Page 1

INDUSTRIAL

DIESEL ENGINE

A-4JA1, A-4JB1

MODELS

©

2003 ISUZU MOTORS LIMITED

WORKSHOP MANUAL

Page 2

FOREWORD

This Workshop Manual is designed to help you perform necessary

maintenance, service, and repair procedures on applicable Isuzu

industrial engines.

Information contained in this Workshop Manual is the latest

available at the time of publication.

Isuzu reserves the right to make changes at any time without prior

notice.

This Workshop Manual is applicable to 1998 and later models.

NOTICE

Before using this Workshop Manual to assist you in

performing engine service and maintenance operations,

it is recommended that you carefully read and throughly

understand the information contained in Section - 1

under the headings “General Repair Instruction” and

“Notes on The Format of This Manual”

Page 3

TABLE OF CONTENTS

SECTION 1. GENERAL INFORMATION.................................. 1

SECTION 2. MAINTENANCE ............................................. 17

SECTION 3. ENGINE ASSEMBLY (1) .................................... 29

(DISASSEMBLY)

SECTION 4. ENGINE ASSEMBLY (2) .................................... 47

(INSPECTION AND REPAIR)

SECTION 5. ENGINE ASSEMBLY (3) .................................... 81

(REASSEMBLY)

SECTION 6. LUBRICATING SYSTEM.................................... 109

SECTION 7. COOLING SYSTEM ......................................... 121

SECTION 8. FUEL SYSTEM............................................... 133

SECTION 9. ENGINE ELECTRICALS ..................................... 147

SECTION 10. TROUBLESHOOTING....................................... 175

SECTION 11. SPECIAL TOOL LIST ........................................ 201

SECTION 12. REPAIR STANDARDS....................................... 205

SECTION 13. CONVERSION TABLE....................................... 219

Page 4

GENERAL INFORMATION

1

SECTION 1

GENERAL INFORMATION

TABLE OF CONTENTS

ITEM PAGE

General repair instructions ....................................................... 2

Notes on the format of this manual................................................. 2

Main data and specifications....................................................... 6

Tightening torque specifications ................................................... 7

Page 5

GENERAL INFORMATION

GENERAL REPAIR INSTRUCTIONS

1. Before performing any service operation with the engine mounted, disconnect the grounding cable

from the battery.

This will reduce the chance of cable damage and burning due to short circuiting.

2. Always use the proper tool or tools for the job at hand.

Where specified, use the specially designed tool or tools.

3. Use genuine ISUZU parts.

4. Never reuse cotter pins, gaskets, O-rings, lock washers, and self locking nuts. Discard them as you

remove them. Replace them with new ones.

5. Always keep disassembled parts neatly in groups. This will ensure a smooth reassembly operation.

It is especially important to keep fastening parts separate. These parts vary in hardness and design,

depending on their installation position.

6. All parts should be carefully cleaned before inspection or reassembly.

Oil ports and other openings should be cleaned with compressed air to make sure that they are

completely free of obstructions.

7. Rotating and sliding part surfaces should be lubricated with oil or grease before reassembly.

8. If necessary, use a sealer on gaskets to prevent leakage.

9. Nut and bolt torque specifications should be carefully followed.

10. Always release the air pressure from any machine-mounted air tank(s) before dismounting the engine

or disconnecting pipes and hoses. To not do so is extremely dangerous.

11. Always check and recheck your work. No service operation is complete until you have done this.

NOTES ON THE FORMAT OF THIS MANUAL

This Workshop Manual is applicable to ISUZU industrial engine or engines which is or are stated in the

title.

When more than two engine models are dealt in the manual, such engines have common parts and

components as well as data and specifications, unless otherwise specified.

1. Find the applicable section by referring to the Table of Contents at the beginning of the Manual.

2. Common technical data such as general maintenance items, service specifications, and tightening

torques are included in the "General Information" section.

The section ENGINE ASSEMBLY is an exception. This parts are divided in three sections to facilitates

indexing.

3. Each section is divided into sub-sections dealing with disassembly, inspection and repair, and

reassembly.

2

Page 6

GENERAL INFORMATION

3

4. When the same servicing operation is applicable to several different units, the manual will direct you

to the appropriate page.

5. For the sake of brevity, self-explanatory removal and installation procedures are omitted.

More complex procedures are covered in detail.

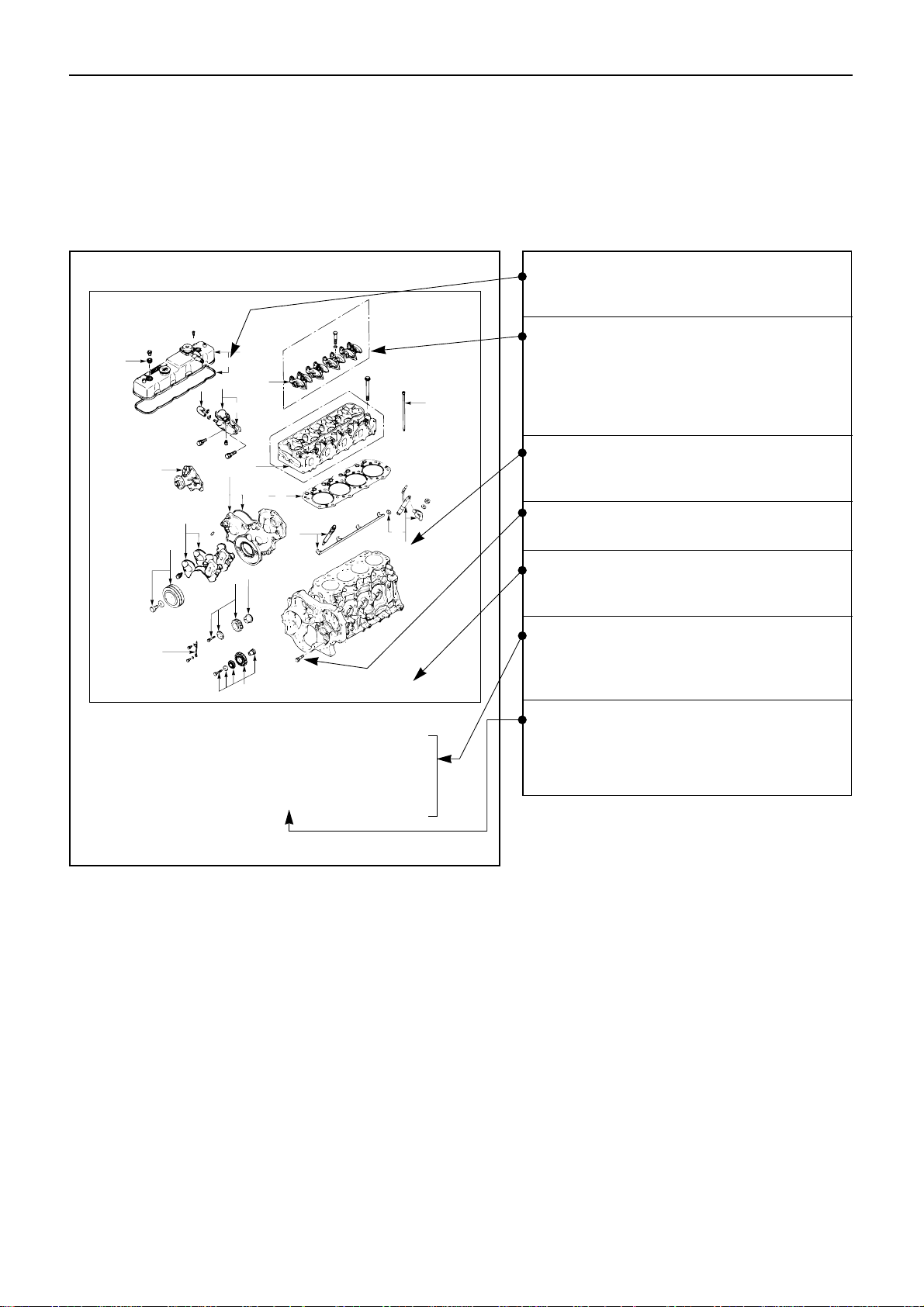

6. Each service operation section in this Workshop Manual begins with an exploded view of the

applicable area. A brief explanation of the notation used follows.

15

14

16

17

11

12

13

3

9

10

5

4

8

7

6

2

1

★

★Repair kit

★

★

★

★

★

Disassembly Steps - 2

1. Water by-pass hose

2. Thermostat housing

3. Water pump

▲ 4. Injection nozzle holder

5. Glow plug and glow plug connector

6. Cylinder head cover

▲ 7. Rocker arm shaft and rocker arm

8. Push rod

▲ 9. Cylinder head

10. Cylinder head gasket

▲ 11. Crankshaft damper pulley with

dust seal

12. Timing gear case cover

13. Timing gear cover

14. Timing gear oil pipe

15. Idler gear “B” and shaft

▲ 16. Idler gear “A”

17. Idler gear shaft

Inverted Engine

Parts marked with an asterisk (*) are

included in the repair kit.

Parts within a square frame are to be

removed and installed as a single unit,

and their disassembly steps or reassembly steps are shown in the

illustrations respectively.

The number tells you the service operation sequence.

Removal of unnumbered parts is unnecessary unless replacement is required.

The "* Repair Kit" indicates that a repair

kit is available.

The parts listed under "Disassembly

Steps" or "Reassembly Steps" are in the

service operation sequence.

The removal or installation of parts

marked with a triangle (▲) is an

important operation. Detailed information is given in the text.

Page 7

GENERAL INFORMATION

4

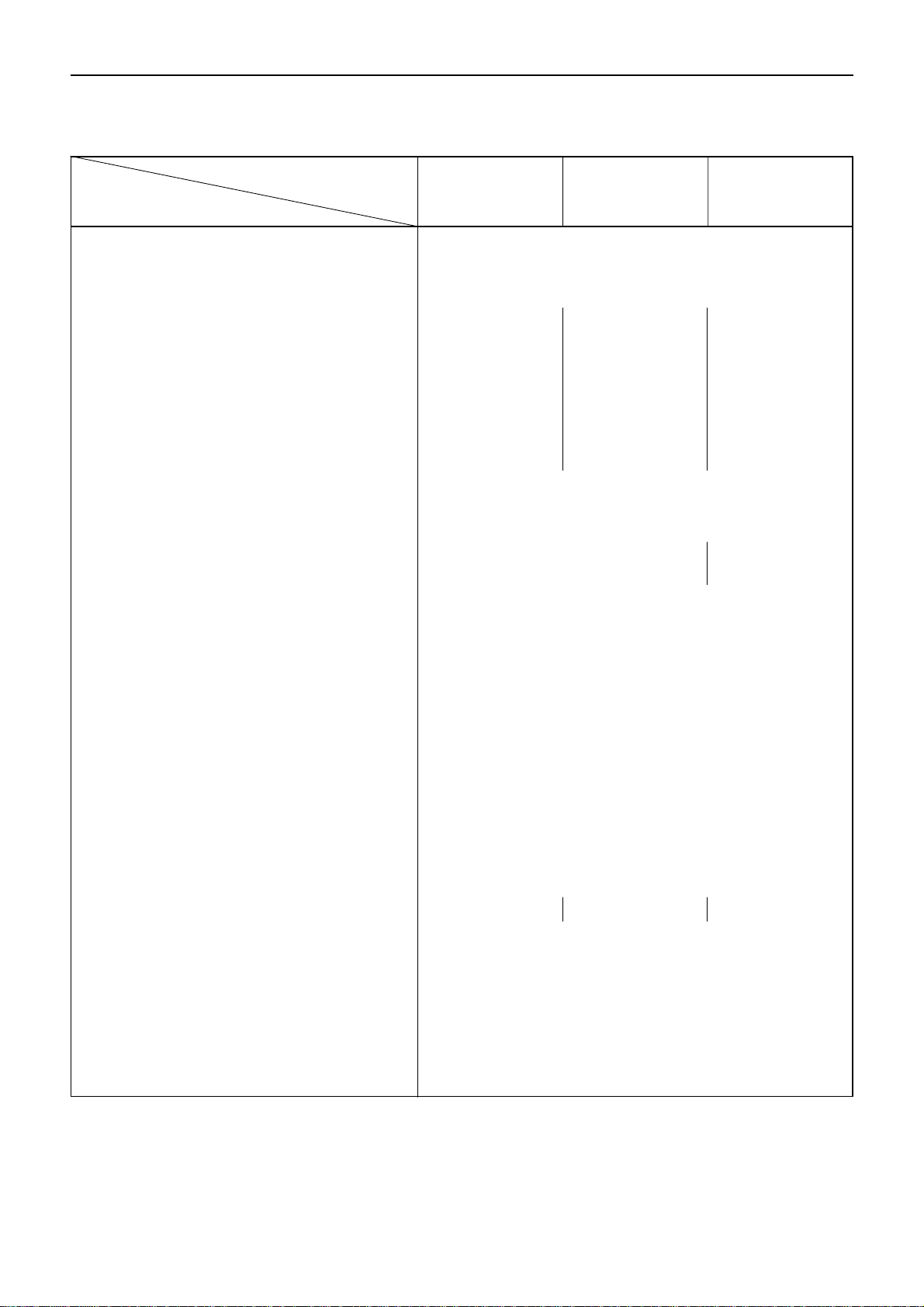

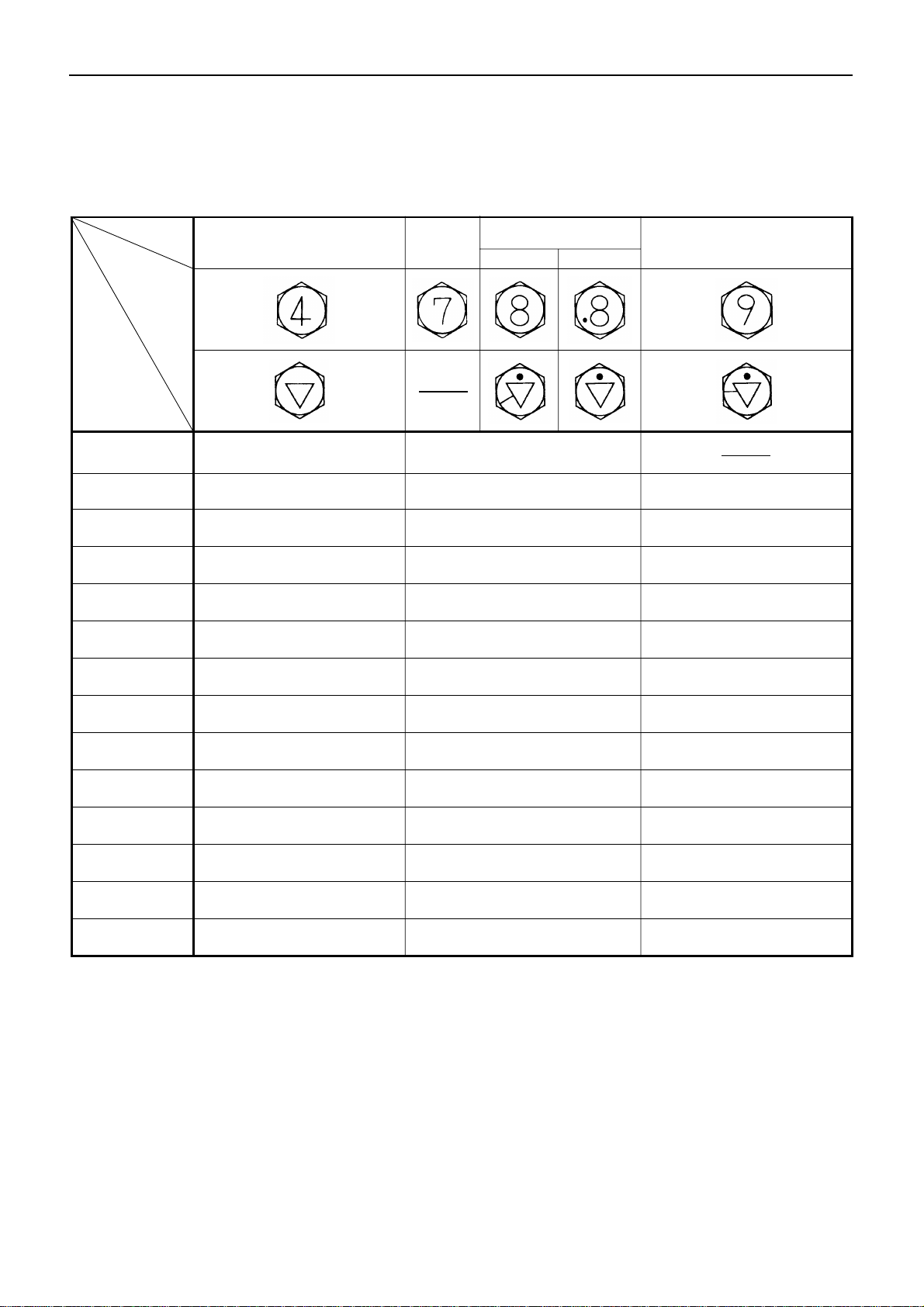

8. The following symbols appear throughout this Workshop Manual. They tell you the type of service

operation or step to perform.

.... Removal .... Adjustment

.... Installation .... Cleaning

.... Disassembly ... Important operation requiring extra care

.... Reassembly .... Specified torque (tighten)

.... Alignment (marks) ....

Special tool use required or

recommended(Isuzu tool or tools)

.... Directional indication ....

Commercially available tool use

required or recommended

.... Inspection .... Lubrication (oil)

.... Measurement .... Lubrication (grease)

.... Sealant application

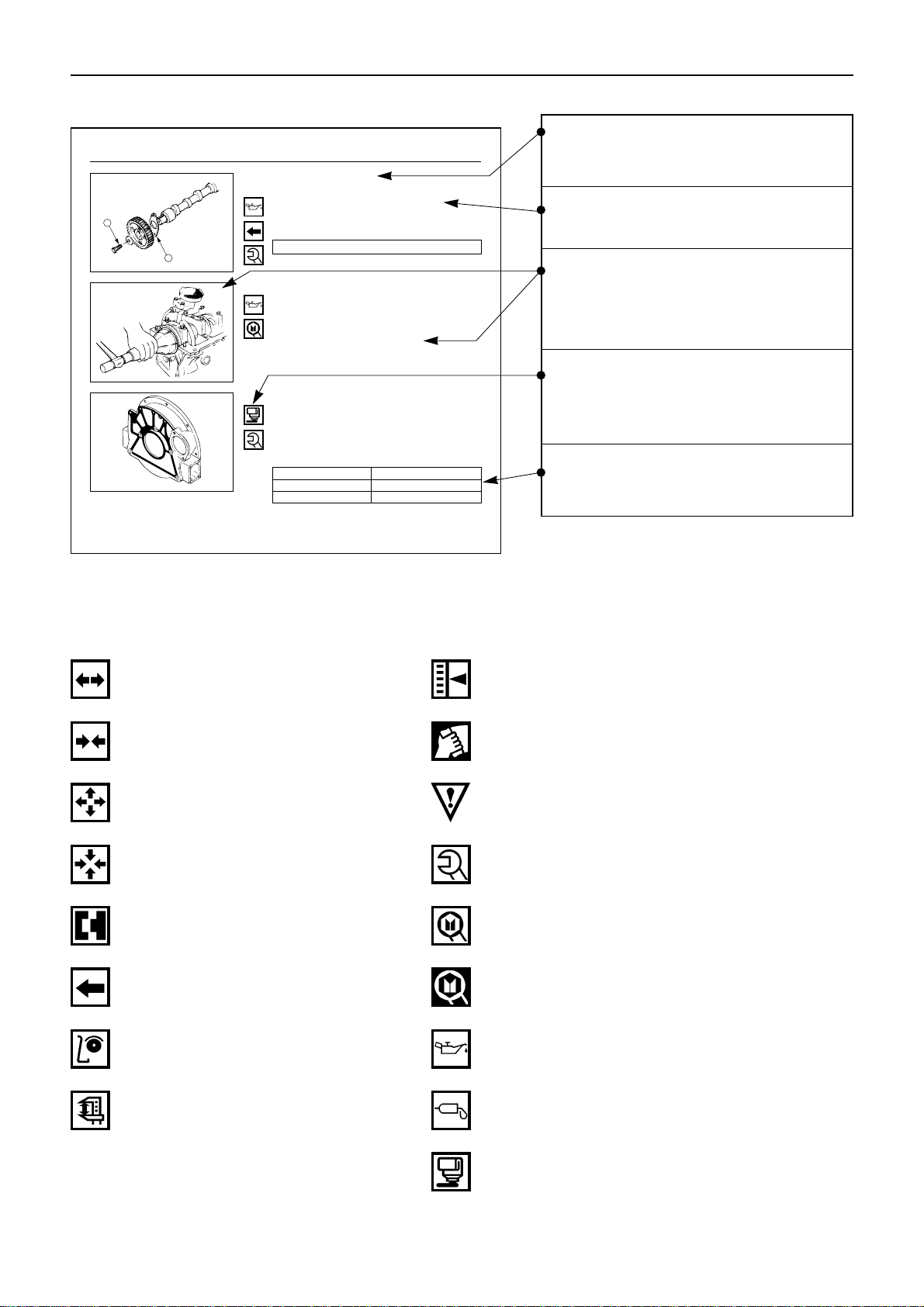

7. Below is a sample of the text of the Workshop Manual.

4. Camshaft Timing Gear

1) Install the thrust plate 1 .

