Page 1

DUAL SERIAL TRANSCEIVER (DST)

82503 PRODUCT FEATURE SET OVERVIEW

Y

Single Component Ethernet* Interface

to Both 802.3 10BASE-T and AUI

Y

Automatic or Manual Port Selection

Y

Manchester Encoder/Decoder and

Clock Recovery

Y

No Glue Interface to Industry-Standard

LAN Controllers

Ð Intel 82586, 82590, 82593 and 82596

Ð AMD 7990 (LANCE*)

Ð National Semiconductor 8390 and

83932 (SONIC*)

Ð Western Digital 83C690

Ð Fujitsu 86950 (Etherstar*)

INTERFACE FEATURES

82503

Y

Y

Y

Y

Y

Y

Y

Y

Diagnostic Loopback

Reset, Low Power Modes

Network Status Indicators

Defeatable Jabber Timer

User Test Modes

10 MHz Transmit Clock Generator

One Micron CHMOS** IV (Px48)

Technology

Single 5-V Supply

TPE

Y

Complies with 10BASE-T, IEEE Std.

802.3i-1990 for Twisted Pair Ethernet

Y

Selectable Polarity Switching

Y

Direct Interface to TPE Analog Filters

Y

On-Chip TPE Squelch

Y

Defeatable Link Integrity (LI)

Y

Support of Cable Lengthsl100m

AUI

Y

Complies with IEEE 802.3 AUI Standard

Y

Direct Interface to AUI Transformers

Y

On-Chip AUI Squelch

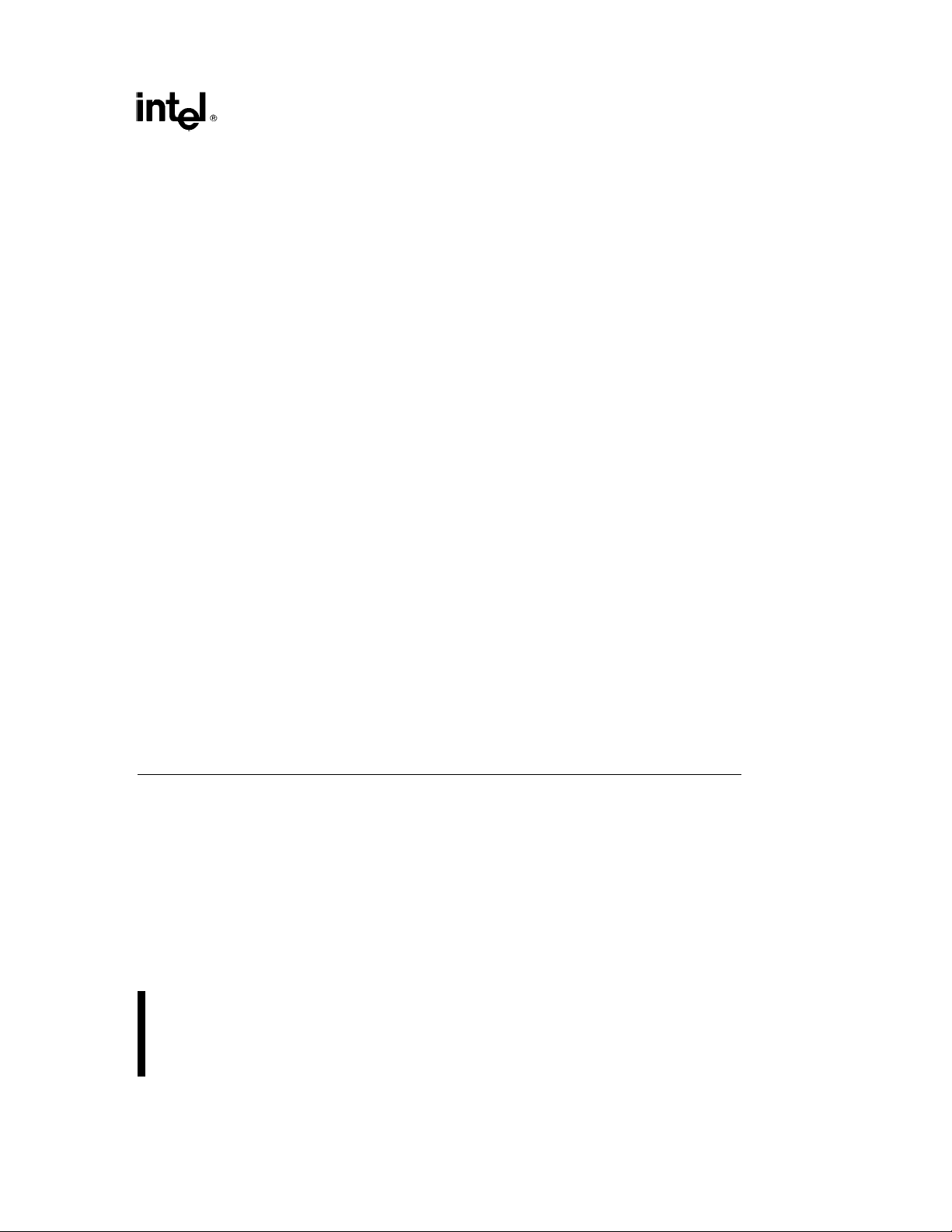

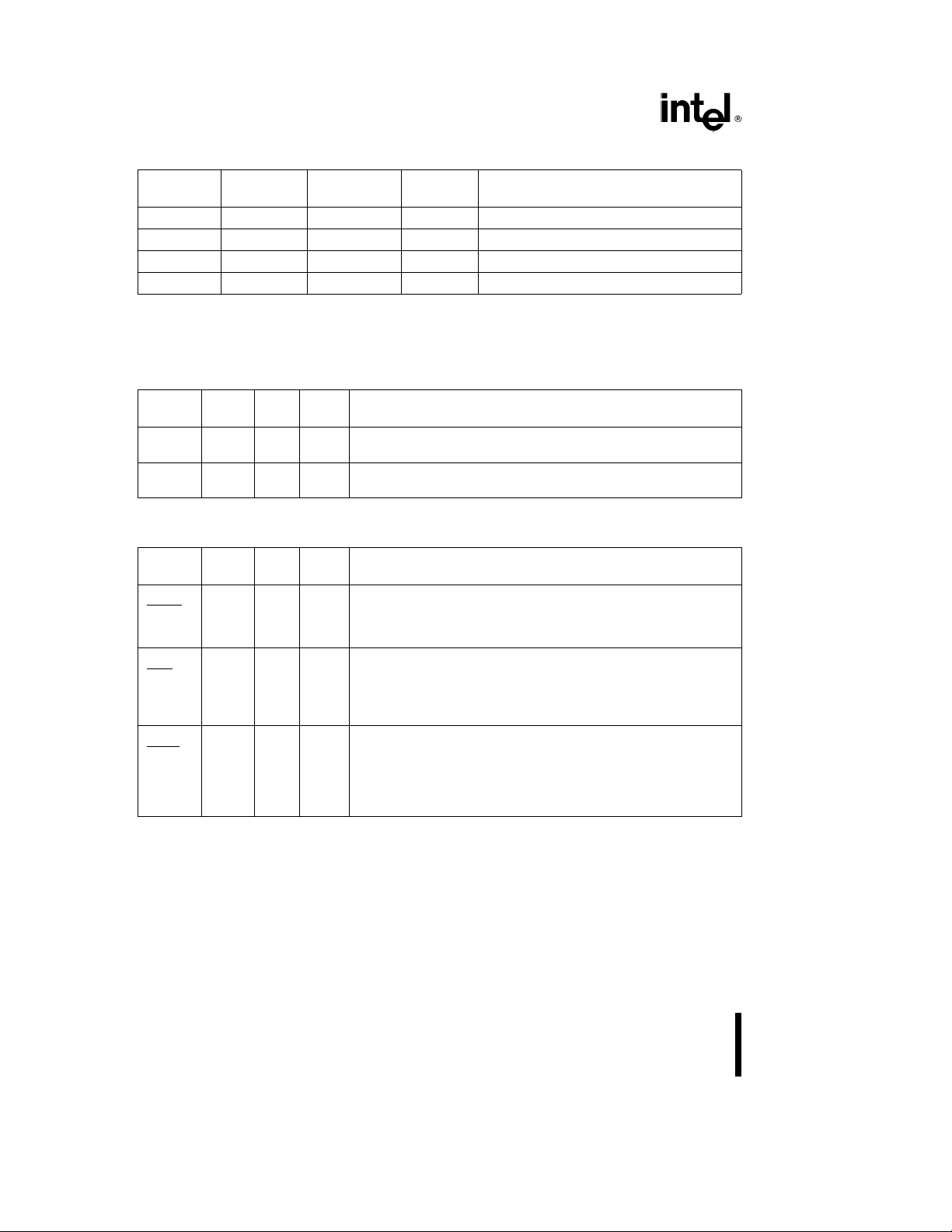

A block diagram of a typical application is shown in Figure 1. The 82503 Dual Serial Transceiver is a high-integration CMOS device designed to simplify interfacing industry standard Ethernet LAN Controllers to IEEE

802.3 local area network applications (10BASE5, 10BASE2, and 10BASE-T). The component supports both

an attachment unit interface (AUI) and a Twisted Pair Ethernet interface (TPE). It allows OEMs to design a

state-of-the-art media interface that is jumperless and fully automatic. The 82503 includes on-chip AUI and

TPE drivers and receivers; it offers designers a cost-effective, integrated solution for interfacing LAN controllers to the wire medium.

**CHMOS is a patented process of Intel Corporation.

*Ethernet is a registered trademark of Xerox Corporation.

LANCE is a registered trademark of Advanced Micro Devices.

Etherstar is a registered trademark of Fujitsu Electronics.

Sonic is a registered trademark of National Semiconductor Corporation.

*Other brands and names are the property of their respective owners.

Information in this document is provided in connection with Intel products. Intel assumes no liability whatsoever, including infringement of any patent or

copyright, for sale and use of Intel products except as provided in Intel’s Terms and Conditions of Sale for such products. Intel retains the right to make

changes to these specifications at any time, without notice. Microcomputer Products may have minor variations to this specification known as errata.

October 1995COPYRIGHT©INTEL CORPORATION, 1996 Order Number: 290421-004

Page 2

82503 Dual Serial Transceiver (DST)

CONTENTS PAGE

1.0 82503 PRODUCT FEATURES

2.0 PIN DEFINITION ААААААААААААААААААААААА 5

2.1 Power Pins АААААААААААААААААААААААААА 6

2.2 Clock Pins ААААААААААААААААААААААААААА 6

2.3 AUI Pins ААААААААААААААААААААААААААААА 6

2.4 TPE Pins АААААААААААААААААААААААААААА 7

2.5 Controller Interface Pins ААААААААААААА 7

2.6 Mode Pins ААААААААААААААААААААААААААА 8

2.7 LED Pins АААААААААААААААААААААААААААА 9

3.0 82503 ARCHITECTURE АААААААААААААА 10

3.1 Clock Generation ААААААААААААААААААА 10

3.2 Transmit Blocks АААААААААААААААААААА 10

3.3 Receive Blocks ААААААААААААААААААААА 11

3.4 Collision Detection ААААААААААААААААА 13

3.5 Link Integrity ААААААААААААААААААААААА 13

3.6 Jabber Function АААААААААААААААААААА 13

3.7 TPE Loopback ААААААААААААААААААААА 13

3.8 SQE Test Function ААААААААААААААААА 14

3.9 Port Selection АААААААААААААААААААААА 14

3.10 LED Description ААААААААААААААААААА 14

3.11 Polarity Switching ААААААААААААААААА 14

3.12 Controller Interface АААААААААААААААА 15

ААААААААА 3

CONTENTS PAGE

4.0 RESET, LOW POWER AND TEST

MODES

4.1 Reset АААААААААААААААААААААААААААААА 16

4.2 Low Power and High Impedance

4.3 Diagnostic Loopback ААААААААААААААА 16

4.4 Customer Test Modes (Continuous

5.0 APPLICATION EXAMPLE АААААААААААА 17

5.1 Introduction АААААААААААААААААААААААА 17

5.2 Design Guidelines АААААААААААААААААА 17

5.3 Layout Guidelines АААААААААААААААААА 17

6.0 PACKAGE THERMAL

SPECIFICATIONS АААААААААААААААААААААА 19

7.0 ELECTRICAL SPECIFICATIONS

AND TIMINGS АААААААААААААААААААААААААА 20

АААААААААААААААААААААААААААААААА 16

Modes

ААААААААААААААААААААААААААААААА 16

AUI/TPE Transmit) АААААААААААААААААА 16

2

Page 3

Figure 1. Application Block Diagram

82503

290421– 1

1.0 82503 PRODUCT FEATURES

The 82503 incorporates all the active circuitry required to interface Ethernet controllers to 10BASE-T

networks or the attachment unit interface (AUI). It

supports a direct no-glue interface to Intel’s family of

high-performance LAN controllers (82586, 82590,

82593, and 82596). The 82503 also provides a direct no-glue interface to the National Semiconductor

8390 and 83932 (SONIC), the Western Digital

83C690, the Advanced Micro Devices 7990

(LANCE) and 79C900 (ILACC), and the Fujitsu

86950 (Etherstar) controllers.

