Page 1

SRKA4/ISP4400 Server System Quick Start Guide

Order Number: A07927-003

How to do basic set-up, boot from the configuration software CD, install the

✏

optional slide rail kit or center-mount kit, and access the product guide from

the CD.

Page 2

Copyright © 1999, 2000 Intel Corporation. All rights reserved. No part of this document may be copied, or reproduced in

any form, or by any means wi t hout prior written consent of I ntel.

Intel Corporation (Intel) mak es no warranty of any kind with regard t o this material, includi ng, but not limited to, t he i m pl i ed

warranties of merchantability and fitness for a particular purpose. Int el assumes no responsibility for any errors that may

appear in this document. Intel makes no commitm ent to update nor to keep current the inf ormation contained in this

document.

†

Third-party brands and names are the property of their respective owners.

Page 3

Contents

Warnings and Cautions........................................................................................................ 6

Safety and Regulatory Requirements................................................................................... 7

Unpack and Inspect the Server............................................................................................ 7

Select Site............................................................................................................................ 8

Space Requirements................................................................................................... 8

General Site Criteria.................................................................................................... 9

Mounting the SRKA4 Server System in a Rack.................................................................... 9

Equipment Rack Precautions..................................................................................... 10

Slide Rail Kit....................................................................................................................... 11

Prepare the Slide Assemblies.................................................................................... 13

Prepare the Server.................................................................................................... 13

Attach EIA Rail Brackets............................................................................................ 14

Attach the Slide Assembly to the Rack...................................................................... 18

Place the Chassis in the Rack................................................................................... 18

Install Handles........................................................................................................... 19

Attach the Front Bezel to the Chassis........................................................................ 19

Removing the Server from the Rack.......................................................................... 19

Center-mount Kit................................................................................................................20

Attach EIA Rail Brackets to the Rack......................................................................... 21

Secure the Chassis to the EIA Brackets.................................................................... 23

Attach the Front Bezel to the Chassis........................................................................ 24

Removing the Server from the Rack.......................................................................... 24

Check Power Cord............................................................................................................. 24

Power Cord Requirements......................................................................................... 24

Connect Monitor, Keyboard, Mouse................................................................................... 25

Rear Panel I/O Ports and Features............................................................................ 25

Chassis Front Controls and Indicators....................................................................... 26

Turn on Video Monitor and Server...................................................................................... 27

Run Power-On Self Test..................................................................................................... 27

Changing the BIOS Setup.................................................................................................. 28

Booting from CD.................................................................................................................29

Changing the Boot Device Priority Temporarily.................................................................. 30

Changing the Boot Device Priority Permanently................................................................. 31

Running the SCSI

When to Run the SCSI

Running the SCSI

Configuring the Adaptec AIC-7880 SCSI Adapter...................................................... 32

Configuring the Adaptec AIC-7899 SCSI Adapter...................................................... 33

Country Kit Contents.......................................................................................................... 33

Server Software Kit.................................................................................................... 33

Quick Start Guide...................................................................................................... 35

Chassis Labels.......................................................................................................... 35

Hardware................................................................................................................... 35

Service Partition (Optional)................................................................................................. 36

Select

Utility........................................................................................... 31

Select

Select

Utility........................................................................... 31

Utility................................................................................... 32

SRKA4 /ISP4400 Server System 3

Page 4

Product Guides...................................................................................................................36

Using the Acrobat .PDF Files..................................................................................... 36

Copying Configuration Software to Diskettes...................................................................... 36

4 Quick Start Guide

Page 5

WARNINGS

READ WARNINGS: Before operating this server, read the warnings

beginning on page 6.

AVOID INJURY: To avoid personal injury when unpacking the server,

use only a mechanical assist unit to lift it off the shipping pallet. The

minimum server configuration weighs 26 kg (57 lbs); the maximum

weighs 40 kg (88 lbs).

Do not attempt to lift or move the server by the handles on the power

supplies.

Use only a hand-truck or other mechanical assist unit to move the server

from one location to another.

SRKA4 /ISP4400 Server System 5

Page 6

Warnings and Cautions

Read and adhere to all warnings, cautions, and notes in this guide and the documents supplied with

the chassis, power supply, baseboard, and accessories. If the instructions for the chassis, base

board, and power supply are inconsistent with these instructions or the instructions for accessories,

contact the supplier to find out how you can ensure that the server meets safety and regulatory

requirements.

WARNINGS

This guide is intended for qualified technical personnel with experience

installing and configuring servers.

SYSTEM POWER ON/OFF: The Power button on the server front

panel DOES NOT remove AC power to the server system. Some

circuitry in the server may continue to operate even though the front

panel Power button is off. Always disconnect the power cord from the

AC power source or wall outlet before performing any of the procedures

in this guide. Failure to do so can result in personal injury or

equipment damage.

HAZARDOUS CONDITIONS, POWER SUPPLY: Hazardous voltage,

current, and energy levels are present inside the power supply. There

are no user-serviceable parts inside the power supply; servicing should

be done by technically qualified personnel.

HAZARDOUS CONDITIONS, DEVICES, AND CABLES: Hazardous

electrical conditions may be present on power, telephone, and

communication cables. Press the Power button to turn off the server

and disconnect the power cord from the AC power source,

telecommunications systems, networks, and modems attached to the

server before removing the cover. Otherwise, personal injury or

equipment damage can result.

CAUTIONS

ELECTROSTATIC DISCHARGE (ESD) AND ESD PROTECTION:

Perform the procedures in this chapter only at an electrostatic discharge

(ESD) workstation since the server components can be extremely sensitive

to ESD. If no such station is available, you can reduce the risk of

electrostatic discharge ESD damage by doing the following:

• Wear an anti-static wrist strap and attach it to a metal part of the server.

• Touch the metal on the server chassis before touching the server

components.

• Keep part of your body in contact with the metal server chassis to dissipate

the static charge while handling the components.

• Avoid moving around unnecessarily.

• Hold the server components (especially boards) only by the edges.

6 Quick Start Guide

Page 7

• Place the server components on a grounded, static-free surface. Use a

conductive foam pad if available but not the component wrapper.

• Do not slide the components over any surface.

COOLING AND AIRFLOW: For proper cooling and airflow, always

install the chassis access cover before turning on the system. Operating the

system without the cover in place can cause overheating and damage to

system components.

Safety and Regulatory Requirements

See the SRKA4/ISP4400 Server System Product Guide for all applicable safety standards,

electromagnetic compatibility (EMC) regulations, and product certification markings.

Intended uses: This product was evaluated for use in computer racks within computer rooms and

similar locations. Other uses require further evaluation.

Unpack and Inspect the Server

Remove the server from the packaging container and check that all the accessories are included.

Inspect the packaging container for evidence of mishandling during transit. If the packaging

container is damaged, photograph it for reference. After removing the contents, keep the damaged

container and the packing materials.

Inspect the server and accessories for damage. If the contents appear damaged, file a damage

claim with the carrier immediately.

SRKA4 /ISP4400 Server System 7

Page 8

Select Site

When selecting the site, make sure that you understand

• Space requirements for the SRKA4 MP server system

• General site criteria

Space Requirements

The space requirements for the SRKA4 MP server system are specified in the following table.

