Page 1

INSTRUCTION

BOOK

CompuLock

Page 2

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed,

including the following. Read all instructions before using this sewing machine.

DANGER – To reduce the risk of electric shock:

1. An appliance should never be left unattended when plugged in. Always unplug this appliance from the

electrical outlet immediately after using and before cleaning.

2. Always unplug before relamping. Replace bulb with same type rated 13.5 Vac, 3 Watts.

3. Do not reach for the appliance that has fallen into water. Unplug immediately.

4. Do not place or store appliance where it can fall or be pulled into a tub or sink. Do not place in or drop

into water or other liquid.

WARNING – To reduce the risk of burns, fire, electric shock, or injury to persons:

1. Do not allow to be used as a toy. Close attention is necessary when this appliance is used by or near

children.

2. Use this appliance only for its intended use as described in this manual. Use only attachments recom-

mended by the manufacturer as contained in this manual.

3. Never operate this appliance if it has a damaged cord or plug, if it is not working properly, if it has been

dropped or damaged, or dropped into water. Return the appliance to the nearest authorized dealer or

service center for examination, repair, electrical or mechanical adjustment.

4. Never operate the appliance with any air opening blocked. Keep ventilation openings of the sewing

machine and foot controller free from accumulation of lint, dust and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

8. To disconnect, turn all controls to the off position, then remove plug outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the sewing machine needle

and knives.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14. Switch the sewing machine off when making any adjustment in the needle area, such as threading

needle, changing needle, threading loopers, or changing presser foot, and the like.

15. Always unplug the sewing machine from the electrical outlet when removing covers, lubricating, or

when making any other user servicing adjustments mentioned in the instruction manual.

SAVE THESE INSTRUCTIONS

When using your overlock machine for the first few times, place some waste fabric under the presser

foot and run the machine without thread for a few minutes. Wipe away any oil which may have ap-

peared.

Page 3

IMPORTANT SAFETY INSTRUCTIONS

SECTION 1 PREPARATION

• Names of Parts...................................................................................................... 3

• Attaching the Waste Chip Box............................................................................... 4

• Storing the Accessory Box .................................................................................... 4

• Standard Accessories............................................................................................ 4

SECTION 2 OPERATING INSTRUCTIONS

• Plug in the Machine and Switch on Power............................................................ 5

• To Sew Using Foot Control ................................................................................... 5

• Controlling Sewing Speed ..................................................................................... 5

• How to Turn Handwheel ........................................................................................ 6

• Opening and Closing the Side Cover.................................................................... 6

• Opening and Closing the Looper Cover................................................................ 7

• The Position of Telescoping Thread Guide Bar .................................................... 7

• Attaching the Spool Cap and Net .......................................................................... 8

• Raising or Lowering the Presser Foot................................................................... 8

• Up/Down Needle Position Key .............................................................................. 8

• Screen Sharpness Adjusting Knob ....................................................................... 8

• How to Set the Needles ........................................................................................ 9

• Safety System......................................................................................................10

• Threading the Machine........................................................................................ 10

* Four – Thread Operation ............................................................................... 11

* Threading the Lower Looper .................................................................... 12–14

* Threading the Upper Looper .................................................................... 15–16

* Threading the Right Needle ..................................................................... 17–18

* How to Use Needle Threader ........................................................................ 18

* Threading the Left Needle ....................................................................... 19–20

* Threading the Double Chain Looper........................................................ 21–23

• Changing to Two – or Three – Thread Serging with Spreader ........................... 23

• Visual Touch Screen Operations ................................................................... 24–25

• To Change Screen Language ............................................................................. 24

• Automatic Thread Tension Display Screen ......................................................... 25

• Choose the Needle and Thread......................................................................25

* Check the Needle.........................................................................................25

• Stitch Package .................................................................................................... 26

• Standard Machine Settings for Automatic Thread Tension ................................. 27

• Stitch Pattern with Machine Setting .................................................................... 28

• Manual Adjustment of Thread Tension ................................................................ 29

• Manual Setting, Memory and View for Thread Tension ................................ 29–30

• Stitch Pattern and Threading ........................................................................ 31–35

1. OVERLOCK4 ................................................................................ 31

2. OVERLOCK 3 (STANDARD), OVEREDGE 3 (STANDARD),

ROLLED HEM 3,FLATLOCK 3 (STANDARD), NARROW HEM,

PICOT EDGE ................................................................................ 31

3. OVERLOCK 3 (WIDE), OVEREDGE 3 (WIDE),

FLATLOCK 3 (WIDE) .................................................................... 32

1

Page 4

4. OVEREDGE 2 (STANDARD), ROLLED HEM 2,

FLATLOCK 2 (STANDARD),

WRAPPED OVERLOCK 2 (STANDARD)........................................ 32

5. OVEREDGE 2 (WIDE), FLATLOCK 2 (WIDE),

WRAPPED OVERLOCK 2 (WIDE) ................................................. 32

6. WRAPPED OVERLOCK 3 .............................................................. 33

7. COVER STITCH .............................................................................. 33

8. OVERLOCK 5 ................................................................................ 34

9. DOUBLE CHAIN ............................................................................ 35

SECTION 3 TEST STITCHING

• Starting Sewing ................................................................................................. 36

• Finishing Sewing ................................................................................................ 36

• Sewing Continuously ........................................................................................ 36

• How to Use the Guide Lines ............................................................................ 36

• Securing Ends.................................................................................................... 37

• Thread Tension Adjustment ............................................................................. 38

* Thread Tension (4 threads) .................................................................... 38–39

* Thread Tension (3 threads) .......................................................................... 40

* Rolled Hem 3 ................................................................................................ 41

* Narrow Hem .................................................................................................. 42

* Picot Edge .................................................................................................... 42

* Thread Tension (2 threads) .......................................................................... 43

* Thread tension (cover stitch) ...................................................................... 44

* Thread tension (double chain)................................................................... 45

• To Adjust Stitch Length ..................................................................................... 46

• To Adjust Differential Feed Ratio ..................................................................... 46

• To Deactivate the Upper Knife ....................................................................... 47

• To Activate the Upper Knife ............................................................................ 47

• Adjustment of Cutting Width........................................................................... 48

• Adjustment of Chaining Finger Setting Knob ................................................ 49

• Adjusting of Foot Pressure................................................................................ 50

• Removing the Presser Foot .............................................................................. 50

• Attaching the Presser Foot .............................................................................. 50

• How to Replace the Needle Plate ................................................................. 50

• How to Replace the Extension Table ............................................................. 51

• How to Change the Upper Looper Position .................................................. 51

SECTION 4 MAINTENANCE

• Replacing the Light Bulb.................................................................................. 52

• Cleaning the Feed Dog................................................................................... 52

• Cleaning the Upper Knife Area ...................................................................... 53

• Replacing the Upper Knife .............................................................................. 53

• Oiling the Machine........................................................................................... 54

• Troubleshooting ................................................................................................ 54

2

Page 5

SECTION 1 PREPARATION

Names of Parts

1 Visual touch screen

3

1

2 Thread guide indication

2

4

5

6

16

7

15

14

12

11

10

9

8

3 Pressure adjusting dial

4 Screen sharpness adjusting knob

5 Up/Down needle position key

6 Side cover

7 Looper cover

8 Handwheel

9 Power switch

10 Differential feed dial

11 Stitch length dial

12 Extension table (A)

13 Double chain looper

17

20

21

19

18

13

14 Lower looper

15 Upper looper

16 Upper knife

17 Chaining finger setting knob

18 Presser foot

19 Needle plate

20 Cutting width adjusting dial

21 Upper knife release knob

3

Page 6

Attaching the Waste Chip Box

Press the waste chip box against the looper

cover and slide it to the left until the pin on the

waste chip box slides into the hole on the side

plate, as illustrated.

2

1

1

2

1

2

6789

11

4

10

12

1 Waste chip box

2 Pin

Storing the Accessory Box

Insert the accessory box into the waste chip box.

1 Waste chip box

2 Accessory box

Standard Accessories

3

5

1 Nets

2 Spool caps

3 Set of needles

4 Upper knife

5 Spreader

6 Screwdriver (large)

7 Screwdriver (small)

8 Tweezers

9 Lint brush

10 Spanner/wrench

11 Oil

12 Needle threader

13 Needle plate (B) for Cover Stitch

14 Presser foot (B) for Cover Stitch

15 Extension table (B)

13

14

15

4

Page 7

SECTION 2 OPERATING INSTRUCTIONS

“ For appliances with a polarized plug (one blade

wider than the other).

To reduce the risk of electric shock, this plug is intended

to fit in a polarized outlet only oneway.

If the plug does not fit fully in the outlet, reverse the

plug.

If it still does not fit, contact a qualified electrician to

install the proper outlet.

Do not modify the plug in anyway.”

* Foot control Model 21371 for use with Sewing

Machine Model 888(Compulock)

(For U.S.A. market only.)

Plug in the Machine and Switch on Power

Before connecting the power supplycord,

make sure the voltage and frequency shown

on the machine conform to your electrlcal

power.

For Your Safety

*While in operation, always keep your eye on

the sewing area,and do not touch any moving parts such as the upper looper, handwheel,

needle or knives.

*Always disconnect the machine from the

power supply:

When leaving the machine unattended.

When attaching or removing parts.

When threading or cleaning the machine.

* Do not place anything on the foot control,

except when in use.

4

3

2

8

1

7

6

5

To Sew Using Foot Control

1 Turn off the power switch. Connect the foot

control plug and the machine plug into to the

machine socket.

2 Connect the power supply plug to your

power supply.

1 Power switch 2 Foot control plug

3 Machine plug 4 Machine socket

5 Power supply plug 6 Power supply

7 Power supply cord 8 Foot control

Controlling Sewing Speed

Sewing speed can be varied by the foot

control.The harder press on the foot control,

the faster the machine runs.

Note:

* The Compulock is equipped with a protective

circuit to prevent overheating.

The machine will stop automatically if it is

running overloaded for a long time.

In such a case, follow the message that

appears on the visual touch screen.

There are five motors for thread tension adjustment inside the machine which make a bit

of noise intializing when first turned on.

This sound is perfectly normal and does not

indicate a malfunction.

