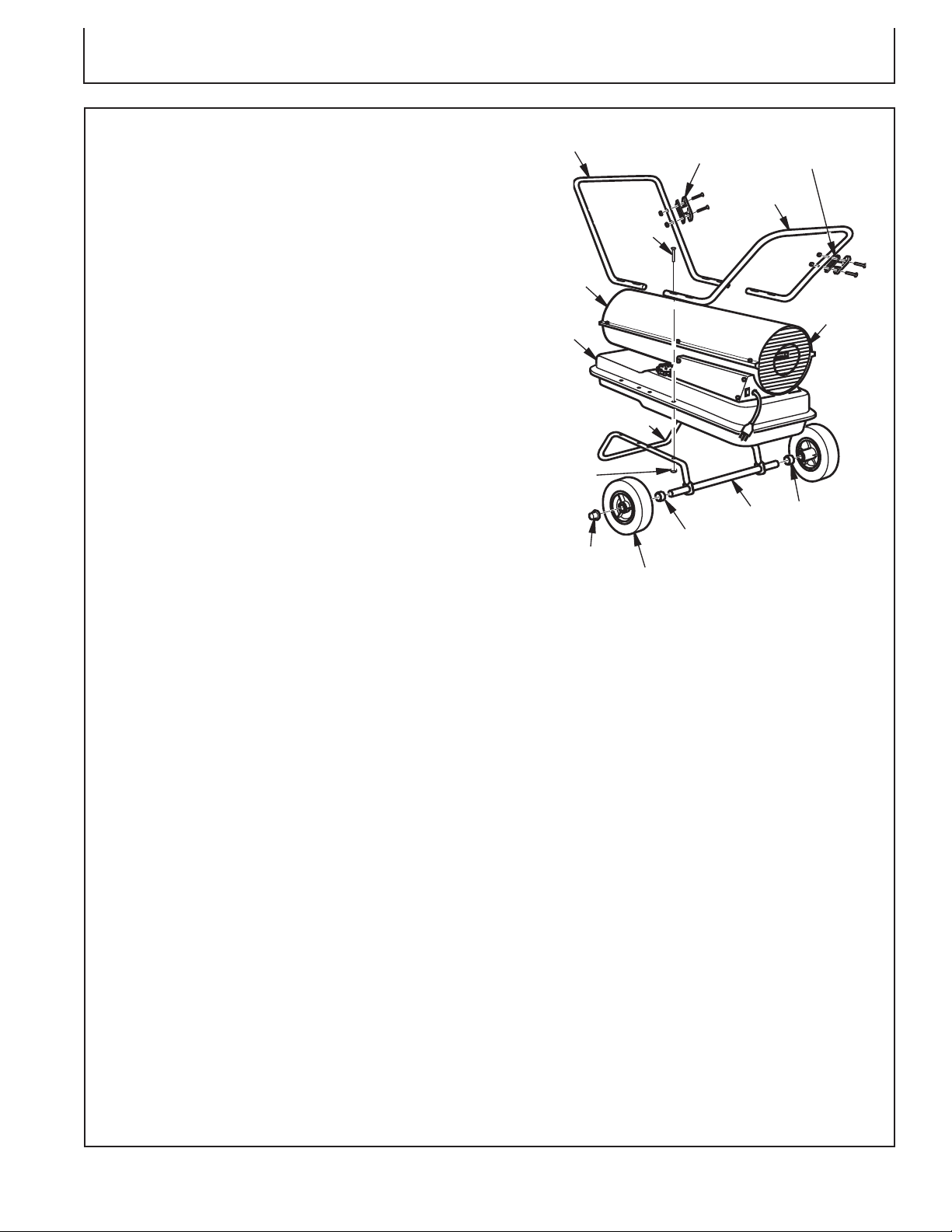

CONTROLS

A

B

C

D

E

F

G

H

I

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

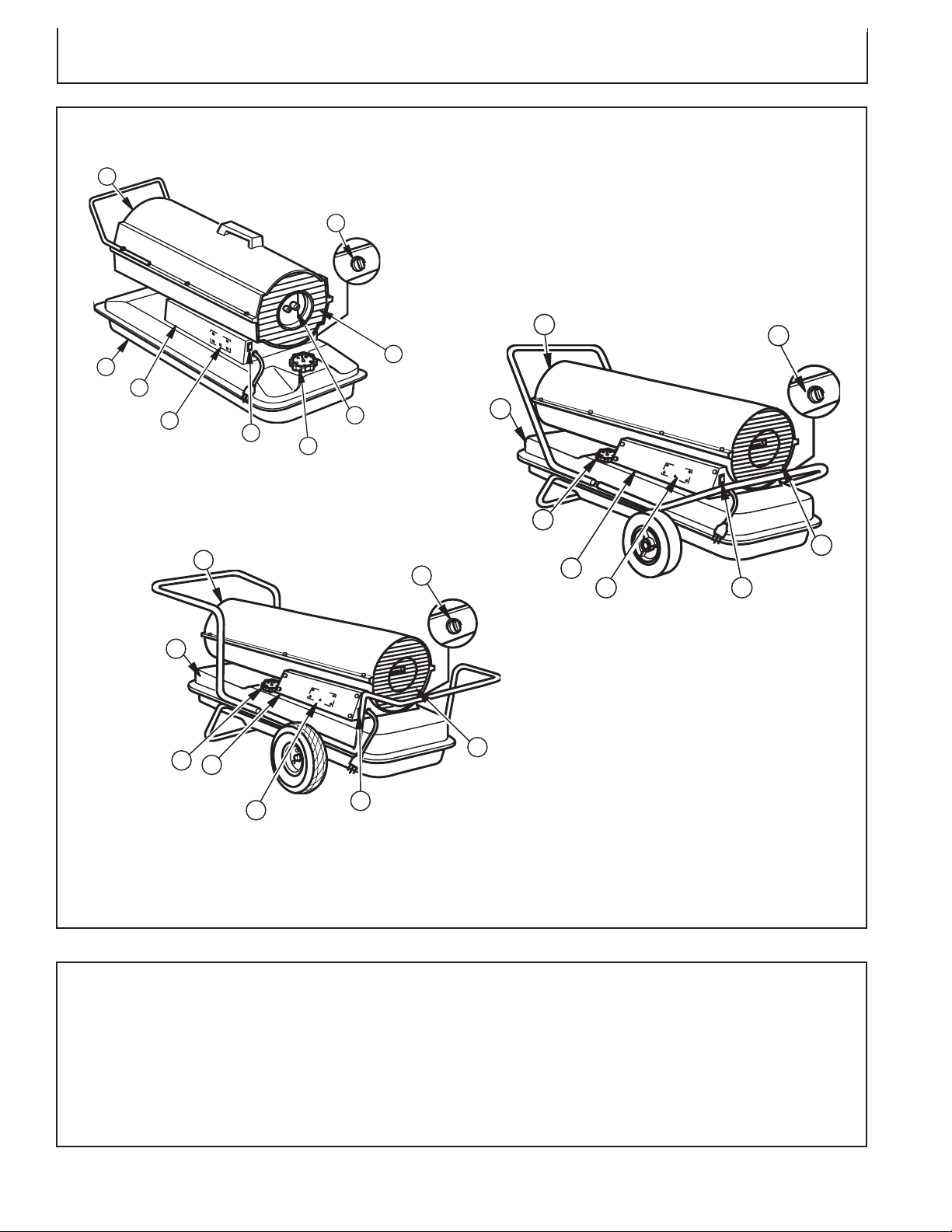

Controls

AC-70

A -- Hot Air Outlet

B -- Thermostat Knob

C -- Fan Guard

AC-165

D -- ON / OFF Switch

w/ Light

E -- Ignition Control Assembly

(On Inside of Side Cover)