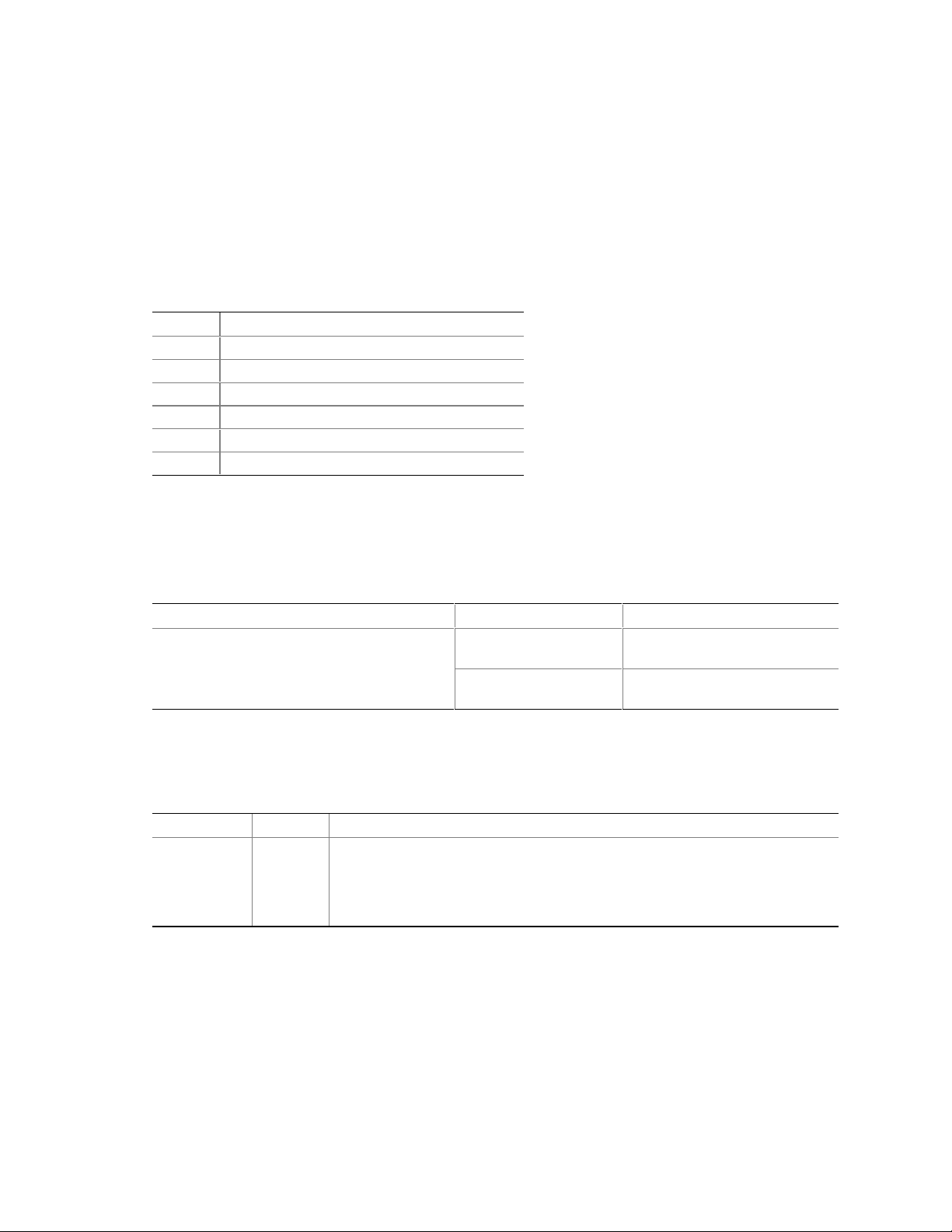

Table 1. SRKA4 MP Server Physical Specifications

Specification Rack Mode Only

Height 4u (7 inches)

Width 17.5 inch rack

Depth 26.5 inches

Weight 57 pounds, minimum configuration

88 pounds, maximum configuration

Required front clearance 3 inches (inlet airflow <35 °C / 95 °F)

Required rear clearance 6 inches (no airflow restriction)

Required side clearance 1 inch

8 Quick Start Guide

OM09980

Figure 1. SRKA4 MP Server System

Page 9

General Site Criteria

The server operates reliably within normal office environmental limits. Select a site that meets

these criteria:

• Near a properly earthed, grounded, three-pronged power outlet

In the United States and Canada: a NEMA 6-15R outlet for 100-120 V and for 200-240 V.

In other geographic areas: a properly earthed, grounded outlet in accordance with the local

electrical authorities and electrical code of the region.

• Clean and relatively free of excess dust.

• Well ventilated and away from sources of heat, with the ventilating openings on the server

kept free of obstructions.

• Away from sources of vibration or physical shock.

• Isolated from strong electromagnetic fields and noise caused by electrical devices such as

elevators, copy machines, air conditioners, large fans, large electric motors, radio and TV

transmitters, and high-frequency security devices.

• Access space provided so the server power cords can be unplugged from the power supply or

the wall outlet; this is the only way to remove AC power from the server.

• Clearance provided for cooling and airflow.

Mounting the SRKA4 Server System in a Rack

The SRKA4 server system is a rack-mounted system, which means that you install it in a rack.

You install the system in either a slide rail or center-mount rack configuration.

