Instruction book

IMPORTANT SAFETY

INSTRUCTIONS

This sewing machine is not a toy. Do not allow children to play with this machine.

The machine is not intended for use by children or mentally infirm persons without supervi-

sion.

This sewing machine is designed and manufactured for household use only.

Read all instruction before using this sewing machine.

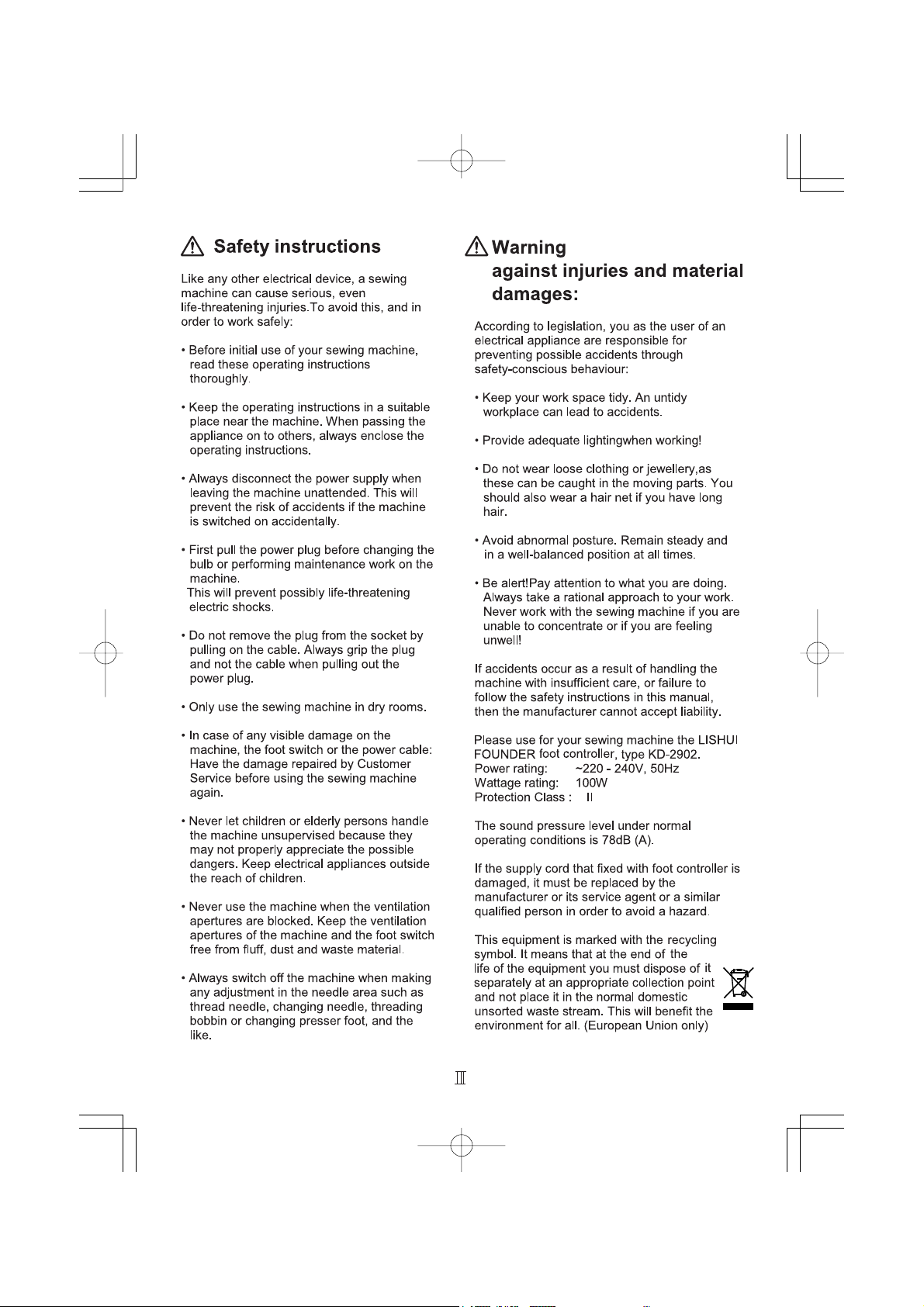

DANGER – To reduce the risk of electric shock:

1. An appliance should never be left unattended when plugged in.

Always unplug this sewing machine from the electric outlet immediately

after using and before cleaning.

2. Always unplug before replacing a sewing machine bulb.

Replace bulb with same type rated 15 watts.

3. Do not reach for the appliance that has fallen into water.

Unplug immediately.

4. Do not place or store appliance where it can fall or be pulled into a tub or

sink. Do not place in or drop into water or other liquid.

WARNING – To reduce the risk of burns, fire, electric shock, or

injury to persons:

1. Do not allow children to play with the machine. The machine is not intended

for use by children or infirme persons without proper supervision.

Do not allow to be used as a toy. Close attention is necessary when this

sewing machine is used by or near children.

2. Use this appliance only for its intended use as described in this owner’s

manual.

Use only attachments recommended by the manufacturer as contained in

this owner’s manual.

3. Never operate this sewing machine if it has a damaged cord or plug, if it is

not working properly, if it has been dropped or damaged, or dropped into

water.

4. Never operate the appliance with any air opening blocked. Keep ventilation

opening of this sewing machine and foot controller free from accumulation of

lint, dust and loosen cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where

oxygen is being administered.

8. To disconnect, turn all controls to the off (“O”) position, then remove plug

from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the

sewing machine needle.

11. Always use the proper needle plate. The wrong plate can cause the needle

to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle causing it

to break.

14. Switch this sewing machine off (“O”) when making any adjustment in the

needle area, such as threading the needle, changing the needle, threading

the bobbin or changing the presser foot, and the like.

15. Always unplug this sewing machine from the electrical outlet when removing

covers, lubricating, or when making any other adjustments mentioned in this

owner’s manual.

SAVE THESE INSTRUCTIONS

The design and specifications are subject to change without a prior notice.

Please note that on disposal, this product must be safely recycled in accordance

with relevant National legistlation relating to electrical/electronic products. If in doubt

please contact your retailer for guidance. (European Union only.)

TABLE OF CONTENTS

1. ESSENTIAL PARTS ......................................................................... 2-3

Name of Parts ................................................................................................ 2

Standard Accessories .................................................................................... 3

2. GETTING READY TO SEW ........................................................... 4-18

Connecting the Machine to the Power Supply ............................................... 4

Foot Control ................................................................................................... 5

Extension Table ............................................................................................. 6

Accessories Storage Box............................................................................... 6

Levelling the Machine .................................................................................... 7

Presser Foot Lifter ......................................................................................... 8

To Attach and Remove the Presser Foot ....................................................... 8

Removing or Inserting the Bobbin Case ........................................................ 9

Removing Bobbin .......................................................................................... 9

Setting Spool Pins ....................................................................................... 10

Winding the Bobbin...................................................................................... 10

Threading Bobbin Case ................................................................................ 11

Threading the Machine ................................................................................ 12

Drawing Up Bobbin Thread ......................................................................... 13

Balancing Needle Thread Tension ............................................................... 14

Changing Needle ......................................................................................... 15

To check the needle ..................................................................................... 15

To Drop or Raise the Feed Dogs ................................................................. 16

Reverse Stitch Button .................................................................................. 16

Pattern Selector Dial .................................................................................... 17

Stitch Length Dial......................................................................................... 17

Stitch Width Dial .......................................................................................... 17

Stich Reference Chart ................................................................................. 18

