Jenn-Air JDS9860AAP, JDS9860ACP, JDS9860BCP, JDS9861AAP Owner's Manual

JENN-AIR DUAL-FUEL DOWNDRAFT SLIDE-IN RANGE

JENN-AIR DUAL-FUEL DOWNDRAFT SLIDE-IN RANGE

PROSTYLE

USER

USER

G U I D E

G U I D E

TABLE OF CONTENTS

Safety Instructions ................................................................... 1-4

Ducting Information.................................................................... 4

Surface Cooking....................................................................... 5-9

Oven Cooking ..................................................................... 10-17

Accessories ................................................................................ 17

Care & Cleaning.................................................................. 18-20

Maintenance ............................................................................... 21

Before You Call for Service ................................................... 22

Warranty .................................................................................... 23

Guide de l’utilisateur................................................................ 24

Guía del Usuario ....................................................................... 48

Form No. B/06/02 Part No. 8113P365-60 74005521 © 2002 Maytag Appliances Sales Co. Litho U.S.A .

IMPORTANT SAFETY INSTRUCTIONS

Installer: Please leave this manual

with this appliance.

Consumer: Please read and keep

this manual for future reference. Keep

sales receipt and/or cancelled check

as proof of purchase.

Model Number

–– –– –– –– –– –– –– –– ––

Serial Number

–– –– –– –– –– –– –– –– ––

Date of Purchase

_______________________________

If you have questions, call:

Jenn-Air Customer Assistance

1-800-688-1100

1-800-688-2080 ( U.S. TTY for hear-

ing or speech impaired)

(Mon.-Fri., 8 am-8 pm Eastern Time)

Internet: http://www.jennair.com

For service information, see page

23.

In our continuing effort to

improve the quality and performance of our cooking

products, it may be necessary to make changes to the

appliance without revising

this guide.

SAFETY INSTRUCTIONS

Warning and Important Safety Instructions

appearing in this guide are not meant to cover

all possible conditions and situations that may

occur. Common sense, caution, and care

must be exercised when installing, maintaining, or operating the appliance.

Always contact your dealer, distributor, service agent, or manufacturer about problems

or conditions you do not understand.

RECOGNIZE SAFETY SYMBOLS,

WORDS, LABELS

WARNING

WARNING – Hazards or unsafe practices

which COULD result in severe personal

injury or death.

CAUTION

CAUTION – Hazards or unsafe practices

which COULD result in minor personal injury.

Read and follow all instructions before

using this appliance to prevent the poten-

tial risk of fire, electric shock, personal injury

or damage to the appliance as a result of

improper usage of the appliance. Use appliance only for its intended purpose as described in this guide.

To ensure proper and safe operation:

Appliance must be properly installed and

grounded by a qualified technician. Do not

attempt to adjust, repair, service, or replace

any part of your appliance unless it is specifically recommended in this guide. All other

servicing should be referred to a qualified

servicer. Have the installer show you the

location of the gas shut off valve and how to

shut it off in an emergency.

Always disconnect power to appliance before servicing.

WARNING:

If the in-

formation in this manual is

not followed exactly, a fire or

explosion may result causing

property damage, personal injury or death.

– Do not store or use gasoline or

other flammable vapors and liquids in the vicinity of this or any

appliance.

– IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical

switch.

• Do not use any phone in your

building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you cannot reach your gas

supplier, call the fire department.

– Installation and service must be

performed by a qualified installer, service agency or the gas

supplier.

WARNING

Because gas may escape from your system which may not be detected by smell

alone, resulting in a potentially extremely

dangerous situation, it is recommended

by gas suppliers that you purchase and

install a UL approved gas detector(s) in

your home. Your local gas supplier can

assist you in obtaining a gas detector.

Please install, maintain and use the gas

detector in accordance with the gas

detector manufacturer’s instructions.

1

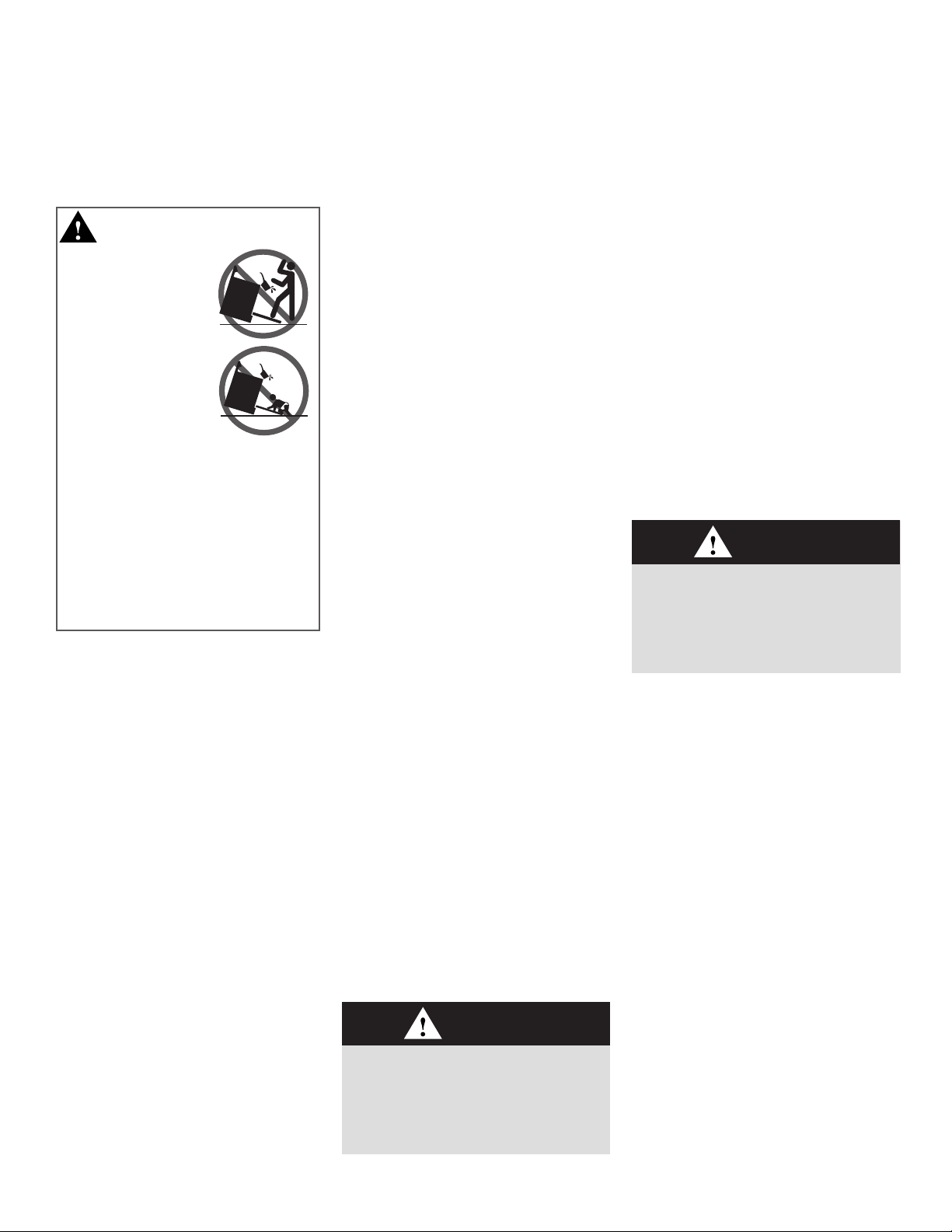

GENERAL

INSTRUCTIONS

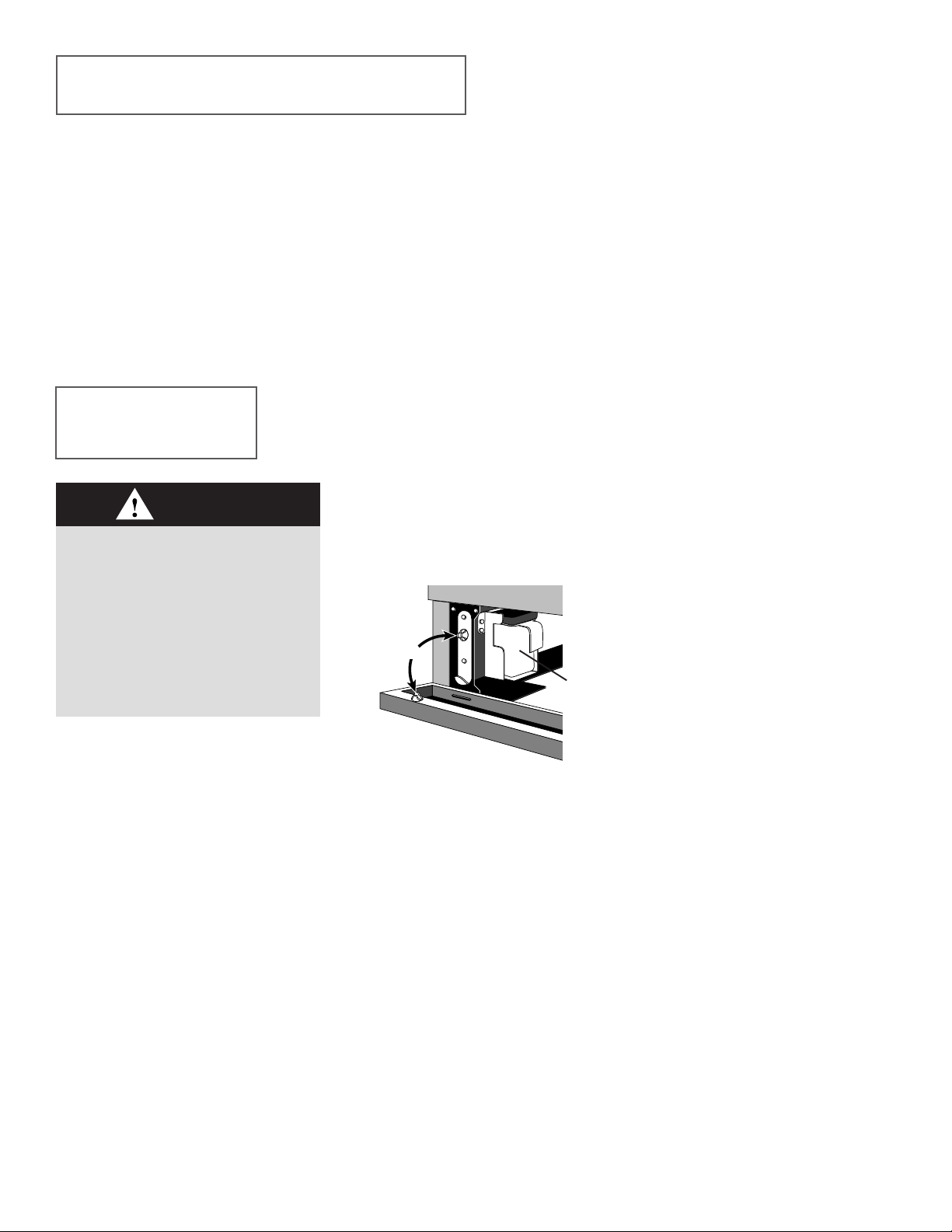

WARNING:

• ALL RANGES

CAN TIP AND

CAUSE INJURIES TO PERSONS

• INSTALL

ANTI-TIP DEVICE PACKED

WITH RANGE

• FOLLOW ALL INSTALLATION INSTRUCTIONS

To reduce risk of tipping of the

appliance from abnormal usage

or by excessive loading of the

oven door, the appliance must

be secured by a properly installed

anti-tip device.

To check if device is properly installed, look

underneath range with a flashlight to make

sure one of the rear leveling legs is properly

engaged in the bracket slot. The anti-tip

device secures the rear leveling leg to the

floor when properly engaged. You should

check this anytime the range has been

moved.

TO PREVENT FIRE OR

SMOKE DAMAGE

Be sure all packing materials are removed

from the appliance before operating it.

Keep area around appliance clear and free

from combustible materials, gasoline, and

other flammable vapors and materials.

If appliance is installed near a window,

proper precautions should be taken to

prevent curtains from blowing over burners.

NEVER leave any items on the cooktop.

The hot air from the vent may ignite flammable items and may increase pressure in

closed containers which may cause them to

burst.

Many aerosol-type spray cans are EXPLOSIVE when exposed to heat and may be

highly flammable. Avoid their use or storage

near an appliance.

Many plastics are vulnerable to heat. Keep

plastics away from parts of the appliance

that may become warm or hot. Do not leave

plastic items on the cooktop as they may

melt or soften if left too close to the vent or

a lighted surface burner.

To eliminate the hazard of reaching over hot

surface burners, cabinet storage should not

be provided directly above a unit. If storage

is provided, it should be limited to items

which are used infrequently and which are

safely stored in an area subjected to heat

from an appliance. Temperatures may be

unsafe for some items, such as volatile liquids, cleaners or aerosol sprays.

IN CASE OF FIRE

Turn off appliance and ventilating hood to

avoid spreading the flame. Extinguish flame

then turn on hood to remove smoke and

odor.

• Cooktop: Smother fire or flame in a pan

with a lid or cookie sheet.

NEVER pick up or move a flaming pan.

• Oven: Smother fire or flame by closing

the oven door.

Do not use water on grease fires. Use baking

soda, a dry chemical or foam-type extinguisher to smother fire or flame.

CHILD SAFETY

CAUTION

NEVER store items of interest to children in cabinets above an appliance or

on backguard of a range. Children climbing on the appliance door to reach items

could be seriously injured.

NEVER leave children alone or unsupervised near the appliance when it is in use or

is still hot.

NEVER allow children to sit or stand on

any part of the appliance as they could be

injured or burned.

Children must be taught that the appliance

and utensils in it can be hot. Let hot utensils

cool in a safe place, out of reach of small

children. Children should be taught that an

appliance is not a toy. Children should not

be allowed to play with controls or other

parts of the unit.

