Page 1

WORKSHOP MANUAL

727 (N SERIES)

ENGINE CONTROL SYSTEM

(4HL1 ENGINE)

SECTION 1A

International Service & Parts

Tokyo, Japan

Page 2

N O T I C E

Before using this Workshop Manual to assist you in performing

vehicle service and maintenance operations, it is recommended

that you carefully read and thoroughly understand the information

contained in Section - 0A under the headings “GENERAL REPAIR

INSTRUCTIONS” and “HOW TO USE THIS MANUAL”.

All material contained in this Manual is based on the latest product

information available at the time of publication.

All rights are reserved to make changes at any time without prior

notice.

Page 3

Engine Control System 1A-1

ENGINE

Engine Control System

CONTENTS

Engine Control System . . . . . . . . . . . . . . . . . . . . 1A-2

Precautions on Service . . . . . . . . . . . . . . . . . . 1A-2

Function and Operation . . . . . . . . . . . . . . . . . . 1A-3

Powertrain System Components . . . . . . . . . . . 1A-9

Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . 1A-20

Strategy-Based Diagnostics . . . . . . . . . . . . . . 1A-38

Functional Check List . . . . . . . . . . . . . . . . . . . 1A-44

Hearing Diagnostic . . . . . . . . . . . . . . . . . . . . . 1A-44

On-Board Diagnostic (OBD) System Check . 1A-47

Inactive CHECK ENGINE Lamp Check . . . . . 1A-50

Unblinking CHECK ENGINE Lamp Check . . . 1A-54

ECM Power Supply and Grounding System Circuit

Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-56

Diagnosis with Tech 2 Scan Tool . . . . . . . . . . 1A-59

Diagnostic Chart . . . . . . . . . . . . . . . . . . . . . . . 1A-88

DTC14 - CMP Sensor System Fault . . . . . . . 1A-93

DTC15 - CKP Sensor System Fault . . . . . . . . 1A-97

DTC18 - Starter Degradation (For Only Vehicles

Equipped with Idle Stop Function) . . . . . . . . 1A-101

DTC22 - IAT Sensor System Fault . . . . . . . . 1A-103

DTC23 - ECT Sensor System Fault . . . . . . . 1A-107

DTC24 - Accelerator Sensor System Fault . 1A-112

DTC25 - Vehicle Speed Sensor System

Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-116

DTC28 - PTO Accelerator Sensor System

Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-120

DTC31 - Idle Up Volume System Fault . . . . 1A-123

DTC33 - VIM Internal Fault (EEPROM Write

Error) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-127

DTC34 - ECM Internal Fault (Charge Circuit

Fault) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-129

DTC35 - VIM Internal Fault (A/D Conversion

Fault) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-132

DTC43 - ITP Sensor System Fault . . . . . . . . 1A-134

DTC44 - EGR Valve Position Sensor System

Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-139

DTC45 - EGR Valve System Fault . . . . . . . . 1A-144

DTC46 - Exhaust Brake System Fault . . . . . 1A-147

DTC51 - ECM Internal Fault (CPU Error / CPU

History Error) . . . . . . . . . . . . . . . . . . . . . . . . 1A-150

DTC52 - ECM Internal Fault

(Sub CPU Error) . . . . . . . . . . . . . . . . . . . . . . 1A-152

DTC61 - Intake Throttle Valve System Fault 1A-154

DTC71 - Barometric Pressure Sensor Fault 1A-157

DTC81 - Clutch Switch System Fault . . . . . . 1A-159

DTC82 - Neutral Switch System Fault . . . . . 1A-163

DTC84 - CAN Communication Fault

(CAN Bus Error) . . . . . . . . . . . . . . . . . . . . . . 1A-166

DTC86 - CAN Communication Fault

(CAN Timeout Error) . . . . . . . . . . . . . . . . . . . 1A-169

DTC115 - Common Rail Pressure Sensor Fixed

Output Fault . . . . . . . . . . . . . . . . . . . . . . . . . 1A-172

DTC1 18 - Common Rail Pressure Fault

(Control System) . . . . . . . . . . . . . . . . . . . . . 1A-177

DTC158 - Injector Power Supply System Short

(Common 1) . . . . . . . . . . . . . . . . . . . . . . . . . 1A-182

DTC159 - Injector Power Supply System Short

(Common 2) . . . . . . . . . . . . . . . . . . . . . . . . . 1A-186

DTC21 1 - Fuel Temperature Sensor System

Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-190

DTC217 - SCV Drive System Short . . . . . . . 1A-195

DTC227 - No Pump Pressure Feed (Fuel Leak)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-198

DTC241 - Idle Position Switch Circuit Open

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-203

DTC242 - Idle Position Switch Circuit Short . 1A-206

DTC245 - Common Rail Pressure Sensor

System Fault . . . . . . . . . . . . . . . . . . . . . . . . 1A-209

DTC247 - SCV Drive System Fault . . . . . . . 1A-215

DTC271 - Cylinder 1 (Injector Drive System)

Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-219

DTC272 - Cylinder 2 (Injector Drive System)

Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-223

DTC273 - Cylinder 3 (Injector Drive System)

Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-227

DTC274 - Cylinder 4 (Injector Drive System)

Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-231

DTC277 - Injector Power Supply System Open

Wiring Fault (Common 1) . . . . . . . . . . . . . . . 1A-235

DTC278 - Injector Power Supply System Open

Wiring Fault (Common 2) . . . . . . . . . . . . . . . 1A-239

DTC416 - Main Relay System Fault . . . . . . . 1A-243

DTC417 - Starter Switch System Fault . . . . 1A-246

DTC543 - High Engine Speed Error . . . . . . . 1A-249

Default Matrix Table . . . . . . . . . . . . . . . . . . . 1A-250

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . 1A-256

Wiring Harness Repair: Shielded Cable . . . . . 1A-257

Removal Procedure . . . . . . . . . . . . . . . . . . . 1A-257

Installation Procedure . . . . . . . . . . . . . . . . . 1A-257

Twisted Leads . . . . . . . . . . . . . . . . . . . . . . . . . 1A-258

Removal Procedure . . . . . . . . . . . . . . . . . . . 1A-258

Installation Procedure . . . . . . . . . . . . . . . . . 1A-258

Weather-Pack Connector . . . . . . . . . . . . . . . . 1A-260

Removal Procedure . . . . . . . . . . . . . . . . . . . 1A-260

Installation Procedure . . . . . . . . . . . . . . . . . 1A-260

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . 1A-261

Com-Pack III . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-262

General Information . . . . . . . . . . . . . . . . . . . 1A-262

Metri-Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A-263

Removal Procedure . . . . . . . . . . . . . . . . . . . 1A-263

Installation Procedure . . . . . . . . . . . . . . . . . 1A-263

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . 1A-263

Page 4

1A-2 Engine Control System

ngine Control System

E

Precautions on Servic e

Circuit test tools

Unless otherwise specified in diagnostic procedures,

do not use Test Light to diagnose the powertrain

electrical system. When diagnostic procedures need

probe connector, use Connector Test Adapter Kit 58840-0385-0.

On-market electrical equipment and vacuum

devices

On-market electrical equipment and vacuum devices

refer to those components that will be installed to

vehicles after shipme nt from manufacturing plants. Be

careful that installation of these components is not

considered during the process of vehicle design.

CAUTION:

Do not install on-market vacuum devices to

vehicles.

CAUTION:

Connect on-market electrical equipment, as well as

its power supplies and grounds, to the circuits

isolated from the electronic control system.

The on-market electrical equipment, even when

installed to vehicles in normal manner, may bring

functional troubles to the electronic control system.

Affected devices include those not connected to the

vehicle electrical equipment system, for example,

mobile phones or radios. Therefore, when you intend to

diagnose the powertrain, check such the on-market

electrical equipment has not been installed to the

vehicle and, if installed, remove it. If faults still occur

even after removal of on-market electric al equipment,

diagnose the vehicle according to normal procedures.

Damage by electrostatic discharge

Electronic components used in the electronic control

system are designed to w ork at very low volta ges and,

for this reason, they are susceptible to damage by

electrostatic discharge and some types of electronic

components may be damaged even by the static

electricity of less th an 100 V that is us ually not sensed

by persons. Persons’ sensitivity level is 4,000 V.

Persons are electrostatically charged in various ways

and the most typical e lectrification sources are f riction

and induction. Shown below are examples.

• Electrification by friction occurs when a person

slides on the seat in the vehicle.

• Electrification by induction occurs when a person

with insulating shoes is standing near a highly

electrifiable substance and touches a ground

momentarily. Electric charges with the same

polarity flow out and resultantly the person is

charged at high opposite polarity. Since static

electric charges cause damages, it is important

when you handle or test electronic components.

CAUTION:

To prevent damages by electrostatic discharge,

follow the guidelines shown below.

• Do not touch ECM connector pins as well as

electronic components soldered to the ECM

circuit board.

• Do not unpack each replacement component

until preparations are completed for the

component.

• Before taking out a component from the

package, connect the package to the normal

grounding line of the vehicle.

• When you intend to slide on the seat, change

the posture from standing to sitting, or wa lk by

a certain distance to handle a component,

touch an appropriate grounding material.

Wire color

All wiring harnesses are id entifi ed using colored jac ket.

The wiring harness used for the main circuit in an

electrical system is identifi ed with sing le color while t he

wiring harness used for the sub- circu it is i dentif ied with

color stripe. The following rule is used in each wiring

diagram to indicate size and color of a wiring harness.

eg. : 0.5 GRN / RED

1

2

3

LNW21ASH000101-X

Legend

1. Red (stripe color)

2. Green (base color)

3. Harness size (0.5 mm

2

)

Page 5

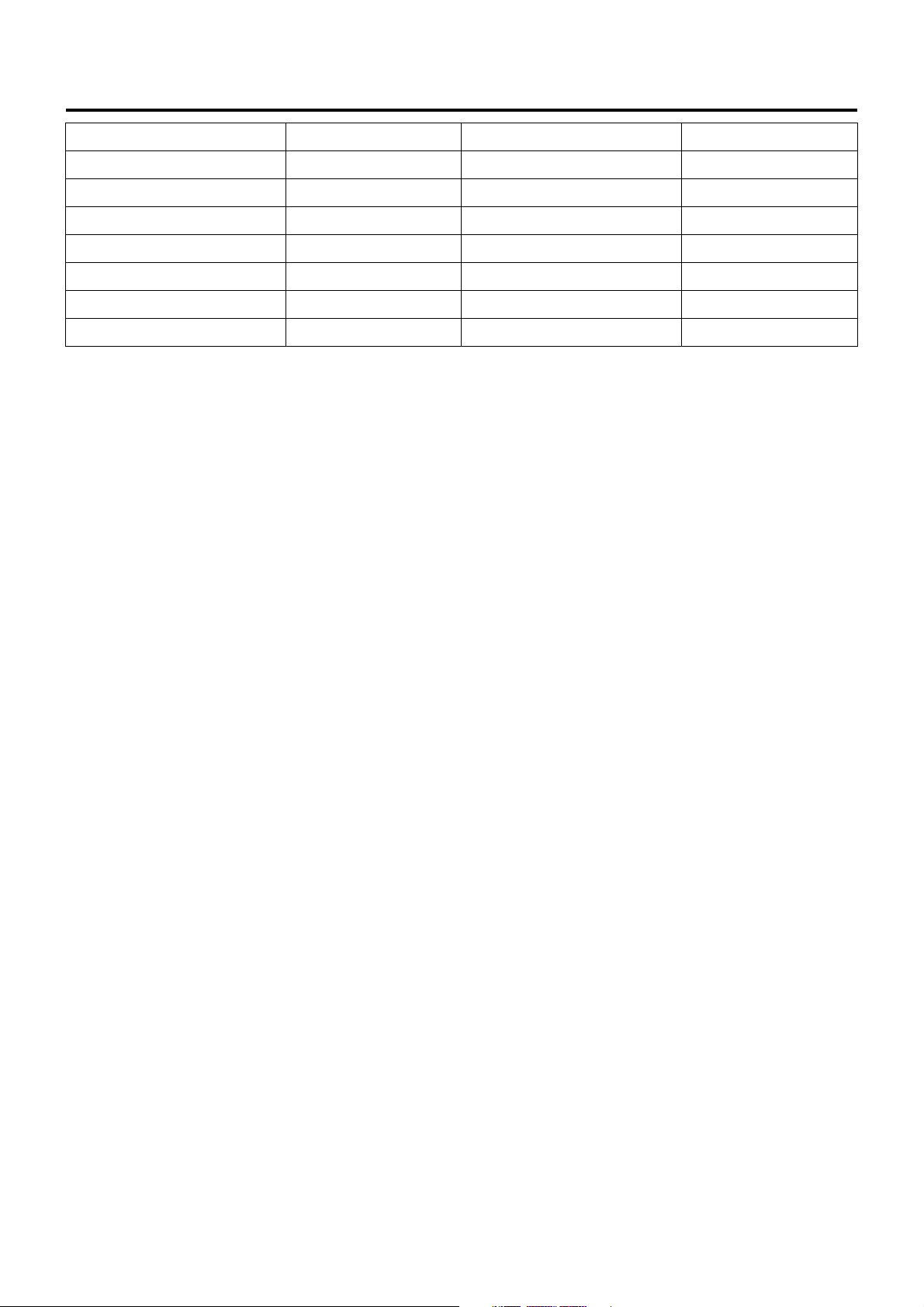

Engine Control System 1A-3

Symbol Color Symbol Color

BBlackBRBrown

W White LG Light green

R Red GR Gray

GGreenP Pink

Y Yellow LB Light blue

L Blue V Violet

OOrange

Function and Operation

Electronic Control System

The electronic control system processes the data,

which has been collected with various types of sensors,

by means of the control program installed to ECM

(engine control module) to totally control engine

parameters such as fuel injection quantity, injection

timing, engine startup, altitude compensation, and

EGR.

ECM

ECM Description

The ECM is mounted in th e inner part of the engine lef t

side cover. The ECM monitors variou s data sent from

diversified sensors and controls systems in the

powertrain. The ECM diagnoses these systems to

detect faults with respect to system operations and

inform the driver of faulty condition via the CHECK

ENGINE lamp (MIL) and stores DTCs (diagnostic

trouble codes). DTC identifies the trouble generation

area to aid repairs by service operators.

Function of ECM

ECM supplies 5 V and 12 V voltages to various sensors

and switches. Since powers are supplied via high

resistances in EC M, Test Light, even when c onnected

to the circuit, will not be lit. In a special case, a no rmal

voltmeter does not indicate correct values since the

resistance of the ins trument i s too low. To get a ccurate

readings, you need a digital voltmeter whose input

impedance is at least 10 MΩ. The special tool 5-88400366-0 is a proper choice for this measurement. In the

ECM, the output c ircuit is controlled by regulati ng the

grounding system or power circuit via transistor or

either of the devices listed below.

• Output driver module (ODM)

• Quad drive module (QDM)

ECM and Components

The ECM is designed to offer excellent drivability and

fuel economy while achieving exhaust gas emission

control requirements. The ECM monitors engine and

vehicle functions via various electronic sensors such as

CKP (crank position) and VS (vehicle speed) sensors.

Voltages from ECM

The ECM supplies reference voltages to various

switches and sensors. Resistances of the ECM are

very high and this allows the ECM to supply voltages to

these devices, and v oltages actually app lied to circuits

are low and even connecting Test Light to individual

circuits may fail turn-on. Since the voltmeter normally

used in service factories has low input impedance,

correct readings m ay not be obtain ed. To get accurate

readings, a digital voltmet er whose input impedanc e is

10 MΩ (for example, 5-8840-0366-0) should be used.

Input/output devices of the ECM include analog-todigital converter, signal buffer, counter, and special

driver. By using electronic switch es, the ECM controls

most system components and turning off a switch

closes the ground circuit. These switches are divided

into four-switch or seve n- sw itc h gr ou ps, a nd th e former

group is called qu ad driv er mo dul e (Q DM) and controls

up to four output pins respectively while the latter group

is called output driver module (ODM) and controls up to

seven outputs respectively. Note that all the outputs are

necessarily not used in the control.

Electrically Erasable Programmable ROM

(EEPROM)

EEPROM is a permanent memory chip and soldered to

the board in the ECM. EEPROM stores program and

calibration data, both of which are necessary for the

ECM to control the powertrain. Different from

conventional ROMs, EEPROM cannot be replaced with

new component. If EEP ROM fails, the complete ECM

assembly must be replaced with new one.

Precautions on ECM Servic e

The ECM is designed to withstand ordinary currents

used in operations of a vehicle. Be careful that the

circuits must not be overloaded. To test the ECM to

check open wiring or short, ECM circuits must be

connected to the ground or voltages must not be

applied to the ECM. To test ECM circuits, the digital

voltmeter 5-8840-0366-0 should always be used.

