Jenn-Air JDS9860CDB00, JDS9860CDB01, JDS9860CDS00, JDS9860CDS01, JDS9860CDS02 Installation Guide

...Page 1

_]ENN-AIRo

INSTALLATIONINSTRUCTIONS

30" (76.2 CM) SLIDE-INDUALFUEL

DOWNDRAFTRANGES

INSTRUCTIONSPOURL'INSTALLATIONDESCUISINIERES

A BI-COMBUSTIBLEENCASTRABLESA EVACUATION

DESCENDANTE DE 30" (76,2 CM)

Table of Contents

RANGE SAFETY .................................................................. 2

INSTALLATION REQUIREMENTS .................................... 4

Tools and Parts ................................................................ 4

Location Requirements .................................................... 4

Venting Requirements ...................................................... 6

Venting Methods .............................................................. 6

Calculating Vent System Length ..................................... 7

Electrical Requirements- U.S.A. Only ............................. 8

Electrical Requirements - Canada Only .......................... 9

Gas Supply Requirements ............................................... 9

Countertop Preparation ................................................. 10

INSTALLATION INSTRUCTIONS .................................... 11

Unpack Range ............................................................... 11

Adjust Leveling Legs...................................................... 11

Install Anti-Tip Bracket ................................................... 11

Install Downdraft System ............................................... 12

Electrical Connection - U.S.A. Only ............................... 16

Make Gas Connection ................................................... 18

Connect Range to Downdraft System ........................... 19

Electronic Ignition System ............................................. 21

Complete Installation ..................................................... 21

GAS CONVERSIONS ........................................................ 22

LP Gas Conversion ........................................................ 22

Natural Gas Conversion ................................................. 23

Table des mati_res

SI_CURITI_ DE LA CUISINII_RE ....................................... 26

EXIGENCES D'INSTALLATION ....................................... 28

Outillage et pieces ......................................................... 28

Exigences d'emplacement ............................................ 28

Exigences concernant I'_vacuation ............................... 30

Methodes d'evacuation ................................................. 31

Calcul de la Iongueur effective du circuit

d'evacuation ................................................................... 32

Specifications 61ectriques - Canada uniquement ......... 33

Sp6cifications de I'alimentation en gaz ......................... 34

Preparation du plan de travail ........................................ 35

INSTRUCTIONS D'INSTALLATION ................................ 35

Deballage de la cuisiniere .............................................. 35

R6glage des pieds de nivellement ................................. 36

Installation de la bride antibasculement ........................ 36

Installation du circuit d'_vacuation par le bas ............... 37

Raccordement au gaz .................................................... 40

Raccordement de la cuisiniere au circuit

d'6vacuation par le bas ................................................. 41

Syst_me d'allumage 61ectronique ................................. 43

Achever I'installation ...................................................... 44

CONVERSIONS POUR CHANGEMENT DE GAZ ........... 44

Conversion pour I'alimentation au propane ................. 44

Conversion pour I'alimentation au gaz naturel .............. 46

iMPORTANT:

Installer: Leave installation instructions with the homeowner.

Homeowner: Keep installation instructions for future reference.

iMPORTANT :

Installateur : Remettre les instructions d'installation au propri6taire.

Propri6taire : Conserver les instructions d'installation pour r6f6rence ult_rieure.

W10253464A

Page 2

RANGE SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

2

Page 3

WARNING: If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or death.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency or

the gas supplier,

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the "What to do if you smell gas" instructions.

In the State of Massachusetts, the following installation instructions apply:

[] Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

[] If using a ball valve, it shall be a T-handle type.

[] A flexible gas connector, when used, must not exceed 3 feet.

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti=tip bracket to rear range foot.

Reconnect the anti=tip bracket, if the range is moved.

Failure to follow these instructions can result in death or serious burns to children and adults.

Page 4

INSTALLATIONREQUIREMENTS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

• Tape measure • Pipe-joint compound

• Phillips screwdriver

• Flat-blade screwdriver • 3/le"(4.8 mm) carbide-tipped

• 1/8"flat-blade screwdriver concrete/ceramic floors)

• Level • Noncorrosive leak-detection

• Hand or electric drill

• Wrench or pliers Conversions

• Pipe wrench • 1/2"combination wrench

• l_e" combination wrench • 1¼.(6 mm) nut driver

• 1/8"(3.2 mm) drill bit (for • 9/32"(7 mm) nut driver

wood floors)

• Marker or pencil

Parts supplied

Check that all parts are included.

• LP/Natural Gas Conversion Kit (taped behind access panel)

• 2- Burner caps

• 3- Burner grates

• 1 -Air grille

• 3- Oven racks

• 1 - Metal ground strap (for 3-wire connection)

• Blower motor

• 2-vent clamps

• Flexible vent

• Flow tester card

• Blower location template

• 4 - #8 x 34" screws (for mounting blower motor bracket

• 2 - #12 x 15/8'' screws (for mounting anti-tip bracket)

• Anti-tip bracket (taped to package containing literature in

oven cavity)

Anti-tip bracket must be securely mounted to the back wall or

floor. Thickness of flooring may require longer screws to

anchor bracket to subfloor. Longer screws are available from

your local hardware store.

Parts needed

• One of the following Jenn-Air wall caps:

Jenn-Air ®5" (12.7 cm) Round Surface Wall Cap Damper

Order Part Number A405

Jenn-Air®6 '' (15.2 cm) Round Surface Wall Cap Damper

Order Part Number A406

Jenn-Air ®3W' x 10" (8.3 x 25.4 cm) Surface Wall Cap Damper

Order Part Number A403

To order, see the "Assistance or Service" section of the Use

and Care Guide.

• Metal ducting

resistant to LP gas

masonry drill bit (for

solution

For LP/Natural Gas

• Masking tape

• Vent clamps

• 2 - 2" x 4" x 834" (5.0 x 10.2 x 22.2 cm) wood spacers (for left

or right side venting)

• Concrete anchors (for concrete floor mounting)

Check local codes and consult gas supplier. Check existing gas

supply and electrical supply. See "Electrical Requirements" and

"Gas Supply Requirements" sections.

IMPORTANT: Observe all governing codes and ordinances. Do

not obstruct flow of combustion and ventilation air.

It is the installer's responsibility to comply with installation

clearances specified on the model/serial rating plate. The

model/serial rating plate is located behind the storage drawer

on the right-hand side of the oven frame.

The range should be located for convenient use in the kitchen.

Recessed installations must provide complete enclosure of

the sides and rear of the range.

To eliminate the risk of burns or fire by reaching over heated

surface units, cabinet storage space located above the

surface units should be avoided. If cabinet storage is to be

provided, the risk can be reduced by installing a range hood or

microwave hood combination that projects horizontally a

minimum of 5" (12.7 cm) beyond the bottom of the cabinets.

All openings in the wall or floor where range is to be installed

must be sealed.

Cabinet opening dimensions that are shown must be used.

Given dimensions are minimum clearances.

The floor anti-tip bracket must be installed. To install the anti-

tip bracket shipped with the range, see "Install Anti-Tip

Bracket" section.

Grounded electrical supply is required. See "Electrical

Requirements" section.

Proper gas supply connection must be available. See "Gas

Supply Requirements" section.

Contact a qualified floor covering installer to check that the

floor covering can withstand at least 200°F (93°C).

Use an insulated pad or 1¼.(0.64 cm) plywood under range if

installing range over carpeting.

IMPORTANT: To avoid damage to your cabinets, check with your

builder or cabinet supplier to make sure that the materials used

will not discolor, delaminate or sustain other damage. This oven

has been designed in accordance with the requirements of UL

and CSA International and complies with the maximum allowable

wood cabinet temperatures of 194°F (90°C).

Mobile Home - Additional Installation Requirements

The installation of this range must conform to the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction and

Safety, Title 24, HUD Part 280). When such standard is not

applicable, use the Standard for Manufactured Home

Installations, ANSI A225.1/NFPA 501A or with local codes.

In Canada, the installation of this range must conform with the

current standards CAN/CSA-A240-1atest edition, or with local

codes.

Mobile home installations require:

• When this range is installed in a mobile home, it must be

secured to the floor during transit. Any method of securing the

range is adequate as long as it conforms to the standards

listed above.

Page 5

Product Dimensions

Cabinet Dimensions

Cabinet opening dimensions shown are for 25" (64.0 cm)

countertop depth, 24" (61.0 cm) base cabinet depth and

36" (91.4 cm) countertop height.

Range may be installed with zero clearance to combustible

construction at the rear and on the sides below the cooktop.

G

F

\

A. 303/4" (78.1 cm)

B. 23V2" (59.7 cm) countertop notch

to rear of cooktop

C. Gas information plate (located on

the right-hand side of the bottom

oven frame)

D. Model/serial number plate (located

on the right-hand side of the

bottom oven frame)

*Range can be raised approximately 1" (2.5 cm) by adjusting the

leveling legs.

**When installed in a 24" (61.0 cm) base cabinet with

25" (63.5 cm) countertop; front of oven door protrudes

21/2'' (6.4 cm) beyond 24" (61.0 cm) base cabinet.

E. 297/6" (75.9 cm)

E 291/16 '' (73.8 cm) from

handle to back of range**

G. 353/4 '' (90.8 cm) height to

underside of cooktop

edge with leveling legs

screwed all the way in*

H

F

A. 13" (33.0 cm) upper cabinet depth

B. 30" (76.2 cm) min. opening width

C. For minimum clearance to the top of the cooktop, see NOTE.

D. 231/4''(59.1 cm) opening depth

E. 30" (76.2 cm) min. opening width

F. Electrical and gas supply - 5V2" (14.0 cm) min. from either cabinet,

10" (25.4 cm) max. from floor. Nothing located in shaded area can

extend more than 2¼" (5.7 cm) from back wall or range will not slide

all the way back. Grounded outlet must be flush mounted.

G. Cabinet door or hinge should not extend into cutout.

H. 18" (45.7 cm)

I. 3" (7.6 cm) min. clearance from both sides of the range to the side

wall or other combustible material.

NOTE: 24" (61.0 cm) minimum when bottom of wood or metal

cabinet is shielded by not less than 1/4"(0.64 cm) flame retardant

millboard covered with not less than No. 28 MSG sheet steel,

0.015" (0.4 mm) stainless steel, 0.024" (0.6 mm) aluminum or

0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance between the top of the cooking

platform and the bottom of an uncovered wood or metal cabinet.

Page 6

IMPORTANT:Thisrangemustbeexhaustedoutdoors.See

"VentingMethods"section.

• Donotterminatetheventsysteminanatticorotherenclosed

area.

• UseaJenn-Airwallcap.

• Ventsystemmustterminatetotheoutside.

• Useonlya6"(15.2cm)roundmetalventora3_¼x10"

(8.3cmx25.4cm)rectangularvent,exceptasfollows:

5"(12.7cm)roundmetalventmustbeusedforventing

lengthsof10ft(3.0m)orless.

• Rigidmetalventisrecommended.Forbestperformance,do

notuseplasticormetalfoilvent.

• Beforemakingcutouts,makesurethereisproperclearance

withinthewallorfloorfortheexhaustvent.

• Donotcutajoistorstudunlessabsolutelynecessary.Ifajoist

orstudmustbecut,thenasupportingframemustbe

constructed.

• Thesizeoftheventshouldbeuniform.

• Theventsystemmusthaveadamper.Ifrooforwallcaphasa

damper,donotusedampersuppliedwiththerangehood.

• Useventclampstosealalljointsintheventsystem.

• Usecaulkingtosealexteriorwallorroofopeningaroundthe

cap.

• Determinewhichventingmethodisbestforyourapplication.

For Best Performance:

• Use 26-gauge minimum galvanized or 25-gauge minimum

aluminum metal vent. Poor quality pipe fittings can reduce

airflow. Flexible metal vent is not recommended.

