Operator′s manual

K 3600 MKII

Please read the operator’s manual carefully and make sure you understand the

instructions before using the machine.

EEEEnnnngggglllliiiisssshh

hh

KEY TO SYMBOLS

Key to symbols

WARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or

fatal injury to the operator or others.

Please read the operator’s manual

carefully and make sure you understand

the instructions before using the machine.

Always wear:

• Approved protective helmet

• Approved hearing protection

• Protective goggles or a visor

• Breathing mask

This product is in accordance with

applicable EC directives.

Other symbols/decals on the machine refer to special

certification requirements for certain markets.

Always disconnect the machine from the

hydraulic hoses before inspection and/or

maintenance of the machine.

Always wear approved protective gloves.

Regular cleaning is required.

Visual check.

Protective goggles or a visor must be worn.

2 – English

CONTENTS

Contents

KEY TO SYMBOLS

Key to symbols ............................................................. 2

CONTENTS

Contents ...................................................................... 3

WHAT IS WHAT?

What is what on the power cutter? ............................... 4

SAFETY INSTRUCTIONS

Steps before using a new power cutter. ....................... 5

Personal protective equipment ..................................... 5

Machine′s safety equipment ........................................ 5

Checking, maintaining and servicing the machine′s

safety equipment ..........................................................

General safety precautions .......................................... 7

General working instructions ....................................... 7

SETTINGS AND ADJUSTMENTS

Drive ............................................................................. 11

Fitting the blade ........................................................... 11

Hydraulic hoses ........................................................... 13

Water hose ................................................................... 13

Water supply ................................................................ 13

Water dosage ............................................................... 13

STARTING AND STOPPING

Starting and stopping ................................................... 14

MAINTENANCE

Maintenance ................................................................ 15

Dismantling the complete guide roller .......................... 15

Assembling the complete guide roller .......................... 15

Drive wheel .................................................................. 16

Replacing the support rollers/guide rollers .................. 16

Reconstructing the blade ............................................. 17

Couplings ..................................................................... 17

Hydraulic hoses ........................................................... 17

Maintenance schedule ................................................. 18

Blades conforming to EN13236 ................................... 18

TROUBLE SHOOTING

Mechanics .................................................................... 19

