Page 1

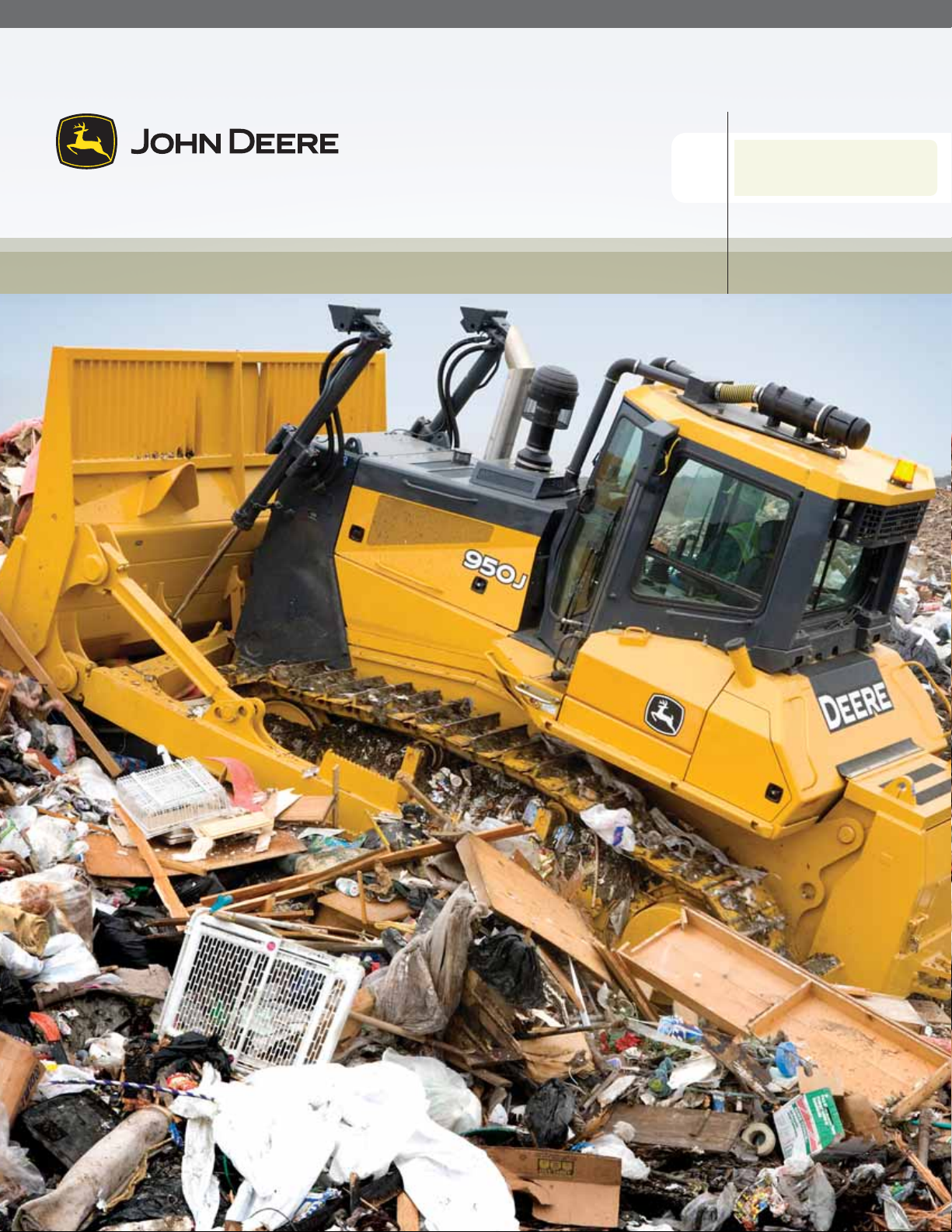

247–335 NET HORSEPOWER

DOZERS

WASTE HANDLERS

J

950J | 1050J

Page 2

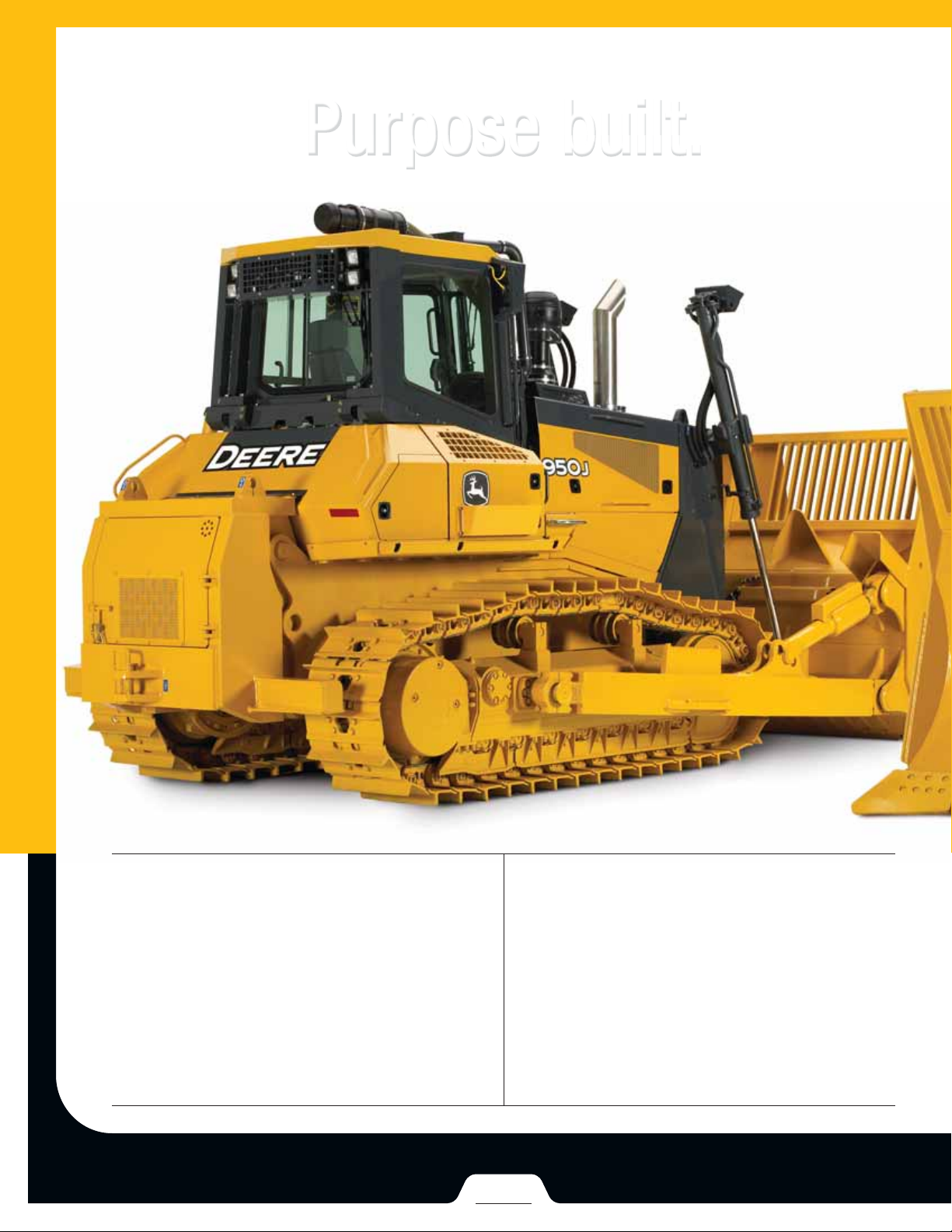

Purpose built.

