Page 1

iRobot® Create

OPEN INTERFACE

www.irobot.com

Page 2

Table of Contents

iRobot Create® Open Interface Overview .................................................3

Physical Connections ..............................................................................4

Mini-DIN Connector ...............................................................................4

Cargo Bay Connector ............................................................................4

Serial Port Settings ................................................................................5

iRobot Create Open Interface Modes .......................................................6

Open Interface Command Reference........................................................7

Getting Started Commands ...................................................................7

Mode Commands .................................................................................7

Demo Commands .................................................................................8

Actuator Commands .............................................................................9

Input Commands ..................................................................................13

Script Commands .................................................................................15

Wait Commands ...................................................................................15

iRobot Create Open Interface Sensor Packets .........................................17

iRobot Create Open Interface Commands Quick Reference .......................22

iRobot Create Open Interface Sensor Packets Quick Reference ................24

2iRobot Create Open Interface (OI) Specification

Page 3

iRobot Create

®

Open Interface

Overview

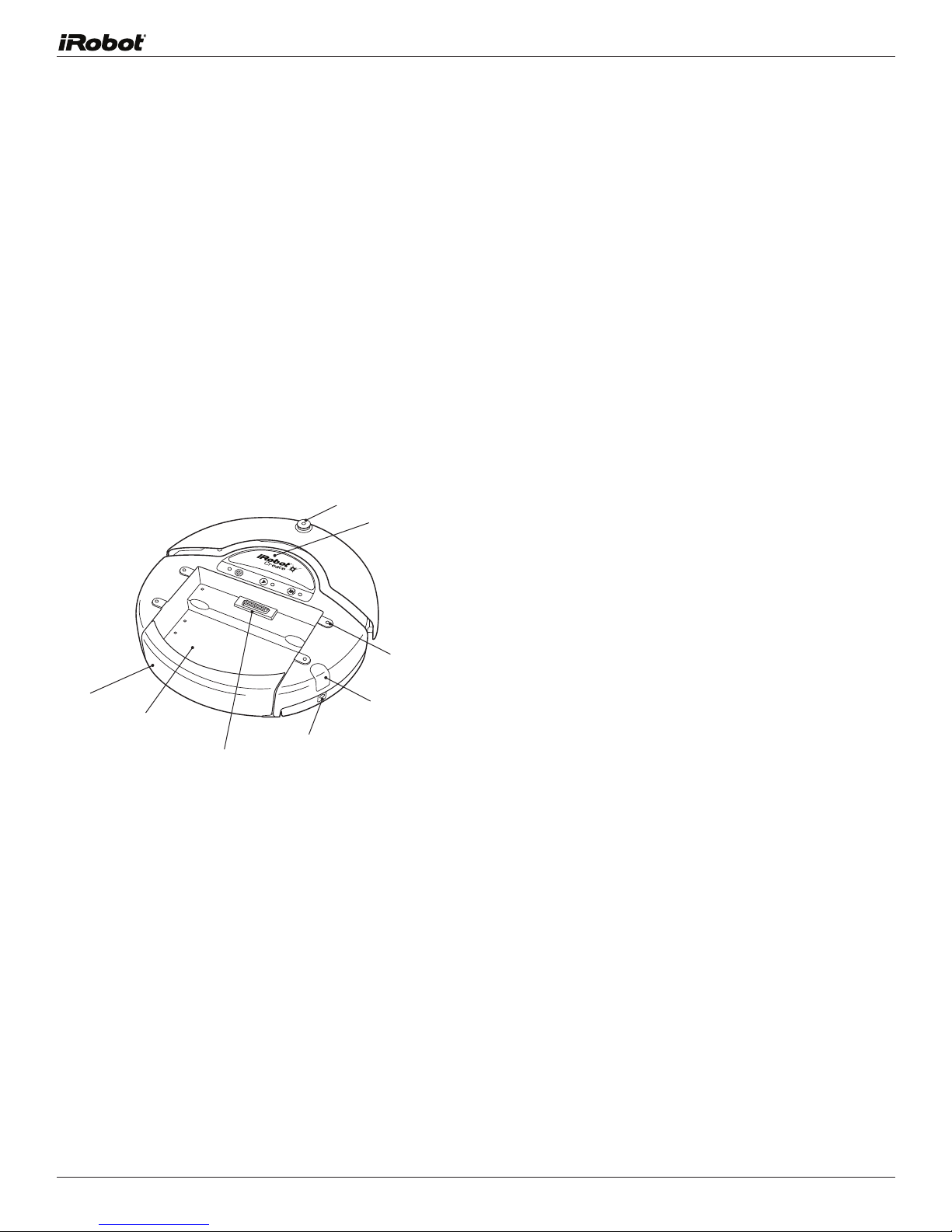

The Create Open Inter face (OI) consists of an electronic

interface and a software interface for controlling Create’s

behavior and reading its sensors. The electronic inter face

includes a 7 pin Mini-DIN connector and a DB-25 connector

in the Cargo Bay for connecting hardware and electronics

for sensors and actuators such as a robotic arm or light

sensor to Create. The software interface lets you manipulate

Create’s behavior and read its sensors through a series of

commands including mode commands, actuator commands,

song commands, demo commands, and sensor commands

that you send to Create’s serial por t by way of a PC or

microcontroller that is connected to the Mini-DIN connector

or Cargo Bay Connector.

Anatomy

Tailgate

Cargo Bay

DB-25

Omnidirectional

IR Receiver

Handle

6-32 Mounting

Cavities

Mini-Din

Charging Socket

3iRobot Create Open Interface (OI) Specification

Page 4

7

4

2

5

6

3

1

123456789101112

141516171717202122232425

13

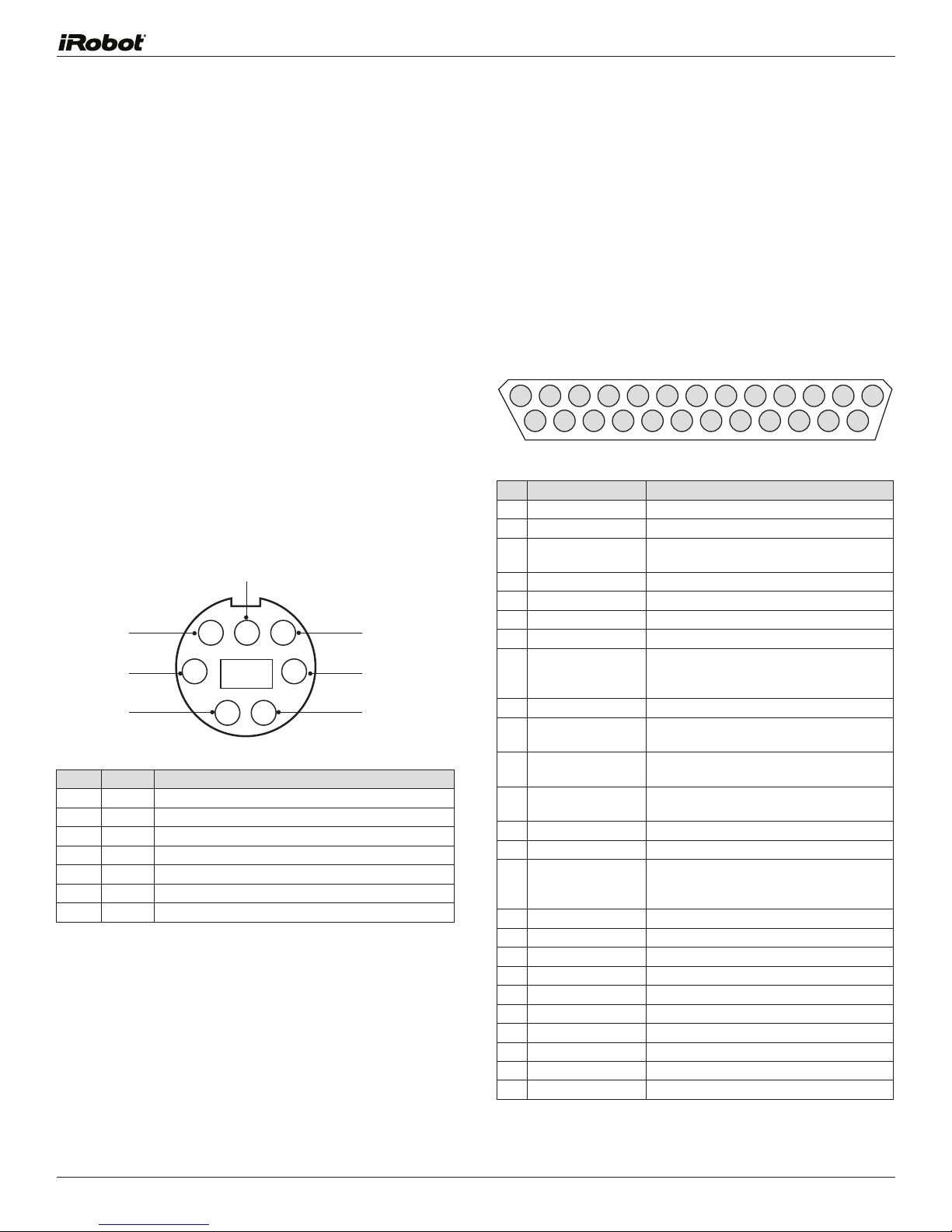

Physical Connections

To use the OI, a processor capable of generating serial

commands such as a PC or a microcontroller must be

connected to the external Mini-DIN connector or the

Cargo Bay Connector on Create. These connectors provide

two-way, serial communication at TTL (0 – 5V) levels. The

connectors also provide an unregulated direct connection

to iRobot Create’s batter y, which you can use to power

the OI applications. The Cargo Bay Connector also provides

a regulated 5V power supply and several input and output

pins (see details below). The Mini-DIN connector is located

in the rear right side of Create, beneath a snap-fit plastic

guard, while the Cargo Bay Connector is located in the front

middle of the cargo bay.

