Page 1

‘:CHARG!NG SYSTEM

PRECAUTIONS

TROUBLESHOOTING

CH.ARGlNG SYSTEM CIRCUIT

ON-VEHICLE INSPECTION

ALTERNATOR

..,**....*..*..,,*....,,.*........ CH-2 *

,,..*.....*..........*..... CH-2

..,n....*.,.,.*...m

.,...,....‘.,,......*~

,,,~,..,*~.......~....,*,,...~....

Page

C.H-3

w-3

CH-7

Page 2

CH-2

CHARGING SY&EM

: PRECAUTIONS

1. Check that the battery cables are connected to the

2. Disconnect the battery cables when the battery is

3. Do not perform tests with a high voltage insulation

4. Never disconnect the battery while the engine is run-

TROUBLESHOOTING

- Precautions, Troubleshooting

._

correct terminals.

given a quick charge.

resistance tester.

ning.

Problem

Discharge warning

light does not light

with ignition ON and

engine not ‘running

Discharge warning

light does not go out

with engine running

(battery requires fre-

quent recharging

Possible cause

Fuse blown

Light burned out

Wiring connection loose

IC regulator faulty

Drive belt loose or worn

Battery cables loose, corroded or worn

Fuse blown

Fusible link blown

IC regulator or alternator faulty

Wiring faulty

Remedy

Check “CHG” and

“IGN” fuses

Replace light

Tighten loose connections

Replace IC regulator

Adjust or replace drive belt

Repair or replace cables

Check “ENG” fuse

Replace fusible link

Check charging system

Repair wiring

Page

CH-7

CH-4

CH-3

Page 3

Ignition Switch

Fuse

:usible

.ink

4LT

MA/

‘M-GE)

,258

:usible

-ink

I/IAIN 2.OL

I

T Battery

P

(MA)

Fusible

Link

AM2 30A

AM2 -0p IG2 (MA) 15~4

c

(MS)

(MS) 7.5A

/

CHG 7.5 A

I

8

I

i

I .

i

m

Alternator

ON-VEHICLE INSPECTION

1

1.

CHECK BATTERY SPECIFIC GRAVITY

(a) Check the specific gravity of each cell.

Standard specific gravity

tieI

fel

002

i

’ 2. CHECK BATTERY TERMINALS, FUSIBLE LINKS AND

c

CHOZRRI

When fully charged at 20°C (66°F):

If not within specifications, charge the battery.

(b) Check the electro!yte quantity of each cell.

If insufficient, refill with distilled (or purified) water.

FUSES

(a) Check that the battery terminals are not loose or cor-

roded.

(b) Check the fusible links and fuses for continuity.

1.25 - 1.27

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

..............................

LUSRlCATlOIjl.SY$T~M

.........................

~.J4~~1

IGAITION SYSTEM 1 ............................. A-12 ;

STIJRiiNG S$&EM .............................

CilARGING SY$?EM

. . ..*.....................,,

A-13 1

A,434

,,

I !. .. Y”

I :

1

(

Page 16

A12 :

SERVICE SPECIFICATIONS

- Enaine.Mechanical

EN$W4~~~WlECHAN~CAL (

‘t&.gy,.::*,. :

.,

Speclfrcations

‘-’ b- ~.

”

r

. . .

;Water Pump - Alternator

,, ‘Crankshaft

-Crankshaft - A/C compressor

,.

‘;

<” :

Engine coolant capacity

MA

,.

MS (GCC Countires’)

MS (Others)

Engine oil capacity

Dry fill

Drain and refill

Battery specific gravity

High-tension cord resistance

Spark plug

Conventional tipped type

Drive belt deflection or tension

.,:

..!

WI Heater or air con.

w/o Heater or air con.

WI Heater or air con.

w/o Heater or air con.

w/ Heater or air con.

w/o Heater or air con.

w/o Oil filter change

w/ Oil filter change

We

Air gap

Platinum tipped type

Type

Air gap 7M-GE

- PS pump New belt

7M-GE MA (GCC Countires’)

7M-GE MA (Others)

7M-GE MS

7M-GTE (M/T)

7M-GTE (A/T)

MA

MS

MA

MS

7M-GE

7M-GTE

7M-GTE

New belt

Used belt

Used belt

New hit

Used belt MA

M/T

A/T

M/T

A/T

Limit

ND

NGK

ND

NGK

ND

NGK

MA

MS

MS

: r’

:

/ w/ IO, kg (22.1 lb, 98 N) w/ SST (Reference)

,. .

IO 7 1.2:mm .0.39 - 0.47 in. 70 - 80 kg

I5 -, 17 mm 0.59 - 0.87 in. 30 - 45 kg

I- 8mm 0.28 - 0.31 in. 55 - 65 kg

3-llmm 0.35 - 0.43 in. ” 25 -‘40 kg

7 1 9.5‘mm 0.28 - 0.374 in. 53 - 77 kg

7;.5 - 9.5 mm 0.295 - 0.374 in. 53 - 77 kg

10.5 .- 12 mm 0.413 - 0.47 in. 30 - 40 kg

IO - 13.,mm

8.1 liters

8.0 liters.

7.5 liters

7.4 liters

8.5 liters

7.8 liters

7.8 liters

7.1 liters

5.0 liters

4.9 liters

5.3 liters

5.1 liters

5.0 liters

3.9 liters 4.1 US qts

4.1 liters

4.2 liters 4.4 us qts

4.4 liters

1.25 - 1.27 when fully charged at 20°C (68°F)

25 kn per cord

Q20R-U

BCPRGEY

0.8 mm

PQ16R

8CPR5EPll

PQ20R-P8

BCPRGEP-N8

1.1 mm

0.8 mm

. .

0.39 - 0.51 in.

8.5 US qts \

8.5 US qts

7.9 us qts

7.8 US qts

9.0 us qts

8.2 US qts

8.2 US qts

7.5 us qts

5.3 us qts

5.2 US qts

5.6 US qts

5.4 us qts

5.3 us qts

4.3 us qts 3.6 Imp. qts

4.7 us qts 3.9 Imp. qts

b.03 1

in.

0.043 in.

0.031 in.

30 - 40 kg

7.1 Imp. qts

7.0 Imp. qts:

6.8 Imp. qts

6.5 Imp. qts

7.5 Imp. qts

6.9 Imp. qts

6.9 Imp. qts

6.2 Imp. qts

4.4 Imp. qts

4.3 Imp. qts

4.7 Imp. qts

4.5 Imp. qts

4.4 Imp. qts

3.4 Imp. qts

3.7 Imp. qts

,:‘GCC Countries:

~~ s;

p;

.5&.,..‘ .,

gg&-&;,., ;.

Saudi Arabia, Sultanate of Oman, Bahrain, United Arab Emirates, Qatar, Kuwait.

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

FI-1

i’.. ;

-EFI SYSTEM

. .

Page

SYSTEM DESCRIPTION

PRECAUTIONS

.............................. .

INSPECTION PRECAUTIONS

TROUBLESHOOTING

DIAGNOSIS SYSTEM

TROUBLESHOOTING WITH

VOLT/OHMMETER (MA)

TROUBLESHOOTING WITH

VOLT/OHMMETER (MS)

FUEL SYSTEM

................................ FI-73,

Fuel Pump ..................................

Cold Start Injector ...........................

Pressure Regulator

Injectors

.............................. ..i

AIR INDUCTION SYSTEM

Air Flow Meter (7M-GE)

Air Flow Meter (7M-GTE)

Throttle Body

.............................. FI-102

Idle Speed Control (ISC) Valve

ELECTRONIC CONTROL SYSTEM .............. FI-110

Location of Electronic Control Parts .......... FI-110

EFI Main Relay

l

Circuit Opening Relay ....................... FI-113

.

............................. Fl-112

Solenoid Resistor

Cold Start Injector Time Switch ...............

Water Temperature Sensor ..................

Fuel Pump Relay and Resistor ............... FI-117

i

‘x

High Temperature Line Pressure -

Up System ............................... FIi119

High Altitude Compensation (HACK

System (7M-GTE)

Oxygen Sensor .............................

Electronic Controlled Unit (ECU) .............

Fuel Cut RPM

..............................

....................... Fl-i.&.

;;:“, F,-,

;a”“-

....

FI-7 . ....................

.......................... FI-12

....................

.................... FI-34

.

.... FI-25

m

.................... FI-57

FI-73

Fl-80

.......................... FI’i84 ..

..

FI-86

..................... FI-96

..................... FI-96

................... FI-98

............... FI-108

........................... Fl-114

FI-115

FI-116

........................

FI-121

FI-122

FI-125

FI-128

.:

Page 32

Circuit

Opening

Fuel Pump Relay

I

VSV (FPU)

Warning

I :..I-, -7-I

Electronic

Load

di!=

Check C&tnector

A/C Compressc

I-=-

Szeed Sensor

ECU

IIIII:IIlI

1

P 1

Igniter w/coil

L-

l---it-

Start‘lnjector Time Switch

Water Te&p. Sensor

TWC

Neutral Start

Switch (A/T)

Page 33

Circuit

Opening

Relay

“CHECK 1 f-- 1 ]

ENGINE”

Warning

Light

ECU

Fuel Pump Relay

: :

:

: :

llll II

I

iIll

+-,llllllllllll

Air Temp. Sensor

Electronic

Load

Check Connector 1 1 1 / 1 1 1 1 1 1 1 1

Igniter w/r-:’ ’

A/C Compressor

& 1 wTwy 1 To Charcoal Canister

:uator

Neutral Start

Switch (A/T)

Page 34

5 (Others)

EFI SYSTEM -

;SYSTEM DESCRIPTION (Cont’d)

STystem Description

,

I

.5:

I

a

.

I I

I

J I

Page 35

FM-GTE

EFI SYSTEM

-.

SYSTEM DESCRIPTION (Cont’d)

- System Description

._

’

FI-5

1

Page 36

1-6 EFI SYSTEM - System Description

‘he .EFI system is composed of 3 basic sub

;ystems; Fuel Induction, Air Induction and

Ziectronic Control.

FUEL SYSTEM

An electric fuel pump supplies sufficient fuel,

under a constant pressure, to the injectors. These

injectors inject a metered quantity of fuel into the

intake manifold in accordance with signals from

the ECU (Electronic Control Unit).

AIR INDUCTION SYSTEM

The air induction system provides sufficient air for

engine operation.

[3: ‘I

i&TRONIC CONTROL SYSTEM

The 7M-GE, 7M-GTE engines are equipped wifh a

Toyota Computer Control System (TCCS) which

centrally controls the EFI, ESA, Diagnosis systems,

etc. by means of an Electronic Control Unit (ECU for-merly EFI computer) employing a microcomputer.

3. Idle Speed Control (IX)

The ECU is programmed with, target idling

speed values to respond to different engine

conditions (coolant temperature, air conditioner on/off, etc.). Sensors transmit signals

to the ECU which control the flow of air

through the bypass of the throttle valve and

adjust idle speed to the target value.

(See pages FI-53, 7 1, 108) ’

4. Diagnosis

The ECU detects any malfunctions or abnor-

malities in the sensor network and tights the

“CHECK ENGINE” warning light on the instrument panel. At the same time, the trouble is

identified and a diagnostic code is recorded

by the ECU.

5. Fail-Safe Function ’

In the event of computer malfunction, a back-

up circuit will take over to provide minimal

drivability. Simultaneously, the “CHECK

ENGINE” warning light will come on.

By means of the ECU, the TCCS controls the

following functions:

Electronic Fuel injection (EFI)

1.

The ECU receivers signals from,various sen-

sors indicating changing engine operating

conditions such as:

Exhaust oxygen content (w/ TWC)

Intake air volume

i

2.

Intake air temperature

Coolant temperature

Engine rpm

Vehicle speed

Acceleration/deceleration etc.

