CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its

constituents are known to the State of

California to cause cancer, birth

defects, and other reproductive

harm.

FOREWORD

The ISUZU industrial diesel engines are a product of ISUZU’s long years of

experience, advanced technology. ISUZU takes great pride in the superior

durability and operating economy of these engines.

In order to get the fullest use and benefit from your industrial engine, it is

important that you operate and maintain it correctly. This Manual is

designed to help you do this.

Please read this Manual carefully and follow its operating and maintenance

recommendations. This will ensure many years of trouble-free and

economical engine operation.

Should your engine require servicing, please contact your nearest ISUZU

engine outlet. He knows your engine best and is ready to meet your

satisfaction.

All information, illustrations, and specifications contained in this Manual are

based on the latest product information available at the time of publication.

ISUZU reserves the right to make changes in this Manual at any time without

prior notice.

WARNING AND CAUTION

SAFETY WARNINGS

WARNING: These mean there is something that could hurt you or other

people.

In the warning area, we tell you what the hazard is. Then we tell you what to do

to help avoid or reduce the hazard. Please read these warnings. If you don’t,

you or others could be hurt.

ENGINE OR EQUIPMENT DAMAGE WARNINGS

CAUTION: These mean there is something that could damage your engine

or equipment.

In the caution area, we tell you about something that can damage your engine or

equipment. Many times, this damage would not be covered by your warranty, and it could

be costly. But the caution will tell you what to do to help avoid the damage.

EMPHASIZED WARNINGS

NOTICE: These mean there is something that needs to be emphasized but

which does not concern the possibility of personal injury or mechanical

damage.

TABLE OF CONTENTS

1. ENGINE EXTERNAL VIEWS .............................................................. 1

1. MODEL 4LE1T............................................................................. 1

2. MODEL 4LE1NA.......................................................................... 3

2. GENERAL INFORMATION ................................................................. 5

1. EPA AND CARB CERTIFIED ENGINE DATA AND

SPECIFICATIONS........................................................................ 5

2. EC EMISSION CONTROL LABLE: ENGINE LABEL

(ONLY EC TYPE) ......................................................................... 18

3. ENGINE IDENTIFICATION........................................................... 19

4. ISUZU ENGINE AFTER SERVICE............................................... 21

3. FUEL, LUBRICANT, AND COOLANT................................................. 22

1. FUEL ............................................................................................ 22

2. LUBRICANT................................................................................. 27

3. COOLANT.................................................................................... 30

4. ENGINE OPERATION......................................................................... 31

1. CHECK BEFORE OPERATION................................................... 32

2. ENGINE STARTING..................................................................... 38

3. CHECK AND OPERATION AFTER THE ENGINE START-UP .... 42

4. CARE IN THE ENGINE OPERATION .......................................... 45

5. ENGINE STOPPING..................................................................... 51

6. OPERATION AND CARE FOR NEW ENGINE ............................ 52

7. ENGINE CARE FOR OVER-COOLING ....................................... 52

8. OPERATION AND CARE FOR TURBOCHARGED ENGINE...... 53

9. STARTING THE ENGINE AFTER BEING LEFT UNUSED

FOR A LONG PERIOD OF TIME ................................................. 54

5. PERIODICAL INSPECTION AND MAINTENANCE ............................ 55

1. LUBRICATING SYSTEM.............................................................. 55

2. COOLING SYSTEM ..................................................................... 64

3. FUEL SYSTEM............................................................................. 70

4. AIR INTAKE SYSTEM.................................................................. 77

5. ENGINE ELECTRICAL ................................................................ 79

6. ENGINE ASSEMBLY AND OTHERS ........................................... 83

6. ENGINE CARE IN COLD SEASON .................................................... 89

1. FUEL ............................................................................................ 89

2. COOLANT.................................................................................... 90

3. ENGINE OIL................................................................................. 92

4. BATTERY ..................................................................................... 92

5. ENGINE STARTING..................................................................... 93

7. ENGINE MAINTENANCE SCHEDULE ............................................... 94

8. SIMPLE ENGINE TROUBLESHOOTING ........................................... 102

1. ENGINE EXTERNAL VIEWS

1

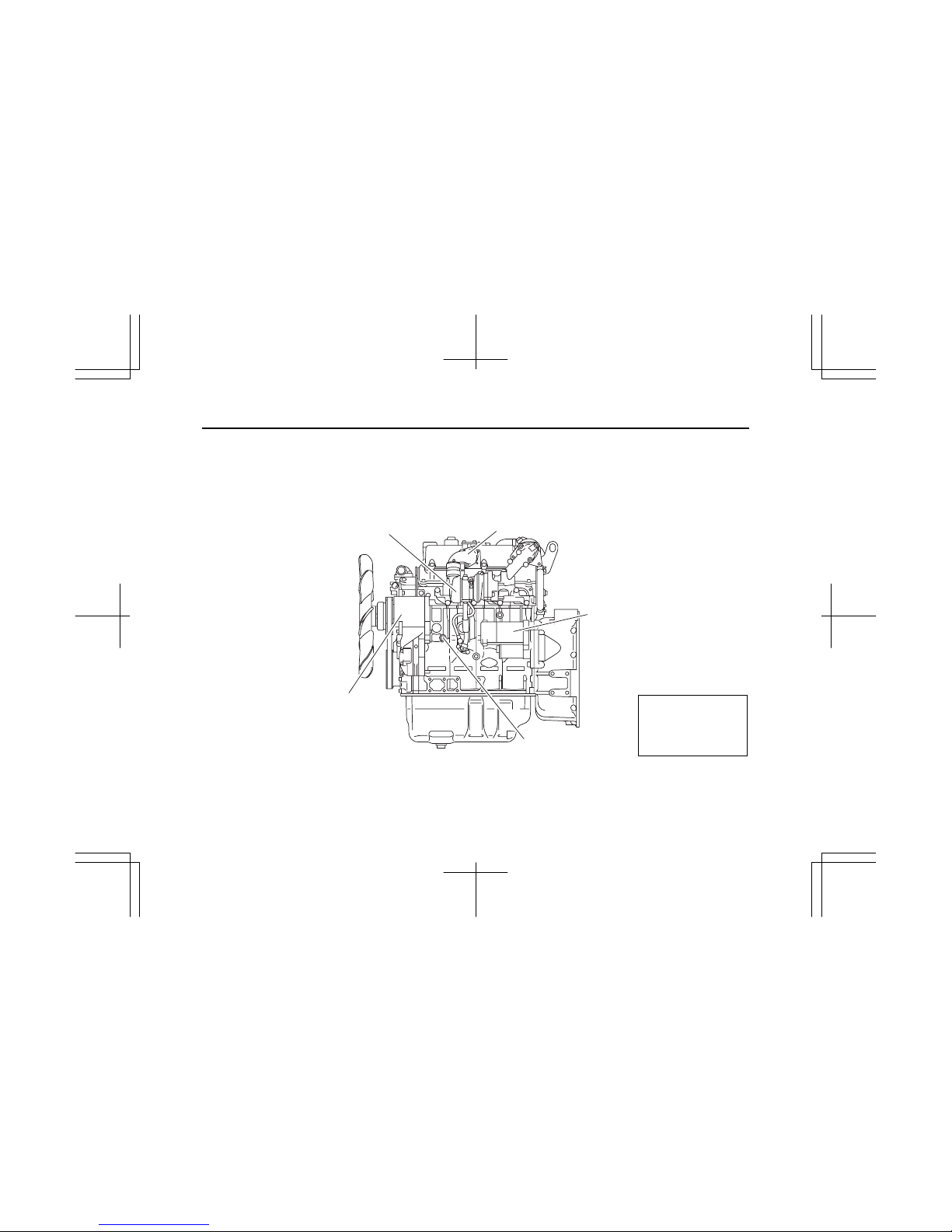

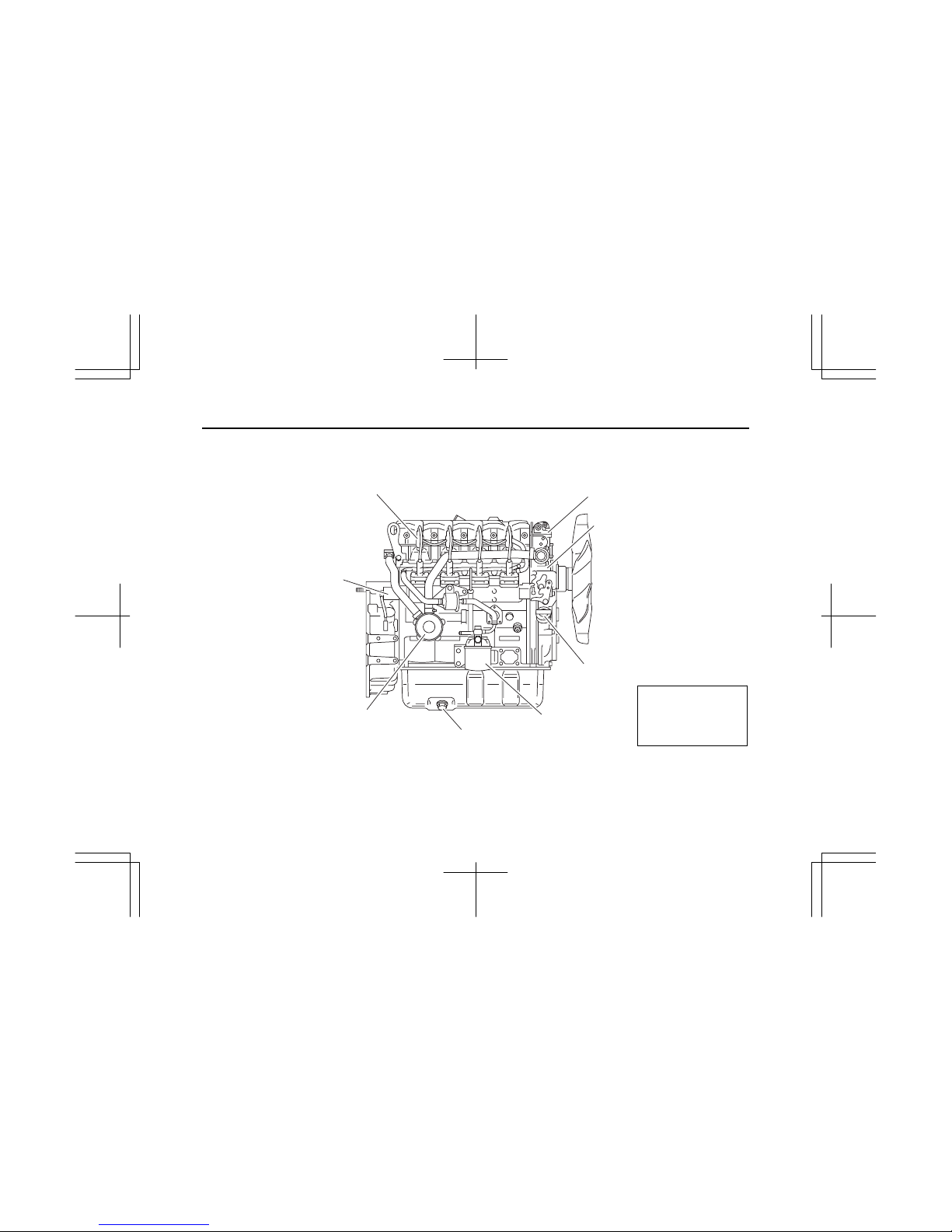

1. MODEL 4LE1T

(1) LH

Air inlet

Generator

Turbocharger

Water drain plug

Starter

IMLE0085

Note:

Engine details may

vary depending on the

specifications.

2

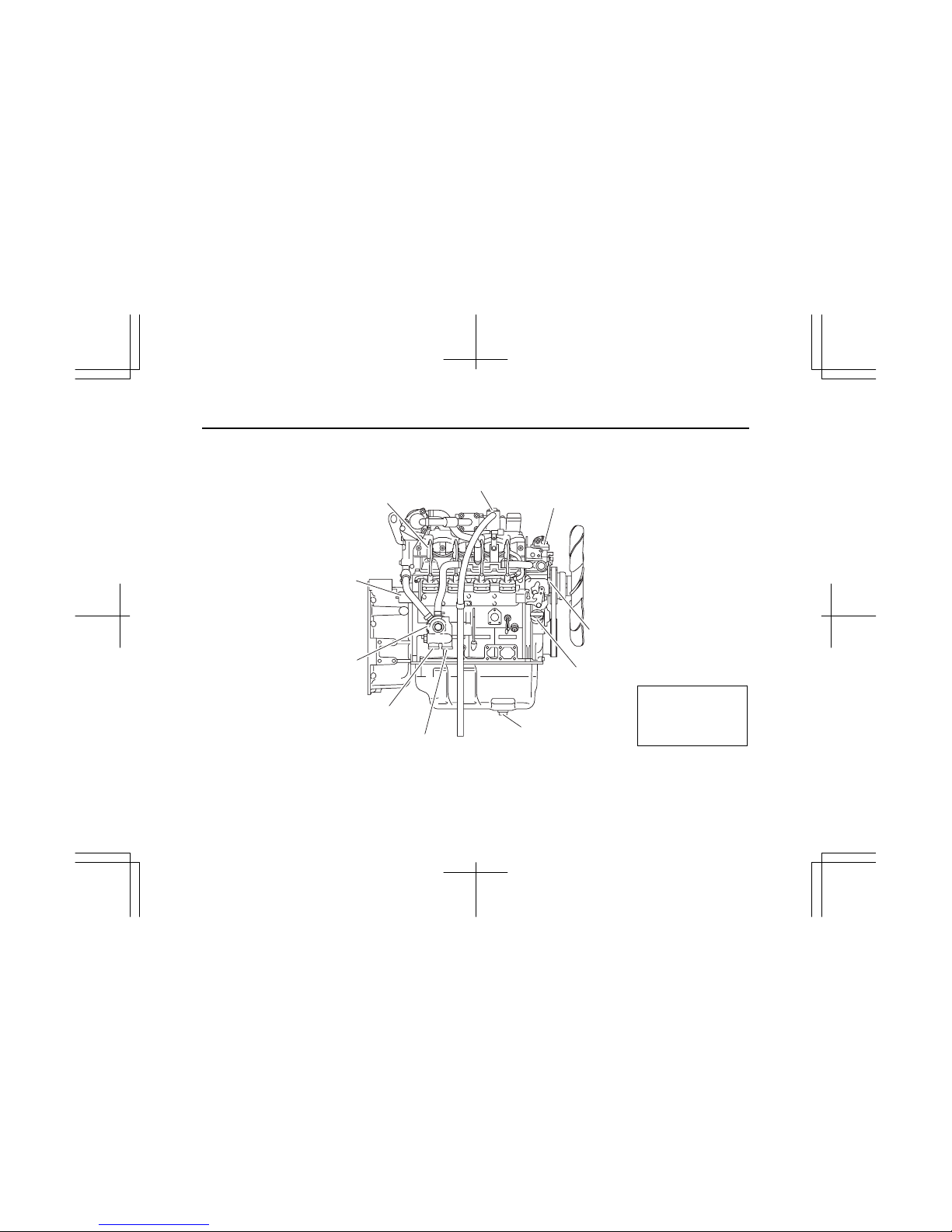

(2) RH

PCV

Nozzle holder

Solenoid stopper

Oil filler cap

Oil drain plug

Oil cooler

From oil filter

To oil filter

Water pump

Thermostat housing

IMLE0086

Note:

Engine details may

vary depending on the

specifications.