TECHNICAL DATA

Extending the hydraulic hoses ..................................... 20

EC-declaration of conformity ........................................ 21

6

English – 3

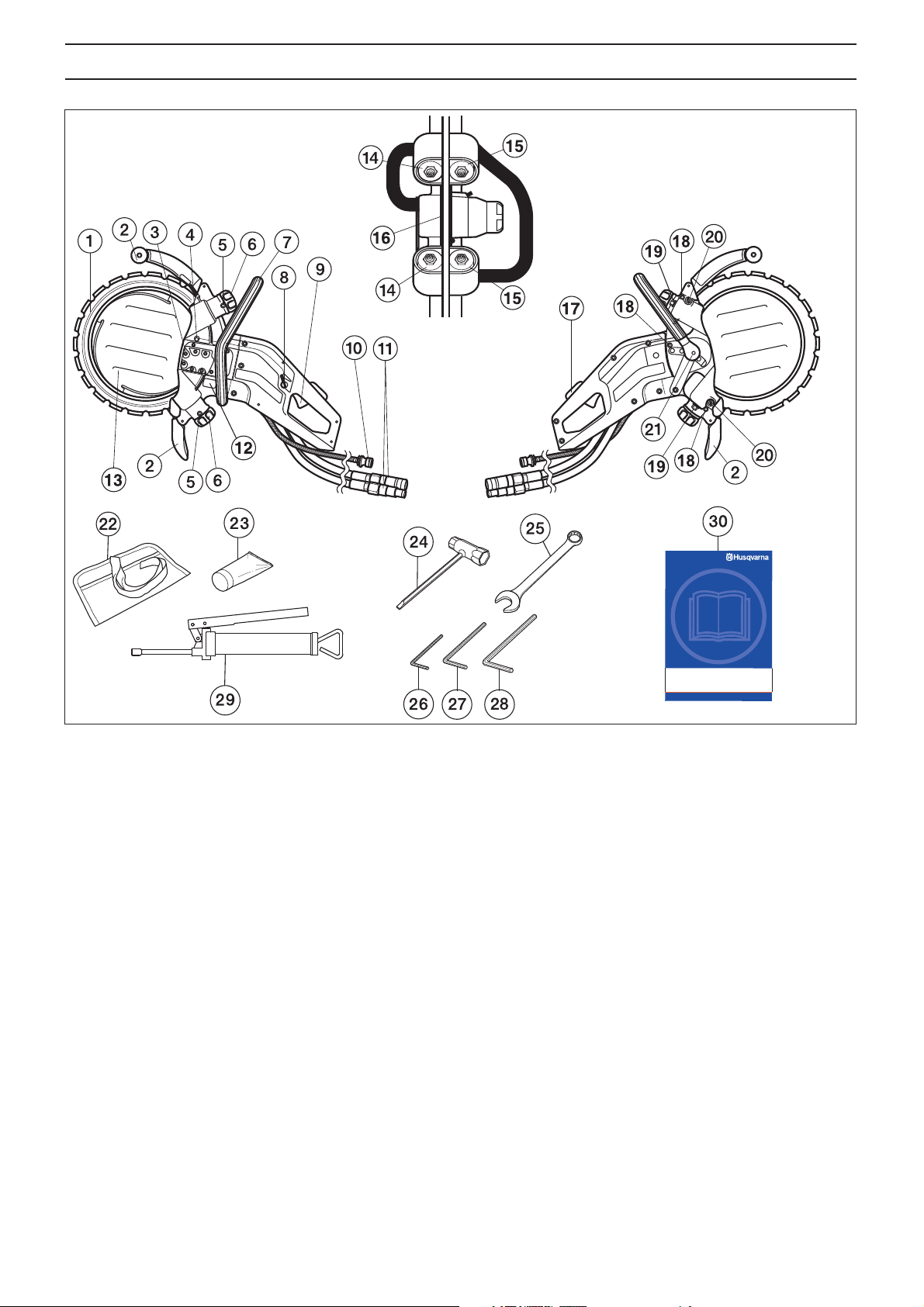

WHAT IS WHAT?

What is what on the power cutter?

1 Diamond blade

2 Blade guard/spray guard

3 Hydraulic motor

4 Locking button for the drive wheel

5 Grease nipples

6 Control for the guide rollers

7 Front handle (adjustable)

8 Water adjustment control

9 Switch

10 Water connector

11 Couplings for hydraulic hoses

12 Rating plate

13 Water disc

14 Support rollers

15 Guide rollers

16 Drive wheel

17 Switch lock and ON/OFF valve for the water

18 Cover screws

19 Locking nuts for the support rollers

20 Adjuster screws

21 Switch lock for the front handle

22 Tool bag

23 Bearing grease

24 Combination spanner

25 19 mm combination spanner

26 4 mm hex key

27 5 mm hex key

28 6 mm hex key

29 Grease gun

30 Operator′s manual

4 – English

SAFETY INSTRUCTIONS

Steps before using a new power cutter.

• This machine is a hydraulically operated power cutter

intended for free-hand cutting. The machine should be

connected to a hydraulic unit with an oil flow of 35-42

litres/min and a maximum pressure of 150 bar.

• Please read the operator’s manual carefully.

• Check the cutting blade’s mounting, see the chapter

”Assembly”.

Let your Husqvarna dealer check the power cutter and make

essential adjustments and repairs.

WARNING! Under no circumstances may the

design of the machine be modified without

!

the permission of the manufacturer. Always

use genuine accessories. Non-authorized

modifications and/or accessories can result

in serious personal injury or the death of the

operator or others.

