Page 1

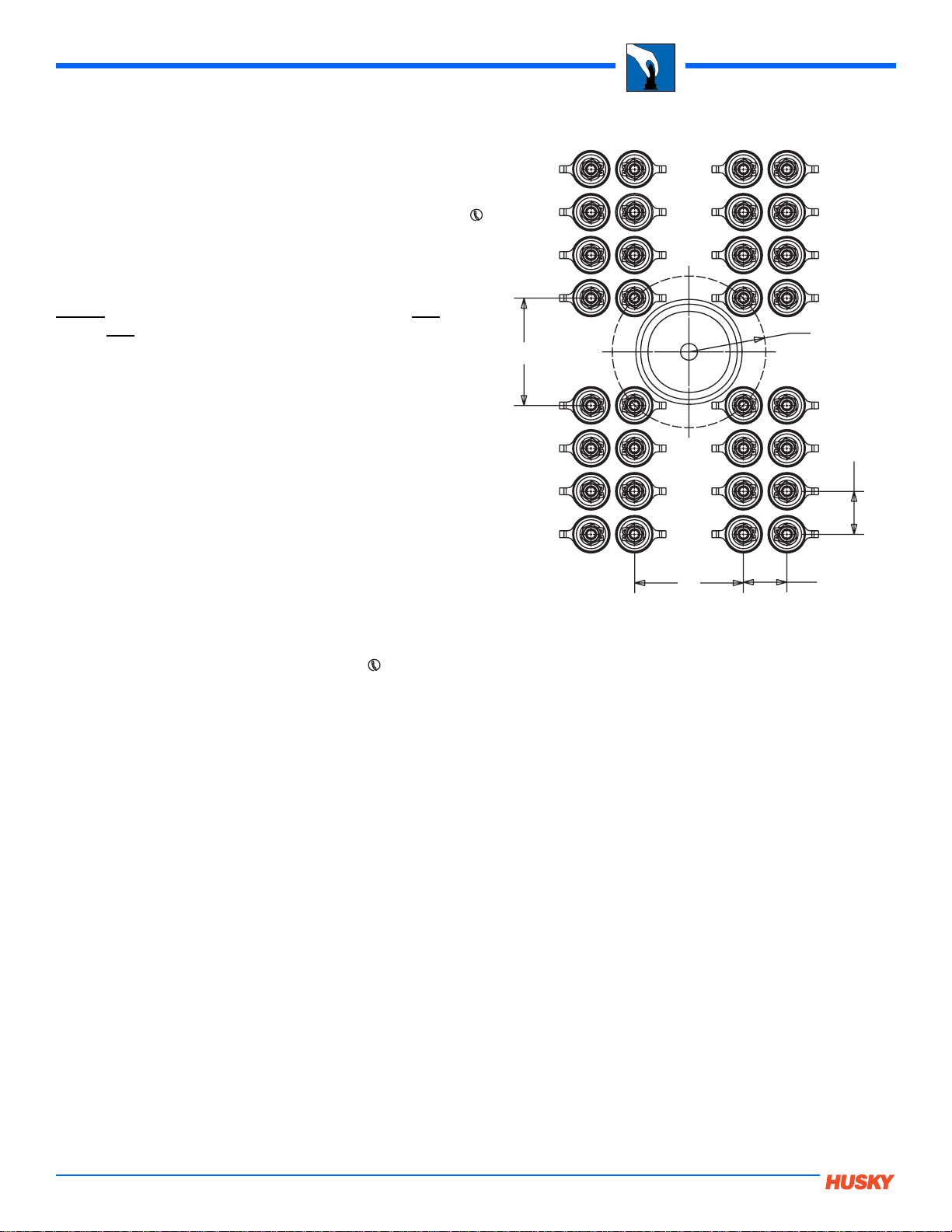

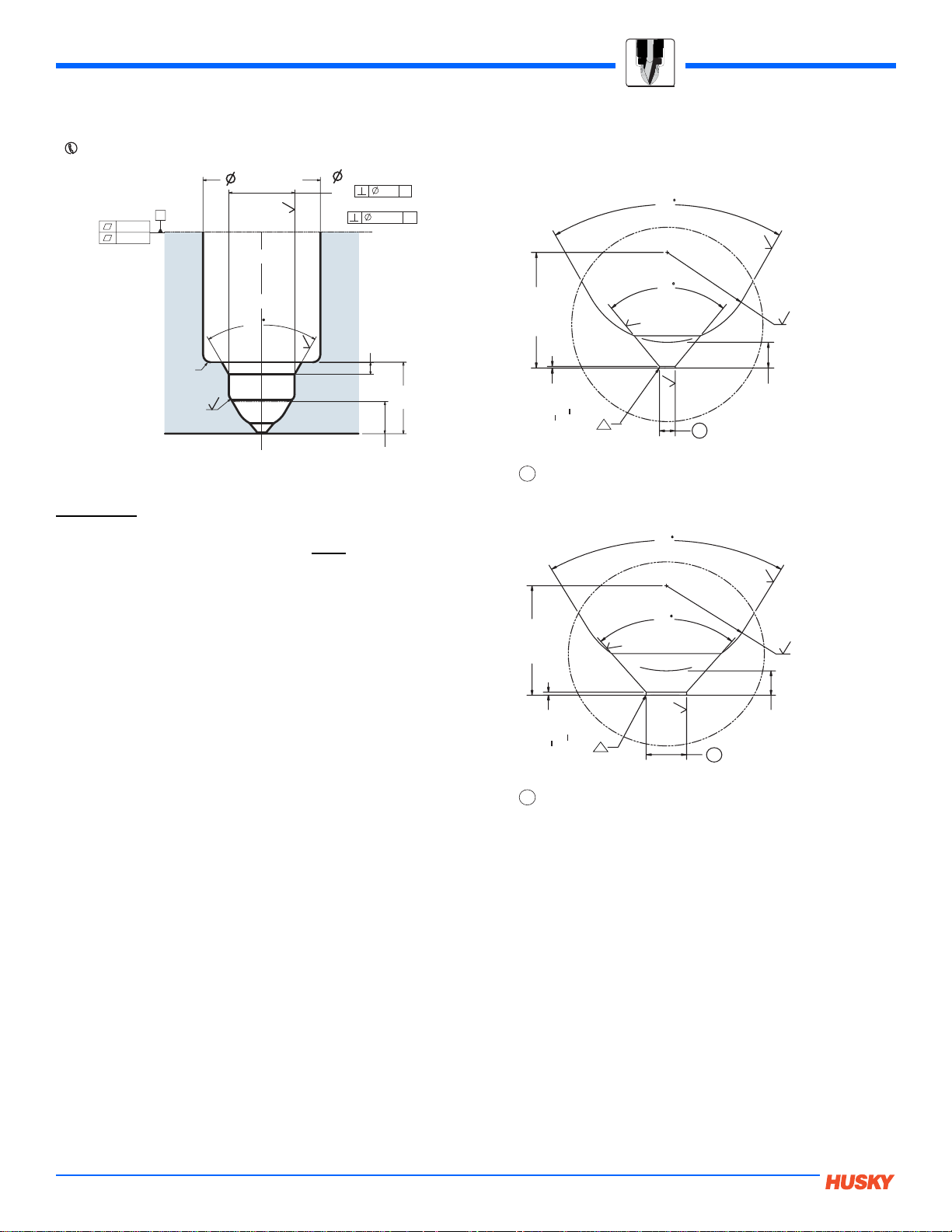

Nozzle Selection Ultra 250

ULTRA 250 DESIGN INFORMATION

Ultra 250 Nozzle Pitch

Minimum nozzle pitch dimensions for the Ultra 25 0 nozz le ar e

provided on the right. For applications that exceed 16 drops, .

Nozzles can be grouped in maximum clusters of 8.

• X and Y must be greater than 45.0mm (1.77”).

NOTE:

The sprue minimum radius 31.8 mm (1.25") and the X

and

Y minimum distances must all be satisfied.

NOTE: Minimum distance between outermost nozzle drop

center to outer edge of the manifold plate is 125mm (4.921”). If

reduced distance is required, contact Husky.

R 31.8

Y

X

[1.25]

18.0

[0.71]

18.0

[0.71]