This component includes three advanced features:

jumperless two-port design capability, automatic port

selection, and polarity switching. The jumperless

TPE or AUI port selection capability allows designers maximum ease-of-use and network flexibility. Automatic port selection ensures complete software

compatibility with existing 10BASE2 and 10BASE5

software drivers. The 82503’s polarity switching feature will detect and correct polarity errors on the

twisted pairÐthe most common wiring fault in twisted pair networks.

The 82503 contains all the circuitry needed to meet

the 10BASE-T specification, including link integrity, a

jabber timer and internal predistortion. Deselecting

link integrity allows the component to be used in

some prestandard networks. The 82503’s jabber

timer prevents the station from continuously transmitting and is defeatable for simple design charac-

terization. The predistortion circuitry eliminates line

overcharge and reduces jitter on 10BASE-T links.

The 82503 can also support twisted pair cable

lengths of up to 200m when placed in TPE Extended

Squelch Mode (XSQ).

This component incorporates six LED drivers to display transmit data, receive data, collision, link integrity, polarity faults and port selections, allowing for

complete network monitoring by the user. The transmit, receive and collision LEDs indicate the rate of

activity by the frequency of flashing. The 82503 also

has a low power mode. During low power, many of

the 82503’s pins are in a high-impedance state to

facilitate board-level testing.

The 82503’s diagnostic loopback control enables it

to route a transmission signal from the LAN controller through its Manchester encoder-decoder circuitry

and back to the LAN controller. This provides effective network node fault detection and isolation capabilities. In addition, the 82503 supports diagnostic

test modes that generate continuous tranmission of

data through the twisted pair port, allowing designers to measure the analog performance of their design.

The 82503 is available in 44-lead PLCC and 44-lead

QFP packages and is fabricated with Intel’s lowpower, high-speed, CHMOS IV technology using a

single 5-V supply.

