Page 1

For DENSO Authorized

ECD Service Dealer Only

Diesel Injection Pump

No. E-03-02

SERVICE MANUAL

Common Rail System for ISUZU

6HK1/6SD1 Type Engine

Operation

June, 2003

-1

00400018

Page 2

GENERAL

The common rail system was designed for electronic control of injection quantity, injection timing and injection pressure to obtain optimal operational control.

Features

• Lower exhaust gas and higher output due to high pressure injection in all usage ranges.

• Reduction in noise and exhaust gas due to injection rate control.

• Improved performance due to increased flexibility in the injection timing setting.

• Independent control of injection pressure in response to engine speed and load.

Main Elements

Manufacturer Vehicle Model Engine Model

6HK1

ISUZU Forward

6SD1 9,800

6WG1 15,600

Cylinder

Configuration

Straight 6

Total

Displacement

(cc)

7,800

0

Page 3

1. Outline

1.1 System Outline

This system also provides the following functions:

• A self-diagnosis and alarm function using computer to diagnose the system’s major

components and alert the driver in the event of a problem.

• A fail-safe function to stop the engine, depending upon the location of the problem.

• A backup function to change the fuel regulation method, thus enabling the vehicle to

continue operation.

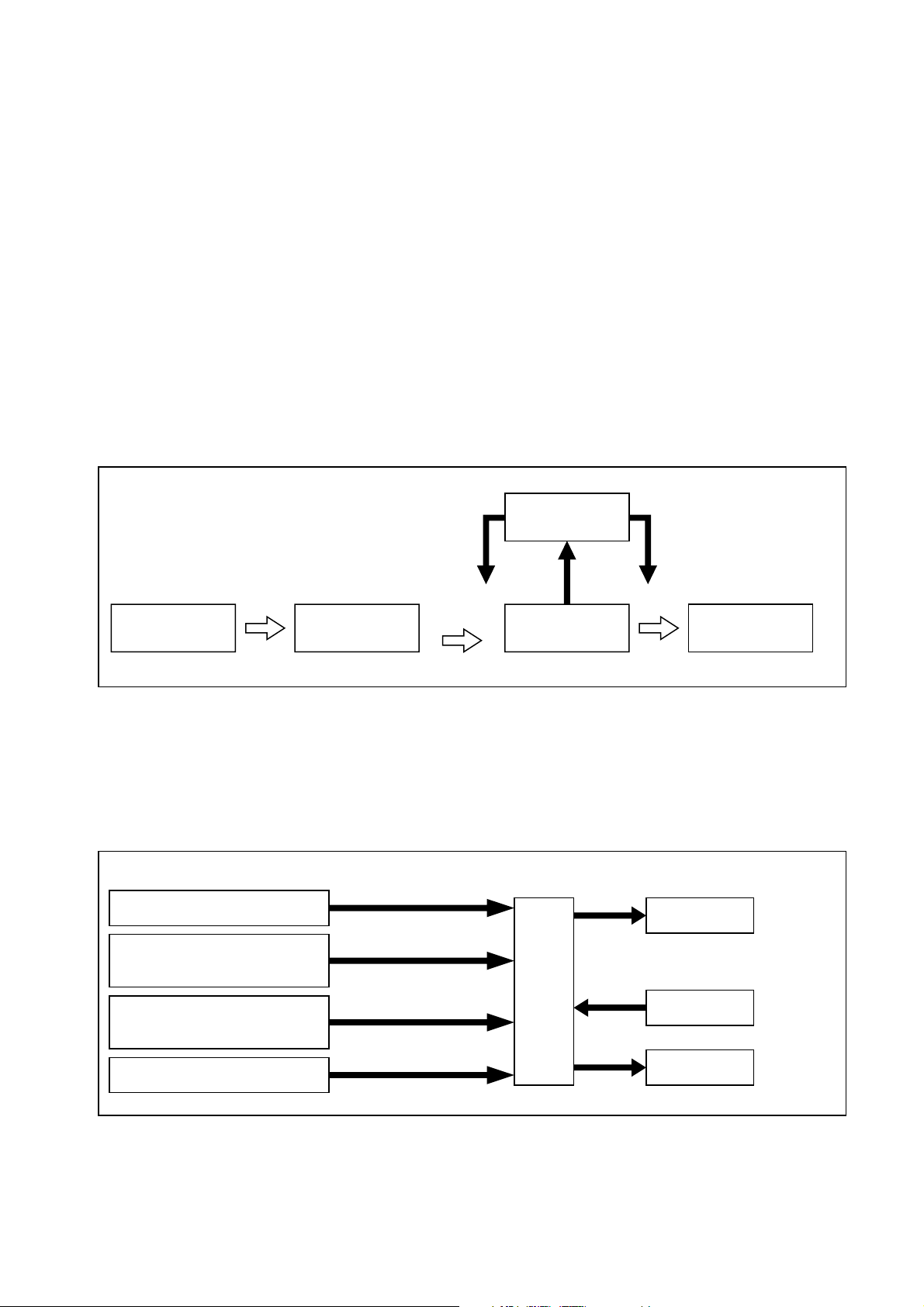

1.2 System Configuration

Divided by function, the system can be classified according to the fuel system and the control

system.

[1] Fuel System

High-pressure fuel that is generated by the supply pump is distributed to the cylinders using a

rail. Electromagnetic valves in the injectors then open and close the nozzle needle valve to control the start and end of fuel injection.

Electronic

control

Solenoid valve to control

the needle lift

Discharge

Fuel tank Supply pump Rail

volume

Injector

Q000080E

[2] Control System

Based on the signals received from various sensors mounted on the engine and the vehicle,

the ECU controls current timing and the duration in which the current is applied to the injectors,

thus ensuring an optimal amount of fuel is injected at an optimal time.