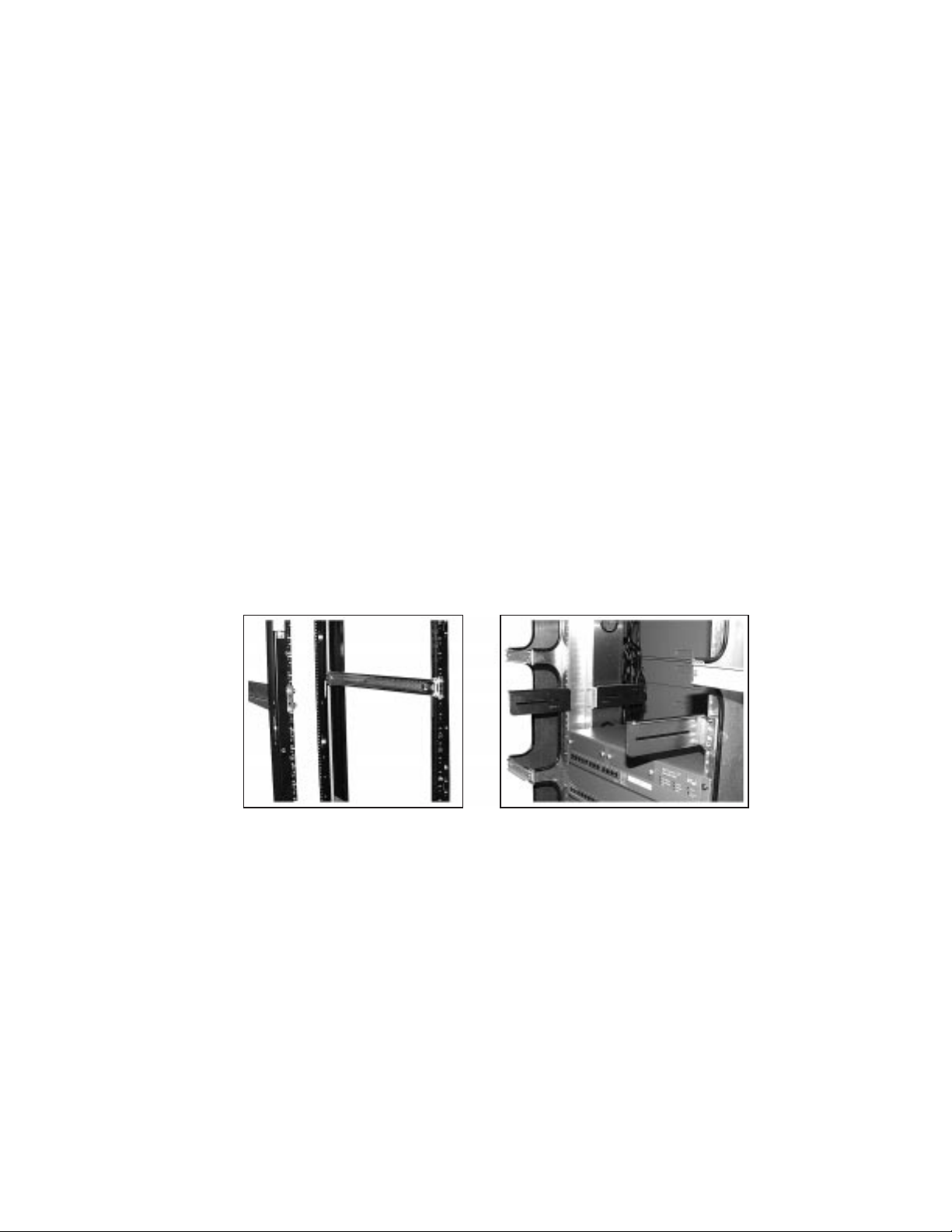

OM09981

Figure 2. Slide Rail

Configuration

Figure 2a. Center-mount

Configuration

The slide rail configuration is shown in Figure 2. There are four posts, each with holes spaced at

small intervals. Each slide rail in the slide rail assembly is connected to the front and back of the

rack. If mounting the server in a slide rail configuration, you only need the slide rail kit. Note the

equipment rack precautions below, and follow the instructions in the “Slide Rail Kit” section on

page 11.

The center-mount configuration is shown in Figure 2a. There is a center bar with holes on each

side. Center-mount brackets are attached to the center bar. If mounting the server in a centermount configuration, you only need the center-mount kit. Note the equipment rack precautions

below, and follow the instructions in the “Center-mount Kit” on page 20.

SRKA4 /ISP4400 Server System 9

Page 10

Equipment Rack Precautions

WARNINGS

MAIN AC POWER DISCONNECT: You are responsible for installing an

AC power disconnect for the entire rack unit. This main disconnect

must be readily accessible, and it must be labeled as controlling power

to the entire unit, not just to the server(s).

G

ROUNDING THE RACK INSTALLATION: To avoid the potential for an

electrical shock hazard, you must include a third wire safety grounding

conductor with the rack installation. If a server power cord is plugged

into an AC outlet that is part of the rack, then you must provide proper

grounding for the rack itself. If server power cords are plugged into

wall AC outlets, the safety grounding conductor in each power cord

provides proper grounding only for the server. You must provide

additional, proper grounding for the rack and other devices installed

in it.

CAUTIONS

Temperature: The operating temperature of the server, when installed in

an equipment rack, must not go below 5 °C (41 °F) or rise above 35 °C

(95 °F). Extreme fluctuations in temperature can cause a variety of

problems in your server.

Ventilation: The equipment rack must provide sufficient airflow to the

front of the server to maintain proper cooling. It must also include

ventilation sufficient to exhaust a maximum of 3,000 Btu's per hour for the

server. The rack selected and the ventilation provided must be suitable to

the environment in which the server will be used.

10 Quick Start Guide

Page 11

Slide Rail Kit

WARNING

Avoid injury: To avoid personal injury when unpacking the server, use

only a mechanical assist unit to lift it off the shipping pallet. The

minimum server configuration weighs 26 kg (57 lbs); the maximum

weighs 40 kg (88 lbs).

Do not attempt to lift or move the server by the handles on the power

supplies.

Use only a hand-truck or other mechanical assist unit to move the server

from one location to another.

To mount the SRKA4 MP server system in a slide rail configuration, install the slide rail kit as

directed in this section. The slide rail kit contains slide rail assemblies, EIA brackets, and several

screws, nuts, and bolts.

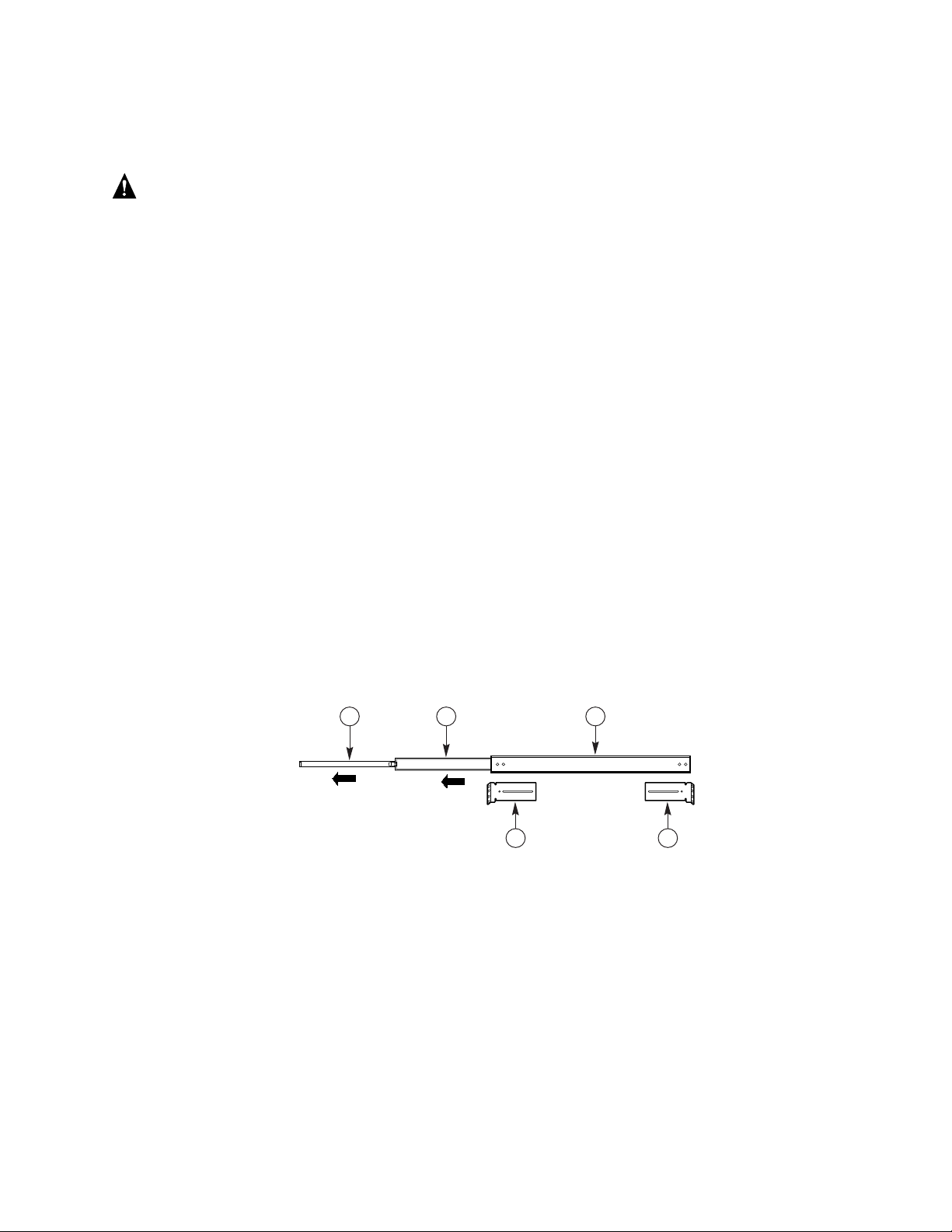

The slide rail kit contains two slide rail assemblies. As shown in Figure 3, the slide rail assembly

contains three moving parts: the inner member, the intermediate member, and the outer member.