F -- Side Cover

AC-115

G -- Fuel Cap / Gauge

H -- Fuel Tank

I -- Air Filter End Cover

10 Operator’s Manual

Page 11

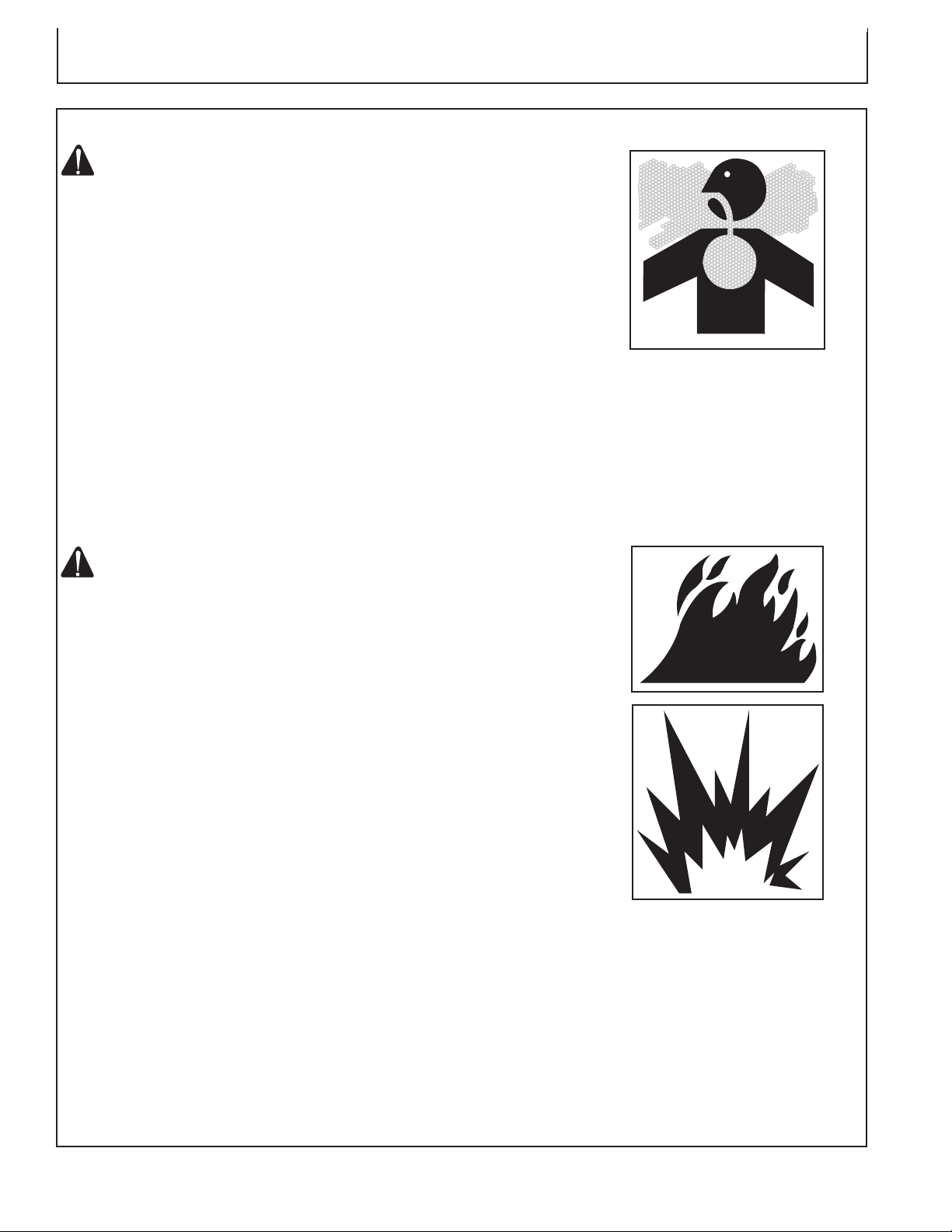

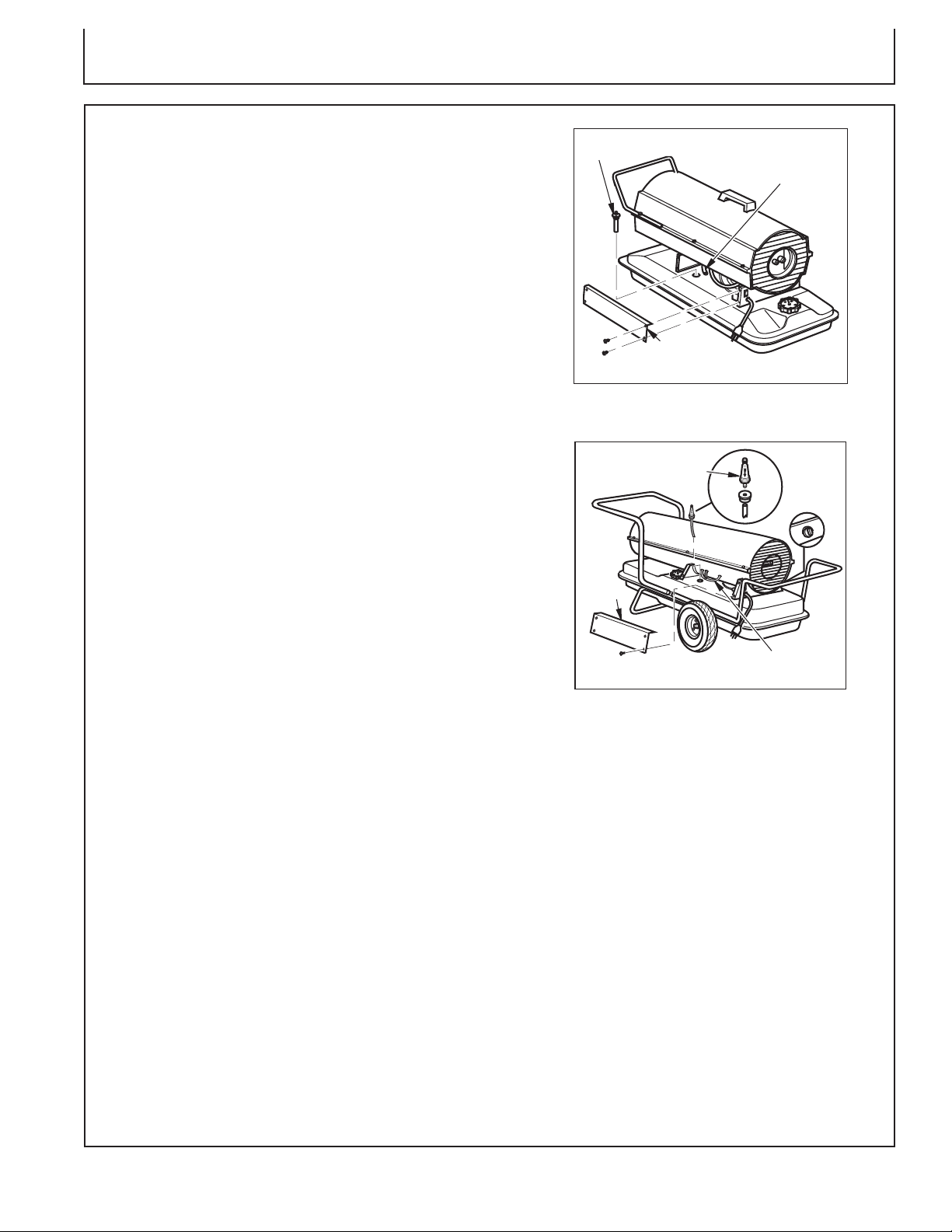

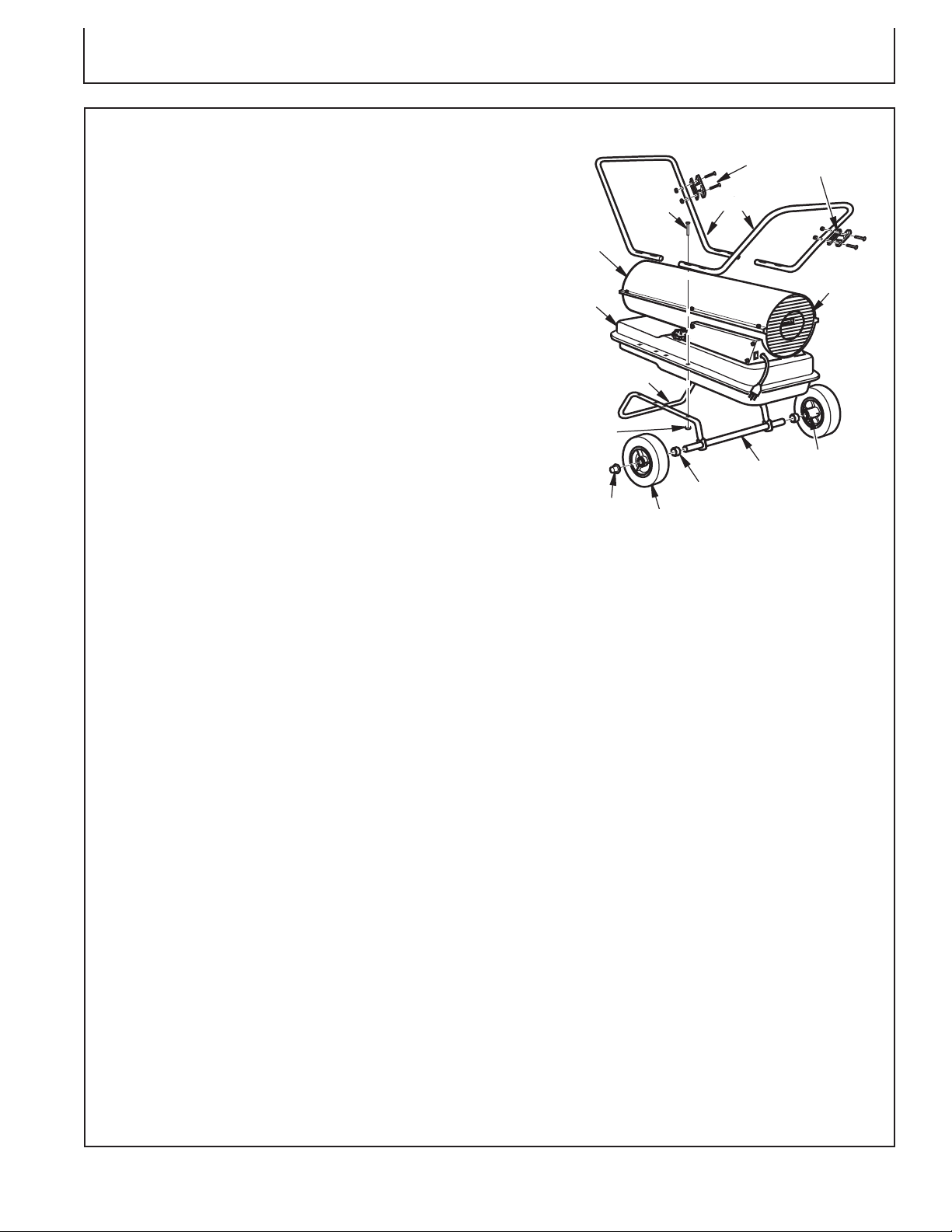

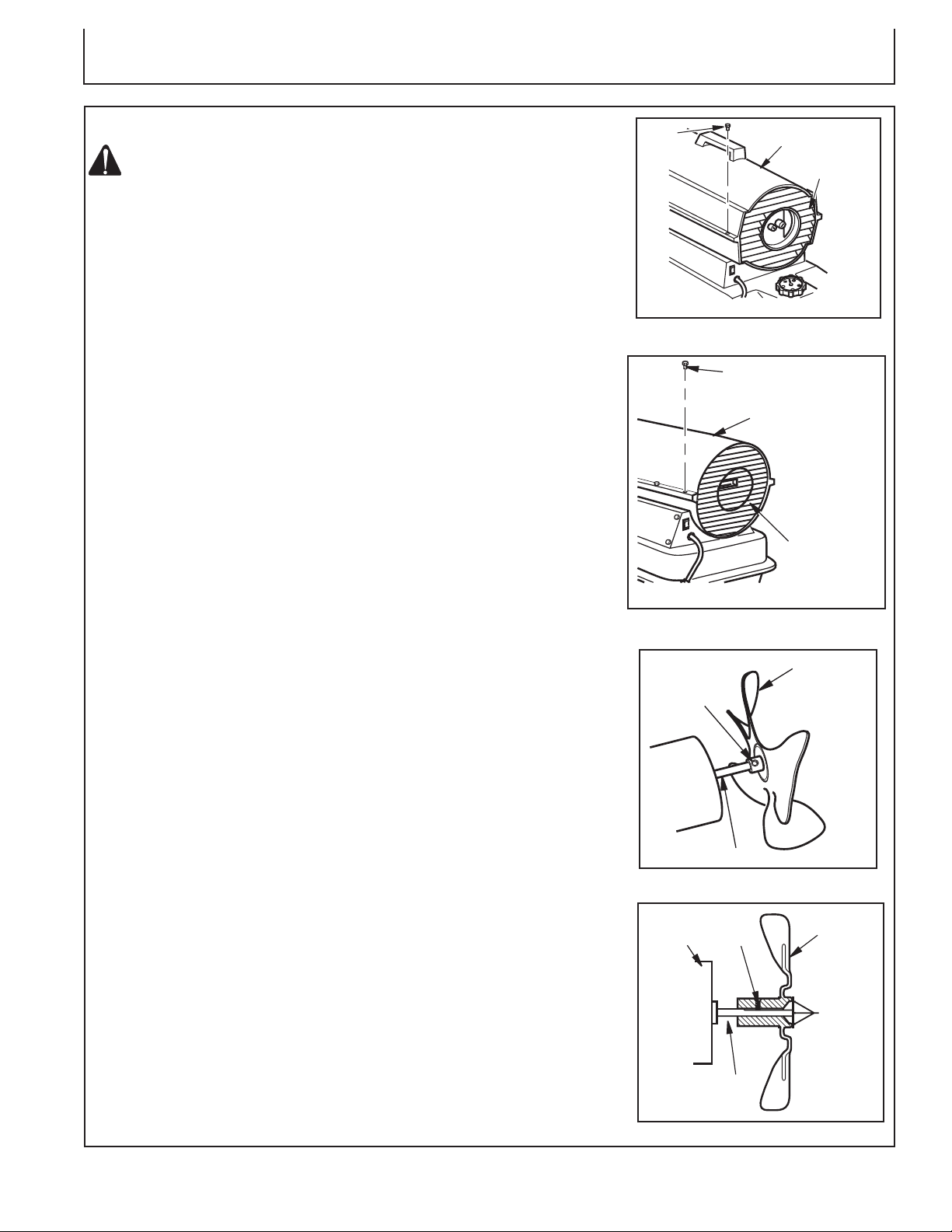

Assembly

Wheel Support

Frame

Fuel

Tank

Flange

Cap Nut

Wheel

Nut

Axle

Extended

Hub

Air

Inlet

Handle

Hot Air

Outlet

Screw

Wheel Spacer

(If Provided)

Cord Cleat with

Bolts and Nuts

Handle

ASSEMBLY

NOTE: For 115 and 165 Models Only

These models are furnished with wheels and a handle.

Some models are furnished with a second handle also.

Wheels, handle(s), and the mounting hardware are found

in the shipping carton.

Tools Needed

• Medium Phillips Screwdriver

• 3/8" Open or Adjustable Wrench

• Hammer

1.

Slide axle through wheel support frame. Install wheel spacers

if provided. Install wheels on axle.

IMPORTANT: When installing wheels, point extended

hub of wheels toward wheel support frame (Fig. 1).

2. Place cap nuts on axle ends. Gently tap with hammer

to secure.

3. Place space heater on wheel support frame. Line up

holes on fuel tank flange with holes on wheel support

frame.

4. Place handle(s) on top of fuel tank flange. Insert

screws through handle(s), fuel tank flange, and wheel

support frame. Attach nut, hand tight after each screw

is inserted.

5. After all screws are inserted, tighten nuts firmly.

(Fig. 1)

Operator’s Manual 11

Page 12

Preparation

VENTILATION

WARNING: PROVIDE A FRESH AIR OPENING OF

AT LEAST THREE SQUARE FEET (2,800 SQUARE

CM) FOR EACH 100,000 BTU / HR RATING.

PROVIDE EXTRA FRESH AIR IF MORE

SPACE HEATERS ARE BEING USED. THE MINIMUM

VENTILATION REQUIREMENTS MUST BE

FOLLOWED TO AVOID RISKS ASSOCIATED WITH

CARBON MONOXID E POISON I NG. MAK E

CERTAIN THESE REQUIREMENTS ARE MET

PRIOR TO OPERATING SPACE HEATER.

Example: A 200,000 Btu / Hr (58.6kw) space heater

requires one of the following:

• a two-car garage door [16 feet (4.88 meter) opening]

raised 5 inches (12.7 cm)

• a single-car garage door [9 feet (2.74 meter) opening]

raised 8 inches (20.3 cm)

• two, 30 inch (76.2 cm) windows raised 15 inches

(38.1 cm)

FUELS

WARNING: USE ONLY KEROSENE, #1/#2 DIESEL/

FUEL OIL, JET A OR JP8 FUELS TO AVOID RISK

OF FIRE OR EXPLOSION. NEVER USE GASOLINE,

OIL DRAINED FROM CRANKCASES, NAPHTHA,

PAINT THINNERS, ALCOHOL OR OTHER HIGHLY

FLAMMABLE FUELS.

Use only kerosene, #1/#2 diesel / fuel oil, JET A or JP-8 fuels.

Heavier fuels such as No. 2 fuel oil or No. 2 diesel fuel may

also be used but will result in:

• noticeable odor

• additional fuel filter maintenance

• the need for nontoxic, anti-icer additives in very cold

weather

Do not use fuels heavier than No. 2 grade or heavy oils such

as oil drained from crankcases. These heavy oils will not

ignite properly and will contaminate the space heater.

IMPORTANT: Use a KEROSENE ONLY (blue) or DIESEL

ONLY (yellow) storage container. Be sure storage container

is clean. Foreign matter such as rust, dirt, or water will cause

the ignition control assembly to shut down space heater.

Foreign matter may also require space heater’s fuel system

to be frequently cleaned.

12 Operator’s Manual

Page 13

Preparation

Clean

Heated

Air Out

Fuel

Filter

Air Line

To Burner

Air Output Filter

Air Pump

Air Intake Filter

Cool Air In

Fan

Combustion

Chamber

Ignitor

Ignition Control

Assembly

Air For Fuel

System

Air For

Combustion

And Heating

Fuel

Nozzle

Fuel

Tank

Motor

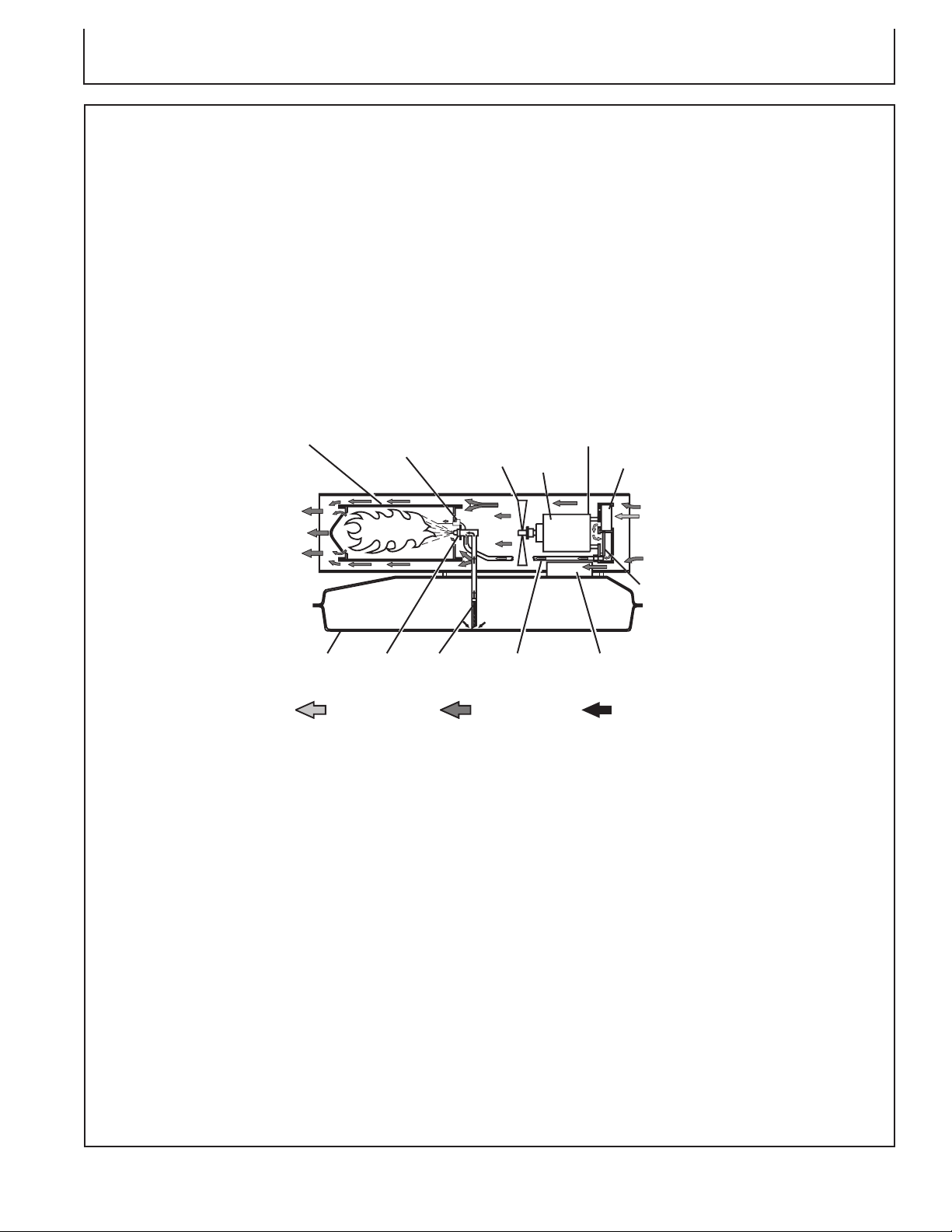

THEORY OF OPERATION

The Fuel System: The air pump forces air through the air line. The air is then pushed through the nozzle. This air

causes fuel to be lifted from the tank. A fine mist of fuel is sprayed into the combustion chamber.

The Air System: The motor turns the fan. The fan pushes air into and around the combustion chamber. This air

is heated and provides a stream of clean, hot air.