3. BASIC SEWING ........................................................................... 19-20

Straight Stitch ......................................................................................... 19-20

Quilting Guide .............................................................................................. 20

4. UTILITY STITCHES ...................................................................... 21-29

Basic Zigzag ................................................................................................ 21

Overcasting .................................................................................................. 21

Mending ....................................................................................................... 22

Blind Stitch .............................................................................................. 22-23

Zipper Sewing ......................................................................................... 24-26

Buttonhole............................................................................................... 27-28

Corded Buttonhole ....................................................................................... 29

5. DECORATIVE STITCHES ............................................................ 30-31

Embroidery .................................................................................................. 30

Satin Stitch................................................................................................... 30

Strech Stitches............................................................................................. 31

6. CARE OF YOUR MACHINE ......................................................... 32-36

Cleaning the Feed Dog ................................................................................ 32

Dismantling and Assembling Hook Race Unit ............................................. 33

Sewing Light ................................................................................................ 34

Oiling............................................................................................................ 34

Troubleshooting ...................................................................................... 35-36

1

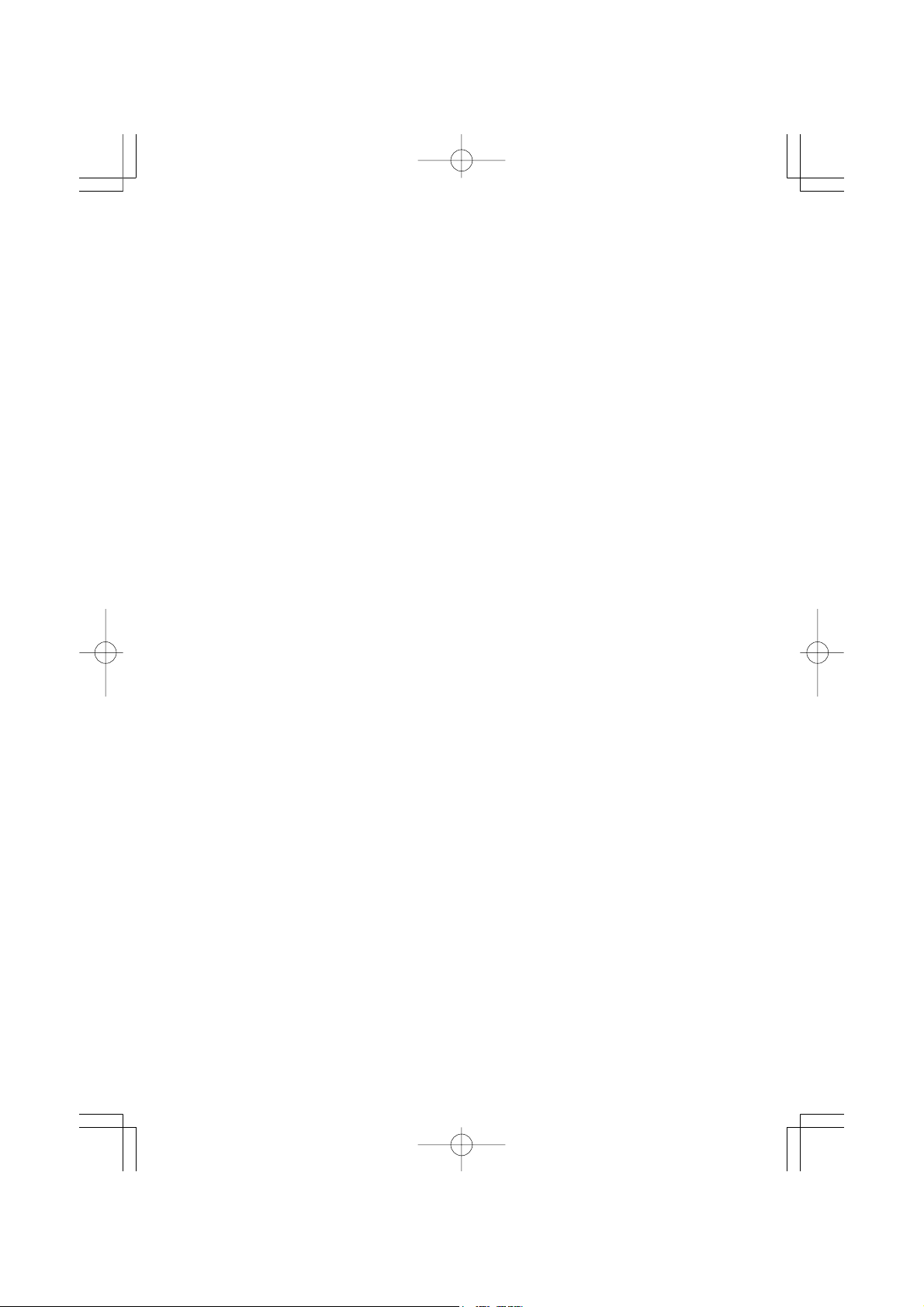

1. ESSENTIAL PARTS

10

11

12

19

23

9

22

20

Name of Parts

17

6

13

15

16

18

7

8

21

5

14

4

1

q Reverse stitch button

w Stitch length dial

3

e Stitch width dial

r Bobbin winder stopper

2

t Bobbin winder spindle

y Spool pins

u Thread tension dial

i Bobbin winder thread guide

o Thread take-up lever

!0 Face plate

!1 Thread cutter

!2 Needle plate

!3 Extension table

!4 Pattern selector dial

!5 Needle clamp screw

!6 Thread guide

!7 Needle

!8 Presser foot

!9 Thumb screw

@0 Presser foot holder

@1 Carrying handle

@2 Handwheel

@3 Stop motion knob

27

@4 Machine socket

@5 Power switch

@6 Free arm

@7 Presser foot lifter

24

25

26

Note:

The specifications are subject to

change without prior notice.

