Page 1

OPERATION AND SERVICE MANUAL

MODEL MDC-360

MAXTEK FILM DEPOSITION CONTROLLER

P/N 179800

S/N _____________

MAXTEK, INC.

http://www.maxtekinc.com

5980 Lakeshore Drive, Cypress, CA 90630-3371

Tel: (714) 828-4200 • Fax: (714) 828-4443

Email: sales@maxtekinc.com • support@maxtekinc.com

Page 2

© 1995-2002 MAXTEK, INC. All rights reserved.

First Edition, March 1995

Second Edition, Revision A, March 1996

Revision B, June 1996

Revision C, December 1996

Revision D, February 1997

Revision E, January 1998

Revision F, March 1998

Revision G, May 1998

Revision H, January 1999

Revision I, November 1999

Revision J, February 2000

Revision K, August 2000

Revision L, October 2002

Revision M, November 2002

Revision N, June 2005

ii

Page 3

WARRANTY

Maxtek, Inc. warrants the product to be free of functional defects in material and

workmanship and that it will perform in accordance with its published

specification for a period of (twenty-four) 24 months.

The foregoing warranty is subject to the condition that the product be properly

operated in accordance with instructions provided by Maxtek, Inc. or has not been

subjected to improper installation or abuse, misuse, negligence, accident,

corrosion, or damage during shipment.

Purchaser's sole and exclusive remedy under the above warranty is limited to, at

Maxtek's option, repair or replacement of defective equipment or return to

purchaser of the original purchase price. Transportation charges must be prepaid

and upon examination by Maxtek the equipment must be found not to comply

with the above warranty. In the event that Maxtek elects to refund the purchase

price, the equipment shall be the property of Maxtek.

This warranty is in lieu of all other warranties, expressed or implied and

constitutes fulfillment of all of Maxtek's liabilities to the purchaser. Maxtek does

not warrant that the product can be used for any particular purpose other than that

covered by the applicable specifications. Maxtek assumes no liability in any

event, for consequential damages, for anticipated or lost profits, incidental

damage of loss of time or other losses incurred by the purchaser or third party in

connection with products covered by this warranty or otherwise.

DISCLOSURE

The disclosure of this information is to assist owners of Maxtek equipment to

properly operate and maintain their equipment, and does not constitute the release

of rights thereof. Reproduction of this information and equipment described

herein is prohibited without prior written consent from Maxtek, Inc.,

5980 Lakeshore Drive, Cypress, California, 90630-3371.

SAFETY

All standard safety procedures associated with the safe handling of

electrical equipment must be observed. Always disconnect power when

working inside the controller. Only properly trained personnel should

attempt to service the instrument.

iii

Page 4

Table of Contents

1. GENERAL DESCRIPTION.............................................................................................1-1

1.1 PURPOSE....................................................................................................................... 1-1

1.2 FEATURES .................................................................................................................... 1-1

1.2.1 EXTENSIVE PROGRAM STORAGE ......................................................................... 1-1

1.2.2 DYNAMIC MEASUREMENT UPDATE RATE.......................................................... 1-1

1.2.3 SUPERIOR GRAPHICS DISPLAY ............................................................................ 1-1

1.2.4 PROGRAM SECURITY.............................................................................................. 1-1

1.2.5 DESIGNED FOR UNATTENDED OPERATION......................................................1-1

1.2.6 FAIL SAFE ABORTS..................................................................................................1-1

1.2.7 ABOR T STATUS RETENTION .................................................................................. 1-2

1.2.8 RUN COMPLETION ON CRYSTAL FAILURE.........................................................1-2

1.2.9 POWER FU L SYSTEM INTERFACE.......................................................................... 1-2

1.2.10 POWER SUPPLY NOISE TOLERANCE............................................................... 1-2

1.2.11 INTERNATIONAL STANDARD POWER CONNECTOR ..................................... 1-2

1.2.12 FIEL D UPGRADABLE.........................................................................................1-2

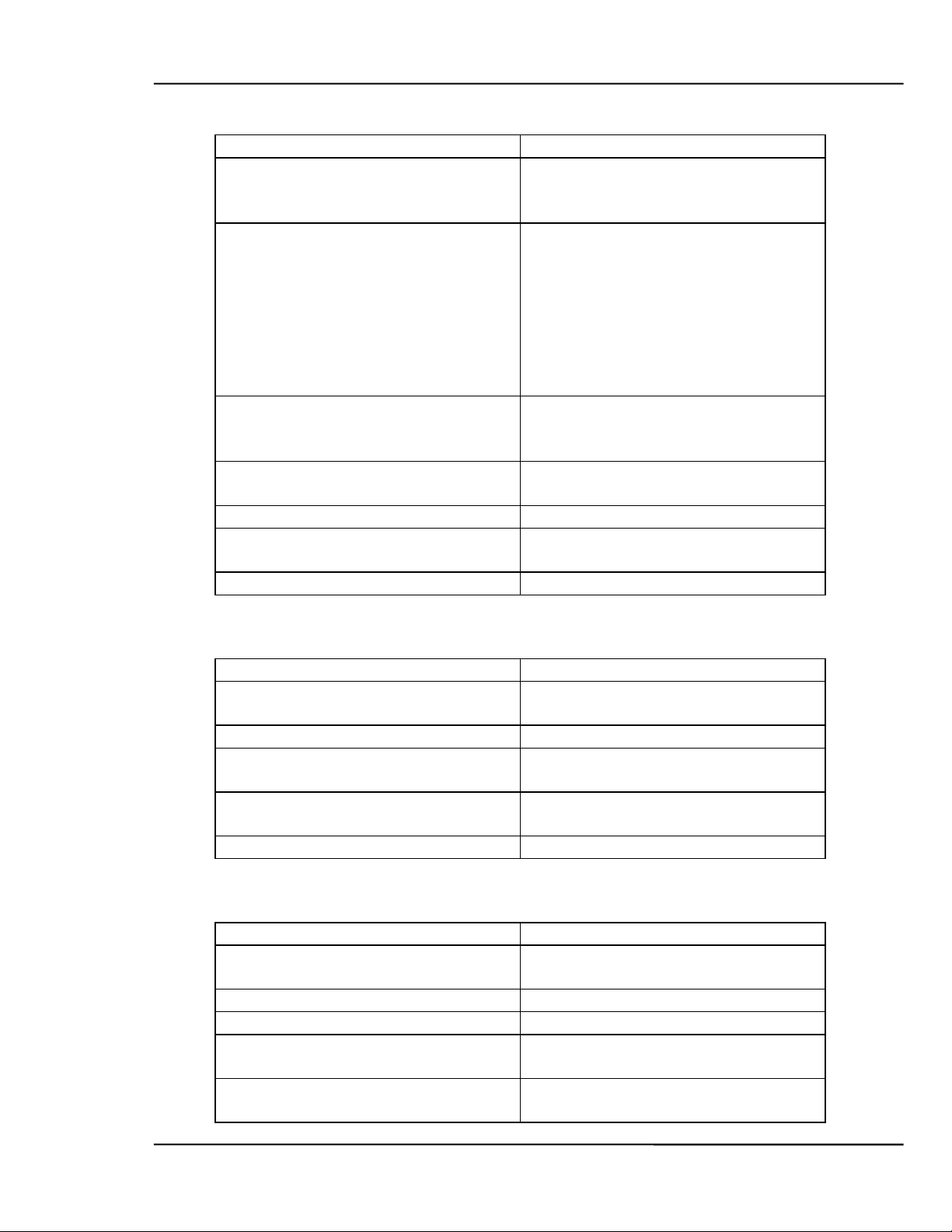

1.3 SPECIFICATIONS......................................................................................................... 1-3

1.3.1 MEASUREMENT.......................................................................................................1-3

1.3.2 DISPLAY....................................................................................................................1-3

1.3.3 COMMUNICATION...................................................................................................1-3

1.3.4 PROGRAM STORAGE CAPACITY ........................................................................... 1-3

1.3.5 PROCESS PARAMETERS ......................................................................................... 1-3

1.3.6 MATER IAL P ARAMETERS ....................................................................................... 1-3

1.3.7 INPUT/OUTPUT CAPABILITY................................................................................. 1-5

1.3.8 SENSOR PARAMETERS............................................................................................ 1-5

1.3.9 SOURCE PARAMETERS...........................................................................................1-5

1.3.10 RECOR DER P ARAMETERS.................................................................................1-6

1.3.11 UTILITY SETUP PARAMETER............................................................................ 1-6

1.3.12 OTHER.................................................................................................................. 1-6

1.4 ACCESSORIES..............................................................................................................1-6

2. FRONT PANEL DISPLAYS AND CONTROLS........................................................... 2-1

2.1 OPERATING DISPLAYS.............................................................................................. 2-1

2.1.1 RATE..........................................................................................................................2-1

2.1.2 POWER...................................................................................................................... 2-1

2.1.3 THICKNESS............................................................................................................... 2-1

2.1.4 LAYER NUMBER ....................................................................................................... 2-1

2.1.5 CRYST AL HEALTH %...............................................................................................2-1

2.1.6 TIME TO GO..............................................................................................................2-2

2.2 PARAMETER/STATUS DISPLAYS............................................................................2-2

2.3 OPERATING CONTROLS............................................................................................2-2

2.3.1 MANUAL KEY ........................................................................................................... 2-2

2.3.2 START KEY................................................................................................................ 2-3

2.3.3 ABORT KEY............................................................................................................... 2-3

2.3.4 RESET KEY................................................................................................................2-3

2.3.5 ZERO KEY.................................................................................................................2-3

2.3.6 SHUTTER KEY .......................................................................................................... 2-3

2.3.7 STATUS KEY.............................................................................................................. 2-3

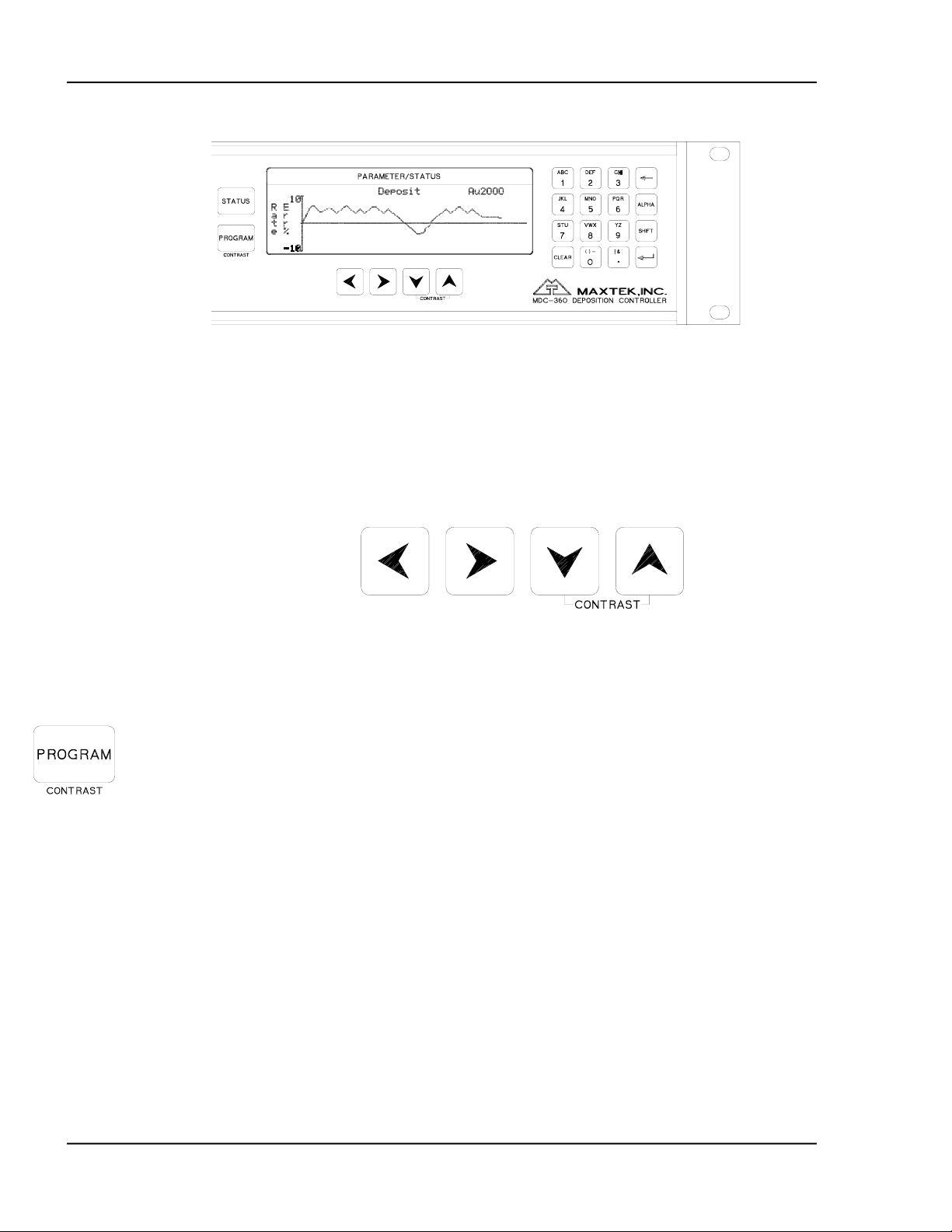

2.3.8 ARROW KEYS............................................................................................................2-4