WARNING! Use of products which cut, grind,

drill, sand or shape material can generate

!

dust and vapors which may contain harmful

chemicals. Know the nature of the material

being worked on and wear appropriate dust

mask or respirator protection.

• Breathing mask

• Heavy-duty, firm grip gloves.

• Tight-fitting, heavy-duty and comfortable clothing that

permits full freedom of movement.

• Use leg-guards recommended for the material to be cut.

• Boots with steel toe-caps and non-slip sole

WARNING! A power cutter is a dangerous

tool if used carelessly or incorrectly and can

!

cause serious, even fatal injuries. It is

extremely important that you read and

understand the contents of this Operator’s

Manual.

Husqvarna Construction Products has a policy of continuous

product development. Husqvarna reserves the right to modify

the design and appearance of products without prior notice

and without further obligation introduce design modifications.

All information and all data in the Operator’s Manual were

applicable at the time the Operator’s Manual was sent to print.

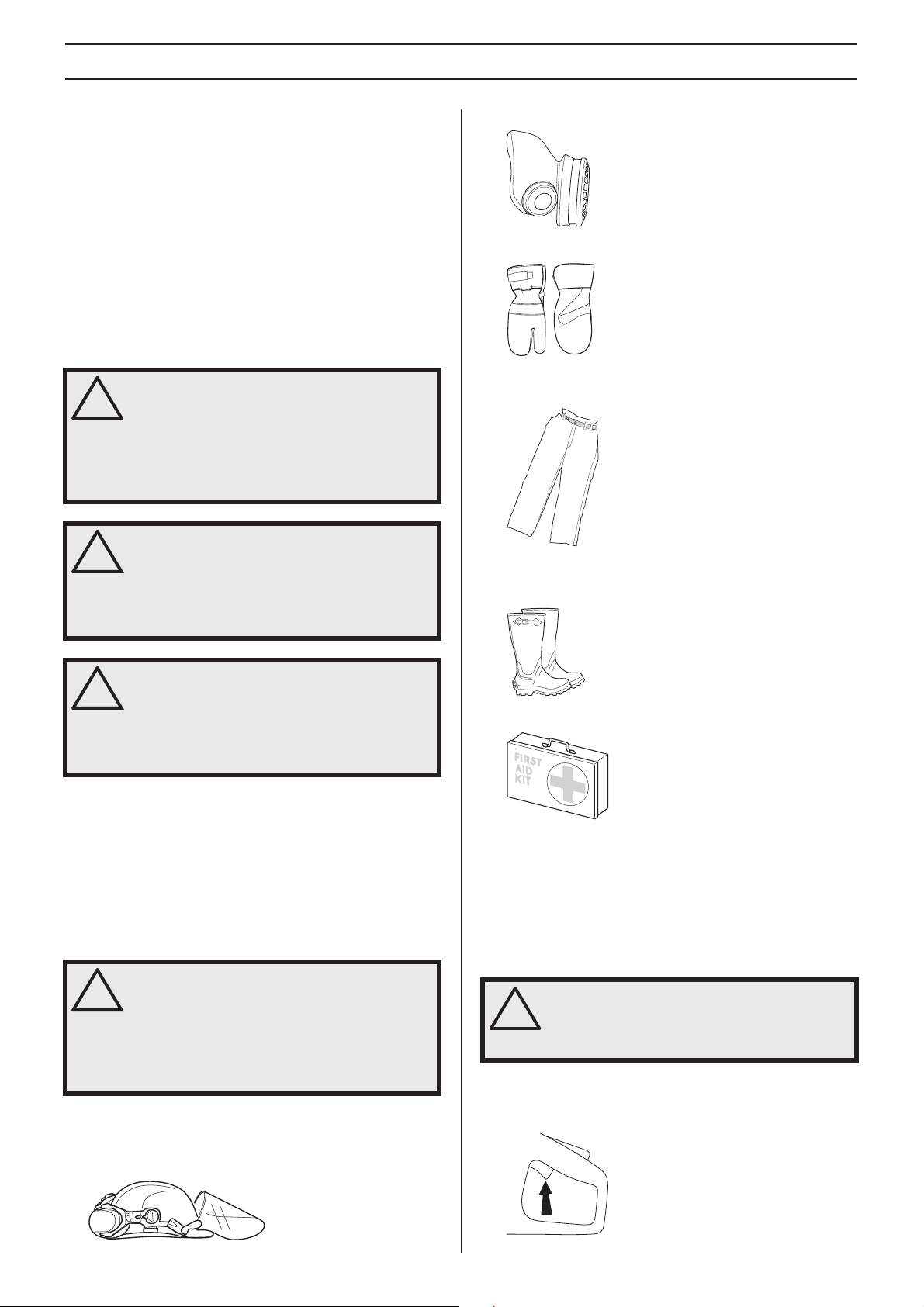

Personal protective equipment

WARNING! You must use approved personal

protective equipment whenever you use the

!

machine. Personal protective equipment

cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident

does happen. Ask your dealer for help in

choosing the right equipment.

• Protective helmet

• Hearing protection

• Protective goggles or a visor

• Always have a first aid kit nearby.

Machine′′′′s safety equipment

This section describes the machine′s safety equipment, its

purpose, and how checks and maintenance should be carried

out to ensure that it operates correctly. See the ”What is

what?” section to locate where this equipment is positioned

on your machine.

WARNING! Never use a machine that has

faulty safety equipment! Carry out the

!

inspection, maintenance and service

routines listed in this section.