Mini-DIN Connector

This diagram shows the pinout of the top view of the female

connector in Create. Note that pins 5,6 and 7 are towards

the outside circumference of Create.

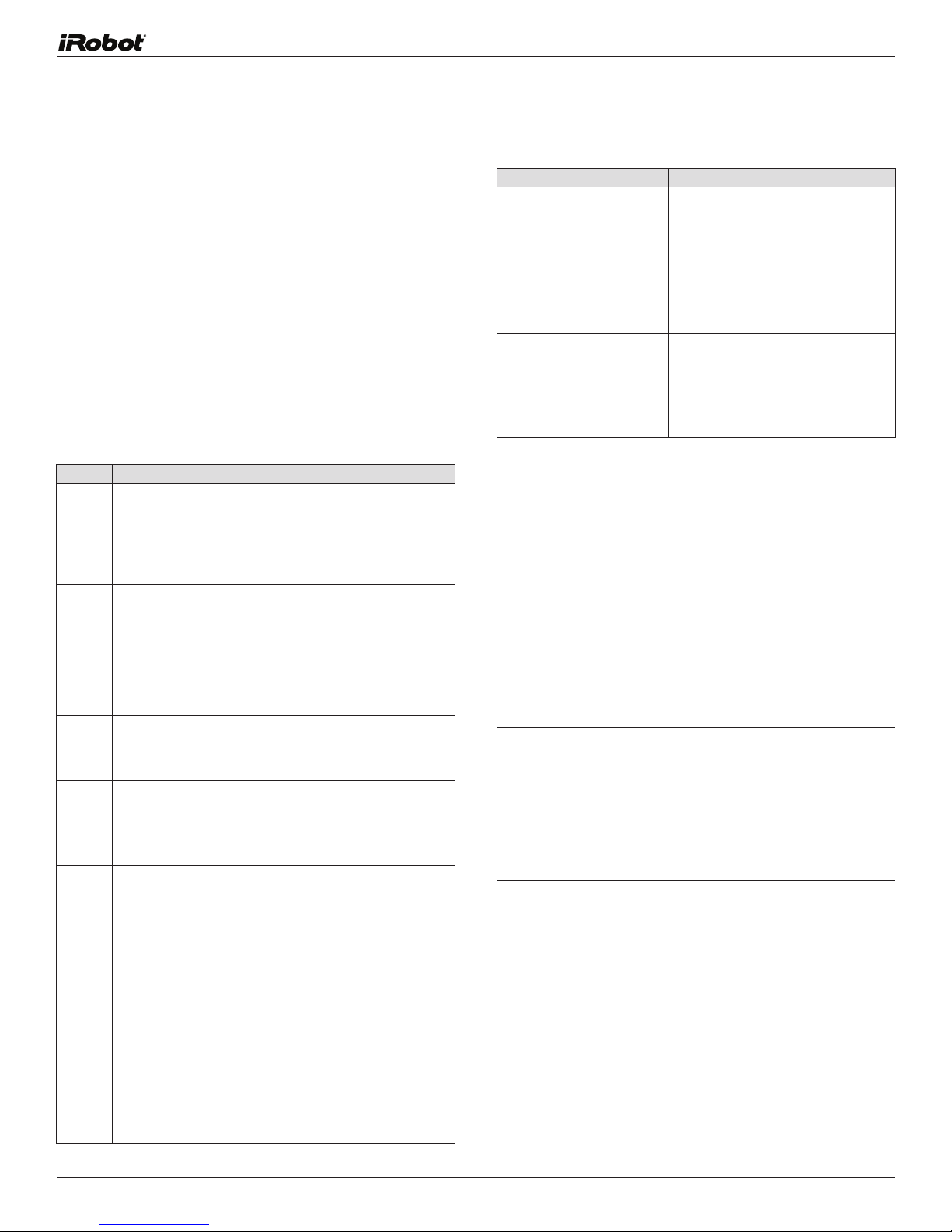

Pin Name Description

1 Vpwr Create battery + (unregulated)

2 Vpwr Create battery + (unregulated)

3 RXD 0 – 5V Serial input to Create

4 TXD 0 – 5V Serial output from Create

5 BRC Baud Rate Change

6 GND Create battery ground

7 GND Create battery ground

Since the RXD and TXD pins use 0 – 5V logic voltage and the

PC serial por ts use dif ferent voltages (rs232 levels), it is

necessary to shift voltage levels. To do this, use an iRobot

Create serial cable rather than a normal serial cable, as

the iRobot Create serial cable contains all of the necessary

hardware to shift the voltage levels, whereas the normal

serial cable does not.

Cargo Bay Connector

The Cargo Bay Connector, located in the front middle of

the cargo bay, contains 25 pins that you can use to attach

electronics for peripheral devices such as additional

sensors. The Cargo Bay Connector provides four digital

inputs, an analog input, three digital output s, three

high-current low side driver outputs (useful for driving

motors), a charging indicator, a power toggle input, serial Tx and

Rx, a 5V reference, batter y ground and batter y voltage.

Pin Name Description

1

RXD 0 – 5V Serial input to Create

2

TXD 0 – 5V Serial output from Create

3 Power control toggle Turns Create on or off on a low-to-high

transition

4 Analog input

5 Digital input 1 0 - 5V digital input to Create

6 Digital input 3 0 - 5V digital input to Create

7 Digital output 1 0 - 5V, 20 mA digital output from Create

8

Switched 5V Provides a regulated 5V 100 mA supply

9 Vpwr Create battery voltage (unregulated), 0.5A

10 Switched Vpwr Provides battery power @ 1.5 A when

11 Switched Vpwr Provides battery power @ 1.5 A when

12 Switched Vpwr Provides battery power @ 1.5 A when

13 Robot charging When Create is charging, this pin is high (5V)

14 GND Create batter y ground

15 Device Detect/Baud

Rate Change Pin

16 GND

17 Digital input 0 0 - 5V digital input to Create

18 Digital input 2 0 - 5V digital input to Create

19 Digital output 0

20 Digital output 2

21 GND Create batter y ground

22 Low side driver 0

23 Low side driver 1

24 Low side driver 2

25 GND

0 - 5V analog input to Create

and analog reference voltage when Create

is switched on

Create is powered on.

Create is powered on.

Create is powered on.

0-5V digital input to Create which can also

be used to change the baud rate to 19200

(see below)

Create battery ground

0 - 5V, 20 mA digital output from Create

0 - 5V, 20 mA digital output from Create

0.5A low side driver from Create

0.5A low side driver from Create

1.5A low side driver from Create

Create battery ground

4iRobot Create Open Interface (OI) Specification

Page 5

Serial Port Settings

Baud: 57600 or 19200 (see below)

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

By default, iRobot Create communicates at 57600 baud.

If you are using a microcontroller that does not support

57600 baud, there are two ways to force Create to switch

to 19200:

Method 1:

When powering on Create, hold down the Play button.

After about 4 seconds, Create plays a tune of descending

pitches. Create will communicate at 19200 baud until the

power is turned off, the battery is removed and reinserted,

the batter y voltage falls below the minimum required for

processor operation, or the baud rate is explicitly changed

by way of the OI.

Method 2:

Use the Baud Rate Change pin (pin 15 on the Cargo Bay

Connector/pin 5 on the Mini-DIN connector) to change

Create’s baud rate. After turning on Create, wait 2 seconds

and then pulse the Baud Rate Change low three times.

Each pulse should last between 50 and 500 milliseconds.

Create will communicate at 19200 baud until the processor

loses battery power or the baud rate is explicitly changed

by way of the OI.

5iRobot Create Open Interface (OI) Specification

Page 6

iRobot Create Open Interface Modes

The Create OI has four operating modes: Of f, Passive,

Safe, and Full. After a battery change or when is first

supplied, the OI is in “off” mode. When it is off, the OI listens

at the default baud rate (57600 or 19200 - see Serial Port

Settings above) for an OI Star t command. Once it receives

the Start command, you can enter into any one of the four

operating modes by sending a mode command to the OI.