2.3.9 PROGRAM KEY......................................................................................................... 2-4

2.3.10 ALPHANUMERIC KEYBOARD............................................................................2-5

3. BENCH CHECKOUT & INSPECTION......................................................................... 3-1

3.1 INSPECTION.................................................................................................................3-1

3.2 INITIAL POWER UP..................................................................................................... 3-1

iv

Page 5

3.3

SAMPLE PROGRAM.................................................................................................... 3-1

3.3.1 MATER IAL #1 PARAMETERS.................................................................................. 3-2

3.3.2 MATER IAL #2 PARAMETERS.................................................................................. 3-3

3.3.3 PROCESS PARAMETERS......................................................................................... 3-4

3.4 SIMULATE OPERATION............................................................................................. 3-4

3.5 MANUAL OPERATION............................................................................................... 3-4

3.6 INSTALLING OPTION BOARDS................................................................................ 3-4

3.6.1 SOURCE-SENSOR BOARD ...................................................................................... 3-5

3.6.2 DISCRETE I/O BOARD............................................................................................. 3-5

3.6.3 IEEE -488 OPTION BOARD...................................................................................... 3-5

3.7 DIGITAL TO ANALOG CONVERTER (DAC) CHECKOUT..................................... 3-5

4. PROGRAMMING AND CONTROLLER SETUP........................................................ 4-1

4.1 GENERAL...................................................................................................................... 4-1

4.1.1 NAVIGATING THE MENU STRUCTURE ................................................................ 4-1

4.1.2 ENTERING ALPHA CHARACTERS.......................................................................... 4-2

4.1.3 ENTERING TIME PARAMETERS............................................................................. 4-2

4.1.4 COPYING AND DELETING ..................................................................................... 4-2

4.1.5 PASSWORD PROTECTION...................................................................................... 4-2

4.1.5.1 VIEW/RUN PROCESS PASSWORD ...........................................................................4-3

4.1.5.2 EDIT PROCESS PASSWORD...................................................................................... 4-3

4.1.5.3 EDIT MATERIAL PASSWORD...................................................................................4-3

4.1.6 ADJUSTING PARAMETER/STATUS DISPLAY CONTRAST................................... 4-3

4.2 GETTING STARTED.................................................................................................... 4-4

4.2.1 UTI LI TY SET UP........................................................................................................ 4-4

4.2.2 DAC SET UP.............................................................................................................. 4-4

4.2.3 SOURCE SETUP....................................................................................................... 4-4

4.2.4 SENSOR SETUP........................................................................................................ 4-7

4.2.4.1 EXAMPLE USING MAXTEK’S RSH-600 SIX CRYSTAL SENSOR HEAD ............4-9

4.2.5 INPUT , OU TPUT AND ACTION SETUP.................................................................. 4-9

4.2.6 DI SPL AY SETUP......................................................................................................4-10

4.2.7 MATER IAL SETUP...................................................................................................4-10

4.2.7.1 POWER RAMPS..........................................................................................................4-11

4.2.7.2 AUTOMATIC CRYSTAL SWITCHING.................................................................... 4-12

4.2.7.3 RATE ESTABLISH..................................................................................................... 4-12

4.2.7.4 RATE RAMPS.............................................................................................................4-12

4.2.7.5 RATE SAMPLE MODE.............................................................................................. 4-12

4.2.7.6 RATE DEVIATION ALARM......................................................................................4-12

4.2.8 PROCESS SETUP.....................................................................................................4-13

4.2.9 STARTING A NEW PROCESS..................................................................................4-13

4.2.10 RESUMING A PROCESS FROM ABORT OR HALT..........................................4-13

4.3 DETAILED PROGRAMMING....................................................................................4-13

4.3.1 VIEW/EDIT PROCESS.............................................................................................4-13

4.3.1.1 DEFINE A PROCESS.................................................................................................. 4-14

4.3.2 VIEW/EDIT MATERIAL...........................................................................................4-16

4.3.2.1 DEFINE A MATERIAL...............................................................................................4-16

4.3.3 SYSTEM SETUP.......................................................................................................4-23

4.3.3.1 EDIT DISPLAY SETUP.............................................................................................. 4-23

4.3.3.2 PROGRAM INPUTS...................................................................................................4-24

4.3.3.3 PROGRAM OUTPUTS................................................................................................4-26

4.3.3.4 PROGRAM ACTIONS................................................................................................4-31

4.3.3.5 EDIT SENSOR SETUP................................................................................................4-33

4.3.3.6 EDIT SOURCE SETUP...............................................................................................4-36

4.3.3.7 EDIT DAC SETUP...................................................................................................... 4-39

4.3.3.8 EDIT UTILITY SETUP...............................................................................................4-39

5. OPERATING THE MDC-360.......................................................................................... 5-1

5.1 SIGN-ON SCREEN........................................................................................................ 5-1

5.2 STARTING A NEW PROCESS .................................................................................... 5-1

5.3 STARTING A NEW LAYER........................................................................................ 5-2

v

Page 6

5.4

RESUMING AN ABORTED OR HALTED PROCESS................................................5-2

5.5 STATUS DISPLAYS ..................................................................................................... 5-3

5.6 VIEWING RESULTS..................................................................................................... 5-4

5.7 MODES .......................................................................................................................... 5-7

5.7.1 PROCESS READY......................................................................................................5-7

5.7.2 ABORT ....................................................................................................................... 5-7

5.7.3 HALT (SOFT ABORT) ............................................................................................... 5-7

5.7.4 IN PROCESS..............................................................................................................5-7

5.7.5 NOT SAMP LI NG........................................................................................................5-7

5.7.6 PROCESS COMPLETE ............................................................................................. 5-7

5.7.7 MANUAL....................................................................................................................5-8

5.7.8 SIMULATE.................................................................................................................5-8

5.8 STATES..........................................................................................................................5-8

5.9 TROUBLE, ERROR AND WARNING MESSAGES ................................................... 5-8

5.9.1 DESCRIPTION .......................................................................................................... 5-9

5.9.1.1 MIN RATE&MAX POWER.......................................................................................... 5-9

5.9.1.2 MAX RATE&MIN POWER.......................................................................................... 5-9

5.9.1.3 SYSTEM SETUP MEMORY CORRUPTED................................................................ 5-9

5.9.1.4 PROCESS MEMORY CORRUPTED........................................................................... 5-9

5.9.1.5 MATERIAL MEMORY CORRUPTED...................................................................... 5-10

5.9.1.6 RATE EST. ERROR.................................................................................................... 5-10

5.9.1.7 CRYSTAL FAILURE.................................................................................................. 5-10

5.9.1.8 SOURCE FAULT........................................................................................................ 5-10

5.9.1.9 SENSOR FAULT......................................................................................................... 5-10

5.9.1.10 TIME POWER............................................................................................................. 5-10

5.9.1.11 RATE DEV. ALARM.................................................................................................. 5-10

5.9.1.12 ALARM ACTION ....................................................................................................... 5-10

5.9.1.13 CRYSTAL MARGINAL ............................................................................................. 5-10

5.9.1.14 RATE DEV. ALERT ................................................................................................... 5-11

5.9.1.15 MAX POWER ALERT................................................................................................ 5-11

5.9.1.16 MIN POWER ALERT................................................................................................. 5-11

5.9.1.17 ALERT ACTION......................................................................................................... 5-11

5.9.1.18 XTAL FAIL SWITCH................................................................................................. 5-11

5.9.1.19 XTAL MRGN SWITCH.............................................................................................. 5-11

5.9.1.20 RATE DEV. ATTEN................................................................................................... 5-11

5.9.1.21 MAXIMUM POWER.................................................................................................. 5-11

5.9.1.22 MINIMUM POWER.................................................................................................... 5-11

5.9.1.23 CHANGE POCKET... .................................................................................................. 5-11

5.9.1.24 CHANGE CRYSTAL.................................................................................................. 5-12

5.9.1.25 ATTENTION ACTION............................................................................................... 5-12

vi

6. TUNING THE MDC-360 CONTROL LOOP................................................................. 6-1

6.1 CONTROL LOOP BASICS...................................................................................................6-1

6.2 CONTROL LOOPS APPLIED TO VACUUM DEPOSITION....................................................... 6-2

6.3 ESTABLISHING MDC-360 CONTROL LOOP PARAMETERS................................................ 6-3

7. INPUT/OUTPUT CHARACTERISTICS........................................................................7-1

7.1 SOURCE CONTROL VOLTAGE OUTPUT.................................................................7-1

7.2 SENSOR INPUT ............................................................................................................ 7-1

7.3 DISCRETE OUTPUTS...................................................................................................7-1

7.4 DISCRETE INPUTS.......................................................................................................7-1

7.5 DIGITAL-TO-ANALOG CONVERTER OUTPUTS.................................................... 7-2

7.6 DIGITAL-TO-ANALOG CONVERTER CONTROL INPUTS.................................... 7-2

8. CONTROLLER INSTALLATION ................................................................................. 8-1

8.1 MOUNTING................................................................................................................... 8-1

8.2 PROPER GROUNDING................................................................................................8-1

8.3 EXTERNAL CONNECTIONS ...................................................................................... 8-1

8.3.1 POWER...................................................................................................................... 8-1

Page 7

8.3.2

VOLTAGE SELECTION............................................................................................ 8-1

8.3.3 GROUND LUG.......................................................................................................... 8-2

8.3.4 REMOTE POWER HANDSET................................................................................... 8-2

8.3.5 SOURCE-SENSOR .................................................................................................... 8-2

8.3.6 RS-232 COMMUNICATION...................................................................................... 8-2

8.3.7 DISCRETE INPUT/OUTPUT.................................................................................... 8-3

8.3.8 DIGITAL-TO-ANALOG CONVERTER (DAC).......................................................... 8-3

9. SYSTEM INSTALLATION............................................................................................. 9-1

9.1 SENSOR HEAD DESCRIPTION.................................................................................. 9-1

9.2 SENSOR HEAD INSTALLATION............................................................................... 9-1

9.3 SENSOR OSCILLATOR............................................................................................... 9-2

9.3.1 INSTALLATION ......................................................................................................... 9-2

9.4 INSTRUMENTATION FEEDTHROUGH.................................................................... 9-2

9.5 SENSOR CRYSTAL REPLACEMENT........................................................................ 9-2

9.6 TYPICAL SYSTEM INSTALLATION......................................................................... 9-3

10. THEORY OF OPERATION......................................................................................10-1

10.1 BASIC MEASUREMENT ............................................................................................10-1

10.2 FILM THICKNESS CALCULATION..........................................................................10-1

10.3 CRYSTAL HEALTH CALCULATION.......................................................................10-3

10.4 RATE CALCULATION................................................................................................10-4