ABOUT YOUR

APPLIANCE

WARNING

NEVER use appliance door, or drawer,

if equipped, as a step stool or seat as this

may result in possible tipping of the

appliance, damage to the appliance, and

serious injuries.

NEVER use appliance as a space heater to

heat or warm a room to prevent potential

hazard to the user and damage to the

appliance. Also, do not use the cooktop or

oven as a storage area for food or cooking

utensils.

For proper performance and operation, do

not block or obstruct the oven vent duct

located on the right side of the air grille.

Avoid touching oven vent area while oven

is on and for several minutes after oven is

turned off. Some parts of the vent and

surrounding area become hot enough to

cause burns. After oven is turned off, do not

touch the oven vent or surrounding areas

until they have had sufficient time to cool.

Other potentially hot surfaces include

cooktop, areas facing the cooktop, oven

vent, surfaces near the vent opening, oven

door, areas around the oven door and oven

window.

2

IMPORTANT SAFETY INSTRUCTIONS, CONT.

Do not touch a hot oven light bulb with a

damp cloth as the bulb could break. Should

the bulb break, disconnect power to the

appliance before removing bulb to avoid

electrical shock.

COOKING SAFETY

Always place a pan on a surface burner

before turning it on. Be sure you know

which knob controls which surface burner.

Make sure the correct burner is turned on

and that the burner has ignited. When cooking is completed, turn burner off before

removing pan to prevent exposure to burner

flame.

Always adjust surface burner flame so that

it does not extend beyond the bottom edge

of the pan. An excessive flame is hazardous,

wastes energy and may damage the appliance, pan or cabinets above the appliance.

NEVER leave a surface cooking operation

unattended especially when using a high

heat setting or when deep fat frying. Boilovers

cause smoking and greasy spillovers may

ignite. Clean up greasy spills as soon as

possible. Do not use high heat for extended

cooking operations.

NEVER heat an unopened container on

the surface burner or in the oven. Pressure

build-up may cause container to burst resulting in serious personal injury or damage

to the appliance.

Use dry, sturdy potholders. Damp potholders may cause burns from steam.

Dishtowels or other substitutes should never

be used as potholders because they can trail

across hot surface burners and ignite or get

caught on appliance parts.

Always let quantities of hot fat used for deep

fat frying cool before attempting to move or

handle.

Do not let cooking grease or other flammable materials accumulate in or near the

rangetop or in the vents. Clean frequently

to prevent grease from accumulating.

NEVER wear garments made of flammable

material or loose fitting or long-sleeved

apparel while cooking. Clothing may ignite

or catch utensil handles.

Always place oven racks in the desired

positions while oven is cool. Slide oven rack

out to add or remove food, using dry,

sturdy potholders. Always avoid reaching

into the oven to add or remove food. If a

rack must be moved while hot, use a dry

potholder. Always turn the oven off at the

end of cooking.

Use care when opening the oven door. Let

hot air or steam escape before moving or

replacing food.

NEVER use aluminum foil inside the grill

area, to cover oven racks or oven bottom.

This could result in risk of electric shock,

fire, or damage to the appliance. Use foil

only as directed in this guide.

PREPARED FOOD WARNING: Follow food manufacturer’s instructions. If a

plastic frozen food container and/or its

cover distorts, warps, or is otherwise damaged during cooking, immediately discard

the food and its container. The food could

be contaminated.

UTENSIL SAFETY

Use pans with flat bottoms and handles that

are easily grasped and stay cool. Avoid using

unstable, warped, easily tipped or loosehandled pans. Also avoid using pans, especially small pans, with heavy handles as they

could be unstable and easily tip. Pans that

are heavy to move when filled with food

may also be hazardous.

Be sure utensil is large enough to properly

contain food and avoid boilovers. Pan size is

particularly important in deep fat frying. Be

sure pan will accommodate the volume of

food that is to be added as well as the bubble

action of fat.

To minimize burns, ignition of flammable

materials and spillage due to unintentional

contact with the utensil, do not extend

handles over adjacent surface burners. Always turn pan handles toward the side or

back of the appliance, not out into the room

where they are easily hit or reached by

small children.

Never let a pan boil dry as this could

damage the utensil and the appliance.

Follow the manufacturer’s directions when

using oven cooking bags.

Only certain types of glass, glass/ceramic,

ceramic or glazed utensils are suitable for

cooktop or oven usage without breaking

due to the sudden change in temperature.

Follow manufacturer’s instructions when

using glass.

This appliance has been tested for safe

performance using conventional cookware.

Do not use any devices or accessories that

are not specifically recommended in this

guide. Do not use eyelid covers for the

surface units, stovetop grills, or add-on

oven convection systems. The use of devices or accessories that are not expressly

recommended in this manual can create

serious safety hazards, result in performance problems, and reduce the life of the

components of the appliance.

HEATING ELEMENTS

NEVER touch oven heating elements,

areas near elements, or interior surfaces of oven.

Heating elements may be hot even though

they are dark in color. Areas near elements

and interior surfaces of an oven may become hot enough to cause burns.

During and after use, do not touch or let

clothing or other flammable materials contact heating elements, areas near elements,

or interior surfaces of oven until they have

had sufficient time to cool.

CLEANING SAFETY

Turn off all controls and wait for appliance

parts to cool before touching or cleaning

them. Do not touch the burner grates or

surrounding areas until they have had sufficient time to cool.

3

Clean appliance with caution. Use care to

avoid steam burns if a wet sponge or cloth

is used to wipe spills on a hot surface. Some

cleaners can produce noxious fumes if applied to a hot surface.

SELF-CLEAN OVEN

Clean only parts listed in this guide. Do not

clean door gasket. The door gasket is essential for a good seal. Care should be taken

not to rub, damage, or move the gasket. Do

not use oven cleaners of any kind in or

around any part of the self-clean oven.

Before self-cleaning the oven, remove air

grille, broiler pan, oven racks and other

utensils and wipe up excessive spillovers to

prevent excessive smoke, flare-ups or flaming. CAUTION: Do not leave food or

cooking utensils, etc. in the oven during the

self-clean cycle.

Slide-in ranges feature a cooling fan which

operates automatically during a clean cycle.

If the fan does not turn on, cancel the clean

operation and contact an authorized

servicer.

It is normal for the cooktop of the range to

become hot during a self-clean cycle. Therefore, touching the cooktop during a clean

cycle should be avoided.

IMPORTANT SAFETY

NOTICE AND

WARNING

The California Safe Drinking Water and

Toxic Enforcement Act of 1986 (Proposition 65) requires the Governor of California to publish a list of substances known to

the State of California to cause cancer or

reproductive harm, and requires businesses

to warn customers of potential exposures

to such substances.

Users of this appliance are hereby warned

that the burning of gas can result in lowlevel exposure to some of the listed substances, including benzene, formaldehyde

and soot, due primarily to the incomplete

combustion of natural gas or liquid petroleum (LP) fuels. Properly adjusted burners

will minimize incomplete combustion. Exposure to these substances can also be

minimized by properly venting the burners

to the outdoors.

Users of this appliance are hereby warned

that when the oven is engaged in the selfclean cycle, there may be some low level

exposure to some of the listed substances,

including carbon monoxide. Exposure to

these substances can be minimized by properly venting the oven to the outdoors

during the self-clean cycle by opening a

window and/or door in the room where

the appliance is located.

IMPORTANT NOTICE REGARDING

PET BIRDS: Never keep pet birds in the

kitchen or in rooms where the fumes from

the kitchen could reach. Birds have a very

sensitive respiratory system. Fumes released during an oven self-cleaning cycle

may be harmful or fatal to birds. Fumes

released due to overheated cooking oil, fat,

margarine and overheated non-stick cookware may be equally harmful.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

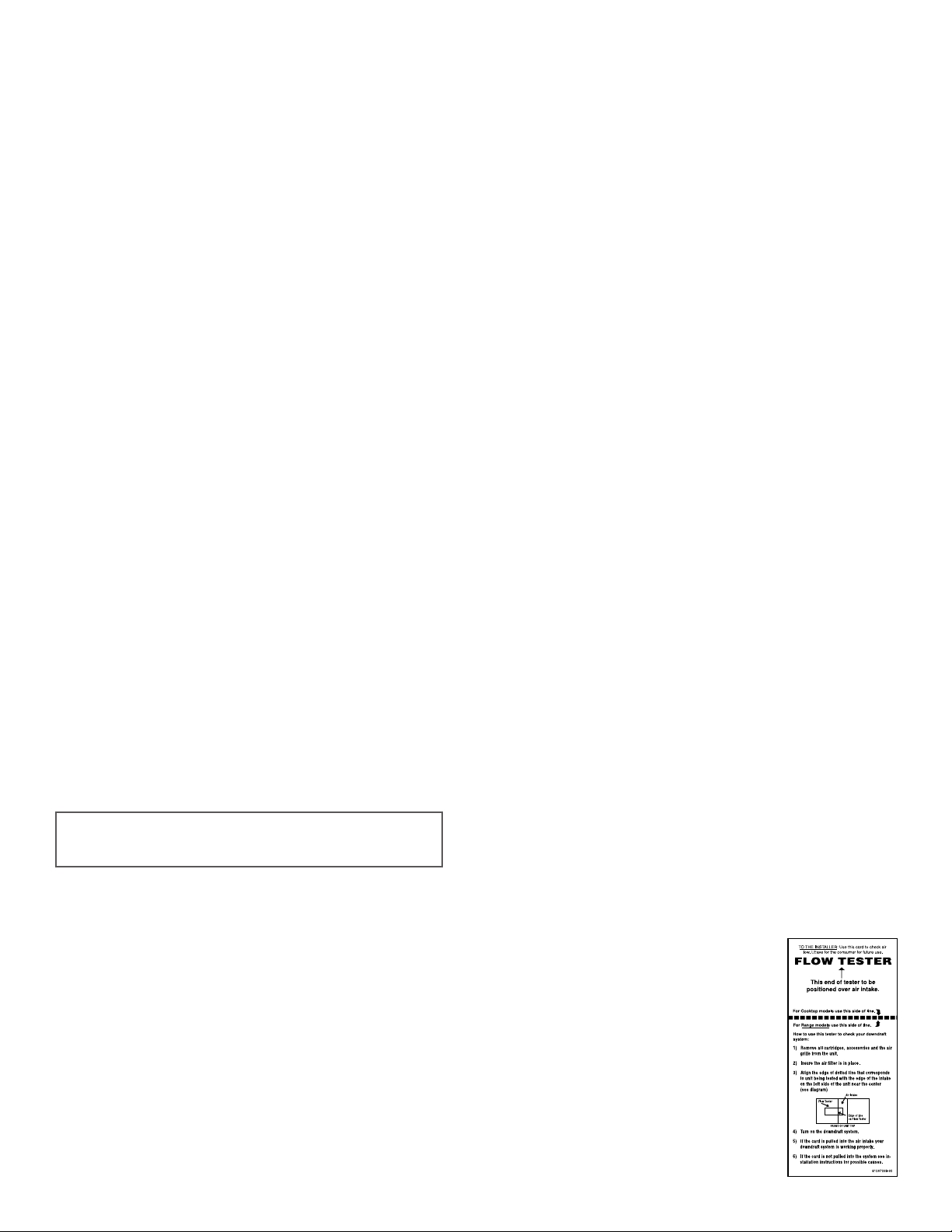

DUCTING INFORMATION

Jenn-Air’s ventilation system is designed to

capture both cooking fumes and smoke

from the cooktop surface. If the system

does not, these are some ducting installation situations to check:

1

• 6" diameter round or 3

gular ducting should be used for duct

lengths 10'-60'. Note: 5" diameter round

ducting may be used if the duct length

is 10' or less.

• No more than three 90° elbows should

be used. Distance between elbows should

/4" x 10" rectan-

be at least two and one half times the

diameter of the duct.

• Recommended Jenn-Air wall cap MUST

be used. Make sure damper moves freely

when ventilation system is operating.

• There should be a minimum clearance of

6" for cooktop installed near a side wall.

If there is not an obvious improper installation, there may be a concealed problem

such as a pinched joint, obstruction in the

pipe, etc. Installation is the responsibility of

the installer and questions should be addressed first by the installer. The installer

should very carefully

check the ducting installation instructions.

• Use the Flow Tester

Card provided with

your appliance to

check the air flow.

4

SURFACE COOKING

SURFACE CONTROLS

CAUTION

• If flame should go out during a cooking operation, turn the burner off. If a

strong gas odor is detected, open a

window and wait five minutes before

relighting the burner.

• Be sure all surface controls are set in

the OFF position prior to supplying

gas to the range.

• NEVER touch cooktop until it has

cooled. Expect some parts of the

cooktop, especially around the burners, to become warm or hot during

cooking. Use potholders to protect

hands.