You can also switch between operating modes at any time

by sending a command to the OI for the operating mode

that you want to use.

Passive Mode

Upon sending the Start command or any one of the demo

commands (which also starts the specific demo, e.g., Spot

Cover, Cover, Cover and Dock, or Demo), the OI enters

into Passive mode. When the OI is in Passive mode, you

can request and receive sensor data using any of the

sensors commands, but you cannot change the current

command parameters for the actuators (motors, speaker,

lights, low side drivers, digital outputs) to something else.

To change how one of the actuators operates, you must

switch from Passive mode to Full mode or Safe mode.

While in Passive mode, you can read Create’s sensors,

watch Create per form any one of its ten built-in demos,

and charge the batter y.

Full Mode

When you send a Full command to the OI, Create enters

into Full mode. Full mode gives you complete control over

Create, all of its actuators, and all of the safety-related

conditions that are restricted when the OI is in Safe mode,

as Full mode shuts of f the cliff, wheel-drop and internal

charger safety features. To put the OI back into Safe mode,

you must send the Safe command.

If no commands are sent to the OI when in Full mode, Create

waits with all motors and LEDs off and does not respond to

Play or Advance button presses or other sensor input.

Note that charging terminates when you enter Full Mode.

Safe Mode

When you send a Safe command to the OI, Create enters into

Safe mode. Safe mode gives you full control of Create, with

the exception of the following safety-related conditions:

• Detection of a cliff while moving forward (or moving

backward with a small turning radius, less than one robot

radius).

• Detection of a wheel drop (on any wheel).

• Charger plugged in and powered.

Should one of the above safety-related conditions occur

while the OI is in Safe mode, Create stops all motors and

reverts to the Passive mode.

If no commands are sent to the OI when in Safe mode, Create

waits with all motors and LEDs off and does not respond to

Play or Advance button presses or other sensor input.

Note that charging terminates when you enter Safe Mode.

6iRobot Create Open Interface (OI) Specification

Page 7

Open Interface Command Reference

The following is a list of all of iRobot Create’s Open Inter face

commands. Each command starts with a one-byte opcode.

Some of the commands must be followed by data bytes.

All of Create’s OI commands including their required data

bytes are described below.

NOTE: Always send the required number of data bytes for

the command, otherwise, the processor will enter and

remain in a “waiting” state until all of the required data

bytes are received.

Getting Started Commands

The following commands star t the Open Inter face and get

it ready for use.

Start Opcode:128 Data Bytes: 0

This command starts the OI. You must always send the Start

command before sending any other commands to the OI.

• Serial sequence: [128].

• Available in modes: Passive, Safe, or Full

• Changes mode to: Passive. Create beeps once to

acknowledge it is starting from “off” mode.

Baud Opcode: 129 Data Bytes: 1

This command sets the baud rate in bits per second (bps)

at which OI commands and data are sent according to the

baud code sent in the data byte. The default baud rate at

power up is 57600 bps, but the star ting baud rate can

be changed to 19200 by holding down the Play button

while powering on Create until you hear a sequence

of descending tones. Once the baud rate is changed, it

persists until Create is power cycled by pressing the power

button or removing the battery, or when the battery voltage

falls below the minimum required for processor operation.

You must wait 100ms after sending this command before

sending additional commands at the new baud rate.

Note: at a baud rate of 115200, there must be at least

200μs between the onset of each character, or some

characters may not be received.

• Serial sequence: [129][Baud Code]

• Available in modes: Passive, Safe, or Full

• Changes mode to: No Change

• Baud data byte 1: Baud Code (0 - 11)

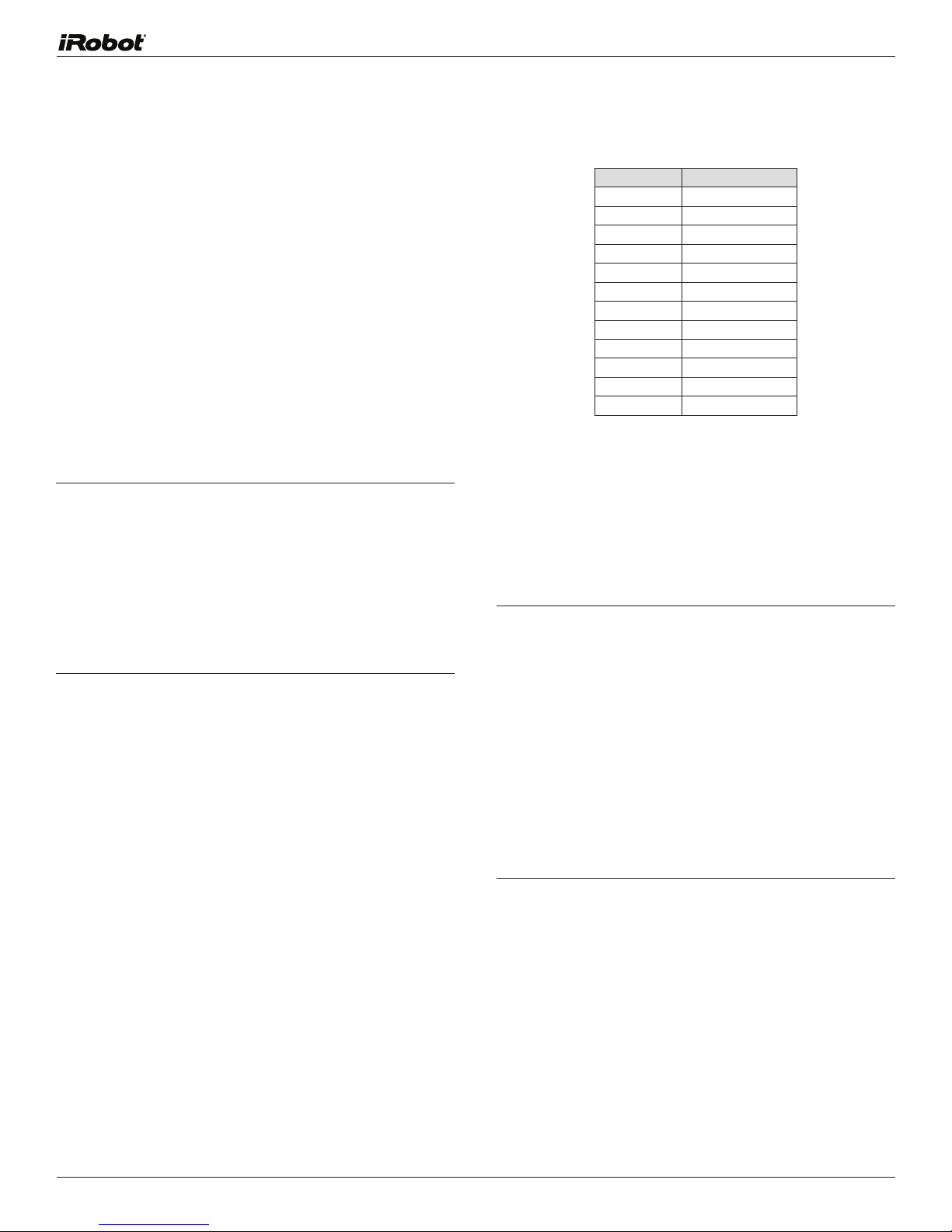

Baud Code Baud Rate in BPS

0

1

2 1200

3 2400

4 4800

5 9600

6

7 19200

8 28800

9

10 57600

11 115200

300

600

14400

38400

Mode Commands

Create has four operating modes: Off, Passive, Safe, and

Full. Create powers on in the Passive mode. The following

commands change Create’s OI mode.

Safe Opcode: 131 Data Bytes: 0

This command puts the OI into Safe mode, enabling user

control of Create. It turns off all LEDs. The OI can be in

Passive, Safe, or Full mode to accept this command.

• Serial sequence: [131]

• Available in modes: Passive, Safe, or Full

• Changes mode to: Safe

Note: The effect and usage of the Control command (130)

is identical to the Safe command. The Control command is

deprecated but is present for backward compatibility with

the Roomba Open Interface. Use Safe command instead.

Full Opcode: 132 Data Bytes: 0

This command gives you complete control over Create

by putting the OI into Full mode, and turning of f the cliff,

wheel-drop and internal charger safety features. That is, in

Full mode, Create executes any command that you send

it, even if the internal charger is plugged in, or the robot

senses a cliff or wheel drop.

• Serial sequence: [132]

• Available in modes: Passive, Safe, or Full

• Changes mode to: Full

Note: Use the Start command (128) to change the mode

to Passive.

7iRobot Create Open Interface (OI) Specification

Page 8

Demo Commands

The following are commands to star t iRobot Create’s

built-in demos.

Demo Opcode: 136 Data Bytes: 1

This command starts the requested built-in demo.

