TE

TXCi

TC 250 2011 - TC 250i 2011 I.E. USA

CARATTERISTICHE - USO - MANUTENZIONE

Dove non diversamente specificato, i dati e le prescizioni si riferiscono a tutti i modelli.

Unless specified, data and presciption are referred to all t he models.

Lorsque non différemment indiqué, les donneé et les instructions se réfèrent à tous les modèles.

Wo nicht anders ausdrücklich angegeben, beziehen sich die Daten und die Vorschriften auf alle Modelle.

Donde no especificado, los datos y resenas se refieren a todos los modelos.

TC

TE 250 - 310 2011 I.E.

TEi 250 2011 I.E. USA

TXCi 250 2011 I.E. USA

SPECIFICATIONS - OPERATION - MAINTENANCE

CARACTERISTIQUES - UTILISATION - ENTRETIEN

MERKMALE - GEBRAUCH - WARTUNG

CARACTERISTICAS - USO - MANTENIMIENTO

IT

IT - 1

ENGLISH

EN

EN - 1

PRESENTATION

Welcome to the Husqvarna motorcycling Family!

Your new Husqvarna motorcycle is designed and manufactured to be the finest in its field.

The instructions in this book have been prepared to provide

a simple and understandable guide for your motorcycle’s

operation and care.

Follow the instructions carefully to obtain maximum performance and your personal motorcycling pleasure. Your

owner’s manual contains instructions for owner care and

maintenance.

The main work of repair or maintenance requires the attention of a skilled mechanic and the use of special tools

and equipment.

Your Husqvarna dealer has the facilities, experience and original parts necessary to properly render this valuable service.

This “Owner’s Manual” is part and parcel of the motorcycle, hence, this had to

remain with the motorcycle even when

sold to another user.

This motorcycle uses components designed thanks to systems and state of the art technologies which are thereafter tested in competition.

In competition motorcycles, every detail is verified after each

race in order to always guarantee better performance. For

correct functioning of the vehicle, it is necessary to follow the

maintenance and control table found on Appendix A.

IMPORTANT NOTICES

1) The TC and TXCi models are guarante-

ed COMPETITION motorcycles exempt from

functional defects, the suggested maintenance table for competition use is shown on

Appendix A.

2) TE vehicles are STREET LEGAL motorcycles (with LIMITED POWER ENGINE); they

are guaranteed exempt from functional defects and covered with legal guarantee, if the

STANDARD CONFIGURATION is maintained

and the suggested maintenance table, shown

on Appendix A is observed.

If TE vehicles are transformed in COMPETITION MOTORCYCLES (with FULL POWER ENGINE), the suggested maintenance table for

competition use is shown on Appendix A.

MOTOCROSS

ENDURO

EN - 2

IMPORTANT

The reference for recognition of the guarantee will be the MOTORCYCLE CONFIGURATION, as shown below:

A) STANDARD MOTORCYCLE, STREET LEGAL: with LIMITED POWER ENGINE

B) COMPETITION MOTORCYCLE, RACING USE: with FULL POWER

ENGINE

This motorcycles was not designed for long

trips with the engine always at maximum

rpm as can occur whilst travelling on roads

or highways. Long trips at full throttle can

cause severe damage to the engine.

This motorcycles is setup for competition use

and therefore guarantees maximum performance with the rider alone. It is thereby not

recommended to use the vehicle on circuits

or off-road with a passenger.

ALWAYS keep in mind that these motorcycles have been designed strictly for competition use, that is, for conditions of usage

very different from those presented on the road.

ALWAYS keep in mind that these motorcycles

have been designed strictly for competition

use, that is, for conditions of usage very different from those presented on the road.

In order to maintain the vehicle’s “Guarantee of Functionality”, the client must follow

the maintenance program indicated in the

user’s manual by carrying out maintenance

checks at authorized HUSQVARNA dealers.

The cost for substituting parts and for the

labour necessary in order to respect the

maintenance plan, is charged to the client.

NOTE: the guarantee is EXTINGUISHED in the

case where the motorcycle is rented.

Important Notice

Read this manual carefully and pay special attention to statements preceeded by the following words:

Warning*: Indicates a possibility of severe

personal injury or loss of life if instructions

are not followed.

Caution*: Indicates a possibility of personal

injury or equipment damage if instructions

are not followed.

Note*: Gives helpful information.

Parts Replacement

When parts replacement is required, use only Husqvarna ORIGINAL parts.

Warning*: After an upset, inspect the motorcycle carefully. Make sure that the throttle,

brake, clutch and all other systems are undamaged. Riding with a damaged motorcycle

can lead to a serious crash.

Warning*: Never attempt to start or operate

your motorcycle unless you are wearing appropriate protective clothing. Always wear a

motorcycle helmet, motorcycle boots, gloves,

goggles and other appropriate protective

clothing.

Warning*: This motorcycle is a state of the

art competition bike. Do not attempt to start

or ride this motorcycle until you have received expert instruction and are in excellent

physical condition.

PRECAUTIONS FOR CHILDREN

WARNING

• Park the vehicle where it is unlikely to

be bumped into or damaged. Even slight or

involuntary bumps can cause the vehicle to

topple over, with subsequent risk of serious

harm to people or children.

• To prevent the vehicle from tipping over,

never park it on soft or uneven ground, nor

on asphalt strongly heated by the sun.

•Engine and exhaust pipes become very hot

during riding. Always park your motorcycle

where people or children can not easily reach these parts, in order to avoid serious

burns.

EN

EN - 3

TABLE OF CONTENTS

PRESENTATION

......................................................................2

IMPORTANT NOTICES

IDENTIFICATION DATA

CONTROL LOCATION ...............................................................6

TECHNICAL DATA

LUBRICATION TABLE, SUPPLIES

CONTROLS

.............................................................................9

APPENDIX

............................................................................54

PRE-DELIVERY INSPECTION

ALPHABETICAL INDEX

.............................................................2

............................................................5

...................................................................7

..............................................8

...................................................55

...........................................................56

Page

PERIODIC MAINTENANCE -ADJUSTMENT .................. Appendix

•References to the “left” or “right” of the motorcycle are in

Note

the sense of a person facing forwards.

•Z: number of teeth

• A: Austria

AUS: Australia

B: Belgium

BR: Brazil

CDN: Canada

CH: Switzerland

D: Germany

A

E: Spain

F: France

FIN: Finland

GB: Great Britain

I: Italy

J: Japan

USA: United States of America

•Where not specified, all the data and the instructions are

referred to any and all Countries.

EN - 4

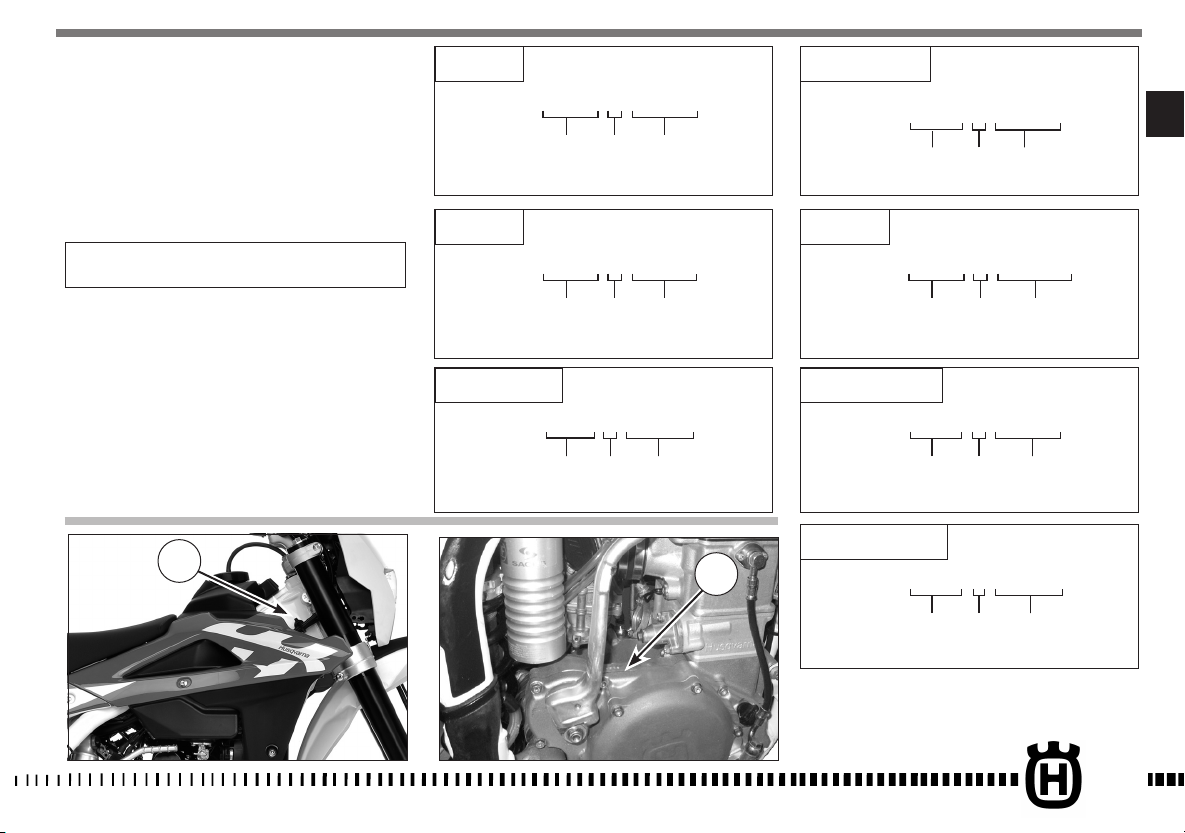

IDENTIFICATION DATA

The engine number is printed on the upper side of the engine

case, whereas the frame number is printed on the steering tube.

Always state the number stamped on the frame

(and write it on this booklet), when placing orders for spare

parts, or when asking for informations about your motorcicle.

TE 250

ZKHA300AABV000001

(l) (▲) (♦)

TE 310 USA

ZKHKCEDG#BV000001

EN

(l) (▲) (♦)

FRAME NUMBER

VEHICLE IDENTIFICATION NUMBER (V.I.N.)

The full 17 digit serial, or Vehicle Identification Number, is stamped on the steering head tube (R.H. side).

(l) = Model designation

(▲) = Model Year (2011)

♦

) = Progressive no.

(

1. Frame serial number

2. Engine serial number

1

TE 310

ZKHA301AABV000001

TE 250 USA

ZKHKCECF#BV000001

(l) (▲) (♦)

(l) (▲) (♦)

TC 250

ZKHA300AABV050001

(l) (▲) (♦)

TC 250 - USA

ZKHTC253#BV000001

(l) (▲) (♦)

TXCi 250 - USA

2

ZKHTX250#BV000001

(l) (▲) (♦)

EN - 5

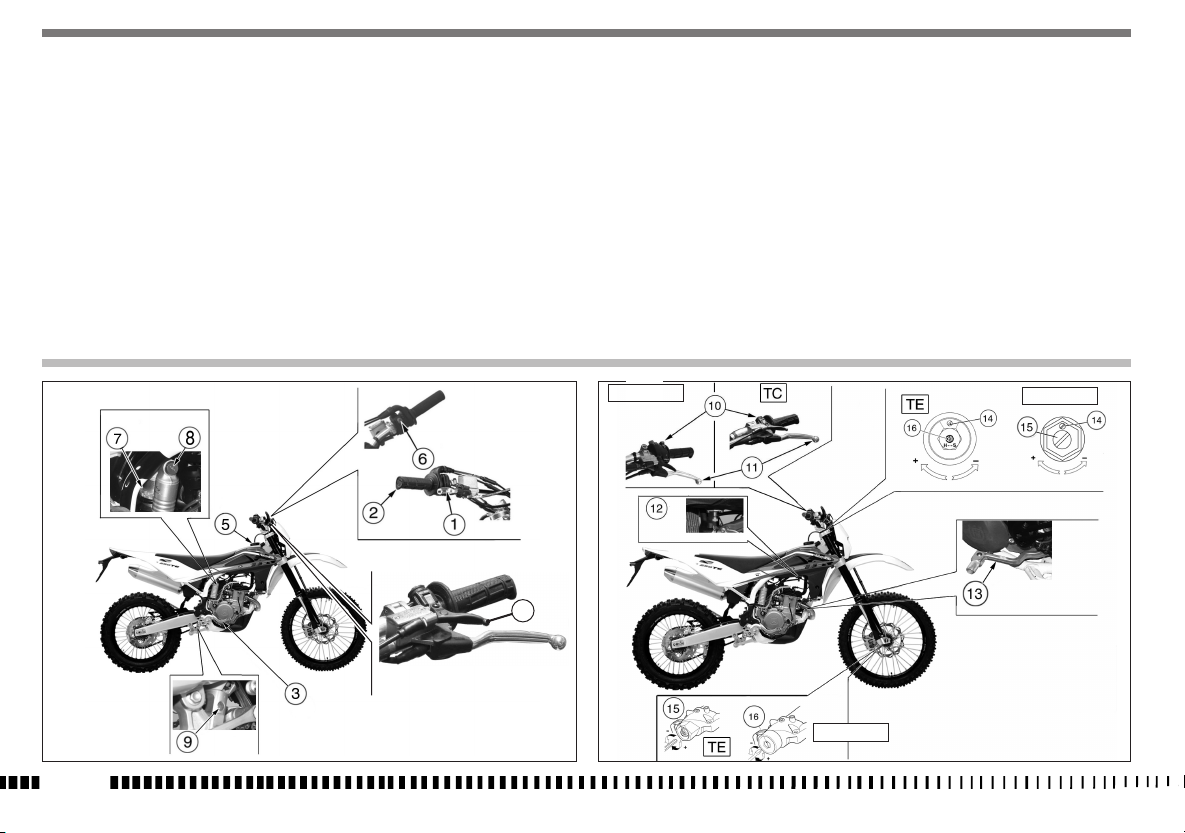

CONTROL LOCATION

1. Front brake lever

2. Throttle grip

3. Rear brake control pedal

4. Choke

5. Fuel tank filler cap

6. R.H. commutator (engine electric start TE - TXCi)

7.Rear shock absorber spring preload adjustment

8. Rear shock absorber compression damper adjustment (low and high damping speeds)

9. Rear shock absorber extension damper adjustment

10. L.H. commutator (TE)

10. Engine stop button (TC)

11.Clutch control lever

12. Fuel cock (TE - TXCi)

13. Gearbox control pedal

14. Air bleeding screw on front fork leg

15. Compression damper adjustment

16. Extension damper adjustment

EN - 6

TC - TXC

4

TC - TXC

TC - TXC

TECHNICAL DATA

ENGINE

Type............................................single cylinder, 4 stroke

Cooling ............ liquid, with electric fan on TE-TXCi models

TC-TE-TXCi 250

Bore ............................................................................. 3,11 in.

