Page 1

Intel®

Xeon® Processor E5-1600 /

2600 / 4600 v3 Product Families

Thermal Mechanical Specification and Design Guide

October 2015

Order No.: 330786-003US

Page 2

You may not use or facilitate the use of this document in connection with any infringement or other legal analysis concerning Intel products described

herein. You agree to grant Intel a non-exclusive, royalty-free license to any patent claim thereafter drafted which includes subject matter disclosed

herein.

No license (express or implied, by estoppel or otherwise) to any intellectual property rights is granted by this document.

All information provided here is subject to change without notice. Contact your Intel representative to obtain the latest Intel product specifications and

roadmaps.

The products described may contain design defects or errors known as errata which may cause the product to deviate from published specifications.

Current characterized errata are available on request.

Copies of documents which have an order number and are referenced in this document may be obtained by calling 1-800-548-4725 or visit http://

www.intel.com/design/literature.htm.

Basis, BlueMoon, BunnyPeople, Celeron, Centrino, Cilk, Flexpipe, Intel, the Intel logo, the Intel Anti-Theft technology logo, Intel AppUp, the Intel

AppUp logo, Intel Atom, Intel CoFluent, Intel Core, Intel Inside, the Intel Inside logo, Intel Insider, Intel NetMerge, Intel NetStructure, Intel RealSense,

Intel SingleDriver, Intel SpeedStep, Intel vPro, Intel Xeon Phi, Intel XScale, InTru, the InTru logo, the InTru Inside logo, InTru soundmark, Iris,

Itanium, Kno, Look Inside., the Look Inside. logo, MCS, MMX, Pentium, picoArray, Picochip, picoXcell, Puma, Quark, SMARTi, smartSignaling, Sound

Mark, Stay With It, the Engineering Stay With It logo, The Creators Project, The Journey Inside, Thunderbolt, the Thunderbolt logo, Transcede, Transrf,

Ultrabook, VTune, Xeon, X-GOLD and XMM are trademarks of Intel Corporation in the U.S. and/or other countries.

*Other names and brands may be claimed as the property of others.

Copyright © 2015, Intel Corporation. All rights reserved.

®

Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Intel

Thermal Mechanical Specification and Design Guide October 2015

2 Order No.: 330786-003

Page 3

Revision History—Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Revision History

Revision

Number

001 Initial release September 2014

002 Added Intel® Xeon® processor E5-4600 v3 product families. June 2015

003 Updated a socket part number on Table 25. October 2015

Description Date

October 2015 Thermal Mechanical Specification and Design Guide

Order No.: 330786-003 3

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Page 4

®

Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families—Contents

Intel

Contents

Revision History..................................................................................................................3

1.0 Introduction................................................................................................................10

1.1 Definition of Terms............................................................................................... 10

2.0 LGA2011-3 Socket Overview....................................................................................... 12

2.1 Socket Components.............................................................................................. 13

2.2 Socket Land Pattern Guidance................................................................................ 17

2.3 Socket Loading Requirements.................................................................................20

2.3.1 Socket Loading Specifications.................................................................... 21

2.4 Socket Maximum temperature................................................................................ 21

2.5 Strain Guidance for Socket....................................................................................22

3.0 Independent Loading Mechanism (ILM) Specifications............................................... 23

3.1 ILM Load Specifications......................................................................................... 24

3.2 ILM Keepout Zones (KOZ)......................................................................................25

3.3 Independent Loading Mechanism (ILM)....................................................................25

3.4 ILM Mechanical Design Considerations and Recommendations.....................................25

3.5 ILM Features........................................................................................................ 26

3.6 Intel® ILM Reference Designs................................................................................. 28

3.6.1 Square ILM.............................................................................................. 28

3.6.2 Narrow ILM.............................................................................................. 30

3.7 ILM Cover............................................................................................................32

3.8 ILM Allowable Board Thickness............................................................................... 33

4.0 Processor Thermal Specifications and Features......................................................... 34

4.1 T

and DTS-Based Thermal Specification Implementation........................................34

case

4.1.1 Margin to Thermal Specification (M)............................................................ 34

4.2 Processor Thermal Features................................................................................... 36

4.2.1 Absolute Processor Temperature................................................................. 36

4.2.2 Short Duration TCC Activation .................................................................. 36

4.3 Processor Thermal Specifications............................................................................ 36

4.3.1 Thermal Specifications...............................................................................37

4.3.2 T

and DTS Based Thermal Specifications.................................................37

CASE

4.3.3 Server Processor Thermal Profiles and Form Factors..................................... 38

4.3.4 Server 4S Processor Thermal Profiles and Form Factors.................................40

4.3.5 Workstation Processor Thermal Profiles and Form Factors..............................41

4.3.6 Embedded Server Processor Thermal Profiles...............................................42

4.3.7 Thermal Metrology.................................................................................... 44

5.0 Processor Thermal Solutions.......................................................................................47

5.1 Processor Boundary Conditions for Shadowed and Spread Core Layouts....................... 47

5.2 Heatsink Design Considerations.............................................................................. 49

5.3 Thermal Design Guidelines..................................................................................... 50

5.3.1 Intel® Turbo Boost Technology................................................................... 50

5.3.2 Thermal Excursion Power........................................................................... 50

5.3.3 Thermal Characterization Parameters.......................................................... 51

5.4 Thermal Interface Material (TIM) Considerations....................................................... 52

5.5 Mechanical Recommendations and Targets............................................................... 53

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Thermal Mechanical Specification and Design Guide October 2015

4 Order No.: 330786-003

Page 5

®

Contents—Intel

Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

5.5.1 Processor / Socket Stackup Height.............................................................. 53

5.5.2 Processor Heatsink Mechanical Targets........................................................ 54

5.6 Heatsink Mechanical and Structural Considerations....................................................55

5.7 Intel Reference Design Heat Sink............................................................................ 55

5.7.1 2U Square Heatsink Performance................................................................ 57

5.7.2 1U Square Heatsink Performance................................................................ 58

5.7.3 1U Narrow Heatsink Performance................................................................ 59

5.7.4 Workstation Tower Active Heatsink Performance........................................... 60

5.7.5 Mechanical Load Range..............................................................................61

5.7.6 Thermal Interface Material (TIM).................................................................61

6.0 Processor Mechanical Specifications........................................................................... 62

6.1 Package Size........................................................................................................62

6.2 Package Loading Specifications............................................................................... 63

6.3 Processor Mass Specification.................................................................................. 64

6.4 Processor Materials............................................................................................... 64

6.5 Processor Markings............................................................................................... 64

6.6 Package Handling Guidelines.................................................................................. 66

7.0 Boxed Processor Specifications...................................................................................67

7.1 Boxed Processor Thermal Solutions......................................................................... 67

7.1.1 Available Boxed Thermal Solution Configurations...........................................67

7.1.2 Intel® Thermal Solution STS200C (Passive/Active Combination Heat Sink

Solution)................................................................................................ 67

7.1.3 Intel® Thermal Solution STS200P and STS200PNRW (Boxed 25.5 mm Tall

Passive Heat Sink Solutions)......................................................................68

7.1.4 Thermal Interface Material (TIM).................................................................68

7.2 Boxed Processor Cooling Requirements....................................................................69

7.3 Mechanical Specifications...................................................................................... 69

7.4 Fan Power Supply [STS200C]................................................................................. 70

7.5 Boxed Processor Contents......................................................................................71

8.0 Quality Reliability and Ecological Requirements..........................................................72

8.1 Use Conditions..................................................................................................... 72

8.2 Intel® Reference Component Validation....................................................................73

8.2.1 Board Functional Test Sequence..................................................................73

8.2.2 Post-Test Pass Criteria Examples.................................................................73

8.2.3 Recommended BIOS/Processor/Memory Test Procedures................................74

8.3 Material and Recycling Requirements.......................................................................74

Appendix A Component Suppliers..................................................................................... 76

Appendix B Mechanical Drawings......................................................................................78

B.1 Large Package Mechanical Drawing Page 1............................................................... 79

B.2 Large Package Mechanical Drawing Page 2............................................................... 80

B.3 Package Mechanical Drawing Page 1........................................................................81

B.4 Package Mechanical Drawing Page 2........................................................................82

B.5 ILM Backplate Keep Out Zone.................................................................................83

B.6 ILM Mounting Hole Keep Out Zone.......................................................................... 84

B.7 Narrow ILM Keep Out Zone.................................................................................... 85

B.8 Narrow ILM 3D Keep Out Zone............................................................................... 86

B.9 ILM Keep Out Zone............................................................................................... 87

B.10 3D Keep Out Zone.............................................................................................. 88

October 2015 Thermal Mechanical Specification and Design Guide

Order No.: 330786-003 5

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Page 6

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families—Contents

B.11 Heat Sink Retaining Ring......................................................................................89

B.12 Heat Sink Spring.................................................................................................90

B.13 Heat Sink Spring Cup.......................................................................................... 91

B.14 1U Narrow Heat Sink Geometry (Page 1)............................................................... 92

B.15 1U Narrow Heat Sink Geometry (Page 2)............................................................... 93

B.16 1U Narrow Heat Sink Assembly (Page 1)................................................................ 94

B.17 1U Narrow Heat Sink Assembly (Page 2)................................................................ 95

B.18 1U Square Heat Sink Geometry (Page 1)................................................................96

B.19 1U Square Heat Sink Geometry (Page 2)................................................................97

B.20 1U Square Heat Sink Assembly (Page 1)................................................................ 98

B.21 1U Square Heat Sink Assembly (Page 2)................................................................ 99

B.22 2U Square Heat Sink Geometry (Page 1).............................................................. 100

B.23 2U Square Heat Sink Geometry (Page 2).............................................................. 101

B.24 2U Square Heat Sink Assembly (Page 1).............................................................. 102

B.25 2U Square Heat Sink Assembly (Page 2).............................................................. 103

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Thermal Mechanical Specification and Design Guide October 2015

6 Order No.: 330786-003

Page 7

®

Figures—Intel

Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Figures

1 Hexagonal Array in LGA2011-3..................................................................................12

2 Socket with Labeled Features.................................................................................... 13

3 Contact Wiping Direction.......................................................................................... 14

4 Contact Tip Offset with Respect to Solder Ball..............................................................15

5 Processor Socket Stack Up........................................................................................16

6 Pick and Place Cover with Labeled Features.................................................................16

7 PnP Cover and Socket Assembly................................................................................ 17

8 Socket 2011-3 Land Pattern......................................................................................18

9 Socket 2011-3 Pad Types and Locations..................................................................... 20

10 Socket Temperature Measurement ............................................................................22

11 Processor Stack.......................................................................................................23

12 ILM Load Plate........................................................................................................ 27

13 ILM Backplate......................................................................................................... 28

14 Exploded Square ILM............................................................................................... 29

15 Assembled Square ILM............................................................................................. 30

16 Exploded Narrow ILM............................................................................................... 31

17 Assembled Narrow ILM.............................................................................................32

18 ILM cover............................................................................................................... 33

19 Margin to Thermal Spec (M)......................................................................................35

20 Typical Thermal Profile Graph (Illustration Only).......................................................... 38

21 Case Temperature (T

22 Case Temperature (T

23 Typical Shadowed Layout......................................................................................... 47

24 Typical Spread Core Layout.......................................................................................48

25 Thermal Characterization Parameters......................................................................... 52

26 Integrated Stack Up Height.......................................................................................53

27 Available Cooling Area for Top of Large and Small IHS..................................................54

28 1U Form Factor Heat Sinks....................................................................................... 56

29 2U Form Factor Heat Sinks....................................................................................... 56

30 Workstation Form Factor Heat Sink............................................................................ 57

31 Processor Package Assembly Sketch...........................................................................62

32 Rendering of Intel® Xeon® processor E5-1600 and E5-2600 v3 product families Small

Form Factor............................................................................................................ 63

33 Rendering of Intel® Xeon® processor E5-1600 and E5-2600 v3 product families Large

Form Factor............................................................................................................ 63

34 Small Package Labeling............................................................................................ 65

35 Large Package Labeling............................................................................................ 66

36 STS200C Active / Passive Combination Heat Sink (with Removable Fan) ........................ 68

37 STS200P and STS200PNRW 25.5 mm Tall Passive Heat Sinks ....................................... 68

38 Fan Cable Connector Pin Out for 4-Pin Active Thermal Solution...................................... 71

39 Intel® Xeon® Processor v3 Product Families Large Package Mechanical Drawing Page 1.... 79

40 Intel® Xeon® Processor v3 Product Families Large Package Mechanical Drawing Page 2.... 80

41 Intel® Xeon® Processor v3 Product Families Small Package Mechanical Drawing Page 1.... 81

42 Intel® Xeon® Processor v3 Product Families Small Package Mechanical Drawing Page 2.... 82

43 ILM Backplate Keep Out Zone................................................................................... 83

44 ILM Mounting Hole Keep Out Zone............................................................................. 84

45 Narrow ILM Keep Out Zone....................................................................................... 85

46 Narrow ILM 3D Keep Out Zone.................................................................................. 86

47 Square ILM Keep Out Zone....................................................................................... 87

48 Square 3D Keep Out Zone........................................................................................ 88

49 Heat Sink Retaining Ring.......................................................................................... 89

50 Heat Sink Spring..................................................................................................... 90

51 Heat Sink Spring Cup............................................................................................... 91

52 1U Narrow Heat Sink Geometry (Page 1).................................................................... 92

