Irinox MF 180.2 Manual

Roll-In Blast Chiller / Shock Freezer |

MF 180.2-MYA |

|

|

MultiFresh Model MF 180.2-MYA |

|

… YOUR TRUSTED KITCHEN ASSISTANT |

|

|

|

The IRINOX ModelMF180..22BlastChiller/ /ShockFreeezershallshall have the followingllo ingcharacteristics:Capacity––(1)(1)singleuniversal- - -anglerollroll-in-inrack;upor to(1)(24)standard12”x20”x2combi-1/2”-ovensteamtrolleytableorpans(1) standardor up bakeryto (12) 18”x26”rack: upfullto size(24) sheet12”x20”x1/2”pans; (1)steamstandardblecombipans-ovenr (12)trolley;18”x x26”controllerfull size– shallsheetfeaturepans;thecontrfollollerwing–controlshall featurepaths:thestandardfollowingmode controlfor chillingpaths:or freezing,standarddynamicmode formodechillingfor chillingor freezing,or freezingdynam(iconmode fordriven)chillingandorpefrsonalizedeezing (iconmodriven)es for customerand personalizedspecific prmoducts;es for coreustomerprobespecific– multi-products;sensor productcore probecore temperature– multi-sensorprobeproductwith five core(5) measuringtemperaturepointsprobeandwith“easyfive-out”(5)feature;measuringplus allpointsthe standard“easy- -featuresout” featurlisted; plusbelowall. the standard features listed below.

Standard Construction Features:

• All type 304 stainless steel construction

•Standard Construction Features:

CFC-free high-density polyurethane insulation

•• All type 304 stainless steel construction

Full width door with low-temperature resistant magnetic gasket

All type 304 stainless steel construction

•●• CFC-free high-density polyurethane insulation Die-stamped interior door liner to magnetically store core

● CFC-free high-density polyurethane insulation

• Full width door with low-temperature resistant magnetic gasket probe

● Full width door with low-temperature resistant magnetic gasket

•• Die-stamped interior to magnetically store core probe

● DieErgonomic-stampededgint rior-freedoorstainlessliner tosteelmagneticallydoor handlestore core probe

•●•ErgonomicApproved R404Aedge--frerefrigerantstainlessusedtteelinl doorsealedhandlesystem

••IntegApprovedat singleR404 compressorrefrigerant useand condenserin sealed system

● High efficiency evaporators with multiple injection points

Approved R404 refrigerant used in sealed system

•●• High performance evaporators with multiple injection points Luminous display with intuitive work-path controls

● High efficiency evaporators with multiple injection points

•• Luminous display with intuitive work-path controls Door hinged right (standard)

● Luminous display with intuitive work-path controls

•• USB port for data transfer to HACCP software, internal

● USBEnd-ofport-cyclefor dataholdtransfermode to HACCP software, internal

• softwareupgradesandandindividualprogramprogramuploadsuploads Energy-efficient, air-cooled, remote condensing unit

••Doorhingedright(standard)

● 2-1/4” thick insulated floor

●•End-of-of-cycle- holdholdmodemode

Energy-efficient, air-cooled, remote condenser

●• Energy-efficient, air-cooled, remote condensing unit

• 2-1/4” thick insulated floor

Unique Design and Performance Features:

Unique Design and Performance Features:

• 4 Standard cycles, 112 product specific cycles, ability to record

up to 38 replicable cycles

● 4 cycles in standard mode, 39 product specific cycles in

• Electronically controlled fans with low power consumption; dynamic mode; ability to record up to 20 replicable cycles

fans stop automatically when door is open into customized recipe book

• Indirect● 30-40%airmoredistributionenergyandefficient,specialwithairflowfasterpatternchillingtotimesensure- all perfectwhile temperaturepreserving theuniformityfreshness and fragrance of the food

● Electronically controlled fans with low power consumption;

• Easy access to clean evaporators and waterproof fans fans stop automatically when door is open

