Page 1

Intel LB440GX 2U Rack Server Chassis

Technical Product Specification

Released version 1.0

August, 1999

245251-001

Page 2

Intel© LB440GX 2U Server Chassis TPS, Rev 1.0

Revision History

Revision Revision History Date

Rev 0.xx Initial release of the Intel LB440GX 2U Rack Server Chassis Technical Product

Specification (Part #245251-001)

Rev 0.9 Revisions 06/99

Rev 1.0 Legal and Trademark Review 8/12/99

03/99

INFORMATION IN THIS DOCUMENT IS PROVIDED "AS IS" WITH NO WARRANTIES WHATSOEVER,

INCLUDING ANY WARRANTY OF MERCHANTABILITY, NONINFRINGMENT OF INTELLECTUAL PROPERTY

RIGHTS OR ANY OTHER RIGHTS OF THIRD PARTIES OR OF INTEL, FITNESS FOR ANY PARTICULAR

PURPOSE, OR ANY WARRANTY OTHERWISE ARISING OUT OF ANY SPECIFICATION, SOFTWARE,

DOCUMENTATION OR OTHER MATERIALS REFERENCED HEREIN. Third parties may have intellectual

property rights which may be relevant to this document and the technologies discussed herein.

Nothing in this document constitutes a guarantee, warranty or license to any intellectual property right, express

or implied, by estoppel or otherwise. Intel makes no representations or warranties and specifically disclaims all

liability as to this document or the information contained herein with respect to sufficiency, reliability, accuracy,

completeness or usefulness of same. Furthermore, Intel makes no commitment to update the information

contained in this document, and Intel reserves the right to make changes at any time, without notice, to the

information contained in this document.

Except as provided in Intel's Terms and Conditions of sale for the products referenced herein, Intel assumes no

liability whatsoever, and Intel disclaims any express or implied warranty, relating to sale and/or use of Intel

products including liability or warranties relating to fitness for a particular purpose, merchantability, or

infringement of any patent, copyright or other intellectual property right. Intel products are not intended for use in

medical, life saving, or life sustaining applications. Intel may make changes to specifications and product

descriptions at any time, without notice. LIMITATION OF LIABILITY

. IN NO EVENT SHALL INTEL BE

LIABLE TO ANY PARTY FOR ANY DAMAGES WHATSOEVER (INCLUDING WITHOUT LIMITATION,

DIRECT, INDIRECT, SPECIAL, CONSEQUENTIAL, LOST PROFITS, BUSINESS INTERRUPTION,

COMPUTER FAILURE OR MALFUNCTION, OR LOST INFORMATION) SUFFERED AS A RESULT OF

USING OR RELIANCE UPON THE INFORMATION CONTAINED HEREIN.The Intel products referred to in this

document may contain design defects or errors known as errata which may cause the product to deviate from

published specifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your

product order.

Copyright © Intel Corporation 1999.

Pentium is a registered trademark of Intel Corporation. MMX is a trademark of Intel Corporation.

*Third-party marks and brands are the property of their respective owners.

ii

Page 3

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

Reference Documents

§ Intel L440GX+ Technical Product Specification (TPS) Rev 1.0

§ Power Supply, 300W, 5 Output, with PFC Rev 2.0

§ Entry-Level Electronics-Bay Specification Rev 0.90

§ ATX Specification Version 2.03

§ SCSI Accessed Fault-Tolerant Enclosures Interface Specification, Conner Peripherals and

Intel Corporation, Revision 1.00, October 17, 1995

§ SCSI Parallel Interface-2, draft proposal revision 20a

Page 4

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

TABLE OF CONTENTS

1 INTRODUCTION........................................................................................................................................1

2 CHASSIS ......................................................................................................................................................1

2.1 CHASSIS COLOR ...................................................................................................................................... 1

2.2 FRONT PANEL FEATURES.........................................................................................................................1

2.3 SECURITY................................................................................................................................................ 1

2.4 I/O PANEL ............................................................................................................................................... 1

2.5 CHASSIS VIEWS....................................................................................................................................... 2

2.6 CHASSIS DIMENSIONS..............................................................................................................................3

3 CHASSIS POWER SUBSYSTEM............................................................................................................... 4

3.1 MECHANICAL OUTLINE............................................................................................................................ 4

3.2 FAN REQUIREMENTS................................................................................................................................ 4

3.3 AC POWER LINE......................................................................................................................................4

3.4 POWER SUPPLY CONNECTOR PIN ASSIGNMENTS....................................................................................... 5

3.4.1 P1 Main Power Connector .............................................................................................................. 5

3.4.2 P10 ATX Aux Power Connector.......................................................................................................6

3.4.3 P2-P8, P11, P12 Peripheral Power Connector.................................................................................6

3.4.4 P9 Floppy Drive Power Connector.................................................................................................. 6

3.5 POWER SUPPLY/CHASSIS CONFIGURATION ...............................................................................................6

4 CHASSIS COOLING...................................................................................................................................7

5 CHASSIS PERIPHERAL BAYS..................................................................................................................8

5.1 3.5" FLOPPY DRIVE BAY.......................................................................................................................... 8

5.2 5.25" DRIVE BAY .................................................................................................................................... 8

5.3 LVD SCSI HOT-SWAP DRIVE BAYS ........................................................................................................ 8

6 FRONT PANEL............................................................................................................................................9

7 HOT-SWAP SCSI SUBSYSTEM............................................................................................................... 10

7.1 SUBSYSTEM PURPOSE ............................................................................................................................ 10