10.5 RATE CONTROL.........................................................................................................10-4

10.6 EMPIRICAL CALIBRATION......................................................................................10-4

10.6.1 FILM DENSITY....................................................................................................10-4

10.6.2 TOOLING FACTOR.............................................................................................10-5

10.6.3 ACOUSTIC IMPEDANCE...................................................................................10-5

11. COMPUTER INTERFACE........................................................................................11-1

11.1 GENERAL.....................................................................................................................11-1

11.2 RS-232 SERIAL INTERFACE .....................................................................................11-1

11.3 RS-485 SERIAL INTERFACE .....................................................................................11-1

11.4 IEEE-488 PARALLEL INTERFACE...........................................................................11-2

11.5 PROTOCOL..................................................................................................................11-2

11.6 DATA TYPES...............................................................................................................11-3

11.7 MESSAGE RECEIVED STATUS................................................................................11-3

11.8 INSTRUCTION SUMMARY.......................................................................................11-4

11.9 INSTRUCTION DESCRIPTIONS................................................................................11-5

12. REPAIR AND MAINTENANCE...............................................................................12-1

12.1 HANDLING PRECAUTIONS......................................................................................12-1

12.2 MAINTENANCE PHILOSOPHY................................................................................12-1

12.3 TROUBLE SHOOTING AIDS.....................................................................................12-2

12.4 RETURNING THE MDC-360 TO THE FACTORY....................................................12-3

13. APPENDIX A...............................................................................................................13-1

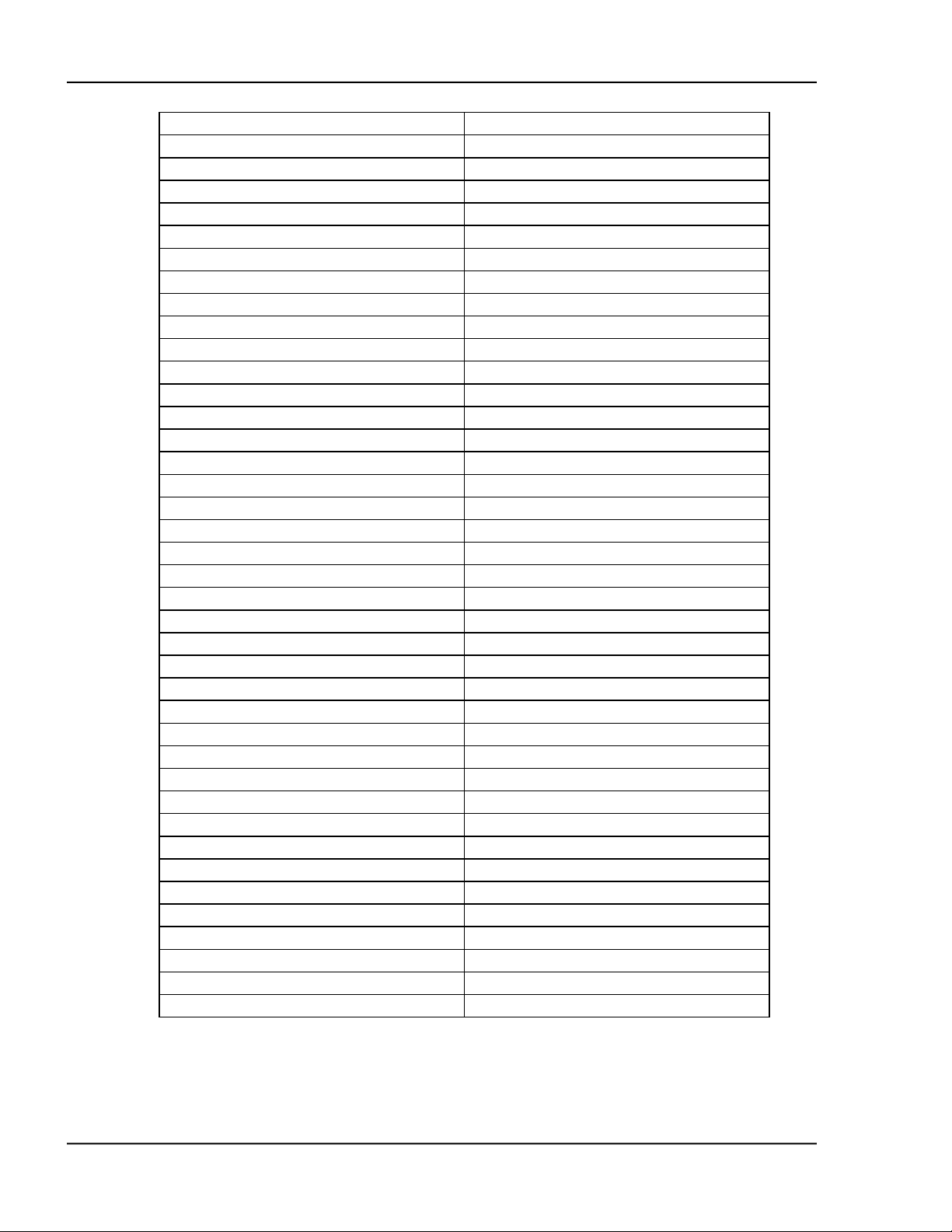

14. APPENDIX B – PARAMETER TEMPLATES........................................................14-2

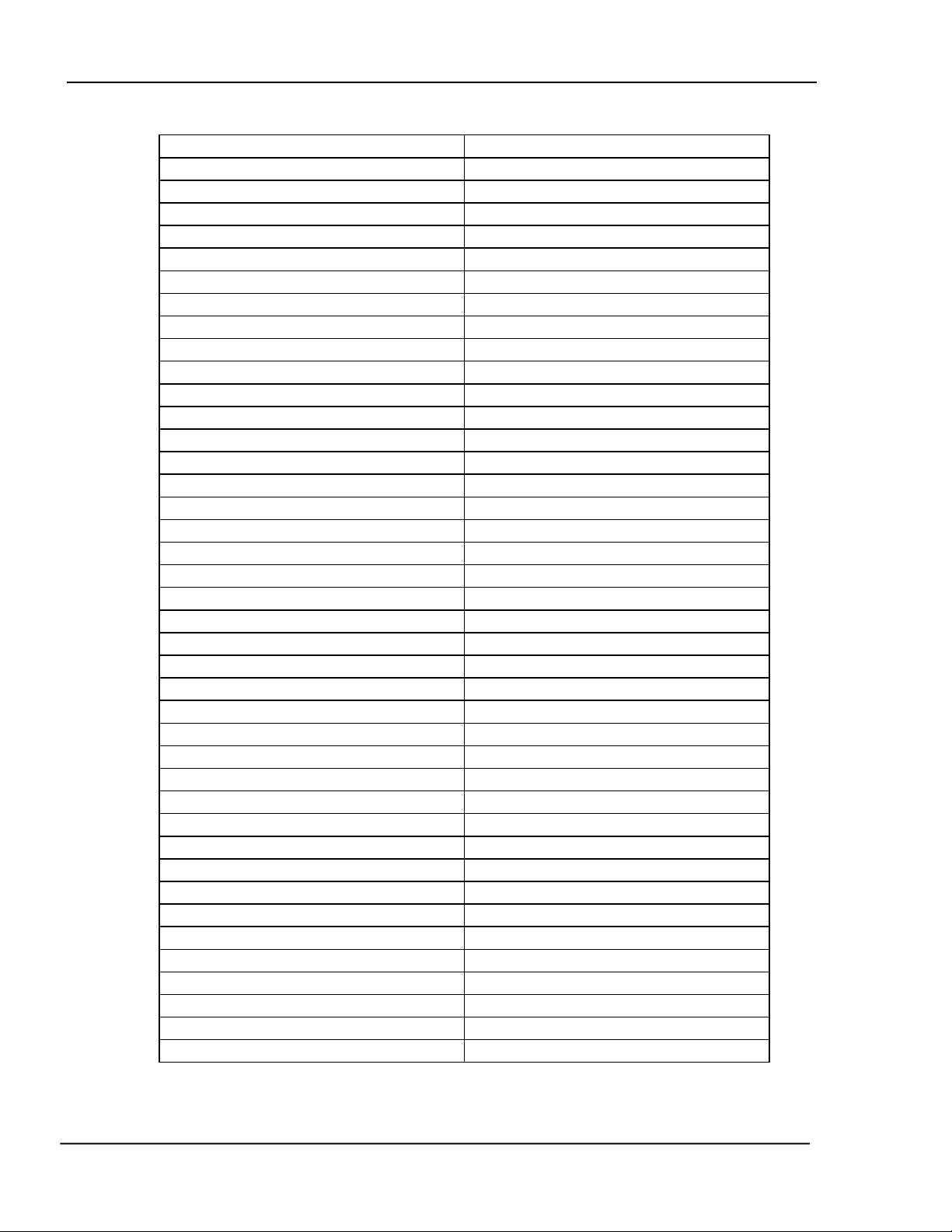

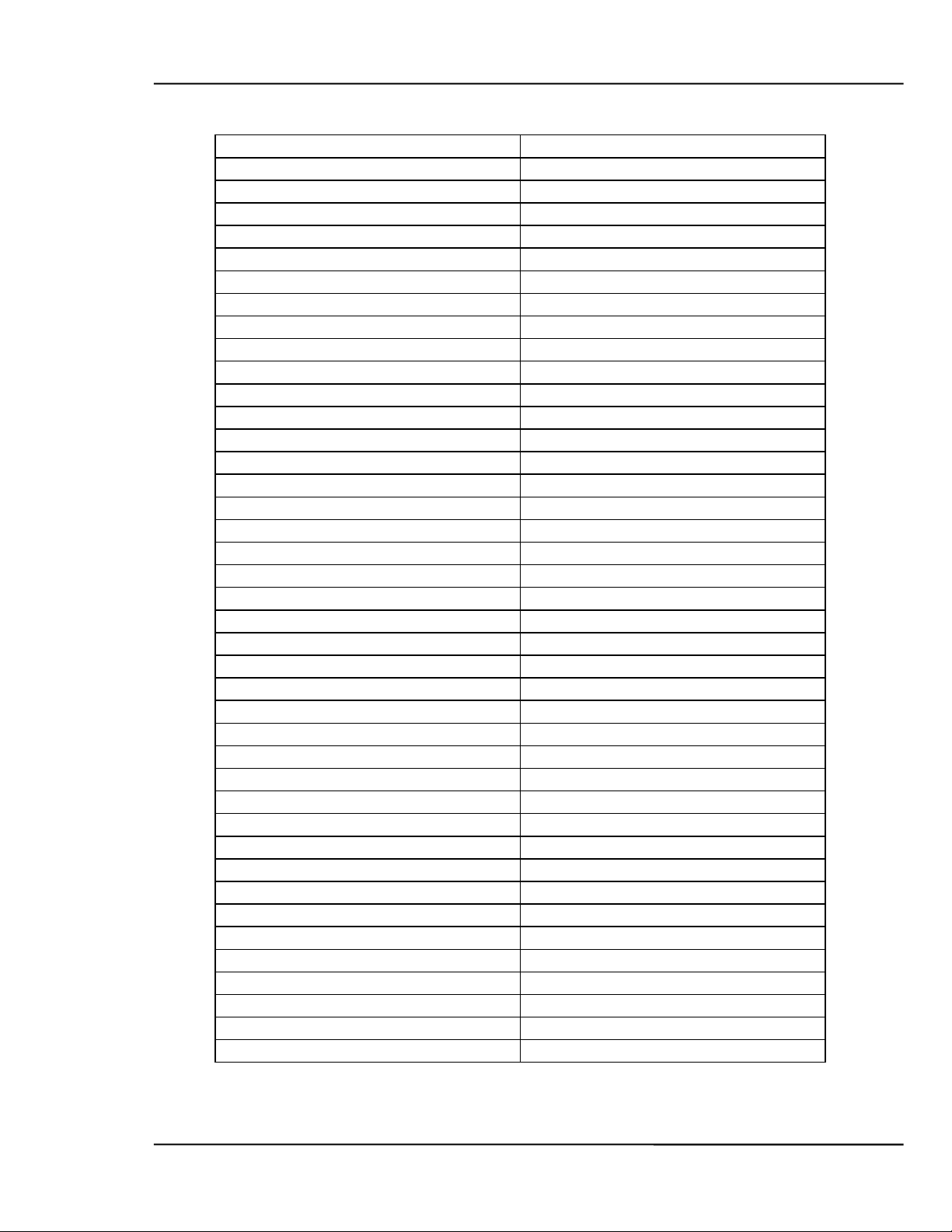

14.1 MATERIAL...................................................................................................................14-3