2

q

e

t

w

r

y

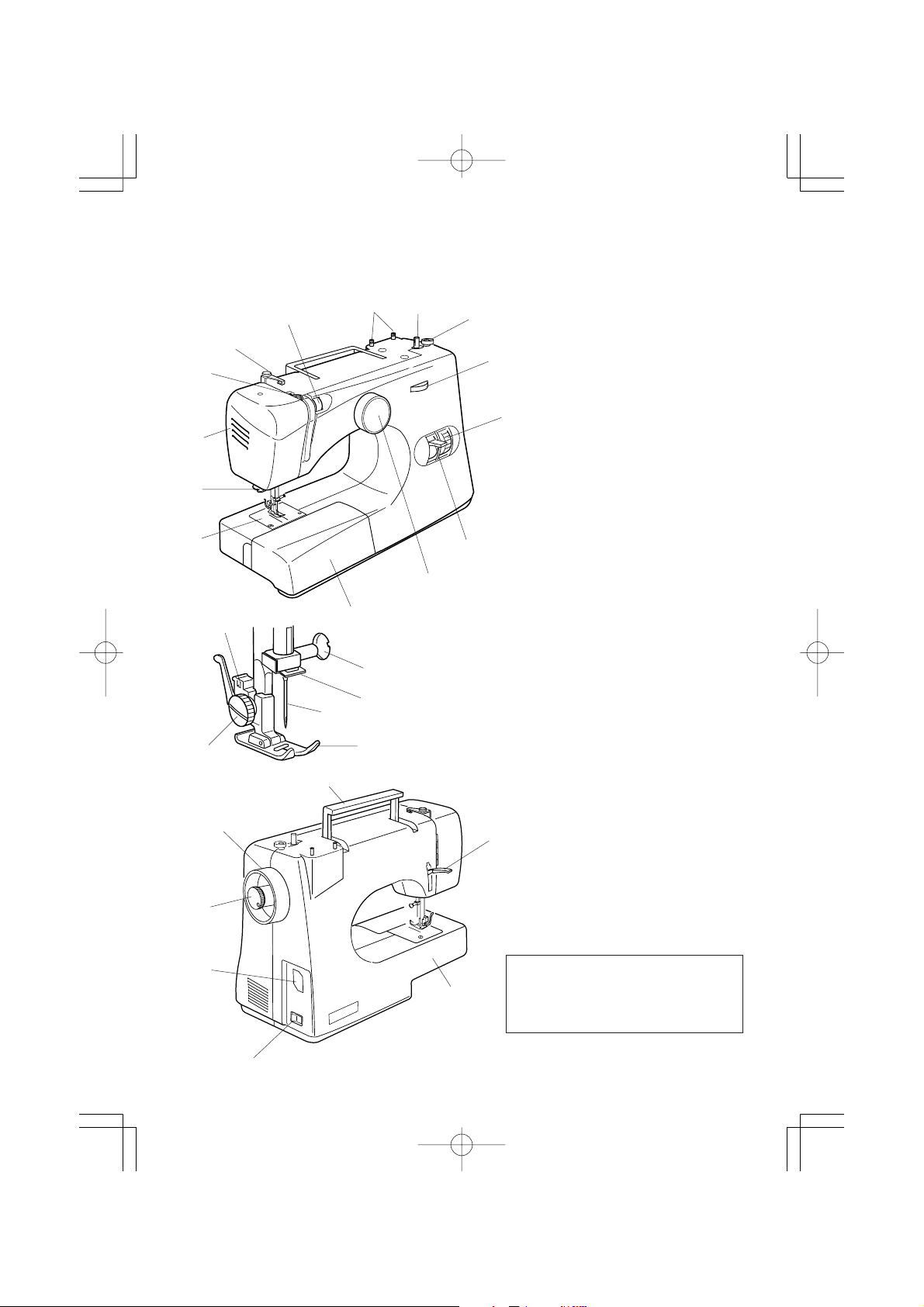

Standard Accessories

q Bobbins

w Screwdriver

e Needle set

r Seam ripper / buttonhole opener

t Quilting guide

y Mchine oil

u Felt

i Zipper foot

o Buttonhole foot

!0 Blind hem foot

!1 Zigzag foot (set on the machine)

u

o

!1

i

!0

3

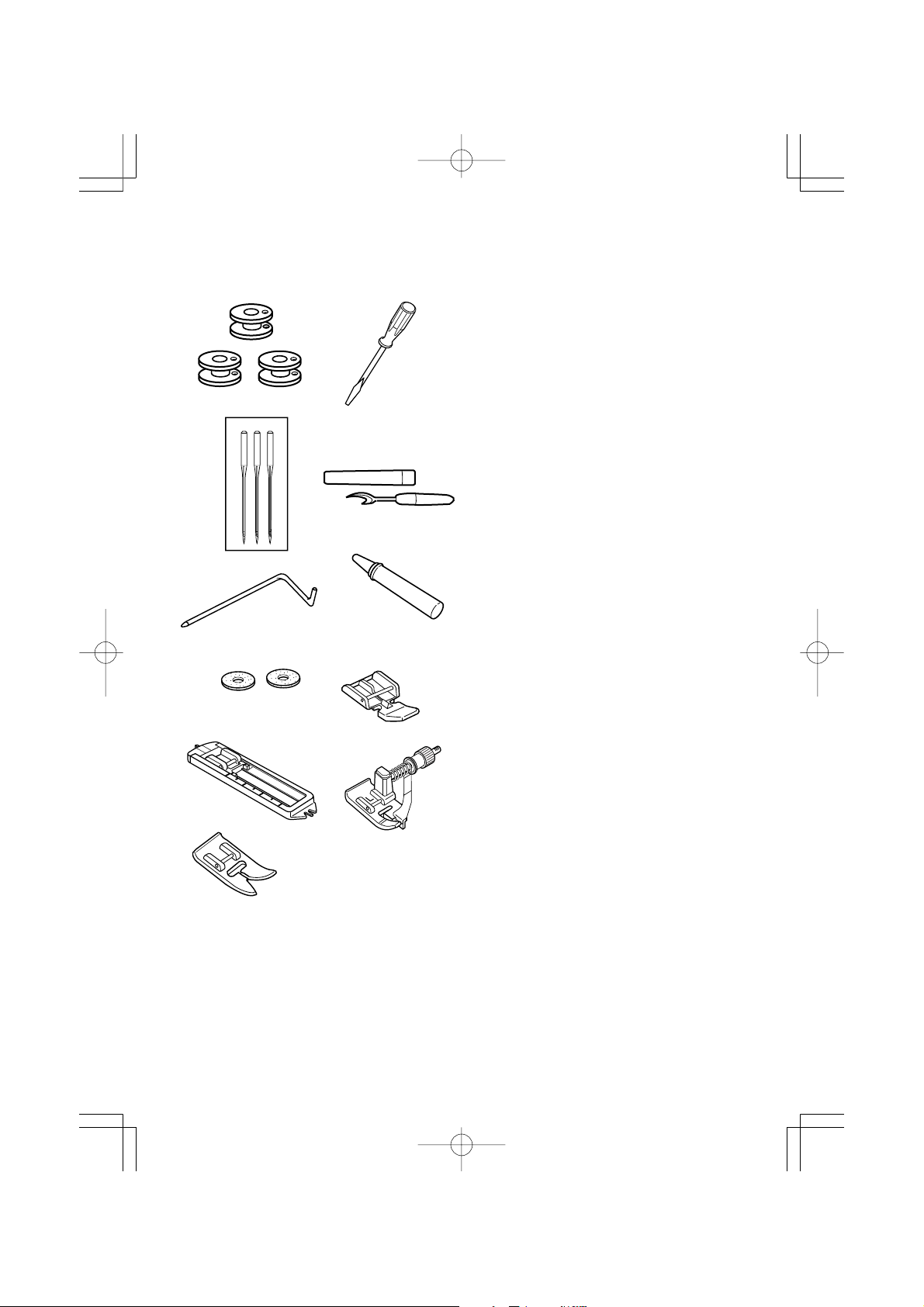

2. GETTING READY TO SEW

w

q

e

y

r

t

Connecting the Machine to the

Power Supply

Before connecting the power cord,

make sure the voltage and frequency

shown on the machine conform to your

electrical power.

1. Turn off the power switch.

2. Insert the machine plug into the

machine socket.

3. Insert the power supply plug into the

outlet .

4. Turn on the power switch to turn on

the power and sewing light.

q Power switch

w Outlet

e Machine socket

r Machine plug

t Foot control

y Power supply plug

4

Foot Control

Sewing speed can be varied by the foot

control.

The harder you press on the control,

the faster the machine runs.

WARNING:

While in operation, always keep your eyes on the sewing area, and do not touch

any moving parts such as the thread take-up lever, handwheel or needle.

Always turn off the power switch and unplug from the power supply:

– when leaving the machine unattended.

– when attaching or removing parts.

– when clearning the machine.

Do not place anything on the foot control, otherwise the machine will run intermittently.

Operating Instructions:

The symbol "O" of a switch indicates the "off" position of a switch.

For an appliance with a polarized plug (one blade wider than the other):

To reduce the risk of electrical shock, this plug is intended to fit in a polarized

outlet only one way.

If it does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install the proper outlet. Do not modify the plug in any way.