The Ignition System: The ignition control assembly provides power to the ignitor. This ignites the fuel / air mixture

in the combustion chamber.

The Flame-Out Control System: This system causes the space heater to shut down if the flame goes out.

Operator’s Manual 13

Page 14

Operation

ON/OFF

Switch with

Light

ON/OFF

Switch with

Light

OPERATION

IMPORTANT: Review and understand the warnings in

the Safety Information section. They are needed to safely

operate this space heater. Follow all local ordinances and

codes when using this space heater.

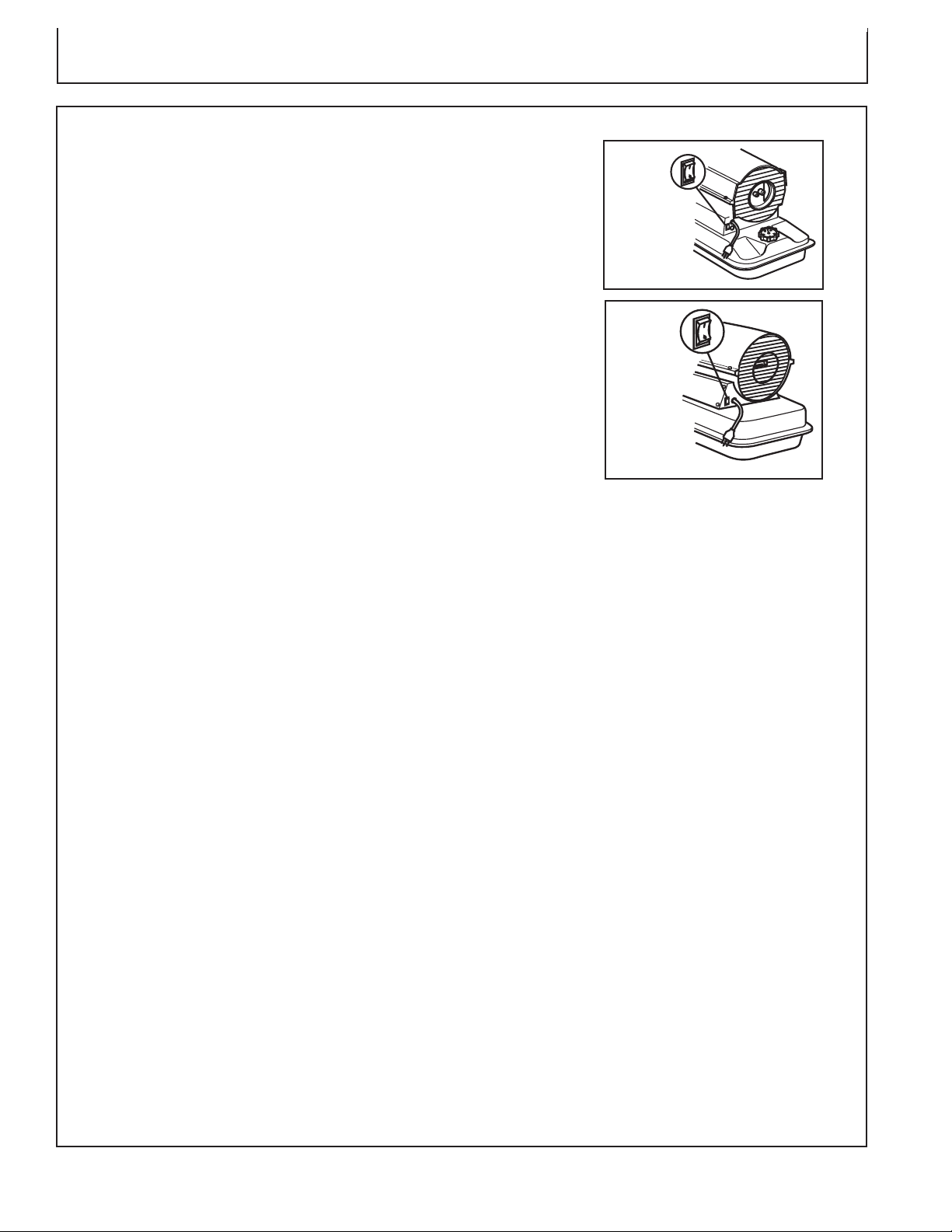

START SPACE HEATER:

1.

Follow all ventilation and safety information.

2. Place the space heater in an area that provides

maximum circulation of the heated air. Follow all location

requirements noted in the Safety Information.

3. Fill fuel tank with kerosene, #1#2 diesel / fuel oil, JET A

or JP-8 fuel.

4. Attach fuel cap.

5. For thermostat models, turn thermostat knob clockwise

to the high position.

6.

Plug space heater’s power cord into approved, grounded,

three-wire extension cord. Extension cord must be at least

six feet (1.8 meters) long.

Extension Cord Size Requirement:

2

• 6 to 10 feet (1.8 to 3 meters) long, use 18 AWG (0.75 mm

rated cord

• 11 to 100 feet (3.3 to 30.5 meters) long, use 16 AWG

(1.0 mm2) rated cord

• 101 to 200 feet (30.8 to 61 meters) long, use 14 AWG

(1.5 mm2) rated cord

7.

Plug extension cord into standard 120 volt / 60 hertz, 3prong grounded outlet. Push ON / OFF switch to ON(|)

position and space heater should start in 5 seconds.

(Fig. 2) If space heater does not start, see

Troubleshooting.

8. Adjust thermostat knob to the desired setting.

Note: A cold space heater may affect the thermostat

setting. This thermostat is a general-heating control.

It is not intended for precise temperature control.

Adjust thermostat until space heater cycles at the

desired setting.

STOP SPACE HEATER:

Push ON / OFF switch to OFF (O) position. Unplug space

heater when not in use.

)

Model: AC-70

Models: AC-115 / 165

(Fig. 2)

14 Operator’s Manual

Page 15

OPERATION (CONTINUED)

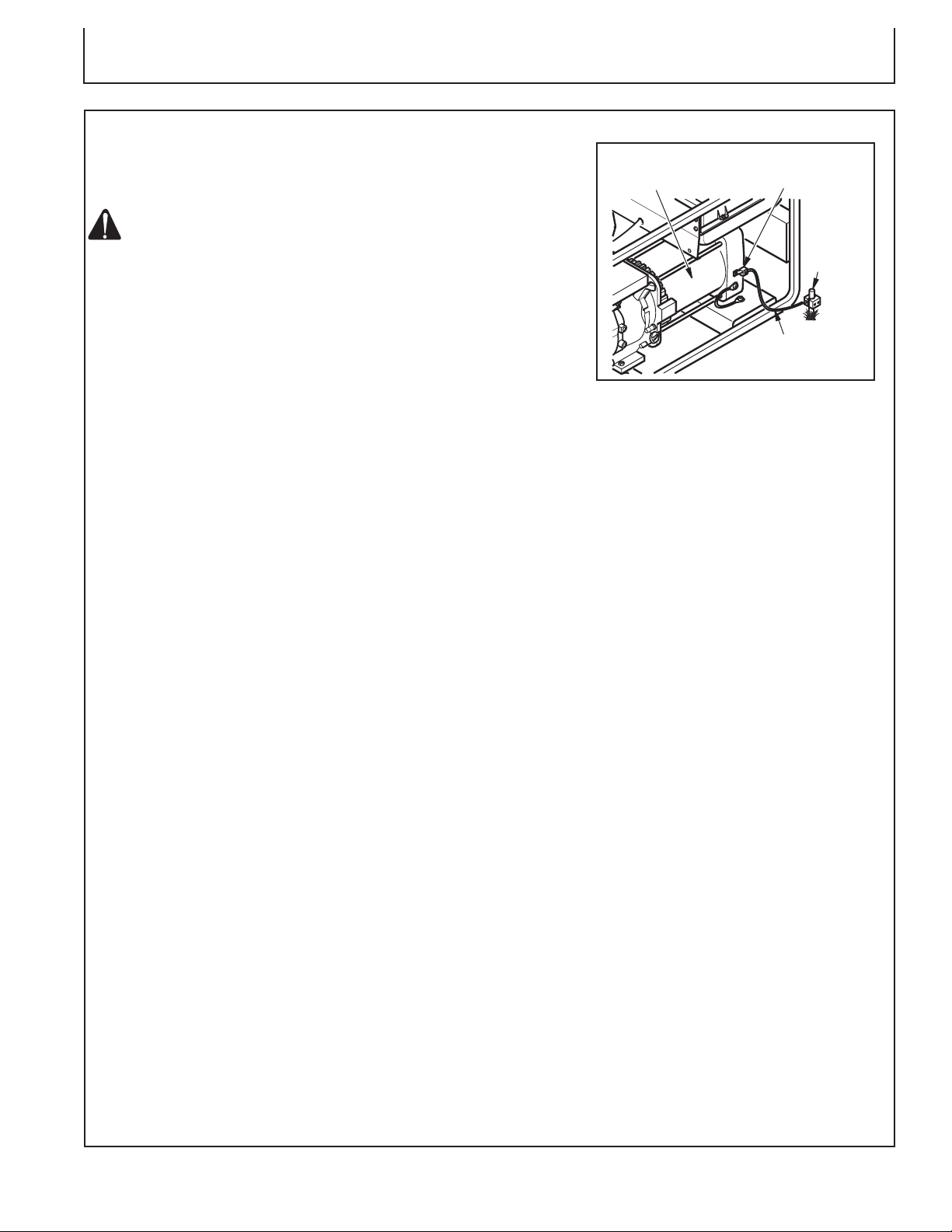

Ground Lug

Ground Wire (#10

AWG - StrandedCopper)

Alternator

Copper

or Brass

Grounding

Point

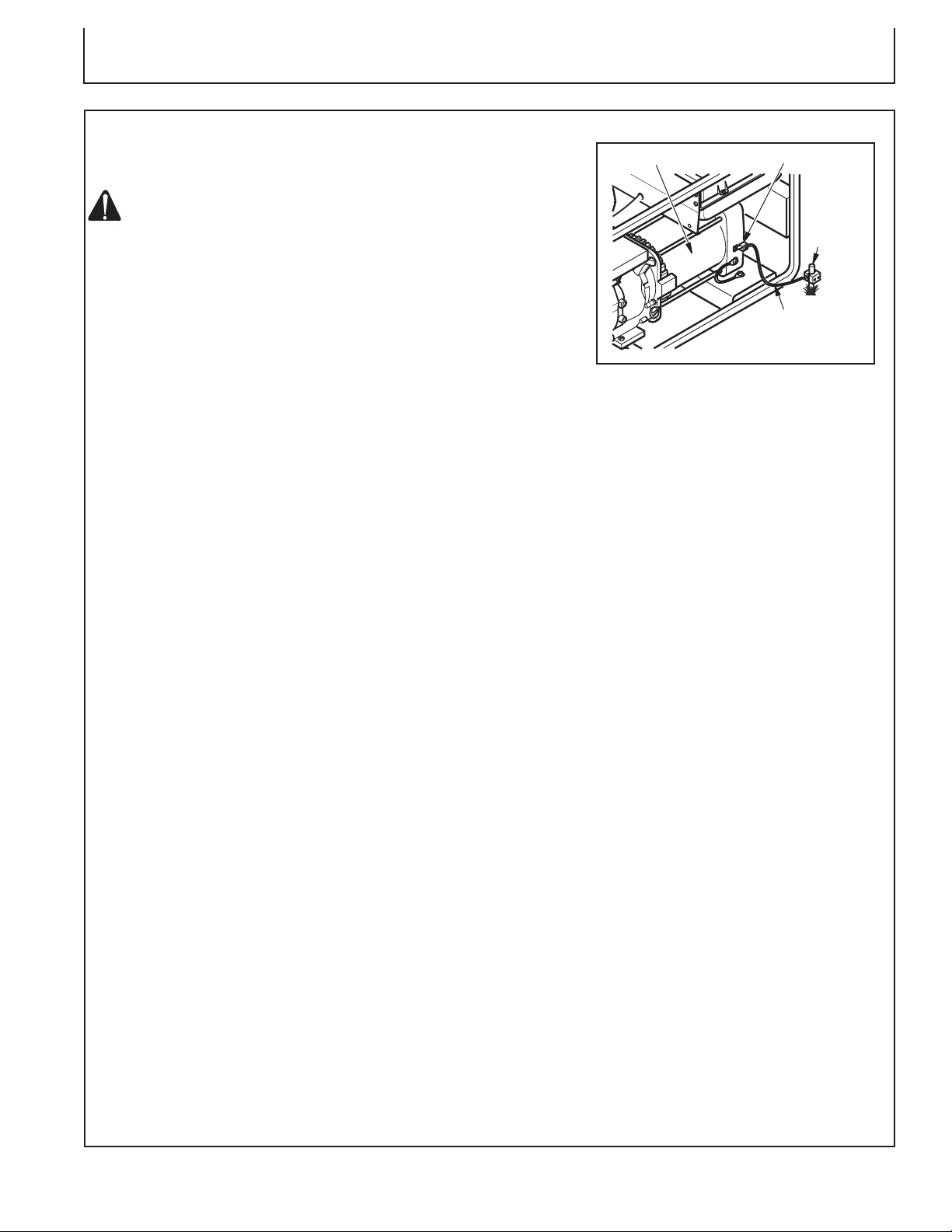

OPERATION WITH PORTABLE SPACE HEATER:

Operation

WAR NING : BE FO RE OPE R ATIN G SPA CE

HEATER OR ANY APPLIANCE FROM A

PORTABLE SPACE HEATER, VERIFY THAT

SPACE HEATER HAS BEEN PROPERLY

CONNECTED TO THE GROUND (FIG. 3).

IMPROPER GROUNDING OR FAILURE TO

GROUND SPACE HEATER CAN RESULT IN

E LE C TR OC U T IO N I F A G RO UN D

FAULT OCCURS. REFER TO OWNER’S

MANUAL SUPPLIED BY SPACE HEATER

MANUFACTURER FOR PROPER GROUNDING

PROCEDURES.

The operating voltage range of the space heater is 108

to 132 Volts (120 Volts +/- 10%). Prior to plugging space

heater into space heater the output voltage should be

verified (if space heater is equipped with the automatic idle

feature, the output voltage should be measured with the

space heater running at full speed). If the voltage does

not measure in this range the space heater should not be

plugged into the space heater.

Refer to Operation, for starting, stopping, and resetting

space heater procedures.

(Fig. 3)

Operator’s Manual 15

Page 16

Troubleshooting

WARNING: HIGH VOLTAGE. NEVER SERVICE SPACE HEATER WHILE IT IS PLUGGED IN,

OPERATING, OR HOT. SEVERE BURNS AND ELECTRICAL SHOCK CAN OCCUR.

Symptom Problem Solution

Motor does not start five

seconds after space heater is

plugged in.

No power to space heater.

ON / OFF switch not in the ON(|)

position.

Thermostat setting is too low.

Bad electrical connection between

motor and ignition control

assembly or ignition control

assembly and power cord.

Binding pump rotor.

Defective ignition control

assembly.

Defective motor.

Blown fuse or ignitor control

assembly.

Check circuit breaker in electrical

panel.

Verify the ON / OFF switch is in

ON (|) position and light is on.

