Page 1

Intel® 6300ESB I/O Controller

Hub

Thermal and Mechanical Design Guide

February 2004

Order Number: 300682-001

Page 2

Contents

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED, BY

ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS PROVIDED IN

INTEL'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY WHATSOEVER, AND INTEL DISCLAIMS

ANY EXPRESS OR IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF INTEL PRODUCTS INCLUDING LIABILITY OR WARRANTIES

RELATING TO FITNESS FOR A P ARTICULAR PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER

INTELLECTUAL PROPERTY RIGHT. Intel products are not intended for use in medical, life saving, life sustaining applications.

Intel may make changes to specifications and product descriptions at any time, without notice.

Designers must not rely on the absence or characteristics of any features or instructions marked “reserved” or “undefined.” Intel reserves these for

future definition and shall have no responsibility whatsoever for conflicts or incompatibilities arising from future changes to them.

®

The Intel

specifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Copies of documents which have an ordering number and are referenced in this document, or other Intel literature may be obtained by calling

1-800-548-4725 or by visiting Intel's website at http://www.intel.com.

AlertVIEW, AnyPoint, AppChoice, BoardWatch, BunnyPeople, CablePort, Celeron, Chips, CT Connect, CT Media, Dialogic, DM3, EtherExpress,

ETOX, FlashFile, i386, i486, i960, iCOMP, InstantIP, Intel, Intel logo, Intel386, Intel486, Intel740, IntelDX2, IntelDX4, IntelSX2, Intel Create & Share,

Intel GigaBlade, Intel InBusiness, Intel Inside, Intel Inside logo, Intel NetBurst, Intel NetMerge, Intel NetStructure, Intel Play, Intel Play logo, Intel

SingleDriver, Intel SpeedStep, Intel StrataFlash, Intel TeamStation, Intel Xeon, Intel XScale, IPLink, Itanium, LANDesk, LanRover, MCS, MMX, MMX

logo, Optimizer logo, OverDrive, Paragon, PC Dads, PC Parents, PDCharm, Pentium, Pentium II Xeon, Pentium III Xeon, Performance at Your

Command, RemoteExpress, Shiva, SmartDie, Solutions960, Sound Mark, StorageExpress, The Computer Inside., The Journey Inside,

TokenExpress, Trillium, VoiceBrick, Vtune, and Xircom are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United

States and other countries.

*Other names and brands may be claimed as the property of others.

Copyright © Intel Corporation, 2004

6300ESB I/O Controller Hub may contain design defects or errors known as errata which may cause the product to deviate from published

2 Intel® 6300ESB I/O Controller Hub Thermal and Mechanical Design Guide

Page 3

Contents

Contents

1.0 Introduction....................................................................................................................................5

1.1 Definition of Terms................................................................................................................5

1.2 Reference Documents....... .......... .........................................................................................6

2.0 Packaging Technology .................................................................................................................7

3.0 Thermal Specifications ................................................................................................................. 9

3.1 Case Temperature and Thermal Design Power ................................................................... 9

3.2 Case Temperature Metrology...............................................................................................9

4.0 Referen ce Th erm al So lution....................................................................................................... 11

4.1 Reliability Requirements.....................................................................................................11

A Mechanical Drawings.................................................................................................................. 13

Figures

1Intel® 6300ESB I/O Controller Hub Package Dimensions..........................................................14

Tables

1 D e fi n ition of Terms....... .......... .......................................................................................................5

2 Reference Documents..................................................................................................................6

3Intel

4 Reliability Requirements.............................................................................................................11

®

6300ESB I/O Controller Hub Thermal Specifications .........................................................9

Revision History

Date Revision Description

February 2004 1.0 Initial release of this document.

Intel® 6300ESB I/O Controller Hub Thermal and Mechanical Design Guide 3

Page 4

Contents

This page intentionally left blank.

4 Intel® 6300ESB I/O Controller Hub Thermal and Mechanical Design Guide

Page 5

1.0 Introduction

As the complexity of computer systems increases, so do the power dissipation requirements. Care

must be taken to ensure that the additional power is prope rly dissipated. Heat may be dissipated

using improved system cooling and/or attaching passive heatsinks.

The objective of thermal management is to ensure that the tempe r atures of all components in a

system are maint ai ned within f u nction al limit s . The func tional te mper ature li mit i s the ra nge withi n

which the electric al circuits may be expected to meet specified perfor mance requirements.

Operation outs ide the functional limit ma y degrade system performance, caus e logic errors, or

cause component and /or s ystem damage. Temperatures exceeding the maximum operatin g limits

may result in irreversible changes in the operating chara cteristics of the component. The goal of

this document is to provide an understanding of the operating limits of the Intel

Controller Hub (ICH).

The simplest and most cost effective method is to improve the inherent sys tem cooling

characteristics through careful design and placement of fans, vents, and ducts. When additional

cooling is req uired, component therm al solutions may be implem ented in conjunctio n with system

thermal solutions. The size of the fan or heatsink may be varied to balance size and space

constraints with acoustic noise.

