INSTALLATION

INSTRUCTIONS

517-278-1226 • tech@jksmfg.com • www.jksmfg.com

491 W. Gareld Avenue, Coldwater, MI 49036

Product: Adjustable Coil Spacers (ACOS™)

Part Number: JKS2210

Welcome

CONGRATULATIONS on your purchase of a new JKS

ACOS™ system! At JKS Manufacturing, we are committed

to providing you with the best products available and your

satisfaction is our rst priority.

PLEASE READ these Installation Instructions carefully,

and save them for future reference, as they contain impor-

tant installation and maintenance information.

Tools Required

Hydraulic Floor Jack and Jack Stands

Metric/Standard Socket Wrench Set

(including a 17mm socket)

6” Socket Extension

8mm and 1/4” Allen Wrenches

Die Grinder with Cut-Off Wheel

(or reciprocating saw)

Grinding Wheel (or similar tool)

File or Deburring Tool

Emory Cloth (or similar paint stripping tool)

1/4” Drill Bit

Rubber or Plastic Mallet *

Tape Measure

Spray Lubricant (WD-40 or similar)

Anti-Seize Lubricant

Medium Strength Threadlocker

Coil Spring Compressor *

Factory Service Manual (recommended)

* Asterisk denotes tools that are not required for some applica-

tions. Thoroughly read instructions rst to determine which tools

will be required for your application.

Important

MOST VEHICLES REQUIRE additional parts or modi-

cations to accommodate the immediate increase in

ride height provided by the ACOS system.

DO NOT EXCEED maximum range of adjustment – see

illustration on page 3.

NOT COMPATIBLE with Rancho, TrailMaster, Rough

Country or Fabtech coil springs.

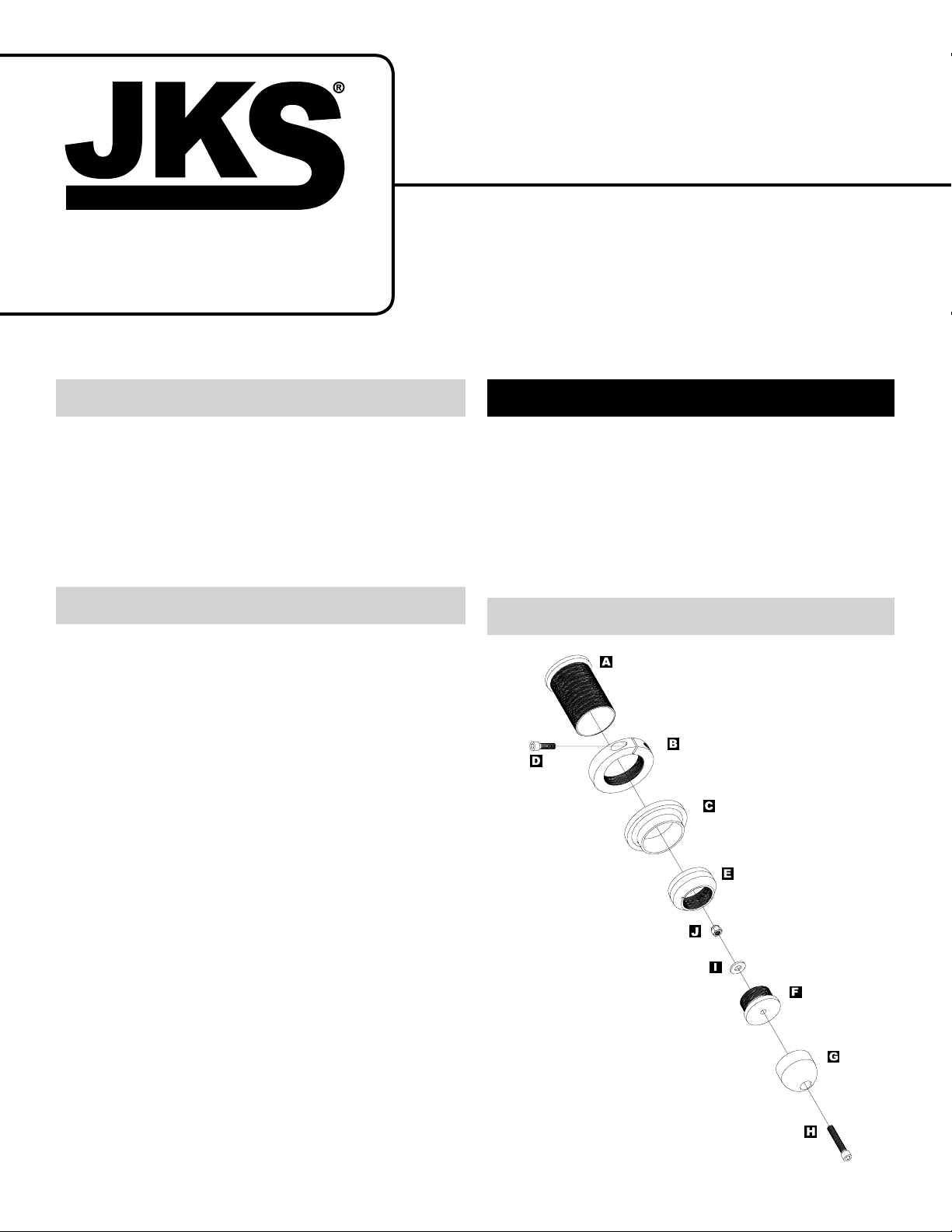

Parts

JKS2 210JKS Adjustable Coil Spacer Installation

Page 1

Description QTY

A

Threaded Tube 2

B

Adjuster Ring 2

C

Isolator Pad 2

D

5/16” x 1-1/4” Cap Bolt 2

E

Bump Stop Adapter 2

F

Bump Stop Plug 2

G

Polyurethane Bump Stop 2

H

10mm x 55mm Cap Bolt 2

I

3/8” Flat Washer 2

J

10mm Locking Nut 2

Installation

1. REMOVE FRONT COIL SPRINGS

Remove the front coil springs per the factory ser-

vice manual instructions for your vehicle.

