ICP PYMC60G5, PYMC48G5, PYMC48G1, PYMC42G5, PYMC42G1 Owner’s Manual

...

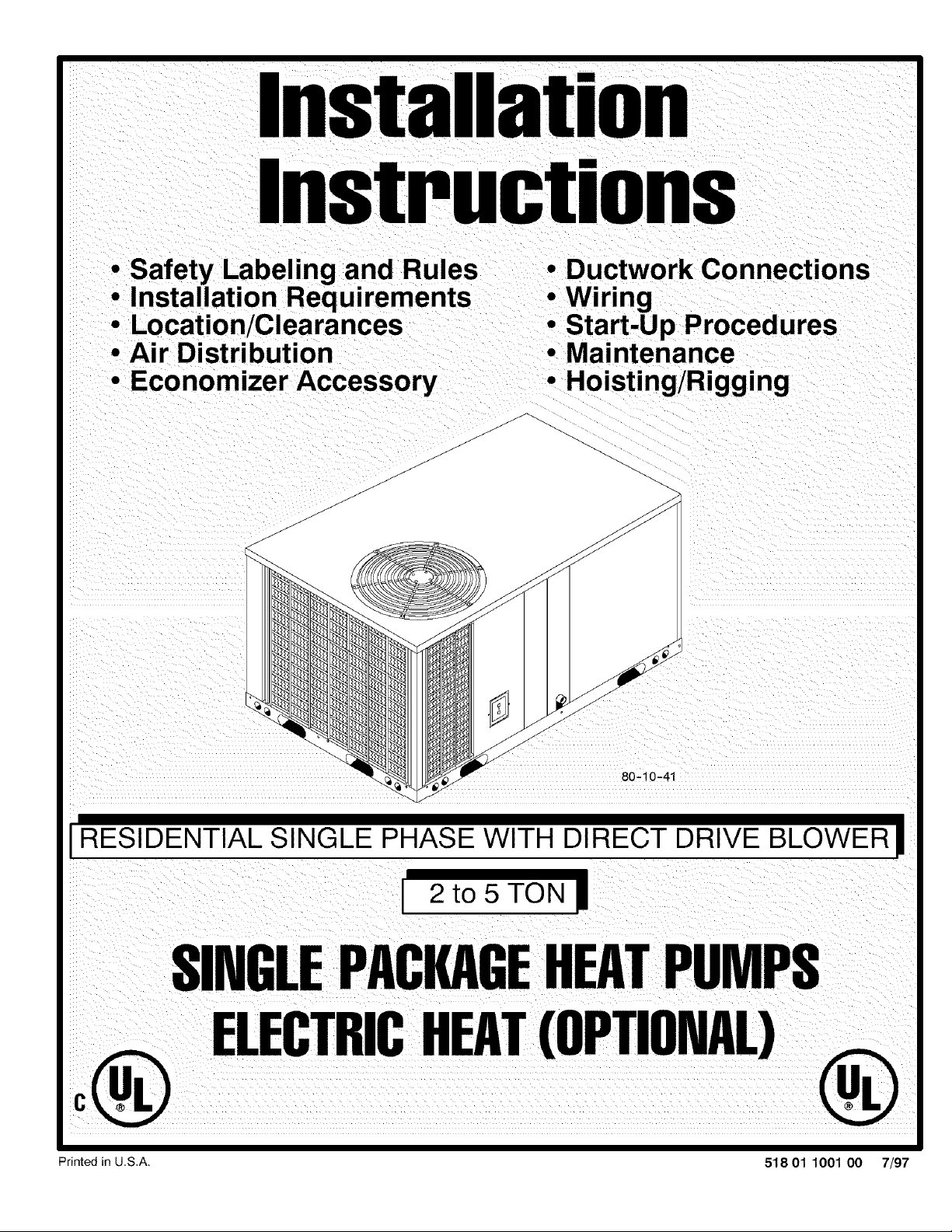

• Safety Labeling and Rules • Ductwork Connections

• Installation Requirements • Wiring

• Location/Clearances • Start-Up Procedures

• Air Distribution • Maintenance

• Economizer Accessory • Hoisting/Rigging

80-10-41

I RESIDENTIAL SINGLE PHASE WITH DIRECT DRIVE BLOWER II

Printed in U.S.A. 518 01 1001 00 7/97

I-

Table Of Contents

1. Safety Labeling and Signal Words ... 1

Danger, Warning and Caution ............... 1

Signal Words .............................. 1

Signal Words in Manuals ................ 1

Product Labeling ........................... 1

Danger Label .......................... 1

Warning Label ......................... 1

Caution Label ......................... 1

2. Unit Dimensions .................... 2

3. Safe Installation Requirements ...... 4

4. Locating The Unit ................... 4

Access Panels ............................. 4

Clearances ................................ 4

Minimum Clearances to Combustible

Construction .......................... 5

Installation ................................. 5

Ground Level Installation ................ 5

Rooftop Installation ..................... 6

Hoisting ................................... 6

Downflow Conversion ....................... 7

Condensate Drain .......................... 8

5. Electrical Wiring .................... 9

Low Voltage Wiring ......................... 9

Low Voltage Wiring With

Economizer Option ..................... 9

Thermostat ................................ 9

Unit Without Economizer ............... 10

Unit With Economizer ................. 10

Ground Connections ....................... 10

Line Voltage Wiring ........................ 10

Converting 230V Units to 208V .............. 10

Field Installed Equipment .............. 10

Final Electrical Check .................. 10-11

6. Air Distribution System ............. 12

Ductwork ................................. 12

Ductwork Insulation ................... 12

Ductwork Connections ................. 12

Filters .................................... 12

7. Economizer Accessory ............. 13

Theory of Operation ........................ 13

Sequence of Operation ..................... 14

Cooling Mode ............................. 14

Heating Mode ............................. 14

8. Start-up Procedures ............... 15

Circulating Air Blower ...................... 15

Determining Blower Speed ............. 15

Speed Taps ............................... 15

Cooling, Heating and Auxiliary