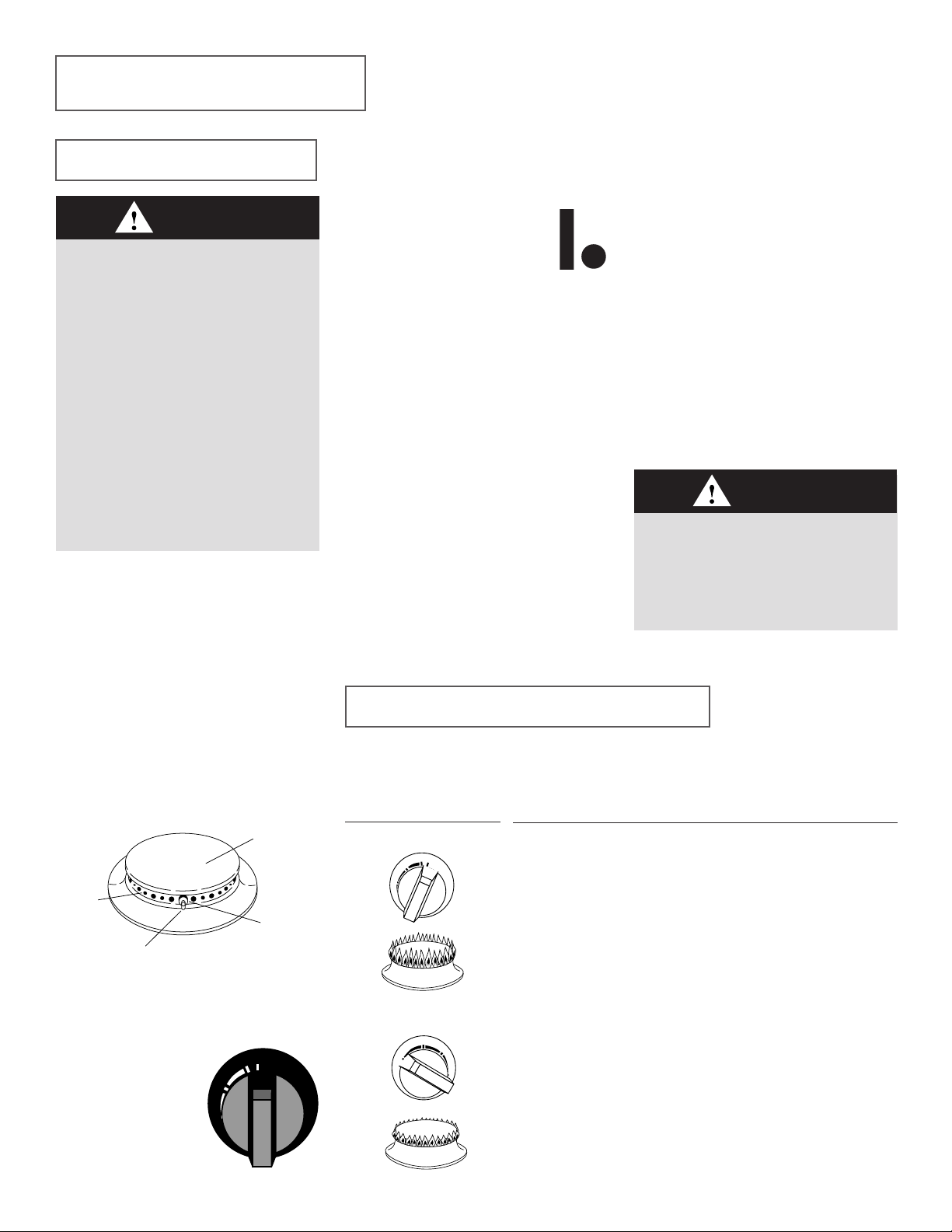

PILOTLESS IGNITION

Pilotless ignition eliminates the need for a

constant standing pilot light. Each surface

burner has a spark ignitor. When cleaning

around the surface burner use care. If

cleaning cloth should catch the ignitor, it

could damage it preventing ignition.

If the surface burner does not light, check if

ignitor is broken, soiled or wet. If clogged,

clean the small port beneath the ignitor

using straight pin.

CAP

PORTS

IGNITOR

PORT BELOW IGNITOR

SURFACE CONTROL

KNOBS

Use to turn on the surface burners. An infinite choice of heat settings is available from

lo to hi. At the hi and

lo setting, a detent or

notch may be felt. The

e

t

i

L

i

H

d

e

M

o

L

knobs can be set on or between any of the

settings.

Graphics next to the knob identify which

burner the knob controls. For

example, the graphic at right

3. After ignition, turn knob clockwise to

desired setting.

• The ignitor will continue to spark

until the knob is turned past the

lite position.

shows the right front burner location.

OPERATING DURING A

SETTING THE

CONTROLS

1. Place a pan on the burner grate. (To

preserve the grate finish, do not operate

the burners without a pan on the grate to

absorb the heat from the burner flame.)

2. Push in knob and turn immediately counterclockwise to the lite setting until

burner ignites.

•A clicking (spark) sound will be heard

and the burner will light. (All ignitors

will spark when any surface burner

knob is turned to the lite position.)

POWER FAILURE

1. Hold a lighted match to the desired

surface burner head.

2. Push in and turn the control knob slowly

to lite.

3. Adjust the flame to the desired level.

CAUTION

•When lighting the surface burners, be

sure all of the controls are in the OFF

position. Strike the match first and

hold it in position before turning the

knob to lite.

SUGGESTED HEAT SETTINGS

The size and type of cookware will affect the heat setting. For information on cookware

and other factors affecting heat settings, refer to “Cooking Made Simple” booklet.

Settings Uses

hi Use hi to bring liquid to a boil, or reach pressure in a

i

L

H

i

t

e

d

e

M

o

L

lo

o

L

M

e

d

f

f

O

H

i

L

i

t

e

pressure cooker. Always reduce setting to a lower heat when

liquids begin to boil or foods begin to cook.

An intermediate flame size is used to continue cooking. Food

will not cook any faster when a higher flame setting is used

than needed to maintain a gentle boil. Water boils at the same

temperature whether boiling gently or vigorously.

Use lo to simmer foods, keep foods warm and melt

chocolate or butter.

Some cooking may take place on the lo setting if the pan is

covered. It is possible to reduce the heat by rotating the knob

toward OFF. Be sure flame is stable.

5

COOKTOP

To prevent the cooktop from discoloring or staining:

•

Clean cooktop after each use.

•

Wipe acid or sugar spills as soon as

the cooktop has cooled.

SEALED BURNERS

The sealed burners on your range are secured to the cooktop cartridge and are not

designed to be removed. Since the burners

are sealed into the cartridge, boilovers or

spills will not seep underneath the cooktop.

However, the burner heads should be

cleaned after each use.

BURNER GRATES

The grates must be properly positioned

before cooking. Improper installation of

the grates may result in chipping of the

cooktop.

NOTES:

•

A properly adjusted burner with clean ports will light within a few seconds. If using

natural gas, the flame will be blue with a deeper blue inner cone.

If the burner flame is yellow or is noisy, the air/gas mixture may be incorrect. Contact

a service technician to adjust. (Adjustments are not covered by the warranty.)

With LP gas, some yellow tips on the flames are acceptable. This is normal and

adjustment is not necessary.

•

With some types of gas, you may hear a “popping” sound when the surface burner

is turned off. This is a normal operating sound of the burner.

•

If the control knob is turned very quickly from hi to lo, the flame may go out,

particularly if the burner is cold. If this occurs, turn the knob to the OFF position,

wait several seconds and relight the burner.

•

To improve cooking efficiency and to prevent possible damage to the range or pan,

the flame must be adjusted so it does not extend beyond the edge of the pan.

Do not operate the burners without a

pan on the grate. The grate’s porcelain finish may chip without a pan to

absorb the heat from the burner flame.

Although the burner grates are durable,

they will gradually lose their shine and/or

discolor, due to the high temperatures of

the gas flame.

6

SURFACE COOKING, CONT.

SEALED BURNER

CARTRIDGE

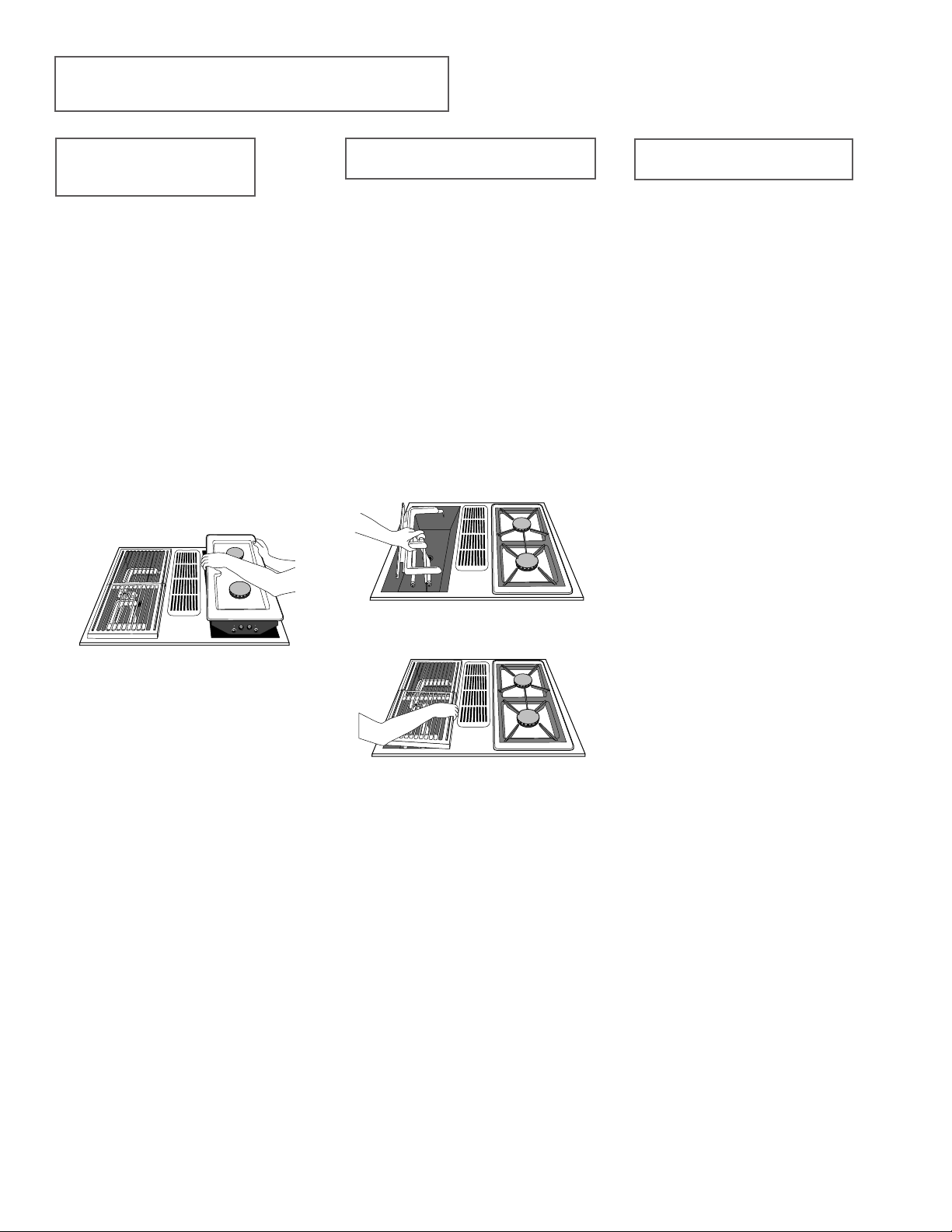

TO INSTALL SEALED BURNER

CARTRIDGE:

1. Be sure control knobs are turned OFF.

2. If the grill burner and grill grates are in

place, remove before installing a burner

cartridge. Clean basin of any grease

accumulation. (See page 20 for cleaning

recommendations.)

3. Position the burner cartridge with the

mixer tube openings and ignitor rods

toward the orifices and terminal receptacle. Slide the cartridge until the tubes

and ignitors engage, then lower the cartridge so that it rests on the range

surface.

TO REMOVE SEALED BURNER

CARTRIDGE:

GRILL INSTALLATION

The grill assembly consists of two grill

grates and a grill burner. Only install the grill

on the LEFT SIDE of your range.

TO INSTALL GRILL:

1. Before installing grill components, be

sure controls knobs are in the OFF

position.

2. Position the grill burner with mixer

tubes and ignitor rod toward the orifices and terminal receptacle. Slide the

burner until the tubes and ignitor engage, then lower the burner until it rests

in the burner basin.

3. Place the grill grates on top of the

rangetop.

USING THE GRILL

• Before the first use, wash grill grates in

hot soapy water, rinse and dry. Then

“season” the surface by wiping on a thin

coating of cooking oil. Remove excess

oil by wiping with paper towel.

This procedure should be repeated when

either: a) cleaning in the dishwasher

since the detergent may remove seasoning or b) anytime a sugar-based

marinade (for example, barbecue sauce)

is going to be used.

• Preheat the grill on Hi for 5 minutes.

Preheating improves the flavor and appearance of meats and quickly sears the

meat to help retain the juices.

• Use nonmetallic spatulas or utensils to

prevent damaging the nonstick grill grate

finish.

• Excessive amounts of fat should be trimmed

from meats. Only a normal amount is

necessary to produce the smoke needed

for that smoked, “outdoor” flavor. Excessive fat can create cleaning and flareup problems.

1. Control knobs should be in the OFF

position and the range should be cool.

2. Lift up the edge of the cartridge until the

bottom of the cartridge clears the basin.

(Lifting the cartridge too high while still

engaged could damage the ignitor rods

and mixer tubes.)

3. To disengage the cartridge, hold by the

sides and pull away from the terminal

receptacle and orifices. Lift out when

fully unplugged.

4. Do not stack cartridges where they may

fall or be damaged.

NOTE: Optional Sealed Burner Car-

tridge, model JGA8100, can replace the

grill burner assembly.

NOTE: Before using the grill for the

first time, heat the grill burner to remove the protective shipping coating.

Heat the grill burner on Hi for 10

minutes and use the vent system to

remove any smoke.

TO REMOVE GRILL:

1. Be sure control knobs are in the OFF

position and the grill components are

cool.

2. Remove grill grates.

3. Lift the burner up slightly. Slide the

burner away from the orifices and terminal receptacle.

• Allowing excessive amounts of grease or

drippings to constantly flare-up voids the

warranty on the grill grates.

• Excessive flare-ups indicate that either

the grill interior needs to be cleaned or

that excessive amounts of fat are in the

meat or the meat was not properly

trimmed.

• Grease drippings will occasionally ignite

to produce harmless puffs of flame for a

second or two. This is a normal part of

the cooking process. NOTE: For infor-

mation on the grease cup, see pg. 20.