) Measurement Location for Large Package ..............................45

CASE

) Measurement Location for Small Package.............................. 46

CASE

October 2015 Thermal Mechanical Specification and Design Guide

Order No.: 330786-003 7

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Page 8

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families—Figures

53 1U Narrow Heat Sink Geometry (Page 2).................................................................... 93

54 1U Narrow Heat Sink Assembly (Page 1).....................................................................94

55 1U Narrow Heat Sink Assembly (Page 2).....................................................................95

56 1U Square Heat Sink Geometry (Page 1).................................................................... 96

57 1U Square Heat Sink Geometry (Page 2).................................................................... 97

58 1U Square Heat Sink Assembly (Page 1).....................................................................98

59 1U Square Heat Sink Assembly (Page 2).....................................................................99

60 2U Square Heat Sink Geometry (Page 1)...................................................................100

61 2U Square Heat Sink Geometry (Page 2)...................................................................101

62 2U Square Heat Sink Assembly (Page 1)................................................................... 102

63 2U Square Heat Sink Assembly (Page 2)................................................................... 103

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Thermal Mechanical Specification and Design Guide October 2015

8 Order No.: 330786-003

Page 9

®

Tables—Intel

Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Tables

1 Terms and Descriptions............................................................................................ 10

2 LGA2011-3 Socket Attributes.................................................................................... 12

3 PIN Count By Pad Definition...................................................................................... 19

4 Socket Load Values..................................................................................................21

5 LGA 2011-3 Maximum Allowable Loads.......................................................................24

6 LGA 2011-3 Minimum Allowable Loads....................................................................... 24

7 LGA 2011-3 Minimum End of Life Loads...................................................................... 25

8 LGA 2011-3 ILM General Keepout Dimensions ............................................................ 25

9 Square ILM Component Thickness and materials..........................................................30

10 Narrow ILM Component Thickness and materials..........................................................32

11 DTS 2.0 Margin From PECI........................................................................................35

12 DTS 2.0 Margin From Processor Register: CSR for PACKAGE_THERM_MARGIN ................ 36

13 Intel® Xeon® Processor E5-1600 and E5-2600 v3 Product Families Stack T

DTS Thermal Profiles and Correction Factors............................................................... 38

14 Intel® Xeon® Processor E5-4600 v3 Product Families Stack Product Family T

DTS Thermal Profiles and Correction Factors............................................................... 40

15 Intel® Xeon® Processor E5-1600 and E5-2600 v3 Product Families 1S Workstation

Stack T

and DTS Thermal Profiles and Correction Factors......................................... 41

case

16 Embedded Server Processor Thermal Profiles.............................................................. 43

17 Processor Boundary Conditions for Shadowed and Spread Core Layouts..........................48

18 Target Stackup Heights From Top of Board to Top of IHS.............................................. 53

19 Available Cooling Area for Large and Small IHS........................................................... 54

20 Heatsink Mechanical Targets..................................................................................... 54

21 Processor Loading Specifications................................................................................64

22 Processor Materials..................................................................................................64

23 Load Limits for Package Handling...............................................................................66

24 Intel

®

Reference or Collaboration Thermal Solutions..................................................... 76

25 LGA2011-3 Socket and ILM Components ....................................................................76

26 List of Mechanical Drawings...................................................................................... 78

case

and

case

and

October 2015 Thermal Mechanical Specification and Design Guide

Order No.: 330786-003 9

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Page 10

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families—Introduction

1.0 Introduction

This document provides specifications and guidelines for the design of thermal and

mechanical solutions for the Intel® Xeon® processor E5-1600, E5-2600, and E5-4600

v3 product families.

The components and information described in this document include:

• Thermal profiles and other processor specifications and recommendations

• Processor Mechanical load limits

The goals of this document are:

• To assist board and system thermal mechanical designers

• To assist designers and suppliers of processor heatsinks

1.1

Definition of Terms

Table 1. Terms and Descriptions

Term Description

Bypass Bypass is the area between a passive heatsink and

DTS Digital Thermal Sensor reports a relative die

FSC Fan Speed Control

IHS Integrated Heat Spreader: a component of the

Square ILM Independent Loading Mechanism provides the force

Narrow ILM Independent Loading Mechanism provides the force

LGA2011-3 Socket The processor mates with the system board through

PECI The Platform Environment Control Interface (PECI) is

any object that can act to form a duct. For this

example, it can be expressed as a dimension away

from the outside dimension of the fins to the nearest

surface.

temperature as an offset from TCC activation

temperature.

processor package used to enhance the thermal

performance of the package. Component thermal

solutions interface with the processor at the IHS

surface.

needed to seat the 2011-LGA package onto the

socket contacts and has 56 × 94mm heatsink

mounting hole pattern

needed to seat the 2011-LGA package onto the

socket contacts and has 56 × 94mm heatsink

mounting hole pattern

this surface mount, 2011-contact socket.

a one-wire interface that provides a communication

channel between Intel processor and chipset

components to external monitoring devices.

continued...

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Thermal Mechanical Specification and Design Guide October 2015

10 Order No.: 330786-003

Page 11

Introduction—Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Term Description

Ψ

CA

Case-to-ambient thermal characterization parameter

(psi). A measure of thermal solution performance

using total package power. Defined as (T

Total Package Power. Heat source should always be

specified for Ψ measurements.

Ψ

CS

Case-to-sink thermal characterization parameter. A

measure of thermal interface material performance

using total package power. Defined as (T

Total Package Power.

Ψ

SA

Sink-to-ambient thermal characterization parameter.

A measure of heatsink thermal performance using

total package power. Defined as (TS – TLA) / Total

Package Power.

T

case

The case temperature of the processor measured at

the geometric center of the topside of the IHS.

Tcase-Max The maximum case temperature as specified in a

component specification.

TCC Thermal Control Circuit: Thermal monitor uses the

TCC to reduce the die temperature by using clock

modulation and/or operating frequency and input

voltage adjustment when the die temperature is very

near its operating limits.

T

CONTROL

T

is a static value below TCC activation used

CONTROL

as a trigger point for fan speed control. When DTS >

T

, the processor must comply to the thermal

CONTROL

profile.

TDP Thermal Design Power: Thermal solution should be

designed to dissipate this target power level. TDP is

not the maximum power that the processor can

dissipate.

Thermal Monitor A power reduction feature designed to decrease

temperature after the processor has reached its

maximum operating temperature.

Thermal Profile Line that defines case temperature specification of a

processor at a given power level.

TIM Thermal Interface Material: The thermally conductive

compound between the heatsink and the processor

case. This material fills the air gaps and voids, and

enhances the transfer of the heat from the processor

case to the heatsink.

T

LA

The measured ambient temperature locally

surrounding the processor. The ambient temperature

should be measured just upstream of a passive

heatsink or at the fan inlet for an active heatsink.

T

SA

The system ambient air temperature external to a

system chassis. This temperature is usually

measured at the chassis air inlets.

U A unit of measure used to define server rack spacing

height. 1U is equal to 1.75 in, 2U equals 3.50 in, and

so forth.

LCC Low Core Count, refers to silicon die size

MCC Mid Core Count, refers to silicon die size

HCC High Core Count, refers to silicon die size

CASE

CASE

– TLA) /

– TS) /

October 2015 Thermal Mechanical Specification and Design Guide

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Order No.: 330786-003 11

Page 12

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families—LGA2011-3 Socket

2.0 LGA2011-3 Socket Overview

This section describes a surface mount, LGA (Land Grid Array) socket intended for the

Intel® Xeon® processor E5-1600 and E5-2600 v3 product families processor-based

platform. The socket provides I/O, power and ground contacts for processor operation.

The socket contains 2011 contacts arrayed about a cavity in the center of the socket

with lead-free solder balls for surface mounting on the motherboard.

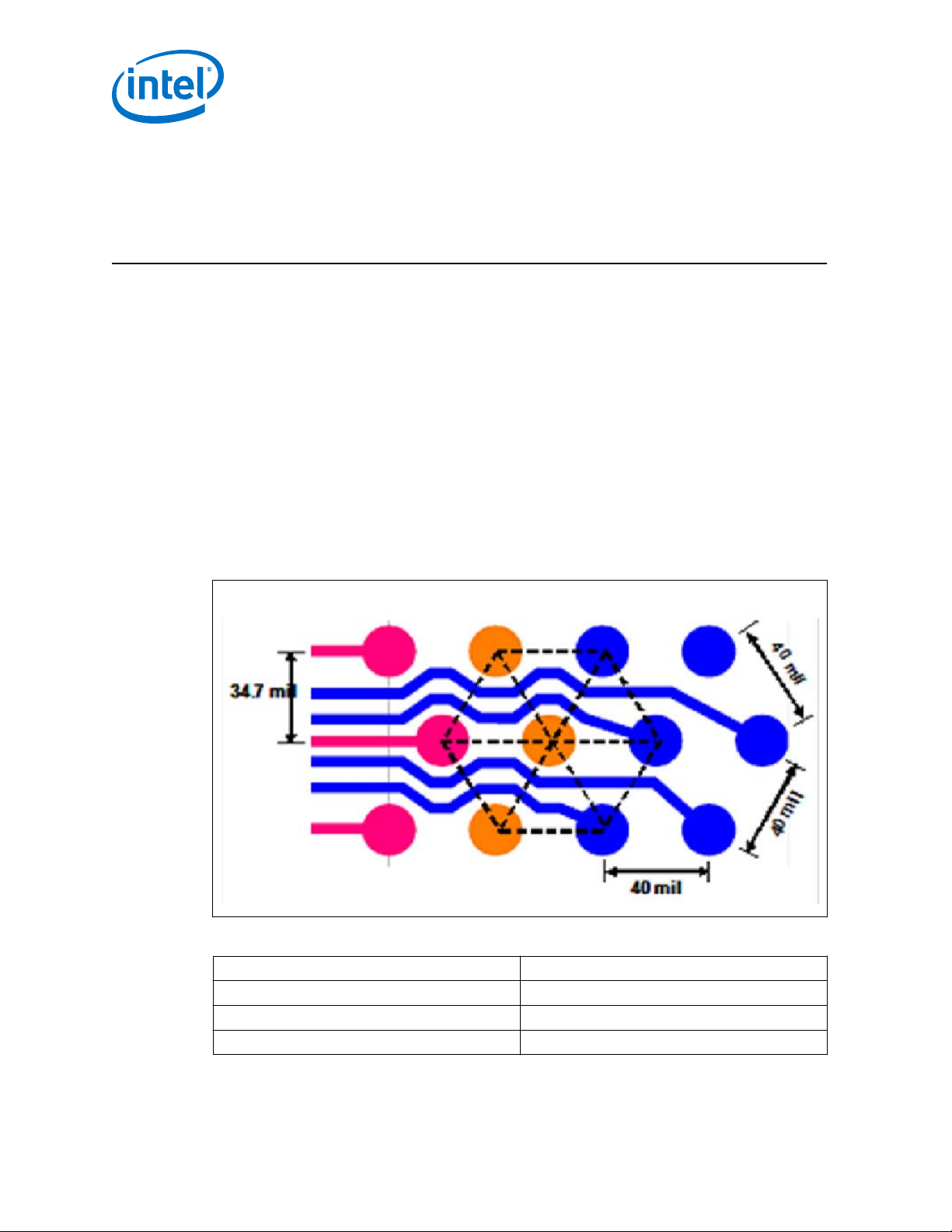

The LGA2011-3 uses a hexagonal area array ball-out which provides many benefits:

• Socket contact density increased by 12% while maintaining 40 mil minimum via

pitch requirements. as compared to a linear array

• Corresponding square pitch array’s would require a 38mil via pitch for the same

package size.

LGA2011-3 has 1.016 mm (40 mil) hexagonal pitch in a 58x43 grid array with 24x16

grid depopulation in the center of the array and selective depopulation elsewhere.