NOTE: Local codes may require a heavier gauge material.

• Metal duct may be reduced to 30-gauge galvanized steel or

26-gauge aluminized steel if allowed by local codes. This

reduction is based on information in the International

Residential Codes Section M1601.1 (2006 edition).

• Do not install 2 elbows together.

• Use no more than three 90° elbows.

If an elbow is used, install it as far away as possible from the

hood's vent motor exhaust opening.

Make sure there is a minimum of 18" (45.7 cm) of straight vent

between the elbows if more than one elbow is used.

• Elbows too close together can cause excess turbulence that

reduces airflow.

• Do not use a 5" (12.7 cm) elbow in a 6" (15.2 cm) or 3V4"x 10"

(8.3 x 25.4 cm) system.

• Do not reduce to a 5" (12.7 cm) system after using a

6" (15.2 cm) or 3V4"x 10" (8.3 x 25.4 cm) fittings.

• Avoid forming handmade crimps. Handmade crimps may

restrict airflow.

Use a Jenn-Air vent cap for proper performance. If an

alternate wall or roof cap is used, be certain the cap size is not

reduced and that it has a backdraft damper.

Use vent clamps to seal all joints in the vent system.

Use caulking to seal exterior wall or roof opening around the

cap.

The length of vent system and number of elbows should be kept

to a minimum to provide efficient performance.

The maximum equivalent length of the vent system is

60 ft (18.3 m). For altitudes above 4,500 ft (1272 m), reduce

recommended vent run by 20% for best performance.

Cold Weather Installations

An additional backdraft damper should be installed to minimize

backward cold air flow and a thermal break installed to minimize

conduction of outside temperatures as part of the vent system.

The damper should be on the cold air side of the thermal break.

Makeup Air

Local building codes may require the use of makeup air systems

when using ventilation systems greater than specified CFM of air

movement. The specified CFM varies from locale to locale.

Consult your HVAC professional for specific requirements inyour

area.

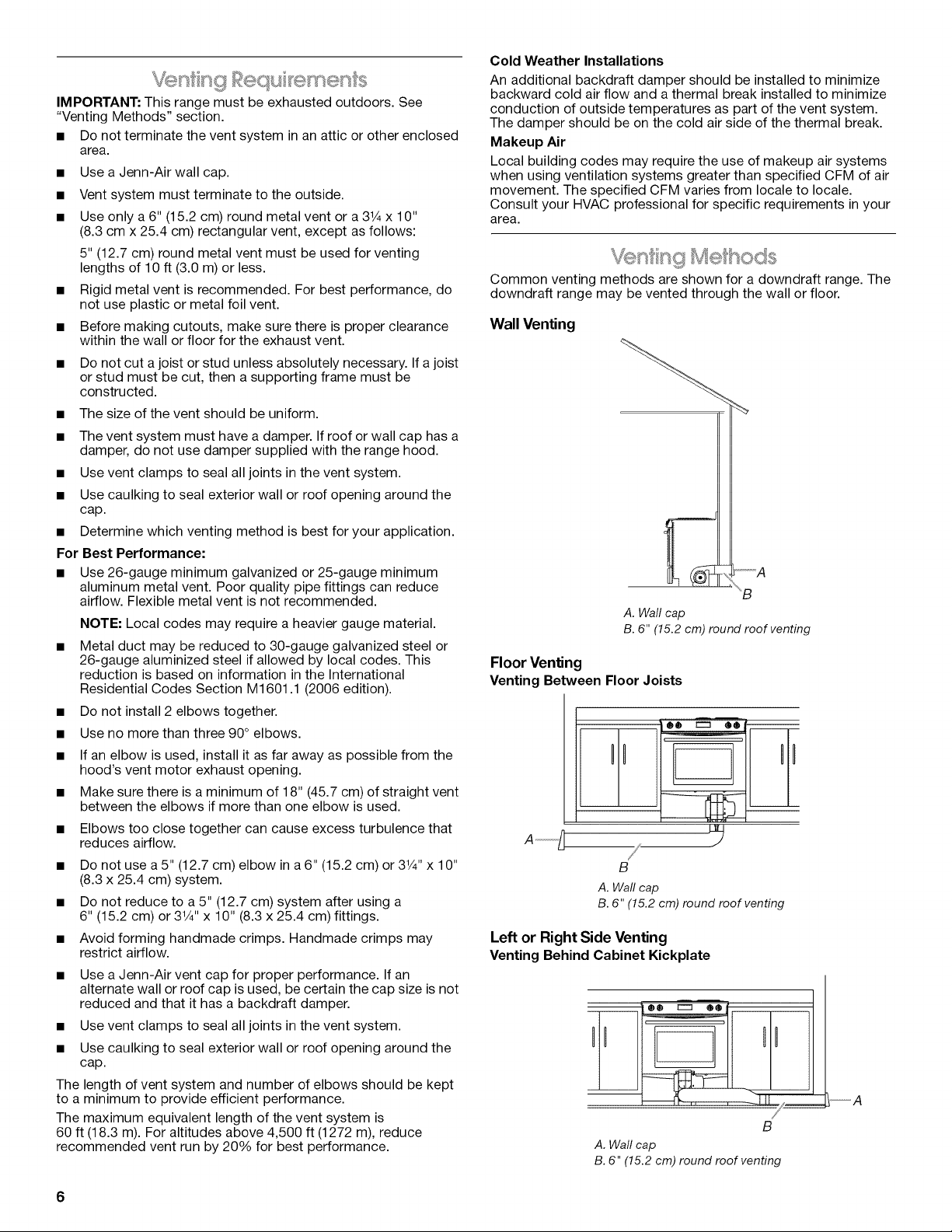

n ng M®t otis

Common venting methods are shown for a downdraft range. The

downdraft range may be vented through the wall or floor.

Wall Venting

B

A. Wall cap

B. 6" (15.2 cm) round roof venting

Floor Venting

Venting Between Floor Joists

0O r-_ 0® --

01

A ..........

B

A. Wall cap

B. 6" (15.2 cm) round roof venting

Left or Right Side Venting

Venting Behind Cabinet Kickplate

B

A. Wall cap

B. 6" (15.2 cm) round roof venting

6

Page 7

ConcreteSlabInstallations - Exhaust Through Wall

B

• To convert blower for high range installations, see the

"Install Downdraft System" section.

To calculate the length of the system you need, add the equivalent

feet (meters) for each vent piece used in the system.

Vent Piece 6" (15.2 cm) Round

J

H

A. Wall cap

B. 6" (15.2 cm) round metal vent

C. 16" (40.6 cm) maximum

D. 6" (15.2 cm) round PVC sewer pipe

E. Concrete slab

F. 6" (15.2 cm) round PVC sewer pipe

G. 6" (15.2 cm) round 90 °PVC sewer pipe elbow

H. Tightly pack gravel or sand completely around pipe.

1.30ft(9.1 m) max.

J. 6" (15.2 cm) round 90 °PVC sewer pipe elbow

K. 6" (15.2 cm) round PVC coupfing

L. 12" (30.5 cm) minimum

Concrete Slab Installations -

Exhaust Through Window Well

IMPORTANT: Window well installationfor electric models only.

B

A _'_

! c

45° elbow 2.5 ft

(0.8 m)

90° elbow 5.0 ft

(1.5 m)

6" (15.2 cm) 0.0 ft

wall cap (0.0 m)

3V4"x 10" (8.3 cm x 25.4 cm) 4.5 ft

to 6" (15.2 cm) transition (1.4 m)

6" (15.2 cm) to 3V4" x 10" 1 ft

(8.3 cm x 25.4 cm) transition (0.3 m)

3V4"x 10" (8.3 cm x 25.4 cm) 5.0 ft

to 6" (15.2 cm) 90 ° elbow (1.5 m)

transition

/

A. Wall cap

B. 12" (30.5 cm) minimum

C. Concrete slab

D. 6" (15.2 cm) round PVC sewer pipe

E. 6" (15.2 cm) round PVC sewer pipe

F. 6" (15.2 cm) round 90 °PVC sewer pipe elbow

G. Tightly pack gravel or sand completely around pipe.

H. 42 ft (12.8 m) max.

I. 6" (15.2 cm) round PVC coupfing

J. 6" (15.2 cm) minimum

K. Window well

IMPORTANT: This range is rated at 60 ft (18.3 m) of straight duct.

Low range is up to 30 ft (9.1 m); high range is 31 ft (9.4 m) to

60 ft (18.3 m).

If equivalent duct length exceeds 30 ft (18.3 m), the blower must

be converted to high range.

• Do not convert to high range for shorter lengths. This will

cause excessive noise, conditioned air loss and affect the

flame pattern on gas ranges.

6" (15.2 cm) to 3V4" x 10" 5.0 ft

(8.3 cm x 25.4 cm) 90° elbow (1.5 m)

transition

3V4"x 10" (8.3 cm x 25.4 cm) 5.0 ft

90° elbow (1.5 m)

3V4"x 10" (8.3 cm x 25.4 cm) 12.0 ft

flat elbow (3.7 m)

3V4"x 10" (8.3 cm x 25.4 cm) 0.0 ft

wall cap (0.0 m)

Page 8

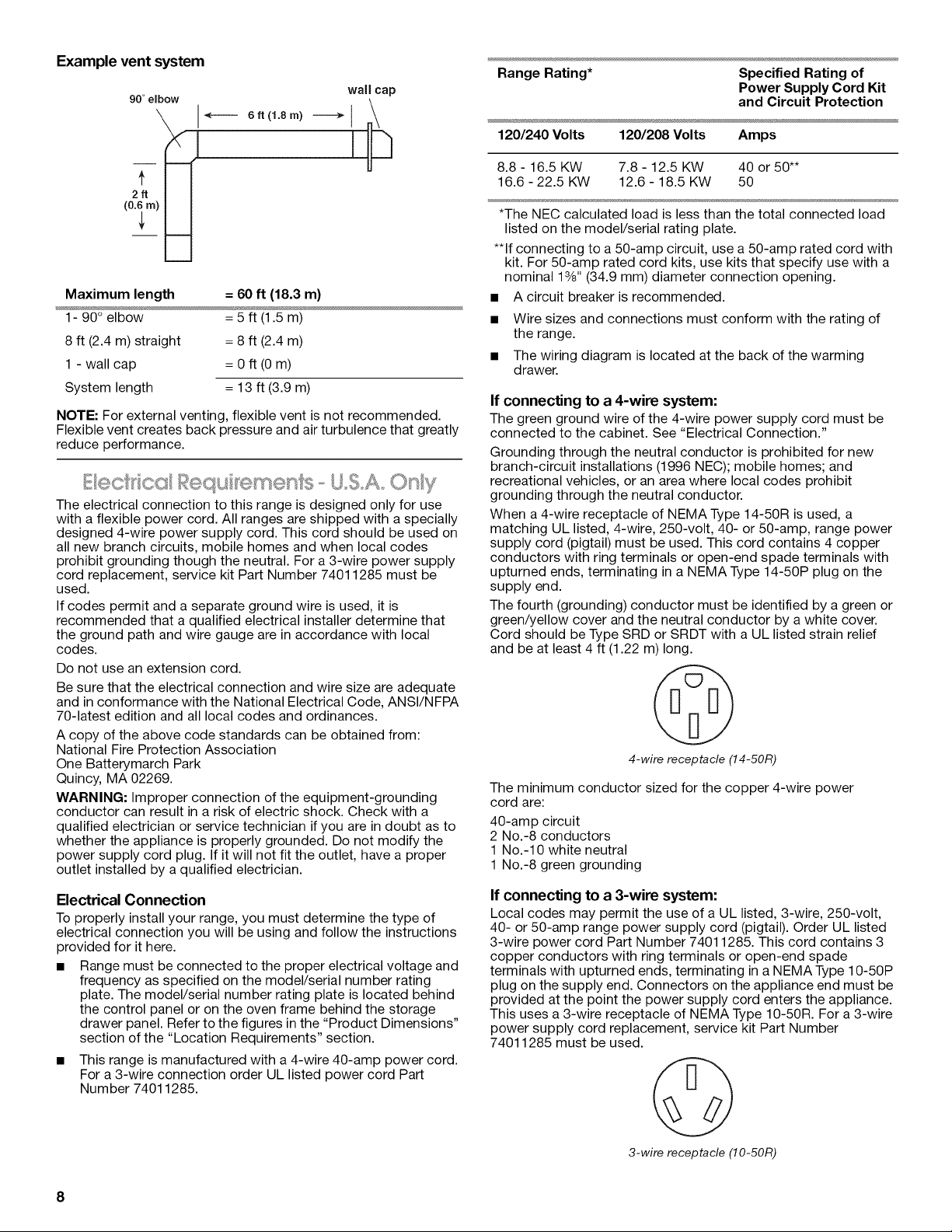

Example vent system

90 ° eNbow

wall cap

Range Rating* Specified Rating of

Power Supply Cord Kit

and Circuit Protection

6 ft (1.8 rn) ----_ _

U

mi

Maximum length = 60 ft (18.3 m)

1- 90° elbow

8 ft (2.4 m) straight = 8 ft (2.4 m)

1 - wall cap = 0 ft (0 m)

System length = 13 ft (3.9 m)

NOTE: For external venting, flexible vent is not recommended.