2) Apply engine oil to the bolt threads 2 .

3) Install the camshaft timing gear with the timing

mark stamped side facing out.

Camshaft Timing Gear Bolt Torque kgf·m(lb.ft/N·m)

11.0 ± 1.0 (79.5 ± 7.2/107.8 ± 9.8)

1

2

13. Crankshaft Rear Oil Seal

1) Apply engine oil to the oil seal lip circumference

and the oil seal outer circumference.

2) Use the oil seal installer to install the oil seal to

the cylinder body.

Oil Seal Installer: 5-8840-0141-0

14. Flywheel Housing

1) Apply liquid gasket to the shaded area shown in

the illustration.

2) Tighten the flywheel housing bolts to the specified torque a little at a time in the sequence

shown in the illustration.

Flywheel Housing Bolt Torque kgf·m(lb.ft/N·m)

M10x1.25 (0.40x0.05) Bolt 5.6±1.0 (40.5±7.2/ 54.9±9.8)

M12x1.25 (0.47x0.05) Bolt 10.5±1.0 (76.0±7.2/103.0±9.8)

M12x1.75 (0.47x0.07) Bolt 9.8±1.0 (71.0±7.2/ 96.0±9.8)

7

4

8

6

10

9

3

2

1

5

This is the item shown in the illustration. It is marked with a triangle

(▲) on the Major Components page.

Letters and numbers contained in a

circle refer to the illustration.

Special tools are identified by the

tool name and/or number.

The illustration shows how the special tool is to be used.

Symbols indicate the type of service

operation or step to be performed. A

detailed explanation of these

symbols follows.

Service data and specifications are

given in this table.

Page 8

GENERAL INFORMATION

9. Measurement criteria are defined by the terms "standard" and "limit".

A measurement falling within the "standard" range indicates that the applicable part or parts are

serviceable.

"Limit" should be thought of as an absolute value.

A measurement which is outside the "limit" indicates that the applicable part or parts must be either

repaired or replaced.

10. Components and parts are listed in the singular form throughout the Manual.

11. Directions used in this Manual are as follows:

Front

The cooling fan side of the engine viewed from the flywheel.

Right

The right hand side viewed from the same position.

Left

The left hand side viewed from the same position.

Rear

The flywheel side of the engine.

Cylinder numbers are counted from the front of the engine.

The front most cylinder is No. 1 and rear most cylinder is the final cylinder number of the engine.

The engine's direction of rotation is counterclockwise viewed from the flywheel.

5

Page 9

GENERAL INFORMATION

MAIN DATA AND SPECIFICATIONS

6

Engine Model

A-4JA1 A-4JB1 4JB1T

Item

Engine type Water cooled, four-cycle, in-line, overhead valve

Combustion chamber type Direct injection

Cylinder liner type Dry

No. of cylinders - Bore x Stroke mm(in.) 4 - 93.0 x 92.0 4 - 93.0 x 102.0 4 - 93.0 x 102.0

(3.66 x 3.62) (3.66 x 4.02) (3.66 x 4.02)

Total piston displacement lit(cid) 2.449 (152.4) 2.771 (169.0) 2.771 (169.0)

Compression ratio (To 1) 18.4 18.2 18.2

*Engine dimensions mm(in.) 805 x 625 x 729 739 x 625 x 746 578 x 771 x 577

Length x Width x Height (31.7 x 24.6 x 28.7) (29.1 x 24.6 x 29.4) (22.8 x 30.4 x 22.7)

*Engine weight (Dry) kg(lb.) 218 (480) 220 (486) 245 (540)

Fuel injection order 1 – 3– 4 – 2

*Fuel injection timing (B.T.D.C.) degrees 14

Specified fuel Diesel fuel

Injection pump In-line plunger, Bosch A type Bosch distributor

VE type

Governor Variable speed mechanical type

*Low idle speed rpm 850 – 1,000

Injection nozzle Multi-hole type

Injection starting pressure kgf/cm2(psi/MPa) 185 (2630/18.1)

Fuel filter type Cartridge papaer element

Water sedimentor (if so equipped) Sediment/water level indicating type

Compression pressure kgf/cm2(psi/MPa) 31 (441/3.04)

Valve clearance (at cold) Intake mm(in.) 0.40 (0.0157)

Exhaust mm(in.) 0.40 (0.0157)

Lubrication method Pressurized circulation

Oil pump Trochoid type

Main oil filter type Cartridge paper element, full flow

Partial oil filter Not equipped

*Lubricating oil volume lit.(qts) 5.5 (5.8) – 6.6 (7.0) 4.6 (4.9) – 6.4 (6.8) 4.6 (4.9) – 6.3 (6.7)

Oil cooler (if so equipped) Water cooled built in oil filter

Cooling method Pressurized forced circulation

Coolant volume lit.(qts) 5.0 (5.3)

Water pump Belt driven impeller type

Thermostat type Wax pellet type

*Alternator V-A 12 – 35

*Starter V-kW 12 – 2.2

Specifications marked with an asterisk (*) will vary according to engine application.

Page 10

GENERAL INFORMATION

7

TIGHTENING TORQUE SPECIFICATIONS

The tightening torque values given in the table below are applicable to the bolts unless otherwise

specified.

STANDARD BOLT kgf·m (lb.ft/N·m)

An asterisk (*) indicates that the bolts are used for female threaded parts that are made of soft materials

such as casting. Those shown in parentheses in the strength class indicate the classification by the old

standard.

M 6 × 1.0

M 8 × 1.25

M10 × 1.25

M12 × 1.25

M14 × 1.5

M16 × 1.5

M18 × 1.5

M20 × 1.5

M22 × 1.5

M24 × 2.0

*M10 × 1.5

*M12 × 1.5

*M14 × 2.0

*M16 × 2.0

0.4 – 0.8

(2.9 – 5.8/3.9 – 7.8)

0.8 – 1.8

(5.8

–

13.0/7.8– 17.7)

2.1 – 3.5

(15.2– 25.3/20.6– 34.3)

5.0

–

7.5

(36.2

–

54.2/49.0– 73.6)

7.8

–

11.7

(56.4

–

84.6/78.5– 114.7)

10.6

–

16.0

(76.7

–

115.7/103.0– 156.9)

15.4

–

23.0

(111.1

–

166.4/151.0– 225.6)

21.0

–

31.6

(151.9

–

228.6/205.9– 307.9)

25.6

–

42.2

(185.2

–

305.2/251.1– 413.8)

36.6

–

55.0

(264.7

–

397.8/358.9– 539.4)

2.0

–

3.4

(14.5

–

24.6/19.6– 32.4)

4.6

–

7.0

(33.3

–

50.6/45.1– 68.7)

7.3

–

10.9

(52.8

–

78.8/71.6– 106.9)

10.2

–

15.2

(73.8

–

110.0/100.0– 149.1)

0.5

–

1.0

(3.6

–

7.2/4.9– 9.8)

1.2

–

2.3

(8.7

–

16.6/11.8– 22.6)

2.8

–

4.7

(20.3

–

34.0/27.5– 46.1)

6.2

–

9.3

(44.8

–

67.3/60.8– 91.2)

9.5

–

14.2

(68.7

–

102.7/93.2– 139.3)

13.8

–

20.8

(99.8

–

150.4/135.3– 204.0)

19.9

–

29.9

(143.9

–

216.3/195.2– 391.3)

27.5

–

41.3

(198.9

–

298.7/269.7– 405.0)

37.0

–

55.5

(267.6

–

401.4/362.9– 544.3)

43.9

–

72.5

(317.5

–

523.9/430.5– 711.0)

2.8

–

4.6

(20.3

–

33.3/27.5– 45.1)

5.8

–

8.6

(42.0

–

62.2/56.9– 84.3)

9.0

–

13.4

(65.1

–

96.9/88.3– 131.4)

13.2

–

19.8

(95.5

–

143.2/129.5 – 194.2)

1.7

–

3.1

(12.3

–

22.4/16.7– 30.4)

3.8

–

6.4

(27.5

–

46.3/37.3– 62.8)

7.7

–

11.6

(55.7

–

83.9/75.5– 113.8)

11.6

–

17.4

(83.9

–

125.6/113.8– 170.6)

16.3

–

24.5

(118.9

–

177.2/159.9– 240.3)

23.4

–

35.2

(169.3

–

254.6/229.5– 345.2)

32.3

–

48.5

(233.6

–

350.8/316.8– 475.6)

43.3

–

64.9

(313.2

–

469.4/424.6– 636.5)

56.5

–

84.7

(408.7

–

612.6/554.1– 830.6)

3.7

–

6.1

(26.8

–

44.1/36.3– 59.8)

7.3

–

10.9

(52.8

–

78.8/71.6– 106.9)

10.9

–

16.3

(78.8

–

118.9/106.9– 159.9)

15.6

–

23.4

(112.8

–

169.3/162.8– 229.5)

Refined

No mark

Non-Refined

4.8 (4T)

8.8(7T)

9.8 (9T)

Strength

Class

Bolt

Identification

Bolt

Diameter ×

pitch (mm)

Page 11

GENERAL INFORMATION

8

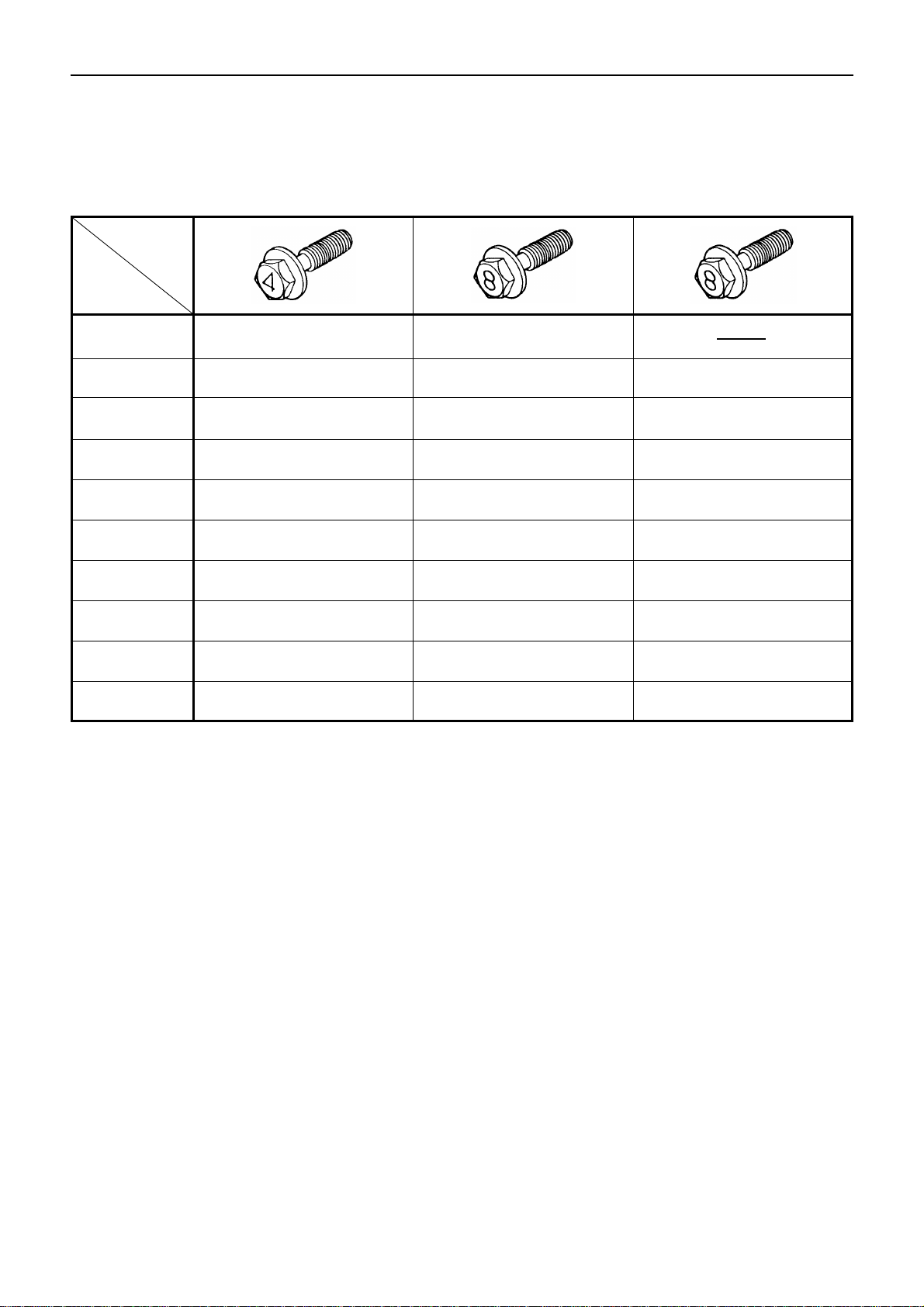

TIGHTENING TORQUE SPECIFICATIONS

The tightening torque values given in the table below are applicable to the bolts unless otherwise

specified.

FLANGED HEAD BOLT kgf·m (lb.ft/N·m)

M 6 × 1

0.5– 0.9 0.6 – 1.2

(3.61– 6.50/4.6

–

8.5 (4.33 – 8.67/5.88 – 11.76)

M 8 × 1.25

1.1

–

2.0 1.4

–

2.9 1.9– 3.4

(7.95– 14.46/10.78– 19.61) (4.33– 8.67/5.88– 11.76) (13.74– 24.59/18.63– 33.34)

M10 × 1.25

2.3

–

3.9 3.6– 6.4 4.3– 7.2

(17.35– 28.20/23.53– 38.24) (26.03– 44.12/35.30– 59.82) (31.10– 52.07/42.16– 70.60)

*M10 × 1.5

2.3

–

3.8 3.5– 5.8 4.1– 6.8

(16.63

–

27.48/22.55– 37.26) (25.31– 41.95/34.32– 56.87) (29.65– 49.18/40.20– 66.68)

M12 × 1.25

5.6– 8.4 7.9– 11.9 8.7– 13.0

(40.50

–

60.75/54.91– 82.37) (57.14– 86.07/77.47– 116.69) (62.92– 94.02/85.31– 127.48)

*M12 × 1.75

3.5

–

9.5 7.3– 10.9 8.1– 12.2

(37.61– 56.41/50.99– 76.49) (52.80– 78.83/71.58– 106.89) (58.58– 88.24/79.43– 119.64)

M14 × 1.5

8.5

–

12.7 11.7– 17.6 12.6– 18.9

(61.48

–

91.85/83.35– 124.54) (84.62– 127.30/114.73– 172.59) (91.13– 136.70/123.56– 185.34)

*M14 × 2

7.6– 11.5 11.1– 16.6 11.8– 17.7

(57.14

–

85.34/77.47– 115.71) (80.28– 120.06/108.85– 162.79) (85.34– 128.02/115.71– 173.57)

M16 × 1.5

11.8– 17.7 17.1

–

26.5 18.0

–

27.1

(85.34

–

128.02/115.71– 173.57) (125.85– 189.50/170.63– 256.93) (130.19– 196.01/176.52– 265.76)

*M16 × 2

11.2– 16.7 16.6– 24.9 17.2– 25.7

(81.00

–

120.79/109.83

–

163.77) (120.06

–

180.10/162.79– 244.18) (124.40– 186.61/168.67– 253.01)

A bolt with an asterisk (*) is used for female screws of soft material such as cast iron.

