Page 1

AC-100LP

SPACE HEATER

Page 2

Introduction

THANK YOU for purchasing a John Deere product.

READ THIS MANUAL carefully to learn how to operate

and service your machine correctly. Failure to do so

could result in personal injury or equipment damage.

This manual and safety signs on your machine may

also be available in other languages. (See your John

Deere dealer to order.)

THIS MANUAL SHOULD BE CONSIDERED a

permanent part of your machine and should remain

with the machine when you sell it.

MEASUREMENTS in this manual are given in both

metric and customary U.S. unit equivalents. Use only

correct replacement parts and fasteners. Metric and

inch fasteners may require a specific metric or inch

wrench.

GENERAL HAZARD WARNING:

FAILURE TO COMPLY WITH THE PRECAUTIONS

AND INSTRUCTIONS PROVIDED WITH THIS

HEATER, CAN RESULT IN DEATH, SERIOUS

BODILY INJU RY AND PROPERTY LOSS

OR DAMAGE FROM HAZARDS OF FIRE,

EXPOSITION, BURN, ASPHYXIATION, AND/OR

CARBON MONOXIDE POISONING.

ONLY PERSONS WHO CAN UNDERSTAND AND

FOLLOW THE INSTRUCTIONS SHOULD USE

OR SERVICE THIS HEATER.

IF YOU NEED ASSISTANCE OR HEATER

INFORMATION SUCH AS AN INSTRUCTIONS

MANUAL, LABELS, ETC. CONTACT THE

MANUFACTURER.

WARNING: FIRE, BURN, INHALATION

AND EXPLOSION HAZARD. KEEP SOLID

COM BUS T IBL E S, SUC H AS BUI LDIN G

MATERIALS, PAPER OR CARDBOARD, A

SAFE DISTANCE AWAY FROM THE HEATER

AS RECOMMENDED BY THE INSTRUCTIONS

NEVER USE THE HEATER IN SPACES WHICH

DO OR MAY CONTAIN VOLATILE OR AIRBORNE

COMBUSTIBLES OR PRODUCTS SUCH AS

GASOLINE, SOLVENTS, PAINT THINNER, DUST

PARTICLES OR UNKNOWN CHEMICALS.

The SERIAL NUMBER is located in the Specification

or Identification Numbers section. Accurately record

all the numbers to help in tracing the machine should

it be stolen. Your dealer also needs these numbers

when you order parts. File the identification numbers

in a secure place off the machine.

WARRANTY is provided from your John Deere

dealer for customers who operate and maintain their

equipment as described in this manual. The warranty

is explained on the warranty certificate shown in this

manual.

This warranty provides you the assurance that your

dealer will back products where defects appear

within the warranty period. Should the equipment

be abused, or modified to change its performance

beyond the original factory specifications, the warranty

will become void.

The heater is designed for use as a construction heater in

accordance with ANSI Z83.7/CGA 2.14. Other standards

govern the use of fuel gases and heating products for

specific uses. Your local authority can advise you about

these. The primary purpose of construction heaters is to

provide temporary heating of buildings under construction,

alteration or repair. Properly used, the heater provides

safe economical heating. Products of combustion are

vented into the area being heated.

We cannot foresee every use which may be made of our

heaters. Check with your local fire safety authority if

you have questions about heater use.

Other standards govern the use of fuel gases and

heat producing products for specific uses. Your local

authorities can advise you about these.

Propane gas is odorless. An odor-making agent is added

to propane gas. The odor helps you detect a propane

gas leak. However, the odor added to propane gas can

fade. Propane gas may be present even though no

odor exists.

Install and use heater with care. Follow all local

ordinances and codes. In the absence of local

ordinances and codes, refer to the Standard for Storage

and Handling of Liquefied Petroleum Gas, ANSI/NFPA

58 and the Propane Installation Code, CAN/CGA

B149.2. This instructs on the safe storage and handling

of propane gases.

WA RN I NG : NO T F OR H OME O R

RECREATIONAL VEHICLE USE.

2 Operator’s Manual

Page 3

Contents

Page

Safety ........................................................................ 4

Controls ................................................................... 9

Preparation ............................................................... 10

Installation ................................................................ 12

Operation ................................................................ 12

Troubleshooting

Service .................................................................... 16

Storage .................................................................... 19

Specifications ......................................................... 20

Wire Diagram ............................................................ 21

Warr

anty .................................................................. 22

Notes ......................................................................... 23

..................................................... 14

All information, illustrations and specifications in this manual are based on the latest

information available at the time of publication. The right is reserved to make changes at any

time without notice.

Operator’s Manual 3

Page 4

W

A

R

N

I

N

G

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

C

A

U

T

I

O

N

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

Safety

RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. When you see this

symbol on your machine or in this manual, be alert to

the potential for personal injury.

Follow recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS

A signal word--DANGER, WARNING or CAUTION--is

used with the safety-alert symbol. DANGER identifies

the most serious hazards.

DANGER or WARNING safety signs are located near

specific hazards. General precautions are listed on

CAUTION safety signs. CAUTION also calls attention

to safety messages in this manual.

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual and on

your machine safety signs. Keep safety signs in good

condition. Replace missing or damaged safety signs.

Be sure new equipment components and repair parts

include the current safety signs. Replacement safety

signs are available from your John Deere dealer.

Read this owner’s manual carefully and completely before

trying to assemble, operate, or service this space heater.

Improper use of this space heater can cause serious injury

or death from burns, fire, explosion, electrical shock, and

carbon monoxide poisoning.

Make certain you read and understand all warnings.

Keep this manual for reference. It is your guide to safe

and proper operation of this space heater.

If you do no understand any part of this manual and need

assistance, contact your John Deere dealer.

4 Operator’s Manual

Page 5

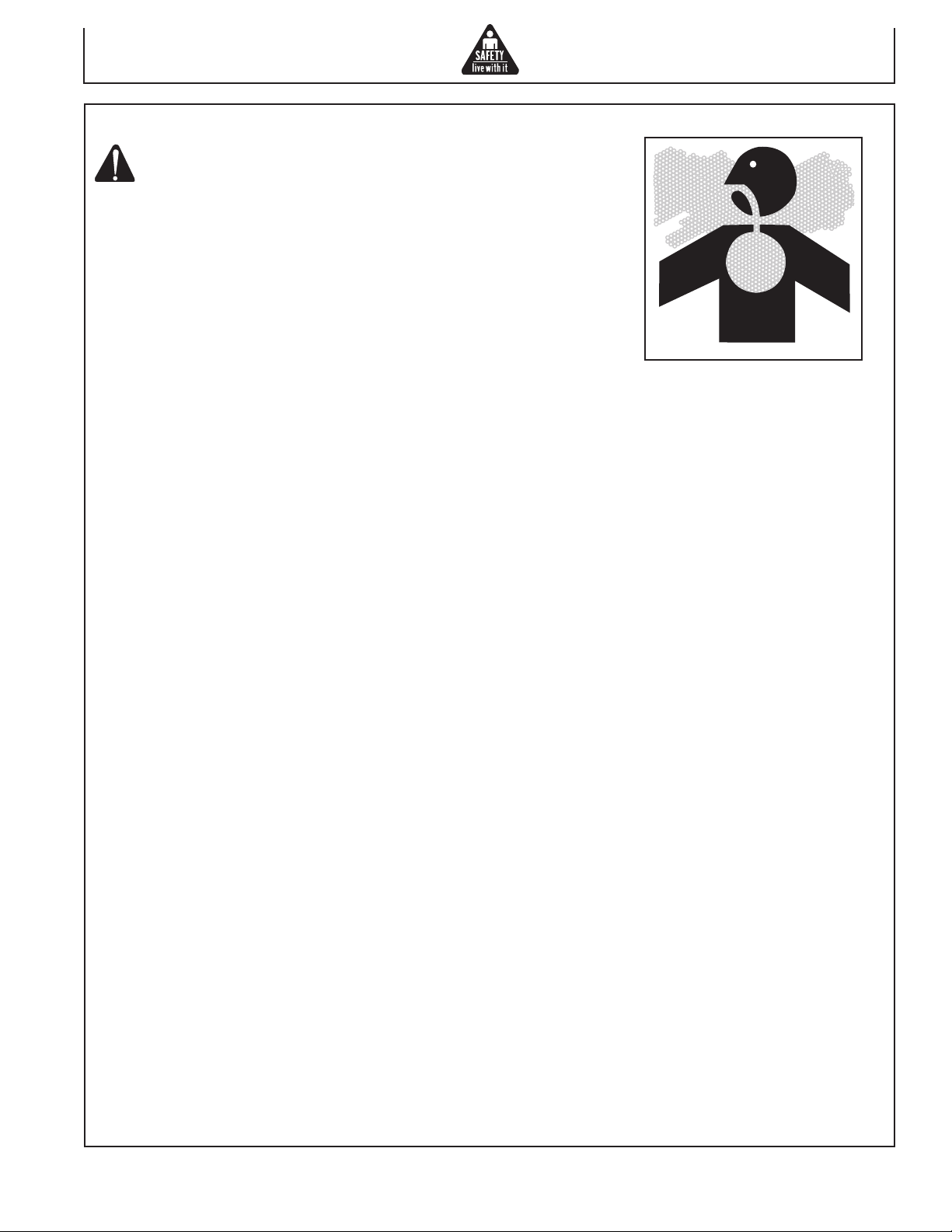

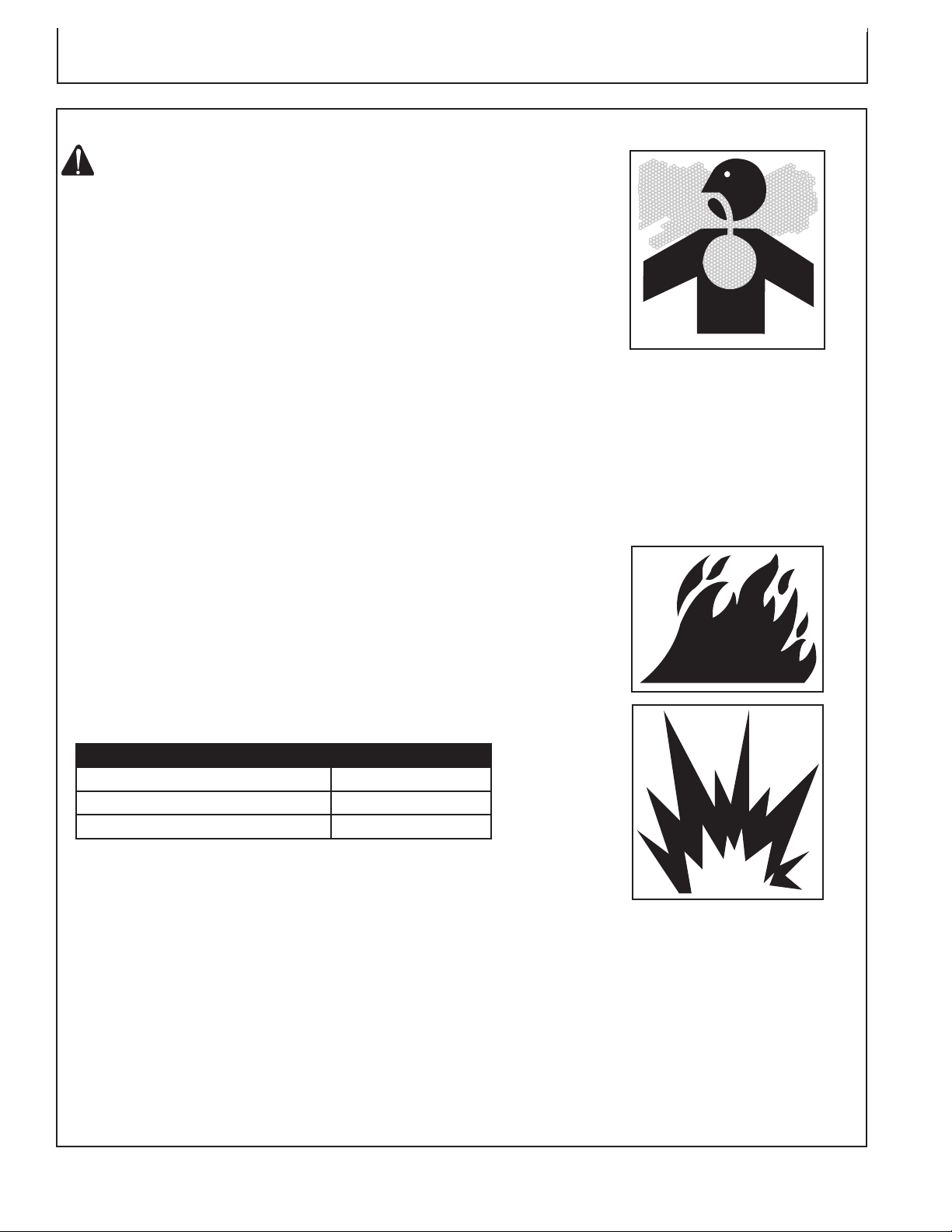

CARBON MONOXIDE - POISONOUS GAS

DANGER: CARBON MONOXIDE POISONING MAY LEAD TO

DEATH!

Space heaters exhaust contains carbon monoxide - a poisonous gas

that can kill you. You CAN NOT smell or see this gas.

Carbon Monoxide Poisoning: Early signs of carbon monoxide poisoning

resemble the flu, with headaches, dizziness, and/or nausea. If you have

these signs, the space heater may not be working properly. Get fresh air at

once! Have space heater serviced. Some people are more affected by carbon

monoxide than others. These include pregnant women, persons with heart

or lung disease or anemia, those under the influence of alcohol, and those

at high altitudes.

Never use a space heater in enclosed or partially-enclosed spaces without

proper ventilation. Use only in well-vented areas. Before using space heater,

provide at least a three-square-foot (2800 square cm) opening of fresh,

outside air for each 100,000 Btu / Hr (30 kw) of rating. Space heaters can

produce high levels of carbon mono

xide very quickly. When you use a space

heater, remember that you cannot smell or see carbon monoxide. Even if you

can’t smell exhaust fumes, you may still be exposed to carbon monoxide.

If you start to feel sick, dizzy, or weak while using a space heater, get to fresh

air RIGHT AWAY. DO NOT DELAY. The carbon monoxide from space heaters

can rapidly lead to full incapacitation and death.

If you experience serious symptoms, get medical attention immediately.

Inform medical staff

that carbon monoxide poisoning is suspected. If you

experienced symptoms while indoors, have someone call the fire department

to determine when it is safe to re-enter the building.