Flexible vent creates back pressure and air turbulence that greatly

reduce performance.

The electrical connection to this range is designed only for use

with a flexible power cord. All ranges are shipped with a specially

designed 4-wire power supply cord. This cord should be used on

all new branch circuits, mobile homes and when local codes

prohibit grounding though the neutral. For a 3-wire power supply

cord replacement, service kit Part Number 74011285 must be

used.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path and wire gauge are in accordance with local

codes.

Do not use an extension cord.

Be sure that the electrical connection and wire size are adequate

and in conformance with the National Electrical Code, ANSl/NFPA

70-latest edition and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269.

WARNING: Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Check with a

qualified electrician or service technician if you are in doubt as to

whether the appliance is properly grounded. Do not modify the

power supply cord plug. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

Electrical Connection

To properly install your range, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

• Range must be connected to the proper electrical voltage and

frequency as specified on the model/serial number rating

plate. The model/serial number rating plate is located behind

the control panel or on the oven frame behind the storage

drawer panel. Refer to the figures in the "Product Dimensions"

section of the "Location Requirements" section.

• This range is manufactured with a4-wire 40-amp power cord.

For a 3-wire connection order UL listed power cord Part

Number 74011285.

120/240 Volts 120/208 Volts Amps

8.8 - 16.5 KW 7.8 - 12.5 KW 40 or 50**

16.6 - 22.5 KW 12.6 - 18.5 KW 50

*The NEC calculated load is less than the total connected load

listed on the model/serial rating plate.

**If connecting to a 50-amp circuit, use a 50-amp rated cord with

kit. For 50-amp rated cord kits, use kits that specify use with a

nominal 13/8"(34.9 mm) diameter connection opening.

• A circuit breaker is recommended.

Wire sizes and connections must conform with the rating of

the range.

The wiring diagram is located at the back of the warming

drawer.

If connecting to a 4-wire system:

The green ground wire of the 4-wire power supply cord must be

connected to the cabinet. See "Electrical Connection."

Grounding through the neutral conductor is prohibited for new

branch-circuit installations (1996 NEC); mobile homes; and

recreational vehicles, or an area where local codes prohibit

grounding through the neutral conductor.

When a 4-wire receptacle of NEMA Type 14-50R is used, a

matching UL listed, 4-wire, 250-volt, 40- or 50-amp, range power

supply cord (pigtail) must be used. This cord contains 4 copper

conductors with ring terminals or open-end spade terminals with

upturned ends, terminating in a NEMA Type 14-50P plug on the

supply end.

The fourth (grounding) conductor must be identified by a green or

green/yellow cover and the neutral conductor by a white cover.

Cord should be Type SRD or SRDT with a UL listed strain relief

and be at least 4 ft (1.22 m) long.

4-wire receptacle (14-50R)

The minimum conductor sized for the copper 4-wire power

cord are:

40-amp circuit

2 No.-8 conductors

1 No.-10 white neutral

1 No.-8 green grounding

If connecting to a 3-wire system:

Local codes may permit the use of a UL listed, 3-wire, 250-volt,

40- or 50-amp range power supply cord (pigtail). Order UL listed

3-wire power cord Part Number 74011285. This cord contains 3

copper conductors with ring terminals or open-end spade

terminals with upturned ends, terminating in a NEMA Type 10-50P

plug on the supply end. Connectors onthe appliance end must be

provided at the point the power supply cord enters the appliance.

This uses a 3-wire receptacle of NEMA Type 10-50R. For a 3-wire

power supply cord replacement, service kit Part Number

74011285 must be used.

3-wire receptacle (10-50R)

8

Page 9

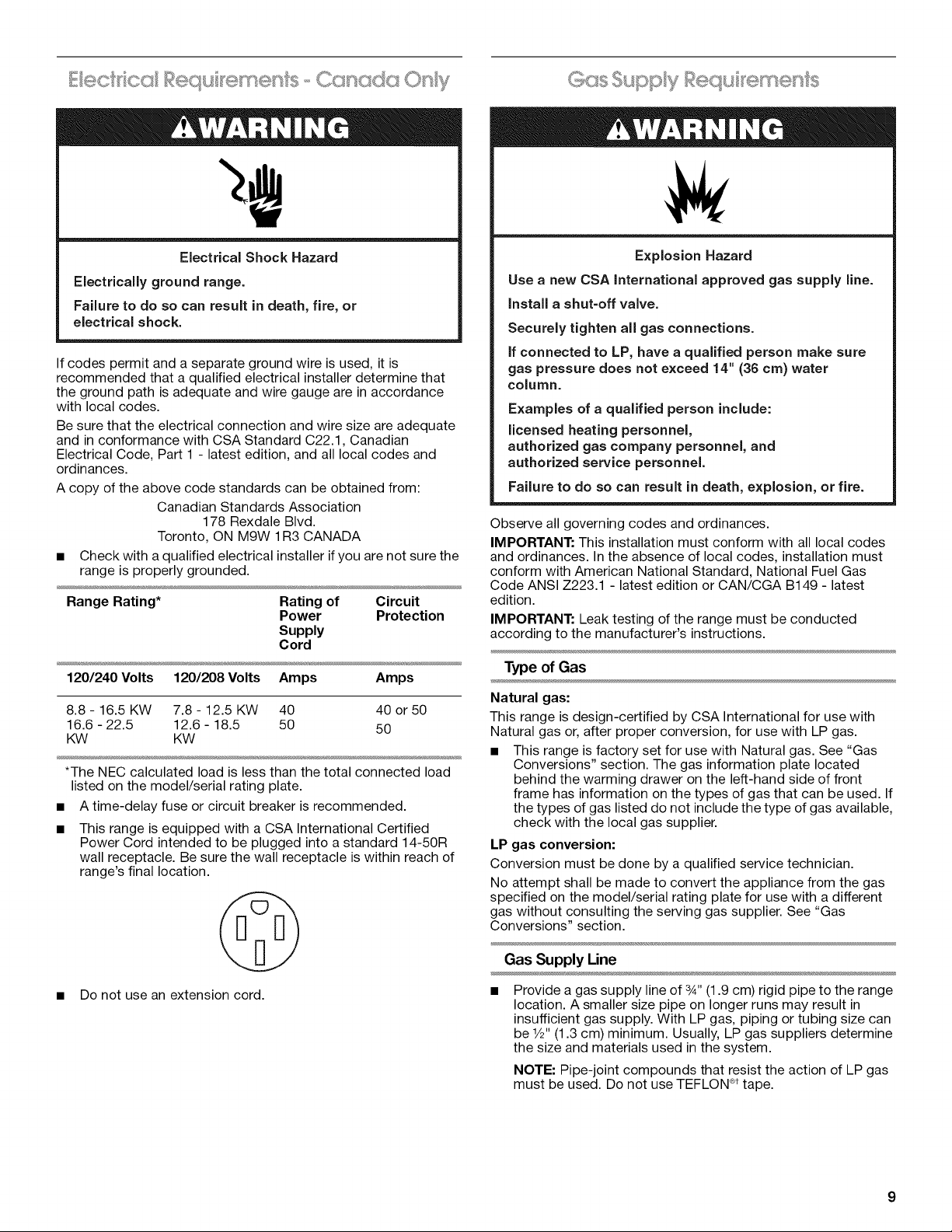

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path is adequate and wire gauge are in accordance

with local codes.

Be sure that the electrical connection and wire size are adequate

and in conformance with CSA Standard C22.1, Canadian

Electrical Code, Part 1 - latest edition, and all local codes and

ordinances.

A copy of the above code standards can be obtained from:

Canadian Standards Association

178 Rexdale Blvd.

Toronto, ON M9W 1R3 CANADA

• Check with a qualified electrical installer if you are not sure the

range is properly grounded.

Range Rating* Rating of Circuit

120/240 Volts 120/208 Volts Arnps Arnps

8.8 - 16.5 KW 7.8 - 12.5 KW 40 40 or 50

16.6 - 22.5 12.6 - 18.5 50 50

KW KW

*The NEC calculated load is less than the total connected load

listed on the model/serial rating plate.

• A time-delay fuse or circuit breaker is recommended.

This range is equipped with a CSA International Certified

Power Cord intended to be plugged into a standard 14-50R

wall receptacle. Be sure the wall receptacle is within reach of

range's final location.

Power Protection

Supply

Cord

Explosion Hazard

Use a new CSA International approved gas supply line.

install a shut-off valve.

Securely tighten all gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 crn) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Observe all governing codes and ordinances.

IMPORTANT: This installation must conform with all local codes

and ordinances. In the absence of local codes, installation must

conform with American National Standard, National Fuel Gas

Code ANSI Z223.1 - latest edition or CAN/CGA B149 - latest

edition.

IMPORTANT: Leak testing of the range must be conducted

according to the manufacturer's instructions.

Type of Gas

Natural gas:

This range is design-certified by CSA International for use with

Natural gas or, after proper conversion, for use with LP gas.

• This range is factory set for use with Natural gas. See "Gas

Conversions" section. The gas information plate located

behind the warming drawer on the left-hand side of front

frame has information on the types of gas that can be used. If

the types of gas listed do not include the type of gas available,

check with the local gas supplier.

LP gas conversion:

Conversion must be done by a qualified service technician.

No attempt shall be made to convert the appliance from the gas

specified on the model/serial rating plate for use with a different

gas without consulting the serving gas supplier. See "Gas

Conversions" section.

• Do not use an extension cord.

Gas Supply Line

Provide a gas supply line of 3A,,(1.9 cm) rigid pipe to the range

location. A smaller size pipe on longer runs may result in

insufficient gas supply. With LP gas, piping or tubing size can

be 1/2"(1.3 cm) minimum. Usually, LP gas suppliers determine

the size and materials used in the system.

NOTE: Pipe-joint compounds that resist the action of LP gas

must be used. Do not use TEFLON ®ttape.

Page 10

Flexible metal appliance connector:

If local codes permit, a new CSA design-certified,

4 to 5 ft (122 to 152.4 cm) long, 1/2"(1.3 cm) or

3A"(1.9 cm) I.D., flexible metal appliance connector may

be used for connecting range to the gas supply line.

Burner Input Requirements

Input ratings shown on the model/serial rating plate are for

elevations up to 2,000 ft (609.6 m).

For elevations above 2,000 ft (609.6 m), ratings are reduced at a

rate of 4% for each 1,000 ft (304.8 m) above sea level (not

applicable for Canada).