Overview

Figure 1. Hexagonal Array in LGA2011-3

Table 2. LGA2011-3 Socket Attributes

LGA2011-3 Socket Attributes

Component Size 58.5 mm (L) X 51 mm (W)

Pitch 1.016 mm (Hex Array)

Ball Count 2011

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Thermal Mechanical Specification and Design Guide October 2015

12 Order No.: 330786-003

Page 13

LGA2011-3 Socket Overview—Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product

Families

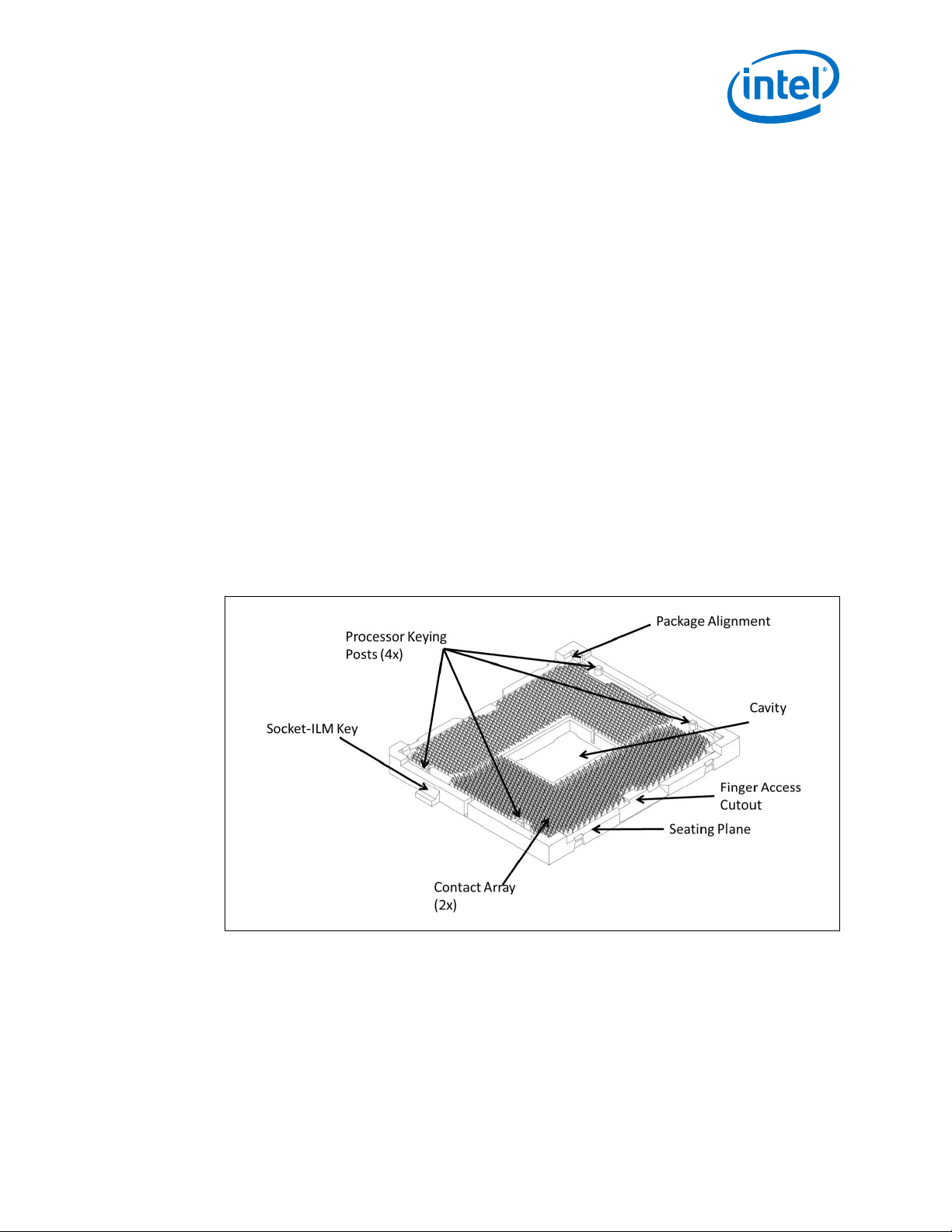

The socket must be compatible with the package (processor) and the Independent

Loading Mechanism (ILM). Internal keying posts ensure socket processor

compatibility. An external socket key ensures ILM and socket compatibility. The ILM

reference design includes a back plate; an integral feature for uniform loading on the

socket solder joints and contacts.

2.1

Socket Components

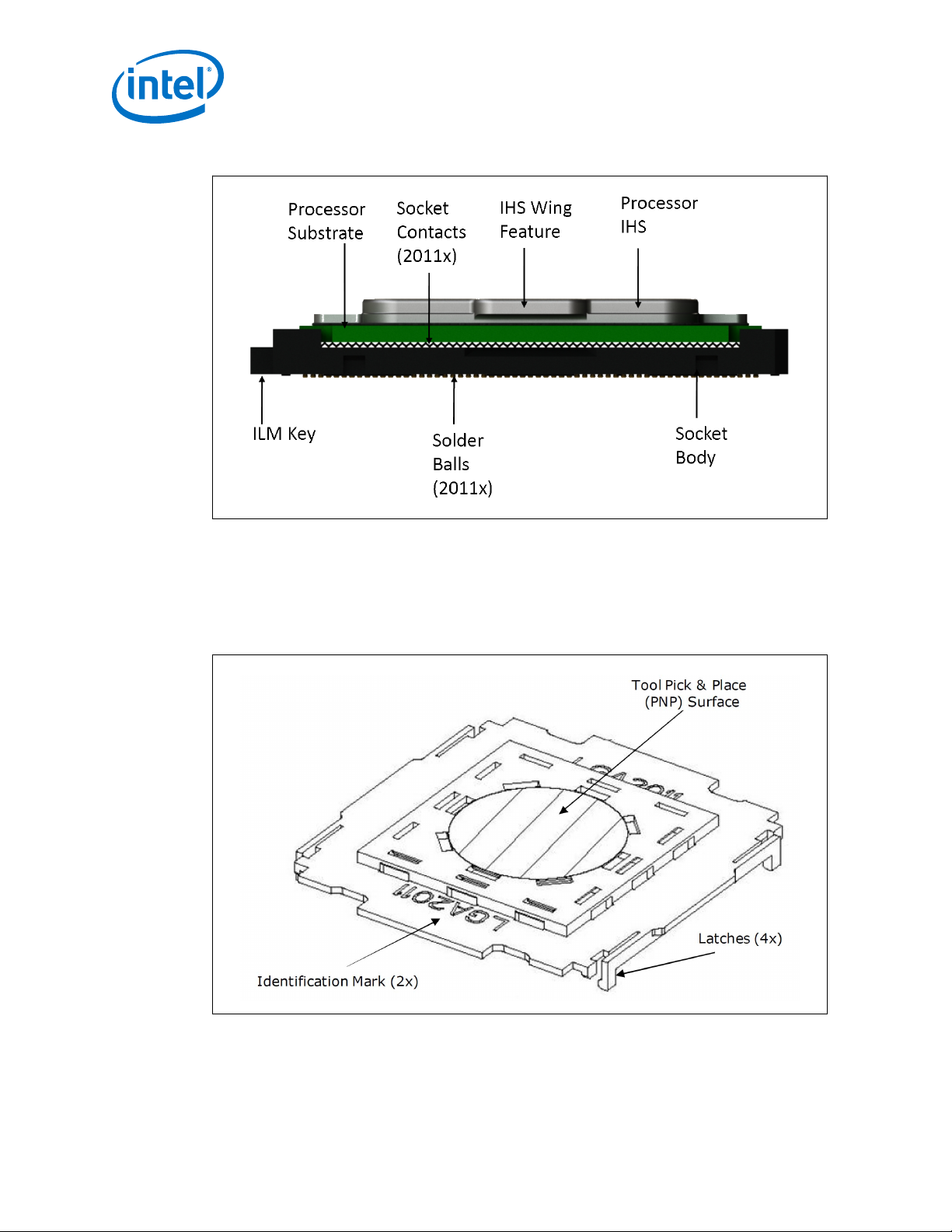

The socket has two main components, the socket body: composed of a housing solder

balls, and processor contacts, and Pick and Place (PnP) cover. The socket is delivered

as a single integral assembly. Below are descriptions of the integral parts of the

socket.

Socket Body Housing

The housing material is thermoplastic or equivalent with UL 94 V-0 flame rating

capable of withstanding 260°C for 40 seconds (typical reflow/rework). The socket

coefficient of thermal expansion (in the XY plane), and creep properties, are such that

the integrity of the socket is maintained for the environmental conditions listed in the

TMSDG.

The color of the housing will be dark as compared to the solder balls to provide the

contrast needed for pick and place vision systems. A labeled representation of the

socket can be seen in the figure below.

Figure 2. Socket with Labeled Features

Solder Balls

A total of 2011 solder balls corresponding to the contacts are on the bottom of the

socket for surface mounting with the motherboard.

The socket has the following solder ball material:

October 2015 Thermal Mechanical Specification and Design Guide

Order No.: 330786-003 13

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Page 14

®

Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families—LGA2011-3 Socket

Intel

• Lead free SAC305 (SnAgCu) solder alloy with a silver (Ag) content 3%, copper

(Cu) 0.5%, tin (Sn) 96.5% and a melting temperature of approximately 217°C.

The immersion silver (ImAg) motherboard surface finish and solder paste alloy

must be compatible with the SAC305 alloy solder paste.

Contacts

The base material for the contacts is high strength copper alloy. For the area on

socket contacts where processor lands will mate, there is a 0.381 mm [0.015 inches]

minimum gold plating over 1.27 mm [0.05 inches] minimum nickel underplate. No

contamination by solder in the contact area is allowed during solder reflow. All socket

contacts are designed such that the contact tip lands within the substrate pad

boundary before any actuation load is applied and remain within the pad boundary at

final installation, after actuation load is applied.

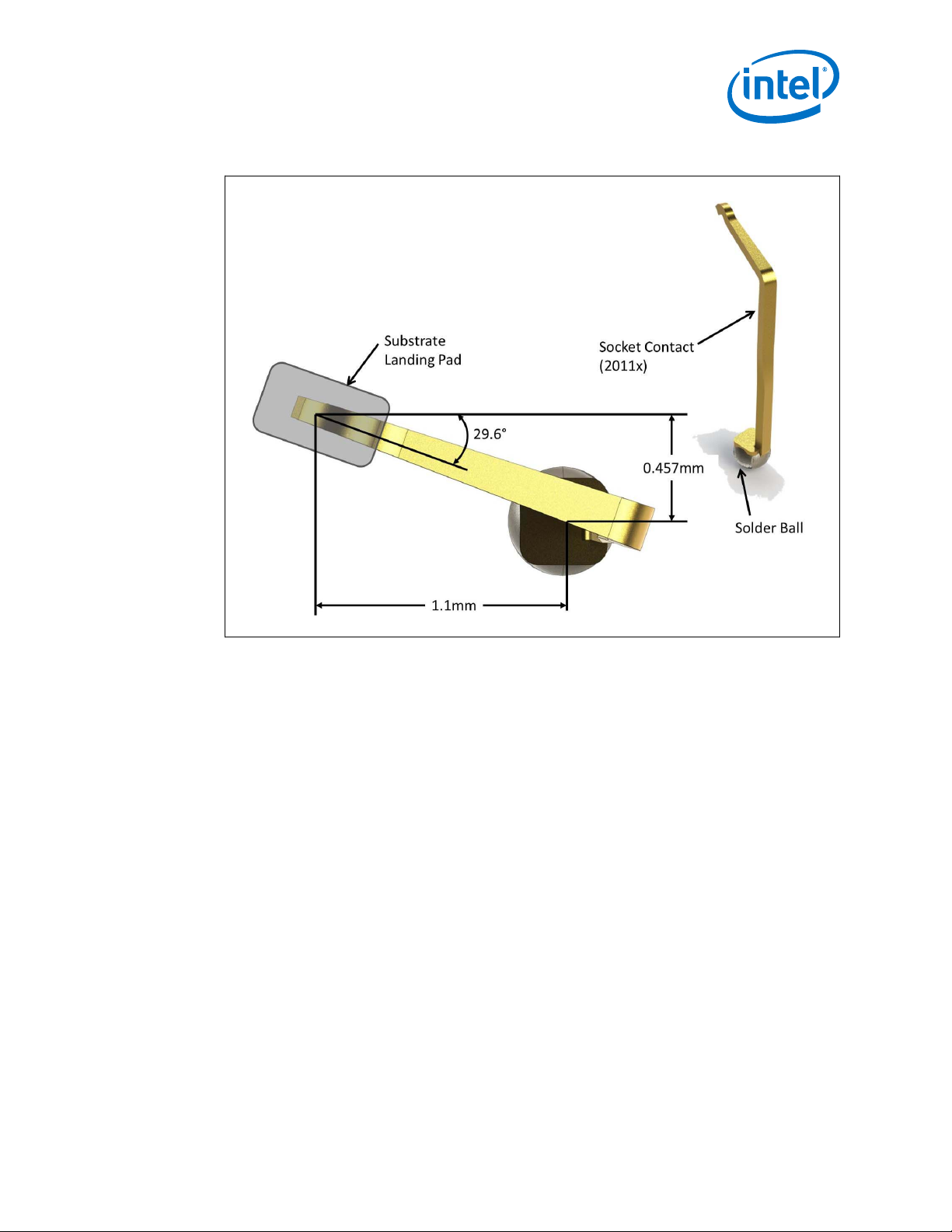

The contacts are laid out in two L-shaped arrays as shown in the figure below. The

detailed view of the contacts indicate the wiping orientation of the contacts in the two

regions to be 29.6°.

Figure 3. Contact Wiping Direction

Overview

The contact between substrate land and socket contact are offset. The following

diagram shows contact offset from solder ball location and orientation of contact tip.

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Thermal Mechanical Specification and Design Guide October 2015

14 Order No.: 330786-003

Page 15

®

LGA2011-3 Socket Overview—Intel

Families

Xeon® Processor E5-1600 / 2600 / 4600 v3 Product

Figure 4. Contact Tip Offset with Respect to Solder Ball

Socket Standoffs

Standoffs on the bottom of the socket base establish the minimum socket height after

solder reflow. The following diagram highlights each feature of the socket-processor

stack up.

October 2015 Thermal Mechanical Specification and Design Guide

Order No.: 330786-003 15

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Page 16

®

Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families—LGA2011-3 Socket

Intel

Figure 5. Processor Socket Stack Up

Overview

Pick and Place Cover

The cover provides a planar surface for vacuum pick up used to place components in

the Surface Mount Technology (SMT) manufacturing line. The proceeding diagram

labels key features of the Pick and Place cover.

Figure 6. Pick and Place Cover with Labeled Features

The cover remains on the socket during reflow to help prevent contamination during

reflow. The cover can withstand 260°C for 40 seconds (typical reflow/rework profile)

and the environmental conditions listed in the TMSDG.

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Thermal Mechanical Specification and Design Guide October 2015

16 Order No.: 330786-003

Page 17

LGA2011-3 Socket Overview—Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product

Families

The following figure diagrams the PnP and socket assembly. To reduce risk of damage

to socket contacts the pick and place (PnP) cover remains on the socket during ILM

installation.