• Serial sequence: [136][Which-demo]

• Available in modes: Passive, Safe, or Full

• Changes mode to: Passive

• Demo data byte 1: Demo number (-1 - 9)

Demo Names, Descriptions and Numbers

Number Demo

-1 (255) Abort current demo

0 Cover

1 Cover and Dock Identical to the Cover demo, with one

2 Spot Cover Create covers an area around its

3 Mouse Create drives in search of a wall. Once

4 Drive Figure Eight Create continuously drives in a figure 8

5 Wimp Create drives forward when pushed from

6 Home

Description

Stops the demo that Create is currently

performing.

Create attempts to cover an entire

room using a combination of behaviors,

such as random bounce, wall following,

and spiraling.

exception. If Create sees an infrared

signal from an iRobot Home Base, it

uses that signal to dock with the Home

Base and recharge itself.

starting position by spiraling outward,

then inward.

a wall is found, Create drives along the

wall, traveling around circumference of

the room.

pattern.

behind. If Create hits an obstacle while

driving, it drives away from the obstacle.

Create drives toward an iRobot Vir tual

Wall as long as the back and sides of

the virtual wall receiver are blinded by

black electrical tape.

A Virtual Wall emits infrared signals

that Create sees with its Omnidirectional

Infrared Receiver, located on top of the

bumper.

Number

7

8

9 Banjo

Demo Description

Tag Identical to the Home demo, except

Create drives into multiple virtual walls

by bumping into one, turning around,

driving to the next virtual wall, bumping

into it and turning around to bump into

the next virtual wall.

Pachelbel Create plays the notes of Pachelbel’s

Canon in sequence when cliff sensors

are activated.

Create plays a note of a chord for each

of its four cliff sensors. Select the

chord using the bumper, as follows:

• No bumper: G major.

• Right/left bumper: D major 7

• Both bumpers (center): C major

You can also call the Cover, Cover and Seek Dock and Spot

Demos using the Opcodes specified below. This is present

for ensuring backward compatibility with the Roomba OI.

Cover Opcode: 135 Data Bytes: 0

This command starts the Cover demo.

• Serial sequence: [135]

• Available in modes: Passive, Safe, or Full

• Changes mode to: Passive

Cover and Dock Opcode: 143 Data Bytes: 0

This command starts the Cover and Dock demo.

• Serial sequence: [143]

• Available in modes: Passive, Safe, or Full

• Changes mode to: Passive

Spot Opcode: 134 Data Bytes: 0

This command starts the Spot Cover demo.

• Serial sequence: [134]

• Available in modes: Passive, Safe, or Full

• Changes mode to: Passive

If you want Create to home in on a

Virtual Wall, cover all but a small

opening in the front of the infrared

receiver with black electrical tape.

Create spins to locate a virtual wall,

then drives toward it. Once Create hits

the wall or another obstacle, it stops.

8iRobot Create Open Interface (OI) Specification

Page 9

Actuator Commands

Drive Direct Opcode: 145 Data Bytes: 4

The following commands control iRobot Create’s actuators:

wheels, speaker, LEDS, dig ital outputs and low side

driver outputs.

Drive Opcode: 137 Data Bytes: 4

This command controls Create’s drive wheels. It takes four

data bytes, interpreted as two 16-bit signed values using

two’s complement. The first two bytes specify the average

velocity of the drive wheels in millimeters per second

(mm/s), with the high byte being sent first. The next two

bytes specify the radius in millimeters at which Create will

turn. The longer radii make Create drive straighter, while

the shorter radii make Create turn more. The radius is

measured from the center of the turning circle to the center

of Create. A Drive command with a positive velocity and a

positive radius makes Create drive forward while turning

toward the left. A negative radius makes Create turn toward

the right. Special cases for the radius make Create turn

in place or drive straight, as specified below. A negative

velocity makes Create drive backward.

NOTE: Internal and environmental restrictions may prevent

Create from accurately carrying out some drive commands.

For example, it may not be possible for Create to drive at

full speed in an arc with a large radius of curvature.

• Serial sequence: [137] [Velocity high byte] [Velocity low byte]

[Radius high byte] [Radius low byte]

• Available in modes: Safe or Full

• Changes mode to: No Change

• Drive data byte 1: Velocity (-500 – 500 mm/s)

• Drive data byte 2: Radius (-2000 – 2000 mm)

Special cases:

Straight = 32768 or 32767 = hex 8000 or 7FFF

Turn in place clockwise = hex FFFF

Turn in place counter-clockwise = hex 0001

Example:

To drive in reverse at a velocity of -200 mm/s while

turning at a radius of 500mm, send the following serial

byte sequence:

[137] [255] [56] [1] [244]

Velocity = -200 = hex FF38 = [hex FF] [hex 38] = [255] [56]

Radius = 500 = hex 01F4 = [hex 01] [hex F4] = [1] [244]

This command lets you control the forward and backward

motion of Create’s drive wheels independently. It takes

four data bytes, which are interpreted as two 16-bit signed

values using two’s complement. The first two bytes specify

the velocity of the right wheel in millimeters per second

(mm/s), with the high byte sent first. The next two bytes

specify the velocity of the left wheel, in the same format.

A positive velocity makes that wheel drive forward, while a

negative velocity makes it drive backward.

• Serial sequence: [145] [Right velocity high byte]

[Right velocity low byte] [Left velocity high byte]

[Left velocity low byte]

• Available in modes: Safe or Full

• Changes mode to: No Change

• Drive Direct data byte 1: Right wheel velocity

(-500 – 500 mm/s)

• Drive Direct data byte 1: Left wheel velocity

(-500 – 500 mm/s)

LEDs Opcode: 139 Data Bytes: 3

This command controls the LEDs on Create. The state of

the Play and Advance LEDs is specified by two bits in the

first data byte. The power LED is specified by two data

bytes: one for the color and the other for the intensity.

• Serial sequence: [139] [LED Bits] [Power Color]

[Power Intensity]

• Available in modes: Safe or Full

• Changes mode to: No Change

• LEDs data byte 1: LED Bits (0 – 10)

Advance and Play use green LEDs. 0 = off, 1 = on

Bit

LED n/a n/a

7 6 5

n/a n/a Advance

4 3 2

n/a Play n/a

1 0

Power uses a bicolor (red/green) LED. The intensity and

color of this LED can be controlled with 8-bit resolution.

• LEDs data byte 2: Power LED Color (0 – 255)

0 = green, 255 = red. Intermediate values are

intermediate colors (orange, yellow, etc).

• LEDs data byte 3: Power LED Intensity (0 – 255)

0 = off, 255 = full intensity. Intermediate values are

intermediate intensities.

Example:

To turn on the Advance LED and light the Power LED green

at half intensity, send the serial byte sequence [139] [8]

[0] [128].

9iRobot Create Open Interface (OI) Specification

Page 10

Digital Outputs Opcode: 147 Data Bytes: 1

Visible LED

470 Ohms

DIGITAL_OUTPUT

+5V

DC MOTOR1N4001

1K Ohms

S8050

ANALOG_OUTPUT

SWITCHED_VPWR

DC MOTOR

LD1

SWITCHED_VPWR

This command controls the state of the 3 digital output

pins on the 25 pin Cargo Bay Connector. The digital outputs

can provide up to 20 mA of current.

• Serial sequence: [147] [Output Bits]

• Available in modes: Safe or Full

• Changes mode to: No Change

• Digital Outputs data byte 1: Output Bits (0 –7);

0 = low (0V); 1 = high (5V).

Example schematics

Warning: When the Robot is switched ON, the Digital

Outputs are High for the first 3 seconds during the

initialization of the bootloader

Example:

To turn on low side driver 2 at 25% and low side driver 0 at

100%, send the serial byte sequence [144][32][0][128]

Low Side Drivers Opcode: 138 Data Bytes: 1

This command lets you control the three low side drivers. The

state of each driver is specified by one bit in the data byte.

Low side drivers 0 and 1 can provide up to 0.5A of current.

Low side driver 2 can provide up to 1.5 A of current. If too

much current is requested, the current is limited and the

overcurrent flag is set (sensor packet 14).

• Serial sequence: [138] [Driver Bits]

• Available in modes: Safe or Full

• Changes mode to: No Change

• Low Side Drivers data byte 1: Driver bits (0 – 7)

Example schematic

Output

PWM Low Side Drivers Opcode: 144 Data Bytes: 3

This command lets you control the three low side drivers

with variable power. With each data byte, you specify the

PWM duty cycle for the low side driver (max 128). For

example, if you want to control a driver with 25% of battery

voltage, choose a duty cycle of 128 * 25% = 32.