• A 1/2"(1.3 cm) male pipe thread is needed for connection

to the female pipe threads of the inlet to the appliance

pressure regulator.

• Do not kink or damage the flexible metal tubing when

moving the range.

Rigid pipe connection:

The rigid pipe connection requires a combination of pipe

fittings to obtain an in-line connection to the range. The rigid

pipe must be level with the range connection. All strains must

be removed from the supply and fuel lines so range will be

level and in line.

Must include a shutoff valve:

The supply line must be equipped with a manual shutoff valve.

This valve should be located in the same room but external to

the range opening, such as an adjacent cabinet. It should be

in a location that allows ease of opening and closing. Do not

block access to shutoff valve. The valve is for turning on or

shutting off gas to the range.

B

x

A

Gas Supply Pressure Testing

Gas supply pressure for testing regulator must be at least

1" water column pressure above the manifold pressure shown on

the model/serial rating plate.

Line pressure testing above 1/2psi gauge (14" WCP)

The range and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of

that system at test pressures in excess of 1/2psi (3.5 kPa).

Line pressure testing at 1/2psi gauge (14" WCP) or lower

The range must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure

testing of the gas supply piping system at test pressures equal to

or less than 1/2psi (3.5 kPa).

The cooktop sides of the slide-in range fit over the cutout edge of

your countertop.

If you have a square finish (flat) countertop and the opening width

is 30" (76.2 cm), no countertop preparation is required.

Formed front-edged countertops must have molded edge shaved

flat 3/8"(1.0 cm) from each front corner of opening.

Tile countertops may need trim cut back 3/8"(1.0 cm) from each

front corner and/or rounded edge flattened.

/

A. Gas supply line

B. Shutoff valve "open" position

C. To range

Gas Pressure Regulator

The gas pressure regulator supplied with this range must be used.

The inlet pressure to the regulator should be as follows for proper

operation:

Natural gas:

Minimum pressure: 5" WCP

Maximum pressure: 14" WCP

LP gas:

Minimum pressure: 11" WCP

Maximum pressure: 14" WCP

Contact local gas supplier if you are not sure about the inlet

pressure.

(1.o_cm)

303A ''

(78.1 cm)

If countertop opening width is greater than 30" (76.2 cm), adjust

the 3/8"(1.0 cm) dimension.

Countertop must be level. Place level on countertop, first side to

side, then front to back. If countertop is not level, range will not be

level. Range must be level for satisfactory baking conditions.

1"®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

10

Page 11

INSTALLATIONINSTRUCTIONS

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

1. Remove shipping materials, tape and film from the range.

Keep cardboard bottom under range.

2. Remove oven racks and parts package from inside oven.

3. To remove cardboard bottom, place range on its back, take

4 cardboard corners from the carton. Stack one cardboard

corner on top of another. Repeat with the other 2 corners.

Place them lengthwise on the floor behind the range to

support the range when it is laid on its back.

4. Using 2 or more people, firmly grasp the range and gently lay

it on its back on the cardboard corners.

5. Pull cardboard bottom firmly to remove.

6. Use an adjustable wrench to loosen the leveling legs.

7. Place cardboard or hardboard in front of range. Using 2 or

more people, stand range back up onto cardboard or

hardboard.

Ad s Levencs egs

1.

If range height adjustment is necessary, use a wrench or pliers

to loosen the 4 leveling legs.

This may be done with the range on its back or with the range

supported on 2 legs after the range has been placed back to a

standing position.

NOTE: To place range back up into a standing position, put a

sheet of cardboard or hardboard in front of range. Using 2 or

more people, stand range back up onto the cardboard or

hardboard.

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti=tip bracket to rear range foot.

Reconnect the anti=tip bracket, if the range is moved.

Failure to follow these instructions can result in death

or serious burns to children and adults.

2.

Adjust the leveling legs to the correct height. Leveling legs can

be loosened to add up to a maximum of 1" (2.5 cm). A

minimum of 3/le"(5 mm) is needed to engage the anti-tip

bracket.

NOTE: If height adjustment is made when range is standing,

tilt the range back to adjust the front legs, then tilt forward to

adjust the rear legs.

3.

When the range is at the correct height, check that there is

adequate clearance under the range for the anti-tip bracket.

Before sliding range into its final location, check that the anti-

tip bracket will slide under the range and onto the rear leveling

leg prior to anti-tip bracket installation.

A p BHi icCe t,

1.

Remove the anti-tip bracket that is taped to the package

containing literature.

2.

Determine which mounting method to use: floor or wall.

If you have a stone or masonry floor you can use the wall

mounting method.

3.

Determine and mark centerline of the cutout space. The

mounting bracket can be installed on either the left side or

right side of the cutout. Position mounting bracket in cutout so

that right (or left) edge of the bracket is 14V4" (36.2 cm) from

centerline, as shown.

- :'.

A. Centerline

B. 141/4'' (36.2 cm)

4. Drill two V8" (3 mm) holes that correspond to the bracket holes

of the determined mounting method. See below.

11

Page 12

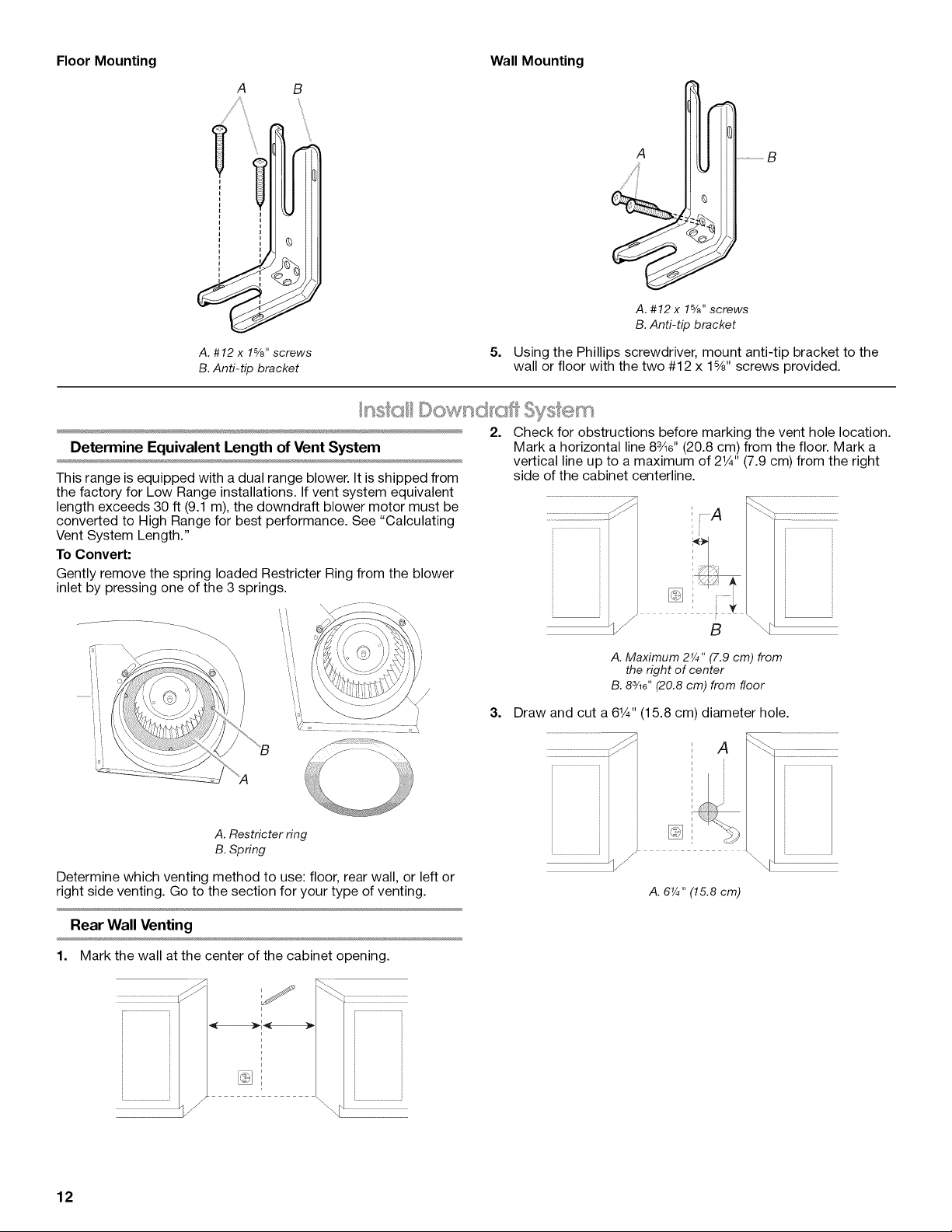

Floor Mounting Wall Mounting

A B

A. #12 x 1%" screws

B. Anti-tip bracket

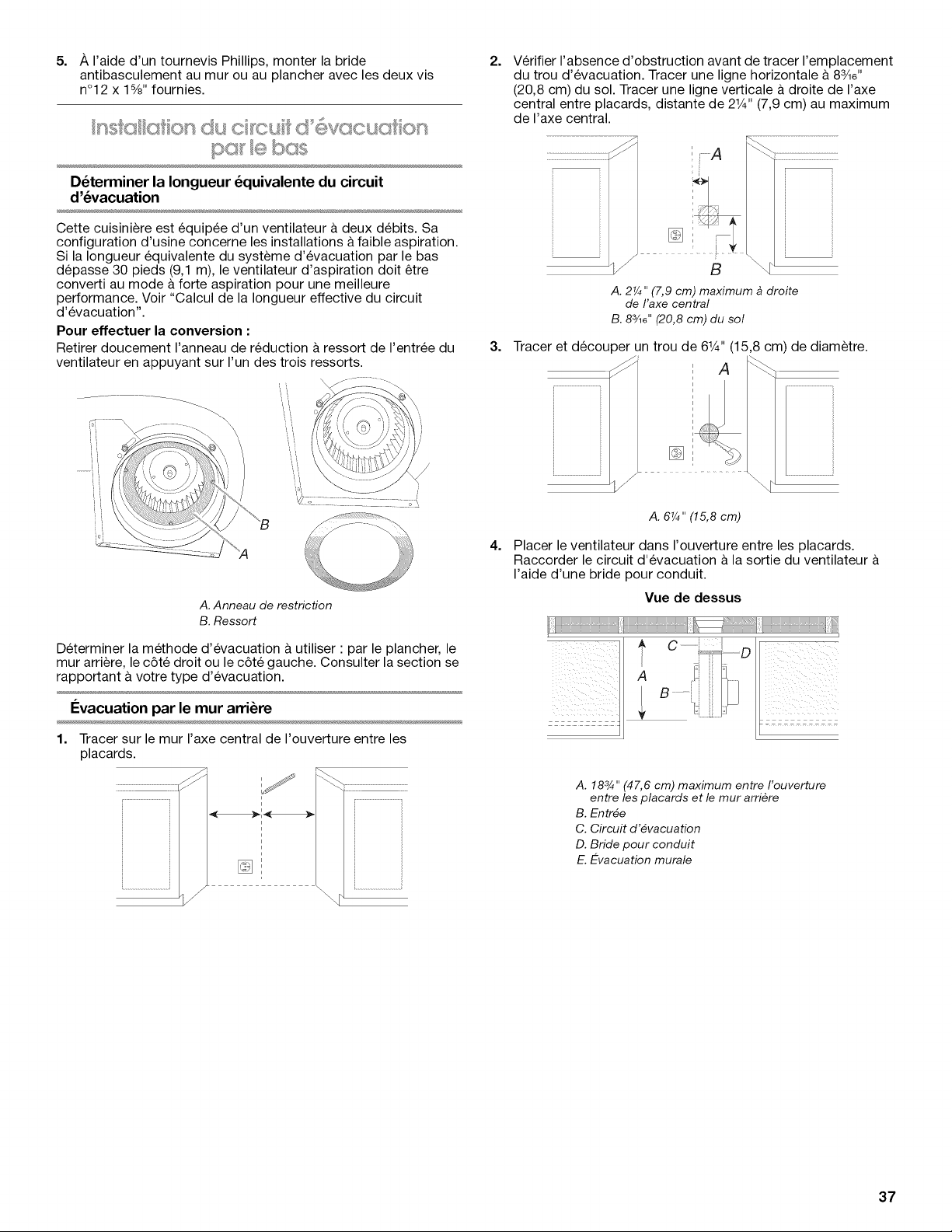

Determine Equivalent Length of Vent System

5=

Using the Phillips screwdriver, mount anti-tip bracket to the

wall or floor with the two #12 x 15/8"screws provided.