7.2 ABSTRACT............................................................................................................................................. 10

7.3 HOT-SWAP BACKPLANE BOARD LAYOUT............................................................................................... 11

7.3.1 Configuration Options................................................................................................................... 11

7.4 FUNCTIONAL DESCRIPTION.................................................................................................................... 12

7.4.1 68 pin LVD high density Hot-Swap Connectors .............................................................................. 12

7.4.2 SCSI Interface............................................................................................................................... 12

8 DUAL-SLOT PCI RISER .......................................................................................................................... 13

9 CHASSIS INTERCONNECTION.............................................................................................................13

9.1 CHASSIS INTERNAL CABLES...................................................................................................................13

9.2 CONNECTOR INTERFACES....................................................................................................................... 14

9.2.1 Hot-Swap Backplane and Peripheral Power Connectors................................................................ 14

10 SUPPORTED INTEL SERVER BOARDS............................................................................................15

10.1 INTEL

iv

L440GX+ DP SERVER BOARD................................................................................................... 15

Page 5

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

11 REGULATORY INFORMATION ........................................................................................................ 16

11.1 REGULATORY COMPLIANCE...................................................................................................................16

11.1.1 Safety Standards ............................................................................................................................ 16

11.1.2 EMC Regulations .......................................................................................................................... 17

11.1.3 Regulatory Compliance Markings..................................................................................................18

11.2 ELECTROMAGNETIC COMPATIBILITY NOTICE (USA)............................................................................... 18

11.2.1 FCC Declaration of Conformity..................................................................................................... 19

11.3 ELECTROMAGNETIC COMPATIBILITY NOTICES (INTERNATIONAL) ............................................................ 19

12 ENVIRONMENTAL LIMITS................................................................................................................ 20

12.1 SYSTEM OFFICE ENVIRONMENT ............................................................................................................. 20

12.2 SYSTEM ENVIRONMENTAL TESTING ....................................................................................................... 20

13 RELIABILITY, SERVICEABILITY, AND AVAILABILITY..............................................................21

13.1 MEAN-TIME-BETWEEN-FAILURE (MTBF)..............................................................................................21

13.2 SERVICEABILITY.................................................................................................................................... 21

Figures

FIGURE 1. ATX 2.03 I/O APERTURE..................................................................................................................... 1

FIGURE 2. FRONT AND REAR CHASSIS VIEWS........................................................................................................2

FIGURE 3. ISOMETRIC VIEW WITHOUT TOP COVER................................................................................................3

FIGURE 4. 80MM SYSTEM FAN.............................................................................................................................. 7

FIGURE 5. FRONT PANEL AND FUNCTIONS ............................................................................................................ 9

FIGURE 6. FUNCTIONAL DIAGRAM OF THE HOT-SWAP SCSI BACKPLANE ............................................................ 11

FIGURE 7. HOT SWAP SCSI BACKPLANE BLOCK DIAGRAM................................................................................. 12

FIGURE 8. ACTIVE PCI RISER BLOCK DIAGRAM.................................................................................................. 13

FIGURE 9. PERIPHERAL POWER CONNECTOR........................................................................................................14

Tables

TABLE 1. CHASSIS DIMENSIONS ..........................................................................................................................3

TABLE 2. POWER SUPPLY OUTPUT SUMMARY...................................................................................................... 4

TABLE 3. 20+4-PIN “MODIFIED ATX” POWER SUPPLY CONNECTOR.....................................................................5

TABLE 4. AUX ATX POWER CONNECTOR ............................................................................................................ 6

TABLE 5. PERIPHERAL POWER CONNECTOR ......................................................................................................... 6

TABLE 6. FLOPPY DRIVE POWER CONNECTOR ..................................................................................................... 6

TABLE 7. HSBP CONFIGURATION JUMPERS....................................................................................................... 11

TABLE 8. PIN TYPES ......................................................................................................................................... 14

TABLE 9. PERIPHERAL POWER CONNECTORS...................................................................................................... 14

TABLE 10. SYSTEM OFFICE ENVIRONMENT SUMMARY.........................................................................................20

v

Page 6

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

1 Introduction

This specification details the feature set of the Intel® LB440GX 2U rack server chassis, an ATX-form

factor server chassis designed for the Intel® L440GX+ server board.

Intel LB440GX features include:

• 2U rack mount chassis (3.46” H x 16.75” W x 28” L)

• One floppy drive

• Two 32-bit/33 MHz PCI slots on the included PCI Riser Card

• Four hot-swap hard drive bays capable of supporting two 1” and two 1.6” LVD SCSI hard drives

• Two system fans

• One 300-Watt PFC PS/2* power supply

2 Chassis

The chassis is 3.46 inches high, 16.75 inches wide, and 28 inches long. The rear I/O panel conforms

to the ATX Specification version 2.03, supporting two expansion cards.

2.1 Chassis Color

The primary exterior chassis color will match Intel Color Standard 513505 (dusty beige).

2.2 Front Panel Features

The front panel is pressed SECC with four removable SCSI drive bays, two 1.6” and two 1”. The front

panel also allows for a floppy drive and full-size CD-ROM. The front panel contains a power button

power indicator LED, and hard drive activity LED’s.

2.3 Security

At the chassis level, no security option is provided (no chassis intrusion).

2.4 I/O panel

All input/output connectors are accessible on the rear of the chassis and an ATX 2.03-compatible

cutout is provided for I/O shield installation. A metal I/O shield with appropriate Electromagnetic

Interference (EMI) gasket is installed in the cutout in order to maintain EMI-compliance levels. The

I/O cutout dimensions (measured in inches) are shown in Figure 1 below.