3

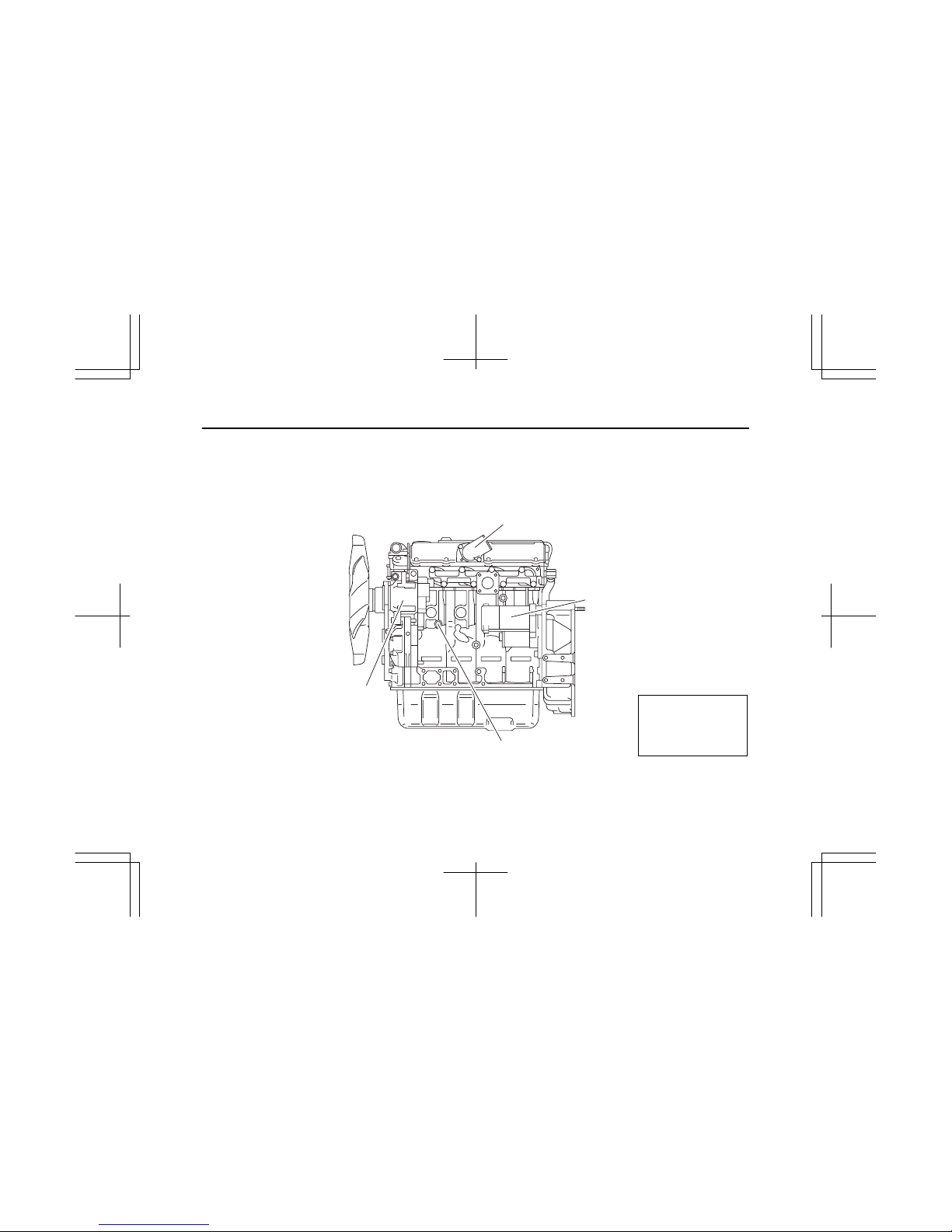

2. MODEL 4LE1NA

(1) LH

Air inlet

Generator

Water drain plug

Starter

IMLE0087

Note:

Engine details may

vary depending on the

specifications.

4

(2) RH

Nozzle holder

Solenoid stopper

Oil filler cap

Oil drain plug

Fuel filter

Oil filter

Thermostat housing

Water pump

IMLE0088

Note:

Engine details may

vary depending on the

specifications.

2. GENERAL INFORMATION

5

1. EPA AND CARB CERTIFIED ENGINE DATA AND SPECIFICATIONS

Se rapporter à la fin de ce document pour les informations EPA en français.

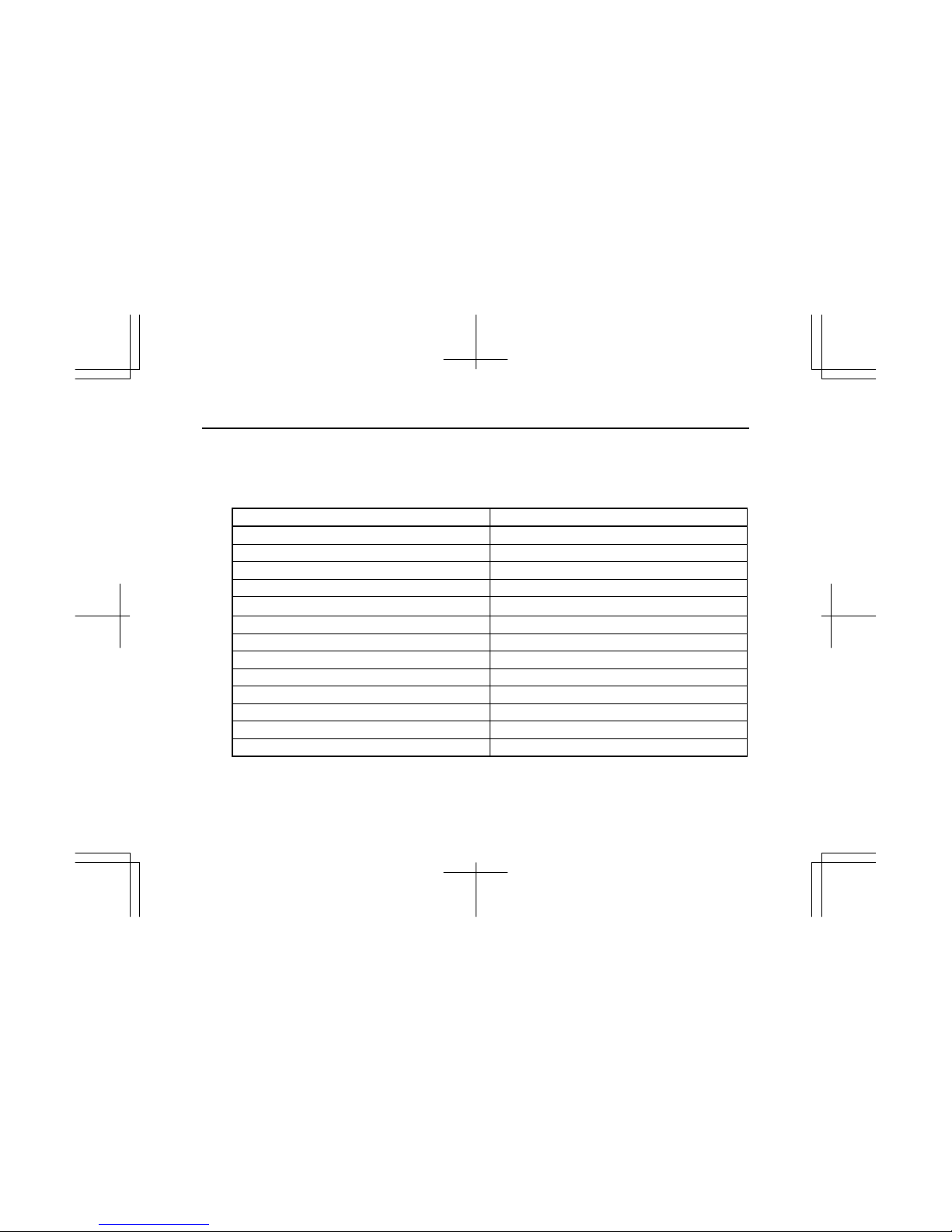

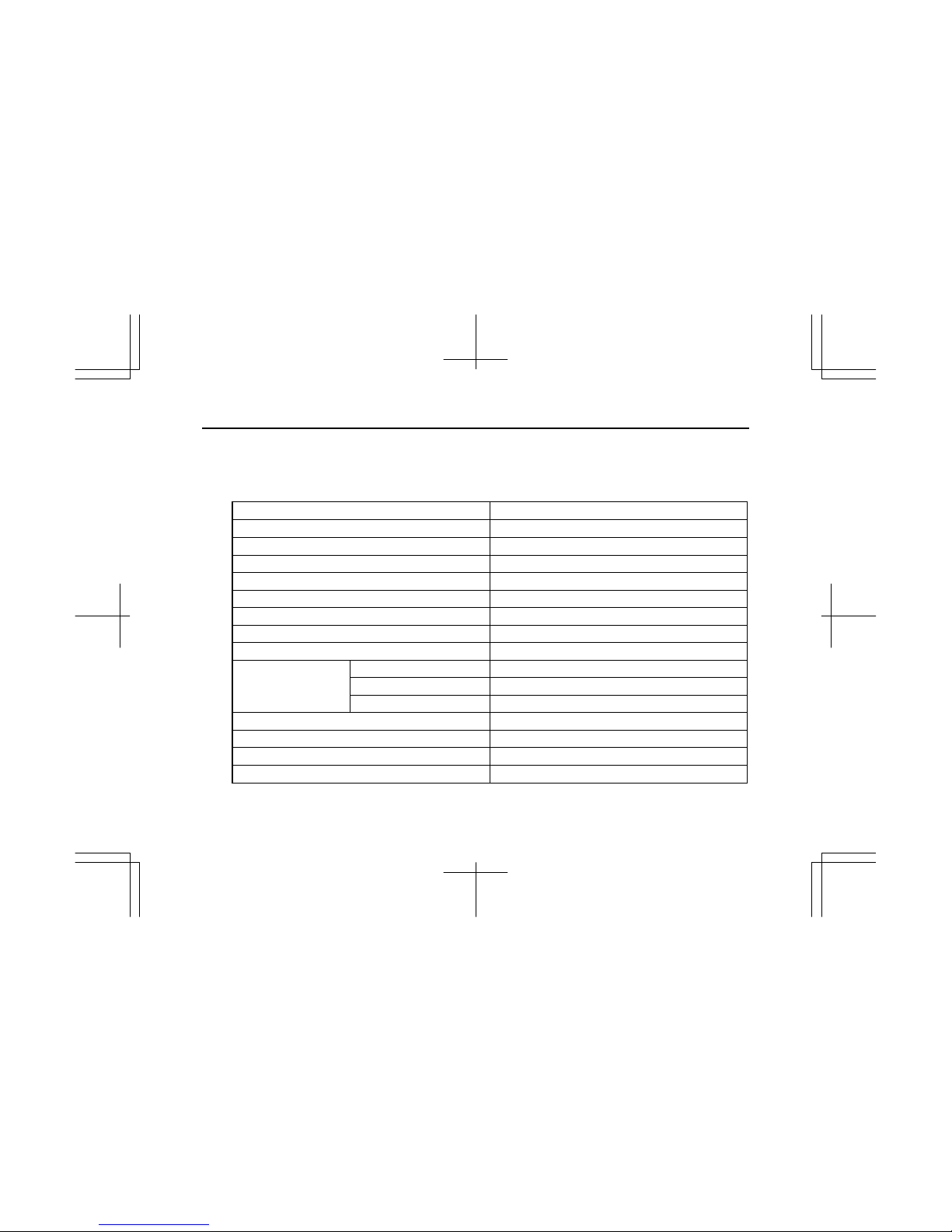

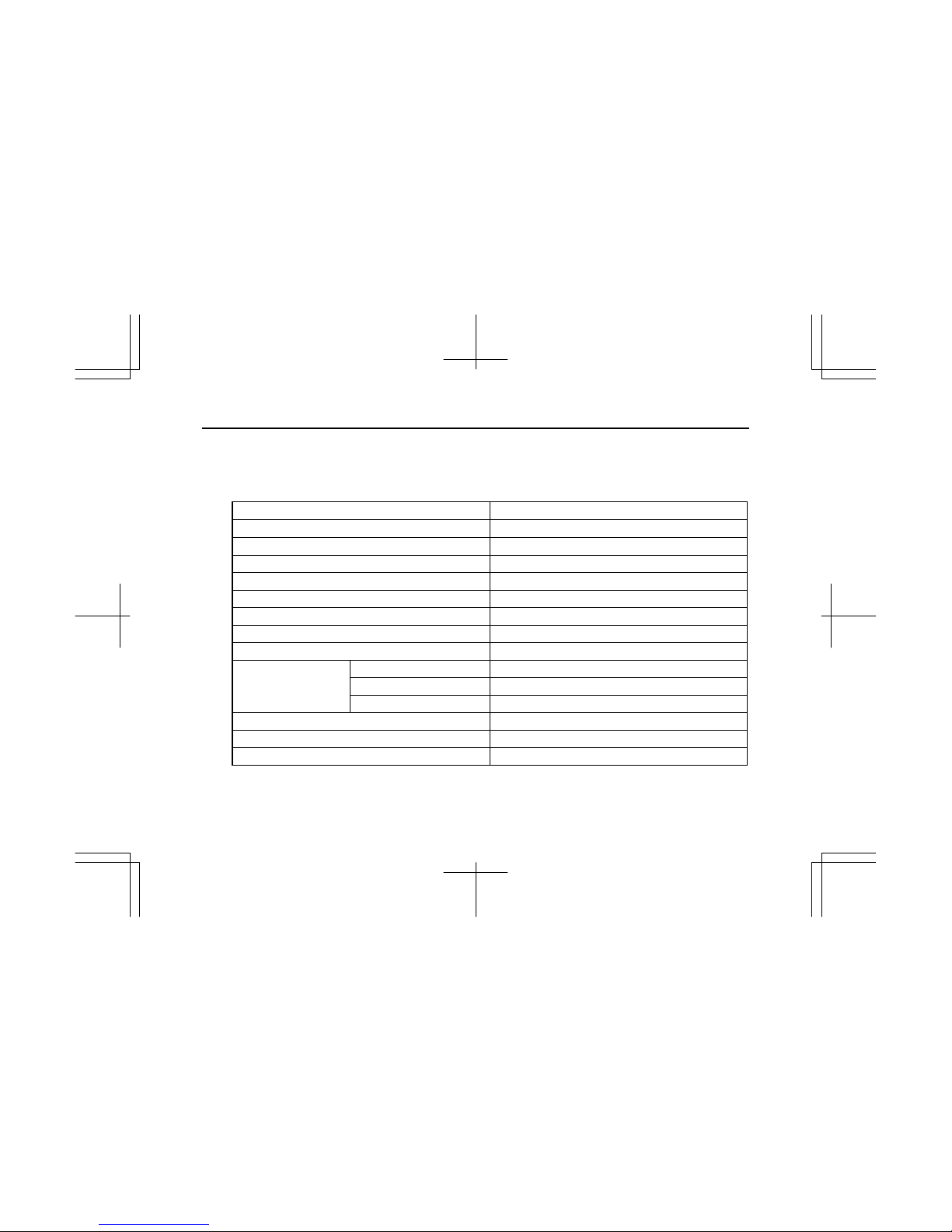

(1) Model AU-4LE1T

ISUZU engine model name AU-4LE1T

Engine family *SZXL02.2UTA

Engine code 4LE1XXXXX-XX

Engine type Water-Cooled, four cycle, in-line overhead valve type

Combustion type Swirl chamber type

No. of cylinders – bore × stroke mm(in) 4 – 85 × 96 (3.35 × 3.78)

Engine displacement L(cid) 2.179 (133)

Compression ratio 21.5 to 1

Firing order 1 – 3 – 4 – 2

*2 Rated power: SAE NET kW(hp)/min

-1

40 (53.6) / 2200

*2 Fuel flow at max rated power (mm3/stroke) 46.3

Exhaust emission control system EM, IDI, TC, EGR

Injection pump Bosch, PFR type

Governor Variable speed, Mechanical type

* Mark ; Put a letter codes for model year on the top of the letters.