3

Page 4

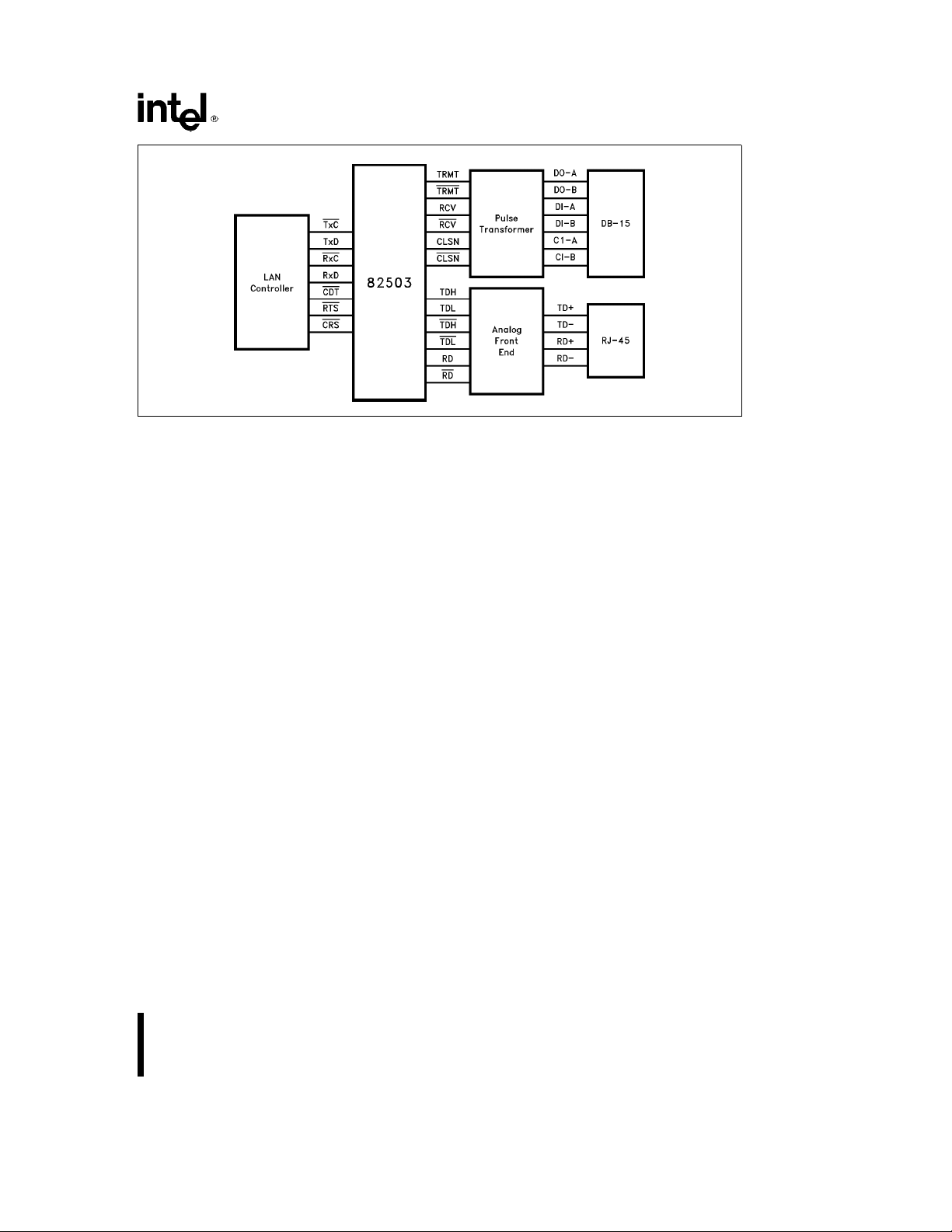

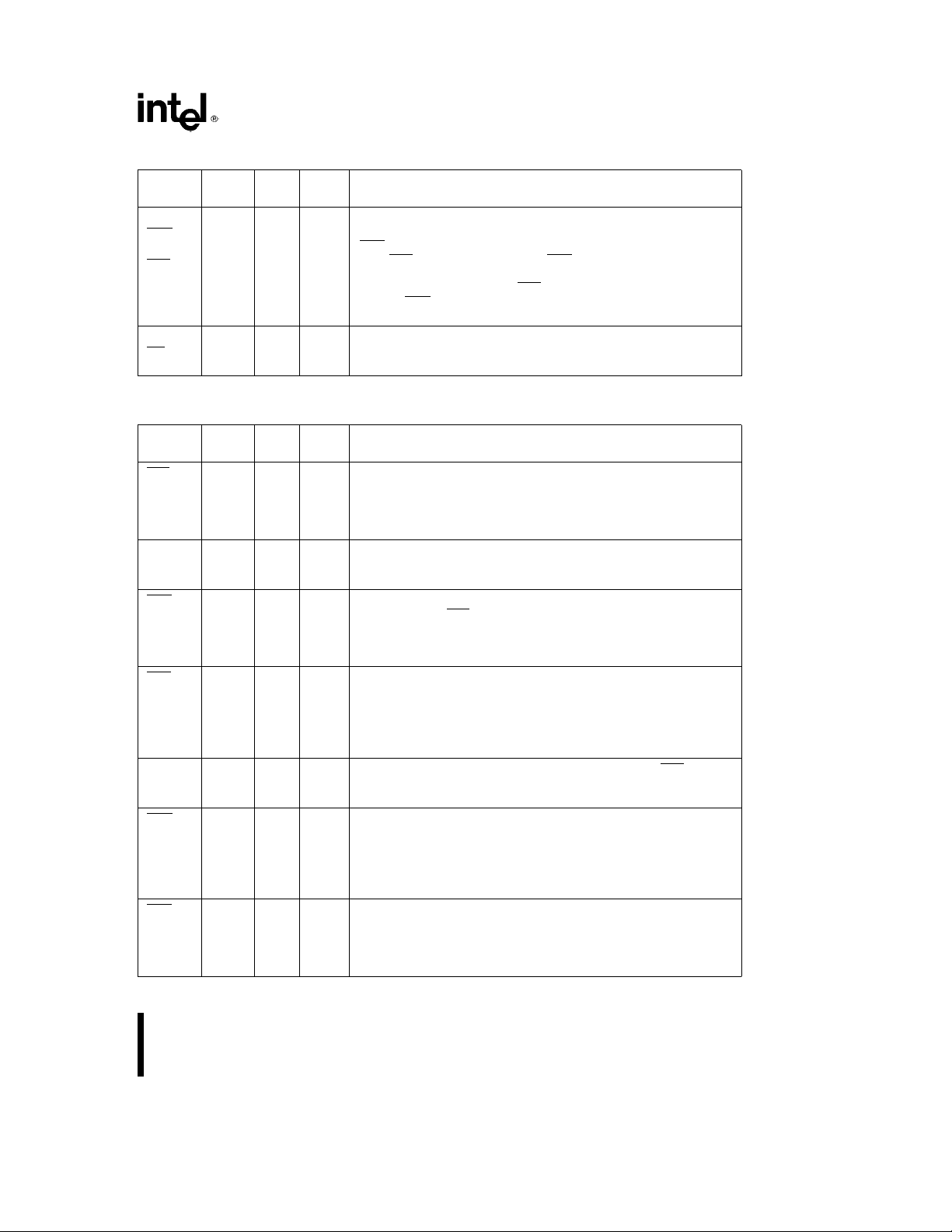

82503

290421– 2

Figure 2. 82503 Functional Block Diagram

4

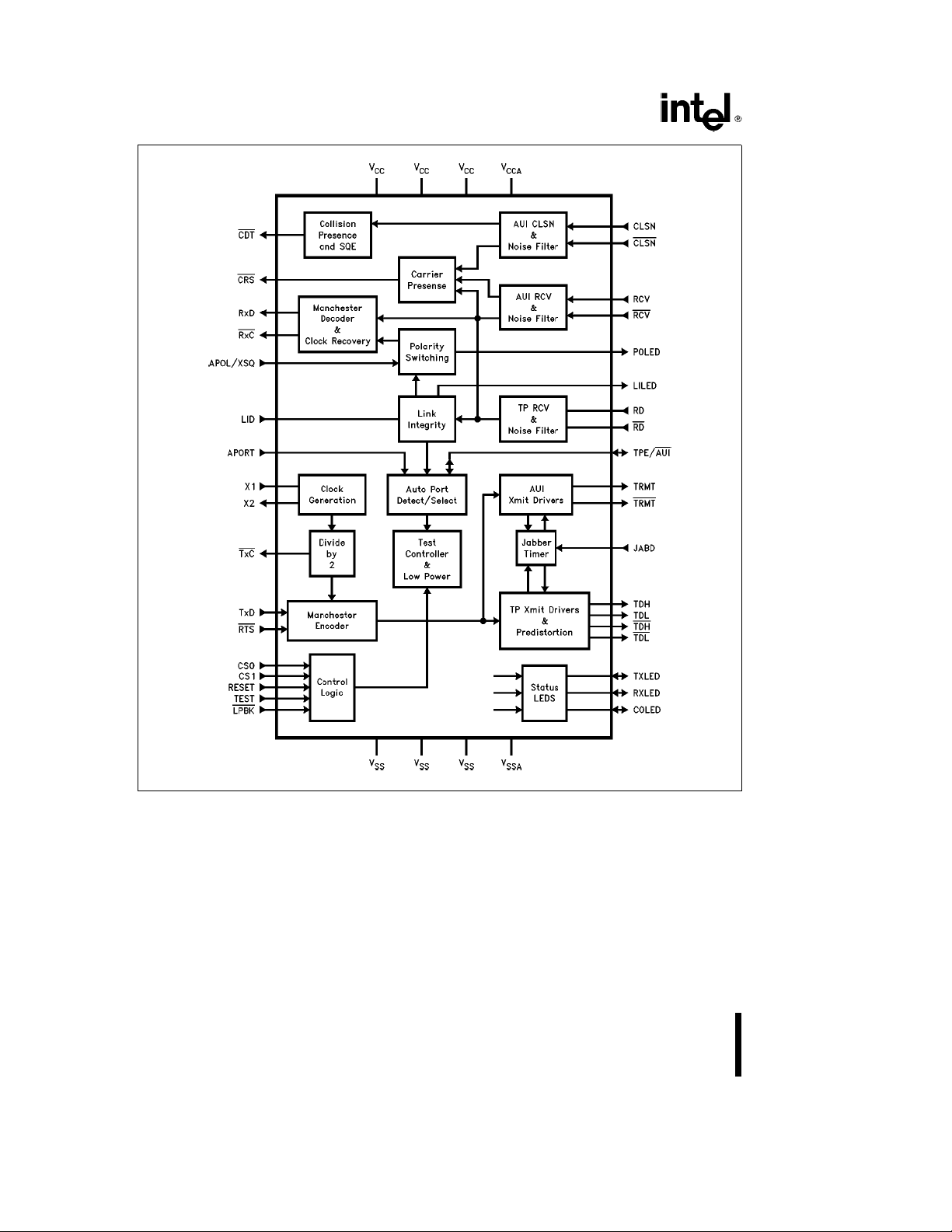

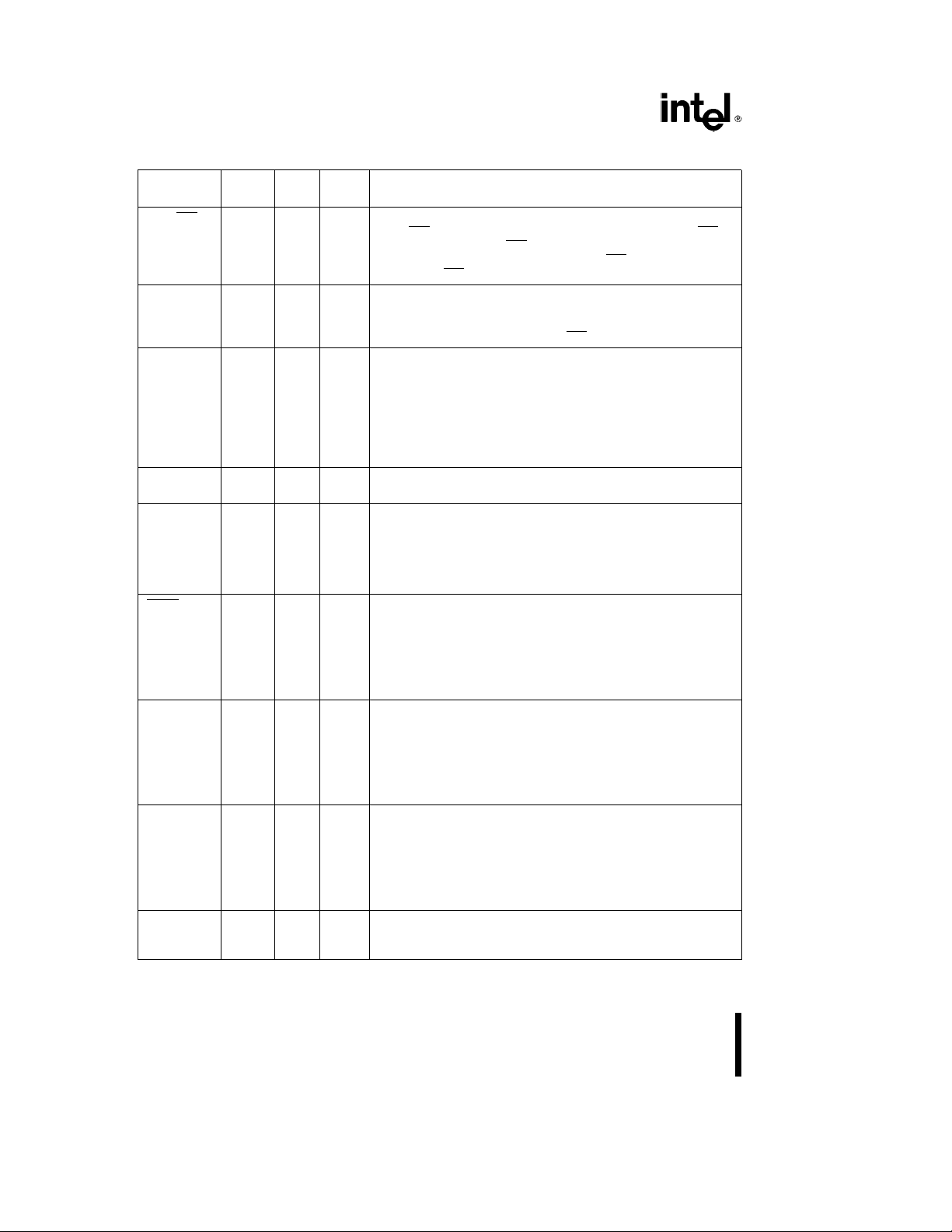

Page 5

2.0 PIN DEFINITION

82503

290421– 3

Figure 3. 44-Lead PLCC Pin Configuration

Figure 4. 44-Lead QFP Pin Configuration

290421– 44

5

Page 6

82503

2.1 Power Pins

Symbol

(1)

V

SS

(1)

V

CC

(1)

V

CCA

(1)

V

SSA

NOTE:

and V

1. V

CC

Separate decoupling and noise conditioning (e.g., ferrite beads) should be used.

PLCC QFP

Pin Pin

Type Name and Function

7, 17, 39 1, 11, 33 Supply Digital Ground.

6, 18, 40 44, 12, 34 Supply Digital VCC. A 5-Vg5% Power Supply.

28 22 Supply Analog VCC. A 5-Vg5% Power Supply.

29 23 Supply Analog Ground.

must be connected to the same power supply. VSSand V

CCA

must be connected to the same ground.

SSA

2.2 Clock Pins

Symbol

X1 21 15 I CLOCK CRYSTAL. A 20 MHz crystal input. This pin can be driven

X2 20 14 O CLOCK CRYSTAL. A 20 MHz crystal output. X1 can be driven with

PLCC QFP

Pin Pin

Type Name and Function

with an external MOS level clock when X2 is left floating.

an external MOS level clock when this pin is left floating.

2.3 AUI Pins

Symbol

TRMT 27 21 O TRANSMIT PAIR. A differential output driver pair that drives the

TRMT

RCV 31 25 I RECEIVE PAIR. A differentially driven input pair which is tied to the

RCV

CLSN 25 19 I COLLISION PAIR. A differentially driven input pair tied to the

CLSN

PLCC QFP

Pin Pin

26 20 O

30 24 I

24 18 I

Type Name and Function

transmit pair of the transceiver cable. The output bit stream is

Manchester encoded. Following the last transition, which is positive

at TRMT, the differential voltage is reduced to zero volts.

receive pair of the Ethernet transceiver cable. The first transition on

RCV is negative-going to indicate the beginning of the frame. The

last transition is positive-going to indicate the end of the frame. The

received bit stream is assumed to be Manchester encoded.

collision presence pair of the Ethernet transceiver cable. The

collision presence signal is a 10 MHz square wave. The first

transition at CLSN is negative-going to indicate the beginning of the

signal; the last transition is positive-going to indicate the end of the

signal.

6

Page 7

2.4 TPE Pins

Symbol

TDH 35 29 O TP TRANSMIT PAIR DRIVERS. These four outputs constitute the

TDH

TDL 34 28 O

TDL

RD 32 26 I TP RECEIVE PAIR. The differential twisted pair receiver. The

RD

PLCC QFP

Pin Pin

37 31 O

36 30 O

33 27 I

Type Name and Function

twisted-pair drivers, which have predistortion capabilities. The TDH/

TDH outputs generate the 10 Mb/s Manchester Encoded data. The

TDL/TDL

occurrences (100 ns pulses). During the second half of a fat bit

(either high or low), the TDL/TDL outputs are inverted with respect

to TDH/TDH

jitter by preventing overcharge on the twisted pair medium.

receiver pair is connected to the twisted pair medium and is driven

with 10 Mb/s Manchester encoded data.

outputs mirror the TDH/TDH outputs except for fat bit

outputs. This signal behavior reduces the amount of

2.5 Controller Interface Pins

Symbol

TxC 93OTRANSMIT CLOCK. A 10 MHz clock output tied directly to the

TxD 16 10 I TRANSMIT DATA. TTL input. NRZ serial data is clocked in on TxD

RTS 15 9 I REQUEST TO SEND. TTL input. An active low input signal

RxC 14 8 O RECEIVE CLOCK. A 10 MHz clock output tied directly to the

RxD 13 7 O RECEIVE DATA. Received NRZ data (synchronous to RxC) passed

CRS 10 4 O CARRIER SENSE. Output that alerts the Ethernet controller that

CDT 12 6 O COLLISION DETECT. Output that indicates presence of a collision.

PLCC QFP

Pin Pin

Type Name and Function

transmit clock pin of the Ethernet controller. Changes sense

depending on controller selected. Active low for Intel and Fujitsu

controller interfaces, active high for National and AMD interfaces.

Can drive one TTL load.

from the Ethernet controller. Connects directly to the transmit data

pin of the Ethernet controller.

synchronous to TxC

port. Changes sense depending on controller selected. Active low

for the Intel controller interface, active high for National, AMD, and

Fujitsu interfaces.

receive clock pin of the Ethernet controller. This clock is the

recovered clock from incoming data on the active port. Changes

sense depending on controller selected. Active low for Intel and

Fujitsu controller interfaces, active high for National and AMD

interfaces. Can drive one TTL load.

to the Ethernet controller. Connect directly to the receive data pin of

the controller. Can drive one TTL load.

data is present on the active port. Connects directly to the carrier

sense pin of the Ethernet controller. Changes sense depending on

controller mode selected. Active low for Intel controller interface,

active high for National, AMD, and Fujitsu interfaces. Can drive one

TTL load.

Connects directly to the collision detect pin of the Ethernet

controller. Changes sense depending on controller selected. Active

low for Intel and Fujitsu controller interfaces, active high for National

and AMD interfaces. Can drive one TTL load.

which enables data transmission on the active

82503

7

Page 8

82503

2.6 Mode Pins

Symbol

TPE/AUI 2 40 I/O PORT SELECT. TTL input/LED output. If APORT is low,

APORT 3 41 I AUTOMATIC PORT SELECTION. TTL input. When high, 82503

APOL/XSQ 4 42 I AUTOMATIC POLARITY CORRECTION/EXTENDED

LID 38 32 I LINK INTEGRITY DISABLE. TTL input. If high, link integrity

CS0 5 43 I CONTROLLER SELECT. Selects the appropriate interface for

CS1 8 2 I

LPBK 11 5 I LOOPBACK. TTL input. An active low input signal that causes

JABD 23 17 I JABBER DISABLE. TTL input. When high, this pin disables the

TEST 19 13 I TEST MODE ENABLE. TTL input. When TEST is high and

RESET 22 16 I RESET. TTL input. When high, resets internal circuitry. On the

PLCC QFP

Pin Pin

Type Name and Function

TPE/AUI

high) or AUI port (TPE/AUI low). If APORT is high, the 82503 will

indicate the port selected by driving TPE/AUI

(AUI). TPE/AUI

will automatically select TPE or AUI port based on presence of

valid link beats or frames on the TPE receive input. Mode

selected will be indicated on TPE/AUI

SQUELCH ENABLE. TTL input. When high, the extended

squelch mode is disabled and automatic polarity correction is

enabled. Both junctions (APOL and XSQ) are enabled when this

pin is at a high impedance state. When low, both functions

become disabled. The presence of a polarity fault on the TPE

receive pair is indicated on POLED regardless of the state of

APOL.

function is disabled. If low, link integrity function is enabled.

the desired Ethernet controller. When CS0/1

Intel controllers. When CS0/1

controllers. When CS0/1

National controllers. When CS0/1

controllers. (See Table 2.)

the 82503 to enter diagnostic loopback mode. The twisted pair

or AUI medium will be removed from the circuit, thus isolating

the node from the network. When not connected, this pin

assumes the inactive (high) state. Diagnostic loopback does not

disable the operation of the link integrity processor, link beat

generator, or automatic port selection.

jabber function. When low, the jabber function is enabled and

the device performs AUI or TP jabber protection for the active

port. If this pin and TEST are asserted during a falling edge of

RESET, the 82503 enters its low power mode; when either this

pin or TEST deasserts, then the 82503 transitions to its normal

operating mode.

RESET is deasserted, a customer test mode is directly

accessed. When driven low, test mode is disabled. If this pin and

JABD are asserted during a falling edge of RESET, the 82503

enters its low power mode; when either this pin or JABD

deasserts, then the 82503 transitions to its normal operating

mode.

falling edge of RESET, either test mode or low power mode can

be entered depending on the state of JABD and TEST.

is an input and selects either the TPE port (TPE/AUI

can drive an LED pull-up.

.

e

0/1, supports Fujitsu

e

1/0, supports Western Digital and

e

1/1, supports AMD

high (TPE) or low

e

0/0, supports

8

Page 9

2.7 LED Pins

Symbol

TxLED 42 36 I/O TRANSMIT LED. LED output. Indicates transmit status of the AUI or

RxLED 43 37 I/O RECEIVE LED. LED output. Indicates receive status of the AUI or

COLED 44 38 I/O COLLISION LED. LED output. Indicates collision status of the AUI

LILED 41 35 O LINK INTEGRITY LED. LED output. Normally on (low) output which

POLED 1 39 O POLARITY INDICATION. LED output. If the 82503 detects that the

PLCC QFP

Pin Pin

Type Name and Function

TPE port. Normally off (high) output. Turns on to indicate

transmission. Flashes at a rate dependent on the level of transmit

activity. Upon entering a customer test mode, this pin must be

driven high either through an LED, or a resistor.

TPE port. Normally off (high) output. Turns on to indicate reception.

Flashes at a rate dependent on the level of receive activity. Upon

entering a customer test mode, this pin must be driven high either

through an LED, or a resistor.

or TPE port. Normally off (high) output. Turns on to indicate

collision. Flashes at a rate dependent on the level of collision

activity. This pin is also used to determine which customer test

modes are entered.

indicates good link integrity on the TPE port during TPE mode.

Remains on when link integrity function has been disabled. Turns off

during AUI mode or when link integrity fails in TPE mode. Minimum

off time is 100 ms, minimum on time is set by the link integrity

function.

receive TPE wires are reversed, POLED will turn on (low) to indicate

the fault. POLED remains on even if APOL/XSQ is high and the

82503 has automatically corrected for the reversed wires.

82503

NOTE:

1. The LED outputs have a weak pull-up capable of sourcing 500 mA. They can sink 10 mA while still meeting TTL levels. All

LEDs can be used as indication pins if no LED is needed. Some of these outputs include pulse width conditioning, which

should be accounted for in software.

9

Page 10

82503

3.0 82503 ARCHITECTURE

3.1 Clock Generation

A 20 MHz parallel resonant crystal is used to control

the clock generation oscillator, which provides the

basic 20 MHz clock source. An internal divide-bytwo counter generates the 10 MHz

required by the IEEE 802.3 specification.