Electric Strip Heat (Heat Pump) ......... 15

Check Before Starting ...................... 15

Circulating Air Blower .................. 15

Sequence of Operation ............ 16-17

9. Operation ......................... 18

Features ............................. 18

Scroll Anti-Cycle Timer ..................... 18

Thermal Expansion Valves .................. 18

Loss of Charge Pressure Switch ............. 18

Defrost Control Time Interval Adjustment ...... 18

Cooling .............................. 18

Turning The Unit Off ....................... 18

Thermostat Fan Switch Operation ............ 19

Adjusting Room Temperatures ............... 19

10. Maintenance ..................... 19

Air Filters, Condenser Coil and

Condensate Drain Maintenance .............. 19

Refrigeration Access Ports .................. 19

Annual Maintenance and Inspection .......... 20

Condenser Fan Motor ................. 20

Blower Motor Access ....................... 20

Method 1and Method 2 ................ 20

Blower Motor Removal Using Method 1 .. 21

Blower Motor and Blower Housing

Removal Using Method 2 .............. 21

Blower Wire Color Identification .............. 21

Circulating Air Blower .................. 21

11. Rigging Instructions .............. 22

I Single Package Heat Pumps Installation Instructions I

1.SafetyLabeling andSignalWords

Danger,Warning and Caution

The signal wordsDANGER, WARNING and CAUTION are

used to identify levels of hazard seriousness. The signal

word DANGER is only used on product labels to signify an

immediate hazard. The signal words WARNING and CAU-

TION will be used on product labels and throughout this

manual and other manuals that may apply to the product.

Signal Words

DANGER - Immediate hazards which WILL result in se-

vere personal injury or death.

WARNING - Hazards or unsafe practices which COULD

result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which COULD

result in minor personal injury or product or property dam-

age.

Danger Label

White lettering on a black background except the word

DANGER which is white with a red background.

Warning Label

White lettering on a black background except the word

WARNING which is black with an orange background.

Signal Words in Manuals

The signal word WARNING is used throughout this manual

in the following manner:

The signal word CAUTION is used throughout this manual

in the following manner:

CAUTION

Product Labeling

Signal words are used in combination with colors and/or

pictures on product labels. Following are examples of prod-

uct labels with explanations of the colors used.