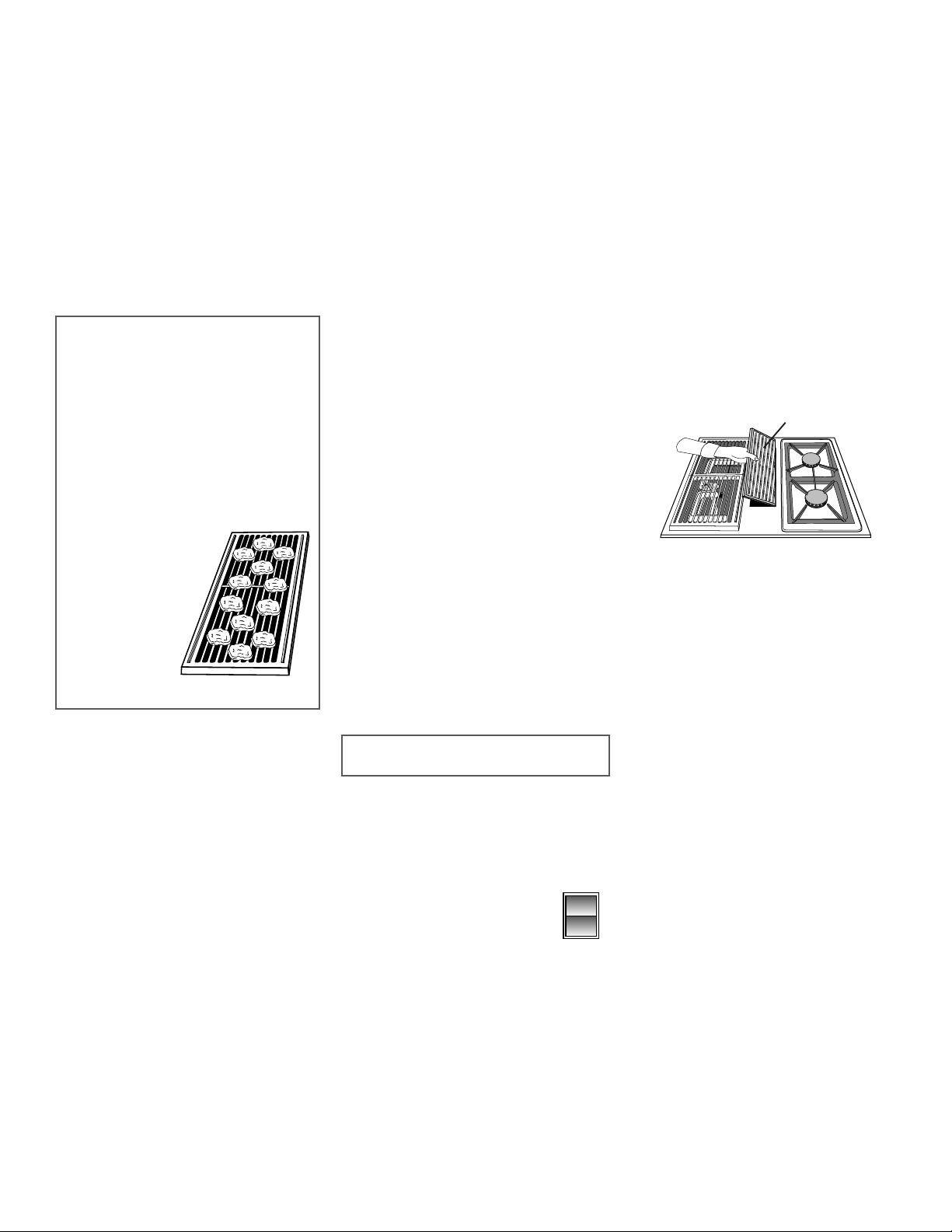

• NEVER LEAVE GRILL UNAT-

TENDED DURING GRILL OPERATION.

7

• SHOULD EXCESS GREASE

CAUSE SUSTAINED FLAREUPS:

1. Turn on the fan manually.

2. Immediately turn grill controls to

Off.

3. Remove meat from grill.

IMPORTANT

• Do not use aluminum foil inside the

grill area.

• Do not use charcoal or wood chips in

the grill area.

• Do not allow burner basin to become

overloaded with grease. Clean frequently.

• Do not cover grates

completely with meat.

Leave air space between each steak,

etc. to allow

proper ventilation as well as

prevent flareups.

GRILLING TIPS

• Be sure to follow directions for using the

grill.

• Suggested cooking times and control

settings (see Grill guide, pg. 9) are approximate due to variations in the foods.

• For best results, buy top grade meat.

Meat that is at least

better than thinner cuts.

• Score fat on edges of steak, but do not

cut into meat, to prevent curling while

cooking.

• For the attractive “branded” look on

steaks, be sure grill is preheated. Allow

one side of meat to cook to desired

3

/4 inch will grill

doneness, or until juices appear on the

top surface, before turning. Turn steaks

and hamburgers just once. Manipulating

food causes loss of juices.

• When basting meats or applying sauces

to foods, remember that excessive

amounts accumulate inside your grill

and do not improve the food flavor.

Apply sauces during the last 15 to 20

minutes of cooking time unless recipe

specifies otherwise. Plus, anytime a sugarbased marinade (for example barbecue

sauce) is going to be used, the grates

should be "seasoned" prior to preheating. (See Using the Grill section.)

• There are many meat marinades which

will help tenderize less expensive cuts of

meat for cooking on the grill.

• Certain foods, such as poultry and nonoily fish, may need some extra fat. Brush

with oil or melted butter occasionally

while grilling.

• Use tongs with long handles or spatulas

for turning meats. Do not use forks as

these pierce the meat, allowing juices to

be lost.

VENTILATION SYSTEM

The built-in ventilation system removes

cooking vapors, odors and smoke from

foods prepared on your cooktop and grill.

• To operate the ventilation sys-

tem manually, push the vent

fan switch located on the control panel.

• The ventilation system will operate au-

tomatically on Hi when the grill burner

is in use.

• The fan can be used to remove strong

odors from the kitchen as when chopping onions near the fan.

Fan

Hi

Lo

CARE AND CLEANING OF

VENTILATION SYSTEM

THE

• Air Grille: The air grille lifts off easily.

Wipe clean or wash in dishwasher or sink

with mild household detergents. To prevent scratching the surface, do not use

abrasive cleaners or scrubbing pads.

• Filter: Turn off ventilation system before

removing. The filter is a permanent type

and should be cleaned when soiled. Clean

in sink with warm water and detergent or

in dishwasher.

IMPORTANT: DO NOT OPERATE SYSTEM WITHOUT FILTER. Filter should al-

ways be placed at an angle. As you face

the front of the range, the top of the filter

should rest against the left side of the vent

opening. The bottom should rest against

the right side of the vent chamber at the

bottom. (Note: If filter is flat against

the fan wall, ventilation effectiveness

is reduced.)

• Ventilation Chamber: This area, which

houses the filter, should be cleaned in the

event of spills or whenever it becomes

coated with a film of grease. It can be

cleaned with paper towel, damp cloth, or

sponge and mild household detergent or

cleanser.

OVEN VENT: The oven vent is located

under the right side of the air grille. When

using or cleaning the oven, hot and moist

air may be noticed in this area. When the

oven is in use, the vent and surrounding

area become hot enough to cause burns.

Be careful not to spill anything into this

vent. The air grille must be removed

before the self-clean cycle.

FILTER

8

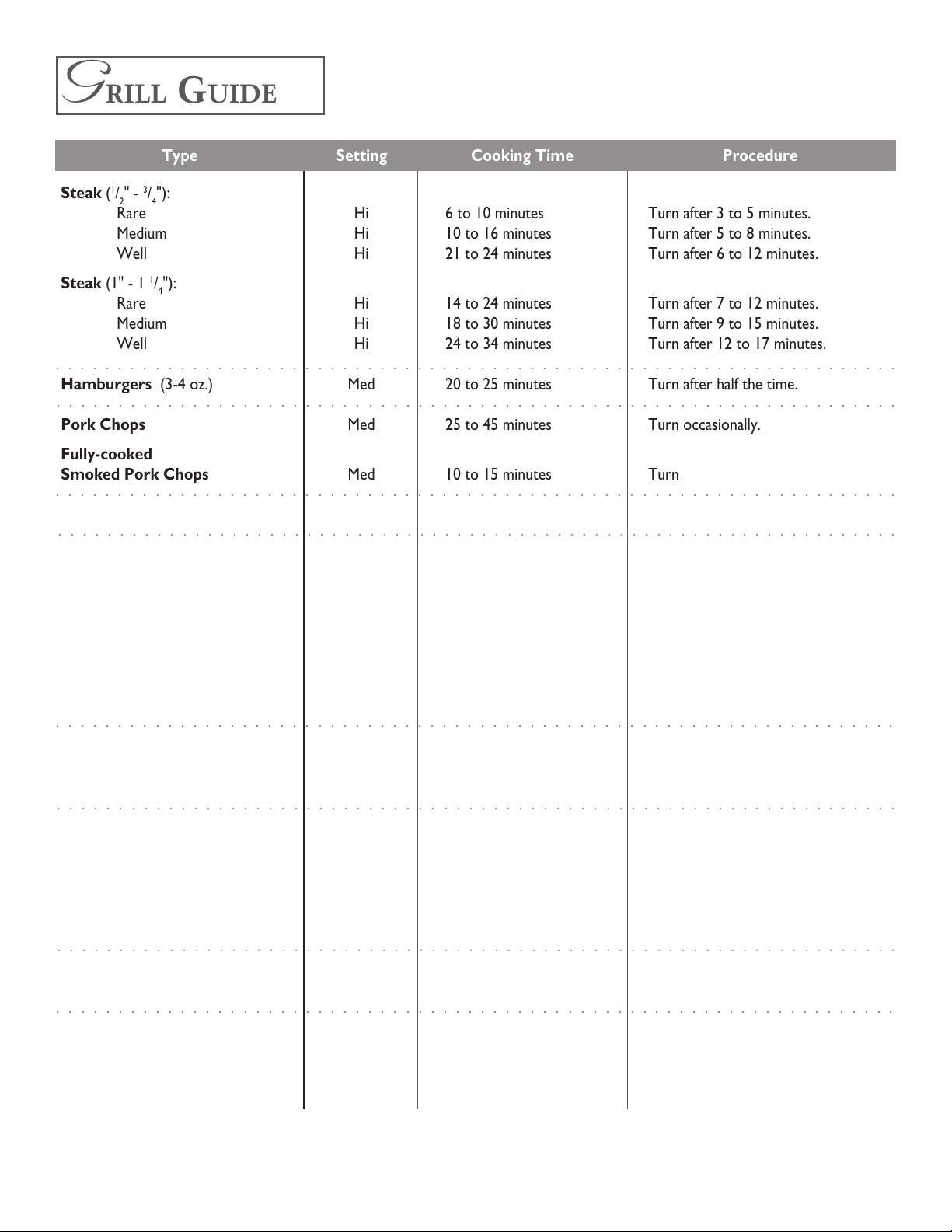

GRILL GUIDE

Type Setting Cooking Time Procedure

Preheat grill on Hi 5 minutes, for best flavor.

Steak (

1

/2" - 3/4"):

Rare Hi 6 to 10 minutes Turn after 3 to 5 minutes.

Medium Hi 10 to 16 minutes Turn after 5 to 8 minutes.

Well Hi 21 to 24 minutes Turn after 6 to 12 minutes.

Steak (1" - 1 1/4"):

Rare Hi 14 to 24 minutes Turn after 7 to 12 minutes.

Medium Hi 18 to 30 minutes Turn after 9 to 15 minutes.

Well Hi 24 to 34 minutes Turn after 12 to 17 minutes.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Hamburgers (3-4 oz.) Med 20 to 25 minutes Turn after half the time.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Pork Chops Med 25 to 45 minutes Turn occasionally.

Fully-cooked

Smoked Pork Chops Med 10 to 15 minutes Turn once. Glaze if desired.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Ham Slices Med 15 to 20 minutes Turn after half the time.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Fully-cooked Sausages:

Hot Dogs, Brats Hi 7 to 12 minutes Turn once.

Polish Hi 13 to 16 minutes Turn occasionally.

Fresh Sausage:

Links Med 15 to 25 minutes Turn occasionally.

Patties (3" dia.) Med 15 to 20 minutes Turn after half the time

Italian Med 25 to 30 minutes Pierce casing with a fork.

Turn once.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Chicken:

Pieces:Bone-in Med 30 to 50 minutes Turn occasionally.

Breasts: Boneless Med 20 to 30 minutes Turn occasionally.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Fish:

Steaks (1") Med 20 to 25 minutes Brush with butter. Turn after

half the time.

1

Fillets (

/2") Med 10 to 15 minutes Start skin side down. Brush

(with skin on) with butter.

Turn after half the time.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Shrimp: (skewered) Med 10 to 20 minutes Turn and brush with butter or

marinade frequently.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Garlic Bread Med 4 to 6 minutes Turn after half the time.

Hot Dog Buns,

Hamburger Buns Med 1 to 2 minutes

Note: This chart is a suggested guide. Cooking times and control settings are approximate due to variations in meats and gas pressure.