Figure 7. PnP Cover and Socket Assembly

Once the ILM with its cover is installed Intel is recommending the PnP cover be

removed to help prevent damage to the socket contacts. To reduce the risk of bent

contacts the PnP Cover and ILM Cover were designed to not be compatible. Covers

can be removed without tools.

The pick and place covers are designed to be interchangeable between socket

suppliers.

2.2

Socket Land Pattern Guidance

The land pattern guidance provided in this section applies to printed circuit board

design. Recommendation for Printed Circuit Board (PCB) Land Patterns is to ensure

solder joint reliability during dynamic stresses, often encountered during shipping and

handling and hence to increase socket reliability.

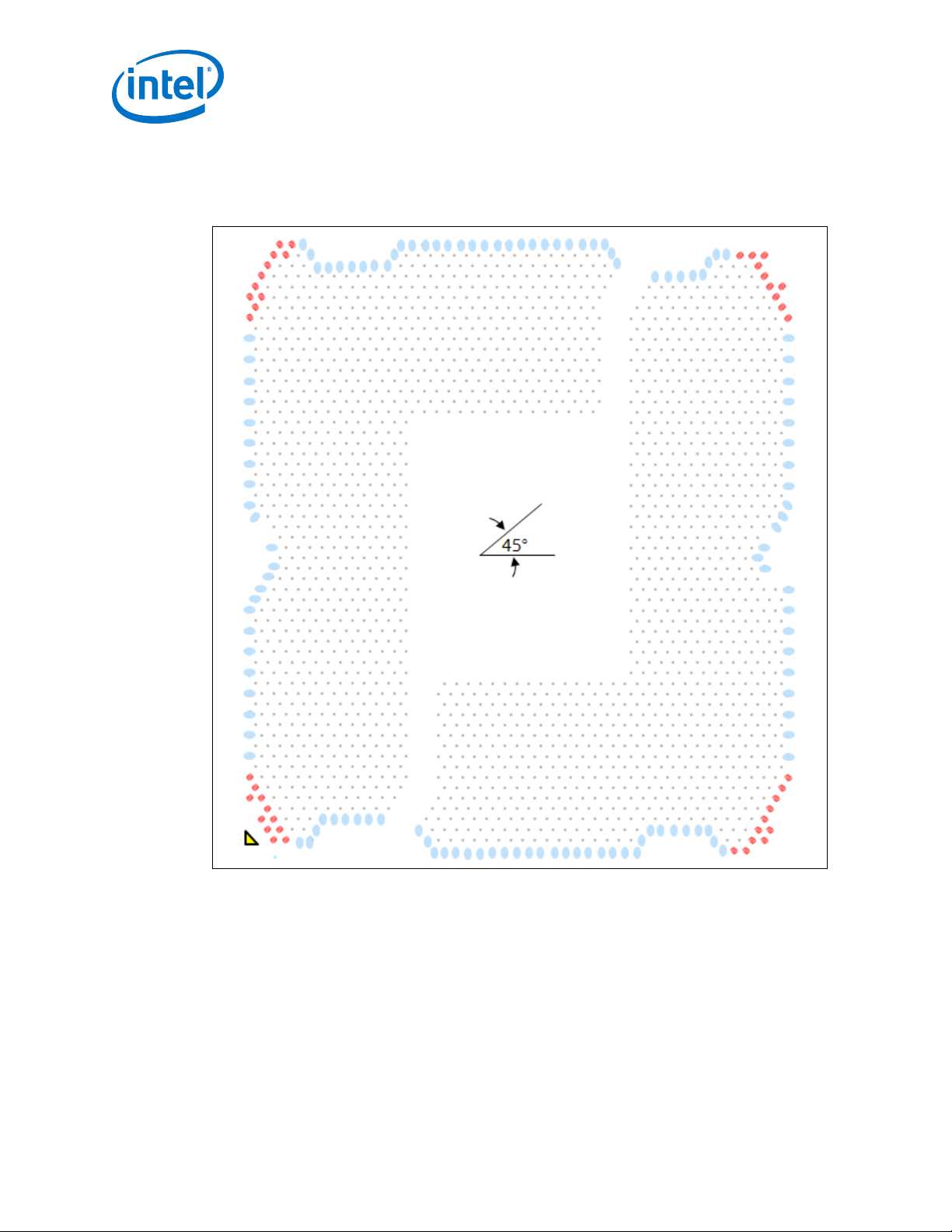

LGA 2011-3 Land Pattern

The land pattern for the LGA2011-3 socket is 40 mils hexagonal array see the

following figure for detailed location and land pattern type.

October 2015 Thermal Mechanical Specification and Design Guide

Order No.: 330786-003 17

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Page 18

®

Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families—LGA2011-3 Socket

Intel

Overview

Note: There is no round-off (conversion) error between socket pitch (1.016 mm) and board

pitch (40 mil) as these values are equivalent.

Figure 8. Socket 2011-3 Land Pattern

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Thermal Mechanical Specification and Design Guide October 2015

18 Order No.: 330786-003

Page 19

®

LGA2011-3 Socket Overview—Intel

Families

Xeon® Processor E5-1600 / 2600 / 4600 v3 Product

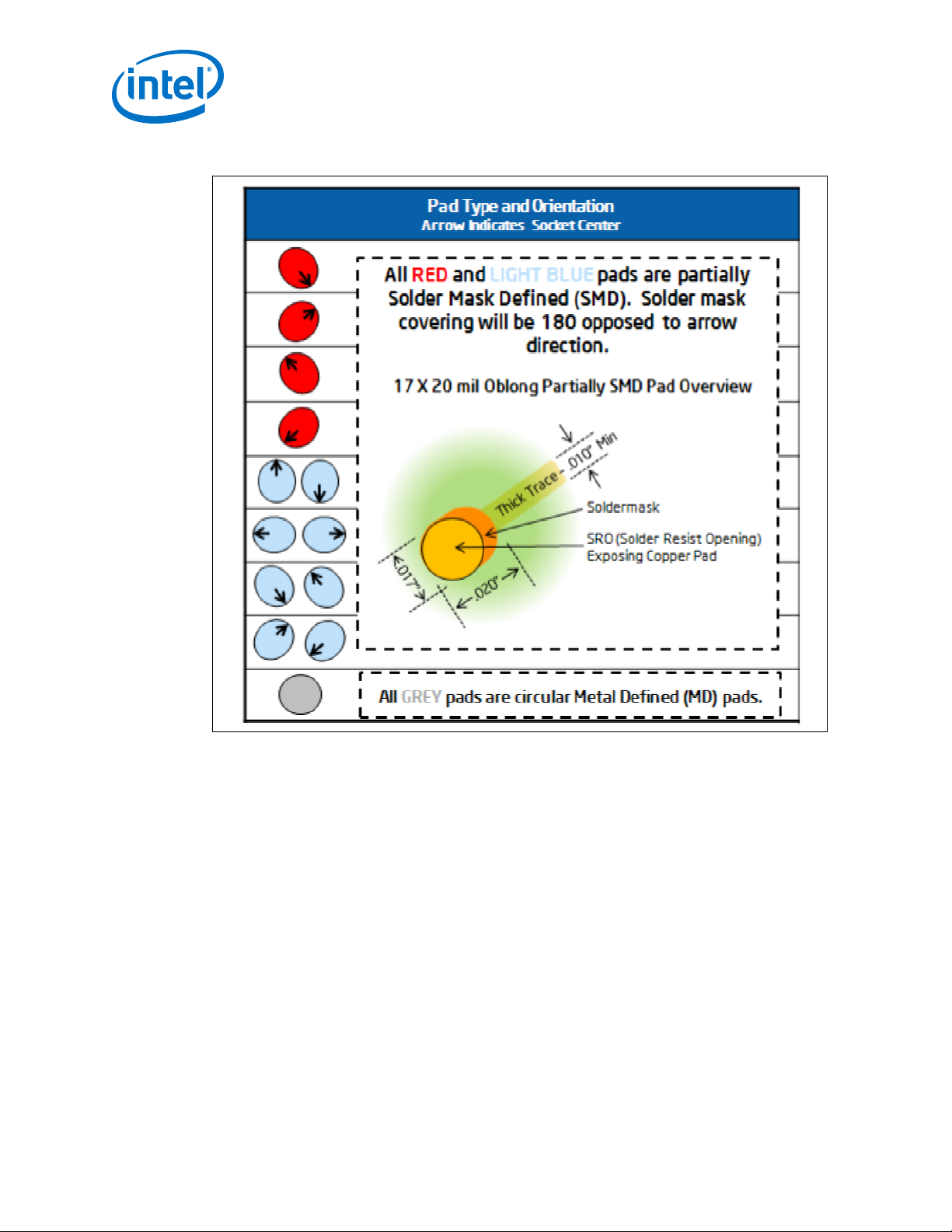

Table 3. PIN Count By Pad Definition

Pad Definition / Padstack Color Quantity

20 X 17 Oblong Partially SMD / O17X20 RED Pins 43

20 X 17 Oblong Partially SMD / O17X20 LIGHT BLUE Pins 123

17 mil Ø MD / C17 GREY Pins 1845

Notes: 1. RED Pins: Corner nCTF pads (43 total) are all designed as 20 X 17 mil oblong partially

soldermask defined pads with an SRO of 17 ±1 mil Ø (shown below). The long axis of the pad is

oriented at 45° from the center of the socket. All nCTF pads require thick traces ideally oriented

at 45° toward the package corner.

2. LIGHT BLUE Pins: Edge CTF pads (total) are all designed as 20 X 17 mil oblong partially

soldermask defined pads with an SRO of 17 ±1 mil Ø (shown below). The long axis of the pad is

oriented at 90° to the socket edge.

3. GREY Pins: Critical to function pins are all designed as 17 mil circular MD (Metal Defined) pads.

Pad Type Recommendations

Intel defines two types of pad types based on how they are constructed. A metal

defined (MD) pad is one where a pad is individually etched into the PCB with a

minimum width trace exiting it. The solder mask defined (SMD) pad is typically a pad

in a flood plane where the solder mask opening defines the pad size for soldering to

the component. In thermal cycling a MD pad is more robust than a SMD pad type. The

solder mask that defines the SMD pad can create a sharp edge on the solder joint as

the solder ball / paste conforms to the window created by the solder mask. For certain

failure modes the MD pad may not be as robust in shock and vibration (S&V). During

S&V, the predominant failure mode for a MD pad in the corner of the BGA layout is

pad craters and solder joint cracks. A corner MD pad can be made more robust and

behave like a SMD pad by having a wide trace enter the pad. This trace should be 10

mil minimum wide but not to exceed the pad diameter and exit the pad at a 45 degree

angle (parallel to the diagonal of the socket). During board flexure that results from

shock & vibration, a SMD pad is less susceptible to a crack initiating due to the larger

surface area. Intel has defined selected solder joints of the socket as non-critical to

function (NCTF) when evaluating package solder joints post environmental testing.

The signals at NCTF locations are typically redundant ground or non-critical reserved,

so the loss of the solder joint continuity at end of life conditions will not affect the

overall product functionality.

The following figure diagrams shape and location of solder pad types for socket

2011-3.

October 2015 Thermal Mechanical Specification and Design Guide

Order No.: 330786-003 19

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Page 20

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families—LGA2011-3 Socket

Figure 9. Socket 2011-3 Pad Types and Locations

Overview

Notes: 1. When ordering PCBs with the Socket R (LGA2011) footprint, it is important to

specify the following verbiage on the FAB drawing as well as within the purchase

requisition: All BGA pads, Soldermask or Metal defined, min/max size tolerance,

should comply with Intel PCB specification, current revision. Nominal BGA pad

size, Soldermask or Metal defined, is Ø +/- 1 mil. This pad size is critical to

function on socket locations.

2. The solder paste stencil aperture recommendation for Socket R (LGA2011) is: 24

mil Ø circular aperture opening with a stencil thickness of 5 mils.

2.3

Socket Loading Requirements

The socket must meet the mechanical loading and strain requirements outlined in the

table below. All dynamic requirements are under room temperature conditions while

all static requirements are under product use condition temperature. Specifically, ILM

and HS load range may vary for different LGA 2011 derivatives (e.g. 2011-0, 2011-1)

due to the package form factor, and the design of loading mechanism and thermal

solution (e.g., HS mass).

