Page 1

Dual-Core Intel® Itanium® Processor

9000 and 9100 Series

Dual-Core Intel® Itanium® Processor 1.6 GHz with 24 MB L3 Cache 9050

Dual-Core Intel® Itanium® Processor 1.6 GHz with 18 MB L3 Cache 9040

Dual-Core Intel® Itanium® Processor 1.6 GHz with 8 MB L3 Cache 9030

Dual-Core Intel® Itanium® Processor 1.42 GHz with 12 MB L3 Cache 9020

Dual-Core Intel® Itanium® Processor 1.4 GHz with 12 MB L3 Cache 9015

Intel® Itanium® Processor 1.6 GHz with 6 MB L3 Cache 9010

Dual-Core Intel® Itanium® Processor 1.66/1.6 GHz with 24 MB L3 Cache 9152

Dual-Core Intel® Itanium® Processor 1.66 GHz with 24 MB L3 Cache 9150M

Dual-Core Intel® Itanium® Processor 1.6 GHz with 24 MB L3 Cache 9150N

Dual-Core Intel® Itanium® Processor 1.66 GHz with 18 MB L3 Cache 9140M

Dual-Core Intel® Itanium® Processor 1.6 GHz with 18 MB L3 Cache 9140N

Dual-Core Intel® Itanium® Processor 1.42 GHz with 12 MB L3 Cache 9120N

Dual-Core Intel® Itanium® Processor 1.66 GHz with 8 MB L3 Cache 9130M

Intel® Itanium® Processor 1.6 GHz with 12 MB L3 Cache 9110N

Datasheet

October 2007

Document Number: 314054-002

Page 2

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED,

BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS

PROVIDED IN INTEL'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY WHATSOEVER,

AND INTEL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF INTEL PRODUCTS INCLUDING

LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY

PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT. Intel products are not intended for use in medical, life saving,

life sustaining applications.

Intel may make changes to specifications and product descriptions at any time, without notice.

Designers must not rely on the absence or characteristics of any features or instructions marked “reserved” or “undefined.” Intel

reserves these for future definition and shall have no responsibility whatsoever for conflicts or incompatibilities arising from future

changes to them

The Dual-Core Intel® Itanium® 9000 and 9100 series processor may contain design defects or errors known as errata which may

cause the product to deviate from published specifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Copies of documents which have an order number and are referenced in this document, or other Intel literature, may be obtained

by calling1-800-548-4725, or by visiting Intel's website at http://www.intel.com.

Intel, Itanium, and the Intel logo are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United

States and other countries.

Copyright © 2002-2007, Intel Corporation

*Other names and brands may be claimed as the property of others.

I2C is a two-wire communication bus /protocol developed by Phillips. SMBus is a subset of the I2C bus/protocol developed by Intel.

Implementation of the I2C bus/protocol or the SMBus bus/protocol may require licenses from various entities, including Phillips

Electronics, N.V. and North American Phillips Corporation.

2 Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet

Page 3

Contents

1 Introduction............................................................................................................... 11

1.1 Overview ......................................................................................................... 11

1.2 Processor Abstraction Layer................................................................................ 11

1.3 Mixing Processors of Different Frequencies and Cache Sizes .................................... 12

1.4 Terminology ..................................................................................................... 12

1.5 State of Data.................................................................................................... 12

1.6 Reference Documents ........................................................................................ 13

2 Electrical Specifications ............................................................................................... 15

2.1 Dual-Core Intel® Itanium® Processor 9000 and 9100 Series System Bus.................. 15

2.1.1 System Bus Power Pins ........................................................................ 15

2.1.2 System Bus No Connect ....................................................................... 15

2.2 System Bus Signals ........................................................................................... 15

2.2.1 Signal Groups ..................................................................................... 15

2.2.2 Signal Descriptions .............................................................................. 17

2.3 Package Specifications ....................................................................................... 18

2.4 Signal Specifications.......................................................................................... 18

2.4.1 Maximum Ratings................................................................................ 22

2.5 System Bus Signal Quality Specifications and Measurement Guidelines ..................... 23

2.5.1 Overshoot/Undershoot Magnitude.......................................................... 23

2.5.2 Overshoot/Undershoot Pulse Duration .................................................... 24

2.5.3 Activity Factor..................................................................................... 24

2.5.4 Reading Overshoot/Undershoot Specification Tables................................. 24

2.5.5 Determining if a System Meets the Overshoot/Undershoot

Specifications...................................................................................... 25

2.5.6 Wired-OR Signals ................................................................................ 25

2.6 Voltage Regulator Connector Signals.................................................................... 27

2.7 System Bus Clock and Processor Clocking............................................................. 31

2.8 Recommended Connections for Unused Pins.......................................................... 33

3 Pinout Specifications................................................................................................... 35

4 Mechanical Specifications............................................................................................. 65

4.1 Processor Package Dimensions............................................................................ 65

4.1.1 Voltage Regulator (MVR) to Processor Package Interface........................... 71

4.2 Package Marking ............................................................................................... 72

4.2.1 Processor Top-Side Marking ..................................................................72

4.2.2 Processor Bottom-Side Marking ............................................................. 73

5 Thermal Specifications ................................................................................................ 75

5.1 Thermal Features ..............................................................................................75

5.1.1 Thermal Alert...................................................................................... 75

5.1.2 Enhanced Thermal Management ............................................................ 76

5.1.3 Power Trip.......................................................................................... 76

5.1.4 Thermal Trip....................................................................................... 76

5.2 Case Temperature ............................................................................................. 76

6 System Management Feature Specifications ................................................................... 79

6.1 System Management Bus ................................................................................... 79

6.1.1 System Management Bus Interface........................................................ 79

6.1.2 System Management Interface Signals ................................................... 79

6.1.3 SMBus Device Addressing ..................................................................... 81

6.2 Processor Information ROM ................................................................................ 82

6.3 Scratch EEPROM ............................................................................................... 85

Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet 3

Page 4

6.4 Processor Information ROM and Scratch EEPROM Supported SMBus

Transactions .....................................................................................................85

6.5 Thermal Sensing Device .....................................................................................86

6.6 Thermal Sensing Device Supported SMBus Transactions..........................................87

6.7 Thermal Sensing Device Registers........................................................................88

6.7.1 Thermal Reference Registers .................................................................88

6.7.2 Thermal Limit Registers ........................................................................89

6.7.3 Status Register....................................................................................89

6.7.4 Configuration Register ..........................................................................89

6.7.5 Conversion Rate Register ......................................................................90

A Signals Reference .......................................................................................................91

A.1 Alphabetical Signals Reference ............................................................................91

A.1.1 A[49:3]# (I/O).......................................................................................91

A.1.2 A20M# (I) .............................................................................................91

A.1.3 ADS# (I/O)............................................................................................91

A.1.4 AP[1:0]# (I/O).......................................................................................91

A.1.5 ASZ[1:0]# (I/O).....................................................................................91

A.1.6 ATTR[3:0]# (I/O) ...................................................................................92

A.1.7 BCLKp/BCLKn (I) ....................................................................................92

A.1.8 BE[7:0]# (I/O).......................................................................................92

A.1.9 BERR# (I/O) ..........................................................................................93

A.1.10 BINIT# (I/O)..........................................................................................94

A.1.11 BNR# (I/O)............................................................................................94

A.1.12 BPM[5:0]# (I/O) ....................................................................................94

A.1.13 BPRI# (I) ..............................................................................................94

A.1.14 BR[0]# (I/O) and BR[3:1]# (I).................................................................94

A.1.15 BREQ[3:0]# (I/O)...................................................................................95

A.1.16 CCL# (I/O) ............................................................................................96

A.1.17 CPUPRES# (O) .......................................................................................96

A.1.18 D[127:0]# (I/O).....................................................................................96

A.1.19 D/C# (I/O) ............................................................................................96

A.1.20 DBSY# (I/O)..........................................................................................96

A.1.21 DBSY_C1# (O).......................................................................................96

A.1.22 DBSY_C2# (O).......................................................................................96

A.1.23 DEFER# (I)............................................................................................96

A.1.24 DEN# (I/O)............................................................................................97

A.1.25 DEP[15:0]# (I/O) ...................................................................................97

A.1.26 DHIT# (I)..............................................................................................97

A.1.27 DPS# (I/O)............................................................................................98

A.1.28 DRDY# (I/O)..........................................................................................98

A.1.29 DRDY_C1# (O).......................................................................................98

A.1.30 DRDY_C2# (O).......................................................................................98

A.1.31 DSZ[1:0]# (I/O) ....................................................................................98

A.1.32 EXF[4:0]# (I/O) .....................................................................................98

A.1.33 FCL# (I/O) ............................................................................................99

A.1.34 FERR# (O).............................................................................................99

A.1.35 GSEQ# (I).............................................................................................99

A.1.36 HIT# (I/O) and HITM# (I/O)....................................................................99

A.1.37 ID[9:0]# (I) ..........................................................................................99

A.1.38 IDS# (I)................................................................................................99

A.1.39 IGNNE# (I)............................................................................................99

A.1.40 INIT# (I)...............................................................................................99

A.1.41 INT (I) ................................................................................................100

A.1.42 IP[1:0]# (I).........................................................................................100

A.1.43 LEN[2:0]# (I/O) ...................................................................................100

A.1.44 LINT[1:0] (I) .......................................................................................100

4 Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet

Page 5

A.1.45 LOCK# (I/O)........................................................................................ 100

A.1.46 NMI (I) ............................................................................................... 101

A.1.47 OWN# (I/O) ........................................................................................ 101

A.1.48 PMI# (I) ............................................................................................. 101

A.1.49 PWRGOOD (I)...................................................................................... 101

A.1.50 REQ[5:0]# (I/O) .................................................................................. 101

A.1.51 RESET# (I) ......................................................................................... 102

A.1.52 RP# (I/O) ........................................................................................... 102

A.1.53 RS[2:0]# (I) ....................................................................................... 103

A.1.54 RSP# (I) ............................................................................................. 103

A.1.55 SBSY# (I/O)........................................................................................ 103

A.1.56 SBSY_C1# (O)..................................................................................... 103

A.1.57 SBSY_C2# (O)..................................................................................... 103

A.1.58 SPLCK# (I/O) ...................................................................................... 103

A.1.59 STBn[7:0]# and STBp[7:0]# (I/O)......................................................... 103

A.1.60 TCK (I) ............................................................................................... 104

A.1.61 TDI (I)................................................................................................ 104

A.1.62 TDO (O).............................................................................................. 104

A.1.63 THRMTRIP# (O) ................................................................................... 104

A.1.64 THRMALERT# (O)................................................................................. 104

A.1.65 TMS (I)............................................................................................... 104

A.1.66 TND# (I/O) ......................................................................................... 104

A.1.67 TRDY# (I) ........................................................................................... 105

A.1.68 TRST# (I) ........................................................................................... 105

A.1.69 WSNP# (I/O)....................................................................................... 105

A.2 Signal Summaries ........................................................................................... 105

Figures

2-1 Generic Clock Waveform .................................................................................... 21

2-2 SMSC Clock Waveform....................................................................................... 22

2-3 System Bus Signal Waveform Exhibiting Overshoot/Undershoot............................... 23

2-4 Processors Power Tab Physical Layout .................................................................. 28

2-5 System Bus Reset and Configuration Timings for Cold Reset.................................... 31

2-6 System Bus Reset and Configuration Timings for Warm Reset ................................. 32

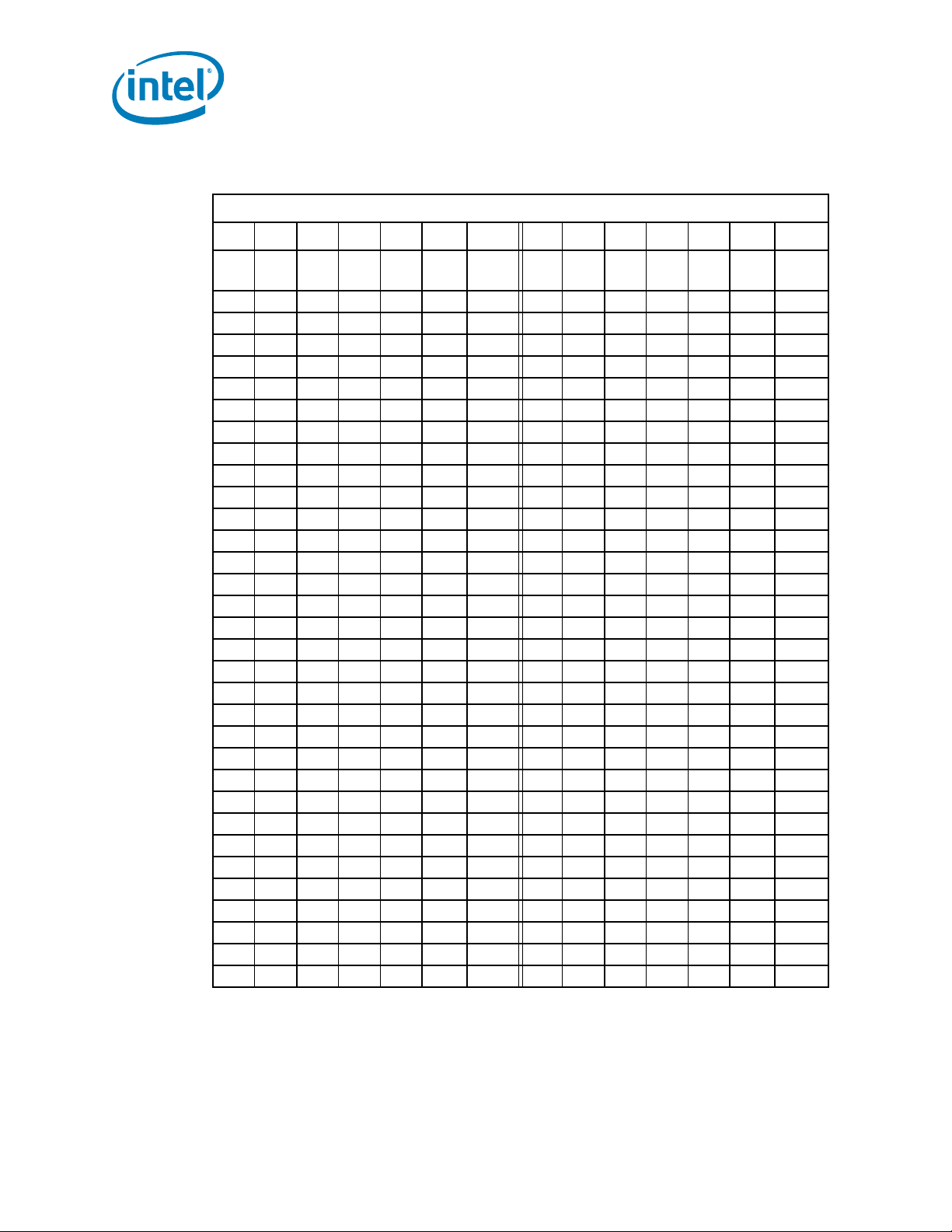

3-1 Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Pinout.......................... 35