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

28

Page 2

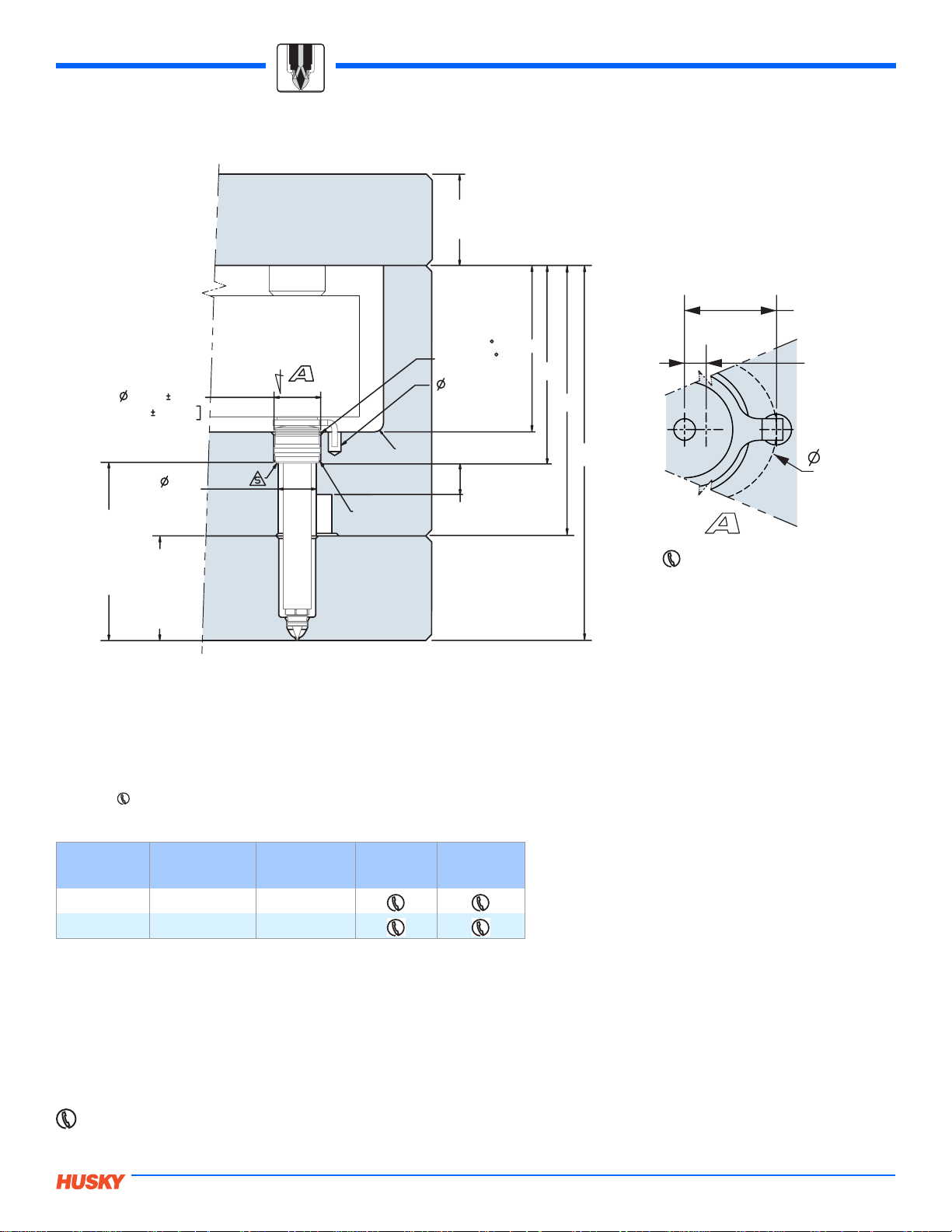

Plate Sizing - Pocket Detail

16.02

[0.631 0.0004

BL

0.01

13.0

[0.51]

R 0.4

[0.02]

0.5 x 45

[0.02 x 45 ]

[0.20 x 0.26 DP.]

R 3.0

[0.12]

40.00

[1.574]

5.0 x 6.5 DP.

10.0

[0.39]

Nozzle SelectionUltra 250 HT-D

12.7

[0.50]

J

K

N

SL

For more than 16 drops.

3.5

[0.14]

20.0

[0.79]

64.66 - 164.66

[2.546 - 6.483]

L

13.00 - 148.8

[0.512 - 5.858]

Nominal dimensions shown for layout purpose only.

Actual dimensions dependent on operating temperatures.

Thermal Calculations

BL / K / L / N / SL - Refer to the plate calculator at http://www.husky.ca/hotrunners/content-316-219.html

- OR -

Contact Husky for plate thickness and critical bore depths.

Ultra 250 HT-D Plate Sizing

Number of

Drops

2 - 4 40.00 (1.574") 55.1 (2.17")

6 - 16 60.00 (2.362") 75.1 (2.96")