• Easy● Indirectto useairtouchdistributionscreenandwithspec7” ialnterfaceairflow pattern to ensure

perfect temperature uniformity

• WIFI for data transfer to HACCP software

● Moisture preservation system by “delta-t” control

• Core● Smudgeprobe-resistantmagneticallyontrollersecuredtouchtopaddoor when not in use

• Shock● Easyfreezingaccess totemperaturewashable evaporatorsuses -40F airand waterproof fans

Item No.__________

Qty. _____________

Project __________

________________

________________

________________

________________

Model MF 180.2

Sizing & Unit Production Guide MF 180.2

Capacity (1) Roll-in Rack for up to (24) 12”x20”x2-1/2”

steam table pans or up to (12) 18”x26” full

Sizing & Unit Production Guide MF 180.2 size sheet pans or (1) standard bakery rack

Combi-Oven Trolley, Standard |

241 |

apacity: (12”x20”x2-1/2”) steam table pans |

|

Blast Chilling Capacity (194F to 37F)*: |

400 lbs |

Capacity: (18”x26”) full size sheet pans |

12 |

Shock Freezing Capacity (194F to 0F)*: |

400 lbs. |

Pan Spacing: |

2-3/4” |

* Per production cycle (depending on product |

|

Blast Chilling Capacity (194F to 37F)*: |

400 lbs. |

density): Blast chilling … up to 90-minute cycle |

|

ShockFrefreezing … up to 240-minute cycle |

|

Capacity (194F to 0F)*: |

400 lbs. |

Options* Per productionand Accessoriescycle (depending(Pleaseon producheck):t density):

Blast chilling … up to 90-minute cycle

• Sous-vide pouch core temperature probe

Shock freezing … up to 240-minute cycle

• Additional (2) food probes

• Liquid probe holder

• PRISON PACKAGE: security fasteners, lockable

Optionsclosure forandcontroller,Accessoriesflexible probe(Pleaseand stainlesscheck): steel top

Sous-vide pouch core temperature probe

• Door hinged left

Flexible core temperature probe (prison package)

• SANIGEN sanitation system

Door hinged left

• Water-cooled, remote condensing unit

Rolling rack: (12) 18”x26x1” sheet pans or (24)

• External ramp required if unit not recessed into

12”x20”x2-1/2” steam table pans floor pit

SANIGEN sanitation system

• 2 Year extended compressor warranty

Water-cooled, remote condenser

• Pass-thru cabinet

Portable HACCP data printer

• Spare parts kit

•KDF

•Condensing unit cover for outdoor useHACCPshippingsoftware– assembly by others

Product Warranty Protection:

- 1 year, parts and labor

Rev. 11/14

IRINOX USA

Phone: 508-230-5818 Fax: 508-230-5819 www.irinoxusa.com email: info@irinoxusa.com