Page 6

1A-4 Engine Control System

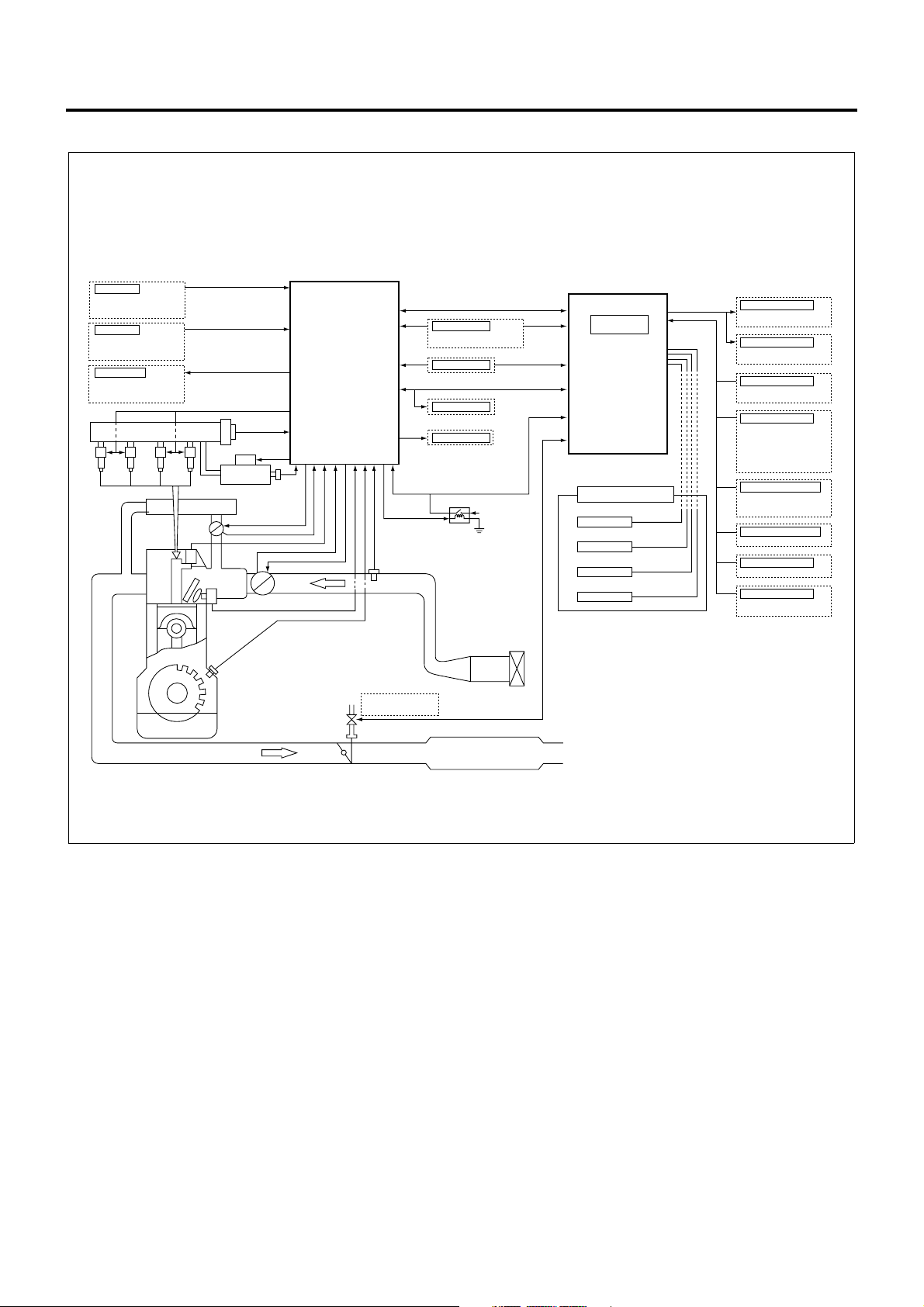

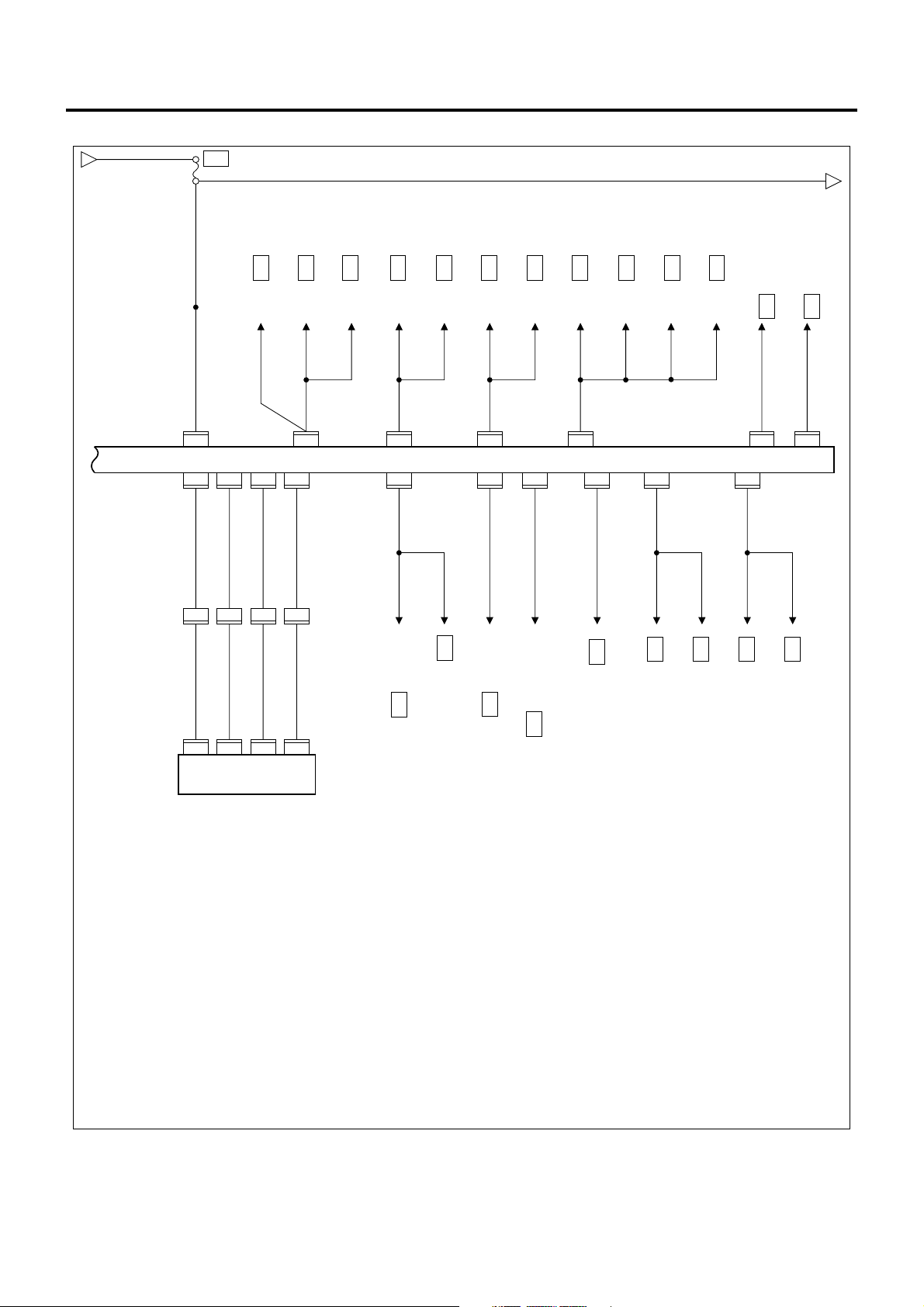

Engine Control System

Accelerator

AP sensor

Idle position switch

Switch

A/C switch

Relay/Lamp

Starter cut relay

Glow relay

Check engine lamp

Common rail

Common rail

Injector

Exhaust

pipe

EGR cooler

pressure sensor

SCV

Supply

pump

EGR valve drive

EGR valve position sensor

CMP sensor

ITP sensor

Intake throttle drive

ECT

FT sensor

ECM

(Engine Control Module)

IAT sensor

CAN

Starter

Ignition switch

Starter switch

Battery

Outer diagnostic unit

Diagnostic switch

Main relay

Battery +

Atomospheric

pressure sensor

VIM

(Vehicle Interface Module)

Vehicle functions

Tachometer

TCM

ABS/ASR ECU

ISS ECU

Relay

ECO Relay,

Exhaust Brake

Lamp

Exhaust Brake Lamp

Glow Lamp

Brake

Stop Lamp Relay

Exhaust Brake Lamp

Transmission

Clutch Switch

Neutral Switch (MT)

Parking

/Neutral (AT)

Switch

Vehicle Speed Sensor

Power Take OFF (PTO)

PTO Switch (

ACTIVE HIGH

ACTIVE LOW

PTO Switch (

PTO Accelerator Sensor

Quick Warm Up System

QWS Switch

Idle

Idle Up Volume

Others

Freezer Switch

Clean Starting Memory

)

)

CKP

Exhaust brake

solenoid valve

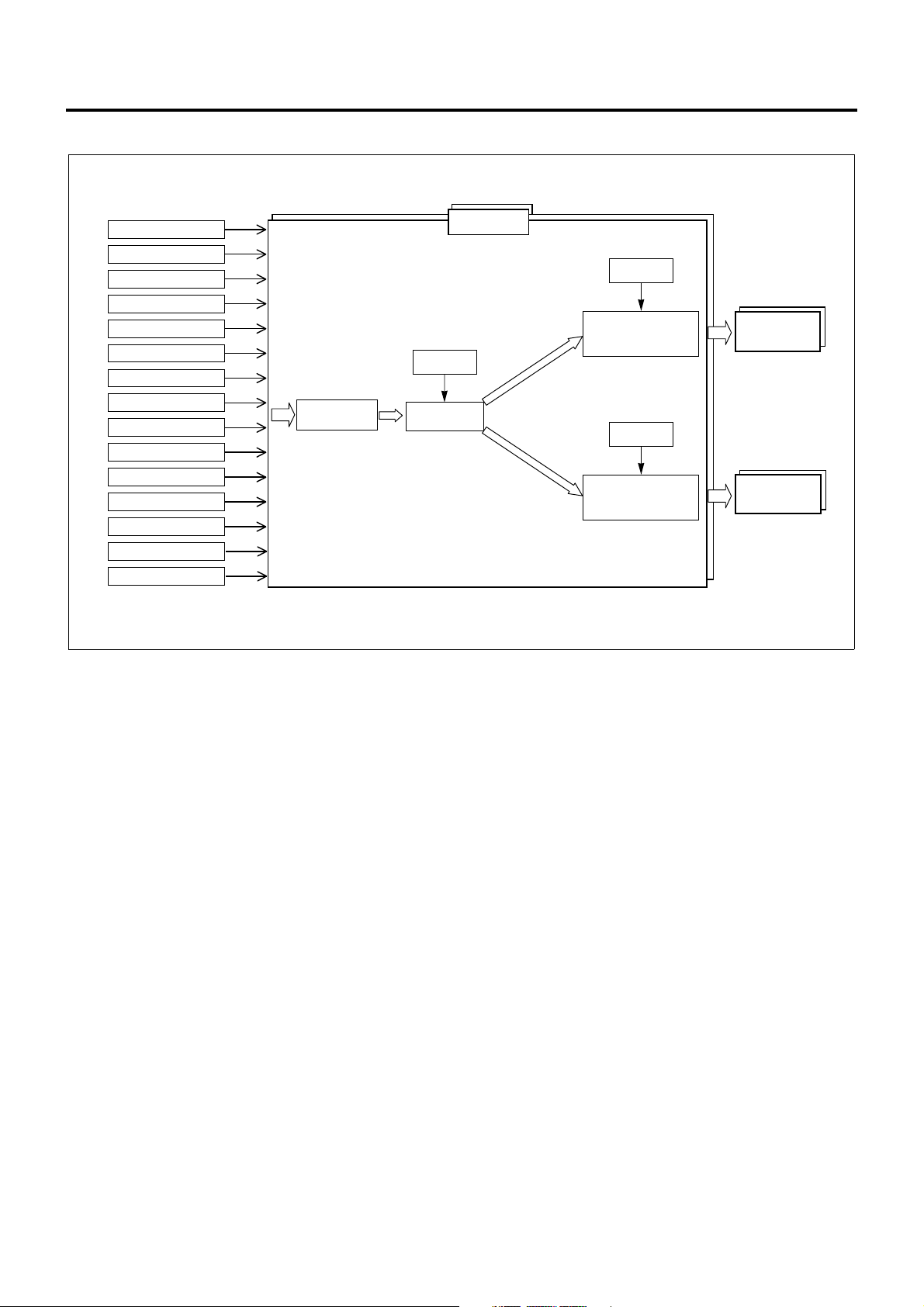

The engine control system comprehends vehicle status

and driver’s i ntention based on the data acquired from

sensors and switches to adapt the engine to chang ing

situation so that the vehicle will achieve optimal running

condition. The heart of the engine control system is

ECM and this device provides direct control tasks for

the engine system, including fuel injection control,

intake throttle control , EGR control, and QWS control.

The ECM also governs vehicle system control

strategies such as ex haust brake control and id le stop

control via VIM. In addition, the ECM communicates

with other key systems, including ABS/ASR system

and clutch free system, via VIM.

LNW21ALF004601-X

Page 7

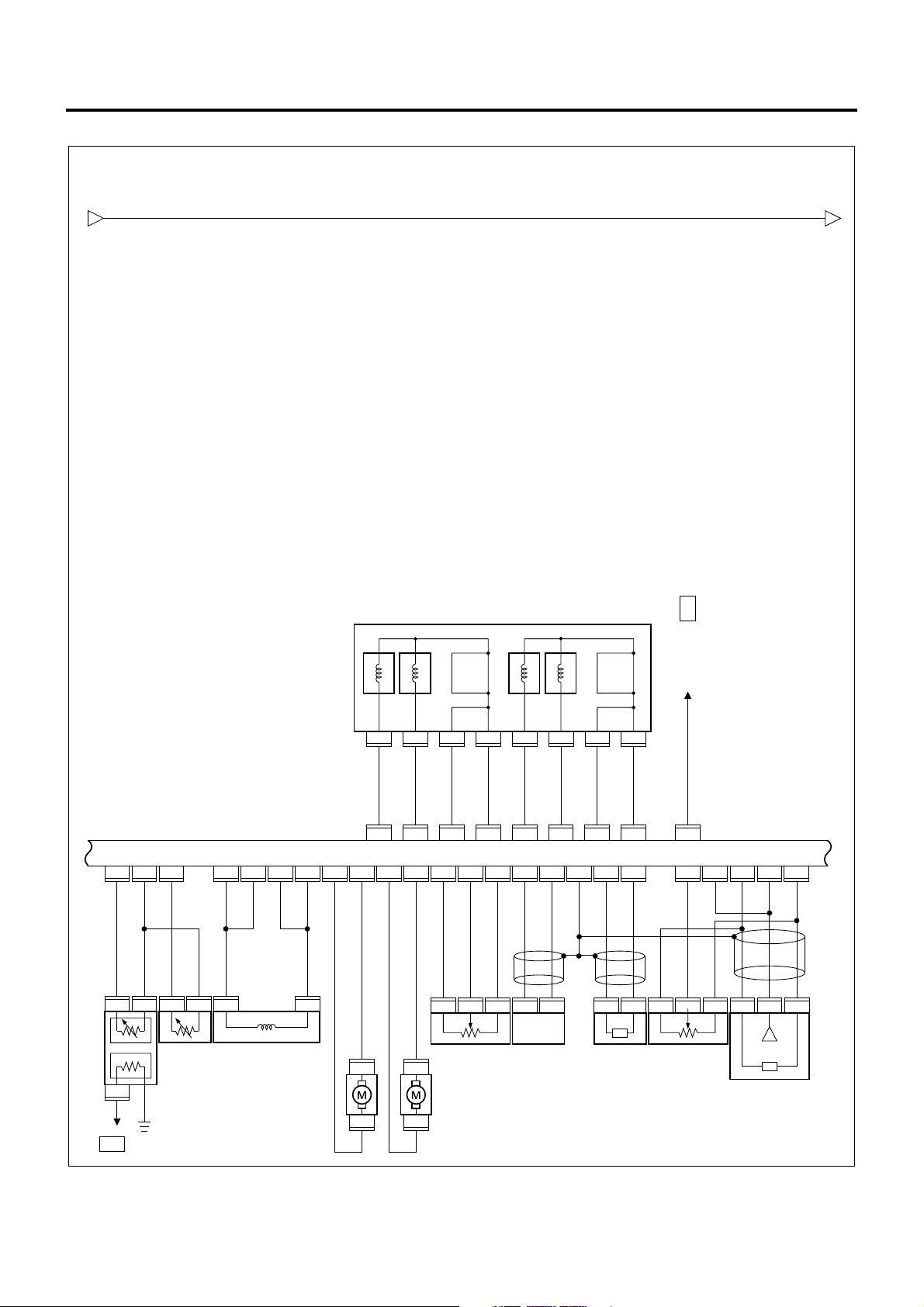

Fuel Injection Control

Engine Control System 1A-5

DTC Detection Status

Battery Voltage

Key Switch Position

Engine Speed

Vehicle Speed

Engine Coolant Temp.

Intake Air Temp.

Fuel Temp.

Common Rail Pressure

Accelerator Pedal Position

Idle Position Switch

Clutch Switch

Neutral Switch

PTO Switch

Idle Stop

Status Judge

Compensation

Desired Injection

Quantity

Determine

ECM

Compensation

Injector

Energize Time/

Timing Determine

Compensation

SCV Position

Determine

Injector

Control

SCV

Control

LNW21AMF005601-X

The fuel injecti on con t rol system manages the i nje ct ion

quantity, injection timing, and injection pressure

according to the status of vehicle. This system changes

the injection quantity using injector operating period,

the injection timing using injector operation timi ng, and

the injection pressure using SCV drive duty,

respectively. The fuel injection co nsists of two stages,

pilot injection and main injection, and the control

system changes the amount and timing in individual

stages according to the conditions encountered.

The ECM uses the data acquired from associated

sensors and switches to judge the current vehicle

status, i.e., startup, idling, PTO, or idle stop, and

calculate the desired injection quantity. Once the

desired injection quantity is determined, ECM

calibrates the value to determine injector energize time,

energize timing, and SCV opening and controls

injectors and the SCV accordingly.

Calculation of Desired Injection Quantity

The ECM calcu lates the basic injecti on quantity using

engine speed, accelerator pedal position, engine

coolant temperature, a nd other necessary parameters

and calibrates this value based on the atmospheric

pressure or the li ke to determine the desire d injection

quantity.

Injector Control

The injector control consists of four stages: "control

stop mode" where the fuel injection is completely

stopped, "split injection mode" where two (or more)

injection shots are mad e for one cylinder at low engine

speeds and temperatures, "fixed injection mode" where

only main injectio n is made at ve ry low engine sp eeds

during startup, and "normal in jection mode" where the

fuel injection is made within normal engine speed

range. The proper mo de is selecte d according to s uch

the parameters as engine speed, engine coolant

temperature, and DTC. The ECM uses the desired

injection quantity, intake air temperature, engine

coolant temperature, and other parameters to

determine injector energize period (desired injection

period) and injector energize timing (desired injection

timing) and control i njectors according to the injec tion

mode selected.

SCV Control (Pump Control)

Pumps are controlled in six stages: "shutoff mode",

"start mode", "wait mode", "restart mode", "feedback

mode", and "deflate mode". The proper mode is

selected according to such the parameters as key

switch position, common rail pressure, and engine

speed. The ECM calcu lates desired injecti on pressure

and pump flow rate for the selected mode based on

intake air temperature, engine coolant temperature,

engine speed, desired injection quantity, and other

necessary parameters. Then , the ECM determines the

SCV opening (SCV drive duty) us ing thes e result s and

controls the SCV.