These signals are utilized by the ECU to

determine the injection duration necessary for

an optimum air-fuel ratio.

Electronic Spark Advance (ESA)

The ECU is programmed with data for

optimum ignition timing under any and all

operating conditions. Using data provided by

sensors which monitor various engine functions (rpm, A/C signal, coolant temperature,

etc.), the microcomputer (ECU) triggers the

spark at precisely the right instant. (See IG

section)

Page 37

EFI SYSTEM

- Precautions, Inspection Precautions

FI-7

PRECAUTIONS

1. Before working on the fuel system, disconnect the

negative terminal from the battery.

NOTE: Any diagnosis code retained by the computer will

be erased when the battery terminal is removed.

Therefore, if necessary, read the diagnosis before

removimg the battery terminal.

2. Do not smoke or work near an open flame when working on the fuel system.

3. Keep gasoline off rubber or leather parts.

._

INSPECTION PRECAUTl.ONS

MAINTENANCE PRECAUTIONS

1. INSURE CORRECT ENGINE TUNE-UP

2. PRECAUTIONS WHEN CONNECTING GAUGE

(a) Connect the tachometer test probe to the terminal

IGO of check connector.

CHECK CONNECTOR LOCATION:

See pages FI-110, 111

(b) Use the battery as the power source for the timing

light, tachometer, etc.

3. IN EVENT OF ENGINE MISFIRE FOLLOWING

PRECAUTIONS SHOULD BE TAKEN

(a) Insure proper connection of battery terminals, etc.

(b) Handle high tension cords carefully.

(c) After repair work, insure that the ignition coil ter-

minals and all other ignition system lines are reconnected securely.

(d) When cleaning the engine compartment, be especial-

ly careful to protect the electrical system from water.

4. PRECAUTIONS WHEN HANDLING OXYGEN SENSOR

(w/ TWCI

(a) Do not allow oxygen sensor to drop or hit against an

object.

(b) Do not allow water to come into contact with the

sensor or attempt to cool it.

Page 38

-8

EFI SYSTEM -.-

IF VEHICLE IS EQUIPPED WITH MOBILE

RADIO SYSTEM (HAM, CB, ETC)

The ECU has been designed so that it will not be affected by

outside interference.

However, if your vehicle is equipped with a CB radio

transceiver, etc. (even one with about 10 W output), it may, at

times, have an affect upon ECU operation, especially if the

antenna and feeder are installed nearby.

Therefore, observe the following precautions:

1. Install the antenna as far as possible from the ECU. The

2. Keep the antenna feeder as far .away as possible from the

3.

4.

Inspection Precautions

ECU is located behind the glove box (MA) or passenger’s

kick panel (MS), so the antenna should be installed in the

rear of the vehicle.

ECU wires at least 20 cm (7.87 in.), and especially, do not

wind them together.

Insure that the feeder and antenna are properly adjusted.

Do not equip your vehicle with a powerful mobile radio

system.

Do not open the cover or the case of the

absolutely necessary. (If the IC terminals are touched, the

IC may be destroyed by static electricity.1

. . .

ECU unless

TM-GE (MS)

7M-GTE

AIR INDUCTION SYSTEM

1.

Separation the engine oil dipstick, oil filler cap, PCV hose,

etc., may cause the engine to run out of tune.

Disconnection, looseness or cracks in the parts of the air

2.

induction system between the air flow meter and cylinder

head will allow air suction and cause the engine to run out

of tune.

Page 39

EFI SYSTEM - inspection Precautions

ELECTRONIC CONTROL SYSTEM

1.

Before removing EFI wiring connectors, terminals, etc.,

first disconnect-the power-by either turning the ignition

switch OFF or disconnecting the battery terminals.

2.

When installing a battery, be especially careful not to

incorrectly connect the positive and negative cables.

3.

Do not permit parts to receive a severe impact during

removal or installation. Handle all EEI parts carefully.

FM066

especially the ECU.

4. Do not be careless during troubleshooting as there are

numerous transistor circuits and even slight terminal contact can cause further troubles.

5.

Do not open the ECU cover.

When inspecting during rainy weather, take care to pre-

6.

vent entry of water. Also, when washing the engine com-

.partment, prevent water from getting on the EFI parts and

wiring connectors.

7. Parts should be replaced as an assembly.

FI-9

.

8. Care is required when pulling out the inserting wiring connectors.

(a) Release the lock and pull out the connector, pulling

on the connectors.

(b) Fully insert the connector and insure that it is locked.

When inspecting a connector with a circuit tester.

9.

(a) Carefully take out the water-proofing rubber if it is a

water-proof type connector.

FlOO95 FlOO91

Page 40

FI-10

EFI SYSTEM

-.

Fco97 FlOO91

I

- inspection Precautions

(b) insert the tester probe into the connector from the

wiring side when-checking the continuity,,amperage

L

or voltage.

(c) Do not apply unnecessary force to the terminal.

(d) After checking, install the water-proofing rubber on

the connector securely.

10. Use SST for inspection or test of the injector, cold start

injector or its wiring connector.

SST 09842-30050 and 09842-30060

L

i. 4

Gasket

I

New

‘Gasket

. FI159

/

FM067 FHOE

FUEL SYSTEM

1.

When disconnecting the high fuel pressure line, a large

amount of gasoline will spill out, so observe the following

procedure.

(a) Put a container under the connection.

(b) Slowly loosen the connection.

(c) Disconnect the connection.

(d) Plug the connection with a rubber plug.

When connecting the flare nut or union bolt on the high

2.

pressure pipe union, observe the following procedure:

(Union bolt type)

(a) Always use a new gasket.

(b) Hand tighten the union bolt.

(c) Tighten the bolt to the specified torque.

Torque: 300 kg-cm (22 it-lb, 29 N*m)

19

Fulcrum Length

54

(Flare nut type)

(a) Apply a thin coat of oil to the flare and tighten the

flare nut.

(b) Then using SST, tighten the nut to the specified tor-

que.

SST 09631-22020

Torque: 310 kg-cm (22 ft-lb, 30 N*m)

NOTE: Use a torque wrench with a fulcrum length of 30

cm (11.81 in.).

Page 41

I

Gro

*

Q

Delivery

Ring pipe

*

Black Ring

-Grommet

EFI SYSTEM

CORRECT i

Delivew

Pipe -

O-Ring

- inspection Precautions

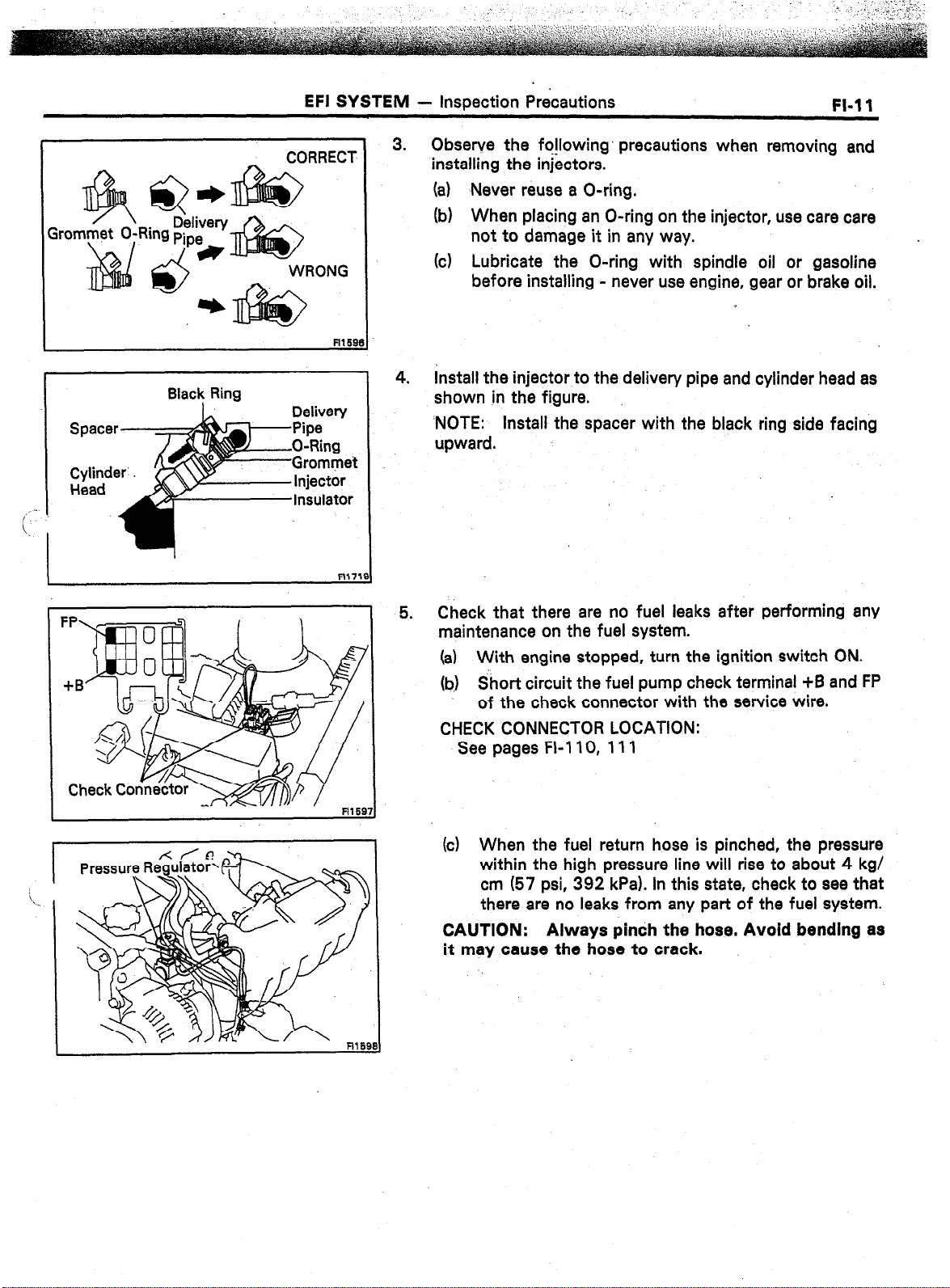

3.

Observe the fo!lowing’ precautions when removing and

installing the injectors.

(a) Never reuse a O-ring.

(b) When placing an O-ring on the injector, use care care

not to damage it in any way.

(c) Lubricate the O-ring with spindle oil or gasoline

before installing - never use engine, gear or brake oil.

4.

Install the injector to the delivery pipe and cylinder head as

shown in the figure.

‘NOTE: Install the spacer with the black ring side facing

upward.

FI-11

Check that there are no fuel leaks after performing any

5.

maintenance on the fuel system.

(a) With engine stopped, turn the ignition switch ON.

(b) Short circuit the fuel pump check terminal +B and FP

of the check connector with the service wire.

CHECK CONNECTOR LOCATION:

See pages FI-110, 111

(c) When the fuel return hose is pinched, the pressure

within the high pressure line will rise to about 4 kg/

cm (57 psi, 392 kPa). In this state, check to see that

there are no leaks from any part of the fuel system.

CAUTION: Always pinch the hose. Avoid bending as

it may cause the hose to crack.

Page 42

1-12

EFI SYSTEM

- Troubleshooting’

TROUBLESH~~TI~~G

. .

TROUBLESHOOTING HlhJTS

1. Engine troubles are usually not caused by the EFI system.

When troubleshooting, always first check the condition of

the other systems.

(a) Electronic source

0 Battery

0 Fusible links

0 Fuses

(b) Body ground

(cl Fuel supply

0 Fuel leakage

0 Fuel filter

0 Fuel pump

(d) Ignition system

0 Spark plug

0 High-tension cord

l

Distributor (7M-GE) or cam position sensor (7MGTE)

0 Igniter and ignition coil

(e) Air induction system

0 Vacuum leaks

(f) Emission control system

0 PCV system

0 EGR system (w/ EGR)

(g) Others

l

Ignition timing (ESA system)

0 Idle speed (ISC system)

2. The most frequent cause of problems is simply a bad dontact in wiring connectors. Always make sure that connec-

tions are secure.