14.2 PROCESS......................................................................................................................14-5

14.3 DISPLAY SETUP.........................................................................................................14-6

14.4 INPUTS .........................................................................................................................14-7

14.5 OUTPUTS .....................................................................................................................14-8

14.6 ACTIONS......................................................................................................................14-9

14.7 SENSOR SETUP.........................................................................................................14-10

14.8 SOURCE SETUP ........................................................................................................14-10

14.9 DAC SETUP................................................................................................................14-11

vii

Page 8

14.10

UTILITY SETUP........................................................................................................14-11

viii

Page 9

Table of Figures

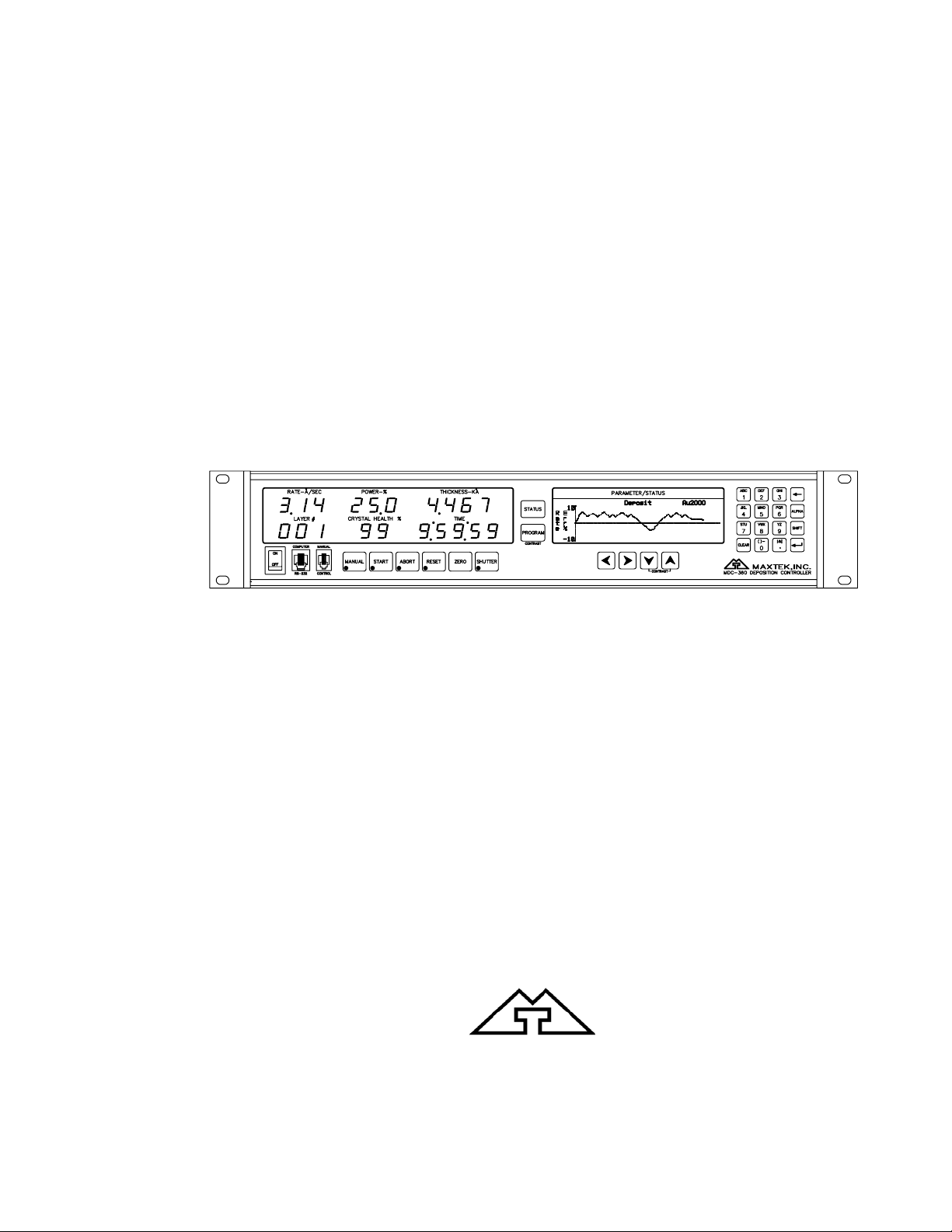

FIGURE 2-1 OPERATING DISPLAY........................................................................................ 2-1

FIGURE 2-2 PARAMETER/STATUS DISPLAY...................................................................... 2-2

FIGURE 2-3 PROGRAMMING SECTION................................................................................ 2-4

FIGURE 2-4 ARROW KEYS...................................................................................................... 2-4

FIGURE 2-5 ALPHANUMERIC KEYBOARD......................................................................... 2-5

FIGURE 3-1 REMOTE POWER HANDSET............................................................................. 3-7

FIGURE 4-1 THE MAIN MENU................................................................................................ 4-1

FIGURE 4-2 SELECT PROCESS SCREEN..............................................................................4-14

FIGURE 4-3 DEFINE PROCESS SCREEN..............................................................................4-14

FIGURE 4-4 SELECT LAYER MATERIAL SCREEN.............................................................4-16

FIGURE 4-5 SELECT MATERIAL SCREEN............................................................................4-16

FIGURE 4-6 DEFINE MATERIAL SCREEN............................................................................4-17

FIGURE 4-7 SYSTEM SETUP MENU SCREEN.....................................................................4-23

FIGURE 4-8 DISPLAY SETUP SCREEN.................................................................................4-23

FIGURE 4-9 SELECT OUTPUT SCREEN ...............................................................................4-27

FIGURE 4-10 PROGRAM OUTPUT SCREEN ........................................................................4-27

FIGURE 4-11 SENSOR SETUP SCREEN................................................................................4-33

FIGURE 4-12 SOURCE SETUP SCREEN................................................................................4-36

FIGURE 4-13 DAC SETUP SCREEN.......................................................................................4-39

FIGURE 4-14 UTILITY SETUP SCREEN................................................................................4-39

FIGURE 5-1 SIGN-ON SCREEN............................................................................................... 5-1

FIGURE 5-2 RUN PROCESS SELECTION SCREEN .............................................................. 5-2

FIGURE 5-3 RATE VS. TIME GRAPH..................................................................................... 5-3

FIGURE 5-4 RATE DEVIATION VS. TIME GRAPH .............................................................. 5-3

FIGURE 5-5 THICKNESS VS. TIME GRAPH.......................................................................... 5-3

FIGURE 5-6 POWER VS. TIME GRAPH.................................................................................. 5-4

FIGURE 5-7 SOURCE/SENSOR STATUS SCREEN................................................................ 5-4

FIGURE 5-8 I/O STATUS SCREEN.......................................................................................... 5-4

FIGURE 5-9 VIEW RESULTS SCREEN................................................................................... 5-6

FIGURE 5-10 RATE VS. TIME PROCESS LOG GRAPH........................................................ 5-6

FIGURE 5-11 TYPICAL PROCESS PROFILE.........................................................................5-13

FIGURE 7-1 PASSIVE INPUT BUFFER CIRCUIT.................................................................. 7-3

FIGURE 7-2 ACTIVE INPUT BUFFER CIRCUIT..................................................................... 7-4

FIGURE 7-3 DAC OUTPUT CIRCUIT...................................................................................... 7-5

FIGURE 7-4 SENSOR INPUT BUFFER CIRCUIT.................................................................. 7-6

FIGURE 7-5 SOURCE OUTPUT DRIVER CIRCUIT............................................................... 7-7

FIGURE 8-1 MDC-360 FRONT PANEL.................................................................................... 8-4

FIGURE 8-2 MDC-360 REAR PANEL...................................................................................... 8-5

FIGURE 8-3 DAC SOCKET CONNECTOR PIN OUT............................................................. 8-6

FIGURE 8-4 SOURCE SOCKET CONNECTOR PIN OUT...................................................... 8-6

FIGURE 8-5 D9S DTE REAR-PANEL RS-232 SOCKET CONNECTOR................................ 8-7

FIGURE 8-6 D37P DISCRETE I/O PLUG CONNECTOR......................................................... 8-8

FIGURE 8-7 RJ11 FRONT PANEL RS-232 CONNECTOR ..................................................... 8-9

FIGURE 8-8 FRONT PANEL MANUAL POWER CONNECTOR.......................................... 8-9

FIGURE 8-9 MDC-360 TOP VIEW (COVER REMOVED).....................................................8-10

FIGURE 9-1 SENSOR OSCILLATOR SCHEMATIC............................................................... 9-4

FIGURE 9-2 SENSOR OSCILLATOR OUTLINE..................................................................... 9-5

FIGURE 9-3 IF-111 INSTRUMENTATION FEEDTHROUGH OUTLINE.............................. 9-6

FIGURE 9-4 SH-102 SENSOR HEAD OUTLINE..................................................................... 9-7

FIGURE 9-5 TYPICAL SYSTEM INSTALLATION................................................................. 9-8

FIGURE 13-1 PLUG PIN OUT - SOURCE CABLE CONNECTOR.........................................13-1

FIGURE 13-2 PLUG PIN OUT - DAC CABLE CONNECTOR................................................13-2

FIGURE 15-1 MENU MAP ........................................................................................................15-1