• Serial sequence: [144] [Low Side Driver 2 Duty Cycle]

• Available in modes: Safe or Full

• Changes mode to: No Change

• Low Side Drivers data byte 1: Duty cycle for low side

• Low Side Drivers data byte 2: Duty cycle for low side

• Low Side Drivers data byte 3: Duty cycle for low side

Bit

7 6

5

4 3

2 1

digital-out-2

(pin 20)

digital-out-1

(pin 7)

0

digital-out-0

(pin 19)

[Low Side Driver 1 Duty Cycle] [Low Side Driver 0 Duty Cycle]

driver 2 (0 - 128)

driver 1 (0 - 128)

driver 0 (0 - 128)

0 = off, 1 = on at 100% PWM duty cycle

Bit

7 6

5 4

3

Output

2 1

Side Driver

2 (pin 24)

Low Side

Driver 1

(pin 22)

0

Low Side

Driver 0

(pin 23)

Example:

To turn on only low side driver 1, send the serial byte

sequence [138] [2].

Note: Speed control of motors uses the PWM Low Side

Drivers Command. This command exists for Backward

compatibility with the Roomba OI.

10iRobot Create Open Interface (OI) Specification

Page 11

Send IR Opcode: 151 Data Bytes: 1

180 Ohms

100 Ohms

IR LED

+5V

LD1

This command sends the requested byte out of low side

driver 1 (pin 23 on the Cargo Bay Connector), using the

format expected by iRobot Create’s IR receiver. You must

use a preload resistor (suggested value: 100 ohms) in

parallel with the IR LED and its resistor in order turn it on.

• Serial sequence: [151][Byte Value]

• Available in modes: Safe or Full

• Changes mode to: No Change

• Send IR data byte 1: Byte value to send (0 - 255)

Example Schematic

Song Opcode: 140 Data Bytes: 2N+2,

where N is the number

of notes in the song

This command lets you specify up to sixteen songs to the OI

that you can play at a later time. Each song is associated

with a song number. The Play command uses the song

number to identify your song selection. Each song can

contain up to sixteen notes. Each note is associated with a

note number that uses MIDI note definitions and a duration

that is specified in fractions of a second. The number of data

bytes varies, depending on the length of the song specified.

A one note song is specified by four data bytes. For each

additional note within a song, add two data bytes.

• Serial sequence: [140] [Song Number] [Song Length]

[Note Number 1] [Note Duration 1] [Note Number 2]

[Note Duration 2], etc.

• Available in modes: Passive, Safe, or Full

• Changes mode to: No Change

• Song data byte 1: Song Number (0 – 15)

The song number associated with the specific song. If

you send a second Song command, using the same song

number, the old song is overwritten.

• Song data byte 2: Song Length (1 – 16)

The lengt h of the song, accor ding to the number o f

musical notes within the song.

• Song data bytes 3, 5, 7, etc.: Note Number (31 – 127)

The pitch of the musical note Create will play, according

to the MIDI note numbering scheme. The lowest musical

note that Create will play is Note #31. Create considers

all musical notes outside the range of 31 – 127 as rest

notes, and will make no sound during the duration of

those notes.

• Song data bytes 4, 6, 8, etc.: Note Duration (0 – 255)

The duration of a musical note, in increments of 1/64th

of a second. Example: a half-second long musical note

has a duration value of 32

11iRobot Create Open Interface (OI) Specification

Page 12

Note Durations

Number

31

32 G#

33

34

35 B

36

37 C#

38

39 D#

40

41 F 87.3 77 F 698.5 113 F 5587.7

42 F# 92.5 78 F# 740.0 114 F# 5919.9

43 G 98.0 79 G 784.0 115 G 6271.9

44 G# 103.8 80 G# 830.6 116 G# 6644.9

45 A 110.0 81 A 880.0 117 A 7040.0

46 A# 116.5 82 A# 932.3 118 A# 7458.6

47 B 123.5 83 B 987.8 119 B 7902.1

48 C 130.8 84 C 1046.5 120 C 8372.0

49 C# 138.6 85 C# 1108.7 121 C# 8869.8

50 D 146.8 86 D 1174.7 122 D 9397.3

51 D# 155.6 87 D# 1244.5 123 D# 9956.1

52 E 164.8 88 E 1318.5 124 E 10548.1

53 F 174.6 89 F 1396.9 125 F 11175.3

54 F# 185.0 90 F# 1480.0 126 F# 11839.8

55 G 196.0 91 G 1568.0 127 G 12543.9

56 G# 207.7 92 G# 1661.2

57 A 220.0 93 A 1760.0

58 A# 233.1 94 A# 1864.7

59 B 246.9 95 B 1975.5

Note

G

A

A# 58.3

C 65.4

D 73.4

E 82.4

Frequency

49.0

51.0 68

55.0

61.7

69.3 73

77.8

Number

60

61

62

63

64

65

66

67

69

70

71 B

72

74 D

75 D#

76

Note

C

C#

D

D#

E

F

F#

G

G#

A

A# 466.2

C 523.3

C#

E 659.3

Frequency

261.6

277.2

293.7

311.1

329.6

349.2

370.0

392.0

415.3 104

440.0

493.9 107

554.4 109

587.3

622.3 111

Number

96

97

98

99

100

101

102

103

105

106

108 C

110 D

112 E

Note

C

C#

D

D#

E

F

F#

G

G# 3322.4

A

A# 3729.3

B

C# 4434.9

D#

Frequency

2093.0

2217.5

2349.3

2489.0

2637.0

2793.8

2960.0

3136.0

3520.0

3951.1

4186.0

4698.6

4978.0

5274.0

12iRobot Create Open Interface (OI) Specification

Page 13

Play Song Opcode: 141 Data Bytes: 1

This command lets you select a song to play from the songs

added to iRobot Create using the Song command. You must

add one or more songs to Create using the Song command

in order for the Play command to work. Also, this command

does not work if a song is already playing. Wait until a

currently playing song is done before sending this command.

Note that the “song playing” sensor packet can be used to

check whether Create is ready to accept this command.

• Serial sequence: [141] [Song Number]

• Available in modes: Safe or Full

• Changes mode to: No Change

• Play Song data byte 1: Song Number (0 – 15)

The number of the song Create is to play.

Input Commands

The following commands let you read the state of Create’s

built-in sensors, digital and analog inputs, and some internal

state variables. Create updates these values internally

every 15 ms. Do not send these commands more frequently

than that.

Query List Opcode: 149 Data Bytes: N + 1,

where N is the number

of packets requested.

This command lets you ask for a list of sensor packets.

The result is returned once, as in the Sensors command.

The robot returns the packets in the order you specify.

• Serial sequence: [149][Number of Packets]

[Packet ID 1][Packet ID 2]...[Packet ID N]

• Available in modes: Passive, Safe, or Full

• Changes mode to: No Change

• Query List data byte 1: Number of packets requested

(0 - 255)

• Query List data bytes 2 - N: IDs of packets requested

(0 - 42)

Example:

To get the state of the left cliff sensor (packet 9) and

the Vir tual Wall detector (packet 13), send the following

sequence:

[149] [2] [9] [13]

Sensors Opcode: 142 Data Bytes: 1

This command requests the OI to send a packet of sensor

data bytes. There are 43 different sensor data packets. Each

provides a value of a specific sensor or group of sensors.

For more information on sensor packets, refer to the next

section, “Create Open Interface Sensor Packets.”

• Serial sequence: [142] [Packet ID]

• Available in modes: Passive, Safe, or Full

• Changes mode to: No Change

• Sensors data byte 1: Packet ID (0 - 42)

Identifies which of the 43 sensor data packets should be

sent back by the OI. A value of 6 indicates a packet with

all of the sensor data. Values of 0 through 5 indicate

specific subgroups of the sensor data (see Sensors

Quick Reference below).

13iRobot Create Open Interface (OI) Specification

Page 14

Stream Opcode: 148 Data Bytes: N + 1,

where N is the number

of packets requested.

This command star ts a continuous stream of data packets.

The list of packets requested is sent every 15 ms, which is

the rate iRobot Create uses to update data.

This is the best method of requesting sensor data if you

are controlling Create over a wireless network (which has

poor real-time characteristics) with software running on a

desktop computer.

• Serial sequence: [148] [Number of packets]

[Packet ID 1] [Packet ID 2] [Packet ID 3] etc.

• Available in modes: Passive, Safe, or Full

• Changes mode to: No Change

• Stream data byte 1: Number of packets requested

(0 - 43)

• Stream data bytes 2 - N: IDs of packets requested

(0 - 42)

The format of the data returned is:

[19][N-bytes][Packet ID 1][Packet 1 data…]

[Packet ID 2][Packet 2 data…][Checksum]

N-bytes is the number of bytes between the n-bytes byte and

the checksum.

The checksum is a 1-byte value. It is the 8-bit complement

of all of the bytes between the header and the checksum.

That is, if you add all of the bytes after the checksum, and

the checksum, the low byte of the result will be 0.

In the above stream segment, Create’s left cliff signal value

was 549 (0x0225) and there was no virtual wall signal.