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Thermal Mechanical Specification and Design Guide October 2015

20 Order No.: 330786-003

Page 21

LGA2011-3 Socket Overview—Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product

Families

2.3.1

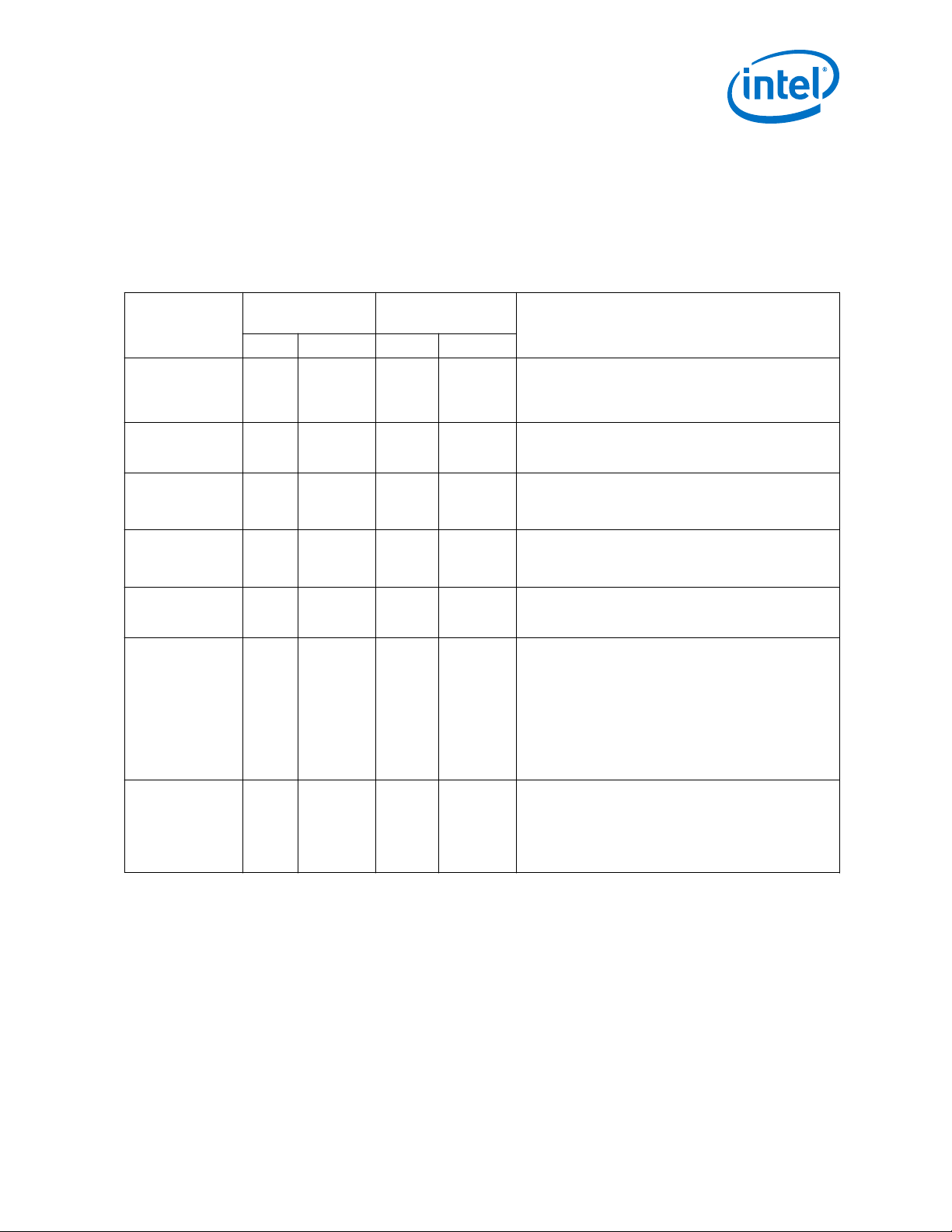

Socket Loading Specifications

The table below provides load specifications for the socket. These mechanical limits

should not be exceeded during component assembly, mechanical stress testing, or

standard drop and shipping conditions. All dynamic requirements are under room

temperature conditions while all static requirements are under 100 °C conditions.

Table 4. Socket Load Values

Parameter Load Limits,

SI Units

Min Max Min Max

Static Compressive

per Contact

Static Compressive

(ILM)

Static Compressive

Beginning of Life

(HS)

Static Compressive

End of Life

(HS)

Static Total

Compressive

Dynamic

Compressive

Board Transient

Bend Strain

15 (gf) 38 (gf) 0.53

445 (N) 712 (N) 100 (lbf) 160 (lbf) The total load applied by the enabling mechanism onto

222 (N) 400 (N) 50 (lbf) 90 (lbf) The total load applied by the heatsink mechanism onto

178 (N) 400 (N) 40 (lbf) 90 (lbf) The total load applied by the heatsink mechanism onto

667 (N) 1068 (N ) 150 (lbf) 240 (lbf) The total load applied by enabling mechanism and heat

NA 588 (N) NA 132 (lbf) Quasi-static equivalent compressive load applied during

NA 500 (ue)

for 62

(mil);

400 (ue)

for 100

(mil)

Load Limits,

Imperial Units

1.34 (ozf) The compressive load applied by the package on the

(ozf)

NA 500 (ue)

for 62

(mil);

400 (ue)

for 100

(mil)

Definition

LGA contacts to meet electrical performance. This

condition must be satisfied throughout the life of the

product

the socket as transferred through the package, contacts

and socket seating plane.

the socket as transferred through the package, contacts

and socket seating plane. Measured at Beginning of Life

the socket as transferred through the package, contacts

and socket seating plane. Measured at End of Life

sink onto the socket as transferred through the

package, contacts and socket seating plane.

the mechanical shock from heatsink, calculated using a

reference 600g heatsink with a 25G shock input and an

amplification factor of 3 (600g x 25G x 3 =441N=99

lbf). This specification can have flexibility in specific

values, but the ultimate product of mass times

acceleration should not exceed this value. Intel

reference system shock requirement for this product

family is 25G input as measured at the chassis

mounting location.

This is the strain on boards near to socket BGA corners

during transient loading events through manufacturing

flow or testing. The test guidance can be found in Board

Flexure Initiative (BFI) strain guidance from your local

CQE.

2.4

Socket Maximum temperature

The power dissipated within the socket is a function of the current at the pin level and

the effective pin resistance. To ensure socket long term reliability, Intel defines socket

maximum temperature using a via on the underside of the motherboard. Exceeding

the temperature guidance may result in socket body deformation, or increases in

thermal and electrical resistance which can cause a thermal runaway and eventual

electrical failure. The guidance for socket maximum temperature is listed below:

• Via temperature under socket <78 °C

October 2015 Thermal Mechanical Specification and Design Guide

Order No.: 330786-003 21

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Page 22

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families—LGA2011-3 Socket

• The specific via used for temperature measurement is located on the bottom of

the motherboard between pins BC1 and BE1.

• The socket maximum temperature is defined at Thermal Design Current (TDC). In

addition, the heatsink performance targets and boundary conditions must be met

to limit power dissipation through the socket.

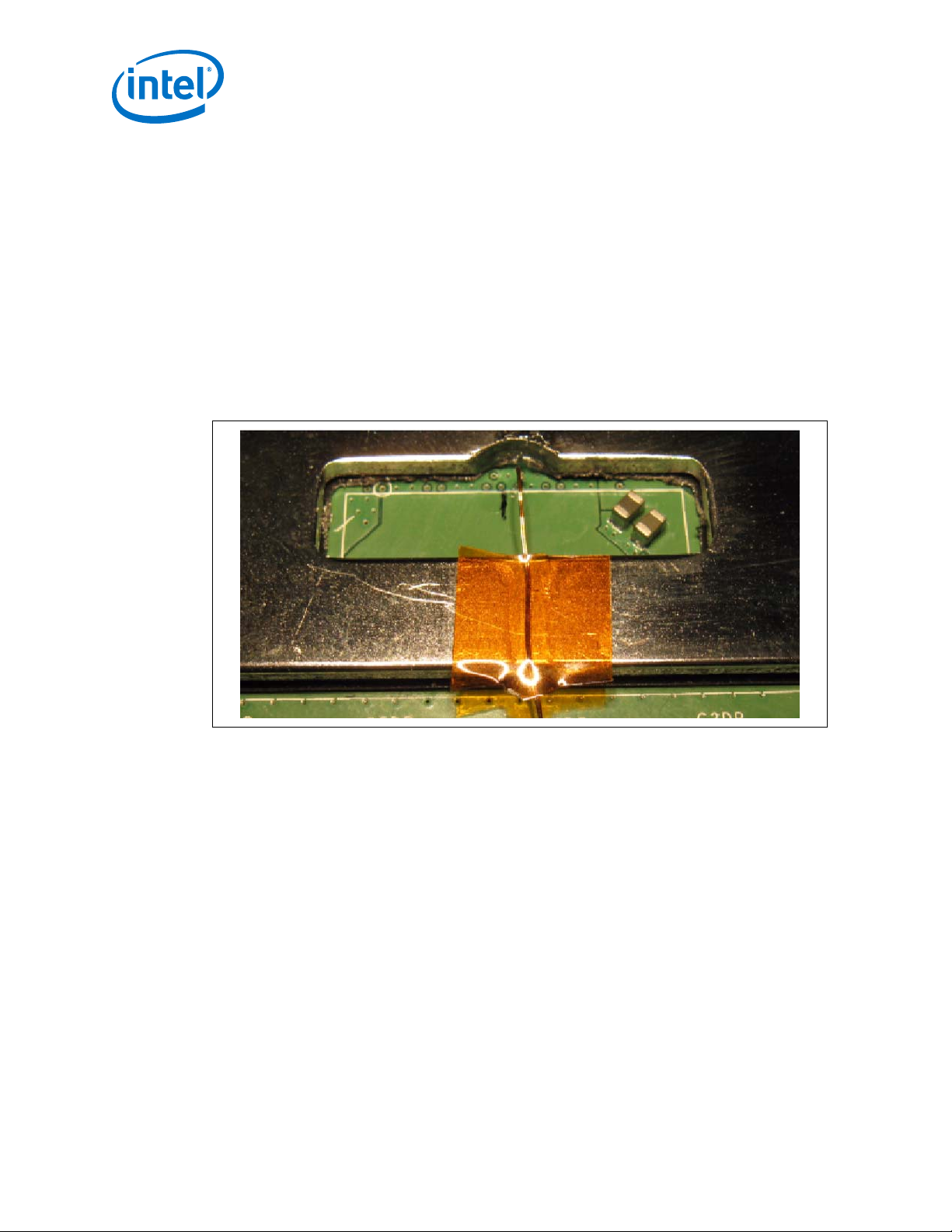

To measure via temperature:

1. Drill a hole through the back plate corresponding to the location of pins BC1 and

BE1.

2. Thread a T-type thermocouple (36 - 40 gauge) through the hole and glue it into

the specific measurement via on the underside of the motherboard.

3. Once the glue dries, reinstall the back plate and measure the temperature

Figure 10. Socket Temperature Measurement

Overview

2.5

Strain Guidance for Socket

Intel provides manufacturing strain guidance commonly referred to as Board Flexure

Initiative or BFI Strain Guidance. The BFI strain guidance apply only to transient bend

conditions seen in board manufacturing assembly environment with no ILM, for

example during In Circuit Test. BFI strain guidance limits do not apply once ILM is

installed. It should be noted that any strain metrology is sensitive to boundary

conditions. Intel recommends the use of BFI to prevent solder joint defects from

occurring in the test process. For additional guidance on BFI, see Manufacturing With

Intel® Components - Strain Measurement for Circuit Board Assembly, also referred as

BFI MAS ( Manufacturing Advantage Services) and BFI STRAIN GUIDANCE SHEET

(LGA2011-3 socket). Consult your Intel Customer Quality Engineer for additional

guidance in setting up a BFI program in your factory.

Note:

When the ILM is attached to the board, the boundary conditions change and the BFI

strain limits are not applicable. The ILM, by design, increases stiffness in and around

the socket and places the solder joints in compression. Intel does not support strain

metrology with the ILM assembled.

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Thermal Mechanical Specification and Design Guide October 2015

22 Order No.: 330786-003

Page 23

®

Independent Loading Mechanism (ILM) Specifications—Intel

2600 / 4600 v3 Product Families

Xeon® Processor E5-1600 /

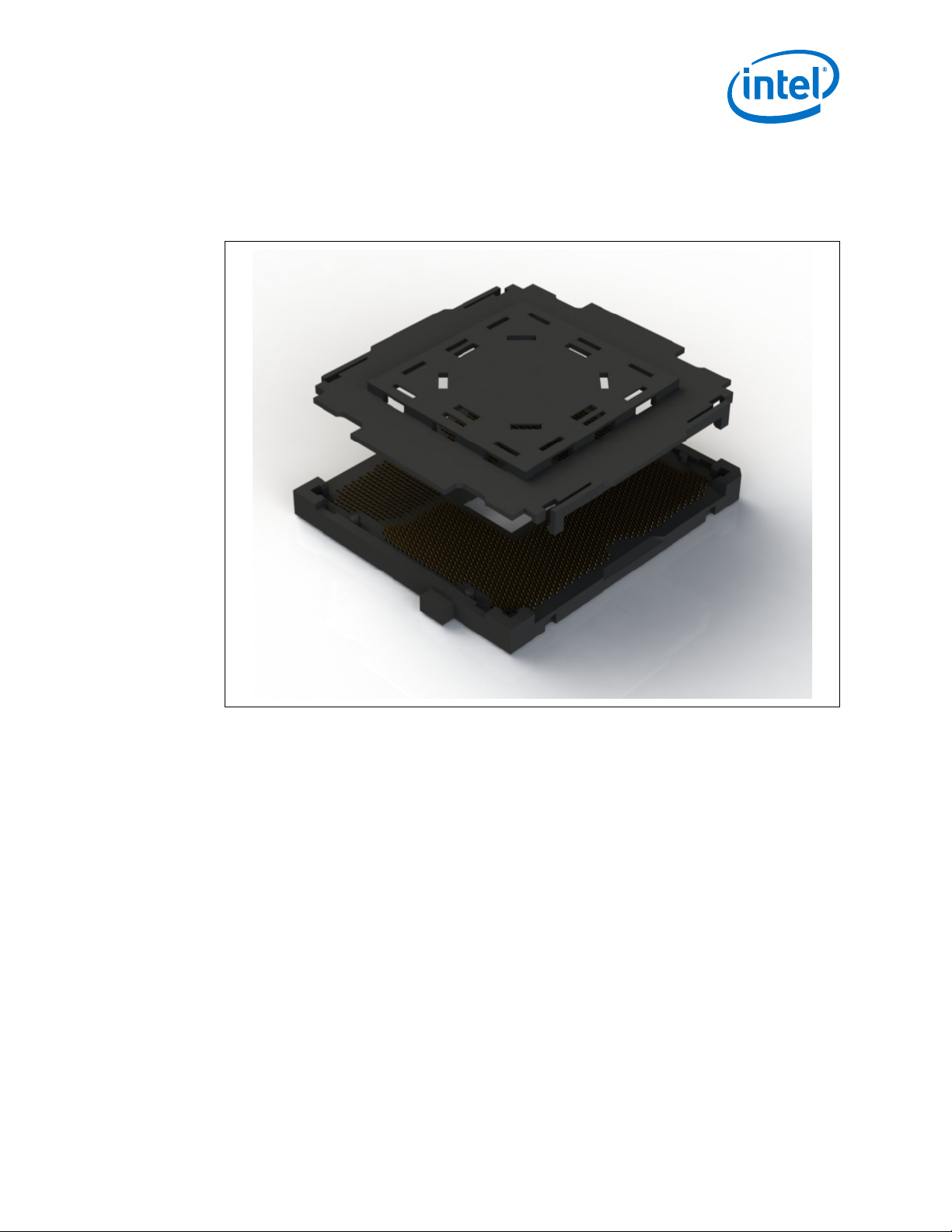

3.0 Independent Loading Mechanism (ILM) Specifications

The Independent Loading Mechanism (ILM) provides the force needed to seat the land

LGA package onto the socket contacts. See image below for total processor stack

consisting of all relevant mechanical components.