5

Page 8

How to Turn Handwheel

Always turn the handwheel toward

you (counterclockwise).

1 Handwheel

1

Opening and Closing the Side Cover

To open:

Push the side cover to the left.

To close:

Push the side cover to the right and

slightly toward the machine body.

1

Side cover

1

For Your Safety:

Always close both the side and looper

covers when the machine is in use.

6

Page 9

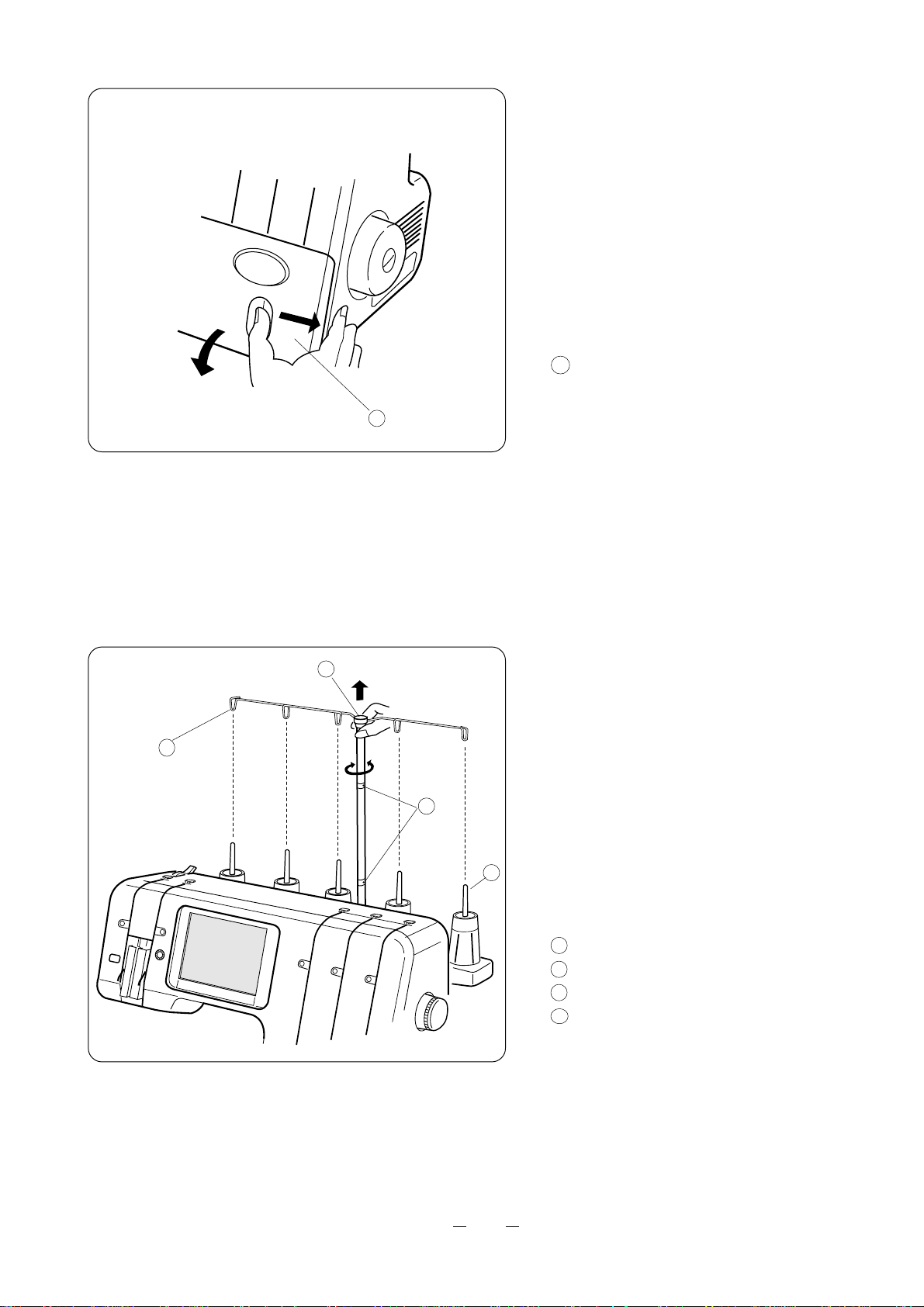

Opening and Closing the Looper Cover

To open:

While pushing with the thumb to the right as far

as it will go, pull looper cover toward you.

To close:

Lift looper cover and push against the machine.

The looper cover snaps into the position

automatically.

1 Looper cover

1

1 , 2

4

The Position of Telescoping Thread

Guide Bar

1

1 Pull the telescoping thread guide bar

up as far as it will go.

2 Turn the thread guide bar until it clicks

into position.

Thread guides should stop directly

2

above the spool pins.

3

1 Telescoping thread guide bar

2 Stoppers

3 Spool pin

4 Thread guide

7

Page 10

Attaching the Spool Cap and Net

1

2

1

5

2

3

4

1 When you use a small thread spool, remove

the spool holder from the spool pin.

Then place the spool with its slit side up, and

put a spool cap on top.

2 If the thread slips down from the spool while

threading or sewing, put a net on the

spool, as illustrated, to prevent jamming.

The nets are supplied with the machine.

1 Spool holder

2 Spool cap

3 Slit

4 Spool pin

5 Net

Raising or Lowering the Presser Foot

By raising or lowering the presser foot lifter,

the presser foot goes up and down.

* While in operation, keep the presser foot

lowered except for when threading the

machine.

Thread tension will be released when the presser

2

1

foot lifter is raised.

1 Presser foot lifter

2 Presser foot

Up/Down Needle Position Key

Press the Up/Down needle position key to bring

the needle to its lowest position.

When pressed again, the needle goes up and stops

1

in the highest position.

1 Up/down needle position key

Screen Sharpness Adjusting Knob

The brightness of the screen can be changed by

turning the sharpness adjusting knob.

1 Screen sharpness adjusting knob

1

8

Page 11

How to Set the Needles

10

12

6

3

4

2

1

9

11

a

8

b

c

5

7

* Please use a size 11 or 14 needle.

* There are 4 holes for inserting needles,

depending on the desired stitch selection.

Make sure all 4 screws are tightened even if

no needle is inserted in the clamp.

1 Needle

2 Flat side

3 Needle clamp screw (4 screws)

4 Screwdriver

5 RB (Right Back)

6 LB (Left Back)

7 RF (Right Front)

8 LF (Left Front)

9 Needle clamp screw for RB

10 Needle clamp screw for LB

11 Needle clamp screw for RF

12 Needle clamp screw for LF

To remove a needle

Disconnect the machine from the power

supply. Raise the needle to its highest posi-

tion.

Then loosen the needle clamp screw to

remove the needle.

To replace a needle

To attach the needle, insert it into the needle

clamp, flat side to the back.

d

e

Slide it all the way up until it stops, then tighten

the needle clamp screw.

a 4 threads or wrapped overlock 3

b 2 or 3 threads

c Cover stitch

d 5 threads

e Double chain

* Do not use any needle which is bent or blunt.

9

Page 12

Safety System

You can operate the machine easily and safely because of the following major safety functions.

The machine does not run when you pressed the foot control because...

1 The looper cover or side cover is opened when you start sewing.

2 Presser foot lifter is raised.

3 The needle plate is not appropriate for the chosen stitch pattern.

4 The upper looper setting dial is in the incorrect position for the chosen stitch pattern.

5 The upper knife is in the incorrect position for the chosen stitch pattern.

The above error messages will appear on the visual touch screen when you press the foot

control.

However, you can press OK key to ignore the warning and accept the upper knife position

(activated or deactivated). This may be appropriate for certain special stitches/operations.

1

6

45

3

2

Threading the Machine

1 Thread guide

2 Double chain looper thread

3 Lower looper thread

4 Upper looper thread

5 Right needle thread

6 Left needle thread

A convenient threading chart is

placed the machine body inside

the looper cover.

7

10

7 Threading chart

*The machine has been threaded

with 4 threads (Overlock 4) at the

factory for popular sewing.