The foot controller Model KD-1902 (USA and Canada market) or KD-2902

(230V,Europe) is used with the sewing machine. Model Sew Simple 113.

5

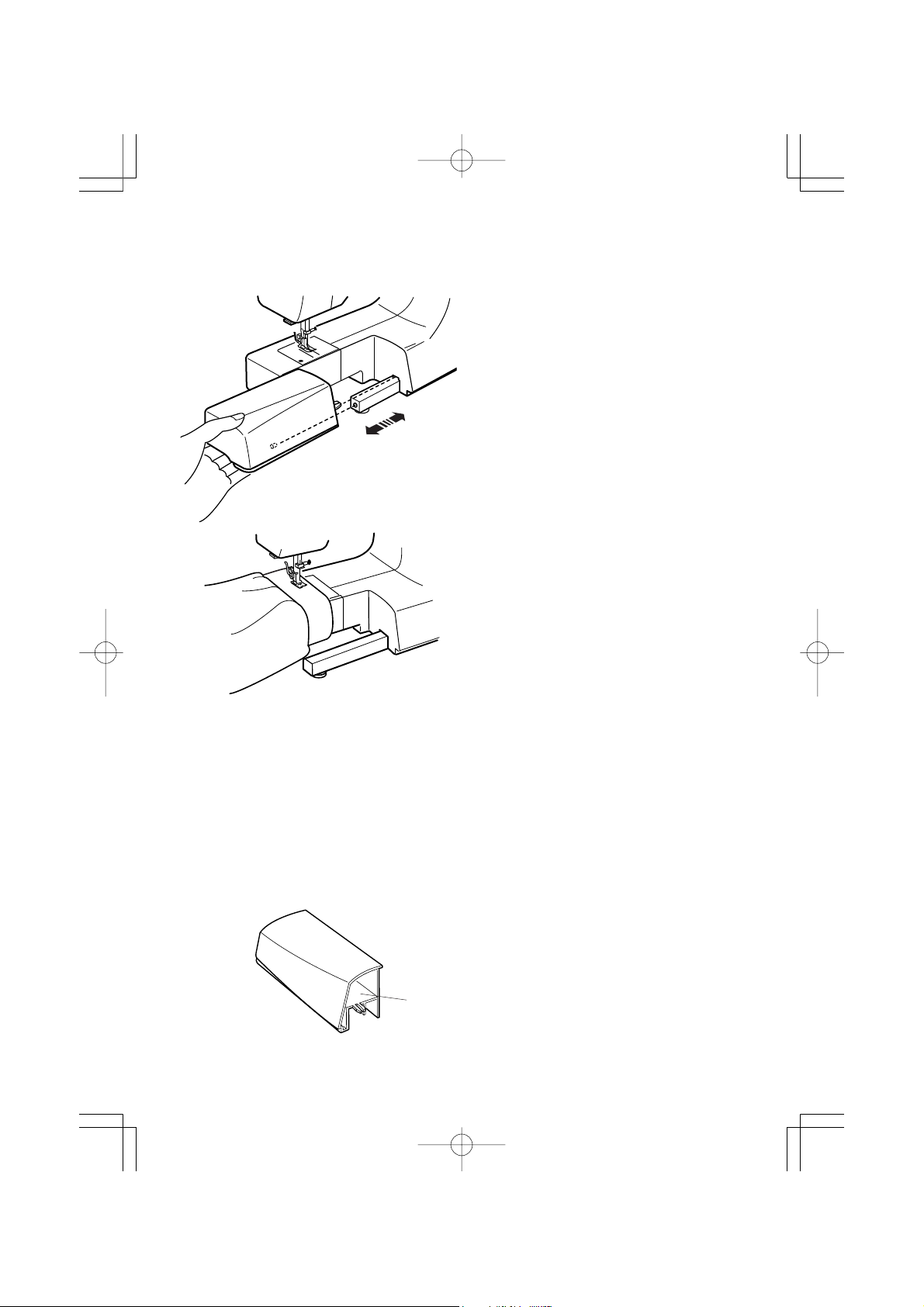

Extension Table

The extension table provides added

sewing surface and can be easily

removed for free arm sewing.

Detaching the table:

Pull the table away from the machine.

Attaching the table:

Push the extension table until it snaps

into the machine.

•Advantages and uses of free arm

sewing:

— Avoid fabric bunching around the

needle when

bartacking to reinforce pockets,

plackets and waistlines.

— For stitching sleeves, waistbands,

pant legs or any circular garment

area

— For darning socks or mending

knees, elbows or areas of wear in

children's clothes

q

Accessories Storage Box

Sewing accessories are conveniently

located in the extension table.

q Accessories storage box

6

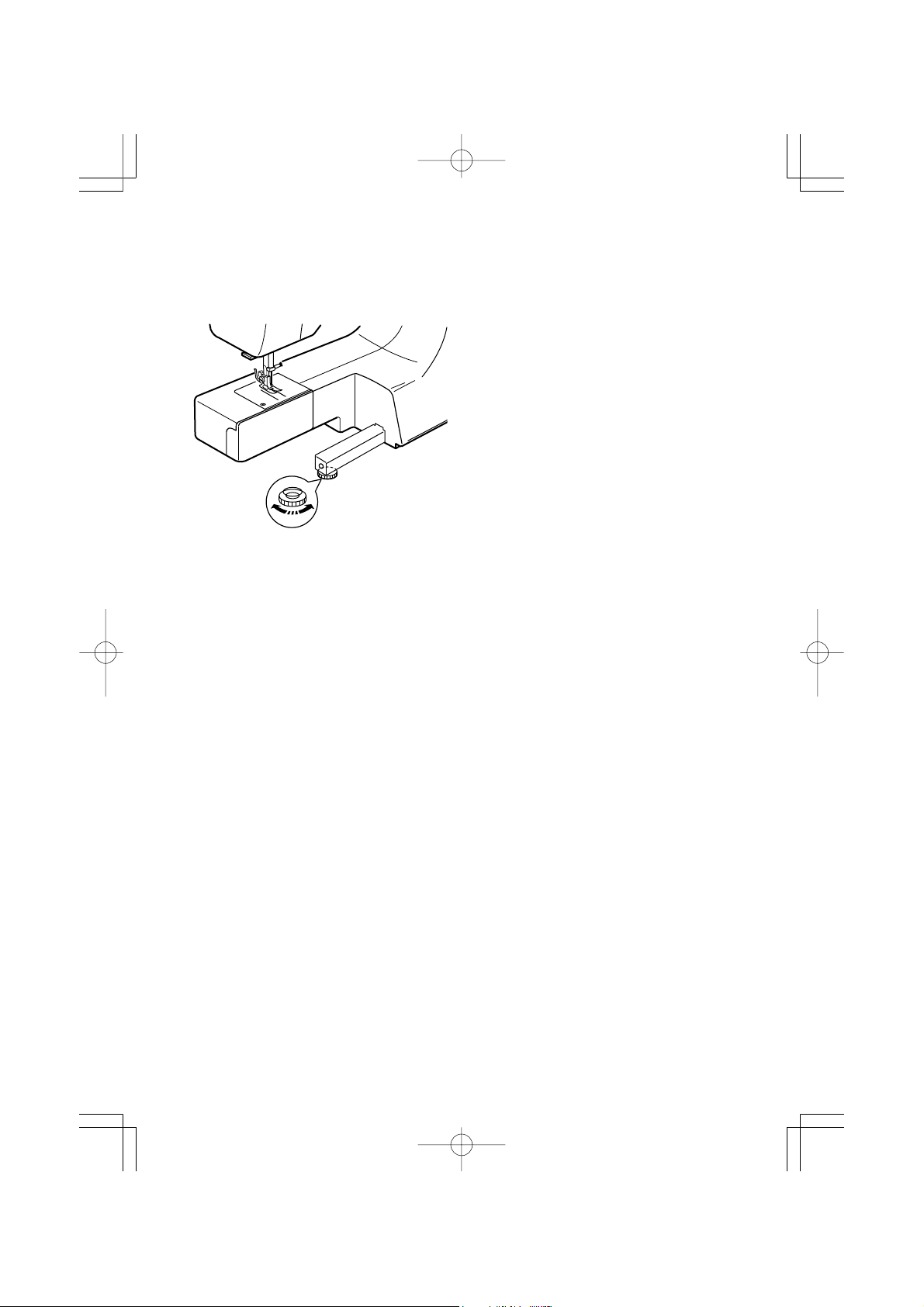

Levelling the Machine

Turn the adjusting foot to adjust its

height so the machine sits stable,

without wobbling.