It is up to you not to request more data than can be sent at

the current baud rate in the 15 ms time slot. For example,

at 57600 baud, a maximum of 86 bytes can be sent in 15 ms:

15 ms / 10 bits (8 data + start + stop) * 57600 = 86.4

If more data is requested, the data stream will eventually

become corrupted. This can be confirmed by checking the

checksum.

The header byte and checksum can be used to align your

receiving program with the data. All data chunks star t with

19 and end with the 1-byte checksum

Pause/Resume Stream Opcode: 150 Data Bytes: 1

This command lets you stop and restart the steam without

clearing the list of requested packets.

• Serial sequence: [150][Stream State]

• Available in modes: Passive, Safe, or Full

• Changes mode to: No Change

• Pause/Resume Stream data byte 1: Requested

stream state (0 - 1)

An argument of 0 stops the stream without clearing the list

of requested packets. An argument of 1 star ts the stream

using the list of packets last requested.

Example:

To get data from Create’s left cliff signal (packet 29)

and Virtual Wall detector (packet 13), send the following

command string to Create:

[148] [2] [29] [13]

NOTE: The left cliff signal is a 2-byte packet and the IR

Sensor is a 1-byte packet.

Create starts streaming data that looks like this:

19 5 29

header n-bytes packet

ID 1

NOTE: Checksum computation: (5 + 29 + 2 + 25 + 13 + 0

+ 182) = 256 and (256 & 0xFF) = 0.

2 25 13 0 182

Packet data

1 (2 bytes)

packet

ID 2

packet

data 2

(1 byte)

Checksum

14iRobot Create Open Interface (OI) Specification

Page 15

Script Commands

Play Script Opcode: 153 Data Bytes: 0

The following commands let you specify a script for iRobot Create

to play at a later time.

Script Opcode: 152 Data Bytes: N + 1

where N is the number

of bytes in the script.

This command specifies a script to be played later. A script

consists of OI commands and can be up to 100 bytes long.

There is no flow control, but “wait” commands (see below)

cause Create to hold its current state until the specified

event is detected.

• Serial sequence: [152] [Script Length] [Opcode 1]

[Opcode 2] [Opcode 3] etc.

• Available in modes: Passive, Safe, or Full

• Changes mode to: No Change

• Script data byte 1: Script Length (0 – 100)

Specifies the length of the script in terms of the

number of commands. Specify a length of 0 to clear

the current script.

• Script data bytes 2 and above: Open Interface commands

and data bytes

Tip: To make a script loop forever, use Play Script (153) as

the last command.

Example Scripts:

This command loads a previously defined OI script into the

serial input queue for playback.

• Serial sequence: [153]

• Available in modes: Passive, Safe, or Full

• Changes mode to: No Change

Show Script Opcode: 154 Data Bytes: 0

This command returns the values of a previously stored

script, starting with the number of bytes in the script and

followed by the script’s commands and data bytes. It first

halts the sensor stream, if one has been started with a

Stream or Pause/Resume Stream command. To restart the

stream, send Pause/Resume Stream (opcode 150).

• Serial sequence: [154]

• Available in modes: Passive, Safe, or Full

• Changes mode to: No Change

Wait Commands

The following commands cause Create to wait for a specific

time, distance, angle of rotation, or event to occur. While

it is waiting, Create does not change its state, nor does it

react to any inputs, serial or other wise. These commands

are intended for use in scripting only.

Drive 40 cm and stop:

152 13 137 1 44 128 0 156 1 144 137 0 0 0 0

Toggle led on bump:

152 17 158 5 158 251 139 2 0 0 158 5 158 251 139 0

0 0 153

Drive in a square:

152 17 137 1 44 128 0 156 1 144 137 1 44 0 1 157

0 90 153

Wait Time Opcode: 155 Data Bytes: 1

This command causes Create to wait for the specified time.

During this time, Create’s state does not change, nor does

it react to any inputs, serial or otherwise.

• Serial sequence: [155] [time]

• Available in modes: Passive, Safe, or Full

• Changes mode to: No Change

• Wait Time data byte 1: Time (0 - 255)

Specifies time to wait in tenths of a second with a resolution

of 15 ms.

15iRobot Create Open Interface (OI) Specification

Page 16

Wait Distance Opcode: 156 Data Bytes: 2

This command causes iRobot Create to wait until it has

traveled the specified distance in mm. When Create travels

forward, the distance is incremented. When Create travels

backward, the distance is decremented. If the wheels

are passively rotated in either direction, the distance is

incremented. Until Create travels the specified distance,

its state does not change, nor does it react to any inputs,

serial or otherwise.

NOTE: This command resets the distance variable that is

returned in Sensors packets 19, 2 and 6.

• Serial sequence: [156] [Distance high byte]

[Distance low byte]

• Available in modes: Passive, Safe, or Full

• Changes mode to: No Change

• Wait Distance data bytes 1-2: 16-bit signed distance

in mm, high byte first (-32767 -32768)

Wait Angle Opcode: 157 Data Bytes: 2

This command causes Create to wait until it has rotated

through specified angle in degrees. When Create turns

counterclockwise, the angle is incremented. When Create

turns clockwise, the angle is decremented. Until Create

turns through the specified angle, its state does not change,

nor does it react to any inputs, serial or otherwise.

NOTE: This command resets the angle variable that is

returned in Sensors packets 20, 2 and 6.

• Serial sequence: [157] [Angle high byte] [Angle low byte]

• Available in modes: Passive, Safe, or Full

• Changes mode to: No Change

• Wait Angle data bytes 1-2: 16-bit signed angle in degrees,

high byte first (-32767 -32768)

To wait for the inverse of an event, send the negative of

its number using two’s complement notation. For example,

to wait for no bumps, send the serial byte sequence [158]

[-5], which is equivalent to [158] [251].

Wait Event: Unsigned Equivalent of Inverse

Event

Wheel Drop 1

Front Wheel Drop 2

Left Wheel Drop 3

Right Wheel Drop

Bump 5 251

Left Bump 6 250

Right Bump 7

Virtual Wall

Wall 9 247

Cliff 10

Left Cliff 11 245

Front Left Cliff 12 244

Front Right Cliff 13 243

Right Cliff 14 242

Home Base 15 241

Advance Button 16 240

Play Button 17 239

Digital Input 0 18 238

Digital Input 1 19 237

Digital Input 2 20 236

Digital Input 3 21 235

OI Mode = Passive 22 234

Number Unsigned Equivalent of Inverse

255

254

253

4

8

252

249

248

246

Wait Event Opcode: 158 Data Bytes: 1

This command causes Create to wait until it detects the

specified event. Until the specified event is detected,

Create’s state does not change, nor does it react to any

inputs, serial or otherwise.

• Serial sequence: [158] [Event number]

• Available in modes: Passive, Safe, or Full

• Changes mode to: No Change

• Wait Event data byte 1: Signed event number

(1 to 20 and -1 to -20)

signed

16iRobot Create Open Interface (OI) Specification

Page 17

iRobot Create Open Interface

Sensor Packets

Create sends back one of 43 different sensor data packets,

depending on the value of the packet data byte, when

responding to a Sensors command, Query List command,

or Stream command’s request for a packet of sensor data

bytes. Some packets contain groups of other packets.

Some of the sensor data values are 16 bit values.

Most of the packets (numbers 7 – 42) contain the value of

a single sensor or variable, which can be either 1 byte or 2

bytes. Two-byte packets correspond to 16-bit values, sent

high byte first.

Some of the packets (0-6) contain groups of the singlevalue packets.

Wait Event: Unsigned Equivalent of Inverse

Group Packet ID Packet Size Contains packets

0

1

2 6 bytes 17 - 20

3 10 bytes

4 14 bytes 27 - 34

5 12 bytes 35 - 42

6 52 bytes 7 - 42

Bumps and Wheel Drops Packet ID: 7 Data Bytes: 1

The state of the bumper (0 = no bump, 1 = bump) and wheel

drop sensors (0 = wheel raised, 1 = wheel dropped) are sent

as individual bits.

Range: 0 - 31

26 bytes 7 - 26

10 bytes 7 - 16

21 - 26

unsigned

Cliff Front Left Packet ID: 10 Data Bytes: 1

The state of the cliff sensor on the front left of Create is

sent as a 1 bit value (0 = no cliff, 1 = cliff).

Range: 0 – 1

Cliff Front Right Packet ID: 11 Data Bytes: 1

The state of the cliff sensor on the front right of Create is

sent as a 1 bit value (0 = no cliff, 1 = cliff)

Range: 0 – 1

Cliff Right Packet ID: 12 Data Bytes: 1

The state of the cliff sensor on the right side of Create is

sent as a 1 bit value (0 = no cliff, 1 = cliff)

Range: 0 – 1

Virtual Wall Packet ID: 13 Data Bytes: 1

The state of the virtual wall detector is sent as a 1 bit value

(0 = no vir tual wall detected, 1 = vir tual wall detected).

Note that the force field on top of the Home Base also trips

this sensor.