Page 13

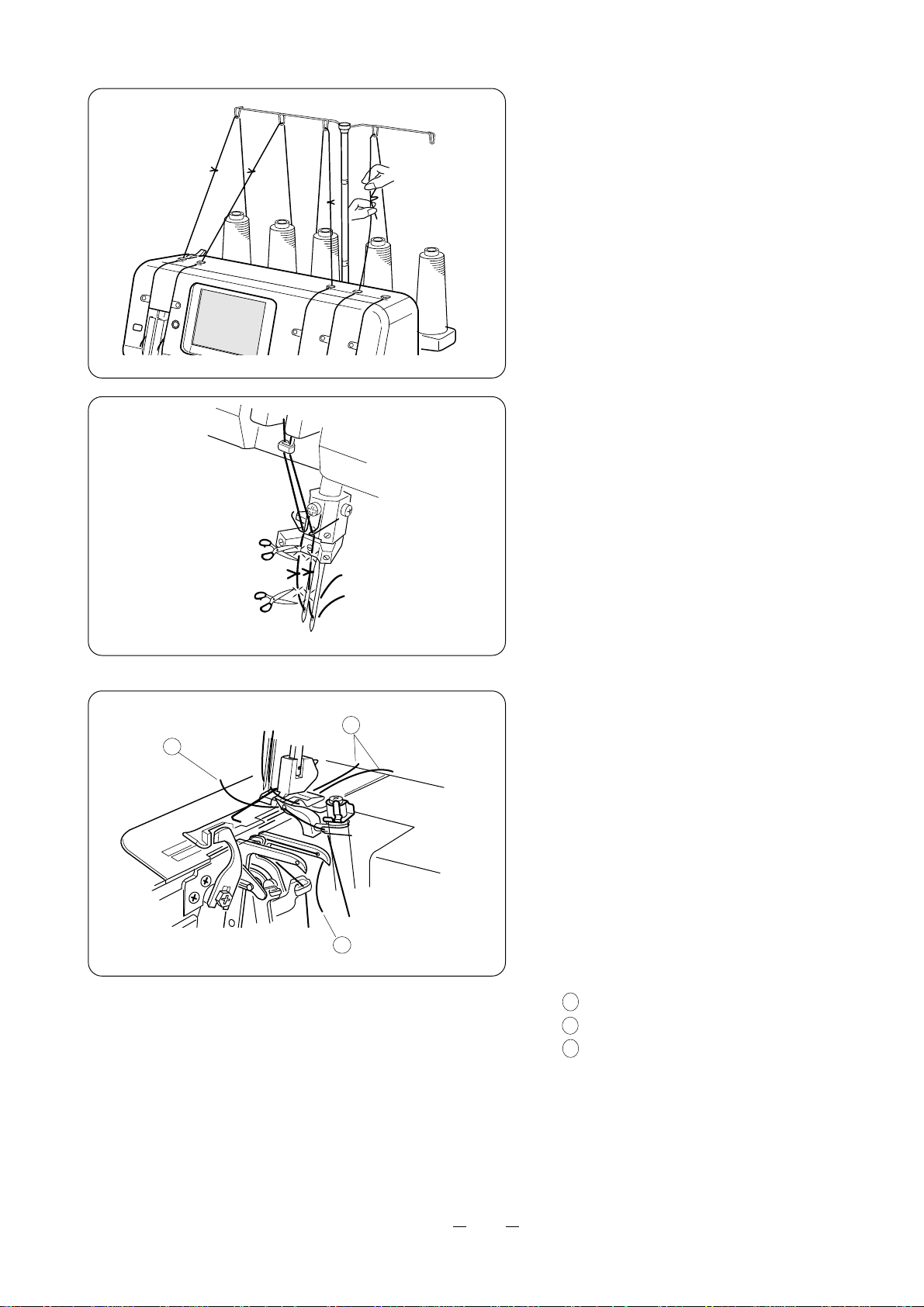

Four- Thread Operation

Turn off the power switch before threading the

machine.

The machine has been threaded at the factory

with short length of thread.

To thread the machine with your own thread,

tie it firmly to the upper end of the thread in the

machine, then raise the presser foot and pull the

other end.

For the needle threads, pull the bottom end of

thread until the knot comes to the needle eye,

and cut on both sides of the knot.

If the machine becomes unthreaded, thread

the lower looper first, then the upper looper,

needle on the right and needle on the left.

* A convenient threading chart is placed the

machine body inside the looper cover.

1, 2, 3

When first threading the machine, or rethreading

3

1

2

after a break, please do the following:

1 Turn the handwheel toward you until the

needles are in the full up position, and pull

out about 10 cm (4”) of thread from the tip

of the upper looper.

2 Pull out 10 cm (4”) of thread from the tip of

the lower looper.

3 Pull out 10 cm (4”) of needle thread and

draw it toward the back of the machine

under the presser foot.

Now, lower the presser foot and sew.

1 Upper looper thread

2 Lower looper thread

3 Needle threads

Incorrect threading will cause skipped

stitches, broken thread or uneven thread

tension.

Before starting to sew, make sure that your

machine is threaded properly.

11

Page 14

Threading the Lower Looper

10

11

1

2

3

Open the looper cover.

Raise the presser foot lifter.

Place a spool of thread on the spool pin

second from the right.

* The points to thread for lower looper

are marked in light green.

* A convenient threading chart is placed

on the machine body inside the looper

cover.

9

6

8

5

4

7

1

1

1 Draw the thread through the thread guide

second from the right from back to front.

1 Thread guide

12

Page 15

2

2

3

3

2 Slide the thread under the top cover thread

guide second from the right side, as illustrated.

2 Top cover thread guide

3 Hold the thread at both ends and tug gently

to ensure the thread is correctly inserted in

the thread tension unit.

3 Thread tension unit

4, 5, 6

6

7, 8

4 Pass the thread through the center of the

looper thread guide, as illustrated.

4 Looper thread guide

5, 6

Pass the thread through the two lower looper

4

5

thread guides, as shown.

5 Lower looper thread guide (1)

6 Lower looper thread guide (2)

7 Pass the thread through the looper thread

take-up lever (lower).

8 Pass the thread through the lower looper

thread guide (3), as illustrated.

7 Looper thread take-up lever (lower)

8

8 Lower looper thread guide (3)

7

13

Page 16

9

10

10

9 Turn the handwheel toward you to move

the lower looper to the right side.

Then, push down the lower looper thread

guide (4) with your finger, as illustrated.

In this way, the lower looper thread guide (4)

and (5) are moved to the right for easy

threading.

9

10 Pass the thread through lower looper thread

guides (4) and (5), as illustrated.

9 Lower looper thread guide (4)

10 Lower looper thread guide (5)

Holding the end of the thread, push the

lower looper thread guide (4) up with your

other hand to return it to its original position,

as illustrated.

Lower looper thread guides (4) and (5) will

return to their original position automatically

when you turn the handwheel toward you.

11

11 Move the lower looper to its rightmost

12

11

12

position by turning the handwheel, and

pass the thread through the hole in the lower

looper with the tweezers 10 cm (4") or more.

Make sure the needle threads are not

tangled in the lower looper and close the

looper cover.

11 Lower looper

12 Needle thread

X= incorrect

= correct

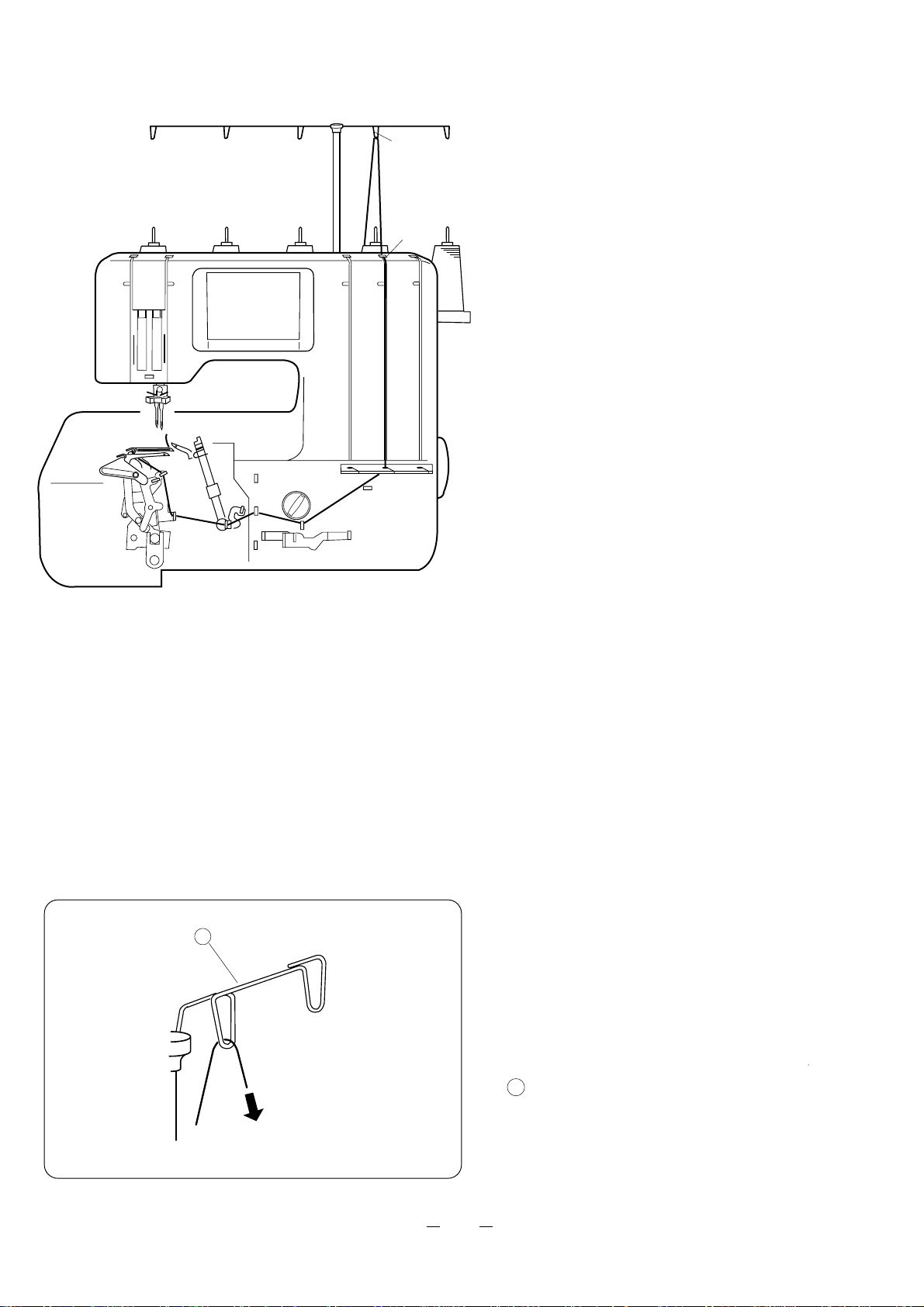

How to Thread Woolly Nylon or

Polyester Thread

1

2

3

* The illustration to the left demonstrates a

convenient way to thread the lower looper

with woolly nylon or polyester thread.

Use the same method with the upper looper.

1 Lower looper

2 Ordinary thread

3 Woolly nylon or polyester thread

14

Page 17

Threading the Upper Looper

1

Open the looper cover.

Raise the presser foot lifter.

* Place a spool of thread on the

2

3

center spool pin.

* The points to thread for the upper

looper are marked in red.

* A convenient threading chart is

placed on the machine body

inside the looper cover.

8

7

5

4

6

1

1

2

2

3

1 Draw the thread through the

center guide from back to front.

1 Thread guide

2 Slide the thread under the top

cover thread guide third from the

right, as illustrated.

2 Top cover thread guide

3 Hold the thread at both ends and

tug gently to ensure the thread is

correctly inserted in the thread

tension unit.

3 Thread tension unit

3

15

Page 18

4, 5

4 Pass the thread through left side of the looper

thread guide.

5 Pass the thread through the upper looper

thread guide (1).

5

4 Looper thread guide

5 Upper looper thread guide (1)

4

6

7, 8

6 Pass the thread through the looper thread

take-up lever (upper).