Bolt head

marking

Nominal

size

(dia. x pitch)

Page 12

GENERAL INFORMATION

9

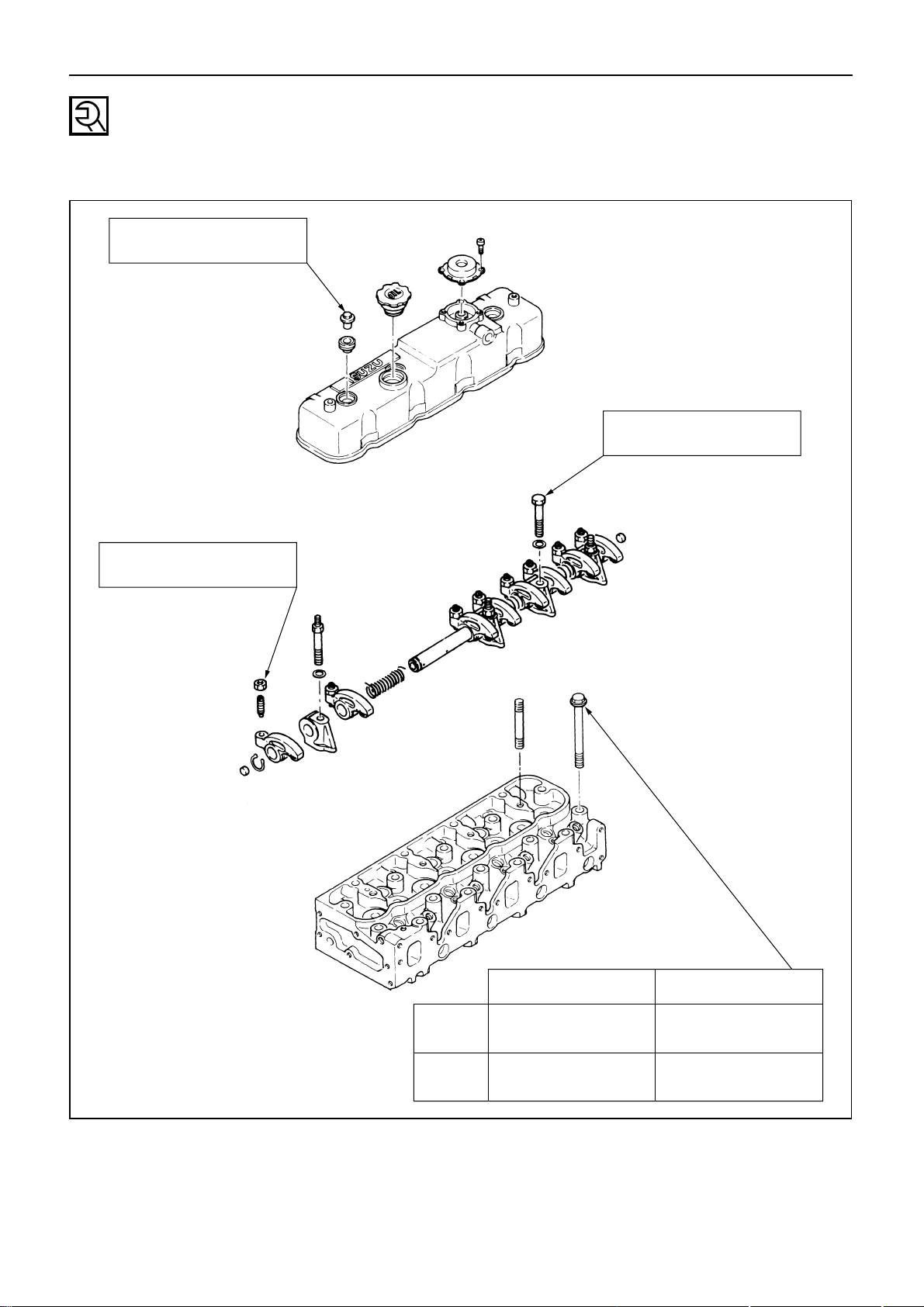

SPECIAL PARTS FIXING NUTS AND BOLTS

Cylinder Head Cover, Cylinder Head, and Rocker Arm Shaft Bracket

kgf·m(lb.ft./N·m)

1.0 – 2.0

(7.2 – 14.4/9.8 – 19.6)

0.8 – 1.8

(5.8 – 13.0/7.8 – 17.6)

1st Step 2nd Step

3.0 – 5.0

(21.7 – 36.1/29.4 – 49.0)

8.2 – 9.2

(59.4 – 66.5/80.4 – 90.2)

8.0 – 9.0

(57.9 – 65.1/78.4 – 88.2)

10.0 – 11.0

(72.4 – 79.6/98.1 – 107.9)

5.0 – 6.0

(36.2 – 43.4/49.0 – 58.8)

New bolt

Reused

bolt

Page 13

GENERAL INFORMATION

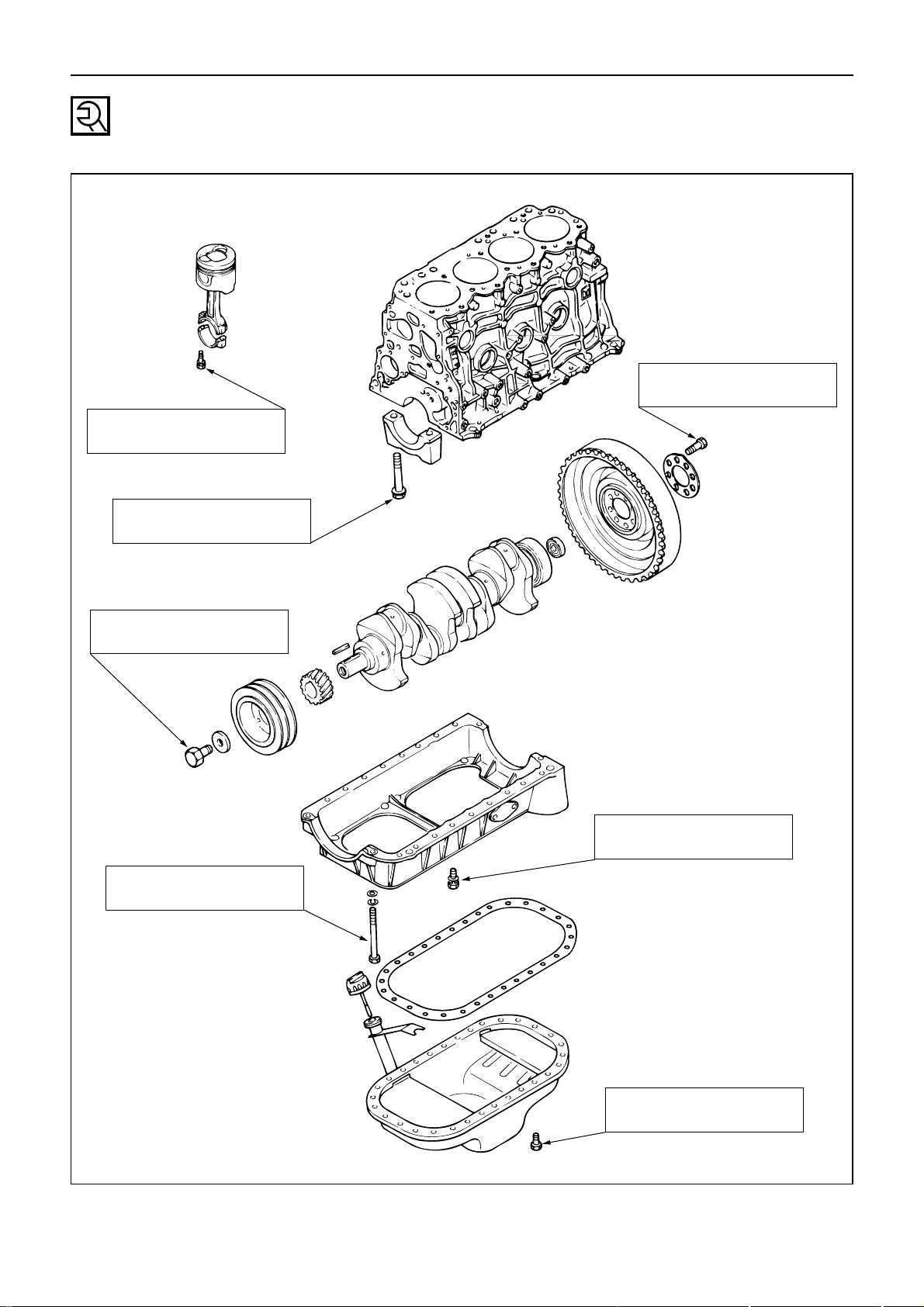

10

Crankshaft Bearing Cap, Connecting Rod Bearing Cap,

Crankshaft Damper Pulley, Flywheel, and Oil Pan

kgf·m(lb.ft./N·m)

8.0 – 9.0

(57.9 – 65.1/78.4 – 88.2)

16.0 – 18.0

(115.7 – 130.2/159.6 – 176.5)

20.1 – 24.5

(145.4 – 177.2/197.1 – 240.3)

1.4 – 2.4

(10.1 – 17.3/13.7 – 23.5)

1.4 – 2.4

(10.1 – 17.3/13.7 – 23.5)

11.5 – 12.5

(83.2 – 90.4/112.8 – 122.6)

14 – 24

(1.4 – 2.4/4.4 – 7.2)

Page 14

GENERAL INFORMATION

11

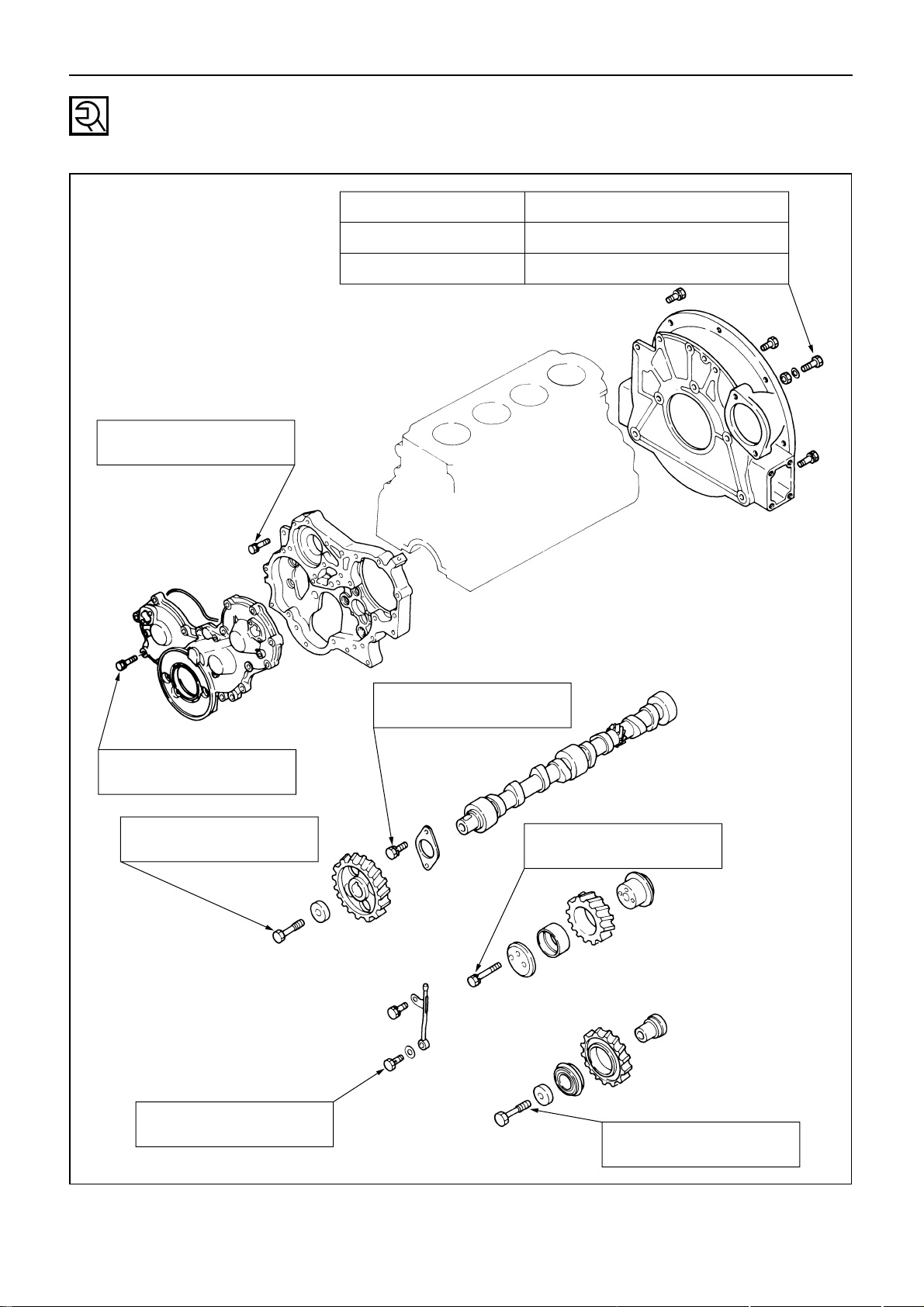

Timing Gear Case, Flywheel Housing, Camshaft, and Timing Gear

kgf·m(lb.ft./N·m)

1.4 – 2.4

(10.1 – 17.3/13.7 – 23.5)

1.4 – 2.4

(10.1 – 17.3/13.7 – 23.5)

10.0 – 12.0

(72.4 – 86.8/98.1 – 117.7)

1.4 – 2.4

(10.1 – 17.3/13.7 – 23.5)

1.4 – 2.4

(10.1 – 17.3/13.7 – 23.5)

1.0 – 1.5

(7.2 – 10.9/9.8 – 14.7)

6.6 – 8.7

(48 – 63/66 – 85)

M10 x 1.25 (0.39 x 0.05) 4.6 – 6.6 (33.3 – 47.7/45.1 – 64.7)

9.6 – 11.6 (69.4 – 83.9/94.1 – 113.8)

8.8 – 10.8 (63.7 – 78.1/86.3 – 105.9)

M12 x 1.25 (0.47 x 0.05)

M12 x 1.75 (0.47 x 0.07)

Page 15

GENERAL INFORMATION

12

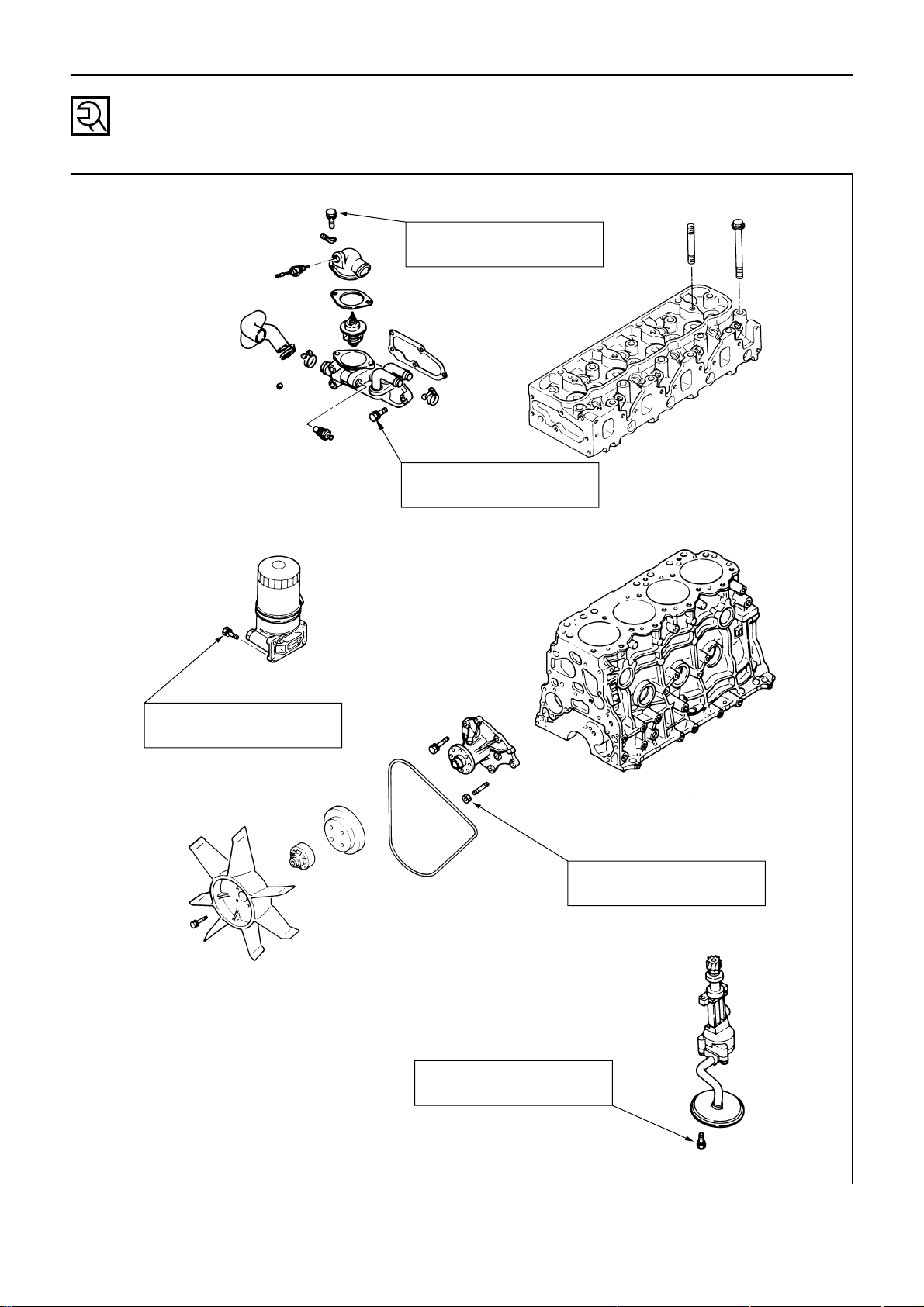

Cooling and Lubricating System

kgf·m(lb.ft./N·m)

1.4 – 2.4

(10.1 – 17.3/13.7 – 23.5)

1.4 – 2.4

(10.1 – 17.3/13.7 – 23.5)

1.4 – 2.4

(10.1 – 17.3/13.7 – 23.5)

1.4 – 2.4

(10.1 – 17.3/13.7 – 23.5)

1.4 – 2.4

(10.1 – 17.3/13.7 – 23.5)

Page 16

GENERAL INFORMATION

13

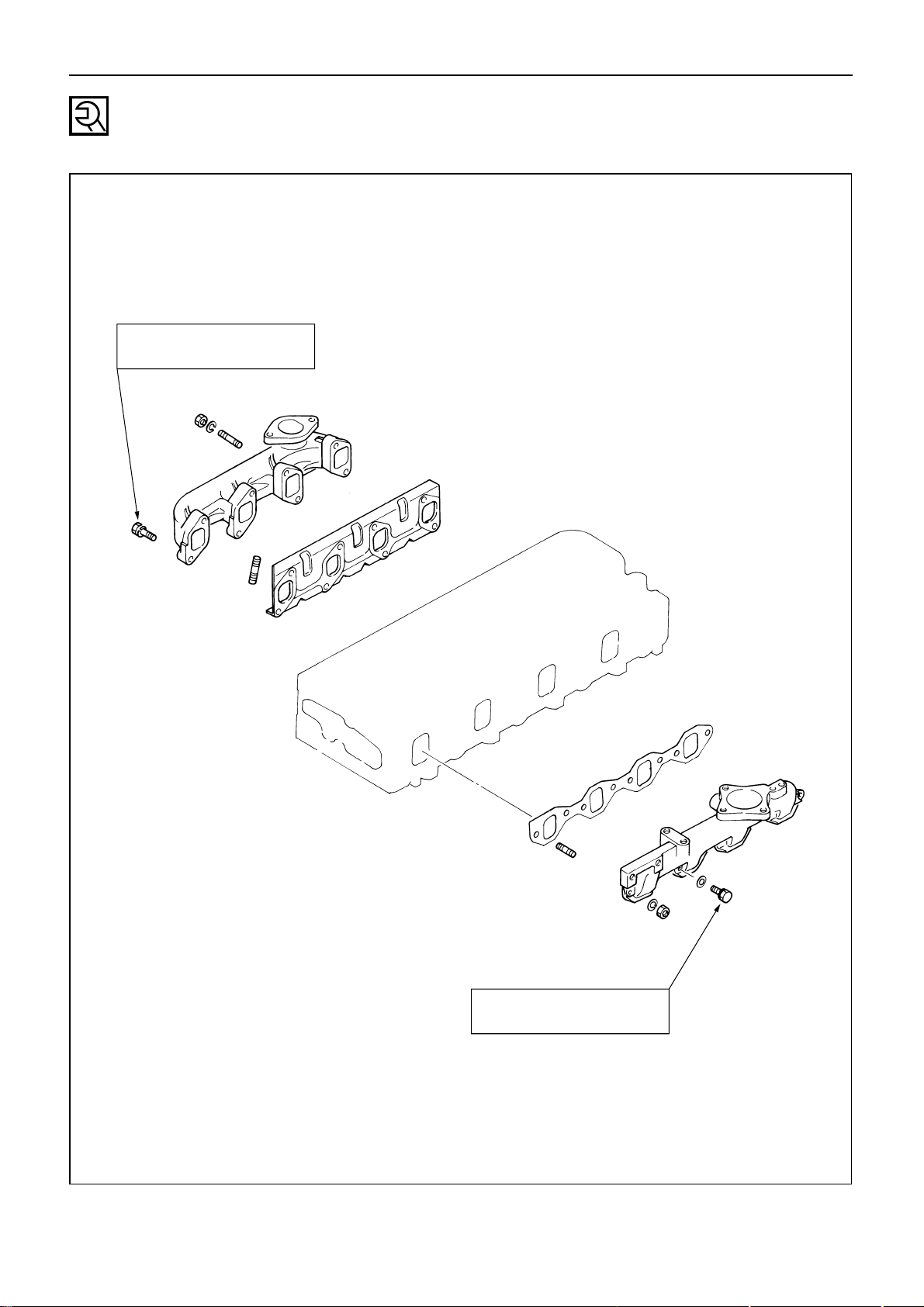

Intake and Exhaust Manifold

kgf·m(lb.ft./N·m)