Stroke .........................................................................2.00 in.

Displacement

.....................................................15,22 cu. in.

Compression ratio .................................................13,6:1

TE 310

Bore .............................................................................3,23 in.

..........................................................................2,26 in.

Stroke

Displacement

Compression ratio ..................................................

......................................................18,46 cu. in.

12,5:1

Starting (TC) .... kick start (with automatic decompressor)

Starting (TE-TXCi) ................................................. electric

TIMING SYSTEM

Type..................4 titanium valves, in a radial arrangement,

operated through bowls by two overhead camshafts driven by

a combined chain/gears system

Valve clearance (with engine cold)

Intake .............................................................. 0,006 in.

Exhaust ............................................................0,008 in.

LUBRICATION

Type...wet crankcase, lobe pump and cartridge and mesh

filters

IGNITION

Type ...........Electronic, inductive discharge, with

adjustable advance (digital control)

Spark plug type ............................................NGK CR9EB

Spark plug gap ...................................... 0.027

÷0,031 in.

FUEL SYSTEM

Type......................................................Electronic injection feed

PRIMARY DRIVE

Drive pinion gear- Clutch ring gear ............................Z 17- Z 54

Transmission ratio ............................................................3,176

CLUTCH

Type...........oil bath multiple disc clutch, hydraulic control

TRANSMISSION

Type...........................................constant mesh gear type

Transmission ratio (TE-TXCi)

1st gear. ...............................................2,142 (z 30/14)

2nd gear ...............................................1,750 (z 28/16)

3rd gear ..............................................1,450 (z 29/26)

4th gear. ...............................................1,227 (z 27/22)

5 th gear. ..............................................1,041 (z 25/24)

6 th gear ...............................................0,884 (z 22/27)

Transmission ratio (TC)

1st gear. ...............................................2,142 (z 30/14)

2nd gear ...............................................1,750 (z 28/16)

3rd gear ..............................................1,450 (z 29/26)

4th gear. ...............................................1,227 (z 27/22)

5 th gear. ..............................................1,041 (z 25/24)

SECONDARY DRIVE

Transmission sprocket- Rear wheel sprocket

(TC) ...........................................................................Z 13- Z 50

(TE-TXCi) ....................................................................Z 13- Z 40

Transmission ratio

(TC) .................................................................................3,846

(TE-TXCi). .........................................................................3,076

FINAL RATIOS (TE-TXCi)

1st gear.....................................20,944

2nd gear ....................................17,104

3rd gear ....................................14,172

4th gear.....................................11,995

5th gear.....................................10,181

6th gear......................................7,964

FINAL RATIOS (TC)

1st gear.....................................26,180

2nd gear ....................................21,380

3rd gear ....................................17,715

4th gear.....................................14,994

5th gear.....................................12,726

EN

EN - 7

FRAME

Type...............Steel single tube cradle (roud, rectangular,

ellipsoidal tubes); light alloy rear frame

FRONT SUSPENSION

Type . . . . . . ”Upside-down” telescopic hydraulic front fork with

advanced axle (adjustable in compression and rebound stroke);

stanchions tubes Ø 1.89 in.

Legs axis stroke ..................................................11.8 in.

REAR SUSPENSION

Type......progressive with hydraulic single shock absorber

Wheel stroke ......................................................11.6 in.

FRONT BRAKE

Type fixed disc Ø 10.23 mm “Wave” type with hydraulic control

and floating caliper

REAR BRAKE

Type.... floating disc, ø 9.45 in. “Wave

” type with

hydraulic control and floating caliper

RIMS

Front .......................................................in light alloy: 1,6x21”

Rear (TE, TXCi) ......................................in light alloy: 2,15x18”

Rear (TC) ..............................................in light alloy: 1,85x19”

TIRES

Front

(TE -TXCi) . . . . ...........................90/90x21”

(TC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80/100 x 21”

Rear

(TE-TXCi) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120/90x18”

(TC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100/90x19”

Cold tire pressure

(front TC) . . . . . . . . . . . . . . . . . . . . . . . . . . .0,9÷1,0 Kg/cm2

(front TE-TXCi) (*) . . . . . . . . . . . . . . . . . . . . 0,9÷1,0 Kg/cm2

(front TE) (%) ...........................1,1 Kg/cm2

(rear TC) ............................0,8÷0,9 Kg/cm2

(rear TE-TXCi) (*) .....................0,8÷0,9 Kg/cm2

(rear TE) (%) . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,0 Kg/cm2

(*) In case of racing use - (%) Road use

DIMENSION, WEIGHT, CAPACITY

Wheelbase

(TE-TXCi) ..................................57.87 in.

(TC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57.48 in.

Overall length

(TC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87.2 in.

(TE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88.98 in.

(TXCi) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85.67 in.

Overall width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32.30 in.

Overall height

(TE-TXCi) ..................................50.79 in.

(TC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51.38 in.

Saddle height

(TC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38.78 in.

(TE-TXCi) ...................................37.4 in.

Minimum ground clearance

(TE-TXCi) ..................................11.42 in.

(TC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12.79 in.

Kerb weight, without fuel

(TC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .lb. 213.8

(TE ) .....................................lb. 225.9

(TXCi) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . lb 219.3

Fuel tank capacity (TC) . . . . . . . Imp. Gall. 1.43, U.S. Gall. 1.72

Fuel tank capacity (TE-TXCi) . Imp. Gall. 1.87, U.S. Gall. 2.25 (0.51

Imp. Qt./0.61 U.S. Qt. reserve included)

Coolant capacity . . . . . . . . . . . . . . . . . . . . . .0.79 Imp. Quarts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.95 U.S. Quarts

Transmission oil

Oil and oil filter replacement .................Imp. Quarts 0.79,

U.S. Quarts 0.95

Oil replacement ...........Imp. Quarts 0.75, U.S. Quarts 0.90

TABLE FOR LUBRICATION, SUPPLIES

Engine, gearbox and primary drive lubricating oil

CASTROL POWER 1 RACING 10W-50

Engine coolant

CASTROL MOTORCYCLE COOLANT

Brake system fluid

CASTROL RESPONSE SUPER DOT 4

Clutch fluid

CASTROL FORK OIL 10W

Grease lubrication

CASTROL LM GREASE 2

Final drive chain lubrication

CASTROL CHAIN LUBE RACING

Front fork oil

Kayaba KHL15-11

Oil for rear shock absorber

CASTROL SYNTHETIC FORK OIL 5W

Electric contact protection

CASTROL METAL PARTS CLEANER

Fillers for radiator

AREXONS TURAFALLE LIQUIDO

EN - 8

CONTROLS

FUEL COCK (TE-TXCi)

The left-side tap (1) is a screw tap: screw the ring nut (A) to close

the tap, loosen the ring nut to open the tap.

WARNING*: Be careful not to touch the hot

engine while operating the fuel valve.

1. Fuel cock

A. Tap ring nut

FUEL INJECTION ENGINE (TE-TXCi)

In fuel-injection vehicles, the fuel pump is built into the tank,

and the fuel-feeding system has no tap ON - OFF - RES.

The quantity of remaining fuel is indicated on the digital dashboard by the special warning light (TE).

EN

1

A

EN - 9

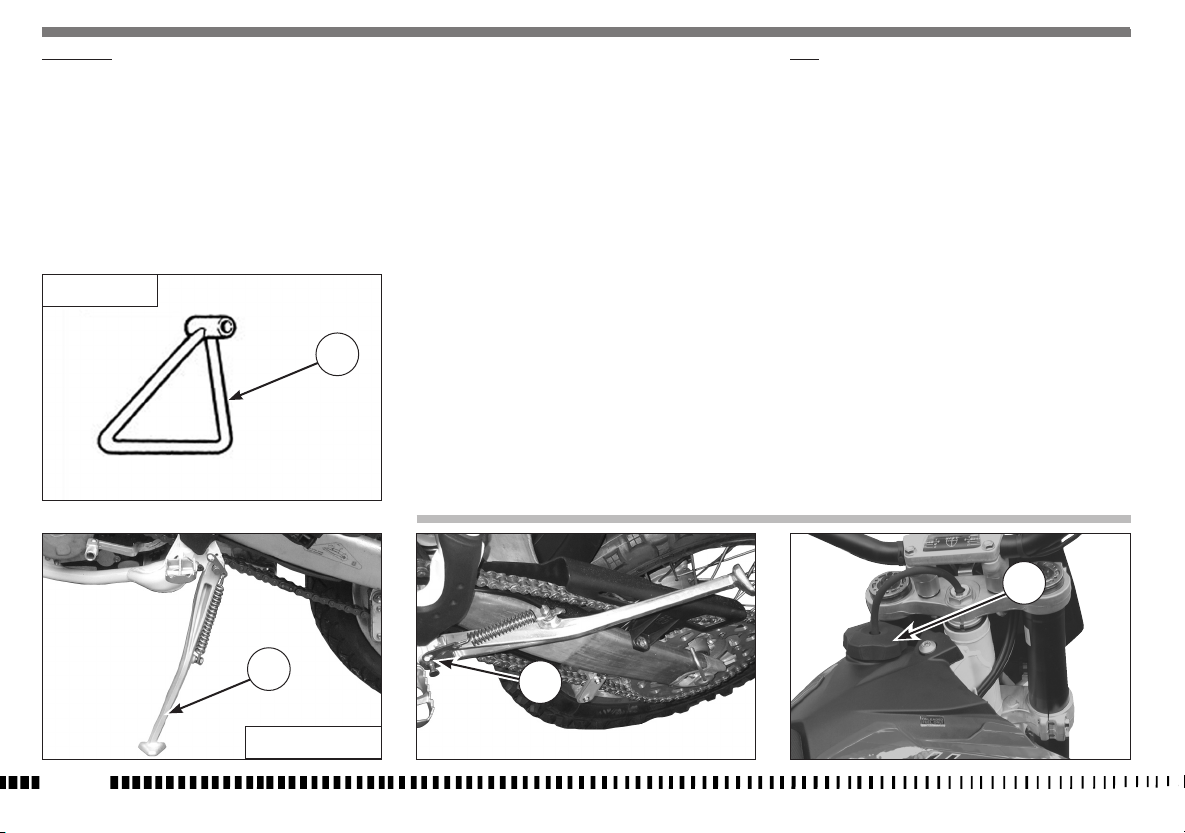

SIDE STAND

A sidestand (1) is supplied with every motorcycle.

WARNING*: The stand is designed to support the weight of the MOTORCYCLE ONLY. Do

not sit on the motorcycle using the stand for

support as this could cause structural failure

to the stand and could cause serious bodily

injury.

Periodically check the side stand (see “Periodical maintenance

card”); check that the springs are not damaged and that the

side stand freely moves. If the side stand is noisy, lubricate the

fastening pivot (A).

FUEL

Recommended fuel: premium grade unleaded fuel. (R.O.N.

98).

Note*: Do not continue operation if the engine pings or knocks. The engine will be damaged and could seize.

WARNING*: If “knocking” or “pinging”

occurs, try a different brand of gasoline or

higher octane grade.

EN - 10

TC

1

1

TE - TXCi

WARNING*: Gasoline is extremely flammable and can be explosive under certain conditions. Always stop the engine and do not

smoke or allow flames or sparks in the area

where the motorcycle is refueled or gasoline

is stored.

WARNING*: Do not overfill the tank. After refueling, make sure the tank cap (2) is closed

securely.

