Janome 4052lx Service Manual

SERVICE MANUAL

4052LX

TABLE OF CONTENTS

LOCATE AND IDENTIFY THE PARTS ....................................................................................1

WHAT TO DO WHEN .......................................................................................................2 - 4

THREADING OF MACHINE...................................................................................................5

SERVICE ACCESS

FACE COVER ........................................................................................................................6

FREE ARM LEGS COVER.....................................................................................................6

FRONT COVER......................................................................................................................7

REAR PANEL .........................................................................................................................8

MECHANICAL ADJUSTMENT

TOP TENSION .......................................................................................................................9

PRESSER BAR HEIGHT AND ALLIGNMENT .....................................................................10

NEEDLE SWING ..................................................................................................................11

STRAIGHT STITCHING (1) .................................................................................................12

NEEDLE DROP (2) ..............................................................................................................13

STRETCH STITCH BALANCE ............................................................................................14

FEED DOG HEIGHT ............................................................................................................15

NEEDLE BAR HEIGHT ........................................................................................................16

NEEDLE TO SHUTTLE TIMING ..........................................................................................17

NEEDLE CLEARANCE TO SHUTTLE ................................................................................18

BACKLASH (BETWEEN LOWER SHAFT GEAR AND SHUTTLE HOOK GEAR) ..............19

NEEDLE POISITION MISALIGNMENT ...............................................................................20

ZERO FEEDING .................................................................................................................21

BUTTONHOLE STITCH BALANCE .....................................................................................22

ZERO FEEDING OF BUTTONHOLE BARTACK .................................................................23

BUTTONHOLE FUNCTION .................................................................................................24

REPLACEMENT AND ADJUSTMENT OF NEEDLE THREADER PLATE ..........................25

MOTOR BELT TENSION .....................................................................................................26

WIRING OF TERMINAL BLOCK .........................................................................................27

OILING .................................................................................................................................28