Figure 11. Processor Stack

The ILM is physically separate from the socket body. The assembly of the ILM is

expected to occur after attaching the socket to the board. The exact assembly location

is dependent on manufacturing preference and test flow.

The mechanical design of the ILM is a key contributor to the overall functionality of the

socket. Intel performs detailed studies on integration of processor package, socket

and ILM as a system. These studies directly impact the design of the ILM. The Intel

reference ILM will be "built to print" from Intel controlled drawings. Intel recommends

using the Intel Reference ILM. Custom non-Intel ILM designs do not benefit from

Intel's detailed studies and may not incorporate critical design parameters.

October 2015 Thermal Mechanical Specification and Design Guide

Order No.: 330786-003 23

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Page 24

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families—Independent Loading

Mechanism (ILM) Specifications

The ILM has two critical functions: evenly deliver and distribute the force to seat the

processor onto the socket contacts and ultimately through the socket solder joints.

Another purpose of ILM is to ensure electrical integrity/performance of the socket and

package.

Socket LGA2011-3 has two POR (Plan of Record) ILMs:

1. Square ILM - This ILM has 80x80mm heatsink mounting hole pattern.

2. Narrow ILM - This ILM has 56x94mm heatsink mounting hole pattern.

3.1

ILM Load Specifications

The Independent Loading Mechanism (ILM) provides the force needed to seat the

package onto the socket contacts.

Maximum Allowable Loads

The table below provides load specifications for the processor package. These

maximum limits should not be exceeded during heatsink assembly, shipping

conditions, or standard use condition. Exceeding these limits during test may result in

component failure or other damage to the system. The processor substrate should not

be used as a mechanical reference or load bearing surface for thermal solutions.

Table 5. LGA 2011-3 Maximum Allowable Loads

Item Maximum

Static Pre-Load Compressive (ILM load) 712N (160 lbf)

Static Pre-Load Compressive (HS load) 400N (90 lbf)

Total Socket Static Compressive (ILM+HS=Socket) 1068N (240 lbf)

Minimum Allowable Loads

The ILM is designed to achieve the minimum Socket Static Pre-Load Compressive load

specification. The thermal solution (heatsink) should apply additional load. The

combination of an ILM and HS will be used to achieve the load targets shown in the

table below.

Table 6. LGA 2011-3 Minimum Allowable Loads

Item Minimum

Static Pre-Load Compressive (ILM load) 445N (100 lbf)

Static Pre-Load Compressive (HS load) 222N (50 lbf)

Total Socket Static Compressive (ILM+HS=Socket) 667N (150 lbf)

End of Life Load Targets

The ILM is designed to achieve the minimum end of life loads for the socket. The

thermal solution (heatsink) should apply a portion of the end of life load. The

combination of an ILM and HS will be used to achieve the load targets shown in the

table below.

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Thermal Mechanical Specification and Design Guide October 2015

24 Order No.: 330786-003

Page 25

Independent Loading Mechanism (ILM) Specifications—Intel® Xeon® Processor E5-1600 /

2600 / 4600 v3 Product Families

Table 7. LGA 2011-3 Minimum End of Life Loads

Item End of Life Minimum

Static Pre-Load Compressive (ILM load) 311N (70 lbf)

Static Pre-Load Compressive (HS load) 178N (40 lbf)

Total Socket Static Compressive (ILM+HS=Socket) 490N (110 lbf)

3.2

ILM Keepout Zones (KOZ)

The table below lists envelope dimensions for ILM KOZ , both topside and backplate.

For detailed views, refer to dimensioned drawings in Mechanical Drawings on page

78.

Table 8. LGA 2011-3 ILM General Keepout Dimensions

Keepout Type Square ILM Narrow ILM

Topside envelope 93x93 mm (3.6x3.7in) 80x107.5 mm (3.15x4.2in)

ILM Hole Location 46x69.2 mm (1.8x2.7 in)

Backplate Envelope 78x84 mm (3.1x3.3 in)

3.3

Independent Loading Mechanism (ILM)

The Independent Loading Mechanism (ILM) provides the force needed to seat the

package onto the socket contacts. The ILM is a mechanical assembly that is physically

separate from the socket body. The assembly of the ILM to the motherboard is

expected to occur after attaching the socket to the board. The exact assembly location

is dependent on manufacturing preference and test flow.

The mechanical design of the ILM is a key contributor to the overall functionality of the

socket. Intel performs detailed studies on integration of processor package, socket

and ILM as a system. These studies directly impact the design of the ILM. The Intel

reference ILM will be "built to print" from Intel controlled drawings. Intel recommends

using the Intel Reference ILM. Custom non-Intel ILM designs do not benefit from

Intel's detailed studies and may not incorporate critical design parameters.

The ILM has two critical functions: deliver the force to seat the processor onto the

socket contacts resulting in even load transfer through the socket solder joints.

Another purpose of ILM is to ensure electrical integrity/performance of the socket and

package.

3.4

ILM Mechanical Design Considerations and Recommendations

An retention/loading mechanism must be designed to support the processor heatsink

and to ensure processor interface with the socket contact is maintained since there

are no features on the socket for direct attachment of the heatsink or retaining the

processor. In addition to supporting the processor heatsink over the processor, this

mechanism plays a significant role in the robustness of the system in which it is

implemented, in particular:

October 2015 Thermal Mechanical Specification and Design Guide

Order No.: 330786-003 25

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Page 26

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families—Independent Loading

Mechanism (ILM) Specifications

• Ensuring that thermal performance of the TIM applied between the IHS and the

heatsink is achievable. TIMs, especially those based on phase change materials,

are very sensitive to applied pressure: the higher the pressure, the better the

initial performance. TIMs such as thermal greases are not as sensitive to applied

pressure. Designs should consider the impact of shock and vibration events on

TIM performance as well as possible decrease in applied pressure over time due to

potential structural relaxation in enabled components.

• Ensuring that system electrical, thermal, and structural integrity is maintained

under shock and vibration events. The mechanical requirements of the attach

mechanism depend on the weight of the heatsink, as well as the level of shock

and vibration that the system must support. The overall structural design of the

baseboard and system must be considered when designing the heatsink and ILM

attach mechanism. Their design should provide a means for protecting the socket

solder joints as well as preventing package pullout from the socket.

• The load applied by the attachment mechanism and the heatsink must comply

with the package specifications, along with the dynamic load added by the

mechanical shock and vibration requirements of the package and socket.

• Load induced onto the package and socket by the ILM may be influenced with

heatsink installed. Determining the performance for any thermal/mechanical

solution is the responsibility of the customer.

A potential mechanical solution for heavy heatsink is the use of a supporting

mechanism such as a backer plate or the utilization of a direct attachment of the

heatsink to the chassis pan. In these cases, the strength of the supporting component

can be utilized rather than solely relying on the baseboard strength. In addition to the

general guidelines given above, contact with the baseboard surfaces should be

minimized during installation in order to avoid any damage to the baseboard.

3.5

Placement of board-to-chassis mounting holes also impacts board deflection and

resultant socket solder ball stress. Customers need to assess the shock for their

designs as heatsink retention (back plate), heatsink mass and chassis mounting holes

may vary.

ILM Features

The ILM is defined by four basic features

1. ILM Loadplate: Formed sheet metal that when closed applies four point loads onto

the IHS seating the processor into the socket

2. ILM Frame: Single piece or assembly that mounts to PCB board and provides the

hinge locations for the levers the ILM frame also contains captive mounts for

heatsink attach. An insulator is pre applied by the vendor to the bottom side of

the ILM frame.

3. ILM Actuation levers: Formed loading levers designed to place equal force on both

ends of the ILM load plate. Some of the load is passed through the socket body to

the board inducing a slight compression on the solder joints

4. ILM Backplate: A flat steel back plate with threaded studs to attach to the ILM

frame. A clearance hole is located at the center of the plate to allow access to test

points and backside capacitors. Two additional cut-outs on the backplate provide

clearance for backside voltage regulator components. An insulator is pre applied

by the vendor to the side with the threaded studs.

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Thermal Mechanical Specification and Design Guide October 2015

26 Order No.: 330786-003

Page 27

Independent Loading Mechanism (ILM) Specifications—Intel

2600 / 4600 v3 Product Families

Heatsink mounting studs on ILM frame allow for topside thermal solution attach to a

rigid structure. This eliminates the motherboard thickness dependency from the

heatsink mechanical stackup. ILM assembly provides a clamping force between the

ILM frame, backplate and board, resulting in reduced board bending leading to higher

solder joint reliability. ILM lever design provides an interlocking mechanism to ensure

proper opening or closing sequence for the operator. This has been implemented in

both square and narrow ILM.

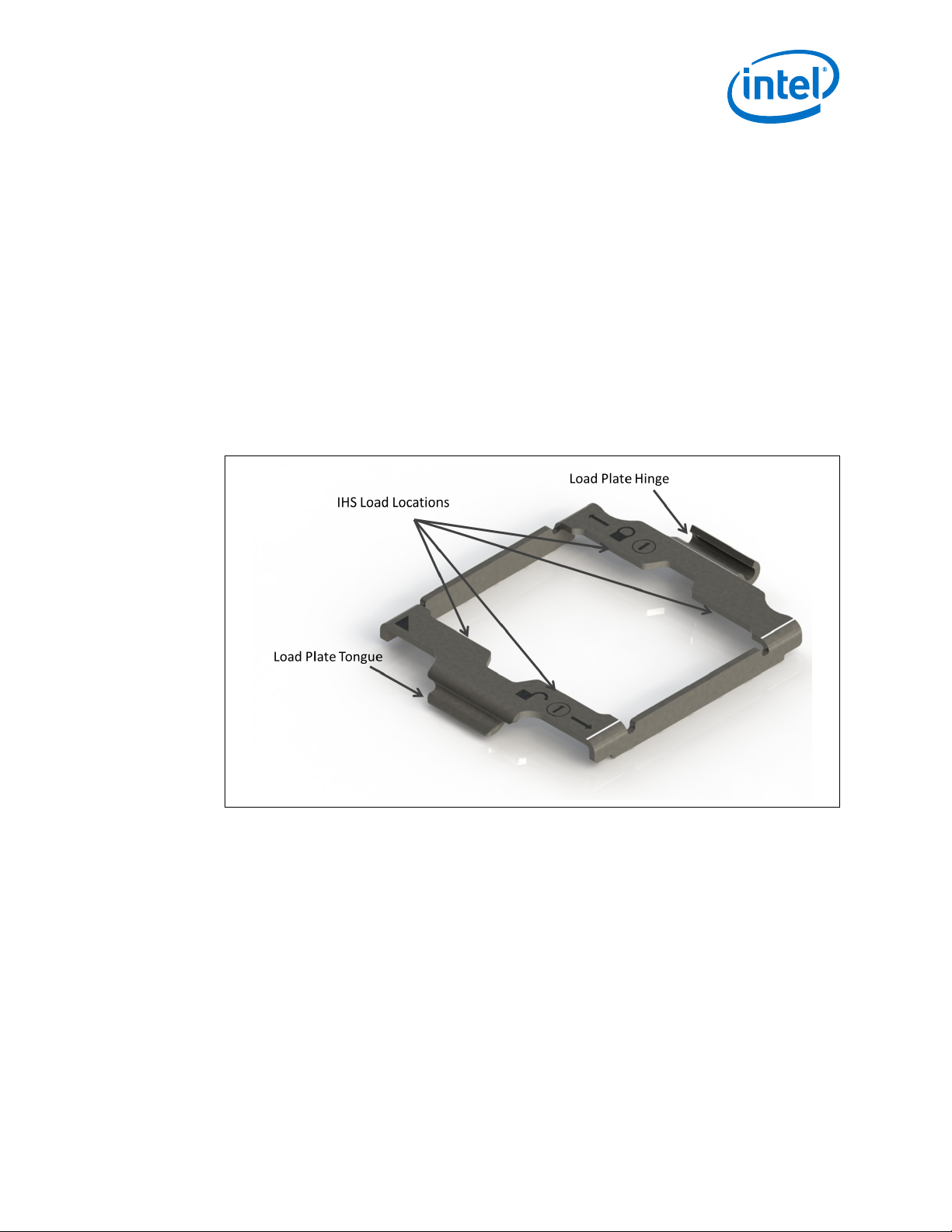

ILM Load Plate Design

Four point loading contributes to minimizing package and socket warpage under non

uniformly distributed load. The reaction force from closing the load plate is transmitted

to the frame and through the captive fasteners to the back plate. Some of the load is

passed through the socket body to the board inducing a slight compression on the

solder joints. The load plate design is common between the two POR ILMS and is

shown in the figure below.