ix

Page 10

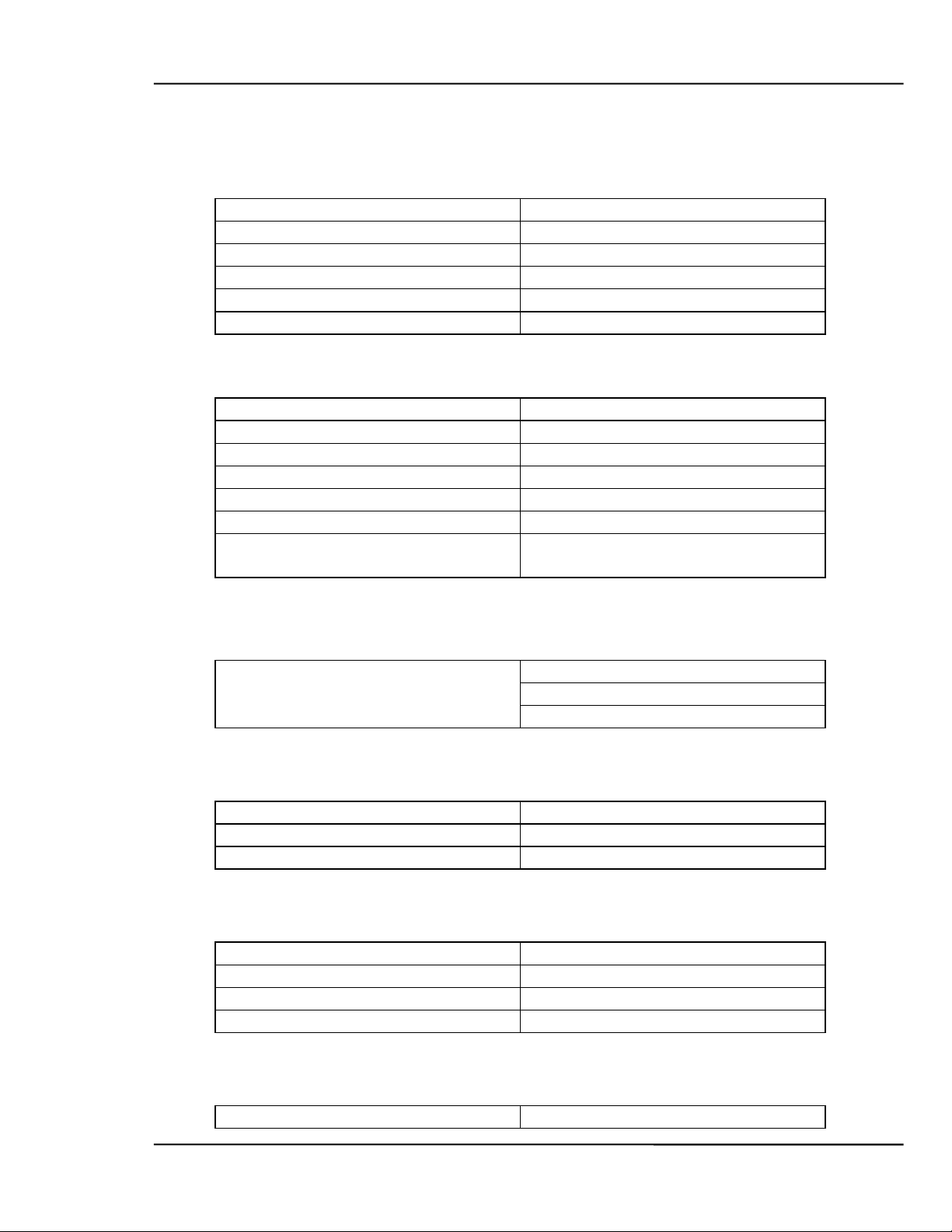

List of Tables

TABLE 5-1 TROUBLE CONDITIONS AND WARNINGS......................................................5-9

TABLE 8-1 DAC SYSTEM INTERFACE CONNECTOR PIN ASSIGNMENTS....................8-6

TABLE 8-2 SOURCE CONTROL SYSTEM INTERFACE CONNECTOR PIN

ASSIGNMENTS ................................................................................................................. 8-6

TABLE 8-3 D9 REAR PANEL RS-232/RS-485 CONNECTOR PIN ASSIGNMENTS............ 8-7

TABLE 8-4 DISCRETE I/O SYSTEM INTERFACE CONNECTOR PIN ASSIGNMENTS....8-8

TABLE 8-5 RJ11 FRONT PANEL RS-232 CONNECTOR PIN ASSIGNMENTS................... 8-9

TABLE 8-6 FRONT PANEL MANUAL POWER CONNECTOR PIN ASSIGNMENTS........ 8-9

TABLE 10-1 MATERIAL DENSITY AND ACOUSTIC IMPEDANCE VALUE...................10-6

TABLE 13-1 SOURCE CONTROL CABLE COLOR CODE - (4 PIN MINI DIN)...............13-1

TABLE 13-2 DAC CABLE COLOR CODE - (7 PIN MINI DIN).........................................13-2

x

Page 11

MDC-360 DEPOSITION CONTROLLER

1. GENERAL DESCRIPTION

1.1 PURPOSE

The MDC-360 provides both automatic control of single or multi-layer film

deposition in either a production or development environment and improved

predictability and repeatability of deposited film characteristics through

dependable digital control of the deposition process. It runs unattended in the

fully automatic mode and provides such features as run completion in the event of

crystal failure, and extensive internal checking. Performance limits and the abort

feature can be set by the user.

1.2 FEATURES

The MDC-360 incorporates numerous features which are economically justifiable

as a result of rapid advances in semiconductor technology and the advent of low

cost microprocessors.

1.2.1 EXTENSIVE PROGRAM STORAGE

The MDC-360 is capable of storing up to 99 processes, 999 layer definitions and

32 complete material definitions. Once a program is entered it will be maintained

in memory for a minimum of 5 years without external power.

1.2.2 DYNAMIC MEASUREMENT UPDATE RATE

Measurement is dynamically adjusted from 0.5 to 10 Hz for optimum resolution

and control.

1.2.3 SUPERIOR GRAPHICS DISPLAY

The MDC-360 features a 256x64 pixel LCD graphics display allowing real time

graphing of important process information such as rate, rate deviation, thickness

and power.

1.2.4 PROGRAM SECURITY

To assure the integrity of stored programs, the MDC-360 incorporates edit

passwords to guard against unauthorized program changes.

1.2.5 DESIGNED FOR UNATTENDED OPERATION

The MDC-360 has been designed for truly automatic operation and toward this

end incorporates extensive internal monitoring and overriding abort circuitry to

minimize the possibility of damage in the event of a failure or other problem in

the total deposition system. In addition there are attention, alert and alarm signals

with adjustable volume for trouble and routine operator call.

1.2.6 FAIL SAFE ABORTS

In the event of an MDC-360 failure, as evidenced by unsatisfactory internal

checks, the MDC-360 will abort the process and shut off all outputs. In addition

to the internal checks, the MDC-360 also provides user enabled aborts on

excessive rate control error or crystal failure.

GENERAL DESCRIPTION 1-1

Page 12

MDC-360 DEPOSITION CONTROLLER

1.2.7 ABORT STATUS RETENTION

In the event that the MDC-360 does abort during the deposition process, pertinent

information is stored at the time of abort. The process can be resumed after the

problem is corrected.

1.2.8 RUN COMPLETION ON CRYSTAL FAILURE

The extensive monitoring and abort functions are designed to protect the system

and/or process from serious and hopefully infrequent malfunctions of the

deposition system. A condition which need not cause an abort is the condition of

crystal failure. The MDC-360 can be set to abort upon crystal failure, or run to

completion using a backup crystal or time/power method.

1.2.9 POWERFUL SYSTEM INTERFACE

Fully programmable discrete inputs and outputs permit the MDC-360 to be easily

interfaced into deposition systems controlling the most complex processes. Also,

source control outputs are fully isolated avoiding ground loop problems. The

MDC-360 also supports input from an optical monitor for optical termination of

film thickness.

1.2.10 POWER SUPPLY NOISE TOLERANCE

Integral RFI filter and large energy storage capacitors will tolerate high levels of

power supply noise and power interruptions of 700 ms or less without effect.

1.2.11 INTERNATIONAL STANDARD POWER CONNECTOR

The power connector is internationally approved and meets IEC (International

Electrotechnical Commission) standards. It allows selection of input power

voltages ranging from 100 to 240 volts at a frequency of 50 or 60 Hz and includes

an integral RFI filter.

1.2.12 FIELD UPGRADABLE

Plug-in interface boards and option boards allow the basic unit to be upgraded in

the field to the maximum system level.

GENERAL DESCRIPTION 1-2

Page 13

MDC-360 DEPOSITION CONTROLLER

1.3 SPECIFICATIONS

1.3.1 MEASUREMENT

Frequency Resolution 0.03 Hz @6.0 MHz

Mass Resolution 0.375 ng/cm

2

Thickness Accuracy 0.5% + 1 count

Measurement Update Rate Dynamically adjusted, 0.5 to 10 Hz

Display Update Rate 10 Hz

Sensor Crystal Frequency 2.5, 3, 5, 6, 9, 10 MHz

1.3.2 DISPLAY

Thickness Display Autoranging: 0.000 to 999.9 KÅ

Rate Display Autoranging: 0.0 to 999 Å/sec

Power Display 0.0 to 99.9%

Time To Go 0 to 9:59:59 H:MM:SS

Crystal Health % 0 to 99%

Layer Number 1 to 999

Graphics Display 256X64 LCD with CCFL

backlighting

1.3.3 COMMUNICATION

RS-232 serial port standard

RS-485 serial port optional

IEEE-488 bus interface optional

1.3.4 PROGRAM STORAGE CAPACITY

Process 99, user definable

Layer 999, user definable

Material 32, user definable

1.3.5 PROCESS PARAMETERS

Process Name 12 character string

Edit password 4 character string

Run/View password 4 character string

Layer# 1 to 999 Material name, Thickness

1.3.6 MATERIAL PARAMETERS

Material Name 10 character string

GENERAL DESCRIPTION 1-3

Page 14

MDC-360 DEPOSITION CONTROLLER

Sensor # 1 to 4

Crystal # 1 to 8

Source # 1 to 4

Pocket # 1 to 8

Material Density 0.80 to 99.9 gm/cm

3

Acoustic Impedance 0.50 to 59.9 gm/cm2 sec

Tooling Factor 10.0 to 499.9%

Proportional gain 0.00 to 9999

Integral Time constant 0 to 99.9 sec

Derivative Time constant 0 to 99.9 sec

Rise to Soak Time 0 to 9:59:59 H:MM:SS

Soak Power 0 to 99%

Soak Time 0 to 9:59:59

Rise to Predeposit Time 0 to 9:59:59

Predeposit Power 0 to 99.9%

Predeposit Time 0 to 9:59:59

Rate Establish Time 0 to 60 sec

Rate Establish Error 0 to 99.9%

Deposition Rate (1 to 5) 00.0 to 999.9 Å/sec

Rate Ramp Start (1 to 4) 0.000 to 999.9 KÅ

Rate Ramp Stop (1 to 4) 0.000 to 999.9 KÅ

Time Setpoint 0 to 9:59:59

Ramp to Feed Time 0 to 9:59:59

Feed Power 0 to 99.9%

Feed Time 0 to 9:59:59

Ramp to Idle Time 0 to 9:59:59

Idle Power 0 to 99.9%

Maximum Power 0 to 99.9%

Power Alarm Delay 0 to 99 sec

Minimum Power 0 to 99.9%

Rate Deviation Attention 0 to 99.9%

Rate Deviation Alarm 0 to 99.9%

Rate Deviation Abort 0 to 99.9%

Sample Dwell % 0 to 100.0%

Sample Period 0 to 9:59:59

Crystal Fail Switch, Time Power, or Halt

Backup Sensor # 1 to 4

Backup Crystal # 1 to 8

Backup Tooling Factor 0 to 499.9%

Material Password 4 character string

The MDC-360 also has a built in material library that contains many common

material names along with their density and acoustic impedance values.

GENERAL DESCRIPTION 1-4

Page 15

MDC-360 DEPOSITION CONTROLLER

1.3.7 INPUT/OUTPUT CAPABILITY

Sensor Inputs 2 Standard and 2 optional BNC inputs

Source Outputs 2 Standard and 2 optional fully

isolated, 2.5, 5, 10 volts @ 20 ma.

0.002% resolution

Discrete Inputs 8 Standard and 8 optional fully

programmable inputs.

The Passive I/O card (PN#179216)

has TTL level inputs activated by a

short across the input pins.

The Active I/O card (PN#179239) has

inputs activated by 12 to 120 volt

AC/DC across the input pins.

Discrete Outputs 8 standard and 8 optional fully

programmable, SPST relay, 120VA,

2A max.

Abort Output 1 standard and 1 optional SPST

Relay, 120VA, 2A max.

Remote Power Handset Front panel, RJH jack

RS-232 Communication Rear panel, 9 pin, Full duplex, DTE

Front panel, RJ11 jack, Full duplex

DAC Recorder Outputs Two 0 to 5 volts, 0.02% resolution

1.3.8 SENSOR PARAMETERS

Number of Crystals 1 to 8

Shutter Relay Type Normally open, normally closed,

dual, or none.

Position Control Manual, direct, BCD, or individual.

Position Drive Up, down, Fast, inline, single step, or

double step.

Feedback Type Individual, BCD, single home, in

position, or no feedback.

Rotator Delay 0 to 99 sec

1.3.9 SOURCE PARAMETERS

Number of Pockets 1 to 8

Shutter Relay Type Normally open, normally closed, or

none.