Turn thermostat knob to a higher

setting.

Check all electrical connections.

If fan does not turn freely, see

"Maintenance: Pump Rotor".

Replace ignition control

assembly.

Replace motor.

See "Maintenance: Ignition

Control Assembly".

16 Operator’s Manual

Page 17

Troubleshooting

WARNING: HIGH VOLTAGE. NEVER SERVICE SPACE HEATER WHILE IT IS PLUGGED IN,

OPERATING, OR HOT. SEVERE BURNS AND ELECTRICAL SHOCK CAN OC

CUR.

Symptom Problem Solution

Motor starts and runs but

space heater does not

ignite

Space heater ignites but

ignition control assembly

shuts space heater off after

a short period of time.

No fuel in tank.

Pump pressure incorrect.

Dirty fuel filter.

Obstruction in nozzle.

Water in fuel tank.

Bad electrical connection

between ignitor and ignition

control assembly.

Defective ignitor.

Defective ignition control

assembly.

Pump pressure incorrect.

Dirty air intake, air output, and/or

lint filter.

Dirty fuel filter.

Obstruction in nozzle.

Photocell assembly not properly

installed (not seeing the flame).

Dirty photocell lens.

Bad electrical connection

between photocell and ignition

control assembly.

Defective photocell.

Defective ignition control

assembly.

Fill tank with kerosene.

See "Maintenance: Pump

Pressure Adjustment".

See "Maintenance: Fuel Filter".

See

"Maintenance:

Nozzle

Assembly".

Drain and flush fuel tank with

clean kerosene.

Check electrical connections.

Replace ignitor, see

"Maintenance: Ignitor".

Replace ignition control

assembly.

See "Maintenance: Pump

Pressure Adjustment".

See "Maintenance: Air Output,

Air Intake, and Lint Filters".

See "Maintenance: Fuel Filter".

See

"Maintenance:

Nozzle

Assembly".

Make sure photocell boot is

properly seated in bracket.

Clean photocell lens.

Check electrical connections.

Replace photocell.

Replace ignition control

assembly.

Operator’s Manual 17

Page 18

Service

MAINTENANCE

PREVENTATIVE MAINTENANCE SCHEDULE:

WARNING: HIGH VOLTAGE. NEVER SERVICE Space heater WHILE IT IS PLUGGED IN, OPERATING,

OR HOT. SEVERE BURNS AND ELECTRICAL SHOCK CAN OCCUR.

Item How Often How to

Fuel tank

Air output and lint

filters

Air intake filter

Fuel filter

Ignitor

Fan blades

Motor

Flush every 150-200 hours of

operation or as needed.

Replace every 500 hours of

operation or once a year.

Wash and dry with soap and

water every 500 hours of operation or as needed.

Clean twice a heating season or

as needed.

No maintenance required.

Clean every season or as

needed.

Not required / permanently

lubricated.

See "Storage: Storing,

Transporting, or Shipping".

See "Maintenance: Air Output,

Air Intake, and Lint Filters".

See "Maintenance: Air Output,

Air Intake, and Lint Filters".

See "Maintenance: Fuel Filter".

See "Maintenance: Fan".

18 Operator’s Manual

Page 19

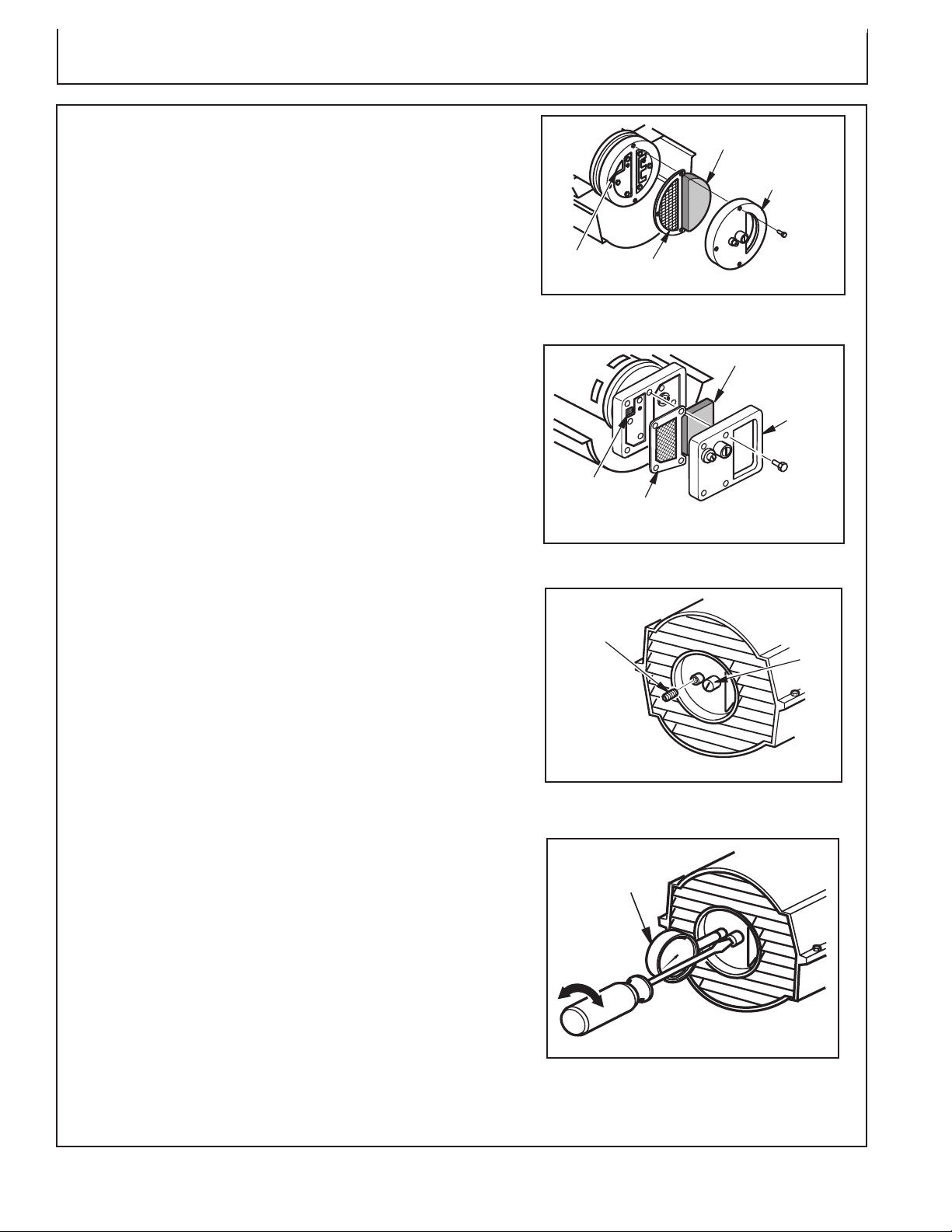

Service

Upper Shell

Fan Guard

Screw

Fan

Guard

Upper Shell

Screw

Motor Shaft

Setscrew

Fan

Motor

Shaft

Fan

Setscrew

Flush

Motor

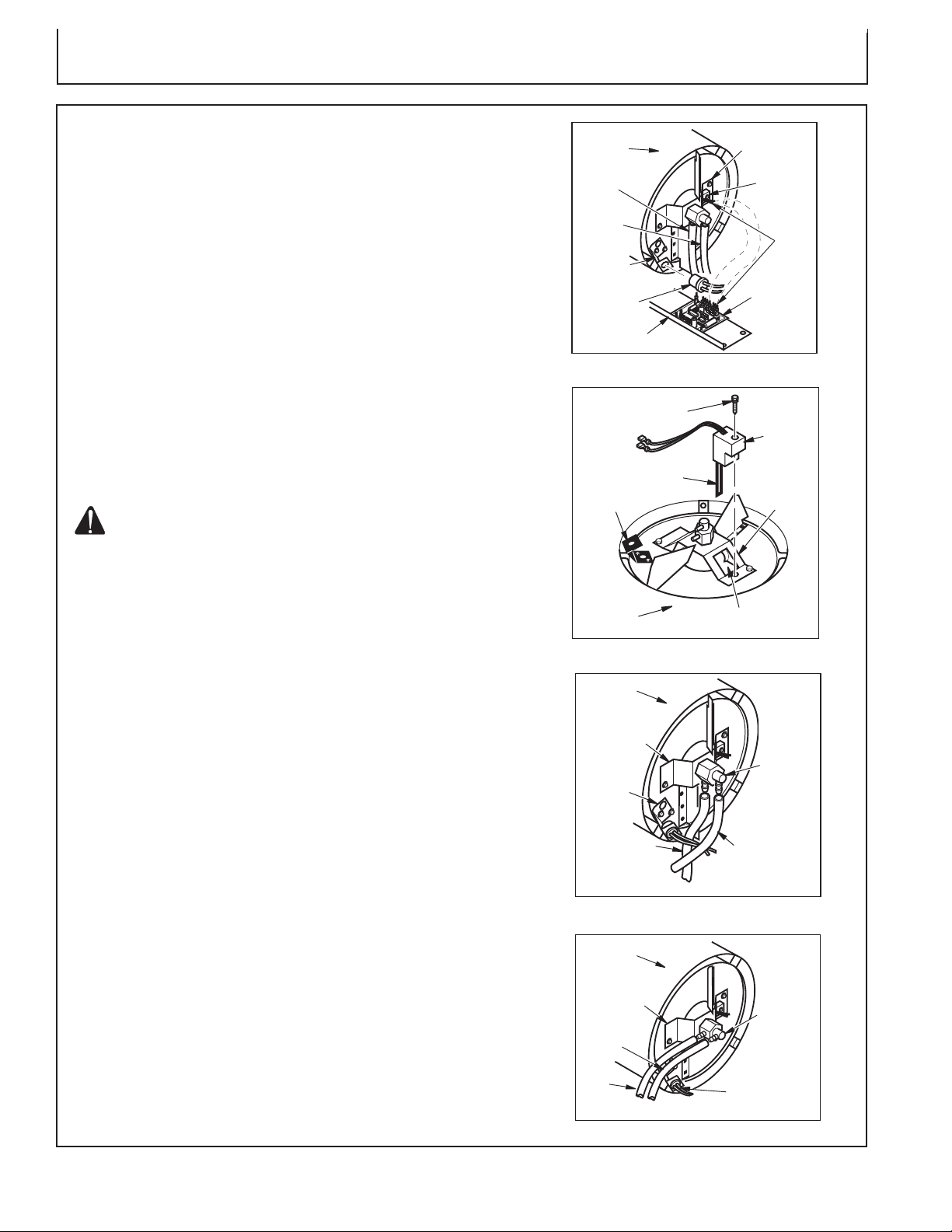

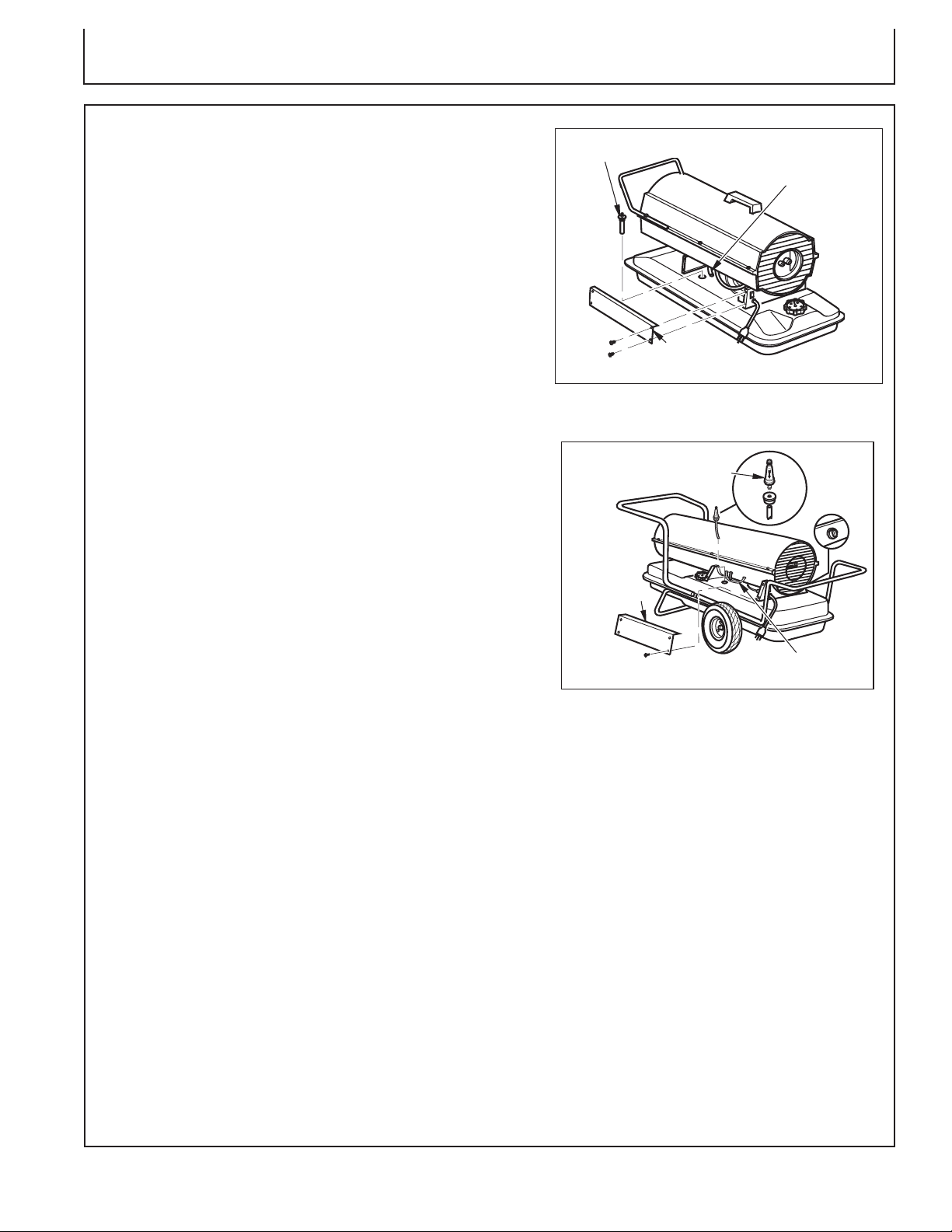

MAINTENANCE (CONTINUED):

WARNING: TO AVOID RISK OF BURN AND

ELECTRICAL SHOCK, NEVER ATTEMPT

TO SERVICE SPACE HEATER WHILE IT IS

PLUGGED IN, OPERATING, OR HOT.