9

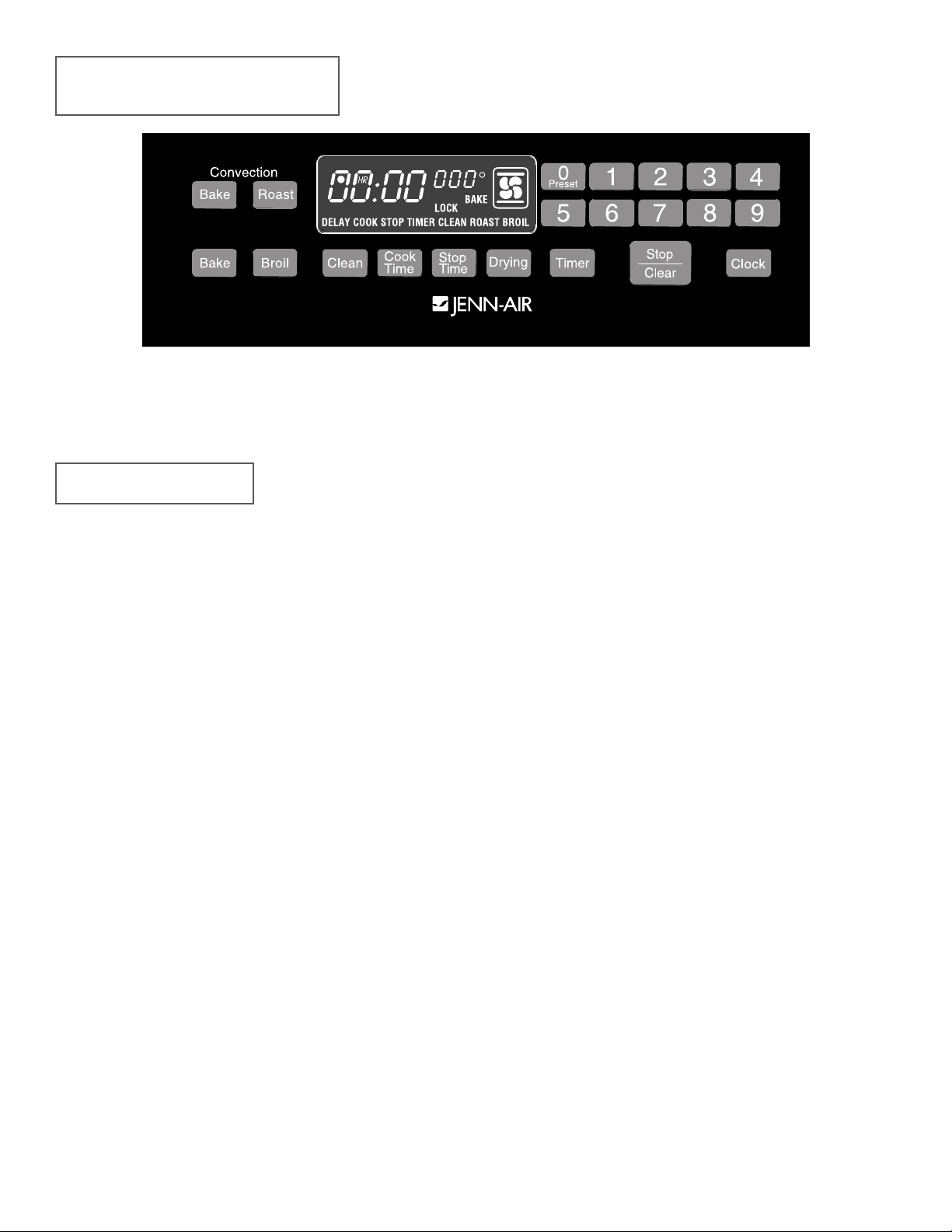

OVEN COOKING

The control panel is designed for ease in programming. The display window on the electronic control shows time of day, timer and oven

functions. Indicator words flash to prompt your programming steps. NOTE: Styling and features may differ slightly depending on the

model. Control panel shown includes convection bake and drying functions.

FUNCTION PADS

• Press the desired pad.

• Press the appropriate number pads to

enter time or temperature.

•A beep will sound when any pad is pressed.

•A double beep will sound if a programming error occurs.

NOTE: Four seconds after entering the

number, the time or temperature will automatically be entered. If more than 30 seconds elapse between touching a function

pad and the number pads, the function will

be canceled and the display will return to

the previous display.

NUMBER PADS

Use to set time or temperature.

STOP/CLEAR

Use to cancel all programming except Clock

and Timer functions.

BAKE

Use for conventional baking or roasting.

1. Press Bake pad.

2. Press Preset (0) pad for 350°F or the

appropriate number pads for desired

temperature.

See page 13 for additional information.

BROIL

Use for top browning and broiling.

1. Press Broil pad.

2. Press Preset (0) pad for HI broil, press

again for LO broil, or press the appropriate number pads to set desired broil

temperature.

See page 14 for additional information.

CLEAN

Use to set self–clean cycle.

1. Press Clean pad.

2. Press Preset (0) pad for “3:00” hours

of cleaning time.

3. If more or less cleaning is desired, press

the appropriate number pads. Cleaning

time may be set between 2 and 4 hours.

See page 18-19 for additional information.

CONVECT BAKE

Use for convection baking.

1. Press Convect Bake pad.

2. Press Preset (0) pad for 325°F or the

appropriate number pads for desired

temperature.

See page 13 for additional information.

CONVECT ROAST

Use for convection roasting.

1. Press Convect Roast pad.

2. Press Preset (0) pad for 325°F or the

appropriate number pads for desired

temperature.

See page 13 for additional information.

10

OVEN COOKING, CONT.

COOK TIME/STOP TIME

Use to program the oven to start and stop

automatically.

1. Press Bake, Convect Bake, or Con-

vect Roast pad. Press the appropriate

number pads for desired temperature.

2. Press Cook Time pad. Press the ap-

propriate number pads to enter cooking

time in hours and minutes.

3. To delay the start of cooking, press

Stop Time pad. Press the appropriate

number pads to enter the time you want

the oven to stop.

See page 14-15 for additional information.

DRYING

Use to dry or dehydrate foods such as fruits,

vegetables and herbs.

1. Press Drying pad.

2. Press Preset (0) pad for 140°F or the

appropriate number pads for the drying

temperature desired.

See page 15-16 for additional information.

SETTING THE CLOCK

1. Press Clock pad.

• The indicator word TIME will flash in

the display.

2. Press the appropriate number pads until

the correct time of day appears in the

display.

When electrical power is supplied or after

a power interruption, the last clock time,

before power was interrupted, will flash.

To recall the time of day when another time

function is showing, press the Clock pad.

Clock time cannot be changed when the

oven has been programmed for clock controlled cooking, self-clean or delayed selfclean.

SETTING THE TIMER

Use to set and then signal the completion

of a time period up to 99 hours and 59

minutes.

The timer can be used independently of any

other oven activity and can be set while

another oven function is operating. The

timer does not control the oven.

1. Press Timer pad.

• The indicator word TIMER will flash

and “0Hr:00” appears in the display.

2. Press the appropriate number pads until

the desired number of minutes or hours

and minutes appear in the display.

Example: To set the Timer for 5

minutes, press the Timer pad and the

number 5 pad. The control will begin

countdown after a four second delay.

HR

0 :05

DELAY COOK STOP TIMER CLEAN ROAST BROIL

Example: To set the Timer for 1 hour

and 30 minutes, press the Timer pad

and the numbers 1,3,0 pads. The control will begin countdown after a four

second delay.

HR

1 :30

DELAY COOK STOP TIMER CLEAN ROAST BROIL

3. The last minute of the countdown will

be displayed as seconds.

4. At the end of the time set, the timer will

beep and “End” will appear in the display. To change the number of timer

beeps and add reminder beeps, see next

column.

TO CANCEL:

1. Press and hold Timer pad for three

seconds. The time of day will reappear.

OR

LOCK

LOCK

BAKE

BAKE

2. Press the Timer pad and the “0” num-

ber pad. After a slight delay the time of

day will reappear.

NOTE: Pressing Stop/Clear pad to cancel

the timer will cancel ALL selected oven functions except the clock and timer.

CONTROL OPTIONS

CONTROL LOCKOUT OPTION

The control touchpads can be locked to

prevent unwanted use. They will not function when locked.

If an oven function is currently being used,

the controls cannot be locked.

The current time of day will remain in the

display when this feature is activated.

SETTING CONTROL LOCKOUT:

1. Press and hold the Stop Time and the

Stop/Clear pads at the same time for

three seconds.

• The indicator word OFF will appear

in the display for 15 seconds. OFF

will reappear for 15 seconds if any

pad is pressed.

TO CANCEL:

Press and hold the Stop Time and the

Stop/Clear pads at the same time for

three seconds. The indicator word OFF

will disappear in the display.

TIMER BEEP OPTIONS

• Option 1: One long beep at the end of

the timer operation, then, one short

beep every 30 seconds for the next five

minutes or until the Stop/Clear pad is

pressed.

• Option 2: One long beep at the end of

the timer operation, then, one short

beep every minute for the next 12

11

hours or until the Stop/Clear pad is

pressed.

• Option 3 (default option): One

beep at the end of the timer operation,

then, no other beeps.

SETTING THE TIMER BEEPS:

1. Press the Timer and Stop/Clear pads

at the same time and hold for three

seconds.

CANCEL CLOCK DISPLAY

OPTION

If you prefer that the time of day not be

displayed:

1. Press Clock and Stop/Clear pads at

the same time and hold for three seconds.

2. Press Clock pad to briefly recall the

time of day, if desired.

OVEN TEMPERATURE

ADJUSTMENT OPTION

If you think the oven should be hotter or

cooler, you can adjust it yourself. To decide

how much to change the thermostat, set

the oven temperature 25°F higher or lower

than the temperature in your recipe, then

bake. The results of the “test” should give

you an idea of how much to adjust the

thermostat.

•A single beep will sound.

• Display will show the indicator word

TIMER and the current option.

2. Press the appropriate number pad (1, 2,

or 3) to select the option you wish. The

current time of day will reappear in the

display after four seconds.

CLOCK CONTROLLED OVEN

COOKING BEEP OPTIONS

• Option 1 (default option): Four

beeps at the end of cooking, then, one

beep every 30 seconds for the next five

minutes or until the Stop/Clear pad is

pressed.

• Option 2: Four beeps at the end of

cooking, then, one beep every minute

for the next 12 hours or until the Stop/

Clear pad is pressed.

• Option 3: Four beeps at the end of

cooking, then, no other beeps.

SETTING CLOCK CONTROLLED

OVEN COOKING BEEPS:

1. Press Cook Time and Stop/Clear

pads at the same time and hold for three

seconds.

•A single beep will sound.

TO RESTORE:

Press the Clock and Stop/Clear pads at

the same time and hold for three seconds.

The time of day will reappear in the display.

AUTOMATIC OVEN TURN

OFF OPTION

The oven will automatically turn off after 12

hours, if you accidentally leave it on. You

can deactivate this feature, if desired.

TO ELIMINATE 12 HOUR TURN

OFF:

1. Press the Clock pad and hold for three

seconds or until “12” appears in the

display. The indicator word TIME will

flash in the display.

2. Press any number pad until 8888 ap-

pears in the display. Current time of day

will reappear in the display after four

seconds.

TO RESTORE:

Press the Clock pad and hold for three

seconds or until 8888 appears. Press “1”

number pad. “12” will appear briefly in the

display followed by the current time of day.

TO ADJUST THE THERMOSTAT:

1. Press the Bake pad.

2. Enter 550° F by pressing the number

pads “5, 5, 0.”

3. Press and hold the Bake pad for sev-

eral seconds until 0° appears in the

display.

4. Press any number pad to change the

temperature. Each time a pad is pressed,

the temperature changes by 5°F.

• Press repeatedly to reach +35°F.

Continue pressing to reduce the

temperature up to -35°F.

5. When you have made the adjustment,

press the Stop/Clear pad and the

time of day will reappear in the display.

The oven will now bake at the adjusted

temperature.

NOTE: It is not recommended to adjust

the temperature if only one or two recipes

are in question.

It is not necessary to readjust the oven

temperature if there is a power interruption. This adjustment will not affect broil or

clean temperatures.

• Display will show the indicator word

COOK and the current option.

2. Press the appropriate number pad (1, 2,

or 3) to select the option you wish. The

current time of day will reappear in the

display after four seconds.

12

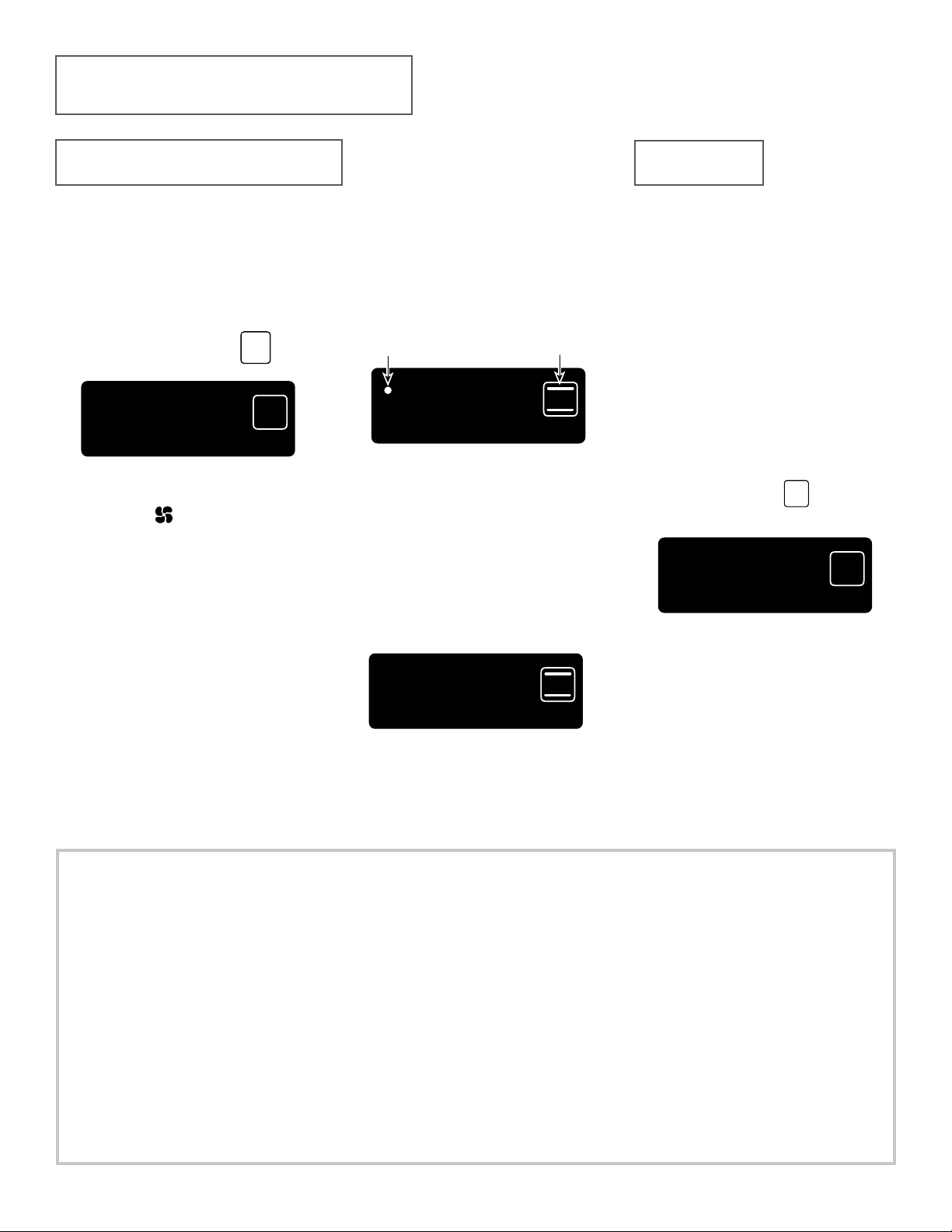

OVEN COOKING, CONT.