When inspecting the connector, pay particular attention to

the following points:

(a) Check to see that the terminals are not bent.

(b) Check to see that the connector is pushed in com-

pletely and locked.

-r

FlO48

(c) Check to see that there is no signal change when the

connector is slightly tapped or wiggled.

3. Sufficiently troubleshoot for other causes before replacing the ECU. The ECU is of high quality and it is expensive.

Page 43

Digital Type

Analog Type

EFI SYSTEM - Troubleshdoting

. .

4. Use a volt/ohmmeter .with high impedance (10 k.RN

minimum) for troubleshooting of the electrical circuit.

(See pages FL34, 57)

FI-13

TROUBLESHOOTING PROCEDURES

SYMPTOM - DIFFICULT TO START OR NO START

(EbIJiiIf)l& WILL NO? CRANK OR CRANK$ SLOWLY)

CHECK ELECTRIC SOURCE

.-

OK

CHECK STARTING SYSTEM

BAD

BAD

w

1. Battery

(1) Connection

(2) Gravity - Drive belt - charging system

(3) Voltage

2. Fusible links

c

1. Ignition switch

2. Starter relay (MS)

3. Starter

4. Neutral start switch (A/T)

5. Wiring/Connection

Page 44

EFI SYSTEM - Troubleshootina

SYMPTOM - DIFFICULT TO START O-R NO START (CRANKS OK)

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code.

(See page FI-26)

Normal code

DOES ENGINE’START WITH

ACCELERATORPEDALDEPRESSED?

NO

i

I

CHECK FOR VACUUM LEAKS IN AIR

INTAKE LINE

OK

I

CHECK IGNITION SPARK ’

7M-GE (See page IO-61

7M-GTE (See page IG-12)

OK

BAD

BAD

Diagnostic code(s) (See pages FI-30,‘31,32)

ISC system

0) ISC valve

(2) Wiring connection

I

1. Oil filler cap

2. Oil dipstick

3. Hose connections

4. PCV hose

5. (w/ EGR)

EGR system - EGR valve stays open

!

.

1. High-tension cords

2. Distributor (‘IM-GE) or cam position

sensor (7M-GTE)

3. Ignition coil

4. Igniter

I

t OK

CHECKSPARKPLUGS

Plug gap:

7M-GE Conventional Tipped Type

0.8 ‘mm (0.031 In.)

7M-GE

: : 1.1 mm (0.043~in.)

.7M-GTE

0.8 mm (0.031 In.)

NOTE: Check compression pressure and

valve clearance if necessary.

Platinum Tipped Type

OK

CONTINUED ON PAGE FI-15

NO

BAD

+

1. Spark plugs

2. Compression pressure

Limit: 9.0 kg/cm2 (128 psi, 883 kPa)

at 250 rpm

3. Valve clearance (Cold)

STD: IN 0.16 - 0.25 mm

(0.008 - 0.010 in.)

EX 0.20 - 0.30 mm

(0.008 - 0.012 in.1

1. Injector - shorted or leaking

2. Injector wiring between resistor and

ECU shorted

3. Cold start injector - Leakage

(See page Fl-80)

4. Cold start injector time switch

(See page Fl-115)

Page 45

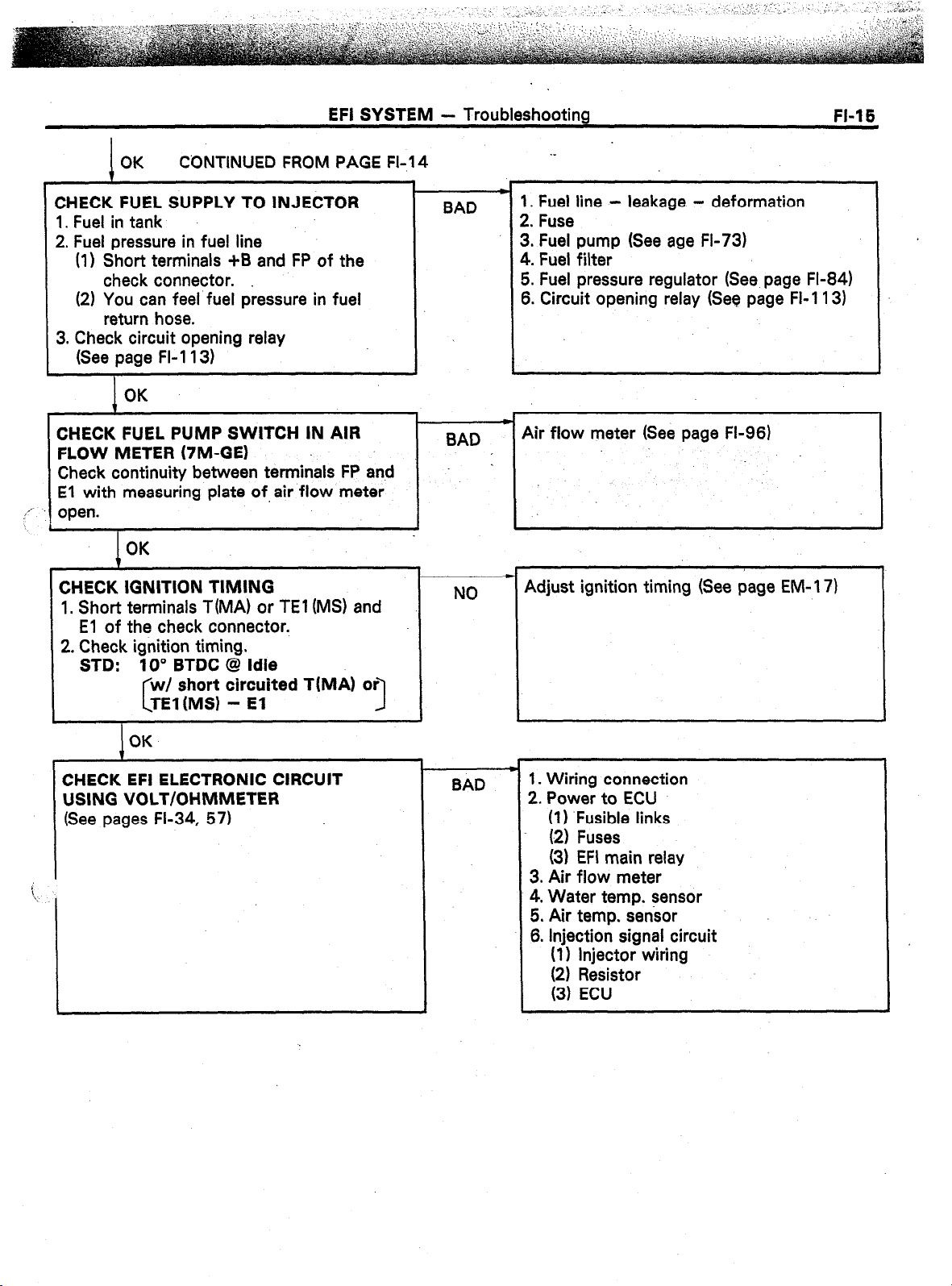

EFI SYSTEM - Troubleshooting

FI-1 E

CONTINUED FROM PAGE FI-14

CHECK FUEL SUPPLY TO INJECTOR

1. Fuel in tank

2. Fuel pressure in fuel line

(1) Short terminals +B and FP of the

check connector.

(2) You can feel fuel pressure in fuel

return hose.

3. Check circuit opening relay

(See page FI-1 13)

OK

CHECK FUEL PUMP SWITCH IN AIR

FLOW METER (7M-GE)

Check continuity between terminals FP and

El with measuring plate of,air flow meter

,,’

open.

L

CHECK IGNITION TIMING

1. Short terminals T(MA) or TEl (MS) and

2. Check ignition timing.

I

OK

I

El of the check connector.

STD: 10’ BTDC @ Idle

short circuited TIMA) or

3

BAD

BAD

NO

._

1. Fuel line - leakage - deformation

2. Fuse

3. Fuel pump (See age FI-73)

4. Fuel filter

5. Fuel pressure regulator (See. page FI-84)

6. Circuit opening relay (See page FI-1 13)

c

Air flow meter (See page FL96)

Adjust ignition timing (See page EM-l 7)

I

OK

BAD

1. Wiring connection

2. Power to ECU

(1) .Fusible links

(2) Fuses

(3) EFI main relay

3. Air flow meter

4. Water temp. sensor

5. Air temp. sensor

6. Injection signal circuit

(1) Injector wiring

Page 46

l-16

EFI SYSTEM - Troubleshooting

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code.

(See page Fl-26)

Normal code

CHECK FOR VACUUM LEAKS IN AIR

INTAKE LINE

OK

I

CHECK FUEL SUPPLY TO INJECTOR

‘*-- Fuel in tank

L. Fuel pressure in fuel line

(1) Short terminals +B and FP of the check

connector.

(2) You can feel fuel pressure in fuel

return hose.

3. Check circuit opening relay

(See page FI-113)

.

SYMPTOM -

Malfunction

code(s)

BAD

BAD

ENGINE OFTEN STALLS

* Diagnostic code(s) (See pages FI-30, 31, 32)

1. Oil filler cap

2. Oil level gauge

3. Hose connections

4. PCV hose

.

1. Fuel line - leakage - deformation

2. Fuse

3. Fuel.pump (See’ page FI-73)

4. Fuel filter

5. Fuel pressure regulator (See page FI-84)

6. Circuit opening relay (See page FI:1 13).

,

OK

CHECK AIR FILTER

I

OK

CHECK IDLE SPEED

STD: 7M-GE

7M-GE

7M-GTE

t

CHECK IGNITION TIMING ‘-

‘I. Short terminals TiMA) or TEl (MS) and

El of the check connector..

2. Check ignition timing.

STD: 10” BTDC @ Idling

OK

CHECK SPARK PLUGS

Plug gap:

7M-GE

0.8 mm (0.031 in.)

7M-GE

1.1 mm (0.043 in.)

7M-GTE

0.8 mm (0.031 in.)

NOTE: Check compression pressure and

-I------- :+ -nyrpCCpn,

wl TWC 700 rpm

w/o TWC 800 rpm

800 rpm

short circuited T(MA) or

Conventional Tipped Type

Platinum Tipped Type

1

-I-

BAD

BAD

NO

BAD -

Element - Clean or replace

w

ISC system

(I 1 Wiring connection

(21 ISC valve

(3) ECU

c

Adjust ignition timing. (See page EM-1 7)

1. Spark plugs

2. Compression pressure

Limit: 9.0 kg/cm2 (128 psi, 883

at 250 rpm

3. Valve clearance (Cold)

STD: IN 0.15 - 0.25 mm

(0.06 - 0.010 in.)

kPa)

Page 47

OK ‘. .CONTINUED FROM PAGE FI-I 6

CHECK COLD START INJECTOR

(See page FI-80)

OK

EFI SYSTEM - Troubleshooting

m

BAD

1. Cold start injector

2. Cold start injector time switch

(See page FL11 5)

FI-17

CHECK FUEL PRESSURE

(See page FI-74)

OK

CHECK INJECTORS

(See page FI-86)

OK

..I

’ CHECK EFI ELECTRONIC CIRCUIT

USING VOLT/OHMMETER

(See pages FI-34, 57)

I

BAD

BAD

BAD

p 1. Fuel pump (See page FL73)

2. Fuel filter

3. Fuel pressure regulator (See page FI-84)

c

Injection condition

1. Wiring connection

2. Power to ECU

(I) Fusible links

(2) Fuses

(3) EFI main relay

3. Air flow meter

4. Water temp. sensor

5. Air temp. sensor

6. Injection signal circuit

(I 1 Injector wiring

SYMPTOM - ENGINE SOMETIMES STALLS

CHECK DIAGNOSIS SYSTEM

I

Check for output of diagnostic code.