Shutter Delay 0.0 to 9.9 sec

Position Control Manual, direct, BCD, or individual.

Position Drive Up, down, Fast, inline, single step, or

double step.

Feedback Type Individual, BCD, single home, in

position, or no feedback.

GENERAL DESCRIPTION 1-5

Page 16

MDC-360 DEPOSITION CONTROLLER

Rotator Delay 0 to 99 sec

Source Voltage Range 2.5, 5, 10 volts

1.3.10 RECORDER PARAMETERS

Recorder #1/#2 Output Rate, rate dev., power or thickness

Recorder #1/#2 Scale Full scale %, 2/3 digit

1.3.11 UTILITY SETUP PARAMETER

Crystal Frequency 2.5, 3, 5, 6, 9, 10 MHz

Simulate Mode On/Off

Interface Address 1 to 32

Attention Volume 0 to 10

Alert Volume 0 to 10

Alarm Volume 0 to 10

Data Points/Minute 30,60,120,300,600 PPM

Time 0 to 23:59

Date MM/DD/YY

1.3.12 OTHER

Input Power Requirements 100, 120, 200, 240 VAC; 50/60 Hz;

25 watts

Operating Temperature Range

0 to 50°C

Physical Weight 10 LB

Physical Size 19” rackmount case

3 1/2” high x 9 3/8” deep

1.4 ACCESSORIES

Part Number Description

179215 Dual Source/Sensor Board

179216 Passive I/O Board

179217 IEEE-488 Communication Board

179218 Internal Storage Data/Time Clock

179219 RS-232 to RS-485 conversion

179220 Remote Power Handset

179239 Active I/O Board

180200-4 DCM-200 software 3.5” diskette

123200-5 SH-102 Sensor Head , cables, and

carousel of 10 each 6MHz Gold SC-

101 sensor crystals

124201-4 SO-100 Oscillator with 6" and 10'

BNC Cables.

GENERAL DESCRIPTION 1-6

Page 17

MDC-360 DEPOSITION CONTROLLER

130200-2 IF-111 Instrument Feedthrough, 1" O-

Ring with 1 electrical connector and

dual 3/16" water tubes.

130204-2 IF-276 Instrumentation Feedthrough,

2 3/4" Conflat® Flange seal with 1

electrical connector and dual 3/16"

water tubes.

150902 SF-120 Combination Sensor Head,

Feedthrough, Cables, Crystals and

Oscillator.

123204-1 Internal Coax Cable 30".

123204-2 Internal Coax Cable 60".

124202-1 BNC Cable Assembly 10'.

124202-2 BNC Cable Assembly 20'

124204 BNC Cable Assembly 6".

103220 SC-101 Carousel of 10 each 6MHz

gold sensor crystals.

103221 SC-102 Carousel of 10 each 6MHz

silver sensor crystals.

Refer to Maxtek Price List for more accessories and other products.

GENERAL DESCRIPTION 1-7

Page 18

Page 19

MDC-360 DEPOSITION CONTROLLER

2. FRONT PANEL DISPLAYS AND CONTROLS

The front panel is divided into two sections, the operating section and the

programming section. The left half of the panel is devoted to the operating

displays and controls. The right half is used for programming, viewing stored

processes, and displaying the status of the selected process.

2.1 OPERATING DISPLAYS

All of the operating displays are updated ten times per second unless the

controller is in the Abort mode. When in the Abort mode, the values of the

operating displays are held constant so the operator will know the values at the

time of the Abort. The controller will also flash the operating displays while in

Abort to alert the operator.

Figure 2-1 Operating Display

2.1.1 RATE

A three digit display with a floatin

g decimal point is used to display deposition

rate in angstroms per second at a resolution of 0.1 Å/sec from 0 to 99.9 Å/sec, and

a resolution of 1.0 Å/se

2.1.2 POWER

A three digit display with a fixed decimal point displays percent of m

c for rates from 100 to 999 Å/sec.

aximum

power with a resolution of 0.1% from 0 to 99.9%. This corresponds to the control

voltage range of 0 to 9.99 v

2.1.3 THICKNESS

Four digits with an autoranging

olts.

decimal point display measured thickness in KÅ

with a resolution of 1 Å from 0 to 9.999 KÅ, a resolution of 10 Å from 10.00 KÅ

to 99.99 KÅ and a resolution of 100 Å from 100.0 KÅ

2.1.4 LAYER NUMB

ER

to 999.9 KÅ.

Three digits display the layer number of the current process.

2.1.5 CRYSTAL

HEALTH %

A two digit display is used to show the health percentage of the sensor crystal in

use. A fresh crystal starts out with a health of 99%.

FRONT PANEL DISPLAYS AND CONTROLS

2-1

Page 20

MDC-360 DEPOSITION CONTROLLER

p

2.1.6 TIME TO GO

Time To Go is displayed in hours, minutes and seconds. This display can be

configured to show the estimated state or layer time or the elapsed process, lay

er

or state times.

2.2 PARAMETER/STATUS DISPLAYS

A graphics display labeled Parameter/Status is used for process programming and

controller setup as w

operator can switch between programming screens and status screens by

ell as displaying run time status and data graphing. The

pressing

the Program and Status keys on the front panel. Upon power up, the

Parameter/Status display automatically reverts to the last viewed status screen.

Detail descriptions of the different programming and status screens can be found

in Section 4 and 5.

Displays the current

rocess name.

Figure 2-2 Parameter/Status Display

2.3 OPERATING CONTROLS

Normal operation of the MDC-360 is controlled by seven operating keys, Manu

Start, Abort, Reset, Zero, Shutter and Status. Except for the Zero and Status key

each of the other keys is equipped with an LED to indicate the controller’s statu

2.3.1 MANUAL KEY

This key is used to toggle the MDC-360 Manual mode on and off. A red light

behind this key indicates the controller is in manual power control mode. This

mode may be selected at any time providing that the controller is not in Abort

mode. The Manual mode indicates that the source control voltage output is bei

contro

voltage remains constant unless incremented up or down by means of the Rem

Power Handset. At entry into the Manual mode, the power is left at the

prior to entry and is thereafter modified only through the Remote Power Handset.

Exit from the manual mode is accomplished by means of the Manual or Reset

key.

Displays the current

material name.

Sample Cr Process Ready

10

R

a

t

e

0

1

Displays the

controller modes,

states or troubles.

Displays the ti

axis scale facto

lled through the Remote Power Handset. In the Manual mode the control

last value

me

r

al,

s,

s.

ng

ote

The MDC-360 can also be aborted through the Remote Power Handset. This

abort feature is active whether or not MDC-360 is in the manual mode.

FRONT PANEL DISPLAYS AND CONTROLS 2-2

Page 21

MDC-360 DEPOSITION CONTROLLER

2.3.2 START KEY

The Start key starts a process, starts a layer, or resumes an aborted process. A

green light behind this key indicates the controller is in process. When this key is

pressed the first time a list of stored processes is displayed in the Parameter/Status

window. The up and down arrow keys can be used to move the cursor to the

desired process. Press the Start key again to start that process. Note that in many

cases messages will be displayed in the Parameter/Status window reminding the

operator to check system set up. Follow the prompt.

2.3.3 ABORT KEY

The Abort key drives the MDC-360 into the Abort mode. All source powers are

set to zero and discrete outputs are set to inactive state. A red light behind this

key indicates the controller is in the abort mode.

2.3.4 RESET KEY

The Reset key is used to clear the controller from Abort mode and put it into the

Ready mode. A yellow light behind this key indicates a Ready mode. The Reset

key is inactive during the In Process mode so that a premature exit from the In

Process mode requires an abort.

2.3.5 ZERO KEY

Pressing the Zero key causes the thickness display to go to zero. This key is

active at all times and if pressed during the deposit state will result in a film

thicker than that desired by an amount equal to the thickness displayed at the time

the display was zeroed.

2.3.6 SHUTTER KEY

This key is used to manually open and close all source shutters. The red light is

illuminated when the active source shutter relay is closed. This key is only active

when the controller is in the Process Ready mode.

2.3.7 STATUS KEY

Pressing the Status key will bring up one of the six run-time status screens.

Repeatedly pressing the key will cycle through the different status screens. Refer

to Section 5 for a detailed description of these status screens.

FRONT PANEL DISPLAYS AND CONTROLS

2-3

Page 22

MDC-360 DEPOSITION CONTROLLER

Figure 2-3 Programming Section

2.3.8 ARROW KEYS

The arrow keys are used to navigate through the programming and setup menu

structure. These keys will auto-repeat if they are held down for more than half a

second.

Figure 2-4 Arrow Keys

2.3.9 PROGRAM KEY

Pressing the programming key will bring up the last viewed programming screen.

If a programming screen is already shown, nothing will happen. This key is also

used in conjunction with the Up and Down Arrow keys to adjust the contrast of

the Parameter/Status display.

FRONT PANEL DISPLAYS AND CONTROLS 2-4

Page 23

MDC-360 DEPOSITION CONTROLLER

2.3.10 ALPHANUMERIC KEYBOARD

Figure 2-5 Alphanumeric Keyboard

The alphanumeric keyboard is used to

edit controller programs. Refer to

Section 4 for the use of each key.

‘Backspace’

‘Enter’

FRONT PANEL DISPLAYS AND CONTROLS

2-5

Page 24

Page 25

MDC-360 DEPOSITION CONTROLLER

3. BENCH CHECKOUT & INSPECTION

3.1 INSPECTION

Your MDC-360 was released to the carrier in good condition and properly

packed. It is essential to all concerned that the contents of the shipment be

carefully examined when unpacked to assure that no damage occurred in transit.

Check the material received against the packing list to be certain that all elements

are accounted for. Items included with your controller are:

1 MDC-360 Deposition Controller

1 Operation and Service Manual

1 Power cord

1 Source cable (4 pin mini DIN connector)

1 Discrete I/O connector kit (37P D shell)

In addition, you may have ordered one or more of the accessories listed in Section

1.4. If there is evidence of loss or damage:

a) Notify the carrier or the carrier agent to request inspection of the loss

or damage claimed.

b) Keep the shipping containers until it is determined whether or not they

are needed to return the equipment to Maxtek.

3.2 INITIAL POWER UP

Upon initial power up the unit will start with all LED’s lighted. The

Parameter/Status display will show the controller Sign-on screen with its

configuration information. The unit will stay in this state until a key is pressed.

When any key on the front panel is pressed, the operating display and the

Parameter/Status display will return to the last viewed screen prior to loss of

power.

3.3 SAMPLE PROGRAM

The sample program listed below is included in the MDC-360 memory at the time

of shipment. It can be used to check out the controller by running it in Simulate

mode. Follow instructions in Section 4 to navigate through the menu structure.

Check the controller parameter values against the sample program for discrepancy

and change if necessary. Note also, if the source or sensor configuration has been

changed during familiarization with the controller programming, appropriate

source and sensor parameter values also need to be retained for the sample

program to run correctly.

Once the sample program has been checked, use the programming Main Menu,

Edit System Setup, Edit Utility Setup, to select Simulate mode ON, then use Start

to select and run the sample program in Simulate mode.