1.4 – 2.4

(10.1 – 17.3/13.7 – 23.5)

1.4 – 2.4

(10.1 – 17.3/13.7 – 23.5)

Page 17

GENERAL INFORMATION

14

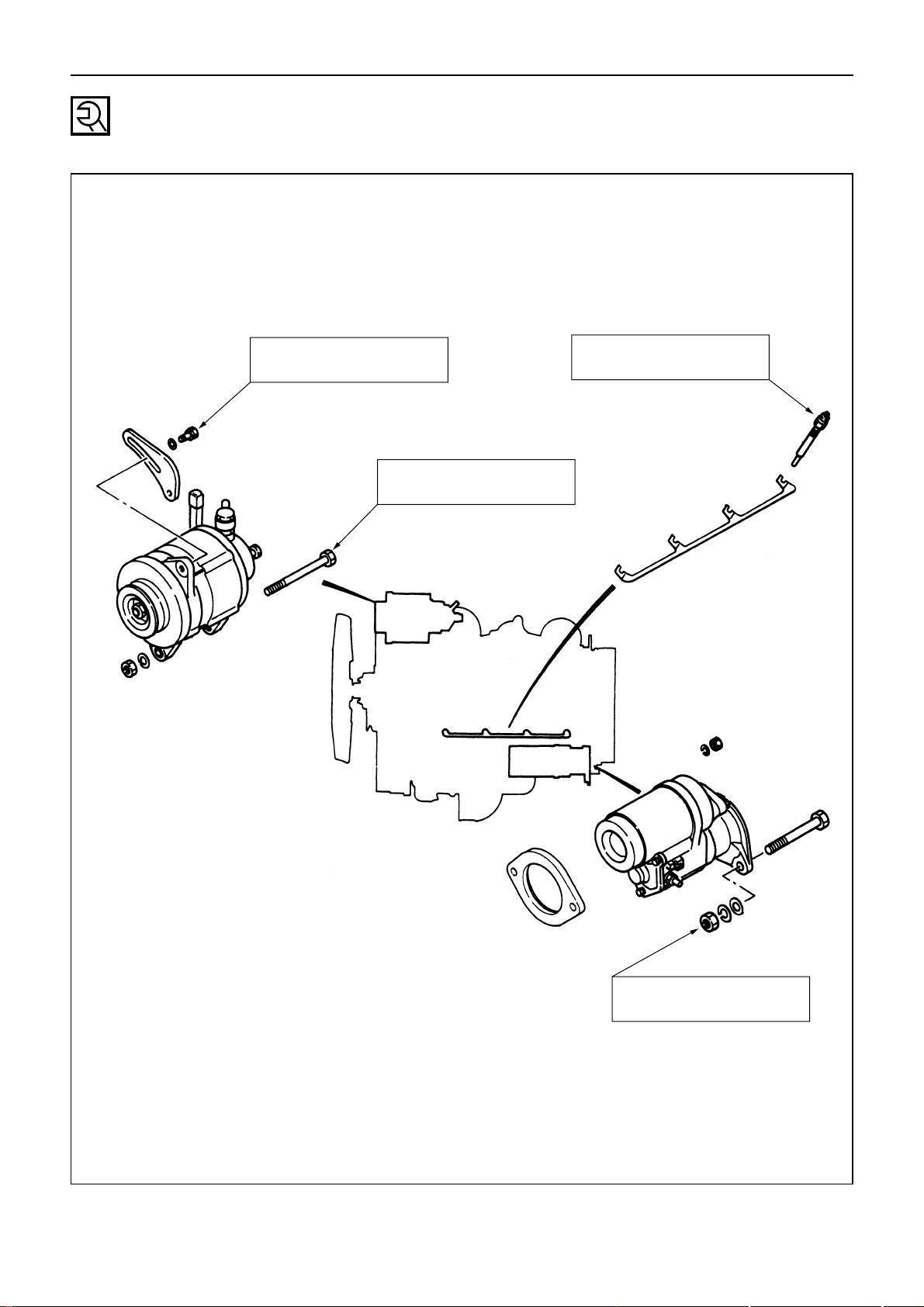

Engine Electrical

kgf·m(lb.ft./N·m)

1.4 – 2.4

(10.1 – 17.3/13.7 – 23.5)

3.6 – 4.6

(26.0 – 33.3/35.3 – 45.1)

2.0 – 2.5

(14.4 – 18.1/19.6 – 24.5)

6.0 – 8.0

(43.4 – 57.9/58.8 – 78.4)

Page 18

GENERAL INFORMATION

15

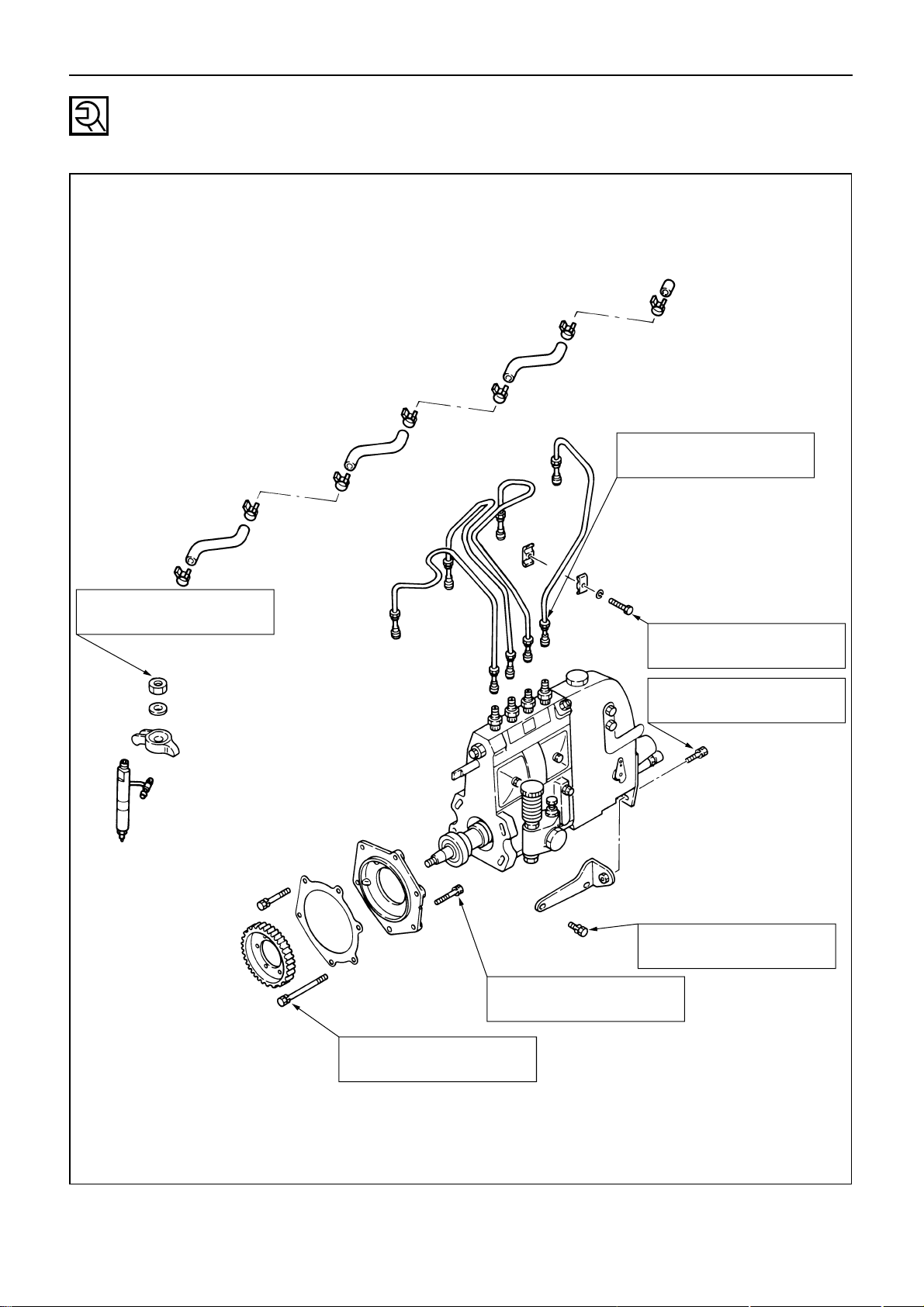

Fuel Injection System

kgf·m(lb.ft./N·m)

3.2 – 4.4

(23.1 – 31.8/31.4 – 43.2)

20 – 4.0

(14.4 – 28.9/19.6 – 39.2)

1.4 – 2.4

(10.1 – 17.3/13.7 – 23.5)

1.4 – 2.4

(10.1 – 17.3/13.7 – 23.5)

1.4 – 2.4

(10.1 – 17.3/13.7 – 23.5)

1.4 – 2.4

(10.1 – 17.3/13.7 – 23.5)

1.4 – 2.4

(10.1 – 17.3/13.7 – 23.5)

Page 19

16

MEMO

Page 20

MAINTENANCE

17

SECTION 2

MAINTENANCE

TABLE OF CONTENTS

ITEM PAGE

Model identification ............................................................. 18

Injection pump identification ...................................................... 18

Lubricating system .............................................................. 18

Fuel system .................................................................... 19

Cooling system ................................................................. 22

Valve clearance adjustment ....................................................... 23

Injection timing ................................................................. 24

Compression pressure measurement ............................................... 26

Recommended lubricants ......................................................... 27

Engine repair kit ................................................................ 28

Page 21

MAINTENANCE

MAINTENANCE

Servicing refers to general maintenance procedures to be performed by qualified service personnel.

Maintenance interval such as fuel or oil filter changes should be refered to “INSTRUCTION MANUAL”.

MODEL IDENTIFICATION

Engine Serial Number

The engine number is stamped on the rear left hand side

of the cylinder body.

INJECTION PUMP IDENTIFICATION

Injection volume should be adjusted after referring to

the adjustment data applicable to the injection pump

installed.

The injection pump identification number (A) is stamped

on the injection pump identifications plate.

Note:

Always check the identification number before beginning a service operation.

Applicable service data will vary according to the identification number. Use of the wrong service data will

result in reduced engine performance and engine

damage.

1 ZEXEL (Manufacturer of the injection pump) identifi-

cation number

2 ISUZU Parts Number

Pump No. . . . . . . . . . . . . . .

NP - PE . . . . . . . . . . . . . . . . . . . . . .

(LICENCE BOSCH)

A

A

…Identification number

In-line type

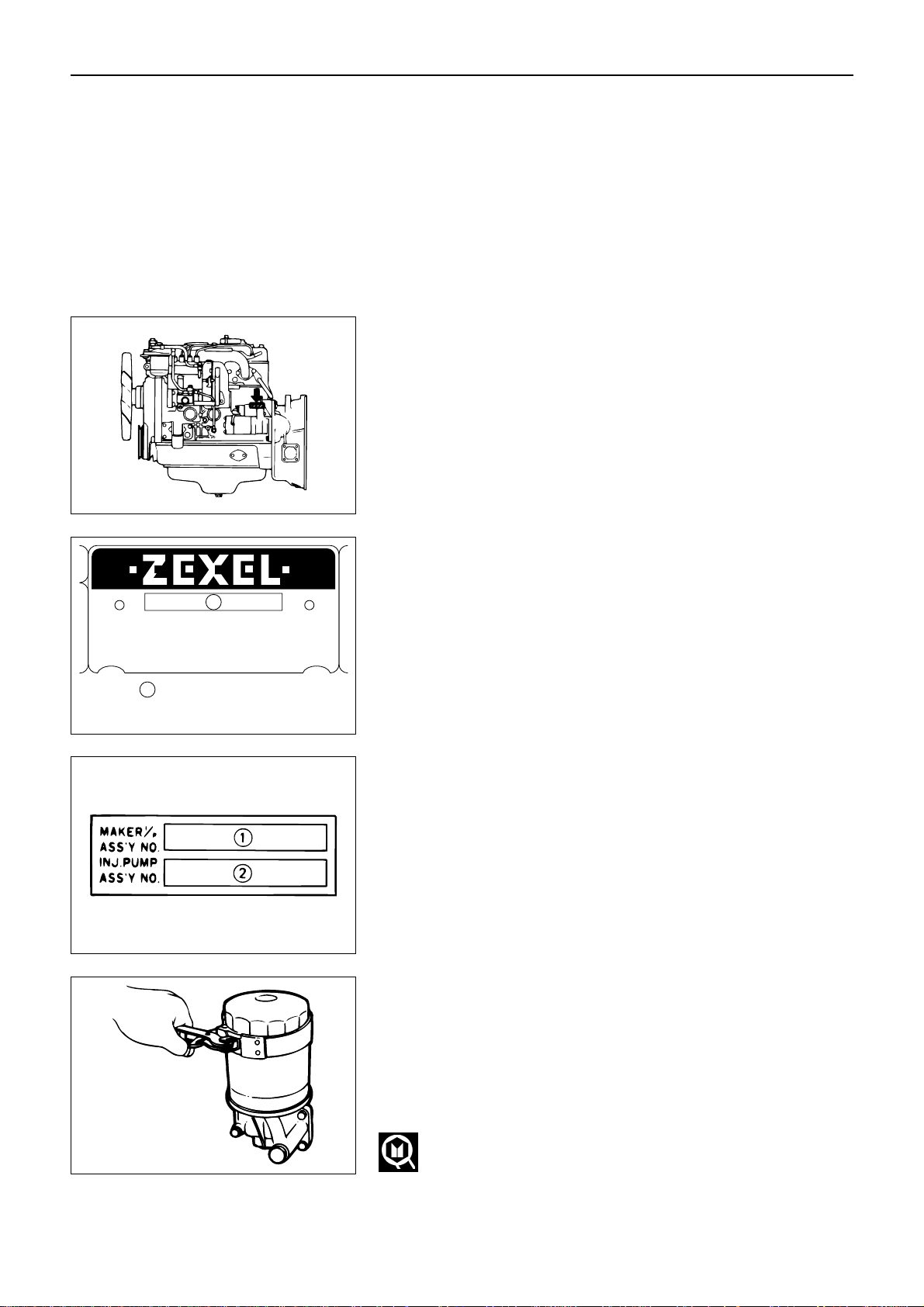

LUBRICATING SYSTEM

Main Oil Filter

Replacement Procedure

1. Loosen the drain plug to drain the engine oil.

2. Wait a few minutes and then retighten the drain

plug.

3. Loosen the used oil filter by turning it counterclockwise with a filter wrench.

Filter Wrench

18

Distributor type

Page 22

MAINTENANCE

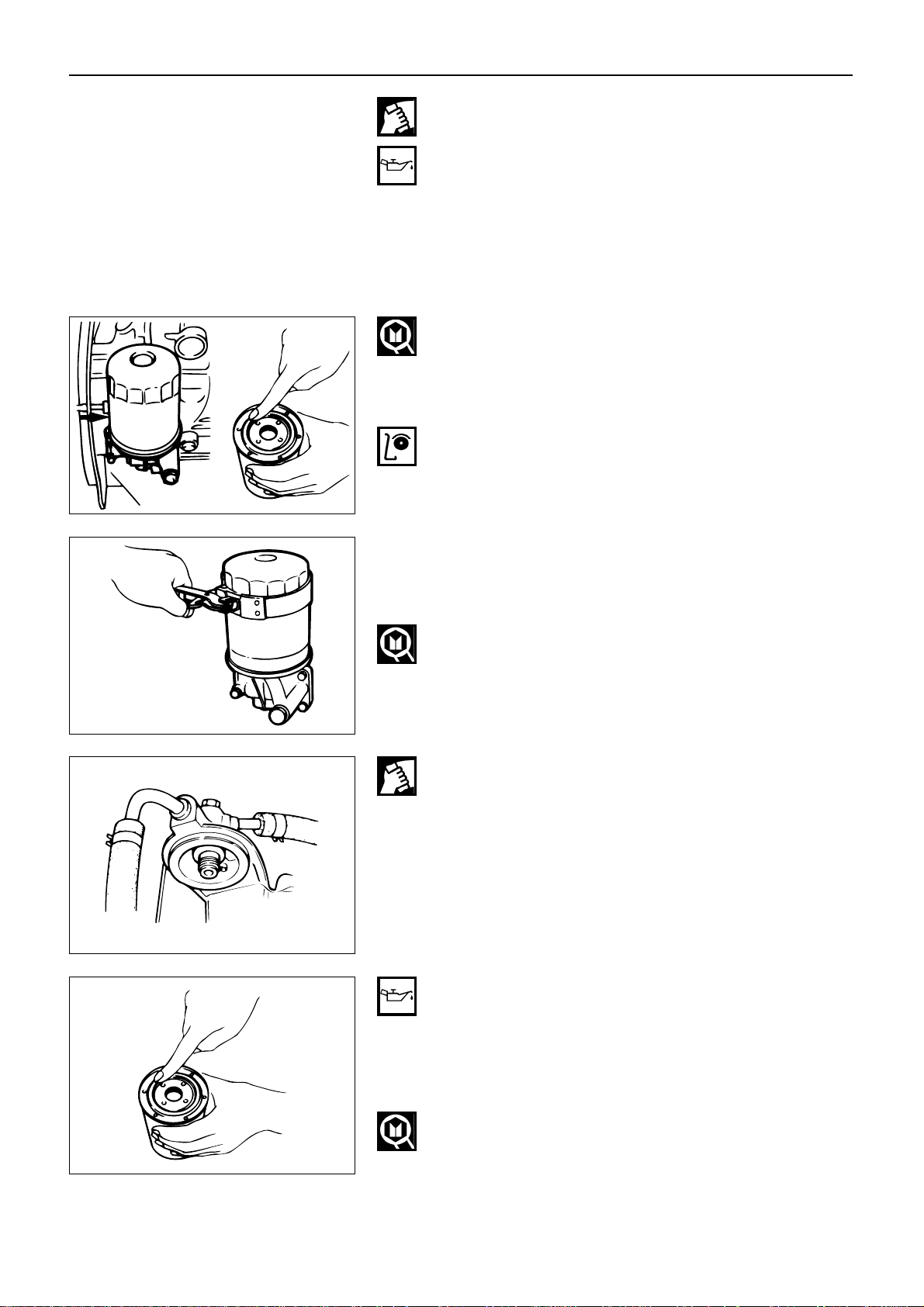

4. Clean the oil cooler fitting face.

This will allow the new oil filter to seat properly.

5. Apply a light coat of engine oil to the O-ring.

6. Turn in the new oil filter until the filter O-ring is

fitted against the sealing face.

7. Use a filter wrench to turn in the filter an additional

1 and 1/4 of a turn.

Filter Wrench

8. Check the engine oil level and replenish to the specified level if required.

9. Start the engine and check for oil leakage from the

main oil filter.

FUEL SYSTEM

Fuel Filter

Replacement Procedure

1. Loosen the used fuel filter by turning it counterclockwise with the filter wrench.

Filter Wrench

2. Clean the upper cover fitting face.

This will allow the new fuel filter to seat properly.

3. Apply a light coat of engine oil to the O-ring.

4. Supply fuel to the new fuel filter to facilitate bleeding.

5. Turn in the new fuel filter until the filter O-ring is fitted against the sealing face.

Be very careful to avoid fuel spillage.