2

A

COLD START

For engine cold starting, the motorcycle features a lever (1) on

the left-hand side of the handlebar. Pull the lever to open the

starting device, vice versa to close it.

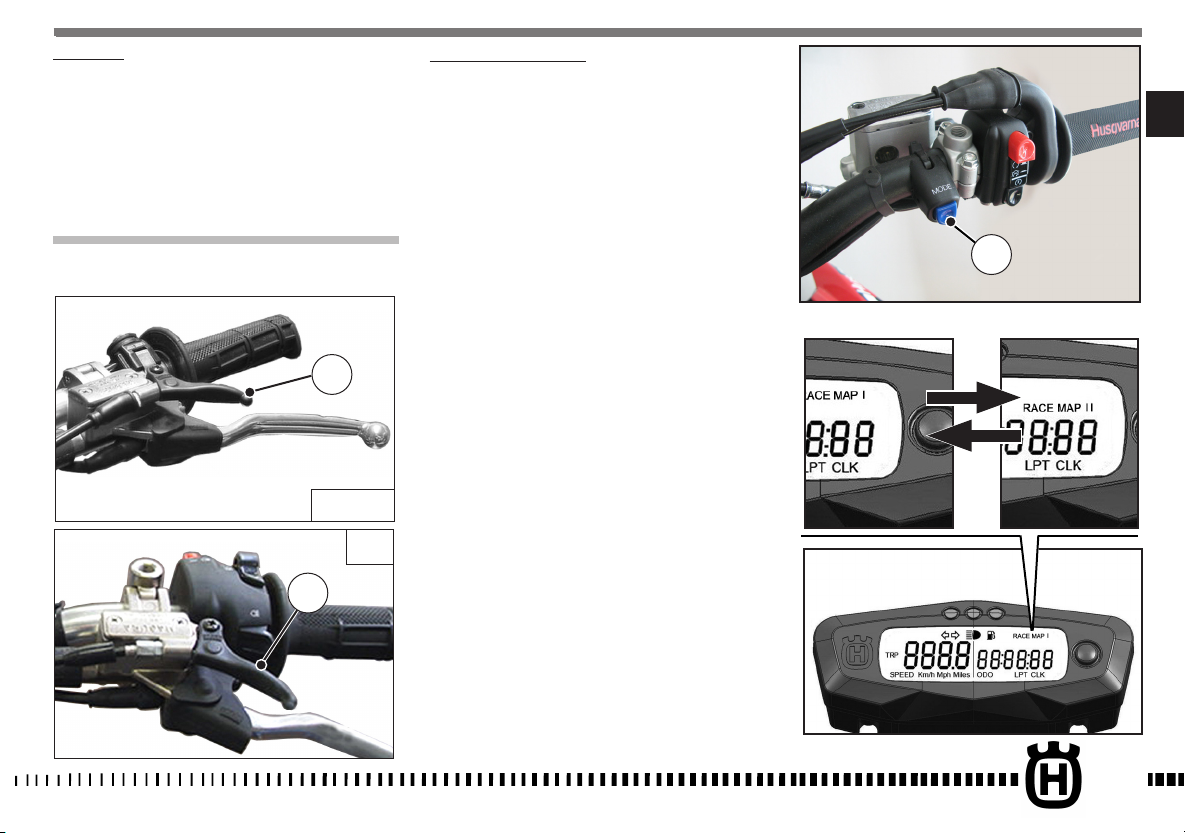

DOUBLE MAP BUTTON (TE)

NOTE:

The button (1) works with full power motorcycles only.

The button (1) allows to modify motorcycle’s performance;

After motorcycle starting, wait for the engine to warm up, then

press the button (1) to toggle through “RACE MAP I” standard

performance to “RACE MAP II” slippery ground performance.

EN

1

TC-TXCi

1

TE

After you switch off the motorcycle, the configuration goes back

to “RACE MAP I” upon the first start-up.

1

EN - 11

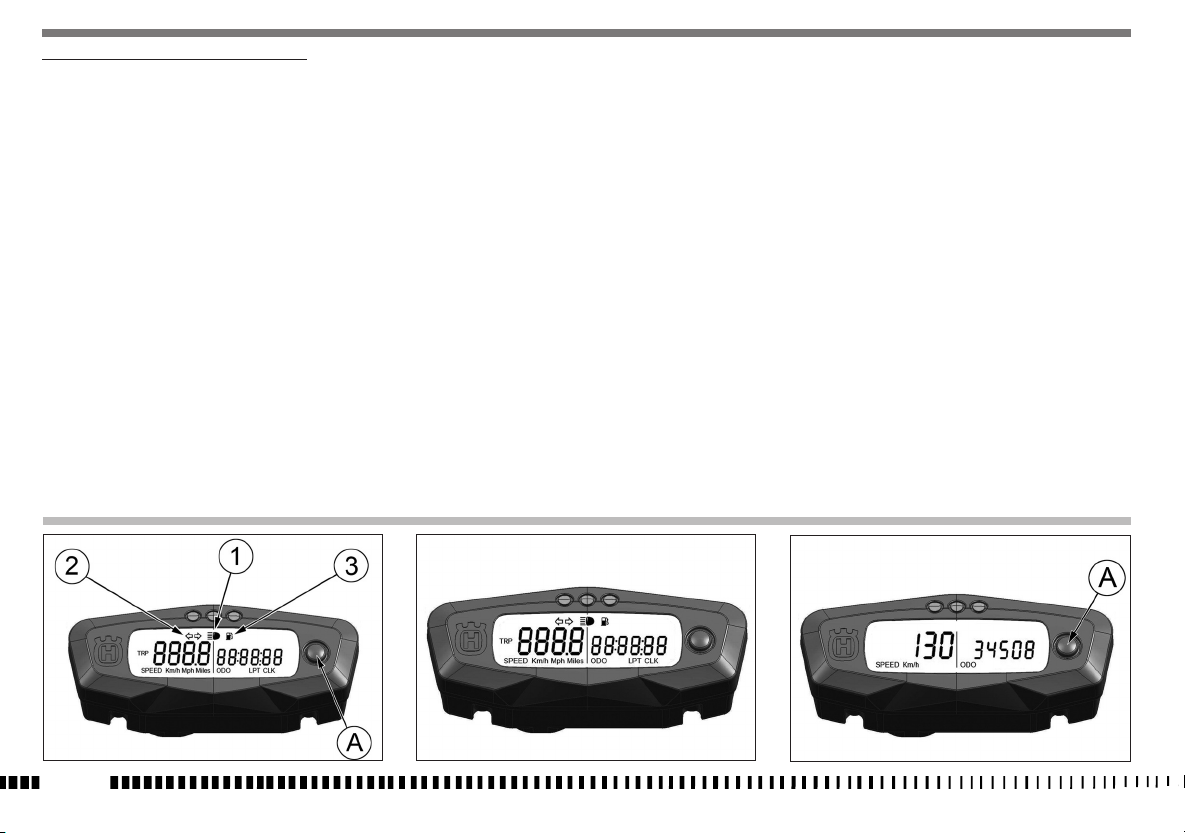

DIGITAL INSTRUMENT, WARNING LIGHTS (TE)

- The instrument functions are the following, as shown below.

1- SPEED (Km/h or mph) / ODO (figure 1)

The motorcycle is equipped with a digital instrument; on the instrument are located 3 warning lights too: high beam, blinkers

and fuel reserve.

1- BLUE warning light “HIGH BEAM”

2- GREEN warning light “BLINKERS”

3- ORANGE warning light “Fuel reserve”

(2,3 l - 2.02 Imp. qt - 2.43 U.S. qt)

Turning the ignition key to the position “IGNITION” the instrument

display illuminates (amber colour).

NOTES

- When linked to the battery,

ment shows the version of the checking SW; after the check,

the instrument shows the last planned function.

- When the motorcycle engine is OFF, the instrument doesn’t

also show its functions.

- To select the instrument functions and to set to zero the functions, use the SCROLL knob (A).

for the first 2 seconds, the instru-

1- SPEED / ODO (figure 1)

2- SPEED / CLOCK (figure 2)

3- SPEED / TRIP (figure 3)

4- SPEED / CHRONO (figure 4)

5- SPEED / RPM (

1- SPEED / ODO (figure 1)

.................

IMPORTANT:: in case of FUEL INJECTION SYSTEM malfunction on the right side of the instrument display will be displayed

the warning message “FAIL”: (see page 14): in this case

contact your local HUSQVARNA Dealer.

engine r.p.m. numerical value

) (figure 5)

- SPEED: motorcycle speed- maximum value: 299 Km/h or 299

mph;

- ODO: odometer- maximum value: 99999 km;

To replace kilometers with miles or miles with kilometers proceed as follows:

1) set to figure 1, stop the engine and push the knob SCROLL

(A);

2) turn the ignition key to the IGNITION position, holding pu-

shed the button SCROLL (A) until the symbol “Km/h” will be

displayed;

3) then the symbols “Km/h” and “Mph Miles” will be displayed

alternatively. Push again the SCROLL (A) button when the

unit you wish to use is displayed.

EN - 12

2- SPEED / CLOCK (figure 2)

- SPEED:

motorcycle speedmaximum value

mph;

clock- Reading from 0:00 to 23:59:59;

- CLOCK:

To reset the clock, push the knob SCROLL (A) for more than 3

seconds in order to increase the hours; release the knob and

then, after 3 seconds, it is possible to increase the minutes;

: 299 Km/h o 299

3- SPEED / TRIP 1 (figure 3)

- SPEED:

motorcycle speedmaximum value

mph

distance- maximum value: 999.9 km (the data will be

- TRIP 1:

lost after battery detachment).

To setup the TRIP, push the SCROLL (A) button holding down

more than 3 seconds

: 299 Km/h o 299

4- SPEED / CHRONO (STP) (figure 4)

- SPEED:

motorcycle speedmaximum value

mph;

miles/kilometers covered time;

- STP 1:

-

Reading from 0:00 to 99:59:59 (the data will be lost after

battery detachment).

To activate the function STP 1, push the knob SCROLL (A) for

more than 3 seconds.

- 1st step: function ON;

- 2nd step: stop to the counters;

- 3rd step: STP 1 zero-setting; TRIP 1 and AVS 1 data zero-setting;

- 4th step: function ON;

- 5th step: stop to the counters;

.............................

and so following

: 299 Km/h o 299

EN

EN - 13

5- SPEED / DIGITAL RPM (figure 5)

- SPEED: velocità- Indicazione max: 299 Km/h o 299 mph

- DIGITAL RPM: MIN. 500, MAX. 14250

The instrument display shows even then informations of the “Neutral” condition and of any possible “Malfunction” of the

INJECTION SYSTEM; this last condition is showed

with absolute priority with respect to any

other information.

NEUTRAL: if the speed is under 20 Km/h (12,5 mph), the “Neutral”

condition the instrument displays the N character before the value

of the speed.

FUEL

WARNING LIGHTS PANEL (TXCi)

The motorcycle is tted with a small warning lights panel

with two warning lights:

1 - Red warning light “POWER”

2 - Yellow warning light “FUEL RESERVE”

EN - 14

MALFUNCTION:

on the right side of the instrument display will be displayed the

warning message “FAIL”

in case of FUEL INJECTION SYSTEM malfunction

.

1

2

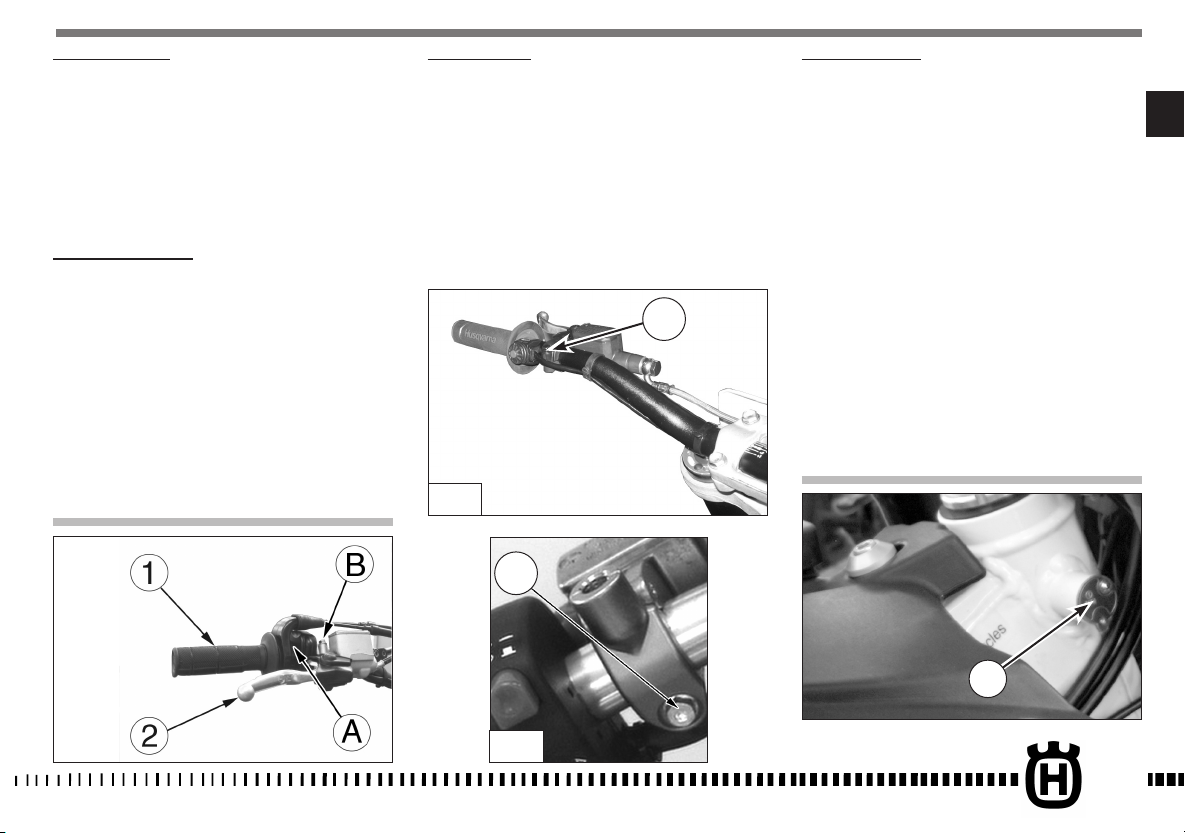

THROTTLE CONTROL

The throttle knob (1), is located on the right hand side of the

handlebar. The position of the throttle control can be adjusted

by loosening the two fastenig screws .