Manifold

Height

J K N

Contact Husky for more information

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

29

2006.08

Page 3

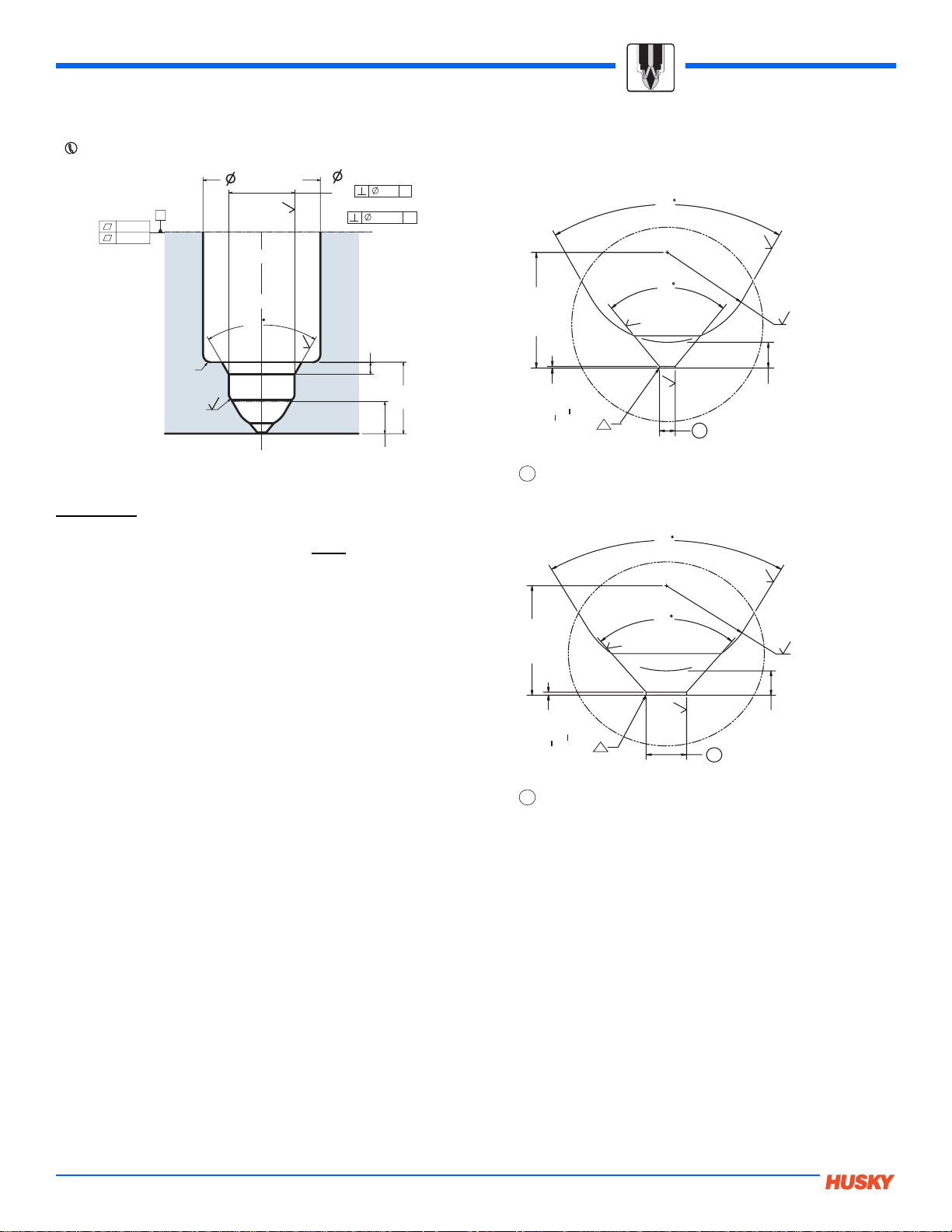

Nozzle Selection Ultra 250 HT-D

[

[

Gate Detail

Contact Husky with any gate insert backup concerns.

7.000 + 0.005

[0.2756 + 0.0002]

0.01

0.0004

A

A

METRIC

IMPERIAL

0.005

0.0002

12.5 [0.49]

A

0.4

60

R 0.8

0.8

1.0 [0.039]

[0.03]

R 0.8

[0.03]

0.8

3.4

7.6

[0.13]

[0.30]

Gate Steel: Hardened tool steels such as 49 - 51 Rc AISI

H13 / DIN 1.2344 provide a good combination

of strength and ductility. Note

: These steels

may not offer the desired r esistance to abrasive

and/or corrosive resins, fillers and/or additives.

Gate Diameter < 1.2mm (0.047")

60

0.8

80

3.60

[0.142]

+ 0.03

0.05

0.002 + 0.001]

G

is application specific, contact Husky prior to machining.

0.4

0.4

S

G

0.8

0.80

SR

[0.110]

[0.031]

SR TAN PT

2.80

Gate Diameter > 1.2mm (0.047")

60

0.8

80

0.8

SR

[0.110]

3.60

0.4

[0.142]

2.80

2006.08

0.4

+ 0.03

S

0.004 + 0.001]

0.10

G

is application specific, contact Husky prior to machining.

G

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

30

0.80

[0.031]