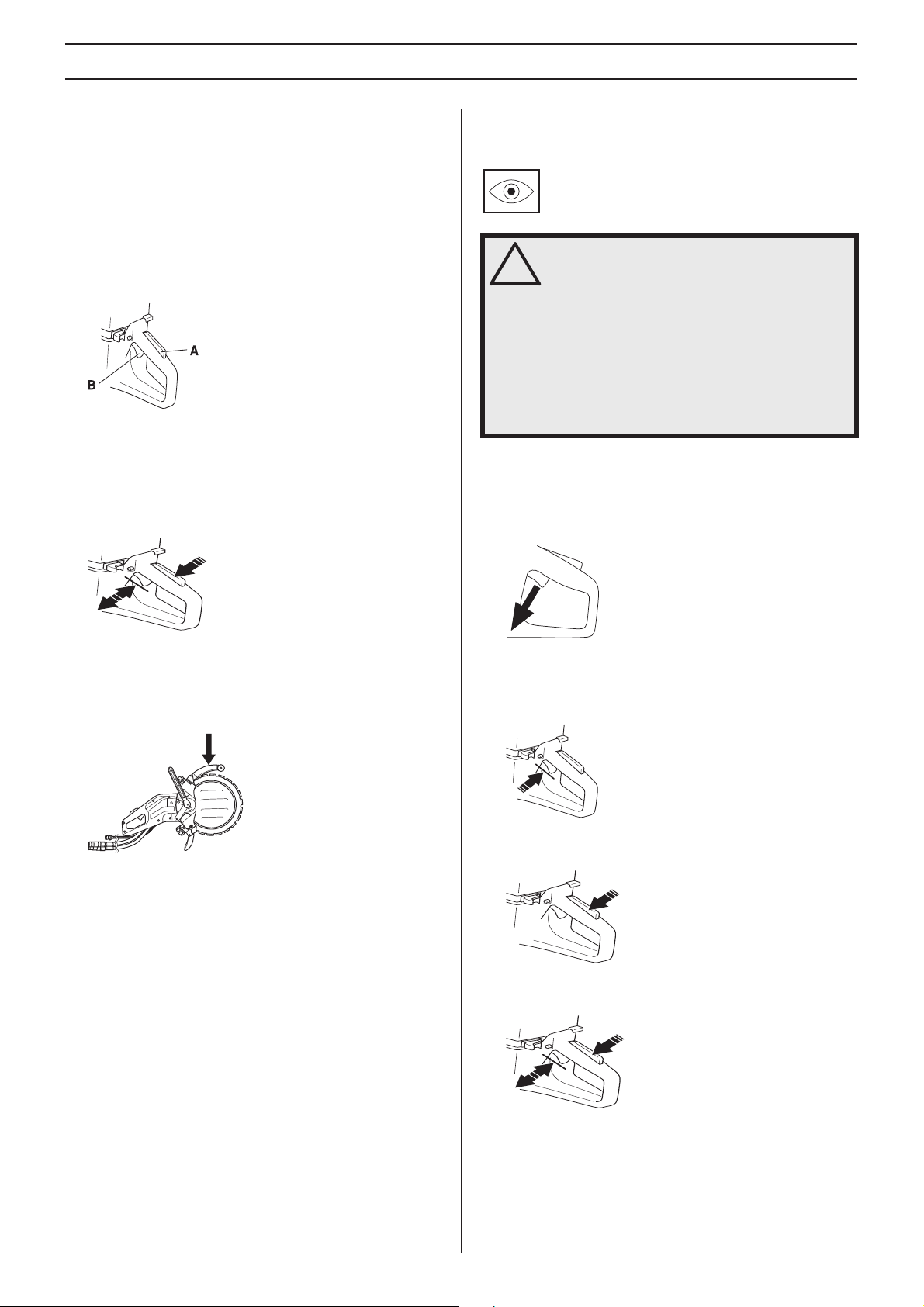

Switch

The switch is used to start and stop the machine.

English – 5

SAFETY INSTRUCTIONS

Switch lock and ON/OFF valve for the water

The switch lock is designed to prevent accidental operation of

the switch. The ON/OFF valve for the water supply is also

controlled with the switch lock.

When the switch lock (A) is pressed in this opens the water

valve and releases the switch (B).

As long as the switch is pressed in the switch lock remains

pressed in and the water valve open.

When you release your grip on the handle this resets both the

switch and the switch lock. This takes place via two

independent return spring systems. This position causes the

machine to stop and the switch to be locked.

The water valve returns to the stop position when the handle

is released.

Checking, maintaining and servicing

the machine

WARNING! All servicing and repair work on

the machine requires special training. This is

!

especially true of the machine

equipment. If your machine fails any of the

checks described below you must contact

your service agent. When you buy any of our

products we guarantee the availability of

professional repairs and service. If the

retailer who sells your machine is not a

servicing dealer, ask him for the address of

your nearest service agent.

Checking the starting and stopping functions of the switch

Start the machine, release the switch, and check that the

machine and blade stop.

′′′′s safety equipment

′′′′s safety

Blade guard

This guard is fitted above the blade and is designed to prevent

parts of the blade or cutting fragments from being thrown

towards the user.

Checking the switch lock

Check that the switch is locked when the switch lock is in its

home position.

Press the switch lock and check that it returns to its home

position when released.

Check that the switch and switch lock move freely and that

their return spring systems function.

6 – English

Start the machine, release the switch, and check that the

machine and blade stop.

SAFETY INSTRUCTIONS

Checking the blade guard

WARNING! Always check that the guard is

correctly fitted before starting the machine.

!

Also check that the blade is fitted correctly

and is not damaged in anyway. A damaged

blade can cause personal injuries. See

instructions under the heading Assembly.

Check that the guard is complete and without any cracks or

deformations.

General safety precautions

• A power cutter is designed to cut hard materials, such as

masonry. Observe the increased risk of kickback when

cutting soft materials. See instructions under the heading

How to avoid kickback.

• Do not use the power cutter until you have read the entire

contents of this Operator’s Manual.

All servicing, in addition to the points listed in the section

”Control, maintenance and service of the power cutter’s

safety equipment”, should be carried out by trained

service specialists.

• Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could affect

your vision, your judgement or your co-ordination.

• Wear personal protective equipment. See instructions

under the heading Personal protective equipment.

• Never use a machine that has been modified in any way

from its original specification.