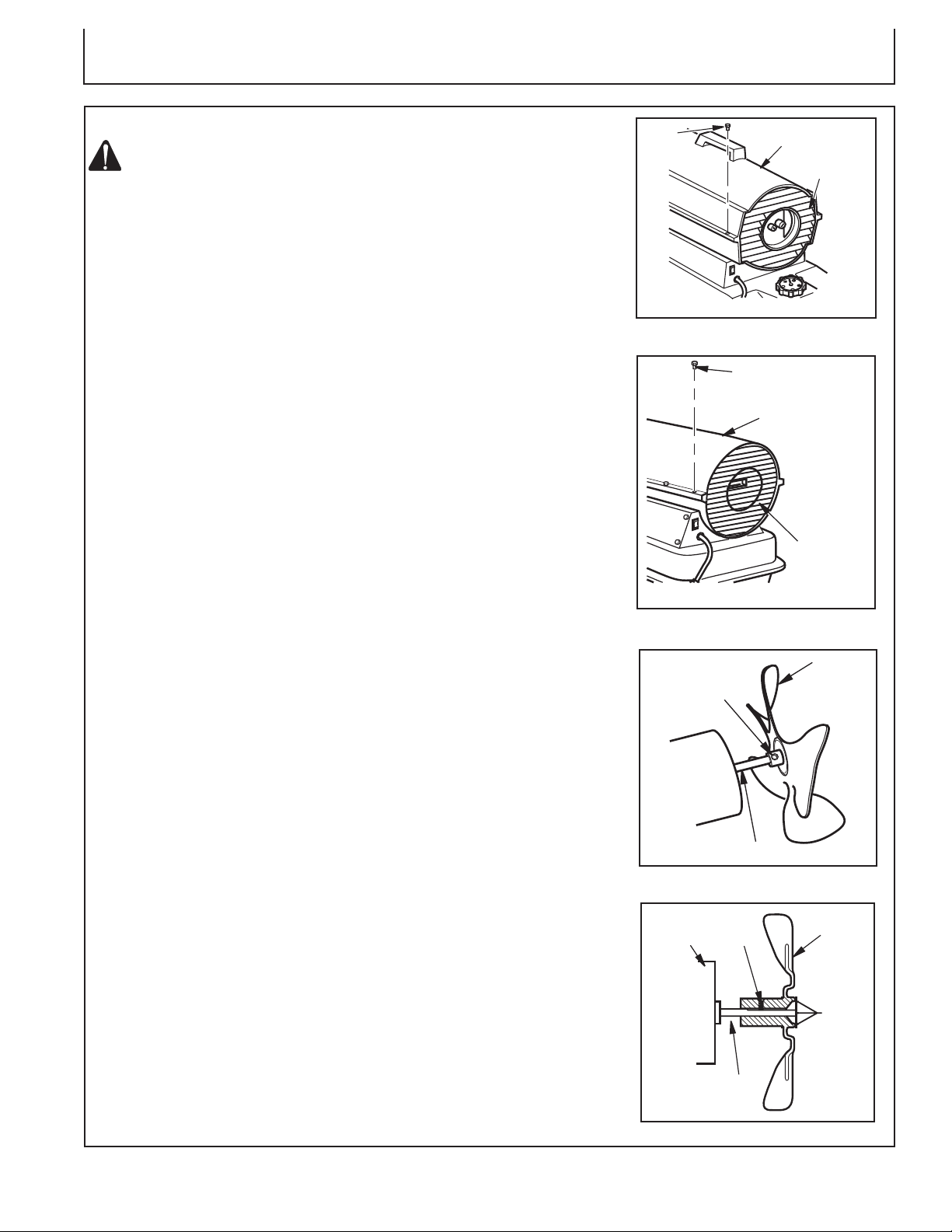

UPPER SHELL REMOVAL:

1. Remove screws along each side of space heater using

5/16" nut-driver. These screws attach upper and lower

shells together. (Fig. 4 or 5)

2. Lift upper shell off.

3. Remove fan guard.

FAN:

IMPORTANT: Remove fan from motor shaft before

removing motor from space heater. The weight of the

motor resting on the fan could damage the fan pitch.

(Fig. 6)

Model: AC-70

(Fig. 4)

1. Remove upper shell. (Fig. 4 or 5)

2. Use 1/8" allen wrench to loosen setscrew which holds

fan to motor shaft.

3. Slip fan off motor shaft.

4. Clean fan using a soft cloth moistened with kerosene

or solvent.

5. Dry fan thoroughly.

6. Replace fan on motor shaft. Place fan hub flush with

end of motor shaft. (Fig. 7)

7. Place setscrew on flat of shaft. Tighten setscrew firmly

(40-50 inch-pounds / 4.5-5.6 n-m).

8. Replace fan guard and upper shell.

Models: AC-115 / 165

(Fig. 5)

(Fig. 6)

Operator’s Manual 19

(Fig. 7)

Page 20

Service

Air Intake Filter

Lint Filter

Filter End

Cover

Air Output Filter

Air Intake Filter

Filter

End

Cover

Lint Filter

Air Output Filter

Pressure

Gauge

Plug

Relief

Valve

Pressure

Gauge

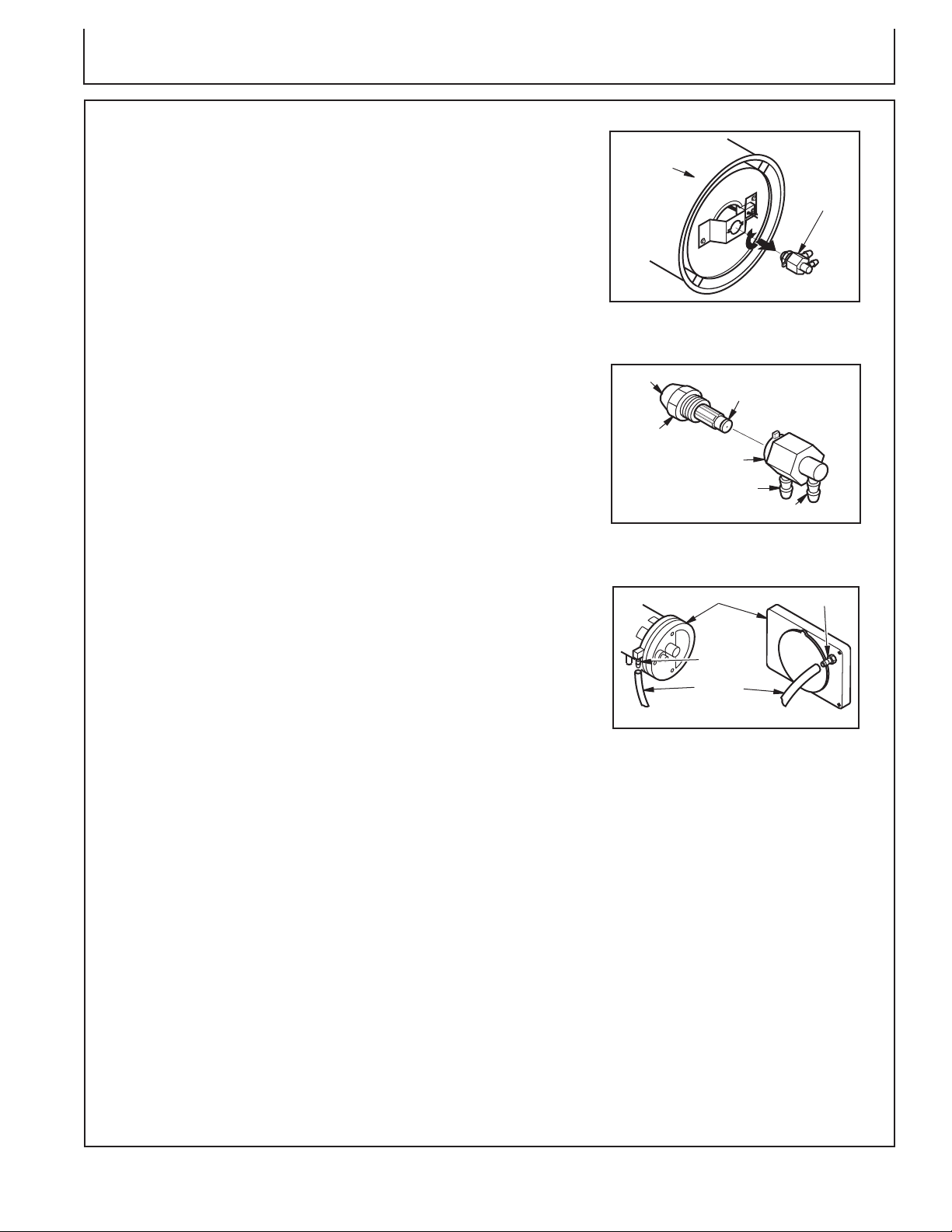

MAINTENANCE (CONTINUED):

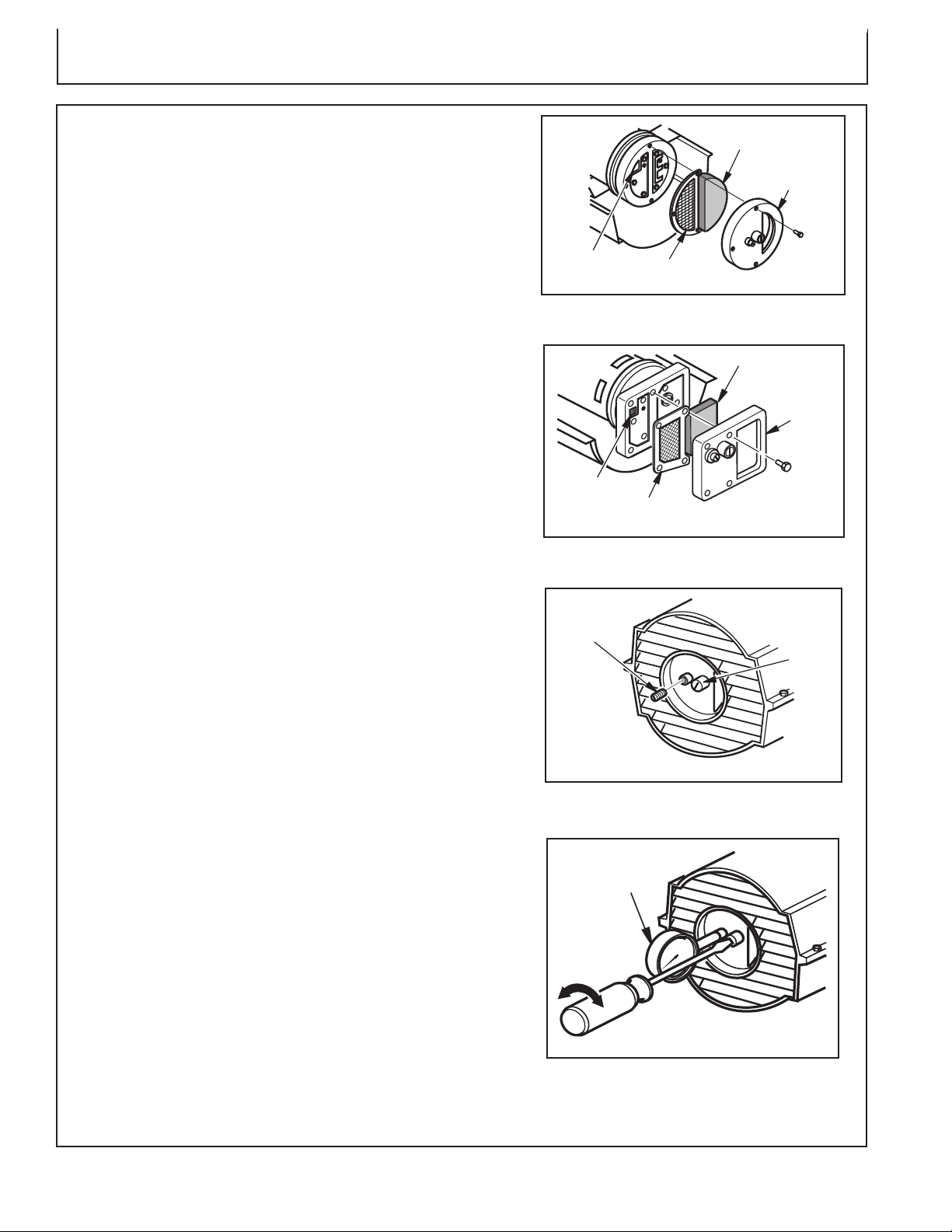

AIR OUTPUT, AIR INTAKE AND LINT FILTERS:

1. Remove upper shell. (Fig. 4 or 5)

2.

Remove filter end cover screws using 5/16" nut-driver.

(Fig. 8 or 9)

3. Remove filter end cover.

4. Replace air output and lint filters.

5. Wash or replace air intake filter (see "Preventative

Maintenance Schedule").

6. Replace filter end cover.

7. Replace fan guard and upper shell.

IMPORTANT: Do not oil filters.

PUMP PRESSURE ADJUSTMENT:

1. Remove pressure gauge plug from filter end cover

(Fig. 10).

2. Install a pressure gauge.

3. Start space heater (See "Operation"). Allow motor to

reach full speed.

4. Adjust pressure. Turn relief valve to right to increase

pressure. Turn relief valve to left to decrease pressure

(Fig. 11). See specifications below for correct pressure

for each model.

Model: Pump Pressure:

70 4.7 PSI

115 5.1 PSI

165 5.6 PSI

Model: AC-70

(Fig. 8)

Models: AC-115 / 165

(Fig. 9)

5. Remove pressure gauge. Replace pressure gauge plug

20 Operator’s Manual

in filter end cover.

Model: AC-70 Shown

(Fig. 10)

Model: AC-70 Shown

(Fig. 11)

Page 21

MAINTENANCE (CONTINUED):

Fuel Filter and

Bushing

Side Cover

Upper Fuel Line

Fuel Filter, Bushing,

and Lower Fuel Line

Upper Fuel Line

Side

Cover

FUEL FILTER:

1. Remove side cover screws using 5/16" nut-driver.

2. Remove side cover.

3. Pull upper fuel line off fuel filter neck (Fig. 12 or 13).

4. Carefully pry bushing, fuel filter, and lower fuel line

(AC-115/165 models only) out of fuel tank (Fig. 13).

5.

Wash fuel filter with clean fuel and replace in tank.