Page 8

1A-6 Engine Control System

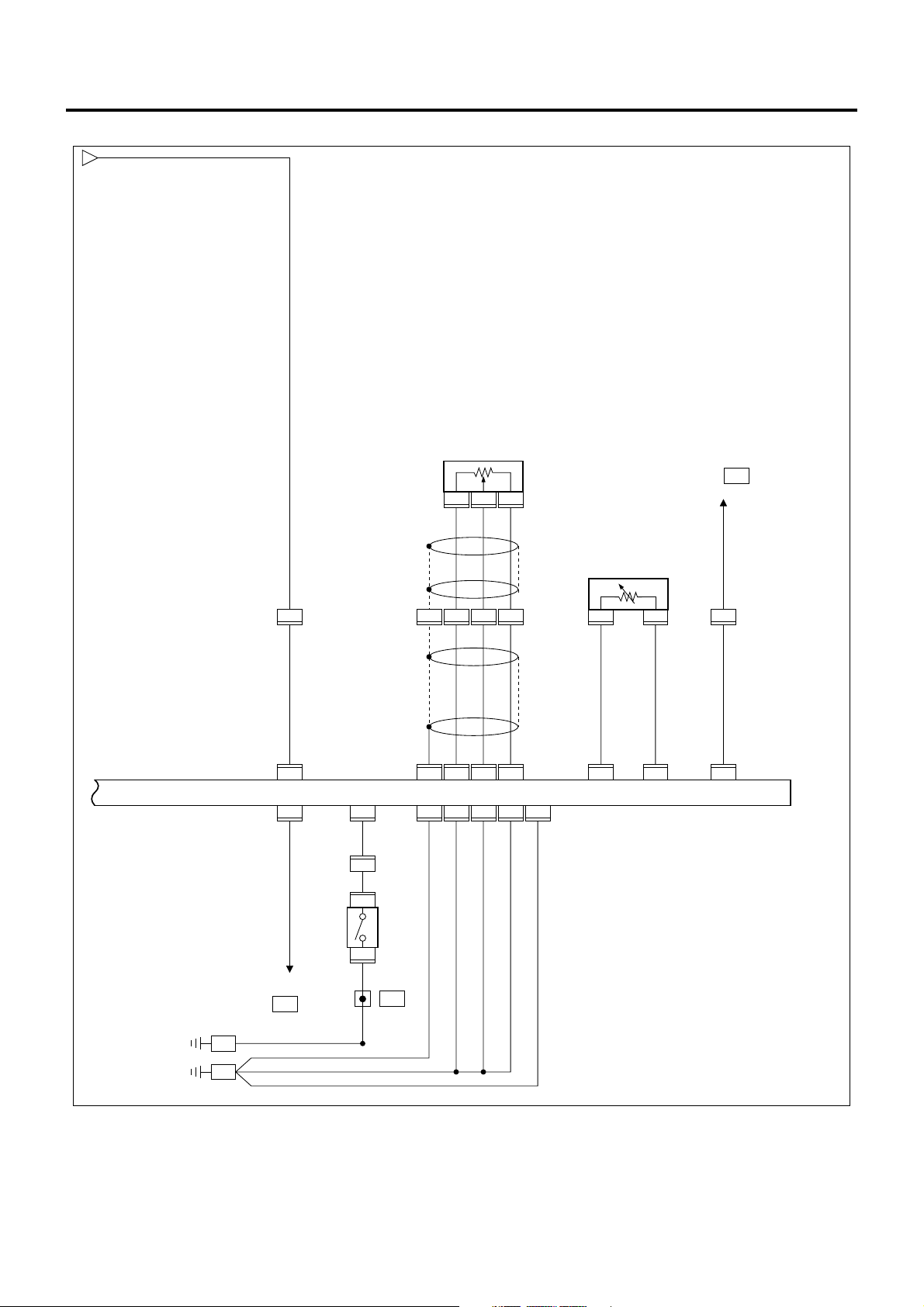

Intake Throttle Control

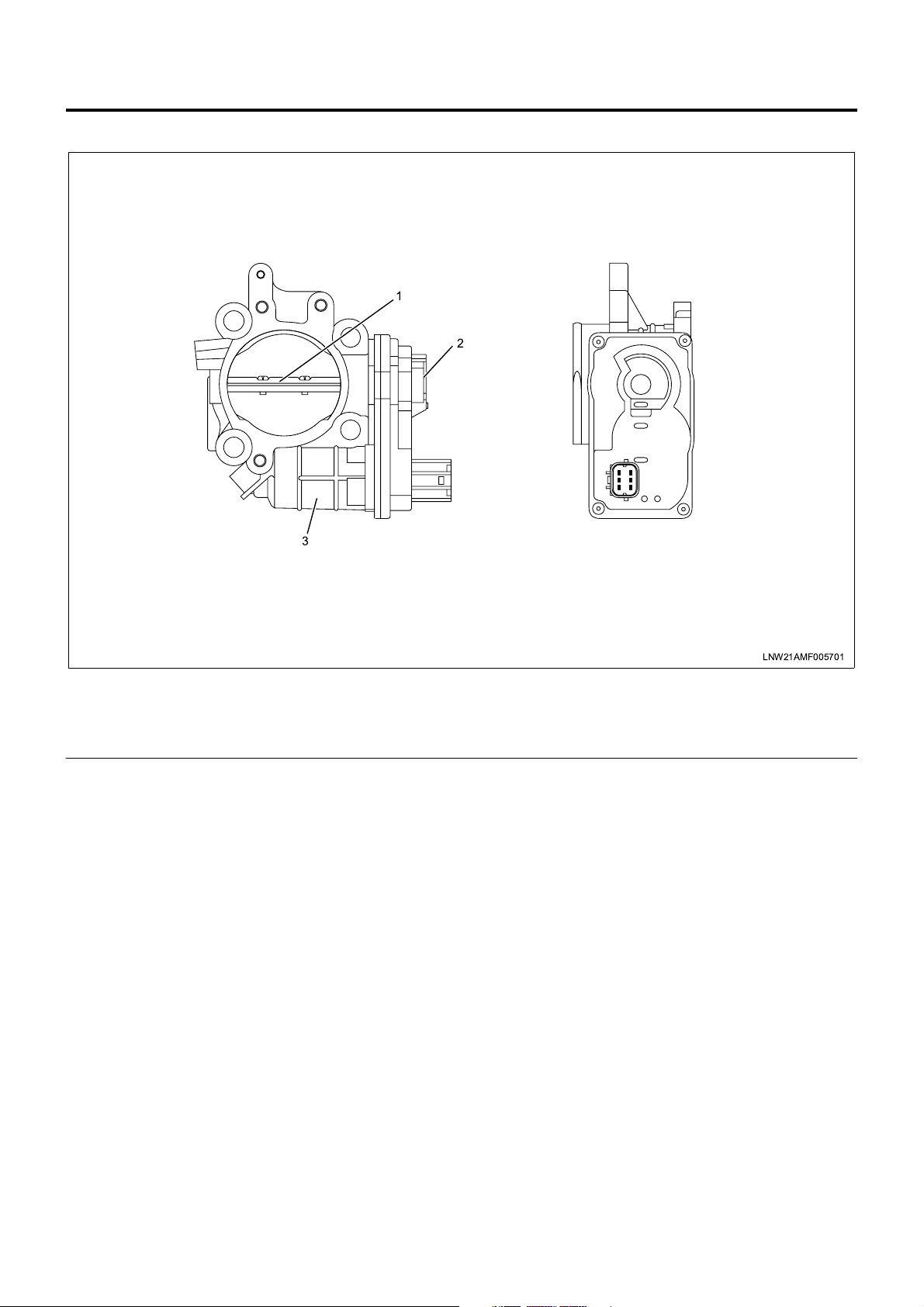

3

1

2

Legend

1. Intake throttle valve

2. ITP (intake throttle position) sensor

The intake throttle control system changes (throttles)

the air according to the vehicle status and reduces

suction noises generated from the working exhaust

brake and acceleration. This control is made by

opening and closing the intake throttle valve. The

intake throttle valve is ope rated by the DC motor and

changing the drive voltage (duty: see Note 1) opens

and closes the v alve. The intake throttle valve i s fully

opened in the normal state (i.e., the DC motor is

inactive) and gradually reduces the opening as the

drive voltage is increased. The ECM uses the ITP

(intake throttle position) sensor to detect the working

condition of the intake throttle valve. When the valve

opening gets smaller (the drive voltage is increased),

the output voltage of the ITP sensor becomes lower.

The valve position is norm ally calculated using engine

coolant temperature, engine speed, and desired

injection quantity, and the DC motor drive voltage is

determined from this calculated value. However, the

ECM completely opens the throttle valve when the

vehicle is in idle stop, DTC is set for the intak e throttle

system, AP sensor system, or EGR system, gear

shifting is perfo rmed (for m anual trans missi on ve hicle ),

the engine coolant temperature is low (less than 70°C),

or the vehicle is i n startup or en gine s tall sta tus wh ile i t

completely close s the valve immediately after the key

LNW21AMF005701

3. Intake throttle DC motor

switch is turned off (within 0.5 to 3.0 seconds).

There is an opposing relationship between intake

throttle control and EGR control. When the intake

throttle valve is opened, the EGR valve is closed, and

vice versa.

Note 1: Duty (%) = Energize ratio

Page 9

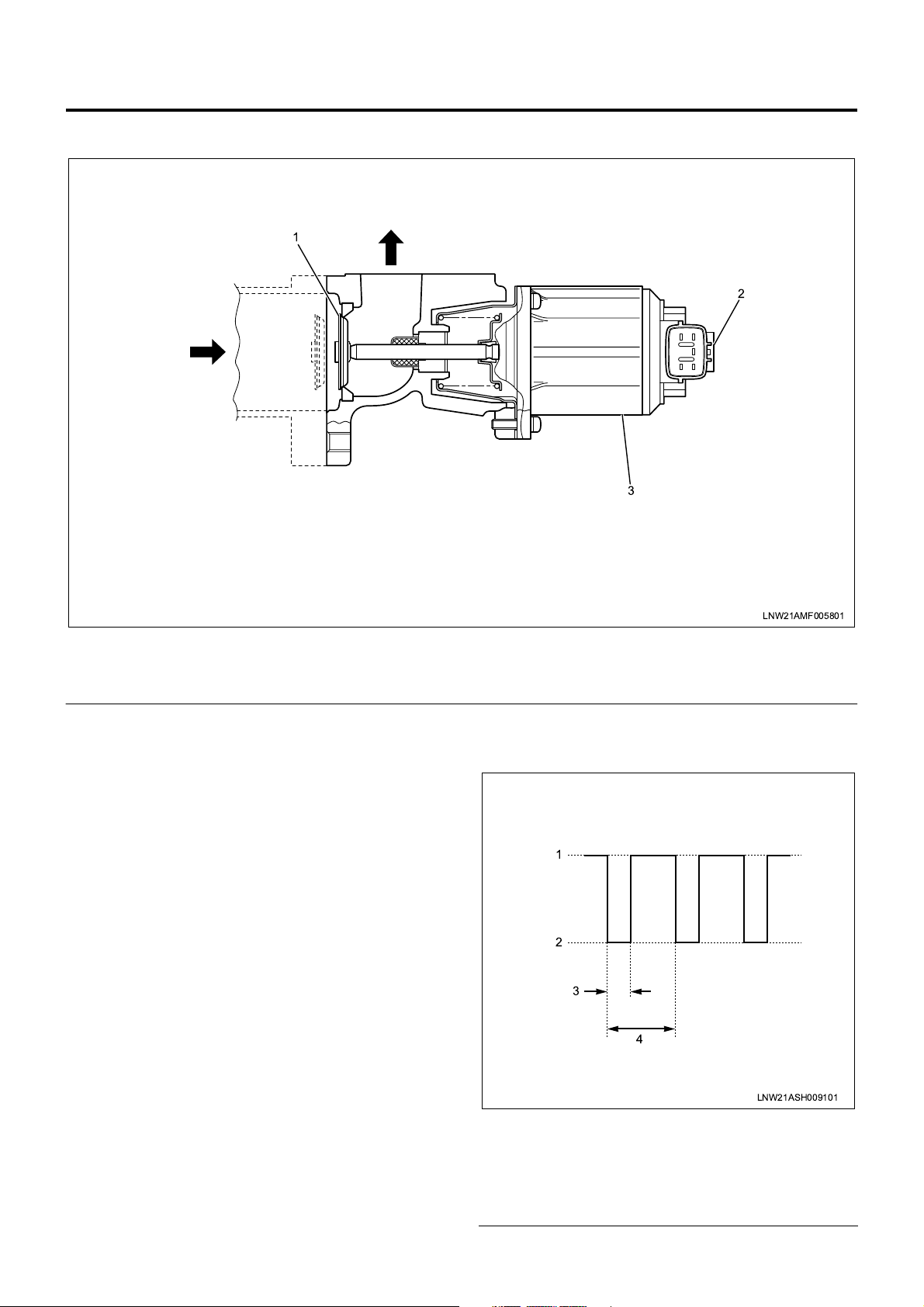

EGR Control

Engine Control System 1A-7

1

2

3

Legend

1. EGR valve

2. EGR valve position sensor

The EGR control system recirculates a portion of

exhaust gas to the intake to drop the combustion

temperature and thus reduce NOx. This control is

made by opening and closing the EGR valve. The EGR

valve is operated by the DC motor and changing the

duty (see Note 1) opens and closes the valve. This

EGR valve is f ully closed in the nor mal state (i.e., the

DC motor is inactive) and gradually enlarges the

opening as the duty is increased. The ECM uses the

EGR valve posit ion sens or to com prehend the working

condition of the EGR valve. When the valve opening

gets larger (the duty is increased), the output voltage of

the EGR valve position sensor becomes higher.

The EGR control is initiated when parameters such as

engine speed, engine coo lant temperatu re, acce lerator

position, atmospheric pressure, and system voltage

meet the required conditions, and the EGR valve

opening is calculated from engi ne c oolan t t emp eratur e ,

engine speed, and desire d inje ction quanti ty. The ECM

determines the drive duty of the DC motor based on

this valve position and drives the motor. The EGR

control is turned off when the exhaust brake is

operated, the PTO is working, the A P sensor fails, the

ECT sensor fails, the EGR system fails, or th e intake

throttle system fails.

There is an opposing relationship between EGR control

and intake throttle control. When the intake throttle

valve is opened, the EGR valve is closed, and vice

versa.

LNW21AMF005801

3. EGR DC motor

Note 1: Duty (%) = T (*) / 5 (msec) × 100

* T = Duty input time (see motor drive voltage

waveform)

1

2

3

4

LNW21ASH009101

Legend

1. 24V

2. 0V

3. T (duty input time)

4. 5 msec

Page 10

1A-8 Engine Control System

QWS Control

The QWS (quick warm- up system) curtails the engine

warm-up time. The glow control covers the engine

warm-up during the period from pre-startup to

immediate completion of startup. The QWS works

when the vehicle meets the required conditions after

engine startup and the dr iv er tu rn s o n th e Q WS s wit ch ,

and lasts until the vehicle deviates from the QWS

working conditions.

QWS working conditions

• The engine coolant is less than 73°C.

• The engine is running at or above 40 0 rpm for at

least 0.5 second.

• Both EGR and PTO controls are disabled.

• The vehicle is free from AP sensor fault, ECT

sensor fault, A/D conversion fault, idle position

switch fault, clutch switch fault, neutral switch fault,

and vehicle speed sensor fault.

• The difference between actual and desired eng ine

speeds is less than 50 rpm.

• The desired engine speed is less than 1000 rpm.

• The vehicle is being off.

• The state where the starter switch is turned off and

the idle position switch is turned on lasts for at

least 0.5 seconds.

Exhaust Brake Control

A valve is instal le d ins id e t he exhaust pipe. Closing this

valve increases the resistance during the exhaust

stroke to enhance the effect of engin e brake. T he drive

source of the exhaust brake valve is vacuum. A

solenoid valve is inst alled to control the vacuum. The

exhaust brake is contr olled by o pening and clo sing this

solenoid electrically. When the engine is running at or

above 500 rpm, the e xhaust cut command is no t sent

from the automatic transmi ssion, and exhaust brake or

QWS working co nditions are completely me t, the VIM

turns on the solenoid valve.

• For a manual transmission vehicle, the clutch

pedal is not pressed. For an automatic

transmission veh icle, the exhaus t brake co mmand

is not sent from the automatic transmission.

• The system voltage stays between 20 V and 30 V .

Idle Stop Control (for Vehicles Equipped with Idle

Stop Control System)

The idle stop control system automatically cuts the

engine to prevent t he black smoke emission f rom the

vehicle that is not running for unloading or other works

(to restart the engine, manual operation is needed).

When all the idle stop conditions are met, the ECM

stops fuel injection and actuate s energy-saving relays

to turn off wipers, mirror defoggers, flashers, seat

heaters, and other electrical equipment.

Idle Stop Control Working Conditions

• The driver fails to apply the parking brak e and the

signal is input from the alarm unit. (Note 1)

• The vehicle ran at or above 5 km/h.

• The vehicle is idling.

• The vehicle speed is 0 km/h.

• The shift lever is in the neutral position.

• The QWS switch is turned off.

• The engine coolant temperature is at least 10°C.

• The battery voltage is at least 22 V.

• DTC has not been detected.

Note 1: When all the following conditions are met, the

parking brake disengagement alarm unit outputs the

idle stop permit signal to the VIM.

• The idle stop main switch is turned on.

• The shift lever is in the neutral position.

• The parking brake is applied.

• The headlamps are turned off.

• Any of doors is opened.

Exhaust Brake Working Conditions

• The vehicle is running at or abo ve 5 km/h or faults

are not detected on the vehicle speed sensor.

• The exhaust brake switch is turned on.

• The engine is running at or above 50 0 rpm for at

least 1 second.

• The idle position switch is turned on and the gear

is engaged.

• The vehicle is not eq uipped with ABS/ASR or the

exhaust brake cut command is not sent from the

ASR.

• The vehicle is free from AP sensor fault, exhaust

brake circuit fault, clutch switch fault, neutral

switch fault, idle position switch fault, A/D

conversion fault (VIM), and CAN timeout (VIM).