We recommend a crystal that meets the following

specifications be used.

Quartz Crystal

#

20 MHzg0.002% at 25§C

#

Accuracyg0.005% over full operating tempera-

#

ture, 0

Ctoa70§C

§

Parallel resonant with 20 pF Load Fundamental

#

Mode

Maximum Series Resistance: R

#

Several vendors have such crystals; either-off-the

shelf or custom made. Two possible vendors are:

1. M-Tron Industries, Inc.

Yankton, SD 57078

Specifications;

Part No. HC49 with 20 MHz, 50 PPM over 0

a

70§C, and 20 pF fundamental load.

2. Crystek Corporation

100 Crystal Drive

Ft. Myers, FL 33907

Part No. 013212

The accuracy of the Crystal Oscillator frequency depends on the PC board characteristics, therefore it is

advisable to keep the X1 and X2 traces as short as

possible. The optimum value of C1 and C2 should

be determined experimentally under nominal operating conditions. The typical value of C1 and C2 is

between 22 pF and 35 pF.

An external 20 MHz MOS-level clock may be applied

to pin X1, if pin X2 is left floating.

g

0.01% clock

SERIES

e

30X

Cto

§

3.2 Transmit Blocks

3.2.1 MANCHESTER ENCODER

The 20 MHz clock is used to Manchester-encode

data on the TxD input. This clock is also divided by

two to produce the 10 MHz clock the LAN controller

needs for synchronizing its RTS

Data encoding and transmission begins with RTS

asserting. Since the first bit of a transmission is a 1,

the first transition is always negative on the transmit

outputs (TRMT or TD pins). Transmission ends

when RTS

positive at the transmit outputs (TRMT or TD pins)

and may occur at the center of the bit cell if the last

data bit to be transmitted is a 1, or at the boundary

of the bit cell if the last data bit to be sent is a 0.

Immediately after the end of a transmission, all signals on the RCV pair (when AUI mode is selected)

are inhibited for 4 to 5 ms. This dead time is necessary for proper operation of the SQE (heartbeat)

test.

3.2.2 AUI CABLE DRIVER

The AUI cable driver (TRMT pair) is a differential

circuit, which interfaces to the AUI cable through a

pulse transformer.

High voltage protection is achieved by using a transformer to isolate the transmit pins (TRMT pair) from

the transceiver cable. The total transmit circuit inductance, including the 802.3 transceiver transformers, should be a minimum of 27 mH for Ethernet applications.

3.2.3 TWISTED PAIR CABLE DRIVER

The twisted pair line drivers (TD pairs) begin transmitting the serial Manchester bit stream 3 bit times

after RTS

tortion algorithm to improve jitter performance for up

to 100 meters of twisted pair cable. The line drivers

reduce their drive level during the second half of

‘‘fat’’ (100 ns) Manchester pulses and maintain a full

drive level during all ‘‘thin’’ (50 ns) pulses and during

the first half of the ‘‘fat’’ pulses. This reduces line

overcharging during ‘‘fat’’ pulses, a major source of

jitter.

deasserts. The last transition is always

is asserted. The line drivers use a predis-

and TxD signals.

10

Page 11

Figure 5. TPE Predistortion

82503

290421– 4

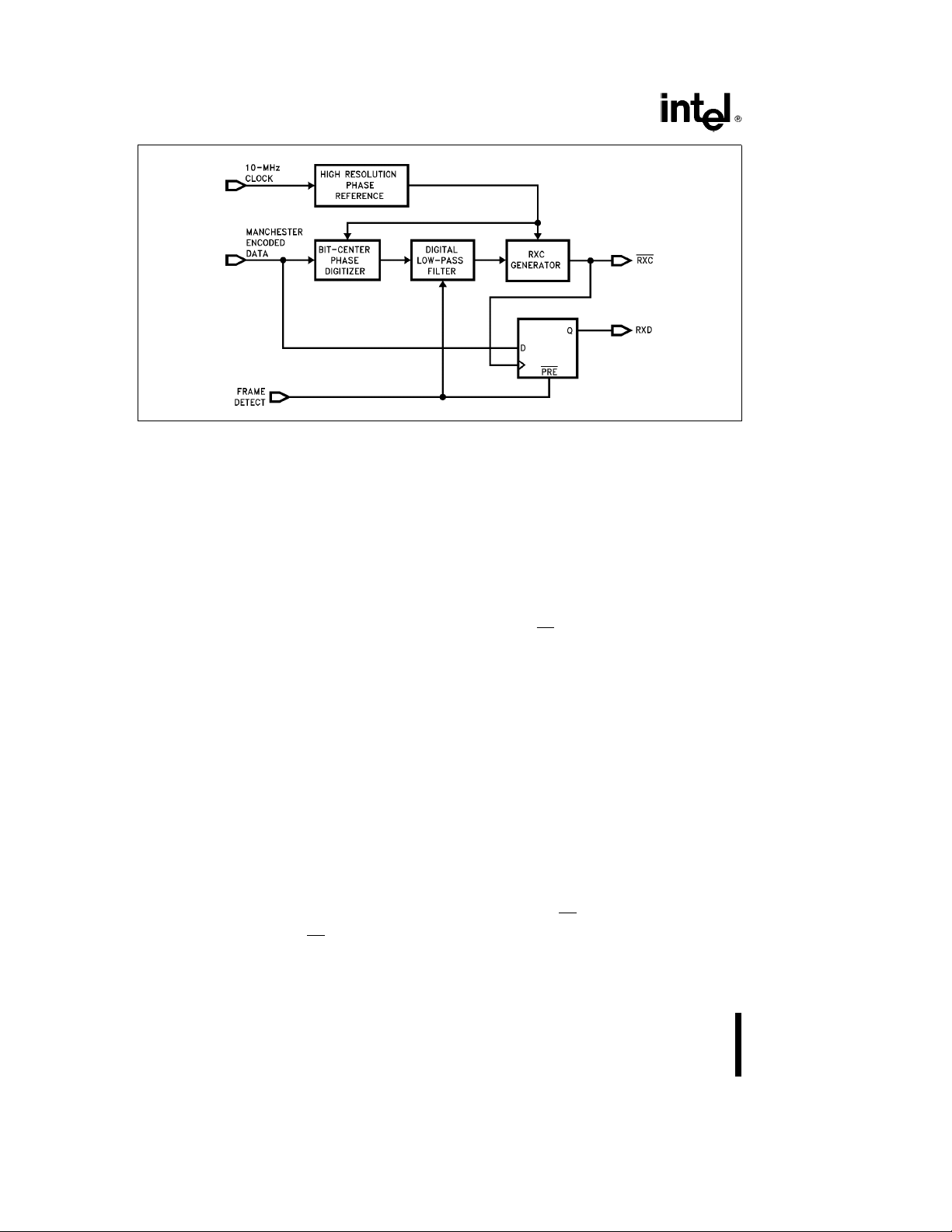

3.3 Receive Blocks

3.3.1 MANCHESTER DECODER AND CLOCK

RECOVERY

The 82503 performs Manchester decoding and timing recovery of the incoming data in AUI and TPE

modes.

The Manchester-encoded data stream is decoded to

separate the Receive Clock (RxC

Data (RxD) from the differential signal. The 82503

uses an advanced digital technique to perform the

decoding function. The use of digital circuitry instead

of analog circuitry (e.g., a phase-lock loop) to perform the decoding ensures that the decoding function is less sensitive to variations in operating conditions.

A high-resolution phase reference is used to digitize

the phase of the incoming data bit-center transition.

The digitizer has a phase resolution of 1/32 of a bit

time.

) and the Receive

The digitized phase is filtered by a digital low-pass

filter to remove rapid phase variations, i.e., phase

jitter. Slow phase variations, such as those caused

by small differences between the data frequency

and the clock frequency, are not filtered by the lowpass filter.

The RxC generator digitally sets the phases of the

two RxC

bit-center transition by (/4 bit time. RxC

transitions to respectively lead and lag the

is used to

recover RxD by sampling the incoming data with an

edge-triggered flip-flop.

Lock is achieved by reducing the time constant of

the digital filter to zero at the start of a new frame.

Any uncertainty in the bit-center phase of the first

transition that is caused by jitter is subsequently removed by gradually increasing the filter time constant during the following preamble. By that time, the

phase of the bit center is output by the filter, and

lock is achieved. Lock is achieved within the first 14

bit times as seen by the AUI inputs. The maximum

bit-cell timing distortion (jitter) tolerated by the Manchester decoder circuitry is

g

18 ns (data) for AUI, andg13.5 ns for TPE (data

g

12 ns (preamble),

and preamble).

11

Page 12

82503

290421– 5

Figure 6. Manchester Decoder and Clock Recovery

3.3.2 AUI RECEIVE AND COLLISION BUFFERS

The AUI receive and collision inputs are driven

through isolation transformers to provide high voltage protection and DC common mode voltage rejection. The incoming signals are converted to digital

levels and passed to the Manchester decoder and

collision detection circuitry.

3.3.3 AUI RECEIVE AND COLLISION SQUELCH CIRCUITS

Both the receive (RCV) and collision (CLSN) pairs

have the following squelch characteristics.

The squelch circuits are turned on at idle.

#

A pulse is rejected if the peak differential voltage

#

is more positive than

pulse width.

A pulse is considered valid if its peak differential

#

voltage is more negative than

width, measured at

25 ns.

The squelch circuits are disabled by the first valid

#

negative differential pulse on either the AUI receive (RCV) or the AUI collision (CLSN) pair.

If a positive differential pulse occurs on either the

#

AUI receive or collision pairs for greater than

160 ns, End of Frame (EOF) is assumed and the

squelch circuitry is turned on.

3.3.4 TPE RECEIVE BUFFER

The TPE receive pins (RD and RD

the twisted pair medium through an analog front

end. The analog front end contains the line coupling

b

160 mV regardless of

b

b

285 mV, is greater than

300 mV and its

) are connected to

devices and EMI filters necessary to conform to the

10BASE-T standards and local RF regulations. The

input differential voltage range for the TPE receiver

is greater than 500 mV and less than 3.1V differential.

3.3.5 TPE RECEIVE SQUELCH CIRCUITS

The TPE receive buffer distinguishes valid receive

differential data, link test pulses, and the idle condition according to the requirements of the 10BASE-T

standard. Signals at the output of the EMI filter (thus

at the RD and RD

All differential pulses of peak magnitude less than

#

300 mV are rejected.

All continuous sinusoids with a differential ampli-

#

tude less than 6.2 V

2 MHz are rejected.

All sine waves of single cycle duration starting

#

with phase 0

than 6.2 V

16 MHz are rejected, if the single cycle is preceeded and followed by 4 bit times of silence

(i.e., a signal less than 300 mV).

3.3.6 TPE Extended Squelch Mode

By placing the 82503 into TPE extended squelch

mode, the 82503 can support cable lengths greater

than the 100m specified in the 10Base-T IEEE standard (802.3i-1990). The squelch thresholds for the

signals at the RD/RD

4.5 dB. This allows Grade 5 twisted-pair cable to be

used to overcome attenuation and multipair crosstalk for cable lengths up to 200 meters.

pair) are rejected as follows:

and a frequency less than

PP

or 180§that have an amplitude less

§

, and a frequency of 2 MHz to

PP

pair are typically reduced by

12

Page 13

82503

TPE extended squelch mode is enabled by presenting a high-impedance (

pin. This can be done by floating the APOL/XSQ pin,

tying APOL/XSQ low through a 100 KX resistor, or

driving APOL/XSQ with a three-state buffer. When

driven high or low using a TTL driver or a low impedance pull-up or pull-down (

squelch is disabled and the driven level at the

APOL/XSQ pin determines the state of the polaritycorrection function (APOL/XSQ

ty correction, APOL/XSQ

rection). The TPE extended squelch feature is transparent to previous steppings of the 82503. Polarity

correction is always enabled when the TPE extended-squelch feature is enabled (APOL/XSQ

The APOL/XSQ pin senses a high-impedance state

by an active-polling circuit implemented at the pin.

Two small polling devices attempt to pull the APOL/

XSQ pin up to V

high-impedance state, the devices will be successful

in pulling the APOL/XSQ pin high and low. If the pin

is driven high or low, the polling devices will not be

able to successfully pull the pin in the opposite direction. In this way, an internal state machine can

correctly determine one of three states of the

APOL/XSQ pin. The pin is polled every 25.6 ms.

l

100 KX) at the APOL/XSQ

k

2KX) extended

e

e

and down to VSS. If the pin is in a

CC

1 enables polari-

0 disables polarity cor-

e

Z).

3.4 Collision Detection

3.4.1 AUI COLLISION DETECTION

Collision detection in the AUI mode is performed by

the attached transceiver, and signalled to the 82503

on the CLSN pair. A 10 MHz

square wave with transition times between 35 ns

and 70 ns indicates the collision. The 82503 reports

this to the LAN controller on the CDT

a

25%, orb15%,

pin.

to the twisted pair medium as an indication to the

remote MAU that the link is good. These pulses will

be transmitted 8 ms to 24 ms after the end of the

last transmission or link test pulse.

The link integrity function continuously monitors activity on the receive circuit. If neither valid data nor

link test pulses are received, the link integrity processor declares the link bad, and disables transmission and reception on the media, loopback, and the

SQE test function. Transmission of link test pulses

and monitoring receive activity are not affected. The

idle time required for the link integrity processor to

determine the link is bad is 50 ms to 150 ms.