R 0.039 MAX, TYP

1.750 ± 0.008

(0.150)

1

0.100 Min keepout around opening

I/O Aperture

Figure 1. ATX 2.03 I/O Aperture

Baseboard

5.196 ± 0.0106.250 ± 0.008

Datum 0,0

(0.650)

Page 7

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

Bays

Bays

Drive LEDs

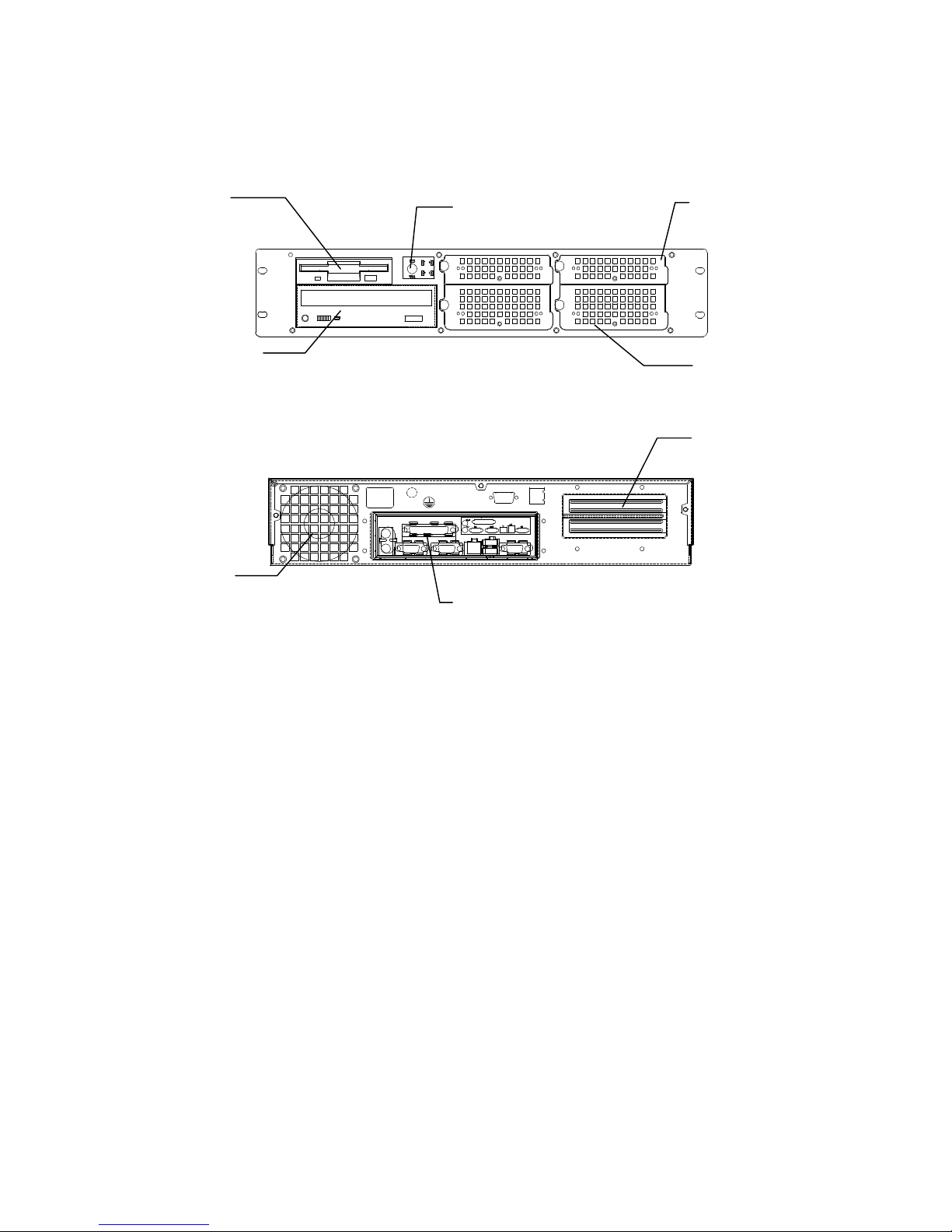

2.5 Chassis Views

Floppy Drive

CD-ROM Drive Bay

Exhaust Grill

Power Switch and

I/O Panel: Keyboard, Mouse, Parallel

Port, 2 Serial Ports, LAN, 2 USB Ports,

and Video

Two 1” Hot-swap Drive

Two 1.6” Hot-swap Drive

Two PCI Bays

Figure 2. Front and Rear Chassis Views

2

Page 8

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

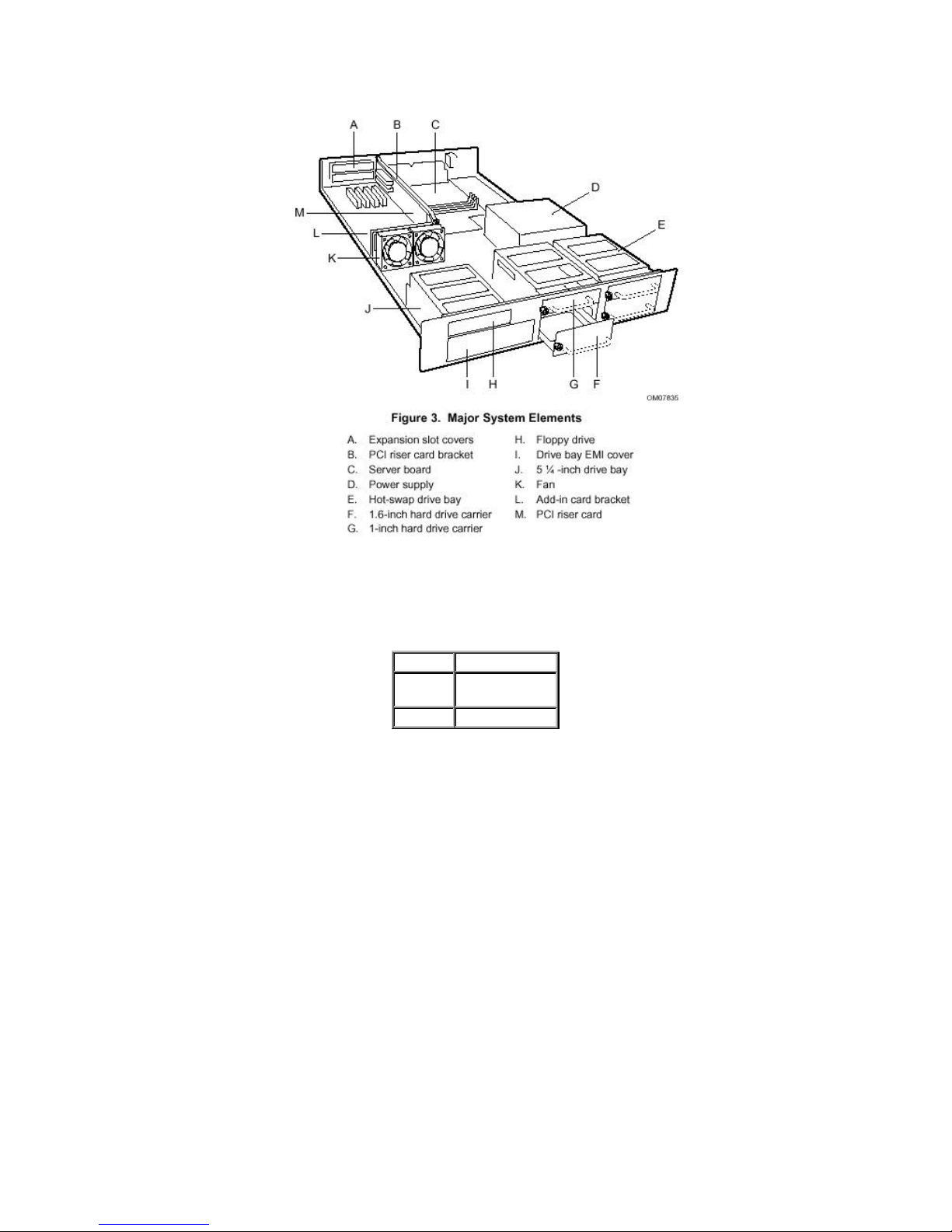

Figure 3. Isometric View without Top Cover

2.6 Chassis Dimensions

Height 2U (80 mm)

Width 16.75” (480

mm)

Depth 28” (711 mm)

Table 1. Chassis Dimensions

3

Page 9

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

3 Chassis Power Subsystem

This chassis uses a single standard PS/2 form factor power supply. Variations may be chosen for

future board sets to satisfy the chassis power, power distribution, thermal performance, acoustic

noise and cost requirements.

The form factor was chosen to optimize the overall chassis dimensions. The typical PS/2 form factor

power supply with a remote enable feature can be used. The remote enable feature permits the

chassis power to be activated from a variety of sources, allowing the implementation of “Wake On

LAN*” (WOL) or other remote management features. The 300-watt PFC (Power Factor Correction)

power supply features a 24-pin main power connector and a 6-pin Auxiliary ATX power connector.