2.

Check for obstructions before marking the vent hole location.

Mark a horizontal line 8¾e" (20.8 cm) from the floor. Mark a

vertical line up to a maximum of 2W' (7.9 cm) from the right

This range is equipped with a dual range blower. It is shipped from

side of the cabinet centerline.

the factory for Low Range installations. If vent system equivalent

length exceeds 30 ft (9.1 m), the downdraft blower motor must be

converted to High Range for best performance. See "Calculating

Vent System Length."

To Convert:

Gently remove the spring loaded Restricter Ring from the blower

inlet by pressing one of the 3 springs.

A. #12 x 1%" screws

B. Anti-tip bracket

\

i

A. Restricter ring

B. Spring

Determine which venting method to use: floor, rear wall, or left or

right side venting. Go to the section for your type of venting.

Rear Wall Venting

1. Mark the wall at the center of the cabinet opening.

i

i

J

A. Maximum 2¼" (7.9 cm) from

the right of center

B. 83/_6'' (20.8 cm) from floor

B

3. Draw and cut a 6%" (15.8 cm) diameter hole.

A

J

J

A. 6¼" (15.8 cm)

12

f

J

Page 13

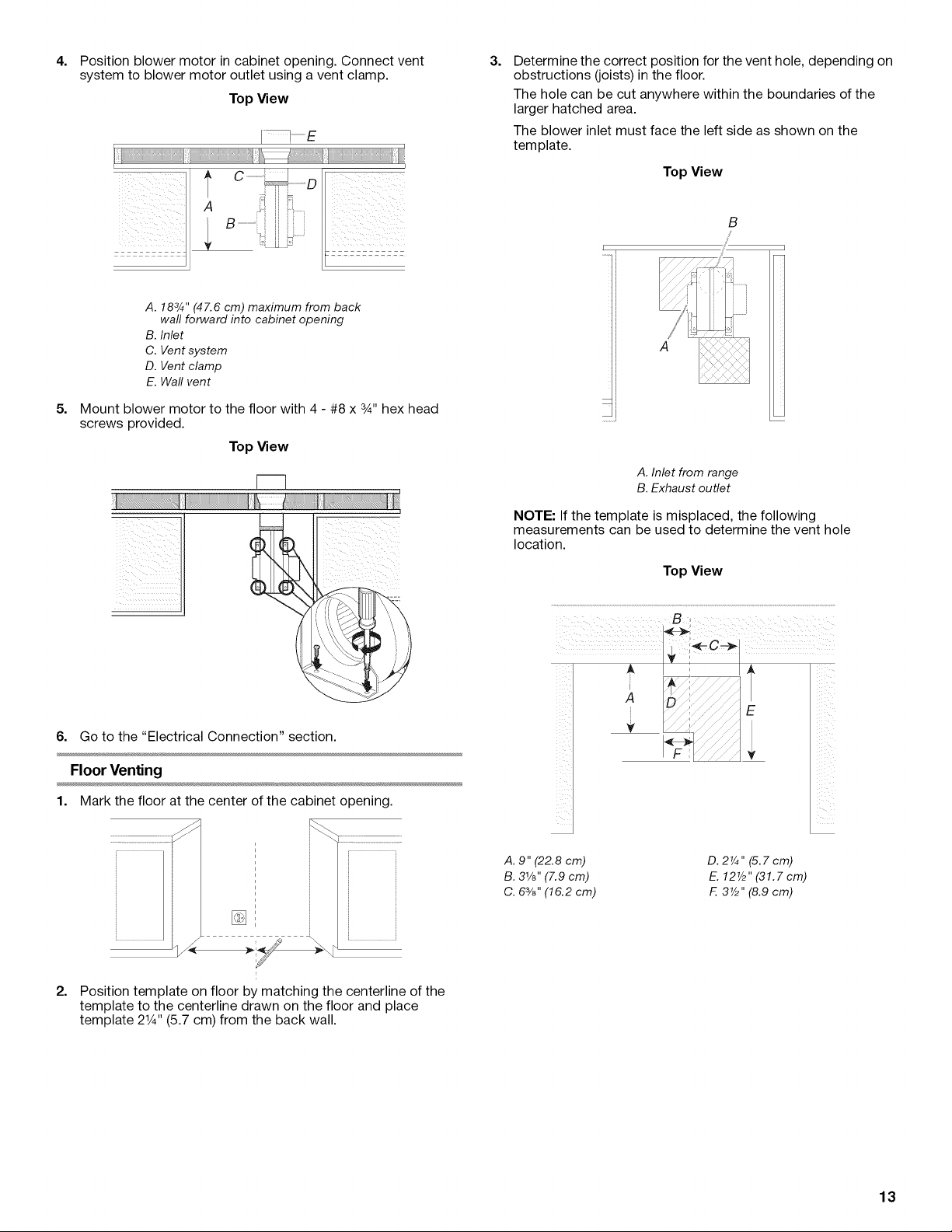

4=

Position blower motor in cabinet opening. Connect vent

system to blower motor outlet using a vent clamp.

Top View

3.

Determine the correct position for the vent hole, depending on

obstructions (joists) in the floor.

The hole can be cut anywhere within the boundaries of the

larger hatched area.

The blower inlet must face the left side as shown on the

template.

Top View

g.....................r iii'

.......

A. 183/4'' (47.6 cm) maximum from back

wall forward into cabinet opening

B. Inlet

C. Vent system

D. Vent clamp

E. Wall vent

5.

Mount blower motor to the floor with 4 - #8 x 3A"hex head

screws provided.

Top View

£

B

i

A. Inlet from range

B. Exhaust outlet

NOTE: If the template is misplaced, the following

measurements can be used to determine the vent hole

Y

location.

Top View

6. Go to the "Electrical Connection" section.

Floor Venting

1. Mark the floor at the center of the cabinet opening.

2. Position template on floor by matching the centerline of the

template to the centerline drawn on the floor and place

template 21¼'' (5.7 cm) from the back wall.

A. 9" (22.8 cm)

B. 31/8'' (7.9 cm)

C. 63/8'' (16.2 cm)

D. 2¼" (5.7cm)

E. 12V2" (31.7 cm)

F. 37/2'' (8.9 cm)

13

Page 14

4. Draw and cut a 61¼'' (15.8 cm) diameter hole.

Left or Right Side Venting

1. Mark cabinet side for either a left or right side vent hole

location.

...........................................

5.

Position blower motor in cabinet opening and mount blower

motor to the floor.

Top View

A. Inlet from range

B. Exhaust outlet

6.

Connect vent system to blower motor outlet with 4 - #8 x 3A"

hex head screws provided.

A. 313/16'' (79.2 cm) to top of cabinet

B. 18" (45.7 cm) from back wall

2.

Mark and cut a 51/2'' (13.9 cm) diameter hole in the desired

cabinet side.

A. 5V2" (13.9 cm) diameter hole

3. Mark and cut a 14" x 11" (35.6 x 27.9 cm) opening in the floor

of the same cabinet as the vent hole opening.

Top View

A. Inlet

B. Vent clamp

C. Floor

D. Vent system

7. Go to the "Electrical Connection" section.

14

A. 11" (27.9 cm) from front of cabinet

B. 14" (35.6 cm) from left side of cabinet

Page 15

4=

Remove 4 Iocknuts on the motor side of the blower and

remove the bracket.

View from Motor Side of Blower

\

A. Electrical connector

5.

Lift and rotate the motor 180° to reposition the electrical

connection.

f ............................. •

f

A. Electrical connector

8.

Position 2 wood spacers and mount them to the floor.

Top View

[

B_

_i_iiiiiilliii_iiiiiii_

ii il _i

.........%iiiii

A. 2" x 4" (5.0 x 10.2 cm) wood spacers

B. 2%" (7.3 cm) from back wall to edge of wood spacer

C. 83/4"(22.2 cm)

D. 2_/_6'' (5.8 cm) centerline of opening to wood spacer

9.

Mount blower motor to wood spacers using 4 - #8 x 3A,,hex

head screws provided.

NOTE: Vent system will be connected after range has been

moved into it's final location. "See Connect Range to

Downdraft System" section.

Top View

B

6.

Rotate bracket 180° and secure with 4 Iocknuts.

!

\

\

7=

Remove the bracket from the other side of the blower motor,

rotate 180° and secure with 4 Iocknuts.

A

i \

A. Wood spacers

B. Mounting bracket

C. Blower

10. Go to the "Electrical Connection" section.

15

Page 16

Power Supply Cord (optional)

This range is shipped with a specially designed 4-wire power

supply cord. This cord should be used on all new branch circuits,

mobile homes and when local codes prohibit grounding though

the neutral. For a 3-wire power supply cord replacement, service

kit Part Number 74011285 must be used.

Electrical Shock Hazard

Disconnect power before servicing.

Use a new 40 amp power supply cord.

Plug into a grounded outlet.

Failure to follow these instructions can result in death,

fire, or electrical shock.

1=

Disconnect power.

2.

Use Phillips screwdriver to remove the terminal block cover

screw located on the back of the range. Pull cover down and

toward you to remove cover.

• Feed the power supply cord through the opening in the

cord/conduit plate on bottom of range. Allow enough

slack to easily attach the wiring to the terminal block.

• Tighten strain relief screw against the power supply cord.

• Feed the flexible conduit through the strain relief, allowing

enough slack to easily attach wiring to the terminal block.

• Tighten strain relief screw against the flexible conduit.

Electrical Connection Options

If your home has: And you will be Go to Section:

connecting to:

4-wire receptacle A UL listed, 4-wire connection:

(NEMA type 14-50R) 250-volt Power supply cord

minimum,

3. Add strain relief.

• Assemble a UL listed strain relief in the opening.

i .-

..... ........ i' ii

...............I

A. UL listed strain relief

power supply

40-amp, range

cord

3-wire receptacle A UL listed,

(NEMA type 10-50R) 250-volt

minimum,

O 40-amp, range

power supply

cord

3-wire connection:

Power supply cord

16

Page 17

4-wire connection: Power Supply Cord

Use this method for:

• New branch-circuit installations (1996 NEC)

• Mobile homes

• Recreational vehicles

• In an area where local codes prohibit grounding through the

neutral

1. Feed the power supply cord through the opening in the cord/

conduit plate on bottom of range. Allow enough slack to easily

attach the wiring to the terminal block.

i

I

A ................ j

::221

i

I_11................ !,,

, i ;:-s

I

I

i .1 I

=

4.

Connect line 1 (black) and line 2 (red) wires to the outer

terminal block posts with 10-32 hex nuts.

5.

Securely tighten hex nuts.

NOTE: For power supply cord replacement, only use a power

cord rated at 250 volts minimum, 40 amps or 50 amps that is

marked for use with nominal 13/8"(3.5 cm) diameter

connection opening, with ring terminals and marked for use

with ranges. For a 3-wire power supply cord replacement,

service kit Part Number 74011285 must be used.

6. Replace terminal block access cover.

3-wire connection: Power Supply Cord (optional)

NOTE: For power supply cord replacement, only use a power

cord rated at 250 volts minimum, 40 amps or 50 amps that is

marked for use with nominal 13/8"(3.5 cm) diameter

connection opening, with ring terminals and marked for use

with ranges.