,dSee page FI-26)

‘I ,.

Normal code

I

CHECK AIR FLOW METER’

(See pages .Fl-96, 98)

I

OK

CHECK WIRING CONNECTORS AND

RELAYS

Check for a signal change when the connec- 3. Circuit opening relay (See page FI-113)

tor or relay is slightly tapped or wiggled.

1 BAD --

Air flow meter

2’ EFI main relay (See page FI 112)

I

Page 48

a

EFI SYSTEM - Troubleshooting

SYMPTOM - ROUGH IrIiLlNG AND/OR MISSING

iECK DIAGNOSIS SYSTEM

leek for output of diagnostic code.

ee page FI-26)

1

Normal code

HECK FOR VACUUM LEAKS IN’AIR

d-FAKE LINE

OK’

I

If* “K AIR FILTER

I

OK

CHECK IDLE SPEED

STD: 7M-GE

7M-GE

7M-GTE

OK

ELEMENT

w/ TWC 700 rpm

w/o TWC 800 rpm

800 rpm

Malfunction

code(s)

BAD

-c Diagnostic code(s) (See pages FI-30, 31, 32)

1, Oil filler cap

2. Oil level gauge

3. Hose connections

4. PCV hose

5. EGR system - EGR vaive stays open (EGR)

Element - Clean or replace

,

SC system

(1) Wiring connection

(2) ISC valve

(3) ECU

I

CHECK IGNITION TIMING

1, Short terminals T(MA) or TEI (MS) and

El of the check connector.

2. Check ignition timing.

STD: IO” BTDC @ Idling

w/ short circuited T(MA)

TEl(MS1 - El

I

i

‘.

I

CHECK SPARK PLUGS

Plug gap:

NOTE: Check compression pressure and

valve clearance if necessary.

OK

7

7M-GE

0.8 mm (0.031 in.)

7M-GE Platinum Tipped Type

1.1 mm (0,043 in.)

7M-GTE

0.8 mm (0.031 in.)

Converitional Tipped Type

OK CONTINUED ON PAGE FI-19

NO

BAD

F Adjust ignition timing. (See page EM-l 7)

1. Spark plugs

2. Compression pressure

Limit: 9.0 kg/cm2 (128 psi, 883

at 250 rpm

3. Valve clearance (Cold)

STD: IN 0.15 - 0.25 mm

(0.08 - 0.010 in.)

EX 0.20 - 0.30 mm

(0.008 - 0.012 in.)

kPa)

Page 49

EFI SYSTEM - Troubleshooting

FI-19

CONTINUED FROM PAGE Fl-18

CHECK COLD START INJECTOR

(See page FI-80)

CHECK FUEL PRES$URE

(See page FL74)

I

CHECK INJECTORS

(See page FI-86)

I

ZHECK EFI ELECTRONIC CIRCUIT

USING VOLT/OHMMETER

(See pages FL34, 57)

I

/OK

OK

I

1

._

t

*

BAD

BAD

1 c 4

8AD

BAD

1. Cold start injector

2. Cold start injector time switch

(See page FL11 5)

c 1. Fuel pump (See page FI-73)

2. Fuel filter

.3. Fuel pressure regulator (See page FI-84)

* Injection condition

c

1. Wiring connection

2. Power to ECU

\‘l’, F;t;e links

(3) EFI main relay

3. Air flow meter

4. Water temp. sensor

5. Air temp. sensor

6. Throttle position sensor

7. Injection signal circuit

(1) injector wiring

L

Page 50

.20

EFI SYSTEM - Troubleshooting __

SYMPTOM -

:HECK ACCELERA

OK

CHECK POWER STEERING !DLE+JP

SYSTEM

OK .

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code.

(See page FI-26) ‘:.

_T I

Normal code

CHECK ISC SYSTEM

OK

‘:

j..l.

BAD

Malfunction

..

code!s)

I

HIGH ENGINE IDLE SPEED (NO DROP)

Linkage - Stuck

* Air valve

I

r

* Diagnostic code(s) (See pages FI-30, 31, 32)

.

BAD

(Air con Throttle posrtron sensor - ECU)

71

I

9

CHECK THROTTLE POSITION SENSOR

1

OK

CHECK FUEL PRESSURE

(See page FI-74)

OK

CHECK COLD START INJECTOR

~ .ee page FI-80)

CHECK INJECTORS (See page FI-86)

I

OK

I

CHECK EFI ELECTRONIC CIRCUIT USING

VOLT/OHMMETER

(See pages FI-34, 57)

t-x-

BAD

BAD

BAD -

Throttle body

7

w Fuel pressure regulator - High pressure

w Cold start injector - Leakage

Injectors - Leakage, Injection quality

1. Wiring connection

2. Power to ECU

(1) Fusible links

(2) Fuses

(3) EFI main relay

3. Air flow meter

4. Water temp. sensor

5. Air temp. sensor

6. Injection signal circuit

(1) Injector wiring

(2) Resistor

(3) ECU

Page 51

EFI SYSTEM - Troubleshooting

-.

FI-21

SYMPTOM - ENGINE BACKFtRES-Lean Fuel Mixture

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code

(See page FI-26)

Normal code

CHECK FOR VACUUM LEAKS IN AIR

INTAKE LINE

1. Short terminals T(MA) or TEl (MS) and

Malfunction

--) Diagnostic code(s) (See pages FI-30, 31, 32)

.code 1s)

BAD -

NO

j

,

1. Oil filler cap

2. Oil dipstick

3. Hose connections

4. PCV hose

Adjust ignition timing. (See page EM-1 7)

1. Cold start injector

2. Cold start injector time switch

(See page FI-115)

CHECK FUEL PRESSURE

(See page FI-74)

I

I

’ “,HECK INJib

‘I- See page FI-86)’

. ., .l

OK

I

CHECK Eii ELECTRONIC ClR&lT

USING VOLT/OHMMETER

(See pages FI-34, 57)

I

BAD

1. Fuel pump (See page‘ FI-73)

2. Fuel filter

3. Fuel pressure regulator (See page Fl-84)

- Injectors - Clogged

BAD

4

BAD

1. Wiring connection

2. Power to ECU

(1) Fusible links

(2) Fuses

(3) EFI main relay

3. Air flow meter

4. Water temp. sensor

5. Air temp. sensor

6. Throttle position sensor

7. Injection signal circuit

(1) Injector wiring

Ii, zesstor

(4) Fuel cut signal

8. Oxygen sensor

Page 52

Ii-22

EFI SYSiiM - Troubleshooting

SYMPTOM - MUFFLER EXPLOSION (AFTER FIRE)

-Rich Fuel Mixture-Misfire

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code

(See page FI-26)

Normal code

CHECK IGNITION TIMING

1. Short terminals TiMA) or TEl (MS) and

El of the check connector.

2. Check ignition timing.

STD: IO” BTDC @ Idling

w/ short circuited TfMA) or

TEl(MS) - El

C

OK

1

CHECK INJECTORS

OK

I

pm Diagnostic code(s) (See pages Fl-30, 31, 32)

Malfunction

code(s)

4

NO

I

BAD

c

Adjust ignition timing. (See page EM- 17)

1. Cold start injector

2. Cold start injector time switch

(See page FI- 115)

I-

BAD

injector - Leakage

I

I

CHECK SPARK PLUGS

Plug gap:

7M-GE

0.8 mm (0.031 in.)

7M-GE

1.1 mm (0.043 in.)

7M-GTE

0.8 mm (OiO31 in.)

NOTE: Check compression pressure and

valve clearance if necessary.

CHECK EFI ELECTRONIC CIRCUIT USING

VOLT/OHMMETER

(See pages Fl-34, 57)

Conventional .Tipped Type

Platinum Tipped Type

OK

NO

BAD -

1. Spark plugs

2. Compression pressure

Limit: 9.0 kg/cm2 (128 psi, 883

at 250 rpm

3. Valve clearance (Cold)

STD: IN 0.15 - 0.25 mm

(0.06 - 0.010 in.)

EX 0.20 - 0.30 mm

(0.006 - 0.012 in.)

1. Throttle position sensor

2. Injection signal circuit

(I) Injector wiring

(2) Resistor

(3) ECU

3. Oxygen sensor

i

kPa)

Page 53

EFI SYSTEM - Troubleshooting

FI-23

SYMPTOM

CHECK CLUTCH AND BRAKE

I

CHECK FOR VACUUM LEAKS IN AIR

INTAKE LINE

CHECK AIR FILTER ELEMENT

,,: -.

. . 1

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code.

(See page FI-26)

I

CHECK IGNITION SPARK

I

OK

1

OK

I

OK

7

I

Normal code

1

7M-GE (See page IO-61

7M-GTE (See page 16-12)

I

OK

I

- ENGINE HESITATES AND/OR POOR ACCELERATION

.

BAD

1

BAD

I-

BAD

i ,

Malfunction

code

I--

I I

BAD

1. Clutch - Slips

2. Brakes - Drag

1. Oil filler cap

2. Oil level gauge

3. Hose connections :

4. PCV hose

5. EGR system - EGR valve stays open (EGR)

Element - Clean or replace

Diagnostic code(s) (See pages FI-30, 31, 32)

.

1. High-tension cords

2. Distributor (7M-GE) or cam position

sensor (7M-GTE)

3. Ignition coil

4. Igniter

4

I

1

J

CHECK IGNITION TIMING

1. Short terminals T(MA1 or TEl (MS) and

El of the check connector.

2. Check ignition timing.

STD: 10” BTDC @ Idling

‘i,

short circuited TiMA) or

I

OK

I

CHECK FUEL PRESSURE

(See page Fl-74)

OK

CHECK INJECTORS

(See page FI-86)

OK

CONTINUED ON PAGE FI-24

NO

I

Adjust. ignition timing. (See page EM- 17)

I

I

BAD

I

BAD

1. Fuel pump (See page Fl-73)

2. Fuel Filter

3. Fuel pressure regulator (See page Fl-84)

c Injection condition

1

Page 54

. .

FI-24

1

OK

CONTINUED FROM PAGE FL23

EFI SYSTEM - Troubleshooting

,)

CHECK SPARK PLUGS

Plug gap:

7M-GE

03 mm (0.031 ,in.)

Conventional Tipped Type

.~

7M-GE Platinum Tipped Type

1.1 mm (0.043 in.)

7M-GTE

0.8 mm (0.031 in.)

NOTE: Check compression prossure and

valve clearance if necessary.

. r

1

.

;HECK EFI ELECTRONIC’CIRCUIT

-;-;ilNG VOLT/OHMMETER

_

(See-pages FI-34;‘57) Y

BAD

BAD

L

1. Spark plugs

2. Compression pressure

Limit: 9.0 kg/cm2 (128 psi, 883

at 250 rpm

3. Valve clearance (Cold)

STD: IN 0.15 - 0.25 m&

(0.06 -‘.O.OlO in.)

EX 0.20 - 0.30 mti

(0.008 - 0.012 in.1

.

c

1. Wiring connection

2. Power to ECU

(I) Fusible links

(2) Fuses

(3) EFI main relay

3. Air flow meter.

4. Water temp. sensor

5. Air temp. sensor

6. Throttle position sensor

7. Injection signal circuit

(I) Injector wiring

(2) Resistor

(3) ECU

kPa)

’

Page 55

EFI SYSTEM

. .

- Diagnosis System

FL25

DIAGNOSIS SYSTEM

__ --

(MA)

The ECU contains a built-in self-diagnosis system by which

troubles with the engine signal network are detected and a

“CHECK ENGINE” warning light on the instrument panel

flashes,

By analyzing various signals as shown in the later table (See

pages Fl-30, 31) the Electronic Control Unit (ECU) detects

system malfunctions which are related to the various operating

parameter sensors or to the actuator. The ECU stores the

failure until the diagnosis system is cleared by removing the EFI

fuse with the ignition switch off.