The following table is a brief overview:

ATX 300W Non-PFC 719680-

002

+5 VDC Output 26 Amp Max

+12 VDC Output 10 Amp Max

-12 VDC Output 0.5 Amp Max

-5 VDC Output 0.25 Amp Max

+3.3 VDC Output 16 Amp Max

+5 VDC Standby 800mA Max

Output balancing Total combined output power of +3.3V

AC Line Voltage Autorange

AC Line Frequency 50/60 Hz

AC Input Current 4.6 Amp at 115 VAC 2.3 Amp at 220 VAC

P/S Rating, Maximum Continuous

Current

and +5V shall not exceed 167 W.

Table 2. Power Supply Output Summary

3.1 Mechanical Outline

The mechanical outline and dimensions of the power supply adhere to the standard PS/2 Form factor.

The approximate dimensions are: 140mm high x 86mm wide x 150mm deep.

3.2 Fan Requirements

The power supply incorporates an 80mm low-acoustic-noise fan to exhaust air. The sound pressure

level is measured at a distance of 0.1 meter from each side of the power supply in a free field. The

worst-case peak value of the measurements shall not exceed 38 dBA at 23°C ± 2°C.

Due to the increased output requirements of the 5V standby circuit, power supply thermal margins

are difficult to maintain while the system is in the “off” state. For this reason, the power supply fan

will run at a reduced RPM when the system is off.

3.3 AC Power Line

The power supply is specified to operate from 100-120VAC, 200-240VAC, at 50 or 60Hz and is autoranging. The power supply is tested to meet these voltages, and has been tested (but not specified)

in a configured system at ± 10% of the voltage ranges, and similarly ± 3Hz on the line input

frequency.