Figure 12. ILM Load Plate

®

Xeon® Processor E5-1600 /

Lever Actuation/Release Forces

Maximum allowable force to actuate the levers not to exceed 4.7 lbf (21 N) at the

point of typical finger placement.

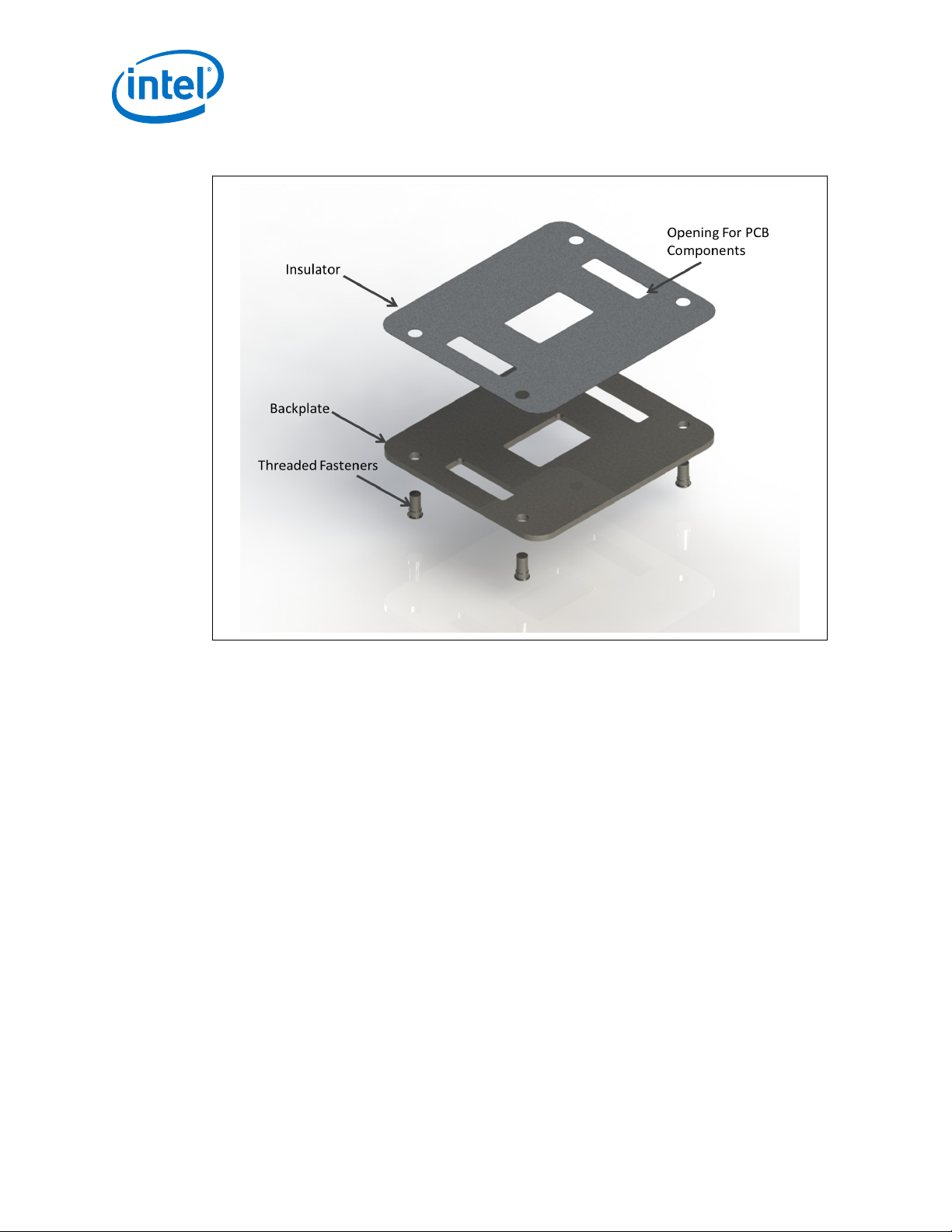

ILM Back Plate Design

The backplate assembly consists of a supporting plate and captive standoffs. It

provides rigidity to the system to ensure minimal board and socket deflection. Four

externally threaded (male) inserts which are press fit into the back plate are for ILM

attachment. Three cavities are located at the center of the plate to allow access to the

baseboard test points and backside capacitors. An insulator is pre-applied to prevent

shorting the board.

October 2015 Thermal Mechanical Specification and Design Guide

Order No.: 330786-003 27

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Page 28

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families—Independent Loading

Figure 13. ILM Backplate

Mechanism (ILM) Specifications

3.6

3.6.1

Intel® ILM Reference Designs

Intel has designed and validated two ILMs compatible with Socket LGA2011-3 :

1. Square ILM - 80x80 mm heat sink mounting hole pattern.

2. Narrow ILM - 56x94 mm heat sink mounting hole pattern.

The two POR ILMs share most components, only the top plate and active lever differ

between the two assemblies.

Square ILM

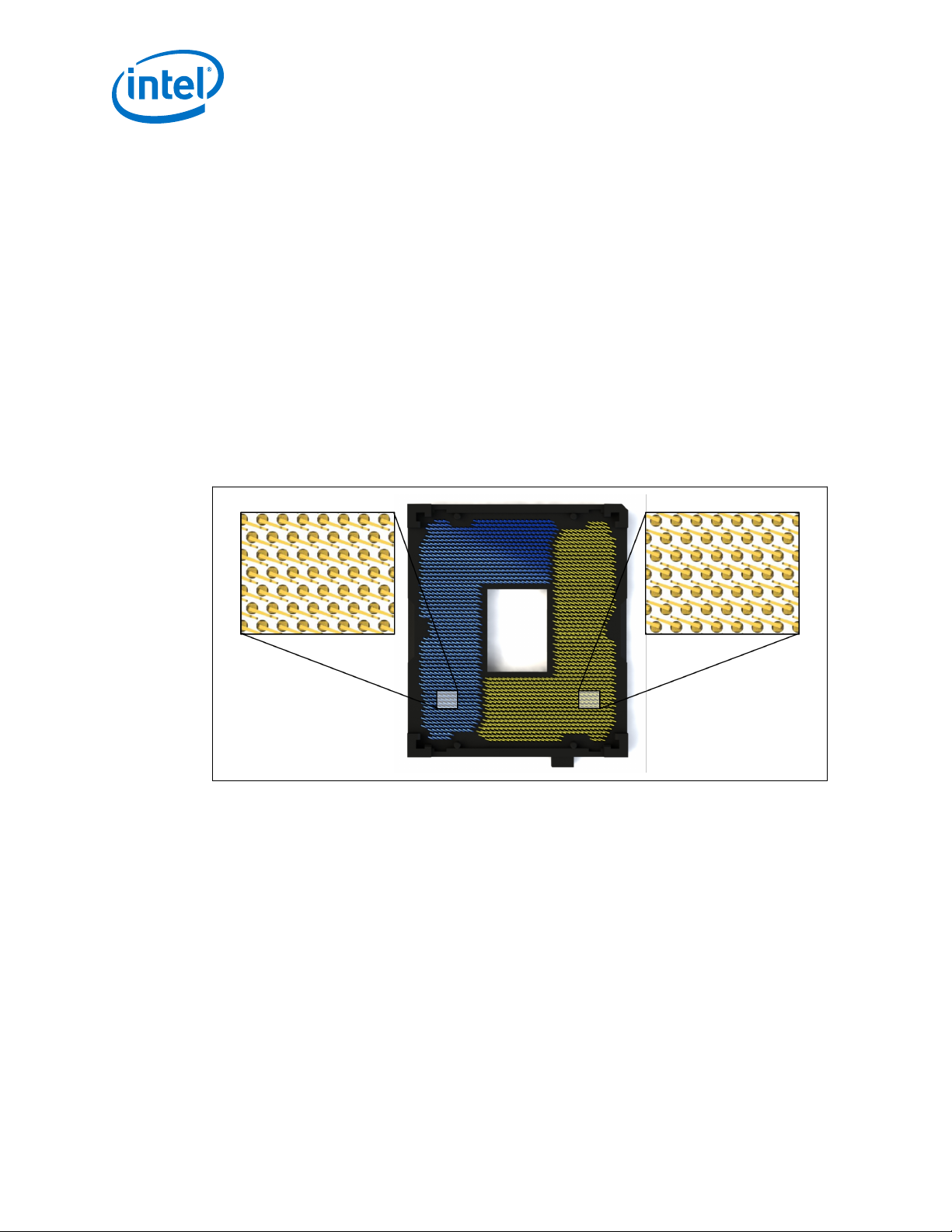

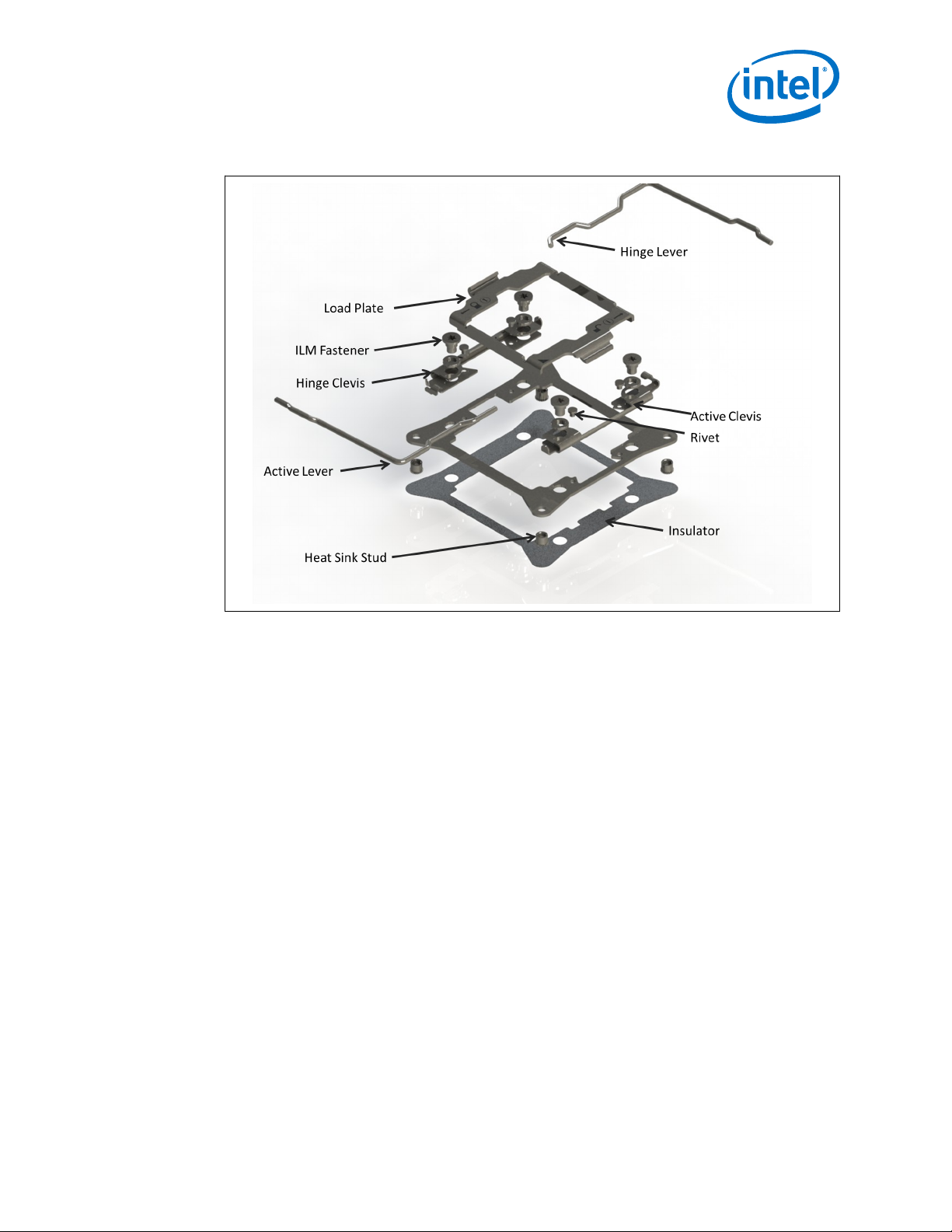

The square ILM consists of two sub assemblies that will be procured as a set from the

enabled vendors. These two components are the ILM assembly and back plate. The

square ILM assembly consists of several pieces as shown and labeled in the following

diagram. The hinge lever, active lever, load plate, top plate,clevises, and the captive

fasteners. For clarity the ILM cover is not shown in this view.

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Thermal Mechanical Specification and Design Guide October 2015

28 Order No.: 330786-003

Page 29

Independent Loading Mechanism (ILM) Specifications—Intel® Xeon® Processor E5-1600 /

2600 / 4600 v3 Product Families

Figure 14. Exploded Square ILM

An assembled view is shown in the following figure.