Once a frame or a sequence of 2 to 10 valid consecutive link test pulses are detected, the Link Integrity

Processor declares the link is good, and reconnects

the transmitter and receiver.

The link integrity function can be disabled by driving

the LID pin high or by disabling automatic port selection (APORT

option is intended primarily for use with pre10BASE-T networks.

e

0) and selecting the AUI port. This

3.6 Jabber Function

The 82503 contains a jabber timer to implement the

jabber function. If a transmission continues beyond

the limits specified, the jabber function inhibits further transmission and asserts the collision indicator,

CDT. The limits for jabber transmission are 20 ms to

150 ms in TPE Mode, and 8 ms to 16 ms in AUI

mode. For both AUI and TPE mode, the transmission inhibit period extends until the 82503 detects

sufficient idle time (between 250 ms and 750 ns) on

the RTS

by driving the JABD high.

signal. The jabber function can be disabled

3.4.2 TPE COLLISION DETECTION

Collision detection in the TPE mode is indicated by

simultaneous transmission and reception on the

twisted pair link segment. The CDT

ed for the duration of both RTS

received data; CRS

either RTS

a collision, the source of RxD will be the received

data. If the received data stream ends before the

transmit data stream, the RxD source will be

changed to transmit data stream until it ends.

or the presence of received data. During

is asserted for the duration of

signal is assert-

and the presence of

3.5 Link Integrity

The 82503 supports the link integrity function as defined by 10BASE-T. During long periods of idle on

the transmitter, link test pulses will be transmitted on

In TPE mode the link integrity function continues to

operate even if the jabber function is inhibiting transmission. Link test pulses continue to be sent and the

receive circuit continues to be monitored. Additionally, the link integrity function reconnects to a restored

link without waiting for the transmit input to go idle

when the jabber function is inhibiting transmission.

3.7 TPE Loopback

In TPE mode the 82503 implements the transmit to

receive loopback (DO to DI) mode specified in the

10BASE-T standard. This mode loops back transmitted data through the receive path.

This function is required to maintain full compatibility

with coax MAUs where the data loopback is a natural result of the architecture.

13

Page 14

82503

The transmit to receive loopback function is disabled

when the jabber function or link integrity function is

inhibiting transmission.

3.8 SQE Test Function

The 82503 supports the SQE test function when in

TPE mode or in Diagnostic Loopback mode. The

82503 will assert its CDT

pin within 0.6 msto1.6ms

after the end of a transmission, and it will remain

asserted for 5- to 15-bit times. If the 82503 is in the

TPE mode and is not in diagnostic loopback mode,

the link integrity function will disable the SQE test

function when it detects a bad link.

3.9 Port Selection

The 82503 features both manual and automatic port

selection. To enable automatic port selection, connect APORT to V

mode and monitors link integrity. If the link is good,

the 82503 stays in TPE mode and pulls TPE/AUI

high to indicate that the TPE port was selected. If

link integrity fails, the 82503 switches to AUI mode

and pulls TPE/AUI

is now active. TPE/AUI

port selection (on for AUI, off for TPE mode). Note

that LILED will be on if TPE mode is selected and off

if AUI mode is selected. If link integrity is disabled

while automatic port selection is enabled, the 82503

defaults to TPE mode. If the 82503 changes ports

while RTS

is active, transmission is terminated with

an End of Frame marker on the old port. Transmission of the remaining packet fragment is not allowed

on the new port. Transmissions will begin with a

complete data packet.

The port can be manually selected by driving

APORT low. TPE/AUI

TPE/AUI

e

selected, the circuitry for the unused port is powered

down. Changing ports requires 100 ms to allow the

circuitry for the new port to resume normal operation.

Configuration

LID APORT TPE/AUI

X 0 0 AUI (TPE Port Powered Down)

X 0 1 TPE (AUI Port Powered Down)

01 X*Automatic Port Selection

11 X*TPE

. The 82503 then starts in TPE

CC

low to indicate that the AUI port

can drive an LED to indicate

e

0 selects AUI mode, and

1 TPE mode. When the port is manually

Table 1. Port Selection

State

3.10 LED Description

The 82503 supports six LED pins to indicate the

status of important states; TPE/AUI

POLED, LILED, RxLED, COLED. Each pin is capable

of directly driving an LED.

3.10.1 TPE/AUI

When automatic port selection is enabled (APORT is

high), TPE/AUI

becomes an LED output and turns

off if TPE mode is selected and on if AUI mode is

selected.

3.10.2 TxLED

Transmit status. This LED is normally off and flashes

at 2.5 Hz, 5 Hz, and 10 Hz to indicate respectively a

low, medium, and high rate of transmit activity.

3.10.3 RxLED

Receive LED. This LED is normally off and flashes at

2.5 Hz, 5 Hz, and 10 Hz to indicate respectively a

low, medium, and high rate of receive activity.

3.10.4 COLED

Collision LED. This LED is normally off and flashes

at 2.5 Hz, 5 Hz, and 10 Hz to indicate respectively a

low, medium, and high rate of collision activity.

3.10.5 POLED

Polarity Fault. This LED is normally off and turns on

to indicate a polarity fault in the receive pair of the

10BASE-T link. Operation of this pin is not affected

by the state of the polarity correction function

(APOL/XSQ

e

X).

3.10.6 LILED

Link Integrity status. When Aport is enabled

(APORT

e

1), this LED is normally on (driven low)

to indicate the presence of a valid 10BASE-T link

when the TPE port is active. The LED will turn off

(driven high) when the link fails. When link integrity is

disabled (LID

(APORT

APORT is disabled (APORT

manually selected (TPE/AUI

e

e

1) while APORT is enabled

1) this LED is turned on (driven low). If

e

0) and the AUI port is

e

0) the LED output is

tristated.

, TxLED,

NOTE:

*TPE/AUI

14

is an output pin when APORTe1.

3.11 Polarity Switching

In TPE mode, the 82503 monitors receive link beats

and end-of-frame delimiters for a possible receiver

Page 15

Figure 7. Polarity Fault State Diagram

82503

290421– 6

polarity error due to crossed wires. If Pin 4 of the

82503 is high and the TPE receive pins are reversed, the 82503 will correct the error by reversing

the signals internally, and turn POLED on (low) to

indicate that the fault has been detected and corrected. The polarity correction function is defeatable

by driving the APOL/XSQ input low. However, the

polarity fault will continue to be indicated on the

POLED.

3.12 Controller Interface

Connecting the 82503 to one of the Intel Ethernet

controllers (82586, 82590, 82593, 82596) requires

no additional components. Simply drive CS0 and

CS1 both low, and connect TxC

RxD, CRS

controller pins.

, CDT, and LPBK

, TxD, RTS, RxC,

to the corresponding

The 82503 also works with other Ethernet controllers without additional components, including the

National Semiconductor 8390 and 83932 (SONIC),

Western Digital 83C690, Fujitsu 86950 (Etherstar),

depending on the state of and CS0 and CS1 inputs.

The interface of the 82503 to the AMD 7990

(LANCE) requires external logic to control the LPBK

pin of the 82503. Note that when an AMD LAN controller is used to interface to the 82503, the LPBK

pin of the 82503 becomes active high. That is, the

82503 enters diagnostic loopback mode when LPBK

pin is high and is in normal operation mode when

pin is low.

LPBK

The logic sense of the 82503 controller pins will

change and should be connected to the controller

pins according to the following table.

15

Page 16

82503

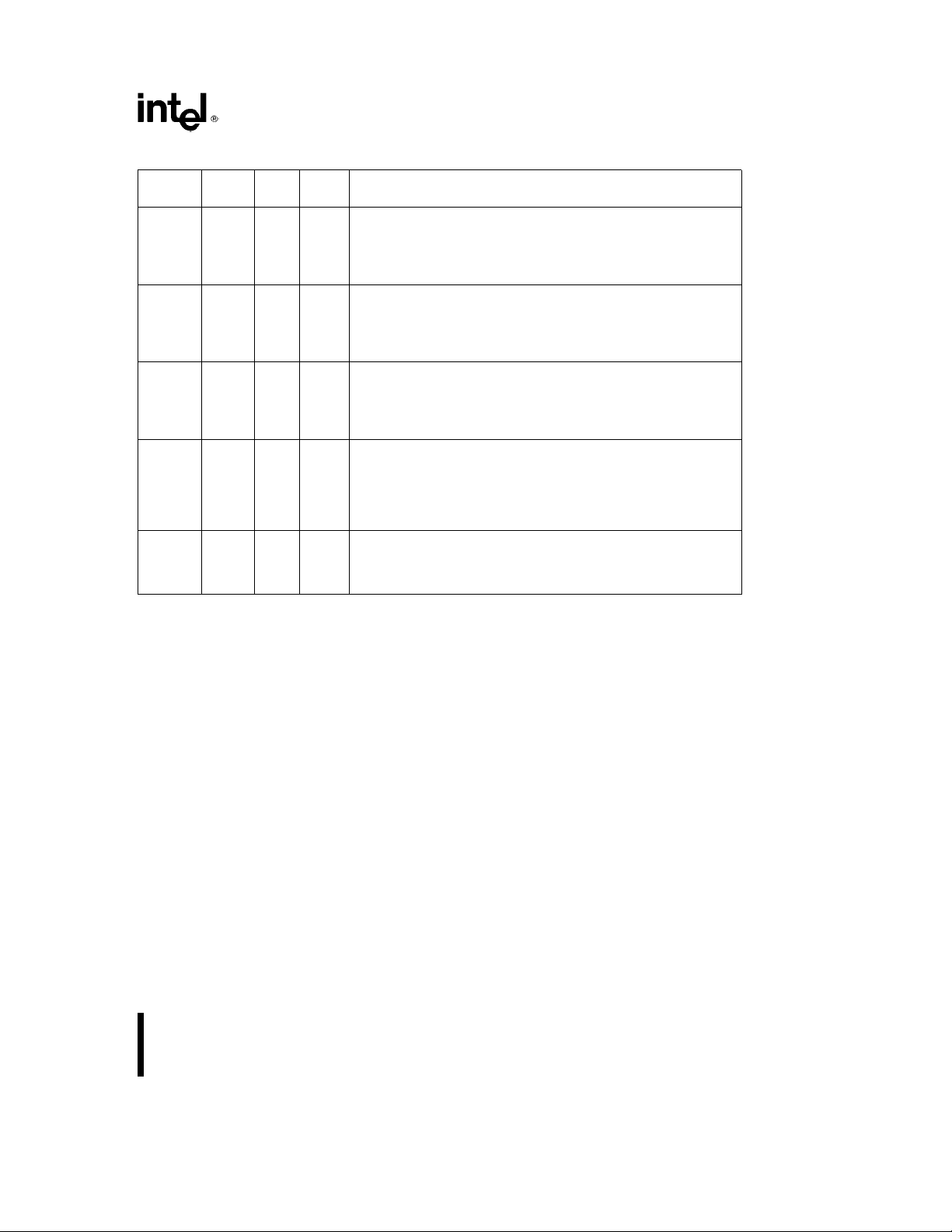

Table 2. Controller Interface Selection

82503

Pin

(1)

CS0

CS1 0 0 1 1

Pin Pin Sense Pin Sense Pin Sense Pin Sense

TxC TxC Low TXC High TCLK High TCKN Low

TxD TxD High TXD High TX High TXD High

RTS

RxC

RxD RxD High RXD High RX High RXD High

CRS

CDT CDT Low COL High CLSN High XCOL Low

LPBK LPBK Low LPBK High LPBK High

NOTES:

1. CS0 and CS1 are intended to be static pins only. Switching CS0 and CS1 during network reception or transmission will

produce unpredictable results.

2. Refer to Section 3.12.

Intel

Controller

825XX

011 0

RTS Low TXE High TENA High TEN High

RxC Low RXC High RCLK High RCKN Low

CRS Low CRS High RENA High XCD High

National, WD AMD

Controllers Controller

8390, 83C690, 7990 (LANCE),

83832 (SONIC) 79C900 (ILACC)

(Note 2)

Fujitsu

Controllers

86950 (Etherstar)

4.0 RESET, LOW-POWER AND

TEST MODES

4.1 Reset

When RESET is asserted the device resets its internal circuits. RESET is required after power up, and

before data can be transmitted or received. It is allowed any time thereafter, but any existing receive or

transmit activity will be lost, and all state machines

(Link integrity, Jabber, and Polarity Correction) return to their initial states. TEST must be held low for

a device reset to prevent entering a test for low power mode. During RESET, TxC

terruption (in Fujitsu mode both TxC

continuously).

continues without in-

and RxC run

4.2 Low Power and High Impedance

Modes

When RESET is deasserted while both TEST and

JABD are held high, the 82503 enters its low power

and high impedance modes. The majority of internal

circuitry is powered down, and many inputs and outputs are three-stated. These pins are: APORT,

APOL/XSQ, LID, TPE/AUI

, RxD, TxD, CRS and CDT. When either JABD

LPBK

or TEST is deasserted, the device begins a power

on cycle which lasts less than 1 ms. During this cycle, all inputs are ignored and all transmissions are

disabled. If RTS

normal operation, the remainder of that packet fragment is not transmitted. Normal transmissions are

resumed at the start of the first complete data packet.

is active when the device returns to

, POLED, LILED, RTS,

4.3 Diagnostic Loopback

This is a diagnostic test mode to help in fault isolation and detection. Serial NRZ data input on TxD is

Manchester encoded and then looped back through

the Manchester decoder (TMD) appearing at the

RxD output. Collision detect is asserted following

each transmission to simulate the SQE test. Output

cable drivers and input amplifiers are disconnected

from the controller interface pins while in this mode.