CAUTION

Do not forget to tighten the screws (A) after

the adjustment.

FRONT BRAKE CONTROL

The brake control lever (2) is located on the right hand side of

the handlebar. The position of the throttle control can be adjusted by loosening the two fastenig screws .

CAUTION

Do not forget to tighten the screws (B) after

the adjustment.

CLUTCH CONTROL

The hydraulic clutch control lever is located on the left-hand side

of the handlebar and is protected against dirt with a rubber

guard.

The clutch control position on the handlebar can be adjusted by

loosening the lower fastening screws (A).

CAUTION

Do not forget to tighten the screws after the

adjustment.

A

TC

A

STEERING LOCK (TE)

The motorcycle is equipped with a steering lock (1) on the R.H.

side of the steering head tube.

To lock it, procede as follows:

turn the handlebar leftwards, place the key in lock and turn

counterclockwise. Push the key inwards (if necessary, turn to

and from). Turn the key clockwise and remove it from the lock.

To unlock the steering lock, reverse the above procedure.

EN

TE

1

EN - 15

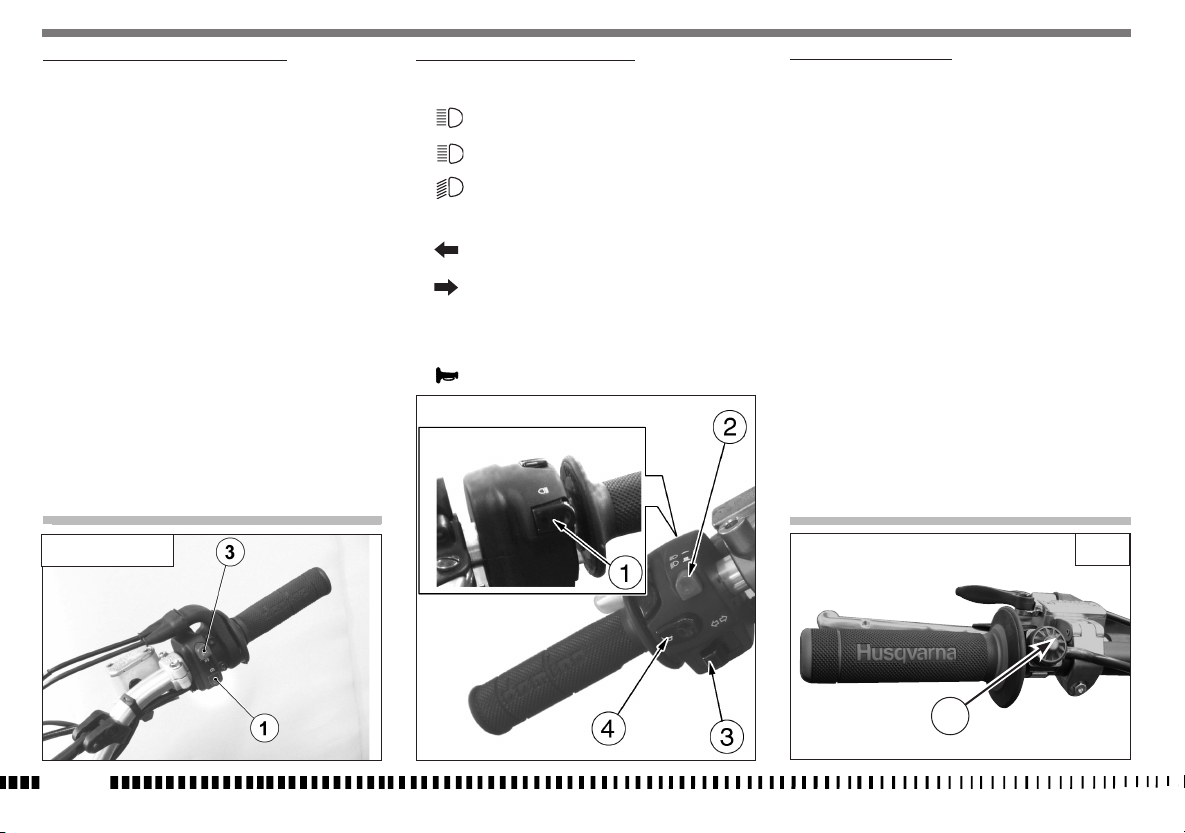

R.H. HANDLEBAR COMMUTATOR (TE-TXCi)

The right commutator has the following controls:

1) Engine start button

3) Engine start - stop switch

L.H. HANDLEBAR COMMUTATOR (TE)

CONTROLS:

High beam flash (self cancelling)

1)

Selection control High beam

2)

Selection control Low beam

Left turn signals (automatic return)

3)

Right turn signals (automatic return)

To deactivate the turn signals, press the control lever after its

returning to center.

Warning horn

4)

ENGINE STOP BUTTON (TC)

On the left side of the handlebar, near the clutch control, is located the engine stop button.

TE - TXCi

EN - 16

TC

1

REAR BRAKE CONTROL

The rear brake control (1) is placed on the right-hand side of

the motorcycle.

1

GEAR SHIFT CONTROL

The lever (1) is placed on the left-hand side of the engine. The

operator must release the lever after each gear change to allow

it to return to its central position before another gear

change can be made.

Neutral position (N) is between first (low) and second gears.

First gear is engaged by pushing the lever downwards; all the

other gears are engaged, by pushing the lever upwards.

The position of the gear shift lever on the shaft can be varied

by:

- loosening screw;

- pulling lever out;

- placing lever in new position on the shaft when the operation

is over tighten the screw and then tightening the screw.

CAUTION*: Do not shift gears without disengaging the clutch and closing the throttle. The

engine could be damaged by overspeed and

shock.

N: Neutral

TC

1

WARNING*: Do not downshift when traveling

at a speed that would force the engine to

overrev in the next lower gear, or cause the

rear wheel to lose traction.

N: Neutral

TE - TXCi

1

EN

EN - 17

RIDING

BEFORE EVERY RIDE MAKE FOLLOWING CHECKS

WARNING!

Before each ride, to prevent accidents or failures during ride,

make sure to go through following list.

1. Check all fluids

A. Engine-transmission oil level

B. fuel level

C. coolant level

Make sure all caps are properly adjusted.

WARNING*: Don’t remove radiator cap when

hot!

2. Check all controls

A. Throttle handgrip

B. Clutch lever

Make sure cables are not damaged and turn smoothly.

3. Check brakes

Look for brake fluid leaks and worn hoses. Check for proper

functioning.

4. Check suspensions

Compress fork and rear suspensions. Look for oil leaks and

ensure proper functioning.

5. Check wheels

Check spokes and look for worn bearings.

Check rims and tyres.

Check tyre pressure.

6. Check chain rollers and sprockets

Check wear on chain rollers and sprockets

Ensure chain is correctly adjusted and lubricated.

7. Check air filter and intake system

Check that air filter is clean

Check all rubber connections and clamps.

8. Check exhaust system

Check hook up, look for cracks

Check muffler.

9. Check torque

A. Spark plug

B. General check of torque

10. Check steering action

Check bearing play.

11. Check the electric system (TE).

Start the engine and check that the front and rear lamps, the

stop light, the turn signals the cluster warning lights and the

horn are working correctly.

WARNING*: Failure to perform these checks

every day before you ride may result in serous damage or a severe accident.

.

RUNNING IN

Before using the motorcycle for sporting activities run in the

engine for two hours at least to increase the life and the performance of the engine.

During the first half-hour of driving we advise keeping a low

speed and avoiding sudden accelerations. Never open the throttle fully.

Change the oil and carry out all the necessary maintenance operations. After the first half-hour of driving, lightly increase the

rev number, but never run the engine at full throttle. Never keep

low speeds when the high gears are inserted.

Slowly drive the motorcycle for two hours before using it for

sporting activities.

CHECKS DURING RUNNING

- SPOKE TENSION OF WHEELS;

- TIGHTENING OF WHEELS;

- FORK PIN TIGHTENING;

- CHAIN ADJUSTMENT;

- STEERING BEARING PLAY;

- HANDLEBAR TIGHTENING;

- ENGINE GRIP TO FRAME;

- SUCTION FITTING GRIP;

- HEAD AND CYLINDER NUTS GRIP;

OFTEN CHECK THE BATTERY CHARGE CONDITION

EN - 18

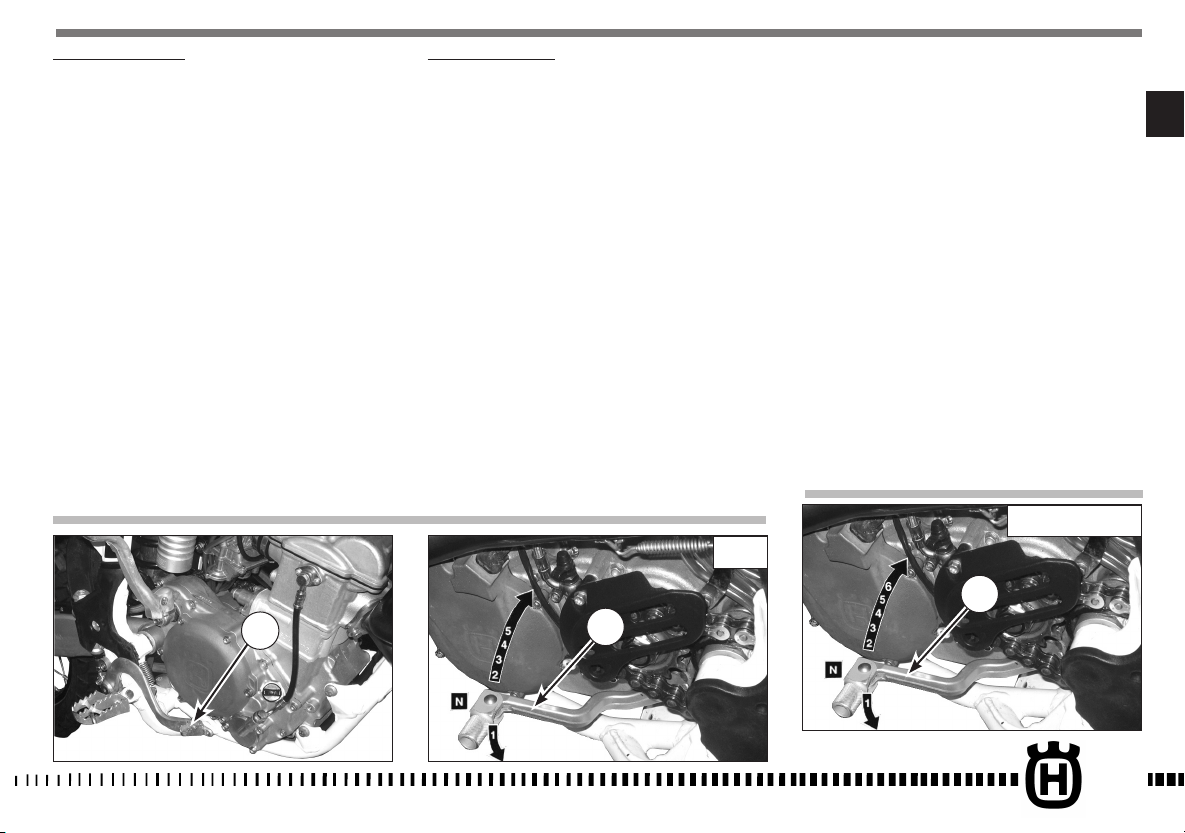

ENGINE START (TC)

While the engine is cold, i.e., after the motorcycle has not been

used for a while or in low ambient temperatures, operate in the

following manner:

1) pull the clutch lever (1);

2) pull the starter lever (2);

3) shift gear pedal (3) to neutral position then release the

clutch control level;

4) COMPLETELY lower the pedal (4) until the engine starts.Bring

the starter lever (2) back to its original position as soon as

the motor can idle. When starting with an already warmed up

engine DO NOT USE the starter. When a cold engine has just

been started, do not increase revs, to ensure an adequate oil

warm-up and circulation.