Introduction

®

6300ESB I/O

This document pres ents the conditions and requirements to properly design a cooling solution for

systems using the Intel 6300ESB ICH. Properly designed solutions should provide adequate

cooling to maintain the Intel 6300ESB ICH case temperatures at or below thermal specifications.

This is accompli shed by providing a low local-ambient temperature, ensuring adequate local

airflow, and minimizing the case to local-ambient thermal resistance. By maintaining the case

temperatures of th e Int el 6300E SB ICH at or be low thos e recommend ed in thi s documen t, a s ystem

designer may ensure the pro per functionality, performance, and reliability of these components.

1.1 Definition of Terms

T able 1. Definition of Terms

Term Definition

BGA

T

case-nhs

T

j-max

TDP

LFM

Ball G rid Array. A package type defined by a resin-fiber substrate, onto wh ich a die is

mounted, bonded and encapsulated in molding compound. The primary electrical interface is

an array of solder balls attached to the substrate opposite the die and molding compound.

The max imum package case temperature w ithout any package thermal solution. Th is

temperature is measured at the geometric cent er of the top of the package case .

The max imum component temperature specifica tion measu red at the hottest point in the

processor die.

Thermal Design Power. Thermal solutions should be de signed to dissipat e this target power

level.

Linear Feet Per Minute. A measure of airflow emitted from a forced convection device, such

as an axial fan or blower.

®

6300ESB I/O Controller Hub Thermal and Mechanical Design Guide 5

Intel

Page 6

Introduction

1.2 Reference Documents

Table 2. Reference Documents

Document Document Number / Location

®

Intel

6300ESB I/O Cont roller Hu b Datasheet 300641

Thermal Design Suggestions fo r Var ious Form Factors http://www.formfactors.org

NOTE: Unless otherwise noted, t hese documents are available through your Intel Field Sales representative

6 Intel

®

6300ESB I/O Controller Hub Thermal and Mechanical Design Guide

Page 7

2.0 Packaging Technology

Packaging Technology

The Intel 6300ESB ICH component is available in a 37.5 mm square package as shown in

Appendix A, “Mechanical Dra wings”. Packa ge inform ation is al so provi ded in th e Intel

I/O Controller Hub Datasheet.

®

6300ESB

®

6300ESB I/O Controller Hub Thermal and Mechanical Design Guide 7

Intel

Page 8

Packaging Technology

This page intentionally left blank.

8

Intel® 6300ESB I/O Controller Hub Thermal and Mechanical Design Guide

Page 9

Thermal Specifications

3.0 Thermal Specifications

3.1 Case Temperature and Thermal Design Power

To ensure proper operation and reliability of the Intel 6300ESB ICH component, the case and

junction temperatures must be at or below the val ues specified in Table 3. System and/or

component level thermal solutions are required to maintain the case temperature below the

maximum temperature specification while dissipating the thermal design power (TDP) listed in

Table 3.

Table 3. Intel

®

6300ESB I/O Controller Hub Thermal Specifications

Parameter Maximum Notes

T

case-nhs

T

j-max

TDP 3.9 W

NOTES:

1. T

thermal solution attached.

2. T

measured at the hottest point in the processor die.

is defi ned as the maximum package case temperature without a

case-nhs

is defined as the maximum compon ent temperature specification

j-max

105 °C 1

11 5 ° C 2

3.2 Case Temperature Metrology

The component case te mpera tur e should b e mea sured by att aching a t hermocoupl e to the geome tric

center of the packag e case top. Refer to Appendix A, “Mechanic al Dra w ings” for package

dimensions.

®

6300ESB I/O Controller Hub Thermal and Mechanical Design Guide 9

Intel

Page 10

Thermal Specifications

This page intentionally left blank.

10

Intel® 6300ESB I/O Controller Hub Thermal and Mechanical Design Guide

Page 11

4.0 Reference Thermal Solution

Based on a component local operating environment of natural convection (zero LFM of airflow)

with a maximum local-ambient temperature of 55° C, the Intel 6300ESB ICH component does not

require an attached heatsi n k to meet therma l specifications. F o r systems where the loca l-ambient

temperatur e is se vere (greater than 55° C, nat ural convection), a component level thermal solution

or system thermal so lut ion impr ovement may be required . Attac hing a heatsin k to th e package cas e

and/or improving airflow at the component may be potential solutions.