6. Use a filter wrench to turn in the fuel filter an additional 1/3 to 2/3 of a turn.

19

Page 23

MAINTENANCE

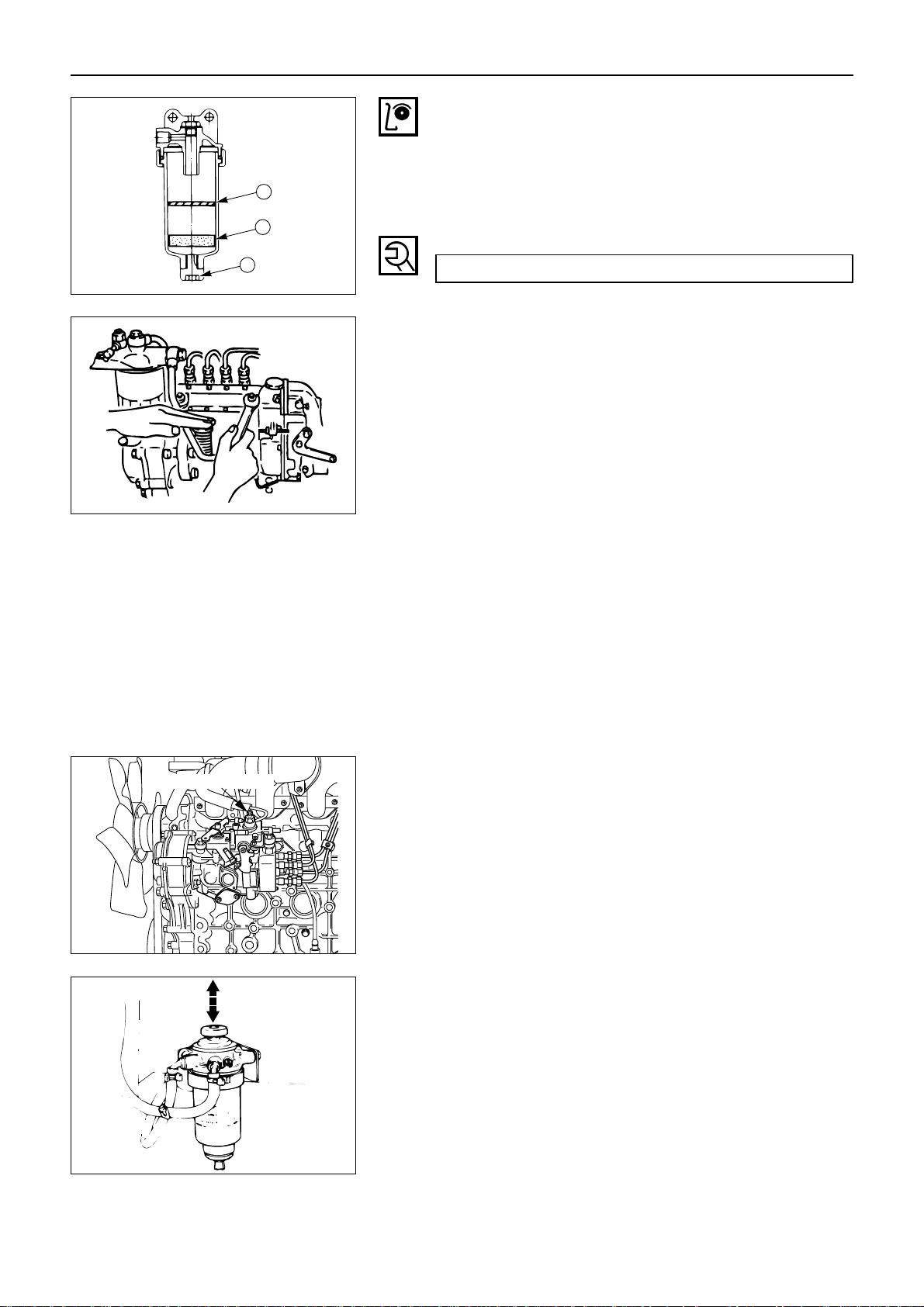

Water Separator (Water Sedimentor)

(Optional Equipment)

Check the water separator float 1 level.

If the float 1 has reached level 2 , loosen the drain plug

3 (at the bottom side of the water separator) to drain

the water.

Drain Plug Torque kgf·m(lb.ft./N·m)

0.9 – 1.5 (6.5 – 10.9/8.8 – 14.7)

1

2

3

Air Bleeding

1. For the engine equipped with in-line type injection

pump

1) Loosen the priming pump cap 1 on the injection

pump.

2) Loosen the fuel return eye bolt 2 on the fuel filter.

3) Operate the priming pump until there are no more

bubbles visible in the fuel being discharged from the

fuel return eye bolt on the fuel filter.

4) Retighten the fuel return eye bolt on the fuel filter.

5) Loosen the bleeder bolt 3 while operating the

injection pump priming pump to check that the air

has been bled completely.

6) Operate the priming pump several times to check for

fuel leakage around the injection pump and the fuel

filter.

2. For the engine equipped with distributor type injection pump

1) Loosen the bleeder screw on the injection pump

overflow valve.

2) Operate the priming pump until fuel mixed with

foam flows from the bleeder screw.

3) Tighten the bleeder screw.

4) Operate the priming pump several times and check

for fuel leakage.

20

080ES004

Air bleeding screw

Page 24

MAINTENANCE

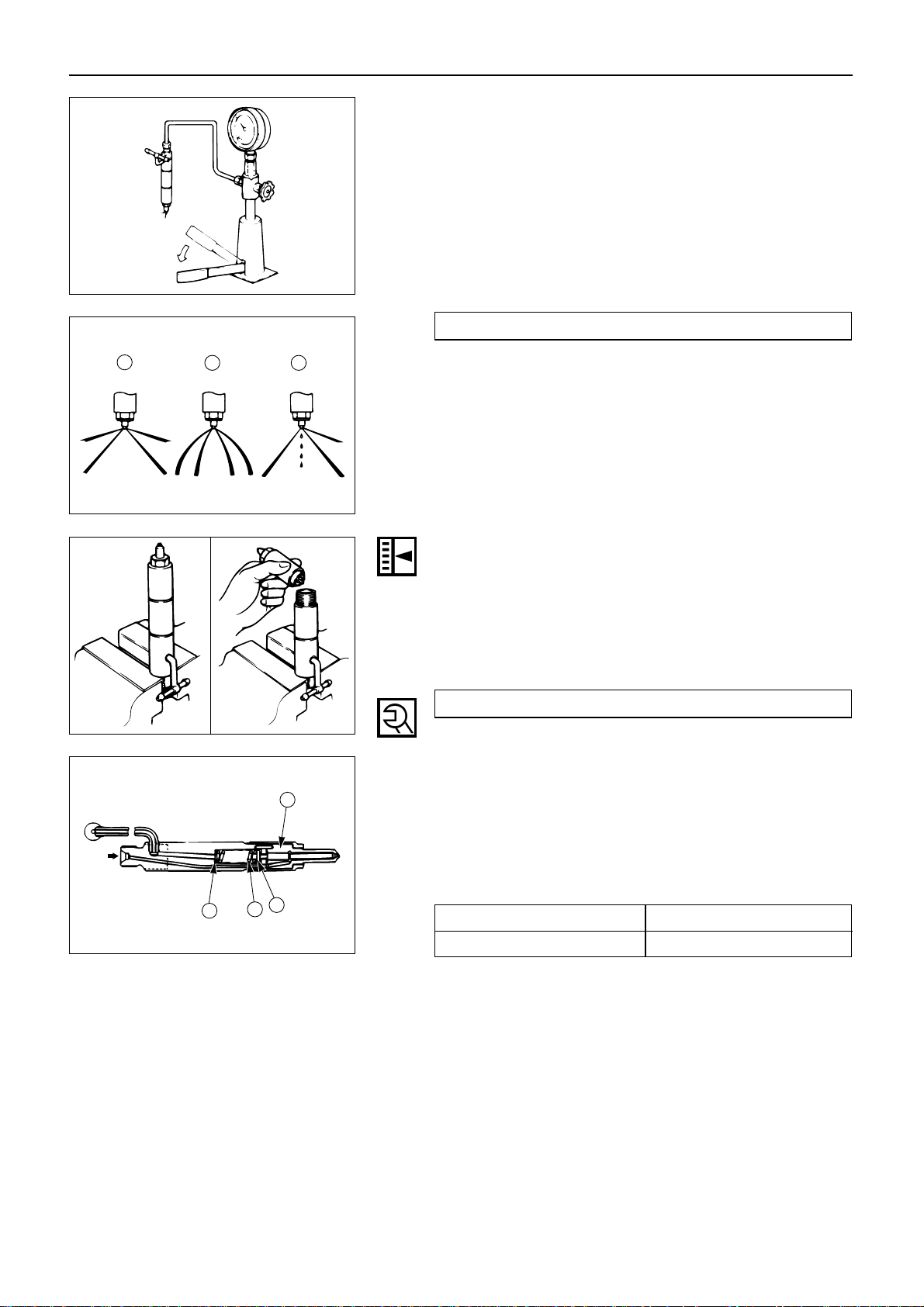

Injection Nozzle

Injection Nozzle Inspection

Use a nozzle tester to check the injection nozzle opening

pressure and the spray condition.

If the opening pressure is above or below the specified

value, the injection nozzle must be replaced or reconditioned.

If the spray condition is bad, the injection nozzle must be

replaced or reconditioned.

Injection Nozzle Opening Pressure kgf/cm2(psi/MPa)

185 (2,630/18.1)

Spray Condition

(1) Correct

(2) Incorrect (Restrictions in orifice)

(3) Incorrect (Dripping)

Injection Nozzle Adjustment

1. Clamp the injection nozzle in a vise.

2. Use a wrench to remove the injection nozzle retaining nut.

3. Install the injection nozzle 1 , the push rod 2 , the

spring 3 , and adjusting shim 4.

Retaining Nut Torque kgf·m(lb.ft./N·m)

4.0 – 5.0 (28.9 – 36.2/39.2 – 49.0)

4. Attach the injection nozzle holder to the injection

nozzle tester.

5. Apply pressure to the nozzle tester to check that the

injection nozzle opens at the specified pressure.

If the injection nozzle does not open at the specified

pressure, install or remove the appropriate number

of adjusting shims to adjust it.

Adjusting Shim Availability mm(in.)

Range 0.50 – 1.50 (0.02 – 0.06)

Increment 0.025 (0.001)

Total No. of Shims 40

(Reference)

Removing or installing one shim will increase or

decrease the nozzle opening pressure approximately

3.77 kgf/cm2(53.6 psi/370kPa).

WARNING:

TEST FLUID FROM THE INJECTION NOZZLE TESTER

WILL SPRAY OUT UNDER GREAT PRESSURE. IT CAN

EASILY PUNCTURE A PERSON’S SKIN. KEEP YOUR

HANDS AWAY FROM THE INJECTION NOZZLE TESTER

AT ALL TIMES.

21

1

2 3

1

2

3

4

Page 25

MAINTENANCE

COOLING SYSTEM

Cooling Fan Drive Belt

Fan belt tension is adjusted by moving the alternator.

A Crankshaft damper pulley

B Alternator pulley

C Cooling fan drive pulley

D Depress the drive belt mid-portion with a 10 kgf (22

lb/98 N) force.

Drive Belt Deflection mm(in.)

10.0 (0.39)

A

C

D

B

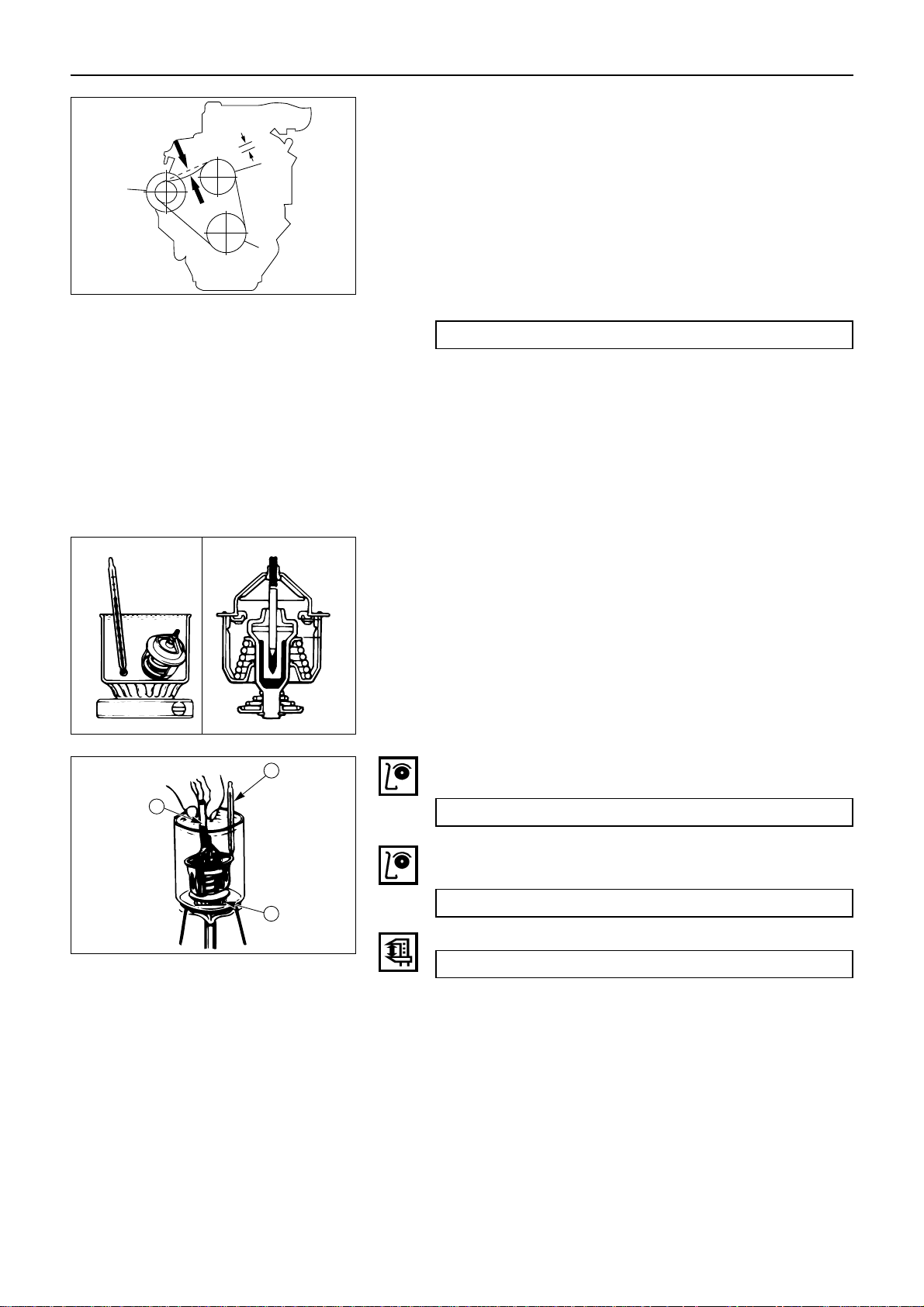

Thermostat

Operating Test

1. Completely submerge the thermostat in water.

2. Heat the water.

Stir the water constantly to avoid direct heat being

applied to the thermostat.

3. Check the thermostat initial opening temperature.

Thermostat Initial Opening Temperature °C(°F)

82 (180)

4. Check the thermostat full opening temperature.

Thermostat Full Opening Temperature °C(°F)

95 (203)

Valve Lift at Fully Open Position mm(in.)

8.0 (0.315)