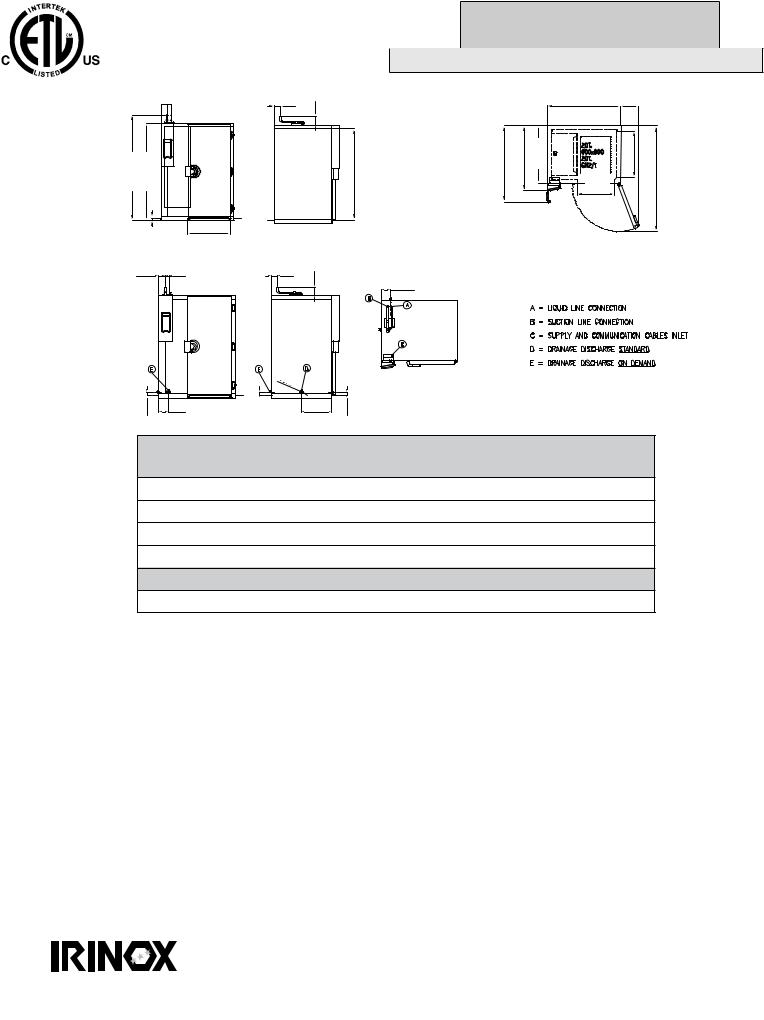

MF 180.2-MYA

...YOUR TRUSTED KITCHEN ASSISTANT

5

55-5/16”'' 4''4”

3 |

3 3/4”'' |

-913/4”'' |

84 |

91 |

- |

84 |

|

|

|

1 |

1 |

'' |

37 2 |

||

'' |

|

|

1/4”-2 |

|

|

24 |

|

|

5” |

7” |

|

D.P. 79-5/16” |

D.P. = Door Passage

|

|

|

63” |

15-3/4” |

1/2”- |

56” |

1/4”-49 |

20T. |

3/4”-39 |

600x800 |

||||

|

|

|

20T. |

|

66 |

|

|

GN2/1 |

|

|

|

(D.P.) 32-1/4” |

91” |

|

|

|

|

|

|

|

|

D.P. = Door Passage |

|

|

5-5/16” 4”

3/4”-2 |

3/4”-2 |

|

7-7/8” |

5” |

|

7” |

|

ø1- |

|

5/16” |

|

20-5/8” |

3/4”-3/4” |

|

|

|

2 |

|

- |

|

2 |

7-7/8”

Drain Position

Cabinet Dimensions and Weight |

Sunken Floor |

|

*See #1 below |

Width |

63” |

Depth |

56” |

Height |

91-3/4” |

Weight (unit) |

1058 lbs. |

Cabinet Electric Data / Power Requirements |

|

208V 60 Hz 3 Phase, 3KW, 9.6 Amp |

|

[D] Drain Connection: 1-1/2” ID [Per local codes]

Installation Notes:

*1. 2-1/2” pit required as floor of cabinet insulated; filler by others may be required.

2.If pit not available an external ramp is required.

3.Cabinet shipped on evaporator coil side.

4.If pass-thru ordered two ramps required.

5.Installation and charging of refrigeration lines are the responsibility of owner or installation contractor.

6.5 wires # 14AWG must be installed by owner or installation contractor between the chiller and the condensing unit. The connection should be performed according to the electrical diagram.

7.If installed outdoors, condensing unit should be protected from direct sunlight and provided with a minimum of 40” air space.

8.If installed over 75’ from chiller, installer must contact IRINOX USA for proper

refrigerant pipe sizing and verify if necessary to install oil separator |

Rev. 11/14 |

Continued product development may necessitate specification changes without notice.

IRINOX USA

Phone: 508-230-5818 Fax: 508-230-5819 www.irinoxusa.com email: info@irinoxusa.com

Loading...

Loading...