6 Looper thread take-up lever (upper)

6

7 Pass the thread through the upper looper

8

7

thread guide (2).

8 Holding the end of the thread with a pair of

tweezers, pass it through the hole in the up-

per looper.

Pull 10 cm (4”) or more of thread through the

hole.

7 Upper looper thread guide (2).

8 Upper looper

2

How to Thread the Upper Looper

2

1

Turn the handwheel toward you until the up per looper comes to the mid point of its travel,

and unhook the thread of the lower looper

from the upper looper.

1 Upper looper

2 Lower looper thread

16

Page 19

Threading the Right Needle

1

Raise the presser foot lifter.

Place a spool of thread on the spool

pin second from the left.

2

3

5

4

* The points to thread for the right needle

are marked in green.

* A convenient threading chart is placed

on the machine body inside the looper

cover.

6

7

8

1

1

2

2

1 Draw the thread through the thread

guide (second from the left) from back

to front.

1 Thread guide

2 Slide the thread under the top cover

thread guide (second from left) from the

right side.

2 Top cover thread guide

17

Page 20

3

4, 5, 6

3 Hold the thread at both ends and tug gently

to ensure the thread is correctly inserted in the

thread tension unit.

3

3 Thread tension unit

4, 5

Pass the thread under the right needle thread

guide, then, pull it up and over the right take-

up lever cover.

5

6 Pass the thread through the needle

thread guide.

4 Right needle thread guide

5 Right take-up lever cover

6 Needle thread guide

4

7, 8

1, 2

2

6

7 Raise the needle bar to its highest point by

turning the handwheel toward you then

thread the needle bar thread guide.

8 Pull out the thread 10 cm (4”) after threading

the right needle.

7 Needle bar thread guide

7

8 Right needle

How to Use Needle Threader

8

3, 4

5

1

5

4

3

Turn off the power switch before using the

needle threader.

1 Hold the threader in your right hand with

the “V” groove and arrow facing toward you.

2 With the thread in your left hand place the

thread in the “Y” groove and turn needle threader

once clockwise to place the “V” groove

and arrow facing up.

3 Holding the thread in your left hand, gently slide

the needle threader down the needle while at

the same time placing enough pressure on the

threader to ensure the inside pin meets the eye

of the needle.

4 Push the pin through the needle eye forming

a thread loop.

5 Remove the threader and draw the loop towards

the back of the needle.

18

1 Holder 2 Arrow 3 Needle thread

4 "Y" Groove 5 "V" Groove

Page 21

Threading the Left Needle

1

Raise the presser foot lifter.

Place a spool of thread on the far

left spool pin.

2

* The points to thread for the left

needle are marked in yellow.

3

5

4

* A convenient threading chart

is placed on the machine body

inside the looper cover.

6

7

8

1

1 Draw the thread through the leftmost

thread guide from back to front.

1

1 Thread guide

2

2

2 Slide the thread under the leftmost

top cover thread guide from the right.

2 Top cover thread guide

19

Page 22

3

3

3 Hold the thread at both ends and tug gently

to ensure the thread is correctly inserted the

thread tension unit.

3 Thread tension unit

4, 5, 6

7, 8

4, 5

Pass the thread below the left needle thread

guide then pull it up and over the left take-up

5

4

6

7

lever cover.

6 Pass the thread through the needle thread

guide.

4 Left needle thread guide

5 Left take-up lever cover

6 Needle thread guide

7 Raise the needle bar to its highest point by

turning the handwheel toward you, then

go over the needle bar thread guide.

8 Pull out the thread 10 cm (4”) after thread ing the left needle.

7 Needle bar thread guide

8 Left needle

8

20

Page 23

Threading the Double Chain Looper

1

Open the looper cover.

Raise the presser foot lifter.

Place the spool of thread on the right

2

3

side spool pin.

* The points to thread for the double

chain

looper are marked in orange.

* A convenient threading chart is placed

on the machine body inside the looper

cover.

12

13

11

10-A

5

4

6

10-B

1

8

9

7

1

1 Draw the thread through the rightmost

thread guide from back to front.

1 Thread guide

2 Pass the thread through the rightmost

2

2

21

top cover thread guide from the right,

as illustrated.

2 Top cover thread guide

Page 24

3

3 Hold the thread at both ends and tug gently

to ensure the thread is correctly inserted in

the thread tension unit.

3 Thread tension unit

4, 5

6, 7, 8, 9, 10

3

4

5

4 Pass the thread through the right side of the

looper thread guide.

4 Looper thread guide

5 Pass the thread through the double chain

looper thread guide (1).

5 Double chain looper thread guide (1)

6–9

Pass the thread through points 6 though 9,

as illustrated.

10 Pass the thread through the lower looper

thread guide (10-A) or double chain

looper thread guide (10-B).

Use lower looper thread guide (10-A) for

overlock 5 and double chain.

Use double chain looper thread guide (10-

B) for cover stitch.

10 -A

7

8

9

10 -B

11 12

11

11 Turn the handwheel toward you to move the

double chain looper to about mid stroke

6

12

11

from left to right.

Then, push down the double chain looper

thread guide with your finger, as illustrated,

so that the double chain looper thread

guides moves to the right for easy threading.

11 Double chain looper thread guide (3)

12 Pass the thread through the looper thread

guides, as shown.

Holding the tip of the thread, push the double

chain looper thread guide up by right hand

to return it to the original position, as

illustrated.

Double chain looper thread guides will return

to their original position automatically when

you turn the handwheel toward you.

12 Double chain looper thread guide (4)

22

Page 25

13

13

14

13 Draw the thread with a pair of tweezers

through the hole in the double chain looper

10 cm (4") or more. Next, make sure that the

needle thread is not tangled in the double

chain looper. Close the looper cover.

15

15

X = incorrect

O = correct

13 Double chain looper

14 Tweezers

15 Needle thread

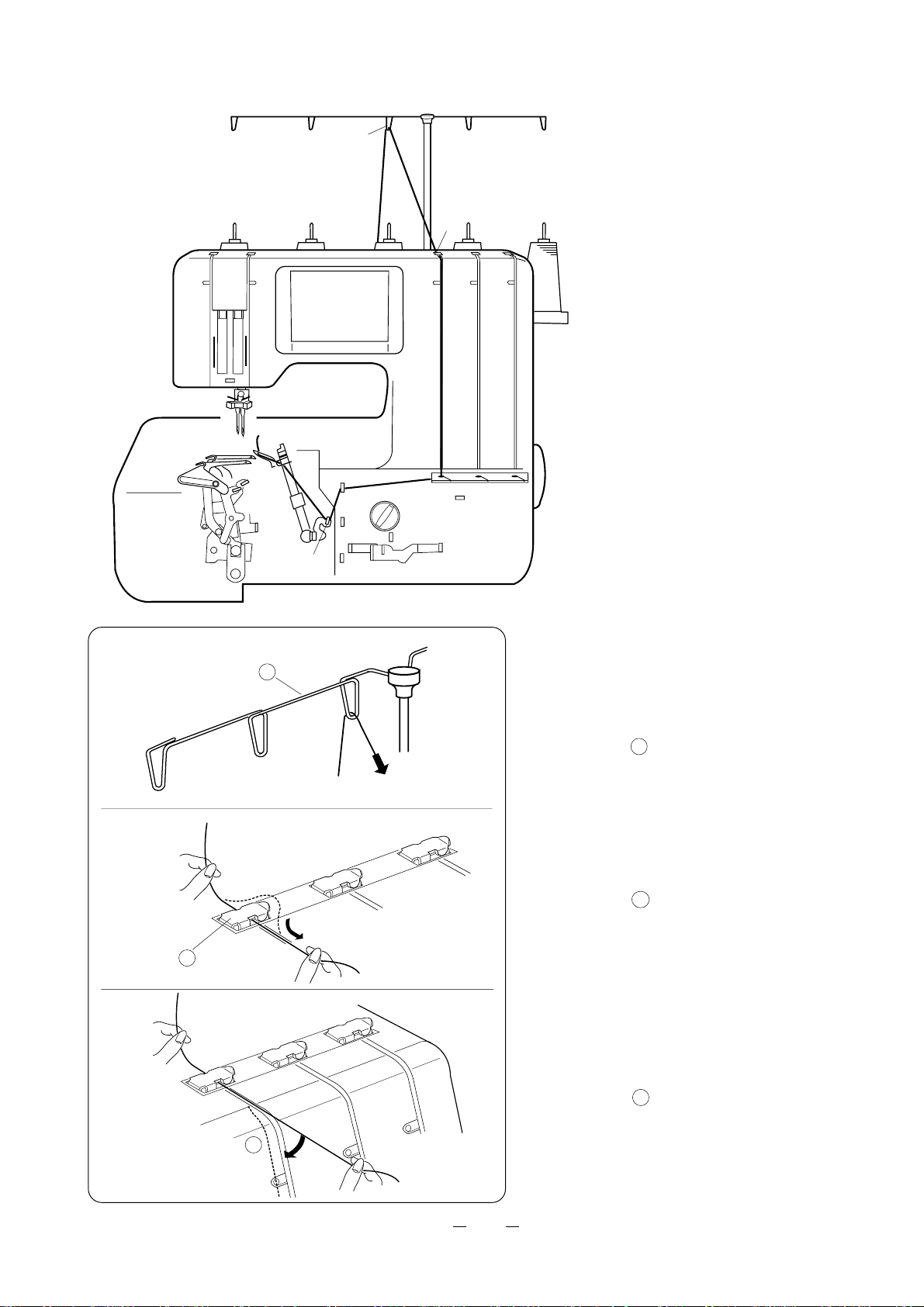

Changing to Two or Three Thread Serging

with Spreader

1

1

If you want to do two or three thread serging

with the spreader, use one or two needle

threads and the lower looper thread.

2 3

1 To attach the spreader

Slide the spreader down into the holder and put

the tip of the spreader into the hole in the upper

A

2

23

looper.

1 Spreader

2 Upper looper

3 Holder

2 To remove the spreader

Pull tab A on the holder toward you lightly.

Push the bottom of the spreader up and pull it

out.

Page 26

Visual Touch Screen Operations

1

1

2

3

1 Turn on the power switch.

The menu screen appears on the visual touch

screen.