The slide rail kit contains four EIA brackets. Two brackets are labeled FL/RR. One is connected

to the front left (FL) of the slide assembly; the other is connected to the rear right (RR). The

remaining two brackets are labeled FR/RL. One is connected to the front right (FR) of the slide

assembly; the other is connected to the rear left (RL). Figure 3 shows where the brackets are

attached to the slide rail assembly.

Screws, lock nuts, and washers are provided for the assembly of each slide rail and attaching the

slide rail to the server. However, you must supply the screws that secure the slide rail to the rack.

A

Figure 3. Slide Assembly Fully Extended

A. Inner member

B. Intermediate member

C. Outer member

D. Front left bracket

E. Rear left bracket

The inner member is the narrowest piece of the slide assembly.

The intermediate member is the middle member of the slide assembly.

The outer member is the widest piece of the slide assembly.

The location of the front left bracket labeled FL/RR.

The location of the rear left bracket labeled FR/RL.

B

D E

C

OM09982

SRKA4 /ISP4400 Server System 11

Page 12

The inner member has a safety latch shown in Figure 4. Without fully extending the slide

assembly, you can move the server in and out from the rack. When the slide assembly is fully

extended, this latch locks the assembly in the fully extended position. When you depress the latch,

you can release the inner member from the rest of the slide assembly.

C

Figure 4. Safety Latch

A. Inner member The inner member is the narrowest piece of the slide assembly.

The inner member is attached to the chassis.

B. Safety latch The safety latch is located on the inner member.

C. Intermediate member The intermediate member slides into the inner member.

B

A

OM09983

WARNING

ANCHOR THE EQUIPMENT RACK: You must anchor the equipment rack

to an unmovable support to prevent it from falling over when the server

is pulled to the front on the slide assembly. The anchors must be able to

withstand a force of up to 113 kg (250 lbs). You must also consider the

weight of any other device installed in the rack.

CAUTION

After completing the rack mount installation, do not depress the safety latch

unless you are removing the chassis from the rack. The purpose of the

safety latch is to prevent the server from unexpectedly sliding out of the

rack.

12 Quick Start Guide

Page 13

Prepare the Slide Assemblies

1. Remove the slide assemblies from the kit.

2. Orient the slide assembly so that the inside of the inner member is facing up and the safety

latch is visible.

3. Fully extend the telescoping slide assembly until the intermediate member hits the safety latch

on the inner member.

4. Depress the safety latch with your thumb. Pull the inner member away from the intermediate

member until the inner member separates from the rest of the slide assembly.

5. Set the intermediate and outer members of the slide assembly aside. You will need them in a

later on.

Prepare the Server

1. Remove six #10-32 x 1/4 long pan-head screws from the kit.

2. Orient the first inner member so that the latch points towards the rear of the chassis. The inner

member is noted by "A" in Figure 5. Notice that the safety latch is pointed towards the rear of

the chassis.

A A A

OM09986

Figure 5. Inner Member Attached to Chassis

3. Align the three holes in the inner member with the three holes in the chassis.

4. Insert and tighten a screw through each hole in the bar and chassis wall.

5. Repeat steps 2 through 4 for the other inner member and other side of the chassis.

SRKA4 /ISP4400 Server System 13

Page 14

Attach EIA Rail Brackets

NOTE

✏

Mounting holes in the vertical rails of equipment racks are commonly

spaced in a 5/8 x 5/8 x 1/2-inch sequence. Perform the following steps

carefully; brackets must be mounted with precision to allow room for the

next server you install in a rack.

At this point, you have removed the inner member from the slide assembly. The outer and

intermediate members comprise the slide assembly. Note the location of the brackets in Figure 3

on page 11.

Attach Front Bracket

1. Remove two #8-32 x 1/2 long pan-head screws, two washers, and two lock nuts from the kit.

2. Extend the intermediate member out from outer member so that the hole at the front end of the

outer member is visible through a rectangular hole in the intermediate member. Item B in

Figure 7 on page 15 shows in what direction you must extend the intermediate member.

Item C in Figure 6 shows the extension of the slide rail assembly. On the left side of the slide

assembly, notice that the screw hole in the outer member is in the center of the rectangular

hole in the intermediate member.

A

B

C

OM09987

Figure 6. FL/RR Bracket and Extended Slide Rail Assembly

A. Front left bracket The front left bracket labeled FL/RR.

B. Lower tongue The correct orientation of the lower tongue of the bracket safety latch.

C. Extended slide

assembly

The intermediate member is extended so that the rectangular hole in the

screw hole in the outer member is centered in the rectangular hole of the

intermediate member.

3. Place one of the brackets labeled FL/RR on the outside of the outer member. The lower

tongue of the bracket must be oriented correctly. Item B in Figure 6 shows the bracket’s

correct orientation.

14 Quick Start Guide

Page 15

4. Place a screw in the holes from inside the intermediate member and tighten with a washer and

lock nut. The correct alignment of the screw, washer, lock nut, bracket, and slide assembly is

shown in Figure 7.

D

C

B

E

F

A

OM09984

Figure 7. Correct Alignment of Screw, Washer, Nut, Bracket,

and Slide Assembly at the Front

A. Extended slide rail

assembly

B. Extension direction The intermediate member is extended in this direction.

C. Rectangular hole Screw hole is centered in the rectangular hole of the intermediate member.

D. Front left bracket Front left bracket labeled FL/RR.

E. Screw Screw used to secure the bracket to the slide rail assembly.

F. Washer and lock-nut Correct orientation of the washer and lock-nut.

The slide rail assembly extended so that the screw hole in the outer member

is centered in the rectangular hole of the intermediate member.

CAUTION

Secure the front bracket. Before continuing, make sure that the screw

connecting the front bracket is tightened securely. If it is not, the rack

installation may not be able to support the weight of the server.

5. Slide the intermediate member back and forth over the screw you just tightened. If the

intermediate member cannot slide over the screw, make sure the screw size is correct.

6. Repeat steps 2 through 5 for the other slide assembly.

SRKA4 /ISP4400 Server System 15

Page 16

Attach Rear Bracket

1. Remove four #8-32 x 1/2 long pan-head screws, four washers, and four lock nuts from the kit.

2. Extend the intermediate member out from outer member so that you have complete access to

the rear part of the outer member. Item B in Figure 9 on page 17 shows in what direction you

must extend the intermediate member. Item C in Figure 8 on page 16 shows the extension of

the slide rail assembly. On the right side of the slide assembly, notice that the three screw

holes in the outer member are accessible.

3. Place one of the brackets labeled FR/RL on the outside of the outer member. The lower

tongue of the bracket must be oriented correctly. Item B in Figure 9 on page 17 shows the

correct orientation.