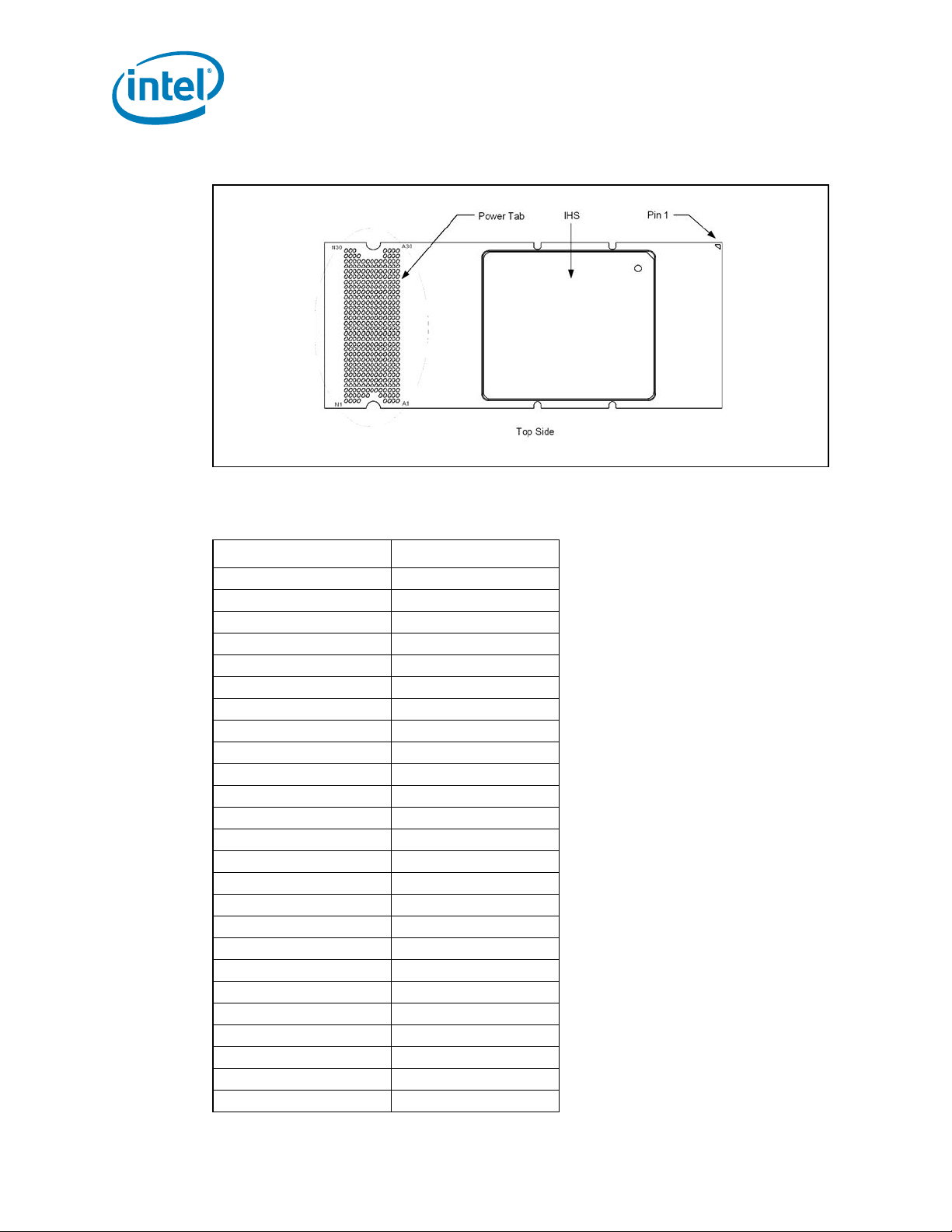

4-1 Processor Package............................................................................................. 66

4-2 Package Height and Pin Dimensions..................................................................... 67

4-3 Processor Package Mechanical Interface Dimensions .............................................. 69

4-4 Processor Package Top-Side Components Height Dimensions .................................. 70

4-5 Processor Package Bottom-Side Components Height Dimensions ............................. 70

4-6 Processor to MVR Interface Loads........................................................................ 71

4-7 Processor Top-Side Marking on IHS ..................................................................... 73

4-8 Processor Bottom-Side Marking Placement on Interposer........................................ 74

5-1 Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Thermal

Features .......................................................................................................... 75

5-2 Itanium® Processor Package Thermocouple Location.............................................. 77

6-1 Logical Schematic of SMBus Circuitry ................................................................... 80

Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet 5

Page 6

Tables

2-1 Itanium® Processor System Bus Signal Groups ......................................................16

2-2 Nominal Resistance Values for Tuner1, Tuner2, and Tuner3.....................................17

2-3 Processor Package Specifications .........................................................................18

2-4 AGTL+ Signals DC Specifications..........................................................................19

2-5 Power Good Signal DC Specifications....................................................................19

2-6 System Bus Clock Differential HSTL DC Specifications.............................................19

2-7 TAP Connection DC Specifications ........................................................................19

2-8 SMBus DC Specifications.....................................................................................20

2-9 LVTTL Signal DC Specifications ............................................................................20

2-10 System Bus Clock Differential HSTL AC Specifications .............................................20

2-11 SMBus AC Specifications.....................................................................................21

2-12 Dual-Core Intel® Itanium® Processor Absolute Maximum Ratings.............................22

2-13 Source Synchronous AGTL+ Signal Group and Wired-OR Signal Group

Absolute Overshoot/Undershoot Tolerance ............................................................25

2-14 Source Synchronous AGTL+ Signal Group Time-Dependent Overshoot/

Undershoot Tolerance for 400-MHz System Bus .....................................................26

2-15 Wired-OR Signal Group (BINIT#, HIT#, HITM#, BNR#, TND#, BERR#)

Overshoot/Undershoot Tolerance for 400-MHz System Bus......................................26

2-16 Source Synchronous AGTL+ Signal Group Time-Dependent Overshoot/

Undershoot Tolerance for 533-MHz System Bus .....................................................26

2-17 Wired-OR Signal Group (BINIT#, HIT#, HITM#, BNR#, TND#, BERR#)

Overshoot/Undershoot Tolerance for 533-MHz System Bus......................................27

2-18 VR Connector Signals .........................................................................................27

2-19 Power Connector Pinouts ....................................................................................28

2-20 Processors Core Voltage Identification Code (VCORE and VCACHE)...........................30

2-21 Connection for Unused Pins.................................................................................33

2-22 TUNER1/TUNER3 Translation Table.......................................................................34

3-1 Pin/Signal Information Sorted by Pin Name ...........................................................36

3-2 Pin/Signal Information Sorted by Pin Location........................................................50

4-1 Processor Package Dimensions ............................................................................67

4-2 Processor Package Mechanical Interface Dimensions...............................................68

4-3 Processor Package Load Limits at Power Tab .........................................................71

5-1 Case Temperature Specification...........................................................................77

6-1 System Management Interface Signal Descriptions.................................................79

6-2 Thermal Sensing Device SMBus Addressing on the Dual-Core Intel

Itanium® Processor 9000 and 9100 series.............................................................81

6-3 EEPROM SMBus Addressing on the Dual-Core Intel® Itanium® Processor

9000 and 9100 Series ........................................................................................82

6-4 Processor Information ROM Format ......................................................................82

6-5 Current Address Read SMBus Packet ....................................................................85

6-6 Random Address Read SMBus Packet ...................................................................86

6-7 Byte Write SMBus Packet....................................................................................86

6-8 Write Byte SMBus Packet....................................................................................87

6-9 Read Byte SMBus Packet ....................................................................................87

6-10 Send Byte SMBus Packet ....................................................................................87

6-11 Receive Byte SMBus Packet.................................................................................87

6-12 ARA SMBus Packet.............................................................................................87

6-13 Command Byte Bit Assignment............................................................................88

6-14 Thermal Sensing Device Status Register ...............................................................89

6-15 Thermal Sensing Device Configuration Register......................................................89

6-16 Thermal Sensing Device Conversion Rate Register..................................................90

®

6 Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet

Page 7

A-1 Address Space Size ........................................................................................... 92

A-2 Effective Memory Type Signal Encoding................................................................ 92

A-3 Special Transaction Encoding on Byte Enables ....................................................... 93

A-5 BR0# (I/O), BR1#, BR2#, BR3# Signals for 2P Rotating Interconnect ...................... 95

A-4 BR0# (I/O), BR1#, BR2#, BR3# Signals for 4P Rotating Interconnect ...................... 95

A-6 BR[3:0]# Signals and Agent IDs ......................................................................... 95

A-7 DID[9:0]# Encoding .......................................................................................... 97

A-8 Extended Function Signals .................................................................................. 98

A-9 Length of Data Transfers .................................................................................. 100

A-10 Transaction Types Defined by REQa#/REQb# Signals........................................... 102

A-11 STBp[7:0]# and STBn[7:0]# Associations .......................................................... 104

A-12 Output Signals ................................................................................................ 105

A-13 Input Signals .................................................................................................. 105

A-14 Input/Output Signals (Single Driver) .................................................................. 106

A-15 Input/Output Signals (Multiple Driver)................................................................ 107

Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet 7

Page 8

Revision History

Document

Number

314054 -002

314054 -001 • Initial release of the document. July 2006

Revision

Number

Description Date

• Updated with 9100 series product information; updated brand name from

“Itanium 2” to “Itanium”.

October 2007

8 Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet

Page 9

Dual-Core Intel® Itanium® Processor 9000 and

9100 Series

Dual-Core Intel® Itanium® Processor 1.6 GHz with 24 MB L3 Cache 9050

Dual-Core Intel® Itanium® Processor 1.6 GHz with 18 MB L3 Cache 9040

Dual-Core Intel® Itanium® Processor 1.6 GHz with 8 MB L3 Cache 9030

Dual-Core Intel® Itanium® Processor 1.42 GHz with 12 MB L3 Cache 9020

Dual-Core Intel® Itanium® Processor 1.4 GHz with 12 MB L3 Cache 9015

Intel® Itanium® Processor 1.6 GHz with 6 MB L3 Cache 9010

Dual-Core Intel® Itanium® Processor 1.66 GHz with 24 MB L3 Cache 9150M

Dual-Core Intel® Itanium® Processor 1.6 GHz with 24 MB L3 Cache 9150N

Dual-Core Intel® Itanium® Processor 1.66 GHz with 18 MB L3 Cache 9140M

Dual-Core Intel® Itanium® Processor 1.6 GHz with 18 MB L3 Cache 9140N

Dual-Core Intel® Itanium® Processor 1.42 GHz with 12 MB L3 Cache 9120N

Dual-Core Intel® Itanium® Processor 1.66 GHz with 8 MB L3 Cache 9130M

Intel® Itanium® Processor 1.6 GHz with 12 MB L3 Cache 9110N

Product Features

Dual Core

— Two complete 64-bit processing cores on one

processor.

EPIC (Explicitly Parallel Instruction Computing)

Technology for current and future requirements of

high-end enterprise and technical workloads

— Provide a variety of advanced

implementations of parallelism, predication,

and speculation, resulting in superior

Instruction-Level Parallelism (ILP).

Hyper-Threading Technology

— Two times the number of OS threads per core

provided by earlier single-thread

implementations.

Wide, parallel hardware based on Intel® Itanium

architecture for high performance:

— Integrated on-die L3 cache of up to 24MB;

cache hints for L1, L2, and L3 caches for

reduced memory latency.

— 128 general and 128 floating-point registers

supporting register rotation.

— Register stack engine for effective

management of processor resources.