2 Each time you press Page key, the visual

touch screen changes, as illustrated.

You can select the desired stitch by press ing one of the stitch pattern keys on the

three “pages.”

1 Page key

2 Stitch pattern key

3 Revert key

* Revert key indicates the current machine

setting.

To Change Screen Language

1

2

1

1 To select the desired language, press the flag

key on the first screen.

1 Flag key

2 Press the desired language key and all

screens will now appear in that language.

24

Page 27

Automatic Thread Tension Display Screen

1 When you select the desired stitch from stitch

1

pattern keys, the thread tensions will be auto matically set.

Settings such as the stitch length and differen tial feed ratio will be indicated on the visual

display screen as well.

Now simply begin sewing.

The following three pages show all the machine

settings related to each stitch type.

2

3

6

1

4

5

10

14

15

16

12

11

10

9

8

7

13

17

1 Stitch pattern

2 Tension setting (automatic setting)

3 Stitch width key (STD/WIDE)

4 Current stitch length setting (Manual set ting)

5 Recommended stitch length (Standard)

6 Needle setting position

7 Recommended thread type (Standard)

8 Recommended differential feed ratio

(Standard)

9 Current differential feed ratio (Manual

setting)

10 Information key

(Press to display recommended needle

position, presser foot, chaining finger set ting knob and extension table.)

11 Manual key

(Manual setting for thread tension.)

12 Menu key

13 Return key

14 Needle setting position

15 Presser foot A or B

16 Chaining finger setting knob (S) or (R)

17 Extension table (A) or (B)

SETTING:

Indicates the required machine settings for

the selected stitch.

Choose the Needle and Thread

The choice of needle and the thread depends on the

fabric you are sewing.In your needle case, you will find

the following needles:

#11 Needle....for lightweight fabrics.

#14 Needle....for medium or medium -heavy weight

fabrics.

Note: These needles are found in the accessory box (see page 4).

25

Check the Needle

1. Look for barbed or blunt point.

2. A damaged needle can cause permanent

snags or runs in knits, fine and silk-like fabrics.

Always buy a good quality thread. It should

resist tangling and be strong, smooth and

consistent in thickness.

Page 28

Stitch Package

1.OVERLOCK 4

2.OVEREDGE 3

STANDARD

3.OVEREDGE 3

WIDE

4.ROLLED HEM 3

5.FLATLOCK 3

STANDARD

6.FLATLOCK 3

WIDE

11.COVER STITCH

7.FLATLOCK 2

STANDARD

12.OVERLOCK 3

STANDARD

8.FLATLOCK 2

WIDE

13.OVERLOCK 3

WIDE

9.OVEREDGE 2

STANDARD

14.ROLLED HEM 2 15.NARROW HEM

10.OVEREDGE 2

WIDE

16.WRAPPED OVERLOCK 3 17.OVERLOCK 5 18.PICOT EDGE

21.DOUBLE CHAIN

19.WRAPPED OVERLOCK 2

STANDARD

20.WRAPPED OVERLOCK 2

WIDE

26

Page 29

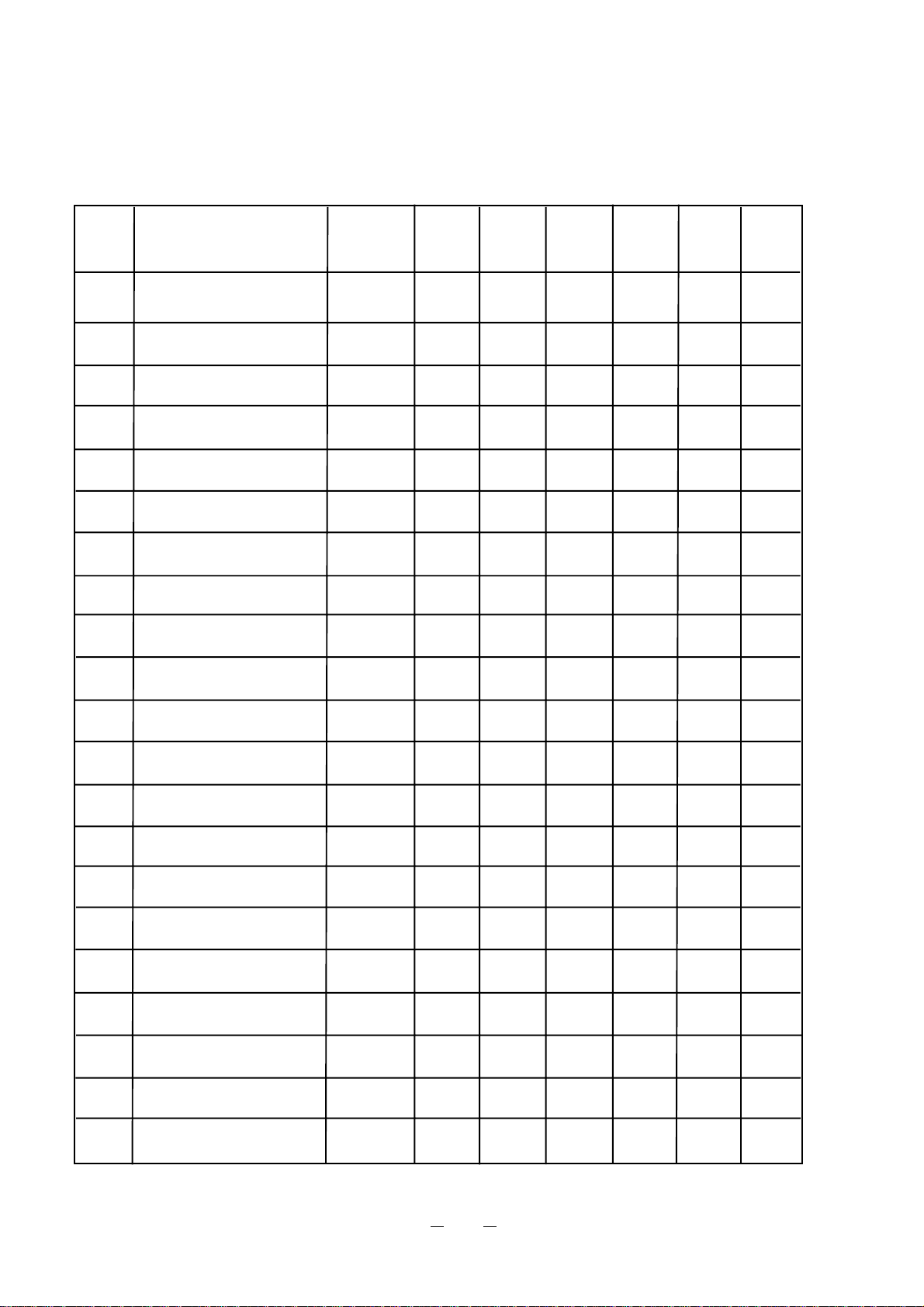

Standard Machine Settings for Automatic Thread Tension

* The automatic thread tension setting on the visual touch

screen is adjusted according to the following table such

as the stitch type, fabric, layers, etc.

Type of thread

* Type of thread:

REG: Polyester thread #60

FINE: Polyester thread #90

WOOLLY: Woolly nylon thread

DECO: Decorative thread

1

OVERLOCK 4

2

OVEREDGE 3

3

OVEREDGE 3

4

ROLLED HEM 3

5

FLATLOCK 3

6

FLATLOCK 3

7

FLATLOCK 2

8

FLATLOCK 2

9

OVEREDGE 2

10

OVEREDGE 2

11

COVER STITCH

Stitch

STANDARD

WIDE

STANDARD

WIDE

STANDARD

WIDE

STANDARD

WIDE

LEFT

NEEDLE

REG

REG

FINE

FINE

REG

REG

RIGHT

NEEDLE

REG

FINE

FINE

FINE

FINE

FINE

REG

UPPER

LOOPER

REG

FINE

REG

WOOLLY

DECO

DECO

LOWER

LOOPER

REG

FINE

REG

WOOLLY

FINE

FINE

DECO

DECO

FINE

REG

DOUBLE

CHAIN

LOOPER

REG

Fabric

WOVEN (MEDIUM)

WOVEN (MEDIUM)

WOVEN (MEDIUM)

WOVEN (LIGHT)

WOVEN (MEDIUM)

WOVEN (MEDIUM)

WOVEN (MEDIUM)

WOVEN (MEDIUM)

WOVEN (MEDIUM)

WOVEN (MEDIUM)

WOVEN (MEDIUM)

Layers

Lay

ers

2

1

1

1

1

1

1

1

1

1

2

Stitch

Length

3.0

3.0

3.0

1.5

3.4

3.4

3.4

3.4

3.0

3.0

3.0

Differential

Feed

Ratio

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

12

OVERLOCK 3

REG

REG

REG

STANDARD

13

OVERLOCK 3

REG

REG

REG

WIDE

14

ROLLED HEM 2

15

NARROW HEM

WRAPPED OVERLOCK 3

16

OVERLOCK 5

17

PICOT EDGE

18

WRAPPED OVERLOCK 2

19

REG

REG

FINE

FINE

REG

REG

FINE

REG

WOOLLY

REG

REG

WOOLLY

WOOLLY

REG

REG

REG

DECO

REG

STANDARD

WRAPPED OVERLOCK 2

20

REG

DECO

WIDE

21

DOUBLE CHAIN

REG

REG

..........This illustration shows the upper looper with the spreader attachment.