B

A

7

q

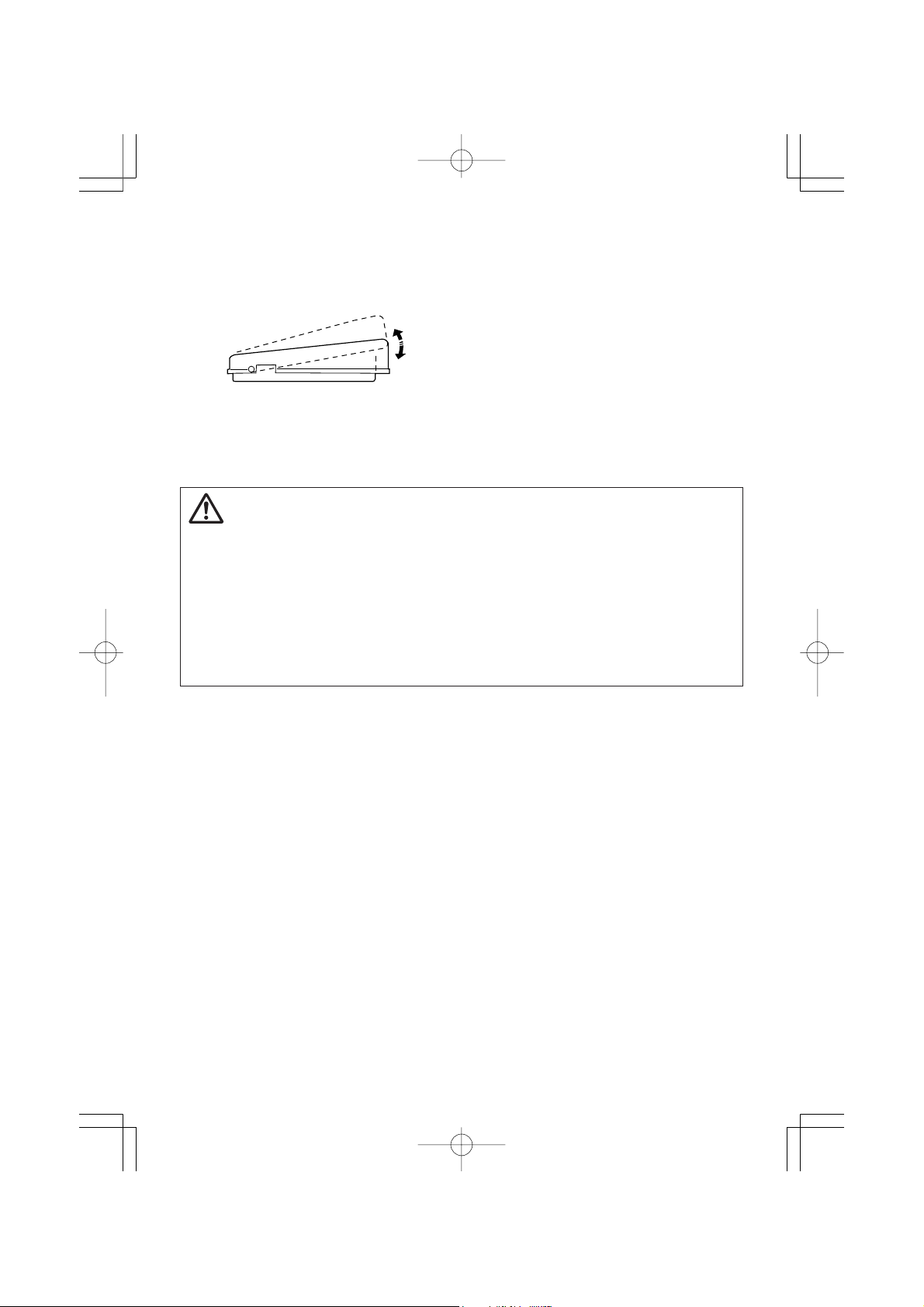

Presser Foot Lifter

The presser foot lifter raises and lowers

your presser foot.

You can raise it about 0.6 cm (1/4˝) higher

than the normal up position for easy

removal of the presser foot or to help you

to place heavy fabric under the foot.