IMPORTANT NOTE IN CASE OF COLD STARTS AT

LOW TEMPERATURES

It is recommended to briefly warm-up the engine at idle until,

after having disengaged the starter, there is a normal response

from the engine when opening the throttle.

In this way the oil can reach all the surfaces needing lubrication

and the coolant will reach the necessary temperature for correct

engine function. Avoid overheating the engine.

IMPORTANT

Never accelerate the engine after a cold start.

WARNING*: Exhaust contains poisonous carbon monoxide gas. Never run the engine in

a closed garage or in a confined area.

Kick start pedal

WARNING*: This high performance motor-

cycle can some times «kick back» strongly

when you are starting it.

Do not attempt to start this motorcycle unless you are wearing high top heavy sided

riding boots. You could seriously hurt you leg

if the kickstarter kicked back and your foot

slipped.

4

EN

3

2

1

EN - 19

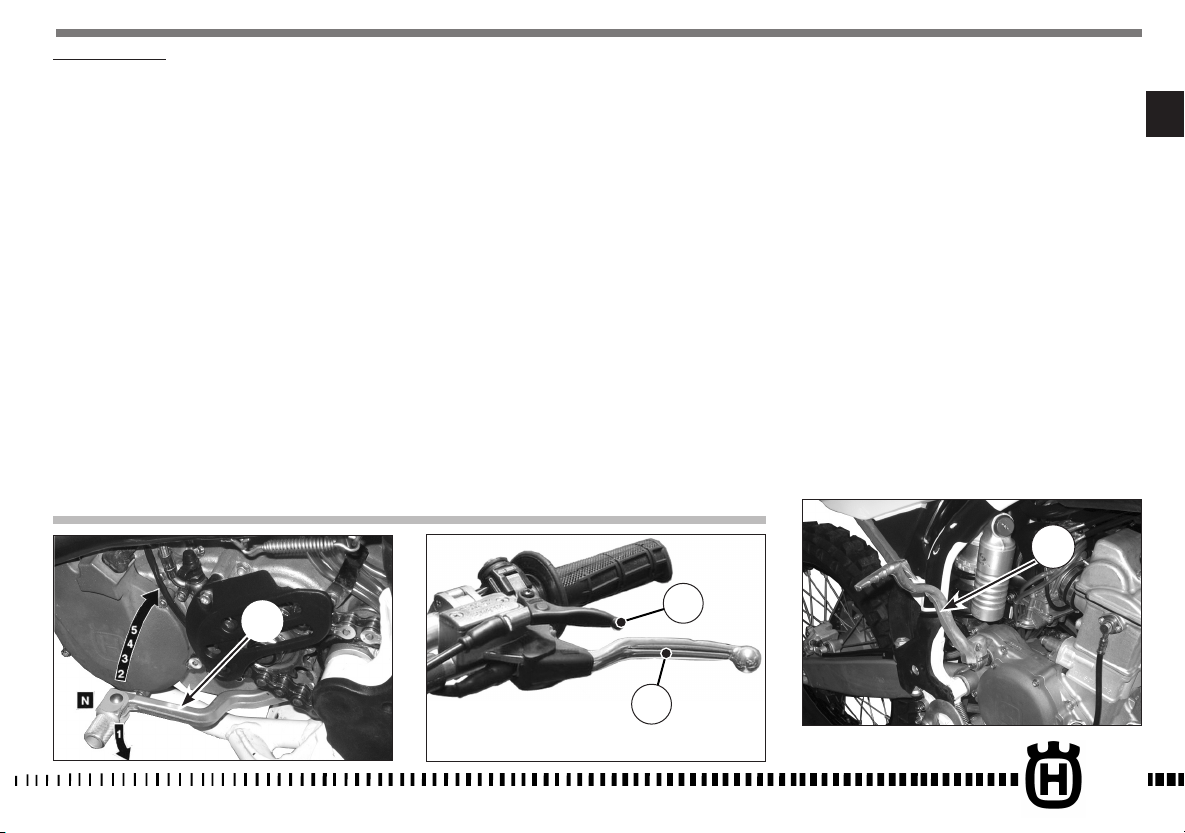

ENGINE START (TE)

With cold engine, as after a prolonged inactivity of the

motorcycle or in presence of a low external temperature,

proceed as follows:

1) set ignition key (1) in IGNITION position (the buzz that you

hear when you turn the key to IGNITION is caused by the

fuel pump which puts the feeding system under pressure);

2) pull the starter lever (2);

3) pull the clutch lever (3);

4) shift gear pedal (4) in neutral position then release the

clutch control lever;

5) Check that the button (5) is in the out position and

press it, followed by the start button (6). Bring the

starter lever (2) back to its original position as

soon as the motor can idle. When starting with an

already warmed up engine DO NOT USE the starter.

When a cold engine has just been started, do not

increase revs, to ensure an adequate oil warm-up

and circulation.

IMPORTANT

NEVER START WITH DISCONNECTED BATTERY.

1

5

6

2

TE

3

IMPORTANT NOTE IN CASE OF COLD STARTS AT

LOW TEMPERATURES

It is recommended to briefly warm-up the engine at idle until,

after having disengaged the starter, there is a normal response

from the engine when opening the throttle.

In this way the oil can reach all the surfaces needing lubrication

and the coolant will reach the necessary temperature for correct

engine function. Avoid overheating the engine.

IMPORTANT

Never accelerate the engine after a cold start.

WARNING*: Exhaust contains poisonous carbon monoxide gas. Never run the engine in

a closed garage or in a confined area.

EN - 20

4

ENGINE START (TXCi)

While the engine is cold, i.e., after the motorcycle has not been

used for a while or in low ambient temperatures, operate in the

following manner:

1) pull the clutch lever (1);

2) pull the starter lever (2);

3) shift gear pedal (3) to neutral position then release the

clutch control level;

4) Check that the button (4) is in the out position and press it,

followed by the start button (5). Bring the starter lever (2)

back to its original position as soon as the motor can idle.

When starting with an already warmed up engine DO NOT

USE the starter. When a cold engine has just been started,

do not increase revs, to ensure an adequate oil warm-up and

circulation.

IMPORTANT NOTE IN CASE OF COLD STARTS AT

2

It is recommended to briefly warm-up the engine at idle until,

after having disengaged the starter, there is a normal response

from the engine when opening the throttle.

In this way the oil can reach all the surfaces needing lubrication

and the coolant will reach the necessary temperature for correct

engine function.Avoid overheating the engine.

LOW TEMPERATURES

EN

1

Never accelerate the engine after a cold start.

WARNING*: Exhaust contains poisonous carbon monoxide gas. Never run the engine in

a closed garage or in a confined area.

IMPORTANT

3

4

5

EN - 21

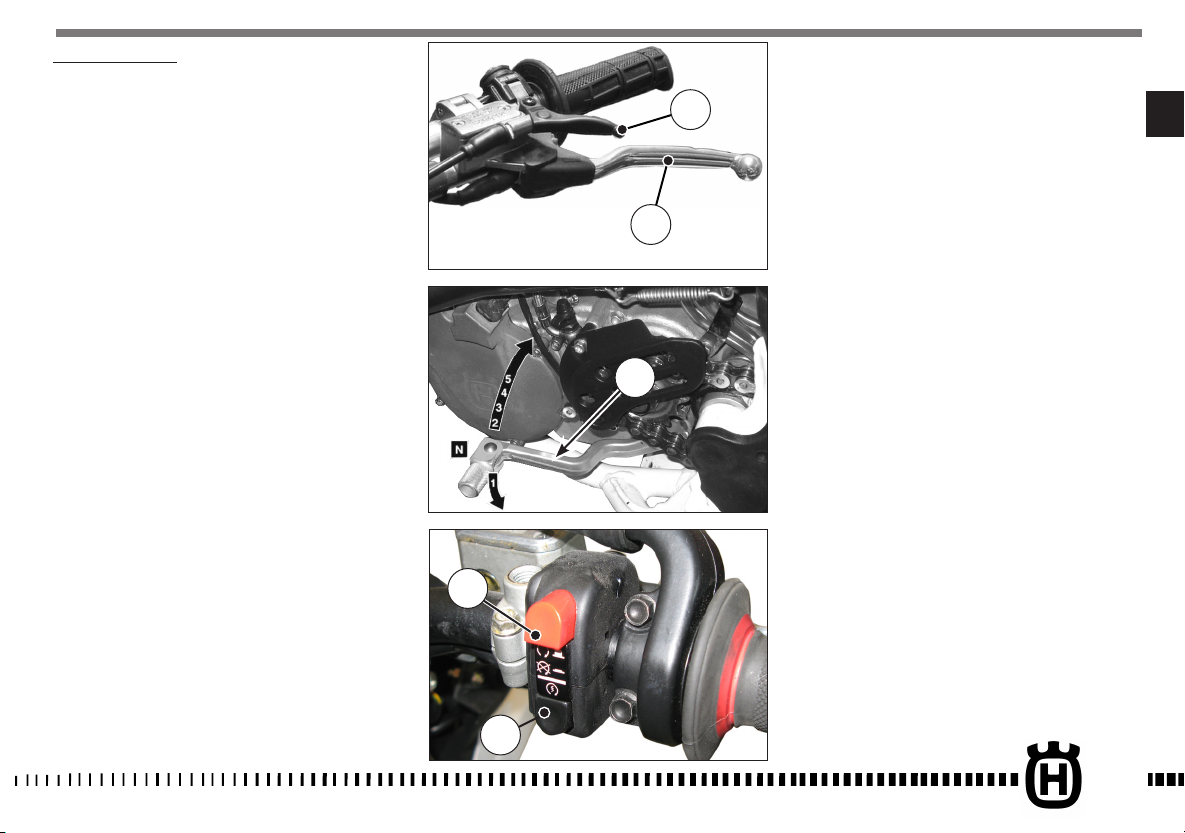

STOPPING THE MOTORCYCLE AND THE ENGINE

- Close the throttle (1) completely so that the engine will help

slow down the motorcycle.

- For normal braking, gradually apply both front and rear brakes while down shifting (for maximum deceleration, apply the

front and rear brakes firmly).

- When stopped, pull the clutch lever and shift gear lever (2) in

neutral position.

- Press the engine stop RED button (3).

- TE: turn towards left the ignition key.

WARNING*: Independent use of the front or

rear brake may be advantageous under certain conditions. Use caution when using the

front brake, especially on slippery surfaces.

Improper use of the brakes can lead to a serious crash.

2

WARNING*: In the event of stuck throttle or

other malfunction which causes the engine to

run uncontrollably, immediately depress the

engine stop button and hold it down. Control

the motorcycle by normal use of the brakes

and steering while holding the engine stop

button down.

TE

EN - 22

TE - TXCi

3

TC

CHECKING THE OIL LEVEL

Keeping the motorbike level and in a vertical position, check the

oil level through the inspection (1) window on the right crankcase.

Make sure the level is in between the MIN and MAX notches.

To fill up, remove the filler cap (2).

Note*: Have this operation made with warmed-up engine.

WARNING*: Be careful not to touch hot engine oil.

1

a

ENGINE OIL REPLACEMENT AND BAG FILTERS-FILTER

CARTRIDGE CLEANING OR REPLACEMENT

WARNING*: Be careful not to touch hot engine oil.

Drain the oil with WARM ENGINE; proceed as follows:

• remove oil filler cap (2);

• remove the engine lower guard (A);

• place an oil drain pan under the engine block;

• Remove the oil drain cap (3), the mesh filter (4) and drain

the old oil;

A

• Clean the mesh filter with benzine;

• in order to replace the filter cartridge (5), unscrew the three

fastening screws then the filter cartridge cover (6).

Once the oil filters have been cleaned-replaced, fit the parts

back in, in the opposite sequence to the disassembly, and pour

in the prescribed amount of oil, as listed in the LUBRICATION

TABLE on page 8.