27

WOVEN (MEDIUM)

WOVEN (MEDIUM)

WOVEN (LIGHT)

WOVEN (LIGHT)

WOVEN (MEDIUM)

WOVEN (MEDIUM)

WOVEN (LIGHT)

WOVEN (MEDIUM)

WOVEN (HEAVY)

WOVEN (MEDIUM)

3.0

2

3.0

2

1.5

1

1.5

1

3.0

2

3.0

2

3.4

1

3.0

2

3.0

2

3.0

2

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.0

Page 30

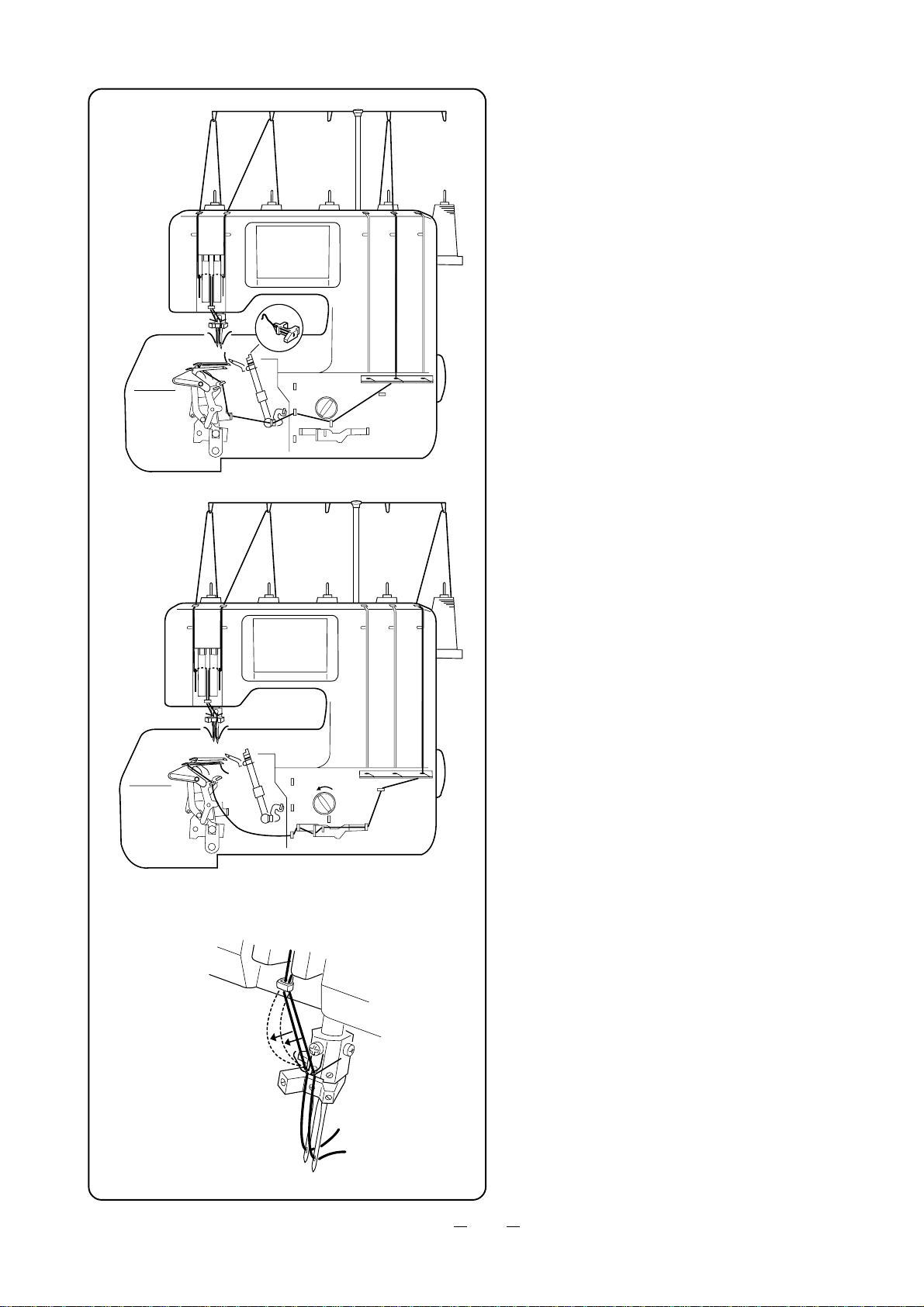

Stitch Pattern with Machine Setting

The machine setting (needle setting positions, type of presser foot, chaining finger position and type of

extension table) is indicated on the visual touch screen when you select the automatic thread tension or

press the Information key.

10

OVERLOCK 4

1

OVEREDGE 3

2

OVEREDGE 3

3

ROLLED HEM 3

4

FLATLOCK 3

5

FLATLOCK 3

6

FLATLOCK 2

7

FLATLOCK 2

8

OVEREDGE 2

9

OVEREDGE 2

STITCH PATTERN

STANDARD

WIDE

STANDARD

WIDE

STANDARD

WIDE

STANDARD

WIDE

NEEDLE

PLATE

LB, RB

RB

LB

RB

RB

LB

RB

LB

RB

LB

PRESSER

FOOT

A

A

A

A

A

A

A

A

A

A

CHAINING

FINGER

S

S

S

R

S

S

S

S

S

S

EXTENSION

TABLE

A

A

A

A

A

A

A

A

A

A

SPREADER

--

--

--

--

--

--

YES

YES

YES

YES

UPPER

KNIFE

POSITION

UP

UP

UP

UP UP

DOWN

DOWN

DOWN

DOWN

UP UP

UP

UPPER

LOOPER

POSITION

UP

UP

UP

UP

UP

UP

UP

UP

11

12

13

14

15

16

17

18

19

20

21

COVER STITCH

OVERLOCK 3

STANDARD

OVERLOCK 3

WIDE

ROLLED HEM 2

NARROW HEM

WRAPPED OVERLOCK 3

OVERLOCK 5

PICOT EDGE

WRAPPED OVERLOCK 2

STANDARD

WRAPPED OVERLOCK 2

WIDE

DOUBLE CHAIN

LF, RF

RB

LB

RB

RB

RB, LB

RB, LF

RB

RB

LB

LF

B

A

A

A

A

A

A

A

A

A

B

R

S

S

R

R

S

S

R

S

S

R

B

A

A

A

YES

A

A

YES

A

A

A

A

YES

YES

B

--

--

--

--

--

--

--

DOWN

UP

UP

UP UP

UP

UP

UP UP

UP

UP

UP

DOWN DOWN

DOWN

UP

UP

UP

UP

UP

UP

UP

28

Page 31

Manual Adjustment of Thread Tension

You can adjust the thread tension by pressing the

+or key to get the desired tension setting.

The actual thread tensions for each thread are

shown above the + / key on the screen.

Memory Key: Memorize the manually set

1

thread tensions.

Recall Memory Key: Recall the memorized

2

2

1

5

6

4

3

3

7

4

5

6

7

manual setting data.

Auto Key: Return to automatic thread

tension display screen.

Menu Key: Return to MENU screen.

Thread Tension Key: Increase thread tension.

Thread Tension Key: Decrease thread ten-

sion.

< >: Indicates the automatic thread tension

setting.

1

Manual Setting, Memory and View for

Thread Tension

Machine setting

You can memorize the number of layers, type

of fabric and type of threads depending on

your needs when setting thread tension manu-

2

1

2

3

3

ally.

1 Press the Memory key.

2 Press FABRIC key to advance to this screen,

then choose the type of fabric you’re using.

Press OK key to memorize or press Return key

to return to previous screen and cancel any

changes.

1

OK Key: Memorize the settings and re-

turn to **MEMO** screen.

2

Return Key: Return to previous screen

and cancel any changes.

3 Press THREAD key to enter settings for each

5

thread.

4

3 Cursor Advance Key: Press to move cursor.

4

29

4 Cursor: Current setting position.

5 Non-cursor position: Represents another.

4 Press LAYERS key to register how many

layers of fabric you’re sewing.

Page 32

1

(To Memorize Settings)

1 After entering your fabric, thread and layers

settings, press the MEM key to save them.

2

2 There are three memory locations. Choose

MEM 1, MEM 2 or MEM 3.

(The number of memory locations changes

depending on the type of stitch.)

3

3 The formerly memorized settings will be

displayed.

4 Press OK key to replace the previous settings

4

1

with the new ones, or press the Return key to

cancel.

1 Return key

(To view Memorized Settings)

1

1 Press Recall Memory key to view the cu

rently memorized settings.

2

2 If more than one memory location is being

used, press Page key to advance to them.

30

Page 33

Stitch Pattern and Threading

1

Depending on which stitch you have selected,

the LED lights on the front of the machine will

turn on to show you which threads should be

used. Also, the visual touch screen will indicate

the correct needle setting.

Press information key to confirm the machine

setting.

The sewing pattern and threading is illustrated,

as follows:

1. OVERLOCK 4

Needle setting position:

2

2. OVERLOCK 3 (STANDARD), OVEREDGE 3

(STANDARD) ROLLED HEM 3, FLATLOCK 3

(STANDARD), NARROW HEM, PICOT EDGE,

Needle setting position:

LB (left back)

RB (right back)

RB (right back)

31

Page 34

3

3. OVERLOCK 3 (WIDE), OVEREDGE 3 (WIDE),

FLATLOCK 3 (WIDE),

Needle setting position:

4

4. OVEREDGE 2 (STANDARD), ROLLED HEM 2

FLATLOCK 2 (STANDARD), WRAPPED

OVERLOCK2 (STANDARD)

Needle setting position: RB (right back)

LB (left back)

5

5. OVEREDGE 2 (WIDE), FLATLOCK 2 (WIDE),

WRAPPED OVERLOCK 2(WIDE),

Needle setting position: LB (left back)

32

Page 35

6

6. WRAPPED OVERLOCK 3

Needle setting position:

LB (left back)

RB (right back)

7

7. COVER STITCH

Needle setting position:

* The threading procedure that you can choose

the needle thread first or the double chain looper

thread.

The end of thread after threading the double

chain looper should be pulled out 5 cm (2”) from

the double chain looper downward for ready to

sew.

Place the needle thread under the presser foot.

* To begin with, raise the presser foot and place

the fabirc at the desired start position.

Lower the presser foot and start to sew.

* To finish sewing, stop the machine at the desired

position on the fabric and raise the needle bar

to its highest position. Raise the presser foot so

that the thread tension unit will release.

Loosen the needle thread tension so that you

can pull the fabric easily.

Hold the edge of fabric and pull out 5 cm (2”)

from machine and cut both needle threads

close to the fabric.

Next, pull the fabric to the back and cut off the

looper thread.

LF (left front)

RF (right front)

33

Page 36

8

8. OVERLOCK 5

Needle setting position:

The threading procedure is as follows:

1 Lower looper thread

2 Upper looper thread

3 Double chain looper thread

4 Left needle thread (LF)

5 Place a sewing test piece under the needle

and lower the presser foot.