SR TAN PT

Page 4

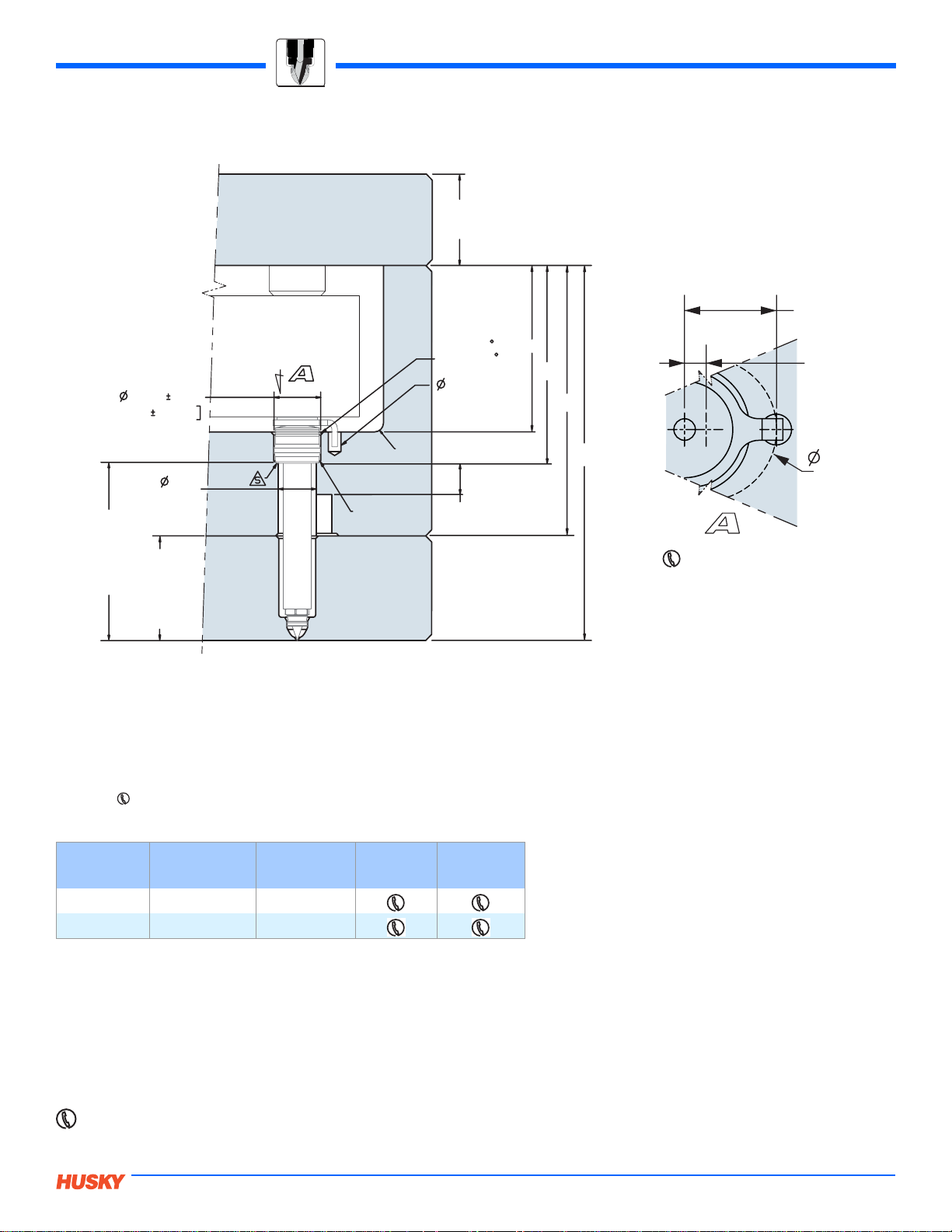

Plate Sizing - Pocket Detail

16.02

[0.631 0.0004

BL

0.01

13.0

[0.51]

R 0.4

[0.02]

0.5 x 45

[0.02 x 45 ]

[0.20 x 0.26 DP.]

R 3.0

[0.12]

40.00

[1.574]

5.0 x 6.5 DP.

10.0

[0.39]

Nozzle SelectionUltra 250 HT-U

12.7

[0.50]

J

K

N

SL

For more than 16 drops.

3.5

[0.14]

20.0

[0.79]

64.66 - 164.66

[2.546 - 6.483]

L

13.00 - 148.8

[0.512 - 5.858]

Nominal dimensions shown for layout purpose only.

Actual dimensions dependent on operating temperatures.

Thermal Calculations

BL / K / L / N / SL - Refer to the plate calculator at http://www.husky.ca/hotrunners/content-316-219.html

- OR -

Contact Husky for plate thickness and critical bore depths.

Ultra 250 HT-U Plate Sizing

Number of

Drops

2 - 4 40.00 (1.574") 55.1 (2.17")

6 - 16 60.00 (2.362") 75.1 (2.96")

Manifold

Height

J K N

Contact Husky for more information

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

31

2006.08

Page 5

Nozzle Selection Ultra 250 HT-U

[

[

Gate Detail

Contact Husky with any gate insert backup concerns.

7.000 + 0.005

[0.2756 + 0.0002]

0.01

0.0004

A

A

METRIC

IMPERIAL

0.005

0.0002

12.5 [0.49]

A

0.4

60

R 0.8

0.8

1.0 [0.039]

[0.03]

R 0.8

[0.03]

0.8

3.4

7.6

[0.13]

[0.30]

Gate Steel: Hardened tool steels such as 49 - 51 Rc AISI

H13 / DIN 1.2344 provide a good combination

of strength and ductility. Note

: These steels

may not offer the desired r esistance to abrasive

and/or corrosive resins, fillers and/or additives.