1 Thermostat

2 Agitating Rod

3 Wooden Piece

1

2

3

22

Page 26

MAINTENANCE

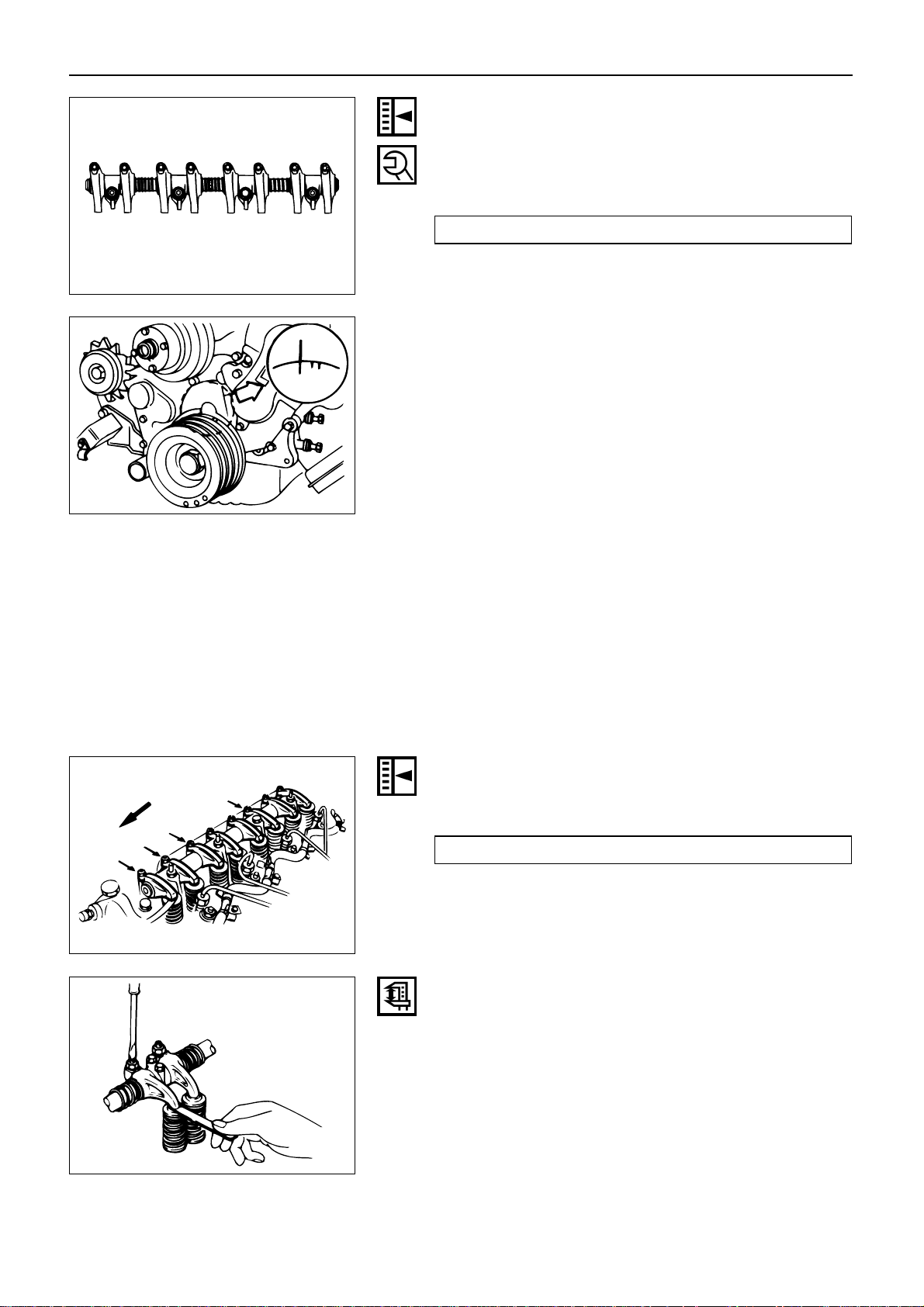

VALVE CLEARANCE ADJUSTMENT

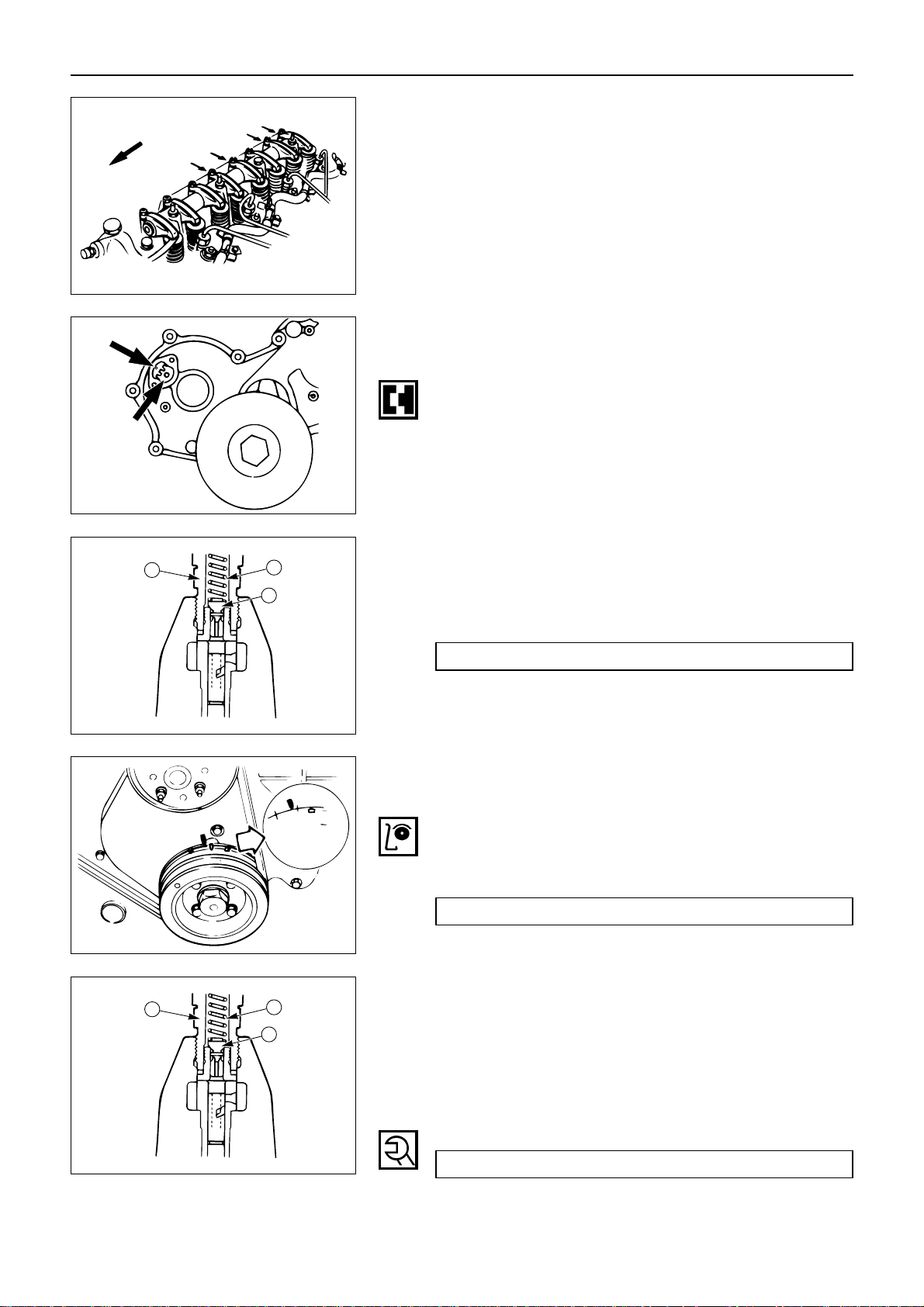

1. Retighten the rocker arm shaft bracket bolts in

sequence as shown in the illustration.

Rocker Arm Shaft Bracket Bolt

Torque kgf·m(lb.ft/N·m)

5.0 – 6.0 (36.2 – 43.4/49.0 – 58.8)

3124

2. Bring the piston in either the No. 1 cylinder or the

No. 4 cylinder to TDC on the compression stroke by

turning the crankshaft until the crankshaft damper

pulley TDC line is aligned with the timing pointer.

TDC

3. Check for play in the No. 1 intake and exhaust valve

push rods.

If the No. 1 cylinder intake and exhaust valve push

rods have play, the No. 1 piston is at TDC on the

compression stroke.

If the No. 1 cylinder intake and exhaust valve push

rods are depressed, the No. 4 piston is at TDC on the

compression stroke.

Adjust the No. 1 or the No. 4 cylinder valve clearances

while their respective cylinders are at TDC on the compression stroke.

Valve Clearance mm(in.)

0.40 (0.016)

Loosen each valve clearance adjusting screw as shown

in the illustration. (At TDC on the compression stroke of

the No. 1 cylinder)

Insert a feeler gauge of the appropriate thickness

between the rocker arm and the valve stem end.

4. Turn the valve clearance adjusting screw until a

slight drag can be felt on the feeler gauge.

5. Tighten the lock nut securely.

23

Page 27

MAINTENANCE

Rotate the crankshaft 360°.

Realign the crankshaft damper pulley TDC line with the

timing pointer.

Adjust the clearances for the remaining valves as shown

in the illustration. (At TDC on the compression stroke of

the No. 4 stroke)

INJECTION TIMING

Injection Timing Confirmation Procedure

1. In-line type injection pump

1) Rotate the crankshaft clockwise to align the cam shaft gear timing mark “O” with the timing gear

case cover pointer.

The No. 1 cylinder will now be at the point where

nearly injection timing.

2) Remove the No. 1 fuel injection pipe.

3) Remove the delivery valve holder 1 , the delivery

valve spring 2 , and the delivery valve 3 .

4) Tighten the delivery valve holder to the specified

torque.

Delivery Valve Holder Torque kgf·m(lb.ft/N·m)

4.0 – 4.5 (28.9 – 32.5/39.2 – 44.1)

1

2

3

5) Operate the injection pump priming pump while

slowly rotating the crankshaft until fuel stops flowing from the delivery valve holder.

6) Conform that the crankshaft damper pulley notched

line is aligned with the timing gear case cover

pointer.

Injection Timing (Static BTDC)

14°

TDC 17

24

7) Remove the delivery valve holder.

8) Install the delivery valve 1 , the delivery valve

spring 2 , and the delivery valve holder 3 .

9) Tighten the delivery valve holder to the specified

torque.

10) Install the fuel injection pipes and tighten them to

the specified torque.

Fuel Injection Pipe Torque kgf·m(lb.ft/N·m)

2.0 – 4.0 (14.4 – 28.9/19.6 – 39.2)

11) Operation to air breeding.

1

2

3

Page 28

MAINTENANCE

25

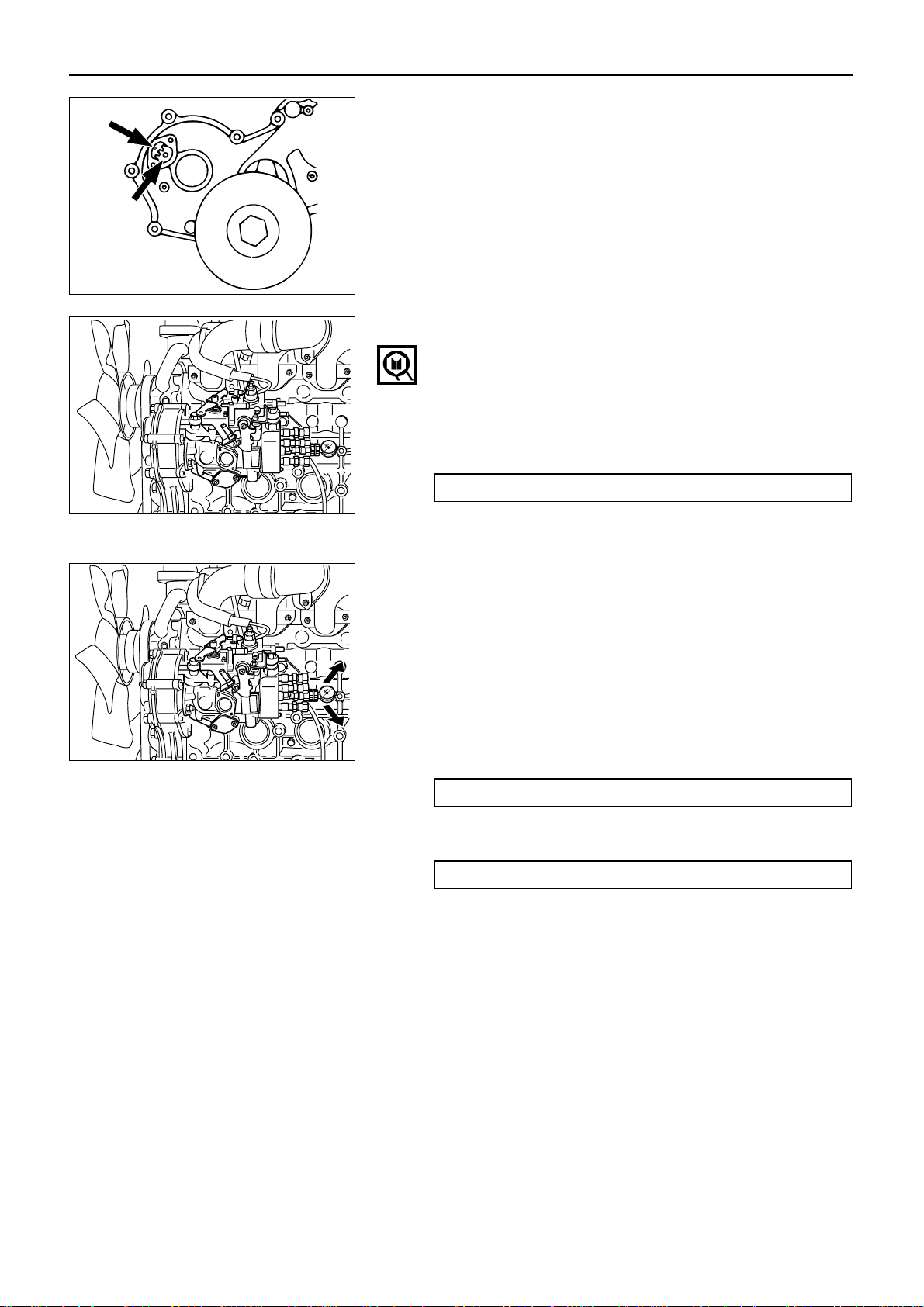

2. Distributor type injection pump

1) Rotate the crankshaft clockwise to align the cam shaft gear timing mark “O” with the timing gear

case cover pointer.

The No. 1 cylinder will now be at the point where

nearly injection timing.

2) Remove injector pump distributor head plug.

3) Fit a dial gauge and set lift to 1 mm (0.039 in).

4) Set crankshaft damper pulley Top Dead Center mark

about 45° before Top Dead Center from the pointer.

5) Set dial gauge in the “0” position.

Measuring device: 5-8840-0145-0

6) Turn the crankshaft a little rightwise and leftwise

and see if the pointer is stable in the “0” position.

7) Turn the crankshaft in the normal direction and read

the measuring device’s indication at TDC.

Starting Timing mm(in.)

0.5 (0.02)

8) If the injection timing is outside the specified range,

continue with the following steps.

9) Loosen the injection pump fixing nuts and bracket

bolts.

10) Adjust the injection pump setting angle.

• If injection timing will be advanced, move the

injection pump away from the engine.

• If injection timing will be retarded, move the

injection pump toward the engine.

Tighten the pump fixing nut, adjust bolt and pump

distribution head plug to the specified torque.

Pump Fixing Bolt kgf·m(lb.ft/N·m)

1.9 (13.7/18.6)

Injection Pump

Distributor Head Plug kgf·m(lb.ft/N·m)

1.7 (12.3/16.7)

080ES002

080ES003

Page 29

MAINTENANCE

26

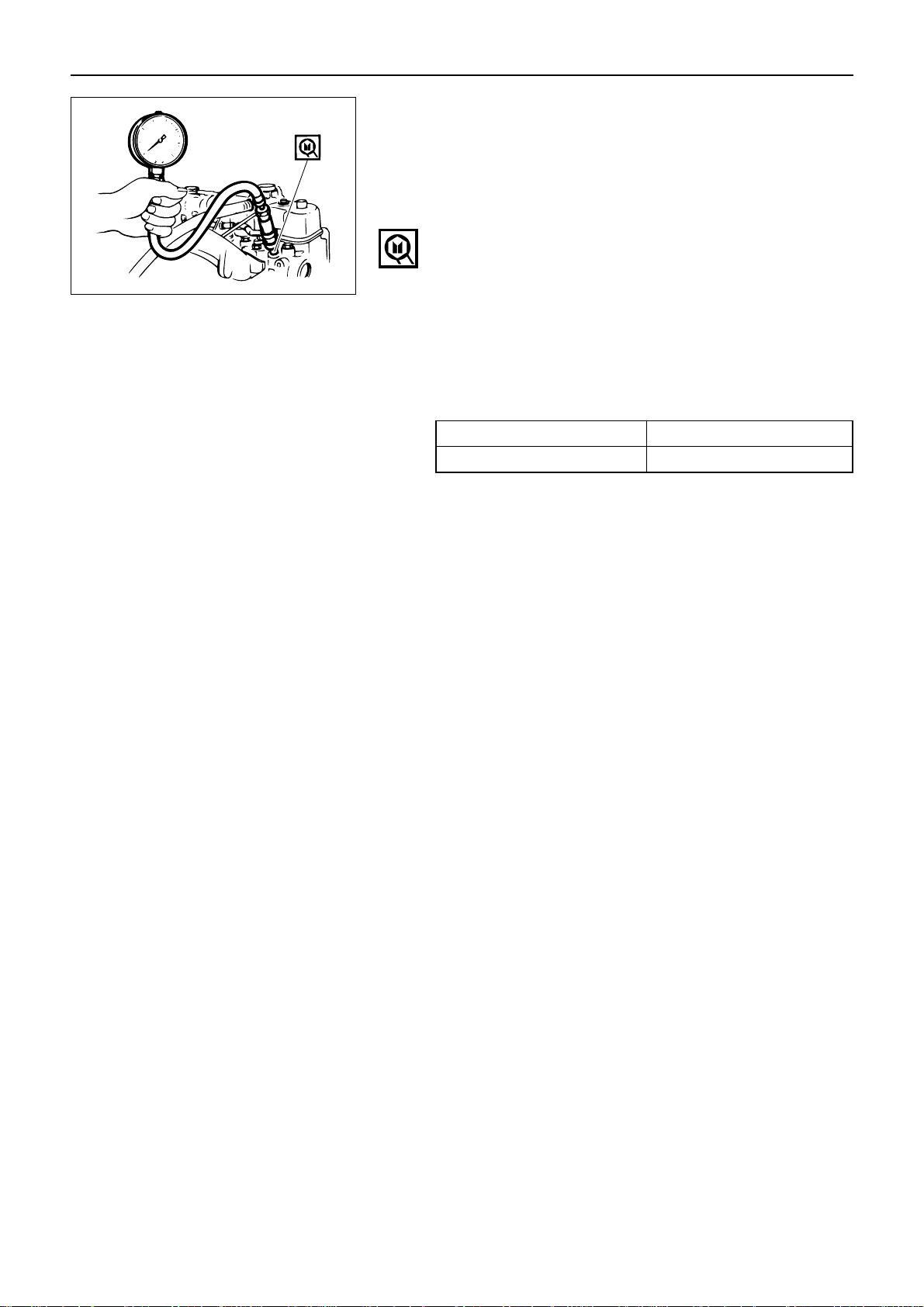

4. Set a compression gauge to the No. 1 cylinder glow

plug hole.

5. Turn the engine over with the starter motor and take

the compression gauge reading.

Compression Pressure kgf/cm2(psi/MPa) at 200 rpm

Standard Limit

31 (441/3.04) 22 (313/2.157)

COMPRESSION PRESSURE MEASUREMENT

1. Start the engine and allow it to run for several

minutes to warm it up.

2. Stop the engine and cut the fuel supply.

3. Remove all of the glow plugs from the engine.

Compression Gauge :5-8840-2675-0

Adapter :5-8840-9029-0

Page 30

MAINTENANCE

27

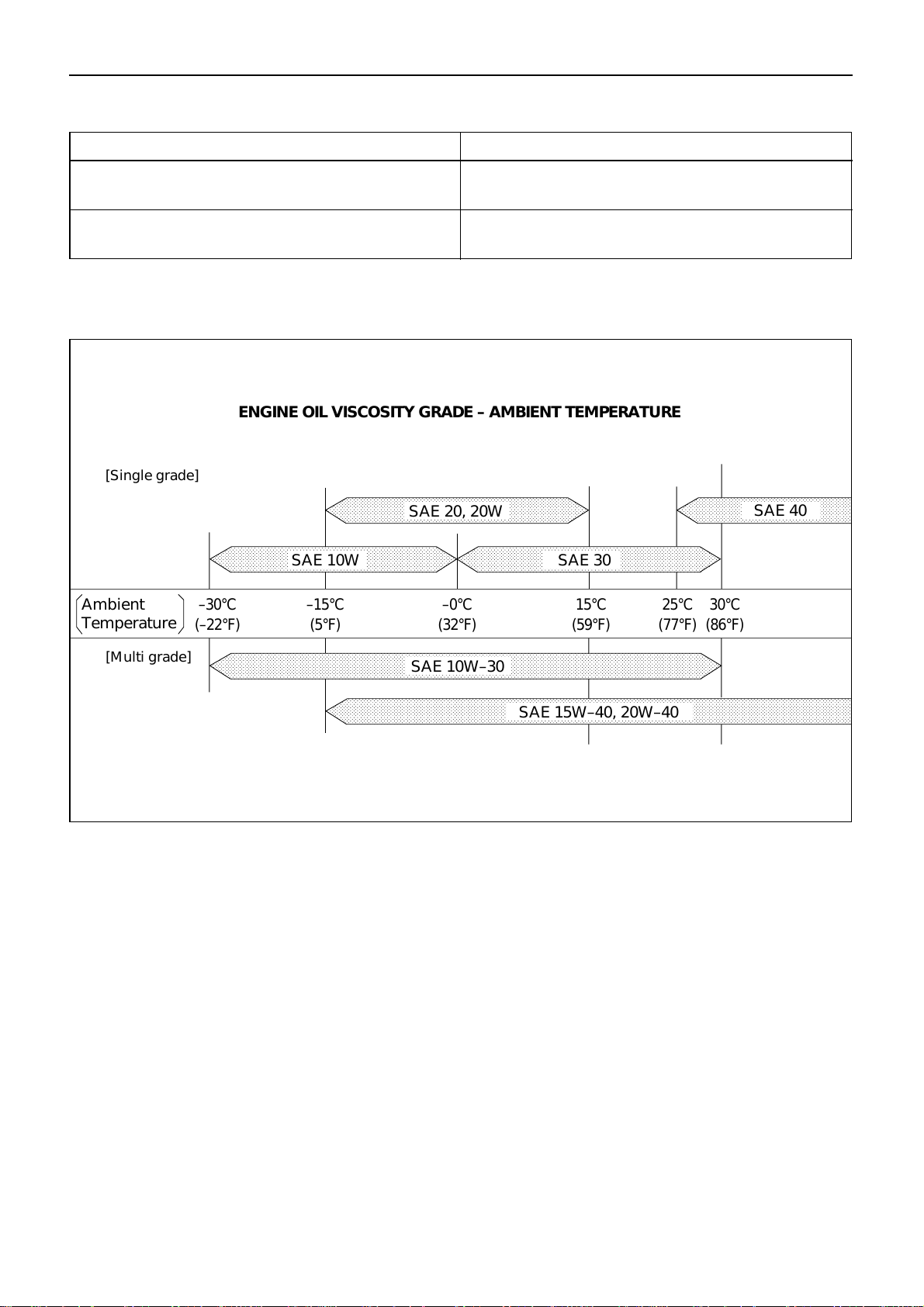

RECOMMENDED LUBRICANTS

ENGINE TYPE TYPES OF LUBRICANTS

Diesel engine oil

Without turbocharger

CC or CD grade

Diesel engine oil

With turbocharger

CD grade

ENGINE OIL VISCOSITY CHART

ENGINE OIL VISCOSITY GRADE – AMBIENT TEMPERATURE

[Single grade]

–0°C

(32°F)

15°C

(59°F)

25°C

(77°F)

30°C

(86°F)

–15°C

(5°F)

–30°C

(–22°F)

[Multi grade]

SAE 40

SAE 20, 20W

SAE 10W–30

SAE 15W–40, 20W–40

SAE 30

Ambient

Temperature

SAE 10W

Page 31

MAINTENANCE

28

ENGINE REPAIR KIT

All of the numbered parts listed below are included in the Engine Repair Kit.