Purpose built.

950J

247 net hp

9.4- or 21.8 cu.-yd. blade

58,462-lb. typical operating weight

When Deere engineers set out to design the ulti-

mate waste handlers, they couldn’t have picked

better platforms. With their full-featured hydro-

static drivetrains, the 950J and 1050J Waste

Handlers deliver automatic power management,

infinite ground speeds, power turns, and all kinds

of hydrostatically driven productivity advantages.

PAG ES

But power and nimble performance are just the

beginning of the John Deere story. To make

them the best possible landfill dozers, Deere

engineers went right to the source — solid waste

managers — to think through the solutions a

purpose-built waste handler can provide. To see

how we applied what we learned, turn the page.

2–3

Page 3

1050 J

335 net hp

11.6-, 15.3-, 25.8-, or 32.8 cu.-yd. blades

80,967-lb. typical operating weight

Rugged and reliable J-Series

are powerful performers,

designed and purpose-built

with extensive input from solid-

waste professionals like you.

John Deere’s full-featured

hydrostatic drivetrains

deliver production-boosting

advantages you don’t get

with other crawlers.

Cooling system enhancements

such as wide-fi n cooler

cores and hydraulic fans with

automatic reversers help

beat the heat, for maximum

uptime and productivity.

Available rear counterweight

“doghouse” provides conven-

ient storage and is an ideal

location for fi re-suppression

system components.

Page 4

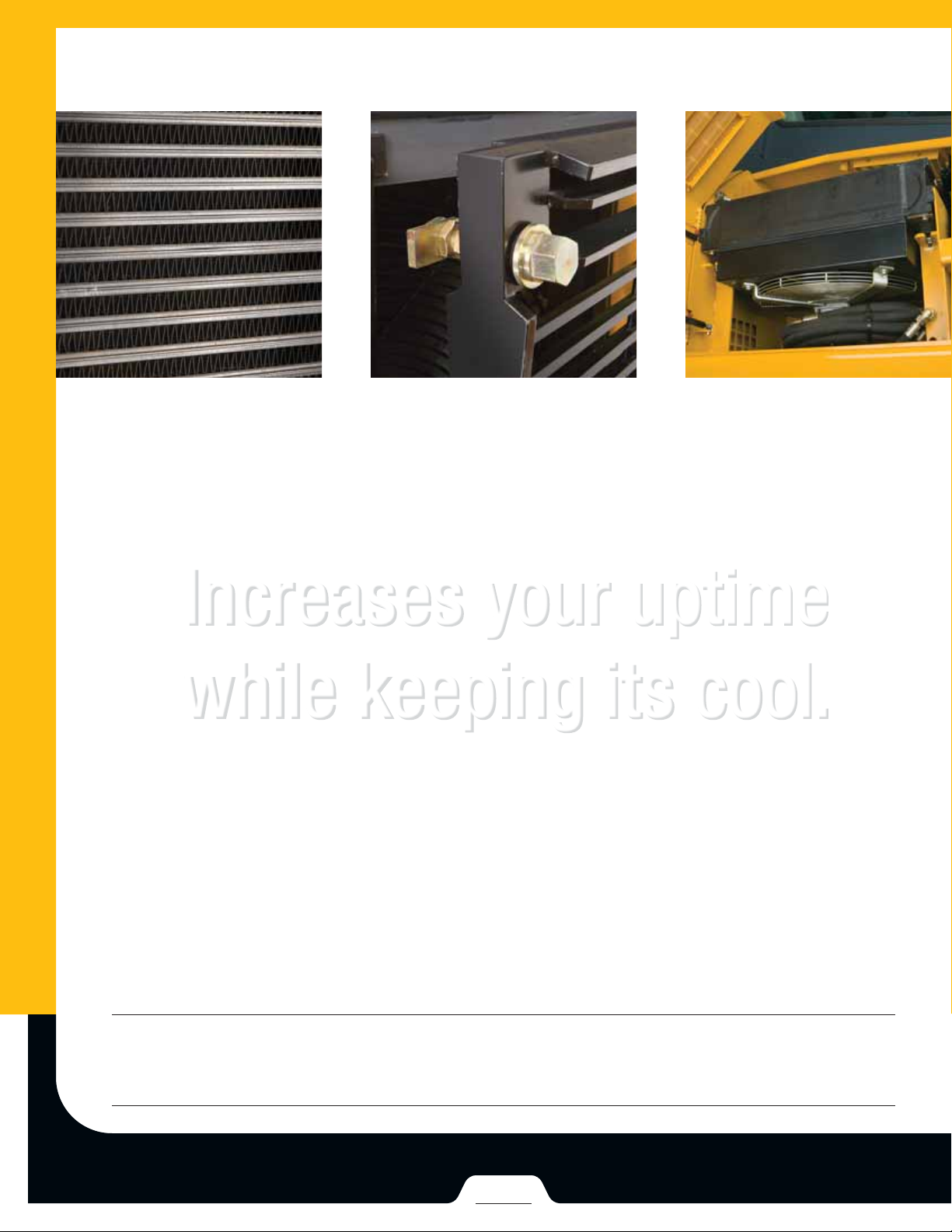

Five-fi n-per-inch engine and charge-air

coolers let dust and debris easily pass through

the cores. For more effi cient cooling and

easier clean-out.

Increases your uptime

Increases your uptime

while keeping its cool.

while keeping its cool.

Quarter-turn latches on the hinged front grille

allow quick and easy access for maintenance

and cleaning.

Hydraulically driven variable-speed suction fans

operate only as needed, reducing noise, fuel con-

sumption, component wear, and operating costs.

If you can’t take the heat, stay out of the landfi ll. We heard that loud and clear. So go ahead and put them

through their paces — the J-Series Waste Handlers have what it takes to keep their cool in a hostile world.

PAG ES

4–5

Page 5

Three-millimeter perforations

in the hood and side shields

act as a “fi rst fi lter,” preventing

entry of most airborne debris.