Y : 2000, 1 : 2001, 2 : 2002, 3 : 2003, 4 : 2004, 5 : 2005, 6 : 2006, 7 : 2007, 8 : 2008, 9 : 2009, Model Year

Engine code varies depending on each engine.

6

ISUZU engine model name AU-4LE1T

Injection nozzles Throttle type

Specified fuel Diesel fuel (ASTM D975 No.2-D)

*2 Starter (V-kW) 12 – 2.2

*2 Alternator (V-A) 12 – 50

Specified engine oil (API grade) Refer to 3.LUBRICANT, Engine Oil Selection.

*2 Lub. oil volume L(qts) 7.6 (8.0) – 10.3 (10.9)

Coolant volume (Engine only) L(qts) 2.8 (3.0)

*2 Engine dry weight kg(lb) 190 (419)

Overall length mm(in) 647.5 (25.5)

Overall width mm(in) 523.6 (20.6)

*2 Engine dimensions

Overall height mm(in) 720.8 (28.4)

Valve clearance (cold) mm(in) 0.4 (0.0157)

Nozzle injection pressure MPa(psi) 14.7 (2132)

*2 Injection timing B.T.D.C. 12°

Maker and type of turbocharger IHI, RHF-3

Specification for items marked with an asterisk (*2) will vary according to the type of equipment in which the

engine is installed.

7

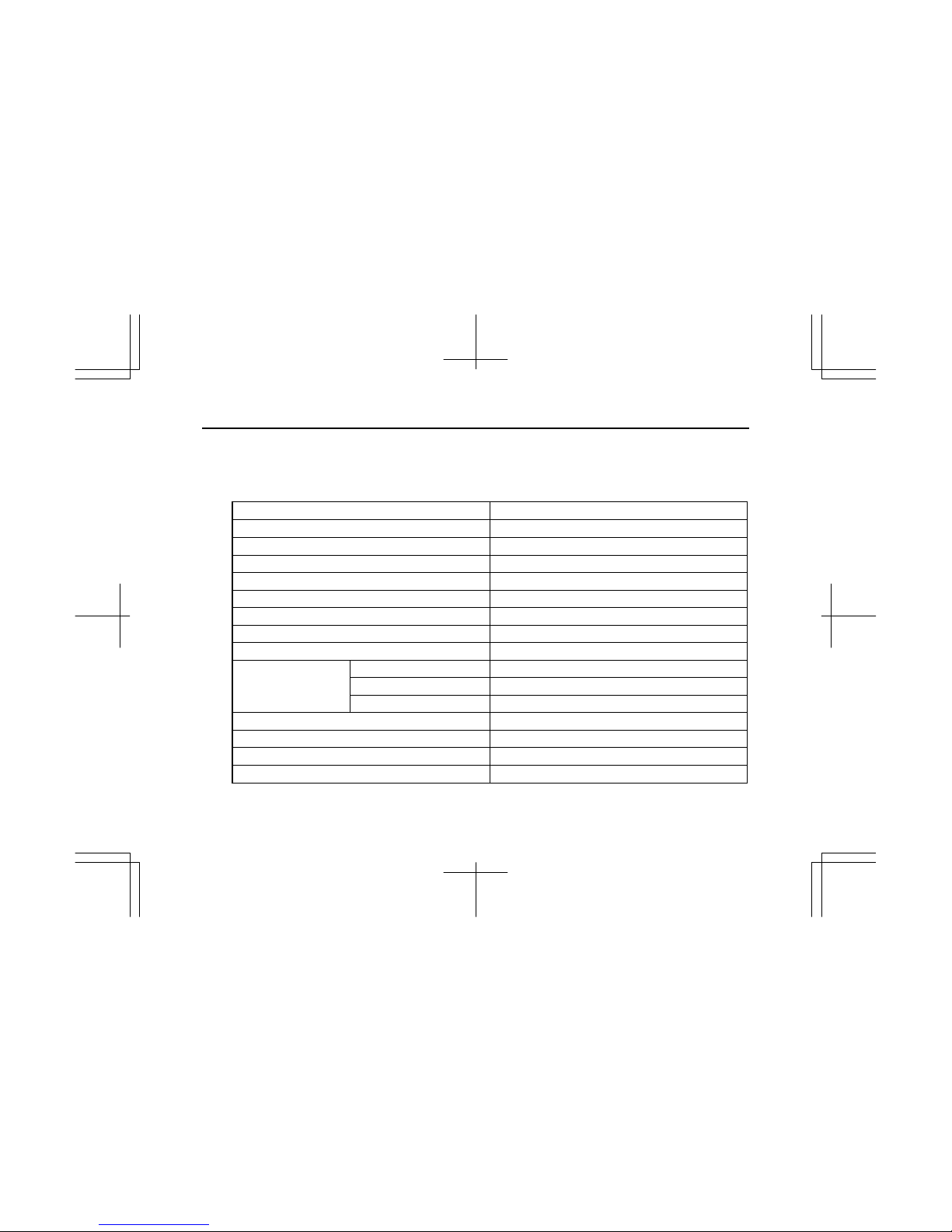

(2) Model BV-4LE1T

ISUZU engine model name BV-4LE1T

Engine family *SZXL02.2VTB

Engine code 4LE1XXXXX-XX

Engine type Water-Cooled, four cycle, in-line overhead valve type

Combustion type Swirl chamber type

No. of cylinders – bore × stroke mm(in) 4 – 85 × 96 (3.35 × 3.78)

Engine displacement L(cid) 2.179 (133)

Compression ratio 21.5 to 1

Firing order 1 – 3 – 4 – 2

*2 Rated power: SAE NET kW(hp)/min

-1

35 (46.9) / 1800

*2 Fuel flow at max rated power (mm3/stroke) 49.7

Exhaust emission control system EM, IDI, TC

Injection pump Bosch, PFR type

Governor Variable speed, Mechanical type

* Mark ; Put a letter codes for model year on the top of the letters.

Y : 2000, 1 : 2001, 2 : 2002, 3 : 2003, 4 : 2004, 5 : 2005, 6 : 2006, 7 : 2007, 8 : 2008, 9 : 2009, Model Year

Engine code varies depending on each engine.

8

ISUZU engine model name BV-4LE1T

Injection nozzles Throttle type

Specified fuel Diesel fuel (ASTM D975 No.2-D)

*2 Starter (V-kW) 12 – 2.0

*2 Alternator (V-A) 12 – 35

Specified engine oil (API grade) Refer to 3.LUBRICANT, Engine Oil Selection.

*2 Lub. oil volume L(qts) 7.6 (8.0) – 10.3 (10.9)

Coolant volume (Engine only) L(qts) 2.8 (3.0)

*2 Engine dry weight kg(lb) 180 (397)

Overall length mm(in) 753.7 (29.7)

Overall width mm(in) 486.2 (19.1)

*2 Engine dimensions

Overall height mm(in) 601.8 (23.7)

Valve clearance (cold) mm(in) 0.4 (0.0157)

Nozzle injection pressure MPa(psi) 14.7 (2132)

*2 Injection timing B.T.D.C. 10°

Maker and type of turbocharger IHI, RHF-3

Specification for items marked with an asterisk (*2) will vary according to the type of equipment in which the

engine is installed.

9

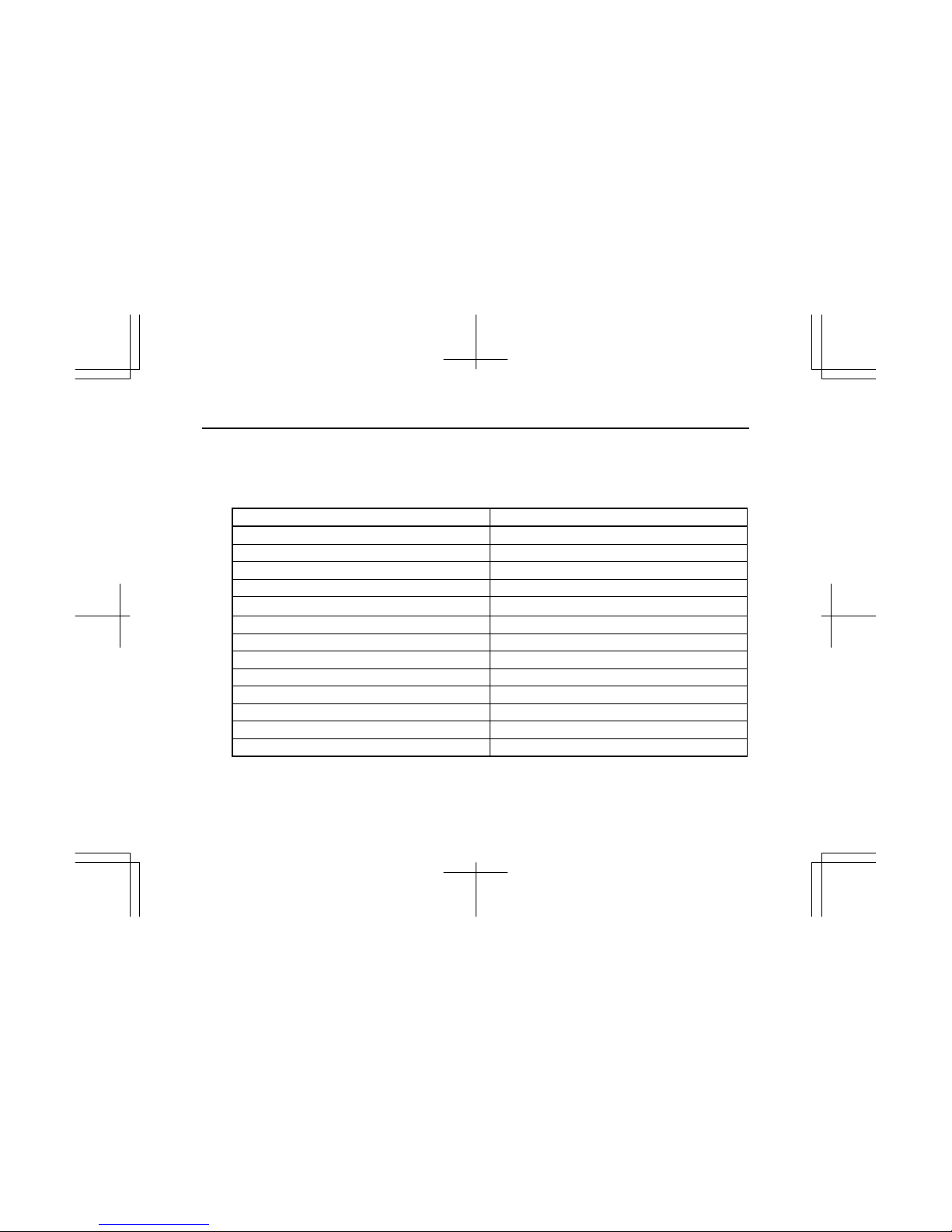

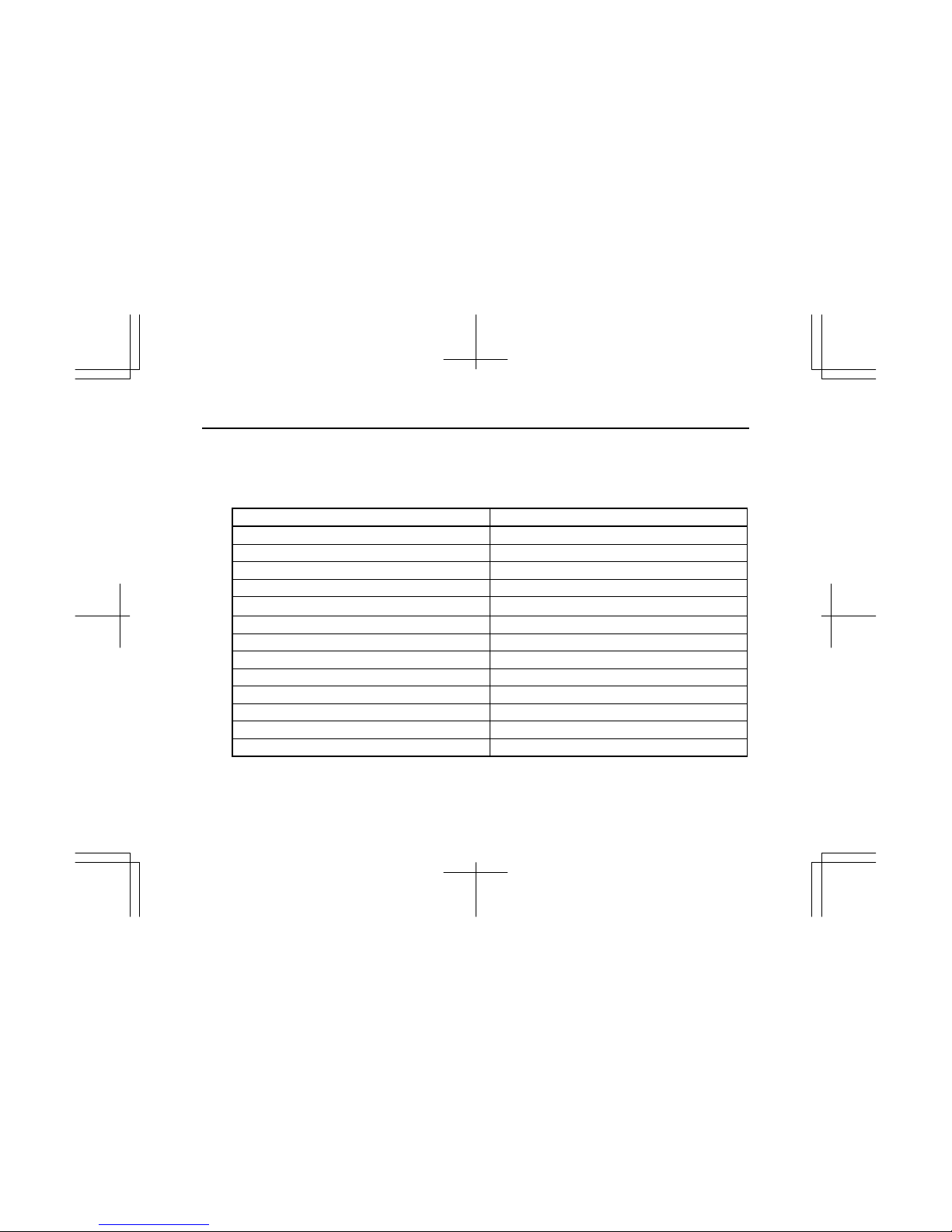

(3) Model AV-4LE1N

ISUZU engine model name AV-4LE1N

Engine family *SZXL02.2VNA

Engine code 4LE1XXXXX-XX

Engine type Water-Cooled, four cycle, in-line overhead valve type

Combustion type Swirl chamber type

No. of cylinders – bore × stroke mm(in) 4 – 85 × 96 (3.35 × 3.78)

Engine displacement L(cid) 2.179 (133)

Compression ratio 21.5 to 1

Firing order 1 – 3 – 4 – 2

*2 Rated power: SAE NET kW(hp)/min

-1

35.9 (48.1) / 2600

*2 Fuel flow at max rated power (mm3/stroke) 35.5

Exhaust emission control system EM, IDI

Injection pump Bosch, PFR type

Governor Variable speed, Mechanical type

* Mark ; Put a letter codes for model year on the top of the letters.