The control system can be broadly classified according to the following electronic components:

sensors, computers, and actuators.

Sensors Computers Actuators

Accelerator sensor

NE sensor

(Crankshaft position sensor)

TDC sensor

(Cylinder recognition sensor)

(Accelerator opening)

(Engine speed)

Cylinder

( )

recognition signal

ECU

Injectors

Fuel injection quantity

( )

and injection timing control etc.

Rail

Other sensors and switches

Supply pump

(Fuel pressure control)

1

Q000081E

Page 4

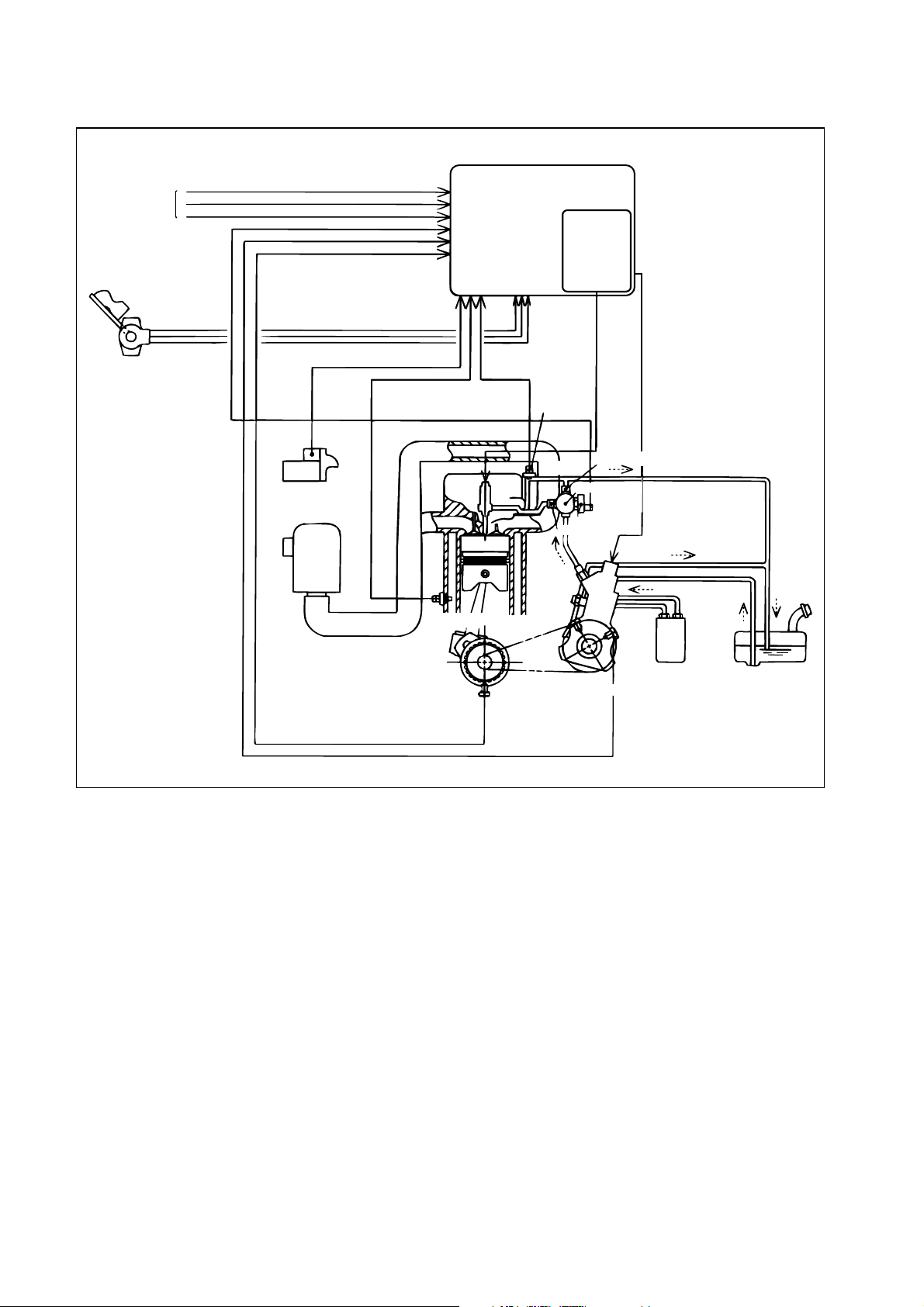

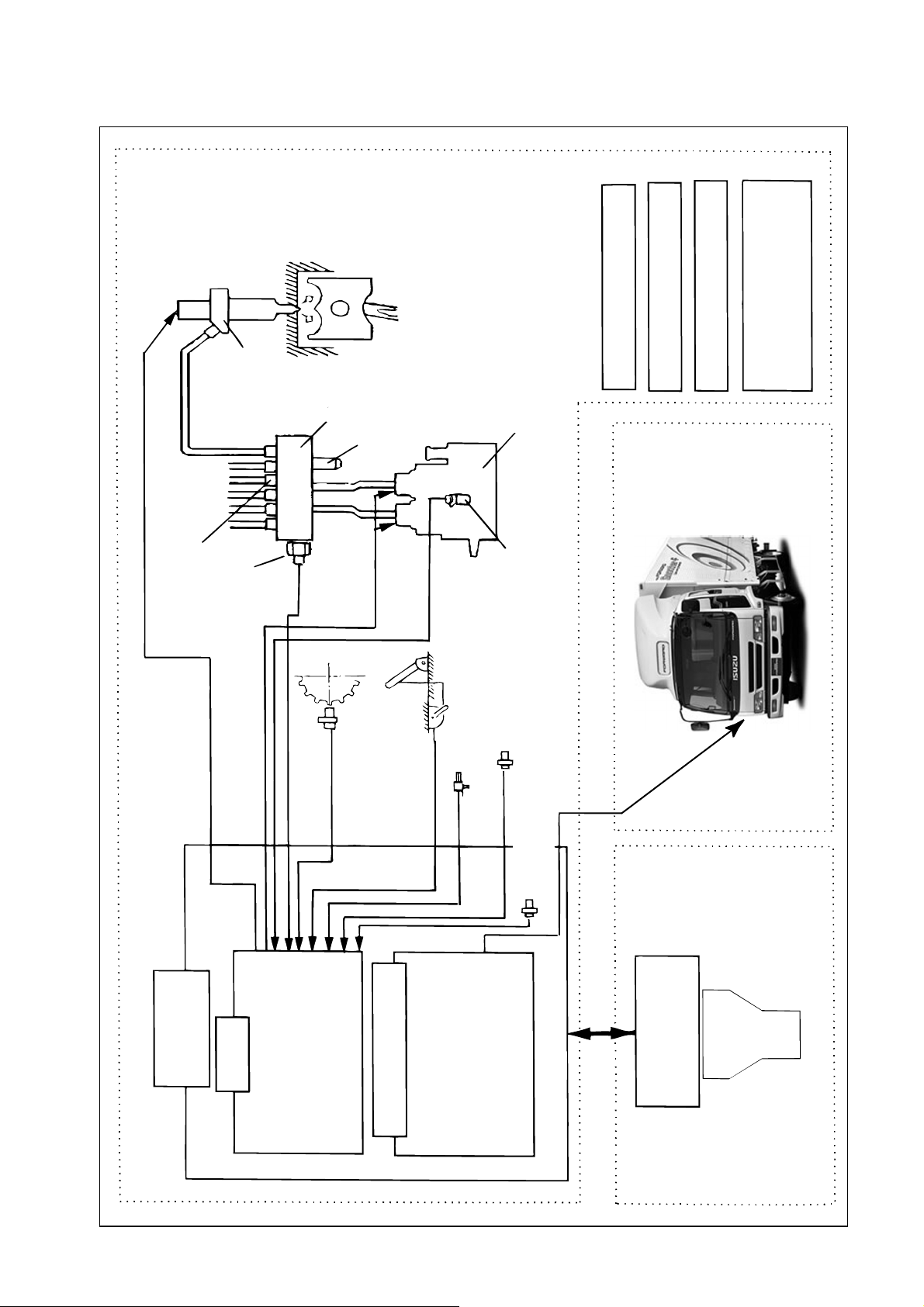

[3] System Configuration (1)

Signals from

switches

ACCP

ECU

Charge-up

circuit

Accelerator position

sensor

Starter signal

Air cleaner

STA

THW

Water temp. sensor

THL

NE sensor

Fuel temp.

sensor

Leak pipe

Rail

Flow damper

Pressure limiter

Supply

pump

Fuel filiter

TDC sensor

Fuel tank

Q000082E

2

Page 5

[4] System Configuration (2)

(inside Head Cover)

Injector

Injection Rate Control

Injection Quantity Control

Injection Timing Control

Injection Pressure Control

(Pressure Control in Rail)

Flow Damper

Rail Pressure sensor

Rail

Pressure Limiter

Crank Position

Sensor (NE Sensor)

Supply Pump

Cylinder Recognition

Sensor (TDC Sensor)

Accelerator Position

Sensor

Coolant Temperature Sensor

Atmospheric Air Temperature Sensor

·

·Fuel Temperature Sensor

·

Boost Pressure Sensor

ECU

Fuel

Injection

·Injection Quantity Control

·Injection Pressure Control

·Injection Timimg Control

Vehicle

Engine

Atmospheric Air

·A/T Control

·Exhaust Break Control

·Engine Shut-down control

·TECHΤ COMMUNICATION

3

(inside ECU)

Pressure Sensor

Communication

(Scan Tool)

Service Tool

TECHΤ

(Dealer)