1

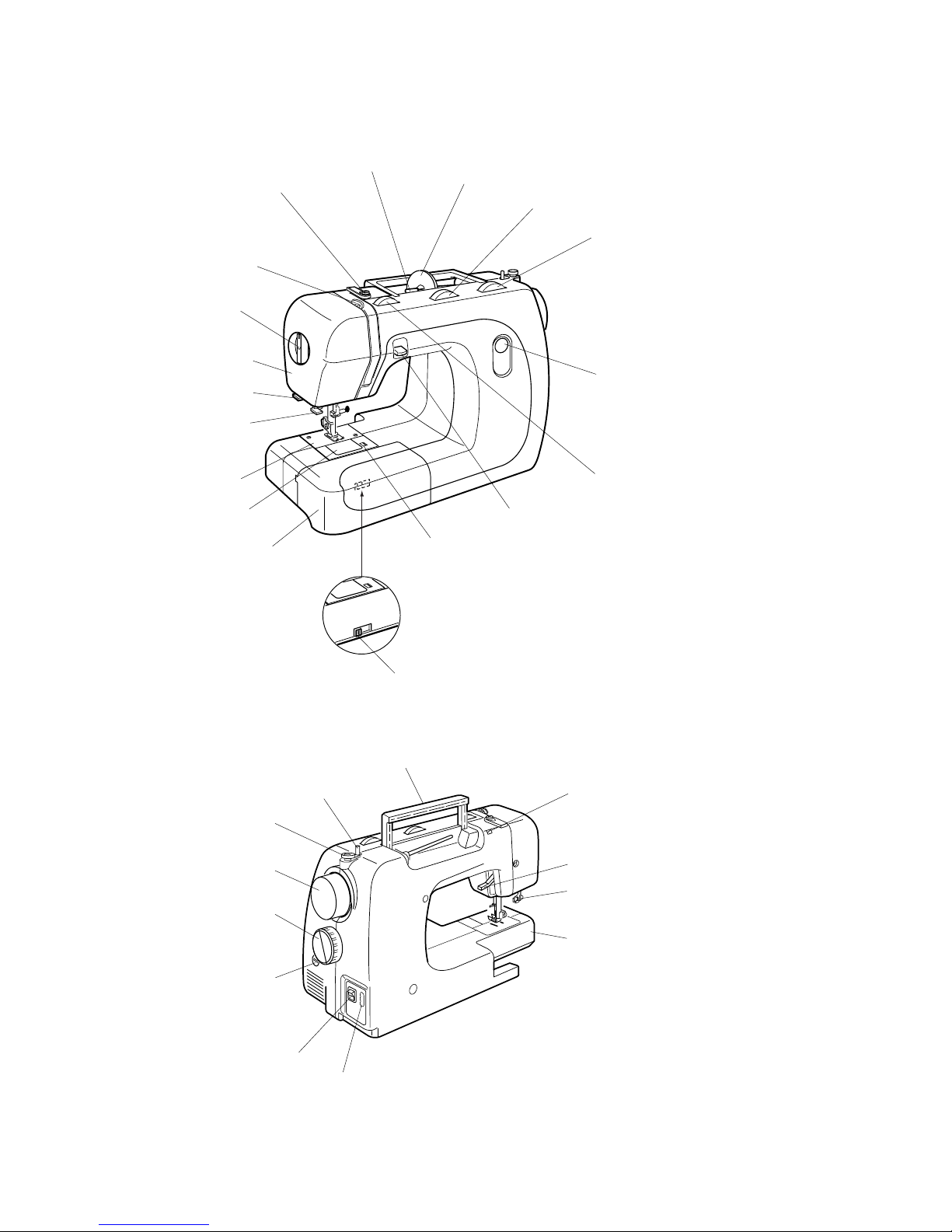

LOCATE AND IDENTIFY THE PARTS

Pattern indicating window

Stitch length dial

Stitch width dial

Spool holder (Large)

Spool pin

Thread tension dial

Bobbin winder thread guide

Thread take-up lever

Pressure adjusting

dial

Face cover

Thread cutter

Needle threader

Needle plate

Hook cover

Extension table

(Accessory box)

Hook cover plate release

button

Reverse stitch button

Drop feed lever

Carrying handle

Bobbin winder spindle

Bobbin winder stopper

Handwheel

Pattern selector dial

Feed balancing dial

Power switch

Machine socket

Free arm

Buttonhole lever

Presser foot lifter

Additional spool pin hole

2

WHA T T O DO WHEN

CONDITION CAUSE HOW TO FIX REFERENCE

1. SKIPPING 1.

NEEDLE IS NOT INSERTED INSERT THE NEEDLE PROPERLY.

STITCHES PROPERLY.

2. NEEDLE IS BENT OR WORN. CHANGE THE NEEDLE.

3. INCORRECTLY THREADED RETHREAD.

4. NEEDLE OR THREAD ARE USE THE RECOMMENDED

INAPPROPRIATE FOR SEWING NEEDLE AND THREAD.

FABRIC BEING SEWN.

5. SEWING ON STRETCH USE A #11 BLUE TIP NEEDLE.

FABRIC

6. PRESSER FOOT PRESSURE ADJUST THE PRESSER BAR

IS TOO WEAK. LEVEL TO MAKE THE

PRESSURE STRONGER.

7. INAPPROPRIATE NEEDLE SEE MECHANICAL P.16

BAR HEIGHT ADJUSTMENT

“NEEDLE BAR HEIGHT”.

8. INAPPROPRIATE NEEDLE SEE MECHANICAL P.17

TO SHUTTLE TIMING ADJUSTMENT

“NEEDLE TO SHUTTLE TIMING”.

9. INAPPROPRIATE NEEDLE SEE MECHANICAL P.18

TO SHUTTLE CLEARANCE ADJUSTMENT “NEEDLE

CLEARANCE TO SHUTTLE.”