Use this method only if local codes permit connecting chassis

ground conductor to neutral wire of power supply cord.

1. Feed the power supply cord through the opening in the cord/

conduit plate on bottom of range. Allow enough slack to easily

attach the wiring to the terminal block.

(! ......_

i:i...... T)_. .......

A .....................J/_ - - "

D

A. Terminal block

B. Ground-link screw

C. Cord/conduit plate

D. Power supply cord wires

2. Use Phillips screwdriver to connect the green ground wire

from the power supply cord to the range with the ground-link

screw. The ground wire must be attached first.

3. Use 3/8"nut driver to connect the neutral (white) wire to the

center terminal block post with one of the 10-32 hex nuts.

.....i

A

C; \,,

F

Ii

il

C

A. Terminal block

B. Ground-link screw

C. Cord/conduit plate

D. Power supply cord wires

E. Metal ground strap

E

B

D

A. 10-32 hex nut

B.Ground-link screw

O.Line 1 (black)

D

D. Green ground wire

E. Neutral (center) wire

F. Line 2 (red)

17

Page 18

2=

Use 3/8"nut driver to connect the neutral (white) wire and

copper ground strap provided to the center terminal block

post with one of the 10-32 hex nuts. The opposite end of the

copper ground strap should be secured to the oven back with

the green ground link-screw.

2. Locate gas 3ressure regulator behind access panel.

A

E

B

C

A. 10-32 hex nut

B. Line 1 (black)

C. Ground-rink screw

D. Neutral (white) wire

E.Line 2 (red)

3. Connect line 1 (black) and line 2 (red) wires to the outer

terminal block posts with 10-32 hex nuts.

4. Securely tighten hex nuts.

5. Replace terminal block access cover.

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut=off valve.

Securely tighten all gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

A. Gas pressure regulator

3=

Apply pipe-joint compound made for use with LP gas to the

smaller thread ends of the flexible connector adapters (see B

and G in the following illustration).

4.

Attach one adapter to the gas pressure regulator and the other

adapter to the gas shutoff valve. Tighten both adapters.

5.

Use a l_e" combination wrench and an adjustable wrench to

attach the flexible connector to the adapters. Check that

connector is not kinked.

A

J

B C

D

E

H G F

A. Gas pressure regulator

B. Use pipe-joint compound.

C. Adapter (must have Y2"male

pipe thread)

D. Flexible connector

E.Manual gas shutoff valve

F Y2"or 3/4"gas pipe

G. Use pipe-joint compound.

H. Adapter

6. Gas supply pipe must not be more than 10" (25.4 cm) above

the floor.

Typical flexible connection

1. Open access panel by grasping sides and pulling upward,

lifting out.

18

A. Flexible connector

B. Manual shutoff valve

C. 10" (25.4 cm) max. straight pipe

Page 19

Complete Connection

1. Open the manual shutoff valve in the gas supply line. The

valve is open when the handle is parallel to the gas pipe.

A. Closed valve

B. Open valve

2=

Test all connections by brushing on an approved noncorrosive

leak-detection solution. If bubbles appear, a leak is indicated.

Correct any leak found.

3=

Remove cooktop burner caps and grates from package

containing parts. Align recess in burner caps with pins in

burner base. Burner caps should be level when properly

positioned. If burner caps are not properly positioned, surface

burners will not light. Place burner grates over burners and

caps.

1=

7. Remove cardboard or hardboard from under the range. Using

2 or more people, gently move range into its final location.

8=

Check that the anti-tip bracket is installed and that electrical

cords are not kinked. Use a flashlight to look underneath the

bottom of the range.

• Look for the anti-tip bracket securely attached to floor or

wall.

Slide range back so rear range foot is under anti-tip

bracket.

A

B

A. Inlet flexible vent

B. Vent clamp

2. Check countertop height to allow range top to clear

countertop. Adjusting leveling legs if necessary.

3. Remove access panel by grasping both sides, pulling upward,

and lifting out.

4. Move range close to cabinet opening.

5. Plug range into grounded outlet (if using a power supply cord).

6. Plug range electrical connector into the downdraft blower

motor.

.......S

9=

Level the range.

a) Place rack in oven.

b) Place level on rack and check levelness of the range, first

side to side; then front to back.

c) If range is not level, pull range forward until rear leveling

leg is removed from the anti-tip bracket.

d) Use a wrench or pliers to adjust leveling legs up or down

until range is level.

e) Push range back into position.

f) Check that rear leveling leg is engaged in anti-tip bracket.

NOTE: Range must be level for satisfactory baking performance.

7. Depending on your installation, connect the flexible vent from

the blower motor inlet to the range using a vent clamp.

A.Power supply cord (onsome installations)

B. Range electrical connector to blower motor

19

Page 20

Wall Venting

C

Floor Venting

Top View

B

/i

/

/

/

i' A

J

A. Range

B. Wall venting outlet

C. Vent clamp

Top View

B

Side Venting (left side venting shown)

Connect flexible vent duct to range and connect vent system

to blower motor outlet.

Top View

A

E

D

C

A. Flexible vent duct to range

B. Vent clamp

C. Range

J

B

D. Vent system

E. Side venting outlet

8. Replace access panel.

A. Range

B. Floor venting outlet

C. Vent clamp

9. Insert downdraft vent filter and place vent cover over opening.

B

A. Filter

B. Grate

10. Reconnect power.

20

Page 21

;'_;_ !I_0t' CDy_,,_:,_J,_

Initial lighting and gas flame adjustments

Cooktop burners use pilotless igniters in place of standing pilots,

When the cooktop control knob is turned to the "LITE" position,

the system creates aspark to light the burner. This sparking

continues, as long as the control knob is turned to "LITE."

Check Operation of Cooktop Burners

Standard Surface Burners

Push in and turn each control knob to the "LITE" position.

The flame should light within 4 seconds. The first time a burner is

lit it may take longer than 4 seconds to light because of air in the

gas line.

If burners do not light properly:

• Turn cooktop control knob to the "OFF" position.

Check that the range is plugged in and the circuit breaker has

not tripped or the household fuse has not blown.

Check that the gas shutoff valves are set to the "open"

position.

Check that burner caps are properly positioned on burner

bases.

Repeat start-up. If a burner does not light at this point, turn the

control knobs to "Off" and contact your dealer or authorized

service company for assistance.

To adjust standard burners:

The flame can be adjusted using the adjustment screw in the

center of the valve stem. The valve stem is located directly

underneath the control knob.

If the "low" flame needs to be adjusted:

1. Light 1 burner and turn to lowest setting.

2. Remove the control knob.

Hold the knob stem in the low position using a pair of pliers. Use

an V8"(3.0 mm) flat-blade screwdriver to turn the screw located in

the center of the control knob stem until the flame is the proper

size.

3. Replace the control knob.

4. Test the flame by turning the control from "LO" to "HI,"

checking the flame at each setting.

5. Repeat above steps for each burner.

Adjust Flame Height

Adjust the height of top burner flames. The cooktop "low" burner

flame should be a steady blue flame approximately 1¼.(0.64 cm)

high.

A

B

A. Low flame

B. High flame

......©I' p ....... .,,/'sloato

1. Check that all parts are now installed. If there is an extra part,

go back through the steps to see which step was skipped.

2. Check that you have all of your tools.

3. Dispose of/recycle all packaging materials.

4. Check that range level. See "Connect Range to Downdraft

System."

5. Use a mild solution of liquid household cleaner and warm

water to remove waxy residue caused by shipping material.

Dry thoroughly with a soft cloth. For more information, see the

"Range Care" section of the Use and Care Guide.

6. Read "Range Use" in the Use and Care Guide.

7. Turn on surface burners and oven. See the Use and Care

Guide for specific instruction on range operation.

If range does not operate, check the following:

• Household fuse is intact and tight, or circuit breaker has not

tripped.

• Range is plugged into an outlet.

• Electrical supply is connected.

• See "Troubleshooting" in the Use and Care Guide.

8.

When the range has been on for 5 minutes, check for heat. If

the range is cold, turn off the range and check that the gas

supply line shutoff valve is open.

• If the gas supply line shutoff valve is closed, open it, then

repeat the 5-minute test as outlined above.

• If the gas supply line shutoff valve is open, close it, and

contact a qualified technician.

If you need Assistance or Service:

Please reference the "Assistance or Service" section of the

Use and Care Guide or contact the dealer from whom you

purchased your range.

21

Page 22

GAS CONVERSIONS

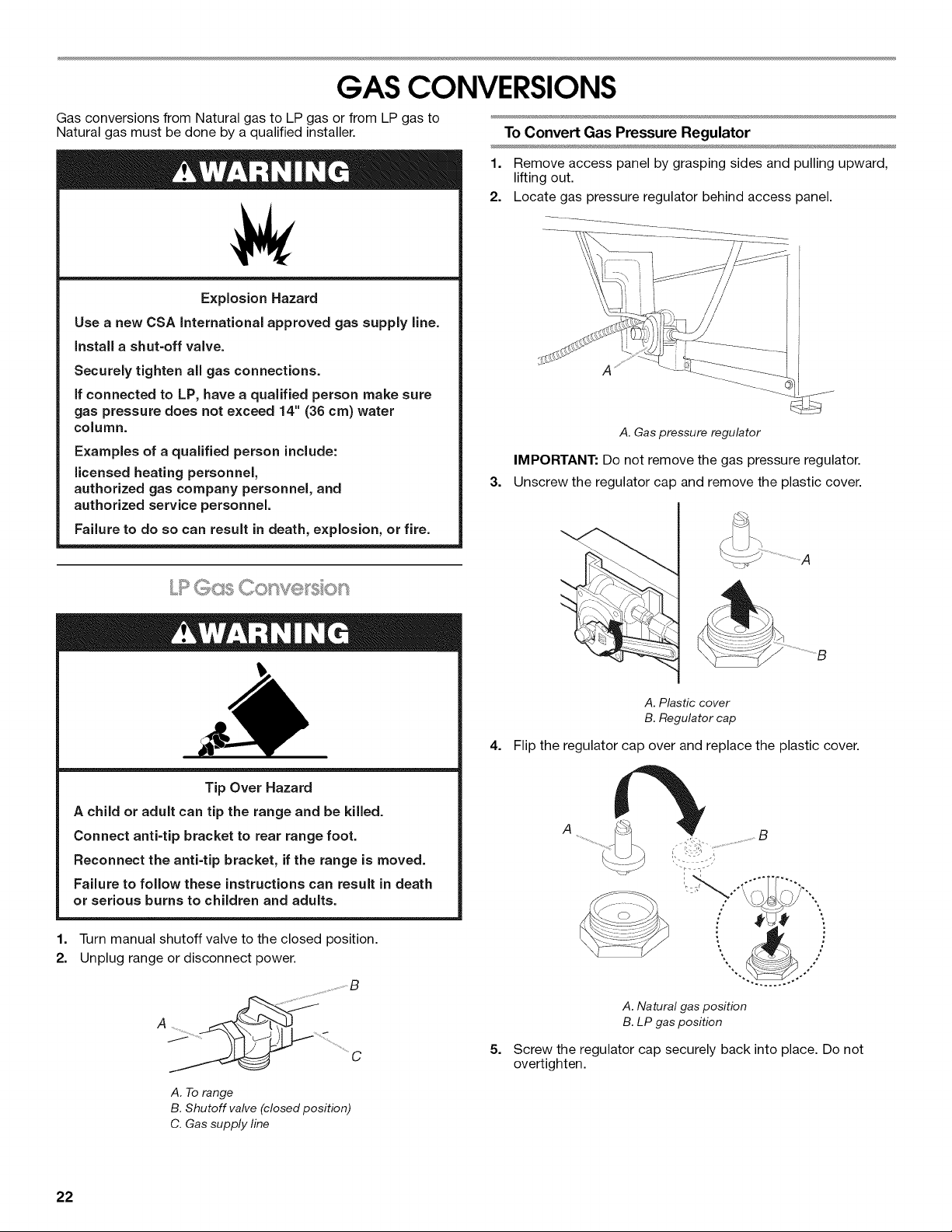

Gas conversions from Natural gas to LP gas or from LP gas to

Natural gas must be done by a qualified installer.