The power supply, in a configured system, is specified to operate without error at full power supply

4

Page 10

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

output load, nominal input voltage, with line source interruptions not to exceed one period of the AC

input power frequency (i.e. 20 milliseconds at 50Hz).

The power supply is not damaged by AC surge ring wave up to 3.0kV/500A. This ring wave is a

100kHz damped oscillatory wave with a specified rise-time for the linear portion of the initial halfcycle of 0.5µsec. Additionally, the chassis will not be damaged by a unidirectional surge waveform of

up to 1.5kV/3000A, with a 1.2µsec rise time and 50µsec duration. Further details on these

waveforms can be obtained in ANSI/IEEE STD C62.45-1992.

3.4 Power Supply Connector Pin Assignments

3.4.1 P1 Main Power Connector

Housing: 24-pin Molex* 39-01-2240, Contact: Molex 39-00-0038

Pin Signal 18 AWG

1 +3.3VDC Orange 13 +3.3VDC Orange

2** +3.3VDC

+3.3V remote sense

3** COM

3.3V remote sense RTN

4 +5VDC Red 16 PS_ON_L Green

5 COM Black 17 COM Black

6 +5VDC Red 18 COM Black

7 COM Black 19 COM Black

8 PWR OK Gray 20 -5V White

9 5VSB Purple 21 +5VDC Red

10 +12VDC Yellow 22 +5VDC Red

11 +12VDC Yellow 23 +5VDC Red

12 +3.3VDC Orange 24 COM Black

Color

Orange

Orange

Black

Black

Pin Signal 18 AWG

Color

14 -12VDC Blue

15 COM Black

Table 3. 20+4-pin “Modified ATX” Power Supply Connector

§ Note**: The 3.3V power and 3.3V remote sense are double crimped into a single contact at

pin 2. The 3.3V remote sense return and COM are double crimped into a single contact at

pin 3.

§ The “Modified ATX” main power connector is configured as the standard ATX 20 (2x10) pin

connector plus a 2x2 (4) pinout designed to supply additional +5VDC to the board. For

connecting this into the Intel L440GX+ server board, use the 24-pin power connector on the

board.

5

Page 11

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

3.4.2 P10 ATX Aux Power Connector

Housing: 6-pin Molex 90331-0010, Contact: Molex 09-50-0277

Pin Signal 18 AWG

Color

1 COM Black 4 +3.3VDC Orange

2 COM Black 5 +3.3VDC Orange

3 COM Black 6 +5VDC Red

Pin Signal 18 AWG

Table 4. Aux ATX Power Connector

3.4.3 P2-P8, P11, P12 Peripheral Power Connector

Housing: Amp 1-480424-0, Contact: Amp 61314-1

Pin Signal 18 AWG

1 +12VDC Yellow

2 COM Black

3 COM Black

4 +5VDC Red

Color

Color

Table 5. Peripheral Power Connector

3.4.4 P9 Floppy Drive Power Connector

Housing: Amp 171822-4

Pin Signal 18 AWG

1 +5VDC Red

2 COM Black

3 COM Black

4 +12VDC Yellow

Color

Table 6. Floppy Drive Power Connector

3.5 Power Supply/Chassis Configuration

The Intel LB440GX 2U rack server platform can only be configured with a single power supply. For

a more detailed specification on the power supply, see document 719680, the specification for the

300-Watt power supply with PFC.

6

Page 12

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

AIR FLOW

80 ±.5

GROUND BLACK

All measurements are in millimeters

4 Chassis Cooling

Two system fans and the power supply fan provide cooling for the processor(s), hard drives, and

add-in cards. Two 80mm system fans are mounted in the middle of the chassis. All chassis fans

provide a single tachometer output for RPM detection that the server board can make available for

server management monitoring and alert functions. Removal of the top cover gives access to the

fans, which then can be easily changed with the system powered down.

3 2 1

230 ±30

ROTATION

71.5 ±.3

SIGNAL AND WIRE COLOR

+12V RED

TACHOMETER

4.-

Φ4.5 DIA

4.0X 2

±.5

25.

CONNECTOR PIN OUT

1

2

3

LABEL SIDE

7

Figure 4. 80mm System Fan

Page 13

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

5 Chassis Peripheral Bays

5.1 3.5" Floppy Drive Bay

The chassis provides for the installation of a 3.5“ floppy drive above the 5.25” CD-ROM drive bay.

Removal of the top cover provides access for replacement of the floppy drive.

5.2 5.25" Drive Bay

The chassis supports one half-height (1.6” high) removable media peripheral devices (typically CDROM). As a guideline based on cooling capabilities, the maximum recommended power per device is

17W. Thermal performance of specific devices must be verified to ensure compliance to the drive

manufacturer’s specifications.

The 5.25" peripherals are removable from the front of the chassis after removal of the top cover.

5.3 LVD SCSI Hot-Swap Drive Bays

The LB440GX 2U rack server chassis supports up to four (two 1” high and two 1.6” high) 3.5" LVD

Ultra-2 SCSI hard drives which are accessible from the front of the chassis. Four low-cost SECC

carriers are provided with the chassis to be installed on the hard drives.

Thermal performance of specific hard drives must be verified to ensure compliance to the drive

manufacturer’s specifications. Peripherals must be specified to operate at a maximum ambient

temperature of 50°C.

8

Page 14

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

6 Front Panel

The front panel board includes the Power On/Off button, a green Power On LED, four green hard

drive activity LED’s (not drive failures), which are visible through the front inlay.

A four-pin connector is provided on the front panel board for connection to the hot-swap backplane

for drive activity of drives number 1 and 2.