HINT: A coil spring compressor is useful for removal.

Depending on the application, it may be necessary to completely or partially remove any of the

following components before spring can be free

from upper mount.

Shock Absorber

Swaybar

Brake Line

ABS Wire

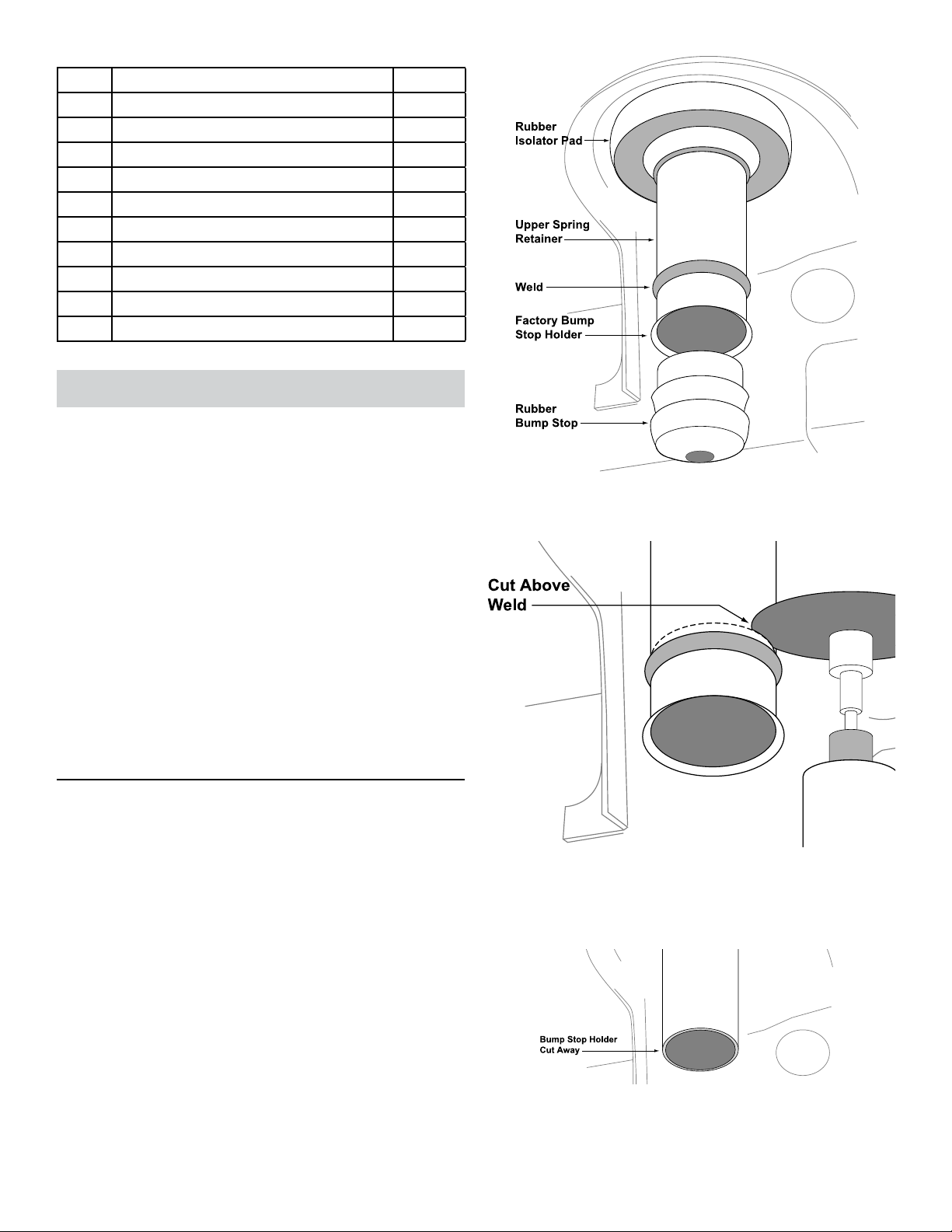

Locate the factory weld that secures the bump

stop holder to the upper coil spring retainer.

2. PREPARE SPRING RETAINER

The factory bump stop holder is welded to the upper spring

retainer and must be permanently removed in order to

install the ACOS™.

Pry the rubber bump stop (jounce bumper) free

from the bump stop holder.

Remove the rubber isolator pad from the upper

coil spring retainer.

2 Page

JKS2 210

Cut away the bump stop holder immediately above

the weld as illustrated. HI NT: A die grinder with

cut-off wheel or reciprocating saw is useful for cutting away the bump stop holder.

Remove any sharp edges from the cut portion of

the upper spring retainer. HINT: A le or deburring

tool is useful for removing sharp edges.

JKS Adjustable Coil Spacer Installation

Loading...

Loading...