2. FABRIC NOT 1. PRESSER FOOT PRESSURE ADJUST THE PRESSER BAR

MOVING IS TOO WEAK. LEVEL TO MAKE THE

PRESSURE STRONGER.

2. INCORRECT F.D. HEIGHT SEE MECHANICAL P.15

ADJUSTMENT “FEED DOG

HEIGHT.”

3. F.D. IS IN DOWN POSITION. RAISE THE F.D. LEVEL.

4. THREAD ON BOTTOM SIDE MAKE SURE TO BRING

OF FABRIC IS JAMMED UP. BOTH NEEDLE AND BOBBIN

THREAD UNDER THE FOOT

WHEN STARTING SEWING.

5. FEED DOG TEETH ARE CHANGE THE FEED DOG.

WORN.

3

CONDITION CAUSE HOW TO FIX REFERENCE

3. BREAKING 1. INITIAL SEWING SPEED IS START WITH MEDIUM SPEED.

UPPER TOO FAST.

2. THREAD PATH IS USE THE PROPER THREAD

INCORRECT. PATH.

3. NEEDLE IS BENT OR DULL. REPLACE WITH A NEW NEEDLE.

4. UPPER THREAD TENSION IS ADJUST UPPER THREAD

TOO STRONG. TENSION CORRECTLY.

5. NEEDLE SIZE IS USE APPROPRIATE NEEDLE

INAPPROPRIATE FOR FOR FABRIC AND THREAD

FABRIC. IN USE.

6. NEEDLE EYE IS WORN. CHANGE THE NEEDLE.

7. NEEDLE HOLE IN NEEDLE REPAIR THE HOLE OR

PLATE IS WORN OR BURRED. REPLACE THE NEEDLE PLATE.

4. BREAKING 1. INCORRECTLY THREADED

THREAD BOBBIN CORRECTLY.

BOBBIN BOBBIN.

2. TOO MUCH THREAD IS ADJUST THE POSITION OF

ON THE BOBBIN. STOPPER.

3. LINT IS STUCK INSIDE THE CLEAN THE SHUTTLE.

BOBBIN HOLDER.

4. THREAD QUALITY IS

CHANGE TO A HIGHER QUALITY

TOO LOW. SEWING THREAD.

5. THREAD IS JAMMING CLEAR OUT THE JAMMING

AROUND THE BOBBIN. THREAD.

5. NEEDLE 1. NEEDLE IS HITTING THE SEE MECHANICAL P.20

BREAKS NEEDLE PLATE. ADJUSTMENT “NEEDLE

POSITION.”

2. NEEDLE IS BENT OR WORN. CHANGE THE NEEDLE.

3. NEEDLE IS HITTING THE SEE MECHANICAL P.18

SHUTTLE. ADJUSTMENT “NEEDLE

CLEARANCE TO SHUTTLE.”

4. THE FABRIC MOVES WHILE SEE MECHANICAL P.11

THE NEEDLE IS PIERCING ADJUSTMENT “NEEDLE

IT, OR THE NEEDLE ZIGZAGS SWING.”

WHILE IN FABRIC.

5.

FABRIC IS BEING PULLED TOO GUIDE THE FABRIC GENTLY

STRONGLY WHILE SEWING. WHILE SEWING.

THREAD

THREAD

4

6. NOISY 1. BACKLASH BETWEEN SEE MECHANICAL P.19

OPERATION SHUTTLE HOOK GEAR AND ADJUSTMENT “BACKLASH

LOWER SHAFT GEAR IS TOO (LOWER SHAFT GEAR).”

GREAT.

2. LOWER SHAFT GEAR IS ELIMINATE THE LOOSENESS.

LOOSE.

3. INAPPROPRIATE BELT SEE MECHANICAL P.26

TENSION. ADJUSTMENT “MOTOR

BELT TENSION.”