A

B

C

OM09988

Figure 8. FR/RL Bracket and Extended Slide Rail Assembly

A. Rear left bracket The rear left bracket labeled FR/RL.

B. Lower tongue The correct orientation of the lower tongue of the bracket safety latch.

C. Extended slide assembly The intermediate member is extended so that the three screw holes on

the outer member are accessible.

4. Place one of the brackets labeled FR/RL on the outside of the outer member. The lower

tongue of the bracket must be oriented correctly. Item B in Figure 6 on page 14 shows the

bracket’s correct orientation.

5. Align the slot in the bracket with the three holes in the outer member so that all three holes in

the outer member are visible through the slot in the bracket.

16 Quick Start Guide

Page 17

6. Place screws in two of the three holes from inside the intermediate member and loosely tighten

with a washer and lock nut. The correct alignment of the screw, washer, lock nut, bracket, and

slide assembly is shown in Figure 9.

E

C

A

B

D

OMO9985

Figure 9. Correct Alignment of the Screw, Washer, Nut, Bracket,

and Slide Assembly at the Rear

A. Extended slide rail

assembly

B. Extension direction The intermediate member is extended in this direction.

C. Rear left bracket Rear left bracket labeled FR/RL.

D. Screw One of two screws used to secure the bracket to the slide rail assembly.

E. Washer and lock-nut Correct orientation of the washer and lock-nut for each screw.

The slide rail assembly extended so that the screw hole in the outer member

is centered in the rectangular hole of the intermediate member.

Notice what screw holes are used on the outer member.

7. Slide the bracket back and forth. Make sure that the screws are loose enough to allow the

bracket to move freely.

8. Repeat steps 2 through 7 for the other slide assembly.

SRKA4 /ISP4400 Server System 17

Page 18

Attach the Slide Assembly to the Rack

1. Obtain at least four screws from your own inventory.

2. Select the holes you are going to use on the rack.

3. Align the holes on one of the front brackets with the holes you selected on the rack. The holes

are noted by "A" in Figure 10.

A

OM09989

Figure 10. Slide Assembly Aligned with Holes in the Vertical Rack

4. As shown in Figure 10, insert two screws in the front bracket and rack holes. Tighten the

screws to secure the front of the slide assembly to the rack.

5. Adjust the rear bracket so that it meets the rear vertical rail of the rack.

6. Insert two screws in the rear bracket and rack holes. Tighten the screws to secure the rear of

the slide assembly to the rack.

7. Repeat steps 2 through 6 for the other slide assembly.

Place the Chassis in the Rack

Lift the chassis with hand-truck or other mechanical assist unit so that the inner members on the

server line up with the slide assembly attached to the rack. Gently push the chassis into the rack.

Make sure that the inner member slides smoothly into the slide assembly in the rack.

18 Quick Start Guide

Page 19

Install Handles

The handles attach to the chassis. As an option, you can also attach the handles to the rack.

1. Make sure that you pull the chassis out of the rack until the safety latch snaps into place.

2. As shown in Figure 11, align the inside top and bottom handles with the top and bottom holes

of the chassis.

OM09999

Figure 11. Handles Aligned with Chassis

3. Place screws in the top and bottom holes on the inside edge of the handle. Tighten both screws

to secure the handle to the chassis.

4. If you want to secure the handle to the vertical rack, place screws in the top and bottom holes

on the outside edge of the handle. Tighten both screws.

Attach the Front Bezel to the Chassis

The front bezel attaches to and protects the front of the server.

1. Make sure that you pull the chassis out of the rack until the safety latch snaps into place.

2. Place the front bezel over the front of the chassis. The edge of the bezel should line up with

the front edges of the chassis. The ball studs on the back of the bezel fit easily into holes on

the front of the server.

3. Gently push the front bezel into the chassis. The front bezel snaps into place.

Removing the Server from the Rack

1. Pull the server out until the safety latches on each side lock into place.

2. Make sure that a hand-truck or other mechanical assist unit is placed directly under the server.

3. Depress the safety latches on both sides and simultaneously pull the chassis out of the slide

assembly.

4. Pull the hand-truck or other mechanical assist unit out along with the chassis.

SRKA4 /ISP4400 Server System 19

Page 20

Center-mount Kit

WARNING

AVOID INJURY: To avoid personal injury when unpacking the server,

use only a mechanical assist unit to lift it off the shipping pallet. The

minimum server configuration weighs 26 kg (57 lbs); the maximum

weighs 40 kg (88 lbs).

Do not attempt to lift or move the server by the handles on the power

supplies.

Use only a hand-truck or other mechanical assist unit to move the server

from one location to another.

To mount the SRKA4 server system on a center-mount configuration, install the center-mount kit

as directed in this section.

The center-mount kit contains four EIA brackets, and several screws, nuts, and bolts. Screws,

nuts, and bolts are provided for securing the brackets to the chassis. However, you must supply the

screws that secure the brackets to the rack.

There are two sets of EIA rail brackets. One set is labeled FL/RR. These brackets are attached to

the front of the slide assembly. The other set is labeled FR/RL. These brackets are attached to the

back of the slide assembly.

WARNING

ANCHOR THE EQUIPMENT RACK: To prevent the equipment rack from

falling over, you must anchor the equipment rack to an unmovable

support. The anchors must be able to withstand a force of up to 113 kg

(250 lbs). You must also consider the weight of any other device

installed in the rack.

20 Quick Start Guide

Page 21

Attach EIA Rail Brackets to the Rack

1. Separate the brackets labeled FR/RL from the brackets labeled FL/RR.

2. Decide what side of the rack is the "front" side of the rack.

3. Place one of the brackets labeled FR/RL on the front right side of the rack as shown in

Figure 12.

4. Make sure that the holes in the bracket are aligned with the holes in the rack, and that there is

at least 4 inches of clearance below the bottom of the bracket. The two screws are noted by

“A” in Figure 12.

A

OM09991

Figure 12. FR/RL Bracket Attached to Right Side of Rack

5. Secure the bracket to the rack with two screws as shown in Figure 12.

6. Place the other bracket labeled FL/RR on the front left side of the rack.

7. Align the holes in the bracket with the holes in the rack. Make sure that the top of the bracket

is level with the other front right bracket already attached to the rack. The two screws are

noted by “A” in Figure 13.

A

OM09994

Figure 13. FL/RR Bracket Attached to Right Side of Rack

8. Secure the bracket to the rack with two screws as shown in Figure 13.

SRKA4 /ISP4400 Server System 21

Page 22

9. Place one of the brackets labeled FR/RL on the rear left side of the rack as shown in Figure 14.

10. Make sure that the holes in the bracket are aligned with the holes in the rack, and that the top

of the bracket is aligned with the top of the front left bracket already attached to the rack.

A

OM09995

Figure 14. FR/RL Bracket Attached to the Rear Left Side of the Rack

11. The two screws are noted by “A” in Figure 14. Secure the bracket to the rack with two screws.

12. Place the remaining bracket labeled FL/RR on the back left side of the rack.

13. Make sure that the holes in the bracket are aligned with the holes in the rack, and that the top

of the bracket is aligned with the top of the front right bracket already attached to the rack.

14. Secure the bracket to the rack with two screws.

15. Loosen the screws for the brackets so that each one can move left and right freely.

22 Quick Start Guide

Page 23

Secure the Chassis to the EIA Brackets

1. Slide the back of the SRKA4 server system into the rack from the front as shown in Figure 15.

The lip on the chassis is noted by "A" in Figure 15, rests on the brackets.