BENCH CHECKOUT & INSPECTION

3-1

Page 26

MDC-360 DEPOSITION CONTROLLER

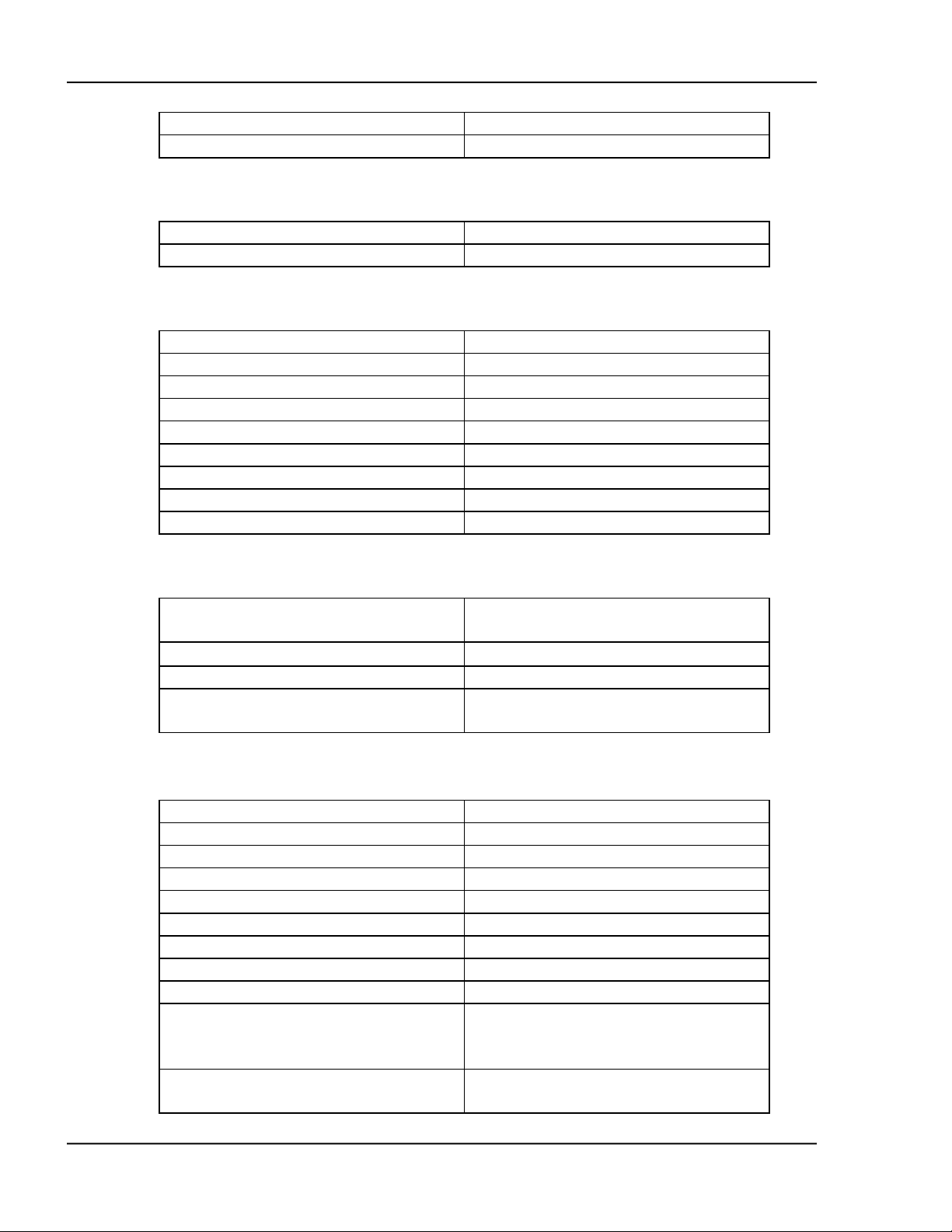

3.3.1 MATERIAL #1 PARAMETERS

Material Name Cr

Sensor # 1

Crystal # 1

Source # 1

Pocket # 1

Material Density 07.20 gm/cm

3

Acoustic Impedance 28.95 gm/cm2 sec

Tooling Factor 70 %

Proportional gain 2400

Integral Time constant 99.9

Derivative Time constant 0.00

Rise to Soak Time 0:00:10 H:MM:SS

Soak Power 5 %

Soak Time 0:00:10

Rise to Predeposit Time 0:00:10

Predeposit Power 9.5 %

Predeposit Time 0:00:05

Rate Establish Time 0 sec

Rate Establish Error 0 %

Deposition Rate #1 10.0 Å/sec

Rate Ramp Start (1 to 4) 999.9 KÅ

Rate Ramp Stop (1 to 4) 999.9 KÅ

Time Setpoint 0

Ramp to Feed Time 0:00:05

Feed Power 7 %

Feed Time 0:00:10

Ramp to Idle Time 0

Idle Power 0

Maximum Power 20 %

Power Alarm Delay 5 sec

Minimum Power 0 %

Rate Deviation Attention 0 %

Rate Deviation Alarm 0 %

Rate Deviation Abort 0 %

Sample Dwell % 100.0 %

Sample Period 0

Crystal Fail Time Power

Backup Sensor # 1

Backup Tooling Factor 100

Backup Crystal # 1

Material Password 0000

3-2 BENCH CHECKOUT & INSPECTION

Page 27

MDC-360 DEPOSITION CONTROLLER

3.3.2 MATERIAL #2 PARAMETERS

Material Name Au

Sensor # 2

Crystal # 1

Source # 1

Pocket # 2

Material Density 19.30 gm/cm

3

Acoustic Impedance 23.18 gm/cm2 sec

Tooling Factor 70 %

Proportional gain 5000

Integral Time constant 99.9

Derivative Time constant 0.00

Rise to Soak Time 0:00:05 H:MM:SS

Soak Power 25 %

Soak Time 0:00:05

Rise to Predeposit Time 0:00:05

Predeposit Power 37.5 %

Predeposit Time 0:00:10

Rate Establish Time 0 sec

Rate Establish Error 0 %

Deposition Rate #1 20.0 Å/sec

Rate Ramp Start (1 to 4) 999.9 KÅ

Rate Ramp Stop (1 to 4) 999.9 KÅ

Time Setpoint 0

Ramp to Feed Time 0:00:05

Feed Power 10 %

Feed Time 0:00:10

Ramp to Idle Time 0

Idle Power 0

Maximum Power 50 %

Power Alarm Delay 5 sec

Minimum Power 0 %

Rate Deviation Attention 0 %

Rate Deviation Alert 0 %

Rate Deviation Alarm 0 %

Sample Dwell % 100.0 %

Sample Period 0

Crystal Fail Time Power

Backup Sensor # 1

Backup Tooling Factor 100

Backup Crystal # 1

Material Password 0000

BENCH CHECKOUT & INSPECTION

3-3

Page 28

MDC-360 DEPOSITION CONTROLLER

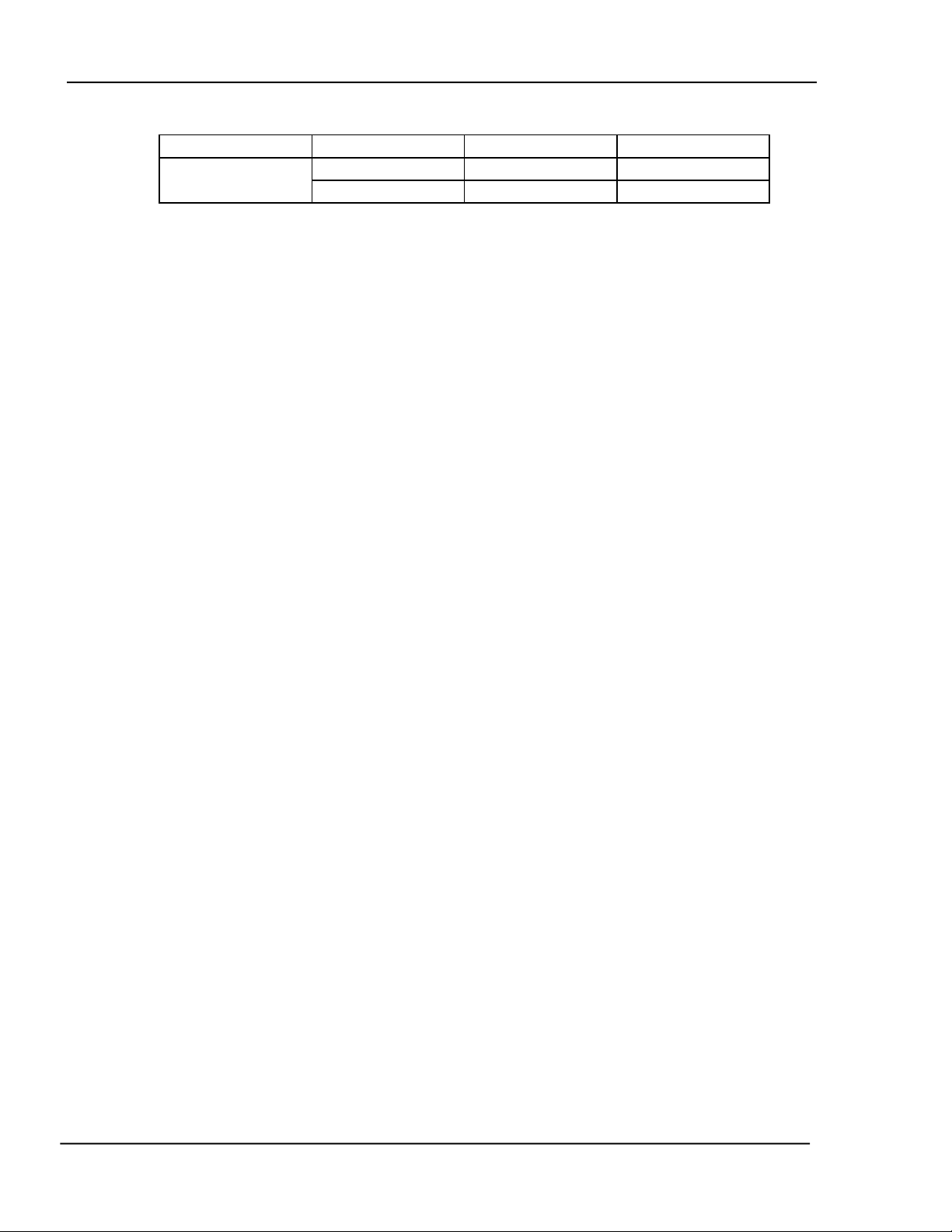

3.3.3 PROCESS PARAMETERS

Process Name Layer No. Thickness Material

Sample 1 0.400 KÅ Cr

2 1.050 KÅ Au

3.4 SIMULATE OPERATION

Testing the MDC-360 is best accomplished by checking its operation in the

Simulate mode. This mode can be selected by using the programming Main

Menu, Edit System Setup, Edit Utility Setup, to select Simulate mode ON, then

use Start to select and run a process in Simulate mode.

The Simulate mode is identical to the Normal mode except that the sensor input is

simulated. For this reason, entry to the Simulate mode will extinguish the Crystal

Failure message if it is flashing. No other difference between the Simulate mode

and the Normal mode occurs until entry to the Deposit State.

3.5 MANUAL OPERATION

Manual Mode is selected by depressing the Manual key. The LED behind the key

will light up indicating the controller is in Manual mode.

The Manual Mode is identical to the normal mode in all respects except that

source power is controlled only through the Remote Power Handset.

The Remote Power Handset has three push buttons, see Figure 3-1. Without any

of the buttons depressed, the output power is maintained at its last value.

Depressing the “PWR UP” button will increase the power, depressing the “PWR

DN” button will decrease the power and depressing the “ABORT” button will put

the controller into the Abort mode.

The Abort Mode is active whether or not the MDC-360 is in Manual Mode and

therefore can be used as a remote “panic button”.

The minimum increment by which the power is increased or decreased is 0.1%.

The Remote Power Handset can also be used to initiate a manual sensor and

crystal change by depressing both the power increase and decrease buttons

simultaneously. Each time a sensor/crystal switch is initiated, the controller will

toggle between the primary and the backup sensor/crystal combination as defined

by the active material’s parameters. The sensor/crystal switching function is only

operational when the controller is not in the Manual Mode.

3.6 INSTALLING OPTION BOARDS

Option boards are most easily installed while the MDC-360 is on the bench.

Figure 8-9 shows the location of the various option boards. Also, they are clearly

marked on the rear panel.