Q000083E

Page 6

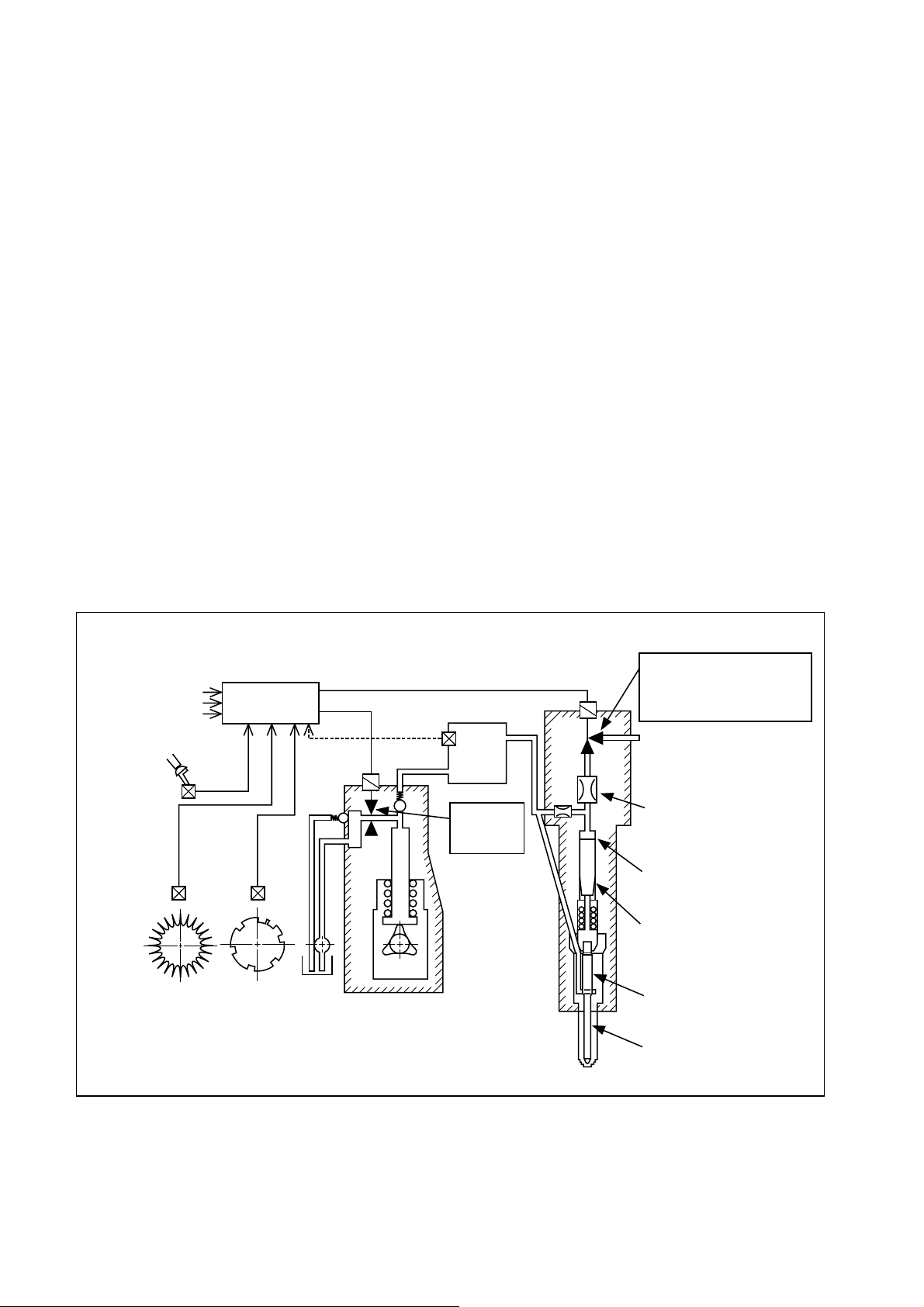

1.3 Construction and Operation of the System

The rail system is comprised of a supply pump, a rail, and injectors, and also includes an ECU

and sensors to regulate those components.

The supply pump generates the internal fuel pressure in the rail. Fuel pressure is regulated by

the quantity of fuel discharged by the supply pump. In turn, the fuel discharge quantity is regulated by electronic signals from the ECU that turn the PCVs (pump control valves) ON and OFF.

Upon receiving fuel pressurized by the supply pump, the rail distributes the fuel to the cylinders.

The pressurized fuel is detected by the rail pressure sensor (installed in the rail) and undergoes

feedback control so that actual pressure will match the command pressure (designated according to the engine speed and load).

Pressurized fuel in the rail passes through the injection pipes that lead to the cylinders, and applies

pressure to the injector nozzles and the control chamber.

The injector regulates injection quantity and timing by turning the TWV (two-way valve) ON and OFF.

When the TWV is ON (current applied), the fuel circuit switches over, causing the high-pressure

fuel in the control chamber to flow out via the orifice. As a result, the force of the high-pressure

fuel at the nozzle valve opening causes the needle valve to lift, thus starting the injection of fuel.

When the TWV is turned OFF (current not applied), the fuel circuit switches over so that highpressure fuel, traveling via the orifice, is introduced to the control chamber. As a result, the needle valve lowers, thus ending the injection of fuel.

Thus, through electronic control, the timing of the current applied to the TWV determines the

injection timing, and the duration in which current is applied to the TWV determines the injection

quantity.

Additional information

(temperature, pressure)