A four-pin connector is provided on the front panel board for connection to the hot-swap backplane

for drive activity of drives number 3 and 4.

A four-pin connector is provided on the front panel board for connection to the baseboard for power

LED.

A two-pin connector is provided on the front panel board for connection to the baseboard for the

power switch.

Power Switch

Power LED

Hard Drive Activity LEDs

Figure 5. Front Panel and Functions

9

Page 15

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

7 Hot-Swap SCSI Subsystem

The Intel LB440GX 2U rack server chassis has two independent, identical hot-swap backplanes.

Each backplane supports two Ultra2 SCSI hot-swappable drives. Two configurable switches on the

back of each backplane (see Figure 11) determine the identification of each drive. The backplanes

are then daisy chained with a standard 68-pin Ultra-2 SCSI cable. The hot-swap SCSI subsystem

supports the following features:

§ Hot-swapping of Ultra-2 SCSI drives, that allows connection of SCSI devices while the power

is on.

§ Full dual mode LVD operation, compliant with Fast, Ultra and Ultra-2 SCSI bus operation.

7.1 Subsystem Purpose

The Intel LB440GX 2U rack server chassis hot-swap SCSI backplane performs the tasks associated

with hot-swappable SCSI drives. The backplane design allows for:

§ Four high density 68 pin connectors for four LVD Ultra-2 compatible SCSI drives

§ Active termination on SCSI bus

§ Per-drive power control, including automatic slot power down upon drive removal

7.2 Abstract

The Intel LB440GX hot-swap SCSI backplane is made up of the following functional blocks:

§ SCSI Bus with Ultra-2 high density LVD 68 pin drive connectors, and active terminators

§ SCSI drive power control

§ Configuration jumpers

10

Page 16

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

7.3 Hot-Swap Backplane Board Layout

The backplanes reside in the hot-swap drive bay of the Intel LB440GX 2U rack server chassis. Note

this is a passive backplane, which means there is no firmware associated with it (no SAF-TE ASIC).

As a result, server management will not be able to determine the status of each drive.

The following diagram shows the layout of components and connectors on the hot-swap SCSI

backplane printed circuit board.

DISK POWER

CONNECTOR

TERMINATOR

ENABLE : SHORT

DIABLE : OPEN

68Pin SCSI CON

NECTOR

SE/LVD SCSI

TERMINATOR

Figure 6. Functional Diagram of the Hot-Swap SCSI Backplane

SCSI ID SW

SW2 SW1 DISK1 DISK0

OFF OFF 1 0

OFF ON 3 2

ON OFF 5 4

ON ON 9 8

7.3.1 Configuration Options

The following table lists all possible SCSI ID switch configurations of the Intel LB440GX hot-swap

SCSI backplane and the resulting SCSI ID for the position of each switch.

11

SW 2 SW 1 ID of Disk 1 ID of Disk

0

OFF OFF 1 0

OFF ON 3 2

ON OFF 5 4

ON ON 9 8

Table 7. HSBP Configuration Jumpers

Page 17

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

7.4 Functional Description

This section defines the architecture of the Intel LB440GX Hot-swap SCSI Backplane, including

descriptions of functional blocks and how they operate. The following figure shows the functional

blocks of the Hot-swap SCSI Backplane. An overview of each block follows.

68P SCSI

Connector

ID SELECT SW

DIP2 DIP1 SLOT0 SLOT1

OFF OFF 1 0

OFF ON 3 2

ON OFF 5 4

ON ON 9 8

EPLD

Drive Power

Control

ID Config

Presence

Presence

SCA-2 Connector 0

(Upper Slot)

SCA-2 Connector 1

LVD/SE Multimode

TERMINATOR

Terminator

Enable Jumper(JP2)

Short : Enable

Open : Disable

(Lower Slot)

Figure 7. Hot Swap SCSI Backplane Block Diagram

7.4.1 68 pin LVD high density Hot-Swap Connectors

The Intel LB440GX contains two hot swap backplane boards with two high-density LVD connectors

on each backplane. The connectors provide power and SCSI signals using a single connector. Each

SCSI drive attaches to the backplane using one of these connectors.

7.4.2 SCSI Interface

The SCSI interface on the Intel LB440GX Hot-swap SCSI Backplane provides the required circuitry

between the SCSI bus and the Adaptec controller, which contains the intelligence for the backplane.

The interface consists of an Altera EPLD. After powering on, the Altera EPLD detects the presence of

disks in the slots and powers them on. The SCSI ID configuration of the disks is configured on the

backplanes by using two DIP-switches located on the boards. See section 7.3.1 for the SCSI ID

configuration options.

12

Page 18

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

8 Dual-Slot PCI Riser

The Intel LB440GX employs a dual-slot PCI riser, which provides two full-length 32-bit/33Mhz PCI.

The riser is an active riser due to the extra PCI Bus Bridge on the card. The riser resides in PCI slot

number 5 of the Intel L440GX+ server board.

P_INT_B <- INT_A

P_INT_C <- INT_B

P_INT_D <- INT_C

P_INT_A <- INT_D

Slot 1 (Upper Slot)

IDSEL 21

PCI Slot5

Primary PCI

IDSEL 20

TI PCI

Bridge

PCI2031

32Bits/33MHz

Secondary PCI

IDSEL 20

Slot 0 (Lower Slot)

P_INT_A <- INT_A

P_INT_B <- INT_B

P_INT_C <- INT_C

P_INT_D <- INT_D

Figure 8. Active PCI Riser Block Diagram

Note: The Intel L440GX+ baseboard provided in the Intel LB440GX system contains 6 PCI slots

and 1 ISA slot. PCI Slot 5 contains the PCI Riser Card. The other slots are inactive and should not be

used. Any (up to two) PCI cards in the system should be inserted in the slots on the PCI Riser card.