Variable-speed engine/

charge-air- and hydraulic/

hydrostatic-cooler fans run

only as needed, reducing

noise, fuel consumption,

cooling component wear,

and operating costs.

No stacked coolers in these

crawlers. Radiators and

engine charge-air coolers

are mounted side-by-side, so

they’re easier to clean.

Suction-type fans

automatically reverse every

30 minutes to blow away

refuse and help prevent

plugging. They can also be

manually activated from the

seat as needed.

Page 6

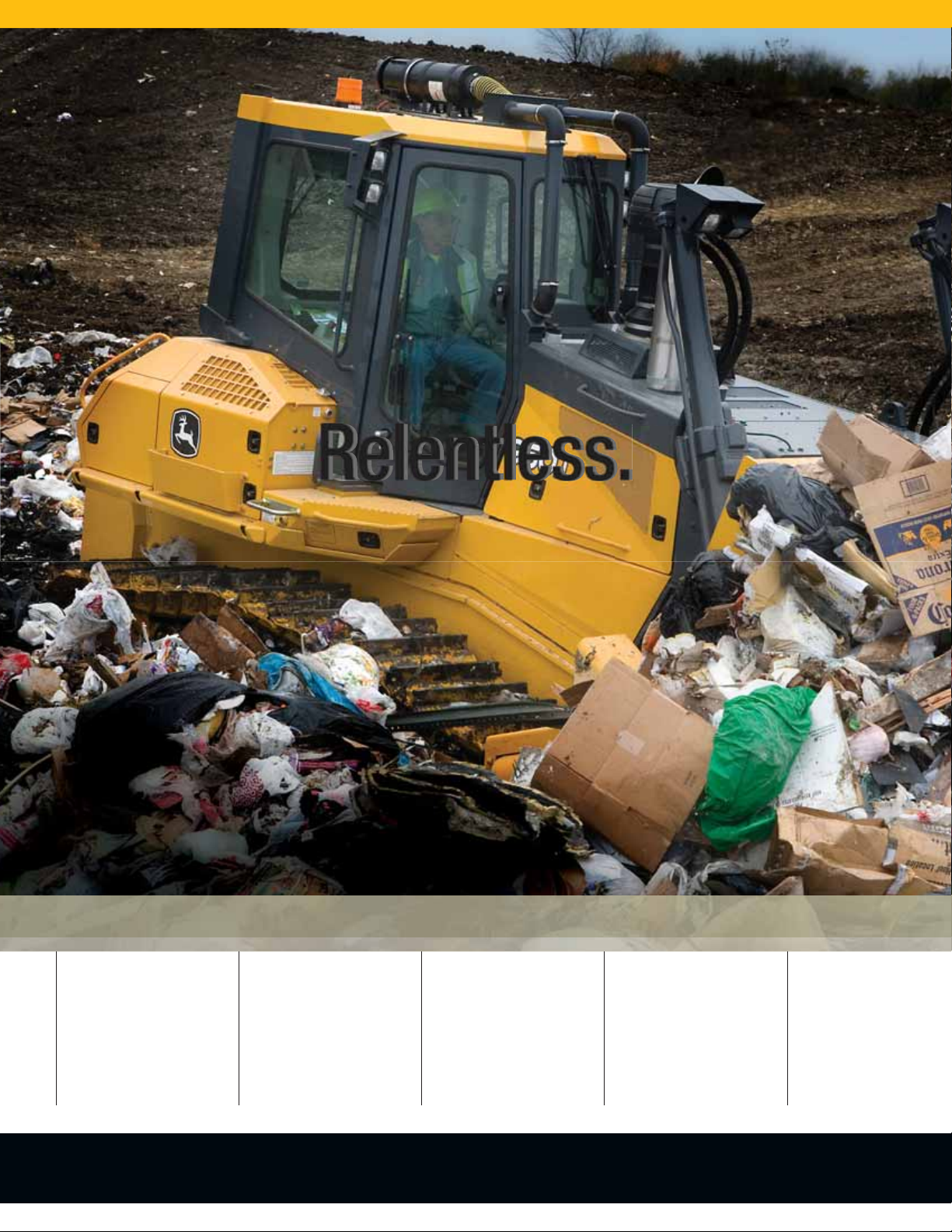

Traditional oval under-

carriage has only one

wear-causing forward-travel

fl ex point. Compared to the

three found on elevated

sprocket undercarriages,

which do you think will last

longer?

Relentless.

Relentless.

Heavy-duty ten-light package

includes four mounted on the

lift cylinders to help illuminate

the way. Lights are guarded

to minimize damage. Cab is

pre-wired for a beacon.

Cab waste barrier prevents

refuse from the tracks

from accumulating in the

powertrain.

Comprehensive hose-guard

system and internal routing

keep hydraulic hoses out of

harm’s way. Generous ground

clearance and smooth belly

guards resist catching and

carrying waste.

Dual-stage pre-cleaner

and under-hood fi lter

help prolong engine life.

Alternator incorporates a

hood-mounted fresh-air

pre-cleaner to help keep out

airborne abrasives.

Turbocharged diesels

deliver impressive power

at a low rpm for enhanced

longevity and optimum fuel

economy. Wet-type cylinder

liners dissipate heat for

reduced ring wear and oil

breakdown.

Page 7

You won’t have operators standing by with a

John Deere waste handler. We sweat the de-

tails to make these crawlers’ bulletproof design

waste proof as well. If something’s susceptible

to damage, we’ve sealed, moved, re-routed, or

re-engineered it — all in the name of uptime.

Optional front and/or rear

striker bars shed material

from the tracks and help

prevent trash buildup around

the idlers. Trapezoidal track

pad cutouts and recessed

sprocket segments resist

undercarriage packing.

Fuel-tank guard and heavy-

duty hinged bottom guards

minimize damage. In addition,

heavy-duty reinforcement

bars on the grille, engine side

shields, and hydraulic/hydro-

static-cooler cover protect vital

components.

You know the cost of fi nal-drive repairs. John Deere’s unique design offers

unsurpassed protection. Bolt-on seal guards provide the fi rst defense.

Debris that gets past this point encounters an oil-fi lled double seal outside

the fi nal drive. If debris penetrates the fi rst seal, oil escapes, setting off

a visual warning within the cab, alerting the operator to shut down the

machine. The second seal maintains oil in the fi nal drives. It’s an early

warning system that can help avoid downtime and expense.

Turbocharger and exhaust-

manifold thermal shield

keeps these high-heat

engine components under

wraps to reduce fi re hazards.

A

C

B

A. Final-drive seal guard

B. Outer seal

C. Inner seal

B

C

A

PAG ES

6–7

Page 8

Replaceable half-shell

bearings within the dozer

push beams provide

longer component life and

simplifi ed replacement.

Sight gauges provide

quick daily checks of hy-

draulic/transmission and

fi nal-drive fl uids. Monitor

signals an alert should

these levels drop.