NEVER operate the space heater in an explosive atmosphere, near

combustible materials or where ventilation is not sufficient to carry away

exhaust fumes. Exhaust fumes can cause serious injury or death.

NEVER run space heaters inside homes, garages, sheds, or other semienclosed spaces without proper ventilation. These spaces can trap poisonous

gases EVEN IF you run a fan or open doors and windows. Use only in wellvented areas. Before using space heater, provide at least a three-square-foot

(2800 square cm) opening of fresh, outside air for each 100,000 Btu / Hr (30

kw) of rating.

If you start to feel sick, dizzy, or weak while using the space heater, shut

if off and get fresh air RIGHT AWAY. See a doctor. You may have carbon

monoxide poisoning.

Install battery-operated carbon monoxide alarms or plug-in carbon monoxide

alarms with battery back-up in your home, according to the manufacturer’s

installation instructions. The carbon monoxide alarms should be certified to

the requirements of the la

(UL 2034, IAS 6-96, or CSA 6.19.01).

test safety standards for carbon monoxide alarms.

Test your carbon monoxide alarm frequently and replace dead batteries.

Operator’s Manual 5

Page 6

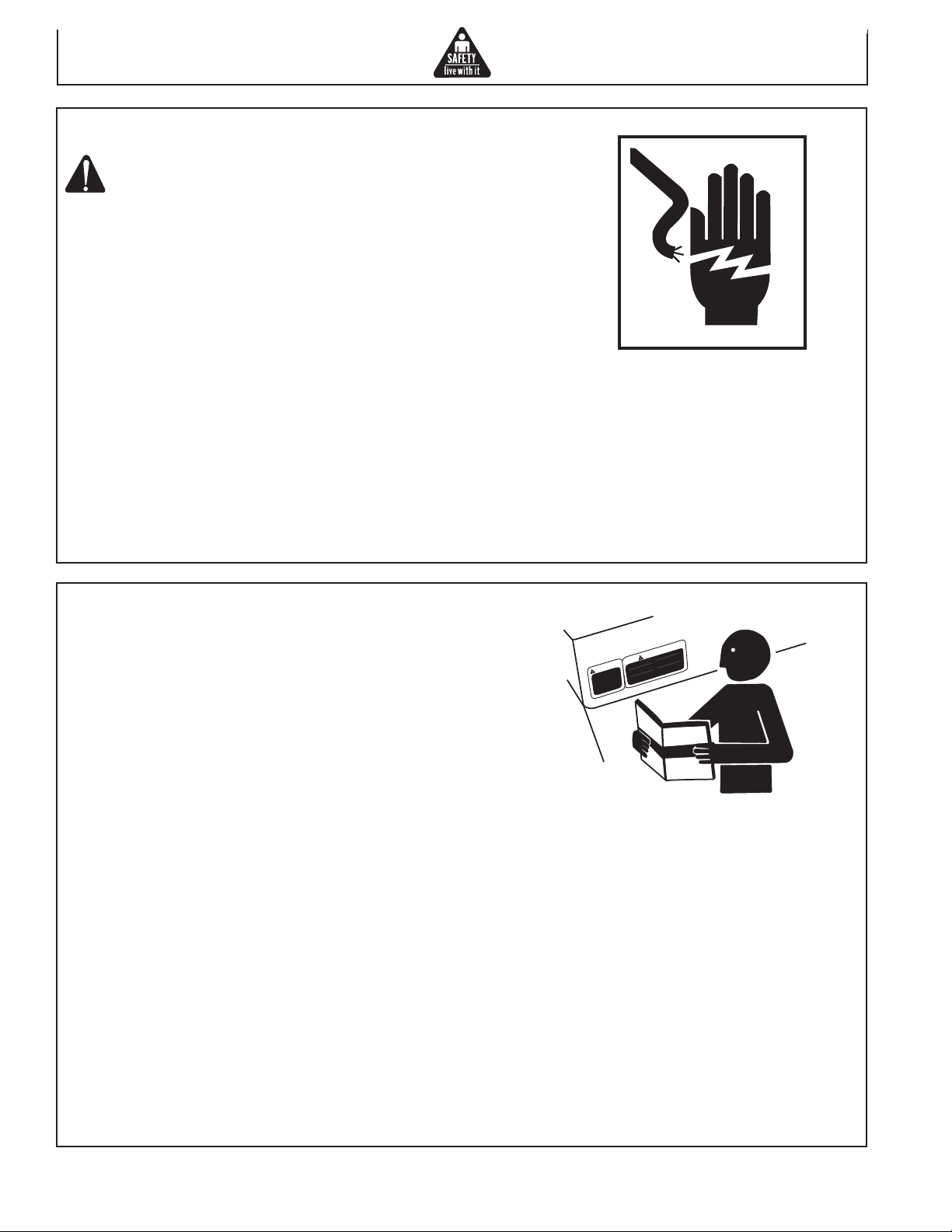

ELECTRICAL HAZARDS

W

A

R

N

I

N

G

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

C

A

U

T

I

O

N

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

DANGER- IMPROPER CONNECTION OF THE EQUIPMENT GROUNDING CONDUCTOR CAN RESULT IN A RISK OF

ELECTROCUTION. CHECK WITH A QUALIFIED

ELECTRICIAN OR SERVICE PERSON IF YOU ARE IN

DOUBT AS TO WHETHER THE UNIT IS PROPERLY

GROUNDED.

Use only the electrical voltage and frequency specified on model

plate. The electrical connections and grounding of the heater shall

follow the National Electric Code, ANSI/NFPA 70 or the Canadian

Electrical Code, Part 1.

Space heater must be grounded. Use only a properly grounded

three-wire extension cord. Plug into grounded outlet only. If it should

malfunction or breakdown, grounding provides a path of least

resistance for electric current to reduce the risk of electric shock.

The space heater is a potential source of electrical shock if not

kept dry. Keep the space heater dry and do not use in rain or wet

conditions. To protect from moisture, operate it on a dry surface

under an open, canopy-like structure. Dry your hands if wet before

touching the space heater.

Check that the entire cord is free of cuts or tears and that the plug

has all three prongs, especially a grounding pin.

IMPORTANT SAFETY INSTRUCTIONS

Make certain you read and understand all warnings. Keep this

manual for reference. It is your guide to safe and proper operation

of this heater.

1. Use only in areas free of flammable vapors or high dust

content.

2. Minimum heater clearances from combustible materials: Outlet:

8 Ft. (2.44 m), Sides: 2 Ft. (60.96 cm), Top: 6 Ft. (1.83 m), Rear:

2 Ft. (60.96 cm)

3. Locate space heater on a stable and level surface while hot or

operating or a fire may occur.

4. Use only in well-vented areas. Before using space heater, provide

at least a three-square-foot (2800 square cm) opening of fresh,

outside air for each 100,000 Btu / Hr (30 kw) of rating.

5. Keep children and animals away from space heater at all times.

6. Use space heater only in accordance with local ordinances and

codes.

7. Keep space heater area clear and free from combustible materials,

gasoline, paint thinner and other flammable vapors and liquids.

8. Never use space heater in living or sleeping areas.

9. Never leave a space heater plugged in wit h o u t adult

supervision if children or animals are likely to be present. Do not

leave heater unattended.

10. Never move, handle or service a hot or operating heater. Severe

burns may result. You must wait 15 minutes after turning heater

off.

6 Operator’s Manual

Page 7

IMPORTANT SAFETY INSTRUCTIONS

W

A

R

N

I

N

G

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

C

A

U

T

I

O

N

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

11. Never attach duct work to front or rear of space heater.

12. Space heaters used in the vicinity of tarpaulins, canvas, or

similar enclosure materials shall be located a safe distance from

such materials. The recommended minimum safe distance is

10 feet (304.8cm). It is further recommended that these enclosure

materials be of a fire retardant nature. These enclosure materials

shall be securely fastened to prevent them from igniting or from

upsetting the space heater due to wind action.

13. Unplug space heater when not in use.

14. Never block air inlet (rear) or air outlet (front) of space heater.

15. This product has been approved for use in the Commonwealth

of Massachusetts.

16. Use only the hose and factory preset regulator provided with

the heater.

17. Use only Propane / L.P. gas set up for vapor withdrawal.

18. For indoor use only. Do not use heater outdoors.

19. Do not use heater in basement or below ground level. Propane /

L.P. gas is heavier than air. If a leak occurs, Propane / L.P. gas

will sink to the lowest possible level.

20. Keep heater at least six feet from Propane / L.P. tank(s). Do

not point heater at Propane / L.P. tank(s) within 20 feet.

21. Keep Propane / L.P. tank(s) below 100° F (37.8° C).

22. Check heater for damage before each use. Do not use

a damaged heater.

23. Check hose before each use of heater. If highly worn or

cut, replace with hose specified by manufacturer before using

heater.

24. Keep heater away from strong drafts, wind, water spray, rain

or dripping water.

25. To prevent injury, wear gloves when handling heater.

26. Do not alter heater. Keep heater in its original state.

27. Do not use heater if altered.

28. Turn off propane supply to heater when not in use.

29. Use only original replacement parts. This heater must use design specific parts. Do not substitute or use generic parts. Improper

replacement parts could cause serious or fatal injuries.

SAVE THESE INSTRUCTIONS

Operator’s Manual 7

Page 8

WEAR PROTECTIVE CLOTHING

Wear close fitting clothing and safety equipment appropriate

to the job.

Wear a suitable hearing protective device such as

earmuffs or earplugs to protect against objectionable or

uncomfortable loud noises.

Operating equipment safely requires the full attention of

the operator. Do not wear radio or music headphones while

operating machine.

PREPARE FOR EMERGENCIES

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital and fire department near your telephone.

Be prepared if a fire starts.

INSPECT SPACE HEATER

Be sure all covers, guards and shields are tight and in

place.

Locate all operating controls and safety labels.

Inspect power cord for damage before using. There is a

hazard of electrical shock from crushing, cutting or heat

damage.

Remove all packing items applied to space heater for

shipment. Remove all items from carton. Check items for

any shipping damage. If space heater is damaged, promptly

inform dealer where you bought space heater.

SERVICE SPACE HEATER SAFELY

Before servicing the space hea

ter, shut off unit and allow

unit to cool down.

Service space heater in a clean dry flat area.

8 Operator’s Manual

Page 9

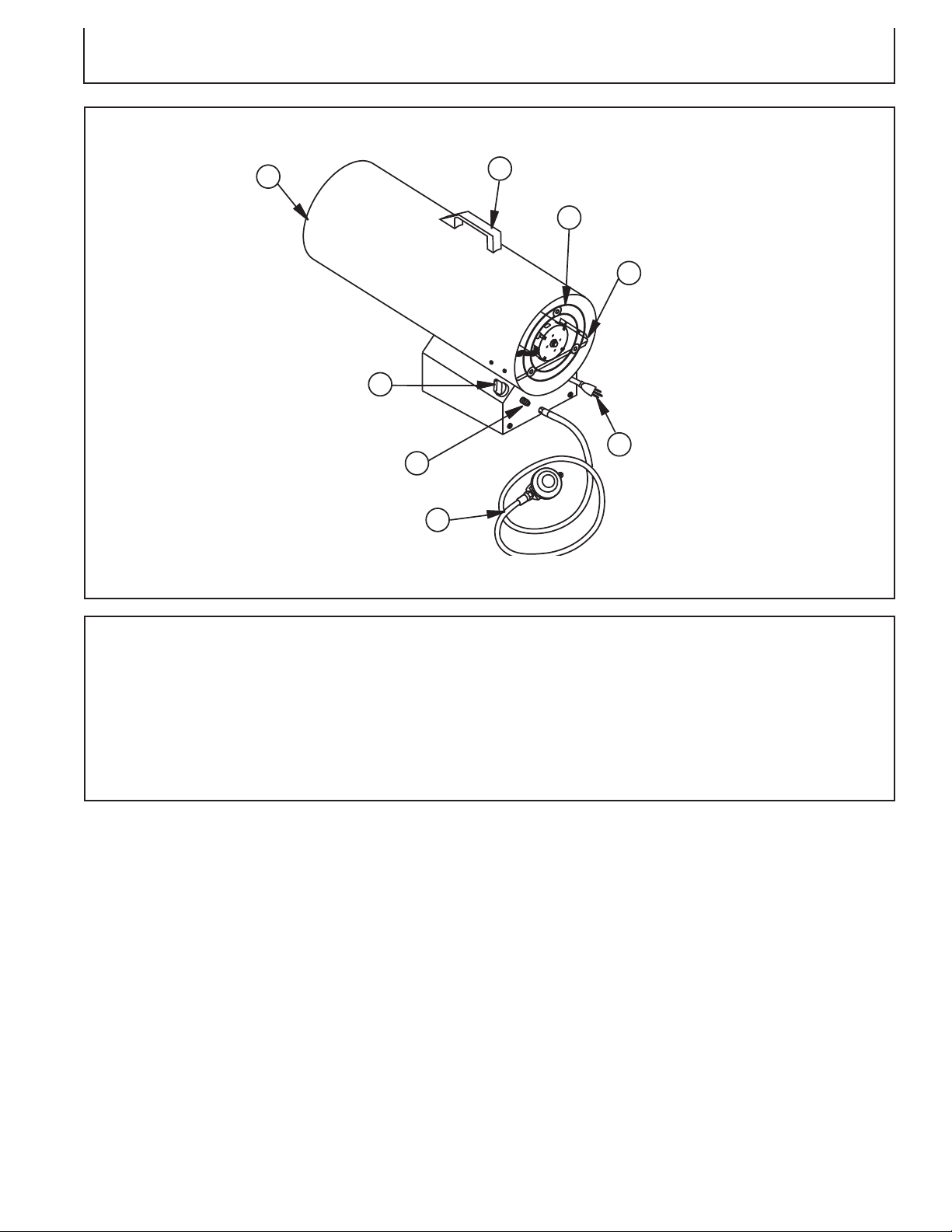

CONTROLS

A

B

C

D

E

F

G

H

AC-100LP

Controls

A -- Hot Air Outlet (Front)

B -- Handle

C -- Fan Guard

D -- Motor Mount

E -- Power Cord

F -- Hose / Regulator Assembly

G -- Inlet Connector

H -- Control Knob

Operator’s Manual 9

Page 10

Preparation

VENTILATION

WARNING: FOLLOW THE MINIMUM FRESH, OUTSIDE

AIR VENTILATION REQUIREMENTS. IF PROPER

FRESH, OUTSIDE AIR VENTILATION IS NOT

PROVIDED, CARBON MONOXIDE POISONING

CAN OCCUR. PROVIDE PROPER FRESH, OUTSIDE

AIR VENTILATION BEFORE RUNNING HEATER.