Range: 0 – 1

unsigned

unsigned

unsigned

unsigned

Bit 7

Sensor n/a n/a

Wall Packet ID: 8 Data Bytes: 1

6

5 4

n/a

Wheeldrop

Caster

3

Wheeldrop

Left

The st ate of the wall sensor is sent as a 1 bit value

(0 = no wall, 1 = wall seen).

Range: 0 – 1

Cliff Left Packet ID: 9 Data Bytes: 1

The state of the clif f sensor on the left side of Create is

sent as a 1 bit value (0 = no cliff, 1 = cliff).

Range: 0 – 1

2 1

Wheeldrop

Right

Bump

Left

unsigned

unsigned

0

Bump

Right

Low Side Driver and Packet ID: 14 Data Bytes: 1

Wheel Overcurrents unsigned

The state of the three Low Side driver and two wheel

overcurrent sensors are sent as individual bits (0 = no

overcurrent, 1 = overcurrent).

Driver Current Limit

LD0 0.5A

LD1 0.5A

LD2 1.6A

Wheels 1.0A

Range: 0 - 31

Bit 7 6 5 4 3 2 1 0

Motor n/a n/a n/a Left Wheel Right Wheel LD-2 LD-0 LD-1

17iRobot Create Open Interface (OI) Specification

Page 18

Unused Bytes Packet IDs: 15 - 16 Data Bytes: 1

Force Field

Green

Buoy

Red

Buoy

Unused bytes: Two unused bytes are sent after the overcurrent

byte when the requested packet is 0, 1, or 6. The value of the

two unused bytes is always 0.

Range: 0

Infrared Byte Packet ID: 17 Data Bytes: 1

unsigned

This value identifies the IR byte currently being received

by iRobot Create. A value of 255 indicates that no IR byte

is being received. These bytes include those sent by the

Roomba Remote, the Home Base, Create robots using the

Send IR command, and user-created devices.

Range: 0 – 255

Dock beam configuration

Sent by iRobot Device

Scheduling Remote

Home Base

Character Value

142 Send All

143

240 Reserved

248

244 Green Buoy

242 Force Field

252 Red Buoy and Green Buoy

250 Red Buoy and Force Field

246

254

Character Name

Seek Dock

Red Buoy

Green Buoy and Force

Field

Red Buoy, Green Buoy and

Force Field

Buttons Packet ID: 18 Data Bytes: 1

unsigned

The state of Create’s Play and Advance buttons are sent as

individual bits (0 = button not pressed, 1 = button pressed).

Range: 0 - 5

Sent by iRobot Device

Remote Control 129 Left

Character Value Character Name

130

131 Right

132 Spot

133 Max

134 Small

135 Medium

136 Large / Clean

137 PAUSE

138 Power

139 arc-forward-left

140 arc-forward-right

141 drive-stop

Forward

Bit 7

Button

6 5

n/a n/a n/a

4

3 2

n/a n/a Advance n/a

1 0

Play

Distance Packet ID: 19 Data Bytes: 2

signed

The distance that Create has traveled in millimeters since the

distance it was last requested is sent as a signed 16-bit value,

high byte first. This is the same as the sum of the distance

traveled by both wheels divided by two. Positive values indicate

travel in the forward direction; negative values indicate travel

in the reverse direction. If the value is not polled frequently

enough, it is capped at its minimum or maximum.

Range: -32768 – 32767

18iRobot Create Open Interface (OI) Specification

Page 19

Angle Packet ID: 20 Data Bytes: 2

signed

Battery Temperature Packet ID: 24 Data Bytes: 1

signed

The angle in degrees that iRobot Create has turned since the

angle was last requested is sent as a signed 16-bit value, high

byte first. Counter-clockwise angles are positive and clockwise

angles are negative. If the value is not polled frequently

enough, it is capped at its minimum or maximum.

Range: -32768 – 32767

NOTE: Create uses wheel encoders to measure distance

and angle. If the wheels slip, the actual distance or angle

traveled may differ from Create’s measurements.

Charging State Packet ID: 21 Data Bytes: 1

unsigned

This code indicates Create’s current charging state.

Range: 0 - 5

Code

0 Not charging

1

2 Full Charging

3 Trickle Charging

4

5 Charging Fault Condition

Charging State

Reconditioning Charging

Waiting

The temperature of Create’s batter y in degrees Celsius.

Range: -128 – 127

Battery Charge Packet ID: 25 Data Bytes: 2

unsigned

The current charge of Create’s batter y in milliamp-hours (mAh).

The charge value decreases as the batter y is depleted

during running and increases when the batter y is charged.

Note that this value will not be accurate if you are using the

alkaline battery pack.

Range: 0 – 65535

Battery Capacity Packet ID: 26 Data Bytes: 2

unsigned

The estimated charge capacity of Create’s battery in milliamphours (mAh). Note that this value is inaccurate if you are using

the alkaline batter y pack.

Range: 0 – 65535

Wall Signal Packet ID: 27 Data Bytes: 2

unsigned

Voltage Packet ID: 22 Data Bytes: 2

unsigned

This code indicates the voltage of Create’s batter y in

millivolts (mV).

Range: 0 – 65535

Current Packet ID: 23 Data Bytes: 2

signed

The current in milliamps (mA) flowing into or out of Create’s

battery. Negative currents indicate that the current is flowing

out of the battery, as during normal running. Positive currents

indicate that the current is flowing into the battery, as during

charging.

Range: -32768 – 32767

The strength of the wall sensor’s signal is returned as an

unsigned 16-bit value, high byte first.

Range: 0-4095

Cliff Left Signal Packet ID: 28 Data Bytes: 2

unsigned

The strength of the left cliff sensor’s signal is returned as an

unsigned 16-bit value, high byte first.

Range: 0-4095

Cliff Front Left Signal Packet ID: 29 Data Bytes: 2

unsigned

The strength of the front left cliff sensor’s signal is returned as

an unsigned 16-bit value, high byte first.

Range: 0-4095

19iRobot Create Open Interface (OI) Specification

Page 20

Cliff Front Right Signal Packet ID: 30 Data Bytes: 2

10K Ohms

+5V

DIGITAL_INPUT

1 2

10K Ohms

Light Dependent Resistor

(LDR)

+5V

ANALOG_INPUT

unsigned

Cargo Bay Analog Signal Packet ID: 33 Data Bytes: 2

unsigned

The strength of the front right cliff sensor’s signal is returned as

an unsigned 16-bit value, high byte first.

Range: 0-4095

Cliff Right Signal Packet ID: 31 Data Bytes: 2

unsigned

The strength of the right cliff sensor’s signal is returned as an

unsigned 16-bit value, high byte first.

Range: 0-4095

Cargo Bay Digital Inputs Packet ID: 32 Data Bytes: 1

unsigned

The state of the digital inputs on the 25-pin Cargo Bay Connector

are sent as individual bits (0 = low, 1 = high (5V)). Note that the

Baud Rate Change pin is active low; it is high by default.

Example Schematic

The 10-bit value of the analog input on the 25-pin Cargo Bay

Connector is returned, high byte first. 0 = 0 volts; 1023 = 5

volts. The analog input is on pin 4.

Range: 0 - 1023

Example Schematic

Charging Sources Available Packet ID: 34 Data Bytes: 1

unsigned

iRobot Create’s connection to the Home Base and Internal

Charger are returned as individual bits, as below.

Range: 0 - 31

Bit

Button n/a

Device Detect pin can be used to change Baud Rate. When

device detect/baud rate change Bit is low, the Baud Rate

is 19200. Otherwise it it 57600

7 6 5

n/a n/a Device

4 3 2

Detect

/Baud

Rate

Change

(pin 15)

Digital

Input 3

(pin 6)

Digital

Input 2

(pin 18)

1 0

Digital

Input 1

(pin 5)

Digital

Input 0

(pin 17)

Range: 0 - 3

1 = charging source present and powered; 0 = charging source

not present or not powered.

Bit

Charging

Source

7 6 5

n/a

n/a n/a n/a

4 3 2

n/a n/a Home

1 0

Base

Internal

Charger

OI Mode Packet ID: 35 Data Bytes: 1

unsigned

Create’s connection to the Home Base and Internal Charger

are returned as individual bits, as below.

Range: 0 - 3

Number Mode

0 Off

1 Passive

2 Safe

3 Full

20iRobot Create Open Interface (OI) Specification

Page 21

Song Number Packet ID: 36 Data Bytes: 1

unsigned

The currently selected OI song is returned.

Range: 0-15

Song Playing Packet ID: 37 Data Bytes: 1

unsigned

The state of the OI song player is returned. 1 = OI song

currently playing; 0 = OI song not playing.

Range: 0-1

Number of Stream Packets Packet ID: 38 Data Bytes: 1

unsigned

The number of data stream packets is returned.

Range: 0-43

Requested Velocity Packet ID: 39 Data Bytes: 2

signed

The velocity most recently requested with a Drive command

is returned as a signed 16-bit number, high byte first.