Page 11

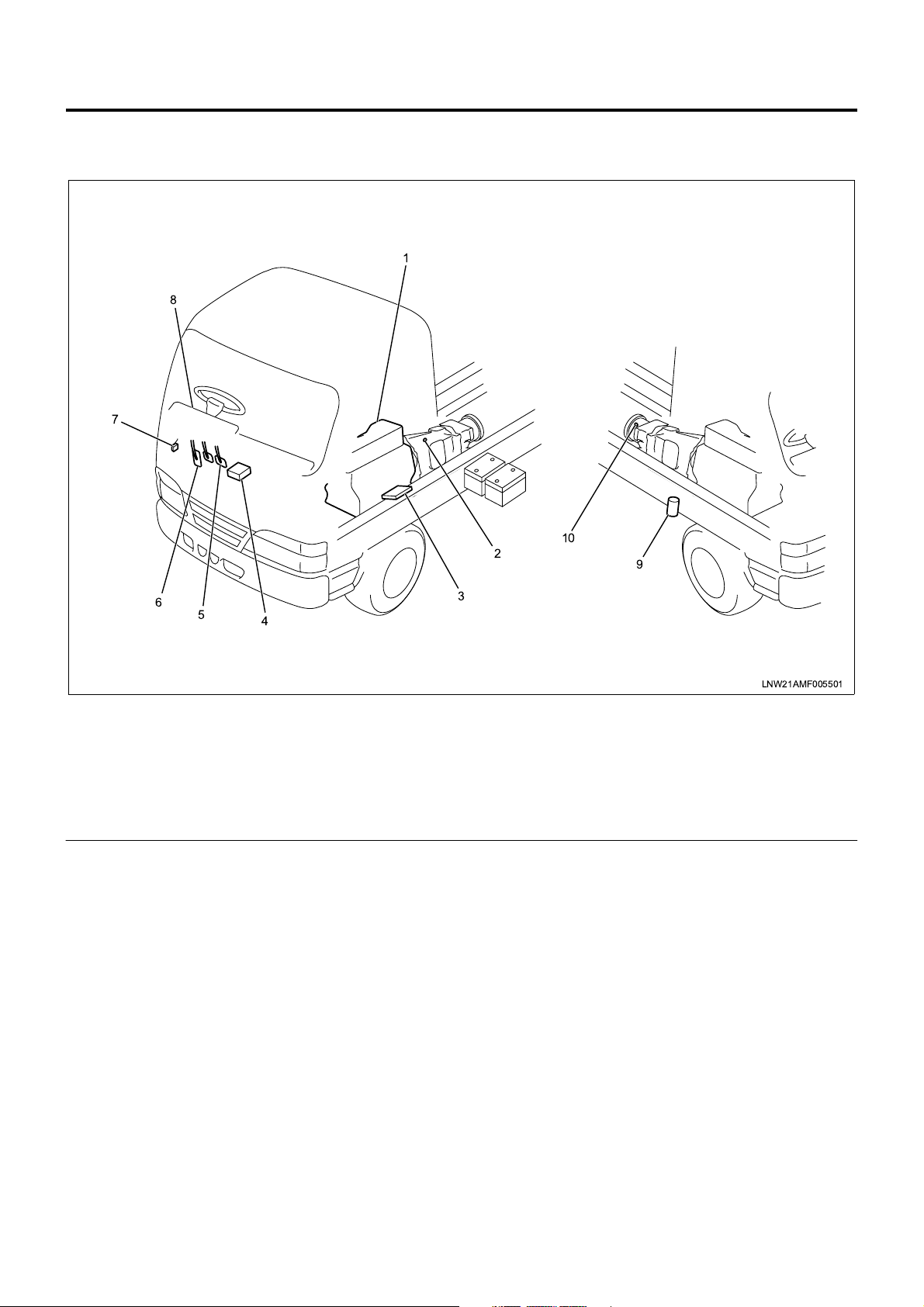

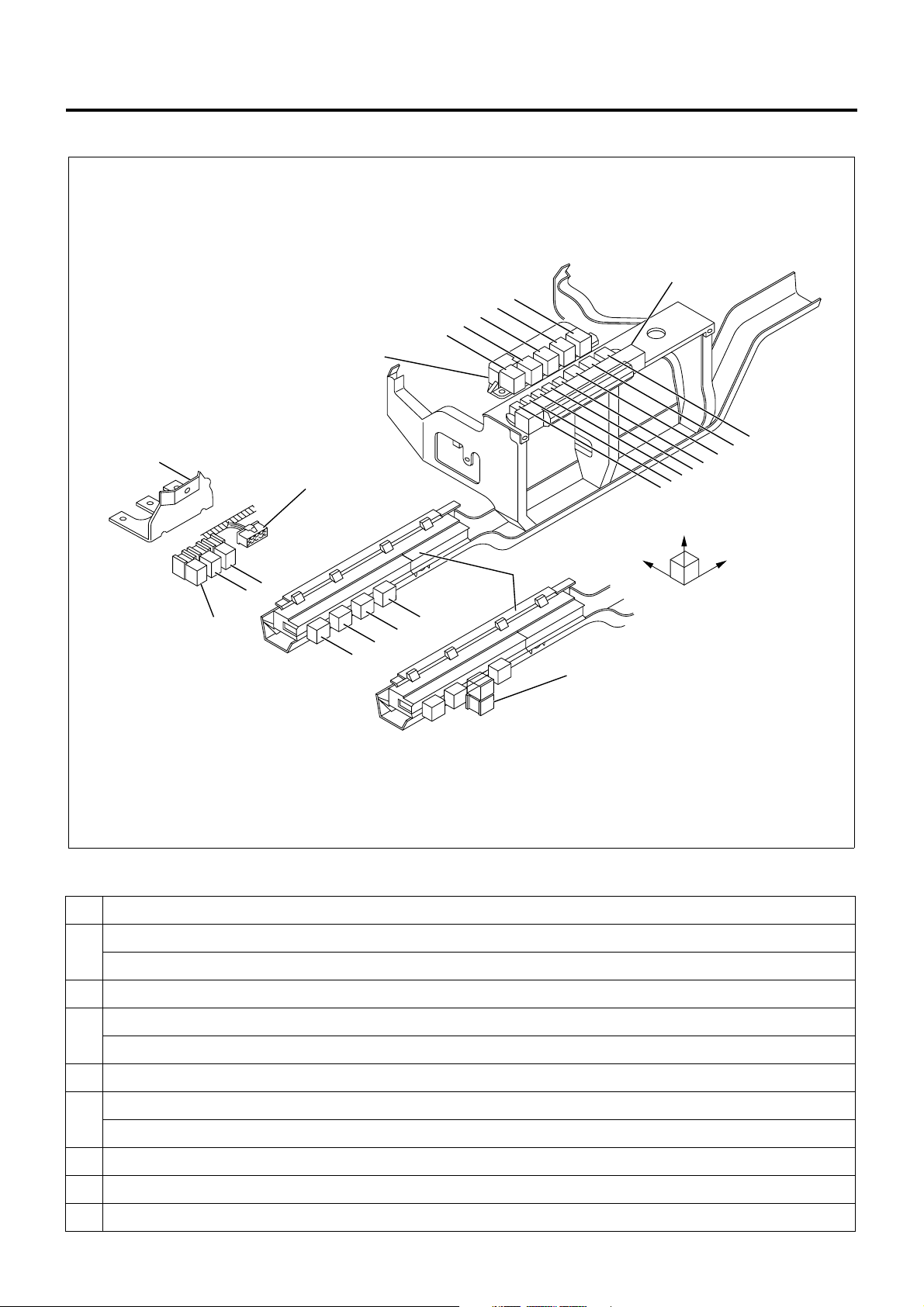

Powertrain System Components

Component Layout - Vehicle Side

8

7

Engine Control System 1A-9

1

6

5

4

Legend

1. Engine

2. Neutral switch

3. ECM (engine control module)

4. VIM (vehicle interface module)

5. Clutch pedal

2

10

3

6. Accelerator pedal

7. DLC (data link connector)

8. CHECK ENGINE lamp (MIL)

9. Exhaust brake solenoid valve

10. VS (vehicle speed) sensor

9

LNW21AMF005501

Page 12

1A-10 Engine Control System

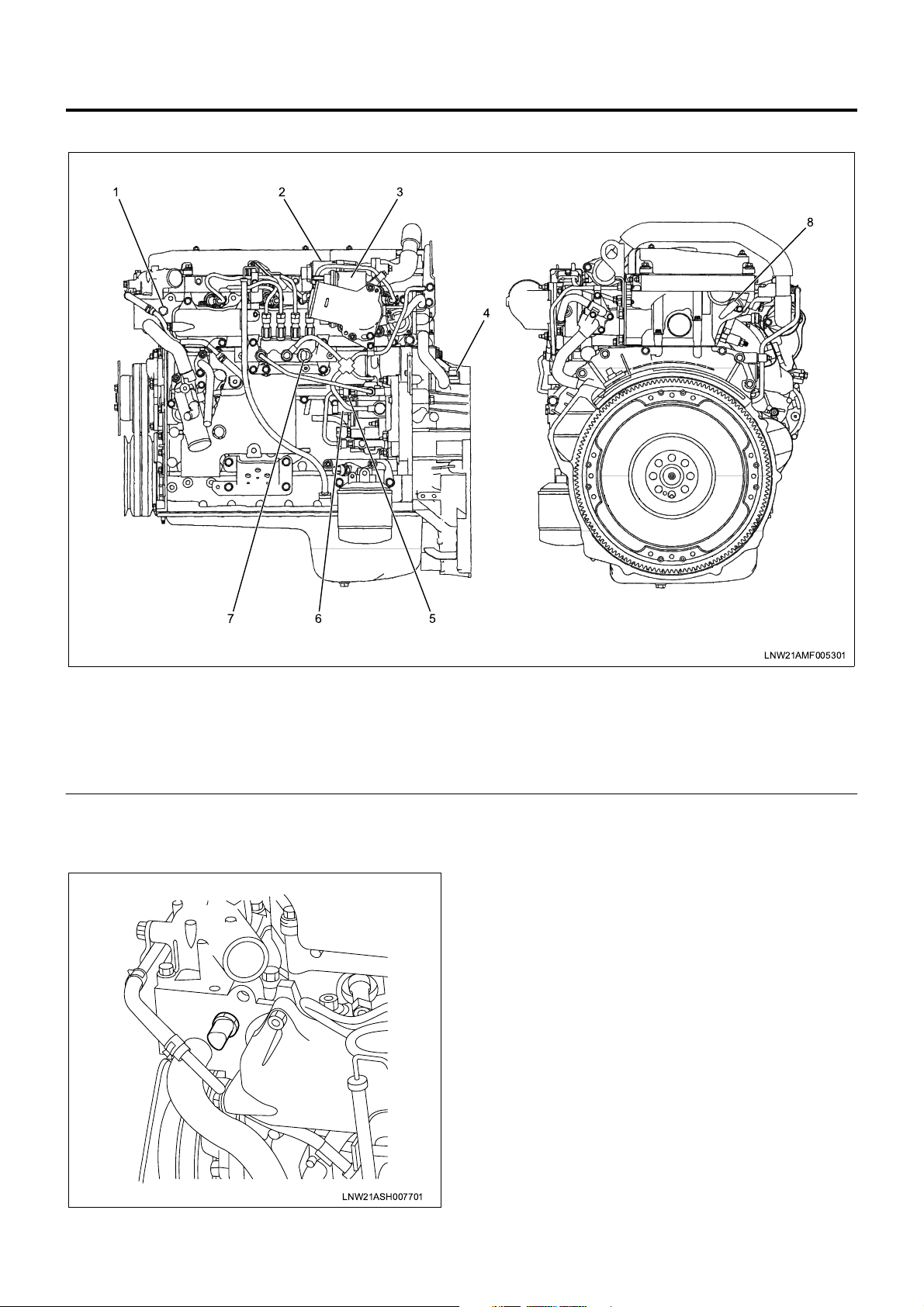

Component Layout - Engine Side

123

8

4

67

Legend

1. ECT (engine coolant temperature) sensor

2. EGR valve

3. Intake throttle valve

4. CKP (crank position) sensor

Function and Operation

ECT Sensor

5

LNW21AMF005301

5. FT (fuel temperature) sensor

6. SCV (suction control valve)

7. Common rail pressure sensor

8. CMP (cam position) sensor

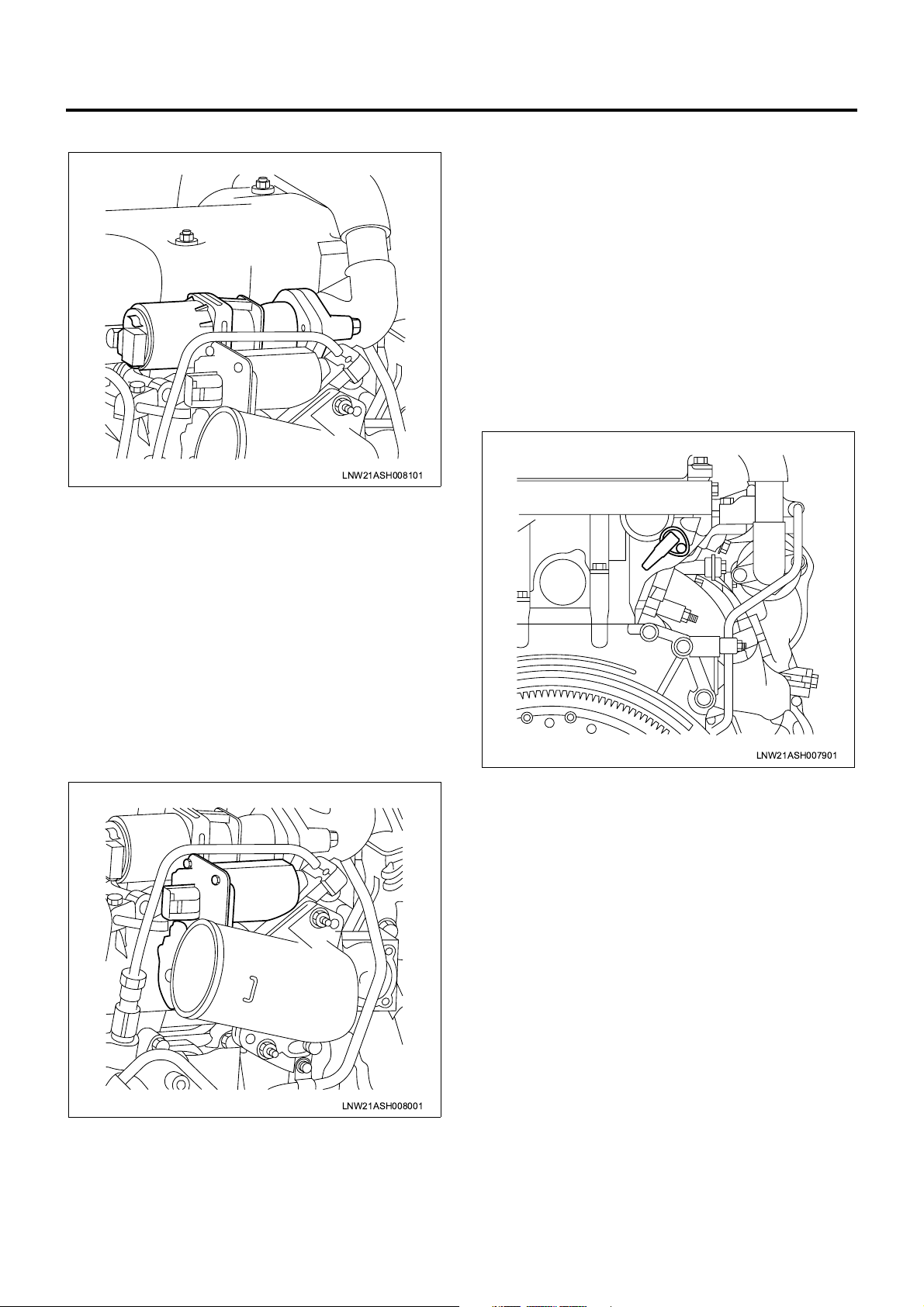

The ECT (engine coolant temperature) sensor is

installed to the thermosta t housing and the thermistor

in the sensor alte rs the resistance in response to the

temperature change. The resistance is decreased

when the coolant temperat ure is high while increased

when the temperature is l ow. The ECM supplies 5 V to

the ECT sensor via pull-up resistance and calculates

the engine coolant temperature from the change in

voltage and uses it in fuel injection control, EGR

control, and other control tasks. This voltage is

decreased when the resistance is large (the

temperature is high) while increased when the

resistance is large (the temperature is low).

LNW21ASH007701

Page 13

Engine Control System 1A-11

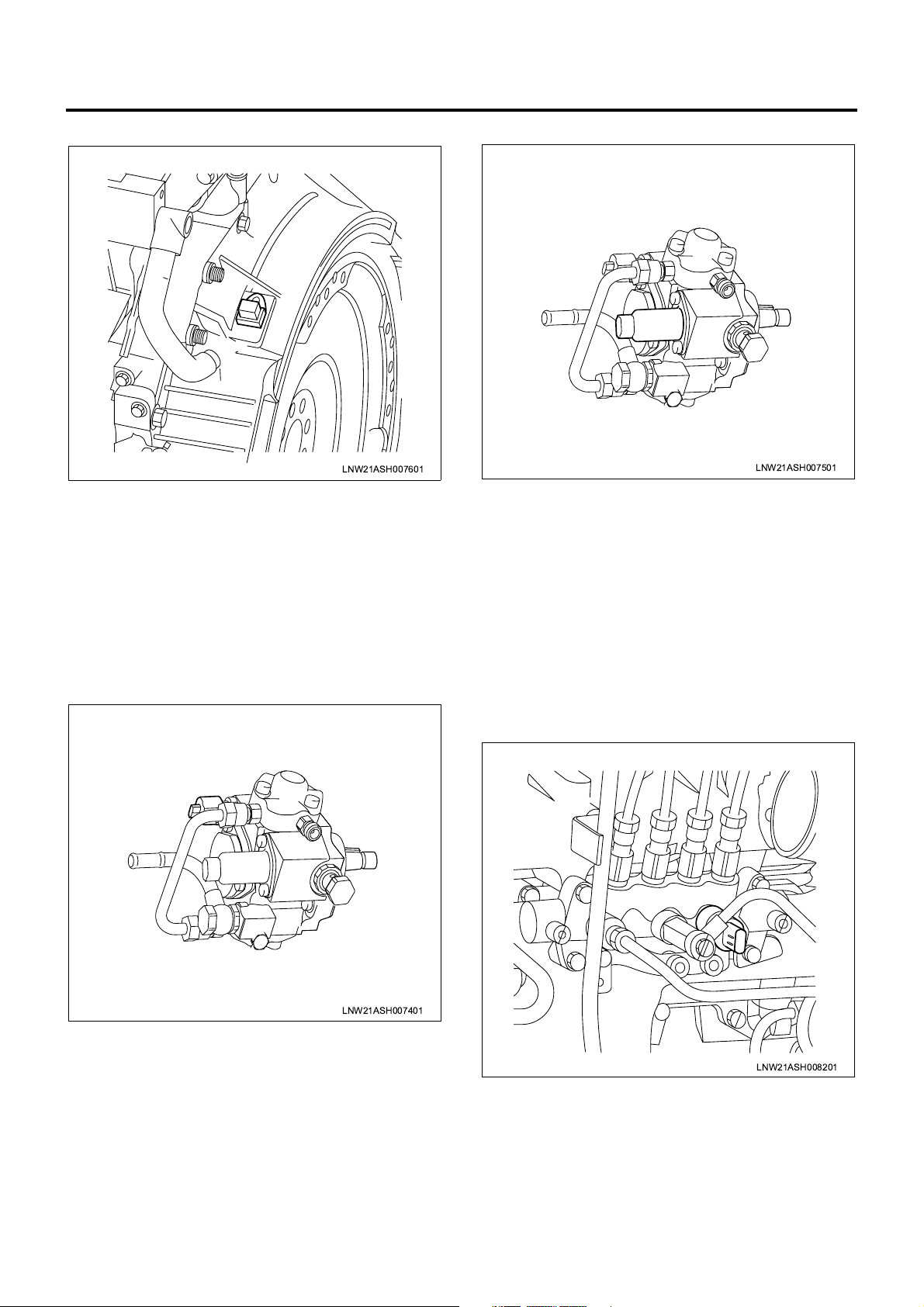

EGR Valve and EGR Valve Position Sensor

LNW21ASH008101

The EGR valve is installe d at the top of the inlet cov er

and operated by a DC motor. The DC motor operates

the EGR valve by changing the duty. The valve is

opened when the duty is inc reased while closed when

the duty is decreased. T he ECM c alculate s the desir ed

EGR valve opening based on the vehicle running

condition and controls the DC motor accordingly.