Explosion Hazard

Use a new CSA International approved gas supply line.

instal a shut=off valve.

Securely tighten all gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

To Convert Gas Pressure Regulator

1. Remove access panel by grasping sides and pulling upward,

lifting out.

2. Locate gas pressure regulator behind access panel.

A.Gaspressure regulator

IMPORTANT: Do not remove the gas pressure regulator.

3.

Unscrew the regulator cap and remove the plastic cover.

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti-tip bracket to rear range foot.

Reconnect the anti-tip bracket, if the range is moved.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Turn manual shutoff valve to the closed position.

2. Unplug range or disconnect power.

A. To range

B. Shutoff valve (closed position)

C. Gas supply line

A. Plastic cover

B. Regulator cap

4. Flip the regulator cap over and replace the plastic cover.

A

A. Natural gas position

B. LP gas position

5.

Screw the regulator cap securely back into place. Do not

overtighten.

22

Page 23

To Convert Surface Burners

1. If installed, remove the burner grates.

2. Remove the burner caps.

3. Using a Phillips screwdriver, remove the burner base.

................................\

5. Replace the Natural gas orifice spud with the correct LP gas

orifice spud. See the "LP Gas Orifice Spud Chart."

6. Replace burner base and hand tighten the screws.

7. Replace burner cap.

8. Repeat steps 1 through 7 for the remaining burners.

9. Place Natural gas orifice spuds in plastic parts bag for future

use and keep with package containing literature.

10. Replace burner grates.

11. Plug in range or reconnect power.

12. Complete installation. See "Make Gas Connection" and

"Electronic Ignition System" sections.

Checking for proper cooktop burner flame is very important.

The small inner cone should have a very distinct blue flame 1¼,,

to 1/2"long. The outer cone is not as distinct as the inner cone.

LP gas flames have a slightly yellow tip.

IMPORTANT: You may have to adjust the "LO" setting for

each cooktop burner.

A. Burner cap

B. Gas tube opening

C. Burner base screws

D. Burner base

4=

Apply masking tape to the end of a %2" (7 mm) nut driver to

help hold the Natural gas orifice spud in the nut driver while

changing it. Press nut driver down onto the Natural gas orifice

spud and remove by turning it counterclockwise and lifting

out. Set Natural gas orifice spud aside.

A

A. Natural gas orifice spud

Use the following chart for correct LP gas orifice spud for each

burner. Refer to the gas information plate on the right-hand side of

the bottom oven frame for proper sizing of LP gas orifice spuds

for each burner location.

LP Gas Orifice Spud Chart

Location Burner Rating Color Number

Right Front 14,000 BTU Red 114L

Right Rear 4,000 BTU Blue 64L

Left Front 8,000 BTU Clear 35L

Left Rear 8,000 BTU Clear 35L

_(i_ %, (__' _'_ '" '*_ _S °' (_i_ii_'d*_lY_t_;_/(_)___''_'_'_........... '_ *_

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti=tip bracket to rear range foot.

Reconnect the anti=tip bracket, if the range is moved.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1=

Turn manual shutoff valve to the closed position.

2.

Unplug range or disconnect power.

...................B

A

........................C

A. To range

B.Shutoff valve(closedposition)

C. Gas supply line

23

Page 24

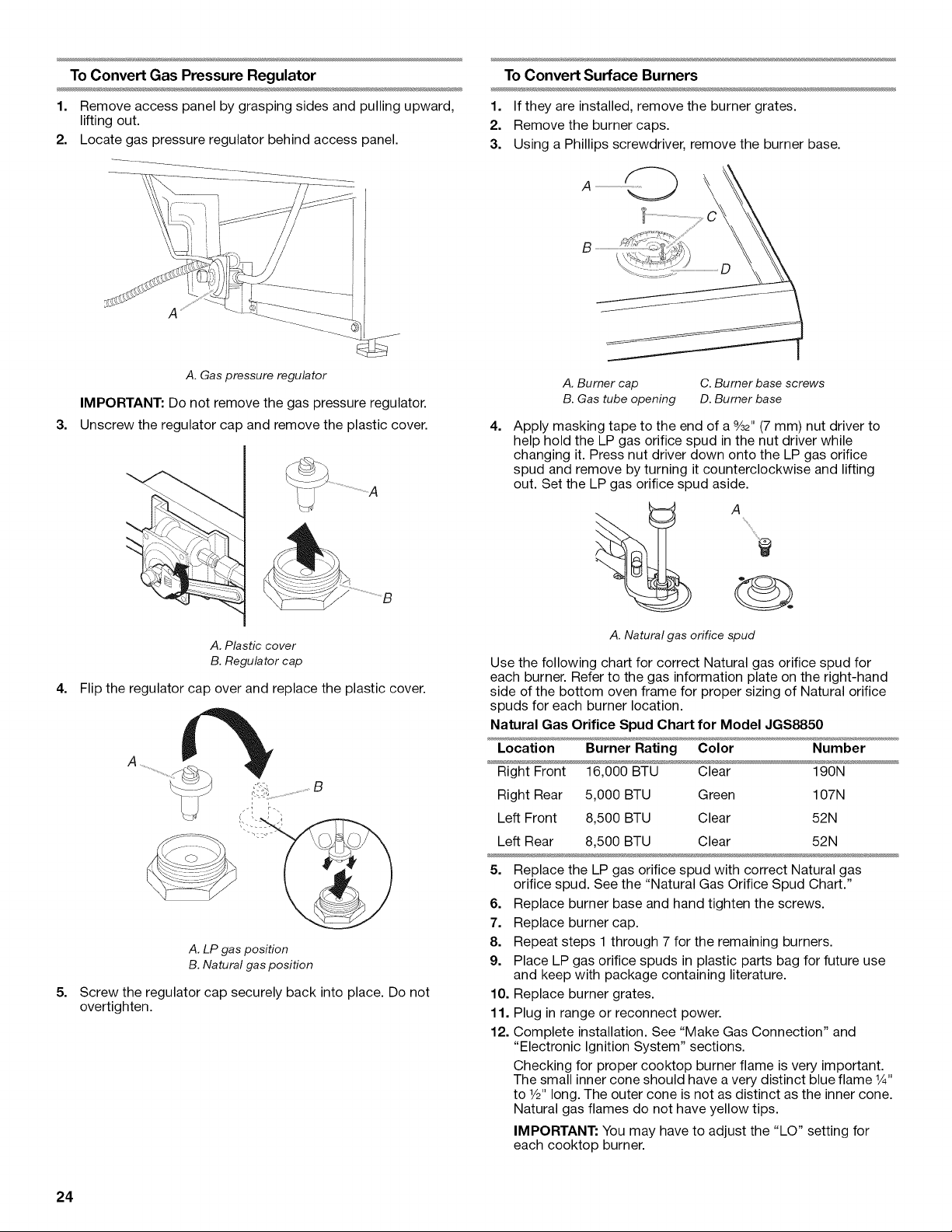

To Convert Gas Pressure Regulator

To Convert Surface Burners

1. Remove access panel by grasping sides and pulling upward,

lifting out.

2. Locate gas pressure regulator behind access panel.

A

A.Gaspressure regulator

IMPORTANT: Do not remove the gas pressure regulator.

3=

Unscrew the regulator cap and remove the plastic cover.

G

1. If they are installed, remove the burner grates.

2. Remove the burner caps.

3. Using a Phillips screwdriver, remove the burner base.

.............................................................._ ,_>_;,,

_-4 .:::z __z_.....................................D

A. Burner cap C. Burner base screws

B. Gas tube opening D. Burner base

4=

Apply masking tape to the end of a 9/32"(7 mm) nut driver to

help hold the LP gas orifice spud in the nut driver while

changing it. Press nut driver down onto the LP gas orifice

spud and remove by turning it counterclockwise and lifting

out. Set the LP gas orifice spud aside.

A. Plastic cover

B. Regulator cap

4=

Flip the regulator cap over and replace the plastic cover.

/-?, ............B

A.LP gasposition

B.Natural gasposition

5=

Screw the regulator cap securely back into place. Do not

overtighten.

A. Natural gas orifice spud

Use the following chart for correct Natural gas orifice spud for

each burner. Refer to the gas information plate on the right-hand

side of the bottom oven frame for proper sizing of Natural orifice

spuds for each burner location.

Natural Gas Orifice Spud Chart for Model JGS8850

Location Burner Rating Color Number

Right Front 16,000 BTU Clear 190N

Right Rear 5,000 BTU Green 107N

Left Front 8,500 BTU Clear 52N

Left Rear 8,500 BTU Clear 52N

5. Replace the LP gas orifice spud with correct Natural gas

orifice spud. See the "Natural Gas Orifice Spud Chart."

6. Replace burner base and hand tighten the screws.

7. Replace burner cap.

8. Repeat steps 1 through 7 for the remaining burners.

9. Place LP gas orifice spuds in plastic parts bag for future use

and keep with package containing literature.

10. Replace burner grates.

11. Plug in range or reconnect power.

12. Complete installation. See "Make Gas Connection" and

"Electronic Ignition System" sections.

Checking for proper cooktop burner flame is very important.

The small inner cone should have a very distinct blue flame W'

to V2"long. The outer cone is not as distinct as the inner cone.

Natural gas flames do not have yellow tips.

IMPORTANT: You may have to adjust the "LO" setting for

each cooktop burner.

24

Page 25

25

Page 26

SECURITEDE LA CUISINIERE

Votre securite et celle des autres est tres importante.

Nous donnons de nombreux messages de s_curit_ importants dans ce manuel et sur votre appareil m_nager. Assurez-vous de

toujours lire tous les messages de s_curit_ et de vous y conformer.

Ce symbole d'alerte de s_curit_ vous signale les dangers potentiels de d_c_s et de blessures graves & vous

et & d'autres.

Voici le symbole d'alerte de s_curit&

Tous les messages de s_curit_ suivront le symbole d'alerte de s_curit_ et le mot "DANGER" ou

"AVERTISSEMENT". Ces mots signifient •

Risque possible de d_cbs ou de blessure grave si vous ne

suivez pas imm_diatement les instructions.

Risque possible de d_cbs ou de blessure grave si vous

ne suivez pas les instructions.

Tousles messages de s_curit_ vous diront quel est le danger potentiel et vous disent comment r_duire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

AVERTISSEMENT •Si les renseignements dans ce manuel ne sont pas exactement

observes, un incendie ou une explosion peut survenir, causant des dommages au

produit, des blessures ou un deces.

- Ne pas entreposer ni utiliser de ressence ou d'autres vapeurs ou liquides inflammables

proximite de cet appareil ou de tout autre appareil electromenager.

-QUE FAIRE DANS LE CAS D'UNE ODEUR DE GAZ :

• Ne pas tenter d'allumer un appareil.

• Ne pas toucher a un commutateur electrique.

• Ne pas utiliser le telephone se trouvant sur les lieux.

• Appeler immediatement le fournisseur de gaz a partir du telephone d'un voisin. Suivre

ses instructions.

• .&.defaut de joindre votre fournisseur de gaz, appeler les pompiers.

- L'installation et rentretien doivent _tre effectues par un installateur qualifie, une agence

de service ou le fournisseur de gaz,

26

Page 27

AVERTISSEMENT : L'odorat ne permet pas toujours la detection d'une fuite de gaz.