Y : 2000, 1 : 2001, 2 : 2002, 3 : 2003, 4 : 2004, 5 : 2005, 6 : 2006, 7 : 2007, 8 : 2008, 9 : 2009, Model Year

Engine code varies depending on each engine.

10

ISUZU engine model name AV-4LE1N

Injection nozzles Throttle type

Specified fuel Diesel fuel (ASTM D975 No.2-D)

*2 Starter (V-kW) 12 – 2.0

*2 Alternator (V-A) 12 – 35

Specified engine oil (API grade) Refer to 3.LUBRICANT, Engine Oil Selection.

*2 Lub. oil volume L(qts) 5.9 (6.2) – 8.4 (8.8)

Coolant volume (Engine only) L(qts) 2.8 (3.0)

*2 Engine dry weight kg(lb) 170 (375)

Overall length mm(in) 695.7 (27.4)

Overall width mm(in) 486.2 (19.1)

*2 Engine dimensions

Overall height mm(in) 601.8 (23.7)

Valve clearance (cold) mm(in) 0.4 (0.0157)

Nozzle injection pressure MPa(psi) 14.7 (2132)

*2 Injection timing B.T.D.C. 13°

Specification for items marked with an asterisk (*2) will vary according to the type of equipment in which the

engine is installed.

11

(4) Model BV-4LE1N

ISUZU engine model name BV-4LE1N

Engine family *SZXL02.2VNC

Engine code 4LE1XXXXX-XX

Engine type Water-Cooled, four cycle, in-line overhead valve type

Combustion type Swirl chamber type

No. of cylinders – bore × stroke mm(in) 4 – 85 × 96 (3.35 × 3.78)

Engine displacement L(cid) 2.179 (133)

Compression ratio 21.5 to 1

Firing order 1 – 3 – 4 – 2

*2 Rated power: SAE NET kW(hp)/min

-1

26.3 (35.3) / 1800

*2 Fuel flow at max rated power (mm3/stroke) 36.5

Exhaust emission control system EM, IDI

Injection pump Bosch, PFR type

Governor Variable speed, Mechanical type

* Mark ; Put a letter codes for model year on the top of the letters.

Y : 2000, 1 : 2001, 2 : 2002, 3 : 2003, 4 : 2004, 5 : 2005, 6 : 2006, 7 : 2007, 8 : 2008, 9 : 2009, Model Year

Engine code varies depending on each engine.

12

ISUZU engine model name BV-4LE1N

Injection nozzles Throttle type

Specified fuel Diesel fuel (ASTM D975 No.2-D)

*2 Starter (V-kW) 12 – 2.0

*2 Alternator (V-A) 12 – 20

Specified engine oil (API grade) Refer to 3.LUBRICANT, Engine Oil Selection.

*2 Lub. oil volume L(qts) 5.9 (6.2) – 8.4 (8.8)

Coolant volume (Engine only) L(qts) 2.8 (3.0)

*2 Engine dry weight kg(lb) 170 (375)

Overall length mm(in) 671 (26.4)

Overall width mm(in) 496 (19.5)

*2 Engine dimensions

Overall height mm(in) 595 (23.4)

Valve clearance (cold) mm(in) 0.4 (0.0157)

Nozzle injection pressure MPa(psi) 14.7 (2132)

*2 Injection timing B.T.D.C. 10°

Specification for items marked with an asterisk (*2) will vary according to the type of equipment in which the

engine is installed.

13

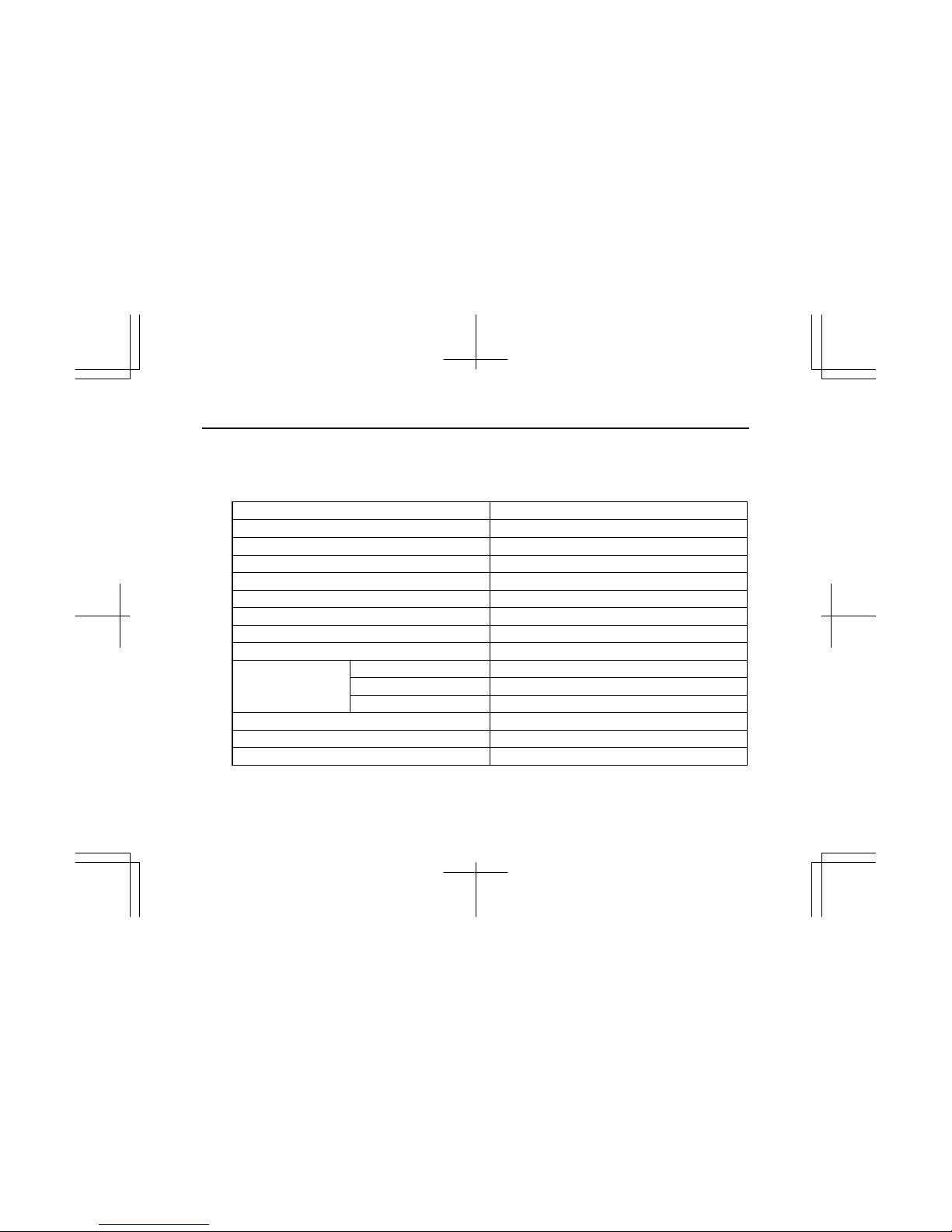

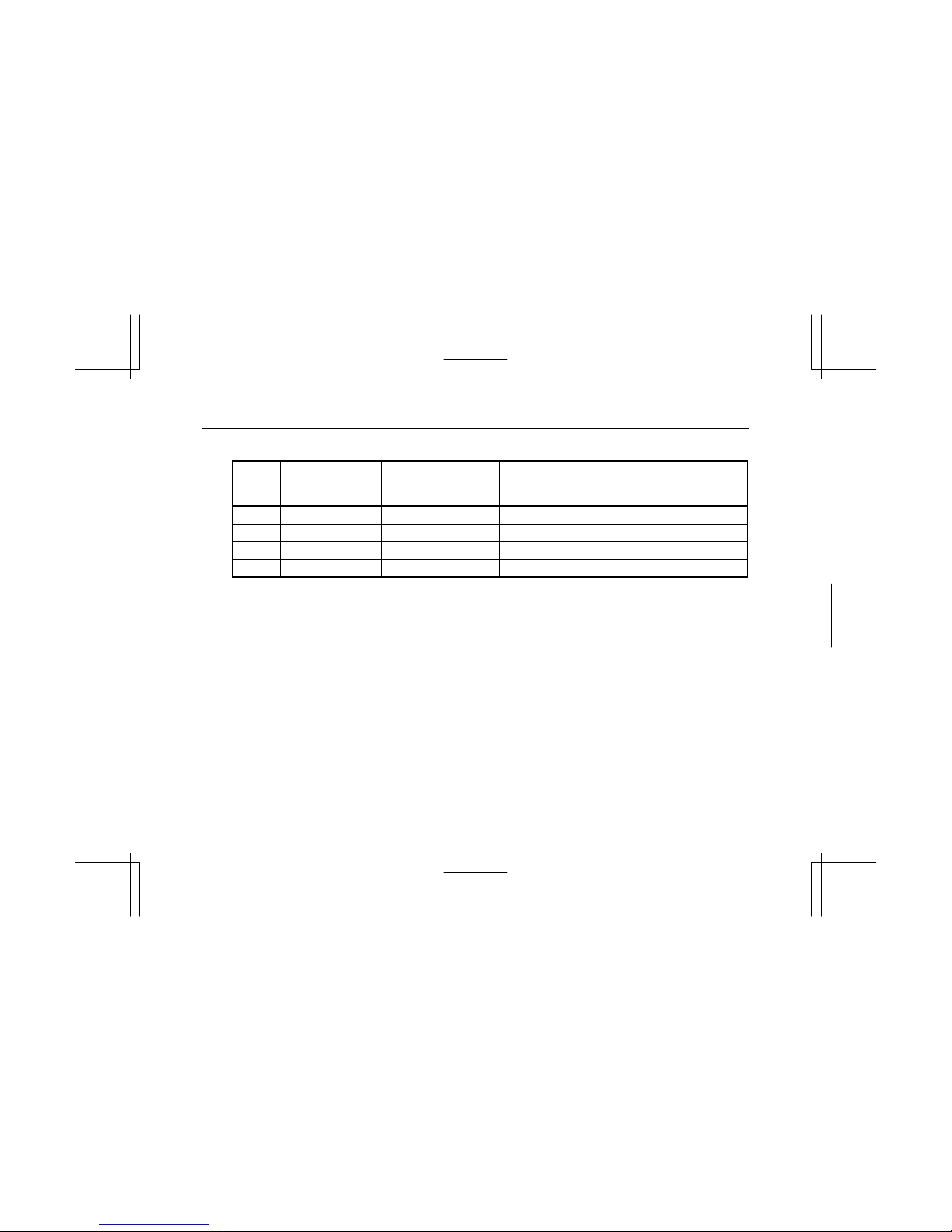

(5) Engine family index

Engine Engine family Engine code

Injection nozzle

opening pressure

MPa(psi)

Injection timing

B.T.D.C.

(Static)

4LE1T *SZXL02.2UTA ALL –– ––

4LE1T *SZXL02.2VTB ALL –– ––

4LE1N *SZXL02.2VNA ALL –– ––

4LE1N *SZXL02.2VNC ALL –– ––

* Mark ; Put a letter codes for model year on the top of the letters.

Y : 2000, 1 : 2001, 2 : 2002, 3 : 2003, 4 : 2004, 5 : 2005, 6 : 2006, 7 : 2007, 8 : 2008, 9 : 2009, Model Year

14

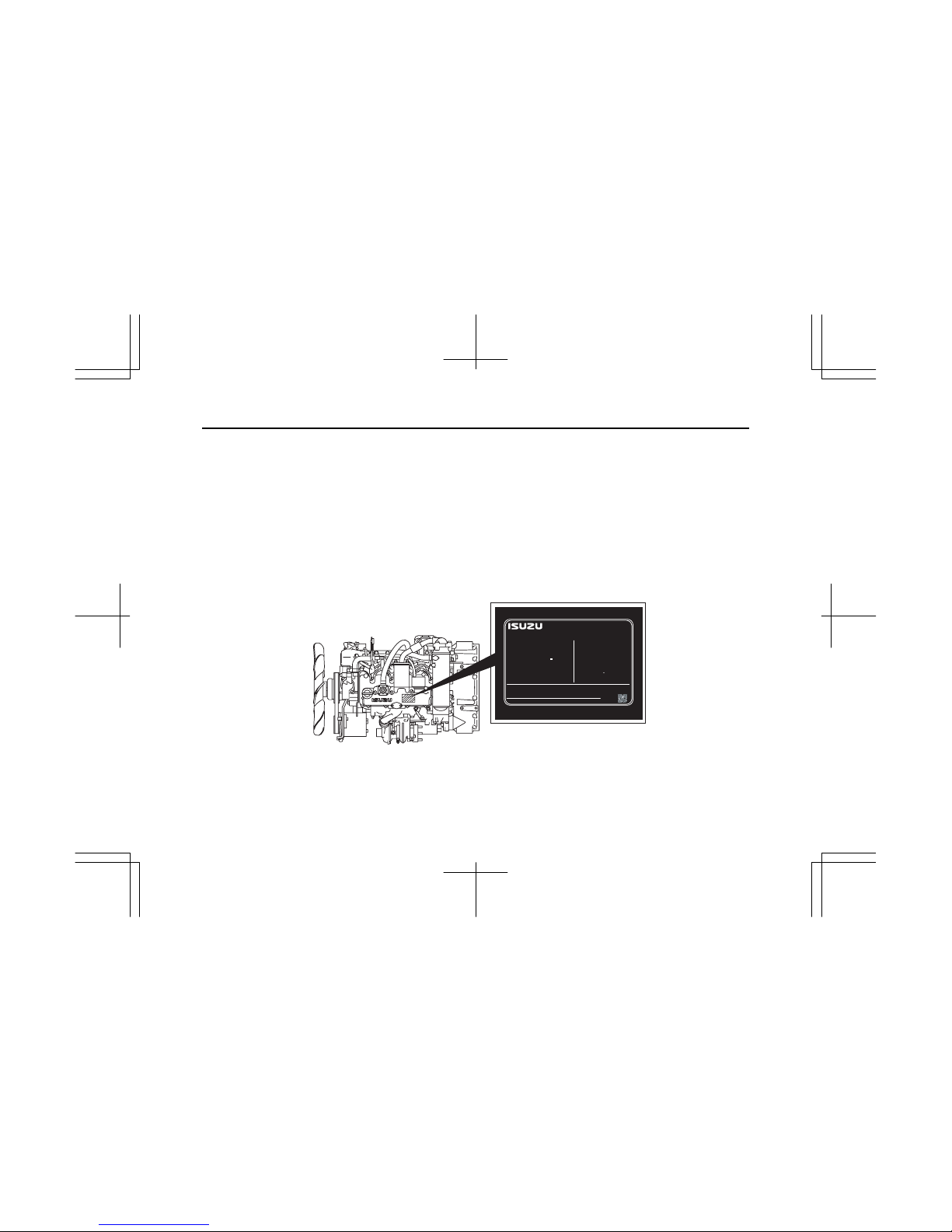

EMISSION CONTROL LABEL: ENGINE LABEL (EPA, EC COMBIND TYPE)

Emission control label is attached at the center of injection pump cover located at the right side of cylinder body, or on the

cylinder head cover.