Provide a fresh air opening of at least three square feet for

each 100,000 Btu/Hr rating. Provide extra fresh air if more

heaters are being used.

PROPANE SUPPLY

Propane / L.P. gas and Propane / L.P. tank(s) are to be

furnished by the user.

Use this heater only with a propane vapor withdrawal

supply system. See Chapter 5 of the Standard for Storage

and Handling of Liquefied Petroleum Gas, ANSI/NFPA 58

and the Propane Installation Code CAN/CGA B149.2. Your

local library or fire department will have this booklet.

The amount of Propane / L.P. gas ready for use from

Propane / L.P. tanks varies. Two factors decide this amount:

1. The amount of Propane / L.P. gas in tank(s)

2. The temperature of tank(s)

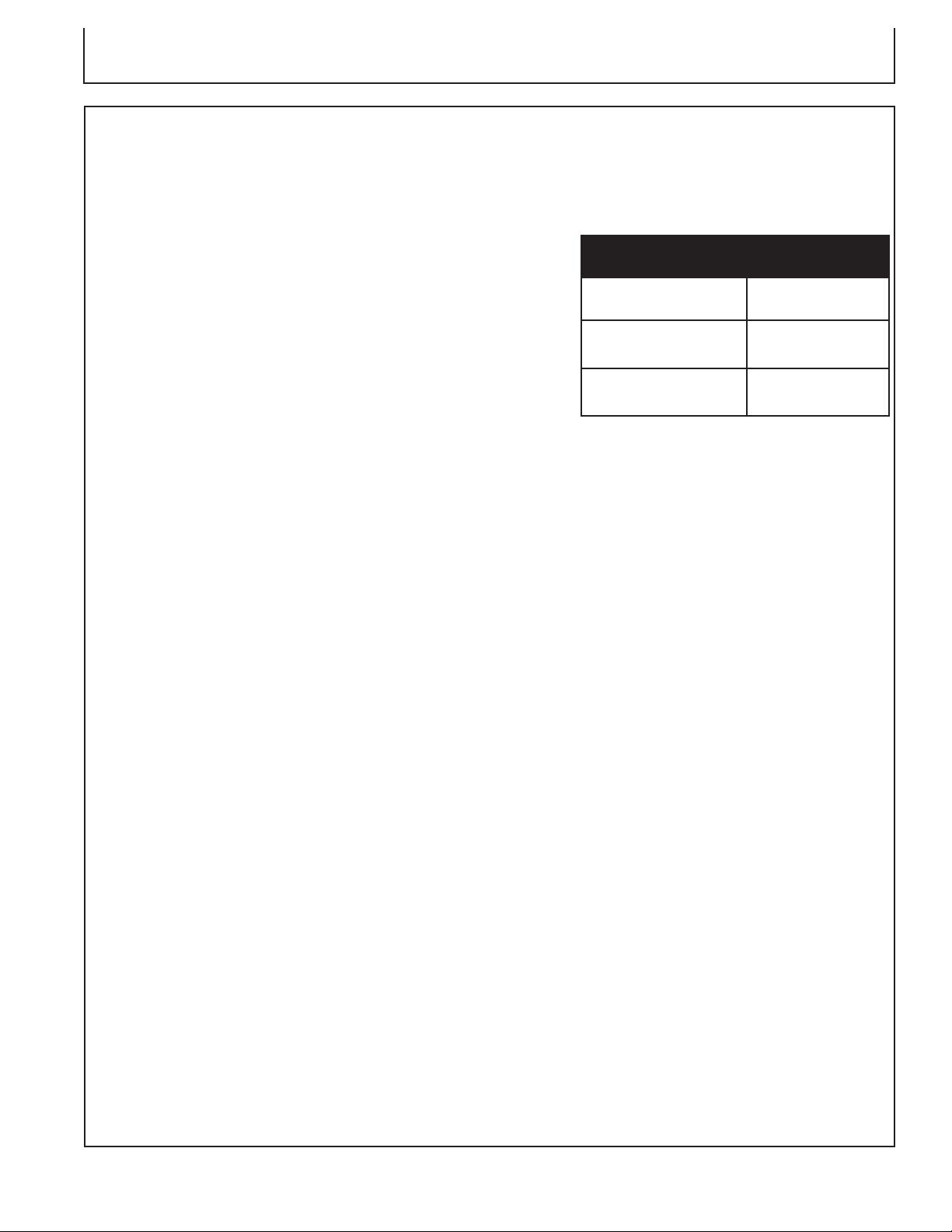

The chart below shows the number of 100 pound (45 kg)

tanks needed to run this heater. Smaller tanks can be used

for limited run times but it is recommended to use larger

tanks for optimum performance.

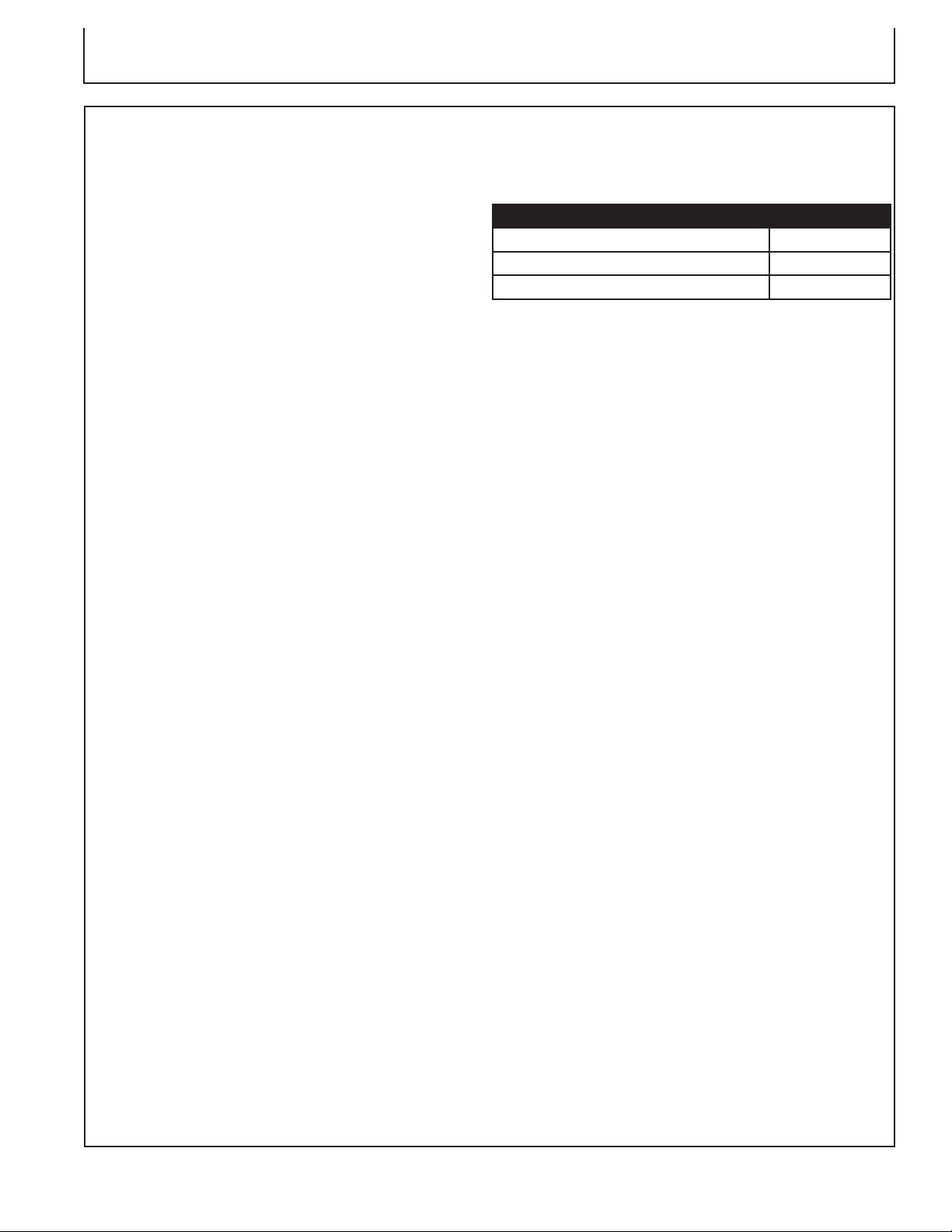

Temperature at Tank # of 100 lbs. Tanks

32°F (0°C) to 20°F (-6.7°C) 2

20°F (-6.7°C) to -10°F (-23.3°C) 3

Below -10°F (-23.3°C) (Use larger tank)

Less gas is vaporized at lower temperatures. You may need

two or more 100 pound (45 kg) tanks or one larger tank in

colder weather. Your local Propane / L.P. gas dealer will

help you select the proper supply system. The minimum

surrounding air temperature rating for each heater is

-20° F (-29° C).

10 Operator’s Manual

Page 11

Preparation

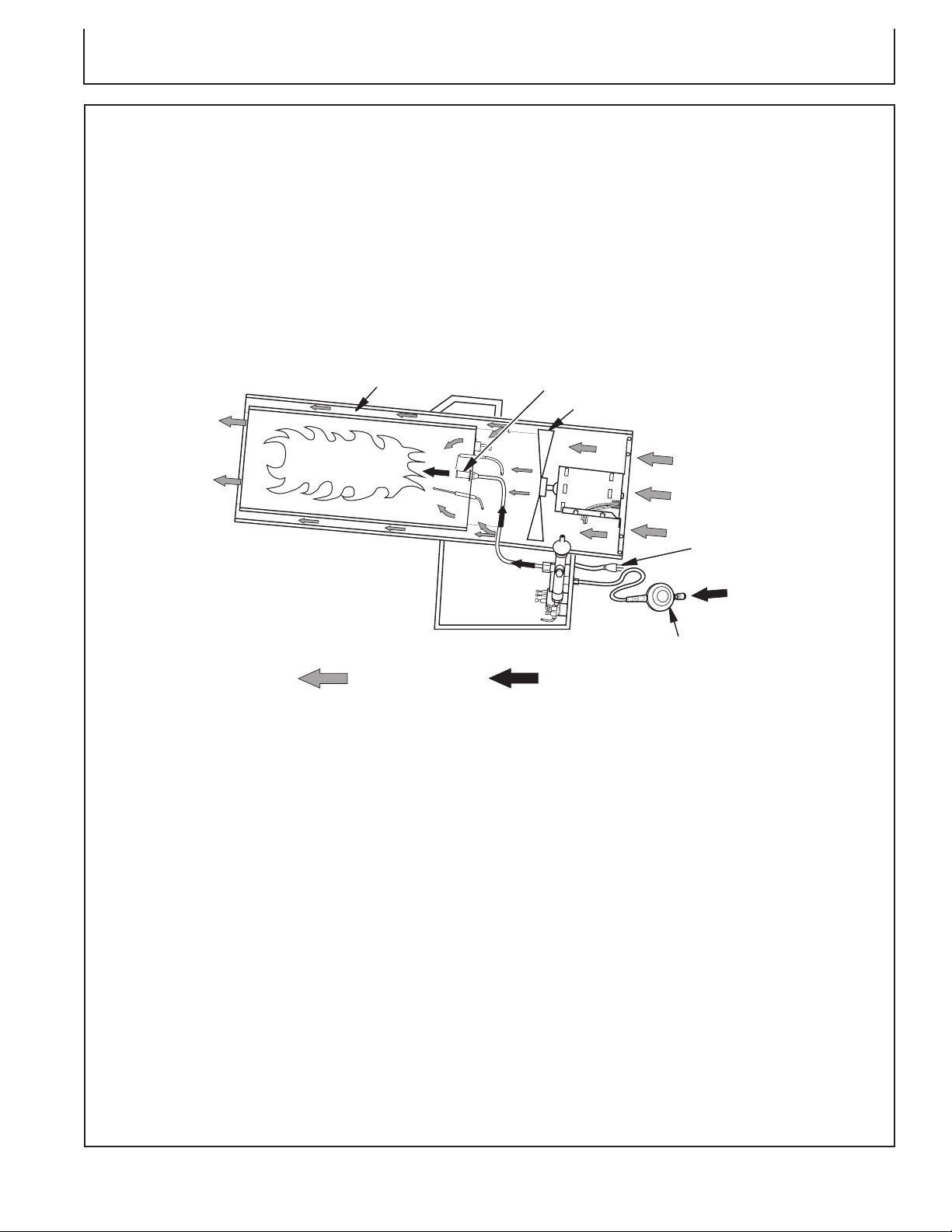

Air For Combustion

And Heating

Fuel

Combustion Chamber

Clean

Heated

Air Out

(Front)

Hose/Regulator

Assembly

Nozzle

Fan

Cool

Air In

(Back)

Power Cord

THEORY OF OPERATION

The Fuel System: The hose / regulator assembly attaches to the Propane / L.P. gas supply. The Propane / L.P.

gas moves through the automatic control valve and out the nozzle.

The Air System: The motor turns the fan. The fan pushes air into and around the combustion chamber. This air

is heated and provides a stream of clean, hot air.

The Ignition System: The spark transformer and ignitor lights the main burner.

The Safety Control System: This system causes the heater to shut down if the flame goes out.