Gate Diameter < 1.2mm (0.047")

60

0.8

80

3.60

[0.142]

+ 0.03

0.05

0.002 + 0.001]

G

is application specific, contact Husky prior to machining.

0.4

0.4

S

G

0.8

0.80

SR

[0.110]

[0.031]

SR TAN PT

2.80

Gate Diameter > 1.2mm (0.047")

60

0.8

80

0.8

SR

[0.110]

3.60

0.4

[0.142]

2.80

2006.08

0.4

+ 0.03

S

0.004 + 0.001]

0.10

G

is application specific, contact Husky prior to machining.

G

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

32

0.80

[0.031]

SR TAN PT

Page 6

Plate Sizing - Pocket Detail

16.02

[0.631 0.0004

BL

0.01

13.0

[0.51]

R 0.4

[0.02]

0.5 x 45

[0.02 x 45 ]

[0.20 x 0.26 DP.]

R 3.0

[0.12]

40.00

[1.574]

5.0 x 6.5 DP.

10.0

[0.39]

Nozzle SelectionUltra 250 HT-T

12.7

[0.50]

J

K

N

SL

For more than 16 drops.

3.5

[0.14]

20.0

[0.79]

64.66 - 164.66

[2.546 - 6.483]

L

13.00 - 148.8

[0.512 - 5.858]

Nominal dimensions shown for layout purpose only.

Actual dimensions dependent on operating temperatures.

Thermal Calculations

BL / K / L / N / SL - Refer to the plate calculator at http://www.husky.ca/hotrunners/content-316-219.html

- OR -

Contact Husky for plate thickness and critical bore depths.

Ultra 250 HT-T Plate Sizing

Number of

Drops

2 - 4 40.00 (1.574") 55.1 (2.17")

6 - 16 60.00 (2.362") 75.1 (2.96")

Manifold

Height

J K N

Contact Husky for more information

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

33

2006.08

Page 7

Nozzle Selection Ultra 250 HT-T

[

[

Gate Detail

Contact Husky with any gate insert backup concerns.

7.000 + 0.005

[0.2756 + 0.0002]

0.01

0.0004

A

A

METRIC

IMPERIAL

0.005

0.0002

12.5 [0.49]

A

0.4

60

R 0.8

0.8

1.0 [0.039]

[0.03]

R 0.8

[0.03]

0.8

3.4

7.6

[0.13]

[0.30]

Gate Steel: Hardened tool steels such as 49 - 51 Rc AISI

H13 / DIN 1.2344 provide a good combination

of strength and ductility. Note

: These steels

may not offer the desired r esistance to abrasive

and/or corrosive resins, fillers and/or additives.

Gate Diameter < 1.2mm (0.047")

60

0.8

80

3.60

[0.142]

+ 0.03

0.05

0.002 + 0.001]

G

is application specific, contact Husky prior to machining.

0.4

0.4

S

G

0.8

0.80

SR

[0.110]

[0.031]

SR TAN PT

2.80

Gate Diameter > 1.2mm (0.047")

60

0.8

80

0.8

SR

[0.110]

3.60

0.4

[0.142]

2.80

2006.08

0.4

+ 0.03

S

0.004 + 0.001]

0.10

G

is application specific, contact Husky prior to machining.

G

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

34

0.80

[0.031]

SR TAN PT

Page 8

Plate Sizing - Pocket Detail

0.01

16.02

[0.631 0.0004]

13.0

[0.51]

R 0.4

[0.02]

0.5 x 45

[0.02 x 45 ]

[0.20 x 0.26 DP.]

R 3.0

[0.12]

40.00

[1.574]

5.0 x 6.5 DP.

10.0

[0.39]

Nozzle SelectionUltra 250 HT-DX

12.7

[0.50]

J

K

N

SL

3.5

[0.14]

20.0

[0.79]

BL

[3.04 - 6.98]

77.16 - 177.16

L

25.5 - 161.3

[1.00 - 6.35]

For more than 16 drops.

Nominal dimensions shown for layout purpose only.

Actual dimensions dependent on operating temperatures.

Thermal Calculations

BL / K / L / N / SL - Refer to the plate calculator at http://www.husky.ca/hotrunners/content-316-219.html

- OR -

Contact Husky for plate thickness and critical bore depths.

Ultra 250 HT-DX Plate Sizing

Number of

Drops

2 - 4 40.00 (1.574") 55.1 (2.17")

6 - 16 60.00 (2.362") 75.1 (2.96")

Manifold

Height

J K N

Contact Husky for more information

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

35

2006.08

Page 9

Nozzle Selection Ultra 250 HT-DX

[

]

[

[

Gate Detail

Contact Husky with any gate insert backup concerns.