Range: -500 - 500 mm/s

Requested Radius Packet ID: 40 Data Bytes: 2

signed

The radius most recently requested with a Drive command

is returned as a signed 16-bit number, high byte first.

Range: -32768 - 32767 mm

Requested Right Velocity Packet ID: 41 Data Bytes: 2

signed

The right wheel velocity most recently requested with a Drive

Direct command is returned as a signed 16-bit number,

high byte first.

Range: -500 - 500 mm/s

Requested Left Velocity Packet ID: 42 Data Bytes: 2

signed

The left wheel velocity most recently requested with a Drive

Direct command is returned as a signed 16-bit number,

high byte first.

Range: -500 - 500 mm/s

21iRobot Create Open Interface (OI) Specification

Page 22

iRobot Create Open Interface

Commands Quick Reference

Create OI Commands Quick Reference Table

Command

Start 128

Opcode

Data Bytes: 1 Data Bytes: 2

Data Bytes: 3 Data Bytes: 4

Etc.

Baud

Control

Safe 131

Full 132

Spot 134

Cover 135

Demo 136 Demos (-1 - 9)

Drive 137 Velocity (-500 – 500 mm/s) Radius (-2000 – 2000 mm)

Low Side Drivers 138 Output Bits (0 – 7)

LEDs 139 LED Bits (0 – 10) Power LED Color

Song 140 Song Number

Play 141 Song Number:

Sensors 142 Packet ID: (0 – 42)

Cover and Dock 143

PWM Low Side

Drivers

Drive Direct 145 Right wheel velocity (-500 – 500 mm/s) Left wheel velocity (-500 – 500 mm/s)

129 Baud Code: (0 – 11)

130

(0 - 15)

(0 – 15)

144 Low Side Driver 2

Duty Cycle (0 - 128)

(0 – 255)

Song Length

(1 - 16)

Low Side Driver 1

Duty Cycle (0 - 128)

Power LED Intensity

(0 – 255)

Note Number 1

(31 – 27)

Low Side Driver 0

Duty Cycle (0 - 128)

Note Duration 1

(0 - 255)

Note Number 2, etc.

Digital Outputs 147 Output Bits (0 –7)

Stream 148 Number of Packets Packet ID 1 (0 – 42) Packet ID 2, etc.

Query List 149 Packet ID 1 (0 – 42) Packet ID 2, etc.

Pause/Resume

Stream

Send IR 151 Byte (0 - 255)

Script 152 Script Length:

Play Script 153

Show Script 154

Wait Time 155 Time (0 – 255

Wait Distance 156

Wait Angle

Wait Event

150 Range: 0-1

(1 – 100)

seconds/10)

Distance (-32767 - 32768 mm)

157

158 Event ID

Angle (-32767 - 32768 degrees)

(1 to 20 and

-1 to -20)

Command Opcode 1 Command Data

Byte 1, etc.

Command Opcode 2 Etc.

22iRobot Create Open Interface (OI) Specification

Page 23

Baud Code (0 – 11)

Baud Code

0

1

2 1200

3 2400

4

5

6

7 19200

8 28800

9 38400

10 57600

11 115200

Baud Rate in BPS

300

600

4800

9600

14400

LEDs Data Byte 1: LED Bits (0 – 10)

Advance and Play use green LEDs: 0 = off, 1 = on

Digital Outputs Data Byte 1: Output Bits (0 –7)

0 = low (0V); 1 = high (5V).

The digital outputs can provide up to 20 mA of current.

Bit

Output

Low Side Drivers Data Byte 1: Output bits (0 – 7)

7

6

5

4

3

2

digital output

2 (pin 20)

1

digital output

1 (pin 7)

0

digital output

0 (pin 19)

0 = off, 1 = on at 100% pwm duty cycle

Bit

Output

7

6

5

4

3

2

Low Side

Driver 2

1

Low Side

Driver 1

0

Low Side

Driver 0

Bit 7

LED n/a n/a

6

5 4

n/a n/a Advance n/a

3 2

1

Play n/a

0

LEDs Data Bytes 2 and 3: Power LED Color and Intensity (0 - 255)

Power uses a bicolor (red/green) LED. The intensity and

color of this LED can be controlled with 8-bit resolution.

LEDs data byte 2: Power LED Color (0 – 255)

0 = green, 255 = red. Intermediate values are intermediate

colors (orange, yellow, etc).

LEDs data byte 3: Power LED Intensity (0 – 255)

0 = off, 255 = full intensity. Intermediate values are

intermediate intensities.

23iRobot Create Open Interface (OI) Specification

Page 24

iRobot Create Open Interface

Sensor Packets Quick Reference

Create sends back one of 43 different sensor data packets

in response to a Sensors command, depending on the value

of the packet ID data byte. Some packets contain groups

of other packets. Group packetsr send their component

values in sequential order. Some of the sensor data values

are 16 bit values. These values are sent as two bytes, high

byte first.

Group Packet Sizes and Contents

Group Packet ID Packet Size

0

1

2

26 bytes

10 bytes

6 bytes 17 - 20

3 10 bytes

4 14 bytes 27 - 34

5 12 bytes 35 - 42

6

52 bytes 7 - 42

Group Packet Sizes and Contents

Contains Packets

7 - 26

7 - 16

21 - 26

Packet Membership

4

27

28

29

30

31

32

33

34

5

35

36

37

38

39 Velocity

40

41 Right Velocity

42

Charging State Codes

Name

Wall Signal

Cliff Left Signal

Cliff Front Left Signal 2

Cliff Front Right Signal

Cliff Right Signal

User Digital Inputs

User Analog Input

Charging Sources

Available

OI Mode

Song Number 1

Song Playing 1

Number of Stream

Packets

Radius

Left Velocity

Bytes Value Range

2

0 - 4095

2

0 - 4095

0 - 4095

2

0 - 4095

2

0 - 4095

1

0 - 31

2

0 - 1023

1 0 - 3

1

0 - 3

0 - 15

0 - 1

1

0 - 42

2 -500 - 500

2 -32768 -

32767

2 -500 - 500

2 -500 - 500

Units

mm/s

mm

mm/s

mm/s

Packet Membership Name

0 1

2 17 IR Byte 1 0 - 255

3 21 Char ging State 1 0 - 5

6

7

Bumps and Wheel

Drops

8

Wall 1

9 Cliff Left

10

Cliff Front Left 1 0 - 1

11 Cliff Front Right 1

12 Cliff Right

13

Virtual Wall

14

Overcurrents 1 0 - 31

15 Unused 1

16 Unused 1 0

18 Buttons 1 0 - 15

19 Distance 2 -32768 -

20 Angle 2 -32768 -

22 Voltage 2 0 - 65535 mV

23 Current 2 -32768 -

24 Batter y Temperature

25 Batter y Charge 2

Battery Capacity 2 0 - 65535 mAh

26

Bytes Value Range Units

1

0 - 31

0 - 1

1 0 - 1

0 - 1

1 0 - 1

1 0 - 1

0

mm

32767

mm

32767

mA

32767

1 -128 - 127 degrees

Celsius

0 - 65535 mAh

Code Charging State

0 Not charging

1 Reconditioning Charging

2 Full Charging

3

Trickle Charging

4 Waiting

5 Charging Fault Condition

Bumps and Wheel Drops

Bit 7 6

Sensor n/a n/a n/a Wheel-

5 4 3 2 1 0

drop

Caster

Low Side Driver and Wheel Overcurrents

Bit

Motor n/a n/a n/a Left

7 6 5 4 3 2 1

Wheel

Wheeldrop

Left

Right

Wheel

Wheeldrop

Right

Low

Side

Driver 2

Bump

Left

Low

Side

Driver 0

Bump

Right

0

Low

Side

Driver 1

24iRobot Create Open Interface (OI) Specification

Page 25

Buttons

Bit

Button n/a

7 6

n/a

5

n/a n/a

Cargo Bay Digital Inputs

Bit

Button

7

6 5

n/a n/a

n/a

4 3

Baud

Rate

Change

(pin 15)

Charging Sources Available

Bit 7 6 5

Charging

Source

n/a n/a n/a n/a

OI Mode

4 3

n/a Advance

Digital

Input 3

(pin 6)

4 3 2

n/a n/a Home

2 1

2

Digital

Input 2

(pin 18)

n/a

1 0

Digital

Input 1

(pin 5)

1 0

Base

0

Play

Digital

Input 0

(pin 17)

Internal

Charger

Number

0 Off

1

2 Safe

3

©2006 iRobot Corporation. All rights reserved.

iRobot, Roomba and Virtual Wall are registered trademarks of iRobot Corporation.

Home Base and Create are trademarks of iRobot Corporation.

U.S. Pat. Nos. 6,594,844 6,690,134, and 6,809,490. Other patents pending.

Mode

Passive

Full

25iRobot Create Open Interface (OI) Specification

Loading...

Loading...