Operator’s Manual 11

Page 12

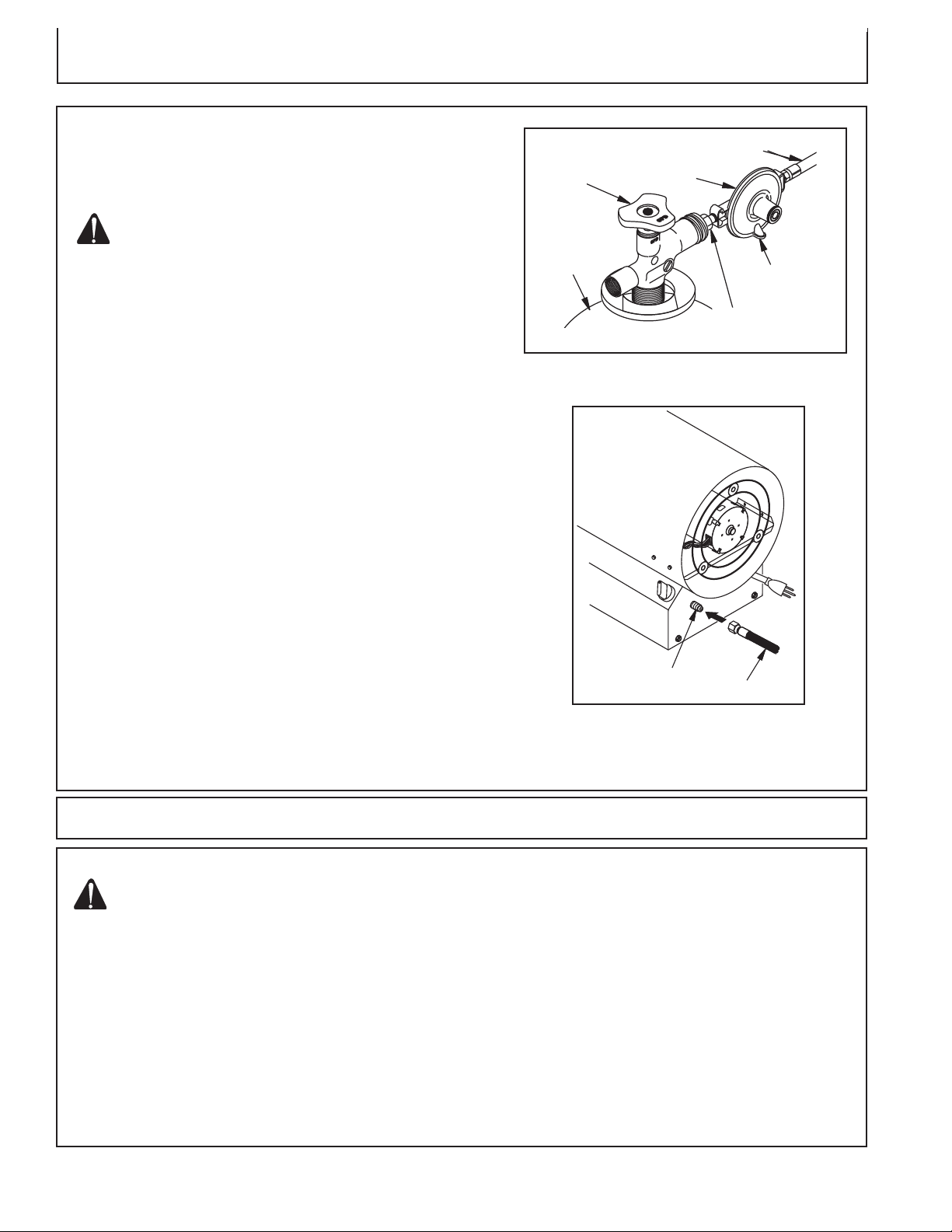

Installation

Hose

Regulator

Vent (pointing

down)

Supply

Valve

Propane

Tank

Fuel Gas

Connector

Hose

Inlet Connector

INSTALLATION

IMPORTANT: Review and understand the warnings in

the Safety Information section. They are needed to safely

operate this space heater. Follow all local ordinances and

codes when using this space heater.

WA RN I NG: TEST ALL GAS PIP ING AND

CONNECTIONS FOR LEAKS AFTER

INSTALLING OR SERVICING. NEVER

USE AN OPEN FLAME TO CHECK FOR

A LEAK. APPLY A MIXTURE OF LIQUID

SOAP AND WATER TO ALL JOINTS.

BUBBLES FORMING SHOW A LEAK.

CORRECT ALL LEAKS AT ONCE.

1. Provide propane supply system

Supply).

2. Connect fuel gas connector fitting on hose / regulator

assembly to Propane / L.P. tank(s). Turn counterclockwise

into threads on tank valve. Tighten firmly using wrench.

IMPORTANT: Tighten regulator with vent pointing down.

Pointing vent down protects regulator from weather

damage. (Fig. 1)

3. Connect hose to inlet connector. Tighten firmly using a

wrench. (Fig. 2)

IMPORTANT: Extra hose or piping may be used if needed.

Install extra hose or piping between hose/regulator

assembly and Propane / L.P. tank. You must use the

regulator supplied with heater.

4. Open propane supply valve on Propane / L.P. tank(s)

slowly.

Note: If not opened slowly, excess-flow check valve on

Propane / L.P. tank will stop gas flow. If this happens,

close propane supply valve and open again slowly.

5. Check all connections for leaks.

6. Close propane supply valve.

(see Propane

(Fig. 1)

(Fig. 2)

Operation

OPERATION

WARNING: FOLLOW THE MINIMUM FRESH,

O U T S I D E A I R V E N T I L AT I O N

REQUIREMENTS. IF PROPER FRESH,

OUTSIDE AIR VENTILATION IS NOT

PROV ID ED , C A RBON MONO XI DE

POISONING CAN OCCUR. PROVIDE

PR OPE R F RES H, OU TSI D E A IR

VENTI L ATION B EF O RE R U NN ING

HEATER.

START SPACE HEATER:

1.

Follow all ventilation and safety information.

2. Place the space heater in an area that provides

maximum circulation of the heated air. Follow all location

requirements noted in

12 Operator’s Manual

the Safety Information.

Page 13

Operation

OPERATION

3. Locate heater on stable and level surface. Make sure

strong drafts do not blow into front or rear of heater.

4. Make sure the control knob is in the OFF position.

5. Plug power cord of heater into a three-prong, grounded

extension cord. Extension cord must be at least 6 feet

(1.83 m) long, UL/CSA listed and of a proper size. See

Extension Cord Chart.

6. Plug extension cord into a 120 volt/60 hertz, 3-hole,

grounded outlet. Motor will start. Fan will turn, forcing

air out front of heater.

7. Open propane supply valve on Propane / L.P. tank(s)

slowly.

Note: If not opened slowly, excess-flow check valve on

Propane / L.P. tank will stop gas flow. You may hear a click

from the excess-flow check valve closing. If this

happens, reset the excess-flow check valve by closing

Propane / L.P. supply valve and open again slowly.

8. Press and hold in control knob. Turn counterclockwise

to the LOW position. Heater should ignite within a few

seconds.

Note: If heater fails to ignite, hose may have air in it. If so,

keep control knob pressed and wait 20 seconds. Release

automatic control knob and wait 20 seconds for unburned

fuel to exit heater. Repeat step 8.

9. After heater ignites, wait 30 seconds. This activates the

automatic control system. Release the control knob.

10. When burner remains lit, set heater at the desired heat

level by turning the control valve counterclockwise. If burner

goes out, turn off gas. Turn control knob fully clockwise to

the lowest position. Check fuel supply. If adequate fuel is

available, restart heater beginning at step 1.

Extension Cord Size Requirement

Length of Cord: Rated Cord:

51 to 100 feet (15.5 to 30.48 m) 16 AWG

101 to 200 feet (30.78 to 60.96 m) 14 AWG

STOP SPACE HEATER:

1. Tightly close propane supply valve on Propane / L.P.

tank(s).

2. Wait a few seconds. Heater will burn gas left in supply

hoses.

3. Turn control knob to the OFF position.

4. Unplug heater.

Operator’s Manual 13

Page 14

Troubleshooting

WARNING: HIGH VOLTAGE. NEVER SERVICE SPACE HEATER WHILE IT IS PLUGGED IN,

OPERATING, OR HOT. SEVERE BURNS AND ELECTRICAL SHOCK CAN OCCUR.

Symptom Problem Solution

Fan does not turn when heater

is plugged in.

Heater will not ignite.

No electrical power to heater.

Fan hitting inside of heater shell.

Fan blades bent.

Defective motor.

User did not follow installation or

operation instructions properly.

Check voltage to electrical outlet. If voltage is good, check heater power cord

for breaks.

Adjust motor / fan mount to keep fan

from hitting inside of heater shell.

Replace fan.

Replace motor.

Repeat installation and operation

instructions.

No spark at ignitor. To test for spark,

see "Service: Ignitor" and follow

step 8. If you see spark at ignitor,

have heater serviced by qualified

service person. If no spark seen:

a. Loose or disconnected ignitor

wire

b. Wrong spark gap

c. Bad ignitor electrode

d. Bad spark transformer

a. Check ignitor wire. Tighten or reattach

loose ignitor wire. See "Maintenance:

Spark Transformer" for ignitor wire

location

b. Set gap between ignitor electrode and

nozzle to .13"/.15" (3.3/3.8 mm)

c. Replace ignitor electrode. See

"Maintenance: Ignitor".

d. Replace spark transformer. See

"Maintenance: Spark Transformer".

14 Operator’s Manual

Page 15

Troubleshooting

WARNING: HIGH VOLTAGE. NEVER SERVICE SPACE HEATER WHILE IT IS PLUGGED IN,

OPERATING, OR HOT. SEVERE BURNS AND ELECTRICAL SHOCK CAN OC

CUR.

Symptom Problem Solution

Heater shuts down while

running.

Propane / L.P. supply may be

inadequate.

High surrounding air temperature

causing thermal limit device to shut

down heater.

Restricted air flow.

Damaged fan.

Excessive dust or debris in

surrounding area.

a. Refill tank

b. Provide additional and/or larger

tanks. See "Preparation: Propane

Supply".

This can happen when running heater

in temperatures above 85° F (30° C).

Run heater in cooler temperatures.

Check heater inlet and outlet. Remove any obstructions.

Replace fan. See "Maintenance:

Fan".

Clean heater. See "Maintenance".

WARNING: Use only in areas free

of high dust content.

Heater producing odor.

Gas leak

Heater operating on a 20 lb.

Propane / L.P. cylinder. Insufficient

Propane / L.P. gas will be supplied

by a 20 lb. cylinder resulting in odor

Propane / L.P. supply tank is "freez

ing up". Evaporation and consumption rate of propane from supply

tank is to great for the size of the

tank and air temperature

Check all connections for leaks. Apply

mixture of liquid soap and water to

gas joints. Bubbles forming show a

leak that must be corrected

To obtain correct mixture of

Propane /

L.P. gas and air, use a larger cylinder

size, i.e. 40 lb. (minimum) or 100 lb.

See "Preparation: Propane

Supply".

a. Use a larger supply cylinder size,

i.e. 40 lb. (minimum) or 100 lb.

b. Reduce consumption rate by

operating the heater at LOW

setting temporarily until frost

disappears from the tank

Operator’s Manual 15

Page 16

Service

MAINTENANCE:

WARNING: TO AVOID RISK OF BURN AND

ELECTRICAL SHOCK, NEVER ATTEMPT

TO SERVICE SPACE HEATER WHILE IT IS

PLUG G ED I N, OP ER AT I NG , OR HO T.

KEEP HEATER CLEAR AND FREE FROM

COMBUSTIBLE MATERIALS, GASOLINE AND

OTHER FLAMMABLE VAPORS AND LIQUIDS

DO NOT BLOCK THE FLOW OF COMBUSTION

OR VENTILATION AIR.

1. Keep heater clean. Clean heater annually or as

needed to remove dust and debris. If heater is dirty or

dusty, clean heater with a damp cloth. Use household

cleaners on difficult spots.

2. Inspect heater before each use. Check connections

for leaks. Apply mixture of liquid soap and water to

connections. Bubbles forming show a leak. Correct

all leaks at once.

3. Inspect hose / regulator assembly before each use. If

hose is highly worn or cut, replace with hose specified

by manufacturer.

4. Have heater inspected yearly by a qualified service

agency.

5. Keep inside of heater free from combustible and

foreign objects. Remove motor and other internal

parts if needed to clean inside of heater.

6. Clean fan blades each season or as needed.

16 Operator’s Manual

Page 17

MAINTENANCE (CONTINUED):