Caution Label

White lettering on a black background except the word

CAUTION which is black with a yellow background.

12J

_ Installation Instructions Single Package Heat Pumps I

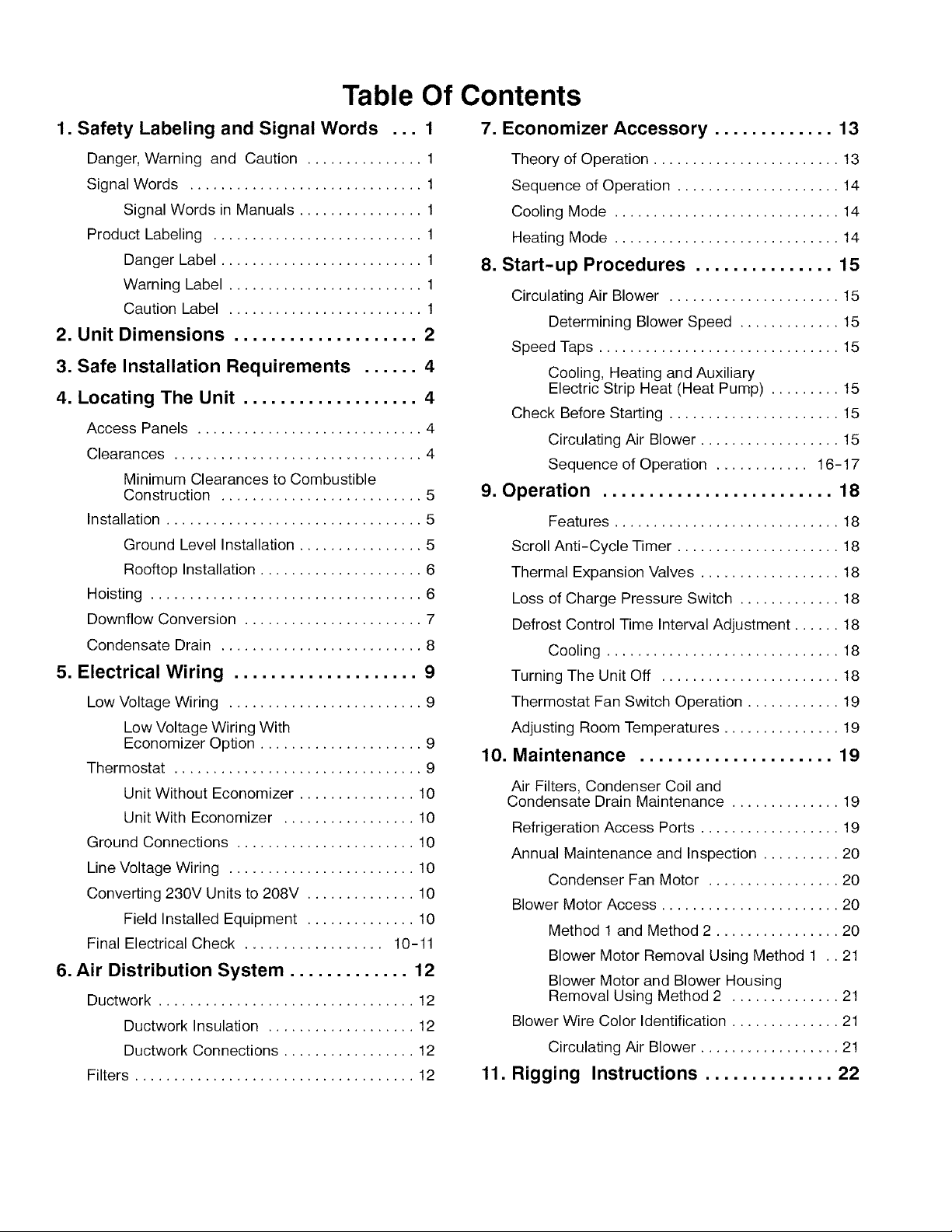

2. UnitDimensions

MODELS:

2- 3 TON

DIM INCHES MILLMETERS

A 32 1/2" 826

B 47 3/8" / 203

C 47 38" /203

D 3 1'8" 79

E /1 //8" 283

F 12" 306

G /4 1_4" 363

H /4 I/4" 363

I /2" 306

J 4" 102

K N/A N/A

L 4 /'4" /08

M 43/8" ///

N /4 //2" 368

P /2 /'4" 3/1

Q /2 1'8" 308

R E4 /4" 363

S /2 /'4" 3E8

LOW VOLTAGE

1/2" CONDUIT

Note: The above dimensions are in inches.