All Dual Source-Sensor boards are identical, as are all Discrete I/O boards. The

input-output configuration of these boards is defined by the position into which

3-4 BENCH CHECKOUT & INSPECTION

Page 29

MDC-360 DEPOSITION CONTROLLER

they are installed. One exception for the Discrete I/O boards is that the jumper J2

on the board installed in the Discrete I/O-2 position has to be connected. This is

required so the controller will acknowledge the second Discrete I/O board. A

Source-Sensor board plugged into the second position will provide sensor inputs

numbers 3 & 4, and source outputs numbers 3 & 4. The IEEE-488 board has a

single slot.

3.6.1 SOURCE-SENSOR BOARD

1. Remove the chassis top cover.

2. Remove the three plastic hole-plugs from the rear panel.

3. Carefully slide the two BNC connectors on the Source-Sensor board into

the two top holes on the rear panel. Then with even pressure, push the

card edge connector down into the Main board J12.

4. Fasten the two BNC connectors using the nuts and washers supplied with

the kit. Make sure the board is properly aligned.

5. Tighten the board down with the tie wrap.

6. Replace the chassis top cover and apply power to the controller.

7. The Sign On screen should acknowledge Source-Sensor 3,4 installed.

3.6.2 DISCRETE I/O BOARD

1. Remove the chassis top cover.

2. Locate Discrete I/O-2 slot and remove the slot cover.

3. Carefully slide the D37 connector of the DIO board into the slot and fasten

it using the hex fasteners and washers supplied with the kit.

4. Fasten the other end of the board to the standoffs using the two # 4-40

screws provided.

5. Plug the 26-pin ribbon connector into the DIO edge connector J1.

6. Replace the chassis top cover and apply power to the controller.

7. The Sign On screen should acknowledge Discrete I/O-2 installed.

3.6.3 IEEE-488 OPTION BOARD

1. Remove the chassis top cover.

2. Locate IEEE-488 option slot and remove the slot cover.

3. Carefully slide the connector of the IEEE-488 board into the slot and fasten

it using the fasteners and washers supplied with the kit.

4. Plug the 20-pin ribbon connector into J7 connector on the Main board.

5. Replace the chassis top cover and apply power to the controller.

6. The Sign On screen should acknowledge IEEE-488 option installed.

3.7 DIGITAL TO ANALOG CONVERTER (DAC) CHECKOUT

The built-in DAC function on the Main board contains two converters, allowing

simultaneous recording of any two of the following four parameters: Rate, Rate

deviation, Power and Thickness. The full scale output of each converter is 5

volts, is single ended and is referenced to ground. Parameter selection for each of

the channels is accomplished independently by making the appropriate choices in

the DAC setup menu.

BENCH CHECKOUT & INSPECTION

3-5

Page 30

MDC-360 DEPOSITION CONTROLLER

In addition to the individual channel output pins there are two control pins which

are common to both channels and are intended to simplify the process of setting

up analog recorders. Connecting the Zero control line to ground will drive both

channel outputs to zero, allowing the recorder zero reference to be easily set.

Releasing the Zero line and connecting the Full Scale line to ground will drive

both channel outputs to full scale for establishing the recorder full scale

calibration.

Each channel can be set independently to convert either the two or the three least

significant digits of the chosen parameter to a proportional analog signal,

corresponding to the DAC setup option chosen. With the three digit setting, a

thickness of 0.500 KÅ would result in an analog output of 2.50 volts, or a scale

factor of 5 mV/Å. If more resolution is desired, either channel can be configured

to convert only the last two digits of the parameter, thus the analog output would

achieve full scale at 99Å. The output scale factor in this configuration is 50

mV/Å.

The above scale factors are based on the assumption that the thickness display is

in the 0 - 9.999 KÅ range. Because the thickness and rate displays are autoranging, the analog output of these variables will also autorange so that in the

above example, if the thickness is in the range of 10 KÅ to 99.9 KÅ, the analog

scale factor would be 50 millivolts per 10 Å, also ten times larger.

The Rate deviation parameter must be handled differently than the other

parameters because it can be negative. Maximum positive error is converted to 5

volts, maximum negative error is converted to 0 volts and zero error is converted

to a mid scale, 2.5 volt, output. Maximum corresponds to 99 or 999, plus 1.

The DAC can be checked by putting the MDC-360 into the Simulate mode and

checking for correspondence between the analog output and the selected front

panel displays.

3-6 BENCH CHECKOUT & INSPECTION

Page 31

MDC-360 DEPOSITION CONTROLLER

Figure 3-1 Remote Power Handset

BENCH CHECKOUT & INSPECTION

3-7

Page 32

Page 33

MDC-360 DEPOSITION CONTROLLER

4. PROGRAMMING AND CONTROLLER SETUP

4.1 GENERAL

4.1.1 NAVIGATING THE MENU STRUCTURE

Before attempting to navigate the menu structure of the MDC-360 controller,

please refer to Section 2 which provides a brief summary of the front-panel

displays and key functions. A graphical menu structure is shown in Figure 15-1.

Note that following power-on, and acknowledgment of the Sign-on screen by

making any key depression, e.g. Reset, the LCD display will return to the display

function being used at the last power-off, i.e. either a status display screen or a

programming function screen.

This may be confusing until the full scope of the controller’s capabilities are

understood. However, as their names suggest, the Status and Program keys select

the display of status information and the display of programming information,

respectively.

So, for example, if having chosen the programming functions with a Program key

depression there is any doubt about the point in the menu system that is then

being displayed, holding down the left-arrow key will eventually display the Main

Menu from which point the desired option can be chosen by selective use of the

Up-arrow and Down-arrow keys to move the cursors to point to an option, and the

Right-arrow key or the Enter key to select the option.

Main Menu

>View/Edit Process <

View/Edit Material

View Results

Edit System Setup

Figure 4-1 The Main Menu

Press the Program key to enter the programming mode. The programming

screens can be visualized as a two dimensional menu format. The Main Menu

is

visualized at the far left, with an increasing level of detail in the menus to the

right. The Left and Right-arrow keys are used to move between menus. The Up

and Down-arrow keys are used to scroll through a list of parameters or option

each menu. To select a menu option, align the cursors with the option, then

s in

press

either the Enter key or the Right-arrow key. This will present the next screen

associated with the selected option. You can always hold down the Left-arrow

4-1PROGRAMMING AND CONTROLLER SETUP

Page 34

MDC-360 DEPOSITION CONTROLLER

key to go back to the Main Menu. Each of the programming screens is described

in detail later in this section.

4.1.2 ENTERING ALPHA CHARACTERS

To enter a name, press the k

ey that contains the letter or character you wish to

enter. Next, press the Alpha key to change the number to the first letter of that

key. K ep pressing the Alpha key

e to get the desired letter. Its upper/lower case

can be toggled by pressing the Shift key. Once the desired letter is achieved,

repeat the above procedure and enter the remainder of the name. Note, the

number 9 key contains characters Y, Z, and ‘space’. Use this key to ente

4.1.3 ENTERING TIME PARAMETERS

The MDC-360 expresses time in 24-hour h:mm:ss format. In p

rogramming a

r a space.

time parameter, the Decimal ‘.’ key is used to separate hour, minute and second.

Hence, 1:45:23 would be entered as “1.45.23” and 0:00:35 entered as “..35”,

followed by the Enter key.

4.1.4 COPYING AND DELETING

A ‘process’ is defined by one or more ‘layers’, and a layer requires

a ‘material’

and a thickness definition. The MDC-360 has the capability of copying and

deleting processes, layers, and materials. Except when copying a layer,

procedures for copying and deleting a process, a layer and a material are the same.

The difference when copying a layer is that layers are pushed-down to make

space for the new layer, and move

up when a layer is deleted.

To copy a process, position the cursor at the process to be copied, then press the

number 1 key. Next, move the cursor to the location where the process is to be

copied and press Enter. The

process will be copied to the new location with the

same name. If there is already a process name at the new location, it will be

overwritten. The copied process sho

confusion. The same procedure applies when copying a material.

When copying a layer, the copied data will be positioned at the selected layer

number. The data of the selected layer, and all following layers, will be p

down one layer. Example, if a layer is copied onto Layer #4 location, the exis

data in Layer #4 will be pushed to Layer #5, Layer #5 to Layer #6, etc., while the

copied data is placed in Layer #4.

To delete a process or a material, mo

A message will pop up asking for verification of the deletion, press 1 to confirm

and 0 to cancel the deletion.

4.1.5 PASSWORD PROTECTION

Each Process has a View/Run password and an Edit password. Each Material has

an Edit password. The three passwords protect against unauthorized operations.

The passwords default to 0000, or no password protection, at the time of

shipment. Refer to the descriptions below to set each password. Note: The

password protection is only meant to deter unsophisticated users. Be sure

4-2 PROGRAMMING AND CONTROLLER SETUP

uld be given a new name to avoid

ushed

ting

ve the cursor to the item and press the 0 key.

to

Page 35

MDC-360 DEPOSITION CONTROLLER

record passwords, because if you forget a password it will not be possible to

gain access to the protected item!

4.1.5.1 VIEW/RUN PROCESS PASSWORD

The View/Run password is required

password, select View/Edit Process from the Main Menu, select the process fro

to view or run a process. To set this

m

the Select Process screen. Move the cursor onto the View/Run password, type in

your password (4 digit string), then press the Enter key. A message will pop up

asking for verification to change the password. Press 1 to confirm and 0 to c

the change. Each time you want to view or run this process, you will now be

ancel

asked to enter the correct password. Note that the Edit Process password takes

precedence over the View/Run password. If you know the Edit password, you

can also view the process. Once

a password other than 0000 has been installed, it

will not be displayed unless re-entered.

4.1.5.2 EDIT PROCESS PASSWORD

The Edit process password is required to edit a process. To set this password

select View/Edit Process from the Main Menu, select the process from th

Process screen. Move the cursor onto the Edit password, type in your passwor

,

e Select

d

(4 digit string), then press the Enter key. A message will pop up asking for

verification to change the password. Press 1 to confirm and 0 to cancel the

change. Each time you want to edit this process, you will be asked to enter

correct password. Once a password other than 0000 has been installed, it will n

be displa

yed unless re-entered.

the

ot

4.1.5.3 EDIT MATERIAL PASSWORD

The Edit material password is required to edit a material. To set this password,

select View/Edit Material from the Main Menu, select the material from the

Select Material screen. Move the cursor down to the Material Password

parameter, the last item in the list, type in your password (4 digit string), then

press the Enter key. A message will pop up asking for verificat

ion to change the

password. Press 1 to confirm and 0 to cancel the change. Each time you want to

edit this material, you will be asked

password other than 0000 has been installed, it will not be displayed unless

to enter the correct password. Once a

re-

entered.

4.1.6 ADJUSTING PARA

The Parameter/Status display contrast can be adjusted by using the Progr

METER/STATUS DISPLAY CONTRAST

am key

in conjunction with the Up-arrow and Down-arrow keys. Hold down the Program

key and press the Up-arrow key to increase the contrast. Likewise, hold down the

Program key and press the Down-arrow key to

decrease the contrast. It may take

several seconds for the change in contrast to become apparent.

4-3PROGRAMMING AND CONTROLLER SETUP

Page 36

MDC-360 DEPOSITION CONTROLLER

4.2 GETTING STARTED

This section lays out the basic programming sequence with programming

examples for initial setup of the MDC-360 deposition controller.

4.2.1 UTILITY SETUP

The only critical parameter in the Utility Setup is the Crystal Frequency

parameter. This parameter must be set for the specific frequency crystals th

at you

plan to use (2.5, 3.0, 5.0, 6.0, 9.0, 10.0 MHz).

There is one other parameter in the Utility Setup menu that may be useful in the

initial setup and testing phase of the MDC-360 and that is the Simulate Mode

parameter. The simulate mode of the MDC-360 provides a means of simulatin

deposition

on the crystal. This mode is useful for testing the setup of the MDC-

g

360 without having to deposit any material.

4.2.2 DAC SETUP

If the DAC (digital to analog) outputs are to be used then these parameters can be

set at this time but it is not necessary for the operation of the controller.

4.2.3 SOURCE SETUP