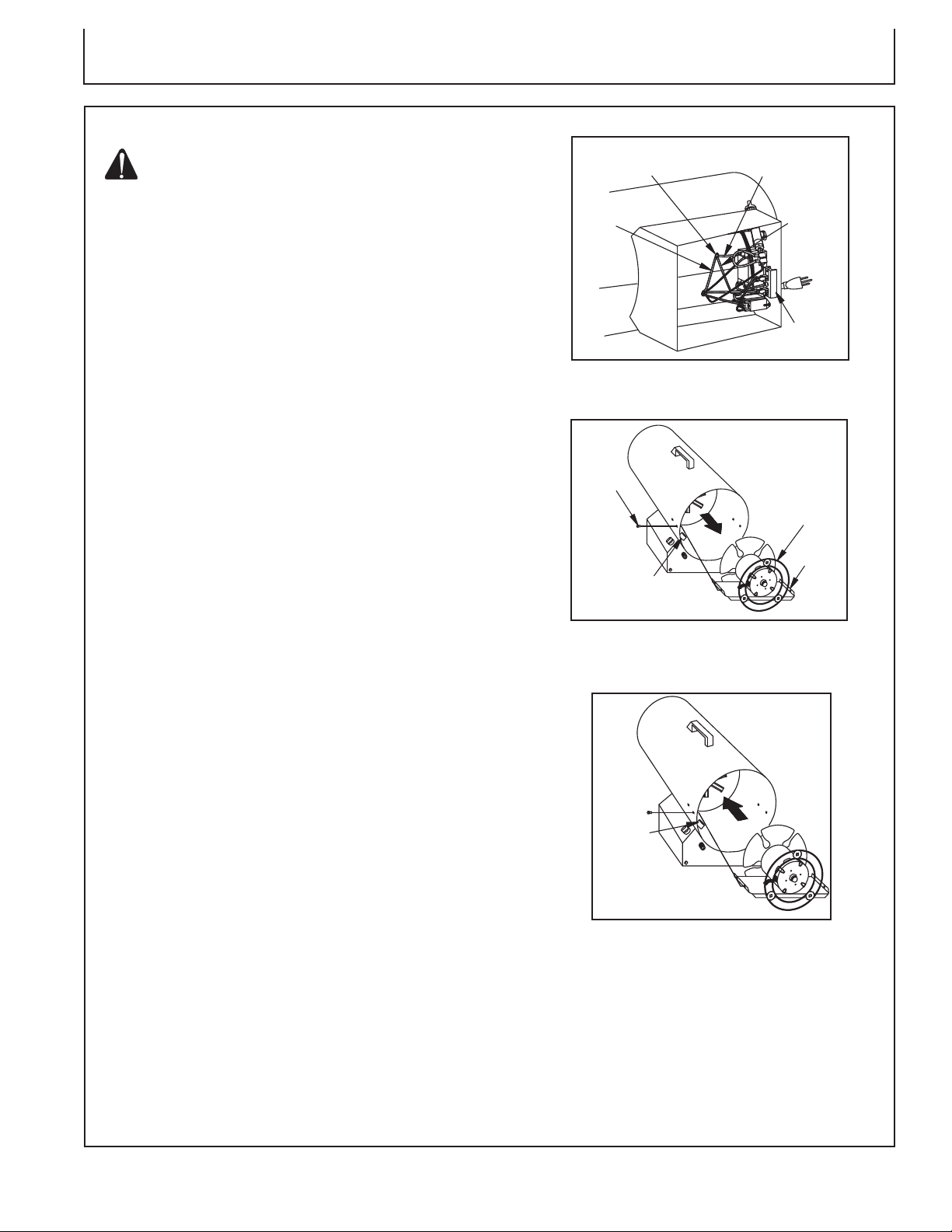

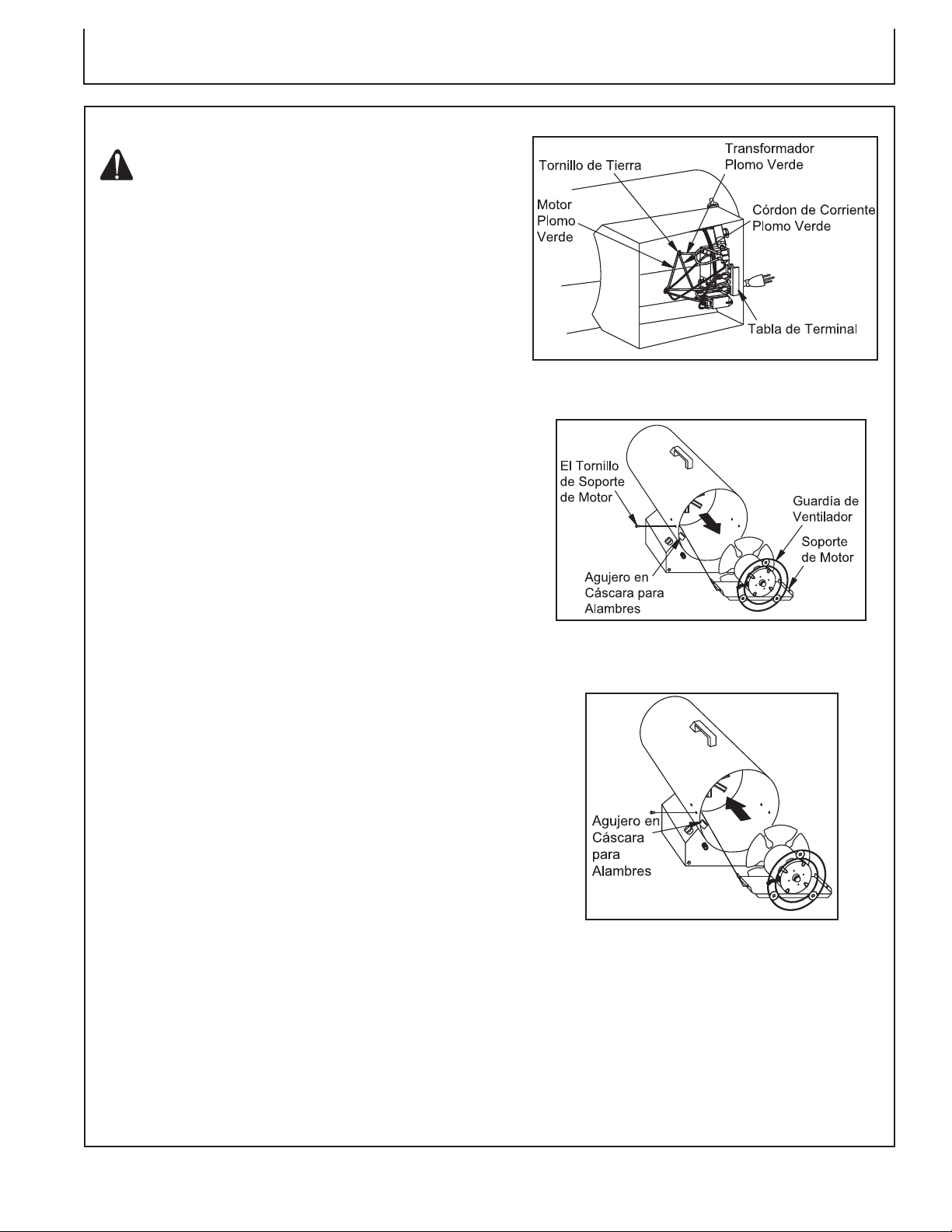

Ground Screw

Terminal

Board

Motor

Green

Lead

Power

Cord

Green

Lead

Transformer

Green Lead

Hole in Shell

for Wires

Motor

Mount

Screw

Fan

Guard

Motor

Mount

Hole in

Shell for

Wires

Service

WARNING: NEVER SERVICE HEATER WHILE

IT IS PLUGGED IN, CONNECTED TO

PROPANE / L.P. SUPPLY, OPERATING OR

HOT. SEVERE BURNS AND ELECTRICAL

SHOCK CAN OCCUR.

MOTOR

:

1. With heater on its side, remove base tray.

2. Access ground screw through underside of heater base.

Remove ground screw. Disconnect the green motor wire

and the green power cord wire from underside of shell

(Fig. 3).

(Fig. 3)

3. Remove black and white motor wires from terminal board

(Fig. 3).

4. Carefully push motor wires through hole in bottom of

shell.

5. Remove screws holding motor mount to shell. Use nutdriver (Fig. 4).

6. Carefully pull motor and fan out of shell.

IMPORTANT: Be careful not to damage fan. Do not set

motor and fan down with the weight resting on fan. This

could damage fan pitch.

7. Use hex wrench to loosen setscrew which holds fan to

motor shaft.

(Fig. 4)

8. Remove fan. Be careful not to damage the fan blade

pitch.

9. Use nut driver to remove two nuts that attach motor to

motor mount.

10. Discard old motor.

11. Attach motor to motor mount with two nuts. Tighten

nuts firmly.

12. Replace fan on motor shaft. Make sure set screw

contacts flat surface on motor shaft.

13. Tighten set screw firmly (40-50 inch-pounds [46.08-

57.60 kilogram-centimeters]).

14. Carefully route motor wires through hole in shell

(Fig. 5). Place motor, motor mount and fan guard

into rear of heater shell.

(Fig. 5)

15. Insert screws through heater shell and into motor

mount. Tighten screws firmly.

16. Turn heater on its side to access opening in bottom of

base. Connect green wires from motor, transformer and

power cord to heater shell using ground nut (Fig. 3).

17. Attach black and white wires to terminal board (see

"Wiring Diagram" for correct locations).

18. Replace base tray.

Operator’s Manual 17

Page 18

Service

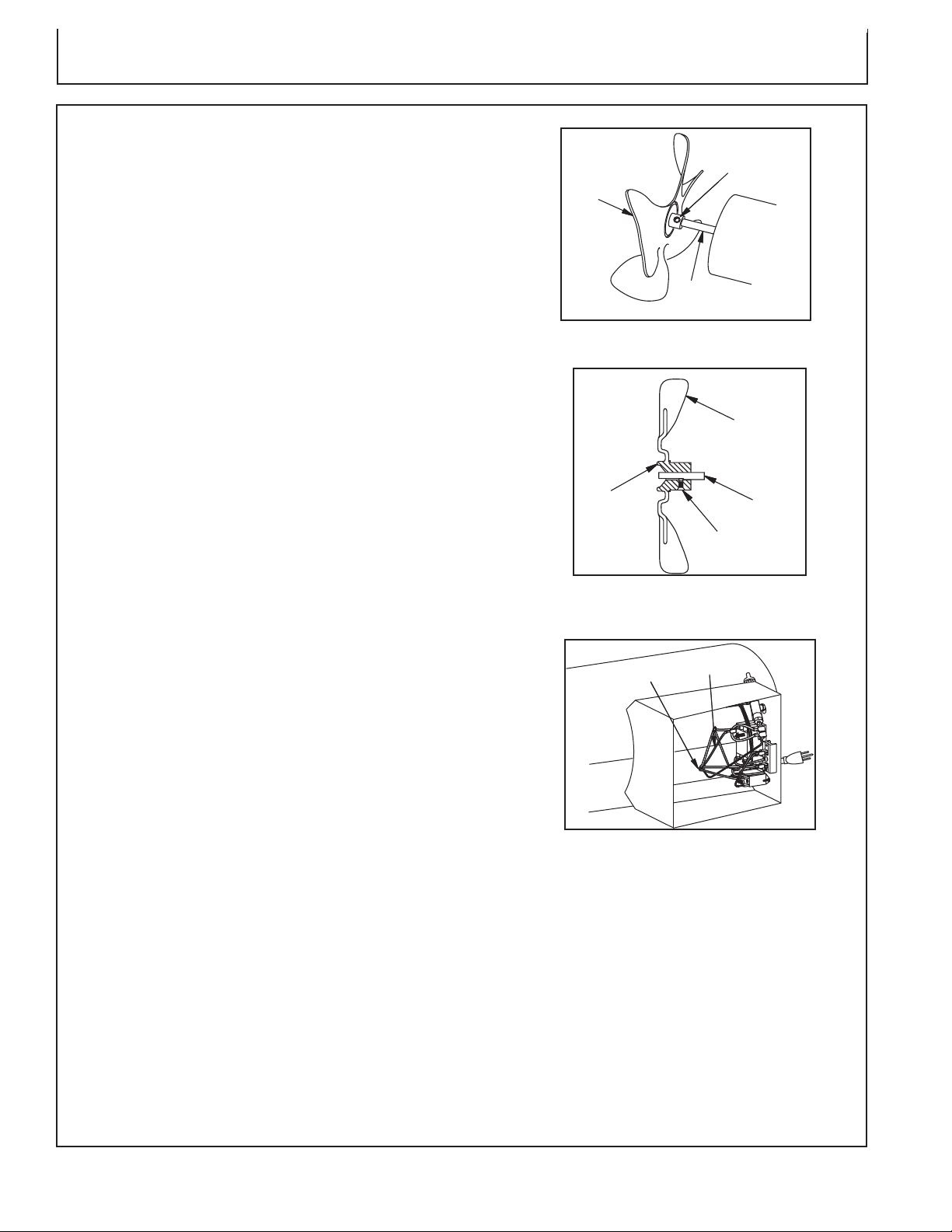

Motor

Shaft

Fan

Setscrew

Fan

Hub

Setscrew

Motor

Shaft

Bushing

Ignitor Wire

MAINTENANCE (CONTINUED):

FAN:

1 Remove motor, motor mount and fan (see "Maintenance:

Motor", steps 1 through 8.).

2. Clean fan using soft cloth moistened with kerosene or

solvent.

3. Dry fan thoroughly.

4. Replace fan on motor shaft. Make sure setscrew is

touching back of flat surface on motor shaft (Fig. 6 and

7).

5. Place setscrew on flat of shaft. Tighten setscrew

firmly (40-50 inch-pounds / 46.08-57.60 kilogramcentimeters).

6. Place motor, motor mount and fan guard into rear of heater

shell (see "Maintenance: Motor", steps 14 through 18).

SPARK TRANSFORMER:

1. Remove base tray.

2. Locate and disconnect white, black and orange wires

from spark transformer. (Fig. 8)

3. Remove two screws holding spark transformer to base.

Remove sheet metal nuts on transformer and install on

new transformer. Discard spark transformer.

4. Install new spark transformer. Position new spark

transformer in same manner as old transformer.

5. Connect white, black and orange wires to new spark

transformer. Connect wires to correct terminals as noted

in step 2.

6. Replace base tray.

(Fig. 6)

(Fig. 7)

(Fig. 8)

18 Operator’s Manual

Page 19

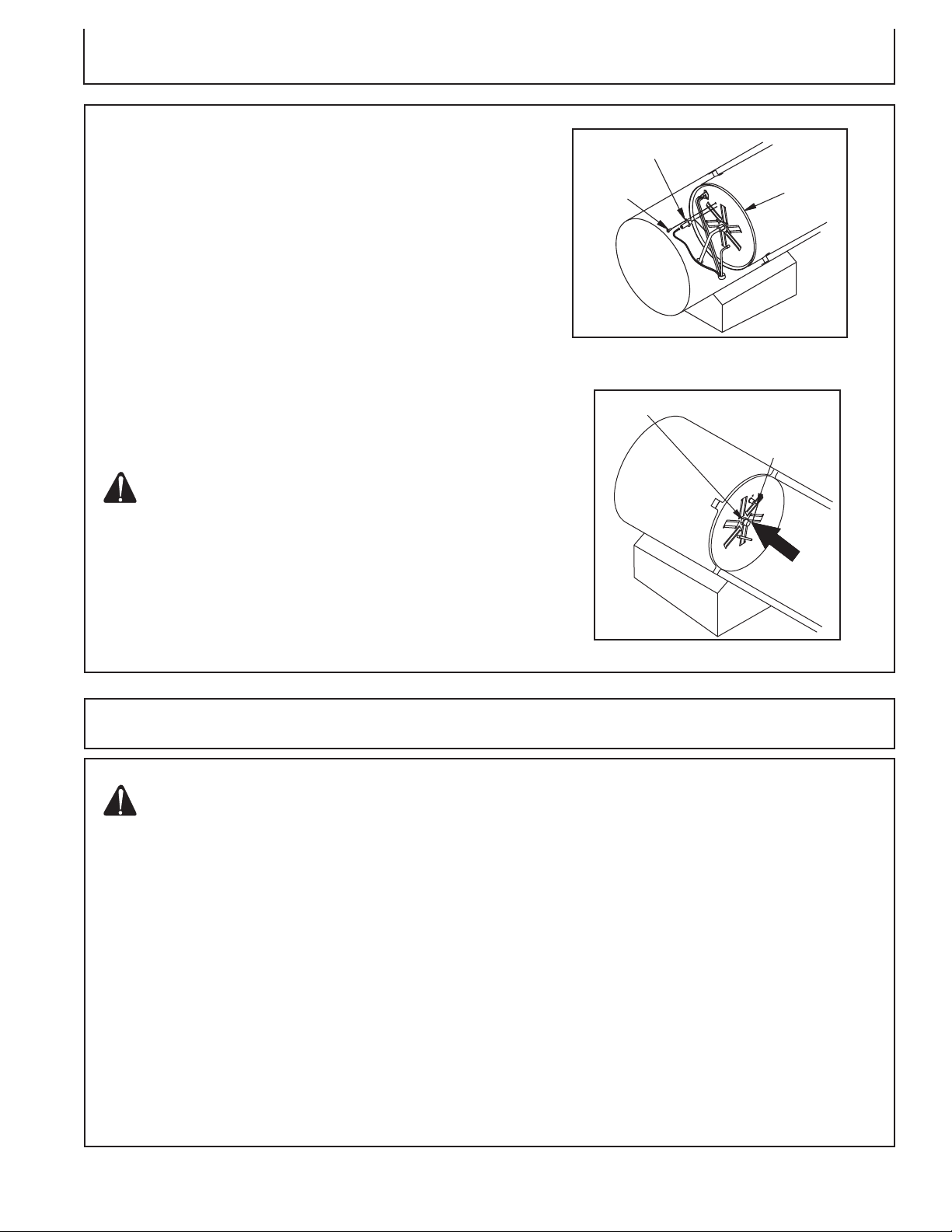

Service

Rear

Head

Ignitor

Ignitor

Mounting

Screw

Burner

Nozzle

Gap

Area

Ignitor

Electrode

MAINTENANCE (CONTINUED):

IGNITOR:

1. Remove motor, motor mount and fan guard (see

"Maintenance: Motor", steps 1 through 6).