A

OM09992

Figure 15. Chassis Slides into the Rack

2. Adjust the chassis so that the slot in each bracket lines up with a hole in the chassis. The

chassis should be centered on the rack.

3. Try to make each bracket flush with the chassis. If necessary, slide the brackets left or right.

4. Using the screws provided in the center-mount kit, attach and tighten a screw through the slot

in the bracket and into the chassis.

A

OM09993

Figure 16. Chassis is Secured to Bracket with One Screw Noted by "A"

SRKA4 /ISP4400 Server System 23

Page 24

Attach the Front Bezel to the Chassis

The front bezel attaches to and protects the front of the server.

1. Make sure that you pull the chassis out of the rack until the safety latch snaps into place.

2. Place the front bezel over the front of the chassis. The edge of the bezel should line up with

the front edges of the chassis. The ball studs on the back of the bezel fit easily into holes on

the front of the server.

3. Gently push the front bezel into the chassis. The front bezel snaps into place.

Removing the Server from the Rack

1. Remove the screws securing the chassis to the brackets.

2. Slide the SRKA4 MP server system out of the rack from the front. Make sure that the tabs at

the rear of the server do not get stuck on the front of the front brackets.

Check Power Cord

WARNING

Do not modify or use a supplied AC power cord if it is not the exact type

required in the region where the server will be installed and used.

Replace the cord with the correct type. Refer to the cord requirements

described below.

Do not plug in the server power cord yet if you will be adding internal

parts (boards, DIMMs, removable media drives). For these installation

procedures, see the SKA4 Baseboard Product Guide.

Power Cord Requirements

• Rating: Cords must be rated for available AC voltage and have a current rating at least 125%

of current rating of server.

• Connector, wall outlet end: Cords must be terminated in grounding-type male plug designed

for use in your region. It must have certification marks showing certification by an agency

acceptable in your region.

• Connector, server end: The connector that plugs into the AC receptacle on the server must

be an IEC 320, sheet C13, type female connector.

• Cord length and flexibility: Cords must be less than 4.5 meters (14.76 feet) long, and must

be a flexible (harmonized) cord or VDE-certified cordage to comply with server’s safety

certifications.

NOTES

✏

Surge suppressor recommended: In geographic regions that are

susceptible to electrical storms, we highly recommend that you plug the

server into a surge suppressor.

24 Quick Start Guide

Page 25

EMI information: For information about complying with electromagnetic

interference regulations, see “Electromagnetic Compatibility” in the

SRKA4/ISP4400 Server System Product Guide.

To view or print a Product Guide: See "Product Guides" on page 34.

Connect Monitor, Keyboard, Mouse

CAUTION

Unplug the server. Before connecting external devices, make sure the

server is not plugged in, or equipment could be damaged.

Rear Panel I/O Ports and Features

D

O N

C

OM10264

A

B

M

K

L

J

G

I

H

E

F

Figure 17. Rear Panel I/O Ports and Features

A. AC input power connector

B. Two optional external SCSI connector ports. The figure shows only

one connector port, but your system has two

C. Hot-plug 64-bit, 33 MHz PCI add-in board slots

D. Hot-plug 64-bit, 66/33 MHz PCI add-in board slots

E. Non-hot-plug 32-bit, 33 MHz PCI add-in board slots. These slots can

also accept an optional Intelligent Chassis Management Bus (ICMB)

SEMCONN 6-pin connector in/out connector, port 1

F. Video connector

G. USB ports 0 (upper) and 1 (lower), 4-pin connectors

H. NIC RJ45 connector

I. Serial port 2 (COM2), 9-pin RS-232 connector

J. IEEE 1284 compliant, 25-pin bi-directional parallel connector

K. Serial port 1 (COM1), 9-pin RS-232 connector

L. PS/2-compatible keyboard connector

M. PS/2-compatible mouse connector

N. HW push button

O. PCI green and amber LEDs on the inside of the chassis

SRKA4 /ISP4400 Server System 25

Page 26

Chassis Front Controls and Indicators

B C

D0

D1

A

D2 D3

OM09997

Figure 18. Front Panel Controls and Indicators

A. Power On/Off button: When activated by momentary contact while the system is off, this button turns

the power subsystem on. If the system is in sleep state, activating the button by momentary contact

brings the system out of sleep state. If you press the button down for more than four seconds, you

override ACPI mode and the power is turned off.

B. Reset button: When activated by momentary contact, this button resets the system. If the reset

button is pushed for four seconds or more, the power button is pushed, and then both the reset and

power buttons are released within one second of each other, the CMOS is cleared.

C. Sleep button: When activated by momentary contact, this button puts an operating system supporting

ACPI mode to sleep (S1). When activated by momentary contact during sleep state, the operating

system becomes active. This system does not have a service mode.

D. Front panel LEDs from left to right:

D0 General System Fault LED: Yellow indicates a system failure

D1 NIC activity LED: Green indicates NIC activity

D2 HDD activity LED: Green indicates any system hard drive activity

D3 Main Power LED: Solid green indicates the presence of DC power in the server

Flashing green indicates that the system is in ACPI sleep mode

26 Quick Start Guide

Page 27

Turn on Video Monitor and Server

1. Make sure all external devices, such as a monitor, keyboard, and mouse, have been connected.

2. If present, remove drive protection card from the diskette drive.

3. Turn on the video monitor.

4. Plug the female end of the server AC power cord into the input receptacle on the back of the

chassis.

5. Plug the male end of the server AC power cord into a wall outlet (a grounded, three-pronged

AC power outlet; see page 9 for outlet information).

NOTE

✏

When you plug the AC power cord into a wall outlet, the server may turn on

and boot automatically. In this case, you do not need to turn the push-button

on/off power switch on the front panel.

6. If the server does not come on when you plug it into the AC outlet, press the push-button

on/off power switch on the front panel. See Figure 18 on page 26.

7. Verify that the main power LED on the front panel is lit. After a few seconds, the Power-On

Self Test (POST) begins. See Figure 18 on page 26.

Run Power-On Self Test

Each time you turn on the system, the BIOS begins executing the Power-On Self Test (POST).

POST discovers, configures, and tests the processors, memory, keyboard, and most installed

peripheral devices. The length of time needed to test memory depends on the amount of memory

installed. POST is stored in flash memory.

1. Turn on your video monitor and system. After a few seconds, POST begins to run and a splash

screen is displayed.

2. While the splash screen is displayed, you can either

• Press <F2> to enter the BIOS Setup. See "Changing the BIOS Setup" on page 28.

OR

• Press <Esc> to change the boot device priority for this boot only. See "Changing the Boot

Device Priority Temporarily" on page 30.

3. After pressing <F2> or <Esc> during POST, you can press <Ctrl+A> to run the SCSISelect

Utility. See "Running the SCSISelect Utility" on page 31.

4. If you do not press <F2> or <Esc> and do NOT have a device with an operating system

loaded, the boot process continues and the system beeps once. The following message is

displayed:

Operating System not found

5. At this time, pressing any key causes the system to attempt a reboot. The system searches all

removable devices in the order defined by the boot priority.

6. If you want to boot from a hard drive loaded with an operating system, make sure that the hard

drive is installed and push the Reset button on the front panel.