4. NOT ENOUGH OIL OIL ALL MOVING PARTS.

5. UPPER SHAFT IS LOOSE. ELIMINATE THE LOOSENESS.

7. DEFORMATION 1. INAPPROPRIATE FEED SEE MECHANICAL P.14

PATTERN BALANCE. ADJUSTMENT “STRETCH

STITCH BALANCE.”

2. INAPPROPRIATE ZIGZAG SEE MECHANICAL P.11

SYNCHRONIZATION. ADJUSTMENT “NEEDLE

SWING.”

3. UPPER THREAD TENSION SEE MECHANICAL P. 9

IS TOO STRONG. ADJUSTMENT “TOP TENSION.”

8. IMPROPER 1. BUTTONHOLE STITCH SEE MECHANICAL P.22

BALANCE IS NOT CORRECT. ADJUSTMENT “BUTTONHOLE

STITCH BALANCE.”

2. CHANGING TO BAR TACK SEE MECHANICAL P.24

IS TOO EARLY OR WILL NOT ADJUSTMENT “BUTTONHOLE

WORK. FUNCTION .”

CONDITION CAUSE HOW TO FIX REFERENCE

BUTTONHOLE

RESULTS

5

THREADING OF MACHINE

THE STEP NUMBE CORRESPONDS WITH THE NUMBER IN THE ILLUSTRATIONS.

DOTTED LINES SHOW THE PLACES WHERE THE THREAD LOOPS AND IS THEN PULLED

TIGHT.

RAISE THE TAKE-UP LEVER TO ITS HIGHEST POSITION BY TURNING THE HANDWHEEL

TOWARD Y OU.

RAISE THE PRESSER FOOT LEVER.

PLACE THE SPOOL ON A PIN WITH THE THREAD COMING FROM THE BACK OF THE SPOOL.

1. DRAW THE THREAD THROUGH THE THREAD GUIDE.

2. HOLDING THE THREAD TAUT WITH YOUR RIGHT HAND, DRAW THE THREAD DOWN INTO

THE TENSION AREA AND THEN AROUND THE CHECK SPRING HOLDER.

3. FIRMLY DRAW THE THREAD UP AND THROUGH THE TAKE-UP LEVER FROM RIGHT TO LEFT.

4. PULL THE THREAD TO THE LEFT, AND SLIP IT INTO THE NEEDLE BAR THREAD GUIDE.

5. THREAD THE NEEDLE FROM FRONT TO BACK.

NOTE: YOU MAY WANT TO CUT THE END OF THE THREAD WITH SHARP SCISSORS

FOR EASIER NEEDLE THREADING.