Convenient test ports, in-

line fl uid-sampling ports,

and diagnostic monitor

keep maintenance and

operating costs to a

minimum.

No need to disconnect

cooling system or hydrau-

lic hoses when tilting the

cab. Built-in jack provides

quick and easy service

access to drivetrain

components. Simplifi es

clean-out, too.

Optional fast-fuel and

engine/splitter box oil-

evacuation systems

help speed and simplify

periodic servicing for

increased uptime.

Big dozer, minimal

Big dozer, minimal

maintenance.

maintenance.

Your maintenance crew won’t have to crawl all over these crawlers to maintain them. Like all Deere

equipment, daily and periodic service points are conveniently grouped, with many behind hinged side

shields that open wide, simplifying fl uid and fi lter checks for increased uptime.

PAG ES

8–9

Page 9

All daily engine-service

checks are accomplished

on the right side. Extended

maintenance intervals let

you go longer between

scheduled service.

Conveniently displayed

periodic lubrication and

maintenance charts help

ensure that nothing is

overlooked.

TMC system provides

detailed diagnostic readings

with easy-to-understand

messages for quick, easy

troubleshooting without

special tools.

Page 10

Major production.

Major production.

These purpose-built waste handlers have every-

thing they need for maximum uptime, minimum

maintenance, and unsurpassed performance. The

J-Series’ hydrostatic-drive system goes beyond

the limits of other dozers, delivering infinite speed

control, power management, and full power turns.

With conventional torque-converter transmission

and clutch/brake or differential steering systems,

other dozers just don’t deliver the same operating

ease. But hydrostatic drive isn’t the only thing

that enables the 950J and 1050J to exceed the

others. Their traditional oval undercarriage design

also incorporates several features that help them

deliver long life and a smooth, productive ride.

PAG ES

10–11

Page 11

Electronic monitor and gauges (including hydraulic/transmission oil

temperature gauge) keep a vigilant watch on vital functions. Issues both

visual and audible warnings.

Spacious and quiet air-conditioned cab provides unsurpassed all-round

visibility and daylong comfort. Insulated HVAC ducting and AC compressor

lines signifi cantly improve cooling effi ciency.

Just set maximum desired

ground speed and power

management does the

rest. As loads change,

the drivetrain automati-

cally powers up or down to

maintain peak engine rpm

and effi ciency. Travel speed

in either direction can also

be limited, to maximize

undercarriage life.

Infi nitely variable track

control lets an operator

speed up or slow power to

each track — for smooth,

full power turns of any

radius. Unlike dozers with

differential steering, tight

turns are possible at any

travel speed.

Hydraulic tilt and available

blade pitch help keep the

load in front of the blade.

Optional trash rack does

its job without sacrifi cing

visibility.

Pilot-operated single lever

gives intuitive, low-effort

control of steering, forward/

reverse travel, and ground

speed. One-hundred

percent of available power

is always applied, regard-

less of the selected speed

range, for top productivity

all the time.

Available extreme-service

pre-cleaner fi lters incom-

ing air, helping make the

sealed and pressurized cab

even more operator friendly.

Page 12

Specifications

Specifications

Specifications

Engine 950J WH

Manufacturer and Model. . . . . . . . . . . . . . . . . . . . . . . . . . Liebherr D 936-L A6

Non-Road Emission Standards . . . . . . . . . . . . . . . . . . . . . certified to EPA Tier 3 emissions

Cylinders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . in-line 6

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 641 cu.in. (10.5 L)

Net Power (ISO9249). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247 hp (184 kW) @ 1,600 rpm

Net Peak Torque (ISO9249) . . . . . . . . . . . . . . . . . . . . . . . . 937 lb.-ft. (1270 Nm) @ 1,400 rpm

Aspiration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . intercooled and turbocharged diesel; engine air dual-stage precleaner with debris screen; alternator air prescreener

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pressure system with full-flow spin-on filter and integrated oil-to-water cooler

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . dual stage dry type with safety element and aspirated precleaner, with in-cab restriction indicator

Cold-Starting Aid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . intake-mounted air-inlet heater

Slope Operation (maximum angle) . . . . . . . . . . . . . . . . . . 45 deg.

Cooling

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . suction-type cooling fan, front mounted, thermostatically controlled; hydrostatically driven with automatic reverser set on

timer every 30 minutes (run time 30 seconds) and manual switch; perforated engine side shields and heavy-duty front grille

with tilt hose protection

Engine Radiator and Charge Air Cooler . . . . . . . . . . . . . . . 5 fins per in.

Engine Coolant Rating. . . . . . . . . . . . . . . . . . . . . . . . . . . . –34 deg. F (–37 deg. C)

Hydraulic/Transmission Cooling. . . . . . . . . . . . . . . . . . . . . oil-to-air heat exchanger with hydrostatically driven, thermostatically controlled cooling fan with auto fan reversing system

Hydrostatic Cooler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 fins per in.

Powertrain

Transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . automatic dual-path, hydrostatic drive; load-sensing feature automatically adjusts speed and power to match changing

load conditions; each individual track is powered by a variable-displacement pump and motor combination; speed-in-

grip with fingertip speed control; infinite speed control; decelerator pedal controls ground speed to stop; dealer selectable

transmission operating parameters; transmission diagnostic test ports

Maximum Speeds (forward and reverse). . . . . . . . . . . 6.8 mph (11 km/h)

Steering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . single-lever steering, direction control, and counterrotation; full power turns and infinitely variable track speeds provide

unlimited maneuverability and optimum control

Final Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . double-reduction planetary final drives mounted independent of track frame and dozer push frame for isolation from

shock loads; the hydraulic drive motors are mounted to the mainframe; final drives are double sealed with electronic

seal-integrity indicator; bolt-on final-drive seal guards

Drawbar Pull. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82,055 lb. (365 kN) @ .09 mph (1.5 km/h)

Service Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . hydrostatic (dynamic) braking stops the machine whenever the direction/steering control lever is moved to neutral or

whenever the combined decelerator/brake pedal is fully depressed

Parking Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . exclusive park brake feature engages wet,multiple-disc brakes whenever the engine stops, the combined decelerator/

brake pedal is fully depressed, the park lock lever is placed in the park position, the emergency travel stop button is

depressed on the dash, the F-N-R control is in the neutral position for more than 7 seconds, or machine motion is sensed

with F-N-R in neutral position; machine cannot be driven with brake applied, reducing wear-out or need for adjustment

Hydraulics

Load-sensing proportional pump-flow control, variable-displacement axial-piston pump

Pump Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68 gpm (258 L/min.) @ 1,600 rpm

System Relief Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . 3,770 psi (26 000 kPa)

Filter, Return Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 micron with 5-micron bypass filter

Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . single joystick lever

Electrical

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 volt

Number of Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Battery Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,000 CCA