The EGR valve po sition senso r is installed to the EGR

valve and sends the voltage signal that w ill change in

response to the EGR va lve opening to the ECM. The

ECM calculates the desired EGR valve opening from

the voltage signal and uses the result in EGR control.

The intake throttle valve is installed to the intake throttle

and operated by a DC motor. The DC motor operates

the intake throttle valv e by changing the drive voltage.

The valve is closed when the drive voltage is increased

while opened when the voltage is decreased. The ECM

calculates the intake throttle valve opening based on

the vehicle running condition and controls the DC

motor accordingly.

The ITP (intake throttle pos ition) sensor is installed to

the intake throttle valve and sends the voltage signal

that will change in response to the throttle valve

opening to the ECM. The E CM calculates the throttle

valve opening from the voltage signal and uses the

result in intake throttle control.

CMP Sensor

Intake Throttle Valve and ITP Sensor

LNW21ASH007901

The CMP (cam position) sensor is installed to each

cylinder head and, when the hol e on the camsha ft gear

passes the sensor, a CMP signal is generated. The

ECM identifies the cylinder from the CMP signal as well

as CKP signal sent from the CKP sensor and

determines the cran k angl e, and u ses t his a ngle in fue l

injection control and engine speed calculation. These

tasks are usually perform ed based on the CKP signal

but if the CKP sensor fails, the CMP signal will

substitute for the CKP signal.

LNW21ASH008001

Page 14

1A-12 Engine Control System

CKP Sensor

LNW21ASH007601

The CKP (crank position) sensor is installed to the

flywheel housing and, when flywheel teeth pass the

sensor, a CKP signal is generated. The ECM ident ifies

the cylinder from the CKP s ignal as well as the CMP

signal sent from the CMP sensor and determines the

crank angle, and uses this angle in fuel injection control

and engine spe ed calculati on. These t asks are usually

performed based on the CKP signal but if the CKP

sensor fails, the CMP signal will substitut e for the C KP

signal.

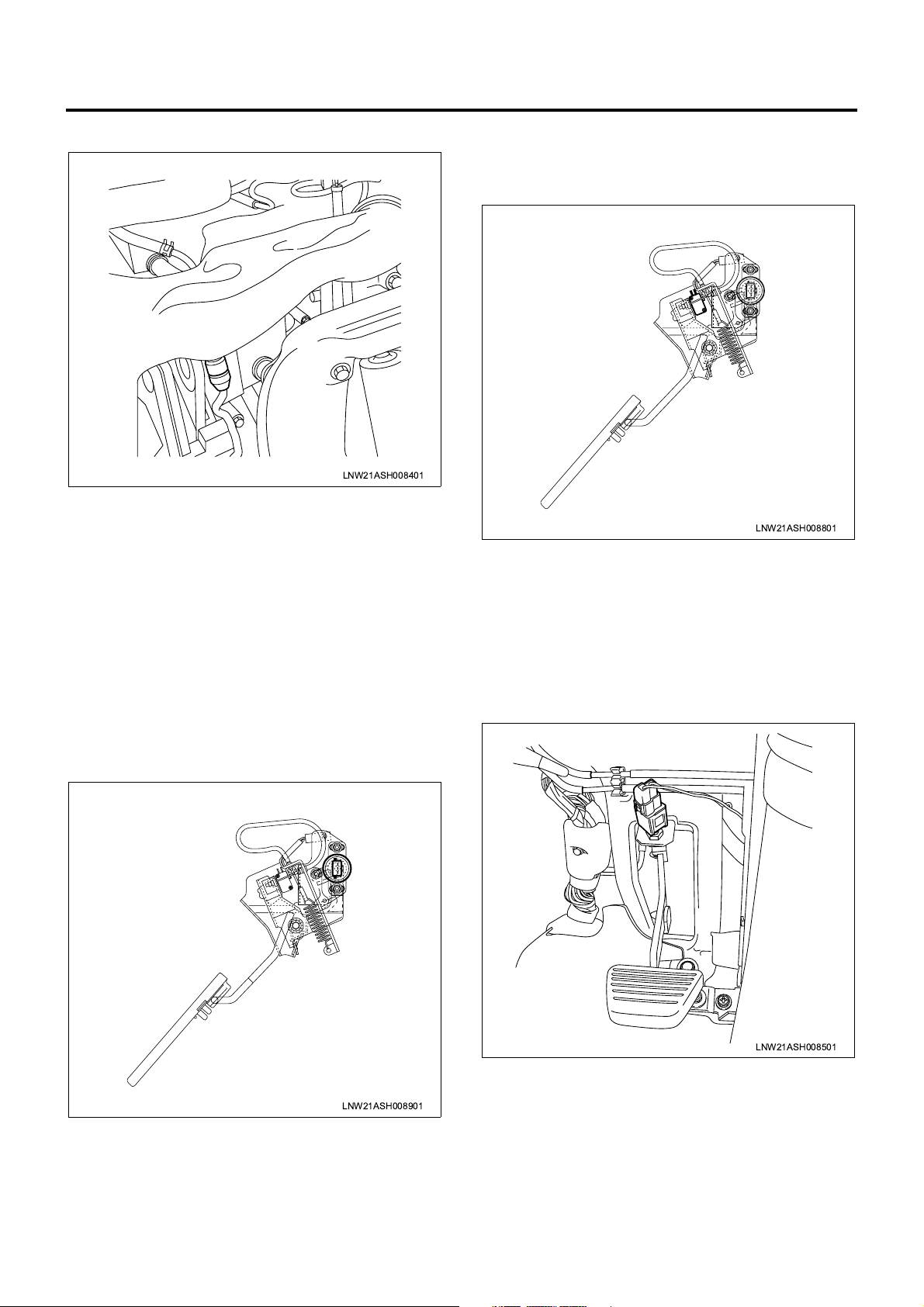

FT Sensor

SCV

LNW21ASH007501

The SCV (suction control valve) is installed to the

supply pump and controls the suction fuel quantity. The

SCV is fully opened in normal state and larger drive

voltage (duty) results in smaller opening. The ECM,

based on the data acquired from sensors, calculates

the desired common rai l pressure and pump flow rate

and compares the calculated desired common rail

pressure to the actual value to determine the SCV

opening. When the actual pressure is lower than the

desired value, the SCV is opened to increase the pump

flow rate. When the actual pr essure is higher than the

desired value, the SCV is closed to decre ase the flow

rate.

LNW21ASH007401

The FT (fuel temperature) sensor is installed to the

supply pump and the thermistor in the sensor alters the

resistance in res pon se to the te mpe ra tur e cha nge. The

resistance is decreased when the fuel temperature is

high while incr eased when the temper ature is low. The

ECM supplies 5 V to the FT sensor via pull-up

resistance and calculates the fuel temperature from the

change in voltage a nd uses it in supply pump control

and other control tasks. This voltage is decreased

when the resistance is smal l (the temperature is high)

while increased when the resistance is large (the

temperature is low).

Common Rail Pressure Sensor

LNW21ASH008201

The common rail pressure sensor is installed to the

supply pump, and detects the fuel pressure in the

common rail, converts the pressure into a voltage

signal, and sends the signal to the ECM. Higher

common rail pressure provides higher voltage while

lower pressure provides lower voltage. The ECM

calculates actual common rai l pressure (f uel pressure)

from the voltage signal and uses the result in fuel

injection control and other control tasks.

Page 15

Engine Control System 1A-13

IAT Sensor

LNW21ASH008401

The IAT (intake air temperature) sens or is installed to

the intake air duct and the thermistor in the sensor

alters the resistance in response to the temperature

change. Higher intake air tem per at ure pr ov id es sm a ller

resistance while lo wer intake air temperature prov ides

larger resistance. The ECM supplies 5 V to the IAT

sensor via pull- up resistance a nd calculates the intake

air temperature from the change i n voltage and us es it

in fuel injection control and other control tasks. The

voltage is decrease d when the resistan ce is small (the

temperature is high) while increased when the

resistance is large (the temperature is low).

voltage signal for us e in fuel inje ction con trol and o ther

diversified control tasks.

Idle Position Switch

LNW21ASH008801

The idle position switch is installed to the accelerator

pedal, and is turne d off when the pedal is presse d and

turned on when the pedal is released. The ECM

receives the on/off signal fro m this idle position switch

for use in exhaust brake control, warm-up control, and

other control tasks.

Clutch Switch

AP Sensor

LNW21ASH008901

The AP (accelerato r pedal position) s ensor is installed

to the top of the accelerator pedal and supplies the

voltage signal that will change in response to

accelerator pedal angle to the ECM. The ECM

calculates the accelerator pedal position from the

LNW21ASH008501

The clutch switc h is i ns tal led to th e c lu tc h p eda l, and i s

turned on when the pedal is pressed and turned off

when the pedal is release d. The VIM receives the on/

off signal from this clutch switch for use in exhaust

brake control and other control tasks.

Page 16

1A-14 Engine Control System

VS Sensor

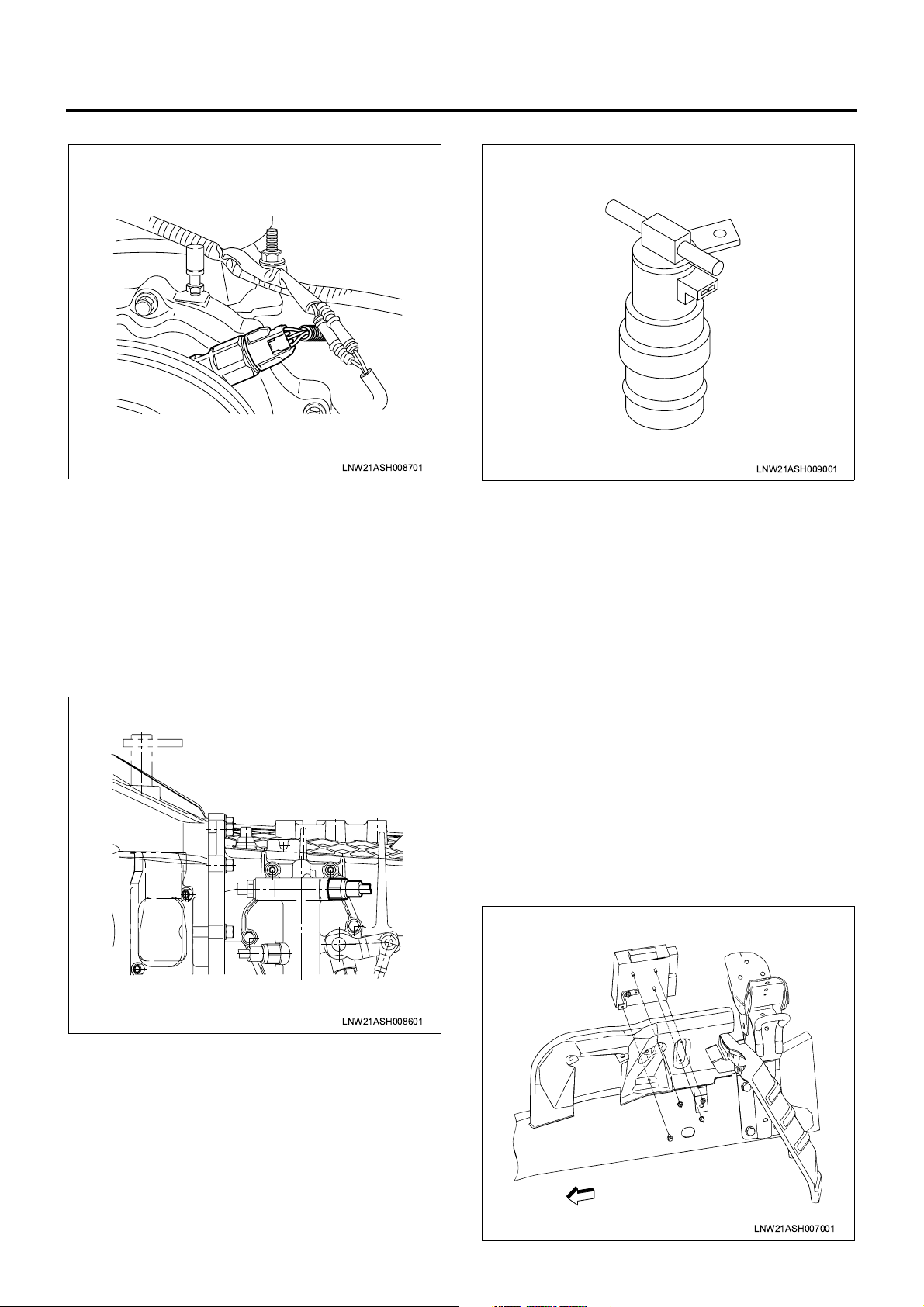

LNW21ASH008701

The VS (vehicle speed) sensor is installed to the

transmission. T he sensor is also equipped with a Hall

effect circuit. The magne t mounted to th e transmis sion

output shaft is rotated together with the shaft to

generate a magnetic field. This Hall effect sensor

interacts with the magnetic field and generates and

sends a signal to the VIM . The VS sens or is ener gized

via meter fu se . T he VI M us es VS s i gn al pu ls es t o j ud g e

the vehicle speed.

Neutral Switch

Exhaust Brake Solenoid Valve

LNW21ASH009001

The exhaust brake solenoid valve is installed to the

rear of the right front wheel frame (s ome vehicle types

have different positions), and opens and closes the

vacuum path connected to the exhaust brake valve.

When this solenoid valve is turned on, the path is

opened and the vacuum is applied to the exhaust brake

valve. When the solenoid valve is turned off, the path is

closed and the atmospheric pressure is applied and

resultantly the exhaust brake valve is released. After

the exhaust brake s witch is turned on and the vehicle

meets all the nece ssary conditions, the E CM turns on

the exhaust brake solenoid valve.

LNW21ASH008601

The neutral switch (P/N switch in case of automatic

transmission) is installed to the transmission (shift lever

in case of automatic transmission), and is turned on

when the shift lever is moved to the neutral position.

The ECM receives the on/off signal from this neutral (or

P/N) switch to control the powertrain so that the dri ver

cannot start the engine as long as the shif t lever is not

in the neutral (or parking) position.

Atmospheric Pressure Sensor

The atmospheric pressure sensor is installed inside the

VIM and converts the atmospheric pressure into a

voltage signal. The VIM calculates the atmospheric

pressure from the voltage signal and sends the result to

the ECM. The ECM u ses this atmosp heric pressure to

calibrate the fuel injection quantity (altitude

compensation).

ECM

LNW21ASH007001

Page 17

Engine Control System 1A-15

The ECM is installed in the inner par t of the engine lef t

side cover. The ECM uses sign als s en t fr om di ve rsified

sensors to control tho se sys tems direc tly rela ted to the

engine, for example, fuel injection control, intake

throttle control, EGR control, and QWS control.