• Never use a machine that is faulty. Carry out the checks,

maintenance and service instructions described in this

manual. Some maintenance and service measures must

be carried out by trained and qualified specialists. See

instructions under the heading Maintenance.

• Never allow anyone else to use the machine without first

ensuring that they have understood the contents of the

operator’s manual.

Transport and storage

Do not store or transport the power cutter with the blade fitted.

Store the power cutter in a lockable area so that it is out of

reach of children and unauthorised persons.

The blade should be removed from the machine after use and

stored well. Store the blade in the dry.

General working instructions

WARNING! This section describes basic

safety directions for using a power cutter.

!

This information is never a substitute for

professional skills and experience. If you get

into a situation where you feel unsafe, stop

and seek expert advice. Contact your dealer,

service agent or an experienced power

cutter user. Do not attempt any task that you

feel unsure of!

Basic safety rules

• Look around you:

- To ensure that people, animals or other things cannot affect

your control of the machine.

- To make sure that none of the above might come into

contact with the cutting equipment.

• Do not use the machine in bad weather, such as dense

fog, rain, strong wind, intense cold, etc. Working in bad

weather is tiring and can lead to dangerous conditions,

e.g. slippery surfaces.

• Never start to work with the power cutter before the

working area is clear and you have a firm foothold. Look

out for any obstacles with unexpected movement. Ensure

when cutting that no material can become loose and fall,

causing operating injury.Take great care when working on

sloping ground.

• Make sure that no clothes or parts of the body come in

contact with the cutting equipment when it is rotating.

• Keep at a safe distance from the cutting equipment when

it is rotating.

• The guard for the cutting equipment must always be on

when the machine is running.

• Ensure that the working area is sufficiently illuminated to

create a safe working environment.

• Do not move the machine when the cutting equipment is

rotating.

• Always ensure you have a safe and stable working

position.

• Make sure that no pipes or electrical cables are routed in

the area to be cut.

English – 7

SAFETY INSTRUCTIONS

Cutting

WARNING! The safety distance for the power

cutter is 15 metres. You are responsible to

!

ensure that animals and onlookers are not

within the working area. Do not start cutting

until the working area is clear and you are

standing firmly.

General

• Start cutting with the machine running at maximum

speed.

• Always hold the machine in a firm grip with both hands.

Hold it so that the thumbs and fingers grip round the

handles.

• Move the blade slowly backwards and forwards to give a

small contact surface between the blade and material to

be cut. This will mean the blade temperature is kept down

resulting in efficient cutting.

• Feed the machine in line with the blade. Side pressure can

destroy the blade and is extremely dangerous.

WARNING! Under all circumstances avoid

cutting with the side of the blade, as this will

!

definitely result in damage, breakage or can

cause serious injuries. Only use the cutting

section.

WARNING! Overexposure to vibration can

lead to circulatory damage or nerve damage

!

in people who have impaired circulation.

Contact your doctor if you experience

symptoms of overexposure to vibration.

These symptoms include numbness, loss of

feeling, tingling, pricking, pain, loss of

strength, changes in skin colour or

condition. These symptoms normally appear

in the fingers, hands or wrists.

Cutting technique

The technique described below is of a general character.

Check the details of each blade concerning individual cutting

characteristics.

• Support the work piece in such a way that it is possible to

predict what will happen, and so that the cut remains open

while cutting.

• Check that the blade is not in contact with anything when

the machine is started.

• Always cut at maximum speed.

• Start cutting gradually, let the machine work without

forcing or pressing the blade.