Alternator Rating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 amp

Lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 total: cab mounted 6 (4 front and 2 rear) and 4 lift cylinder; and 2 rear reflectors

PAGES

12–13

Page 13

Undercarriage 950J WH

Tracks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . track frame with front and rear track guides and sprocket guard; features deep-heat-treated, sealed, and lubricated track

links and through-hardened, sealed, and lubrica ted rollers for maximum wear resistance; extreme-duty shoes for severe

applications

Track Gauge (standard). . . . . . . . . . . . . . . . . . . . . . . . . . . 6 ft. 6 in. (1981 mm)

Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . sealed and lubricated

Track/Carrier Rollers (each side) . . . . . . . . . . . . . . . . . . . . 7/2

Track Chain Pitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.5 in.(216 mm)

Sprocket Segments (each side). . . . . . . . . . . . . . . . . . . . . 5

Shoes (each side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Ground Contact Area

22-in. (560 mm) Grouser Width . . . . . . . . . . . . . . . . . 5,194 sq. in. (33 510 cm

24-in. (610 mm) Grouser Width . . . . . . . . . . . . . . . . . 5,658 sq. in. (36 502 cm

26-in. (660 mm) Grouser Width . . . . . . . . . . . . . . . . . 6,122 sq. in. (39 494 cm

2

)

2

)

2

)

Track Length on Ground . . . . . . . . . . . . . . . . . . . . . . . . . . 9 ft. 10 in. (2992 mm)

Oscillation at Front Idler . . . . . . . . . . . . . . . . . . . . . . . . . . 5.6 in. (141 mm)

Ground Pressure (with blade)

22 in. (560 mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.9 psi (75 kPa)

24 in. (610 mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.0 psi (69 kPa)

26 in. (660 mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.3 psi (64 kPa)

Serviceability

Integral bottom protection; engine and mid-frame reinforced guards; hinged bottom access covers; hydraulic hose “O”-ring face seal connectors

Sight Gauges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . hydraulic reservoir, final-drive dual-cone seal, and radiator

Refill Capacities*

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141 gal.(535 L)

Cooling System with Recovery Tank . . . . . . . . . . . . . . 16.4 gal. (62 L)

Splitter Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 gal. (5.6 L)

Engine Oil with Filter. . . . . . . . . . . . . . . . . . . . . . . . . . 11.4 gal. (43 L)

Final Drive (each) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.2 gal.(19.5 L)

Hydraulic/Transmission Reservoir and Filter . . . . . . . . 50 gal. (189 L)

*Please follow drain and refill procedures and volumes listed in the operator’s manual.

Operating Weights

Includes Waste-Handling Package, 24-in. (610 mm)

Extreme-Service Shoes With Trapezoidal Holes,

and Semi-U Blade with Trash Rack. . . . . . . . . . . . . . . 58,462 lb. (26 518 kg)

Tractor Shipping Weight Includes Coolant,Lubricants,

20% Fuel, and Standard Track Pads (without

blade or attachments). . . . . . . . . . . . . . . . . . . . . . . . . 49,351 lb. (22 385 kg)

Optional Components

Extreme-Service Grousers With Trapezoidal Holes

22 in. (560 mm) . . . . . . . . . . . . . . . . . . . . . . . . . – 401 lb. (– 182 kg)

24 in. (610 mm). . . . . . . . . . . . . . . . . . . . . . . . . . in base

26 in. (660 mm . . . . . . . . . . . . . . . . . . . . . . . . . . 209 lb. (95 kg)

Auxiliary Hydraulic Controls and Plumbing for

Rear Attachments

Dual-Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . 278 lb. (126 kg)

Single-Function . . . . . . . . . . . . . . . . . . . . . . . . . . 150 lb. (68 kg)

Blade Liner for Semi-U Blade . . . . . . . . . . . . . . . . . . . 937 lb. (425 kg)

Extended Rigid Drawbar . . . . . . . . . . . . . . . . . . . . . . . 804 lb. (365 kg)

Powered Cab Air Precleaner System* . . . . . . . . . . . . . 249 lb. (113 kg)

Push Plate

Semi-U Blade. . . . . . . . . . . . . . . . . . . . . . . . . . . . 569 lb. (258 kg)

Straight Blade. . . . . . . . . . . . . . . . . . . . . . . . . . . . 472 lb. (214 kg)

Rear Counterweight . . . . . . . . . . . . . . . . . . . . . . . . . . 7,055 lb. (3200 kg)

With Storage Compartment . . . . . . . . . . . . . . . . . 6,120 lb. (2776 kg)

Striker Bars

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 511 lb. (232 kg)

Rear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161 lb. (73 kg)

Trash Rack for Semi-U Blade . . . . . . . . . . . . . . . . . . . 683 lb. (310 kg)

Wear Plates for Push Beams. . . . . . . . . . . . . . . . . . . . 436 lb. (198 kg)

*Note:Adds 12 in. (296 mm) to overall tractor height.

Page 14

Machine Dimensions

J

A

K

I

G

D

F

E

H

L

B

M

C

Overall Height Over Cab* . . . . . . . . . . . . . . . . . . . . . . . 11 ft. 3 in. (3.43 m)

A

(with straight blade)

950J WH

B Overall Length (without blade) . . . . . . . . . . . . . . . . . . . 15 ft. 3 in. (4.66 m)

C Height of Grousers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 in. (71.5 mm)

D Ground Clearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 in.(545 mm)

E Total Width Over Blade-Mounting Trunnions . . . . . . . . . 9 ft. 10 in. (3.00 m)

F Overall Width

22-in. (560 mm) Shoes . . . . . . . . . . . . . . . . . . . . . . . . 8 ft. 4 in. (2.54 m)

24-in. (610 mm) Shoes . . . . . . . . . . . . . . . . . . . . . . . . 8 ft. 6 in. (2.59 m)

26-in. (660 mm) Shoes . . . . . . . . . . . . . . . . . . . . . . . . 8 ft. 8 in. (2.64 m)

*

NOTE:Illustration shows optional cab-roof-mounted cab air precleaner system. Overall height does NOT include this option.With powered cab air precleaner system add 12 in. (296 mm).

Blade Specs

without trash rack with trash rack

Semi-U Blade Weight with Standard Cutting Edges

and Cupped End Bits without Spill Guard . . . . . . . . . . 4,835 lb.(2193 kg) 5,518 lb. (2503 kg)

Weight of Push Beams and Tilt Cylinders

With Mechanical Pitch Adjustment . . . . . . . . . . . . . . . 3,594 lb. (1630 kg) 3,594 lb. (1630 kg)

With Power Pitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4,023 lb. (1825 kg) 4,023 lb. (1825 kg)

SAE Capacity (semi-U) . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.4 cu. yd. (7.19 m

3

) 21.8 cu. yd. (16.65 m3)

G Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 ft. 11 in. (1.5 m) 7 ft. 8 in. (2.3 m)

H Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 ft. 1 in. (3.69 m) 12 ft. 1 in. (3.69 m)

I Lifting Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 ft. 0 in. (1.22 m) 4 ft. 0 in. (1.22 m)

J Blade Digging Depth. . . . . . . . . . . . . . . . . . . . . . . . . . . 20 in. (511 mm) 20 in. (511 mm)

K Maximum Blade Pitch Adjustment . . . . . . . . . . . . . . . . 10 deg. 10 deg.