EN

3

4

6

5

2

EN - 23

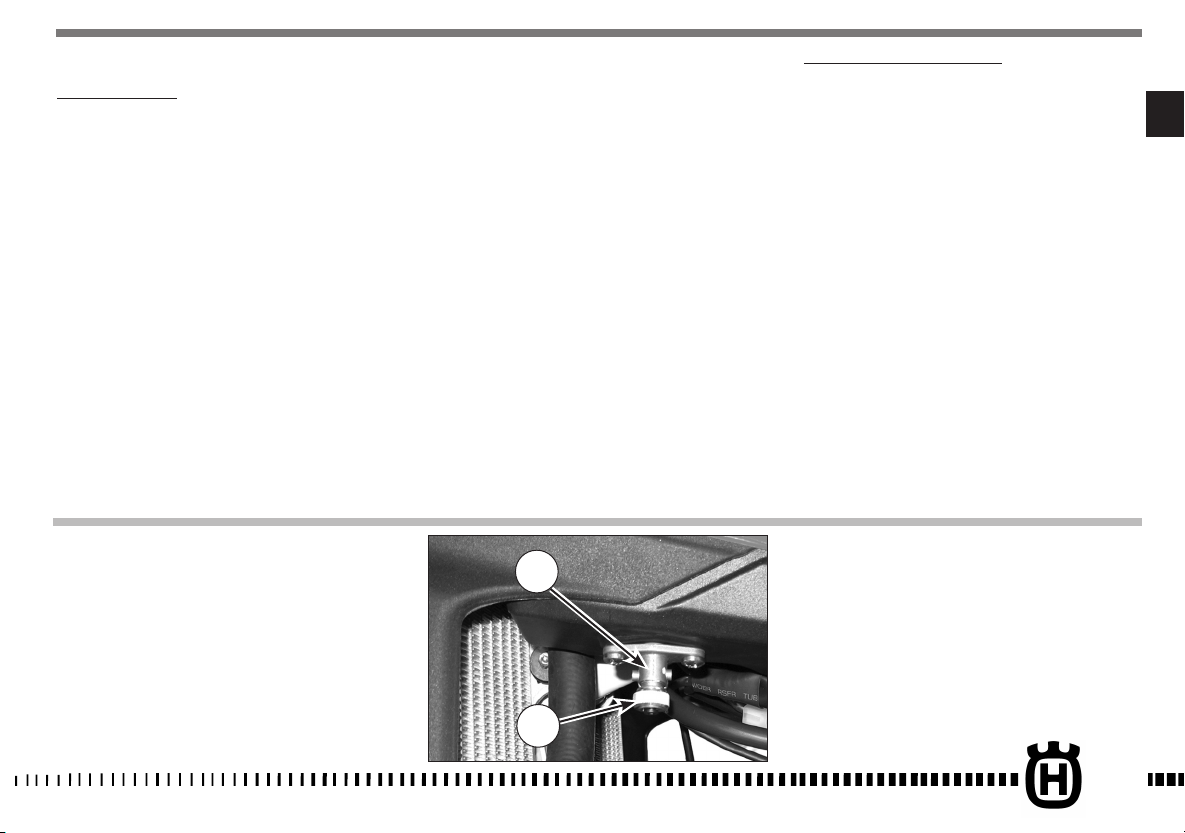

COOLANT LEVEL CHECK

Check level (1) in right-hand radiator when engine is cold (place

the motorcycle so that it is perpendicular to the ground). The coolant should be approximately 10 mm above cells and besides.

The radiator cap (A) is provided of two unlocking positions, the

first being for the previous pressure discharge in the cooling

system.

WARNING

Avoid removing radiator cap when engine

is hot, as coolant may spout out and cause

scalding.

WARNING

TE-TXCi: Remember that the electric fan (B)

can start even with the main switch in the

OFF position; please avoid to operate near

the fins of the fan.

NOTE

Difficulties may arise in eliminating coolant

from varnished surfaces. If this occurs, wash

off with water.

EN - 24

1

A

B

REPLACEMENT OF COOLING FLUID

Place a vessel on the L.H. side of the cylinder, under the Piping (1).

Remove the exhaust pipe (a). Loosen the pipe strap (2) of the piping

(1), take the pipe off the fitting that secures it to the engine, then

SLOWLY open the R.H. radiator cap (3); slope the motorcycle on the

left side to drain the coolant easily in the vessel.

Once over, fit the pipe back in (1) and secure it with the strap (2).

Fit the exhaust pipe back in.

Pour the necessary quantity of coolant in the radiator then warm up

the engine in order to eliminate any possible air bubble.

a

1

Periodically check the connecting hoses (see “Periodical maintenance card”): this will avoid coolant leakages and consequent

engine seizure: If hoses (A) show cracks, swelling or hardenings

due to sheats desiccation, their replacement shall be advisable.

Check the correct tightening of the clamps (B).

3

A: Piping

B: Clamps

EN

A

B

A

B

2

A

EN - 25

THROTTLE CABLE ADJUSTMENT

To check the correct adjustment of the throttle operate as follows:

- remove the upper rubber cap (1);

by moving cable (2) back and forth check for 2 mm. clearance;

-

- should the clearance be incorrect, unblock the counter ringnut (3) and turn the adjusting screw (4) (by unscrewing it,

the clearance is reduced, while by screwing screw (4) it is

increased);

- tighten the counter ring-nut again (3).

WARNING*: Operation with damaged throttle cable could result in an unsafe riding condition.

WARNING*: Exhaust gas contains poisonous

carbon monoxide gas. Never run the engine

in a closed area or in a confined area.

NOTE

In case of throttle control cables (1) and (2) replacement it

is necessary to respect, during reassembly, the measure Á

(10mm/0.4 in.), as shown in the picture. Then reassemble

guard cover (B) using screw (3) and adjust throttle control

cables on handlebar as described at side.

To replace throttle control cables, first remove tha fuel tank.

EN - 26

ADJUSTING THE IDLE

Adjust the carburetor with warm engine and with the throttle

control in closed position. Proceed as follows:

- turn the idle speed adjustment screw (3) on the throttle body,

located on the right side of the vehicle, until the idle speed of

1,950 RPM is reached (turn clockwise to increase the speed

and anti-clockwise to reduce the speed).

3

EN

EN - 27

SPARK PLUG CHECK

Use NGK CR9EB spark plug (2); the gap is 0.027÷0.031 in.

A wider gap may cause difficulties in starting engine and in

overloading coil.

A gap that is too narrow may cause difficulties when accelerating, when idling the engine or when performing at low

speeds.

Clean the dirt away from the base of the spark plug before removing it from the cylinder after removing the cap (1).

It is very useful to examine the state of the spark plug just after it

has been removed from the engine since the deposits on the plug

and the colour of the insulator provide useful indications.

2

Correct heat rating:

The tip of the insulator should be dry and the colour should be

light brown or grey.

High heat rating:

In this case, the insulator tip is dry and covered with dark deposits.

Low heat rating:

In this case, the spark plug is overheated and insulator tip is

vitreous, white or grey in colour.

CAUTION*: Select a spark plug with a colder

or hotter heat range carefully and cautiously. A spark plug with too hot a heat range

may lead to preignition and possible engine

damage. A spark plug with too cold a heat

range may foul as the result of too much carbon buildup.

Before refitting the plug, thoroughly clean the

electrodes and the insulator using a brass-metal

brush.

Apply a little graphite grease to the spark plug

thread; fit and screw the spark plug by hand then

tighten to the torque of 10÷12 Nm- 7.4÷8.9 ft/

lb. Loosen the spark plug then tighten it again

to the torque of 10÷12 Nm- 7.4÷8.9 ft/lb.

Spark plugs which have cracked insulators or

corroded electrodes should be replaced.

EN - 28

1

AIR FILTER CHECK (TC-TXCi)

Turn rear pin (1) counterclockwise, remove the saddle from the

front afstening screw.

TXCi: Take out the battery (A) and place it sideways on the vehicle.

Remove screw (3) and the filter (4). Separate filter (5) from

frame (6).

1

AIR FILTER AND CLEANING

Wash the filter with a specific detergent (“CASTROL FOAM AIR

FILTER CLEANRR” or similar) then dry it fully (wash filter with

gasoline only in case of necessity).

Plunge the filter in special oil for filters (“CASTROL FOAM AIR

FILTER OIL” or similar), then wring it to drain superfluous oil.

CAUTION*: Do not use gasoline or a low flashpoint solvent to clean the element. A fire or

explosion could result.

CAUTION*: Clean the element in a well ventilated area, and do not allow sparks or flames anywhere near the working area.

ASSEMBLY

To ensure tight fit, slightly (C) grease filter edge on side facing

filter housing.

While re-inserting the filter into its housing, make surs that

piece (A) is turned upwards and edge (B) is on the left lower

side of the filter case. Reassemble the parts previously removed

(battery: connect the positive cable first).

CAUTION*: If the element assembly is not

installed correctly, dirt and dust may enter

and the engine resulting in rapid wear of the

piston rings and cylinder.

UPPER SIDE

TC-TXCi

LEFT SIDE

EN

A

4

3

5

6

EN - 29

AIR FILTER CHECK (TE)

Turn rear pin (1) counterclockwise, remove the saddle from the

front afstening screw.

Take out the battery (A) and place it sideways on the vehicle.

Remove screw (3) and the filter (4). Separate filter (5) from

frame (6).

1

AIR FILTER AND CLEANING

Wash the filter with a specific detergent (CASTROL FOAM AIR

FILTER CLEANER or similar) then dry it fully (wash filter with

gasoline only in case of necessity).

Plunge the filter in special oil for filters (CASTROL FOAM AIR

FILTER OIL or similar) then wring it to drain superfluous oil.

CAUTION*: Do not use gasoline or a low flashpoint solvent to clean the element. A fire or

explosion could result.

CAUTION*: Clean the element in a well ventilated area, and do not allow sparks or flames anywhere near the working area.

ASSEMBLY

To ensure tight fit, slightly (C) grease filter edge on side facing

filter housing.

While re-inserting the filter into its housing, make surs that piece

(A) is turned upwards and edge (B) is on the left lower side of

the filter case. Reassemble the parts previously removed (battery: connect the positive cable first).

CAUTION*: If the element assembly is not

installed correctly, dirt and dust may enter

and the engine resulting in rapid wear of the

piston rings and cylinder.

UPPER SIDE

TE

LEFT SIDE

A

EN - 30

4

3

5

6

STEERING WHEEL BALL PLAY ADJUSTMENT

To ensure maximum safety, the steering wheel should always be

regulated so that the handlebars steering the motorcycle rotate

freely without play. To check steering wheel adjustment, place

kick stand or other support under the engine so that the front

wheel is raised from ground.

Place slight pressure on the tips of the handlebars to rotate steering wheel; the handlebars should also rotate without effort.

Stand in front of the motorcycle and grasp the lower end of

the fork rods sliders moving them in the direction of their axis.

Se si avverte gioco occorrerà eseguire la regolazione operando

come segue:

- loosen steering sleeve nut (1).

- Loosen four screws that fix steering head to fork rods (3).

Turn the steering ring nut (2) clockwise of the steering sleeve

proper tool, to adjust play properly.

- Tighten steering sleeve nut (1) to a torque setting of 57,9÷65,1

Lb/ft; (78,4÷88,3 Nm).

- Tighten four screws on the steering head (3) to a torque of

22,5÷26,5 Nm (16.6÷19.5 Lb/ft).

CAUTION*: Do not ride a motorcycle with damaged steering stem bearings. An unsafe

handling condition can result.

LOCK ADJUSTMENT

The lock can be changed, using the adjusting units on the sides

of the steering tube, as follows: loosen the ring nut (1) and turn

the adjusting screw (2) until you have the desired angle, then

tighten the ring nut again (1). Change by the same amount on

both sides.

EN

3

1

1

2

2

EN - 31

ADJUSTMENT OF THE CONTROL LEVER AND CHECK OF THE

FRONT BRAKE FLUID LEVEL

The adjuster (2), located on the control lever, allows adjusting

of the free play (a).

Free play (a) must be at least 3 mm (0.1 in.).

The level of the fluid in pump reservoir must never be below

the minimum value (1), which can be checked from the window

on the rear side of the pump body.

A decrease of the fuel level will let air into the sustem, hence

an extension of the level stroke.

WARNING*: If the brake lever feels mushy

when it is applied, there may be air in

the brake lines or the brake may be

defective. Since it is dangerous to operate

the motorcycle under such conditions, have

the brake checked immediately by an

authorized HUSQVARNA dealer.

CAUTION*: Do not spill brake fluid on to any

painted surface or lenses.

CAUTION*:Do not mix two brands of fluid.

Change the brake fluid in the brake line if

you wish to switch to another fluid brand.

CAUTION*: Brake fluid may cause irritation.

Avoid contact with skin or eyes. In case of

contact, flush thoroughly with water and call

a doctor if your eyes were exposed.

A: to encrease clearance

B: to decrease clearance

EN - 32

1

+

B

-

2

A

REAR BRAKE PEDAL POSITION ADJUSTMENT

The position of the rear foot brake pedal as to the footrest may

be adjusted according to the individual needs. For the adjusting

proceed as follows:

- loosen the screw (1);

- turn the cam (2) in order to adjust the brake pedal idle stroke

(A);

- the operation done, tighten the screw (1).

The adjusting operation carried out, adjust the idle stroke of the

pedal as follows.

REAR BRAKE IDLE STROKE ADJUSTMENT

The rear brake foot pedal should have a (B) 5 mm (0.2 in.) idle

stroke before starting the true braking action.

Should this not happen, operate as follows:

- loosen nut (3);

operate the pump rod (4) to increase or decrease the idle stroke;

-

- tighten nut (3) at the end of the operation.

WARNING

When the idle stroke figures are not met, the

brake pads will be subjected to a fast wear

that may bring to the TOTAL BRAKE INEFFECTIVENESS.

B

EN

EN - 33

CHECKING THE FLUID LEVEL

The level (A) must be set between the pump tank notches.