The link integrity and polarity fault detection functions are not inhibited by diagnostic loopback mode.

If otherwise enabled, they continue to function.

4.4 Customer Test Mode (Continuous AUI/TPE Transmit)

In this mode, the 82503 continuously transmits data

without the intervention of a LAN controller. Transmission is at 10 MHz (11-bit pattern), and can occur

on either the TPE or AUI port. The jabber timer is

disabled in this mode, allowing users to easily test

the 10BASE-T harmonic content specification and

the quality of their analog front end design without

complex software exercisers.

Customer Test ModeÐand Low Power Mode are selected at the deassertion of RESET as shown in the

following table. (Note that the 82503 must be in nonloopback mode before it can enter the customer test

mode.)

16

Page 17

Table 3. Test and Low Power Mode Selection

RESET TEST JABD TxLED

v

v

v

NOTE:

1. A standard LED connection to these pins is sufficient to pull them to a logic 1.

0 X X X X Normal Mode

1 0 1 1 1 Cont Tx 10 MHz

1 1 X X X Low Power

(1)

RxLED

(1)

COLED

(1)

82503

Mode Selected

The port on which the continuous transmit appears

is determined by the APORT and TPE/AUI

automatic port selection is enabled (APORT

then the TPE port broadcasts the continuous transmit. If manual port selection is enabled (APORT

0), then TPE/AUI selects the port (1 for TPE, 0 for

AUI). Test mode is disabled when TEST is deasserted and the device is reset.

pins. If

e

5.0 APPLICATION EXAMPLE

5.1 Introduction

The 82503 is designed to work directly with the Intel

LAN controllers (82586, 82590, 82593, and 82596),

as well as AMD’s Am7990, National Semiconductor’s 8390, Western Digital’s 82C690, and Fujitsu’s

86950. The serial interface signals connect directly

between one of the aforementioned LAN controllers

and the 82503 without the need for external logic.

This example is targeted toward interfacing the

82503 to the Intel 82596 in a two-port (TPE/AUI)

application.

5.2 Design Guidelines

AUI Pulse Transformer

In order to meet the 16V fault tolerance specification

of 802.3 a pulse transformer is recommended for the

transmit, receive and collision pairs. The transformer

should be placed between the TRMT, RCV, and

CLSN pairs of the 503, and the DO, DI, and CI pairs

respectively, of the AUI (DB-15 connector). The

pulse transformer should have a parallel inductance

of 75 mH minimum (100 mH recommended).

Several vendors stock such transformers. Two possible vendors are:

1. Pulse Engineering (P/N PE-64103)

2. Valor Electronics (P/N LT6003)

Terminating Resistors

1)

The terminating resistors used across the receive

and collision pairs are recommended to be 78.7 X

e

g

1%.

Analog Front-End

The 82503 provides six TPE pins (TDH, TDH

, RD, and RD) that connect to the Analog Front

TDL

End through a resistor summing network (Figure 7).

AFE solutions can be made discretely or purchased

from several manufacturers. Two different solutions

are described in Application Note 356. The example

shown here uses a Pulse Engineering AFE package

PE65434 which includes EMI filter, isolation transformer, and common mode choke. The output of the

AFE connects directly to the 10BASE-T connector

(RJ-45).

Decoupling

It is recommended that 0.01 mF X7R and 0.001 mF

NPO decoupling capacitors be placed between the

V

and V

CCA

Clock Generation

The clock input to the 82503 can be from a clock

oscillator or a crystal. If a clock oscillator is used, X1

should be driven, and X2 left floating. If a crystal

oscillator is used, refer to Section 3.1 for crystal

specifications.

A complete 82596/82503 TPE/AUI Ethernet Solution is shown at the end of this section.

of the 82503 to V

CCD

SSA

5.3 Layout Guidelines

General

The analog section, as well as, the entire board itself

should conform to good high-frequency practices

and standards to minimize switching transients and

parasitic interaction between various circuits. To

achieve this, the following guidelines are presented.

and V

, TDL,

SSD

.

17

Page 18

82503

18

290421– 7

Figure 8. Application Example Schematic

Page 19

82503

Make power supply and ground traces as thick as

possible. This will reduce high-frequency cross coupling caused by the inductance of thin traces.

Connect logic and chassis ground together.

Separate and decouple all of the analog and digital

power supply lines.

Close signal paths to ground as close as possible to

their sources to avoid ground loops and noise cross

coupling.

Use high-loss magnetic beads on power supply distribution lines.

Crystal

The crystal should be adjacent to the 82503 and

trace lengths should be as short as possible. The X1

and X2 traces should be symmetrical.

82503 Analog Differential Signals

The differential signals from the 82503 to the transformers, analog front end, and the connectors

should be symmetrical for each pair and as short as

possible. Differential signal layout should be performed to a characteristic impedance of 78X (for

AUI) or 100X (for TPE).

As a general rule, the trace widths should be one to

three times the distance between the PCB layers to

eliminate excessive trace inductance.

The differential signals should also be isolated from

the high speed logic signals on the same layer as

well as on any sublayers of the PCB.

Group each of the circuits together, but keep them

separate from each other. Separate their grounds.

In layout, the circuitry from the connectors to the

filter network, should have the ground plane removed from beneath it. This will prevent ground

noise from being induced into the analog front end.

All trace bends should not exceed 45 degrees.

6.0 PACKAGE THERMAL

SPECIFICATIONS

The 82503 Dual Serial Transceiver is specified for

operation when case temperature (T

range of 0

Ctoa85§C. The case temperature can

§

be measured in any environment, to determine if the

82503 is within the specified operating range. The

case temperature should be measured at the center

of the top surface opposite the pins.

The acceptable operating ambient temperature (T

is guaranteed as long as T

bient temperature can be calculated from the i

is not violated. The am-

C

and ijcfrom the following equations:

e

T

T

T

a

T

J

J

A

Pci

C

e

T

A

e

T

C

a

b

Pci

Pc(i

jc

ja

b

ijc)

ja

Values for ijaand ijcare given in Table 4 for the 44lead PLCC and 44-lead QFP packages. Various values for i

maximum T

various airflows.

at different airflows. Table 5 shows the

ja

allowable (without exceeding TC)at

A

Table 4. Thermal Resistance

(

C/Watt) ijcand i

§

ijavs AirflowÐft/min (m/s)

Package ijc0 200 400 600 800 1000

44-Lead 19 57 48 43 41 39 37

PLCC

44-Lead 26 98 94 78 70 66 64

QFP

(0) (1.01) (2.03) (3.04) (4.06) (5.07)

Table 5. Maximum TAat Various Airflows

ijavs AirflowÐft/min (m/s)

Package 0 200 400 600 800 1000

44-Lead 66 71 73 74 75 76

PLCC

44-Lead 49 51 59 63 65 66

(0) (1.01) (2.03) (3.04) (4.06) (5.07)

QFP

) is within the

C

ja

)

A

ja

19

Page 20

82503

7.0 ELECTRICAL SPECIFICATIONS AND TIMINGS

ABSOLUTE MAXIMUM RATINGS

Case Temperature Under Bias ААААААА0§Ctoa85§C

Storage Temperature ААААААААААb65§Ctoa140§C

NOTICE: This is a production data sheet. The specifications are subject to change without notice.

*

WARNING: Stressing the device beyond the ‘‘Absolute

Maximum Ratings’’ may cause permanent damage.

These are stress ratings only. Operation beyond the

‘‘Operating Conditions’’ is not recommended and extended exposure beyond the ‘‘Operating Conditions’’

may affect device reliability.

All Output and Supply Voltages АААААb0.5V toa7V

All Input Voltages АААААААААААААb1.0V toa6.0V

DC CHARACTERISTICS (T

e

0§Ctoa85§C, V

C

(1)

CC

e

5Vg5%, V

CCA

e

5Vg5%)

Symbol Parameter Min Max Units Test Conditions

(2)

VIL(TTL)

VIH(TTL)

(2)

I

LI

VOL(MOS)

Input Low Voltage

(2)

Input High Voltage 2.0 V

Input Leakage Current

(3)

Output Low Voltage 0.45 V I

VOH(MOS) Output High Voltage 3.9 V I

VOL(LED)

(4)

Output Low Voltage 0.45 V I

VOH(LED) Output High Voltage 3.9 V I

I

R

V

LP

DIFF

IDF

(TPE)

Leakage Current, Low

Power Mode

Input Differential Resistance

(7)

Input Differential Accept

(5)

Input Differential Reject

Input Differential Accept (XSQ) (Note 8)

Input Differential Reject (XSQ)

(8)

RS(TPE)

V

(AUI)

IDF

Output Source Resistance 6 13 XlI

(9)

Input Differential Accept

Input Differential Reject

V

ODF

NOTES:

1. The voltage levels for RCV, CLSN, and RD pairs are

2. TTL Input Pins: TxD, RTS

3. MOS Output Pins: TxC

4. LED Pins: TPE/AUI

5. Pins: APORT, APOL/XSQ, LID, TPE/AUI

CDT

6. Pins: RD to RD

7. TPE Input Pins: RD, and RD

8. Typically it is

9. TPE Output Pins: TDH, TDH

10. AUI Input Pins: RCV, and CLSN pairs.

11. AUI Output Pins: TRMT pair.

(10)

(AUI)

, CS0, CS1, JABD, TEST, and RESET.

Output Differential Voltage

, TPE/AUI, APORT, APOL/XSQ, LID, CS0, CS1, LPBK, JABD, TEST, RESET.

, RxD, RxC, CRS, CDT.

, TxLED, RxLED, COLED, POLED, LILED. VOLmeasured 10 ns after falling edge of TxC.

, RCV to RCV, and CLSN to CLSN.

b

4.5 dB below normal squelch level.

. See Section 3.3.4 and Section 3.3.5.

, TDL, and TDL.RSmeasures VCCor VSSto Pin.

, POLED, LILED, RTS, LPBK, RxD, TxD, CRS,

b

0.3 0.8 V

g

g

(6)

10 kX dc

g

0.500

g

0.300

g

0.450

b

0.75V toa8.5V.

g

g

0.300 V

g

g

0.180 V

g

g

0.160 V

g

1.20 V

CC

10 mA 0.0VsV

10 mA 0.0VsV

V

s

I

e

4mA

OL

eb

500 mA

OH

e

10 mA

OL

eb

500 mA

OH

s

I

3.1 VP5 MHzsfs10 MHz

3.1 V

1.5 V

P

P

P

e

25 mA

l

LOAD

P

P

VCC, RESETe1

V

CC

20

Page 21

82503

DC CHARACTERISTICS (T

e

0§Ctoa85§C, V

C

CC

e

5Vg5%, V

e

5Vg5%) (Continued)

CCA

Symbol Parameter Min Max Units Test Conditions

I

(AUI) AUI Output Short Circuit Current

OSC

VU(AUI) Output Differential Undershoot

V

(AUI) Differential Idle Voltage

ODI

ICC(HOT) Power Supply Current

I

CC

I

CC

I

CCSB

Power Supply Current 75 mA APORTe1

Power Supply Current 60 mA APORTe0

Standby Supply Current

PD (HOT) Power Dissipation

(11)

(12)

(13)

(12)

g

150 mA Short Circuit to VCCor GND

b

100 mV

g

40 mV

65 mA APORTe1

1 mA Low Power Mode, 20 mA Typical

0.38 W APORTe1, Continuous Transmission

on AUI

PD Power Dissipation 0.40 W APORTe1, Continuous Transmission

on AUI

PD

SB

(14)

C

IN

NOTES:

11. Measured 8.0 ms after last positive transition of data packet.

12. I

CC

and load resistors removed.

13. Pins CS0 and CS1 connected to V

from power down assertionÐnot tested.

14. Characterized, not tested. (Controller interface and mode pins only.)

Standby Power Dissipation

Input Capacitance 10 pF at fe1 MHz

HOT measurements made at T

(13)

ea

85§C. Additionally, TRMT, TRMT, TDH, TDH, TDL, TDL are loaded with 20 pF

C

or VSSthrough a 2.5 kX (or less) resistor. I

CC

5.25 mW Low Power Mode, 105 mW Typical

is typically at 20 mA after 30s

CCSB

AC TIMING CHARACTERISTICS

290421– 8

Figure 9. MOS Input Voltage Levels

(TTL Compatible) for Timing Measurements

(TxD, RTS, TPE/AUI, APORT, APOL/XSQ,

LID, LPBK

, JABD, TEST, and RESET).

290421– 10

Figure 11. Voltage Levels for Differential Input

Timing Measurements (RCV and CLSN Pairs).

290421– 9

Figure 10. Voltage Levels for MOS Level

Output Timing Measurements

(TxC, RxD, RxC, CRS, and CDT).

290421– 11

Figure 12. Voltage Levels for TRMT Pair

Output Timing Measurements.

21

Page 22

82503

AC TIMING CHARACTERISTICS (Continued)

290421– 13

290421– 12

Figure 13. Voltage Levels for

TDH, TDL, TDH

, and TDL.

AC MEASUREMENT CONDITIONS

1. T

e

0§Ctoa85§C, V

C

CC

e

5Vg5%.