VIM

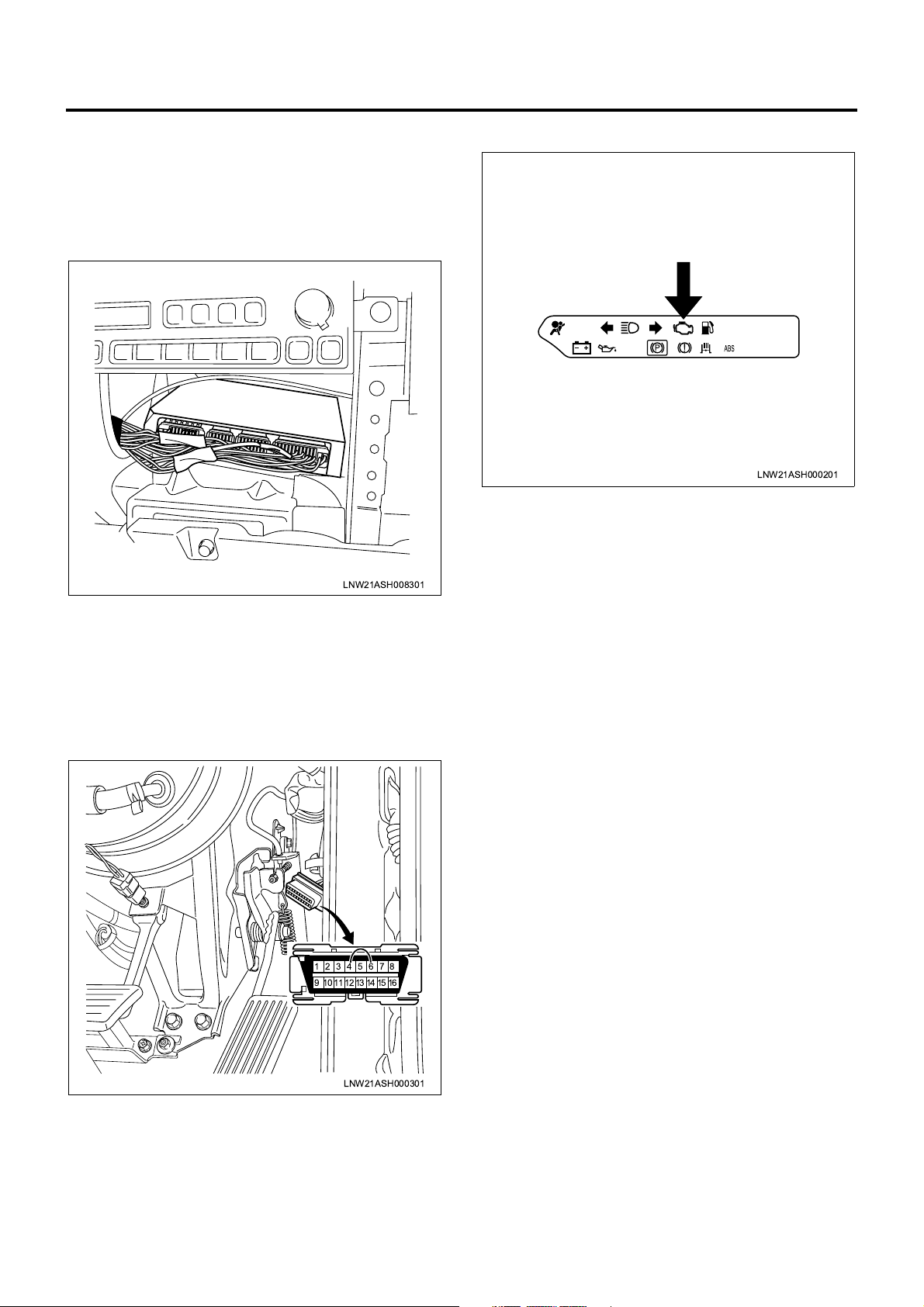

LNW21ASH008301

The VIM is installed inside the center console in the

cab, and transmits signals sent from diversified

switches and sensors and drives powertrain actuators

such as exhaust brake, relays, and warning lamps

according to the commands from the ECM.

CHECK ENGINE Lamp (MIL)

LNW21ASH000201

The CHECK ENGINE lamp (MIL) is built in the meter

panel and informs th e driver of faulty status of e ngine

or associated syst ems. When the ECM detec ts a fault

by means of its diagnostic function, this CHECK

ENGINE lamp is turned on. A fter the diagnostic sw itch

is turned on (DLC pins are shorted), the CHECK

ENGINE lamp blinks to inform the mechanic of

detection of DTC.

DLC

87654321

161514131211109

LNW21ASH000301

DLC (data link connec tor) is installed to the da sh side

pane of the driver ’s seat and acts as a communicat ion

interface between external diagnostic tool and onboard controllers. The DLC can also function as a

diagnostic switch and when DLC pins are shorted , this

diagnostic switch is turned on.

Page 18

1A-16 Engine Control System

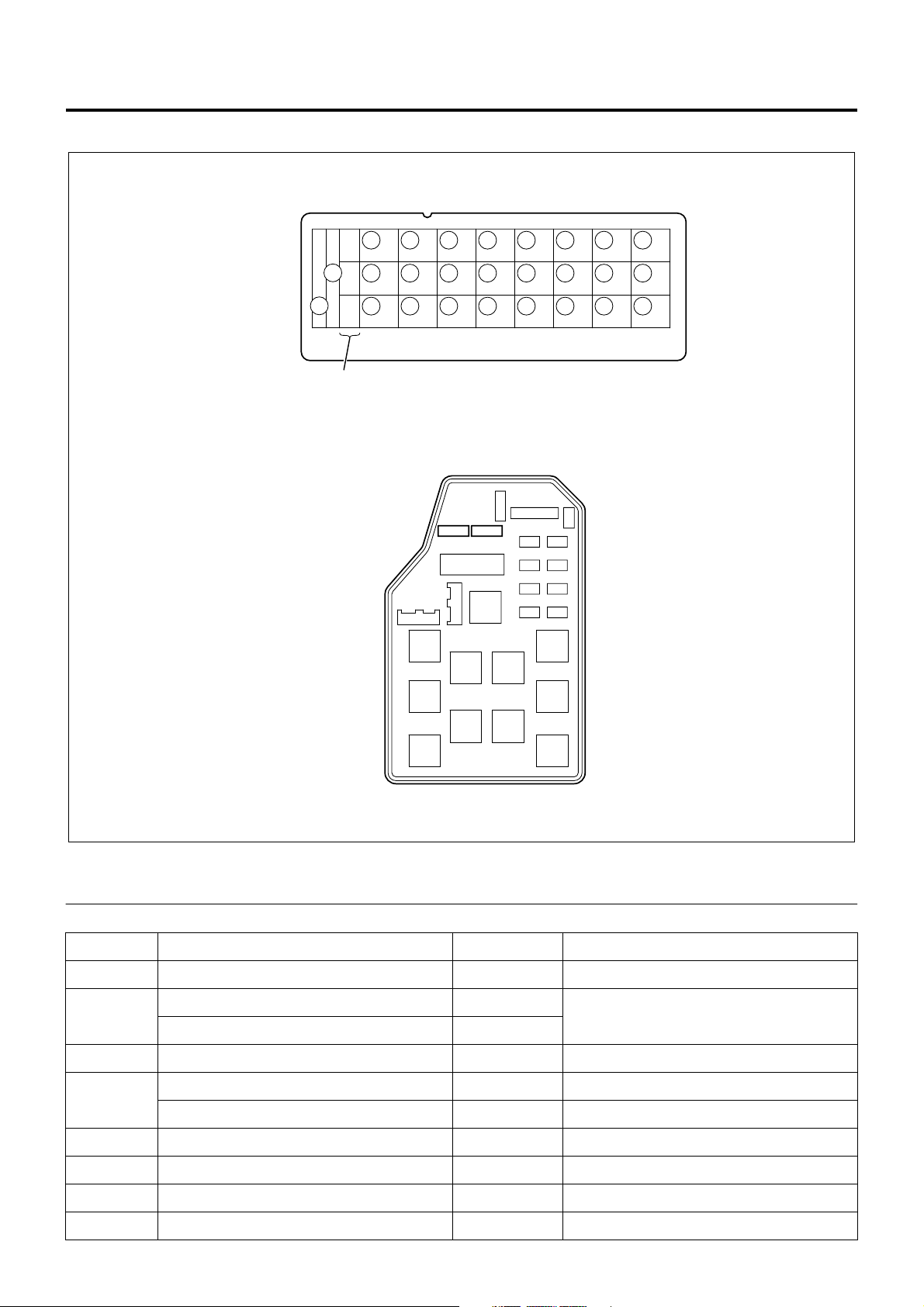

Fuse Layout

[Fuse Box Label, In Glove Box]

22

19

16

13

10

1

4

7

25

23

26

[Fuse Box, Front Left of Radiator]

24

1

20

21

17

18

27 28

14

15

11

12

2

5

8

6

9

3

LNW21ALF000401-X

Legend

1. Spare fuse

No. Indication on label Capacity Devices connected

1 CONTROLLER 10A Control unit

HAZARD,HORN (12V) 15A

2

Hazard warning flashing lamp, horn

HAZARD,HORN (24V) 10A

3—10A—

AIR CON (12V) 10A Air conditioner

4

HEATER,AIR CON (24V) 15A Heater, air conditioner

5 FUEL, SEAT HEATER (24V) 10A Fuel, seat heater

6 ABS, HAB, RETARDER (24V) 15A ABS, HAB, retarder

7 ROOM LAMP 15A Room lamp

8 STOP LAMP 10A Stop lamp

Page 19

Engine Control System 1A-17

No. Indication on label Capacity Devices connected

9 POWER WINDOW (24V) 20A Power window

10

11 FOG.CORNER 10A Fog lamp, cornering lamp

12 ELEC.PTO (24V) 10A PTO switch (electric PTO)

13 WIPER,WASHER 15A Wiper, window washer

14 TURN 10A Turn signal lamp

15

16

17 MIRROR 10A Electrically operated mirror

18 CIGAR,AUDIO 10A Cigarette lighter, audio

19

20

21 AIR BAG 10A SRS airbag

TAIL.ILLUMI (12V) 15A

Tail lamp

TAIL.ILUMI (24V) 10A

GENERATOR (12V) 15A Generator

ELEC.PTO (24V) 20A PTO solenoid valve (electric PTO)

MIRROR HEAT (12V) 10A Heated side mirror

ENG.CONT (24V) 15A ECM

METER (12V) 10A

Meter

METER (24V) 15A

ENGINE STOP (12V) 10A Engine stop

HSA (24V) 10A HSA

22 STARTER 10A Starter

23 H/LAMP RH 10A Headlamp, RH

24 H/LAMP LH 10A Headlamp, LH

25

26 POWER WINDOW (12V) 30A Power window

External Fuse Box

No. Indication on label Capacity Devices connec te d

27 MARKER LAMP 10A Marker lamp

28 COND FAN 10A Condenser fan

HEATER (12V) 30A Heater

ENG CONTROLLER (24V) 30A ECM (except for turbocharged vehicles)

Page 20

1A-18 Engine Control System

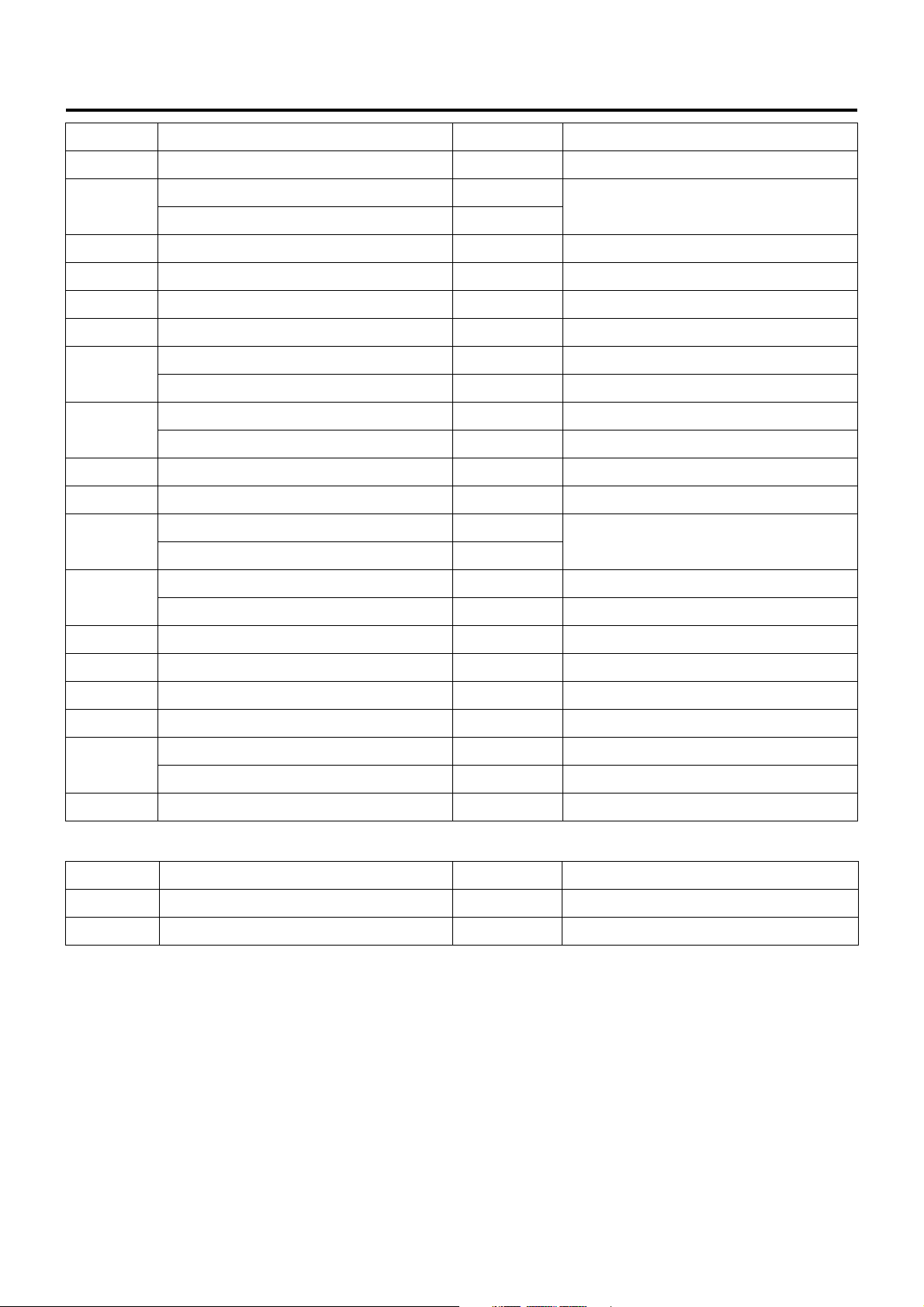

Relay Layout

Relay Box No.2

Bracket

Spare Power Circuit

18

16

15

14

13

Relay Box No.1

8

7

6

5

Upper

12

11

10

9

20

19

Cooler Relay

1

4

3

2

No. Legend

12 V: On relay

1

24 V: C harge relay

2 Horn relay

Fuse &

Relay Box

RightFront

17

LNW21ALF006101-X

12 V: ABS, VSV, FICD, EXH brake, valve (12 V)

3

24 V: Headlamp relay

4Tail relay

12 V: Headlamp relay

5

24 V: 4WD relay

6 Dimmer relay

7 Power window relay

8 Fog lamp relay

Page 21

No. Legend

9 Cornering lamp relay

10 Air conditioner thermo relay

12 V: C harge relay

11

24 V: Key on relay

12 Heater & air conditioner relay

24 V: PTO cut relay for electric PTO in fire engine (MT)

24 V: PTO solenoid relay for electric PTO (AT)

12 V: Exhaust brake cut relay (MT)

13

24 V: Idle on relay for fire engine (AT)

24 V: Idle stop, wiper relay (with CFS (clutch free system))

24 V: PTO solenoid relay for electric PTO (MT)

24 V: PTO buzzer relay for electric PTO (AT)

12 V: OD off relay (AT)

14

24 V: Idle keep relay for fire engine (AT)

Engine Control System 1A-19

24 V: Idle stop, radio relay (with CFS)

24 V: PTO main relay for electric PTO (MT)

24 V: Garbage relay for garbage collector (AT)

15

24 V: Indicator lamp relay for fire engine (AT)

24 V: Idle stop, engine control module relay (with CFS)

4WD relay

16

24 V: Idle stop, mirror relay (with CFS)

24 V: Full automatic air conditioner, high relay

17

24 V: Automatic air conditioner, high relay

24 V: Shift lock relay for fire engine (AT)

24 V: Shift relay for fire engine (AT)

18

24 V: PTO main relay for electric PTO (MT)

19 24 V: PTO solenoid relay for electric PTO (MT)

20 24 V: PTO cut relay for electric PTO (MT)

Page 22

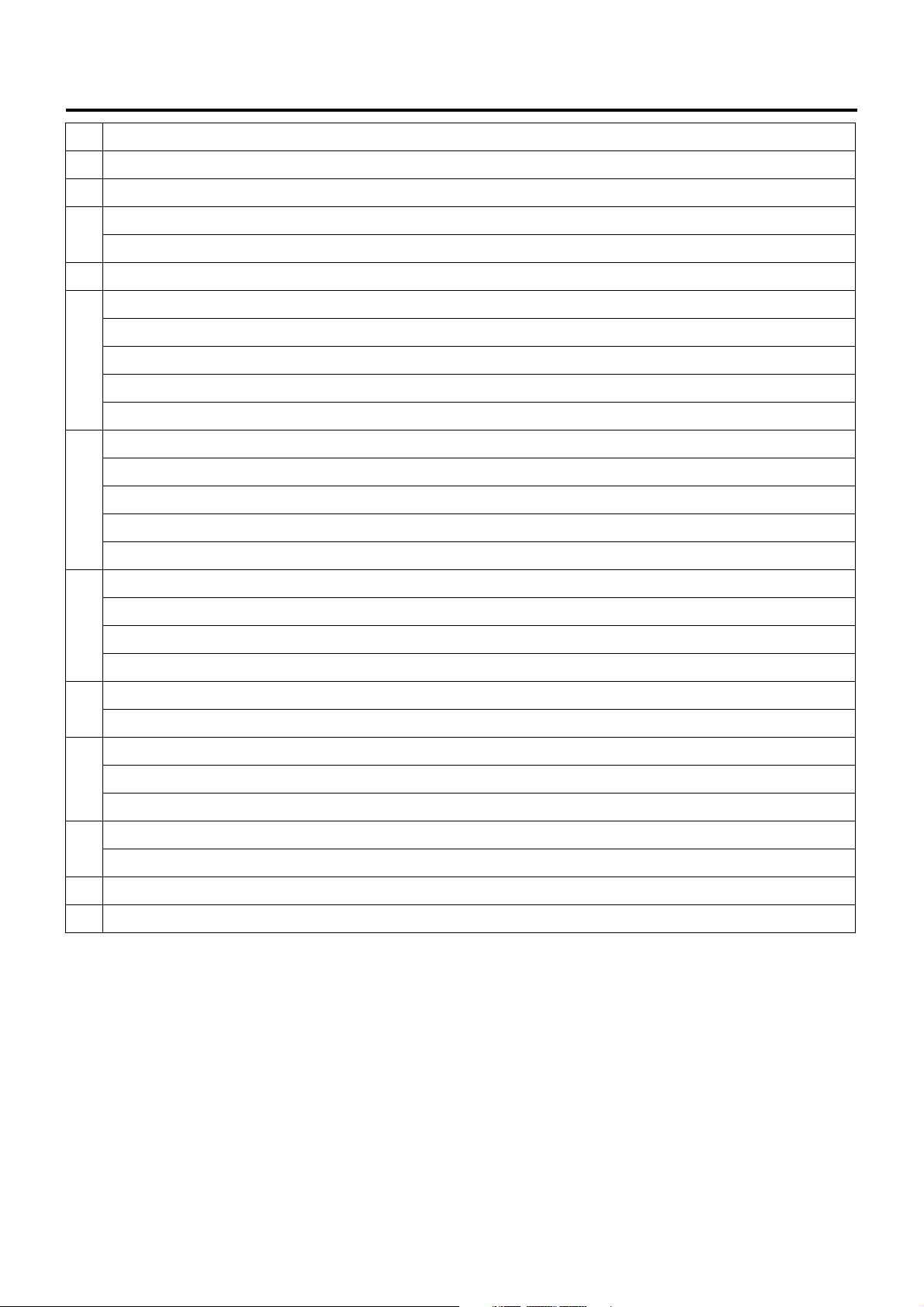

1A-20 Engine Control System

Circuit Diagram

ECM Circuit Diagram

Starter

Switch (ON)