q Normal up position

w Highest position

w

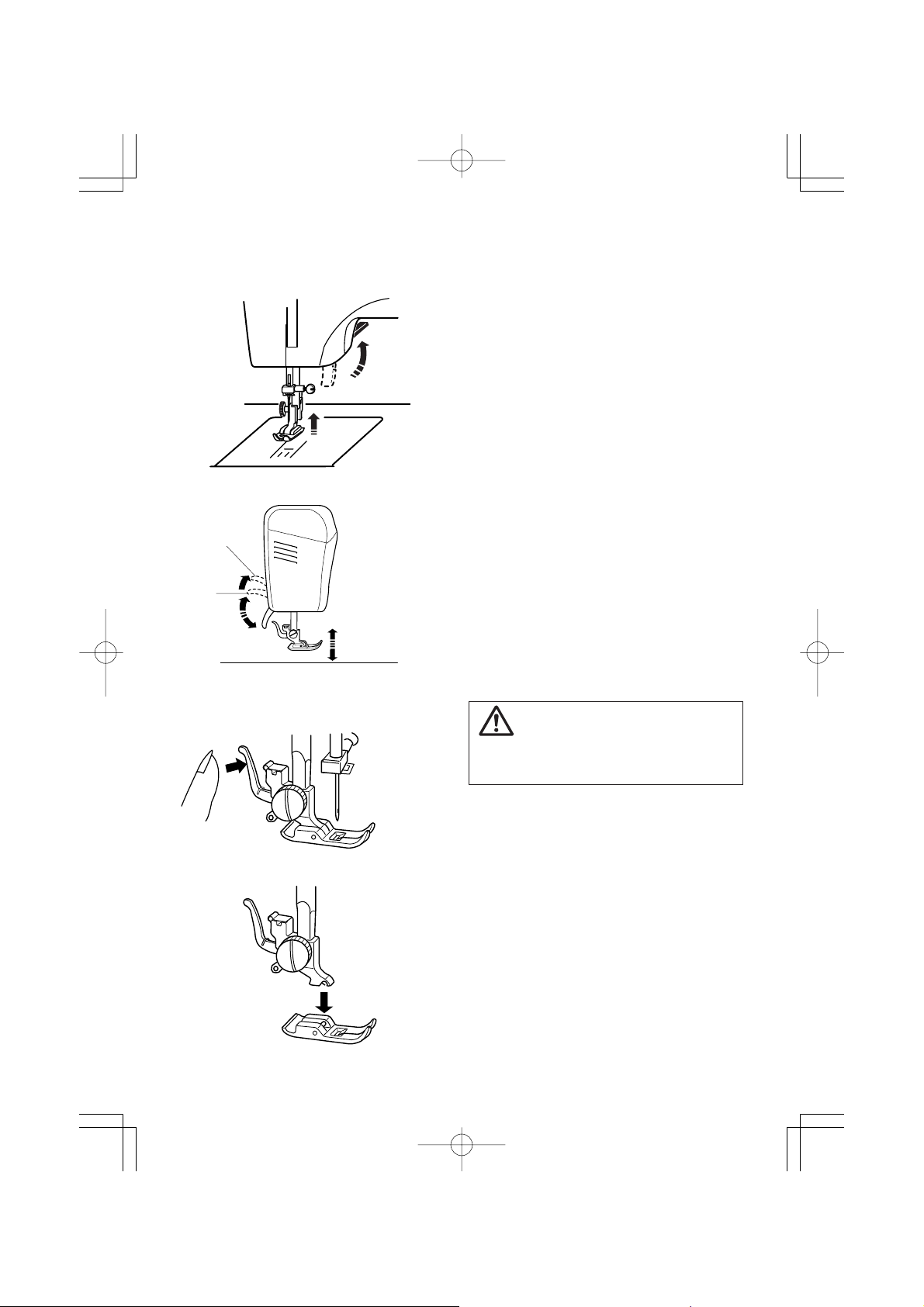

To Attach and Remove the Presser Foot

CAUTION:

Turn off the power switch when

changing a presser foot.

To remove:

Turn the handwheel toward you to raise

the needle to its highest position.

Raise the presser foot.

Press the lever on the back of the foot

holder.

The presser foot will drop off.

To attach:

Place the presser foot so the pin on the

foot lies just under the groove of the foot

holder.

Lower the foot holder to lock the foot in

place.

8

q

Removing or Inserting the Bobbin Case

Open the hook cover.

q Hook cover

Raise the needle by turning the

handwheel toward you.

Take out the bobbin case by holding

the latch.

w Latch

w

e

When inserting the bobbin case, place the

horn into the recess of the hook race.

e Horn

Removing Bobbin

Release the latch and the bobbin will

fall out easily.

9

Setting Spool Pins

The spool pins are used for holding the

spool of thread in order to feed thread to

the machine.

To use, pull up the spool pin. Push down

for storage.

z

x

vb n

m

c

Winding the Bobbin

z Release stop motion knob by turning

it counterclockwise.

x Draw the thread from spool.

Guide the thread around the bobbin

winder thread guide.

c Insert the thread through the hole in

the bobbin from the inside to the

outside.

Put the bobbin on the bobbin winder

spindle.

v Push it to the right.

b With the free end of the thread held in

your hand, depress the foot control.

Stop the machine when it has made a

few turns, and cut the thread close to

the hole in the bobbin.

n Depress the foot control again.

When the bobbin is fully wound, stop

the machine.

Return the bobbin winder spindle to

its original position by moving the

spindle to the left, and cut the thread.

m Tighten stop motion knob by turning

it clockwise.

10

z

If the bobbin is not wound evenly, open

the face plate (see page 34) and

loose the screw and move the bobbin

winder thread guide up or down to

adjust.

q Screw

q

Threading Bobbin Case

z Place the bobbin into the bobbin

case.

Make sure the thread unwinds in the

direction of arrow.

x

c

x Pull the thread into the bobbin case

slot.

c Draw the thread under the tension

spring and into the delivery eye.

* Leave about 10 cm (4˝) of free

thread.

11

v

b

z

c

z

x

Threading the Machine

Raise the take–up lever to its highest

position by turning the handwheel toward

you.

Raise the presser foot.

Place a spool on the spool pin as shown,

with thread coming from back of the

spool.

x

z Draw the thread into thread guide

using both hands.

x While holding the thread near spool,

draw thread down into the tension

area and then around the check

spring holder.

v

c

c Firmly draw the thread up and

through the take-up lever from right

to left.

b

v Draw the thread down and slip it into

needle bar thread guide.

b Thread the needle eye from front to

back.

12

z

x

Drawing Up Bobbin Thread

z Raise the presser foot and hold the

needle thread lightly with your left

hand.

x Turn the handwheel slowly toward

you with your right hand until the

needle goes down and continue

turning the handwheel until the take–

up lever is at its highest position.

Lightly draw up the needle thread

forming a loop of the bobbin thread.

c

c Pull 15 cm (6˝) of both threads back

and under the presser foot.

13

q

w

e

y

r

t

Balancing Needle Thread Tension

z Correct tesion:

The thread tension is adjusted

depending on the sewing materials,

layers of fabric and sewing method.

* The ideal straight stitch has threads

looked between two layers of fabric,

as illustrated (magnifies to show

detail).

* For an ideal zigzag stitch, the bobbin

thread does not show on the right side

(top side) of the fabric, and the

needle thread shows slightly on the

wrong side (bottomside) of the fabric.

q Needle thread (Top thread)

w Bobbin thread (Bottom thread)

e Right side (Top side) of fabric

r Wrong side (Bottom side) of fabric

t Thread tension dial

y Setting mark

x Needle thread tension is too tight:

The bobbin thread (bottom thread) will

appear on the right side (top side) of

the fabric.......Loosen the needle

thread tension by moving the dial to a

lower number.

c Needle thread tension is too loose:

The needle thread (top thread) will

appear on the wrong side (bottom

side) of the fabric.......Tighten the

needle thread tension by moving the

dial to a higher number.

14

Light

weight

Midium

weight

Heavy

weight

Fabrics

Crepe de Chine, Voile, Lawn,

Organdy,

Georgette,

Tricot

Linens, Cotton, Pique,

Serge, Double Knits,

Percale

Denim, Tweed,

Gabardine,

Coating, Drapery and

Upholstery Fabric

Changing Needle

CAUTION:

Turn off the power switch when

changing needles.

Raise the needle by turning the

handwheel toward you and lower the

presser foot.

Loosen the needle clamp screw by

turning it counterclockwise.

Remove the needle from the clamp.

Insert the new needle into the clamp

with the flat side away from you.

When inserting the needle into the

clamp, push it up as far as it will go and

tighten the clamp screw firmly with the

screwdriver.

* Check your needles frequently for

barbed or blunted points. Snags and

runs in knits, fine silks and silk-like

fabrics are permanent and are almost

always caused by a damaged needle.

To check the needle

Place the flat side of the needle on

something flat (needle plate, glass etc.).

The clearance between the needle and

flat surface should be consistent. Never

use a bent or blunt needle.

Thread

Fine Silk

Fine Cotton

Fine Synthetic

Fine Cotton

Covered Polyester

50 Silk

50 to 80 Cotton

50 to 60 Synthetic

Cotton Covered Polyester

50 Silk

40 to 50 Cotton

40 to 50 Synthetic

Cotton Covered Polyester

9 or 11

11 or 14

14

16

15

To Drop or Raise the Feed

Dogs

Remove the extension table from the

machine by pulling it to the left.

Open the shuttle cover by pulling down

the embossed part on the left of the

cover.

q To drop the feed dogs, push feed

lever down in the direction of the

arrow as illustrated.

w To raise the feed dogs, push feed

lever up in the direction of the arrow

as illustrated, and then turn

handwheel towards you.

Feed dogs must be up for normal

sewing.