2. The AC MOS, TTL and differential signals are referred to in Figures, 8, 9, 10, 11, 12, and 13.

3. AC loads

a. MOS: 20 pF total capacitance to ground.

b. AUI Differential: a 10 pF total capacitance from each terminal to ground and a load resistor of 78X

g

in parallel with a 27 mH

1% inductor between terminals.

c. TPE: 20 pF total capacitance to ground.

4. All parameters become valid 200 ms after the supply voltage and input clock has stabilized, or after RESET

deasserts.

Figure 14. Voltage Levels for Differential Input

Timing Measurements (RD Pair).

g

1%

CLOCK TIMING

(15)

Symbol Parameter Min Typ Max Units

t

1

t

2

t

3

t

4

t

5

NOTE:

15. Refers to External Clock Input.

X1 Cycle Time 49.995 50.005 ns

X1 Fall Time 5 ns

X1 Rise Time 5 ns

X1 Low Time 15 ns

X1 High Time 15 ns

Figure 15. X1 Input Voltage Levels for Timing Measurements

22

290421– 14

Page 23

Controller Interface Timings (Intel Mode)

TRANSMIT TIMINGS (Intel)

Symbol Parameter Min Typ Max Units

t

10

t

11

t

12

t

13

t

14

t

15

t

16

t

17

TxC Cycle Time 99.99 100.01 ns

TxC High/Low Time 40 ns

TxC Rise/Fall Time 5 ns

TxD and RTS Rise/Fall Time 10 ns

TxD Setup Time to TxC

TxD Hold Time from TxC

RTS Setup Time to TxC

RTS Hold Time from TxC

v

v

v

v

45 ns

0ns

45 ns

0ns

82503

Figure 16. Transmit Timing (Intel)

290421– 15

23

Page 24

82503

RECEIVE TIMING (Intel)

Symbol Parameter Min Typ Max Units

t

20

t

21

t

22

t

23

t

24

t

25

t

26

t

27

t

28

RxC Cycle Time 96 100 ns

RxC High Time 36 ns

RxC Low Time 40 ns

RxC Rise/Fall Time 5 ns

RxC Delay from CRS

RxD Rise/Fall Time 5 ns

RxD Setup from RxC

RxD Hold from RxC

CRS Deassertion Hold Time from RxC High 10 40 ns

v

v

v

30 ns

30 ns

1100 1400 ns

Figure 17. Receive Timing (Intel)

290421– 16

24

Page 25

Controller Interface Timings (National Mode)

TRANSMIT TIMINGS (National)

Symbol Parameter Min Typ Max Units

t

30

t

31

t

32

t

33

t

34

t

35

t

36

NOTE:

16. All delay and width measurements on TxC are made at 1.5V.

TXC Cycle Time

TXC High/Low Time 40 50 ns

TXC Rise/Fall Time at 20% to 80% 5 ns

TXD Setup Time to TXC

TXD Hold Time from TXC

TXE Setup Time to TXC

TXE Hold Time from TXC

(16)

99.99 100.01 ns

u

u

u

u

20 ns

0ns

20 ns

0ns

82503

Figure 18. Transmit Timing (National)

290421– 17

25

Page 26

82503

RECEIVE TIMINGS (National)

Symbol Parameter Min Typ Max Units

t

40

t

41

t

42

t

43

t

44

t

45

t

46

t

47

NOTE:

17. All delay and width measurements on RXC are made at 1.5V.

RxC Cycle Time 96 100 ns

RxC High/Low Time

RxC Rise/Fall Time at 20% to 80% 5 ns

RXD Rise/Fall Time at 20% to 80% 5 ns

RXD Setup Time to RxC

RXD Hold Time from RxC

RxC Delay from CRS

RxC Continuing Beyond CRS

(17)

u

40 50 60 ns

u

u

v

30 ns

20 ns

1400 ns

5 cycles

26

290421– 18

Figure 19. Receiving Timings (National)

Page 27

Controller Interface Timing (AMD Mode)

82503

TRANSMIT TIMINGS

Symbol Parameter Min Typ Max Units

t

50

t

51

t

52

t

53

t

54

t

55

t

56

t

57

NOTE:

18. Delay times for TX, TENA, and TCLK are measured from 0.8V for falling edges, and 2.0V for rising edges.

(18)

(AMD)

TCLK Cycle Time 99.99 100.01 ns

TCLK High Time (@0.8V to 2.0V) 45 50 58 ns

TCLK Low Time (@2.0V to 0.8V) 45 50 58 ns

TCLK Rise/Fall Time (@0.8V to 2.0V) 2.5 5 ns

TX Setup Time to TCLK

TX Hold Time from TCLK

TENA Setup Time to TCLK

TENA Hold Time from TCLK

u

u

Figure 20. Transmit Timings (AMD)

u

u

20 ns

5ns

20 ns

5ns

290421– 19

27

Page 28

82503

RECEIVE TIMINGS

Symbol Parameter Min Typ Max Units

t

60

t

61

t

62

t

63

t

64

t

65

t

66

t

67

t

68

NOTE:

19. Delay times for RX, RENA, and RCLK are measured from 0.8V for falling edges and 2.0V for rising edges.

(19)

(AMD)

RCLK Cycle Time 96 100 ns

RCLK High Time (@0.8V to 2.0V) 38 50 ns

RCLK Low Time (@2.0V to 0.8V) 38 50 ns

RCLK Rise/Fall Time (@0.8V to 2.0V) 2.5 5 ns

RX Rise/Fall Time (@0.8V to 2.0V) 2.5 5 ns

RX Hold time from RCLK

RX Setup Time to RCLK

RENA Deassertion Hold Time from RCLK

RCLK Delay from RENA

Figure 21. Receive Timings (AMDÐStart of Frame)

u

u

u

u

10 ns

45 ns

40 50 80 ns

450 ns

290421– 20

28

290421– 21

Figure 22. Receive Timings (AMDÐEnd of Frame)

Page 29

Controller Interface Timings (Fujitsu Mode)

TRANSMIT TIMINGS (Fujitsu)

Symbol Parameter Min Typ Max Units

t

70

t

71

t

72

t

73

t

74

t

75

t

76

NOTE:

20. Timing measurements are referenced at 1.5V level.

TCKN Cycle Time 99.99 100.01 ns

TCKN High/Low Time

TCKN Rise/Fall Time at 20% to 80% 5 ns

TXD Setup Time to TCKN

TXD Hold Time from TCKN

TEN Setup Time to TCKN

TEN Hold Time from TCKN

(20)

40 50 ns

(20)

v

(20)

v

(20)

v

(20)

v

20 ns

0ns

20 ns

0ns

82503

Figure 23. Transmit Timings (Fujitsu)

290421– 22

29

Page 30

82503

RECEIVE TIMINGS (Fujitsu)

Symbol Parameter Min Typ Max Units

t

80

t

81

t

82

t

83

t

84

t

85

t86XCD Deassertion Hold Time from RCKN

t

87

t

88

NOTE:

21. Timing measurements are referenced at 1.5V.

RCKN Cycle Time 96 100 ns

RCKN High/Low Time

RCKN Rise/Fall Time at 20% to 80% 5 ns

RXD Setup Time from RCKN

RXD Hold Time from RCKN

XCD Assertion Hold Time from RCKN

XCD Deassertion Setup Time from RCKN

RCKN Delay from XCD

(21)

u

(21)

35 50 60 ns

(21)

v

(21)

v

(21)

v

(21)

v

(21)

v

20 ns

10 ns

010 ns

120 ns

80 130 ns

1400 ns

30

290421– 23

Figure 24. Receive Timings (FujitsuÐStart of Frame)

290421– 24

Figure 25. Receive Timings (FujitsuÐEnd of Frame)

Page 31

TPE Timings

TPE TRANSMIT TIMINGS

Symbol Parameter Min Typ Max Units

t

t

t

t

t

t

t

t

t

t

t

90

91

92

93

94

95

96

97

98

99

100

TxD to TD Bit Loss at Start of Packet 2 bits

TxD to TD Steady State Propagation Delay 400 ns

TxD to TD Startup Delay 600 ns

TDH and TDL Pairs Edge Skew (@VCC/2) 1.5 3 ns

TDH and TDL Pairs Rise/Fall Times (@0.5V to V

b

0.5V) 2 5 ns

CC

TDH and TDL Pairs Bit Cell Center to Center 99 100 101 ns

TDH and TDL Pairs Bit Cell Center to Boundary 49 50 51 ns

TDH and TDL Pairs Return to Zero from Last TDH

u

250 400 ns

Link Test Pulse Width 98 100 102 ns

Last TD Activity to Link Test Pulse 8 13 24 ms

Link Test Pulse to Data Separation 190 200 ns

82503

Figure 26. TPE Transmit Timings (Start of Frame)

Figure 27. TPE Transmit Timings (End of Frame)

290421– 25

290421– 26

31

Page 32

82503

290421– 27

Figure 28. TPE Transmit Timings (Link Test Pulse)

TPE RECEIVE TIMINGS

Symbol Parameter Min Typ Max Units

t

t

t

t

t

t

t

t

t

105

106

107

108

109

110

111

112

113

RD to RxD Bit Loss at Start of Packet 4 19 bits

RD to RxD Invalid Bits Allowed at Start of Packet 1 bits

RD to RxD Steady State Propagation Delay 400 ns

RD to RxD Start UP Delay 2.4 ms

RD Pair Bit Cell Center Jitter

RD Pair Bit Cell Boundary Jitter

g

13.5 ns

g

13.5 ns

RD Pair Held High from Last Valid Positive Transition 230 400 ns

CRS Assertion Delay (Intel, NS, and Fuji Mode) 700 ns

(AMD Mode) 1500 ns

CRS Deassertion Delay 450 ns

32

290421– 28

Figure 29. TPE Receive Timings (Start of Frame)

Page 33

290421– 29

Figure 30. TPE Receive Timings (End of Frame)

TPE COLLISION TIMINGS

Symbol Parameter Min Typ Max Units

t

115

t

116

t

117

t

118

Onset of Collision (RD Pair and RTS Active) to CDT Assert 900 ns

End of Collision (RD Pair or RTS Inactive) to CDT Deassert 900 ns

CDT Assert to RxD Sourced from RD Pair 900 ns

CDT Deassert (RD Pair Inactive) to RxD Sourced from TxD 900 ns

82503

Figure 31. TPE Collision Timings (Start of Collision)

290421– 30

33

Page 34

82503

290421– 31

Figure 32. TPE Collision Timings (End of Collision)

TPE LINK INTEGRITY TIMINGS

Symbol Parameter Min Typ Max Units

t

120

t

121

t

122

NOTES:

20. Linkbeats closer in time to this value are considered noise, and are rejected.

21. Linkbeats further apart in time than this value are not considered consecutive, and are rejected.

Last RD Activity to Link Fault (Link Loss Timer) 50 100 150 ms

Minimum Received Linkbeat Separation

Maximum Received Linkbeat Separation

(20)

(21)

25 7ms

25 50 150 ms

34

290421– 32

Figure 33. TPE Link Integrity Timings

Page 35

AUI Timings

AUI TRANSMIT TIMINGS

Symbol Parameter Min Typ Max Units

t

t

t

t

t

t

125

126

127

128

129

130

TxD to TRMT Pair Steady State Propagation Delay 200 ns

TRMT Pair Rise/Fall Times 3 5 ns

Bit Cell Center to Bit Cell Center of TRMT Pair 99.5 100 100.5 ns

Bit Cell Center to Bit Cell Boundary of TRMT Pair 49.5 50 50.5 ns

TRMT Pair Held at Positive Differential at Start of Idle 200 ns

TRMT Pair Return tos40 mV from Last Positive Transition 8.0 ms

290421– 33

Figure 34. AUI Transmit Timings

82503

AUI RECEIVE TIMINGS

Symbol Parameter Min Typ Max Units

t

t

t

t

t

t

135

136

137

138

139

140

RCV Pair Rise/Fall Times 10 ns

RCV Pair Bit Cell Center Jitter in Preamble

RCV Pair Bit Cell Center/Boundary Jitter in Data

g

12 ns

g

18 ns

RCV Pair Idle Time after Transmission 8 ms

RCV Pair Return to Zero from Last Positive Transition 160 ns

CRS Assertion Delay (Intel, National, Fujitsu Modes) 100 ns

(AMD Mode) 1050 ns

t

t

141

142

CRS Deassertion Delay 350 ns

CRS Inhibited after Frame Transmission 4 4.3 5 ms

290421– 34

Figure 35. AUI Receive Timings

35

Page 36

82503

AUI COLLISION TIMINGS

Symbol Parameter Min Typ Max Units

t

t

t

t

t

t

t

145

146

147

148

149

150

151

CLSN Pair Cycle Time 80 118 ns

CLSN Pair Rise/Fall Times 10 ns

CLSN Pair Return to Zero from Last Positive Transition 160 ns

CLSN Pair High/Low Times 35 70 ns

CDT Assertion Time 75 ns

CDT Deassertion Time 300 ns

CRS Deassertion Time (Intel Mode Only, RCV Pair Idle) 450 ns

290421– 35

Figure 36. AUI Collision Timings

AUI NOISE FILTER TIMINGS

Symbol Parameter Min Typ Max Units

@

t

t

152

153

RCV Pair Noise Filter Pulse Width Accept (

CLSN Pair Noise Filter Pulse Width Accept (

b

285 mV) 25 ns

@

b

285 mV) 25 ns

290421– 36

Figure 37. AUI Noise Filter Timings

36

Page 37

82503

LOOPBACK TIMINGS

Symbol Parameter Min Typ Max Units

t

155

t

156

t

157

t

158

t

159

t

160

NOTE:

22. Guarantees proper processing of transmitted packets. Violation of this specification will not result in spurious data trans-

mission. Incoming data packets occuring during transitions on LPBK

TxD to RxD Bit Loss at Start of Packet 16 bits

TxD to RxD Steady State Propagation Delay 600 ns

TxD to RxD Startup Delay 2.2 ms

SQE Test Wait Time 0.6 1.2 1.6 ms

SQE Test Duration 0.5 0.8 1.5 ms

LPBK Setup/Hold Times to RTS

(22)

1.0 ms

will not be accepted.