— Support for predication and speculation.

Extensive RAS features for business-critical

applications:

— Full SMBus compatibility.

— Enhanced machine check architecture with

extensive ECC and parity protection.

— Enhanced thermal management.

— Built-in processor information ROM (PIROM).

— Built-in programmable EEPROM.

— Socket Level Lockstep

— Core Level Lockstep

a. This feature is applicable to only the 9100 series processors

®

Intel® Virtualization Technology for virtualization for

data-intensive applications.

— Reduces virtualization complexity.

— Improves virtualization performance.

— Increases operating system compatibility.

Intel® Cache Safe Technology ensures mainframecaliber availability.

— Minimize L3 cache errors.

Outstanding Energy Efficiency.

— 20 percent less power than previous Intel

Itanium processor.

— 2.5 times higher performance per watt.

High-bandwidth system bus for multiprocessor

scalability:

— Up to 8.53GB/s bandwidth.

— 128-bit wide data bus.

— 50-bits of physical memory addressing and

64-bits of virtual addressing.

— Up to four physical processors on the same

system bus at 400-MHz or 533-MHz data bus

frequency.

— Expandable to systems with multiple system

buses.

Features to support flexible platform environments:

— IA-32 Execution Layer supports IA-32

application binaries.

— Bi-endian support.

— Processor abstraction layer eliminates

processor dependencies.

667-MHz, 1.66-GHz, 3-load bus

— This feature enables increased bandwidth for

Enterprise and HPC.

Demand Based Switching (DBS)

— Provides additional power management

capability.

a

a

Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet 9

Page 10

The Dual-Core Intel® Itanium® processor 9000 and 9100 series delivers new levels of flexibility,

reliability, performance, and cost-effective scalability for your most data-intensive business and

technical applications. With double the performance of previous Intel Itanium processors, the DualCore Intel Itanium processor 9000 and 9100 series provides more reasons than ever to migrate your

business-critical applications off RISC and mainframe systems and onto cost-effective Intel

architecture servers. The Dual-Core Intel Itanium processor 9000 and 9100 series provides close to

triple the amount of L3 cache (24 megabytes), Hyper-Threading Technology for increased

performance, Intel® Virtualization Technology for improved virtualization, Intel® Cache Safe

Technology for increased availability, and 20 percent lower power consumption.

Dual-Core Itanium®-based systems are available from leading OEMs worldwide and run popular 64bit operating systems such as Microsoft* Windows Server* 2003; Linux* from SuSE, Red Hat, Red

Flag, and other distributions; HP NonStop*; OpenVMS*; and HP-UX*. More than 7,000 applications

are available for Itanium-based systems, from vendors such as Microsoft, BEA, IBM, Ansys, Gaussian,

Symantec/VERITAS, Oracle, SAP, and SAS. And with industry support growing and future Intel

Itanium processor family advances already in development, your Itanium-based server investment

will continue to deliver performance advances and savings for your most demanding applications.

§

10 Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet

Page 11

Introduction

1 Introduction

1.1 Overview

The Dual-Core Intel Itanium processor 9000 and 9100 series employs Explicitly Parallel

Instruction Computing (EPIC) design concepts for a tighter coupling between hardware

and software. In this design style, the interface between hardware and software is

engineered to enable the software to exploit all available compile-time information and

efficiently deliver this information to the hardware. It addresses several fundamental

performance bottlenecks in modern computers, such as memory latency, memory

address disambiguation, and control flow dependencies. The EPIC constructs provide

powerful architectural semantics and enable the software to make global optimizations

across a large scheduling scope, thereby exposing available Instruction Level

Parallelism (ILP) to the hardware. The hardware takes advantage of this enhanced ILP,

and provides abundant execution resources. Additionally, it focuses on dynamic runtime optimizations to enable the compiled code schedule to flow at high throughput.

This strategy increases the synergy between hardware and software, and leads to

greater overall performance.

The Dual-Core Intel Itanium processor 9000 and 9100 series provides a 6-wide and 8stage deep pipeline, running at up to 1.6 GHz. This provides a combination of abundant

resources to exploit ILP as well as increased frequency for minimizing the latency of

each instruction. The resources consist of six integer units, six multimedia units, two

load and two store units, three branch units, two extended-precision floating-point

units, and one additional single-precision floating-point unit per core. The hardware

employs dynamic prefetch, branch prediction, a register scoreboard, and non-blocking

caches to optimize for compile-time non-determinism. Three levels of on-die cache

minimize overall memory latency. This includes up to a 24 MB L3 cache, accessed at

core speed, providing up to 8.53 GB/sec. of data bandwidth. The system bus is

designed to support up to four physical processors (on a single system bus), and can

be used as an effective building block for very large systems. The balanced core and

memory subsystem provide high performance for a wide range of applications ranging

from commercial workloads to high-performance technical computing.

The Dual-Core Intel Itanium processor 9000 and 9100 series supports a range of

computing needs and configurations from a two-way to large SMP servers. This

document provides the electrical, mechanical and thermal specifications for the DualCore Intel Itanium processor 9000 and 9100 series for use while employing systems

with the processors.

1.2 Processor Abstraction Layer

The Dual-Core Intel Itanium processor 9000 and 9100 series requires implementationspecific Processor Abstraction Layer (PAL) firmware. PAL firmware supports processor

initialization, error recovery, and other functionality. It provides a consistent interface

to system firmware and operating systems across processor hardware

implementations. The Intel® Itanium® Architecture Software Developer’s Manual,

Volume 2: System Architecture, describes PAL. Platforms must provide access to the

firmware address space and PAL at reset to allow the processors to initialize.

Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet 11

Page 12

Introduction

The System Abstraction Layer (SAL) firmware contains platform-specific firmware to

initialize the platform, boot to an operating system, and provide runtime functionality.

Further information about SAL is available in the Intel®Itanium®Processor Family

System Abstraction Layer Specification.

1.3 Mixing Processors of Different Frequencies and

Cache Sizes

All Dual-Core Intel Itanium processor 9000 and 9100 series on the same system bus

are required to have the same cache size (24 MB, 18 MB, 12 MB, 8 MB or 6 MB) and

identical core frequency. Mixing components of different core frequencies and cache

sizes is not supported and has not been validated by Intel. Operating system support

for multiprocessing with mixed components should also be considered.

While Intel has done nothing to specifically prevent processors within a multiprocessor

environment from operating at differing frequencies and differing cache sizes, there

may be uncharacterized errata that exist in such configurations. Customers would be

fully responsible for validation of system configurations with mixed components other

than the supported configurations described above.

1.4 Terminology

In this document, “the processor” refers to the “Dual-Core Intel Itanium processor

9000 and 9100 series” processor, unless otherwise indicated.

A ‘#’ symbol after a signal name refers to an active low signal. This means that a signal

is in the active state (based on the name of the signal) when driven to a low level. For

example, when RESET# is low, a processor reset has been requested. When NMI is

high, a non-maskable interrupt has occurred. In the case of lines where the name does

not imply an active state but describes part of a binary sequence (such as address or

data), the ‘#’ symbol implies that the signal is inverted. For example, D[3:0] = ‘HLHL’

refers to a hex ‘A’, and D [3:0] # = ‘LHLH’ also refers to a hex ‘A’ (H = High logic level,

L = Low logic level).

The term “system bus” refers to the interface between the processor, system core logic,

and other bus agents. The system bus is a multiprocessing interface to processors,

memory, and I/O.

A signal name has all capitalized letters, for example, VCTERM.

A symbol referring to a voltage level, current level, or a time value carries a plain

subscript, for example, V

1.5 State of Data

The data contained in this document is subject to change. It is the best information

that Intel is able to provide at the publication date of this document.

, or a capitalized, abbreviated subscript, for example, TCO.

core

12 Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet

Page 13

Introduction

1.6 Reference Documents

The reader of this specification should also be familiar with material and concepts

presented in the following documents:

Intel®Itanium®2 Processor Specification Update

Intel® Itanium® Architecture Software Developer’s Manual, Volume 1:

Application Architecture

Intel® Itanium® Architecture Software Developer’s Manual, Volume 2: System

Architecture

Intel® Itanium® Architecture Software Developer’s Manual,

Volume 3: Instruction Set Reference

®

Itanium®2 Processor Reference Manual for Software Development and

Intel

Optimization

Intel®Itanium®Processor Family System Abstraction Layer Specification

ITP700 Debug Port Design Guide

System Management Bus Specification

Note: Contact your Intel representative or check http://developer.intel.com for the latest

revision of the reference documents.

§

Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet 13

Page 14

Introduction

14 Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet

Page 15

Electrical Specifications

2 Electrical Specifications

This chapter describes the electrical specifications of the Dual-Core Intel Itanium

Processor 9000 and 9100 series.

2.1 Dual-Core Intel® Itanium® Processor 9000 and

9100 Series System Bus

Most Dual-Core Intel Itanium processor 9000 and 9100 series signals use the Itanium

processor’s assisted gunning transceiver logic (AGTL+) signaling technology. The

termination voltage, V

reference voltage. The buffers that drive most of the system bus signals on the

processor are actively driven to V

times and reduce noise. These signals should still be considered open-drain and require

termination to V

terminated to V

termination, in which case, the termination is provided by external resistors connected

to V

CTERM

.

CTERM

CTERM

, is generated on the baseboard and is the system bus high

CTERM

during a low-to-high transition to improve rise

CTERM

which provides the high level. The processor system bus is

at each end of the bus. There is also support of off-die

AGTL+ inputs use differential receivers which require a reference signal (V

used by the receivers to determine if a signal is a logical 0 or a logical 1. The processor

generates V

source.

on-die, thereby eliminating the need for an off-chip reference voltage

REF

2.1.1 System Bus Power Pins

VCTERM (1.2 V) input pins on the processor provide power to the driver buffers and ondie termination. The GND pins, in addition to the GND input at the power tab connector,

provide ground to the processor. Power for the processor core is supplied through the

power tab connector by V

to provide power to the system management bus (SMBus). The V

pins must remain electrically separated from each other.

Core

, V

Cache, Vfixed.

2.1.2 System Bus No Connect

All pins designated as “N/C” or “No Connect” must remain unconnected.

2.2 System Bus Signals

2.2.1 Signal Groups

Table 2-1 shows processor system bus signals that have been combined into groups by

buffer type and whether they are inputs, outputs, or bidirectional, with respect to the

processor.

). V

REF

The 3.3 V pin is included on the processor

, 3.3 V, and GND

CTERM

REF

is

Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet 15

Page 16

..

Table 2-1. Itanium® Processor System Bus Signal Groups

Group Name Signals

AGTL+ Input Signals BPRI#, BR[3:1]#, DEFER#, GSEQ#, ID[9:0]#, IDS#, RESET#1, RS[2:0]#,

AGTL+ I/O Signals A[49:3]#, ADS#, AP[1:0]#, BERR#, BINIT#, BNR#, BPM[5:0]#1, BR0#,

AGTL+ Output Signals FERR#, THRMTRIP#, DBSY[1:0]#, DRDY[1:0]#, SBSY[1:0]#

Special AGTL+ Asynchronous

Interrupt Input Signals

Power Good Signal

HSTL Clock Signals BCLKn, BCLKp

TAP Input Signals

TAP Output Signals

System Management Signals13.3 V, SMA[2:0], SMSC, SMSD, SMWP, THRMALERT#

Power Signals GND, VCTERM

LVTTL Power Pod Signals

Other TERMA, TERMB, TUNER1, TUNER2, TUNER3, VCCMON, VSSMON

Notes:

1. Signals will not be terminated on-die even when on-die termination (ODT) is enabled. See the Intel®Itanium

2 Processor Hardware Developer’s Manual for further details.

1

1

1

1

RSP#, TRDY#

D[127:0]#, DBSY#, DEP[15:0]#, DRDY#, HIT#, HITM#, LOCK#,

REQ[5:0]#, RP#, SBSY#, STBN[7:0]#, STBP[7:0]#, TND#

A20M#, IGNNE#, INIT#, LINT[1,0], PMI#

PWRGOOD

TCK, TDI, TMS, TRST#

TDO

CPUPRES#, OUTEN, PPODGD#

Electrical Specifications

®

All system bus outputs should be treated as open drain signals and require a high-level

source provided by the V

AGTL+ inputs have differential input buffers which use V

output signals require termination to V

CTERM

supply.

as a reference level. AGTL+

. In this document, “AGTL+ Input Signals”

CTERM

REF

refers to the AGTL+ input group as well as the AGTL+ I/O group when receiving.

Similarly, “AGTL+ Output Signals” refers to the AGTL+ output group as well as the

AGTL+ I/O group when driving.

The Test Access Port (TAP) connection input signals use a non-differential receiver with

levels that are similar to AGTL+. No reference voltage is required for these signals. The

TAP Connection Output signals are AGTL+ output signals.

The processor system bus requires termination on both ends of the bus. The processor

system bus supports both on-die and off-die termination controlled by two pins, TERMA

and TERMB. Please see the TERMA and TERMB pin description in Section 2.2.2.

The HSTL clock signals are the differential clock inputs for the processor. The SMBus

signals and LVTTL power pod signals are driven using the 3.3 V CMOS logic levels listed

in Table 2-8 and Table 2-9, respectively.