ROOF CURB MODELS:

2- 3 TON

DIM INOHES MILLIMETERS

A 42 34" /086

B 39 34" /0/0

C /8'r 457

D /8" 457

E 3 3_a" 95

F 42 34" / 086

G 39 3_a" /OE0

H E8" 457

K _ 14" 356

ELECTRIC HEAT POWER

1", 1-1/2", 2" CONDUIT

UNIT ELECTRICAL POWER

3/4", 1 ", 1-1/4" CONDUIT

"F'"

UNIT BASE SHOWN SEPARATELY

TO ILLUSTRATE BOTTOM

DUCT OPENINGS

* Roof curbs are also available in 8" (203mm) and 24" (610mm) heights (K dimension).

8_/_/3

I Single Package Heat Pumps Installation Instructions

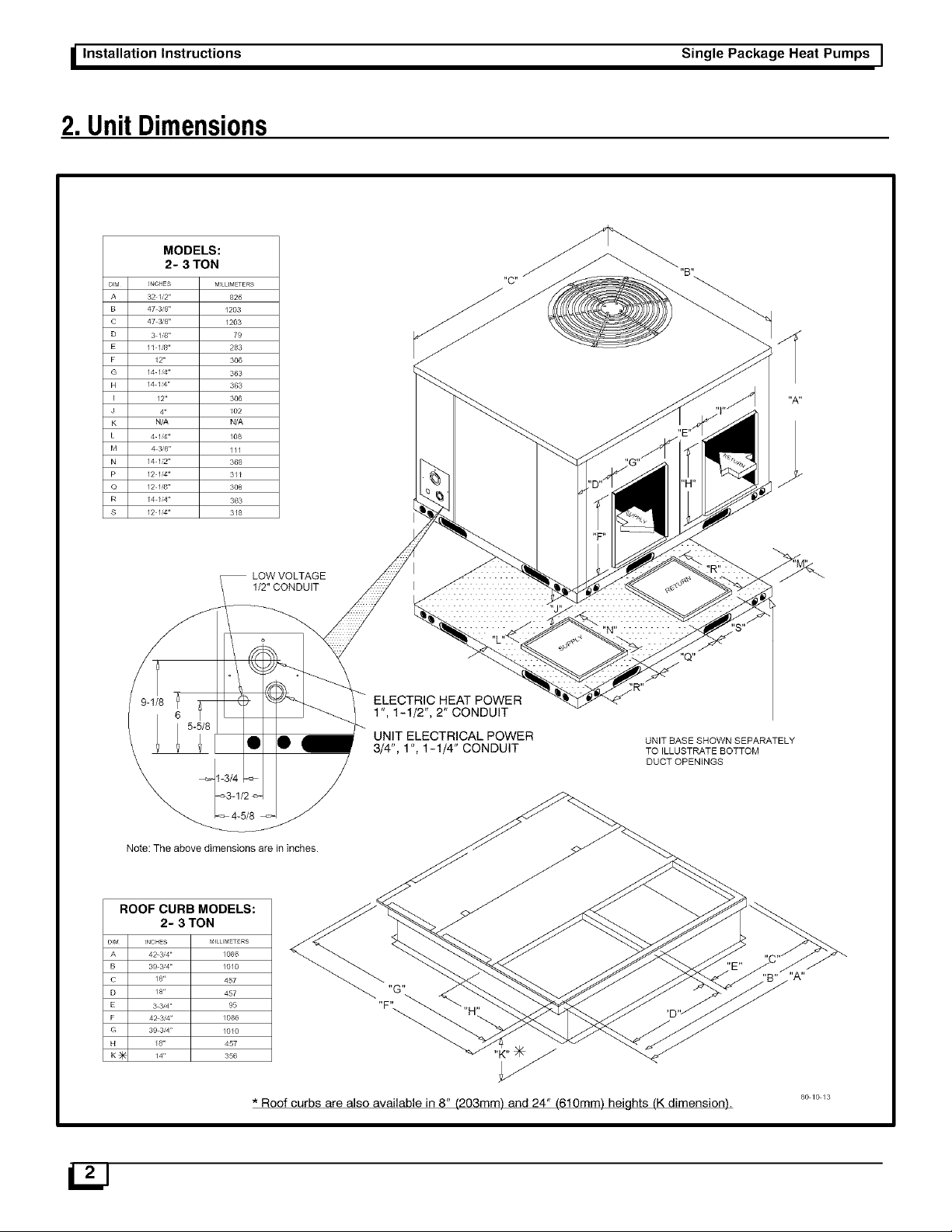

UNIT DIMENSIONS

MODELS:

31/2 - 5 TON

DIM INCHES MI L METERS

A 36" 9/4

B 47 38" / 203

C 73" /854

D 4 58" //7

E 15" 38I

F 12" 307

G /8 3/4" 476

H /8 3_4" 476

J E2" 305

J /02

K N/A

L 4 I '4" / 08

M 5 F4" E33

N 12 F4" 311

P E9" 483

Q 15" 381

R 19" 483

S /2 //4" 3/1

• /6 78" 429

I

I

I

Note: Above dimensions are in inches

ROOF CURB MODELS:

31/2 - 5 TON

DIM INCHES

A 67 3;4rr

B 64 3;4rr

C 23"

D 23"

E 2 //2"

F 42 3;4"

G 39 3t_4rr

H 23"

I /2"

J 12"

K _ /4"

f_'ILLIMETERS

/721

1645

1086

/010

LOW VOLTAGE

1/2" CONDUIT

584

584

64

584

305

305

356

ELECTRIC HEAT POWER

1", 1-1/2", 2" CONDUIT

UNIT ELECTRICAL POWER

3/4", 1", 1-1/4" CONDUIT

,,p.

UNIT BASE SHOWN SEPARATELY

TO _LLUSTRATE BOTTOM

DUCT OPENINGS

* Roof curbs are also available in 8" (203mm) and 24" (610mm) heights (K dimension).

80 /0 /4

_ Installation Instructions Single Package Heat Pumps I

3.SafeInstallationRequirements

• Seal supply and return air ducts.

Installation or repairs made by unqualified per-

sons can result in hazards to you and others.

Installation MUST conform with local building

codes or, in the absence of local codes, with the

National Electrical Code NFPA70-1990 or current

edition or in Canada CSA C22.1 - Canadian Elec-

trical Code Part 1 or current edition.

The information contained in this manual is in-

tended for use by a qualified service technician

familiar with safety procedures and equipped

with the proper tools and test instruments.

Failure to carefully read and follow all instruc-

tions in this manual can result in unit malfunction,

property damage, personal injury and/or death.