SRKA4 /ISP4400 Server System 27

Page 28

NOTE

✏

The SRKA4 server system is shipped with the diskette drive set as the first

boot device. Therefore, the server tries to boot from a diskette rather than

from the CD-ROM, regardless of whether there is a CD in the CD-ROM. If

you want to set the CD-ROM as the first boot device for this boot only, press

<Esc>. If you want to permanently set the CD-ROM as the first boot device,

press <F2> to change the boot device priority in the BIOS setup.

7. After POST completes, the system beeps once. If you have an operating system loaded, the

operating system takes control of the server system.

Changing the BIOS Setup

During POST, you can change BIOS settings. These changes are retained until you change the

BIOS settings again.

The instruction set below guides you through the task of changing the boot device priority. This

boot device priority is retained for all future boot processes. After you complete the instructions

below, the server system boots from the CD-ROM drive first. The second and third boot devices

are the diskette drive and hard drive respectively. For more information about changing BIOS

settings, see Chapter 2 in the SKA4 Baseboard Product Guide.

1. Boot the server. The CD can be in the drive or not.

2. Quickly press the <F2> key. A prompt may or may not appear. After a few bootup tests are

completed, the main BIOS Setup screen appears.

3. From the Setup screen, select Boot Menu. Press <Enter>.

4. Select Boot Device Priority, and press <Enter>.

5. In the Boot Device Priority screen, use the up- or down-arrow keys to select "ATAPI

CD-ROM Drive", or the appropriate SCSI CD-ROM drive, then press the <+> key to move it

to the top of the list.

6. Now set the second boot device to Diskette Drive and the third boot device to Hard Drive.

7. Press the <F10> key to save your changes and exit Setup.

8. When the Exit prompt appears, press <Enter> again.

9. The bootup process continues. When finished, an system prompt is displayed.

10. Make sure the CD is in the drive, and boot the server.

28 Quick Start Guide

Page 29

Booting from CD

A

B

A

B

OM09998

Figure 19. 5.25-inch CD-ROM Device (top),

.5-inch Slim-line CD-ROM Drive (bottom)

A. Open/close push-button switch

B. CD tray, CD with label side up

CAUTION, handle CD only by the edges

Handle the CD by its inner and outer edges. Do not touch the side without

the label (the data side).

CAUTION, CD contains only a limited OS

The CD contains a limited OS with enough function to let you boot from the

CD and copy and use the utility and manual files from the CD.

But this limited operating system is NOT intended to be copied onto

diskettes or onto your hard disk as a full-function operating system that

†

supports networking or Windows

must buy the operating system of your choice and install it on the server.

. To run your server and applications, you

SRKA4 /ISP4400 Server System 29

Page 30

NOTE

✏

The server was shipped with the diskette drive set as the first boot device.

The server will, therefore, try to boot from diskette rather than from the

CD-ROM. Even with the CD in the drive, the server might continue to

display “Operating System Not Found”. Follow the steps in “Changing the

Boot Device Priority Temporarily”.

1. Open the CD tray by pressing the open/close button on the front panel of the CD-ROM drive.

The tray will slide out of the drive.

2. Open the CD case. Press down on the center hub of the case to release the CD.

3. Gently grasp the center hole and outer edge of the CD. Remove it from the case, and place it

label-side showing in the CD tray.

4. For .5-inch CD-ROMs, slide the CD tray into the drive. For other CD-ROMs, press the

open/close button or gently push on the CD tray—it automatically slides into the drive.

5. Push the reset switch on the front panel to restart the server.

6. When POST completes, the server boots from the CD, installs a mouse driver, and displays the

CD-ROM menu bar. Use the arrow keys to scroll through the menu bar and to view the tasks

in the pop-up menus.

Changing the Boot Device Priority Temporarily

During POST, you can change the boot device priority for the current boot process. The changes

made during this instruction set are not retained for the next boot process.

1. Boot the server. The CD must be in the drive.

2. At any time during POST, press <Esc>. When POST completes, a pop-up Boot menu appears.

3. Use the arrow keys to highlight the device you want the server system to boot from first. For

example, if you want the server system to boot from the CD-ROM first, you select "CD-ROM

Drive".

NOTE

✏

One of the selections on the pop-up Boot menu is <Enter Setup>.

Selecting this option brings you into the BIOS setup. For more information

about the BIOS setup, see "Changing the BIOS Setup" on page 28.

4. Press <Enter>.

5. The bootup process continues. When finished, a system prompt is displayed.

30 Quick Start Guide

Page 31

Changing the Boot Device Priority Permanently

You can change the boot device permanently. Until you change the boot device priority again via

this instruction set, the boot device priority does not change.

1. Quickly press the <F2> key. A prompt may or may not appear. After a few bootup tests

complete, the main BIOS Setup screen appears.

2. From the Setup screen, select Boot Menu. Press <Enter>.

3. Select Boot Device Priority, and press <Enter>.

4. In the Boot Device Priority screen, use the up- or down-arrow keys to select "ATAPI

CD-ROM Drive", or the appropriate SCSI CD-ROM drive, then press the <+> key to move it

to the top of the list.

5. Now set the second boot device to Diskette Drive and the third boot device to Hard Drive.

6. Press the <F10> key to save your changes and exit Setup.

7. When the Exit prompt appears, press <Enter> again.

8. The bootup process continues. When finished, an OS prompt displays.

9. Make sure the CD is in the drive, and boot the server.

Running the SCSI

Each host adapter includes an onboard SCSISelect configuration utility that allows you to

configure/view the settings of the host adapters and devices in the server.

After pressing <F2> or <Esc> during POST, the splash screen is replaced by text.

The system first finds the Adaptec

"Adaptec AIC-7880 SCSI BIOS V x.xxx" where x.xxx is the version number of the SCSISelect

utility. Pressing <Ctrl+A> at this time allows you to configure the Adaptec AIC-7880 SCSI host

adapter.

If you do not press <Ctrl+A>, the system finds the Adaptec AIC-7899 SCSI host adapter and

displays the message "Adaptec AIC-7899 SCSI BIOS V x.xxx" where x.xxx is the version number

of the SCSISelect utility. Pressing <Ctrl+A> at this time allows you to configure the Adaptec

AIC-7899 SCSI host adapter.

Once you enter the configuration menus for one of the host adapters, you cannot switch to the

other adapter. For example, once you press <Ctrl+A> to configure the Adaptec AIC-7899 SCSI

host adapter, you have to reboot the system to configure the Adaptec AIC-7880 SCSI host adapter.

When to Run the SCSI

Use the SCSISelect utility to

• Change default values

• Check and/or change SCSI device settings that may conflict with those of other devices in the

server

• Do a low-level format on SCSI devices installed in the server

Select

†

AIC-7880 SCSI host adapter and displays the message

Select

Utility

Utility

SRKA4 /ISP4400 Server System 31

Page 32

Running the SCSI

Select

Utility

1. When this message appears on the video monitor:

Press <Ctrl><A> for SCSISelect(TM) Utility!

2. Press <Ctrl+A> to run the utility. When the main menu for the host adapter appears, choose

the adapter that you want to configure—each SCSI bus accepts up to 15 devices.

Use the following keys to navigate through the menus and submenus.