BAKING AND ROASTING

1. Place oven racks on proper rack posi-

tions. (See page 17.)

2. Press Bake, Convect Bake or Con-

vect Roast pad.

• The indicator word BAKE will flash.

• 000 and the oven icon will

appear.

5:30

• When convection cooking is selected,

a fan icon will also appear.

3. Press the Preset (0) pad to set 350°F

automatically. When convection cooking, 325°F will be automatically set when

Preset (0) is pressed. Or press the

appropriate number pads for the desired oven temperature.

• The temperature can be set from

100° to 550° F.

• After four seconds the oven will begin

to heat.

– the bake icon (top and bottom

bars) will light;

–a red preheat indicator will light;

0 0 0

BAKE

– and 100° or the actual oven tem-

perature, whichever is higher, will

appear in the display.

– when convection cooking the fan

icon will begin to rotate.

PREHEAT

INDICATOR

BAKE

ICON

1 0 0

5:30

• The temperature in the display will

increase in 5° increments until the

oven reaches the preset temperature.

• When the oven is preheated, the

oven will beep and the preheat indicator light will go off in the display.

Allow 7–14 minutes for the oven to

preheat.

BAKE

3 5 0

5:40

4. At the end of cooking, turn the oven off

by pressing the Stop/Clear pad. Remove food from oven. The oven will

continue operating until the Stop/Clear

pad is pressed.

BAKE

BROILING

Broil in the oven cavity. For best results,

use a pan designed for broiling.

For additional broiling tips, refer to the

“Cooking Made Simple” booklet.

SETTING THE CONTROLS FOR

BROILING

1. Place the oven rack on the proper rack

position.

2. Press the Broil pad.

• The indicator word BROIL will flash.

000 and the oven icon will

appear.

0 0 0

5:30

BROIL

3. Press the Preset (0) pad to enter HI

broil. Press again to set LO broil.

• The oven has a variable broil feature

which means a specific broil temperature can be selected. To select a

specific temperature, press the

appropriate number pads for the temperature desired after 000 appears in

the display.

NOTES:

BAKING AND ROASTING

• If more than 30 seconds elapse between pressing a function pad and

pressing a number pad, the display will

return to the previous display.

• To recall the set temperature during

preheat, press the appropriate Bake,

Convect Bake or Convect Roast

pad. The set temperature will be displayed briefly and then return to the

ongoing program.

• To change the oven temperature during

cooking, press the appropriate Bake,

Convect Bake or Convect Roast pad

and the appropriate number pads for the

desired oven temperature.

• You may find that the cooking times and

temperatures vary slightly from your old

oven. This is normal. Every oven has its

own characteristics.

• As a general rule, when convection

baking, set the oven temperature

°

F lower than the conventional

25

recipe or prepared mix directions.

13

Baking time will be the same or a

few minutes less than the directions.

• When convection roasting, roasting times are generally 25–30%

less. (Maintain conventional roasting

temperatures.)

• See roasting chart in “Cooking Made

Simple” booklet for recommended

roasting temperature and times.

• For additional baking, roasting and convection cooking tips, see “Cooking

Made Simple” booklet.

• Four seconds after entering HI, LO

or a temperature, the broil icon will

come on and the indicator word

BROIL will remain in the display.

BROIL

ICON

H I

5:30

BROIL

4. Place food in the oven leaving the oven

door open to the first stop position

(about 4 inches).

5. Press the Stop/Clear pad to turn off

oven when food is cooked.

NOTES:

BROILING

• Hi broil is used for most broiling. Use

lo broil when broiling longer cooking

foods to allow them to cook to well

done without excessive browning.

• A cooling fan will automatically

turn on during broiling. If it does

not operate, contact an authorized servicer.

• Never cover broiler pan insert with

aluminum foil. This prevents fat from

draining to the pan below.

• Expect broil times to be longer and

browning to be slightly lighter if appliance is installed on a 208 volt circuit.

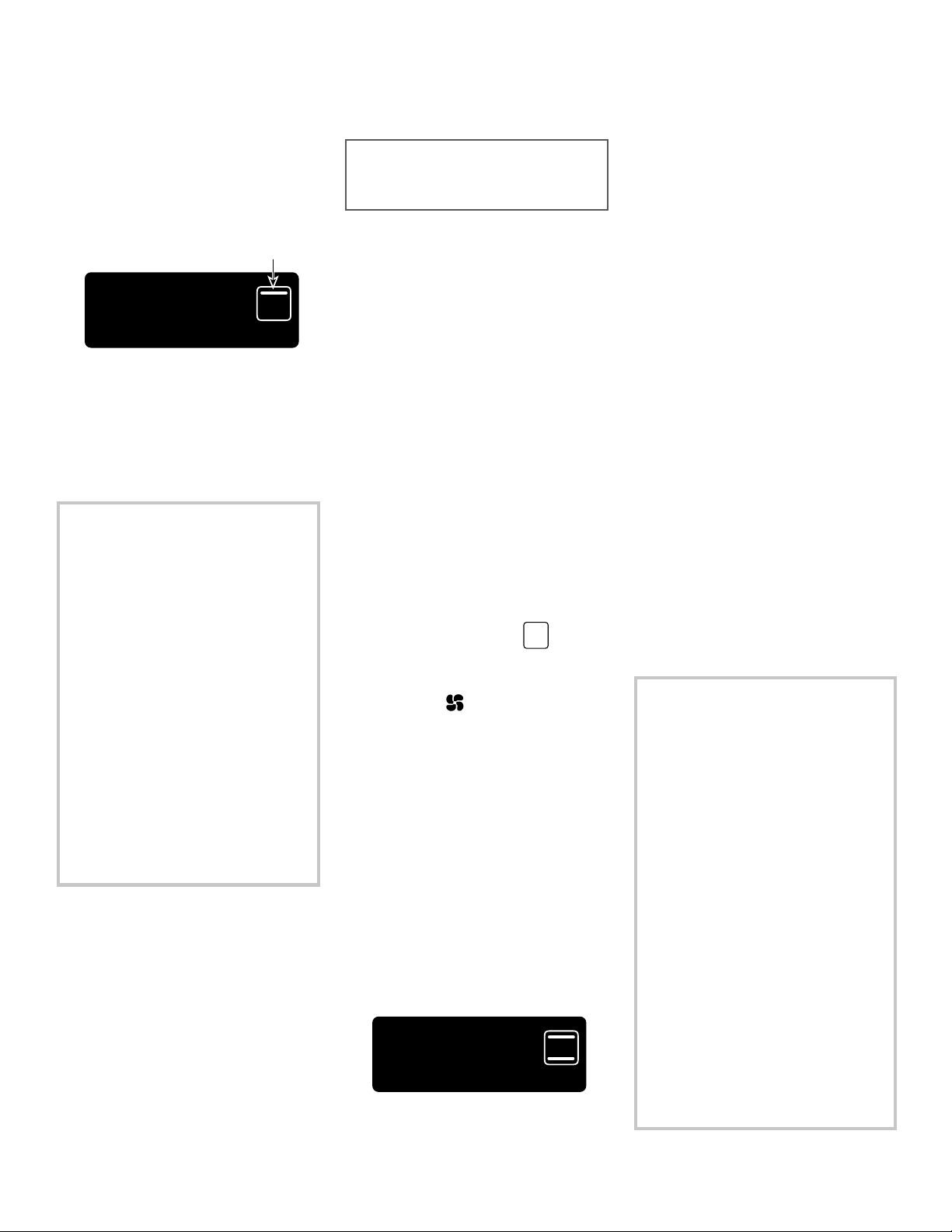

CLOCK CONTROLLED

OVEN COOKING

Use to program the oven to start and stop

automatically.

The clock must be functioning and set at the

correct time of day for this feature to

operate correctly.

The feature can be used with either oven

cooking or self-cleaning. See pages 18-19

for instructions on delaying the start of a

clean cycle.

SETTING THE CONTROLS

TO START IMMEDIATELY AND

TURN OFF AUTOMATICALLY:

1. Press the Bake, Convect Bake or

Convect Roast pad.

• The indicator word BAKE will flash.

• 000 and the oven icon will

appear.

• When convection cooking is selected,

a fan icon will also appear.

2. Press the Preset (0) pad to set 350°F.

(When convection cooking, 325°F will

be automatically set.) Or press the appropriate number pads for the desired

oven temperature.

3. Press the Cook Time pad. The indica-

tor words COOK TIME will flash and

the display will show “0HR:00”.

4. Press appropriate number pads to enter

cooking hours and minutes.

Example: If cooking time selected for

baking is 2 hours and 30 minutes, the

display will show:

HR

1 0 0

2 :30

DELAY COOK STOP TIMER CLEAN ROAST BROIL

LOCK

°

BAKE

5. At the end of the programmed Cook

Time, the oven will shut off automatically, “End” will appear in the display and

a beep will be heard four times. Press

the Stop/Clear pad.

If the program is not cancelled, there

will be one beep every 30 seconds for

five minutes. (If you wish to change the

beeps at the end of clock controlled

cooking, see page 12.)

TO DELAY THE START AND TURN

OFF AUTOMATICALLY:

1–4. Follow preceding steps 1–4.

5. Press the Stop Time pad. Indicator

words STOP and TIME will flash. Display

will show the calculated stop time based

on the current time of day and the cook

time that you entered previously.

6. Press the appropriate pads to enter the

time you wish the oven to stop. A stop

time can only be accepted for later in the

day.

cont.

NOTES:

CLOCK CONTROLLED

OVEN COOKING

• If more than 30 seconds elapse

between pressing a function pad

and pressing the appropriate number pads, the oven is NOT set and

display will return to the previous

display.

• Highly perishable foods such as

dairy products, pork, poultry or

seafood are not recommended for

delayed cook operations.

• Clock controlled baking is not recommended for baked items that

require a preheated oven, such as

cakes, cookies, pies and breads.

• Cook time can be set for up to 11

hours and 59 minutes (11:59).

14

OVEN COOKING, CONT.

Example: If at 10:00 you set the oven

for 350°F and 2 hours and 30 minutes of

cooking time, the calculated stop time

would be “12:30”.

If you want the stop time to be 1:00,

press the number pads “1,0,0”. Four

seconds later, the display will show 1:00

along with the indicator words DELAY,

STOP TIME.

1 :00

DELAY COOK STOP TIMER CLEAN ROAST BROIL

7. At the end of the delayed period, the

DELAY indicator word will go off and

the oven will begin to heat.

8. At the end of the clock controlled Cook

Time, the oven will shut off automatically, “End” will appear in the display and

a beep will be heard four times. Press

the Stop/Clear pad.

If the program is not cancelled, there

will be one beep every 30 seconds for

five minutes. (If you wish to change the

beeps at the end of clock controlled

cooking, see page 12.)

LOCK

BAKE

DRYING PAD

For drying fruits, vegetables, herbs, etc.

Use a drying rack for best results. It allows

air to circulate evenly around the foods.

1. Press the Drying pad.

• 000, the oven icon and convection fan

icon will appear.

2. Press the Preset (0) pad for 140°F or

press the appropriate number pads for

the desired drying temperature.

• The temperature may be set between

100°-200°F.

• If the temperature is set for under

100°F or over 200°F, the control will

beep twice and default to 100°F or

200°F respectively.

3. The oven door needs to be opened

slightly to allow moisture to escape from

the oven during the drying process.

• Open the oven door slightly.

• Place the magnetic door spacer (Part

No. 8010P146-60) over the plunger

switch at the

upper right

side of the

oven frame.

The spacer

provides a gap

between the

oven frame and the oven door allowing moisture to escape.

• Gently close the door until the spacer

magnet makes contact with the oven

door. The magnet will hold the spacer

in the proper position during the

drying process and allows the door to

be opened at any time during drying

without losing proper positioning.

NOTE: If the spacer is not placed

correctly, the convection fan will not

operate.

Follow the drying guide on page 16 for

drying times. Cool foods to room

temperature before testing for

doneness.

4. When drying is complete, turn the oven

off by pressing the Cancel pad. Using a

potholder, remove the magnetic spacer.

NOTE: Please keep the magnetic spacer

in a safe and convenient place for easy

access. To replace, call 1-800-688-8408

to order Part No. 8010P146-60.

NOTE: If moisture collects around the

oven vent area, remove the air grille

during the drying operation.

NOTES:

DRYING

• To purchase a drying rack, contact

your Jenn-Air dealer for the

“DRYINGRACK” Accessory Kit or

call 1-800-688-8408.