4. Locating TheUnit

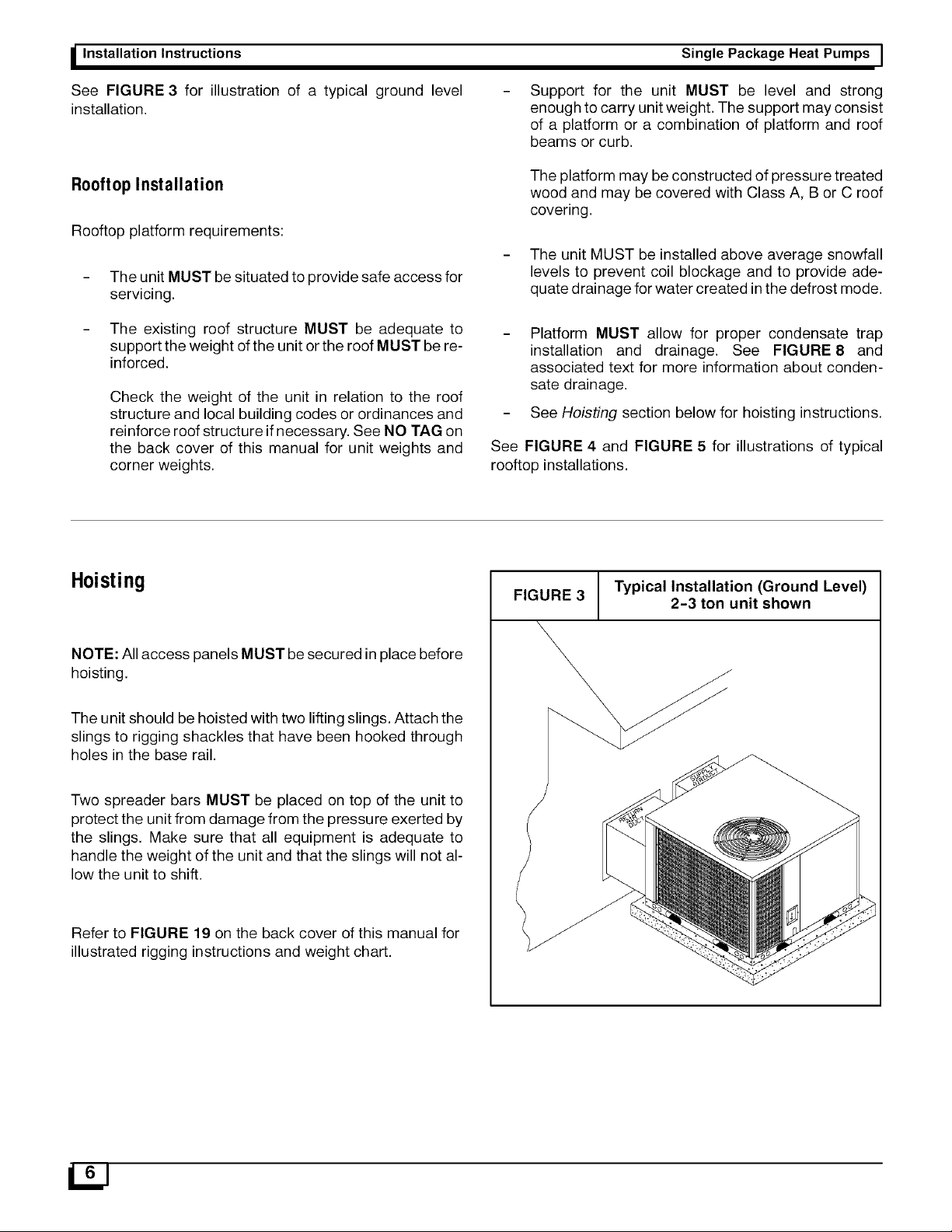

The unit is designed for outdoor installation only. The unit

may be installed on a concrete slab (or other adequate plat-

form) at ground level, oron a rooftop with an adequate plat-

form or a roof curb. Typical installations are shown in

FIGURE 3 through FIGURE 5.

• Check to see that filters are installed correctly and

are the proper type and size.

NOTE: It is the personal responsibility and obligation of the

customer to contact a qualified installer to ensure that the

installation is adequate and conforms to governing codes

and ordinances.

Access Panels

CAUTION

Unit will NOT operate properly without all access pan-

els in place.

Unit MUST NOT be moved unless all access panels are

in place.

Avoid installations under roof overhangs without guttering.

Water draining from the roof onto the unit could produce ex-

cessive noise, and may cause ice to build up on coil or fan.

Roof top installations are acceptable providing the roof will

support the unit and provisions are made for water drain-

age and for the noise or vibration through the structure.

IJJ

See FIGURE 1 on page 5 for a general view of unit and

location of access panels.

Clearances

The location MUST allow for minimum clearances and

should not be adjacent to a patio or other area where the

unit's operating sound level might be objectionable. Local

codes MUST be observed.

Minimum clearances, as specified below and in FIGURE 2,

MUST be maintained from adjacent structures to provide

adequate air circulation and room for service personnel.