The gaskets marked with an asterisk (*) are also included in the Top Overhaul Kit.

3

15

13

12

2

17

18

14

1

11

7

16

8

9

4

19

6

10

19

20

19

5

* 1. Cylinder head gasket

* 2. Cylinder head cover gasket

* 3. Head cover cap nut gasket

4. Drain cock gasket

5. Crankshaft rear oil seal

6. Gear case gasket

7. Gear case cover gasket

8. Oil pan drain plug gasket

9. Oil pan gasket

10. Oil filter gasket

11. Water pump gasket

12. Water outlet pipe gasket

* 13. Thermostat housing gasket

* 14. Intake manifold gasket

* 15. Exhaust manifold gasket

16. Crankshaft front oil seal

* 17. Nozzle holder O-ring

* 18. Nozzle holder gasket

19. Joint bolt gasket

20. Vacuum pump pipe gasket

Page 32

ENGINE ASSEMBLY ( 1 )

29

SECTION 3

ENGINE ASSEMBLY ( 1 )

TABLE OF CONTENTS

ITEM PAGE

General description .............................................................. 30

Disassembly .................................................................... 31

Page 33

ENGINE ASSEMBLY ( 1 )

ENGINE ASSEMBLY

GENERAL DESCRIPTION

This illustration is based on the A-4JA1 engine.

30

The A-4J Series of industrial engines features the unique ISUZU troidal square combustion chamber. This

design provides superior fuel economy for a wide range.

Auto-thermatic pistons with cast steel struts are used to reduce thermal expansion and resulting engine

noise when the engine is cold.

Chrome plated dry type cylinder liners provide the highest durability.

The laminated steel sheet cylinder head gasket is very durable.

This type of gasket eliminates cylinder head bolt retightening.

The tufftrided crankshaft has a long service life. Because it is tufftrided, it cannot be reground.

The crankshaft main bearings and the connecting rod bearings are aluminum plated. These bearings are

especially sensitive to foreign material such as metal scraps. It is very important that the oil ports and

other related parts be kept clean and free of foreign material.

Page 34

ENGINE ASSEMBLY ( 1 )

DISASSEMBLY

These disassembly steps are based on the A-4JA1 engine.

31

Disassembly Steps - 1

1. Cooling fan and spacer

2. Cooling fan drive belt

3. Cooling fan drive pulley

4. Alternator and adjusting plate

5. Fuel pipe (Fuel filter to

injection pump)

6. Fuel pipe (Fuel filter to feed pump)

7. Fuel pipe (Fuel filter leak off)

8. Fuel filter

9. Oil pipe (Injection pump to cylinder

body)

10. Rear engine hanger

11. Fuel leak off pipe

▲ 12. Fuel injection pipe with clip

▲ 13. Injection pump

14. Intake manifold

15. Starter

16. Oil filter

17. Oil pressure switch

18. Cooling water rubber hose

19. Cooling water intake pipe

20. Front engine hanger

▲ 21. Exhaust manifold

21 20 18 3 7 8 5 13 14 12

11

10

16 17 19 4 2 1 6 9 15

Page 35

ENGINE ASSEMBLY ( 1 )

Important Operations (Disassembly Steps - 1)

12. Fuel Injection Pipe with Clip

1) Loosen the injection pipe sleeve nuts at the delivery

valve side.

Do not apply excessive force to the injection pipes.

2) Loosen the injection pipe clips.

3) Remove the injection pipes.

13. Injection Pump

1) Remove the six injection pump bracket bolts from

the cylinder body timing gear case.

2) Remove the injection pump rear bracket bolts from

the rear bracket.

3) Pull the injection pump with the injection pump

timing gear free from the rear.

Note:

Plug the injection pump delivery holder ports with the

shipping caps (or the equivalent) to prevent the entry of

foreign material.

21. Exhaust Manifold

Loosen the exhaust manifold bolts a little at a time

in the numerical order shown in the illustration.

4851

2673

32

Page 36

ENGINE ASSEMBLY ( 1 )

15

14

16

17

11

12

13

3

9

10

5

4

8

7

6

2

1

★

★Repair kit

★

★

★

★

★

33

Disassembly Steps - 2

1. Water by-pass hose

2. Thermostat housing

3. Water pump

▲ 4. Injection nozzle holder

5. Glow plug and glow plug connector

6. Cylinder head cover

▲ 7. Rocker arm shaft and rocker arm

8. Push rod

▲ 9. Cylinder head

10. Cylinder head gasket

▲ 11. Crankshaft damper pulley with

dust seal

12. Timing gear case cover

13. Timing gear cover

14. Timing gear oil pipe

15. Idler gear “B” and shaft

▲ 16. Idler gear “A”

17. Idler gear shaft

Inverted Engine

Page 37

ENGINE ASSEMBLY ( 1 )

34

14

6

7

16

15

4

9

8

12

10

13

11

3

3a

★

2

5

1a

1

★

★Repair kit

Disassembly Steps - 3

1. Oil pan

1a. Oil pan (If so crankcase equipped)

2. Crankcase (If so equipped)

▲ 3. Flywheel

3a. Rear flywheel (If so equipped)

4. Flywheel housing

5. Oil pump with oil pipe

▲ 6. Camshaft with camshaft timing

gear and thrust plate

7. Timing gear case

▲ 8. Connecting rod cap with

lower bearing

▲ 9. Piston and connecting rod with

upper bearing

▲ 10. Crankshaft bearing cap with

lower bearing

11. Crankshaft thrust bearing

12. Crankshaft with crankshaft timing gear

▲ 13. Crankshaft upper bearing

▲ 14. Tappet

15. Crankshaft rear oil seal

16. Cylinder body

Page 38

ENGINE ASSEMBLY ( 1 )

Important Operations (Disassembly Steps - 2)

4. Injection Nozzle Holder

1) Remove the nozzle holder bracket nuts.

2) Use the nozzle holder remover and the sliding

hammer to remove the nozzle holder together

with the holder bracket.

Nozzle Holder Remover: 5-8840-2034-0

Sliding Humme: 5-8840-0019-0

7. Rocker Arm Shaft and Rocker Arm

Loosen the rocker arm shaft bracket bolts in numerical order a little at a time.

Note:

Failure to loosen the rocker arm shaft bracket bolts in

numerical order a little at a time will adversely effect the

rocker arm shaft.

1342

9. Cylinder Head

Loosen the cylinder head bolts in numerical order a

little at a time.

Note:

Failure to loosen the cylinder head bolts in numerical

order a little at a time will adversely effect the cylinder

head lower surface.

1

2

3

4

5

6

7

8

9

10

11

1213

14

15

16

17

35

Page 39

ENGINE ASSEMBLY ( 1 )

11. Crankshaft Damper Pulley with Dust Seal

1) Block the flywheel with a piece of wood to prevent it from turning.

2) Use the damper pulley remover to remove the

damper pulley.

Damper Pulley Remover

16. Idler Gear “A”

Measure the camshaft timing gear backlash, the

crankshaft timing gear backlash, and the idler gear

“A” end play before removing the idler gear “A”

and shaft.

Timing Gear Backlash Measurement

1) Set a dial indicator to the timing gear to be measured.

Hold both the gear to be checked and the adjoining

gear stationary.

2) Move the gear to be checked as far as possible to

both the right and the left.

Take the dial indicator reading.

If the measured value exceeds the specified limit,

the timing gear must be replaced.

Timing Gear Backlash mm(in.)

Standard Limit

0.10–0.17 (0.0039–0.0067) 0.30 (0.012)

Idler Gear “A” End Play Measurement

Insert a feeler gauge between the idler gear and the

thrust collar to measure the gap and determine the idler

gear end play.

If the measured value exceeds the specified limit, the

thrust collar must be replaced.

Idler Gear End Play mm(in.)

Standard Limit

0.07 (0.0028) 0.30 (0.012)

36

Page 40

ENGINE ASSEMBLY ( 1 )

Important Operations (Disassembly Steps - 3)

3. Flywheel

1) Block the flywheel with a piece of wood to prevent it from turning.

2) Loosen the flywheel bolts a little at a time in the

numerical order shown in the illustration.

1

2

3

4

5

6

6. Camshaft with Camshaft Timing Gear and Thrust

Plate

1) Remove the thrust plate bolts.

2) Pull the camshaft free along with the camshaft

timing gear and the thrust plate.

Note:

Be careful not to damage the camshaft journal, the cam,

and the camshaft during the disassembly procedure.

8. Connecting Rod Cap with Lower Bearing

If the connecting rod lower bearings are to be reinstalled, mark their fitting positions by tagging each

bearing with the cylinder number from which it was

removed.

9. Piston and Connecting Rod with Upper Bearing

1) Remove carbon deposits from the upper portion

of the cylinder wall with a scraper before removing the piston and connecting rod.

2) Move the piston to the top of the cylinder and

tap it with a hammer grip or similar object from

the connecting rod lower side to drive it out.

37

If the connecting rod upper bearings are to be reinstalled, mark their fitting positions by tagging each

bearing with the cylinder number from which it was

removed.

Page 41

ENGINE ASSEMBLY ( 1 )

10. Crankshaft Bearing Cap with Lower Bearing

1) Measure the crankshaft end play at the center

journal of the crankshaft.

Do this before removing the crankshaft bearing

caps.

If the measured value exceeds the specified

limit, the crankshaft thrust bearing must be

replaced.

Crankshaft End Play mm(in.)

Standard Limit

0.10 (0.0039) 0.30 (0.0118)

2) Loosen the crankshaft bearing cap bolts in

numerical order a little at a time.

If the crankshaft bearings are to be reinstalled,

mark their fitting positions by tagging each

bearing with the cylinder number from which it

was removed.

13. Crankshaft Upper Bearing

If the crankshaft upper bearings are to be reinstalled,

mark their fitting positions by tagging each bearing

with the cylinder number from which it was

removed.

14. Tappet

If the tappets are to be reinstalled, mark their fitting

positions by tagging each tappet with the cylinder

number from which it was removed.

15. Crankshaft Rear Oil Seal (Axial Type)

Remove the flywheel housing.

With the oil seal pushed in deep, install the special

tool as shown in the illustration and remove the oil

seal.

Oil Seal Remover: 5-8840-2360-0

38

3

4

10

7

9

8

2

6

5

1

Page 42

ENGINE ASSEMBLY ( 1 )

39

DISASSEMBLY

SINGLE UNIT

ROCKER ARM SHAFT AND ROCKER ARM

Disassembly Steps

▲ 1. Rocker arm shaft snap ring

▲ 2. Rocker arm

▲ 3. Rocker arm shaft bracket

4. Rocker arm

5. Rocker arm shaft spring

6. Rocker arm shaft snap ring

7. Rocker arm shaft

2

6

1

7

5

4

3

Page 43

ENGINE ASSEMBLY ( 1 )

Important Operations

1. Rocker Arm Shaft Snap Ring

2. Rocker Arm

3. Rocker Arm Shaft Bracket

1) Use a pair of snap ring pliers to remove the

snap rings.

2) Remove the rocker arms.

3) Remove the rocker arm shaft bracket.

If the rocker arms and rocker arm shaft brackets

are to be reinstalled, mark their installation

positions by tagging each rocker arm and rocker

arm shaft bracket with the cylinder number from

which it was removed.

40

Page 44

ENGINE ASSEMBLY ( 1 )

CYLINDER HEAD

41

1

2

3

5

6

7

4

Disassembly Steps

▲ 1. Split collar

2. Valve spring upper seat

3. Valve spring

▲ 4. Intake and exhaust valves

5. Valve stem oil seal

6. Valve spring lower washer

7. Cylinder head

Page 45

ENGINE ASSEMBLY ( 1 )

42

Important Operations

1. Split Collar

1) Place the cylinder head on a flat wooden

surface.

2) Use the spring compressor to remove the split

collar.

Do not allow the valve to fall from the cylinder

head.

Spring Compressor: 9-8523-1423-0

4. Intake and Exhaust Valve

If the intake and exhaust valves are to be reinstalled,

mark their installation positions by tagging each

valve with the cylinder number from which it was

removed.

If there is excessive valve wear or damage, the valve

must be replaced.

Refer to Page 50 of “Inspection and Repair” for the

valve and valve seat insert procedure.

Note:

If there is excessive valve guide wear or damage, the

valve guide must be replaced.

Refer to Page 49 of “Inspection and Repair” for the valve

guide replacement procedure.

The valve and the valve guides must be replaced as a

set. Never replace only one or the other.

Page 46

ENGINE ASSEMBLY ( 1 )

43

PISTON AND CONNECTING ROD

6

2

7

4

3

5

1

Disassembly Steps

▲ 1. Connecting rod bearing

▲ 2. Piston ring

▲ 3. Piston pin snap ring

▲ 4. Piston pin

5. Connecting rod

▲ 6. Piston pin snap ring

▲ 7. Piston

Page 47

ENGINE ASSEMBLY ( 1 )

Important Operations

1. Connecting Rod Bearing

If the connecting rod bearings are to be reinstalled,

mark their fitting positions by tagging each bearing

with the cylinder number from which it was

removed.

2. Piston Ring

1) Clamp the connecting rod in a vise.

Take care not to damage the connecting rod.

2) Use a piston pin replacer to remove the piston

rings.

Piston Ring Replacer

Do not attempt to use some other tool to

remove the piston rings. Piston ring stretching

will result in reduced piston ring tension.

3. Piston Pin Snap Ring

4. Piston Pin Snap Ring

Use a pair of snap ring pliers to remove the piston

pin snap rings.

5. Piston Pin

7. Piston

Tap the piston pin out with a hammer and a brass

bar.

If the pistons are to be reinstalled, mark their installation positions by tagging each piston with the

cylinder number from which it was removed.

44

Page 48

ENGINE ASSEMBLY ( 1 )

45

CAMSHAFT, CAMSHAFT TIMING GEAR, AND THRUST PLATE

1

2

3

4

Disassembly Steps

▲ 1. Camshaft timing gear

▲ 2. Thrust plate

3. Feather key

4. Camshaft

Page 49

ENGINE ASSEMBLY ( 1 )

Important Operations

1. Camshaft Timing Gear

2. Thrust Plate

1) Clamp the camshaft in a vise.

Take care not to damage the camshaft.

2) Use the universal puller 1 to pull out the

camshaft timing gear 2 .

Universal Puller: 5-8840-0086-0

3) Remove the thrust plate 3 .

46

3

2

1

Page 50

ENGINE ASSEMBLY ( 2 )

47

SECTION 4

ENGINE ASSEMBLY ( 2 )

TABLE OF CONTENTS

ITEM PAGE

Inspection and repair ............................................................ 48

Page 51

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is

discovered during inspection.

ENGINE ASSEMBLY ( 2 )

CYLINDER HEAD

Cylinder Head Lower Face Warpage

1. Use a straight edge and a feeler gauge to measure

the four sides and the two diagonals of the cylinder

head lower face.

2. Regrind the cylinder head lower face if the measured values are greater than the specified limit but

less than the maximum grinding allowance.

If the measured values exceed the maximum grinding allowance, the cylinder head must be replaced.

Cylinder Head Lower Face Warpage mm(in)

Standard Limit

Maximum Grinding

Allwance

0.05

0.2 (0.008) 0.3 (0.012)

(0.002) or less

Cylinder Head Height (Reference) mm(in)

Standard Limit

91.95 (3.620) – 92.05 (3.624) 91.65 (3.60)

Note:

If the cylinder head lower face is reground, valve

depression must be checked.

EF

A

B

C

D

H

48

Exhaust Manifold Fitting Face Warpage

Use a straight edge and a feeler gauge to measure the

manifold cylinder head fitting face warpage.

Regrind the manifold cylinder head fitting faces if the

measured values are greater than the specified limit but

less than the maximum grinding allowance.

If the measured values exceed the maximum grinding

allowance, the cylinder head must be replaced.

Page 52

ENGINE ASSEMBLY ( 2 )

49

VALVE GUIDE

Valve Stem and Valve Guide Clearance

Measuring Method - I

1. With the valve stem inserted in the valve guide, set

the dial indicator needle to “0”.

2. Move the valve head from side to side.

Read the dial indicator.

Note the highest dial indication.

If the measured values exceed the specified limit,

the valve and the valve guide must be replaced as a

set.

Valve Stem Clearance mm(in)

Standard Limit

Intake Valve

0.039 – 0.069 0.20

(0.0015 – 0.0027) (0.008)

Exhaust Valve

0.064 – 0.096 0.25

(0.0025 – 0.0038) (0.0098)

Manifold Fitting Face Warpage mm (in)

Standard Limit

Maximum Grinding

Allwance

0.05

0.2 (0.008) 0.4 (0.016)

(0.002) or less

Measuring Method - II

1. Measure the valve stem outside diameter.

Refer to the Item “Valve Stem Outside Diameter”.

2. Use a caliper calibrator or a telescoping gauge to

measure the valve guide inside diameter.

Valve Guide Replacement

Valve Guide Removal

Use a hammer and the valve guide replacer to drive out

the valve guide from the cylinder head lower face.

Valve Guide Replacer: 9-8523-1212-0

Page 53

ENGINE ASSEMBLY ( 2 )

50

Valve Guide Installation

1. Apply engine oil to the valve guide outer circumference.

2. Attach the valve guide replacer to the valve guide.

3. Use a hammer to drive the valve guide into position

from the cylinder head upper face.

Valve Guide Replacer: 9-8523-1212-0

4. Measure the height of the valve guide upper end

from the upper face of the cylinder head.

Valve Guide Upper End Height (H)

(Reference) mm(in)

13.0 (0.512)

Note:

If the valve guide has been removed, both the valve and

the valve guide must be replaced as a set.

H

VALVE AND VALVE SEAT INSERT

Valve Stem Outside Diameter

Measure the valve stem diameter at three points.

If the measured value is less than the specified limit, the

valve and the valve guide must be replaced as a set.

Valve Stem Outside Diameter mm(in)

Standard Limit

Intake Valve

7.949 – 7.961 7.88

(0.3129 – 0.3134) (0.3102)

Exhaust Valve

7.921 – 7.936 7.88

(0.3118 – 0.3124) (0.3102)

Valve Thickness

Measure the valve thickness.

If the measured value is less than the specified limit, the

valve and the valve guide must be replaced as a set.

Intake and Exhaust Valve Thickness mm(in)

Standard Limit

1.8 (0.071) 1.5 (0.059)

Page 54

Valve Contact Width

1. Check the valve contact faces for roughness and

unevenness.