6. Attach upper fuel line to fuel filter neck.

7. Replace side cover.

Service

Model: AC-70

(Fig. 12)

Models: AC-115 / 165

(Fig. 13)

Operator’s Manual 21

Page 22

Service

Fuel Line Hose

Air Line

Hose

Nozzle/

Adapter

Assembly

Combustion

Chamber

Photocell

Bracket

Nozzle

Adapter

Bracket

Nozzle/

Adapter

Assembly

Combustion

Chamber

Air Line

Hose

Nozzle

Adapter

Bracket

Fuel

Line

Hose

Photocell

Bracket

Photocell

Bracket

Air Line

Hose

Fuel

Line

Hose

Combustion

Chamber

Photocell

Assembly

Ignitor

Nozzle

Adapter

Bracket

Ignition

Control

Assembly

Side Cover

Ignitor

Wire

Photocell

Bracket

Ignitor

Ignitor Screw/

Washer Assembly

Nozzle

Adapter

Bracket

Ignitor

Element

Combustion

Chamber

Nozzle Adapter

Bracket Opening

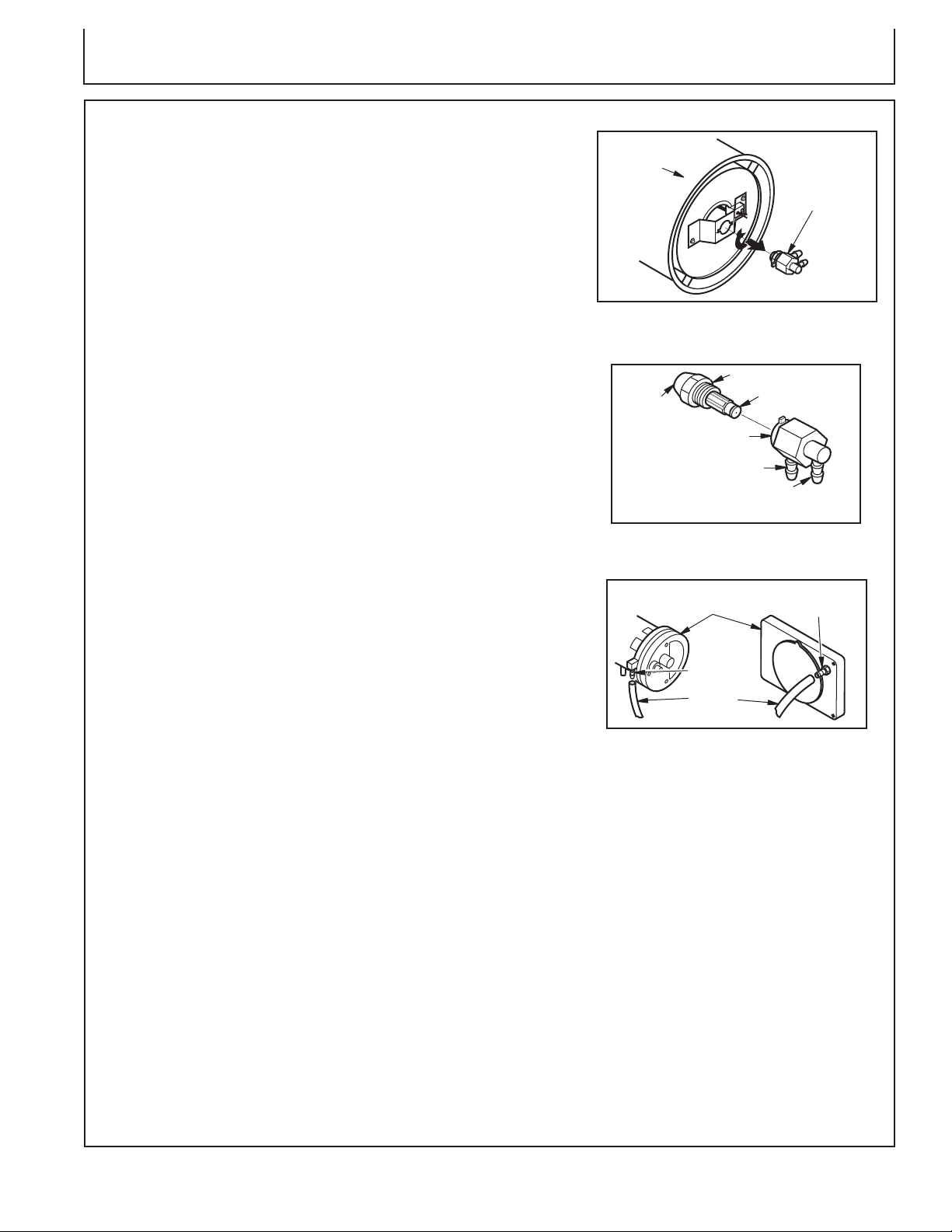

MAINTENANCE (CONTINUED):

IGNITOR:

1. Remove upper shell and fan guard (See "Maintenance:

Upper Shell Removal").

2. Remove fan.

3. Remove 4 side cover screws with a 5/16" nut driver.

Remove side cover (Fig. 12 or 13).

4. Disconnect ignitor wires from ignition control assembly

(Fig. 14). Pull the ignitor wires up through the hole in the

lower shell.

5. Disconnect fuel line hose and air line hose. Remove

photocell from photocell bracket (Fig. 14).

6. Remove combustion chamber. Stand combustion

chamber on end with nozzle adapter bracket on top (Fig.

15).

7. Remove ignitor screw with a 1/4" nut driver. Carefully

remove ignitor from nozzle adapter bracket.

CAUTION: DO NOT BEND OR STRIKE IGNITOR

ELEMENT. HANDLE WITH CARE.

(Fig. 14)

8. Carefully remove replacement ignitor from packing.

9. Carefully guide ignitor into opening in nozzle adapter

bracket. Do not strike ignitor element. Attach ignitor to

nozzle adapter bracket with screw using a 1/4" nut driver

(Fig. 16). Torque .90 to 1.69 N-m (8 to 15 in-lbs) Do not

over torque.

10. Replace combustion chamber.

11. Route the ignitor wires back down through the hole

in the lower shell. Connect wires to the ignition control

assembly (Fig. 15).

12. Replace side cover (Fig. 13 or 14).

13. Connect and route fuel line hose and air line hose

to nozzle adapter assembly. See "Maintenance: Fuel

and Air Line Replacement and Proper Routing".

14. Replace photocell in photocell bracket. Route wires

as shown in either Fig. 16 or Fig. 17.

15. Replace fan.

16. Replace fan guard and upper shell.

22 Operator’s Manual

(Fig. 15)

Model: AC-70

(Fig. 16)

Models: AC-115 / 165

(Fig. 17)

Page 23

Service

Nozzle/

Adapter

Assembly

Combustion

Chamber

Nozzle Face

Nozzle

Nozzle Sleeve

Nozzle Adapter

Air Line

Fitting

Fuel Line Fitting

Air Hose

Pump End Cover

Barb

Fitting

115/165 Models70 Models

Barb Fitting

MAINTENANCE (CONTINUED):

NOZZLE ASSEMBLY:

1. Remove upper shell (See "Maintenance: Upper Shell

Removal")

2. Remove fan (See "Maintenance: Fan").

3.

Remove fuel and air line hoses from nozzle assembly

(Fig. 16 or Fig. 17).

4. Turn nozzle assembly 1/4 turn to left and pull toward motor

to remove (Fig. 18).

5. Place plastic hex-body into vise and lightly tighten.

6. Carefully remove nozzle from the nozzle adapter using 5/8"

socket wrench (Fig. 19).

7. Blow compressed air through face of nozzle. This will free any

dirt in nozzle area.

8. Inspect nozzle sleeve for damage.

9. Replace nozzle into nozzle adapter until nozzle seats. Tighten

1/3 turn more using 5/8" socket wrench 4.5 to 5.1 N-m (40 to

45 in-lbs). See Fig. 19.

10. Attach nozzle assembly to burner strap (Fig. 18).

11. Attach fuel and airline hoses to nozzle assembly.

See "Maintenance: Fuel and Air Line Replacement

and Proper Routing".

12. Replace fan (See "Maintenance: Fan").

13. Replace fan guard and upper shell (See "Maintenance:

Upper Shell Removal").

(Fig. 18)

(Fig. 19)

FUEL AND AIR LINE REPLACEMENT AND PROPER

ROUTING:

1. Remove upper shell (See "Maintenance: Upper Shell

Removal").

(Fig. 20)

2. Remove side cover screws using 5/16" nut driver (Fig. 12

or 13).

3. Remove side cover.

4. Inspect fuel and air line hoses for cracks and/or holes. If fuel

line hose is damaged, disconnect from nozzle adapter (Fig.

16 or 17) and from fuel filter (See "Maintenance:Fuel Filter").

If air line hose is damaged, disconnect from nozzle adapter

(Fig. 16 or 17) and from barb fitting on pump end cover (Fig.

20).

5. Install new air and/or fuel line. Attach one end of air line hose

to barb fitting on pump end cover (Fig. 20) and the other end

to nozzle adapter (Fig. 16 or 17). Attach one end of fuel line

hose to fuel filter (see "Maintenance: Fuel Filter") and the

other end to nozzle adapter (Fig. 16 or 17).

Note: Route hoses as shown in see Fig. 16 or 17, according to

model. Hoses are not to touch photocell bracket.

6. Replace side cover.

7. Replace upper shell and fan guard (See "Maintenance: Upper

Shell Removal").

Operator’s Manual 23

Page 24

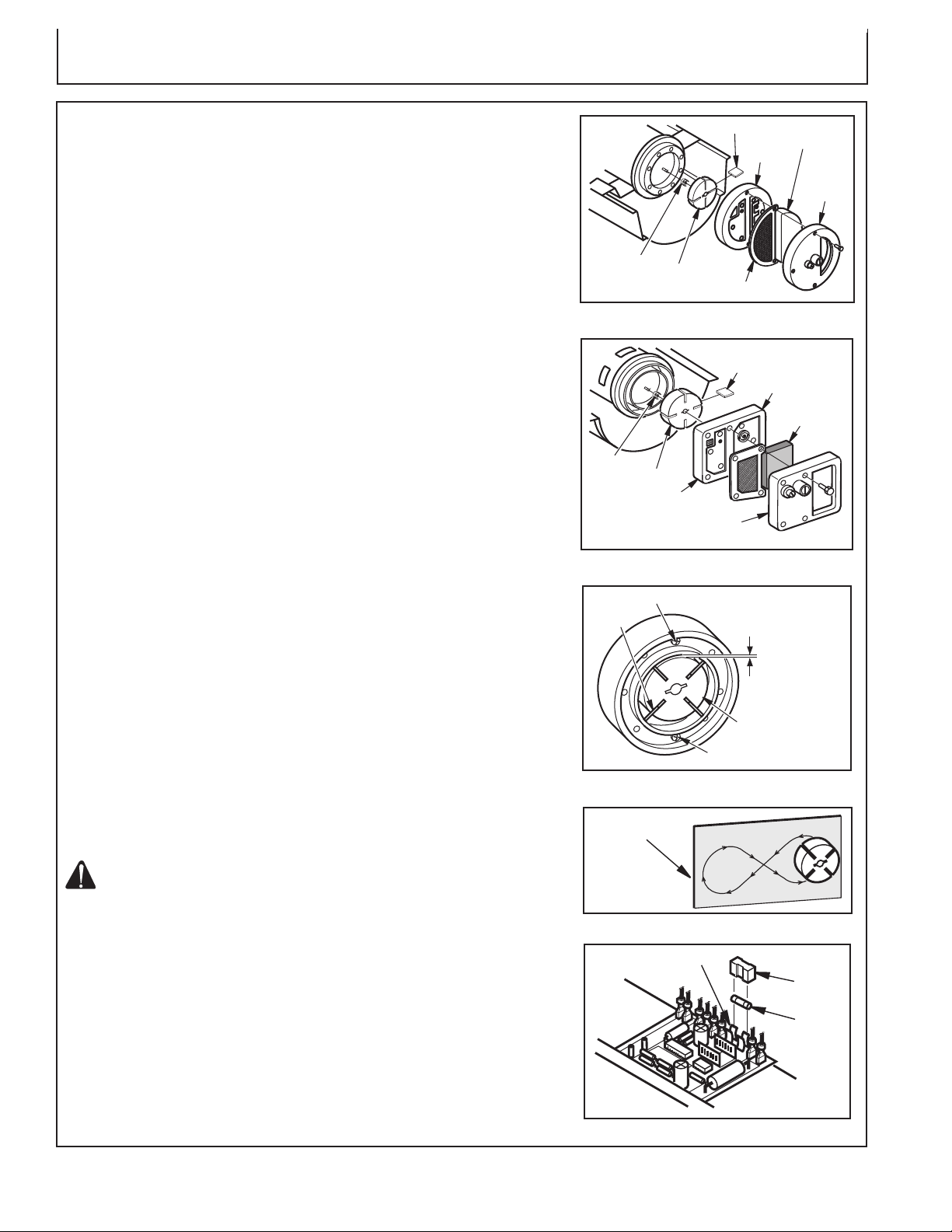

MAINTENANCE (CONTINUED):

Pump

Plate

Insert

Rotor

Blade

Filter

End

Cover

Air Intake

Filter

Air Output Filter

Insert

Blade

Rotor

Pump Plate

Air

Intake

Filter

Air Output Filter

Filter End Cover

Gap Adjusting Screw

Rotor

Blade

.003”/.004”

(.076-.101 mm)

Gap Measured

With Feeler

Gauge

Gap Adjusting Screw

Sandpaper

Fuse Clips

Fuse

Fuse

Cover

Service

PUMP ROTOR: (

1. Remove upper shell (See

Procedure if Rotor is Binding)

"Maintenance: Upper Shell

Removal").

2. Remove filter end cover screws using 5/16" nut driver

(Fig. 21 or 22).

3. Remove filter end cover and air filters.

4. Remove pump plate screws using 5/16" nut-driver.

5. Remove pump plate.

6. Remove rotor, insert, and blades (Fig. 21 or 22).

7. Check for debris in pump. If debris is found, blow out

with compressed air.

8. Install insert and rotor.

9. Check gap on rotor. Adjust to .076/.101 mm (.003”/.004”)

if needed (Fig. 23).

Note: Rotate rotor one full turn to ensure the gap is

.076/.101 mm (.003"/.004") at tightest position.

Adjust if needed.

10. Install blades, pump plate, air filters, and filter end

cover.

11. Replace fan guard and upper shell (see "Maintenance:

Upper Shell Removal").

12. Adjust pump pressure (see "Maintenance:Pump

Pressure Adjustment").

Model: AC-70

(Fig. 21)

Models: AC-115 / 165

(Fig. 22)

Note: If rotor is still binding, proceed as follows.

13. Perform steps 1 through 6.

14. Place fine grade sandpaper (600 grit) on flat surface.

Sand rotor lightly in a “figure 8” motion four times (Fig.

24).

15. Reinstall insert and rotor.

16. Perform steps 10 through 12.

IGNITION CONTROL ASSEMBLY:

WARNING: HIGH VOLTAGE!

1. Unplug space heater.

2. Remove side cover screws (4) using 5/16" nut-driver

to expose ignition control assembly.

3. Remove fuse cover (Fig. 25).

4.

Remove fuse from fuse clips (see Fig. 25).

5. Replace fuse with fuse of the same type and rating

(GMA-10). Do not substitute a fuse with a higher current

rating.

6. Replace fuse cover (Fig. 25).

7. Replace side cover.

24 Operator’s Manual

(Fig. 23)

(Fig. 24)

(Fig. 25)

Page 25

Storage

STORAGE

STORING, TRANSPORTING OR SHIPPING:

Note: If shipping, transport companies require fuel tanks

to be empty.

1. Drain fuel tank.

Note: Some models have drain plug on underside of fuel

tank. If so, remove drain plug to drain all fuel. If

space heater does not have drain plug, drain fuel

through fuel cap opening. Be sure all fuel is

removed.

2. Replace drain plug if provided.

3. If any debris is noted in old fuel, add 1 or 2 quarts

of clean kerosene to tank, stir, and drain again. This

will prevent excess debris from clogging filters during

future use.

4. Replace fuel cap or drain plug. Properly dispose of

old and dirty fuel. Check with local automotive service

stations that recycle oil.

5.

If storing, store space heater in dry place. Make sure

storage place is free of dust and corrosive fumes.

IMPORTANT: Do not store kerosene over summer

months for use during next heating season. Using old

fuel could damage space heater.