Engine load

ECU

TWV control pulse

Rail pressure sensor

Supply Pump

Rail

Injection

pressure

control

Injector

TWV

· Injection quantity control

· Injection timing control

· Injection rate control

Leak

Orifice

Control chamber

Hydraulic piston

Nozzle

Needle

Q000084E

4

Page 7

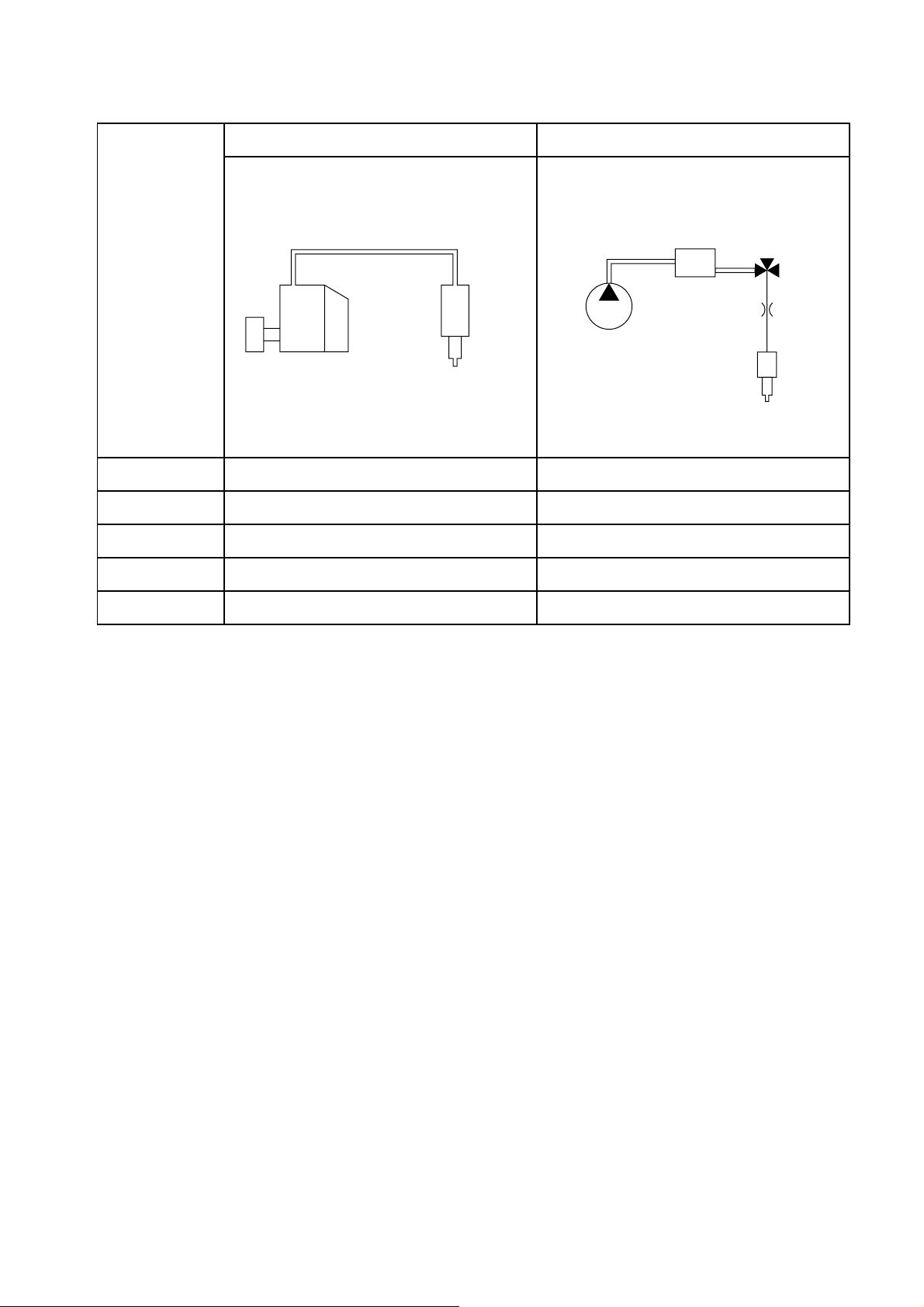

1.4 Comparison to Conventional Pump

Inline Type Common Rail System

System

Injection quantity

regulation

Injection timing

regulation

Distribution of

generated pressure

Distribution

Injection pressure

regulation

Pipe

Instantaneous high

pressure

Timer

Governor

Pump

Pump (governor)

Pump (timer)

Pump

Pump

(Dependent on engine speed and injection volume)

Nozzle

Rail

Constant high

pressure

Supply pump

Injector

ECU, injector (TWV)

ECU, injector (TWV)

Supply pump

Rail

Supply pump (PCV)

Q000085E

5

Page 8

2. Construction and Operation of Components

2.1 Supply Pump [1] Outline

The function of the supply pump is to regulate the fuel discharge volume, thus generating internal

fuel pressure in the rail.

[2] Construction

The supply pump consists of a feed pump, similar to that of the conventional in-line pump, and

the PCVs (pump control valves), provided at each cylinder, to regulate the fuel discharge volume.

The supply pump uses a three-lobe cam to reduce the number of engine cylinders supplied by

the pump to one-third (e.g. a two-cylinder pump for a six-cylinder engine). Furthermore,

smooth and stable rail pressure is obtained because the rate at which fuel is pumped to the rail

is the same as the injection rate.

PCV (Pump Control Valve)

Feed pump

Gear of TDC sensor

6

3-lobe cam

Q000086E

Page 9

[3] Operation

A: The PCV remains open during the plunger’s downward stroke, allowing low-pressure fuel to

be drawn into the plunger chamber by way of the PCV.

B: If the valve remains open because current is not applied to the PCV, even after the plunger

begins its upward stroke, the fuel that was drawn in returns via the PCV, without being pressurized.

C: When current is applied to the PCV in order to close the valve at the timing that accommo-

dates the required discharge volume, the return passage closes, causing pressure in the

plunger chamber to rise. The fuel then passes through the delivery valve (check valve) to the

rail. As a result, an amount of fuel that corresponding to the plunger lift after the PCV closes

becomes the discharge volume, and varying the timing of the PCV closure (plunger prestroke) varies the discharge volume, thus regulating rail pressure.

A’: After surpassing the maximum cam lift, the plunger begins its downward stroke, causing

pressure in the plunger chamber to decrease. At this time, the delivery valve closes, thus

stopping the pumping of the fuel. In addition, because current to the PCV valve is cut off, the

PCV opens, allowing low-pressure fuel to be drawn into the plunger chamber. Thus, the

pump assumes condition “A”.

Cam lift

PCV

operation

Pump operation

PCV

Plunger

Discharge

Suction process Delivery process

Pre-stroke

Valve

closed

A B C A'

Valve open

Delivery valve

Increasing

dischargevolume

Reducing discharge volume

φd

Discharging required

dischrge volume

Rail

volume

Q=

πd

2

(H-h)

4

h

H

Q000087E

7

Page 10

[4] PCV (pump control valve)

The PCV regulates the volume of fuel discharged by the supply pump in order to regulate rail

pressure. The volume of fuel discharged by the supply pump to the rail is determined by the

time at which current is applied to the PCV.

PCV relay

PCV

Key switch

+B

PCV1

PCV2

ECU

Q000088E

[5] Trochoid Type Feed Pump

The feed pump, which is housed in the supply pump, draws fuel up from the tank and delivers

it to the chamber via the fuel filter. The feed pump rotor is driven by the camshaft.

The rotation of the camshaft causes the outer and inner rotors to rotate. At this time, the suction

port side pump chamber volume (the space surrounded by the outer and inner rotors) increases

gradually, causing the fuel entering from the fuel inlet to be drawn into the pump chamber via

the suction port. Along with the rotation of the rotor, the fuel that has been drawn in moves towards the discharge port and is discharged. The discharged fuel travels via the fuel outlet and

is fed into the supply pump body.