2. Remove orange ignitor wire from ignitor.

3. Remove ignitor mounting screw from rear head using

nut-driver or standard screwdriver (Fig. 9).

4. Remove ignitor from rear head.

5. Install new ignitor. Attach ignitor to rear head with

ignitor mounting screw.

6. Attach ignitor wire.

7. Check gap between ignitor electrode and nozzle

to .13"/.15" (3.3/3.8 mm) (Fig. 10).

8. Test for spark. Plug into extension cord and watch for

spark between ignitor electrode and nozzle.

WA R NI NG: MA KE S UR E HE AT ER I S

DISCONNECTED FROM PROPANE

SUPPLY. HEATER COULD IGNITE

CAUSING SEVERE BURNS.

(Fig. 9)

9. Place motor, motor mount and fan guard into rear

of heater shell (see "Maintenance: Motor", steps 14

through 18).

CAUTION: DISCONNECT HEATER FROM

PROPANE / L.P. SUPPLY TANK(S).

1. Store Propane / L.P. tank(s) in safe manner. See

Chapter 5 of Standard for Storage and Handling of

Liquefied Petroleum Gases

, ANSI/NFPA 58 and the

Propane Installation Code CAN/CGA B149.2. Follow

all local codes. Always store Propane / L.P. tanks

outdoors.

2. Place plastic cover caps over brass fittings on inlet

connector and hose / regulator assembly.

3. Store in dry, clean and safe place. Do not store

hose / regulator assembly inside heater combustion

chamber.

4. When taking heater out of storage, always check

inside of heater. Insects and small animals may place

foreign objects in heater. Keep inside of heater free

from combustible and foreign objects.

(Fig. 10)

Storage

Operator’s Manual 19

Page 20

Specifications

ITEM SPECIFICATION

Model Size AC-100LP

Output Rating (BTU / Hr) 65,000 85,000 100,000

Fuel Propane Vapor Only

Fuel Consumption:

(Gal. Per Hr / Liters Per Hr) 0.7 / 2.65 0.9 / 3.52 1.1 / 4.16

(Pounds Per Hr / Kilograms Per Hr) 3.0 / 1.36 3.9 /1.77 4.6 / 2.09

Supply Pressure to Regulator:

Minimum (for input adjustment) 10 PSI / 65.98 kPa

Maximum Tank Pressure

Regulator Outlet Pressure Factory Preset

Manifold Pressure 10" WC / 25.4 cm

Hot Air Output (Approx.) 475 CFM / 144.78 cubic meter/minute

Motor RPM 3200

Motor HP 1/10

Electric Input 120V / 60Hz

Amperage (Normal Run) 2.9

Ignition Continuous

Ignitor Gap 0.13 in / 0.15 in (3.3 mm / 3.8 mm)

Shipping Weight

(Approximate Pounds /

Kilograms) 29 / 13.15

Space Heater Weight

(Approximate Pounds /

Kilograms) 23 / 10.43

RECORD SERIAL NUMBER

Write you model number, machine serial number and

date of purchase in the spaces provided below. Your

dealer needs this information when ordering parts.

Model No. ______________________________________________

Machine Serial No. _______________________________________

Date of Purchase ________________________________________

(To be filled in by purchaser)

20 Operator’s Manual

Page 21

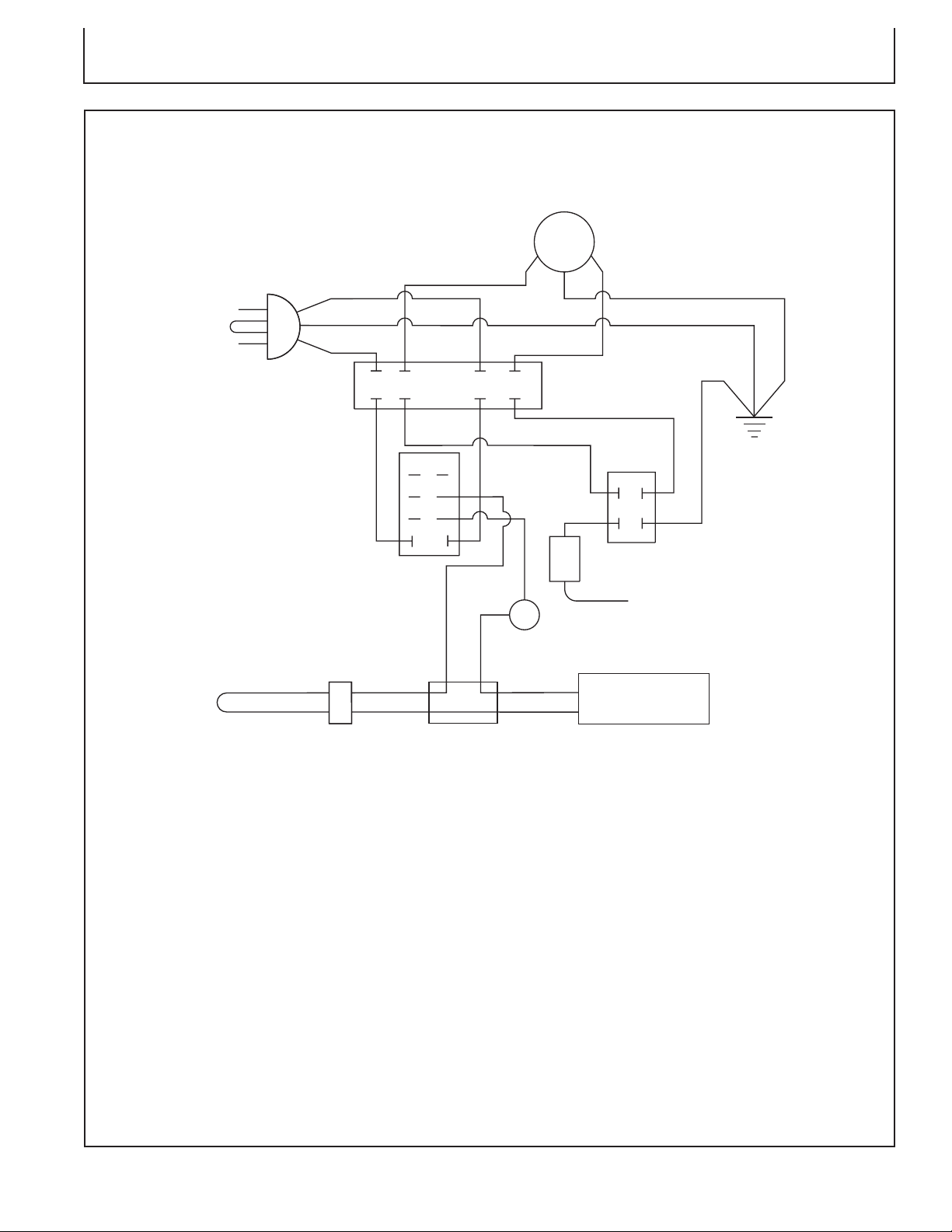

Wire Diagram

Black

Green

White

Motor

Ignitor

Orange

Blue

Blue

Auto Control

Valve

Thermocouple

1 2

3 4

5 6

87

Thermal Switch

Terminal Board

Blue

Black

Ignition

Control

White

Relay

Green

Green

Black

Black

White

White

Green

Power

Cord

Operator’s Manual 21

Page 22

STATEMENT OF WARRANTY

John Deere warrants all parts, (except those referred to below), of your new space heater

to be free from defects in materials and workmanship during the following periods:

For One (1) Year from the date of original purchase.

Defective parts not subject to normal wear and tear will be repaired or replaced at

our option during the warranty period. In any event, reimbursement is limited to the

purchase price paid.

EXCLUSIONS

1. This warranty does not cover parts damaged due to normal wear, misapplication,

misuse, operation at other than recommended. Failure to follow recommended

operating and maintenance procedures also voids warranty.

2. The use of other than genuine manufacturer repair parts will void warranty.

3. Warranty will be void if used in any application other than consumer / homeowner.

Parts returned, prepaid to our factory or to an Authorized John Deere Service Center

will be inspected and replaced free of charge if found to be defective and subject

to warranty. There are no warranties which extend beyond the description of the

face hereof. Under no circumstances shall the manufacturer bear any responsibility

for loss of use of the unit, loss of time or rental, inconvenience, commercial loss or

consequential damages.

For Service or Warranty Consideration, contact

Mi-T-M

®

Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

22 Operator’s Manual

Page 23

Notes

Operator’s Manual 23

Page 24

Introduction

MERCI de la confiance témoignée par l’achat d’un

produit John Deere.

LIRE CE MANUEL ATTENTIVEMENT AFIN de pouvoir

utiliser et entretenir correctement votre appareil, sinon

des dommages corporels ou matériels pourraient en

résulter. Ce manuel et les symboles de sécurité sur votre

appareil peuvent également être disponible en d’autres

langues. (Voir votre concessionnaire John Deere pour

les commander.)

CE MANUEL DOIT ÊTRE CONSIDÉRÉ comme faisant

partie intégrante de votre appareil et doit l’accompagner

en cas de revente.

LES MESURES dans ce manuel sont indiquées à la fois

dans leurs équivalents métriques et en unités usuelles

des USA. Utiliser seulement les pièces de rechange

et les éléments de fixation corrects. Les éléments de

fixation métriques et en pouces peuvent nécessiter des

clés spécifiques à leurs système d’unités.

AVERTISSEMENT GÉNÉRAL DE RISQUE :

LISEZ ATTENTIVEMENT ET ENTIÈREMENT CE

MANUEL D’UTILISATION AVANT DE TENTER

D’ASSEMBLER, DE FAIRE FONCTIONNER OU

DE RÉPARER CE RADIATEUR. UNE MAUVAISE

UTILISATION DE CET APPAREIL DE CHAUFFAGE

PEUT CAUSER DE GRAVES BLESSURES, VOIRE

LA MORT, SUITE À DES BRÛLURES, UN INCENDIE,

UNE EXPLOSION, UNE DÉCHARGE ÉLECTRIQUE

OU UN EMPOISONNEMENT AU MONOXYDE DE

CARBONE.

LISEZ ET COMPRENEZ TOUS LES AVERTISSEMENTS.

CONSERVEZ CE MANUEL POUR CONSULTATION

FUTU RE . IL VO U S PERM ET TRA DE FAIR E

FONCTIONNER CET APPAREIL DE CHAUFFAGE

CORRECTEMENT ET EN TOUTE SÉCURITÉ.

AVERTISSEMENT: RISQUE D’INCENDIE,

DE BRÛLURES,D

MAINTENIR LES MATÉRIAUX COMBUSTIBLES

SOLI DE S, TELS Q UE LES MATÉRI AU X DE

CONSTRUCTION, LE PAPIER OU LE CARTON À

UNE DISTANCE RESPECTUEUSE DE L

DE CHAUFFAGE TEL QU

DANS LES INSTRUCTIONS. NE JAMAIS SE SERVIR

’APPAREIL DE CHAUFFAGE DANS DES

DE L

ENDROITS QUI CONTIENNENT OU QUI PEUVENT

CONTENIR DES COMBUSTIBLES EN SUSPENSION

OU DES PRODUITS TELS QUE L

DISSOLVANTS, LES DILUANTS DE PEINTURE, LES

PARTICULES DE POUSSIÈRE OU DES PRODUITS

CHIMIQUES INCONNUS.

’INHALATION ET D’EXPLOSION.

’APPAREIL

’IL EST RECOMMANDÉ

’ESSENCE, LES

Le NUMÉRO DE SÉRIE de l’appareil se situe dans la

section Caractéristiques ou Numéros d’Identification.

Noter correctement tous les numéros afin de faciliter les

recherches en cas de vol. Les communiquer également

au concessionnaire lors de toute commande de pièces.

Ranger les numéros d’identification dans un endroit sûr

et séparé de l’appareil.

LA GARANTIE fait partie du programme de soutien John

Deere destiné aux clients qui utilisent et entretiennent

leur équipement tel qu’il est décrit dans ce manuel. Les

conditions de garantie dont bénéficie cet appareil figurent

sur le certificat de garantie dans ce manuel.

Cette garantie vous fournit l’assurance que votre

concessionnaire fournira du support pour les produits

où des défauts apparaîtraient au cours de la période

de garantie. Toute utilisation abusive de l’équipement

ou modification visant à dépasser les performances

spécifiées par le constructeur annuleront la garantie.

Cet appareil est conçu comme appareil de chauffage

pour le travail en bâtiment conformément à ANSI Z83.7/

CGA 2.14. D

des gaz combustibles et des produits de chauffage à

utilisations spécifiques. Les autorités locales peuvent

vous conseiller à ce sujet. L

appareils de chauffage de construction est de fournir

un chauffage temporaire aux bâtiments en construction,

sous transformations ou en réparations. Quand il est

utilisé correctement, l

chauffage économique et sans danger. Les produits

de combustion sont évacués dans l

chauffé.

Nous ne pouvons pas prévoir tous les emplois

possibles de nos appareils de chauffage.

les responsables locaux de la sécurité incendie si

vous avez des questions à propos de l

l’appareil de chauffage.