6 Turn the handweel toward you and sew 2 to

3 stitches and pull the sewing test piece so

that the double chain looper

thread comes out of the needle plate hole.

7 Thread the right needle thread , then place it

under the presser foot together with the right

needle thread and double chain looper

threads.

LF (left front)

RB (right back)

1

2

3

4

* Make it easier to begin sewing...

Cut the fabric as shown so that the presser

foot can be placed beside the fabric, then

sew 2-3 stitches by turning the handwheel.

When you start sewing the next piece of fab ric, the thread chain is already made so that

you don’t need to cut the corner of fabric.

123 cm (1.2’’)

Cut off

3

Upper knife

4

Cutting line

34

Page 37

9. DOUBLE CHAIN

9

Needle setting position:

Threading procedure;

1 Double chain looper thread

2 Left needle thread

Bring the left needle thread under the presser

foot, put a sewing test piece on the needle

plate and lower the presser foot.

Turn the handwheel toward you to sew 2 to

3 stitches and pull the sewing test piece so

that the double chain looper thread comes

through the needle plate hole.

Draw out threads about 10 cm (4”) under the

presser foot.

LF (left front)

35

Page 38

1, 2

3

SECTION 3 TEST STITCHING

Starting Sewing

1 Insert the fabric under the toe of the presser

foot.

(It is not necessary to raise the presser foot

except when performing cover stitch or

overlock 5.)

2 Turn the handwheel gently toward you a

couple of turns and check the thread

chain. Then start sewing slowly.The fabric

will be automatically fed.

Guide the fabric in the desired direction.

Finishing Sewing

3 When stitching is completed, continue to run

the machine slowly to produce a thread

chain for about 12 cm ( 5”) while pulling the

thread chain slightly to the back.

4

4 Cut the threads with the thread cutter as

illustrated, leaving about a 5 cm (2") thread

chain hanging from the end of the fabric.

Sewing Continuously

Insert the next fabric under the toe of the

presser foot, then start sewing.

(It is not necessary to raise the presser foot

for ordinary fabric.)

* For heavy weight fabric, raise the presser

foot and insert the fabric in front of the knife.

Then lower the foot and sew.

How to Use the Guide Lines

On the top of the looper cover are guide

lines indicating the distance from the needle

position. The distance from both the left (L)

and right (R) needle are shown.

36

Page 39

1

A

Securing Ends

To avoid unravelling, it is necessary to leave

B

C

D

a thread chain about 5 cm (2”) long at the

beginning and the end of the seam.

To secure the beginning and end of a seam

choose one of the following methods:

At the Beginning

A. Separate the end of the threads and knot.

B. Thread the chain through a large eyed

needle, and weave that chain through

the overlock stitches on the fabric.

C. Cut the chain at the edge of the fabric.

Then apply a small amount of seam

sealant (Fray Check TM or Fray-No-More TM)

on the end of the threads.

D. Backstitching

1 Before putting your fabric in the machine,

sew a thread chain about 5 cm (2”) long

behind the needle.

2 Put your fabric in the machine. Then serge

a few stitches and stop.

3 Raise the presser foot and bring the thread

chain to the left around and under the

presser foot.

4 Place the thread chain between the presser

foot and upper knife, holding it in position

as you lower the presser foot to sew.

5 After sewing about 2.5 cm (1”), move the

chain to the right and under the upper knife,

cutting the chain as you sew.

2

3

4

At the End of Seam

You can use the same methods as above

to secure the end of the seam (except

“Backstitching” ), or the following methods:

1 Serge one stitch off the end of seam.

2 Raise the needle and presser foot, and

gently pull the threads off the chaining

finger.

3 Turn the fabric over.

4 Serge about 2.5 cm (1”) over the stitching

and angle off the fabric.

37

Page 40

Thread Tension Adjustment

Thread Tension (4 threads)

Correct tension

The illustration at left shows sewing results with

correct tension settings. However, adjusting the

thread tension may be required depending on

1

the type of fabric and thread being used.

To begin with, select the stitch pattern key and

sew a test piece.

If the tension balance on the test piece is not

satisfactory, you can adjust the thread tension

manually, as follows:

4

3

1

4

3

2

2

5

6

7

8

7

5

6

1 Press Manual key to select the manual thread

tension display screen.

2 Press Thread tension keys to adjust the [+/- ]

thread tensions manually.

1 Wrong side of fabric

2 Right side of fabric

3 Right needle thread

4 Left needle thread

5 Upper looper thread

6 Lower looper thread

7 Left needle thread tension

Wrong tension

The illustration shows sewing results when

the left needle thread tension is too loose.

Remedy:

Tighten left needle thread tension.

Wrong tension

5

1

4

3

2

6

8

The illustration shows sewing results when

the right needle thread tension is too loose.

Remedy:

8 Right needle thread tension

38

Tighten right needle thread tension.

Page 41

Wrong tension

The illustration shows sewing results when the

5

1

6

upper looper thread tension is too tight and/

or lower looper thread tension is too loose.

Remedy:

Loosen upper looper thread tension and/or

tighten lower looper thread tension.

2

4

3

10

9

1

6

4

2

3

5

1 Wrong side of fabric

2 Right side of fabric

3 Right needle thread

4 Left needle thread

5 Upper looper thread

6 Lower looper thread

9 Upper looper thread tension

10 Lower looper thread tension

Wrong tension

The illustration shows sewing results when the

lower looper thread tension is too tight and/

or upper looper thread tension is too loose.

Remedy:

Loosen lower looper thread tension and/or

tighten upper looper thread tension.

9 10

39

Page 42

Thread Tension (3 threads)

4

5

1

2

3

8

7

6

4

5

1

3

2

(Standard stitch width)

Correct tension

The illustration at left shows sewing results with

correct tension settings. However, adjusting the

thread tension may be required depending on

the type of fabric and thread being used.

To begin with, select the stitch pattern and sew

a test piece.

If the tension balance on the test piece is not

satisfactory, you can adjust the thread tension

manually, as follows.

1 Wrong side of fabric

2 Right side of fabric

3 Right needle thread

4 Upper looper thread

5 Lower looper thread

6 Right Needle thread tension

7 Upper looper thread tension

8 Lower looper thread tension

Wrong tension

The illustration shows sewing results when the

needle thread tension is too loose.

Remedy:

Tighten needle thread tension.

5

1

2

3

1

2

3

4

Wrong tension

The illustration shows sewing results when the

lower looper thread tension is too tight and/or

upper looper thread tension is too loose.

Remedy:

Loosen lower looper thread tension and/or

tighten upper looper thread tension.

Wrong tension

5

4

The illustration shows sewing results when the

upper looper thread tension is too tight and/or

lower looper thread tension is too loose.

Remedy:

Loosen upper looper thread tension and/or

tighten lower looper thread tension.

40

Page 43

Rolled Hem 3, Narrow Hem and

Picot Edge

Adjusting the thread tension may be required

depending on the type of fabric and thread

being used.

To begin with, select the automatic thread

tension display screen of the each stitch

patern to sew a test piece.

If the tension balance on the test piece is not

satisfactory, you can adjust the thread tension

manually, as follows:

Rolled Hem 3

6

Correct Tension

The illustration at left shows sewing results with

1

5

correct tension settings.

2

3

1

5

3

2

4

4

7

8

9

Wrong tension

The illustration shows the sewing results when

the right needle thread tension is too loose.

Remedy:

Tighten the right needle thread tension.

1 Wrong side of fabric

2 Right side of fabric

3 Right needle thread

4 Upper looper thread

5 Lower looper thread

6 Manual thread tension display screen

7 Right needle thread tension

8 Upper looper thread tension

9 Lower looper thread tension

41

- For better results Pull the end of thread chain to the back lightly

at the beginning and end of sewing.

Page 44

Narrow Hem

Correct Tension

1

5

2

3

1

5

2

3

6

4

4

The illustration at left shows sewing results with

correct tension settings.

1

Wrong side of fabric

2 Right side of fabric

3 Right needle thread

4 Upper looper thread

5 Lower looper thread

6 Right needle thread tension

Wrong tension

The illustration shows the sewing results when

theupper looper thread tension is too loose

and/ or lower looper thread tension is too tight.

Remedy:

Tighten the upper looper thread tension and/

or loosen the lower looper thread tension.

Picot Edge

1

5

2

3

1

5

2

3

4

4

Correct Tension

The illustration at left shows sewing results with

correct tension settings.

Wrong tension

The illustration shows the sewing results when

theupper looper thread tension is too loose.

Remedy:

Tighten the upper looper thread tension.

- For better results Pull the fabric lightly to the back while sewing.

42

Page 45

Thread Tension ( 2 threads)

(Standard stitch width)

Correct tension

Adjusting the thread tension may be required

1

3

2

depending on the type of fabric and thread

being used.

To begin with, select the stitch pattern key

and sew a test piece.

If the tension balance on the test piece is not

satisfactory, you can adjust the thread ten sion manually, as follows;

4

1

3

2

4

1

3

5 6

Wrong tension

The illustration shows sewing results when the

lower looper thread tension is too tight and/

or needle thread tension is too loose.

Remedy:

Loosen lower looper thread tension and/or

tighten needle thread tension.

1 Wrong side of fabric

2 Right side of fabric

3 Right needle thread

4 Lower looper thread

5 Right needle thread tension

6 Lower looper thread tension

Wrong tension

The illustration shows sewing results when the

needle thread tension is too tight and/or

lower looper thread tension is too loose.

Remedy:

Loosen needle thread tension and/or tighten

lower looper thread tension.

2

4

43

Page 46

Thread Tension (Cover Stitch)

Correct tension

Adjusting the thread tension may be required

1

5

2

depending on the type of fabric and thread

being used.

To begin with, select the stitch pattern key

and sew a test piece.

If the tension balance on the test piece is not

satisfactory, you can adjust the thread ten sion manually, as follows.

3

1

5

2

3

1

5

4

6 7 8

4

Wrong tension

The illustration shows sewing results when the

right needle thread tension is too loose.

Remedy:

Tighten right needle thread tension.