Volume decreased

(while moving to discharge port)

Outer rotor

Suction

port

From fuel tank

To pump chamber

Inner rotor

Discharge port

Volume increased

(while drawing in fiel)

[6] Coupling

The coupling is an intermediary device that transmits

the engine driving torque to the supply pump camshaft.

Volume decreased

(while discharging fuel to discharge port)

Volume increased

(while drawing in fiel)

Q000090E

Coupling

Q000091E

8

Page 11

2.2 Common Rail [1] Construction

The functionof the rail is to distribute the high-pressure

fuel pressurized by the supply pump to each cylinder

injector.

The rail pressure sensor, flow damper, and pressure

limiter are mounted on the rail.

Flow damper

A fuel injection pipe is attached to the flow damper to

deliver high-pressure fuel to the injector.

The pressure limiter piping is routed back to the fuel tank.

[2] Flow Damper

The flow damper reduces pressure pulsation in the

high-pressure pipe, thus delivering fuel to the injectors

at a stable pressure. Furthermore, in the event an excessive flow of fuel, the flow damper shuts off the fuel

passage, thus preventing the abnormal fuel flow.

When abnormal amount of fuel flows the high-pressure is applied to the piston. As shown in the illustration, this causes the piston and ball to move right, until

the ball reaches the seat and closes the fuel passage.

Pail pressure sensor

Stopped

During damping

During abnormal flow such as

excessive injection volume

Piston

Pressure limiter

Q000092E

Ball

Seat

Q000093E

[3] Pressure Limiter

The function of the pressure limiter is to dispel abnormally

high pressure by opening its valve to release pressure.

The pressure limiter operates (opens the valve) when

rail pressure reaches approximately 140MPa.

Then, when the pressure decreases to approximately

30MPa, the pressure limiter resumes (closes the valve)

its function to maintain pressure.

NOTE:

Do not attempt to remove or to reinstall the flow damper, pressure limiter, or rail pressure

sensor.

Pc

Q000094E

9

Page 12

[4] Rail Pressure Sensor

The rail, the rail pressure sensor is mounted on the rail and detects the fuel pressure. It is a

semi-conductor type of pressure sensor that utilizes the properties of silicon to change its electrical resistance when pressure is applied.

A-VCC

VPC

A-GND

VPC

ECU

+5V

5

4

3

2

1

Output voltage (V)

0

50 100 150

Pressure PC (MPa)

Q000095E

2.3 Injector [1] Outline

The function of the injector is to inject high-pressure fuel from the rail into the engine combustion chamber at the proper timing, quantity, ratio, and atomization, in accordance with signals

from the ECU.

The TWV (two-way solenoid valve) regulates pressure in the control chamber in order to control

the beginning and end of injection.

The orifice restrains the opening speed of the nozzle valve to regulate the injection ratio.

The command piston transmits pressure from the control chamber to the nozzle needle valve.

The nozzle atomizes the fuel.

Start of Injection (TWV ON)

Rail pressure sensor

ECU

Supply pump

Injection pressure

control

Rail

TWV

Leak

Orifice

Control chamber

Command piston

Nozzle

End of Injection (TWV OFF)

Rail pressure sensor

ECU

Supply pump

Injection pressure

control

Rail

TWV

Leak

Orifice

Control chamber

Command piston

Nozzle

10

Q000096E

Page 13

[2] Construction

The injector consists of the nozzle portion (similar to that of the conventional type), the orifice

(which regulates the injection ratio), the command piston, and the two-way solenoid valve

(TWV).

Upper body

O-ring

TWV

O-ring

Nozzle

Retaining nut

Orifice 2

Orifice 1

Command piston

Lower body

Guide bushing

Washer

Spring

Pressure pin

Tip packing

11

Q000097E

Page 14

[3] Operation

The TWV portion of the injector consists of two valves, an inner valve (fixed) and an outer valve

(movable). Both valves are precision-fitted on the same axis. The valves respectively form inner

and outer seats, and either of the seats opens selectively depending upon whether the TWV is

ON or OFF.

a. No Injection

When no current is applied to the solenoid, the valve spring and hydraulic pressure forces

push the outer valve downward, causing the outer seat to remain closed. Because the rail

high pressure is applied to the control chamber via the orifices, the nozzle remains closed

without injecting fuel.

b. Begin Injection

When current is applied to the TWV, the solenoid force pulls the outer valve upward, causing

the outer seat to open.

As a result, fuel from the control chamber flows out via the orifice, causing the needle to lift

and to start fuel injection. Furthermore, the injection ratio increases gradually in accordance

with the movement of the orifice. As the application of current continues to apply, the injector

reaches its maximum injection ratio.

c. End Injection

When current to the TWV is cut off, the valve spring and hydraulic force (fuel pressure) cause

the outer valve to descend and the outer seat closes. At this time, high-pressure fuel from the

rail is immediately introduced into the control chamber, causing the nozzle to close suddenly.

As a result, injection ends swiftly.

Inner valve

Outer valve

Outer seat

Orifice 2

Orifice 1

Rail

(constant high pressure)

18-130 MPa

Command piston

Nozzle

Control chamber

No Injection Begin Injection End Injection

Q000098E

12

Page 15

[4] Circuit Diagram

COMMON2

ECU

Constant current

circuit

COMMON1

2WV #1 (1st cylinder)

2WV #2 (5th cylinder)

2WV #3 (3rd cylinder)

2WV #4 (6th cylinder)

2WV #5 (2nd cylinder)

2WV #6 (4th cylinder)

Constant current

circuit

Charging circuit

Q000099E

WARNING:

High voltage is applied to the wires connected to COMMON1, COMMON2, and the TWV

#1-#6 terminals of the ECU. Exercise extreme caution to prevent electric shock.