1

2

3

4

5

6

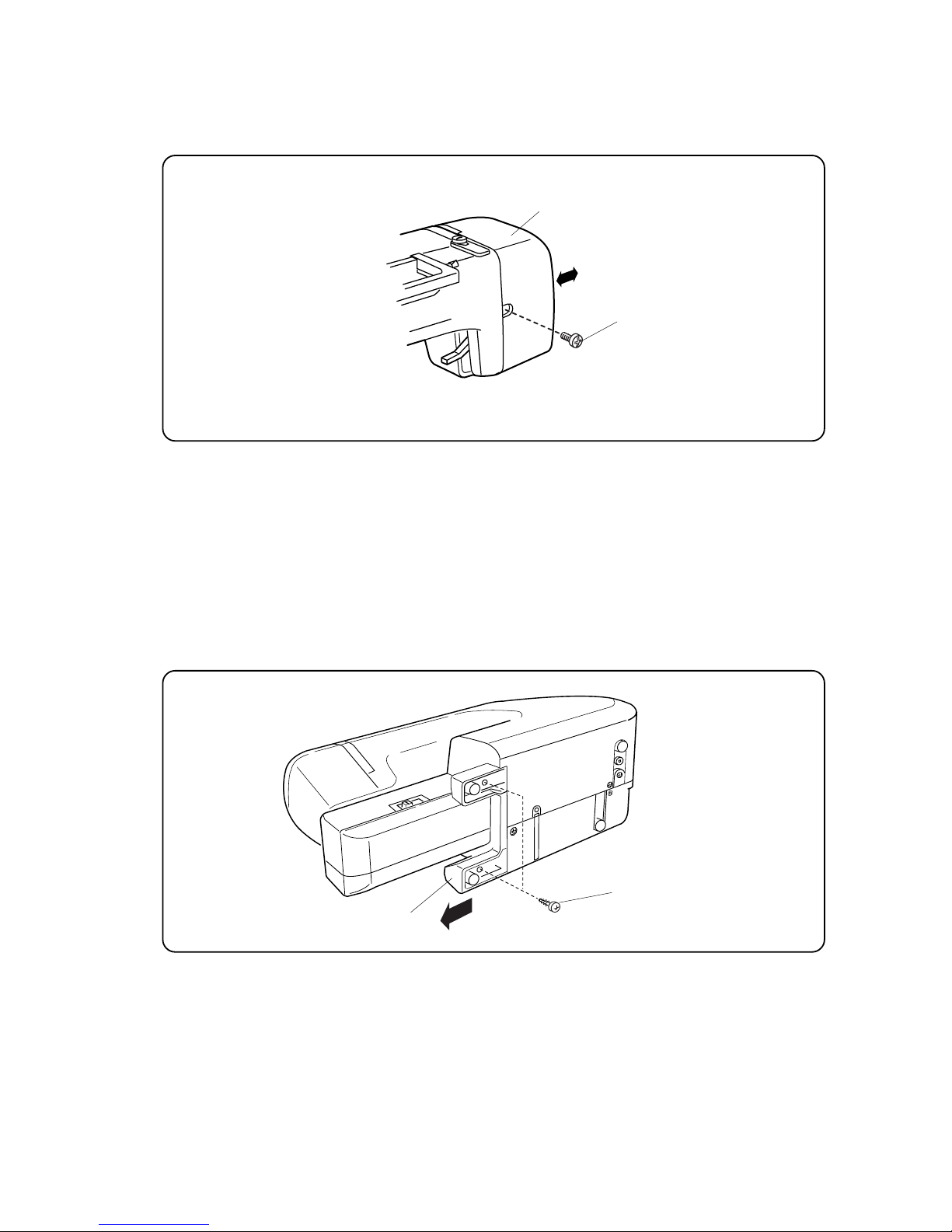

SERVICE ACESS (1)

TO REMOVE:

REMOVE THE SETSCREW (B) TO TAKE OUT THE FACE COVER (A).

TO ATTACH:

TO REPLACE, FOLLOW THE ABOVE PROCEDURE IN REVERSE.

FREE ARM LEGS COVER

TO REMOVE:

1. REMOVE THE SETSCREW (C).

2. REMOVE THE FREE ARM LEGS COVER (D).

TO ATTACH:

TO REPLACE, FOLLOW THE ABOVE PROCEDURE IN REVERSE.

SETSCREW (C)

FREE ARM LEGS COVER (D)

FACE COVER

FACE COVER (A)

SETSCREW (B)