1 Wrong side of fabric

2 Right side of fabric

3 Left needle thread

4 Right needle thread

5 Double chain looper thread

6 Left needle thread tension

7 Right needle thread tension

8 Double chain looper thread tension

Wrong tension

The illustration shows sewing results when

the double chain looper thread tension is

too tight.

Remedy:

Loosen double chain looper thread ten sion.

Note:

2

3

4

If the double chain looper thread tension

is loosened too much, it may cause miss ing stitches.

44

Page 47

Thread Tension (Double Chain)

Correct tension

Adjusting the thread tension may be required

depending on the type of fabric and thread

1

4

2

being used.

To begin with, select the stitch pattern key

and sew a test piece.

If the tension balance on the test piece is not

satisfactory, you can adjust the thread ten sion manually, as follows;

3

1

4

2

3

5

5

6

Wrong tension

The illustration shows sewing results when the

left needle thread tension is too loose.

Remedy:

Tighten left needle thread tension.

1 Wrong side of fabric

2 Right side of fabric

3 Left needle thread

4 Double chain looper thread

5 Left needle thread tension

6

6 Double chain looper thread tension

45

Page 48

To Adjust Stitch Length

Turn the stitch length dial until the desired

stitch length appears on the screen.

The larger the number, the longer the stitch.

3

2

3

The stitch length can be adjusted from 1 to

5 mm.

The amount of stitch length is indicated on

the automatic thread tension and manual

thread tension screen.

1.5

1

1 Recommended stitch length (standard)

2 Current stitch length (manual setting)

3 Stitch length dial

To Adjust Differential Feed Ratio

Turn the differential feed dial to adjust the

3

1

2

4

feed ratio.

The number on the screen indicates the ratio

between the main and the sub feed motion.

The differential feed ratio (1.0) indicates the

neutral position.

The differential feed ratio is displayed on both

the automatic thread tension and manual

thread tension screen.

1 Recommended differential feed ratio

(standard)

2 Current setting of the differential feed ra-

tio (manual setting)

3 Differential feed dial

How to Adjust

If the fabric becomes stretched when sewn,

turn the dial counterclockwise (toward 2.2).

4 Stretched

5

If the fabric becomes compressed when

sewn, turn the dial clockwise (toward 0.5)

5 Compressed

46

Page 49

To Deactivate the Upper Knife

1 Turn off the power switch and unplug the

machine.

2

1

2

2 Open the looper and side covers.

3 Pull out the upper knife release knob and

slide it down along the guide until it comes

to its lowest position.

4 Close the looper and side covers.

1 Upper knife release knob

2 Upper knife

1

To Activate the Upper Knife

1 Turn off the power switch and unplug the

2

1

machine.

2 Open the looper and side covers.

3 Pull out the upper knife release knob and

slide it up along the guide until it comes

to its highest position.

4 Close the looper and side covers.

47

Page 50

Adjustment of Cutting Width

When the cutting width is too narrow or too

wide in relation to the seam width, adjust it

as follows:

1 Turn off the power switch and unplug the

machine.

1

2

2 Open the looper and side covers.

3 Turn the cutting width adjusting dial to move

the cutting blades to the desired position.

1 Cutting width adjusting dial

2 Lower knife

3 Standard setting

3

2

If the cutting width is too narrow, turn the

cutting width adjusting dial clockwise.

The lower knife will move right.

If the cutting width is too wide,turn the cut ting width adjusting dial counterclockwise.

The lower knife will move left.

4 Close the looper and side covers.

48

Page 51

Adjustment of Chaining Finger Setting

Knob

4

3

A

1

B

(Changing between Standard Serging or Rolled

Hem)

1 Turn off the power switch and unplug the

machine.

2 Open the looper and side covers.

3 Push the cutting width adjusting dial to the

right as far as it will go, then move the

chaining finger setting knob to the guide line

“S”(for Standard serging) or “R” (for Rolled

hem).

Release the cutting width adjusting dial to

the left gently.

4 Close the looper and side covers.

1 Chaining finger

2 Guide line (S)

3 Cutting width adjusting dial

4 Chaining finger setting knob

5 Guide line (R)

1

2

4

4

5

49

Page 52

Adjusting of Foot Pressure

1

1

A

3

2

B

Depending on the type of fabric, the foot

pressure may have to be decreased or

increased.

A : To increase

B : To decrease

1 Pressure adjusting dial

2 Standard setting position

3 Setting mark

Note: The standard setting of presser dial is that

the standard setting position meets the

setting mark,as illustrated.

Removing the Presser Foot

3

4

2

1 Raise the needle and presser foot.

2 Press the lever on the back of the foot holder.

The presser foot will drop off.

1 Presser foot lifter

2 Foot holder

3 Lever

4 Needle

Attaching the Presser Foot

Place the presser foot so that the pin on the

foot lies just under the groove of the foot

holder.

Lower the foot holder to lock the foot in place.

Raise the presser foot lifter to check that the

presser foot is secure.

* The visual touch screen will indicate which

presser foot (A or B) should be used, based

on the sewing conditions.

How to Replace the Needle Plate

1 Open the looper and side covers.

2 Remove the needles and presser foot.

Return the chaining finger to the “R”

position.

3 Remove the needle plate set screw and the

needle plate.

* Attach the needle plate (A) or (B)

depending on the visual touch screen

1

indication.

1 Needle plate set screw

50

Page 53

How to Replace the Extension Table

The visual touch screen will indicate when you

should replace the extension table.

Open the looper cover and pull off the

extension table (A). Snap the extension table (B)

onto the looper cover .

2

1 Extension table (A)

2 Looper cover

1

3

3 Extension table (B)

* Make sure both the upper looper and the

upper knife have been dropped to their

lowest positions (deactivated), replace the

needle plate, pressure foot and move the

chaining finger to “R” position before

attaching the extension table (B).

* Replacement of the extension table is

required for the cover stitch and double chain

stitch sewing.

How to Change the Upper Looper

Position

The visual touch screen will indicate when it is

necessary to activate or deactivate the upper

looper.

Turn the upper looper release dial to the right

1

to activate.

Turn the upper looper release dial to the left to

deactivate (lowest position).

1 Upper looper release dial

51

Page 54

SECTION 4 MAINTENANCE

Replacing the Light Bulb

1 Turn of the power switch and unplug the

machine.

1

Loosen the face plate set screw, and remove

the face plate.

To remove:

2 Pull out the lamp socket from the holder and

remove the light bulb from the lamp socket.

To replace:

3 Put a new bulb in the lamp socket.

4 Attach the face plate and tighten the set

screw.

1, 2, 3, 4

1

5, 6

1 Face plate

2 Light bulb

3 Holder

3

2

2

Cleaning the Feed Dog

1 Open the looper and side covers.

2 Remove the needles and presser foot.

3 Move the chaining finger setting knob to

“R” position.

4 Remove the needle plate set screw and the

needle plate.

5 Remove the lint around the feed dogs

with the lint brush.

3

6 Replace the needle plate, presser foot and

needles.

Close the looper and side covers.

1 Needle plate

2 Needle plate set screw

3 Lint brush

52

Page 55

1, 2, 3

Cleaning the Upper Knife Area

1 Turn off the power switch and unplug the

machine.

2 Open the looper cover.

Brush the waste chips to the front with a

lint brush.

* You may also use a vacuum cleaner to clean

the upper knife area or feed dog.

Replacing the Upper Knife

To Remove:

1 Turn off the power switch and unplug the

machine.

2 Open the looper cover.

3 Turn the handwheel toward you until the

upper knife reaches its highest position.

4 Remove the hexagon bolt and the upper

knife.

3

1

2

A

3

1

2

To attach:

1 Insert a new upper knife into the groove of

the knife holder.

Then tighten the hexagon bolt slightly.

2 Turn the handwheel toward you until the up per knife reaches its lowest position.

Loosen the hexagon bolt, and adjust the

position of the upper knife so that its blade

overlaps the edge of lower knife 0.8 mm to

1.5 mm (3/64”), as shown.

Then, tighten the hexagon bolt firmly.

3 Close the looper and side covers.

1 Upper knife

2 Hexagon bolt

3 Lower knife

A 0.8 to 1.5 mm (3/64”)

53

Page 56

Oiling the Machine

Open looper cover and side covers.

It is recommended to apply oil once a

week in normal use, once in ten hours in

continuous use.

Apply a few drops of fine quality sewing

machine oil to the parts indicated with arrows.

Troubleshooting

Condition

The fabric is not being

fed smoothly.

The needle breaks.

The thread breaks.

Skipped stitches.

The seam is not

sewn neatly.

Seam puckering.

The machine does

not operate.

The fabric is not

cut neatly.

Touch screen is not clear. 1. The screen brightness is not adjusted properly. Turn the knob to correct.

Cause Reference

1. The feed dog is packed with lint. See page 52.

2. The presser foot has been raised. Lower the presser foot.

1. The needle is incorrectly inserted.

2. The needle is bent or blunt.

3. The fabric is being pulled too strongly.

1. The machine is not correctly threaded.

2. The needle or looper thread tension is too tight.

3. The needle is incorrectly inserted.

1. The needle is bent or blunt.

2. The machine is not correctly threaded.

1. The needle and/or looper thread tensions are not correctly

adjusted.

2. The machine is not correctly threaded.

3. The needle and/or the thread are not suitable for the fabric

being sewn.

4. The thread is not correctly inserted in the tension unit.

1. The needle or looper thread tension is too tight.

2. The machine is not correctly threaded.

3. The differential feed dial is not correctly adjusted.

1. The machine has not been plugged in firmly.

2. The power switch is turned off.

1. The position of the upper knife is not adjusted properly. See page 53.

2. The upper knife is dull. Replace the upper knife.

See page 9.

See page 9.

Pull the fabric lightly.

See pages 10–23 and 31–35.

See pages 38–45.

See page 9.

See page 9.

See page 10–23 and 31–35.

See pages 38–45.

See pages 10–23 and 31–35.

See pages 25,27.

See pages 13,15,18,20 and 22.

See pages 38–45.

See pages 10–23 and 31–35.

See page 46.

See page 5.

See page 5.

(See page 8.)

54

Loading...

Loading...