16 Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet

Page 17

Electrical Specifications

2.2.2 Signal Descriptions

Appendix A, “Signals Reference”, contains functional descriptions of all system bus

signals and LVTTL power pod signals. Further descriptions of the system management

signals are contained in Chapter 6. The signals listed under the “Power” and “Other”

group are described here:

V

CTERM

GND System ground.

N/C No connection can be made to these pins.

TERMA, TERMB The processor uses two pins to control the on-die termination

TUNER1, TUNER2,

TUNER3 The TUNER1 Pin can either be left as a no-connect or left

VCCMON, VSSMON These pins allows remote measurement of on-die Vcore voltage.

System bus termination voltage.

function: TERMA and TERMB. Both of these termination pins

must be pulled to VCTERM in order to terminate the system bus

using the on-die termination resistors. Both of these termination

pins must be pulled to GND in order to use off-die termination.

connected to VCTERM via resistor for the majority of platforms

supporting the Dual-Core Intel Itanium processor 9000 and

9100 series. The TUNER2 resistor is used to control the

termination resistance for the system bus I/O buffers. A lower

resistance will cause a lower on-die termination resistance. Ondie termination mode will only be selected if the TERMA and

TERMB pins are terminated as indicated above. The TUNER3 pin

will not be required for the majority of platforms supporting the

Dual-Core Intel Itanium processor 9000 and 9100 series. The

TUNER3 pin is used only in the case where A[21:17]# are driven

to all zeros or all ones during the configuration cycles at reset.

When all zeros or all ones are observed by the processor the

presence of the TUNER3 and TUNER1 pins is used to determine

system bus frequency. See Table 2-22 for the various TUNER pin

combinations and resulting system bus frequency and slew rate

combination.

No connections that constitute a current load can be made to

these pins.

Table 2-2. Nominal Resistance Values for Tuner1, Tuner2, and Tuner3

5-Load Platform (Ohms)

Tuner1: NC

Tuner2: 150

Tuner3: NC

Notes:

1. Depending on system configuration, the processor may or may not require a resistor on the

Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet 17

400 MHz

1

1

TUNER pin. OEMs may leave the pin unconnected or connect it to VCTERM through a 150

or 100 ohm resistor. If A[21:17]:# are driven to all 0’s or all 1’s at reset, see Table 2-22

for proper use of the TUNER Pins.

3-Load Platform (Ohms)

Tuner1: NC

Tuner2: 150

Tuner3: NC

400 MHz

1

1

3-Load Platform (Ohms)

Tuner1: NC

Tuner2: 150

Tuner3: NC

533 MHz

1

1

Page 18

2.3 Package Specifications

Table 2-3 through Table 2-9 list the DC voltage, current, and power specifications for

the processor. The voltage and current specifications are defined at the processor pins.

Operational specifications listed in Table 2-3 through Table 2-9 are only valid while

meeting specifications for case temperature, clock frequency, and input voltages.

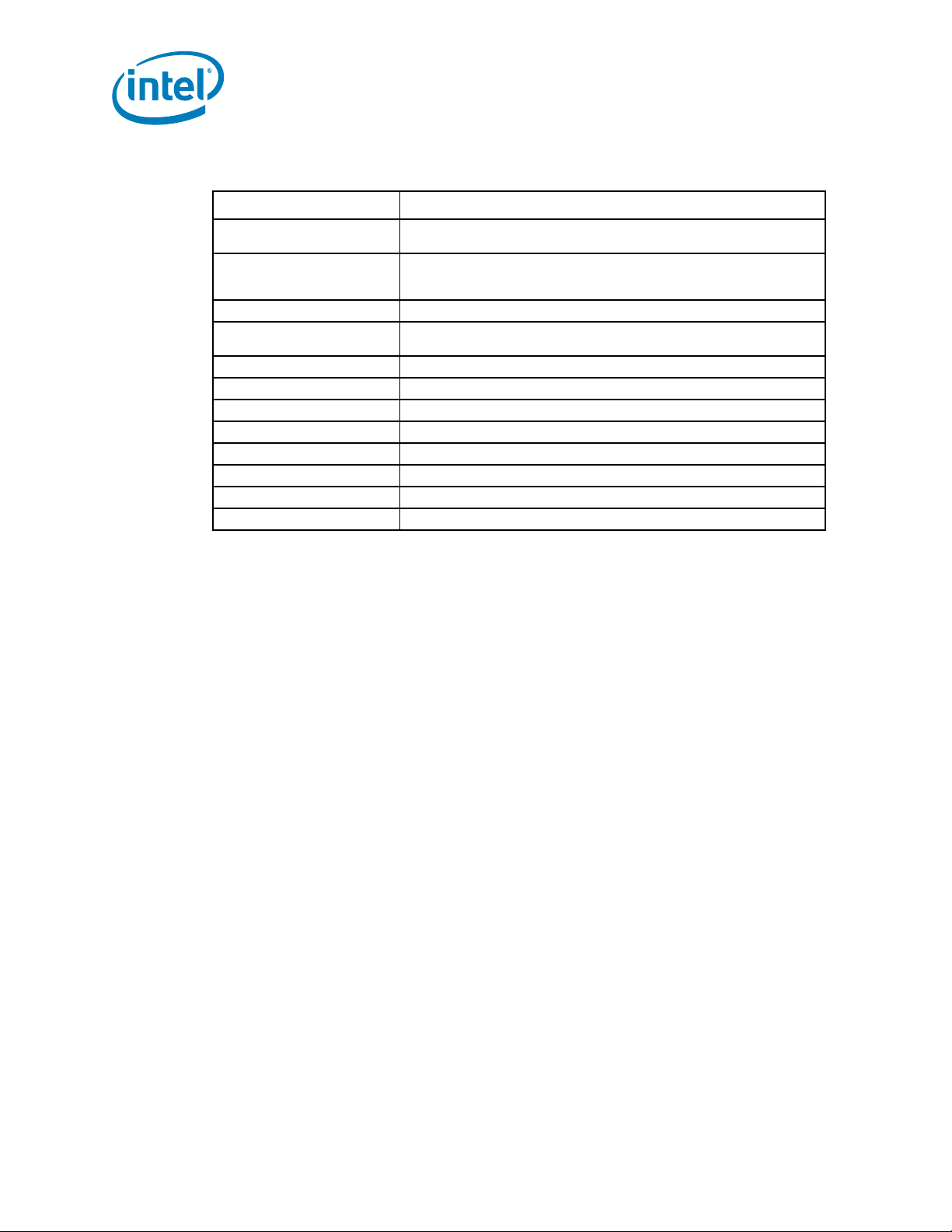

Table 2-3. Processor Package Specifications

Electrical Specifications

Symbol Parameter

V

core, PSVCC

V

cache, PSVcache

V

fixed, PSVfixed

V

CTERM

R

TERM

V

TAP

I

core,PS

I

cache,PS

I

fixed,PS

I

CTERM

PS

TT

PWR

max

PWR

TPE

PWR

TDP

Notes:

1. The range for Vcore is 1.0875 V to 1.25 V.

2. Vcache typical is 1.025 V.

3. The processor system bus is terminated at each end of the system bus. The processor supports both on-die

and off-die termination which is selected by the TERMA and TERMB pins. Termination tolerance is ±15% for

on-die termination measured at VOL and ±1% for off-die termination.

4. This is measured for On-Die Termination with a 45-ohm pull up resistor.

5. Max power is peak electrical power that must be provided for brief periods by the VR.

6. Represents the TDP level that should be used for system thermal design. Sustained power for all real-world

applications will remain at or below this power level.

from the Voltage

Regulator

from the Voltage

Regulator

from the Voltage

Regulator

Termination Voltage All 1.2-1.5% 1.2 1.2+1.5% V

Recommended Termination

Resistance

Test Access Port Voltage

)

(VCC

TAP

Core Current Required from

Power Supply

Cache Current Required from

Power Supply

Fixed Current Required from

Power Supply

Termination Voltage Current All 7.2 A

Power Supply Slew Rate for

the Termination Voltage at the

Processor Pins

Max Power All 177 W

Thermal Power Envelope All 130 W

Thermal Design Power – dual

core

Thermal Design Power –

single core

Core

Frequency

All VID-17 mV VID VID+17 mV V

All VID-17 mV VID VID+17 mV V

All 1.25-20 mV 1.25 1.25+20 mV V

All 45-15% 45 45+15% Ohm

All 1.2-1.5% 1.2 1.5 V

All 2.8 89 121 A

All 2.0 17 18 A

All 0.7 9.2 11 A

All 0.05 A/ns

All 104 W

1.6 GHz 75 W

Minimum Typ Maximum Unit Notes

1

2

3

4

5

6

2.4 Signal Specifications

This section describes the DC specifications of the system bus signals. The processor

signal’s DC specifications are defined at the processor pins. Table 2-4 through Table 2-9

describe the DC specifications for the AGTL+, PWRGOOD, HSTL clock, TAP port, system

management, and LVTTL signals. Please refer to the ITP700 Debug Port Design Guide

for the TAP connection signals’ DC specifications at the debug port.

18 Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet

Page 19

Electrical Specifications

Table 2-4. AGTL+ Signals DC Specifications

Symbol Parameter

V

IL

V

IH

V

OL

V

OH

I

OL

I

OL

I

L

C

AGTL+

Notes:

1. The typical transition point between VIL and VIH assuming 125 mV V

V

REF_low

and V

2. Parameter measured into a 22.5 ohm resistor to 1.2 V. Minimum VOL and IOL are guaranteed by design/

characterization.

3. Calculated using off-die termination through two 45 ohm ±1% resistors in parallel.

4. Calculated using on-die termination to a 45 ±15% resistor measured at VOL.

5. At 1.2 V ±1.5%. V

6. Total of I/O buffer with ESD structure and processor parasitics if applicable. Capacitance values guaranteed

by design for all AGTL+ buffers.

Input Low Voltage All 0.625 V

Input High Voltage All 0.875 V

Output Low Voltage All 0.3 0.4 V

Output High Voltage All V

Output Low Current @ 0.3 V All 34 mA

Output Low Current @ 0.3 V All 17 mA

Leakage Current All ±100 µA

AGTL+ Pad Capacitance All 2 pF

levels are V

levels are V

REF_low

±100 mV, respectively, for a system bus agent using on-board termination. V

REF

±125 mV, respectively, for a system bus agent using on-die termination.

REF

, minimum Vpin V

CTERM

Core

Frequency

, maximum.

CTERM

Minimum Typ Maximum Unit Notes

1

1

2

,

CTERM

minimum

V

CTERM

REF

V

,

CTERM

maximum

uncertainty for ODT. V

V

REF_high

3

4

5

6

and

REF_high

Table 2-5. Power Good Signal DC Specifications

Symbol Parameter Minimum Maximum Unit Notes

V

IL

V

IH

Input Low Voltage 0.440 V

Input High Voltage 0.875 V

Table 2-6. System Bus Clock Differential HSTL DC Specifications

Symbol Parameter Minimum Maximum Unit Notes

V

IH

V

IL

V

X

C

CLK

Input High Voltage 0.78 1.3 V

Input Low Voltage –0.3 0.5 V

Input Crossover Voltage 0.55 0.85 V

Input (Pad) Capacitance 1.75 pF

Table 2-7. TAP Connection DC Specifications

Symbol Parameter Minimum Maximum Unit Notes

V

IL

V

IH

V

OL

V

OH

I

OL

I

IC

Notes:

1. There is a 100 mV hysteresis on TCK.

2. VIH, MAX = 1.5 V + 5%, VOH, MAX = 1.2 V +5%.

3. There is no internal pull-up. An external pull-up is always assumed. Max voltage tolerated at TDO is 1.5 V.

4. Per input pin.

Input Low Voltage –0.3 0.5 V

Input High Voltage 1.1 1.57 V

Output Low Voltage 0.3 V

Output High Voltage 1.2 V

Output Low Current 20 mA

Input Current 690 uA

1

1, 2

2, 3

4

Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet 19

Page 20

Table 2-8. SMBus DC Specifications

Symbol Parameter Minimum Typ Maximum Unit Notes

3.3V VCC for the System Management

Components

V

V

V

I

I

I

I

I

IL

IH

OL

3.3V

OL

OL2

LI

LO

Input Low Voltage –0.3 0.3*3.3 V V

Input High Voltage 2.31 3.47 V Max =

Output Low Voltage 0.4 V

3.3V Supply Current 5.0 30.0 mA

Output Low Current 3 mA

Output Low Current 6 mA

Input Leakage Current 10 µA

Output Leakage Current 10 µA

Notes:

1. The value specified for IOLapplies to all signals except for THRMALERT#.

2. The value specified for I

applies only to THRMALERT#, which is an open drain signal.

OL2

Table 2-9. LVTTL Signal DC Specifications

Symbol Parameter Minimum Maximum Unit Notes

V

IL

V

IH

V

OL

V

OH

Input Low Voltage 0.8 V

Input High Voltage 2.0 3.63 V

Output Low Voltage 0.4 V

Output High Voltage 2.4 V

Electrical Specifications

3.14 3.3 3.47 V 3.3 V ±5

3.3 +5%

Min +

0.7*3.3V

1

2

Table 2-10 through Table 2-11 list the AC specifications for the processor’s clock and

SMBus (timing diagrams begin with Figure 2-1). The processor uses a differential HSTL

clocking scheme with a frequency of 200, 266, or 333 MHz. The SMBus is a subset of

the I2C* interface which supports operation of up to 100 kHz.