METRIC

IMPERIAL

[0.2756 +0.0002]

0.005

0.0002

7.000 + 0.005

0.01

0.0004

A

A

A

6.00 + 0.05

[0.236

R 0.8

[0.03]

+ .002]

0.8

12.5 [0.49]

60

90

0.4

0.8

B

R 0.2

[0.08]

MAX

1.30 [0.051]

REF

15.9 [0.63]

REF

INT PT

7.35

[.289]

Gate Steel: Hardened tool steels such as 49 - 51 Rc AISI

H13 / DIN 1.2344 provide a good combination

of strength and ductility. Note

: These steels

may not offer the desired r esistance to abrasive

and/or corrosive resins, fillers and/or additives.

REF

0.79

20.1

Gate Diameter < 1.2mm (0.047")

0.4

80

0.4

0.8

FULL SR

0.80

G

[0.031]

REF

[.15]

SR CENTER

3.8

+0.03

0.05

G

is application specific, contact Husky prior to machining.

S

0.002 + 0.001]

Gate Diameter > 1.2mm (0.047")

REF

[.15]

SR CENTER

3.8

0.4

80

0.8

SR TAN PT

FULL SR

2006.08

0.4

+ 0.03

S

0.10

0.004 + 0.001]

G

is application specific, contact Husky prior to machining.

G

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

36

0.80

[0.031]

SR TAN PT

Page 10

Plate Sizing - Pocket Detail

16.02

[0.631 0.0004]

0.01

13.0

[0.51]

R 0.4

[0.02]

[0.02 x 45 ]

[0.20 x 0.26 DP.]

R 3.0

[0.12]

40.00

[1.574]

0.5 x 45

5.0 x 6.5 DP.

10.0

[0.39]

Nozzle SelectionUltra 250 HT-TX

12.7

[0.50]

J

K

N

SL

3.5

[0.14]

20.0

[0.79]

BL

[3.04 - 6.98]

77.16 - 177.16

L

25.5 - 161.3

[1.00 - 6.35]

For more than 16 drops.

Nominal dimensions shown for layout purpose only.

Actual dimensions dependent on operating temperatures.

Thermal Calculations

BL / K / L / N / SL - Refer to the plate calculator at http://www.husky.ca/hotrunners/content-316-219.html

- OR -

Contact Husky for plate thickness and critical bore depths.

Ultra 250 HT-TX Plate Sizing

Number of

Drops

2 - 4 40.00 (1.574") 55.1 (2.17")

6 - 16 60.00 (2.362") 75.1 (2.96")

Manifold

Height

J K N

Contact Husky for more information

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

37

2006.08

Page 11

Nozzle Selection Ultra 250 HT-TX

[

[

Gate Detail

Contact Husky with any gate insert backup concerns.

METRIC

IMPERIAL

[0.2756 +0.0002]

0.005

0.0002

7.000 + 0.005

0.01

0.0004

A

A

A

6.00 + 0.05

[0.236

R 0.8

[0.03]

+ .002]

0.8

12.5 [0.49]

60

90

0.4

0.8

B

R 0.2

[0.08]

MAX

1.30 [0.051]

REF

15.9 [0.63]

REF

INT PT

7.35

[.289]

Gate Steel: Hardened tool steels such as 49 - 51 Rc AISI

H13 / DIN 1.2344 provide a good combination

of strength and ductility. Note

: These steels

may not offer the desired r esistance to abrasive

and/or corrosive resins, fillers and/or additives.

REF

20.1 [0.79]

Gate Diameter < 1.2mm (0.047")

0.4

80

0.4

0.8

FULL SR

0.80

[0.031]

G

SR TAN PT

REF

[.15]

SR CENTER

3.8

+0.03

0.05

G

is application specific, contact Husky prior to machining.

S

0.002 + 0.001]

Gate Diameter > 1.2mm (0.047")

REF

[.15]

SR CENTER

3.8

0.4

80

0.8

FULL SR

2006.08

0.4

+ 0.03

S

0.10

0.004 + 0.001]

G

is application specific, contact Husky prior to machining.

G

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

38

0.80

[0.031]

SR TAN PT

Page 12

Plate Sizing - Pocket Detail

-

-

WIRE GROOVE

Nozzle SelectionUltra 250 HS

75.3 [2.97]

60.0 [2.36]

(X2)

58

(X2)

40

REF12.45 [0.490]

45

10.0 [0.39]

WIRE GROOVE

REF30.64 [1.206]

REF19.93 [0.785]

REF

[1.012]

25.71

58

40

(X2)

(X2)

WIRE GROOVE

12.7 [0.50]

M6 X 12.0 DP. (X4)

80.0 [3.15]

M6 X 12.0 DP. (X4)

47.0 [1.85]

-

+

+

21.10 0.01

[0.831 0.0004]

15.10 [0.594]

-

+

PL

-

+

18.10 0.01 [0.713 0.0004]

5.00 [0.197]

BL

BL +

PL -

LOC. RING RELIEF

LR DIA.