The location of emission control label attached on the engine may vary depending on the engine specification.

The following is the sample of a label required for engine emission control information, along with location.

4LE1T

ENGINE FAMILY

ENGINE CODE

MODEL

POWER CATEGORY

ADVERTISED POWER (SAE NET)

: XX.X kW / XXXX RPM

FUEL RATE : XX mm

/st.

3

VALVE LASH (COLD)

INL/EXH : XX / XX mm.

INITIAL INJECTION TIMING

CURB IDLE : XXX RPM

EMISSION CONTROL INFORMATION

ISUZU MOTORS LTD. MADE IN JAPAN

THIS ENGINE COMPLIES WITH U.S. EPA REGULATIONS FOR XX MY

NONROAD DIESEL ENGINES AND CALIFORNIA REGULATIONS FOR XX

MY OFF-ROAD DIESEL ENGINES.

EXHAUST EMISSION CONTROL SYSTEM

SEE SERVICE MANUAL FOR

MODEL SPECIFICATIONS.

ENGINE FAMILY : XXXXXXXXXX

ENGINE TYPE : XXXXXXXXXX

THIS ENGINE IS CONFORMED 97/68/EC DIRECTIVE.

ENGINE I.D.NUMBER :

XXXX-XXXX

TYPE APPROVAL NUMBER : XXXXXXXXXXXXXXXXXX

XXXXXX

: XX-XXXXX

: XXXXXXXXX-XX

: XXXXXXX.XXXX

: XX < kW < XX

XXXXXXXXXXXXXXXXXX

: XXXXXXXXXXXXXXXXXX

LOW SULFUR FUEL OR ULTRA LOW

SULFUR FUEL ONLY

XXXXXXXXXX XXXXXXXXXX

: XXX BTDC

IMLE0097

15

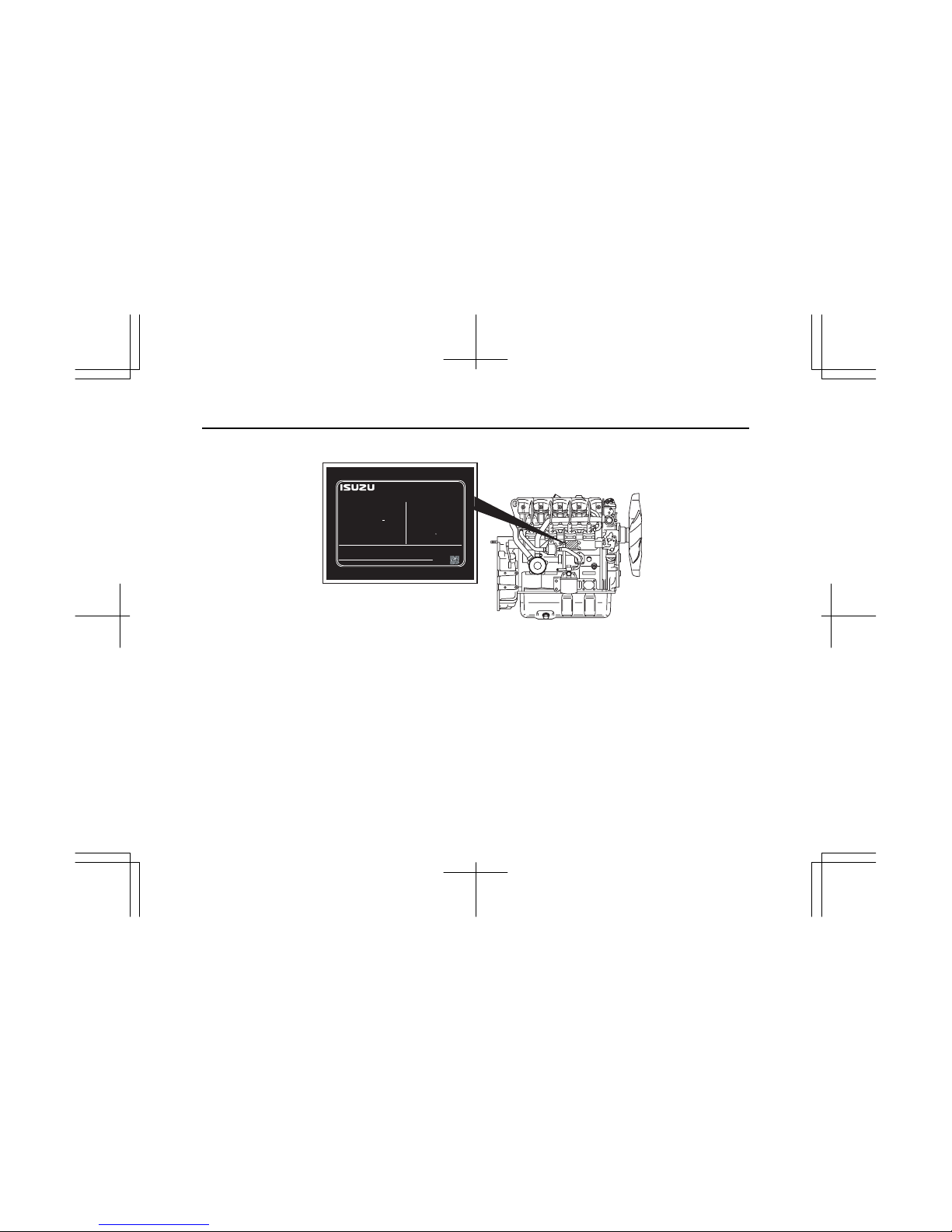

4LE1NA

ENGINE FAMILY

ENGINE CODE

MODEL

POWER CATEGORY

ADVERTISED POWER (SAE NET)

: XX.X kW / XXXX RPM

FUEL RATE : XX mm

/st.

3

VALVE LASH (COLD)

INL/EXH : XX / XX mm.

INITIAL INJECTION TIMING

CURB IDLE : XXX RPM

EMISSION CONTROL INFORMATION

ISUZU MOTORS LTD. MADE IN JAPAN

THIS ENGINE COMPLIES WITH U.S. EPA REGULATIONS FOR XX MY

NONROAD DIESEL ENGINES AND CALIFORNIA REGULATIONS FOR XX

MY OFF-ROAD DIESEL ENGINES.

EXHAUST EMISSION CONTROL SYSTEM

SEE SERVICE MANUAL FOR

MODEL SPECIFICATIONS.

ENGINE FAMILY : XXXXXXXXXX

ENGINE TYPE : XXXXXXXXXX

THIS ENGINE IS CONFORMED 97/68/EC DIRECTIVE.

ENGINE I.D.NUMBER :

XXXX-XXXX

TYPE APPROVAL NUMBER : XXXXXXXXXXXXXXXXXX

XXXXXX

: XX-XXXXX

: XXXXXXXXX-XX

: XXXXXXX.XXXX

: XX < kW < XX

XXXXXXXXXXXXXXXXXX

: XXXXXXXXXXXXXXXXXX

LOW SULFUR FUEL OR ULTRA LOW

SULFUR FUEL ONLY

XXXXXXXXXX XXXXXXXXXX

: XXX BTDC

IMLE0110

16

EMISSION CONTROL LABEL: ENGINE LABEL (ONLY EPA TYPE)

Emission control label is attached at a visible point on the equipment.

ENGINE FAMILY

ENGINE CODE

MODEL

POWER CATEGORY

ADVERTISED POWER (SAE NET)

: XX.X kW / XXXX RPM

FUEL RATE : XX mm

/st.

3

VALVE LASH (COLD)

INL/EXH : XX / XX mm.

INITIAL INJECTION TIMING

CURB IDLE : XXX RPM

EMISSION CONTROL INFORMATION

ISUZU MOTORS LTD. MADE IN JAPAN

THIS ENGINE COMPLIES WITH U.S. EPA REGULATIONS FOR XX MY

NONROAD DIESEL ENGINES AND CALIFORNIA REGULATIONS FOR XX

MY OFF-ROAD DIESEL ENGINES.

EXHAUST EMISSION CONTROL SYSTEM

SEE SERVICE MANUAL FOR

MODEL SPECIFICATIONS.

XXXXXX

: XX-XXXXX

: XXXXXXXXX-XX

: XXXXXXX.XXXX

: XX < kW < XX

XXXXXXXXXXXXXXXXXX

: XXXXXXXXXXXXXXXXXX

LOW SULFUR FUEL OR ULTRA LOW

SULFUR FUEL ONLY

XXXXXXXXXX XXXXXXXXXX

: XXX BTDC

ENGINE I.D.NUMBER :

XXXX-XXXX

IMLE0105

17

FUEL TYPE IN USE LIMITATION LABEL (FOR EPA)

The fuel type in use limitation label is attached on the filler neck of the fuel tank.

Contents of the label:

LOW SULFUR OR ULTRA LOW SULFUR DIESEL FUEL ONLY

IMLE0066

18

2. EC EMISSION CONTROL LABEL: ENGINE LABEL (ONLY EC TYPE)

Emission control label is attached at the front of injection pump cover located at the right side of cylinder body or the

cylinder head cover.

The following is the detail of a label required for engine emission control information, along with location.

EMISSION CONTROL INFORMATION

ISUZU MOTORS LTD. MADE IN JAPAN

ENGINE FAMILY : XXXXXXXXXX

ENGINE TYPE : XXXXXXXXXX

THIS ENGINE IS CONFORMED 97/68/EC DIRECTIVE.

ENGINE I.D.NUMBER :

XXXX-XXXX

TYPE APPROVAL NUMBER : XXXXXXXXXXXXXXXXXX

XXXXXX

IMLE0106

19

3. ENGINE IDENTIFICATION

(1) Position of Display

The engine serial number is stamped on the front upper right side of

the cylinder body, and the engine model is cast on the rear lower right

side of cylinder body just above the oil cooler.

Further, engine model is described also on an ID label on the top of the

cylinder head cover.

20

Engine model Serial number

4LE1 000000

IMLE0092

21

(2) Confirmation of Engine Serial Number

It is advisable to check the engine serial number, engine model name

and type of machine together with the equipment manufacturer’s name,

as it is required when you contact the distributor for repair service or

parts ordering.

WAR NIN G:

Conduct confirmation of engine serial number with the engine

stopped.

To avoid being injury, don’t check it, while the engine is still

hot.

4. ISUZU ENGINE AFTER SERVICE

(1) Isuzu Engine After Service

Please feel free to contact your ISUZU dealer for periodical inspection

and maintenance.

(2) Isuzu Genuine Parts

The ISUZU genuine parts are identical with those of used in the engine

production, and accordingly, they are warranted by ISUZU MOTORS

LIMITED.

The ISUZU genuine parts are supplied by the ISUZU distributors or the

authorized parts suppliers. Please designate "ISUZU Genuine Parts"

when you need engine parts.

IMLE0073

IMWG0005

3. FUEL, LUBRICANT, AND COOLANT

22

1. FUEL

(1) Fuel Selection

The following specific advantages are required for the diesel fuel.

1) Must be free from minute dust particles.

2) Must have adequate viscosity.

3) Must have high cetane value.

4) Must have high fluidity at low temperature.

5) *Low sulfur or ultra low sulfur diesel fuel only.

6) Must have little residual carbon.

* EPA regulations

Diesel fuels

Applicable Standard Recommendation

JIS (JAPANESE INDUSTRIAL STANDARD) NO. 2

DIN (DEUTSCHE INDUSTRIE NORMEN) DIN 51601

SAE (SOCIETY OF AUTOMOTIVE ENGINEERS)

Based on SAE-J-313C

NO. 2-D

BS (BRITISH STANDARD)

Based on BS/2869-1970

Class A-1

If fuel other than the specified one is used, engine function will be lowered.

23

(2) Fuel Requirements

CAUTION:

Use of other types of fuel than ultra low-sulfur fuel may not

conform to emission regulations.

CAUTION:

The fuel injection pump, injection nozzle or other parts of the

fuel system and engine can be damaged if you use any fuel or

fuel additive other than those specifically recommended by

Isuzu.

Such damage is not Isuzu’s responsibility, and is not covered

by the Warranty. To help avoid fuel system or engine damage,

please heed the following:

•

Some service stations mix used engine oil with diesel fuel.

Some manufacturers of large diesel engines allow this;

however, for your diesel engine, do not use diesel fuel

which has been contaminated with engine oil. Besides

causing engine damage, such fuel can also affect emission

control. Before using any diesel fuel, check with the

service station operator to see if the fuel has been mixed

with engine oil.

•

Do not use any fuel additive (other than as recommended

under "Biocide" in this section). At the time this manual

was printed, no other fuel additive was recommended.

(See your authorized dealer to find out if this has changed.)

•

Take care not to run out of diesel fuel. If you do run out of

fuel, you may need to bleed air out of the fuel injection

pump to re-start the engine after fuel has been added.

24

Your engine is designed to use either Number 1-D or Number 2-D diesel fuel.

However, for better fuel economy, use Number 2-D diesel fuel whenever

possible. At temperatures less than -7°C, (20°F), Number 2-D fuel may

pose operating problems (see "Cold Weather Operation" which follows). At

colder temperatures, use Number 1-D fuel (if available) or use a "winterized"

Number 2-D (a blend of Number 1-D and Number 2-D). This blended fuel is

usually called Number 2-D also, but can be used in colder temperatures than

Number 2-D fuel which has not been "winterized. " Check with the service

station operator to be sure you get the properly blended fuel. Note that

diesel fuel may foam during a fill-up. This can cause the automatic pump

nozzle to shut off even though your tank is not full.

CAUTION:

Do not use home heating oil or gasoline in your diesel engine;

either may cause engine damage.

(3) Replacement Fasteners

CAUTION:

Fuel may be under pressure. Remove the fuel cap slowly to

prevent fuel from spraying out and causing injury.

NOTICE:

Always use diesel fuel.

Use of low quality fuel may adversely affect the engine parts,

and cause failure.

Use of other than specified fuel may adversely affect the

engine or emission control system and cause failure.

If other than specified diesel fuel is used, the machine may not

conform to specifications.

25

(4) Handling of the Fuel

The fuel containing dust particles or water will cause engine failure.

Therefore, the following notice must be observed.

1) Take care to prevent the fuel from entry of dust particles or water when

filling the fuel tank.

When fueling is done from an oil drum directly, keep the drum

stationary over a long time so that clean fuel can be used after the dust

particles or water is completely sedimented.

2) Always fully fill the fuel tank. Drain the sedimented particles in the fuel

tank frequently by opening the tank draining hole.

(5) Water in Fuel

During refueling, it is possible for water (and other contaminants) to be

pumped into your fuel tank along with the diesel fuel. This can

happen if a service station does not regularly inspect and clean its fuel

tanks, or if a service station receives contaminated fuel from its

supplier(s).

To protect your engine from contaminated fuel, there is a fuel filter

system on the engine which allows you to drain excess water.

26

WAR NIN G:

The water/diesel fuel mixture is flammable, and could be hot.

To help avoid personal injury and/or property damage, do not

touch the fuel coming from the drain valve, and do not expose

the fuel to open flames or sparks. Be sure you do not overfill

the container. Heat (such as from the engine) can cause the

fuel to expand. If the container is too full, fuel could be forced

out of the container. This could lead to a fire and the risk of

personal injury and/or machine or equipment damage.

(6) Fuel Filter

1) Be sure to use the genuine fuel filter. The fuel injection system is

precision structure so that its filter has a finer mesh than conventional

one to extend life of the system. Be sure to use "Genuine fuel filter".