ADJUSTMENT OF THE HYDRAULIC CLUTCH CONTROL LEVER

Free play (A) must be at least 3 mm (0.1 in.).

The lever position can be adjusted for any driver hand size.

To decrease the lever distance from the handle grip, rotate the

adjuster (B) CLOCKWISE.

To increase the lever distance from the handle grip, rotate the

adjuster (B) COUNTERCLOCKWISE.

B

EN - 34

A

ADJUSTING THE SUSPENSIONS ACCORDING TO PARTICULAR TRACK CONDITIONS

The following information is a useful guide for setting up the

suspensions according to the road conditions.

Always start from the standard calibration before making any

change on the suspensions. Afterwards, increase or decrease the

adjusting clicks one at a time.

HARD GROUND

Fork: softer compression adjustment.

Shock absorber: softer compression adjustment.

The softer adjustment for the two suspensions is also used both

in compression and in extension when driving at top speed, in

order to have better grip of the tires.

SANDY GROUND

Fork: have a harder compression adjustment, or replace the

standard spring with a harder one, and make a softer compression adjustment and a harder extension adjustment at the same

time.

Shock absorber: have a harder compression, and expecially a

harder extension adjustment. Work on the spring preload to

lower the motorcycle rear side.

MUDDY GROUND

Fork: have a harder compression adjustment, or replace the

standard spring with a harder one.

Shock absorber: have a harder compression and extension

adjustments, or replace the standard spring with a harder one.

Work on the spring preload to lift the motorcycle rear side.

We advise replacing the springs of both suspensions to compensate the weight increase due to the piling of the mud.

NOTE:

When the fork results as either too soft or too hard for any

adjustment conditions, check the oil level inside the forkrod.

The level can either be too low or too high. Remember that too

much oil inside the fork will involve a more frequent air drainage. When the suspensions do not react to the changes of calibration, check that the adjusting units are not blocked.

EN

EN - 35

ADJUSTING THE FORK

a) COMPRESSION (TC-TXCi: LOWER REGISTER; TE: UPPER REGI-

STER)

Standard calibration : -9 clicks (TC-TXCi);

Standard calibration : -13 clicks (TE)

To reset to the standadr calibration turn register (A) clockwise

until the position of fully closed is reached then, turn back by

the mentioned clicks. To obtain a smoother braking action, turn

the register anticlockwise. Reverse the operation in order to obtain a harder action.

b) EXTENSION (TC: LOWER REGISTER; TE: UPPER REGISTER)

Standard calibration : -15 clicks (TE);

Standard calibration : -13 clicks (TC-TXCi).

To reset to the standard calibration turn register (C) clockwise to reach the position of fully closed; then, turn back by the

mentioned clicks. To obtain a smoother braking action, turn the

register anticlockwise. Reverse the operation in order to obtain

a harder action.

c) AIR VENT (to carry out after each competition, or monthly).

Set the motorcycle on a central stand and release the fork fully

and loosen the air vent valve (D). Once this operation is over,

tighten the valve.

WARNING: Never force the adjusting screws

beyond the maximum opening and closure

positions.

OIL FORK LEVEL

For the regular fork operation, both legs must be provided with

the necessary oil quantity. Remove the forkrods form the fork to

check the oil level inside the forkrods. Work as follows:

- remove the power rod caps;

- remove springs from the stems letting the oil drop into the

latter;

- bring forks to stroke end;

- check that the level is at distance of 140 mm(5.5 in.) below

the upper limit of rods.

OIL QUANTITY IN EACH FORK LEG

- TC-TXCi: 352 cm

- TE: 646 cm

3

(21.5 cu. in.)

3

(39.4 cu. in.)

a)

EN - 36

D

A

TC

b)

C

TC - TXCi

a)

TE

A

NOTE

Flexibility index for the serial springs:

K=8,8 N/mm (TC-TXCi)

K=89,2 N/mm (TE)

NOTE

Always replace both the spring and the spacers to keep the preload value unchanged.

HANDLEBAR POSITION AND HEIGHT CHANGE

The handlebar position (a) and height (b) can be changed for

better suiting Your driving requirements. To effect these operations, remove the upper clamp (1) and the lower one (2), after

removing the fixing srews (3) and (4).

a) Handlebar position change

Turn the lower clamp (2) 180° to move forward or backward

(10mm- 0.04in.) the handlebar position with respect to the

original setup.

1

A

3

2

b) Handlebar height change

Remove the lower spacer (A) then replace the screw (4) with a

new one of L=65 mm (2.56 in.) height.

Once these operations are completed, tighten the screws (3) to

2,75-3,05 kgm (27-30 Nm; 19.9-22 Lb/fts) and the screws (4)

to 2,0-2,2 kgm (19,6-21,6 Nm; 14.5-15.9 Lb/fts).

1

4

3

2

A

EN

b)

D

C

TE

EN - 37

ADJUSTING THE SHOCK ABSORBER

The rear shock absorber must be adjusted according to the rider

weight and track conditions.

Proceed as follows:

1. With motorcycle on the stand, measure distance (A).

2. Take the normal riding position on the motorcycle with all

your riding apparel.

3. With somebody’s help, take the new distance (A).

B: axis of the panel screw

C: axis of rear wheel pin

4. The difference between these two measurements constitutes

the “SAG” of the motorcycle’s rear end.

Suggested SAG: 4 in. with cold shock absorber. 3.7 in. with

warmed up shock absorber.

5. To get the right SAG according to your weight, adjust the

shock absorber spring preload as described at side.

WARNING*: Never disassemble shock absorber, which contains highly compressed

nitrogen. Contact your Dealer for such major

service. Do not incinerate.

ADJUSTING THE SHOCK ABSORBER SPRING PRELOAD

Proceed as follows:

1. First turn counterclockwise fastening rear pin (1) then remove saddle, screws (2) and R.H. side panel (3).

2

EN - 38

3

2. Clean ringnut (1) and adjusting nut (2) of the spring (3).

3. Either with a hook wrench or an aluminium punch, loosen

the ringnut .

4. Turn the adjusting nut as required.

5. When the adjusting operation is over (according to your

weight and riding style), tighten the ringnut. (Torque for

both ringnuts: 5 Kgm; 49 Nm; 36.2 ft/lb).

6. Reassemble R.H. side panel and saddle.

SHOCK ABSORBER DAMPING ADJUSTMENT

Adjustment of the compression stroke is independent from the

rebound stroke.

A) COMPRESSION - Standard calibration:

1) Low damping speed:

- 15 clicks (± 2 clicks)

(register 4)

B) EXTENSION - Standard calibration:

- 18 clicks (± 2 clicks)

To reset the standard calibration, turn lower register (5) clockwise until reaching fully closed position. Return then back for the

mentioned clicks. In order to obtain a smooth braking

action, turn the register anticlockwise. Reverse the operation

in order to obtain a harder braking action.

EN

WARNING*:Be careful not to touch hot

exhaust pipe while adjusting the shock abosrber.

4

6

1

3

2

2) High damping speed:

- 15 clicks (± 2 clicks)

(register 6)

To reset the standard calibration, turn upper registers (4) and

(6) clockwise until reaching fully closed position.

Return then back for the mentioned clicks. In order to obtain a

smooth braking action, turn the registers anticlockwise.

the operation in order to obtain a harder braking action.

Reverse

5

EN - 39

CHAIN ADJUSTMENT (Fig. A)

Chain should be checked, adjusted and lubricated as per the

Maintenance Chart to ensure security and prevent excessive

wear. If the chains becomes badly worn or is poorly adjusted

(i.e., if it is too loose or too taught), it could escape from sprocket or break.

To adjust the rear chain it is necessary to lower the rear part of

motorcycle so to line up the drive sprocket axle, the rear swing

arm axle and the rear wheel axle as shown on drawing. Than

let turn three times the rear wheel. Now the chain should not

be tight.

FAST ADJUSTMENT (Fig. B)

In the point shown in the figure, fit a bush (a), 35 mm diameter

(or alternatively a shim in the same size) and make sure the

lower branch (C) of the chain is slightly taut.

If it is not, proceed as follows:

- on the right side, with a 27 mm Allen screwdriver, loosen the

locking nut (1) of the wheel pin;

- with a 12 mm screwdriver, loosen the check nuts (2) on both

chain stretchers and work on the screws (3) to achieve the

right tension;

- when the adjustment is over, tighten the check nuts (2) and

the wheel pin nut (1).

When the adjustment is over check the wheel for alignment.

a

Fig. B

C

1

Fig. A

EN - 40

2

3

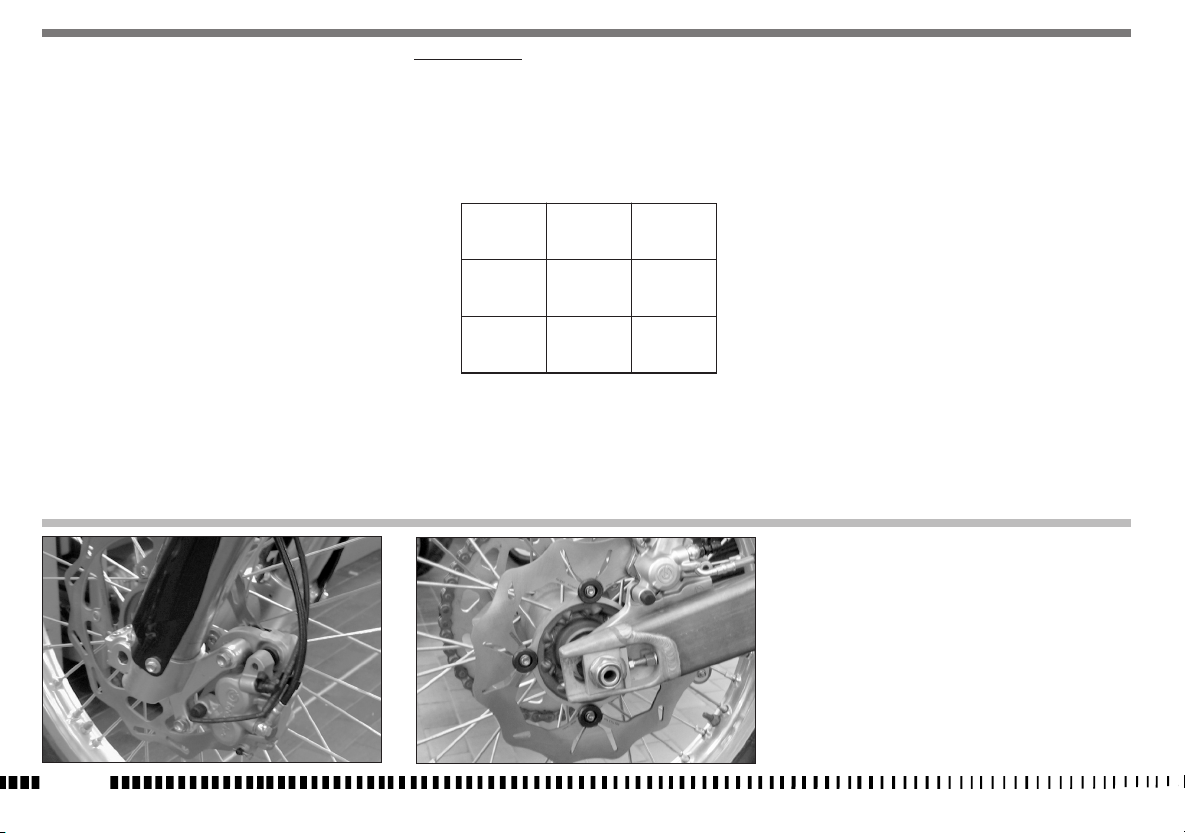

CHECKING THE WEAR OF CHAIN, PINION AND SPROCKET

Proceed as follows:

- fully stretch the chain with the adjusting screws.

- mark 20 chain links.

- measure the distance “A” between 1st pin center and 21 st

pin center.

STANDARD

LIMIT

WEAR

317,5 mm 323 mm

12,5 in 12,72 in

Check the pinion damages or wear and replace it should the

wear degree be as the one shown in figure.

Remove the wheel and check the wear of the rear sproket teeth.

The below figure shows the outline of teeth in normal and excessive wear. Should the sprocket be badly worn out, replace it

by loosening the six fastening screws to the hub.

WARNING*: Misalignment of the wheel will

result in abnormal wear and may result in

an unsafe riding condition.

Note*: In muddy and wet conditions, mud

sticks to the chain and sprockets resulting

in an overtight chain. The pinion, the chain,

and the rear sprocket wheel wear increases

when running on muddy ground.

Normal

consumption

LUBRICATING THE CHAIN

Lubricate the chain following these instructions.

WARNING * : Never use grease to lubricate

the chain. Grease helps to accumulate dust

and mud, which act as abrasive and hepl to

rapidly wear out the chain, the sprocket, and

the crown.

Disassembling and cleaning

When particularly dirty, remove and clean the chain before

lubrication.

Work as follows:

1 - Set a stand or a block under the engine and see that the rear

wheel is lifted from the ground.

Remove: screws (1), transmission sprocket guard (2), clip

(3), master link (4) and transmission chain (5);

To reassemble, reverse the above procedure.