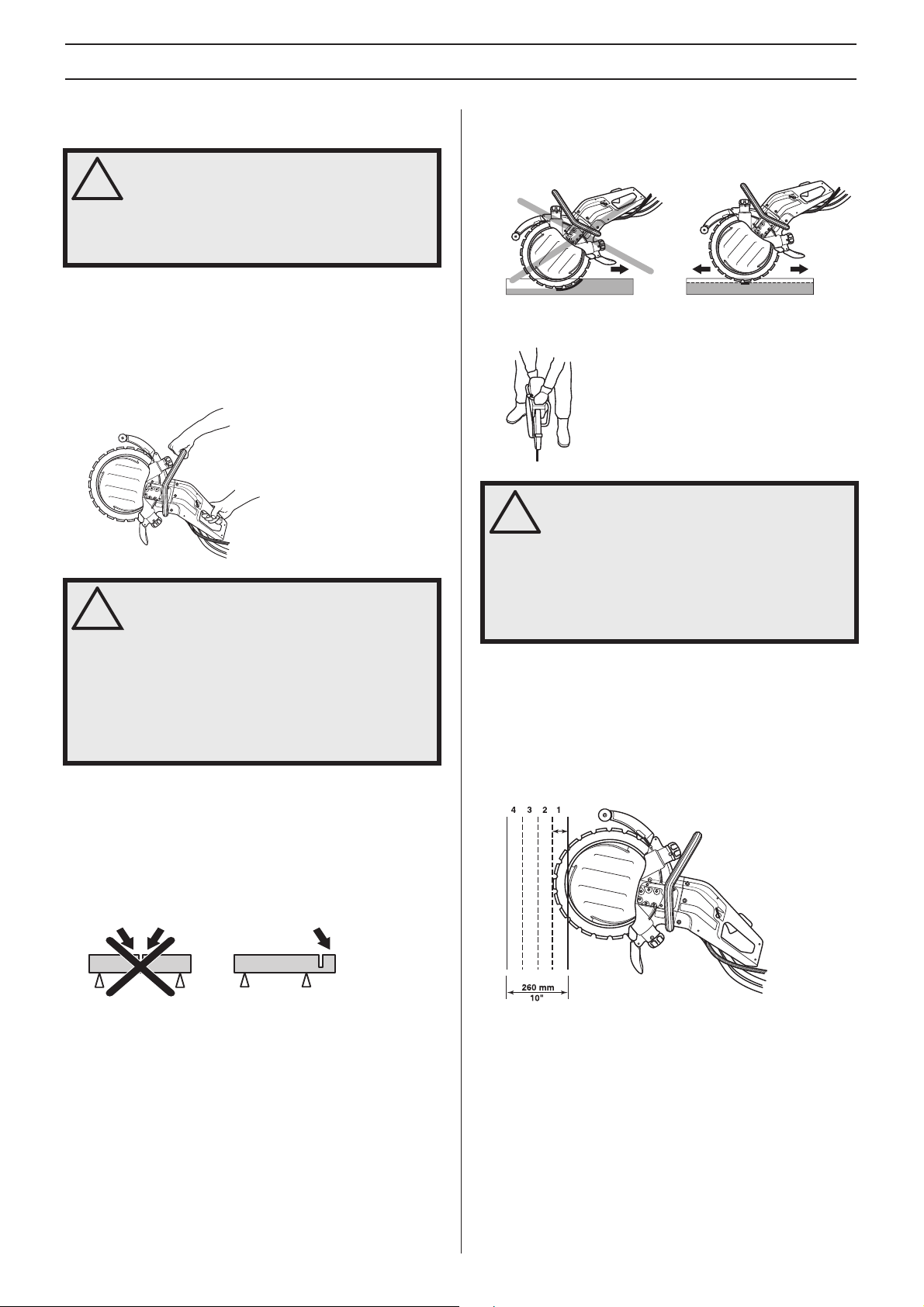

Do not pull the power cutter to one side, this

can cause the blade to jam or break

resulting in injury to people.

Cutting depth

K3600 MKII can cut up to a depth of 260 mm (10 inches).

Making a guide cut of 50-70 mm (2-3 inches) first, gives you

better control of the machine. This means the water disc can

penetrate into the workpiece and help control the machine.

Attempting to saw the entire depth in one run takes longer.

Working with several runs, 3 to 4 when the cut is 260 mm (10

inches) in depth, is much quicker.

8 – English

Loading...

Loading...