2) Replacement interval may be shortened depending on the

characteristic of fuel. Clogged fuel filter may cause to result in stopping

the engine. In a place where fuel gets mixed with foreign matter,

perform early inspection and periodic replacement.

Depending on the machine, the electromagnetic type fuel pump is

equipped in this engine. Periodical replacement or cleaning is required

for this pump filter. (Refer to Filter Replacement or Cleaning)

When the filter exchange of this pump is necessary, please inquire at

your machine supply source or contact ISUZU dealer.

(7) Biocides

In warm or humid weather, fungus and/or bacteria may form in diesel

fuel if there is water in the fuel.

27

CAUTION:

Fungus or bacteria can cause fuel system damage by

plugging the fuel lines, fuel filters or injector. They can also

cause fuel system corrosion.

If fungus or bacteria has caused fuel system problems, you should

have your authorized dealer correct these problems. Then, use a

diesel fuel biocide to sterilize the fuel system (follow the biocide

manufacturer’s instructions). Biocides are available from your dealer,

service stations, parts stores and other automotive places. See your

authorized dealer for advice on using biocides in your area and for

recommendations on which biocides you should use.

(8) Smoke Suppressants

Because of extensive testing of treated fuel versus untreated fuel, the

use of a smoke suppressant additive is not recommended because of

the greater possibility of stuck rings and valve failure, resulting from

excessive ash deposits.

2. LUBRICANT

The quality of engine oil may largely affect engine performance, startability

and engine life.

CAUTION:

Use of unsuitable engine oil will result in piston ring, piston and

cylinder seizure and accelerate the sliding surface wear

causing increased oil consumption, lowered output and, finally

engine failure. To avoid this, use the specified engine oil.

28

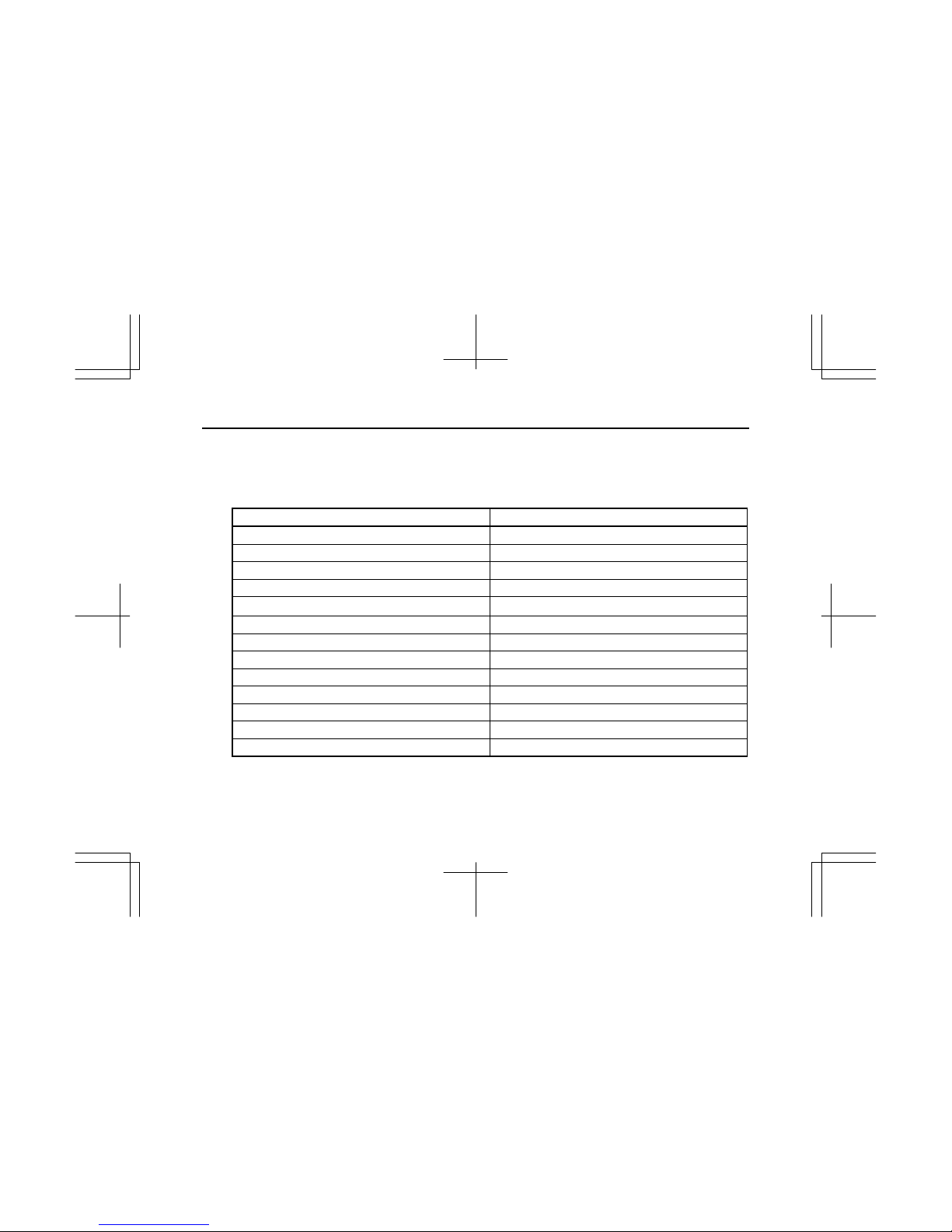

(1) Engine Oil Selection

For engine oil, use API grade: CD,CE,CF,CF-4,CH-4,CI-4,CI-4 plus or

ACEA grade: A3/B3,A3/B4,A5/B5,E2,E3,E4,E5,E7 or JASO grade:

DH-1.

The brands/types of oil described below can be used regardless of

specified API or ACEA grade above. Their qualities are guaranteed by

ISUZU.

GRADE

LUBRICATION MAKER BRAND/TYPE

API ACEA JASO

Diesel engine

crankcase

ISUZU GENUINE

ISUZU GENUINE

ISUZU GENUINE

Caltex/Chevron

Shell

Elf

Tot a l

Castrol

BP

IDEMITSU

ExxonMobil

BESCO MULTI-Z TYPE CE (10W-30)

*BESCO MULTI-Z (10W-30)

BESCO S-3 (10W, 20W, 30, 40)

Delo CXJ (15W-40/20W-50/40)

Delo 400 Multigrade (15W-40)

Rimula X (15W-40)

Rimula D (15W-40/30/40)

Perfo 3F (15W-40)

Rubia XT (15W-40)

RX Super Plus (15W-40)

Tection J Plus (15W-40)

BP Vanellus C6 (15W-40)

APOLLOIL EX (10W-40)

APOLLOIL TOUGH RUNNER (10W-30,15W-40)

APOLLOIL MULTI RUNNER (10W-30, 15W-40)

*2 APOLLOIL SUPER WIDE DH-1(10W-30, 15W-40)

Essolube XTJ (15W-40)

Exxon/Essolube XD-3 (15W-40)

Mobil Delvac 1300 Super (15W-40)

Mobil Delvac 1 (5W-40)

CE

CD/CF/CF-4

CD

CF

CE/CF/CI-4

CH-4

CF

CF-4/CE

CF-4

CH-4

CH-4

CH-4

CF

CF

CF-4/CE

CF-4

CF-4

CI-4

CI-4 Plus

CI-4 Plus

E3/E5

E3

B2/E2

E2

E3

E3/B3

E3

E7/E5

E7/E5/E4/E3

DH-1

DH-1

DH-1

DH-1

DH-1

DH-1

DH-1

DH-1

DH-1

DH-1

DH-1

* Initial Engine Oil from Engine plant

*2 Initial Engine Oil from Engine plant (Only a Part of Models)

29

(2) Oil Viscosity

Engine oil viscosity largely affect engine startability, performance, oil

consumption, speed of wearing and occurrence of seizure, etc. Using

lubricants whose viscosity selected according to the atmospheric

temperature is important.

CAUTION:

1. Using a mixture of different brand or quality oils will

adversely affect the original oil quality; therefore, never mix

up different brand or different type oils.

2. Don’t use API, CA, CB grade and reconstituted engine oil.

3. Engine damage due to improper maintenance, or using oil

of the improper quality and/or viscosity, is not covered by

the warranty.

SAE 20, 20W

SAE 20, 20W

SAE 30

SAE 30

SAE 10W

SAE 10W

SAE 40

SAE 40

30 C

(86 F)

-25 C

(-13 F)

25 C

(77 F)

15 C

(59 F)

-0 C

(32 F)

-15 C

(5 F)

SAE 10W-30

SAE 10W-30

SAE 15W-40, 20W-40

SAE 15W-40, 20W-40

[Single-grade]

[Multi-grade]

Ambient

Temperature

SAE 20, 20W

SAE 30

SAE 10W

SAE 40

SAE 10W-30

SAE 15W-40, 20W-40

-20 C

(-4 F)

SAE 5W-20

SAE 5W-20

SAE 5W-20

ENGINE OIL VISCOSITY GRADE - AMBIENT TEMPERATURE

IMLE0040

30

3. COOLANT

Always refer to the chart to determine the correct cooling water to

antifreeze solution mixing ratio.

CAUTION:

1. Supplement inhibitors or additives claiming to provide

increases cooling capability that have not been specifically

approved by Isuzu are not recommended for addition to the

cooling system.

2. When supplying or replacing coolant, do not use water of

well or river, but be sure to use tap water (soft water),

distilled water or demineralized water.

3. It is strongly recommended to use Isuzu genuine engine

coolant or equivalent for addition or replacement.

4. Coolants from other brands often do not contain

anti-corrosive, and use of such products could result in

corrosion of the engine and radiator.

5. If the density of Isuzu genuine engine coolant exceeds

60%, the reduced specific heat characteristic of the coolant

could result in overheating. If the densit

y

is below 20%, the

anticorrosion characteristic may degrade. Adjust the

coolant density in the range from 20% to 60% according to

the situation.

10 20 30 40 50

0

-20

-40

-50

-10

-30

0

Mixing ratio (%)

Freezing point (℃)

IMJJ0025

4. ENGINE OPERATION

31

Engine Exhaust Gas Caution

(Carbon Monoxide)

WAR NIN G:

Do not breathe exhaust gas because it contains carbon

monoxide, which by itself has no color or odor. Carbon

monoxide is a dangerous gas. It can cause unconsciousness

and can be lethal.

We recommend that the exhaust system be inspected by

competent technician:

•

Each time the machine has an oil change.

•

Whenever a change is noticed in the sound of the exhaust

system.

•

Whenever the exhaust system is damaged or becomes

corroded.

See "Maintenance Schedule" in Section 8 of this manual for

parts requiring inspection.

Do not run the engine in confined areas (such as garages or

next to a building) any more than needed to move the machine

or the equipment.

Keep the exhaust tailpipe area clear of snow and other

material to help reduce the buildup of exhaust gases or the

equipment. This is particularly important when parked in

blizzard conditions.

32

1. CHECK BEFORE OPERATION

WAR NIN G:

For Safety’s sake, conduct the inspection before start-up with

the engine stopped.

CAUTION:

As the remote filter is used, the engine oil is filled above the

specified level. (Turbocharged engine only)

Adjust the engine oil level as required.

(1) Engine Oil Level

1) Place the engine on a level surface.

2) Remove the dipstick from the crankcase, wipe it with clothing.

Insert it fully and take out it gently again.

Without turbocharger

With turbocharger

Dipstick

Dipstick

IMLE0067

33

Check the oil level by the level marks on the dipstick. The oil level

must be between the "Max" level mark and the "Min" level mark as

illustrated.

Take care not to add too much engine oil.

• Drain oil to the max. oil level if oil level is above the max. level

mark.

• Add oil to the max. oil level if oil level is below the min. level mark.

3) Also check the sample oil on the dipstick for fouling and degrees of

viscosity.

CAUTION:

Oil level check must be made ten or twenty minutes later after

the engine has been stopped. When the oil level check is

necessary while the engine is running, stop the engine and

keep it stationary ten or twenty minutes until the oil thoroughly

flows down to the crankcase.

4) Oil is poured either through the oil filler at the front of the cylinder head

cover or through the oil filler on the right side of the timing gear case.

A certain period of time is required before the engine oil completely

flows down from the oil filler to the crankcase.

Check the oil level ten or twenty minutes after oil replenishment.

CAUTION:

If the engine oil is splashed on the fan belt, it causes belt

slippage or slackness; therefore, take care to avoid it.

Max. level

Min. level

Dipstick

IMLE0068

Oil filler cap

IMLE0093

34

WAR NIN G:

1. In adding oil, take care not to spill it. If you spill oil on

engine or equipment, wipe it properly, or this could lead to a

fire and the risk of personal injury and/or equipment

damage.

2. For model that employs the closed PCV, excessive oil may

cause hunting in oil pressure, increase in the oil

temperature, oil seepage from the intake system and

engine oil intrusion into the combustion chamber, resulting

in engine damage.

(2) Fan Belt Check

Check the fan belt for tension and abnormalities.

WAR NIN G:

For the sake of safety, before conducting fan belt check, make

sure that the engine is stopped and is not be operated during

check.

1) When the belt is depressed with the thumb (about 100 N (22 lb)

pressure) at the midway between the alternator pulley and fan pulley,

the belt tension is correct as the following:

Fan belt slackness : 8 – 10 mm (0.31 – 0.39 in)

When the belt tension is too high, it will result in alternator failure.

Contrarily, loose belt will cause belt slippage which may result in

damaged belt and abnormal noise.

IMLE0012

35

2) Check the belts. Replace them if any damage is found.

CAUTION:

Replace all belts as a set even when one is not usable.

Single belt of similar size must not be used as a substitute for

a matched belt set. Otherwise, premature belt wear would

result because of uneven belt length.

(3) Coolant Level Check

1) Without the reserve tank

Remove the radiator filler cap, and check the coolant level as well as

the degrees of fouling.

Proper coolant level is about 10 mm higher from the radiator core top.

2) With the reserve tank

The coolant level must be between "FULL" and "LOW" marks on the

reserve tank.

Check and see that the level is correct.

When the coolant level is lower than the "LOW" mark, replenish the

reserve tank by the filler port, but when the reserve tank is empty,

replenish by the radiator filler port.

WAR NIN G:

When removing the radiator filler cap while the engine is still

hot, cover the cap with clothing, then turn it slowly to

g

radually

release the internal steam pressure. This will prevent you

from getting burnt with hot steam spouted out from the filler

port.

CAUTION:

Use Isuzu genuine anti-freeze (ethylene-glycol based) or

equivalent with the specified mixing ratio.

36

(4) Radiator Cap Condition

After the replenishment of the coolant, install the radiator cap.

Make sure the cap is securely installed.

(5) Battery Cable Connection

Check the battery cable connections for looseness or corrosion.

The loosened cable connection will result in hard engine starting or

insufficient battery charge.

The battery cables must be tightened securely.

CAUTION:

Never reverse "+" and "–" terminals when reconnecting cables

after disconnection.

Even a short period of reverse connection will damage the

electrical parts.

Terminal

Battery cable

Battery cable

24V

Terminal

12V

Battery cable

IMLE0069

37

(6) Battery Electrolyte Level

The amount of electrolyte in the batteries will be reduced after

repeated discharge and recharge.

Check the electrolyte for the level in the batteries, replenish with a

commercially available electrolyte such as distilled water, if necessary.