A “CHECK ENGINE” warning light on the instrument panel

informs the driver that a malfunction has been detected.

The light goes out automatically when the malfunction has

been cleared.

The diagnostic code can be read by the number of the blinks of

the “CHECK ENGINE” warning light when T and El are short-

circuit.

(MS)

The ECU contains a built-in self-diagnosis system by which

troubles with the engine signal network are detected and a

“CHECK ENGINE” warning light on the instrument panel

flashes.

By analyzing various signals as shown in the later table (See

page FI-32) the Electronic Control Unit (ECU) detects system

malfunctions which are related to the various operating

parameter sensors or to the actuator. The ECU stores the

failure until the diagnosis system is cleared by removing the EFI

fuse with the ignition switch off.

In the ECU, a test mode function has been added to the functions of the self-diagnosis system of the previous diagnosis

mode (normal mode) for the purpose of detecting malfunctions

such as poor contact which are difficult to detect in the normal

mode. This function fills up the self-diagnosis system. The test

mode can be implemented by the technician to follow the procedures of appropriate check terminal connection and operation described in later (See page FI-28).

In the normal mode, the self-diagnosis system monitors 14

items, indicated by the codes except for code No. 51 as shown

in FI-32. A “CHECK ENGINE” warning light on the instrument

panel informs the driver that a malfunction has been detected.

The light goes out automatically when the malfunction has

been cleared.

The diagnostic code can be read by the number of the blinks of

the “CHECK ENGINE” warning light when TEl and El are

short-circuited.

Page 56

FI-26

EFI SYSTEM -

-.

In the test mode, seven items, indicated by code

24, 41, 42, 43, and 5 1, as shown in FI-32 are m

malfunction is detected in any one of the systems

code Nos. 13, 22, 24, and 41 the ECU lights the “CHECK

ENGINE” warning light to warm the technician that the malfunction has been detected. In this case, TE2 and El terminals

on the check connector should be connected as shown later

(See page FI-28)

In the test mode, for all seven conditions shown above in code

Nos. 13 function is stored in the ECU memory while the ignition switch

remains on. Also, when a malfunction occurs for-the four conditions from code Nos. 13 - 41, the “CHECK ENGINE” warning

light remains on. However, once the ignition switch is turned to

OFF, the ECU erases all of the malfunctions in the memory. The

diagnostic mode (normal or test) and the output of the “CHECK

ENGINE” warning light can be selected by the TEl , TE2 and El

terminal connections on the check connector, as shown in the

later.

Diagnosis System

51, even if the malfunction is corrected, the mal-

i

“CHECK ENGINE” Warning Light

“CHECK ENGINE” WARNING LIGHT CHECK

1. The “CHECK ENGINE” warning light will come on when

the ignitiorqw:@ch is placed at ON and the engine is not

running.

2. When the engine is started, the “CHECK ENGINE” warning

light should go out.

If the light remains on, the diagnosis system has detected

a malfunction or abnormality in the system.

-y.

OUTPUT OF DIAGNOSIS CODES

(MA)

To obtain an output of diagnostic codes, proceed as follows:

1. Initial conditions

(a)’ Battery voltage about 11 volts

(b) Throttle valve fully closed (throttle position sensor

IDL points closed)

(cl Transmission in neutral position

(d) Accessory switches OFF

,’

Turn the ignition switch to ON. Do not start the engine.

2.

Page 57

Osc db-5 hus

4J

EFI SYSTEM

-.

-7.

- Diagnosis System

w

FI-27

3. Using a service- wire, short terminals T(MA) or TEr(MS)

and El of the check connector.

CHECK CONNECTOR LOCATION:

See pages FI-110, 111

4. Read the diagnosis code as indicated by the number of

flashes of the “CHECK ENGINE” warning light.

“CHECK ENGINE” Warning Light

Code No. 13 Code No. 32

(Seconds)

FlO29

Diagnosis. code (See pages FI-30, 31, 32)

(a) Normal System Operation

l

The light will alternately blink on and off for 0.25

second intervals.

.)

(b) Malfunction Code Indication i

l

The light will blink the number of times equal to

the malfunction code indication with pauses asfollows:

1.

Between the first digit and se&d digit, 1.5

seconds.

2.

Between code and code, 2.5 se$onds.

3. Before repeating all malfunction codes, 4.5

seconds.

0 The diagnostic code series will be repeated as long

as the “CHECK ENGINE” connector terminals

T(TE1) and El are shorted.

NOTE: In event of a number of trouble codes, indication

will begin from the small value and continue to the larger

in

order.

After the diagnosis check, remove the service wire.

Page 58

EFI SYSTEM;

Diagnosis System

I

Fl281

S)

Test mode

To obtain an output of diagnostic codes, proceed as follows:

1. Initial conditions

Battery voltage about 1 1 volts

(a)

(b) Throttle valve fully closed (throttle position sensor

(c) Transmission in neutral position

(d) Accessory switches OFF

2. Using a service wire, short terminals TE2 and El of the

check connector.

*-heengine and run the vehicle at a speed of IO km/h

(6 mph) or higher. __--

------) -.

IDL points closed)

_ ___ _.--.--.

-----.-q

/---’

i

j

\

I

4. Simulate the conditions of the malfunction described by

the user.

Using a service wire, short terminals TEl and .El of the

5.

check connector.

NOTE:

l

The test mode will not start if terminals TE2 and El are connected after the ignition switch is turned on, or terminals TE2

and El are connected after terminals TEI and El are con-

nected.

0 The starter signal and vehicle speed signal will be diagnosed

by the ECU as malfunctions, and codes No. 42, and 43 will

be output, if the operation in 3. above is not performed.

Read the diagnosis code as indicated by the number of

6.

flashes of the “CHECK ENGINE” warning light.

(See page FI-27)

7. After the diagnosis check, remove the service wires.

l

Page 59

MS EFI 15iA

LHD

EFI 15A

EFI SYSTEM

CANCELLING OUT DIAGNOSTIC CODE

1.

2.

- Diagnosis System

FI-29

After repair of the trouble area, the diagnostic code

retained in memory by the ECU must be cancelled out by

removing the EFI fuse 15A for 30 seconds or more,

depending on ambient temperature (the lower the temperature, the longer the fuse must be left out) with the

ignition switch off.

NOTE:

l

Cancellation can also be done by removing the battery”

negative (-1 terminal, but in this case other memory

systems (clock etc.) will also be cancelled out.

l

If the diagnostic code is not cancelled out, it will be

retained by the ECU and appear along with a new code

in event of future trouble.

l

If it is necessary to work on engine components requiring removal of the battery terminal, a check must first

be made to see if a diagnostic code has been recorded.

After cancellation, road test the vehicle to check that a

“normal” code is now read on the “CHECK ENGINE”

warning light.

If the same diagnostic code is still indicated, it means that

the trouble area has not been repaired thoroughly.

EFI 15A

R16C

FI26:

DIAGNOSIS INDICATION

(I) When 2 or more codes are indicated, the lowest number

(code) will appear first.

However, no other code will appear along with code No.

11.

(2) All detected diagnostic codes, except 51 and 53, will be

retained in memory by the ECU from the time of detection

until cancelled out.

(3) Once the malfunction is cleared, the “CHECK ENGINE”

warning light on the instrument panel will go out but the

diagnostic code(s) remain stored in ECU memory (except

for codes 51 and 53).

Page 60

I-30

d

.EFl SYSTE.M -

DIAGNOSTIC CODES (MA)

Diagnosis System

Code

; No.

I

- nnrulno4 Norma’

11

24

Number of

Che;;;;gine

nn n

i-

I

ECU (+B) fl n

gnition Signal

I!

Fll608

(

3xygen Sensor

!

signal

FIl609

1

Water Temp.

Sensor Signal

,-

Fll81t

Intake Air Tern

1

Fll81

Fl161

Fl18

FIZE

System

Sensor Signal

Air-flow

Meter Signal

(‘IM-GE)

Air Flow

Meter Signal

(7M-GTE)

HAC Sensor

Signal

Turbocharger

Pressure

n

Sensor Signal

SHl,d

I

Diagnosis

This appears when none of

the other codes area identified.

Momentary interruption in

power supply to ECU.

Jo “NE” or “G” signal to

ICU within 2 seconds after

engine has been cranked.

Uo “NE” signal to ECU when

sngine Sp88d is above

1,000 rpm.

No “IGF” signal to ECU

8 times in succession.

i-

E

Ietectinn of oxygen sensor

t

jeterioration.

C

i

Open or short circuit in wate

temp. sensor signal.

Open or short circuit in intake

P.

air temp. sensor signal.

I7M-GE)

Open circuit in VC signal or

short circuit between VS and

E2 when idle contacts are

c tosed.

(7M-GTE)

Open or Short circuit in air

flow meter signal.

(‘IM-GE)

Open circuit in E2 or short

circuit between VC and VS.

(‘IM-GTE)

Open or short circuit in HAC

sensor signal

‘3

Turbocharger pressure is

abnormal.

Open or short circuit in

throttle position sensor signal.

Trouble area

0

Ignition switch circuit

Ignition switch T

0

Main relay circuit

0

1 Main relay

l

I

1 ECU

1 Distributor circuit

r Distributor

) Starter signal circuit

b ECU

) Distributor circuit

B Distributor

B ECU

B Ignition and ignition coil

circuit

8 Igniter and ignition coil

0 ECU

0 Oxygen sensor circuit

l

Oxygen sensor

0 ECU

0 Water temp. sensor

@muit

‘8 Water temp. sensor

l

ECU

0 Intake air temp. sensor

circuit

8 Intake air temp. sensor

. ECU

0 Air flow meter circuit

0 Air flow meter

0 ECU

0 Air flow meter Circuit

0 Air flow meter

0 ECU

0 HAC sensor circuit

l

HAC sensor

l

ECU

0 Turbocharger

8 Air flow meter

0 Intercooler system

0 ECU

,

0 Throttle position s8nsC

circuit

0 Throttle position sensor

0 ECU

I

See

page

FI-41

IG-3

IG-3

!I-5 1

l-l 2

FI-4’

Fl-48

FI-44

FI-4‘

FI-51

)r

, FI-4

Page 61

EFI SYSTEM

__

DIAGNOSTIC CODES (MA) (Cont’d)

- Diagnosis System

FI-31

:odc

No.

42

52

Number of

Check engine

System

Diagnosis

blinks

No “SPD” signal for 5

seconds when engine speed

Vehicle Speed

Sensor Signal

is between 2,500 rpm and

4,500 rpm and coolant temp.

is below 80°C (176’F) except

FI161

when racing the engine.

No “STA” signal to ECU until

Starter Signal

FHBl

Knock Sensor

Signal

Fl181

Knock Control

signal in ECU

FIlei

engine speed reaches 800

rpm with vehicle not moving.

Open or short circuit in knock

sensor signal.

Knock control in ECU faulty.

No “IDL” signal, “NSW”

Switch Signal

signal or “A/C” signal to

ECU, with check terminals

El and T shorted.

‘1 WI TWC vehicles only

‘2 7M-GTE only

“3 Abnormalities in the air flow meter may also be detected.

Trouble area

l

Vehicle speed sensor

circuit

l

Vehicle speed sensor

. ECU ’

l

Ignition switch circuit

l

Ignition switch

l

ECU

l

Knock sensor circuit

l

Knock sensor

l

ECU

I

. ECU

l

A/C switch circuit

l

A/C switch

l

A/C am&fire

l

Neutral start switch

‘“q

circuit ’

l

Neutral start switch

0 Throttle position sensor

circuit

l

Throttle position sensor

l

ECU

See

page

FL50

Number of

Check engine

blinks

m Normal

11

nn

12

n nn

-

13

nnnn,

-

14

-LJUlJUL 1 Ignition Signal 1 *

fl1604

FI1605

FHBOB

Fl1807

System

ECU (B)

RPM Signal

RPM Signal

DIAGNOSTIC CODES (MS)

Diagnosis

This appears when none of

the other codes are identified.

l

Ignition switch circuit

l

Momentary interruption in

power supply to ECU.