Table 2. Navigation Keys

Press To

ESC Exit the utility

Enter Select an option

↑ Return to a previous option

↓ Move to the next option

F5 Switch between color and monochrome

F6 Reset to host adapter defaults

Configuring the Adaptec AIC-7880 SCSI Adapter

The following menu is displayed when you configure the Adaptec AIC-7880 SCSI adapter.

Table 3. Main Menu

Host Adapter Option Comment

AIC-7880 Ultra/Ultra W at Bus:Device 00:01h Configure/View Host

Adapter Settings

SCSI Disk Utilities Press <Enter> to view the SCSI

Press <Enter> to view the

Configuration Menu.

Disk Utilities Menu.

Make a selection and press <Enter>.

When you are finished, press <Esc> and make your selection from the following menu.

Table 4. Exit Menu

Feature Option Comment

Exit Utility? Yes

No

When you finish configuring your SCSI devices, select Yes and press <Enter>.

When this message appears:

Please press any key to reboot

Press any key, and your server will reboot.

32 Quick Start Guide

Page 33

Configuring the Adaptec AIC-7899 SCSI Adapter

The Adaptec AIC-7899 SCSI adapter has two busses. Select the bus from the following menu.

Table 5. Main Menu

Menu Item Menu Option

You have an AIC-7899 adapter in your system. Move

the cursor to the bus:device:channel of the one to be

configured and press <Enter>.

<F5> - Toggle color/monochrome

After selecting the bus, the following menu is displayed.

Table 6. Menu for each SCSI Channel

Host Adapter Option Comment

AIC-7899 at

Bus:Device:Channel

01:06:A (or 01:06:B)

Configure/View Host

Adapter Settings

SCSI Disk Utilities Press <Enter> to view the SCSI Disk Utilities

When you are finished, press <Esc> and make your selection from the following menu.

Bus:Device:Channel

01:06:A

01:06:B

Press <Enter> to view the Configuration Menu.

Menu. This menu allows you to format hard

disks and/or verify disk media.

Table 7. Exit Menu

Feature Option Comment

Exit Utility? Yes

No

When you finish configuring your SCSI devices, press <Esc>. Then select

Yes and press <Enter>. When this message appears:

Please press any key to reboot

Press any key, and the server reboots.

Country Kit Contents

Server Software Kit

The server software kit includes the server software kit CD. The CD includes

• Product guides

• Device drivers

• SSU and DPC utilities

• Service partition software

• FRU and SDR Load utilities

SRKA4 /ISP4400 Server System 33

Page 34

Product Guides

The server software kit contains two product guides: the SKA4 Baseboard Product Guide and the

SRKA4/ISP4400 Server System Product Guide. The SKA4 Baseboard Product Guide contains

information about the baseboard only and does not include any information specific to the

SRKA4 MP server system. The SRKA4/ISP4400 Server System Product Guide contains

information specific to the SRKA4 MP server system and refers to the SKA4 Baseboard Product

Guide for a detailed description of the baseboard.

For more information about how to read and print these product guides, see "Product Guides" on

page 36.

Device Drivers

The server software kit contains the following drivers.

• SCSI Drivers Adaptec AIC- 7899 SCSI controller

Windows NT† 4.0, Win9X, MS-DOS†, NetWare† 4.X/5.X

NetWare 4.2/5.0

UnixWare† 7.1

Solaris† 7

• SCSI Drivers Adaptec AIC-7880 SCSI controller

Windows NT 4.0, Win9X, DOS

NetWare 4.2/5.0

UnixWare 7.1

UnixWare 2.1

Solaris 7

• Video Drivers ATI Rage2 PCI video

Rage IIc Windows NT 4.0

Rage IIc Windows 95

Solaris 7

UnixWare 7.X

• PCI HP SW Stacks

Windows NT 4.0

Windows 2000

NetWare 4.2/5.0

UnixWare 7.x

• 82559 Network Interface Card (NIC)

Windows NT 4.0

Windows 95

NetWare 4.2/5.0

UnixWare 7.x

Solaris 7

34 Quick Start Guide

Page 35

SSU and DPC Utilities

The server software kit contains many utilities, including System Setup Utility (SSU) and the

Direct Platform Control (DPC) console.

The SSU can be run locally and remotely through a network or modem. The SSU provides a

graphical user interface (GUI) over an extensible framework for server configuration.

The DPC console is run remotely through a modem or direct connection. This interface allows

remote server management.

For more information on both utilities, see the SKA4 Baseboard Product Guide.

Service Partition Software

If purchased, service partition software is included in the server software kit. Software includes

Remote Diagnostics and Service Partition Admin utilities.

FRU and SDR Load Utilities

The Field Replacement Unit (FRU) and Sensor Data Record (SDR) load utility is a DOS-based

program used to update the server management subsystem’s product level FRU, SDR, and the

Desktop Management Interface (DMI) nonvolatile storage components (EEPROMs).

Quick Start Guide

A printed version of this guide is included in the country kit.

Chassis Labels

The country kit contains labels for the chassis. Place these labels on the server system so that the

label's information is easily viewed by anybody accessing server system components.

Hardware

The country kit contains several pieces of hardware and license agreements. They include

• A generic license

• A center-mount and peripheral slide rail assembly

• A power cord

SRKA4 /ISP4400 Server System 35

Page 36

Service Partition (Optional)

When you are setting up your server system, you can install a service partition on your hard drive.

The service partition includes utilities, diagnostics, and other software that a person could run

locally or remotely to assist in system management. The service partition uses approximately

30 to 40 MB of hard disk space.

It is highly recommended that you install the service partition before installing the operating

system. See the Service Partition section in the Installation Guide for the Intel Server Control for

more information. This document is included in the country kit for your system.

Product Guides

Using the Acrobat .PDF Files

Before you can print the SRKA4/ISP4400 Server System Product Guide or the SKA4 Baseboard

Product Guide from Acrobat, you must connect a printer to the parallel port.

1. From the CD-ROM menu bar, select Read/Print Manuals and press <Enter>. The Adobe

Acrobat reader will be automatically installed on RAM disk d: (simulated disk drive in RAM

memory) and automatically started. The reader lets you view and print out a copy of the

product guide.

2. After the reader starts, a pop-up menu displays a list of several manuals. If you are not sure

which manual applies to your server, check the title page of this guide for the correct product

reference.

3. Use your mouse or the up- and down-arrow keys to select the manual. Double click the left

mouse button or press <Enter> to load the .PDF file for the manual.

4. Use your mouse or the tab key to select the .PDF file for the manual. Double click the left

mouse button or press an arrow key and <Enter> to view the .PDF file.

5. Follow the program options and prompts. If you need to access the Help menu, double click

on Help or press <Alt+h>.

Copying Configuration Software to Diskettes

When you copy software from the CD onto diskettes, device drivers suitable for several different

operating systems are copied onto the diskettes. However, your operating system will read only

those drivers it can recognize, so you cannot usually check the directory of a diskette that is not

formatted for your operating system. Instead, you might see a message to the effect, “disk not

formatted, do you want to format it now?” Don’t worry; the drivers for YOUR operating system

are on the diskette and available to load on the system.

1. Before starting, make sure that you have several blank high-density diskettes.

2. From the CD-ROM menu bar, select Create Diskettes and press <Enter>.

3. Follow the prompts to copy the software onto the diskettes.

4. When finished, from the CD-ROM menu bar, select Quit to DOS and press <Enter>.

5. Remove the CD from the CD-ROM drive.

36 Quick Start Guide

Loading...

Loading...