Reverse Stitch Button

As long as you keep the reverse stitch

button depressed, the machine sews

backwards.

16

q

q

Pattern Selector Dial

Raise the needle and presser foot.

Turn the pattern selector dial to set the

letter corresponding to the desired

pattern.

q Setting mark

Note:

Do not turn the pattern selector dial

while the needle is in the material.

Stitch Length Dial

Turn the stitch length dial to set the

1

desired stitch length at the setting mark.

The higher the number, the longer the

2

stitch length.

q Setting mark

3

Stitch Width Dial

Turn the stitch width dial to set the the

2

4

desired stitch width at the setting mark.

The higher the number, the wider the

stitch width.

q Setting mark

17

Stitch Reference Chart

Stitch patterns

Straight stitch

A

Zigzag

Blind hem

B

Box stitch

C

Three step zigzag

D

stich

Blind stitch

E

Buttonhole

Single overlock stitch

F

Stitch

length

1.5-4

1-3

0.5-3

1-3

0.5-1

Stitch

width

0-5

5

5

5

5

Presser foot Drop feed

Honeycomb stitch

G

Slant over edge

H

Zigzag stretch stitch

I

Straight stretch stitch

Double overlock stitch

J

Free-hand embroidery

18

4

0

5

0-5

Removed

3. BASIC SEWING

12 3 4 5

A

1

2

3

1

Straight Stitch

Machine Setting

1 Stitch Pattern : A

2 Stitch Length : 1.5-4

3 Stitch Width : 0

4 Thread Tension : 2-6

5 Presser foot : Zigzag foot

z Raise the presser foot and position

the fabric with its edge lining up with

a seam guide line on the needle

plate.

Lower the needle into the fabric.

Lower the presser foot and smooth

the threads toward the back.

Depress the foot control.

Gently guide the fabric along the

guide line letting the fabric feed by

itself.

x For fastening the end of seams,

press the reverse stitch button and

sew several reverse stitches.

Raise the presser foot and remove

the fabric, drawing the threads to the

back.

c Draw the threads up and into the

thread cutter.

The threads are cut the proper

length for starting the next seam.

19

To change sewing direction

Stop the machine and turn the handwheel

toward you to bring the needle down into

the fabric.

Raise the presser foot.

Pivot the fabric around the needle to

change sewing direction as desired.

Lower the presser foot and continue

sewing.

Using the seam guides on the needle

plate

The seam guides on the needle plate help

you to measure seam width.

Quilting Guide

12 3 4

A

1

2

3

1

Machine Setting

5

1 Stitch Pattern : A

2 Stitch Length : 1.5-4

3 Stitch Width : 0

4 Thread Tension : 2-6

5 Presser foot : Zigzag foot

1. Slide the quilting guide through the

hole on top of the pressure foot

holder.

2. Move the quilting guide to the required

stitch distance.

3. Sew, tracing the previous stitching

with the quilting guide.

20

4. UTILITY STITCHES

A

Basic Zigzag

12 3 4

12 3 4

1

2

3

1

2

3

4

4

5

Machine Setting

1 Stitch Pattern : A

2 Stitch Length : 0.5-4

3 Stitch Width : 3-5

4 Thread Tension : 2-5

5 Presser foot : Zigzag foot

Zigzag stitch is widely used for

overcasting, sewing on buttons etc.

Overcasting

5

Machine Setting

1 Stitch Pattern : D, (H)

2 Stitch Length : 1.5-4, (4)

3 Stitch Width : 5

4 Thread Tension : 2-6

5 Presser foot : Zigzag foot

Use these stitches for overcasting

rough edges.

21

Mending

12 3 4

12 3 4

1

2

3

1

2

3

4

4

Machine Setting

5

1 Stitch Pattern : D, (G)

2 Stitch Length : 1.5-4, (4)

3 Stitch Width : 5

4 Thread Tension : 2-6

5 Presser foot : Zigzag foot

To sew fabric sdge select the multi-

zigzag stitch.

Blind Stitch

Machine Setting

5

1 Stitch Pattern : E

2 Stitch Length : 1-3

3 Stitch Width : 5

4 Thread Tension : 2-4

5 Presser foot : Blind hem foot

[A]

[B]

q

q

w

w

z Fold up the hem and fold it back to

from a 0.4 to 0.7cm (1/4˝) allowance

as illustrated.

q Wrong side of the fabric

w 0.4 to 0.7 cm (1/4˝)

[A] Heavy weight fabrics

[B] Fine or medium weight fabrics

22

x Position the fabric so that the needle

just pierces the edge of the fold

when the needle swings to the

extreme right.

Lower the presser foot.

t

r

y

e

c Turn the guide screw to adjust the

guide aligning with the folded edge.

Sew along the folded edge guiding

the fabric so the needle catches the

folded edge.

e Guide screw

r Guide

t Folded edge

v Open the fold flat.

y Right side of the fabric

* If the needle drops far left, the

stitches will show on the right side of

the fabric.

23

1

234

A

1

2

3

Zipper Sewing

Machine Setting

5

1

1 Stitch Pattern : A

2 Stitch Length : 1.5-4

3 Stitch Width : 0

4 Thread Tension : 3-6

5 Presser foot : Zipper foot

*To snap on the zipper foot

Fit the pin on the zipper foot into the

groove on the foot holder.

- To sew the left side of the zipper,

attach the zipper foot on the righthand side.

- To sew the right side of the zipper,

attach the zipper foot on the left-hand

side.

*Fabric preparation

Place right side (Top sides of fabric

together and sew to the end of the

zipper opening.

Reverse stitch to lock the stitches.

Increase stitch length to 4 and set

needle thread tension at 0.

Sew the zipper opening with the basting

stitch.

24

z

x

*To sew

1 Fold back the left seam allowance.

Turn under the right seam allowance

to make a 1/8” (0.2 to 0.3cm) fold.

Place the zipper teeth next to the fold

and pin in place.

2 Attach the zipper foot with the pin of

the foot on the right-hand side.

Lower the zipper foot on the top side

at the bottom of the zipper so that the

needle pierces the fabric next to the

fold and the zipper tape.

Sew through all layers next to the

fold.

c

3 Stop just before the zipper foot

reaches the slider on the zipper tape

about 2” (5.0cm) from the top of the

zipper. Lower the needle slightly into

the fabric, raise the foot.

Open the zipper to move the slide

behind the zipper foot. Lower the foot

and stitch the remainder of the seam,

making sure the fold is even.

25

v

4 Close the zipper and spread the

fabric flat with the right side (Top

side) of fabric facing up.

b

n

5 Move the zipper foot to the left pin.

Guide the edge of the foot along the

zipper teeth and stitch through the

garment and zipper opening.

6 Stop at about 2” (5.0cm) from the top

of the zipper.

Lower the needle slightly into the

fabric, raise the foot.

Open the zipper to move the slider

behind the zipper foot. Lower the foot

and stitch the remainder of the seam,

making sure the fold is even.

26

12 3 4

1

2

3

4

(C)

(B)

Buttonhole

Machine Setting

5

1 Carefully mark buttonhole length on fabric.

(A)

2 Move the slider (A) toward you so that

1 Stitch Pattern : (BH)

2 Stitch Length : 0.5-1

3 Stitch Width : 5

4 Thread Tension : 1-5

5 Presser foot : Buttonhole foot

Place the fabric under the foot with the

buttonhole marking running toward you.

the top mark (C) on the slider meets the

start mark (B). Line up the markings on

the starting point on the fabric.

Note: The scale on the slider is

engraved in centimeters.