No “NE” or “G” signal to

ECU within 2 seconds after

engine has been cranked.

No “NE” signal to ECU when

engine speed is above

1,000 rpm.

No. “IGF” signal to ECU

6 - 8 times in succession.

Ignition switch

l

Main relay circuit

l

Main relay

l

ECU

l

Distributor circuit

0 Distributor

l

Starter signal circuit

. ECU

l

Distributor circuit

l

Distributor

. ECU

l

Igniter and ignition coil

circuit

0 Igniter and ignition coil

. ECU

Trouble area

.t

See

page

FI-62

IG-3

IG-3

Fl-70

Page 62

FI-32

I

EFI SYSTEM -

DIAGNOSTIC CODES (MS) (Cont’d)

Diagnosis System

‘.

1

ode

‘( <;

r

32

41

Number of

Check engine

System

Diagnosis

Trouble area

blinks

0 Water temp. sensor

. .

clrcult m n

0 Water temp. sensor

0 ECU _

0 Intake air temp. sensor

circuit

0 intake air temp. sensor

. ECU

0 Air flow meter circuit

:

JUMJJJL

FllBlO

fll611

Intake Air Temp.

Open or short circuit in intake

Sensor Signal air temp. sensor signal.

Open circuit in VC signal or

JJJJ n f

F11612

closed.

.

i Air flow meter circuit

Fl1613

Fl1614

I

I

Open or short circuit in

throttle position sensor signal.

I

0 Throttle position sensor

circuit

0 Throttle position sensor

. ECU

!

No “SPD” signal for 5

seconds when engine speed

0 Vehicle speed sensor

See

paw

FI-68

FI-67

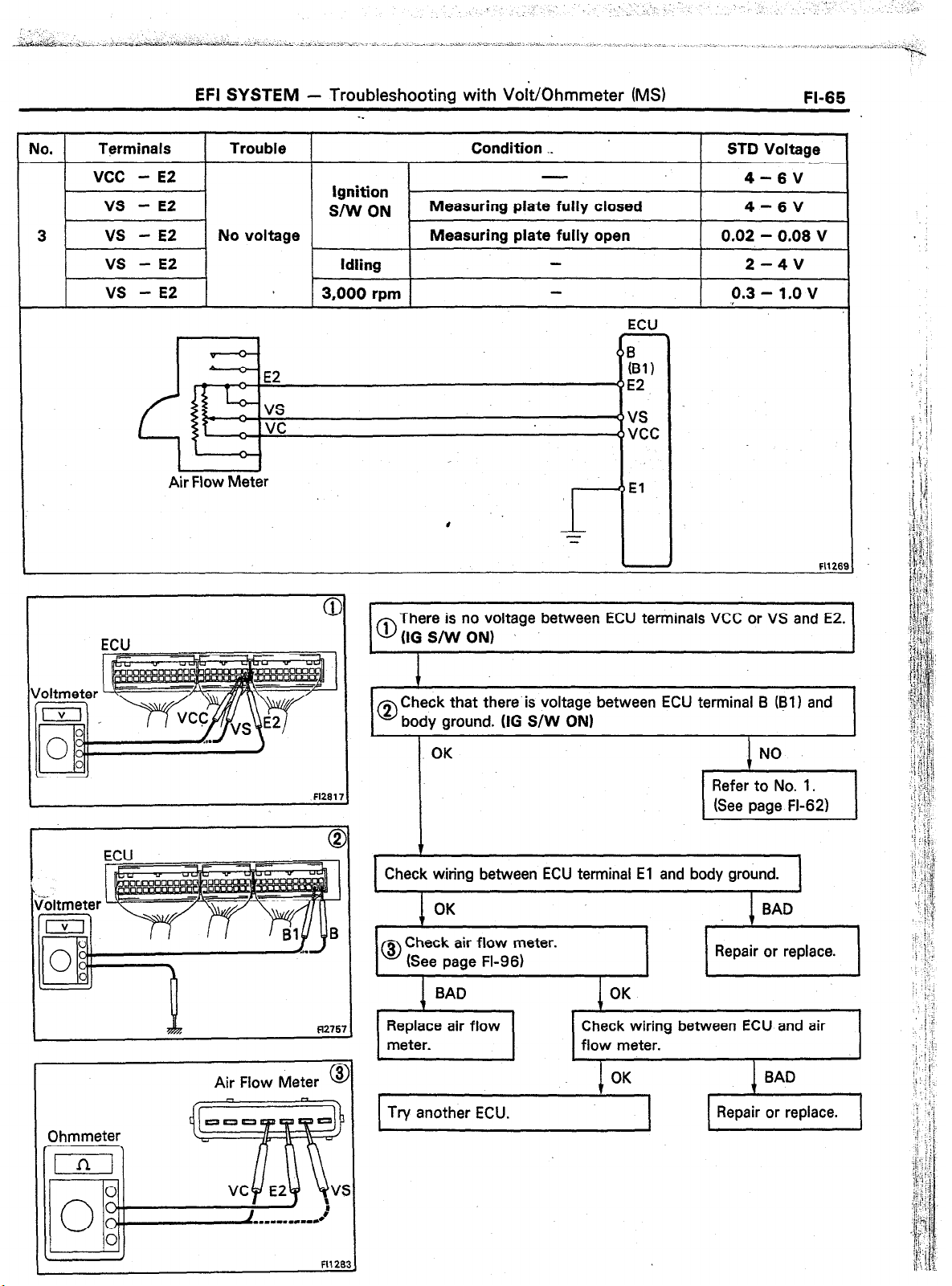

4-65

FI-6!

FM

i

? -.

.I

.^

42

43

nnnruvl

is below 80°C (176°F) except

fl16151

I

when racing the engine.

No “STA” sianal to ECU until

0 Ignition switch circuit

m Starter Signal /~~n~i,‘,pee~;~ct-;~~~ng : ;;;on switch

Fl1616

0 Knock sensor

52

53

JjJJMJjn

I

w6,9 Kn$c~i~“,“,‘;“’ Knock control in ECU faulty.

Eyn$ Sensor ~~n~op:~~ circuit in knock : :gk sensor

F11616

l

0 A/C compressor relay

A/C Com-

pressor

Relay Signal

Z

f12611

Open or short circuit in

A/C compressor relay signal.

a A/C compressor relay

. ECU

0 A/C switch circuit

0 A/C switch

0 A/C amplifire

No “IDL” signal, “NSW”

51

l

0 Neutral start switch

0 Throttle position sensor

0 Throttle position Sensor

. ECU

F11617

FM

circuit

ECU

circuit

Neutral start switch

circuit

circuit

Page 63

EFI SYSTEM

- Diagnosis System

FI-33

INSPECTION OF DIAGNOSIS .ClRCUlT

._

Fuse IGN

“CHECK ENGINE”

Fl291

1.

Dose “CHECK ENGINE” warning light come

on when ignition switch is at ON?

I

Does “CHECK ENGINE” warning light come

on when ECU terminal W is grounded to the

body?

+NO

Check bulb, fuse and wiring between ECU and

ignition switch.

Does “CHECK ENGINE” warning light go off

when the engine is started?

NO

Check wiring between ECU and

“CHECK ENGINE” warning light.

1 OK

Is there diagnostic code output when check

connector terminals T(MA) or TEl (MS) and

El are short circuited?

I

YES

Does “CHECK ENGINE” warning light go out NO

after repair according to malfunction code?

&

YES System Normal

l-l

Check wiring between

YES ECU terminal El and body

- ground.

__c ECU

OK

Try another

+ SAD

Repair or replace

YES

. System Normal

t

Check wiring between ECU terminal T and check

NO connector terminal T(MA) or TEl (MS), and ECU

I

* terminal El and check connector terminal El.

I

) Further repair required.

I

System OK

Cancel out diagnostic code.

Page 64

-34

EFI SYSTEM - Troubleshooting with Volt/dhmmeter (MA)

. .

TROUBLESHOOTING WITH

VOLT/OHMMETER (MA)

OTE: The following troubleshooting prosdures are designed for inspection of each separte system, and therefore the actual procedure

lay vary somewhat. However, troubleshooting

hould be performed refering to the inspection

lethods described in this manual.

Jefore beginning inspection, it is best to first make

3 simple check of the fuses, fusible links and the

:ondition of the connectors.

LOCATION OF FUSES AND FUSIBLE LINKS

1 Relay Block (RHD)

No.

r

I

The following troubleshooting procedures are

based on the supposition that the trouble lies in

either a short or open circuit in a component out-

side the computer or a short circuit within the

computer.

If engine trouble occurs even though proper

operating voltage is detected in the computer con-

nectar, then it can be assumed that the ECU is

faulty and should be replaced.

No. 1 Relay Block (LHD)

61 I

Fuse IGN’

Fusible Link

ALT

(7M-GE) 1.259 \

(7M-GTE) 1 OCjA

No. 2

Relay Block

Fusible Link

AM2 30A

Fuse IdN 7.5A

EFI Main Relay

Fuse EFI 15A

Page 65

EFI SYSTEM - Troubleshooting with Volt/Ohmmeter (MA)

*For

cruise

control

. .

EFI SYSTEM CHECK PROCEDURE

NOTE:

l

Perform all voltage measurements with the connectors

connected.

0 Verify that the battery voltage is 11V or above when

the ignition switch is at “ON”.

Using a voltmeter with high-impedance (IO kQ/V

minimum), measure the voltage at each terminal of the

wiring connectors.

FI-35

I )

ECU

+B

Terminals of ECU (7M-GE)

Symbol ) Terminal Name

E01 POWER GROUND

E02 POWER GROUND

No. 10 INJECTOR (No. 1 and 4)

No. 20

STA STARTER SWITCH

No. 30 INJECTOR (No. 3 and 5)

STJ

NSW NEUTRAL START SWITCH (A/T)

ISC 1 ISC MOTOR NO. 1 COIL ox OXYGEN SENSOR vc

ISC 3

ISC 2

ISC 4 ISC MOTOR NO. 4 COIL Ll ECT COMPUTER +B EFI MAIN RELAY

ECU Terminals

INJECTOR (No. 2 and 6)

COLD START INJECTOR

El COMPUTER GROUND

N/C *CLUTCH SWITCH (M/T)

ISC MOTOR NO. 3 COIL E2 SENSOR GROUND

ISC MOTOR NO. 2 COIL VSV 1 VSV (AIR CONTROL)

GQ

DISTRIBUTOR VSVP VSV (FPU) IG S/W IGNITION SWITCH

VF CHECK CONNECTOR

Gl DISTRIBUTOR

1 Symbol) Terminal Name

T CHECK CONNECTOR

G2 DISTRIBUTOR

VTA THROTTLE POSITION SENSOR

NE DISTRIBUTOR

IDL THROTTLE POSITION SENSOR

IGT IGNITER

IGF IGNITER

THW WATER TEMP. SENSOR

KNK KNOCK SENSOR LP HEADLIGHT RELAY

1 L2 ECT COMPUTER

1 M-REL EFI MAIN RELAY (COIL)

Symbol

L3 ECT COMPUTER

EGR

A/C A/C MAGNET SWITCH

SPD SPEEDOMETER

W WARNING LIGHT

FPR FUEL PUMP RELAY

DFG

THA

ECT

vs AIR FLOW METER

BATT BATTERY

+Bl

Terminal Name

vsv

(EGR)

DEFOGGER RELAY

AIR TEMP. SENSOR

ECT COMPUTER

THROTTLE POSITION SENSOR

AIR FLOW METER

EFI MAIN RELAY

F10574

Page 66

FI-36 EFI SYSTEM -

Troubleshooting with VoltjOhmmeter (MA)