October 2015 Thermal Mechanical Specification and Design Guide

Order No.: 330786-003 29

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Page 30

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families—Independent Loading

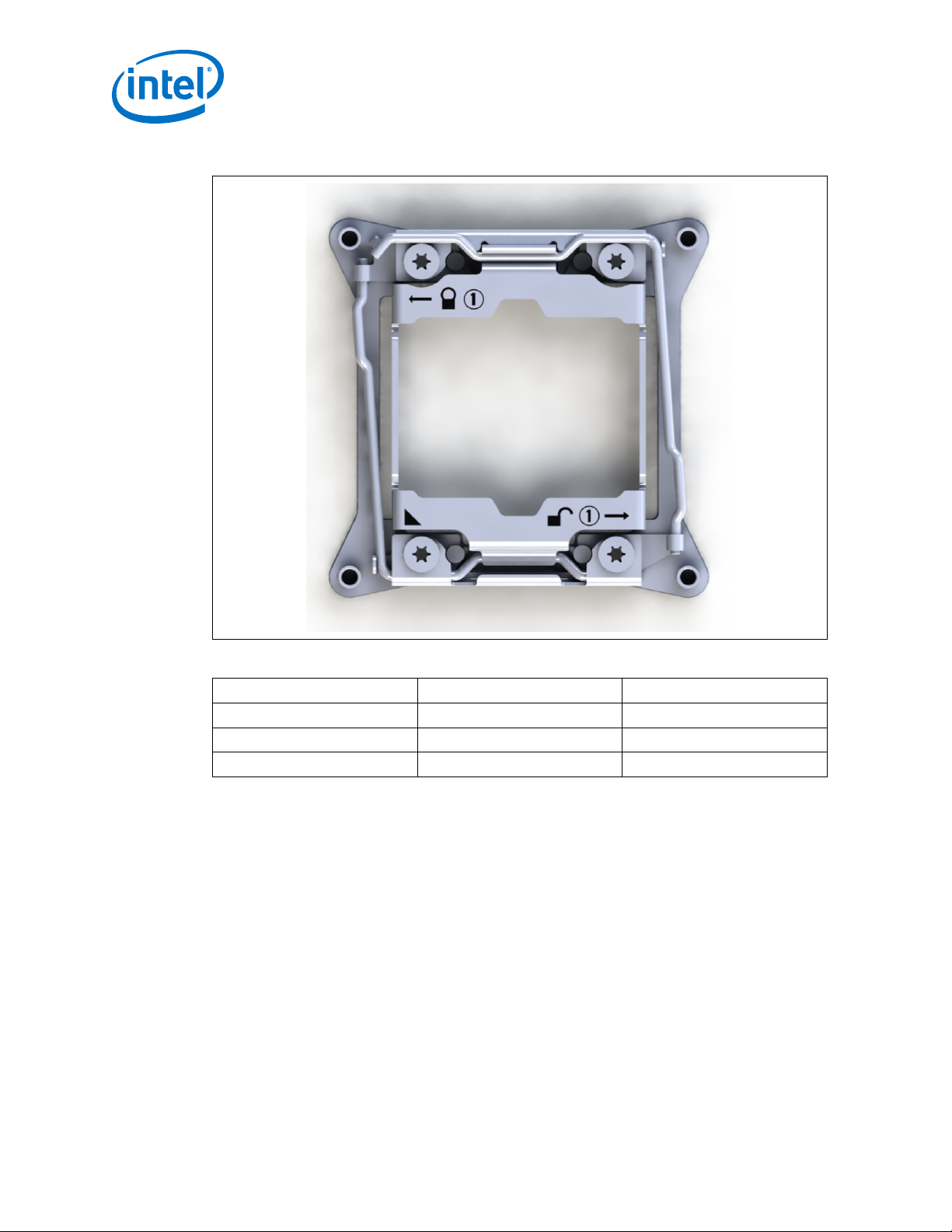

Figure 15. Assembled Square ILM

Mechanism (ILM) Specifications

Table 9. Square ILM Component Thickness and materials

Component Thickness Material

ILM Frame 1.20 mm 310 Stainless Steel

ILM Load Plate 1.50 mm 310 Stainless Steel

ILM Back Plate 2.20 mm S50C low Carbon Steel

The square ILM supports the legacy 80x80 mm heat sink mounting patterns used in

some form factors.

3.6.2

Narrow ILM

The narrow ILM consists of two sub assemblies that will be procured as a set from the

enabled vendors. These two components are the ILM assembly and back plate. The

ILM assembly is shown in the following figure.

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Thermal Mechanical Specification and Design Guide October 2015

30 Order No.: 330786-003

Page 31

Independent Loading Mechanism (ILM) Specifications—Intel

2600 / 4600 v3 Product Families

Figure 16. Exploded Narrow ILM

®

Xeon® Processor E5-1600 /

The narrow ILM assembly consists of several pieces as shown and labeled above. The

hinge lever, active lever, load plate, top plate, clevises, ILM cover, and the captive

fasteners. For clarity the ILM cover is not shown in this view. An assembled view is

shown in the following figure. The Narrow ILM maintains the structure and function of

the square ILM but utilizes separate clevises riveted onto the ILM frame.

October 2015 Thermal Mechanical Specification and Design Guide

Order No.: 330786-003 31

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Page 32

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families—Independent Loading

Figure 17. Assembled Narrow ILM

Mechanism (ILM) Specifications

Table 10. Narrow ILM Component Thickness and materials

Component Thickness Material

ILM Frame 1.50 mm 310 Stainless Steel

ILM Clevis 0.80 mm 301 Stainless Steel

ILM Load Plate 1.50 mm 310 Stainless Steel

ILM Back Plate 2.20 mm S50C low Carbon Steel

The narrow ILM supports a smaller east west dimension constraint conducive for use

in space constrained form factors.

3.7

ILM Cover

Intel has developed a cover that will snap on to the ILM for the LGA2011 socket

family.

The ILM cover is intended to reduce the potential for socket contact damage from the

operator / customer fingers being close to the socket contacts to remove or install the

pick and place cover. By design the ILM cover and pick and place covers can not be

installed simultaneously. This cover is intended to be used in place of the pick and

place cover once the ILM is assembled to the board. The ILM will be offered with the

ILM cover pre assembled as well as a discrete part.

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Thermal Mechanical Specification and Design Guide October 2015

32 Order No.: 330786-003

Page 33

Independent Loading Mechanism (ILM) Specifications—Intel® Xeon® Processor E5-1600 /

2600 / 4600 v3 Product Families

Figure 18. ILM cover

• Pre-assembled by the ILM vendors to the ILM load plate. It will also be offered as

a discrete component.

• The ILM cover will pop off if a processor is installed in the socket.

• Maintain inter-changeability between validated ILM vendors for LGA2011-3 socket.

• The ILM cover for the LGA2011-3 socket will have a flammability rating of V-0 per

UL 60950-1.

Note: Intel recommends removing the Pick and Place cover (PnP) of the socket body in

manufacturing as soon as possible at the time when ILM is being installed.

ILM Cover Attach/Removal Force

The required force to remove the ILM cover shall not exceed 7.6 N when the load is

applied by finger at the center of cover.

3.8

ILM Allowable Board Thickness

The ILM components described in this document will support board thickness in the

range of 1.5748 - 2.54 mm (0.062" - 0.100"). Boards (PCBs) not within this range

may require modifications to the back plate or other ILM components retention.

Contact the component suppliers (Component Suppliers on page 76) for

modifications.

October 2015 Thermal Mechanical Specification and Design Guide

Order No.: 330786-003 33

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Page 34

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families— Processor Thermal

Specifications and Features

4.0 Processor Thermal Specifications and Features

4.1

4.1.1

T

and DTS-Based Thermal Specification

case

Implementation

Thermal solutions should be sized such that the processor complies to the T

thermal profile all the way up to TDP, because, when all cores are active, a thermal

solution sized as such will have the capacity to meet the DTS thermal profile, by

design. When all cores are not active or when Intel Turbo Boost Technology is active,

attempting to comply with the DTS thermal profile may drive system fans to speeds

higher than the fan speed required to comply with the T

thermal profile at TDP.

CASE

In cases where thermal solutions are undersized, and the processor does not comply

with the T

is kept lower than TDP, AND the actual T

thermal profile at TDP, compliance can occur when the processor power

CASE

is below the T

CASE

thermal profile at that

CASE

lower power.

In most situations, implementation of DTS thermal profile can reduce average fan

power and improve acoustics, as compared to T

DTS < T

CONTROL

, the processor is compliant, and T

CONTROL

-based fan speed control. When

and DTS thermal profiles can

CASE

be ignored.

Margin to Thermal Specification (M)

To simplify processor thermal specification compliance, the processor calculates and

reports margin to DTS thermal profile (M) using the following method.

Processor reads firmware programmable values:

1. TCC_OFFSET: In-band: TEMPERATURE_TARGET[27:24]. BIOS must write in a

value before CPL3.

CASE

Processor gathers information about itself:

1. Processor stores the intercept and slope terms (TLA and ΨPA) from the DTS

Thermal Profile for that particular SKU (one-time read only)

2. Processor reads its own energy consumption and calculates power, P

3. Processor reads its own temperature, DTS

Finally, processor calculates the margin value (M) to the specification (solid black line

in the graph below). The PECI command for reading margin (M) is RdPkgConfig(),

Index 10.

M < 0 indicates gap to spec,

processor needs more cooling (for example, increase fan

speed)

M > 0 this indicates margin to spec, processor is sufficiently cooled

Graphically, this is represented below. T

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

Thermal Mechanical Specification and Design Guide October 2015

34 Order No.: 330786-003

CONTROL_OFFSET

is not writable to a register.

Page 35

Processor Thermal Specifications and Features—Intel® Xeon® Processor E5-1600 / 2600 / 4600

v3 Product Families

Figure 19. Margin to Thermal Spec (M)

DTS 2.0 processor Margin values can be obtained via PECI or Processor register see

documentation below as well as Intel® Xeon® Processor E5-1600 and E5-2600 v3

Product Families, Volume 2 of 2, Registers Datasheet and Intel® Xeon® Processor

E5-1600 and E5-2600 v3 Product Families, Volume 1 of 2, Electrical Datasheet

Table 11. DTS 2.0 Margin From PECI

Service Index

Value

(IV)

(decimal)

Thermal Margin 10 0x0000 15:0--Package

Note: Refer to Intel® Xeon® Processor E5-1600 and E5-2600 v3 Product Families, Volume 2 of 2, Registers Datasheet and

Intel® Xeon® Processor E5-1600 and E5-2600 v3 Product Families, Volume 1 of 2, Electrical Datasheet for further

details

October 2015 Thermal Mechanical Specification and Design Guide

Order No.: 330786-003 35

Parameter

Value

(word)

RdPkgConfig()

Data

(dword)

Temperature

margin in 8.8

format, 32:16-Reserved

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families

WrPkgConfi

g()

Data

(dword)

N/A Package temperature

Description

margin with regards to

DTS Thermal Profile.

Positive indicates

thermal margin, and

package is less than DTS

thermal profile

Page 36

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families—Processor Thermal

Specifications and Features

Table 12. DTS 2.0 Margin From Processor Register: CSR for PACKAGE_THERM_MARGIN

Bus:1 Device:30 Function:0 Offset:E0

Bit Attr Default Description

31:16 RSVD-P 0000h Reserved--Protected

15:0 R0-V 0000h THERM_MARGIN--This field provides Platform

Note: • Refer to Intel® Xeon® Processor E5-1600 and E5-2600 v3 Product Families, Volume 2 of 2, Registers Datasheet and

Intel® Xeon® Processor E5-1600 and E5-2600 v3 Product Families, Volume 1 of 2, Electrical Datasheet for full

documentation of registers and field descriptions

Firmware with running average of the instantaneous

temperature margin above Tspec in 2's complement

8.8 format. This is the recommended field for

Platform firmware to use for fan control. When this

value is negative, it indicates a firmware must

increase the fan speed. With a positive value,

firmware may decrease the speed of the fan

4.2

4.2.1

4.2.2

4.3

Processor Thermal Features

Absolute Processor Temperature

The processor has a software readable field in the TEMPERATURE_TARGET register

that contains the minimum temperature at which the Thermal Control Circuit (TCC)

will be activated and PROCHOT_N will be asserted.

Intel does not test any third party software that reports absolute processor

temperature. As such, Intel cannot recommend the use of software that claims this

capability. Since there is part-to-part variation in the TCC (thermal control circuit)

activation temperature, use of software that reports absolute temperature could be

misleading.

Short Duration TCC Activation

Systems designed to meet thermal capacity may encounter short durations of

throttling, also known as TCC activation, especially when running nonsteady processor

stress applications. This is acceptable and is functionally within the intended

temperature control parameters of the processor. Such short duration TCC activation

is not expected to provide noticeable reductions in application performance, and is

typically within the normal range of processor to processor performance variation.

Processor Thermal Specifications

The processor requires a thermal solution to maintain temperatures within operating

limits. Any attempt to operate the processor outside these limits may result in

permanent damage to the processor and potentially other components within the

system. Maintaining the proper thermal environment is key to reliable, long-term

system operation.

A complete solution includes both component and system level thermal management

features. Component level thermal solutions can include active or passive heatsinks

attached to the processor integrated heat spreader (IHS). Typical system level

thermal solutions may consist of system fans combined with ducting and venting.

Intel® Xeon® Processor E5-1600 / 2600 / 4600 v3 Product Families