27

q

w

3 Set the pattern selector dial at " ".

Sew forward until you reach the marking

of your buttonhole q.

Stop sewing at a left stitch.

4 Set the pattern selector dial at " ".

Sew 5 stitches. Stop sewing at a right

stitch.

5 Set the pattern selector dial at " ".

Sew until you reach the marking of

the buttonhole w.

Stop sewing at a right stitch.

6 Set the pattern selector dial at " ".

Sew a few bartacks and raise the

needle from the fabric.

Set the stitch length dial to "0" and the

pattern selector dial at straight sewing.

Sew a few locking stitches.

7 Remove the fabric from the machine and

cut the sewing thread. Insert a pin inside

the bartack.

Then cut the opening with a seam ripper.

Take care not to cut the stitches.

28

12 3 4

1

2

3

4

q

Corded Buttonhole

Machine Setting

5

1 Stitch Pattern : (BH)

2 Stitch Length : 0.5-1

3 Stitch Width : 5

4 Thread Tension : 1-5

5 Presser foot : Buttonhole foot

z With the buttonhole foot is raised,

hook the cord on the cord spur at the

back of the buttonhole foot.

q Spur

Bring the ends toward you under the

buttonhole foot until they clear the

front end.

Hook the filler cord into the forks on

the front of foot to hold thhem tight.

x Lower the needle into the garment

where the buttonhole will start and

lower the foot.

Depress the foot control gently and

sew the buttonhole.

Each side of the buttonhole and the

bartacks will be shown over the cord.

The sewing process is the same as

the ordinary buttonhole

(see page 27).

c Remove the fabric from the machine,

and cut the sewing threads.

Pull the left end of the filler cord to

tighten it.

Thread the end through a darning

needle, draw to the other side of the

fabric and cut.

29

5. DECORATIVE STITCHES

A

12 3 4

1

2

3

1

Embroidery

Machine Setting

1 Stitch Pattern : A

2 Stitch Length : Any

3 Stitch Width : 0 or 5

4 Thread Tension : 1-4

* Presser foot : Removed

Drop feed dog (see page 16).

Remove the presser foot and attach the

darning plate.

Lower feed dog and move the hooped

fabric slowly in the desired direction

until the fabric has been embroidered.

Satin Stitch

12 3 4

1

2

3

4

Machine Setting

5

1 Stitch Pattern : A

2 Stitch Length : 0.5-1

3 Stitch Width : 3-5

4 Thread Tension : 2-6

5 Presser foot : Zigzag foot

Satin stitching can be used for sewing

initials, patterns, applique, etc.

30

4

Stretch Stitches

1

234

1

2

3

Machine Setting

1 Stitch Pattern : F-J

2 Stitch Length : 4

3 Stitch Width : 5

5

4 Thread Tension : 1-4

5 Presser foot : Zigzag foot

Use this stitch with knitted, tricot or

other stretchy fabrics.

The stitch enables your seam to stretch

without breaking the thread.

31

6. CARE OF YOUR MACHINE

Cleaning the Feed Dog

CAUTION:

Turn off the power switch and/or

unplug the machine before cleaning

the feed dog.

Remove the needle and the presser foot.

Remove the needle plate set screw and

remove the needle plate.

With a brush, clean out dust and lint

clogging the feed dog teeth.

Reset the needle plate.

32

w

w

q

w

Dismantling and Assembling

Hook Race Unit

CAUTION:

Turn off the power switch and/or unplug

the machine.

To dismantle hook race unit:

Raise the needle to its highest position and

open the hook cover.

Open the hinged latch of bobbin case and

take it out of the machine.

Open the hook race ring holders and remove

the hook race ring.

Remove the hook.

w

t

u

r

e

* Clean the hook race with a brush and a

soft dry cloth.

q Bobbin case

w Hook race ring holders

e Hook race ring

r Hook

y

t Hook race

To assemble hook race unit:

Hold the hook by the center pin and fit it

carefully back into the hook race, forming

a perfect circle with the shuttle driver.

Attach the hook race ring making sure the

bottom pin fits into the notch.

Lock the hook race ring by turning the

holders back into position. Insert the bobbin

case.

y Pin

u Notch

33

Sewing Light

The sewing light is located behind the face

plate.

To change the bulb, take the face plate off

the sewing machine by loosening the

setscrew.

* Unplug the power supply before changing

the bulb.

* Do not dismantle the machine other than

explained in this manual.

•To remove ......... Push the bulb up and

turn to the left.

•To replace ......... Push the bulb up and

turn to the right.

CAUTION:

The bulb could be HOT.

Protect your fingers when handle it.

Oiling

CAUTION:

Turn off the power switch and/or

unplug the machine.

Oil the points as shown at least once a year.

Use good quality sewing machine oil. One or

two drops of oil is sufficient.

Remove excess oil, otherwise it may stain

fabric.

In case machine is not used for an extended

time, oil it before sewing.

- Oil behind the face plate

Remove the cap, screw and face plate.

Oil the point as indicated in the illustration.

- Oiling the shuttle hook area

Remove the hook race ring and hook.

Oil the point as indicated in the illustration.

34

Troubleshooting

Condition

The needle

thread breaks.

The bobbin

thread breaks.

The needle

breaks.

Cause

1. The needle thread is not threaded properly.

2. The needle thread tension is too tight.

3. The needle is bent or blunt.

4. The needle is incorrectly inserted.

5. The fabric is not being drawn to the back

when sewing is finished.

6. The thread is either too heavy or too fine for

the needle.

1. The bobbin thread is not threaded properly

in the bobbin case.

2. Lint has collected in the bobbin case.

3. The bobbin is damaged and doesn't turn

smoothly.

1. The needle is incorrectly inserted.

2. The needle is bent or blunt.

3. The needle clamp screw is loose.

4. The tension of the needle thread is too tight.

5. The fabric is not drawn to the back when

sewing is finished.

6. The needle is too fine for the fabric being

sewn.

7. The pattern selector dial had been turned

while the needle was in the material.

Reference

See Page 12

See Page 14

See Page 15

See Page 15

See Page 19

See Page 15

See Page 11

Clean the bobbin

case.

Replace

bobbin.

See Page 15

See Page 15

See Page 15

See Page 14

See Page 19

See Page 15

See Page 17

Skipped stitches

1. The needle is incorrectly inserted.

2. The needle is bent or blunt.

3. The needle and/or threads are not suitable

for the work being sewn.

4. The needle thread is not threaded properly.

35

See Page 15

See Page 15

See Page 15

See Page 12

CauseCondition

Reference

Seam puckering

Stitches form

loops

below the work

The cloth is not

feeding smoothly.

The machine does

not work.

1. The needle thread tension is too tight.

2. The machine is not threaded correctly.

3. The needle is too heavy for the fabric

being sewn.

4. The stitches are too coarse for the fabric

being new line sewn.

* When sewing extremely light weight

materials, place a sheet of paper

underneath the fabric.

1. The needle thread tension is too loose.

2. The needle is either too heavy or too

fine for the thread.

1. The feed dog is packed with lint.

2. The stitches are too fine.

1. The machine is not plugged in.

2. Thread is caught in the hook race.

3. Stop motion knob is loosen for

bobbin winding.

See Page 14

See Page 12

See Page 15

Make the

stitches denser.

See Page 14

See Page 15

See Page 32

Make the

stitches coarser.

See Page 4

See Page 33

See Page 10

The machine does

not run smoothly

and is noisy.

1. Threads have been caught in hook

mechanism.

2. The feed dog is packed with lint.

36

See page 33

See Page 32

Loading...

Loading...