Terminals of ECU. (7M;GTE)

Symbol Terminal Name Symbol Terminal Name Symbol Terminal Name

EOI

E02 POWER GROUND VTA

No, 10 INJECTOR (No. 1 and 4)

No. 20 INJECTOR (No. 2 and 6) IDL

STA STARTER SWITCH IGT IGNITER OIL OIL PRESSURE SWITCH

No. 30 INJECTOR (No. 3 and 5) IGdA IGNITER THA AIR TEMP. SENSOR

STJ

rEl COMPUTER GROUND KNKl KNOCK SENSOR

NSW

IGdB

ISC 1

r

ISC 3 ISC MOTOR NO. 3 COIL

ISC 2 ISC MOTOR NO. 2 COIL Ll ECT COMPUTER IG S/W IGNITION SWITCH

ISC 4 ISC MOTOR NO. 4 COIL

ECU Terminals

POWER GROUND G2 CAM POSITION SENSOR A/C A/C MAGNETIC SWITCH

N/C

THROTTLE POSITION SENSOR

NE CAM POSITION SENSOR

THROTTLE POSITION SENSOR

COLD START INJECTOR

NEUTRAL START SWITCH (A/T)

IGF

THW WATER TEMP. S

IGNITER ECT ECT COMPUTER

ENSOR 1 FC 1 CIRCUITOPENING RELAY

‘CLUTCH SWITCH (M/T) KNK2 KNOCK SENSOR 1 vc )

SPD SPEEDOMETER

W

WARNING LIGHT

FPR FUEL PUMP RELAY

t HAC 1 tl

LTITUDE COMPENSATION

, .xNSOR

THROTTLE

AIR

FLOW I

IGNITER ox OXYGEN SENSOR KS AIR FLOW METER

ISC MOTOR NO. 1 COIL E2 SENSOR GROUND BATT BATTERY

vsv VSV (FPU)

+B EFI MAIN RELAY

HT OXYGEN SENSOR +Bl EFI MAIN RELAY

GO

CAM POSITION SENSOR L2 ECT COMPUTER

VF CHECK CONNECTOR

CAM POSITION SENSOR L3 ECT COMPUTER LP HEADLIGHT RELAY

Gl

CHECK CONNECTOR

T

M-REL

EFI MAIN RELAY (COIL)

EGR VSV (EGR)

TIL

TURBO INDICATOR

DFG DEFOGGER RELAY

I

+

*For cruise control

E2 Ll L2 L3 A/C W OIL ECT FC KS +B +Bl

F10574 Fll 99:

Page 67

EFI SYSTEM

- Troubleshooting with’ Volt/Ohmmeter (MA)

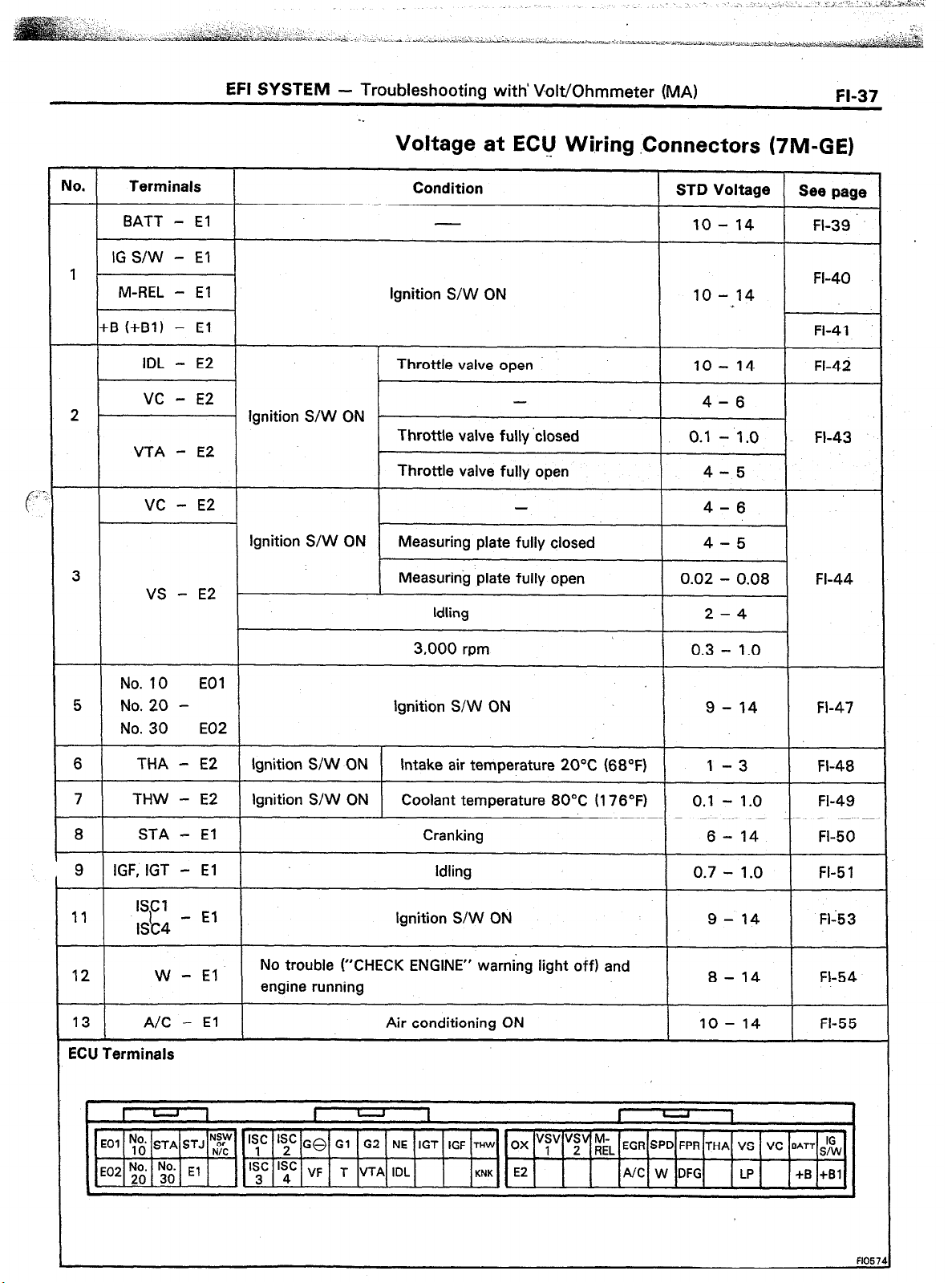

Voltage at EClJ Wiring .Connectors (TIM-GE)

FI-37

IO.

Terminals

BATT - El

Condition STD Voltage

10 - 14 FI-39

See page

IG S/W - El

1 FI-40

M-REL - El

Ignition S/W ON 10 - 14

+B (+Bl) - El FI-41

IDL - E2 Throttle valve open 10 - 14 FI-42

vc

- E2

-

4-6

2 Ignition S/W ON -

Throttle valve fully ‘closed

0.1

- 1.0

FI-43

VTA - E2

Throttle valve fully open 4-5

VC - E2 4-6

Ignition S/W ON

Measuring plate fully closed 4-5

3 Measuring plate fully open 0.02 - 0.08 FI-44

VS - E2

Idling 2-4

3,000 rpm 0.3 - 1.0

No. 10 EOI

5 No. 20 - Ignition S/W ON 9 - 14 FI-47

No. 30

6

THA - E2 Ignition S/W ON Intake air temperature 20°C (68°F) 1 -3 FI-48

7 THW - E2

8 STA - El

9 IGF, IGT - El

11

ISCI

I&4

12 W - El

13 A/C - El

E02

Ignition S/W ON Coolant temperature 80°C II 76’F)

Cranking

Idling

0.1 - 1 .O

6 - 14

0.7 - 1.0

FI-49

FI-50

FI-5 1

- El Ignition S/W ON 9-14 Fl-53

No trouble (“CHECK ENGINE” warning light off) and

engine running

Air conditioning ON IO - 14

8 - 14 FI-54

FI-55

ECU Terminals

4

N:y Is’ Is’

GO Gl G2 NE IGT IGF

THW

OX

“s, “;“riL

EGR SPD FPR THA VS VC BATT IG

‘~,~] E2

/UC W:G up +S :,:I

F1057

Page 68

EFI SYSTEM

- Troubleshooting with Volt/Ohmmeter (MA)

. .

Voltage at ECU Wiring Connectors (7M-GTE)

No.

Terminals

BATT - El 10 - 14

IG S/W - El

1

M-REL - El Ignition S/W ON 10 - 14

+B (+Bl) - El

IDL - E2 Throttle valve open 10 - 14 FI-42

VC - E2

2 . Ignition S/W ON

VTA - E2

i

KS - Body

gnMid

4

vc - Body

groulld

No. 10

EOl

5 No. 20 -

No. 30 E02

Condition STD Voltage Sea page

FI-39

FI-40

*

FI-41

4-6.

Throttle valve fully closed 0.1 - 1.0 FI-43

Throttle valve fully open 4-5

Ignition S/W ON 4-6

FI-45

Cranking or running 2-4

Ignition S/W ON 4-6

Fl-46.

Ignition S;W CN 9 - 14 Fl-47

6

7

8

THA - E2 Ignition S/W ON Intake air temperature 20°C (68°F) 1 -3 FI-48

THW - E2 Ignition S/W ON Coolant temperature 80°C (176°F) 0.1 - 1 .O FI-49

STA - El Cranking 6-14 FI-50

9 IGF, IGT - El Idling

10 IGdA, IGdB -

11

I Cl

7

ISC4

12

13 A/C

El Idling 1-3 FI-52

- El Ignition S/W ON

W - El

- El

No trouble (“CHECK ENGINE” warning light off) and

engine running

Air conditioning ON 10 - 14

540 mmHg (21.26 in.Hg. 72.0 kPa) Approx. 2.8

14 HAC - E2

Ignition S/W ON

750 mmHg (29.53 in.Hg, 100.0 kPa) Approx. 3.6

ECU

Terminals

U

I

‘yc ‘;c GQ Gl G2 NE IGT IGF ~Hln, OX “;’ HT r;,

‘;’ ‘sd: VF T VTA IDL

1 I

WA

““1” K;K E2 Ll L2 L3 NC W OIL ECT FC KS +B +Bl

-

EGR

SPD FPR THA

I

HAC

VC ‘JAn&

0.7 - 1.0 FI-5 1

9 - 14 FI-53

8 - 14 FI-54

FI-55

FI-56

1

m\

0

DF

TIL LP

Page 69

EFI SYSTEM

- Troubleshooting with~Volt/Ohmmeter (MA)

FI-39

lo.

1

Terminals Trouble

I

BAT1 -El No voltage

IO S/W - El No voltage lgnitlon switch ON

1 M-REL - El 1 No voltage 1

1 +B (+Bl) - El1 No voltage

Fusible

Link

Battery

I

Fusible Link

. BATT - El

0

ConcJition

ignition switch ON I IO-14v

lgnitlon switch ON lo-14v

ECU

+Bl

+B

M-REL

IG S/W

El

STD Voltage

IO- l4V

10 - 14 v

Voltmeter

V+

J

ECU

I,

ECU

n

BATT

BATT I!

@ There is no voltage between ECU terminals BATT and El.

1

Check that there is voltage between ECU terminal BATT and

0

body ground.

NO OK

Check wiring between ECU terminal El and body

0

OK

ground.

I

BAD

H

Replace.

I I

Repair or replace.

I ’ I

I

I

I

Check wiring between ECU terminal

and battery.

I

I I I J

I

I

I

Page 70

FI-40

EFI SYSTEM - Troubleshooting with Volt/Ohmmeter (MA)

. IG S/W - El --

There is no voltage between ECU terminals IG S/W and El.