-

SR

97.01

+0.02

-0.00

63.0 [2.480]

3.819

+0.001

-0.000

Orifice

34.12

+0.02

1.343

-0.00

R 1.5 [0.06]

R 0.50 [0.020]

R 1.50 [0.059]

0.5 [0.02] X 30

R 0.50 [0.020]

+0.001

-0.000

*Refer to following page for definitions. Ultra 250 Hot Sprue

Contact Husky for more information

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

39

2006.08

Page 13

Nozzle Selection Ultra 250 HS

Dimensions

Ultra 250 Hot Sprue ‘A’ Dimension Chart (Thermal Gate)

PL (Plate Length) LR DIA LR RELIEF DIA RAD ORIFICE

101.31 (3.99")

HT-D/HT-T/HT-U: 86.22 (3.394") - 206.4 (8.129")

HT-DX/HT-TX: 98.76 (3.888") - 219.02 (8.622")

101.57 (4")

100 (3.94")

120 (4.72")

125 (4.92")

160 (6.30")

Design Criteria

• Ultra 250 hot sprues are designed using customer specified PL, LR, RAD, orifice, melt operating temperature, and

mold temperature.

• If required PL is outside published range, extended lead times may apply. Please contact Husky.

• Actual BL dimension is a function of PL, tip selection, nozzle housing selection and operating conditions.

• Actual BL dimension will be provided after system design. If a specific BL is required please contact Husky

105 (4.13")

105 (4.13")

105 (4.13")

124 (4.88")

129 (5.08")

163.71 (6.45")

FLAT

10.00 (.394")

12.70 (.500")

15.50 (.610")

6.35 (.25")

8.00 (.315")

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

40

Page 14

Gate Detail HT-D / HT-T / HT-U

[

[

Contact Husky with any gate insert backup concerns.

Nozzle SelectionUltra 250 HS

7.000 + 0.005

[0.2756 + 0.0002]

0.01

0.0004

A

A

METRIC

IMPERIAL

0.005

0.0002

12.5 [0.49]

A

0.4

60

R 0.8

0.8

1.0 [0.039]

[0.03]

R 0.8

[0.03]

0.8

3.4

7.6

[0.13]

[0.30]

Gate Steel: Hardened tool steels such as 49 - 51 Rc AISI

H13 / DIN 1.2344 provide a good combination

of strength and ductility. Note

: These steels

may not offer the desired r esistance to abrasive

and/or corrosive resins, fillers and/or additives.

Gate Diameter < 1.2mm (0.047")

60

0.8

80

3.60

[0.142]

+ 0.03

0.05

0.002 + 0.001]

G

is application specific, contact Husky prior to machining.

0.4

0.4

S

G

0.8

0.80

SR

[0.110]

[0.031]

SR TAN PT

2.80

Gate Diameter > 1.2mm (0.047")

60

0.8

80

0.8

SR

[0.110]

3.60

[0.142]

0.4

2.80

Contact Husky for more information

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

41

0.4

0.80

+ 0.03

S

0.004 + 0.001]

0.10

G

is application specific, contact Husky prior to machining.

G

[0.031]

SR TAN PT

2006.08

Page 15

Nozzle Selection Ultra 250 HS

Gate Detail HT-DX / HT-TX

Contact Husky with any gate insert backup concerns

METRIC

IMPERIAL

[0.2756 +0.0002]

0.005

0.0002

7.000 + 0.005

0.01

0.0004

A

A

A

R 0.8

12.5 [0.49]

60

1.30 [0.051]

[0.03]

0.4

6.80 [0.268]

0.8

R 0.8

[0.03]

20

0.8

15.9 [0.63]

0.8

R 3.0

[0.12]

Gate Steel: Hardened tool steels such as 49 - 51 Rc AISI

H13 / DIN 1.2344 provide a good combination

of strength and ductility. Note

: These steels

may not offer the desired r esistance to abrasive

and/or corrosive resins, fillers and/or additives.

20.1 [0.79]

Gate Diameter < 1.2mm (0.047")

60

0.8

80

3.60

[0.142]

+ 0.03

0.05

0.002 + 0.001]

G

is application specific, contact Husky prior to machining.

0.4

0.4

S

G

0.8

0.80

SR

[0.110]

[0.031]

SR TAN PT

2.80

Gate Diameter > 1.2mm (0.047")

60

0.8

3.60

[0.142]

+ 0.03

0.10

G

is application specific, contact Husky prior to machining.

0.4

S

0.004 + 0.001]

80

0.4

0.8

SR

[0.110]

0.80

[0.031]

G

SR TAN PT

2.80

2006.08

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

42

Loading...

Loading...