• Most fruits and vegetables dry well

and retain their color when dried at

140° F. For optimal flavor, dry herbs

at 100° F, however, at this lower

temperature expect extended drying

times of up to 8 hours.

• The length of drying times vary due to

the following: Water and sugar content of food, size of food pieces,

amount of food being dried, humidity

in the air.

• Check foods at the minimum drying

time. Dry longer if necessary.

• More than one rack of food may be

dried at the same time. However,

additional drying time is needed.

• Fruits that turn brown when exposed

to air should be treated with an antioxidant. Try one of the following

methods:

1. Dip fruit in a mixture of two

parts bottled lemon juice to one

part cool water.

2. Soak fruit in a solution of 1 tsp.

ascorbic acid or commercial antioxidant to 1 quart of cold water.

• Foods may drip during the drying

process. After drying high acid or

sugary foods, clean the oven bottom

with soap and water. The porcelain

oven finish may discolor if acid or

sugary food soils are not wiped up

prior to high heat or a self-cleaning

cycle.

• Refer to other resources at your local

library or call your local County Extension service for additional information.

15

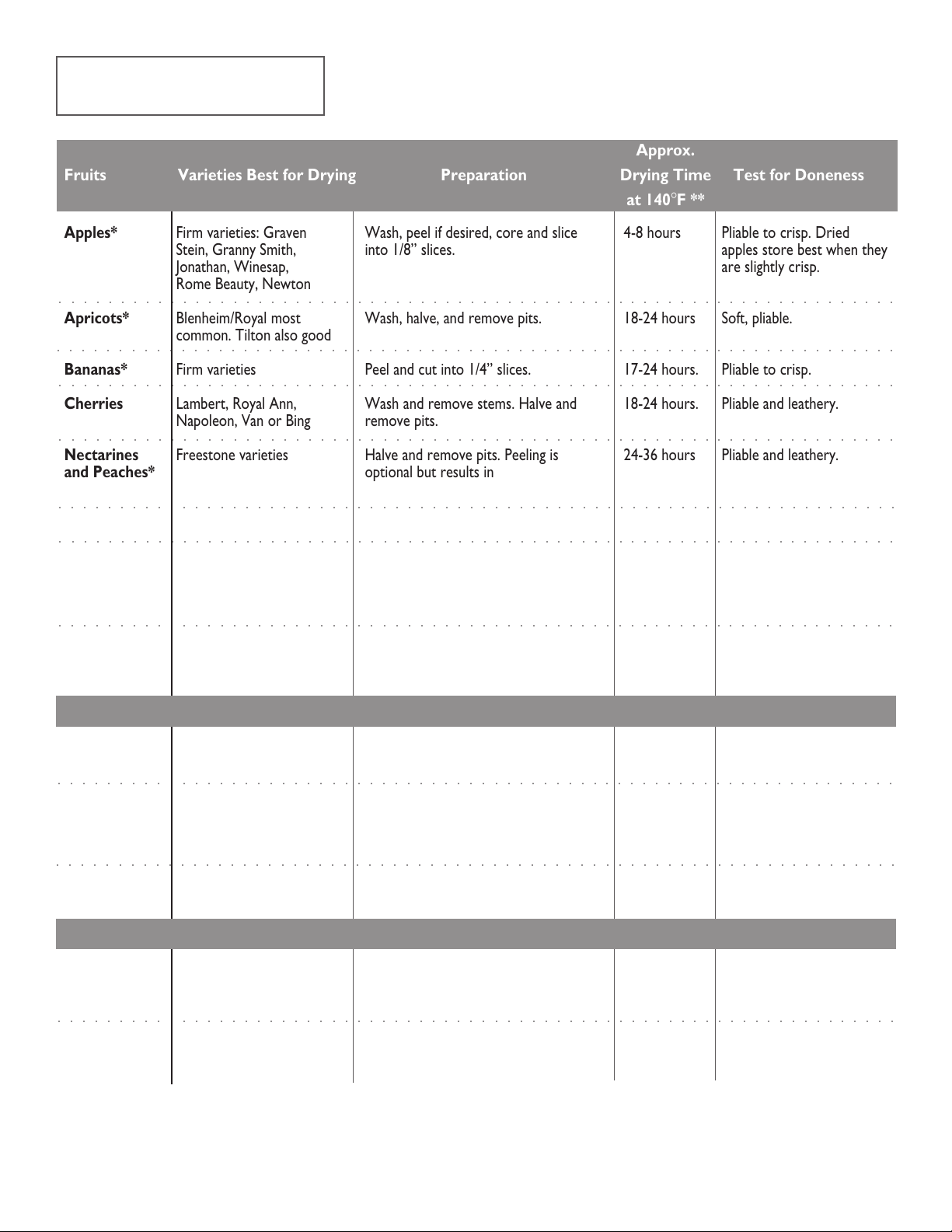

DRYING GUIDE

Approx.

Fruits Varieties Best for Drying Preparation Drying Time Test for Doneness

at 140

°

F **

Apples* Firm varieties: Graven Wash, peel if desired, core and slice 4-8 hours Pliable to crisp. Dried

Stein, Granny Smith, into 1/8” slices. apples store best when they

Jonathan, Winesap, are slightly crisp.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Apricots* Blenheim/Royal most Wash, halve, and remove pits. 18-24 hours Soft, pliable.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Bananas* Firm varieties Peel and cut into 1/4” slices. 17-24 hours. Pliable to crisp.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Cherries Lambert, Royal Ann, Wash and remove stems. Halve and 18-24 hours. Pliable and leathery.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Nectarines Freestone varieties Halve and remove pits. Peeling is 24-36 hours Pliable and leathery.

and Peaches* optional but results in better-looking

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Pears* Bartlett Peel, halve and core. 24-36 hours Soft and pliable.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Pineapple Fresh or canned Wash, peel and remove thorny eyes. Canned: Soft and pliable.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Orange and Select rough-skinned fruit Wash well. Thinly peel the outer 1/16 1-2 hours Tough to brittle.

Lemon Peel Do not dry the peel of fruit to 1/8” of the peel. Do not use the

Rome Beauty, Newton

common. Tilton also good

Napoleon, Van or Bing remove pits.

dried fruit.

Slice length wise and remove the small 14-18 hours

core. Cut crosswise into 1/2” slices. Fresh:

12-16 hours

marked “color added” white bitter pith under the peel.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Vegetables

Tomatoes Plum, Roma Halve, remove seeds. Place tomatoes 12-18 hours Tough to crisp.

skin side up on rack. Prick skins.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Carrots Danvers Half Long, Do not use carrots with woody fiber or 4-8 hours Tough to brittle.

Imperator, Red Cored pithy core. Wash, trim tops and peel if

Chantenay desired. Slice crosswise or diagonally

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

in 1/4” slices. Steam blanch for 3 min.

Hot Peppers Ancho, Anaheim Wash, halve and seed. Prick 4-6 hours Pods should appear shriveled,

skin several times. dark red and crisp.

Herbs

Parsley, Mint, Rinse in cold water. Leave stems on 1-3 hours Brittle and crumbly.

Cilantro, Sage, until leaves are dry, then discard.

Oregano

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Basil Cut leaves 3 to 4” from top of plant 2-5 hours Brittle and crumbly.

just as buds appear. Rinse leaves in

cold water.

*Fruits requiring an antioxidant to prevent discoloration and loss of nutrients. Refer to the notes on page 15 for

specific methods.

** 12 Hour Off will not occur during drying functions.

16

OVEN COOKING, CONT.

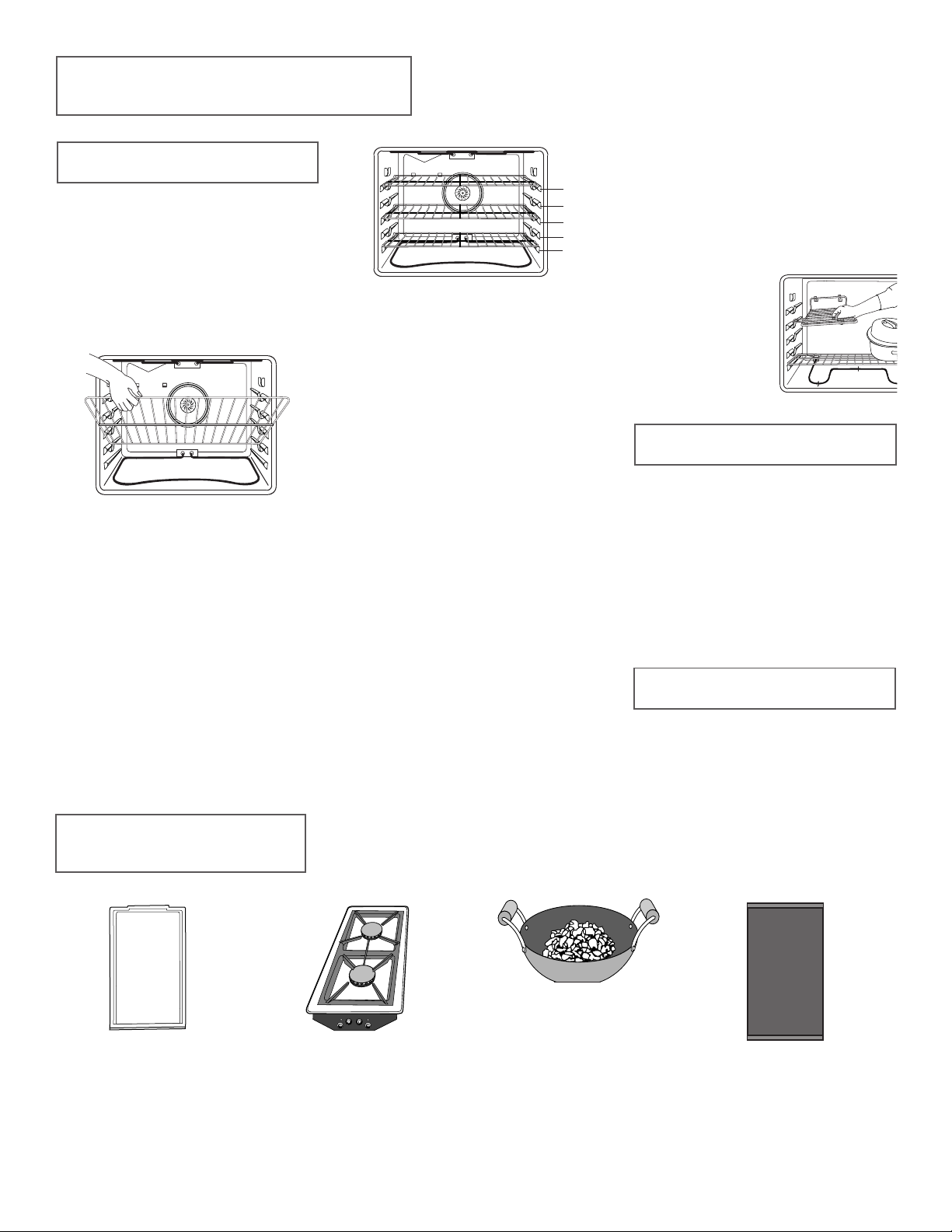

OVEN RACKS

The oven has three racks. All racks are

designed with a lock-stop edge.

TO REMOVE OVEN RACKS:

Pull rack straight out until it stops at the

lock-stop position; lift up on the front of the

rack and pull out.

TO REPLACE OVEN RACKS:

Place rack on the rack support in the oven;

tilt the front end up slightly; slide rack back

until it clears the lock-stop position; lower

front and slide back into the oven.

5

4

3

2

1

Three-rack Convection

Baking (Racks 1, 3 and 5)

RACK 4:

Use for two-rack baking and for broiling.

RACK 3:

Use for most baked goods on a cookie

sheet or jelly roll pan, layer cakes, fruit pies, or

frozen convenience foods, and for broiling.

RACK 2:

Use for roasting small cuts of meat, casseroles, baking loaves of bread, bundt cakes

or custard pies, and two-rack baking.

RACK 1:

Use for roasting large cuts of meat and

poultry, frozen pies, dessert souffles or

angel food cake, and two-rack baking.

HALF RACK ACCESSORY

A half rack, to increase oven capacity, is

available as an accessory. It fits in the left,

upper portion of the oven and provides

space for a vegetable dish when a large

roaster is on the lower

rack. Contact your

Jenn-Air dealer for the

“HALFRACK” Accessory Kit or call 1-800688-8408.

COOLING FAN

The cooling fan will automatically turn on

during cleaning, broiling and some baking

operations. It is used to keep internal parts

on the control panel cool. The fan will

automatically turn off when parts have

cooled. The fan may continue to operate

after the oven has been turned off. This is

normal.

RACK POSITIONS

RACK 5:

Use for toasting bread or broiling very thin

foods.

ACCESSORIES

Gas Griddle – AG302

Self-draining griddle makes many

favorite foods easier to fix. Family-sized surface lets you cook

several pancakes, hamburgers, or

grilled sandwiches at a time. Has

a black non-stick finish.

Sealed Burner Module –

JGA8100ADB (black)

JGA8100ADW (white)

The grill assembly can be removed and a sealed burner cartridge can be installed.

MULTIPLE RACK COOKING:

Two rack: Use rack positions 2 and 4,

or 1 and 4.

Three rack: (convection functions only)

Use rack positions 1, 3 and 5. See illustration.

Wok Accessory – AO142

Ideal for stir frying, steaming,

braising, and stewing. Wok has

nonstick finish, wood handles,

cover, steaming rack, rice

paddles and cooking tips. Flat

bottom wok can be used on

ALL cartridges.

17

OVEN LIGHT

The oven light automatically comes on

when the door is opened. When the door

is closed, press the Oven Light switch on

the control panel to turn the light on or off.

Grill Cover – AG341

Attractive grill cover protects

grill when not in use. Textured

steel in black or white with

molded handles.