9 Chassis Interconnection

9.1 Chassis Internal Cables

Front panel board to hot-swap backplanes

§ A four-pin connector connect the front panel board to the second hot-swap backplane to

transfer drive activities to the LED indicators of drives 3 and 4.

§ A four-pin connector connects the front panel board to the first hot-swap backplane to

transfer drive activities to the LED indicators of drives 1 and 2.

Front panel board to server board

§ A two-pin connector cable provides Power On/Off function.

§ A four-pin connector cable connects the server board to the front panel board to provide

server board power status.

13

Page 19

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

Server board to hot-swap backplanes

§ An Ultra-2 SCSI cable (68-pin) is provided to interface from the installed server board to

the two hot-swap backplanes.

§ Two high-density 68-pin connectors in each backplane provide interface between the hotswap SCSI backplane and hot-swap SCSI devices.

9.2 Connector Interfaces

Each pin is classified by type, as shown in the following table.

Type Description

PWR Power connection (power or

I/O Bi-directional signal

O Output signal

I Input signal

O/C Open-collector output signal

O/D Open-drain output signal

ground)

Table 8. Pin Types

9.2.1 Hot-Swap Backplane and Peripheral Power Connectors

The hot-swap backplane power connector and peripheral power connectors are a standard fourpin shrouded plastic PC power connectors with mechanical keying. Connector pinout is shown

below.

Figure 9. Peripheral power connector

Name Pin Description

+12V 1 +12 Volt power supply (yellow

GND 2 0V Electrical ground (black wire)

GND 3 0V Electrical ground (black wire)

+5V 4 +5 Volt power supply (red wire)

wire)

Table 9. Peripheral power connectors

14

Page 20

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

10 Supported Intel Server Boards

The following is a summary of the feature sets for Intel server boards supported by the Intel

LB440GX 2U rack server chassis. Please refer to the appropriate server board Technical Product

Specification for greater detail.

10.1 Intel L440GX+ DP Server Board

§ Support for Single or Dual Pentium® II processors of identical speed and stepping, current

revision

§ Designed around the Intel® 440GX AGPSet, PIIX4e, I/O APIC devices for full MPS 1.4 compliance.

§ 100MHz System Bus (Front Side Bus)

§ Support for up to 2 GB 100MHz “PC/100” compliant registered or 1GB of unbuffered ECC or Non-

ECC SDRAM DIMMs (4 sites)

§ Dual Peer PCI buses providing 6 PCI slots.

§ Adaptec* AIC-7896 Dual function PCI SCSI controller providing Ultra2 (LVDS) wide and Ultra

wide SCSI channels. Support for Adaptec ARO-1130U2 RAIDPort* “zero channel” RAID

controller.

§ Intel® 82559 PCI 10/100Mbit Ethernet controller with integrated physical layer. Onboard RJ-45

Network connector.

§ Cirrus Logic* GD5480 PCI SVGA graphics controller, 2MB of Synchronous Graphics memory

(SGRAM)

§ PCI IDE controller (in PIIX4E) providing dual independent Ultra DMA/33 IDE interfaces, each able

to support 2 IDE drives.

§ Compatibility I/O device integrating floppy, dual serial and parallel ports, all connectors provided.

§ Universal Serial Bus (USB) support with two USB connectors.

§ Integration of server management features, including thermal, voltage, fan, and chassis

monitoring into one controller. Emergency Management Port (EMP) feature. Introducing Platform

Event Paging (PEP) Feature enabling remote notification of significant server management

events.

§ Flash BIOS support for all of the above.

15

Page 21

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

11 Regulatory Information

11.1 Regulatory Compliance

11.1.1 Safety Standards

UL 1950 - CSA 950-95, 3rd Edition, July 28, 1995

The Standard for Safety of Information Technology Equipment including Electrical Business

Equipment. (USA and Canada). This product has been evaluated and complies with UL1950 – CSA

950-95 3rd Edition. However, if a UL1950 2nd Edition modem telecommunications add-in card is used,

the system will be deemed to comply with UL 1950 2nd Edition/CSA950-93.

EN 60 950, 2nd Edition, 1992

The Standard for Safety of Information Technology Equipment including Electrical Business

Equipment. (European Union)

IEC 950, 2nd edition, 1991

The Standard for Safety of Information Technology Equipment including Electrical Business

Equipment. (International)

EMKO-TSE (74-SEC) 207/94

Summary of Nordic deviations to EN 60 950. (Norway, Sweden, Denmark, and Finland)

16

Page 22

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

11.1.2 EMC Regulations

FCC Class B

Title 47 of the Code of Federal Regulations, Parts 2 and 15, Subpart B, pertaining to unintentional

radiators. (USA)

CISPR 22, 2nd Edition, 1993, Amendment 1, 1995

Limits and methods of measurement of Radio Interference Characteristics of Information Technology

Equipment. (International)

EN 55 022, 1995

Limits and methods of measurement of Radio Interference Characteristics of Information Technology

Equipment. (Europe)

EN 50 082-1, 1992

Generic Immunity Standard. Currently, compliance is determined via testing to IEC 801-2, -3 and -4.