D’autres normes déterminent l’utilisation des gaz

combustibles et des produits de chauffage à utilisations

spécifiques. Les autorités locales peuvent vous

conseiller à ce sujet.

Le gaz de propane n’a pas d’odeur. Un agent qui

fabrique une odeur est ajouté au gaz de propane.

Cette odeur vous aide à détecter une fuite de propane.

Cependant, l

peut s

’estomper. Le gaz de propane peut être présent

même s’il n’y a pas d’odeur.

Installer et utiliser l’appareil de chauffage avec soin.

Respecter toutes les ordonnances et codes locaux. S

n’y a pas d’ordonnances et de codes locaux, consulter

La Norme pour l

Gaz de Pétrole Liquéfié, ANSI/NFPA 58 et le Code

d’Installation de Propane, CAN/CGA B149.2. Vous y

trouverez des instructions décrivant la façon la plus sûre

pour entreposer et manipuler les gaz propane.

’autres normes gouvernent l’utilisation

’usage principal des

’appareil de chauffage fournit un

’endroit qui est

Consulter

’utilisation de

’odeur qui est ajouté au gaz de propane

’il

’Entreposage et la Manipulation du

AVERTISSEMENT: NE PAS UTILISER DANS

LES DOMICILES OU LES CAMPING-CARS.

24 Manuel de l’utilisateur

Page 25

Table des matières

Page

Sécurité ................................................................... 26

Commandes .............................................................31

Préparation .............................................................. 32

Installation ................................................................ 34

Fonctionnement ...................................................... 34

Dépannage ............................................................... 36

Entretien .................................................................38

Entreposage ............................................................. 41

Caractéristiques ..................................................... 42

Schéma de câblage ................................................. 43

Garantie ...................................................................44

Note .......................................................................... 45

Toutes les informations, illustrations et caractéristiques contenues

dans la présente publication sont à jour au moment de la publication,

le constructeur se réservant le droit d’apporter sans notification toute

modification jugée appropriée.

Manuel de l’utilisateur 25

Page 26

W

A

R

N

I

N

G

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

C

A

U

T

I

O

N

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

Sécurité

RECONNAITRE LES SYMBOLES DE SÉCURITÉ

Voici le symbole d’alerte de sécurité. Lorsqu’il apparaît

sur votre appareil ou dans ce manuel, rester conscient du

risque potentiel de blessures.

Respecter tous les conseils de sécurité ainsi que les

consignes générales de prevention des accidents.

COMPRENDRE LES MOTS D’ALERTE

Un mot d’alerte—DANGER, AVERTISSEMENT ou

ATTENTION—est utilisé avec le symbole d’alerte de

sécurité. Le terme DANGER identifie les dangers les

plus graves.

Les signes de sécurité avec DANGER ou AVERTISSEMENT

se trouvent près des dangers spécifiques. Les signes de

sécurité avec ATTENTION se réfèrent à des précautions

d’ordre général. Le terme ATTENTION demande aussi

de prêter attention aux messages de sécurité dans ce

manuel.

RESPECTER LES CONSEILS DE SÉCURITÉ

Lire attentivement tous les conseils de sécurité contenus

dans ce manuel et ceux apposés sur l’appareil. Veiller à ce

que les signes de sécurité soient lisibles. Remplacer ceux

qui manqueraient ou seraient endommagés. S’assurer

que les nouveaux composants ou pièces de rechange

incluent les signes de sécurité courants. Des signes de

rechange sont disponibles chez votre concessionnaire

John Deere.

Lisez attentivement et entièrement ce manuel d’utilisation

avant de tenter d’assembler, de faire fonctionner ou de

réparer ce radiateur. Une mauvaise utilisation de cet

appareil de chauffage peut causer de graves blessures,

voire la mort, suite à des brûlures, un incendie, une

explosion, une décharge électrique ou un empoisonnement

au monoxyde de carbone.

Lisez et comprenez tous les avertissements. Conservez

ce manuel pour consultation future. Il vous permettra de

faire fonctionner cet appareil de chauffage correctement

et en toute sécurité.

Si vous ne comprenez pas toute partie de ce manuel

et avez besoin d’assistance, prenez contact avec votre

concessionnaire John Deere.

26 Manuel de l’utilisateur

Page 27

OXYDE DE CARBONE – GAZ TOXIQUE

DA NG ER :

CARBONE PEUT ÊTRE MORTEL

L’E MP OI SO NNE ME NT A U MO NO XY DE DE

!

Le gaz d’échappement du carburant contient de l’oxyde de carbone

– un gaz toxique qui peut vous tuer. Vous NE POUVEZ PAS sentir ou

voir ce gaz.

Empoisonnement au monoxyde de carbone: Les premiers symptômes d’un

empoisonnement au monoxyde de carbone ressemblent à la grippe avec des

maux de tête, des vertiges ou de la nausée. Si vous avez ces symptômes, il se

pourrait que l’appareil de chauffage ne fonctionne pas bien. Respirez tout de suite

de l’air frais ! Faites réparer

l'appareil de chauffage

. Certaines personnes sont

plus affectées par le monoxyde de carbone que d’autres. Celles-ci comprennent

les femmes enceintes, les personnes souffrant de maladies cardiaques ou

pulmonaires ou d’anémie, celles qui sont en état d’ébriété et celles qui vivent à

haute altitude.

Ne jamais se servir d’un carburant dans des espaces fermés ou partiellement

fermés sans ventilation appropriée. Ne l’utilisez que dans des endroits bien

aérés. Avant d’utiliser l’appareil de chauffage, aménagez une ouverture d’air

frais provenant de l’extérieur d’au moins

0,28 m² (3 pi²) pour chaque 30 kW

(100 000 BTU/h) de puissance. Les l'appareil de chauffage peuvent produire

de hauts niveaux d’oxyde de carbone très rapidement. Pendant l’utilisation

d’un carburant, se rappeler que vous ne pouvez pas sentir ou voir l’oxyde de

carbone. Même si vous ne sentez pas les gaz d’échappement, vous pouvez

tout de même être exposé à l’oxyde de carbone.

Si vous commencez à vous sentir malade, étourdi, ou faible pendant

l’utilisation d’un l'appareil de chauffage, sortez au grand air immédiatement.

NE PAS ATTENDRE. L’oxyde de carbone provenant des l'appareil de

chauffage peut rapidement être la cause d’une incapacité complète ou de

mort.

En cas des symptômes sérieux, trouver de l’aide médicale immédiatement.

Informer le personnel médical qu’une intoxication à l’oxyde de carbone est

possible. Si vos symptômes sont apparus à l’intérieur, ne pas retourner dans

le bâtiment avant que les sapeurs pompiers s’assurent que le bâtiment est

sans danger.

NE JAMAIS utiliser le l'appareil de chauffage dans une atmosphère explosible,

près de matériaux combustibles ou dans un endroit où la ventilation n’est pas

suffisante pour évacuer les gaz d’échappement. Les gaz d’échappement

peuvent être la cause de blessures graves ou de mort.

NE JAMAIS se servir d’un l'appareil de chauffage à l’intérieur, que ce soit

dans des maisons, garages, sous-sols, vides de comble ou vides sanitaire, et

autres espaces fermés ou partiellement fermés, sans ventilation appropriée.

Le fait d’ouvrir des fenêtres et des portes ou d’utiliser des ventilateurs

n’empêchera pas l’accumulation d’oxyde de carbone dans la maison.

Ne

l’utilisez que dans des endroits bien aérés. Avant d’utiliser l’appareil de

chauffage, aménagez une ouverture d’air frais provenant de l’extérieur d’au

moins 0,28 m² (3 pi²) pour chaque 30 kW (100 000 BTU/h) de puissance.

Si vous commencez

à vous sentir malade, étourdi, ou faible tout en en

utilisant le réchauffeur de l’espace, a fermé si au loin et obtient l’air frais

TOUT DE SUITE. Voir le docteur. Vous pouvez avoir l’empoisonnement

d’oxyde de carbone.

Installer des alarmes d’oxyde de carbone à piles ou des alarmes d’oxyde de

carbone avec batterie de secours qui se branche dans votre maison, selon

les instructions d’installation du fabricant. Les alarmes d’oxyde de carbone

doivent être conforme aux exigences des dernières normes de sécurité pour

les alarmes d’oxyde de carbone. (UL 2034, IAS 6-96, ou CSA 6.19.01).

Tester votre alarme d’oxyde de carbone fréquemment et remplacer les piles

à plat.

Manuel de l’utilisateur 27

Page 28

RISQUES ÉLECTRIQUES

W

A

R

N

I

N

G

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

C

A

U

T

I

O

N

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

DANGER - UN BRANCHEMENT INCORRECT DU CONDUCTEUR DE

MISE À LA TERRE DE L’ÉQUIPEMENT PEUT ENTRAÎNER

DES RISQUES D’ÉLECTROCUTION. VÉRIFIER AVEC UN

DÉPANNEUR OU UN ÉLECTRICIEN QUALIFIÉ EN CAS DE

DOUTES CONCERNANT LA MISE À LA TERRE.

N’utiliser que la tension et la fréquence électrique indiquées sur la plaque

signalétique. Le câblage électrique et la mise à la terre de l’appareil de

chauffage doivent respecter le Code National Electrique, ANSI/NFPA 70 ou

le Code Canadien Electrique, Partie 1.

L’appareil de chauffage doit être mis à la terre. N’utiliser qu’une rallonge

électrique trifilaire avec mise à la terre. Ne le brancher que dans une prise

avec mise à la terre. En cas de mauvais fonctionnement ou de panne, la

mise à la terre fournit un chemin de moindre résistance au courant électrique,

réduisant ainsi les risques de décharge électrique.

L’appareil de chauffage est une source potentielle de décharge électrique s’il

n’est pas gardé au sec. Maintenir l’appareil de chauffage au sec et ne pas

l’utiliser par temps de pluie ou dans des conditions humides. Pour protéger

l’appareil de chauffage contre l’humidité, ne s’en servir que sur une surface

sèche et sous une structure ouverte tel qu’un auvent. Ne jamais toucher

l’appareil de chauffage avec les mains mouillées.

Vérifier que toute la rallonge est en bon état, sans entailles ou déchirures et

que la fiche a bien trois broches, et surtout une lame de terre.

CONSEILS DE SÉCURITÉ IMPORTANTS

Assurez-vous vous lire et comprendre tous les avertissements.

Gardez ce manuel pour la référence. C’est votre guide de

fonctionnement sûr et approprié de ce réchauffeur.

1. N’utilisez que dans des endroits libres de vapeur inflammable et

de poussière.

2. Distance minimale de tout matériau combustible : 2,44 m (8 pi)

de toute sortie d’air brûlant, 1,83 m (6 pi) du dessus et 60,96 cm

(2 pi) des côtés et de l’admission d’air.

3. Placez l’appareil de chauffage sur une surface stable et de niveau

lorsqu’il est chaud ou lorsqu’il est en marche, pour éviter tout

risque d’incendie.

4. Ne l’utilisez que dans des endroits bien aérés. Avant d’utiliser

l’appareil de chauffage, aménagez une ouverture d’air frais

provenant de l’extérieur d’au moins

0,28 m² (3 pi²) pour chaque

30 kW (100 000 BTU/h) de puissance.

5. Gardez les enfants et les animaux éloignés de l’appareil de

chauffage en tout temps.

6. Ne se servir de l’appareil de chauffage que conformément aux

ordonnances et codes locaux.

7. S’assurer que la zone où se trouve l’appareil de chauffage est

libre de toute substance combustible, d

’essence, de diluant de

peinture et d’autres liquides et vapeurs inflammables.

8. Ne jamais se servir de l’appareil de chauffage dans les espaces

d’habitation.

9. Ne jamais laisser un appareil de chauffage branché sans la

surveillance d

animaux soient présents. Ne pas laisser l

’un adulte s’il est possible que des enfants ou

’appareil de chauffage

sans surveillance.

10. Ne jamais déplacer, manipuler ou réparer un appareil

de chauffage chaud ou en marche. Des blessures graves

pourraient en résulter. Il faut attendre 15 minutes après l

de l

’appareil.

28 Manuel de l’utilisateur

’arrêt

Page 29

CONSEILS DE SÉCURITÉ IMPORTANTS

W

A

R

N

I

N

G

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

W

A

R

N

I

N

G

S

I

N

T

H

E

M

A

N

U

A

L

S

.

C

A

U

T

I

O

N

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

O

C

A

U

T

I

O

N

S

I

N

O

T

H

E

M

A

N

U

A

L

S

11. N’installer jamais de système de conduits d’air à l’avant ou à

l’arrière de l’appareil de chauffage.

12. Les appareils de chauffage à proximité de bâches, de toiles

et d’autres matériaux semblables doivent être maintenus

à une bonne distance de ces derniers. La distance

minimale de sécurité recommandée est de 3,05 m (10 pi).

De plus, il est conseillé d’utiliser des bâches de protection

ignifuges. Ces matériaux doivent être solidement attachés

pour les empêcher de s’enflammer ou de nuire à l’appareil

de chauffage sous l’action du vent.

13.

Débranchez l’appareil lorsqu’il n’est pas utilisé.

14. N

e bloquez jamais la prise d’air (à l’arrière) ou la sortie d’air

(en avant) de l’appareil de chauffage.

15. Cet appareil a été approuvé pour être utilisé dans l’état du

Massachusetts.

16. Ne se servir que du tuyau et du détendeur programmés en

usine fournis avec cet appareil de chauffage.

17. Utiliser uniquement des réservoirs de Propane/GPL équipés

pour le soutirage de gaz.

18. S’utilise uniquement à l’intérieur. Ne pas se servir de l’appareil

de chauffage à l’extérieur.

19. Ne pas se servir de l’appareil de chauffage dans un sous-sol

ou sous le niveau du sol. Le gaz Propane/GPL est plus lourd

que l’air. Si une fuite se produit, le gaz Propane/GPL s’enfoncera

au niveau le plus bas possible.

20. Maintenir l

’appareil de chauffage à une distance minimale

de 6 pieds (1m 82) du/des réservoir(s) de Propane/GPL. Ne

pas orienter l’appareil de chauffage vers un/des réservoir(s) de

Propane/GPL se trouvant à moins de 20 pieds (6m10).

21. Maintenir le/les réservoirs de Propane/GPL en dessous de

100° F (37.8°C).

’assurer que l’appareil de chauffage n’est pas endommagé

22. S

avant chaque utilisation. Ne pas se servir d’un appareil

endommagé.