CARE & CLEANING

CLEAN PAD

• Clean oven

frame, door

frame (area

outside of gasket) and

around the

opening in the door gasket with a nonabrasive cleaner such as Bon Ami*. These

areas are not exposed to cleaning temperatures.

• Remove oven racks. If racks are left in

during a clean cycle, it may impair function and they will discolor. Turn off the

oven light and close door.

• Remove air grille.

* Brand names for cleaning products are

registered trademarks of the respective

manufacturers.

SETTING THE CONTROLS FOR A

SELF–CLEAN CYCLE:

1. Close the oven door.

2. Press the Clean pad.

• The indicator word CLEAN will flash.

The display will show “– – : – –” along

with the oven icon .

• If the door has not been closed, the

display will show “door”.

3. Press Preset (0) pad for “3:00” hours of

cleaning time for an average soiled oven.

• The cleaning time can be varied depending on the amount of soil. Press

the appropriate number pads to set

any amount of time between 2 and 4

hours. “2:00” hours of cleaning for

light soil, up to “4:00” hours of cleaning for heavy soil.

• Four seconds after entering the cleaning time, the oven door will automatically lock. The indicator word LOCK

will appear in the display along with

the clean icon (top and bottom bars).

4 :00

DELAY COOK STOP TIME CLEAN ROAST BROIL

LOCK

BAKE

4. When the cleaning time has been com-

pleted, the indicator word CLEAN will

turn off. The indicator word LOCK will

remain on until the oven has cooled.

When the oven has cooled, the indicator word LOCK will turn off and the

door will automatically unlock.

10 :00

DELAY COOK STOP TIME ROAST BROIL

Automatic lock is still engaged.

Door cannot be opened until

LOCK is no longer displayed.

TO DELAY THE START OF A

CLEAN CYCLE:

1–3. Follow steps 1–3.

4. Press the Stop Time pad. Indicator

words STOP TIME will flash in the

display and the calculated stop time will

also appear in the display.

5. Press the appropriate number pads to

enter the stop time you desire. (A stop

time can only be accepted for later in

the day.)

Example: If at 9:00 you set the oven to

LOCK

BAKE

NOTES:

• To prevent damage to oven door, do

not attempt to open oven door when

the LOCK indicator word is displayed.

• During the cleaning process, the kitchen

should be well ventilated to help eliminate normal odors associated with cleaning. Odors will lessen with use.

• It is normal for flare-ups, smoking or

flaming to occur during cleaning if the

oven is heavily soiled. It is better to

clean the oven regularly rather than to

wait until there is a heavy buildup of soil.

• Wipe up excess grease or spillovers to

prevent flare-ups. For ease in cleaning,

the bake element in the oven can be

lifted slightly (1 inch).

• It is normal for parts of the range to

clean for three hours, the calculated

stop time would be “12:00”. The display

will show:

12:00

DELAY COOK STOP TIMER CLEAN ROAST BROIL

If you want the stop time to be 1:00,

press the number pads “1,0,0”. Four

seconds later the display will show 1:00

and the indicator word DELAY.

1 :00

DELAY COOK STOP TIMER CLEAN ROAST BROIL

6. When the oven begins to clean, the

clean icon (top and bottom bars) will

come on. The indicator word DELAY

will go off.

7. When the clean time has been com-

pleted, the indicator word CLEAN will

turn off. The indicator word LOCK will

remain on until the oven has cooled.

When the oven has cooled, the indicator word LOCK will turn off and the

door will automatically unlock.

become hot during a clean cycle. Avoid

touching cooktop, door, window or oven

vent area during a clean cycle.

•A cooling fan will automatically turn on

during cleaning. If it does not operate,

contact an authorized servicer.

• Wipe up sugary and acidic spillovers

such as sweet potatoes, tomato or milkbased sauces prior to a self-clean cycle.

Porcelain enamel is acid resistant, not

acid proof and may discolor if spills are

not wiped up before a self-clean cycle.

•A white discoloration may appear after

cleaning if acidic or sugary foods are not

wiped up before the clean cycle. This

discoloration is normal and will NOT

affect performance.

LOCK

LOCK

BAKE

cont.

18

CARE & CLEANING, CONT.

TO CANCEL SELF–CLEAN:

1. Press the Stop/Clear pad. The door

will be locked while the LOCK indicator

word remains in the display.

Depending on the length of time the

oven had been cleaning, it may take up

to an hour for the oven to cool down.

When the oven is cool, the door will

automatically unlock and it can be

opened.

CLEANING

PROCEDURES

CAUTION

• Be sure appliance is off and all

parts are cool before handling or

cleaning. This is to avoid damage and possible burns.

• To prevent staining or discoloration,

clean appliance after each use.

• If a part is removed, be sure it is

correctly replaced.

• Moderate/Heavy Soil –– Wipe with

one of the following - Bon Ami, Smart

Cleanser, or Soft Scrub* - using a damp

sponge or soft cloth. Rinse and dry.

Stubborn soils may be removed with a

damp Scotch-Brite* pad; rub evenly with

the grain. Rinse and dry. To restore

luster and remove streaks, follow with

Stainless Steel Magic Spray.

• Discoloration –– Using a damp sponge

or soft cloth, wipe with Cameo Stainless

Steel Cleaner*. Rinse immediately and

dry. To remove streaks and restore luster, follow with Stainless Steel Magic

Spray.

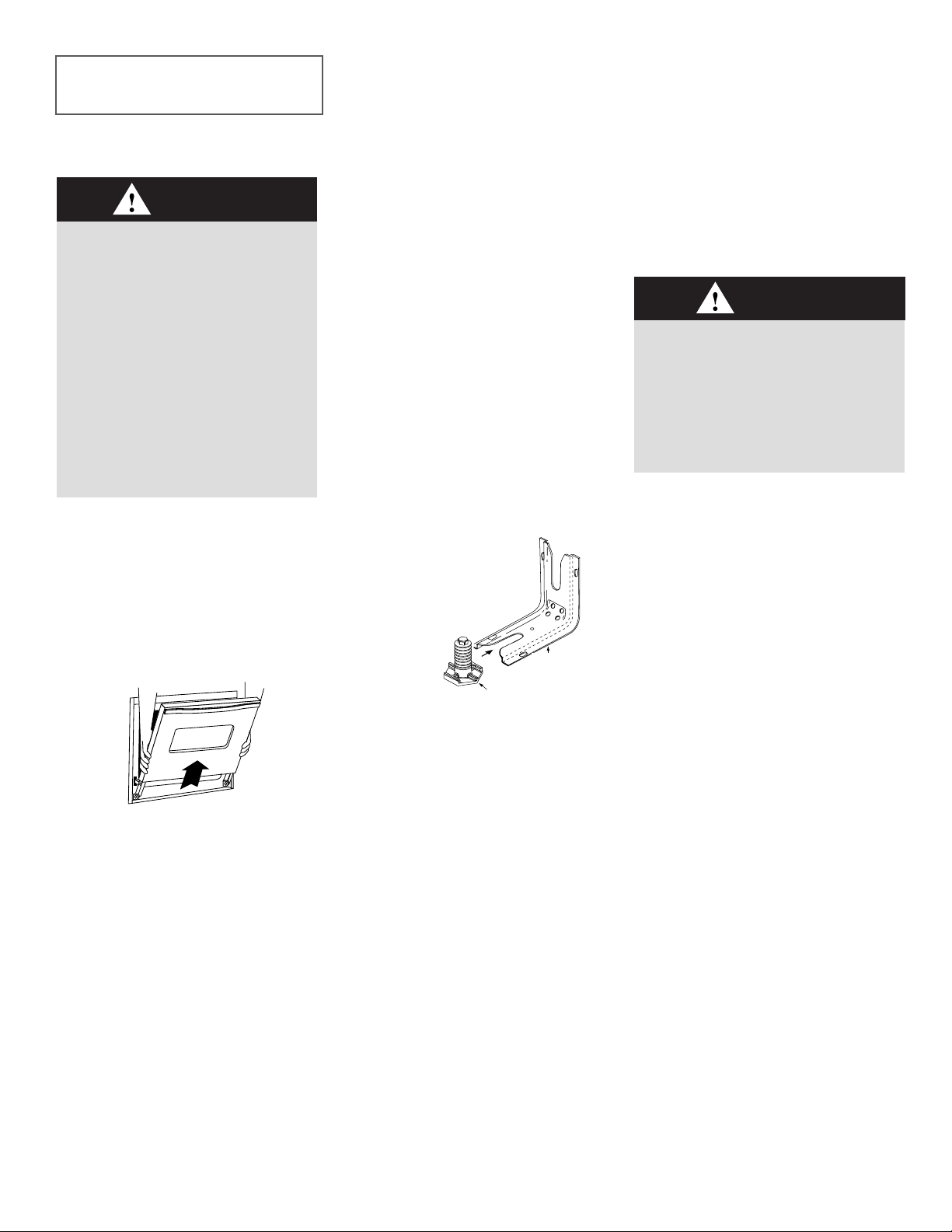

ACCESS PANEL

The access panel is easily opened or removed. To open panel, grasp upper corners and pull forward and down. To close

panel, lift up and insert prongs into catches

in the range.

PRONGS

PRONGS

GREASE

CUP

BROILER PAN AND INSERT

• Place soapy cloth over insert and pan; let

soak to loosen soil.

• Wash in warm soapy water. Use scouring pad to remove stubborn soil.

• Broiler pan and insert can be cleaned in

dishwasher.

CLOCK AND CONTROL

PANEL AND PAD AREA

• To activate “Control Lock” for cleaning,

see page 11.

• Wipe with a damp cloth and dry.

• Glass cleaners may be used if sprayed on

a cloth first. DO NOT spray directly on

control pad and display area.

CONTROL KNOBS

• Remove knobs in the OFF position by

pulling forward.

• Wash, rinse and dry. Do not use abrasive cleaning agents as they may scratch

the finish.

• Turn on each burner to be sure the

knobs have been correctly replaced.

STAINLESS STEEL

• DO NOT USE ANY CLEANING

PRODUCT CONTAINING CHLORINE BLEACH.

• ALWAYS WIPE WITH THE GRAIN

WHEN CLEANING.

• Daily Cleaning/Light Soil –– Wipe

with one of the following - soapy water,

white vinegar/water solution, Formula

409 Glass and Surface Cleaner* or a

similar glass cleaner - using a sponge or

soft cloth. Rinse and dry. To polish and

help prevent fingerprints, follow with

Stainless Steel Magic Spray (Jenn-Air

Model A912, Part No. 20000008)**.

* Brand names for cleaning products are registered trademarks of the respective manufacturers.

** To order direct, call 1-800-688-8408.

• Wash with soap and water, a glass cleaner

or mild liquid sprays.

• Do not use excessive amounts of water.

• To prevent scratching or dulling of the

finish, do not use mildly abrasive, abrasive, harsh or caustic cleaners such as

oven cleaners.

NOTE: To avoid the possibility of accidentally disconnecting any part of the ventilation system, do not use the area behind the

access panel for storage.

SEALED GAS BURNER

CARTRIDGE -PORCELAIN

ENAMEL

Porcelain enamel is glass fused on metal and

may crack or chip with misuse. It is acid

resistant, not acid proof. All spillovers,

especially acid or sugar spillovers, should

be wiped up immediately with a dry cloth.

• When cool, wash with soapy water, rinse

and dry.

• Never wipe off a warm or hot surface

with a damp cloth. This may cause cracking or chipping.

• Never use oven cleaners, abrasive or

caustic cleaning agents on exterior finish

of range.

19

OVEN WINDOW – GLASS

• Avoid using excessive amounts of water

which may seep under or behind glass

causing staining.

• Wash with soap and water. Rinse with

clear water and dry. Glass cleaner can

be used if sprayed on a cloth first.

• Do not use abrasive materials such as

scouring pads, steel wool or powdered

cleaners as they will scratch glass.

OVEN RACKS

• Clean with soapy water.

• Remove stubborn soil with cleansing

powder or soap-filled scouring pad. Rinse

and dry.

• If over time, racks do not slide out easily,

wipe the rack edge and rack support

with a small amount of vegetable oil to

restore ease of movement, then wipe off

excess oil. Likewise, place one drop of

vegetable oil on rack guides.

NOTE: Remove oven racks during a clean

cycle. If racks are left in the oven, it may impair

function and they will discolor.

OVEN INTERIORS

• Follow instructions on page 18 to set a

self-clean cycle.

SEALED GAS BURNER

ASSEMBLY

• Allow burner and grates to cool. Wash

with soapy water and a plastic scouring

pad. For stubborn soils, clean with a

soap-filled, nonabrasive pad or a sponge

and a commercial Cooktop Cleaning

Creme (Part #20000001)**.

• Clean gas ports with a soft bristle brush

or straight pin, especially the port below

the ignitor. Do not enlarge or distort

holes.

• Be careful not to get water into burner

ports.

• When cleaning, use care to prevent damage to the ignitor. If the ignitor is soiled,

wet or damaged the surface burner will

not light.

GRILL ASSEMBLY –

BASIN – PORCELAIN

The basin is located under the grill burner

and/or cartridges. Clean after each use of

the grill.

• To remove light soil, clean with soapy

water or spray with cleansers such as

Fantastik* or Formula 409*. For easier

cleanup: a) spray with a household

cleanser; b) cover with paper towels; c)

add small amount of hot water to keep

the paper towels moist; d) cover and

wait 15 minutes; and e) wipe clean.

• To remove moderate soil, scrub with

Bon Ami*, a soft scrub cleanser or plastic

scrubber.

Note: Check the grease drain after each

use of the grill or grill accessories. To clean:

Pour about

mixed with 1 teaspoon dish detergent down

the drain.

GRATES – CAST ALUMINUM

COATED

FINISH

• Wash cool grates (DO NOT IMMERSE

HOT GRILL GRATES IN WATER) with

detergent in hot water in the sink or

wash them in the dishwasher. Be sure to

remove all food residue before cooking

on the grill grates again.

1

/3 cup of very hot tap water