13

Page 16

2.4 Sensors and Relays [1] NE Sensor (crankshaft position sensor)

When the signal holes on the flywheel move past the

sensor, the magnetic line of force passing through the

coil changes, generating alternating voltage.

The signal holes are located on the flywheel at 7.5-degree

intervals. There are a total of 45 holes, with holes missing

in three places. Therefore, every two revolutions of the

engine outputs 90 pulses.

This signal is used to detect the engine speed and the

crankshaft position in 7.5-degree intervals.

[2]

TDC sensor (cylinder recognition sensor)

Similar to the NE sensor, the sensor utilizes the alternating

voltage generated by the changes in the magnetic line of

force passing through the coil.

The disc-shaped gear located in the center of the supply

pump camshaft has a cog (U-shaped cutout) at 120-degree

intervals, plus one tooth in an additional location. Accordingly, every two revolutions of the engine outputs seven

pulses. The combination of the NE pulse, TDC pulse is recognized as the No. 1 cylinder reference pulse.

NE (crankshaft angle) sensor

Q000100E

TDC (cylinder recognition) sensor

Q000101E

A combination of the NE pulse and the TDC pulses are

used for the cylinder reference pulse, and the irregular

pulse is used to determine the No. 1 cylinder.

No.6 cylinder TDC pulse

0°CR 120°CR 240°CR 360°CR 480°CR 600°CR 720°CR

Aux. NE pulse

NE pulse

#1 TDC #5 TDC #3 TDC #6 TDC #2 TDC #4 TDC #1 TDC

75°CR 75°CR 75°CR 75°CR 75°CR 75°CR 75°CR

02468101214

024681012140246

8

0246810121402468101214

10

12

TDC

NE

No.1 cylinder TDC pulse

No.1 cylinder recognition pulse

105°CR

024681012

0246

ECU

Input circuit

Input circuit

Q000102E

8

No.1 cylinder NE reference pulse

No.6 cylinder NE reference pulse

Q000103E

14

Page 17

[3] Water Temperature Sensor (THW made another

manufacturer)

The water temperature sensor detects the temperature

of the engine coolant water and outputs it to the ECU.

The sensor uses a thermistor, which varies resistance

according to temperature. As the ECU applies voltage

to the thermistor, it uses a voltage resulting from the

division of the computer internal resistance and the

thermistor resistance to detect the temperature.

Q000104E

VTHW

A-GND

ECU

VTHW

+5V

5

4

3

2

1

Output voltage (V)

0

-40 -20 0 20 40 60 80 100 120 THW

Coolant temperature (°C)

Q000105E

[4] Fuel Temperature Sensor (THL)

The fuel temperature sensor detects the fuel temperature and outputs it to the ECU. The sensor

uses a thermistor, which varies resistance according to temperature. As the ECU applies voltage to the thermistor, it uses a voltage resulting from the division of the computer internal resistance and the thermistor resistance to detect the temperature.

VTHL

ECU

VTHL

+5V

5

4

3

A-GND

Output voltage (V)

15

2

1

-40-20 0 20406080100120 THL

0

Fuel temperature (°C)

Q000106E

Page 18

[5] Accelerator Position Sensor

This sensor converts the angle of the pedal effort applied to the accelerator pedal into electrical

signals and sends them to the ECU. The accelerator sensor uses hall elements. A magnet is

mounted on the shaft that moves in unison with the accelerator pedal, and the magnetic field

orientation changes with the rotation of the shaft. The changes in the magnetic field orientation

generate voltage.

ECU

Hall elements

(2 pieces)

Magnets

(1 pair)

A-Vcc

VACCP1

A-GND

Amplifier

No. 1

A-Vcc

VACCP2

A-GND

Amplifier

No. 2

+5V

+5V

VAccp1

VAccp2

(V)

[6] Idle Set Button (made by another manufacturer)

A control knob is installed within reach of the driver,

enabling the driver to set the idle rpm. It increases idle

rpm using the idle-up switch, and decreases idle rpm

to the normal rate using the idle-down switch.

4.0

3.0

2.0

1.0

V

0

IGt

50 100

Accelerator opening (%)

Accp

Idle-up switch

Idle-down switch

Q000107E

ECU

Q000108E

[7] Main Relay

To supply current to the ECU, the main relay points close when current is applied to the main

relay coil.

[8] PCV Relay

The PCV relay supplies current to the supply pump PCV (discharge volume control valve).

16

Page 19

3. Various Types of Control

This system controls the fuel injection quantity and injection timing more optimally than the mechanical

governor or timer used in conventional injection pumps.

For system control, the ECU makes the necessary calculations based on signals received from

sensors located in the engine and on the vehicle in order to control the timing and duration in

which current is applied to the injectors, thus realizing optimal injection.

[1] Fuel Injection Rate Control Function

The fuel injection rate control function controls the ratio of the quantity of fuel that is injected

through the nozzle hole during a specified period.

[2] Fuel Injection Quantity Control Function

The fuel injection quantity control function, replaces the conventional governor function, and

controls fuel injection to achieve an optimal injection quantity based on the engine speed and

the accelerator opening.

[3] Fuel Injection Timing Control Function

The fuel injection timing control function, replaces the conventional timer function, and controls

the fuel injection to achieve an optimal injection timing according to the engine speed and the

injection quantity.

[4] Fuel Injection Pressure Control Function (Rail Pressure Control Function)

The fuel injection pressure control function (rail pressure control function) uses a rail pressure

sensor to measure fuel pressure, and feeds this data to the ECU to control the pump discharge

quantity.

Pressure feedback control is implemented to match the optimal quantity (command quantity)

set according to the engine speed and the fuel injection quantity.