The battery electrolyte level checking procedure will vary with battery

type. Follow the equipment manufacturer’s instructions.

CAUTION:

Do not replenish with dilute sulfuric acid in the daily service.

WAR NIN G:

1. When inspecting the batteries, be sure to stop the engine.

2. As diluted sulfuric acid is used as electrolyte, be careful not

to stain your eyes, hands, clothes, and metals with the

electrolyte. If it gets in your eye, wash with a large amount

of water at once. Then go and see a doctor.

3. As highly flammable hydrogen gas is rising from the

batteries, do not make a spark or use fire in any other way

near the batteries.

4. When handling such metallic articles as a tool near the

batteries, be sure not to contact

○

+

terminal. As the

machine body is

○

−

, it may cause a big danger.

5. When disconnecting the terminals, start with

○

−

terminal.

When connecting them, connect the

○

−

terminal last.

Regular position

Shortage

Proper

Excess

IMWG0013

38

2. ENGINE STARTING

(1) Pre-starting Preparation

1) Make sure that all hydraulic control levers etc. on the equipment are in

the NEUTRAL position.

2) Set the engine stop knob in the START position. (It is unnecessary for

the engine equipped with the engine shutdown switch.)

3) Switch ON the battery switch (if so equipped).

4) Insert the starter switch key into the switch key hole.

Turn the key clockwise to DRIVE position and, make sure that the

meters and warning lamps are actuated.

OFF

DRIVE

START

AUTO RETURN

IMWG0014

In case of the type with QOS system

IMLE0041

In case of the type with control resistance

39

(2) Pre-heating Procedures

As an engine starting aid, pre-heating is required in a cold engine

starting.

The type with QOS system:

This pre-heating uses "QOS," a quick pre-heating system which

automatically controls pre-heating time utilizing coolant temperature to

conduct the irreducible minimum of pre-heating.

1) Turn the key to the DRIVE position, and the glow plugs built in the

engine will grow red-hot to pre-heat the engine. At this time the

pre-heating indicator lamp on the meterboard is actuated.

2) When the pre-heating indicator lamp goes out, try starting the engine at

once.

Relationship between water temperature and pre-heating time (For

ref.)

20°C (68°F) ········· About 0.5 sec.

5°C (35°F) ··········· About 1.5 sec.

0°C (32°F) ··········· About 2 sec.

-15°C (5°F) ·········· About 6.3 sec.

The type with a control resistance

1) Turn the starter switch key counter-clockwise to PRE-HEAT position in

order to heat the glow plugs on the engine.

The Pre-heating time of 5 seconds is required until the control

resistance coil becomes red.

2) Turn the starter switch key clockwise to START position as soon as the

control resistance coil red heat.

40

WAR NIN G:

Make sure that there is no flammable near outlet port of

exhaust gas at engine starting. It is very dangerous due to

deformation, discoloration or a fire.

(3) Engine Starting

1) Depress the engine throttle lever or throttle pedal and turn the starter

switch key clockwise to START position.

The cranking period must not exceed ten seconds.

Continuous starter operation of more than ten seconds will lead to

overdischarge of the batteries as well as starter seizure.

Release the starter switch after the engine starts.

The switch will return to the "DRIVE" position automatically.

For the engine equipped with a safety unit, the starter circuit is

automatically turned off when the engine starts. This prevents the

starter from overrunning.

If the engine cannot be started in one time attempt, keep the batteries

and the starter stationary at least 30 seconds for their functional

recovery, then repeat the pre-heating and the starting operations.

CAUTION:

Continuous re-engagement of the starter to the flywheel ring

g

ear without giving them a break will result in the damaged

starter pinion gear and flywheel ring gear.

2) If, despite repeated operations, the engine does not start, wait for a

minute or more until the functions of the batteries and starter are

recovered and then repeat pre-heating and starting operations.

41

3) When repeating starting operation, return the key to the OFF position

and then pre-heat and start the engine once again.

If the engine still remains unstarted, something may be wrong with the

engine. Check the repeated parts to locate the cause.

CAUTION:

Do not use starting "aids" in the air intake system. Such aids

can cause immediate engine damage.

42

3. CHECK AND OPERATION AFTER THE

ENGINE START-UP

(1) Warming-up Operation

Do the warming-up operation at 1000 min-1 about ten minutes after the

engine has started.

As the lubrication for the entire engine systems will be done in this

warming-up, do not speed up and load it abruptly.

Particularly, observe this in cold season operation.

(2) Check after the Engine Start-up

Check the following items in the engine warming-up operation.

Engine oil pressure

Although the engine oil pressure gauge readings vary depending on

ambient temperature, a type of oil or engine specification, the gauge

registers the values of the following in the warming-up.

Oil pressure : 147 kPa (21 psi) /1000min

-1

294 kPa (43 psi) /1800min

-1

343 to 686 kPa (50 to 100 psi) /2200min

-1

In the oil pressure warning lamp type, make sure that the lamp is off.

Charge condition

The charge condition is normal when once the ammeter registers plus

side greatly in the engine starting, then gradually the meter registering

will be minimized.

In the warning lamp type, make sure that the lamp is completely off

during the warming-up.

43

Engine noise and exhaust smoke color

Pay attention to engine noise and, if any abnormal noise is heard,

check the engine to detect the cause.

Check the fuel combustion condition by exhaust smoke color.

The exhaust smoke color after engine warming-up and at no-load

operation.

Colorless or light blue.... Normal (Perfect combustion)

Black color..................... Abnormal (Imperfect combustion)

White color.................... Abnormal (Oil coming up and coming down)

CAUTION:

Engine noise after start-up might be noisy than that of

warmed-up engine and, the exhaust smoke color also being

more whitish than the normal condition.

However, it will be normalized after warming-up engine.

Leakage in the systems

CAUTION:

When checking, leaking liquid from engine may be splattered

during engine operation. It may cause a burn. Approach the

engine gradually from a long distance and then check it.

44

Check the following items:

• Lube oil leakage

Check both sides and bottom of the engine assembly for lube oil

leaks, paying particular attention to the lube oil pressure gauge

pipe joint, lube oil filter and lube oil pipe joints.

• Fuel leakage

Check the fuel injection pump, fuel lines and fuel filter for leakage.

• Coolant leakage

Check the radiator and water pump hose connections also the

water drain cocks on the radiator and cylinder body for leakage.

• Exhaust smoke or gas leakage.

Checking coolant level

The coolant level could drop depending on the equipment because the

mixed air is expelled in about 5 minutes after the engine started.

Stop the engine, remove radiator cap, and add coolant.

WAR NIN G:

Hot steam will rush out and you could get burnt, if the radiator

cap is removed when the engine is hot.

Cover the radiator cap with a thick cloth and loosen the cap

slowly to reduce the pressure, then remove the cap.

45

4. CARE IN THE ENGINE OPERATION

In the engine operation, always pay attention to the following items if the

engine indicates any sign of abnormalities.

(1) Engine Oil Pressure

Engine oil pressure is normal when the oil pressure gauge shows the

values of the following in the engine warmed-up condition.

Oil pressure : 147 kPa (21 psi) /1000min

-1

294 kPa (43 psi) /1800min

-1

343 to 686 kPa (50 to 100 psi) /2200min

-1

In the continuous engine operation, engine oil pressure is slightly lower

than the pressure at start-up time.

Also, make sure that the oil warning lamp is off.

If, in continuous engine operation, the engine oil pressure warning

lamp is off, engine oil pressure is normal.

When the engine oil pressure gauge shows the following abnormal

conditions, stop the engine immediately and check the engine oil

amount in the oil sump and oil leakage:

• The engine oil pressure gauge shows below 200 kPa (28 psi)

though the engine speed is raised.

• The oil pressure gauge indicator oscillates greatly in the engine

low speed range.

• When the engine oil pressure warning lamp goes on and off

repeatedly.

When not lack of engine oil or no oil leakage is found, contact your

equipment supplier to determine the cause of the abnormal reading.

46

(2) Coolant Temperature

The engine performance will be adversely affected if engine coolant

temperature is too hot or too cold.

The normal coolant temperature is 75 to 90°C (167 to 194°F).

Overheating

WAR NIN G:

If the Engine Coolant Temperature Gage shows an overheat

condition or you have other reason to suspect the engine may

be overheating, continued operation of the engine (other than

as spelled out here) even for a short period of time may result

in a fire and the risk of personal injury and severe vehicle or

equipment damage. Take immediate action as outlined

following.

If you see or hear escaping steam or have other reason to suspect

there is a serious overheat condition, stop and park the machine or

equipment as soon as it is safe to do so and then turn off the engine

immediately and get out of the machine or equipment.

The engine cooling system may overheat if the engine coolant level is

too low, if there is a sudden loss of engine coolant (such as hose

splitting) or if other problems occur. It may also temporarily overheat

during severe operating condition such as:

• Climbing a long hill on a hot day.

• Stopping after high rpm.

47

If the Engine Coolant Temperature gage shows an overheat condition,

or you have reason to suspect the engine may be overheating, take the

following step:

• If your air conditioner (if equipped) is on, turn it off. And turn on

the heater.

• Don’t turn off your engine.

• With the transmission in Neutral, increase the engine speed to

about one-half full operating speed or 1200 RPM, maximum.

Bring the idle speed back to normal after two or three minutes.

If the engine coolant temperature does not start to drop within a minute

or two:

• Let the engine run at normal idle speed for two or three minutes.

If the engine coolant temperature does not start to drop, turn off the

engine and get out of the machine or equipment then proceed as

follows:

WAR NIN G:

To help avoid being burned-

•

Do not open the engine access cover if you see or hear

steam or engine coolant escaping from the engine

compartment. Wait until no steam or engine coolant can

be seen or heard before opening the engine cover.

•

Do not remove the radiator cap or engine coolant reserve

tank cap if the engine coolant in the tank is boiling. Also

do not remove the radiator cap while the engine and

radiator are still hot. Scalding fluid and steam can be

blown out under pressure if either cap is taken off too soon.

48

If no steam or engine coolant can be seen or heard, open the engine

access cover. If the engine coolant is boiling, wait until it stops before

proceeding. Look at the see-through reserve tank. The engine

coolant level should be between the "MAX" and "MIN" marks on the

reserve tank. If necessary, pour engine coolant into the reserve tank

only, never directly into the radiator. Also, do not check engine

coolant level at the radiator.

Make sure the fan belts are not broken, or off the pulleys and that the

fan turns when the engine is started.

If the engine coolant level in the reserve tank is low, look for leaks at

the radiator hoses and connections, heater hoses and connections,

radiator, and water pump. If you find major leaks, or spot other

problems that may have caused the engine to overheat, do not run the

engine until these problems have been corrected. If you do not find a

leak or other problem, carefully add engine coolant to the reserve tank.

(Engine coolant is a mixture of ethylene glycol antifreeze and tap water

(soft water), distilled water or demineralized water. See "Engine Care

in cold season" in Section 6 for the proper antifreeze and mixture.)

WAR NIN G:

To help avoid being burned, do not spill antifreeze or engine

coolant on the exhaust system or hot engine parts. Under

some conditions the ethylene glycol in engine coolant is

combustible.

49

If the engine coolant level in the reserve tank is at the correct level but

there is still an indication on the instrument panel of an overheat

condition:

• YOU MUST LET ENGINE COOL FIRST. You may then add

engine coolant directly to the radiator.

Once the Engine Coolant Temperature Gage no longer signals an

overheat condition, you can resume operating at a reduced speed.

Return to normal operating after about ten minutes if the gage pointer

does not again show an overheat condition.

If no cause for the overheat condition was found, see a qualified

service technician.

Overcooling

The engine operation at low coolant temperature will not only increase

the oil and fuel consumption but also will lead to premature parts wear

which may result in engine failure.

50

(3) Engine Hourmeter (Engine Operation Hour Indicating)

(If so equipped)

This meter indicates the engine operation hours. Make sure that the

meter is always working during engine operation.

Periodical engine maintenance is scheduled on the operation hours

indicated on the hourmeter.

(4) Liquid and Exhaust Smoke Leakage

Be careful with lubricant, fuel, coolant and exhaust smoke leakage.

(5) Abnormal Engine Noise

Pay attention to the noise from the engine or other related parts,

checking if the noise is normal.

(6) State of the Exhaust Smoke

Be careful with exhaust smoke color, check if it is whitish or blackish.

51

5. ENGINE STOPPING

1) Make sure that all of the control levers on the equipment are in

NEUTRAL position.

2) Before stopping the engine, cool down the engine by operating it at low

idle speed about three minutes.

In this operation, check the engine noise and the engine oil pressure

for abnormalities.

CAUTION:

In the turbocharged engine, if the engine is stopped

instantaneously, a dry condition produced by high temperature

will take place in the turbocharger rotating parts which may

cause lack of lubrication. This will result in turbocharger

failure.

3) To stop the engine, turn the starter switch key to OFF position. The

engine stop solenoid automatically shut off the fuel to stop the engine.

Switch off the battery (if so equipped).

CAUTION:

Leaving the starter switch key in the DRIVE position for a long

while after the engine has been stopped, will discharge the

batteries wastefully.

52

6. OPERATION AND CARE FOR NEW

ENGINE

Your ISUZU engine is carefully tested and adjusted in the factory, however,

further, thorough run-in (i.e. break-in) operation is necessary.

If the new engine is harshly operated, lubricating oil film will be reduced

leading to abnormal wear or seizure. Particularly, avoid a harsh engine

operation within the initial 100 operation hours observing the following

notice.

1) Do the warming-up operation continuously until the engine is

warmed-up. In this operation, do not race the engine.

2) Also do not operate the engine with rapid acceleration, rapid machine

starting and continuous high speed operation.

7. ENGINE CARE FOR OVER-COOLING

Engine over-cooling cause premature wear and increased fuel consumption.

When the coolant temperature is not raised to 75 to 90°C (167 to 194°F)

indefinitely, take an action to recover this with means of radiator curtain or

such like.

53

8. OPERATION AND CARE FOR

TURBOCHARGED ENGINE

(1) Engine Starting

The warming-up operation of the engine should be done in the way

separately described. In addition, ensure the bearings supporting the

rotating parts of the turbocharger are sufficiently lubricated.

1) Do not race cold engine.

2) When starting the engine after a long period (more than one month) of

standing, proceed as follows:

Pour engine oil into the turbocharger through the oil inlet port with the

air intake duct and oil inlet side pipe removed. Then turn the impeller

by hand to thoroughly lubricate the bearings.

3) When pouring oil in, do not allow dust particles and other foreign

materials to enter through the opening.

On completion of this operation, securely install the oil pipe and air

intake duct.

(2) Engine Stopping

Whenever stopping the engine, the last about 3 minutes of operation

should be at idle. After hard operation, at least 5 minutes of operation

should be at idle until the turbocharger cools down. This allows the

turbocharger to return to idle speed while engine oil pressure is

available for lubrication.

CAUTION:

Failure to cool down turbocharger at idle could result in

insufficient lubrication of its bearings and their shortened life.

54

9. STARTING THE ENGINE AFTER BEING

LEFT UNUSED FOR A LONG PERIOD OF

TIME

When the machine or equipment is left unused for "more than three

months" without running the engine (warming up), conduct a thorough

inspection of the machine before starting the engine.

Crank the engine for 10 seconds and then stop it for 30 seconds with the

fuel cut. Repeat this procedure for three times. This sends the oil to each

part.

After starting the engine, be sure to warm it up for more than ten minutes at

1000 min

-1

.