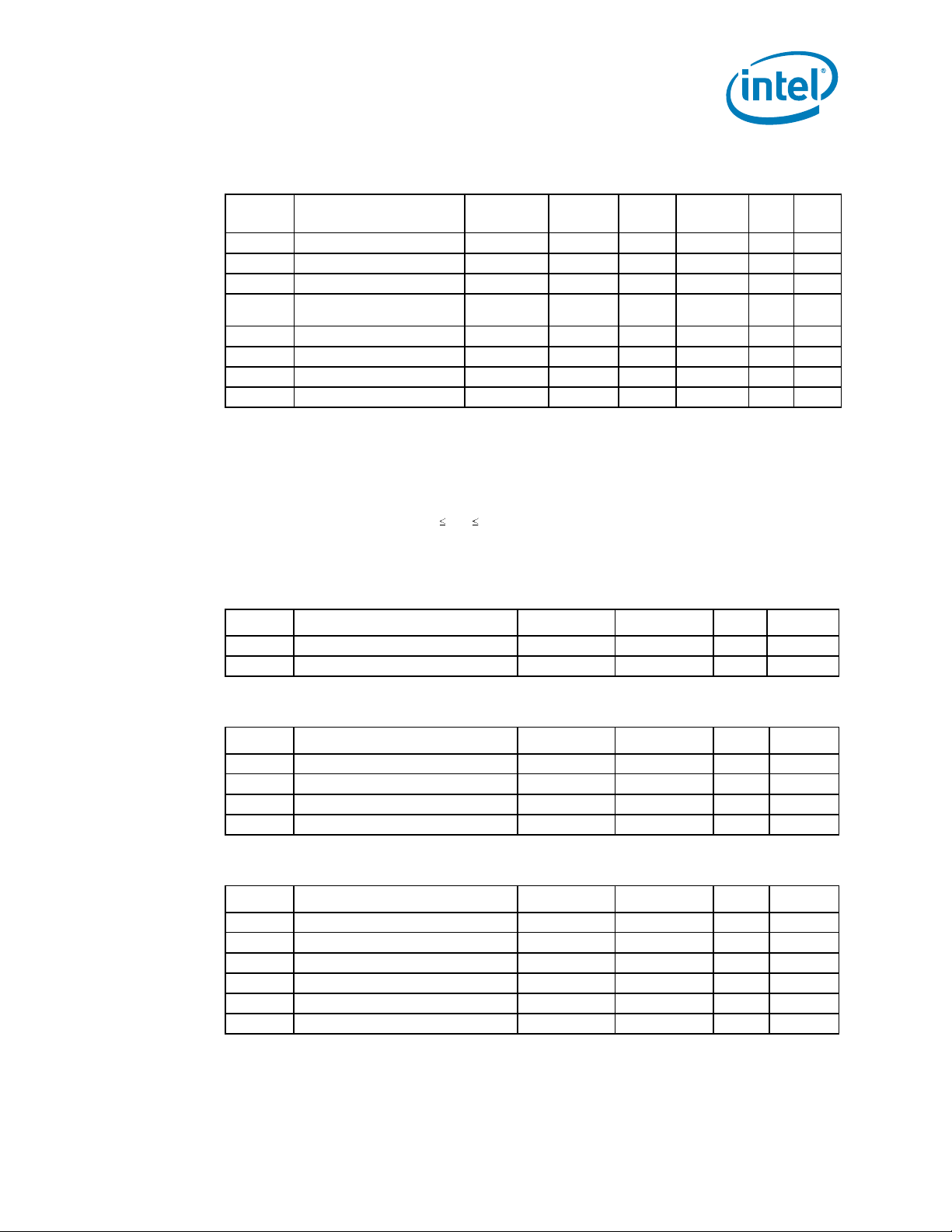

Table 2-10.System Bus Clock Differential HSTL AC Specifications (Sheet 1 of 2)

System

Symbol Parameter

T

BCLKp Period 200 5.0 ns Figure 2-1

period

T

skew

f

BCLK

T

jitter

T

high

T

low

T

period

T

skew

f

BCLK

T

jitter

T

high

T

low

System Clock Skew 200 100 ps

BCLKp Frequency 200 200 200 MHz Figure 2-1

BCLKp Input Jitter 200 100 ps Figure 2-1

BCLKp High Time 200 2.25 2.5 2.75 ns Figure 2-1

BCLKp Low Time 200 2.25 2.5 2.75 ns Figure 2-1

BCLKp Period 266 3.75 ns Figure 2-1

System Clock Skew 266 60 ps

BCLKp Frequency 266 266 266 MHz Figure 2-1

BCLKp Input Jitter 266 50 ps Figure 2-1

BCLKp High Time 266 1.69 1.88 2.06 ns Figure 2-1

BCLKp Low Time 266 1.69 1.88 2.06 ns Figure 2-1

Bus

Clock

(MHz)

Minimum Typ Maximum Unit Figure Notes

1

2

3

4

4

5

2

3

4

4

20 Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet

Page 21

Electrical Specifications

Table 2-10.System Bus Clock Differential HSTL AC Specifications (Sheet 2 of 2)

System

Symbol Parameter

T

rise

T

fall

V

PP

Notes:

1. The system clock skew is ±100 ps.

2. Measured on cross-point of rising edge of BCLKp and falling edge of BCLKn. Long-term jitter is defined as peak-to-peak variation

measured by accumulating a large number of clock cycles and recording peak-to-peak jitter.

3. Cycle-to-cycle jitter is defined as peak-to-peak variation measured over 10,000 cycles peak-to-peak jitter.

4. Measured on cross point of rising edge of BCLKp and falling edge of BCLKn.

5. The system clock skew is ±60 ps.

6. V

PPmin

7. The measurement is taken at 40-60% of the signal and extrapolated to 20-80%.

BCLKp Rise Time

BCLKp Fall Time

Minimum Input Swing All 600 mV Figure 2-1

is defined as the minimum input differential voltage which will cause no increase in the clock receiver timing.

7

7

Bus

Clock

(MHz)

All 333 500 667 ps Figure 2-1 20–80%

All 333 500 667 ps Figure 2-1 20–80%

Minimum Typ Maximum Unit Figure Notes

6

Table 2-11. SMBus AC Specifications

Symbol Parameter Minimum Maximum Unit Notes

f

SMSC

T

SMSC

t

high

t

low

t

rise

t

fall

t

VALID

t

SU

t

HLD

t

FREE

Notes:

1. Please refer to Figure 2-2 for the Standard Microsystems Corporation (SMSC)* clock waveform.

2. Bus Free Time is the minimum time allowed between request cycles.

SMSC Clock Frequency 100 kHz

SMSC Clock Period 10 µs

SMSC Clock High Time 4.0 µs

SMSC Clock Low Time 4.7 µs

SMSC Clock Rise Time 1.0 µs

SMSC Clock Fall Time 0.3 µs

SMBus Output Valid Delay 1.0 µs

SMBus Input Setup Time 250 ns

SMBus Input Hold Time 0 ns

Bus Free Time 4.7 µs

1

1

1

1

2

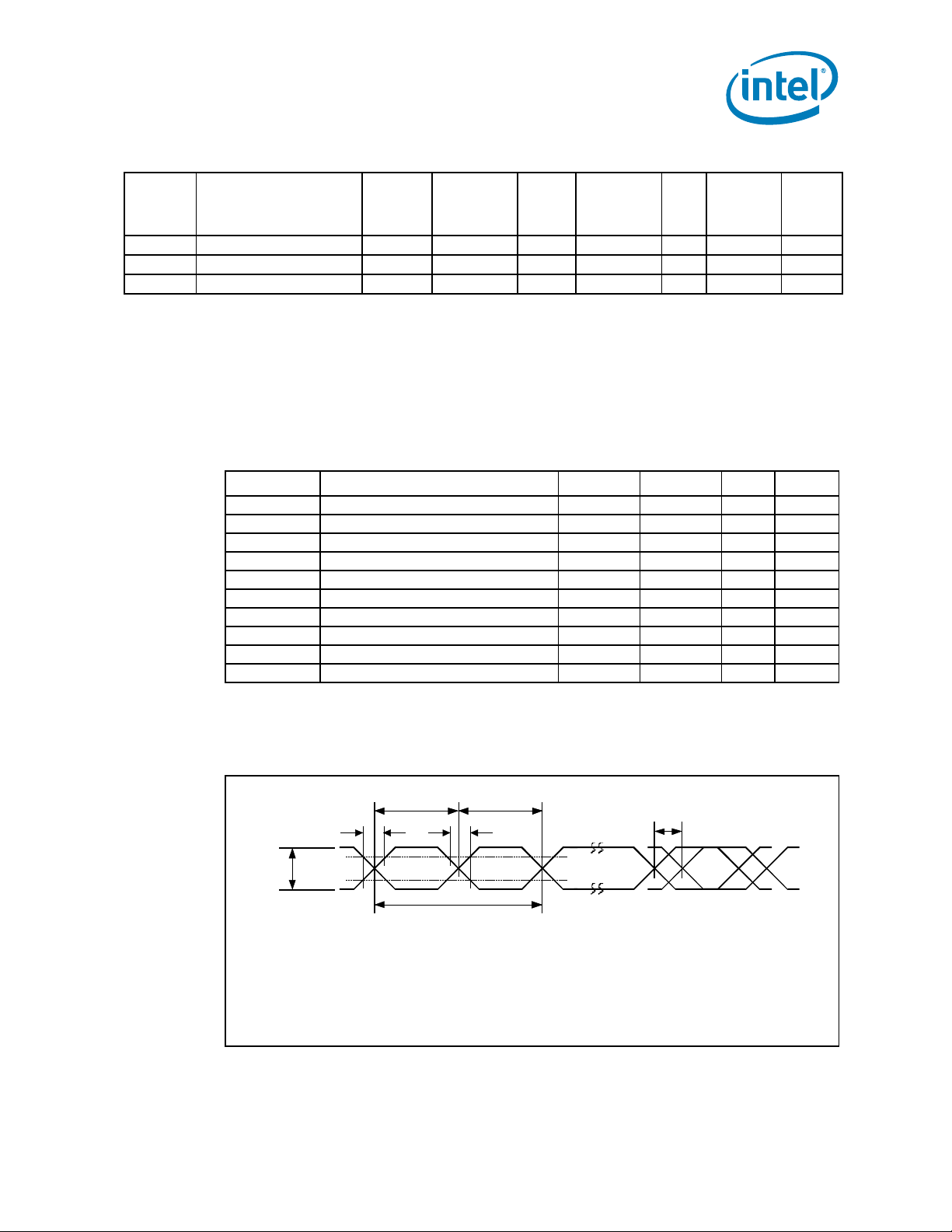

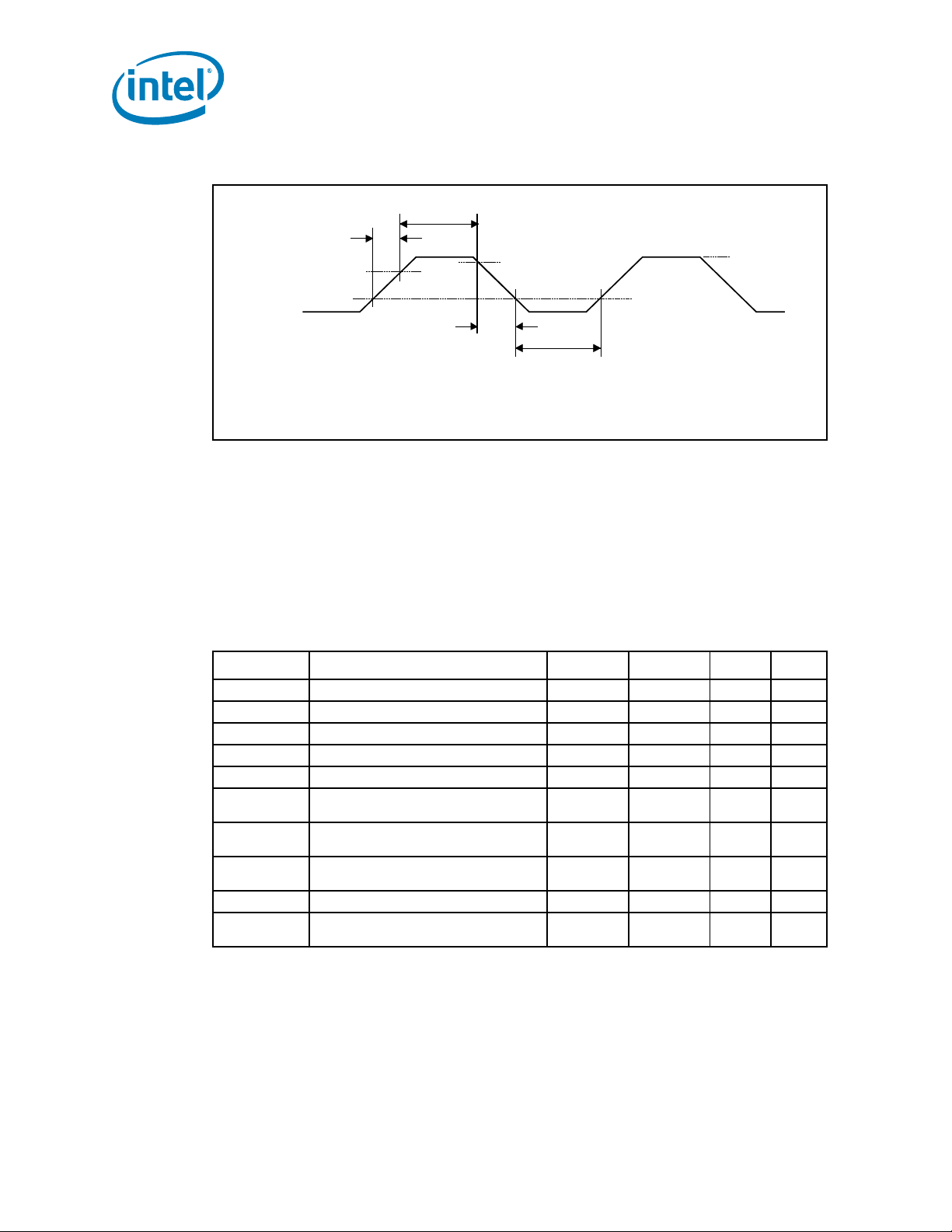

Figure 2-1. Generic Clock Waveform

T

high

T

rise

V

Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet 21

80%

pp

20%

T

Rise Time

=

rise

T

Fall Time

=

fall

T

High Time

=

high

T

Low Time

=

low

T

period

period

T

jitter

V

pp

T

low

T

fall

BCLKN

BCLKP

=T

Period

=

Long Term Peak-to-Peak Jitter

=

Peak-to-Peak Swing

=

T

jitter

000615

Page 22

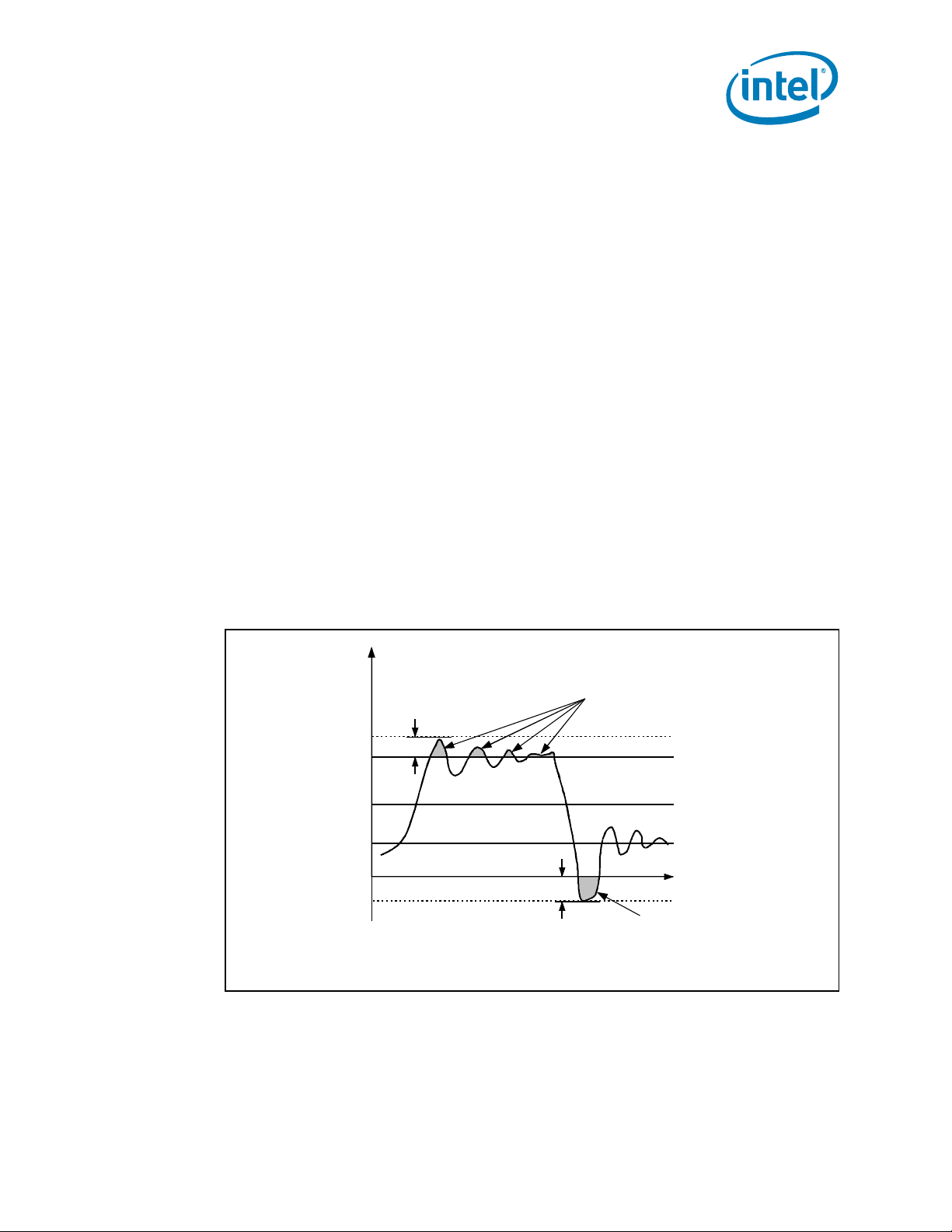

Figure 2-2. SMSC Clock Waveform

T

rise

75% V

T

T

rise

fall

cc

cc

Rise Time

=

Fall Time

=

SMSC

25% V

2.4.1 Maximum Ratings

Table 2-12 contains the processor stress ratings. Functional operation at the absolute

maximum and minimum is neither implied nor guaranteed. The processor should not

receive a clock while subjected to these conditions. Functional operating conditions are

given in the DC tables. Extended exposure to the maximum ratings may affect device

reliability. Furthermore, although the processor contains protective circuitry to resist

damage from static electric discharge, one should always take precautions to avoid

static voltages or electric fields.

T

T

T

high

T

fall

high

low

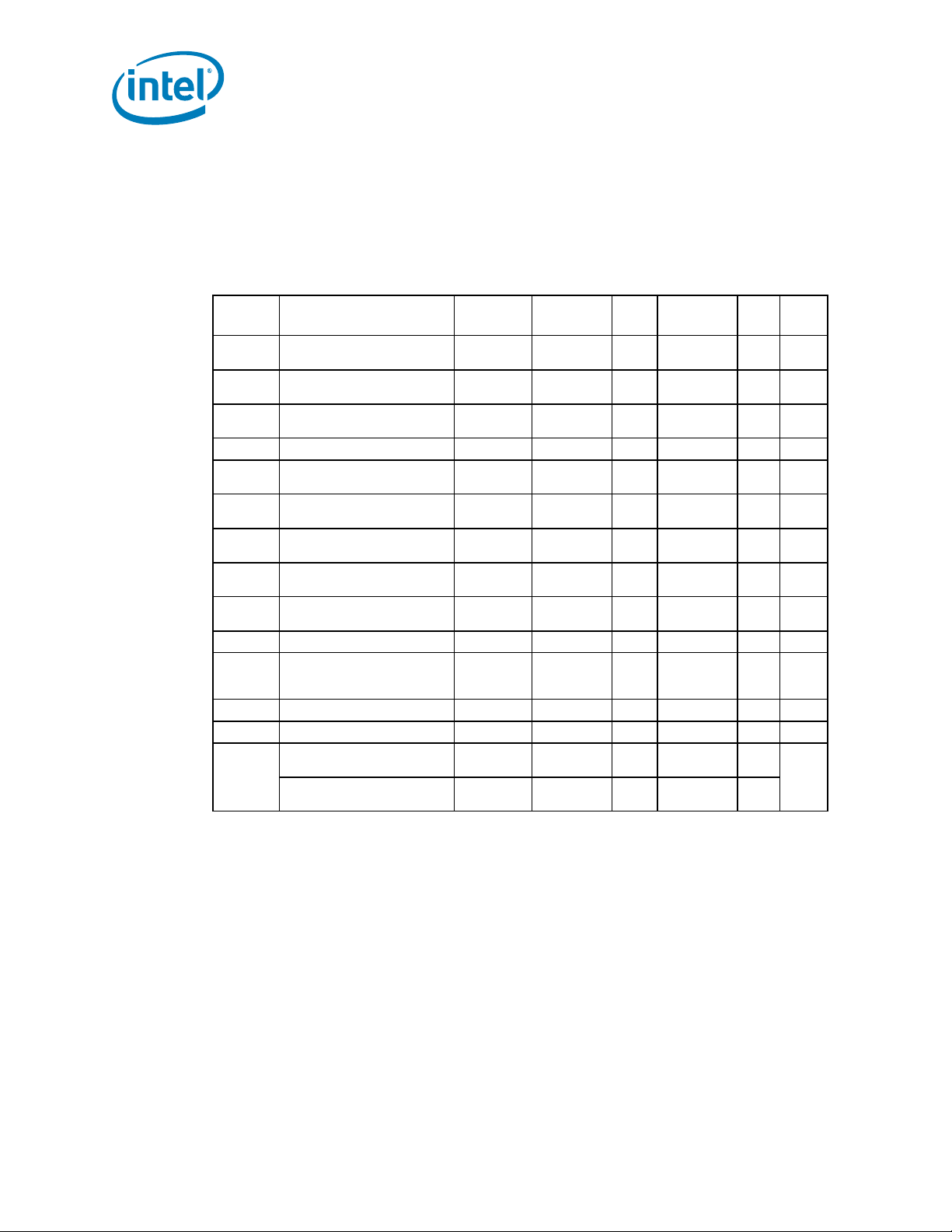

High Time

=

Low Time

=

90% V

Electrical Specifications

V (3.3V)

cc

T

low

cc

000618

Table 2-12. Dual-Core Intel® Itanium® Processor Absolute Maximum Ratings

Symbol Parameter Minimum Maximum Unit Notes

T

storage

T

shipping

V

core

V

cache

V

fixed

3.3V Any 3.3 V Supply Voltage with Respect to

V

in, SMBus

V

in, AGTL+

V

CTERM

V

in,TAP

Notes:

1. Storage temperature is temperature in which the processor can be stored for up to one year.

2. Shipping temperature is temperature in which the processor can be shipped for up to 24 hours.

3. Parameters are from third-party vendor specifications.

4. Maximum instantaneous voltage at receiver buffer input.

5. Specification includes V

respect to GND.

Processor Storage Temperature –10 45 °C

Processor Shipping Temperature –45 75 °C

Any V

Any V

Any V

GND

SMBus Buffer DC Input Voltage with

Respect to GND

AGTL+ Buffer DC Input Voltage with

Respect to GND

Any V

TAP Buffer DC Input Voltage with Respect

to GND.

Voltage with Respect to GND -0.3 1.55 V

core

Voltage with Respect to GND -0.3 1.55 V

cache

Voltage with Respect to GND -0.3 1.55 V

fixed

–0.3 5.5 V

–0.1 6.0 V

–0.45 1.65 V

Voltage with Respect to GND -0.45 1.65 V

CTERM

-0.45 1.65 V

in,AGTL+

and V

in,AGTL+ ASYNCHRONOUS

(AGTL+ asynchronous buffer DC input voltage with

1

2

3

3

4, 5

4

22 Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet

Page 23

Electrical Specifications

2.5 System Bus Signal Quality Specifications and

Measurement Guidelines

Overshoot (or undershoot) is the absolute value of the maximum voltage above the

nominal V

undershoot specifications limit transitions beyond V

edge rates. The processor can be permanently damaged by repeated overshoot or

undershoot events on any input, output, or I/O buffer if the charge is large enough

(that is, if the overshoot/undershoot is great enough). Determining the impact of an

overshoot/undershoot condition requires knowledge of the magnitude, the pulse

duration, and the activity factor (AF).

2.5.1 Overshoot/Undershoot Magnitude

Magnitude describes the maximum potential difference between a signal and its voltage

reference level. For the processor, both are referenced to GND, as shown in Figure 2-3.

It is important to note that overshoot and undershoot conditions are separate and their

impact must be determined independently. Overshoot/undershoot magnitude levels

must observe the absolute maximum specifications listed in Table 2-13 through

Table 2-17. These specifications must not be violated at any time, regardless of bus

activity or system state. Within these specifications are threshold levels that define

different allowed pulse duration. Provided that the magnitude of the overshoot/

undershoot is within the absolute maximum specifications, the pulse magnitude,

duration, and activity factors must all be used to determine if the overshoot/

undershoot pulse is within specifications.

voltage (or below GND), as shown in Table 2-3. The overshoot/

CTERM

or GND due to the fast signal

CTERM

Figure 2-3. System Bus Signal Waveform Exhibiting Overshoot/Undershoot

000588

Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet 23

Page 24

Electrical Specifications

2.5.2 Overshoot/Undershoot Pulse Duration

Pulse duration describes the total time that an overshoot/undershoot event exceeds the

overshoot/undershoot reference voltage (V

encompass several oscillations above the reference voltage. Multiple overshoot/

undershoot pulses within a single overshoot/undershoot event may need to be

measured to determine the total pulse duration.

Note: Oscillations below the reference voltage cannot be subtracted from the total overshoot/

undershoot pulse duration.