Operator’s Manual 25

Page 26

Specifications

ITEM SPECIFICATION

Model Size 70 115 165

Output Rating (BTU / Hr) 70,000 115,000 165,000

Fuel Use only kerosene, #1/#2 diesel / fuel oil, JET A

or JP-8 fuels*

Fuel Tank Capacity

(U.S. Gal. / Liters) 5 / 18.9 9 / 34 13.5 / 51

Fuel Consumption

(Gal. Per Hr / Liters Per Hr) .52 / 1.97 .85 / 3.00 1.2 / 4.54

Pump Pressure (psi) 4.7 5.1 5.6

Electric Requirements 120V / 60 HZ 120V / 60 HZ 120V / 60 HZ

Amperage (Normal Run) 2.8 3.6 3.6

Motor RPM 3440 3400 3400

Hot Air Output (CFM) 360 490 575

Motor HP 1/8 1/5 1/5

Shipping Weight

(Approximate Pounds /

Kilograms) 36 / 16.3 56 / 25.4 71 / 32.2

Space heater Weight without Fuel

(Approximate Pounds /

Kilograms) 32 / 14.5 48 / 21.8 61 / 27.7

* Use of #2 diesel & fuel oil will result in noticeable odor and could require additional fuel filter maintenance. Use in

extreme cold temperatures may require nontoxic anti-icer additives.

RECORD SERIAL NUMBER

Write you model number, machine serial number and

date of purchase in the spaces provided below. Your

dealer needs this information when ordering parts.

Model No. ______________________________________________

Machine Serial No. _______________________________________

Date of Purchase ________________________________________

(To be filled in by purchaser)

26 Operator’s Manual

Page 27

STATEMENT OF WARRANTY

John Deere warrants all parts, (except those referred to below), of your new space heater

to be free from defects in materials and workmanship during the following periods:

For Two (2) Years from the date of original purchase.

Defective parts not subject to normal wear and tear will be repaired or replaced at

our option during the warranty period. In any event, reimbursement is limited to the

purchase price paid.

EXCLUSIONS

1. This warranty does not cover parts damaged due to normal wear, misapplication,

misuse, operation at other than recommended. Failure to follow recommended

operating and maintenance procedures also voids warranty.

2. The use of other than genuine manufacturer repair parts will void warranty.

3. Warranty will be void if used in any application other than consumer / homeowner.

Parts returned, prepaid to our factory or to an Authorized John Deere Service Center

will be inspected and replaced free of charge if found to be defective and subject

to warranty. There are no warranties which extend beyond the description of the

face hereof. Under no circumstances shall the manufacturer bear any responsibility

for loss of use of the unit, loss of time or rental, inconvenience, commercial loss or

consequential damages.

For Service or Warranty Consideration, contact

Mi-T-M

®

Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

Operator’s Manual 27

Page 28

Notes

28 Operator’s Manual

Page 29

Notes

Operator’s Manual 29

Page 30

Introduction

MERCI de la confiance témoignée par l’achat d’un

produit John Deere.

LIRE CE MANUEL ATTENTIVEMENT AFIN de pouvoir

utiliser et entretenir correctement votre appareil, sinon

des dommages corporels ou matériels pourraient en

résulter. Ce manuel et les symboles de sécurité sur votre

appareil peuvent également être disponible en d’autres

langues. (Voir votre concessionnaire John Deere pour

les commander.)

CE MANUEL DOIT ÊTRE CONSIDÉRÉ comme faisant

partie intégrante de votre appareil et doit l’accompagner

en cas de revente.

LES MESURES dans ce manuel sont indiquées à la fois

dans leurs équivalents métriques et en unités usuelles

des USA. Utiliser seulement les pièces de rechange

et les éléments de fixation corrects. Les éléments de

fixation métriques et en pouces peuvent nécessiter des

clés spécifiques à leurs système d’unités.

LES CÔTÉS DROITS ET GAUCHES de l’appareil

sont déterminés en faisant face au côté moteur de

l’appareil.

Le NUMÉRO DE SÉRIE de l’appareil se situe dans la

section Caractéristiques ou Numéros d’Identification.

Noter correctement tous les numéros afin de faciliter les

recherches en cas de vol. Les communiquer également

au concessionnaire lors de toute commande de pièces.

Ranger les numéros d’identification dans un endroit sûr

et séparé de l’appareil.

LA GARANTIE fait partie du programme de soutien John

Deere destiné aux clients qui utilisent et entretiennent

leur équipement tel qu’il est décrit dans ce manuel. Les

conditions de garantie dont bénéficie cet appareil figurent

sur le certificat de garantie dans ce manuel.

Cette garantie vous fournit l’assurance que votre

concessionnaire fournira du support pour les produits

où des défauts apparaîtraient au cours de la période

de garantie. Toute utilisation abusive de l’équipement

ou modification visant à dépasser les performances

spécifiées par le constructeur annuleront la garantie.

30 Operator’s Manual

Page 31

Table des matières

Page

Sécurité ................................................................... 32

Commandes .............................................................38

Assemblage ............................................................. 39

Préparation .............................................................. 40

Fonctionnement ...................................................... 42

Dépannage ............................................................... 44

Entretien .................................................................46

Remisage ................................................................ 53

Caractéristiques ..................................................... 54

Garantie ...................................................................55

Note .......................................................................... 56

Toutes les informations, illustrations et caractéristiques contenues

dans la présente publication sont à jour au moment de la publication,

le constructeur se réservant le droit d’apporter sans notification toute

modification jugée appropriée.

Operator’s Manual 31

Page 32

W

A

R

N

I

N

G

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

C

A

U

T

I

O

N

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

Sécurité

RECONNAITRE LES SYMBOLES DE SÉCURITÉ

Voici le symbole d’alerte de sécurité. Lorsqu’il apparaît

sur votre appareil ou dans ce manuel, rester conscient du

risque potentiel de blessures.

Respecter tous les conseils de sécurité ainsi que les

consignes générales de prevention des accidents.

COMPRENDRE LES MOTS D’ALERTE

Un mot d’alerte—DANGER, AVERTISSEMENT ou

ATTENTION—est utilisé avec le symbole d’alerte de

sécurité. Le terme DANGER identifie les dangers les

plus graves.

Les signes de sécurité avec DANGER ou AVERTISSEMENT

se trouvent près des dangers spécifiques. Les signes de

sécurité avec ATTENTION se réfèrent à des précautions

d’ordre général. Le terme ATTENTION demande aussi

de prêter attention aux messages de sécurité dans ce

manuel.

RESPECTER LES CONSEILS DE SÉCURITÉ

Lire attentivement tous les conseils de sécurité contenus

dans ce manuel et ceux apposés sur l’appareil. Veiller à ce

que les signes de sécurité soient lisibles. Remplacer ceux

qui manqueraient ou seraient endommagés. S’assurer

que les nouveaux composants ou pièces de rechange

incluent les signes de sécurité courants. Des signes de

rechange sont disponibles chez votre concessionnaire

John Deere.

Lisez attentivement et entièrement ce manuel d’utilisation

avant de tenter d’assembler, de faire fonctionner ou de

réparer ce radiateur. Une mauvaise utilisation de cet

appareil de chauffage peut causer de graves blessures,

voire la mort, suite à des brûlures, un incendie, une

explosion, une décharge électrique ou un empoisonnement

au monoxyde de carbone.

Lisez et comprenez tous les avertissements. Conservez

ce manuel pour consultation future. Il vous permettra de

faire fonctionner cet appareil de chauffage correctement

et en toute sécurité.

Si vous ne comprenez pas toute partie de ce manuel

et avez besoin d’assistance, prenez contact avec votre

concessionnaire John Deere.

32 Operator’s Manual

Page 33

OXYDE DE CARBONE – GAZ TOXIQUE

DA NGE R:

CARBONE PEUT ÊTRE MORTEL

L’ EMP OIS ONN EME NT AU MO NOX YDE D E

!

Le gaz d’échappement du carburant contient de l’oxyde de carbone

– un gaz toxique qui peut vous tuer. Vous NE POUVEZ PAS sentir

ou voir ce gaz.

Ne jamais se servir d’un carburant dans des espaces fermés ou partiellement

fermés sans ventilation appropriée. Ne l’utilisez que dans des endroits bien

aérés. Avant d’utiliser l’appareil de chauffage, aménagez une ouverture

d’air frais provenant de l’extérieur d’au moins 0,28 m² (3 pi²) pour chaque

30 kW (100 000 BTU/h) de puissance. Les groupes électrogènes peuvent

produire de hauts niveaux d’oxyde de carbone très rapidement. Pendant

l’utilisation d’un carburant, se rappeler que vous ne pouvez pas sentir ou voir

l’oxyde de carbone. Même si vous ne sentez pas les gaz d’échappement,

vous pouvez tout de même être exposé à l’oxyde de carbone.

Si vous commencez à vous sentir malade, étourdi, ou faible pendant

l’utilisation d’un carburant, sortez au grand air immédiatement. NE PAS

ATTENDRE. L’oxyde de carbone provenant des groupes électrogènes peut

rapidement être la cause d’une incapacité complète ou de mort.

En cas des symptômes sérieux, trouver de l’aide médicale immédiatement.

Informer le personnel médical qu’une intoxication à l’oxyde de carbone est

possible. Si vos symptômes sont apparus à l’intérieur, ne pas retourner

dans le bâtiment avant que les sapeurs pompiers s’assurent que le bâtiment

est sans danger.

NE JAMAIS utiliser le carburant dans une atmosphère explosible, près

de matériaux combustibles ou dans un endroit où la ventilation n’est pas

suffisante pour évacuer les gaz d’échappement. Les gaz d’échappement

peuvent être la cause de blessures graves ou de mort.

NE JAMAIS se servir d’un carburant à l’intérieur, que ce soit dans des

maisons, garages, sous-sols, vides de comble ou vides sanitaire, et autres

espaces fermés ou partiellement fermés, sans ventilation appropriée. Le fait

d’ouvrir des fenêtres et des portes ou d’utiliser des ventilateurs n’empêchera

pas l’accumulation d’oxyde de carbone dans la maison. Ne l’utilisez que

dans des endroits bien aérés. Avant d’utiliser l’appareil de chauffage,

aménagez une ouverture d’air frais provenant de l’extérieur d’au moins

0,28 m² (3 pi²) pour chaque 30 kW (100 000 BTU/h) de puissance.

Les premiers symptômes d’un empoisonnement au monoxyde de carbone

ressemblent à la grippe avec des maux de tête, des vertiges ou de la nausée.

Si vous avez ces symptômes, il se pourrait que l’appareil de chauffage ne

fonctionne pas bien. Respirez tout de suite de l’air frais ! Faites réparer le

radiateur. Certaines personnes sont plus affectées par le monoxyde de carbone

que d’autres. Celles-ci comprennent les femmes enceintes, les personnes

souffrant de maladies cardiaques ou pulmonaires ou d’anémie, celles qui sont

en état d’ébriété et celles qui vivent à haute altitude.

Installer des alarmes d’oxyde de carbone à piles ou des alarmes d’oxyde

de carbone avec batterie de secours qui se branche dans votre maison,

selon les instructions d’installation du fabricant. Les alarmes d’oxyde de

carbone doivent être conforme aux exigences des dernières normes de

sécurité pour les alarmes d’oxyde de carbone. (UL 2034, IAS 6-96, ou

CSA 6.19.01).

Tester votre alarme d’oxyde de carbone fréquemment et remplacer les

piles à plat.

Operator’s Manual 33

Page 34

CONSIGNES DE SÉCURITÉ LORS DU RAVITAILLEMENT EN

CARBURANT

Utilisez seulement du kérosène, du diesel ou mazout nº 1 et nº 2 et

des combustibles JET A ou JP-8 afin d’éviter tout risque d’incendie ou

d’explosion. N’utilisez jamais d’essence, de naphte, de diluant pour

peinture, d’alcool ou autre combustible hautement inflammable.

Le personnel responsable de l’alimentation en carburant doit être

qualifié et complètement familier avec les instructions du fabricant et

avec les règlements en vigueur concernant l’alimentation en carburant

des appareils de chauffage.

Il faut utiliser seulement le type de carburant indiqué sur la plaque

signalétique de l’appareil de chauffage.

Avant de procéder à l’alimentation en carburant, il faut éteindre toute

flamme, y compris la veilleuse, le cas échéant, et permettre à l’appareil

de chauffage de se refroidir.

Pendant l’alimentation, il faut inspecter toutes les canalisations de

carburant et leurs connexions pour vérifier s’il y a des fuites. Toute

fuite doit être réparée avant de remettre en marche l’appareil de

chauffage.

Il ne faut jamais entreposer à l’intérieur du bâtiment une quantité de

carburant supérieure à celle nécessaire pour une journée près de

l’appareil de chauffage. Les réserves de carburant doivent demeurer

à l’extérieur du bâtiment.

Tout stockage de combustible doit être situé à plus de 7,62 m (25 pi) des

appareils de chauffage, des chalumeaux, des appareils de soudage et

autres sources d’allumage similaires (sauf le réservoir de carburant intégré

à l’appareil de chauffage).

Dans la mesure du possible, l’entreposage du carburant doit se limiter aux

endroits où le plancher ne permettra pas au carburant de se répandre ou

d’être allumé par une flamme à un niveau inférieur.

L’entreposage du carburant doit se conformer aux règlements en

vigueur.

Respecter tous les réglements de sécurité concernant la

manipulation sans danger de carburant. Manier le carburant dans

des récipients de sécurité. Si le récipient n’a pas de bec, se servir

d’un entonnoir.

Ne pas trop remplir le réservoir de carburant, laisser toujours de la place

pour que le carburant se dilate.

Ne jamais remplir le réservoir de carburant lorsque le moteur tourne.

Arrêter le carburant et lui permettre de refroidir avant de le ravitailler

en carburant. L’essence renversée sur les parties chaudes du

moteur pourrait s’enflammer.

Ne remplir le réservoir de carburant que sur une surface nue. Lors

du ravitaillement en carburant, écarter le réservoir de toute source de

chaleur, d’étincelles ou de flammes nues.

Remplir toujours le réservoir de carburant dans un endroit avec une

bonne ventilation pour éviter d’inhaler des vapeurs dangereuses.

N’entreposer JAMAIS le carburant de votre carburant dans la maison.

L’essence, le propane, le kérosène, et autres liquides inflammables

doivent être entreposés en dehors des espaces habités dans des

récipients de sécurité (pas en verre) clairement étiquetés. Ne pas

les entreposer près d’un appareil alimenté en combustible, tel qu’un

chauffe-eau au gaz naturel dans un garage. Si du carburant est

renversé ou si le récipient n’est pas fermé correctement, des vapeurs

invisibles provenant du carburant peuvent voyager le long du sol et

peuvent être enflammées par la veilleuse de l’appareil ou par des arcs

des interrupteurs électriques dans l’appareil.

34 Operator’s Manual

Page 35

RISQUES ÉLECTRIQUES

DANGER - Un branchement incorrect du con-

ducteur de mise à la terre de l’équipement

peut entraîner des risques d’électrocution.

Vérifier avec un dépanneur ou un électricien

qualifié en cas de doutes concernant la mise

à la terre.

N’utilisez que la tension et la fréquence électrique indiquées sur

la plaque signalétique.