Les distributeurs de gaz recommandent I'emploi d'un detecteur de gaz (homologation UL ou CSA).

Pour d'autre information, contacter le fournisseur de gaz local.

En cas de detection d'une fuite de gaz, executer les instructions "Que faire dans le cas d'une odeur de gaz".

Dans 1'12tatdu Massachusetts, les instructions d'installation suivantes sont applicables •

[] Les travaux d'installation et r_paration doivent 6tre executes par un plombier ou tuyauteur qualifi_ ou licenci_, ou par le

personnel qualifi_ d'une entreprise licenci_e par 1'12tatdu Massachusetts.

[] Si une vanne & boisseau sph_rique est utilis_e, elle doit comporter une manette "T".

[] Si un conduit de raccordement flexible est utilis_, sa Iongueur ne doit pas d_passer 3 pi.

Risque de basculement

Un enfant ou une personne adulte peut faire basculer la cuisiniere ce qui peut causer un d_ces.

Joindre la bride antibasculement au pied arriere de la cuisiniere.

Joindre de nouveau la bride antibasculement si la cuisiniere est d_plac_e.

Le non-respect de ces instructions peut causer un d_ces ou des brQlures graves aux enfants et

aux adultes.

27

Page 28

EXIGENCESD'INSTALLATION

®_ _ _O ¸ S_

Rassembler les outils et composants necessaires avant

d'entreprendre I'installation. Lire et observer les instructions

fournies avec chacun des outils de la liste ci-dessous.

Outils n_cessaires

• Metre-ruban •

• Tournevis Phillips

• Tournevis a lame plate •

• Tournevis a lame plate de 1/8"

• Niveau

• Perceuse manuelle ou •

electrique

• Cle ou pince

• Cle a tuyauterie

• Cle mixte de 134d'

• Foret de 1/8"(3,2 mm) (pour

planchers en bois)

• Marqueur ou crayon

Pi_ces fournies

Verifier que toutes les pieces sont presentes.

• Ensemble de conversion pour gaz propane/naturel (fixe au

support du detendeur a I'arriere de la cuisiniere)

• 2- Chapeaux de brQleur

• 3 - Grilles de brQleur

• 1 -Grille &air

• 3- Grilles de four

• 1 - Bande metallique de mise & la terre (pour un

raccordement & 3 conducteurs)

• Moteur du ventilateur

• 2 - Brides pour conduit

• Conduit flexible

• Fiche de test du debit

• Gabarit pour I'emplacement du ventilateur

• 4 vis n° 8 x 3_,,(pour le montage de la bride du ventilateur)

• 2 vis n°12 x 1%" (pour le montage de la bride

antibasculement)

• Bride antibasculement (fixee par du ruban adhesif & la

pochette contenant la documentation dans la cavite du four)

La bride antibasculement doit _tre bien fixee & la cloison

arriere ou au plancher. La profondeur du plancher peut

necessiter des vis plus Iongues pour I'ancrage de la bride

dans le sous-plancher. Des vis plus Iongues sont disponibles

aupres de votre quincaillerie locale.

Compose d'etancheite des

raccords filetes - resistant au

gaz propane

Foret a ma£sonnerie a pointe

carburee de 346"(4,8 mm)

(pour planchers en beton/

ceramique)

Solution non-corrosive de

detection des fuites

Pour conversions pour gaz

propane/naturel

• Cle mixte de 1/2"

• Tourne-ecrou de 1¼.(6 mm)

• Tourne-ecrou de 9/32"(7 mm)

• Ruban adhesif de masquage

et peces

Pi_ces n_cessaires

• L'une des bouches de decharge murales Jenn-Air suivantes :

Clapet de bouche de decharge murale en surface rond de

5" (12,7 cm) de Jenn-Air ®

Commander la piece numero A405

Clapet de bouche de decharge murale en surface rond de

6" (15,2 cm) de Jenn-Air ®

Commander la piece numero A406

Clapet de bouche de decharge murale en surface rond de

31¼"x 10" (8,3 x 25,4 cm) de Jenn-Air ®

Commander la piece numero A403

Pour commander, voir la section "Assistance ou service" du

Guide d'utilisation et d'entretien.

• Conduit metallique

• Brides de conduit

• 2 cales en bois 2" x 4" x 83_'' (5 x 10,2 x 22,2 cm) (pour

evacuation par la gauche ou par la droite)

Chevilles a beton (pour montage sur sol en beton)

Verifier les codes Iocaux et consulter le fournisseur de gaz.

Verifier I'alimentation en gaz et I'alimentation electrique

existantes. Voir les sections "Specifications electriques" et

"Specifications de I'alimentation en gaz".

IMPORTANT : Observer les dispositions de tous les codes et

reglements en vigueur. Ne pas obstruer le flux de combustion et

de ventilation.

C'est & I'installateur qu'incombe la responsabilite de respecter

les distances de separation exigees pour I'installation,

specifiees sur la plaque signaletique de I'appareil. Plaque

signaletique (situee sur le c6te droit du chassis du four,

derriere le panneau du tiroir de remisage)

La cuisiniere doit _tre installee a un endroit pratique dans la

cuisine.

Dans le cas d'une cuisiniere encastree, I'enceinte doit

recouvrir completement les c6tes et I'arriere de la cuisiniere.

Afin de supprimer le risque de brQlures ou d'incendie lie au fait

de se pencher au-dessus des unites de surface chauffees, le

rangement en placard au-dessus des unites de surface doit

_tre evit& Si le rangement en placard est envisage, le risque

peut _tre reduit par I'installation d'une hotte de cuisiniere ou

un ensemble hotte/micro-ondes operant horizontalement sur

un minimum de 5" (12,7 cm) au-del& du bas des placards.

28

Page 29

Toutes les ouvertures dans metour ou meplancher de

I'emplacement d'installation de la cuisiniere doivent etre

scellees.

Respecter les dimensions indiquees pour les ouvertures &

decouper dans les placards. Ces dimensions constituent les

valeurs minimales des degagements de separation.

La bride antibasculement de plancher doit etre installee. Pour

I'installation de la bride antibasculement expediee avec la

cuisiniere, voir la section "Installation de la bride

antibasculement".

Une source d'electricite avec liaison a la terre est necessaire.

Voir la section "Specifications electriques".

Une source de gaz adequate doit etre disponible. Voir la

section "Specifications de I'alimentation en gaz".

Contacter un installateur de revetement de sol qualifie, qui

pourra determiner si le revetement de sol peut resister a une

temperature d'au moins 200°F (93°C).

Dans le cas de I'installation de la cuisiniere par dessus un

tapis, placer sous la cuisiniere une plaque d'appui isolee, ou

une plaque de contreplaque de 1¼,,(0,64 cm).

IMPORTANT : Afin d'eviter d'endommager les placards, consulter

le constructeur de la maison ou le fabricant des placards pour

determiner si les materiaux utilises peuvent subir un changement

de couleur, une destratification ou d'autres dommages. Ce four a

ete con£_uconformement aux exigences des normes UL et CSA

International et respecte les temperatures maximales permises de

194°F (90°C) pour les placards en bois.

Dimensions du produit

G

F

\ E

R_sidence mobile -- Specifications additionnelles

respecter Iors de I'installation

L'installation de cette cuisiniere doit etre conforme aux

dispositions de la norme Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280 (anciennement Federal

Standard for Mobile Home Construction and Safety, Title 24, HUD

Part 280). Lorsque cette norme n'est pas applicable, I'installation

doit satisfaire aux criteres de la norme Standard for Manufactured

Home Installations, ANSI A225.1/NFPA 501A ou aux dispositions

des codes Iocaux.

Au Canada, r installation de cette cuisiniere doit satisfaire aux

stipulations de la version la plus recente de la norme CAN/CSA-

A240 ou des codes Iocaux en vigueur.

Crit_res a respecter pour une installation en r_sidence

mobile :

Dans le cas de I'installation de cette cuisiniere dans une

residence mobile, la cuisiniere doit etre fixee au plancher

durant tout deplacement du vehicule. Toute methode de

fixation de la cuisiniere est adequate dans la mesure oQ elle

satisfait aux criteres des normes mentionnees ci-dessus.

A. 303/4"(78,1 cm)

B. 23V2" (59, 7 cm) entre le coin du

plan de travail et I'arriere de la table

de cuisson

C. Plaque signal_tique (situ_e sur le

c6t_ droit du chassis du four,

derriere le tiroir de remisage)

D. Plaque signal_tique (situ_e en bas

Ddroite du chassis du four)

E.29%" (75,9cm)

F. 291/16'' (73,8 cm)entre la

poign_e et I'arrierede la

cuisiniere**

G.Hauteurjusqu'D la partie

inf_rieurede la table de

cuisson avec les pieds de

nivellement

completement abaiss_s :

353/4 '' (90,8 cm)

*La cuisiniere peut etre surelevee d'environ 1" (2,5 cm) en

ajustant les pieds de nivellement.

**Dans le cas d'une installation dans un placard inferieur de 24"

(61 cm) avec plan de travail de 25" (63,5 cm), I'avant de la porte

du four sera en saillie de 21/2'' (6,4 cm) au-del& du placard

inferieur de 24" (61 cm).

29

Page 30

Dimensions du placard

Les dimensions d'ouverture de placard indiquees sont valides

pour une installation avec une profondeur de plan de travail de

25" (64,0 cm), une profondeur de placard inferieur de 24"

(61,0 cm) et une hauteur de plan de travail de 36" (91,4 cm).

La cuisiniere peut etre installee sans aucun degagement entre une

construction combustible a I'arriere et sur les c6tes, sous la table

de cuisson.

H

F

A. Profondeur des placards sup_rieurs : 13" (33,0 cm)

B. Largeur de I'ouverture 30" (76,2 cm) min.

C. Pour la distance fibre minimale vers la partie sup_rieure de la table

de cuisson, voir la REMARQUE.

D. Profondeur de I'ouverture 23%" (59,1 cm)

E. Largeur de I'ouverture 30" (76,2 cm) min.

F. Afimentation _lectrique et alimentation en gaz- s_paration de 5,5"

(14 cm) min. par rapport au placard et 10" (25,4 cm) max. au-

dessus du sol. Aucun _l_ment situ_ dans la zone ombr_e ne doit

d_passer de plus de 2¼" (5, 7 cm) du mur arriere, sans quoi il sera

impossible de remettre la cuisiniere bien en place. La prise de

courant (avec liaison _ la terre) doit _tre monroe en affleurement.

G. La porte ou charniere du placard ne doit pas d_passer _ I'int_rieur

de I'ouverture.

H. 18" (45,7 cm)

I. D_gagement de 3" (7,6 cm) min. entre les deux c6t_s de la

cuisiniere et les parois lat_rales ou d'autres mat_riaux combustibles.

REMARQUE • Distance de separation minimale de 24" (61 cm)

Iorsque le fond d'un placard de bois ou de metal est protege par

une planche ignifugee d'au moins 1/4"(0,64 cm) recouverte d'une

feuille metallique d'epaisseur egale ou superieure & : acier calibre

28 MSG, acier inoxydable 0,015" (0,4 mm), aluminium 0,024"

(0,6 mm), ou cuivre 0,020" (0,5 mm).

Distance de separation minimale de 30" (76,2 cm) entre le dessus

de la table de cuisson et le fond d'un placard de bois ou de metal

non protege.

IMPORTANT : Cette cuisiniere doit etre ventilee vers I'exterieur.

Voir la section "Methodes d'evacuation".

• Ne pas terminer le circuit d'evacuation dans un grenier ou

dans un autre espace ferme.

• Utiliser une bouche de decharge murale Jenn-Air.

• Le circuit doit evacuer Fair a I'exterieur.

Utiliser uniquement un conduit metallique rond de

6" (15,2 cm) ou un conduit rectangulaire de 3_¼x 10"

(8,3 cm x 25,4 cm), sauf dans les cas suivants :