I Single Package Heat Pumps

While minimum clearances are acceptable for safety rea-

sons, they may not allow adequate air circulation around

the unit for proper operation. Whenever possible, it is desir-

able to allow additional clearance, especially around the

condenser inlet and discharge openings.

FIGURE1 _ Access Panels

Blower Access Panel

Installation Instructions

FIGURE 2 (Typical 2 to 3 ton unit shown)

(914mm) 0"

J 30" 30"

(762mm) (762mm)

Minimum Clearances

0" (2" (50mm) on 4 & 5 ton units

48" (1220mm) on all units with

economizer

/ 30"

(762mm)

80-00-01

I Electrical AccessPanel

Do NOT install the unit in a location that will permit dis-

charged air from the condenser to recirculate to the con-

denser inlet.

CAUTION

Do NOT operate unit in a corrosive atmosphere con-

taining chlorine, fluorine, or any other corrosive chem-

icals.

Minimum Clearances to Combustible Construction

Supply and Return Air Ducts ...................... 0"

Duct Connection Side (no economizer)

...... 0" (2" (50mm) on 4 & 5 ton models)

Duct Connection Side (with economizer) . 48" (1220mm)

Compressor Access Panel Side ......... 30" (762mm)

Blower Access Panel Side .............. 30" (762mm)

Electrical Access Panel Side ............ 30" (762mm)

Clearance between 3 Ft. Overhang

and Top of Unit ............ 30" (762mm)

Combustible Base

(Wood or Class A, B or C

roof covering material) ................. 0"

Installation

CAUTION

Unit will NOT operate properly unless it is installed lev-

el front to rear and side to side.

The slope MUST NOT be greater than 1/8" per foot

(lOmm per meter). For side to side leveling, the control

box side MUST always be lower.

GroundLevel Installation

Ground level platform requirements:

The unit MUST be situated to provide safe access for

servicing.

Platform may be made of either concrete or pressure

treated wood and MUST be level and strong enough

to support unit weight.

Position platform separate from building foundation.

Install in well-drained area, with top surface of plat-

form above grade level and above the average winter

snow levels to prevent coil blockage.

Platform MUST be high enough to allow for proper

condensate trap installation and drainage. See Fig-

ure 8 and associated text for more information about

condensate drainage.

_Installation Instructions

Single Package Heat Pumps I

See FIGURE 3 for illustration of a typical ground level

installation.

Rooftop Installation

Rooftop platform requirements:

The unit MUST be situated to provide safe access for

servicing.

The existing roof structure MUST be adequate to

support the weight of the unit orthe roof MUST be re-

inforced.

Check the weight of the unit in relation to the roof

structure and local building codes or ordinances and

reinforce roof structure ifnecessary. See NO TAG on

the back cover of this manual for unit weights and

corner weights.

Support for the unit MUST be level and strong

enough to carry unit weight. The support may consist

of a platform or a combination of platform and roof

beams or curb.

The platform may be constructed of pressure treated

wood and may be covered with Class A, B or C roof

covering.

The unit MUST be installed above average snowfall

levels to prevent coil blockage and to provide ade-

quate drainage for water created in the defrost mode.

Platform MUST allow for proper condensate trap

installation and drainage. See FIGURE8 and

associated text for more information about conden-

sate drainage.

See Hoisting section below for hoisting instructions.

See FIGURE 4 and FIGURE 5 for illustrations of typical

rooftop installations.

Hoisting

NOTE: All access panels MUST be secured inplace before

hoisting.

The unit should be hoisted with two lifting slings. Attach the

slings to rigging shackles that have been hooked through

holes in the base rail.

Two spreader bars MUST be placed on top of the unit to

protect the unit from damage from the pressure exerted by

the slings. Make sure that all equipment is adequate to

handle the weight of the unit and that the slings will not al-

low the unit to shift.

Refer to FIGURE 19 on the back cover of this manual for

illustrated rigging instructions and weight chart.

FIGURE 3

Typical Installation (Ground Level)

2-3 ton unit shown

Loading...

Loading...