Make smooth the valve contact surfaces.

2. Measure the valve contact width.

If the measured value exceeds the specified limit,

the valve seat insert must be replaced.

Valve Contact Width mm(in)

Standard Limit

Intake 1.7 (0.067) 2.2 (0.087)

Exhaust 2.0 (0.079) 2.5 (0.098)

Valve Depression

1. Install the valve 1 to the cylinder head 2 .

2. Use a depth gauge or a straight edge with steel rule

to measure the valve depression from the cylinder

head lower surface.

If the measured value exceeds the specified limit,

the valve seat insert must be replaced.

Valve Depression mm(in)

Standard Limit

Intake 0.73 (0.029) 1.28 (0.050)

Exhaust 0.70 (0.028) 1.20 (0.047)

ENGINE ASSEMBLY ( 2 )

1

2

51

Valve Seat Insert Replacement

Valve Seat Insert Removal

1. Arc weld the entire inside circumference 1 of the

valve seat insert 2.

2. Allow the valve seat insert to cool for a few minutes.

This will invite contraction and make removal of the

valve seat insert easier.

1

2

3

4

Page 55

ENGINE ASSEMBLY ( 2 )

3. Use a screwdriver 3 to pry the valve seat insert

free.

Take care not to damage the cylinder head 4 .

4. Carefully remove carbon and other foreign material

from the cylinder head insert bore.

52

Valve Seat Insert Installation

1. Carefully place the attachment 1 (having a smaller

outside diameter than the valve seat insert) on the

valve seat insert 2 .

Note:

The smooth side of the attachment must contact the

valve seat insert.

2. Use a bench press 3 to gradually apply pressure to

the attachment and press the valve seat insert into

place.

Note:

Do not apply an excessive amount of pressure with the

bench press. Damage to the valve seat insert will result.

1

2

3

Valve Seat Insert Correction

1. Remove the carbon from the valve seat insert surface.

2. Use a valve cutter (15°, 45°, and 75° blades) to

minimize scratches and other rough areas. This will

bring the contact width back to the standard value.

Remove only the scratches and rough areas. Do not

cut away too much. Take care not to cut away

unblemished areas of the valve seat surface.

Valve Seat Angle 45°

Note:

Use an adjustable valve cutter pilot.

Do not allow the valve cutter pilot to wobble inside the

valve guide.

30˚

90˚

150˚

Page 56

Valve Spring Tension

Use a spring tester to measure the valve spring tension.

If the measured value is less than the specified limit, the

valve spring must be replace.

Valve Spring Tension kgf(lb/N)

Compressed Height Standard Limit

38.9 mm (1.53 in)

32.6 29.0

(71.9/319.6) (63.9/284.4)

ENGINE ASSEMBLY ( 2 )

3. Apply abrasive compound to the valve seat insert

surface.

4. Insert the valve into the valve guide.

5. Turn the valve while tapping it to fit the valve seat

insert.

6. Check that the valve contact width is correct.

7. Check that the valve seat insert surface is in contact

with the entire circumference of the valve.

53

VALVE SPRING

Valve Spring Free Height

Use a vernier caliper to measure the valve spring free

height.

If the measured value is less than the specified limit, the

valve spring must be replaced.

Valve Spring Free Height mm(in)

Standard Limit

49.7 (1.96) 48.2 (1.90)

Valve Spring Inclination

Use a surface plate and a square to measure the valve

spring inclination.

If the measured value exceeds the specified limit, the

valve spring must be replaced.

Valve Spring Inclination mm(in)

Standard Limit

1.5 (0.06) or less 2.5 (0.098)

Square

Page 57

Rocker Arm Shaft Outside Diameter

Use a micrometer to measure the rocker arm fitting

portion outside diameter.

If the measured value is less than the specified limit, the

rocker arm shaft must be replaced.

Rocker Arm Shaft Outside Diameter mm(in)

Standard Limit

18.98 – 19.00 (0.747 – 0.748) 18.85 (0.742)

ENGINE ASSEMBLY ( 2 )

ROCKER ARM SHAFT AND ROCKER ARM

Rocker Arm Shaft Run-Out

1. Place the rocker arm shaft on a V-block.

2. Use a dial indicator to measure the rocker arm shaft

central portion run-out.

If the run-out is very slight, correct the rocker arm

shaft run-out with a bench press. The rocker arm

must be at cold condition.

If the measured rocker arm shaft run-out exceeds

the specified limit, the rocker arm shaft must be

replaced.

Rocker Arm Shaft Run-Out mm(in)

Standard Limit

0.2 (0.008) 0.6 (0.024)

54

Rocker Arm Shaft and Rocker Arm Clearance

1. Use either a vernier caliper or a dial indicator to

measure the rocker arm bushing inside diameter.

Rocker Arm Bushing Inside Diameter mm(in)

Standard Limit

19.01 – 19.03 (0.748 – 0.749) 19.05 (0.750)

2. Measure the rocker arm shaft outside diameter.

If the measured value exceeds the specified limit,

replace either the rocker arm or the rocker arm shaft.

Rocker Arm and Rocker Arm Shaft Clearance mm(in)

Standard Limit

0.01 – 0.05 (0.0004 – 0.002) 0.2 (0.008)

Page 58

ENGINE ASSEMBLY ( 2 )

3. Check that the rocker arm oil port is free of obstructions.

If necessary, use compressed air to clean the rocker

arm oil port.

55

Rocker Arm Correction

Inspect the rocker arm valve stem contact surfaces for

step wear 1 and scoring 2 .

If the contact surfaces have light step wear or scoring,

they may be honed with an oil stone.

If the step wear or scoring is severe, the rocker arm must

be replaced.

CYLINDER BODY

Cylinder Body Upper Face Warpage

1. Remove the cylinder body dowel.

2. Remove the cylinder liner.

Refer to “Cylinder Liner Replacement”.

1

2

3. Use a straight edge 1 and a feeler gauge 2 to

measure the four sides and the two diagonals of the

cylinder body upper face.

1

2

Cylinder Body Upper Face Warpage mm(in)

Standard Limit

0.05 (0.002) or less 0.2 (0.008)

If the measured value is more than the limit, the

cylinder body must be replaced.

EF

A

B

C

D

Page 59

ENGINE ASSEMBLY ( 2 )

Cylinder Body Height (Reference) mm(in)

Standard

247.945 – 248.105 (9.7616 – 9.7679)

4. Reinstall the cylinder liner.

Refer to “Cylinder Body Bore Measurement”.

5. Reinstall the cylinder body dowel.

56

Cylinder Liner Bore Measurement

Use a cylinder indicator to measure the cylinder bore at

measuring point 1 in the thrust X – X and axial Y – Y

directions of the crankshaft.

Measuring Point 1 : Maximum wear portion

[11 – 15 mm (0.43 – 0.59 in)]

If the measured value exceeds the specified limit, the

cylinder liner must be replaced.

Cylinder Liner Bore mm(in)

Standard Limit

93.021 – 93.060 (3.662 – 3.663) 93.10 (3.665)

Note:

The inside of the dry type cylinder liner is chrome

plated. It cannot be rebored or honed.

If the inside of the cylinder liner is scored or scorched,

the cylinder liner must be replaced.

1

X

X

YY

Cylinder Liner Projection Inspection

1. Hold a straight edge 1 along the top edge of the

cylinder liner to be measured.

2. Use a feeler gauge 2 to measure each cylinder liner

projection.

Cylinder Liner Projection mm(in)

Standard

0 – 0.10 (0 – 0.0039)

The difference in the cylinder liner projection height

between any two adjacent cylinders must not

exceed 0.03 mm (0.0012 in).

1

2

Page 60

ENGINE ASSEMBLY ( 2 )

Cylinder Liner Replacement

Cylinder Liner Removal

1. Insert the cylinder liner remover 1 into the cylinder

body (from the lower side of the cylinder body) unit

it makes firm contact with the cylinder liner.

Cylinder Liner Remover: 5-8840-2039-0

(A-4JA1, A-4JB1)

2. Use a bench press 2 to slowly force the cylinder

liner from the cylinder body.

3. Discard the cylinder liner.

Note:

Take care not to damage the cylinder body upper face

during the cylinder liner removal procedure.

4. Measure the cylinder body upper face warpage.

Refer to “Cylinder Body Upper Face Warapage”.

1

2

57

Cylinder Liner Grade Selection

Measure the cylinder body inside diameter and select

the proper cylinder liner grade number corresponding to

the cylinder body inside diameter.

Standard Fitting Interference (Reference) mm(in)

0.001 – 0.019 (0.00004 – 0.00075)

If the cylinder liner fitting interference is too small,

engine cooling efficiency will be adversely affected.

If the cylinder liner fitting interference is too large, it will

be difficult to insert the cylinder liner into the cylinder

body.

Cylinder Body Bore Measurement

1. Take measurements at measuring point 1 across

positions (“W – W”), (“X – X”), (Y – Y) and (Z – Z).

Measuring Point 1 : 98 mm (3.86 in)

2. Calculate the average value of the four

measurements to determine the correct cylinder

grade.

Cylinder Liner Grade

Nominal Cylinder Body

Liner Grade

Dimension Bore Diameter

95.001 – 95.010

1

(3.74019 – 3.74055)

95.011 – 95.020

2

(3.74059 – 3.74094)

95.021 – 95.030

3

(3.74098 – 3.74133)

95.031 – 95.040

4

(3.74138 – 3.74173)

φ95

X

W

YY

Z

Z

W

X

Page 61

ENGINE ASSEMBLY ( 2 )

Cylinder Liner Installation

1. Cylinder Liner Installation Using The Special Tool.

1) Use new kerosene or diesel oil to thoroughly

clean the cylinder liners and bores.

2) Use compressed air to blow-dry the cylinder

liner and bore surfaces.

Note:

All foreign material must be carefully removed from the

cylinder liner and the cylinder bore before installation.

58

3) Insert the cylinder liner 1 into the cylinder body

2 from the top of the cylinder body.

1

2

3

4) Set the cylinder liner installer 3 to the top of the

cylinder liner.

Cylinder Liner Installer: 5-8840-2040-0

5) Position the cylinder body so that the installer

center 3 is directly beneath the bench press

shaft center 4.

Note:

Check that the cylinder liner is set perpendicular to the

bench press and that there is no wobble.

6) Use the bench press to apply a seating force of

500 kgf (1,102.5 lb/4,900 N) to the cylinder liner.

7) Apply a force of 2,500 kgf (5,512.5 lb/24,500 N)

to fully seat the cylinder liner.

8) After installing the cylinder liner, measure the

cylinder liner projection.

Refer to “Cylinder Liner Projection Inspection”.

2. Cylinder Liner Installation Using Dry Ice

If the cylinder liner is a chrome plated dry type, it is

advisable to use dry ice during the installation

procedure.

Cooling the cylinder liner with dry ice will cause the

cylinder liner to contact, thus making installation

easier.

Note:

It is important that the cylinder liner be inserted to the

cylinder body immediately after it has been cooled.

3

4

Page 62

ENGINE ASSEMBLY ( 2 )

WARNING:

DRY ICE MUST BE USED WITH GREAT CARE. CARELESS HANDLING OF DRY ICE CAN RESULT IN SEVERE

FROSTBITE.

Piston Selection

Select the same grade number as the one for the

cylinder liner inside diameter.

Grade of cylinder

Grade of piston Combination

inside diameter

AX AX OK

CX CX OK

AX CX NG

CX AX NG

59

Page 63

ENGINE ASSEMBLY ( 2 )

Piston Grade Selection

Measure the cylinder liner bore. Then select the

appropriate piston grade for the installed cylinder liner.

1. Measure the cylinder liner bore.

There are two measuring points ( 1 and 2 ).

Measure the cylinder liner bore in four different

direction (W – W, X – X, and Z – Z) at both measuring points.

Calculate the average value of the eight measurements to determine the correct cylinder liner bore.

Measuring Points 1 :

20 mm (0.79 in) for all A-4J models

2 :

140 mm (5.51 in) for A-4JA1

160 mm (6.30 in) for A-4JB1

Cylinder Liner Bore mm(in)

Standard Limit

93.021 – 93.060 (3.662 – 3.663) 93.10 (3.665)

Note:

It is most important that the correct piston grade be

used. Failure to select the correct piston grade will result

in engine failure.

X

X

YY

W

W

Z

Z

1

2

60

2. Measure the piston outside diameter.

Piston Measuring Point 1 : 70 mm (2.76 in)

Piston Grade mm(in)

Grade

Piston Outside Diameter

4JA1 4JB1

AX

92.979 – 92.994 92.989 – 93.004

(3.6606 – 3.6611) (3.6610 – 3.6615)

CX

92.995 – 93.010 93.005 – 93.020

(3.6612 – 3.6618) (3.6616 – 3.6622)

Cylinder Liner and Piston Clearance mm(in)

0.017 – 0.055 (0.0007 – 0.0022)

Note:

:Cylinder liner kit clearances are preset. However, the

cylinder liner installation procedure may result in slight

decreases in cylinder liner clearances. Always measure

the cylinder liner clearance after installation to be sure

that it is correct.

1

Page 64

ENGINE ASSEMBLY ( 2 )

61

TAPPET AND PUSH ROD

Visually inspect the tappet camshaft contact surfaces for

pitting, cracking, and other abnormal conditions. The

tappet must be replaced if any of these conditions are

present.

Refer to the illustration at the left.

1 Pitting

2 Cracking

3 Normal contact

4 Irregular contact

5 Irregular contact

Note:

The tappet surfaces are spherical. Do not attempt to

grind them with an oil stone or similar tool in an effort to

repair the tappet. If the tappet is damaged, it must be

replaced.

123

45

Tappet Outside Diameter

Measure the tappet outside diameter with a micrometer.

If the measured value is less than the specified limit, the

tappet must be replaced.

Tappet Outside Diameter mm(in)

Standard Limit

12.97 – 12.99 (0.5106 – 0.5114) 12.95 (0.5098)

Page 65

ENGINE ASSEMBLY ( 2 )

Tappet and Cylinder Body Clearance mm(in)

Standard Limit

0.03 (0.0012) 0.1 (0.0039)

62

Push Rod Curvature

1. Lay the push rod on a surface plate.

2. Roll the push rod along the surface plate and measure the push rod curvature with a thickness gauge.

If the measured value exceeds the specified limit,

the push rod must be replaced.

Push Rod Curvature mm(in)

Limit

0.3 (0.012)

3. Visually inspect both ends of the push rod for

excessive wear and damage. The push rod must be

replaced if these conditions are discovered during

inspection.

CAMSHAFT

Visually inspect the journals, the cams, the oil pump

drive gear, and the camshaft bearings for excessive

wear and damage. The camshaft and the camshaft

bearings must be replaced if these conditions are

discovered during inspection.

Camshaft Journal Diameter

Use a micrometer to measure each camshaft journal

diameter in two directions ((X – X) and (Y – Y)). If the

measured value is less than the specified limit, the

camshaft must be replaced.

Camshaft Journal Diameter mm(in)

Standard Limit

49.945 – 49.975 49.60

(1.9663 – 1.9675) (1.953)

X

X

YY

Page 66

ENGINE ASSEMBLY ( 2 )

Cam Height

Measure the cam height (H) with a micrometer. If the

measured value is less than the specified limit, the

camshaft must be replaced.

Cam Height H mm(in)

Standard Limit

42.08 (1.65) 41.65 (1.64)

H

63

Camshaft Run-Out

1. Mount the camshaft on V-blocks.

2. Measure the run-out with a dial indicator.

If the measured value exceeds the specified limit,

the camshaft must be replaced.

Camshaft Run-Out mm(in)

Standard Limit

0.02 (0.0008) 0.10 (0.004)

Camshaft and Camshaft Bearing

Use an inside dial indicator to measure the camshaft

bearing inside diameter.

Camshaft Bearing Inside Diameter mm(in)

Standard Limit

50.0 – 50.03 50.08

(1.9685 – 1.9697) (1.9716)

If the clearance between the camshaft bearing inside

diameter and the journal exceeds the specified limit, the

camshaft bearing must be replaced.

Camshaft Bearing Clearance mm(in)

Standard Limit

0.05 (0.002) 0.12 (0.005)

Camshaft Bearing Replacement

Camshaft Bearing Removal

1. Remove the cylinder body plug plate.

2. Use the camshaft bearing replacer to remove the

camshaft bearing.

Bearing Replacer: 5-8840-2038-0

Page 67

ENGINE ASSEMBLY ( 2 )

Camshaft Bearing Installation

1. Align the bearing oil holes with the cylinder body oil

holes.

2. Use the camshaft bearing replacer installer to install

the camshaft bearing.

Bearing Replacer: 5-8840-2038-0

64

Camshaft End Play

1. Before removing the camshaft gear 1, push the

thrust plate 2 as far as it will go toward the camshaft gear 3.

2. Use a feeler gauge to measure the clearance

between the thrust plate and the camshaft journal.

If the measured value exceeds the specified limit,

the thrust plate must be replaced.

Camshaft End Play mm(in)

Standard Limit

0.050 – 0.114 (0.002 – 0.0045) 0.2 (0.008)

1

2

3

Thrust Plate Replacement

Thrust Plate Removal

1. Use the universal puller 1 to remove the camshaft

timing gear 2 .

Universal Puller: 5-8840-0086-0

2. Remove the thrust plate 3 .

1

2

3

Thrust Plate Installation

1. Install the thrust plate.

2. Apply engine oil to the bolt setting face and the bolt

threads.

3. Install the camshaft gear.

Camshaft Gear Torque kgf·m(lb.ft/N·m)

10.0 – 12.0 (72.4 – 86.8/98.1 – 117.7)

Page 68

ENGINE ASSEMBLY ( 2 )

CRANKSHAFT AND BEARING

Inspect the surface of the crankshaft journals and

crankpins for excessive wear and damage.

Inspect the oil seal fitting surfaces for excessive wear

and damage.

Inspect the oil ports for obstructions.

Note:

To increase crankshaft strength, tufftriding (Nitrizing

Treatment) has been applied. Because of this, it is not

possible to regrind the crankshaft surfaces.

65

Crankshaft Tufftriding Inspection

1. Use an organic cleaner to thoroughly clean the

crankshaft. There must be no traces of oil on the

surfaces to be inspected.

2. Prepare a 5 – 10% solution of ammonium cuprous

chloride (dissolved in distilled water).

3. Use a syringe to apply the solution to the surface to

be inspected.

Hold the surface to be inspected perfectly horizontal

to prevent the solution from running.

Note:

Do not allow the solution to come in contact with the oil

ports and their surrounding area.

The portion to be tested

shall be held horizontally

so as not to let the test

solution flow.

The sliding surface

of the pin

or journal.

Test liquid should

not be applied to

the area around the

oil port.

Approximately

10mm

Judgment

1. Wait for thirty to forty seconds.

If there is no discoloration after thirty or forty sec-

onds, the crankshaft is usable.

If discoloration appears (the surface being tested

will become the color of copper), the crankshaft

must be replaced.

2. Steam clean the crankshaft surface immediately

after completing the test.

Page 69

Crankshaft Run-Out

1. Set a dial indicator to the center of the crankshaft

journal.

2. Gently turn the crankshaft in the normal direction of

rotation.

Read the dial indicator as you turn the crankshaft.

If the measured value exceeds the specified limit,

the crankshaft must be replaced.

Crankshaft Run-Out mm(in)

Standard Limit

0.05 (0.002) or less 0.08 (0.0031)

ENGINE ASSEMBLY ( 2 )

Note:

The ammonium cuprous chloride solution is highly corrosive. Because of this, it is imperative that the surfaces