23. Vérifier l

’état du tuyau avant chaque utilisation de l’appareil

de chauffage. Si le tuyau est très usé ou entaillé, le remplacer

avec un tuyau spécifié par le fabricant avant d’utiliser l’appareil

de chauffage.

24. Maintenir l’appareil de chauffage à l’écart de forts courants d’air,

du vent, des giclements d’eau, de la pluie ou d’eau qui

goutte.

25. Pour éviter les blessures, porter des gants lors du maniement

de l’appareil de chauffage.

26. Ne pas modifier l

’appareil de chauffage. Maintenir l’appareil

de chauffage dans son état original.

27. Ne pas se servir de l

28. Fermer l

’approvisionnement en propane de l’appareil quand il

’appareil de chauffage s’il a été altéré.

ne sert pas.

29. Ne se servir que de pièces de rechange d’origine. Cet appareil

ne doit utiliser que des pièces à caractéristiques spécifiques.

Ne pas substituer ou utiliser des pièces de rechange génériques.

Des pièces de rechange incorrectes peuvent être la cause de

blessures graves ou mortelles.

CONSERVER CES INSTRUCTIONS

Manuel de l’utilisateur 29

Page 30

PORTER DES VÊTEMENTS DE PROTECTION

Porter des vêtements ajustés et un équipement de sécurité

adapté au travail.

Porter un dispositif protecteur d’audition approprié tel que

des couvre-oreilles ou des bouche-oreilles pour se protéger

contre des bruits forts réprehensibles ou inconfortables.

La pleine attention de l’opérateur est requise afin d’utiliser

l’équipement en toute sécurité. Ne pas porter des écouteurs

de radio ou de musique tout en actionnant la machine.

PRÉPARATION POUR LES URGENCES

Garder une trousse des premiers secours et un extincteur

à portée de la main.

Garder les numéros d’urgence des docteurs, du service

d’ambulance, de l’hôpital et des pompiers en cas d’urgence

près du téléphone.

Etre prêt si un incendie débute.

INSPECTER L’APPAREIL DE CHAUFFAGE

S’assurer que tous les couvercles, gardes et plaques de

protection sont serrés et bien en place.

Repérer toutes les commandes et les étiquettes de

sécurité. Inspectez le cordon pour déceler les dommages

avant utilisation. Il y a un risque de choc électrique de

l’écrasement, de la coupure ou du dommage par la

chaleur.

Oter tous les éléments d

’emballage appliqués sur

l’appareil de chauffage pour son transport. Enlever tous

les articles du carton. Vérifier que les articles n

été endommagés pendant le transport. Si l

’ont pas

’appareil de

chauffage est endommagé, il faut rapidement informer

le concessionnaire où vous avez acheté l

’appareil de

chauffage.

FAIRE L’ENTRETIEN DE L'APPAREIL DE CHAUFFAGE

EN TOUTE SÉCURITÉ

Avant d

’entretenir l’appareil de chauffage, mettre

l’appareil à l’arrêt et permettre à l’appareil de refroidir.

Faire l’entretien de l’appareil de chauffage dans un endroit

propre, sec et plat.

Faire l’entretien du de l'appareil de chauffage dans un endroit

propre, sec et plat.

30 Manuel de l’utilisateur

Page 31

A

B

C

D

E

F

G

H

COMMANDES

AC-100LP

Commandes

A -- Sortie d’air chaud (Avant)

B -- Poignée

C -- Grille de protection du

ventilateur

D -- Support du moteur

E -- Cordon d’alimentation

F -- Assemblage du tuyau/

détendeur

G -- Raccord de la prise d’air

H -- Bouton de commande

Manuel de l’utilisateur 31

Page 32

Préparation

VENTILATION

AVERTISSEMENT: RESPECTER LES NORMES

MINIMALES DE VENTILATION DES LOCAUX. SI

UNE VENTILATION ADÉQUATE PAR APPORT

D’AIR FRAIS EXTÉRIEUR N’EST PAS ASSURÉE,

UNE INTOXICATION À L’OXYDE DE CARBONE

EST POSSIBLE. CET APPORT D’AIR FRAIS DOIT

AUSSI ÊTRE ASSURÉ AVANT MÊ M E LE

DÉMARRAGE DE L’APPAREIL DE CHAUFFAGE.

Prévoir une ouverture d’air frais d’au moins 0,28 m² (3

pieds²) pour chaque 100,000 Btu/Heure de puissance.

Fournir davantage d’air frais si plus d’un appareil de

chauffage est utilisé.

ALIMENTATION EN PROPANE

Le gaz Propane/GPL et le/les réservoir(s) de Propane/GPL

doivent être fournis par l’utilisateur.

Ne se servir de cet appareil de chauffage qu’avec un

système d’alimentation de Propane qui assure un soutirage

de vapeur. Voir Chapitre 5 de La Norme pour l

et la Manipulation du Gaz de Pétrole Liquéfié, ANSI/NFPA

58 et le Code d’Installation de Propane, CAN/CGA B149.2.

Votre bibliothèque locale ou les responsables locaux de la

sécurité incendie auront cette brochure.

’Entreposage

Le débit de gaz disponible en sortie du réservoir est

variable. Il dépend de deux facteurs:

1. La qua n tité de gaz Propane / GPL dans le/les

réservoir(s)

2. La température du/des réservoir(s.)

Le tableau ci-dessous montre le nombre de réservoirs de

100 livres (45 kg) nécessaires pour faire fonctionner cet

appareil de chauffage. Des réservoirs plus petits peuvent

être utilisés pour une utilisation de courte durée mais il

est conseillé de se servir de grands réservoirs pour une

performance optimale.

Température au réservoir Nombres de réservoirs de

100 livres (45 kg)

32°F (0°C) to 20°F (-6.7°C) 2

20°F (-6.7°C) to -10°F (-23.3°C) 3

En dessous de -10°F (-23.3°C) (Se servir d’un réservoir

plus grand)

Moins de gaz est vaporisé à des températures plus basses.

Vous aurez peut être besoin de deux ou plus réservoirs

de 100 livres (45 kg) ou d’un réservoir plus grand lors de

températures très froides. Votre fournisseur local de gaz

Propane/GPL vous aidera à sélectionner le bon système

d’alimentation. Les appareils de chauffage sont certifiés

pour fonctionner jusqu’à une température ambiante

minimum de –20° F (-29° C).

32 Manuel de l’utilisateur

Page 33

THÉORIE DE FONCTIONNEMENT

Préparation

Système d

’alimentation en carburant: L’assemblage du tuyau/détendeur est relié à l’alimentation de gaz

Propane/GPL. Le gaz Propane/GPL se déplace à travers le bouton de commande et sort par la buse.

Le système d

’admission d’air: Le moteur fait tourner le ventilateur. Le ventilateur pousse l’air à l’intérieur et

autour de la chambre de combustion. L’air est chauffé et fournit un courant d’air propre et chaud.

Le circuit d’allumage : Le transformateur d’allumage et l’allumeur allument le brûleur principal.

Le système de contrôle de sécurité: Ce système provoque l’arrêt de l’appareil de chauffage en cas d’extinction

de la flamme.

Manuel de l’utilisateur 33

Page 34

Installation

INSTALLATION

IMPORTANT: Revoir et comprendre les avertissements de la

partie Information de Sécurité. Ils sont requis pour faire fonctionner

cet appareil de chauffage sans danger. Se conformer à tous les

règlements et codes locaux lors de l’utilisation de cet appareil de

chauffage.

AVERTISSEMENT : TESTER TOUTE LA TUYAUTERIE

ET TOUS LES RACCORDS AFIN DE S’ASSURER

QU’IL N’Y A AUCUNE FUITE APRÈS L’INSTALLATION

OU L’ENTRETIEN. NE JAMAIS SE SERVIR D’UNE

FLAMM E N UE POUR T RO U VE R UN E FUITE.

APPLIQUER UN MÉLANGE D’EAU ET DE SAVON

LIQUIDE À TOUS LES JOINTS. L’APPARITION DE

BULLES INDIQUE UNE FUITE. RECTIFIER TOUTES

LES FUITES IMMÉDIATEMENT.

1. Fournir le système d’alimentation en propane (voir Alimentation

en Propane).

2. Raccorder l’ajustage du connecteur de gaz combustible

de l’assemblage du tuyau/détendeur au/aux réservoirs de

Propane/GPL. Tourner dans le sens contraire des aiguilles

d’une montre dans le filetage de la valve du réservoir. Serrer

solidement en se servant d’une clé.

IMPORTANT: Serrer le détendeur en s’assurant que la bouche

d’aération est orientée vers le bas. Le fait d’orienter la bouche

d’aération vers le bas protége le détendeur de dégâts dus aux

intempéries. (Fig. 1)

3. Raccorder le tuyau au raccord de la prise d’air. Serrer solidement

en se servant d’une clé. (Fig. 2)

IMPORTANT: De la tuyauterie ou du tuyau supplémentaire

peuvent être utilisés si nécessaire. Installer le tuyau ou la

tuyauterie supplémentaire entre l’assemblage du tuyau/détendeur

et le réservoir de Propane/GPL. Vous devez vous servir du

détendeur fourni avec l’appareil de chauffage.

4. Ouvrir lentement le robinet d’alimentation de propane du/des

réservoir(s) de Propane/GPL.

Note: Si le robinet d’alimentation n’est pas ouvert lentement, le

clapet d’excés de débit du réservoir de Propane/GPL coupera

l’alimentation en gaz. En ce cas, fermer le robinet d’alimentation

de Propane et le rouvrir lentement.

5. Vérifier tous les raccords afin de s’assurer qu’il n’y a pas de

fuites.

6. Fermer le robinet d’alimentation de Propane.

(Fig. 1)

(Fig. 2)

Fonctionnement

FONCTIONNEMENT

AVERTISSEMENT: RESPECTER LES NORMES MINIMALES

DE VENTILATION DES LOCAUX. SI UNE VENTILATION

ADÉQUATE PAR APPORT D’AIR FRAIS EXTÉRIEUR

N’EST PAS ASSURÉE, UNE INTOXICATION À L’OXYDE

DE CARBONE EST POSSIBLE. CET APPORT D’AIR

FRAIS DOIT AUSSI ÊTRE ASSURÉ AVANT MÊME LE DÉ

MARRAGE DE L’APPAREIL DE CHAUFFAGE.

POUR DÉMARRER L’APPAREIL DE CHAUFFAGE:

1. Respecter toutes les consignes de ventilation et de sécurité.

2. Placer l’appareil de chauffage de façon à fournir une circulation

d’air chaud maximale. Suivre toutes les exigences d’emplacement

précisées sous la rubrique d’Information de Sécurité.

34 Manuel de l’utilisateur

Page 35

Fonctionnement

FONCTIONNEMENT

3. Placer l

S’assurer que des courants d’air forts ne soufflent pas dans l’avant

ou l’arrière de l’appareil de chauffage.

4. S

(OFF).

5. Brancher le cordon d

une rallonge électrique trifilaire avec mise à la terre. La rallonge

électrique doit mesurer au moins 6 pieds (1,80 m), être de classe

UL/CSA et de section suffisante. Voir le tableau de rallonge

électrique.

6. Brancher la rallonge électrique dans une prise de courant à trois

branches de 120 volts/60 hertz avec mise à la terre. Le moteur

démarrera. Le ventilateur se mettra à tourner et forcera l

par l’avant de l’appareil de chauffage.

7. Ouvrir lentement le robinet d

réservoir(s) de propane/GPL.

Note: Si le robinet d

clapet d’excès de débit sur le réservoir dePpropane/GPL coupera

l’alimentation en gaz

clapet d

d’excès de débit en fermant le robinet d’alimentation en propane/GPL

et le rouvrir lentement.

’appareil de chauffage sur une surface stable et plane.

’assurer que le bouton de commande est en position d’arrêt

’alimentation de l’appareil de chauffage dans

’air à sortir

’alimentation en propane du/des

’alimentation n’est pas ouvert lentement, le

. Vous entendrez peut être un déclic provenant du

’excès de débit qui se ferme. En ce cas, réenclencher le clapet

Exigences des dimensions

de rallonge électrique

Longueur rallonge: Calibre AWG de

la rallonge:

51 à 100 pieds

(15.5 à 30.48 m)

101 à 200 pieds

(30.78 à 60.96 m)

16 AWG

14 AWG

8. Pousser et continuer d’appuyer sur le bouton de commande. Tourner

dans le sens inverse des aiguilles d

BAS (low). L

secondes.

Note : Si l’appareil de chauffage ne s’allume pas, il se peut qu’il y ait

’air dans le tuyau. En ce cas, continuer d’appuyer sur le bouton de

de l

commande et attendre 20 secondes. Relâcher le bouton de commande

et attendre 20 secondes pour que le combustible résiduel s

l’appareil de chauffage. Répéter l’étape 8.

9. Attendre 30 secondes après l’allumage de l’appareil de chauffage.

Ceci déclenche le système de contrôle automatique. Relâcher le

bouton de commande.

10. Quand le brûleur reste allumé, mettre l’appareil de chauffage à

la température désirée en tournant le bouton de commande dans

le sens inverse des aiguilles d

fermer le gaz. Tourner complètement le bouton de commande

jusqu’à la position la plus basse. Vérifier l’approvisionnement en

combustible. Si l

redémarrer l’appareil de chauffage en commençant par l’étape 1.

POUR ARRÊTER L’APPAREIL DE CHAUFFAGE :

1. Bien fermer le robinet d’alimentation en propane du/des réservoir(s)

de Propane/GPL.

2. Attendre quelques secondes. L

gaz qui reste dans les tuyaux d’alimentation.

3. Tourner le bouton de commande jusqu

4. Débrancher l

’appareil de chauffage devrait s’allumer en quelques

’approvisionnement en combustible est suffisant,

’appareil de chauffage.

’une montre jusqu’à la position

’évacue de

’une montre. Si le brûleur s’éteint,

’appareil de chauffage va brûler le

’à la position d’arrêt (OFF).

Manuel de l’utilisateur 35

Page 36

Dépannage

AVERTISSEMENT : HAUTE TENSION. NE JAMAIS FAIRE L’ENTRETIEN DE L’APPAREIL DE

CHAUFFAGE PENDANT QU’IL EST BRANCHÉ, EN MARCHE OU CHAUD. DES BRÛLURES

GRAVES ET DES DÉCHARGES ÉLECTRIQUES POURRAIENT EN RÉSULTER.

Symptôme Problème Solution

Le ventilateur ne tourne pas

quand l’appareil de chauffage