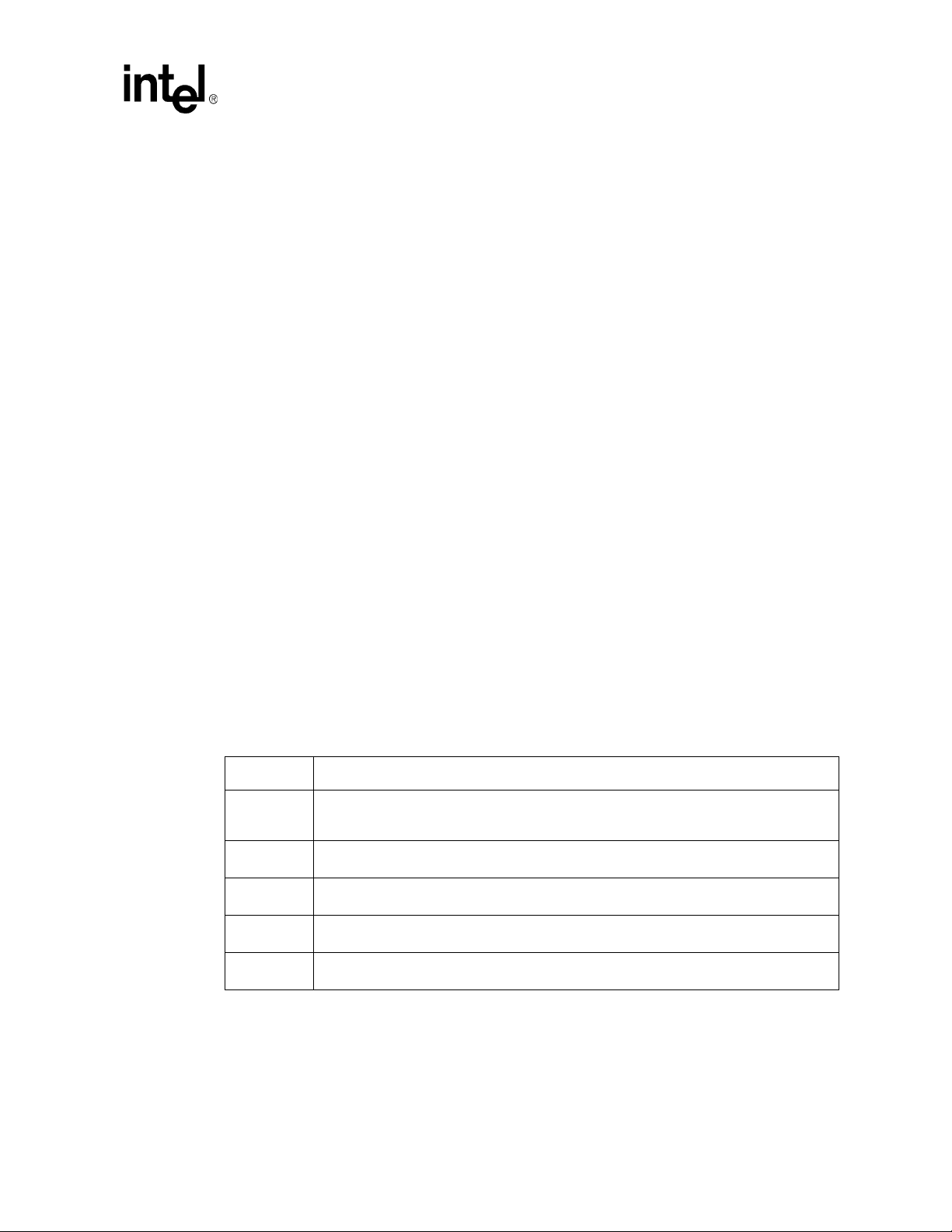

4.1 Reliability Requirements

If an atta ched heatsink is implemented due to a severe component local operating environment, the

reliabi lity requiremen ts in Table 4 are recommended. Each motherboard, heatsink, and attach

combination may vary the mechanical loading of the component. It is recommended that the user

carefully evaluate the reliabili ty of the completed assembly pri or to use in high volume.

Table 4. Reliability Requirements

1

Test

Mechanical Shock 50g, board level, 11 ms ec, 3 shocks/axis Visual check and electrical functi onal test

Random Vibration

Temper ature Life

Thermal Cycling

Humidity 85% relative humidity, 55° C, 1000 hours Visual check

NOTES:

1. The above tests should be performed on a sample size of at least 12 assemblies from 3 lots of material.

2. Additional pass/fail criteria may be added at the discretion of the user.

7.3g, board level, 45 min/ axis, 50 Hz to

2000 Hz

85° C, 2000 hours total, checkpoints at

168, 500 , 1000, an d 2000 hour s

-5° C to +70° C, 500 cycles, ° C/min rise

and fal l

Requirement Pass/Fail Criteria

Reference Thermal Solution

2

Visual check and electrical functi onal test

Visual check

Visual check

®

6300ESB I/O Controller Hub Thermal and Mechanical Design Guide 11

Intel

Page 12

Reference Thermal Solution

This page intentionally left blank.

12

Intel® 6300ESB I/O Controller Hub Thermal and Mechanical Design Guide

Page 13

Appendix A Mechanical Drawings

Figure 1 shows the package dimensions for the Intel 6300ESB ICH. Unless otherwis e specified,

the unit s in th e f ig u r e ar e in mi llimeter s.

Mechanical Drawings

®

6300ESB I/O Controller Hub Thermal and Mechanical Design Guide 13

Intel

Page 14

Mechanical Drawings

®

Figure 1. Intel

6300ESB I/O Controller Hub Package Dimensions

14 Intel

®

6300ESB I/O Controller Hub Thermal and Mechanical Design Guide

Loading...

Loading...