0

(IG S/W ON1

1

Voltmeter

1

Check that there is voltage between ECU terminal IG S/W and

CD

body ground. (IG S/W ON)

NO OK

Check wiring between ECU terminal El and body

ground.

’ OK

Try another ECU.

Check fuse, fusible links and BAD

. M-REL - El

There is no voltage between ECU terminals M-REL and El.

0

(IG S/W ON)

1

Check that there is voltage between ECU terminal M-REL and

0

body ground. (IG S/W ON)

Repair or replace.

Voltmeter

Ed ., +

NO OK

Check wiring between ECU terminal El and body

ground.

OK

Try another ECU.

Check EFI main relay and wiring

harness.

I

Try another ECU.

I

I

I

BAD

c Replace.

Replace or repair.

4

Page 71

EFI SYSTEM

- Troubleshooting with Volt/Ohmmeter (MA)

. +B (+Bl) - El

There is no voltage between ECU terminals +B

0

(IO SAN ON)

I

0 Check that there is voltage between ECU terminal +B (+Bl 1

and body ground. (IO S/w ON)

I

I

NO OK

Check wiring between ECU terminal El and body ground.

FI-41

I

OK

Try another ECU.

Check fuse, fusible links and wiring BAD

harness.

I

I

I I I

I

OK

1

Check EFI main relay.

(See page FI-1 12)

OK

Refer to M-REL - El trouble

section.

I

I

1 I I

H

I I

BAD

I

BAD

Replace or repair.

Repair or replace.

* Replace.

I

I

1

Page 72

;I-42

EFI SYSTEM - Troubleshooting with Volt/Ohmmeter (MA)

NO,

2 }-I No voltage / s$t;;N -

Terminals

IDL - E2

VTA - E2

I

I

Throttle Position Sensor

Trouble

I I

I I

I

l

IDL - E2

Condition ..

Throttle valve open

Throttle valve fully closed

Throttle valve fully c

STD Voltage

10 - 14 v

o.‘: I;,; v

4-5v

I

Ei

IDL

VTA

VC

El

I

Voltmeter

R102,

FlO31

There is no voltage between ECU terminals IDL and E2.

0

(IO S/W ON) (Throttle valve open)

c

c

I

Check that there is voltage between ECU terminal +B (+Bl)

0

and body ground. (IO S/W ON)

, 1

OK ’

1

1 1 Check wiring between ECU terminal El and body ground.1

t

Refer to No. 1.

(See page FI-41)

BAD

7

- Replace or repair.

I

,

I@ Check throttle position sensor.

OK

BAD

I

1

1

1

OK

Check wiring between ECU and

throttle position sensor.

b

h

1

BAD

.

1

Page 73

EFI SYSTEM

- Troubleshooting with Volt/Ohmmeter (MA)

l

(r:

VC - E2

There is no voltage between ECU terminals VC and E2.

0

(IO

S/W ON)

FI-43

Voltmeter

v:

El

c

ECU A VTA

I

cc

1

Check that there is voltage between ECU terminal +6 (+El) and

body ground. (IO S/W ON)

OK

Check throttle position sensor,

CD

(See page FI-102)

BAD

I

Repair or replace.

I

I I I’

1

Try another ECU.

I

. VTA - E2

@There is no specified voltage at ECU terminals VTA and E2.

(IG S/W ON)

I 1

OK

Check wiring between ECU and throttle

nosition sensor. I

I

OK

1

1

I I

1 :;;i. or replace 1

1

T

BAD

I

I

Voltmeter

m

ECU vc

Fll62f

1

Check that there is voltage between ECU terminal VC and E2.

0

(IO S/W ON)

OK

1

1

t

Check wiring between ECU and

throttle position sensor.

I

1

OK

I

Try another ECU.

I

7

H

J I I

BAD

I

Repair or replace.

I

I

Page 74

WI4

EFI SYSTEM

- Troubleshooting with Volt/Ohmmeter (MA)

No.

I

Terminals

VC

vs

‘7M-GE only

- E2

- E2

Trouble Condition --

I

No voltage

Air flow meter

Ignition

S/W ON

Idling

3,000 rpm

Measuring plate fully closed 4-6V

Measuring plate fully open

-.

ST0 Voltage

4-6V

0.02 - 0.08 V

2-4V

0.3 - 1 .o v

ECU

Voltmeter

V’

E3lL

Voltmeter

Air Flow Meter (j)

There is no voltage between ECU terminals VC or VS and E2.

0

IIG s/w ON)

i

Check that there is voltage between ECU terminal +B (+Bl)

0

and body ground. (IG S/W ON)

OK

I

1 Check wiring between ECU terminal El and body ground. I 1

t

OK

I

Check air flow meter.

0

(See page FI-96)

Check wiring between ECU and air

flow meter.

OK

,

1 Repair or replace.

NO

Refer to No. 1.

(See page FI-41)

1

Try another ECU.

Repair or replace.

Page 75

EFI SYSTEM

- Troubleshooting with Volt/Ohmmeter (MA)

FI-45

MO.

‘4 -

‘7M-GTE only

I

Terminals

KS - Body

vc -

ground

Body

ground

Trouble

No voltage

Air Flow Meter

_ Ivc

Condition

Ignition’S/W ON

Cranking or running

Ignition S/W ON

. KS - Body ground

STD Voltage

4-6V

2-4V

ECU,

z31,

VC

KS

El

r

FFA7m

F1257i

There is no voltage between ECU terminals KS and body

0

ground. (IO S/W ON)

I

Check that there is voltage between

0

and body ground. (IG S/W ON)

I

OK

i

Check wiring between ECU terminal El and body

0

ground.

L

I

OK

Check air flow meter.

(See page FL981

I I

Check wiring between ECU and air

Repair or replace.

BAD

I

Oh

Try another ECU.

BAD

Repair or replace.

Page 76

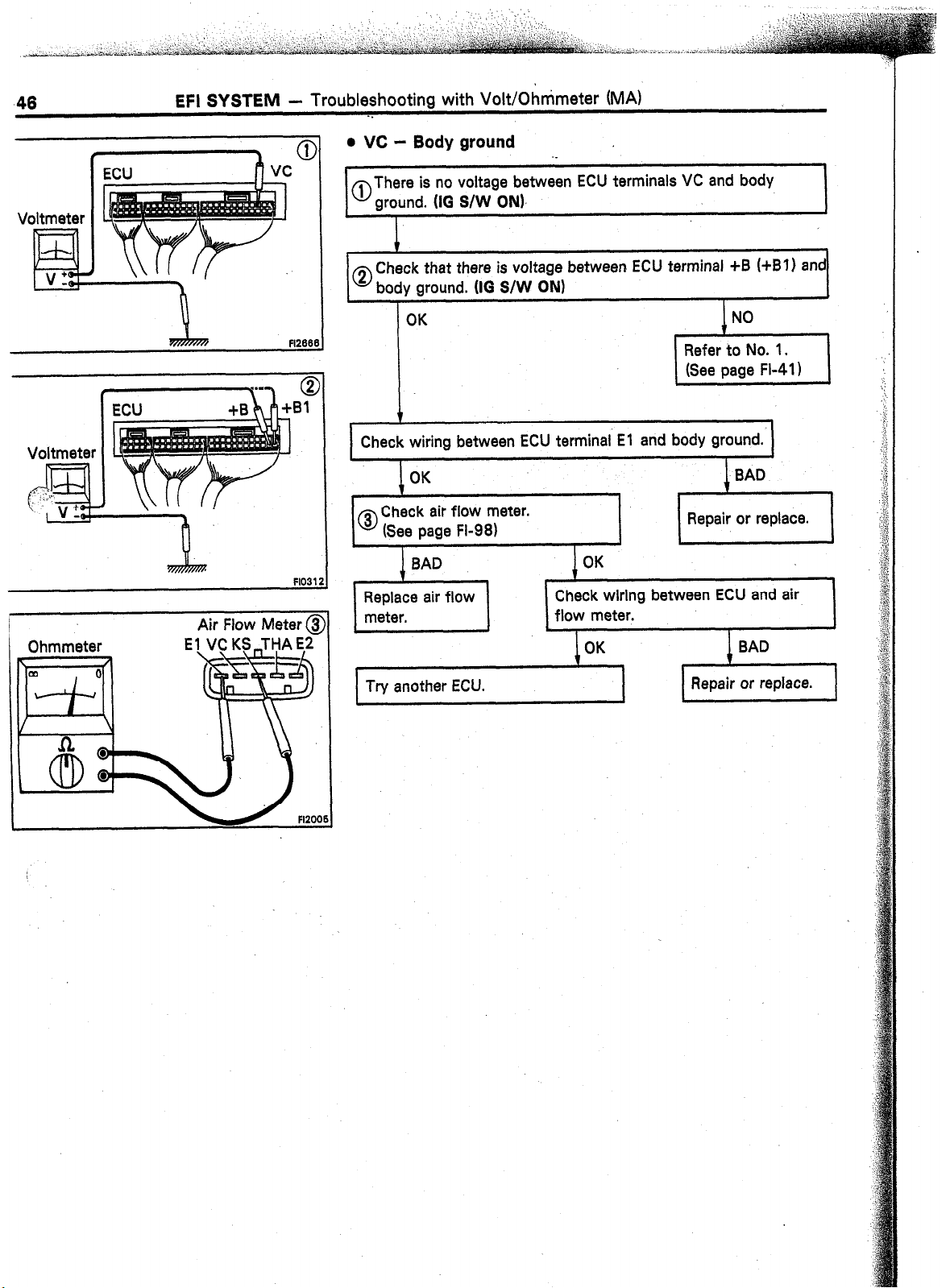

46

EFI SYSTEM - Troubleshooting with VoWOhnimeter (MA)

. .

Voltmeter

V:

d

Voltmeter

Air Flow

Meter @

. vc -

al

0

Check wiring between ECU terminal El and body ground.

Body ground

There is no voltage between ECU terminals VC and body

ground. (10 S/W ON),

Check that there is voltage between ECU terminal +B

body ground. (IO

S/W ON)

Check wiring between ECU and air

(+Bl)

and

Try another ECU.

Page 77

EFI SYSTEM - Troubleshooting with Volt/Ohmmeter (MA)

JO.

5

Terminals

No. IO

No. 20 No. 30

Fusible

Link

Battery f

EOl

E02

MAIN 2.OL

8

T

-

I

=

Trouble

No voltage Ignition switch ON

Ignition Switch

I

Condition

c

S-m Voltage

ECU

-“No. 10

-T

9-14v

FIZE

No. 2C

Voltmeter

A\

Solenoid Resistor

nr R?r

There is no voltage between ECU terminal No. 10, No. 20

0

and/or No. 30 and EOl or E02. (IO S/W ON)

1.

Check that there is specified voltage between resistor terminal

0

+B and body ground. STD voltaae:

NO

1

1

Check fuse, fusible links

and ignition switch.

I

Check wiring between

resistor and battery.

Check that there is specified voltage between resistor terminal

@ (No. IO, No. 20 or No. 30) and body ground.

I

OK

1

I

BAD

I

BAD

9 - 14 V

- Repair or replace.

,

- Repair or replace.

j ‘,.“.““!

Check resistance of magnetic coil in

0

I

each lniector.

I

.

Replace resistor.

I 1

J I

.

i

1

I

I

Page 78

FI-48

EFI SYSTEM -

Troubleshooting with Volt/Ohmmeter.(MA)

UO.

6

IM-GE

Terminals

THA - E2

1 I

Air Temp. Sensor

(Air Flow Meter)

Trouble

No voltage IG S/W ON

ECU

+B

(+Bl)

E2

THA

lE1

Condition ._

Intake air temperature 20°C (68°F) 1 -3v

7M-GTE

THA

E2

I

ir Temp. Sensor

iir Flow Meter)