7

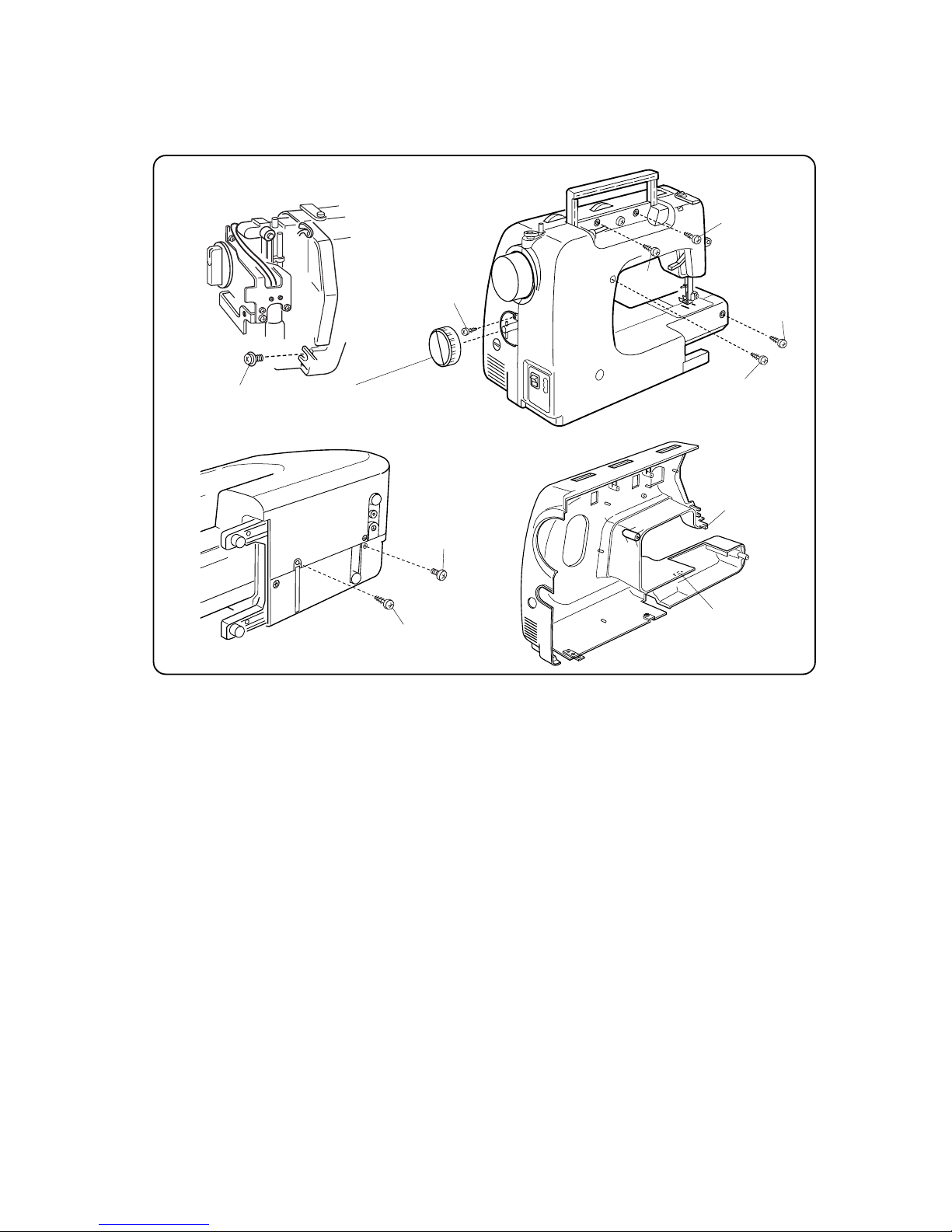

TO REMOVE:

1. REMOVE THE FACE COVER AND FREE ARM LEGS COVER (SEE PAGE 6.)

2. REMOVE THE PATTERN SELECTOR DIAL (K), AND SETSCREWS (A) - (G)

3. LOOSEN SETSCREW (H).

4. DISENGAGE THE FRONT COVER HOOK (I), (J) AND THEN REMOVE THE FRONT COVER.

TO ATTACH:

TO REPLACE, FOLLOW THIS PROCEDURE IN REVERSE.

PATTERN SELECTOR

DIAL (K)

(A)

(B)

(C)

(D)

(E)

(F)

(G)

(H)

(I)

(J)

SERVICE ACCESS (2)

FRONT COVER

Loading...

Loading...