L’appareil de chauffage doit être mis à la terre. N’utilisez qu’une

rallonge électrique trifilaire avec mise à la terre. Ne le branchez

que dans une prise avec mise à la terre. En cas de mauvais

fonctionnement ou de panne, la mise à la terre fournit un chemin

de moindre résistance au courant électrique, réduisant ainsi les

risques de choc électrique.

Le carburant est une source potentielle de choc électrique si il

n’est pas gardé au sec. Maintenir le carburant au sec et ne pas

l’utiliser par temps de pluie ou dans des conditions humides.

Pour protéger le carburant contre l’humidité, s’en servir sur une

surface séche et sous une structure ouverte tel qu’un auvent.

Ne jamais toucher le carburant avec les mains mouillées.

Vérifier que toute la rallonge est en bon état, sans entailles ou

déchirures et que la fiche a bien trois broches, et surtout une

lame de terre.

Operator’s Manual 35

Page 36

CONSEILS DE SÉCURITÉ IMPORTANTS

W

A

R

N

I

N

G

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

C

A

U

T

I

O

N

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

1. N’utilisez que dans des endroits libres de vapeur inflammable

et de poussière.

2. Distance minimale de tout matériau combustible : 2,44 m

(8 pi) de toute sortie d’air brûlant, 1,22 m (4 pi) du dessus

et 1,22 m (4 pi) des côtés et de l’admission d’air.

3. Placez l’appareil de chauffage sur une surface stable et de

niveau lorsqu’il est chaud ou lorsqu’il est en marche, pour

éviter tout risque d’incendie.

4. Ne l’utilisez que dans des endroits bien aérés. Avant

d’utiliser l’appareil de chauffage, aménagez une ouverture

d’air frais provenant de l’extérieur d’au moins 0,28 m² (3 pi²)

pour chaque 30 kW (100 000 BTU/h) de puissance.

5. Gardez les enfants et les animaux éloignés de l’appareil de

chauffage en tout temps.

6. Ne mettez jamais l’appareil de chauffage en marche lorsque

la chambre de combustion est chaude ou si du carburant

s’y est accumulé.

7. Lorsque utilisé avec un thermostat, l’appareil de chauffage

peut démarrer en tout temps.

8. Lorsque l’appareil est déplacé ou entreposé, il doit demeurer

de niveau avec le sol pour éviter des fuites de carburant.

9. Utilisez l’appareil de chauffage en respectant les règlements

et les normes locales.

10. N’utilisez jamais d’essence, de vidange de bloc-cylindre,

de naphte, de diluant de peinture, d’alcool ou autre

combustible hautement inflammable.

11. N’utilisez jamais l’appareil de chauffage en présence

d’essence, de solvant à peinture ou d’autre vapeur

hautement inflammable.

12. N’utilisez jamais l’appareil de chauffage dans une chambre

à coucher ou un salon.

13. Ne laissez jamais un appareil de chauffage branché sans

supervision lorsque des enfants ou des animaux pourraient

être présents.

14. Il ne faut jamais déplacer, manipuler, remplir ou réparer

un appareil de chauffage chaud, en marche ou

branché.

15.

N’installez jamais de système de conduits d’air à l’avant ou

à l’arrière de l’appareil de chauffage.

16. N’attachez jamais l’appareil de chauffage à un réservoir

de carburant externe.

17. Les appareils de chauffage à proximité de bâches, de toiles

et d’autres matériaux semblables doivent être maintenus

à une bonne distance de ces derniers. La distance

minimale de sécurité recommandée est de 3,05 m (10 pi).

De plus, il est conseillé d’utiliser des bâches de protection

ignifuges. Ces matériaux doivent être solidement attachés

pour les empêcher de s’enflammer ou de nuire à l’appareil

de chauffage sous l’action du vent.

18.

Débranchez l’appareil lorsqu’il n’est pas utilisé.

19.

Ne bloquez jamais la prise d’air (à l’arrière) ou la sortie d’air

(en avant) de l’appareil de chauffage.

CONSERVER CES INSTRUCTIONS

36 Operator’s Manual

Page 37

PORTER DES VÊTEMENTS DE PROTECTION

Porter des vêtements ajustés et un équipement de sécurité

adapté au travail.

Porter un dispositif protecteur d’audition approprié tel que

des couvre-oreilles ou des bouche-oreilles pour se protéger

contre des bruits forts réprehensibles ou inconfortables.

La pleine attention de l’opérateur est requise afin d’utiliser

l’équipement en toute sécurité. Ne pas porter des écouteurs

de radio ou de musique tout en actionnant la machine.

PRÉPARATION POUR LES URGENCES

Garder une trousse des premiers secours et un extincteur

à portée de la main.

Garder les numéros d’urgence des docteurs, du service

d’ambulance, de l’hôpital et des pompiers en cas d’urgence

près du téléphone.

Etre prêt si un incendie débute.

INSPECTER LE DE L'APPAREIL DE CHAUFFAGE

S’assurer que tous les couvercles, gardes et plaques de

protection sont serrés et bien en place.

Repérer toutes les commandes et les étiquettes de

sécurité.

Inspecter le cordon de secteur pour déceler tout dommage

avant utilisation. Il y a un risque de choc électrique en

cas d’écrasement, de coupures ou de lésions dûes à la

chaleur.

FAIRE L’ENTRETIEN DU DE L'APPAREIL DE CHAUFFAGE

EN TOUTE SÉCURITÉ

Avant d’entretenir le de l'appareil de chauffage, débrancher

tout l’équipement et la batterie (s’il en est équipé) et permettre

à l’appareil de refroidir.

Faire l’entretien du de l'appareil de chauffage dans un endroit

propre, sec et plat.

Operator’s Manual 37

Page 38

COMMANDES

A

B

C

D

E

F

G

H

I

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

Commandes

AC-70

AC-165

A -- Sortie d'air chaud

B -- Bouton du

thermostat

C -- Grille de protection

du ventilateur

D -- Interrupteur de marche/arrêt

avec voyant

E -- Assemblage de la commande

d'allumage (monté à l'arrière

du panneau latéral)

F -- Panneau latéral

AC-115

G -- Bouchon et jauge de

carburant

H -- Réservoir de carburant

I -- Couvercle des filtres à air

38 Operator’s Manual

Page 39

ASSEMBLAGE

Armature

de montage

des roues

Rebord du

réservoir de

carburant

Écrou

borgne

Écrou

Roue

Essieu

Moyeu

étendu

Entrée

d’air

Poignée

Sortie

d’air

chaud

Vis

Entretoise de

roue (si fournie)

Enrouleur de

cordon avec

boulons et écrous

Assemblage

NOTA:

Pour les modèles 115 et 165 uniquement.

Ces modèles sont équipés de roues et d’une poignée.

Certains modèles sont équipés d’une seconde poignée.

Les roues, la ou les poignées, et les pièces de montage se

trouvent dans le carton d’expédition.

Outils nécessaires:

• Tournevis cruciforme moyen

• Clé à molette ou ouverte de 3/8 po

• Marteau

1.

Faites glisser l’essieu par l’armature de montage des

roues. Si des entretoises sont fournies, installez-les.

Installez les roues sur l’essieu.

IMPORTANT : En installant les roues, pointez le moyeu

le plus long des roues vers l’armature de montage des

roues (voir figure 1).

2. Placez des écrous borgnes aux extrémités de l’essieu.

Tapez doucement avec un marteau pour les fixer en

place.

3. Déposez l’appareil de chauffage sur l’armature de

montage des roues. Alignez les trous qui se trouvent

sur le rebord du réservoir de carburant avec ceux qui

se trouvent sur l’armature de montage des roues.

4.

Placez la ou les poignées sur le rebord du réservoir de

carburant. Insérez les vis à travers la ou les poignées, le

rebord du réservoir de carburant et l’armature de montage

des roues. Une fois la vis insérée, vissez l’écrou avec vos

doigts.

5. Quand toutes les vis sont insérées, serrez les écrous

fermemen

(Fig. 1)

Operator’s Manual 39

Page 40

Préparation

VENTILATION

AVERTISSEMENT : PRÉVOIR UNE OUVERTURE D’AIR

FRAIS D’AU MOINS 0,28 M² (3 PI²) POUR CHAQUE

100 000 BTU/H DE PUISSANCE. FOURNIR DAVANTAGE

D’AIR FRAIS SI PLUS D’UN APPAREIL DE CHAUFFAGE

EST UTILISÉ. IL FAUT RESPECTER LES EXIGENCES

MINIMALES DE VENTILATION POUR ÉVITER LES

RISQUES ASSOCIÉS À L’EMPOISONNEMENT AU

M ONO X YDE DE CA R BON E . V ÉRI F IER QUE

CES EXIGENCES SONT RESPECTÉES AVANT DE

M ET TR E L’AP PAREI L DE CH AU FFAGE EN

MARCHE.

Exemple : Un appareil de 58,6 kW (200 000 Btu/h) exige

l’une des ouvertures suivantes :

• une double porte de garage [ouverture de 4,88 m (16 pi)]

soulevée de 12,7 cm (5 po)

• une porte de garage simple [ouverture de 2,74 m (9 pi)]

soulevée de 20,3 cm (8 po)

• deux fenêtres de 76,2 cm (30 po) soulevées de 38,1 cm

(15 po)

CARBURANTS

AVERTISSEMENT : N’UTILISER QUE DU KÉROSÈNE, DU

DIESEL OU MAZOUT N° 1 OU N° 2, ET DES

COMBUSTIBLES JET A OU JP-8 AFIN D’ÉVITER TOUT

RISQUE D’INCENDIE OU D’EXPLOSION. N’UTILISEZ

JAMAIS D’ESSENCE, D’HUILE VIDANGÉE DE

BLOC-CYLINDRE, DE NAPHTE, DE DILUANTS POUR

PEINTURE, D’ALCOOL OU D’AUTRES CARBURANTS

HAUTEMENT INFLAMMABLES.

N’utilisez que du kérosène, du diesel ou mazout nº 1 ou nº 2

ou des combustibles JET A ou JP-8. Des combustibles plus

lourds, comme le mazout n° 2 ou le carburant diesel n° 2,

peuvent également être employés, mais il en résultera :

• la production d’une odeur perceptible

•

l’entretien supplémentaire du filtre à combustible

• le besoin d’utiliser des additifs antigivrants non toxiques

par temps très froid

N’utilisez pas de combustibles plus lourds que ceux de

calibre n° 2 ou d’huiles lourdes telles que celles provenant

de carters de moteurs. Ces huiles lourdes ne brûleront pas

bien et contamineront l’appareil de chauffage.

IMPORTANT : N’utilisez que des contenants POUR LE

KÉROSÈNE (bleu) ou POUR LE DIESEL (jaune) pour

entreposer le carburant. Assurez-vous que le contenant

d’entreposage est propre. La présence de matières

étrangères telles que la rouille, les saletés ou l’eau provoquera

une panne de l’assemblage de la commande d’allumage de

l’appareil de chauffage. La présence de matières étrangères

exigera aussi que le système de carburant de l’appareil de

chauffage soit nettoyé plus souvent.

40 Operator’s Manual

Page 41

Préparation

Sortie d’air

chauffé propre

Filtre à

carburant

Conduite d’air

vers le brûleur

Filtre de

sortie d’air

Pompe

à air

Filtre de

prise d’air

Entrée

d’air frais

Ventilateur

Chambre de combustion

Allumeur

Assemblage de la

commande de l’allumeur

Air pour le

système de

carburant

Air pour la

combustion et

le chauffage

Carburant

Buse

d’aération

Réservoir de

carburant

Moteur

THÉORIE DE FONCTIONNEMENT

Système d’alimentation en carburant : la pompe à air force l’air dans la canalisation. L’air est ensuite poussé à

travers la buse d’aération. Cet air fait en sorte que du carburant est aspiré du réservoir. Une fine brume de carburant

est vaporisée dans la chambre de combustion.

Système d’admission d’air : le moteur fait tourner le ventilateur. Le ventilateur pousse l’air à l’intérieur et autour

de la chambre de combustion. L’air est chauffé et fournit un courant d’air propre et chaud.

Circuit d’allumage : l’assemblage de la commande d’allumage fournit le courant à l’allumeur. Cela allume le

mélange de carburant et d’air dans la chambre de combustion.

Système de contrôle de l’extinction de la flamme : ce système provoque l’arrêt de l’appareil de chauffage en

cas d’extinction de la flamme.

Operator’s Manual 41

Page 42

Fonctionnement

Interrupteur

de marche/

arrêt avec

voyant

Interrupteur

de marche/

arrêt avec

voyant

FONCTIONNEMENT

IMPORTANT : Lisez et comprenez les avertissements de

la rubrique Informations relatives à la sécurité. Ils sont

requis pour faire fonctionner cet appareil de chauffage sans

danger. Conformez-vous à tous les règlements et codes

locaux lorsque vous utilisez cet appareil de chauffage.

POUR DÉMARRER LE RADIATEUR:

1. Suivez toutes les consignes sur la ventilation et la

sécurité.

2. Placez l’appareil de chauffage de façon à fournir une

circulation maximale d’air chaud. Suivez toutes les

exigences d’emplacement précisées à la rubrique

Informations relatives à la sécurité.

3. Remplissez le réservoir de carburant avec du kérosène,

du diesel ou du mazout n °1 ou n °2 ou du carburant

d’aviation JET A ou JP-8.

4.

Replacez le bouchon du réservoir de carburant.

5. Sur les modèles à thermostat, tournez le bouton du

thermostat dans le sens des aiguilles d’une montre pour

le mettre au plus chaud.

6.

Branchez le câble d’alimentation de l’appareil de chauffage

dans une rallonge électrique trifilaire approuvée avec mise

à la terre. La rallonge électrique doit mesurer au moins

1,80 m (6 pi).

Exigences des dimensions de la rallonge électrique:

De 1,8 à 3 m de long (6 à 10 pi), utilisez un cordon de norme

américaine AGW 18 (0,75 mm

De 3,3 m à 30,5 m de long (11 à 100 pi), utilisez un câble

de norme américaine AWG 16 (1,0 mm

De 30,8 m à 61 m de long (101 à 200 pi), utilisez un câble

de norme américaine AWG 14 (1,5 mm

7.

Branchez la rallonge électrique dans une prise de courant

à trois branches ordinaire de 120 volt/60 hertz avec mise

à la terre. Appuyez sur l

le mettre en marche (|); l’appareil de chauffage devrait

se mettre en route dans les 5 secondes qui suivent. Si

l’appareil de chauffage ne s’allume pas, consultez la

rubrique Dépannage. (Fig. 2)

8.

Réglez le bouton du thermostat à la position de votre choix.

NOTE : Un appareil de chauffage froid peut affecter le réglage

du thermostat. Ce thermostat sert de commande générale

de la chaleur. Il n’est pas conçu pour un contrôle précis

de la température. Ajustez le thermostat jusqu’à ce que le

cycle de l’appareil de chauffage soit réglé selon vos

besoins.

2

)

2

)

2

)

’

interrupteur de marche/arrêt pour

Modèle: AC-70

Modèles: AC-115 / 165

(Fig. 2)

POUR ARRÊTER L’APPAREIL DE CHAUFFAGE:

Appuyez sur le commutateur marche/arrêt à la position

d’arrêt (O). Débranchez l’appareil lorsqu’il n’est pas

utilisé.

42 Operator’s Manual