SBF

60A

100A

SBF

Battery

Intake

Throttle

DC Motor

ITP

Sensor

EGR

DC Motor

Starter

Switch (ST)

SBF

50A

SBF

60A

SBF

50A

M+

M-

M+

M-

#19

15A

#22

10A

SBF

30A

M

M

Starter

Relay

Glow

Plug

Main Relay

CHECK ENGINE

A/C Condenser

A/C Magnetic

Cut Relay

To Starter

Lamp

Clutch

Starter

Glow

Relay

0.75B/O 0.5L

0.5Y/B

0.75W/R

0.5B/W

0.5B/R

0.5W/G

1.25W/R

1.25W/R

1.25W/R

0.5L/Y

0.5L/Y

0.75W/G

0.75R

0.5G/Y

0.75W/B

0.75L/Y

109 90

99

13

113

102

98

114

115

116

117

118

16

ECM

35

69

59

58

84

94

108

110

49

46

48

91

83

80

81

74

75

43

42

24

23

88

112

0.5L/W

0.5L/R

0.5B/Y

0.5W/L

0.5R/B

0.5G/W

0.5R/G

0.85L/B

0.85O

0.75W/R

0.75W/R

0.75L

0.75L

1.25W

1

2

1.25L/W

0.75G/W

0.75B

1.25R

4

5

1.25L/R

0.75W/Y

0.75L

0.5SB

0.5GR/W

Idle Position Switch

Scan Tool Communication

Diagnostic Switch

AP

Sensor

ECT

Sensor

FT

Sensor

IAT

Sensor

SCV

Cylinder 1 Injector

Cylinder 4 Injector

Cylinder 3 Injector

Cylinder 2 Injector

DLC

EGR Valve

Position

Sensor

Common Rail

Pressure

Sensor

CKP

Sensor

CMP

Sensor

0.5Y

0.5W

0.5G

0.5G

0.5R

0.5W/R

0.5W/L

0.5L/R

0.5L/W

0.5B

68

0.5R

63

67

66

64

25

6

8

27

26

89

97

87

95

119

120

121

0.5W

0.5B

0.85B

1.25B

1.25B

1.25B

VIM

0.5B

LNW21AXF002601-X

Page 23

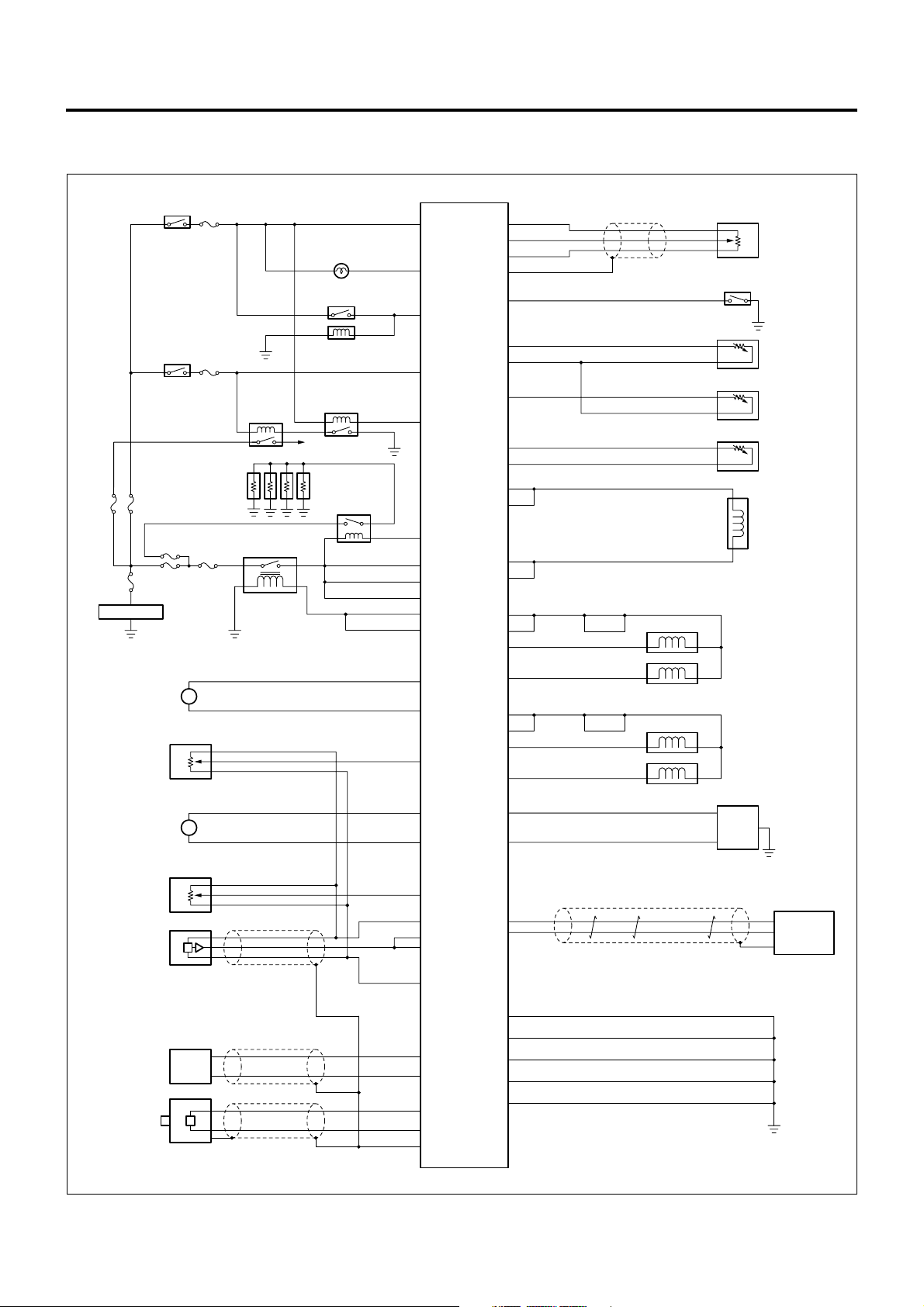

VIM Circuit Diagram

Engine Control System 1A-21

SBF

50A

SBF

100A

Battery

Starter SW (ON)

Starter SW (ST)

SBF

SBF

30A

50A

#19

15A

Exhaust

Brake Lamp

Exhaust

Brake Solenoid

PTO Lamp

PTO SW

#22

Main Relay

10A

Glow Lamp

ECO Relay

Clutch SW

Exhaust Brake SW

Warm Up SW

M/T : N A/T : P or N

Freezer SW

CFS Non Vehicle

PTO ECU

CFS Vehicle

CFS

0.85B/O

0.3BR/W

0.5LG/B

0.5V/W

0.5B/W

1.25W/R

1.25W/R

1.25W/R

0.3O/L

0.5G/Y

0.5W/L

0.5LG/R

0.5BR/R

0.5B/G

0.5L/B

36

0.5B/R

4

2

7

46

38

75

76

16

0.3B/G

53

0.3LG/B

56

18

59

17

15

19

57

54

0.5BR

0.5B/R

0.3B/L

0.5G/Y

0.5G

0.5L/R

0.5LG

A/T ECU

Tachometer

ABS/ASR

ECU

Sound Alarm

(Simplified ISS)

CFS ECU

42

3

49

50

12

44

47

V I M

27

26

48

0.5W

0.5R

0.5B

0.5G/W

Lamp

Fail Relay

ECM

Brake SW

+B

Stop

Lamp Relay

Other ECU

PTO

Accelerator

Sensor

Idle Up

Volume

VS Sensor

0.5Y/BR

0.5Y/G

0.5R/B

0.5Y

0.5Y/G

9

0.5SB

24

34

31

71

30

14

0.5B

73

0.85B

60

0.85B

39

0.85B

52

0.85B

66

Diagnostic SW

DLC

Scan Tool Communication

LNW21AXF002301-X

Page 24

1A-22 Engine Control System

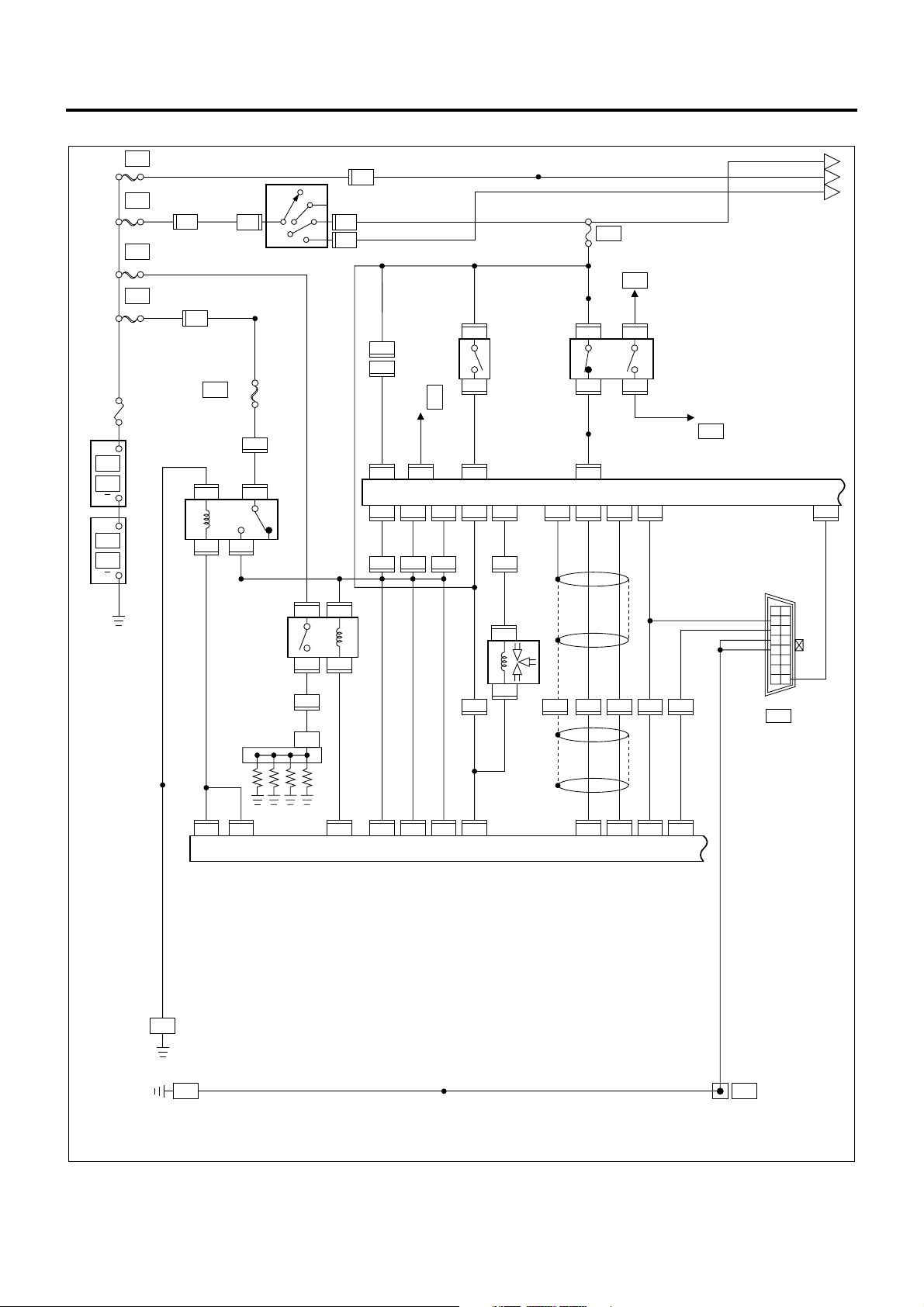

ECM/VIM Circuit Diagram (1/5)

MAIN

KEY

GLOW

ECM

2L

+

P-1

P-2

+

P-3

P-4

Frame

SBF-1 80A/100A

SBF-2 50A

3 W/L

SBF-3 60A

SBF-5

50A

3 W/G 3 W/G

0.5

B

B-67

B-67

1

H-6

3

4

3B/Y

3B/W

5 W/B 5 W/B 3 W/B

OFF

ACC

H-7

B-67

21

3 W/L

ON

B

ST

Starter Switch

2

H-7

F-25 30A

ENG.CONT

X-18

Main Relay

X-182X-18

0.5

L/Y

0.5

L/Y

117

J-191

3

5

W/R

Glow Plug

0.5

L/Y

3

J-191

W/G

W/G

W/G

3

2

2

118

H-4

X-18

0.3

B/O

1

B-355

B-354

1

Air Bleed Connector

0.3

J-191

0.85

B/O

98

P

10 49

B-352

B-349

38

1.25

W/R

H-4

Glow Relay

1.25

W/R

114

J-191

0.5

LG/L

B-352

B-34975B-349

1.25

W/R

8

H-4 H-4

1.25

W/R

J-191

9

3

B/L

1

3

0.5

B/L

W/R

2

X-224X-22

X-225X-22

3

3

B/G

2

H-105

3

0.5

B/G

W/G

E-3

B/O

B-258 (2)

CFS Control Unit

W/L

76

1.25

0.85

W/R

B/O

67

0.85

B/O

1.25

0.75

W/R

B/O

0.75

B/O

115

116

J-191

0.5

0.5

B-352

B-349

J-191

B-89

B-89

H-5

109

1

2

49

36

0.5

LG/B

0.5

LG/B

8

0.5

B/O

Clutch Switch

B-352

2

19

H-4

2

J-31

J-31

1

B-350

0.5

B

Exhaust Brake

Solenoid Valve

ECM

F-16 15A

ENG. CONT

PTO Cut Relay

B/O

B/O

0.5

0.5

B-216 (4)

0.5

R/Y

21

B-89 B-89

Clutch PTO Switch

B-894B-89

3

0.5

0.5

G/O

B/O

0.5

B/O

49

B-352

VIM

B-350

B-350

B-350

26

65

0.5R0.5

W

4

H-413H-412H-48H-81H-8

0.5R0.5

W

97

J-19189J-19188J-191

24

27

0.5

LB

0.5

GR/W

J-191

PTO Solenoid M/T Relay

B-64 (3)

0.5 LB

0.5 GR/W

0.5 B

0.5 B

Diagnostic Connector

0.85

B

112

12345678

B-79

A

C

B

B-352

9

10111213141516

0.5 L

9

Left Side Frame

Right Frame (Front)

3

B

J-9

(Center)

B-274

3 B 1.25 B

6

8

B-274

Joint Connector

LNW21AXF002701-X

Page 25

Engine Control System 1A-23

ECM/VIM Circuit Diagram (2/5)

Charge Relay

0.3

B

0.5

LG/R

B-35166B-349

B-352

39

3B/Y

X-1

Idling Stop &

Warm Up Switch

(10A)Fuse

F-10

52

(4)

B-172

Joint

Connector

0.3

B/R

0.5

B

35

B-31 B-31

B-312B-31

6

0.5

LG/R

12

TAIL,ILLUMI

B-352

B-35073B-349

60

3B/W

67

1.25B

8

F-10

GND

B-274

Warm Up Switch

(10A)Fuse

VIM

B-349

71

F-19

Meter

1

2

Joint

Connector

31

H-5

0.85

B/Y

0.5

B/Y

1

J-50

J-50

2

0.5

B/G

14

H-4

0.5

B/G

44

B-352

SIG SIG5VGND

B-34934B-349

31

15A

B-172

Neutral

Switch

(M/T)

TCM

B-47

(JATCO)

0.3

W/L

0.3

W/L

44

B-352

12

Inhibitor Switch

(AISIN)

NP

J-69

J-69

5

W/L

W/L

0.5

0.5

0.5

W/R

20

H-4622H-46

0.5

W/R

7

X-33

X-33

6

8

Diode

X-33

9

0.5

B/G

44

B-352

B-349

30

A

3W/B

C

B D

12

X-12 X-12

X-12

3

5

B/R

FUEL, SEAT HEATER

0.5

B/R

0.5

5

B/R

B-69

B-69

2

0.5

LG/R

50

B-352

X-12

10A

F-5

Switch

Exhaust Brake

0.5W/R

Heater & A/C

Relay

4

0.5B 0.5B

0.5

BR

62

B-319 B-319

B-3195B-319

3

12

TAIL,ILLUMI

B-352

B-352

47

0.85

0.5

L/B

0.5

0.85

B

B

B

B

B

0.5

0.85

0.85

0.5

0.5Y0.5

Y/BR

B-2821B-3253B-282

R/B

1

PTO Accelerator Sensor

0.5

0.5

Y/BR

Y/G

1

B-2812B-2813B-281

Idle Control Switch

0.5

R/B

Y/BR

55

0.5

Y/BR

1

J-1662J-166

0.5Y0.5

H-4H-8

0.5Y0.5

R/B

73

H-8 H-8

0.85

R/B

J-166

L/B

3

J-7

1

PTO Accelerator Sensor

Compressor

Left Frame (Front)

B-346

LNW21AXF002801-X

Page 26

1A-24 Engine Control System

ECM/VIM Circuit Diagram (3/5)

D

3B/W

0.5

B/W

F-22

STARTER

10A

0.5B/W

E

B-259 6

CFS C/U

0.5

B/W

B-352

B-351

0.3

B/L

H-8

0.3

B/L

J-1778J-17719J-17720J-177

0.5

L/R

46

B-351

B-35117B-351

15

19

12

7

B/R

0.5

LG/W

0.5

H-8

G/Y

11

G/Y

57

0.5

18

H-817H-8

0.5

EHCU

G/B

0.3

B-351

B-229 5 (AISIN)

TCM

18

B-47 20 (JATCO)

TCM

B/G

0.3

B-351

B-229 23 (AISIN)

TCM

53

B-47 13 (JATCO)

TCM

0.3

LG/B

B-351

B-230 7 (AISIN)

TCM

56

B-47 8 (JATCO)

TCM

B-52 8 (Tachometer)

Meter

0.5

LG

59

B-351

0.3

LG

B-229 1 (AISIN)

TCM

0.5

LG

B-48 4 (JATCO)

TCM

B-259 1

CFS

X-15 3

B-147 3 (Idling Stop)