L Maximum Tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 in. (930 mm) 37 in. (930 mm)

M Overall Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 ft.10 in. (6.05 m) 19 ft. 10 in. (6.05 m)

PAGES

14–15

Page 15

Rear Ripper 950J WH

S

O

N

P

P

1

R

Q

R

3-shank parallelogram ripper with hydraulic pitch adjustment and 2 hole shank positions

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7,286 lb.(3305 kg)

N Ripping Depth

Maximum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 in. (749 mm)

Minimum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 in. (449 mm)

O Lifting Height

Maximum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 in. (755 mm)

Minimum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 in. (459 mm)

P Overall Length (attachment raised). . . . . . . . . . . . . . . 5 ft. 2 in. (1.6 m)

P' Overall Length (attachment lowered) . . . . . . . . . . . . . 6 ft. 4 in. (1.9 m)

Q Toolbar Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 ft. 2 in. (2.2 m)

R Distance Between Teeth. . . . . . . . . . . . . . . . . . . . . . . 3 ft. 3 in. (1.0 m)

S Maximum Pitch Adjustment . . . . . . . . . . . . . . . . . . . . 25 deg.

Page 16

Specifications

Specifications

Specifications

Engine 1050J WH

Manufacturer and Model. . . . . . . . . . . . . . . . . . . . . . . . . . Liebherr D 946-L A6

Non-Road Emission Standards . . . . . . . . . . . . . . . . . . . . . certified to EPA Tier 3 emissions

Cylinders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . in-line 6

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 732 cu.in. (12.0 L)

Net Power (ISO9249). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335 hp (250 kW) @ 1,800 rpm

Net Peak Torque (ISO9249) . . . . . . . . . . . . . . . . . . . . . . . . 1,254 lb.-ft. (1700 Nm) @ 1,400 rpm

Aspiration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . intercooled and turbocharged diesel; engine air dual-stage precleaner with debris screen; alternator air prescreener

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pressure system with full-flow spin-on filter and integrated oil-to-water cooler

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . dual-stage dry type with safety element and aspirated precleaner,with dash-mounted restriction indicator

Cold-Starting Aid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . intake-mounted air-inlet heater

Slope Operation (maximum angle) . . . . . . . . . . . . . . . . . . 45 deg.

Cooling

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . suction-type cooling fan, front mounted, thermostatically controlled; hydrostatically driven with automatic reverser set on

timer every 30 minutes (run time 30 seconds) and manual switch; perforated engine side shields and heavy-duty front grille

Engine Radiator and Charge Air Cooler . . . . . . . . . . . . . . . 5 fins per in.

Engine Coolant Rating. . . . . . . . . . . . . . . . . . . . . . . . . . . . –34 deg. F (–37 deg. C)

Hydraulic/Transmission Cooling. . . . . . . . . . . . . . . . . . . . . oil-to-air heat exchanger with hydrostatically driven, thermostatically controlled cooling fan with auto fan reversing system

Hydrostatic Cooler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 fins per in.

Powertrain

Transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . automatic dual-path, hydrostatic drive; load-sensing feature automatically adjusts speed and power to match changing

load conditions; each individual track is powered by a variable-displacement pump and motor combination; speed-in-grip

with fingertip speed control; infinite speed control; decelerator pedal controls ground speed to stop; dealer selectable

transmission operating parameters; transmission diagnostic test ports

Maximum Speeds (forward and reverse). . . . . . . . . . . 6.8 mph (11 km/h)

Steering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . single-lever steering, direction control, and counterrotation; full power turns and infinitely variable track speeds provide

unlimited maneuverability and optimum control

Final Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . double-reduction planetary final drives mounted independent of track frame and dozer push frame for isolation from

shock loads; the hydraulic drive motors are mounted to the mainframe; final drives are double sealed with electronic

seal-integrity indicator; bolt-on final-drive seal guards

Drawbar Pull. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116,901 lb. (520 kN) @ .09 mph (1.5 km/h)

Service Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . hydrostatic (dynamic) braking stops the machine whenever the direction/steering control lever is moved to neutral or

whenever the combined decelerator/brake pedal is fully depressed

Parking Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . exclusive park brake feature engages wet,multiple-disc brakes whenever the engine stops, the combined decelerator/

brake pedal is fully depressed, the park lock lever is placed in the park position, the emergency travel stop button is

depressed on the dash, the F-N-R control is in the neutral position for more than 7 seconds, or machine motion is sensed

with F-N-R in neutral position; machine cannot be driven with brake applied, reducing wear-out or need for adjustment

Hydraulics

Load-sensing proportional pump-flow control, variable-displacement axial-piston pump

Pump Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68 gpm (258 L/min.) @ 1,600 rpm

System Relief Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . 3,700 psi (26 000 kPa)

Filter, Return Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 microns with 5-micron bypass filter

Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . single joystick lever

Electrical

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 volt

Number of Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Battery Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,000 CCA

Alternator Rating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 amp

Lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 total: cab mounted 6 (4 front and 2 rear) and 4 lift cylinder; and 2 rear reflectors

PAGES

16–17

Page 17

Undercarriage 1050J WH

Tracks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . track frame with front and rear track guides and sprocket guard; features deep-heat-treated, sealed, and lubricated track

links and through-hardened, sealed, and lubrica ted rollers for maximum wear resistance; extreme-duty shoes for severe

applications

Track Gauge (standard). . . . . . . . . . . . . . . . . . . . . . . . . . . 7 ft. 2 in. (2180 mm)

Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . sealed and lubricated

Track/Carrier Rollers (each side) . . . . . . . . . . . . . . . . . . . . 7/2

Track Chain Pitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.5 in.(216 mm)

Sprocket Segments (each side). . . . . . . . . . . . . . . . . . . . . 5

Shoes (each side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Track Length on Ground . . . . . . . . . . . . . . . . . . . . . . . . . . 10 ft. 5 in. (3175 mm)

Oscillation at Front Idler . . . . . . . . . . . . . . . . . . . . . . . . . . 13 in. (330 mm)

Ground Contact Area

24-in. (610 mm) Grouser Width . . . . . . . . . . . . . . . . . 6,004 sq. in. (38 735 cm

26-in. (660 mm) Grouser Width . . . . . . . . . . . . . . . . . 6,496 sq. in. (41 910 cm