/GND). The total time could

CTERM

2.5.3 Activity Factor

Activity factor (AF) describes the frequency of overshoot (or undershoot) occurrence

relative to a clock. Since the highest frequency of assertion of any common clock signal

is every other clock, an AF = 1 indicates that the specific overshoot (or undershoot)

waveform occurs every other clock cycle. Thus, an AF = 0.01 indicates that the specific

overshoot (or undershoot) waveform occurs one time in every 200 clock cycles. For

source synchronous signals (data, and associated strobes), the activity factor is in

reference to the strobe edge. The highest frequency of assertion of any source

synchronous signal is every active edge of its associated strobe. So, an AF = 1

indicates that the specific overshoot (or undershoot) waveform occurs every other

strobe cycle. The specifications provided in Table 2-14 through Table 2-17 show the

maximum pulse duration allowed for a given overshoot/undershoot magnitude at a

specific activity factor. Each table entry is independent of all others, meaning that the

pulse duration reflects the existence of overshoot/undershoot events of that magnitude

ONLY. A platform with an overshoot/undershoot that just meets the pulse duration for a

specific magnitude where the AF <1, means that there can be no other overshoot/

undershoot events, even of lesser magnitude (if AF = 1, then the event occurs at all

times and no other events can occur).

Note: AF for the common clock AGTL+ signals is referenced to BCLKn, and BCLKp frequency.

The wired-OR Signals (BINIT#, HIT#, HITM#, BNR#, TND#, BERR#) are common

clock AGTL+ signals.

Note: AF for source synchronous (2x) signals is referenced to STBP#[7:0], and STBN#[7:0].

2.5.4 Reading Overshoot/Undershoot Specification Tables

The overshoot/undershoot specification for the processor is not a simple single value.

Instead, many factors are needed in order to correctly interpret the overshoot/

undershoot specification. In addition to the magnitude of the overshoot, the following

parameters must also be known: the width of the overshoot and the AF. To determine

the allowed overshoot for a particular overshoot event, the following must be done:

1. Determine the signal group that the particular signal falls into. For AGTL+ signals

operating in the 2x source synchronous domain, use Table 2-14 through

Table 2-16. If the signal is a wired-OR AGTL+ signal operating in the common clock

domain, use Table 2-15 through Table 2-17.

2. Determine the magnitude of the overshoot, or the undershoot (relative to GND).

3. Determine the activity factor (how often does this overshoot occur?).

4. Next, from the appropriate specification table, determine the maximum pulse

duration (in nanoseconds) allowed. The pulse duration shown in the table refers to

the period where either the maximum overshoot (for high phase) and undershoot

(for low phase) occurred.

24 Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet

Page 25

Electrical Specifications

5. Compare the specified maximum pulse duration to the signal being measured. If

the pulse duration measured is less than the pulse duration shown in the table,

then the signal meets the specifications.

6. Undershoot events must be analyzed separately from overshoot events, as they are

mutually exclusive.

2.5.5 Determining if a System Meets the Overshoot/Undershoot

Specifications

The overshoot/undershoot specifications listed in Table 2-13 through Table 2-17 specify

the allowable overshoot/undershoot for a single overshoot/undershoot event. However,

most systems will have multiple overshoot and/or undershoot events that each has

their own set of parameters (duration, AF and magnitude). While each overshoot on its

own may meet the overshoot specification, the total impact of all overshoot events may

cause the system to fail. A guideline to ensure a system passes the overshoot and

undershoot specifications is shown below:

1. Ensure that no signal ever exceeds V

2. If only one overshoot/undershoot event magnitude occurs, ensure that it meets the

specifications listed in Table 2-13 through Table 2-17.

3. If multiple overshoots and/or multiple undershoots occur, measure the worst-case

pulse duration for each magnitude and compare the results against the AF = 1

specifications. If all of these worst-case overshoot or undershoot events meet the

specifications (measured time < specifications) in the table (where AF = 1), then

the system passes.

CTERM

or GND.

2.5.6 Wired-OR Signals

To ensure platform compatibility between the processors, system bus signals must

meet certain overshoot and undershoot requirements. The system bus wired-OR

signals (BINIT#, HIT#, HITM#, BNR#, TND#, BERR#) have the same absolute

overshoot and undershoot specification as the Source Synchronous AGTL+ Signals, but

they have different time-dependent overshoot/undershoot requirements.

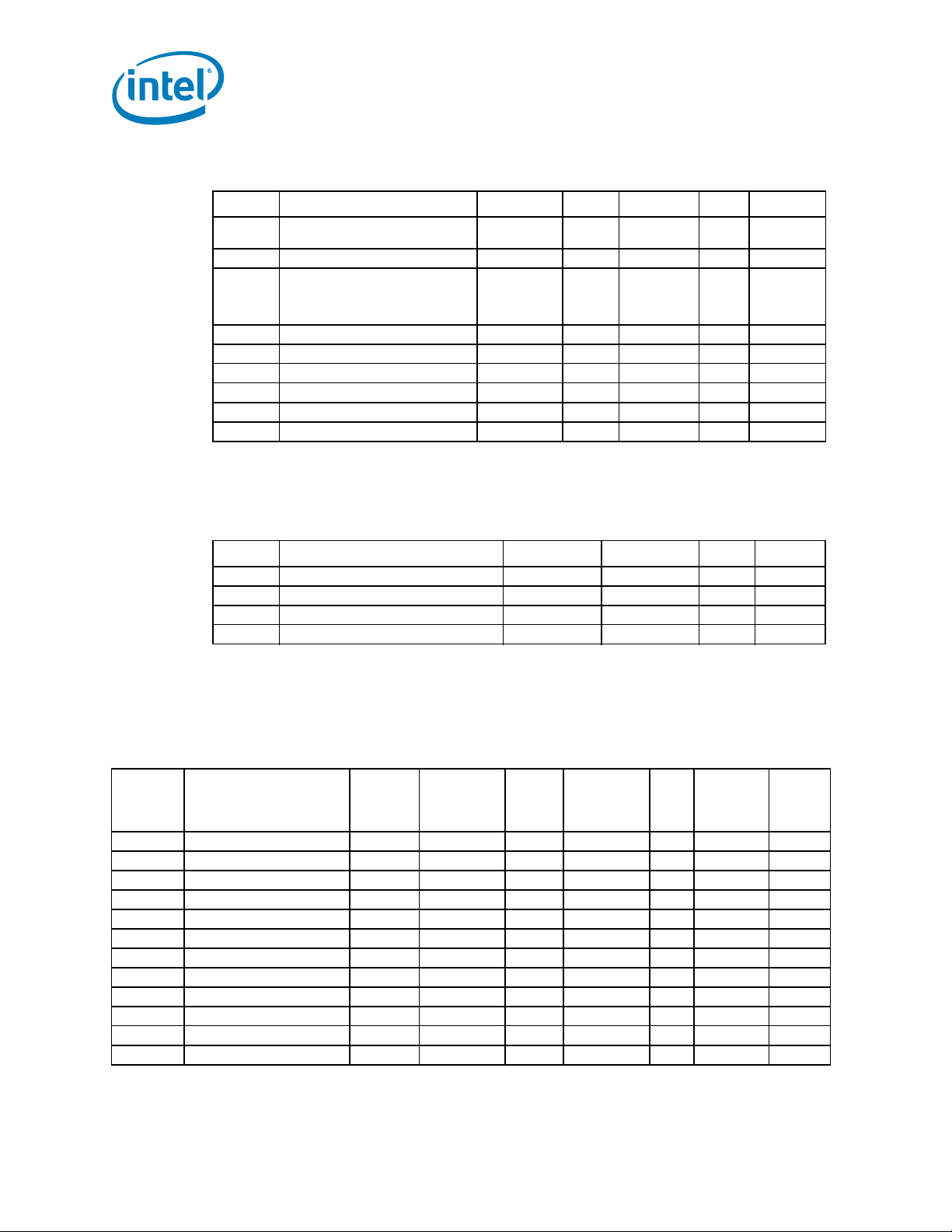

Table 2-13. Source Synchronous AGTL+ Signal Group and Wired-OR Signal Group Absolute

Overshoot/Undershoot Tolerance

Parameter Description Specification Units

V

CTERM

V

MAX

V

MIN

Overshoot Time dependent overshoot amount above V

Undershoot Time dependent undershoot amount below GND.

Notes:

1. These parameters cannot be specified in absolute terms.

Notes: The following notes apply to Table 2-14 through Table 2-17:

1. Absolute Maximum Overshoot magnitude of 1.65 V must never be exceeded.

2. Absolute Maximum Overshoot is measured referenced to GND. Pulse duration of overshoot is measured

relative to V

3. Absolute Maximum Undershoot and Pulse Duration of undershoot is measured relative to GND.

4. Ringback below V

5. Lesser undershoot does not allocate overshoot with longer duration or greater magnitude.

6. All values specified by design characterization.

I/O power supply voltage (nominal). 1.20 V

Maximum absolute voltage for system bus signals at the input

of the receiver buffers.

Minimum absolute voltage for system bus signals at the input

of the receiver buffers.

CTERM .

.

CTERM

cannot be subtracted from overshoots/undershoots.

CTERM

1.65 V

–0.45 V

1

1

Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet 25

Page 26

Electrical Specifications

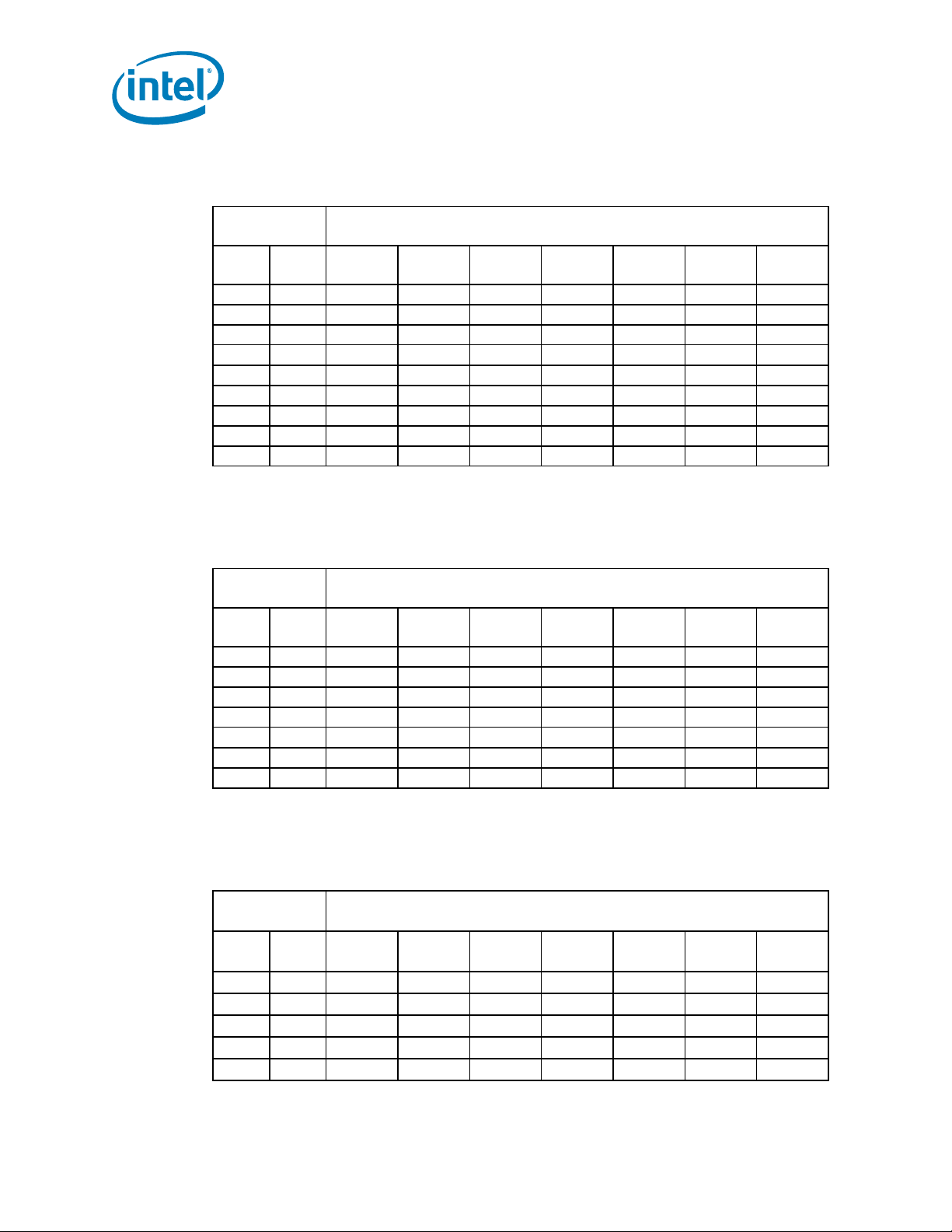

Table 2-14. Source Synchronous AGTL+ Signal Group Time-Dependent Overshoot/

Undershoot Tolerance for 400-MHz System Bus

Absolute

Maximum (V)

Overshoot

1.65 –0.45 0.0035 0.0036 0.0037 0.0040 0.0121 0.0241 0.1207

1.55 –0.35 0.0124 0.0168 0.0255 0.0520 0.1309 0.2626 1.3107

1.45 –0.25 0.1304 0.1755 0.2671 0.5438 1.3629 2.5 2.5

1.35 –0.15 1.3163 1.7815 2.5 2.5 2.5 2.5 2.5

1.25 –0.05 2.5 2.5 2.5 2.5 2.5 2.5 2.5

Notes:

1. Activity Factor = 1 means signal toggles every 5 ns.

Under-

shoot

1.6 –0.4 0.0039 0.0040 0.0045 0.0157 0.0396 0.0799 0.3996

1.5 –0.3 0.0405 0.0546 0.0833 0.1682 0.4279 0.8546 2.5

1.4 –0.2 0.4136 0.5581 0.8524 1.7215 2.5 2.5 2.5

1.3 –0.1 2.5 2.5 2.5 2.5 2.5 2.5 2.5

AF = 1

1

AF = 0.75 AF = 0.5 AF = 0.25 AF = 0.1 AF = 0.05 AF = 0.01

Pulse Duration (ns)

Table 2-15. Wired-OR Signal Group (BINIT#, HIT#, HITM#, BNR#, TND#, BERR#)

Overshoot/Undershoot Tolerance for 400-MHz System Bus

Absolute

Maximum (V)

Overshoot

1.65 –0.45 0.0166 0.0192 0.0306 0.0614 0.1539 0.3067 1.5374

1.55 –0.35 0.1659 0.2216 0.3342 0.6676 1.6734 3.3413 5

1.45 –0.25 1.7343 2.3194 3.4995 5 5 5 5

1.35 –0.15 5 5 5 5 5 5 5

Notes:

1. Activity Factor = 1 means signal toggles every 10 ns.

Under-

shoot

1.6 –0.4 0.0506 0.0674 0.1017 0.2032 0.5090 1.0213 5

1.5 –0.3 0.5413 0.7218 1.0840 2.1814 5 5 5

1.4 –0.2 5 5 5 5 5 5 5

AF = 1

1

AF = 0.75 AF = 0.5 AF = 0.25 AF = 0.1 AF = 0.05 AF = 0.01

Pulse Duration (ns)

Table 2-16. Source Synchronous AGTL+ Signal Group Time-Dependent Overshoot/

Undershoot Tolerance for 533-MHz System Bus (Sheet 1 of 2)

Absolute

Maximum (V)

Overshoot

1.65 –0.45 0.0026 0.0027 0.0028 0.0030 0.0091 0.0181 0.0902

1.55 –0.35 0.0093 0.0126 0.0191 0.0387 0.0980 0.1963 0.9822

1.45 –0.25 0.3095 0.4191 0.6366 1.2965 1.875 1.875 1.875

26 Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet

Under-

shoot

1.6 –0.4 0.0029 0.0030 0.0034 0.0118 0.0297 0.0600 0.2989

1.5 –0.3 0.0303 0.0409 0.0625 0.1268 0.3178 0.6406 1.875

AF = 11AF = 0.75 AF = 0.5 AF = 0.25 AF = 0.1 AF = 0.05 AF = 0.01

Pulse Duration (ns)

Page 27

Electrical Specifications

Table 2-16. Source Synchronous AGTL+ Signal Group Time-Dependent Overshoot/

Undershoot Tolerance for 533-MHz System Bus (Sheet 2 of 2)

Absolute

Maximum (V)

1.4 –0.2 0.9925 1.3358 1.875 1.875 1.875 1.875 1.875

1.35 –0.15 1.875 1.875 1.875 1.875 1.875 1.875 1.875

1.3 –0.10 1.875 1.875 1.875 1.875 1.875 1.875 1.875

Notes:

1. Activity Factor = 1 means signal toggles every 3.75 ns.

Pulse Duration (ns)

Table 2-17. Wired-OR Signal Group (BINIT#, HIT#, HITM#, BNR#, TND#, BERR#)

Overshoot/Undershoot Tolerance for 533-MHz System Bus

Absolute

Maximum (V)

Overshoot

1.65 –0.45 0.01248 0.0144 0.0230 0.0461 0.1155 0.2301 1.1530

1.55 -0.35 0.1250 0.1668 0.2507 0.5004 1.2537 2.5059 3.75

1.45 –0.25 1.3013 1.7396 2.6246 3.75 3.75 3.75 3.75

1.35 –0.15 3.75 3.75 3.75 3.75 3.75 3.75 3.75

Notes:

1. Activity Factor = 1 means signal toggles every 7.5 ns.

Under-

shoot

1.6 –0.4 0.0380 0.0507 0.0763 0.1522 0.3814 0.7627 3.75

1.5 –0.3 0.4054 0.5424 0.8163 1.6302 3.75 3.75 3.75

1.4 -0.2 3.75 3.75 3.75 3.75 3.75 3.75 3.75

AF = 1

1

AF = 0.75 AF = 0.5 AF = 0.25 AF = 0.1 AF = 0.05 AF = 0.01

Pulse Duration (ns)

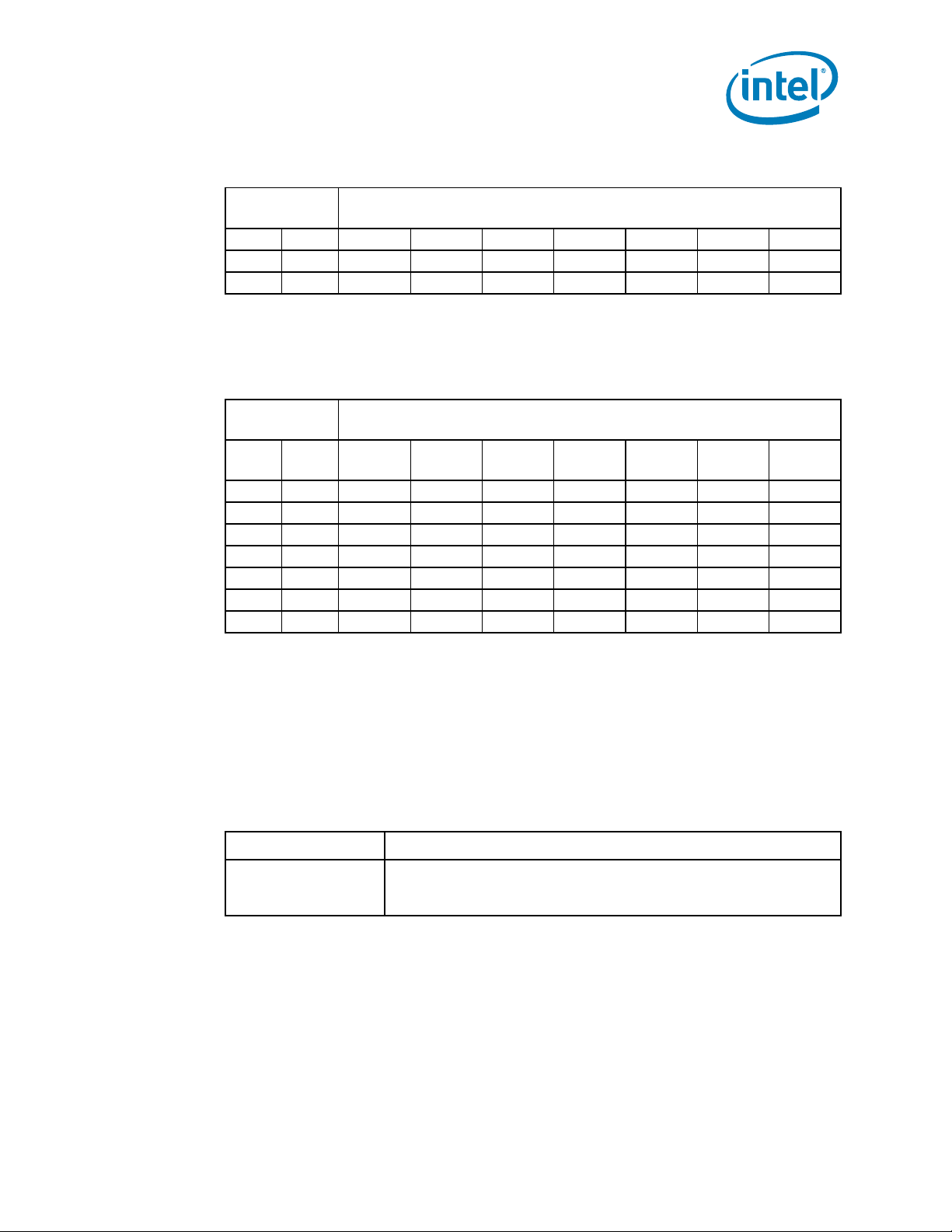

2.6 Voltage Regulator Connector Signals

The VR module consists of three DC-DC converters, V

Table 2-18 lists all of the signals which are part of the processor package VR output

connector.

Table 2-18. VR Connector Signals

Group Name Signals

Voltage Regulator

Connector

PPODGD#, CPUPRES#, GND, Vid_valid, Vid_Core[5:0],

Vid_cache [5:0], Vcache_sense, Gnd_sense, Vcore_sense,

Vfixed_sense, OUTEN.

Warning: If the VR cannot supply the voltages requested by the components in the processor

package, then it must disable itself.

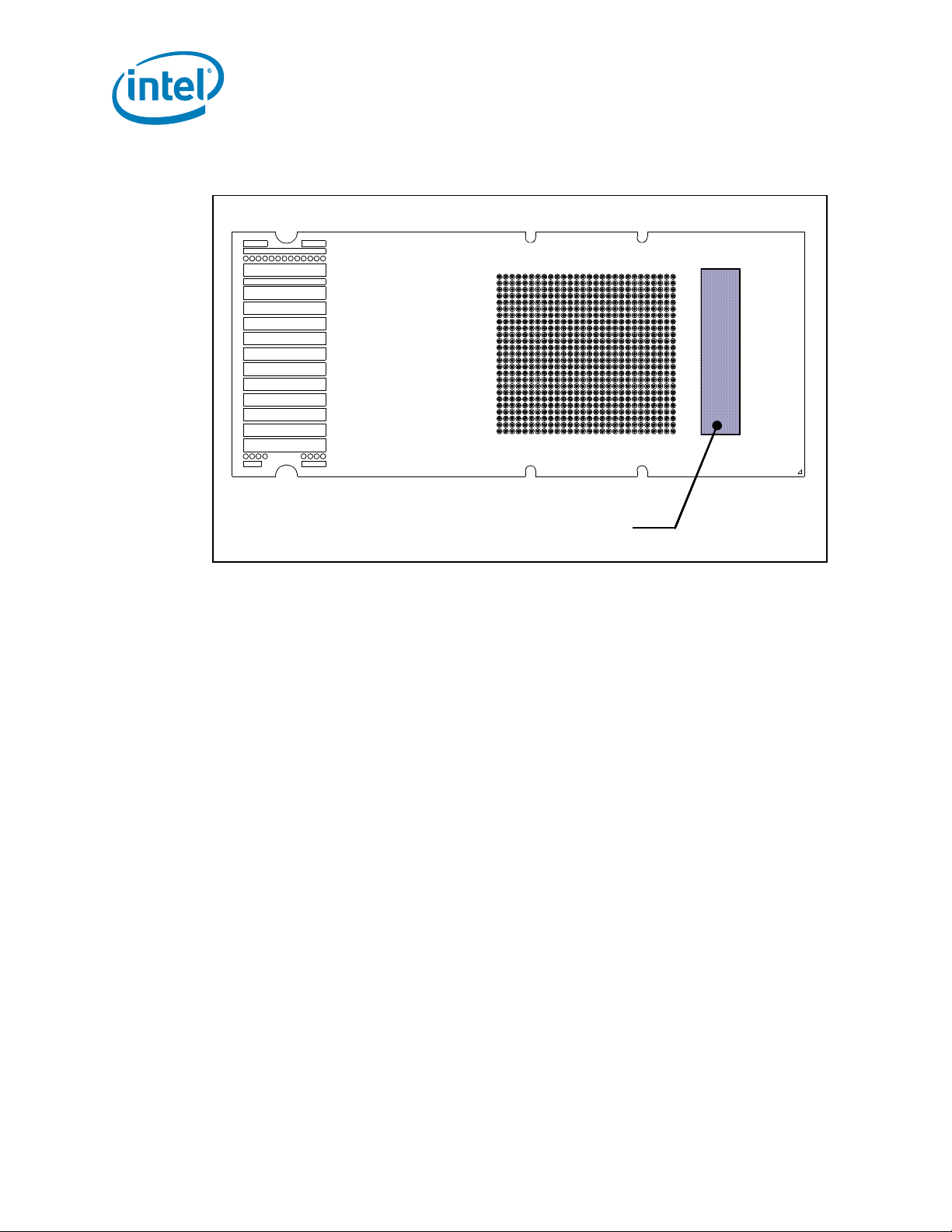

Figure 2-4 shows the top view of the processor package power tab. See Table 2-19 for

power tab connector signals.

core

, V

cache

, and V

fixed

.

Dual-Core Intel® Itanium® Processor 9000 and 9100 Series Datasheet 27

Page 28

Figure 2-4. Processors Power Tab Physical Layout

Table 2-19. Power Connector Pinouts (Sheet 1 of 2)

Electrical Specifications

001356

Power Tab VR Pads Description

A1 - C1 GND

L1 - N1 GND

A2 PPODGD#

B2 CPUPRES#

D1, K1, C2, D2, E2 Vfixed

H2 - N2 Vfixed

A3 Vid_valid

B3 Vid_core [0]

C3 Vid_core [1]

D3 Vid_core [2]

E3 Vid_core [3]

F3 Vid_core [4]

G3 Vid_core [5]