Parking Warning Unit

Idling Stop ECM Relay

0.5

LG

0.5

0.5

G

G/Y

54

B-3513B-352

VIM

B-351

14

0.5

BR

0.5

BR

Y/G

0.5

B-52 17 Speed Meter

Meter

B-35242B-352

0.3

BR/W

J-32 3

Speed Sensor

4

0.3

O/L

B-51 6 EXH Brake W/L

B-52 15 Glow Indicator Lamp

Meter

0.5

W/O

B-352

11

B-259 19

CFS C/U

B-352

48

0.5

G/W

X-3 2

Stop Lamp Relay

B-352

7

0.5

V/W

B-84 2

B-66 2

PTO Switch (M/T)

Stop Lamp Switch

B-77 1

Dump Control Switch

Meter

LNW21AXF002901-X

Page 27

ECM/VIM Circuit Diagram (4/5)

Engine Control System 1A-25

E F

0.5B/W

Injector

E-5 (1)

E- 11154E- 11119E- 111

22

0.5

0.5

0.5

R/B

0.5

Y/B

R/G

G/W

0.5

G/W

1

E-902E-902E-931E-931E-116

E-90

3

0.5

G/W

Fuel

Temperature

(FT) Sensor

Meter

B-52 (5)

No.2 No.3 No.4 No.1

E-115

6

0.75

L

E- 11133E- 11134E- 11117E- 11112E- 11129E- 11146E- 11145E- 111

0.75

W/R

0.75

W/R

16

0.75

0.75

L

W/R

Suction Control

Valve (SCV)

0.75L0.75

0.75

L

E-116

0.75

0.75

W/G

0.75

E-114

E-114

R

L/Y

0.75

L/Y

3

Intake Throttle DC Motor

6

R

0.75

R

2

E-1153E-1158E-1155E-1151E-1154E-115

0.75

W/Y

E-115

E- 1114E- 111

2

7

0.75

0.75

1.25

1.25

L/R

R

2426

G/W

B

ECM

E- 1111E- 11156E- 11136E- 11137E- 11152E- 11118E- 11135E- 111

0.75

W/B

0.75

E-94

E-94

L/Y

G/Y

W

4

E-1142E-1141E-1141E-982E-98

Intake Throttle

4

Position (ITP)

Sensor

EGR DC Motor

6

39

0.5

0.5

0.5

R

0.5

0.5

W/L

W/R

Crank Position

(CKP) Sensor

Magnetic Clutch

3013793215

0.5

W

0.75

W/R

13

E- 111

E- 111

2

0.5

Y

EGR Position

Sensor

E- 11138E- 111

21

0.5G0.5

0.5

R

W

1.25

1.25

L/W

W

E- 111E- 111E- 111E- 111E- 111E- 111

0.5

0.5

0.5

B

L/W

L/R

3

E-1122E-1121E-943E-942E-943E-1132E-1131E-113

Cam Position

(CMP) Sensor

E- 111

E- 111

455

0.5

G

0.5G0.5

R

Common Rail

Pressure Sensor

LNW21AXF003301-X

Page 28

1A-26 Engine Control System

ECM/VIM Circuit Diagram (5/5)

F

0.5

B/W

Accelerator Sensor

B-2802B-2801B-280

3

Meter

B-51 5

(CHECK ENGINE Lamp)

Right Frame (Front)

B-274

0.5

L

30

H-5

0.5

B/W

113

J-191 J-191

ECM

J-191

102

0.5

B/R

Starter

Cut Relay

X-26

J-191

110

0.5

W/L

2

H-8

0.5

W/L

1

B-75

Accelerator

Pedal

Switch

B-75

2

0.5

B

10

1.25

B

B-172

6

Joint

Connector

3

3B

10

H-4

H-43H-42H-4

0.5

L

0.5

B/Y

108

J-19190J-191

5V GNDSIG 5V SIG

J-191

J-191

95

0.75

1.25

B

B

121

L/R

L/W

1

0.5

0.5

L/R

L/W

94

84

J-191

J-191

J-191

J-191

J-191

120

119

87

0.5

1.25

1.25

B

B

B

0.85

J-190

O

J-191

IAT Sensor

2

83

J-190

1

0.5

L/B

91 99

J-191

0.5

0.5

0.5

Y/B

4

H-8

0.5

Y/B

Left Frame (Center)

J-9

LNW21AXF003101-X

Page 29

Component Layout

Engine Control System 1A-27

56

55

54

53

52

51

50

49

48

47

41,42,43,44,45,46

40

57

39

32

31

1

2,3

4

5

6

7

8

9

25

24

10

12

11

13

14

15

16

17

Legend

33,34,35,36,37,38

26,27,28,29,30

23

22

21

20

1 B-172 Joint connector

2 X-12 Heater and air conditioner relay (825/151)

3 X-33 Diode (810/002)

4 B-349, 350, 351,

VIM (826/646)

352

5 J-31 Exhaust brake magnetic valve (156/086)

6 J-50 Neutral switch (230/171)

7 J-166 PTO accelerator sensor (101/867)

8 P-5 Frame ground

9 P-1 & P-2 Battery

10 P-3 & P-4 Battery (24 V)

11 E -3 Glow plug (011/010)

12 E-115 Injector (040/031)

13 E-113 Common rail pressure sensor (040/21 1)

14 E-94 EGR vacuum sensor (057/667)

14 E-94 EGR valve (057/001)

15 E-114 Intake throttle position sensor (025/373)

18

19

LNW21ALF006301

Page 30

1A-28 Engine Control System

15 E-114 Intake throttle motor (025/373)

16 E-98 Crank position sensor (826/648)

17 E-112 Cam position sensor (040/001)

18 E-96 Timing control valve (040/001)

18 E-111 ECM (060/613)

19 H-105 Intermediate connector

20 J-190 IAT sensor (060/820)

21 E-116 Su ction co ntr ol valv e (040/001)

22 E-93 Fuel temperature sensor (040/205)

23 E-90 Engine coolant temperature sensor (060/129)

24 J-69 Inhibitor switch (249/001)

25 J-9 Left frame (center) ground

26 F-5 Fuel seat heater fuse (810/005)

27 F-16 ENG.CONT fuse (810/005)

28 F-19 Meter fuse (810/005)

29 F-22 Starter fuse (810/005)

30 F-25 Engine controller (main) fuse (810/005)

31 B-346 Left frame (front) fuse

32 J-7 Compressor connector

33 SBF-1 Main slow blow fuse (810/174)

34 SBF-2 Key switch slow blow fuse (810/174)

35 SBF-3 Glow slow blow fuse (810/174)

36 SBF-5 ECM slow blow fuse (810/174)

37 X-18 Main relay (828/531)

38 X-22 Glow relay (060/046)

39 J-177 EHCU (350/089)

40 B-274 Right frame (front) ground

41 H-4 Intermediate connector

42 H-5 Intermediate connector

43 H-7 Intermediate connector

44 H-8 Intermediate connector

45 H-6 Intermediate connector

46 H-46 Intermediate connector

47 B-354 Air ve nt conn ec tor

47 B-355 Air ve nt conn ec tor

48 B-89 Clutch switch (825/021)

49 B-67 Starter switch (431/103)

50 B-69 Exhaust brake switch (825/001)

51 B-79 Diagnostic connecto r (DL C)

52 B-75 Accelerator switch (101/079)

53 B-280 Accelerator position sensor (101/243)

54 B-282 & B-325 PTO accelerator connector

55 B-281 Idle up position switch (101/262)

56 B-51 & 52 Meter warning (821/001)

57 B-31 Warm-up switch (825/423)

Page 31

Connector List

Engine Control System 1A-29

No. Connector face

B-31

B-51

B-52

1

9 10111213 14 151617181920

1 23

456

123

45

No. Connector face

87654321

B-79

006-024

5678234

020-024

005-025

B-89

B-172

1

1221331441551661771881992010211122

161514131211109

016-033

1

2

002-011

022-005

B-67

B-67

B-69

B-69

241

3

1 2

34

8

1526374

B-274

004-035

B-280

004-015

1523674

B-281

008-028

8

008-021

B-282

123

123

123

000-012

003-098

003-064

003-015

B-75

12

002-022

B-325

2 1

002-015

Page 32

1A-30 Engine Control System

No. Connector face

B-346

38 37 28

B-349

367435733472337132703169306829

76 75 66

2765266425632462236122

B-350

B-351

215920581957185617551654155314

No. Connector face

E-90

000-037

67

022-025

60

012-054

52

016-067

E-93

E-94

E-98

12

3

003-095

12

002-208

1423

5

005-034

1 2

002-178

B-352

B-354

B-355

E-3

13 12 3

1110987654

51 50 41240139

49 48 47 46 45 44 43 42

1

1

1

026-013

001-003

001-034

001-029

E-111

E-112

E-113

E-114

17

18

19

20

21

22

23

9

10

6

7

44

45

63

64

11

8

46

65

12

13

14

15

16

36 37 38 39 40 41 42 4328 29 3025 26 27 31 32 33 34 35

55

56

57

47

48

49

50

51

52

53

66

67

68

69

54

70

71

72

73

58

74

75

76

77

24

54

59

60

78

79

3

61

62

21

80

81

081-001

123

003-097

123

003-111

14253

6

006-084

Page 33

Engine Control System 1A-31

No. Connector face

E-115

E-116

H-4

H-4

1526374

1 2

9876

2019 18 17 1651415413312211110

12345

1011 12 13 1415

6789

1718 19 20

16

No. Connector face

8

008-046

J-31

J-50

002-178

J-177

020-002

J-177

020-001

12

12 11 10 9 8 7 6 5 4 3

22 21 20 19 18 17 16 15 14 13

34 33 32 31 30 29 28 27 26 25

12

12

3456789101112

13 1415 16 17 18 19 20 21 22

252423 26 27 28 29 30 31 32 33 34

21

24

002-008

002-210

034-001

23

034-002

H-46

H-46

H-105

J-9

123 456

7 8 9 10 11 12 13 14

15 16 17 18 19 20 21 22

1

2

34 56

113

112

111

110

109

108

107

123456

78912 11 101314

15161720 19 182122

022-013

J-191

121 120 1 19

118 117

116 115 114

105

97

89

104

96

88

103

95

87

102

94

86

101

93

85

100

92

84

99

91

83

106

98

90

82

040-004

P-1

022-012

(24V)

000-028

P-2

006-005

(24V)

000-029

P-3

000-012

(24V)

000-029

Page 34

1A-32 Engine Control System

No. Connector face

P-4

(24V)

P-5

(24V)

1

24

X-12

X-18

3

5

1

2

345

000-028

000-021

005-012

005-023

H-5

H-6

123

789

13 14 15

19 20 21

25 26 27

31 32 33

34 35 36 37

1

456

10 11 12

16 17 18

22 23 24

28 29 30

38 39 40

2

H - 6

654

12 11 10

18 17 16

24 23 22

30 29 28

40 39 38

2

34353637

LNW21ASH010801

1

321

987

15 14 13

21 20 19

27 26 25

33 32 31

X-33

X-22

123

78910 11412513614

1

23

4

5

014-003

005-013

12

1234

5678

910111213

14 1516 17 18

H - 7

H - 8

21

4321

8765

13 1211 10 9

18 1716 15 14

LNW21ASH010901

Page 35

H-7 H-8

Engine Control System 1A-33

ECM Pinouts

1

2

12

1234

5678

910111213

14 1516 17 18

H - 6

H - 7

H - 8

2

1

21

4321

8765

13 1211 10 9

18 1716 15 14

LNW21ASH010901

123

789

13 14 15

19 20 21

25 26 27

31 32 33

34 35 36 37

456

10 11 12

16 17 18

22 23 24

28 29 30

38 39 40

654

12 11 10

18 17 16

24 23 22

30 29 28

40 39 38

321

987

15 14 13

21 20 19

27 26 25

33 32 31

34353637

LNW21ASH010801

LNW21ALF004501

Page 36

1A-34 Engine Control System

45

3

12

2423222120191817161514131211109876

43 42 41 40 39 38 37 36 35 34 33 32 31 30 29 28 27 26 25

62 61 60 59 58 57 56 55 54 53 52 51 50 49 48 47 46 45 44

81 80 79 78 77 76 75 74 73 72 71 70 69 68 67 66 65 64 63

106107108109110111 112113

98 99

100101102103104105

90 91 92 93 94 95 96 97

82 83 84 85 86 87 88 89

119 120

117

114 115

121

118

116

LNW21ASF002001

81-Way Connector (Engine side)

Pin No. Connected to Pin No. Connected to

1 Inj ec tors #1 and #3 42 Injector #3 (cylinder 4)

2 Inj ec tors #1 and #3 43 Injector #1 (cylinder 1)

3— 44 —

4 Inj ec tors #2 and #4 45 —

5 Injectors #2 and #4 46 Sensor ground (ECT, FT)

6 CKP sensor (–) 47 —

7 — 48 FT sensor signal

8 CMP sensor signal 49 ECT sensor signal

9— 50 —

10 — 51 —

11 — 52 —

12 — 53 —

13 Air conditioner 54 —

14 — 55 —

15 — 56 —

16 Intake throttle DC motor (+) 57 —

17 — 58 EGR DC motor (–)

18 — 59 EGR DC motor (+)

19 — 60 —

20 — 61 —

21 — 62 —

22 — 63 5 V sensor power (ITP, common rail

pressure, EGR)

23 Injector #4 (cylinder 2) 64 5 V sensor ground 1 (ITP)

24 Injector #2 (cylinder 3) 65 —

Page 37

Engine Control System 1A-35

Pin No. Connected to Pin No. Connected to

25 CKP sensor (+) 66 Common rail pressure sensor signal

26 Shield ground (CMP, CKP, common rail

pressure)

27 CMP sensor ground 68 EGR valve position sensor signal

28 — 69 ITP sensor signal

29 — 70 —

30 — 71 —

31 — 72 —

32 — 73 —

33 — 74 SCV (LO)

34 — 75 SCV (LO)

35 Intake throttle DC motor (–) 76 —

36 — 77 —

37 — 78 —

38 — 79 —

39 — 80 SCV (HI)

40 — 81 SCV (HI)

41———

67 Common rail pressure sensor signal

40-Way Connector (Vehicle side)

Pin No. Connected to Pin No. Connected to

82 — 102 Starter cut relay

83 5 V sensor power 2 (IAT) 103 —

84 AP sensor signal 104 —

85 — 105 —

86 — 106 —

87 Casing ground 107 —

88 DLC (Tech 2 communications) 108 Shield ground (AP)

89 VIM (CAN communications) 109 Starter switch (ON)

90 5 V sensor power 2 (AP) 110 Idle position switch

91 IAT sensor signal 111 —

92 — 112 DLC (diagnostic switch)

93 — 113 Starter switch (ST)

94 5 V sensor ground 2 (AP) 114 ECM power

95 Signal ground 115 ECM power

96 — 116 ECM power

97 VIM (CAN communications) 117 Main relay

98 Glow relay 118 Main relay

Page 38

1A-36 Engine Control System

Pin No. Connected to Pin No. Connected to

99 CHECK ENGINE lamp 119 ECM power ground

100 — 120 ECM power ground

101 — 121 ECM power ground

VIM Pinouts

LNW21AMF005101

Page 39

Engine Control System 1A-37

312

45

40

414939

42 4643 474544

1312

11971086

48

50 51

14

53

52 5554

20 2115 191816 17

5956 5857

25 26246427

22

6260236361

28

29 3632 33 3430 3531

65

68 69 70 7167 746676

37 38

7372

75

LNW21ASF001901

26-Way Connector

Pin No. Connected to Pin No. Connected to

1 — 39 VIM power ground

2 Exhaust brake solenoid valve 40 —

3 ECO (power save) relay 41 —

4 Exhaust brake lamp 42 Glow lamp

5—43—

6 — 44 Neutral (P/N) switch

7PTO switch45 —

8 — 46 Starter switch (ST)

9 DLC (diagnostic switch) 47 Freezer switch

10 — 48 Stop lamp switch

11 — 49 Clutch switch

12 Warm-up (QWS) switch 50 Exhaust brake switch

13 — 51 —

16-Way Connector

Pin No. Connected to Pin No. Connected to

14 VS sensor signal 52 VIM power ground

15 ABS/ASR controller 53 AT controller

16 AT controller 54 Voice alarm unit (idle stop)

17 ABS/ASR controller 55 —

18 AT controller 56 AT controller

19 ABS/ASR controller 57 ABS/ASR controller

20 — 58 —

21 — 59 AT con tr oll er

Page 40

1A-38 Engine Control System

12-Way Connector

Pin No. Connected to Pin No. Connected to

22 — 60 S ign al gr oun d

23 — 61 —

24 DLC (Tech 2 communic atio ns) 62 —

25 — 63 —

26 ECM (CAN communications) 64 —

27 ECM (CAN communications) 65 Shield ground (CAN communications)

22-Way Connector

Pin No. Connected to Pin No. Connected to

28 — 66 VIM power ground

29 — 67 —

30 Idle up volume 68 —

31 PTO accelerator sensor signal 69 —

32 — 70 —

33 — 71 5 V sensor ground 1 (PTO, IDL UP)

34 5 V sensor power 1 (PTO, IDL UP) 72 —

35 — 73 Casing ground

36 Starter switch (ON) 74 —

37 — 75 VIM power

38 VIM power 76 VIM power

Strategy-Based Diagnostics

Strategy-Based System Diagnostics

The system diag nostic is a unifo rm approach to repai r

all electrical/electronic (E/E) systems. In the E/E

system, different from genera l vehicle problems, faults

frequently occur along the steps shown as follows.

1. Initial stage:

• A single fault occurs for a short while and,

therefore, the customer may miss it. In this

stage, the customer complaint is unclear and

the fault cannot be reprod uced. But, the ECM

may have stored the fault.

= Past fault

2. Middle stage:

• A single fault occurs for a short while but is

observed intermittent ly. It always occurs und er

certain conditions. The customer complaint

(description of fault) is clear but fault

occurrence conditions are unidentified. If you

comprehend these conditions, you can

reproduce the trouble.

= Intermittent fault (intermittent)

3. Realistic fault:

• The fault occurs certainly and the customer

complaint is realistic and clear. You can

reproduce the fault. However, there may exist

two or more causes.

= Current fault

The diagnostic flo w can always be use d to resolve an

E/E system problem and is a starting point when

repairs are necessa ry. The fo llowing steps will instr uct

the technician how to proceed with a diagnosis:

1. Verify the customer complaint:

• To verify the customer complaint, the technician

should know the normal operation of the

system.

2. Perform preliminary checks:

• Conduct a thorough visual inspection.