Figure 38. Loopback Timings

290421– 37

37

Page 38

82503

JABBER TIMINGS

Symbol Parameter Min Typ Max Units

t

165

t

166

t

167

LED TIMINGS

Symbol Parameter Min Typ Max Units

Maximum Length Transmission before Jabber Fault (TPE) 20 25 150 ms

Maximum Length Transmission before Jabber Fault (AUI) 10 13 18 ms

Minimum Idle Time to Clear Jabber Function 250 420 750 ms

Figure 39. Jabber Timings

t

t

t

t

170

171

172

173

TxLED, RxLED, COLED On Time 50 450 ms

TxLED, RxLED, COLED Off Time 50 ms

LILED On Time 50 ms

LILED Off Time 100 ms

290421– 38

38

290421– 39

Figure 40. LED Timings

Page 39

82503

MODE TIMINGS

(23, 24)

Symbol Parameter Min Typ Max Units

t

175

t

176

t

177

t

178

NOTES:

23. Guarantees Proper processing of data packets. Violation of these specifications will not affect the integrity of the network.

24. Mode pins are: APORT, APOL/XSQ, LID, JABD, and TPE/AUI

25. Any data received within 100 ms of a mode transmission will be considered invalid.

Mode Pins Setup to RTS

Mode Pins Hold from RTS

v

u

Mode Pins Setup to RD Active

Mode Pins Hold from RD Active

(25)

(25)

100 ms

100 ms

100 ms

100 ms

.

290421– 53

Figure 41. Mode Timings

39

Page 40

82503

RESET, TEST, AND LOW POWER MODE TIMINGS

Symbol Parameter Min Typ Max Units

t

t

t

180

181

182

TEST and JABD Setup Time to RESET

RESET Pulse Width 300 ns

Low Power Mode Deactivation from TEST and JABD

Figure 42. Reset Timings (Test Mode)

v

50 ns

v

1ms

290421– 41

40

290421– 43

Figure 43. Reset Timings (Start of Low Power Mode)

290421– 42

Figure 44. Reset Timings (End of Low Power Mode)

Page 41

PACKAGE DIMENSIONS

PLASTIC LEADED CHIP CARRIER

Figure 45. Principle Dimensions and Data

82503

290421– 45

Figure 46. Molded Details

290421– 46

41

Page 42

82503

290421– 47

Figure 47. Terminal Details

42

290421– 48

Figure 48. Standard Package Bottom View (Tooling Option 1)

Page 43

Figure 49. Standard Package Bottom View (Tooling Option II)

82503

290421– 49

Figure 50. Detail J. Terminal Detail

290421– 50

43

Page 44

82503

290421– 51

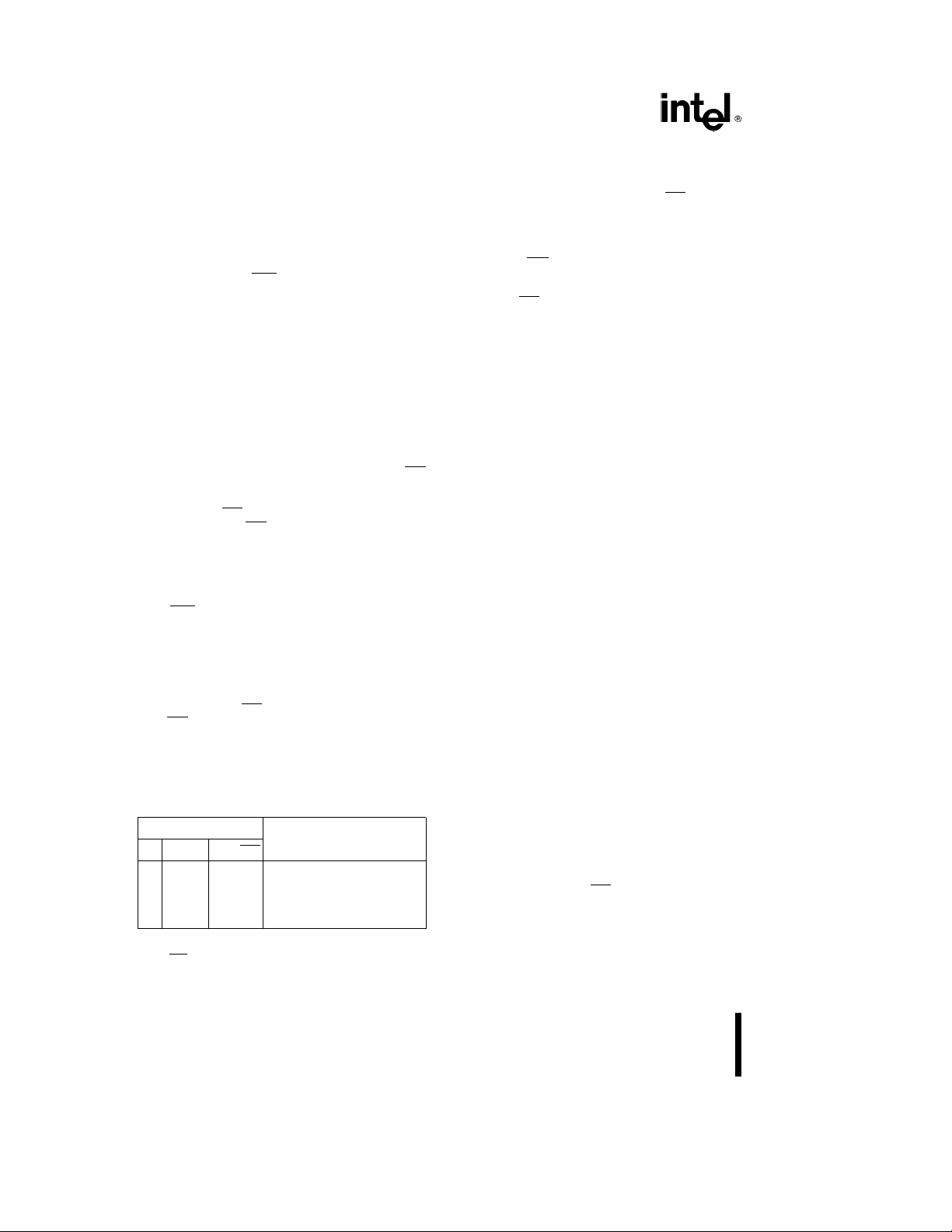

Figure 51. Detail L. Terminal Details

NOTES:

The above diagrams use a 20-lead PLCC package to show symbols for package dimensions. The table below indicates

dimensions in mm that are specific to the 44-lead PLCC package.

1. All dimensions and tolerances conform to ANSI Y14.5M-1982.

2. Datum plane ÐHÐ located at top of mold parting line and coincident with top of lead, where lead exits plastic body.

3. Datums D–E and F–G to be determined where center leads exit plastic body at datum plane ÐHÐ.

4. To be determined at seating plane ÐCÐ.

5. Dimensions D

6. Pin 1 identifier is located within one of the two defined zones.

7. Locations to datum ÐAÐ and ÐBÐ to be determined at plane ÐHÐ.

8. These two dimensions determine maximum angle of the lead for certain socket applications. If unit is intended to be

socketed, it is advisable to review these dimensions with the socket supplier.

9. Controlling dimension, inch.

10. All dimensions and tolerances include lead trim offset and lead plating finish.

11. Tweezing surface planarity is defined as the furthest any lead on a side may be from the datum. The datum is established by touching the outermost lead on that side and parallel to D–E or F–G.

and E1do not include mold protrusion.

1

Symbol Description Min Max

A Overall Height 4.19 4.57

A

1

Distance from Lead Shoulder to Seating Plane 2.29 3.05

D Overall Package Dimension 17.4 17.7

D

1

D

2

Plastic Body Dimension 16.5 16.7

Foot Print 15.0 16.0

E Overall Package Dimension 17.4 17.7

E

1

E

2

Plastic Body Dimension 16.5 16.7

Foot Print 15.0 16.0

CP Seating Plans Coplanarity 0.00 0.10

TCP Tweezing Coplanarity 0.00 0.10

LT Lead Thickness 0.23 0.38

44

Page 45

44-LEAD QUAD FLATPACK PACKAGE

82503

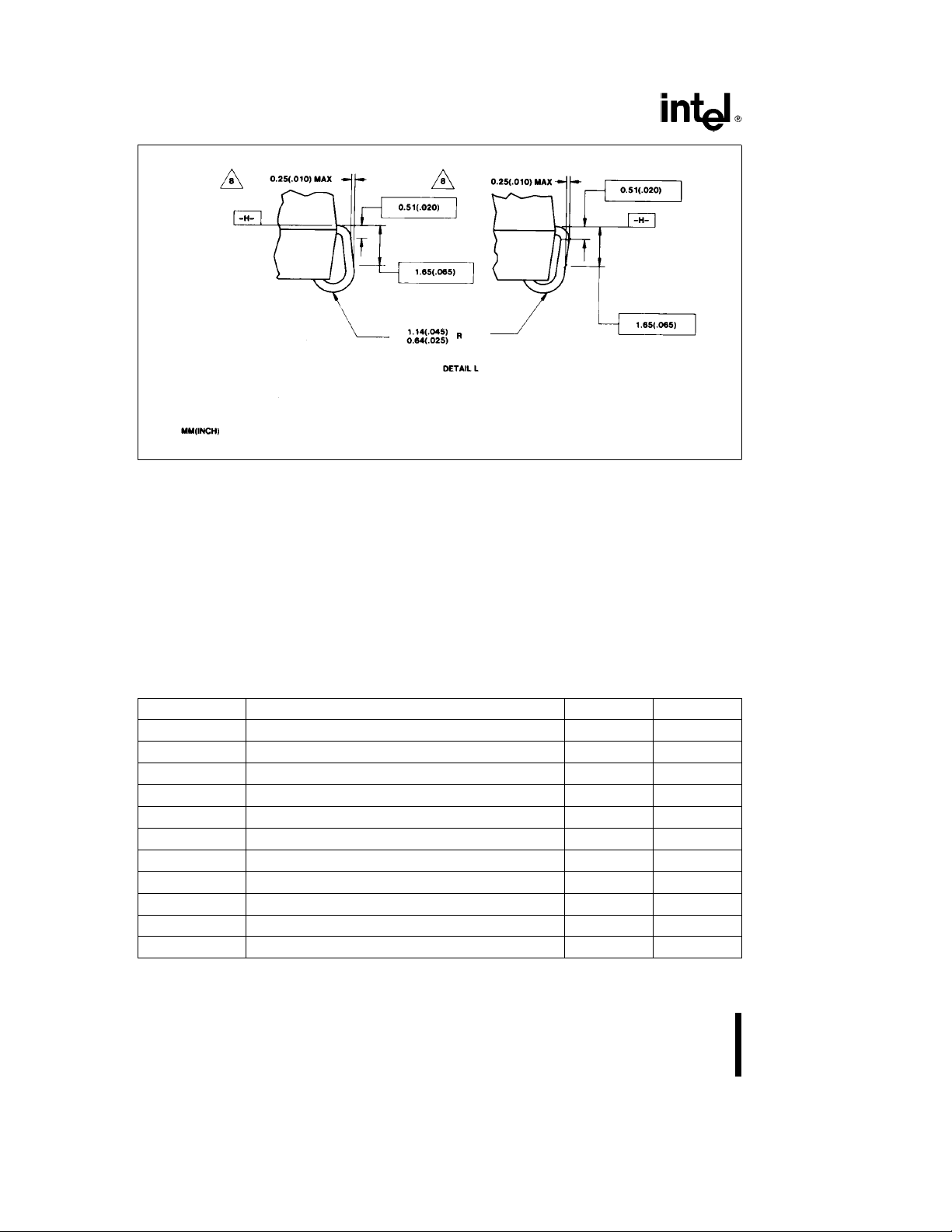

Figure 52. 44-Lead Quad Flatpack Package

Symbol Description Min Nom Max

A Package Height 2.35

A1 Stand Off 0 0.60

B Lead Width 0.2 0.3 0.4

C Lead Thickness 0.1 0.15 0.2

D

1

E

1

e

1

Package Body 10

Package Body 10

Lead Pitch 0.65 0.8 0.95

D Terminal Dimension 12.0 12.4 12.8

E Terminal Dimension 12 12.4 12.8

L

1

Foot Length 0.38 0.58 0.78

Y Coplanarity 0.1

T Lead Angle 0 10

NOTE:

Unless otherwise specified, all units are in millimeters.

290421– 52

§

45

Loading...

Loading...