28-in. (710 mm) Grouser Width . . . . . . . . . . . . . . . . . 6,998 sq. in. (45 149 cm

2

)

2

)

2

)

semi-U dozer blade with power tilt U blade with power tilt and

Ground Pressure (with blade) . . . . . . . . . . . . . . . . . . . . .

and mechanical pitch adjustment mechanical pitch adjustment

24 in. (610 mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.8 psi (95 kPa) 14.0 psi (97 kPa)

26 in. (660 mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.8 psi (88 kPa) 13.1 psi (90 kPa)

28 in. (710 mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.0 psi (83 kPa) 12.2 psi (84 kPa)

Serviceability

Sight Gauges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . hydraulic reservoir, final-drive dual-cone seal, and radiator

Refill Capacities*

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171.7 gal.(650 L)

Cooling System with Recovery Tank . . . . . . . . . . . . . . 15.1 gal. (57 L)

Splitter Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 gal. (6 L)

Engine Oil with Filter. . . . . . . . . . . . . . . . . . . . . . . . . . 9.0 gal. (34 L)

Final Drive (each) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.9 gal.(19 L)

Hydraulic/Transmission Reservoir and Filter . . . . . . . . 55.5 gal. (210 L)

*Please follow drain and refill procedures and volumes listed in the operator’s manual.

Operating Weights

SAE Operating Weight Includes Standard Equipment,

Semi-U Blade with Trash Rack,24-in. (610 mm)

Extreme-Service Shoes with Trapezoidal Holes,

Full Fuel Tank, and 175-lb. (79 kg) Operator

Optional Components

Extreme-Service Shoes With Trapezoidal Holes

24 in. (610 mm). . . . . . . . . . . . . . . . . . . . . . . . . . in base

26 in. (660 mm). . . . . . . . . . . . . . . . . . . . . . . . . . 520 lb. (236 kg)

28 in. (710 mm). . . . . . . . . . . . . . . . . . . . . . . . . . 1,049 lb. (476 kg)

Auxiliary Dual-Function Hydraulic Controls and

Plumbing for Rear Attachments . . . . . . . . . . . . . . 313 lb. (142 kg)

Blade Liner for Semi-U Blade . . . . . . . . . . . . . . . . . . . 1,311 lb. (595 kg)

Pin Puller (hydraulic). . . . . . . . . . . . . . . . . . . . . . . . . . 130 lb. (59 kg)

Powered Cab Air Precleaner System* . . . . . . . . . . . . . 249 lb. (113 kg)

Push Plate for Semi-U Blade. . . . . . . . . . . . . . . . . . . . 798 lb. (362 kg)

Rear Counterweight

With Drawbar. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8,772 lb. (3979 kg)

With Storage Compartment . . . . . . . . . . . . . . . . . 7,714 lb. (3499 kg)

Trash Rack

For Semi-U Blade. . . . . . . . . . . . . . . . . . . . . . . . . 1,104 lb. (501 kg)

For U-Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,184 lb.(537 kg)

Wear Plates for Push Beams. . . . . . . . . . . . . . . . . . . . 752 lb. (341 kg)

*Note:Adds 12 in. (296 mm) to overall tractor height.

. . . . . . . .

80,967 lb. (36 726 kg)

Page 18

Machine Dimensions 1050J WH

J

A

K

I

G

D

F

E

H

L

B

M

C

Overall Height Over Cab* . . . . . . . . . . . . . . . . . . . . . . . 11 ft. 11 in. (3.63 m)

A

B Overall Length (without blade) . . . . . . . . . . . . . . . . . . . 16 ft. 0 in. (4.88 m)

C Height of Grousers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 in. (84 mm)

D Ground Clearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 in.(635 mm)

E Total Width Over Blade-Mounting Trunnions . . . . . . . . . 10 ft. 4 in. (3.15 m)

F Overall Width

24-in. (610 mm) Extreme-Duty Single-Bar

Grouser Shoes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 ft. 2 in. (2.79 m)

26-in. (660 mm) Extreme-Duty Single-Bar

Grouser Shoes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 ft. 4 in. (2.84 m)

28-in. (711 mm) Extreme-Duty Single-Bar

Grouser Shoes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 ft. 6 in. (2.90 m)

*

NOTE:Illustration shows optional cab-roof-mounted cab air precleaner system. Overall height does NOT include this option.With powered cab air precleaner system add 12 in. (296 mm).

Blade Specs

(with push beams, cupped end bits, and tilt cylinders)

semi-U dozer blade U dozer blade

semi-U dozer blade with trash rack U dozer blade with trash rack

Weight

With Mechanical Pitch Adjustment . . . . . . . . . . . . . . . 13,318 lb. (6041 kg) 14,420 lb. (6541 kg) 14,908 lb. (6762 kg) 16,092 lb. (7299 kg)

With Power Tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13,567 lb. (6154 kg) 14,670 lb. (6654 kg) 15,157 lb. (6875 kg) 16,341 lb. (7412 kg)

With Standard Cutting Edges . . . . . . . . . . . . . . . . . . . 7,033 lb. (3190 kg) 8,135 lb. (3690 kg) 8,622 lb. (3911 kg) 9,806 lb. (4448 kg)

SAE Capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.6 cu. yd. (8.92 m

3

) 25.8 cu.yd. (19.79 m3) 15.3 cu. yd. (11.8 m3) 32.8 cu.yd. (25.05 m3)

G Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 ft. 5 in. (1.7 m) 7 ft. 10 in. (2.4 m) 5 ft. 5 in. (1.7 m) 7 ft. 10 in. (2.4 m)

H Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 ft. 3 in. (4.03 m) 13 ft. 3 in. (4.03 m) 14 ft.2 in. (4.3 m) 14 ft. 2 in. (4.3 m)

I Lifting Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 ft. 7 in. (1.4 m) 4 ft. 7 in. (1.4 m) 4 ft. 7 in. (1.4 m) 4 ft. 7 in. (1.4 m)

J Blade Digging Depth. . . . . . . . . . . . . . . . . . . . . . . . . . . 22 in. (570 mm) 22 in. (570 mm) 22 in. (570 mm) 22 in. (570 mm)

K Maximum Blade Pitch Adjustment . . . . . . . . . . . . . . . . 10 deg. 10 deg. 10 deg. 10 deg.