5. PERIODICAL INSPECTION AND MAINTENANCE

55

1. LUBRICATING SYSTEM

WAR NIN G:

1. During inspection and service, a burn injury may occur due

to hot engine body, coolant or engine oil. For the sake of

safety, conduct service work after the engine is stopped

and cools down sufficiently.

2. It is very dangerous to inspect and service the rotating

parts. For the sake of safety, conduct service work after

the engine is stopped. Also, make sure that it is not

started during work.

Servicing of the engine oil or the oil filter element will affect on the engine

performance as well as the engine life.

Change the engine oil and the oil filter element periodically with the

specified ones. (Refer to 3.2. LUBRICANT.)

(1) Engine Oil and Oil Filter Element Change

Engine oil change and oil filter element change must be made

according to the following change schedule. For the engine equipped

with the oil filter warning lamp, if the lamp comes on while driving, the

filter element is clogged. Replace the element regardless of the change

interval.

Change interval

Engine Oil················· Cartridge type : Every 250 operating hours

Remote filter type : Every 500 operating hours

Oil Filter Element······ Every 500 operating hours

56

Engine oil draining

WAR NIN G:

To help avoid the damage of being burned, do not drain oil

while the engine is still hot.

One-touch type

1) Wipe clean around the oil filler cap taking care so that no foreign

particles entry. Remove the filler cap.

2) Loosen the cap of oil drain cock and remove it. Connect the oil drain

hose to the oil drain cock and drain the oil.

3) After the completion of draining, disconnect the hose and wipe off the

oil on the drain cock.

4) Turn the cap of oil drain cock slightly and settle it. From that position,

turn more about 60 to 90 degrees.

Oil filler cap

IMLE0093

IMWG0035

57

Drain plug type

1) Wipe clean around the oil filler cap taking care so that no foreign

particles entry. Remove the filler cap.

2) Remove the drain plug by loosening it, and then drain oil.

3) After oil has been drained completely, replace the packing of the drain

plug with a new one, and then install the plug.

4) Tighten the drain plug.

Torque (drain plug) : 78.4 Nm (8.0 kgm)

CAUTION:

Use a receptacle to receive the drained oil so that the engine

and equipment may not be stained with the drained oil.

Oil filler cap

IMLE0093

58

4LE1T

Oil drain plug

Oil filler cap

Oil filler cap

Oil level gauge

IMLE0094

59

4LE1NA

Oil drain plug

Oil filler cap

Oil filler cap

Oil level gauge

IMLE0095

60

Oil filter element removal

Use a filter wrench to remove the cartridge type oil filter element.

There may remain the used engine oil in the cartridge, and care should

be taken not to spill it when removing the filter.

Discard the used filter.

Remote filter typeCartridge type

Cartridge

Cartridge

IMLE0070

61

Oil filter element installation

1) Apply lightly engine oil to the O-ring.

2) Turn in new cartridge until its sealed face comes in contact with

the O-ring.

3) Use a filter wrench to further turn in the cartridge.

Oil filter element tightening torque : 14.7 – 20.6 Nm (1.5 – 2.1 kgm)

Engine oil refilling

1) Disconnect the oil drain hose and reinstall the cap of drain cock. (One touch type)

Install the drain plug. (Drain plug type)

2) Fill with new engine oil by the oil filler port.

Wait about fifteen minutes until the oil gets down to the oil pan.

Then check the oil level with a dipstick.

Do not insert the dipstick by force. The dipstick may be broken.

WAR NIN G:

1. In adding oil, take care not to spill it. If you spill oil, wipe it

properly, or this could lead to a fire.

2. Do not leave any flammables such as cloth or gloves in the

engine compartment. It may result in a fire.

IMWG0034

62

CAUTION:

1. Prevent dust particles from entering through filler port at

replenishment. Be careful, entry of dust particles may

cause engine damage or accident.

2. Replenishment of oil above "Max" level or below "Min" level

may cause engine damage or accident. Drain oil to the

"Max" level if the oil level is above "Max" level. Also,

replenish oil to the "Max" level if the oil level is below "Min"

level.

(2) Check after Oil and Filter Changes

The remote-type oil filter is used so that it takes time to pressure-feed

oil to each part of engine after oil filter is changed. Idle approx. 30

seconds at the first start-up after oil filter is changed. Do not perform

sudden loading or rapid acceleration. In addition, the time to

pressure-feed oil can be shortened by filling engine oil into oil filter.

Oil leakage check

Idle the engine to raise the oil pressure, then check for oil leakage.

Oil level recheck

Stop the engine and keep it stationary about twenty minutes.

Use the dipstick to recheck the oil level.

Replenish with engine oil, if necessary, to the specified level.

CAUTION:

When the engine is started, the oil level will slightly drop from

the initial level as the oil fully comes into the entire oil circuit.

63

(3) Engine Oil Additives

Engine oils contain a variety of additives. Your engine should not

need any extra additives if you use the recommended oil quality and

change intervals.

(4) Used Oil Disposal

Do not dispose of used engine oil (or any other oil) in a careless

manner such as pouring it on the ground, into sewers, or into streams

or bodies of water. Instead, recycle it by taking it to a used oil

collection facility which may be found in your community. If you have

a problem disposing of your used oil, it is suggested that you contact

your dealer or service station.

(This also applies to diesel fuel which is contaminated with water.

See "Diesel Fuel" in Section 3.)

(5) Used Engine Oil

WAR NIN G:

Used engine oil contains harmful contaminants that have

caused skin cancer in laboratory animals. Avoid prolonged

skin contact. Clean skin and nails thoroughly using soap and

water - not mineral oil, fuels, or solvents.

Launder or discard clothing, shoes or rags containing used

engine oil.

Discard used engine oil and other oils properly.

64

2. COOLING SYSTEM

(1) Fan Belt Tension Adjustment

Adjust fan belt tension when belt slackness is greater than the

specified amount and when the belts are replaced.

WAR NIN G:

To help avoid being injury, check and adjust fan belt tension

with engine stopped.

Belt tension

Belt tension is normal when it is depressed with the thumb at the

midway between the fan pulley and alternator pulley. (about 100 N (22

lb) depressing force.)

Fan belt slackness : 8 – 10 mm (0.31 – 0.39 in)

IMLE0012

65

Adjusting procedure

Belt tension adjustment is made by pivoting the alternator at the

alternator mounting bolt.

1) Loosen the lock nut and the alternator mounting bolt.

2) Pivot the alternator at the mounting bolt by adjusting the adjusting bolt.

3) Tighten the mounting bolt and the lock nut.

Tightening torque : 23.5 Nm (2.4 kgm) (M8 bolt or nut)

48.1 Nm (4.9 kgm) (M10 bolt or nut)

CAUTION:

Belt tension may vary slightly after the alternator is fixed.

Therefore, recheck the belt tension after tightening the bolts.

4) After the adjustment, operate the engine about five minutes at a low

idle speed and recheck the belt tension. Particularly, pay attention to

this matter when installing new belts. Belt tension may vary due to the

initial belt conforming.

(2) Fan Belt Change

Use of fan belt with poor quality will result in premature belt wear or

belt elongation leading to engine damage such as overheat.

Therefore use of the ISUZU genuine fan belts are highly

recommended.

When you check the belt and find the following condition, replace the

belt with new one.

1) No adjustment margin of the belt.

2) Abnormal wear, damages, or cracks on the belt.

3) Brake noise occurs while driving even if belt tension is adjusted.

Adjusting

bolt

Lock nut (loosen)

Mounting bolt

(loosen)

IMLE0096

66

(3) Coolant Change

CAUTION:

Use Isuzu genuine anti-freeze (ethylene-glycol based) or

equivalent with the specified mixing ratio.

If oil is in coolant, contact "ISUZU Distributor" as soon as possible.

CAUTION:

The coolant must be changed at intervals of 12 months.

If the coolant is being fouled greatly, it will lead to engine

overheat or coolant blow-off from the radiator and cause a

burn. Shorten the interval of changing.

Coolant draining

1) Remove the radiator cap.

Open the drain cock at the radiator lower part to drain the coolant in

the radiator.

WAR NIN G:

When removing the radiator filler cap while the engine is still

hot, cover the cap with a rag, then turn it slowly to release the

internal steam pressure. This will prevent a person from

scalding with hot steam spouted out from the filler port.

67

2) Drain away the coolant from the engine by loosening the water drain

plug at the rear of alternator on the left side of cylinder body.

Filling with coolant

1) Close or tighten the coolant drain plug.

2) Fill up the radiator with the coolant until the level comes up to the filler

port neck.

Fill gradually to prevent air entry.

Coolant volume (Engine only) :

Refer to "Main Data Specifications"

3) Loosen the air bleeder plug of the EGR cooler to bleed air from the

EGR cooler. (Turbocharged engine only)

CAUTION:

If loosening the air bleeder plug, be sure to replace it with new

one.

IMLE0021

Air Bleeder Plug

IMLE0056

68

4) Tighten the plug when the coolant spills over from the air bleeder plug.

(Turbocharged engine only)

CAUTION:

1. Take care to prevent the spilt coolant from getting the

exhaust system parts wet.

2. If you spill coolant, wipe it properly, or this could lead to a

fire.

Torque (Air bleeder plug) : 24.5 to 30.5 Nm (2.5 to 3.1 kgm)

5) Add coolant in the radiator and reservoir tank.

6) With the coolant poured, operate the engine about five minutes at a

low idle speed, then the air contained in the coolant circuit is bled.

The coolant level will drop.

Stop the engine to replenish with the coolant.

(4) Cleaning outside of Radiator

Mud or dried grass caught between radiator fins will block the air flow,

resulting in lower cooling efficiency.

Clean the radiator fins with steam or compressed water.

For the cleaning interval, refer to the instruction manual prepared by

the equipment manufacturer.

If the fins are stuffed, however, clean them at any time. Further, if the

fins are deformed, repair or replace them.

69

(5) Cooling System Circuit Cleaning

When the cooling system circuit is fouled with water scales or sludge

particles, cooling efficiency will be lowered.

Periodically clean the circuit interior with a cleaner.

Cooling system cleaning interval : Every 12 months or 1000 operation

hours.

70

3. FUEL SYSTEM

The fuel injection pump and fuel injection nozzle are precisely

manufactured, and therefore, using the fuel which contains water or dust

particles will result in either injection pump plunger seizure or injection

nozzle seizure, and the fouled fuel filter element with sludge or dust

particles lead to decreased engine output.

In addition, clogged filter element can cause low output or automatic air

bleeding failure.

Perform inspection and maintenance periodically as follows:

(1) Removal of Water from the Fuel

The water sedimenter is provided to separate the water contained in

the fuel.

The sedimenter housing contains a float which moves up and down in

accordance with level change of the separated water.

Be sure to drain the separated water when the float has come up to the

element part.

Draining procedure:

With the water sedimenter lever positioned just above the fuel remains

off, loosen the air bleeding plug at the top of the water sedimenter, and

then loosen the drain plug at the bottom of the case to drain the

separated water.

After draining, be sure to tighten the plugs and conduct air bleeding of

fuel.

Be careful not to over-tighten the air bleeding plug.

Torque (Drain plug) : 1.0 to 2.0 Nm (0.1 to 0.2 kgm)

Torque (Air bleeding plug) : 1.5 to 3.0 Nm (0.15 to 0.31 kgm)

Lever

Drain plug

Element

Float

Air bleeding plug

IMLE0057

71

CAUTION:

1. If the cup is removed without turning the fuel filter lever just

above, the fuel may flow out.

2. The cartridge and cup contain fuel. Take care not to spill it

during disassembly.

3. Perform the "fuel system air bleeding" after the water in the

fuel is drained.

(2) Fuel System Air Bleeding

The entry of air into the fuel system will cause hard engine starting or

engine malfunction.

When once the servicing such as emptying the fuel tank, draining for

the water sedimenter, and the fuel filter element change is done, be

sure to conduct air bleeding.

Because of the "automatic air-bleeding system" being employed, turn

the starter switch to the "Drive" position and activate the

"electromagnetic pump" to bleed the air.

Air bleeding procedure:

1) When the "starter switch" is set to the "Drive" (ON) position to activate

the electromagnetic pump, fuel is forcibly sent to the fuel valve of each

injection pump and further to the leak-off pipe of each nozzle holder,

where air in the fuel leaks off automatically to the fuel tank.

2) Start the engine and check the fuel system for leakage.

CAUTION:

Start the engine and check the fuel system for leakage.

Leakage causes a fire.

Injection pump

IMLE0022

72

(3) Fuel Filter Element Change

Change interval

Fuel filter element change inerval:Every 500 operating hours

CAUTION:

The fuel filter element may be clogged faster depending on the

amount of dust particles in the fuel. Therefore, the element

may need to change more often than Change interval above.

If the low engine output or engine stall is found, the change of

fuel filter element may recover them.

Change procedure

1) Use a specified filter wrench to remove the cartridge.

2) Apply lightly fuel to the gasket of a new cartridge, and turn in the

cartridge until its sealed face comes in contact with the O-ring. Then,

tighten the cartridge to the correct tightening torque.

Torque (Cartridge) : 13.7 Nm (1.4 kgm)

(4) Water Sedimenter Element Cleaning

Cleaning interval

Fuel filter element cleaning interval : Every 500 operating hours

Cartridge

IMLE0058

73

Cleaning procedure

1) Turn the water sedimenter lever to the closed position.

CAUTION:

If the cup is removed without turning the lever as instructed,

the fuel may flow out.

2) Loosen the ring nut, remove the cup, and take out the element.

3) Clean the cup and element, install new packing on the ring nut.

4) Tighten the cup to the body securely with the ring nut.

5) After installation, turn the water sedimenter lever to the open position.

CAUTION:

1. With the lever positioned just above the fuel remains off,

and therefore, the engine cannot be started.

2. During removal, be careful not to stain the parts around

with the fuel in the cup.

3. After changing fuel filter element, conduct fuel air bleeding.

74

C

O

OPEN

Lever

Element

Cup

Drain plug

Ring nut

Air bleeder plug

CLOSE

IMLE0059

75

(5) Filter Replacement or Cleaning

Depending on the machine, the electromagnetic type fuel pump is

equipped in this engine.

Filters inside of the pump consist of paper type and steel mesh type.

Replace the paper-type filter at intervals of 500 operating hours. Clean

the steel mesh-type filter at intervals of 500 operating hours.

CAUTION:

When removing the filter, always replace the gasket and clean

the magnet part inside of the cover.

1) Remove the wirings attached on the pump cover. Rotate the cover with

a wrench and remove it.

CAUTION:

In detaching the cover, place a tray to prevent the fuel

contained in the pump from spilling over the engine.

Also, make sure that there is no flammable near the fuel

pump.

2) Remove the filter and replace or clean it.

Paper type

Remove the filter and the gasket, then install new ones.

Make the interval of replacement service shorten depending on fuel

management and supply.

Steel mesh type

Remove the filter and the gasket. Clean the filter with the compressed

air and rinse it in the fuel oil before installing the filter and the gasket.

Make the interval of cleaning service shorten depending on fuel

management and supply.

Filter

Cover

Electromagnetic

pump

Gasket

Gasket

IMHK0376

76

3) Install the cover. When installing, use a wrench and fully tighten it to

the end.

CAUTION:

After installing the cover, be sure to check airtightness.

(6) Governor Control Seals

As the governor (timing gear case) is precisely adjusted, most of the

controls are sealed, please do not break them. When the adjustment is

necessary, contact with your machine supply source.

CAUTION:

The manufacturer does not warrant the claim on the engine

with the broken governor seals.

77

4. AIR INTAKE SYSTEM