(Europe)

VCCI Class B (ITE)

Implementation Regulations for Voluntary Control of Radio Interference by Data Processing

Equipment and Electronic Office Machines. (Japan)

ICES-003, Issue 2

Interference Causing Equipment Standard, Digital Apparatus. (Canada)

Australian Communication Authority (ACA)

Australian C-tick mark, limits and methods of measurement radio interference characteristics of

information technology equipment to ASNZS 3548 (Australian requirements based on CISPR 22

requirements).

New Zealand Ministry of Commerce

Australian C-tick mark, limits and methods of measurement radio interference characteristics of

information technology equipment to ASNZS 3548 (New Zealand requirements based on CISPR 22

requirements). New Zealand authorities accept ACA C-Tick Compliance Mark.

17

Page 23

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

11.1.3 Regulatory Compliance Markings

This product is provided with the following Product Certification Markings.

• UL, cUL Listing Marks

• CE Mark and CE Declaration of Conformity

• The CE marking on this product indicates that it is in compliance with the European

community’s EMC (89/336/EEC) and low voltage directives (73/23/EEC)

• NEMKO Mark

• German GS Mark

• FCC, Class B Markings (Declaration of Conformity)

• ICES-003 (Canada Compliance Marking)

• C-Tick Mark (Australia Compliance Marking)

11.2 Electromagnetic Compatibility Notice (USA)

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off

and on; the user is encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Any changes or modifications not expressly approved by the grantee of this device could void the

user’s authority to operate the equipment. The customer is responsible for ensuring compliance of

the modified product.

Only peripherals (computer input/output devices, terminals, printers, etc.) that comply with FCC Class

B limits may be attached to this computer product. Operation with noncompliant peripherals is likely

to result in interference to radio and TV reception.

All cables used to connect to peripherals must be shielded and grounded. Operation with cables,

connected to peripherals that are not shielded and grounded may result in interference to radio and

TV reception.

✏

NOTE

If a Class A device is installed within this system, then the system is

to be considered a Class A system. In this configuration, operation of

this equipment in a residential area is likely to cause harmful

interference.

18

Page 24

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

11.2.1 FCC Declaration of Conformity

Product Type: BAR2

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: 1) This device may not cause harmful interference, and 2) this device must accept any

interference received, including interference that may cause undesired operation.

Intel Corporation

5200 N.E. Elam Young Parkway

Hillsboro, OR 97124-6497

Phone: 1-800-628-8686

Cet appareil numérique respecte les limites bruits radioélectriques applicables aux appareils

numériques de Classe B prescrites dans la norme sur le matériel brouilleur: “Appareils

Numériques”, NMB-003 édictée par le Ministre Canadian des Communications.

(English translation of the notice above) This digital apparatus does not exceed the Class B limits for

radio noise emissions from digital apparatus set out in the interference causing equipment standard

entitled “Digital Apparatus,” ICES-003 of the Canadian Department of Communications.

11.3 Electromagnetic Compatibility Notices (International)

(English translation of the notice above) This is a Class B product based on the standard of the

Voluntary Control Council For Interference (VCCI) from Information Technology Equipment. If this is

used near a radio or television receiver in a domestic environment, it may cause radio interference.

Install and use the equipment according to the instruction manual.

When used near a radio or TV receiver, it may become the cause of radio interference.

Read the instructions for correct handling.

This equipment has been tested for radio frequency emissions and has been verified to meet

CISPR 22 Class B.

19

Page 25

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

12 Environmental Limits

12.1 System Office Environment

Parameter Limits

Operating Temperature +5oC to +35oC with the maximum rate of change not to

exceed 10oC per hour.

Non-Operating

Temperature

Non-Operating Humidity 95%, non-condensing @ 30oC

Acoustic noise < 45 dBA in an idle state at typical office ambient

Operating Shock No errors with a half sine wave shock of 2G (with 11

Package Shock Operational after a 24 inch free fall, although cosmetic

ESD 20kV per Intel Environmental test specification

-40oC to +70oC

temperature (65-75F)

millisecond duration).

damage may be present

Table 10. System Office Environment Summary

12.2 System Environmental Testing

The system will be tested per the Environmental Standards Handbook, Intel Doc.#662394-03. These

tests shall include:

Temperature Operating and Non-Operating

Humidity Non-Operating

Packaged and Unpackaged Shock

Packaged and Unpackaged Vibration

AC Voltage, Freq. & Source Interrupt

AC Surge

Acoustics

ESD

EMC Radiated Investigation

20

Page 26

Intel© LB440GX 2U Rack Server Chassis TPS Rev 1.0

1 minute

13 Reliability, Serviceability, and Availability

13.1 Mean-Time-Between-Failure (MTBF)

MTBF data was being collected at the time of the generation of this specification. It will be provided

in a future revision of this specification or a Specification Update.

13.2 Serviceability

The system is designed to be serviced by qualified technical personnel only.

The desired Mean Time To Repair (MTTR) of the system is 30 minutes including diagnosis of the

system problem. To meet this goal, the system enclosure and hardware have been designed to

minimize the MTTR.

Following are the maximum times that a trained field service technician should take to perform the

listed system maintenance procedures, after diagnosis of the system.

Remove cover

Remove and replace hard disk drive 1 minute

Remove and replace 5 ¼ peripheral device 5 minutes

Remove and replace power supply 5 minutes

Remove and replace rear drive bay fans 3 minutes

Remove and replace front system fan 5 minutes

Remove and replace expansion board 5 minutes

Remove and replace front panel board 5 minutes

Remove and replace baseboard (with no expansion boards) 10 minutes

Overall MTTR 20 minutes

21

Loading...

Loading...