L Maximum Tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 ft. 5 in. (1043 mm) 3 ft.5 in. (1043 mm) 3 ft. 5 in. (1043 mm) 3 ft.5 in. (1043 mm)

M Overall Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 ft.4 in. (6.5 m) 21 ft. 4 in. (6.5 m) 22 ft. 8 in. (6.9 m) 22 ft.8 in. (6.9 m)

PAGES

18–19

Page 19

S

O

N

P

P

1

R

Q

R

Q

P

1

P

N

S

O

1050J WASTE HANDLER WITH SINGLE-SHANK REAR RIPPER

Rear Ripper 1050J

Parallelogram ripper with hydraulic pitch adjustment

multi-shank (3) with

single-shank (3-hole height hydraulic pitch (2-hole height

adjustment in each shank) adjustment in each shank)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7,974 lb.(3617 kg) 10,509 lb. (4767 kg)

N Ripping Depth

Maximum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 ft. 11 in. (1201 mm) 2 ft. 7 in. (791 mm)

Minimum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 in. (421 mm) 19 in. (476 mm)

O Lifting Height

Maximum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 ft. 5 in. (1040 mm) 3 ft. 3 in. (985 mm)

Minimum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 in. (260 mm) 19 in. (476 mm)

P Overall Length (attachment raised). . . . . . . . . . . . . . . 6 ft. 0 in. (1.8 m) 6 ft. 0 in. (1.8 m)

P' Overall Length (attachment lowered) . . . . . . . . . . . . . 7 ft. 9 in. (2.4 m) 7 ft. 9 in. (2.4 m)

Q Toolbar Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 ft. 4 in. (1.3 m) 8 ft. 0 in. (2.4 m)

R Distance Between Teeth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 ft. 7 in. (1.1 m)

S Maximum Pitch Adjustment . . . . . . . . . . . . . . . . . . . . 31 deg. 31 deg.

1050J WASTE HANDLER WITH MULTI-SHANK REAR RIPPER

Page 20

950J / 1050J WASTE HANDLERS

Key: ● Standard equipment ▲ Optional equipment *See your John Deere dealer for further information.

Base Landfill

Machine Package Engine

●●

Certified to EPA Tier 3 emissions

●●Spin-on vertical oil filter with anti-drainback valve

●●Fuel system includes precleaner with water separator

▲ ● Alternator air prescreener

●●Oil-to-water engine oil cooler

▲ ● Thermal shield for turbocharger and exhaust manifold

●●Electronic engine throttle control

●●Key start switch with electric shutoff

●●Intake-mounted air-inlet heater

Cooling

▲ ● Hydraulically driven fans for engine and hydraulic cooling

●●Radiator and charge air cooler rated 5 fins per in.

systems with automatic reverser on timer and manual switch

●●Radiator and charge air cooler side-by-side design

●●Transmission cooler with hydraulically driven cooling fan

●●Transmission cooler rated 5 fins per in.

● Perforated and corrugated side-shield opening

Powertrain

●●Infinitely variable speed to match ground speed to load

●●Integral final-drive seal protection with in-cab warning before

▲

failure

Bolt-on final-drive seal guards

●

●●Diagnostic test ports

Hydraulics

●●

Two-function hydraulics

●●10/5-micron dual-stage filter element

●●Hydraulic/transmission oil reservoir with service shutoff

●●O-ring seal connectors

●●Diagnostic test ports

Electrical

●●Positive-terminal battery covers

●●Master disconnect

●●Electrically activated battery

● Pre-wired for beacon

Undercarriage

●●Oscillating track frames

▲▲Segmented sprockets

●●Heavy-duty sealed and lubricated track chain

Base Landfill

Machine Package Undercarriage

(continued)

●●Half-shell push-beam bearings

●●Integrated track-frame cover

Operator’s Station

●●Modular-design ROPS/FOPS isolation-mounted cab with left

●●Heater (35,000 Btu) and air conditioning (28,000 Btu)

and right access

●●Pressurized and filtered ventilation with 3-speed blower

●●Left and rear sliding windows

●●Dome light

●●Rubber floor mats

●●Slip-resistant steps

●●Air-suspension fabric seat

●●Adjustable armrests, backrest, height, weight, and fore-aft

●●2-in. (50 mm) seat belt with retractor

●●Radio ready

●●12-volt/10-amp power port

●●Cup holder

●●Interior-mounted rearview mirror

▲ ● Hydraulic oil temperature gauge

Landfill Guarding

▲ ● Bottom tank guards

● Protection bars on side covers

● Protection bars for engine side doors

● Belly pan sealing

● Seal between cab and mainframe

▲ ● Trunnion guard for tilt-cylinder hoses

▲ Striker bars

▲ Blade trash rack

Overall Vehicle

●●

One-piece unitized mainframe

●●On-board cab-tilt system

●●Rear retrieval hitch

●●Rear attachment mounting points integral to mainframe

●●Sight gauges for hydraulic, transmission, and final-drive

▲▲Counterweight with storage compartment

seal fluids

▲▲Hydraulic blade pitch available

▲▲JDLink

TM

CONTROL OWNING AND OPERATING COSTS

Customer Personal Service (CPS) is part of John Deere’s proactive,fix-before-fail strategy on machine maintenance that will help control costs, increase profits, and reduce

stress. Included in this comprehensive lineup of ongoing programs and services are:

Fluid analysis program

major components so you’ll know if there’s a problem

formance. Fluid analysis is included in most extended coverage and preventive-maintenance agreements.

Component life-cycle data

of components and lets you make informed decisions on machine maintenance by telling

you approximately how many hours of use you can expect from an engine, transmission,

or hydraulic pump.This information can be used to preempt catastrophic downtime by

servicing major components at about 80 percent of their life cycle.

DKA91050WH Litho in U.S.A. (07-04)

– tells you what’s going on inside

– gives you vital information on the projected life span

Net engine power is with standard equipment including air cleaner,

exhaust system, alternator, and cooling fan

specified per ISO9249.

(3050 m) altitude.

No derating is required up to 10,000-ft.

at test conditions

all

before

you see a decline in per-

of your machine’s

Specifications and design subject to change without notice.Wherever applicable, specifications are in accordance with SAE standards.

Except where otherwise noted, these specifications are based on units with standard equipment, modular ROPS/cabs, full fuel tanks,

and 175-lb. (79 kg) operators.

Preventive Maintenance (PM) agreements

ing a machine for a given period of time.They also help you avoid downtime by ensuring that critical maintenance work gets done right and on schedule. On-site preventive

maintenance service performed where and when you need it helps protect you from

the expense of catastrophic failures and lets you avoid waste-disposal hassles.

Extended coverage

of time so you can effectively manage costs.Whether you work in a severe-service

setting or just want to spread the risk of doing business, this is a great way to customfit coverage for your operation.And an extended coverage contract also travels well

because it’s backed by John Deere and is honored by

Customer Support Advisors (CSAs)

personal

quality to Customer Personal Service (CPS). Certified CSAs have the knowledge

and skills for helping make important decisions on machine maintenance and repair.

Their mission is to help you implement a plan that’s right for

the burden of machine maintenance off your shoulders.

– gives you a fixed cost for machine repairs for a given period

– give you a fixed cost for maintain-

all

– Deere believes the CSA program lends a

Deere construction dealers.

your

business and take

Loading...

Loading...