Input signal

Accelerator sensor

NE sensor

(Crankshaft position sensor)

TDC sensor

(Cylinder recognition sensor)

Rail pressure sensor

Various sensors

·Coolant temperature sensor

·Fuel temperature sensor

·Atmospheric air temperature

sensor etc.

Fuel control computer

(ECU)

Atmospheric air

pressure sensor

Control output

Fuel injection rate control

Fuel injection quantity control

Fuel injection timing control

Fuel injection pressure control

Diagnosis

17

Q000109E

Page 20

3.1 Fuel Injection Rate Control [1] Main Injection

Same as conventional fuel injection.

[2] Pilot Injection

Pilot injection is the injection of a small amount of fuel

Pilot injection

Main injection

prior to the main injection.

While the adoption of higher pressure fuel injection is

associated with an increase in the injection rate, the

lag (injection lag) that occurs from the time fuel is injected until combustion starts cannot be reduced be-

Q000110E

low a certain value. As a result, the quantity of fuel

injected before ignition increases, resulting in explosive combustion together with ignition, and

an increase in the amount of NOx and noise. Therefore, by providing a pilot injection, the initial

injection rate is kept to the minimum required level dampening, the explosive first-period combustion and reducing NOx emissions.

TDC

Combustion

process

Injection rate

Heat generation

rate

High injection

rate

Large pre-mixture

combustion

(NOx, noise)

Ignition delay

Delta injection

Small injection amount

prior to ignition

Pilot injection

Improvement

Small pre-mixture

combustion

Q000111E

[3] Split Injection

When the rotation is low at starting time, a small

amount of fuel is injected several times prior to main

injection.

18

Split injection

Q000112E

Page 21

4. Reference

4.1 Diagnosis Code

Failure Mode Diagnosis Light Pattern

NE sensor system

Aux. NE sensor system

Rail abnormal high pressure (Sensors’ failure)

Rail pressure sensor output is abnormally

constantly

Rail abnormal pressure (overcharged by supply

pump)

Rail abnormal pressure (control system)

Injection quantity adjustment resistor

Coolant temperature sensor

Fuel temperature sensor

Atmospheric air temperature sensor

Accelerator sensor 1

Accelerator sensor 2

Accelerator sensor

Atmospheric air pressure sensor

Starter S/W

Flow damper

TWV driving circuit open

TWV driving circuit short (+B)

TWV driving circuit short (GND)

Supply pump does not send pressurized fuel to

rail, or pressure limiter operates

Supply pump does not send necessary

pressurized fuel due to fuel leakage

PCV system short (+B)

(Coil or harness)

PCV system open/short (GND)

(Coil or harness)

Abnormal A/D convension

ECU

PCV and relay system

Diagnosis

(Light for 20 seconds at 700rpm or less) 15

B

B

(constantly lit up) 245

A

A

A

A

A

(not lighting) 23

C

C

C

A

A

A

C

C

#1: 261

#2: 262

C

#3: 263

#4: 264

#5: 265

#6: 266

#1: 271

#2: 272

A

#3: 273

#4: 274

#5: 275

#6: 276

Common 1system

A

A

Common 2system

Common 1system

Common 2system

A

A

A

A

PCV1: 217

PCV2: 218

PCV1: 247

PCV2: 248

A

A

A

Code

14

115

151

118

34

211

22

24

24

28

71

417

158

159

158

159

226

227

35

—

421

19

Page 22

Failure Mode Diagnosis Light Pattern

Main relay

Boost pressure sensor

Abnormally high boost pressure

Abnormally low boost pressure

Diagnosis

Code

B

C

C

C

416

32

A: 42

B: 32

65

Overrun1 (Software)

Overrun2 (Hardware)

Abnormal output by accelerator sensor1

Abnormal output by accelerator sensor2

Abnormal watch dog timer

Charge circuit failure

C

C

A

A

A

A

—

543

24

24

35

35

20

Page 23

4.2 Circuit Diagram

START

Key "ON" Relay

LOCK

ACC

ON

PCV Relay

12V

Crank Position Sensor

(NE Sensor)

Cylinder Recognition Sensor

(TDC Sensor)

Sensor 1

Accelerator Sensor

Sensor 2

Injection Quantity

Adjustment Resistor

Atmospheric Air

Temperature Sensor

Fuel Temperature

Sensor

Coolant Temperature

Sensor

Main Relay

STA/SW

KEY/SW

KEY/SW

+BP

+BP

M-REL

M-REL

GND

GND

P-GND

P-GND

NE+

NE-

NE-SLD

G+

G-

G-SLD

J1708A

J1708B

ACC1-VCC

ACC2-VCC

ACC1

ACC2

ACC1-GND

ACC2-GND

FQ1

FQ2

FQ3

FQ-GND

THA

THF

THV

TH-GND

PCV1

PCV1

PCV2

PCV2

DIAG-L

DG/SW

COMMON1

COMMON1

COMMON2

COMMON2

TWV1

TWV1

TWV2

TWV2

TWV3

TWV3

TWV4

TWV4

TWV5

TWV5

TWV6

TWV6

AT-REL

EXB-REL

EXB/SW

IDLUP/SW

IDLDWN/SW

TM/SW

N/SW

CL/SW

MCLR/SW

MF AM/SIG

MF AM/USE

Pressure Control

Val ve

Diagnosis Light

Diagnosis S/W

A/T Relay

Exhaust Break

Relay

Idle-up S/W

Idle-down S/W

Transmission S/W

Neutral S/W

Clutch S/W

TWV

Exhaust

Break S/W

Memory Clear S/W

MF AM/SIG

MF AM/USE

Rail Pressure

Sensor

Boost Pressure

Sensor

PFUEL-VCC

PFUEL

PFUEL

PFUEL-GND

A-VCC

PBOOST

A-GND

21

CHECKER

TACHO

Tool Display

Tachometer

Case GND

Q000113E

Loading...

Loading...