EN

Excessive

consumption

EN - 41

2 - Check that the chain is neither worn out nor damaged. If the

rollers or the links are damaged, replace the chain by following the instructions given in the Periodical Maintenance

Table.

3 - Check that neither the sprocket nor the crown are damaged.

4 - Wash and clean the chain as described hereunder.

Washing the chain without OR (TC)

Wash using either oil or diesel oil. When using gasoline or tricloroetilene, clean and lubricate the chain to prevent oxidation.

Washing the chain with OR (TE-TXCi)

Wash using oil, diesel oil, or paraffin oil. Never use gasoline,

tricloroetilene, or solvents, as the OR may suffer damages.

Use instead special sprays for chains with OR.

Lubricating the chain without OR (TC)

First dry, then plunge the chain in a bisulphide molybdenum

lubricant, or in high viscosity engine oil. Warm up the oil before

use.

Lubricating the chain with OR (TE-TXCi)

Lubricate all metallic and rubber (OR) elements using a brush,

and use engine oil with SAE 80-90 viscosity for the internal and

external parts.

5 - If the chain has been cut, reassemble using a joint.

6 - Assemble the joint spring (a) by turning the closed side to the

chain direction of rotation as shown in figure below.

NOTE*: Even if all the joints are reusable when in good conditions, for safety purposes we advise using new joints when

reassembling the chain.

7 - Accurately adjust the chain as described on page 40.

4

1

WARNING: The chain oil has NEVER to get in

contact with the tires or the rear brake disk.

Chain tension rollers, chain driving roller,

chain guide, chain runner

Check the wear of the above mentioned elements and replace

them when necessary.

WARNING*: Check the chain guide alignement, and remember that a bent element

can cause a rapid wear of the chain. In this

case, a chain fleeting from the sprocket may

ensue.

a

EN - 42

2

3

1- Chain tension roller

2- Chain driving roller

3- Chain guide

4- Chain slider

a- Joint spring

REMOVING THE FRONT WHEEL

Set a stand or a block under the engine and see that the front

wheel is lifted from the ground. Loosen the bolts (1) holding

the wheel axle (2) to the front fork stanchions.

Hold the head of the wheel axle (2) in place, unscrew the bolt

(3) on the opposite side; draw the wheel axle out.

NOTES

Do not operate the front brake lever when the wheel has been

removed; this causes the caliper piston to move outwards. After

removal, lay down the wheel with brake disc on top.

1

EN

1

3

2

EN - 43

REASSEMBLING THE FRONT WHEEL

Fit the L.H. spacer on the wheel hub.

Fit the wheel between the front fork legs so that the brake disc

is fitted into the caliper.

Fit the wheel axle (2) from the R.H. side, after greasing it and

push it to the stop on the L.H. leg; during this operation, the

wheel should be turned. Tighten the screw (3) on the fork L.H.

side but DO NOT lock it. Now, pump for a while, pushing the

handlebar downwards until you are sure that the fork legs are

perfectly aligned.

Lock: the screws (1) on the R.H. leg (10,4 Nm/ 1,05 Kgm/ 7.7

ft-lb), the screw (3) on the L.H. side (51,45 Nm/ 5,25 Kgm/

38 ft-lb), the screws (1) on the L.H. leg (10,4 Nm/ 1,05 Kgm/

7.7 ft-lb).

1

2

1

NOTE

After reassembly, pump the brake control lever until the pads

are against the brake disc.

EN - 44

3

REMOVING THE REAR WHEEL

Unscrew the nut (1) of the wheel pin (3) and extract it. It is

not necessary to unloose the chain adjusters (2); in this way,

the chain tension will remain unchanged after the reassembly.

Extract the complete rear wheel, by taking care of the spacers

located at the hub sides.

To reassemble, reverse the above procedure remembering to

insert the disc into the caliper.

NOTES

Do not operate the rear brake pedal when the wheel has been

removed; this causes the caliper piston to move outwards.

After removal, lay down the wheel with brake disc on top.

After reassembly, pump the brake control pedal until the pads

are against the brake disc.

EN

1

2

EN - 45

TYRES

Care should be taken to keep the tyres properly inflated. See

"Technical data" chart at the beginning of the manual for correct tyre inflation pressure.

BRAKES

The mayor components are brake master cylinder with its lever

(front) or pedal (rear), brakeline, caliper assembly and disc.

LEGEND

1. Front brake control lever

2. Front brake pump with oil reservoir

3. Front brake hose

4. Front brake caliper

5. Front brake disc

6. Rear brake oil tank

7. Rear brake hose

8. Rear brake caliper

9. Rear brake disc

10. Rear brake pump

11. Rear brake control pedal

EN - 46

2

1

6

10

3

11

8

7

9

5

4

BRAKE PADS REMOVAL

- Remove springs (1).

- Remove pins (2).

- Remove pads.

CAUTION!

Don’t operate the brake lever or pedal while

removing the pads.

FRONT

PADS WEAR

Inspect pads for wear.

Service limit “ A” is: 3,8 mm (0.15 in.).

If service limit is exceeded, always replace the pads in pairs.

PADS CLEANING

Be careful that no disc brake fluid or any oil gets on brake pads

or discs. Clean off any fluid or oil that inadverently gets on the

pads or disc with alcohol.

Replace the pads with new ones if they cannot be cleaned satisfactorily.

PADS INSTALLATION

- Install new brake pads.

- Reassemble the two pins (2) and the springs (1)

FRONT

EN

1

1

2

2

2

2

1

1

REAR

REAR

FRONT REAR

EN - 47

WARNING!

Do not attempt to ride the motorcycle until

the brake lever or pedal are

fully effective. Pump the brake

lever or pedal until the pads are against the

discs.

The brake will not function on the first application of the lever or pedal.

BRAKE DISC WEAR

Measure the thickness of each disc at the point where it has

worn the most. Replace the disc if it has worn past the service

limit.

Disc Thickness

SERVICE

DISC STANDARD LIMIT

Front 3 mm 2,5 mm

(0.12 in.) (0.1 in.)

Rear 4 mm 3,5 mm

(0.16in.) (0.14in.)

EN - 48

DISC CLEANING

Poor braking can also be caused by oil on the disc. Oil or grease

on the disc must be cleaned off with a high flash-point oil free

solvent, such as acetone or lacquer thinner.

EN

EN - 49

EXHAUST MUFFLER

The muffler reduces the noise of the exhaust gases, but it is an

integral part of the exhaust as well. As such, its conditions affect

the motorcycle performance.

When the noise on the exhaust is too high, it means that the

deadening material set on the holed tube inside the muffler

is deteriorated.

BATTERY (TE-TXCi)

The sealed battery does not require any maintenance work.

When electrolyte leaks, or other failures to the electrical system

are detected, apply to the HUSQVARNA Dealer.

If the vehicle remains unused for long periods, it is recommended to remove battery from electrical system and store it

in a dry place.

- After an intensive use of the battery, it’s advisable a standard

low charge (12V-7Ah battery: 0.7A for 8 hours).

-- Rapid recharging is advised only in situations of extreme necessity since the life of lead elements is drastically reduced

(7A for 0.5 hours with 12V-7Ah batteries).

BATTERY CHARGER

To gain access to the battery (2):

- first turn counterclockwise fastening rear pin (1) then remove

the saddle;

- first remove the BLACK or BLUE negative cable, then the RED

positive cable (when reassembling, first connect the RED positive cable, then the BLACK or BLUE negative cable);

- remove the battery (3) from its housing.

Check, using a voltmeter, that battery voltage is not less than

12,5 V.

If not, the battery needs to be charged.

Using a battery charter with a constant voltage, first connect

the RED positive cable to the battery’s positive terminal then

the BLACK or BLUE negative cable to the battery’s negative ter-

minal.

Apply to the constant voltage of 14,4 V a current of “x” Ampere

as results in the belowe diagram (depending on the amount of

carging required).

EN - 50

2

The voltage reaches a constant value only after a few hours,

therefore it is suggested NOT to measure it immediately after

having charged or discharged the battery.

Always check the charge level bifore reinstalling it on the vehicle.

The battery should be kept clean and the terminals coated with

grease.

WARNING*: The battery contains sulfuric

acid. Avoid contact with skin, eyes or clothing. Antidote: EXTERNAL - Flush with water.

INTERNAl - Drink large quantities of water or

milk. After milk take magnesia, beaten eggs

or vegetable oil. Call physician immediately.

Eyes: Flush with water for no less than 15

minutes and get prompt medical attention.

INDICATIVE VALUES RELATIVE TO THE CHARGING TIME DEPENDING ON BATTERY STATUS

VOLTAGE * (V) % CHARGE CHARGE TIME (THE “AMPERE” RATED CURRENT TO APPLY IS: 0,1x BATTERY RATED

CAPACITY)

WARNING*: In case on unused of the battery

it has to be , in any case, re-charged with

slow cycle (0,7A for 8 hours for batteries

12V-7Ah) at least every 3 weeks.

WARNING*: Batteries produce explosive gas,

ventilate when charging or using in enclosed

space. When using a battery charger before

turning on the charger. This procedure prevents sparks at the battery terminals which

could ignite any battery gases.

EN

> 12,7 100 _

~12,5 75 4h

~12,2 50 7h

~12,0 25 11h

~11,8 0 14h

EN - 51

HEADLAMP BULBS REPLACEMENT (TE)

To gain access to the healamp bulbs, proceede as follows:

- remove the upper fastening screw of the the headlamp carrier to

the instrument panuel support (A);

- push forward the headlamp carrier (B) and pull it towards the

high (C) in order to uncouple from the two lower supports.

- remove the headlamp carrier;

C

A

- remove the two filaments bulb (7) connector (2) and the boot

(3);

- remove the screw (6);

- release the bulb holding spring (4) and then the bulb itself.

To replace the parking light bulb (5) extract it from the inside

cover.

After replacement, reverse operations for reassembly.

3

5

4

TAIL LIGHT

The back light is a LED light.

EN - 52

B

5

6

4

7

3

2

REPLACING THE NUMBER PLATE LAMP (TE)

- loosen screw (1) and remove the number plate bulb (2) from

the mudguard;

- take bulb holder (3) and bulb (4) out of the support;

- pull the bulb (4) to detach it from bulb holder.

Once the bulb has been replaced, reverse the above procedure

to reassemble.

2

1

3

ADJUSTMENT OF HEADLIGHT (TE)

When checking the proper orienting of headlight, inflate tires

at right pressure, sat a person on the saddle and place the motorcycle perpendicular with its longitudinal axis 10 meter (33

ft) from a wall or screen. Then trace an horizontal line equal to

the height of headlight center and a vertical one in line with its

longitudinal axis.

If possibile, execute this operation in a shadowy place.

When the low beam is on, the upper boundary limit between

dark and lit zone should be 9/10 th of headlight center from

groud.

Adjust the preadlamp aiming by turning screw (1) to lower or

lift the high beam.

EN

1

4

EN - 53

APPENDIX

AFTER-RACE CHECK POINTS

After racing, first clean the motorcycle and then inspect the

entire motorcycle, with special attention to the items listed in

«MAINTENANCE» table (Appendix A), such as the air cleaner,

carburetor, brakes, etc.

Carry out general lubrication, and make adjustment as necessary.

- Lubricate the drive chain and all the cables.

- Spray oil on all unpainted metal surfaces to prevent rusting.

Avoid getting oil on rubber parts or in the brakes.

- Set the motorcycle on a box or stand so that both wheels are

raised off the ground. (If this cannot be done, put boards under the front and rear wheels to keep dampness away from

the tire rubber).

- Tie a plastic bag over the exhaust pipe to prevent moisture

from entering.

- Put a cover over the motorcycle to keep dust and dirt from

collecting on it.

To put the motorcycle back into the use after storage.

- Make sure the spark plug is tight.

- Fill the fuel tank.

- Run the engine to warm the oil then drain the oil.

- Put in fresh transmission oil.

- Check all the points listed under the inspection and Adjustment Section (Appendix A).

- Lubricate the points (listed in the Lubrication Section (Appendix A).

CLEANING

IMPORTANT RECOMMENDATION

Premised that, before the motorcycle washing, it is necessary to

protect opportunely from the water the following parts:

a) Rear opening of the muffler;

b) Clutch and brake levers, hand grips, handlebar commutators;

c) Air cleaner intake;

d) Fork head, wheel bearings;

e) Rear suspension links,

It is necessary ABSOLUTELY TO AVOID THAT

HIGH PRESSURE JETS OF WATER OR AIR come

to contact with THE ELECTRICAL PARTS AND

FUEL INJECTION PARTS, especially the electronic control unit and the sensors group

M.A.Q.S. and the dashboard.

After washing

- Remove the plastic bags, and clean the air cleaner intake.

- Lubricate the points listed in the Maintenance Table (Appendix A).

- Briefly warm-up the engine

- Test the brakes before riding the motorcycle.

WARNING*: Never wax or lubricate the

brake disc. Loss of braking and an accident

could result. Clean the disc with an oilless

solvent such ans acetone. Observe the solvent warnings.

EN - 54

Olio motore Controllo livello

Olio miscela benzina Controllo livello